Patents

Literature

48results about How to "Improve blower efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

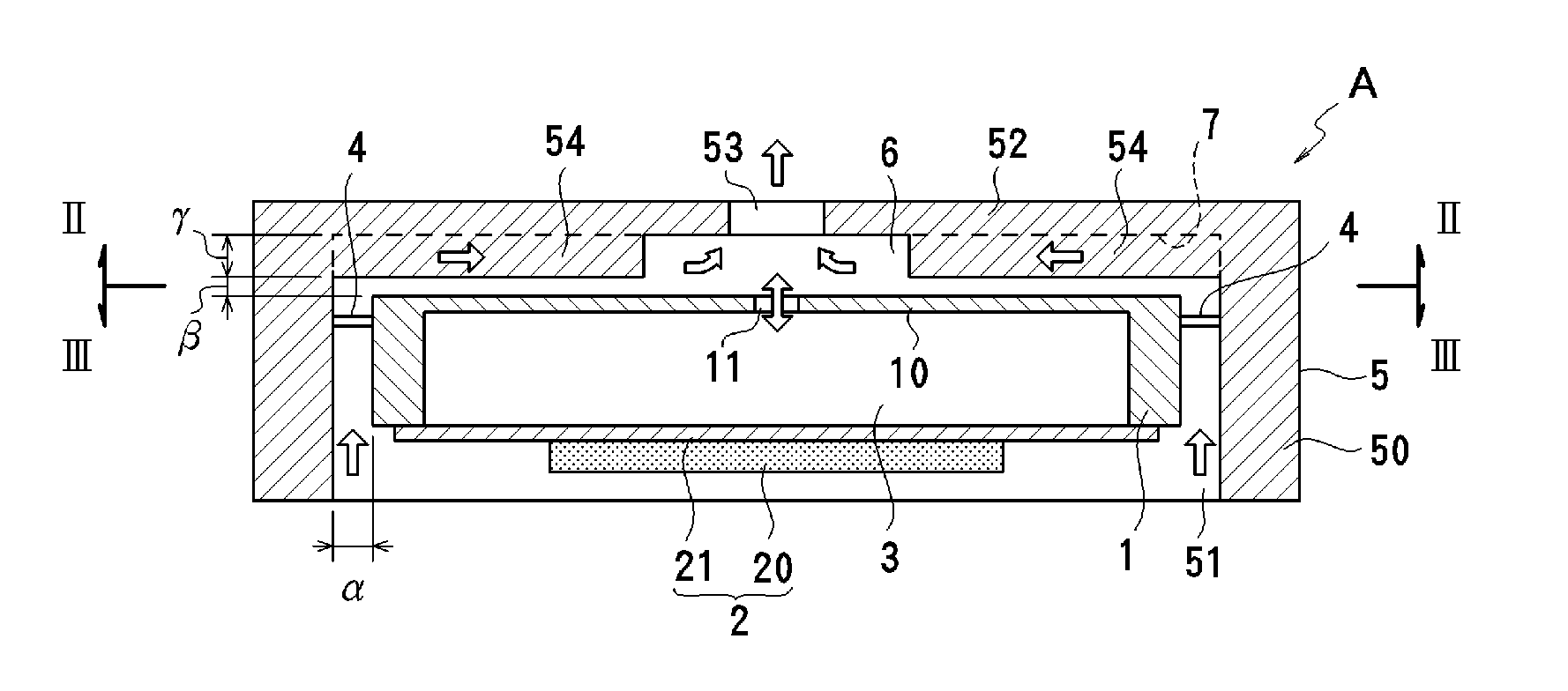

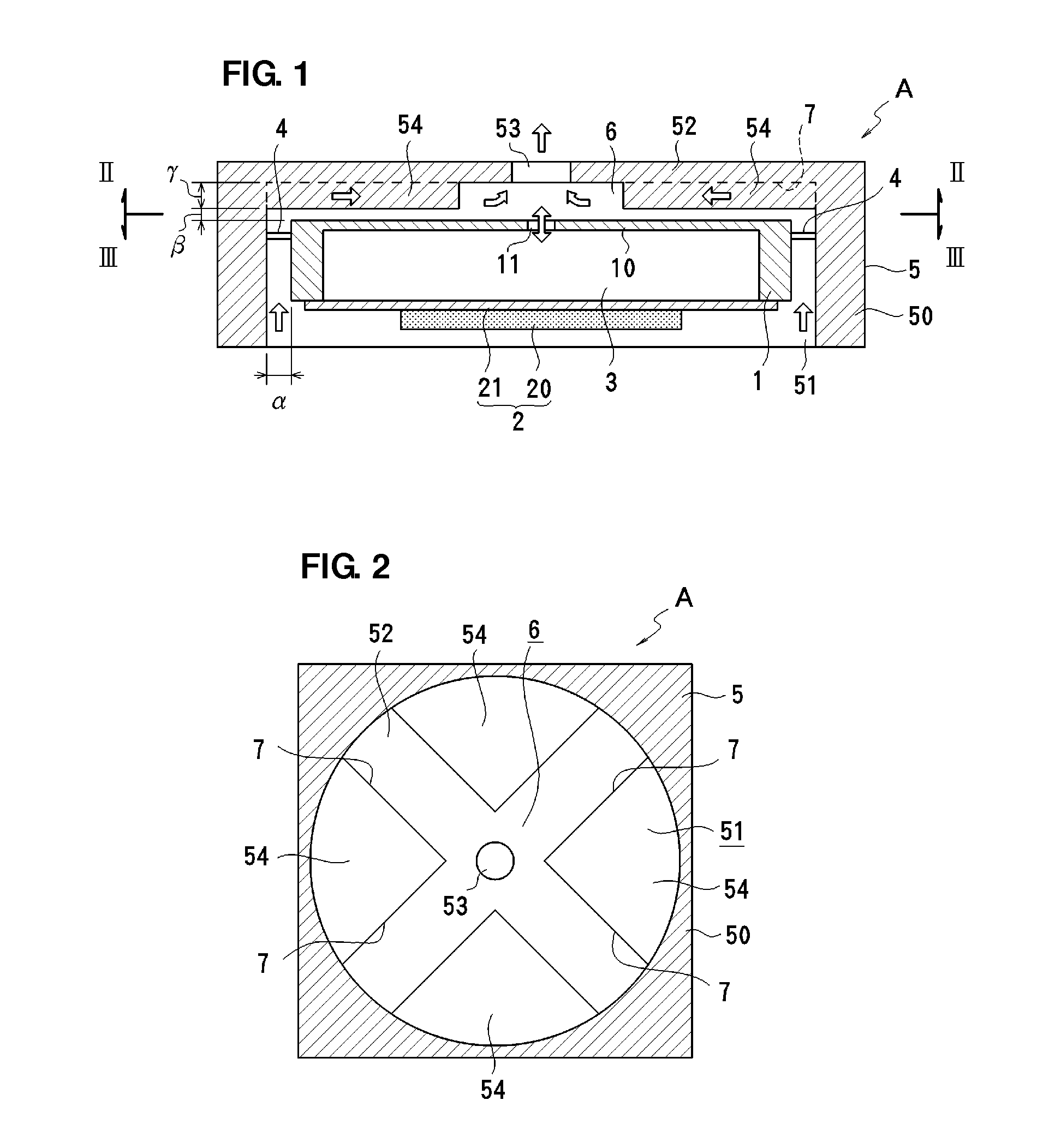

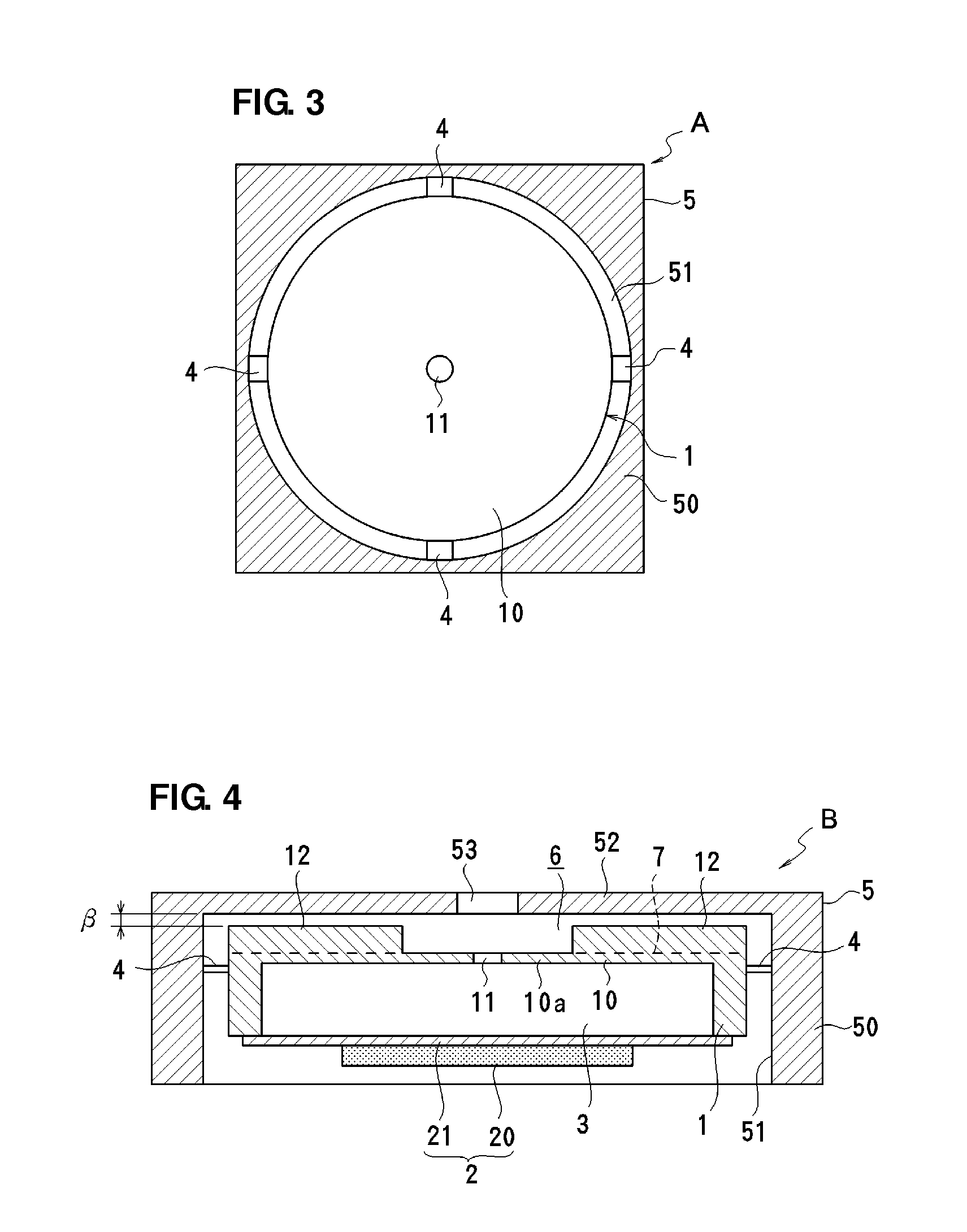

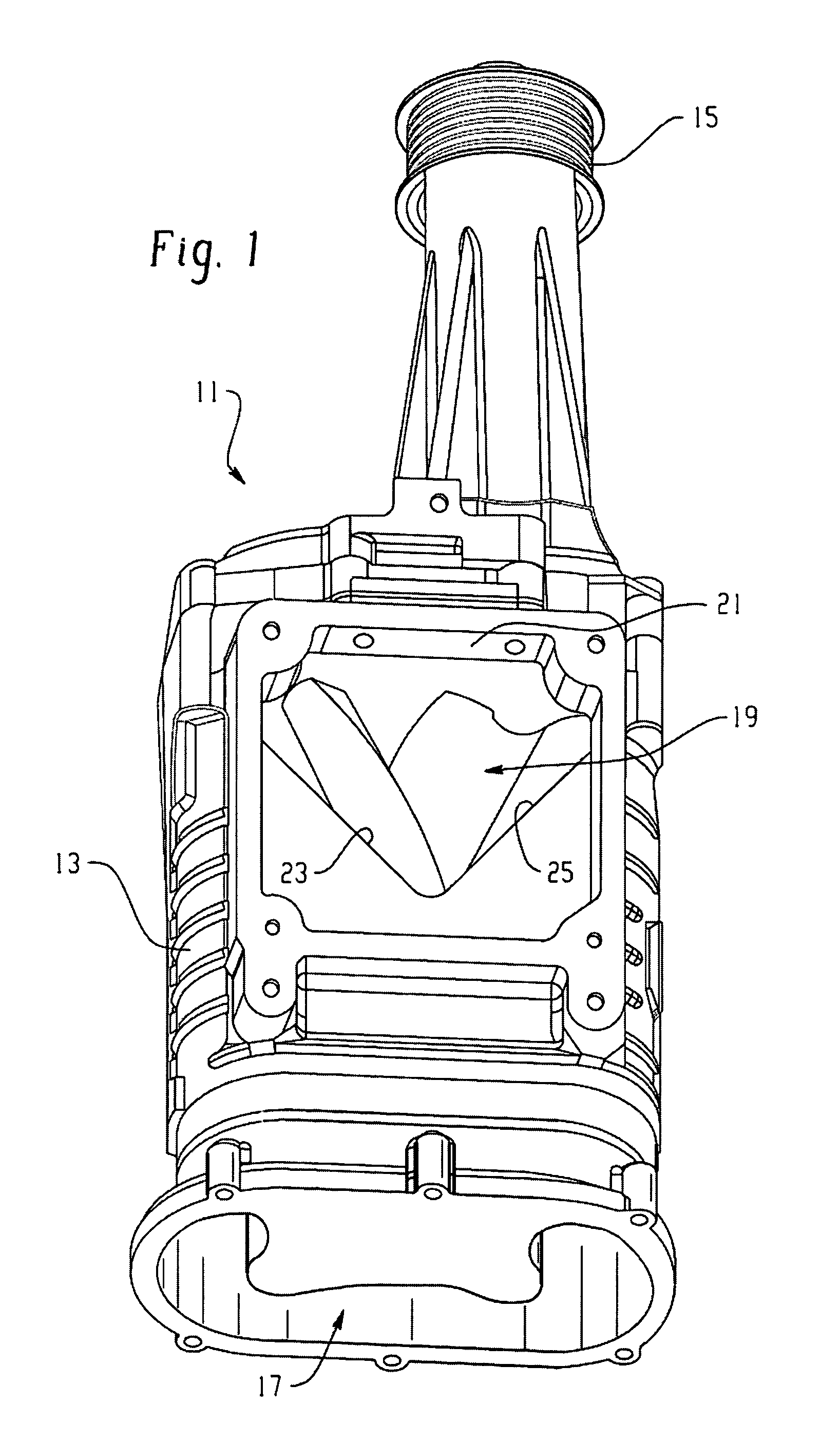

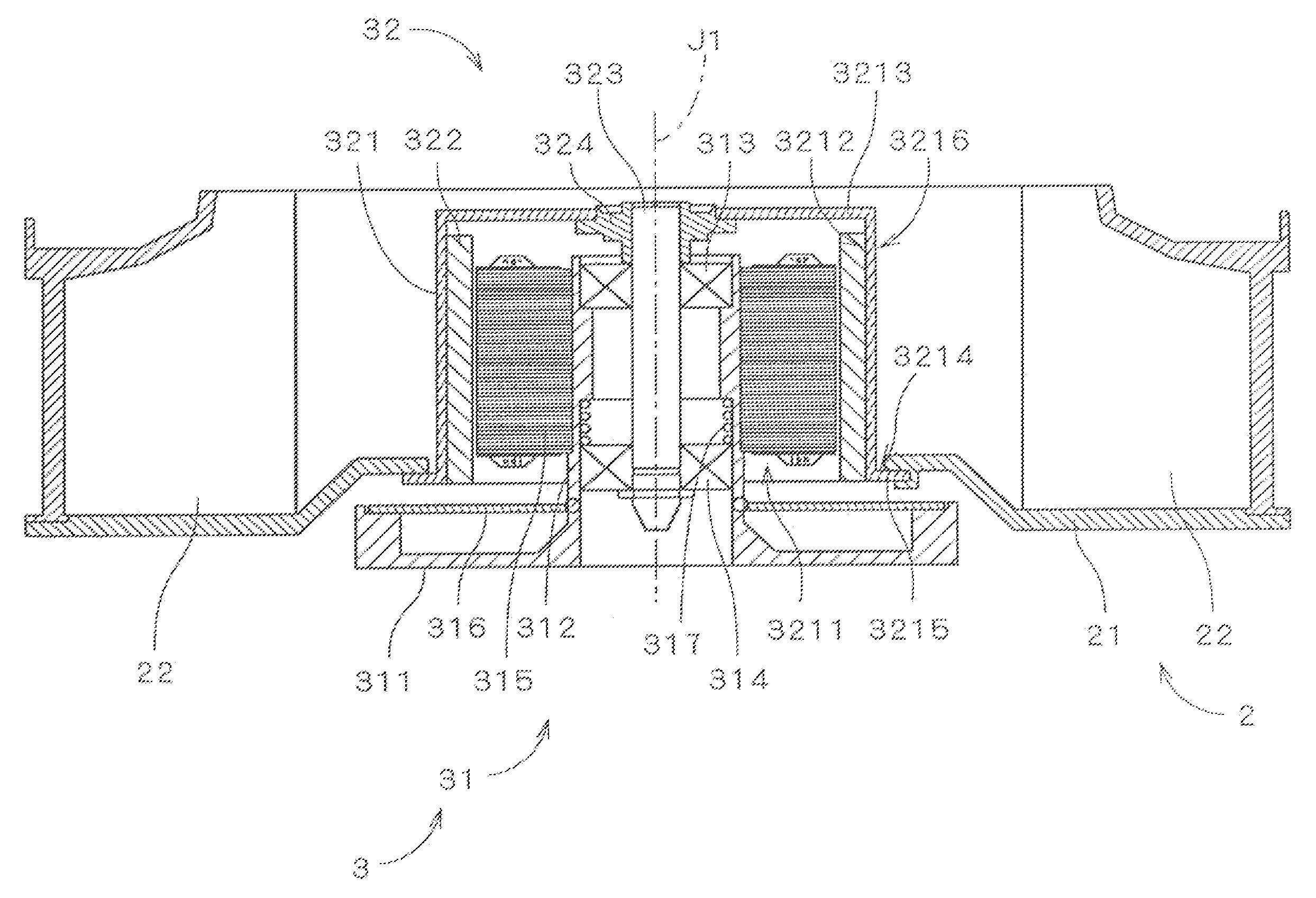

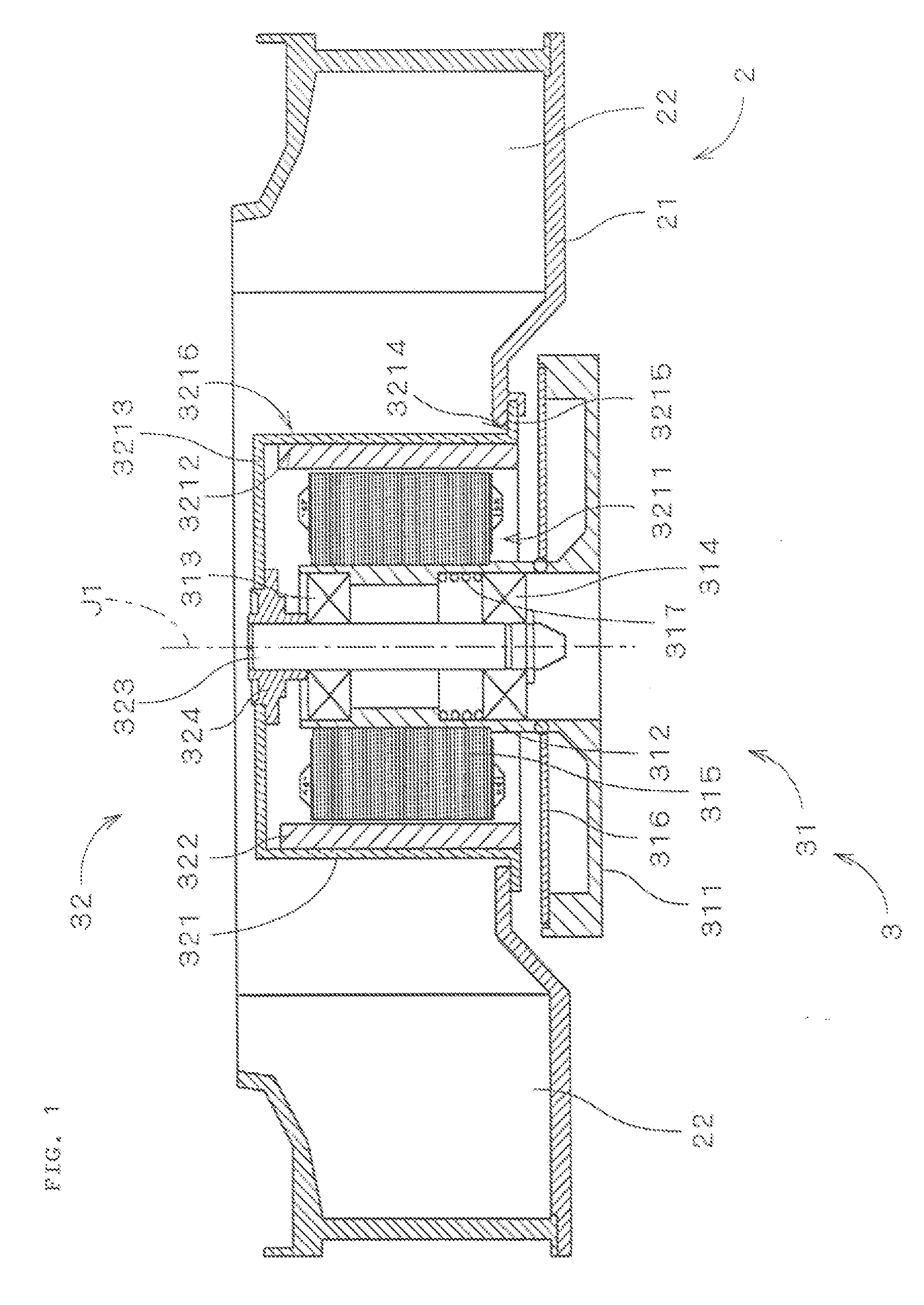

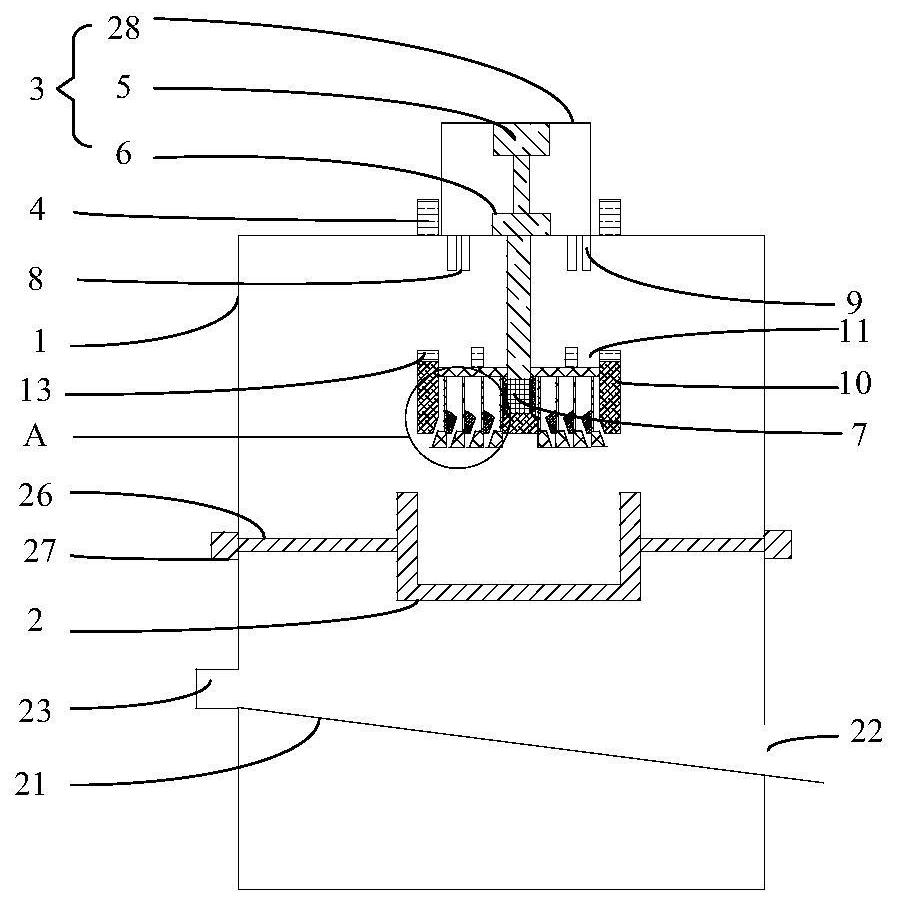

Piezoelectric micro-blower

ActiveUS20110076170A1Improve vibrationIncrease displacementFlexible wall reciprocating enginesFlexible member pumpsElectricityEngineering

A piezoelectric micro-blower includes an inner case to which a peripheral portion of a vibrating plate including a piezoelectric element is fixed such that a blower chamber is defined between the inner case and the vibrating plate and an outer case arranged to cover an outer periphery of the inner case with a gap therebetween. The inner case is elastically retained in the outer case by a plurality of connecting portions. A first opening is provided in a top plate portion of the inner case that faces a central portion of the vibrating plate, and a second opening is provided in a top plate portion of the outer case that faces the first opening. A central space is provided between the top plate portions, and fluid introduced from the outside is guided to the central space through the gap between the inner and outer cases. The vibrating plate is driven in a bending mode so that air is sucked into the central space and is discharged through the second opening. The connecting portions prevent leakage of vibration of the vibrating plate from the inner case to the outer case, thereby reducing energy loss.

