Patents

Literature

67results about How to "Shorten the time span" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

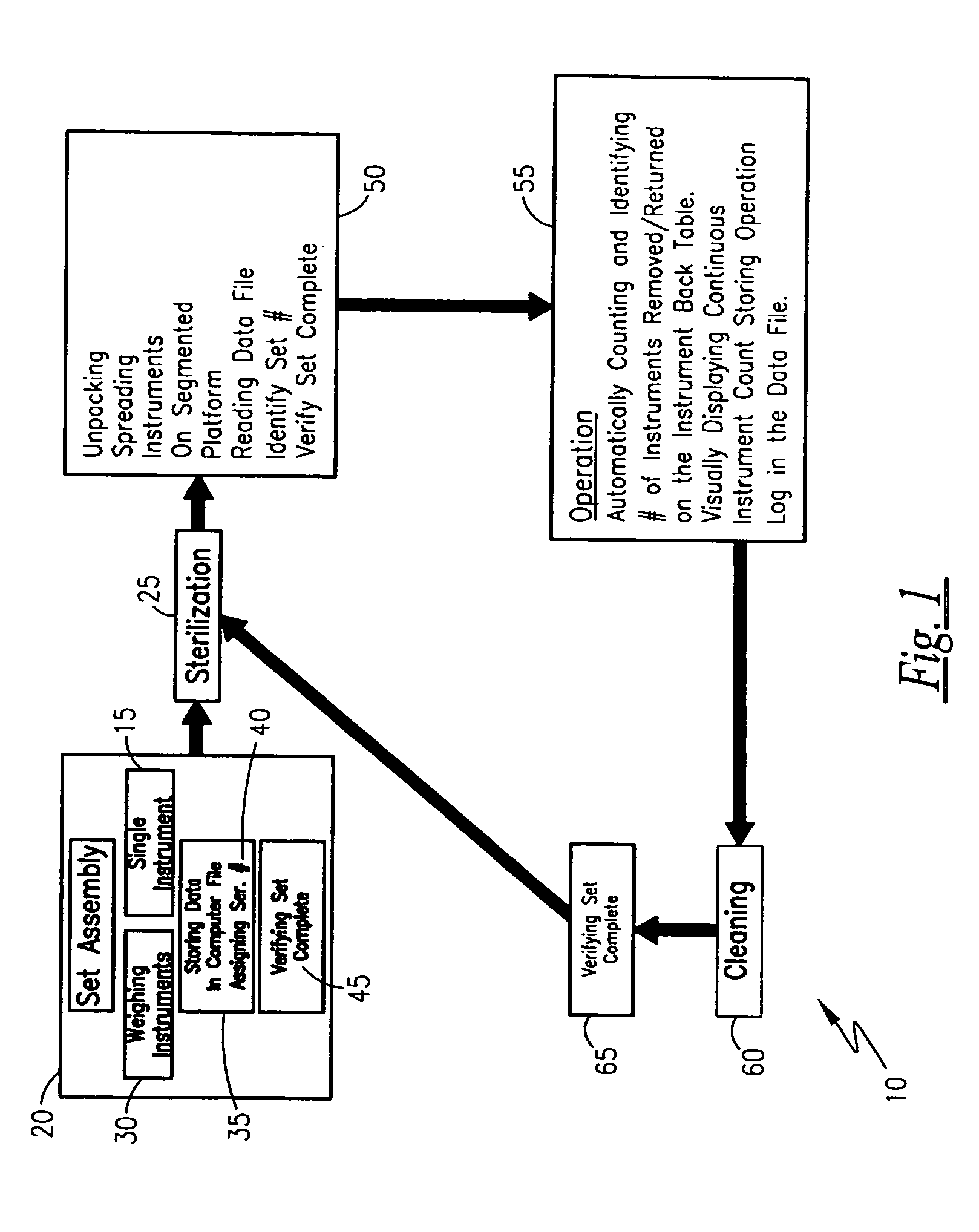

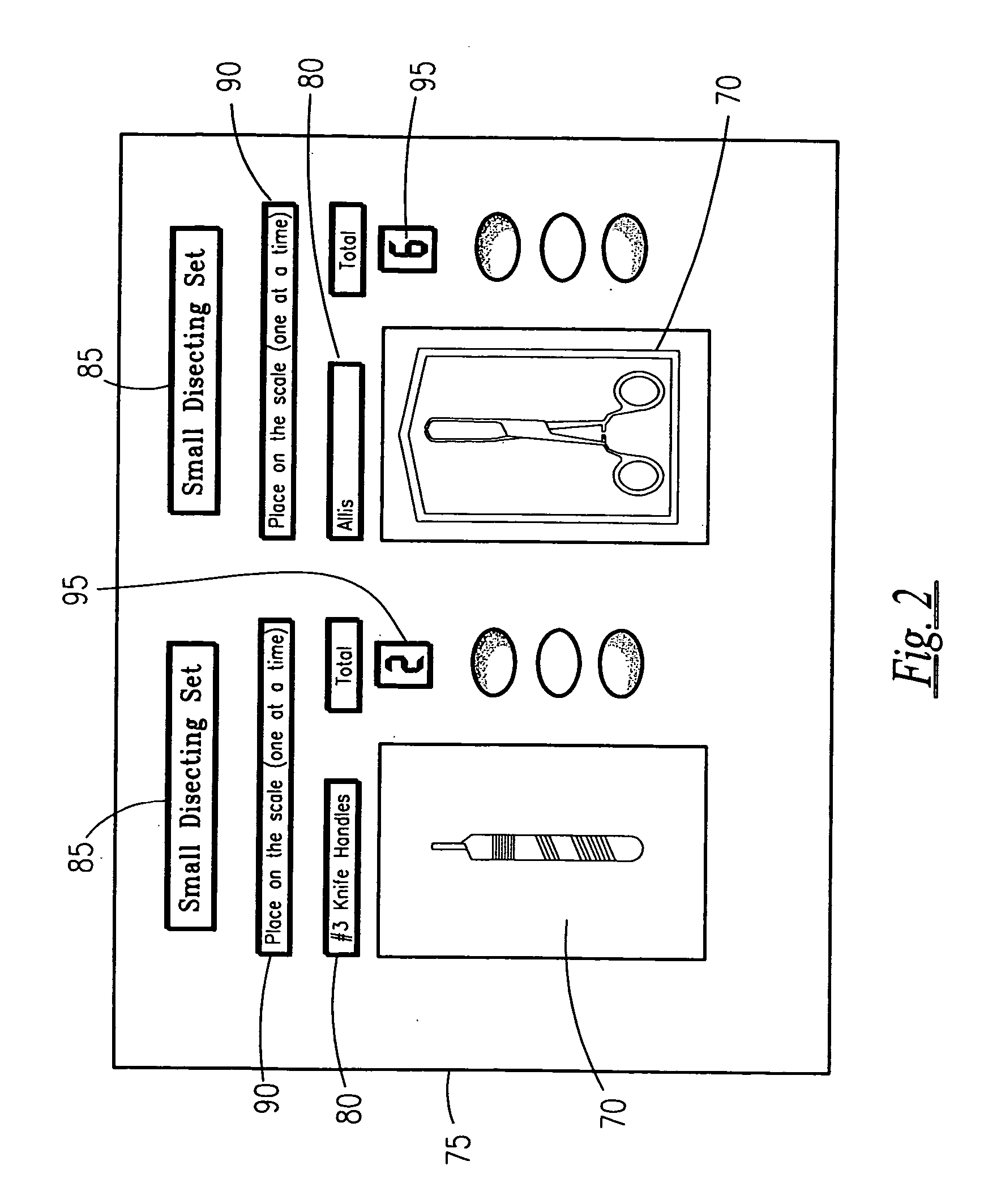

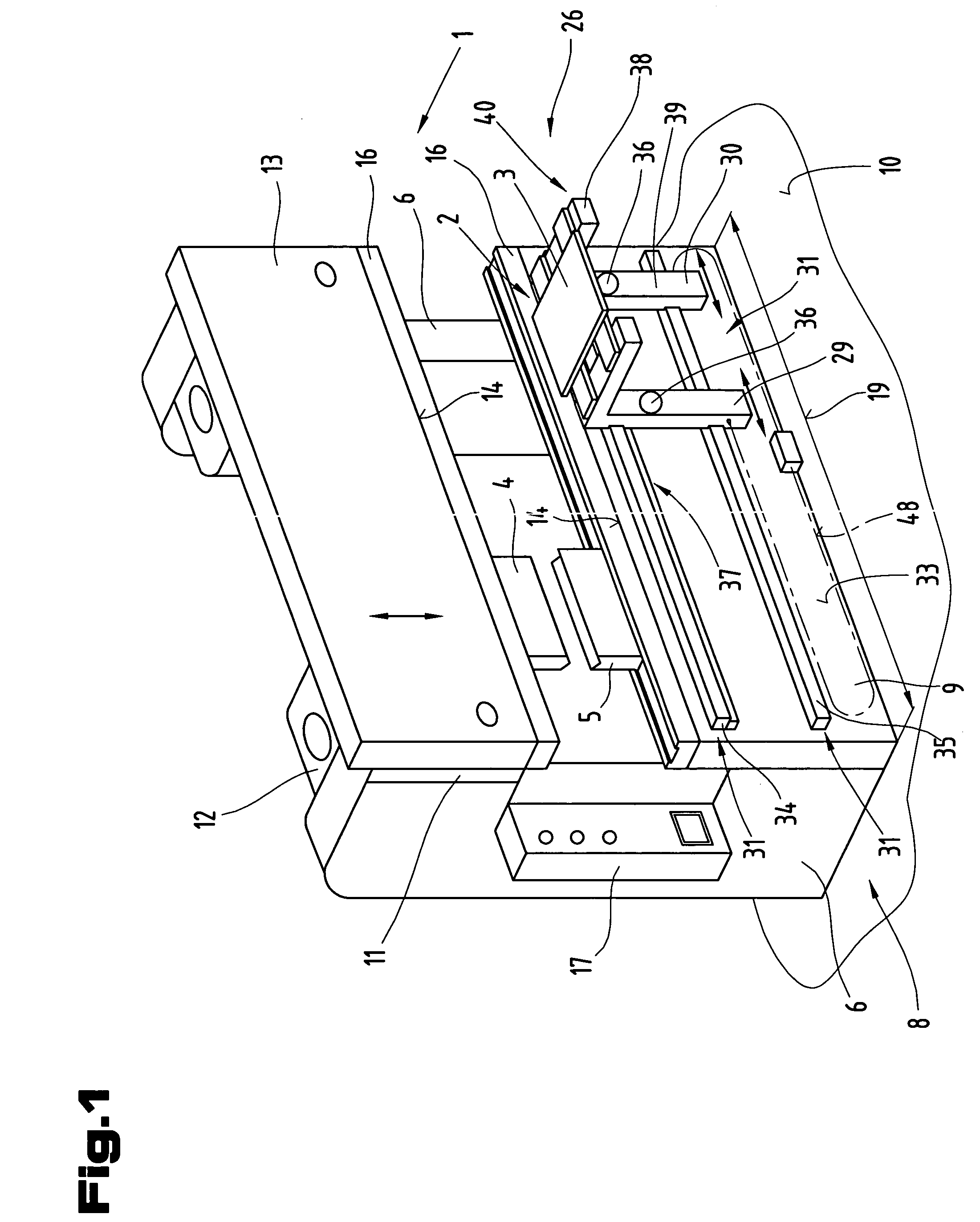

Method and equipment for automated tracking and identification of nonuniform items

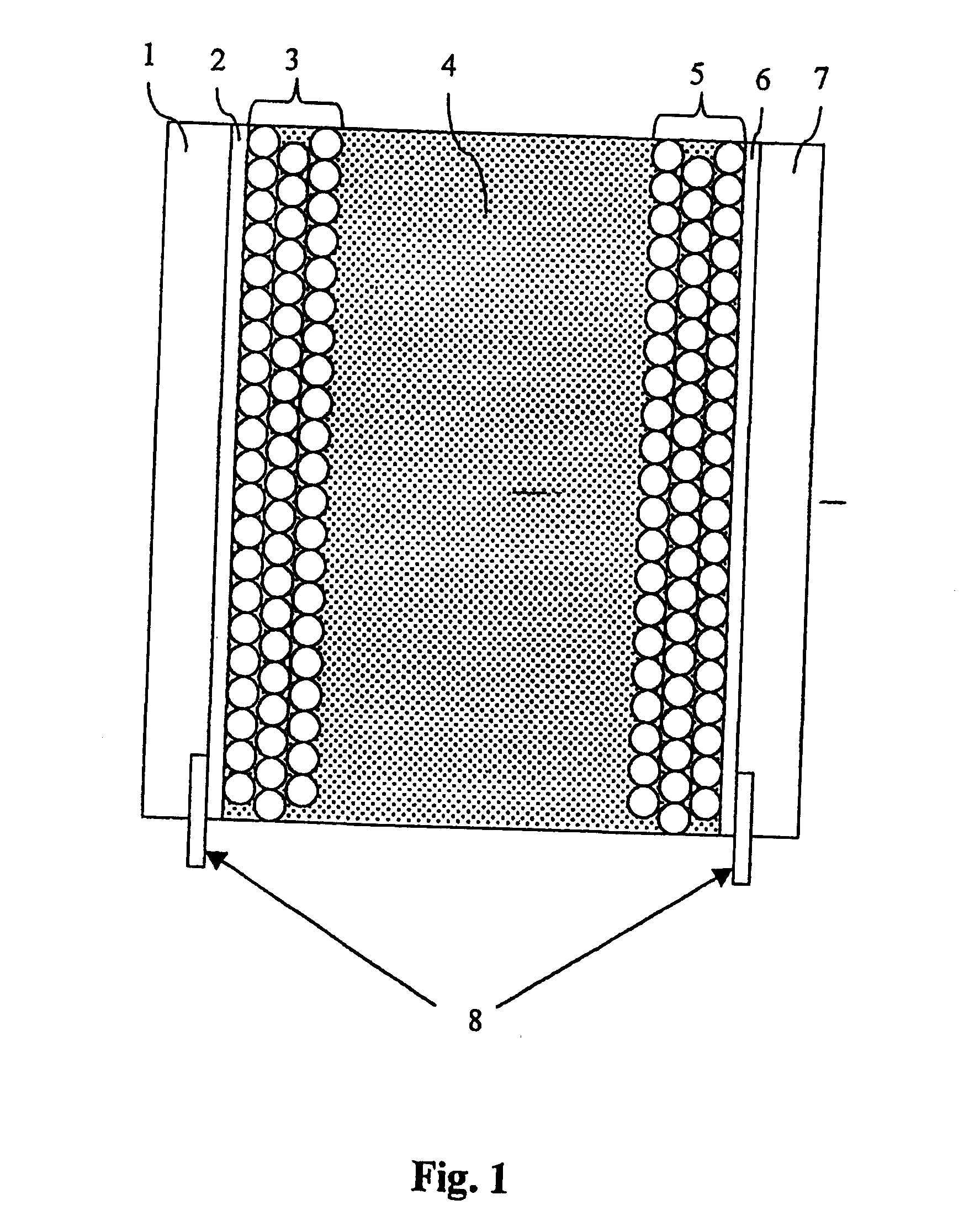

InactiveUS7180014B2Increased real-time accounting accuracyShorten the time spanSurgeryDigital computer detailsSurgical operationImaging processing

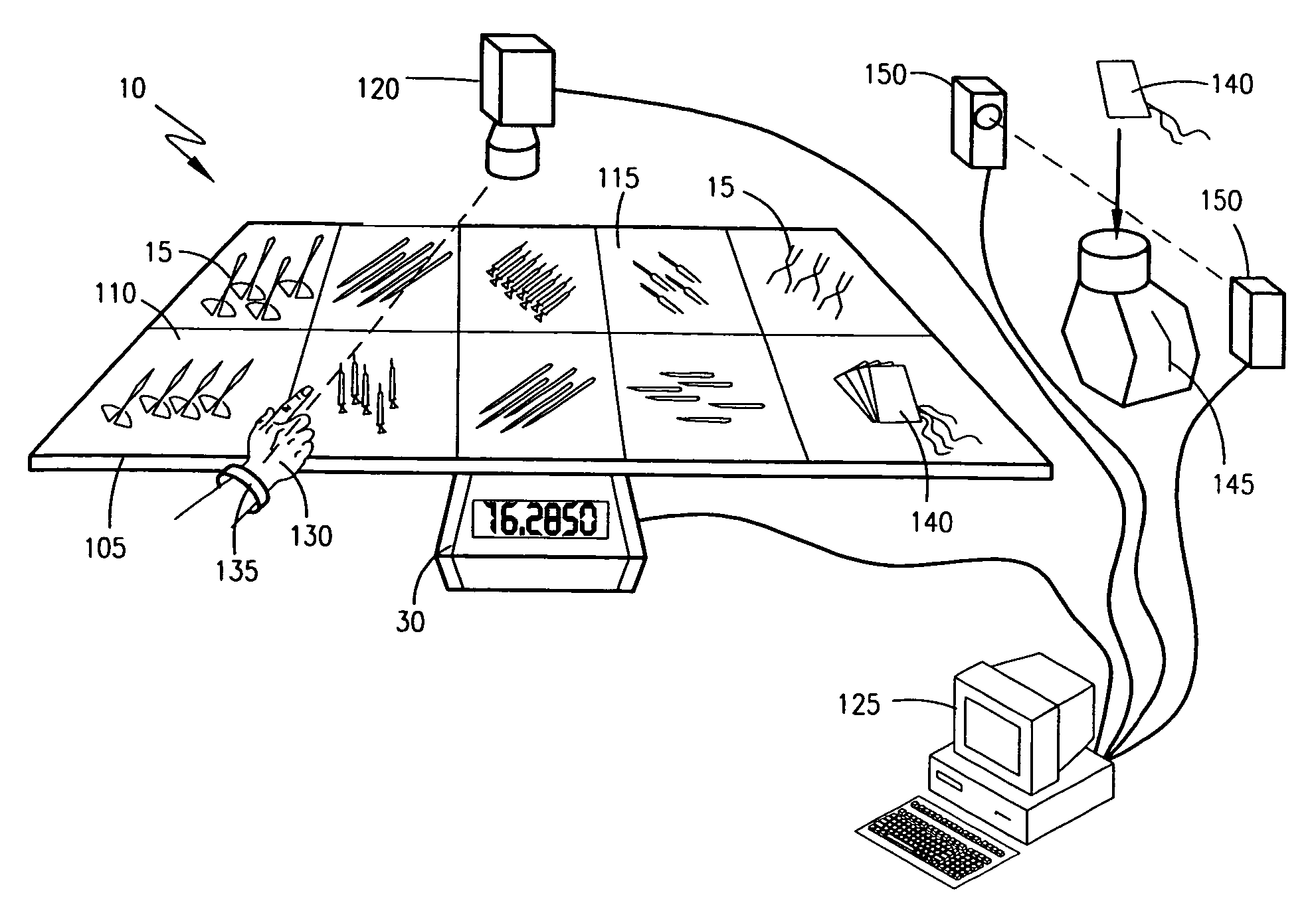

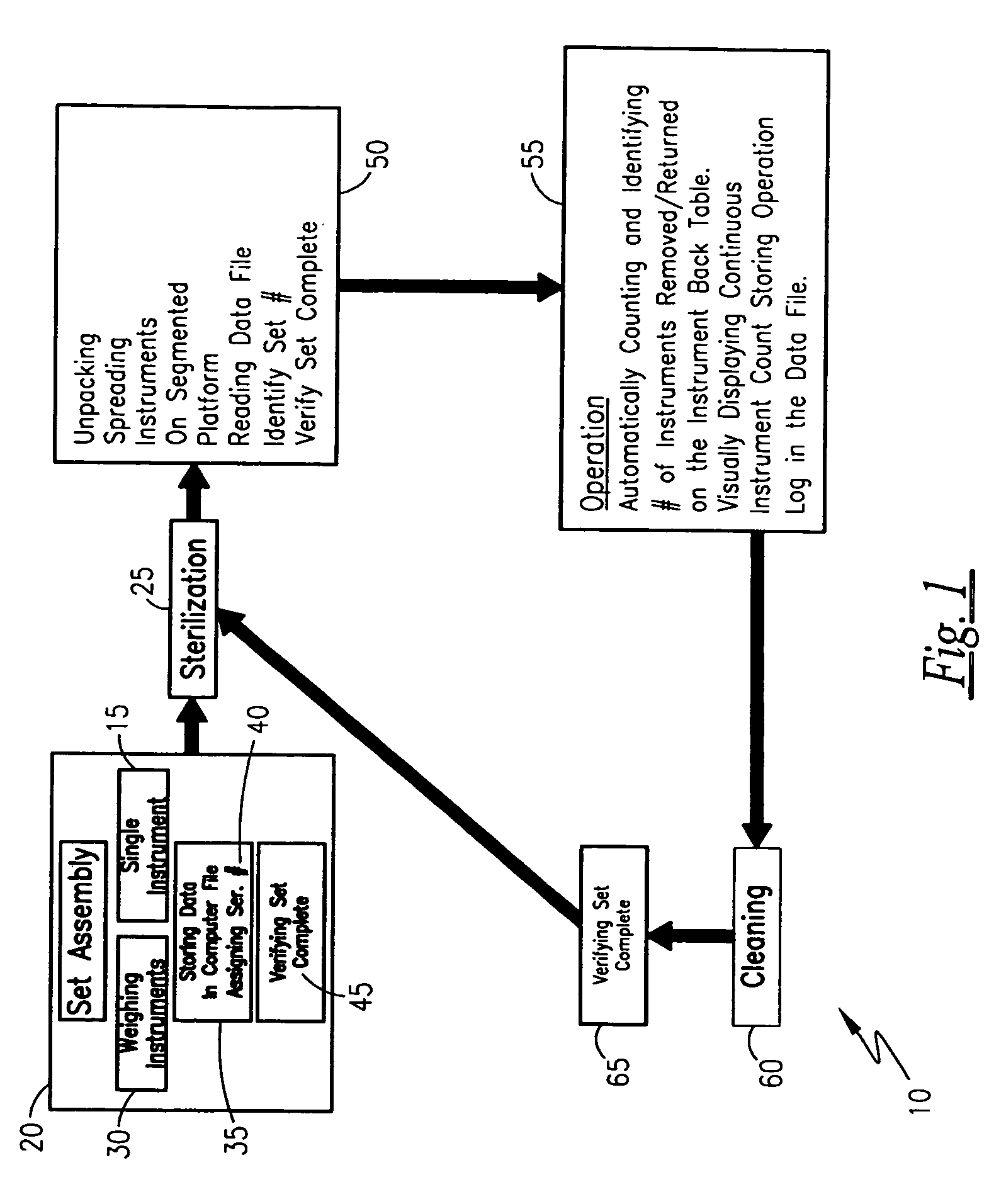

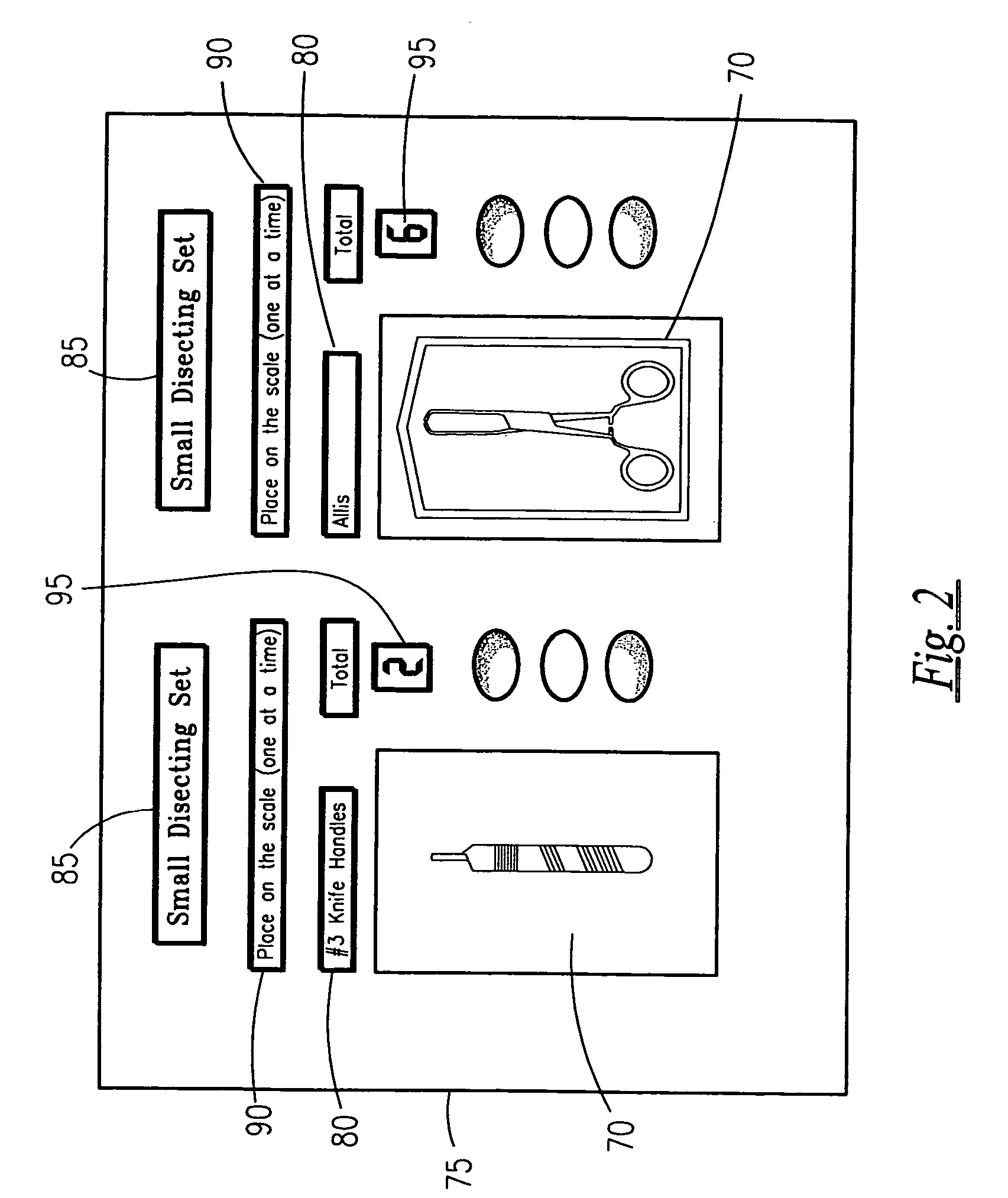

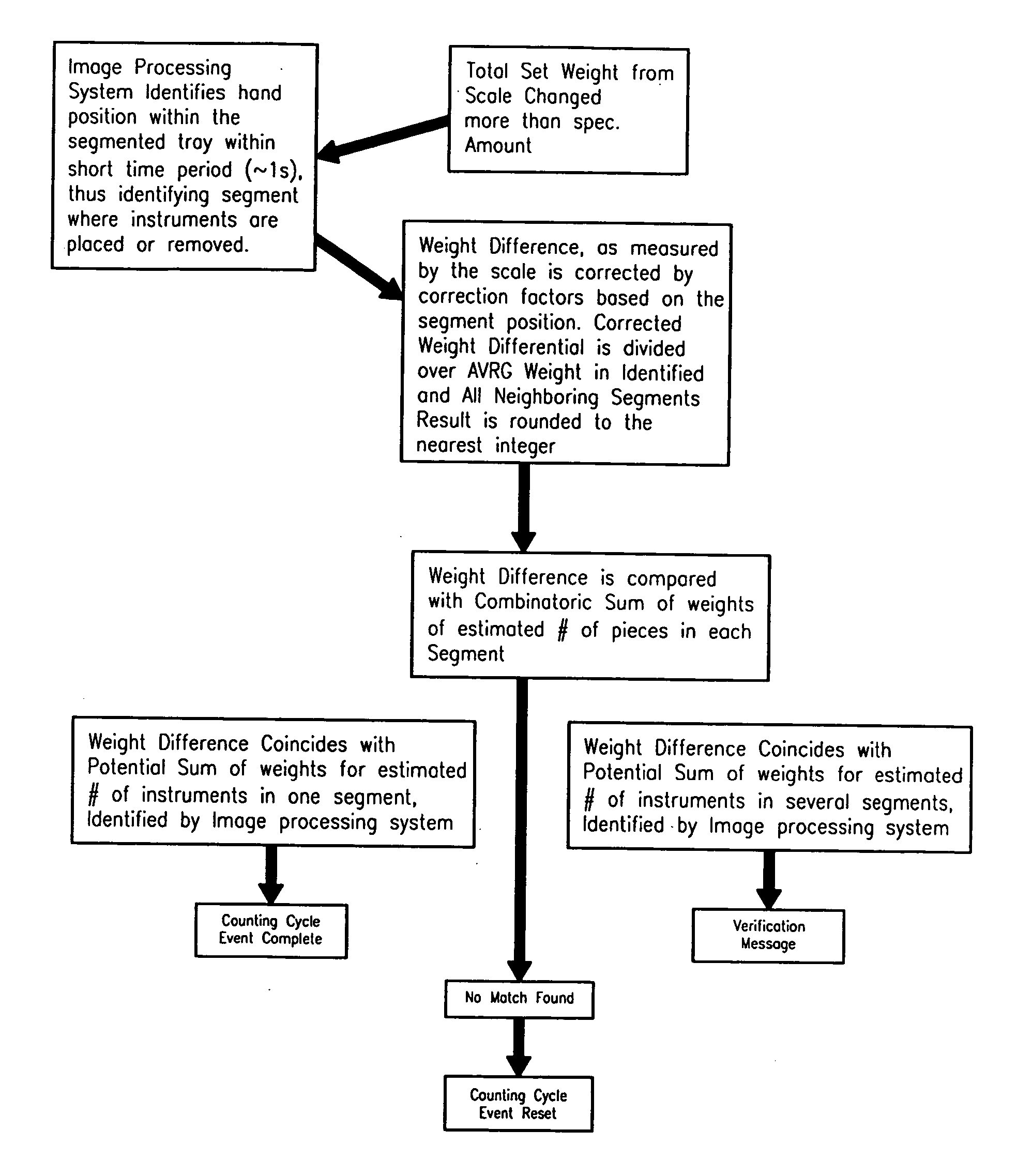

An apparatus comprising of a segmented instrument tray, precision scale, image processing system, photoelectric sensors and a Personal Computer (PC) is disclosed. Said apparatus provides an automated and accurate tracking of surgical instruments used during surgical operating procedure by counting and identifying a specific quantity and instrument type, which are removed from a sterilized instrument tray to be used during the procedure and subsequently returned to the tray upon procedure completion, thus preventing an accidental leaving of an instrument inside of a patient and significantly reducing time spent by the operation staff for the instrument accounting.

Owner:FARBER BORIS +3

Method and equipment for automated tracking and identification of nonuniform items

InactiveUS20040186683A1Increased real-time accounting accuracyShorten the time spanSurgeryDigital computer detailsSurgical operationImaging processing

An apparatus comprising of a segmented instrument tray, precision scale, image processing system, photoelectric sensors and a Personal Computer (PC) is disclosed. Said apparatus provides an automated and accurate tracking of surgical instruments used during surgical operating procedure by counting and identifying a specific quantity and instrument type, which are removed from a sterilized instrument tray to be used during the procedure and subsequently returned to the tray upon procedure completion, thus preventing an accidental leaving of an instrument inside of a patient and significantly reducing time spent by the operation staff for the instrument accounting.

