Patents

Literature

503 results about "Dust emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three Controls of Dust Emission in the Desert. 1. Soil moisture binds soil particles together, making the surface more resistant to erosion. 8 Higher temperatures due to climate change could lead to increased evaporation and decreased precipitation, which may boost dust emission from California’s desert regions.

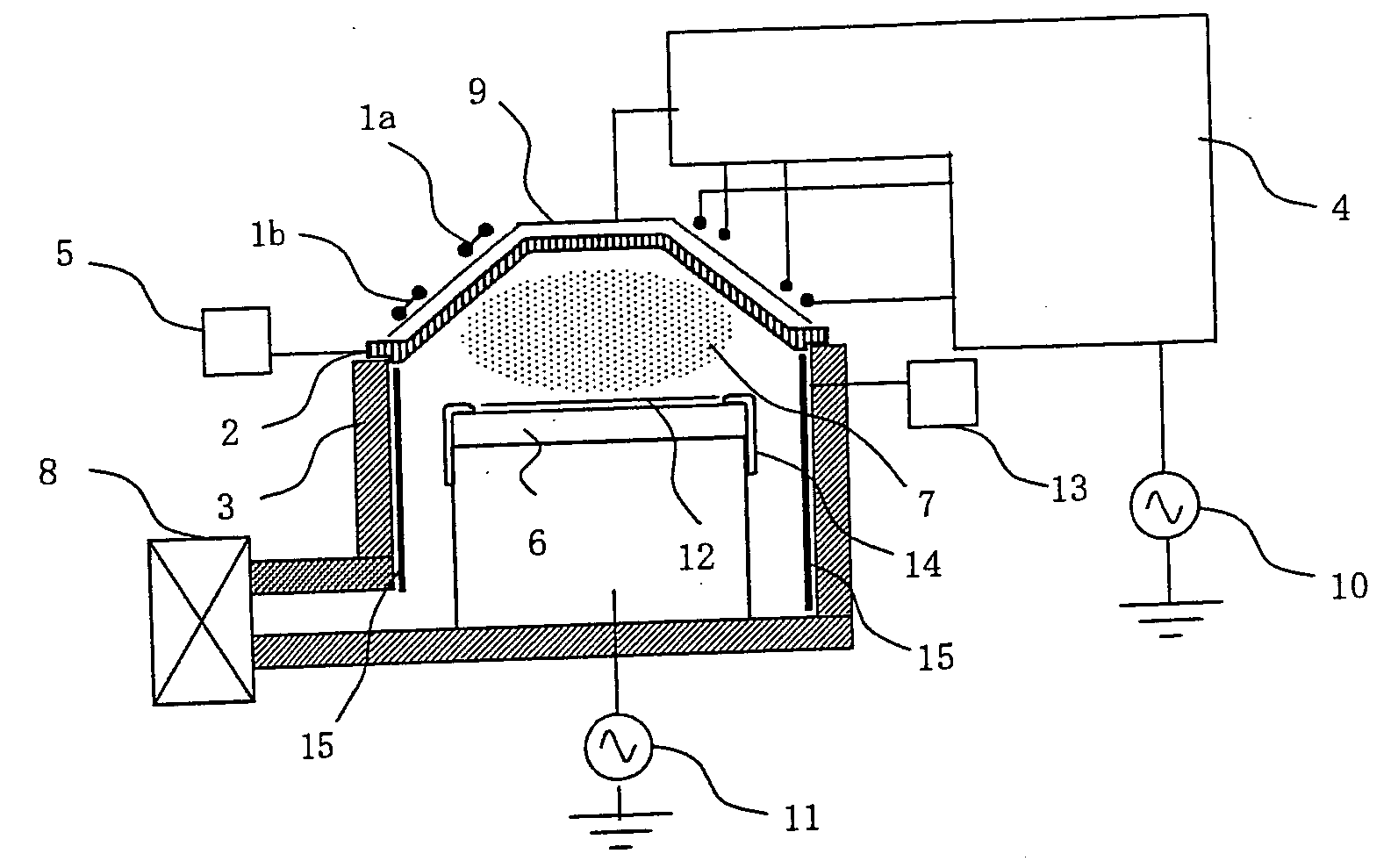

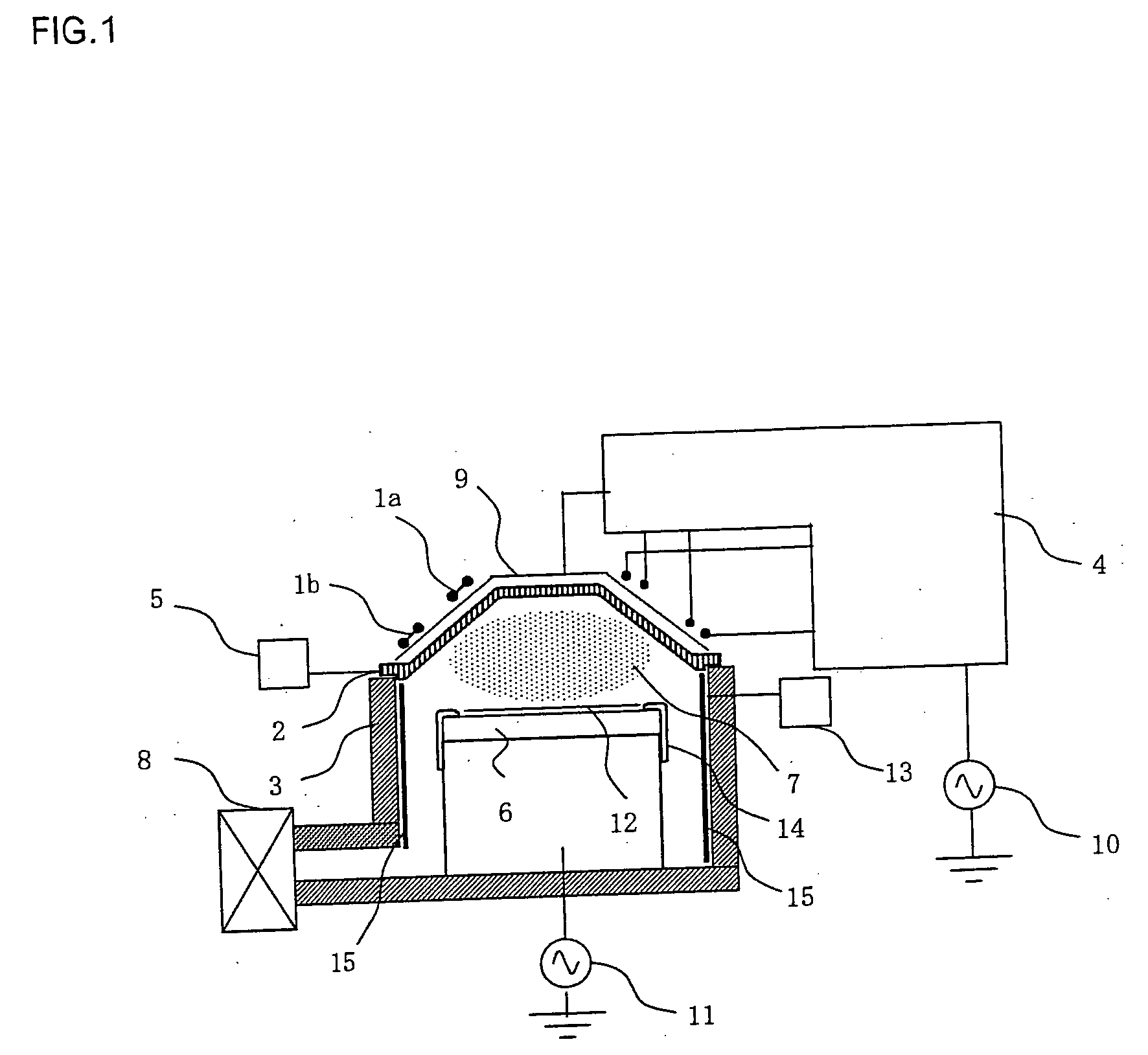

Method of cleaning etching apparatus

ActiveUS20060191555A1Clean interiorMaintain repeatabilityHollow article cleaningElectrostatic cleaningBoron trichlorideOxygen

To provide a cleaning method for an etching apparatus for a metal film that efficiently removes an etching residue deposited in an etching process chamber, assures the reproducibility of the etching performance, and keeps the etching process chamber in a low-dust-emission condition. Each time one workpiece with a metal film is etched (S1), the interior of the vacuum chamber is cleaned by replacing the workpiece with a dummy substrate (S2), performing a first step of plasma processing using oxygen (O2) and carbon tetrafluoride (CF4) to remove a carbon-based deposit pile (S3), and performing a second step of plasma processing using boron trichloride (BCl3) and chlorine (Cl2) to remove a residue that could not be removed by the first step and an etching residue of the metal film (S4).

Owner:HITACHI HIGH-TECH CORP

Coking coal dust shaping technique

A process method of coking coal dust forming chiefly aims at settling the problem about a second dust emission in the course of transportation. First, the large quantity of small smut produced by a fluidized bed can be collected by a dust precipitator, be conveyed to a smut collecting storehouse, and constantly transmitted into a high pressure molding machine by an incessant closed conveyer. The feeding mouth of the high pressure molding machine is provided with a repressing screw to ensure the smut entering a high pressure rolling pair to be with certain pressure. Then the smut can be extruded into effigurate briquette, which at last is conveyed into a production coal conveying system after the molding. The process can prevent the production coal from producing the second dust emission during the transportation, thus reducing the engineering investment and environmental pollution with the advantages of less floor space and increasing the coke yield produced by coke oven.

Owner:SHANDONG IRON & STEEL CO LTD

Compositions for dust suppression and methods

InactiveUS20090090890A1Erosion minimizationImprove propertiesOther chemical processesCentrifugesDisposal wasteMineral flotation

The present invention relates to compositions useful for the suppression of fugitive dust emissions and methods of suppressing dust emissions by application of an aqueous solution comprising a surfactant, wetting agent and an acrylic copolymer. The compositions of the invention are effective in wetting, penetrating and improving particle cohesion and reducing water evaporation. They can also be used as a knockdown agent for airborne dust and for minimising soil and dust erosion, blowing and loss from roads and bulk solids, mineral flotation processes, waste management applications and as a binding agent.