Owner:MURATA MFG CO LTD

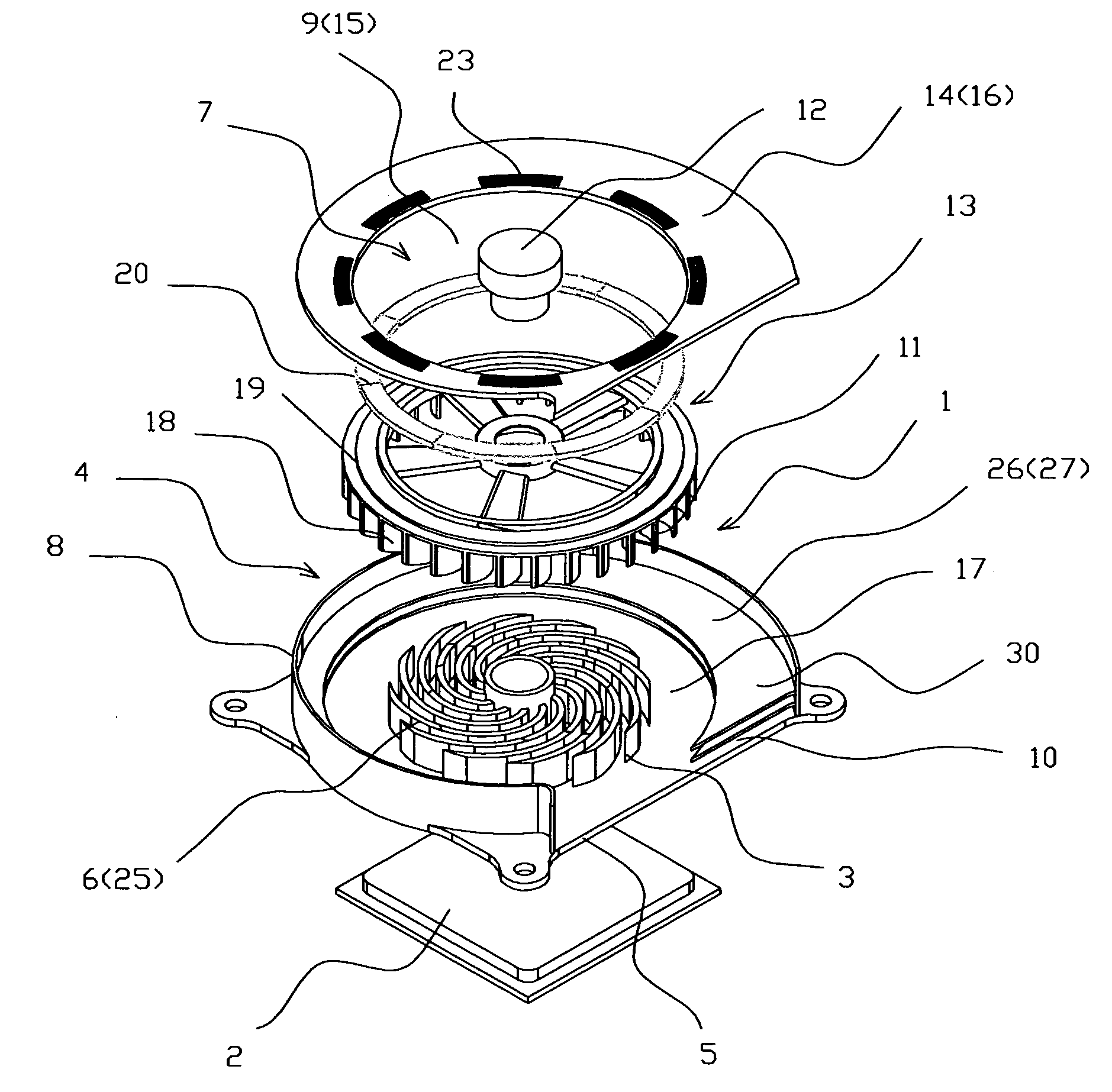

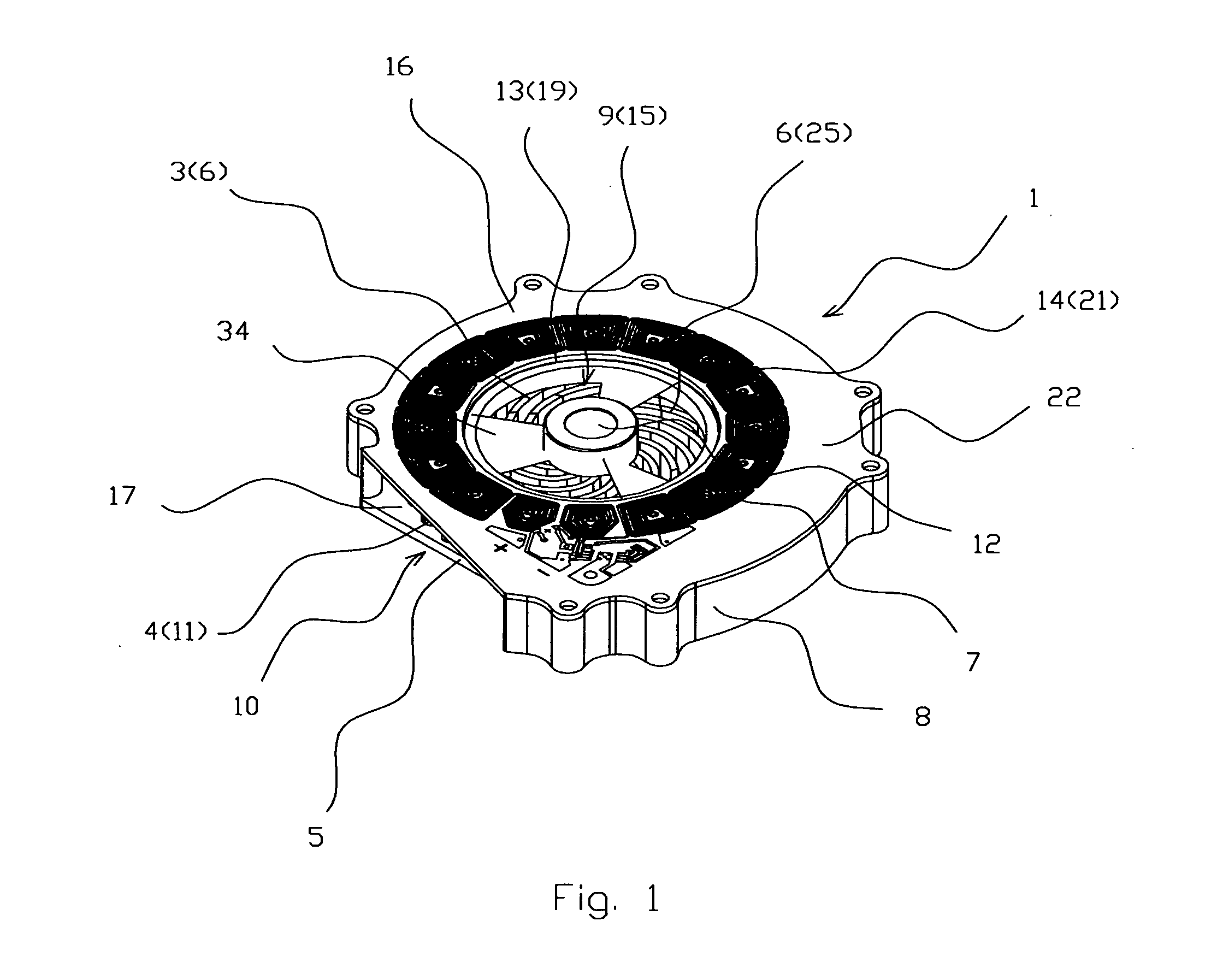

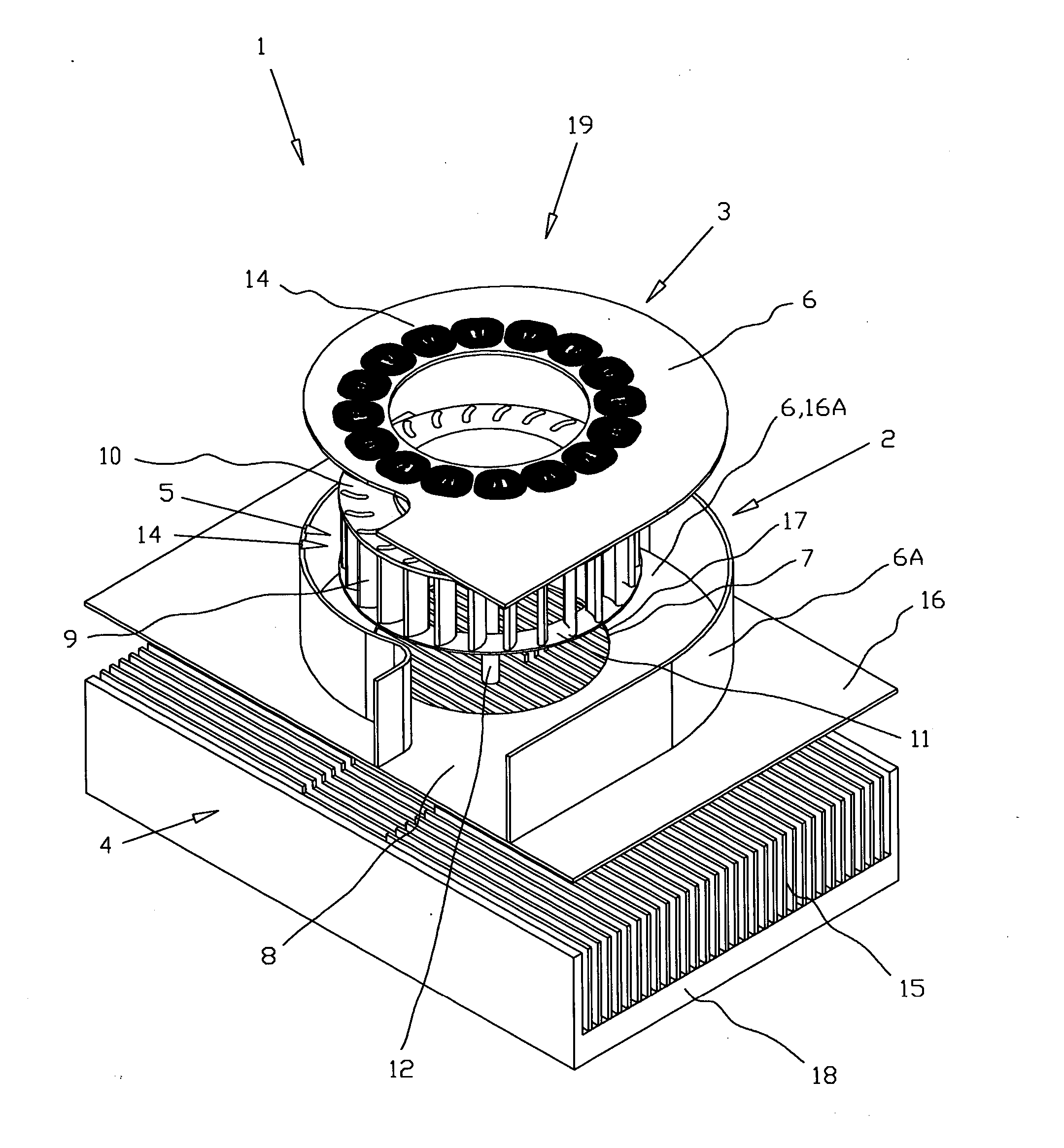

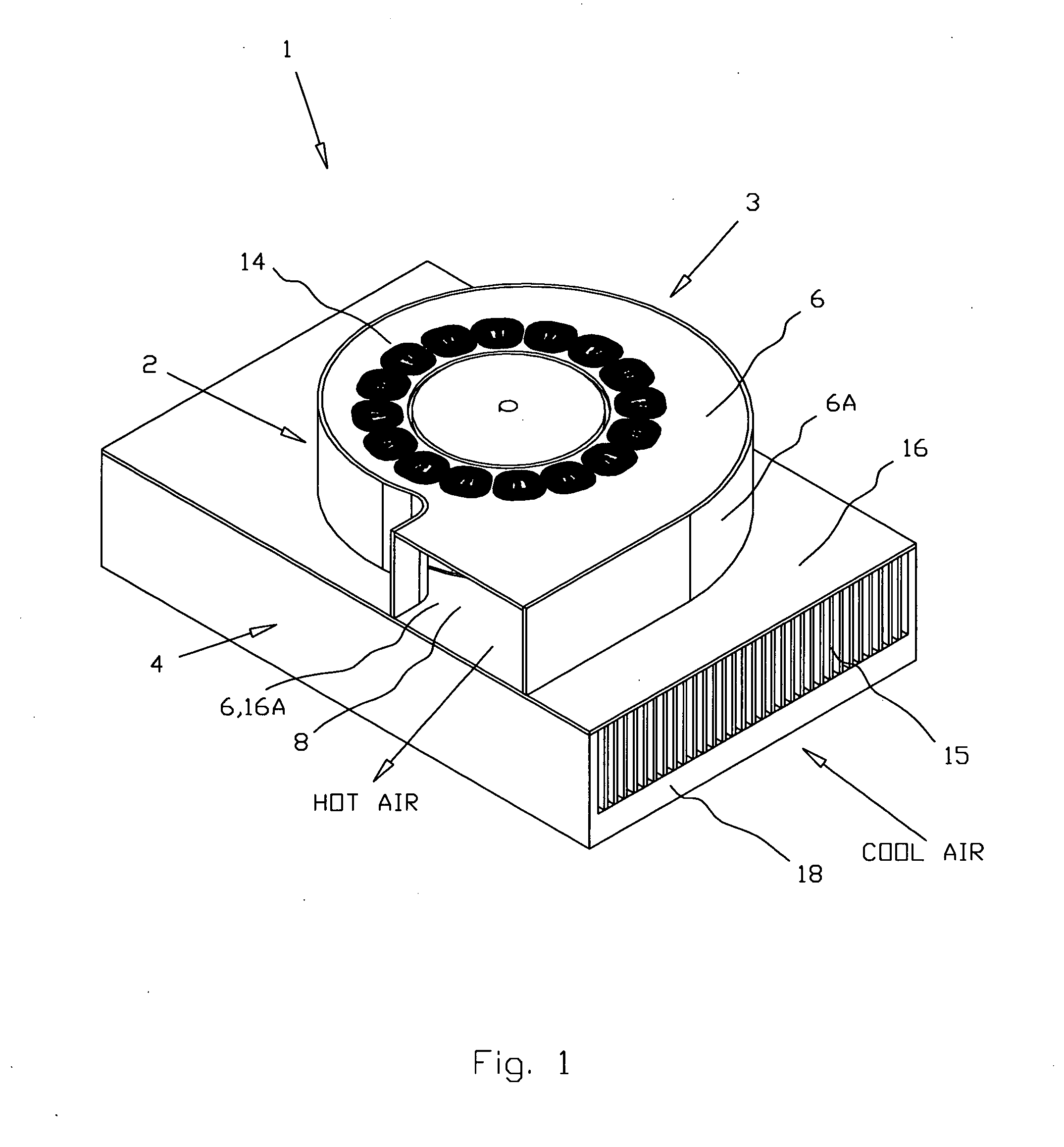

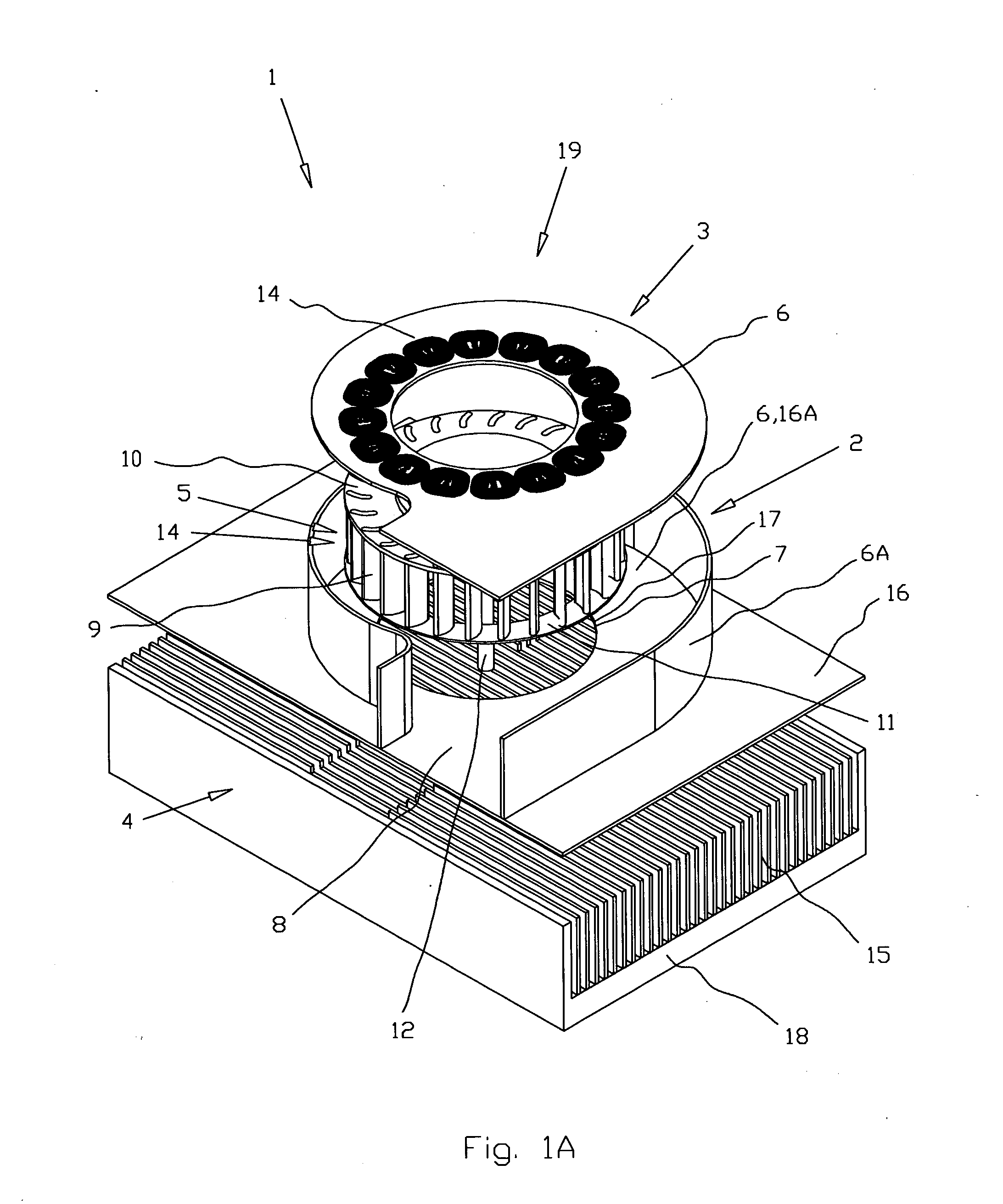

Integrated cooler for electronic devices

InactiveUS20060021735A1Improve performanceSmall spacingSemiconductor/solid-state device detailsSolid-state devicesImpellerEngineering

An integrated cooler comprises a heatsink integrated with a centrifugal blower. The heatsink comprises a base and heat exchanging means. The centrifugal blower comprises an electric motor, a casing with inlet and at least one outlet, a radial impeller and an axle. The electric motor comprises a magnetized rotor and a flat stator with an opening coincided with blower inlet thus the stator serves as an upper side of the casing. The base made as a lower side of the casing and provides thermal contact with the electronic device and the heat exchanging means. The radial impeller comprises magnetic means thus serving as the magnetized rotor. The heat exchanging means located inside of the radial impeller and surrounded by the blades thus cooling gas flows through the blower inlet, the heat exchanging means, the radial impeller and the at least one blower outlet in a series way.

Owner:INDAL DESIGN LAB

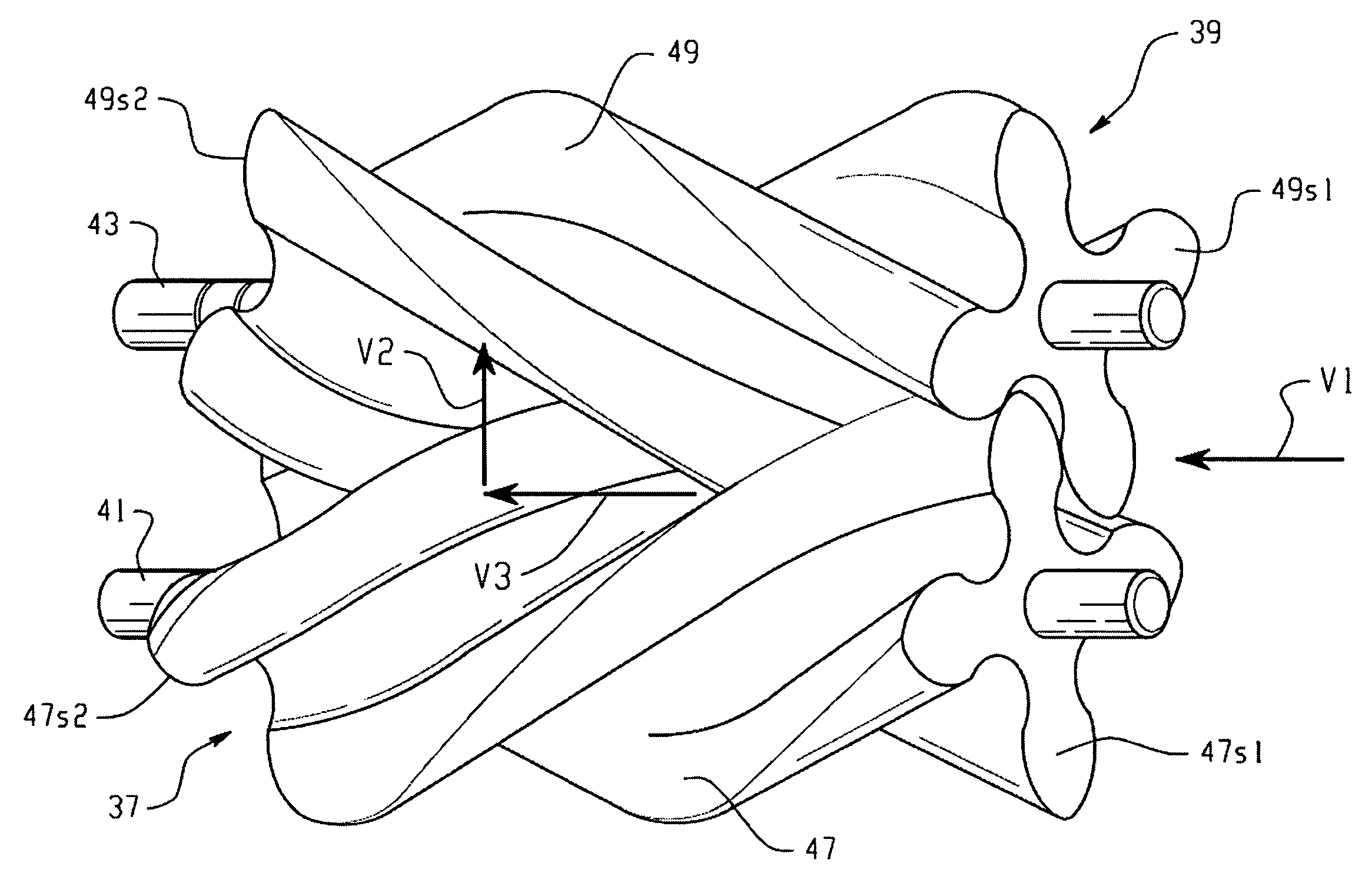

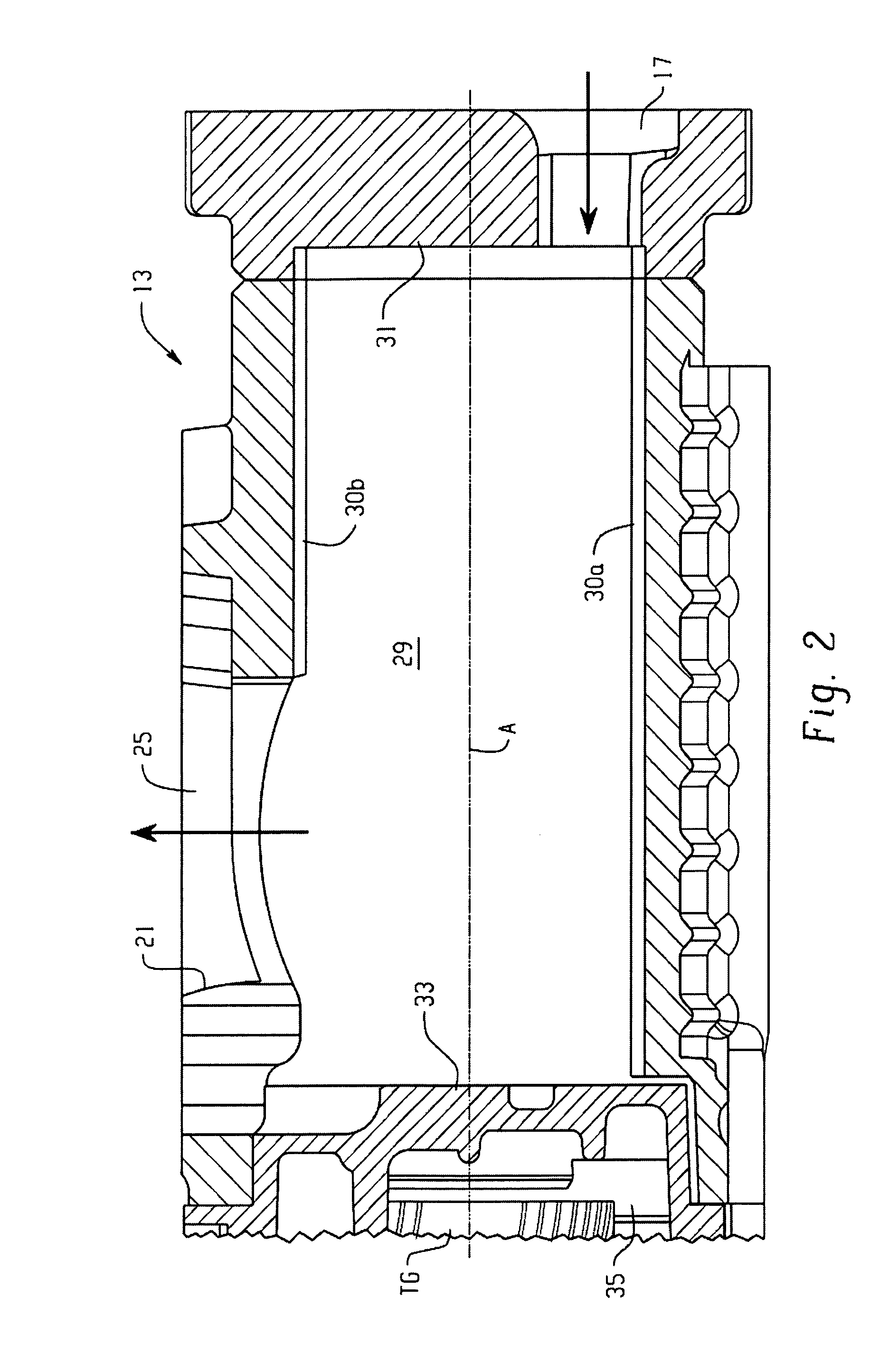

Optimized helix angle rotors for Roots-style supercharger

ActiveUS7488164B2Improve blower efficiencyImprove thermal efficiencyOscillating piston enginesEngine of counter-engagement typeEngineeringHelix angle

A method of designing rotors for a Roots blower comprising a housing having cylindrical chambers, the housing defining an outlet port (19). The blower includes meshed, lobed rotors (37,39) disposed in the chambers, each rotor including a plurality N of lobes (47,49), each lobe having first (47a,49a) and second (47b,49b) axially facing end surfaces. Each lobe has its axially facing surfaces defining a twist angle (TA), and each lobe defines a helix angle (HA). The method of designing the rotor comprises determining a maximum ideal twist angle (TAM) for the lobe as a function of the number N of lobes on the rotor, and then determining a helix angle (HA) for each lobe as a function of the maximum ideal twist angle (TAM) and an axial length (L) between the end surfaces of the lobe. A rotor designed in accordance with this method is also provided.

