Patents

Literature

1538results about "Engine of intermeshing engagement type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

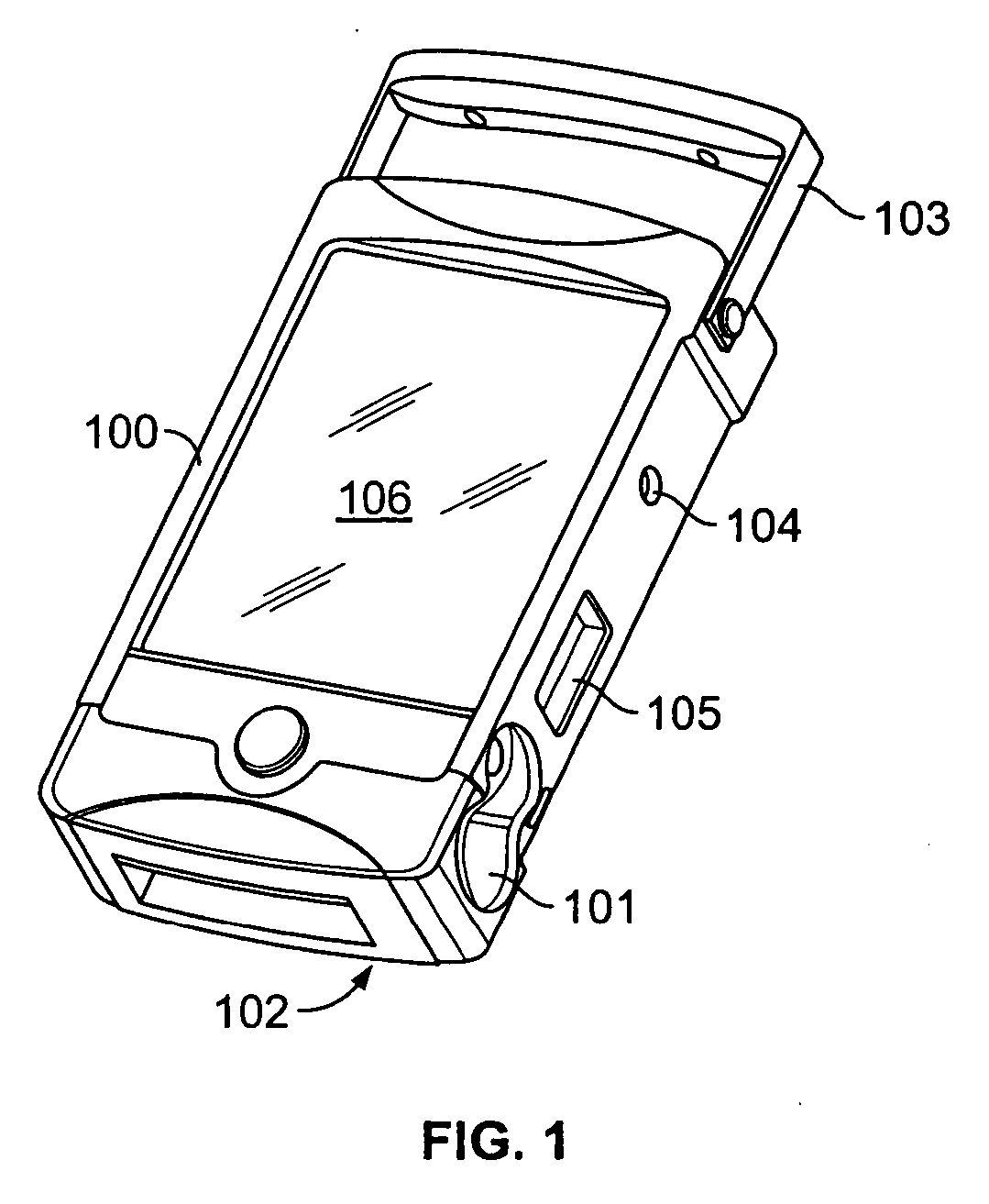

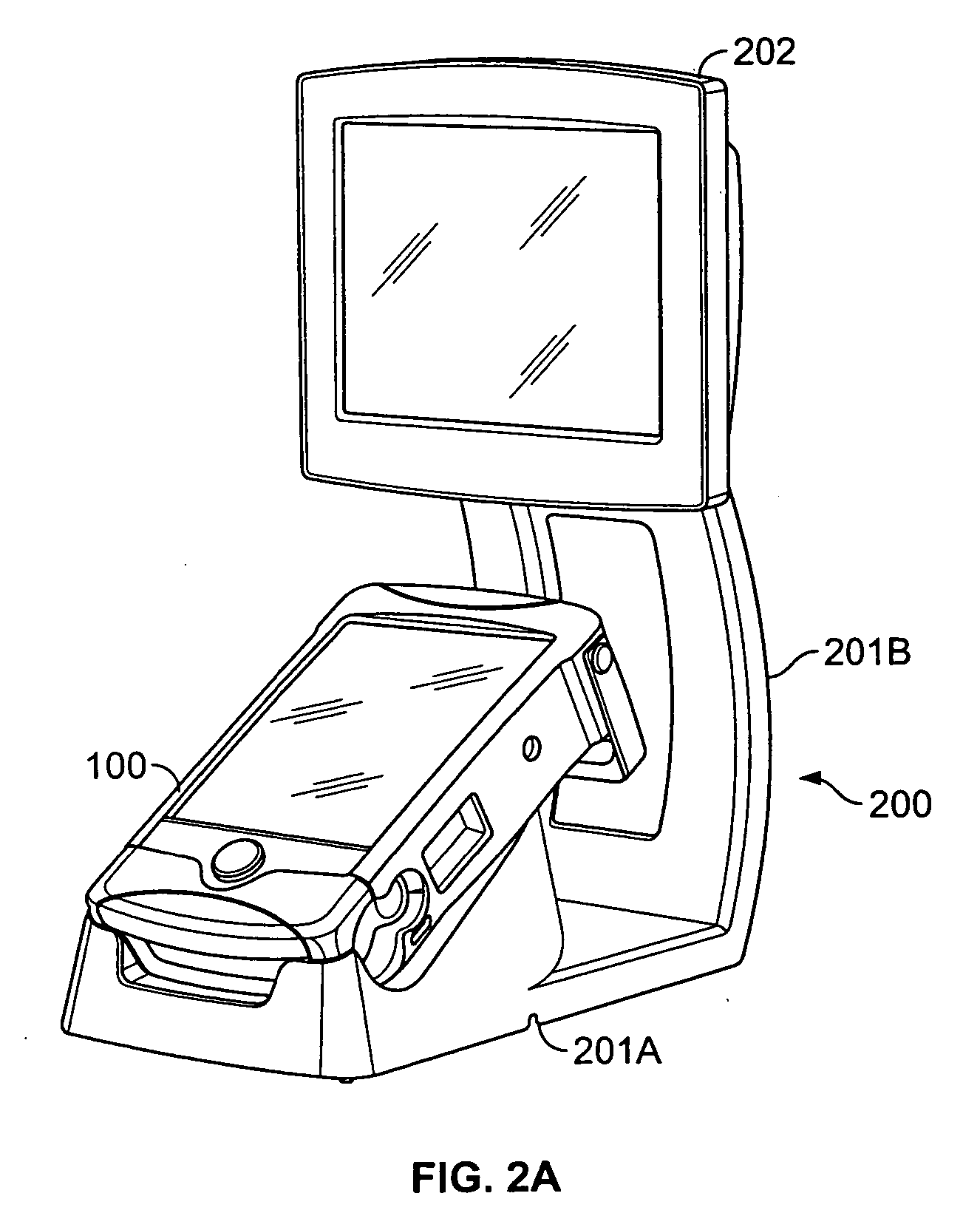

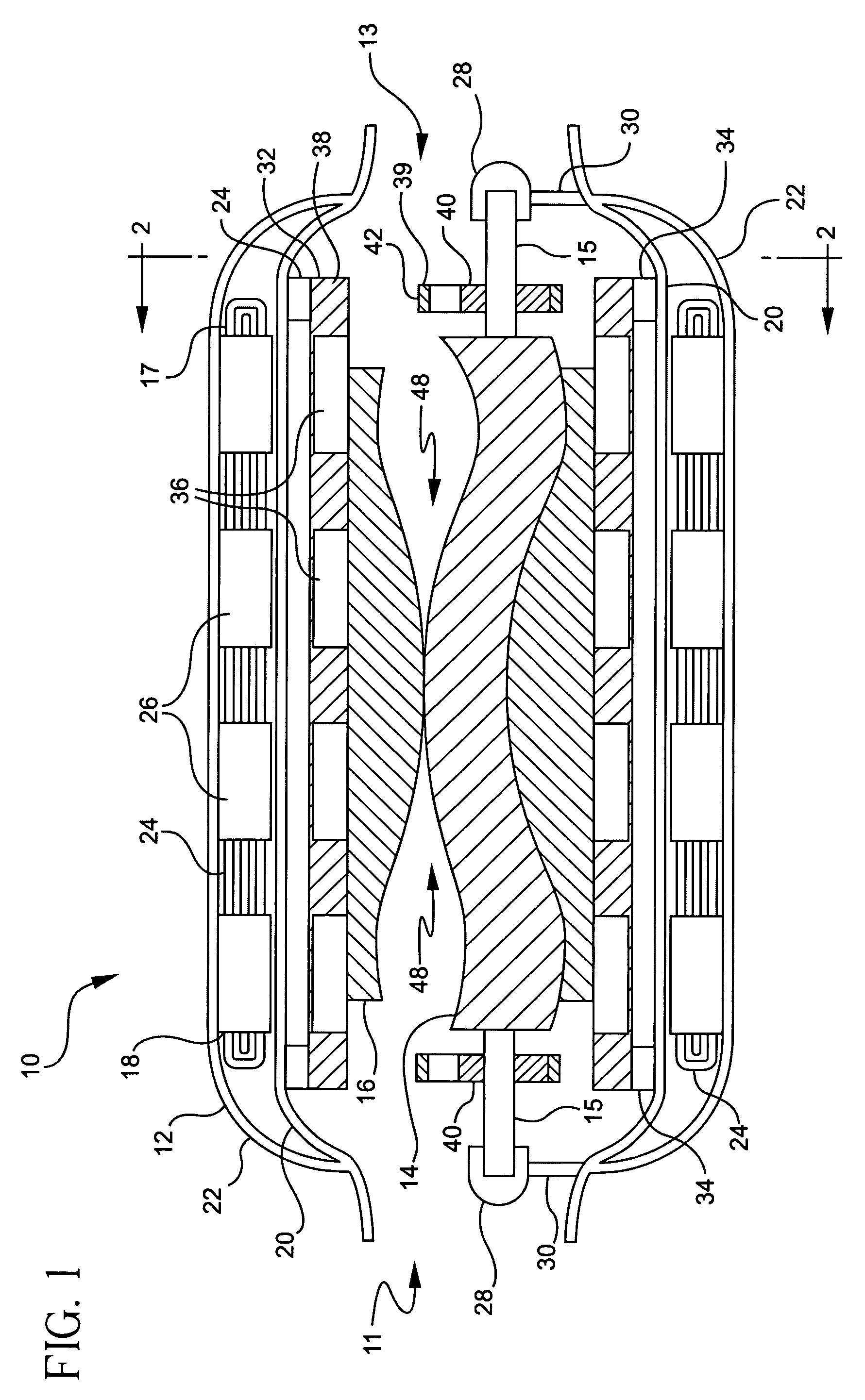

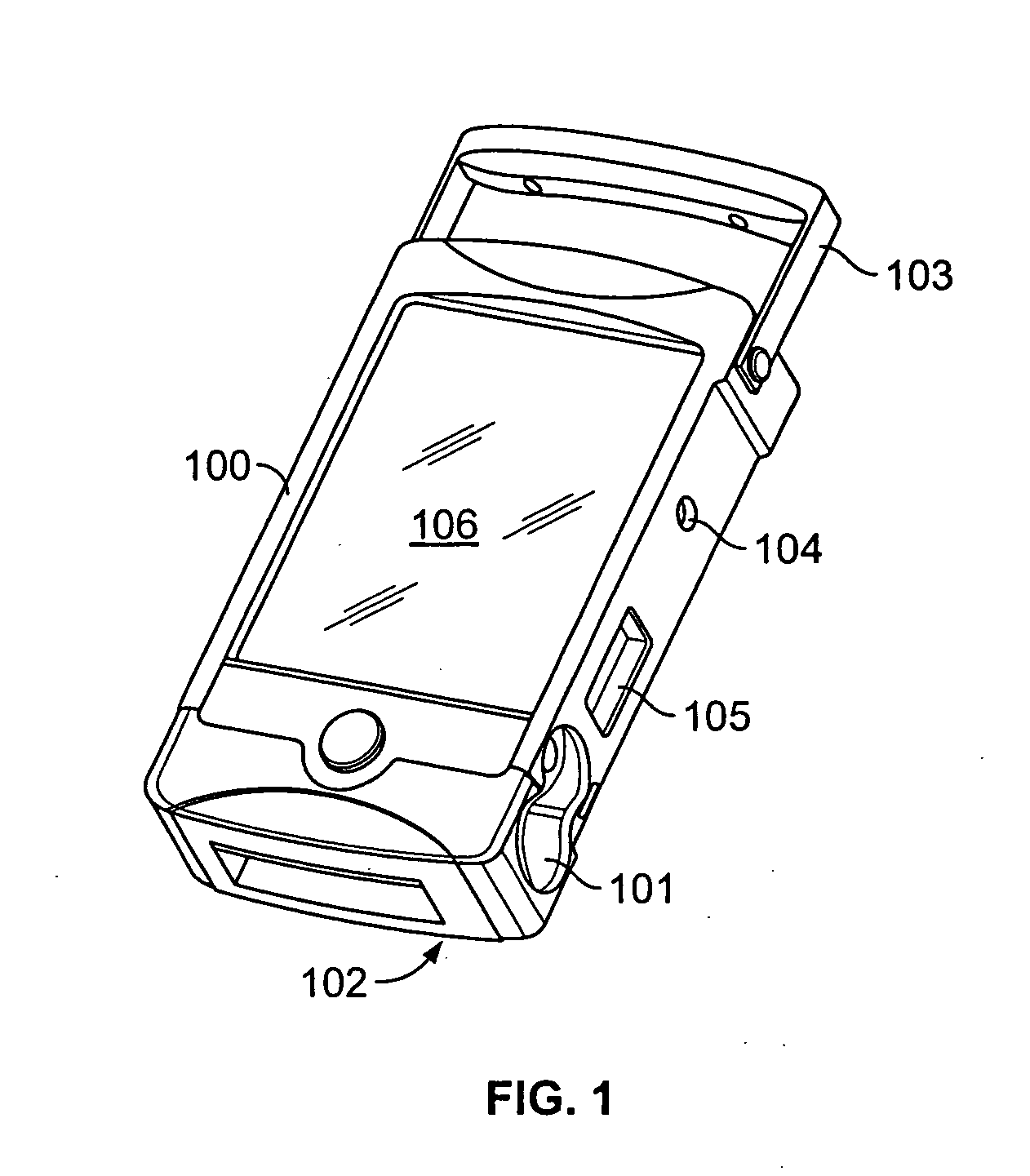

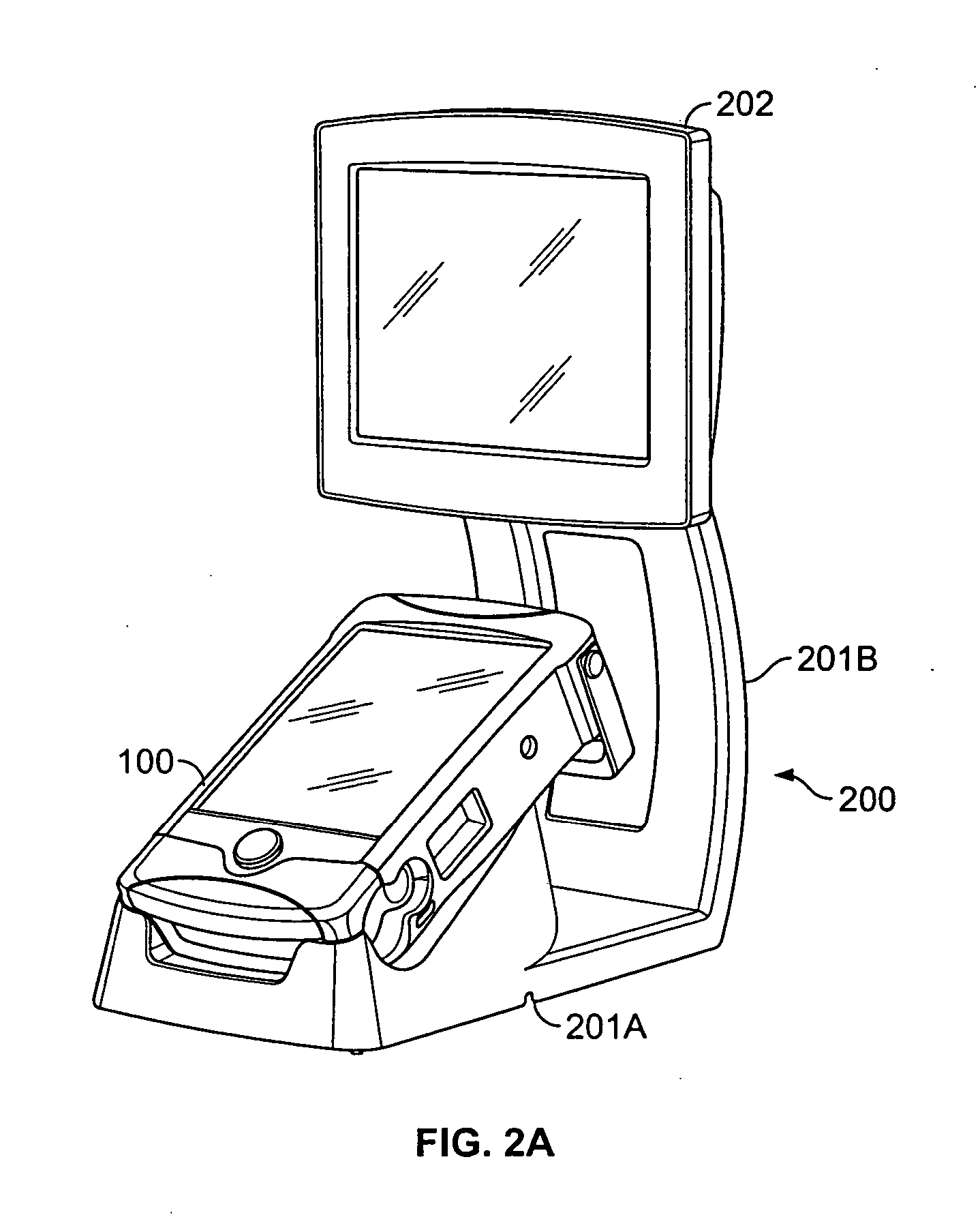

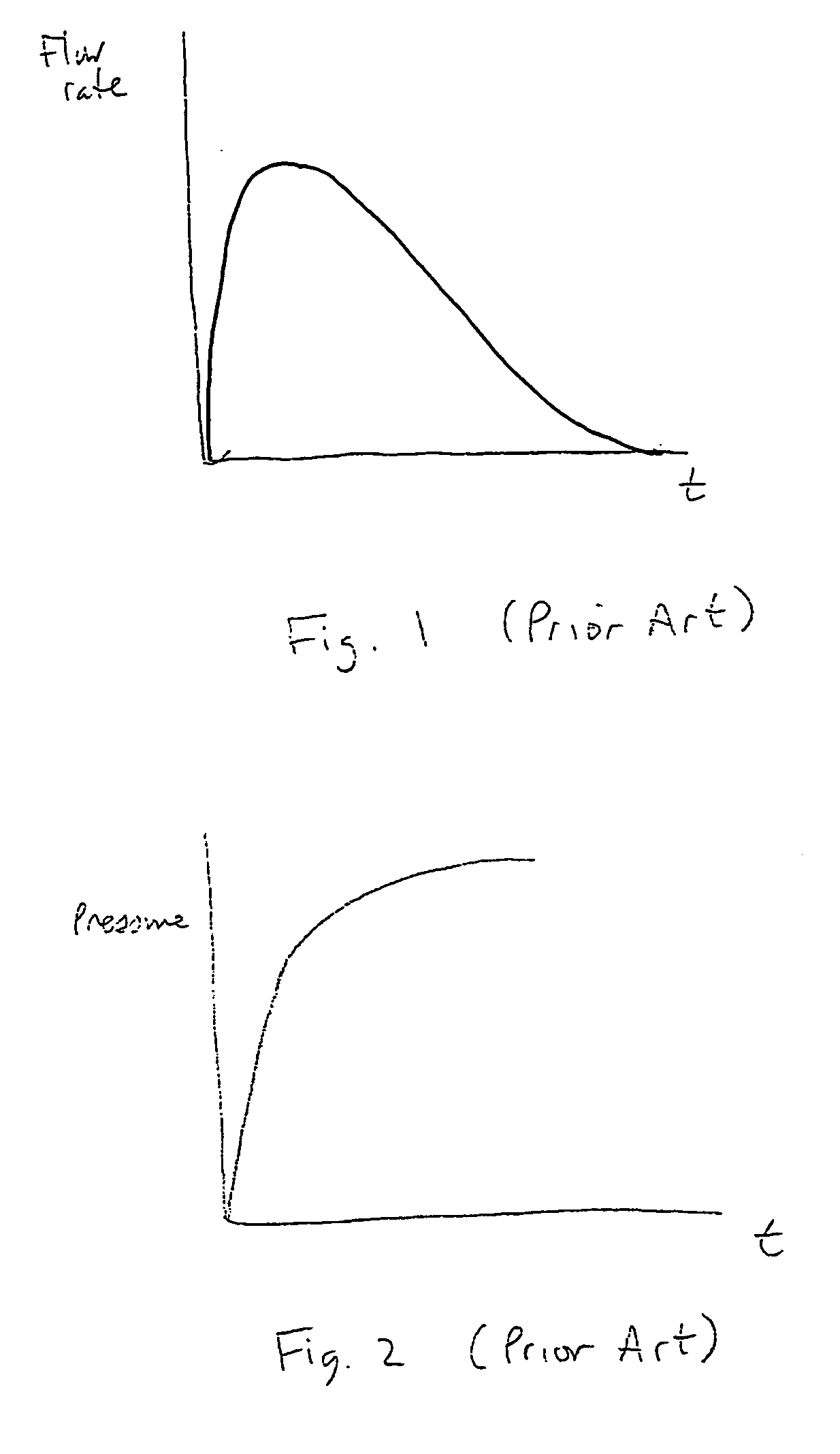

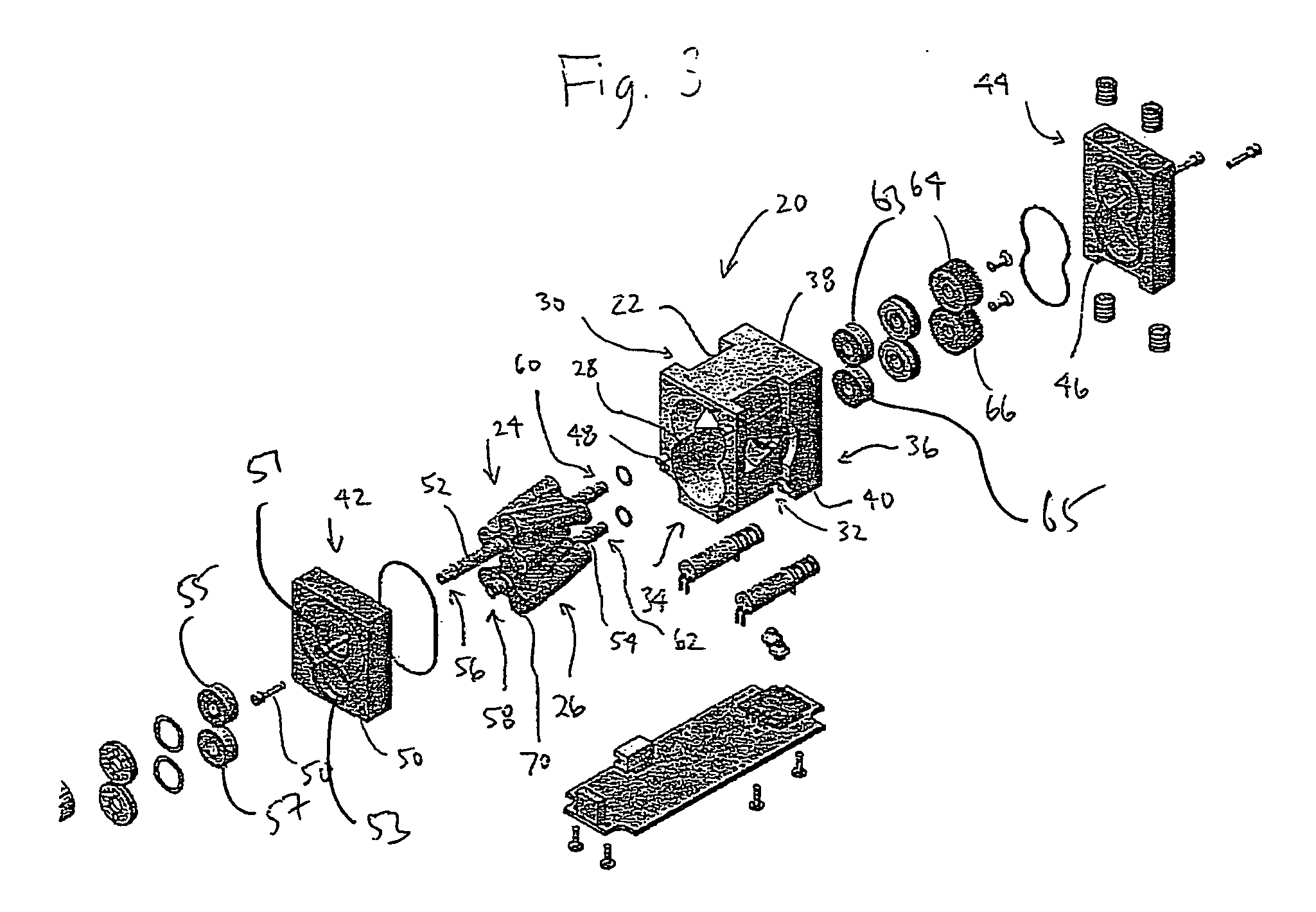

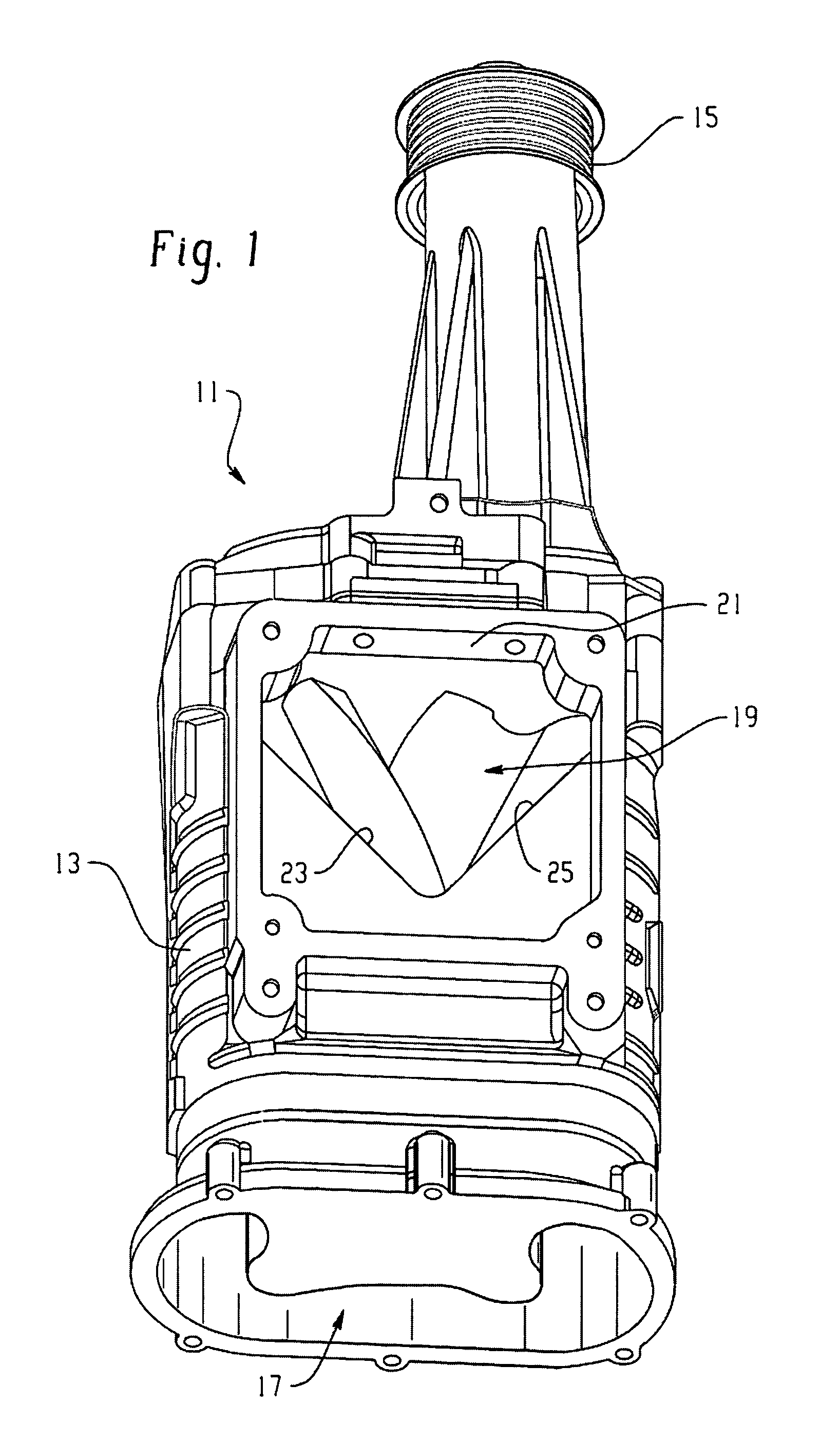

Portable ventilator system

ActiveUS20050051168A1Reduce power consumptionSmall sizeMechanical/radiation/invasive therapiesPhysical therapyPortable ventilatorsEngineering