Owner:FARBER BORIS +3

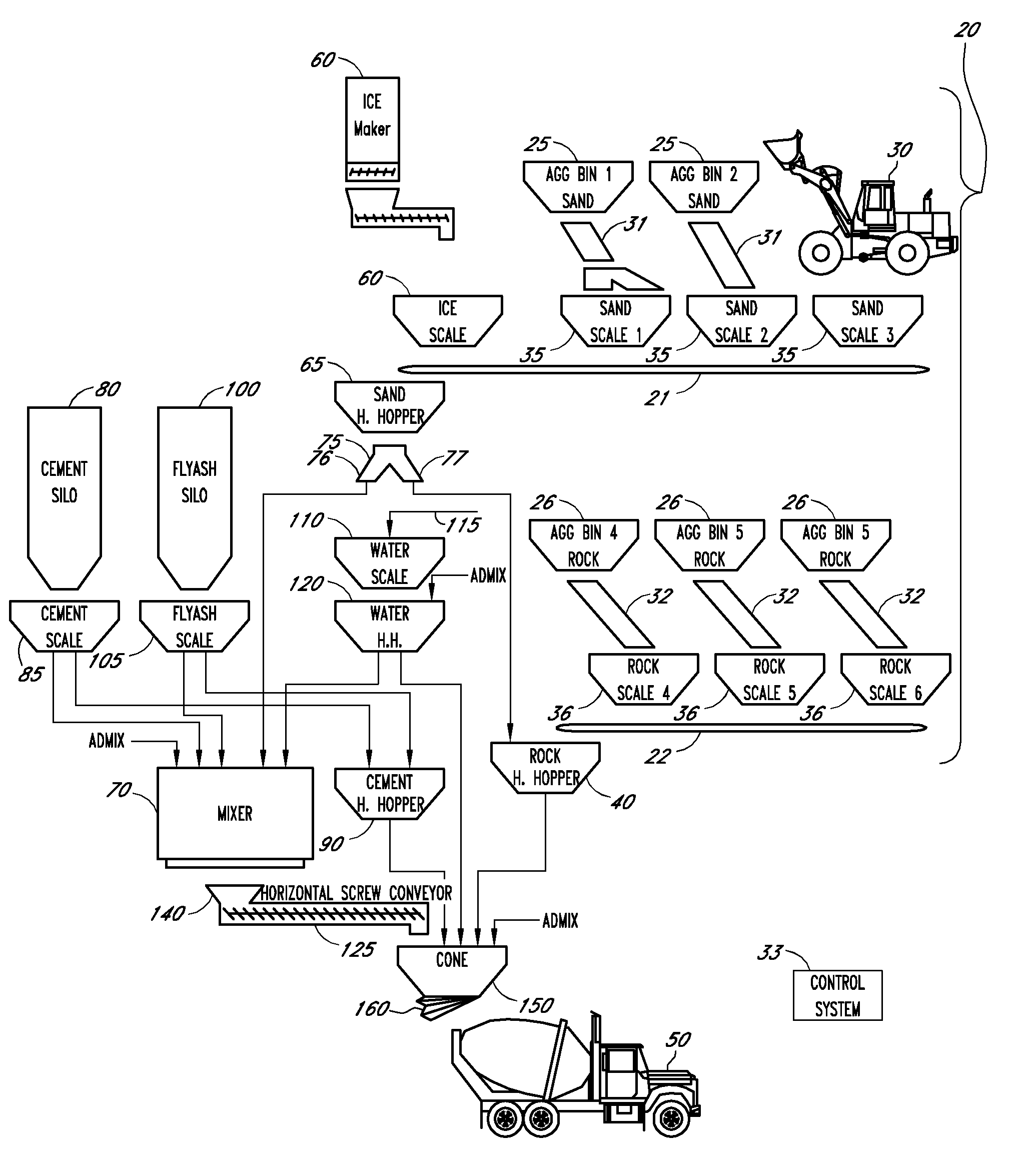

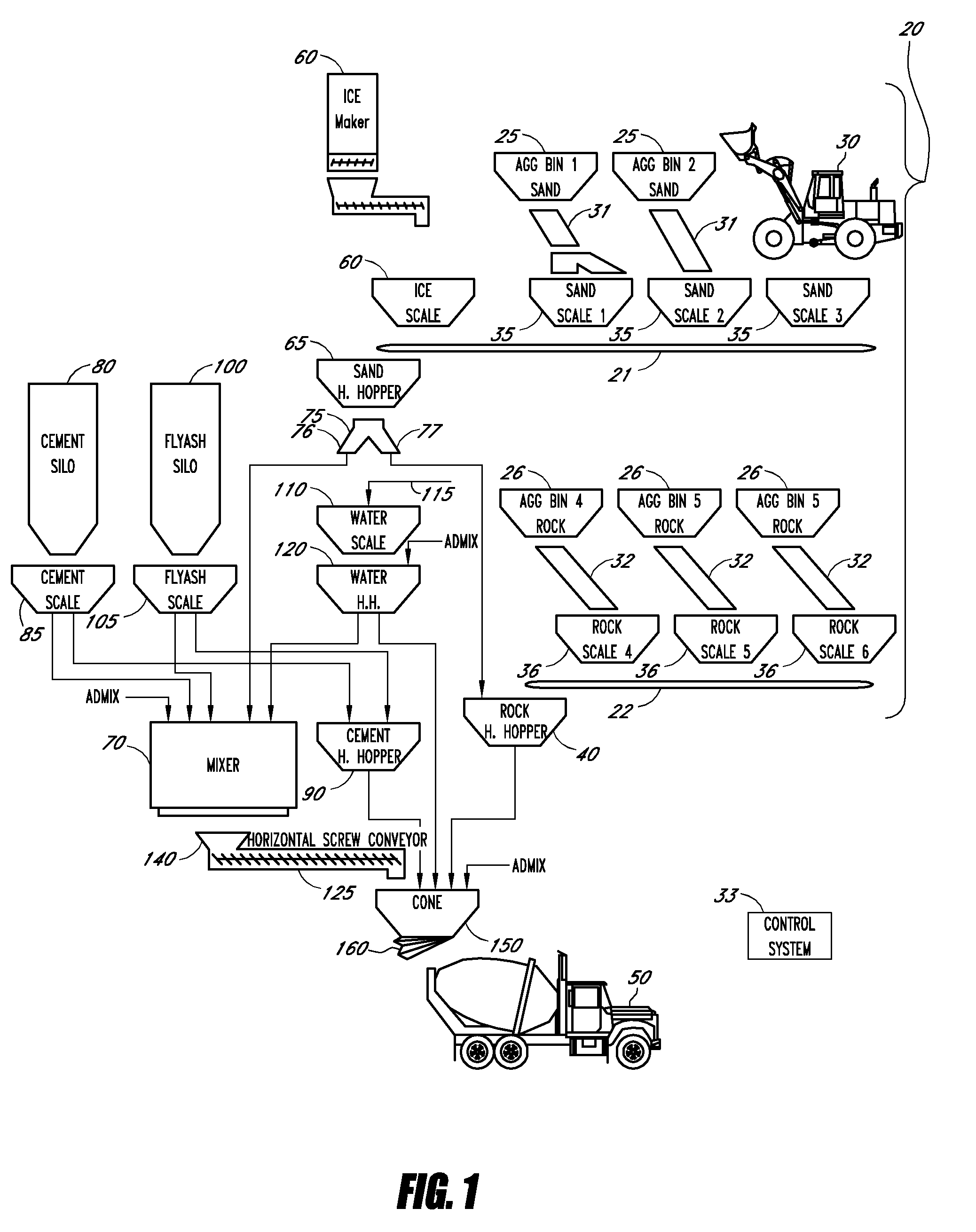

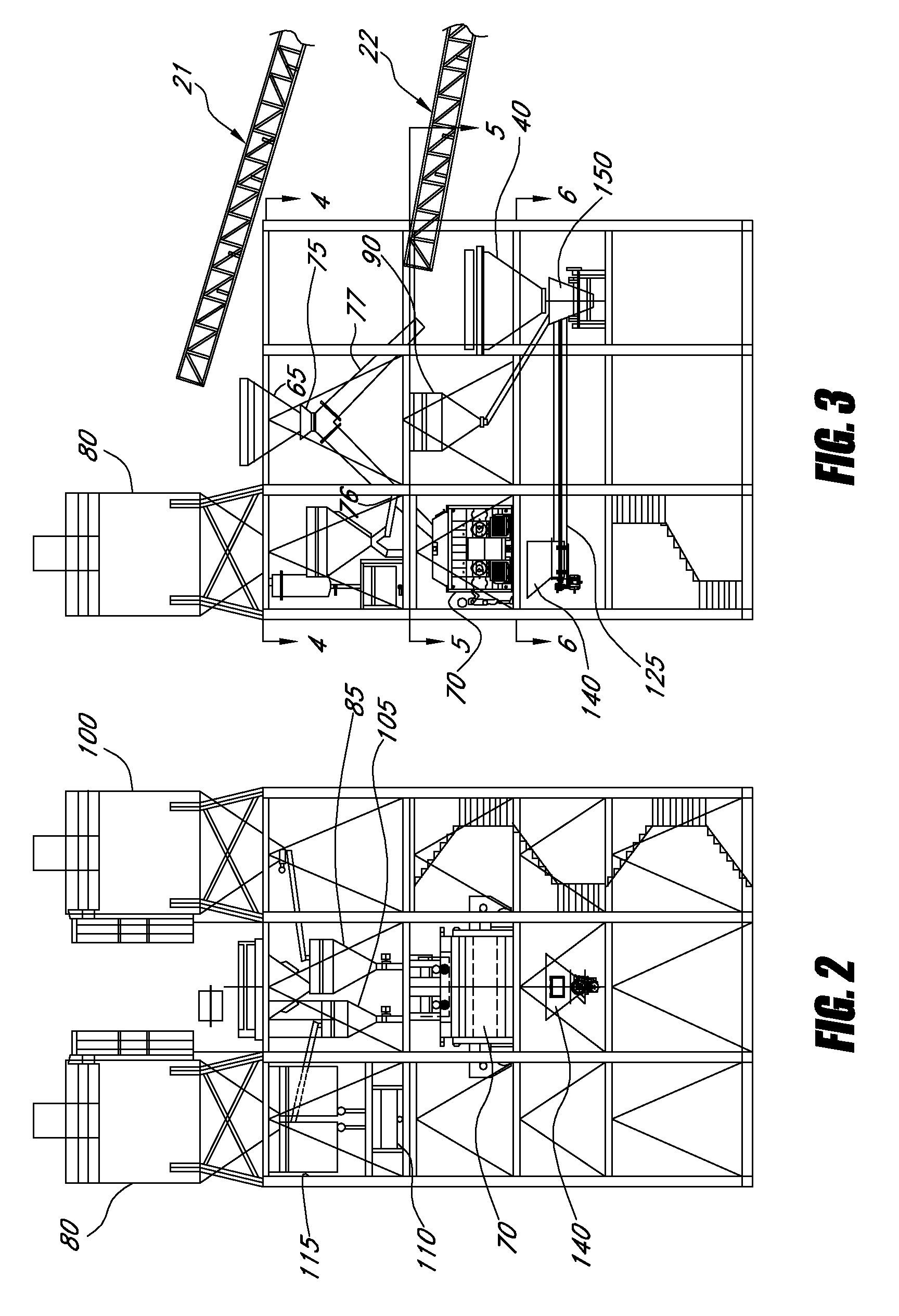

Apparatus and method for producing concrete

InactiveUS20080273415A1Shorten the time spanMore hydrateMixing operation control apparatusIngredients proportioning apparatusTruckHigh strength concrete

Apparatus and methods produce substantially continuous batches of high-strength concrete. Portland cement, flyash, sand, water, and concrete chemical additives are premixed in a multi-stage process, prior to final mixing with the coarse aggregates. In sequence, the complete mixing process includes: 1) a twin-shaft compulsory mixer to blend the materials, then disposing the mixture into; 2) a horizontal screw conveyor, continuously mixing as the mixture passes through the housing, thereby disposed simultaneously with the coarse aggregates into; and 3) the mixer concrete delivery truck, wherein the concrete is mixed further.

Owner:JONEL ENG

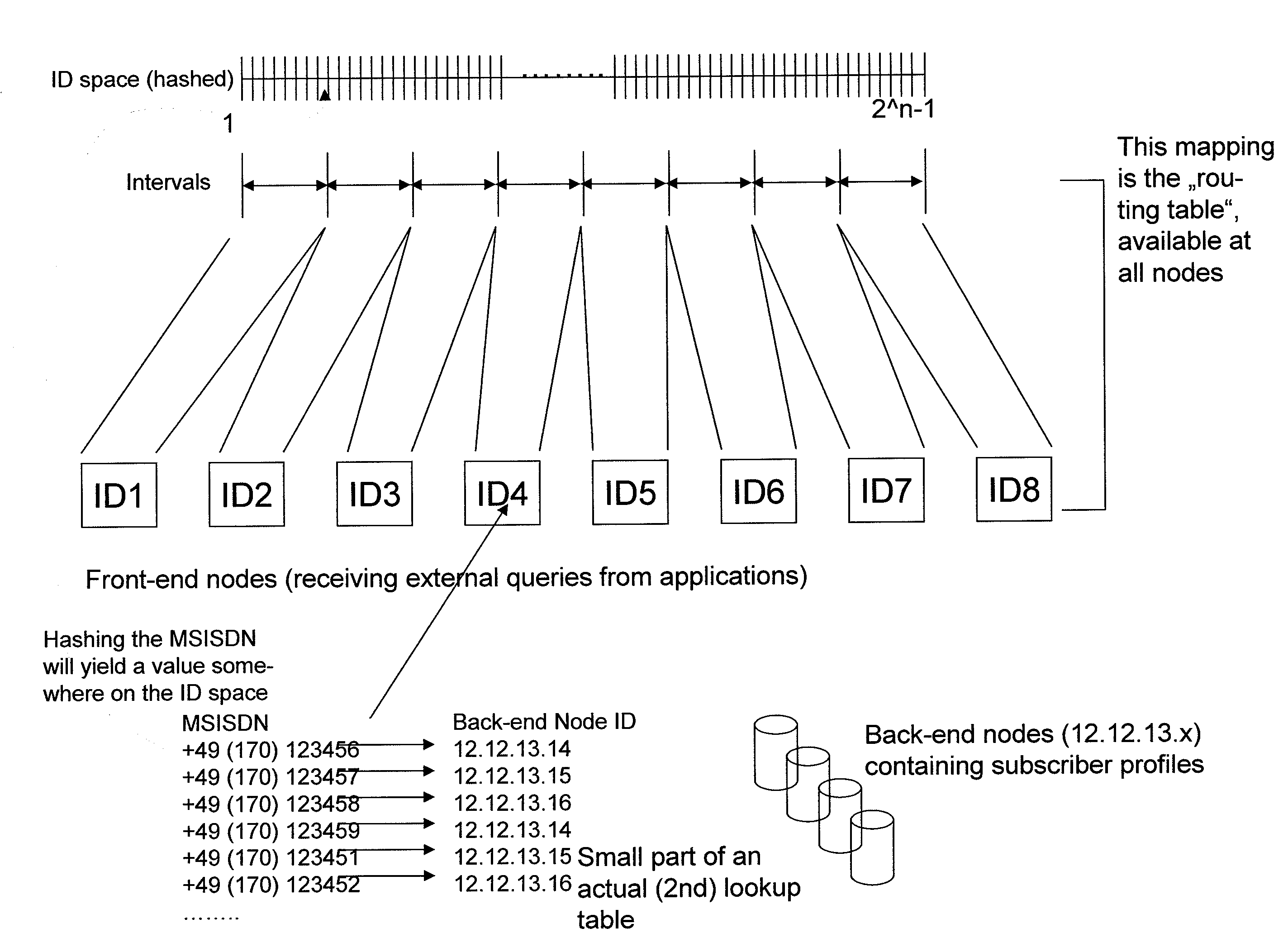

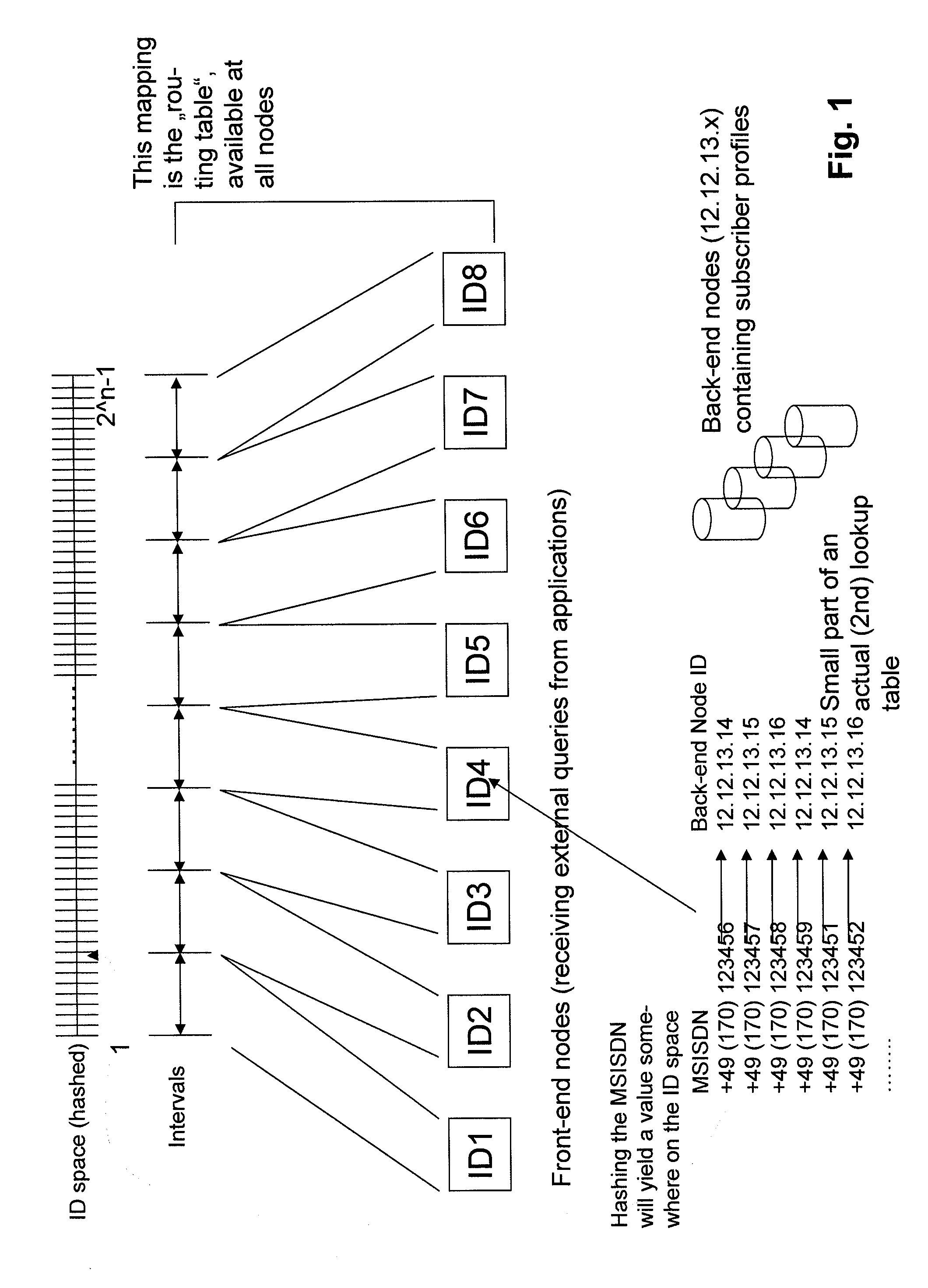

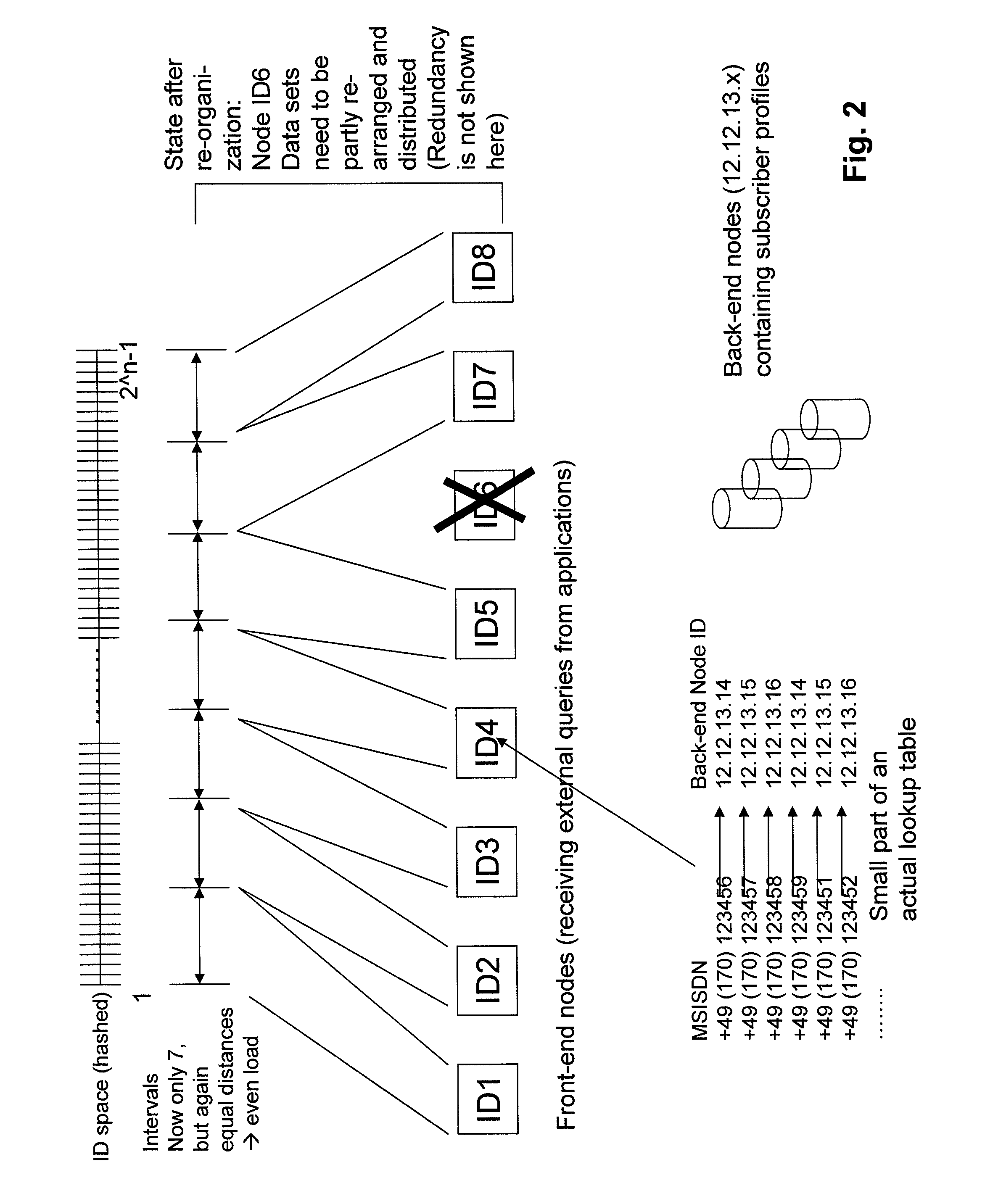

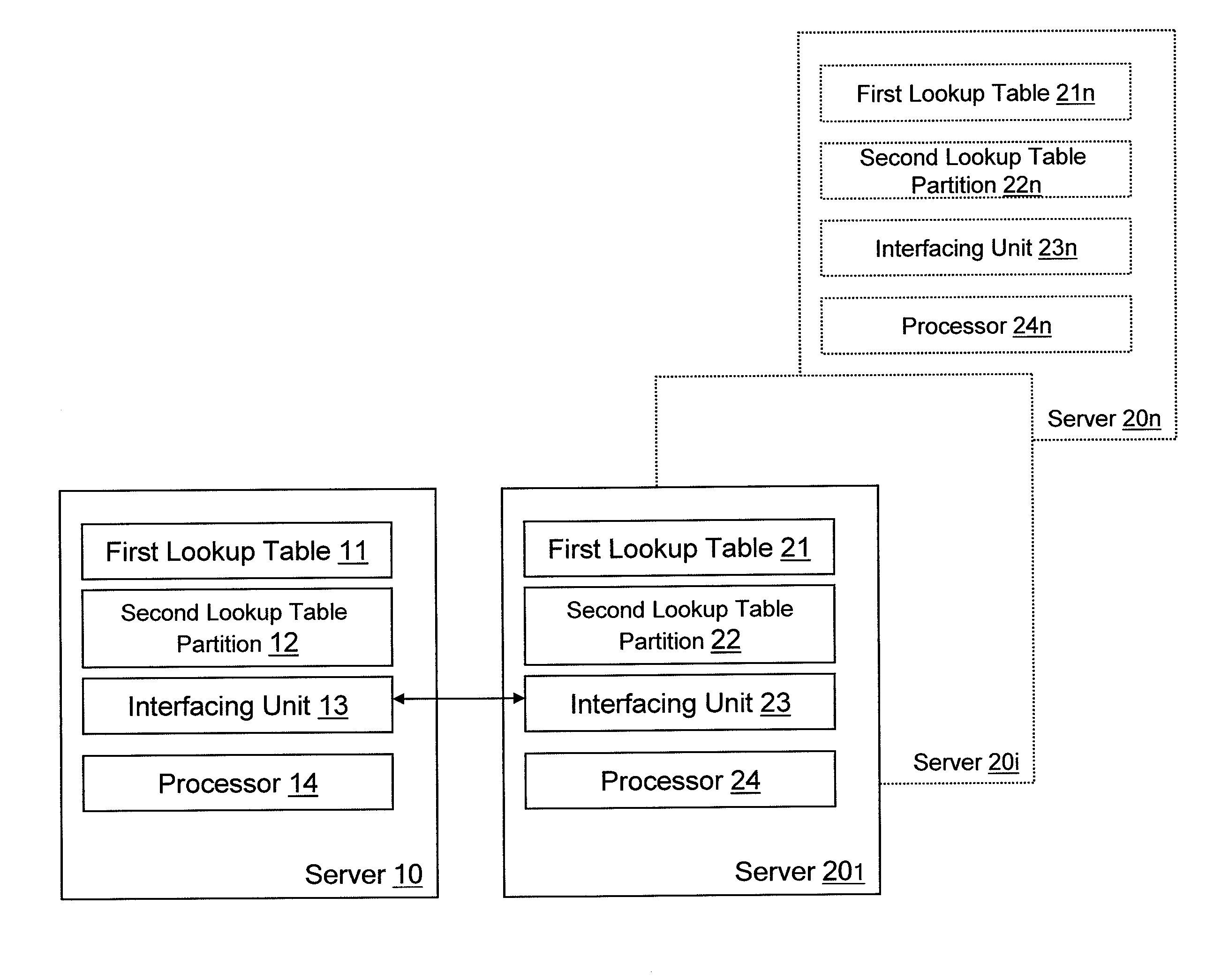

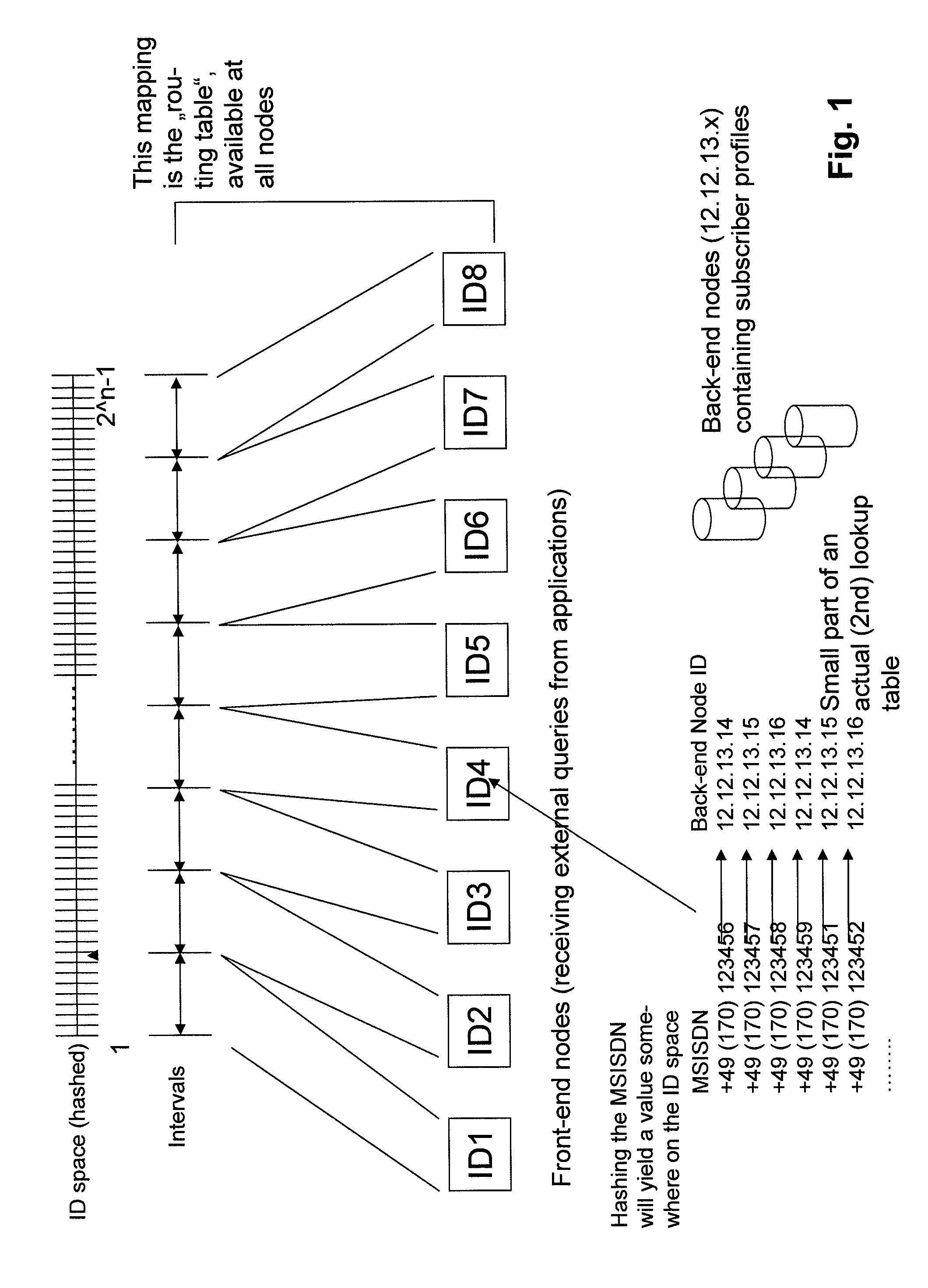

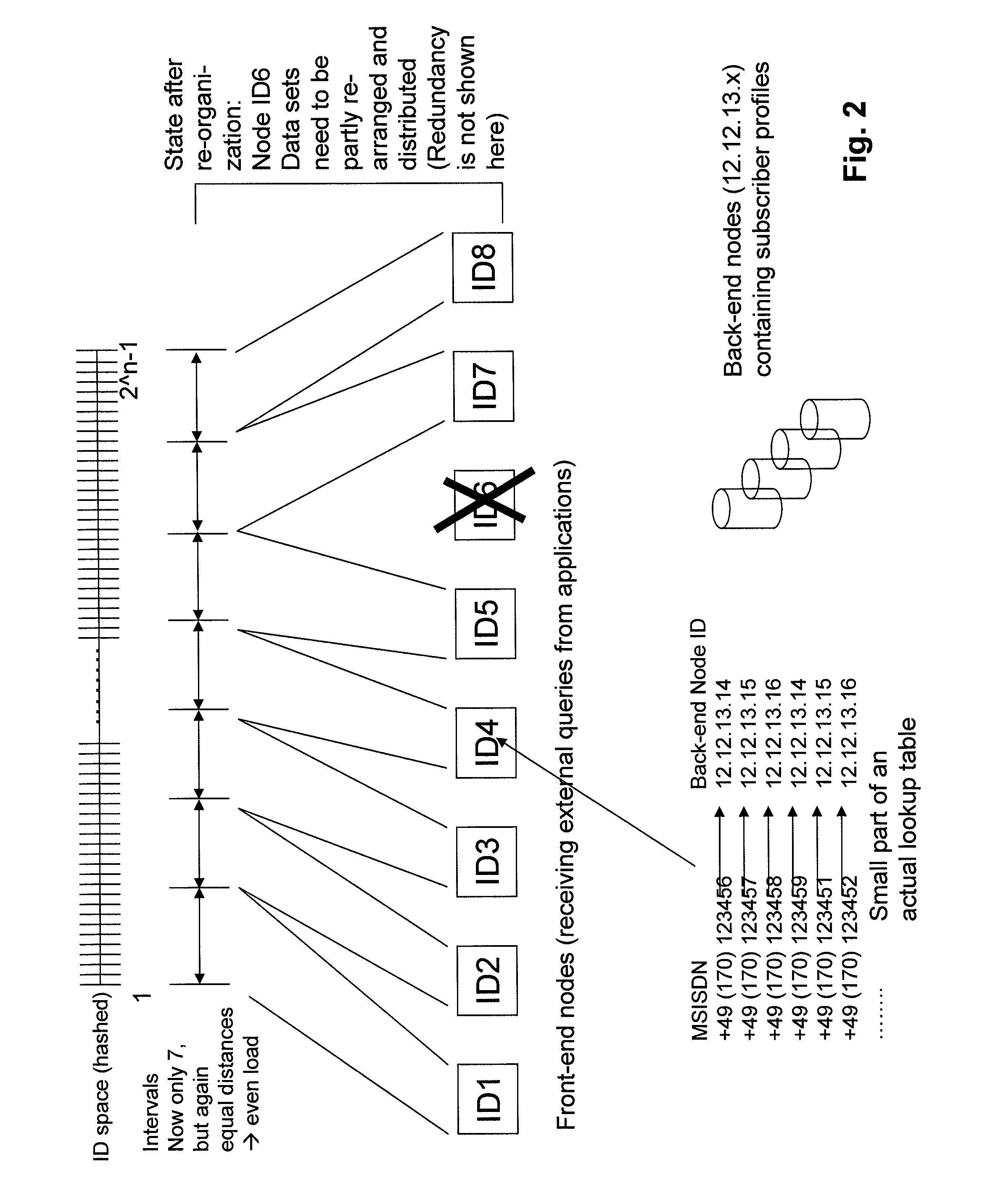

Load distribution in distributed database system

ActiveUS20090157684A1Evenly loadedShorten the time spanProgram controlData switching networksLookup tableLoad distribution

A state change in a network comprising a master server among a plurality of servers is determined, at the master server, a first lookup table is calculated, said first lookup table indicating respective partitions of a second lookup table distributed among active servers of said plurality of servers, the calculated first lookup table is distributed to each active server, and based on the first lookup table, at the master server, a modified partition of the second lookup table is generated.

Owner:NOKIA SOLUTIONS & NETWORKS OY

Distributed database system using master server to generate lookup tables for load distribution

ActiveUS7984183B2Shorten the time spanAvoid excessive controlDigital computer detailsProgram controlLookup tableLoad distribution

A state change in a network comprising a master server among a plurality of servers is determined, at the master server, a first lookup table is calculated, said first lookup table indicating respective partitions of a second lookup table distributed among active servers of said plurality of servers, the calculated first lookup table is distributed to each active server, and based on the first lookup table, at the master server, a modified partition of the second lookup table is generated.

Owner:NOKIA SOLUTIONS & NETWORKS OY

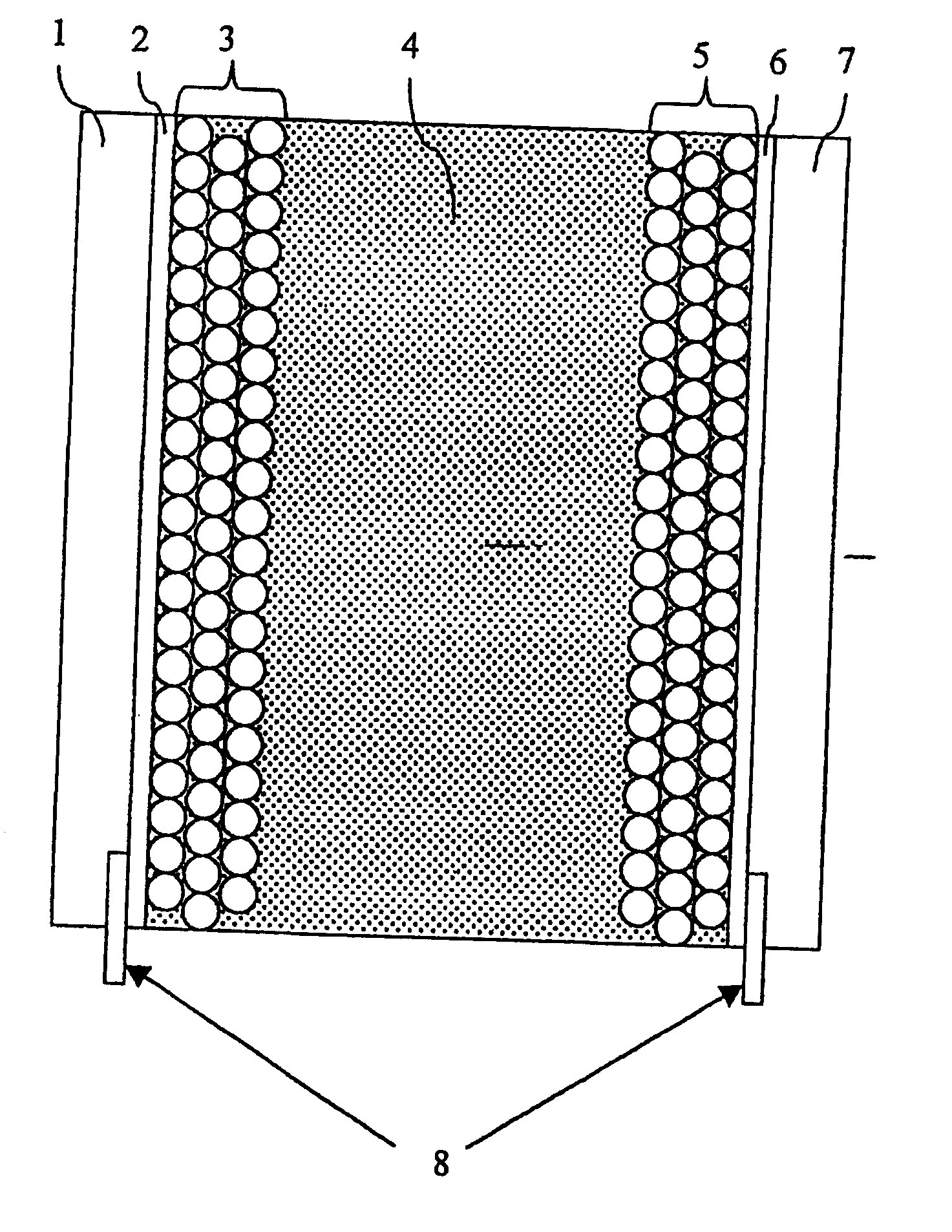

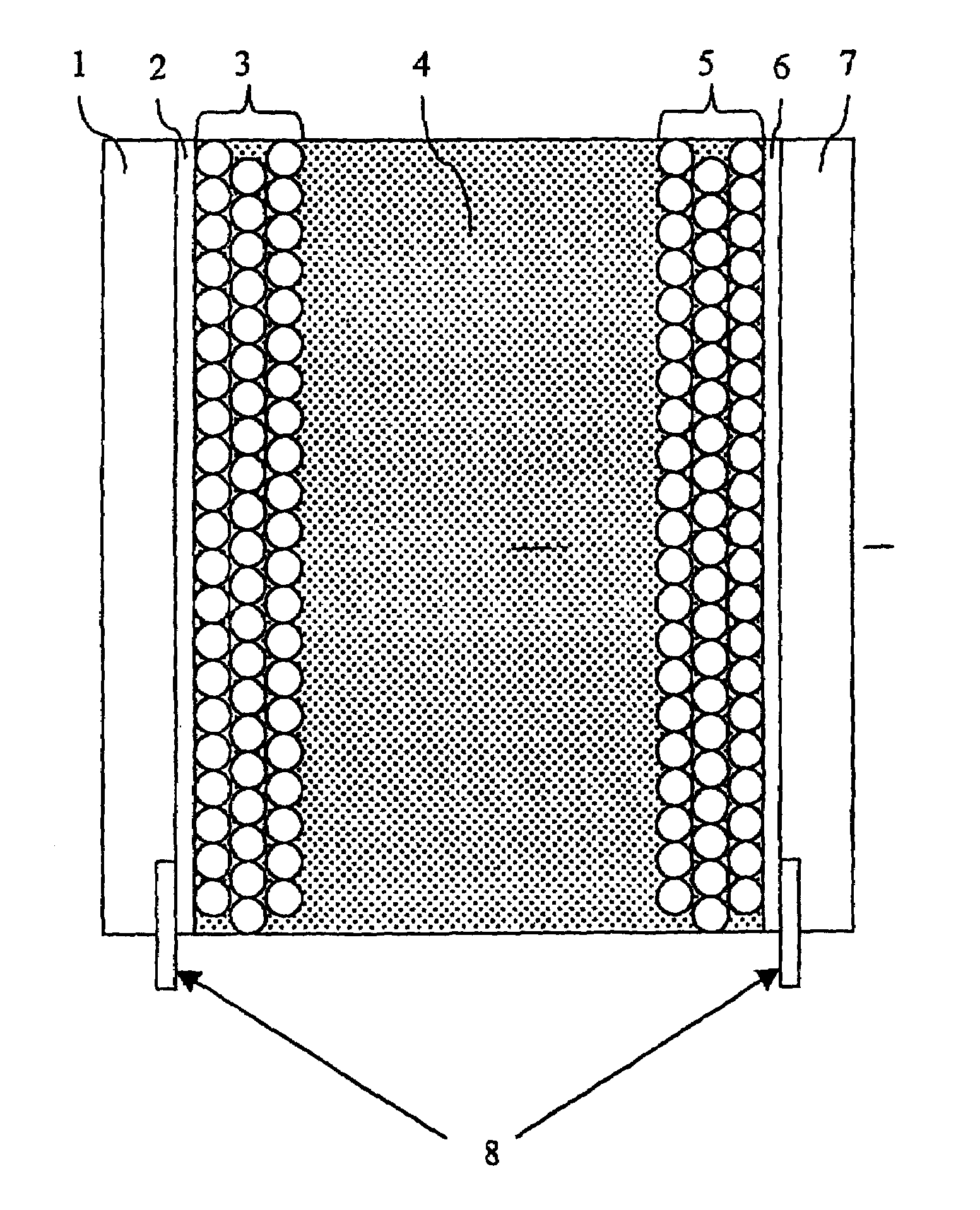

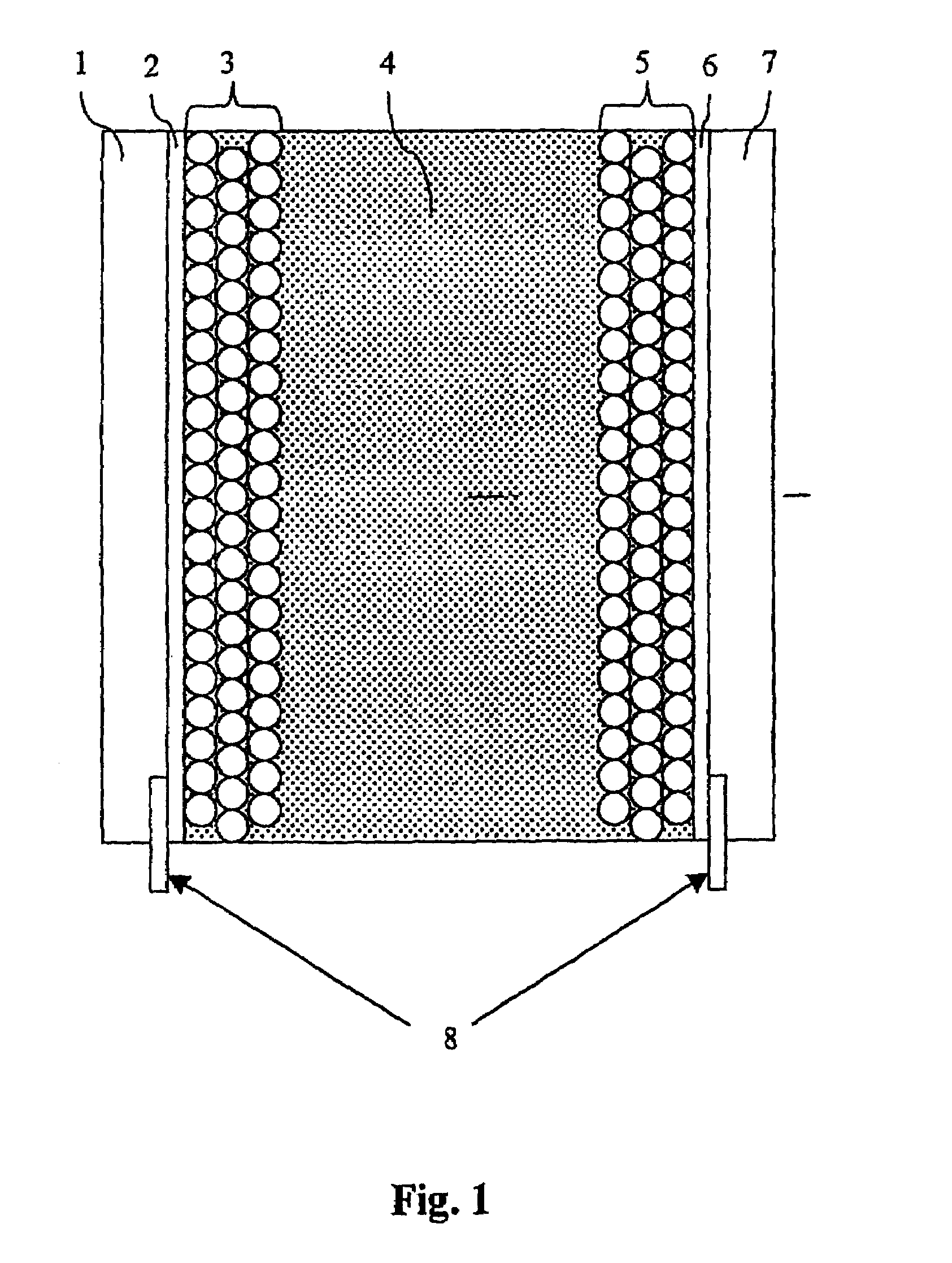

Electrochromic device based on nanocrystalline materials

InactiveUS20050104136A1Change color quicklyEnhance memoryTransistorSolid-state devicesPotential differenceEngineering