Owner:EATON INTELLIGENT POWER LTD

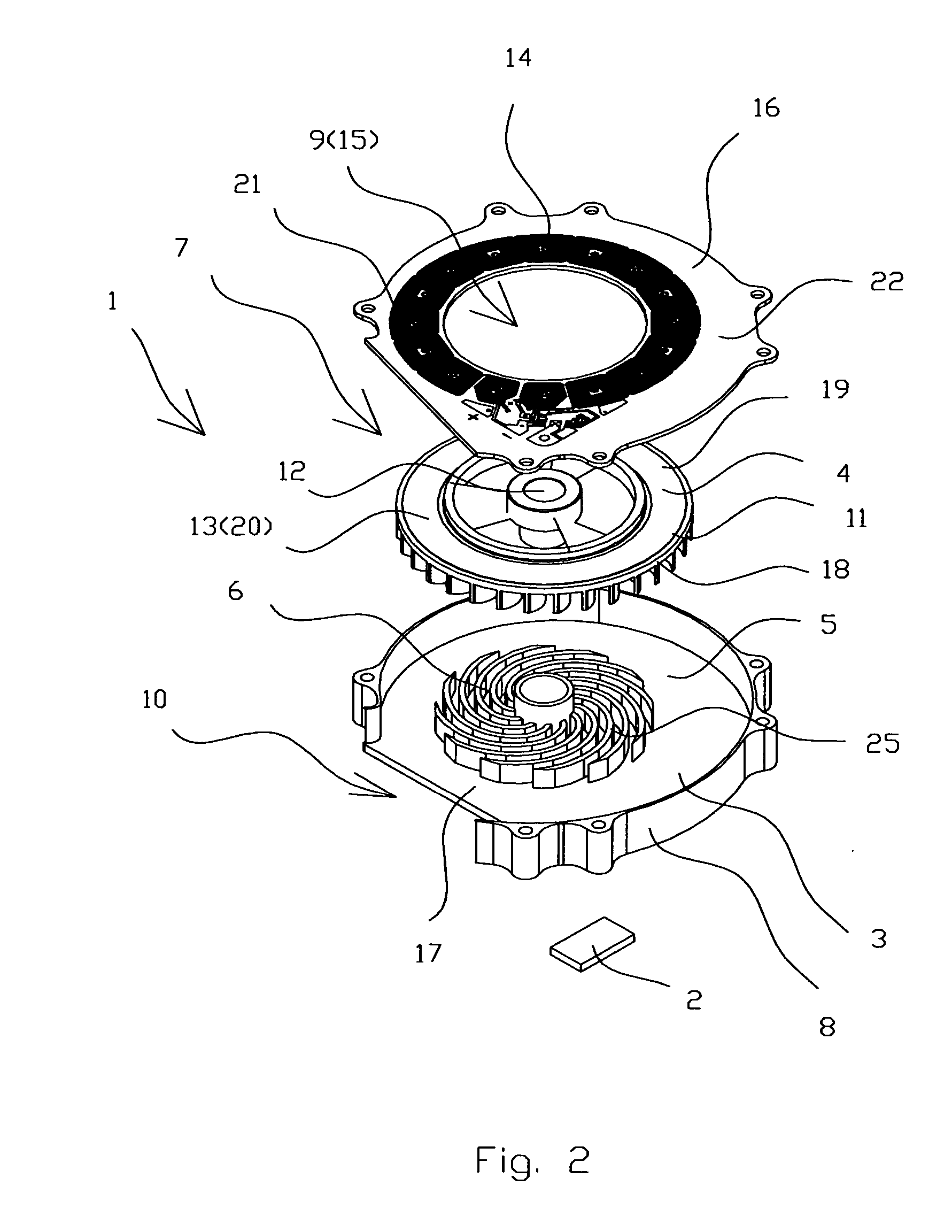

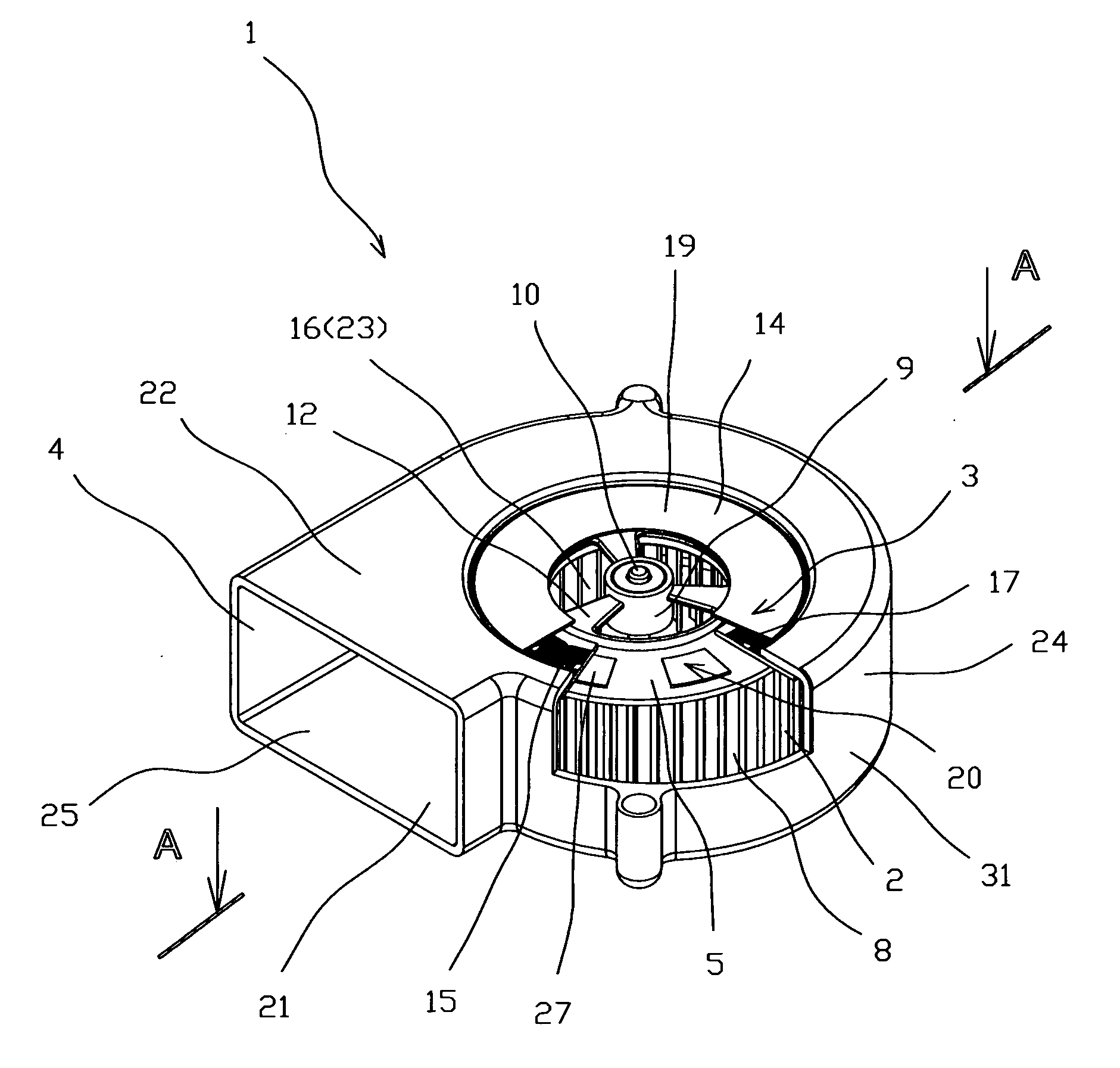

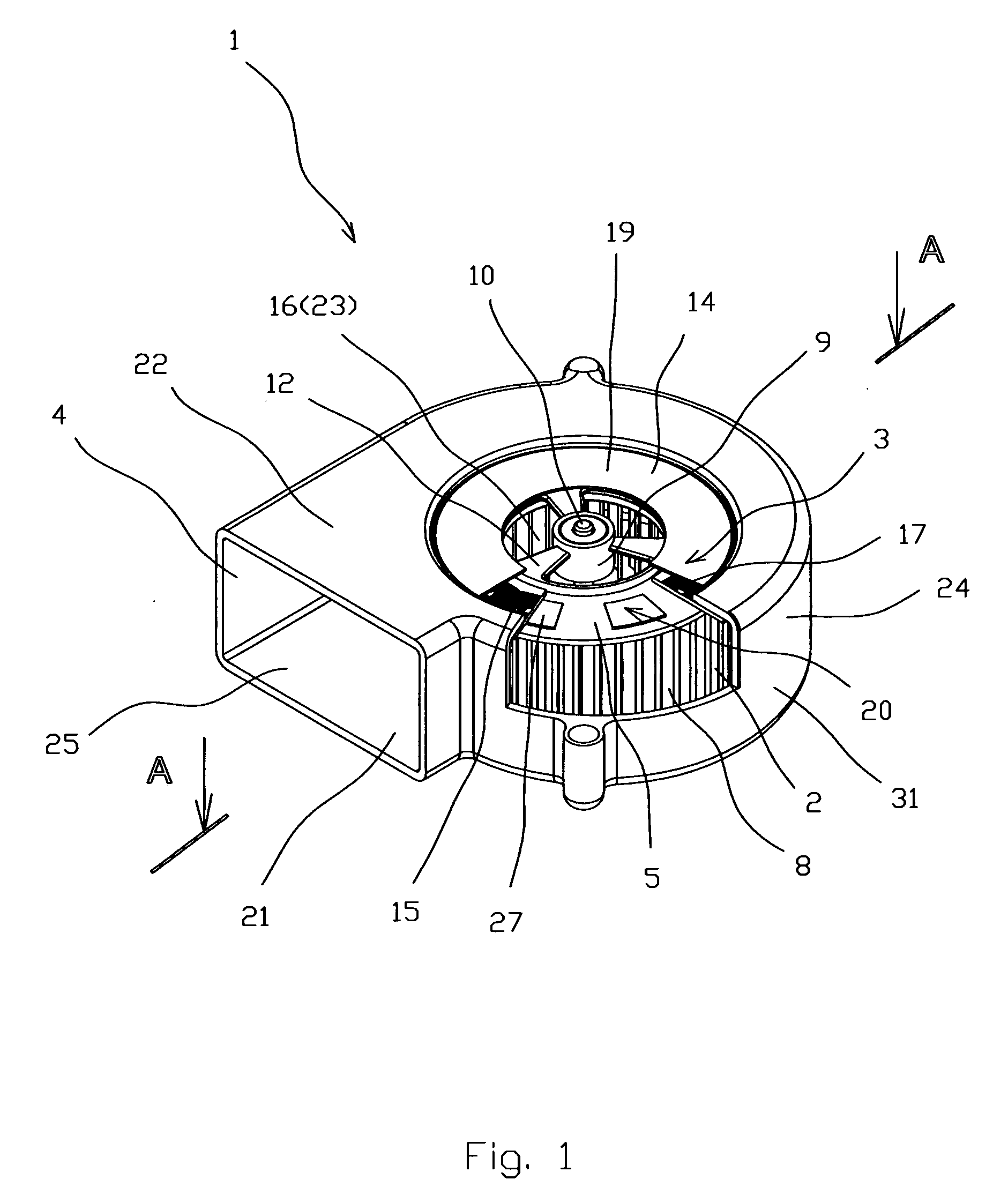

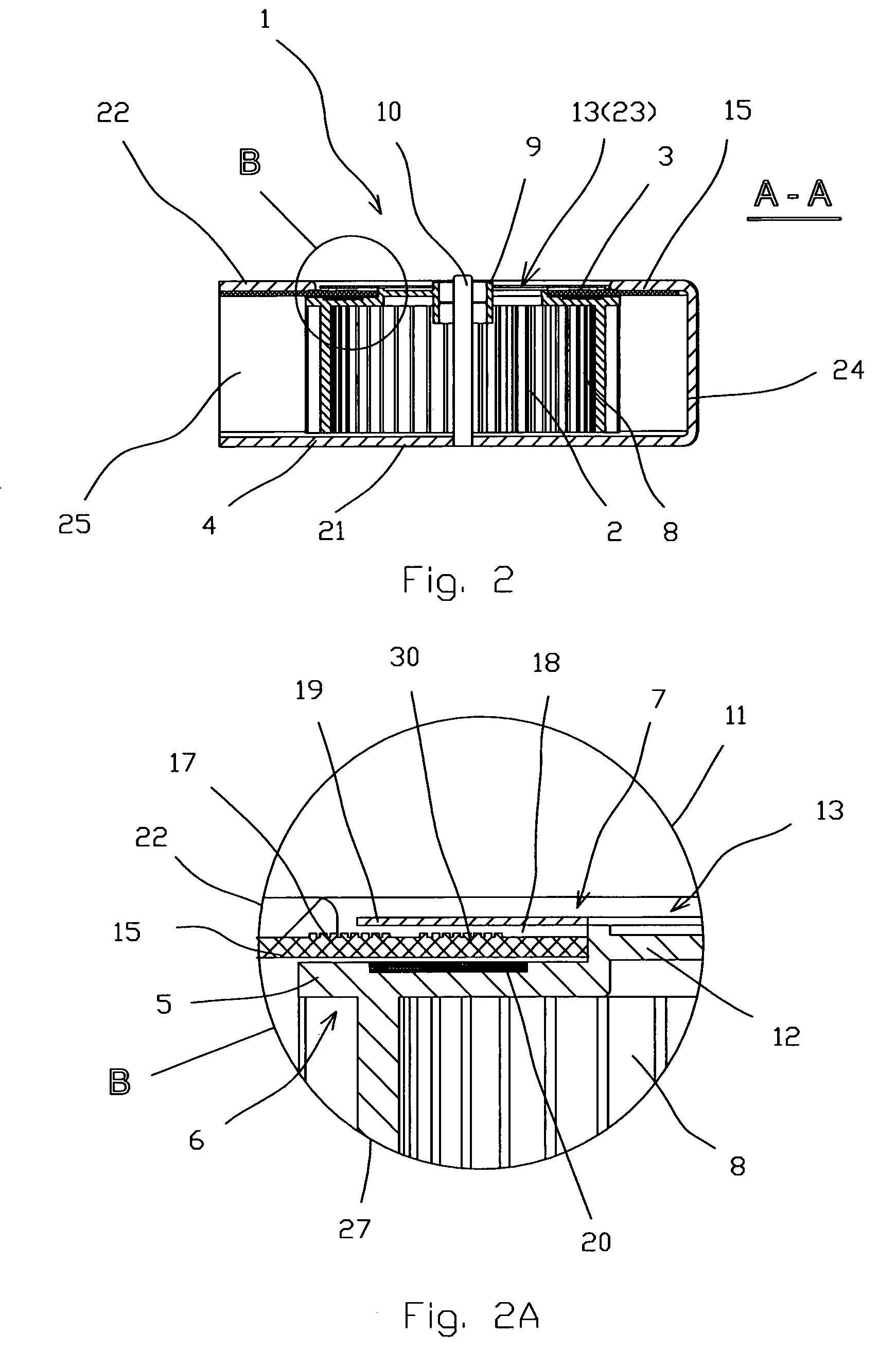

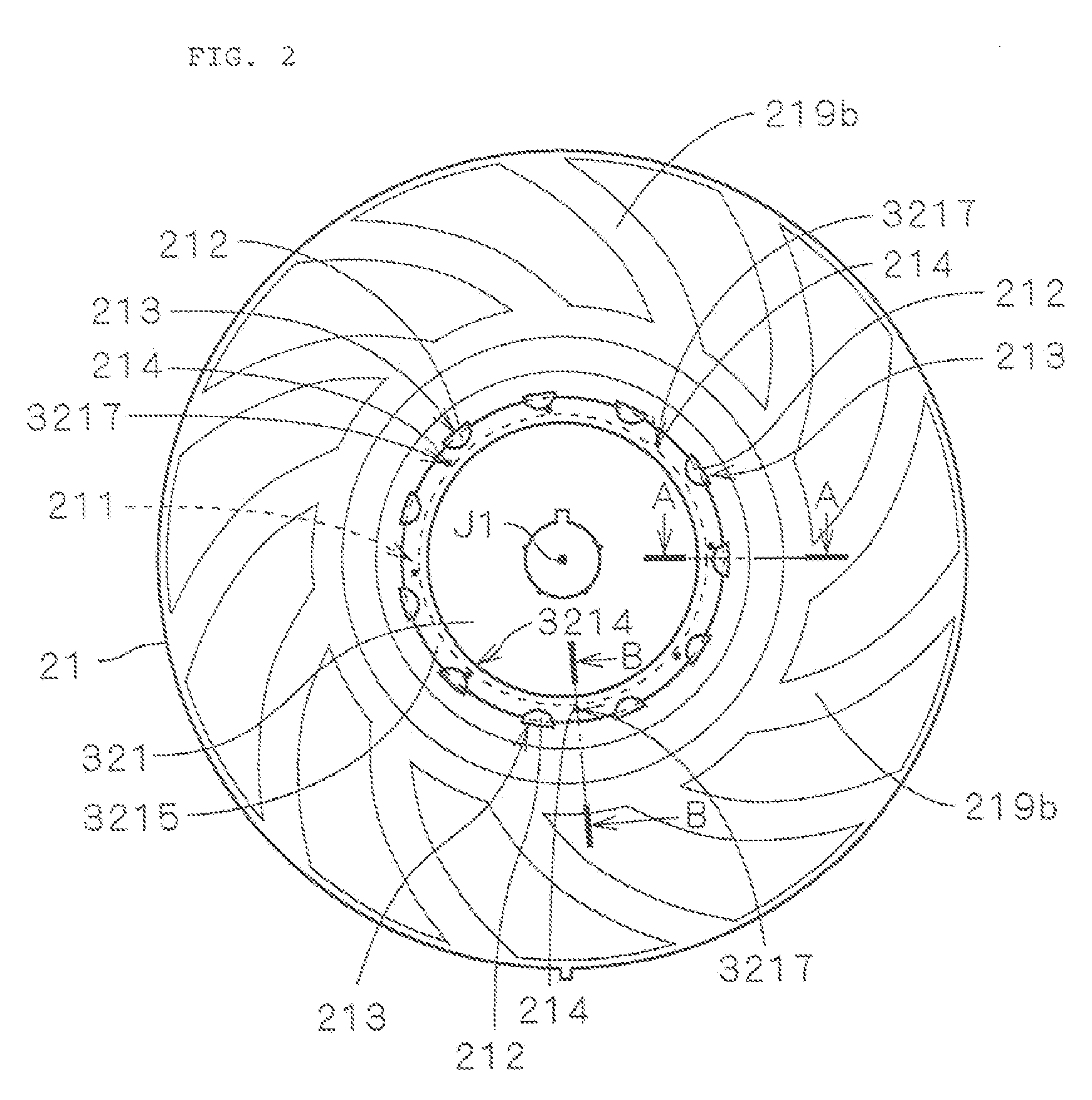

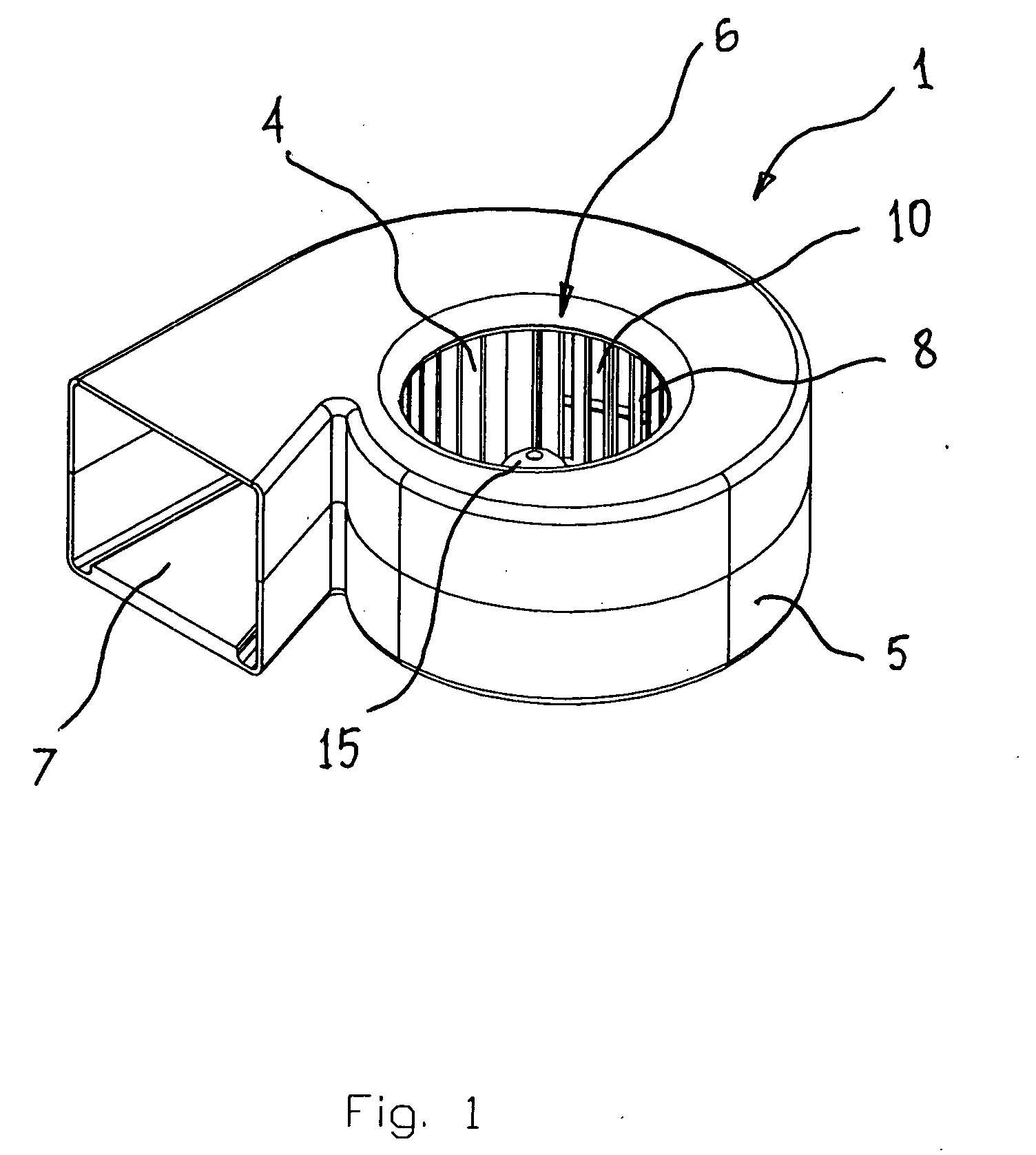

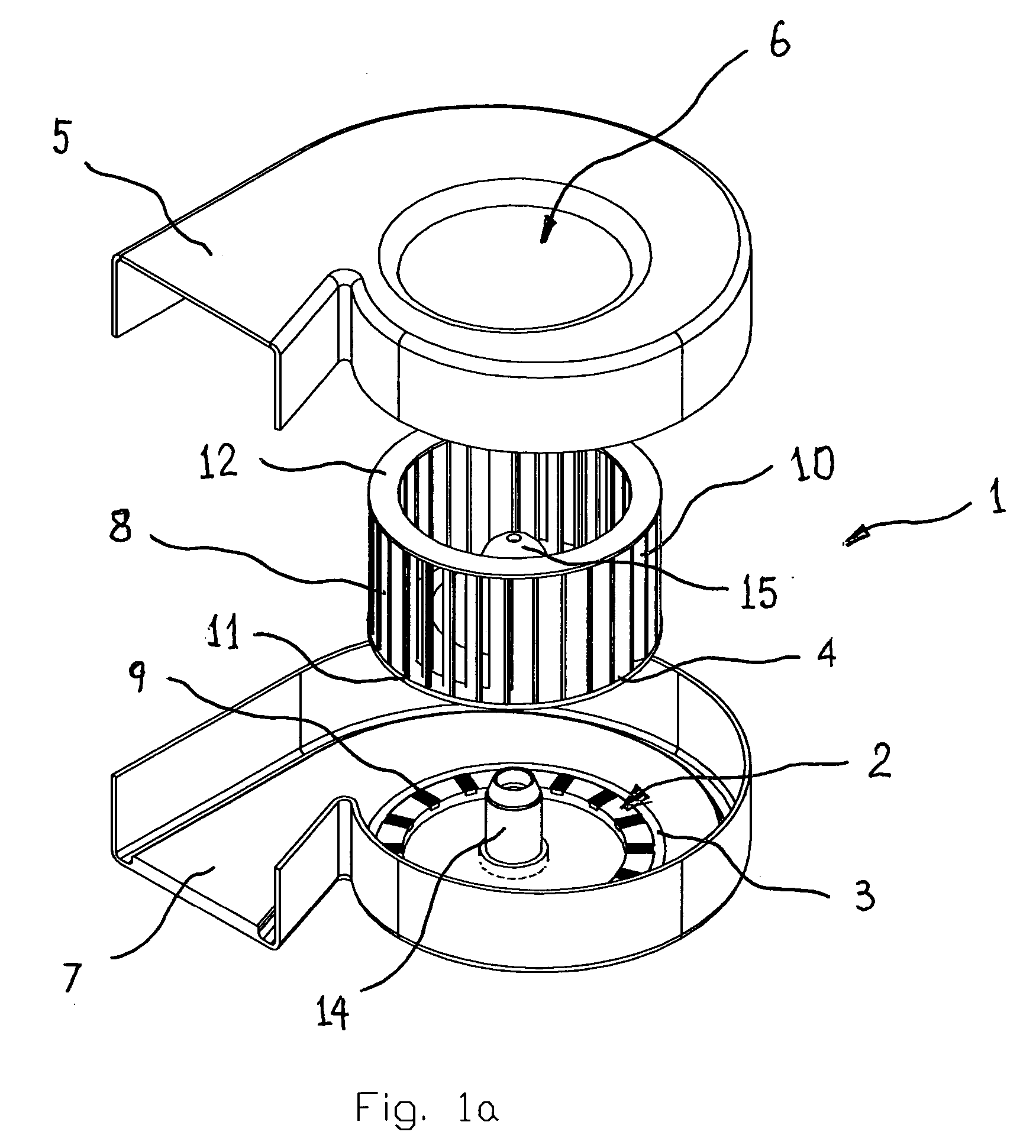

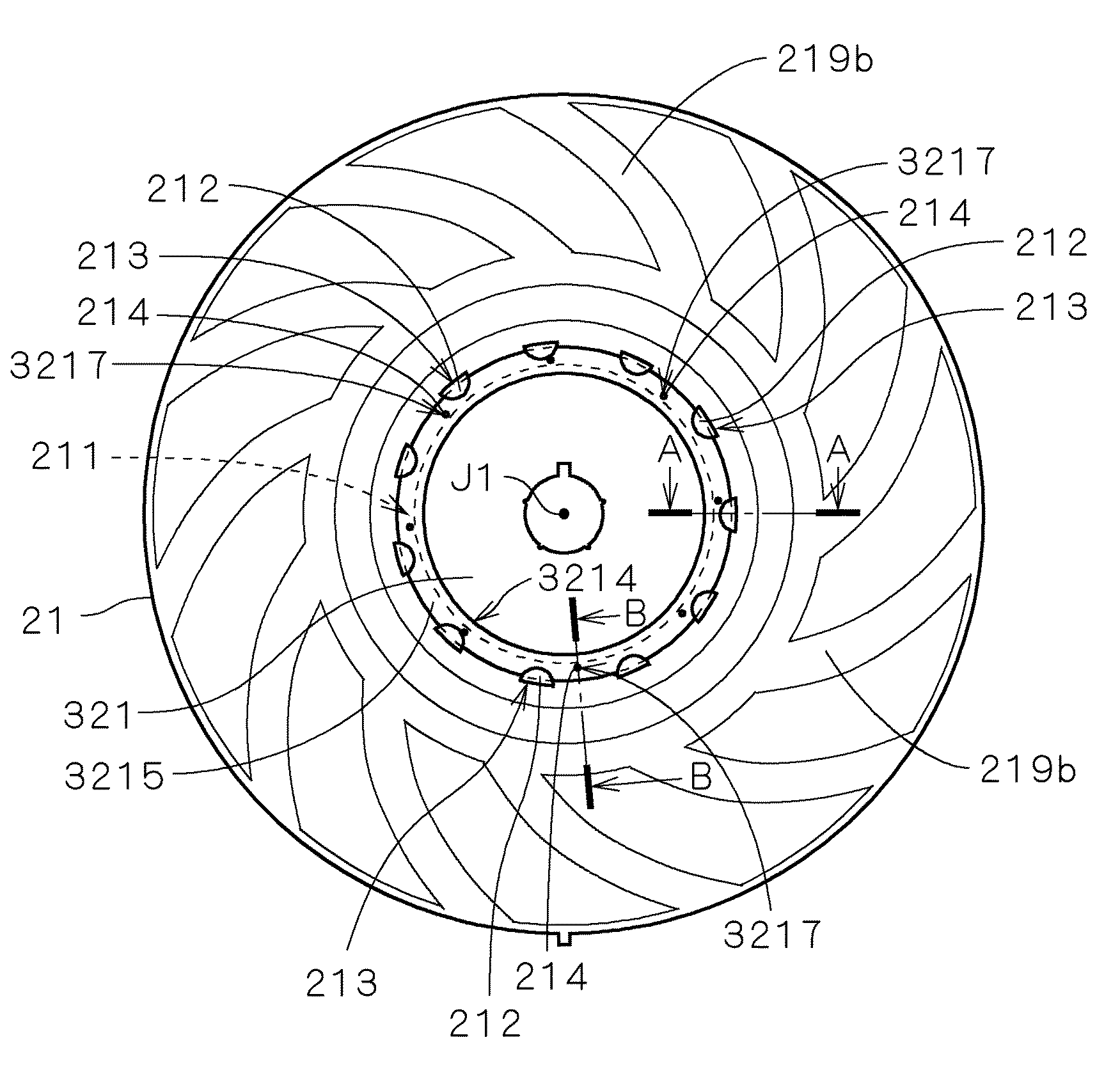

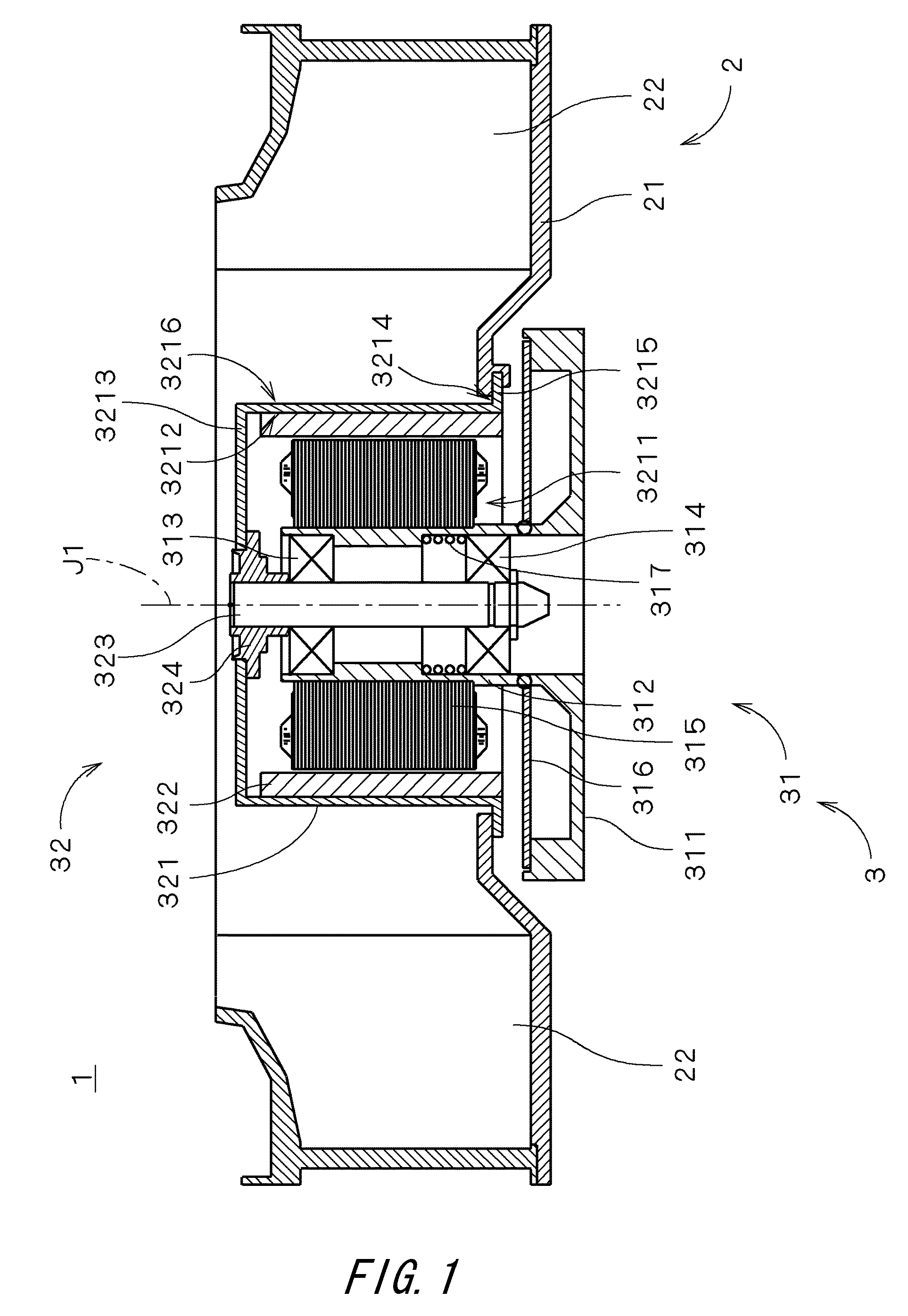

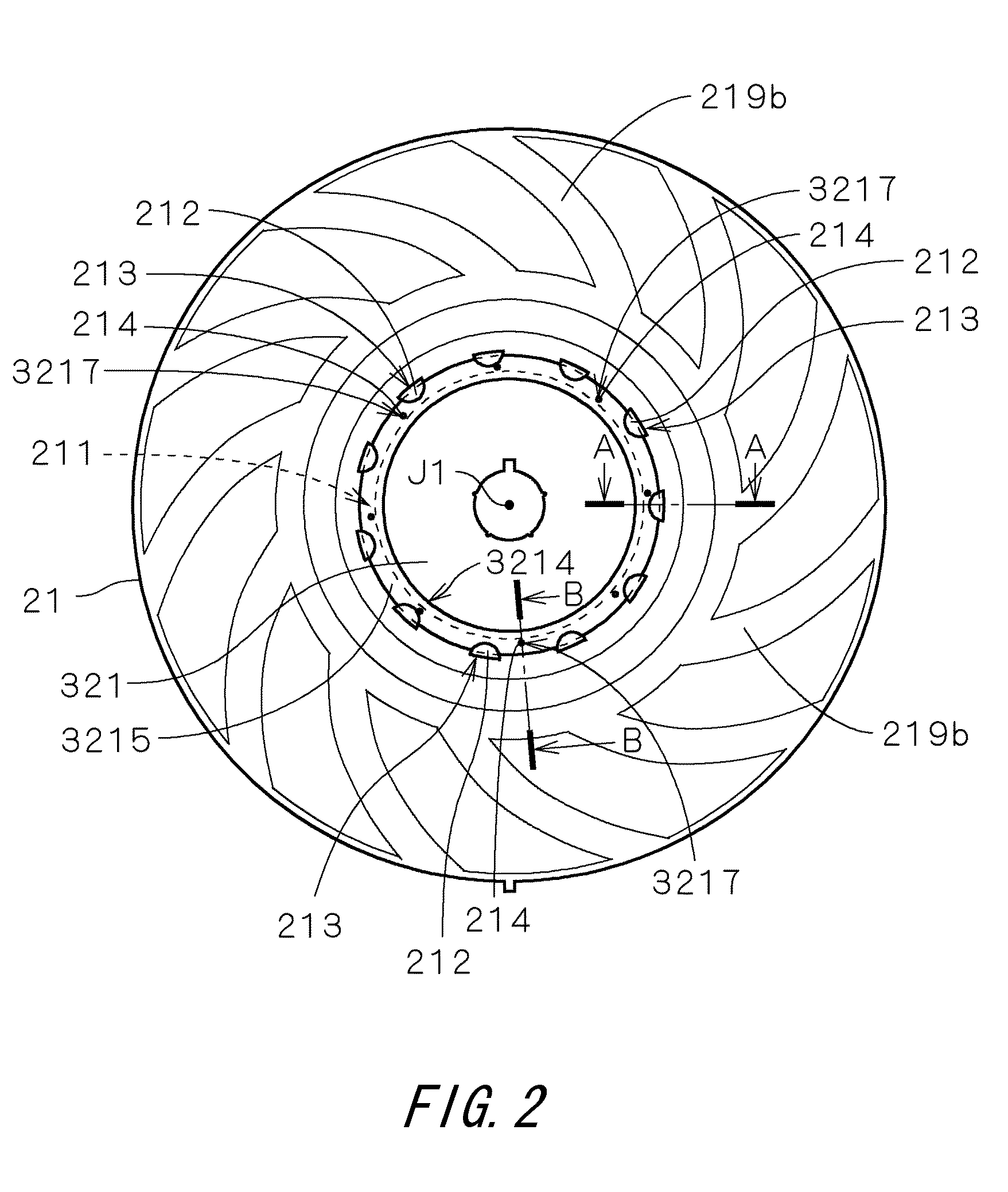

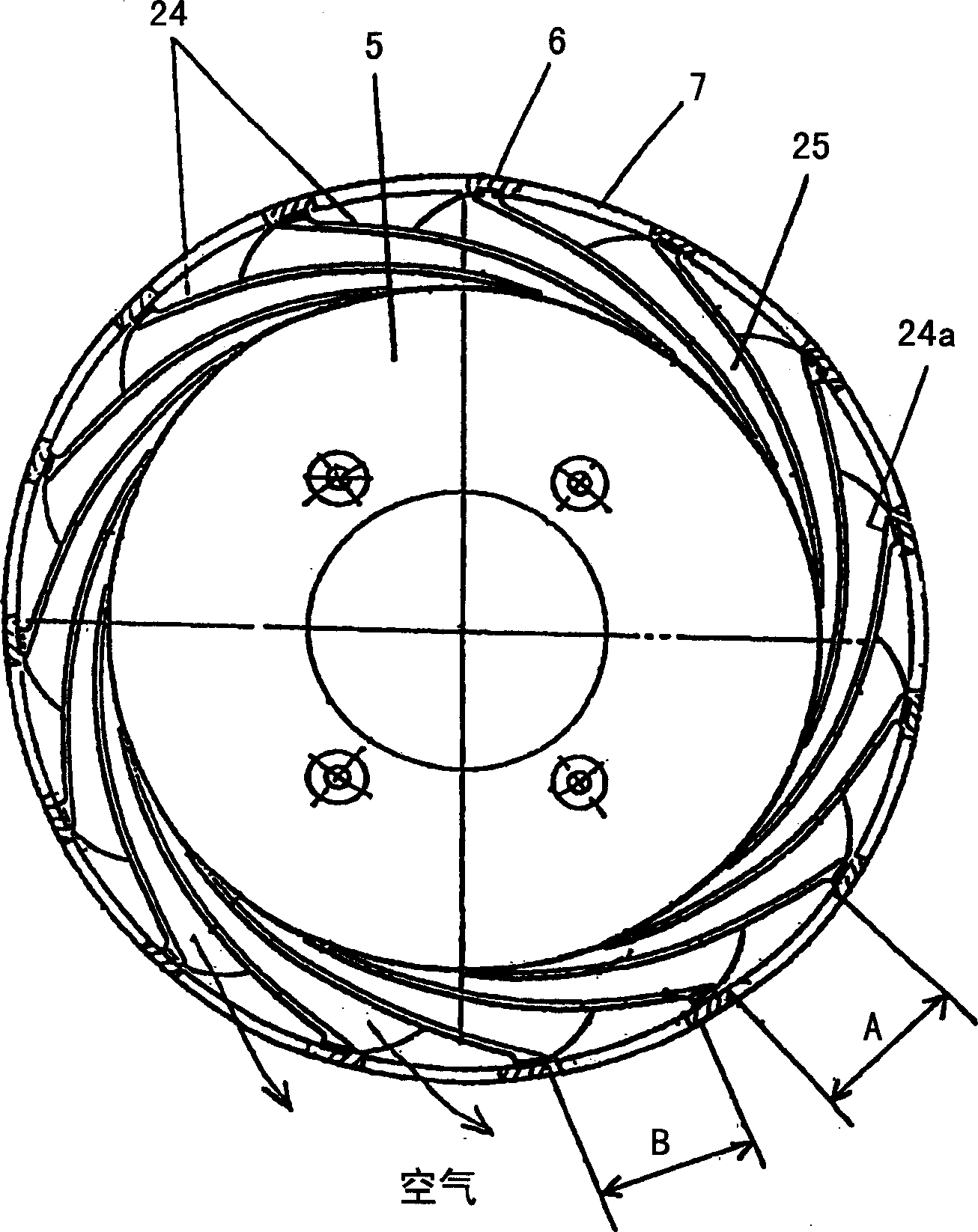

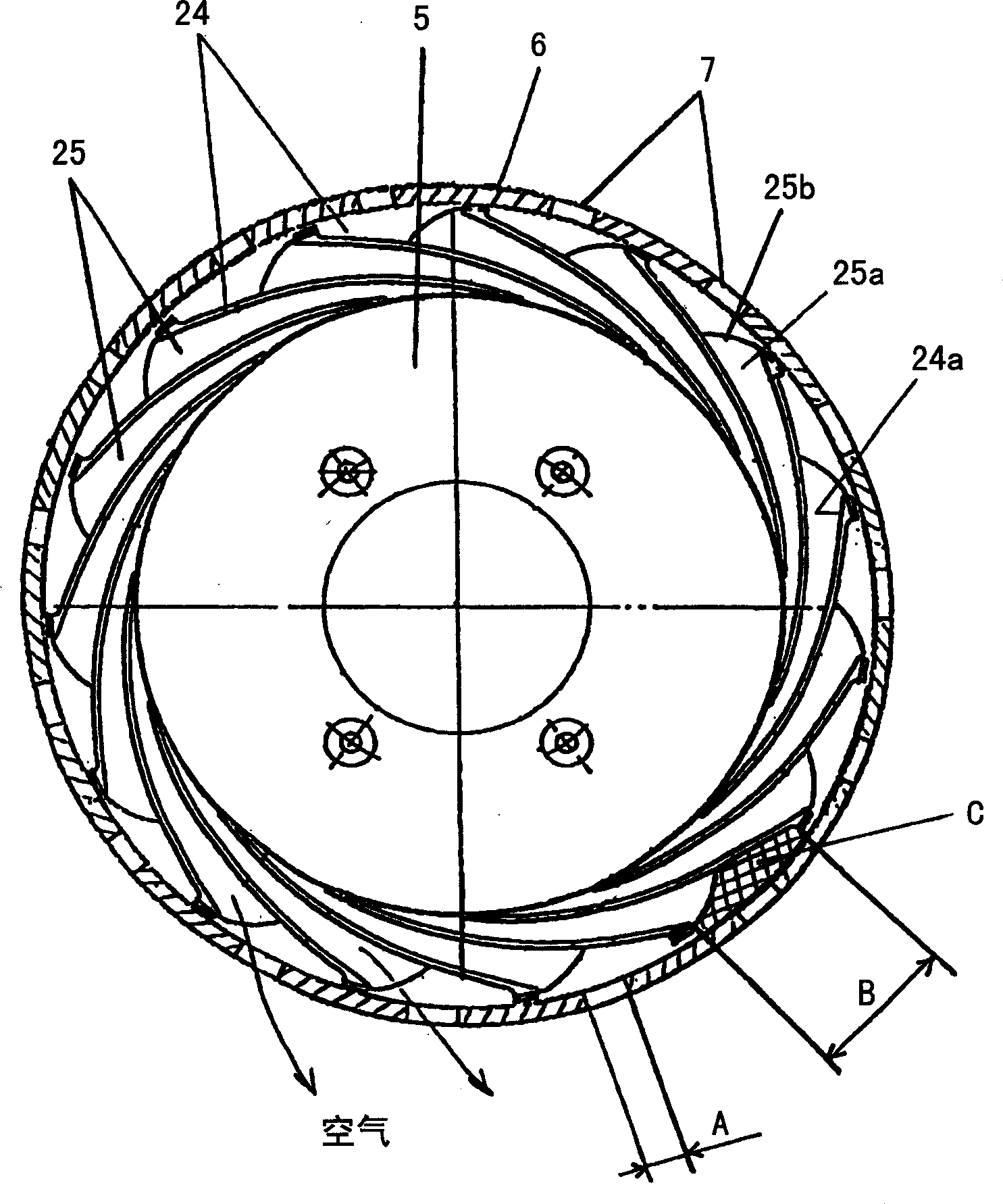

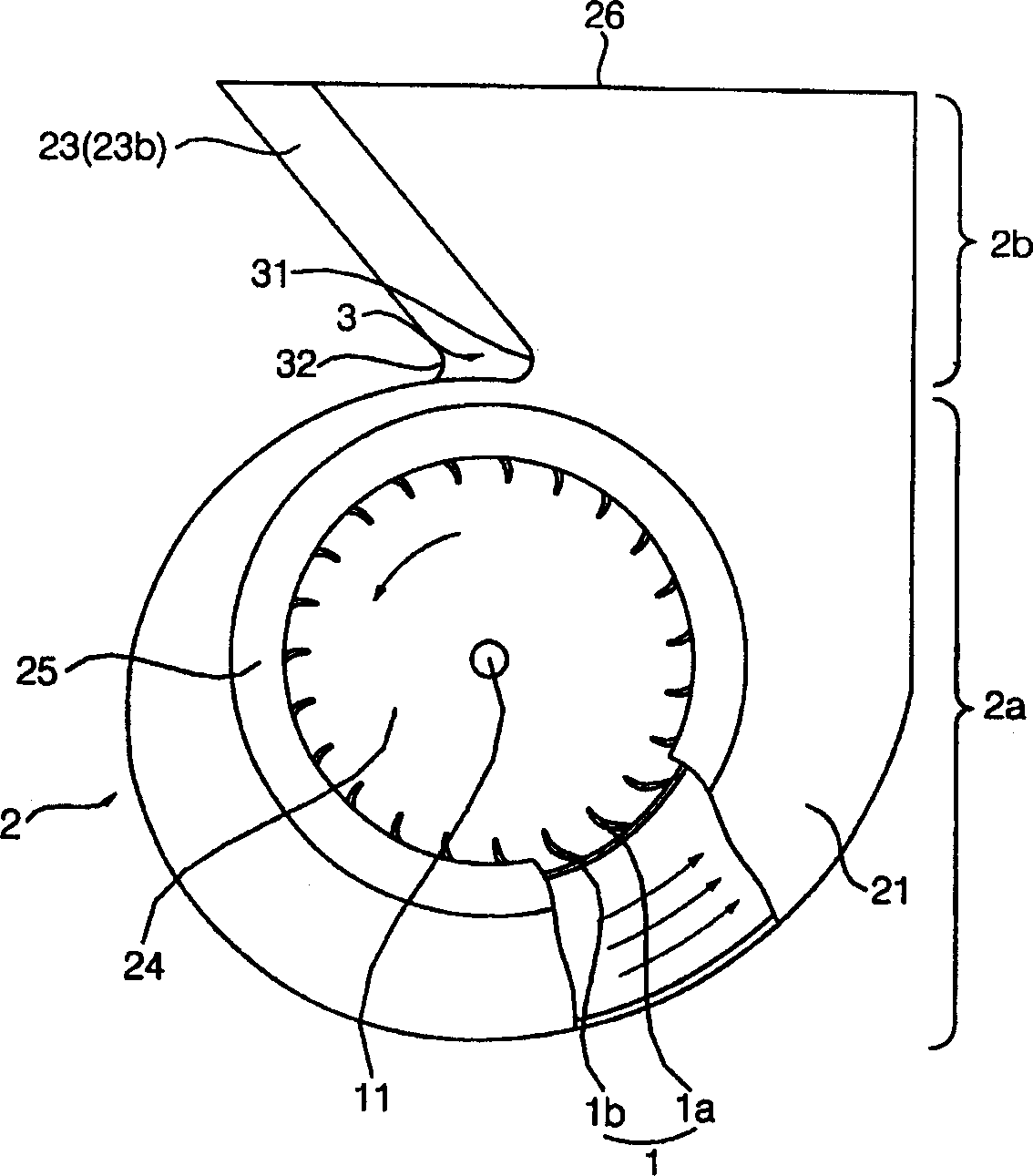

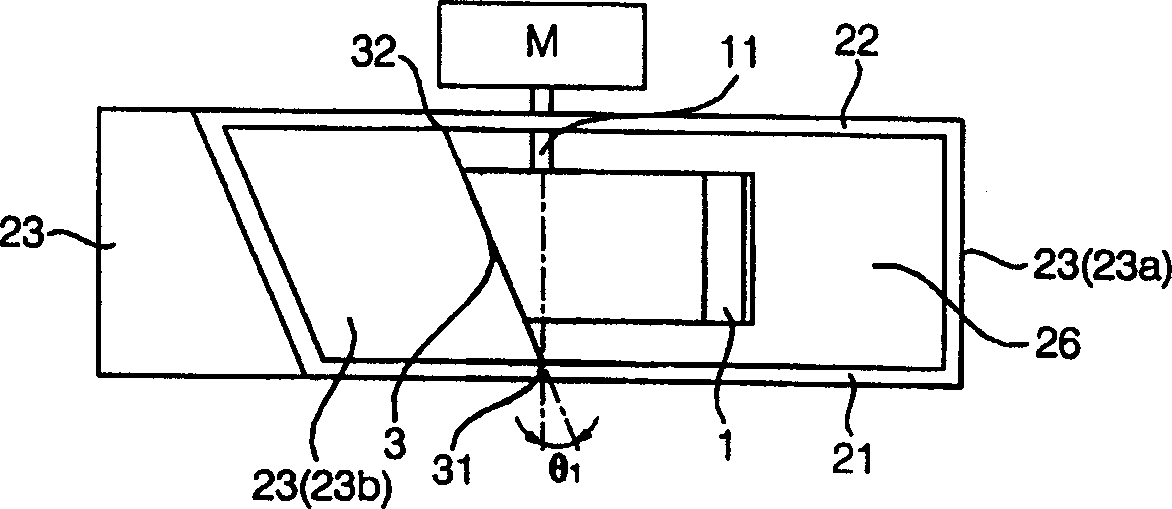

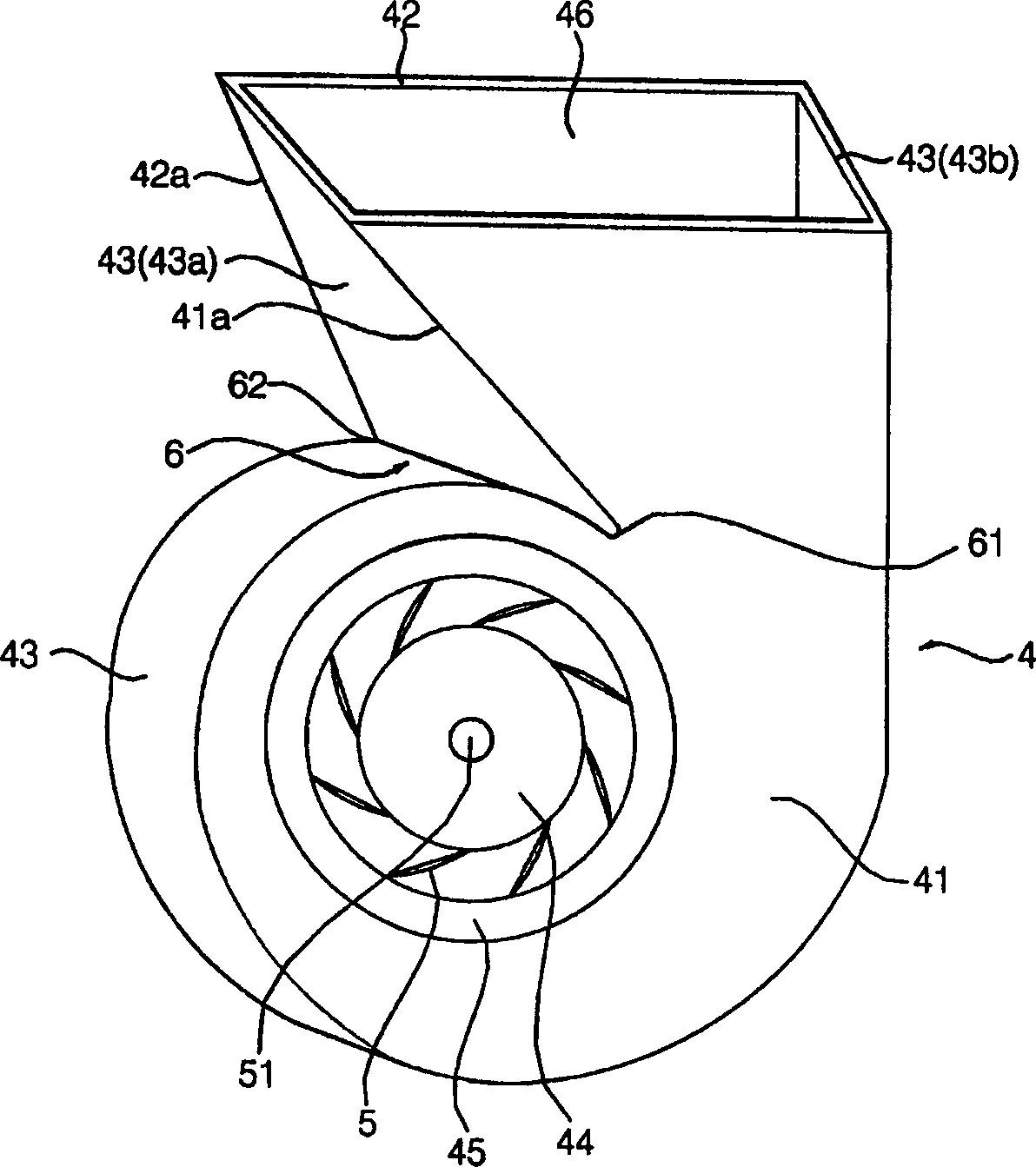

High efficient compact radial blower

InactiveUS20080101966A1Improve efficiencyImprove performanceEngine manufacturePump componentsImpellerEngineering

A radial blower comprising an impeller, an electric drive and a housing. The impeller comprises an impeller disk with the first and second sides, radial blades protruded from the first side, a central hub mounting on an axle, and an inflow hub integrated with the impeller disk. The electric drive comprises a magnetized rotor located from the second side of the impeller disk and a stator with a central opening surrounded by circumferentially arrayed flat coil windings. The magnetized rotor comprises spaced apart by an axial gap a flat ferromagnetic ring and a layer of magnetic means. The housing comprises a base, a shaped upper side, and a side part. The shaped upper side at least partially surrounds the magnetized rotor. The stator at the outer is rigidly bounded with the shaped upper side while the inner part of the stator is placed at the axial gap.