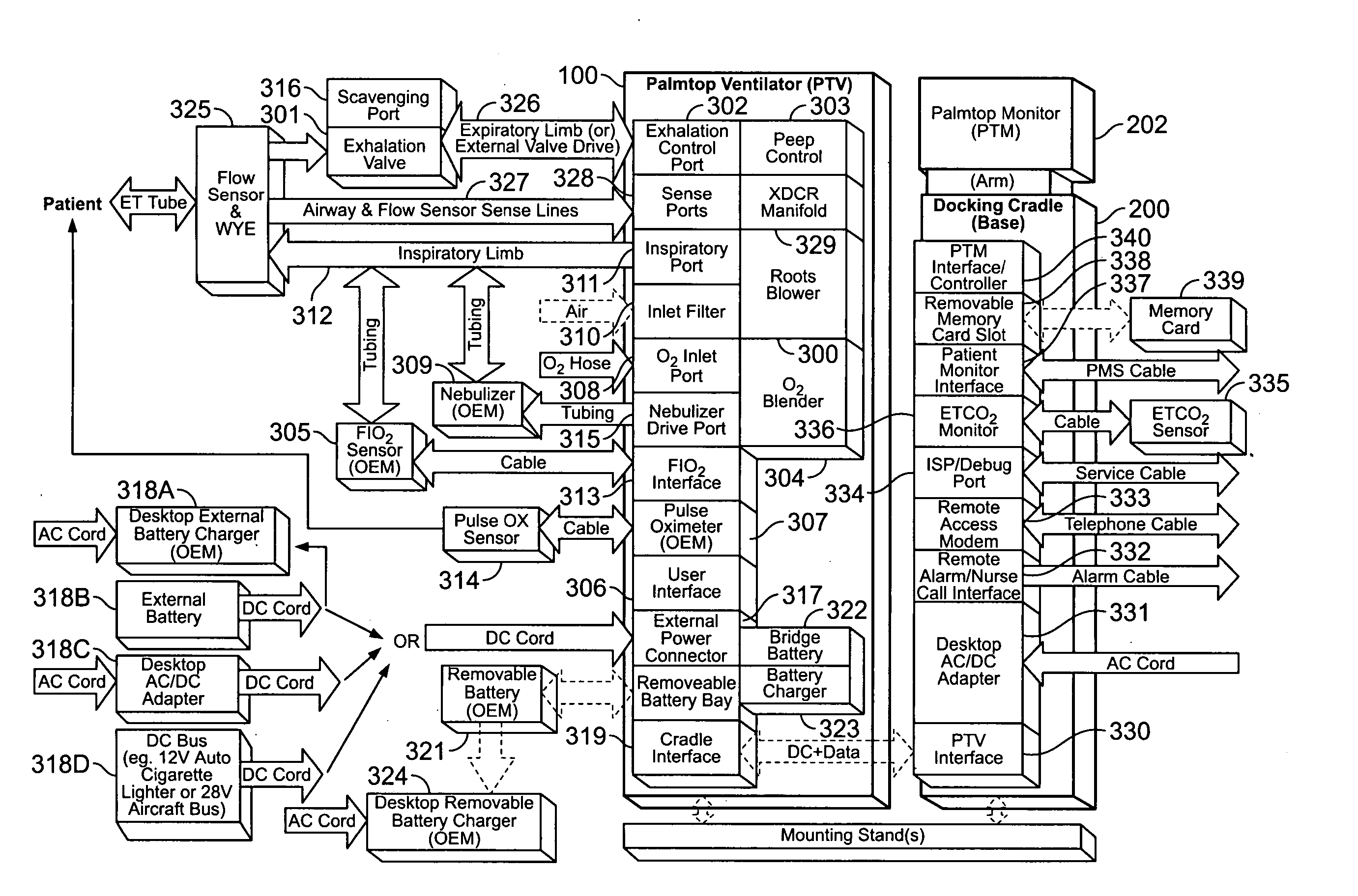

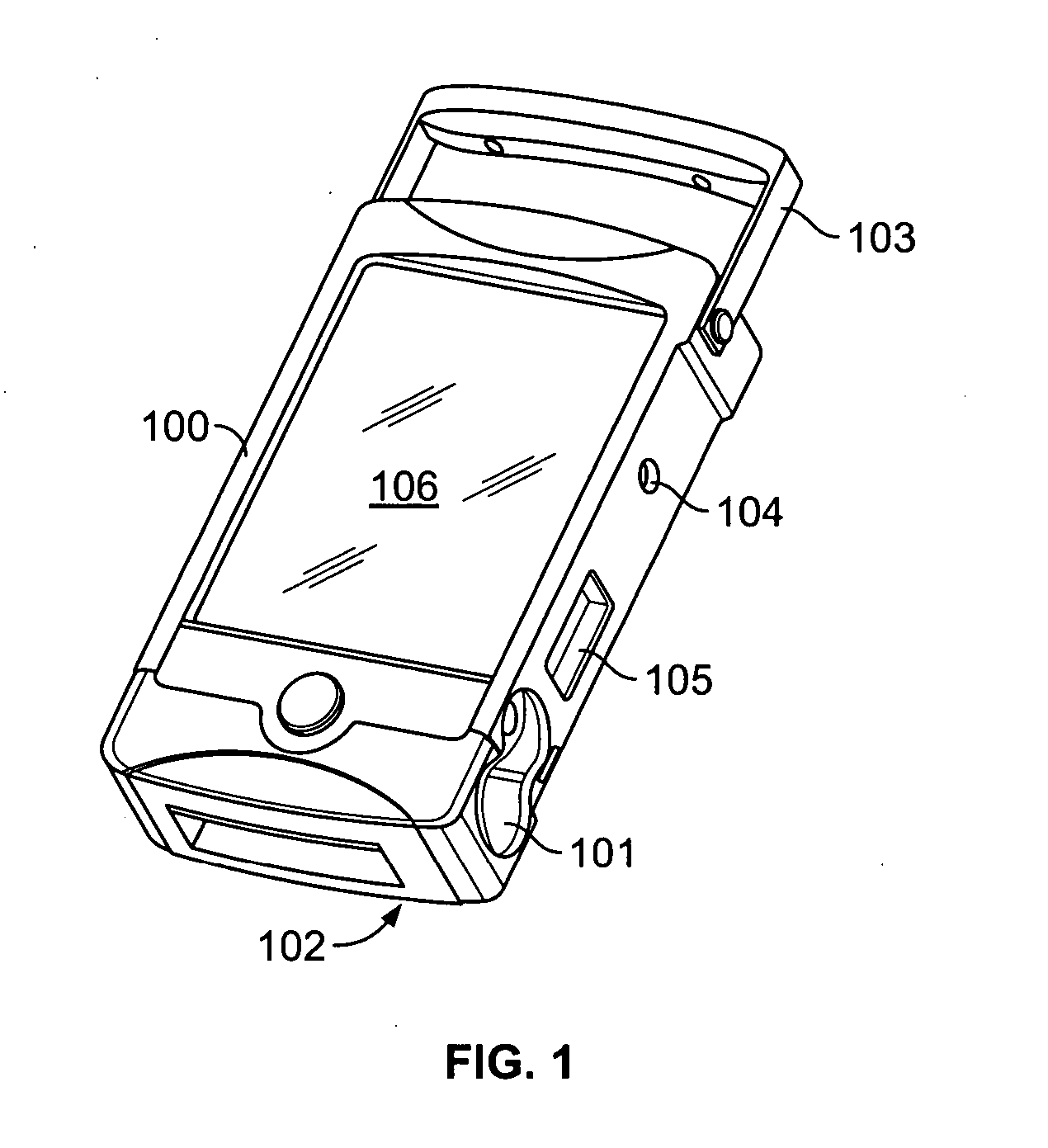

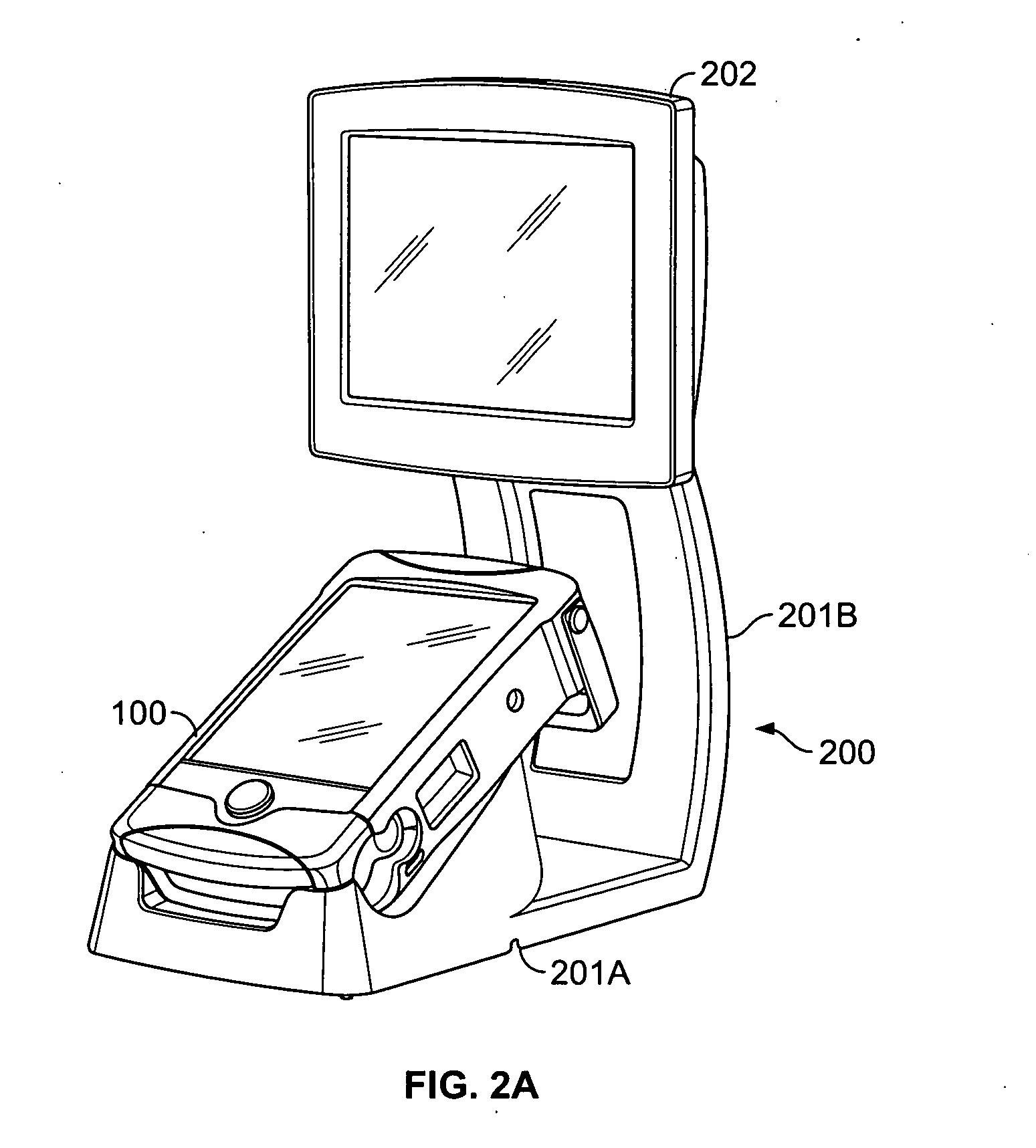

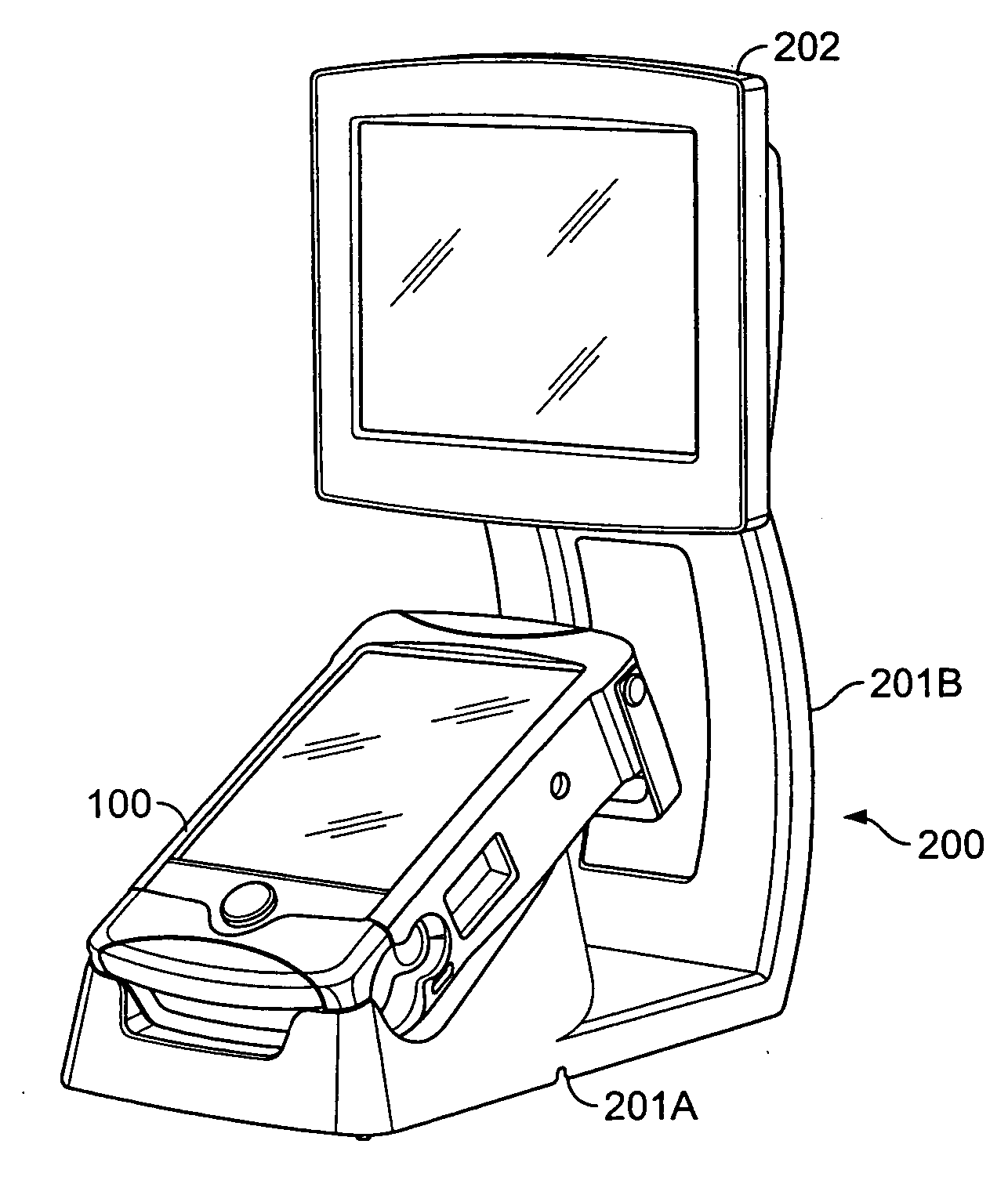

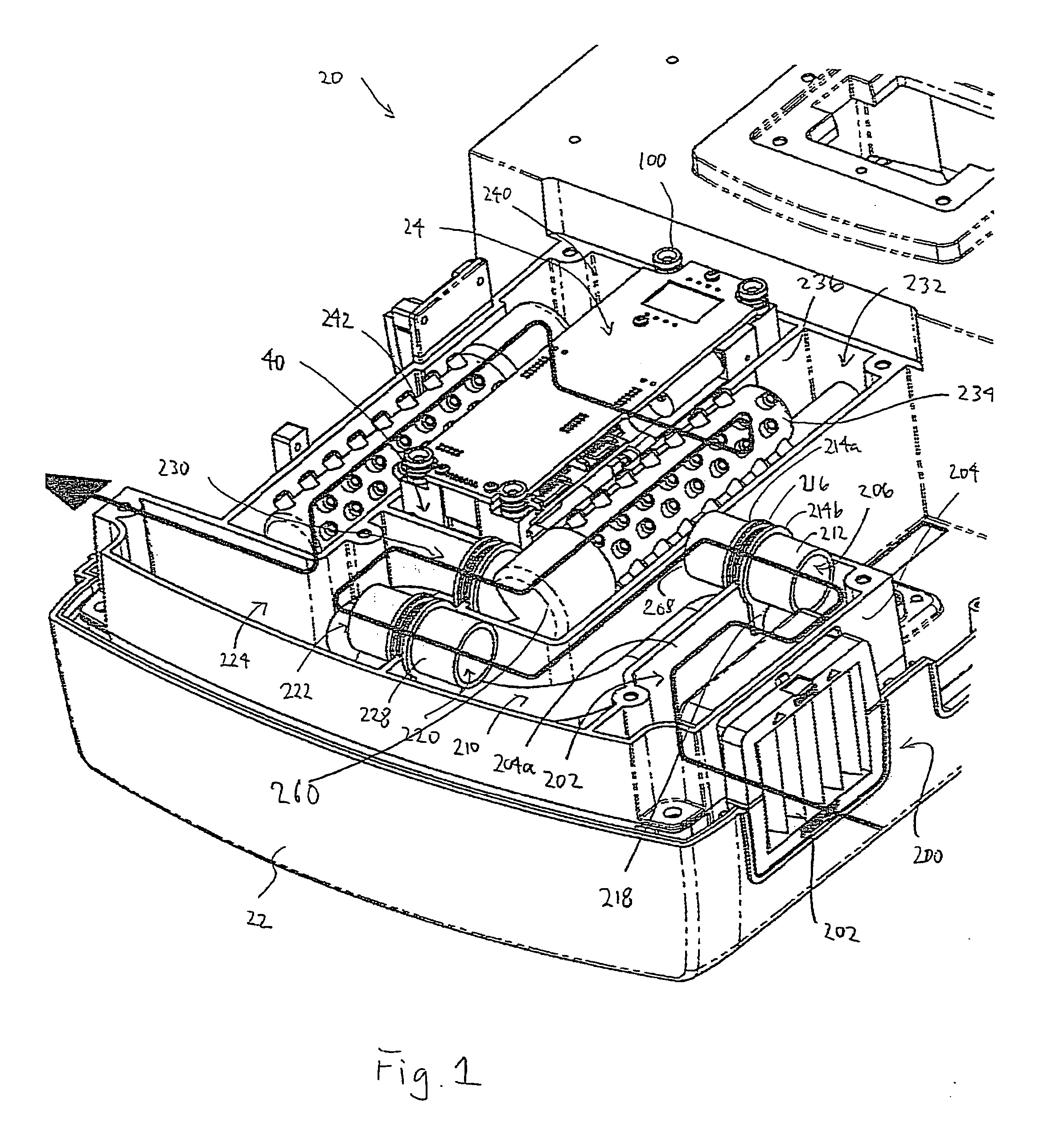

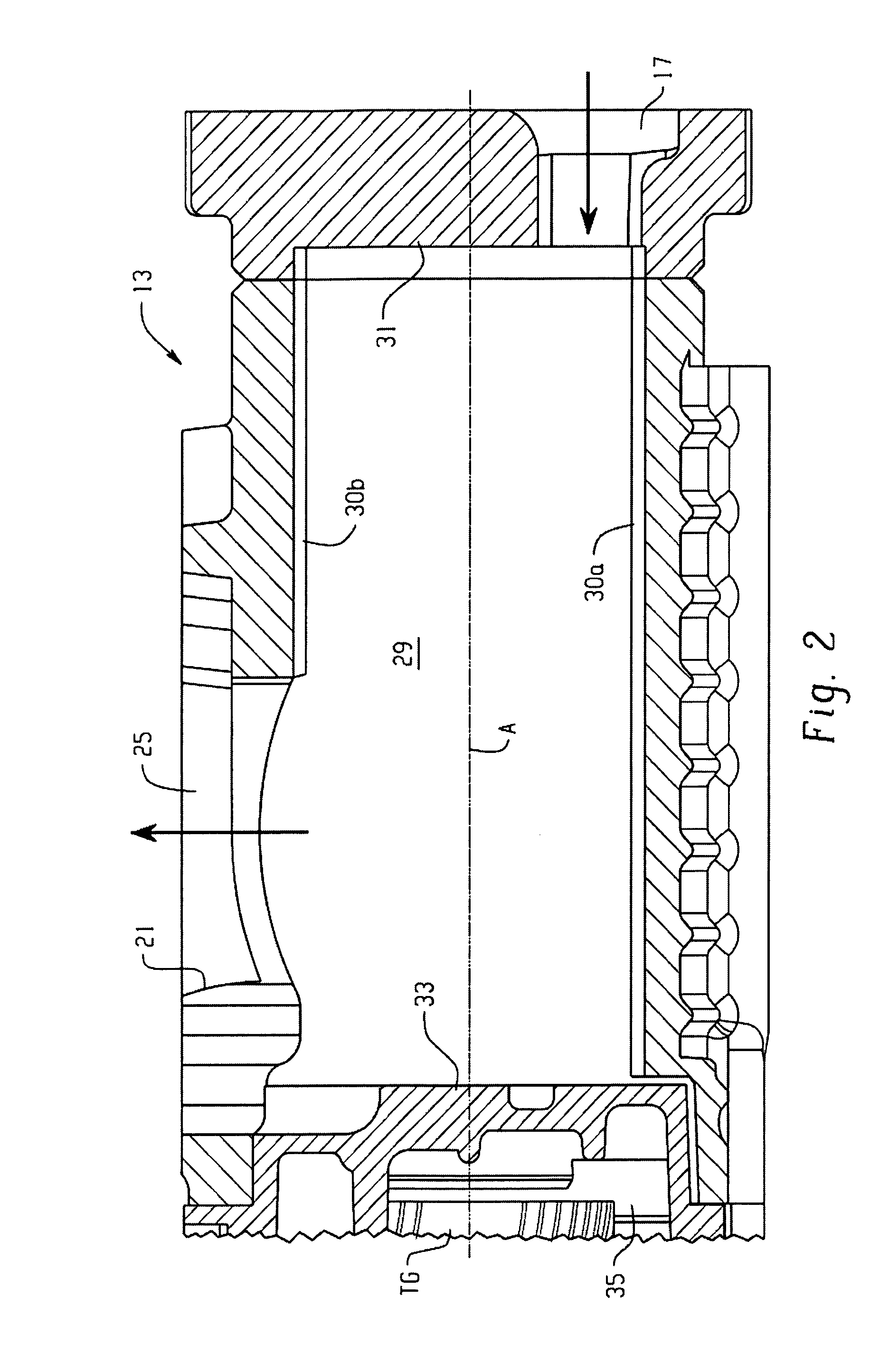

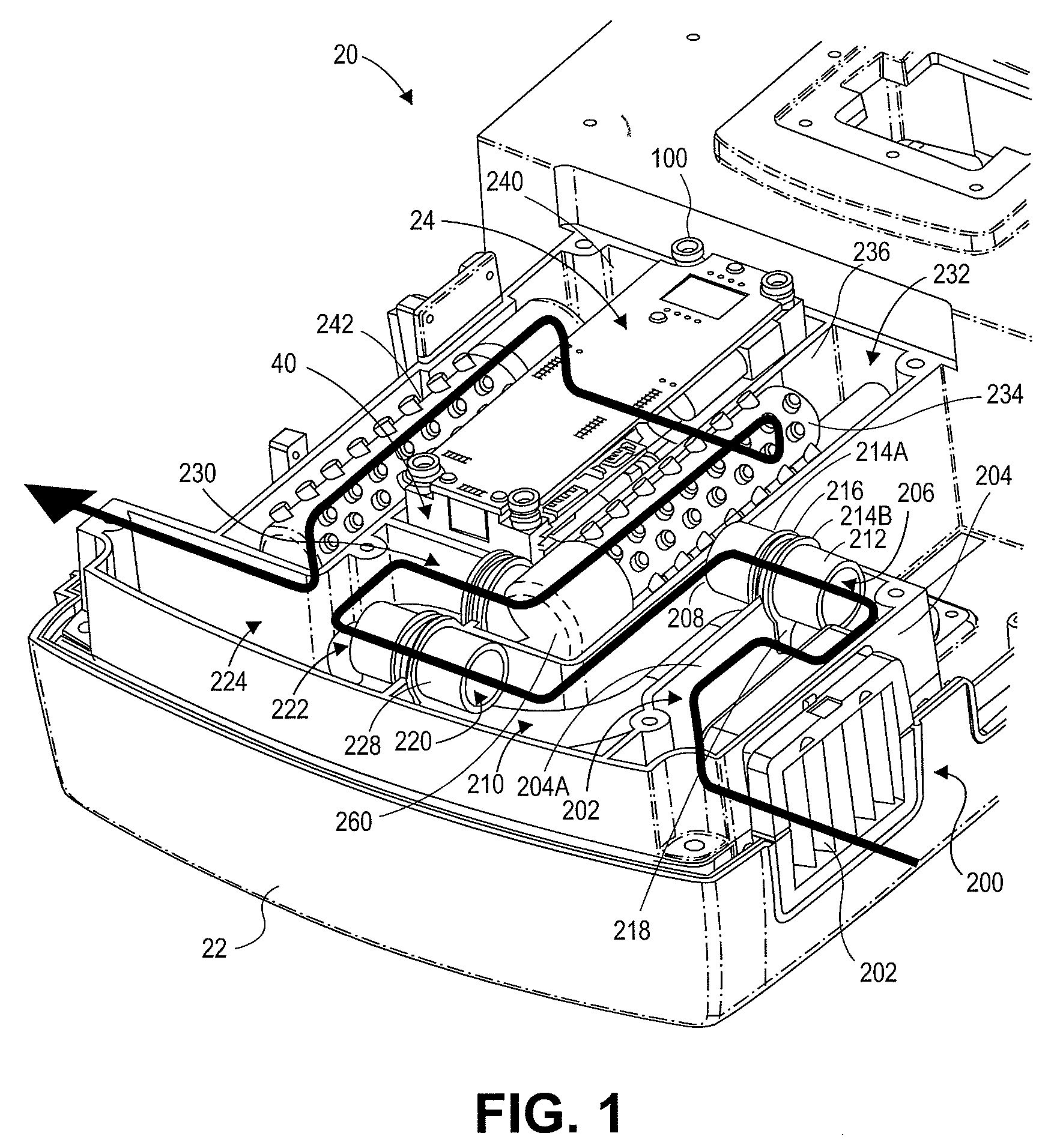

A portable ventilator uses a Roots-type blower as a compressor to reduce both the size and power consumption of the ventilator. Various functional aspects of the ventilator are delegated to multiple subassemblies having dedicated controllers and software that interact with a ventilator processor to provide user interface functions, exhalation control and flow control servos, and monitoring of patient status. The ventilator overcomes noise problems through the use of noise reducing pressure compensating orifices on the Roots blower housing and multiple baffling chambers. The ventilator is configured with a highly portable form factor, and may be used as a stand-alone device or as a docked device having a docking cradle with enhanced interface and monitoring capabilities.

Owner:VYAIRE MEDICAL 203 INC

Portable ventilator system

ActiveUS20060144396A1Reduce power consumptionSmall sizeLiquid surface applicatorsPowdered material dispensingPortable ventilatorsEngineering

A portable ventilator uses a Roots-type blower as a compressor to reduce both the size and power consumption of the ventilator. Various functional aspects of the ventilator are delegated to multiple subassemblies having dedicated controllers and software that interact with a ventilator processor to provide user interface functions, exhalation control and flow control servos, and monitoring of patient status. The ventilator overcomes noise problems through the use of a noise attenuating system comprising noise reducing pressure compensating orifices on the Roots blower housing and multiple noise reducing chambers. The ventilator is configured with a highly portable form factor, and may be used as a stand-alone device or as a docked device having a docking cradle with enhanced interface and monitoring capabilities.

Owner:VYAIRE MEDICAL 203 INC

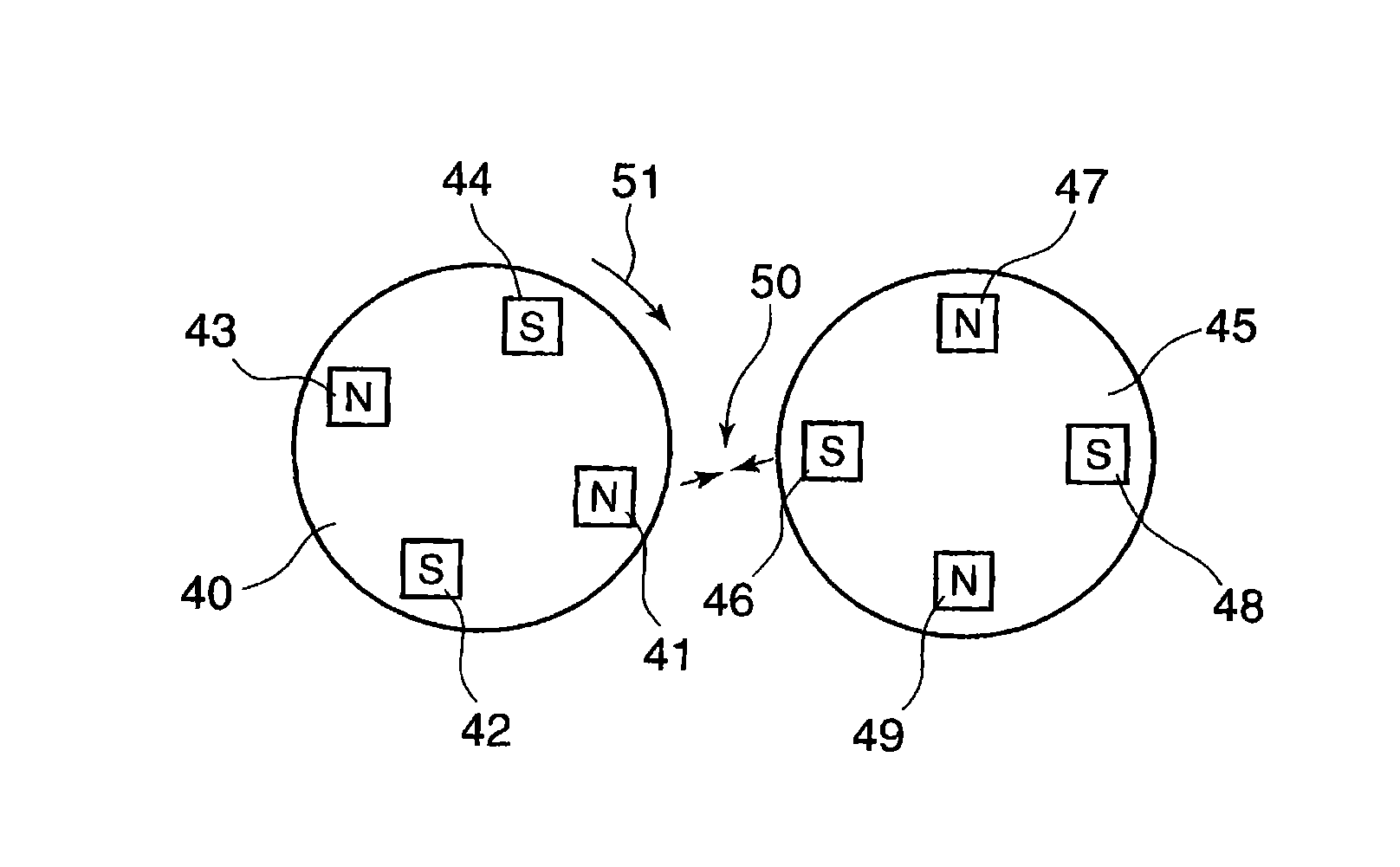

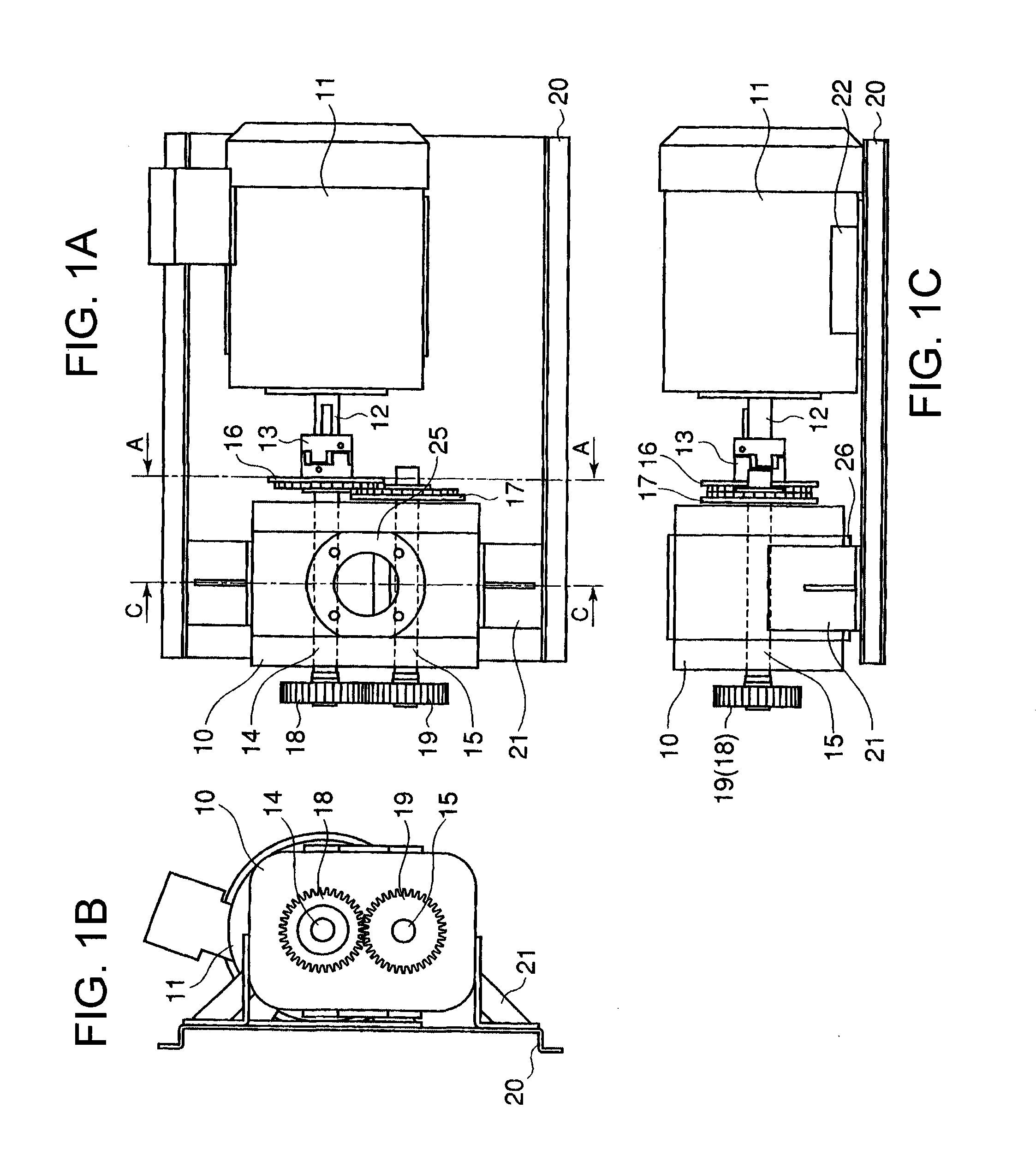

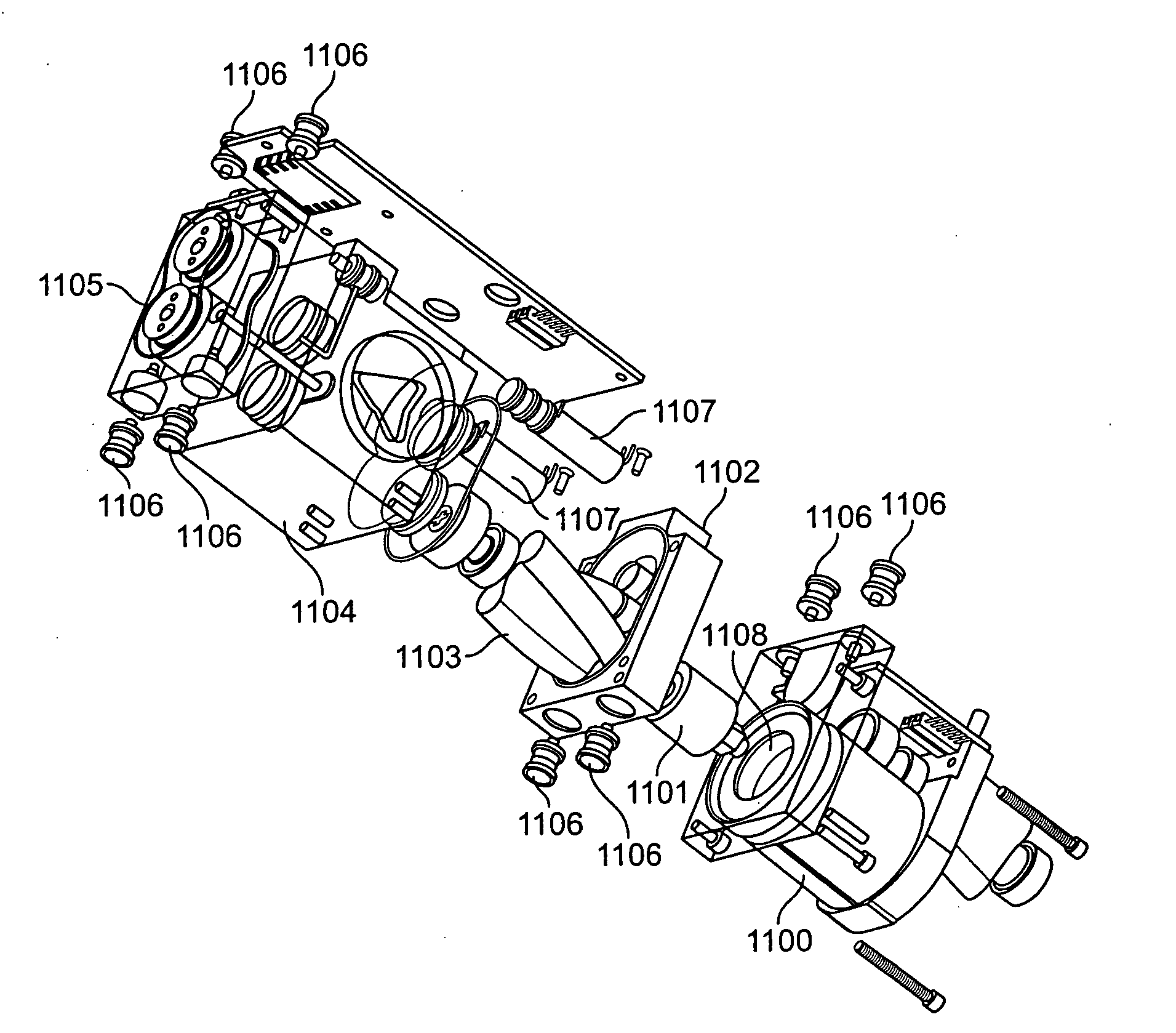

Drive transmission mechanism between two or more rotary shafts and oil-free fluid machine equipped with the mechanism

InactiveUS20080181804A1Reduced service lifeEliminate pollutionDynamo-electric brakes/clutchesEngine of counter-engagement typePlastic materialsOil free

A drive transmission mechanism for transmitting torque between two or more rotary shafts in synchronization with one another without need for lubrication thereby eliminating occurrence of oil contamination, and an oil-free fluid machine equipped with the mechanism, are provided. A magnetic drive disk 16 and a synchronization gear 18 are attached to a rotary shaft 14 connected to a drive motor 11, a magnetic drive disk 17 and a synchronization gear 19 is attached to a rotary shaft 15, torque transmission from the rotary shaft 14 to the rotary shaft 15 is carried out in two ways, via the magnetic drive disks 16, 17 and via the synchronization gears 18, 19, and at least one of the synchronization gears is made of plastic material. With the construction, torque transmit load between the rotary shafts via the synchronization gears is decreased, and a plastic gear or gears can be adopted for synchronization gears without reducing life of the gears without need for lubrication oil.

Owner:ANEST IWATA CORP

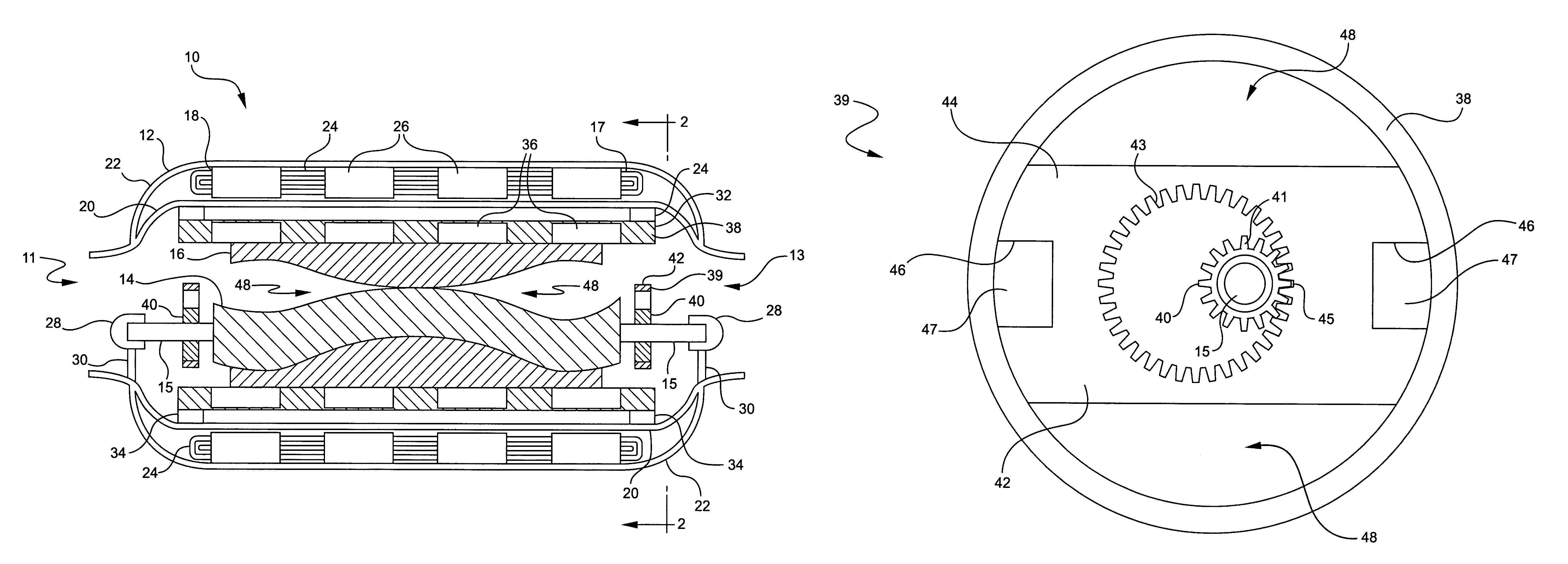

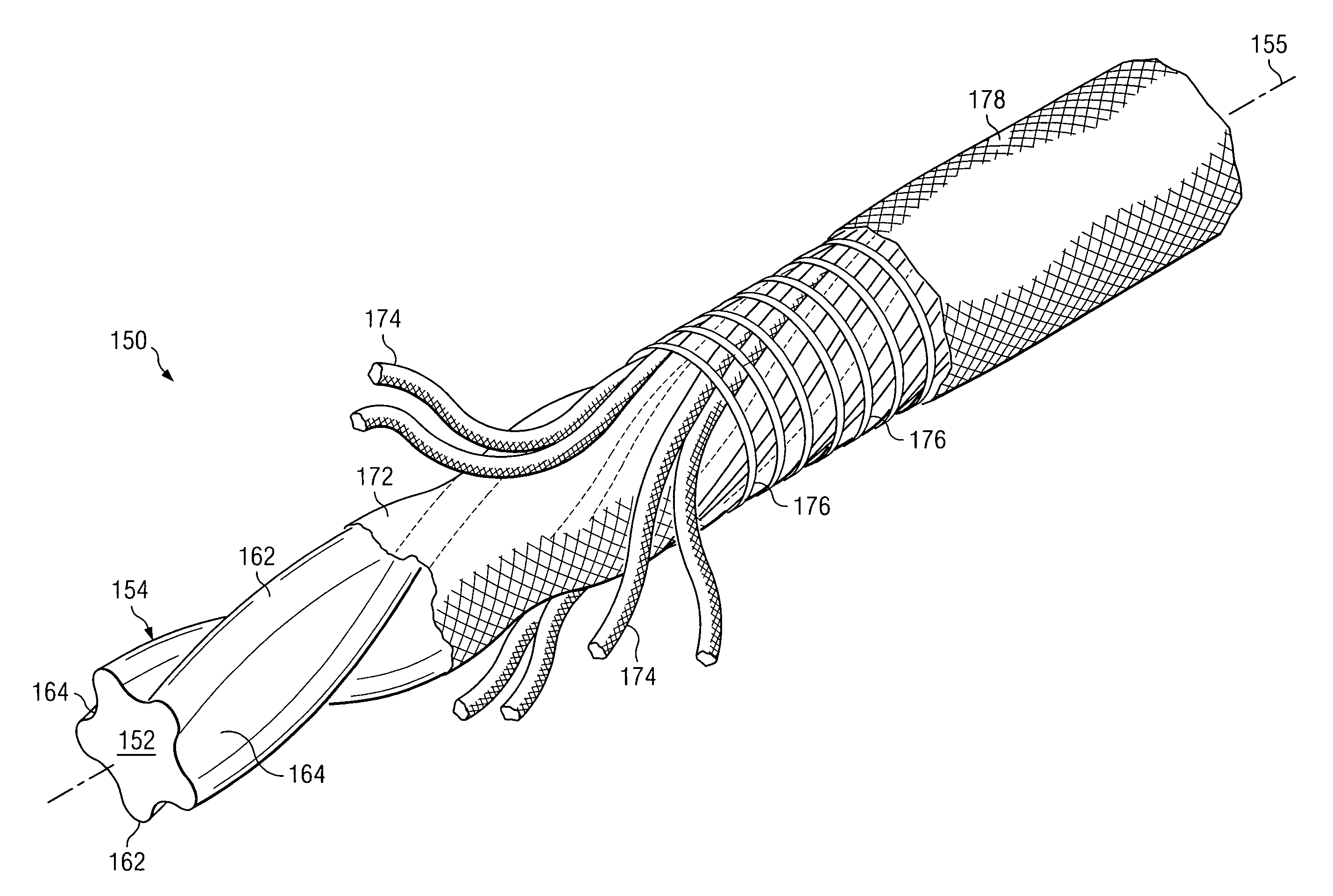

Direct drive linear flow blood pump

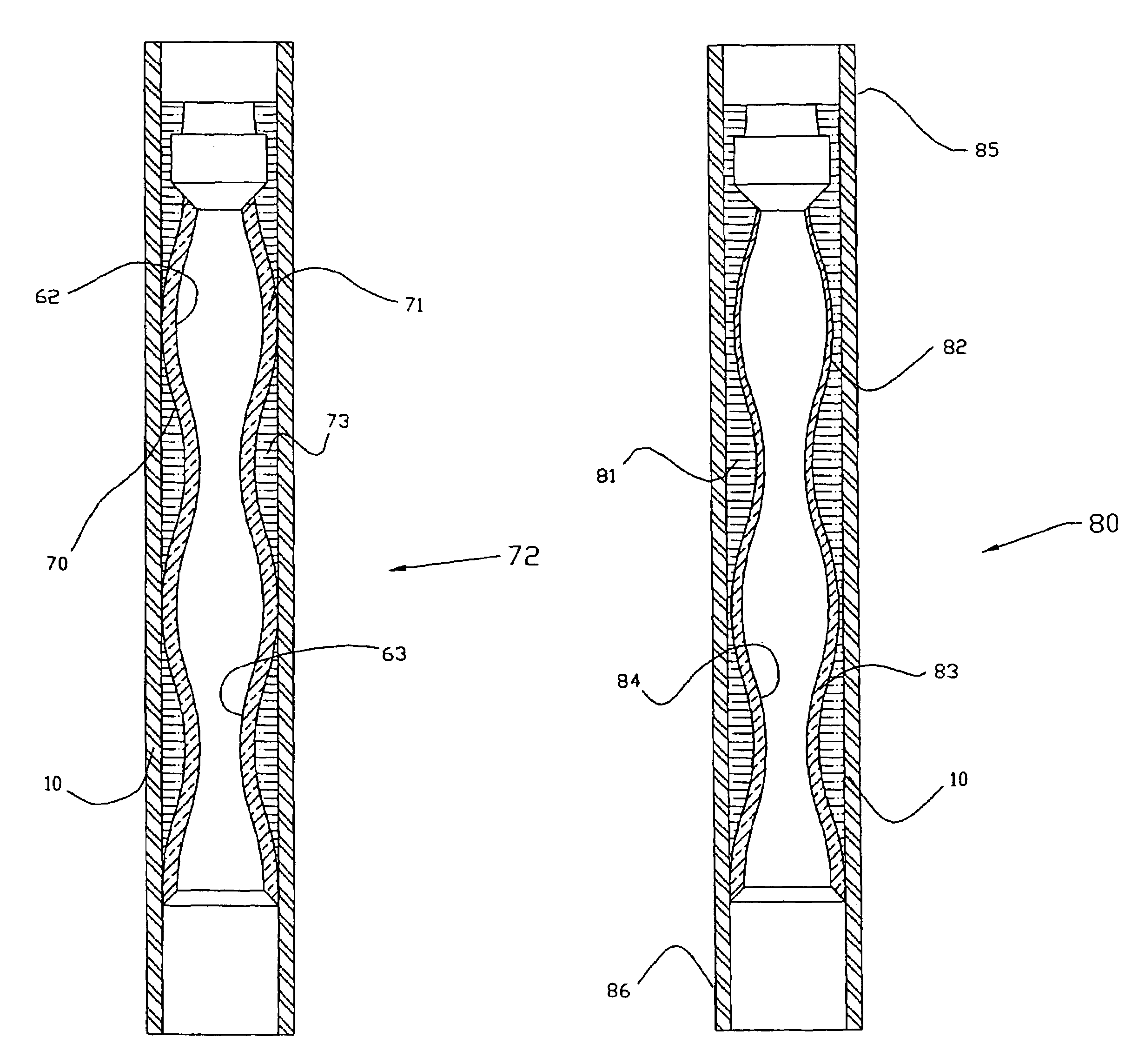

A ventricular assistive device (VAD) based on a progressive cavity pump includes a pump housing having an inlet and an outlet, a pump stator contained within the pump housing, a pump rotor rotatably disposed within the pump stator, a motor including a motor rotor contained within the pump housing and a direct drive means connected between the motor rotor and an axial shaft of the pump rotor for rotating the pump rotor. The motor rotates the motor rotor, which in turn rotates the pump rotor through the direct drive means. The rotation of the pump rotor within the pump stator forms a plurality of cavities that carry blood forward through the pump housing from the inlet to the outlet as the motor drives the direct drive means.