Owner:3M INNOVATIVE PROPERTIES CO

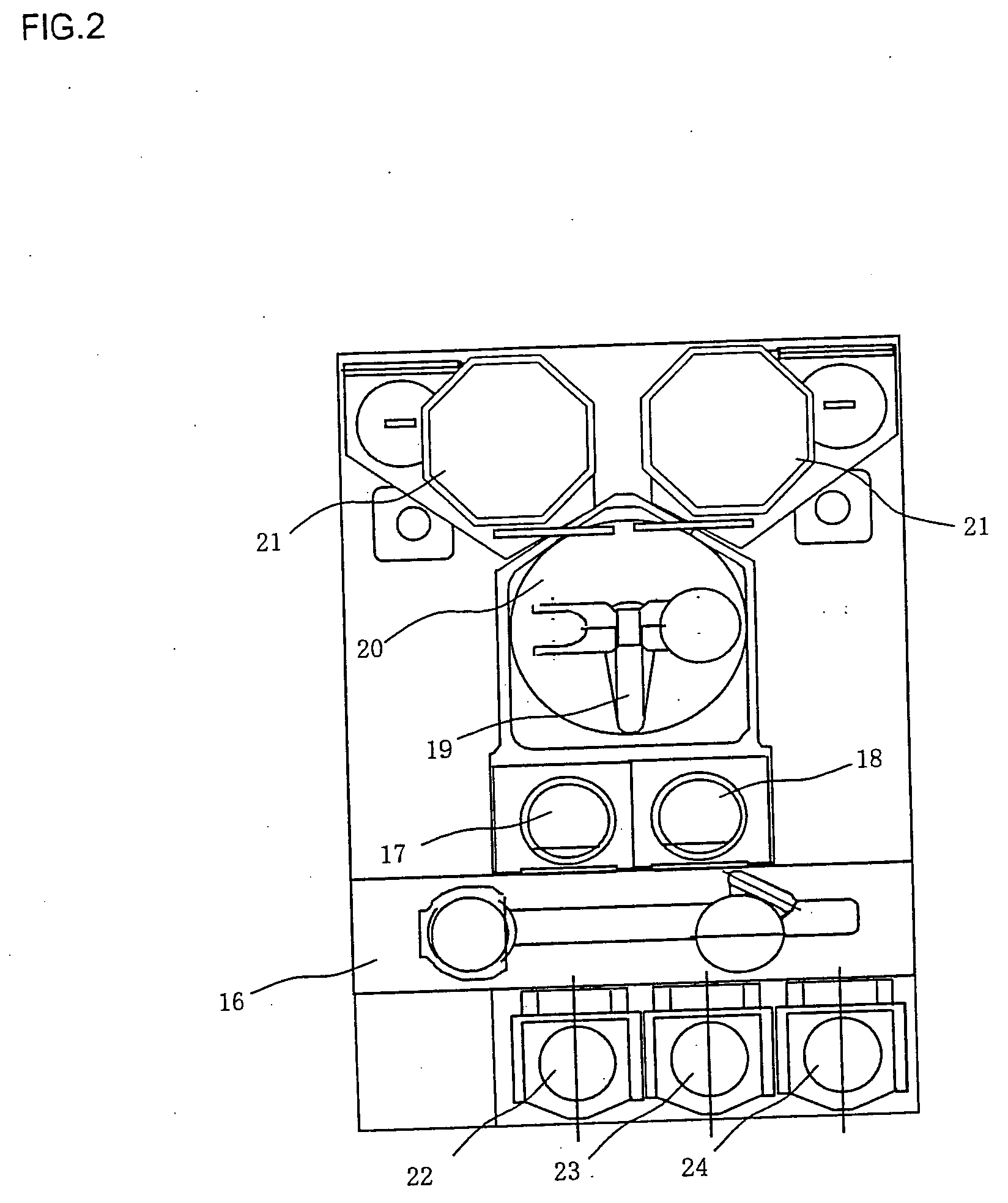

Iron mine sintering flue gas segmented circulation method

ActiveCN103499216AGuaranteed emission reductionAvoid enrichmentIncreasing energy efficiencyWaste heat treatmentFlue gasDust emission

The invention discloses an iron mine sintering flue gas segmented circulation method. Sintering flue gas high in O2 content on the tail portion of a sintering machine is circulated to the interior of a head flue cover of a sintering feed surface of the head portion of the sintering machine, flue gas of two to three bellows highest in SO2 content in a bellow on the tail portion of the sintering machine is conveyed to a desulfurization system to be desulfurized, and flue gas in other bellows is circulated to a middle flue cover of a sintering feed surface of the middle portion of the sintering machine. After segmented flue gas circulation is adopted, SO2 will not be accumulated in sintering ore, dust emission is reduced by 20-40%, NOx emission is reduced by 20-40%, dioxin emission is reduced by 50-80%, and CO2 emission is reduced by 20-45%.