Owner:INDAL DESIGN LAB

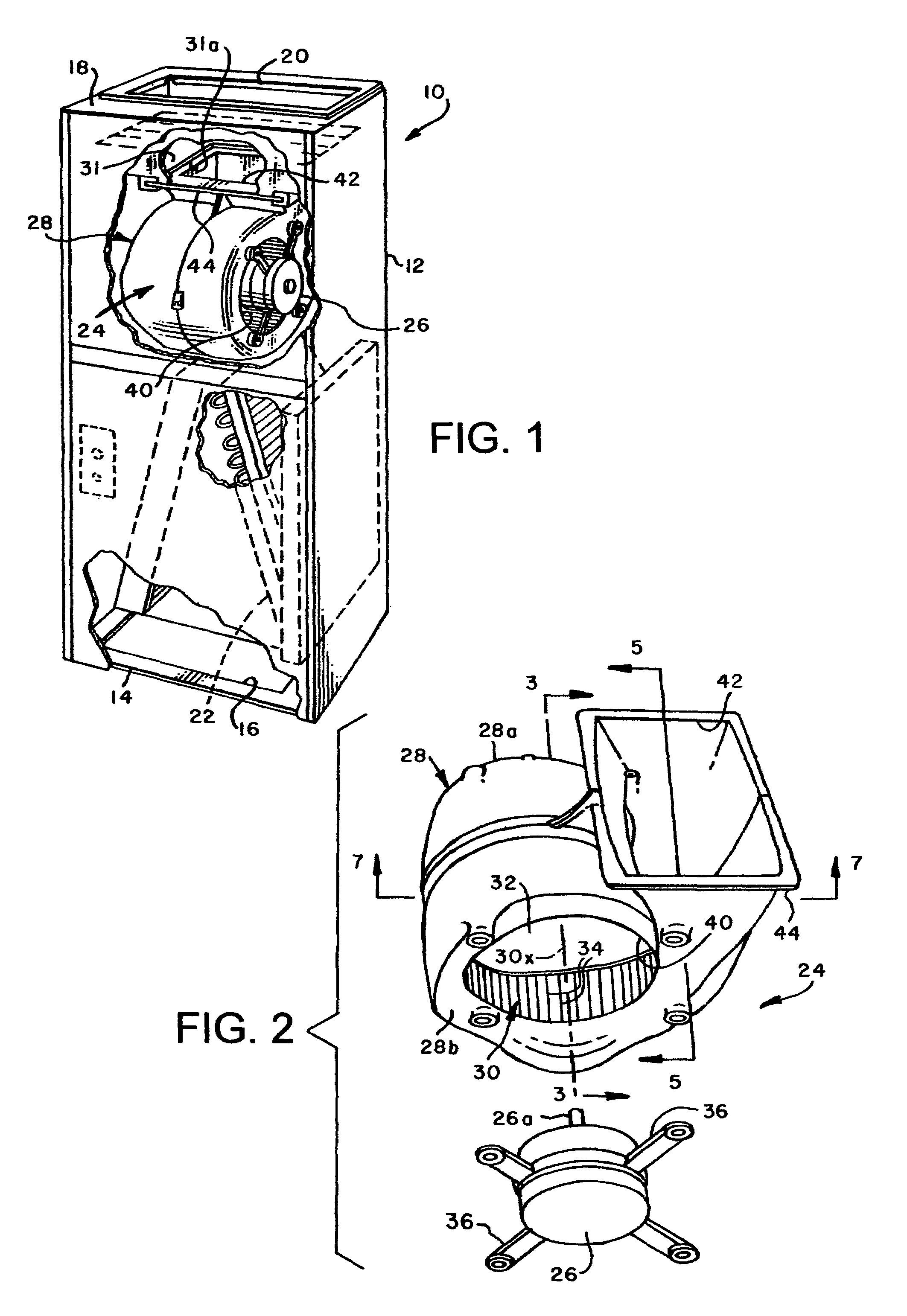

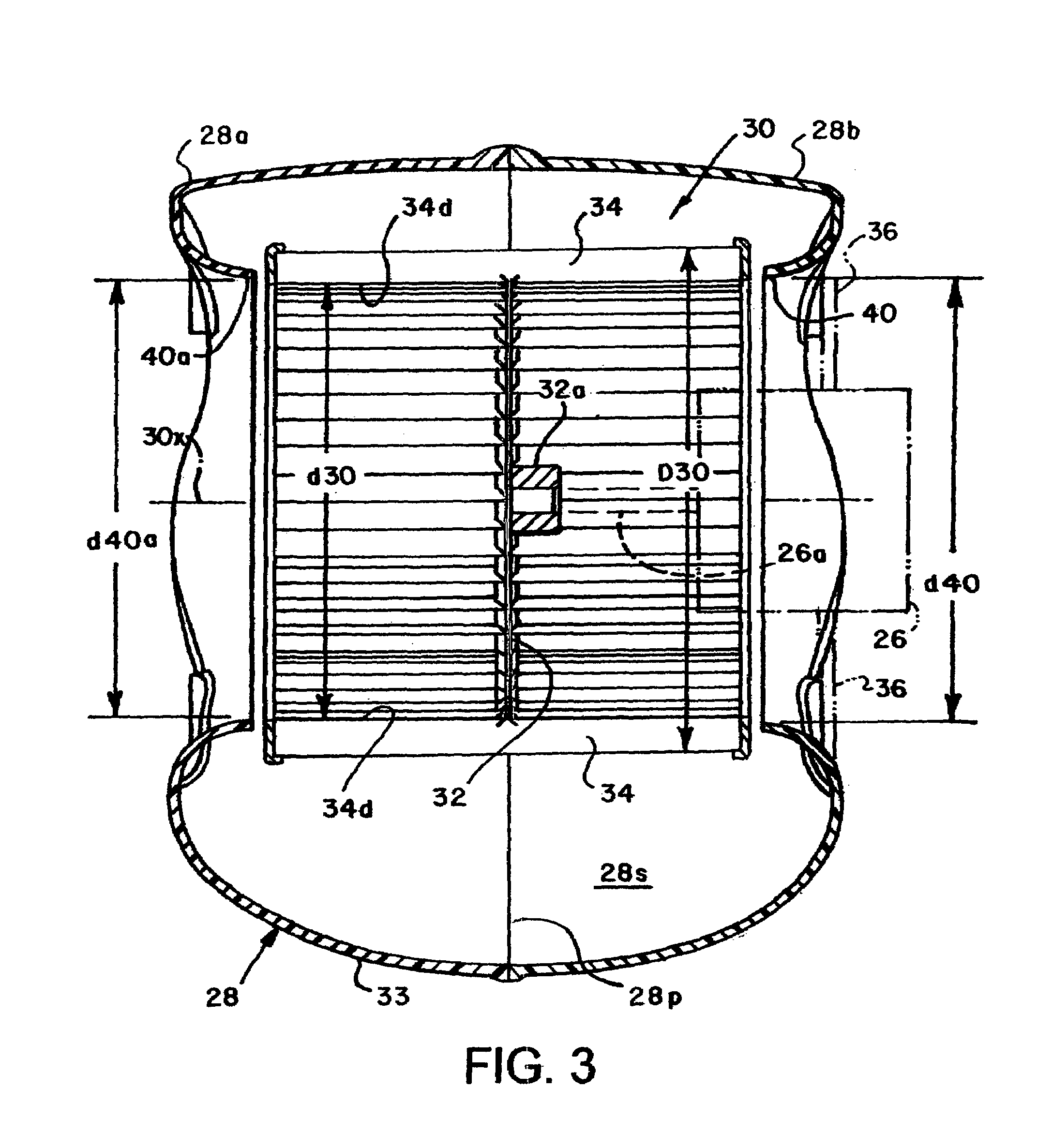

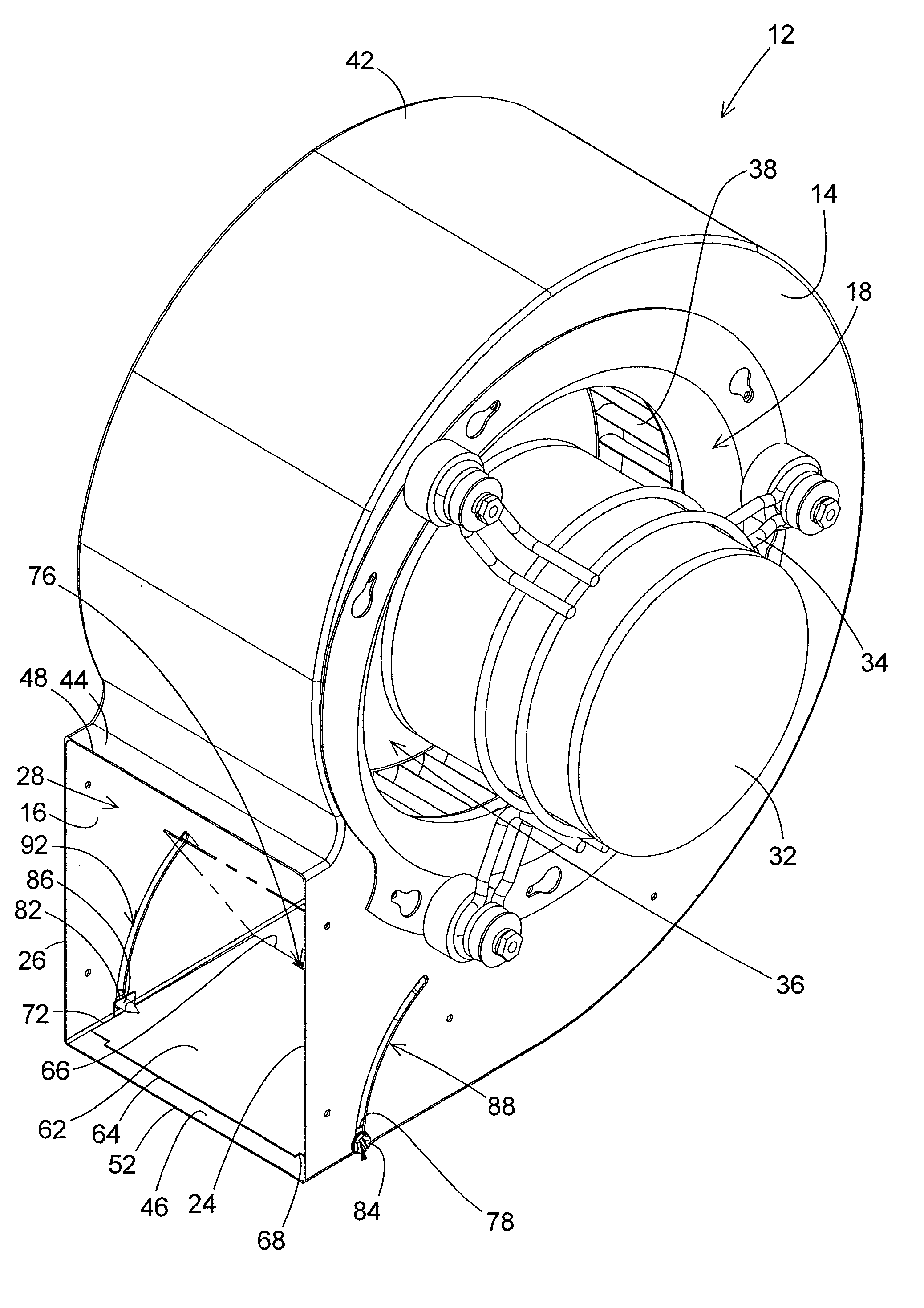

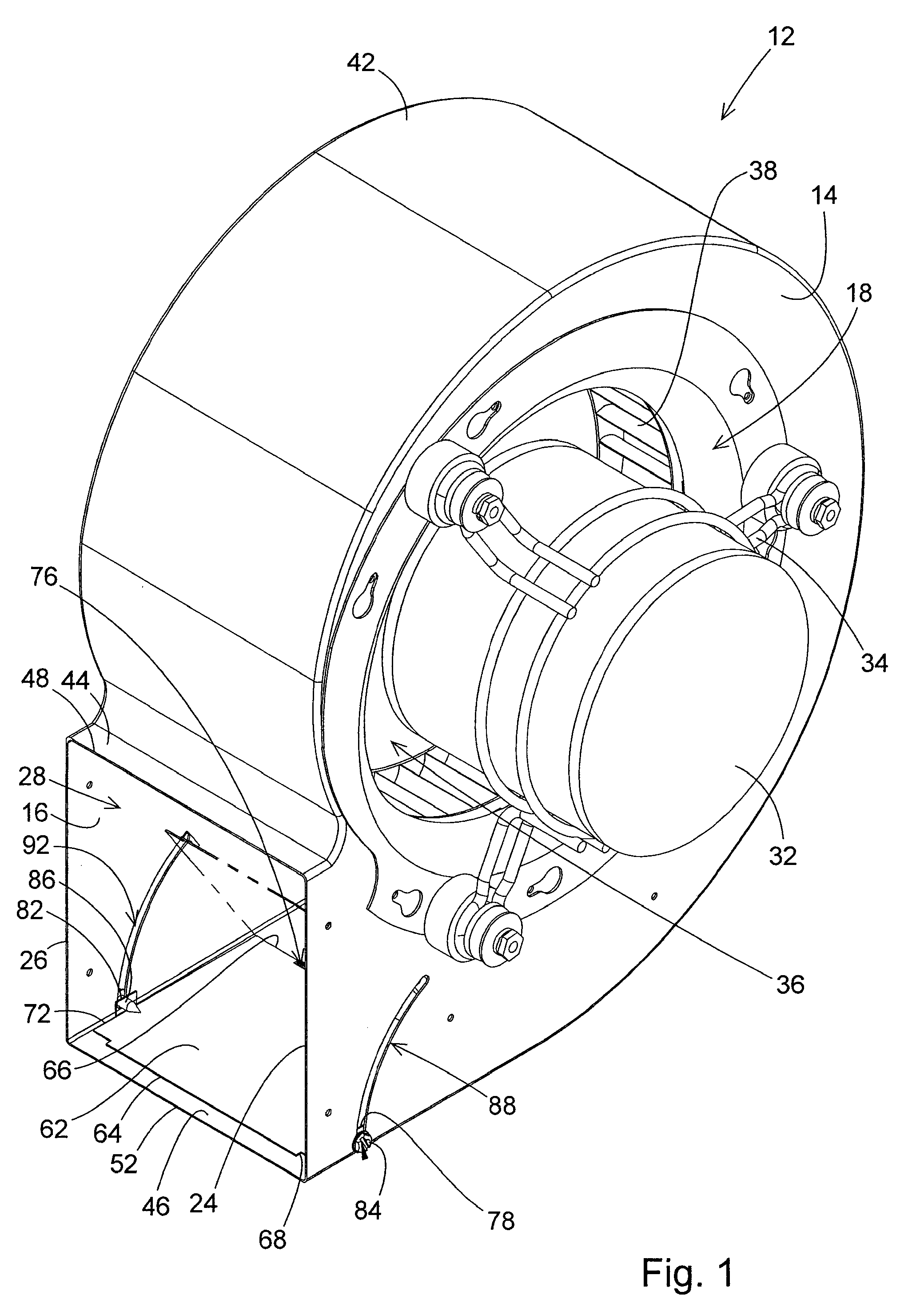

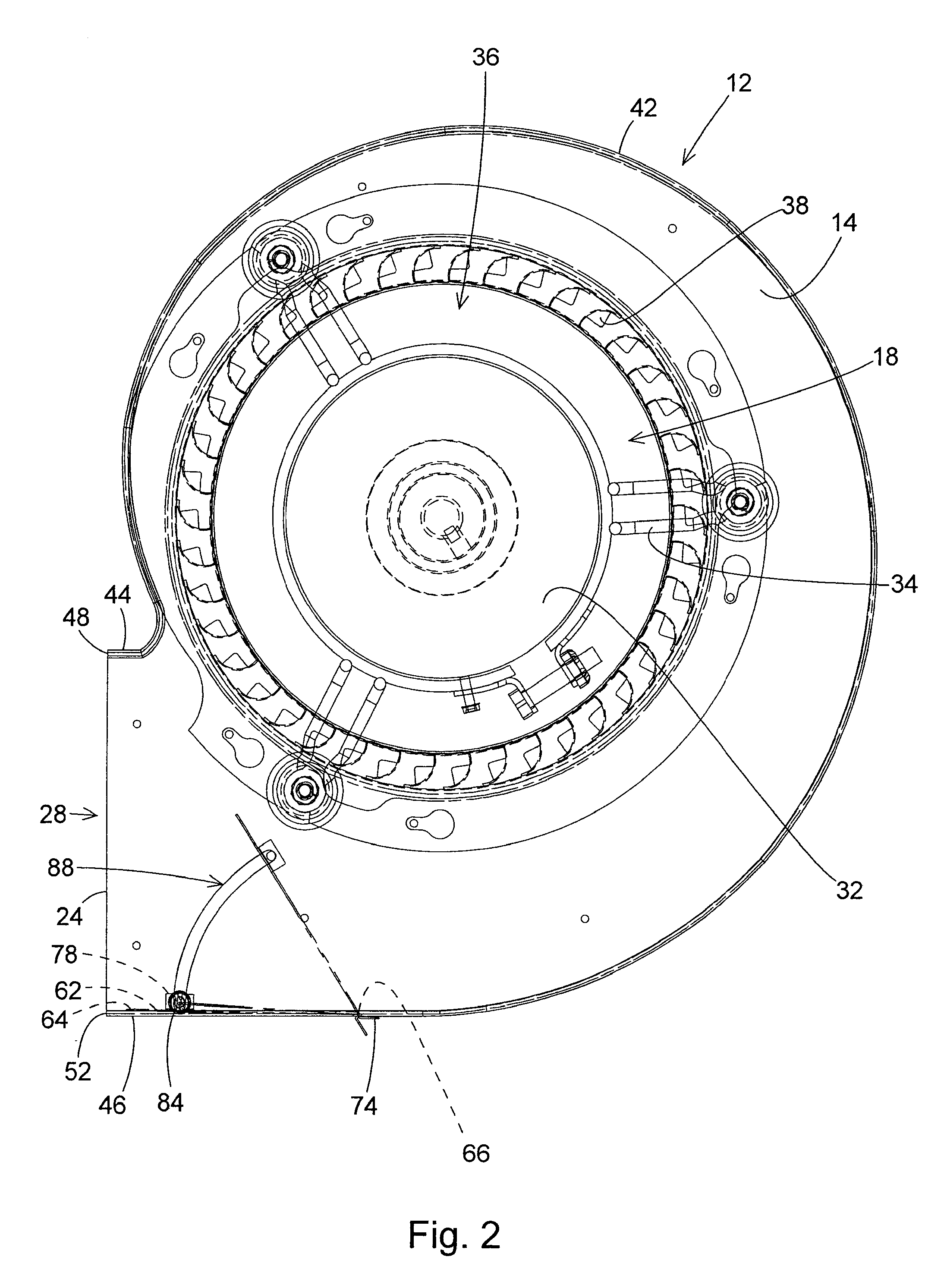

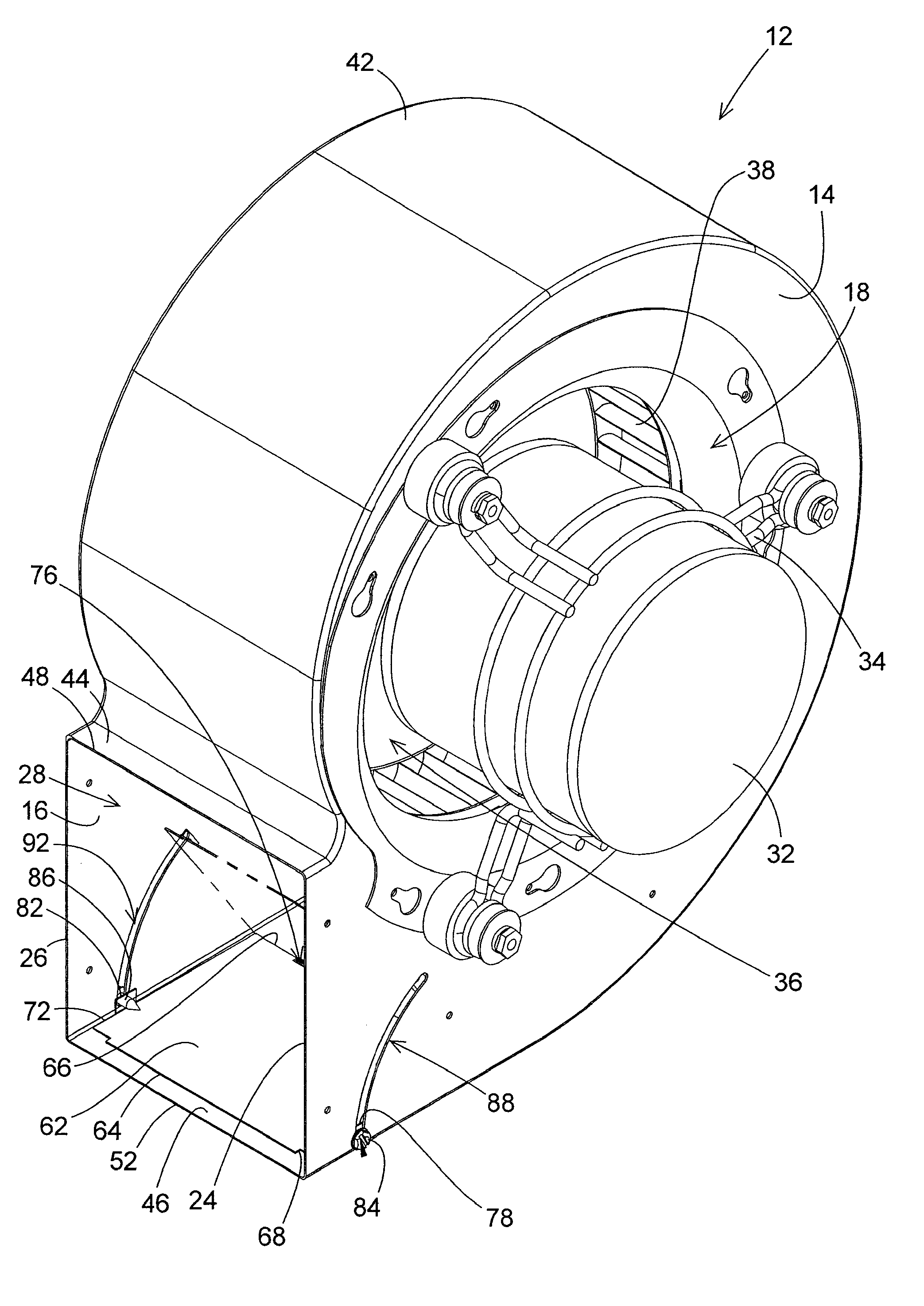

Centrifugal blower for air handling equipment

InactiveUS7591633B2Improve blower efficiencyAcoustic emission reductionPump componentsStatorsImpellerAirflow

An air handling blower for HVAC equipment includes a blower housing adapted to accommodate centrifugal impellers of selected inside and outside diameters of the impeller blades wherein the inside diameter of the largest diameter impeller accommodated by the housing is not less than the outside diameter of the smallest diameter impeller accommodated by the housing without loss of performance. The blower housing preferably has a continuously increasing cross-sectional airflow area for air being discharged from the blower and extending from a cutoff edge to an outlet.

Owner:TRANE INT INC

Fan assembly

InactiveUS20070014675A1Improve fan efficiencyPrevent thermal deformationPump componentsPiston pumpsImpellerEngineering

A fan assembly includes an impeller portion generating an air flow and a motor that rotates the impeller portion about a center axis. The impeller portion is attached to a yoke of a rotor portion of the motor and is rotated with the yoke. A circular portion of the impeller is attached to a bottom opening of the yoke having a cylindrical shape whose top is covered by insert molding. Therefore, the impeller and the yoke may be securely fixed to each other. In addition, an outer side surface of the yoke is exposed to outside air such that the space arranged inward from the plurality of blades may be enlarged.

Owner:NIDEC CORP

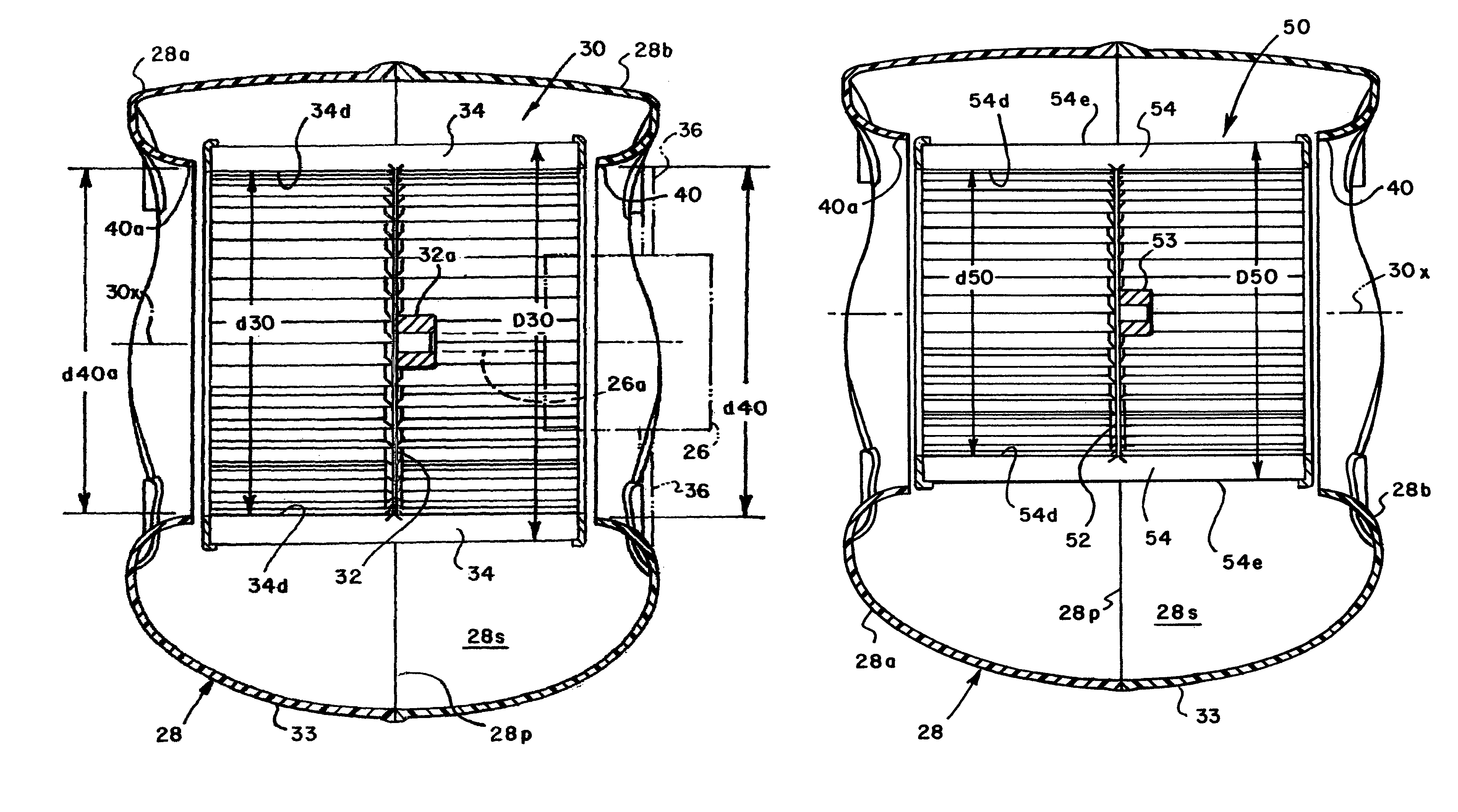

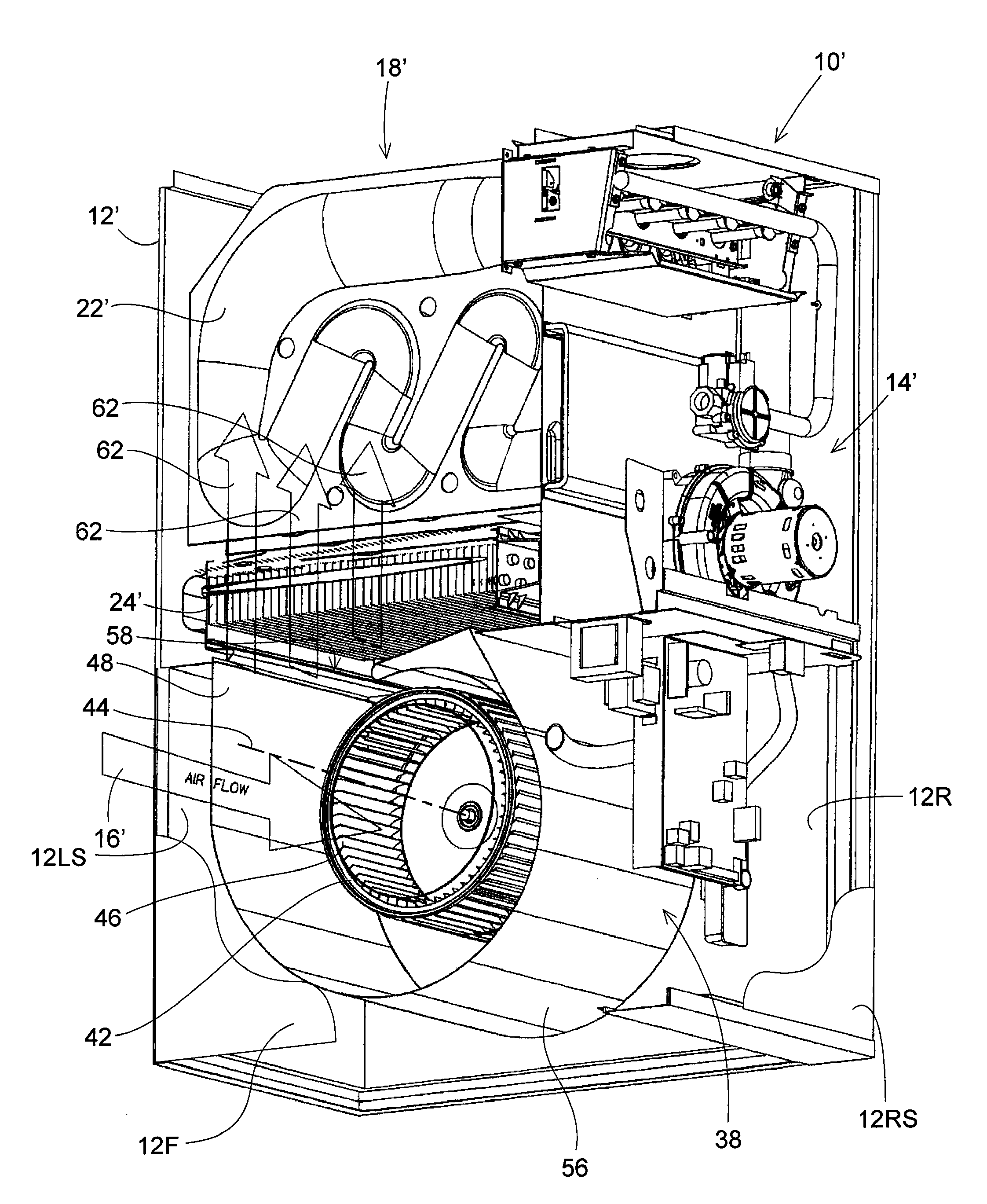

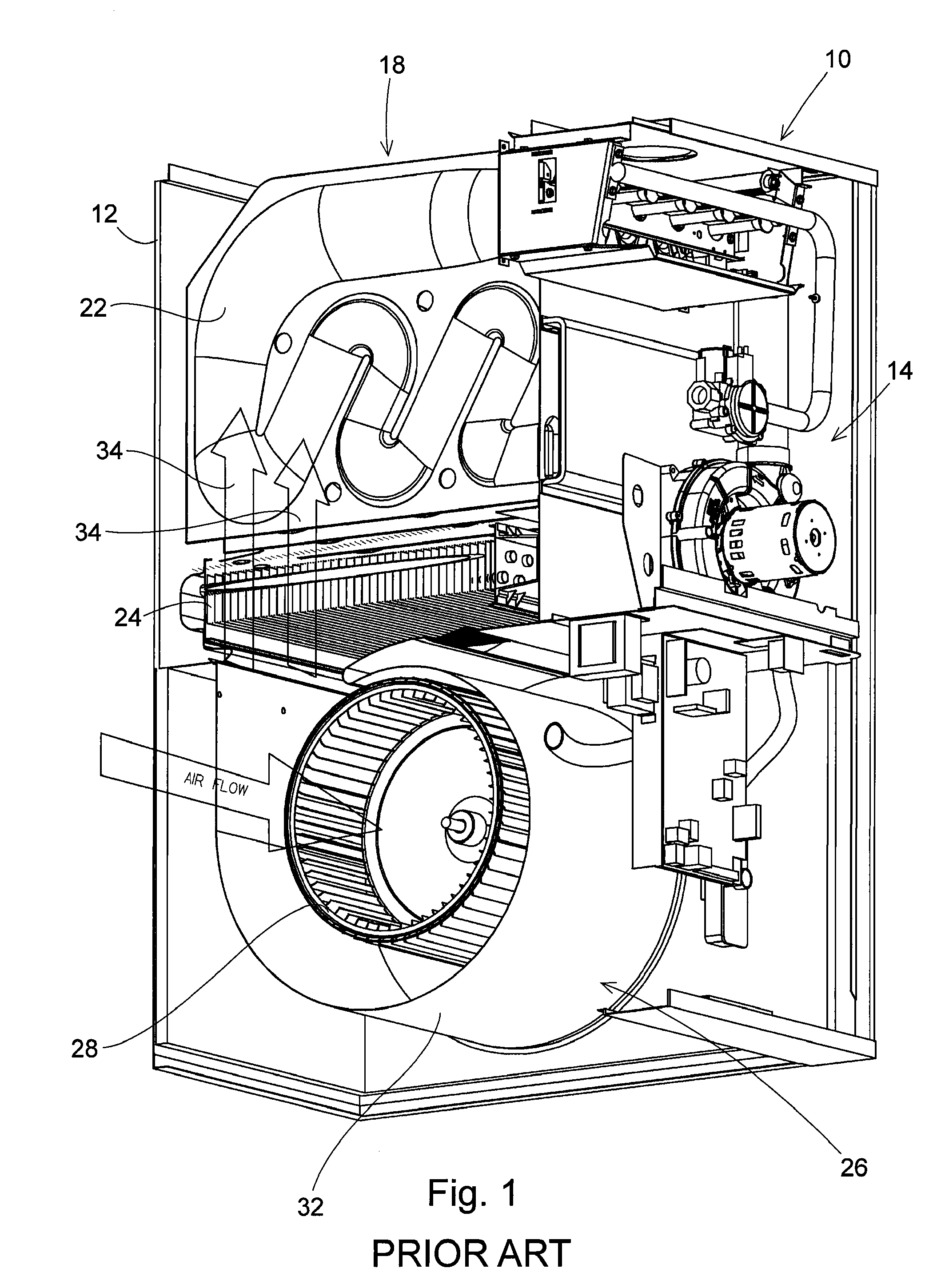

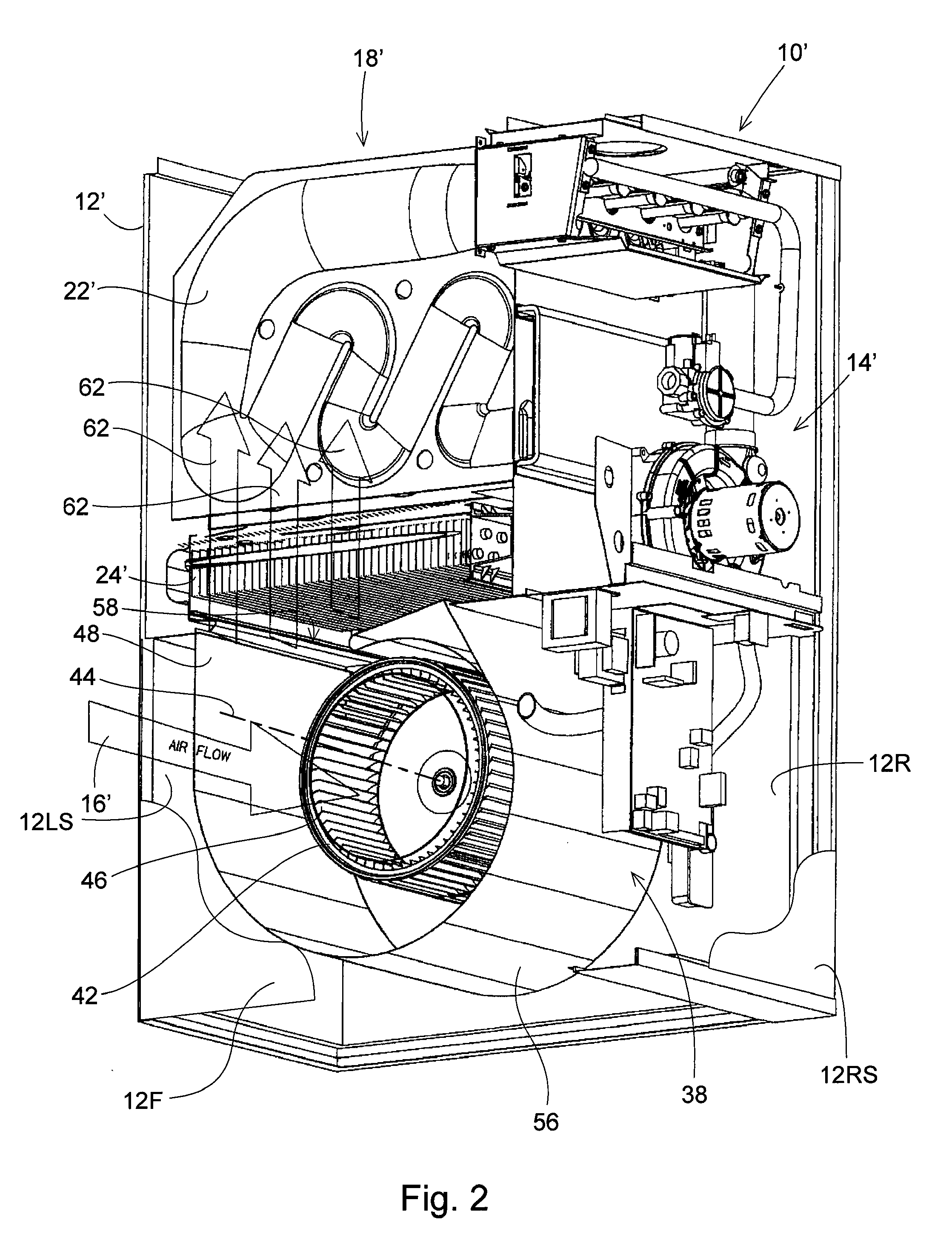

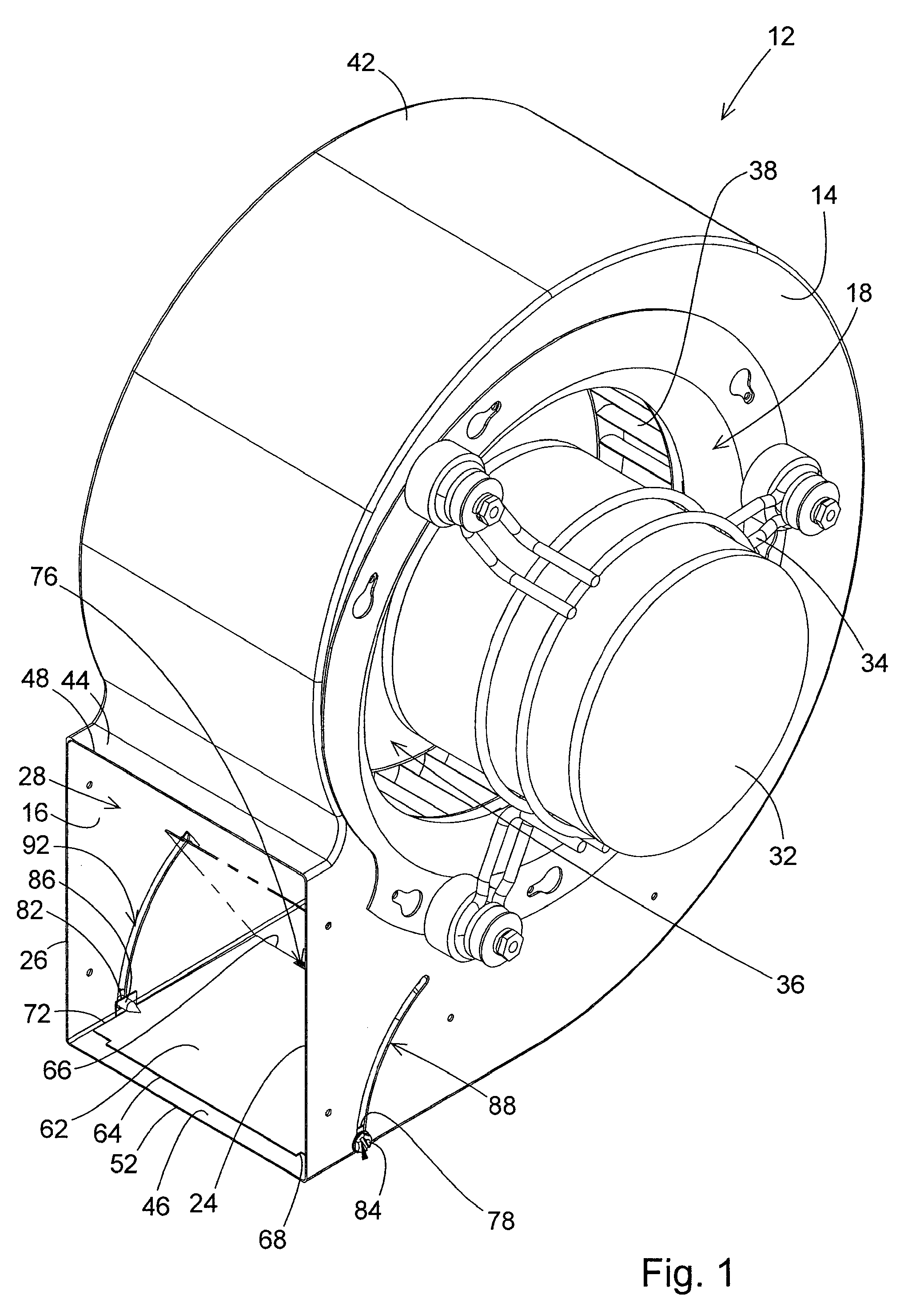

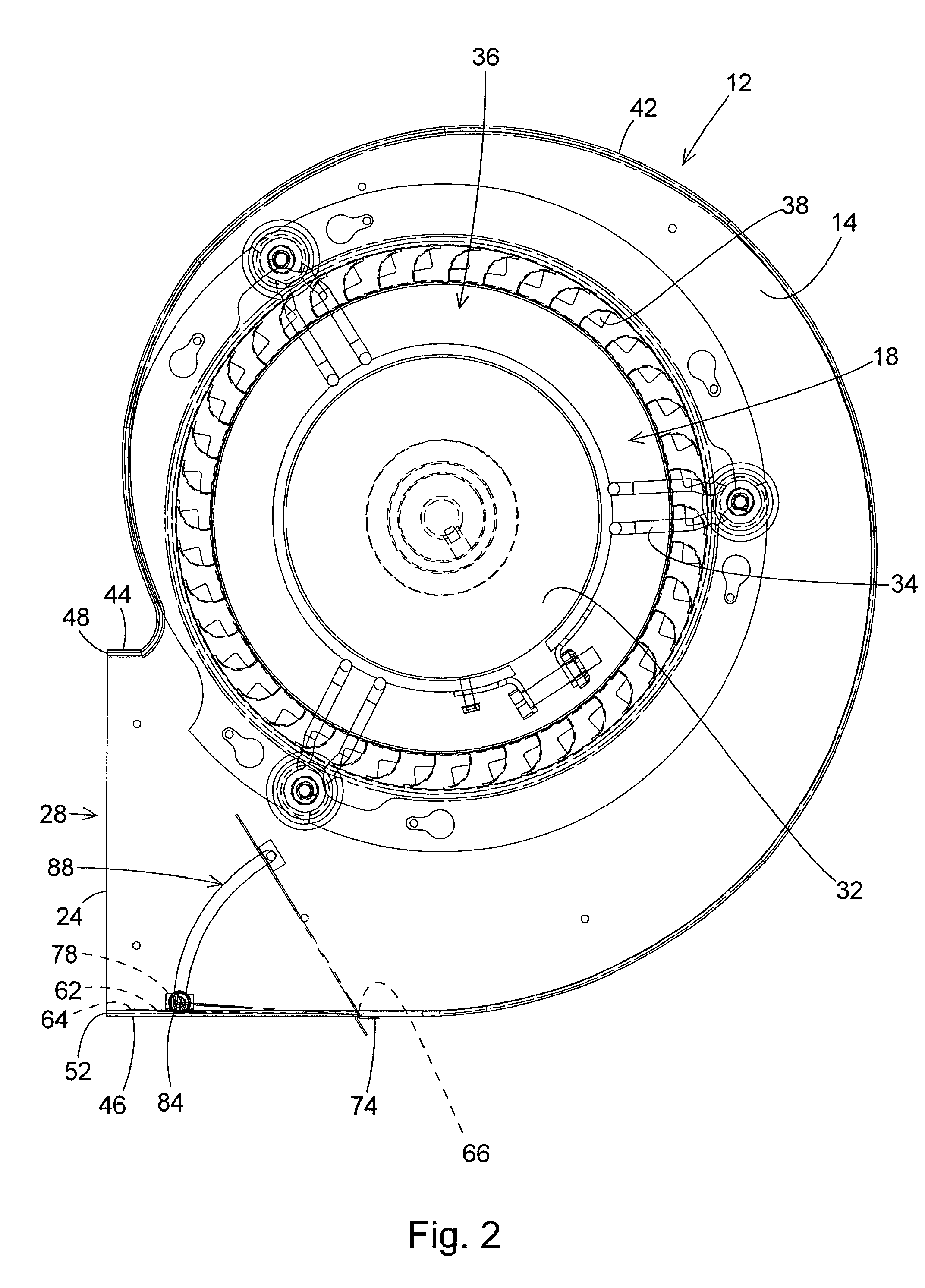

Furnace Air Handler Blower Housing with an Enlarged Air Outlet Opening

ActiveUS20090114206A1Overcomes efficiency problemLess pressure dropPump componentsAir heatersAir handlerWaste management

An air distribution blower housing for an air handler such as a residential furnace is designed with an enlarged air outlet opening that slows down and spreads out the air flow from the blower housing over a greater area of the furnace heat exchanger. The blower housing thereby enables less air pressure drop through the heat exchanger, which increases the efficiency of the blower motor operation. The design of the blower housing also efficiently turns the velocity head of the air flow through the housing to usable static air pressure at the housing air outlet. The enlarged air outlet opening of the blower housing is achieved without increasing the exterior diameter dimensions of the blower housing whereby the blower housing is used in a compact enclosure for residential use. This is accomplished by utilizing a volute outer wall of the blower housing that has an exponentially increasing expansion angle in the direction of air flow through the blower housing.