An electrochromic device, comprising a first electrode (3), a second electrode (5) and an electrolyte (4) separating the electrodes (3, 5), where at least one of said first and second electrodes includes an electrically active structure which have an at least dual state visual appearance depending on the potential difference between the first and the second electrode.

Owner:NTERA LTD (IE)

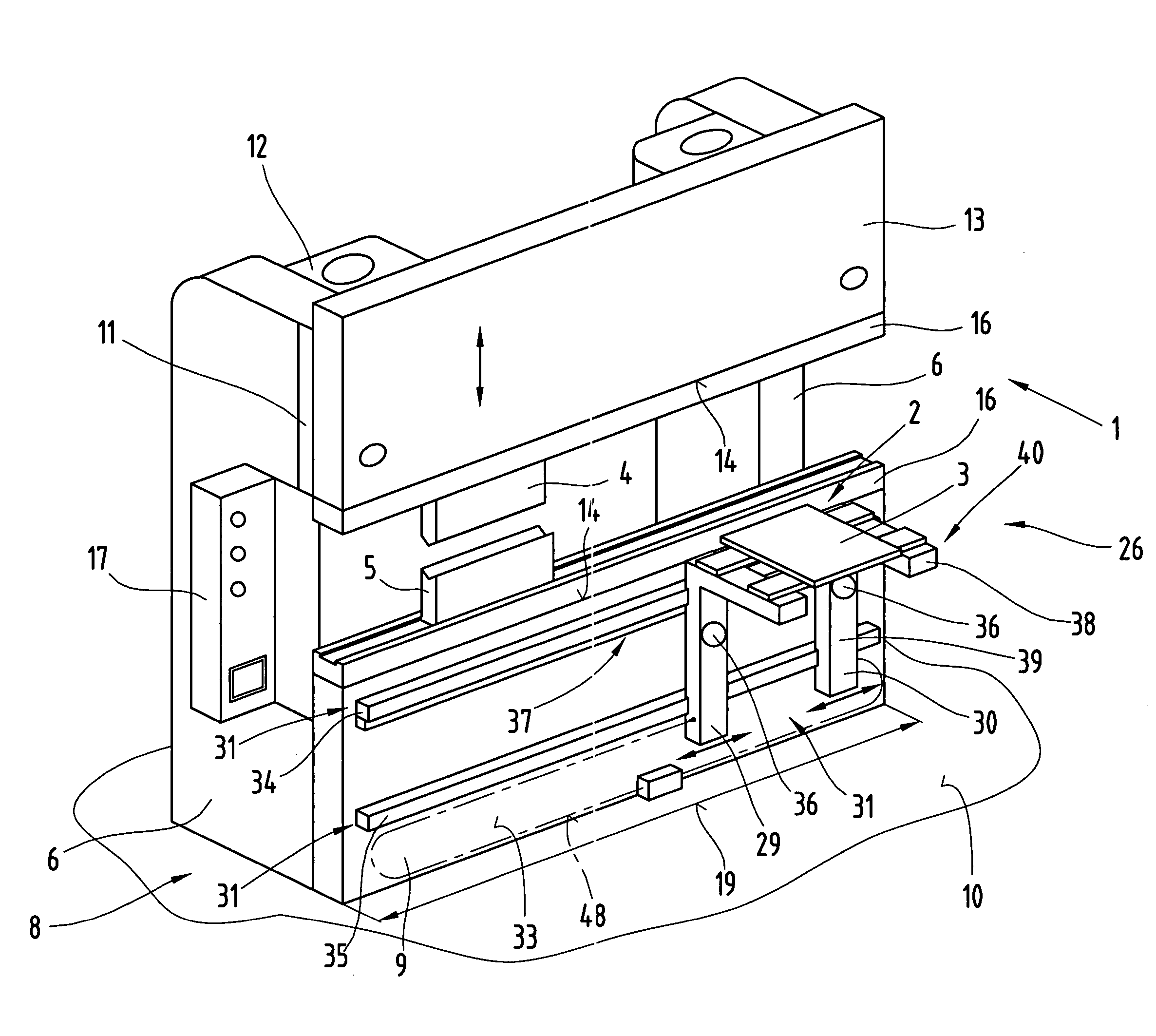

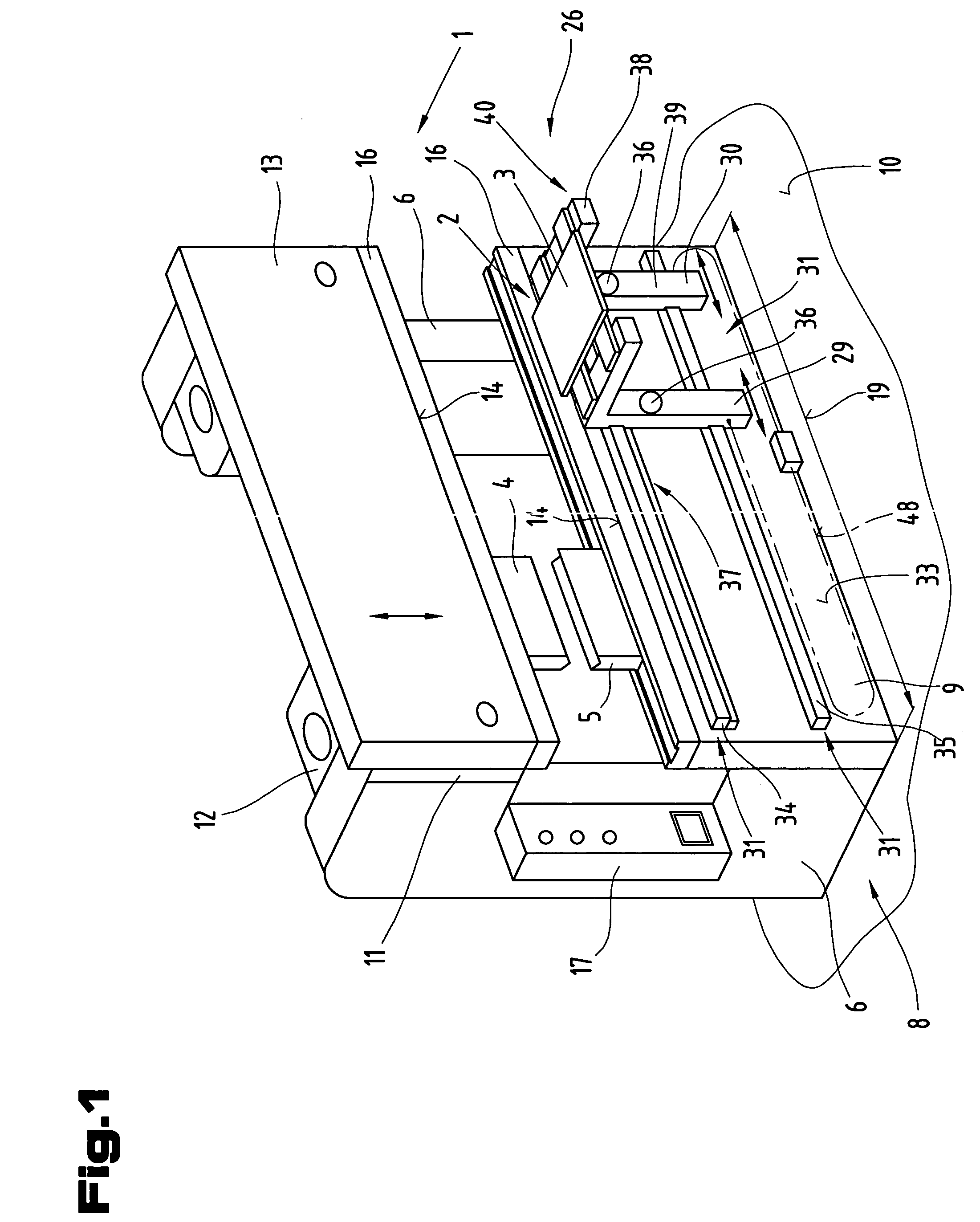

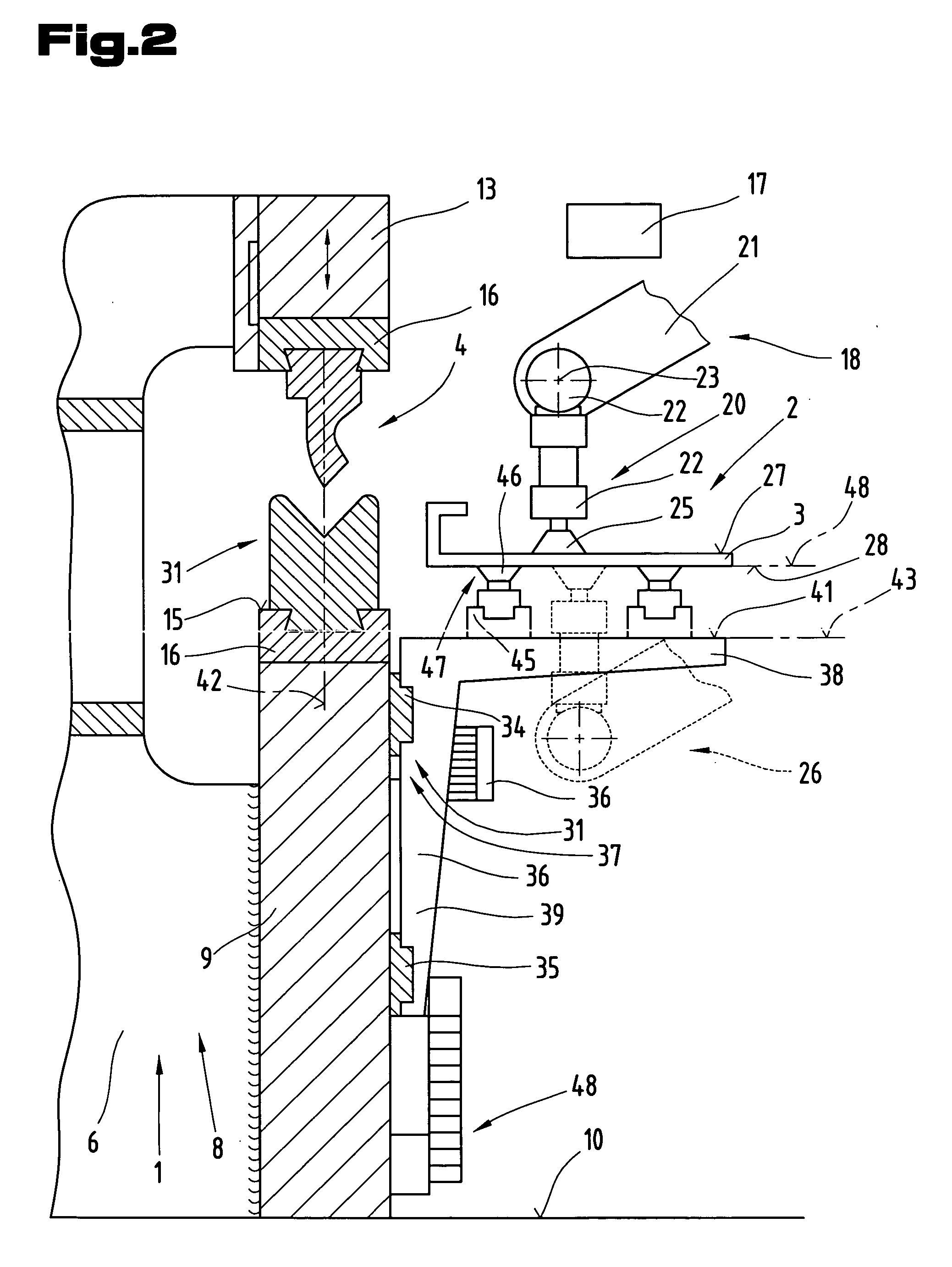

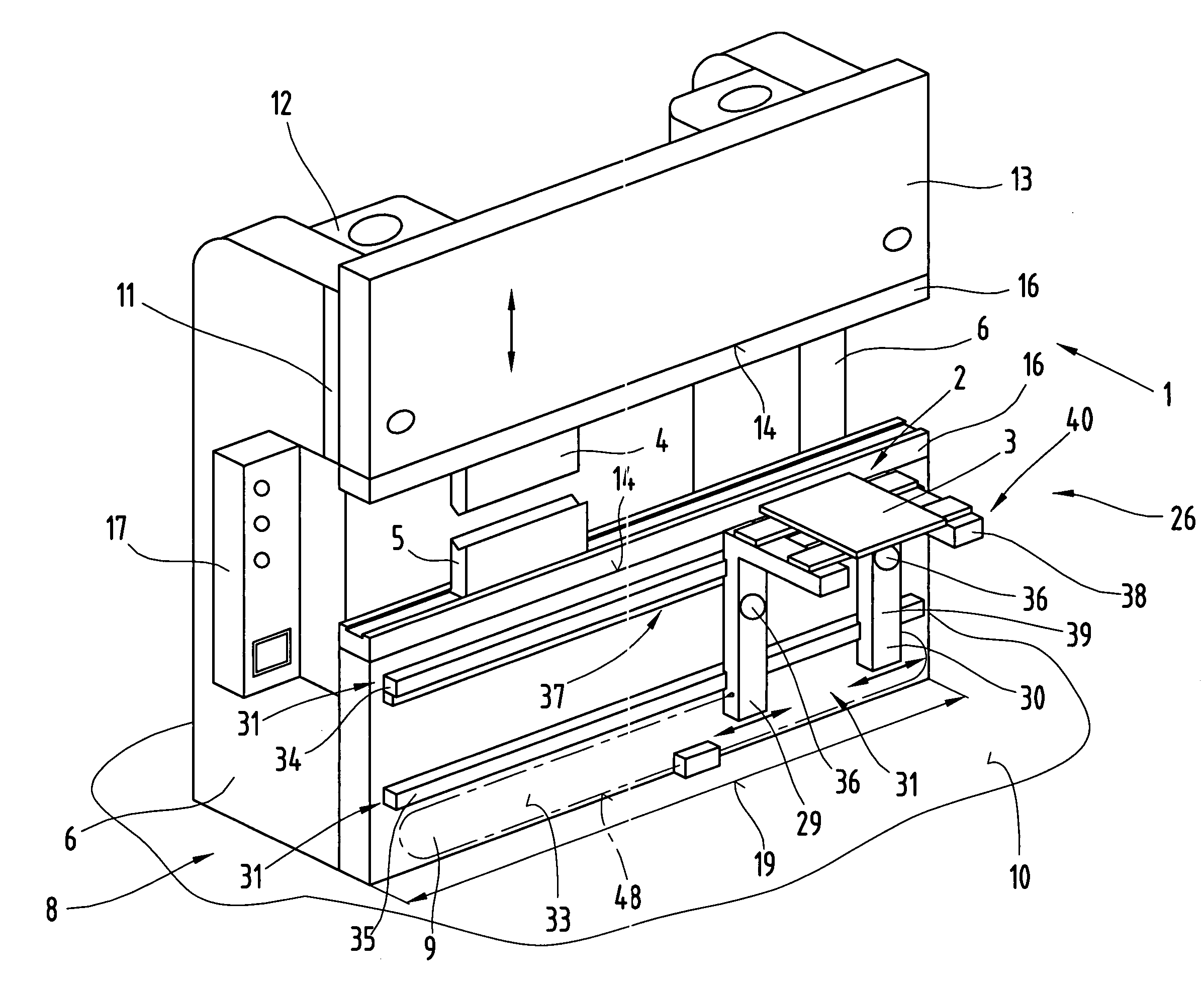

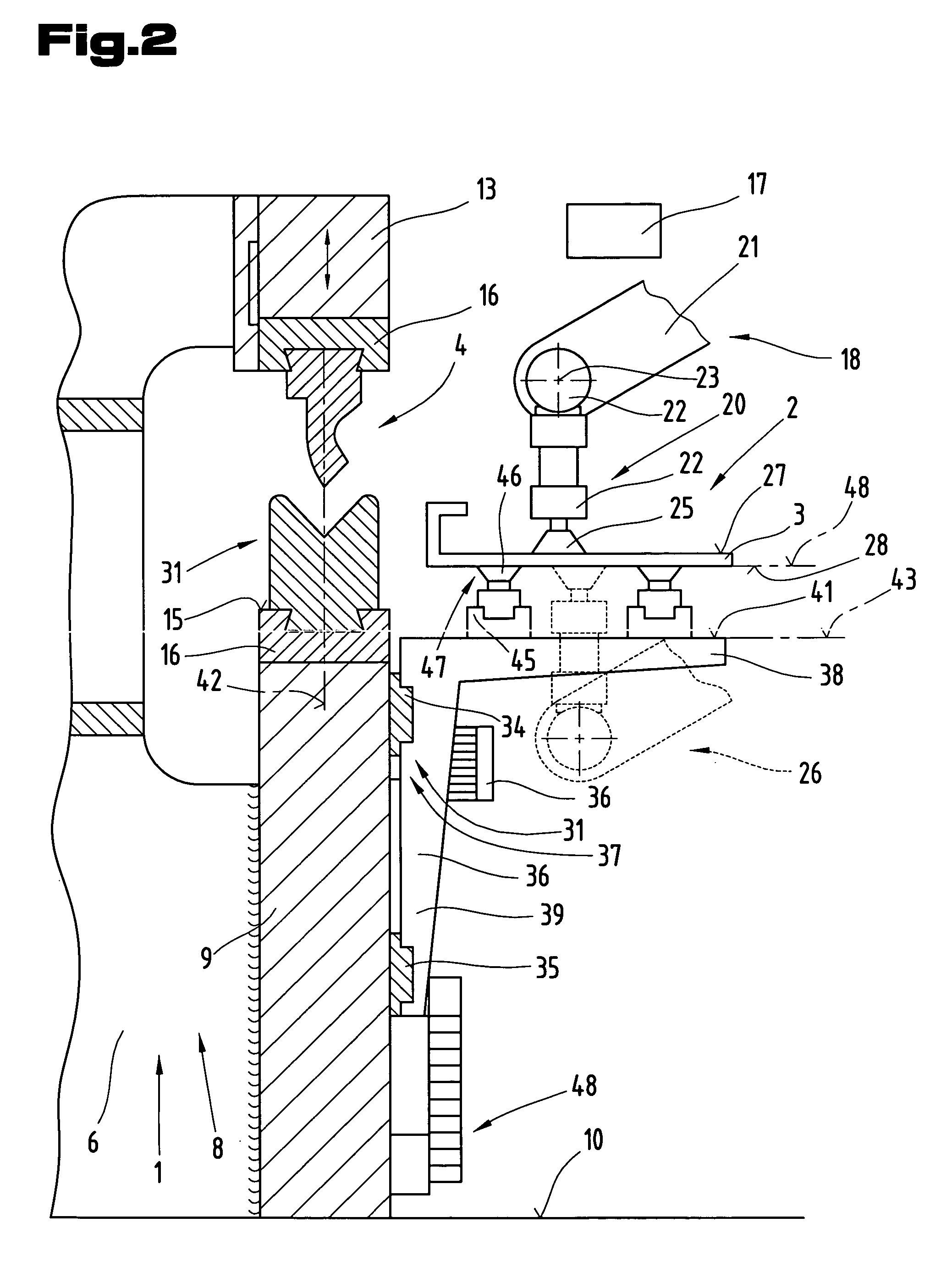

Metal sheet folding device with depositing/positioning device

ActiveUS20060179913A1Shorten the time spanSave free timeMetal-working feeding devicesShaping safety devicesEngineeringMetal sheet

A metal sheet folding device, particularly a folding press, comprising a table beam stationarily arranged on a machine frame, and a press beam arranged on the machine frame in guide arrangements with a driving device. The press beam is adjustable in relation to the table beam. Furthermore, provision is made for a sheet depositing / positioning device for at least one metal sheet plate or at least one workpiece for intermediately positioning the latter for carrying out a gripping operation with the gripping device of a handling system. The device is supported on the machine frame preferably on the table beam and adjustable in a linear guide arrangement in the direction of the longitudinal expanse of the table beam over at least part of the length.

Owner:TRUMPF MASCHEN AUSTRIA

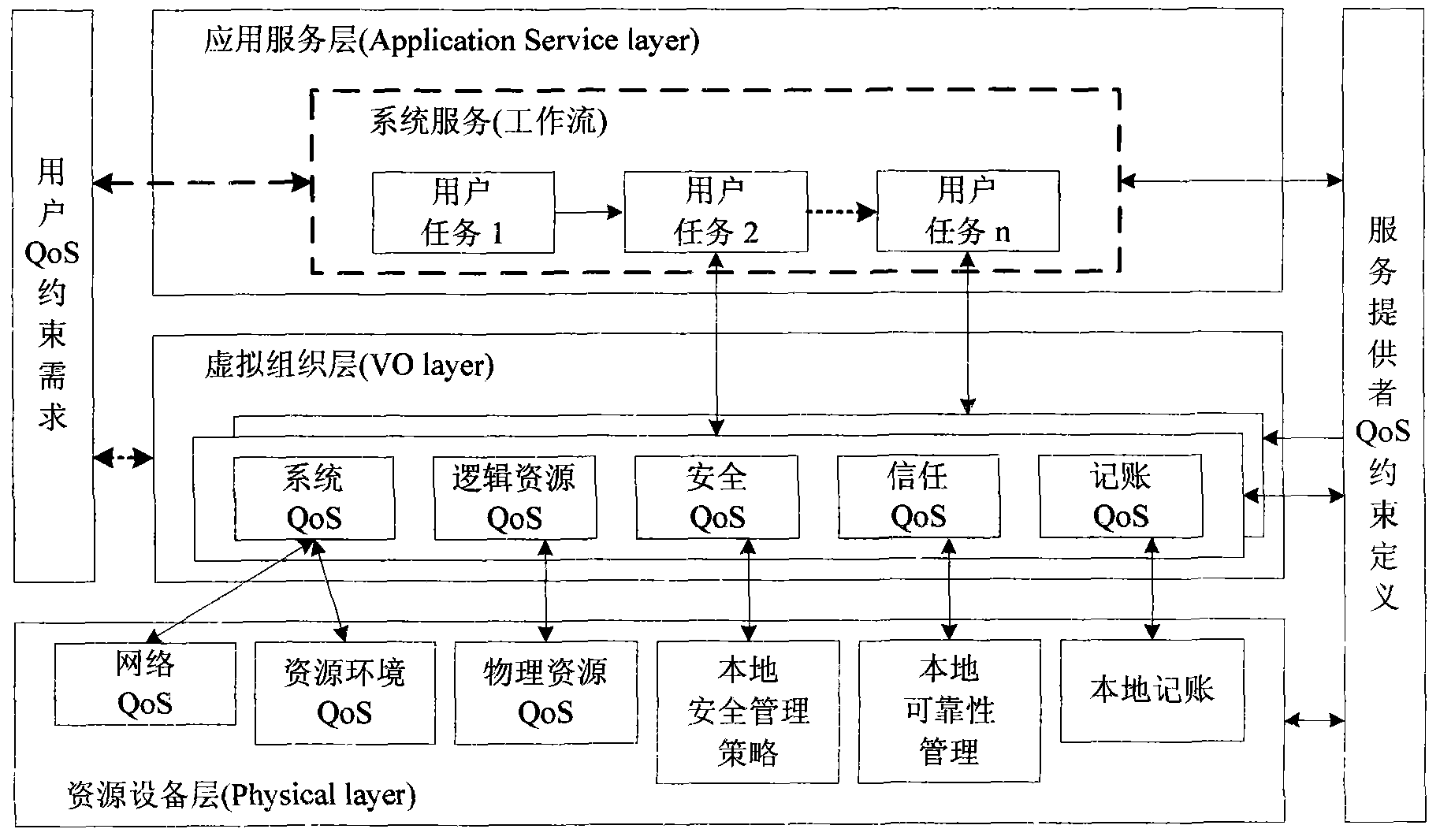

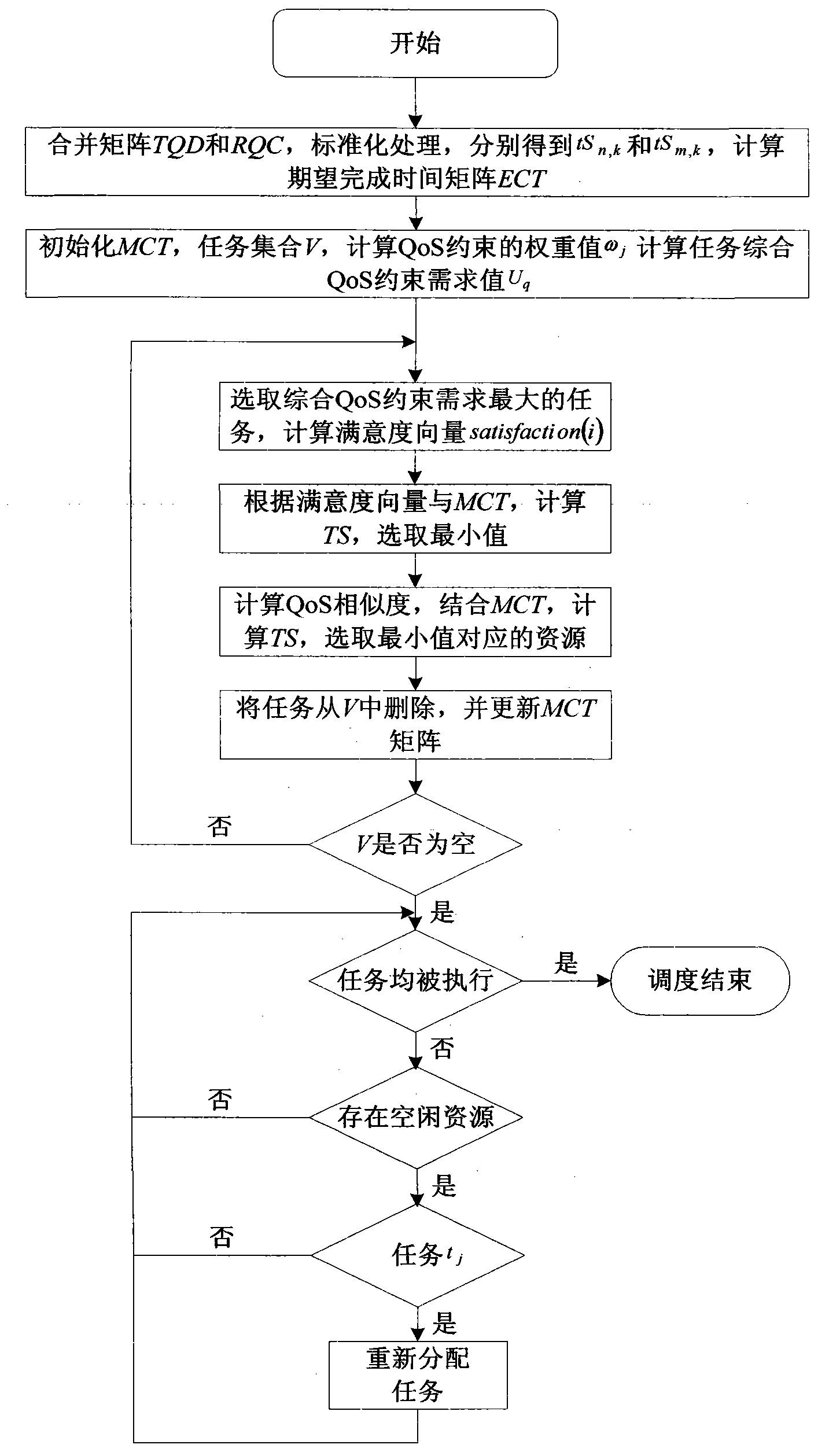

Cloud storage task scheduling method on condition of multiple QoS constraints

The invention discloses a cloud storage task scheduling method on the condition of multiple QoSconstraints. According to the technical scheme, the cloud storage task scheduling method comprises normalization of the QoS constraints, user satisfaction degrees, QoS acquaintance degree measurement and weights of all the QoS constraints. In the process of using the cloud storage task scheduling method, when a user uses data in cloud storage, the data currently in the cloud storage can be scheduled reasonably on the premise that services required by the multiple QoS constraints are guaranteed.

