Patents

Literature

1177 results about "Chain conveyor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A chain conveyor is a type of conveyor system for moving material through production lines. Chain conveyors utilize a powered continuous chain arrangement, carrying a series of single pendants. The chain arrangement is driven by a motor, and the material suspended on the pendants are conveyed. Chain conveyors are used for moving products down an assembly line and/or around a manufacturing or warehousing facility.

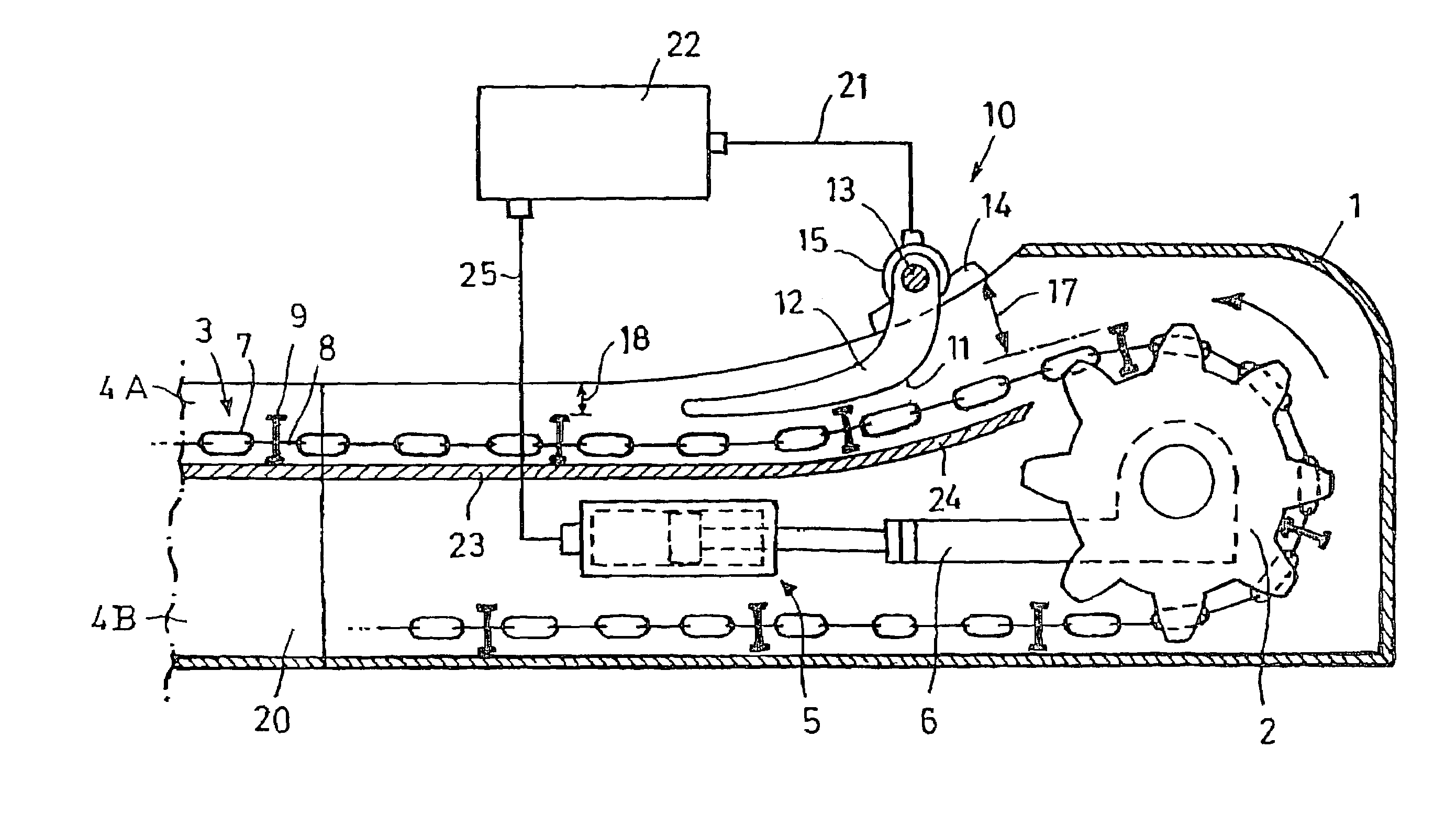

Device for detecting the tension of scraper chains

InactiveUS7117989B2Not easy to wearEasy to replaceConveyorsControl devices for conveyorsEngineeringChain conveyor

A device for detection and adjustment of the tension of a scraper chain of a chain conveyor, in particular of a face conveyor, having a tensionable return station, on which a spoked chainwheel to reverse the scraper chain, having chain links and scrapers attached thereto, is supported between the bottom race and the top race. The devices including a sensor which determines the tension of the scraper chain at the return station and the sensor having a swivellable sensor body coupled with a shaft encoder. The sensor body being in the top race and in contact with the upper face of the scraper chain in a measurement zone with provision being made in the measuring zone for vertical play for the run of the scrapers and / or the chain links.

Owner:DBT

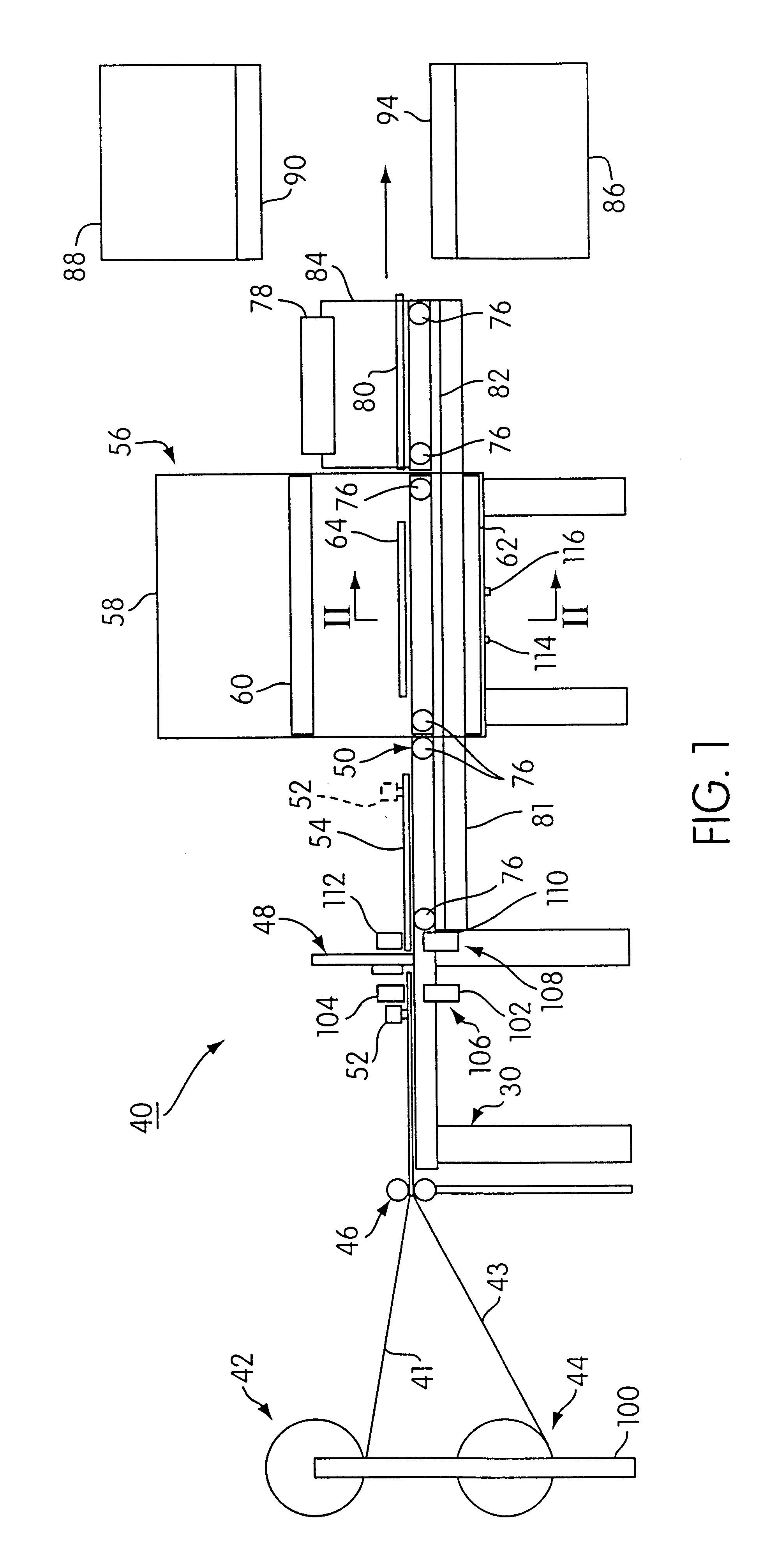

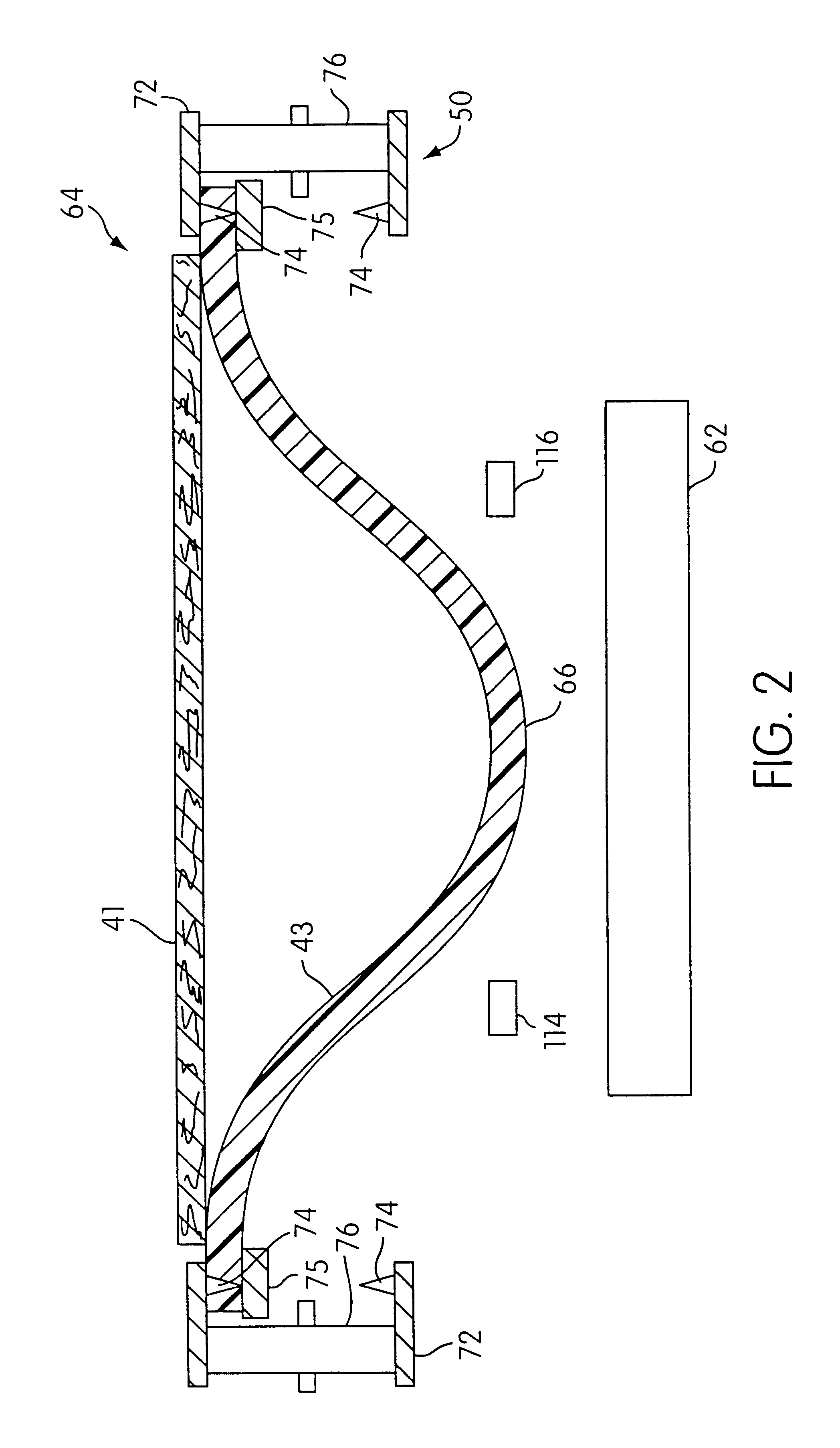

Apparatus and method for forming an interior panel for a vehicle

An apparatus for forming an interior panel for a vehicle door includes mandrels which hold rolls of vinyl laminate and fiberglass reinforcing mat and from which sheets of vinyl laminate and reinforcing mat are pulled in overlying relation with respect to each other. The vinyl and mat sheets are tacked together, cut to a predetermined length by a cutting mechanism, and moved into a heater by a pin-chain conveyor system. In the heater, the vinyl and mat are heated until the vinyl, which is supported at its edges by the pin-chain conveyor, sags a sufficient amount to indicate that the vinyl is sufficiently softened. The heated vinyl and mat are then moved to a vacuum mold part and thereafter a vacuum is applied to draw the vinyl to a molding surface of the vacuum mold part. A vacuum assist, carried on a carrier, engages the mat and heated vinyl within the vacuum mold part to press the mat into the heated vinyl to partially embed the mat into the vinyl to secure the mat to the vinyl. Thereafter, a foamable and curable urethane substrate material is poured into the formed vinyl and mat. A cooperating opposed mold part engages the vacuum mold part and applies heat and pressure to form the urethane substrate material and to cure th e substrate material into a relatively rigid substrate which is reinforced by the mat.

Owner:GRUPO ANTOLIN IRAUSA

Manufacture process of all waste paper dried noodle cardboard paper

ActiveCN102041750AEfficient use ofLow costSpecial paperWaste product additionHigh concentrationFiber

The invention discloses a manufacture process of all waste paper dried noodle cardboard paper, comprising the following steps: A: conveying the waste paper to a pulper through a scraper chain conveyor, and crushing the waste paper into paper pulp; B: conveying the paper pulp to a high concentration desander, and further removing the heavy impurities; C: screening out the pulp dregs and the impurities containing the heavy impurities from the paper pulp in a rough pulp tower by utilizing a three-section rough screen system; D: carrying out slag removal on the long fiber pulp by utilizing a long fiber three-section low concentration desander system, then feeding the fine pulp after the long fiber three-section low concentration desander into a three-section fine screen system to screen finely, and finally performing the paper making by utilizing a long fiber grinding back pool, a bottom machine chest and a paper remover; and E: carrying out slag removal on the short fiber pulp by utilizing a short fiber three-section low concentration desander system, and finally performing the paper making by utilizing a core machine chest and a paper remover. By utilizing the process provided by the invention, the product having the quality same as that of the dried noodle cardboard paper which is manufactured by the raw material of wood pulp can be produced, thereby greatly reducing the cost and ensuring the effective use of renewable resources.

Owner:东莞理文造纸厂有限公司

Full-automatic and high-speed casing production line system for cupped beverage

InactiveCN102556395AReduce labor costsIncrease productivityPackaging bottlesProduction lineControl system

The invention discloses a full-automatic and high-speed casing production line system for cupped beverage, which comprises an automatic shunting machine, an automatic posture trimming machine, an automatic whole-column sequencing machine, an automatic grouping system and an automatic casing system, which are arranged in sequence, and the system further comprises a control system, wherein the automatic shunting machine is a belt conveyor having a shunting function; the automatic posture trimming machine is a reshaping conveyor composed of a segment of belt conveyor and a segment of round belt conveyor, which are arranged in parallel; the automatic whole-column sequencing machine is a scraper chain conveyor I having a combining function; and the automatic grouping system comprises an automatic grouping conveyor for conveying a whole column of cupped beverage, an automatic grouping machine and an automatic grouping worktable; the automatic casing system comprises an automatic case unpacking machine, an automatic case body conveyor, an automatic casing machine, a vision detecting system, a belt weigher and an automatic casing sealing machine. Compared with the prior art, the full-automatic and high-speed casing production line system for the cupped beverage, disclosed by the invention, has the advantages of saving the labor cost and improving the production efficiency.

Owner:石家庄爱驰自动化设备有限公司

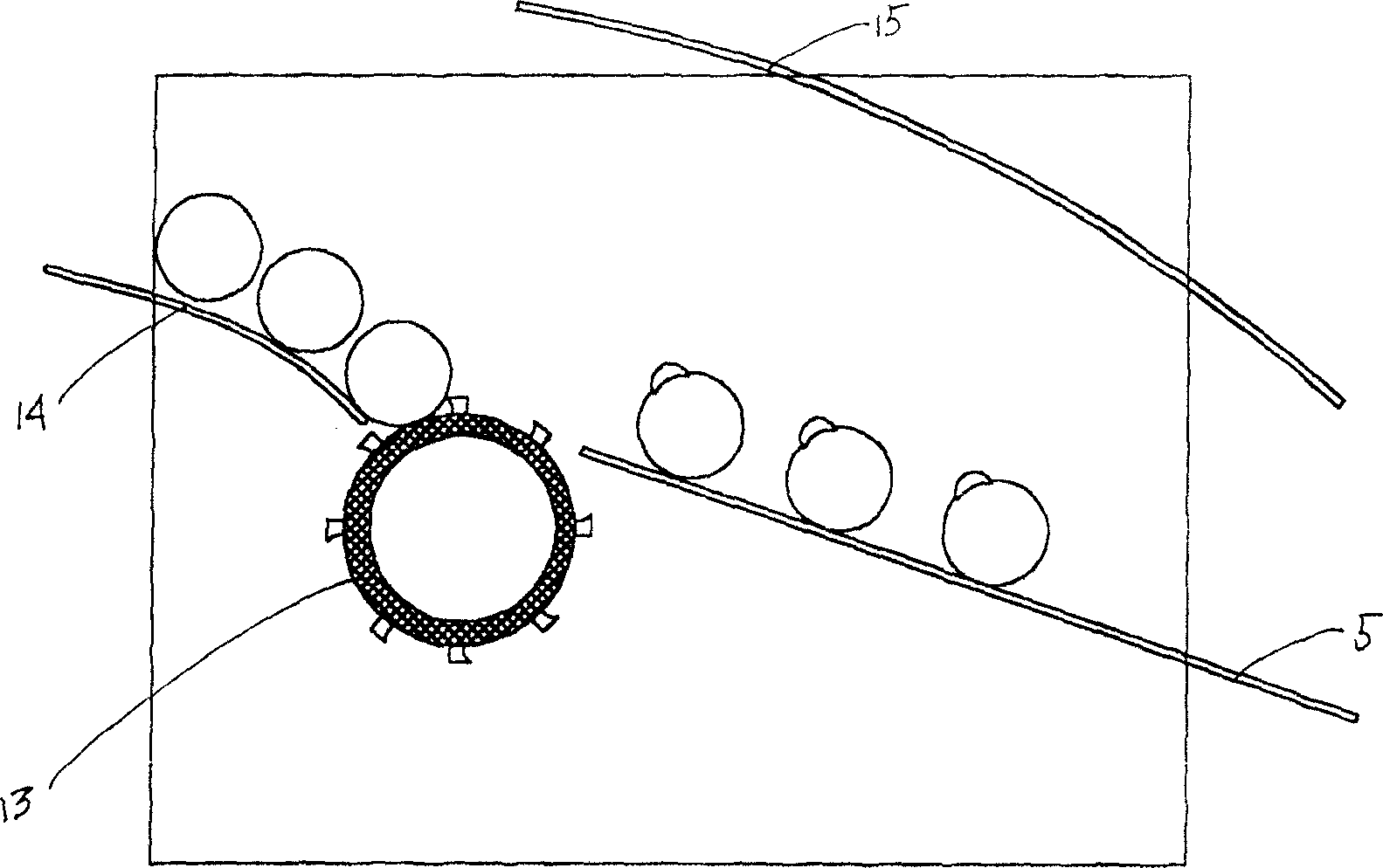

Peeling machine for orange

InactiveCN1631272AHigh success rate of one-time peelingImprove productivityVegetable peelingFood treatmentProduction rateSEMI-CIRCLE

Disclosed is an orange barking machine, which comprises a peel cutting device, a barking device, a transfer arrangement connected therewith, a mated sprinkling arrangement, and an electric controller, the peel cutting device comprises a high speed rotating peel cutting knife roller, an upper guide plate and a lower guide plate, the peel cutting knives on the knife roller are arranged along the single-head spiral lines at equal appearing interval on the roller surface, the barking device comprises bicycle chain conveyor belt and shift rod rows, each husking roll is equipped with even teeth in the shape of semi-circles with coated silicone rubber material.

Owner:象山双鱼轻工机械有限公司

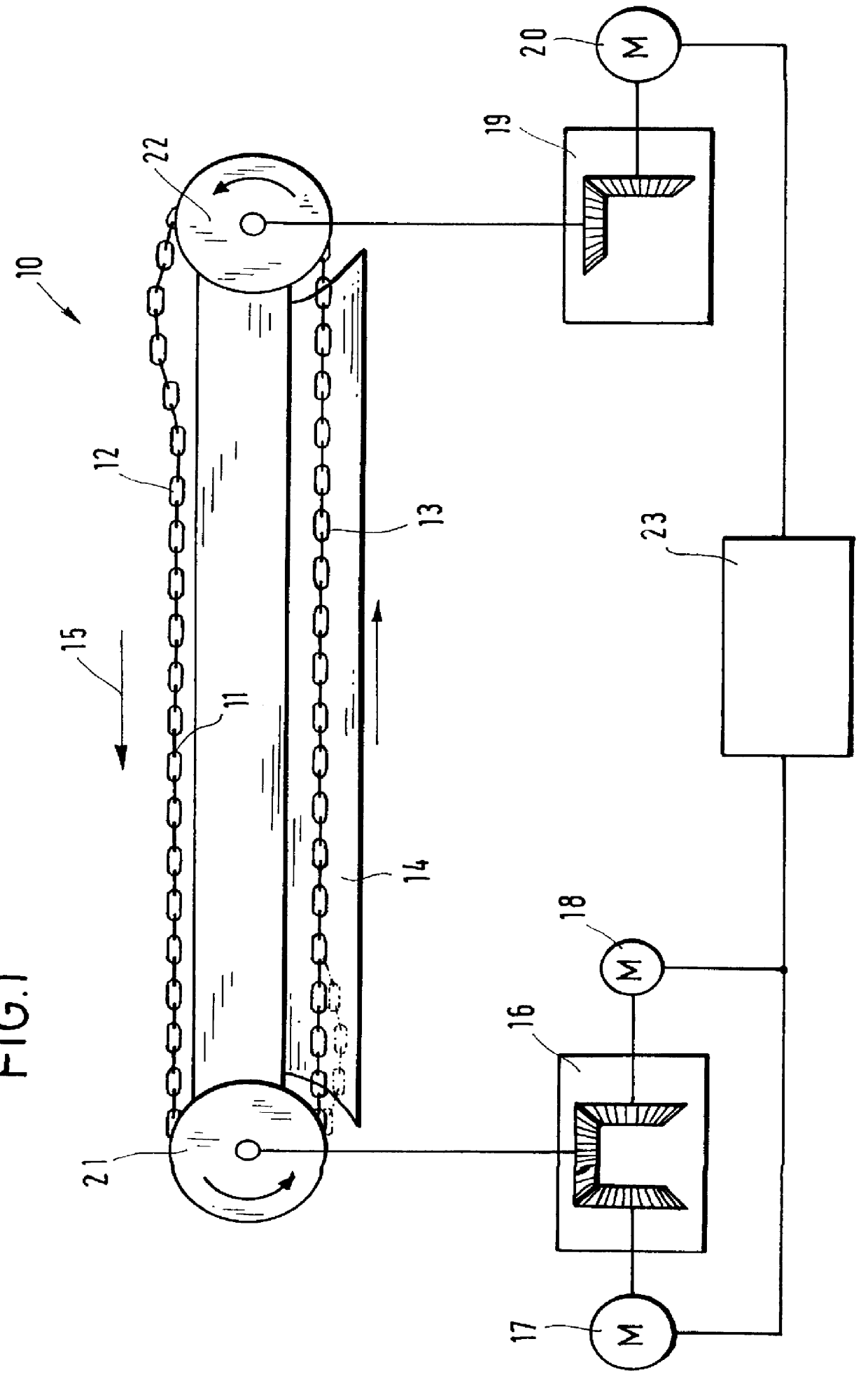

Method for controlling drives of conveying machinery

InactiveUS6029799AEasy loadingReduce outputConveyorsControl devices for conveyorsLow loadChain conveyor

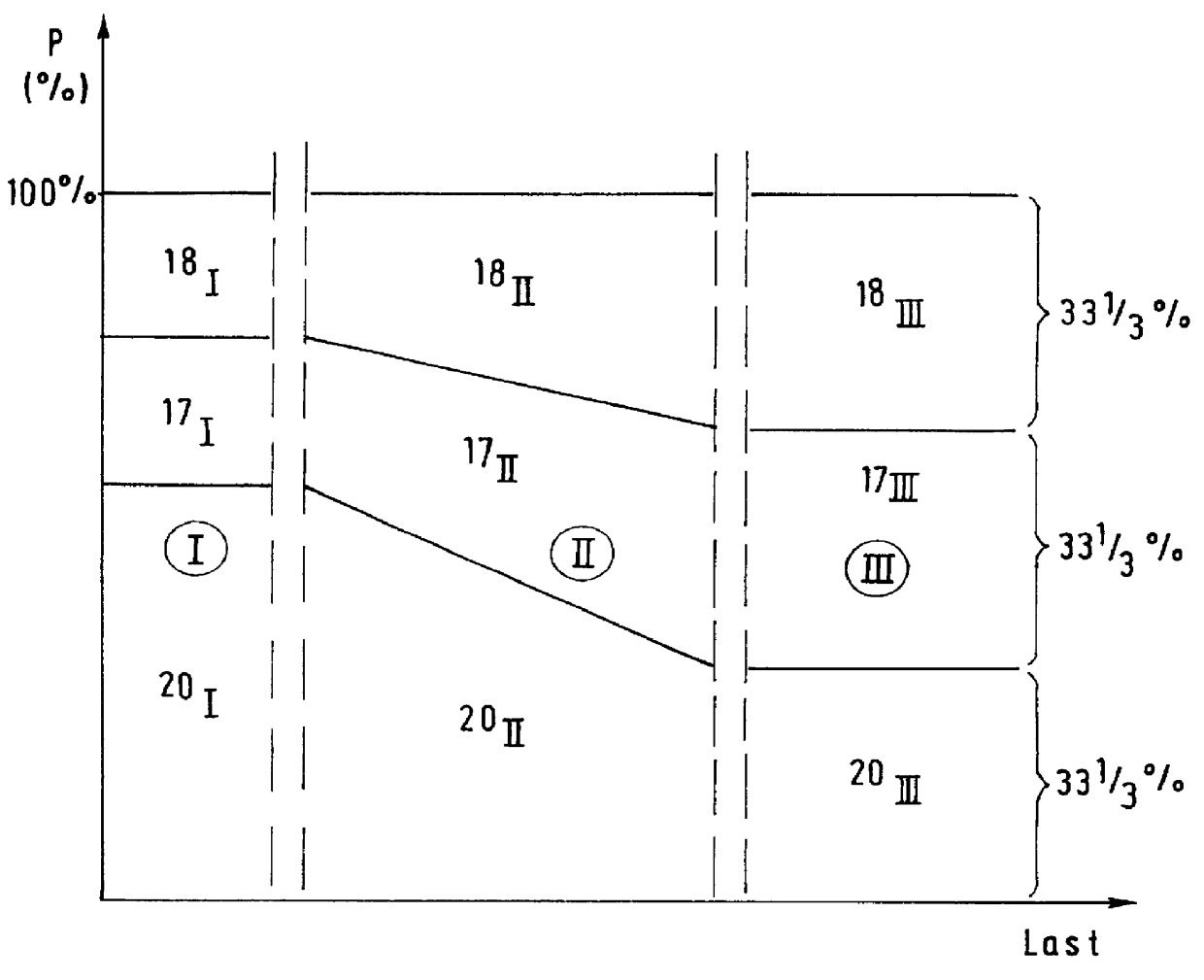

A method for controlling the main and auxiliary drives of conveyors, for example, in underground mining. The drives are controlled as a function of the loading of the conveyor in such a way that in a low load range of the conveyor the auxiliary drive produces a higher output (20I) than the main drives and as the load increases the output advantage of the auxiliary drive in relation to the main drives is reduced. This special load distribution to auxiliary and main drives has the advantage that sagging of the conveyor element, for example the chain of a scraper chain conveyor in the inaccessible and concealed lower strand, close to the main drive, can be prevented. The risk of damage to the machine frame or conveyor chain is thereby reduced.