Owner:CHANG SHELDON

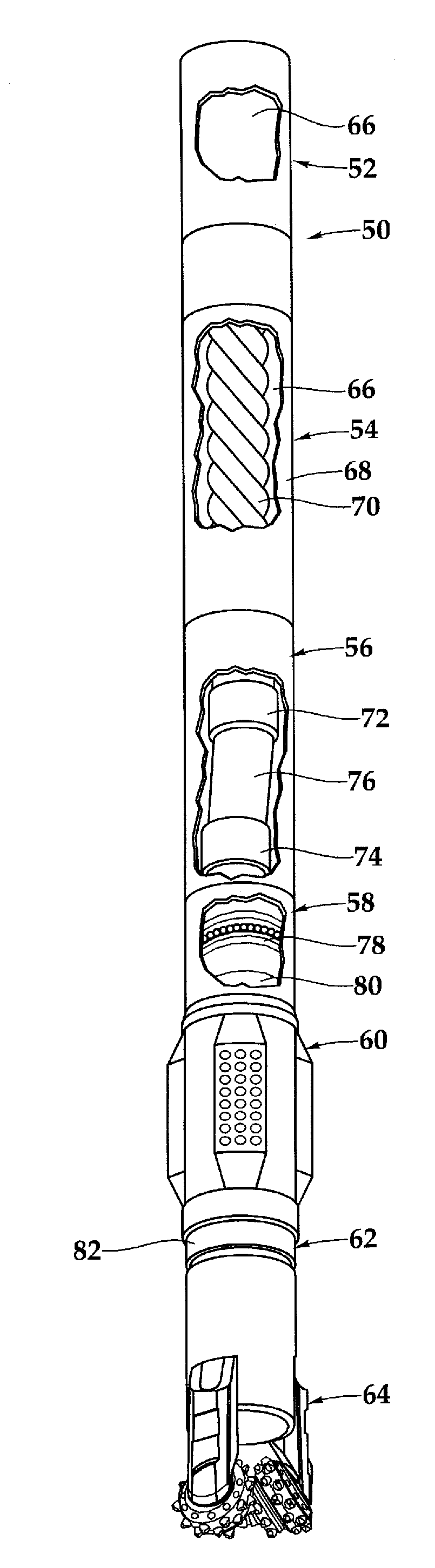

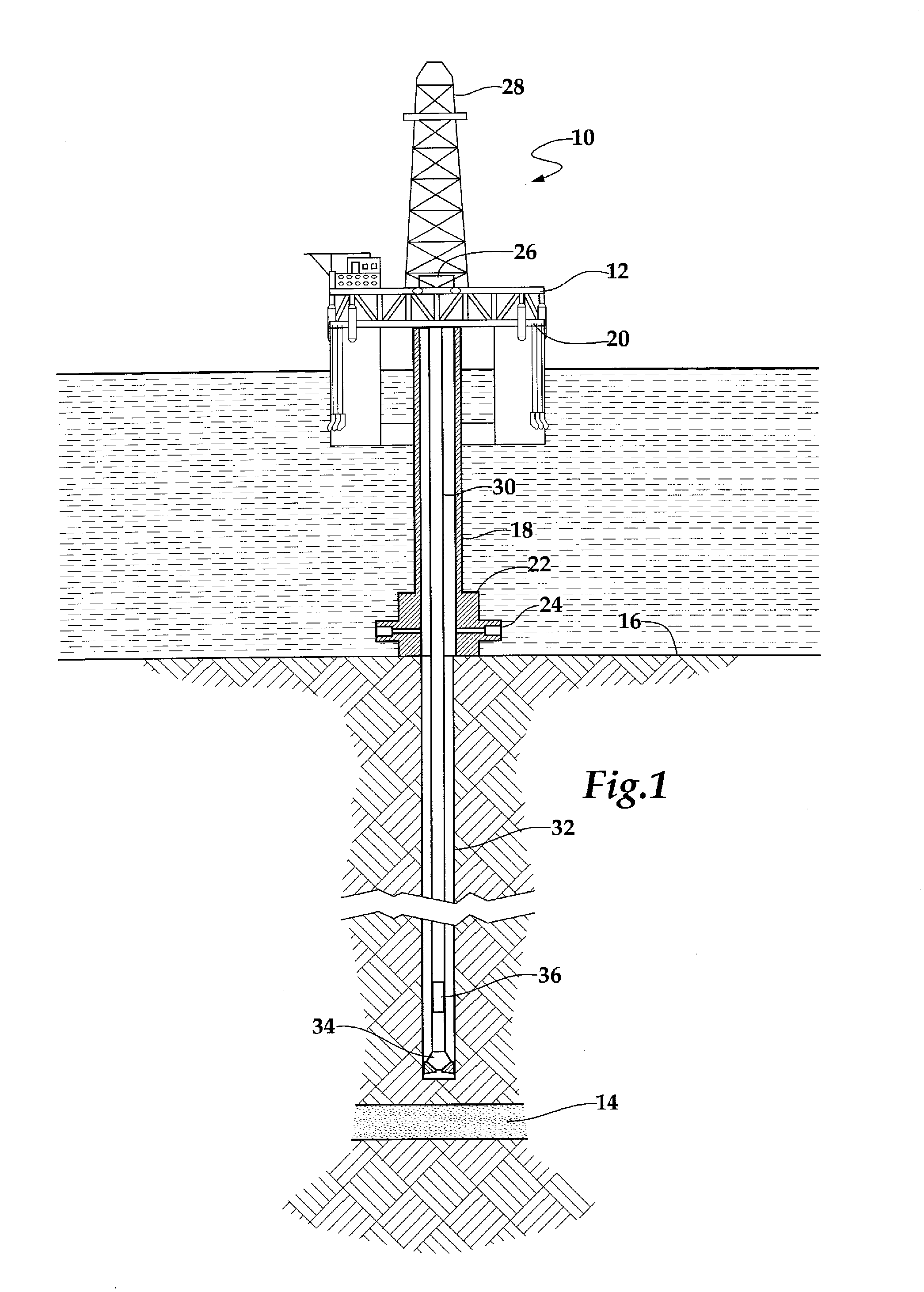

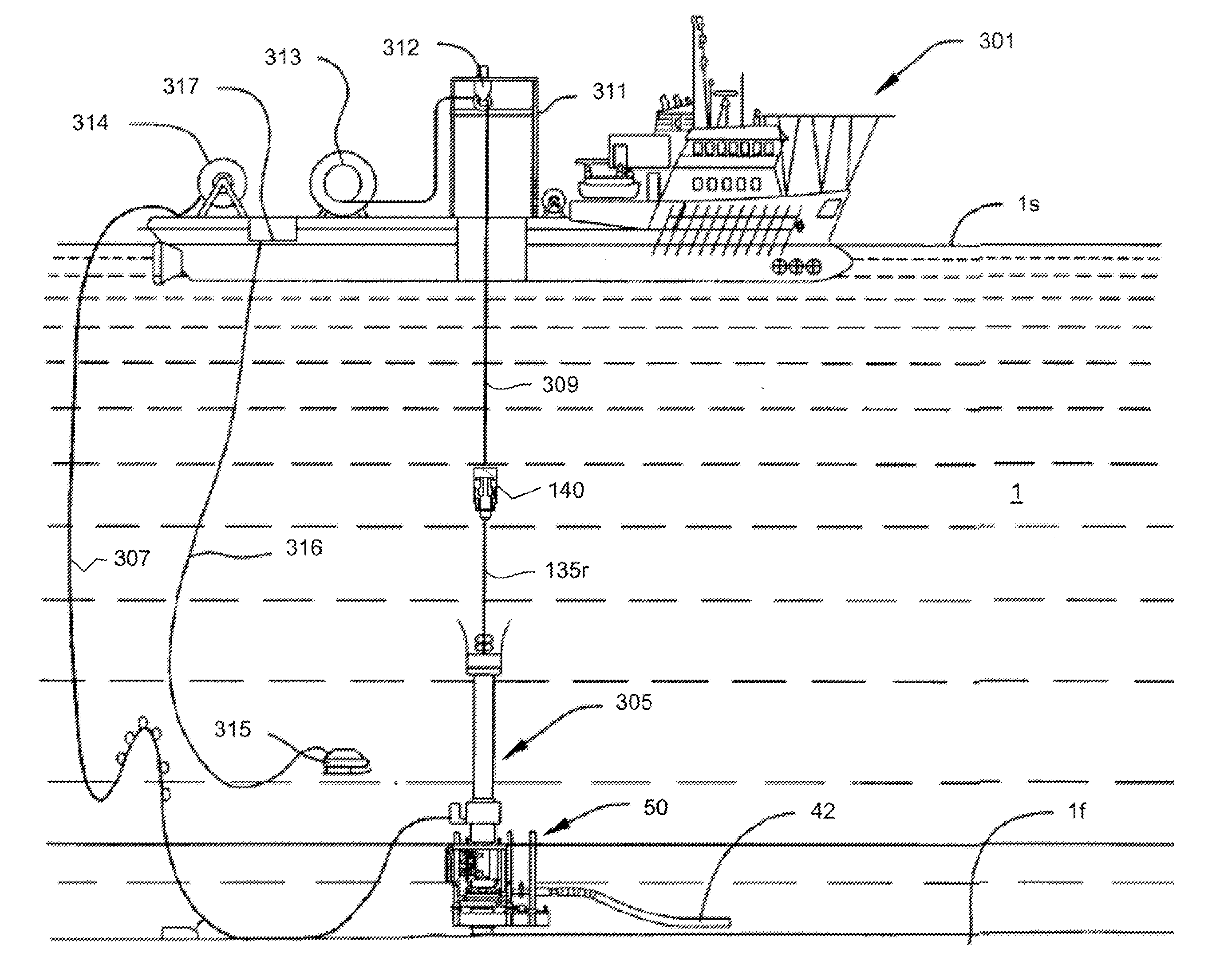

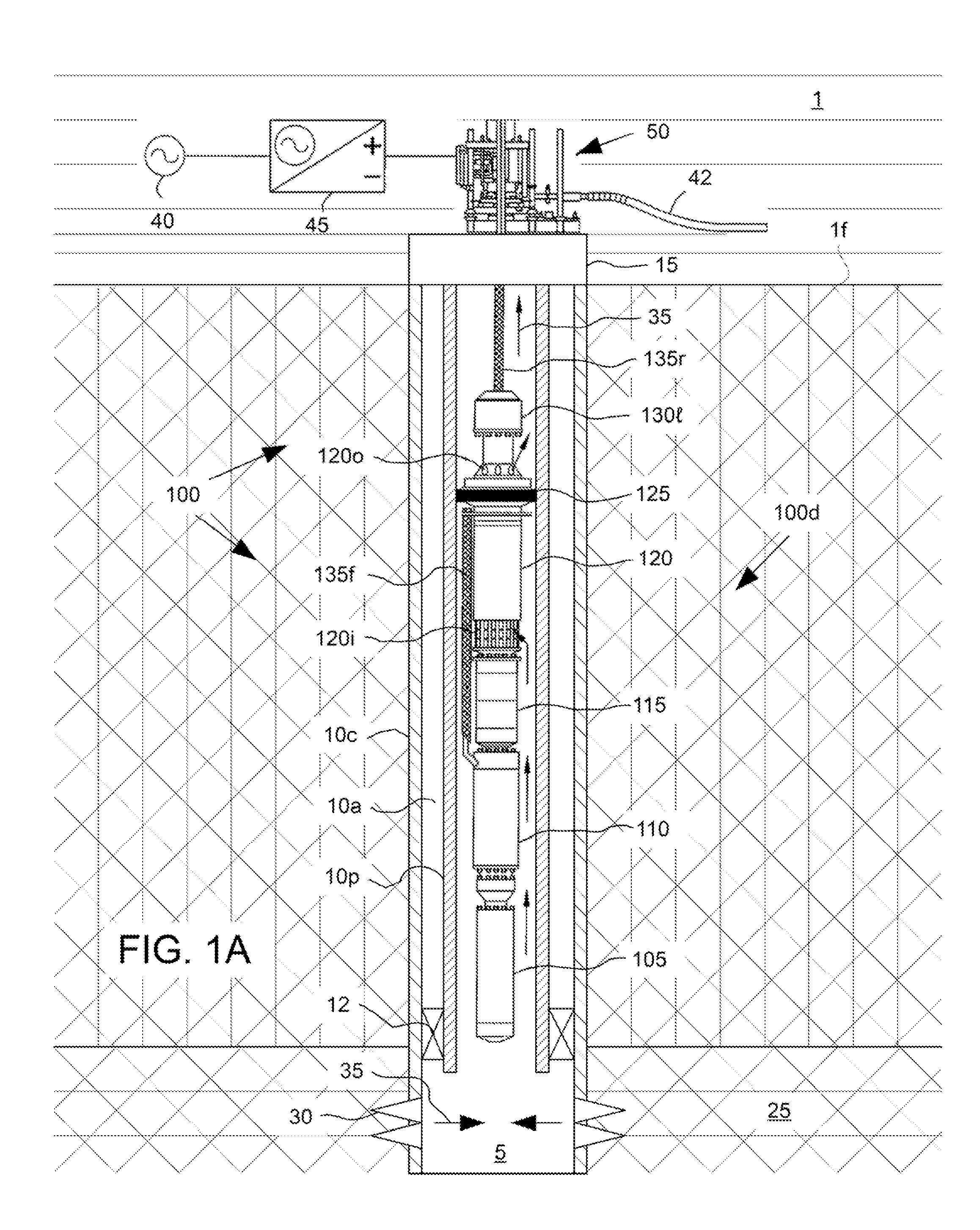

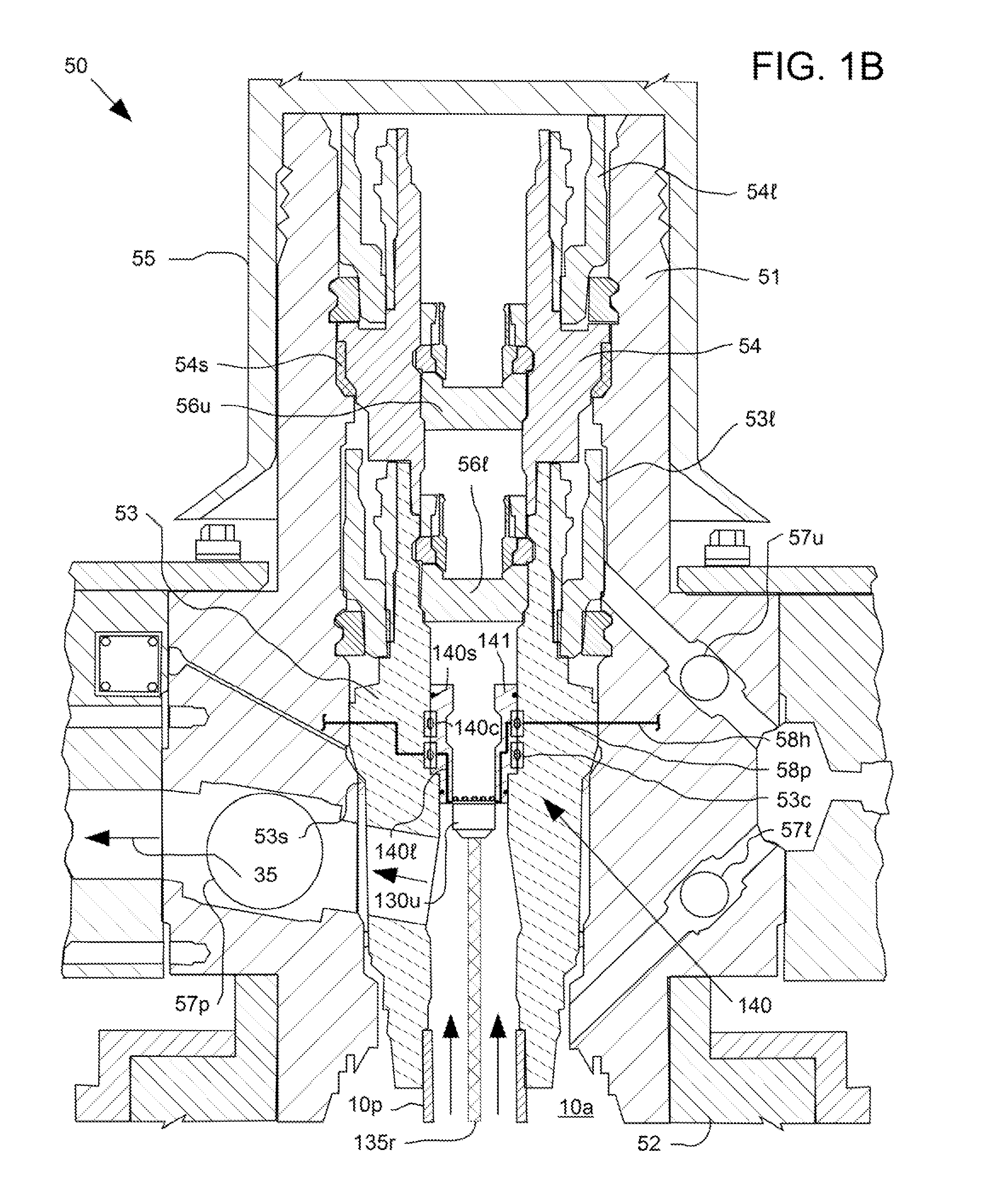

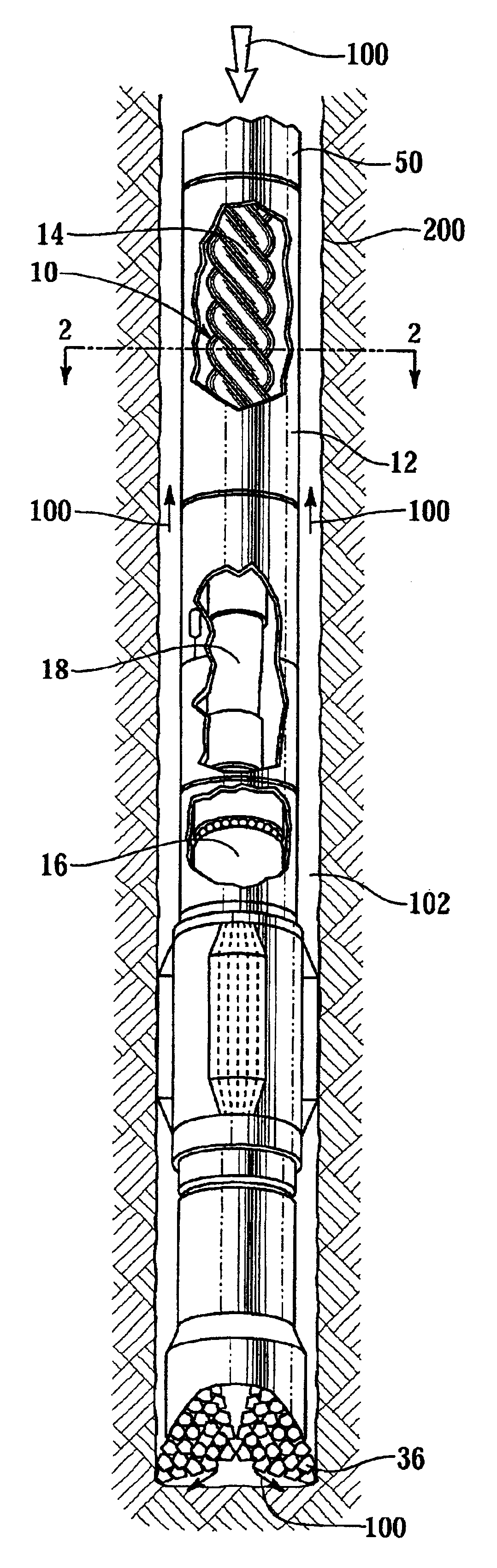

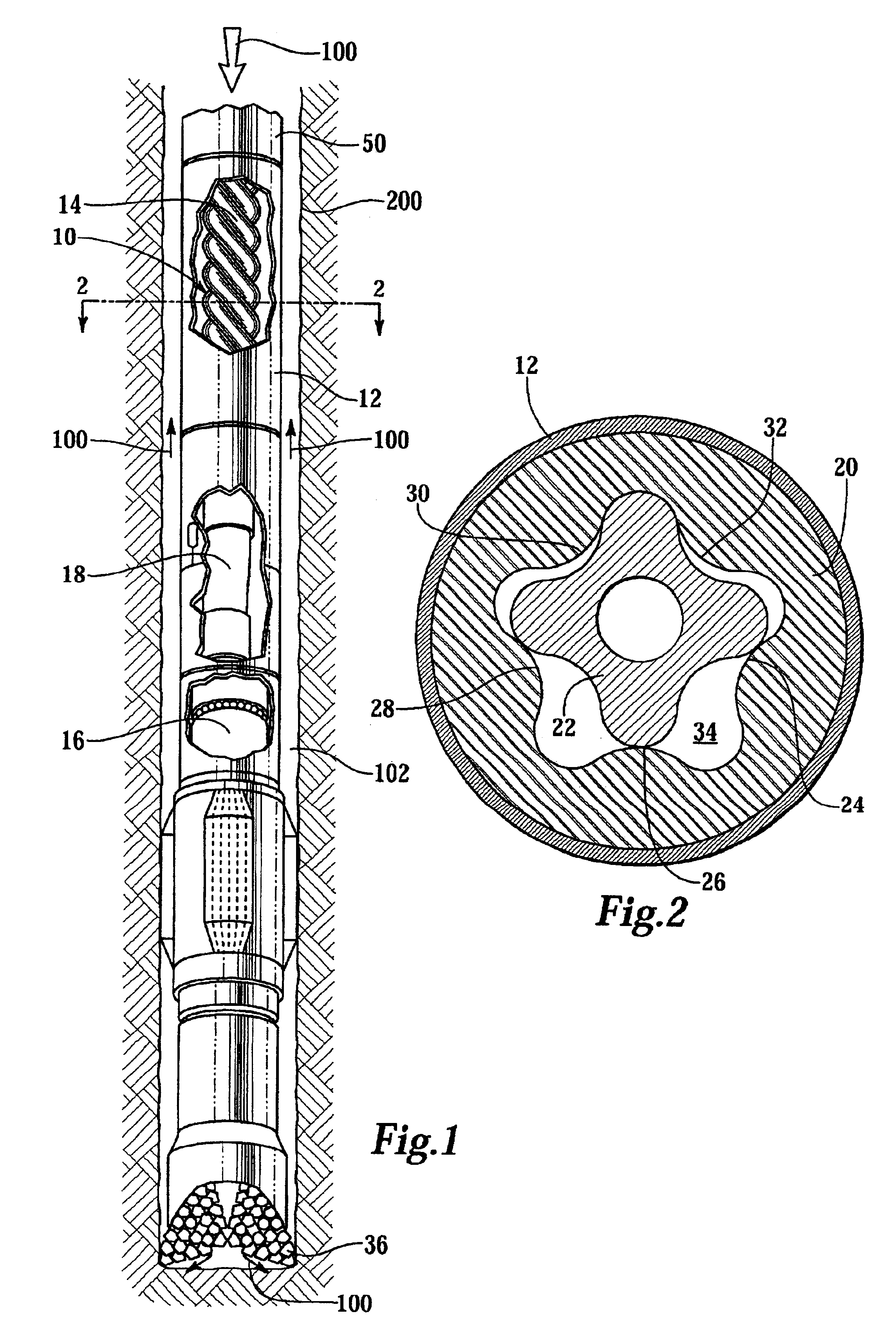

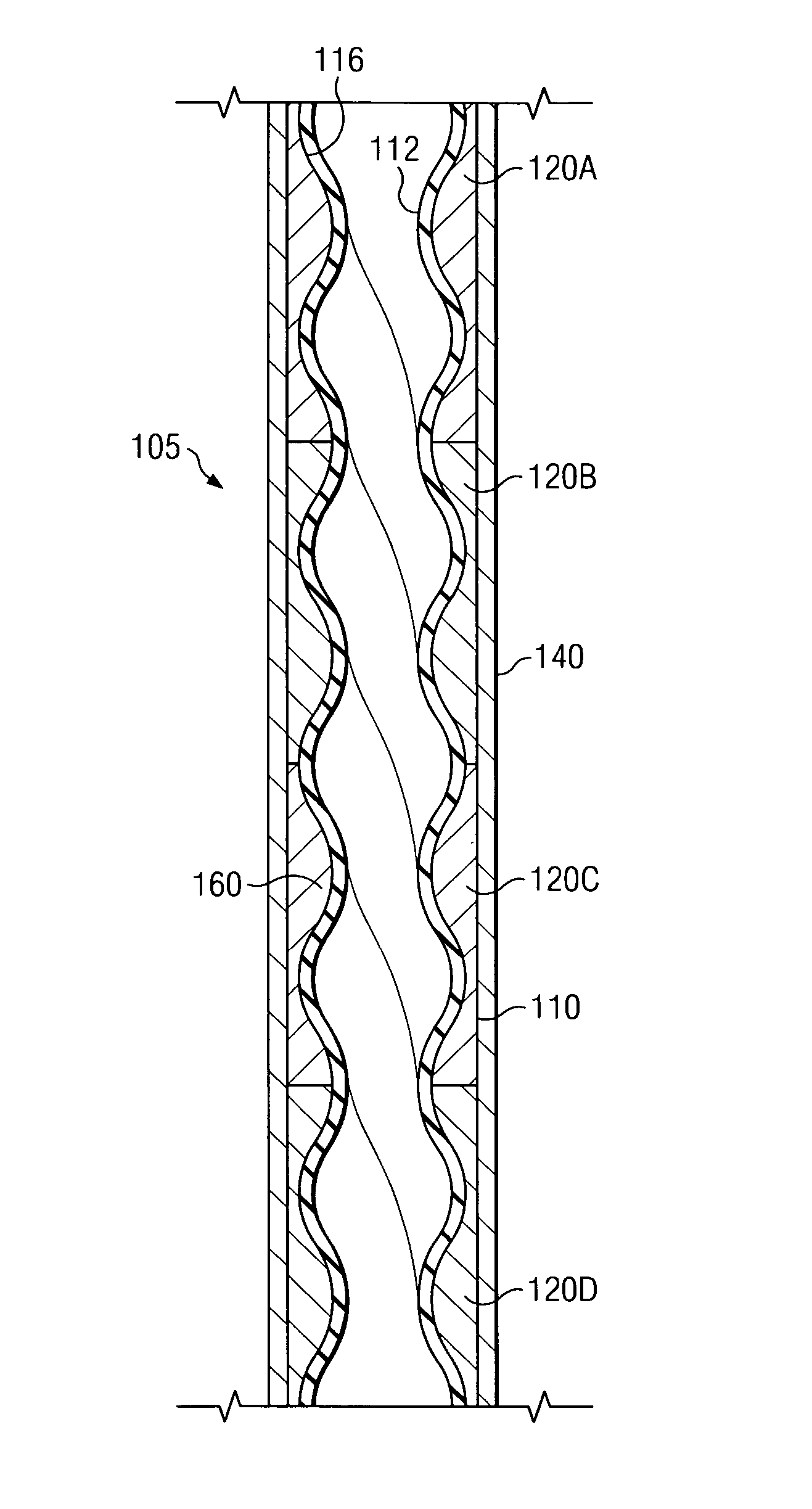

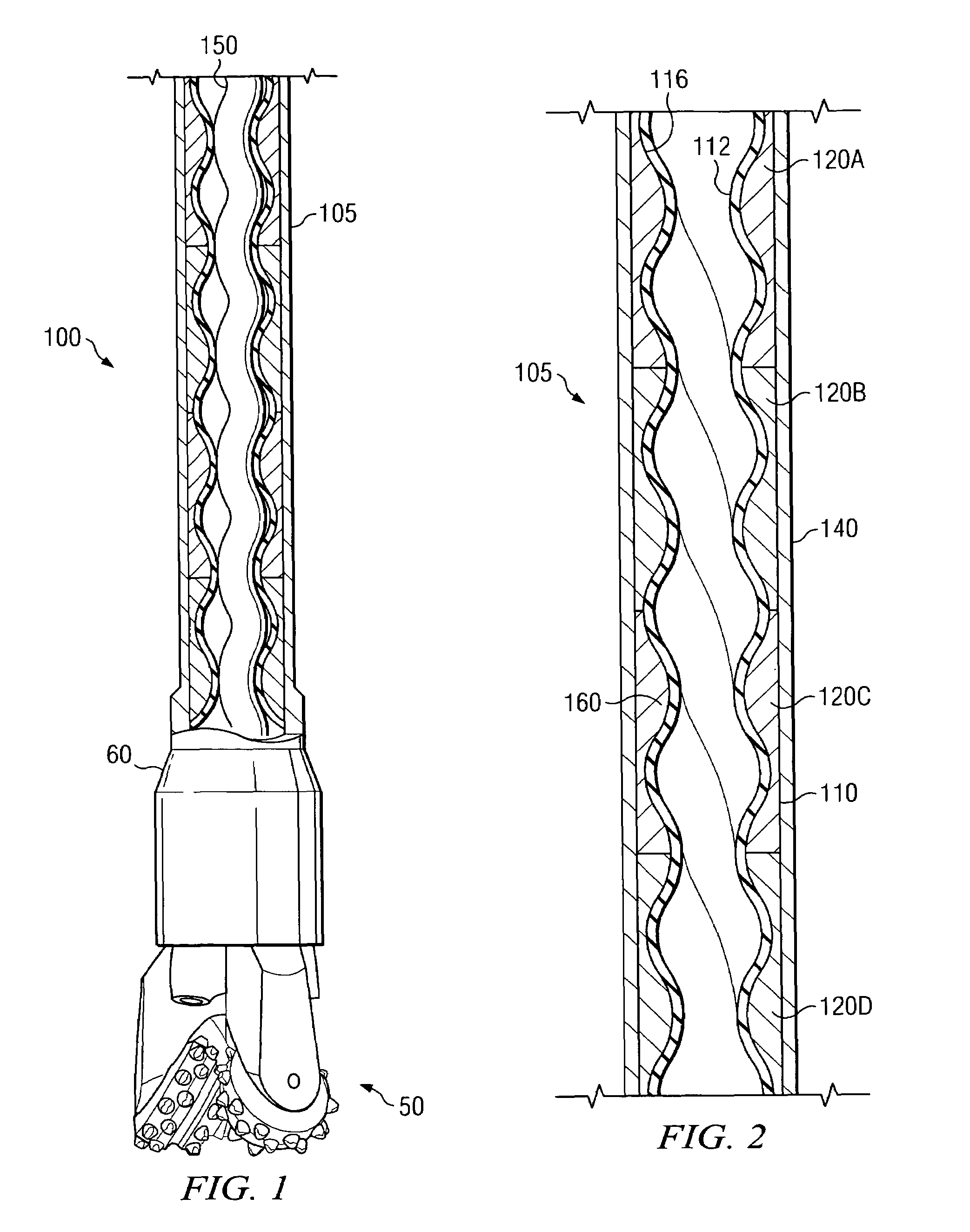

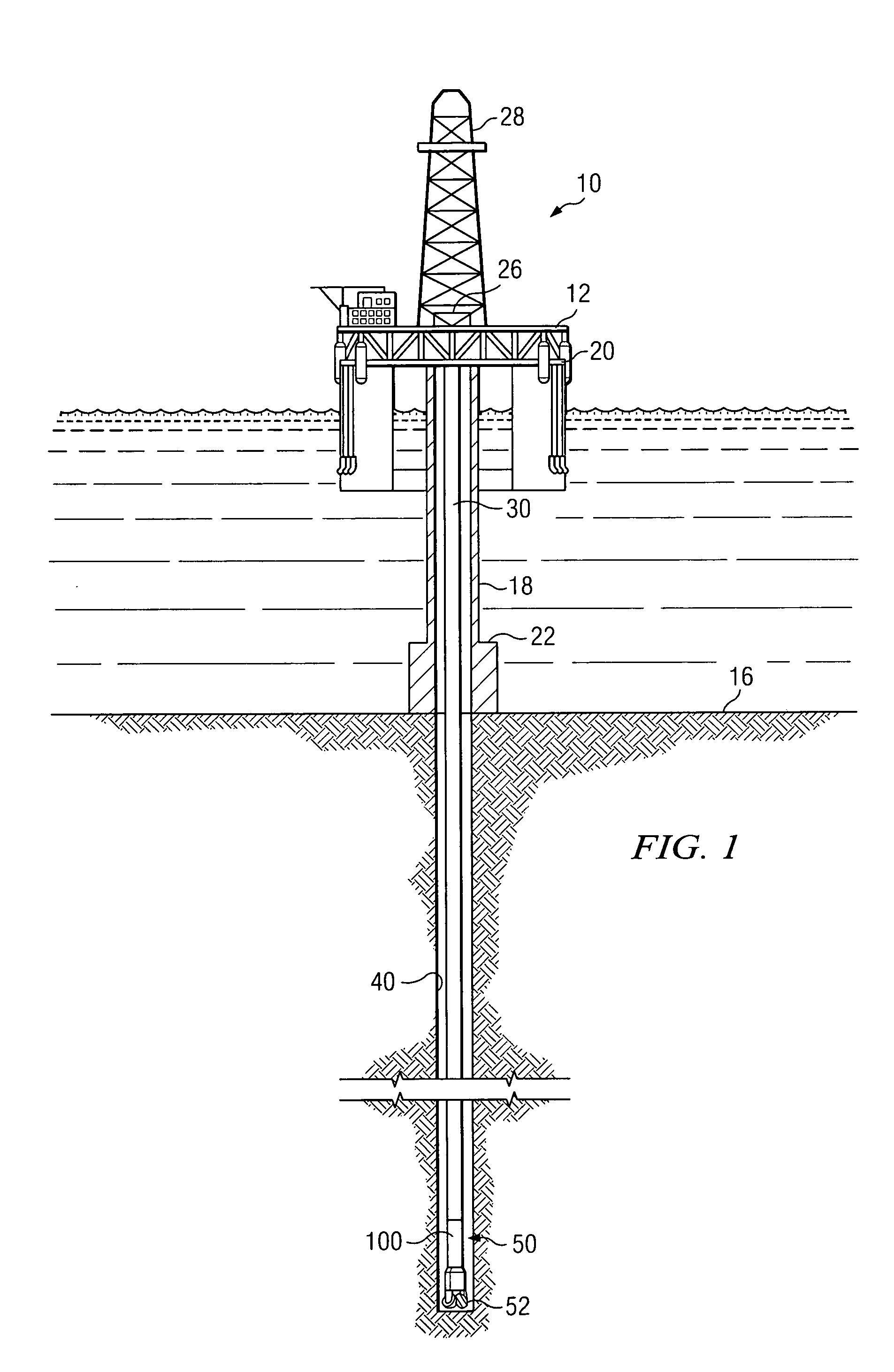

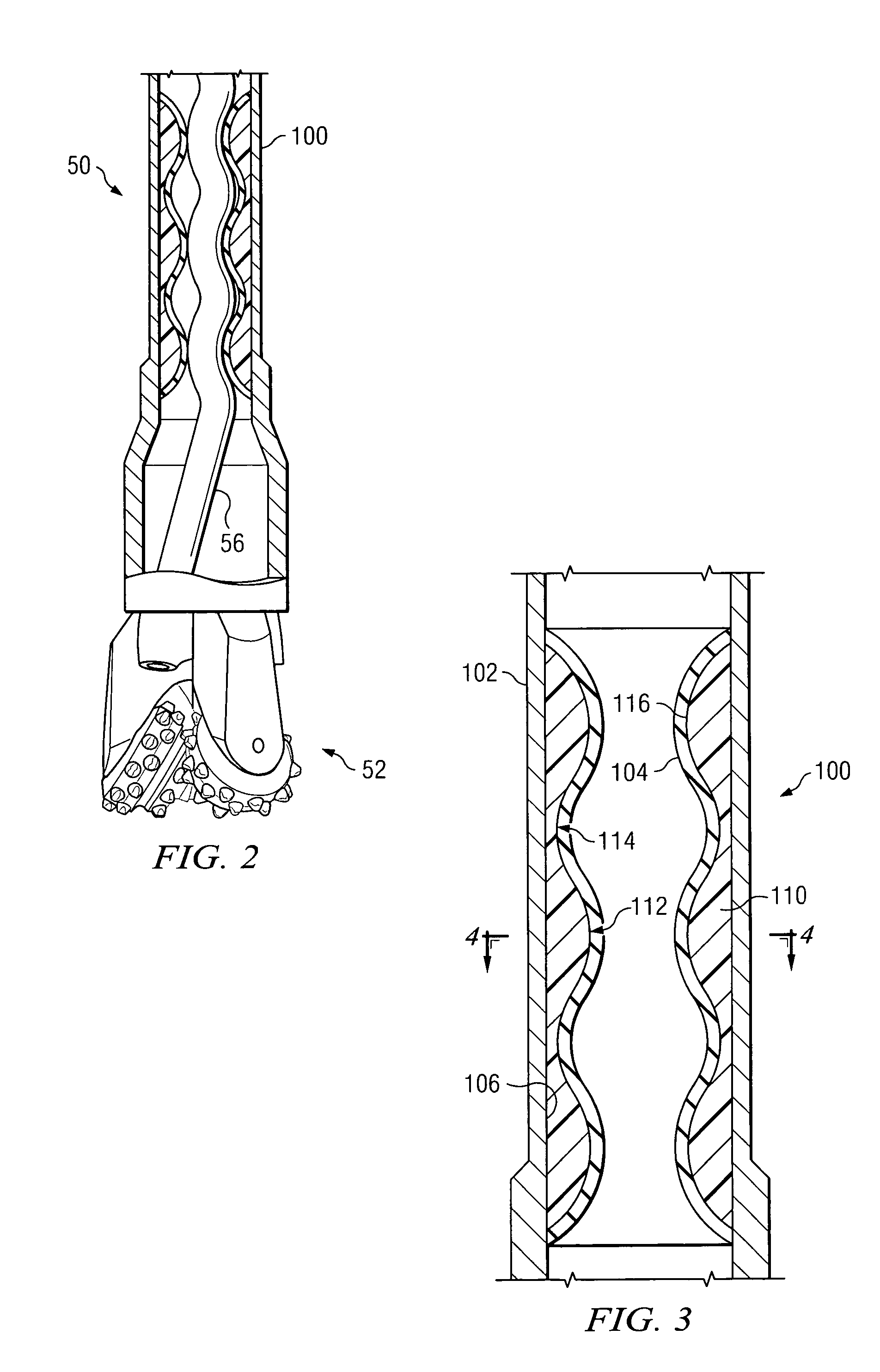

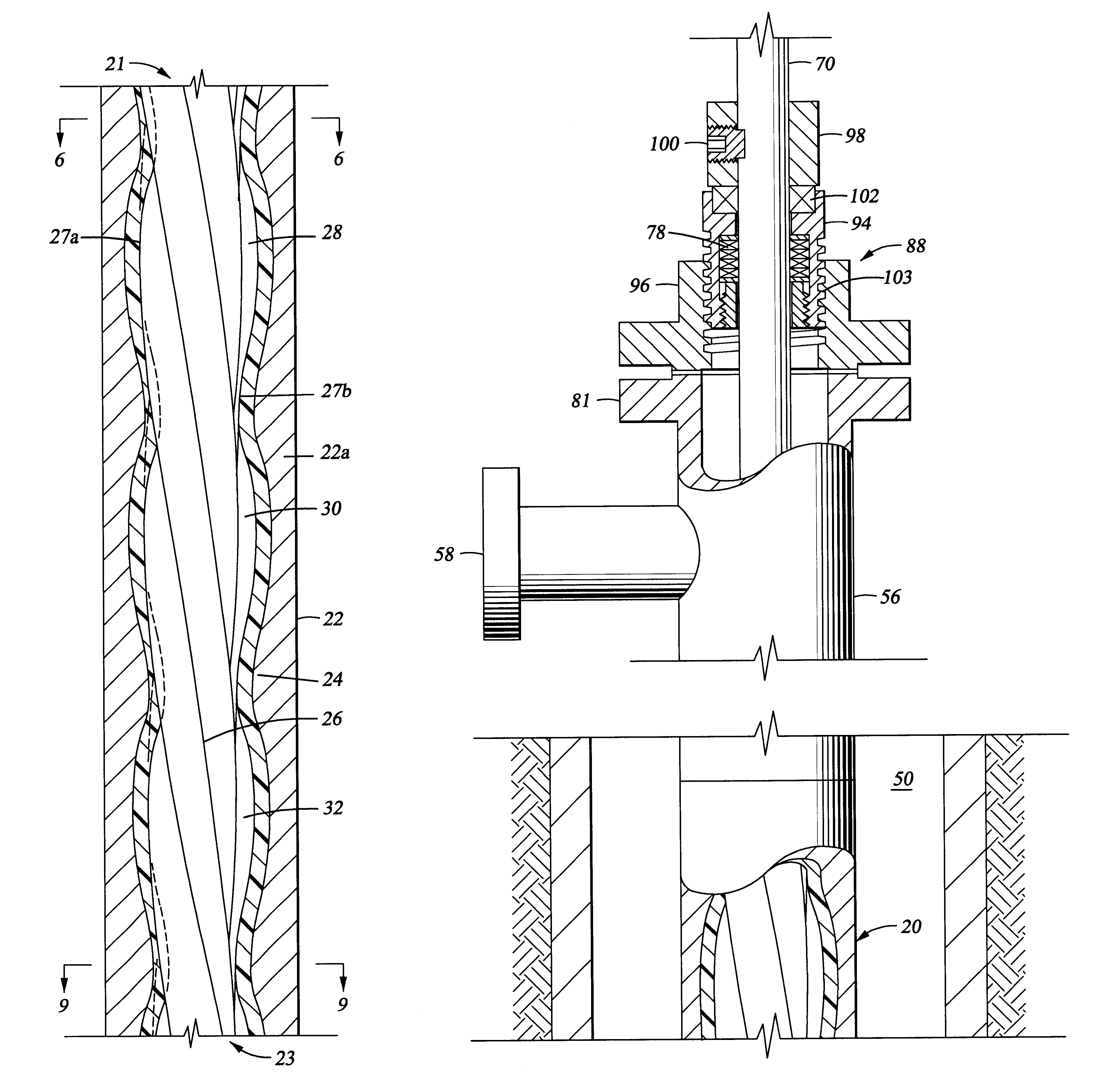

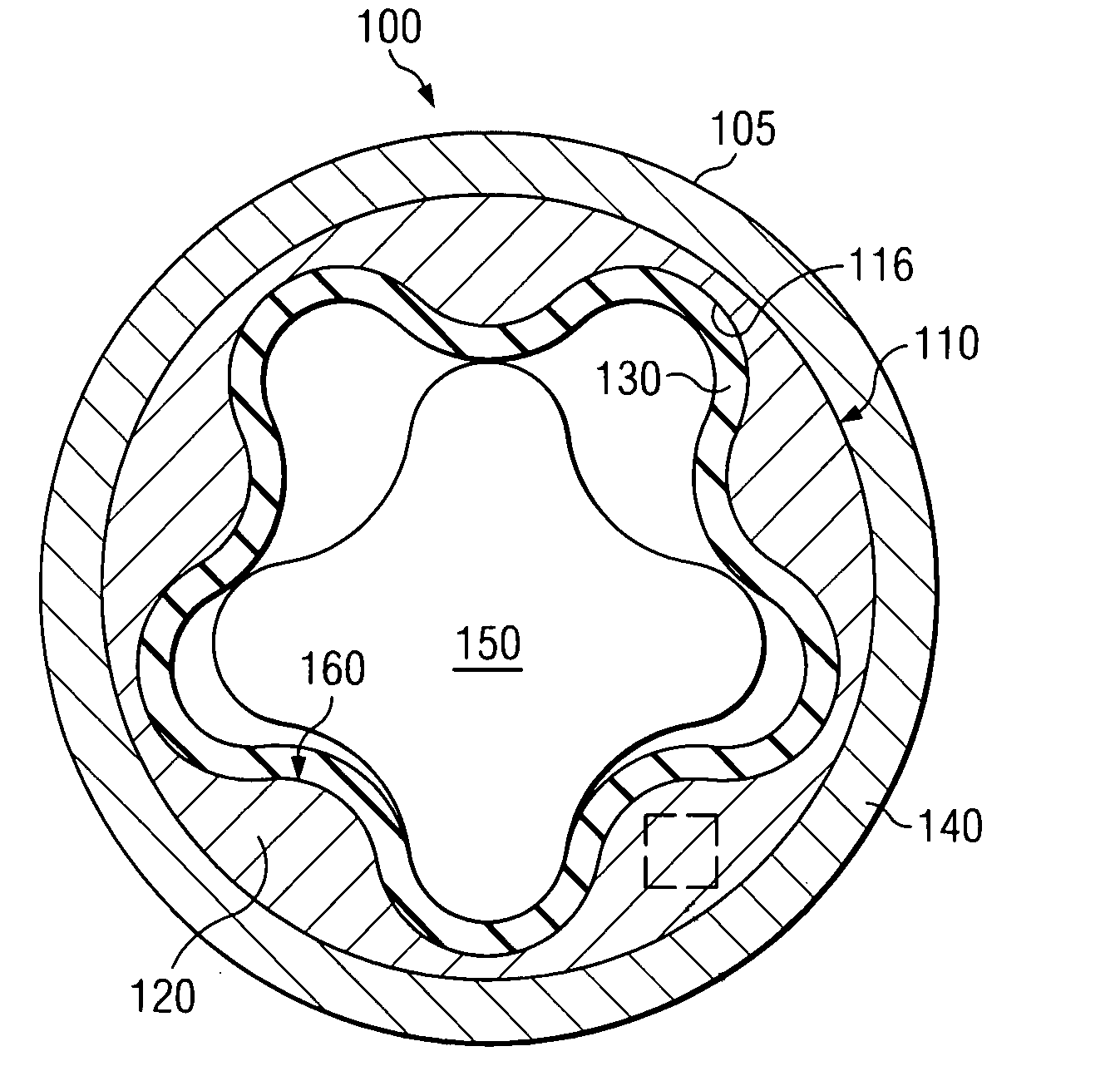

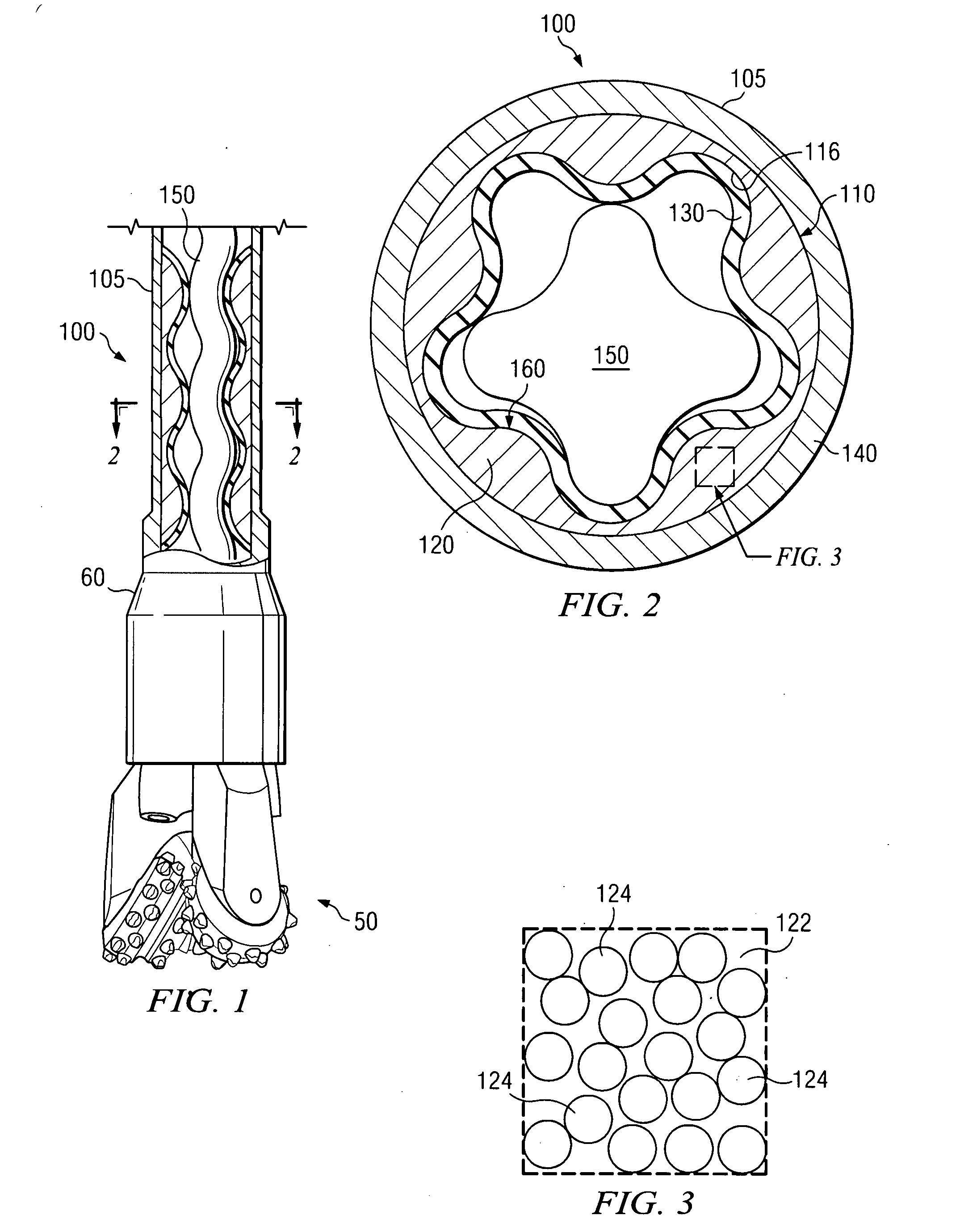

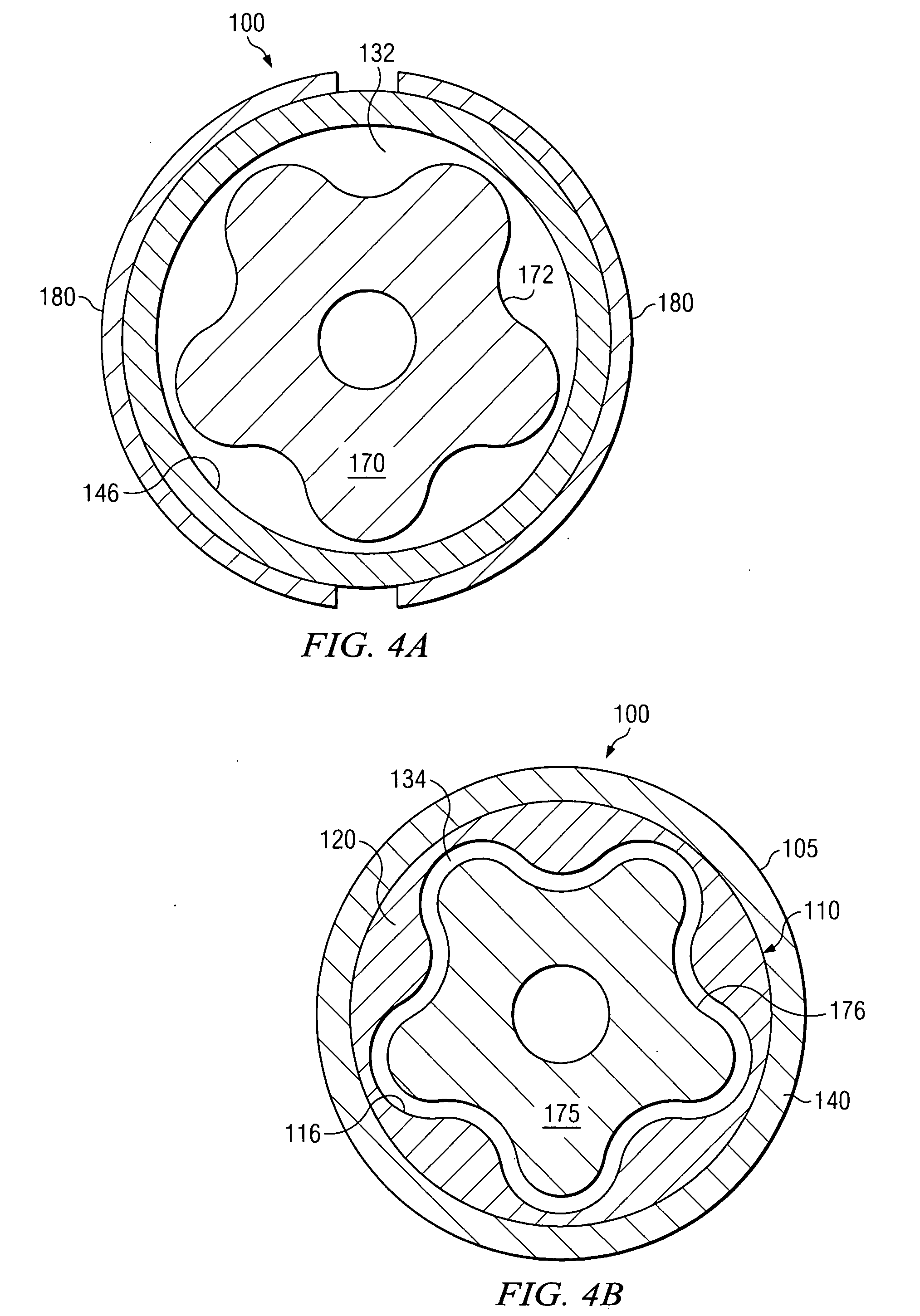

Apparatus and method for high temperature drilling operations

InactiveUS20100038142A1High mechanical loadPump componentsOscillating piston enginesEngineeringWellbore