Owner:CENT SOUTH UNIV

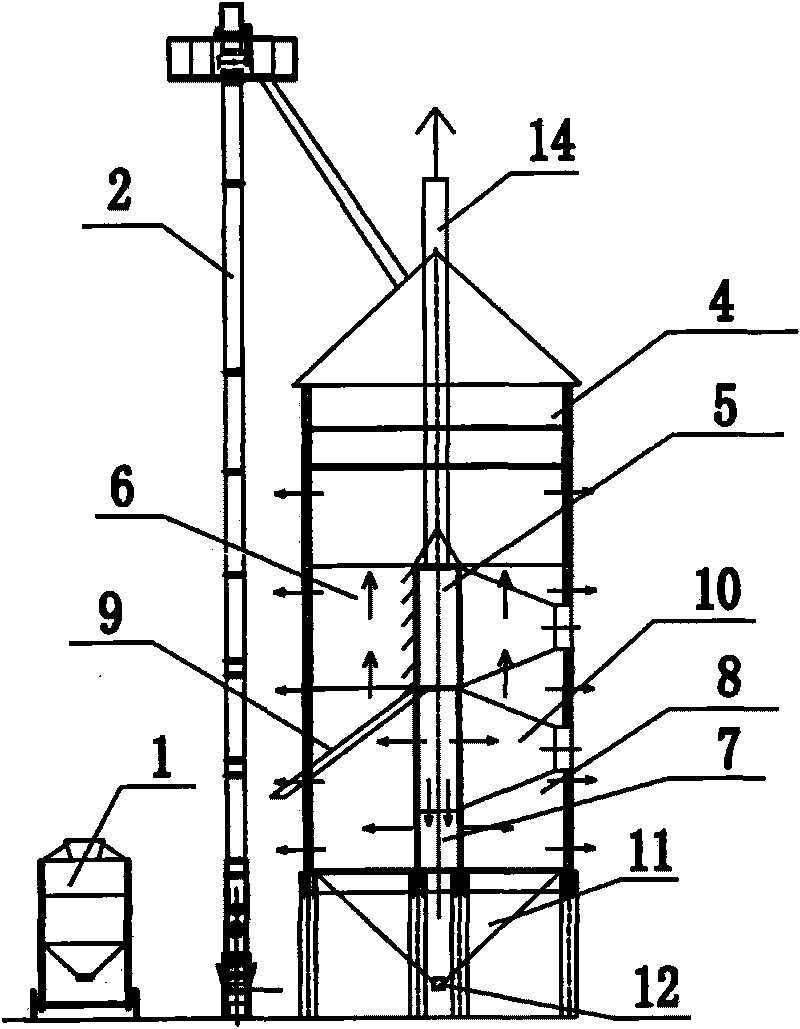

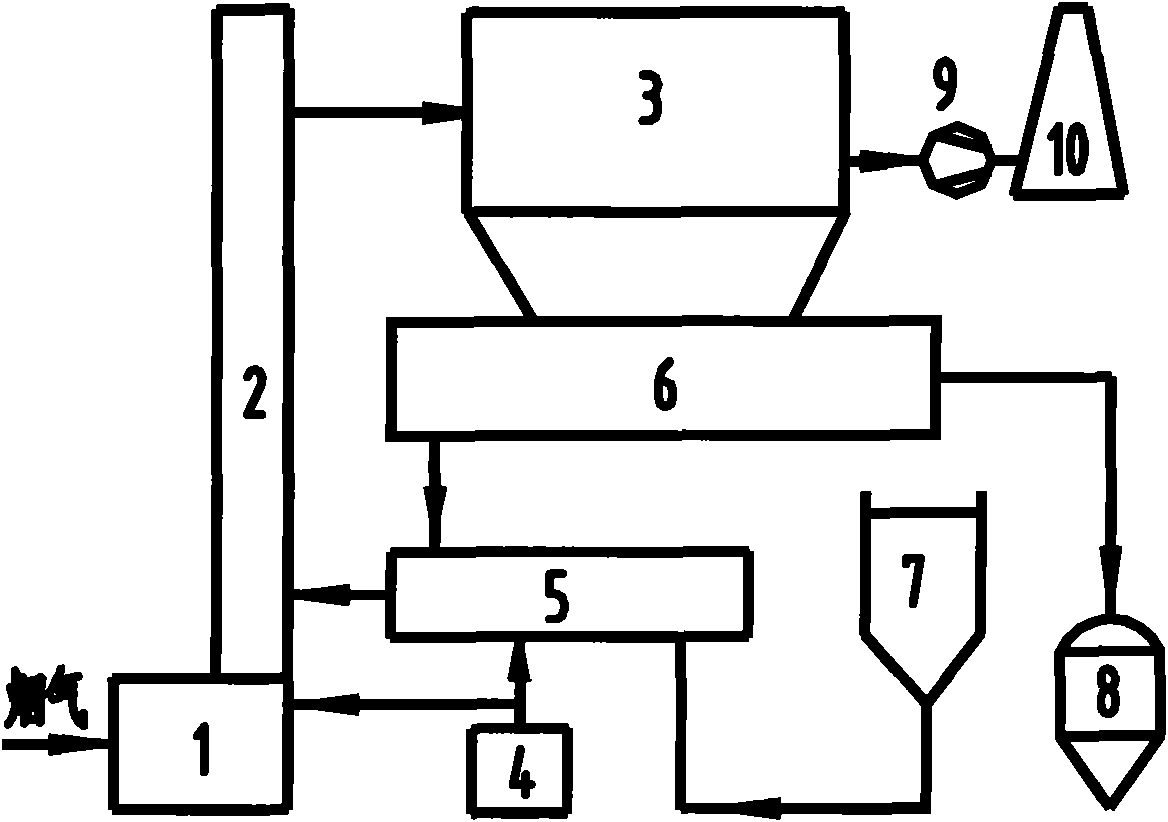

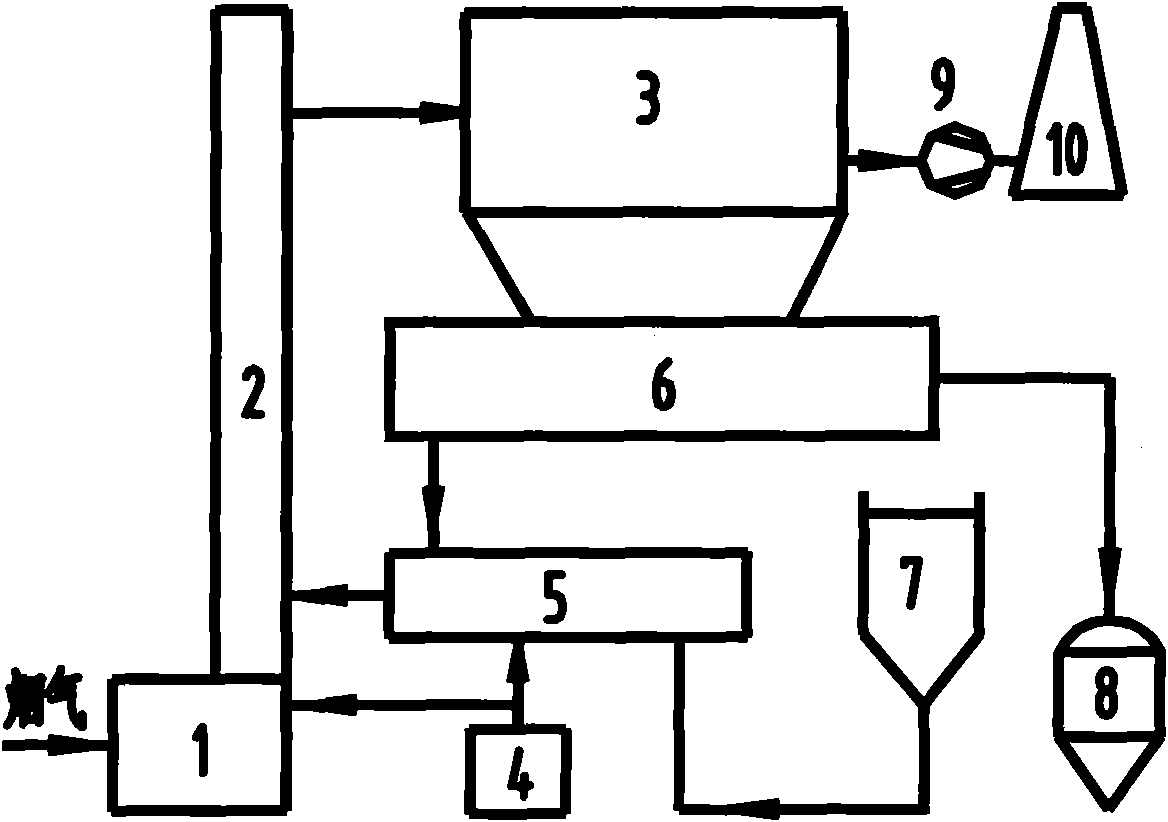

Centralized drying system of high-humidity grain and drying method thereof

InactiveCN101731327AImprove drying efficiencyReduce consumptionFood processingClimate change adaptationLiquid wasteEngineering

The invention relates to a centralized drying system of high-humidity grain and a drying method thereof. According to the grain deliver direction, the centralized drying system comprises a preliminary cleaning machine, a wet grain hoister, a wet grain dryer, a conveyor, a middle hoister, a main drying tower, a dry grain conveyor, a dry grain hoister and a dry grain storage silo which are successively connected, wherein the main drying tower successively comprises a high-temperature drying section, a low-temperature drying section and a cooling section; the system also comprises a hot-blast stove, a heat exchanger, a dust remover and a smoke draught fan which are successively connected, wherein the smoke draught fan is connected with the wet grain drier; the heat exchanger is connected to the main high-temperature drying section by an air heater, and the air heater is connected to the low-temperature drying section by a thermosistor; the heat exchanger is connected with the wet grain drier by a wind stopping device and an air cooler; and ambient air is communicated with the air cooler by the cooling section. The drying system can fully utilize natural air and recycle the waste heatand waste gas of the drying system to efficiently dry in an energy saving mode and reduce drying waste gas, waste liquid and dust emission; the drying system has favourable drying effect and is especially suitable for drying a great quantity of high-wet grain in a centralized mode.

Owner:SOUTH CHINA AGRI UNIV

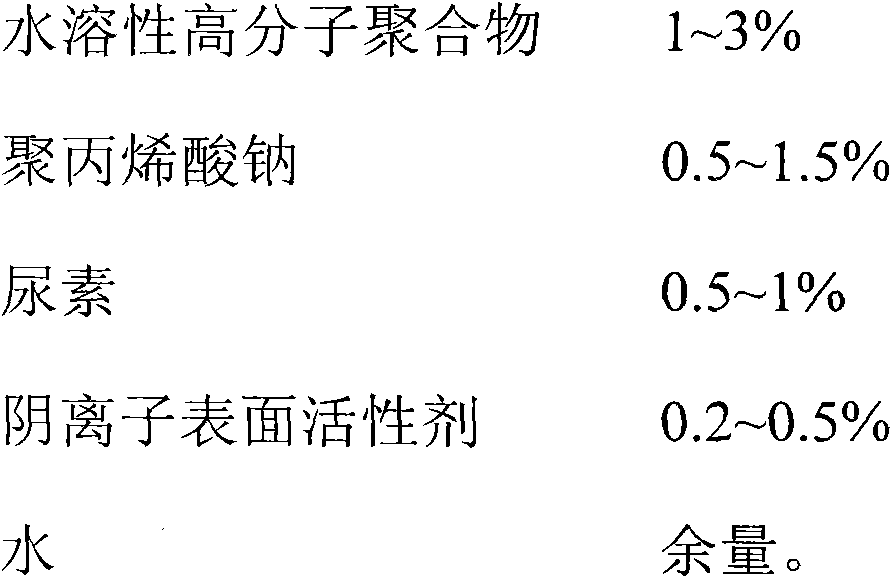

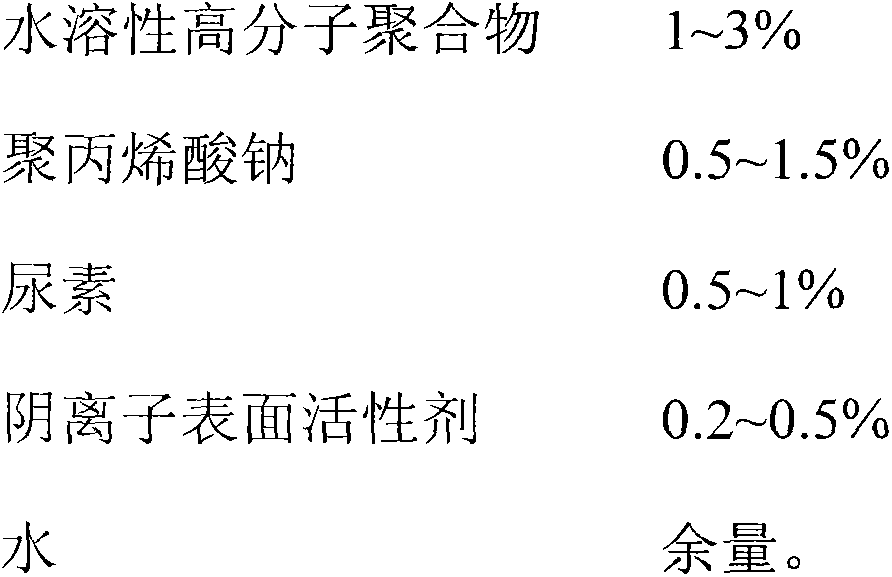

Road surface dust suppressant and preparation method thereof

InactiveCN103965834ASolve pollutionSolve the problem of rolling dustOther chemical processesRoad surfaceDust emission

The present invention discloses a road surface dust suppressant and a preparation method thereof, wherein the road surface dust suppressant comprises 1-3% of a water-soluble macromolecule polymer, 0.5-1.5% of sodium polyacrylate, 0.5-1% of urea, 0.2-0.5% of an anionic surfactant, and the balance of water. According to the present invention, the road surface dust suppressant can be applied in road dust suppression, earth work dust emission treatment in mine exploitation, mine field road transportation and municipal construction, and other fields so as to effectively solve the problem of dust pollution, ensure transportation safety and health safety of motorcyclists and staffs around, reduce the maintenance cost of the transportation equipment, increase the service life of the equipment, and especially solve the problem of rolling dust emission of the heavy duty transportation tool.

