Patents

Literature

1270results about "Weighing apparatus for continuous material flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

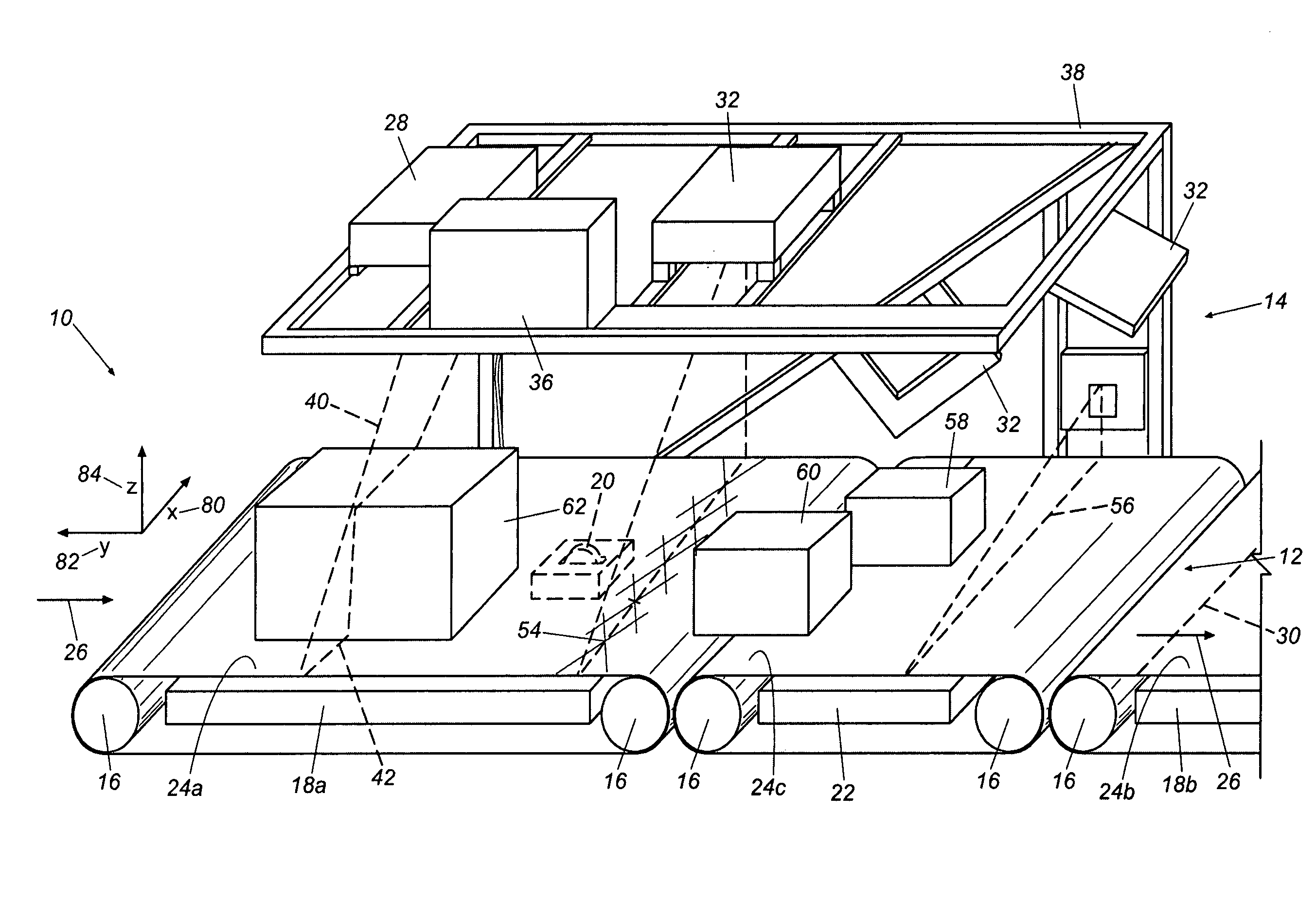

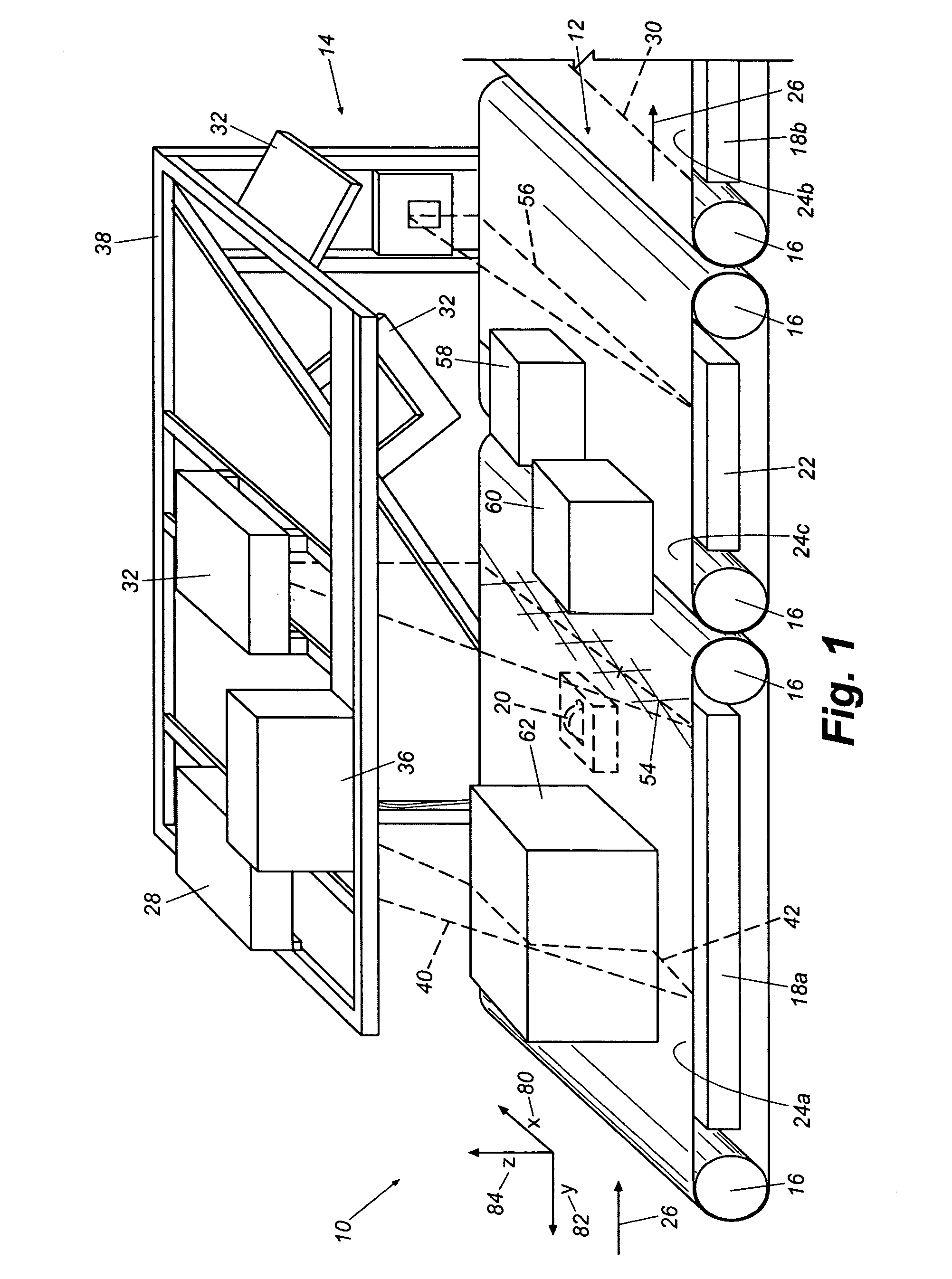

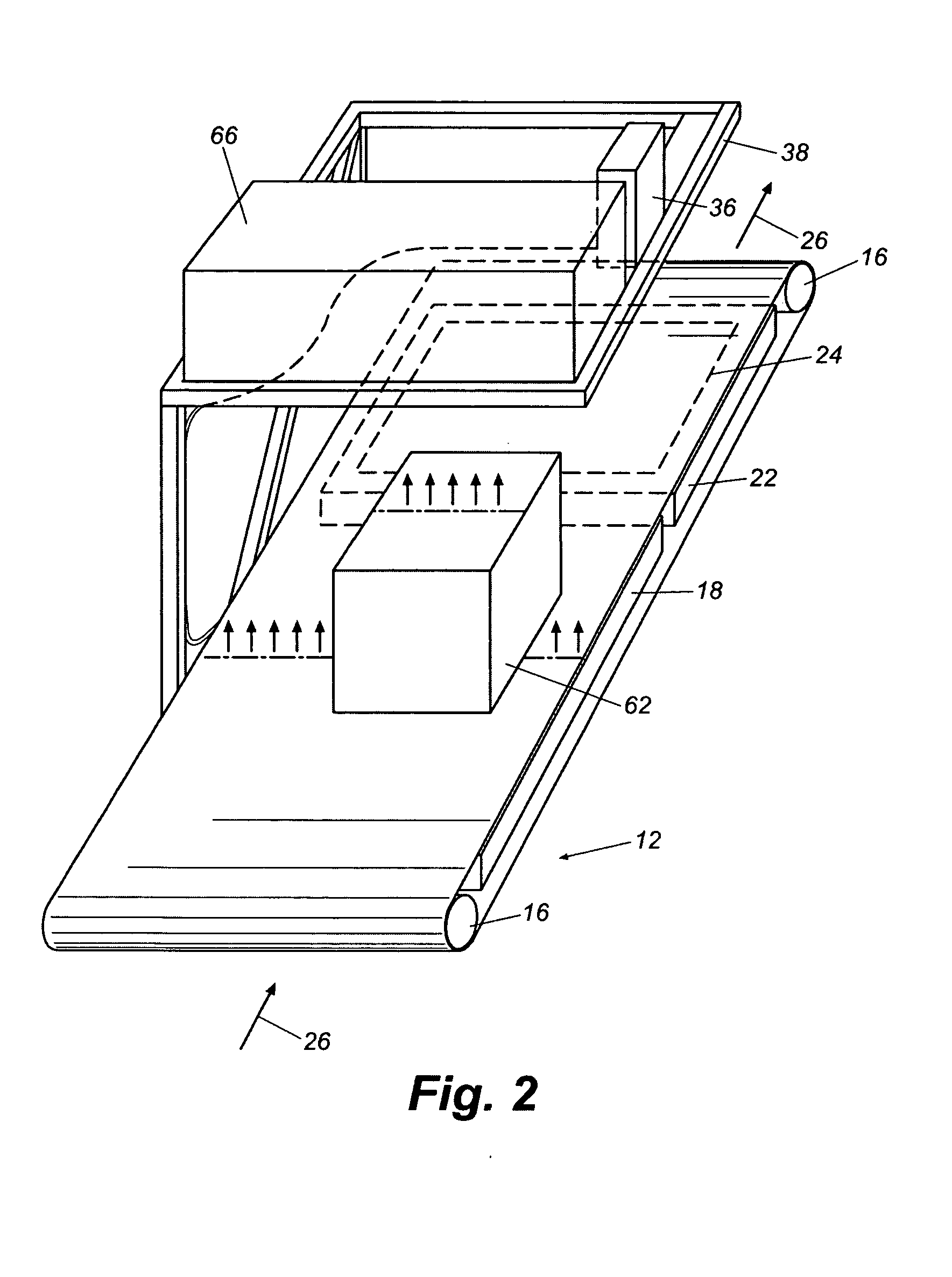

Dimensioning and weighing system

InactiveUS20080035390A1Electric/magnetic depth measurementWeighing apparatus for continuous material flowComputer science

An apparatus for measuring the weight of items on a conveyor includes a scale that generates a first signal corresponding to the weight of the items. A movable platform transports the items to the scale and generates a second signal corresponding to position of the items in relation to the scale. A dimensioner examines the items and generates a third signal representative of whether the items are singulated or nonsingulated. A processor receives the second and third signals and determines whether to associate the first signal with information stored in memory about a particular item based upon whether the particular item is singulated or nonsingulated.

Owner:ACCU SORT SYST

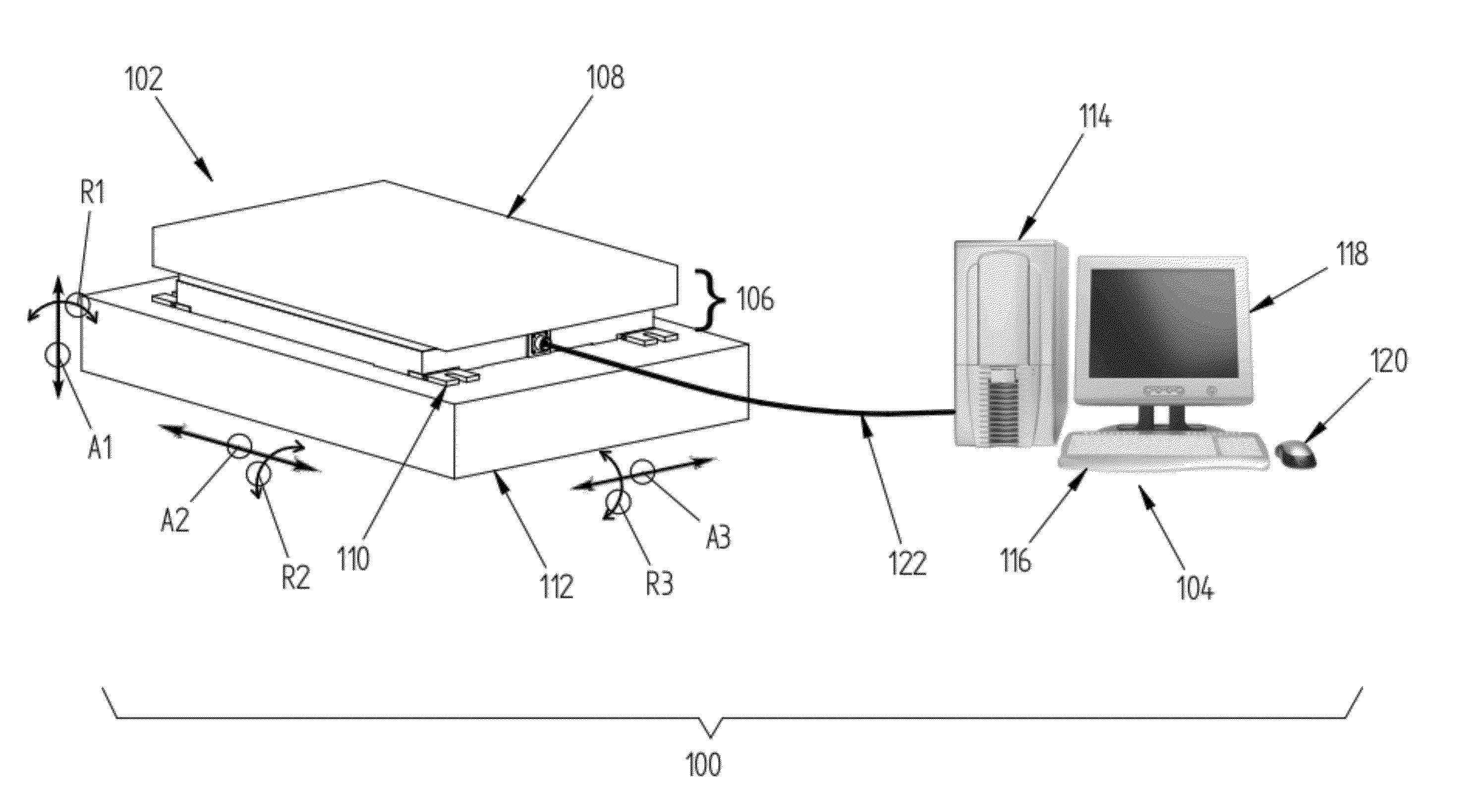

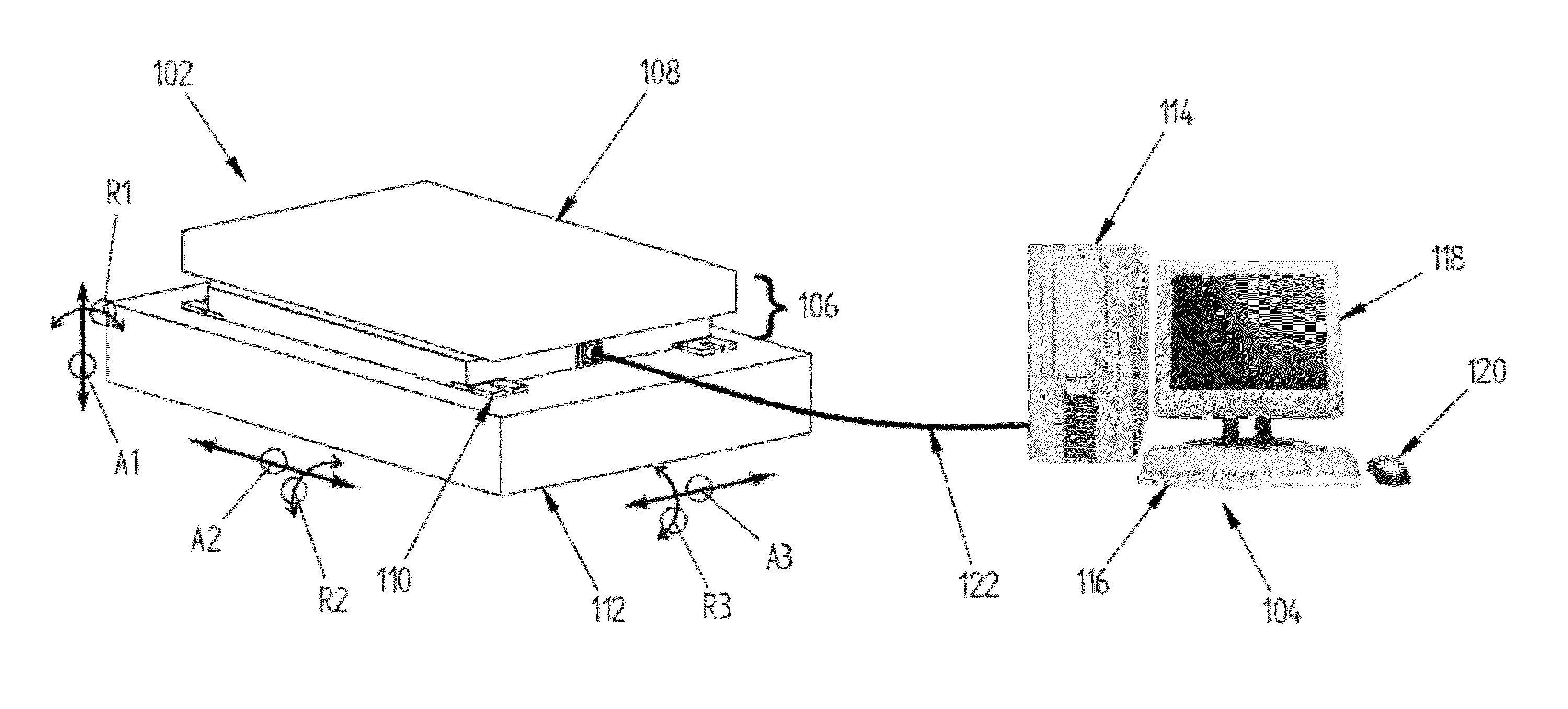

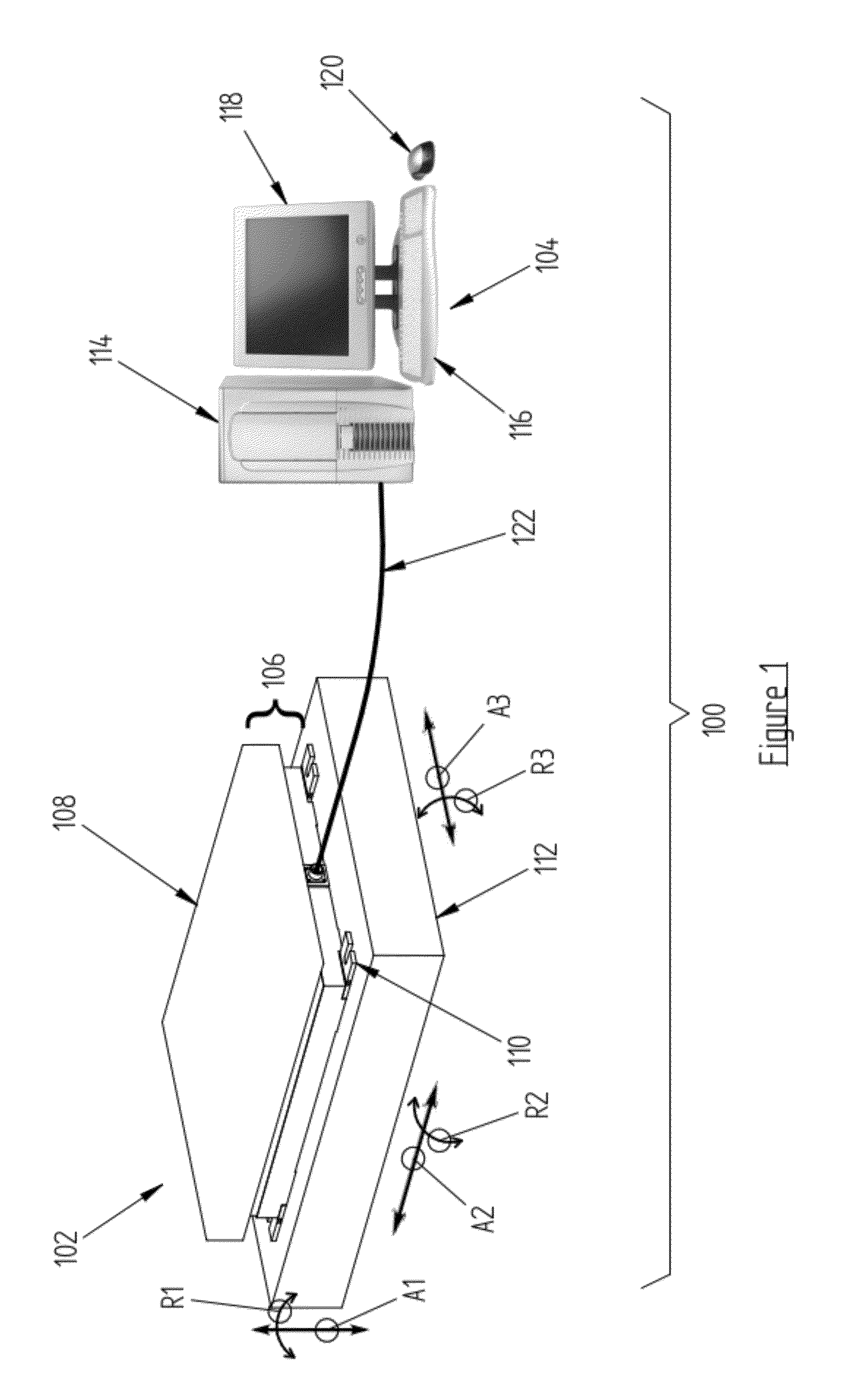

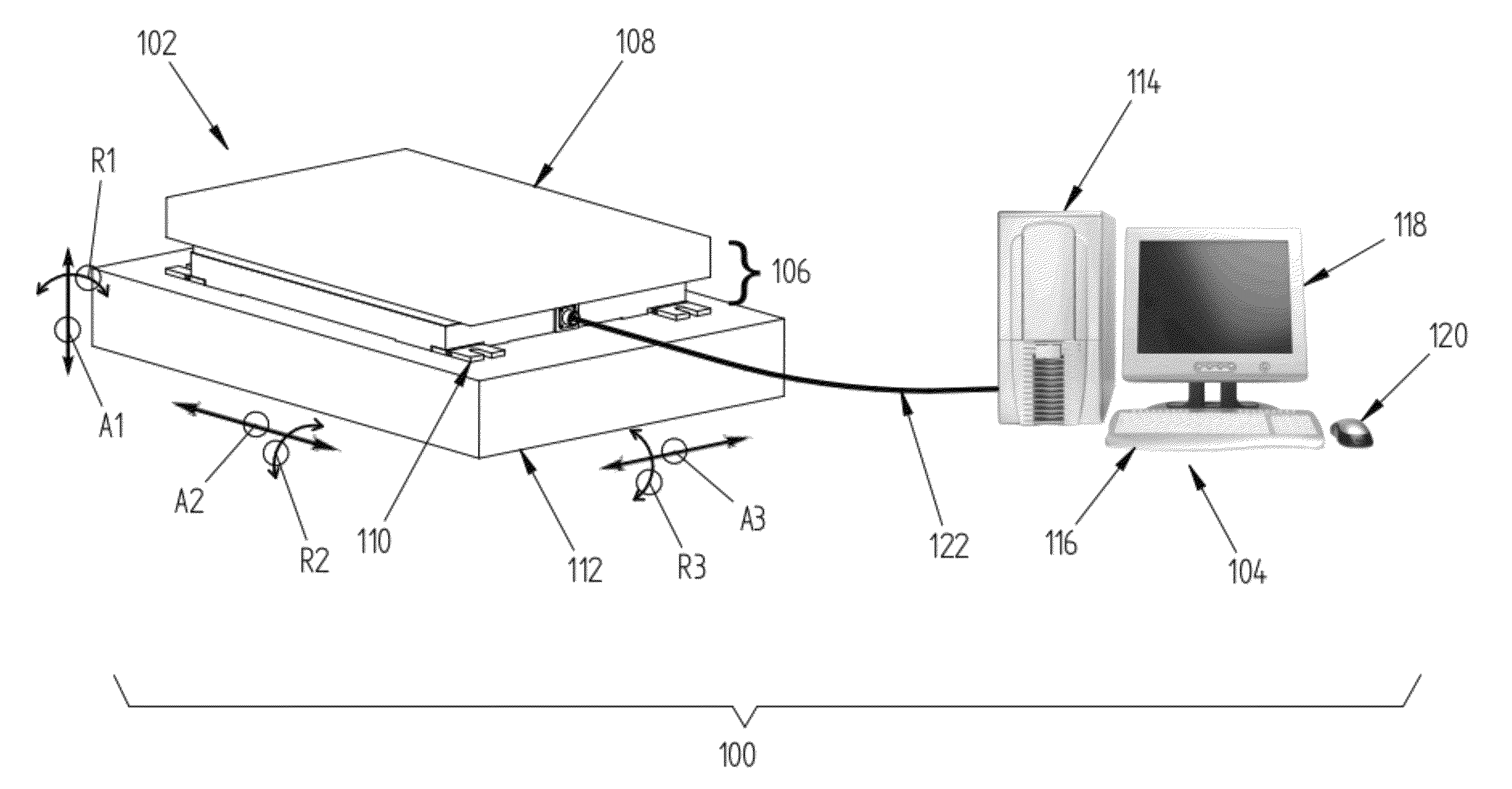

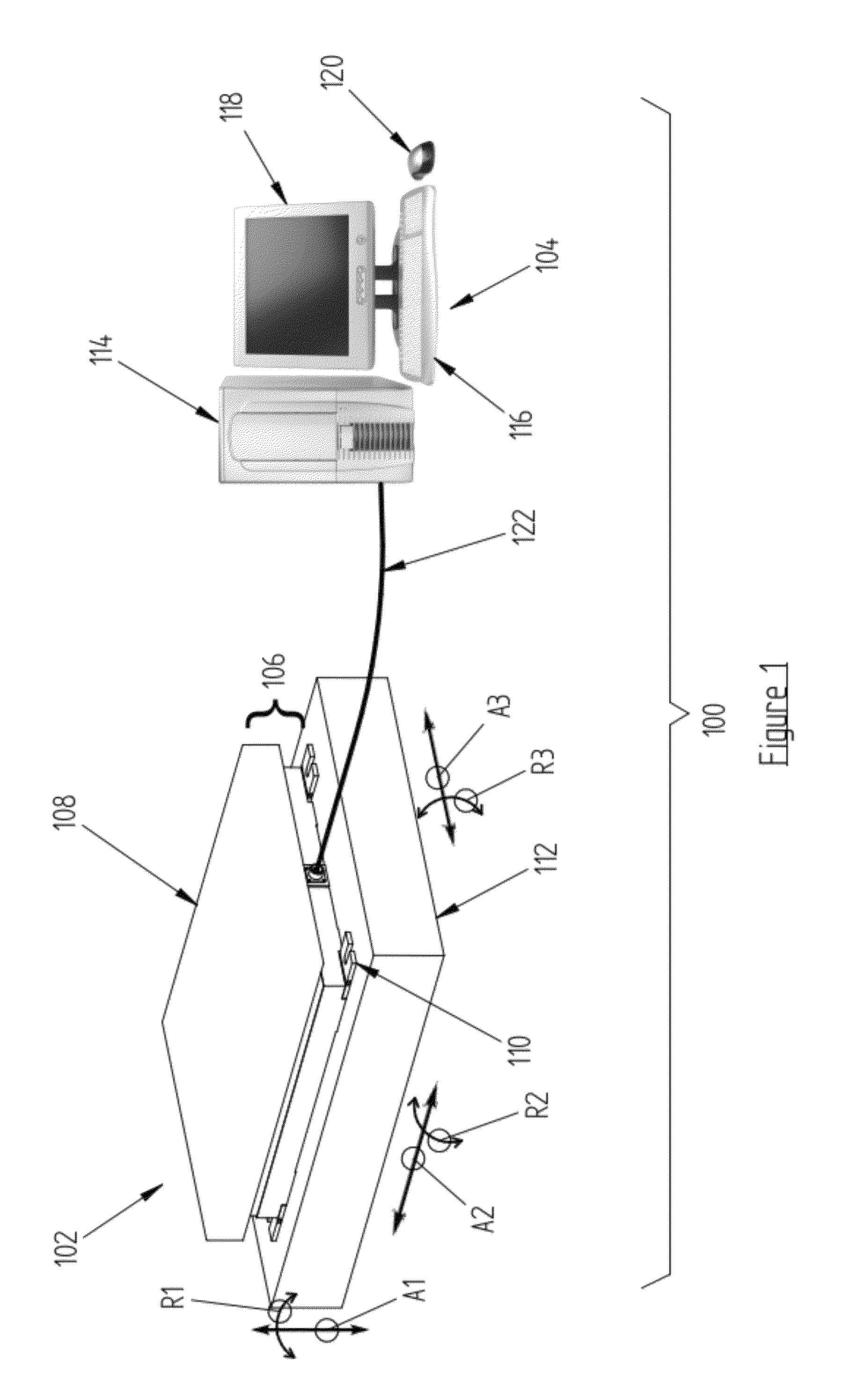

Force and/or motion measurement system having inertial compensation and method thereof

ActiveUS8315823B2Accurate compensationAccurately determineForce measurementDiagnostic recording/measuringMeasurement deviceSeries compensation

According to one aspect of the invention, a force measurement system includes a force measurement assembly, a motion base configured to displace the force measurement assembly, and an inertial compensation system configured to determine the inertial forces and / or moments resulting from the displacement of the force measurement assembly by the motion base. According to another aspect of the invention, a method for accurately determining the forces and / or moments applied to a surface of a force measurement device by a subject disposed thereon is disclosed, which includes the step of determining, by using an inertial compensation system, the inertial forces and / or moments resulting from the displacement of a force measurement assembly by a motion base. According to still another aspect of the invention, a force and / or motion measurement system having inertial compensation includes a motion acquisition system having a plurality of motion sensing devices configured to capture a subject's movement.

Owner:BERTEC

Force Measurement System Having Inertial Compensation

ActiveUS20120271565A1Accurate force measurementAccurate compensationForce measurementInertial sensorsAccelerometerAngular velocity

A force measurement system having inertial compensation includes a force measurement assembly with at least one accelerometer configured to measure the acceleration thereof. According to one aspect of the invention, the force measurement system additionally includes at least one angular velocity sensor configured to measure the angular velocity of the force measurement assembly. According to another aspect of the invention, the force measurement system additionally includes a data processing device with a computer-readable medium loaded thereon that is configured to execute a calibration procedure for determining the inertial parameters of the force measurement assembly by utilizing the measured acceleration of the force measurement assembly while the force measurement assembly is subjected to a plurality of applied linear and / or rotational motion profiles. According to still another aspect of the invention, the at least one accelerometer is disposed on the force transducer.

Owner:BERTEC

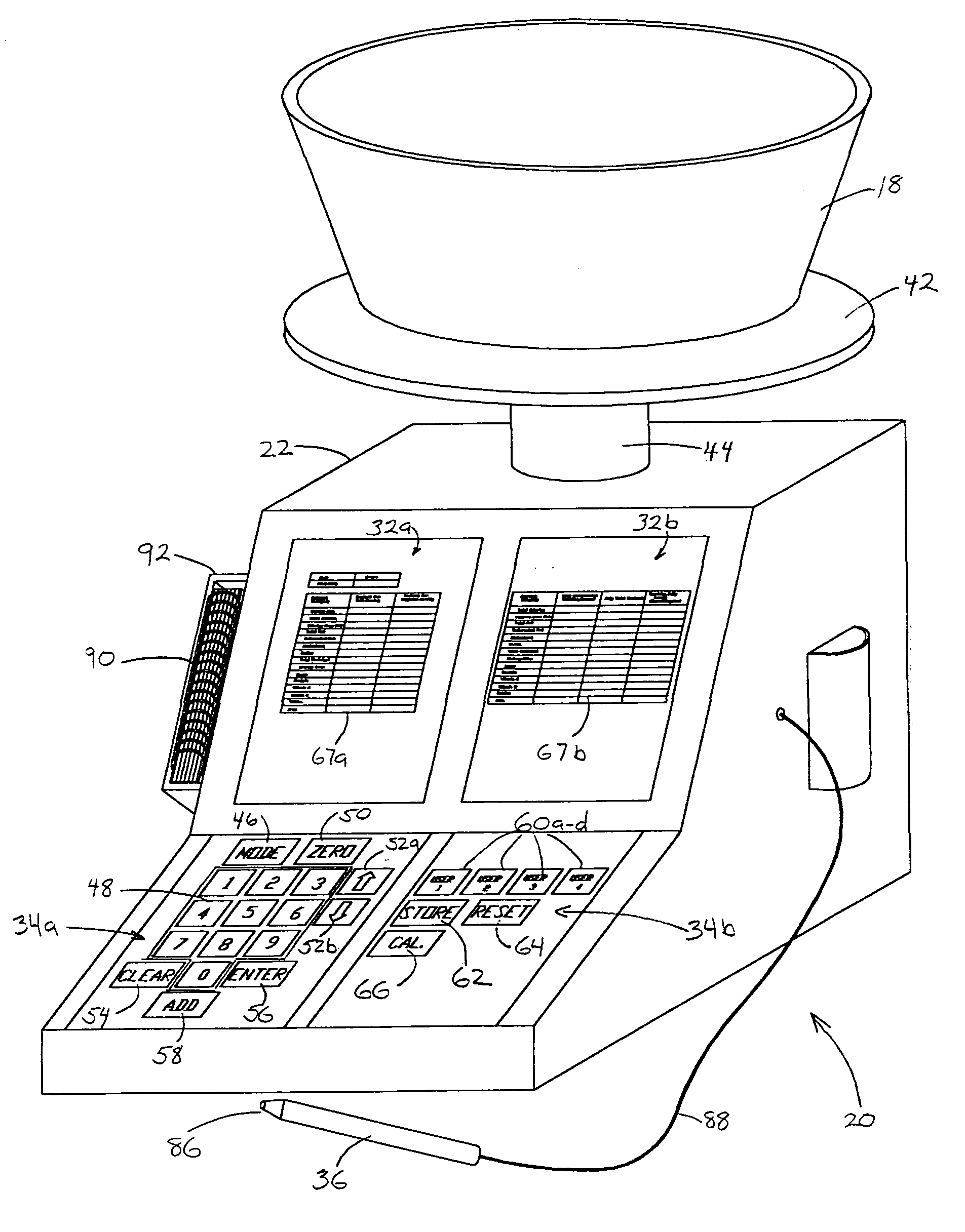

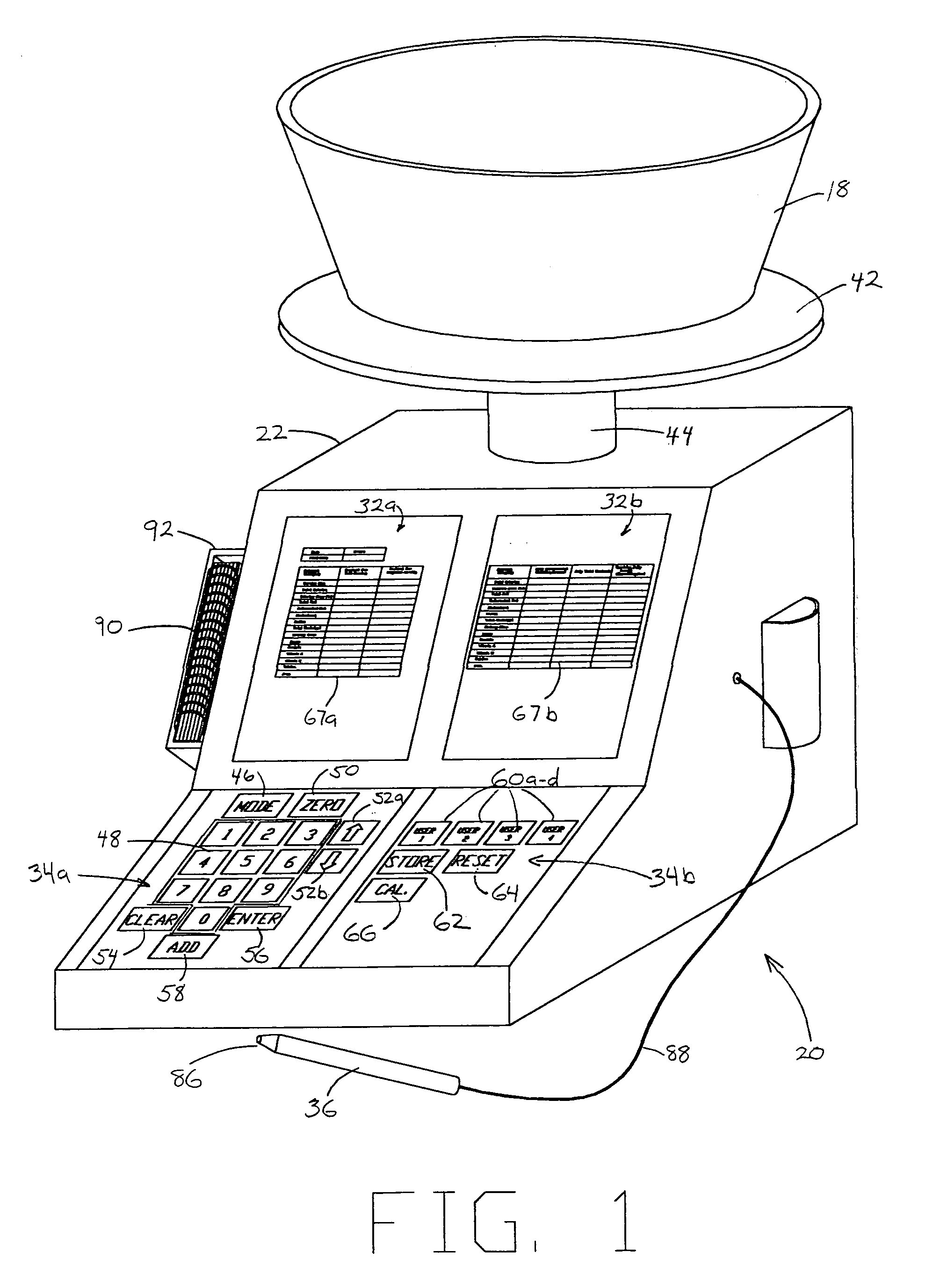

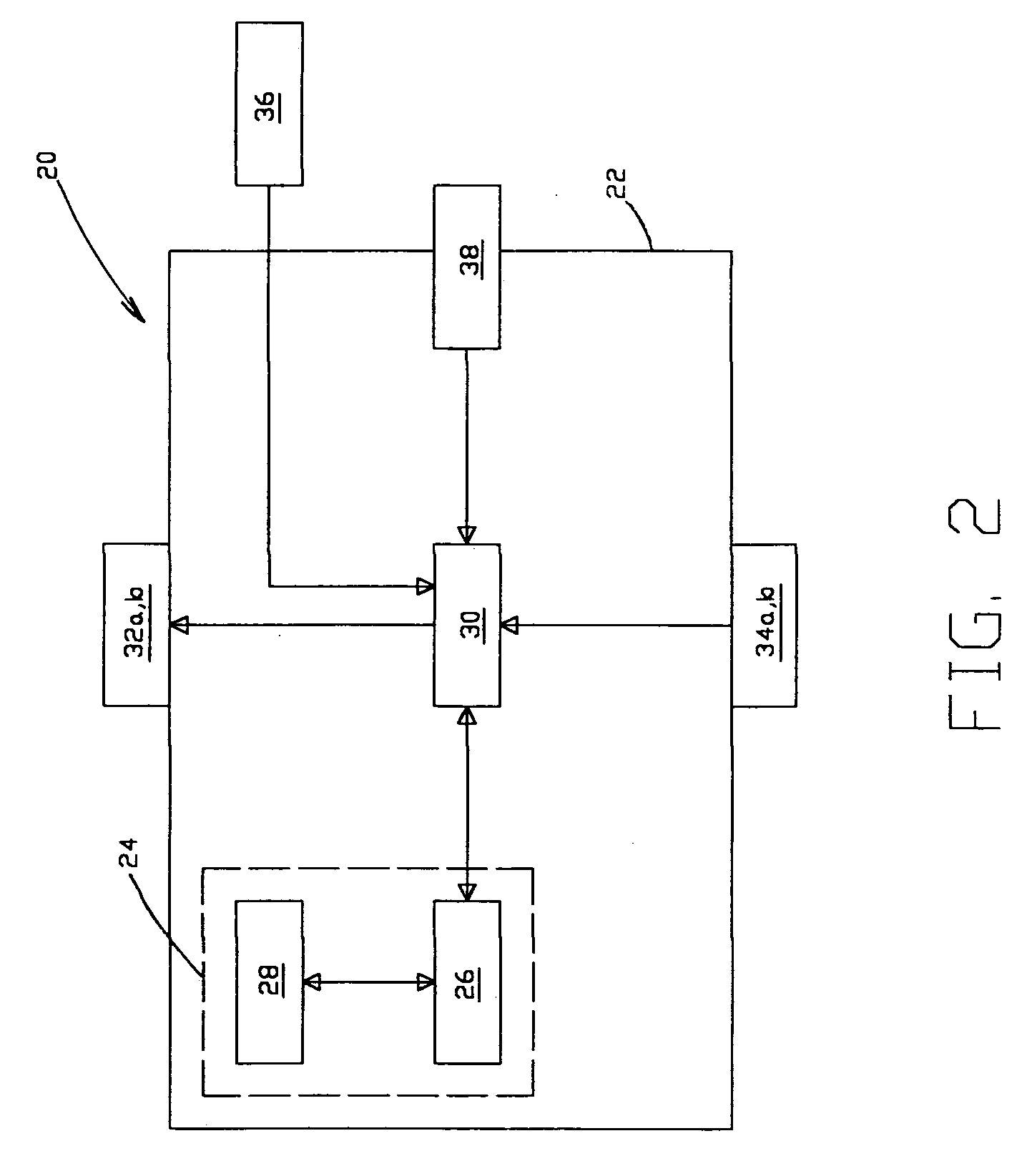

Computerized dietetic scale

InactiveUS6978221B1Convenient and simple and rapid to useEasily compared for accuracyTime indicationSurgeryNutritionBarcode

A dietetic scale and method for calculating and tracking nutritional content information. The scale includes a bar code reader for identifying a food product from its package, with food content data per unit weight of the product being retrieved from a database. The database is a compilation of standardized nutrition facts promulgated by the FDA or other authority for the food products, with the bar code being correlated with the food products by means of their individual UPC numbers. The scale cumulatively sends the nutritional content data for servings of food products consumed over a predetermined interval of time, and then compares the summed values with a predetermined goal that includes minimums and maximums for selected contents. The information may be outputted to a digital flashcard or other electronic storage media for subsequent retrieval and analysis.