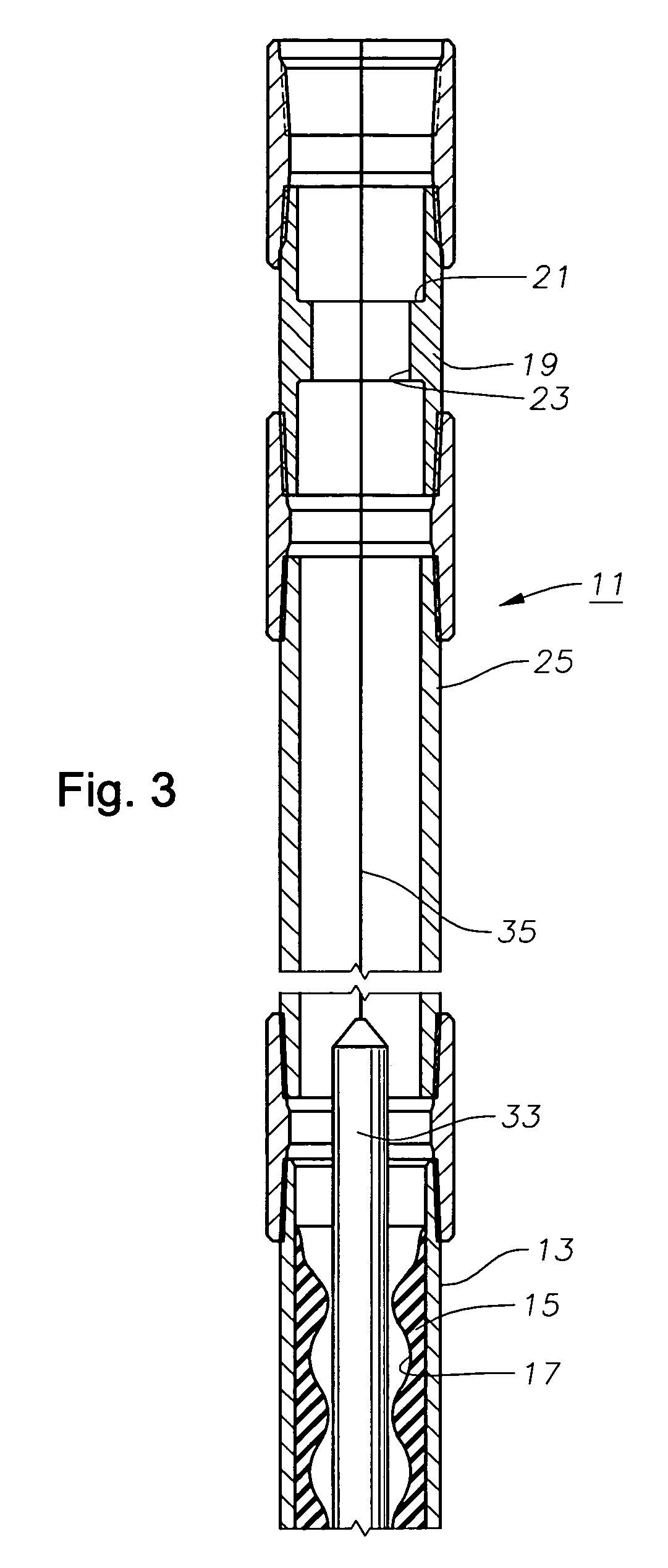

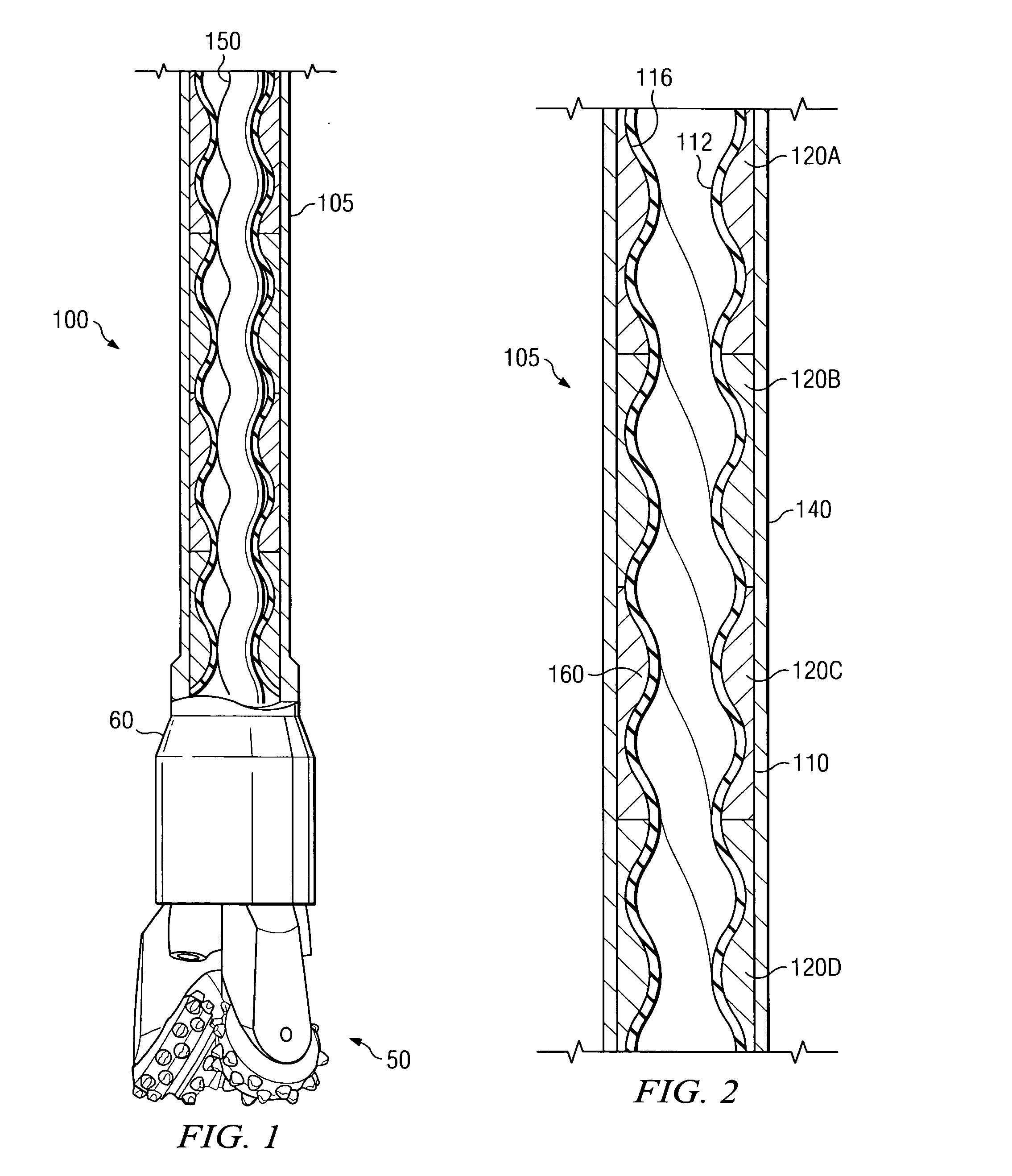

An apparatus (50) for drilling a wellbore that transverses a subterranean hydrocarbon bearing formation. The apparatus (50) includes a drill string (52) having an inner fluid passageway (66). A drill bit (64) is disposed at a distal end of the drill string (52) and is operable to rotate relative to at least a portion of the drill string (52). A fluid motor (54) is disposed within the drill string (52) and is operable to rotate the drill bit (64) in response to a circulating fluid received via the inner fluid passageway (66) of the drill string (52). The fluid motor (54) has a stator (68) with (n) lobes and a rotor (70) with (n−1) lobes. The stator (68) includes an inner surface formed from a first material and the rotor (70) includes an outer surface formed from a second material that is dissimilar to the first material.

Owner:HALLIBURTON ENERGY SERVICES INC

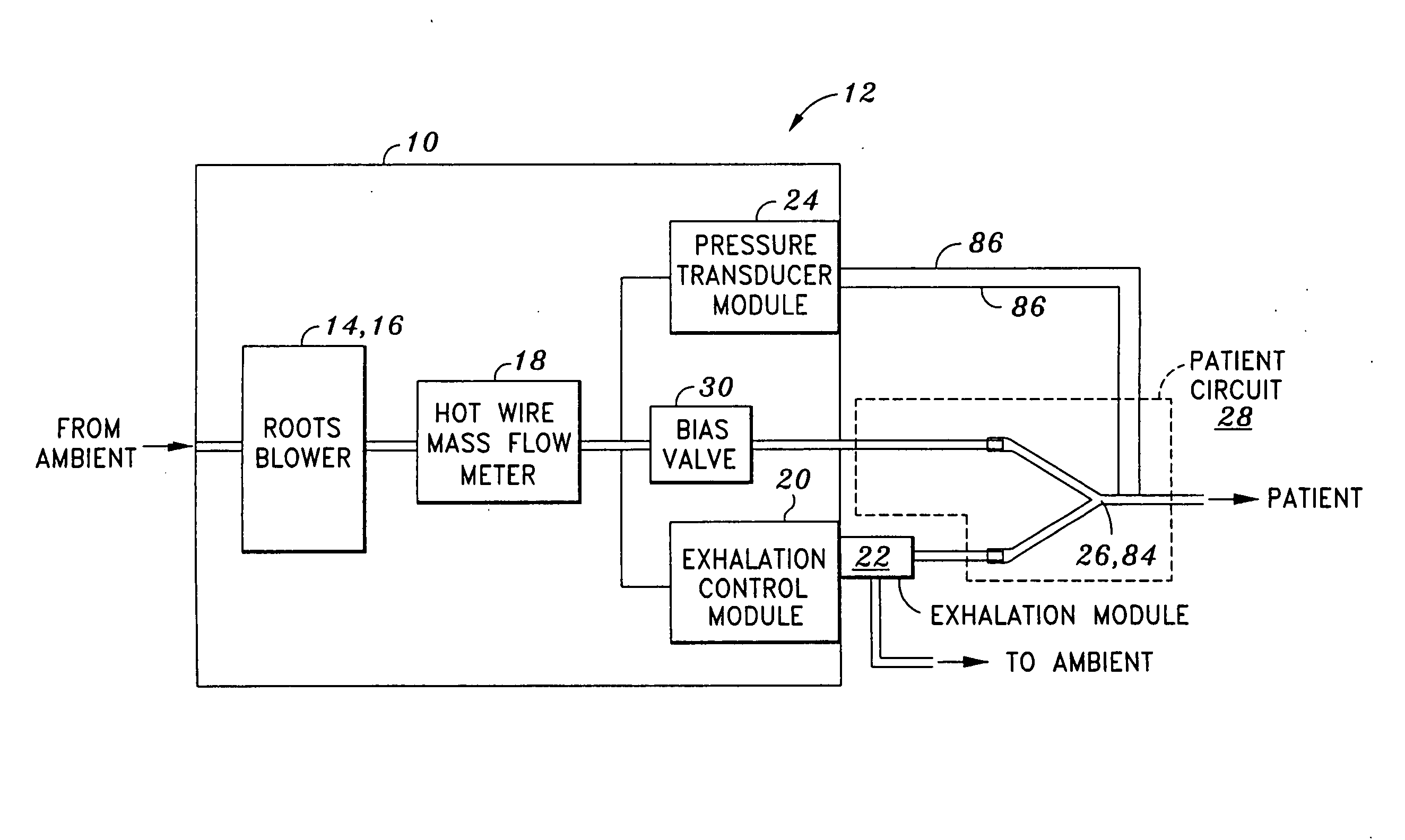

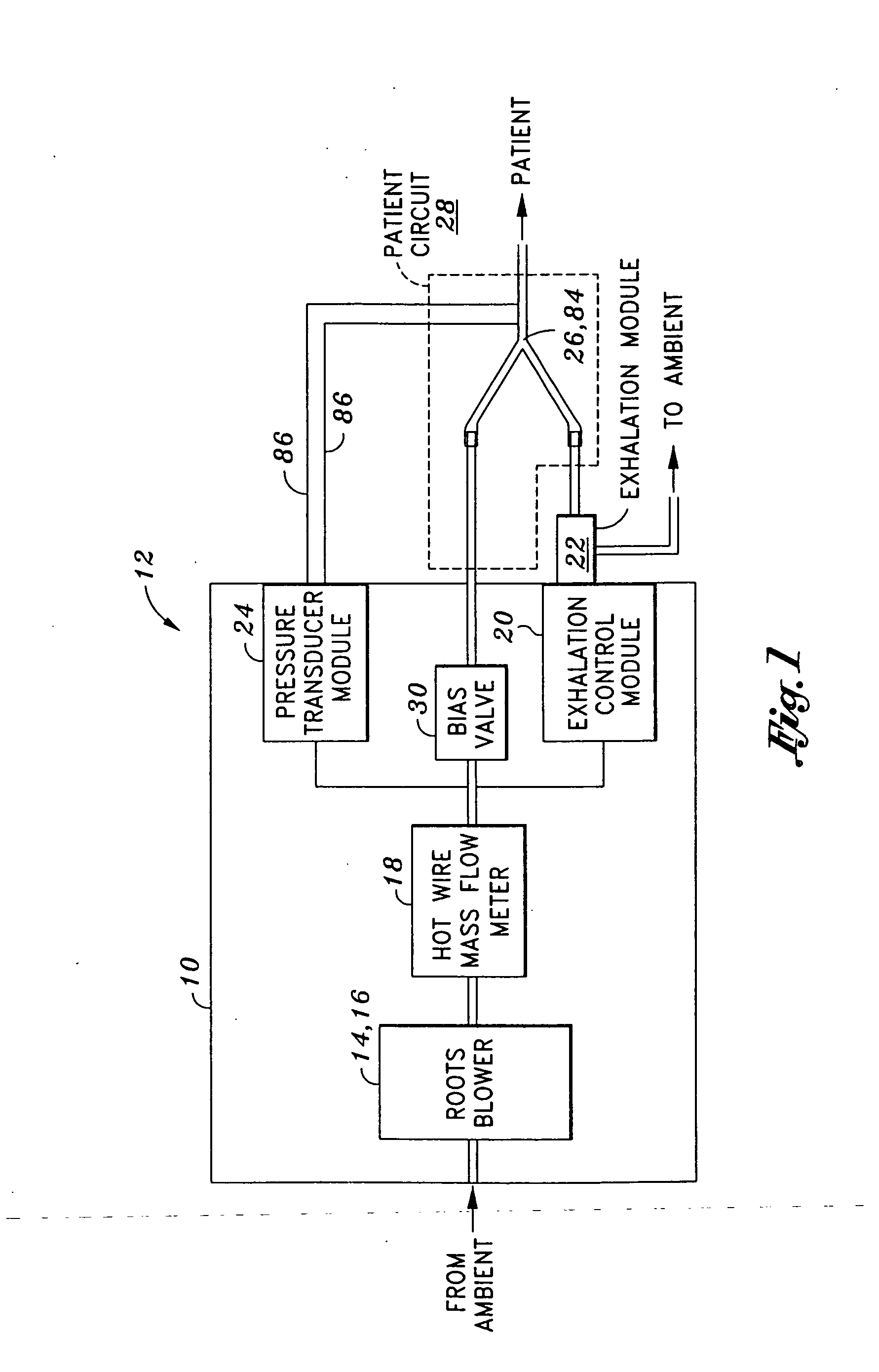

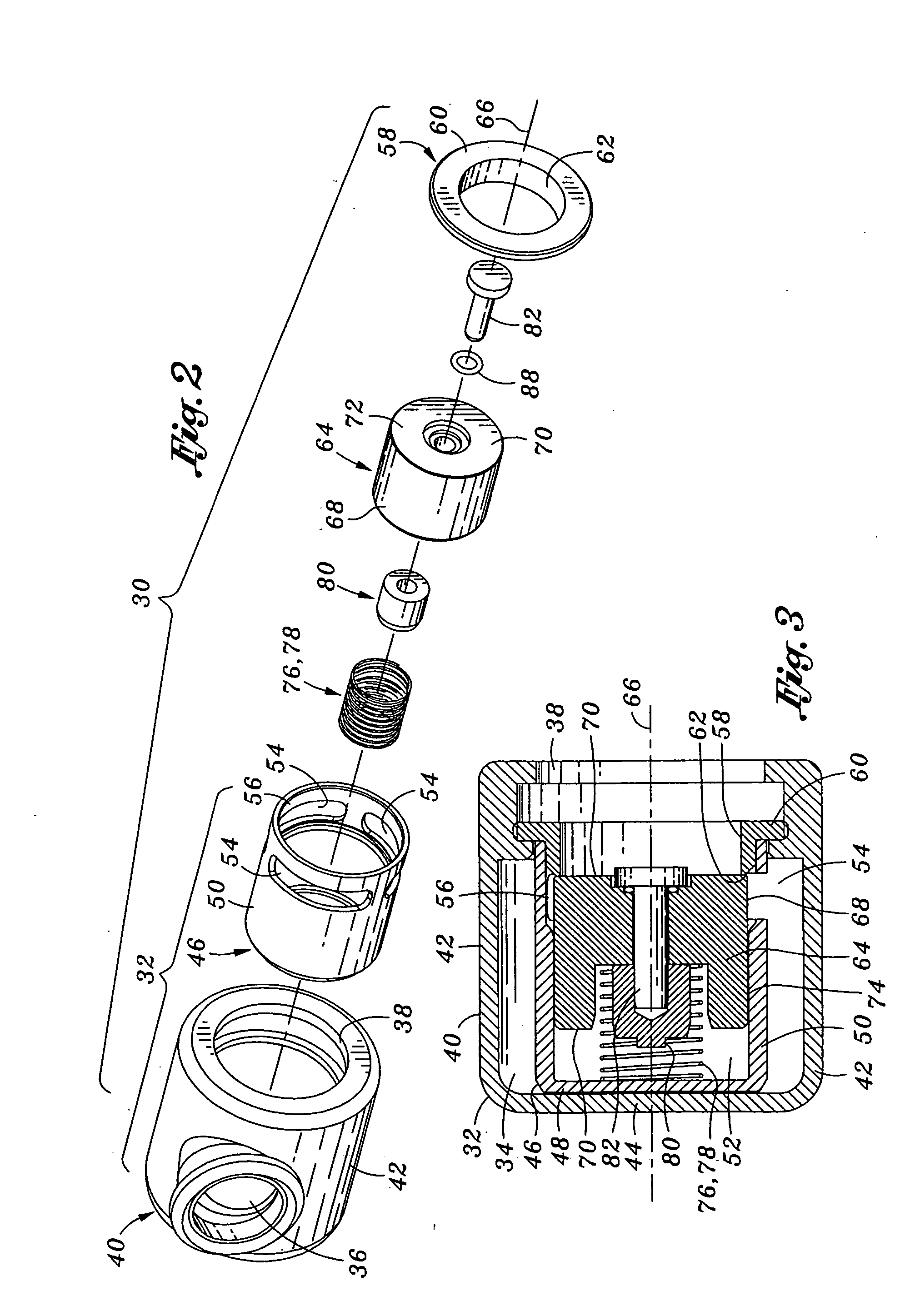

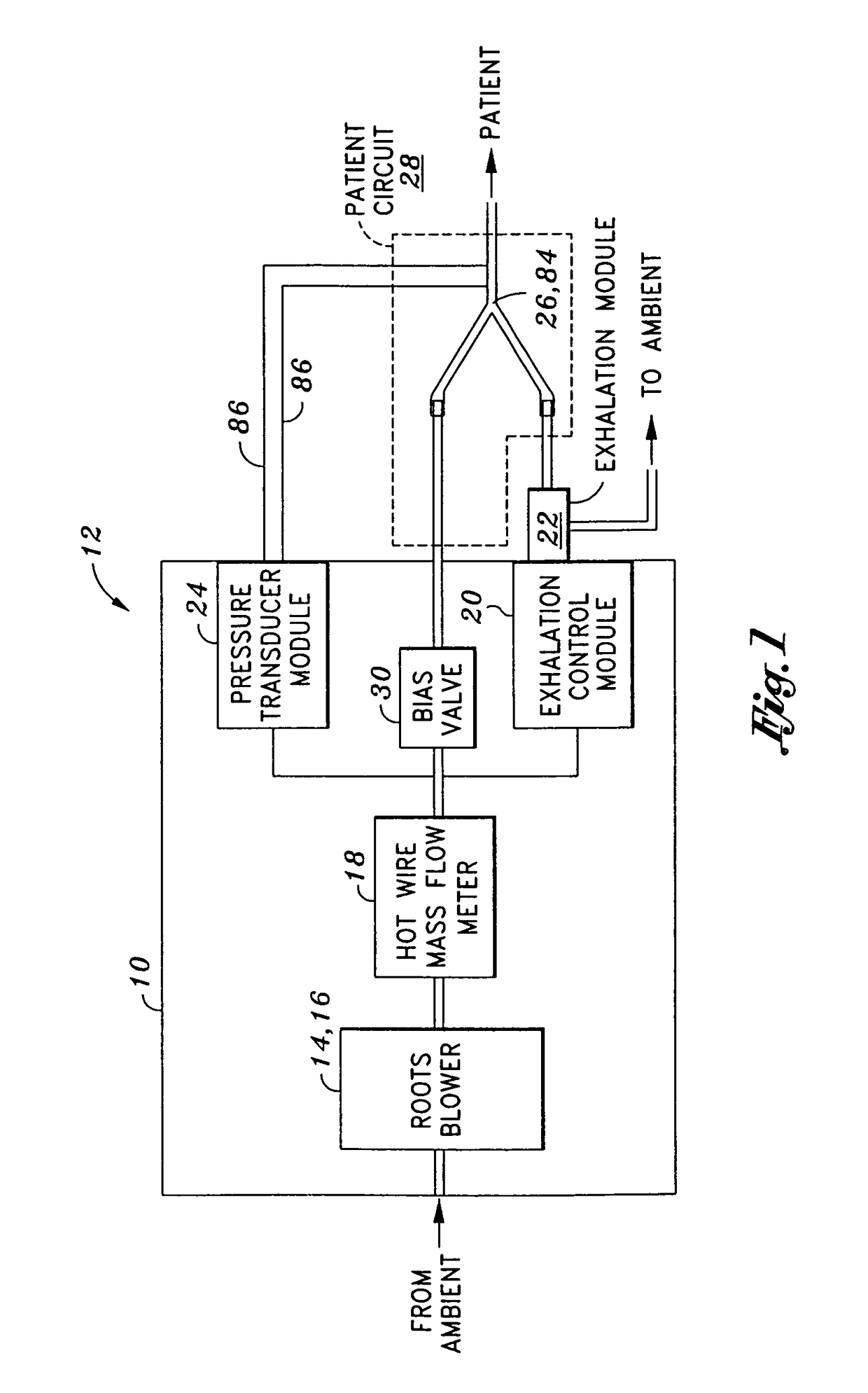

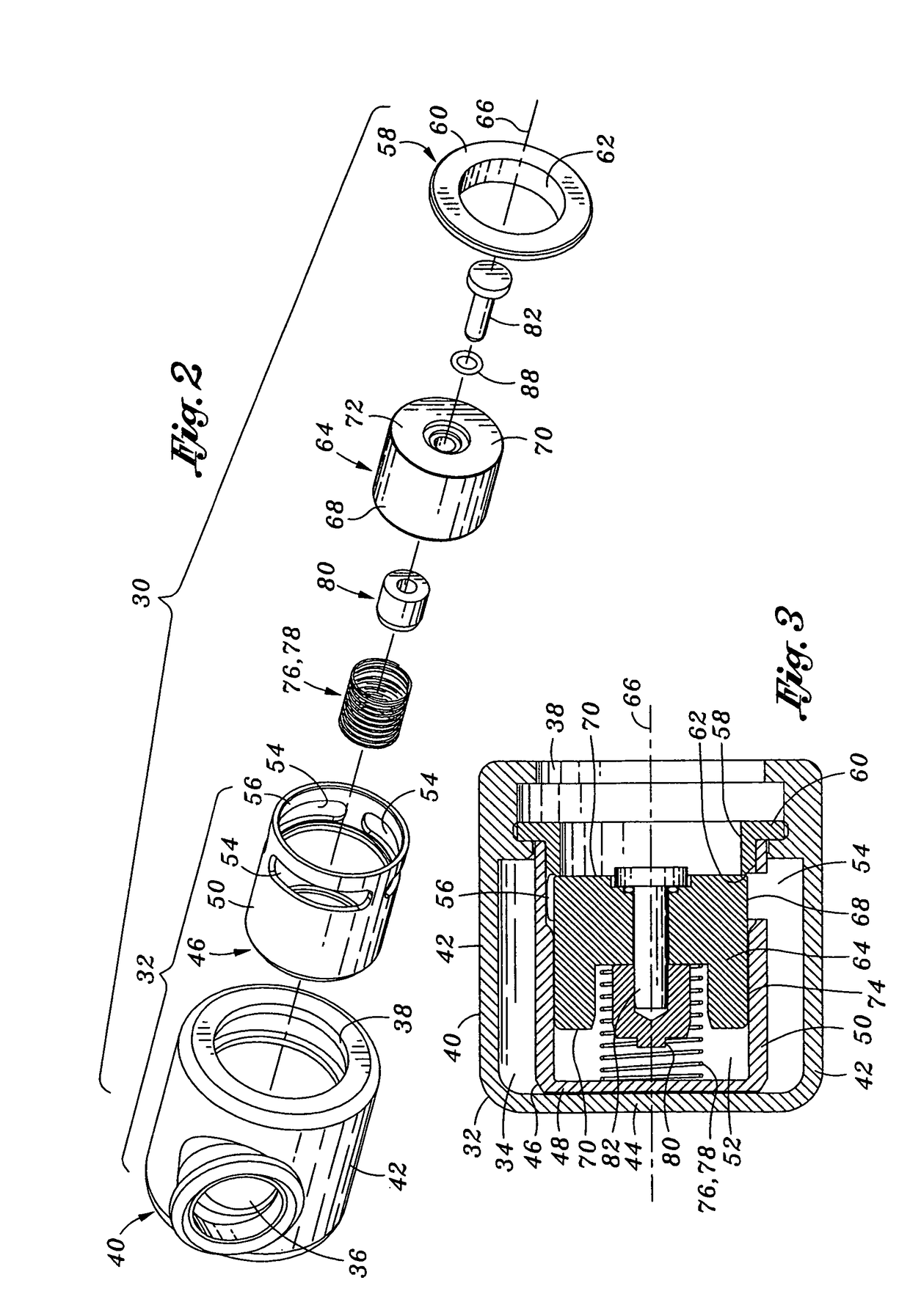

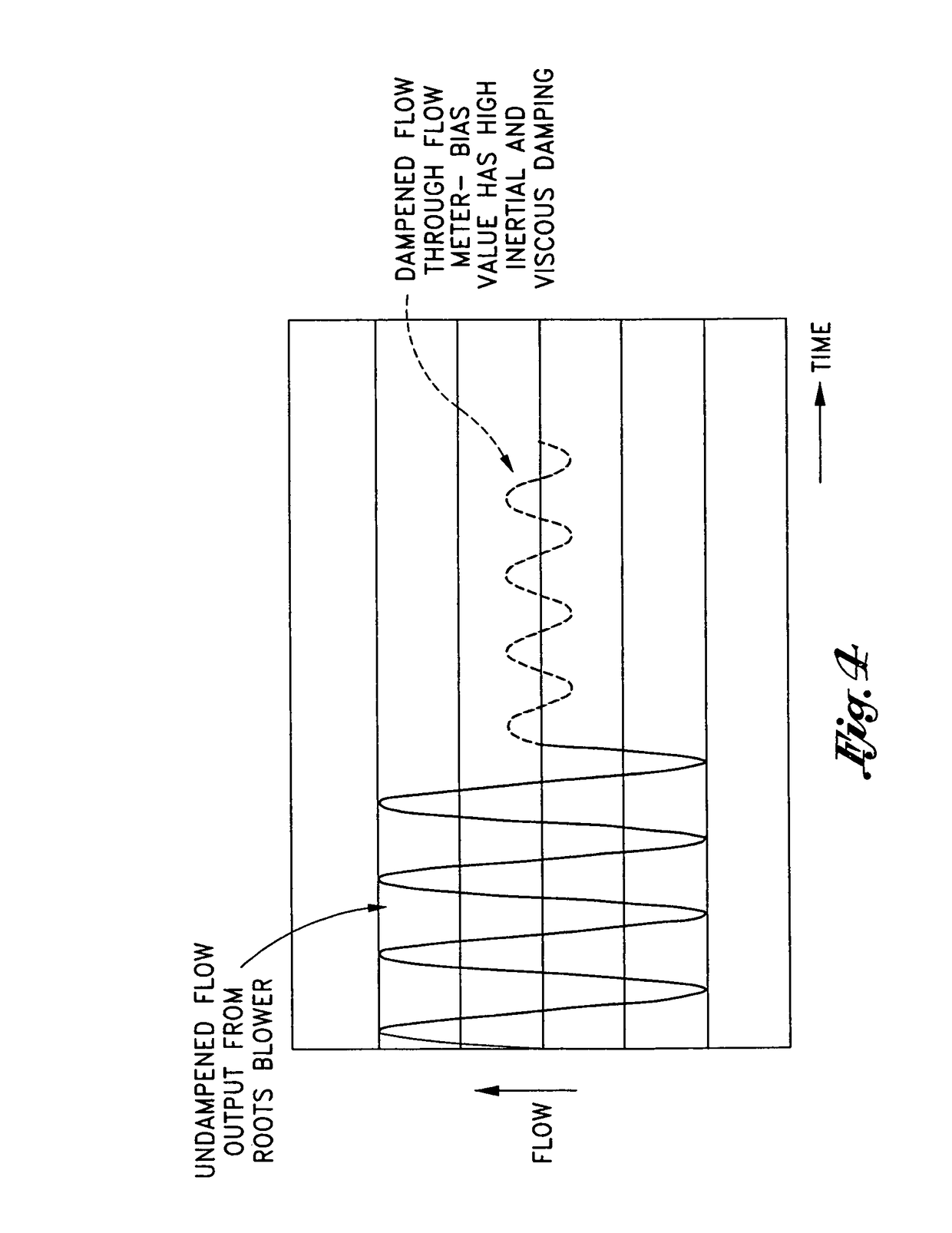

Mechanical ventilation system utilizing bias valve

ActiveUS20060249153A1Accurate measurementViscous dampingRespiratorsOperating means/releasing devices for valvesPositive pressureEngineering

A portable mechanical ventilator having a Roots blower is configured to provide a desired gas flow and pressure to a patient circuit. The mechanical ventilator includes a flow meter operative to measure gas flow produced by the Roots blower and an exhalation control module configured to operate an exhalation valve connected to the patient circuit. A bias valve connected between the Roots blower and the patient circuit is specifically configured to generate a bias pressure relative to the patient circuit pressure at the exhalation control module. The bias valve is further configured to attenuate pulsating gas flow produced by the Roots blower such that gas flowing to the mass flow meter exhibits a substantially constant pressure characteristic. The bias pressure facilitates closing of the exhalation valve at the start of inspiration, regulates positive end expiratory pressure during exhalation, and purges sense lines via a pressure transducer module.