Owner:RIZHAO K GREEN ENVIRONMENTAL SCI & TECH

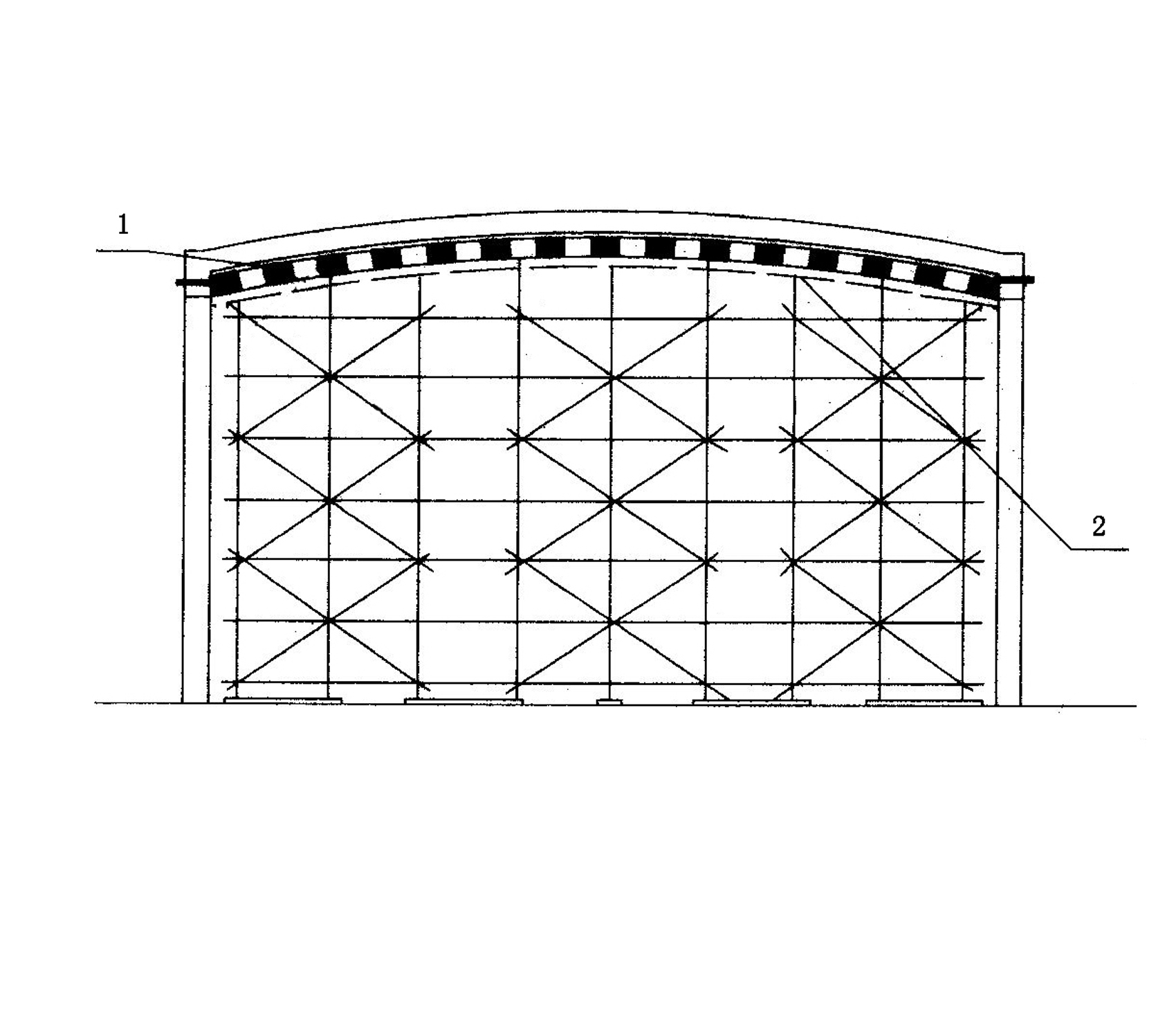

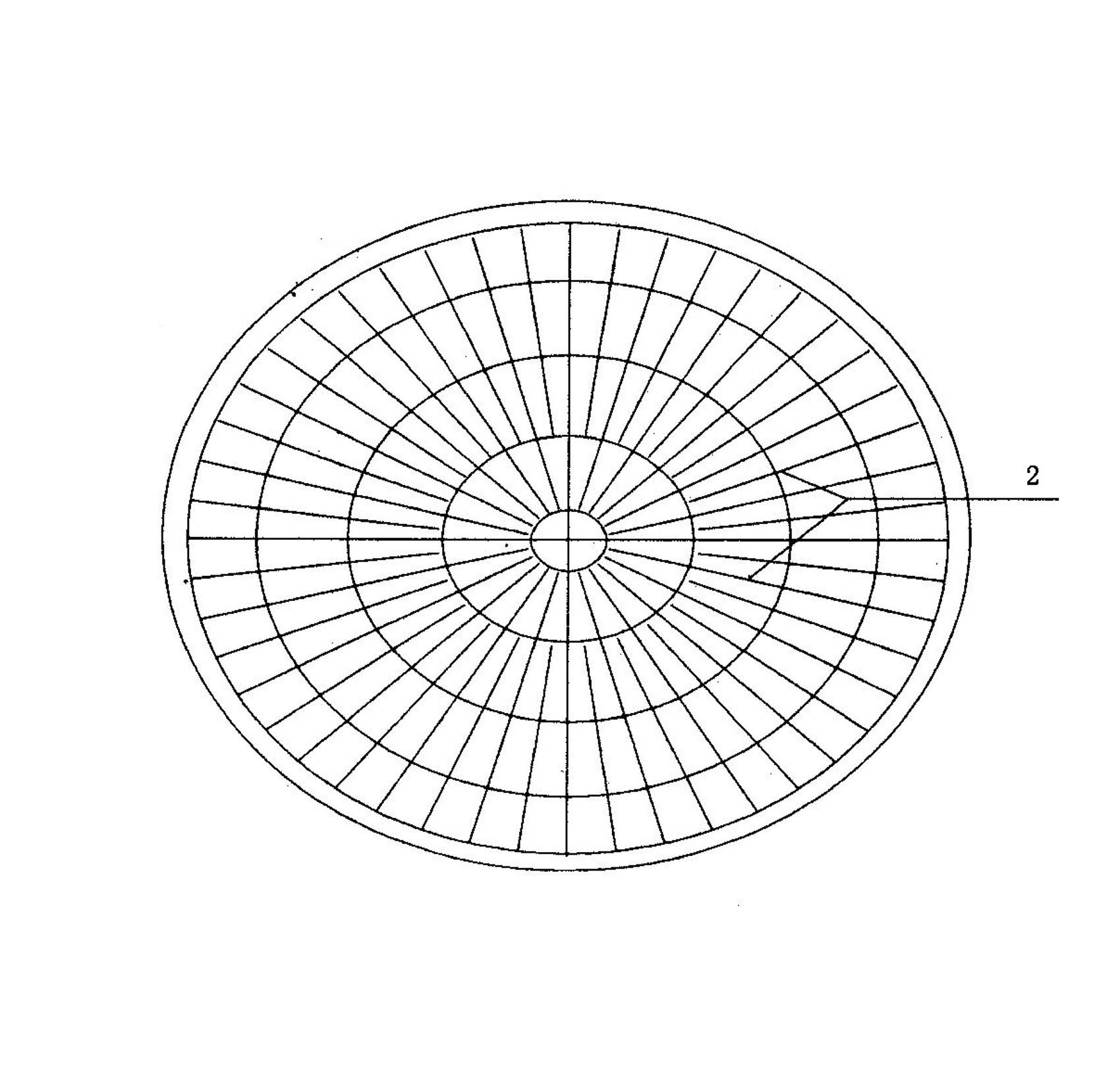

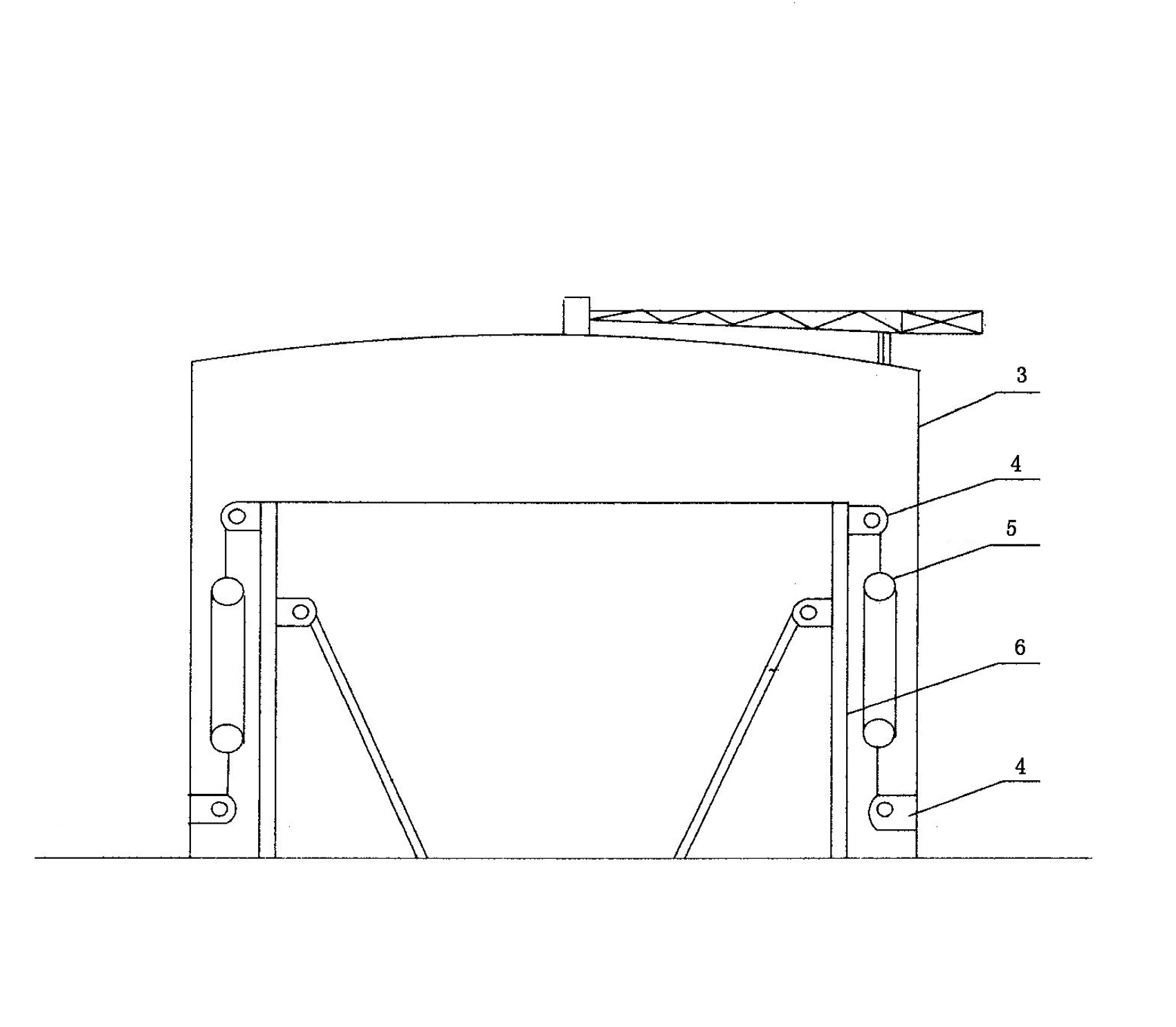

Construction method of soil covering tank

ActiveCN101852031AReduce construction intensityEmission reductionArtificial islandsUnderwater structuresRebarDust emission

The invention relates to a construction method of a soil covering tank for storing product oil and the like, which comprises the following steps of: (A) building a tank chamber of a soil covering tank: firstly, carrying out earth excavation with a method combining a back-acting shovel and manual excavation; then, manufacturing a ring beam, precasting concrete blocks on the spot according to the radian of the ring beam, and building the concrete blocks; carrying out the engineering of steel bars: welding steel bars by machining, and manually binding the steel bars on the spot; carrying out the engineering of templates and scaffolds: taking a bamboo plywood as a top plate template of a concrete thin shell of the tank chamber, designing a camber at the middle part, and taking scaffold tubes as bottom template brackets of the thin shell of the tank; then, carrying out concrete engineering and asphalt sand construction; and finally, carrying out waterproof engineering, thereby completing the construction of the tank chamber of the soil covering tank; and (B) installing a storage tank body of the soil covering tank: firstly, precasting the storage tank body; then, installing a tank bottom plate; installing the tank body, and welding the storage tank; and finally, testing and inspecting to complete the whole construction process of the soil covering tank after the construction is qualified. The invention reduces the occurrence of accidents, increases the benefit and reduces the dust emission.