Owner:CATERPILLER GLOBAL MINING EURO GMBH

Conveyor-type automatic oil mist coating machine

ActiveCN102601005AReduce fuel consumptionReduce laborLiquid surface applicatorsSpraying apparatusProduction lineFuel tank

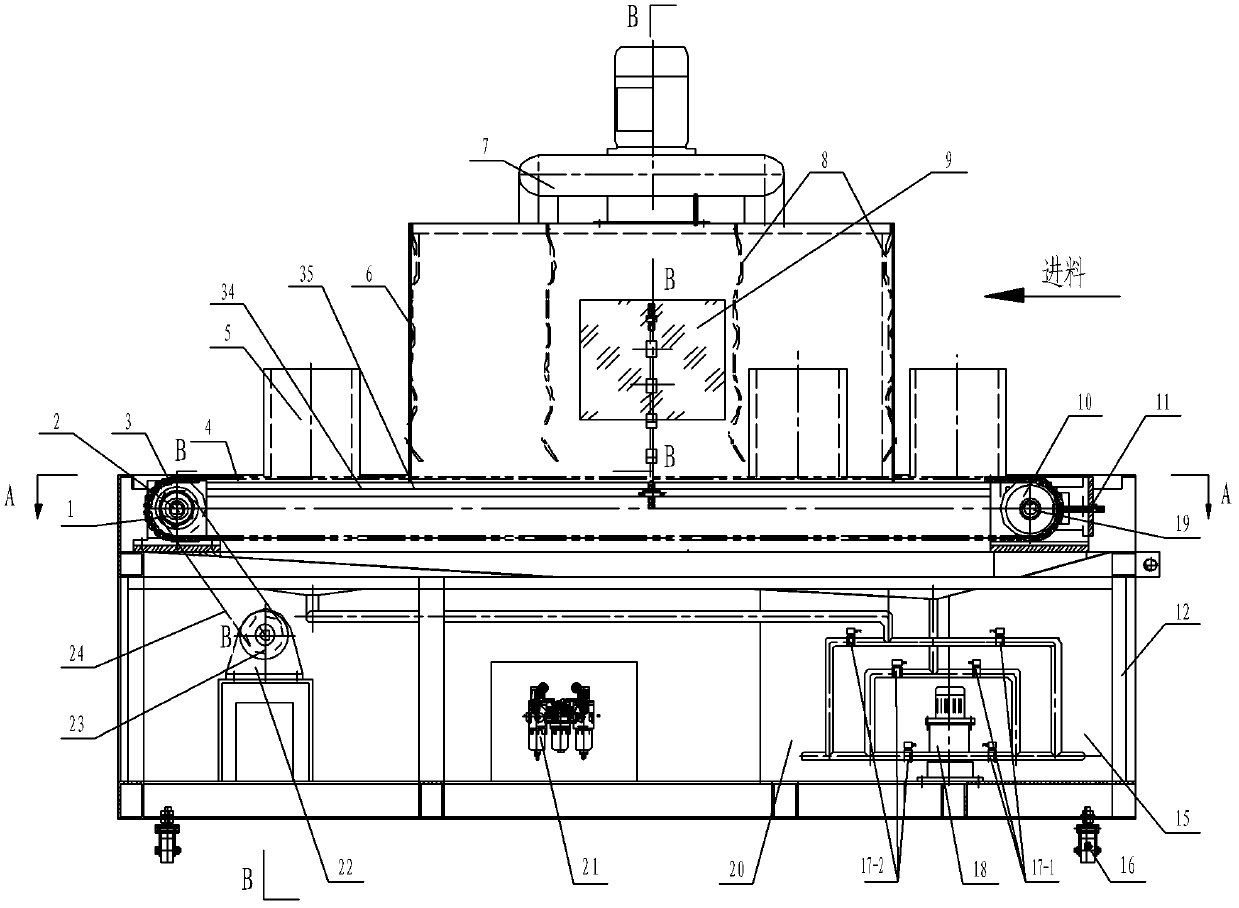

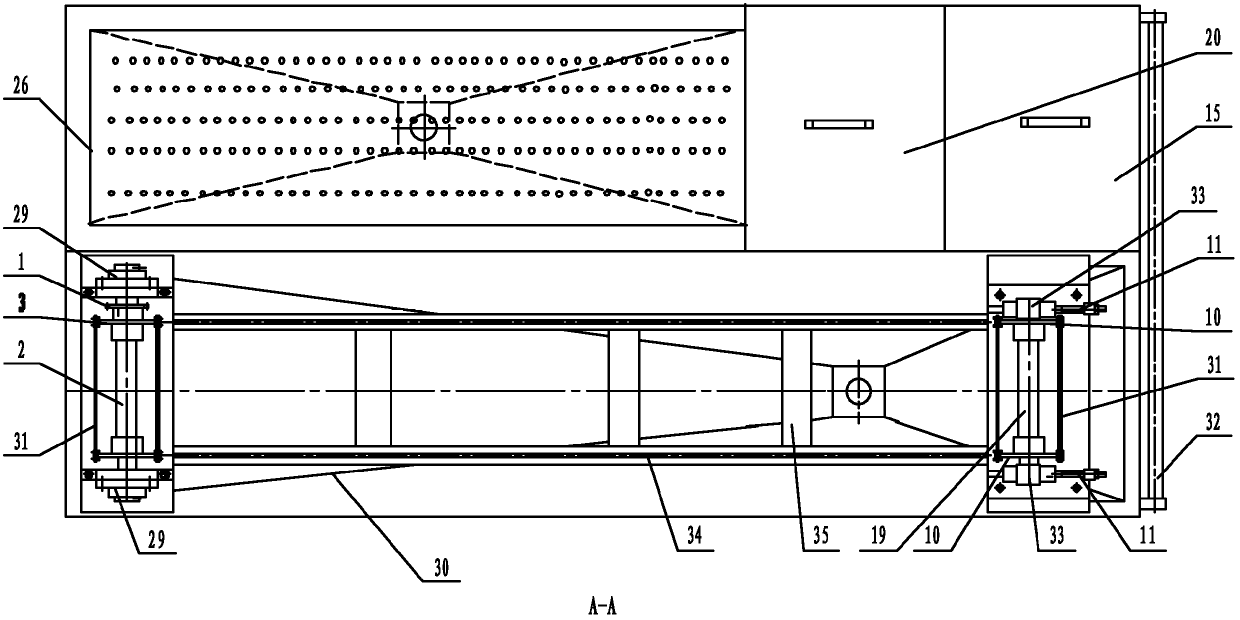

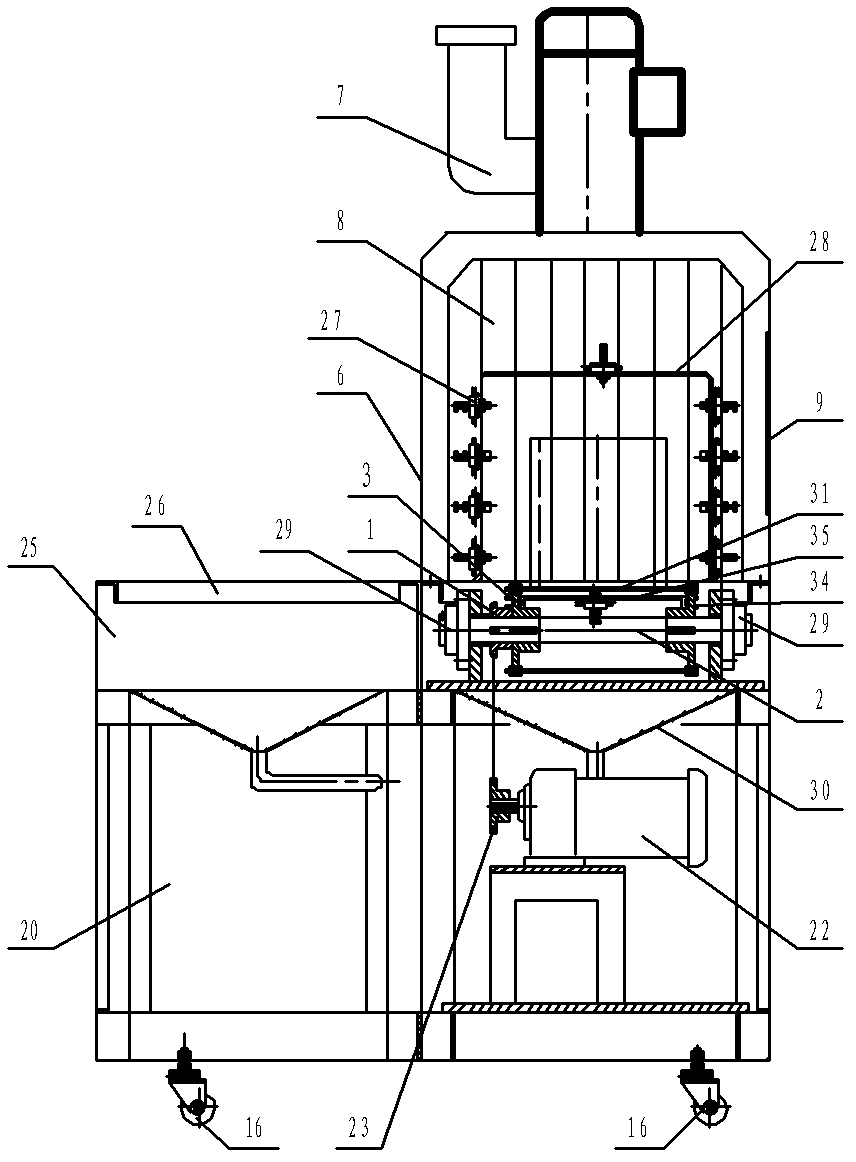

The invention relates to a conveyor-type automatic oil mist coating machine, wherein the conveyor-type automatic oil mist coating machine is characterized in that: the coating machine is fixed with a spraying chamber on a frame in the middle of a chain conveyor line; gates of which a workpiece passes in and out are arranged on right and left sides of the spraying chamber; a plurality of atomizing oil nozzles are fixed on an atomizing shelf inside the spraying chamber; an oil mist separator is fixed at the top of the spraying chamber; an inlet of the oil mist separator is communicated with an inner cavity of the spraying chamber; an exhaust port and an oil drainage port are respectively communicated with an exhaust pipe and an oil tank; an air inlet of an air source processing member distributed on the coating machine is communicated with an air source supply device; an outlet of the air source processing member is communicated with the air inlet of each atomizing oil nozzle; an oil inlet of an oil pump distributed on the coating machine is communicated with the oil tank; the oil outlet of the oil pump is communicated with the oil inlet of each atomizing oil nozzle; and the oil outlets of an oil collecting tank arranged below a concave work bench and a conveyer line of the coating machine are respectively communicated with the oil tank. According to the coating machine disclosed by the invention, the automatic degree is high; oil and manpower are saved, and the coating machine can be independently operated and also can form an automatic pipeline together with an interface of a workpiece production line.

Owner:盐城新时代智能检测设备制造厂

Rotating filter cartridge type air dust remover

InactiveCN101264406AEfficient removalConstant dust removal effectDispersed particle filtrationHigh humidityChain type

The invention discloses a rotary drum type dust remover, comprising a housing, a plurality of filter cylinders arranged in the intracavity of the housing for isolating dust, a main motor for driving filter cylinders, an impulse sweep system for cleaning the deposit dust on the surface of the filter cylinder, a chain typed scraper chain conveyor for cleaning dust, a spiral ash transportor and a dust discharge valve. The dust remover has the advantages of low dust concentration requirement for the air to be purified, ability to remove dust in various environments, and stable dust removal efficiency; and high temperature resistance, high humidity resistance, acid and alkaline corrosion resistance, electrostatic prevention as the filtered cloth material is stainless steel material; and ability to be used independently, also to be used multi-parallelly, and to select the number of single machine in an unit according to different discharge standard.