Owner:RUDY RICHARD J

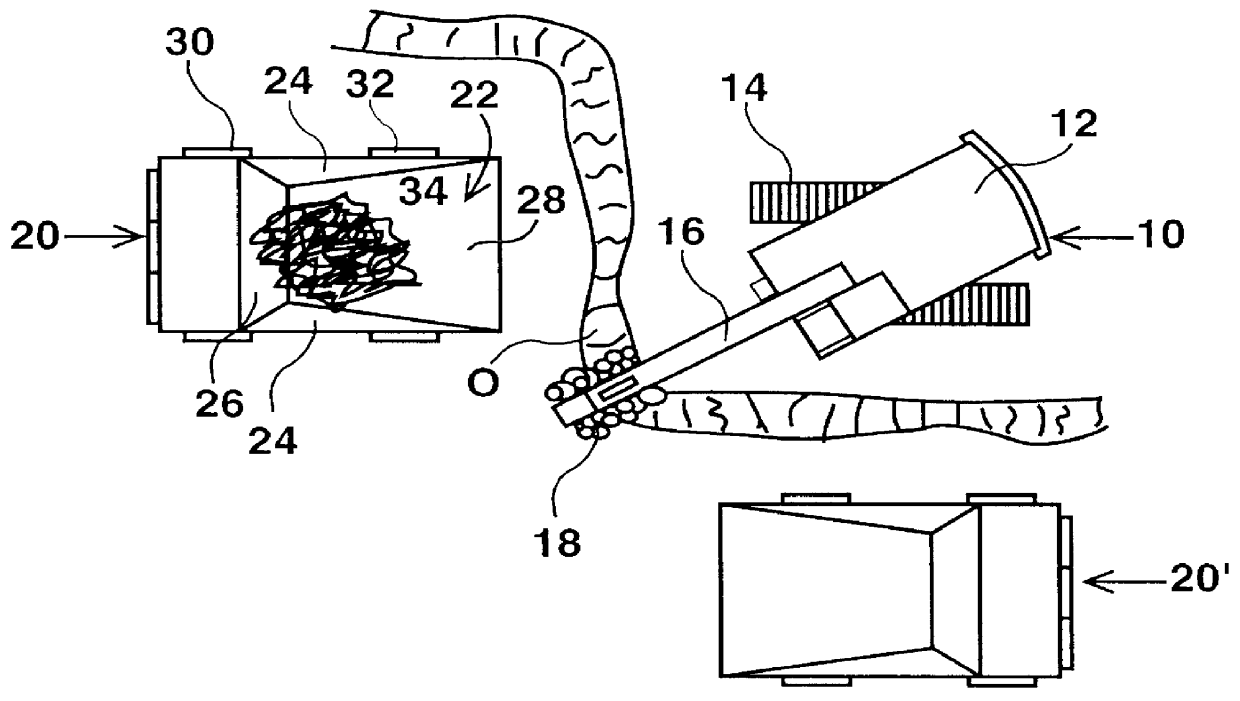

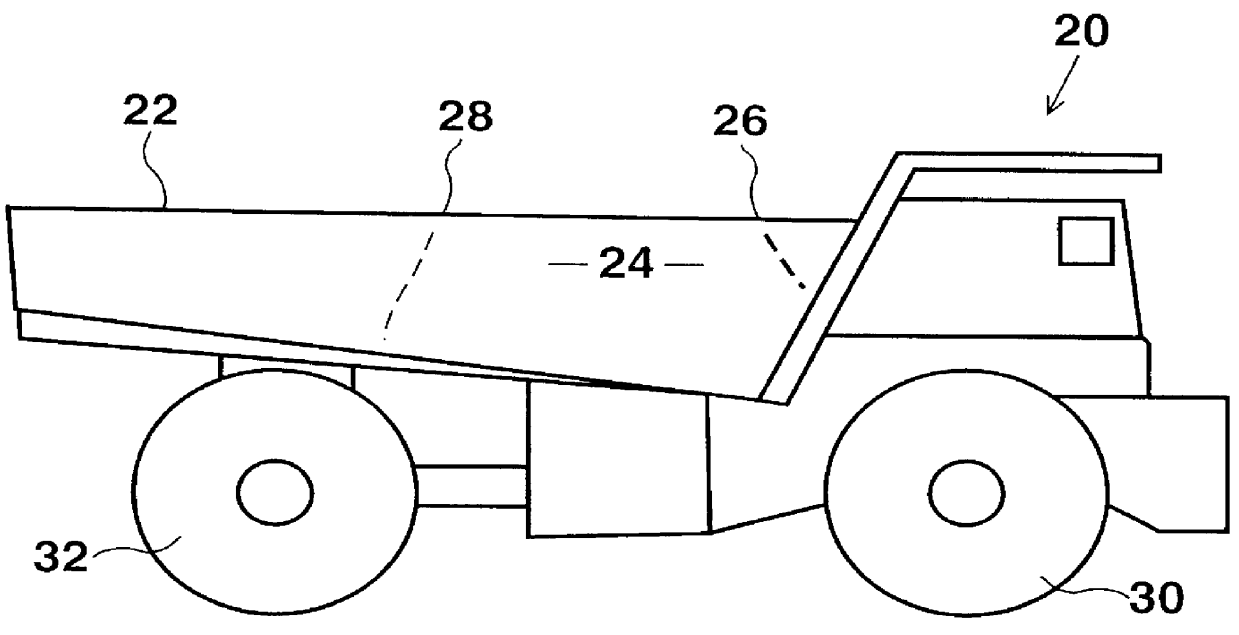

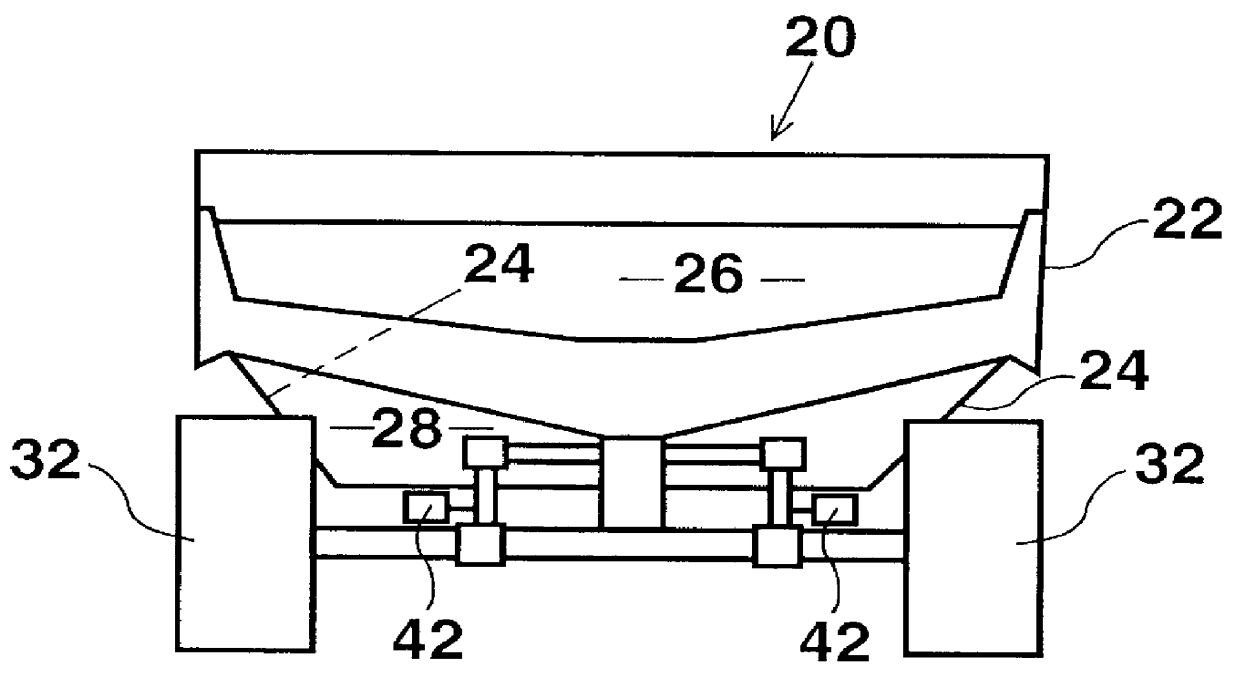

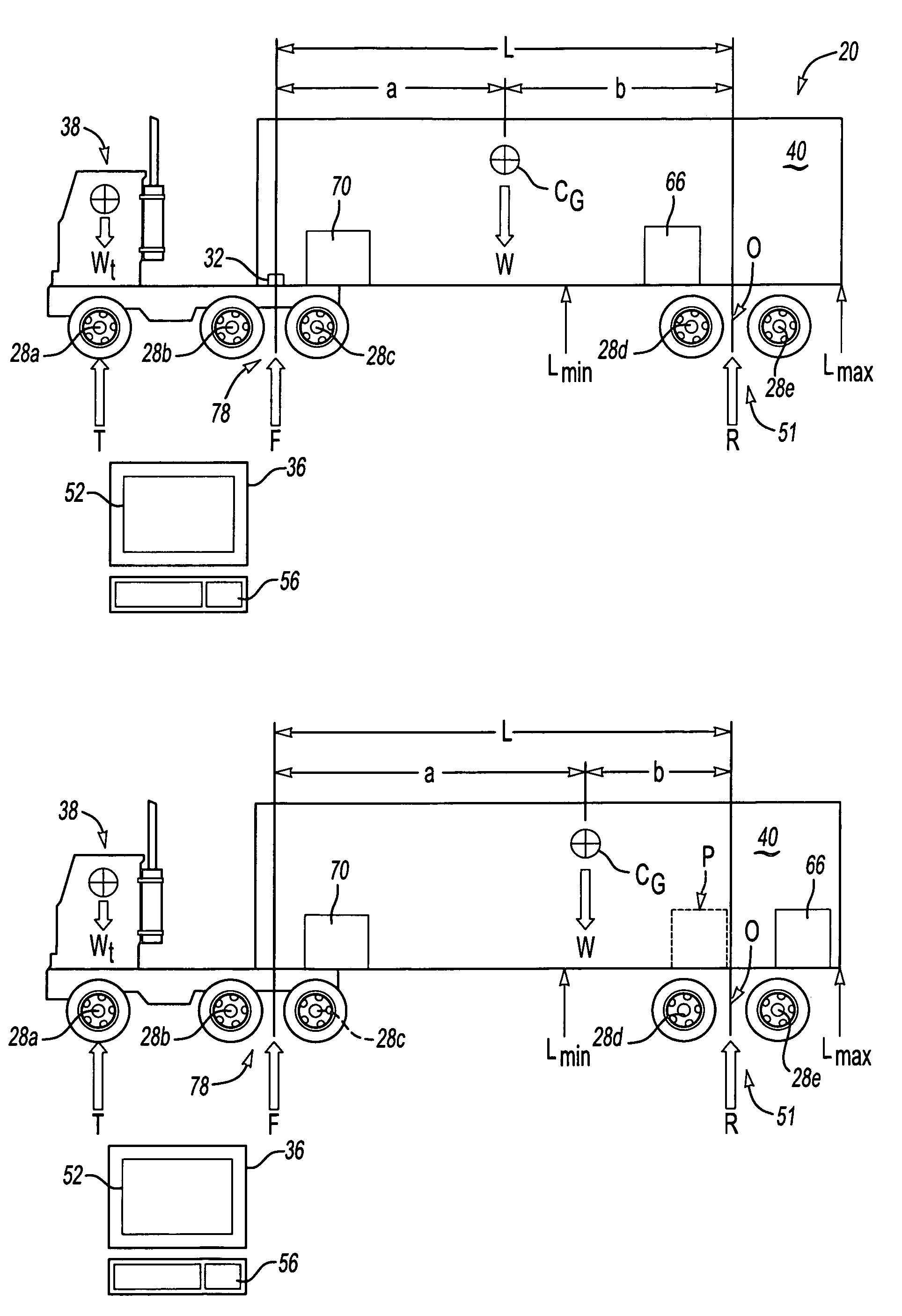

Load distribution system for haulage trucks

InactiveUS6157889AMechanical machines/dredgersMeasurement arrangements for variableAutomated algorithmEngineering

Weight sensors coupled to the bed of a conventional haulage truck measure the weight applied to each tire strut as the truck is being loaded. Based on the weight applied to each strut, the exact position of the center of gravity of the load in the truck's bed is calculated and displayed on a monitor relative to a target position deemed optimal for uniform weight distribution. Based on this information, the operator of the loading machine can complete the loading operation in such a way as to shift the center of gravity toward the chosen target position. In another embodiment of the invention, an automated algorithm calculates and displays where the next bucket load should be dropped, based on its approximate weight, in order to shift the center of gravity toward the target location.

Owner:MODULAR MINING SYSTEMS

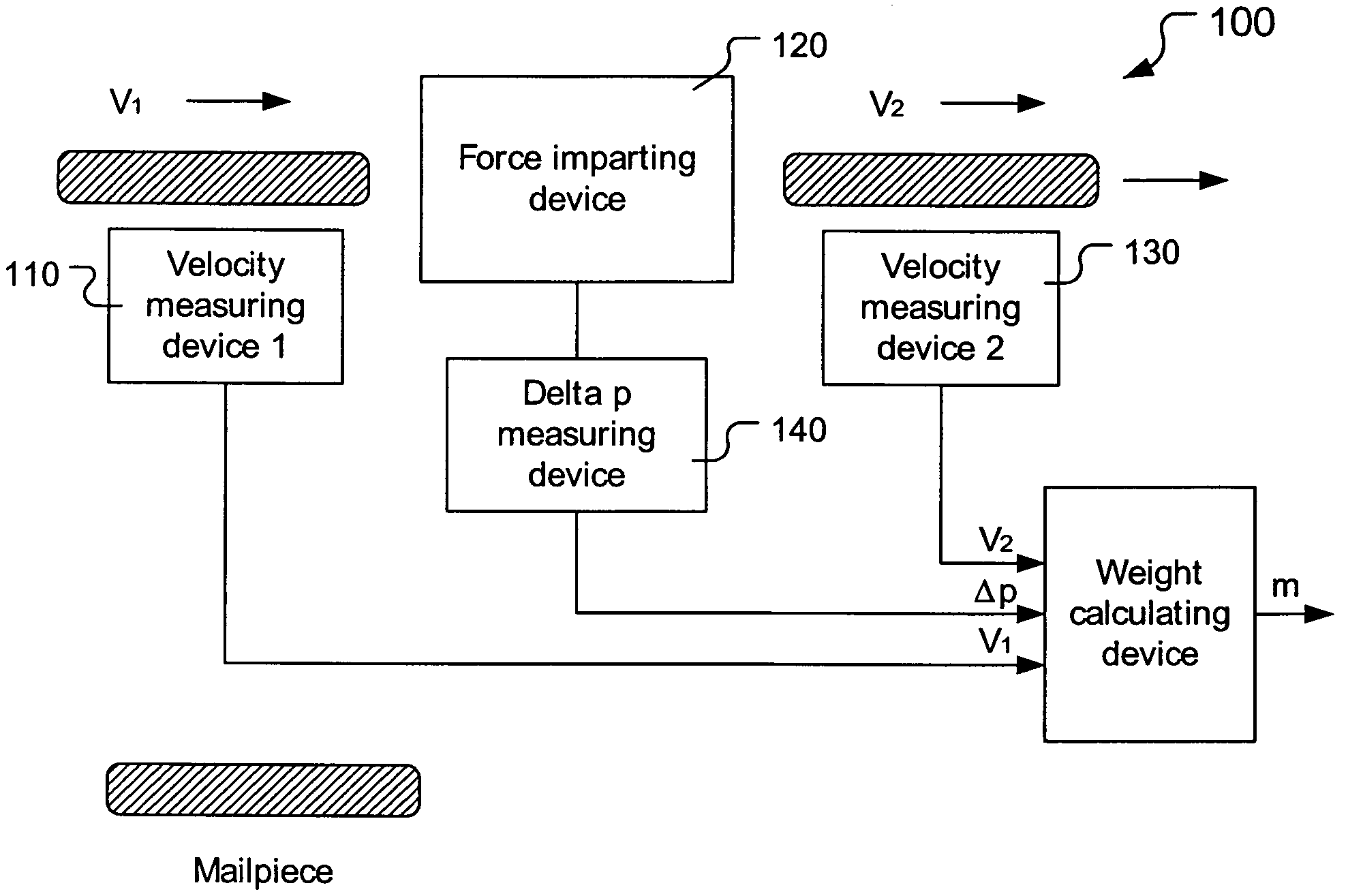

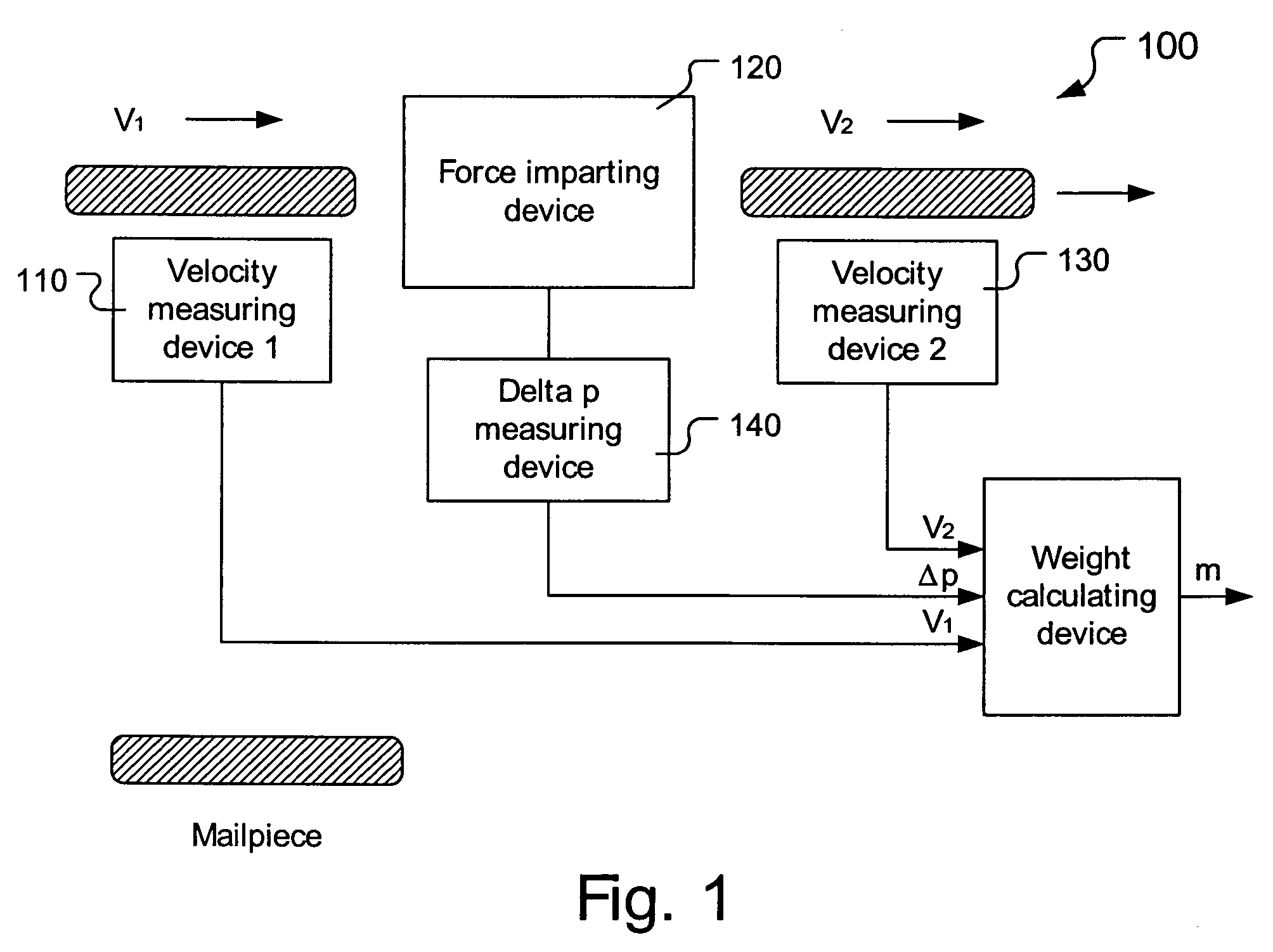

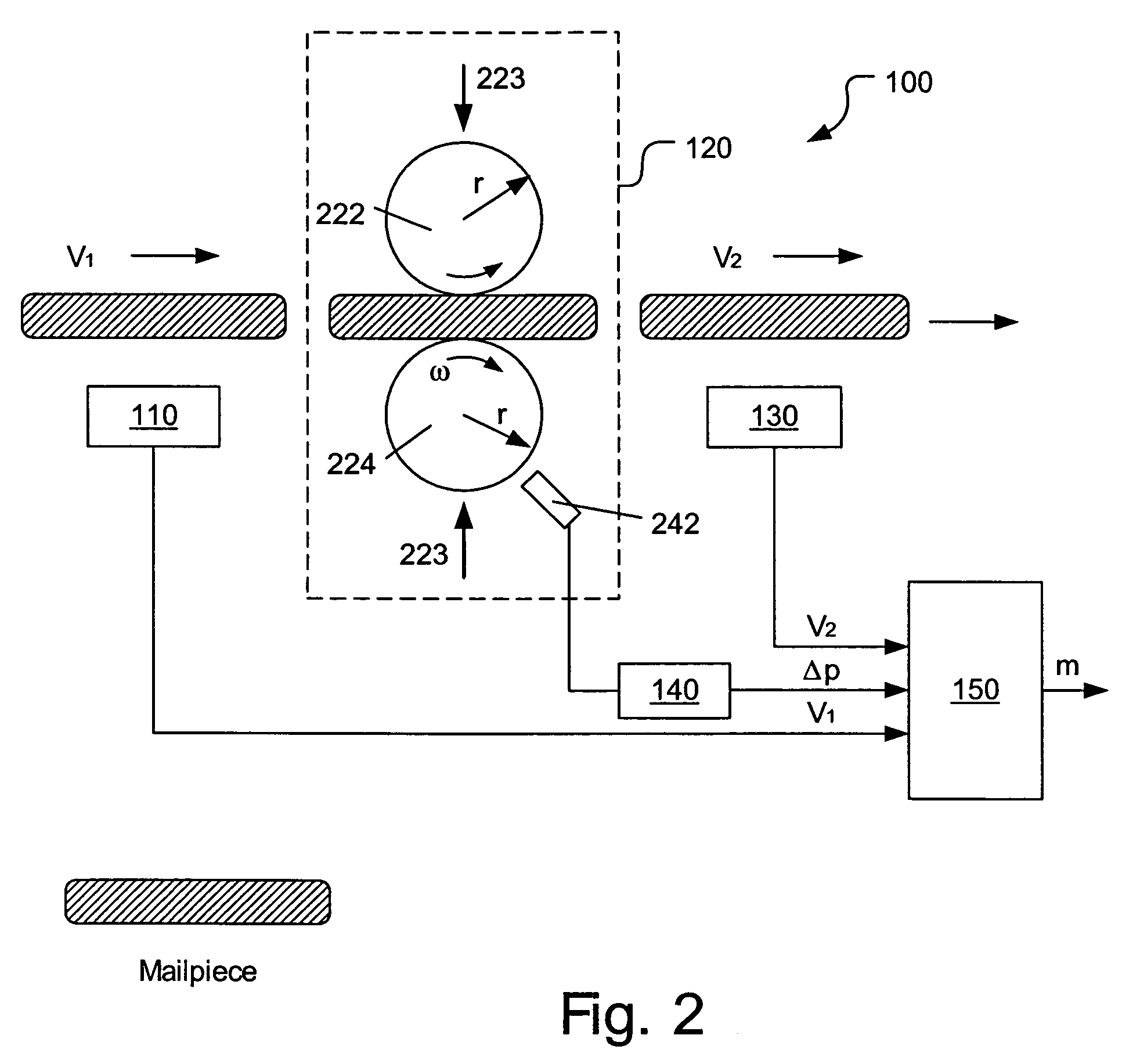

Method and apparatus for determining weight of moving mailpieces

The invention pertains to a mailpiece weight measuring apparatus for use with a high speed automatic mailpiece processing system. The weight measuring apparatus measures the inertial mass of the mailpiece as the weight equivalent. The apparatus includes a device for determining a first velocity of a mailpiece, a device for imparting a force to the mailpiece in a direction co-linear with the first velocity so that the mailpiece exits said force impacting device at a second velocity, a device for determining the second velocity of the mailpiece, a device for determining a change in a parameter proportional to the force imparted on the mailpiece, and a device for determining the weight of the mailpiece based upon the determined first velocity, second velocity and change in the parameter.

Owner:DMT SOLUTIONS GLOBAL CORP

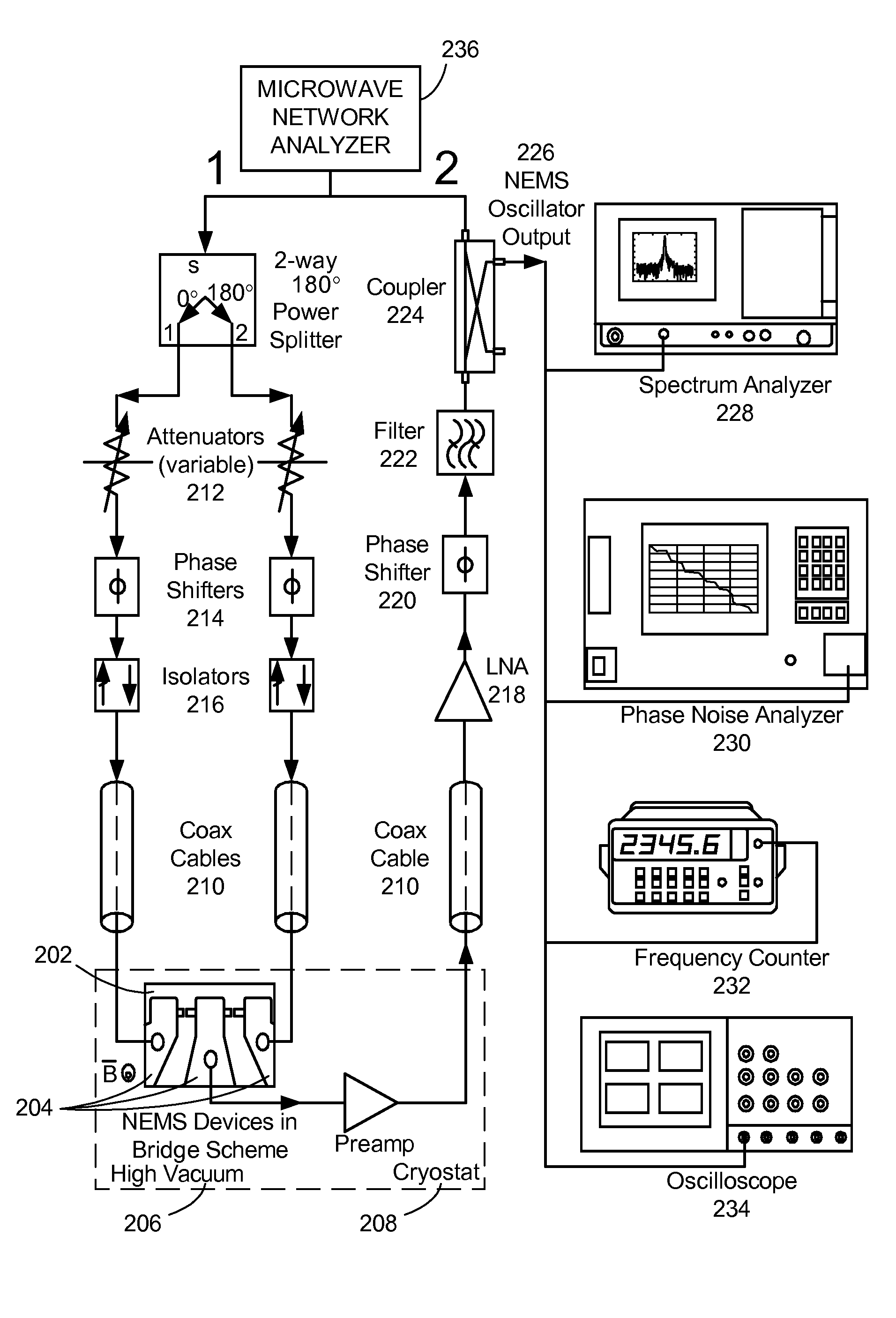

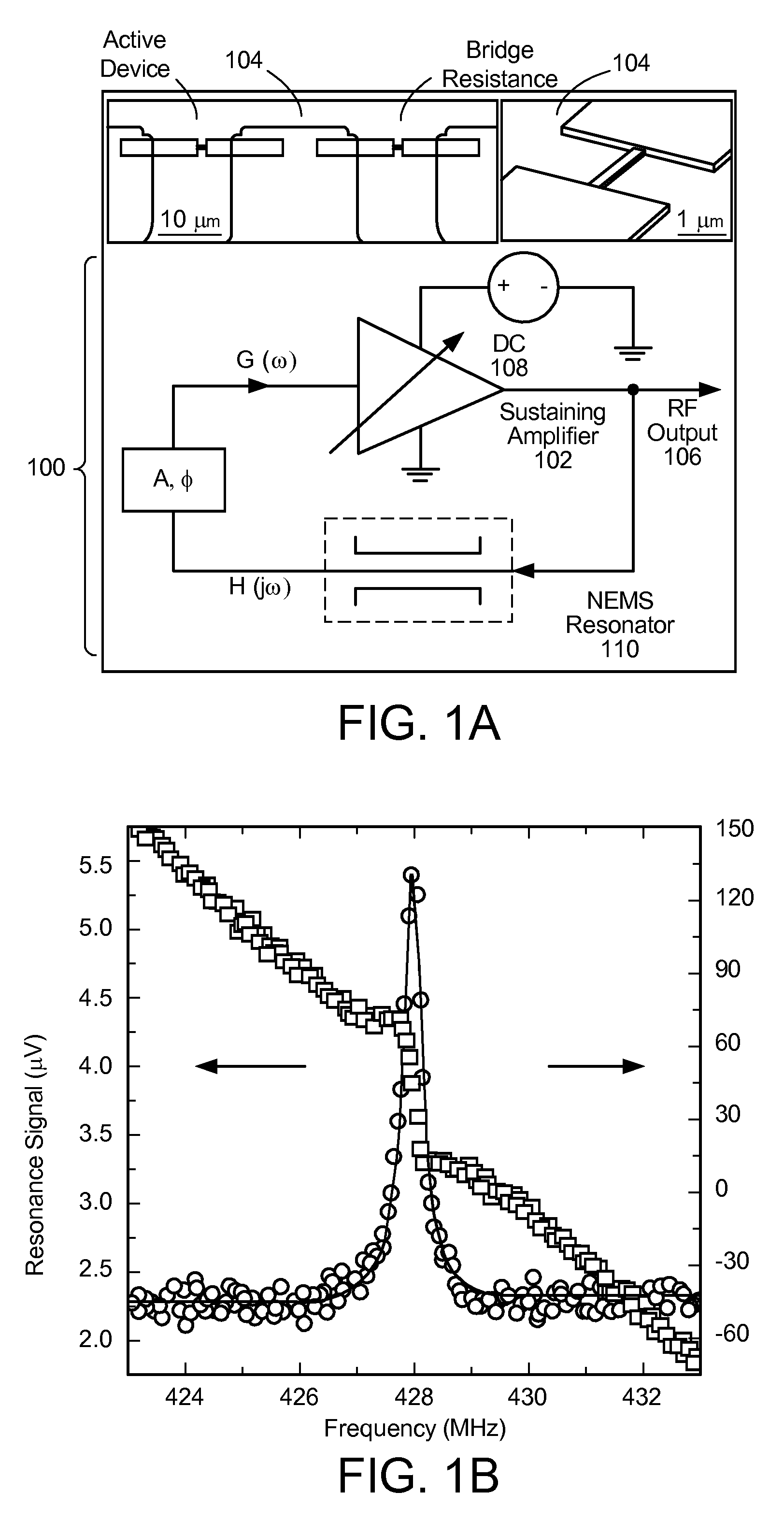

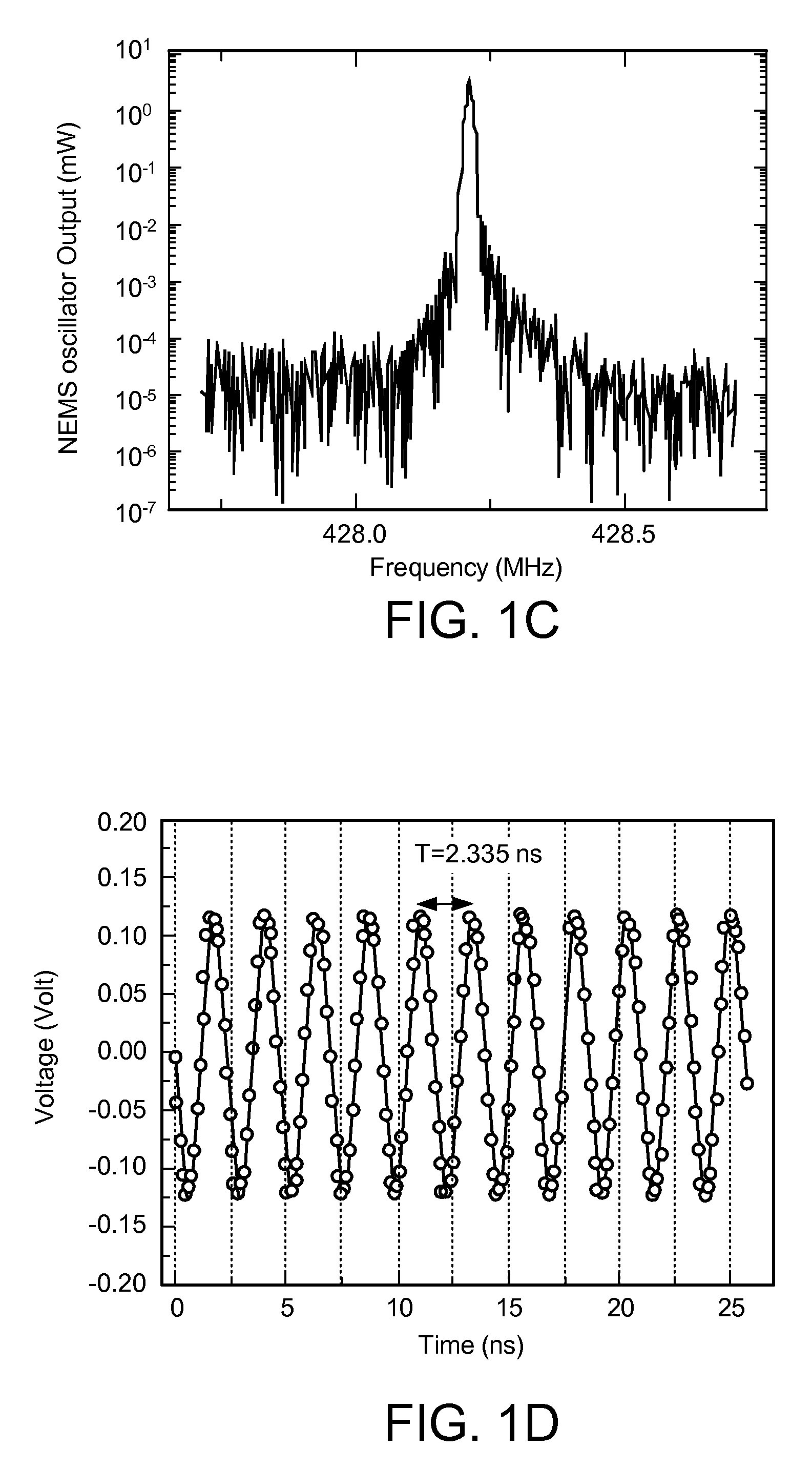

Ultra-high frequency self-sustaining oscillators, coupled oscillators, voltage-controlled oscillators, and oscillator arrays based on vibrating nanoelectromechanical resonators

ActiveUS7724103B2Noteworthy performanceNoteworthy stabilityMaterial analysis using sonic/ultrasonic/infrasonic wavesWeighing apparatus using elastically-deformable membersBeam resonatorVIT signals