Owner:中国化学工程第四建设有限公司

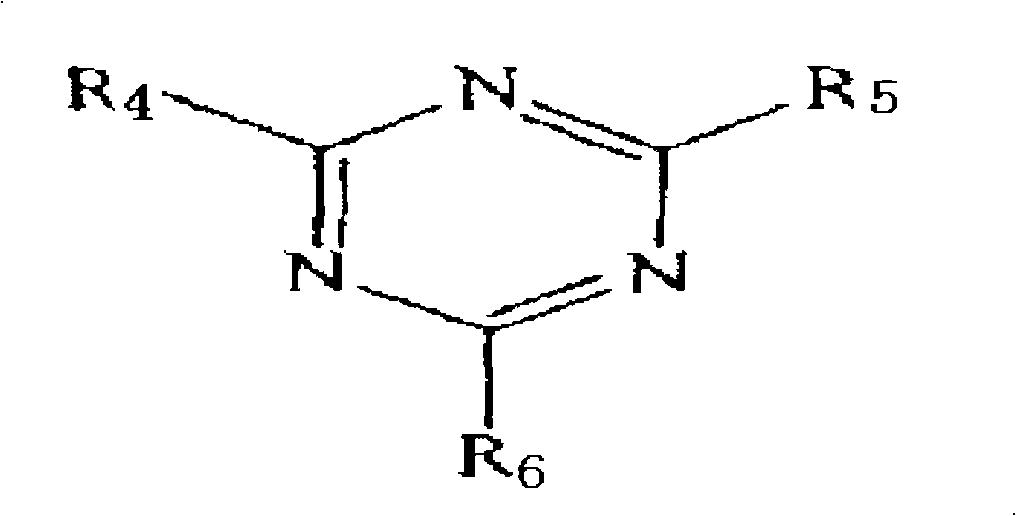

Flame-retardant anti-dropping resin composition

InactiveCN101348603AExcellent and durable flame retardantLittle impact on mechanical propertiesPolyesterFiber

The invention discloses a flame-retardant anti-dripping resin compound, consisting of 100 weight portions of thermoplastic resin, 0.01-5 weight portions of modified polytetrafluoroethylene anti-dripping agents and 20 to 40 weight portions of environment-friendly flame retardant containing phosphorus and / or nitrogen. The resin compound has strong anti-dripping effect and heat resisting performance, is level and smooth in exterior appearance, and can endow polyester fiber products with excellent enduring flame retardancy without using halogen (Cl and Br) flame retardant. The resin compound has the advantages of high oxygen index, droplet resistance, low heat release rate, no halogen, little toxicity, low smoke dust emission, little influence on the mechanical properties of base materials, etc.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