Owner:VYAIRE MEDICAL 203 INC

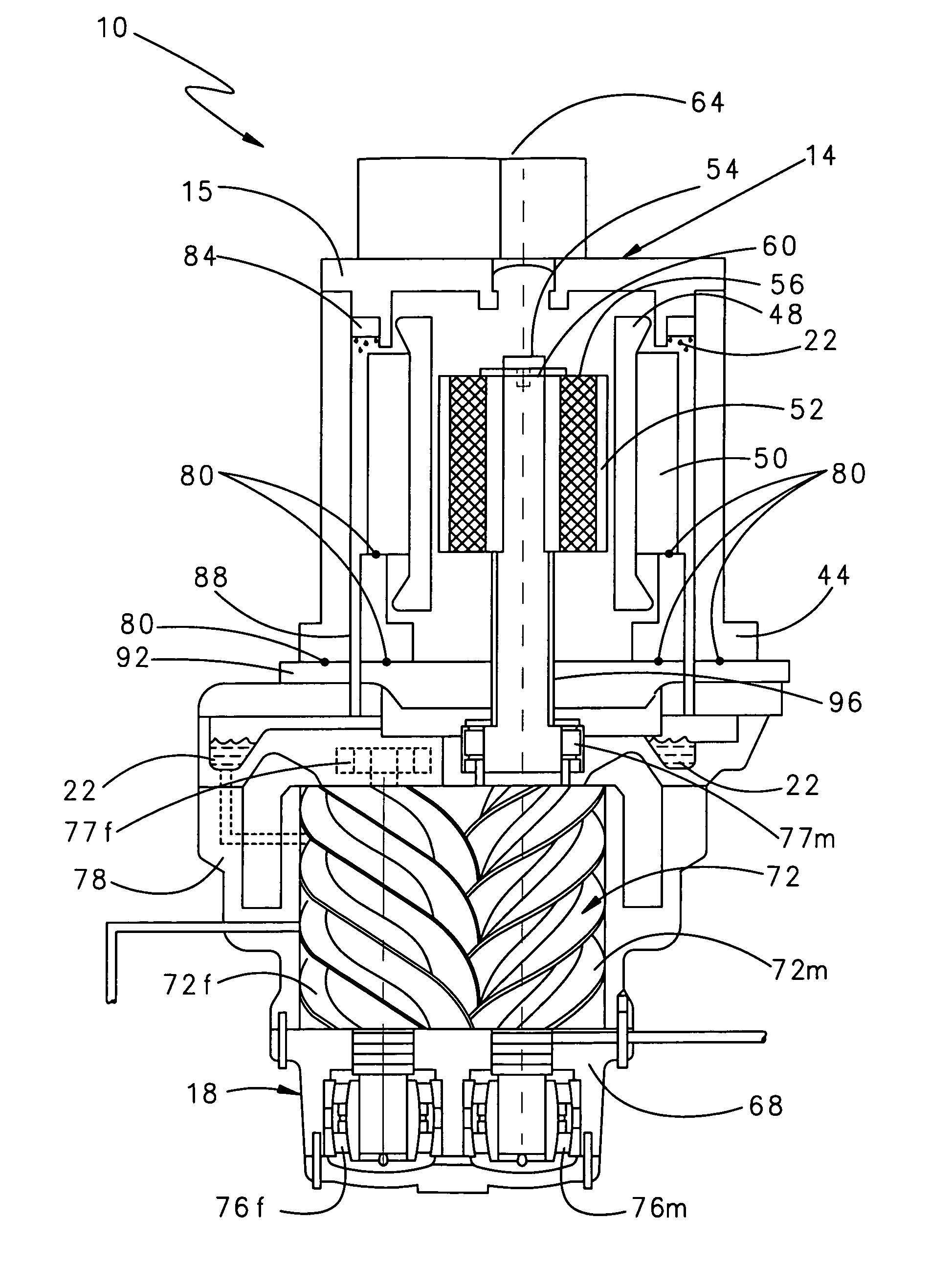

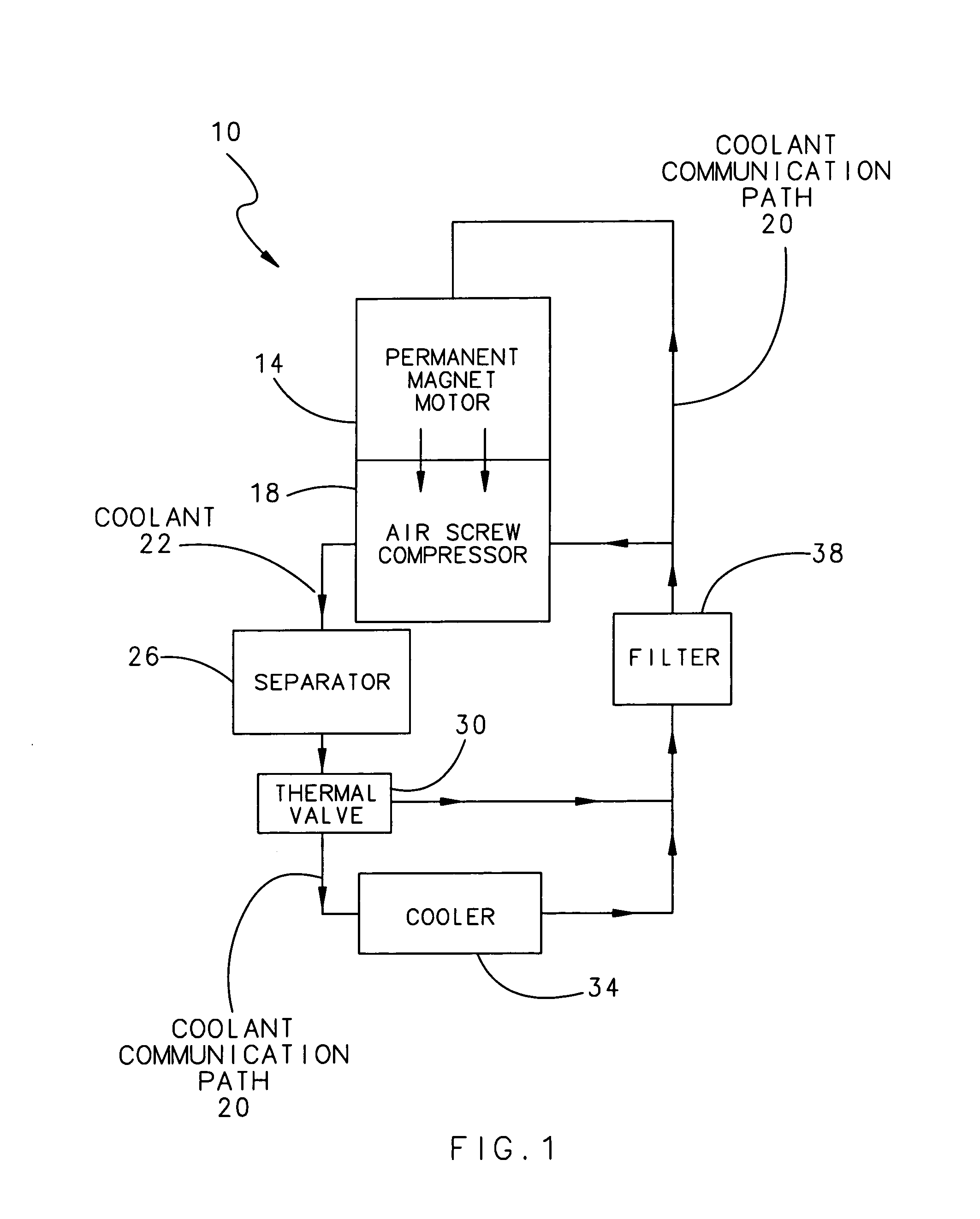

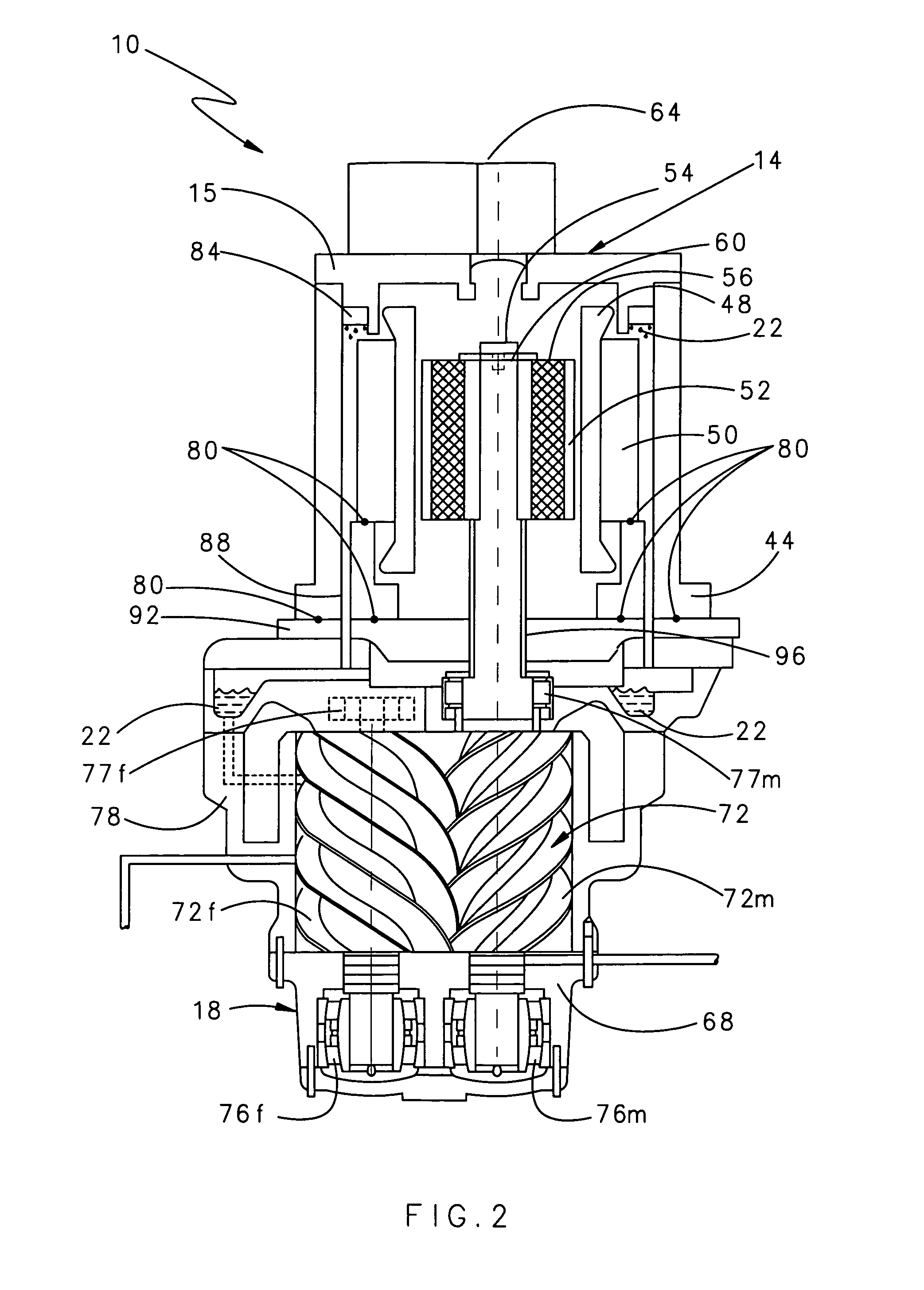

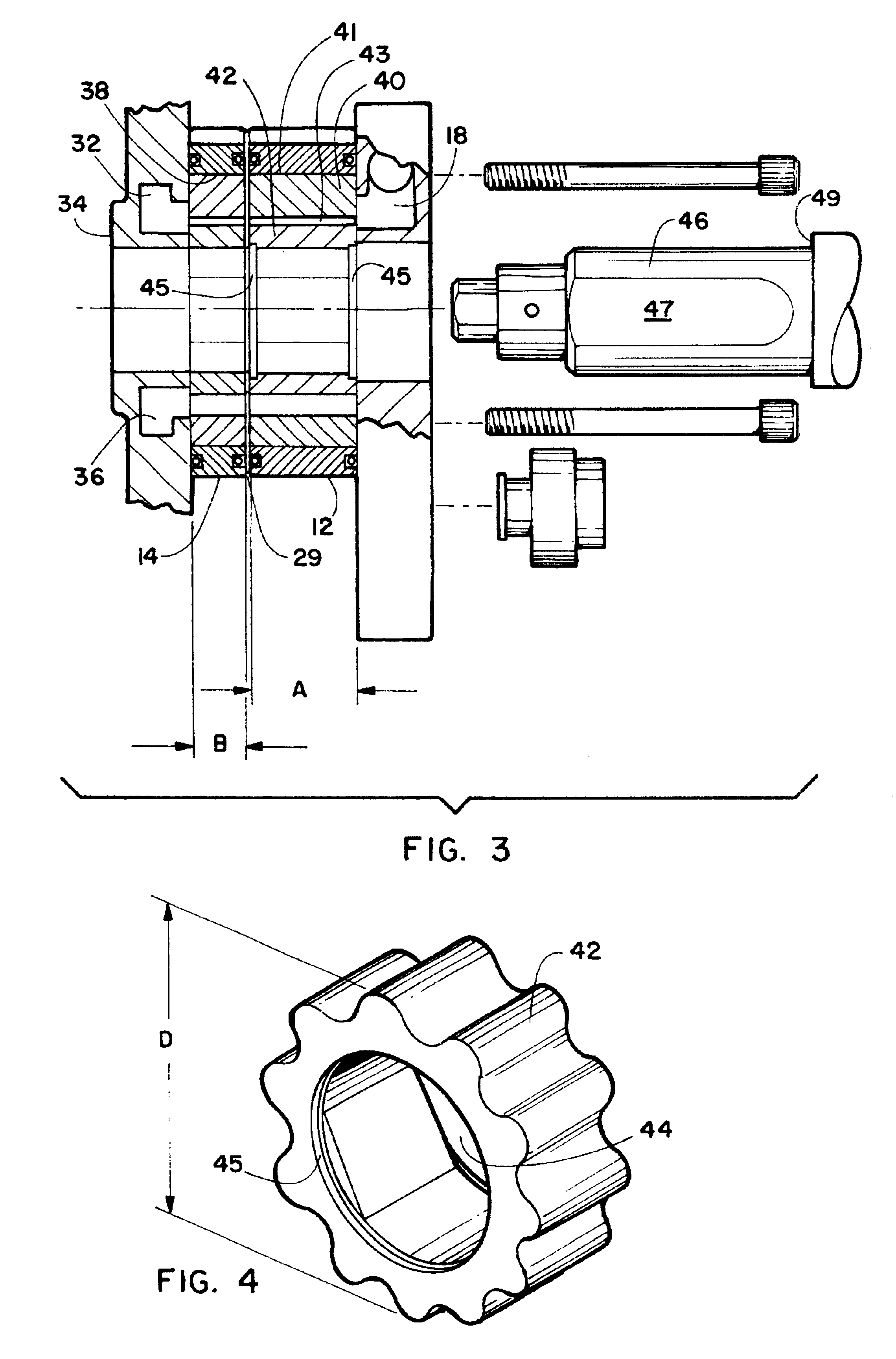

Lubricant cooled integrated motor/compressor design

InactiveUS20070241627A1Prevent overboard leakageThe process is compact and efficientRotary/oscillating piston combinations for elastic fluidsEngine of counter-engagement typePermanent magnet motorGear train

A compressor system according to the present invention utilizes direct rotational input from a permanent magnet motor to generate compressed air. The permanent magnet motor is mounted directly to an air screw compressor. The rotational input is provided by the permanent magnet motor to the air screw compressor without a gear train. The permanent magnet motor and associated variable speed drive controls the rotational speed of the permanent magnet motor and hence the screw compressor. Differing motors may selectively mount, and provide rotational input to, the air screw compressor.

Owner:SULLAIR CORP

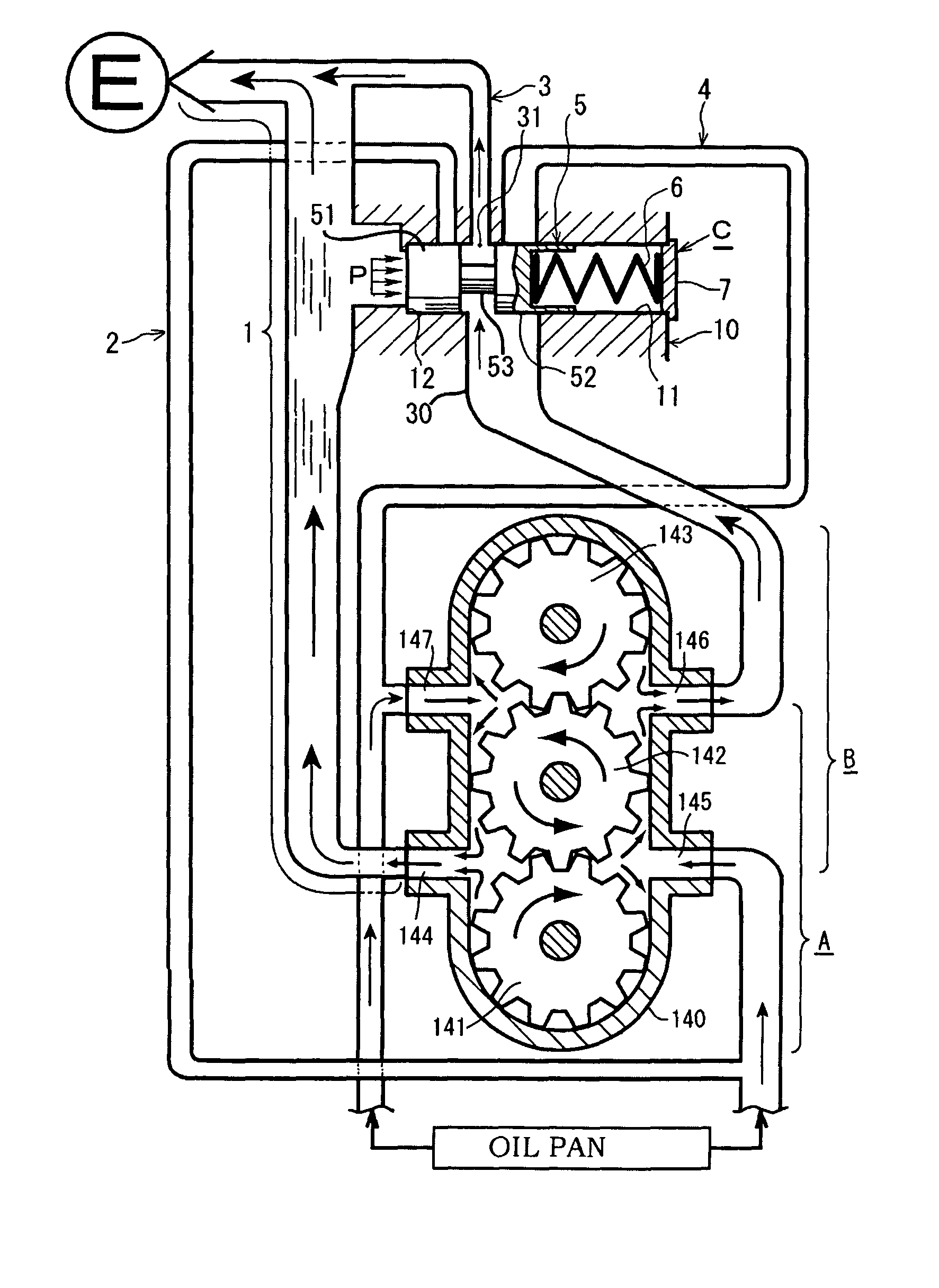

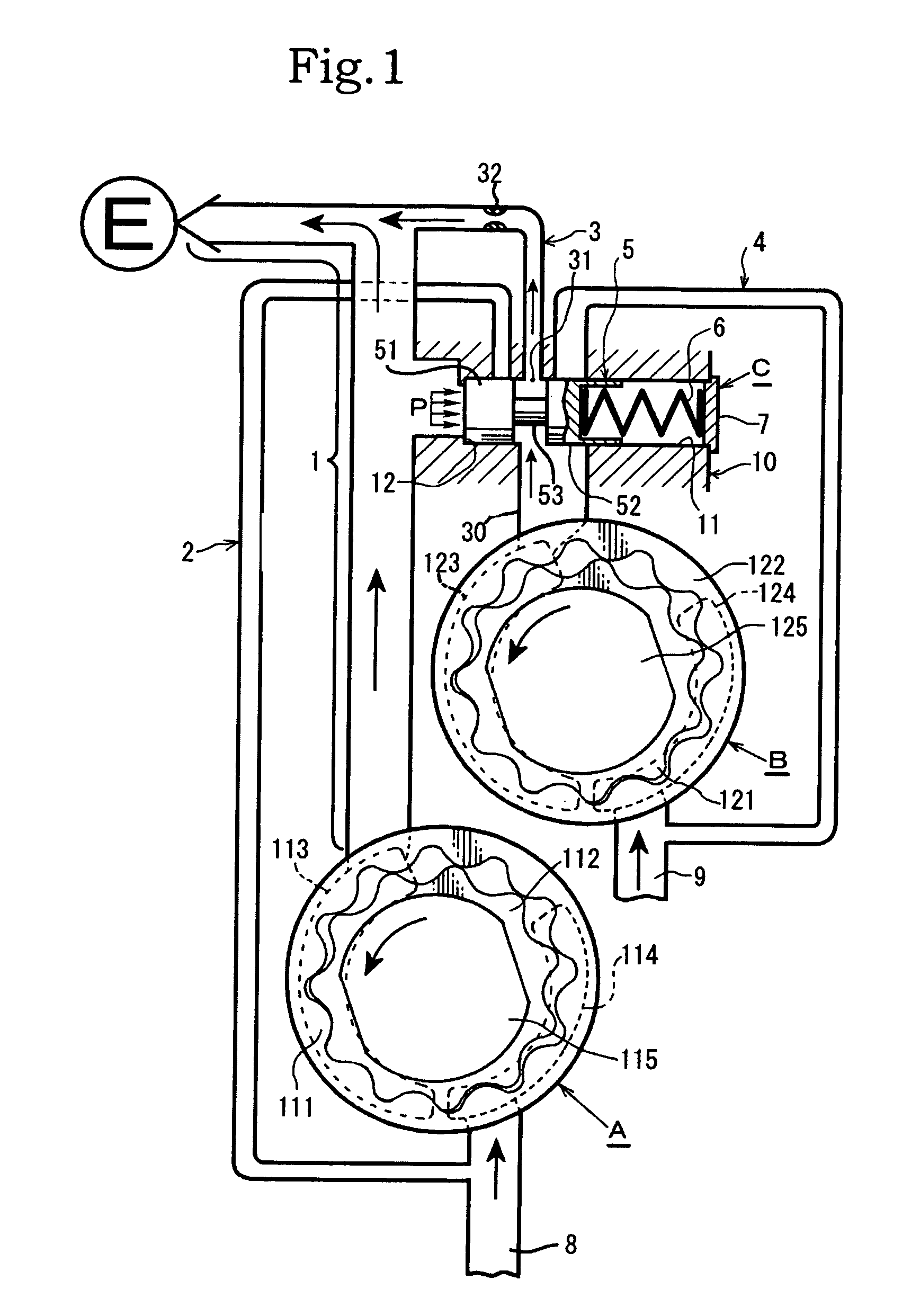

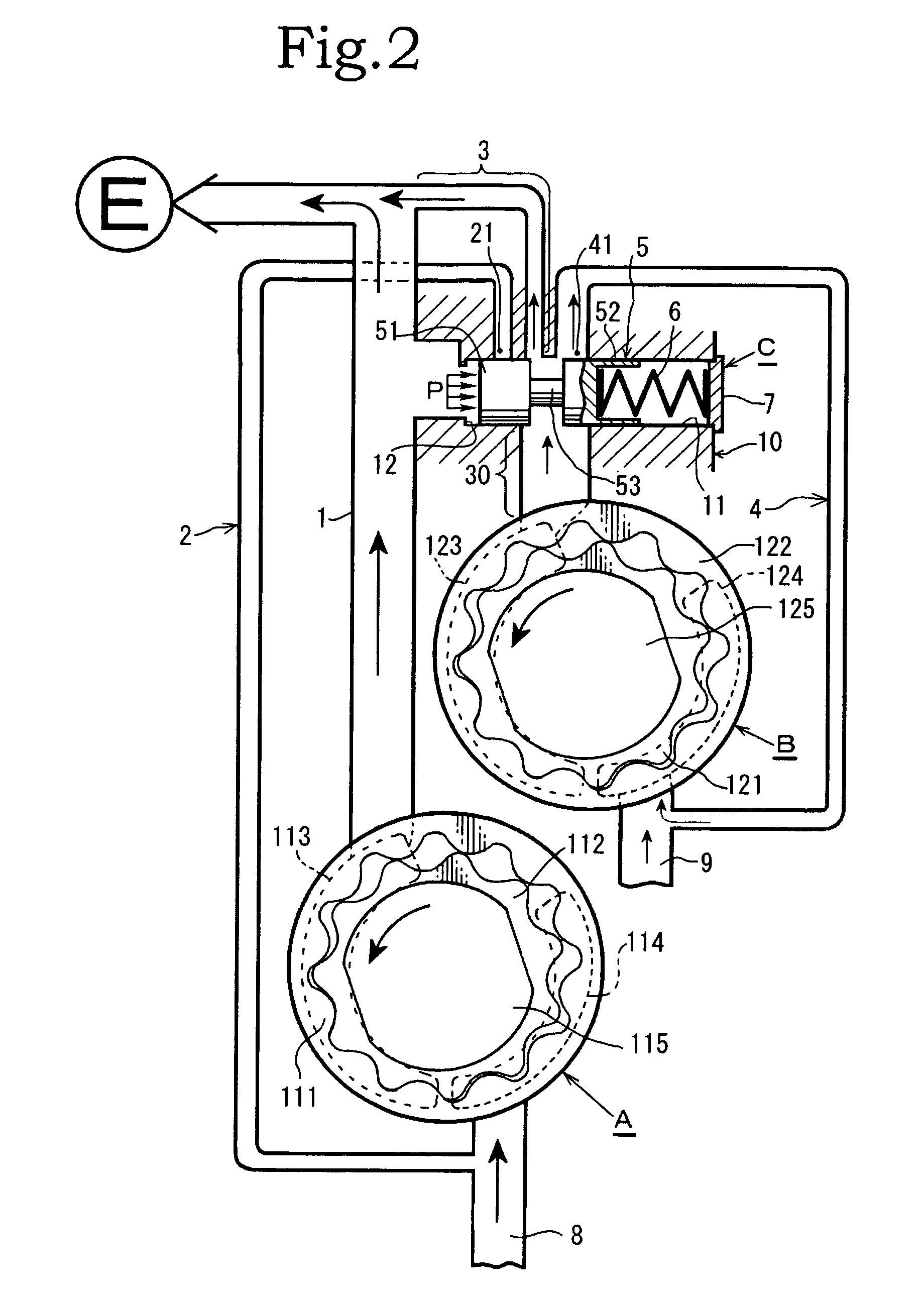

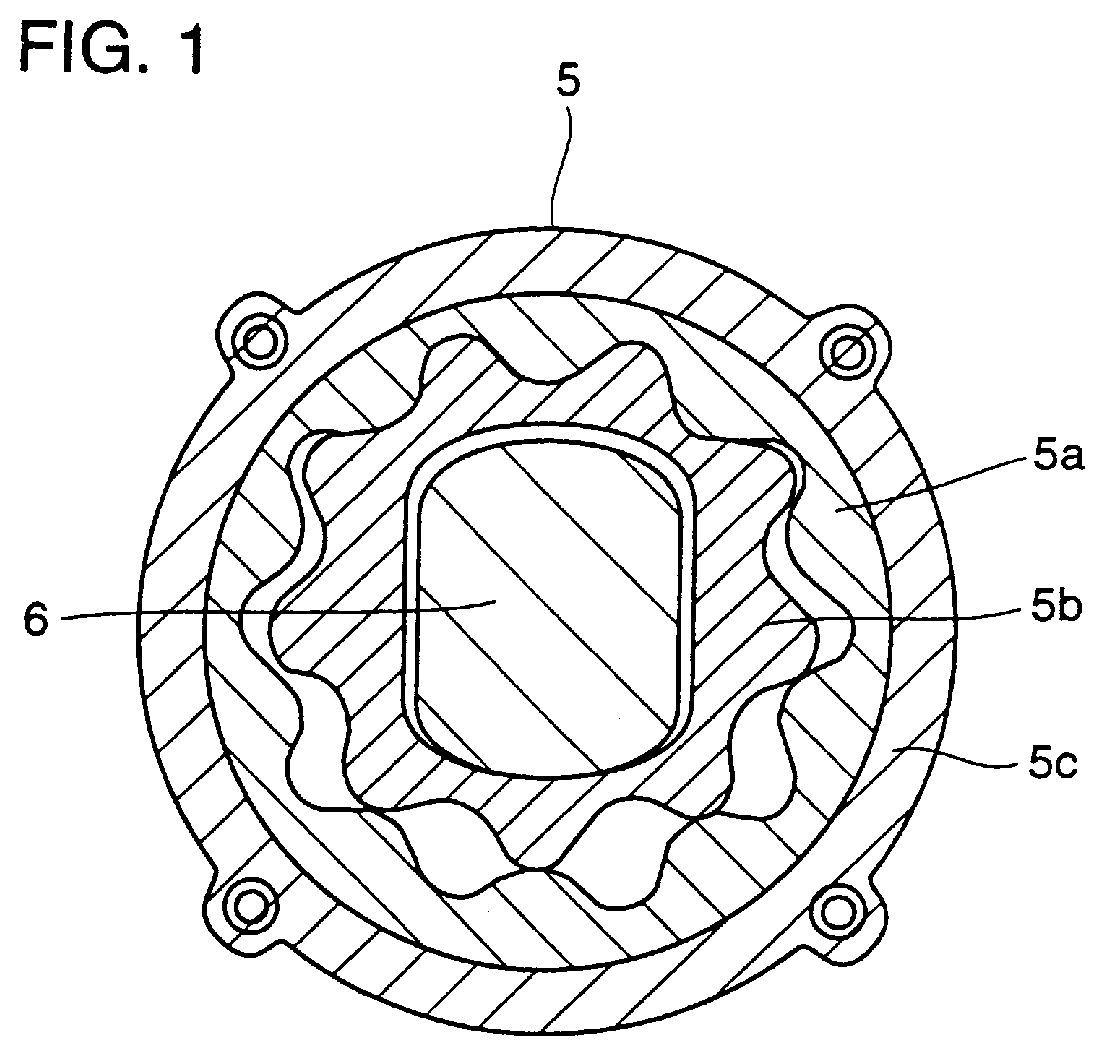

Oil pump pressure control device

InactiveUS8038416B2Drop in overall pump pressureWork moreOscillating piston enginesEngine of counter-engagement typeControl valvesReturn channel

A device including a first discharge passage from a first rotor assembly to an engine, a first return passage that returns to an intake side of the first rotor assembly, a second discharge passage from a second rotor assembly to the engine, a second return passage that returns to an intake side of the second rotor assembly, and a pressure control valve whose valve main body is provided between a discharge port from the second rotor assembly and the first discharge passage. The first discharge passage and the second discharge passage are coupled, and a flow passage control is executed in each of: a low revolution range; an intermediate revolution range; and a high revolution range.

Owner:YAMADA MANUFACTURING CO LTD

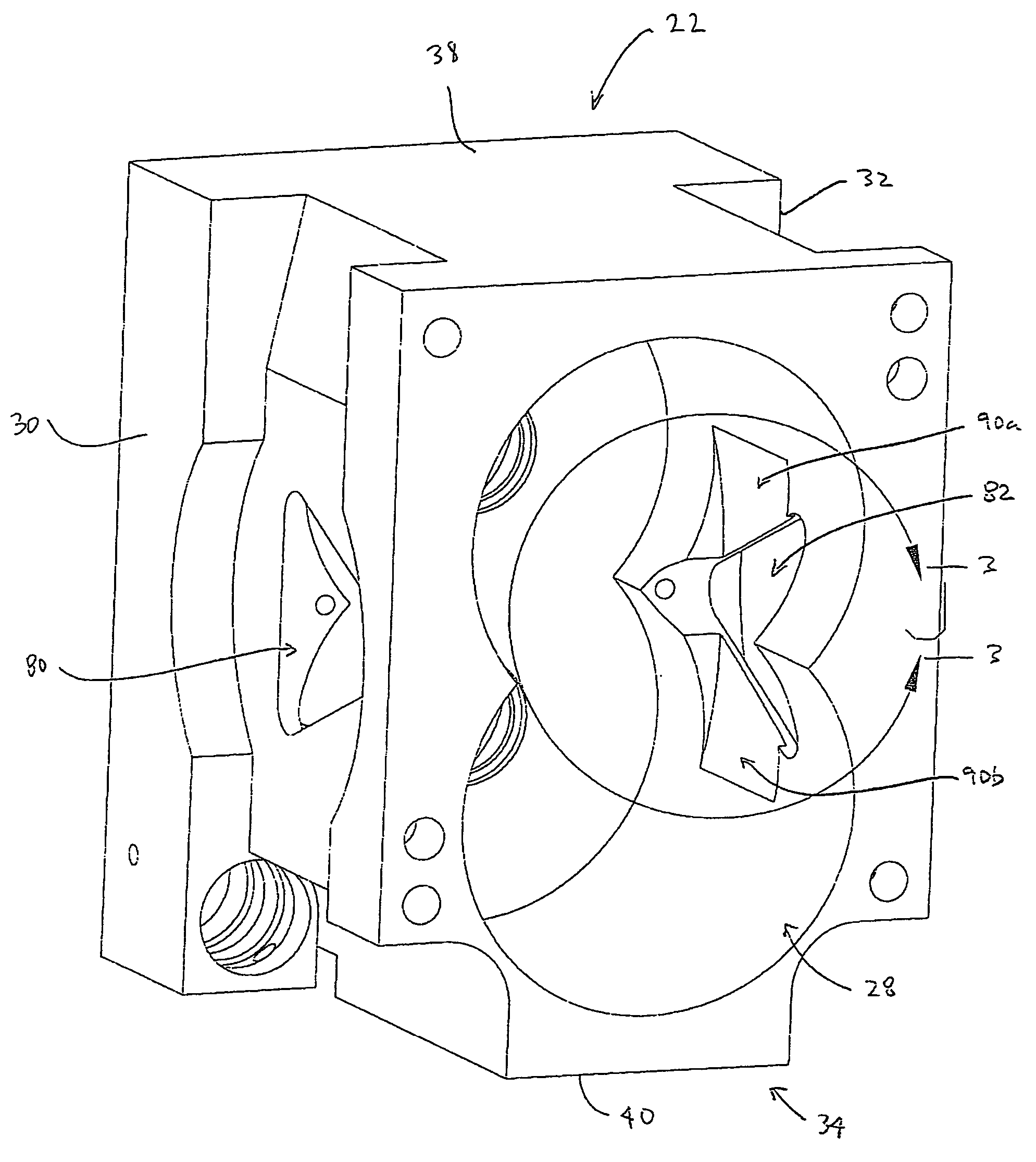

Portable ventilator system

InactiveUS20060213518A1Small sizeReduce power consumptionMechanical/radiation/invasive therapiesPhysical therapyPortable ventilatorsEngineering

A portable ventilator uses a Roots-type blower as a compressor to reduce both the size and power consumption of the ventilator. Various functional aspects of the ventilator are delegated to multiple subassemblies having dedicated controllers and software that interact with a ventilator processor to provide user interface functions, exhalation control and flow control servos, and monitoring of patient status. The ventilator overcomes noise problems through the use of noise reducing pressure compensating orifices on the Roots blower housing and multiple baffling chambers. The ventilator is configured with a highly portable form factor, and may be used as a stand-alone device or as a docked device having a docking cradle with enhanced interface and monitoring capabilities.

Owner:VYAIRE MEDICAL 203 INC

Mechanical ventilation system utilizing bias valve

ActiveUS8118024B2Small powerSmall sizeRespiratorsOperating means/releasing devices for valvesTransducerEngineering

A portable mechanical ventilator having a ROOTS® blower is configured to provide a desired gas flow and pressure to a patient circuit. The mechanical ventilator includes a flow meter operative to measure gas flow produced by the ROOTS® blower and an exhalation control module configured to operate an exhalation valve connected to the patient circuit. A bias valve connected between the ROOTS® blower and the patient circuit is specifically configured to generate a bias pressure relative to the patient circuit pressure at the exhalation control module. The bias valve is further configured to attenuate pulsating gas flow produced by the ROOTS® blower such that gas flowing to the mass flow meter exhibits a substantially constant pressure characteristic. The bias pressure facilitates closing of the exhalation valve at the start of inspiration, regulates positive end expiratory pressure during exhalation, and purges sense lines via a pressure transducer module.

Owner:VYAIRE MEDICAL 203 INC

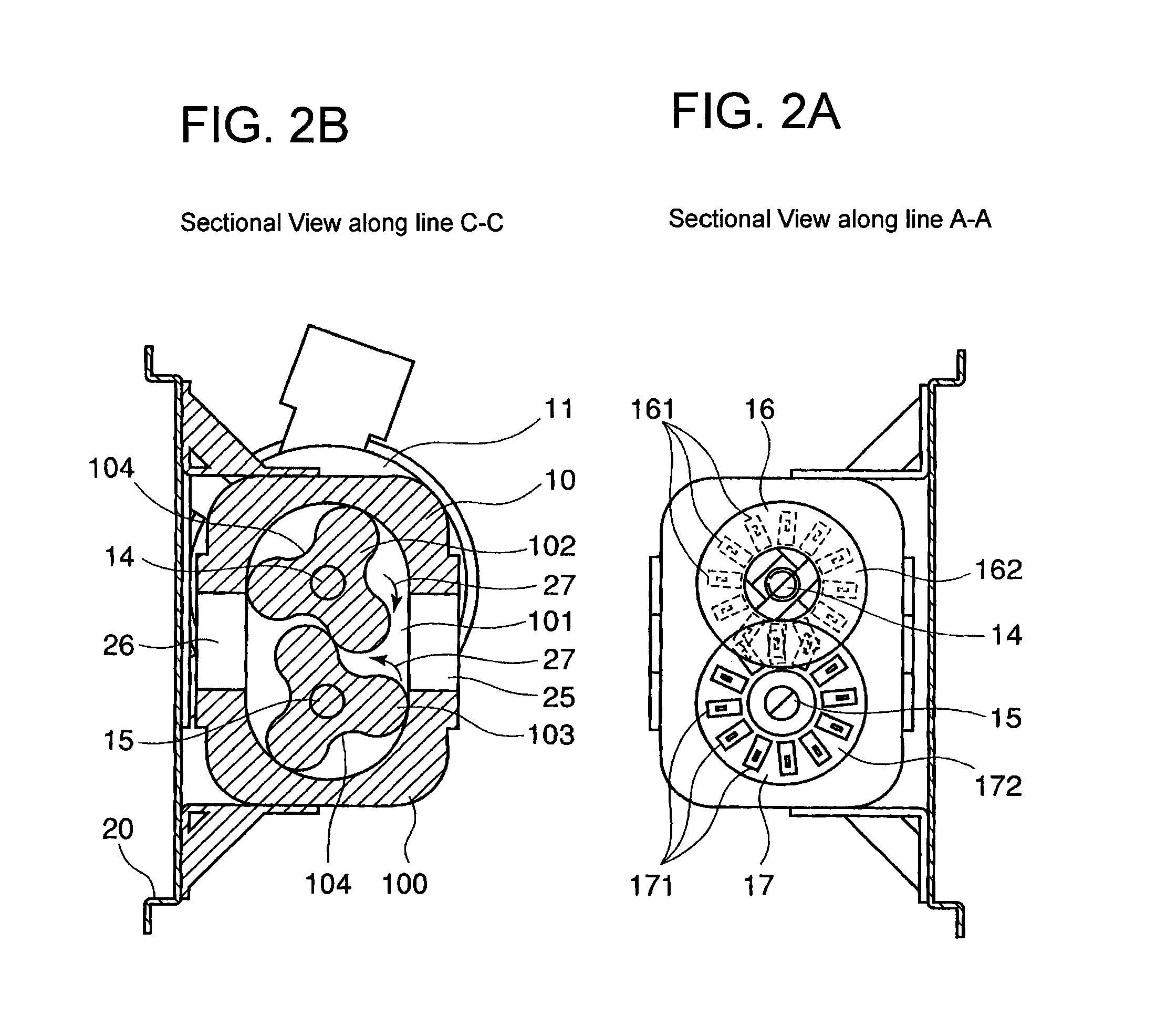

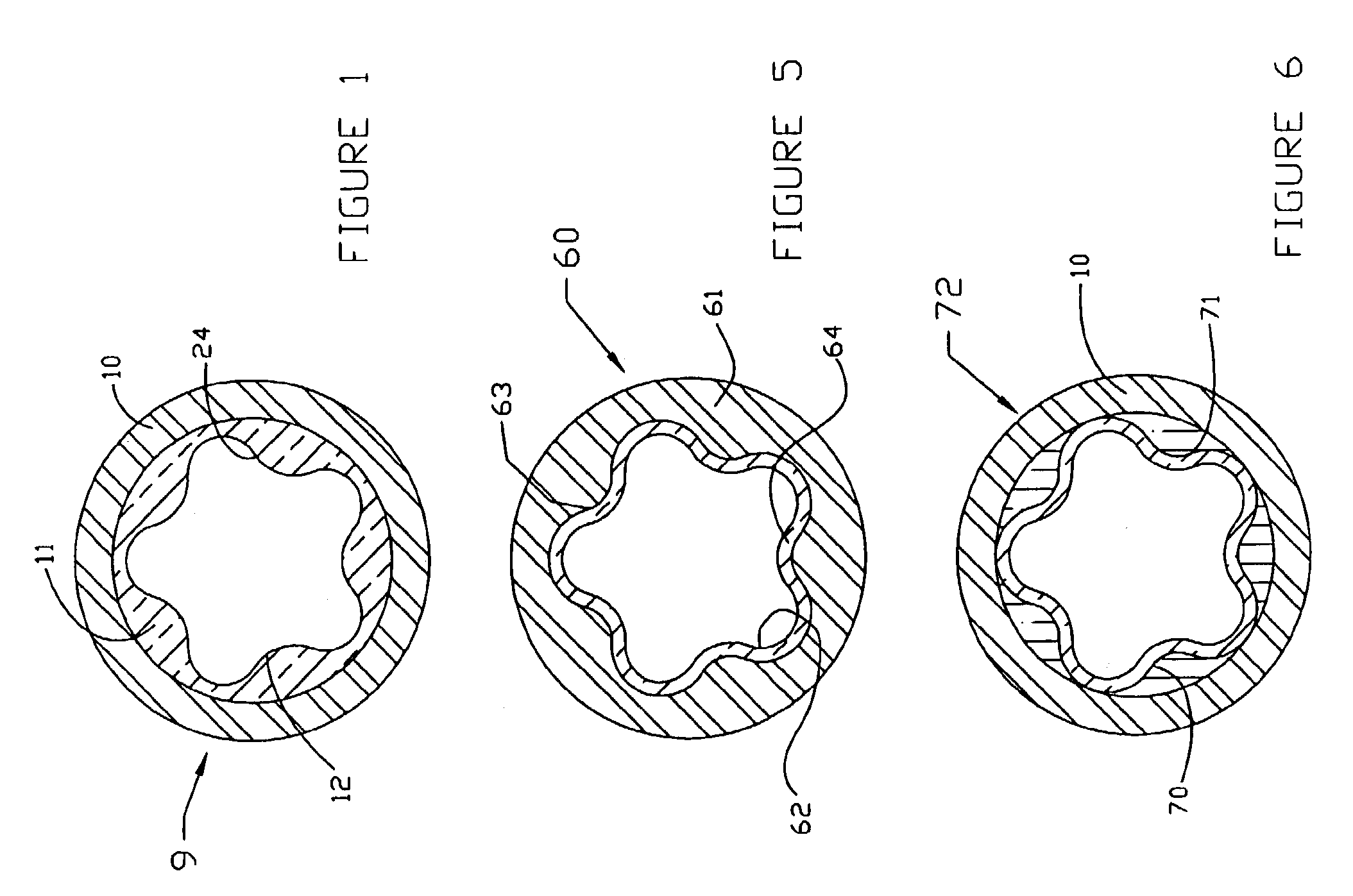

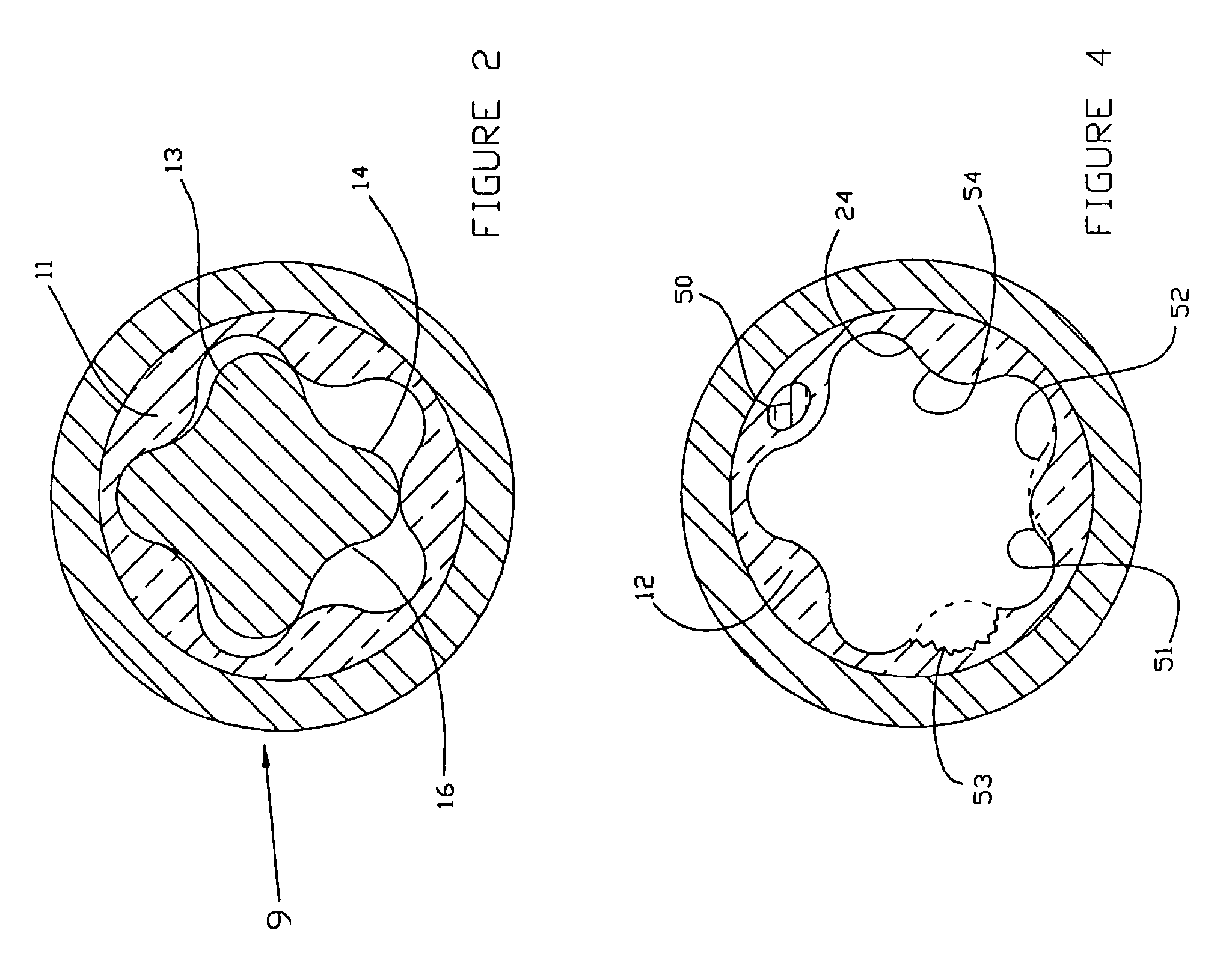

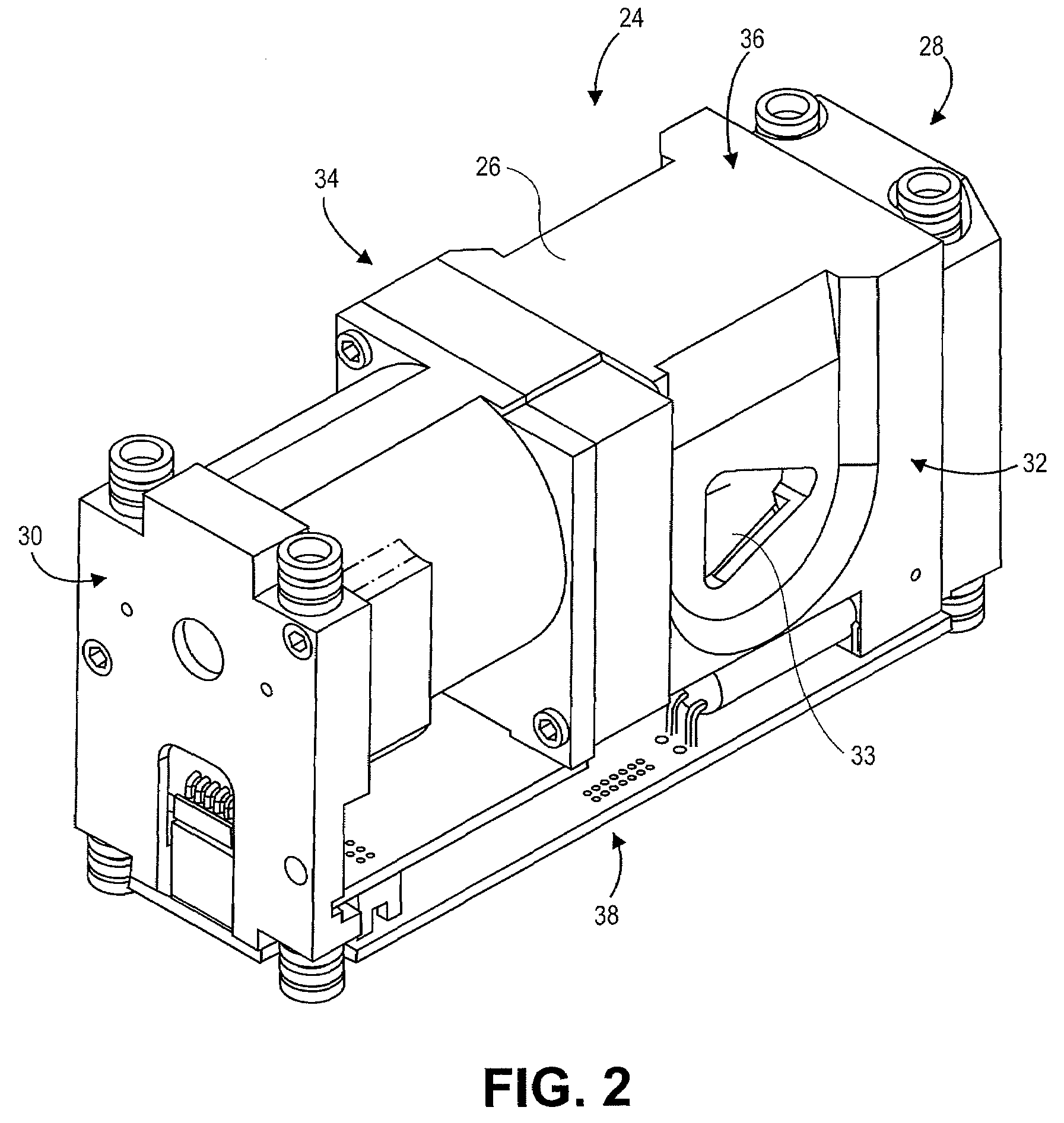

Method and apparatus for reducing noise in a roots-type blower

InactiveUS20050112013A1Reduce noisePhysical therapyEngine of counter-engagement typeNoise levelEngineering

A Roots-type blower comprises a housing defining a rotor chamber and an inlet and outlet to the rotor chamber. First and second rotors are mounted in the rotor chamber, each rotor defining a plurality of lobes, adjacent lobes and the housing cooperating to define gas transport chambers. The blower is configured so that a net flow rate of gas into a gas transport chamber is generally or approximately constant, whereby a change in gas pressure in the gas transport chamber is generally or approximately linear, as the gas transport chamber approaches the outlet. In one embodiment, this is accomplished by providing flow channels extending from the outlet towards the inlet, and from the inlet towards the outlet, corresponding to each rotor. The flow channels permit gas to flow from the high pressure outlet to a gas transport chamber and from the gas transport chamber to the low pressure inlet. The resulting amelioration of pressure spikes associated with flow back substantially reduces the operational noise level of the blower.