Owner:CALIFORNIA INST OF TECH

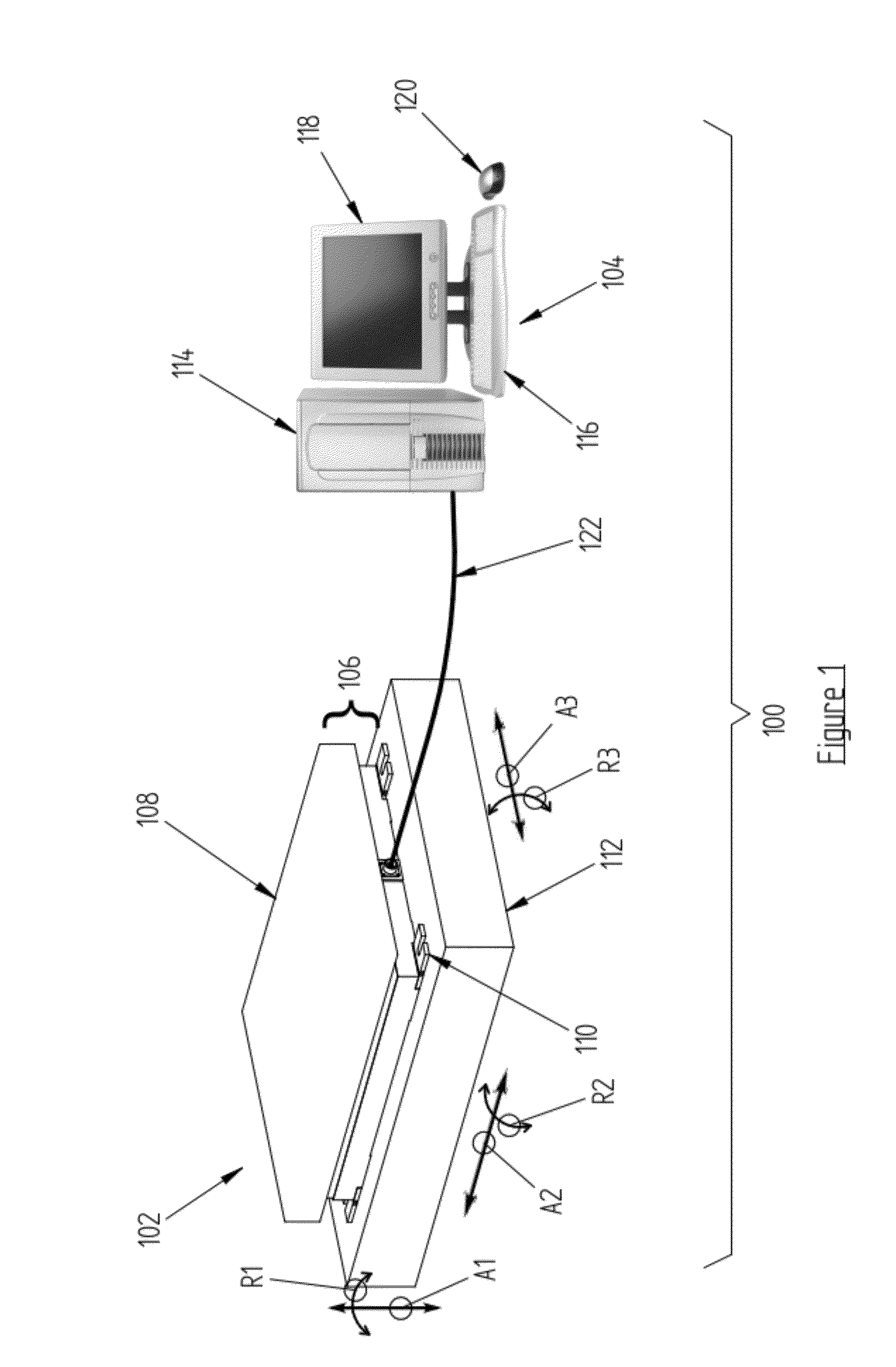

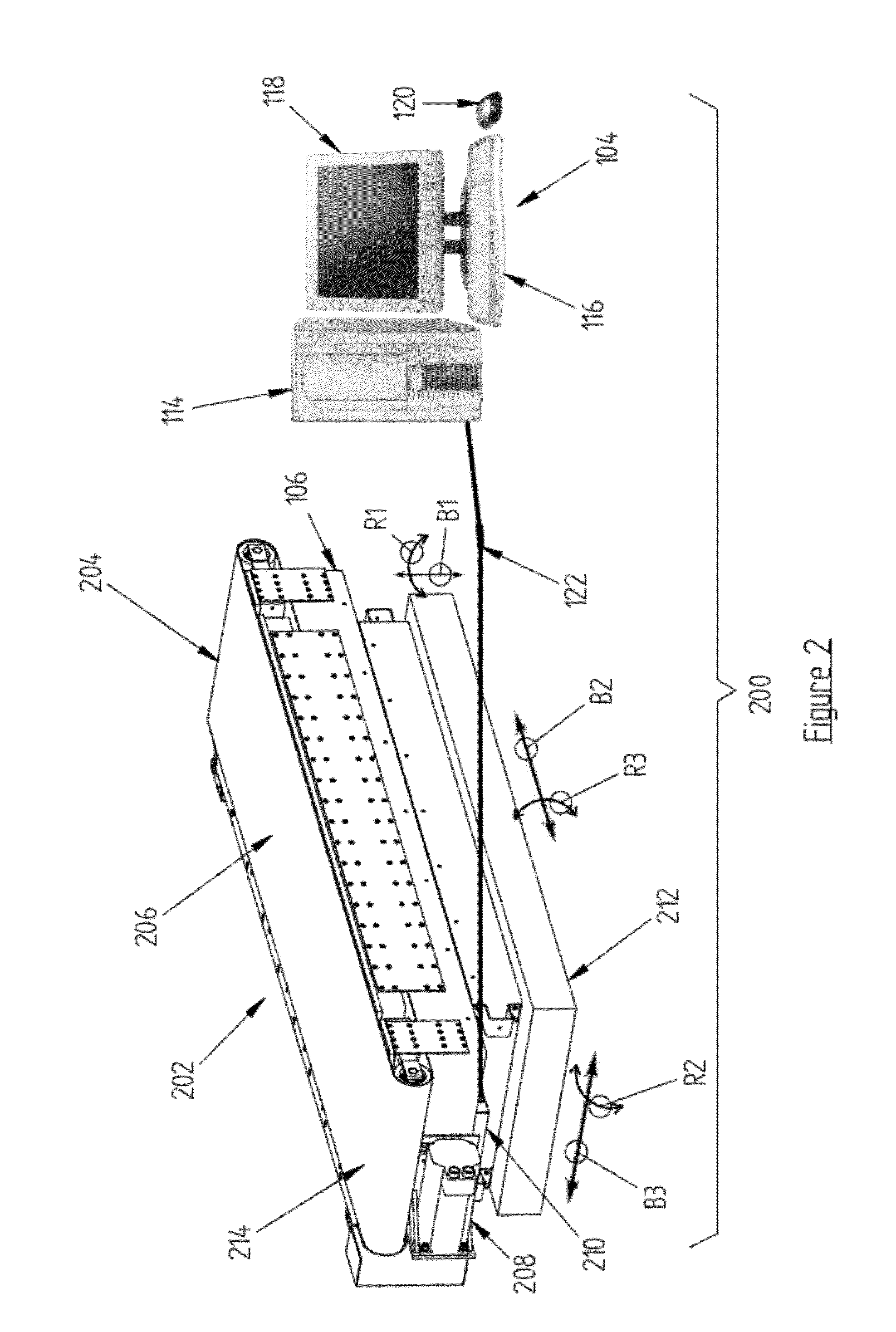

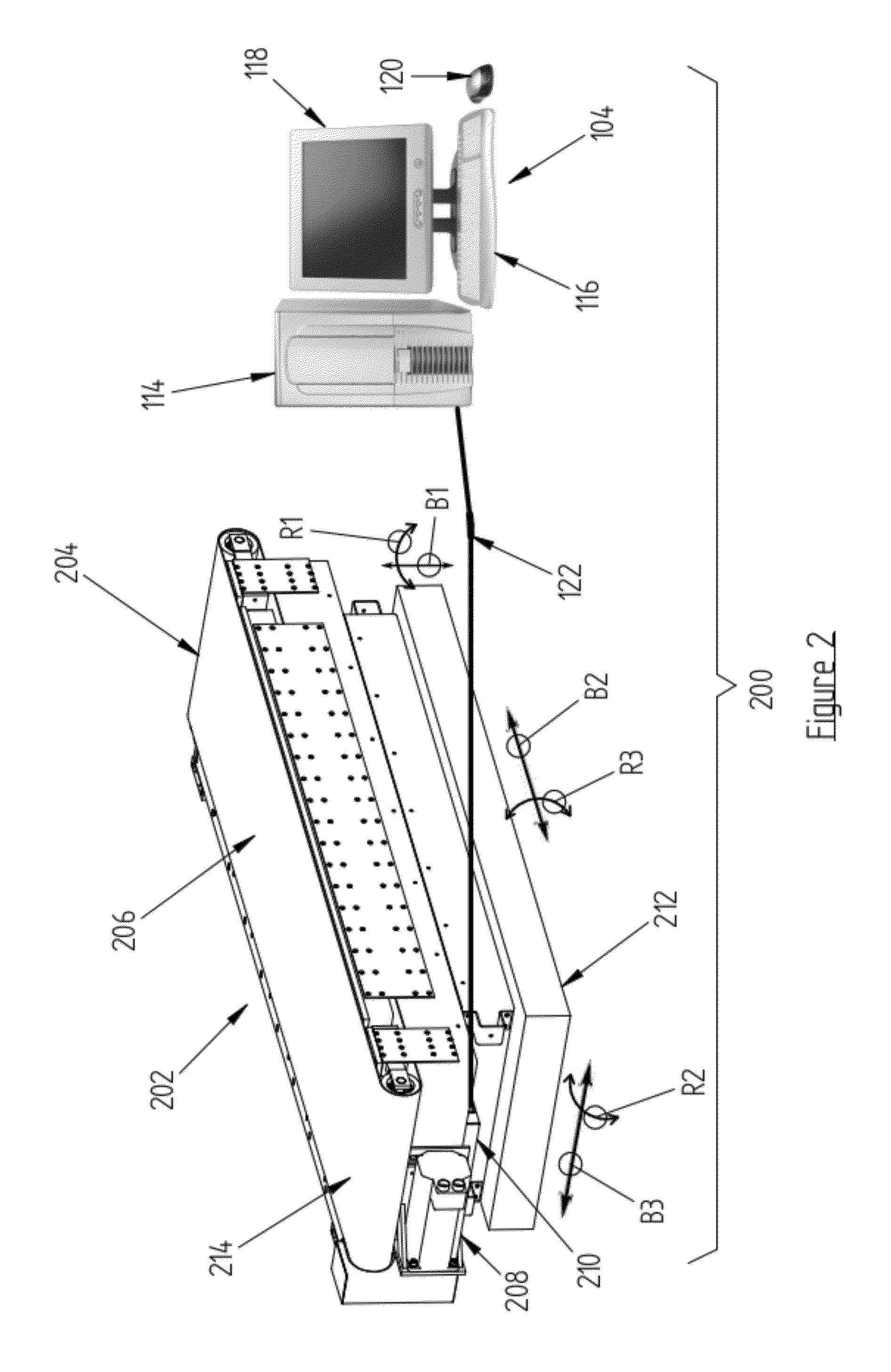

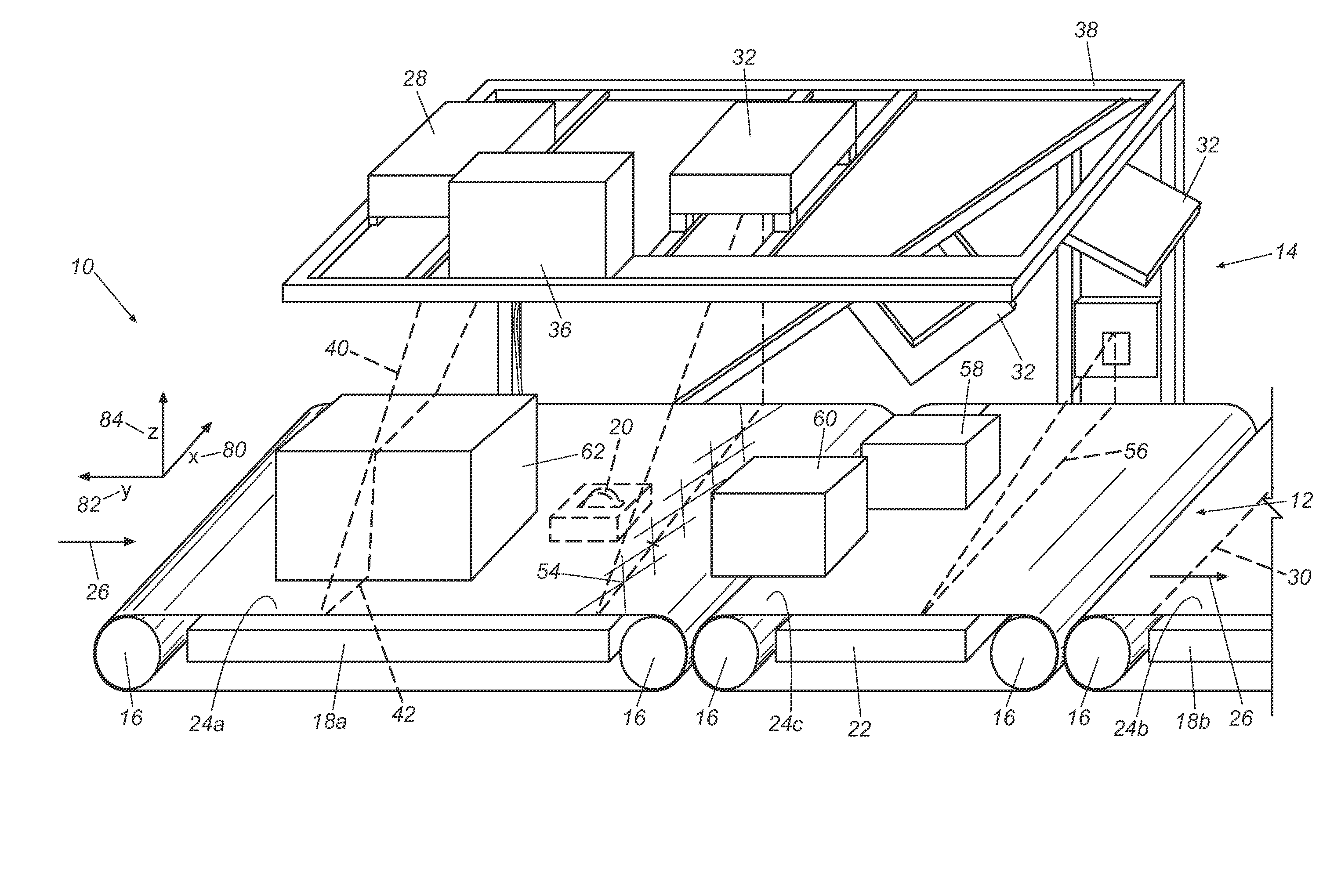

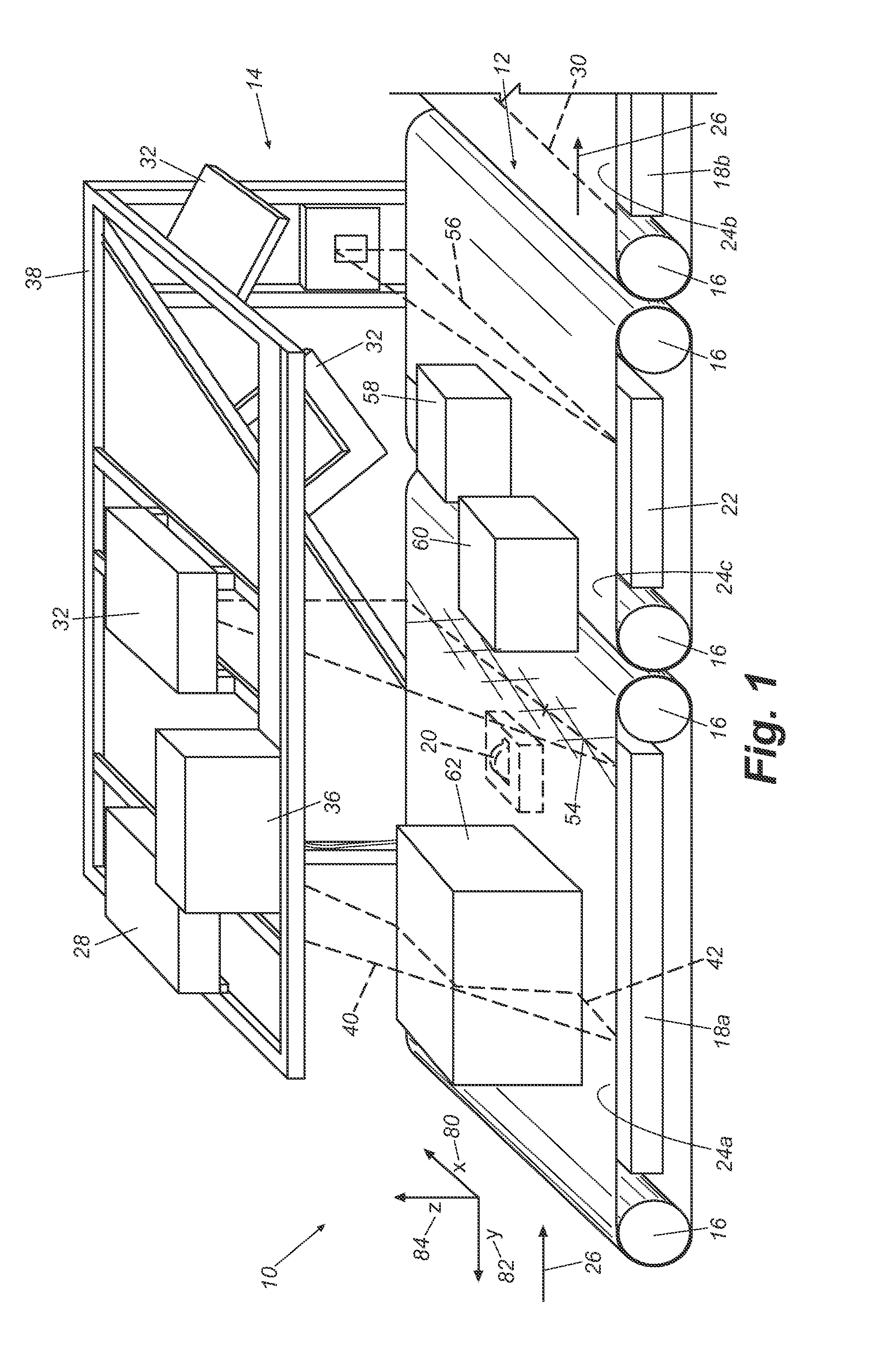

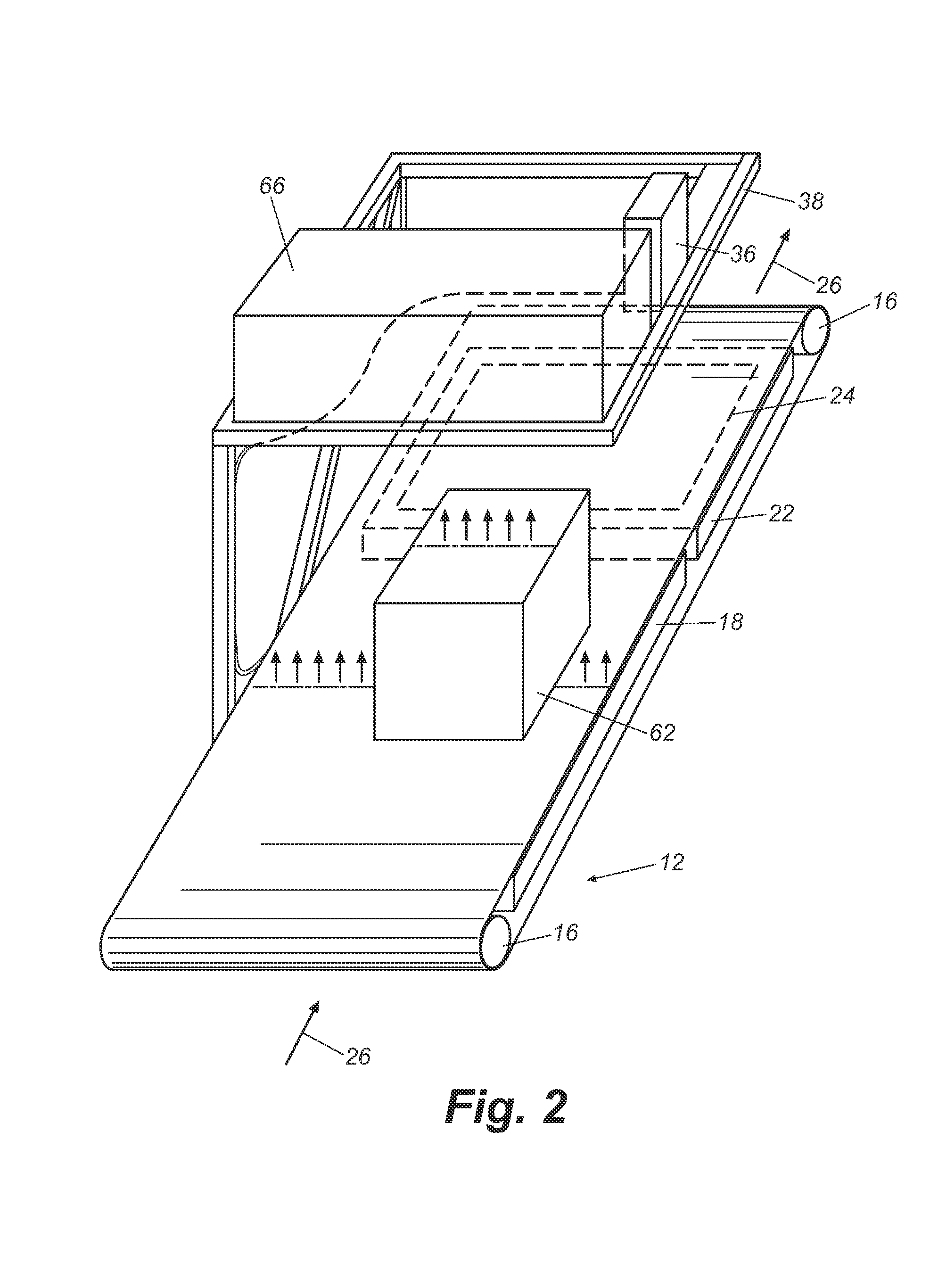

Apparatus and method for measuring the weight of items on a conveyor

ActiveUS20080164074A1Using optical meansWeighing apparatus for materials with special property/formComputer science

An apparatus for measuring the weight of items on a conveyor includes a scale that generates a first signal corresponding to the weight of the items. A movable platform transports the items to the scale and generates a second signal corresponding to position of the items in relation to the scale. A dimensioner examines the items and generates a third signal representative of whether the items are singulated or nonsingulated. A processor receives the second and third signals and determines whether to associate the first signal with information stored in memory about a particular item based upon whether the particular item is singulated or nonsingulated.

Owner:DATALOGIC AUTOMATION

Force measurement system having inertial compensation

ActiveUS8315822B2Accurate compensationAccurate force measurementForce measurementInertial sensorsAccelerometerAngular velocity

A force measurement system having inertial compensation includes a force measurement assembly with at least one accelerometer configured to measure the acceleration thereof. According to one aspect of the invention, the force measurement system additionally includes at least one angular velocity sensor configured to measure the angular velocity of the force measurement assembly. According to another aspect of the invention, the force measurement system additionally includes a data processing device with a computer-readable medium loaded thereon that is configured to execute a calibration procedure for determining the inertial parameters of the force measurement assembly by utilizing the measured acceleration of the force measurement assembly while the force measurement assembly is subjected to a plurality of applied linear and / or rotational motion profiles. According to still another aspect of the invention, the at least one accelerometer is disposed on the force transducer.

Owner:BERTEC

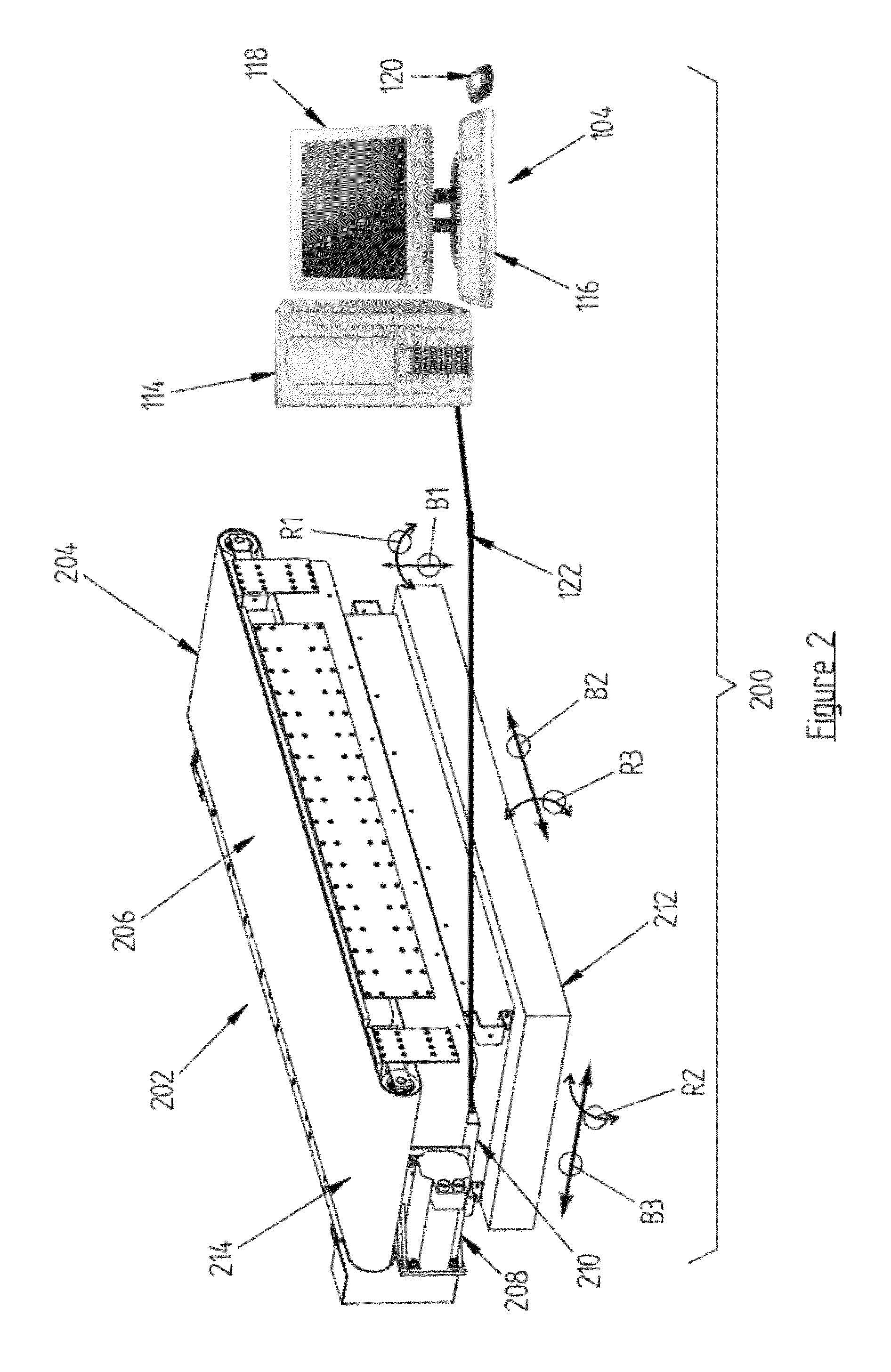

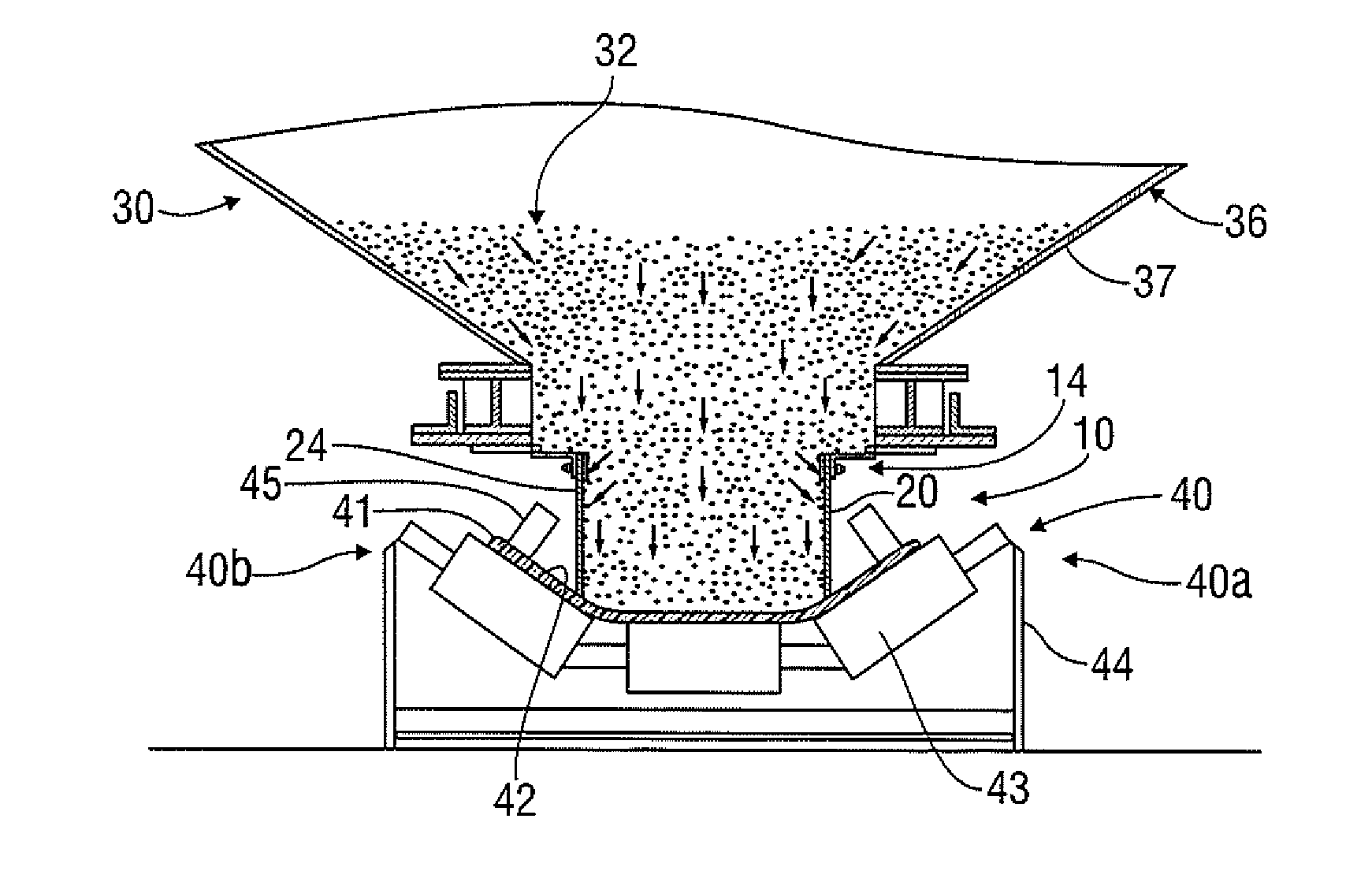

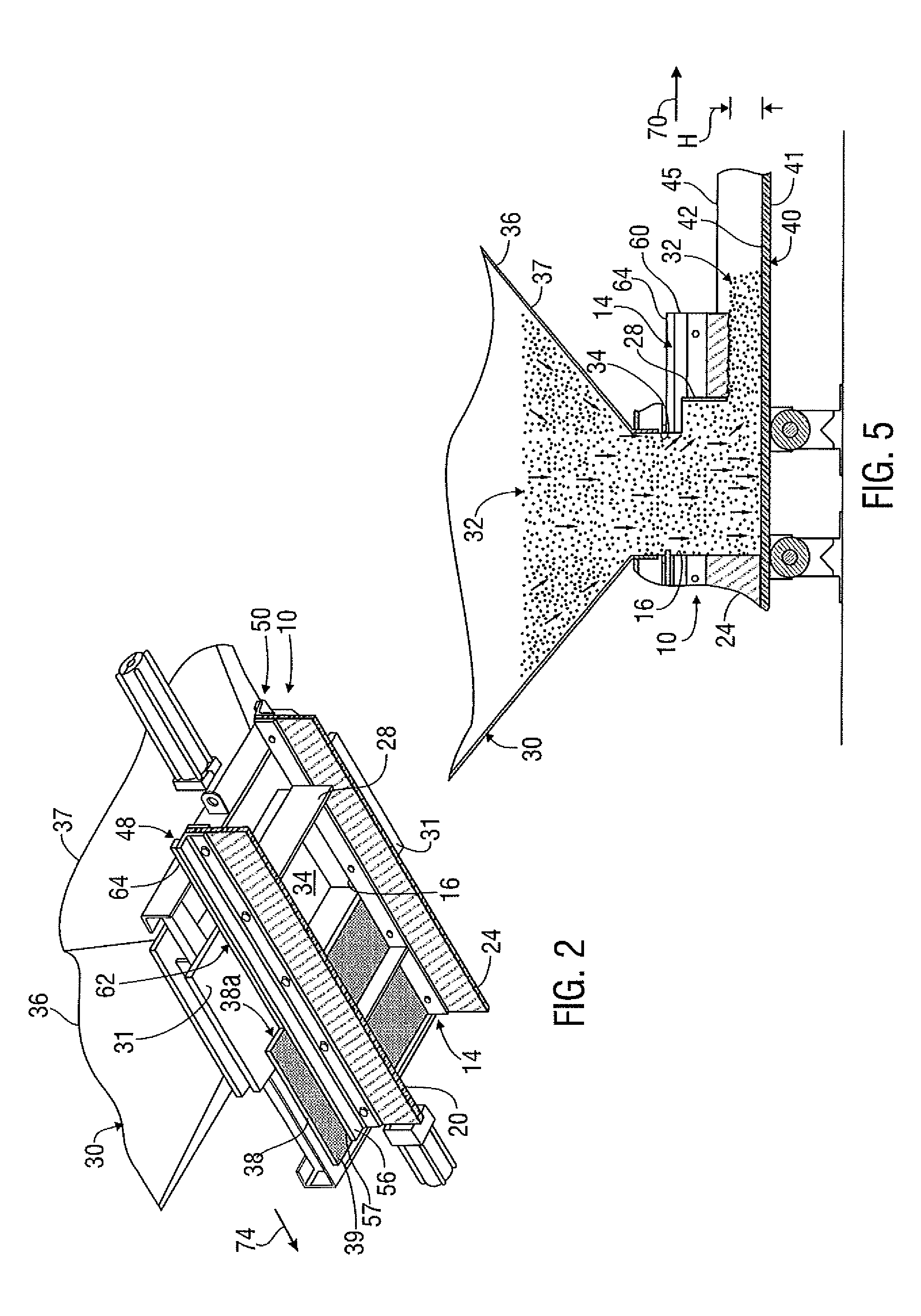

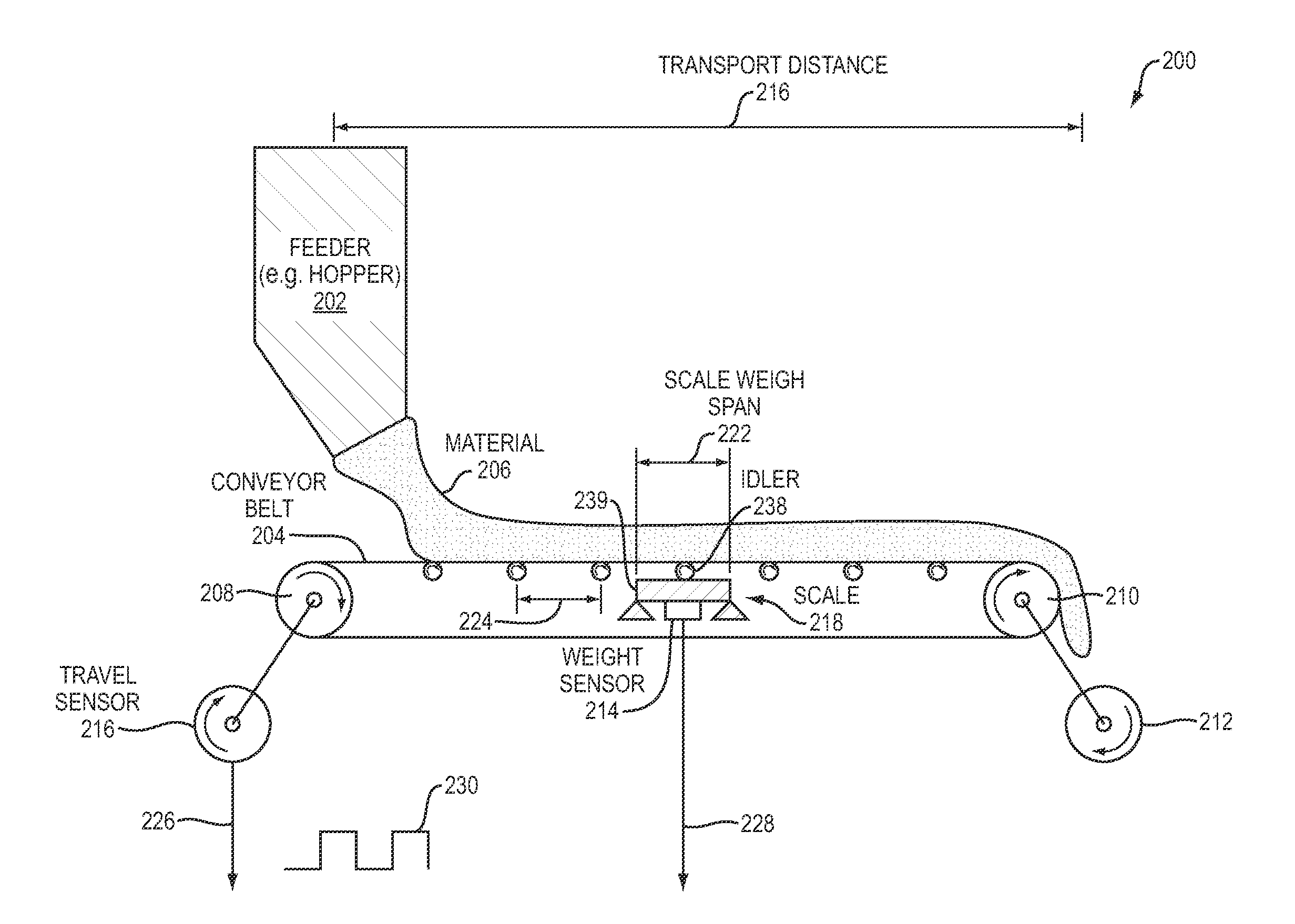

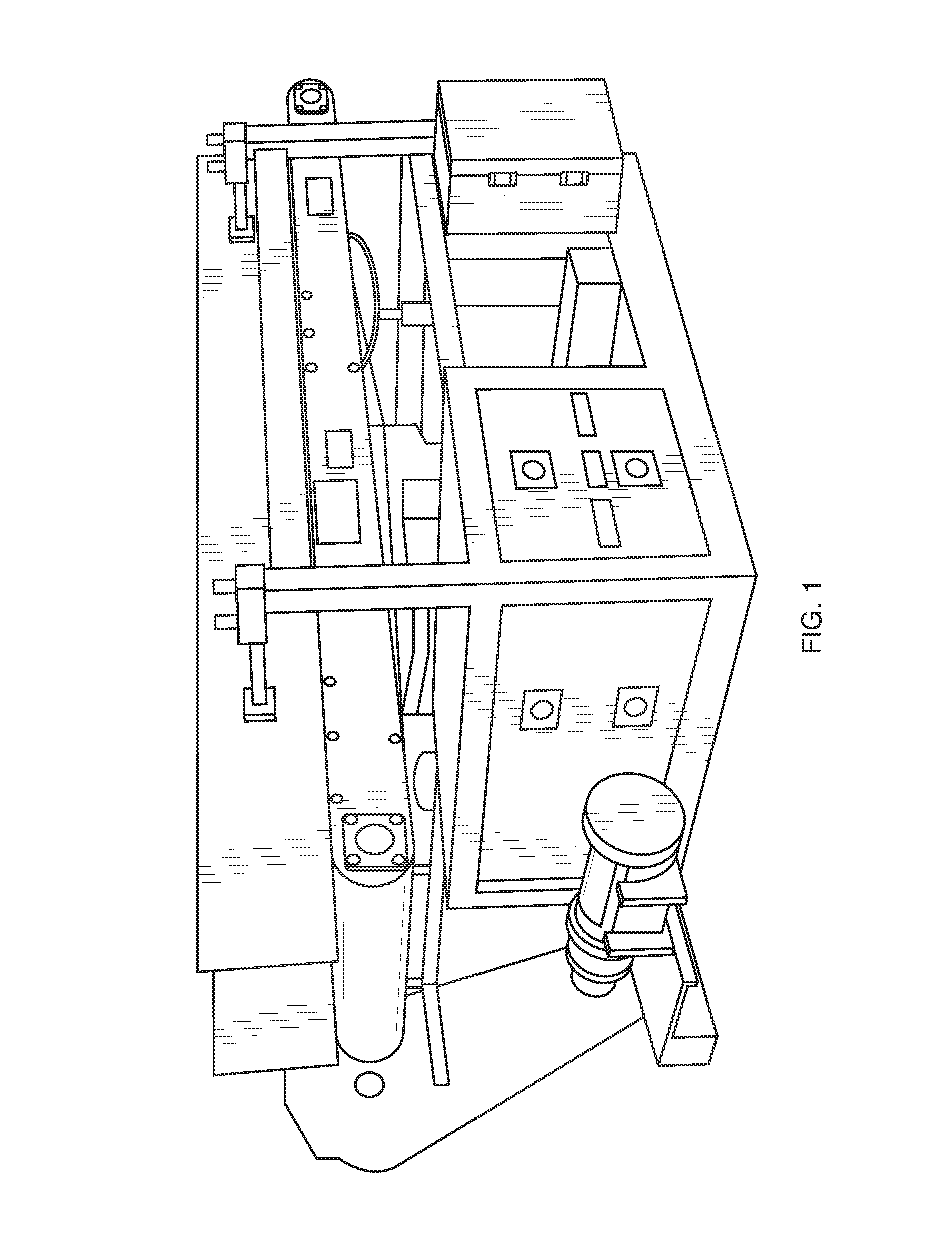

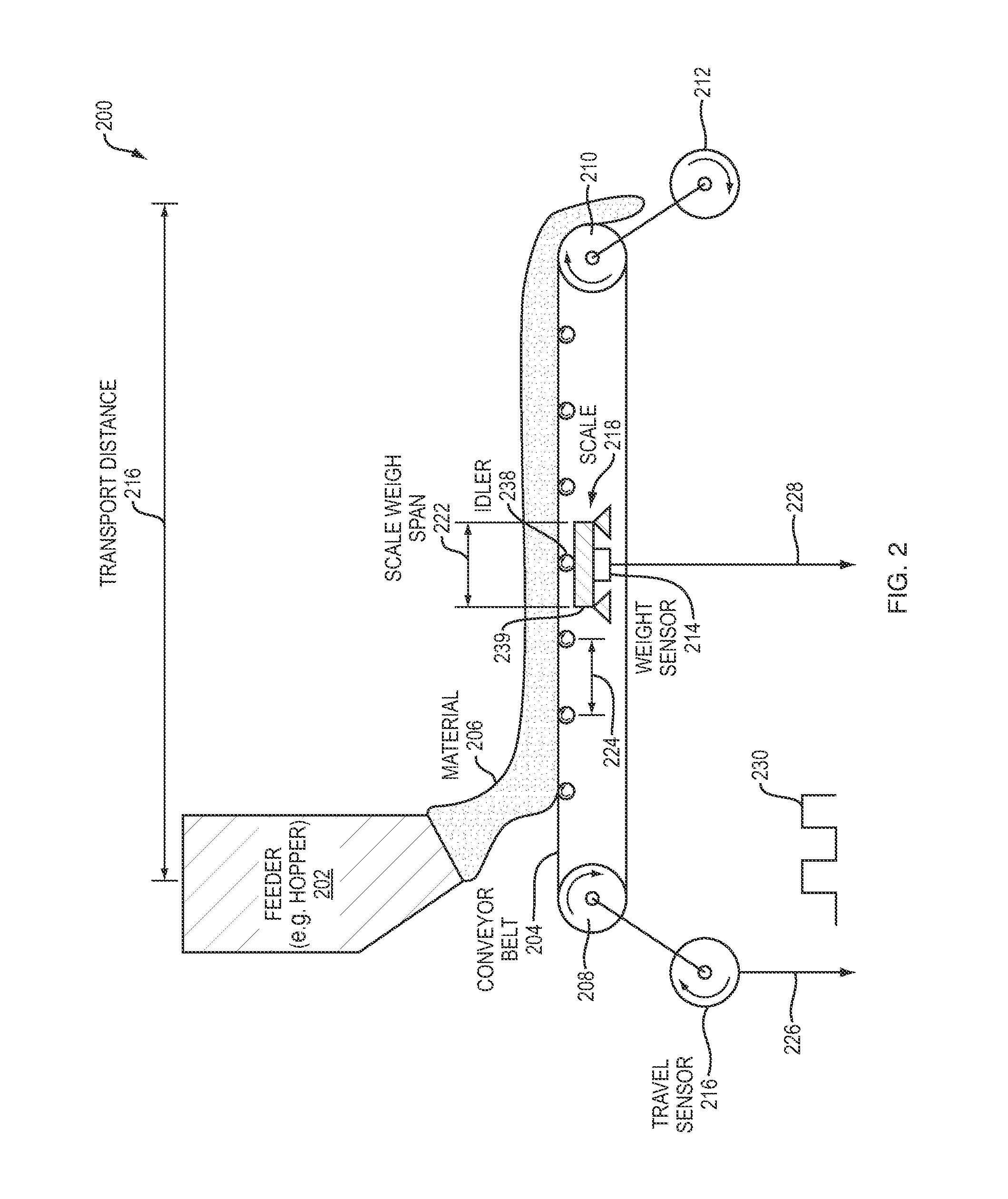

Apparatus and Methods for Assisting in Controlling Material Delivered on a Conveyor

ActiveUS20140044507A1Control devices for conveyorsWeighing apparatus for continuous material flowElectronic controllerConveyor belt

Method of controlling the amount of material delivered by conveyor belt includes measuring the speed of the conveyor belt or a drive pulley that drives the conveyor belt. A weighing device weighs material dispensed onto the conveyor belt from at least one material dispenser. Based at least in part upon such speed and weight measurements, an electronic controller maintains or changes the speed of the conveyor belt by dictating the output of at least one motor that drives the drive pulley.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

