Electronic belt scale tobacco scrap automatic removal device for tobacco

The technology of an electronic belt scale and a rejecting device, which is applied in the field of tobacco machinery and equipment, can solve the problems that the weighing and measuring area cannot be installed with a presser belt, affects the measurement accuracy of the electronic belt scale, and has hidden dangers in product quality, so as to improve the measurement accuracy and equipment effectiveness. High operating rate, simple structure, and the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

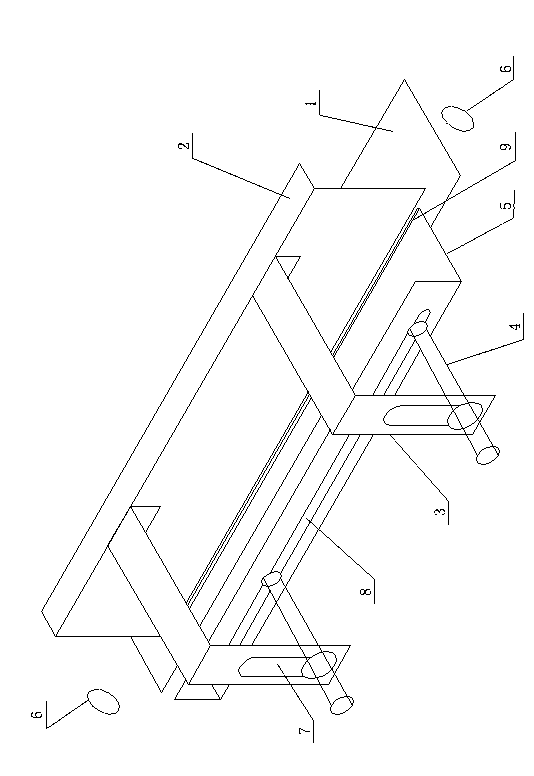

[0010] like figure 1 The shown electronic belt scale wire automatic removal device for tobacco includes a belt scale belt 1 and a belt scale frame 2 above the belt scale belt 1 , and there is a certain gap between the belt scale belt 1 and the belt scale frame 2 . A fixed plate 3 is fixedly connected to the upper part of the frame 2 of the belt scale, and a horizontally arranged cylinder 4 is installed on the outer end of the fixed plate 3. A movable push plate 5 is installed on the telescopic end of the front portion of the cylinder 4, and the front end of the movable push plate 5 is provided with a folding The edge 9 and the folded edge 9 correspond to the gap between the belt scale belt 1 and the belt scale frame 2, and the height of the folded edge 9 is equal to or smaller than the gap height between the belt scale belt 1 and the belt scale frame 2. A pair of micro-infrared through-type beam-type through-fire detection switches 6 are arranged at both ends of the belt scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com