Owner:JIANGSU HUAZHENG ENVIRONMENTAL PROTECTION TECH CO LTD

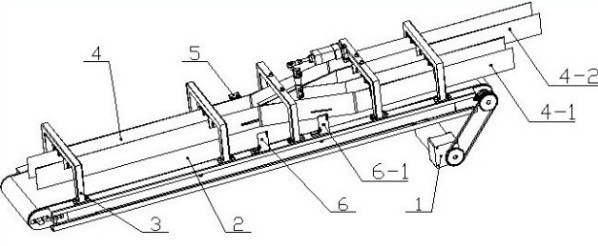

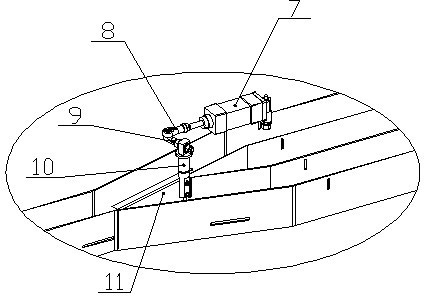

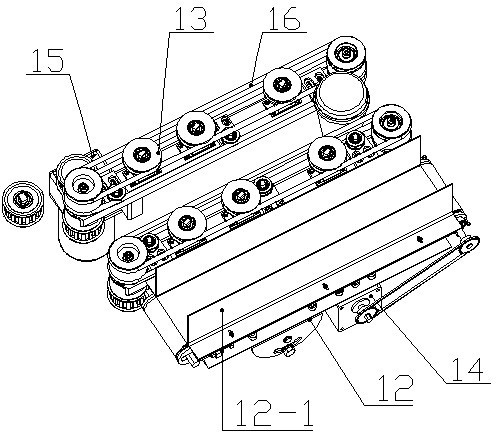

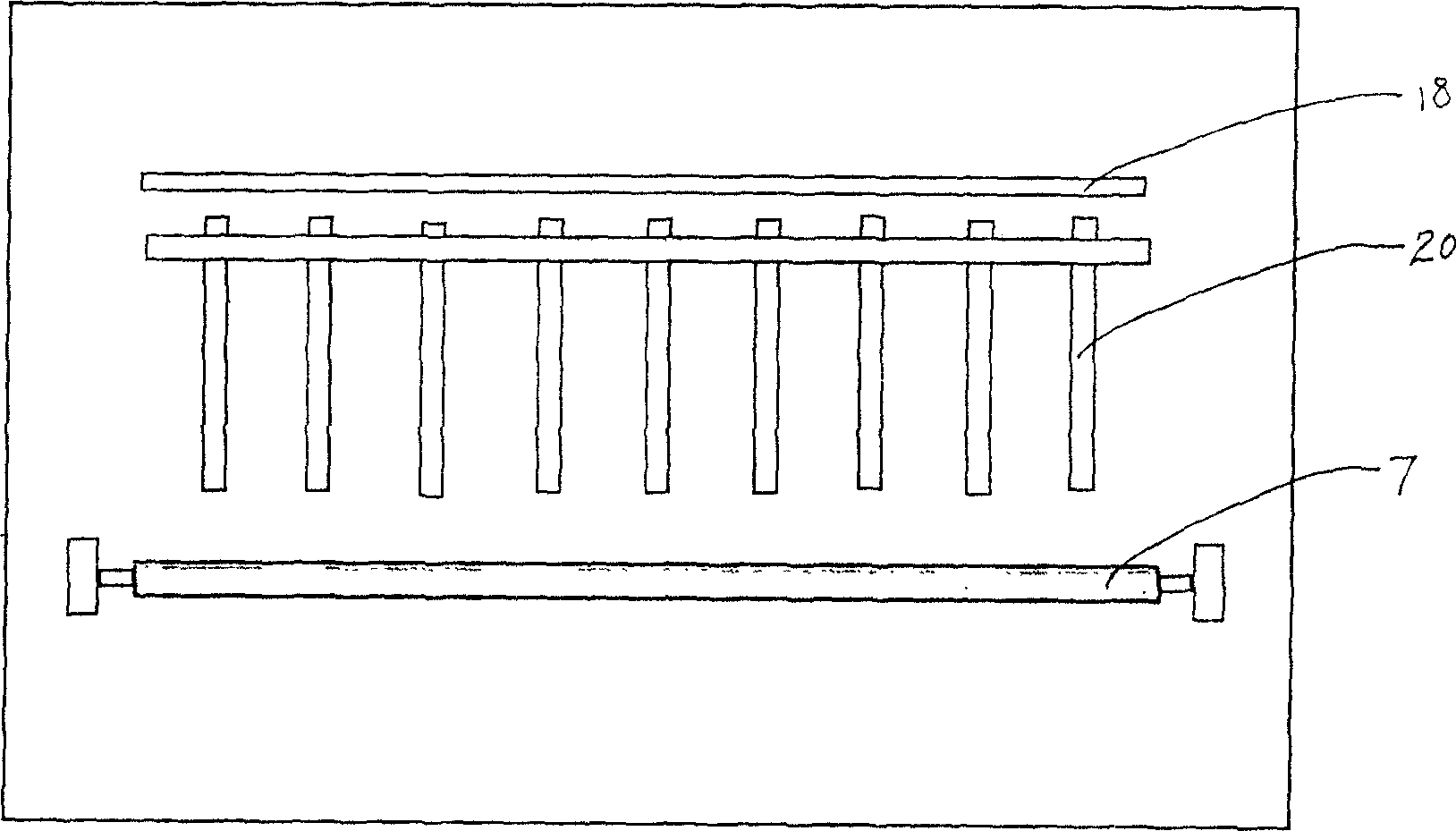

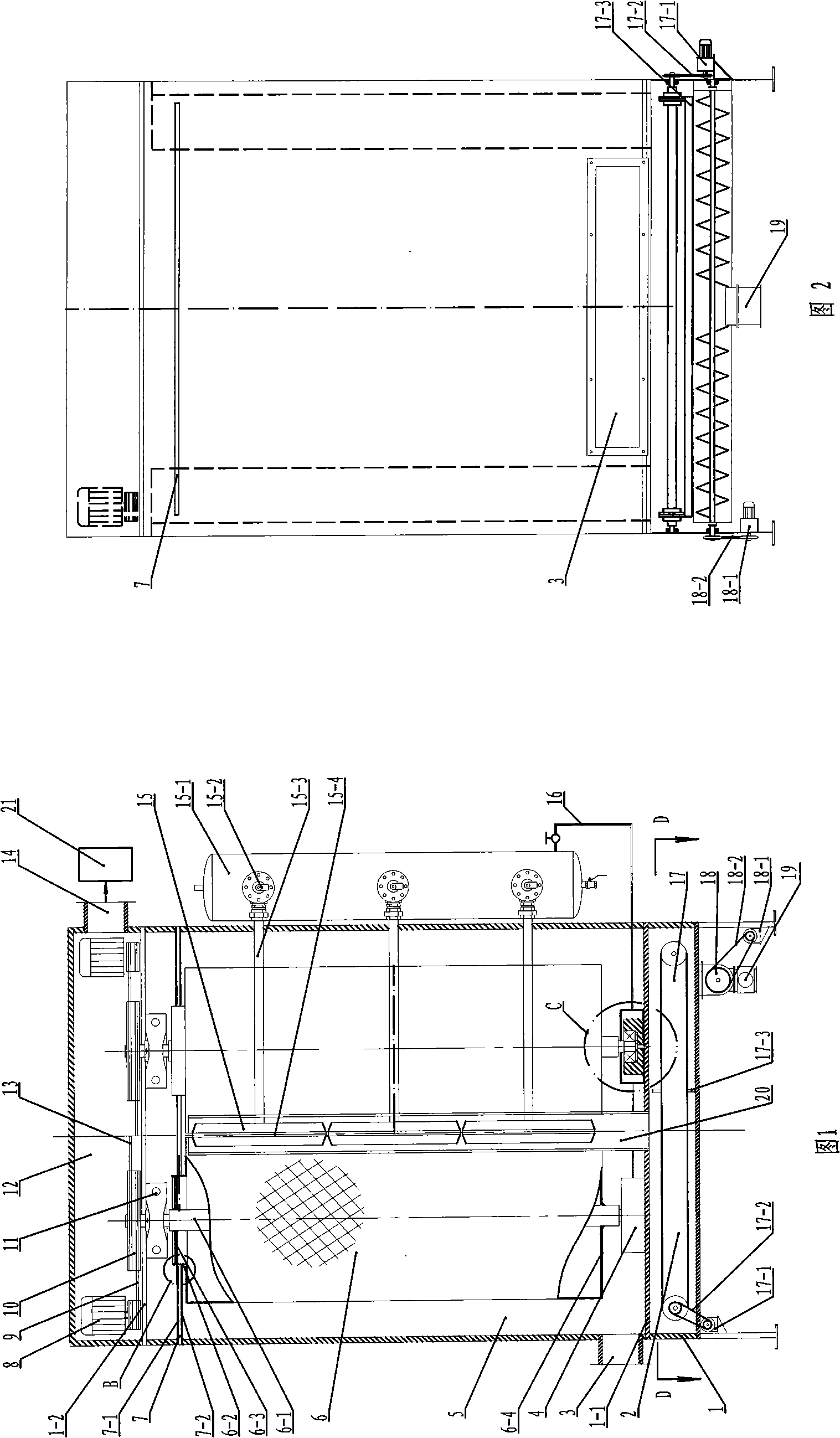

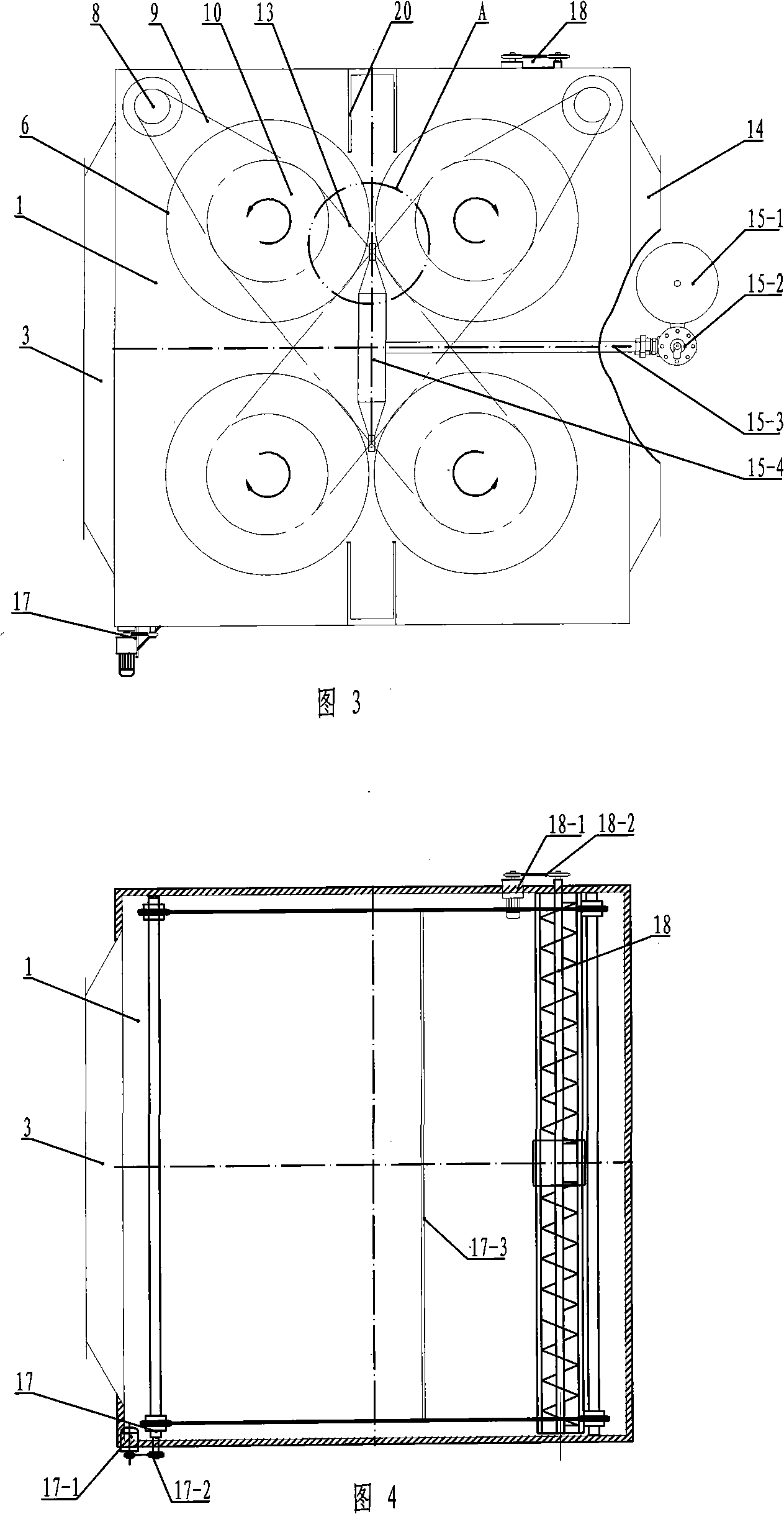

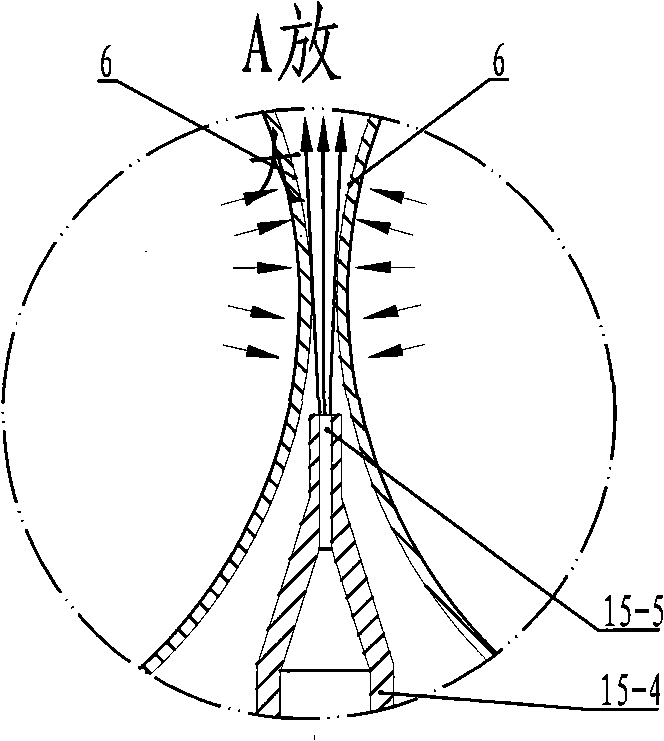

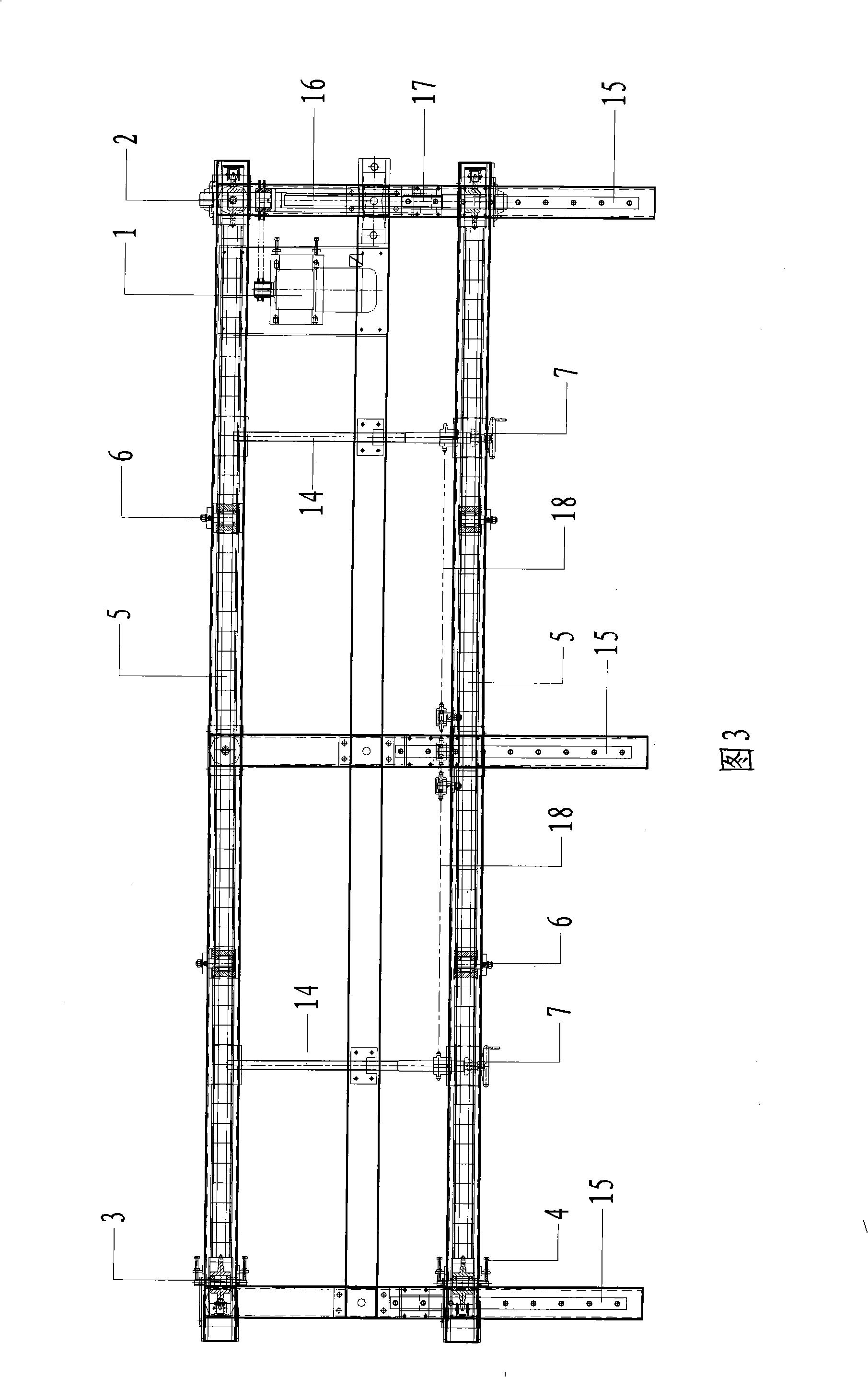

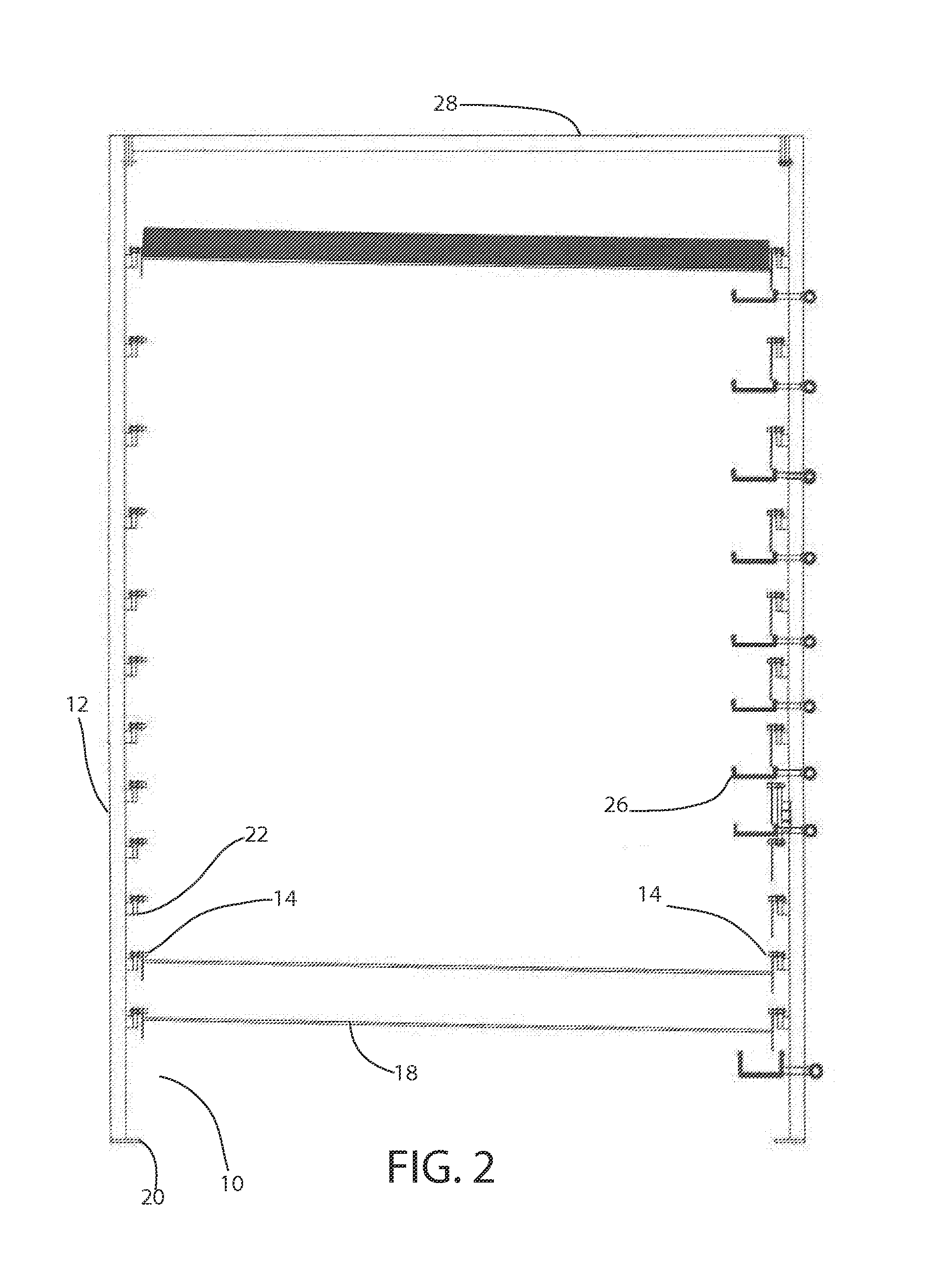

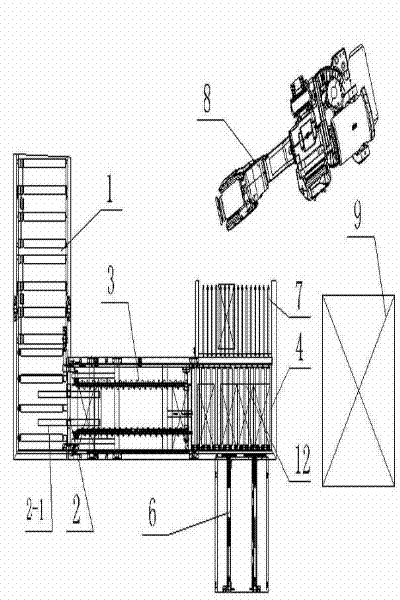

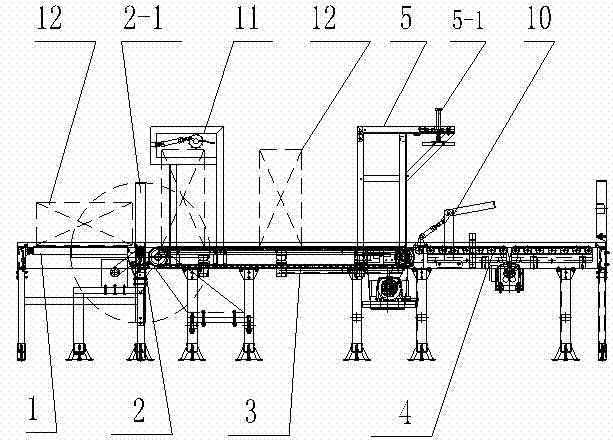

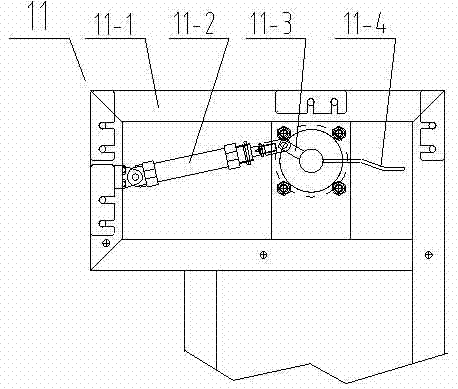

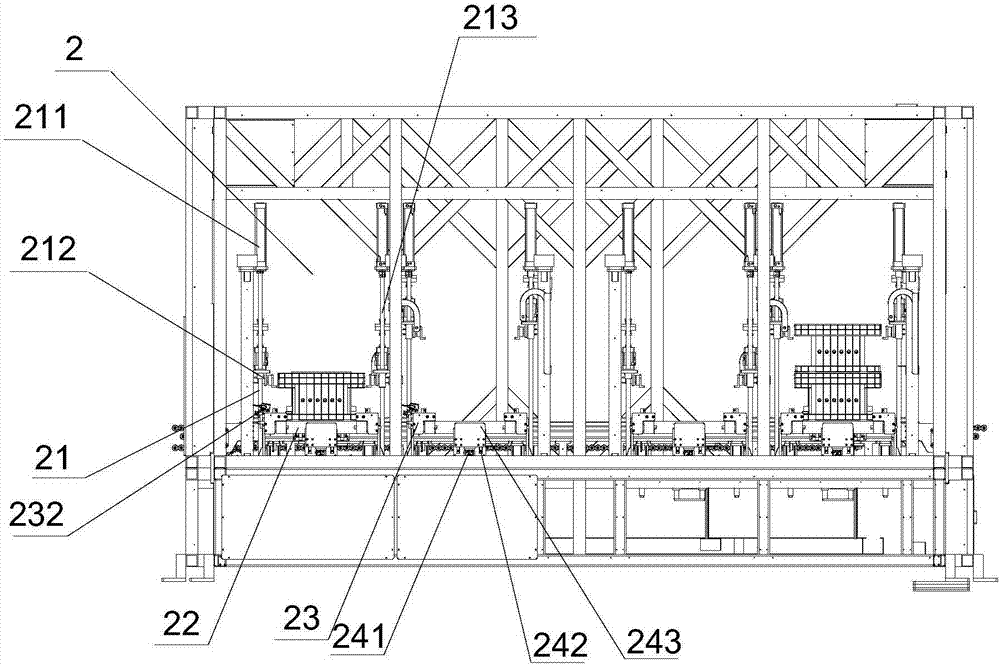

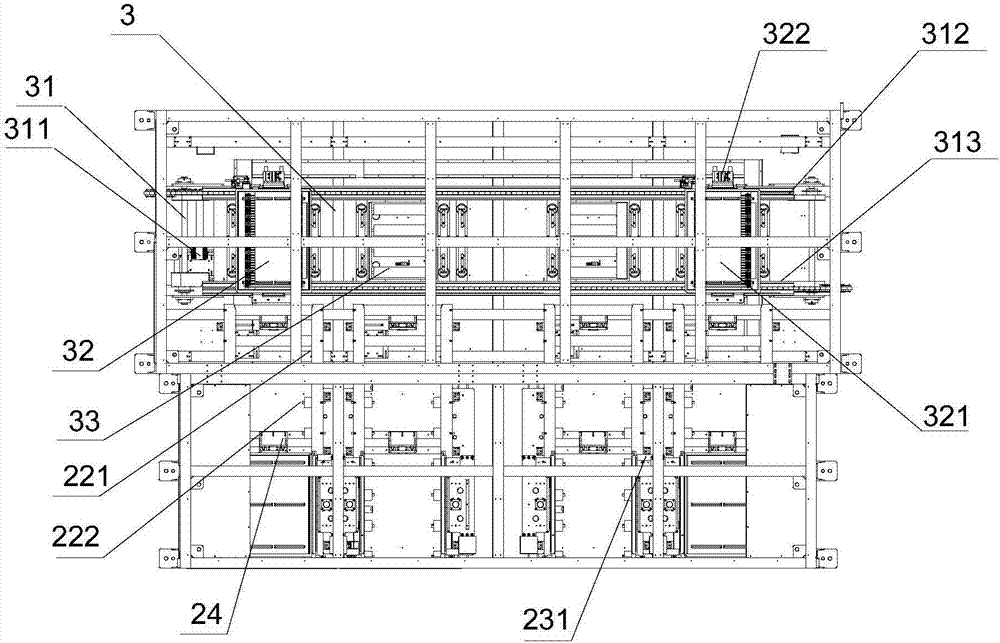

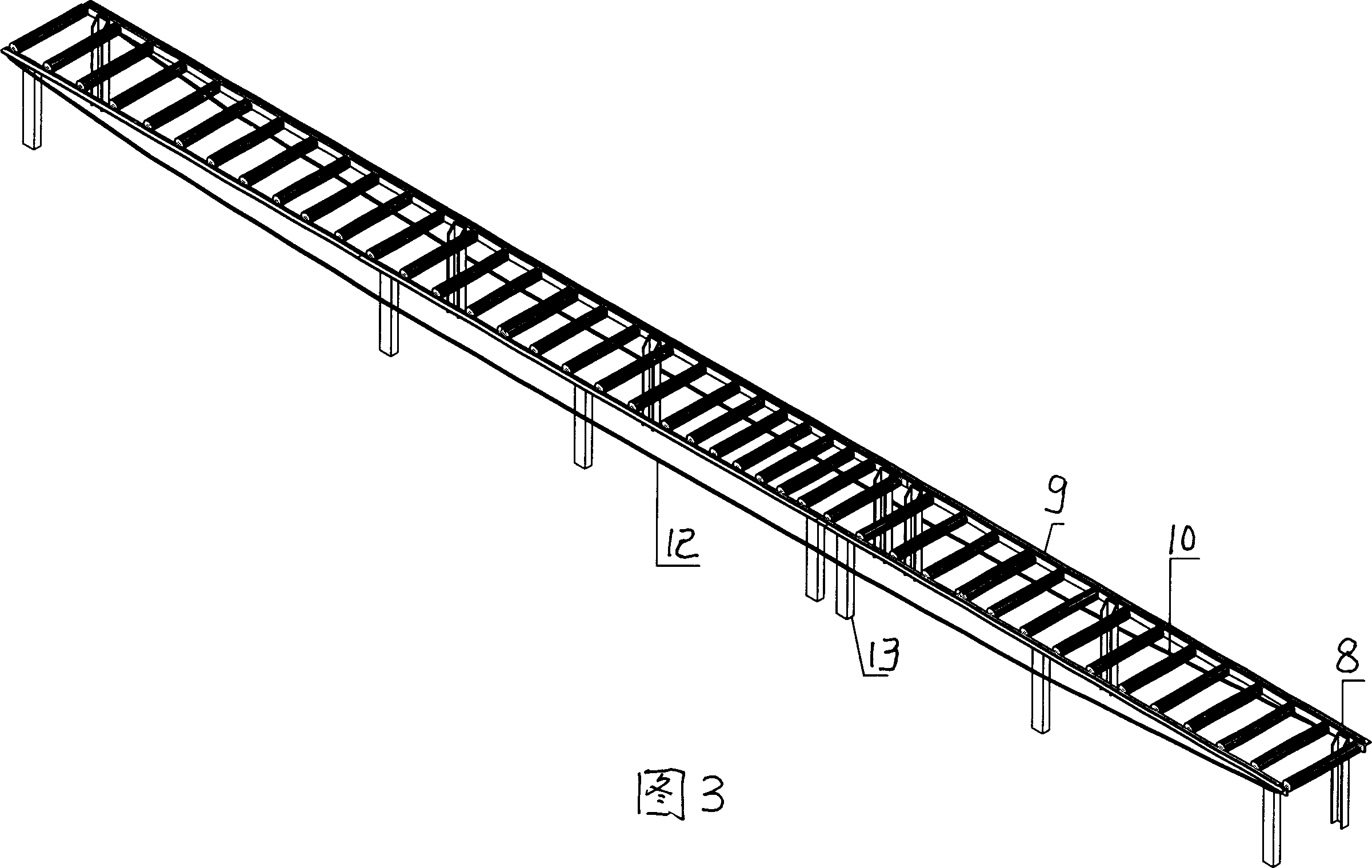

Process for producing unit plate of unit-type curtain wall and operation console thereof

A method for producing unit plate of unit curtain wall and operating desks thereof are disclosed. The production includes six working procedures: 1) the assembly of a metal framework; 2) the installation of inner lining plates and heat insulation cotton; 3) quality inspection for the metal framework; 4) the assembly of panels (including the inspection of glass raster); 5) glue injection; and 6) the mounting and the packaging of exterior decorate lines. The operating desks for the working procedures adopt chain conveyers provided by the invention respectively. Each chain conveyer can work for transmission independently and also can work with the whole work line. The adopted chain conveyer is mainly composed of a drive motor and speed reduction unit (1), a roller chain conveying pedrail (5), and a fixed frame (8) and a movable frame (9) which are parallel to each other. The pedrail type conveyer adopted by the invention has good function for regulating width and height, carries out the quality control for the whole work line, greatly improves the efficiency of the production line for the unit curtain wall, and reduces the labor intensity of the worker.

Owner:ZHONGSHAN SHENGXING

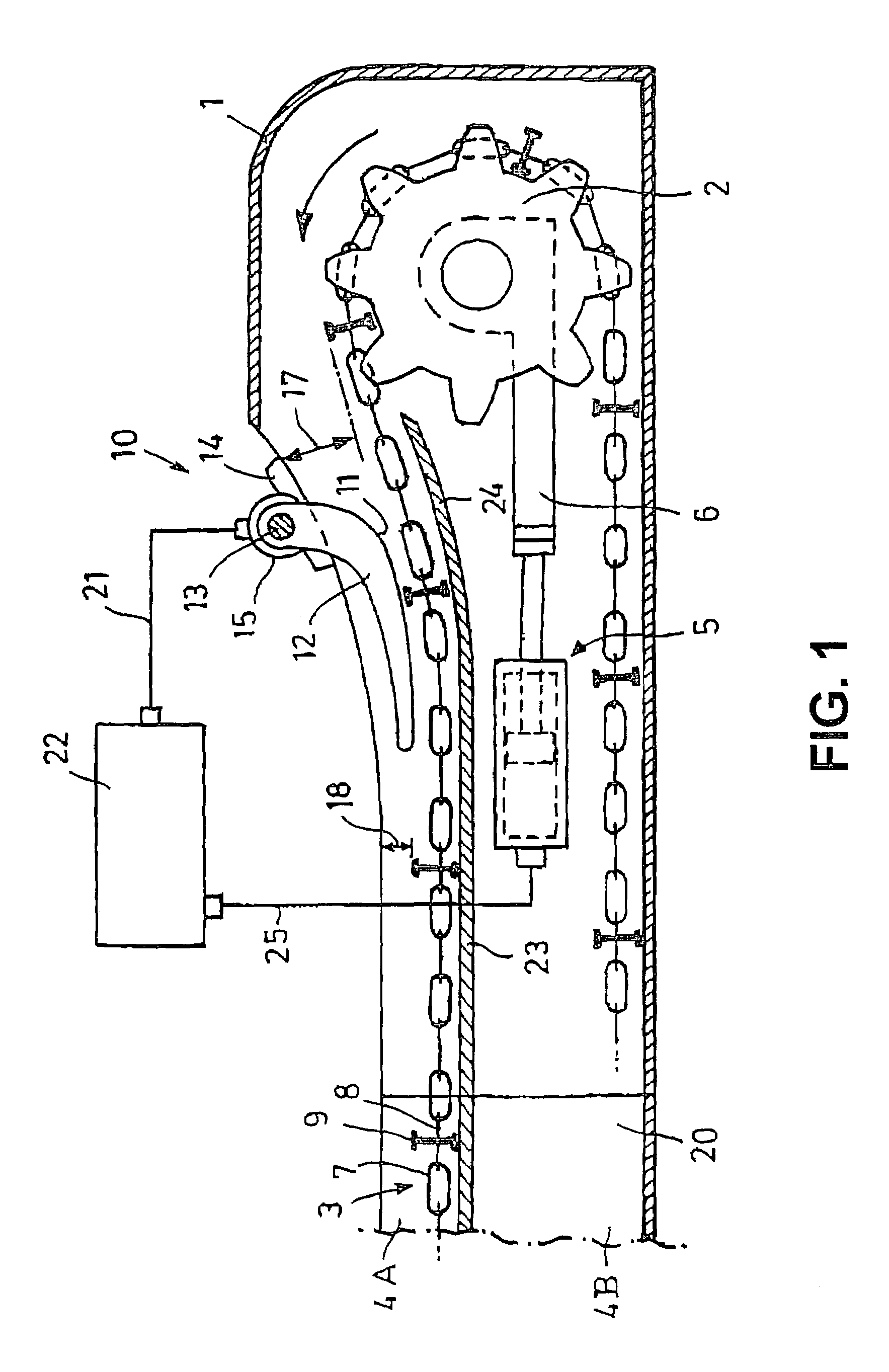

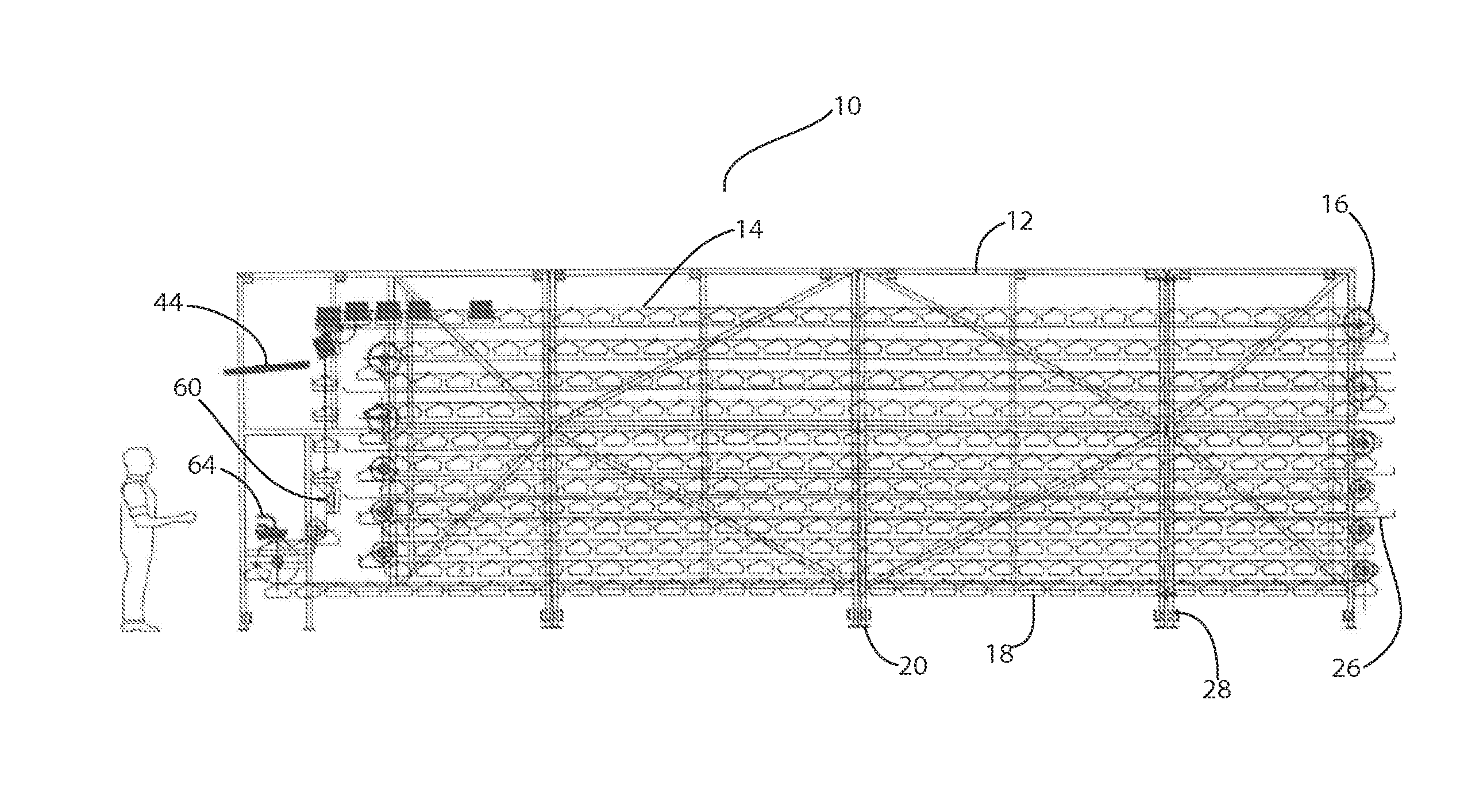

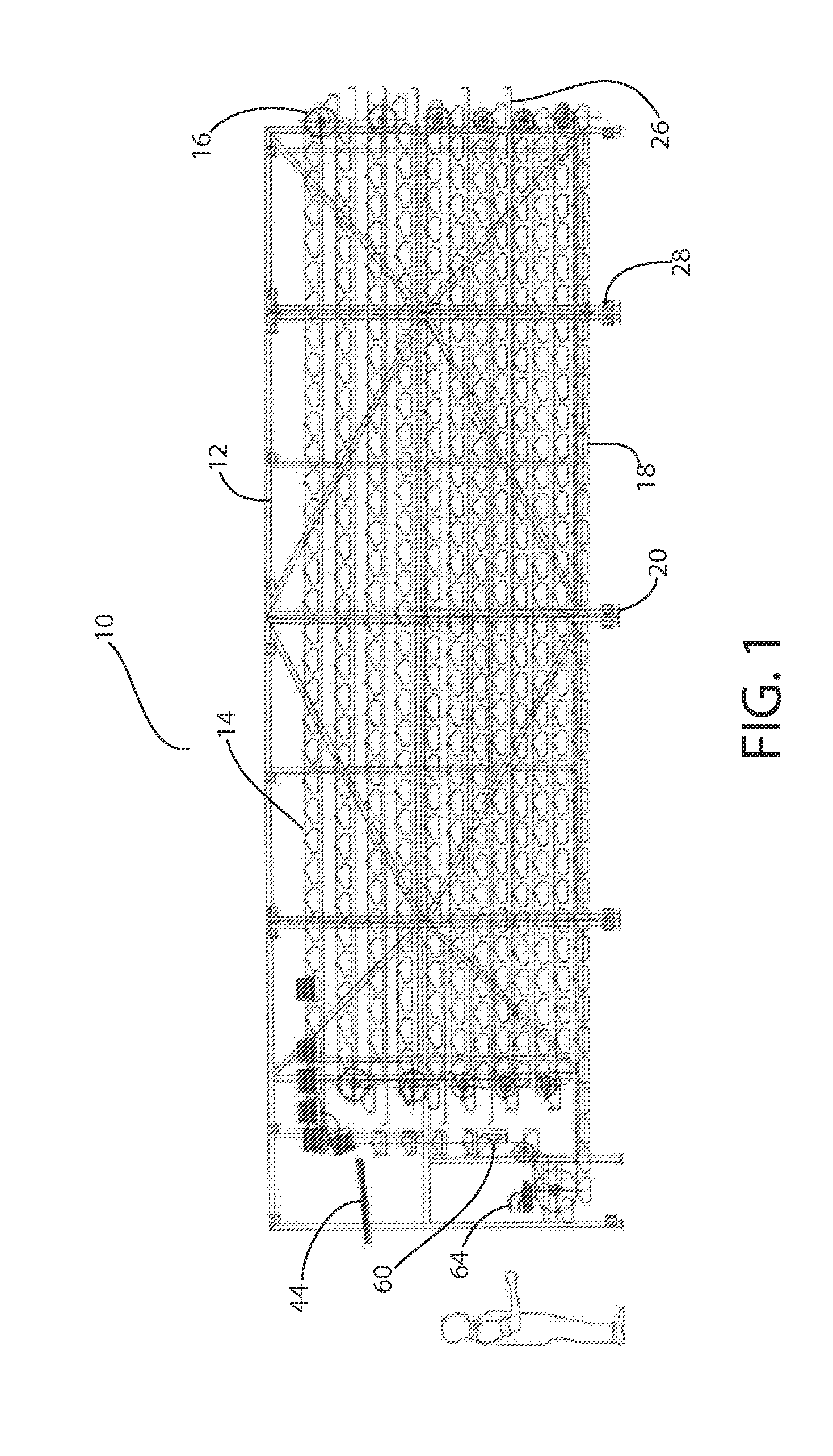

Automated hydroponic growing and harvesting system for sprouts

InactiveUS20150250115A1Safe disposalLittle to laborAgriculture gas emission reductionCultivating equipmentsFisheryChain conveyor

An automated hydroponic growing and harvesting system for sprouts includes a continuous serpentine chain conveyor transporting suspended trays through a tray preparation zone where trays are cleaned, a seeding zone where a layer of seeds is deposited across each tray, a germination zone where environmental conditions and nutrients and water are provided for germination, a growing zone where lighting, nutrients and water are provided for growth, and a harvesting zone where sprouts are dumped from each tray.

Owner:SNOWBIRD ENVIRONMENTAL SYST

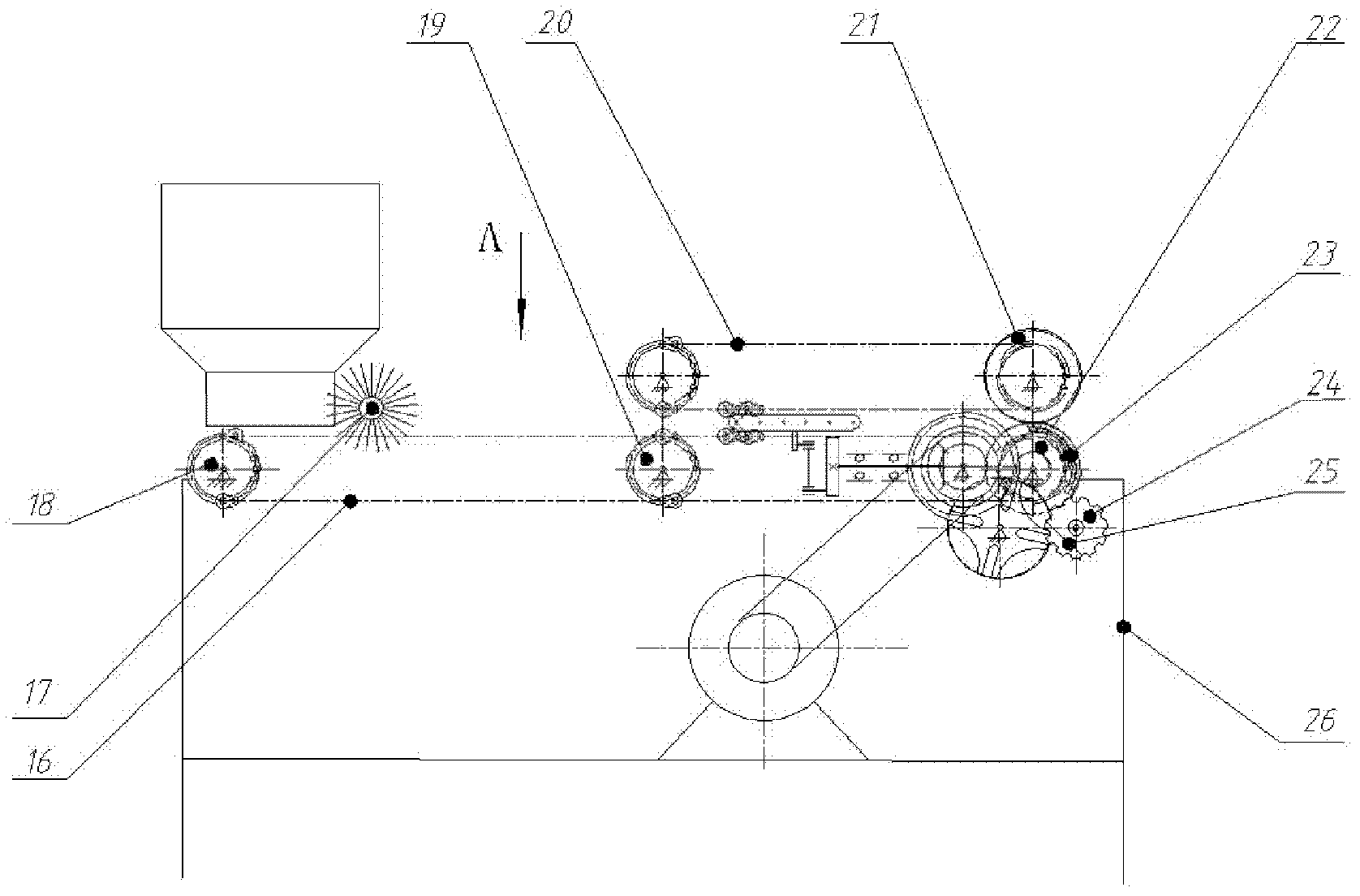

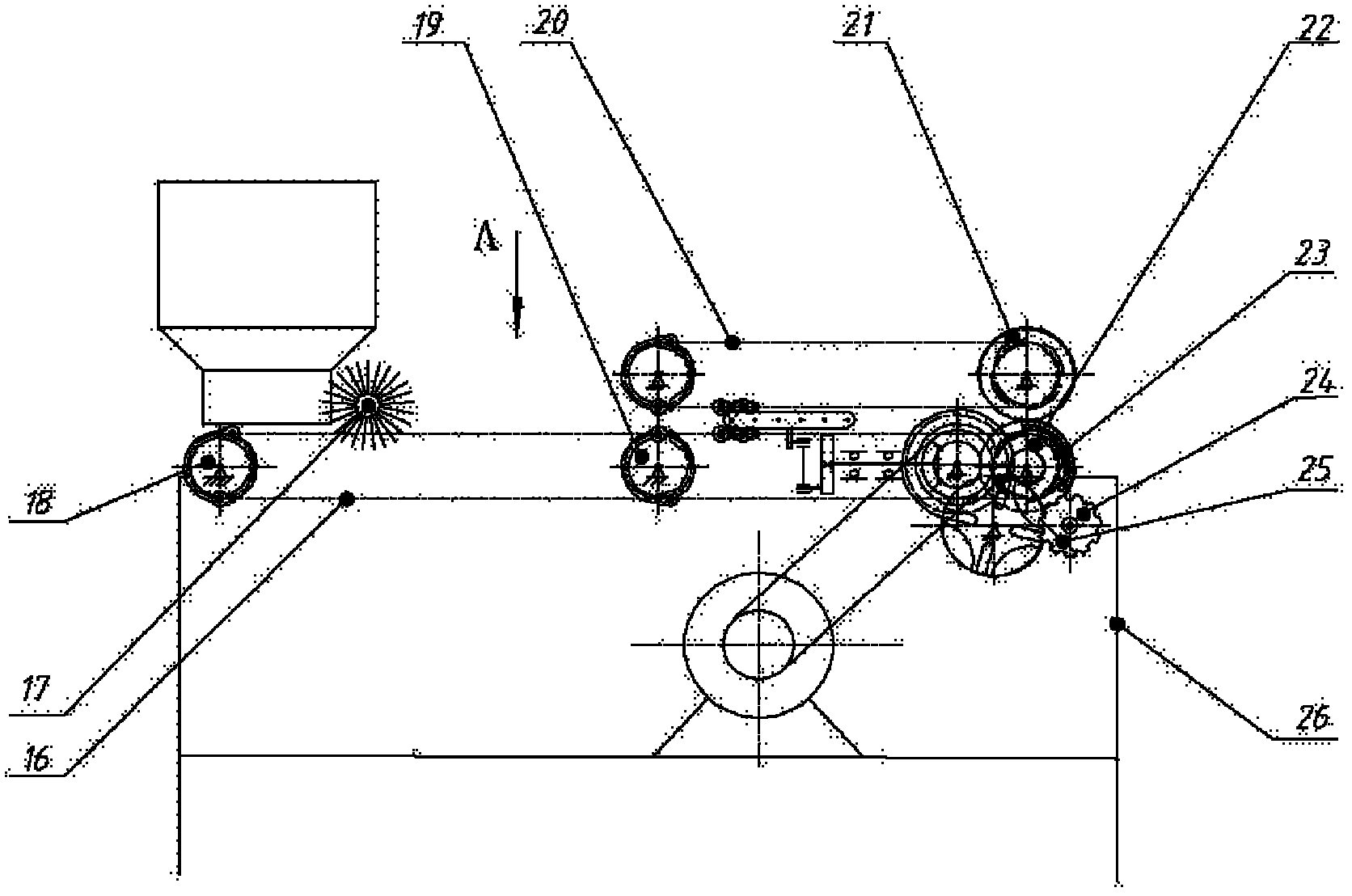

Automatic kernel-removing slicing machine for Chinese dates

ActiveCN102357906AAchieve rotationGood synchronizationFruit stoningMetal working apparatusChain conveyorEngineering

The invention discloses a rolling chain type conveyer, which is used for orientating and transporting Chinese dates, namely horizontally placing the Chinese dates along an axial direction and feeding in a parallel manner. A hairbrush on the upper part of a roller allows only one row of Chinese dates to pass through; a friction plate on the lower part of the roller is used for realizing rotation of the roller; two rows of chains and four rollers are used for positioning and clamping the Chinese dates when the kernels are removed, thereby providing a condition for punch kernel-removing; conveying, kernel-removing and slicing are driven by a same motor; synchronism is excellent; a centric slider crank mechanism is used as a kernel-removing mechanism; and after kernel-removed Chinese dates are moved to the tail end of a conveying chain, the Chinese dates are guided to move to a cutter slot type feeding wheel by an adjustable protecting plate and then are sliced by a blade, thereby forming a plurality of concentric annular slices. The integration of orientating, kernel-removing and slicing is realized.