Owner:REGAL BELOIT AMERICA

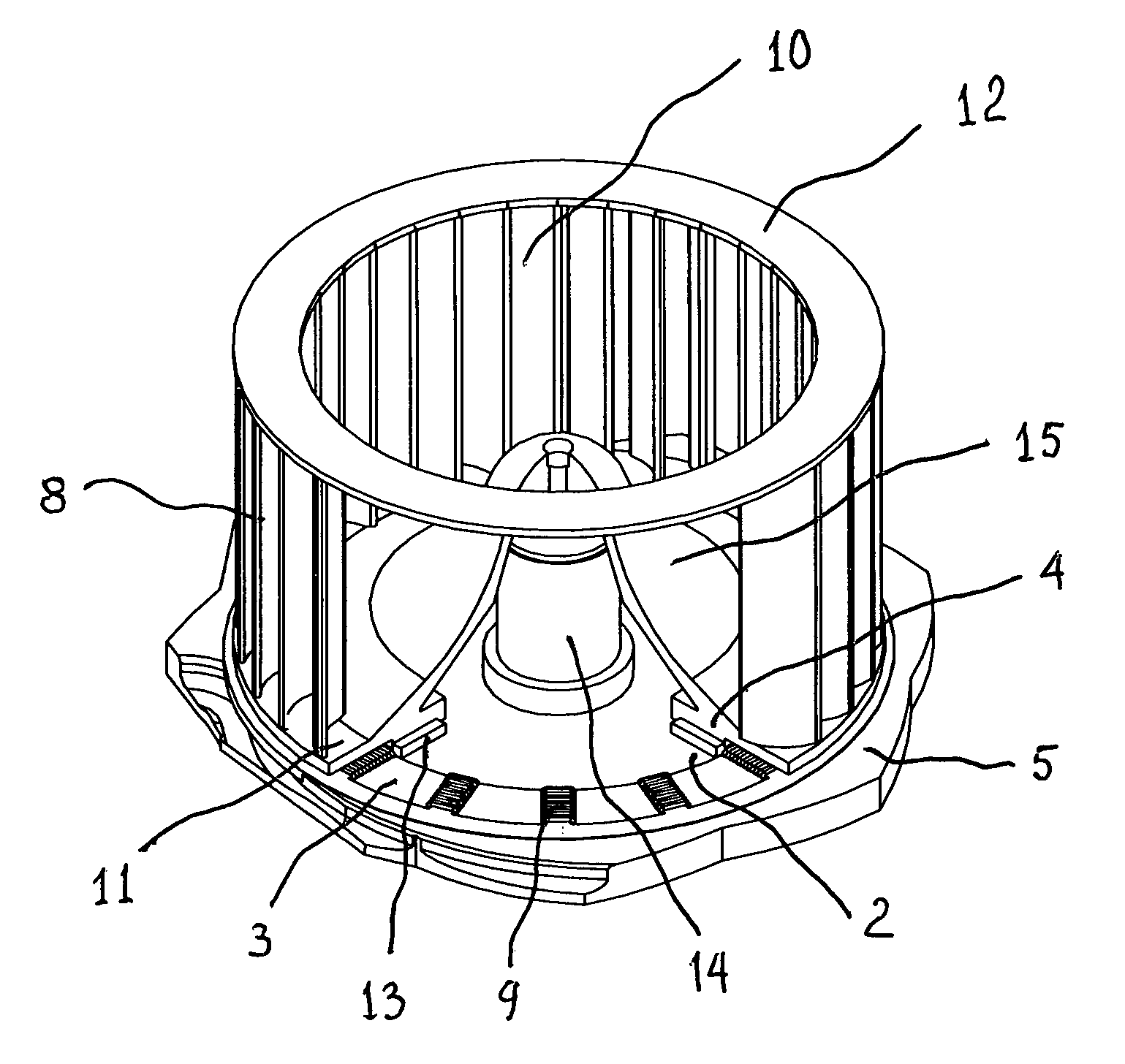

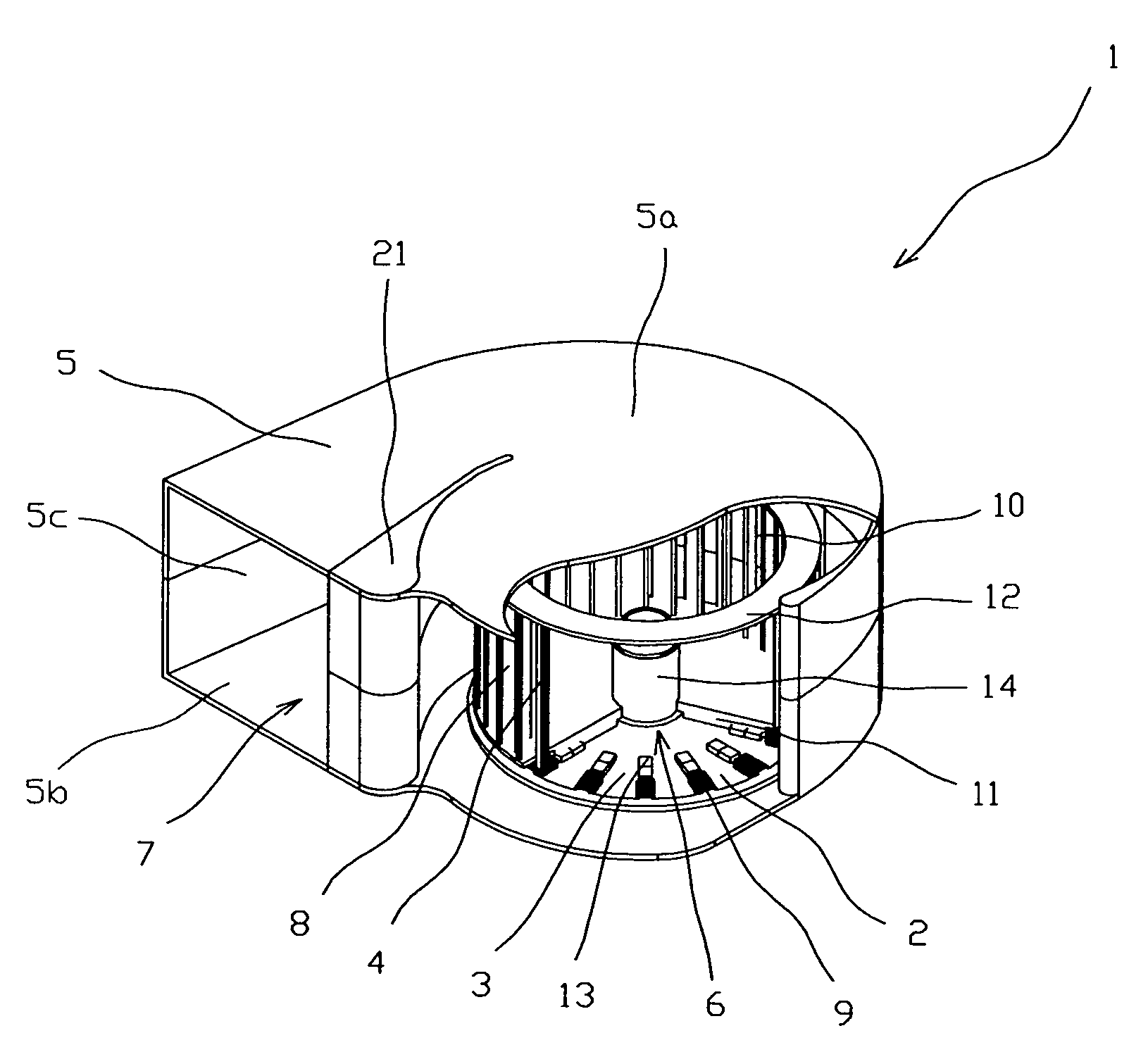

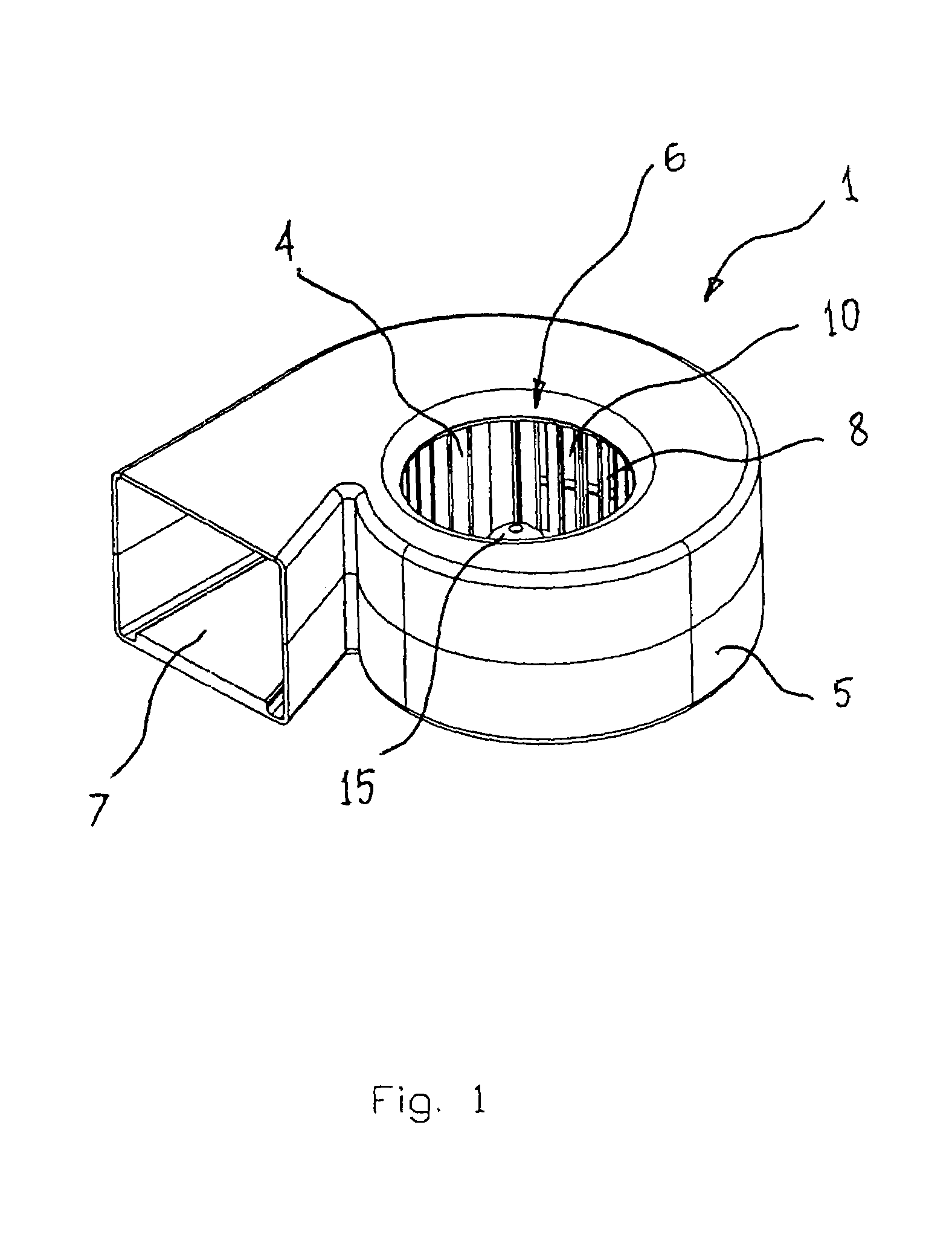

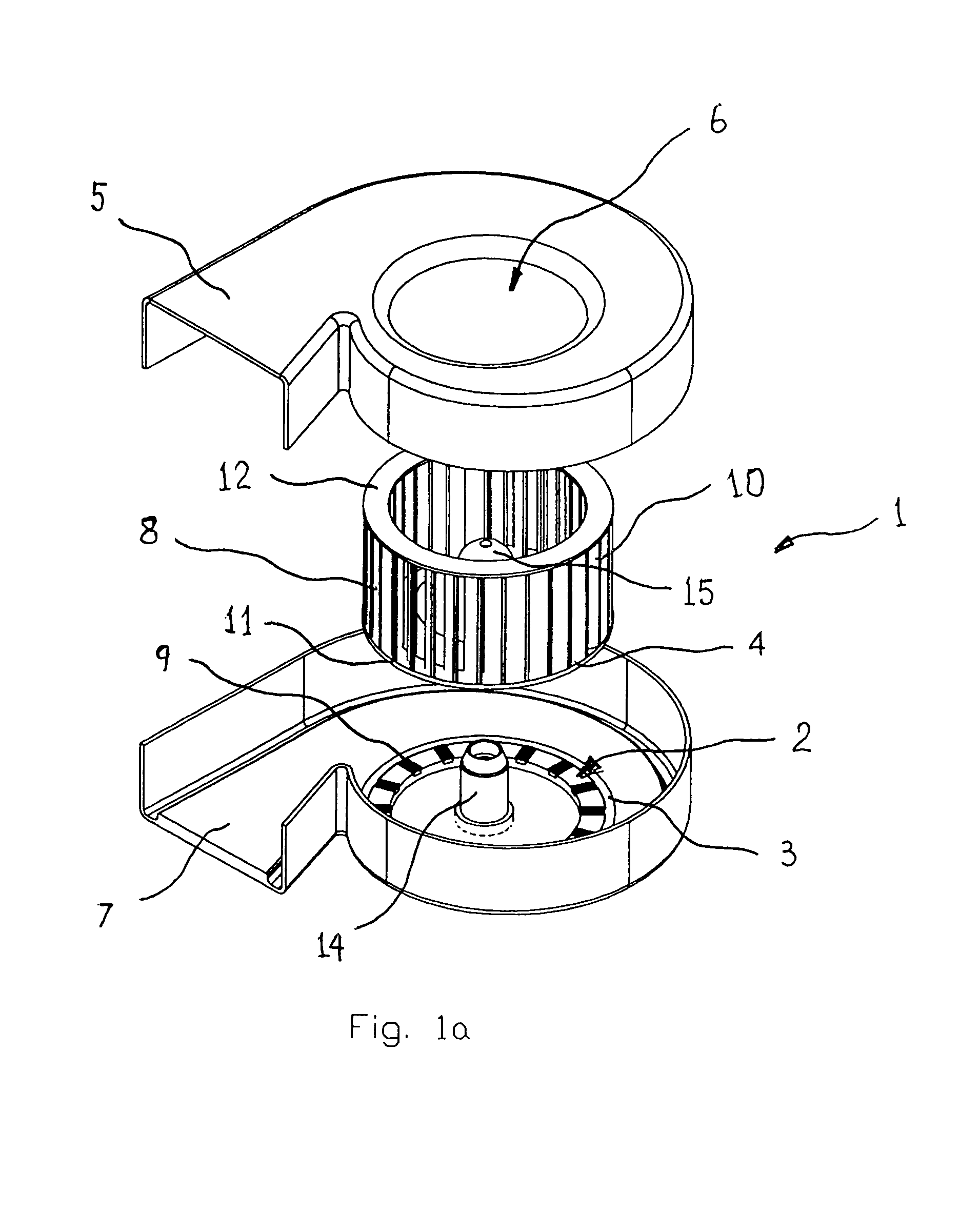

Integrated blower for cooling device

InactiveUS20060006745A1Improve performanceReduce sound levelPump componentsMechanical energy handlingImpellerEngineering

An integrated blower for cooling device comprises an electric drive with at least one set of a flat stator and a magnetized rotor, a casing with an inlet and an outlet, and radial impeller. The flat stator integrated with the casing thus the flat stator serves as at least a part of the casing, and the magnetized rotor integrated with the radial impeller. The flat stator comprises circumferential arrayed coils with magnetic axes coincide with a plane of the flat stator. The radial impeller comprises blades attached to a backplate and a shroud, and circumferential arrayed magnetic means thus serve as the magnetized rotor. The magnetic means placed and magnetized along the plane of the flat stator thus magnetic axes of the coils and the magnetic means located at one plane substantially.

Owner:INDAL DESIGN LAB

Air Distribution Blower Housing with Adjustable Restriction

InactiveUS20090274551A1Reduced blower efficiencyEasy to addPump componentsWind motor controlEngineering

Owner:UNICO INC

Air distribution blower housing with adjustable restriction

InactiveUS8197193B2Improve blower efficiencyLow efficiencyPump componentsWind motor controlEngineering

Owner:UNICO INC

Integrated blower for cooling device

InactiveUS7173353B2Improve performanceReduce sound levelPump componentsMechanical energy handlingImpellerEngineering

An integrated blower for cooling device comprises an electric drive with at least one set of a flat stator and a magnetized rotor, a casing with an inlet and an outlet, and radial impeller. The flat stator integrated with the casing thus the flat stator serves as at least a part of the casing, and the magnetized rotor integrated with the radial impeller. The flat stator comprises circumferential arrayed coils with magnetic axes coincide with a plane of the flat stator. The radial impeller comprises blades attached to a backplate and a shroud, and circumferential arrayed magnetic means thus serve as the magnetized rotor. The magnetic means placed and magnetized along the plane of the flat stator thus magnetic axes of the coils and the magnetic means located at one plane substantially.

Owner:INDAL DESIGN LAB

Fan

ActiveUS20080112810A1Improve fan efficiencyPrevent thermal deformationPropellersPump componentsImpellerAirflow

Owner:NIDEC CORP

Integrated blade cooler for electronic components

InactiveUS20050031447A1Improve blower efficiencyImprove thermal efficiencyPump componentsReaction enginesImpellerElectricity

An integrated blade cooler for electronic components comprises a blower with a radial impeller and a casing, an electric drive with a magnetic rotor and a stator, and a heatsink with heat-exchanging means and a base providing thermal contact with said electronic component and said heat-exchanging means. The casing of the impeller has an inlet and an outlet; said impeller comprises blades, a backplate disk and an axis of rotation; and the heat-exchanging means of the heatsink clothed in a cover plate with an outflow opening that being coincided with said inlet so that cooling gas flows through said heat-exchanging means, said blower inlet, said radial impeller and said blower outlet in a series way. The stator of the electric drive is made as a part of said casing of the blower so that said outflow opening serves as said inlet, and the radial impeller comprises magnetic means serving as a magnetic rotor of said electric drive. The stator is made as printed circuit board. At least part of said cover plate is made as a part of said casing so that said outflow opening serves as said inlet of the blower. The stator is located perpendicularly to the axis of rotation, and said magnetic means magnetized in the direction parallel to said axis of rotation. The heatsink has a recess on the side of an outflow opening, and the blower is located in said recess.

Owner:ROTYS

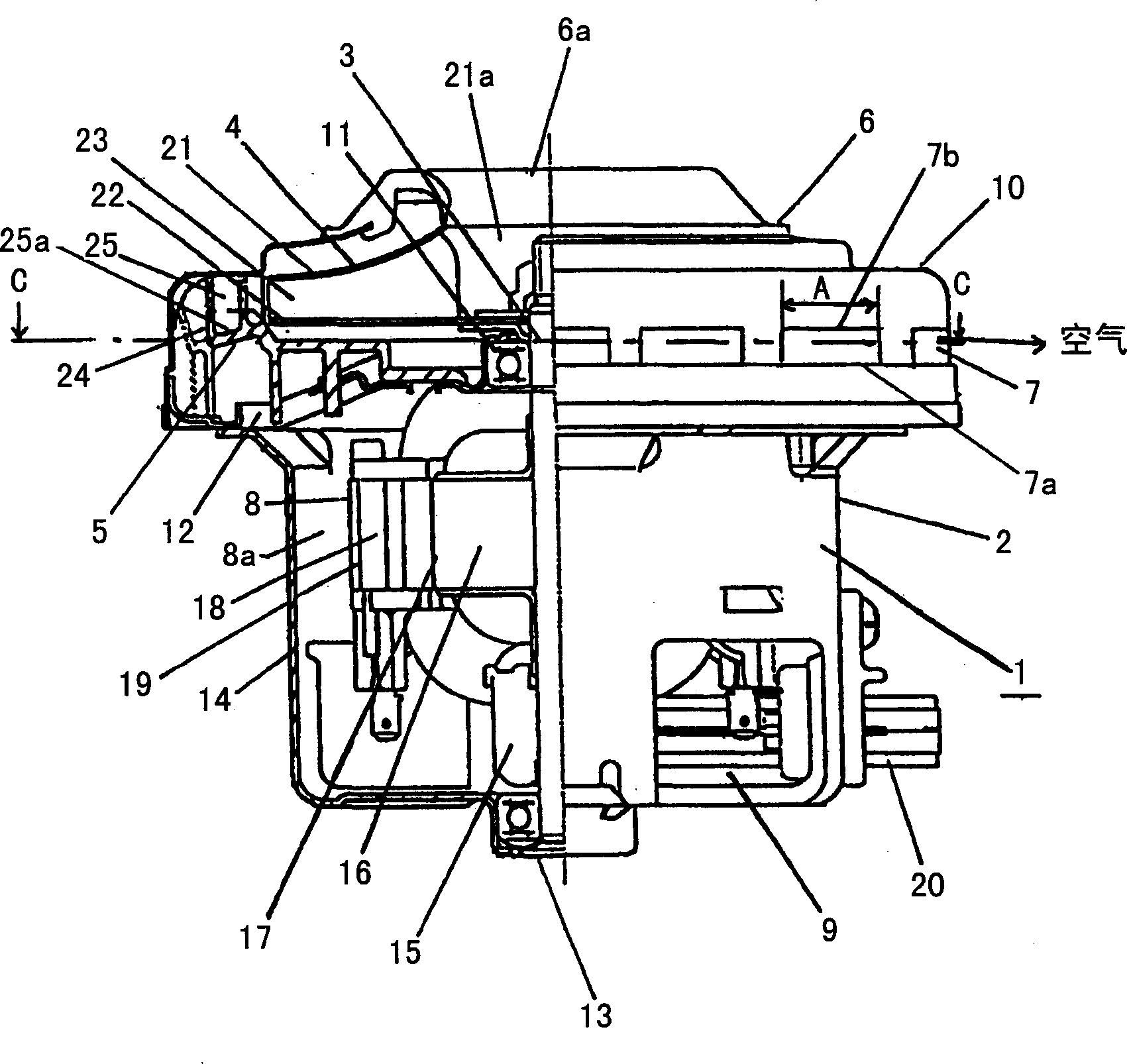

Electric fan and electric dust collector using said fan

InactiveCN1495366ASmooth dischargeImprove blower efficiencyEngine manufacturePump componentsImpellerAirflow

An electric blower (1) includes a stator (19) and a rotor (17). An impeller (4) is fixedly installed on a rotation shaft (3) of the rotor. A casing (6) encloses the impeller (4). The casing is provided with a number of exhaust openings (7) through which a part of an air stream suctioned by the impeller (4) is discharged, wherein each of the exhaust openings (7) is a form of a hole.

Owner:PANASONIC CORP

Blower

A blower having a turbo fan is installed in a scroll housing with a cutoff. The cutoff has an inclination angle of approximately 50 to 80 DEG , so that it is possible to draw in an increased amount of air while reducing the flow resistance of air. Accordingly, blowing efficiency is improved while simultaneously reducing the generation of noise and vibration.

Owner:LG ELECTRONICS INC

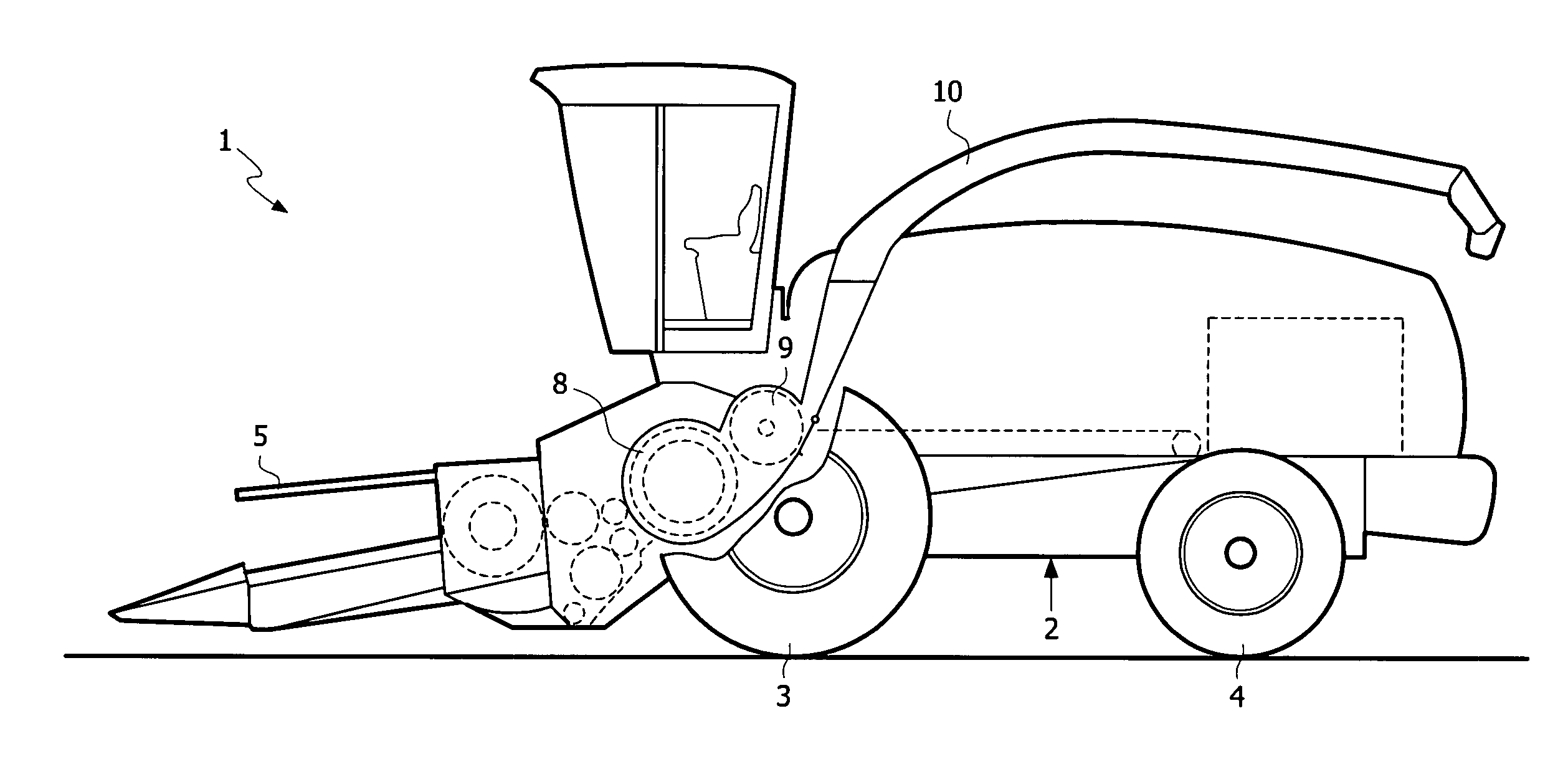

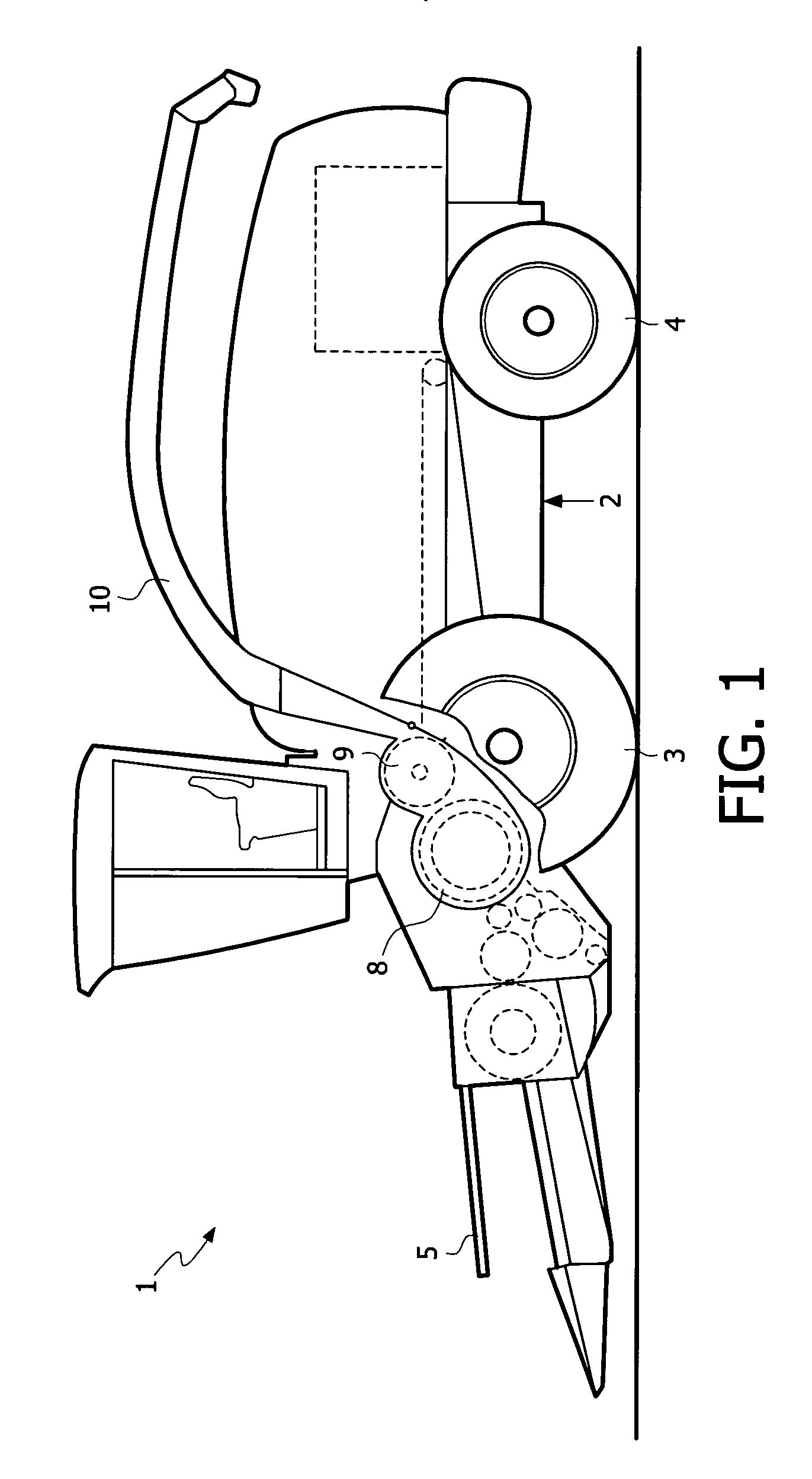

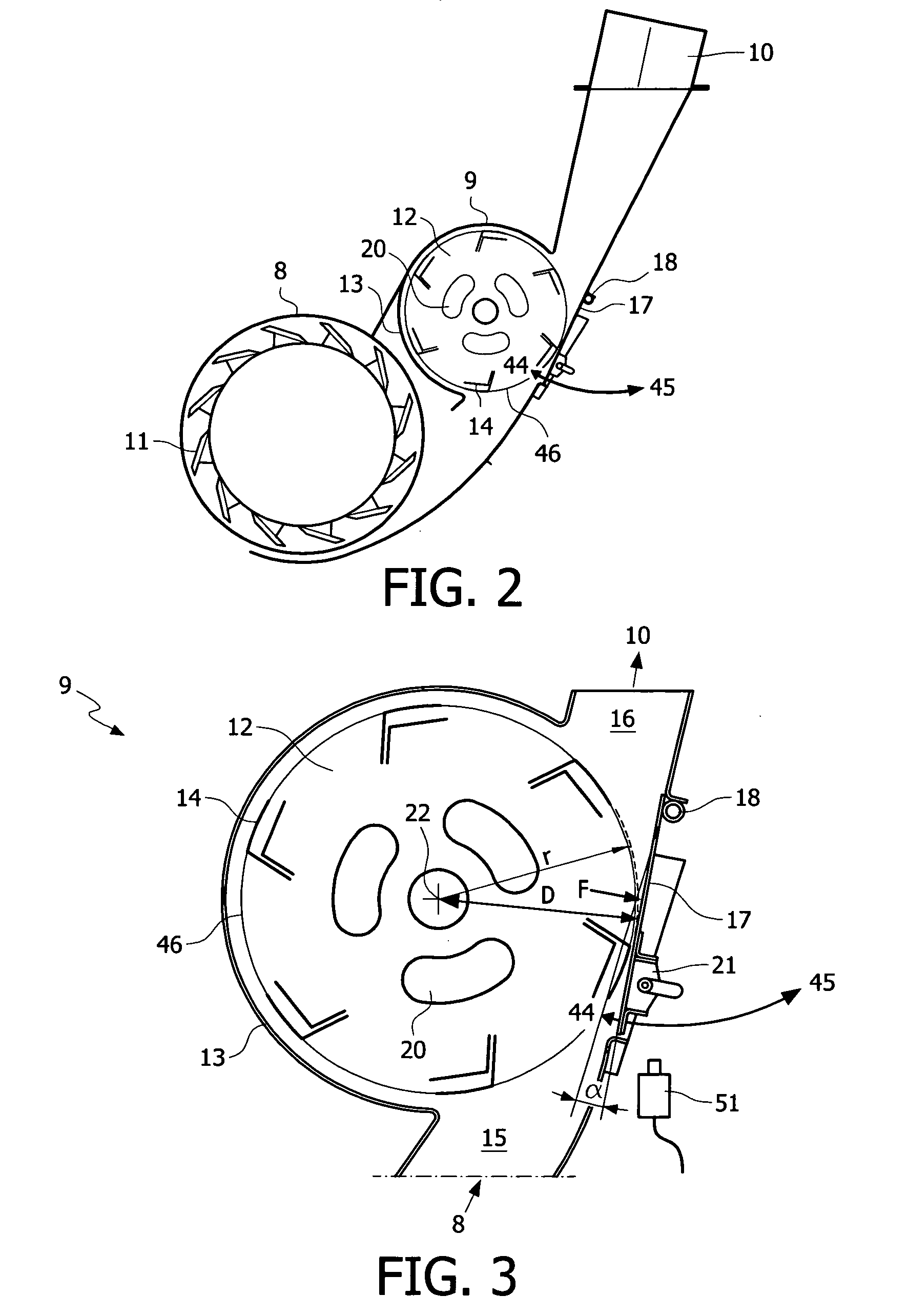

Forage harvester blower

The present invention relates to a forage harvester blower including a blower rotor having a plurality of generally radially extending rotor paddles which operate in a corresponding substantially cylindrical housing, characterised in that said housing is provided with adjustment mechanism for at least locally adjusting the diameter of the housing. The present invention further relates to a method for optimising the operation of a forage harvester blower and to a method for preventing damage to a forage harvester blower during operation.

