Organic solid waste fermentation box

A technology of organic solid waste and fermentation tank, which is applied in the direction of organic fertilizer, organic fertilizer equipment, organic fertilizer preparation, etc., can solve the problems of inaccurate control, inability to effectively control fermentation temperature, slow fermentation process, etc., and improve fermentation efficiency. , to achieve the effect of effective control and high blowing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

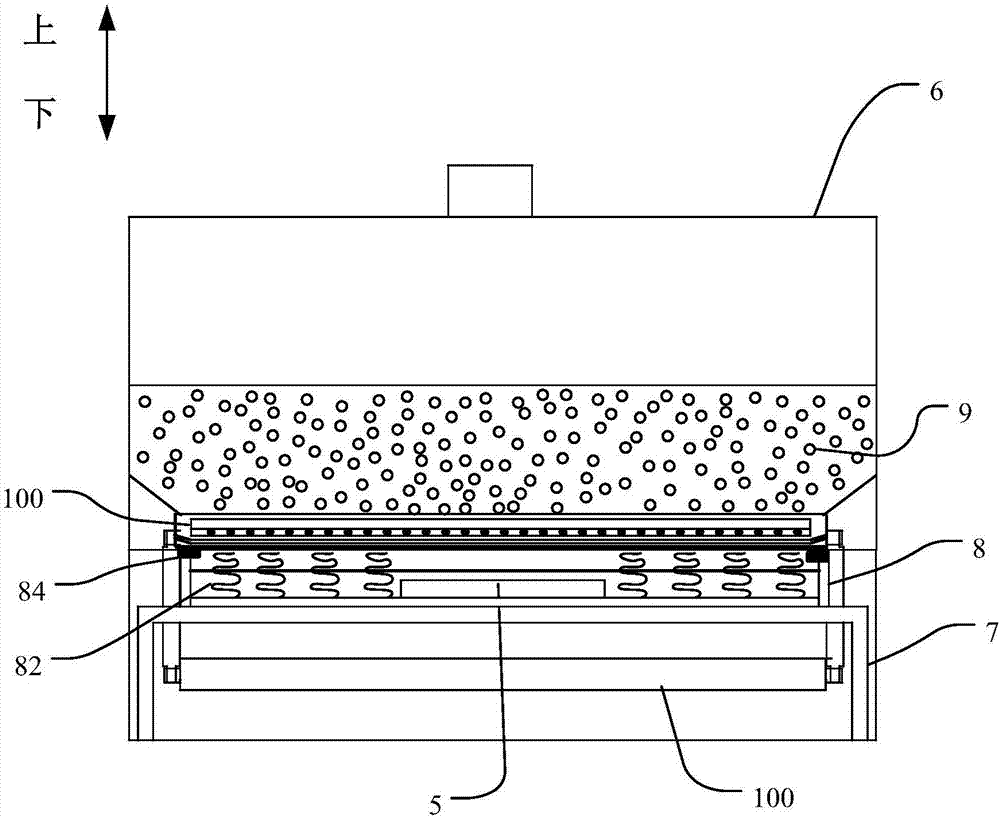

[0038] Such as Figure 1-12 As shown, the present invention provides an organic solid waste fermentation tank, which is used for fermenting organic solid waste materials, such as straw and feces. The organic solid waste fermentation tank includes a tank body 6 , a chain conveyor 200 and an air duct 8 .