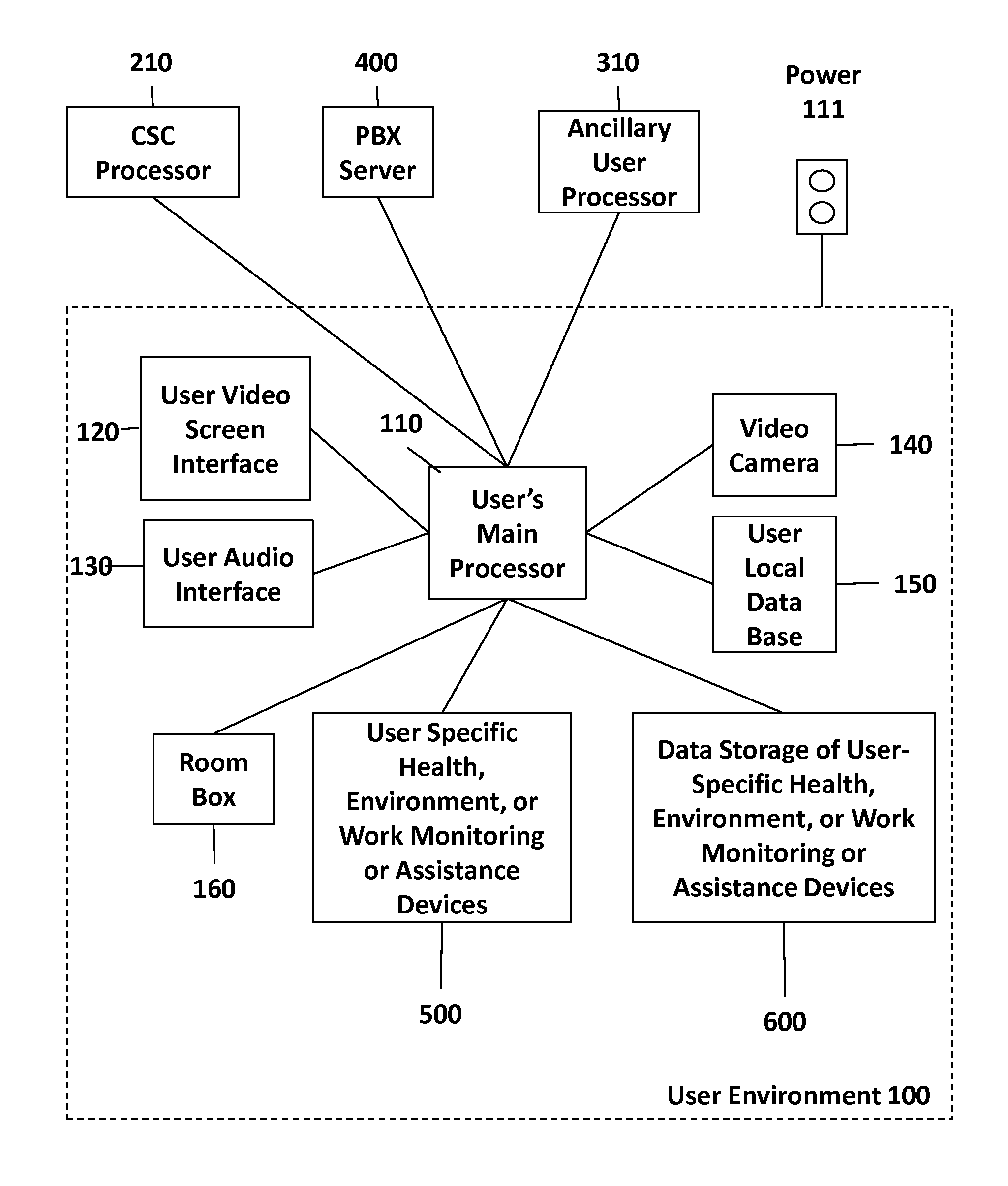

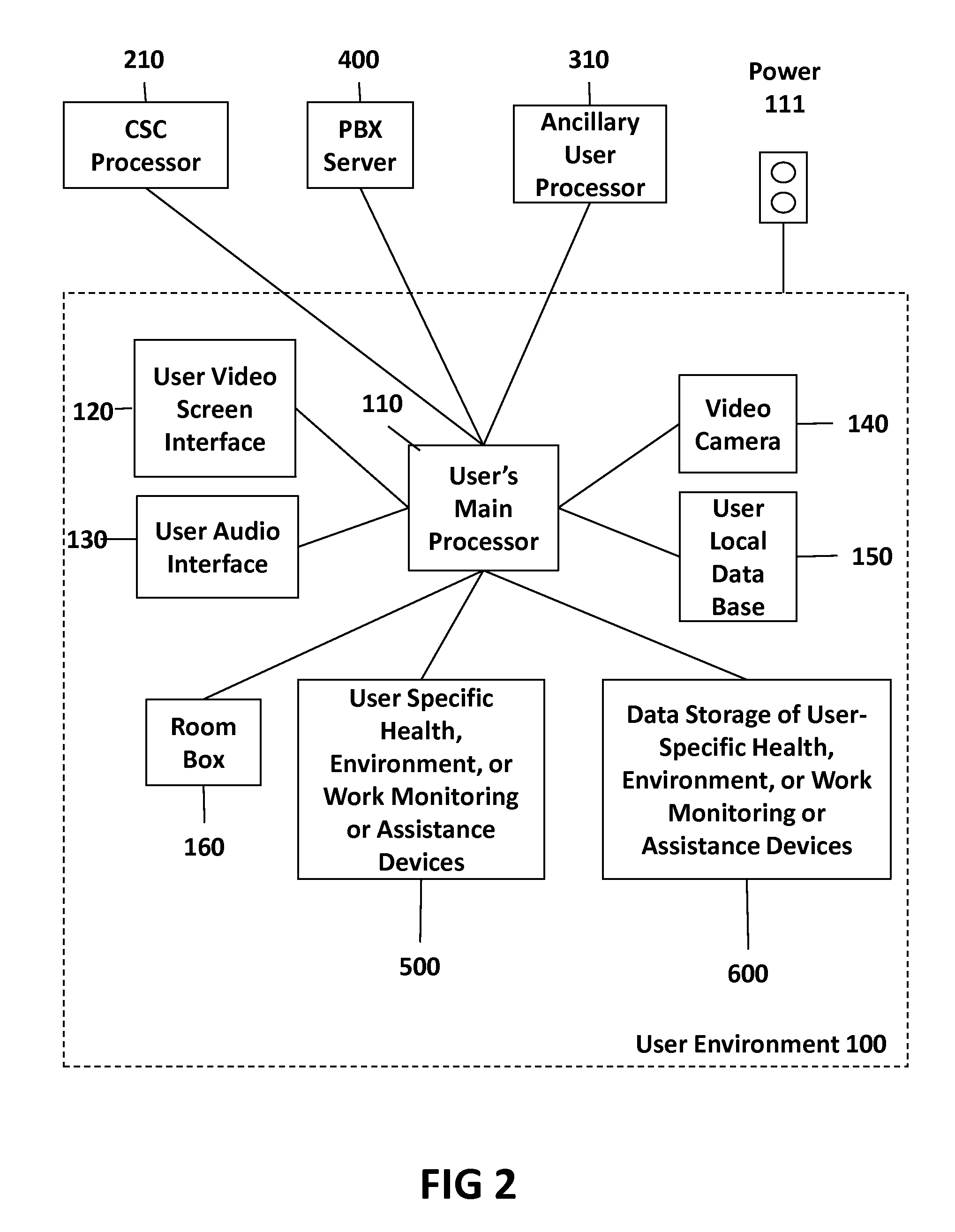

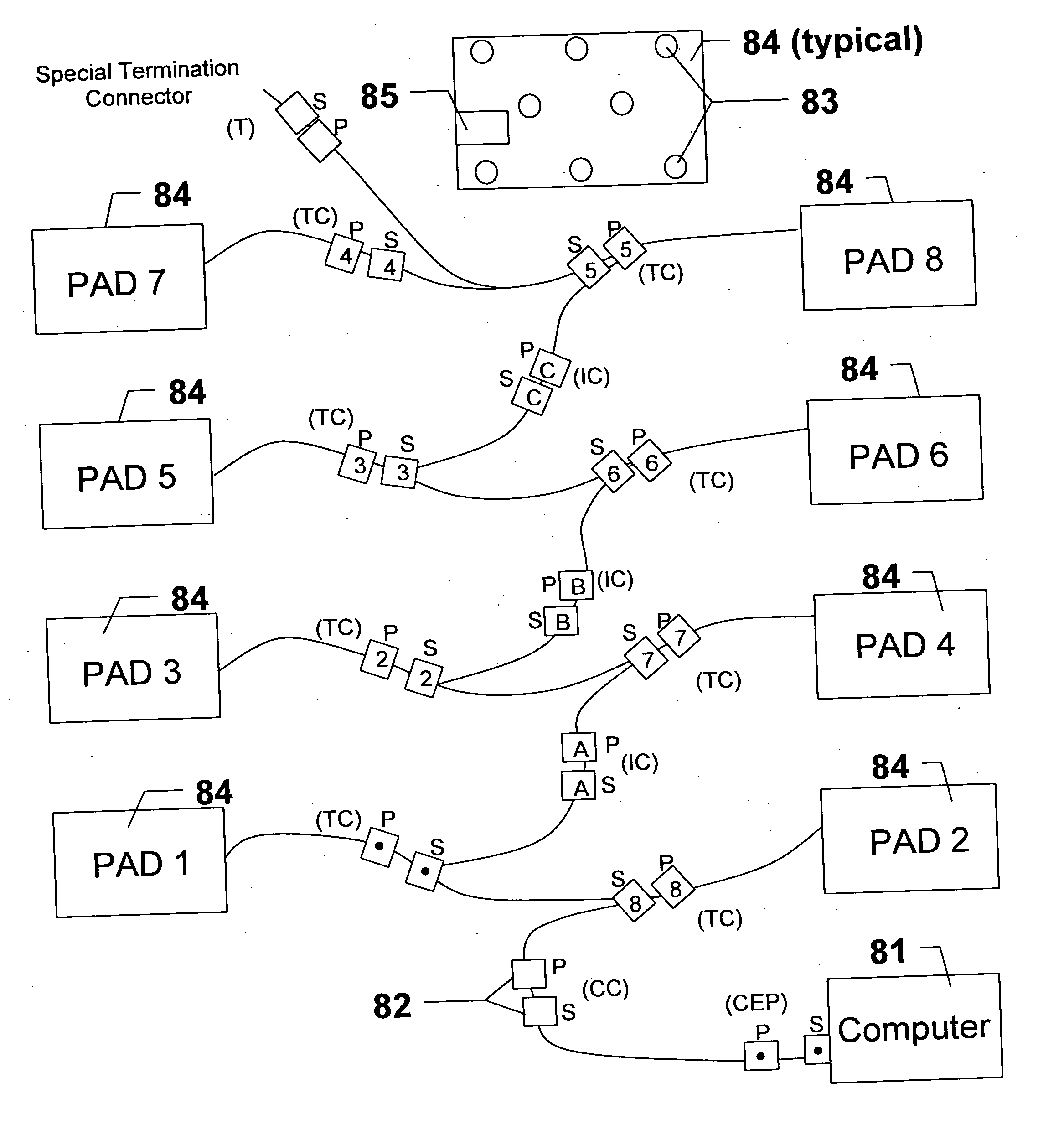

Human Care Sentry System

InactiveUS20130150686A1Facilitates real-timeFacilitates continuous assessmentTelevision conference systemsPerson identificationCOLA (software architecture)Software architecture

Disclosed is a process and composition of matter to support safe, assisted, independent living. The process is to create ubiquitous monitoring of the invention user's activities, physiology, and environment; analyze information from monitoring and sensing devices; and act on the information in a prioritized manner to address emergent events, and potentially undesirable conditions. The invention uses a software architecture and schema called Adaptive Scalable Plug&play Infrastructure for Responsive Engineering (ASPIRE).

Owner:PNP INNOVATIONS

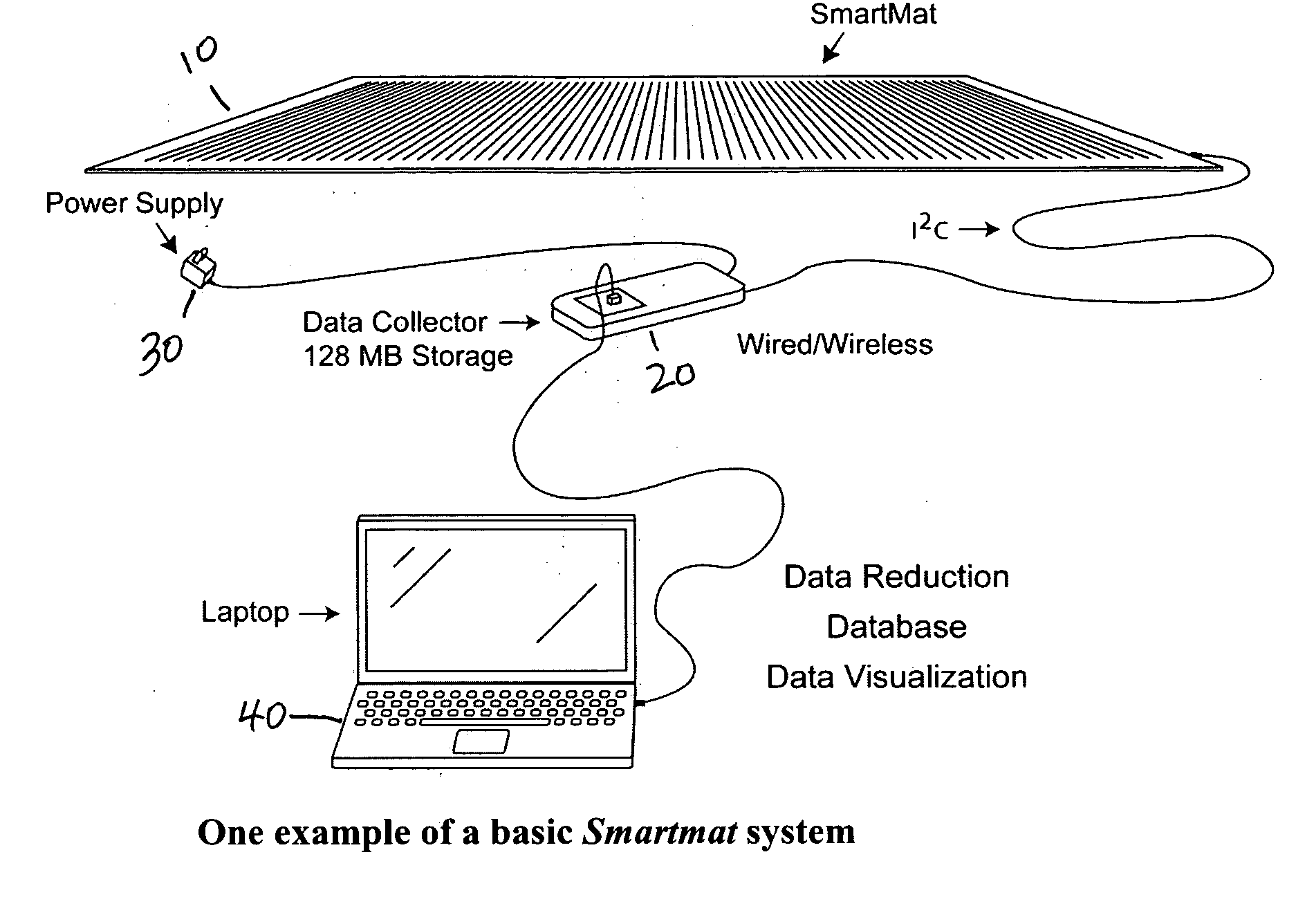

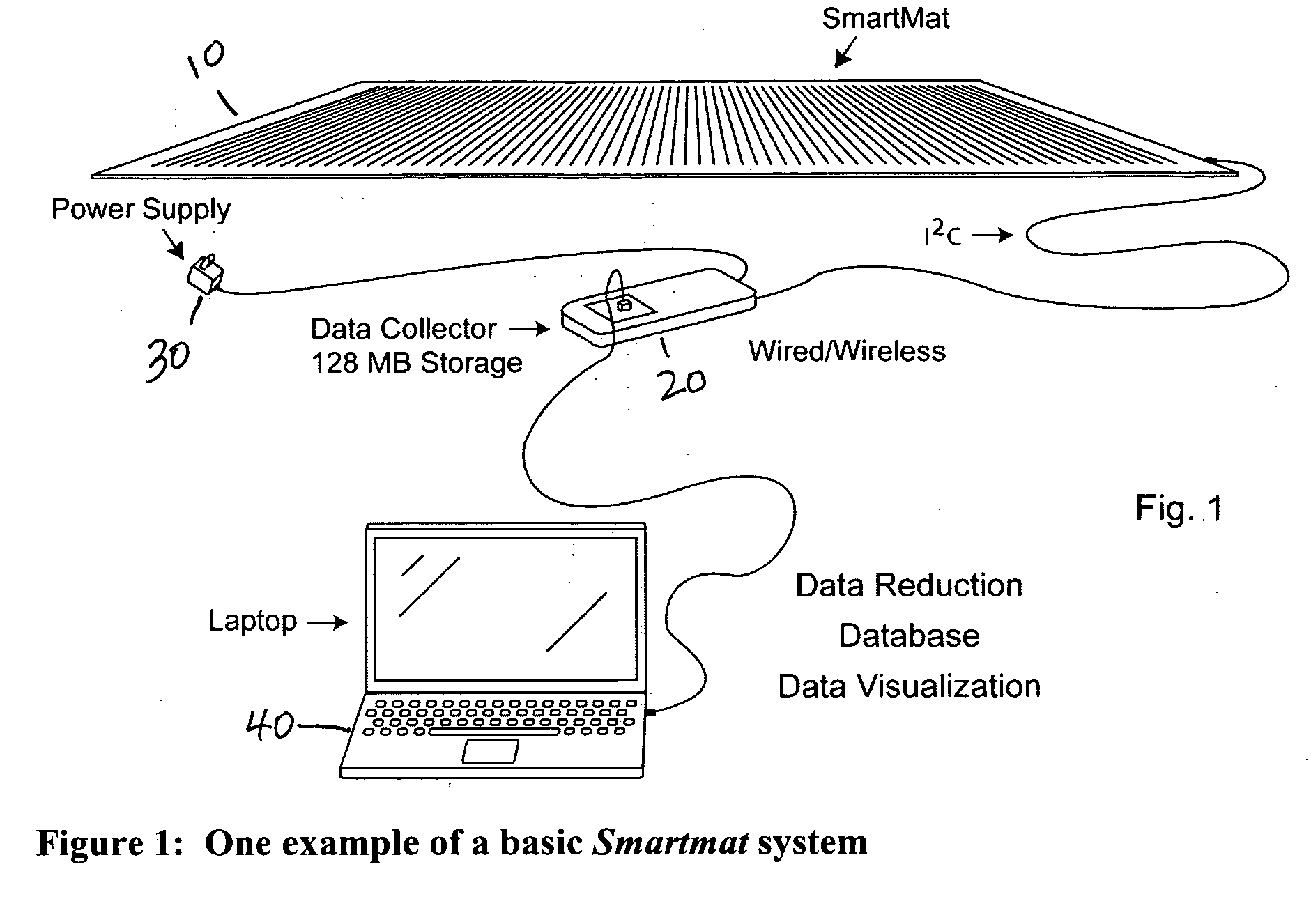

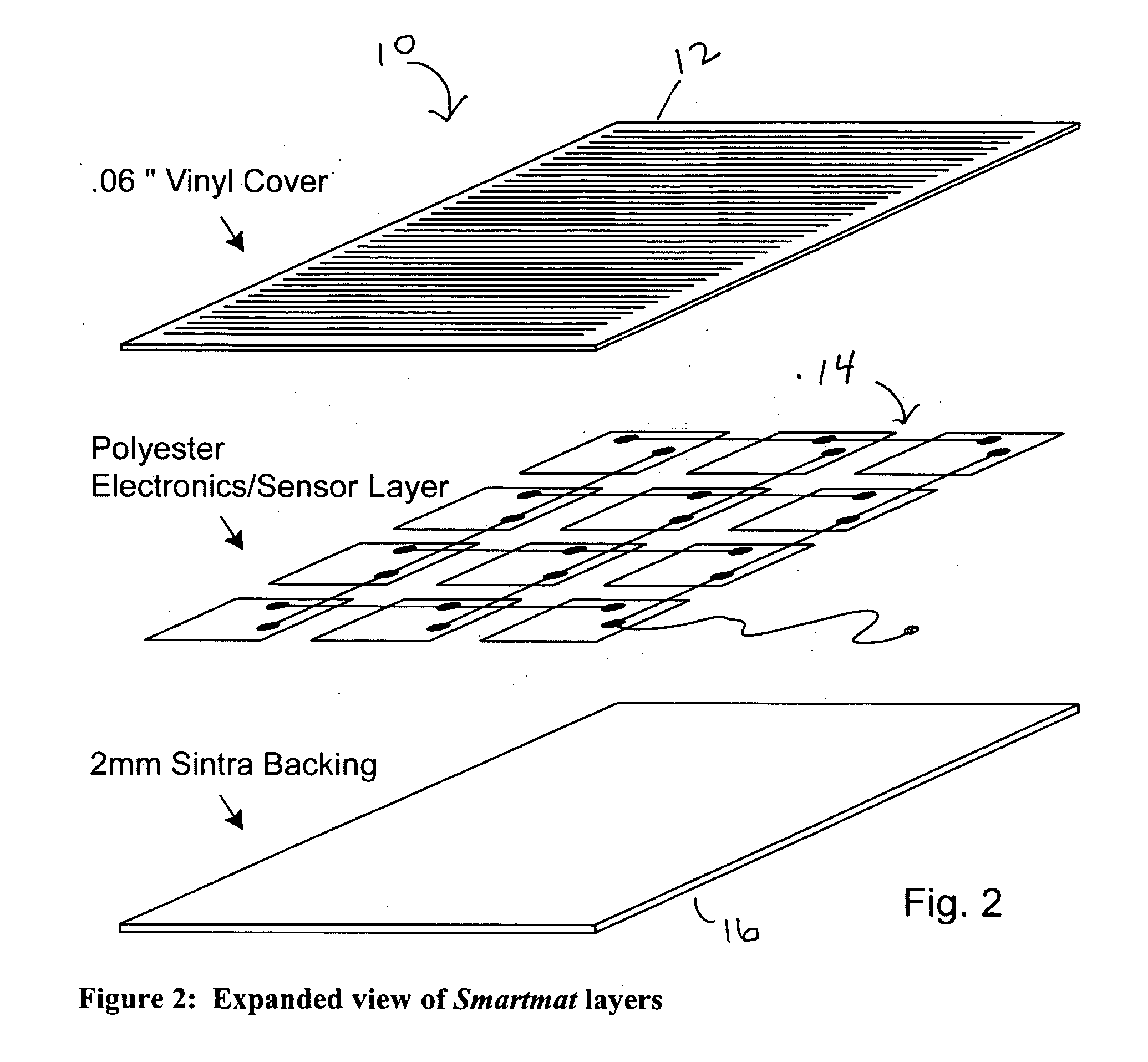

Systems and methods for area activity monitoring and personnel identification

ActiveUS20060171570A1Increase opportunitiesIncrease probabilityElectric signal transmission systemsDigital data processing detailsObject basedLight activation

“Smartmat” (Smartmat Area Activity Monitor and Personnel Identification System) monitors and identifies people, animals and other objects that pass through a control volume. Among other attributes, the exemplary system implementation can count, classify and identify objects, such as pedestrians, animals, bicycles, wheelchairs, vehicles, rollerbladers and other objects, either singly or in groups. Exemplary Smartmat implementations differentiate objects based on weight, footprint and floor / wall pressure patterns such as footfall patterns of pedestrians and other patterns. The system may be applied to security monitoring, physical activity monitoring, market traffic surveys and other traffic surveys, security checkpoint / gate monitoring, traffic light activation and other device activation such as security cameras, and other monitoring applications. Smartmat may be portable or permanently installed.

Owner:ARTIS LLC

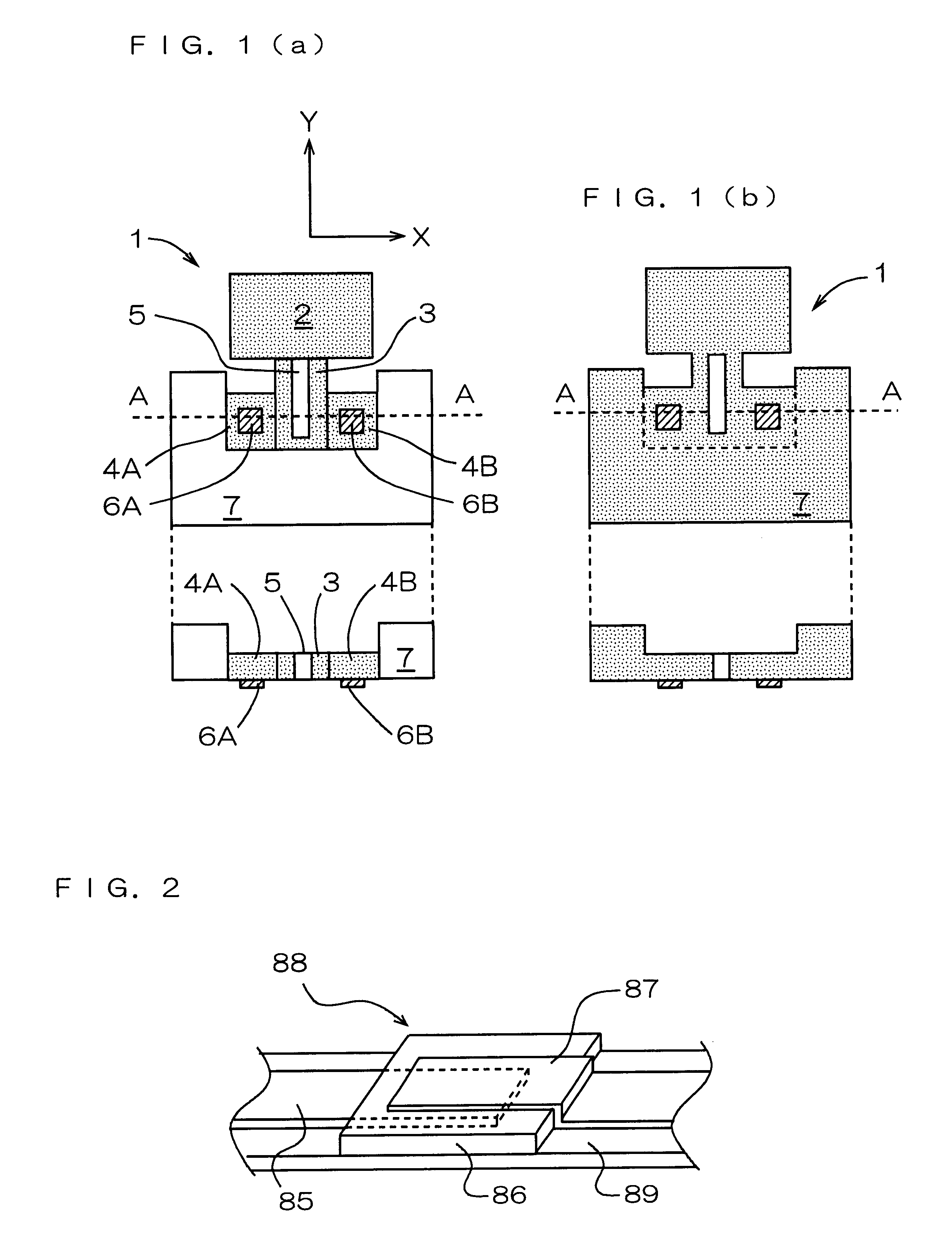

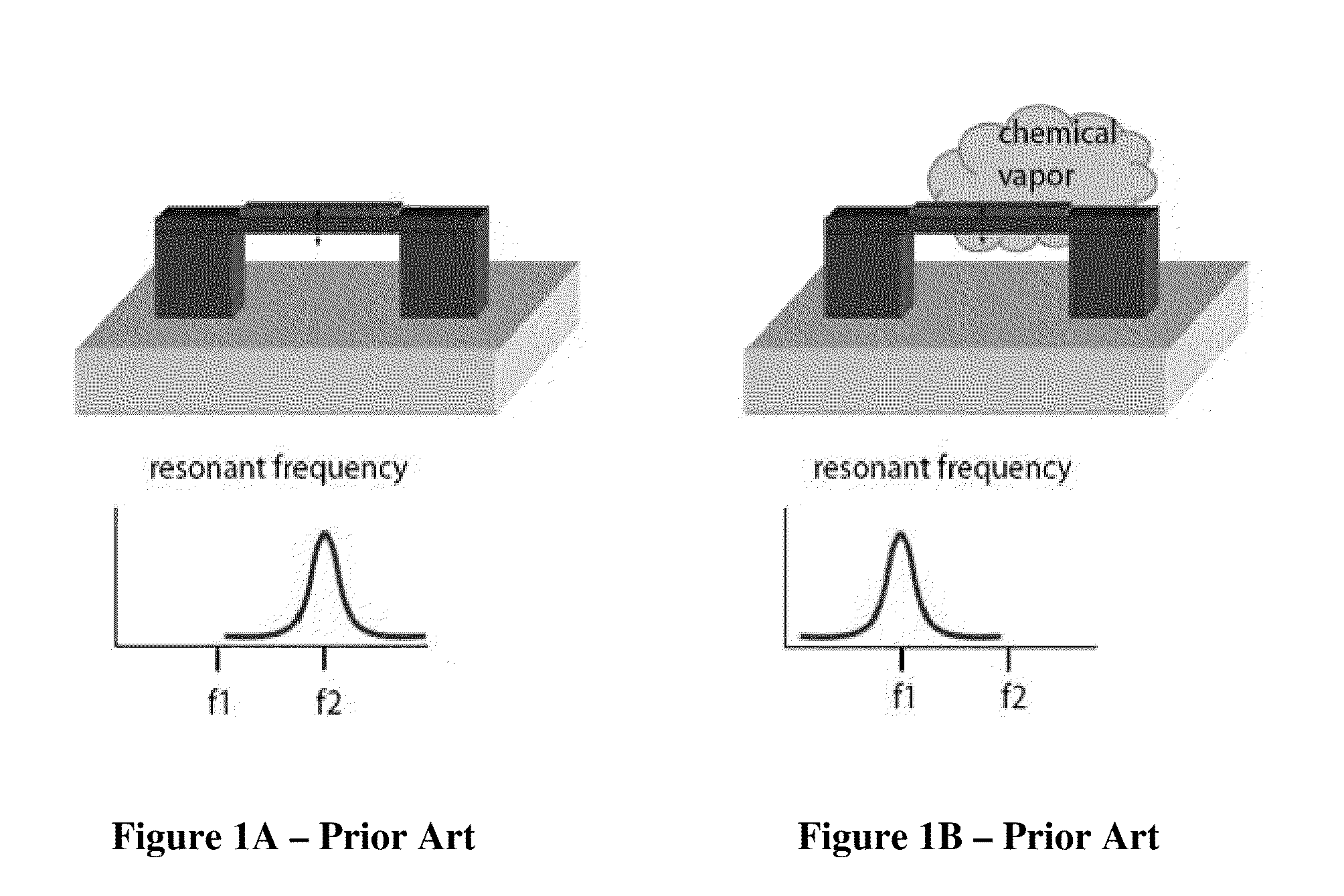

Mass sensor and mass sensing method

InactiveUS6457361B1Analysing fluids using sonic/ultrasonic/infrasonic wavesBioreactor/fermenter combinationsEngineeringMechanical engineering

A mass sensor including: a connecting plate having one or more slit(s) and / or opening portion(s) formed therein and / or having a thin-walled portion and a thick-walled portion formed therein; a diaphragm joined with the connecting plate at respective side surfaces; a piezoelectric element; a sensing plate with the piezoelectric element being provided at least at one part on at least one surface of the sensing plate, which has its side surface joined with a side surface of the connecting plate in the direction perpendicular to the joining direction of the diaphragm and the connecting plate; and a sensor substrate with which at least a part of side surfaces of the connecting plate as well as the sensing plate are joined, and the diaphragm, the connecting plate, the sensing plate, and the piezoelectric element form a resonating portion. The mass sensor can conveniently be used for determining the mass of a substance to be sensed by measuring changes in resonant frequencies caused by changes in the mass of the diaphragm on which a catching substance for catching a substance to be sensed by reacting only with the object of sensing is applied.