Owner:启东市天汾电动工具技术创新中心

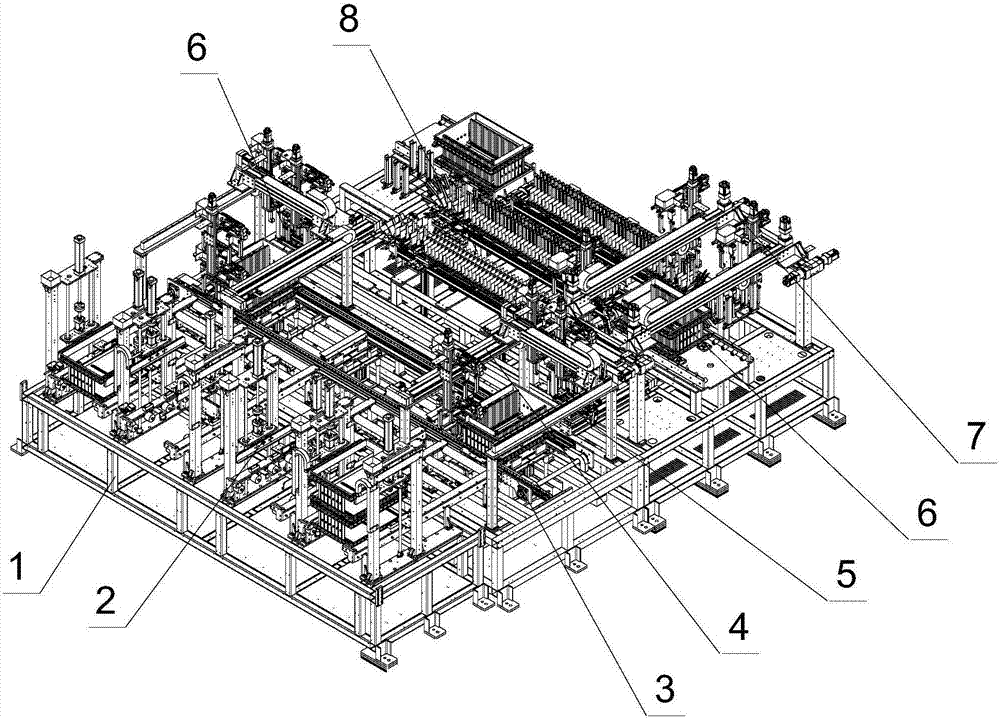

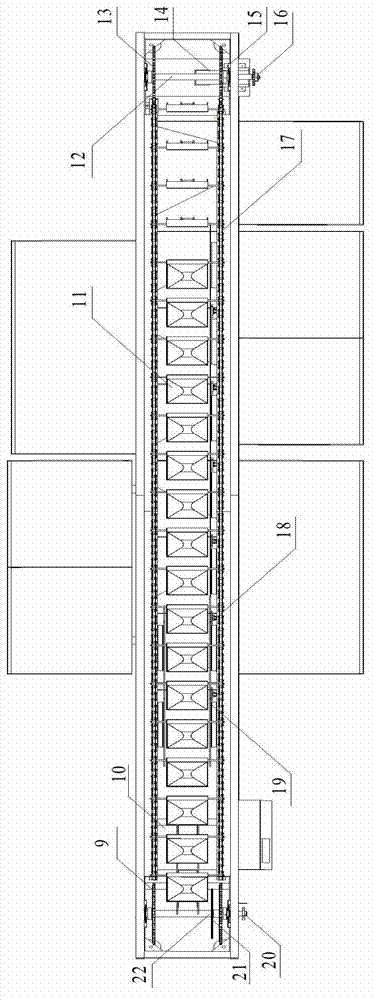

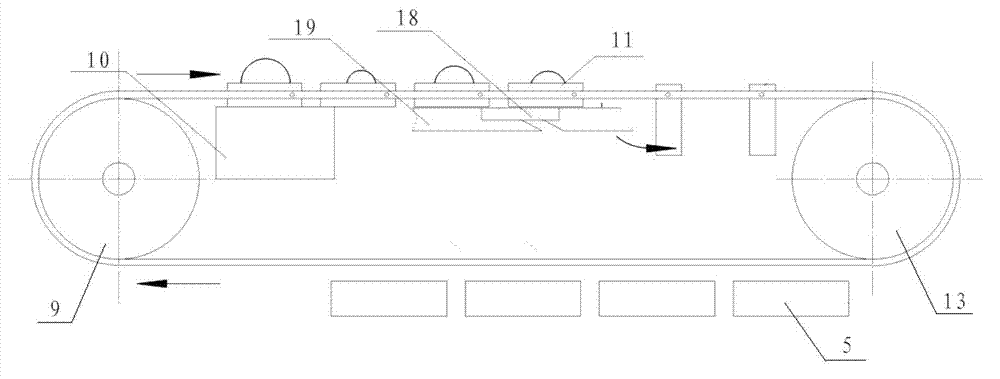

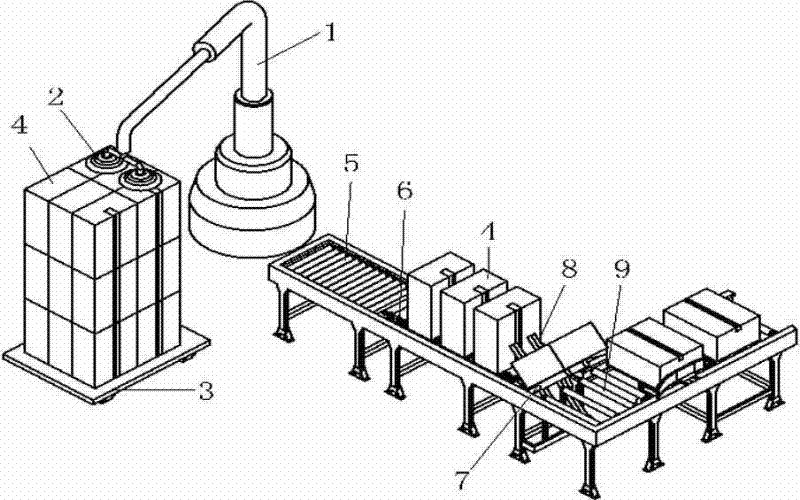

Automatic conveying and stacking method and device for standard boxes

ActiveCN102190157AReduce labor intensityImprove work efficiencyStacking articlesDe-stacking articlesControl signalChain conveyor

The invention discloses an automatic conveying and stacking method and an automatic conveying and stacking device for standard boxes. In the invention, the standard boxes are flatly put on a roller conveyor and conveyed, a turnover mechanism turns the standard boxes 90 degrees and vertically puts the standard boxes on a stacking chain conveyor, the stacking chain conveyor conveys the standard boxes to a roller conveying type stacking conveyor, the front end of the stacking conveyor is provided with a box pressing device which can press a standard box at the foremost end of the stacking conveyor according to a requirement of a control signal, a box pushing mechanism at the tail of the stacking conveyor can push more than two standard boxes onto a box stacking fork, and a robot simultaneously grabs the more than two standard boxes on the box stacking fork and moves the standard boxes onto a stacking tray for stacking. The automatic conveying and stacking device can stack the standard boxes according to the required stacking height, stacking rule and the like, can greatly improve work efficiency and reduce labor intensity of workers, and has the advantages of high reliability and high automation degree.

Owner:GUIYANG PUTIAN LOGISTICS TECH

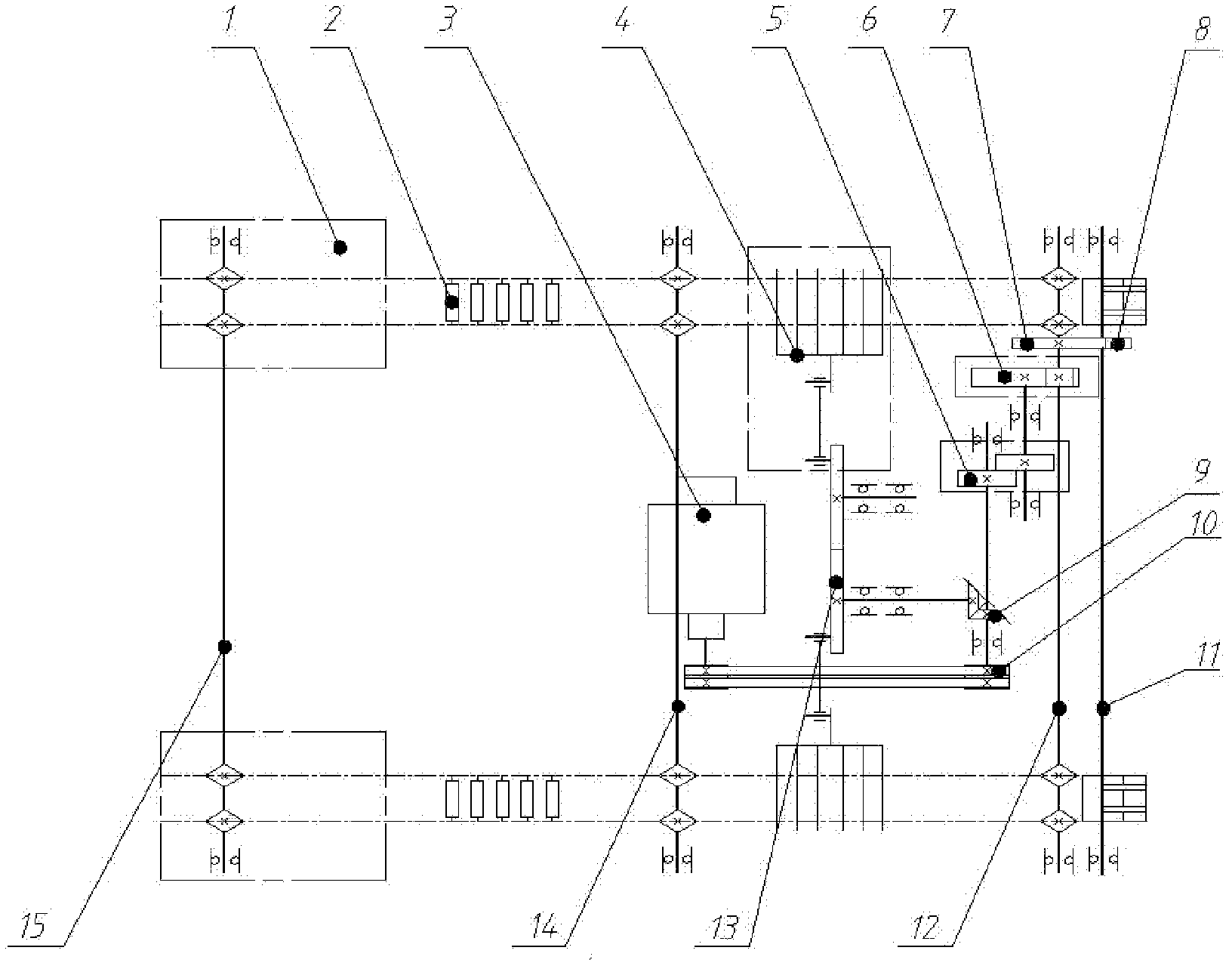

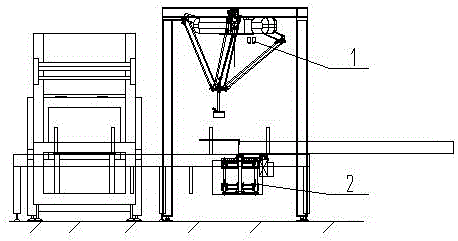

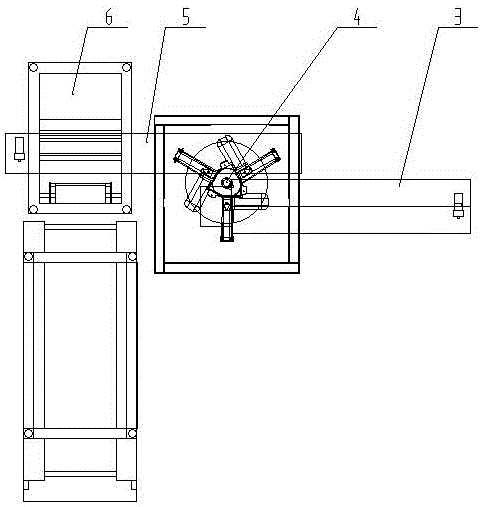

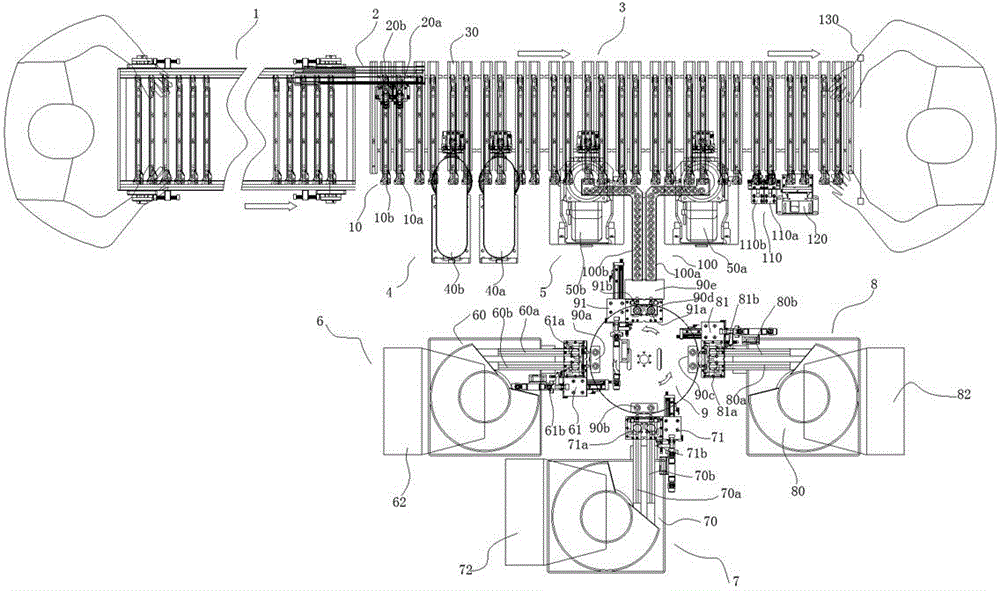

Automatic feeding and discharging machine for soft pack lithium batteries

ActiveCN107082243AEnsure consistencyReduce manual operationsFinal product manufactureStacking articlesLogistics managementElectrical battery

An automatic feeding and discharging machine for soft pack lithium batteries comprises a rack, a pallet stack demolishing and conveying unit, a speed chain conveyor unit, a pallet feeding and discharging manipulator unit, a battery code scanning and rotating unit, a bad battery unit, a waterwheel feeding and discharging manipulator unit, a battery transfer waterwheel and a controller. The pallet stack demolishing and conveying unit, the speed chain conveyor unit, the pallet feeding and discharging manipulator unit, the battery code scanning and rotating unit, a bad battery station, the waterwheel feeding and discharging manipulator unit, the battery transfer waterwheel and the controller are all mounted on the rack. All the units are connected with the controller in a signal manner. The automatic feeding and discharging machine has the beneficial effects that by means of the automation scheme, battery turnover and data acquisition are integrated into one set of system, the manual operation is reduced, the production efficiency is improved, and the consistency of the batteries is guaranteed; the state information of the batteries is looked for at the right moment; and the conveyor line mode is adopted and can be docked with the logistics line and equipment such as a palletizing machine.

Owner:ZHEJIANG HANGKE TECH

Thermolytic distillation of carbonaceous material

InactiveUS6051110AEquipment is cheapEasy to adaptCharging-discharging device combinationsPreheating coke ovensDistillationClosed loop

In apparatus for thermolytic distillation of lump carbonaceous material, an enclosure contains a degassing bath, a reactor bath and a quenching bath. A closed loop continuous chain conveyor drives a plurality of baskets carrying carbonaceous material through the three baths of the enclosure. The carbonaceous material is degassed in hot distillate, then immersed in molten lead in the absence of oxygen to produce char and vapor by thermolytic distillation. The char is quenched with water in the absence of oxygen. At least a portion of the vapor is condensed to produce combustible distillate.

Owner:TERRAMEX

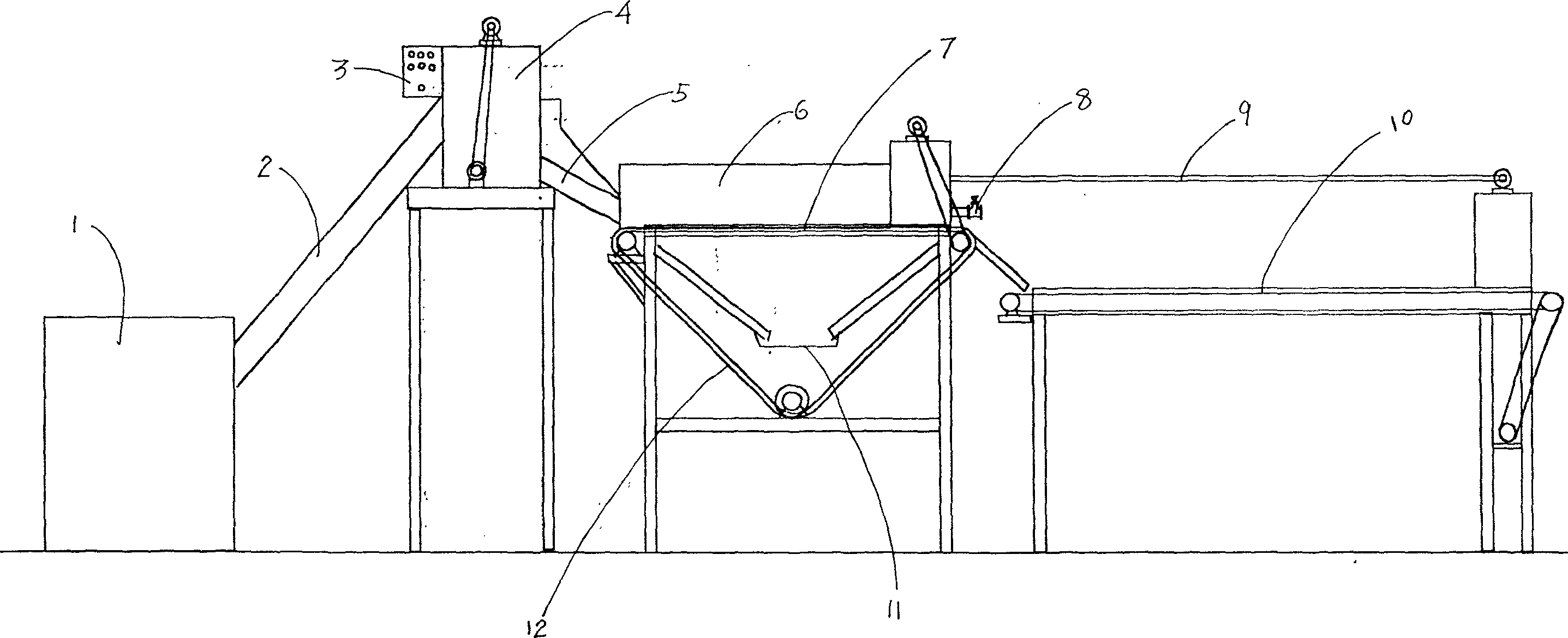

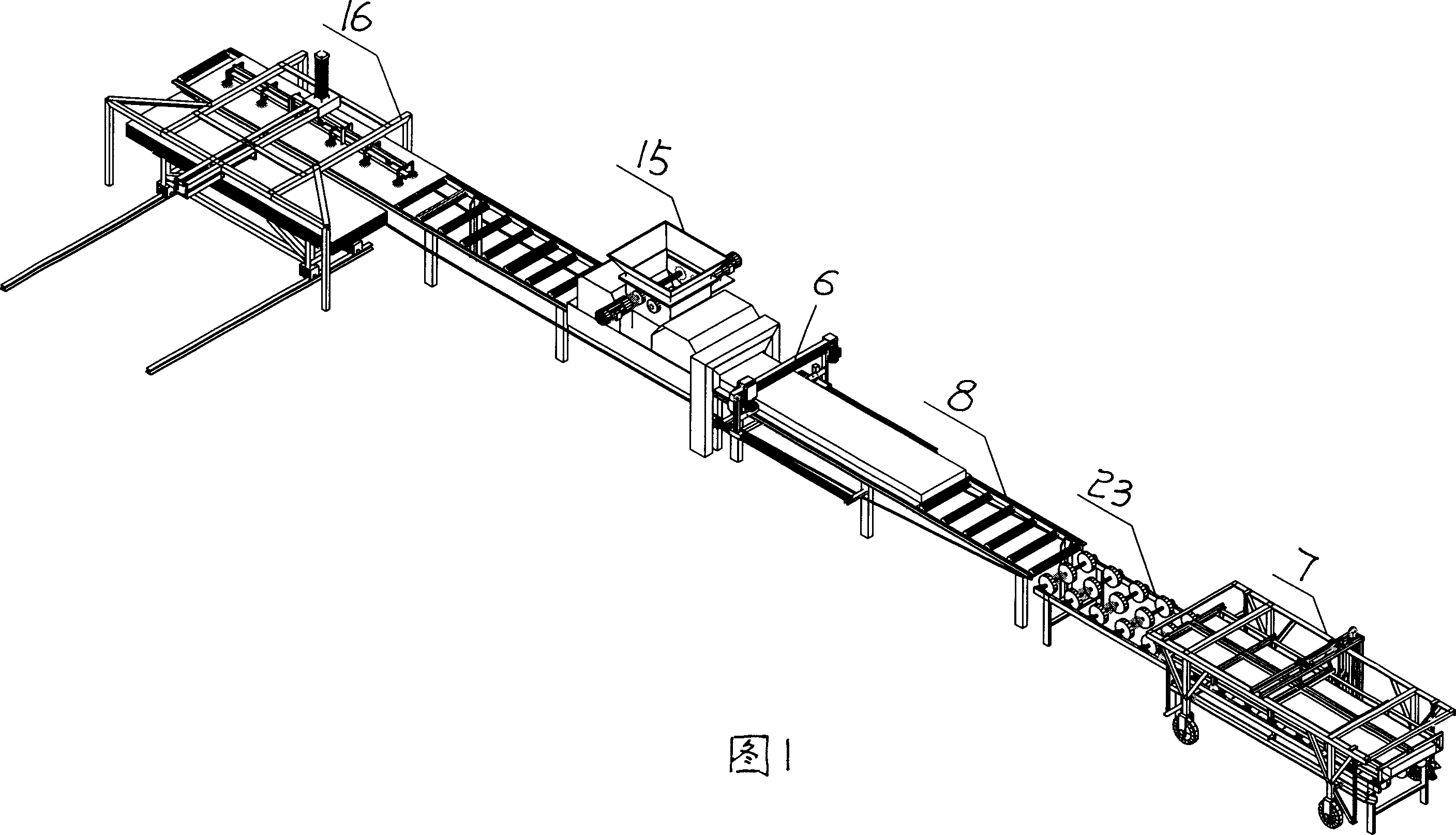

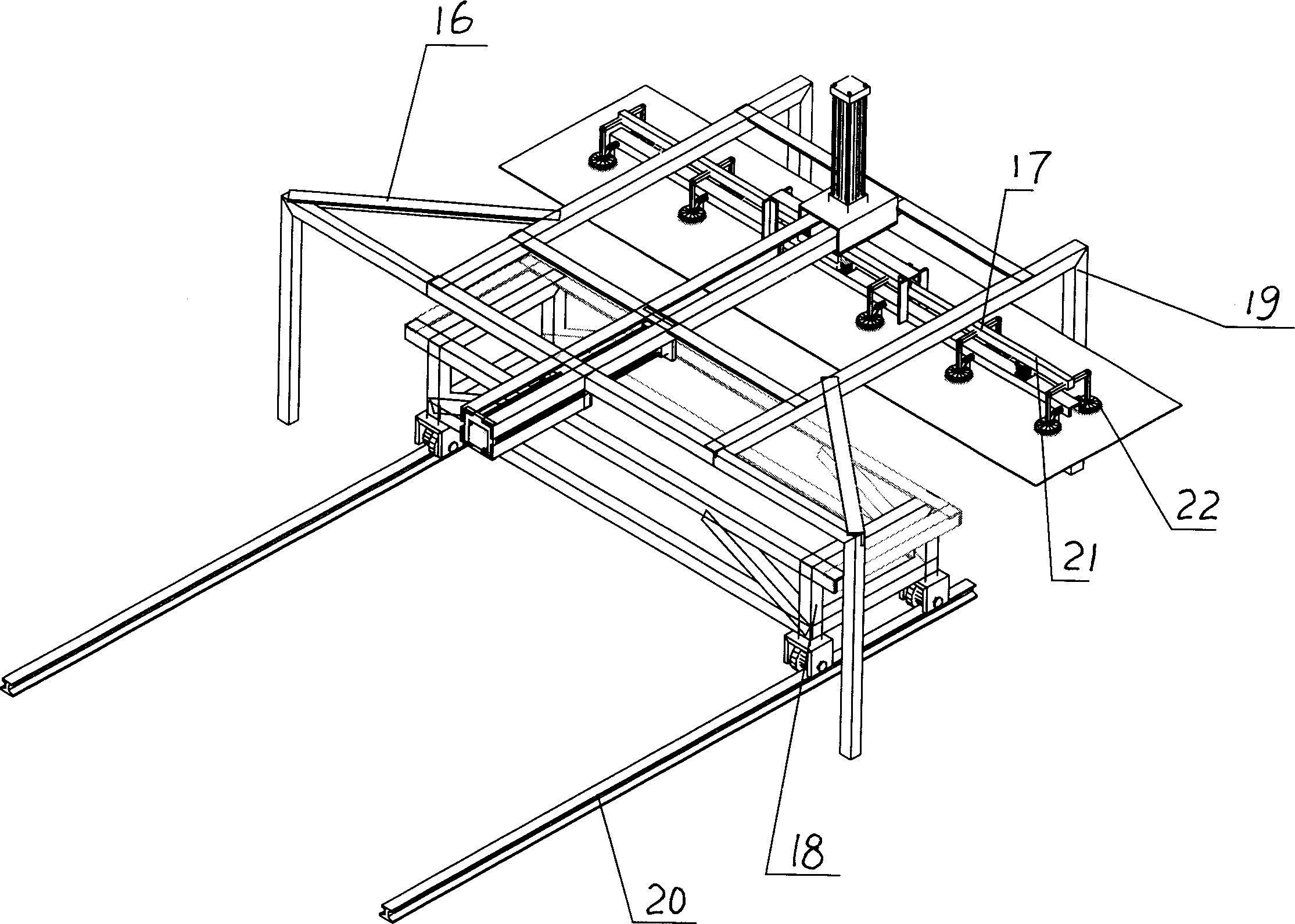

Light weight wall board production technology and equipment complex thereof

InactiveCN1730259AOvercome the high priceSmall investmentShaping conveyorsProduction lineChain conveyor

A productive technology of light wallboard and complete sets of equipment comprise extrusion worm presses and other devices: A. upper trigger, B. chain delivery machine. C. Synchronous cut-off machine, D. glidewheel conveyer, E. lower trigger. The invention overcomes the defects of needing moving host machine when extrusion worm presses producting wallboard, needing large production field, investing greatly in field building, and not facilitating to product automation scope production. Meanwhile, it also overcomes the defects of the high price of the device introduced from foreign, the large investment, and the bad adaptation. Automatic production line of the invention possesses host machine fixing, making template move through chain-driven which is controlled, so the consistency of production is enhanced, quality is steady and reliable, the wallboard production is accomplished to produce on full-automatic flow line, price is cheap and quality is high, and it is adaptive for every kinds of building material producing enterprise to invest. The invention is mainly used in producing light wallboard used in building material.

Owner:周正华 +1

Special-shaped tobacco carton automatic stacking and packing method

InactiveCN106742281AImplement the rotation functionReduce run pathConveyorsControl devices for conveyorsCartonOrder form

The invention discloses a special-shaped tobacco carton automatic stacking and packing method. The method comprises the following steps: 1) order data is read, and a corresponding relation between a stacking manipulator and sorting system real-time orders is set; 2) tobacco cartons are conveyed to the end part of a tobacco carton conveying device and stopped on a baffle plate; 3) a camera and a light source are triggered to shoot; and data of the tobacco cartons is transmitted to the stacking manipulator; 4) according to the orders and the tobacco carton size data, the stacking manipulator grabs the tobacco cartons to stack on a lifting mechanism in sequence; and tobacco stacks are lifted to reach a chain conveyor; 5) the chain conveyor conveys the tobacco stacks to a packing machine for plastic packing; and 6) a labeling machine prints information of the tobacco cartons and labeling time. The method has the following advantages: the method can realize automatic detection, automatic stacking and automatic packing of the special-shaped tobacco cartons according to real-time sorting data; the stacking manipulator can realize the grabbing stability and efficiency; the lifting mechanism shortens the path of the stacking manipulator to improve the stacking efficiency; and the chain conveyor adopts a poking plate form to convey the tobacco stacks, and is provided with multiple poking plates for improving the stacking efficiency.