Owner:PULMONETIC SYST

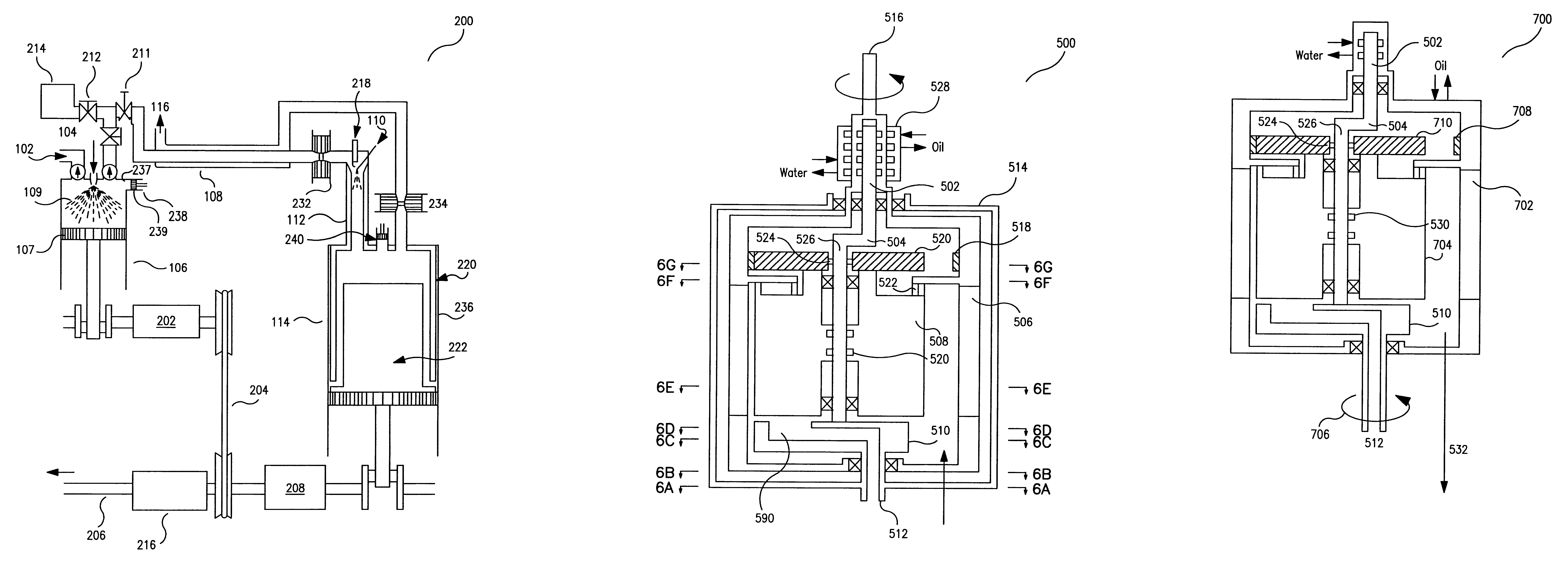

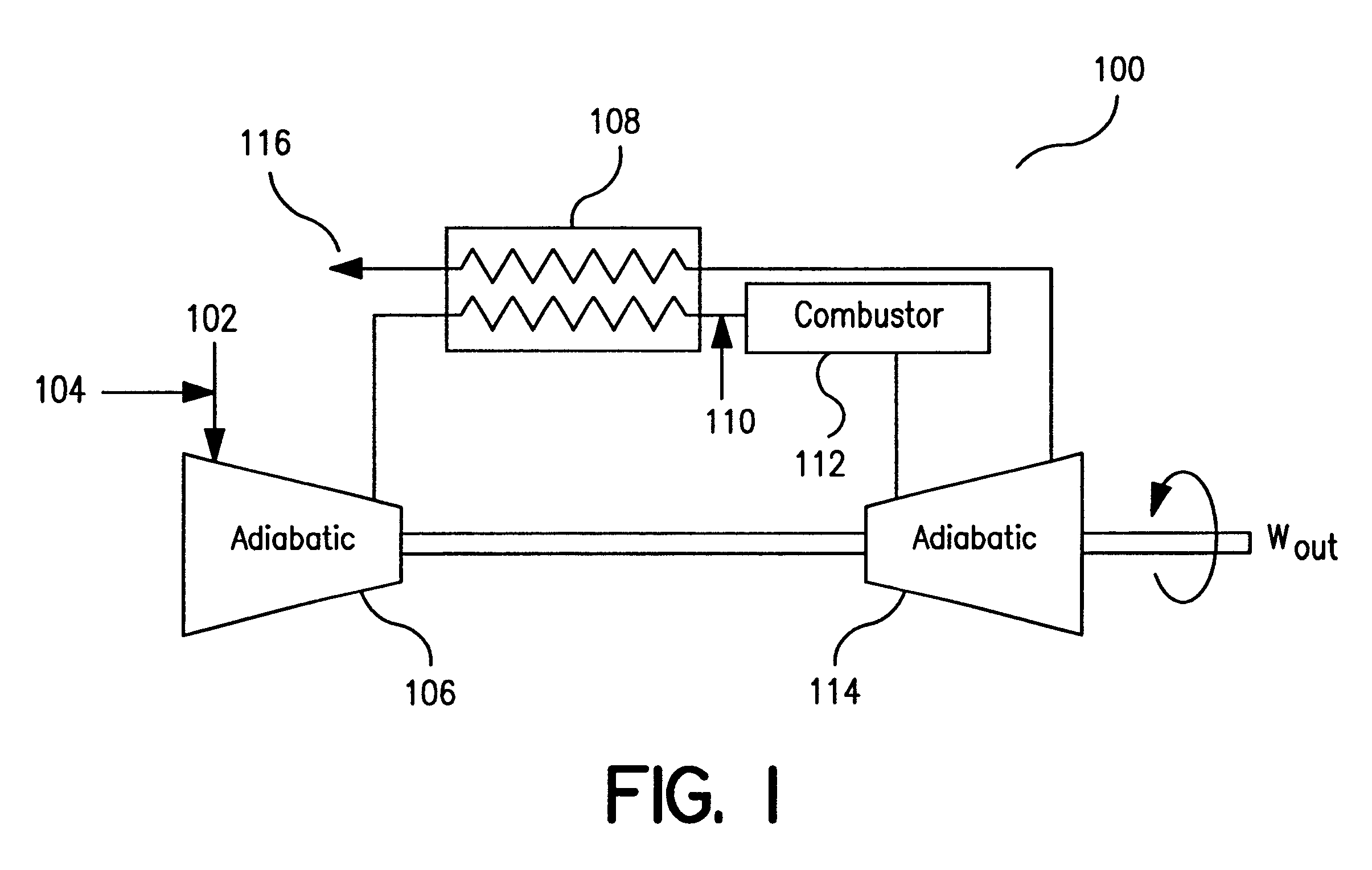

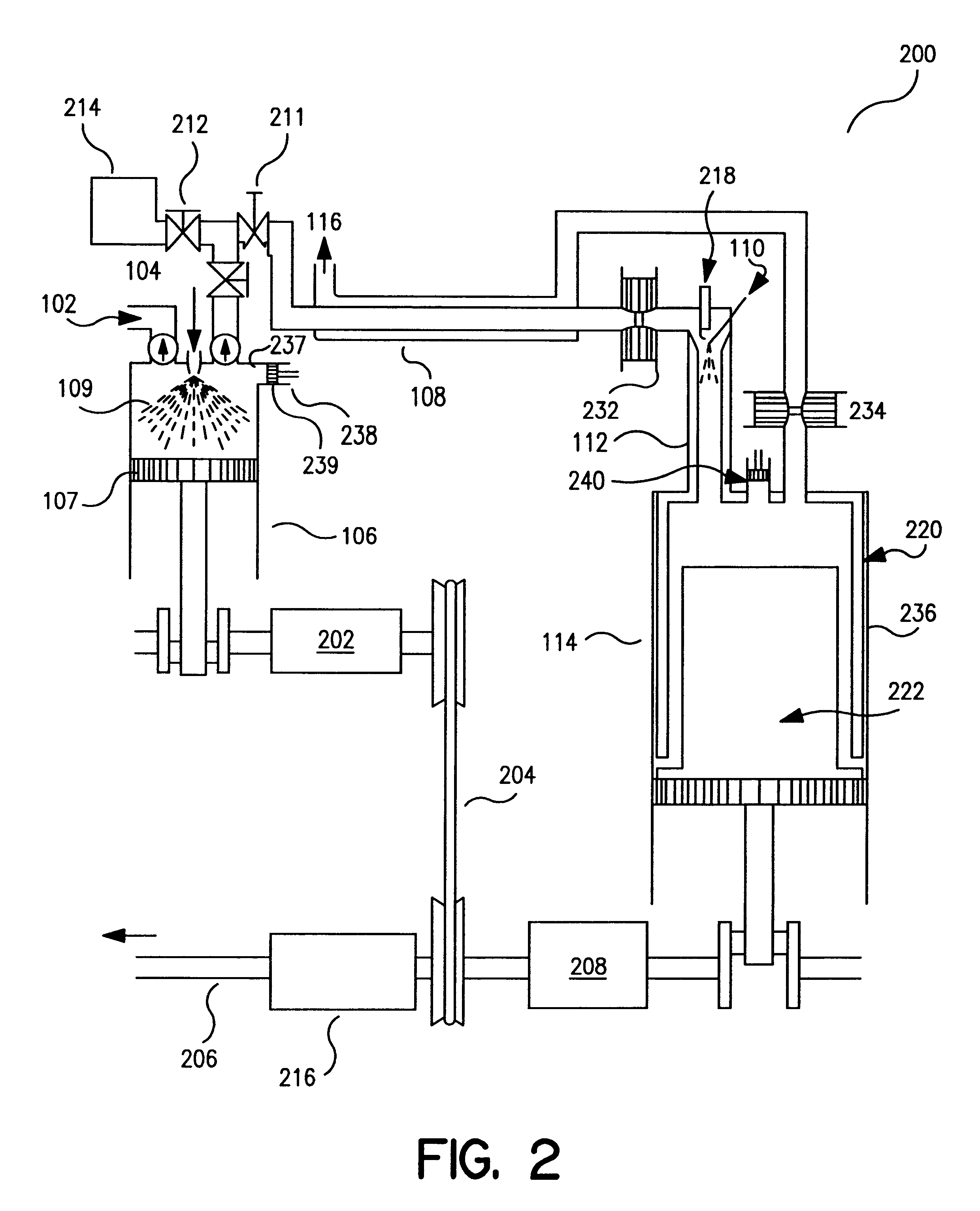

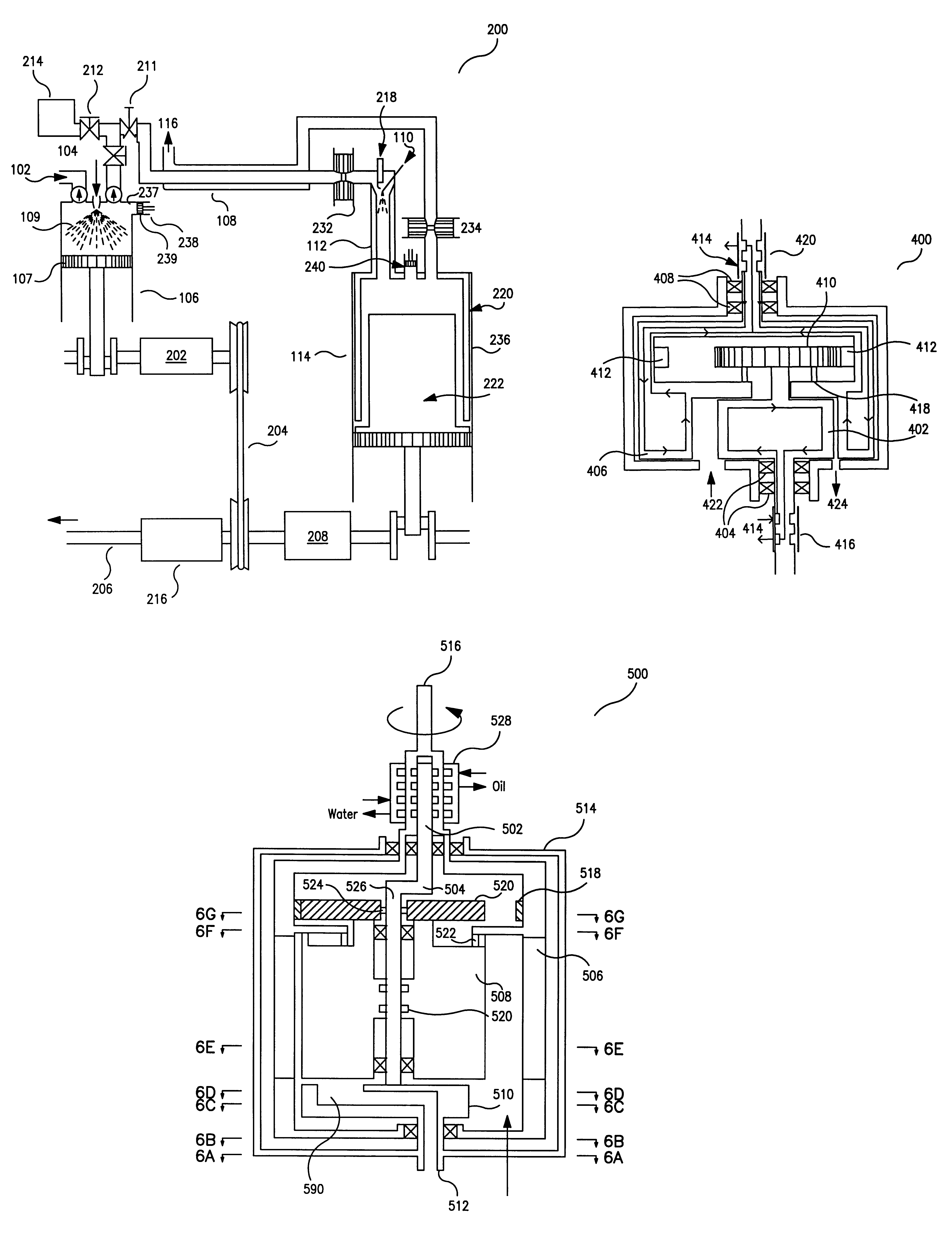

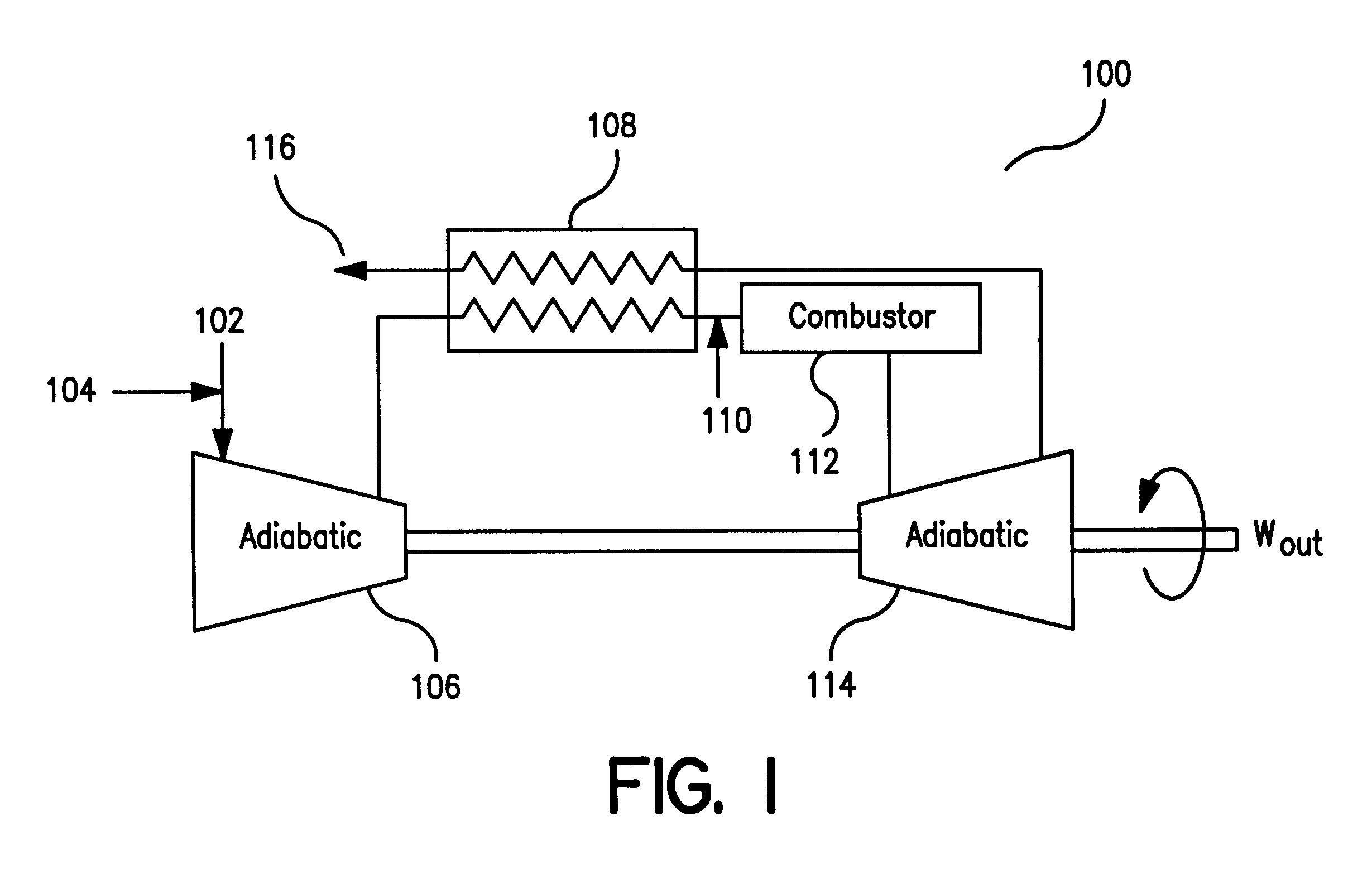

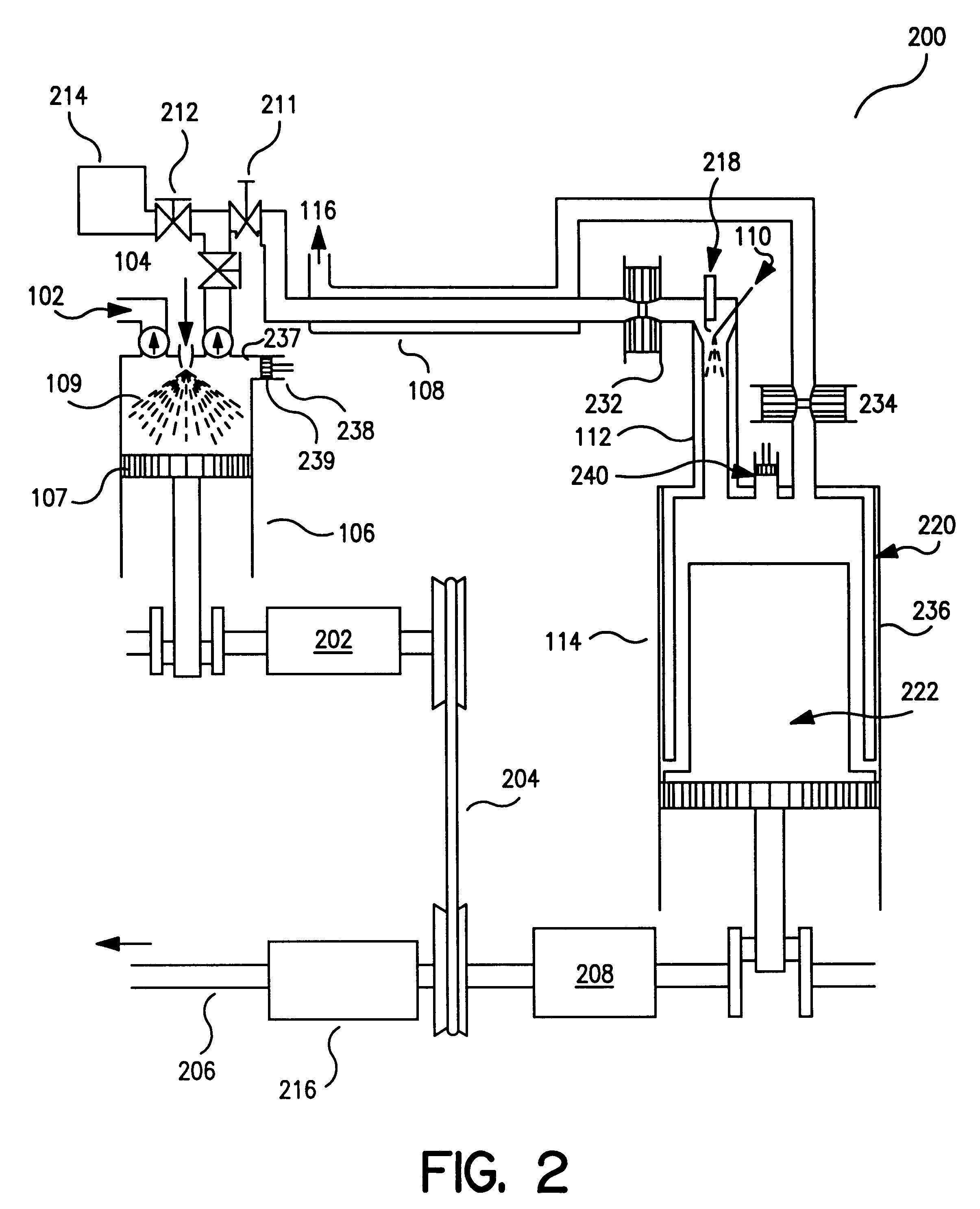

Quasi-isothermal Brayton Cycle engine

InactiveUS6530211B2Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesEngine of arcuate-engagement typeBrayton cycleCombustor

Owner:HOLTZAPPLE MARK T +1

Quasi-isothermal Brayton cycle engine

InactiveUS6336317B1Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesCombination enginesBrayton cycleCombustor

An engine is disclosed. According to one embodiment of the present invention, the engine comprises a compressor, and combustor, and an expander. The compressor compresses ambient air. The combustor burns the compressed air, and produces exhaust gasses. The expander receives the exhaust gases from the combustor, and expands the exhaust gasses. The compressor may be a gerotor compressor or a piston compressor having variable-dead-volume control. The expander may be a gerotor expander or a piston expander having variable-dead-volume control. In another embodiment, an engine comprises a piston compressor, a combustor, a piston expander, and a pressure tank. The piston compressor compresses ambient air. The combustor burns the compressed air, and produces exhaust gasses. The piston expander receives the exhaust gasses from the combustor, and expands the exhaust gasses. The pressure tank receives and stores the compressed air from the compressor. In another embodiment, a gerotor compressor or a gerotor expander comprises an inner gerotor, and an outer gerotor. The inner gerotor and the outer gerotor are driven so that they do not touch. The gerotors may be cantilevered or non-cantilevered.

Owner:TEXAS A&M UNIVERSITY

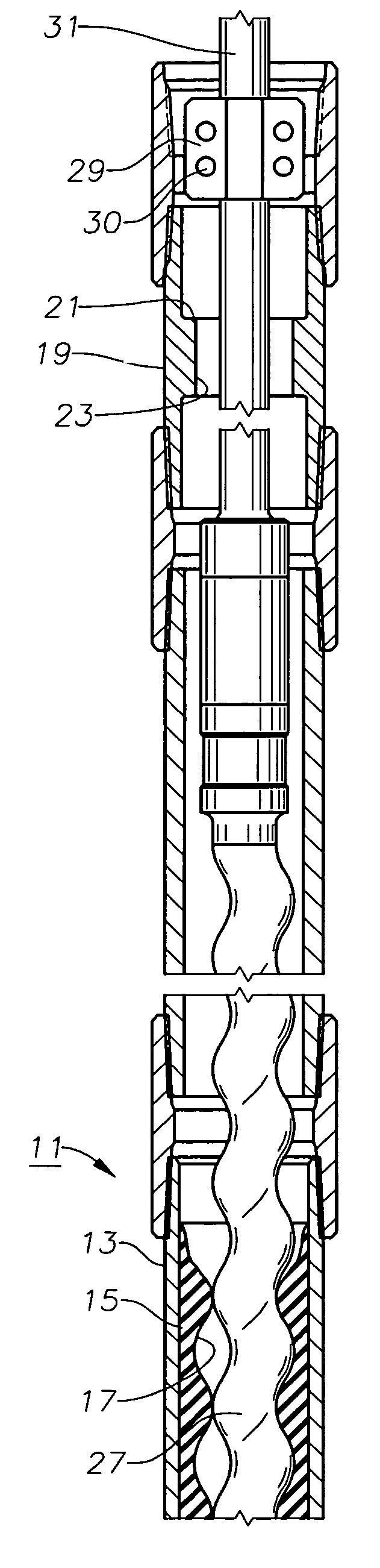

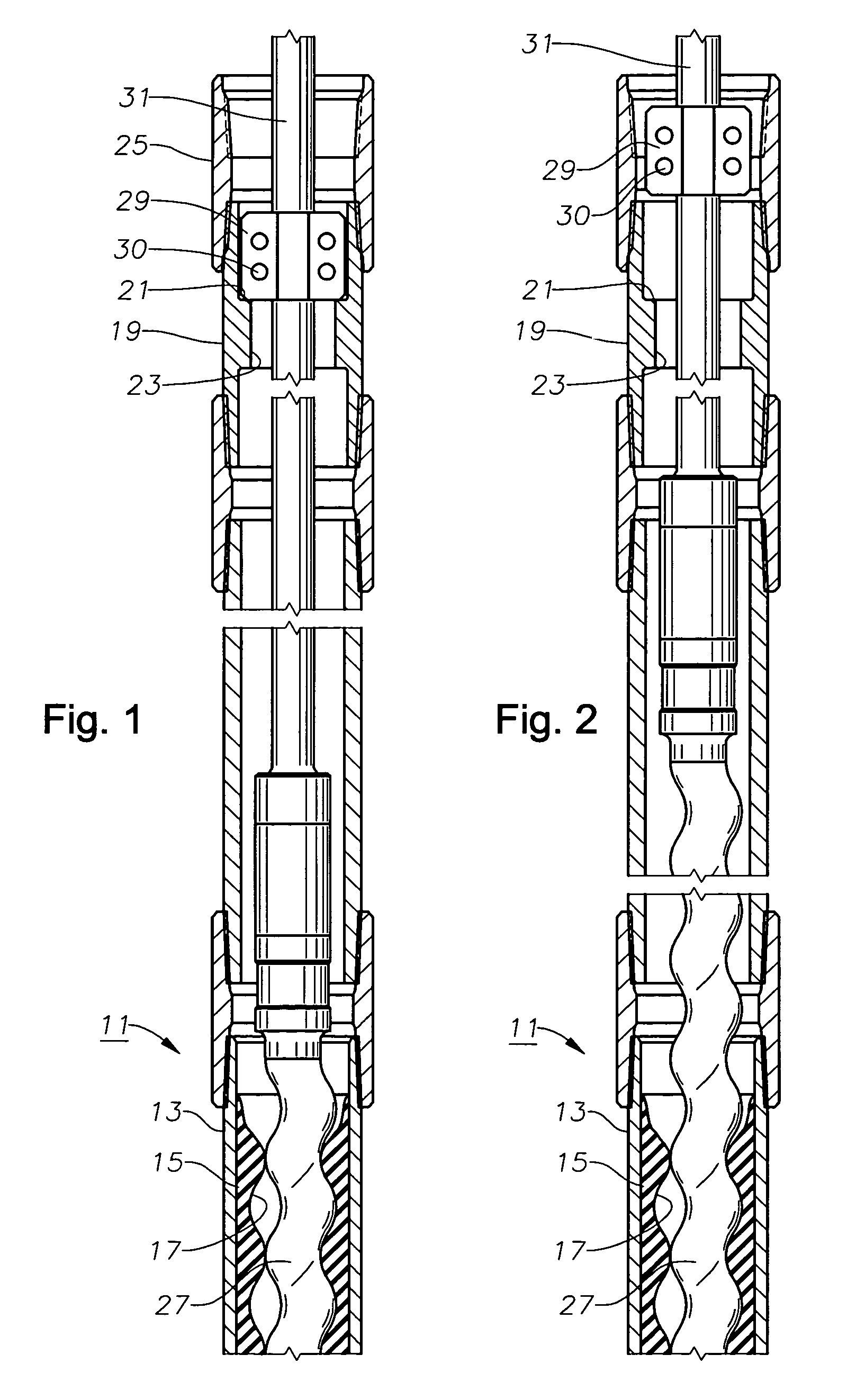

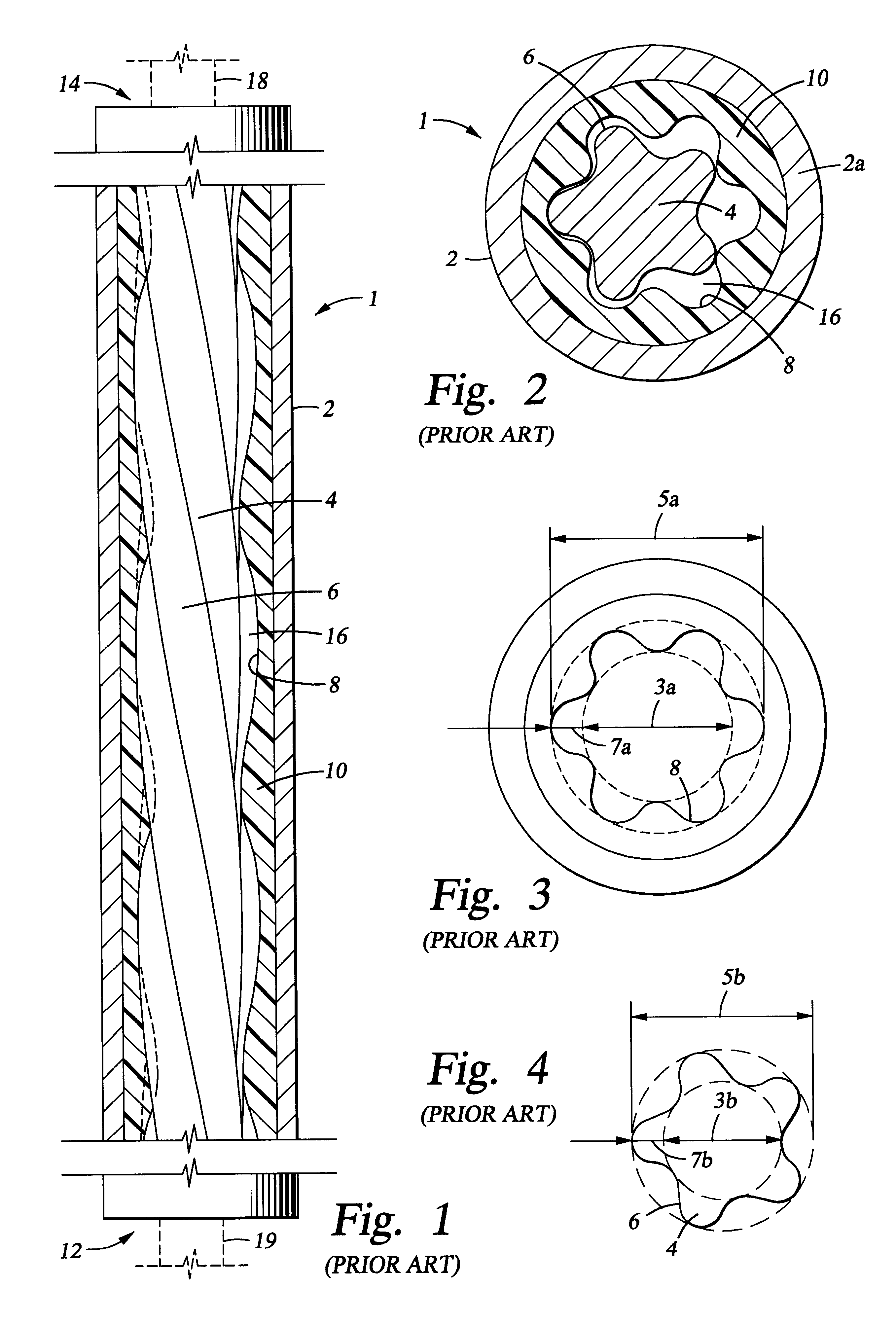

Method and apparatus for aligning rotor in stator of a rod driven well pump

InactiveUS7201222B2Oscillating piston enginesEngine of intermeshing engagement typeMechanical engineeringHelix

A progressing cavity rod-driven well pump utilizes a tag shoulder above a helical passage of the stator. The pump stator is located at the lower end of a string of tubing. The tag shoulder is more restrictive than a passage through the tubing. A pump rotor is secured to a string of rods and has a stop located above the rotor. The rotor is lowered on the rods until the stop lands on the tag shoulder. Then the operator lifts the rods and the rotor to accommodate for expected stretch during operation. By removing the rods and rotor, monitoring tools can be lowered through the tag shoulder and stator.

Owner:BAKER HUGHES INC

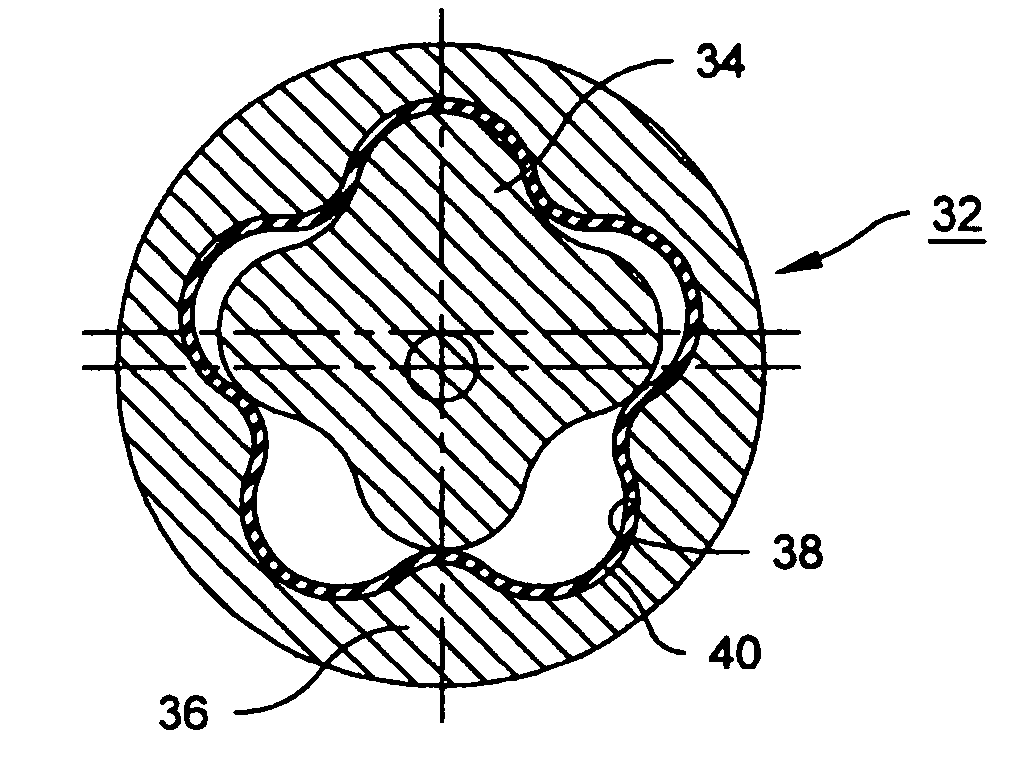

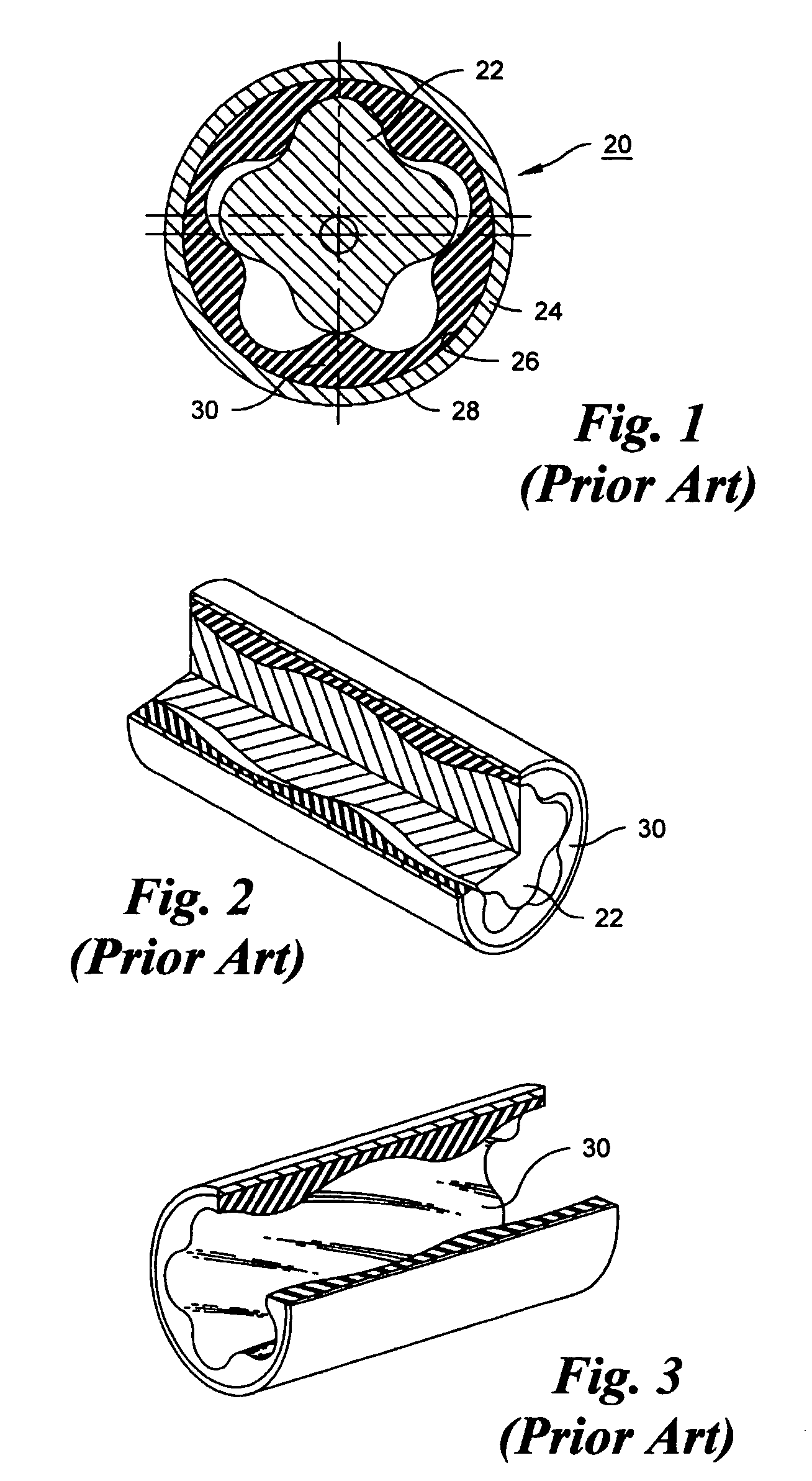

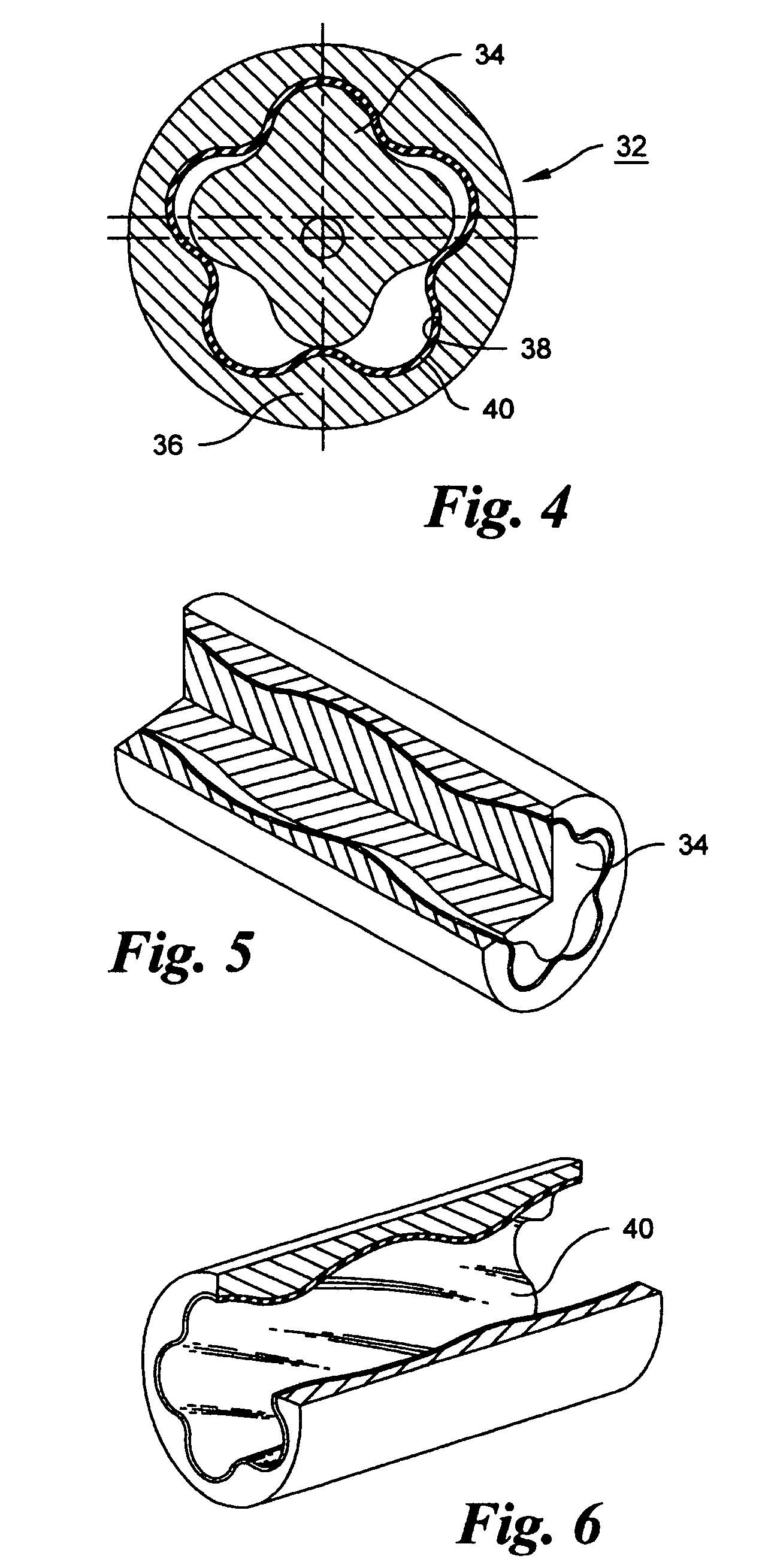

Progressive cavity pump/motor stator, and apparatus and method to manufacture same by electrochemical machining

ActiveUS7192260B2Improve heat transfer performanceReduce adverse effectsElectrolysis componentsEngine of intermeshing engagement typeElastomerElectricity

Electrochemical machining is used to generate the helical lobe profiles of the stator of a progressive cavity pump or motor. A thin, elastomeric liner, of uniform thickness is bonded either to the interior of the stator, or to the exterior of the rotor. Where the elastomeric liner is to be bonded to the interior of the stator, bonding is improved by electrically etching the interior of the stator during the electrochemical machining process to produce a roughened surface.