Owner:李飞

Metal sheet folding device with depositing/positioning device

ActiveUS7210328B2Shorten the time spanSave free timeMetal-working feeding devicesShaping safety devicesEngineeringMetal sheet

Owner:TRUMPF MASCHEN AUSTRIA

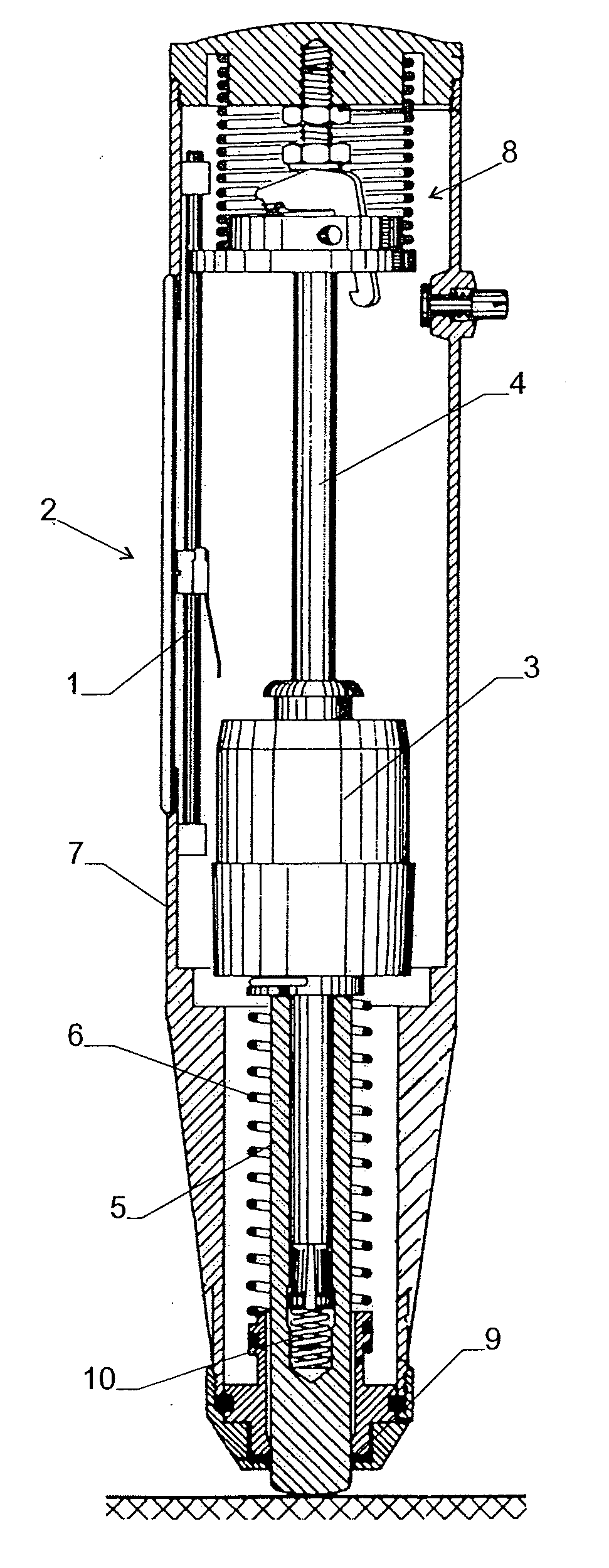

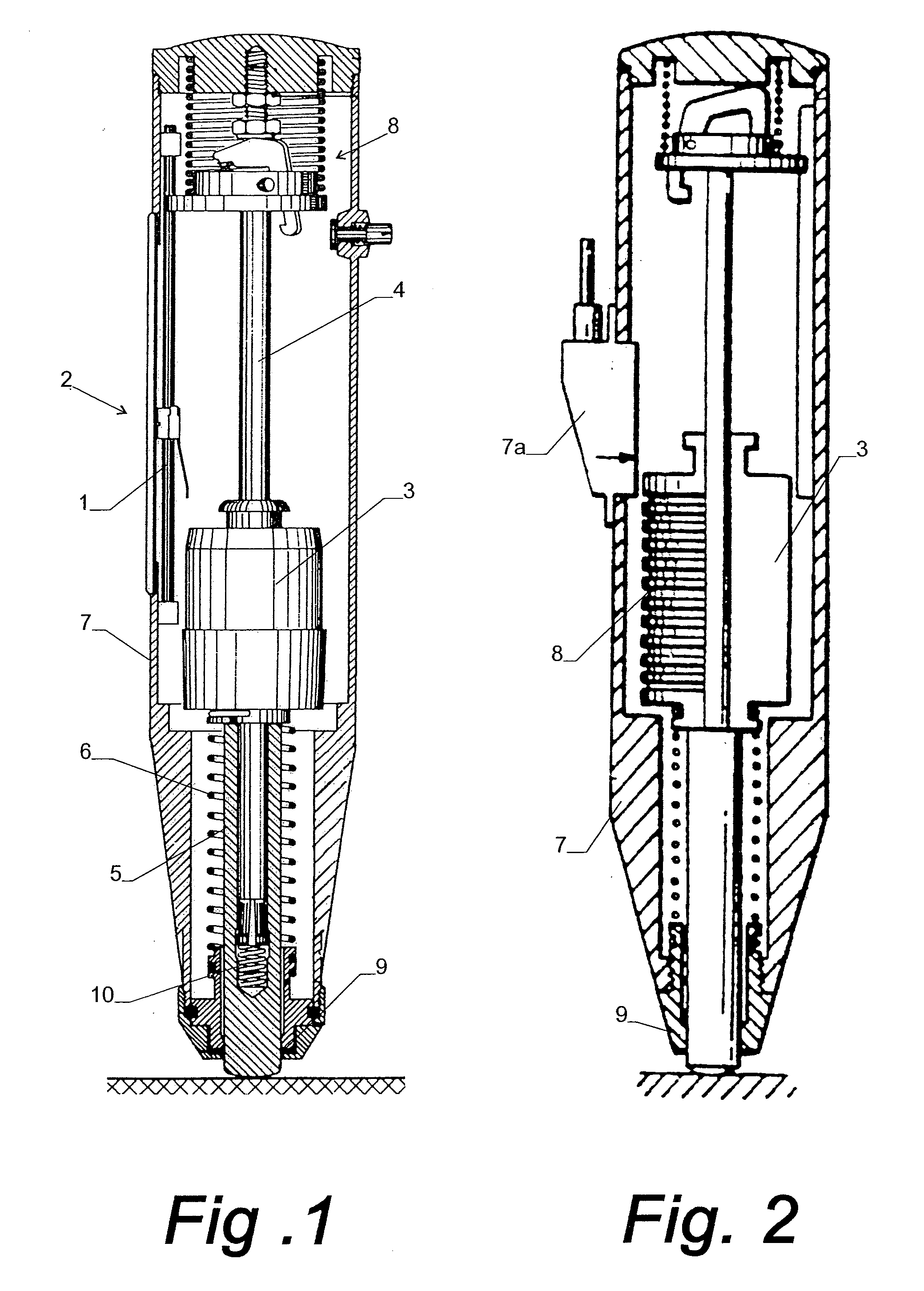

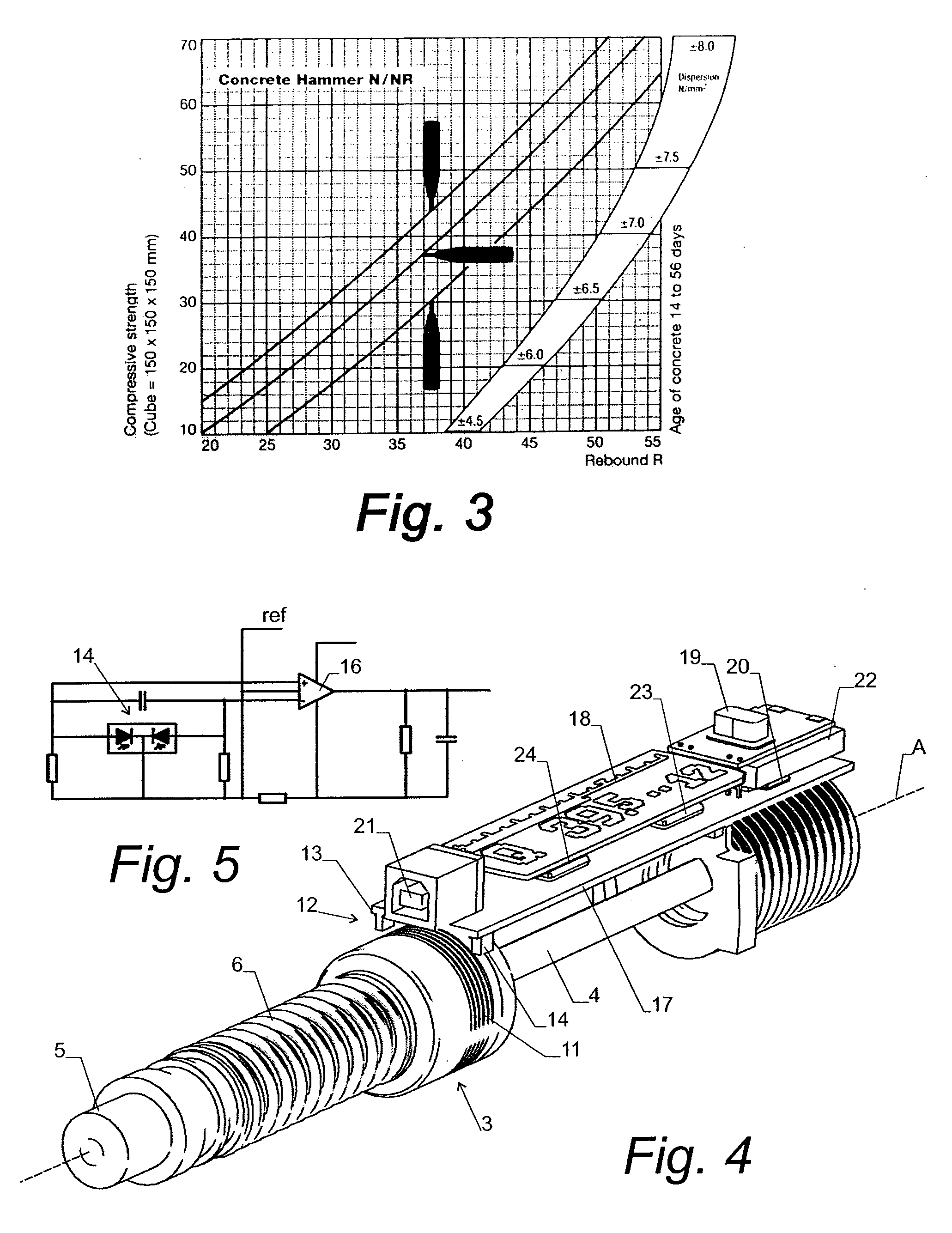

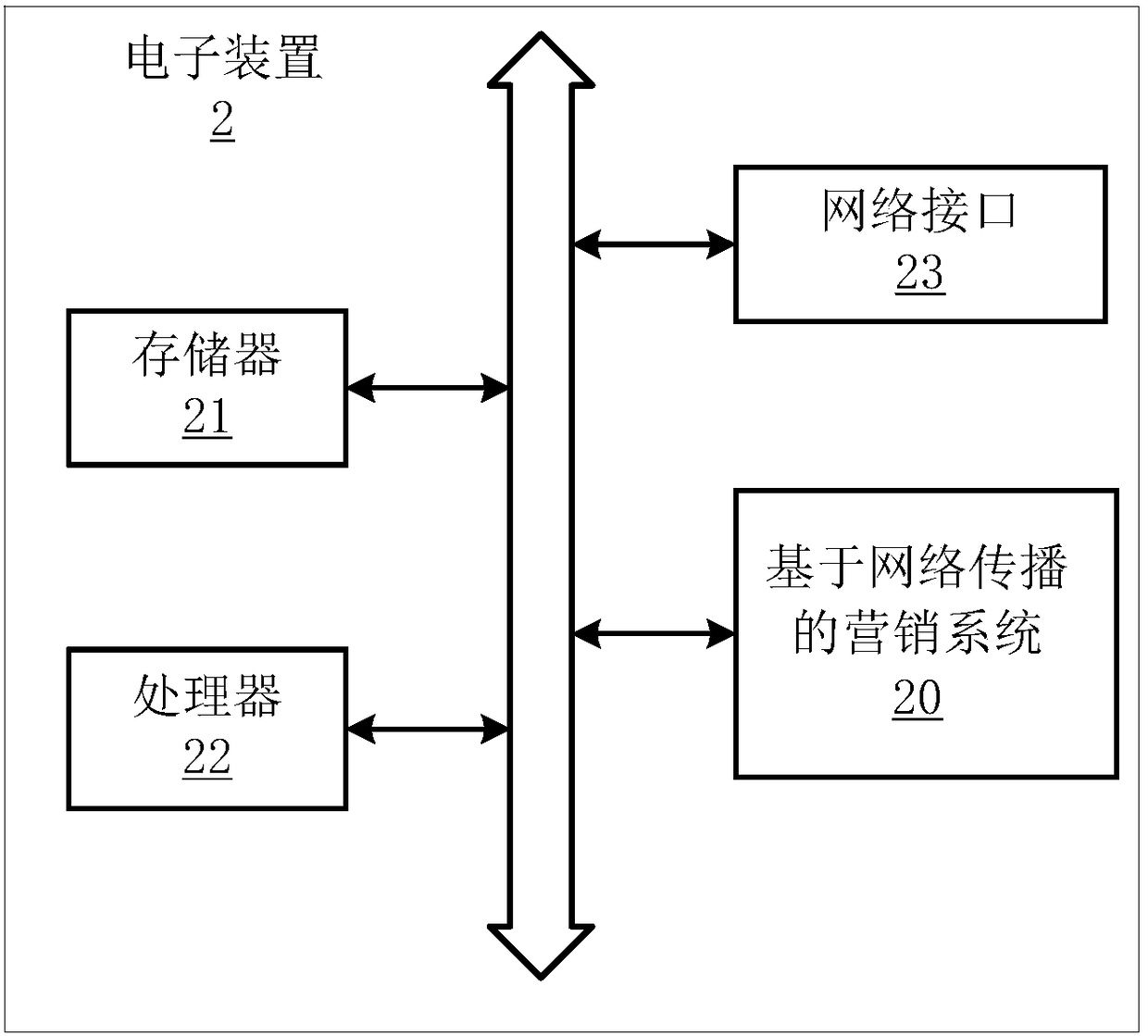

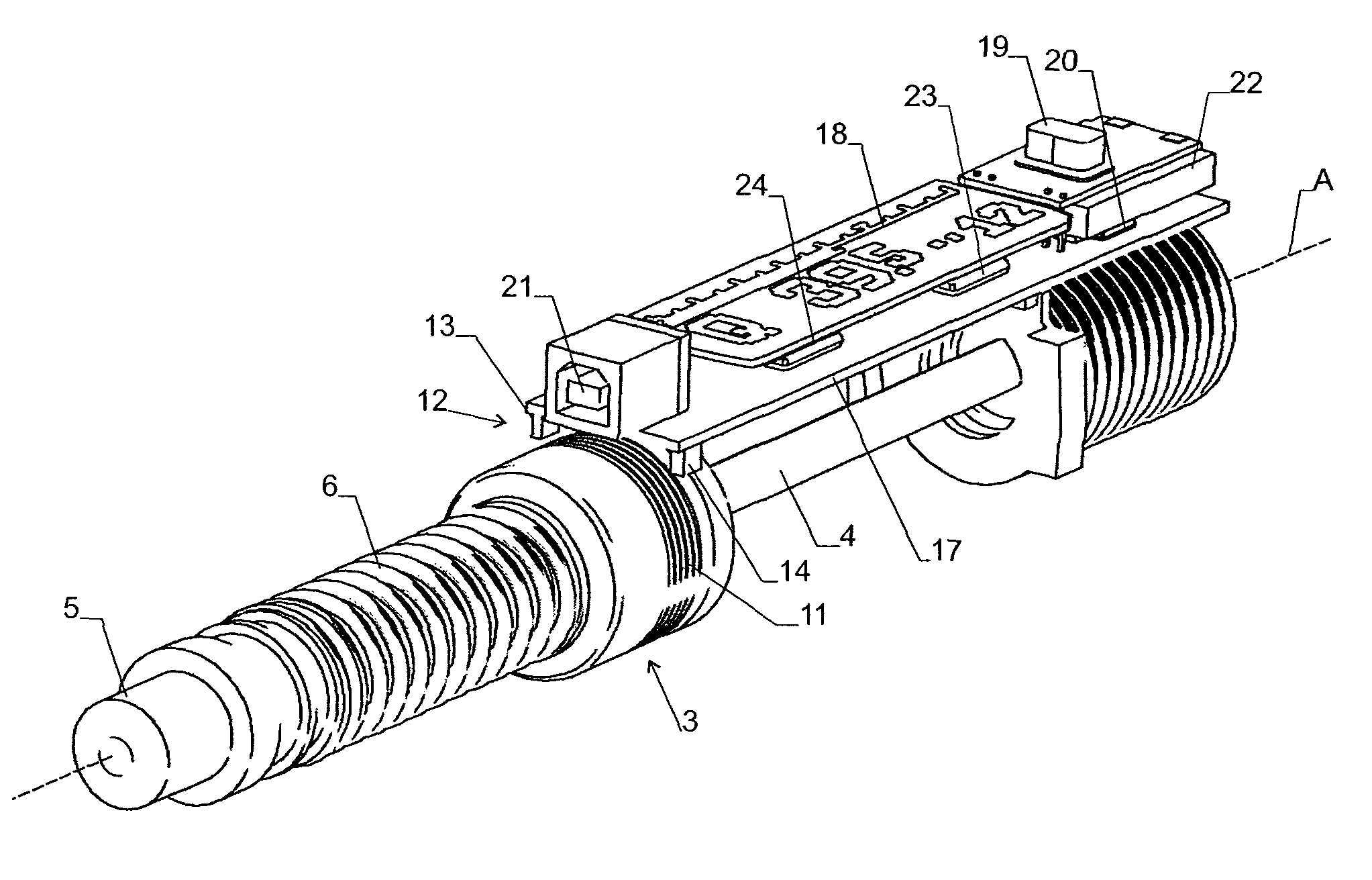

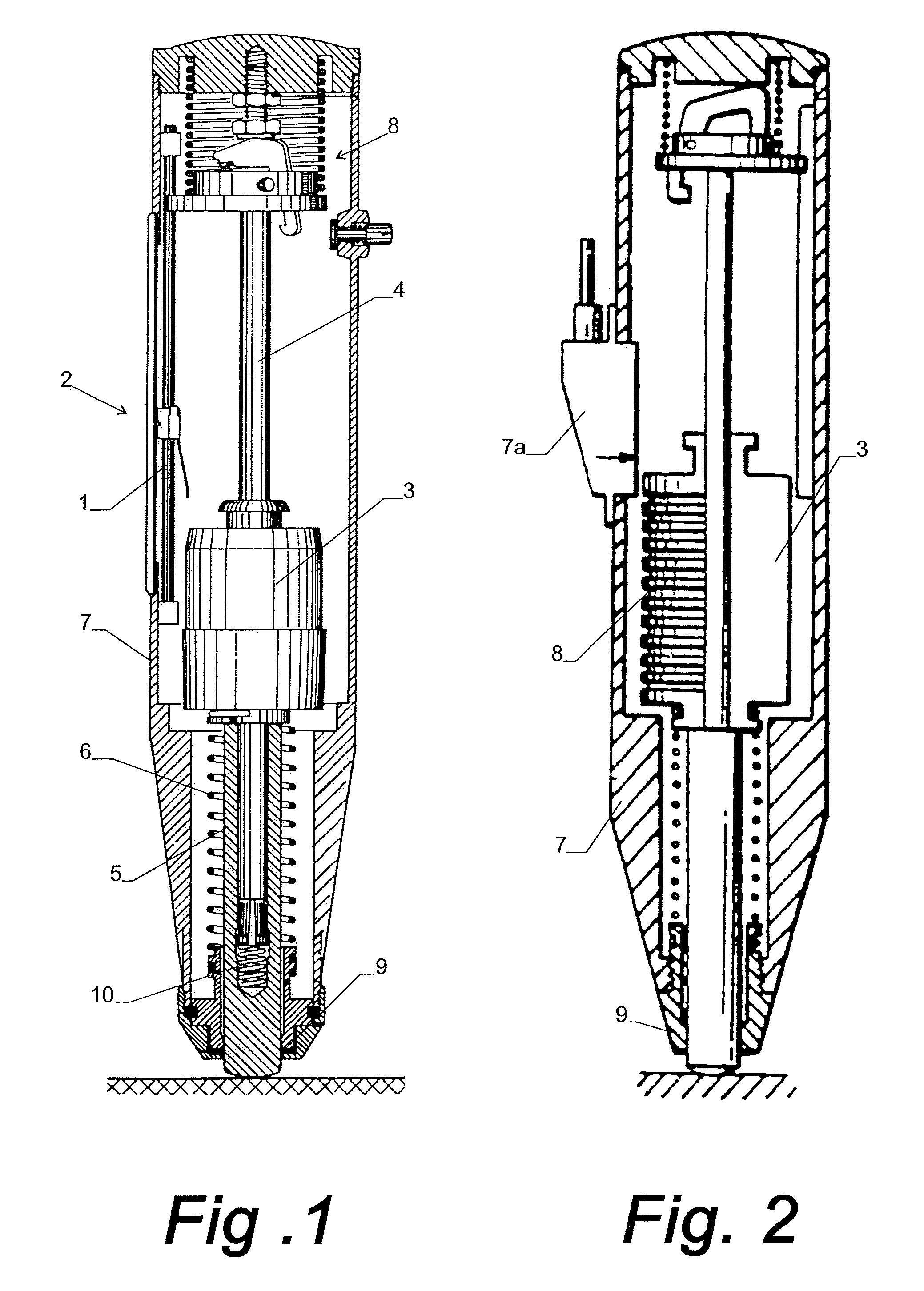

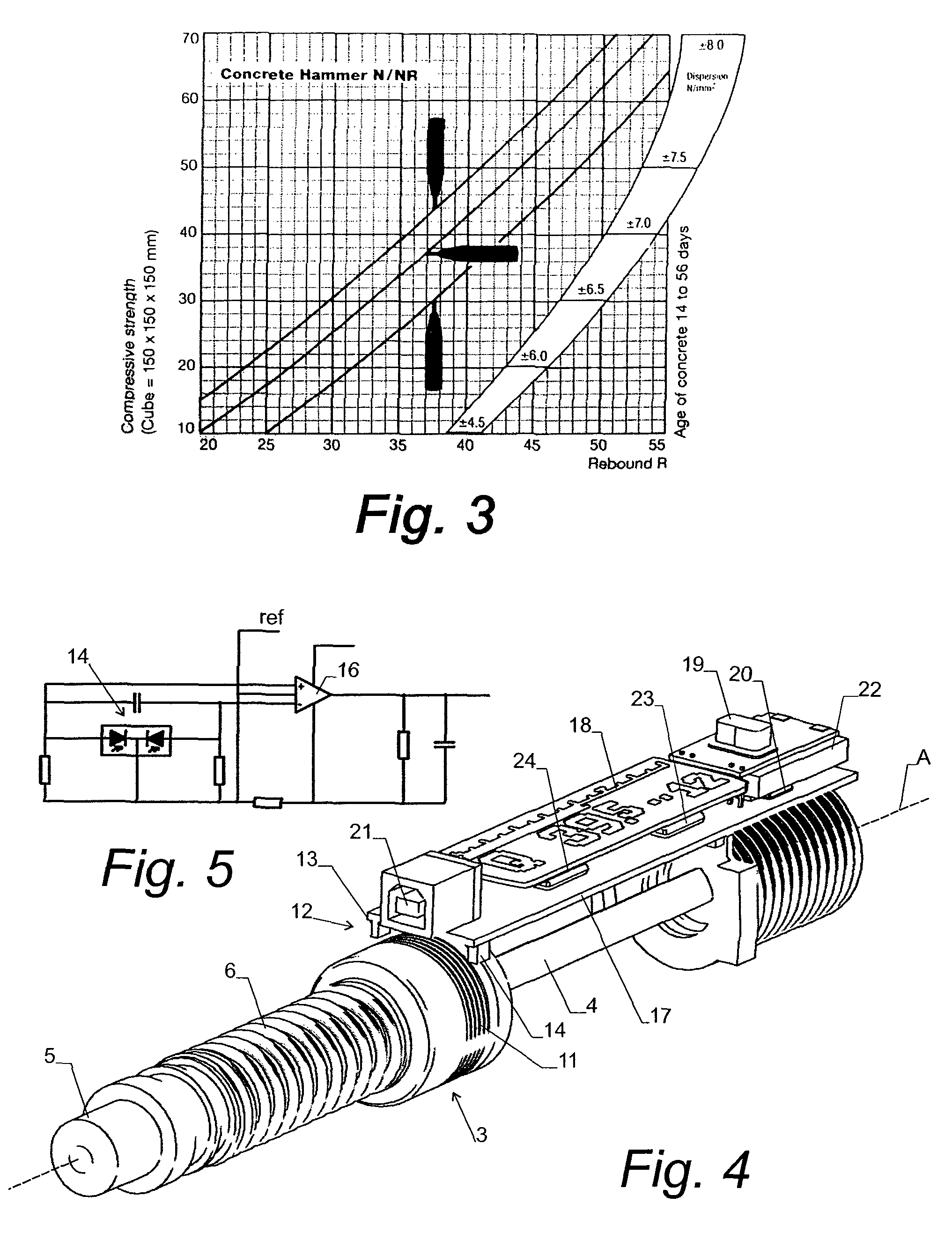

Method and apparatus for the non-destructive measurement of the compressive strength of a solid

ActiveUS20100307258A1Not easy to make mistakesRecognize and eliminate influenceMaterial testing goodsInvestigating material hardnessNon destructiveEngineering

An apparatus and a method are described that determine the compressive strength of a solid by rebound. The method and apparatus have a reduced sensitivity to error sources, i.e. gravity, internal friction and operator interference (unsteady holding of the instrument). The improvements are achieved by contactless measuring of the quotient of rebound to inbound velocity recorded immediately before and after the impact. Matching the mass of the mallet (3) to the plunger (5) yields higher efficiency, less angular variation of the impact energy and lighter weight. Added benefits of the invention are: Extended range of measurement and simplified mechanical adjustments, calibration and maintenance.

Owner:BRANDESTINI MARCO

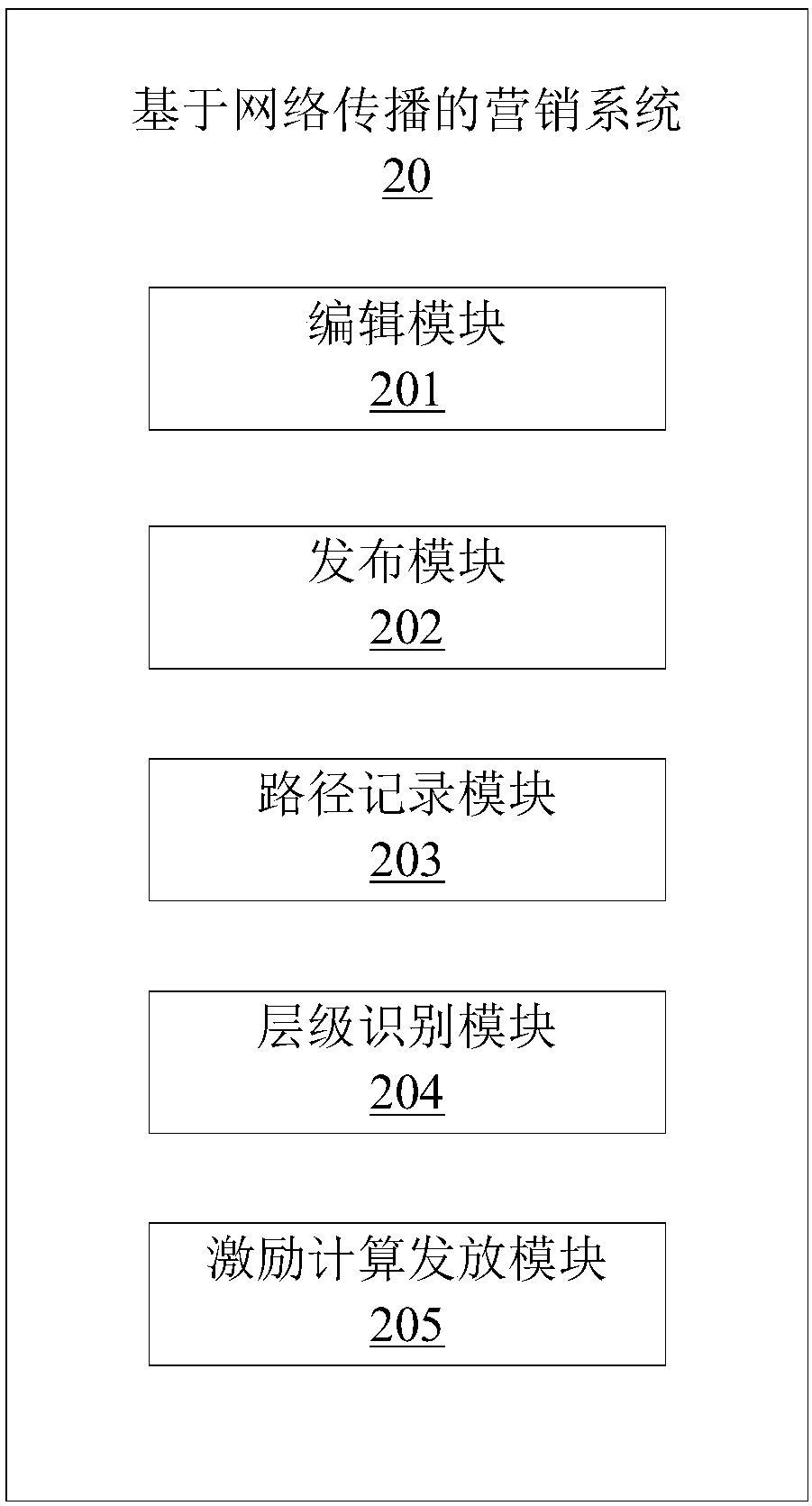

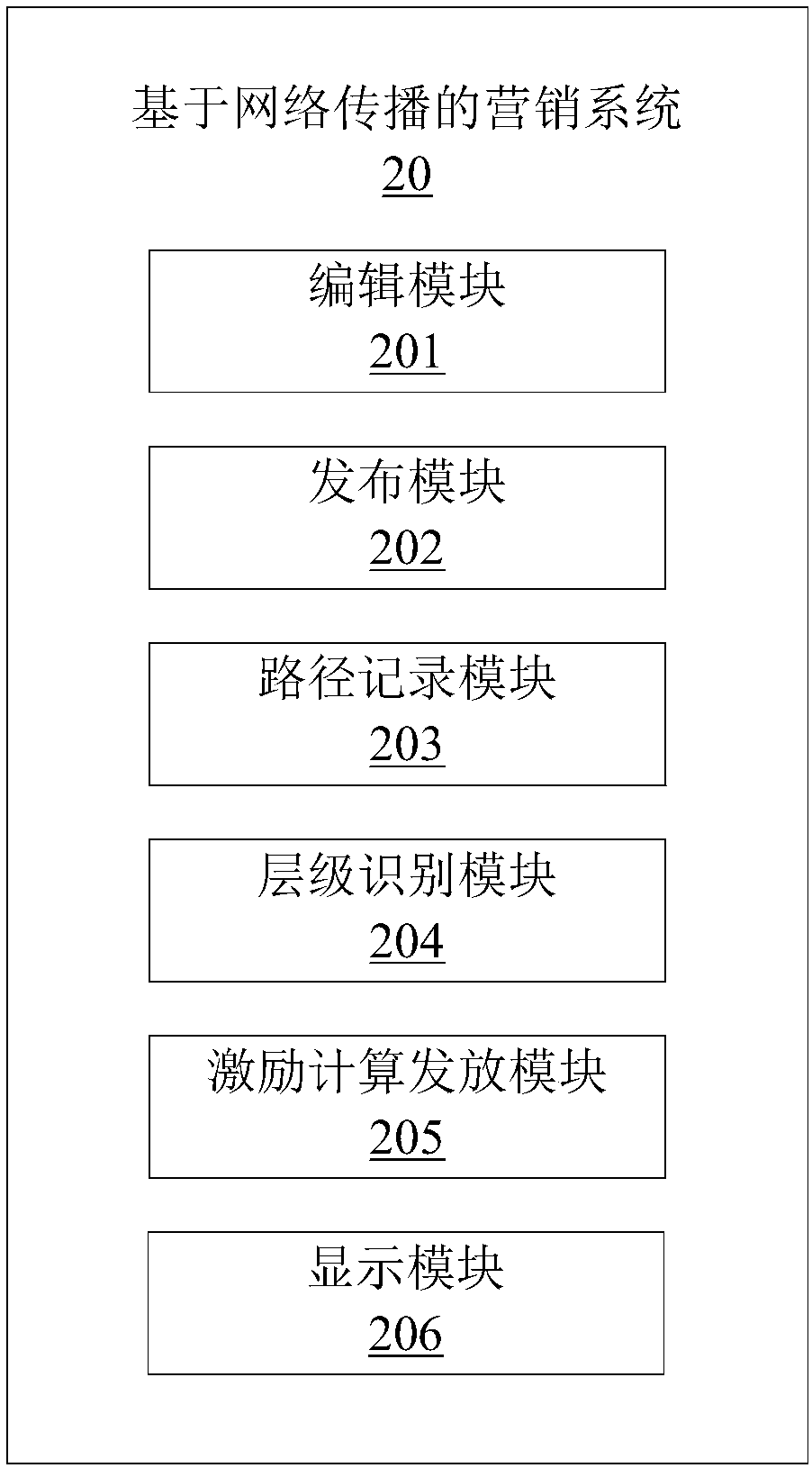

H5 activity page propagation-based marketing method, electronic device and storage medium

InactiveCN108256897ALow costShorten the time spanDiscounts/incentivesAdvertisementsPropagatorThe Internet

The invention discloses an H5 activity page propagation-based marketing method and belongs to the technical field of the internet. The H5 activity page propagation-based marketing method comprises thefollowing steps of S1, editing to generate an H5 activity page; S2, associating the generated H5 activity page with a two-dimensional code or a short link, and then issuing the generated H5 activitypage; S3, recording the propagation path of the H5 activity page; S4, determining a hierarchical relationship between each propagator and a customer based on the recorded propagation path of the H5 activity page; S5, according to the transaction amount of the customer and the hierarchical relationship between the propagator and the customer, calculating an excitation amount for propagators in eachof all levels according to a preset excitation calculation rule and correspondingly issuing the excitation amount to the accounts of propagators in each level. According to the invention, the information of current activity propagators is automatically recorded in the actively propagation process. The propagation process of an activity and the excitation amount are conveniently and completely displayed to propagators. Therefore, the process of the activity is more transparent.