Owner:ETABONG QINGDAO TOBACCO MACHINERY

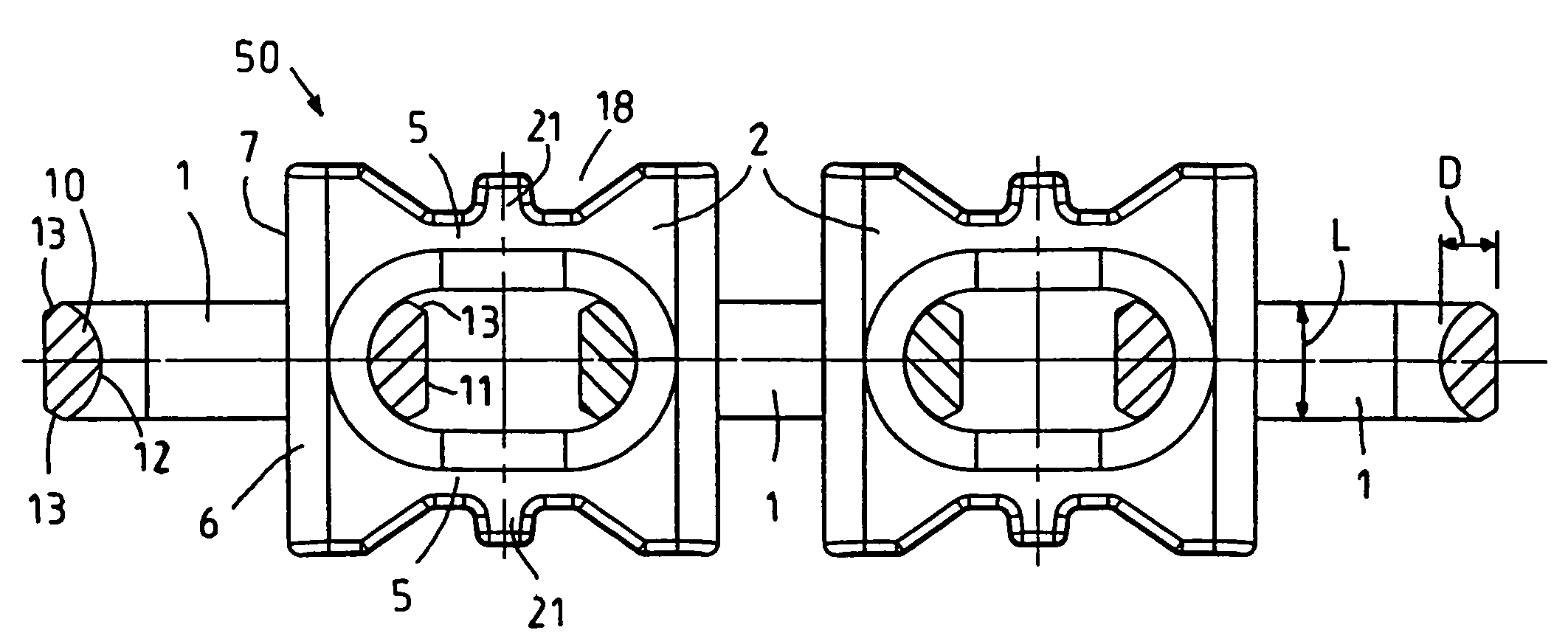

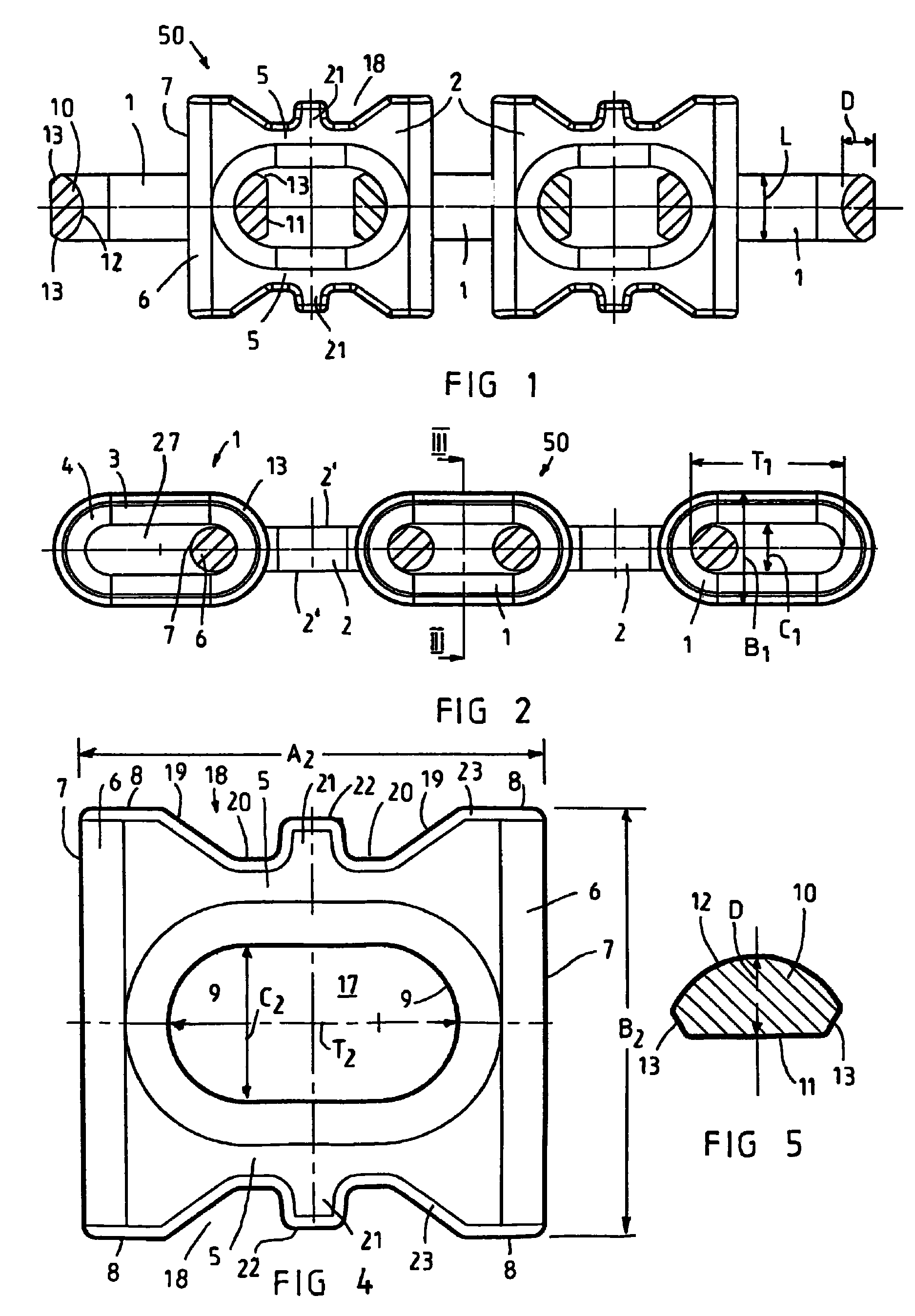

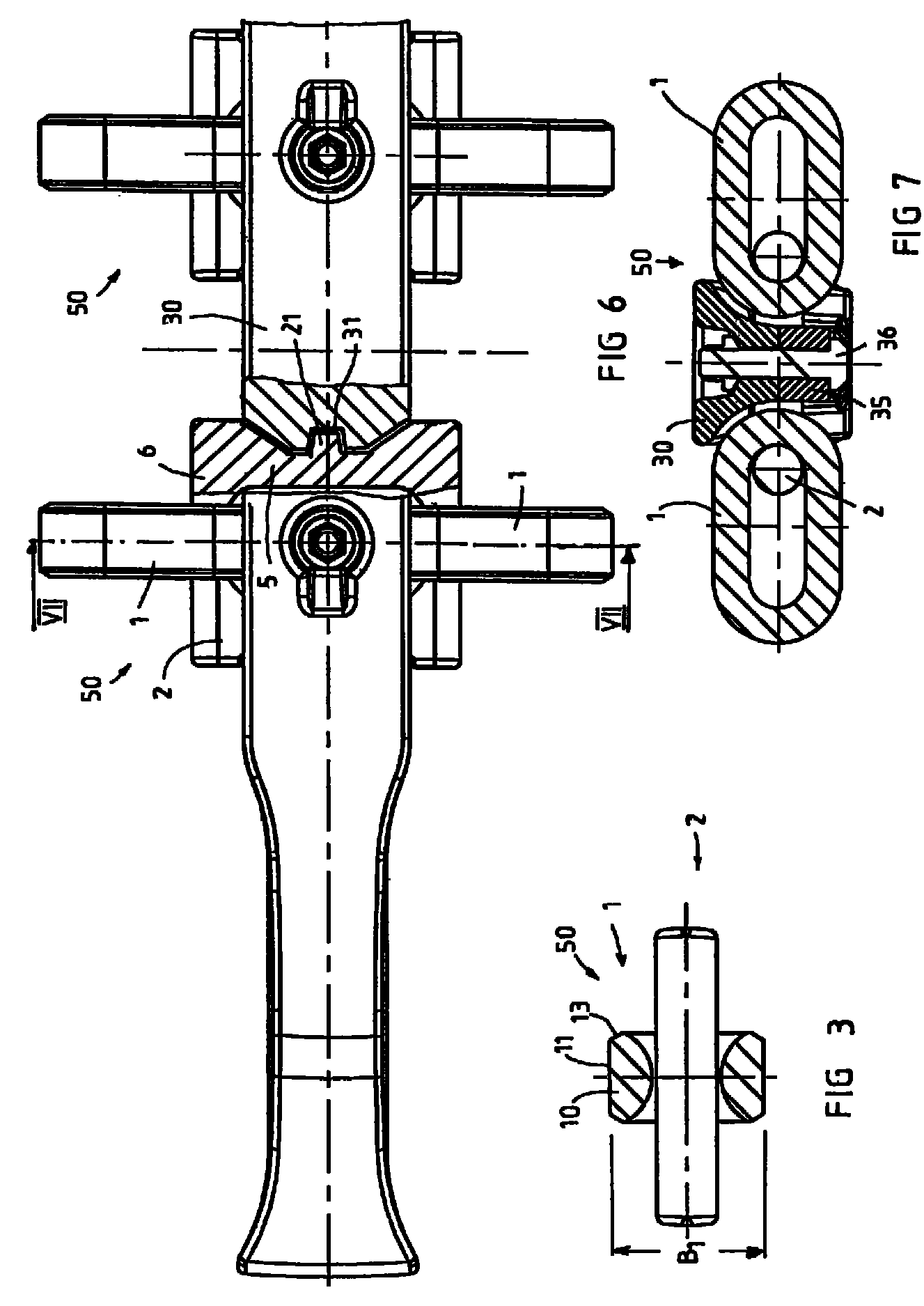

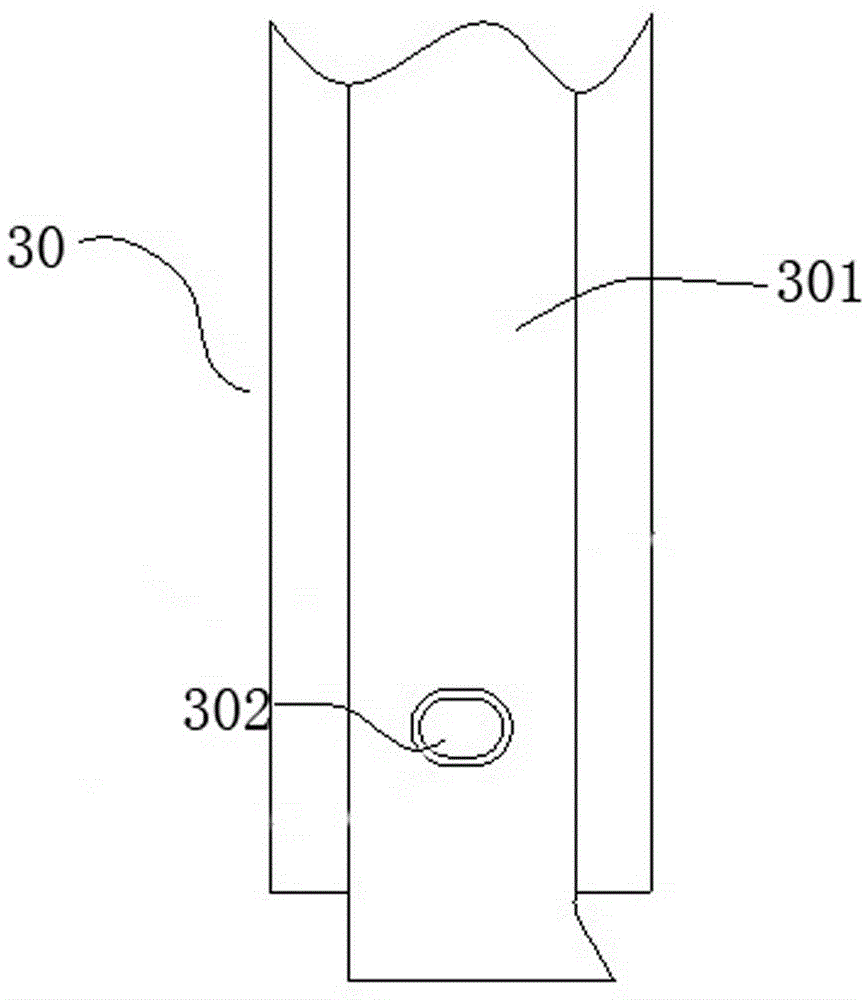

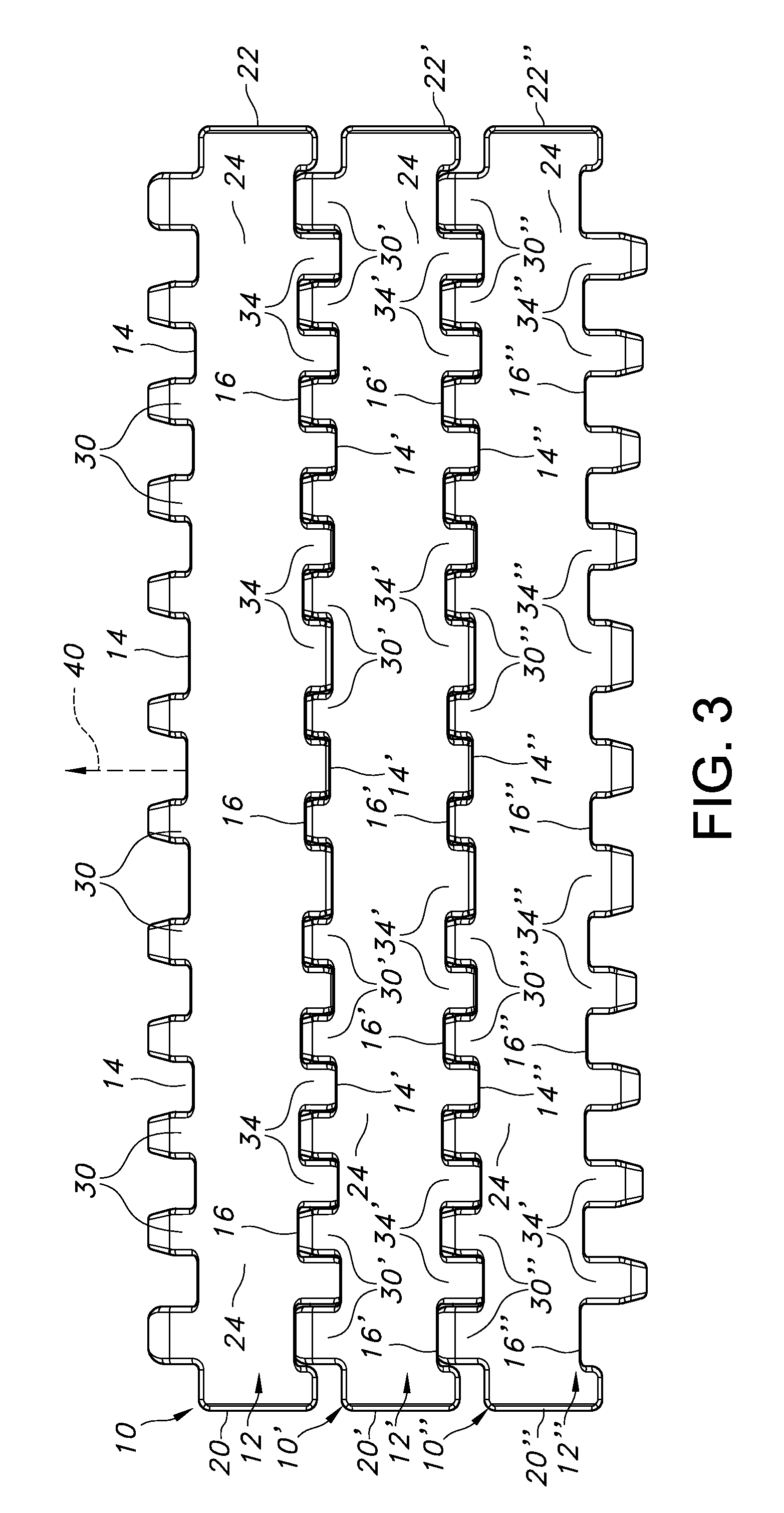

Link chain for chain conveyors and chain wheel thereof

ActiveUS7997402B2Easy to useGood load running characteristicConveyorsGearing elementsSprocketChain conveyor

Owner:CATERPILLAR INC

Fruit weighing and sorting system

InactiveCN103157606ARealize automatic controlHigh precisionSortingAutomatic controlAgricultural engineering

The invention relates to the field of agricultural machines and especially relates to a fruit weighing and sorting system. The fruit weighing and sorting system comprises a chain-type conveyer, fruit cups, operation guide rails, a weighing mechanism, a discharging mechanism and a controller. Hinged ends of the fruit cups are connected to two parallel chains of the chain-type conveyer by articulated shafts. Gaps allowing upward / downward movement are formed between the fruit cups and the articulated shafts. The discharging mechanism is arranged at a gap of the operation guide rails. The weighing mechanism is connected to the controller. The controller is connected to the discharging mechanism. The fruit weighing and sorting system realizes automatic control of fruit weighing and sorting, has a high weighing and sorting precision and a high automation degree, and saves a manpower cost.

Owner:CHINA AGRI UNIV

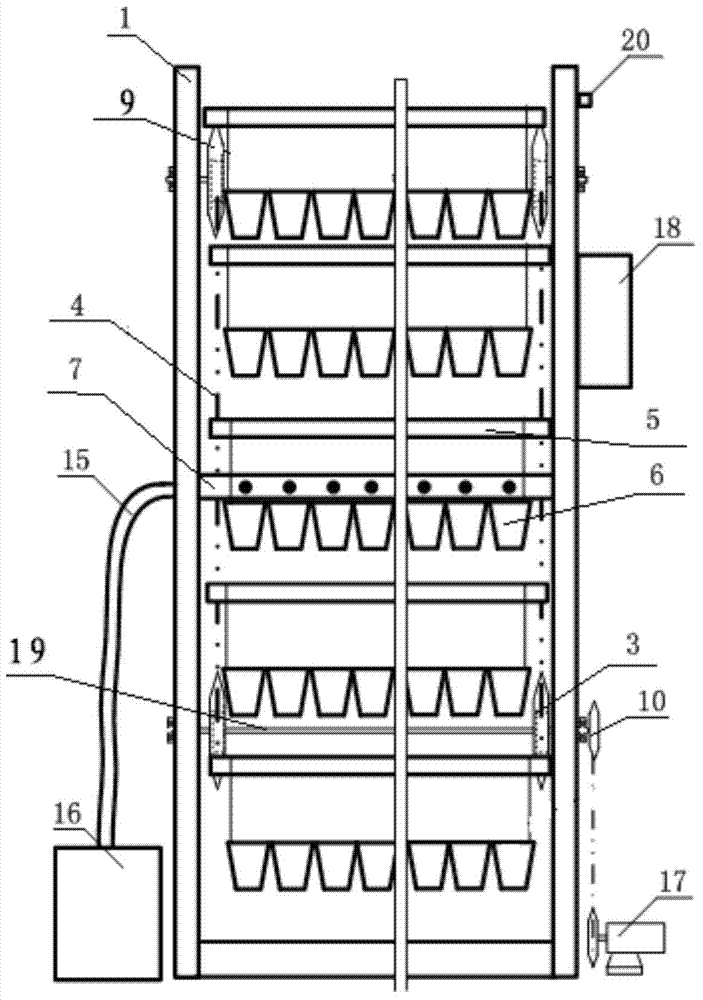

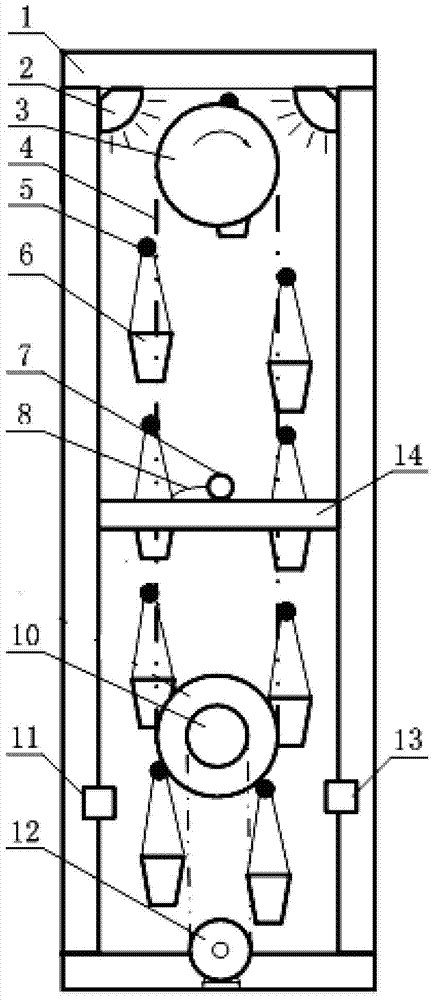

Three-dimensional rotating cultivation device

ActiveCN103477894AAchieve uniformityMeet uniformityGreenhouse cultivationReceptacle cultivationEngineeringChain conveyor

The invention relates to the field of agricultural machinery, in particular to a three-dimensional rotating cultivation device which comprises a support and a chain-type conveying mechanism arranged on the support. Multiple horizontal hanging rods are arranged on the chain-type conveying mechanism, and multiple cultivation containers are hung on each hanging rod. In this way, multiple rows of the cultivation containers are hung on the hanging rods to rotate up and down along with the chain-type conveying mechanism, and plants in the cultivation containers of each row can be rotated to an outer-layer illumination plane to contact with sunlight, so that illumination uniformity of the plants in the cultivation containers can be realized; light supplementing lamps are arranged at positions corresponding to the cultivation containers on the support, so that light supplementing can be performed on the cultivation plants at night, and requirements on illumination uniformity of the plants at night can be met.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

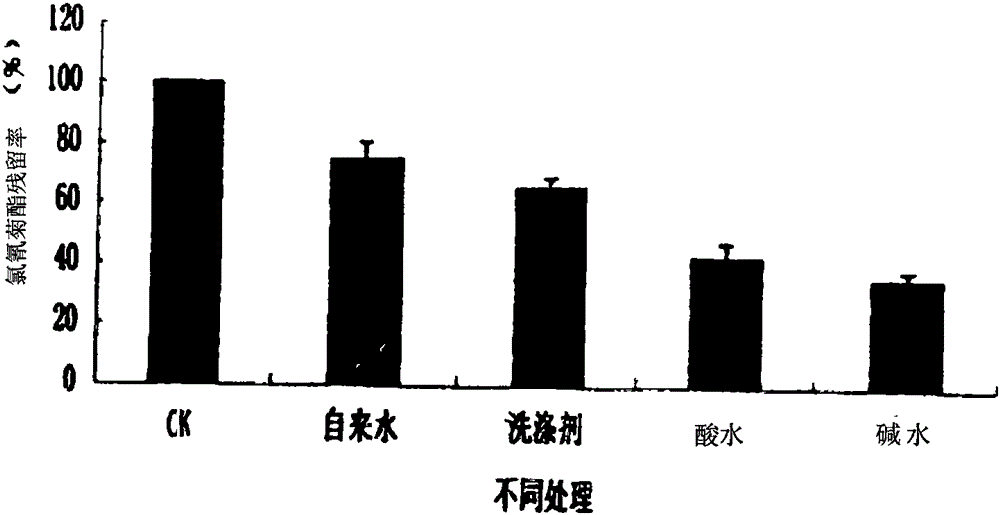

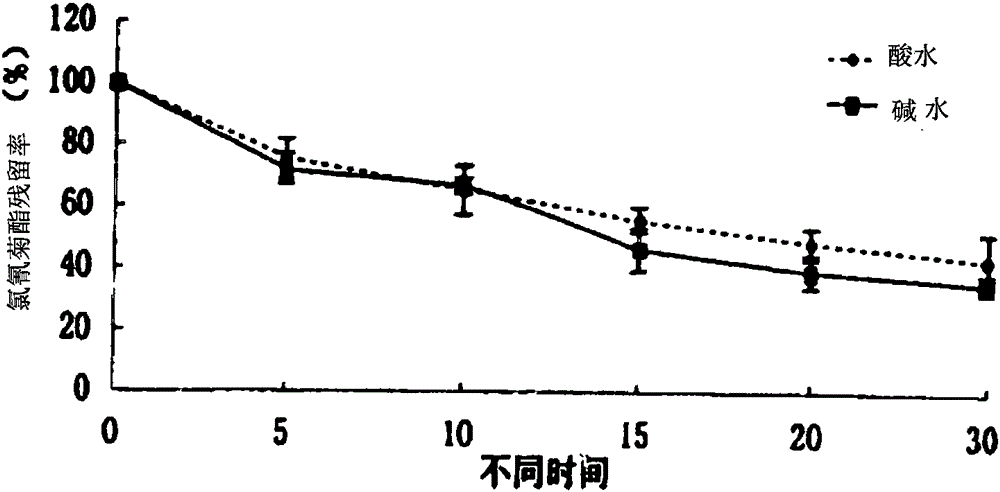

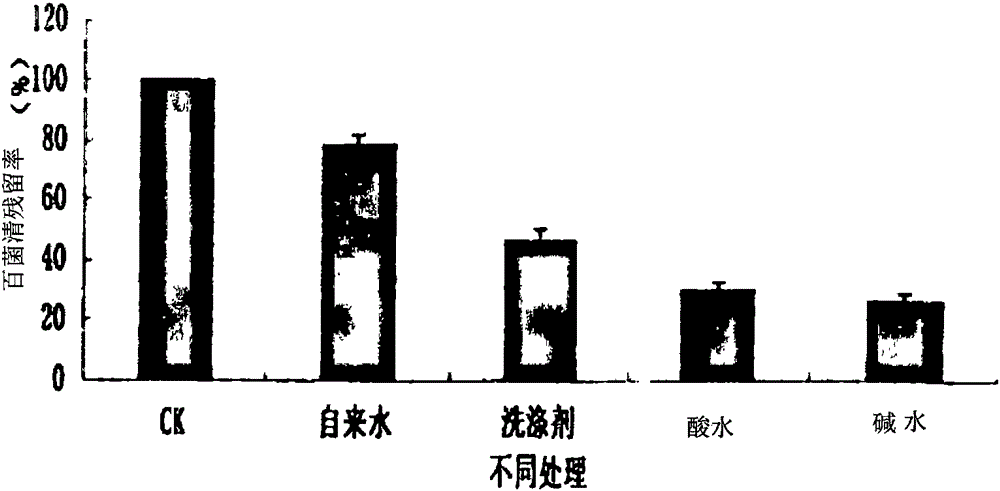

Fruit and vegetable pesticide residue degradation equipment and method based on water magnetization and electrolysis technology

PendingCN105707660ADrug resistanceChange in permeabilityFood scienceElectrolysed waterPesticide residue

The invention discloses fruit and vegetable pesticide residue degradation equipment and method based on a water magnetization and electrolysis technology. The equipment comprises a magnetized and electrolysed water producing device and a degradation equipment body, wherein the degradation equipment body comprises a chain conveyor, a plurality of fruit and vegetable placement cages suspended below a rail of the chain conveyor at equal intervals as well as acidic potential water tank sets, alkaline potential water tank sets and pure water tanks which are sequentially arranged below the rail; the magnetized and electrolysed water producing device is connected with the acidic potential water tank sets and the alkaline potential water tank sets through liquid conveying pipes respectively; a plurality of slow descending platforms corresponding to the acidic potential water tank sets, the alkaline potential water tank sets and the pure water tanks are further arranged on the rail. By means of the characteristics of magnetized and electrolysed water, pesticide residues on fruits and vegetables can be degraded rapidly and efficiently, and the equipment is environment-friendly and reliable in the degradation process and is very suitable for large-scale degradation of fruit and vegetable pesticide residues.