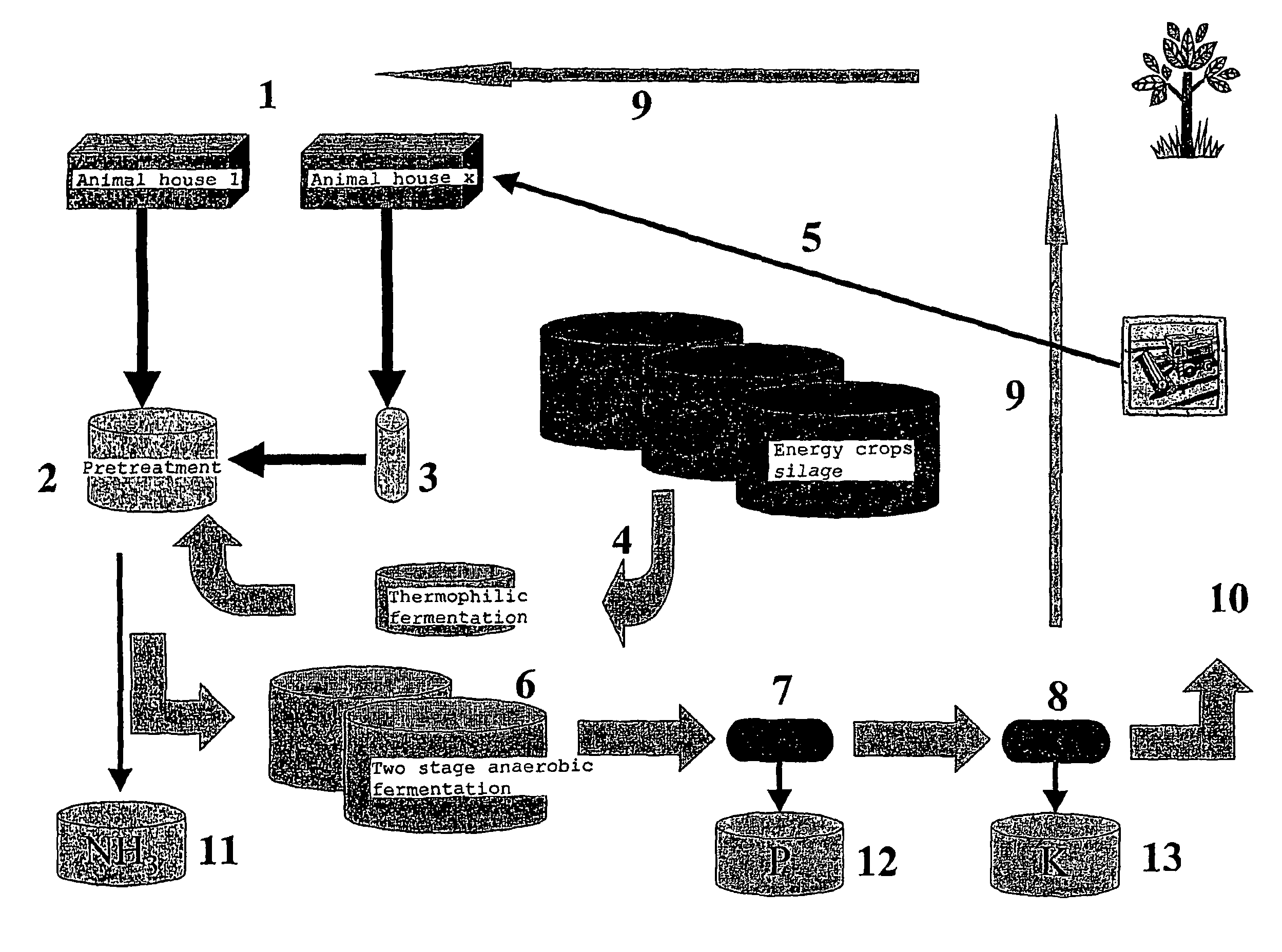

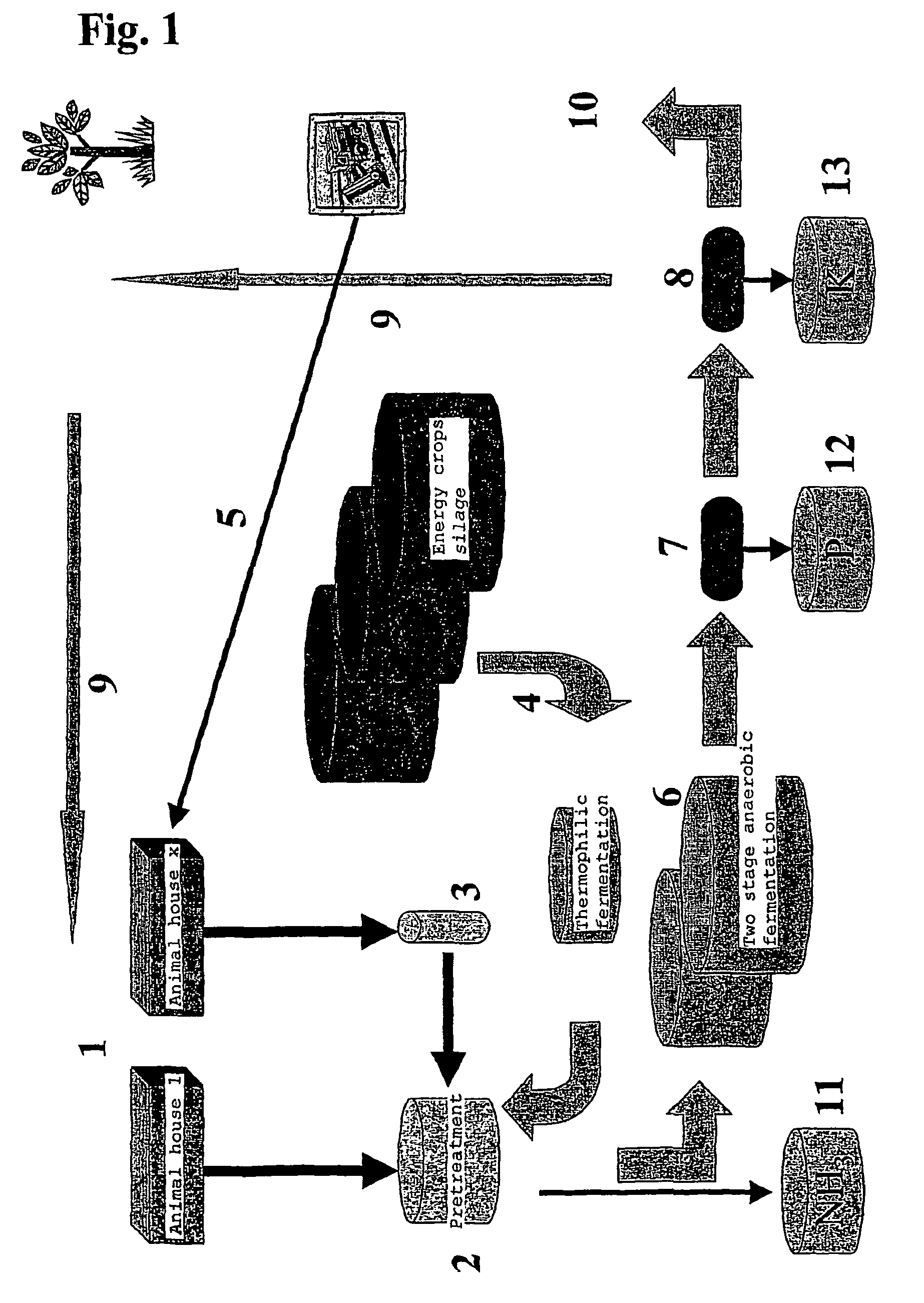

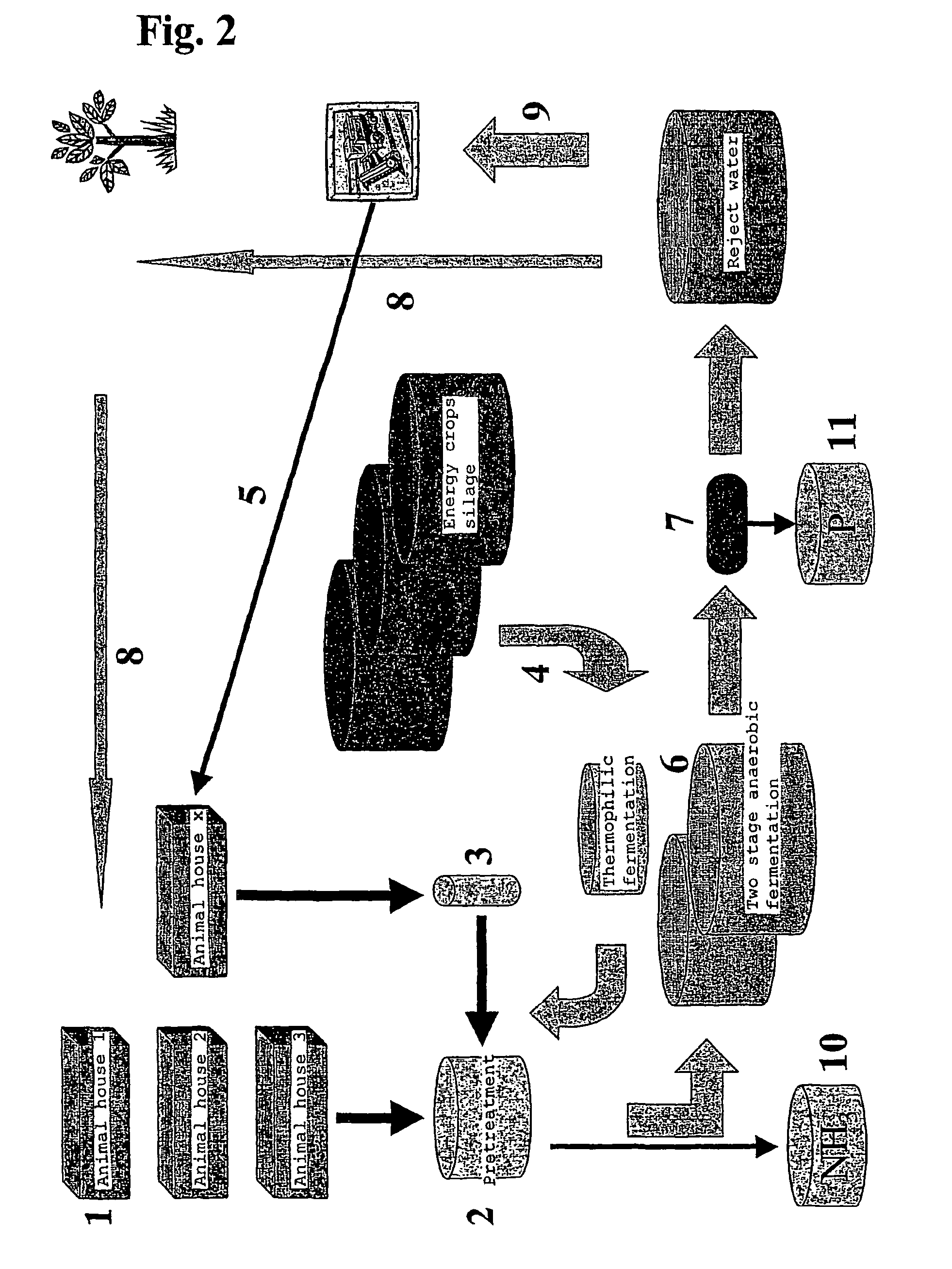

Concept for slurry separation and biogas production

InactiveUS7883884B2High yieldNot subsidisedBio-organic fraction processingAnimal corpse fertilisersEngineeringBiogas production

The present invention concerns an anaerobic digestion of animal manures, energy crops and similar organic substrates. The process is capable of refining nutrients comprised in the digested biomass to fertilizers of commercial quality. The invention also provides a method for oprocessing animal carcasses or fractions thereof including meat and bone meal etc., with the objective of providing an alternative means for processing the organic waste material of animal origin while at the same time facilitating the production of fertilizers. The risk of spreading BSE prions or any other prions to animals or humans is thus substantially reduced if not eliminated. The biogas and slurry separation system according to the present invention is preferably integrated with the operations of animal husbandries into a total concept in which the internal and external performances of animal husbandries are optimised. The internal performances concern quality aspects related to the management of the animal houses and include industrial hygiene, animal welfare, gaseous and dust emissions and food safety. The external performances concern mainly energy production and emissions to the environment of nutrients and greenhouse gases and the sale of high quality food product.

Owner:GFE PATENT AS

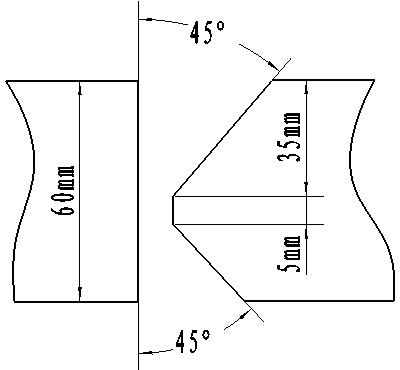

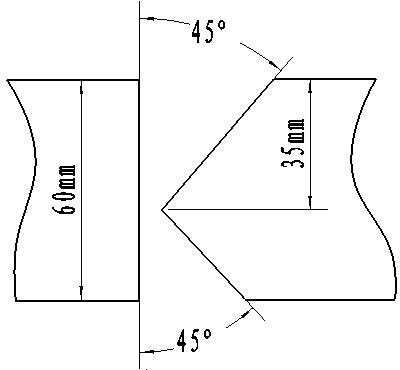

Submerged-arc welding root welding and back chipping process of thick plate with K-type groove

InactiveCN102554416AShorten welding auxiliary timeShorten welding timeArc welding apparatusThick plateSlag

The invention discloses a submerged-arc welding root welding and back chipping process of a thick plate with a K-type groove. The K-type groove is an asymmetric K-type groove, an upper open angle and a lower open angle of the groove are both 45 degrees to 50 degrees, and truncated edges are not reserved at the root. During assembly, groove clearance of 2mm to 3mm is reserved. During welding, solid gas protection welding wires under pulse current are adopted for backing welding of a root pass of the front side of a K-type groove test piece, and after the root pass is thoroughly fused, a part of weld metal penetrates through the reverse side of the groove to achieve backing welding. After welding, back chipping of the reverse side is performed. Finally, gas shielded welding under large current is adopted for fusion welding of the roof of the reverse side groove, and gas rich in argon is used as protective gas. The submerged-arc welding root welding and back chipping process reduces time for slag removal of root pass of submerged-arc welding and polishing and finishing of the reverse side groove of the welding test piece, improves welding efficiency by more than 30%, removes a carbon arc gouging process, decreases welding noises and dust emission, lowers labor intensity of welders and reduces time for damaging workers under high-decibel noises.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

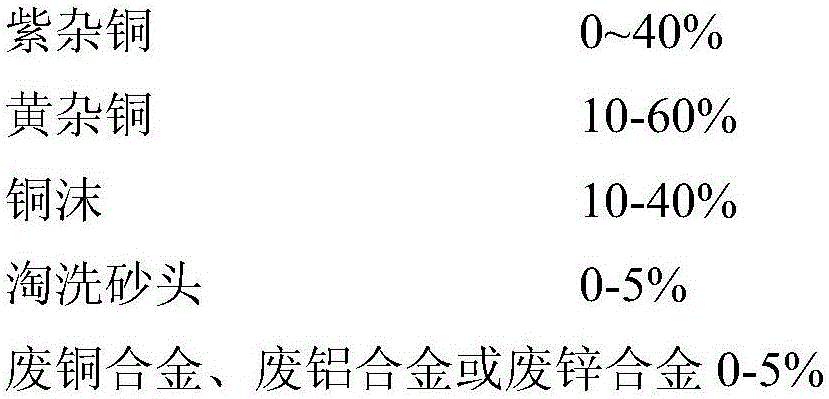

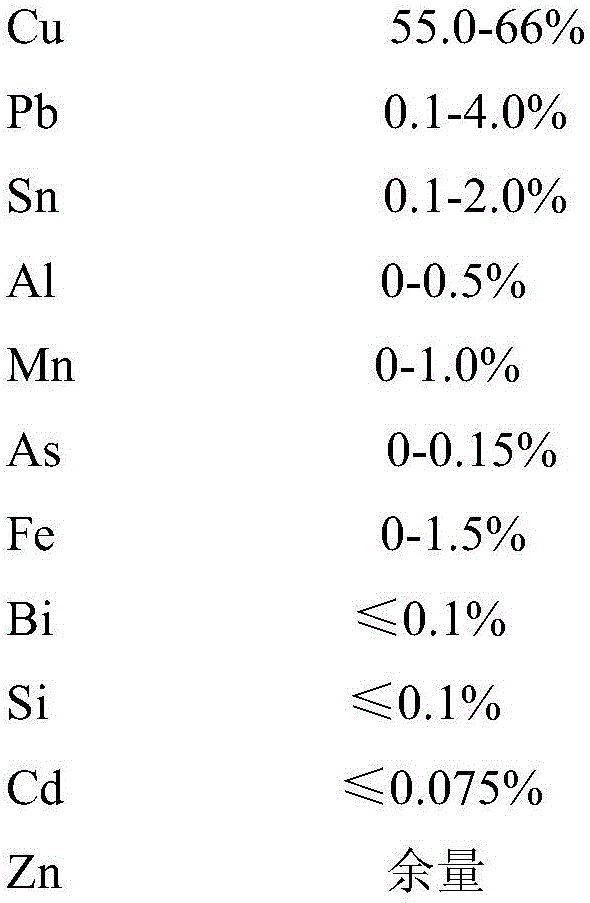

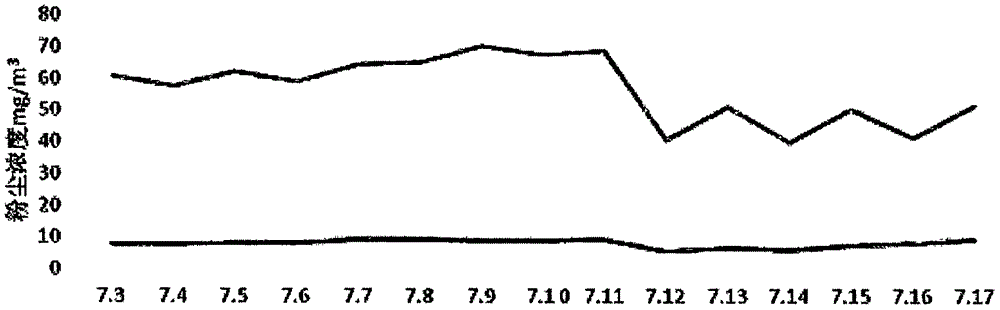

Method for directly producing copper alloy from scrap copper

ActiveCN106350689APhotography auxillary processesProcess efficiency improvementClosed loopWastewater