Owner:BLUE LEAF I P INC

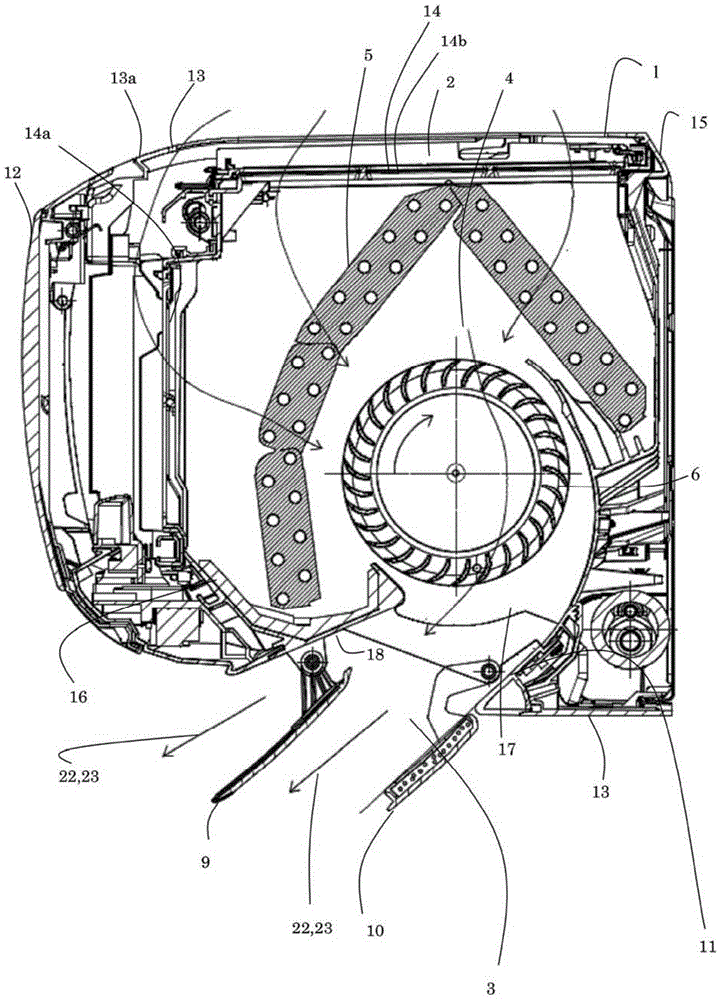

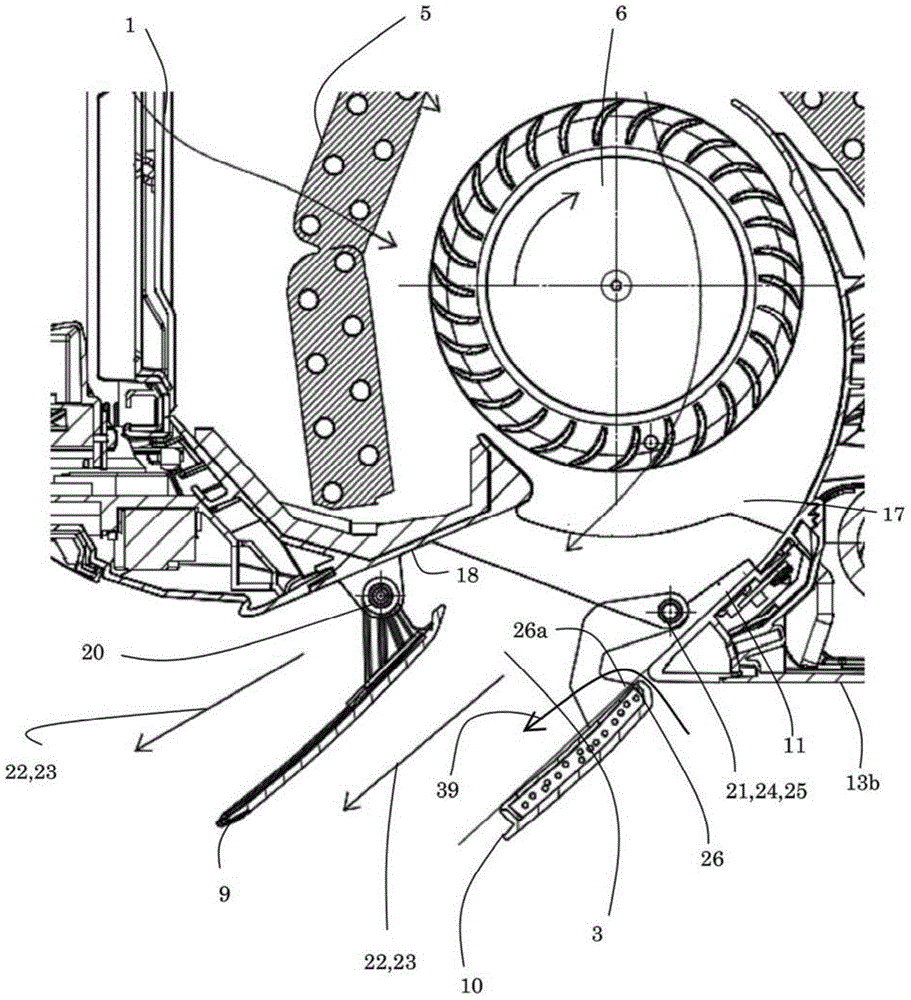

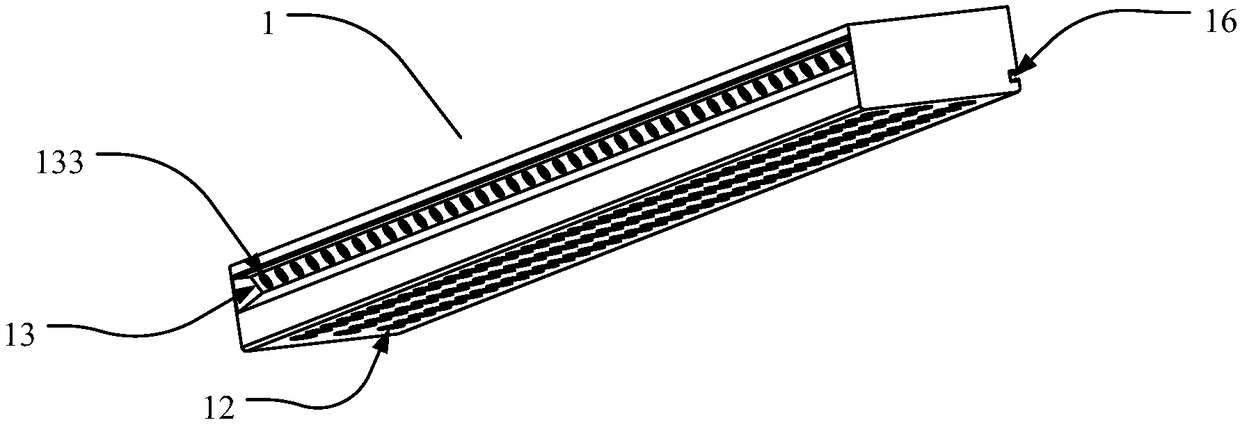

Air conditioner indoor unit and air conditioner

ActiveCN104422028AImprove blower efficiencyMechanical apparatusLighting and heating apparatusMoisture condensationOperation mode

The invention aims to provide an air conditioner indoor unit which has high blast efficiency and meanwhile can restrain moisture condensation of upper and lower wind plates, and an air conditioner. The air conditioner has a capacity-based-priority mode in which an upper surface in an upstream side end portion of upper and lower wind plates on lower sides is located on an extension cord of a lower side housing or at a position lower than the extension cord of a lower side housing, and a general refrigeration operation mode in which the upper surface in the upstream side end portion of upper and lower wind plates on lower sides is located at a position higher than the extension cord of the lower side housing. The distance between the upper and lower wind plates on lower sides and the lower side housing in the general refrigeration operation mode is longer than the distance between the upper and lower wind plates on lower sides and the lower side housing in the capacity-based-priority mode.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

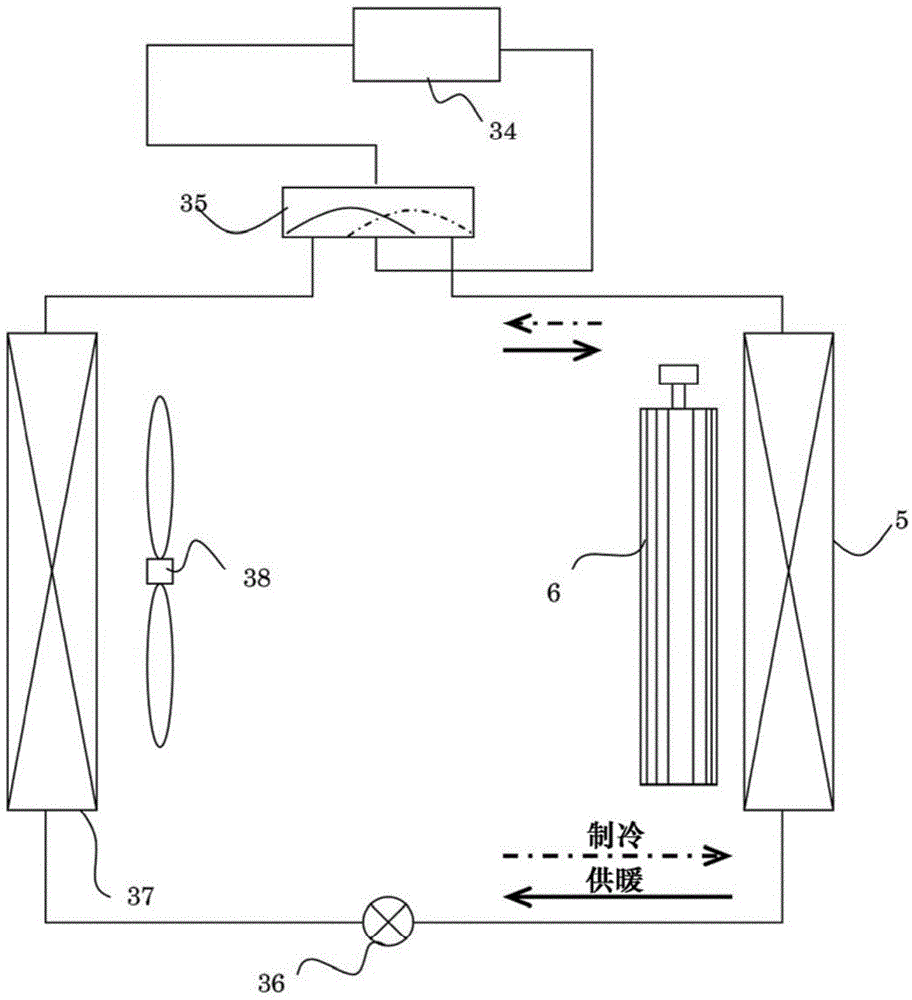

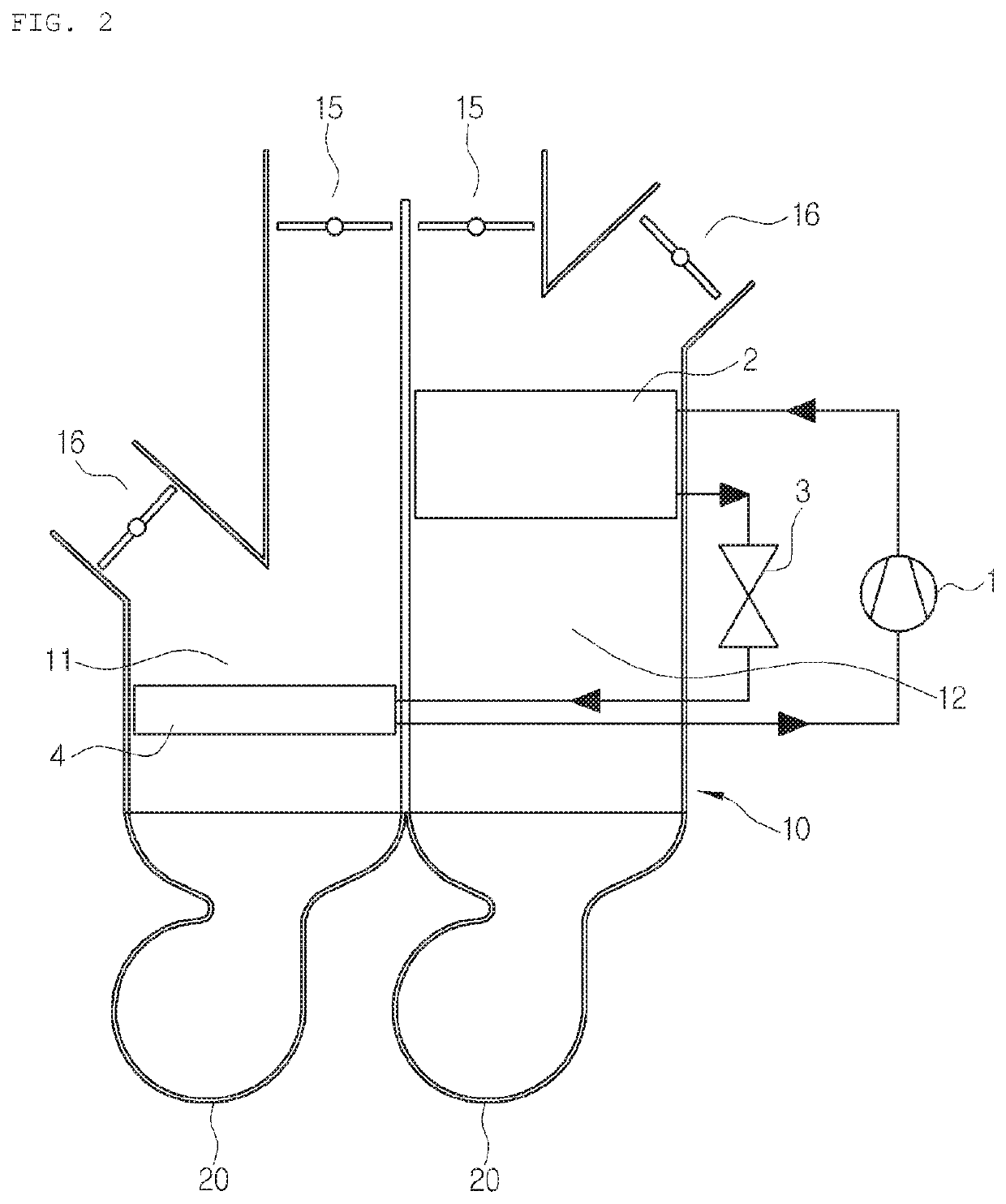

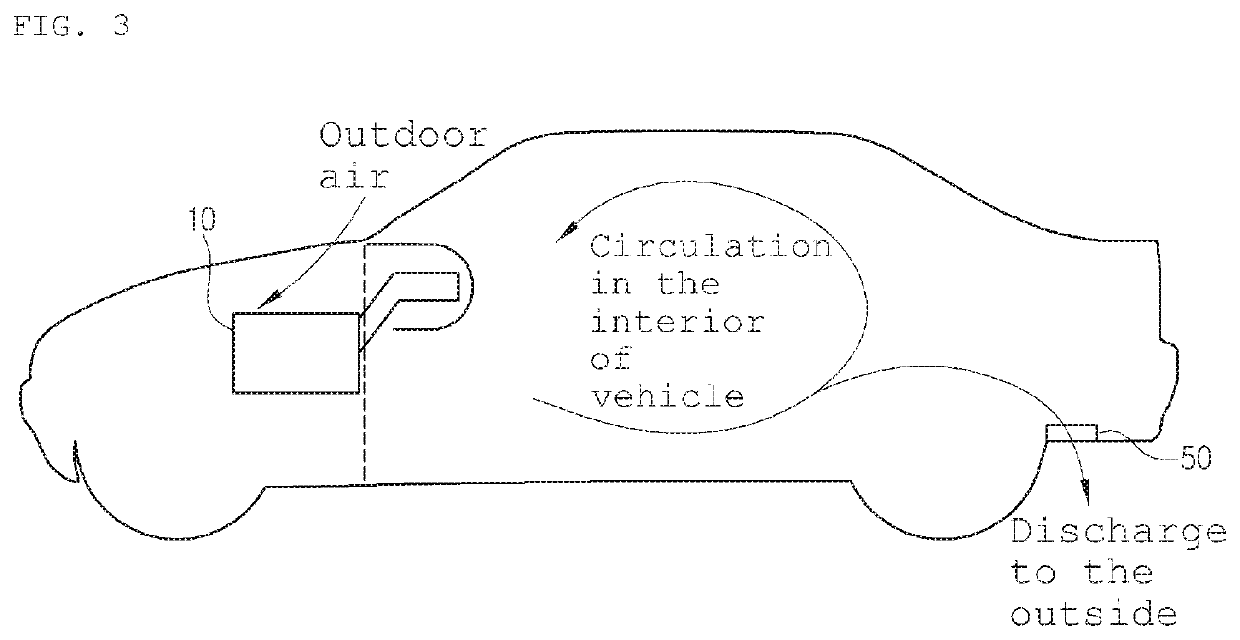

Air conditioner for vehicle

ActiveUS20200031197A1Fast fillLow densityAir-treating devicesVehicle heating/cooling devicesCold airAir blower

The present invention relates to an air conditioner for a vehicle, which includes a cold air passageway and a warm air passageway, and two blowers disposed in the air passageways, thereby rapidly ventilating the interior of the vehicle using the two blowers.

Owner:HANON SYST

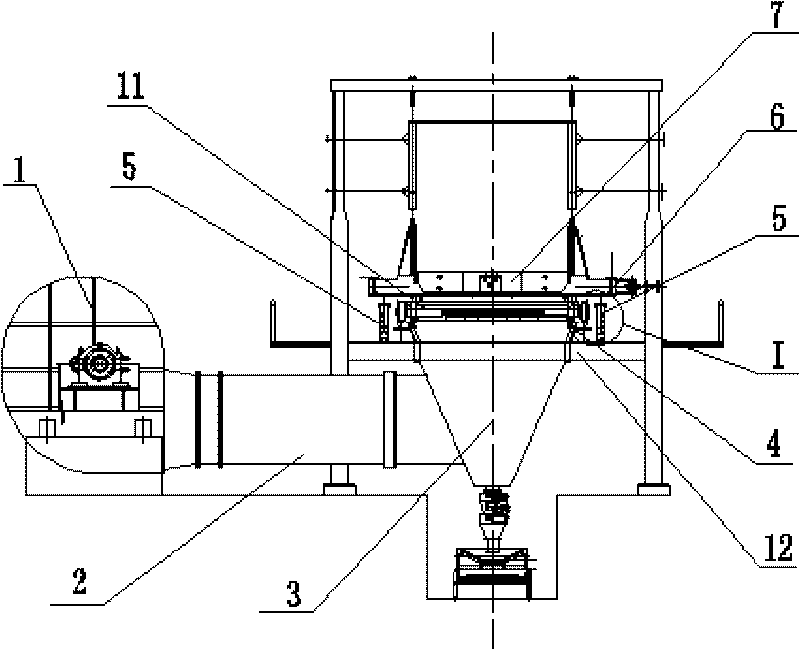

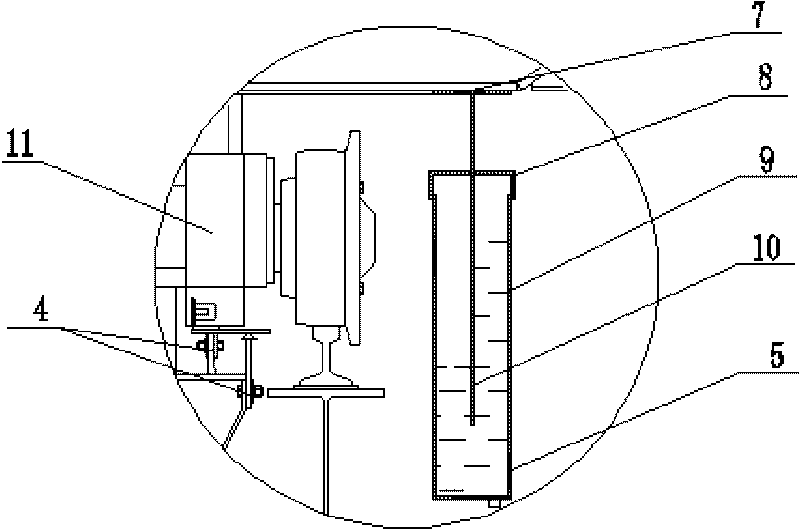

Flexible sealing and water sealing rotary forced-air cooler

InactiveCN101762159ADynamic flexible seal structure remains unchangedGuaranteed reliabilityEngine sealsFurnace typesElectricityEngineering

This invention discloses a flexible sealing and water sealing rotary forced-air cooler, adopting multiple air blowers to connect with an air box through an air pipe, wherein the outer circumference of the top of the air box is connected with a side of a flexible sealing device, the other side of the flexible sealing device is connected with a rotary beam of a trolley, a water sealing device is respectively installed at the outsides of the flexible sealing device and the rotary beam, the outer circumference of the trolley is movably connected with a rotary sealing device, the water sealing device comprises an annular water tank the top of which is connected with a cover board, the centre of the annular water tank is provided with an annular clapboard, the annular clapboard is fixed at the bottom of the trolley, and the annular water tank is fixed on a flat slab of the stand. The connection scheme of the flexible sealing device and the flat slab of the stand overcomes the disadvantages of the gap existence, gas leakage, low working efficiency of annular cooler and electricity waste of the movable-static flexible sealing which uses a rubber sealing plate as a main body, and the invention is suitable for cooling different kinds of ores rotating on trolley.

Owner:XIANGTAN COAL MINING MACHINERY & ELECTRIC INDAL

Double-head fixing type axial flow fan

PendingCN110657118AImprove stabilityGood limit effectPump componentsMechanical energy handlingPhysicsElectric machinery

The invention discloses a double-head fixing type axial flow fan. The axial flow fan comprises a motor body, fan blades, a fixing bearing, and a machine shell, wherein the motor body is provided witha rotating shaft outputting rotating power, and the motor body comprises a stator and a rotor; the fan blades are assembled to one end of the rotating shaft; the fixing bearing comprises a head end bearing, and a tail end bearing which are arranged at the two axial ends of the rotor, and the head end bearing and the tail end bearing are fixed coaxial with the rotating shaft; the machine shell is wrapped on the outer side of the motor body; and the head end bearing and the tail end bearing are wrapped by a head wrapping ring and a tail wrapping ring respectively, the head wrapping ring and thetail wrapping ring are fixed to the machine shell through flow guiding pieces and connecting ribs, a hollow part is formed between the adjacent connecting ribs, and the machine shell forms a through air channel parallel to the axis direction of the rotating shaft. According to the double-head fixing type axial flow fan, the rotating shaft of the motor is limited by two bearings which are relatively far away from each other, and the two bearings are firmly fixed, so that vibration and jitter during operation of the axial flow fan can be controlled, and the influence of the arranged bearings onoverall wind resistance is very small.

Owner:CINDERSON TECH (SUZHOU) CO LTD

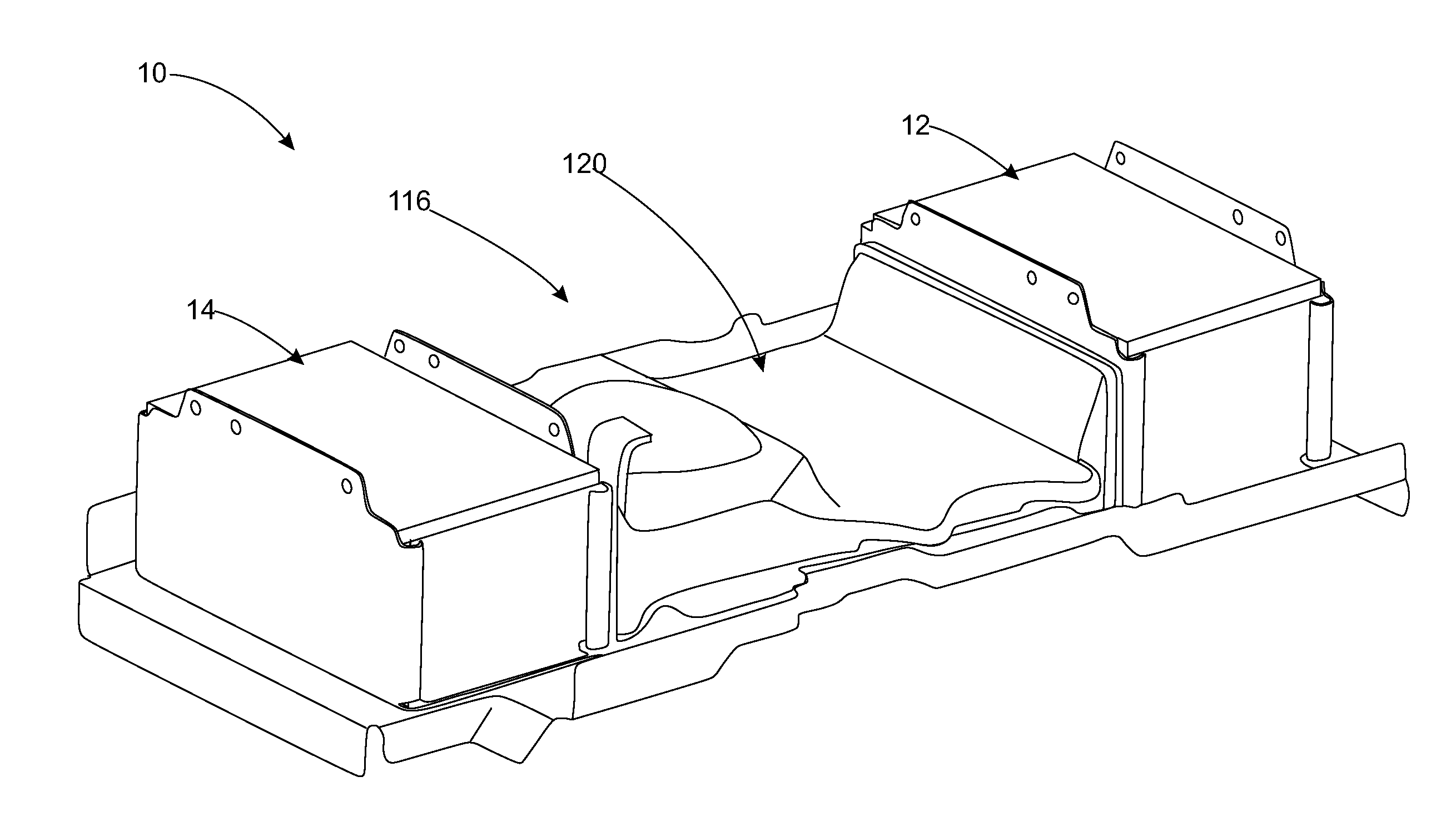

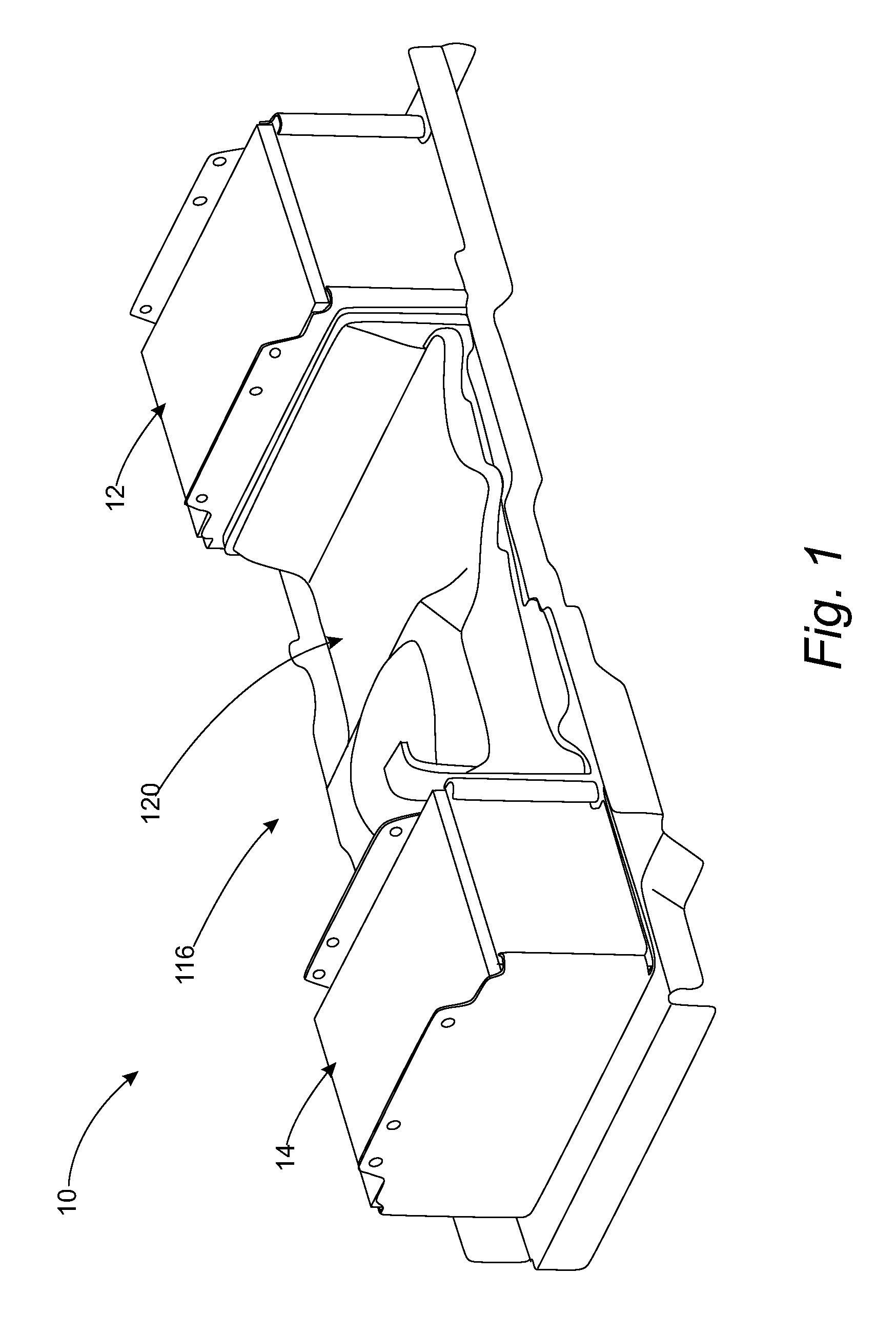

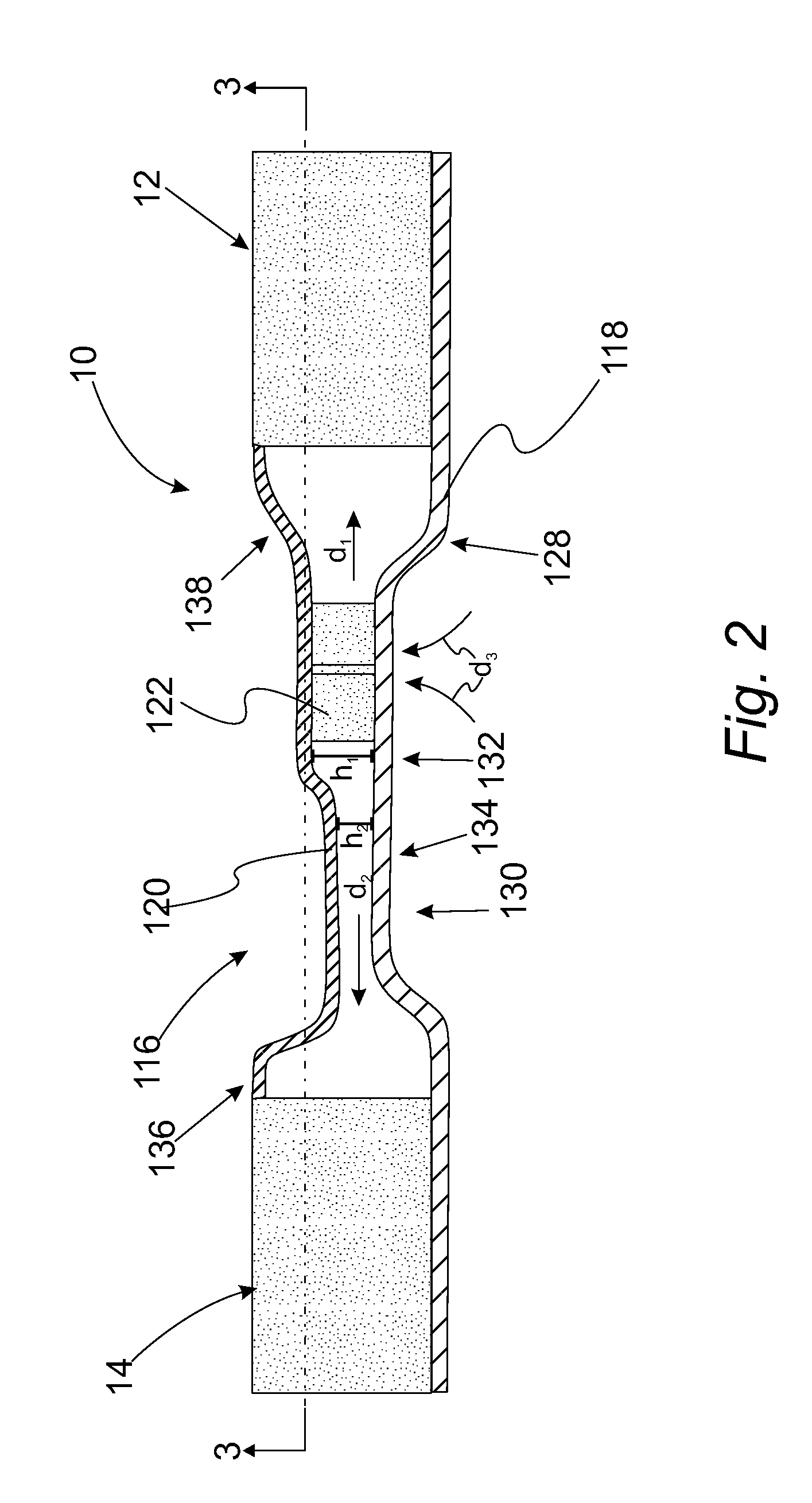

Integrated and Optimized Battery Cooling Blower and Manifold

InactiveUS20130273399A1Equally distributedImprove blower efficiencySecondary cellsCell component detailsBattery cellElectrical and Electronics engineering

A battery pack having an integrated cooling system which includes a first battery module including a first plurality of battery cells separated by a first plurality of channels, a second battery module including a second plurality of battery cells separated by a second plurality of channels, and a fan that creates air flow between the first and second plurality of channels. The battery pack also includes a manifold having a first conduit section lead from the fan to the first plurality of channels and a second conduit section lead from the fan to the second plurality of channels. Characteristically, the fan is positioned in the manifold where it creates the air flow that is directed by the manifold to the first plurality of channels and the second plurality of channels.

