High-speed evaporation and circulation steam engine for directly spraying liquid onto hot wall

A steam engine and rapid evaporation technology, which is applied in the field of steam engines, can solve the problems of low thermal efficiency, bulky boiler cycle steam engine, and small application range, and achieve the effects of high thermal efficiency, small vibration, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

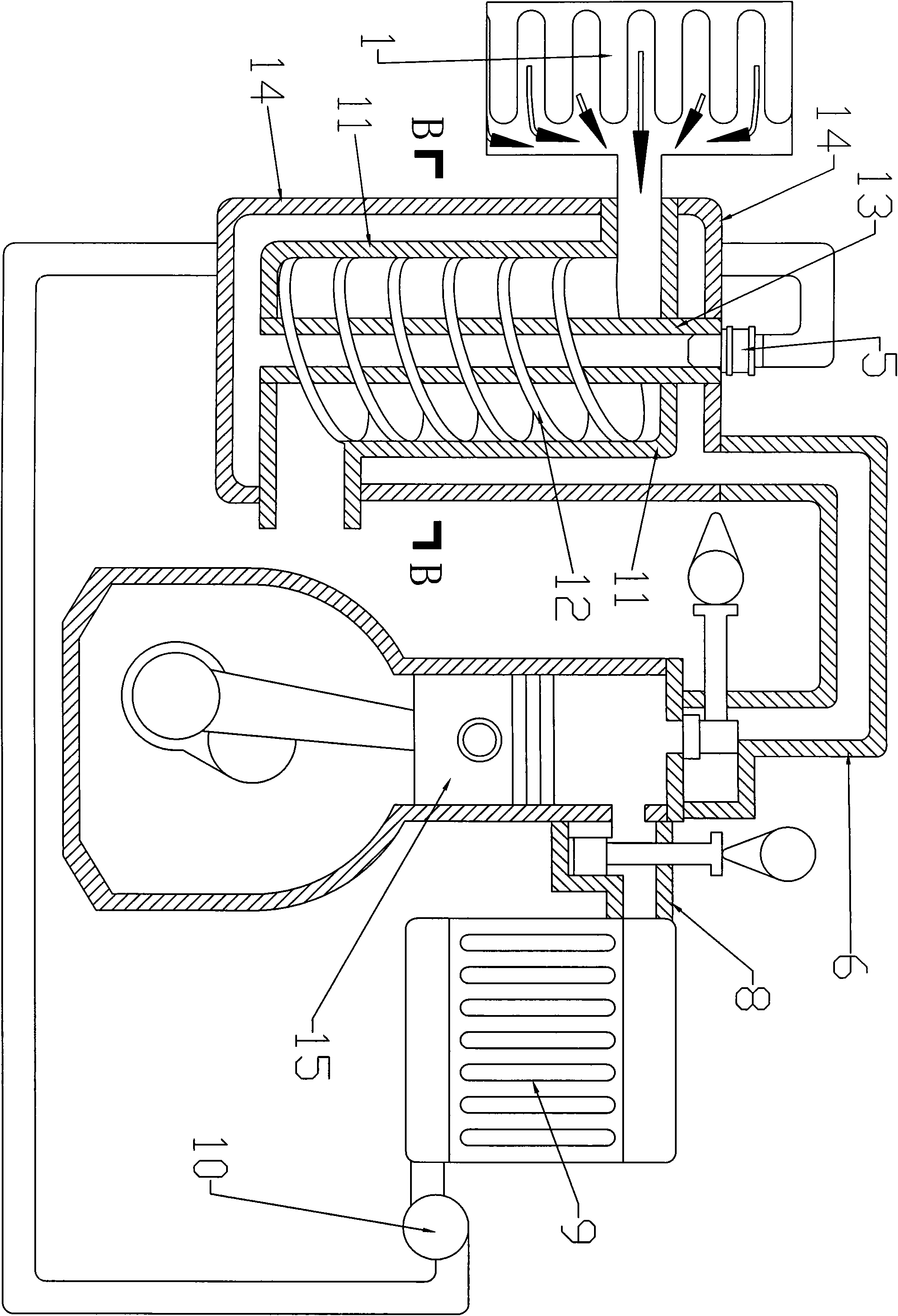

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: the present invention has six technical schemes;

