Fall apart tray treatment system in smoke box solid tray stack disassembling process

A technology for cigarette boxes and trays, which is applied in the destacking of objects, conveyor objects, transportation and packaging, etc., can solve the problems of increasing investment in cigarette factories, increasing the load of logistics channels, occupying manpower and material resources, etc., to improve the effective operation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

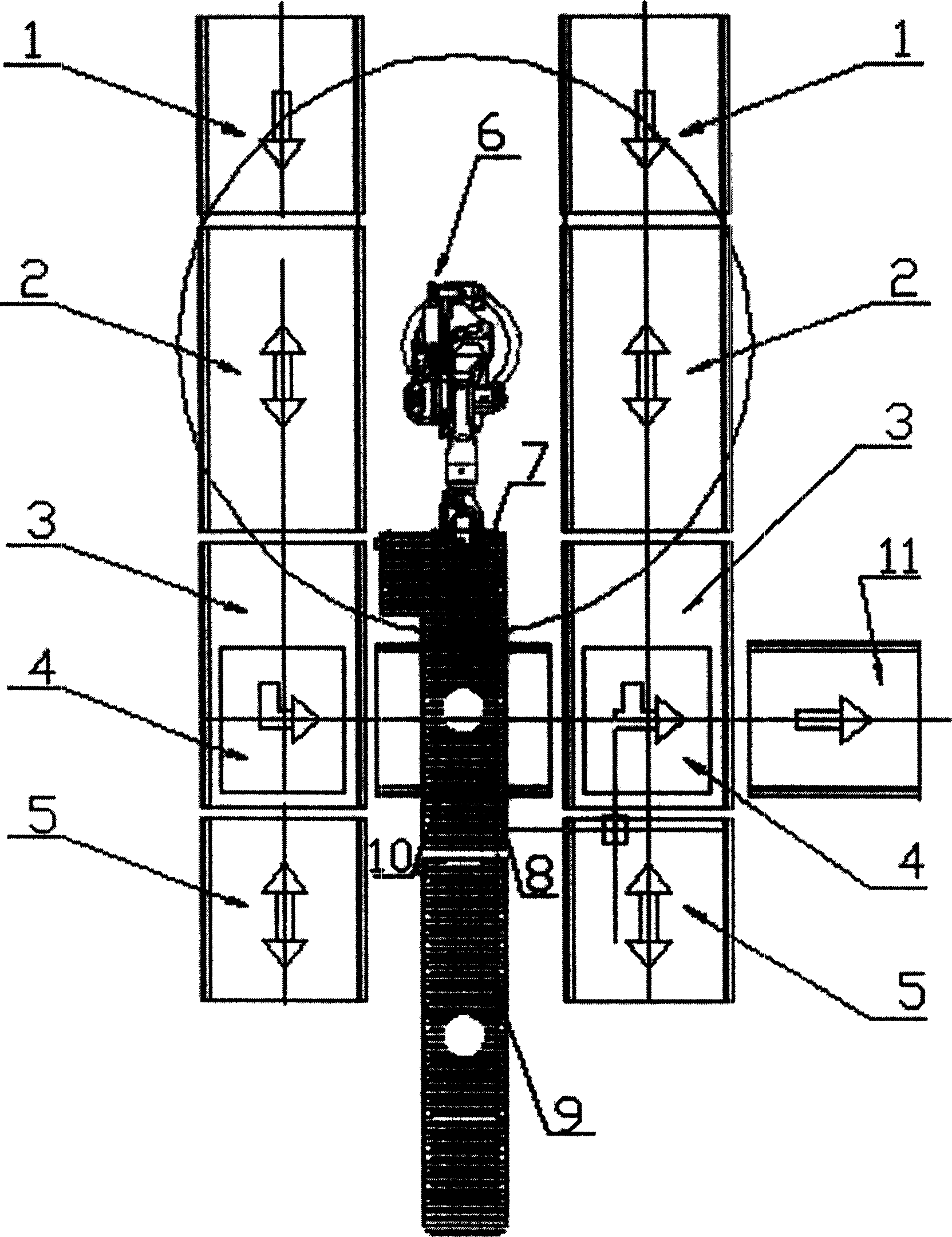

[0009] Embodiment, by the chain conveyor (1), the unstacking station chain conveyor (2), the empty pallet channel chain conveyor (3), (4), the robot (6), the finished cigarette box roller conveyor Machines (7), (8), (9) and empty pallet chain conveyor (11) are used to process the scattered disks during the unstacking process of the smoke box solid pallet, which is characterized in that the empty pallet chain conveyor (4) The rear of the chain conveyor is provided with a temporary storage processing position (5).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com