Owner:NGK INSULATORS LTD

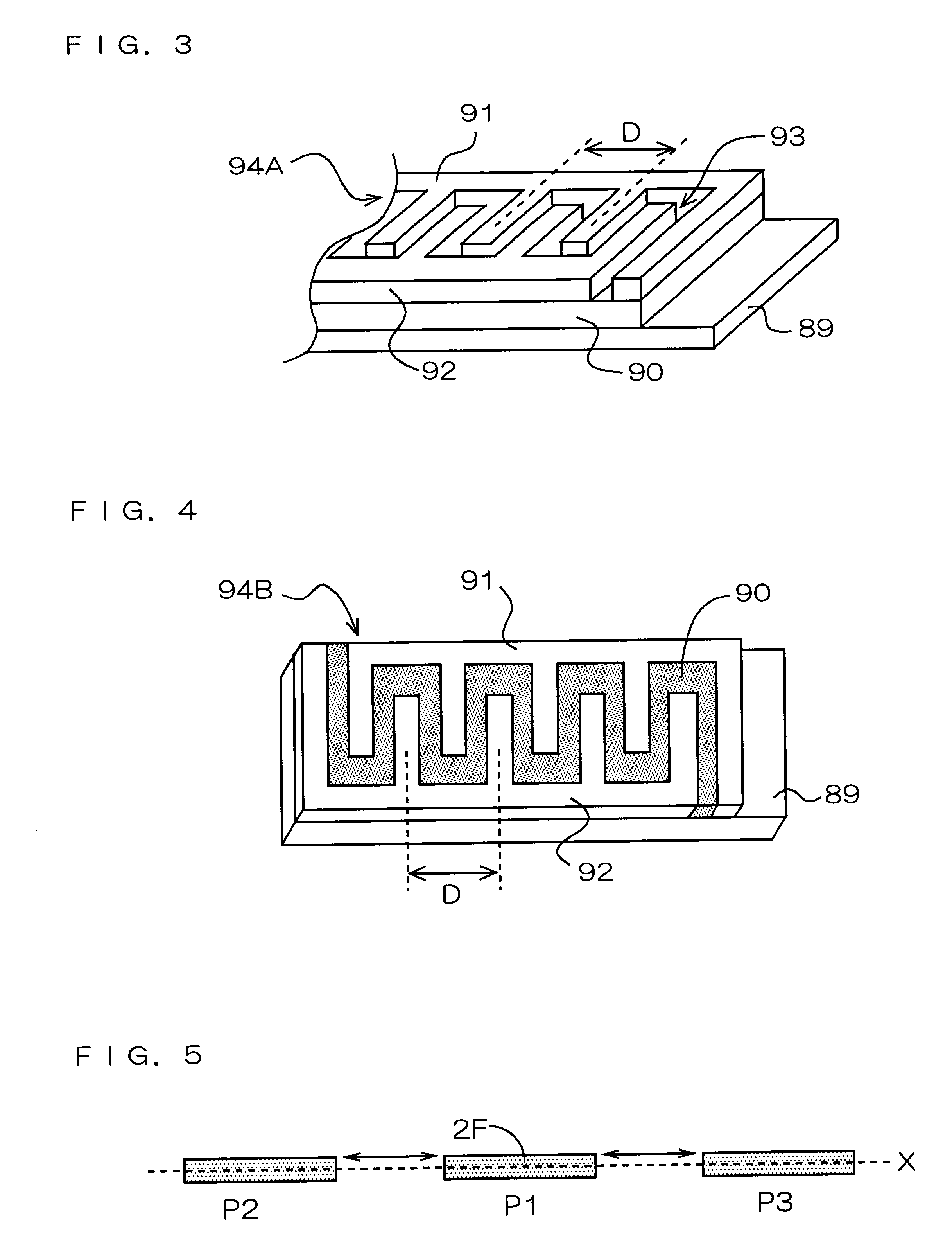

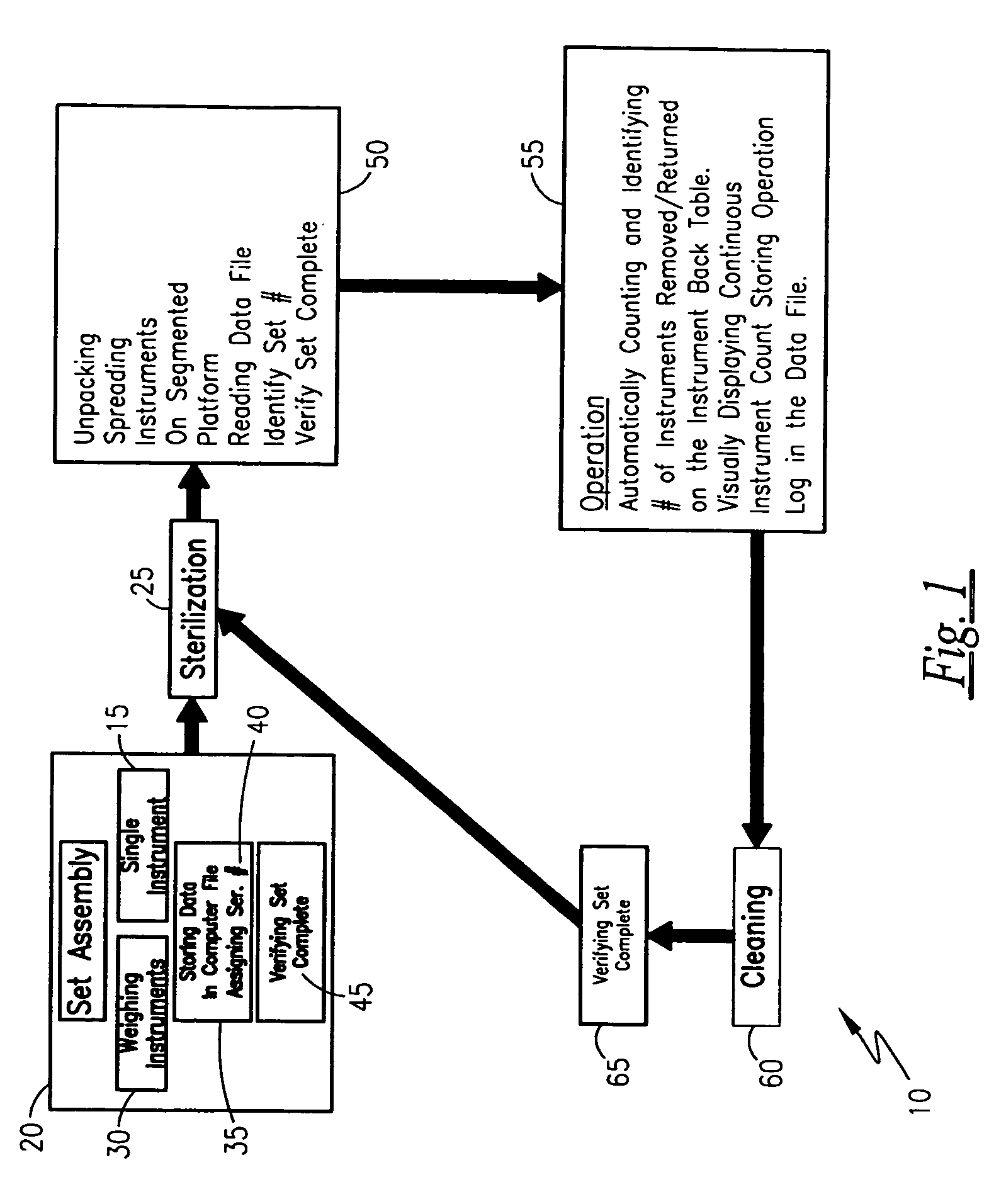

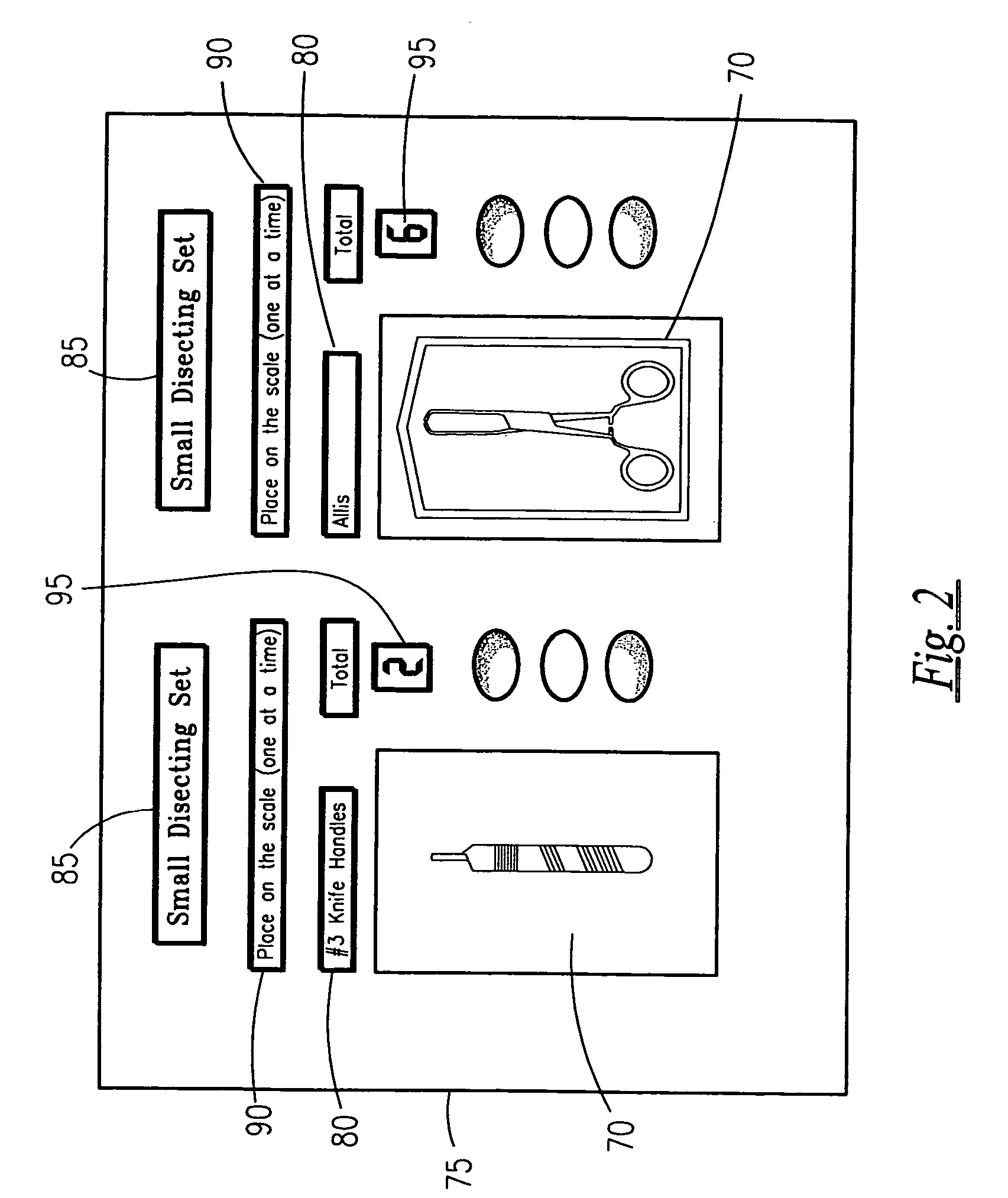

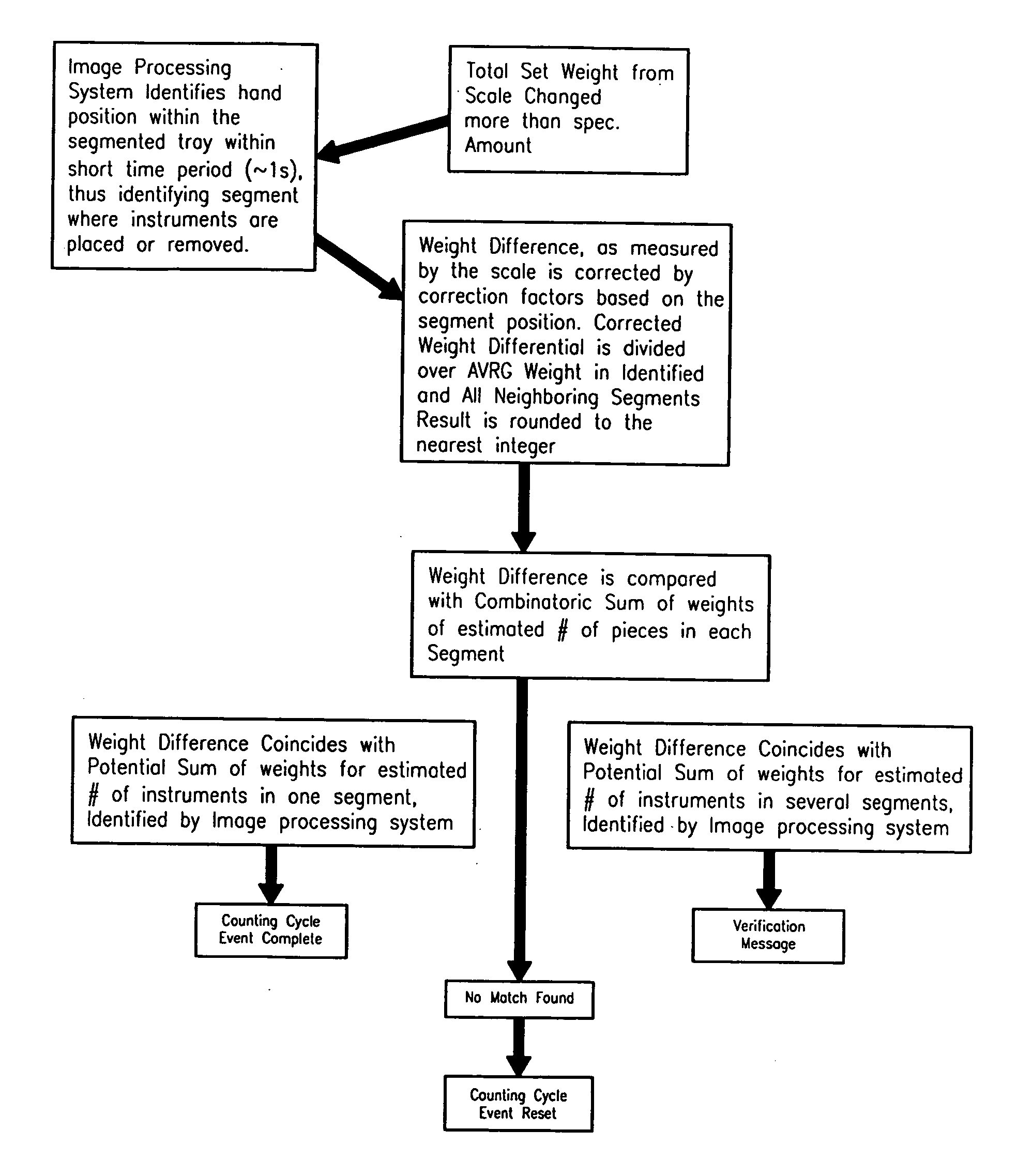

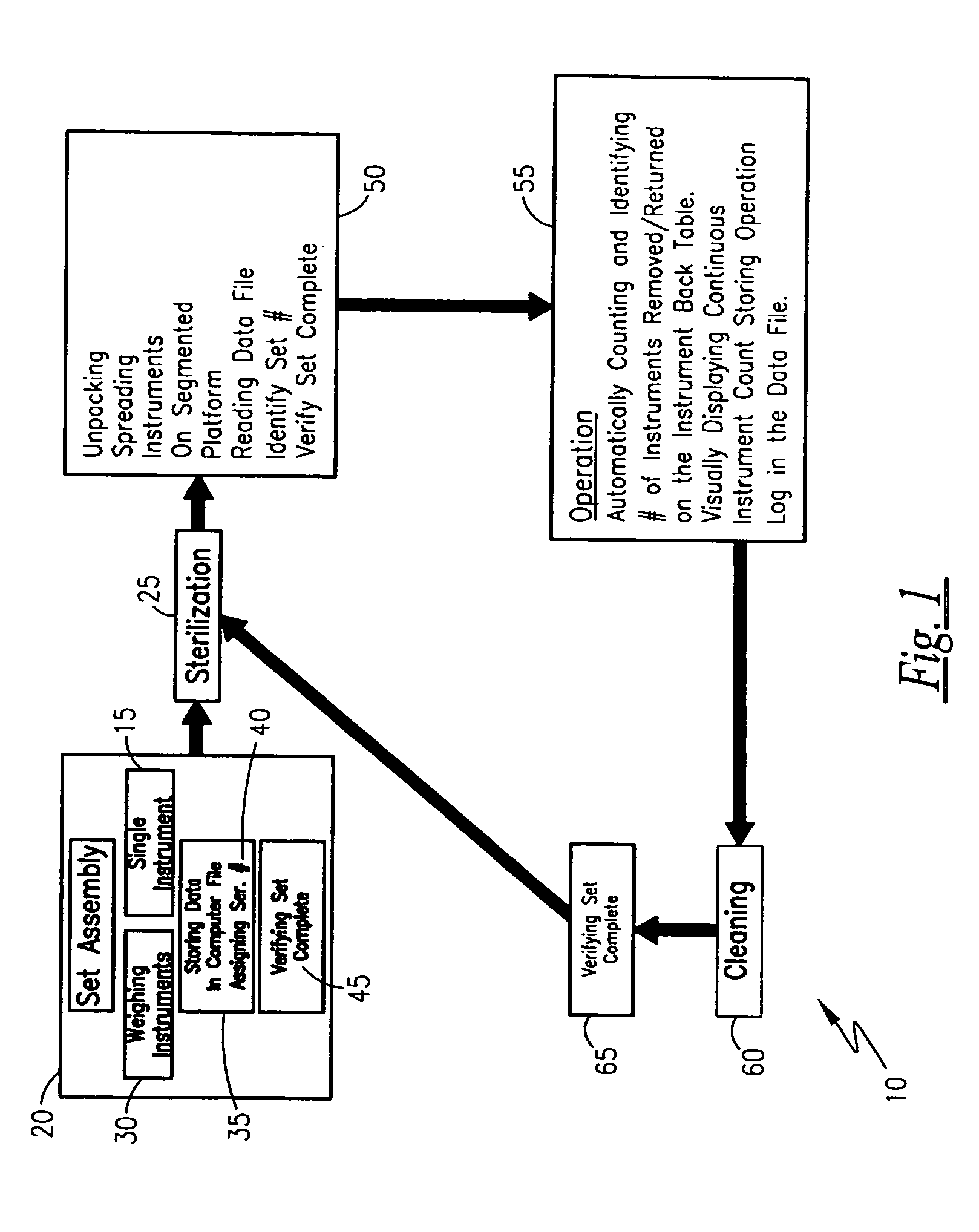

Method and equipment for automated tracking and identification of nonuniform items

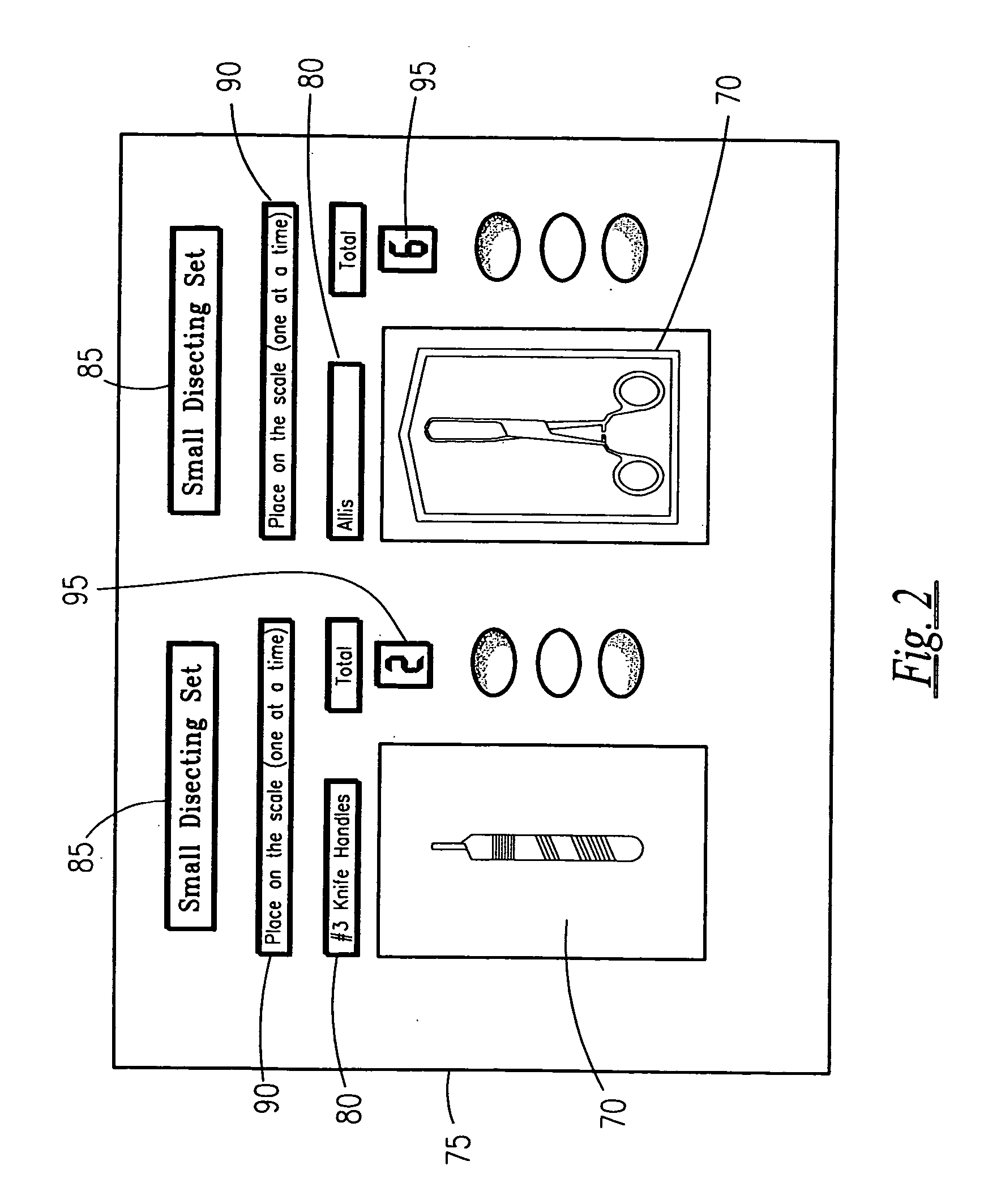

InactiveUS7180014B2Increased real-time accounting accuracyShorten the time spanSurgeryDigital computer detailsSurgical operationImaging processing

An apparatus comprising of a segmented instrument tray, precision scale, image processing system, photoelectric sensors and a Personal Computer (PC) is disclosed. Said apparatus provides an automated and accurate tracking of surgical instruments used during surgical operating procedure by counting and identifying a specific quantity and instrument type, which are removed from a sterilized instrument tray to be used during the procedure and subsequently returned to the tray upon procedure completion, thus preventing an accidental leaving of an instrument inside of a patient and significantly reducing time spent by the operation staff for the instrument accounting.

Owner:FARBER BORIS +3

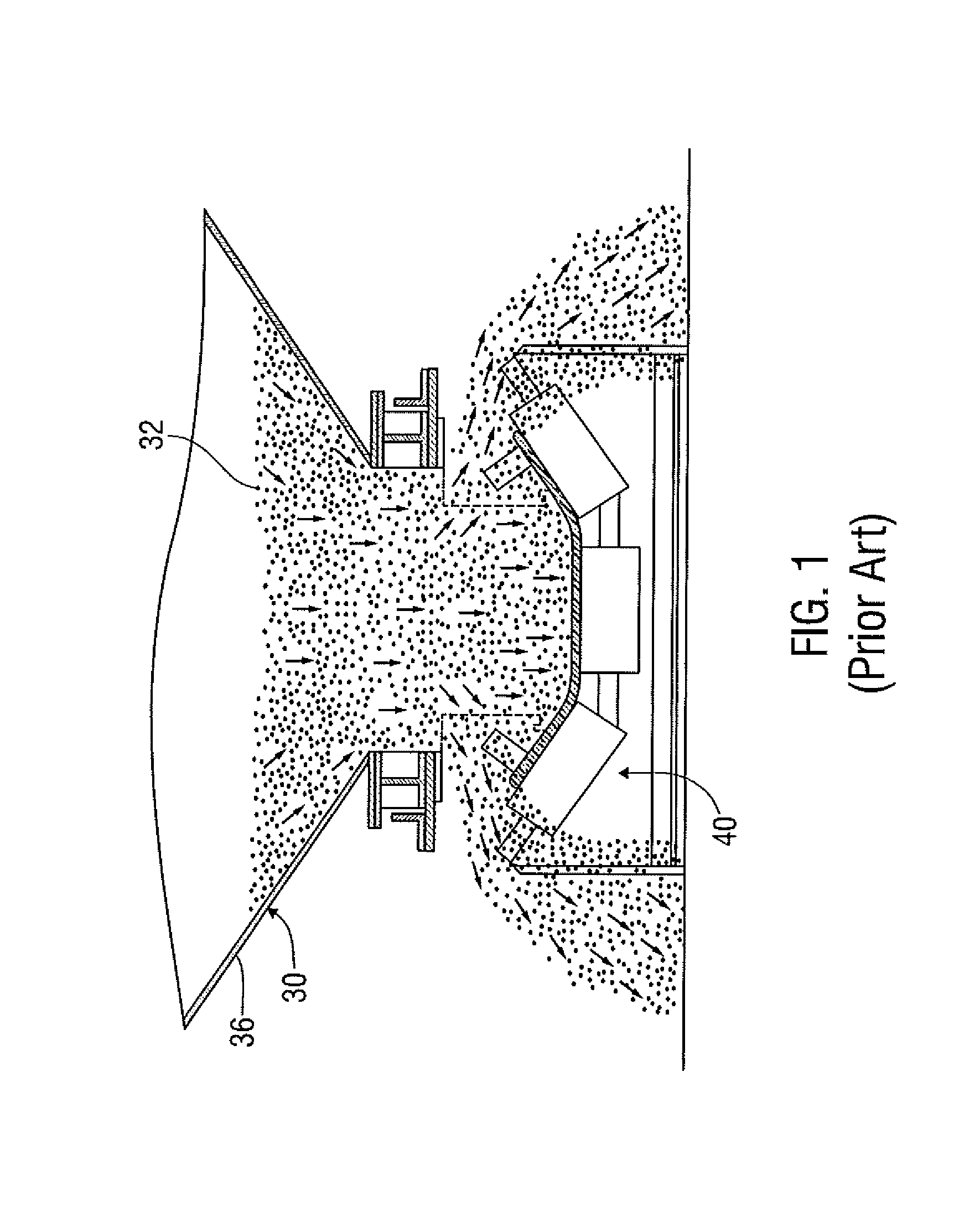

System and methods for belt conveyor weighing

ActiveUS20140062709A1Mass flow measurement devicesWeighing apparatus for materials with special property/formObservational errorSnack food

Imperfections in conveyor belting and its supporting elements can adversely affect weighing accuracy of belt scales, particularly when weighing and / or metering low density materials, such as those encountered in the snack food industry. A system and methods for a belt conveyor according to an embodiment of the present invention provide simultaneous benefits of both short and long weigh spans. According to an embodiment of the present invention, a virtual weigh span may be programmably set to adjust for variations in the belt conveyor weighing system. Advantages include, higher degrees of accuracy and calibration to account for changes in the belt or belting system over time using non-mechanical adjustments. In addition, weight measurement error producing effects, some that may not be particularly known, may be reduced.

Owner:HYER IND

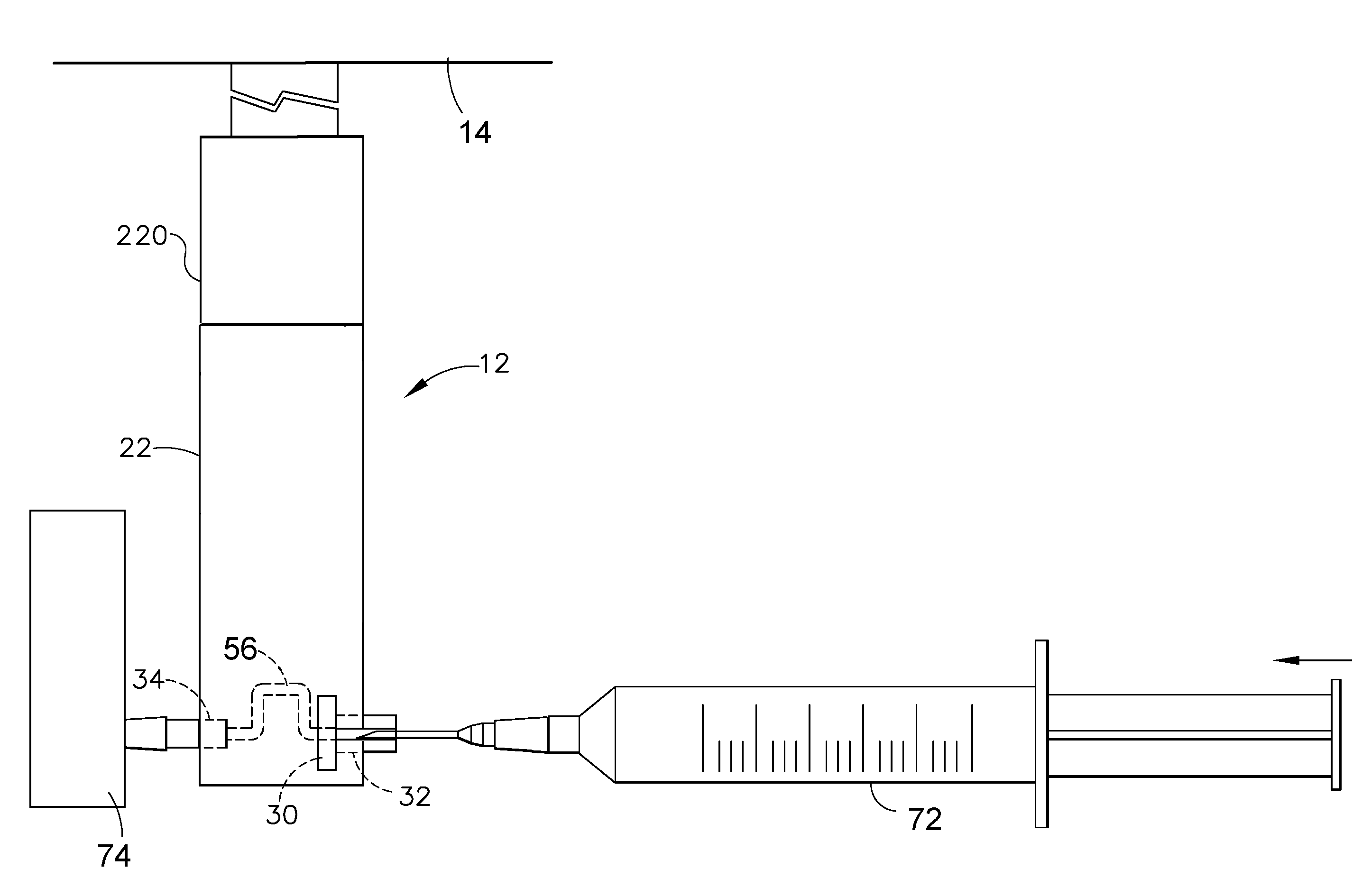

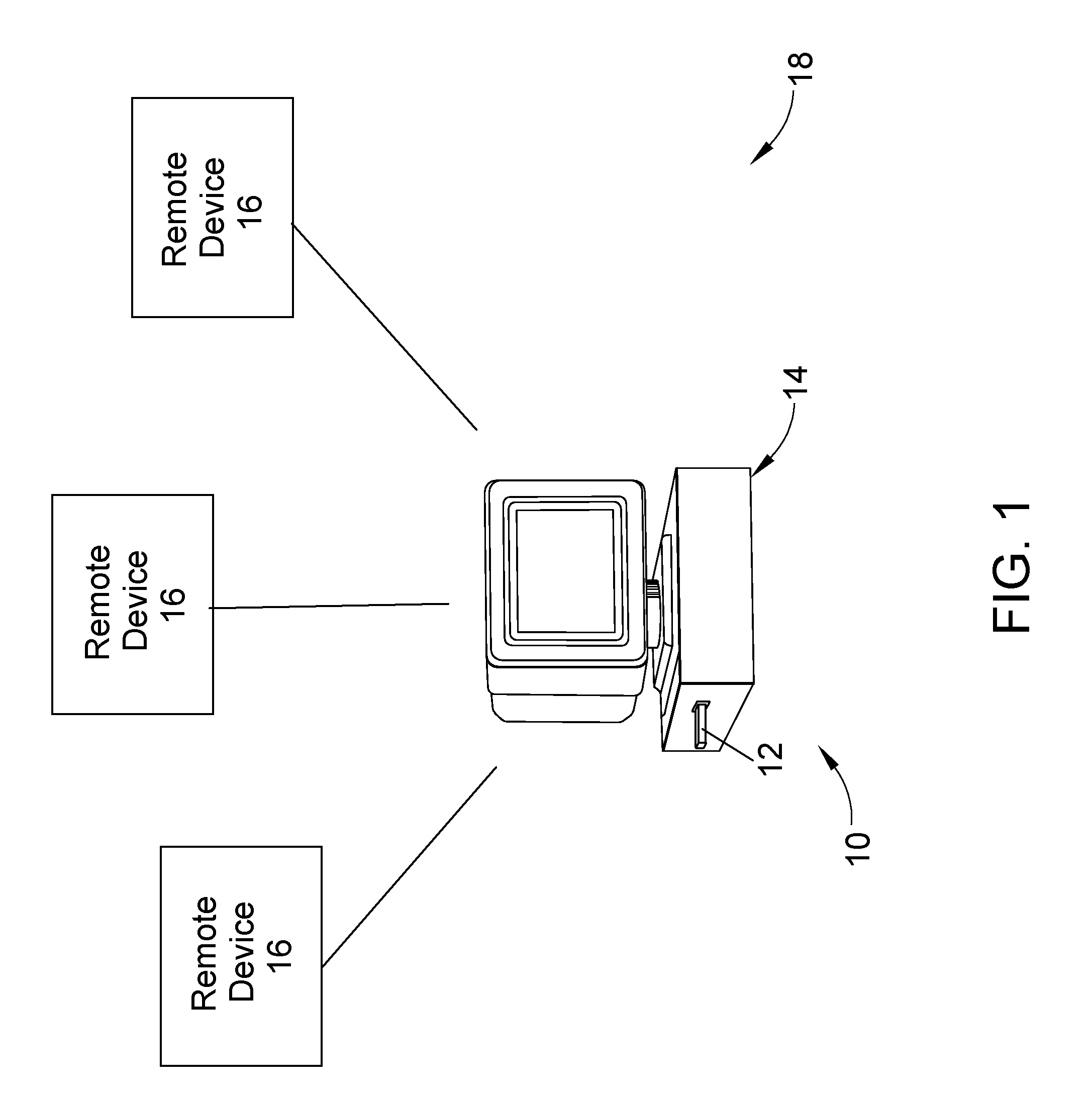

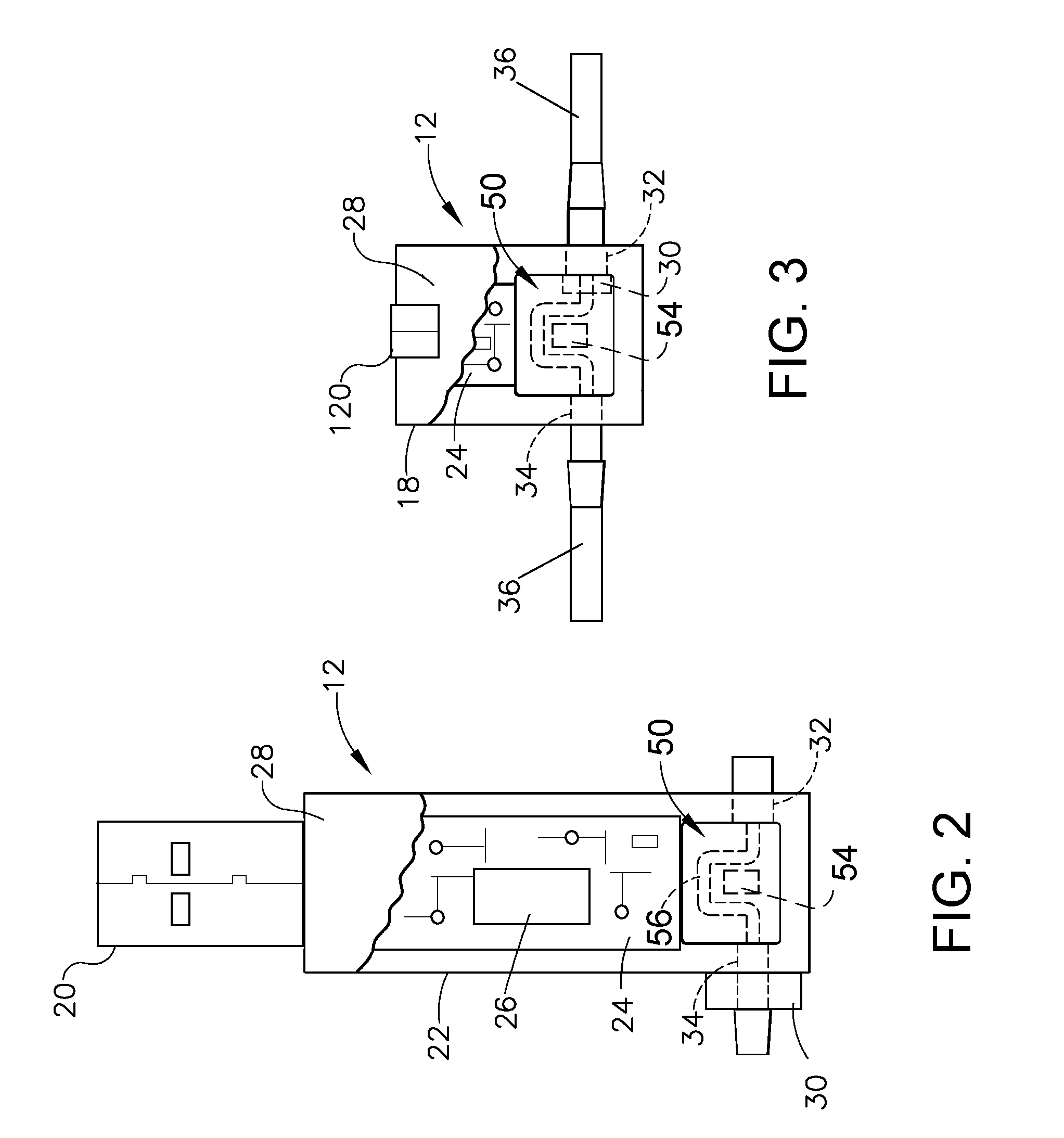

Sensing and analysis system, network, and method

ActiveUS7483805B2Inflated body pressure measurementFluid pressure measurement by electric/magnetic elementsElectricityElectronic unit

A sensing and analysis system, method, and network that make use of a very portable and compact sensor unit and a physically separate electronic unit that serves to power and control the sensor unit, process and optionally display the output of the sensor unit, and transmit the sensor output to other locations, such as over a network. The sensor unit includes a housing, a sensing element within the housing and responsive to an input, and electronic circuitry within the housing and in communication with the sensing element to produce an electrical output based on an output signal generated by the sensing element. A communication providing device delivers instructions generated by the electronic unit to the sensor unit and delivers the electrical output from the sensor unit to the electronic unit.

Owner:INTEGRATED SENSING SYST INC

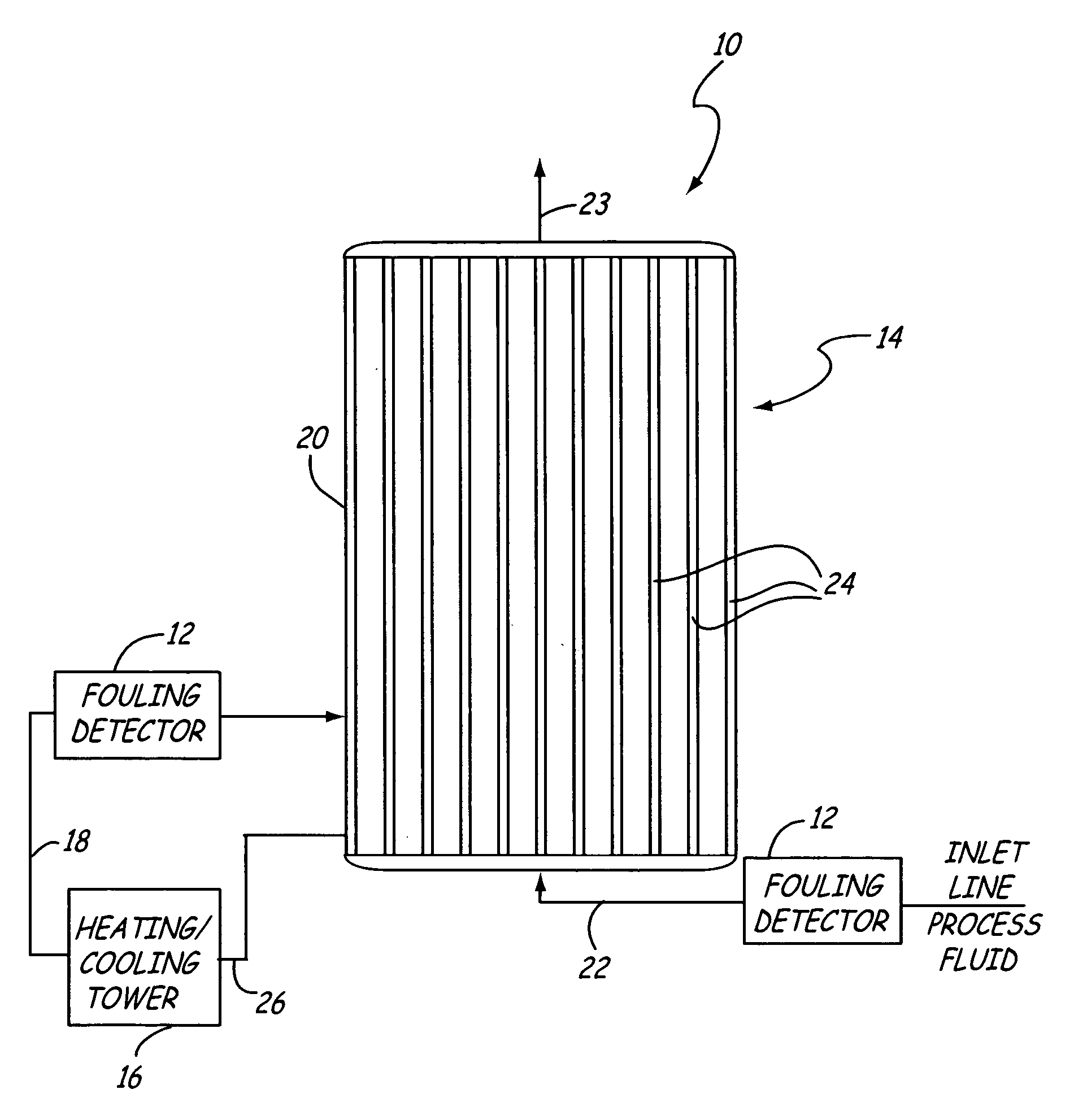

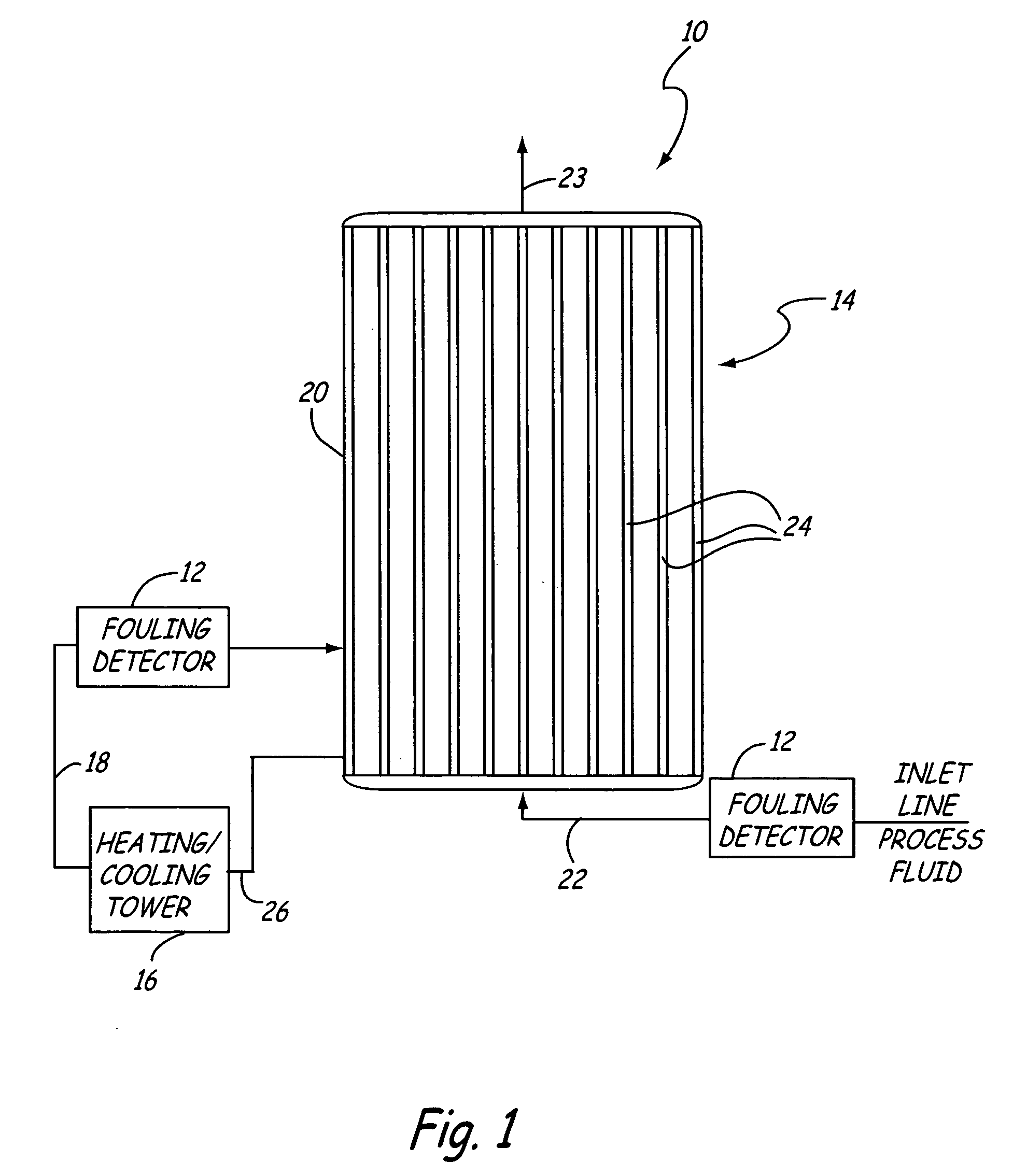

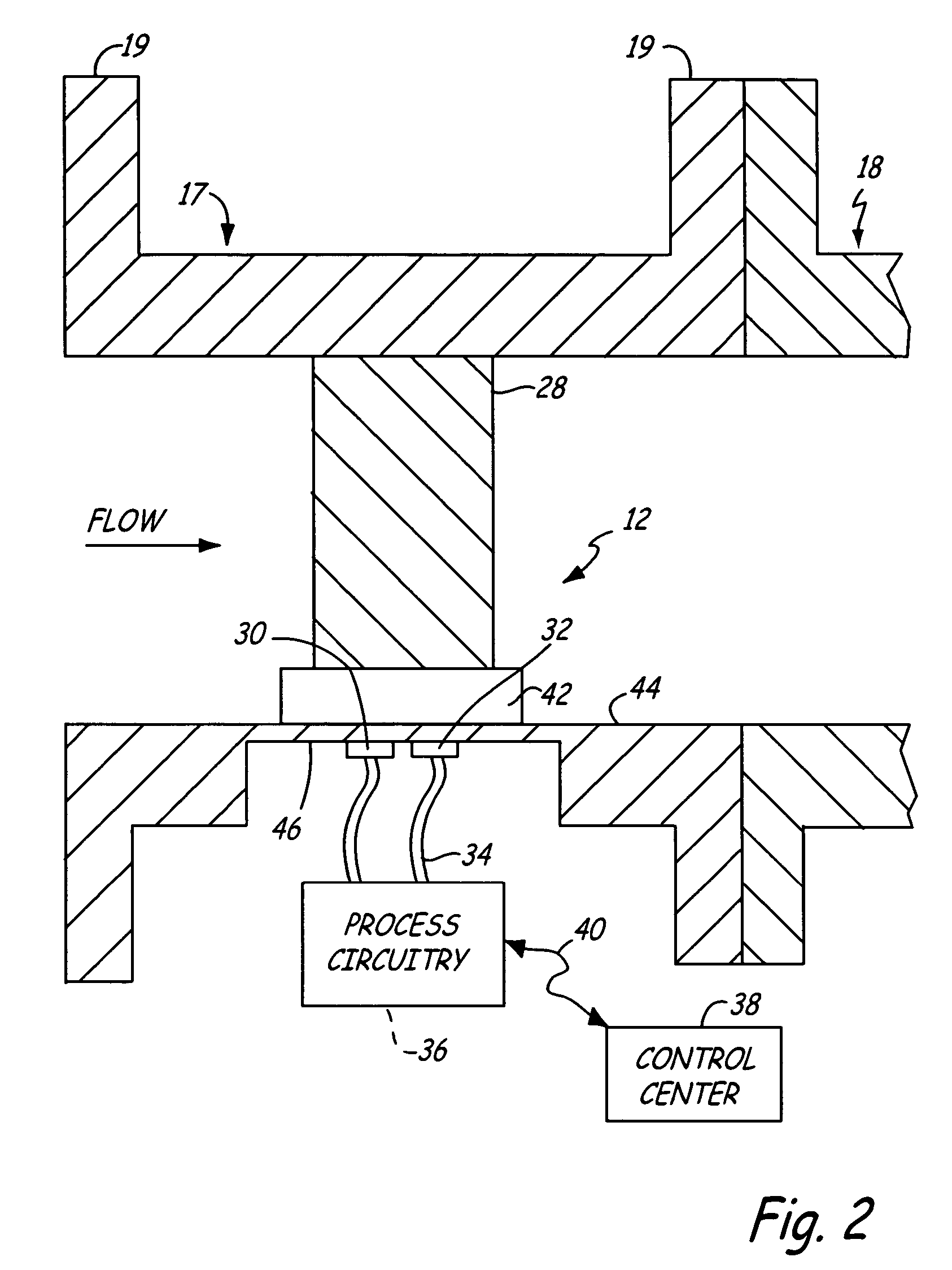

Fouling and corrosion detector for process control industries

ActiveUS20060037399A1Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringFrequency response

A method for inferring possible or impending corrosion or fouling of process elements from fluid flowing in a pipe of an industrial process is described. A frequency response of a body is measured. The measured frequency response is compared against a stored value. Corrosion or fouling of the process elements is identified based upon the comparison between the measured frequency response and the stored value.

Owner:ROSEMOUNT INC

Method and equipment for automated tracking and identification of nonuniform items

InactiveUS20040186683A1Increased real-time accounting accuracyShorten the time spanSurgeryDigital computer detailsSurgical operationImaging processing

An apparatus comprising of a segmented instrument tray, precision scale, image processing system, photoelectric sensors and a Personal Computer (PC) is disclosed. Said apparatus provides an automated and accurate tracking of surgical instruments used during surgical operating procedure by counting and identifying a specific quantity and instrument type, which are removed from a sterilized instrument tray to be used during the procedure and subsequently returned to the tray upon procedure completion, thus preventing an accidental leaving of an instrument inside of a patient and significantly reducing time spent by the operation staff for the instrument accounting.