Owner:PING AN TECH (SHENZHEN) CO LTD

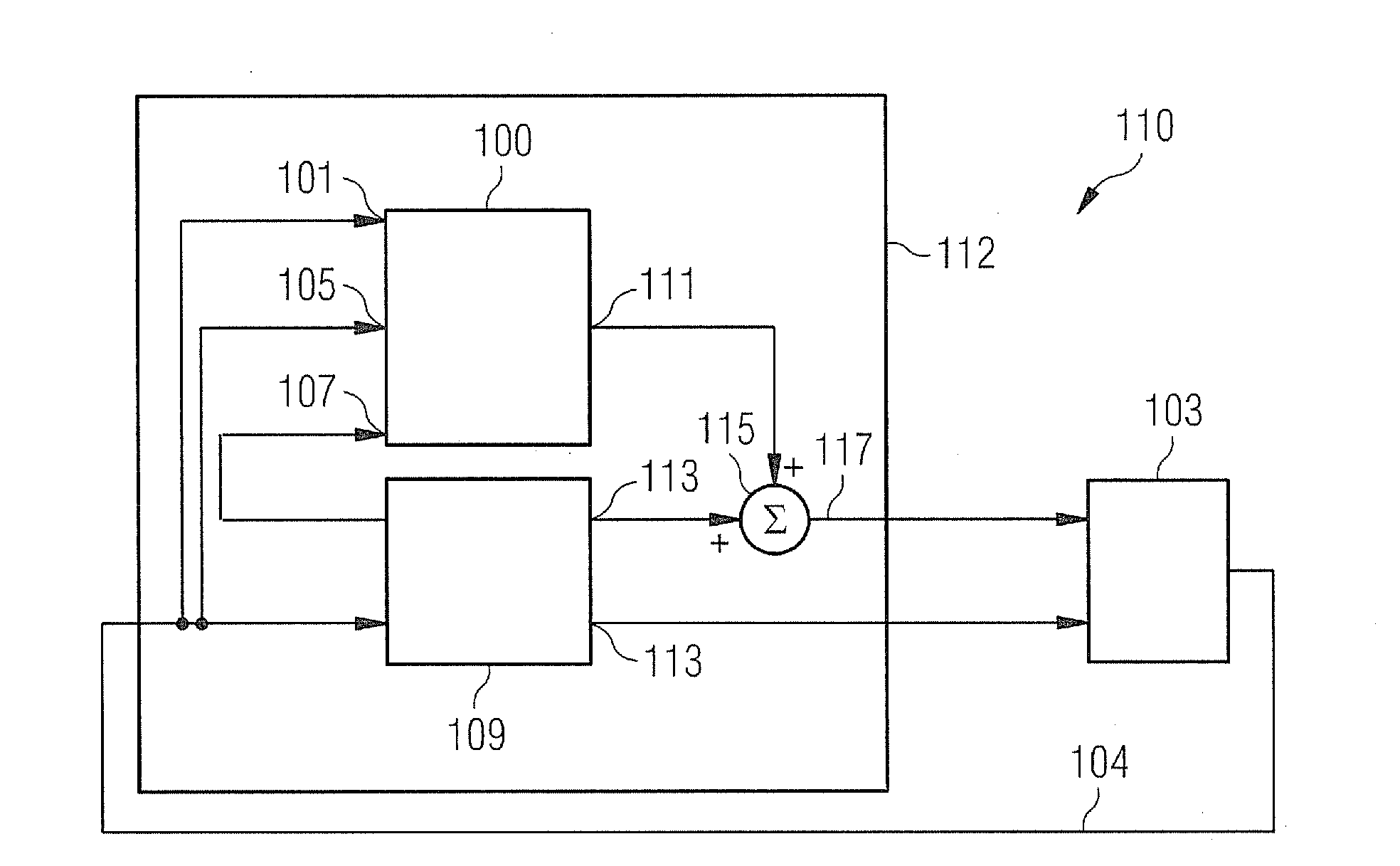

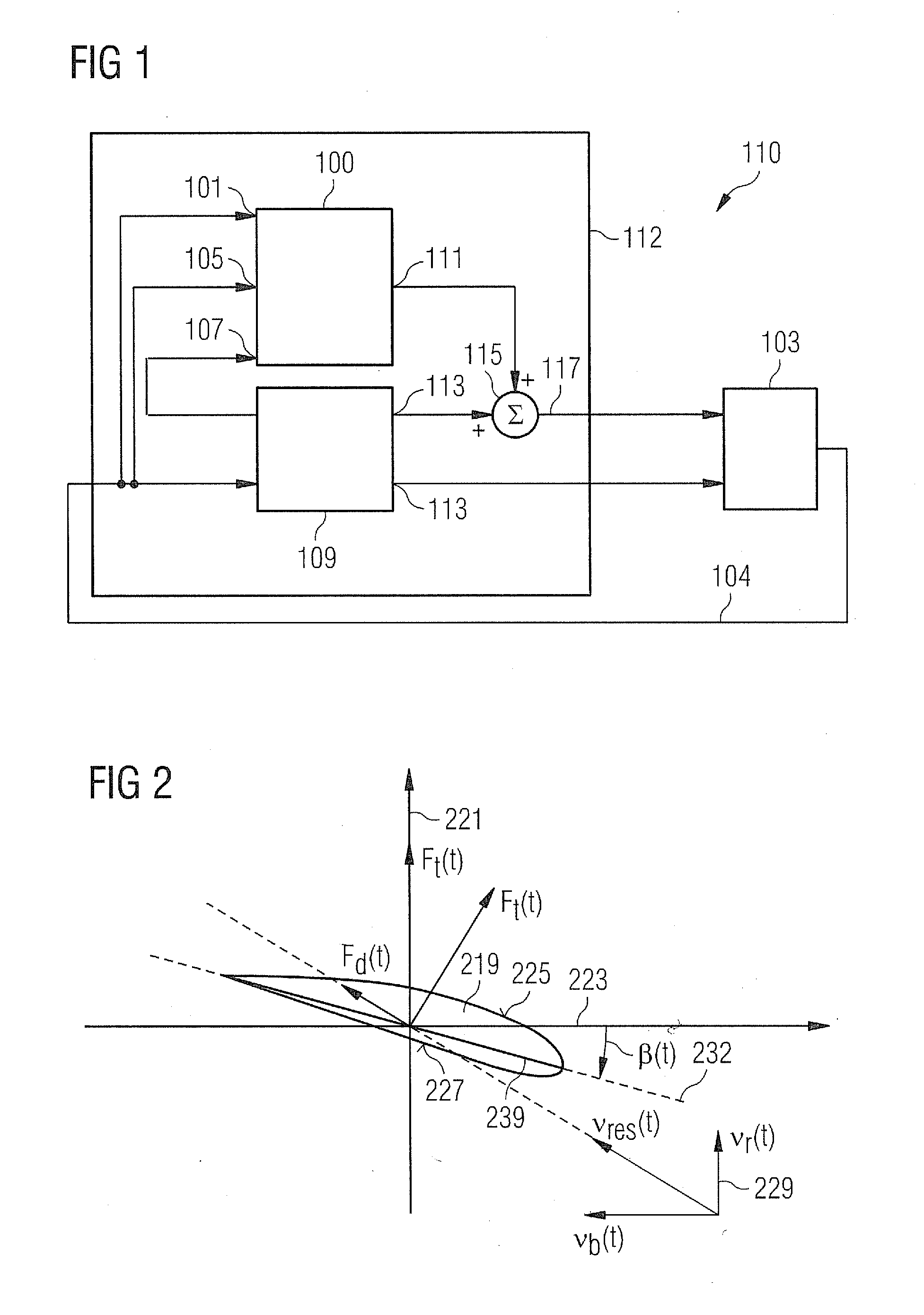

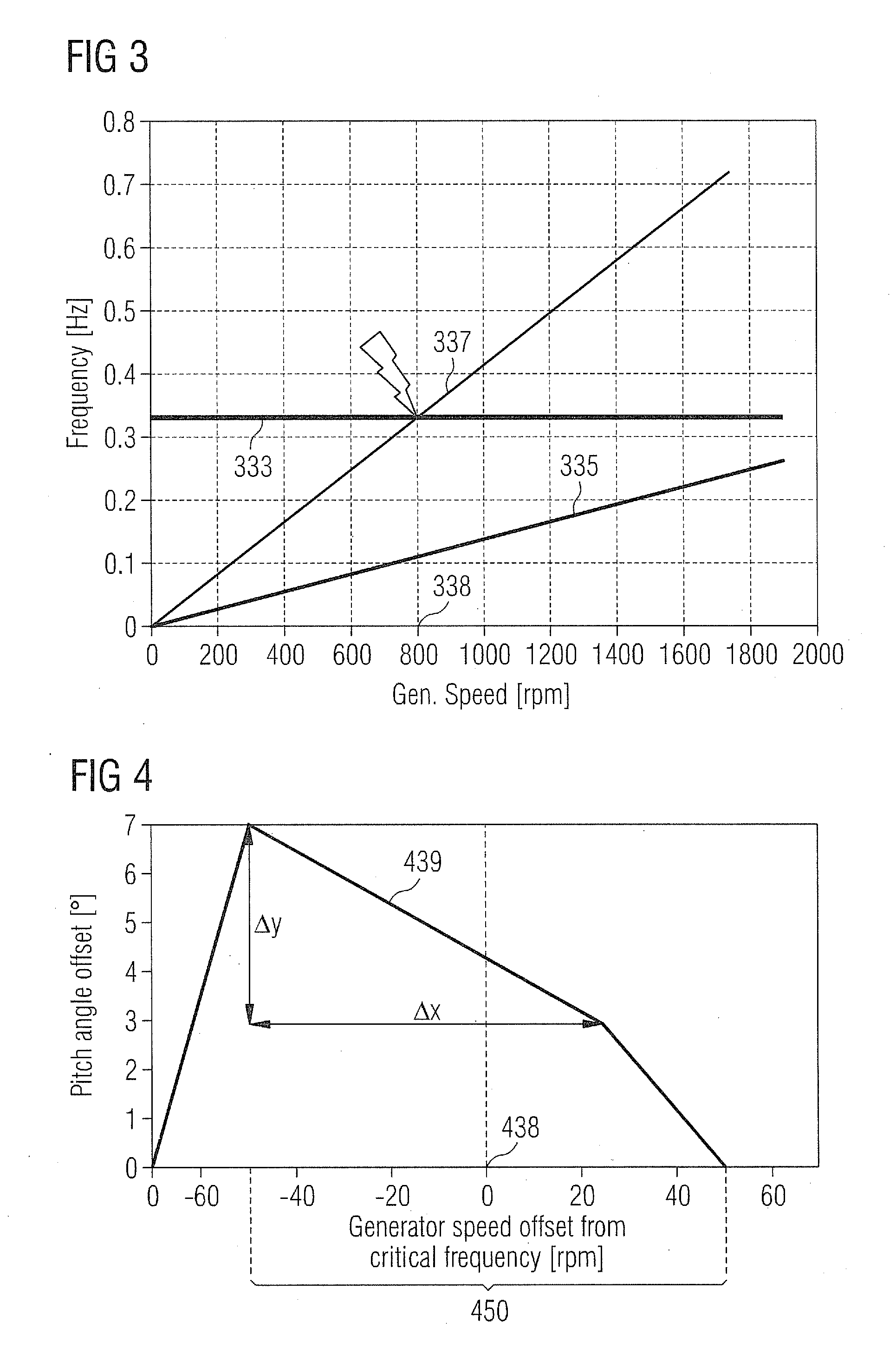

Methods and systems for determining a pitch angle offset signal and for controlling a rotor frequency of a rotor of a wind turbine for speed avoidance control

A method for determining and applying a pitch angle offset signal for controlling a rotor frequency of a rotor of a wind turbine is disclosed. The method includes obtaining a motion quantity indicative of a motion of the rotor and determining the pitch angle offset signal based on the motion quantity such that the pitch angle offset signal is adapted to be used for adjusting a blade pitch angle of a rotor blade mounted at the rotor for controlling the rotor frequency in order to reduce a time span during which the rotor is in a critical motion region. A corresponding system and a method for controlling a rotor frequency are also disclosed.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Method and apparatus for the non-destructive measurement of the compressive strength of a solid

ActiveUS8261620B2Not easy to make mistakesRecognize and eliminate influenceInvestigating material hardnessNon destructiveEngineering

An apparatus and a method are described that determine the compressive strength of a solid by rebound. The method and apparatus have a reduced sensitivity to error sources, i.e. gravity, internal friction and operator interference (unsteady holding of the instrument). The improvements are achieved by contactless measuring of the quotient of rebound to inbound velocity recorded immediately before and after the impact. Matching the mass of the mallet (3) to the plunger (5) yields higher efficiency, less angular variation of the impact energy and lighter weight. Added benefits of the invention are: Extended range of measurement and simplified mechanical adjustments, calibration and maintenance.

Owner:BRANDESTINI MARCO

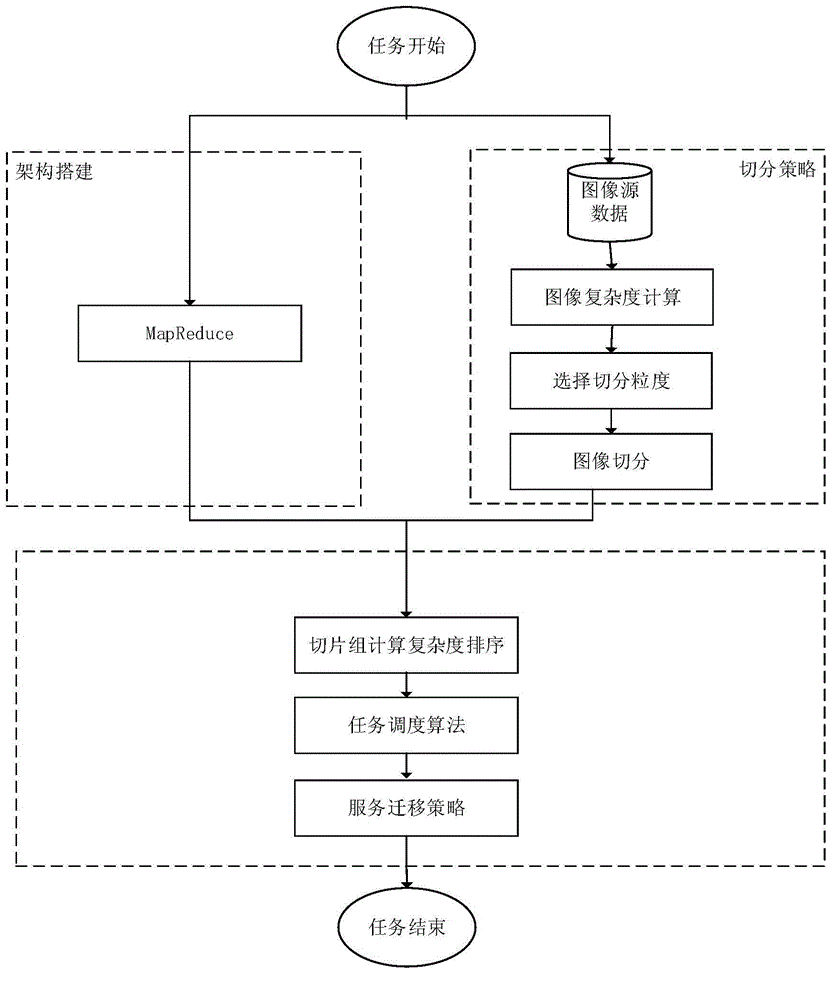

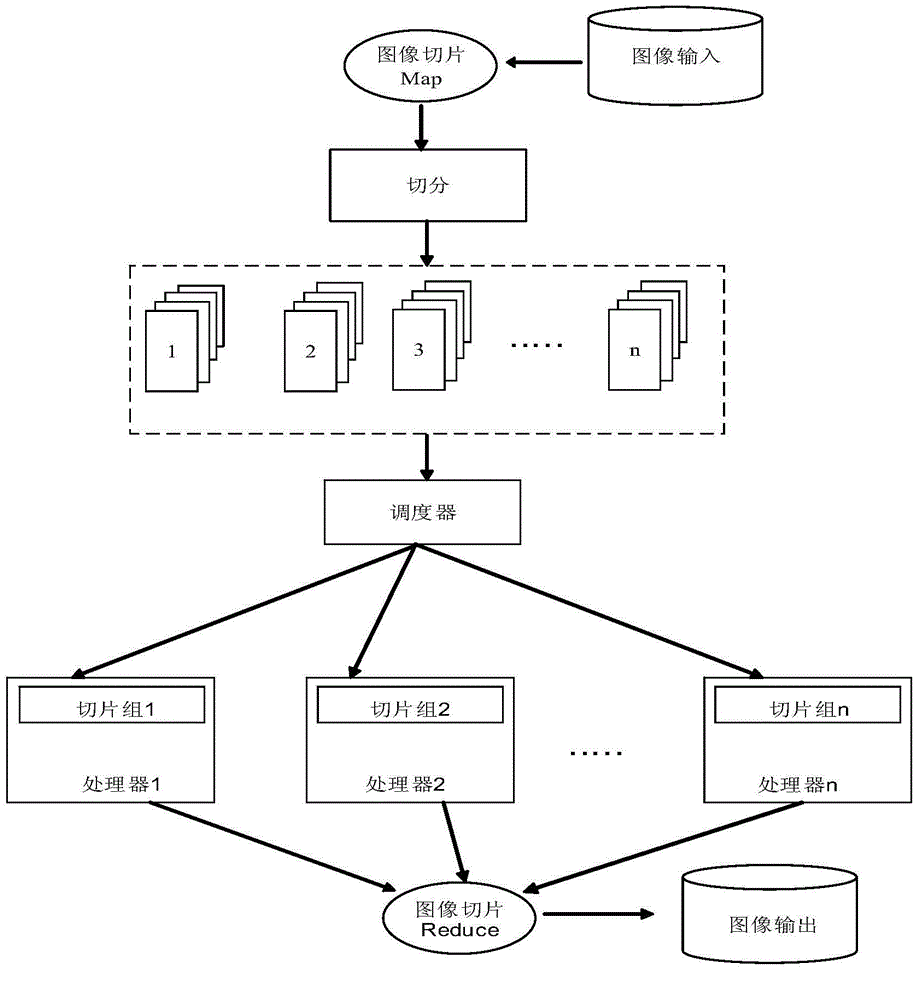

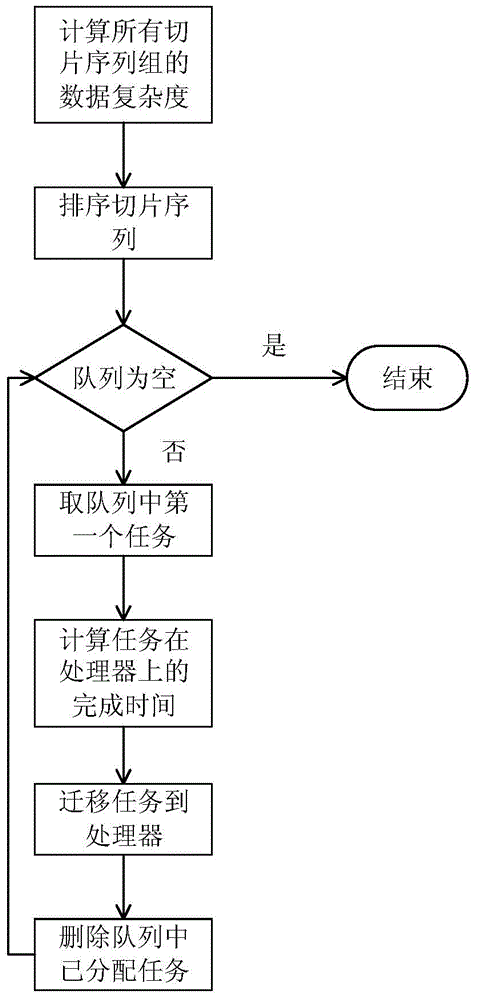

Medical image segmenting and dispatching method

ActiveCN104537682AHigh speedShorten the time spanImage analysisResource allocationPattern recognitionImaging processing

The invention relates to a medical image processing method and provides a medical image segmenting and dispatching method. The method is characterized by comprising the following steps: performing slice segmentation on a source image of a to-be-processed medical image, and forming at least one image group by virtue of the slices; distributing the image groups to slave servers for performing data processing by virtue of the system, wherein the image groups correspond to the slave servers one by one; detecting whether the slave servers normally operate by the system, if so, performing normal data processing, otherwise performing migration service processing; and finally, detecting the processing progress of the slave servers in real time by the system, and when all the slave servers finish the data processing, performing data integration after processing, and outputting the image. According to the mode, the image processing speed of the medical image is improved. The invention is applicable to the medical image segmenting and dispatching method.

Owner:四川众亿得科技有限责任公司

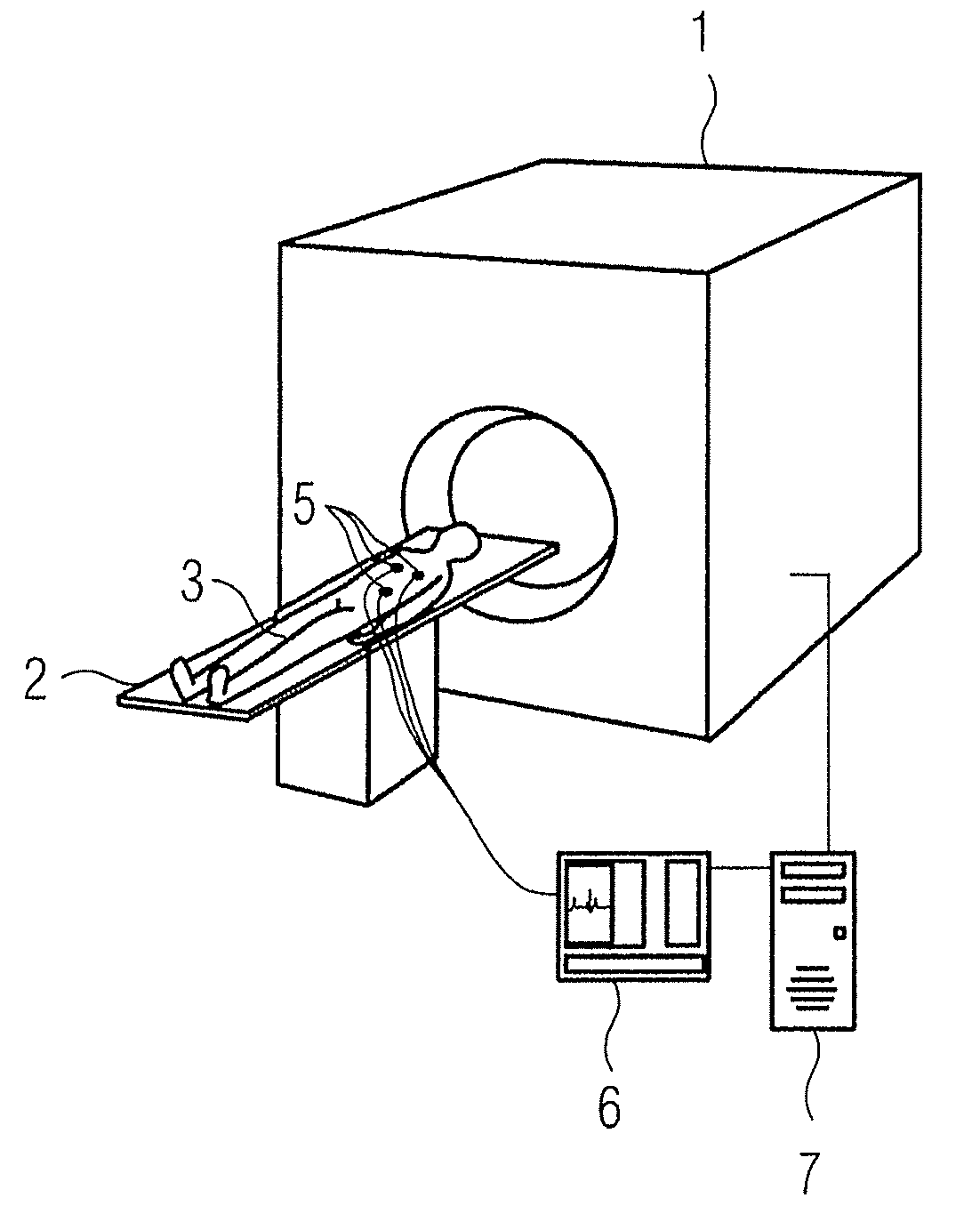

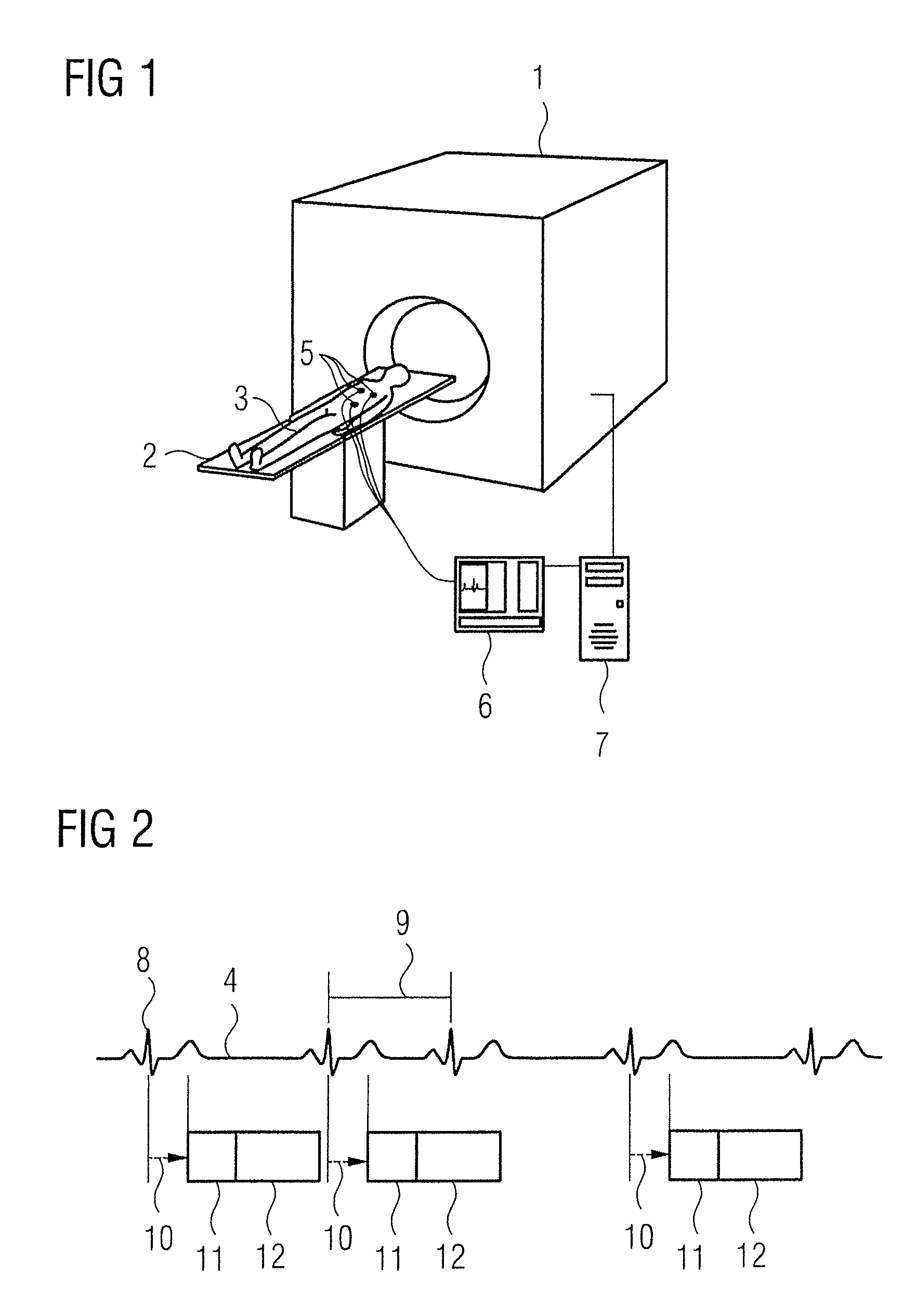

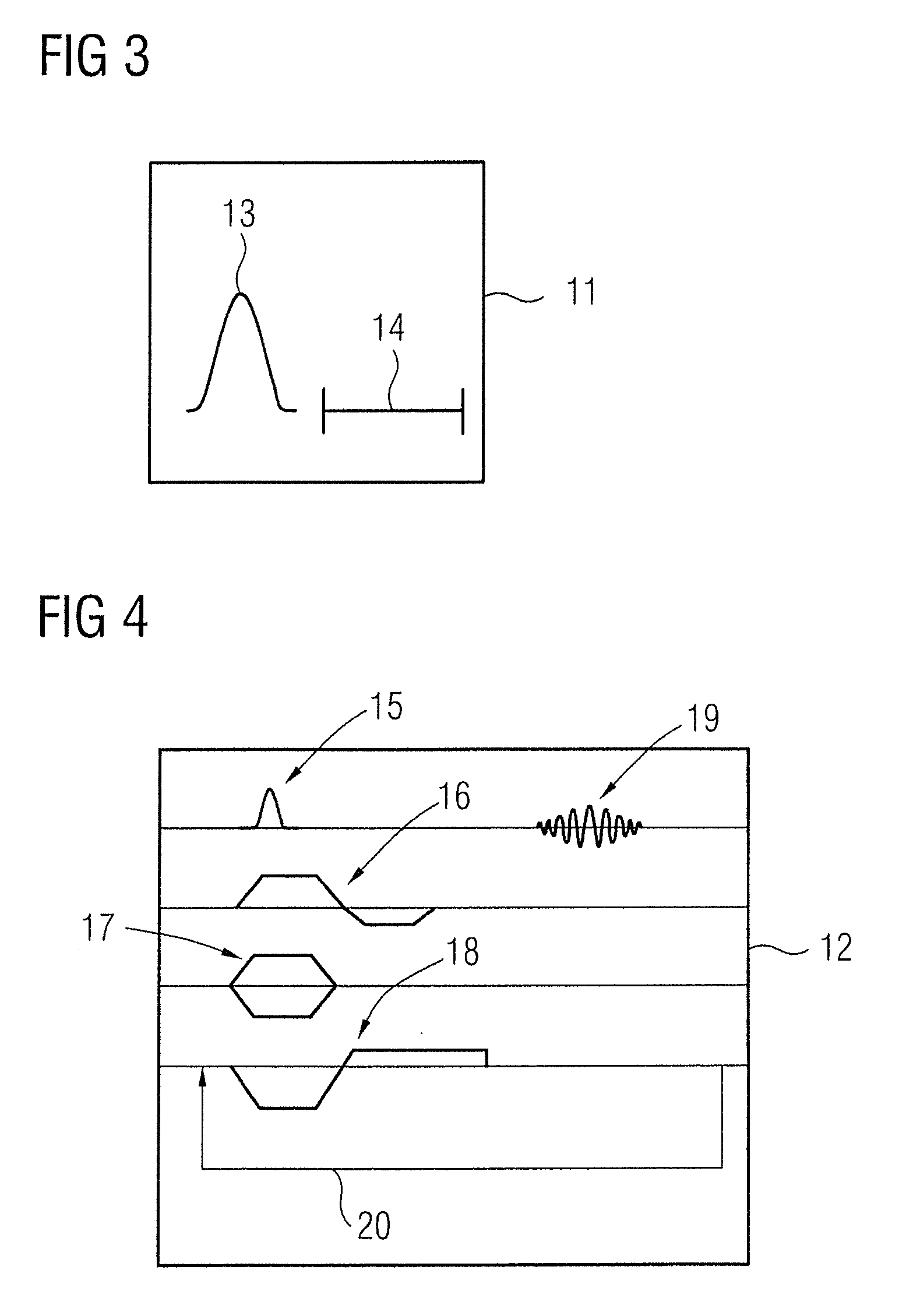

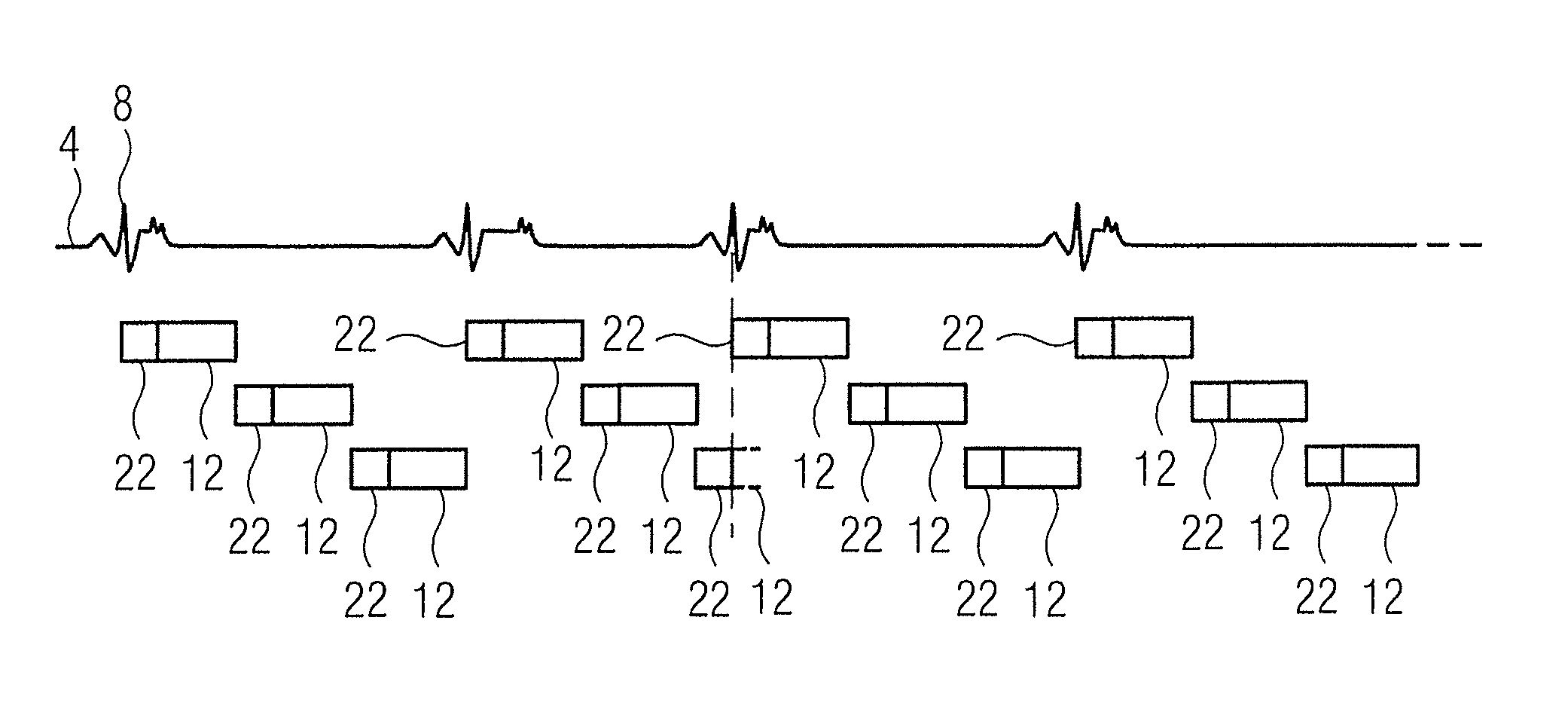

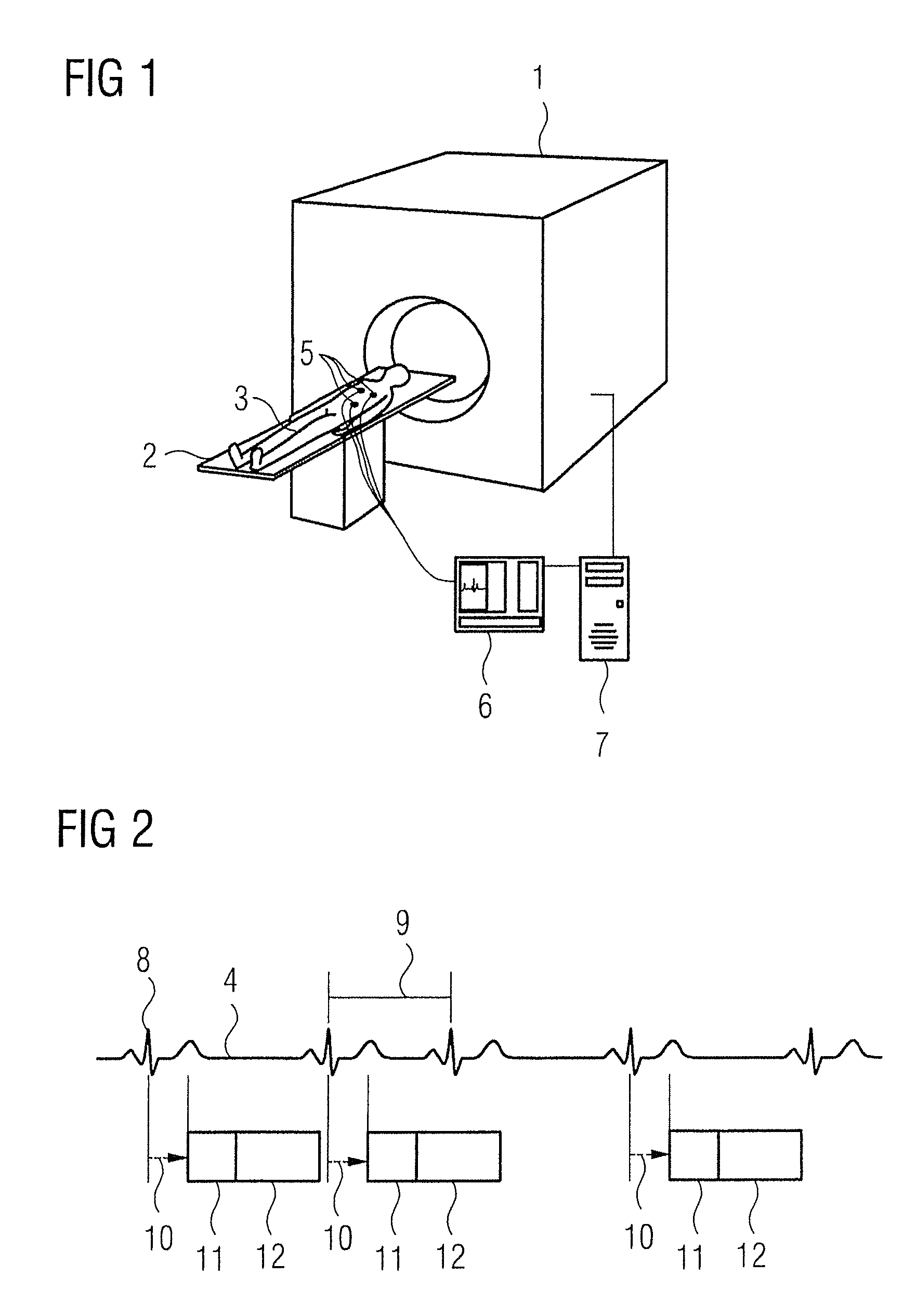

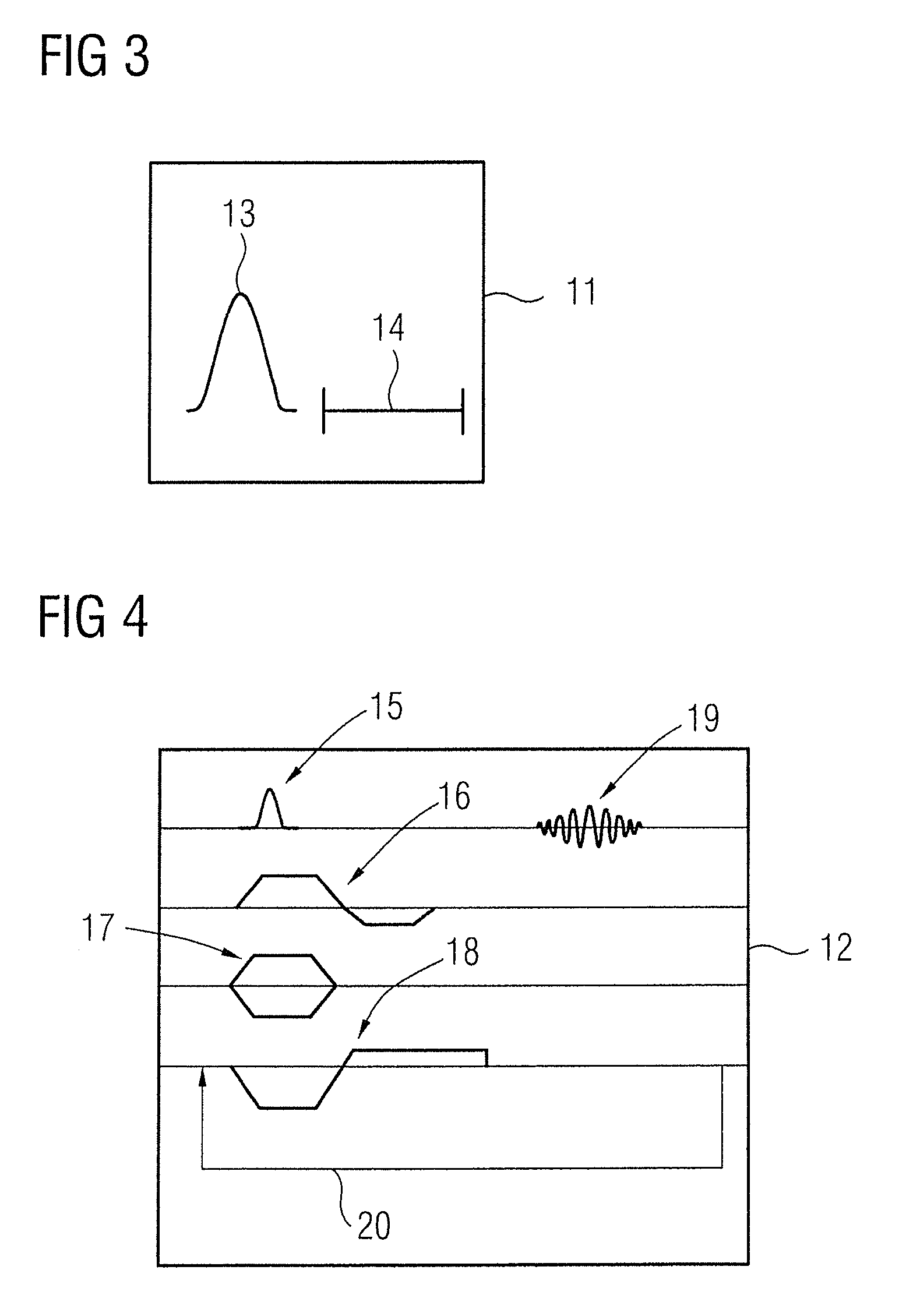

Method and magnetic resonance tomography apparatus for triggered acquisition of magnetic resonance data

ActiveUS20100277173A1Reliable and disruption-free data acquisitionShorten the time spanElectrocardiographySensorsData setResonance

In a method and magnetic resonance tomography apparatus for triggered implementation of a measurement (composed of partial measurements) in the magnetic resonance tomography apparatus, at least one image data set is determined from the data acquired within the scope of the partial measurements, and for triggering a reference point of the movement phase of the movement is used. The image data set is acquired in segments; the reference point is detected by a control device independent of a partial measurement, and the partial measurement following the detected reference point is conducted depending on the independently detected reference point. The wait time that specifies the interval from the end of the partial measurement to the beginning of the next partial measurement is adapted depending on the point in time of detection.