Owner:LEHR PRECISION

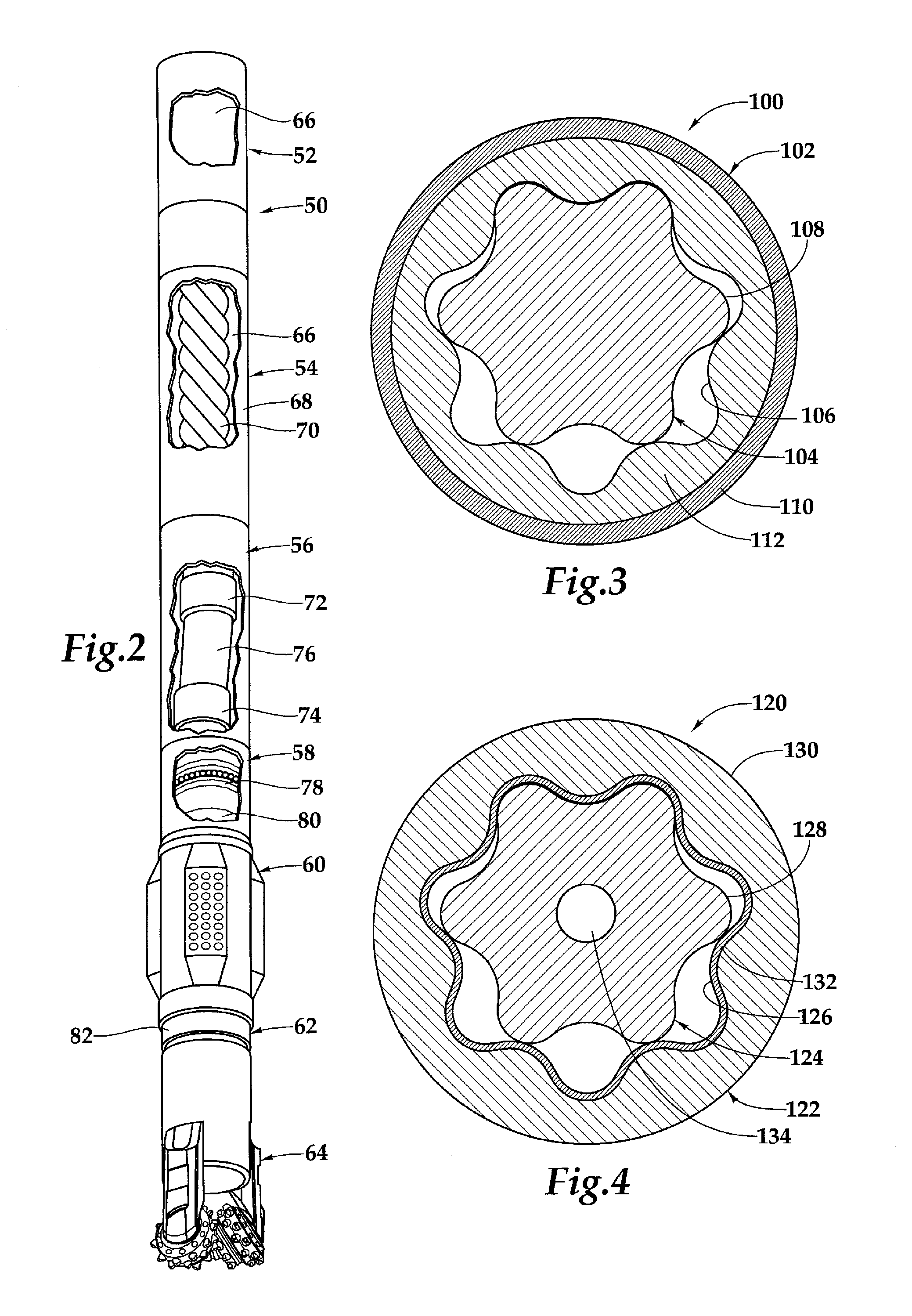

Stator for down hole drilling motor

InactiveUS6905319B2Reduced susceptibility to stator damageSufficient wear characteristicOscillating piston enginesEngine of intermeshing engagement typeDrill holePhysics

An improved down hole drilling motor suitable for drilling applications. The down hole drilling motor comprising a stator disposed in the tubular housing. The stator includes an internal cavity having one or more lobes. A rotor operatively positioned in the cavity of the stator is adapted to cooperate with the one or more lobes of the stator. The stator comprising a compound having improved manufacturing and performance characteristics.

Owner:HALLIBURTON ENERGY SERVICES INC

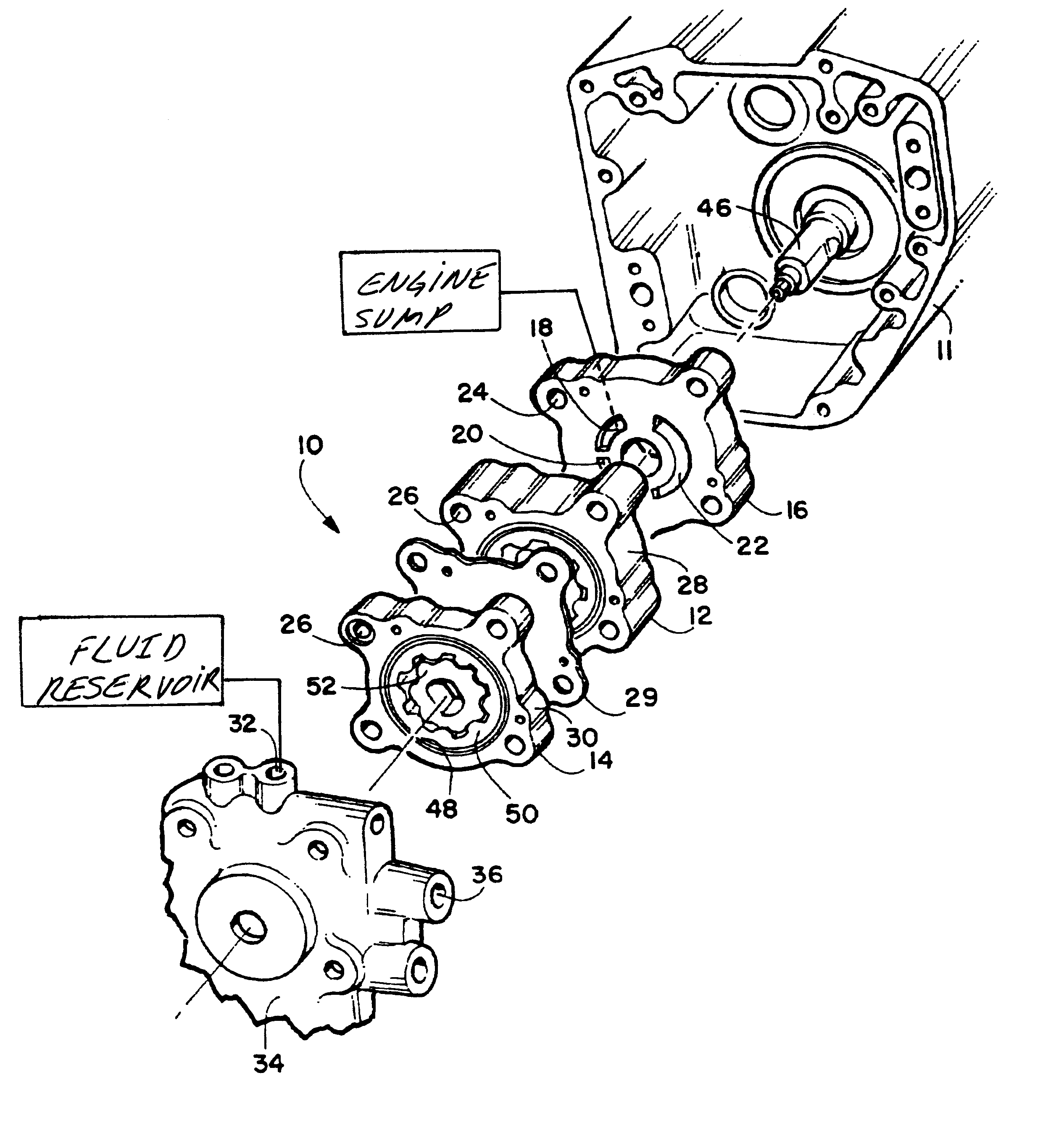

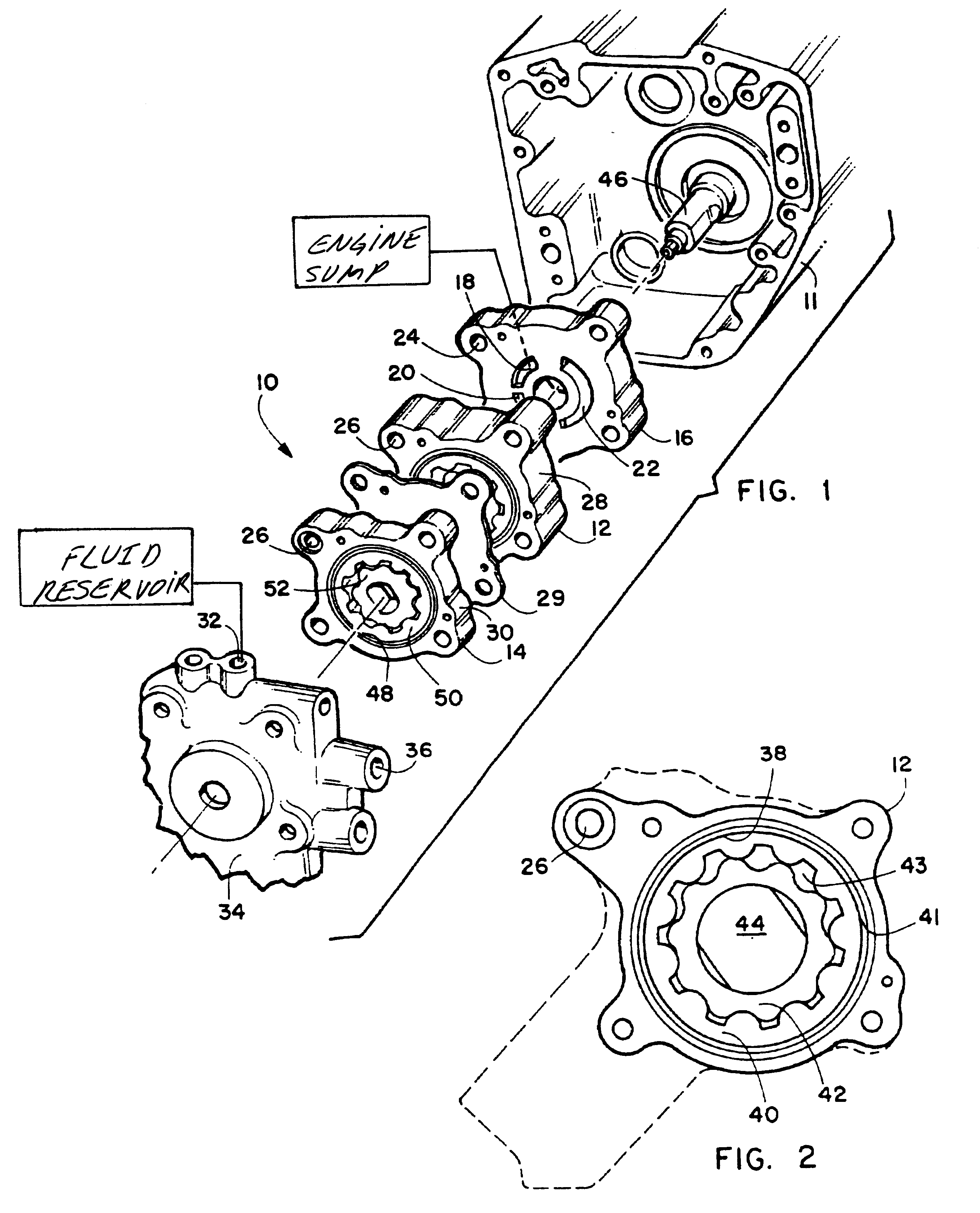

Oil pump

InactiveUS6679692B1Easy to replacePromote repairRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesFuel tankEngineering

A modular oil pump for use in combination with an internal combustion engine having a dry sump lubrication system. The device features a first gerotor pump having an intake port engageable in communication with at least one engine sump and having an discharge port engageable in sealed communication with a fluid reservoir for the dry sump system. A second gerotor pump, engageable in sealed communication with the fluid reservoir has a discharge port fluidly engageable with the engine lubrication system oil supply conduit. Both the first pump and second pump are assembled from separate housings, and cooperatively engaged inner and outer gears sized for rotation and in line mounting on the engine crankshaft inside a cavity in the housings. The volume pumping capacity of the first pump at a ratio to efficiently drain fluid and gas from the engine sumps and supply the reservoir with a constant supply of lubrication fluid. The device may be assembled from a kit having a plurality of different sized components to adjust the ratio of the pumping volume of the first pump to the second pump.

Owner:FEULING JAMES J

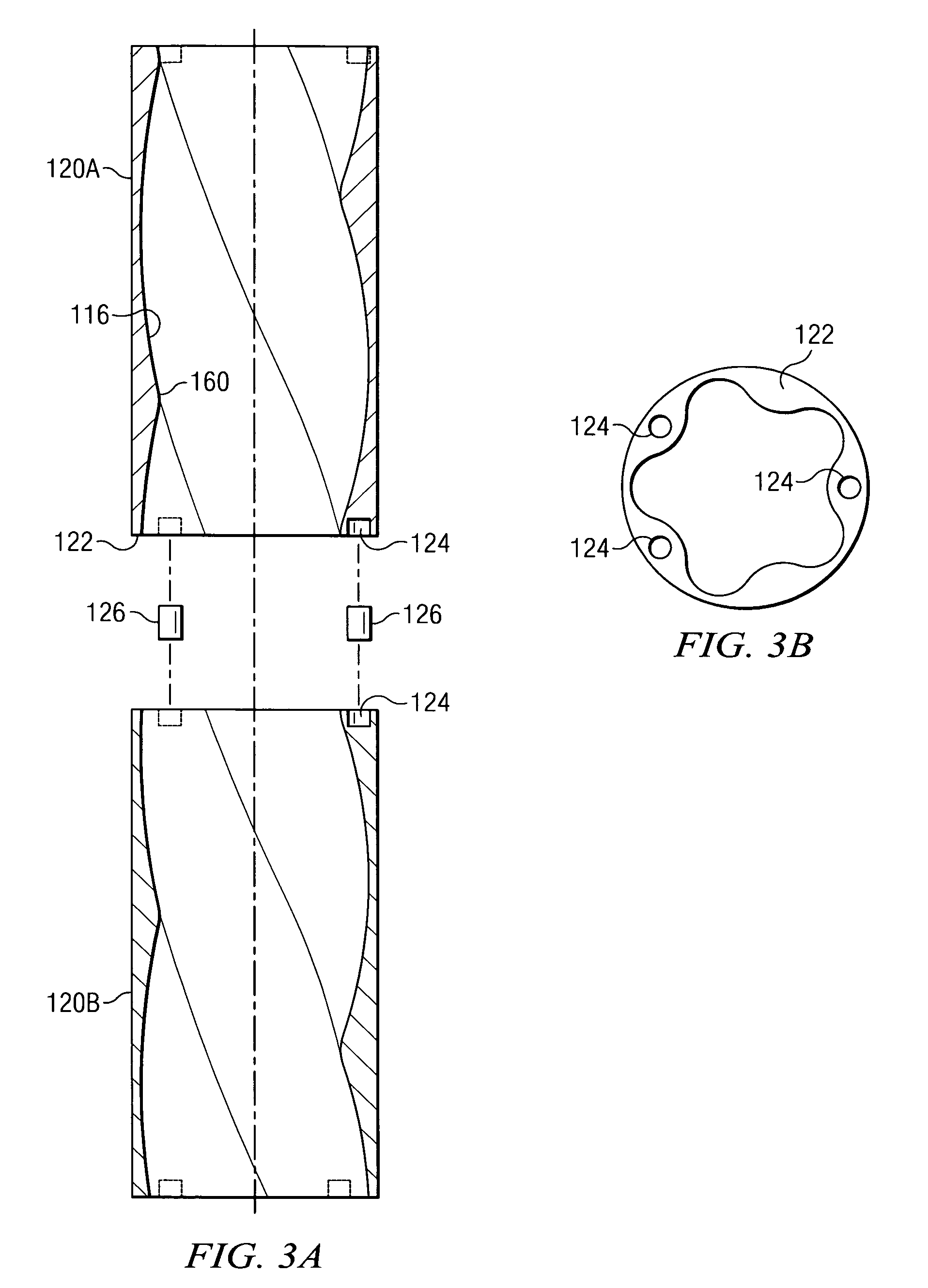

Progressing cavity stator including at least one cast longitudinal section

InactiveUS7396220B2Increased torque outputSimple and inexpensive to manufactureOscillating piston enginesEngine of intermeshing engagement typeElastomerHigh torque

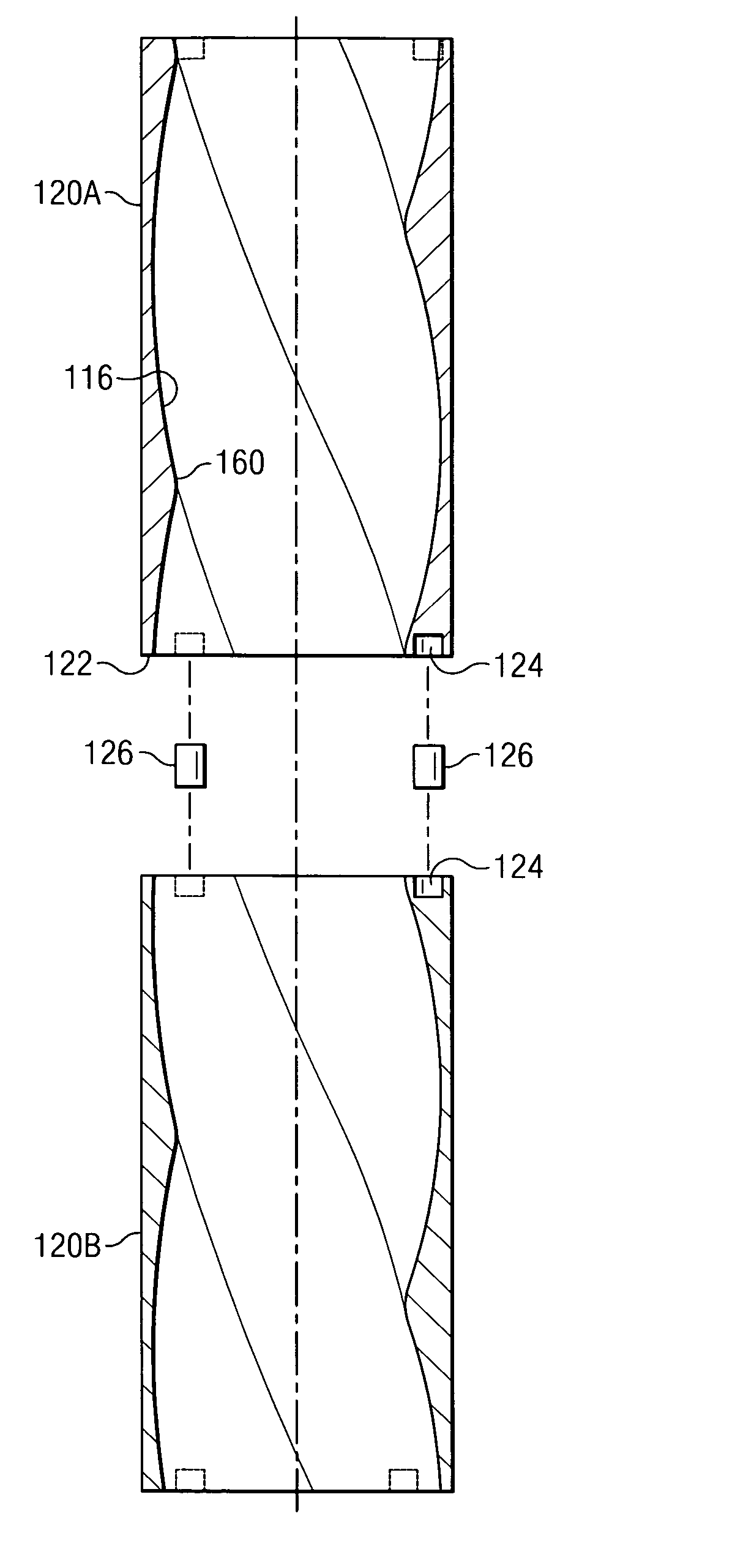

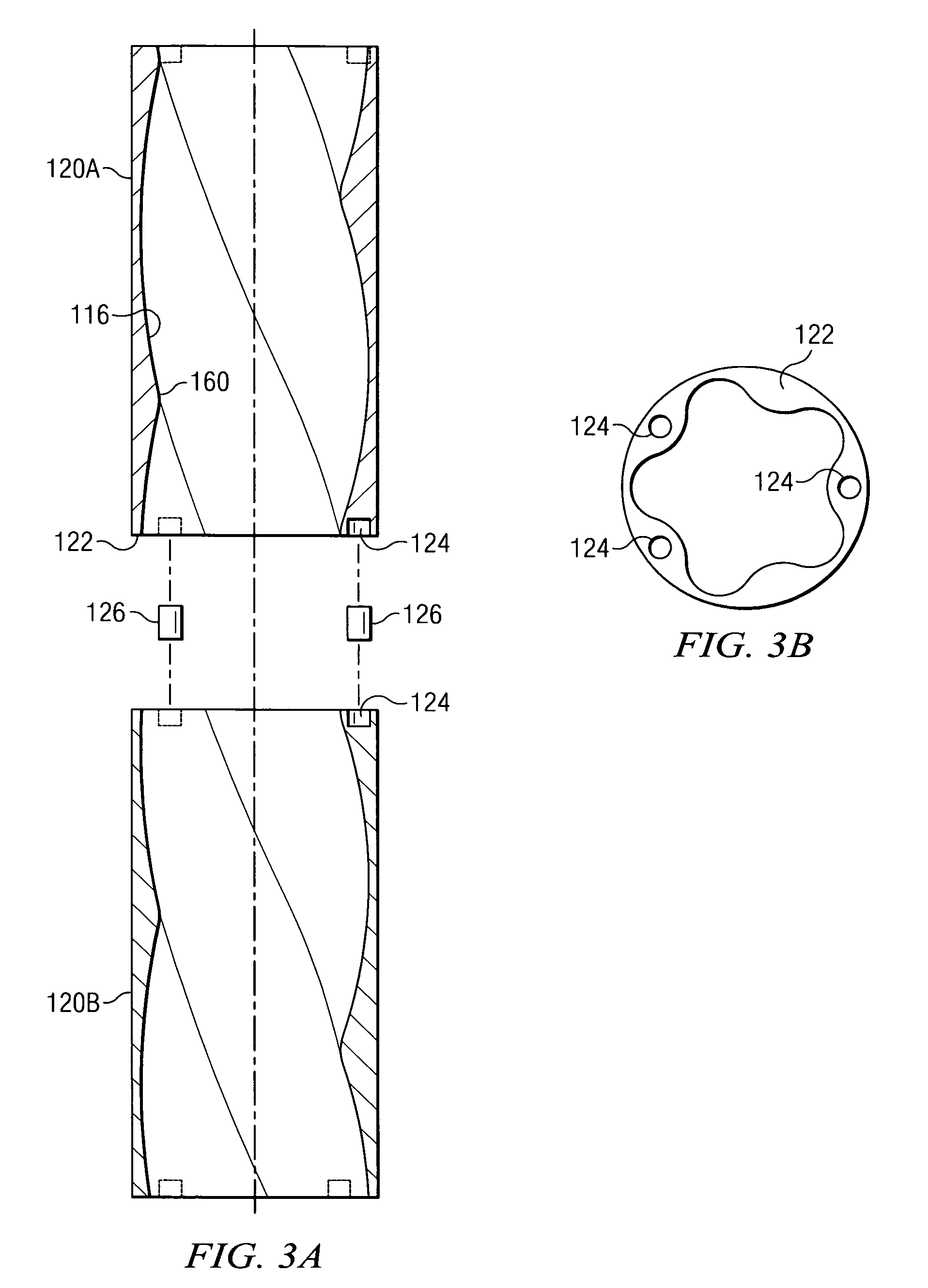

A progressing cavity stator and a method for fabricating such a stator are disclosed. Exemplary embodiments of the progressing cavity stator include a plurality of rigid longitudinal stator sections concatenated end-to-end in a stator tube. The stator sections are rotationally aligned so that each of the internal lobes extends in a substantially continuous helix from one end of the stator to the other. The stator further includes an elastomer liner deployed on an inner surface of the concatenated stator sections. Exemplary embodiments of this invention include a comparatively rigid stator having high torque output and are relatively simple and inexpensive to manufacture as compared to prior art rigid stators.

Owner:SMITH INT INC

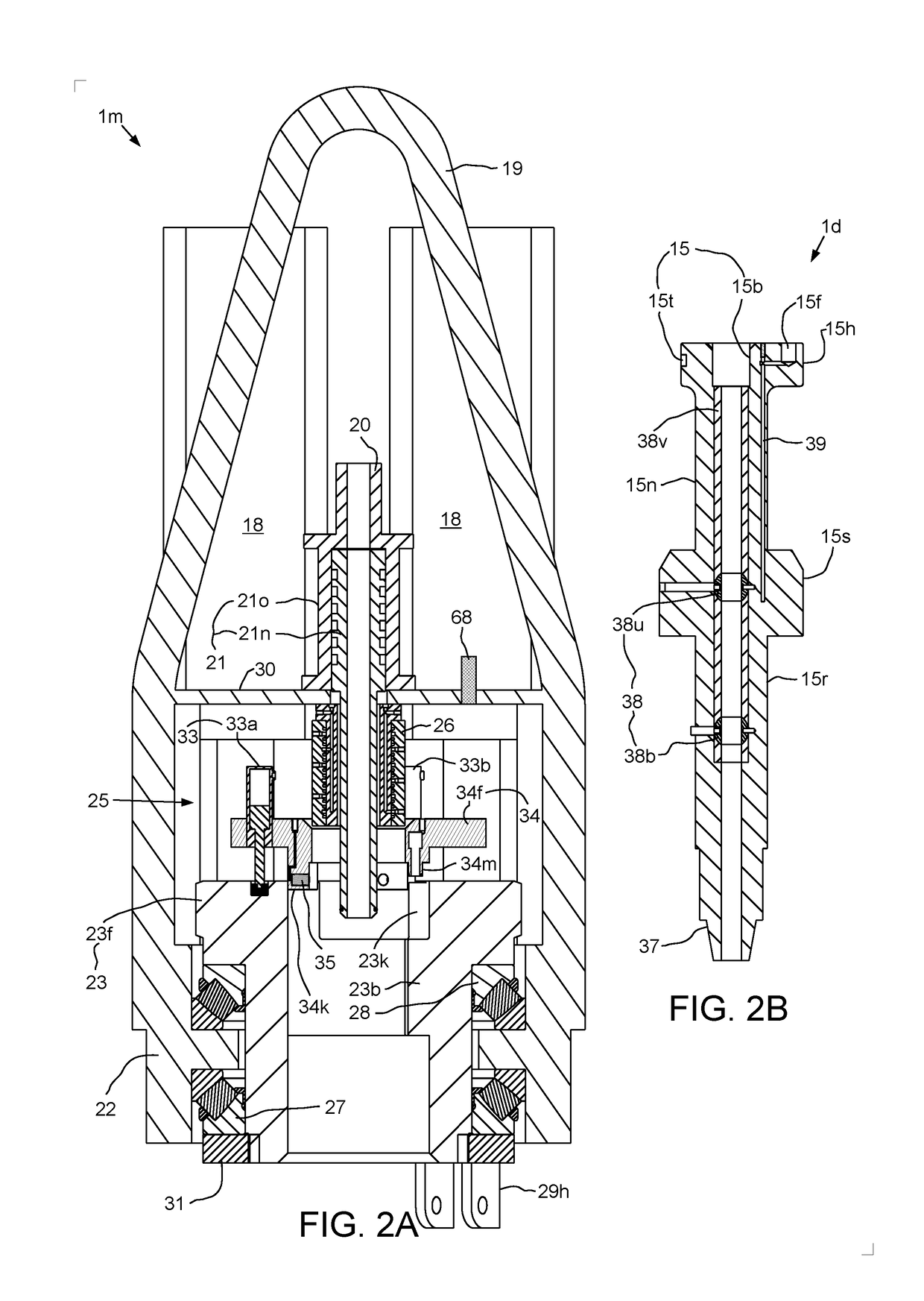

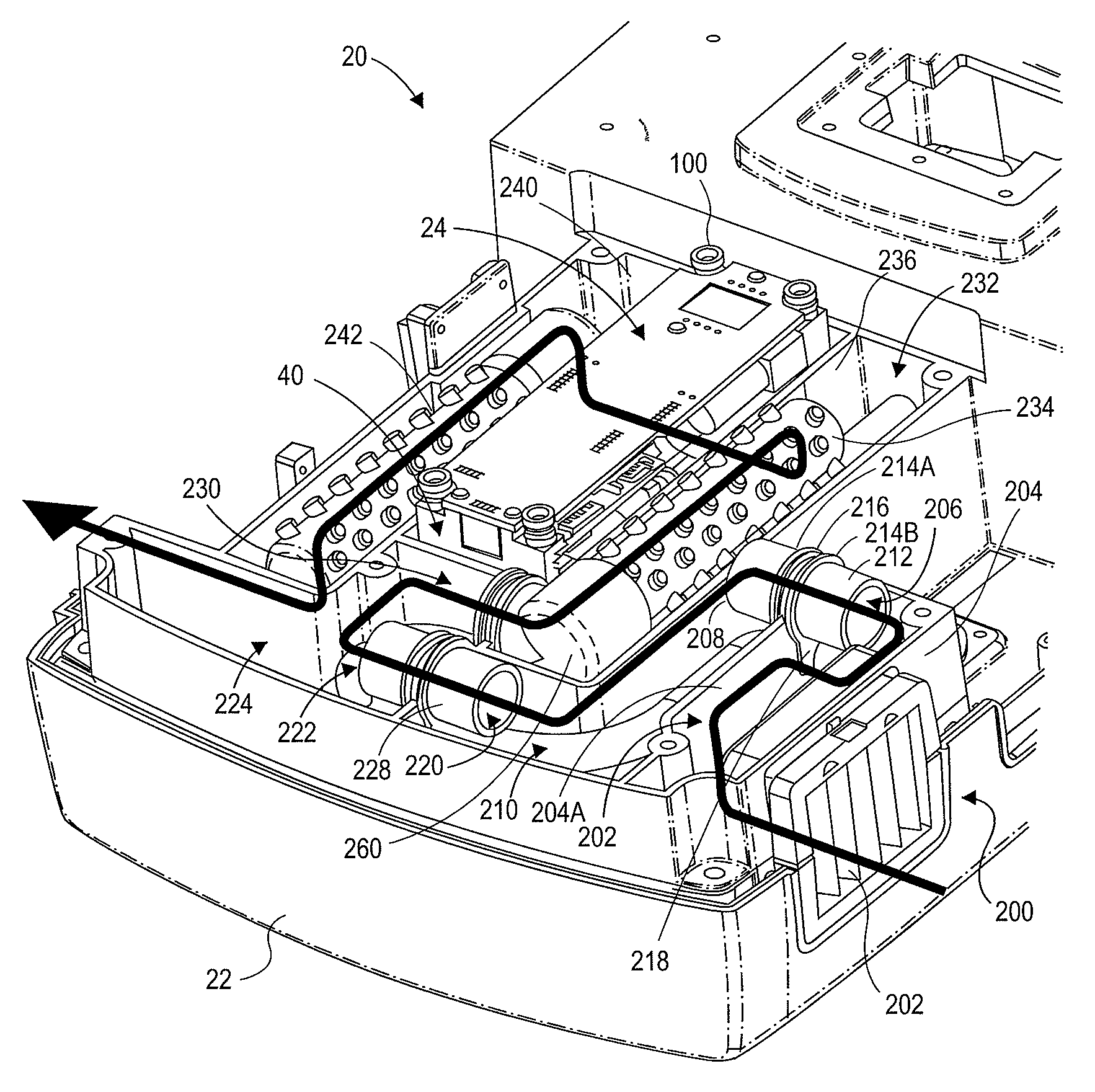

Method and apparatus for attenuating compressor noise

ActiveUS20050166921A1Reduce noiseReduce the amount of noiseRespiratorsOperating means/releasing devices for valvesPortable ventilatorsEngineering

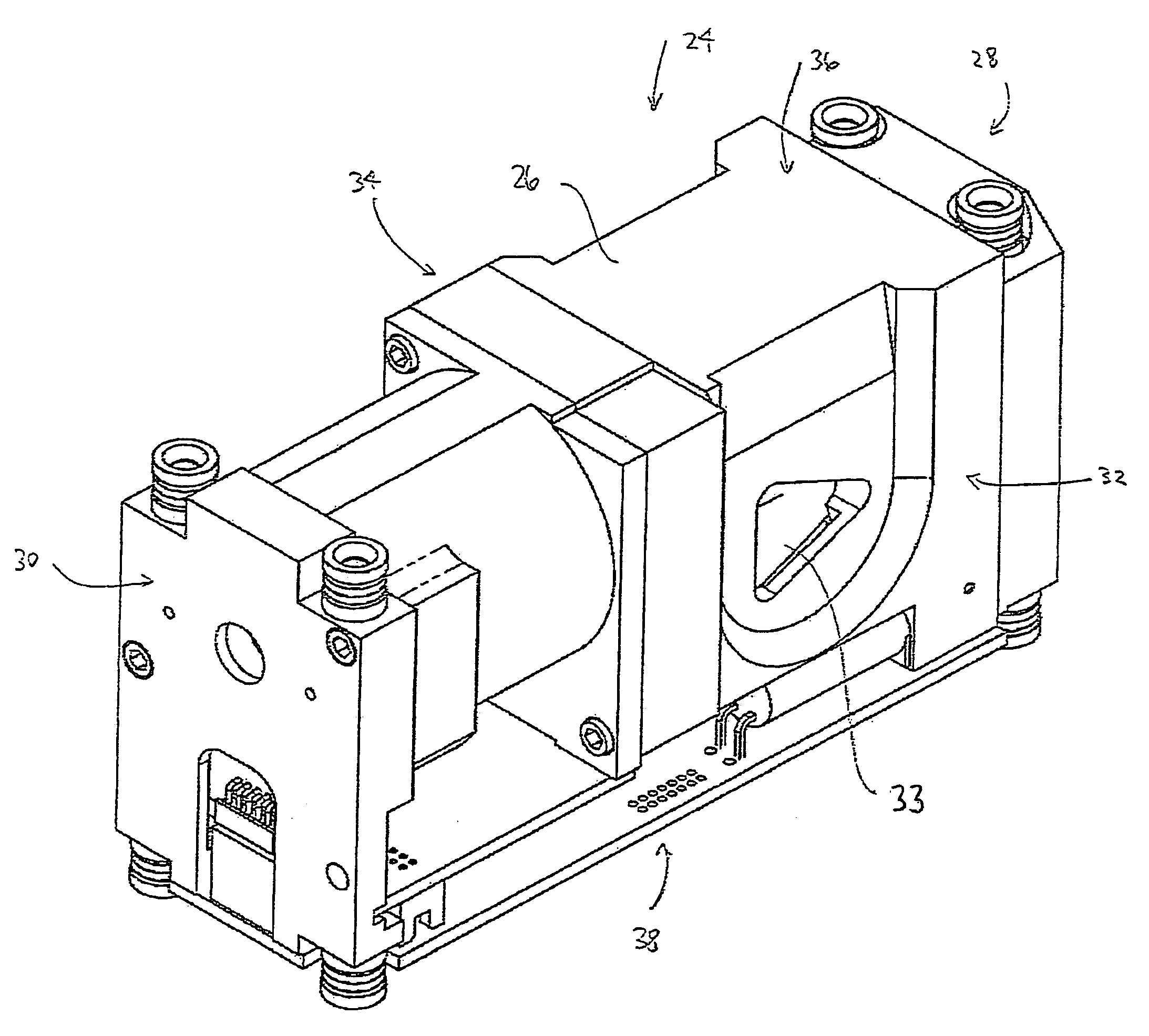

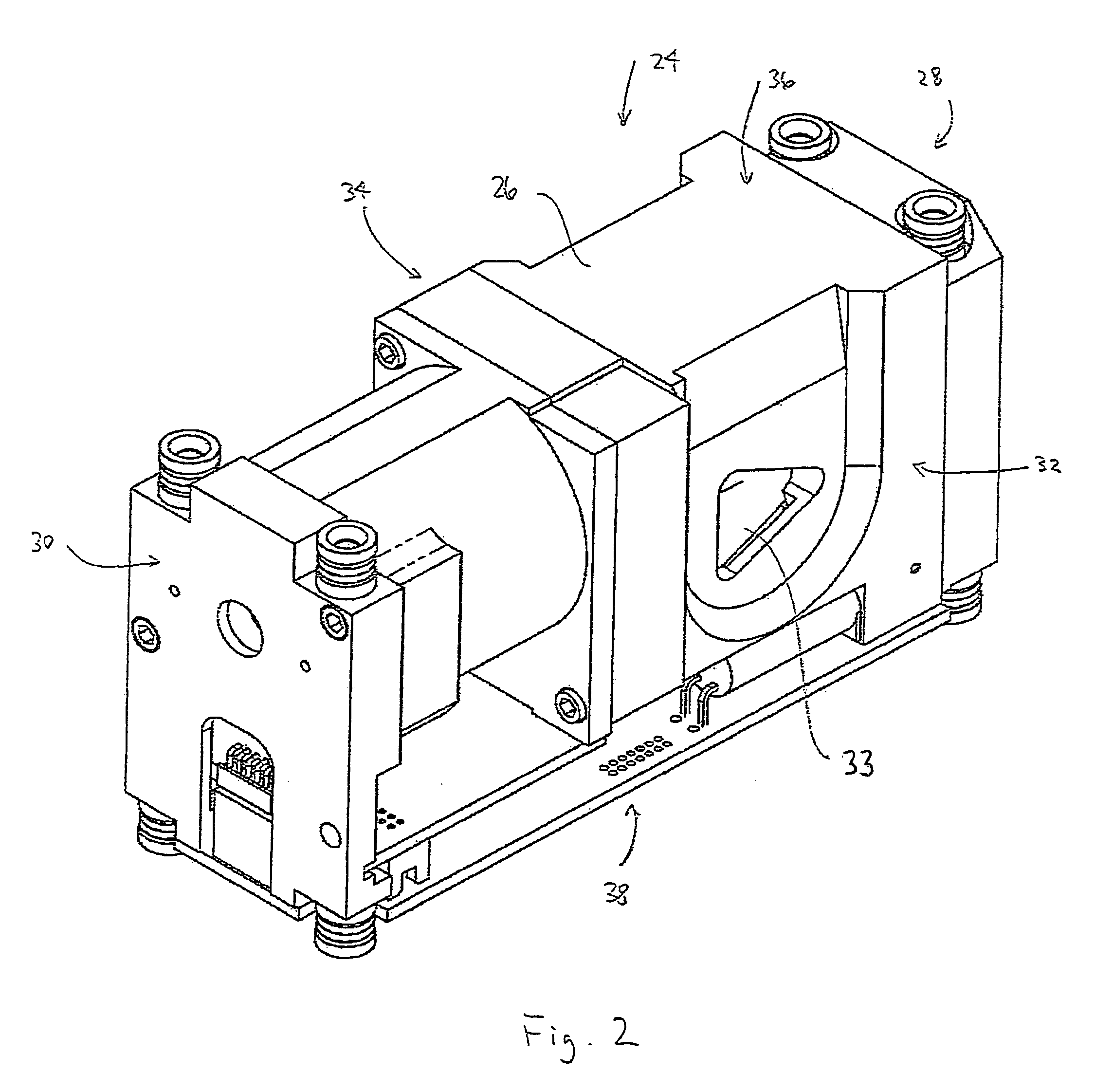

The invention comprises a method and apparatus for reducing the noise generated by compressors, including Roots-type blowers. The invention has particular use for reducing noise generated by compressors used in mechanical ventilators, though the advantages thereof may be realized in many different applications. One embodiment of the invention comprises a noise-attenuating gas flow path for a compressor contained in a portable ventilator housing. In one embodiment, the gas flow path comprises a plurality of chambers interconnected by flow tubes. The flow path is folded so as to fit into the limited space of a portable ventilator housing. The dimensions of the chambers and the flow tubes are selected so that an impedance mismatch is created between the chambers and the flow tubes. In one embodiment of the invention, the flow path comprises one or more perforated tubes located in one or more of the chambers. The perforated tube has a port through which gas is accepted and at least one exterior tube through which gas exits. Impedance mismatches are created between the inlet chamber and the exterior tubes and between the exterior tubes and the chamber in which the perforated tube is located, which are useful in attenuating noise. One embodiment of the invention comprises a noise attenuating mounting system for a compressor. The mounting system comprises flexible mounts that cooperate to dampen vibrations generated by the compressor.

Owner:VYAIRE MEDICAL 203 INC

Progressive cavity pump/motor

InactiveUS6881045B2Accurate verificationOscillating piston enginesEngine of intermeshing engagement typeEngineeringDrill bit

A progressive cavity pump or motor, particularly suitable for hydrocarbon recovery operations, includes a rotor 20 and a stator 10. Fluid pressure in cavities between the stator and the rotor create torque which rotates the bit. An interior surface of the stator is rigidly secured to the outer housing of the pump stator and defines an interior profile. A substantially uniform thickness elastomeric layer 62 is supported on the outer housing. The pump rotor has an exterior profile which corresponds with the interior profile of the elastomeric layer.