Owner:FARBER BORIS +3

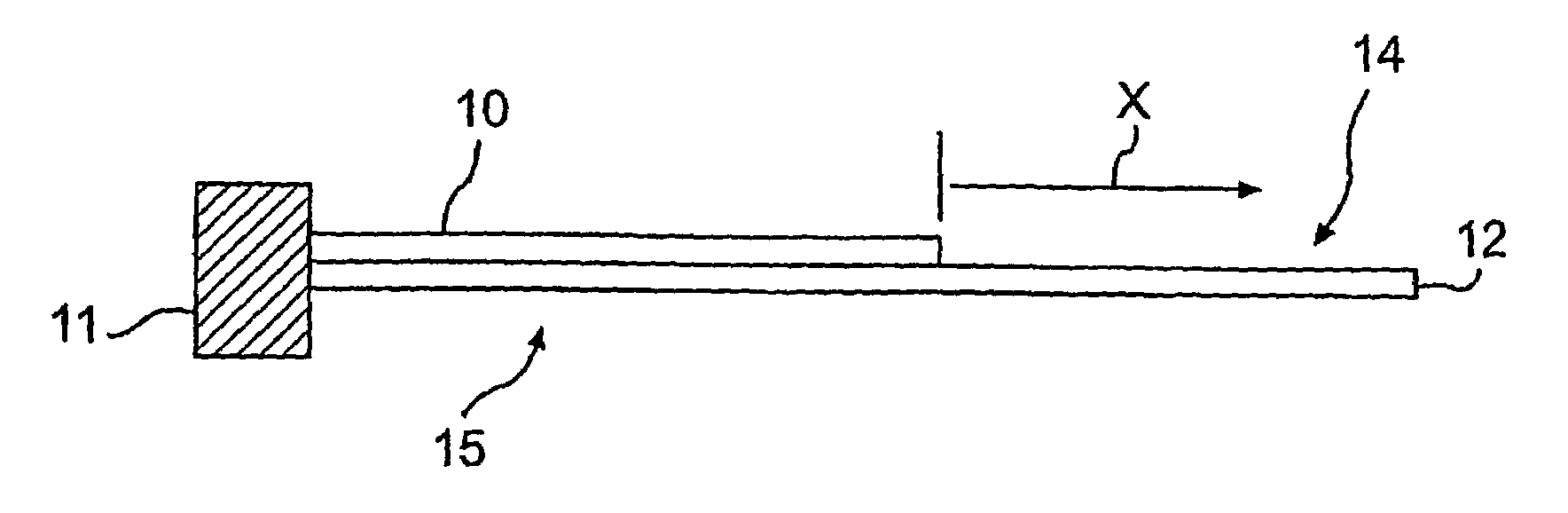

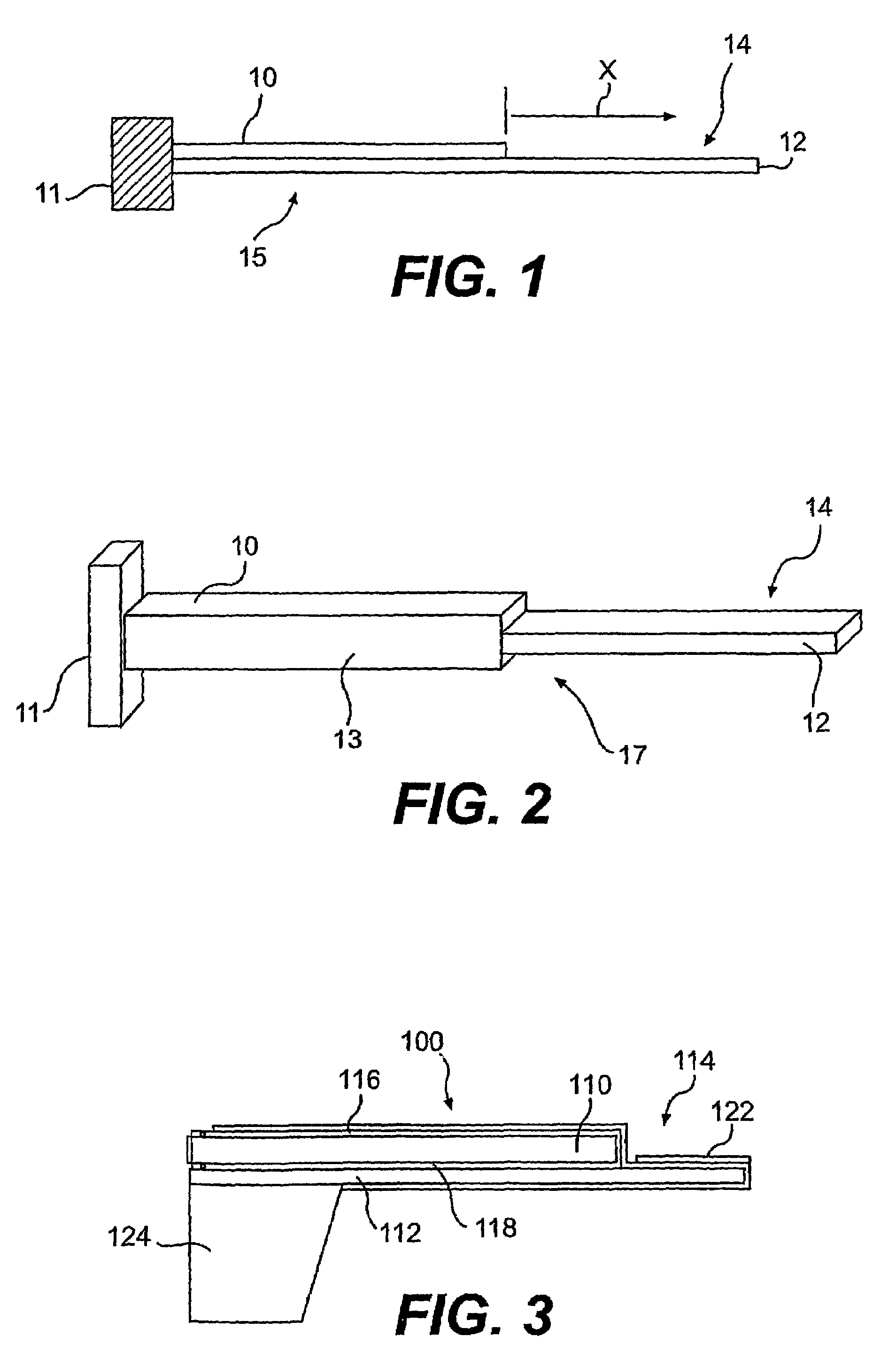

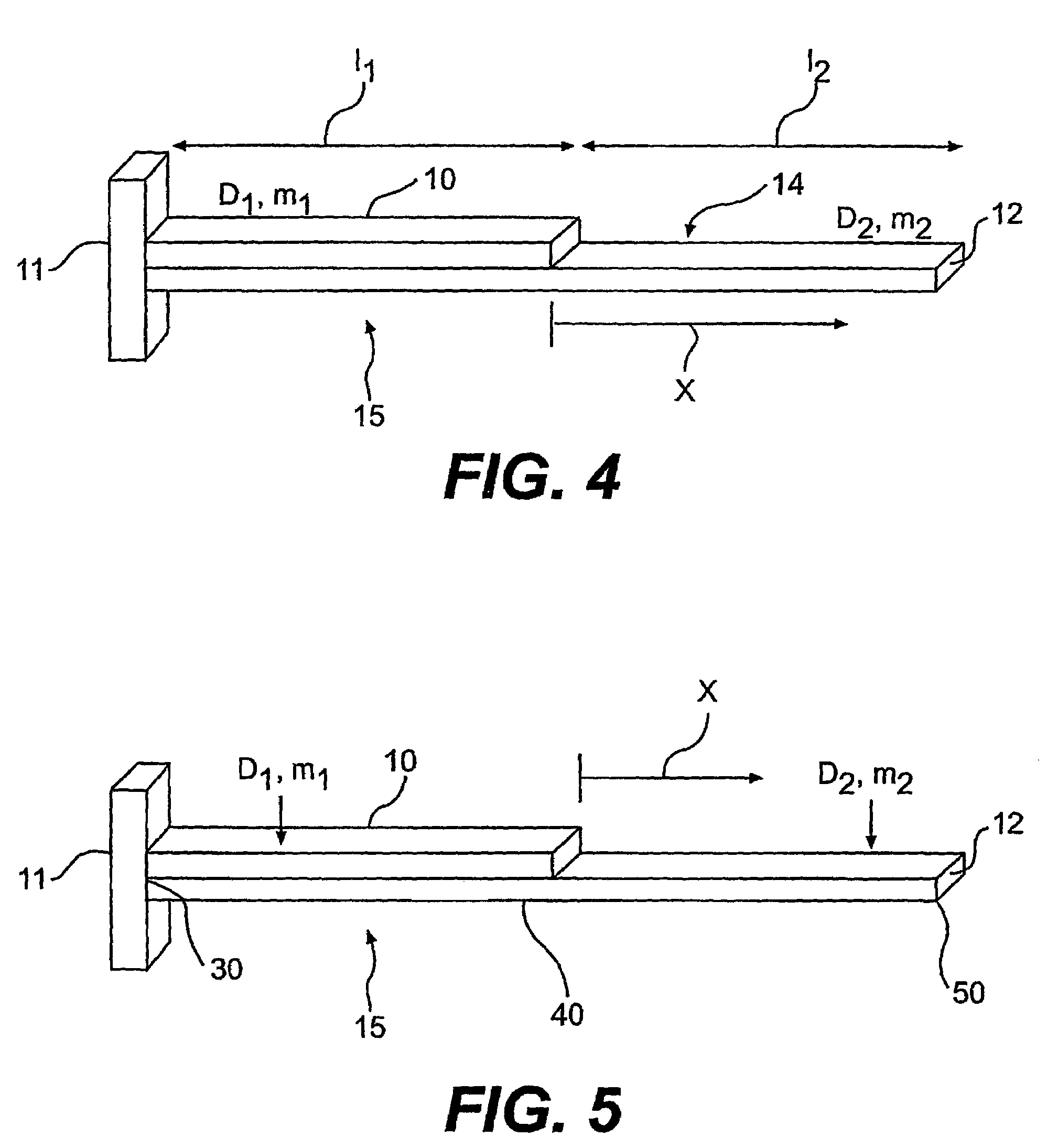

Piezoelectric cantilever sensors

ActiveUS7458265B2Less lengthVibration measurement in solidsWeighing by removing componentViscous liquidAnalyte

A piezoelectric cantilever with a non-piezoelectric, or piezoelectric tip useful as mass and viscosity sensors. The change in the cantilever mass can be accurately quantified by monitoring a resonance frequency shift of the cantilever. For bio-detection, antibodies or other specific receptors of target antigens may be immobilized on the cantilever surface, preferably on the non-piezoelectric tip. For chemical detection, high surface-area selective absorbent materials are coated on the cantilever tip. Binding of the target antigens or analytes to the cantilever surface increases the cantilever mass. Detection of target antigens or analytes is achieved by monitoring the cantilever's resonance frequency and determining the resonance frequency shift that is due to the mass of the adsorbed target antigens on the cantilever surface. The use of a piezoelectric unimorph cantilever allows both electrical actuation and electrical sensing. Incorporating a non-piezoelectric tip (14) enhances the sensitivity of the sensor. In addition, the piezoelectric cantilever can withstand damping in highly viscous liquids and can be used as a viscosity sensor in wide viscosity range.

Owner:DREXEL UNIV

Sensing and analysis system, network, and method

ActiveUS20080154535A1Inflated body pressure measurementFluid pressure measurement by electric/magnetic elementsElectricityEngineering

A sensing and analysis system, method, and network that make use of a very portable and compact sensor unit and a physically separate electronic unit that serves to power and control the sensor unit, process and optionally display the output of the sensor unit, and transmit the sensor output to other locations, such as over a network. The sensor unit includes a housing, a sensing element within the housing and responsive to an input, and electronic circuitry within the housing and in communication with the sensing element to produce an electrical output based on an output signal generated by the sensing element. A communication providing device delivers instructions generated by the electronic unit to the sensor unit and delivers the electrical output from the sensor unit to the electronic unit.

Owner:INTEGRATED SENSING SYST INC

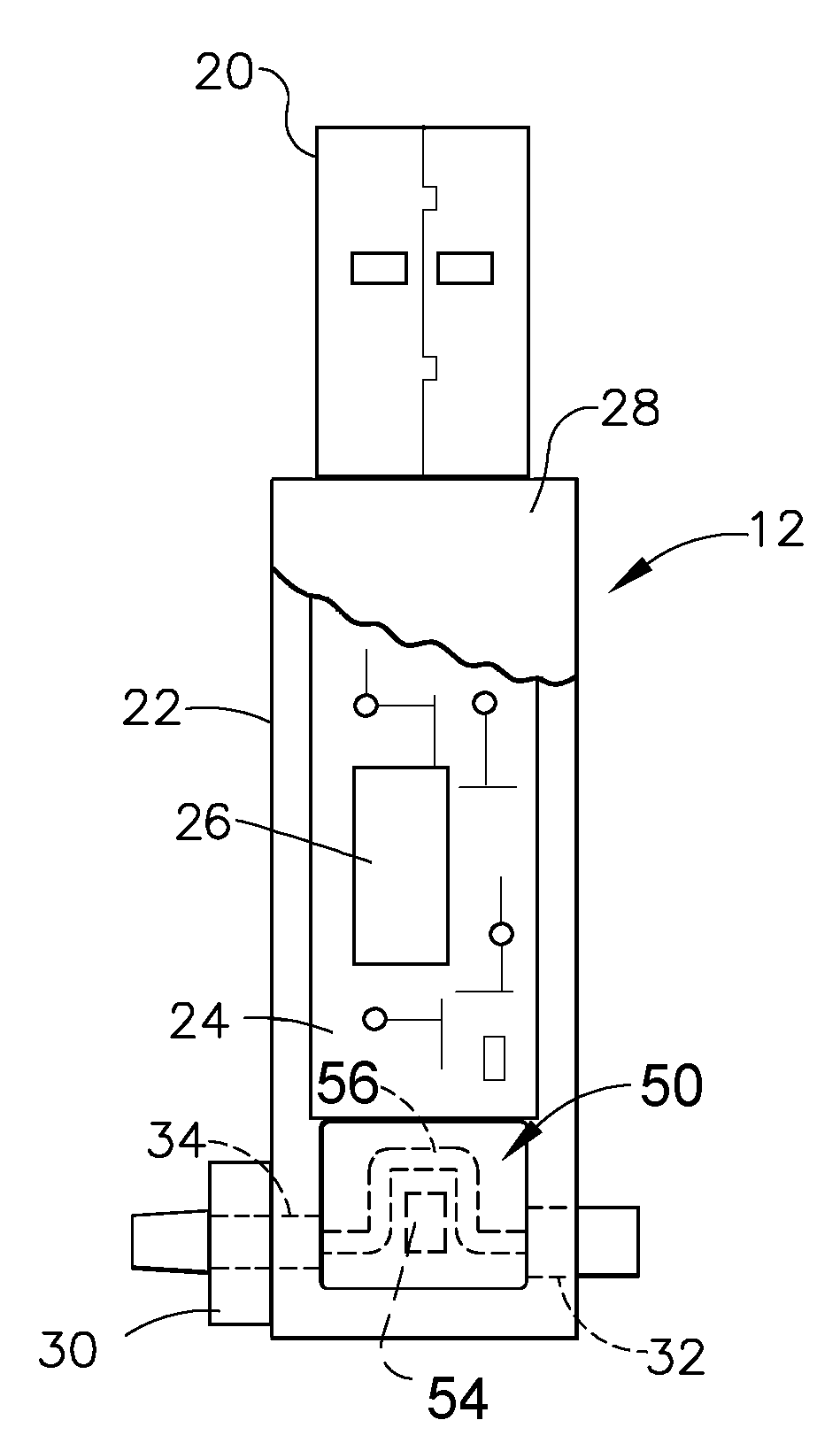

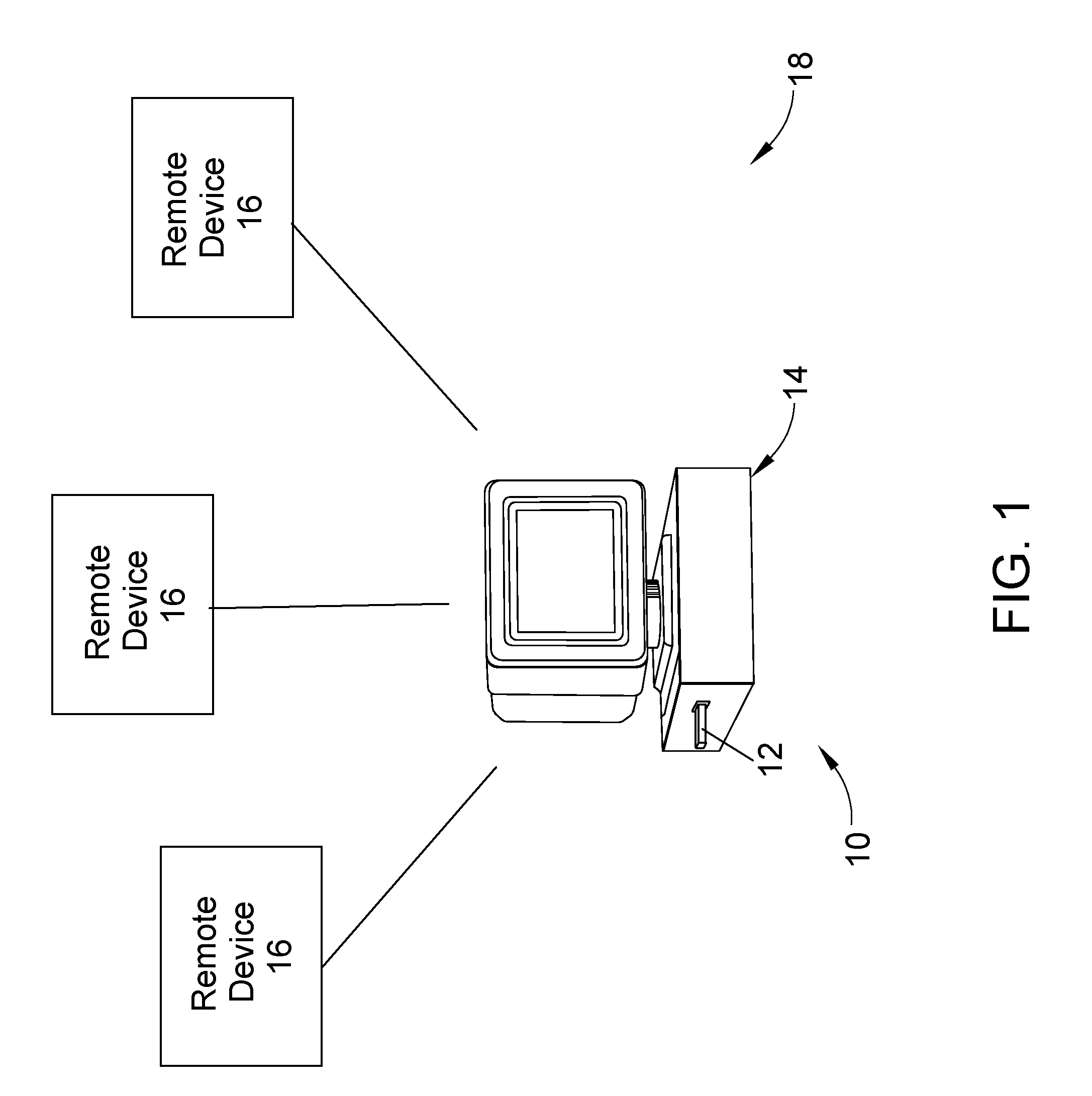

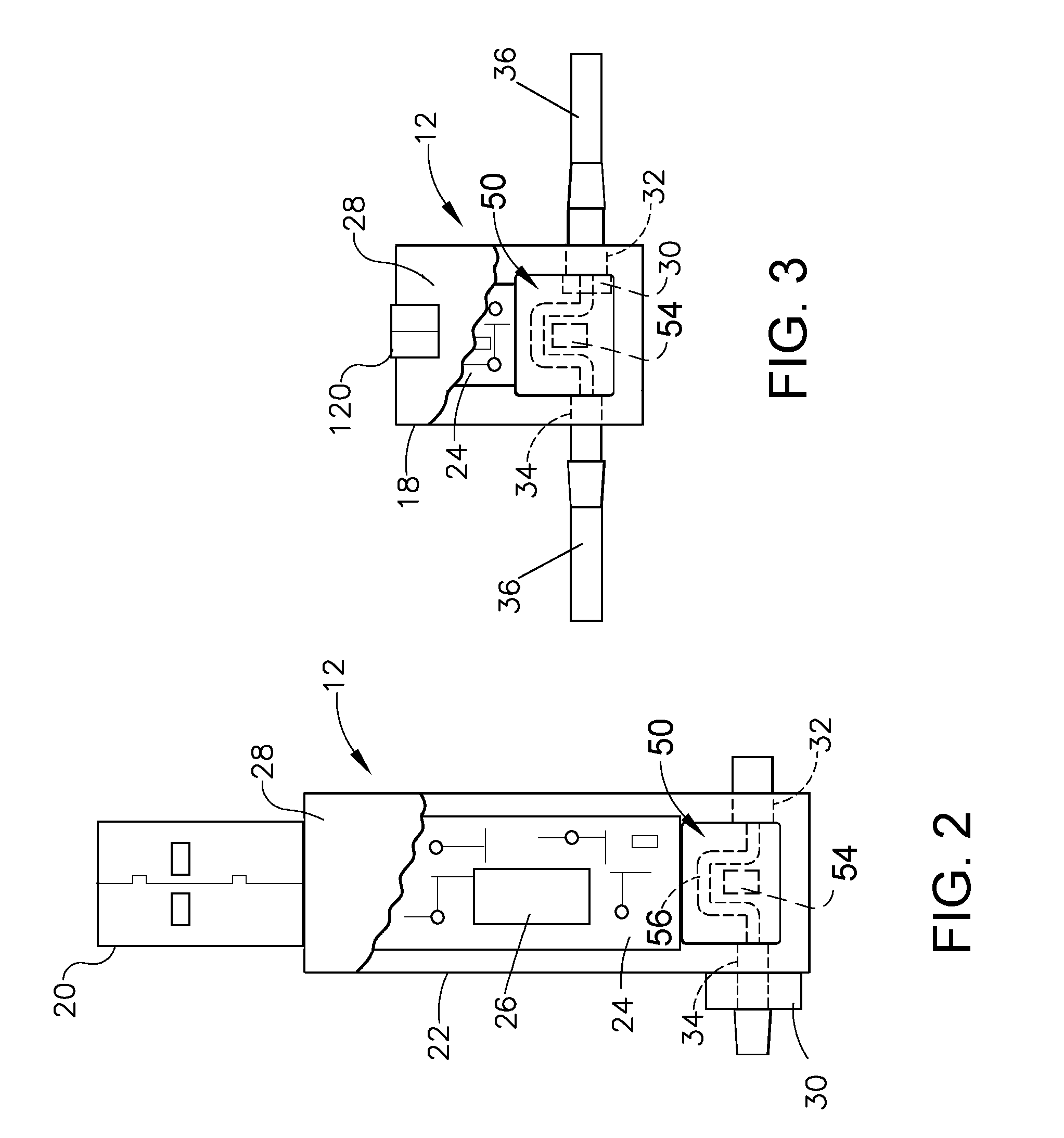

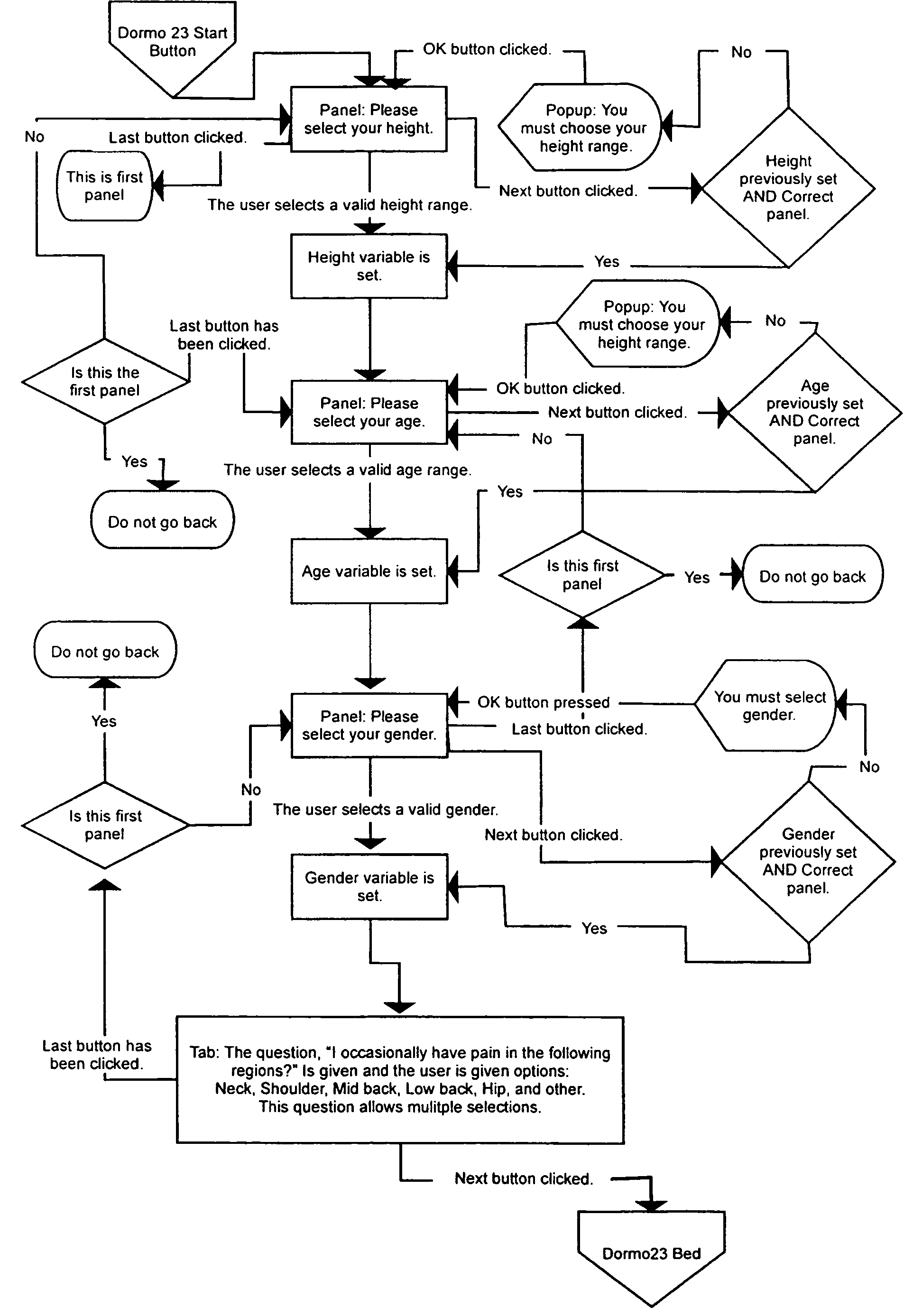

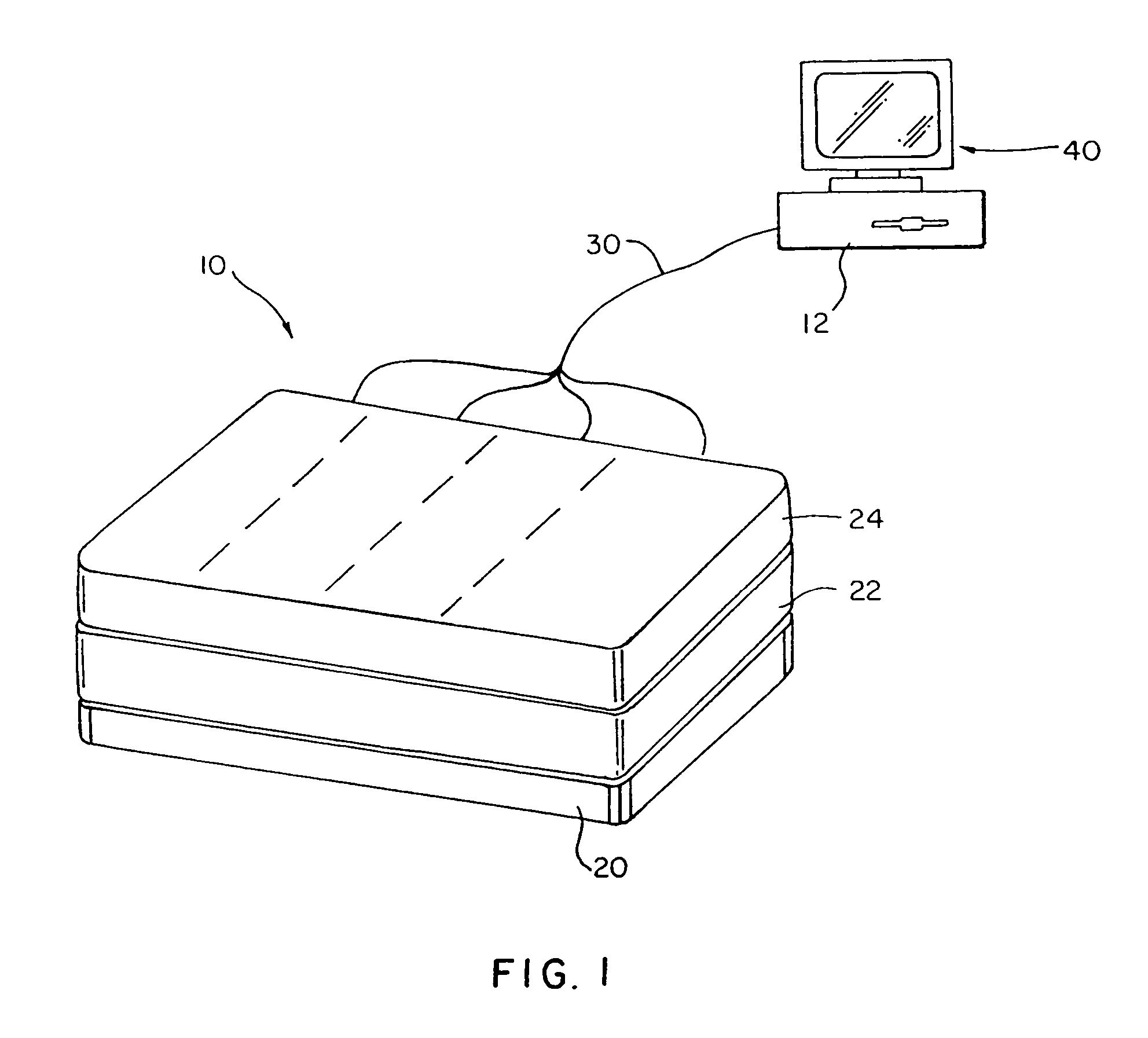

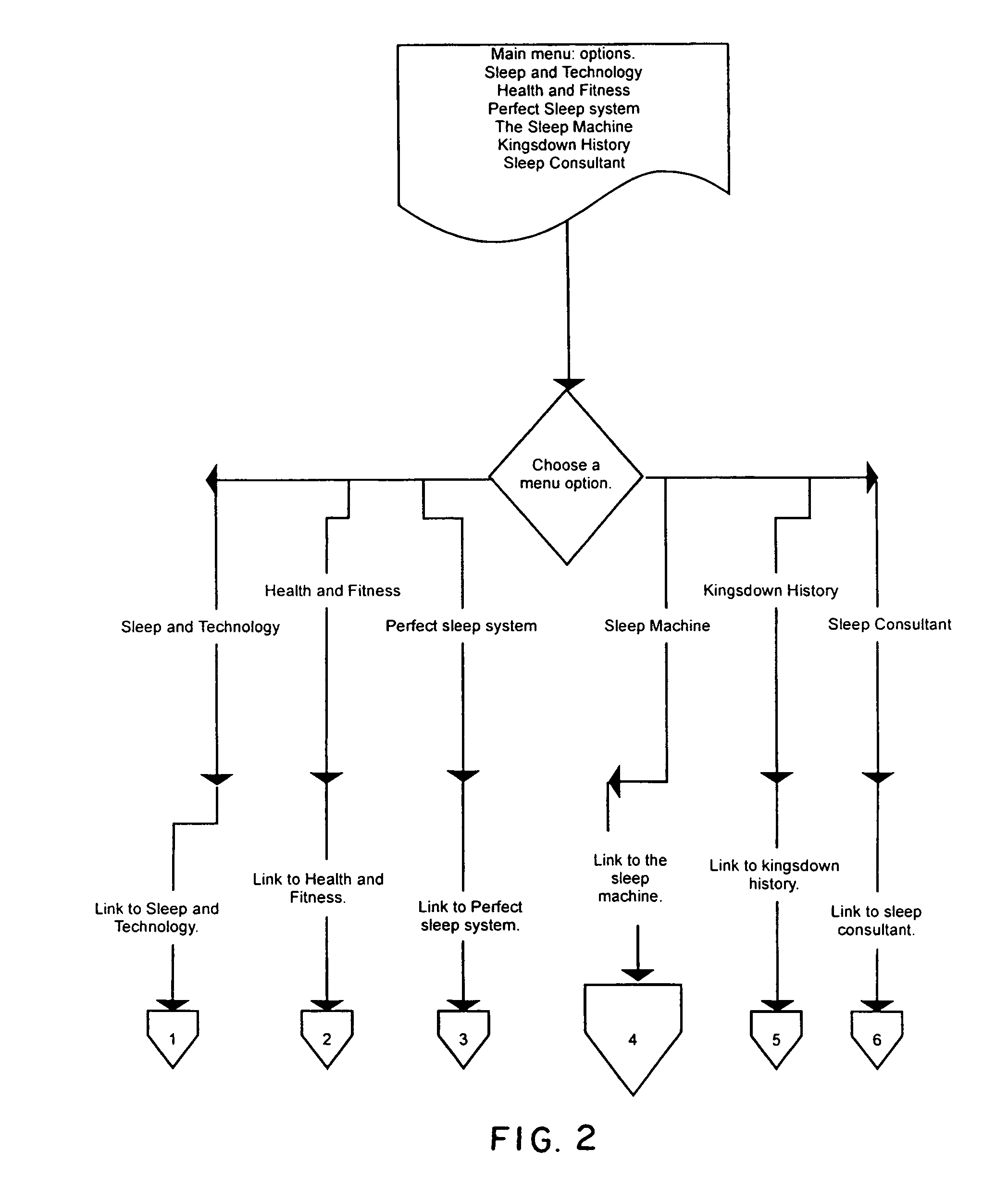

Automatic mattress selection system

InactiveUS6990425B2Choose accuratelyThe process is fast and accurateInflated body pressure measurementFluid pressure measurement by electric/magnetic elementsSelection systemComputer science

A person shopping for a mattress is helped to select a physiologically suitable mattress by a system which uses a questionnaire to elicit important information from the person. The questionnaire is processed automatically to generate a recommendation of which available mattress system is most suitable for the person.

Owner:KINGSDOWN INC

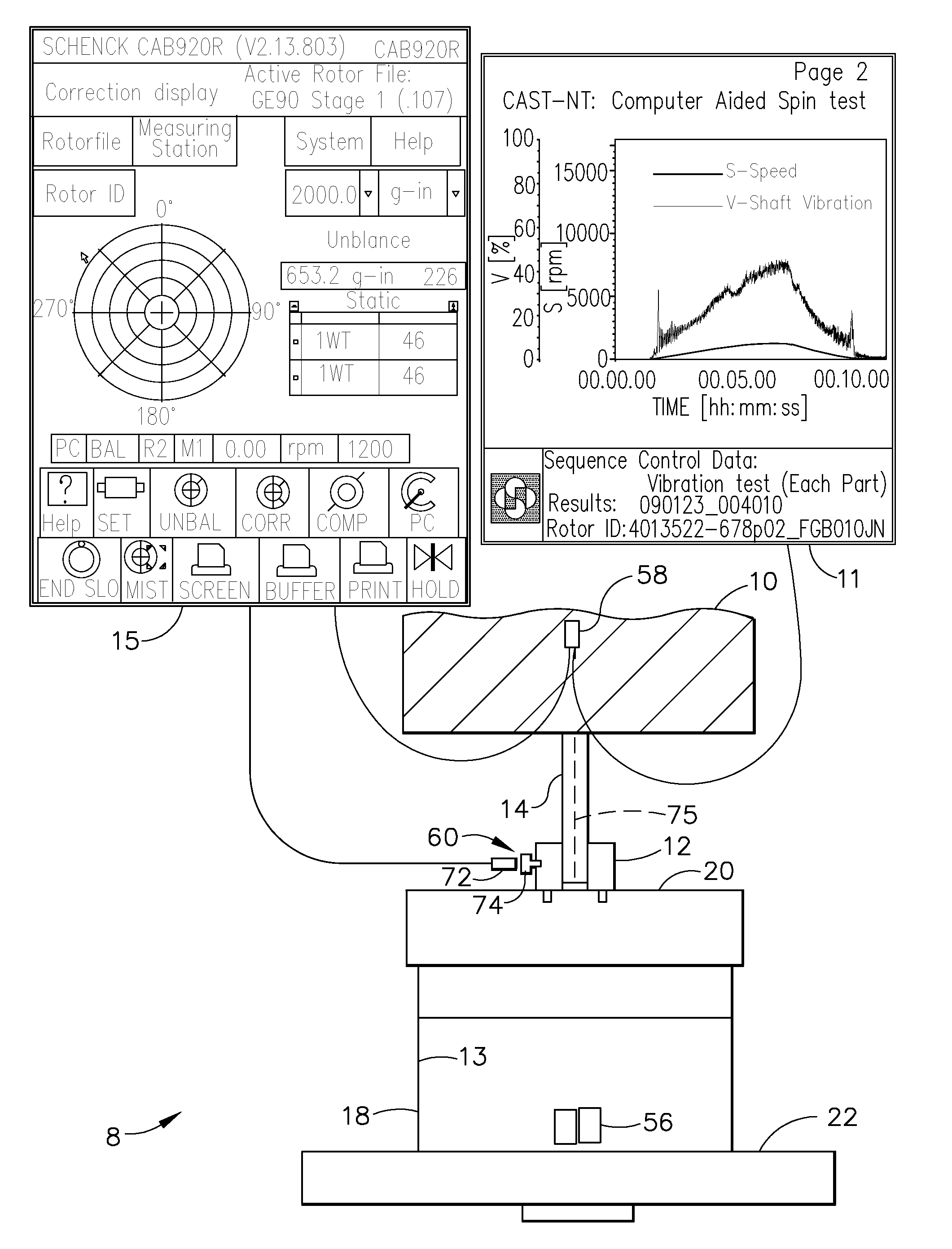

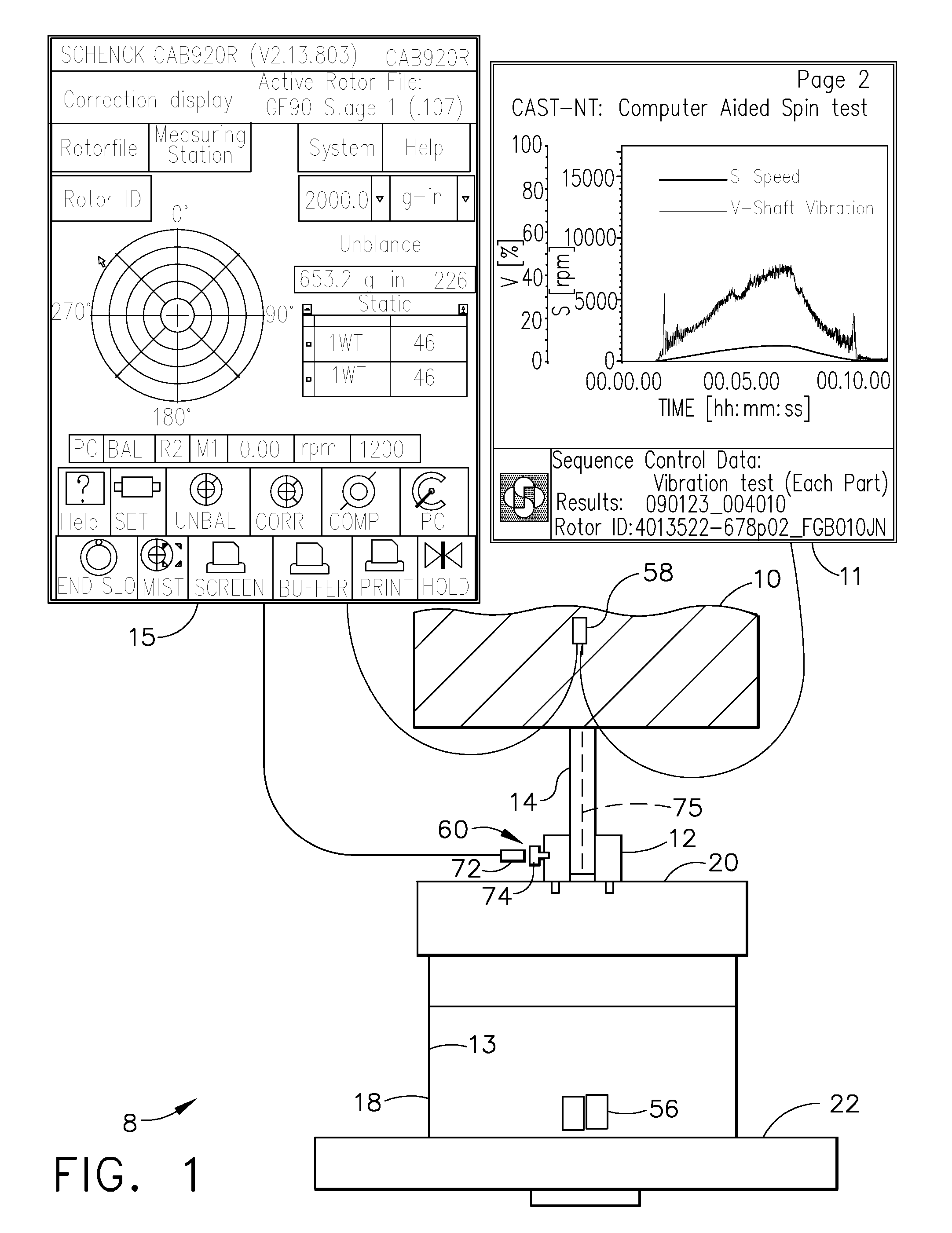

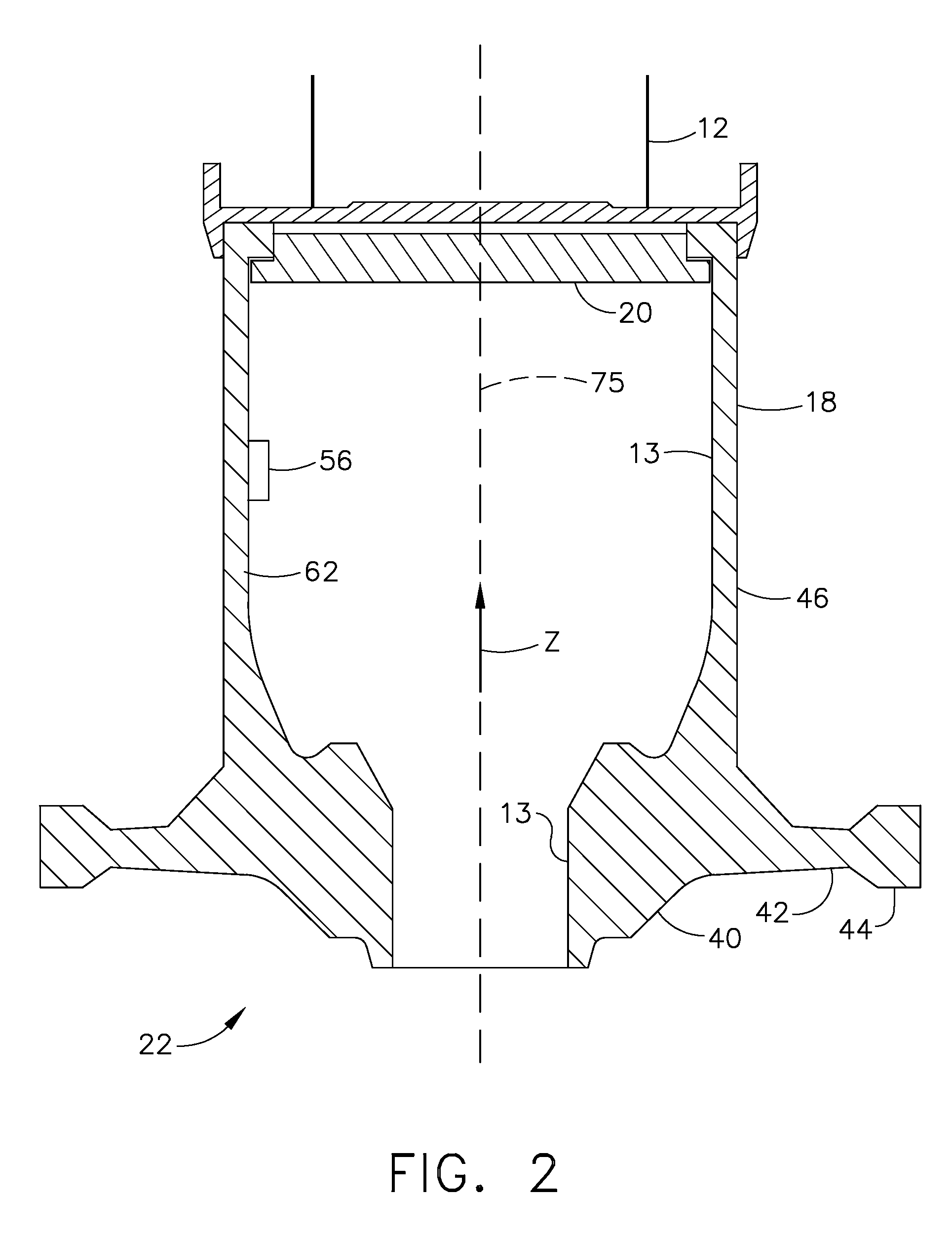

Method and apparatus for pre-spinning rotor forgings

ActiveUS20100212422A1Relieve forging induced residual stressAvoid excessive rotationForce measurementStatic/dynamic balance measurementHigh densityRotation velocity

A method and system for relieving forging induced residual stresses in a rotor forging balances a pre-spin machine with the forging mounted thereon at a first rotational speed and then pre-spins the forging with it mounted on the machine at a substantially greater second rotational speed. A one per rev sensor is used for determining a weight placement angle and a vibration sensor is used for determining an amount of weight to add to a spinning assembly including the forging during the balancing. High-density non-metallic balance weights adhesively attached on an inside surface of the forging or spinning assembly may be used. The rotational inertia of the spinning assembly may be checked during a spin up period by determining a rate of rotational acceleration vs. torque applied to the spinning assembly and used to stop the pre-spinning if it is to great.