Owner:GM GLOBAL TECH OPERATIONS LLC

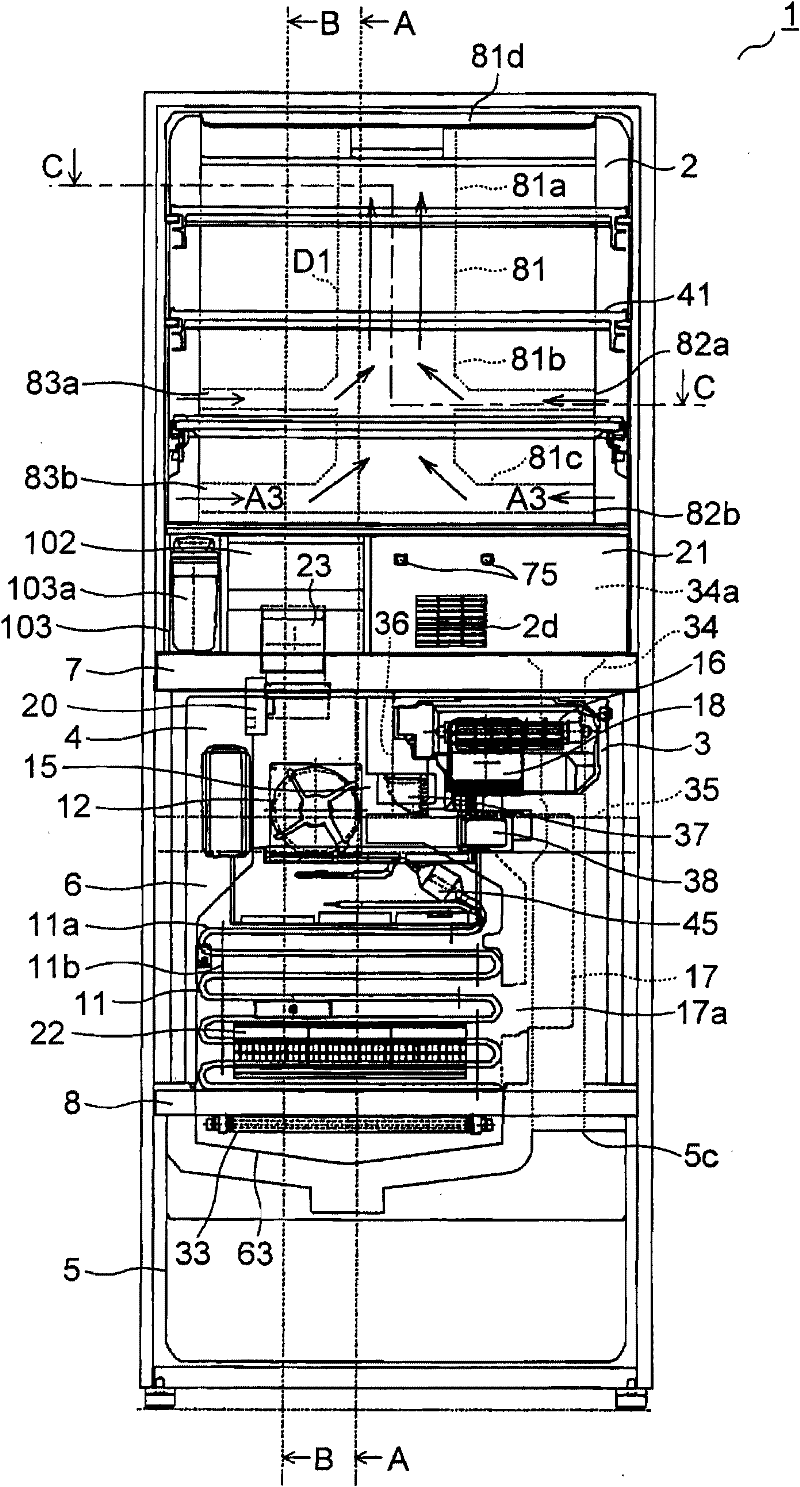

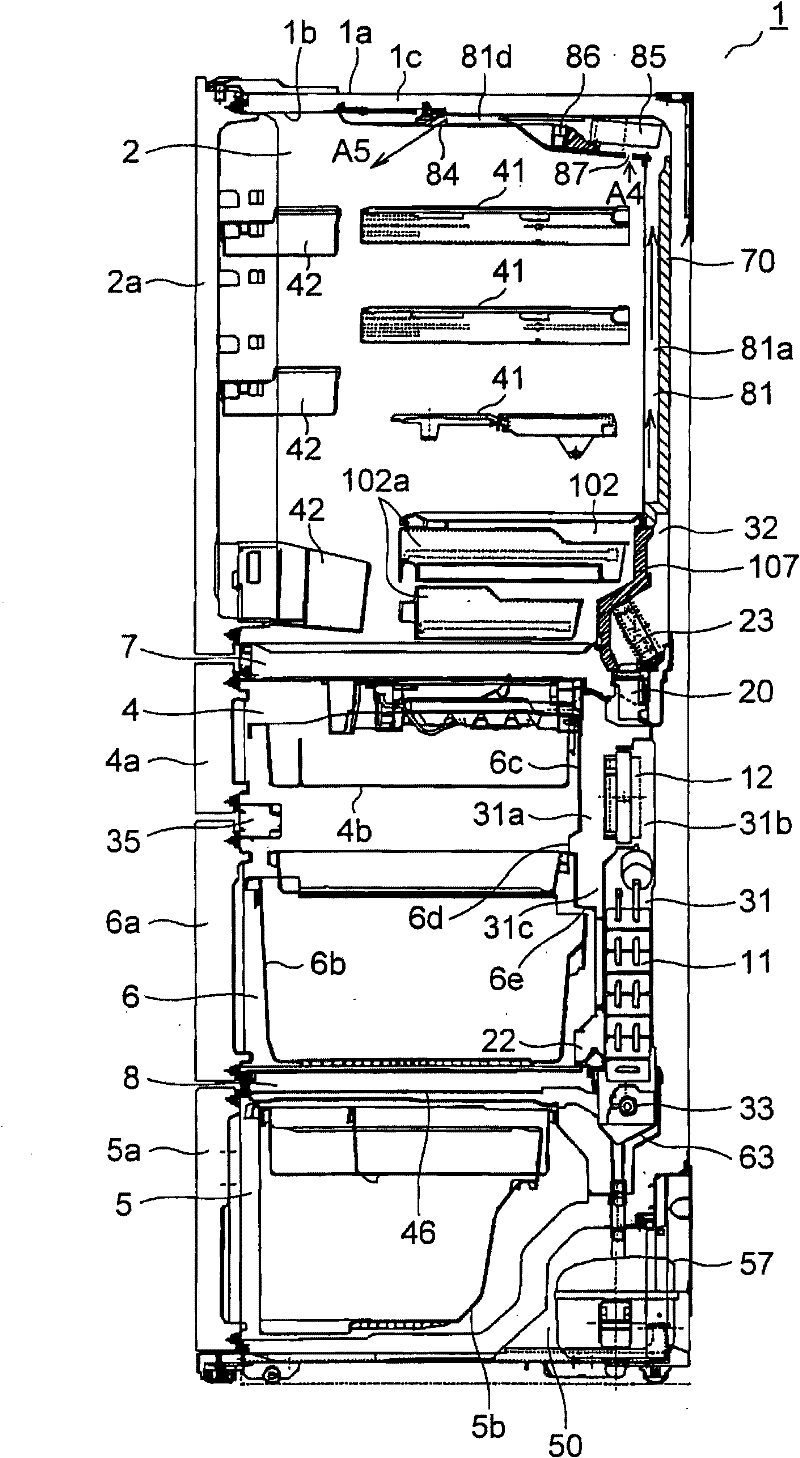

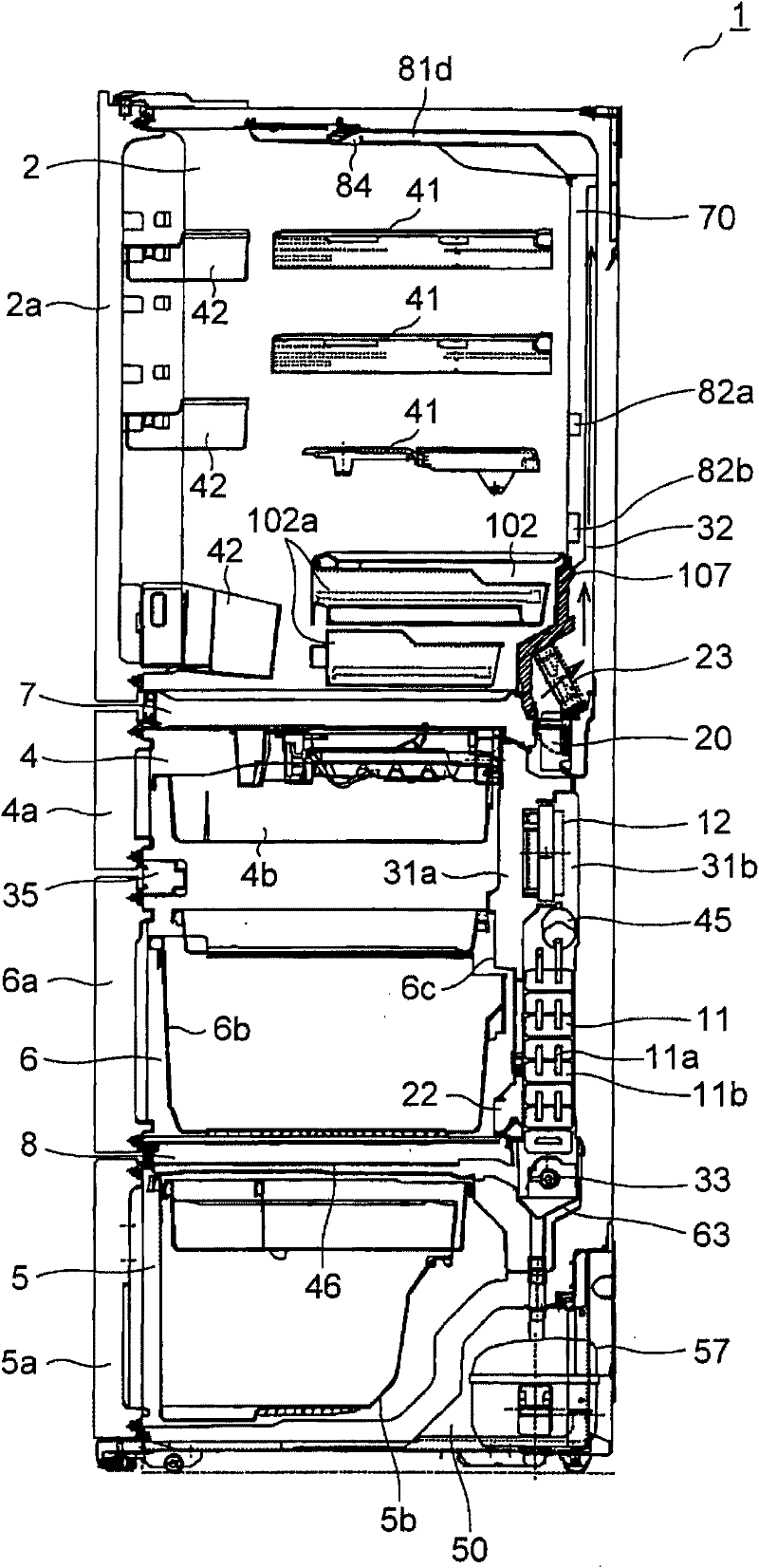

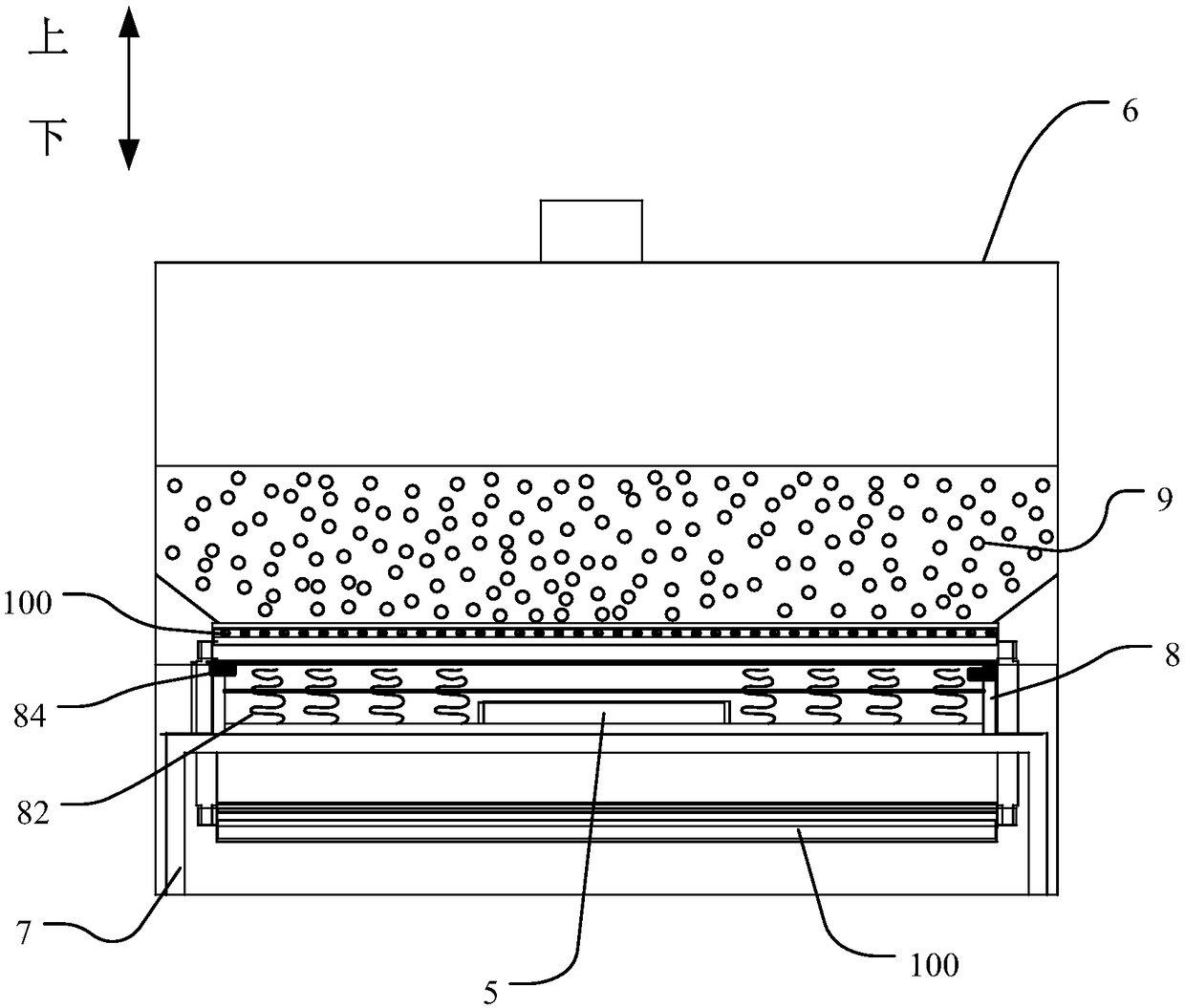

Refrigerator

ActiveCN102132115AImprove sterilization effectDecrease disappearLighting and heating apparatusCooling fluid circulationCold airEngineering

A refrigerator is provided with a storage chamber (2) for housing stored items, a back plate (72) that covers the back surface of the storage chamber (2) from left to right, a condenser (11) for generating cold air, a cold air pathway (32) for circulating the cold air generated by the condenser (11) in order to send the cold air into the storage chamber (2) via first outlets (73a-73c, 74a-74c), a circulation pathway (81) for circulating the cold air in the storage chamber (2) using a circulation blower (85) without going through the condenser (11), and an ion generator (86) that is provided in the circulation pathway (81). The cold air pathway (32) and the circulation pathway (81) are provided to the rear of the back plate (72) of the storage room (2) from left to right.

Owner:SHARP KK

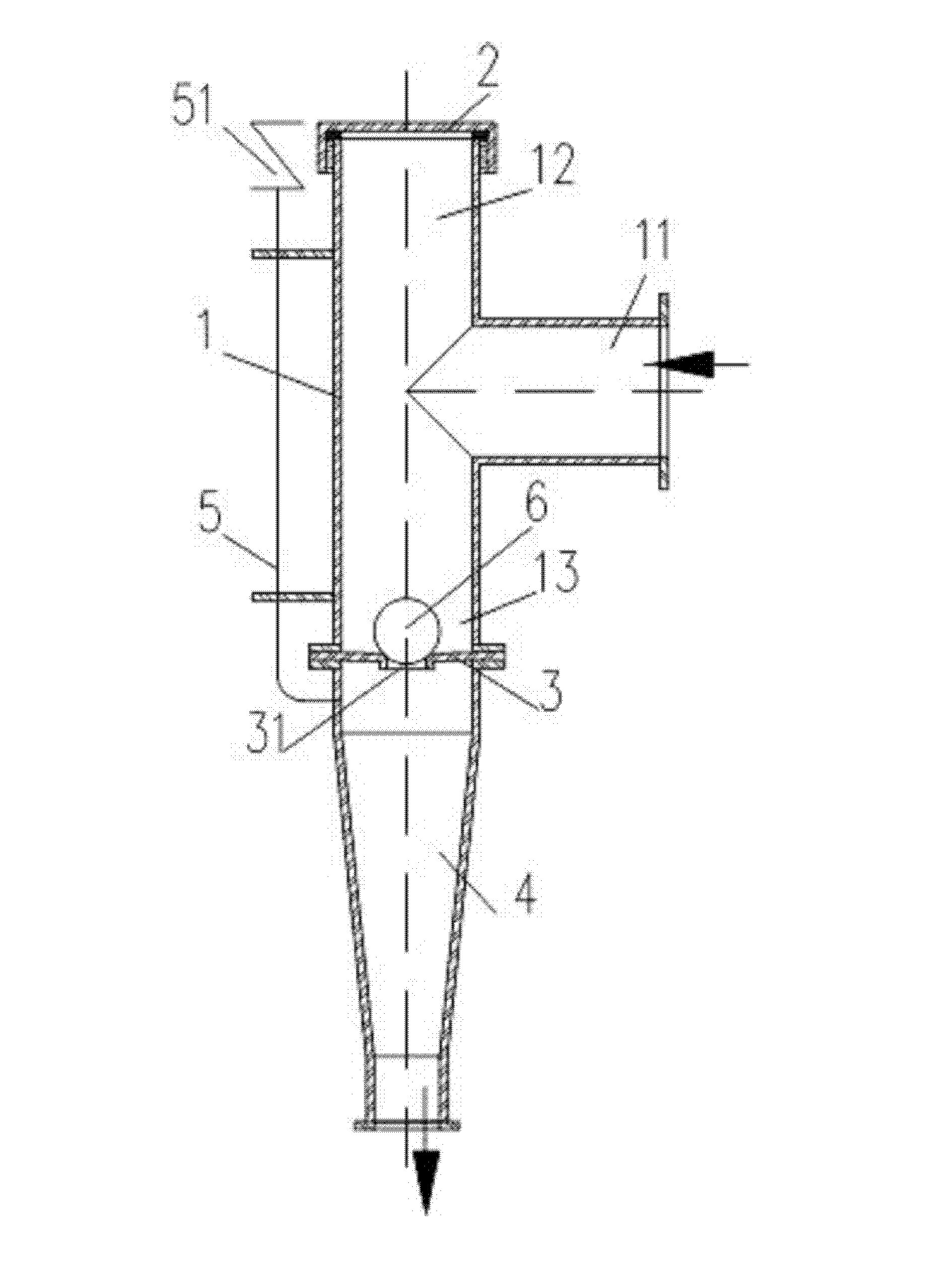

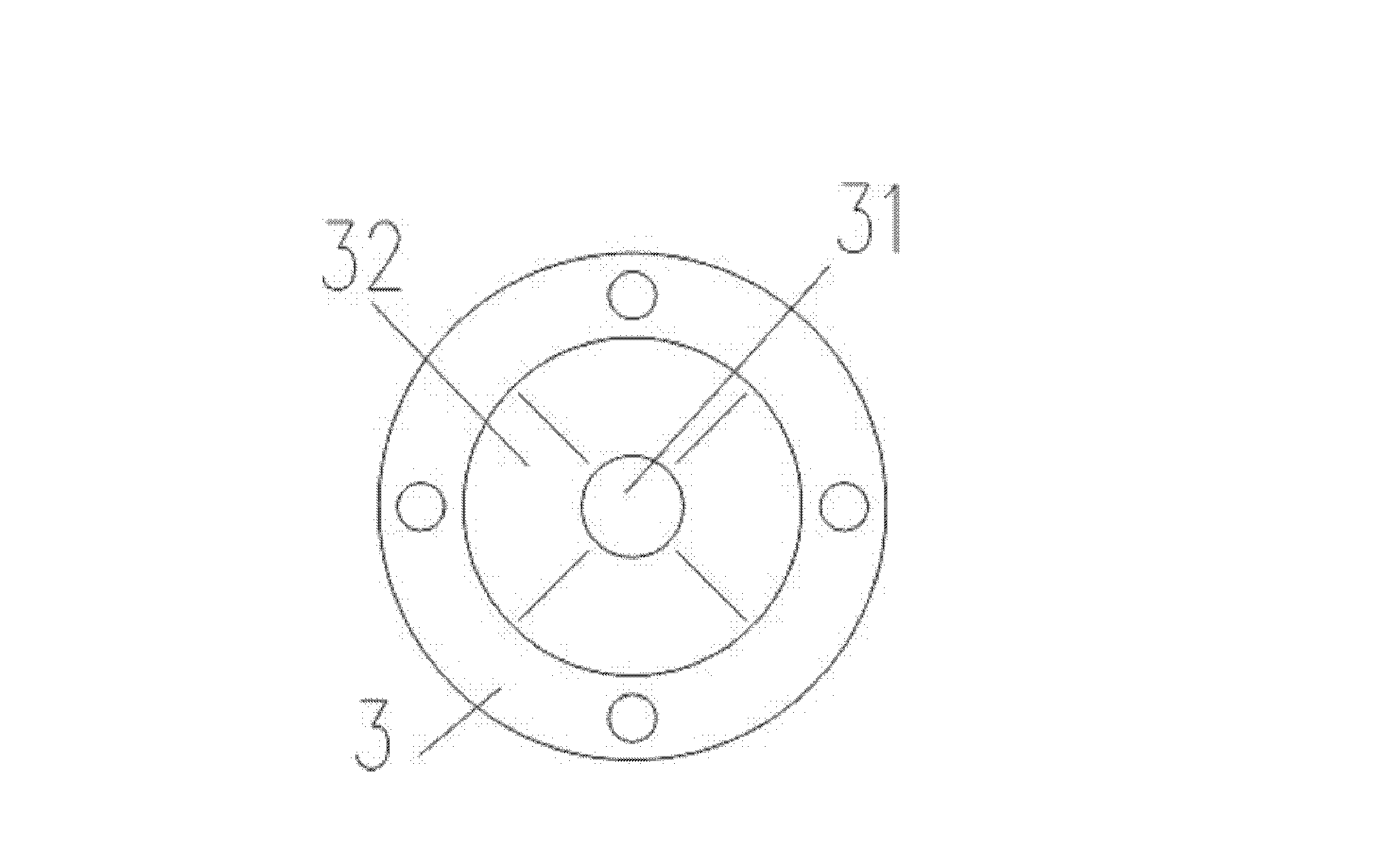

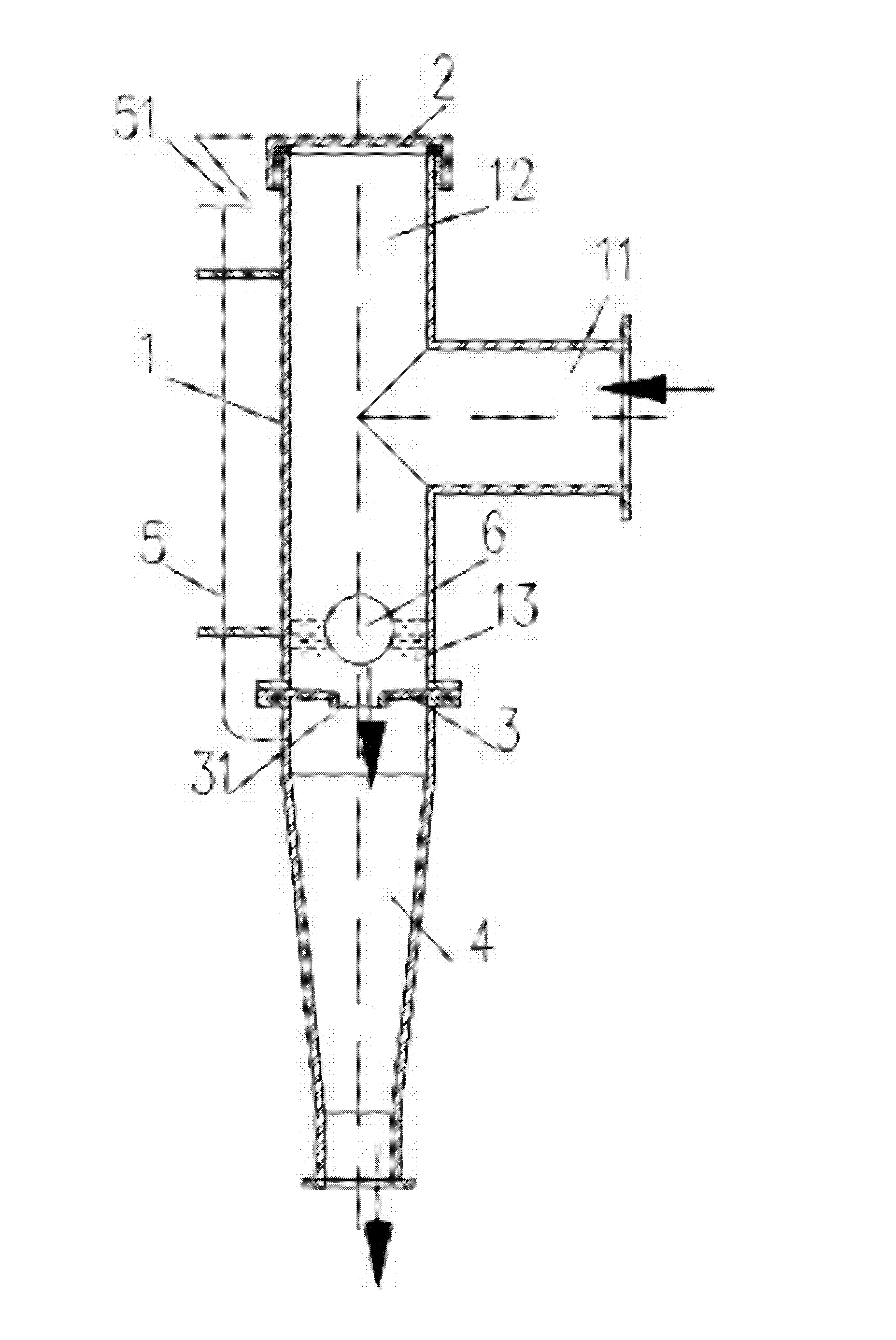

Device for discharging percolate generated by aerobic fermentation of solid organic waste

InactiveCN102583716ADischarge in timeEfficient dischargeTreatment using aerobic processesSustainable biological treatmentFailure rateEnvironment effect

The invention discloses a device for discharging percolate generated by aerobic fermentation of solid organic waste. The device comprises a drainage tee, wherein the first end of the drainage tee is communicated with a percolate discharge pipe; the second end of the drainage tee is provided with a detachable flushing cover cap; the third end of the drainage tee is communicated with a reducing pipe through a drainage plate; drainage holes are formed in the drainage plate; drainage floating balls are arranged on the drainage holes; and the reducing pipe is communicated with an air-permeating pipe. The discharge device can discharge the percolate effectively in time, has a stable discharge effect and a good environment effect, overcomes the defects that the storage water is smelly and the like, and has the beneficial effects of simple structure, operation flexibility, low failure rate, convenience for repairing and cleaning and the like. The device avoids short stream of stack blast air from a percolate pipe and improves blasting efficiency.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

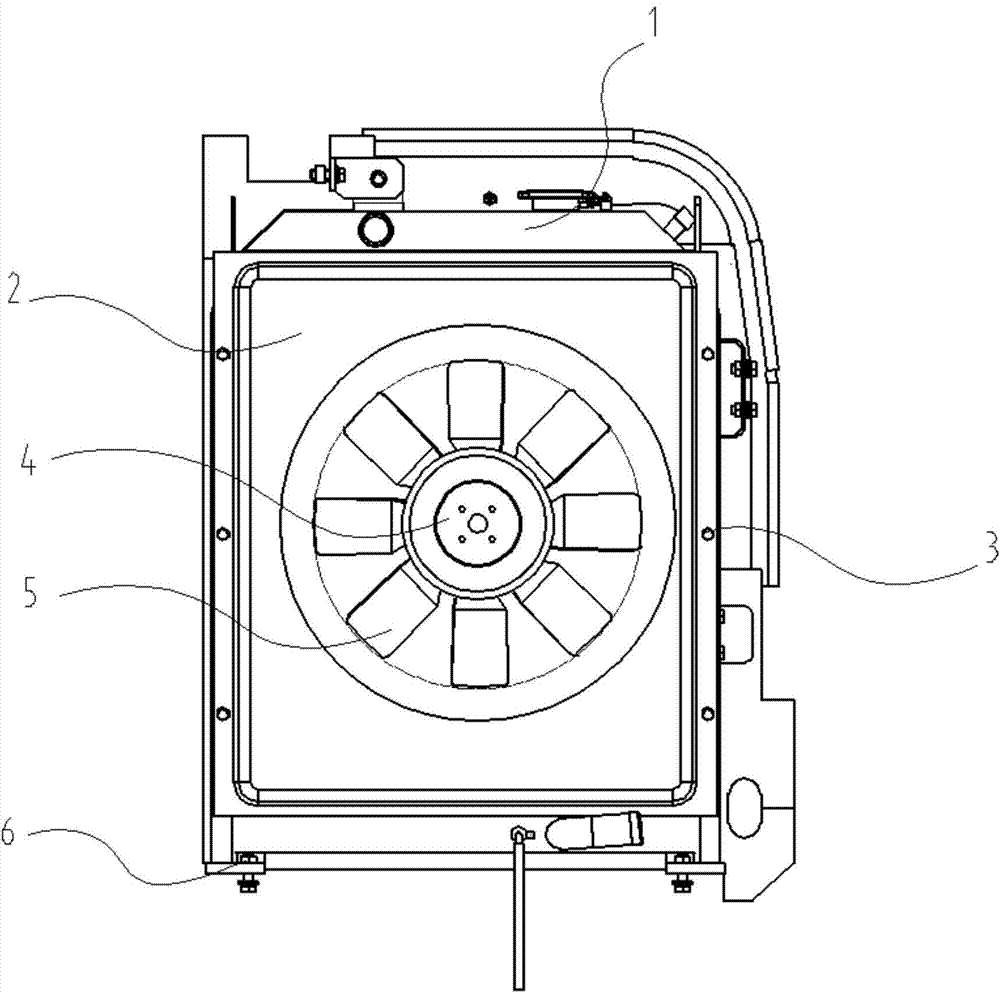

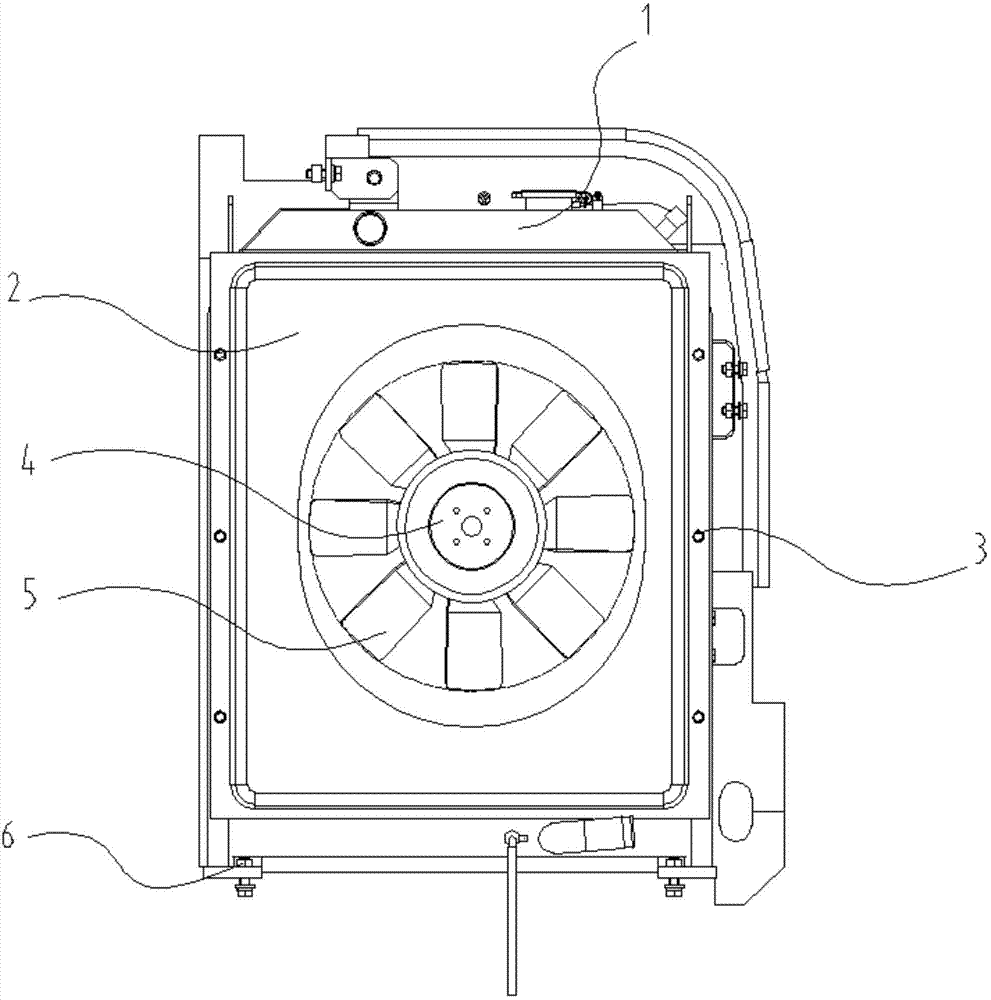

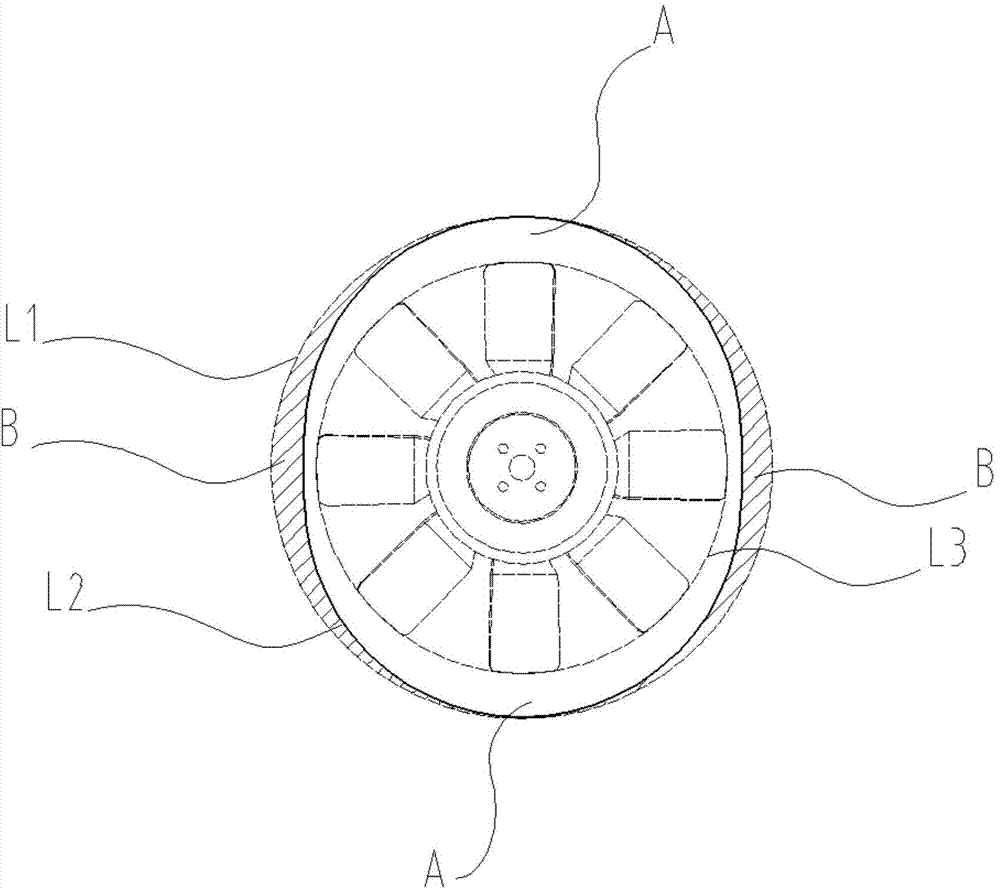

Heat dissipating system

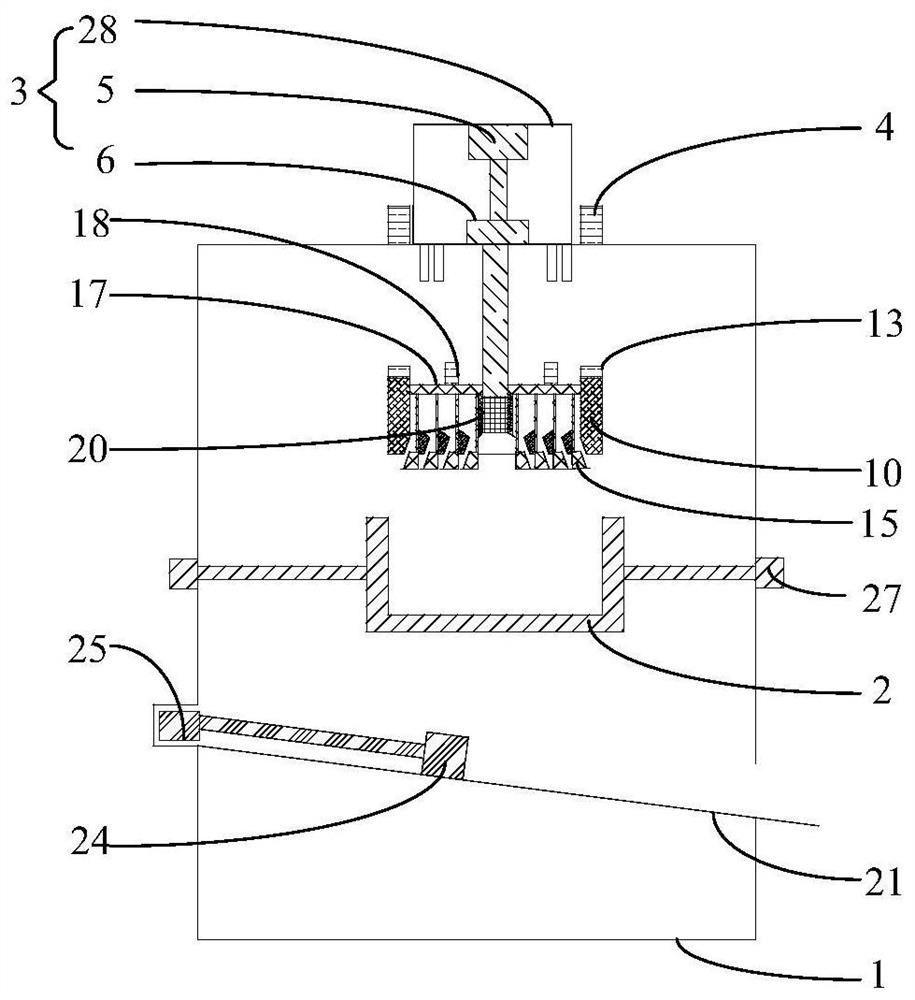

InactiveCN103867280AGuaranteed Clearance RequirementsImprove blower efficiencyAir coolingMachines/enginesVibration amplitudePlate heat exchanger

The invention relates to a heat dissipating system. The heat dissipating system is used for solving the disadvantages of the existing heat dissipating systems that the air blasting rate of a fan is relatively low and the heat dissipating effect is poor caused due to the fact that the gap area between an air guiding hood and tips of fan blades is too large. The heat dissipating system provided by the invention comprises a heat exchanger and a fan facing to the heat exchanger, wherein an air guiding hood of a ventilating duct is formed between the fan and the heat exchanger, the fan is located in the air guiding hood, the internal hole of a position, where the fan is located, of the air guiding hood is a long circular hole, and the size of the long circular hole in the horizontal direction is smaller than that of the long circular hole in the vertical direction. According to the heat dissipating system, the characteristic that upward-downward vibration amplitude of an engine directly driven fan is greater than left-right horizontal vibration amplitude of the engine directly driven fan is utilized, the internal hole of the air guiding hood is designed into the long circular hole, then, the gap demand on upward-downward vibration of the fan is guaranteed, and gaps between the left and right sides of the air guiding hood and the tips of the fan blades are reduced, so that the air blasting rate of the fan is increased, and then, the heat dissipating effect of a heat dissipater is improved.