Owner:SIEMENS HEALTHCARE GMBH

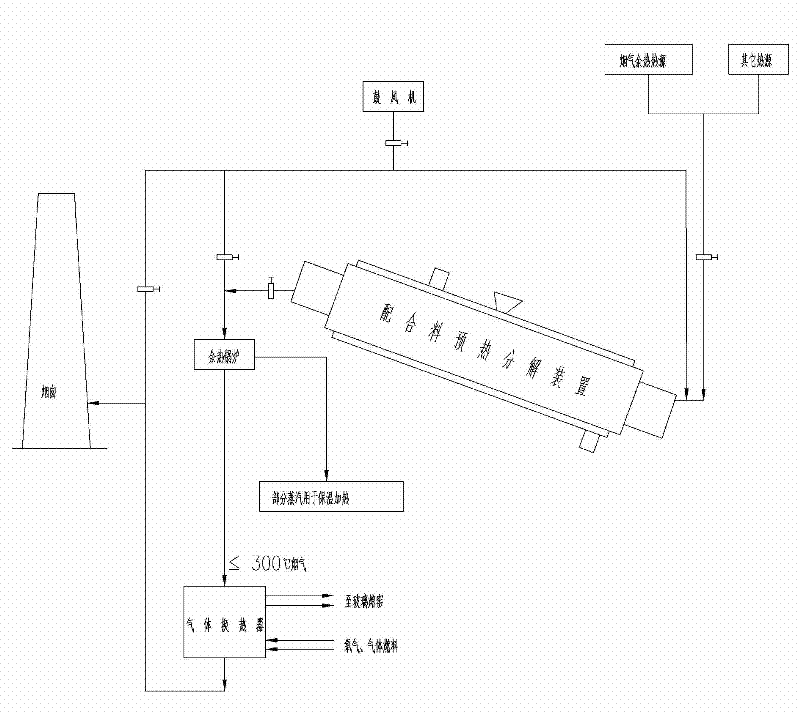

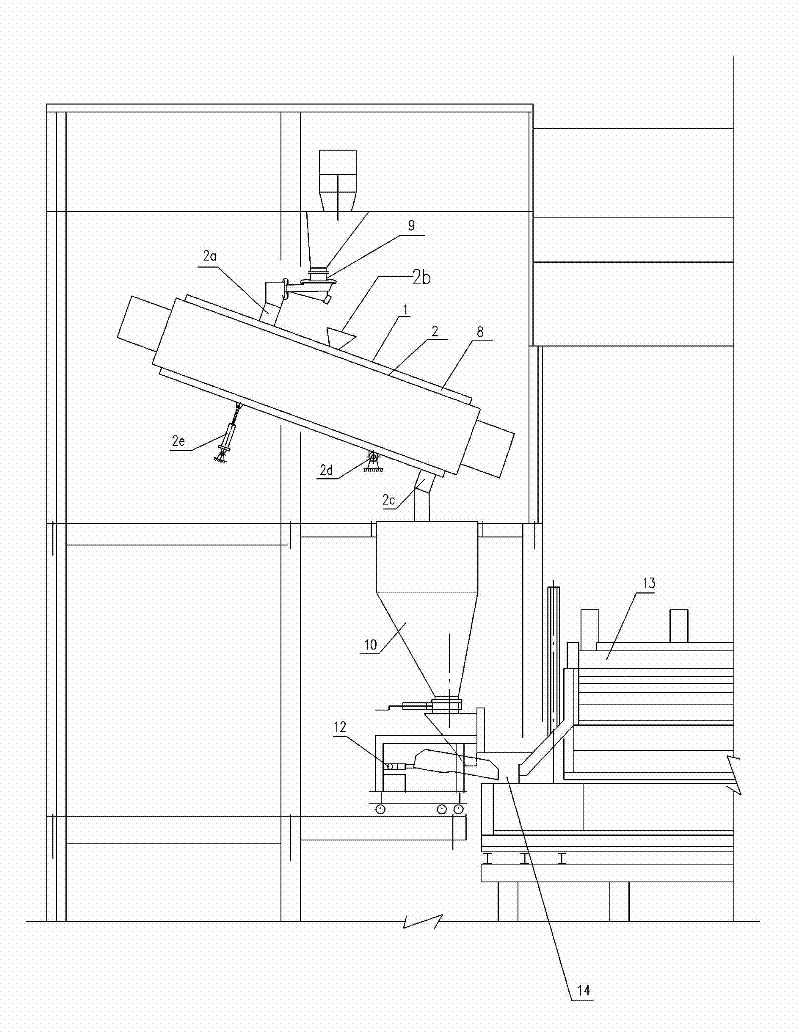

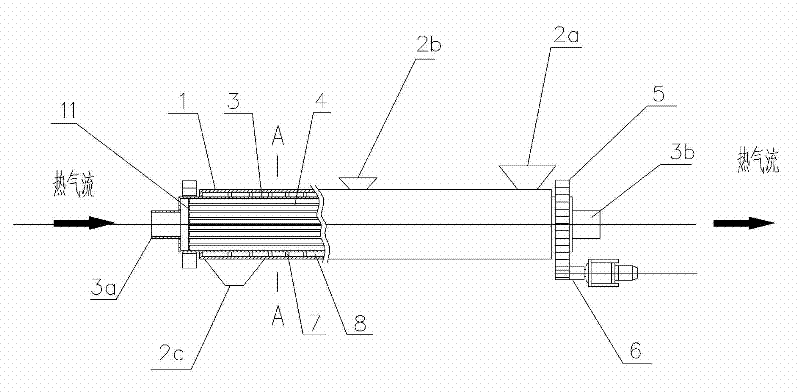

Flue gas latent energy recovery method in glass smelting kiln

ActiveCN102336510AStable deliveryAvoid layeringGlass furnace apparatusGlass productionThermal energyEnergy recovery

The invention relates to a high-temperature flue gas latent energy recovery method in a glass smelting kiln, comprising the following three stages of: 1, regulating the high-temperature flue gas led out from the glass smelting kiln to 800-1000 DEG C, conveying the regulated flue gas into a batch preheating and decomposing device to preheat and decompose the batch at outside of the kiln, and heating up the batch from room temperature to 280-608 DEG C; 2, introducing the flue gas, which is not more than 608 DEG C and is processed in the batch preheating and decomposing device, into an exhaust-heat boiler; 3, introducing the flue gas, which is not more than 300 DEG C and is processed in the exhaust-heat boiler, into a gas heat exchanger, and heating the combustion-supporting gas. With the method, energy consumption of glass smelting is reduced, energy is saved, and dust emission is reduced; fuel and combustion-supporting oxygen can be further saved by not less than 20%; thermal energy of the flue gas is recovered fully; and the batch preheating and decomposing device can shorten a pre-smelting section of the smelting kiln and reduce investment on the kiln.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

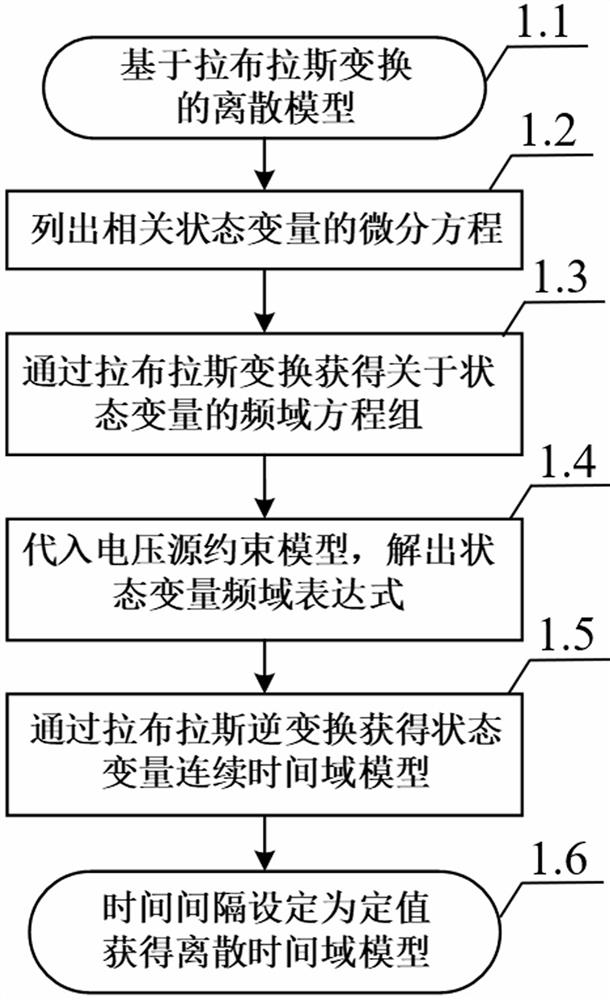

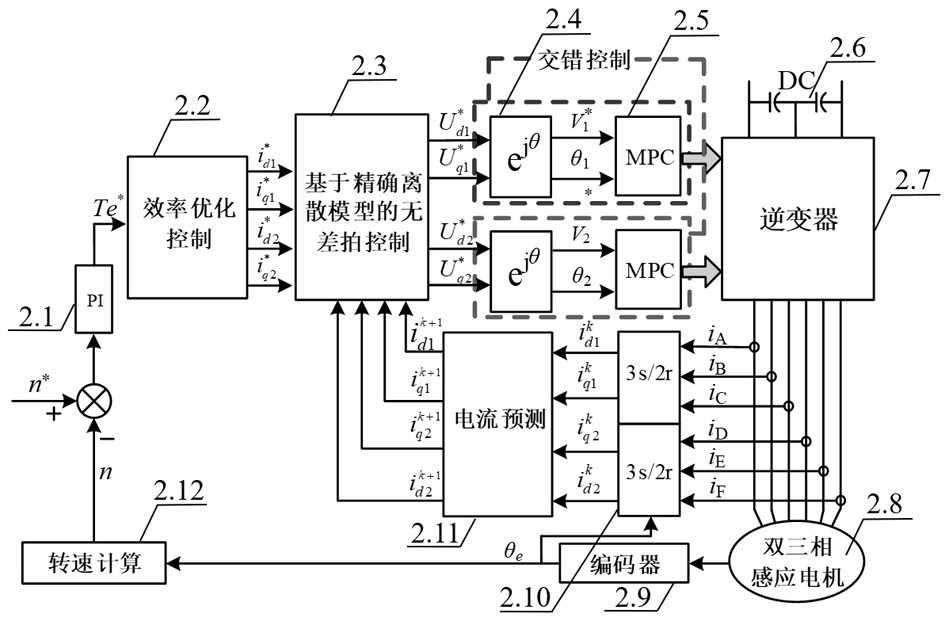

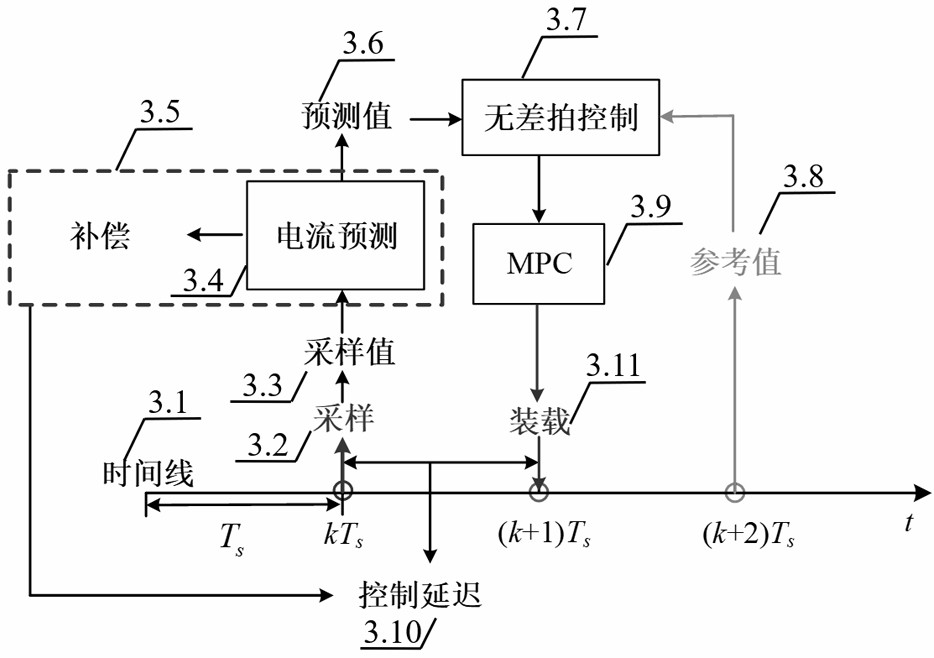

Discrete modeling and control method of dual three-phase induction motors under low switching frequency

ActiveCN111817627AEasy to controlReduce switching frequencyElectronic commutation motor controlAC motor controlMathematical modelSwitching frequency

The invention discloses a discrete modeling and control method for double three-phase induction motors under low switching frequency, and belongs to the field of electricians, motors and power electronics. Aiming at a low switching frequency working condition, the discrete modeling method provided by the invention obtains a motor discrete mathematical model which is more accurate than traditionalEuler discrete modeling by means of Laplace transformation and the like. Meanwhile, the double-winding staggered model predictive control method provided by the invention makes full use of the characteristic of high control freedom degree of the double three-phase induction motors, halves the control delay caused by low switching frequency through the staggered control of the two sets of three-phase windings, reduces the time span of predictive control, effectively improves the control effect, and reduces the switching frequency. According to the positive and negative small vector interleavingcontrol, two inverters are set to preferentially output opposite redundant small vectors, so that the change rate of the midpoint voltage of the bus is reduced, and the switching frequency is furtherreduced.

Owner:华夏天信智能物联股份有限公司

Electrochromic device based on nanocrystalline materials

InactiveUS7508009B2Change color quicklyEnhance memoryNanoopticsNon-linear opticsPotential differenceEngineering

An electrochromic device, comprising a first electrode (3), a second electrode (5) and an electrolyte (4) separating the electrodes (3, 5), where at least one of said first and second electrodes includes an electrically active structure which have an at least dual state visual appearance depending on the potential difference between the first and the second electrode.

Owner:NTERA LTD (IE)

Cultivation method for increasing survival rate of paeonia suffruticosa

InactiveCN107197739AGrow fastImprove survival rateCalcareous fertilisersAnimal corpse fertilisersSocial benefitsPaeonia suffruticosa

The invention discloses a cultivation method for increasing the survival rate of paeonia suffruticosa, and relates to the field of planting technologies for paeonia suffruticosa. The cultivation method includes steps of (1), selecting lands; (2), clearing the lands; (3), selecting seeds; (4), treating the seeds; (5), sowing the seeds; (6), carrying out transplanting; (7), applying fertilizers. The cultivation method has the advantages of high growth speed, survival rate and ornamental value, gorgeous flower colors and excellent economic and social benefits.

Owner:ANHUI MEILAN LANDSCAPE ENG CO LTD

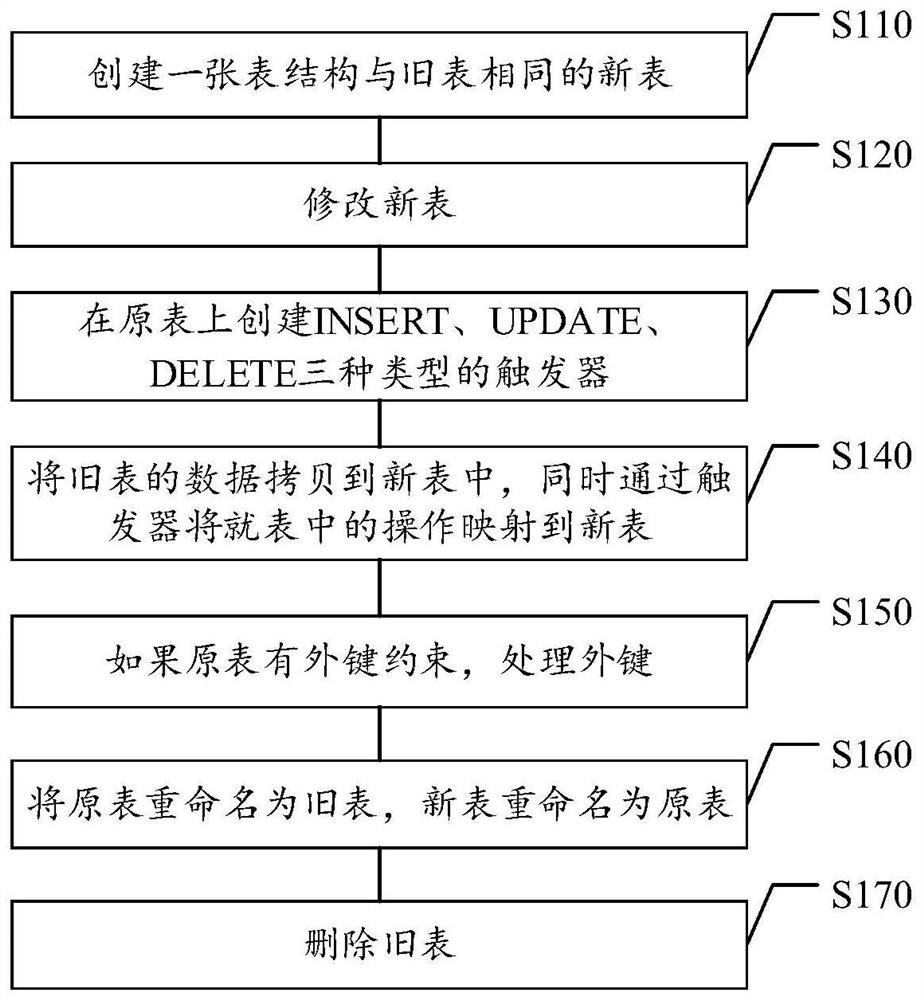

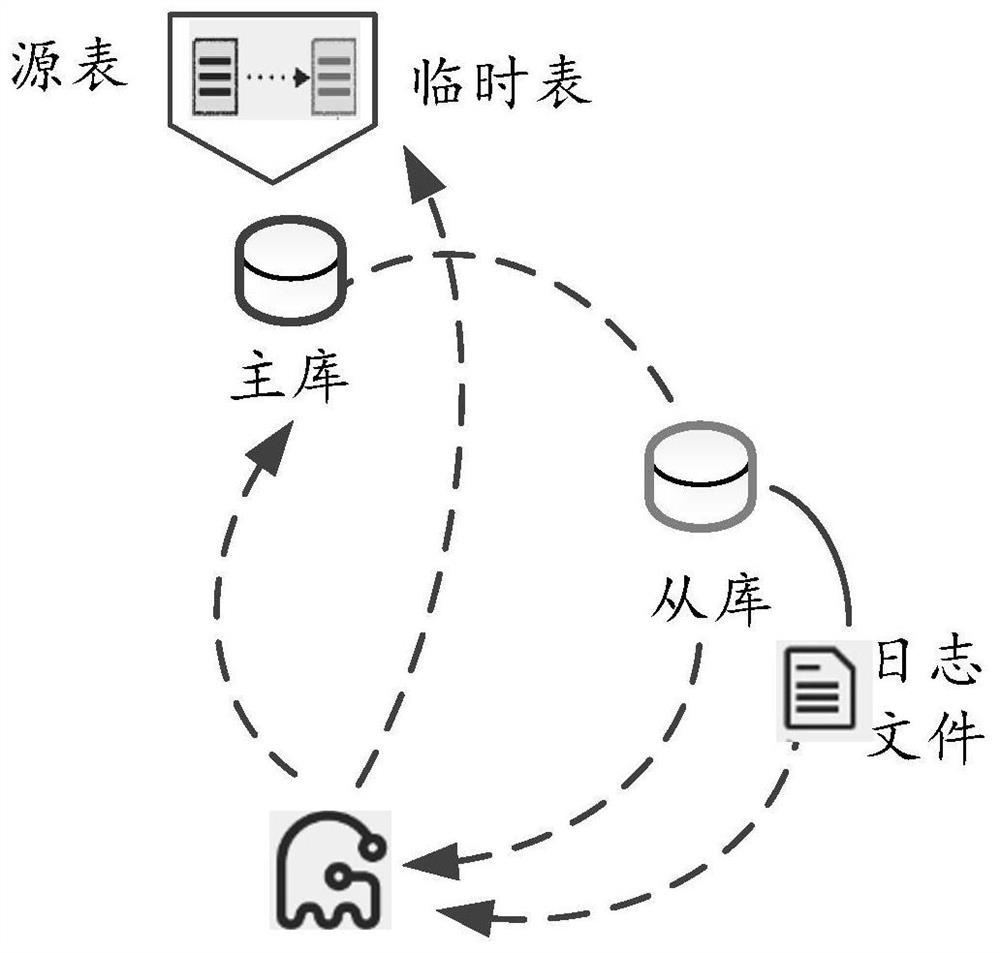

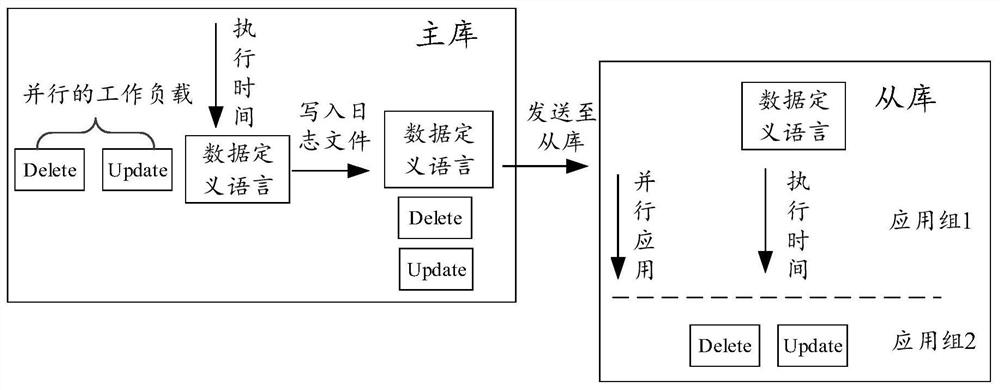

Index creation method and device, electronic equipment and storage medium

PendingCN111752901AImprove service reliabilityShorten the time spanRelational databasesFile system functionsLogfileTable (database)

The embodiment of the invention provides an index creation method and device, electronic equipment and a storage medium, and relates to the technical field of databases. The method comprises the stepsof obtaining a database index creation statement, and writing the database index creation statement into a first system table; writing the database index creation statement into the first log file, and sending log information corresponding to the database index creation statement in the first log file to a slave library so that the slave library plays back the log information; and reading the database index creation statement from the first system table, and executing the database index creation statement. According to the invention, the time for a master library and a slave library to integrally complete index creation can be shortened.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Method and magnetic resonance tomography apparatus for triggered acquisition of magnetic resonance data

ActiveUS8519706B2Reliable and disruption-free data acquisitionShorten the time spanElectrocardiographyMagnetic measurementsData setResonance

In a method and magnetic resonance tomography apparatus for triggered implementation of a measurement (composed of partial measurements) in the magnetic resonance tomography apparatus, at least one image data set is determined from the data acquired within the scope of the partial measurements, and for triggering a reference point of the movement phase of the movement is used. The image data set is acquired in segments; the reference point is detected by a control device independent of a partial measurement, and the partial measurement following the detected reference point is conducted depending on the independently detected reference point. The wait time that specifies the interval from the end of the partial measurement to the beginning of the next partial measurement is adapted depending on the point in time of detection.

Owner:SIEMENS HEALTHCARE GMBH

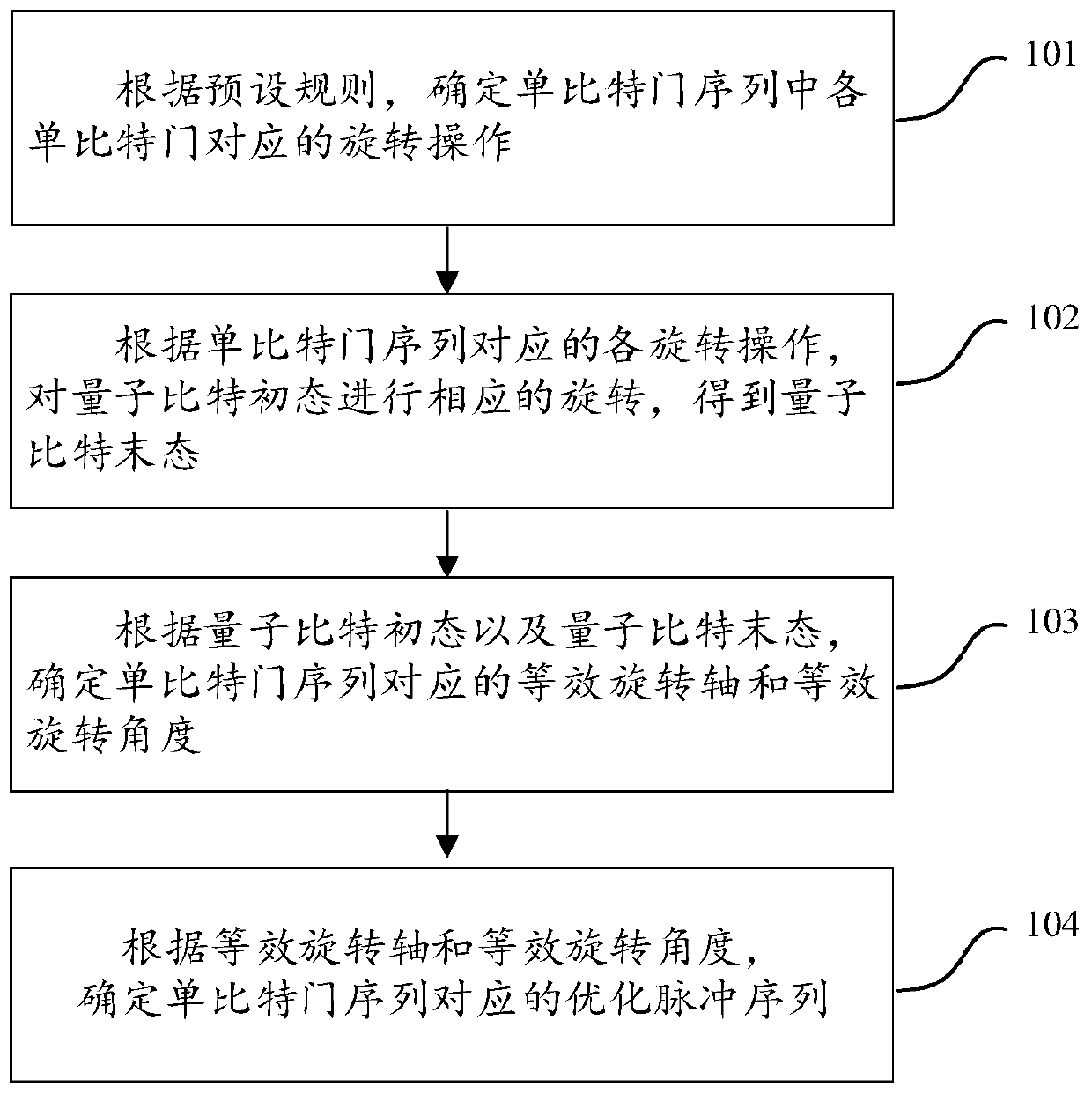

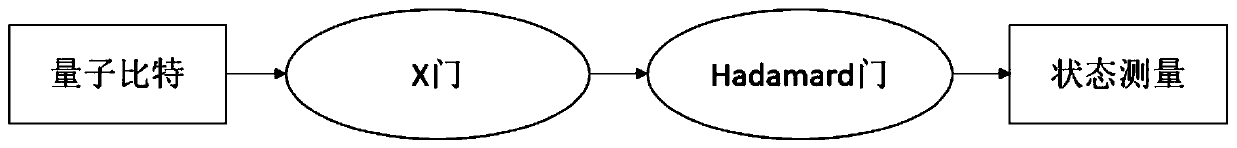

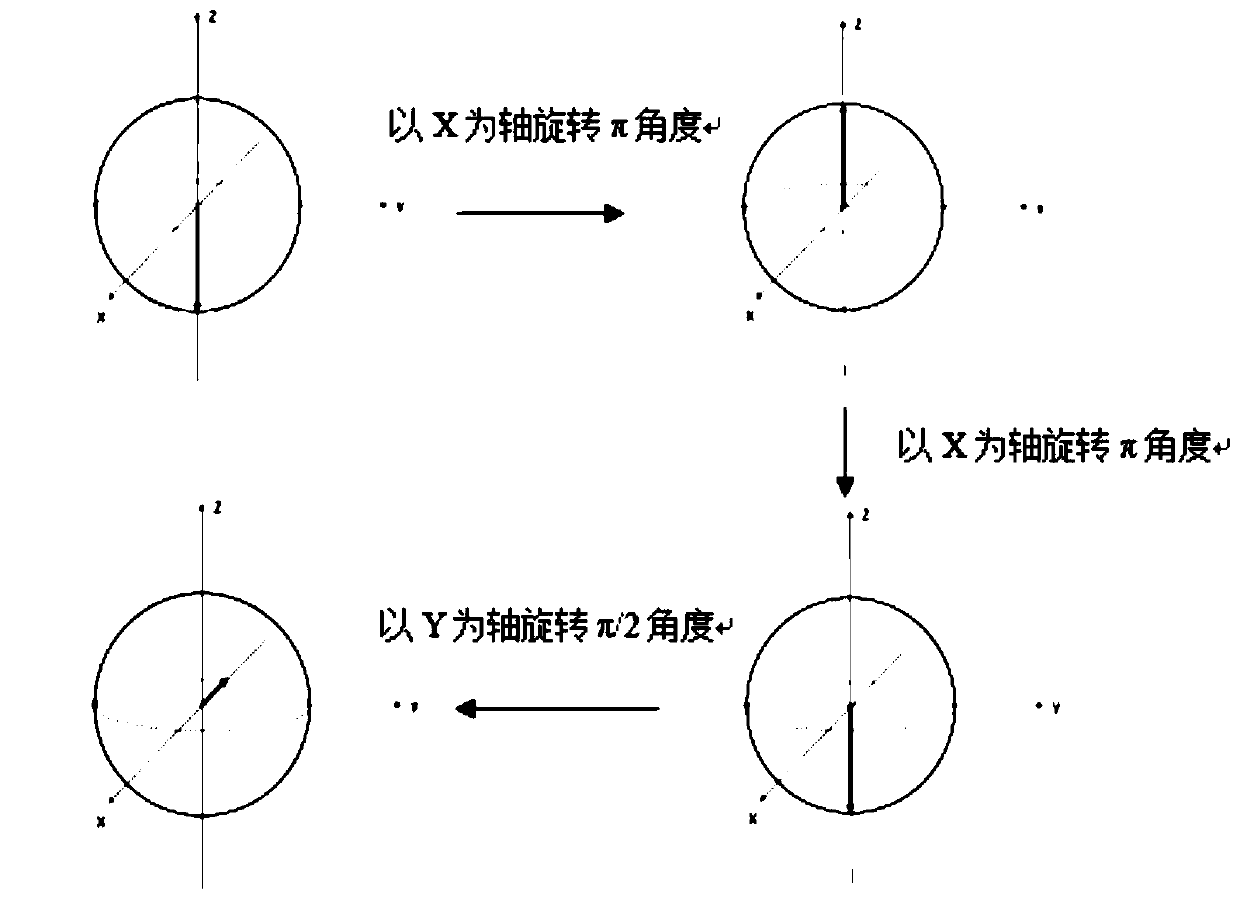

Optimization method and device for calculating single-bit gate sequence by superconducting quantum, and medium

ActiveCN111275196AReduce in quantityShorten the time spanQuantum computersEnergy efficient computingMicrowaveParticle physics

The invention discloses an optimization method and device for calculating single-bit gate sequence by superconducting quantum, and a medium, and is used for solving the problems that the time span ofan input microwave pulse sequence is too long, quantum bit degradation is caused, and the uncertainty of a superconducting quantum calculation result is caused. The method comprises the following steps: determining a rotation operation corresponding to a single-bit gate sequence according to a preset rule; according to each rotation operation corresponding to the single-bit gate sequence, correspondingly rotating the initial state of the quantum bit to obtain a final state of the quantum bit; determining an equivalent rotation axis and an equivalent rotation angle corresponding to the single-bit gate sequence according to the quantum bit initial state and the quantum bit final state; and determining an optimized pulse sequence corresponding to the single-bit gate sequence according to theequivalent rotation axis and the equivalent rotation angle. According to the method, the time span of microwave pulse input corresponding to the single-bit gate sequence can be shortened, so that thesame quantum bit final state can be obtained on the premise that the decoherence degree of quantum bits is minimum, and the calculation accuracy is improved.