Owner:李仲秋 +2

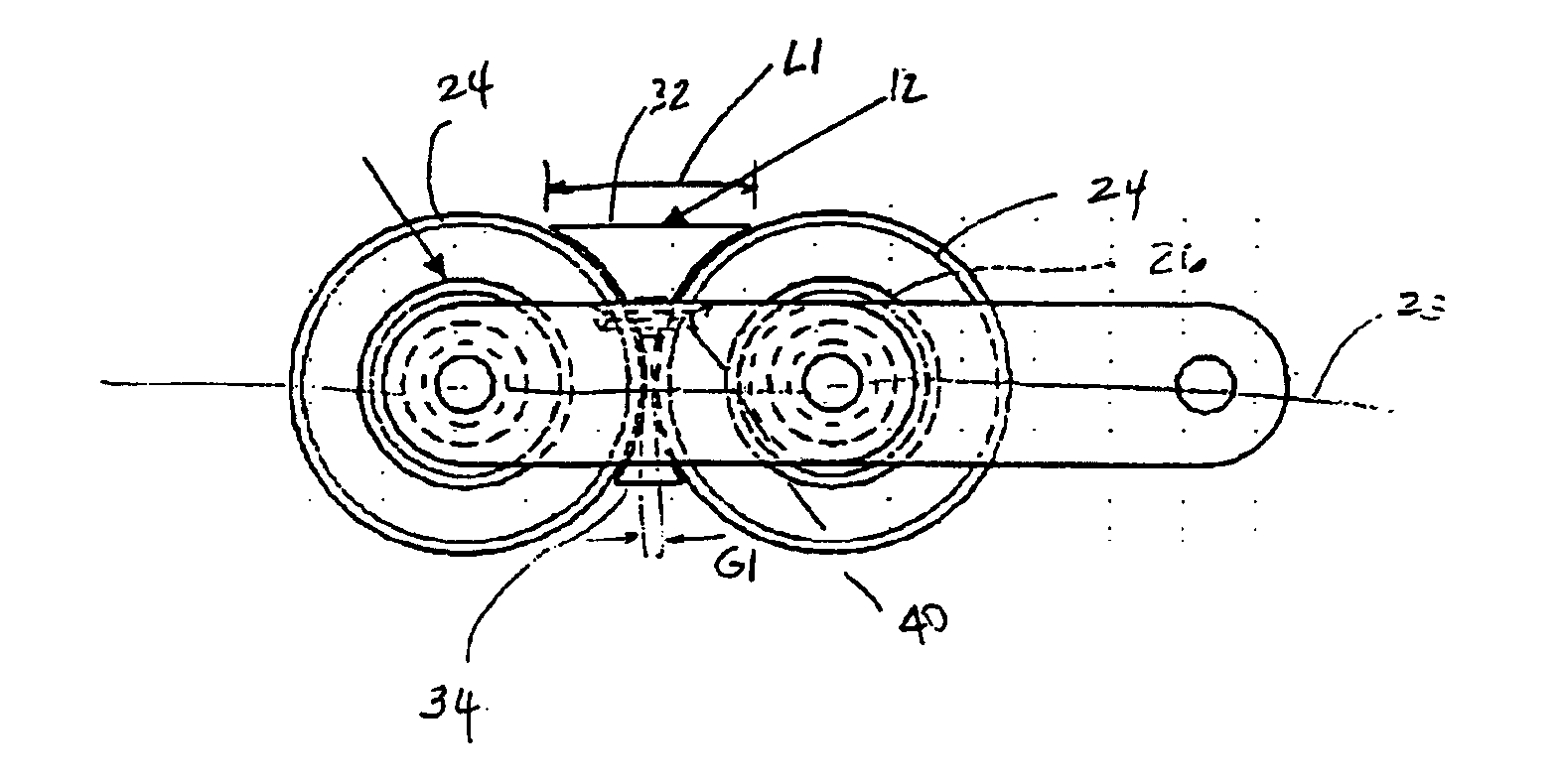

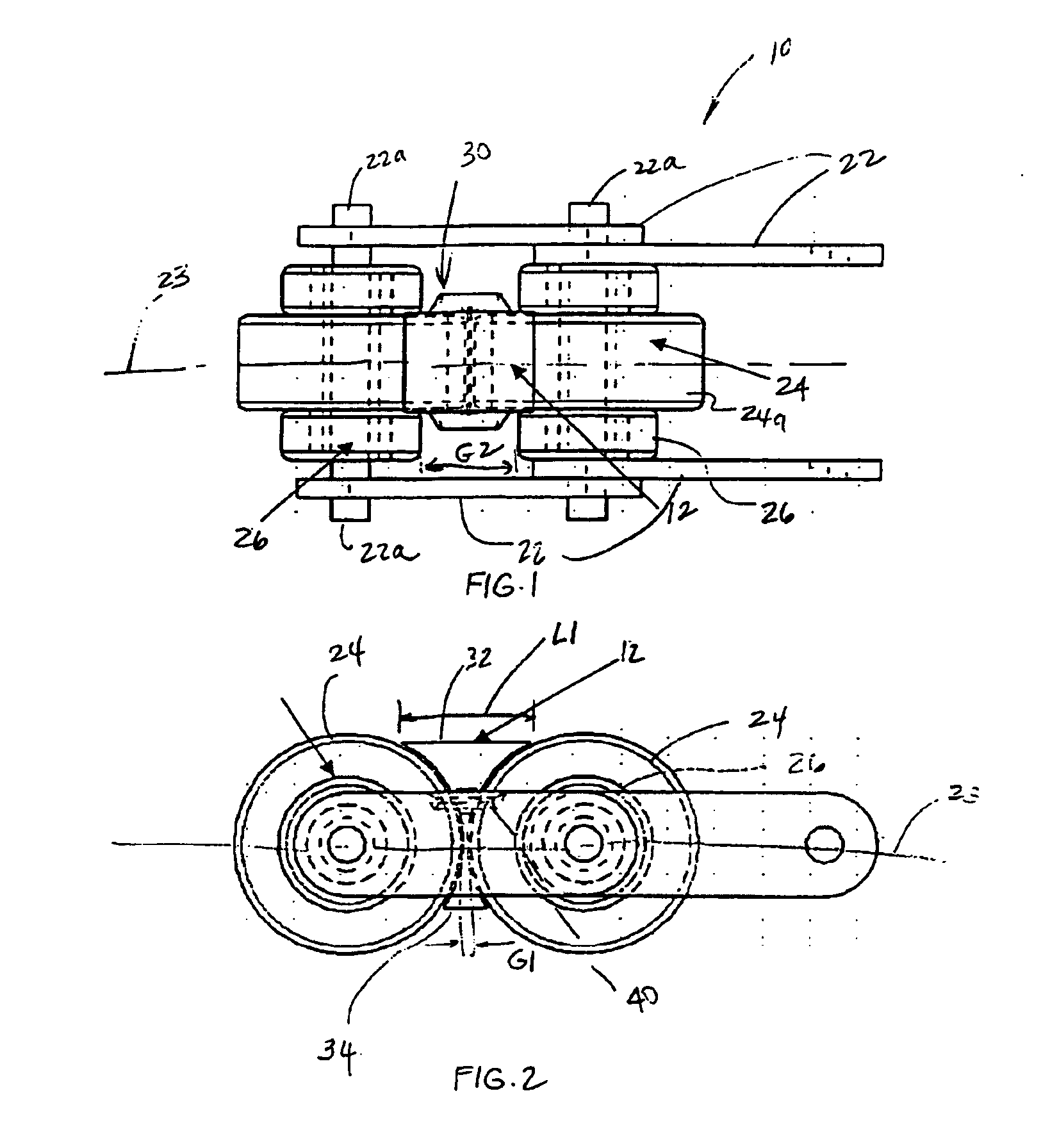

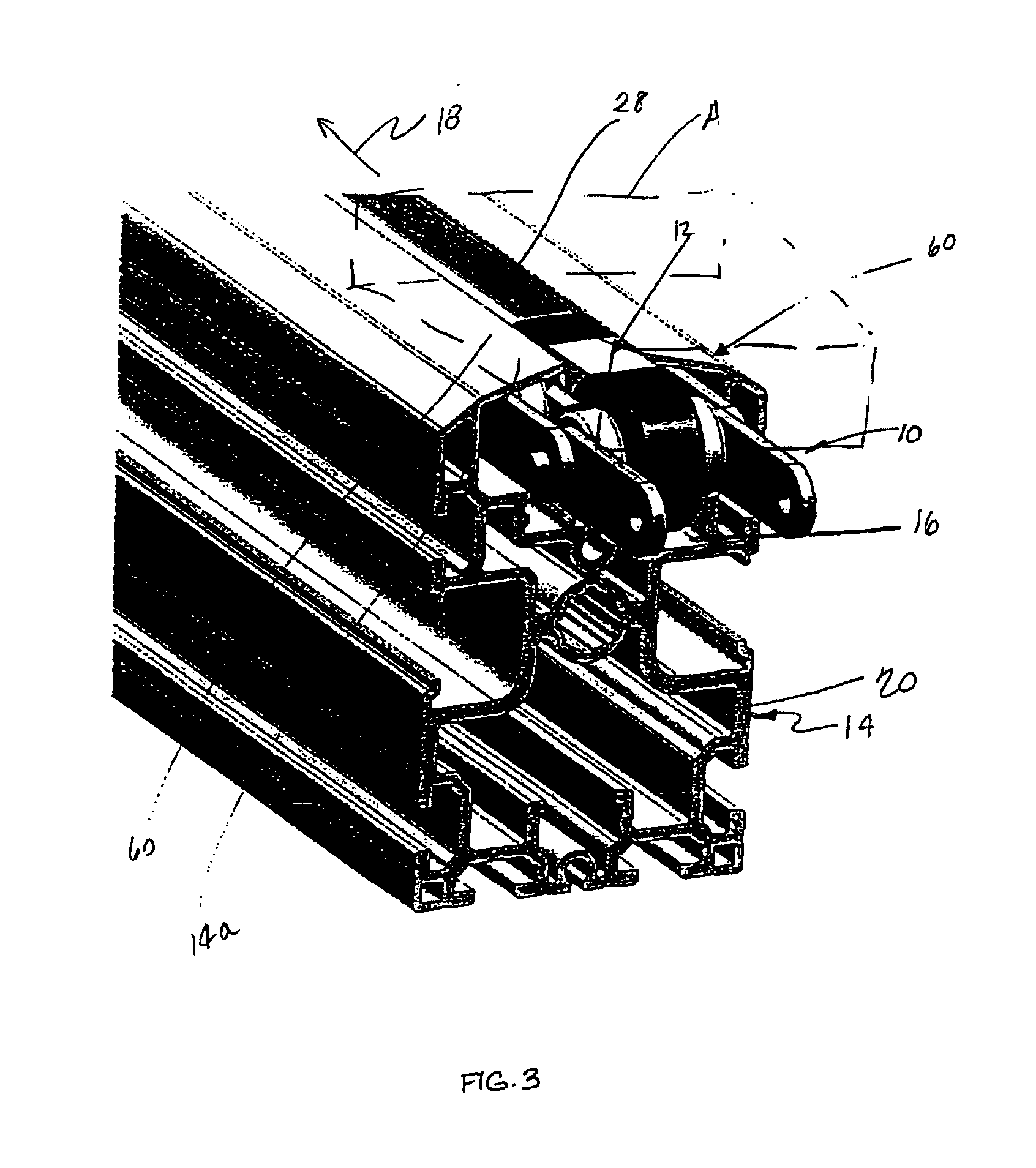

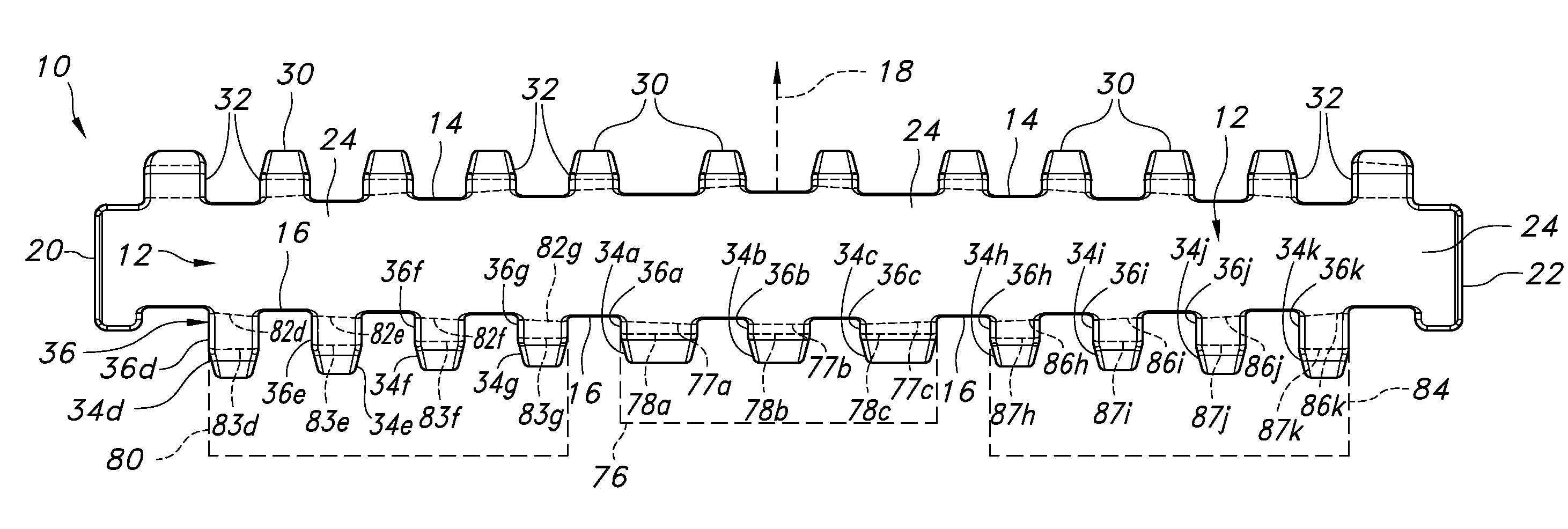

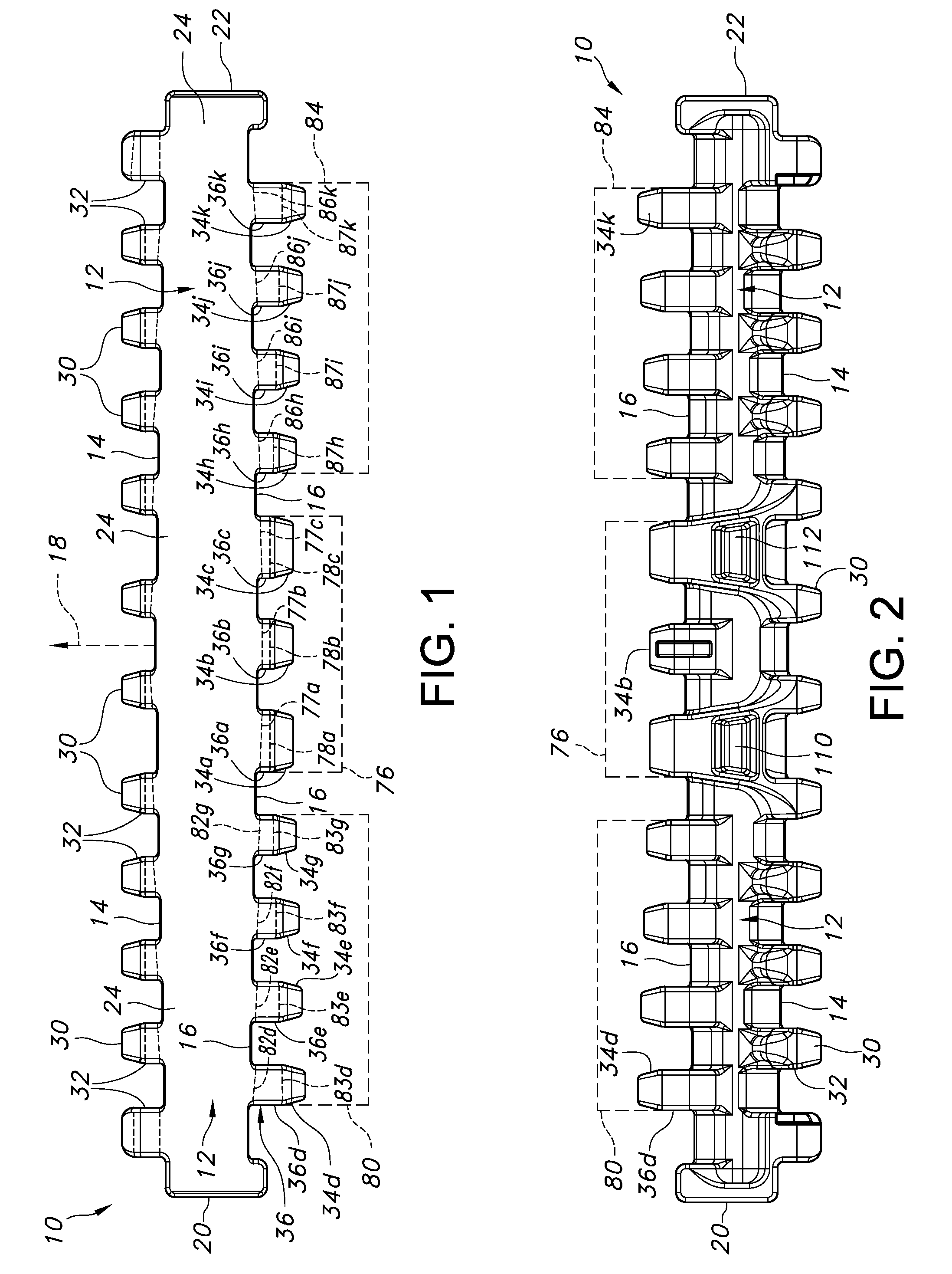

Chain conveyor and clip

A chain conveyor includes a plurality of load rollers, a plurality of drive rollers, which are arranged in pairs, and a pair of spaced apart rows of interconnecting linkages aligned generally parallel to the longitudinal axis of the chain conveyor. The load rollers and the drive rollers are rotatably mounted between the linkages with the load rollers positioned between the pairs of drive rollers. The diameter of each load roller is larger than the diameter of each drive roller. The load rollers and the drive rollers are spaced along the longitudinal axis wherein the chain conveyor includes gaps between the outer surfaces of adjacent load rollers and between the outer surfaces of adjacent driver rollers. The chain conveyor further includes a clip, which is supported by the load rollers and includes a substantially rigid body, which has an upper surface spanning between the outer surfaces of adjacent load rollers with a length along the longitudinal axis greater than the gap between the adjacent load rollers to thereby substantially close the gap between the adjacent load rollers. The body also includes a lower surface, which spans between the outer surfaces of adjacent load rollers and has a length along the longitudinal axis greater than the gap between the adjacent load rollers to thereby prevent the clip from being ejected from between the adjacent load rollers.

Owner:AUTOMATION & MODULAR COMPONENTS

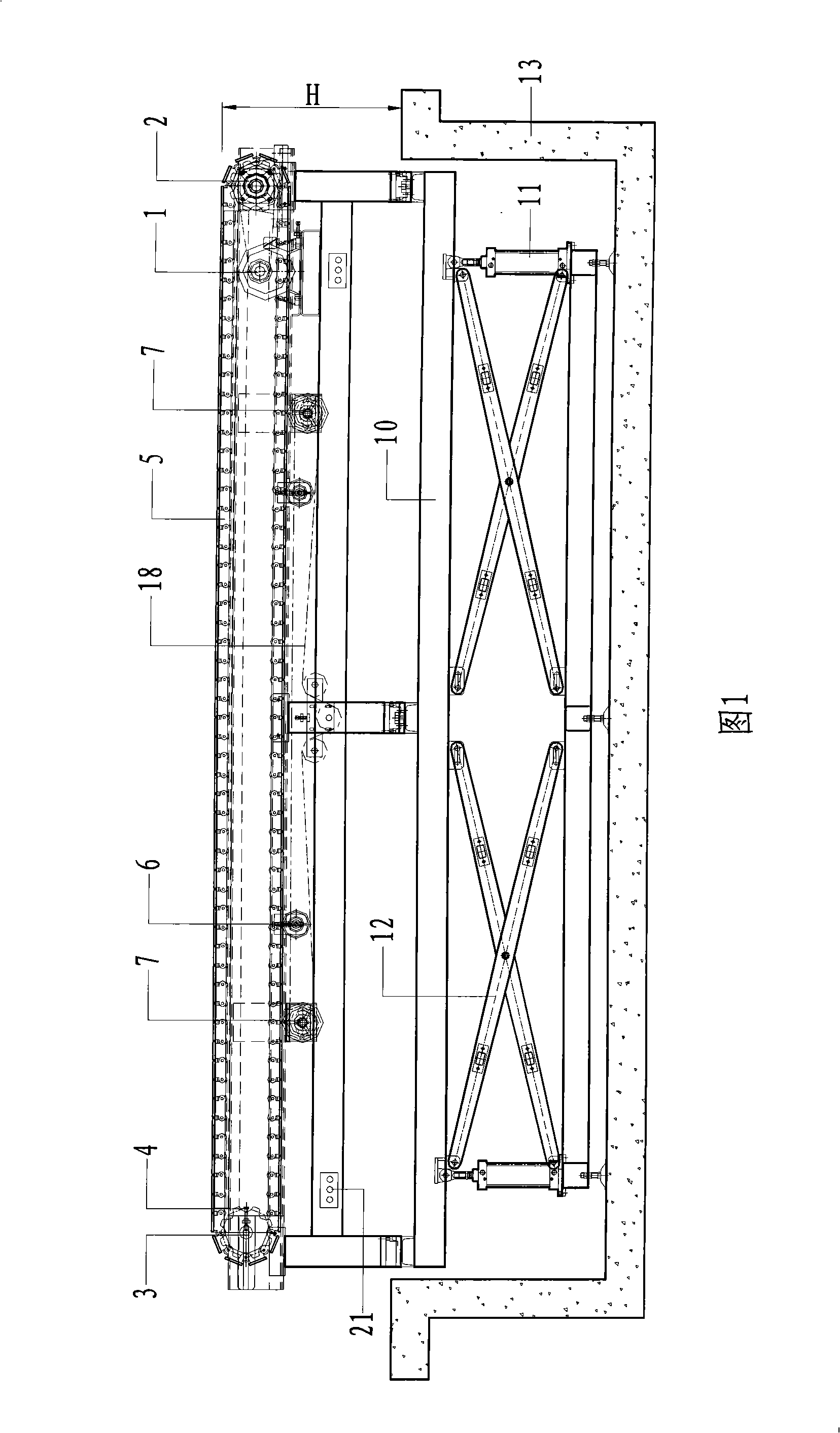

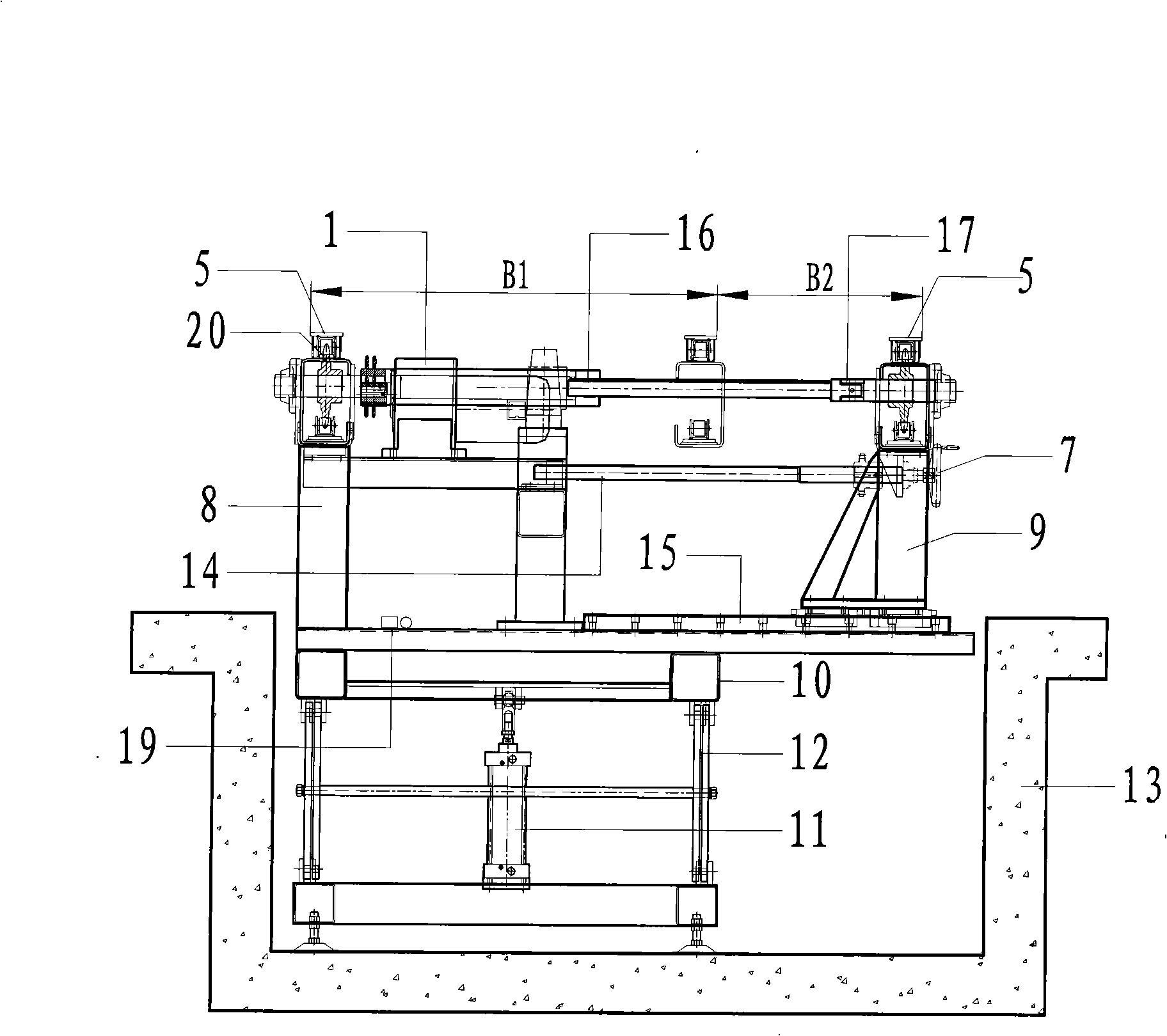

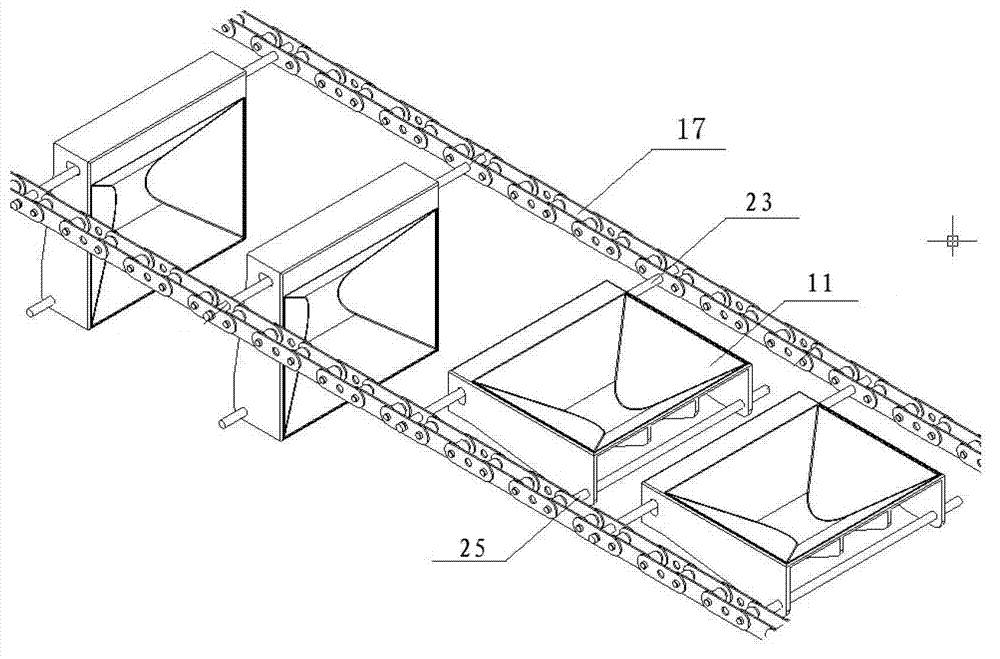

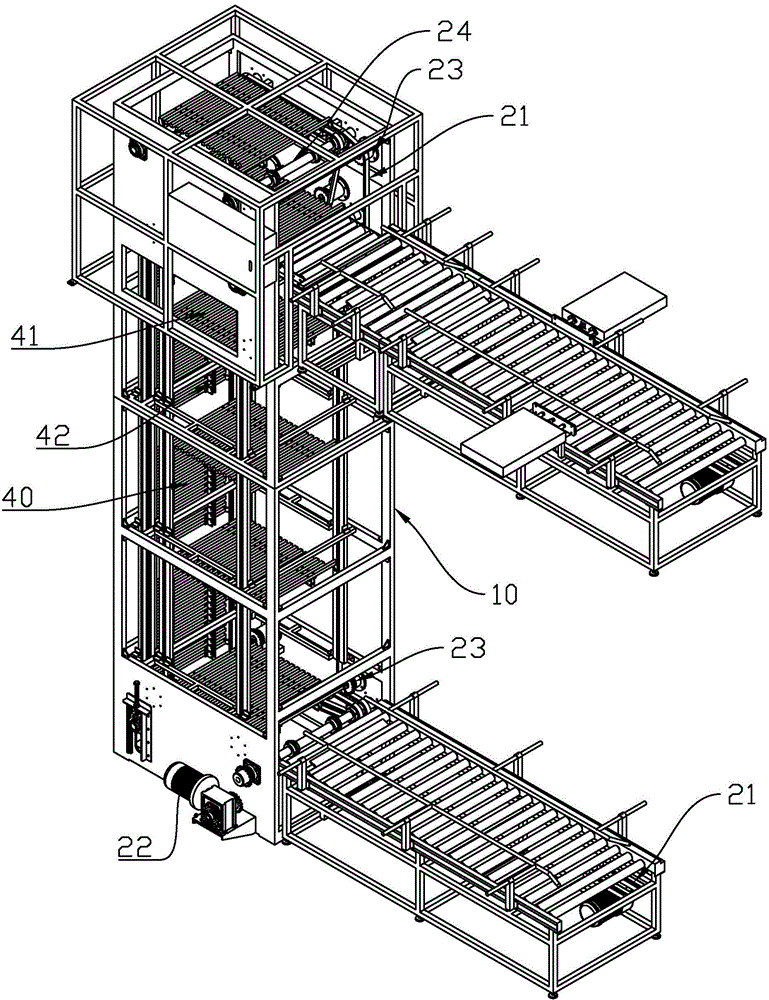

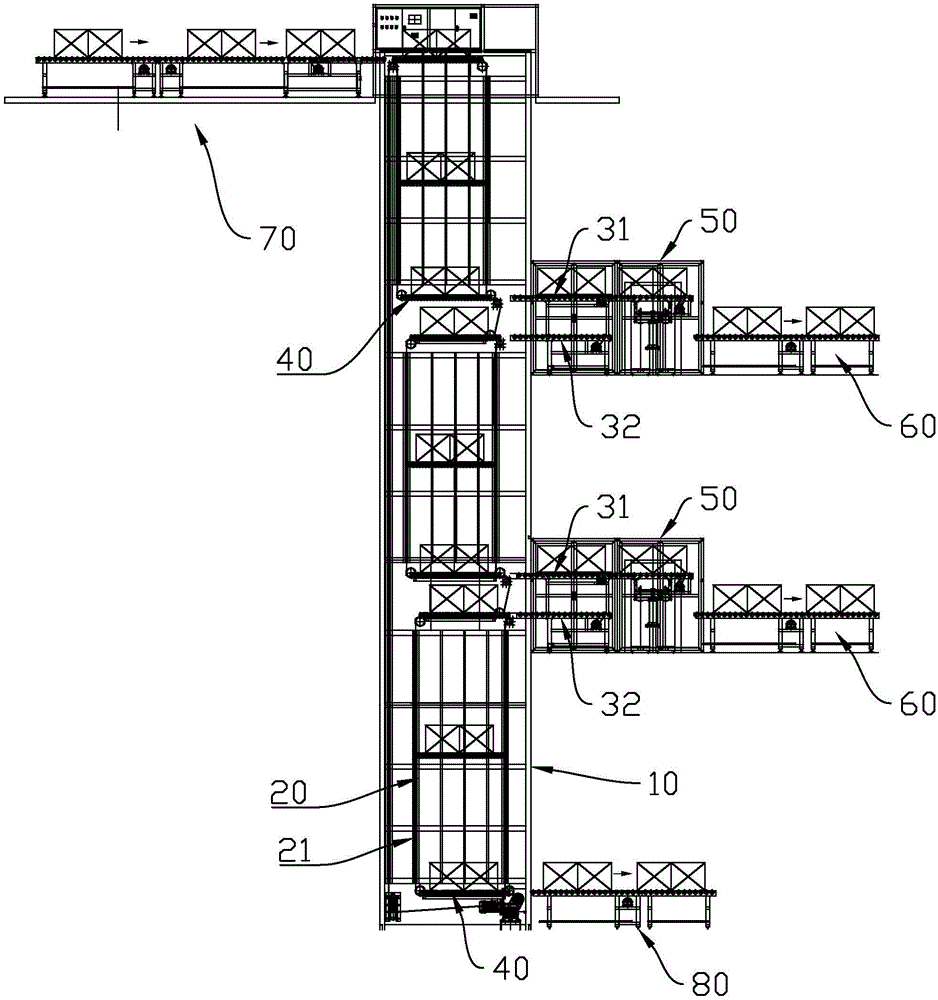

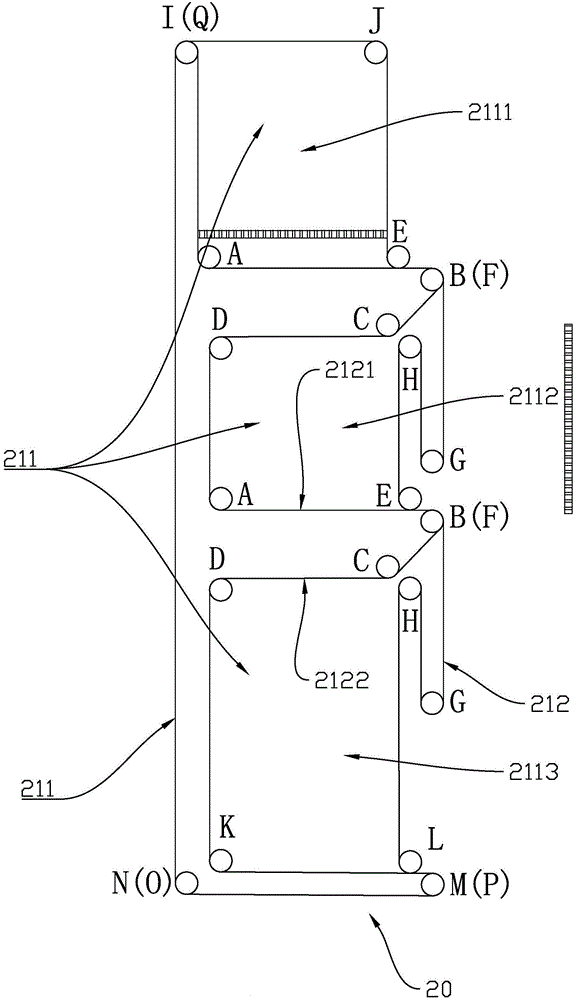

Multilayer interconnection shutter lifting device

ActiveCN104058241ARealize multi-layer interoperable transportationImprove delivery efficiencyConveyor partsMechanical conveyorsButt jointEngineering

The invention relates to a multi-layer interconnection shutter lifting device, which is characterized by comprising a rack, a circulating chain conveyor, a connecting platform and pallets. The circulating chain conveyor comprises symmetrically arranged circulating conveying chains, and each chain is provided with a plurality of vertical conveying sections for vertically conveying articles and a plurality of horizontal conveying sections for horizontally conveying articles, wherein the horizontal conveying section comprises first and second horizontal conveying sections which are arranged up and down in parallel at intervals and have opposite conveying directions, and the connecting platform is respectively butt-jointed with the first and second horizontal conveying sections of each layer; the pallets are sectionally and densely distributed on the chains, and vertically and horizontally convey the articles along the rotation direction of the chains in a circulating way, so that the articles at the vertical conveying section are horizontally conveyed to the first connecting platform through the first horizontal conveying section, the articles on the second connecting platform are vertically conveyed to a first horizontal conveying section at the adjacent layer through the second horizontal conveying section, and the articles can be conveyed between layers in an interconnection way through the vertical conveying and the horizontal conveying of the chains, and thus the articles can be conveyed upwards or downwards to any layer.