Owner:LIUZHOU LIUGONG EXCAVATORS +2

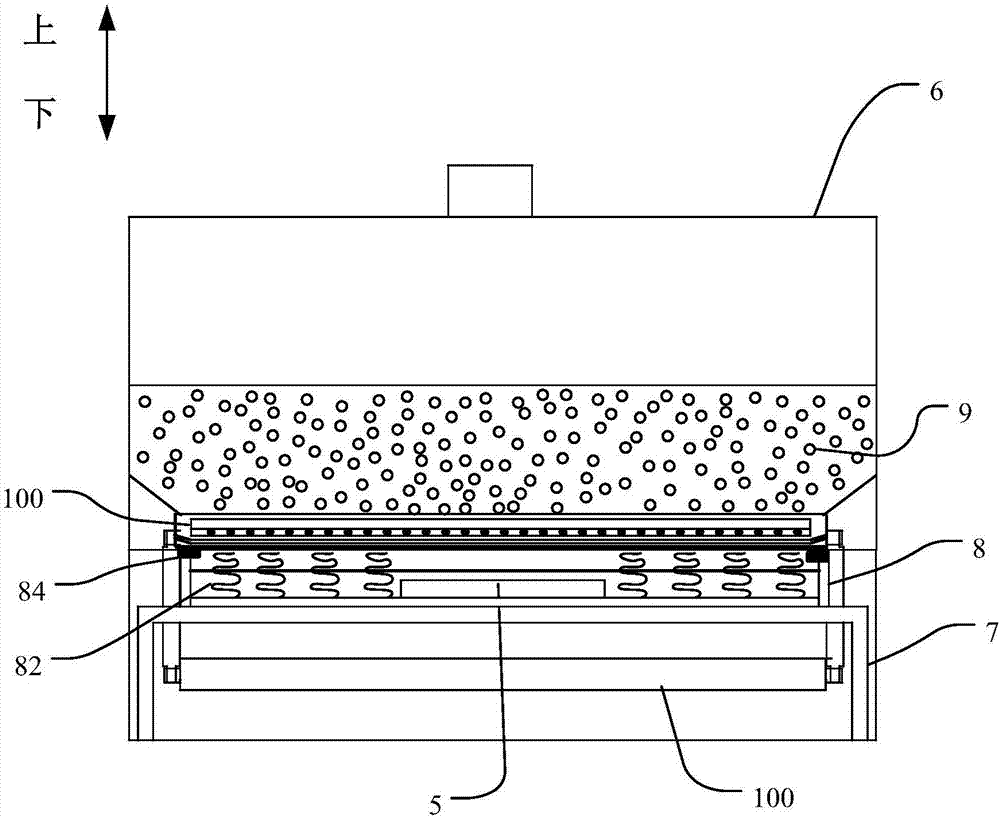

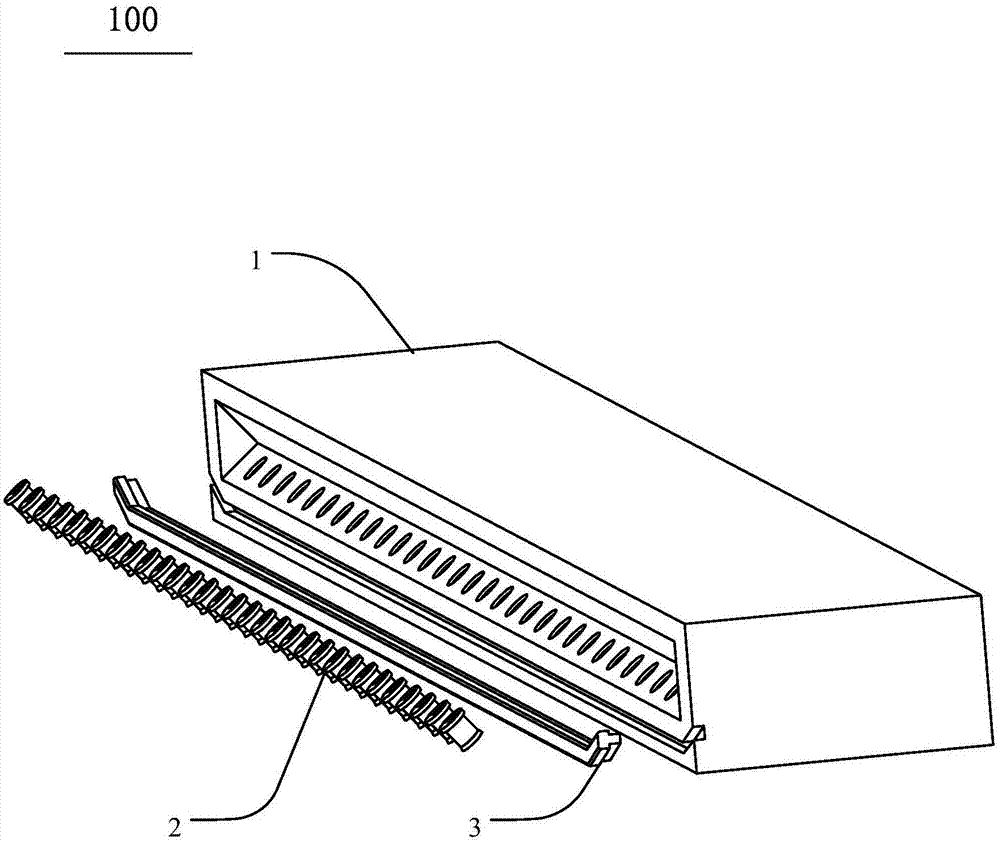

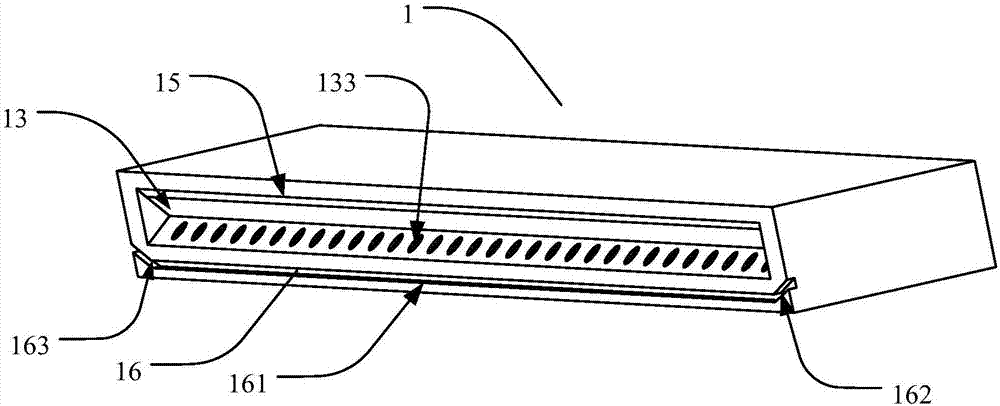

Organic solid waste fermentation box

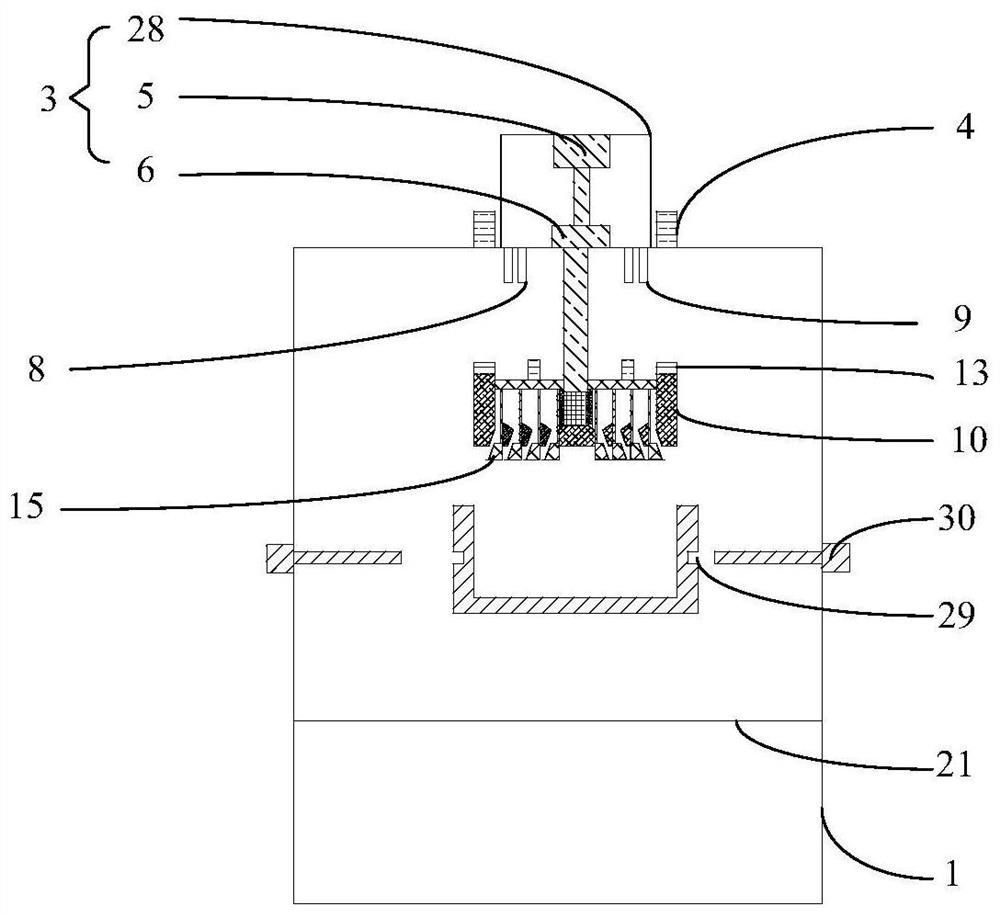

ActiveCN107382399AReduce lossesImprove blower efficiencyBio-organic fraction processingFertiliser treatment heating/coolingFlueEngineering

An organic solid waste fermenting box comprises a box body, a chain plate conveyor which is arranged in the box body, and is used for carrying and conveying a fermented material, the chain plate conveyor comprises a bracket and a plurality of chain plate components supported on the bracket, the plurality of chain plate components are sequentially connected to form a closed-loop structure, the chain plate components comprise upper layer chain plate components and lower layer chain plate components, wherein the upper chain plate components are used to carry the fermented material; the organic solid waste fermenting box further comprises an air flue, the air flue is fixed on the bracket of the chain plate conveyor, and is located between the upper layer chain plate components and the lower layer chain plate components of the chain plate conveyor, wherein the upper end of the air flue abuts on the first outer wall of the upper layer chain plate components. The organic solid waste fermenting box establishes a stable air supply system for the fermented material through the reasonable connection and layout of the air flue and the chain plate components, so that hot air containing oxygen is effectively blown into the fermented material to achieve the effective control of fermentation environment, and the fermentation efficiency is greatly improved.

Owner:河北跃洋生物科技有限公司

Coal mine quality detection device

ActiveCN112595568AAvoid affecting test resultsIncrease impactPreparing sample for investigationFuel testingMining engineeringMechanical engineering

The invention discloses a coal mine quality detection device, which comprises a pulverizer, and the pulverizer comprises: a shell, which is internally equipped with a grinding bowl, and is provided with a spray head and a blast pipe on the top surface; a grinding block, which is located above the grinding bowl, and has a top face sinking downwards to form a cavity, wherein the cavity is fixedly connected with an elastic rod and provided with at least one circle of spraying holes in a penetrating mode, and a first electromagnet is arranged at the top of the side wall of the cavity; a first driving mechanism, which is arranged on the outer side of the top of the shell, drives the grinding block to rotate along the horizontal plane and vertically move up and down, and is externally equipped with a second electromagnet; a blocking piece, which comprises a plurality of hole plugs, wherein any hole plug is fixedly provided with a connecting rod, the connecting rod is connected with a sieve tray, a third electromagnet is arranged on the top surface of the sieve tray, the bottom surface of the hole plug horizontally extends to form an abutting edge, and a spring is further arranged betweenthe sieve tray and the bottom surface of the cavity. A coal mine sample can be automatically cleaned after being ground, and the influence on the detection result of a next ground coal mine sample isavoided.

Owner:通标标准技术服务(天津)有限公司

Organic Solid Waste Fermentation Box

ActiveCN107235755BReduce lossesImprove blower efficiencyBio-organic fraction processingOrganic fertiliser preparationClosed loopPulp and paper industry

The invention discloses an organic solid waste fermentation box, which comprises a box body, a chain scraper conveyor and air channels, wherein the chain scraper conveyor is arranged in the box body, and is used for bearing and conveying fermented materials; the chain scraper conveyor comprises a support, and a plurality of chain plate components supported on the support; the chain plate components are sequentially connected to form a closed loop structure and comprise upper-layer chain plate components and lower-layer chain plate components; the upper-layer chain plate components are used for bearing the fermented materials; the air channels are fixed onto the support of the chain plate conveyor and located between the upper-layer chain plate components and the lower-layer chain plate component of the chain scraper conveyor; the upper ends of the air channels press against first outer walls of the upper-layer chain plate components. According to the organic solid waste fermentation box, through reasonable connection and layout between the air channels and the chain plate components, a stable air supply system of the fermented materials is established, so that oxygen-containing hot air can be effectively blown into the fermented materials, the effective control of a fermented environment is realized, and the fermentation efficiency is greatly improved.

Owner:陕西鄜州神鹿生态产业有限公司

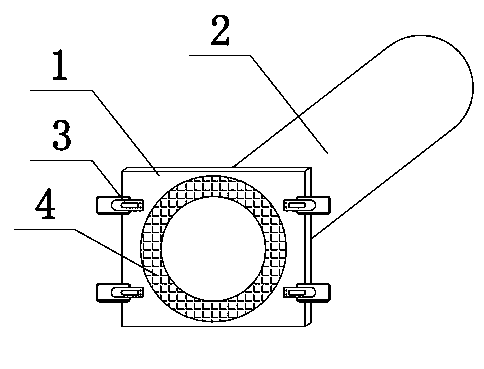

Connecting device of oil press and ground cage

The invention discloses a connecting device, and particularly relates to a connecting device of an oil press and a ground cage. The connecting device comprises a sealing plate, a through hole is formed in the sealing plate, a connecting pipe is arranged at a position, corresponding to the through hole, on the sealing plate, shackles are arranged on the sealing plate, and a sealing ring is arranged on the sealing plate 1. The sealing plate is hermetically connected with an outlet of an air blower through the shackles, and high-speed airflow blown by the air blower is enabled to fully enter the inside of a workshop through the connecting pipe, so that air blowing efficiency of the air blower is improved; the sealing ring is arranged on the sealing plate, so that air impermeability in connection of the sealing plate and the outlet of the air blower is further improved.

Owner:SICHUAN DEYANG NIANFENG FOOD

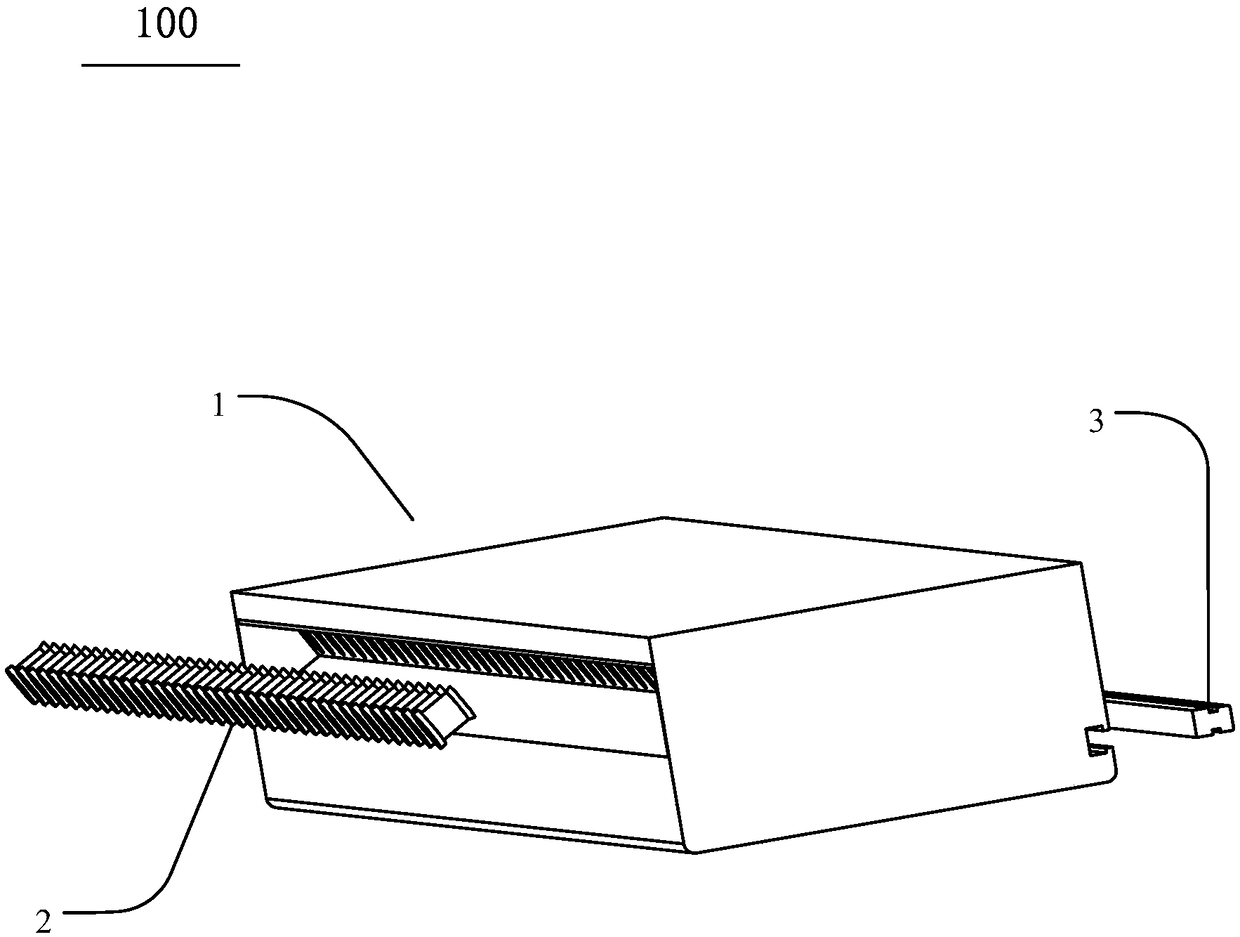

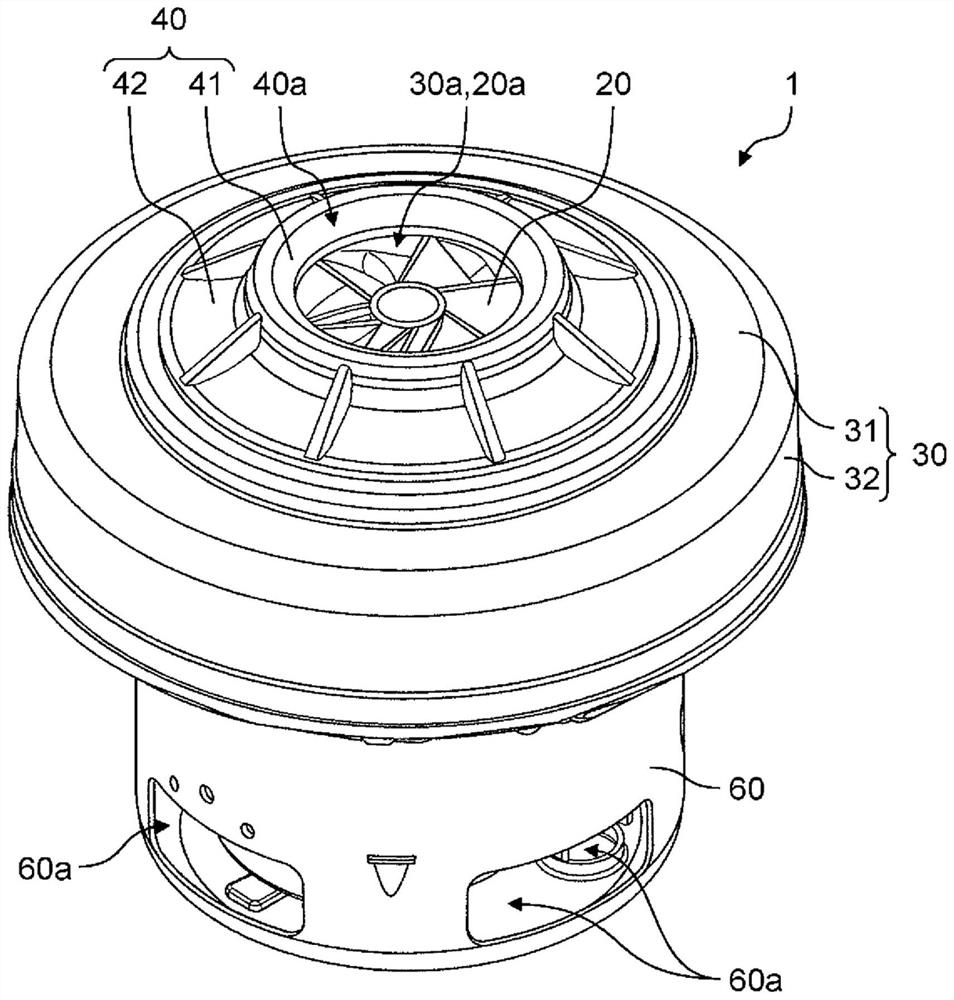

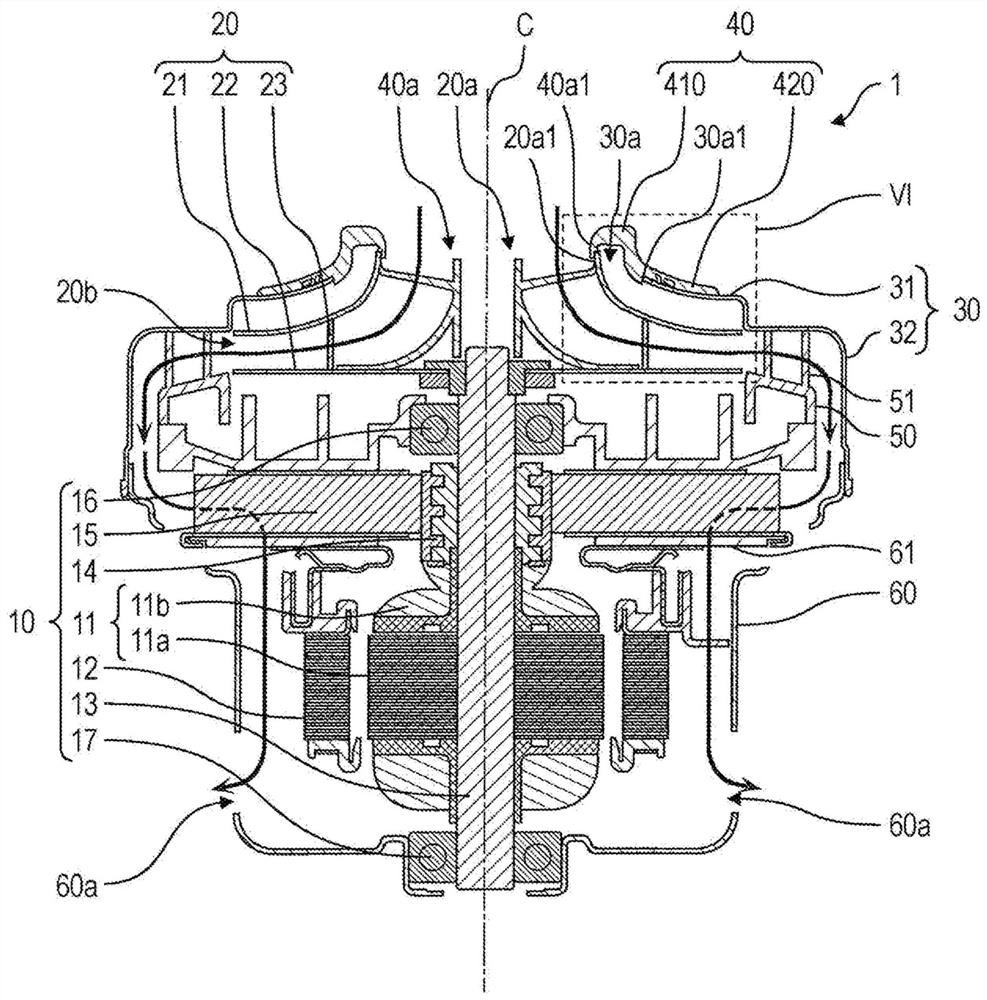

Electric blower

InactiveCN113348306AImprove blower efficiencyImprove air tightnessPump componentsRadial flow pumpsRotational axisRotor (electric)

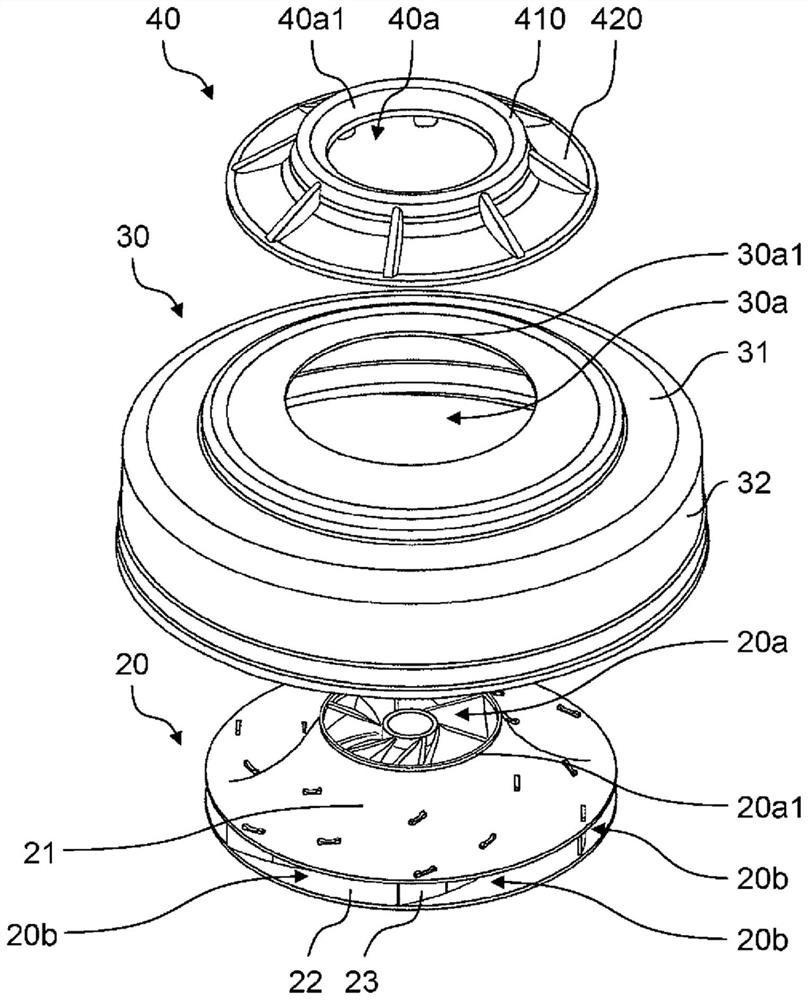

An electric blower (1) comprises: a rotor (11) having a rotary shaft (13); a centrifugal fan (20) which is attached to the rotary shaft and has a first opening (20a); a fan case (30) which covers the centrifugal fan and has a second opening (30a), an opening end thereof being located outward of an opening end of the first opening; and a fan case spacer (40) which is attached to the fan case and has a third opening (40a) which communicates with the first opening. The fan case spacer (40) has: a spacer part (410) which closes off a space between the opening end of the first opening and the opening end of the second opening; and a cover part (420) which extends outward from the opening end of the second opening and covers an outer surface of the fan case. The cover part (420) has a ring-shaped protrusion (421) which protrudes toward the outer surface of the fan case and surrounds the second opening. The protrusion (421) is located between the opening end of the second opening and a tip part (422) of the cover part, and contacts the outer surface of the fan case.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Efficient energy-saving centrifugal blower

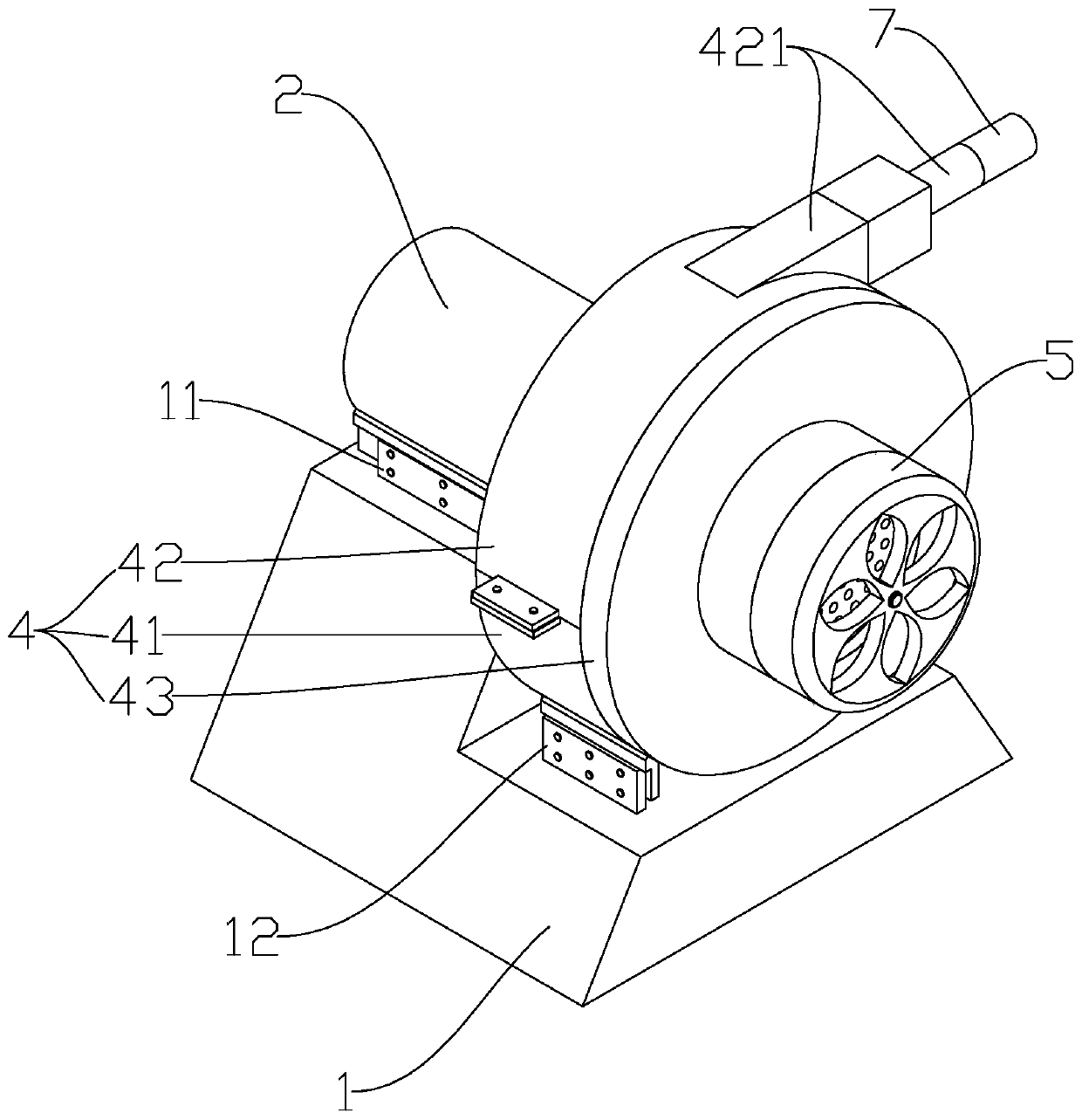

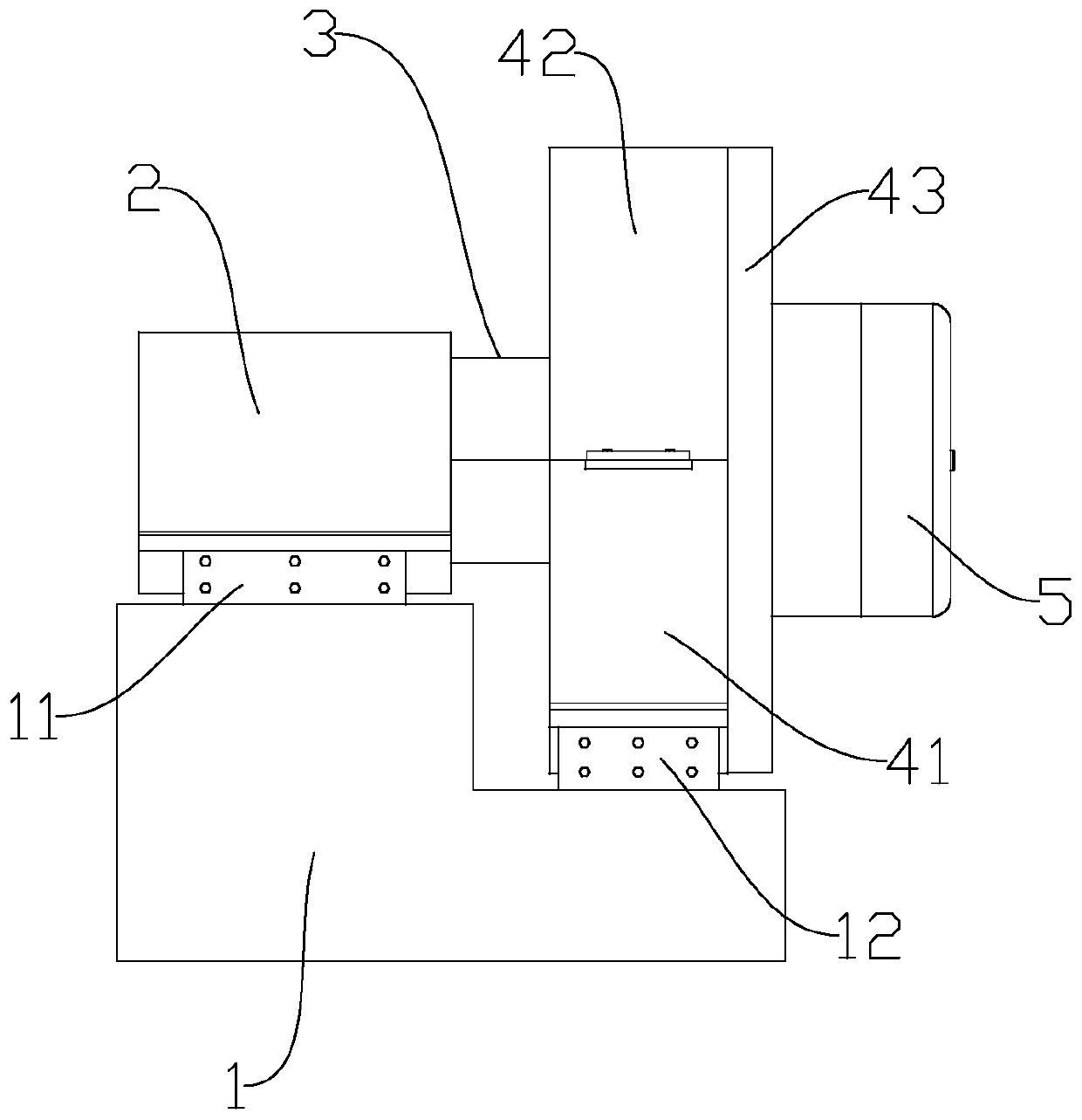

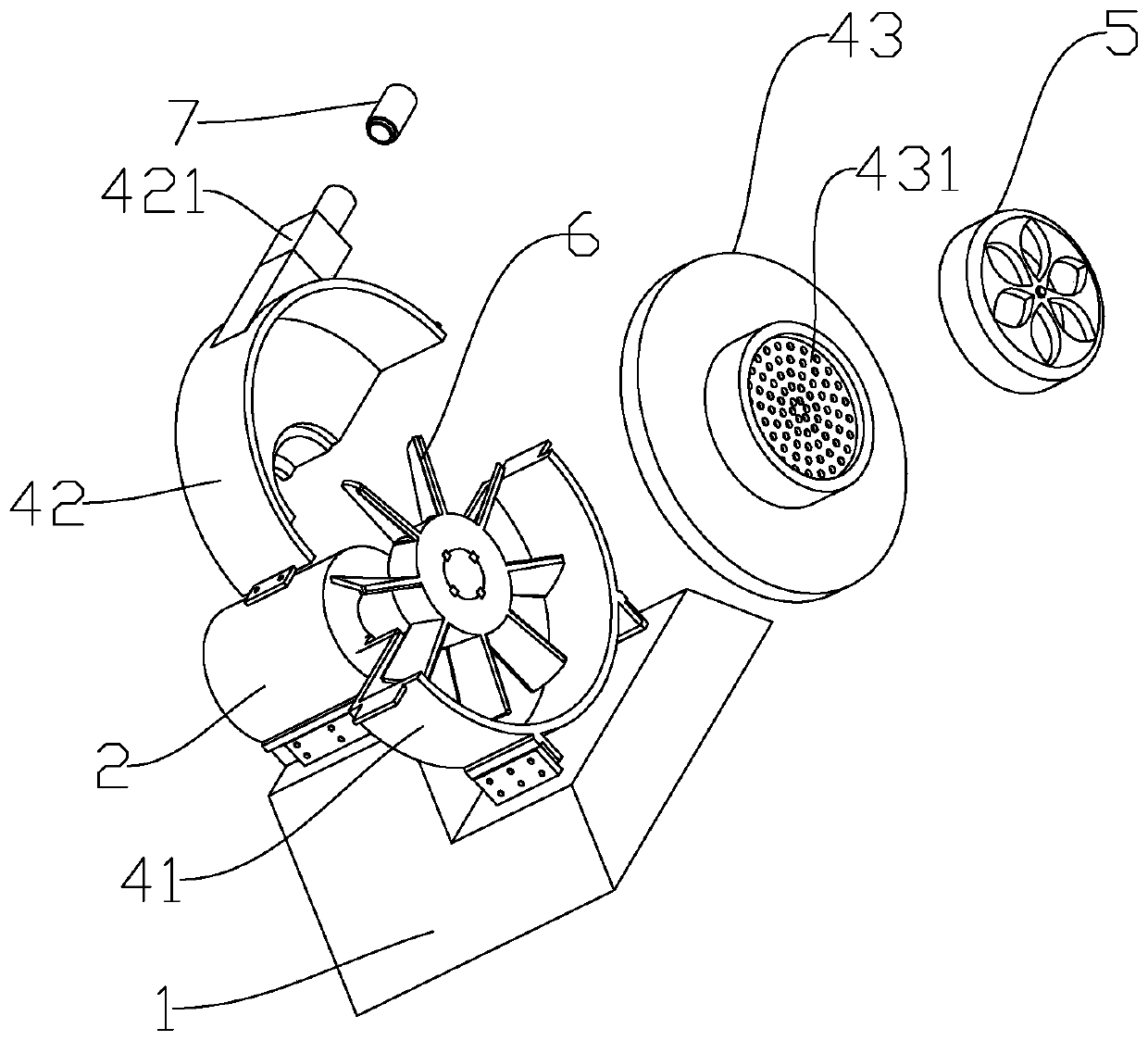

ActiveCN110529404AImprove blower efficiencyReduce energy consumptionPump componentsPump installationsImpellerEfficient energy use

The invention discloses an efficient energy-saving centrifugal blower which comprises a machine base, and a motor is arranged on the machine base; the output end of the motor penetrates through the sealing sleeve and is connected with an impeller in the machine shell. The machine shell comprises a lower machine shell body, an upper machine shell body and a side cover. The impeller comprises blades, the blades are the shape of curved surfaces, and the curvature radius of each blade is 60-80; wind gathering folded edges are further arranged on the blades; the distance between each wind gatheringfolded edge and the corresponding blade is 8-15mm, and the distance is gradually reduced along the direction close to the center of the blades; an air outlet is formed in the upper machine shell body, the size of the cross section in the air outlet is reduced in a two-step mode, and the air outlet is sequentially divided into a first pressurizing area, a pressure stabilizing area and a second pressurizing area in the air flowing direction. According to the efficient energy-saving centrifugal air blower, the impeller is reasonable in design and good in air buckling effect, the air blowing efficiency is improved, energy consumption is reduced, the air outlet of the upper machine shell body is reasonable in design, air exhausting is smoother, the overall working efficiency is improved, and therefore the purposes of high efficiency and energy saving are achieved.

Owner:德耐尔能源装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com