Owner:SHANDONG INSPUR SCI RES INST CO LTD

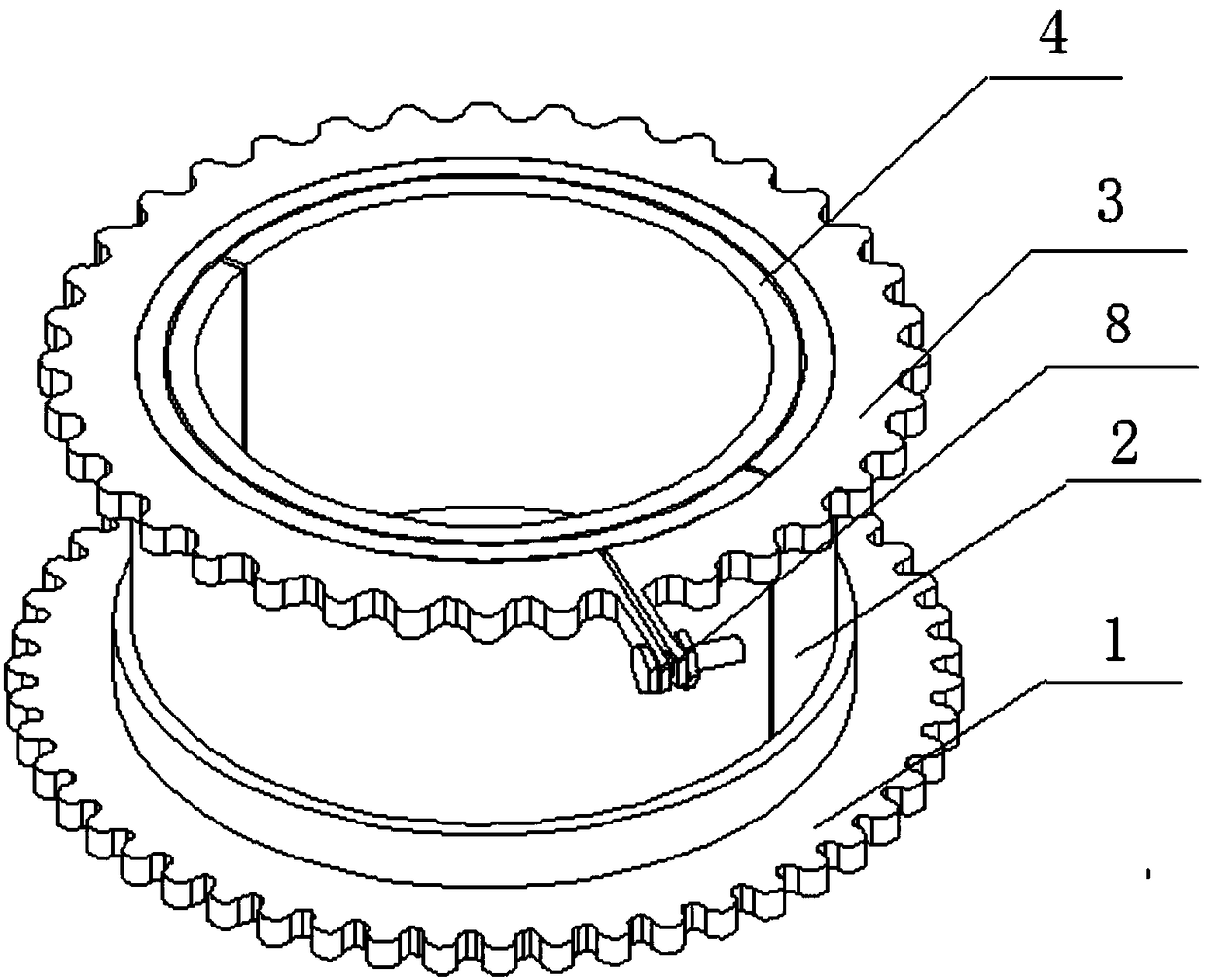

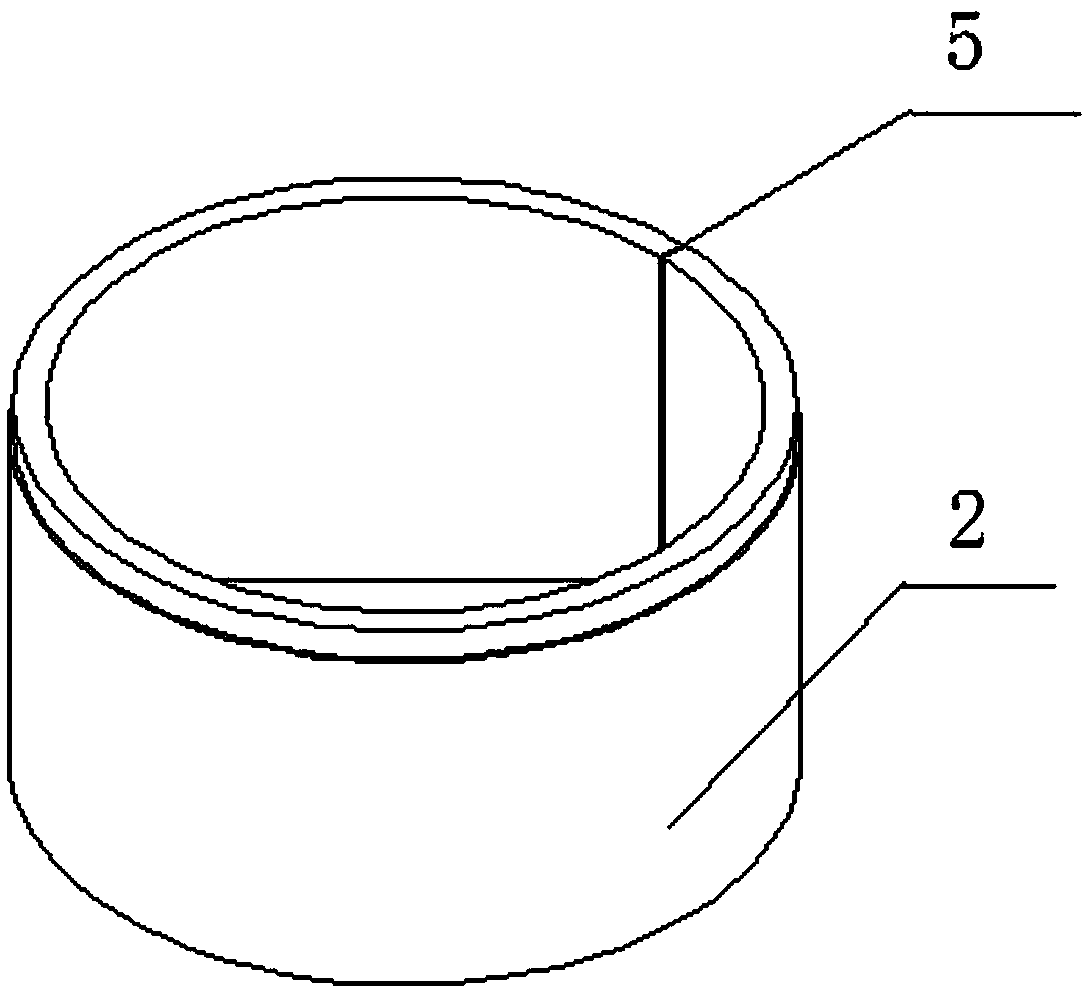

Mould and method for preparing permeable concrete permeation coefficient measuring sample

PendingCN109115582AEasy to manufactureEasy to disassemble and cleanPreparing sample for investigationEngineeringPermeation

The invention discloses a mould and a method for preparing a permeable concrete permeation coefficient measuring sample. The mould comprises a side die, a bottom die and a fastener. The side die is anannular structure. The side part of the annular structure is provided with a gap along an axis direction thereof. An inner layer of the side die is provided with a layer of a rubber skin layer. The side part of the rubber skin layer is also provided with a gap along the axis direction thereof. The side die is locked on the bottom die, so the bottom of the side die is closed. The fastener is locked on an outer circle of the side die and used for fastening the side die.

Owner:广西建设职业技术学院

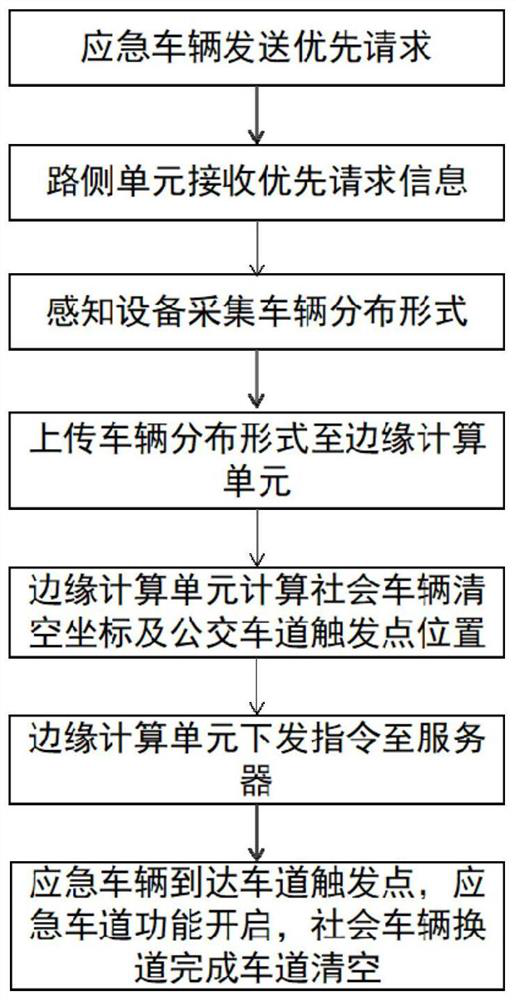

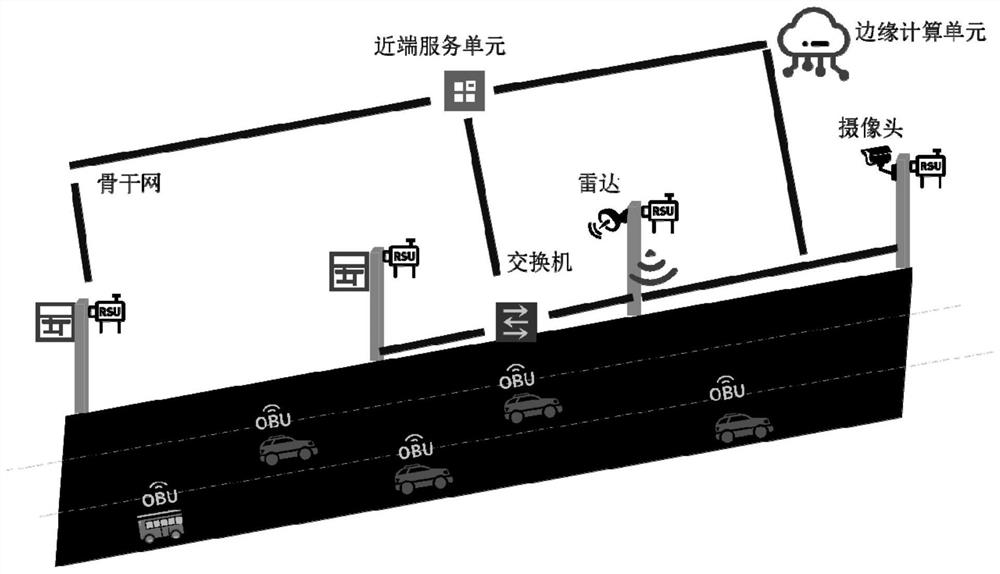

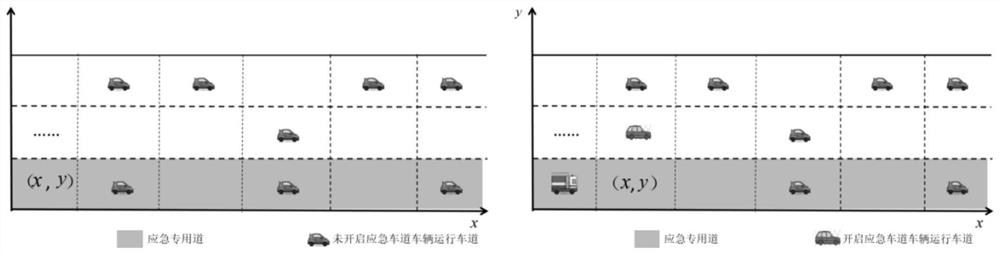

Emergency vehicle priority passing control method based on intelligent network connection environment

PendingCN113920762ASolve function open timeShorten the time spanDetection of traffic movementTransmissionIntelligent NetworkEdge computing

The invention discloses an emergency vehicle priority passing control method based on an intelligent network connection environment, relates to the technical field of urban intelligent traffic, solves the technical problem that an existing emergency vehicle cannot pass smoothly preferentially, and the method comprises the following steps: step 1, an emergency vehicle running at a set speed sends a priority passing signal, the road side unit receives the priority request information; 2, a roadside sensing unit collects a lane vehicle distribution state and uploads the lane vehicle distribution state to an edge computing unit; 3, the edge computing unit calculates an emergency lane inspiration point and lane changing coordinates of social vehicles according to the position and speed of the emergency vehicle and the distribution pattern of the vehicles on the lane and sends the emergency lane inspiration point and the lane changing coordinates to a near-end server; 4, the near-end server issues the information to each vehicle, and the social vehicle starts to be emptied according to the planned position when the emergency vehicle runs to the trigger point; the defect that no emergency lane is arranged on an urban road is overcome, and the running speed and rescue quality of emergency vehicles are improved.

Owner:湖南湘江智能科技创新中心有限公司

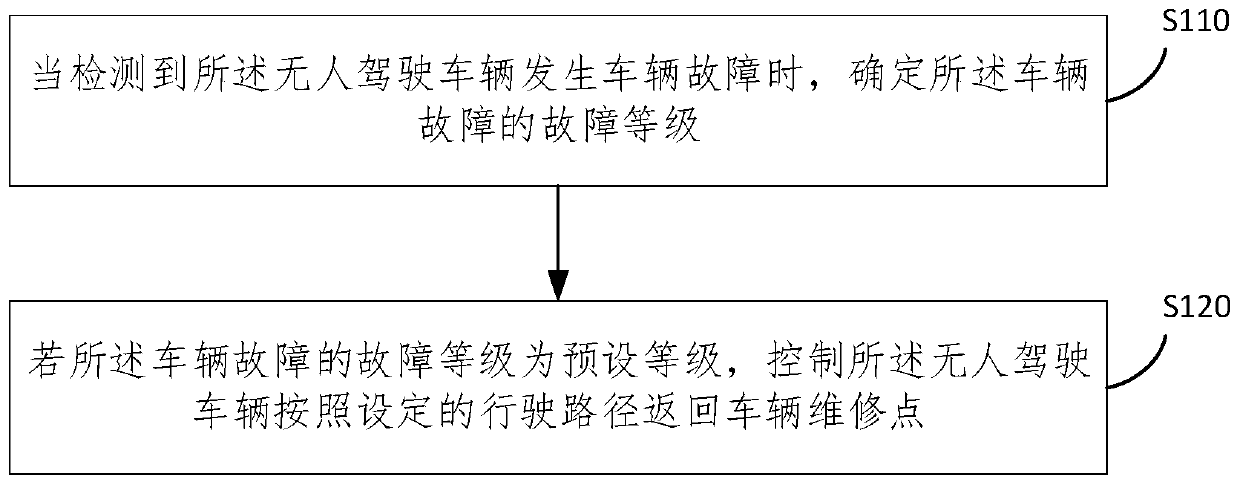

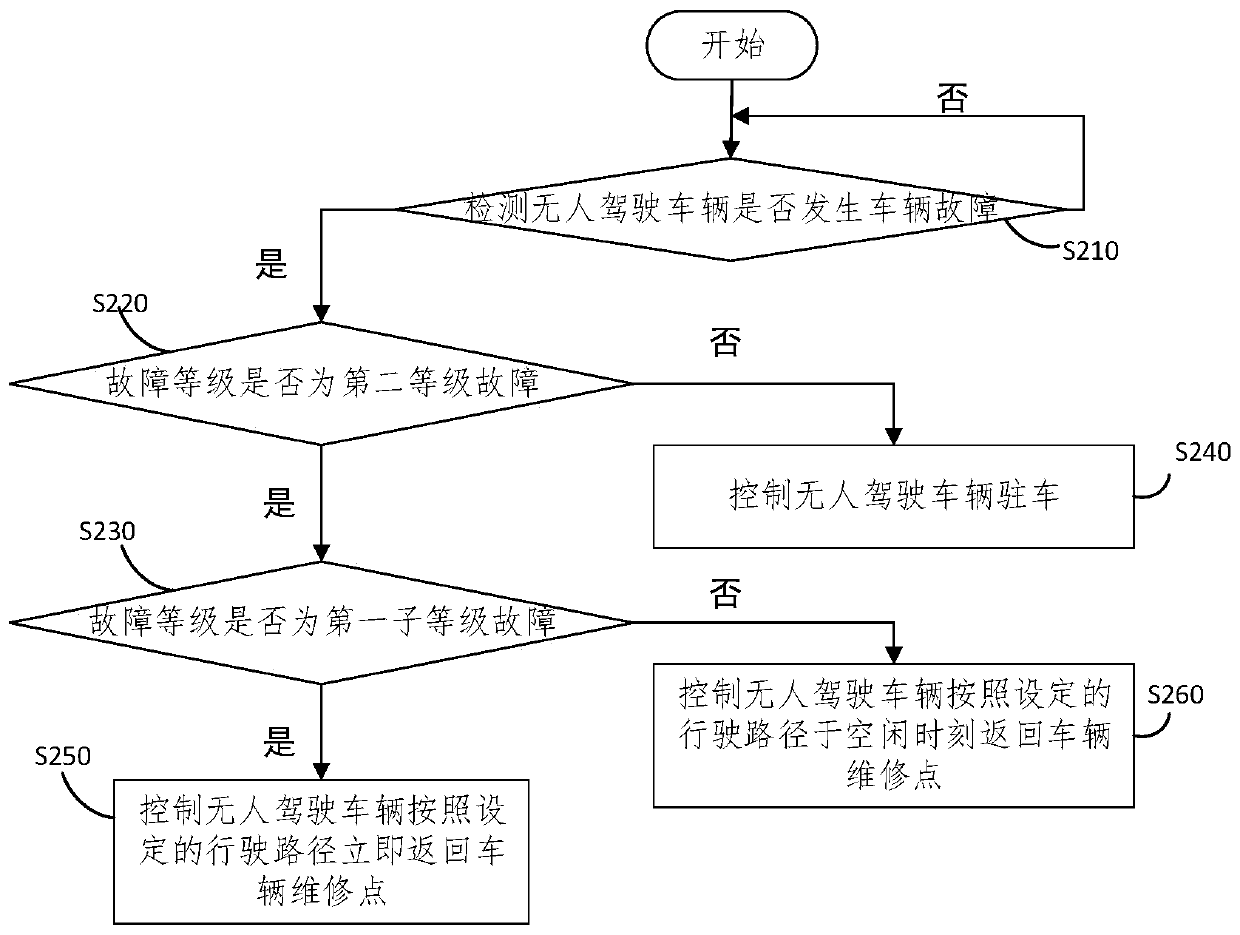

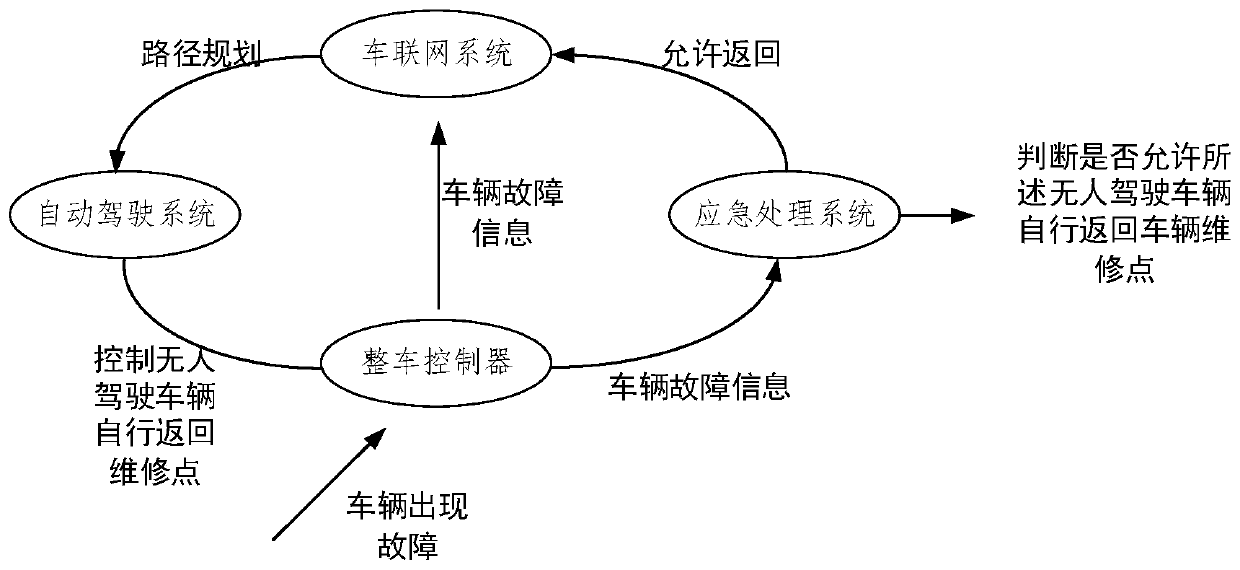

Unmanned vehicle fault processing method and device, electronic equipment and storage medium

InactiveCN111123887AShorten the time spanReduce maintenance costsRegistering/indicating working of vehiclesElectric testing/monitoringReliability engineeringReal-time computing

An embodiment of the invention relates to an unmanned vehicle fault processing method and an unmanned vehicle fault processing device, electronic equipment and a storage medium. The unmanned vehicle fault processing method comprises the steps of: determining a fault level of a vehicle fault when the vehicle fault of an unmanned vehicle is detected; and if the fault level of the vehicle fault is apreset level, controlling the unmanned vehicle to return to a vehicle maintenance point according to a set driving path. According to the unmanned vehicle fault processing method and the unmanned vehicle fault processing device, the problems of long time span from fault occurrence to good maintenance, high maintenance cost and easiness in further causing safety accidents in case of vehicle fault of the existing unmanned vehicle can be solved.

Owner:NEOLIX TECH CO LTD

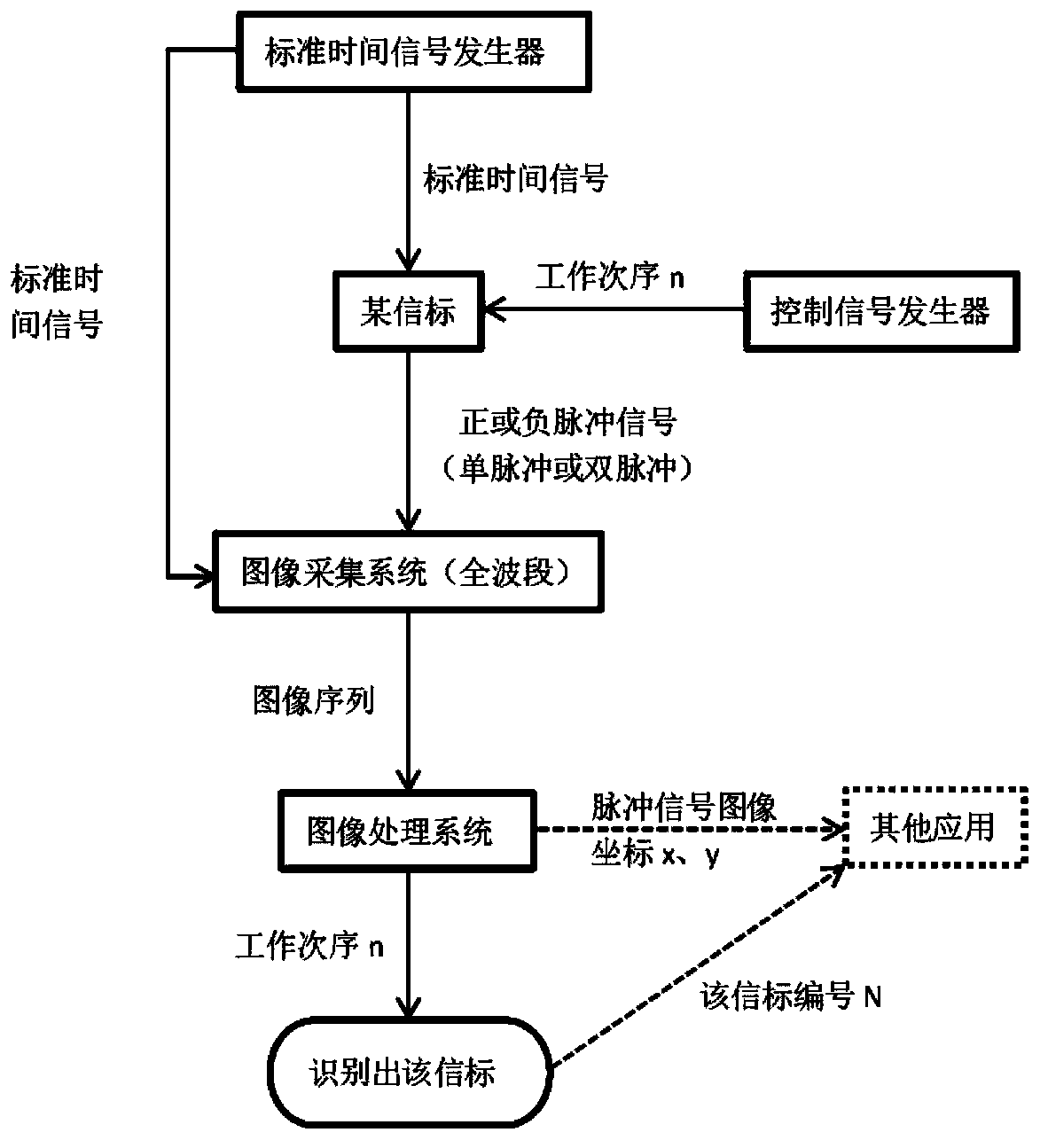

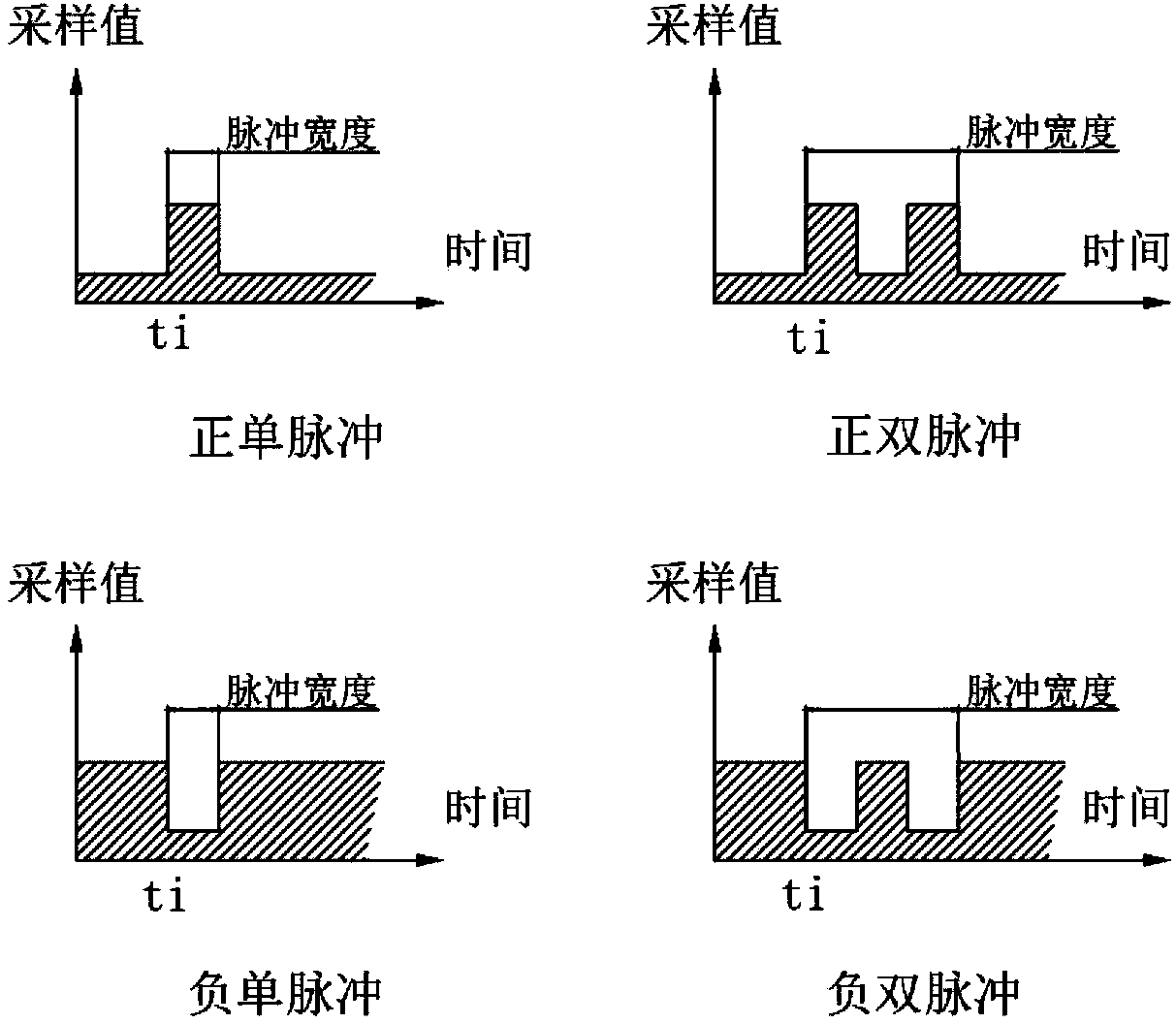

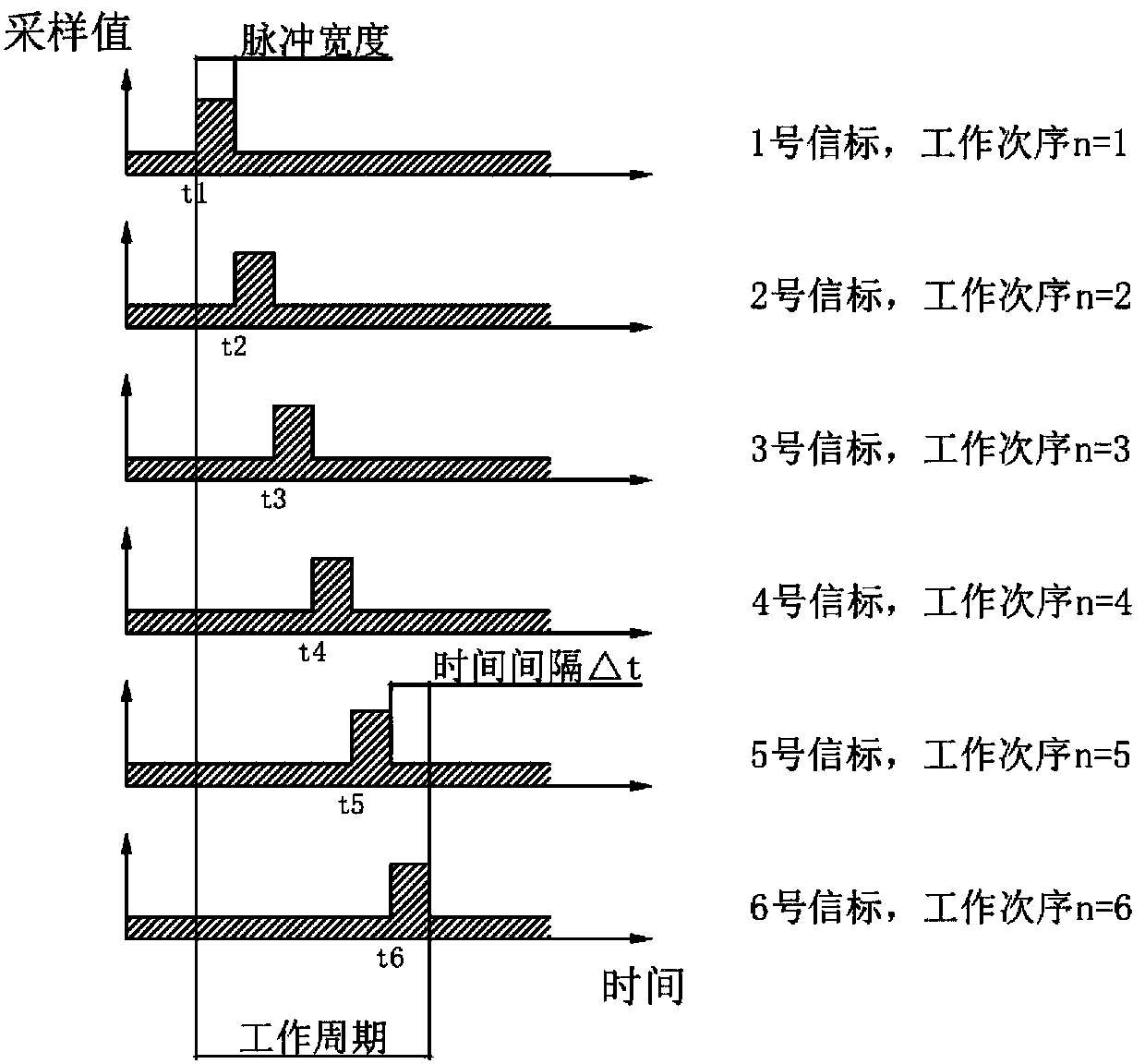

Water lamp beacon rapid identifying system

ActiveCN104331680AImprove recognitionShorten the time spanCharacter and pattern recognitionIdentification systemBeacon

A water lamp beacon rapid identifying system can be used to identify rapidly beacon that is large in terms of amount in environment in the field of computer vision. The system includes a beacon system and an image collecting system, wherein a beacon system consists of a plurality of beacons, and the beacons operate in a water lamp manner, and emit in sequence pulse signals. An image coordinate that a pulse signal occurs and the occurrence time can be obtained through analysis of an image sequence. Since operating sequence of each beacon is known, the image coordinate of the collected pulse signal can be corresponded to a beacon number to thereby implement rapid identification of a larger number of beacons.