Owner:ROBBINS & MYERS ENERGY SYST

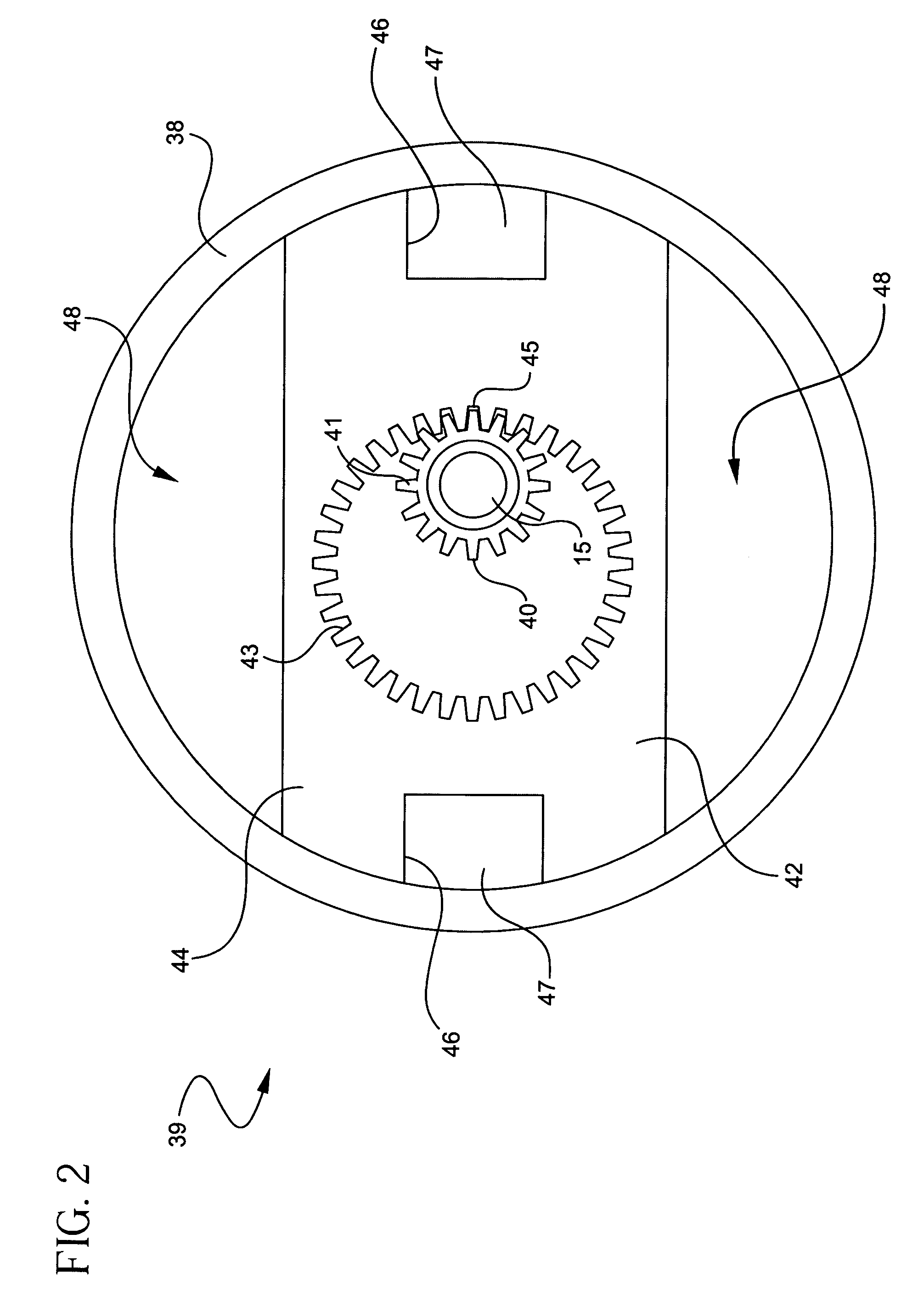

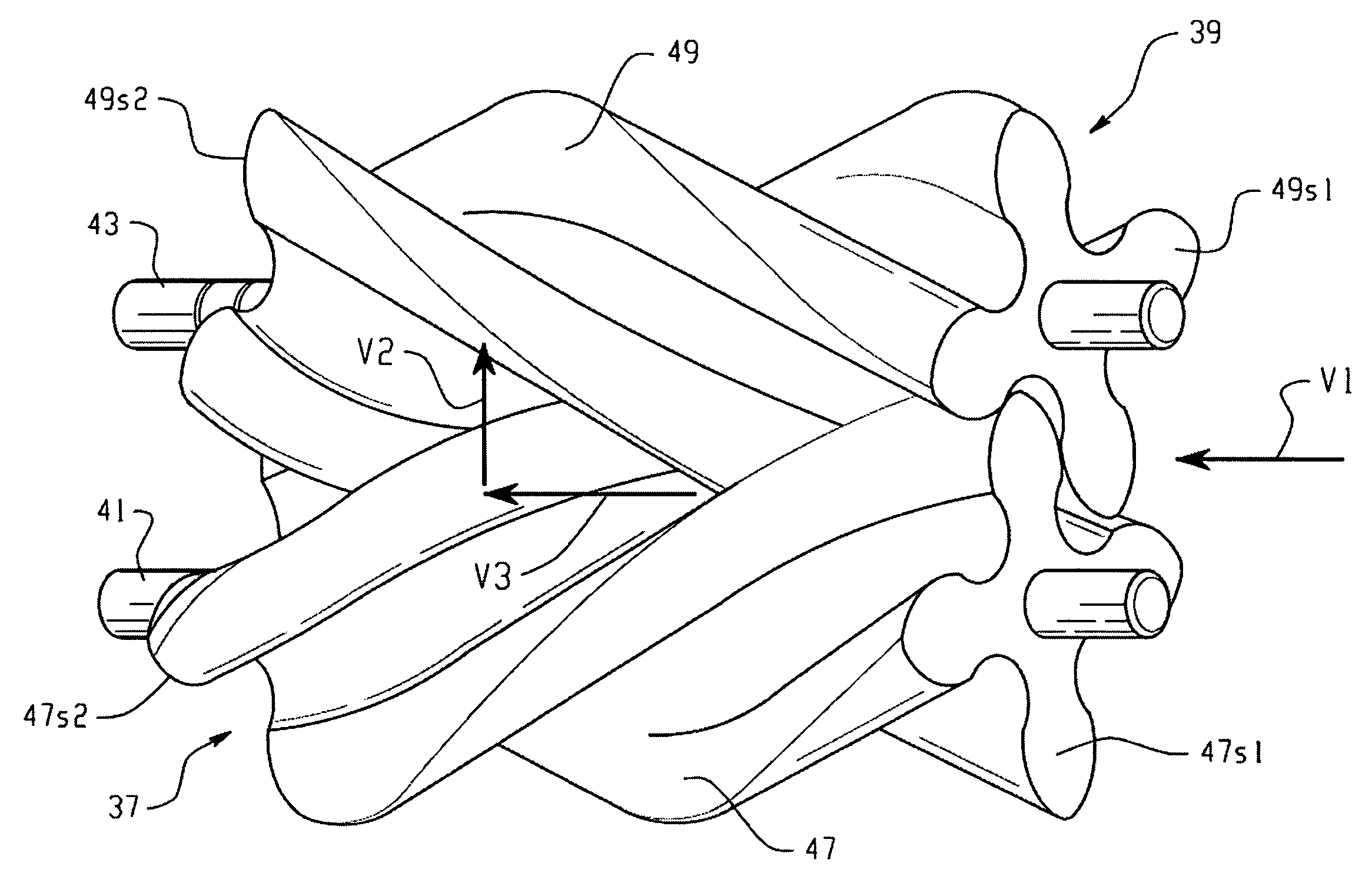

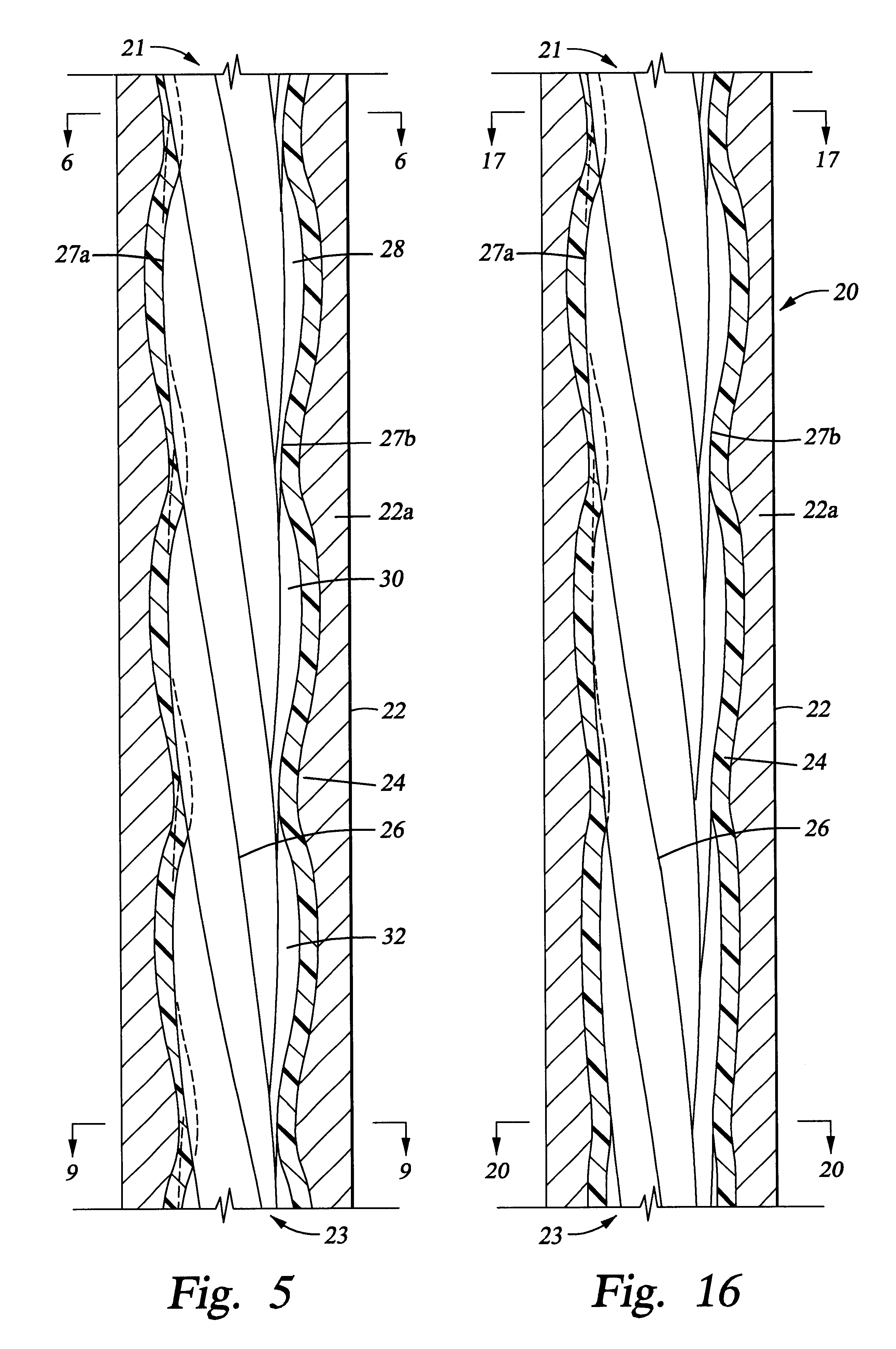

Optimized helix angle rotors for Roots-style supercharger

ActiveUS7488164B2Improve blower efficiencyImprove thermal efficiencyOscillating piston enginesEngine of counter-engagement typeEngineeringHelix angle

A method of designing rotors for a Roots blower comprising a housing having cylindrical chambers, the housing defining an outlet port (19). The blower includes meshed, lobed rotors (37,39) disposed in the chambers, each rotor including a plurality N of lobes (47,49), each lobe having first (47a,49a) and second (47b,49b) axially facing end surfaces. Each lobe has its axially facing surfaces defining a twist angle (TA), and each lobe defines a helix angle (HA). The method of designing the rotor comprises determining a maximum ideal twist angle (TAM) for the lobe as a function of the number N of lobes on the rotor, and then determining a helix angle (HA) for each lobe as a function of the maximum ideal twist angle (TAM) and an axial length (L) between the end surfaces of the lobe. A rotor designed in accordance with this method is also provided.

Owner:EATON INTELLIGENT POWER LTD

Progressing cavity stator including at least one cast longitudinal section

InactiveUS20060182644A1Prevent rotationIncreased torque outputOscillating piston enginesEngine of intermeshing engagement typeElastomerHigh torque

A progressing cavity stator and a method for fabricating such a stator are disclosed. Exemplary embodiments of the progressing cavity stator include a plurality of rigid longitudinal stator sections concatenated end-to-end in a stator tube. The stator sections are rotationally aligned so that each of the internal lobes extends in a substantially continuous helix from one end of the stator to the other. The stator further includes an elastomer liner deployed on an inner surface of the concatenated stator sections. Exemplary embodiments of this invention include a comparatively rigid stator having high torque output and are relatively simple and inexpensive to manufacture as compared to prior art rigid stators.

Owner:SMITH INT INC

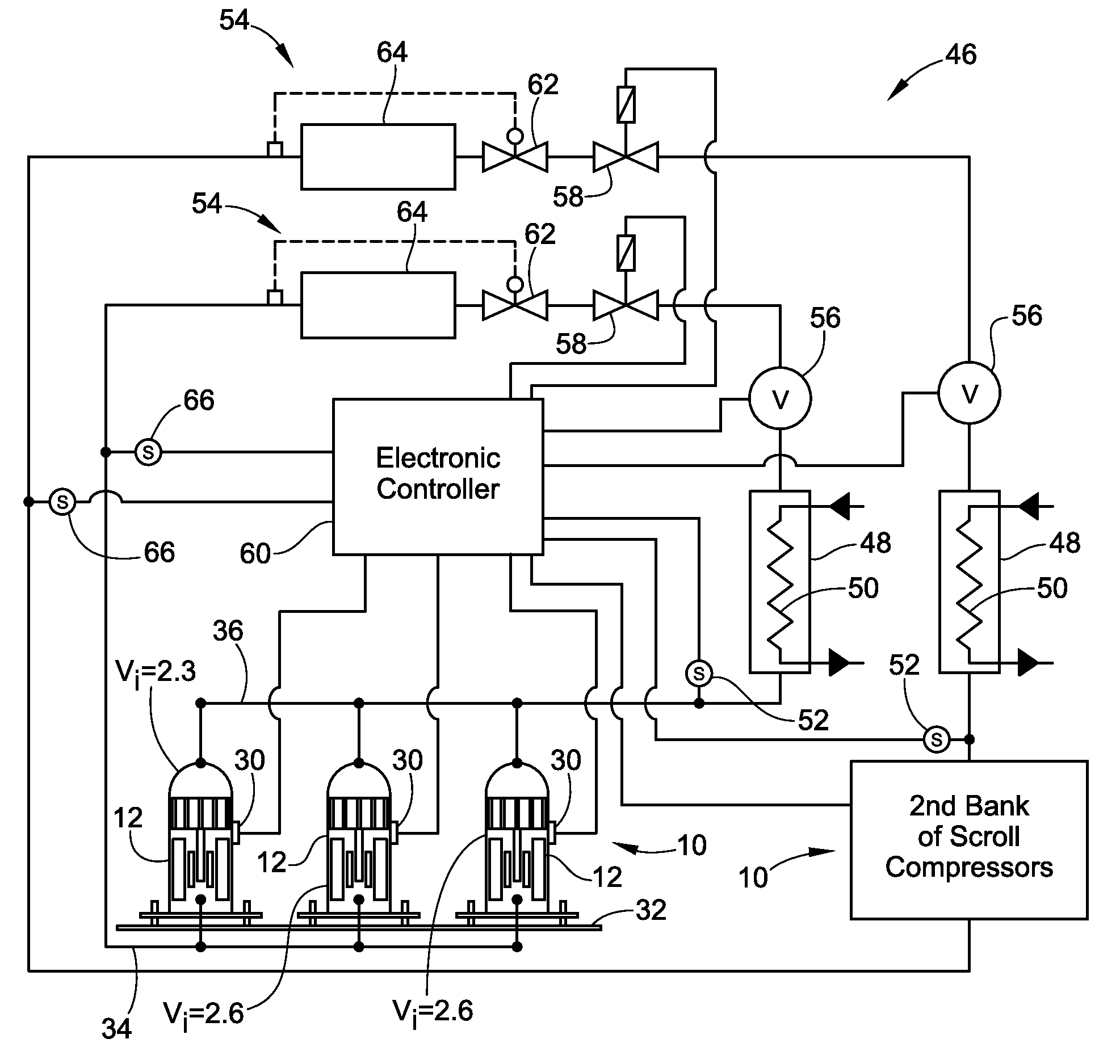

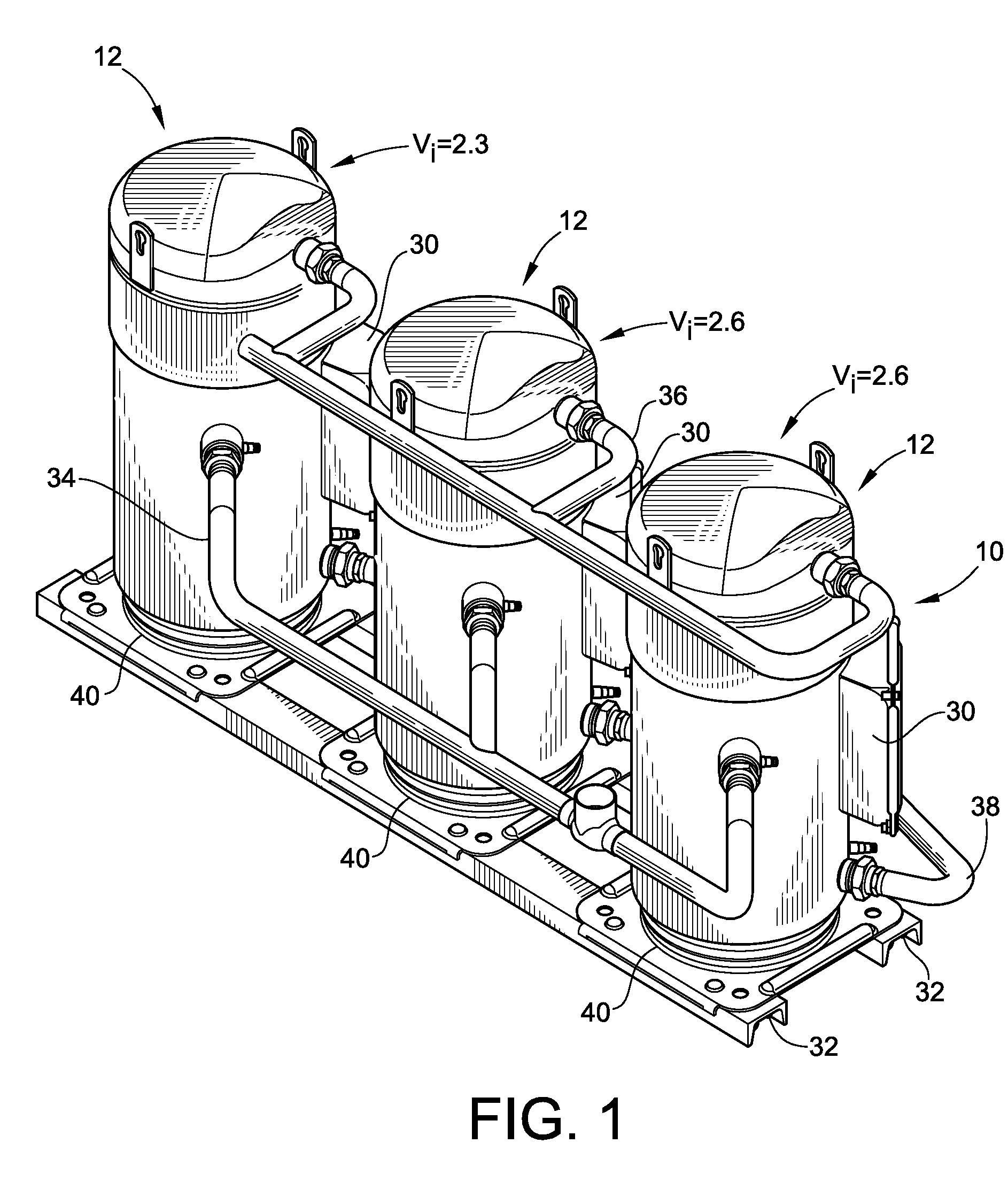

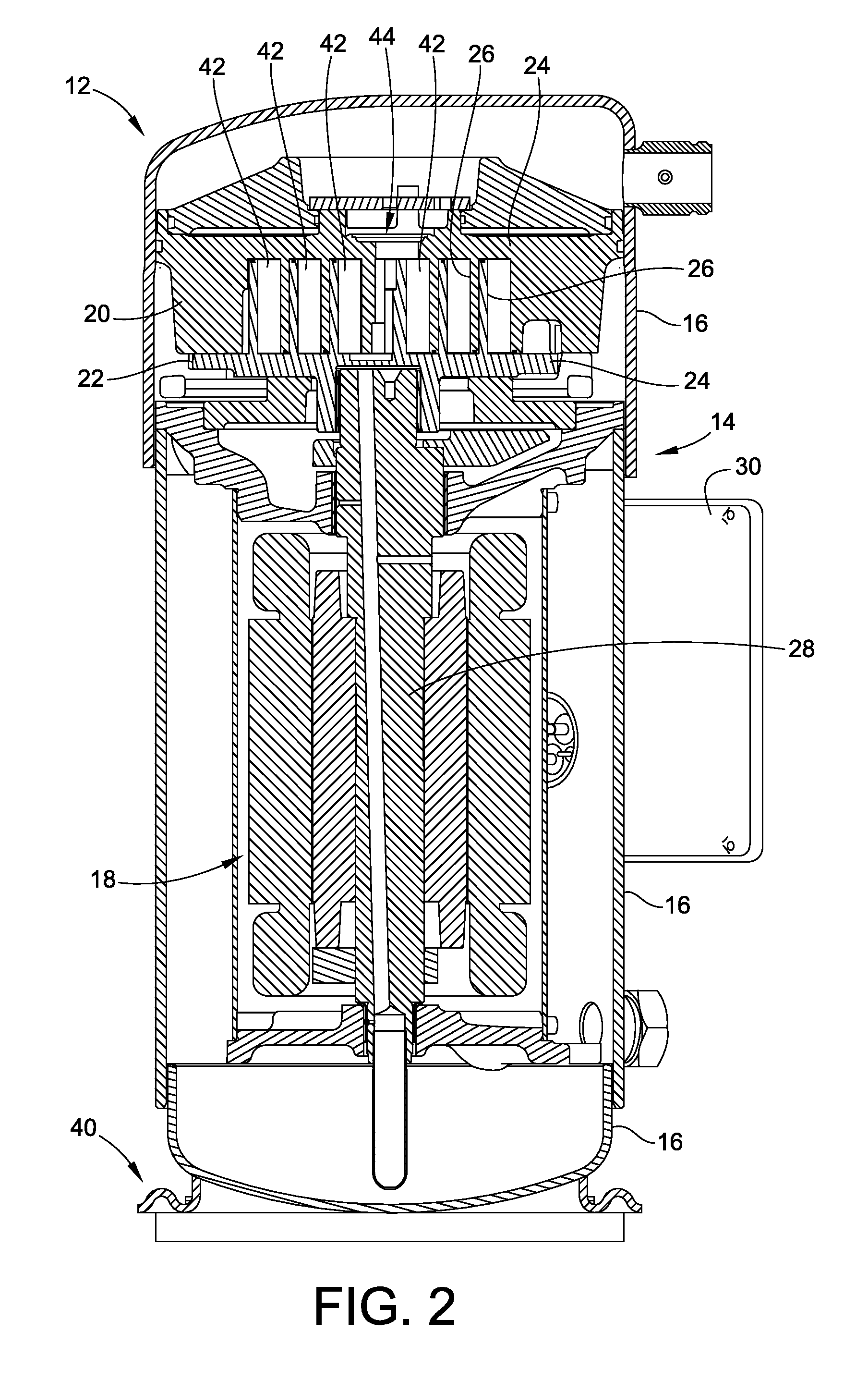

Scroll Compressors with Different Volume Indexes and Systems and Methods for Same

InactiveUS20100186433A1Improve efficiencyRotary/oscillating piston combinations for elastic fluidsCompressorEngineeringScroll compressor

Owner:BITZER KUEHLMASCHINENBAU GMBH

Composite material progressing cavity stators

InactiveUS20050089429A1Extended service lifeImprove reliabilityOscillating piston enginesEngine of intermeshing engagement typeElastomerFiber-reinforced composite

A progressing cavity stator is provided. The progressing cavity stator includes a fiber reinforced composite component providing an internal helical cavity having at least one helical groove and an elastomeric liner disposed on an internal surface of the fiber reinforced composite component. In various exemplary embodiments, the fiber reinforced composite component includes a plurality of fibers disposed in a matrix material, the plurality of fibers being disposed such that distinct portions thereof follow correspondingly distinct directions. Exemplary embodiments of this invention may advantageously exhibit a prolonged service life in downhole applications as compared to conventional progressing cavity stators. A replaceable progressing cavity insert for a stator is also provided. Methods for fabricating progressing cavity stators and progressing cavity inserts are also provided.

Owner:DYNA DRILL TECH

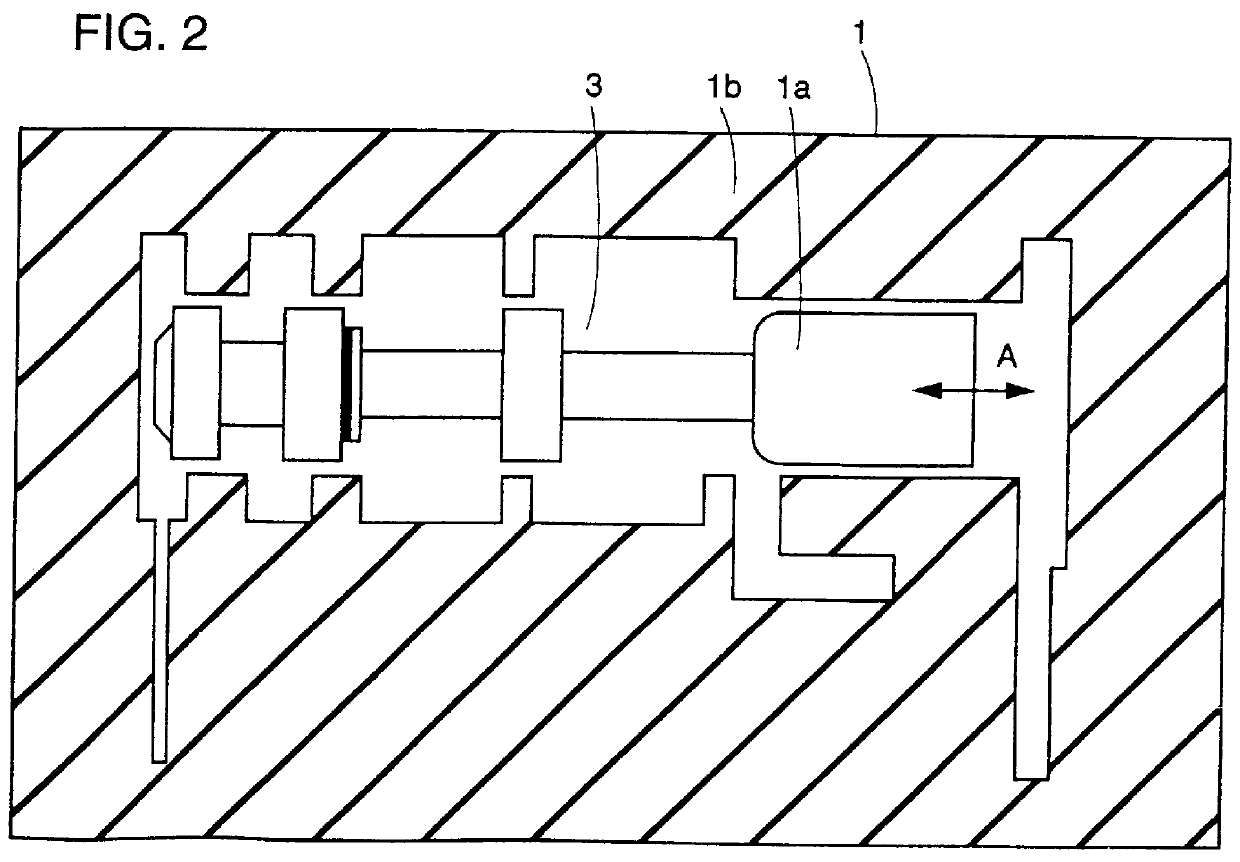

Adjustable fit progressive cavity pump/motor apparatus and method

InactiveUS6358027B1Oscillating piston enginesSealing arrangement for pumpsInterference fitEngineering

The present invention provides an adjustable rotor and / or stator, so that the interference fit and / or clearance can be adjusted. The rotor and / or stator are tapered to provide a difference in fit between the rotor and stator by longitudinal adjustment of their relative position. In one embodiment, the adjustment may occur while the PCP in mounted downhole in a wellbore. In another embodiment, the adjustment may occur automatically depending on sensor input of operating conditions of the PCP.

Owner:WEATHERFORDLAMB

Braze or solder reinforced moineu stator

InactiveUS20080304992A1Extended service lifeImprove efficiencyOscillating piston enginesEngine of intermeshing engagement typeElastomerState of art

A Moineau style stator includes a helical reinforcement component that provides an internal helical cavity. A resilient liner is deployed on an inner surface of the helical reinforcement component. The helical reinforcement component includes a solder or braze material and is typically metallurgically bonded to an inner wall of a stator tube. In exemplary embodiments, the helical reinforcement component includes a composite mixture of solder and aggregate. Exemplary embodiments of this invention address the heat build up and subsequent elastomer breakdown in the lobes of prior arts stators by providing a helical reinforcement component. Solder reinforced stators tend to be less expensive to fabricate than reinforced stators of the prior art.

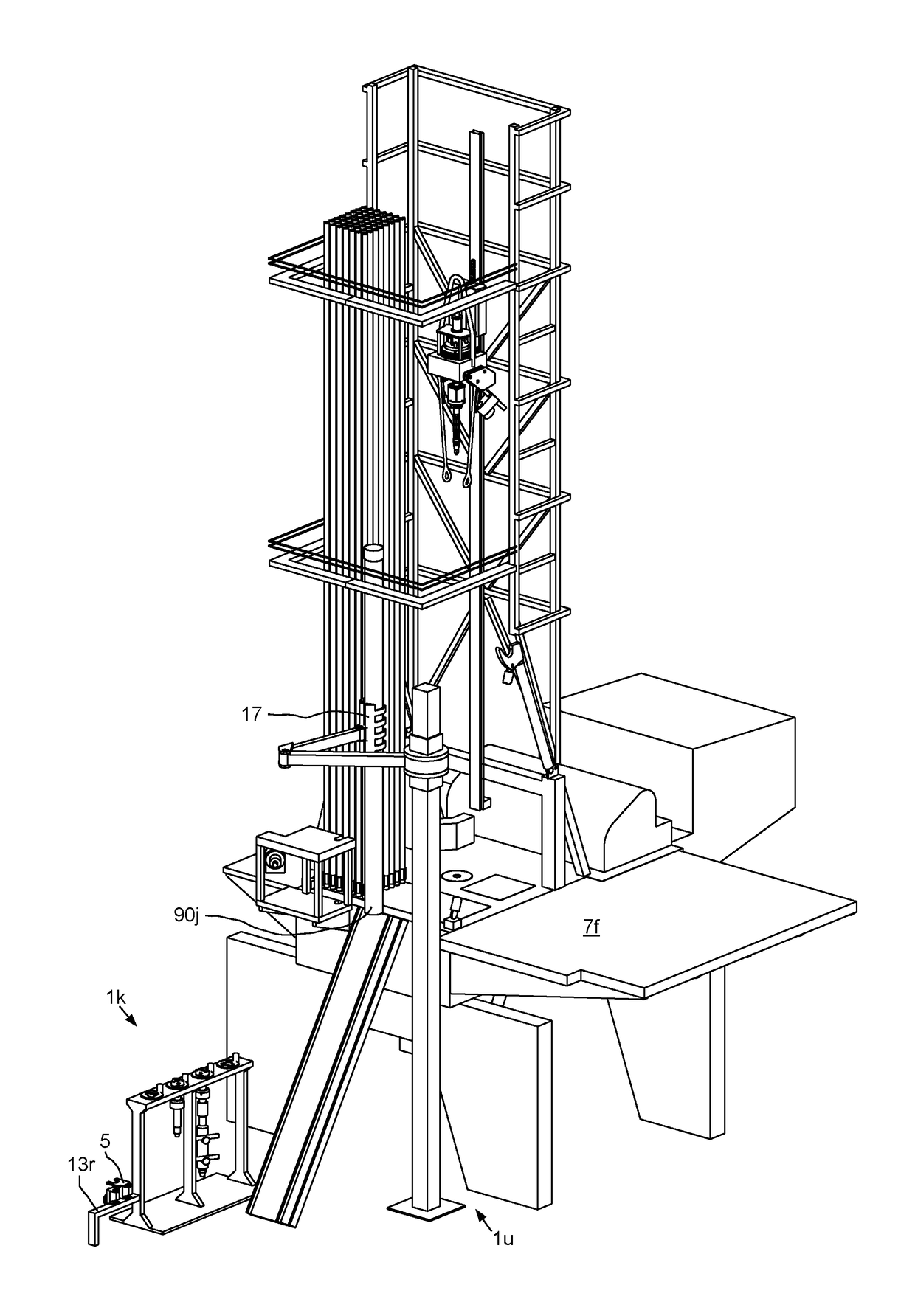

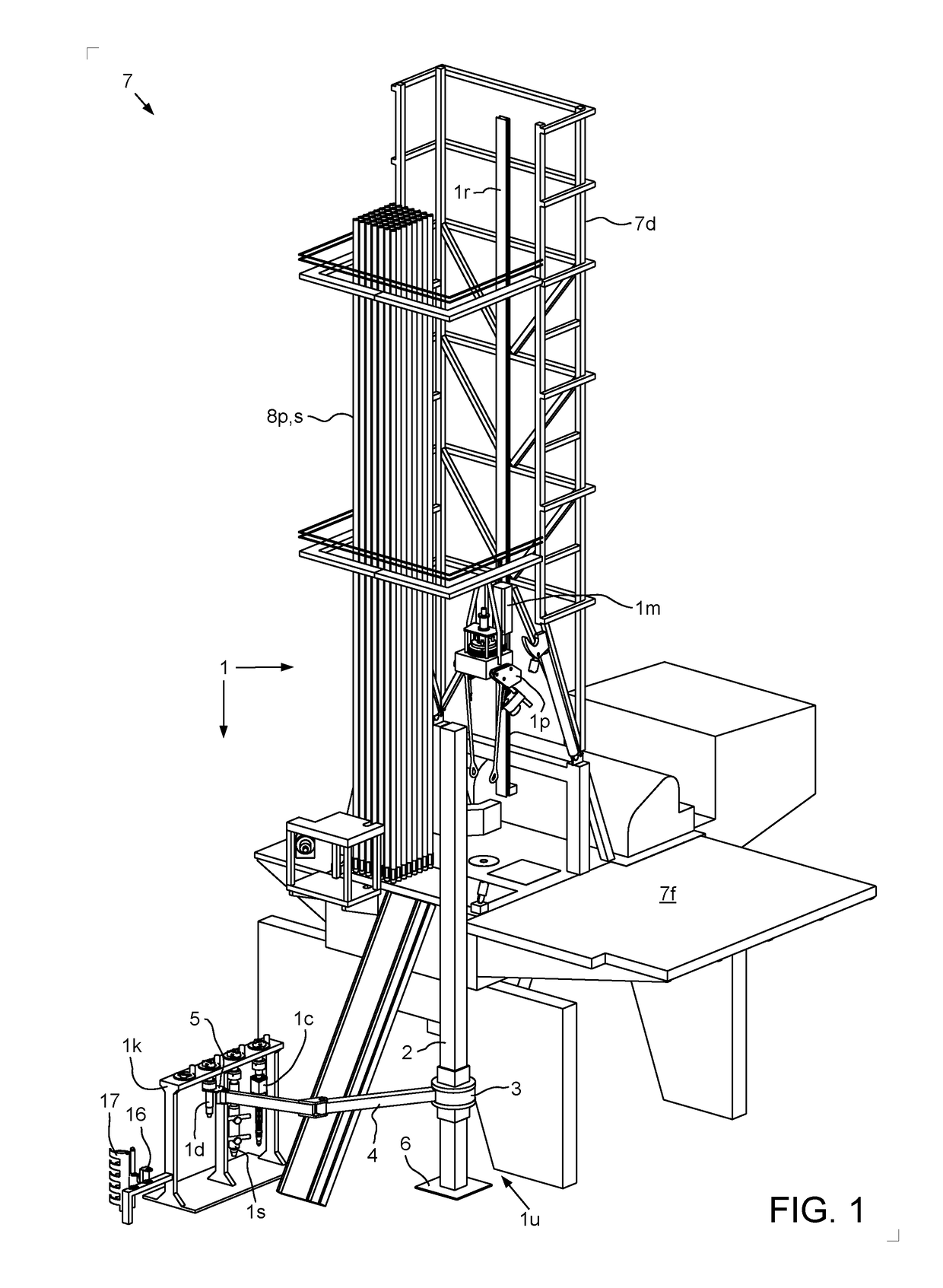

Genset for top drive unit

A system includes an accessory tool selected from a group consisting of a casing unit, a cementing unit, and a drilling unit; and a genset mounted to the accessory tool and comprising: a fluid driven motor having an inlet and an outlet for connection to a control swivel of the system; an electric generator connected to the fluid driven motor; a manifold having an inlet for connection to the control swivel and an outlet connected an accessory tool actuator; and a control unit in communication with the electric generator and the manifold and comprising a wireless data link.

Owner:WEATHERFORD TECH HLDG LLC

Method and apparatus for attenuating compressor noise

ActiveUS7527053B2Reduce noiseReduce the amount of noiseRespiratorsOperating means/releasing devices for valvesPortable ventilatorsEngineering

The invention comprises a method and apparatus for reducing the noise generated by compressors, including Roots-type blowers. The invention has particular use for reducing noise generated by compressors used in mechanical ventilators, though the advantages thereof may be realized in many different applications. One embodiment of the invention comprises a noise-attenuating gas flow path for a compressor contained in a portable ventilator housing. In one embodiment, the gas flow path comprises a plurality of chambers interconnected by flow tubes. The flow path is folded so as to fit into the limited space of a portable ventilator housing. The dimensions of the chambers and the flow tubes are selected so that an impedance mismatch is created between the chambers and the flow tubes. In one embodiment of the invention, the flow path comprises one or more perforated tubes located in one or more of the chambers. The perforated tube has a port through which gas is accepted and at least one exterior tube through which gas exits. Impedance mismatches are created between the inlet chamber and the exterior tubes and between the exterior tubes and the chamber in which the perforated tube is located, which are useful in attenuating noise. One embodiment of the invention comprises a noise attenuating mounting system for a compressor. The mounting system comprises flexible mounts that cooperate to dampen vibrations generated by the compressor.

Owner:VYAIRE MEDICAL 203 INC

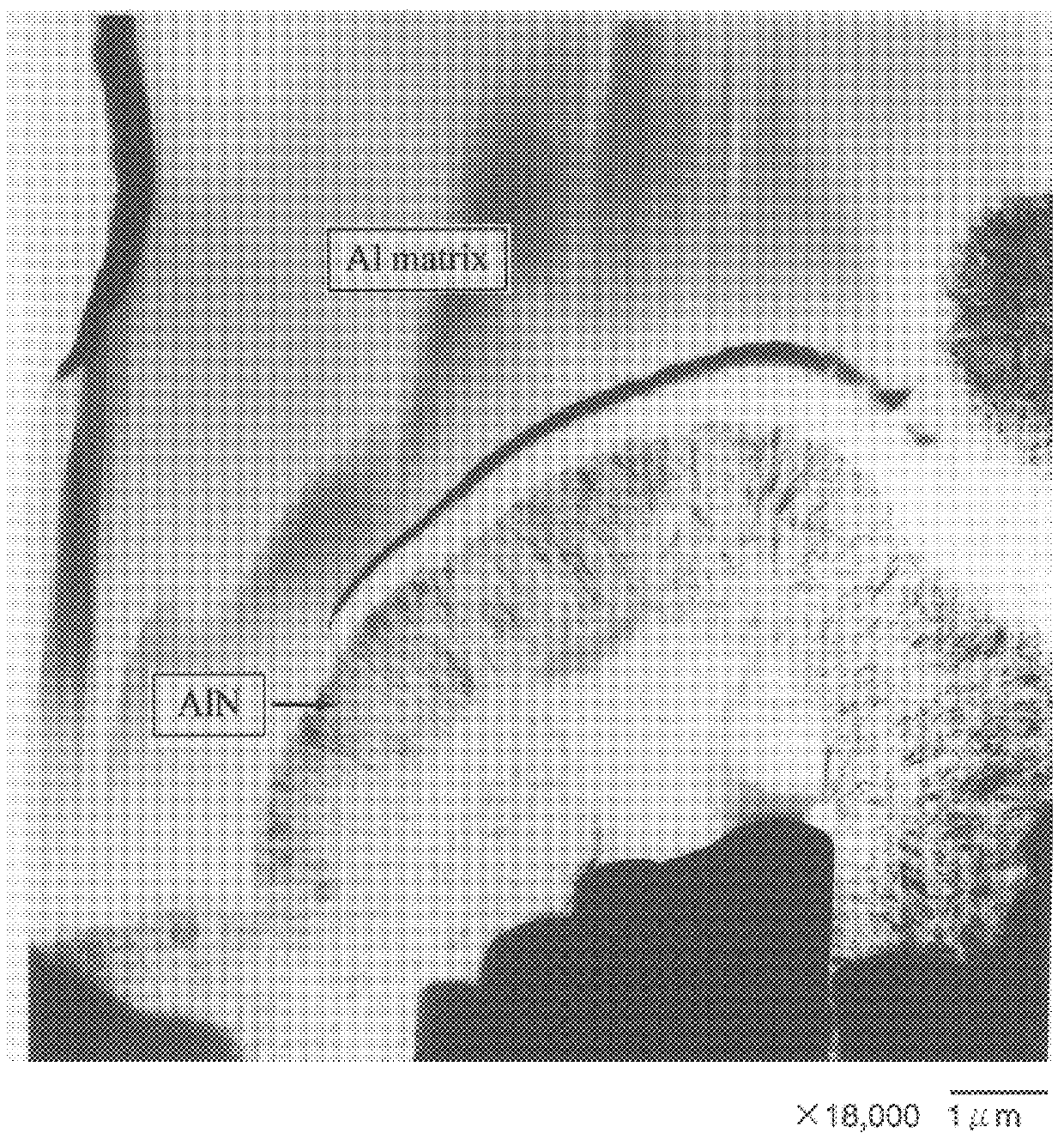

Sliding member and oil pump

InactiveUS6089843AIncrease heatIncrease resistanceOscillating piston enginesEngine of intermeshing engagement typePorosityDrive shaft

An outer rotor and an inner rotor are formed of sintered aluminum alloy. The sintered aluminum alloy contains 0.5 wt % to 11 wt % of aluminum nitride. Porosity of the sintered aluminum alloy for outer rotor is 3 vol % to 15 vol %. Porosity of the sintered aluminum alloy for inner rotor is 2 vol % to 10 vol %. Outer rotor and inner rotor are set in a pump case. A rotary driving shaft formed of steel is inserted to a through hole of inner rotor. A press fit member is inserted at a press fit surface of inner rotor and rotary driving shaft. Accordingly, sliding members formed of sintered aluminum alloy which reduces seizure and abrasive wear of the inner and outer rotors can be provided, and in addition, an oil pump of which wear and damage at the inner rotor inner diameter surface is suppressed, can be provided.

Owner:SUMITOMO ELECTRIC IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com