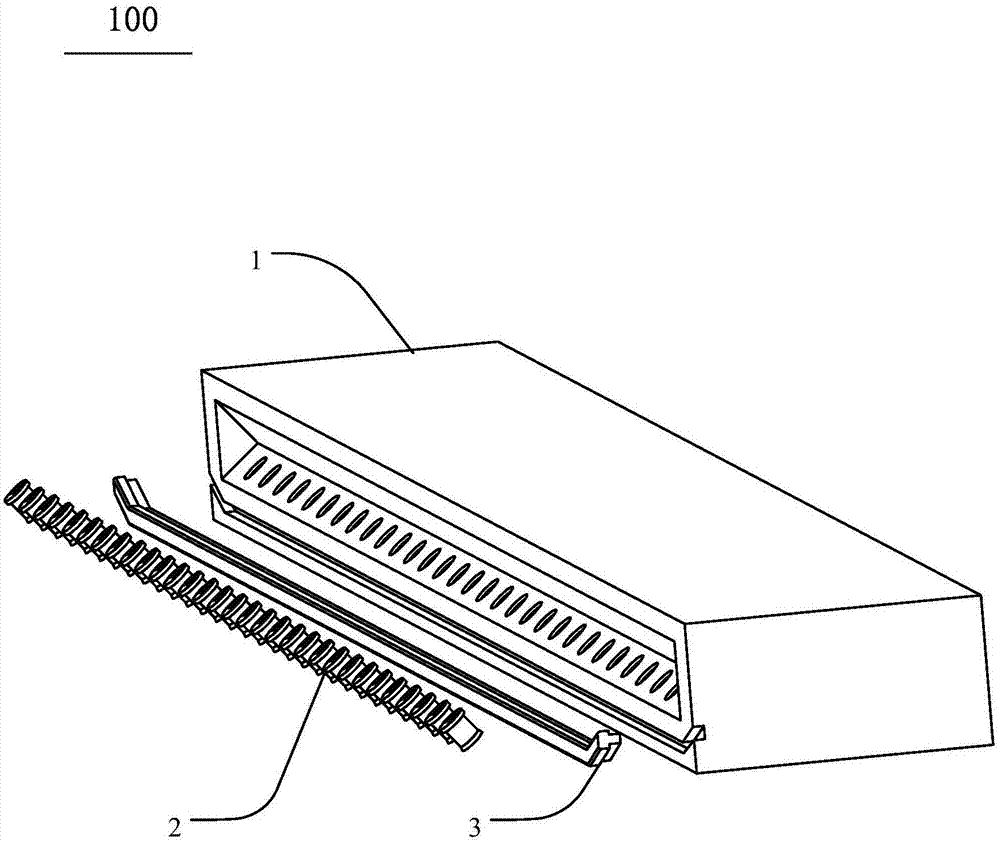

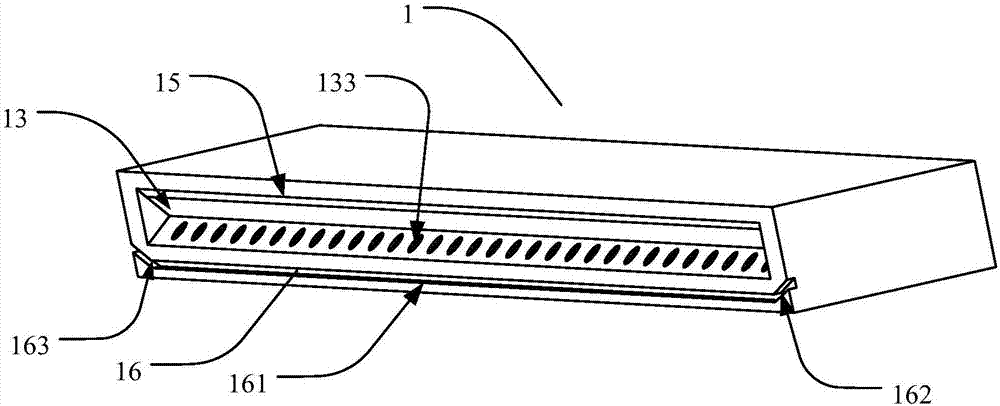

[0039] refer to figure 1 , the chain plate conveyor is arranged in the box body 6 for carrying and transporting fermentation materials, the chain plate conveyor 200 includes a bracket 7, and a plurality of chain plate assemblies 100 supported on the bracket 7, multiple The chain plate assemblies 100 are sequentially connected to form a closed-loop structure. The cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com