Owner:深圳市亿境虚拟现实技术有限公司

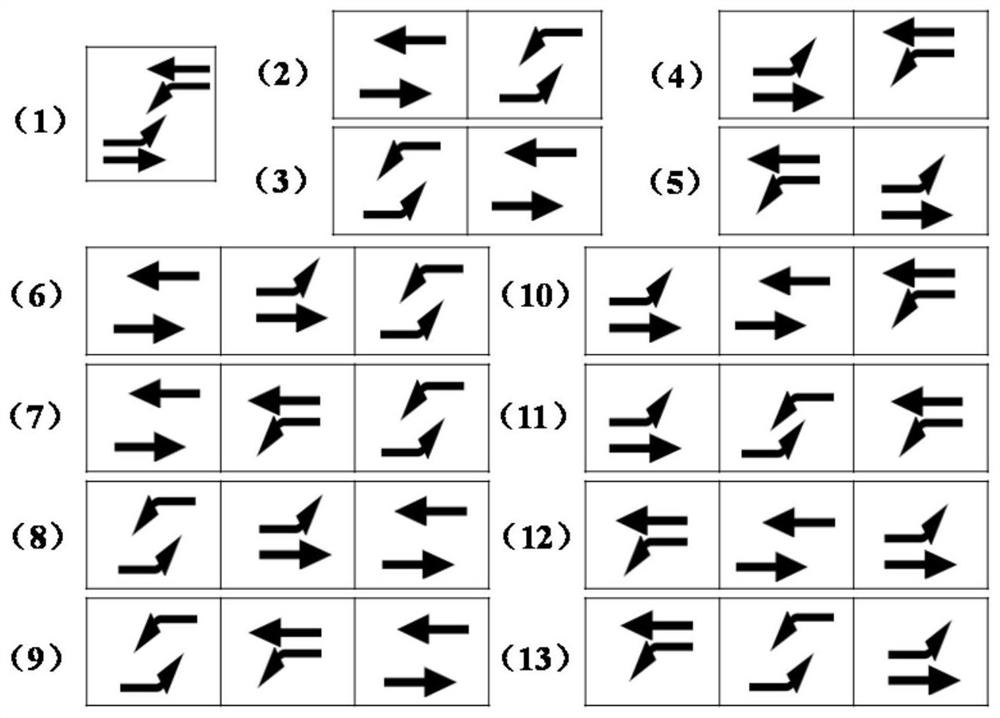

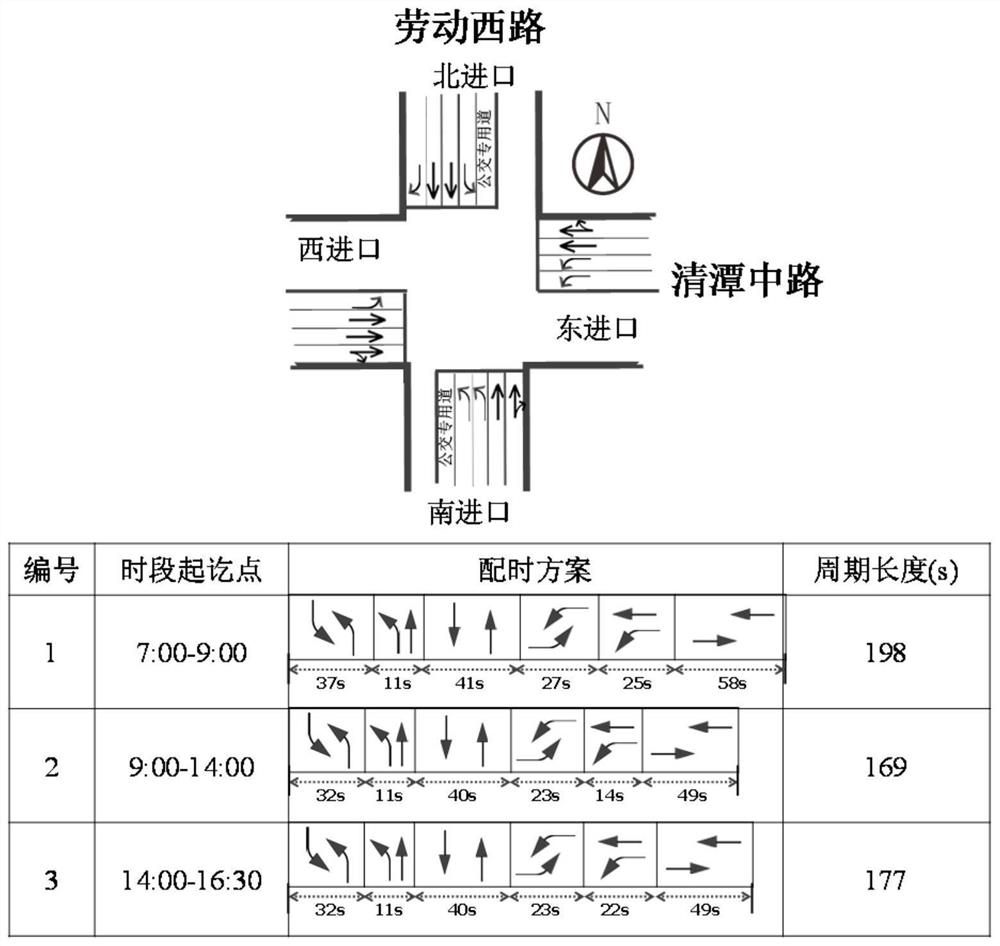

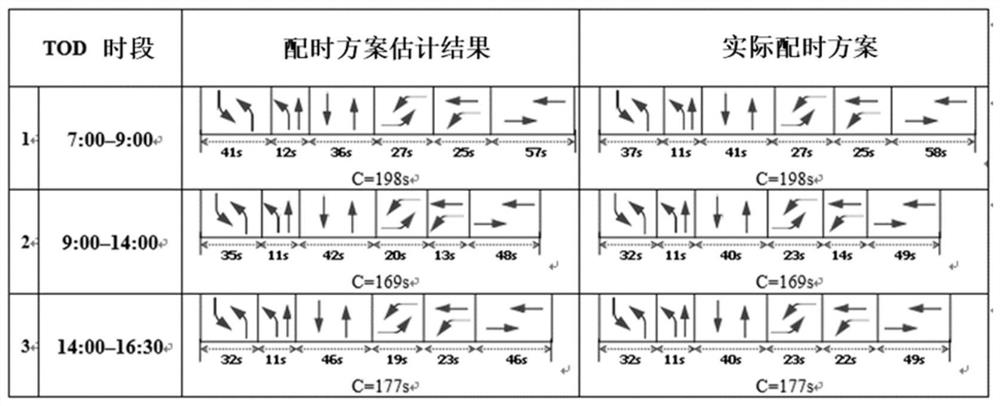

Intersection timing scheme estimation method based on electronic police checkpoint data

ActiveCN112201061AAvoid overestimation errorImprove noise immunityRoad vehicles traffic controlAlgorithmEstimation methods

The invention relates to an intersection timing scheme estimation method based on electronic police checkpoint data. The method comprises the following steps: 1) constructing a double-layer planning problem model for intersection timing scheme estimation; 2) acquiring constraint conditions of period length, phase difference and green signal ratio estimation; 3) for all possible phase combinationsof the controlled flow direction, defining a dumb variable representing the relationship between the turn-on sequence of the green light time of the straight flow direction and the left-turn flow direction and the length of the green light, and obtaining a constraint condition of a phase structure; and 4) solving a double-layer planning problem of intersection timing scheme estimation by adoptinga least square method in combination with constraint conditions of period length, phase difference, phase structure and green signal ratio estimation to obtain a final estimated timing scheme. Compared with the prior art, the method has the advantages of full-parameter estimation, high estimation precision, wide applicability and the like.

Owner:TONGJI UNIV

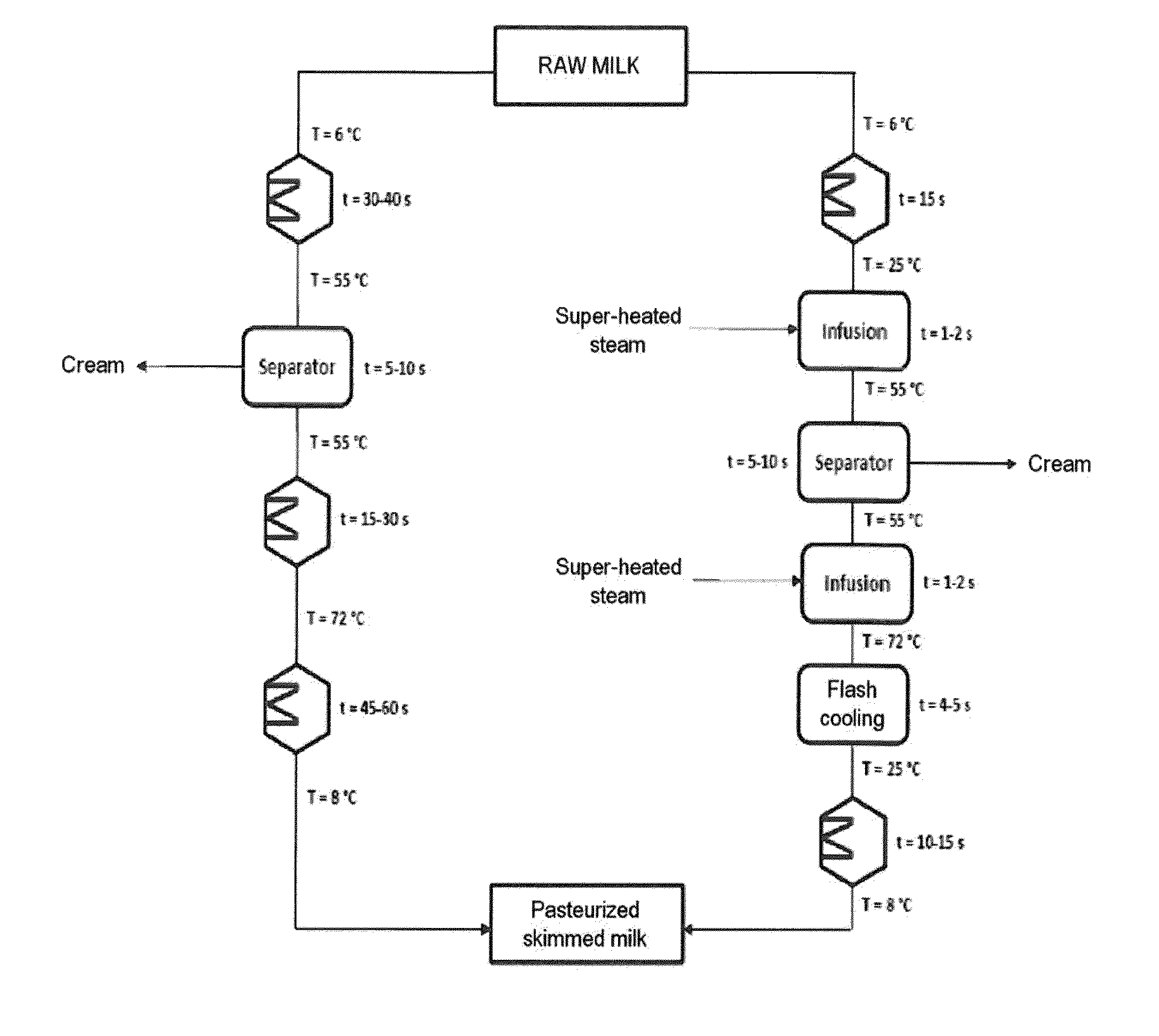

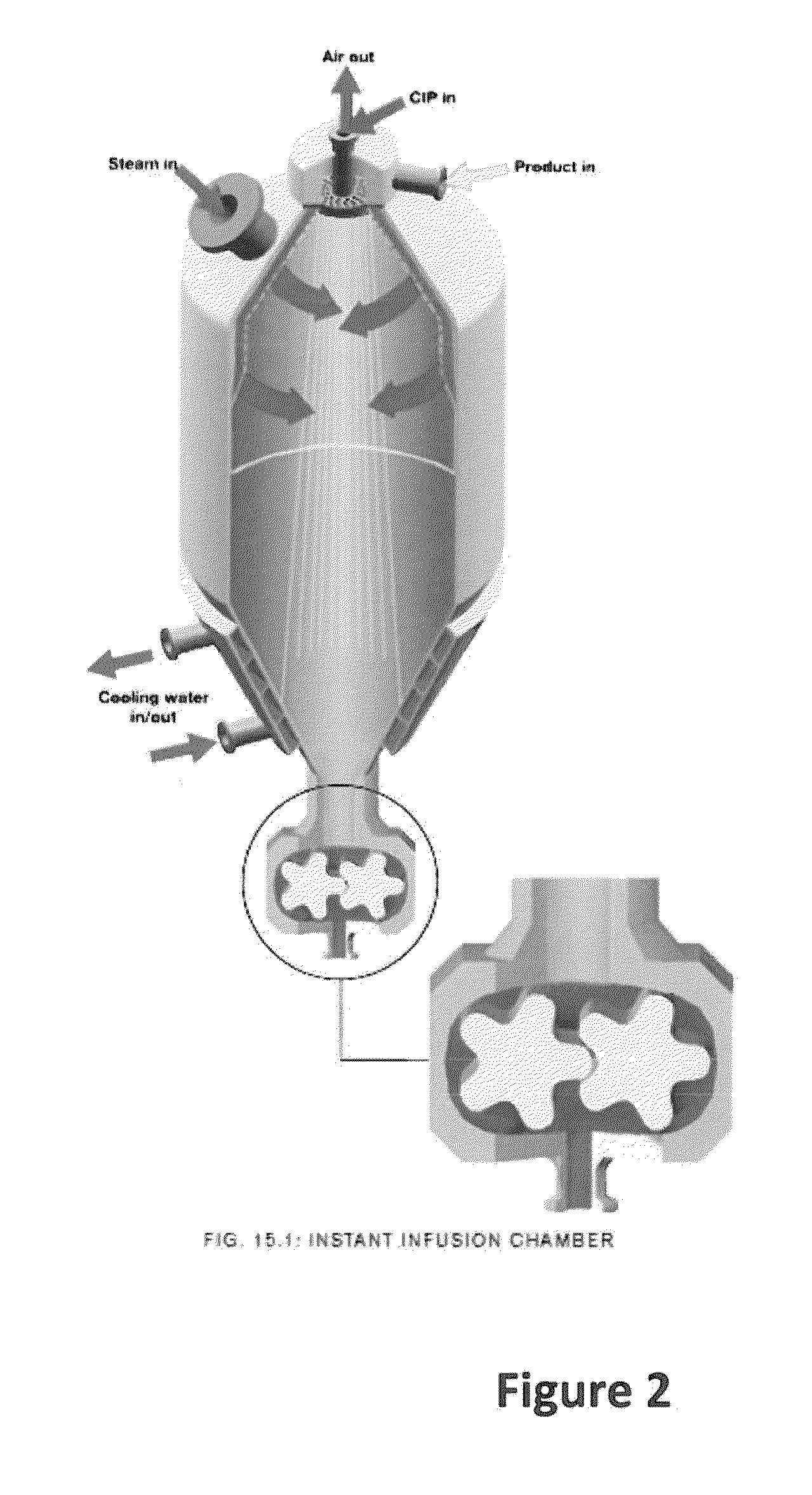

Process for producing low microbial count milk products

ActiveUS20160000100A1Reduce microbial loadPromote microbial growthMilk preparationMilk preservationMicroorganismPre treatment

A process is proposed for producing low microbial count whole milk products, in which(a1) optionally, the milk product from which microbes are to be removed is subjected to a heat pre-treatment in a heat exchanger and warmed to temperatures in the range from 25 to 30° C.,(a2) the optionally pre-treated milk product is heated by infusion to temperatures from 50 to 75° C., and pasteurized in the course thereof, and(a3) the pasteurized product is cooled by flash cooling.A similar method is likewise disclosed for producing low microbial count skimmed milk products which, as the most important intermediate step, further additionally contains the process of separating off the cream.

Owner:DMK DEUT MILCHKONTOR

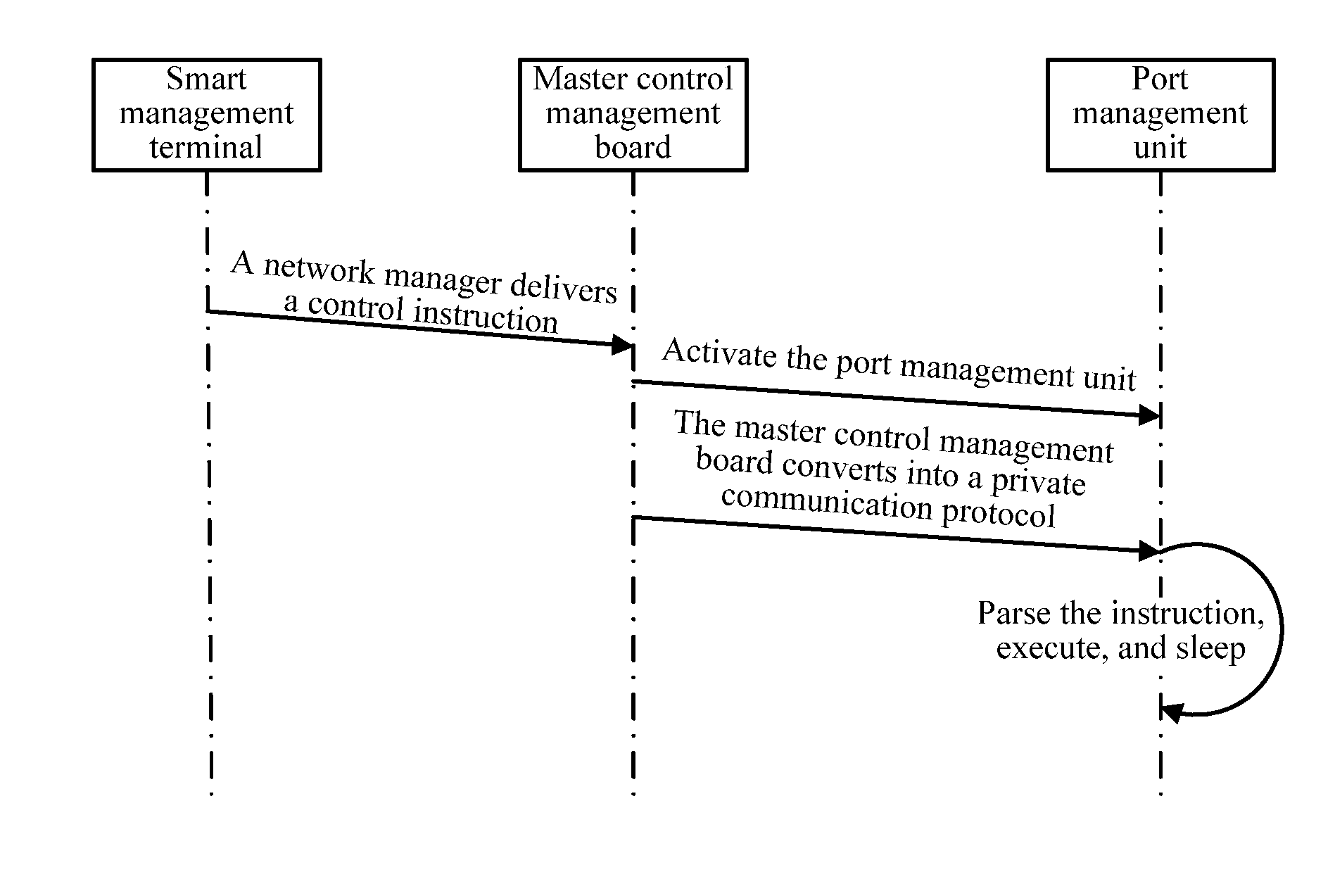

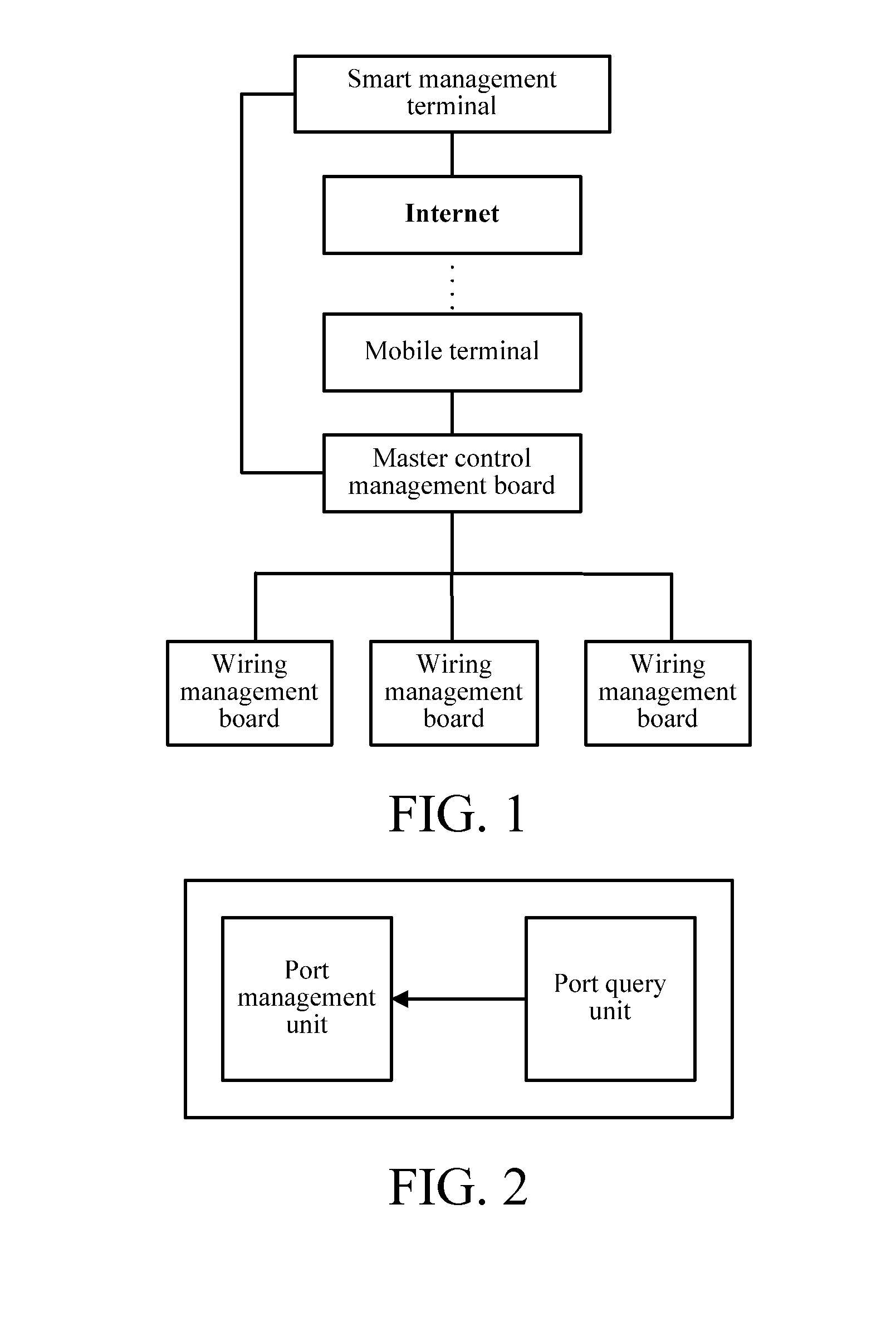

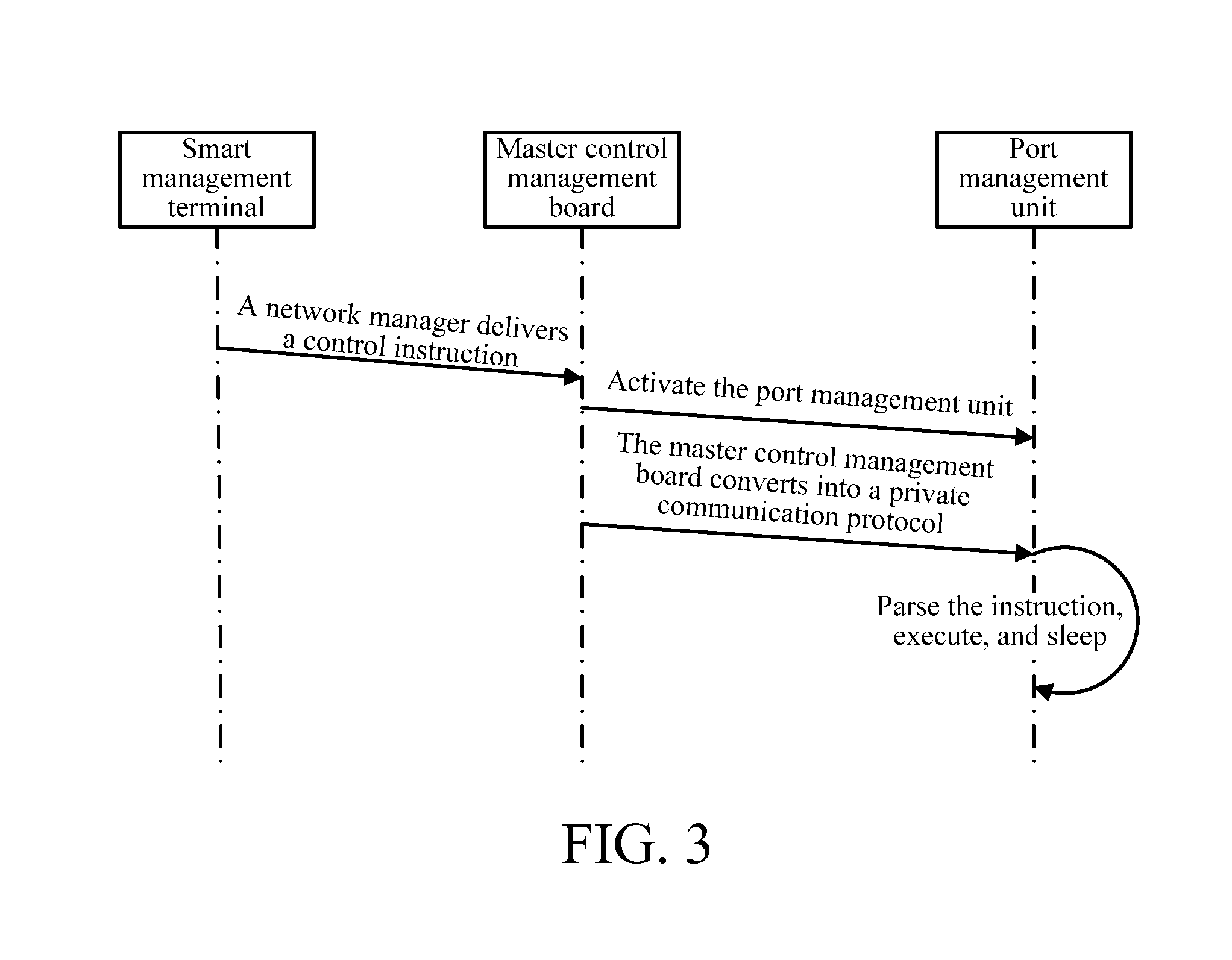

Smart odn system of low power consumption

ActiveUS20150222971A1Doubling operation timeExtend battery lifeMultiplex system selection arrangementsLaser detailsThe InternetControl line

The present invention discloses a smart ODN system of low power consumption, and the system is related to the ODN field and includes a smart management terminal, a master control management board, and several wiring management boards, where the smart management terminal is directly connected to the master control management board, and is also connected to the master control management board through the Internet and a mobile terminal, the master control management board is connected with several wiring management boards, each wiring management board includes a PMU and a PQU, which are independent from each other, the PQU is connected to a CPU of a wiring management board through a control line; the PMU is configured to collect and store information data of a port and communicate with the master control management board or the smart management terminal; the PQU independent from the CPU independently performs the query operation on a wiring port, and promptly obtains a port connection status. The present invention more than doubles operation time of a smart ODN management system, extends battery life of the whole system when a mobile power supply provides power for the system, shortens a time span taken by the system to respond to port changes, and improves operation efficiency of the system.

Owner:FENGHUO COMM SCI & TECH CO LTD

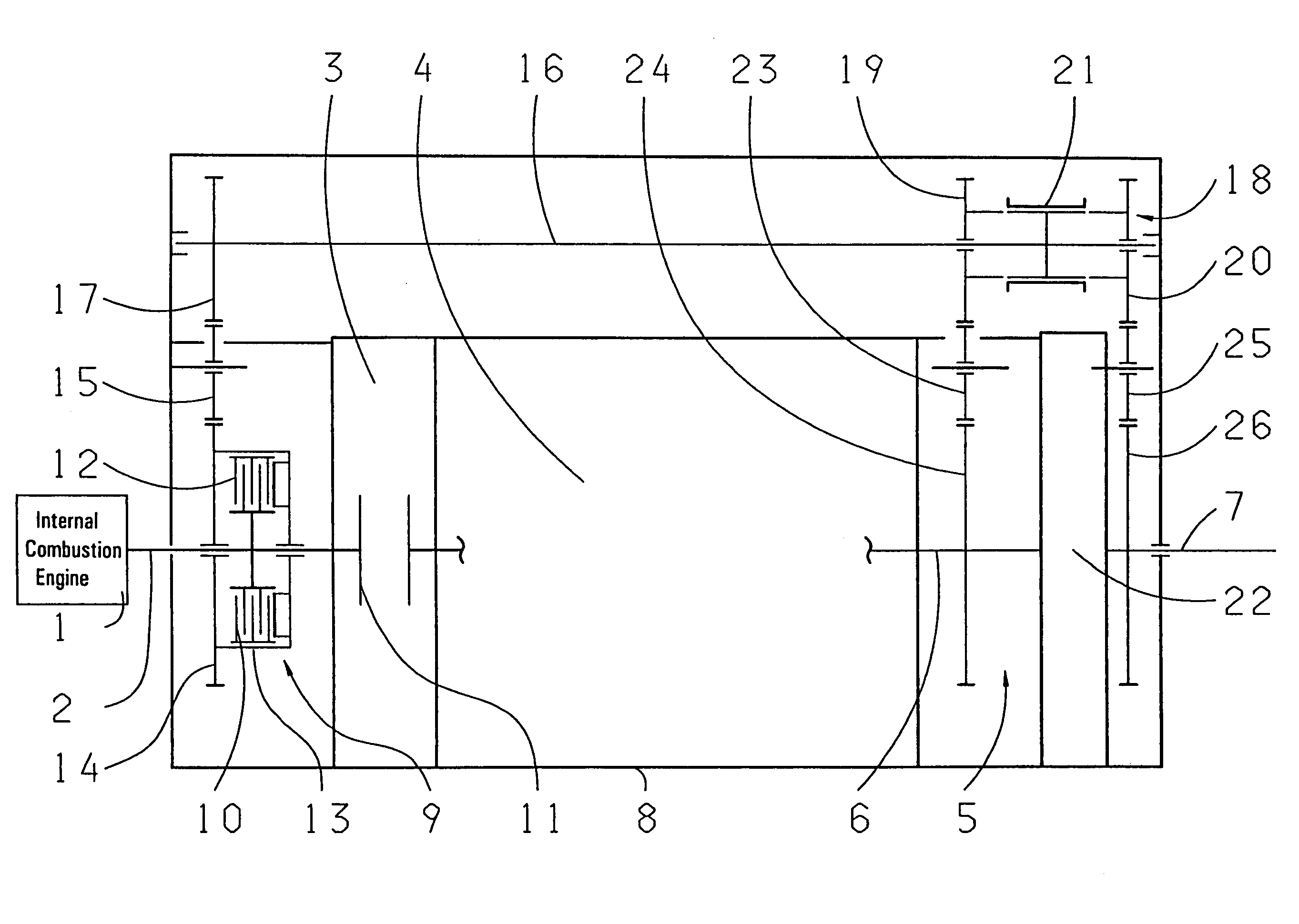

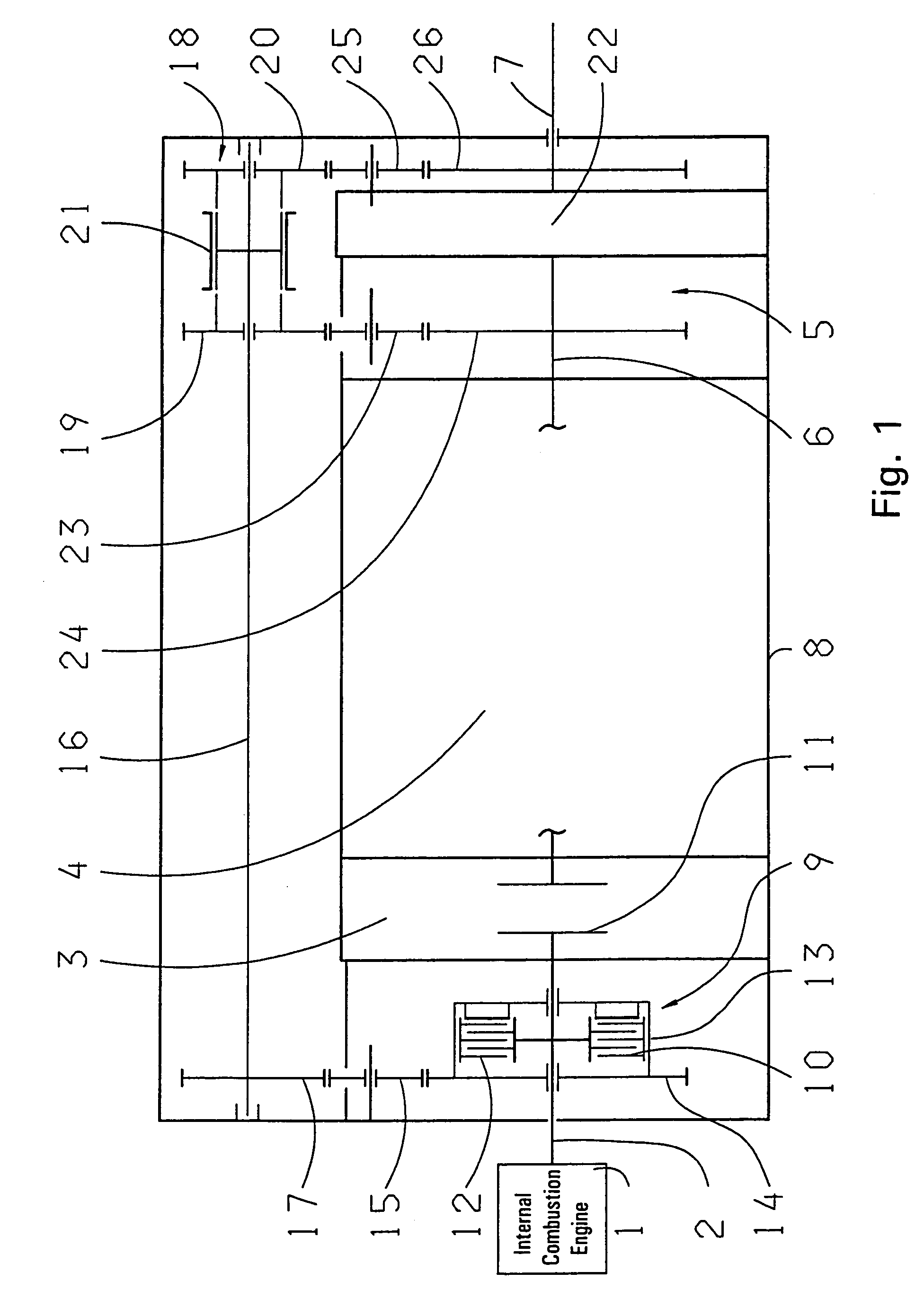

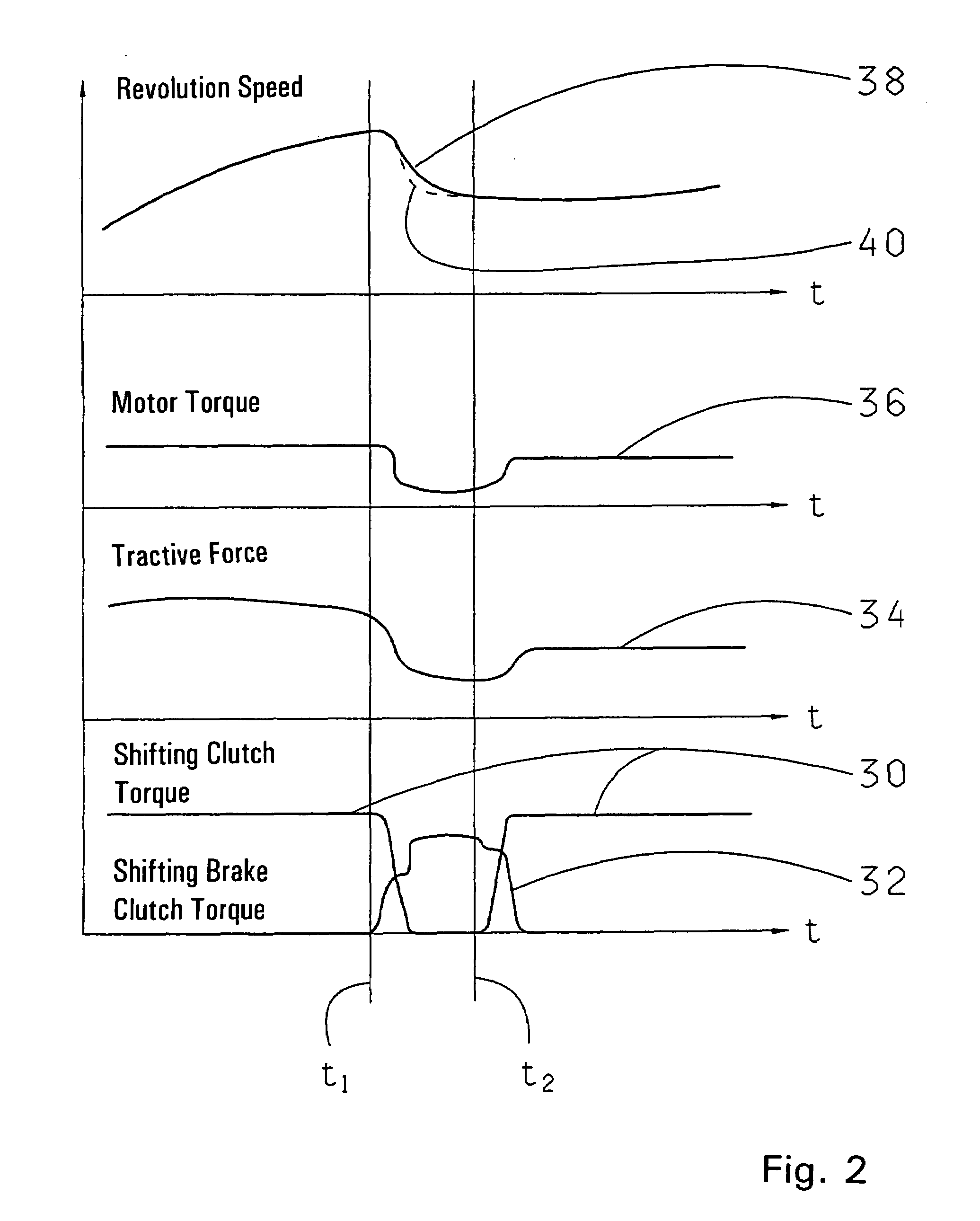

Drive device comprising a gearbox

InactiveUS7461568B2Reduce tractionMain engine torque is advantageously reducedToothed gearingsGearing controlGear wheelEngineering

A drive device for a transmission (4), a main engine and a shifting clutch (3). In order to reduce the phase of tractive force interruption during switching operations, the drive device has a shifting brake clutch (9), located between the engine and the shifting clutch, such that during switching operations, intersecting disengaging and engaging processes of both clutches (3 or 9), provide for support of the main engine torque in a gear output (5).

Owner:ZF FRIEDRICHSHAFEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com