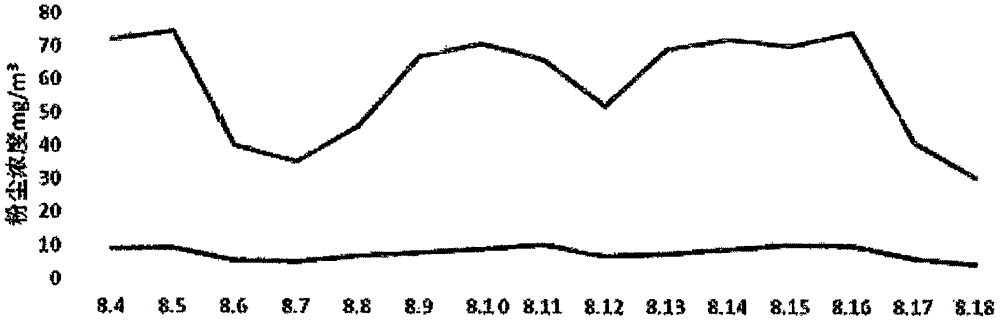

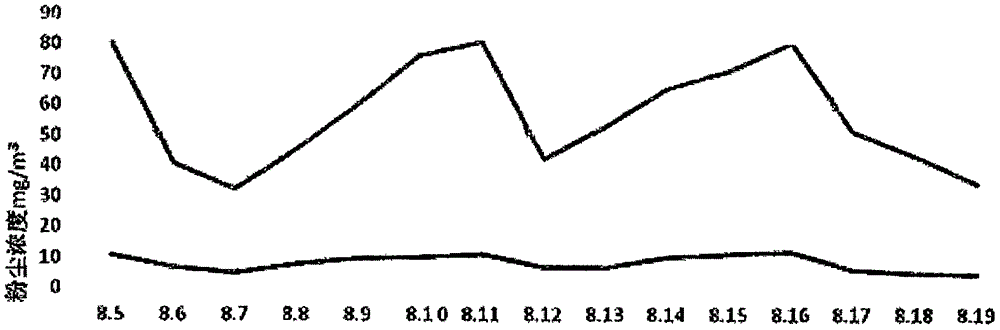

The invention relates to a method for directly producing copper alloy from scrap copper. The method is characterized by including the steps of a) sorting and removing impurities in the collected scrap copper; b) pretreating the sorted scrap copper; c) matching various scrap copper according to target product compositions; d) conveying the materials to a smelting furnace according to a ratio, smelting and refining; e) subjecting ingots to subsequent thermal processing and cold processing according to product requirements so as to obtain standard copper alloy products; f) subjecting smelting furnace ash to ball milling, and removing iron with strong magnets to obtain elutriation sand; g) collecting dust generated in the whole technological process, carrying out four-stage dust removal with dust emission concentration at an exhaust outlet being 60 mg / m<3>, and using the collected smelting dust as a zinc and copper smelting material; h) collecting wastewater in the production process, purifying the wastewater, and using purified water as circulating water in the scrap copper production process. An environment-friendly closed-loop scrap copper recycling system is provided in the method.

Owner:NINGBO CHANGZHEN COPPER CO LTD

Process and equipment for dust collection and heat recovery by converter gas dry method

InactiveCN101942538ASave industrial waterMaximum recyclingManufacturing convertersIncreasing energy efficiencyBaghouseSpark arrestor

The invention provides an optimized process scheme and equipment aiming at the problems existing in the recovery technology of the conventional converter gas dry method. In the process scheme and the equipment, physical sensible heat between 800-1,000 DEG C and 200 DEG C of converter gas is recovered by using a high-efficient heat pipe exhaust-heat boiler, and hidden danger of system explosion is eliminated by using a spark arrestor at the same time. A nitrogen pulse bag-type dust collector replaces an electrostatic dust collector, so that the equipment has the advantages of simple structure, low fault rate and high dust collection efficiency. Compared with the recovery technology of the conventional converter gas dry method, the process scheme and equipment have obvious improvements on benefits, which are shown as reduction in dust emission load, reduction in energy and water consumption, increase in steam recovery, small equipment investment, safe and reliable process and the like.

Owner:北京国华新兴节能环保科技有限公司

Compositions for dust suppression and methods

InactiveUS8052890B2Erosion minimizationImprove propertiesOther chemical processesCentrifugesDisposal wasteEvaporation

Owner:3M INNOVATIVE PROPERTIES CO

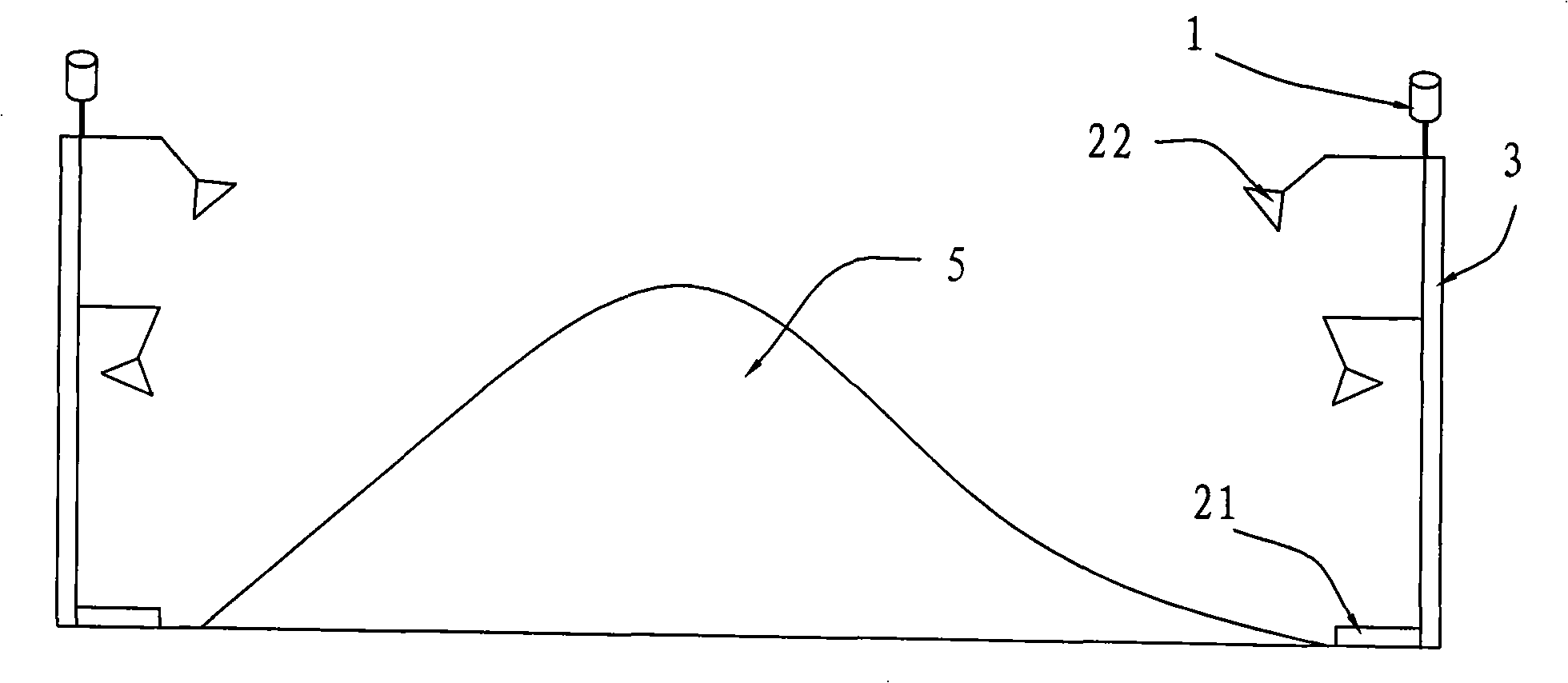

Automatic spraying and dust-preventing method, and dust-preventing apparatus

The invention relates to an automatic spray device for blocking dust, including an automatic induction mechanism, a spray mechanism, a spray control mechanism and a dust suppression mechanism; the spray mechanism controls the spray mechanism by the induction signal of the automatic induction mechanism. The invention also provides an automatic spray dust blocking method; the automatic induction mechanism induces environmental parameters and sends the induction signals of the environment parameters to the spray control mechanism, according to the induction signals the spray control mechanism sends instruction to control the spray mechanism to spray or stop spaying fluid to the dust suppression mechanism and / or a material heap. The automatic spray device can realize full automatic management or adopt manual management, thus having convenient use, obvious effect and being capable of treating the pollution problem caused by aeolian erosion and dust emission from working surfaces; meanwhile, the automatic spray device can achieve the functions of auto-regulation, spraying, water conservation, self cleaning, waterproof property, dust collecting, and so on according to the external environment.