Owner:GENERAL ELECTRIC CO

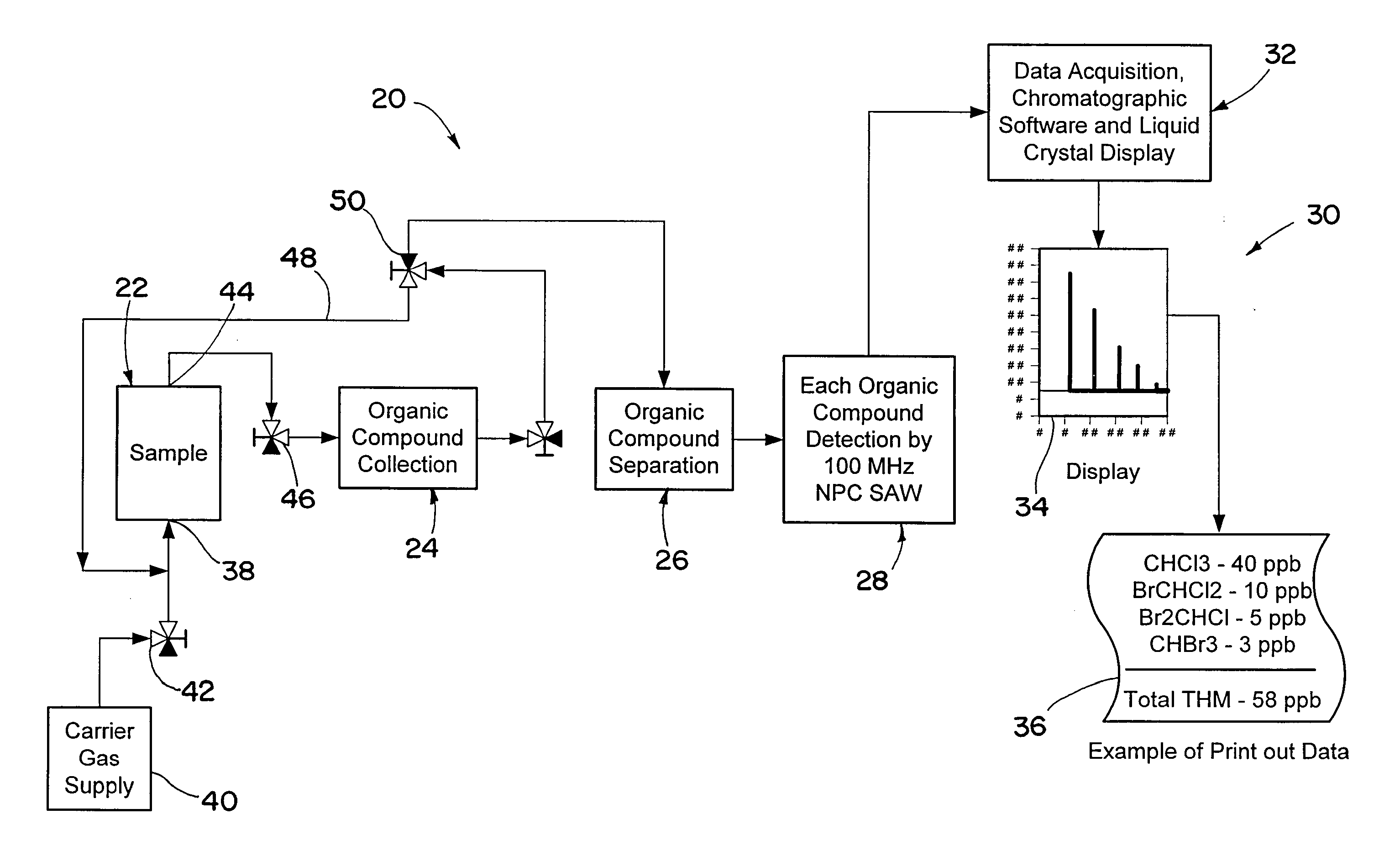

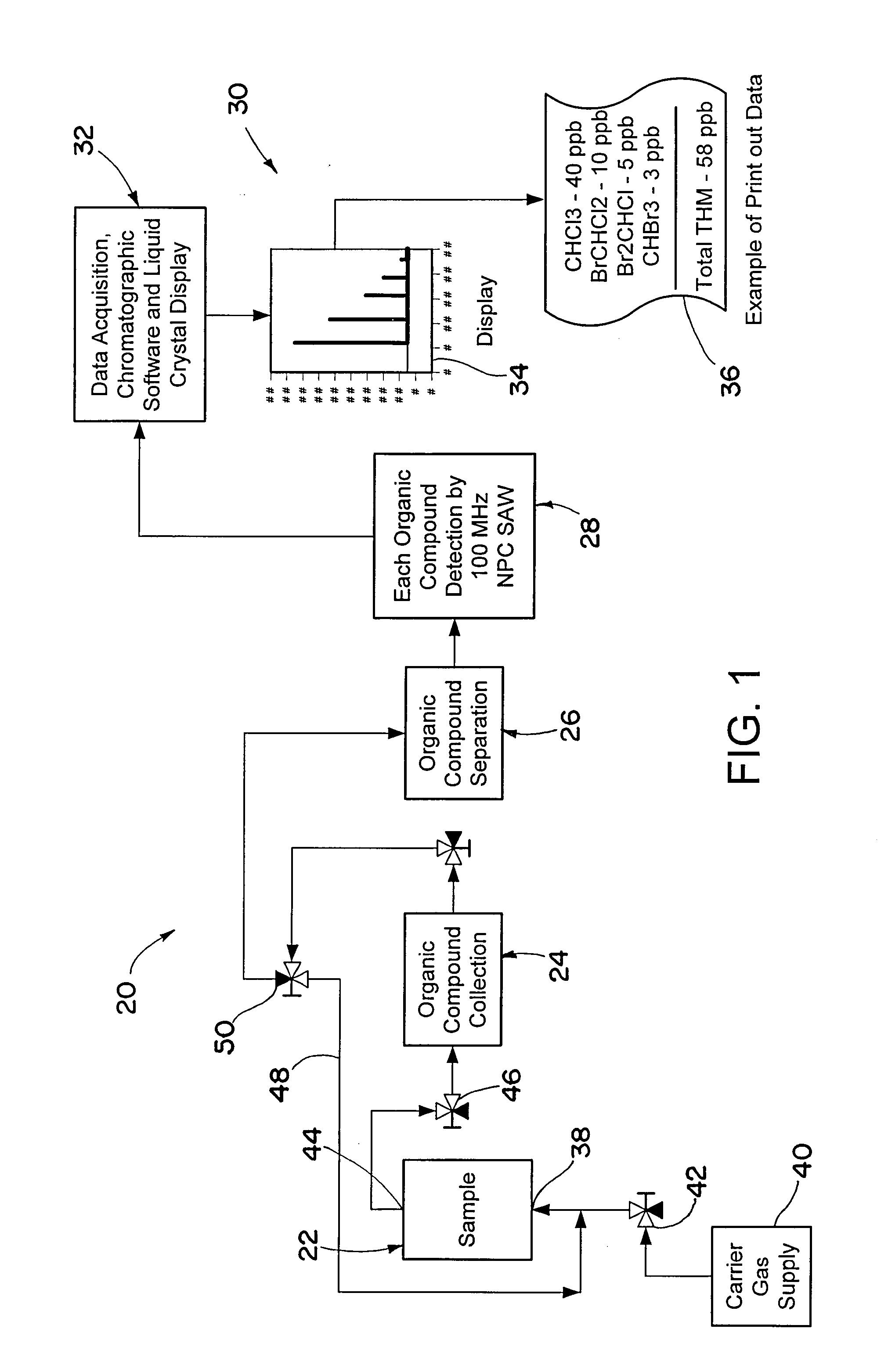

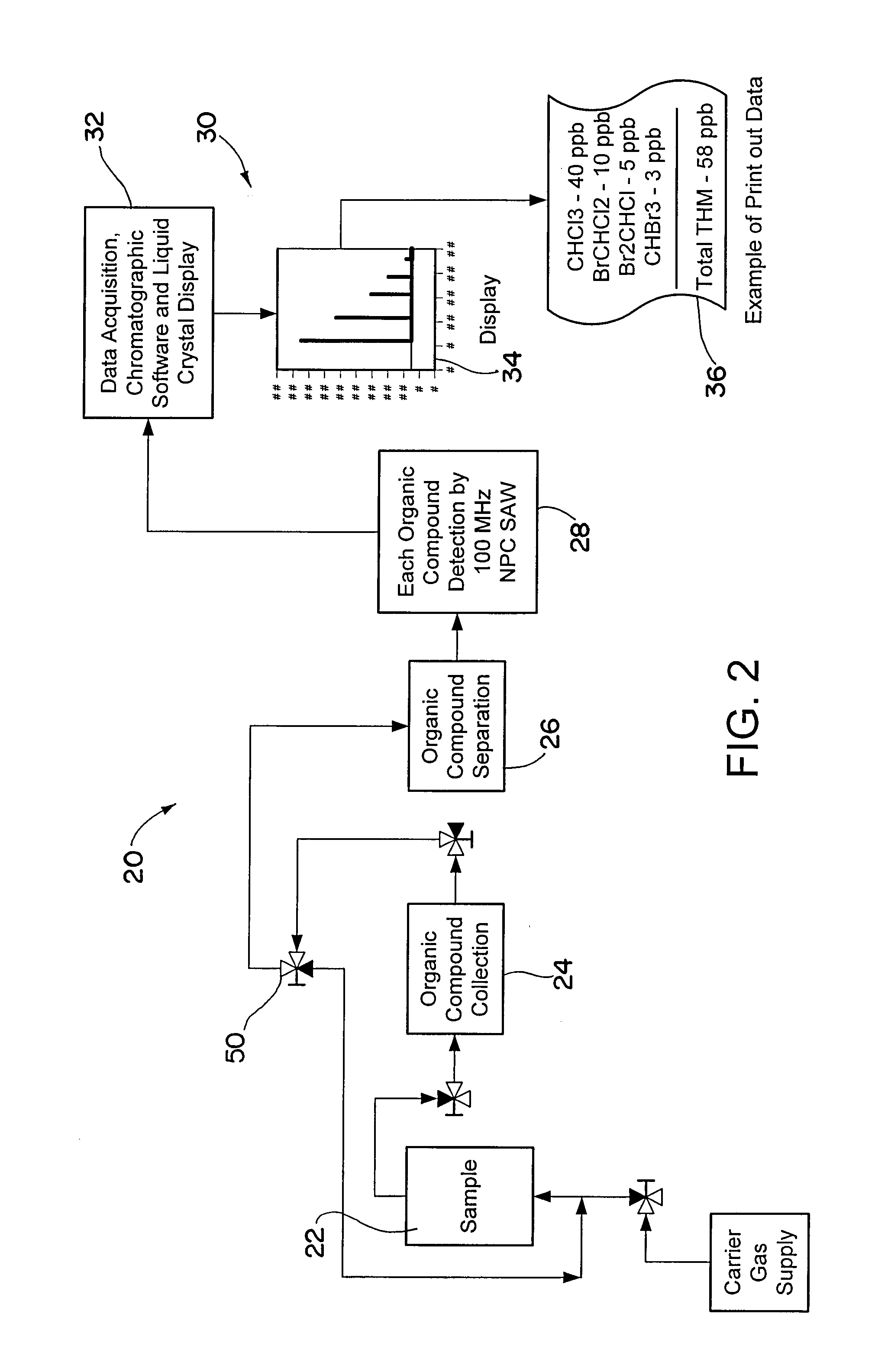

Portable analytical system for detecting organic chemicals in water

ActiveUS20080289397A1Easy to manufactureEliminate needMaterial analysis using sonic/ultrasonic/infrasonic wavesWeighing apparatus using elastically-deformable membersBromineBromoform

A portable analytical system for detecting organic chemicals in water comprising a miniature preconcentrator and a SAW detector, the latter being characterized by a nanoporous carbon coating that provides improved response compared to prior art polymer coatings, particularly when detecting low concentrations of trihalomethane chemicals, such as chloroform and bromoform.

Owner:PARKER INTANGIBLES LLC

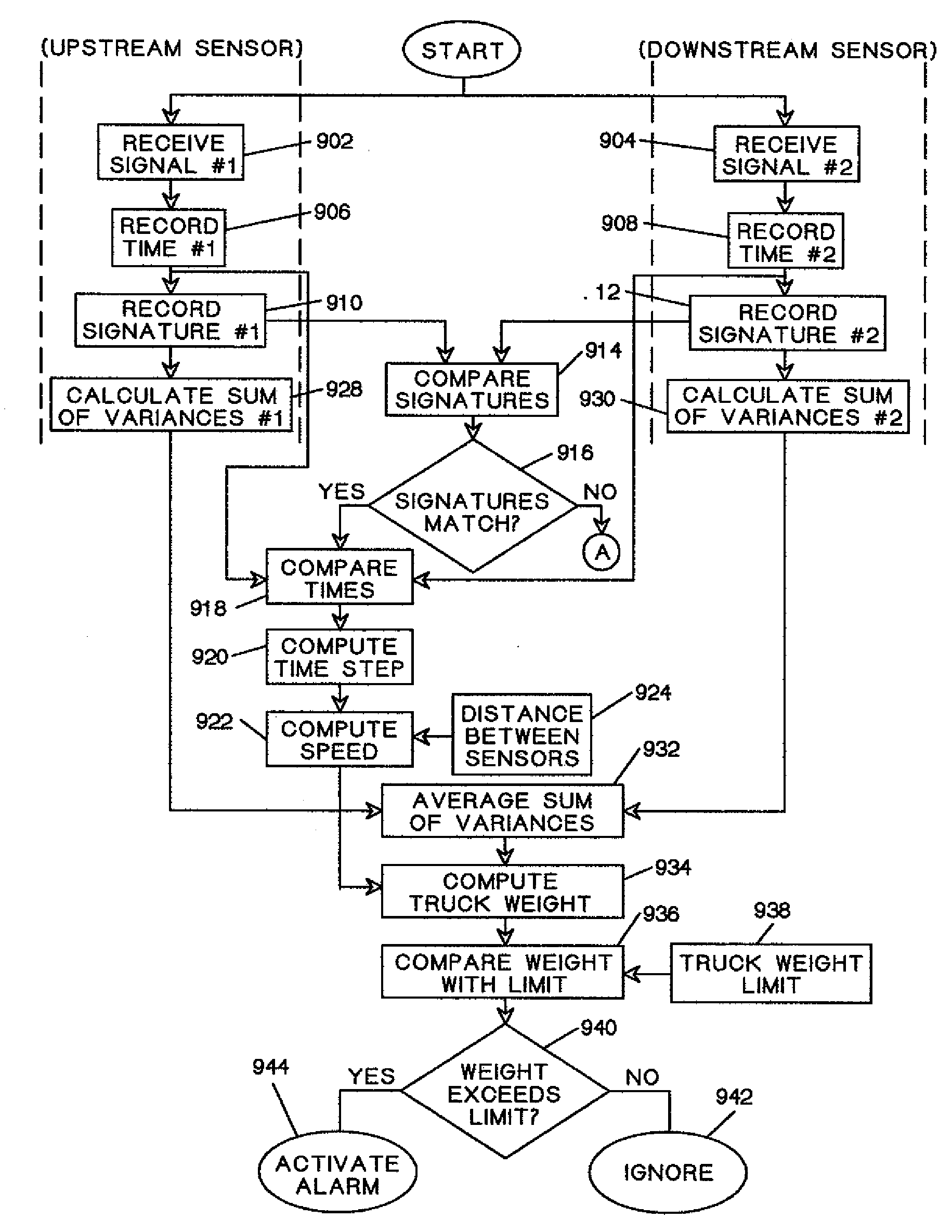

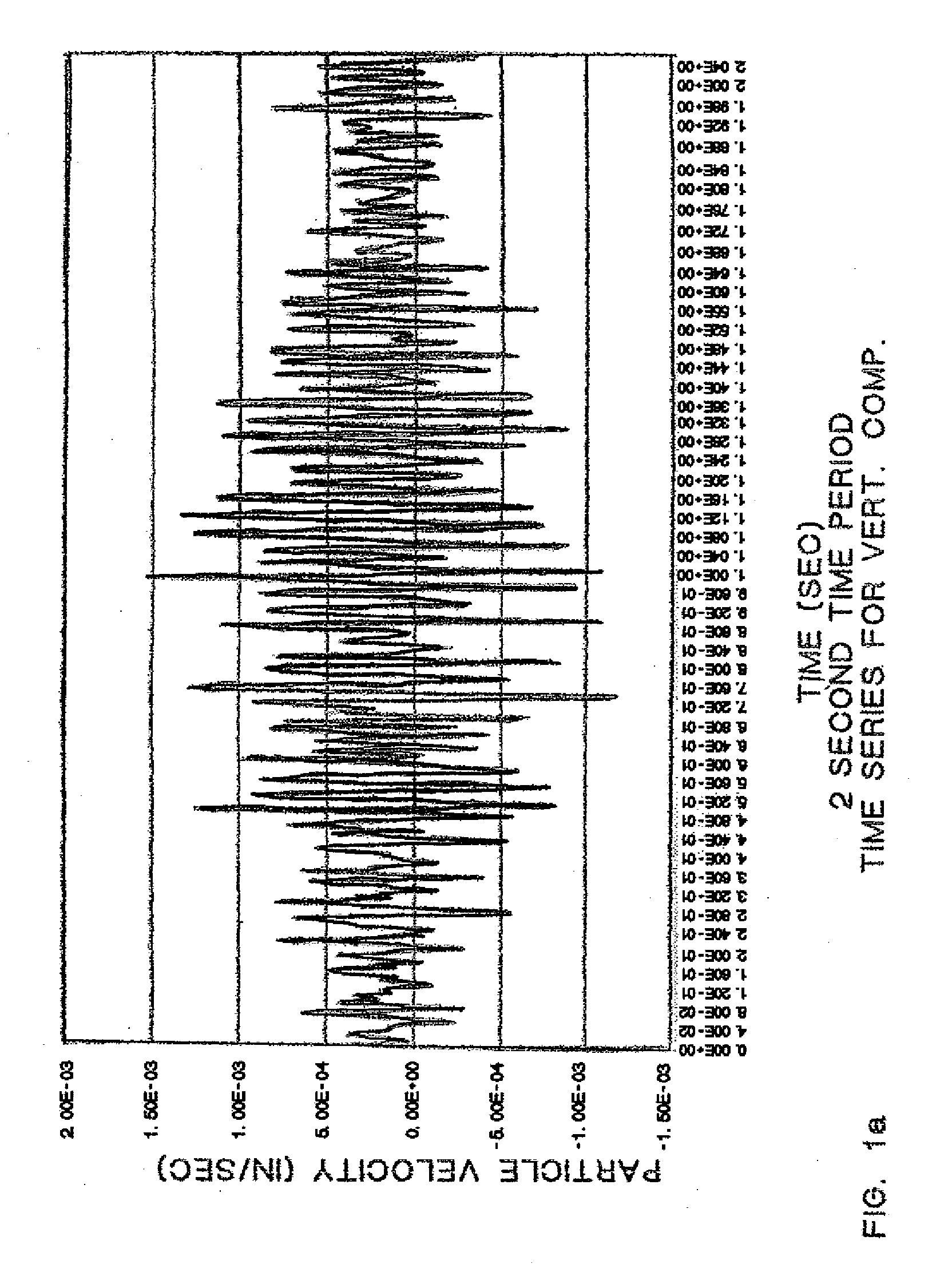

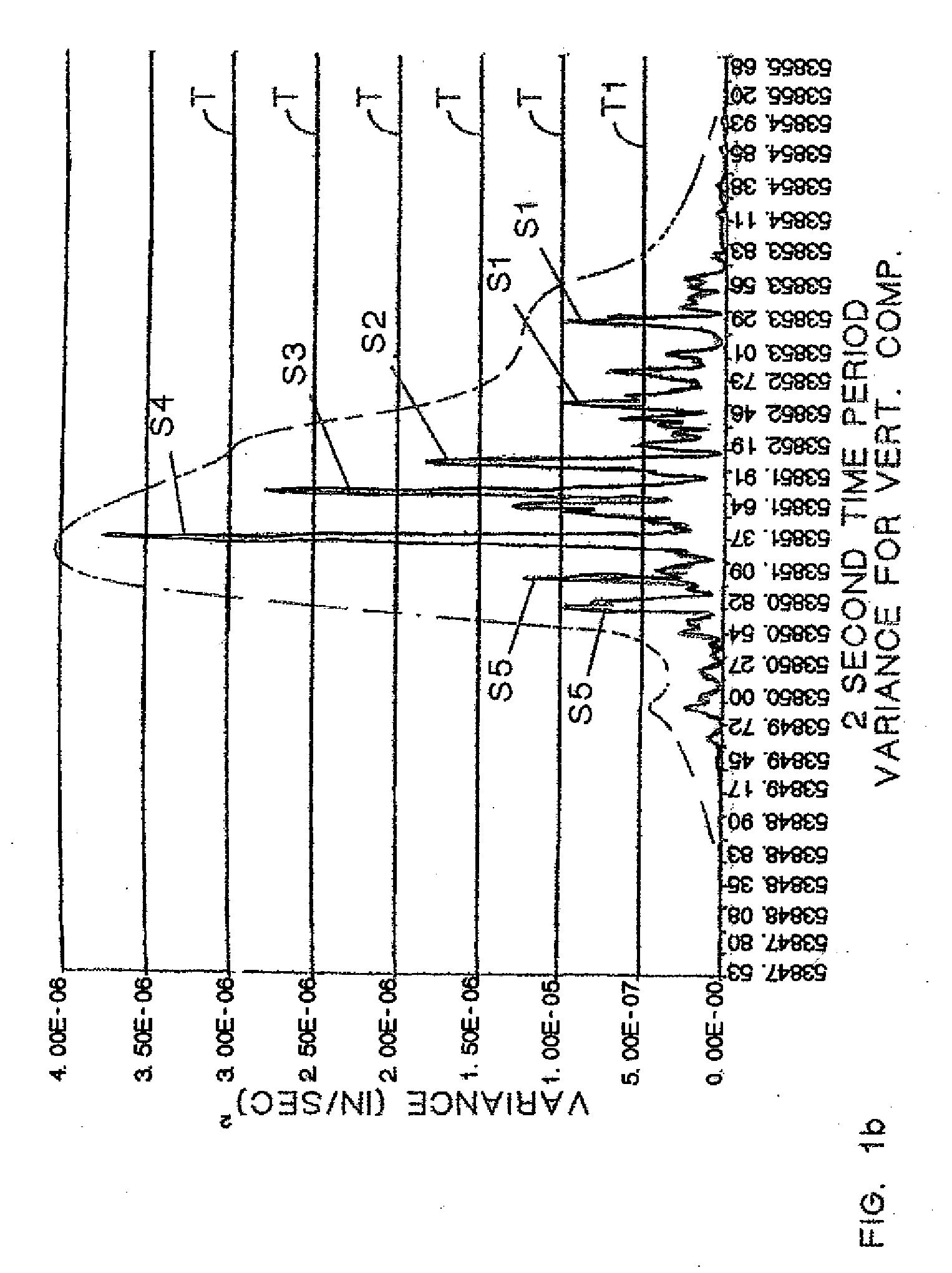

Method for weighing vehicles crossing a bridge

A method for weighing vehicles moving on a bridge deck pavement is provided. At least one vibration sensor is mounted on a lower side of the pavement to sense low frequency pavement vibrations generated by moving vehicle wheels and propagated in waves in the pavement. Vibration sensor output signals are provided to a computing device. Sensed vibration energy rate is computed and, with signals from vibration sensors mounted at two locations separated by a known longitudinal distance, vehicle speed is also computed. The weight of the vehicle is determined as the product of a calibration coefficient and the ratio of sensed vibration energy rate to velocity. Using vibration sensor signals indicative of wheel generated vibrations in the very near field and summing vibration energy rates computed from these signals during vehicle passage over the vibration sensors the weight of individual vehicles is computed when other moving vehicles are present.

Owner:TATOM FR B +1

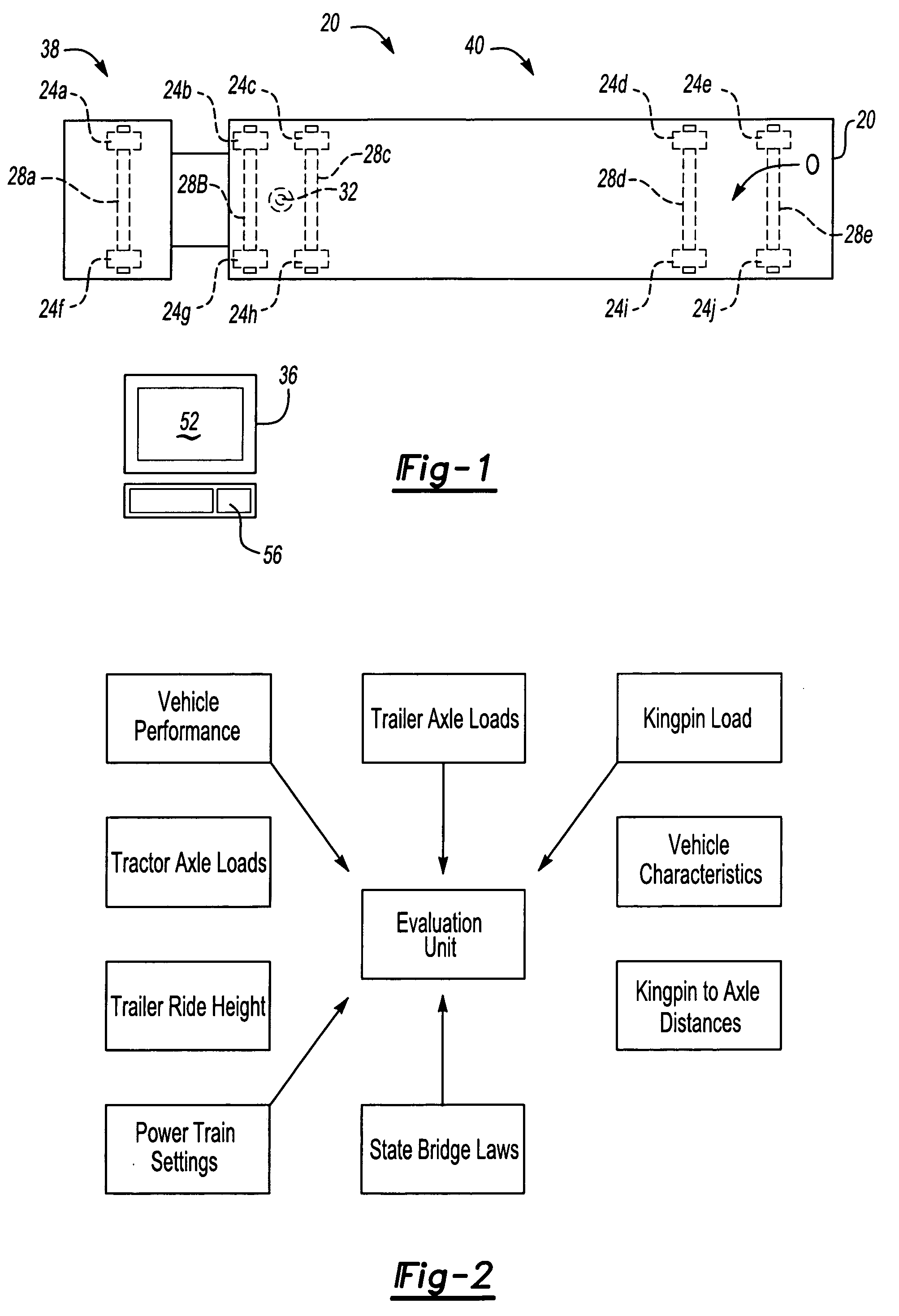

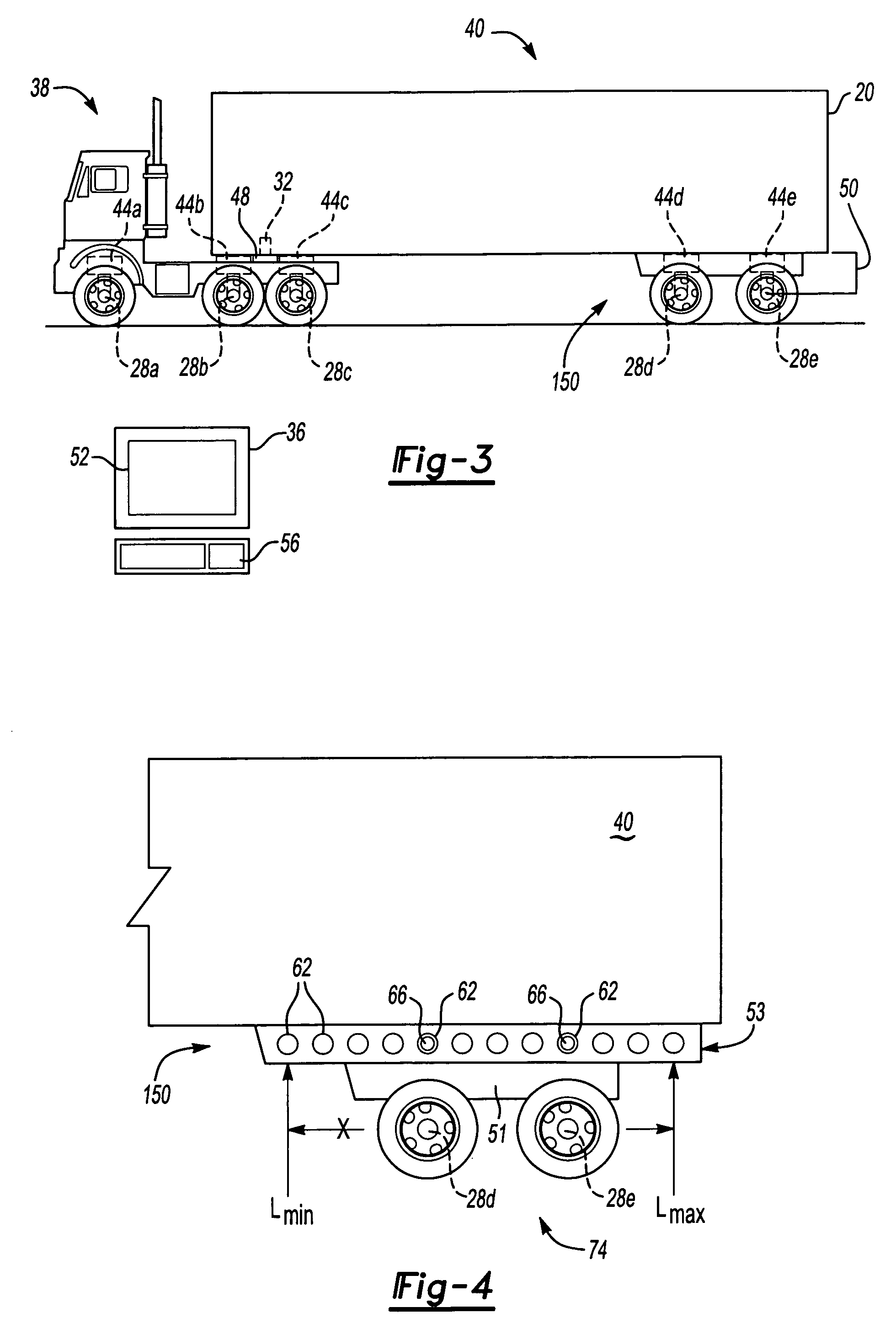

Intelligent load distribution system

InactiveUS7072763B2Improve performanceWeighing apparatus testing/calibrationDigital computer detailsLoad generationEngineering

A vehicle information system has a first load sensor for generating a first load signal based on a first vehicle load. A first position sensor generates a first position signal based on a position of a vehicle axle. A second position sensor generates a second position signal based on a position of a vehicle kingpin. A memory unit stores vehicle optimization data. An evaluation unit is in communication with the first load sensor, the first position sensor, the second position sensor and the memory unit. A general user interface for receiving input is also in communication with the evaluation unit. The evaluation unit makes an evaluation of the first load signal, the first position sensor, the second position signal, and any input and generates a vehicle optimization instruction relating to a distance between the axle and the kingpin.

Owner:ARVINMERITOR TECH

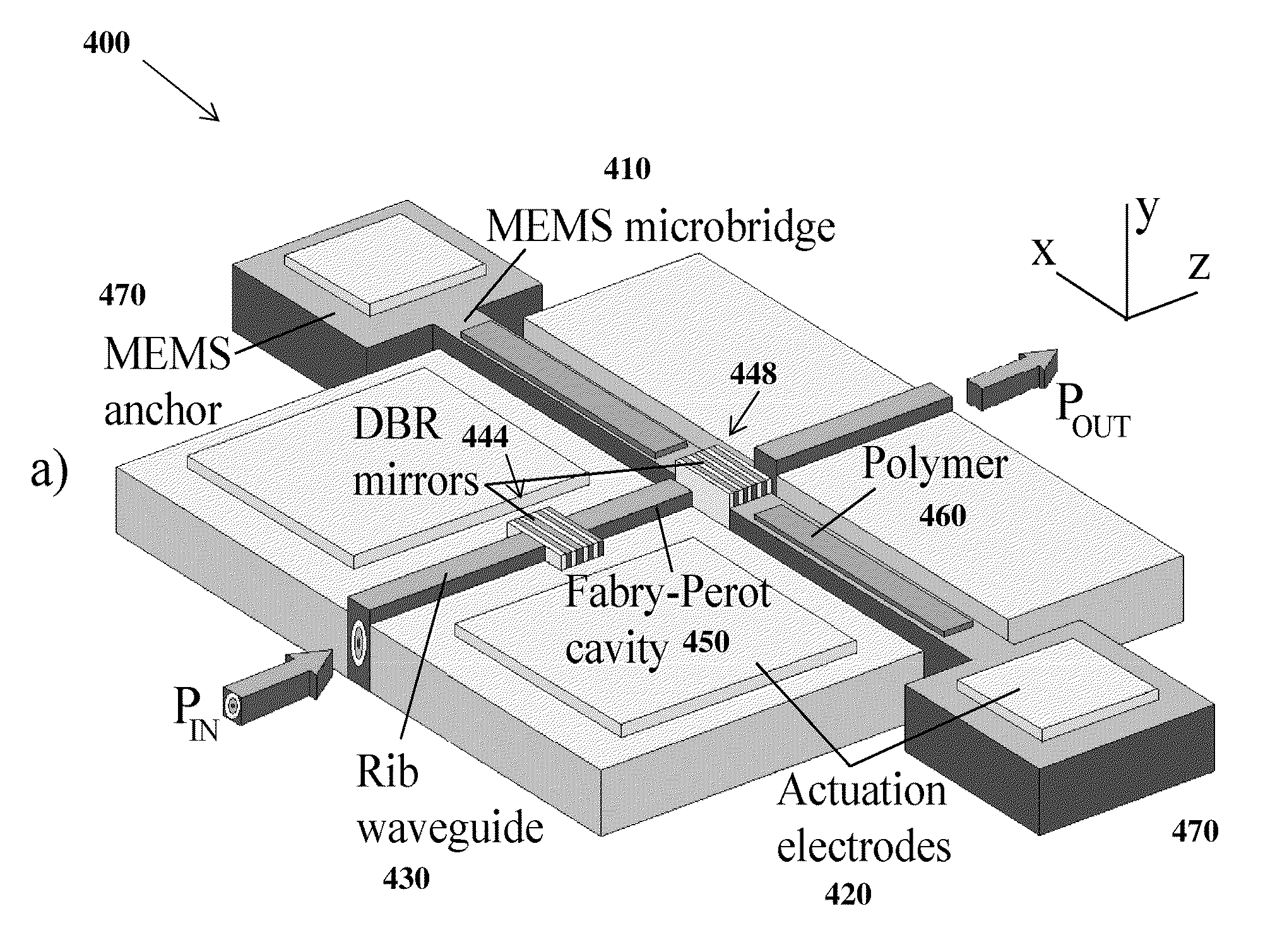

Optical MEMS Chemical Sensor Array

ActiveUS20100238454A1High selectivityIncrease flexibilityMaterial analysis using immobilised reagentsMaterial analysis using sonic/ultrasonic/infrasonic wavesSensor arrayWaveguide

A change in mass of a microbridge in a mass sensor can be sensed by applying a time-varying amplitude modulated electrostatic force to excite the microbridge into resonance at the frequency of amplitude modulation. An optical energy is then transmitted at a wavelength close to a resonant wavelength of a Fabry-Perot microcavity, which is formed by etching a movable reflective mirror into a region of the microbridge and by etching a fixed reflective minor in a region spaced apart from the microbridge. The two mirrors are interconnected by an optical waveguide. The movable mirror and fixed mirror reflect the optical energy to a receiver, and a change in the Fabry-Perot microcavity's reflectivity is interferometrically determined. The change in reflectivity indicates a change in the microbridge's resonant frequency due to increased mass of the microbridge resulting from sorption of a target chemical by a layer of chemoselective material deposited on the microbridge.