Owner:深圳市瑞杰机电工程有限公司

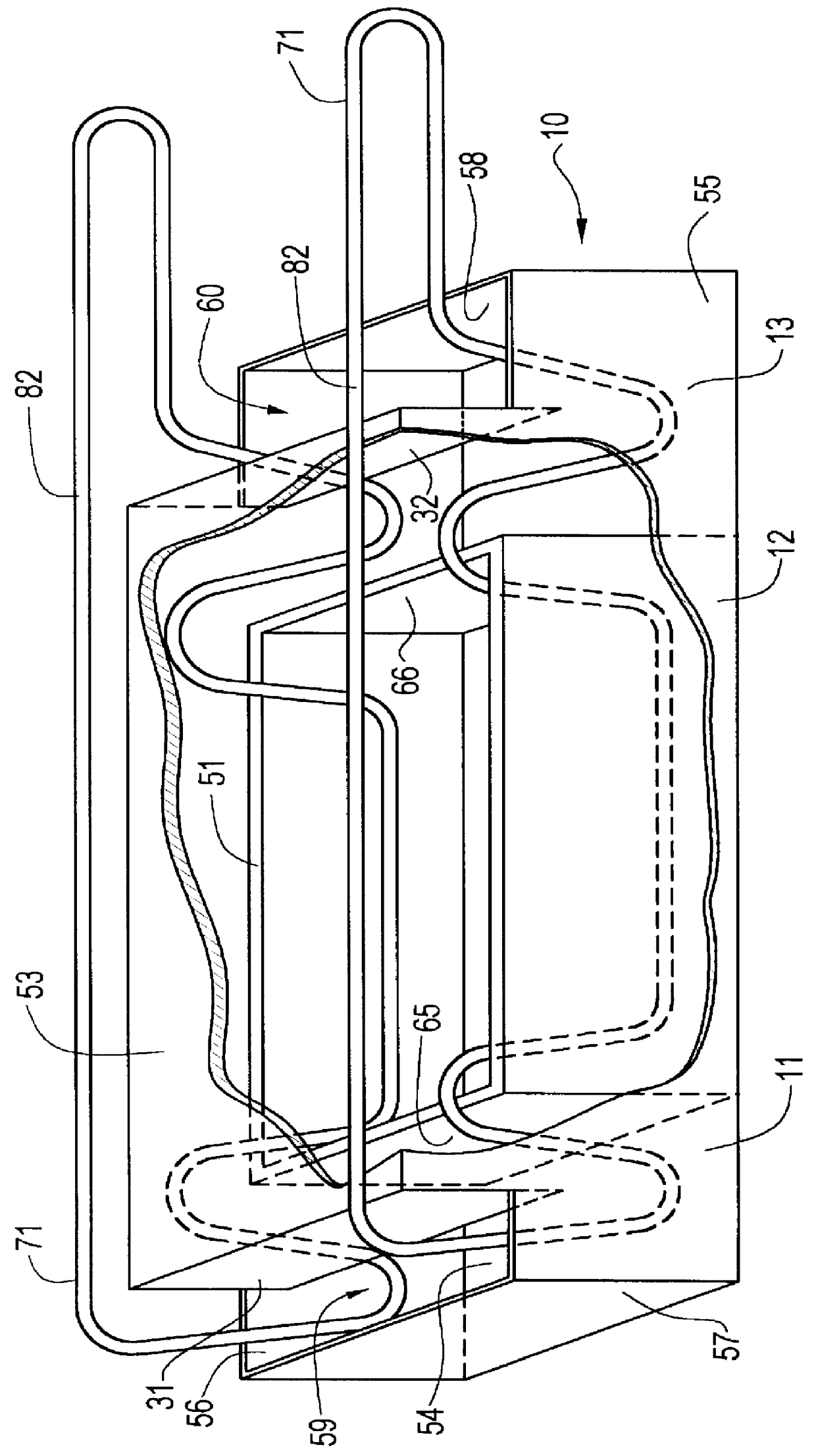

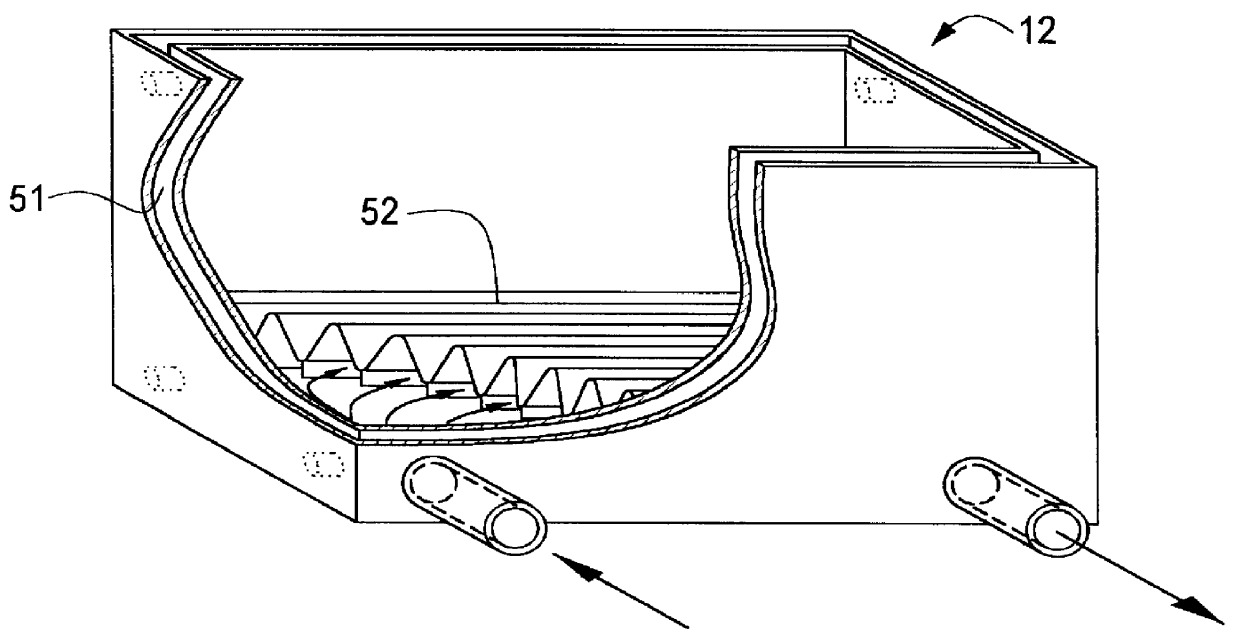

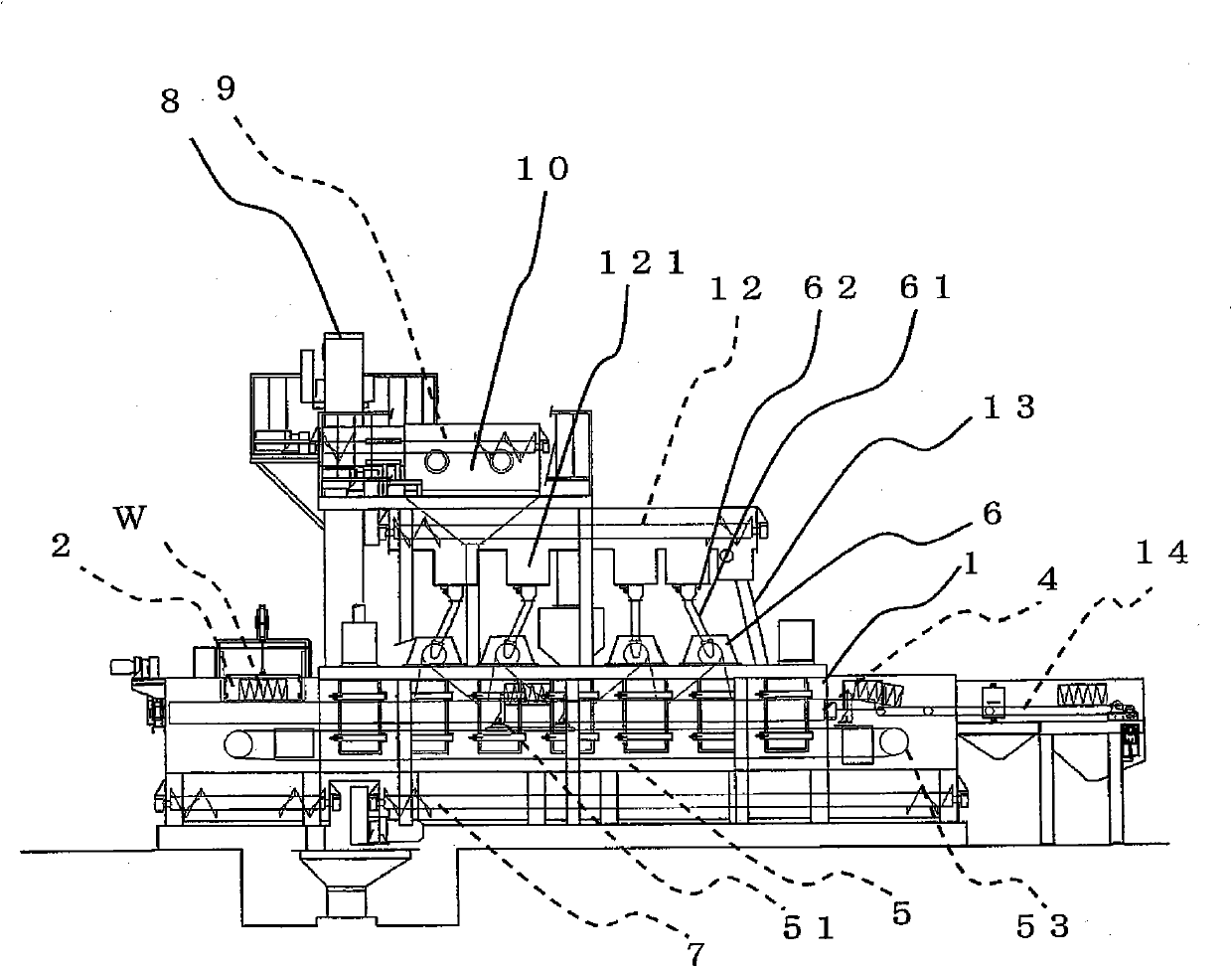

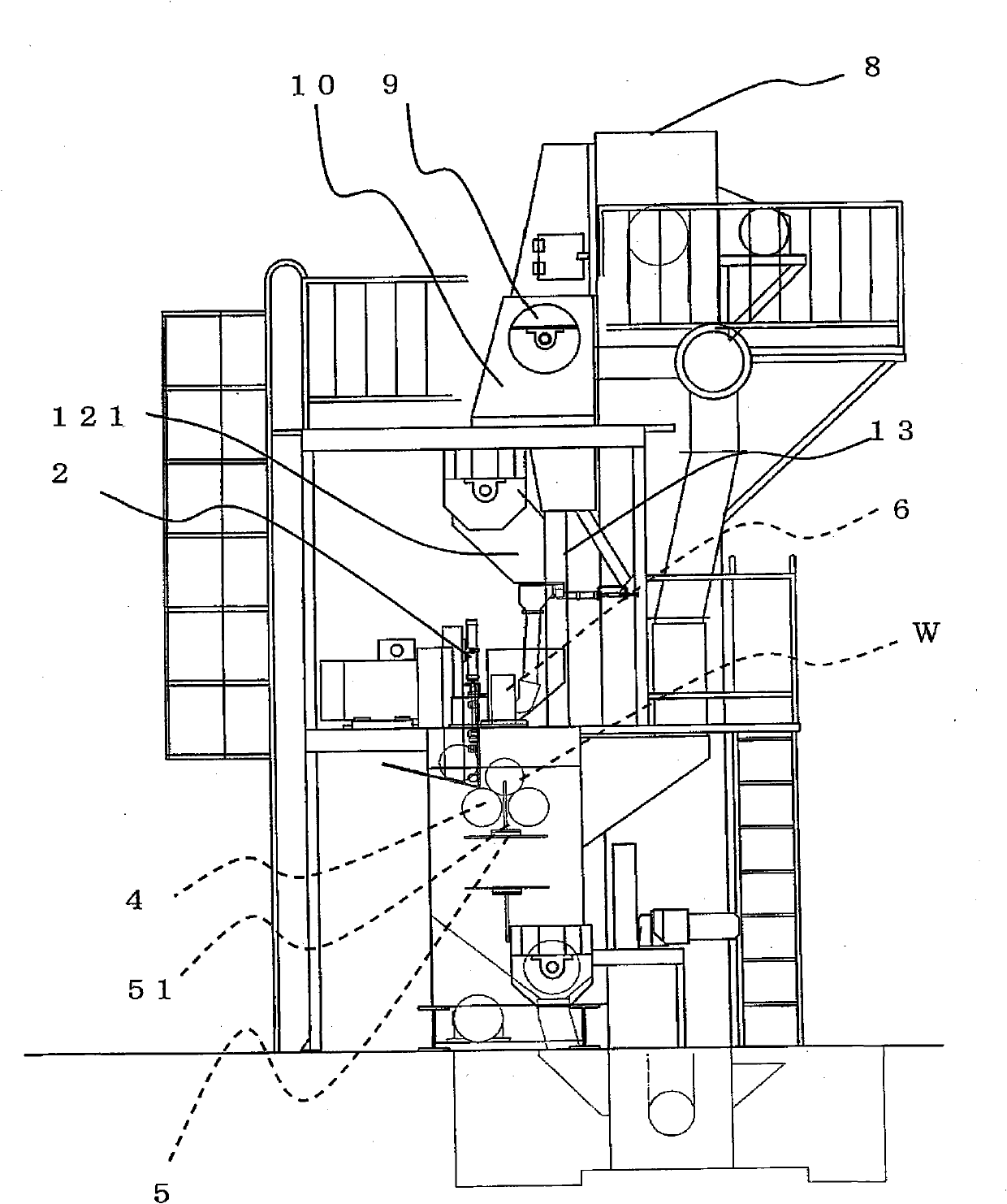

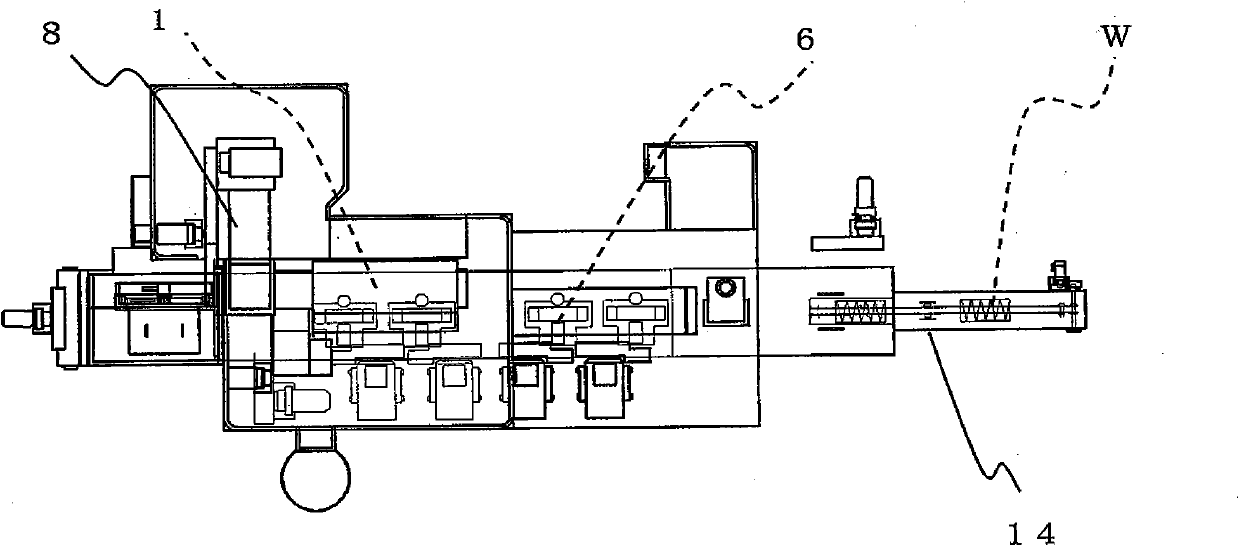

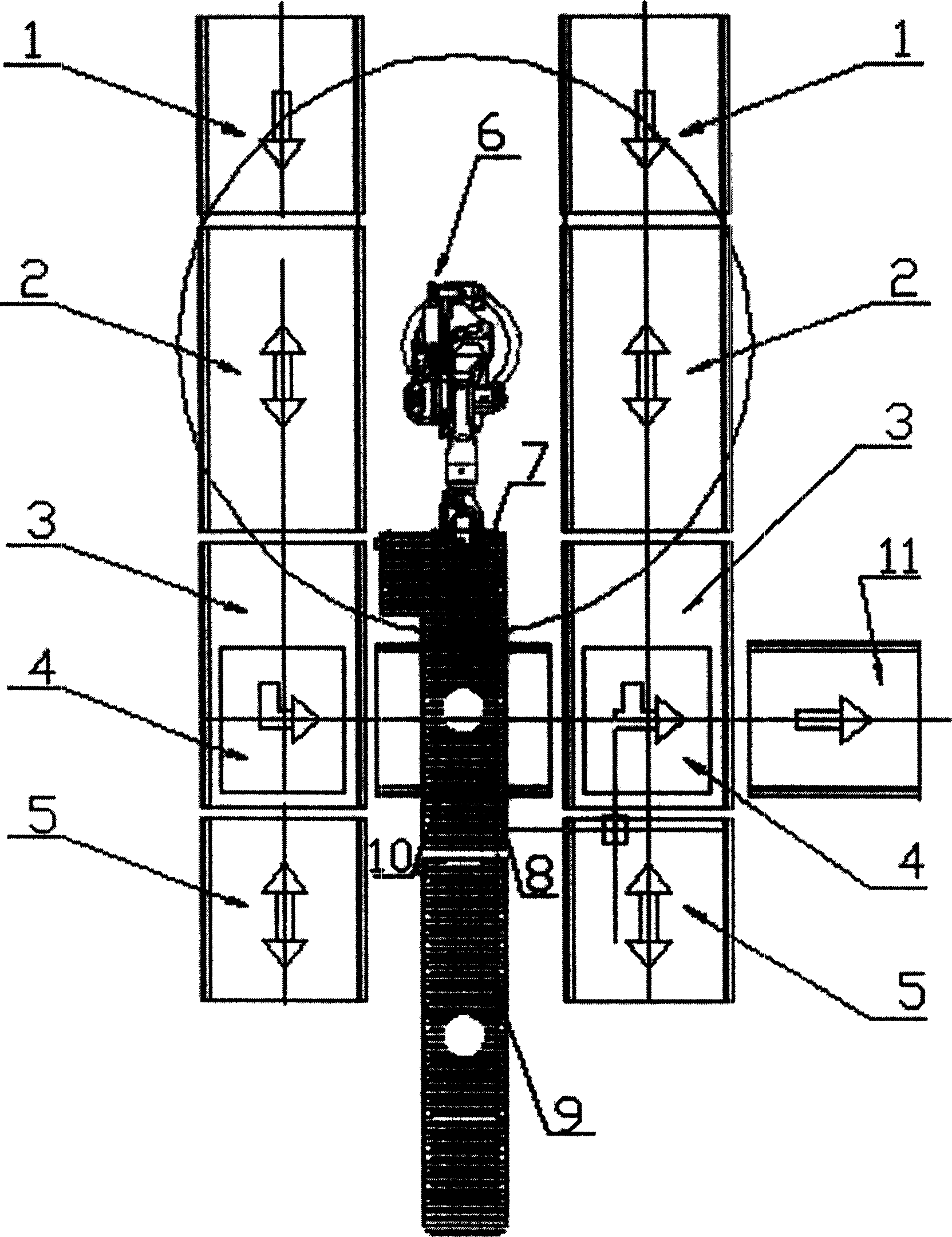

Continuous conveyor type peen vulcanizing device and method

The present invention provides a continuous conveyor type peen vulcanizing device and method, capable of keeping postures of cylindrical metal products such as screw spring and implementing stable peen vulcanization treatment. Inside a cavity (1) having a feed strobe (2), a chain conveyor (5) having an accessory (51) for pressing ends (W1) of a product (W) to be processed is provided, two rotating rollers (4) having drive sources are arranged on two sides of the chain conveyor in parallel, the rotating rollers (4) are formed in cylinder shapes capable of rotating along an identical direction, such that the product (W) to be processed is rotated and simultaneously is conveyed. A centrifugal type projection device (6) is arranged on the upper side of the cavity (1), so as to perform peen vulcanization to a whole surface of the product (W) to be processed without leakage. Projection material is recovered by a lower spiral conveyer (7), and is conveyed to the upper side of the cavity by a bucket elevator (8) to reuse.

Owner:SINTOKOGIO LTD

Fall apart tray treatment system in smoke box solid tray stack disassembling process

InactiveCN1590256AAvoid inefficient workImprove effective operation rateDe-stacking articlesConveyor partsCartonEngineering

An idle pallets treating system used in detaching the stack of cigarette cartons is composed of a chain conveyer, the chain conveyer for the stack-detaching position, the chain conveyer for idle pallet channel, robot, the roller conveyers for cigarette cartons, and the chain conveyer for idle pallet. It features that a chain conveyer for the temporary storage position and a bidirectional chain conveyer used as the storage position of idle pallets are additionally used.

Owner:云南紫金科贸有限公司

Full-automatic drawer sliding rail assembling machine

ActiveCN104647029AEasy to operateReduce manual labor intensityAssembly machinesDrawersChain conveyorManipulator

The invention discloses a full-automatic drawer sliding rail assembling machine which comprises a sliding rail main body storage stay wire, a first suction manipulator, a chain conveyor, reaming equipment, riveting equipment, a pin feeding device, a roller feeding device, a spacer feeding device, a rotating disc type assembly table, a second suction manipulator, a finished product roller moving stay wire, a roller axial gap detection device and an oiling device, wherein the sliding rail main body storage stay wire is arranged upstream the chain conveyor, the reaming equipment is positioned at the downstream of the first suction manipulator, and the riveting equipment is installed on the chain conveyor and is positioned at the downstream of the reaming equipment and on the same side as the reaming equipment. According to the full-automatic drawer sliding rail assembling machine, full-automatic assembly of pins, rollers and spacers into a finished roller can be realized, the finished roller can be automatically screwed and riveted on a drawer sliding rail main body, meanwhile, roller axial gap detection on a finished drawer sliding rail and anti-rust oil coating in riveting positions can be automatically completed, manual operation is matched, and the full-automatic drawer sliding rail assembling machine has the advantages of simplicity in operation, low manual labor intensity and high assembling production efficiency.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

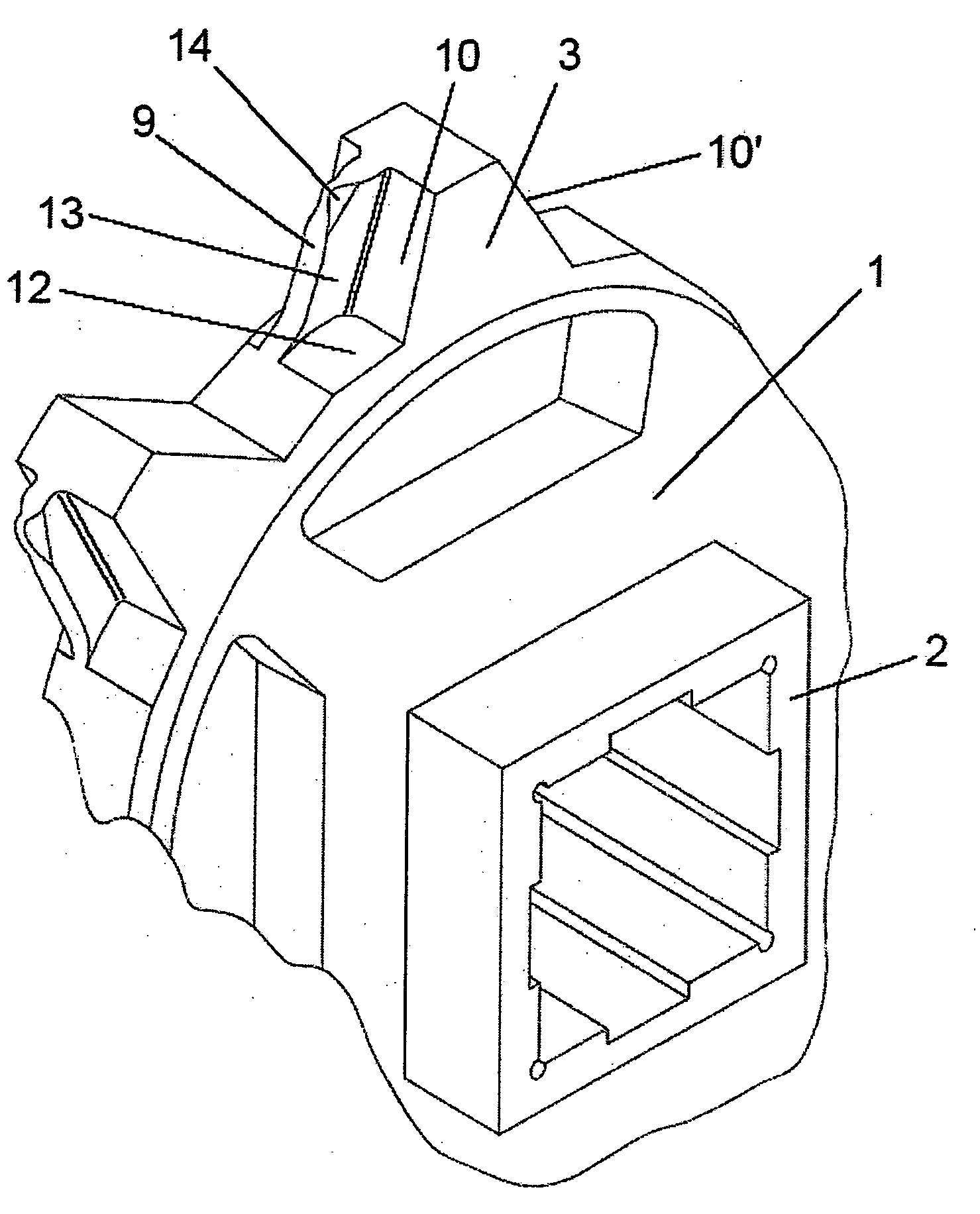

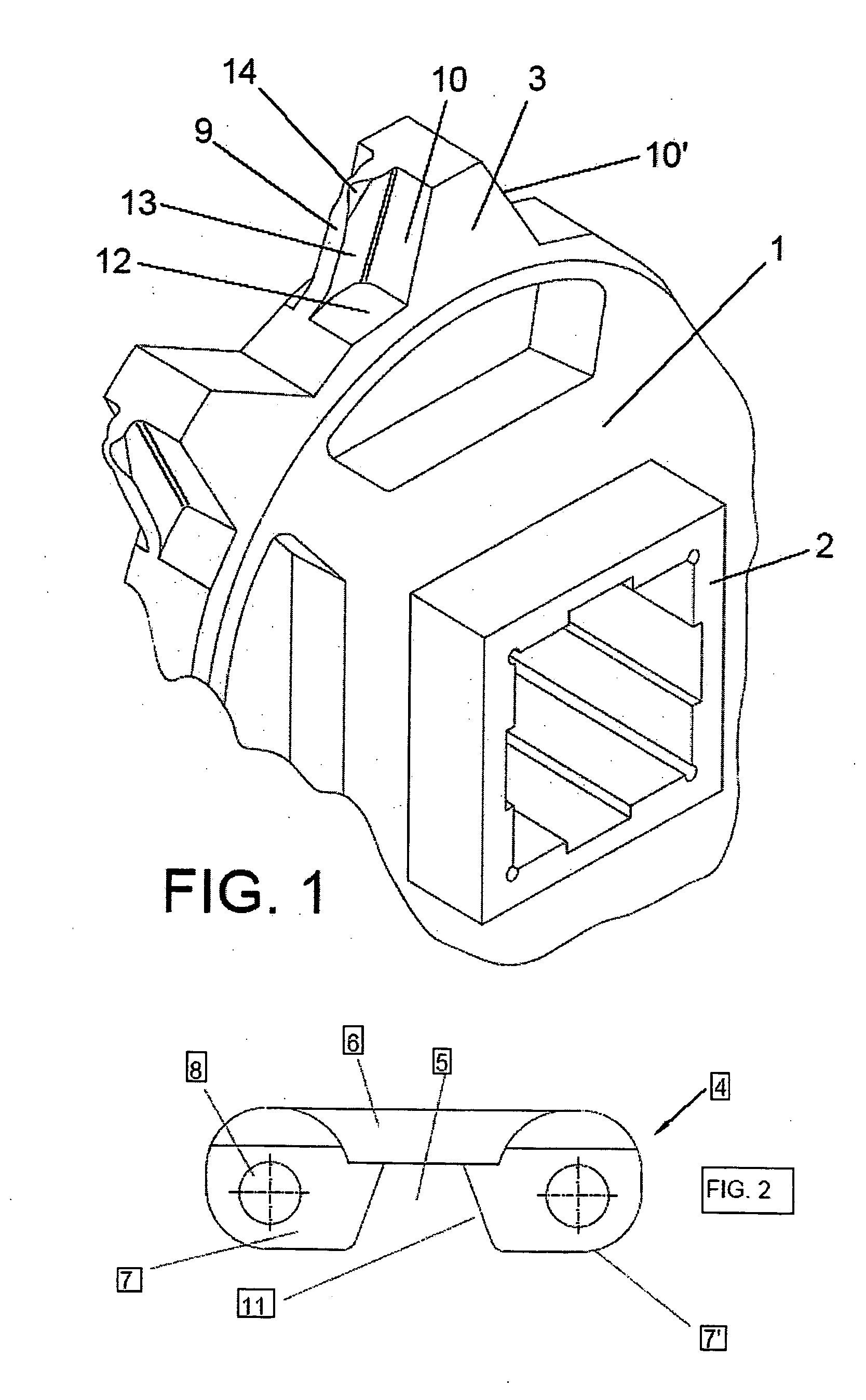

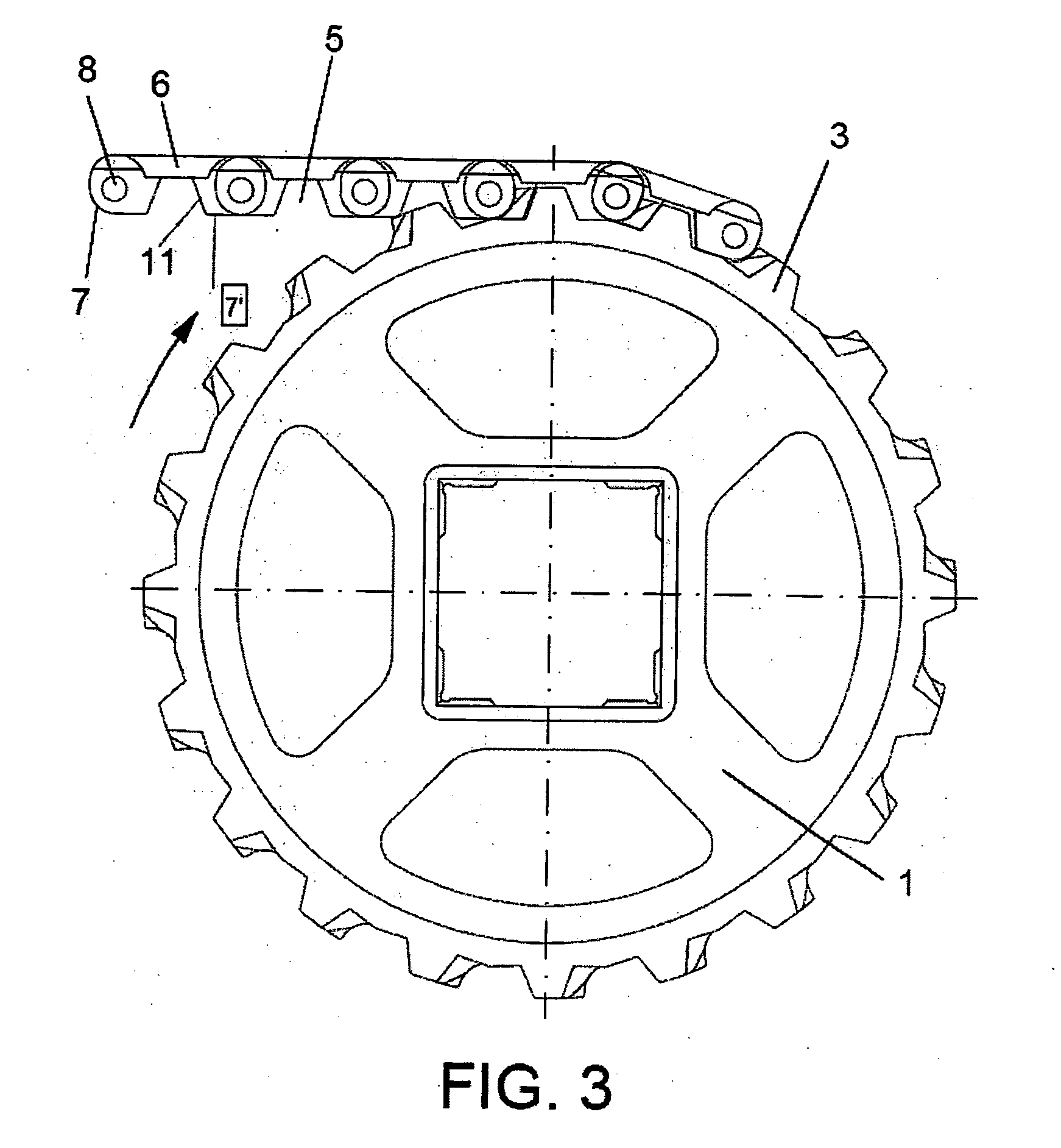

Driving crown for chain conveyors

Designed to immobilise the chain conveyor to ensure that it does not move transversally, and to make it easier to clean it, the main characteristics being that each one of its cogs (3) is equipped, only on its rear wall (10), with a crest (9) that is off-centre with respect to the imaginary plane and runs perpendicular to the centreline of the crown, which has to be inserted between the protrusions on the links that form the chain. The layout of this crest (9) is trapezoidal and isosceles, diverging towards the cog (3), and the lateral surfaces are concave, in such a way that the aforementioned lateral surfaces are joined to the marginal surfaces of the surface (10) of the cog (3), in a markedly rounded way, so there are no sharp edges, which makes it easy to clean the crown when, for example, a jet of water is sprayed onto it.