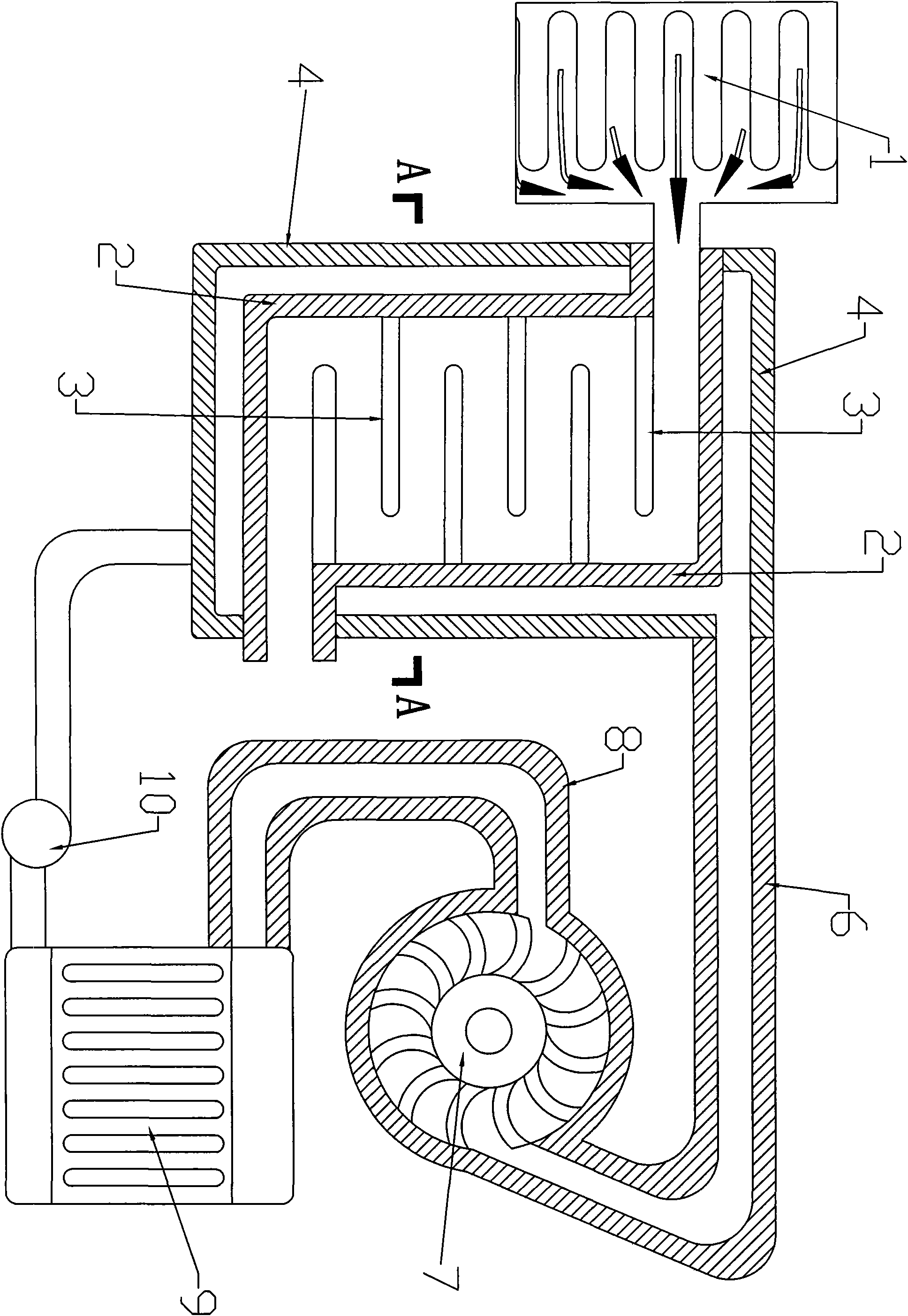

[0025] figure 1 The first embodiment shown is the heat source transverse counterflow type, which is composed of a spray nozzle 5, a rectangular hot wall 2, a steam turbine 7, a steam conduit 6, an exhaust pipe 8, a condensing radiator 9, a water pump 10, and a rectangular evaporator cover 4 Composed of transverse guide spacer 3. A plurality of transverse guide partitions are arranged inside the rectangular hot wall 2, and the rectangular hot wall 2 is covered with a rectangular evaporator cover 4, which forms an evaporation chamber. Several spray nozzles 5 are arranged around the rectangular evaporator cover 4, and the spray nozzles 5 extend into the evaporation chamber. The top of the evaporating device is the inlet of the heat source 1, and the bottom is the outlet of the heat source 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com