Owner:UNITED STATES OF AMERICA

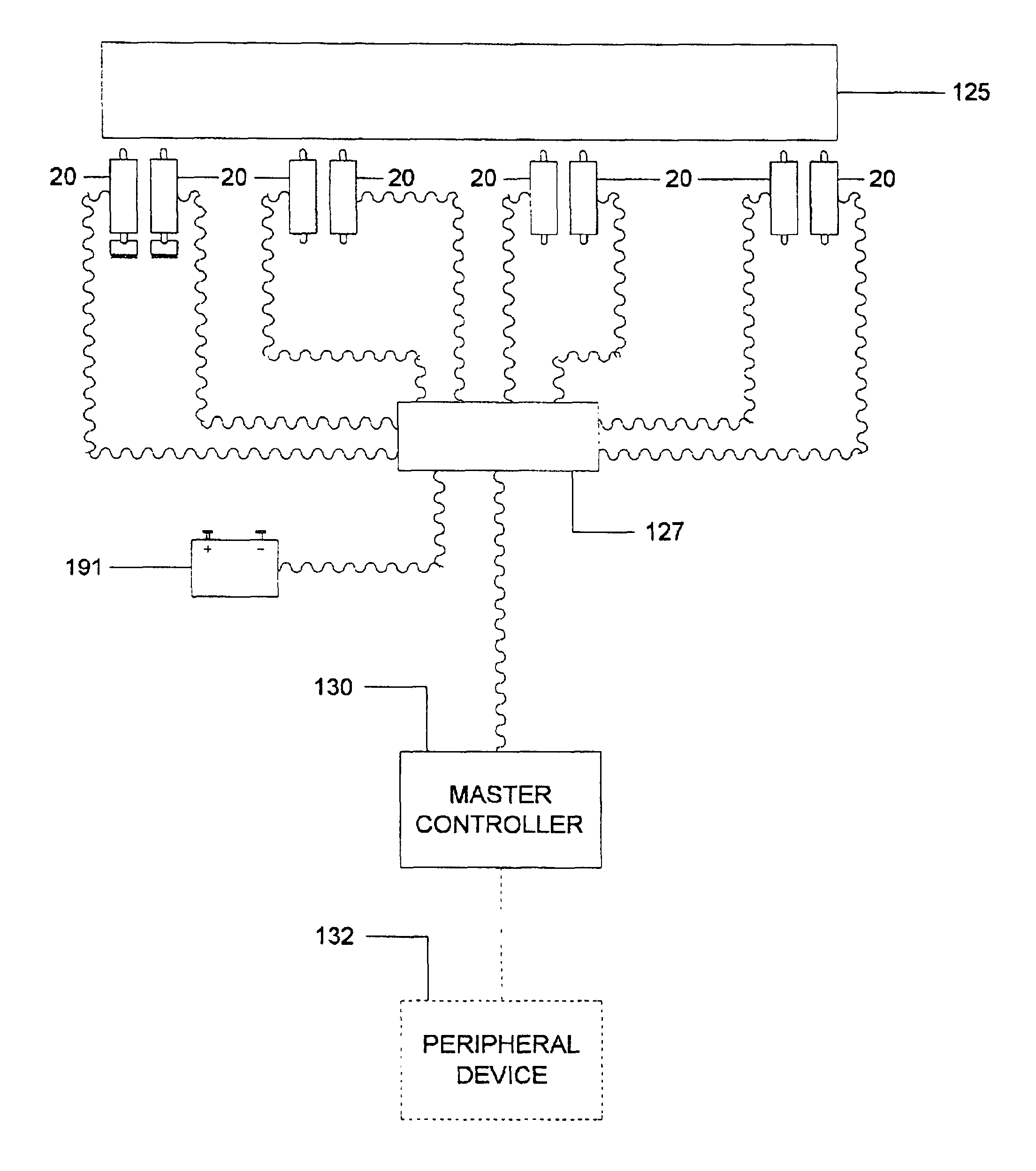

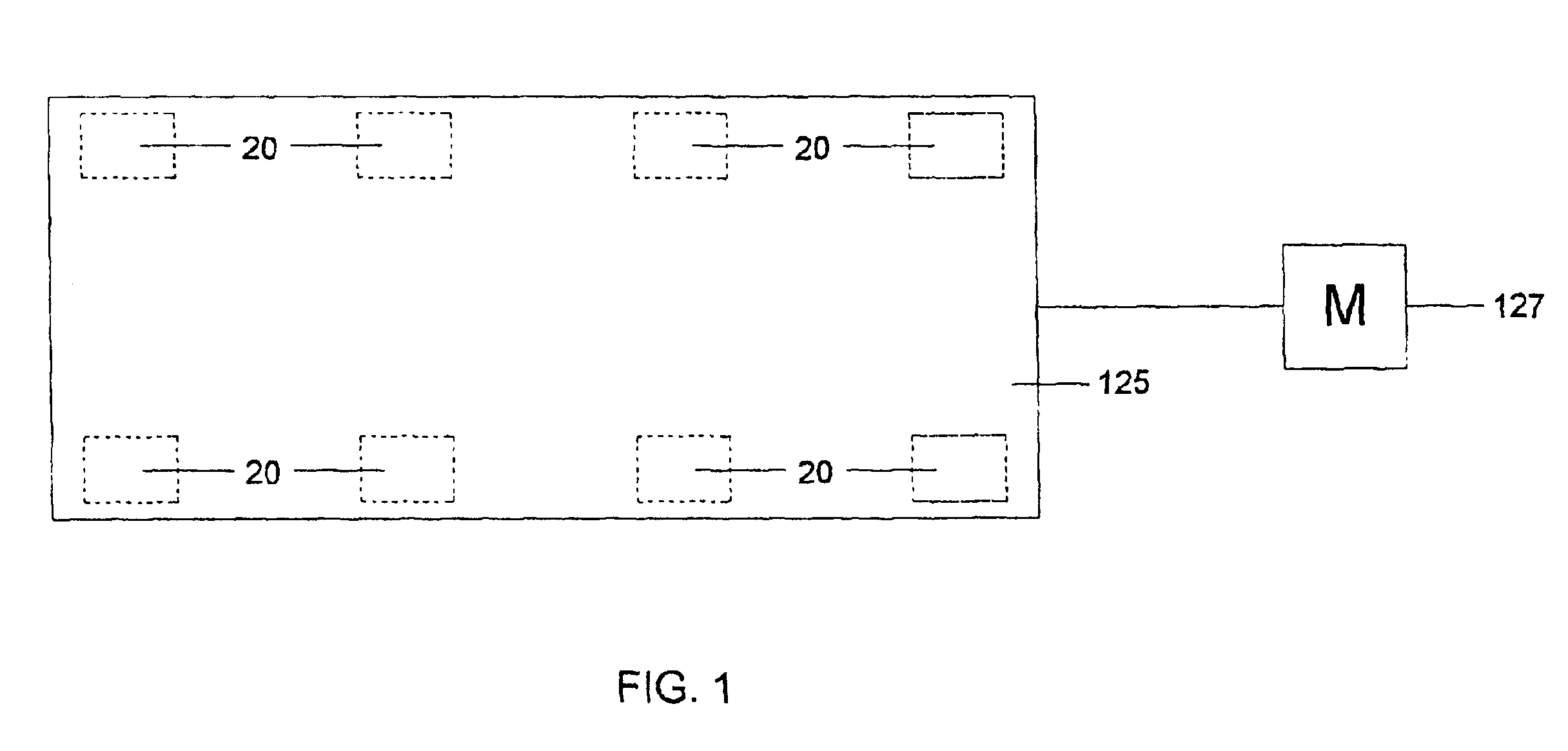

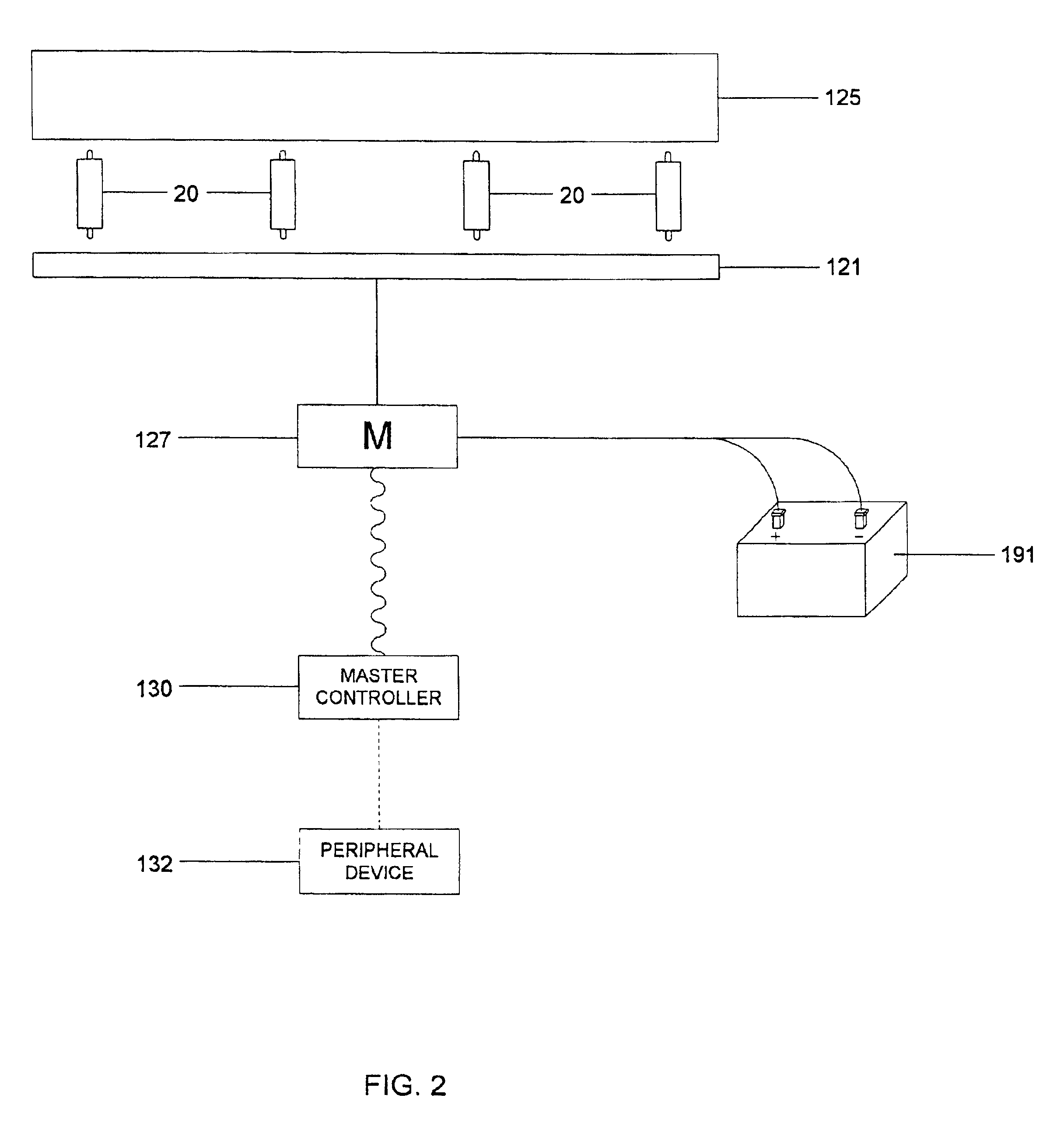

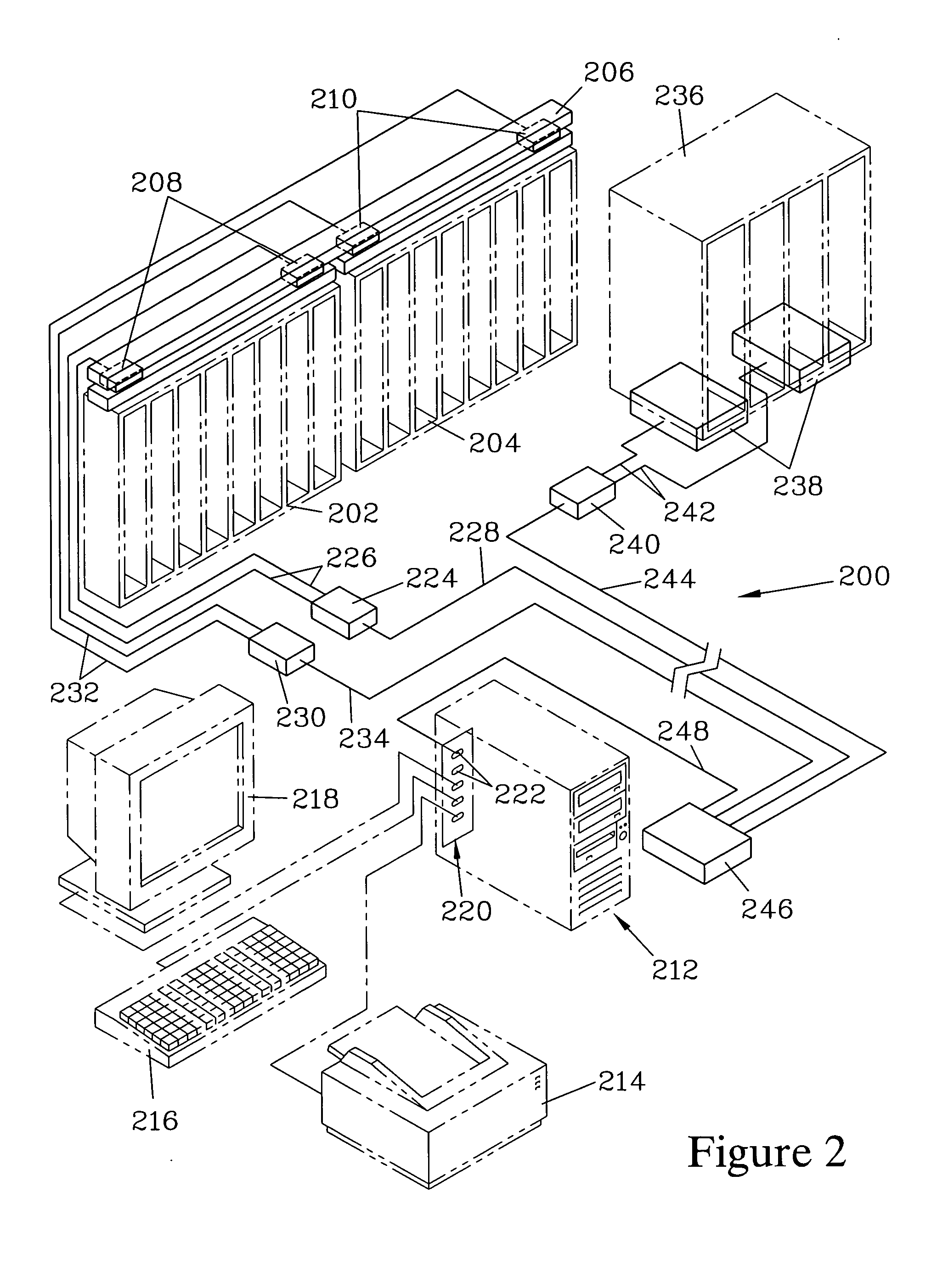

RF multiple load cell scale

InactiveUS6919516B2Eliminate needEnergy efficient ICTWeighing apparatus using elastically-deformable membersMicrocomputerTransceiver

Load cells forming one or more weighing scales are connected to each other and to a common concentrator which communicates to a master controller in the control house via RF wireless communication. The load cells are polled by and provide weight reading to concentrator to the master controller. A digital load cell is used which includes a rocker pin, guided beam, torsion ring or other counterforce, a circuit board mounted on the counterforce and an enclosure sealing the circuit board and all but the load bearing surfaces of the counterforce and a mounded antenna. The circuit board includes a microcomputer and a transceiver. RF communication is provided with the circuit board through a antenna mounted on the enclosure. One or a number of load cells may be connected to a computer or controller to form one or more weighing scales with one or more weighing scales connect to a control house through wireless RF communication. The preferred embodiment uses passive receivers for receiving the signals and waveguide to minimize power requirements.

Owner:METTLER TOLEDO INC

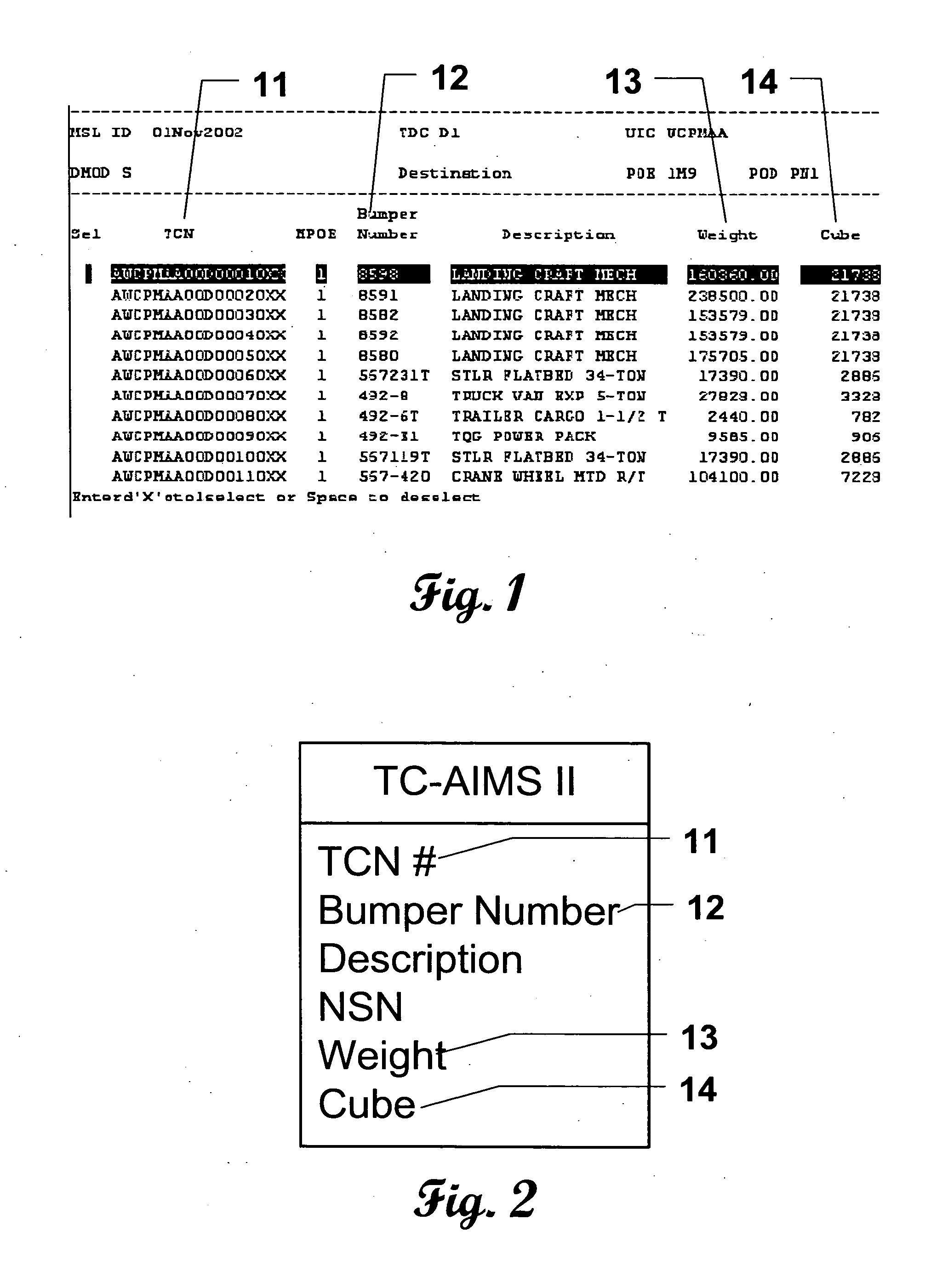

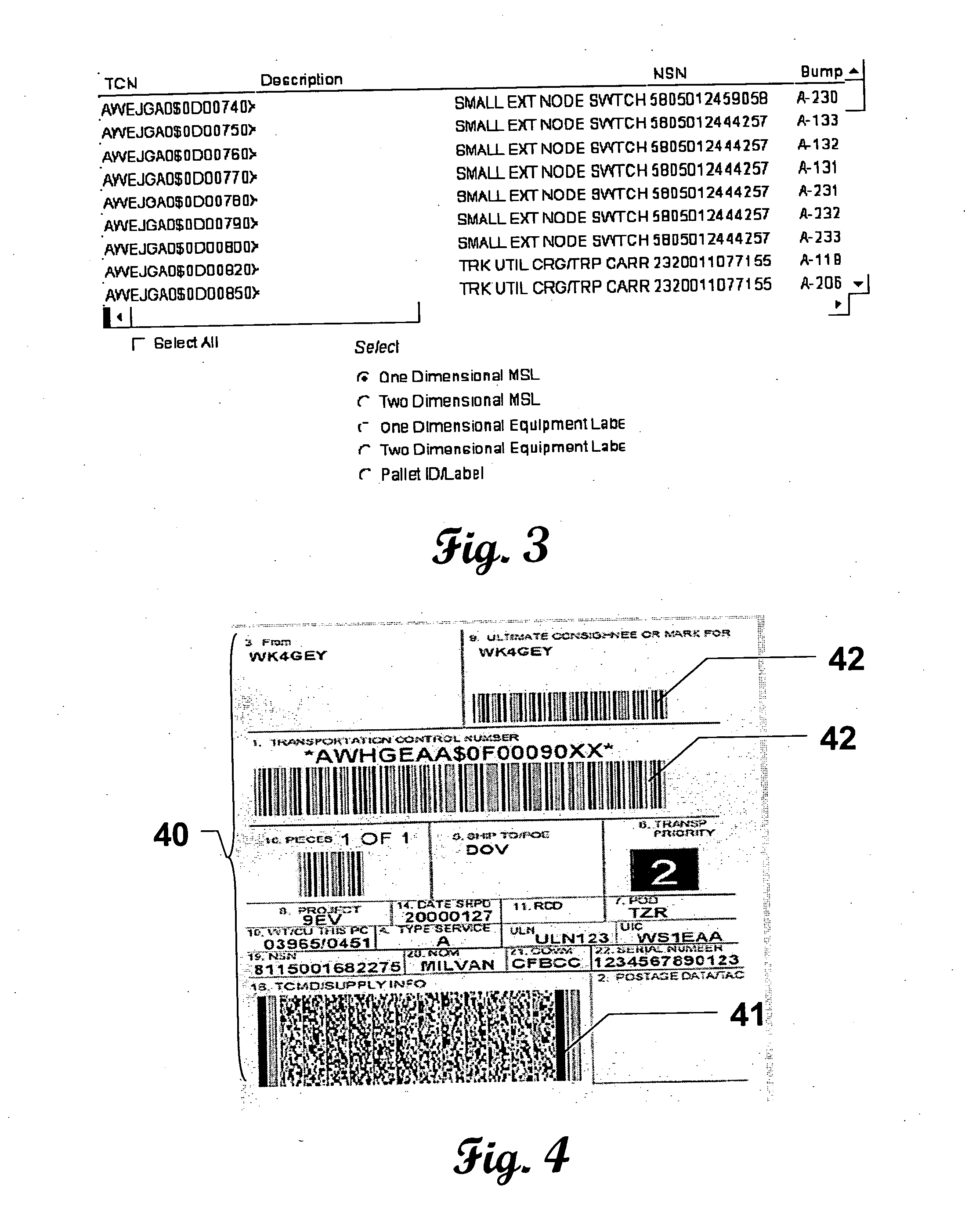

System and method for indentifying, validating, weighing and characterizing moving or stationary vehicles and cargo

InactiveUS20060111868A1Accurate dataEliminate errorsDigital computer detailsWeighing apparatus for materials with special property/formElectronic communicationEngineering

An asset identification and information infrastructure management (AI3M) device having an automated identification technology system (AIT), a Transportation Coordinators' Automated Information for Movements System II (TC-AIMS II), a weigh-in-motion system (WIM-II), and an Automated Air Load Planning system (AALPS) all in electronic communication for measuring and calculating actual asset characteristics, either statically or in-motion, and further calculating an actual load plan.

Owner:UT BATTELLE LLC

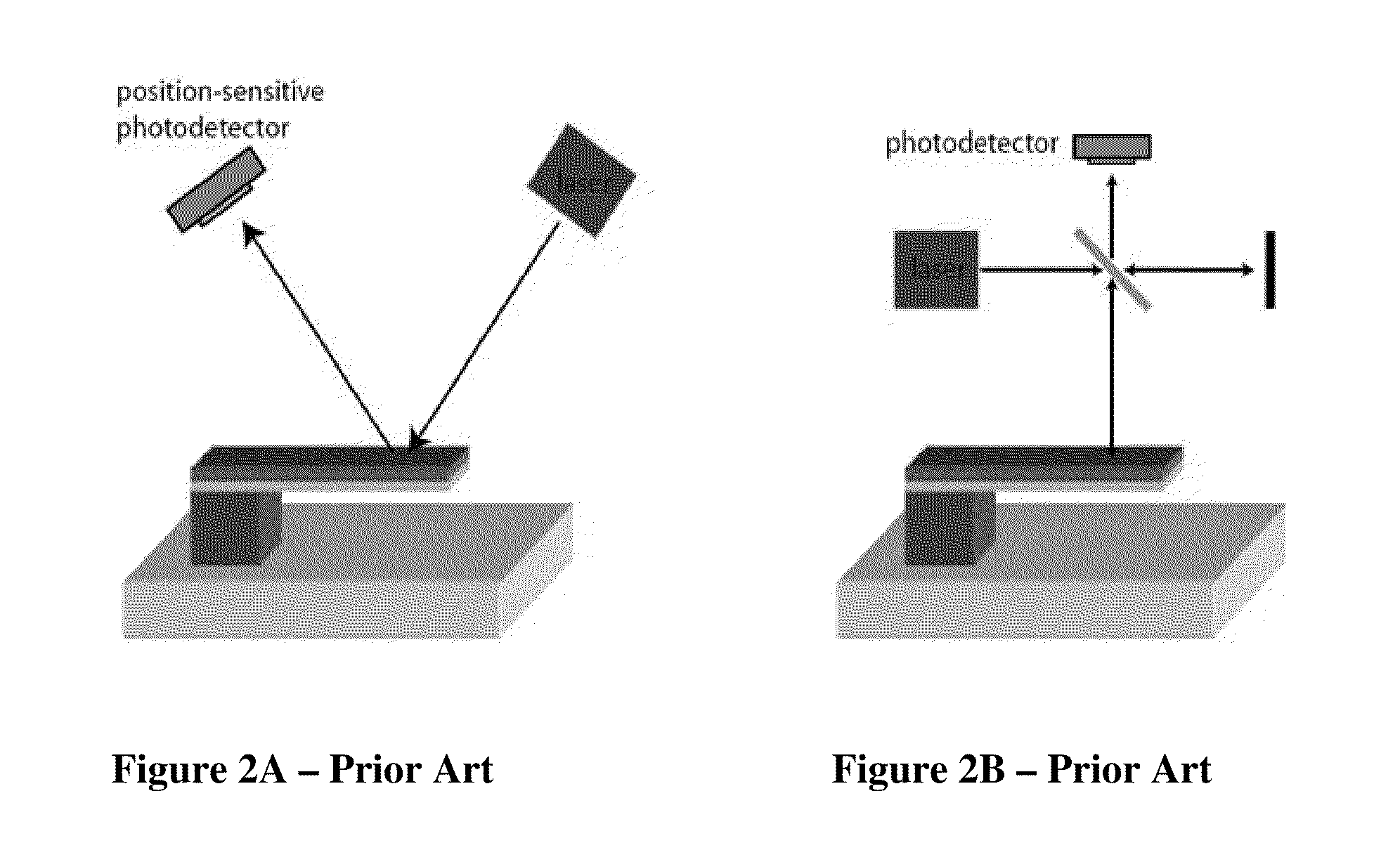

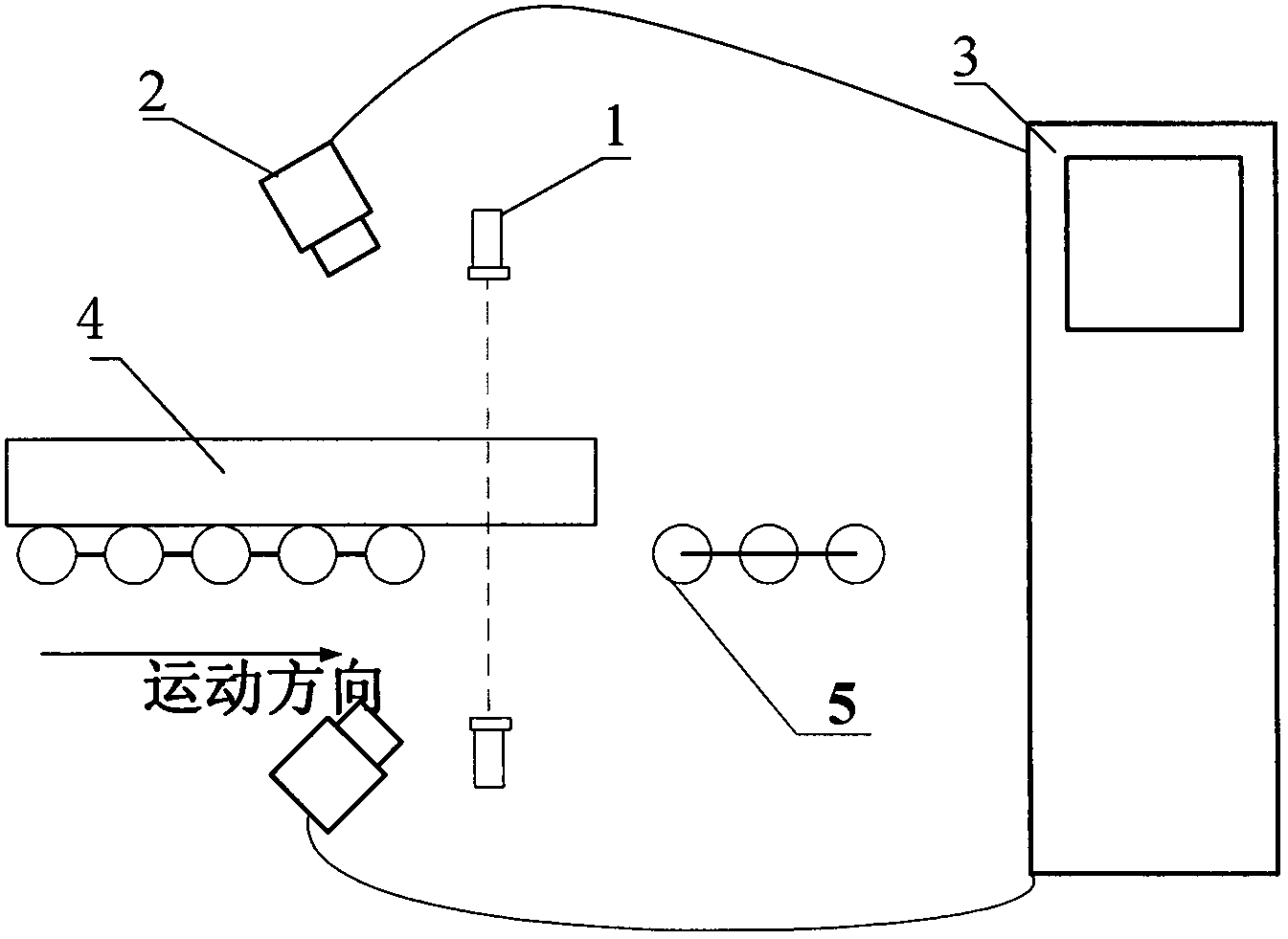

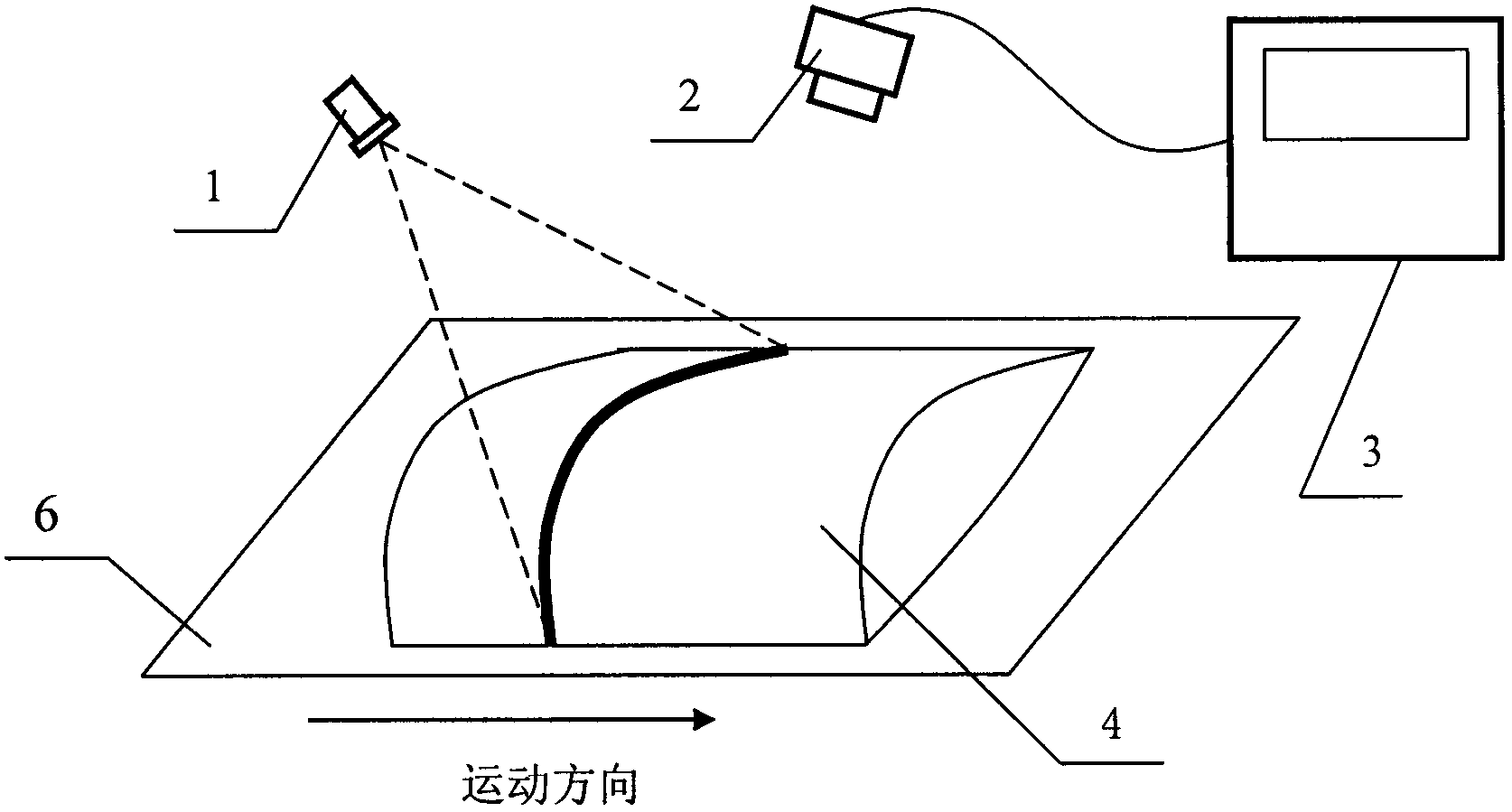

Method and system for measuring volumes and weights of continuously conveyed long objects based on optical measurement

InactiveCN102679915AEasy to addUsing optical meansWeighing apparatus for continuous material flowData processing systemObject based

The invention discloses a method and a system for measuring volumes and weights of continuously conveyed long objects based on optical measurement. The sectional areas, the volumes and the weights of the continuously conveyed long objects are measured by a non-contact optical method. One or a plurality of light projectors 1 and one or a plurality of image sensors 2 are arranged within a certain distance surrounding the measured continuously conveyed long objects 4, the image sensors are connected with a data processing system 3 via a bus, the data processing system processes image data acquired by the image sensors, and the volumes and / or the weights of the objects to be measured are calculated by the aid of conveying speed and density data of the objects. The method and the system have the advantages that the cross sectional areas of the continuously conveyed objects can be accurately measured in a non-contact manner, and the volumes and / or the weights of the objects passing through a fixed plane can be calculated. Interference to a conveying system is avoided, the system can be conveniently added surrounding existing conveying equipment to be used for measuring the volumes and the weights of the objects, and is particularly suitable for measuring objects in a non-contact manner, such as hot rolling billets and pulverized coal.

Owner:HEBEI UNIV OF TECH

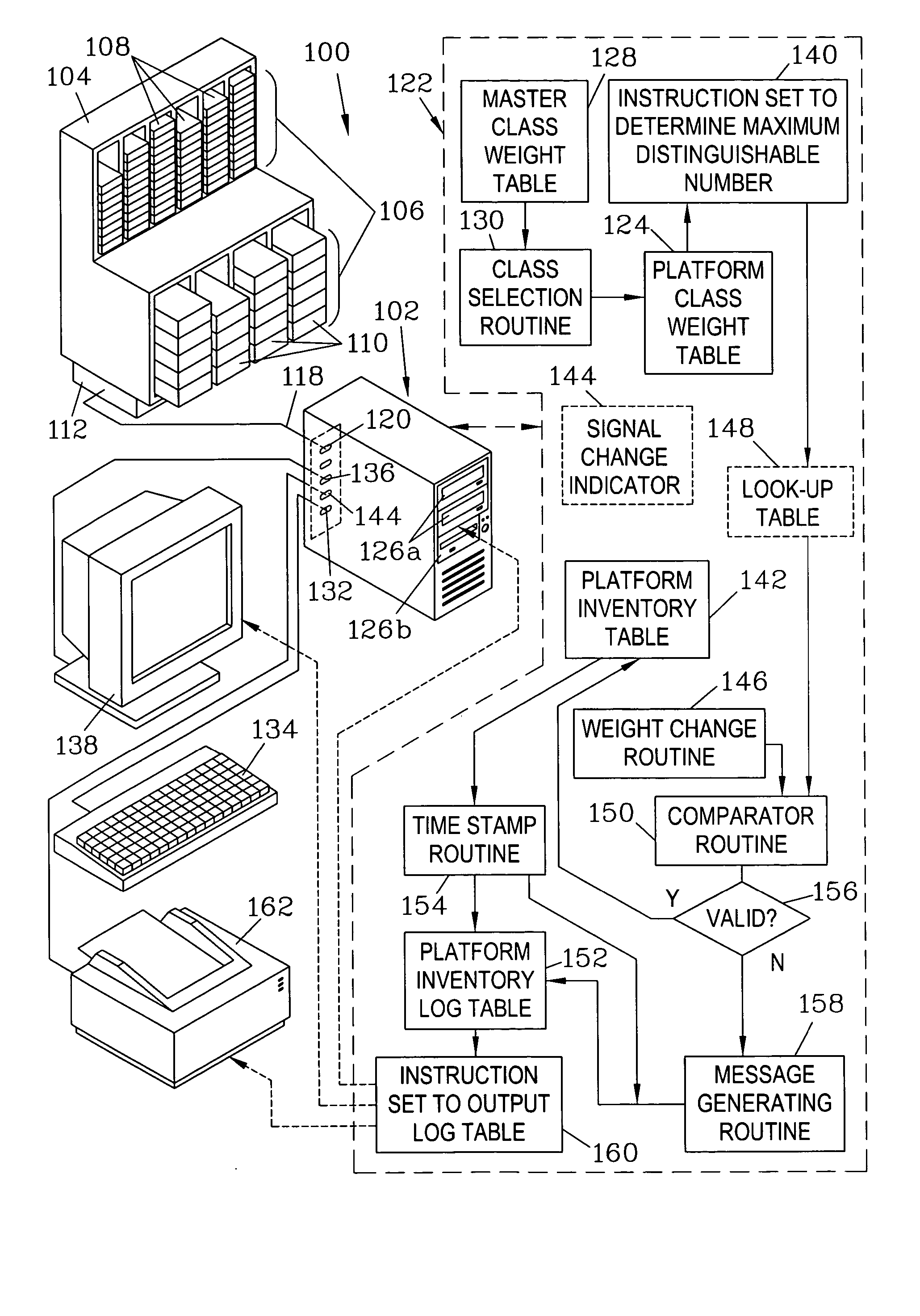

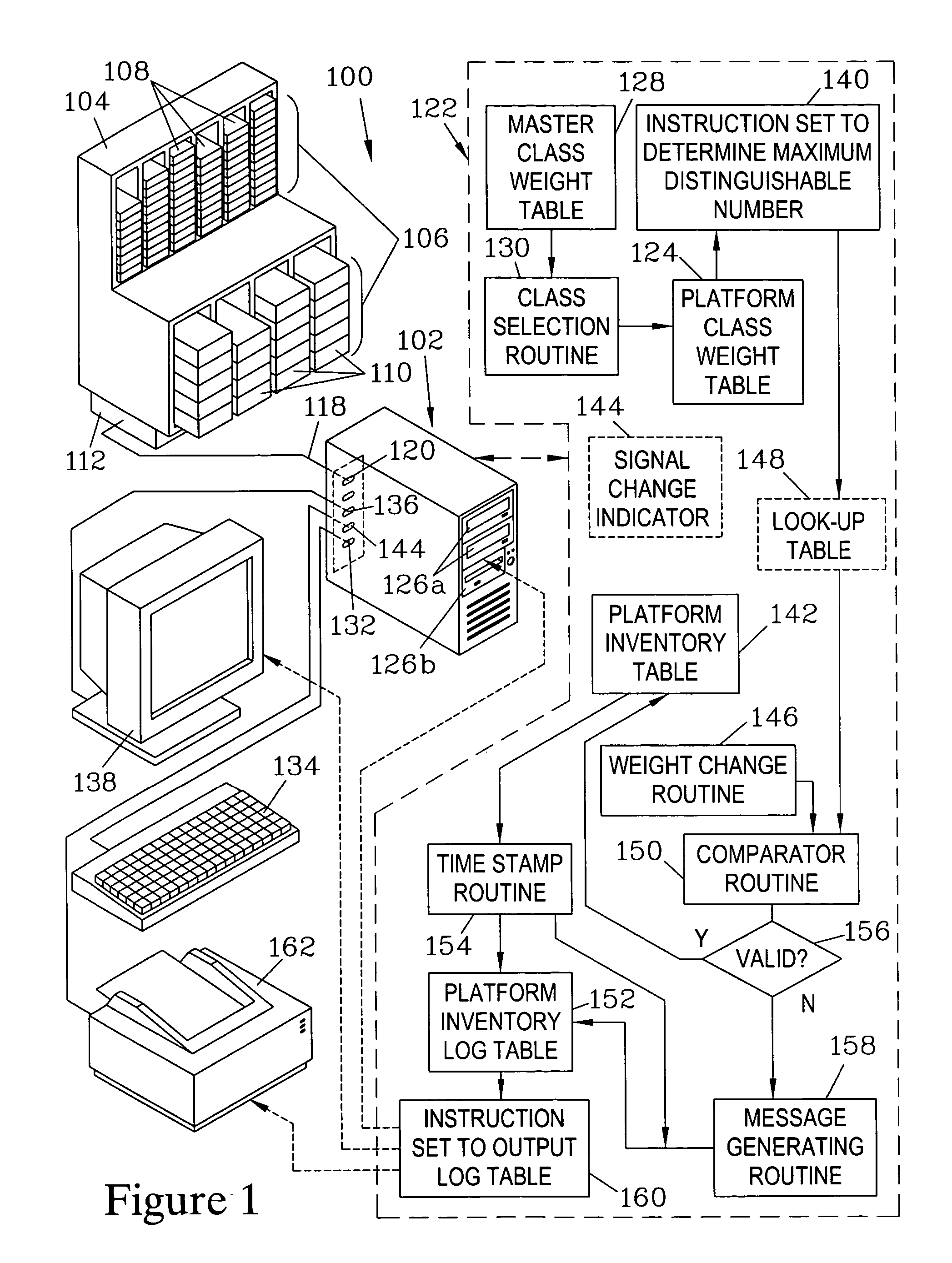

Inventory monitoring system

InactiveUS20050077352A1Improve distributionIncrease maximum distinguishable numberDigital computer detailsWeighing apparatus for materials with special property/formMonitoring systemSingle item

An inventory monitoring system measures changes in weight of an inventory stored on one or more scales. The inventory items are divided into classes by weight, and the system determines the maximum number of items that can be in a combination while maintaining a distinct combined weight. Items are then removed or added, and the change in weight on the scales is correlated to a change in the number of inventory items to track the number of items removed or added over time. In a combined system, scanners are employed to track inventory received or sold, and data from the scanners relating to the items in the inventory is filtered out for comparison to the inventory changes indicated by changes in weight. The system has particular utility for monitoring inventories of cigarettes.

Owner:INVENTROL

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com