Owner:AFHER EUROBELT

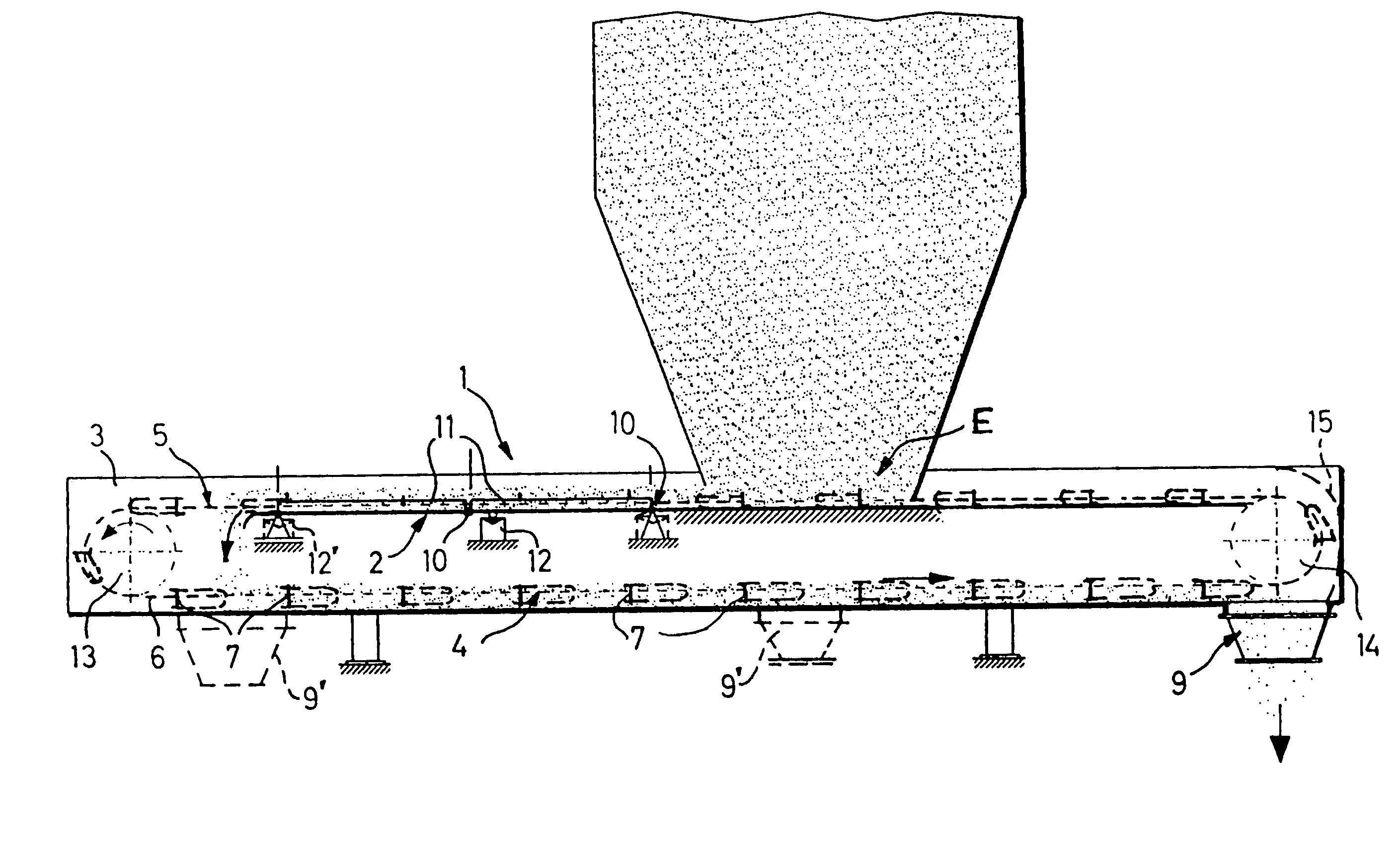

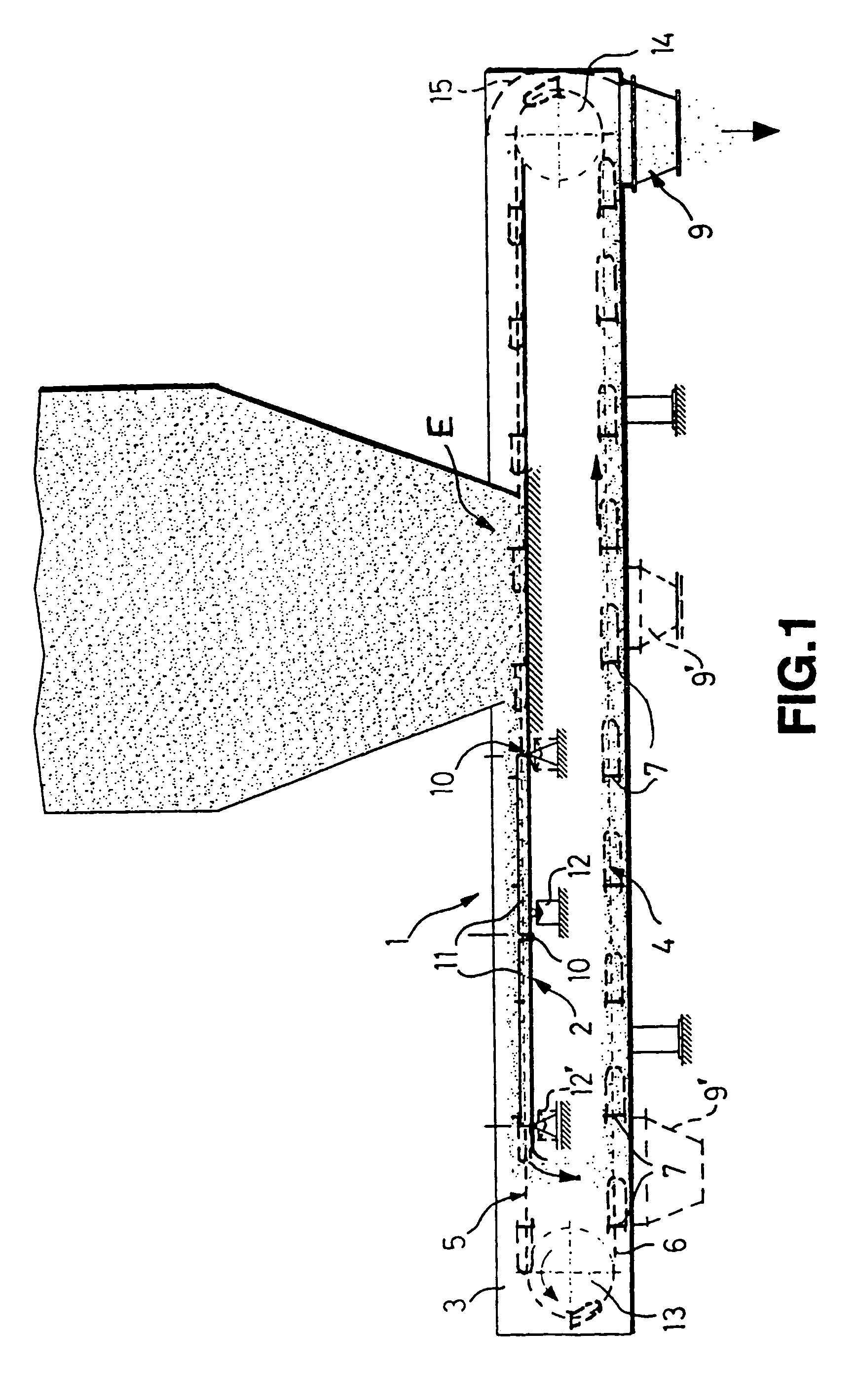

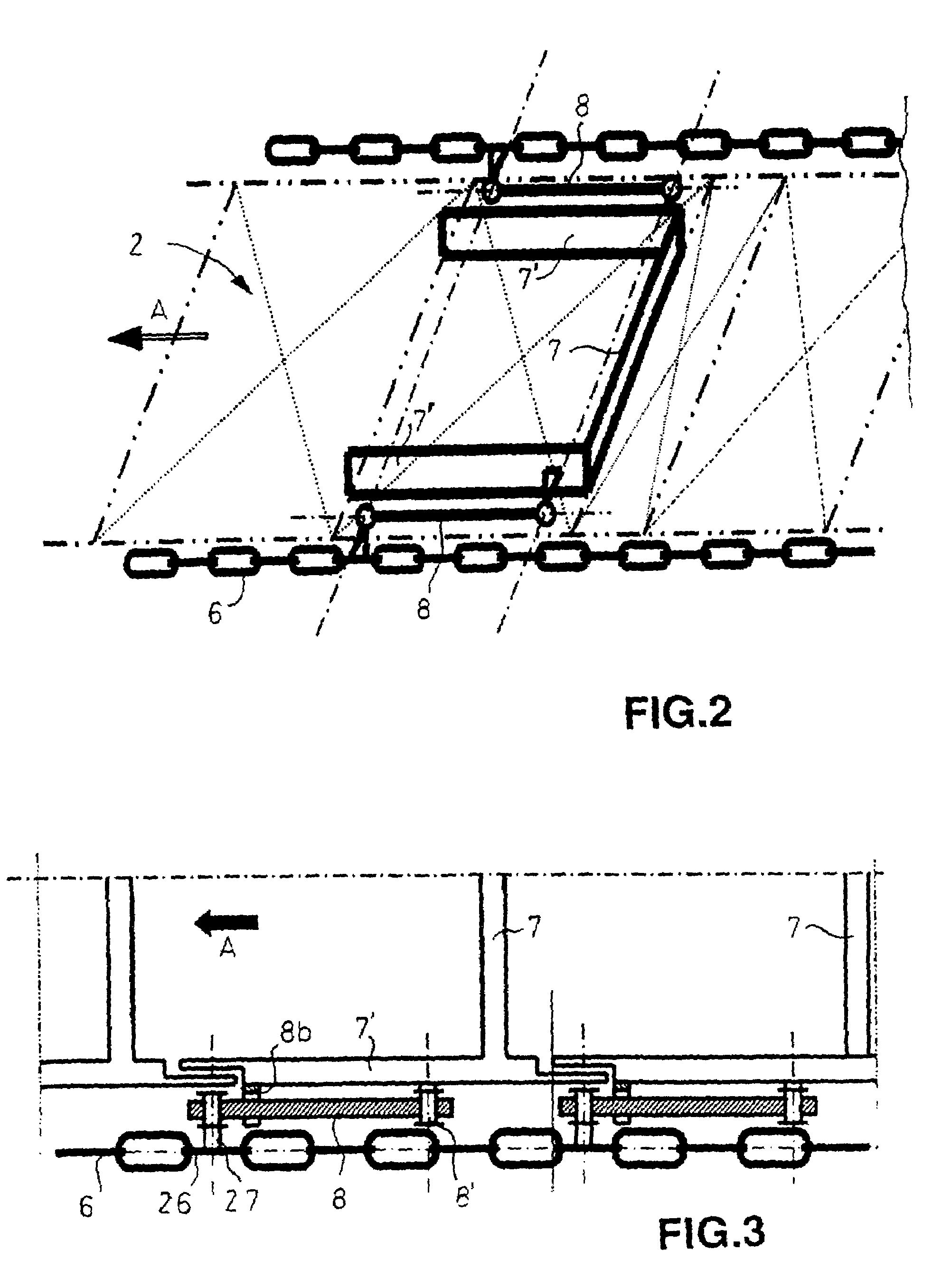

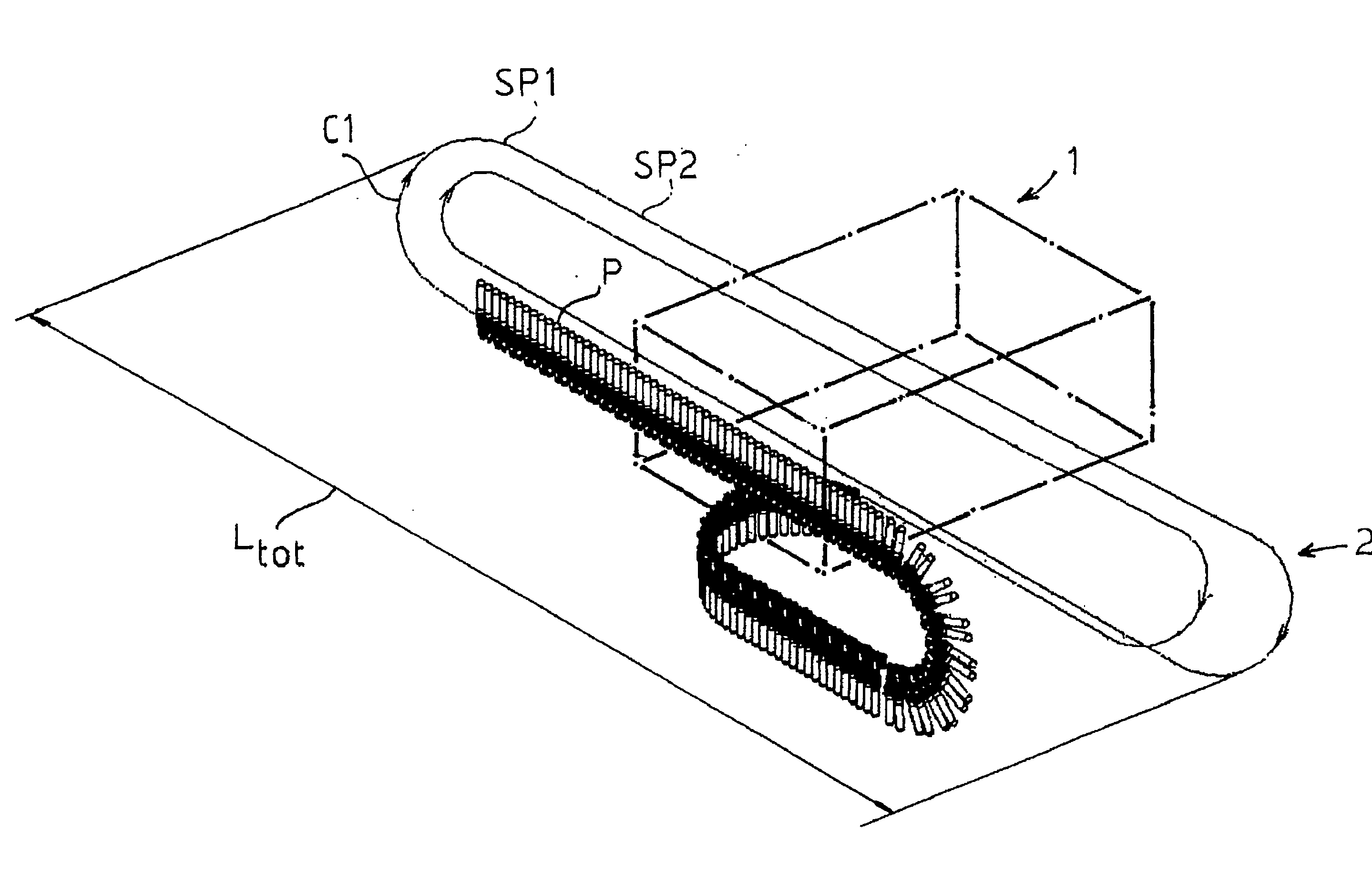

Chain conveyor in the form of scales

InactiveUS6964550B2Reduce wearReduce tearingConveyorsWeighing apparatus for continuous material flowBand shapeChain conveyor

A chain conveyor for gravimetrically measuring / dosing materials, especially bulk materials. The conveyor includes a housing / trough in which at least two chain conveyors with strip-shaped driving elements attached thereto rotate, wherein a measuring bridge that is supported on at least one force measuring device is arranged between the inlet and an outlet hole. The driving elements are mounted with multiple articulations on the conveyor chains, more particularly, said driving elements are inserted with positive-fit by lateral hinge bolts in the chain links located on the upper edge and configured to be placed flatly in the measuring bridge.

Owner:PFISTER

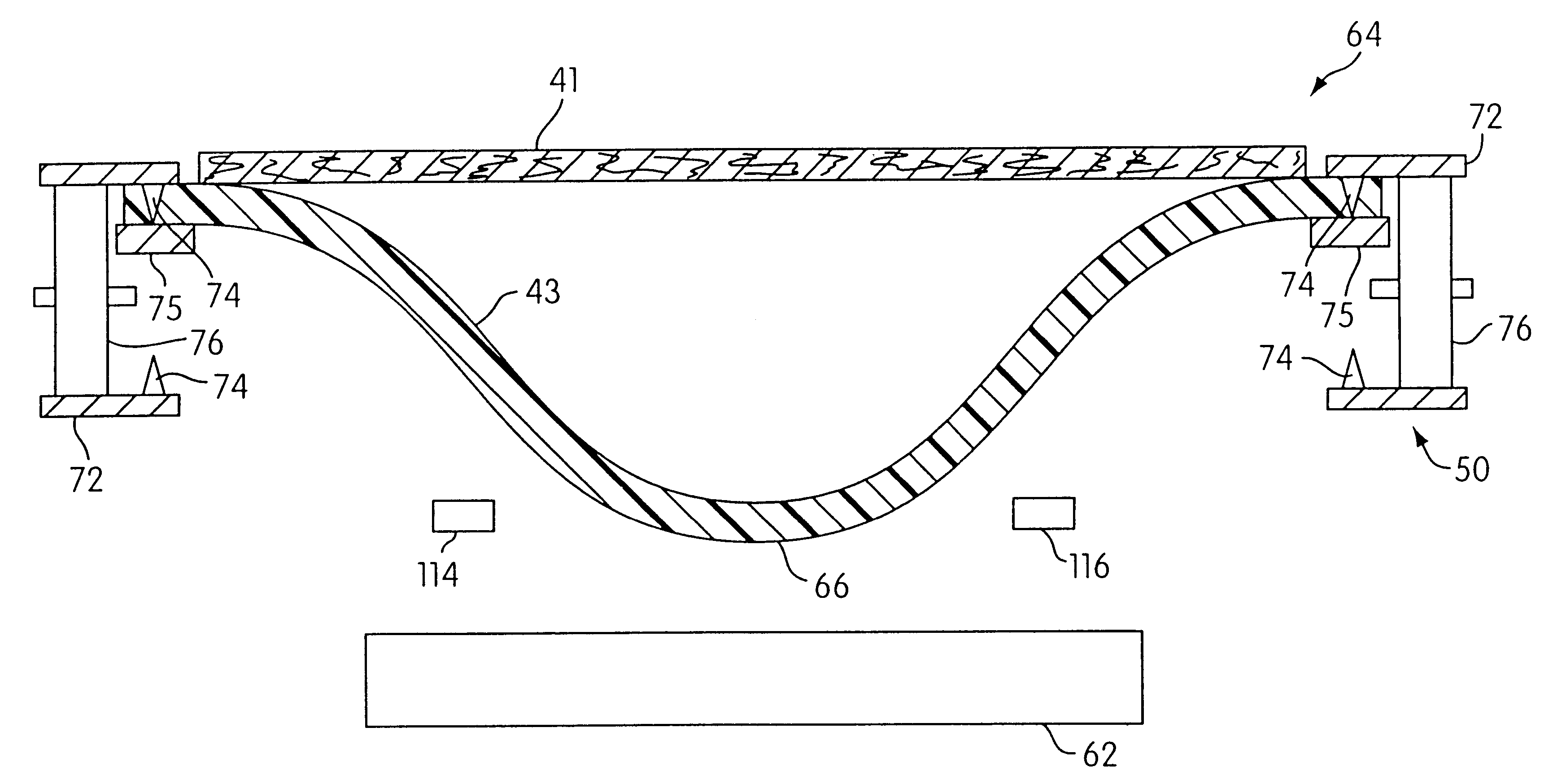

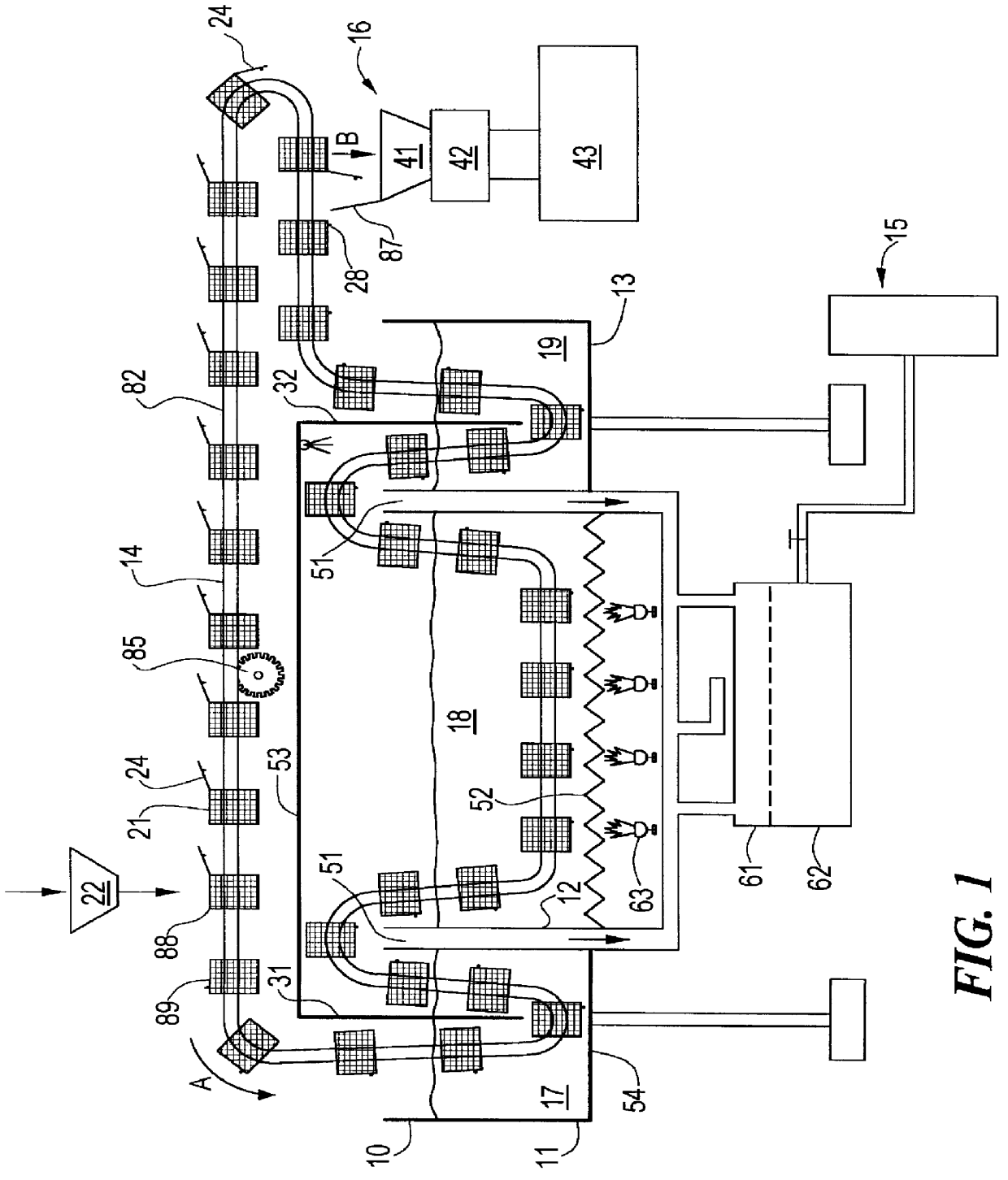

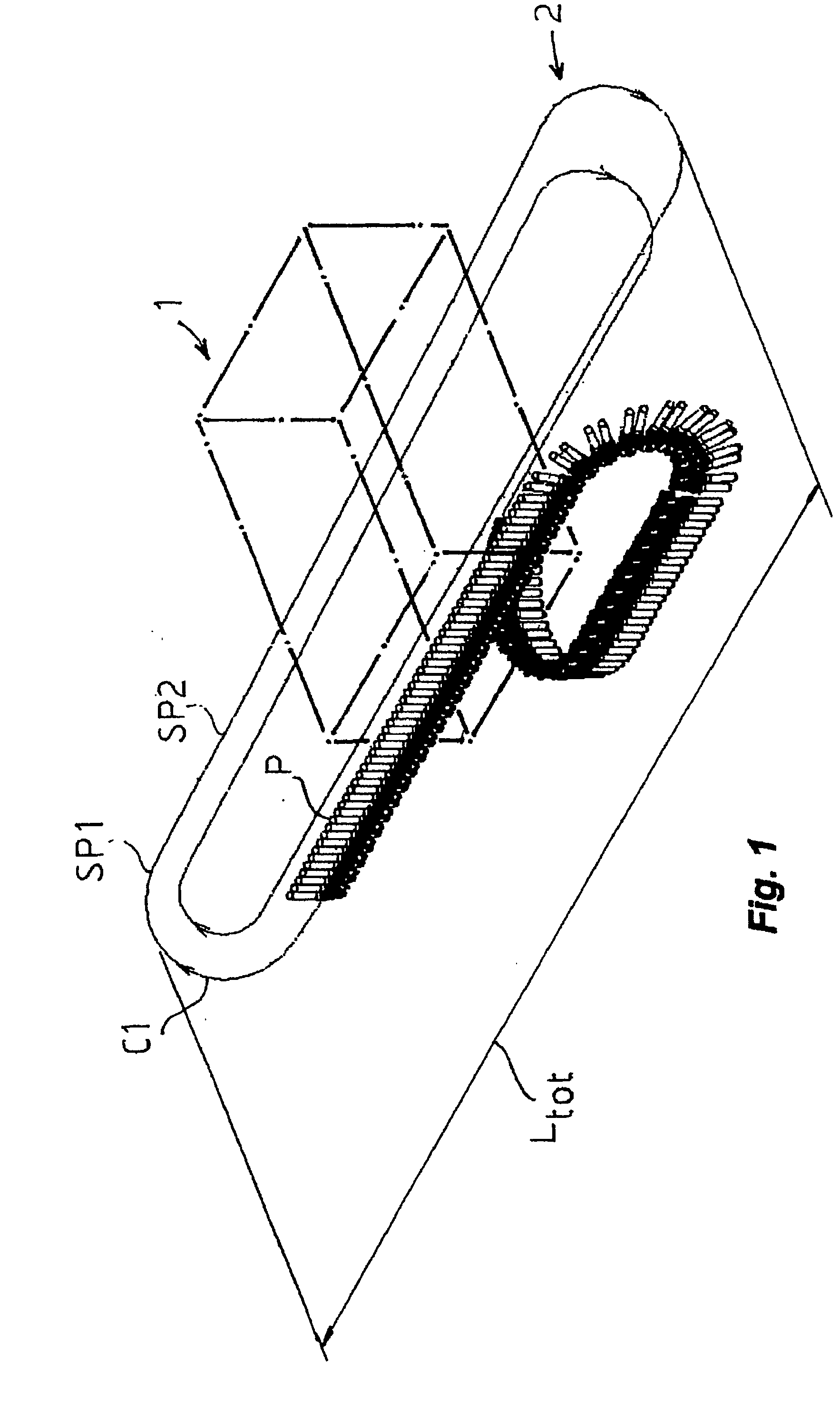

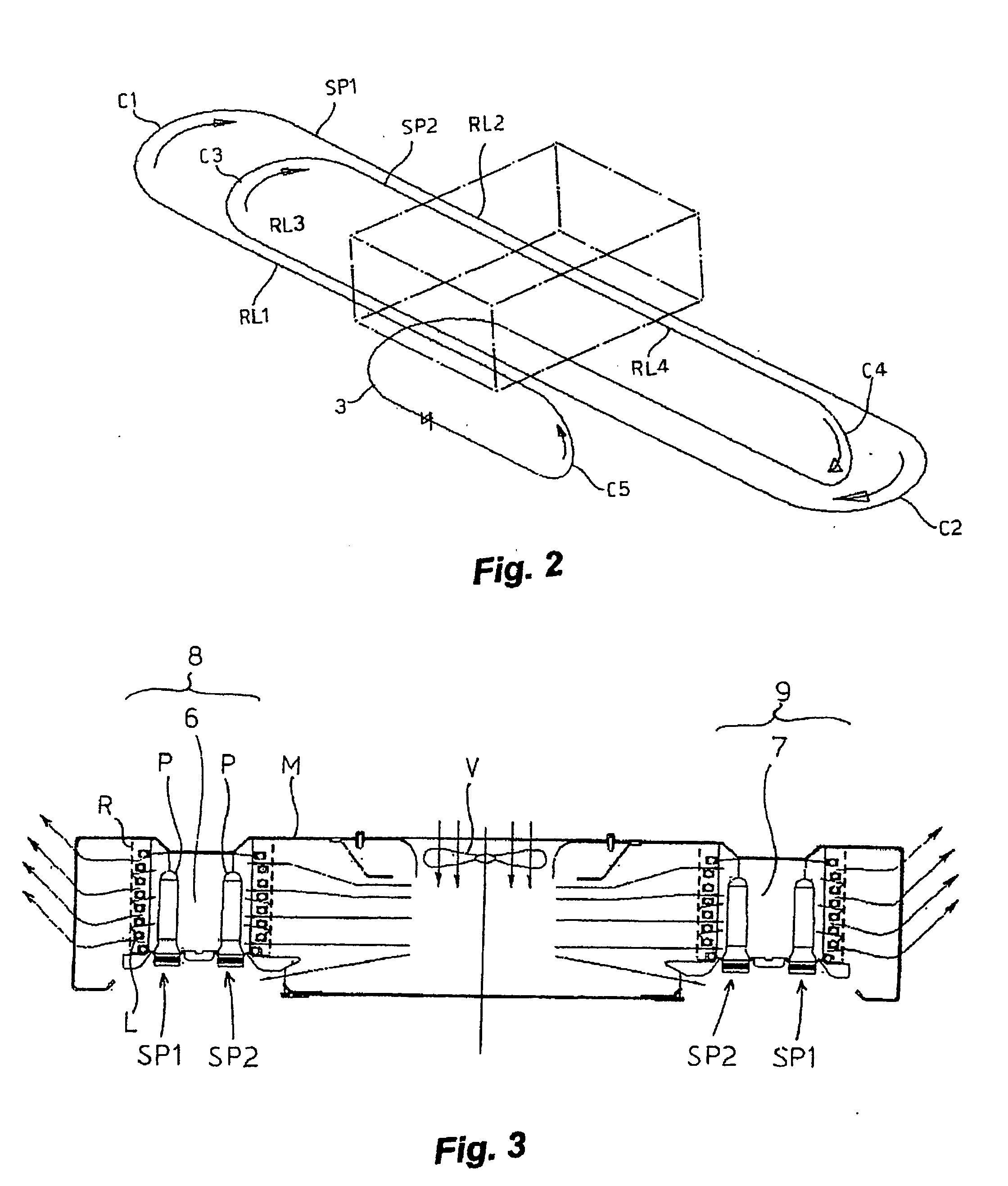

Plant and Method for Thermally Conditioning Plastic Items

InactiveUS20070224307A1Control DimensionsEasy constructionConfectionerySweetmeatsChain conveyorEngineering

The method for thermally conditioning preforms in accordance with the invention comprises the following steps:—Placing the preforms on a chain conveyor (2);—Conveying the preforms through a first thermal conditioning stage (1) and subjecting them to a first heating or cooling heat exchange;—Removing the preforms from the first thermal conditioning stage and holding them outside for a predetermined amount of time in order to redistribute the temperature inside the preforms;—Subjecting the preforms to at least a second heating or cooling heat exchange in a second thermal conditioning stage (1) or in the first thermal conditioning state. The invention also concerns the plants for heating or cooling preforms in accordance with the above method.

Owner:SIPA SOCIETA INDUSTRIALIZZAZIONE PROGETTAZIONE E AUTOMAZIONE SPA

Radius chain modular conveyor

A radius chain conveyor structure and method for traveling along curved paths in both left and right directions and having the capability to carry very small and delicate articles.

Owner:HABASIT AG

Automatic unstacking and conveying method and device for standard boxes

ActiveCN102190148ARealize automatic depalletizingRealize unstackingDe-stacking articlesConveyor partsEngineeringChain conveyor

The invention discloses an automatic unstacking and conveying method and an automatic unstacking and conveying device for standard boxes. In the method, a sucking disc fixture arranged on a robot grabs the standard boxes, and puts the standard boxes on a roller conveying type stacking conveyor in a vertical mode; the conveying tail of the stacking conveyor is connected with a stacking chain conveyer; the conveying tail of the stacking chain conveyor is provided with a positioning block and a separation mechanism; the rear end of the separation mechanism is provided with a conveying mechanism; and a crossed separation fork of the separation mechanism rotates 90 degrees, so that a standard box at the foremost end is turned 90 degrees and is stably put on the conveying mechanism, and the conveying mechanism conveys the standard box of which the conveying surface is converted to the next required procedure, so the standard boxes can be automatically unstacked and conveyed. The invention can realize functions of automatically unstacking, separating, turning, changing a direction for conveying and the like, and can greatly improve work efficiency and reduce labor intensity of workers.

Owner:GUIYANG PUTIAN LOGISTICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com