Owner:北京首创大气环境科技股份有限公司

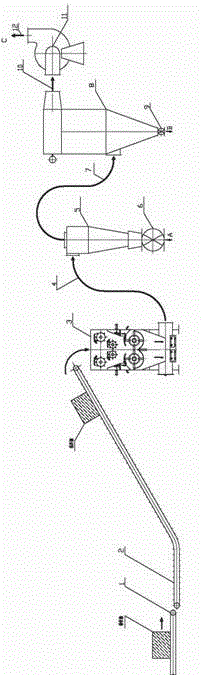

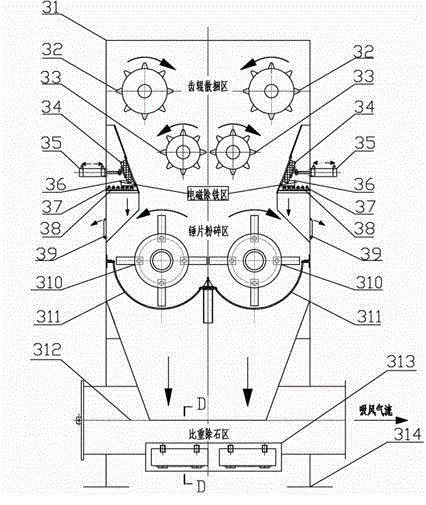

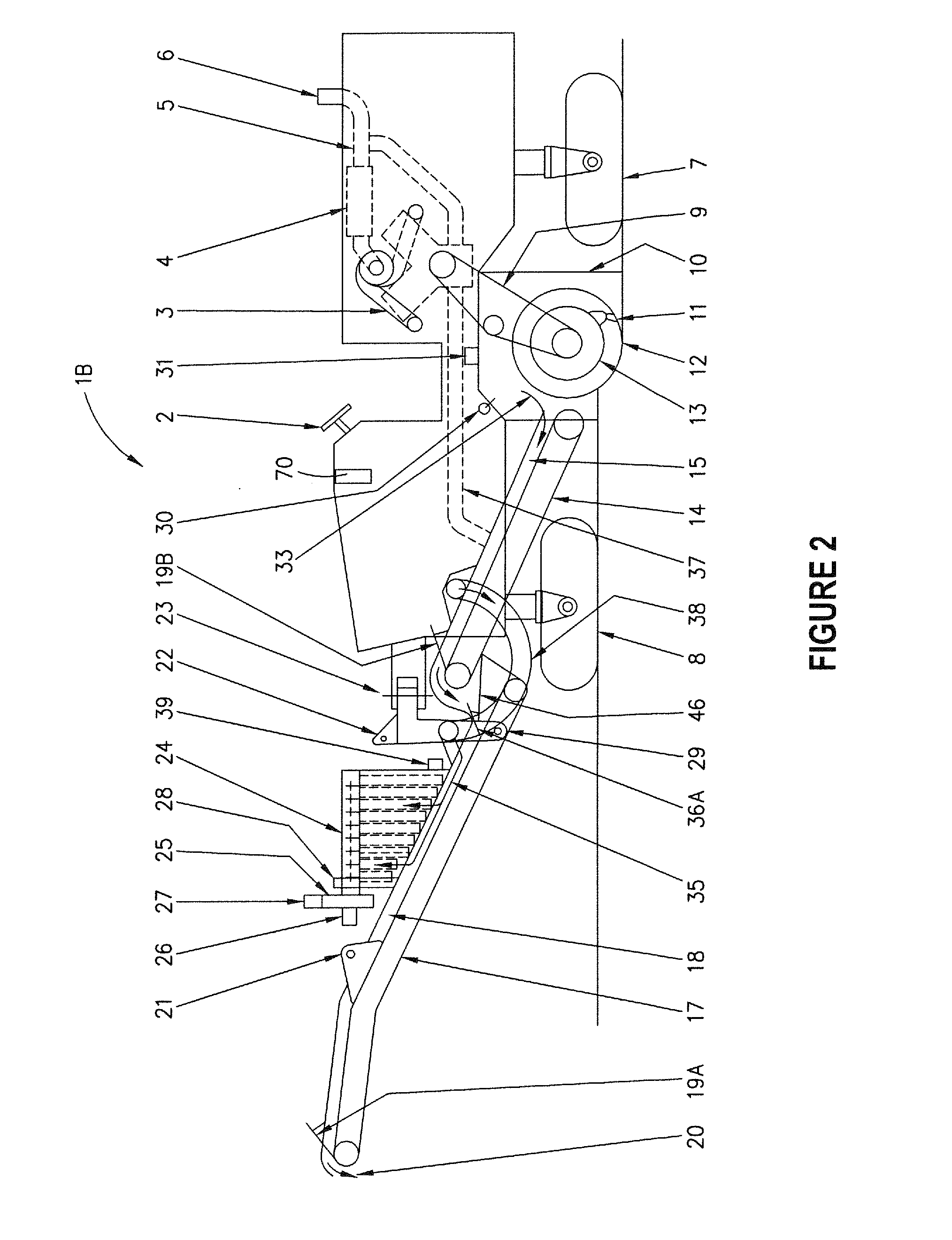

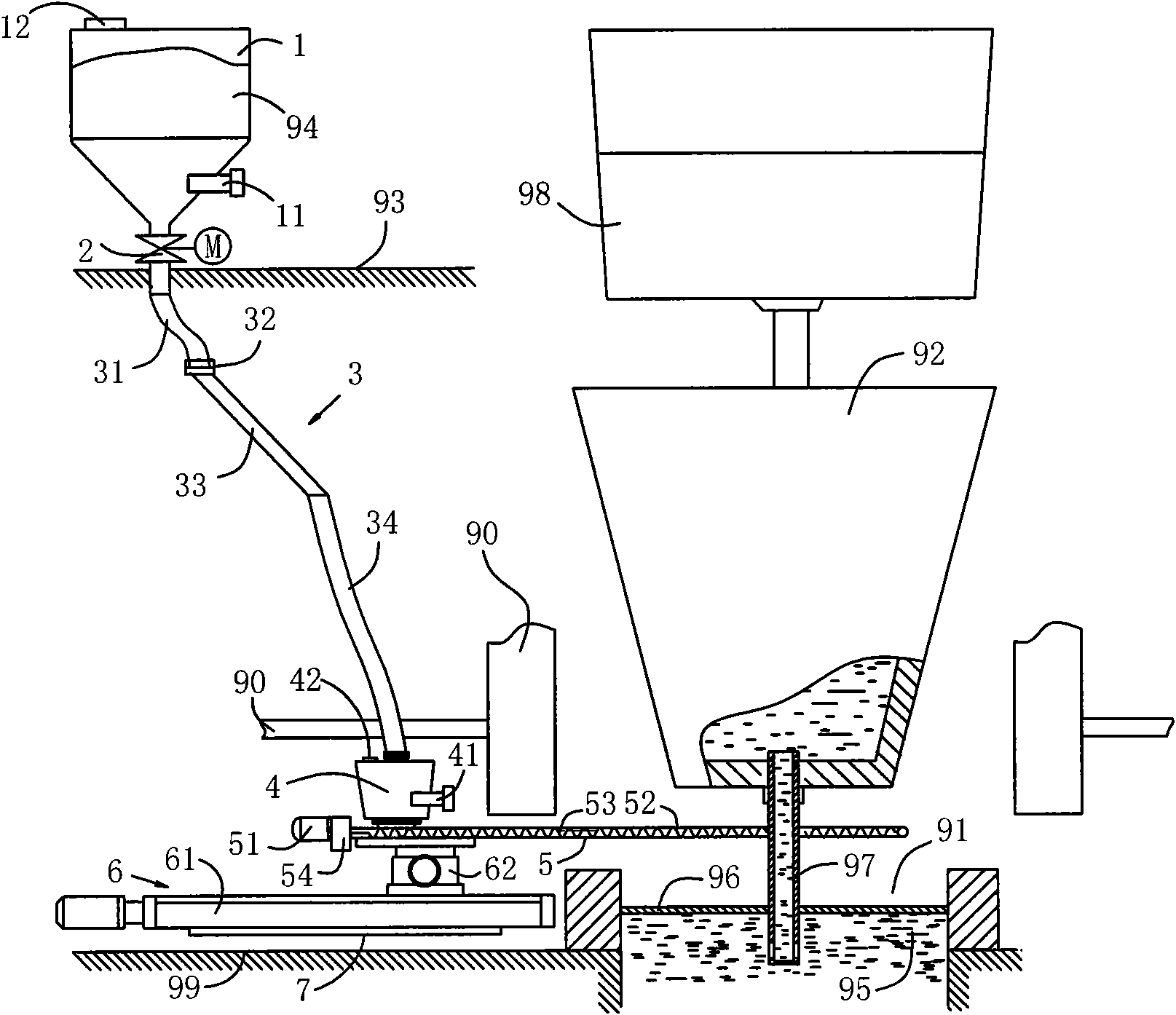

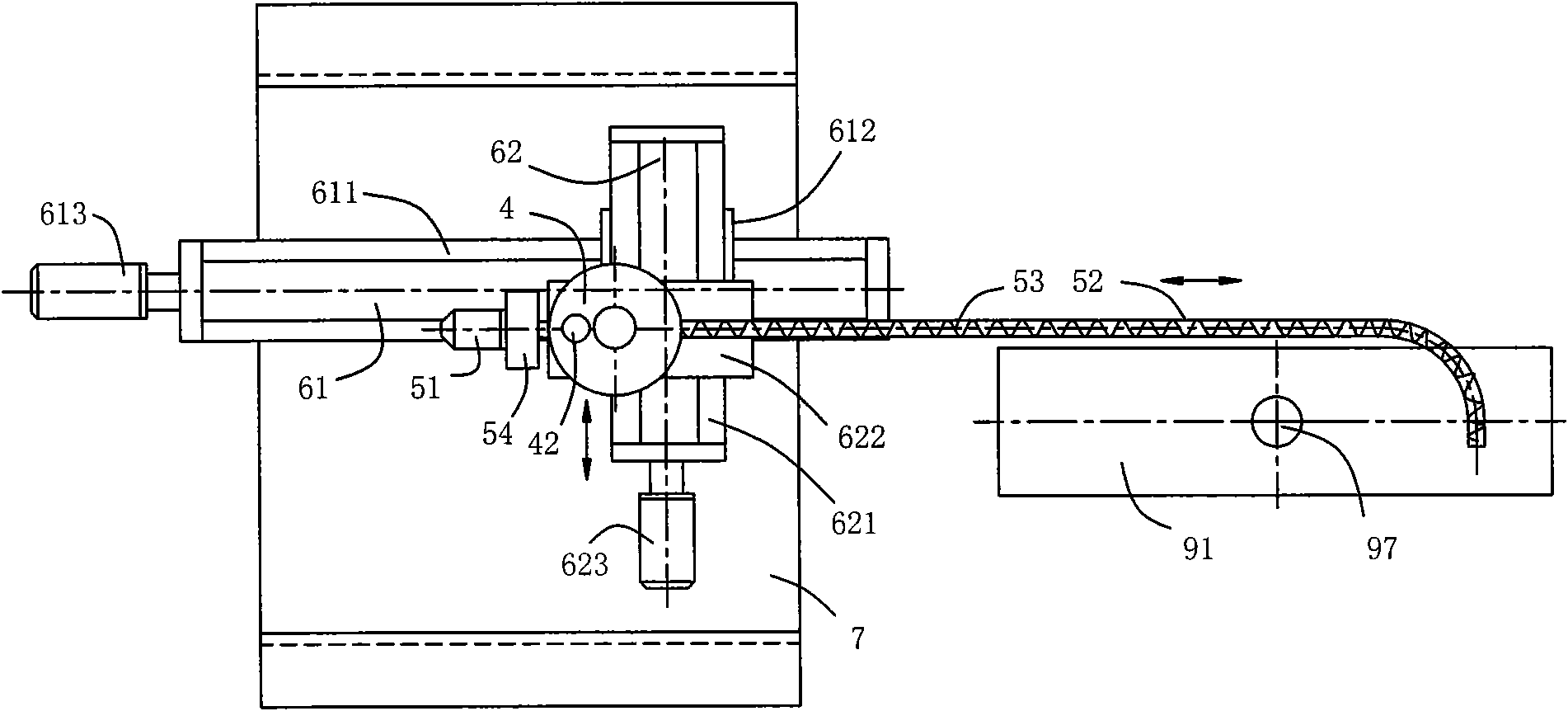

Crop straw bundle negative-pressure coarse grinding method and crop straw bundle negative-pressure coarse grinding equipment

ActiveCN104624344ARealize large-scale clean continuous coarse crushingNovel and reliable processGrain treatmentsEnvironmental resistanceEngineering

The invention relates to a coarse straw bundle negative-pressure coarse grinding method. The coarse straw bundle negative-pressure coarse grinding method is characterized in that a straw bundle passes through an un-roping belt conveyor, an inclined scraper conveyor, a vertical type straw bundle coarse grinder, an air suction tube, a cyclone separator, an unloading air sealer, an air suction tube, a pulse bag dust collector, a dust-collecting air sealer, an air suction tube, a high-pressure draught fan and an air outlet tube; the vertical type straw bundle coarse grinder, the air suction tube, the cyclone separator, the unloading air sealer, the air suction tube, the pulse bag dust collector, the dust-collecting air sealer, the air suction tube, and the high-pressure draught fan are connected through the air suction tube, so that the straw bundle coarse grinding is continuously performed under a negative-pressure pneumatic transmission state. The vertical type straw bundle coarse grinder is characterized by being vertically arranged, wherein a gear roller bundle-off region, an electromagnetic iron removal region, a hammer sheet crushing region and a specific gravity stone removal region are arranged in a crusher tank body from top to top in sequence. According to the detection, the dust emission of the coarse straw bundle negative-pressure coarse grinding method meets the national environmental-friendly standards. The coarse straw bundle negative-pressure coarse grinding method realizes large-scale clean continuous coarse grinding of the straw bundle, can be applied to the fields of straw manmade plates, straw energy resources, straw feed and the like, and provides a novel and reliable process and complete equipment.

Owner:SHANGHAI COMPAK ENVIRONMENTAL PROTECTION EQUIP CO LTD

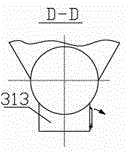

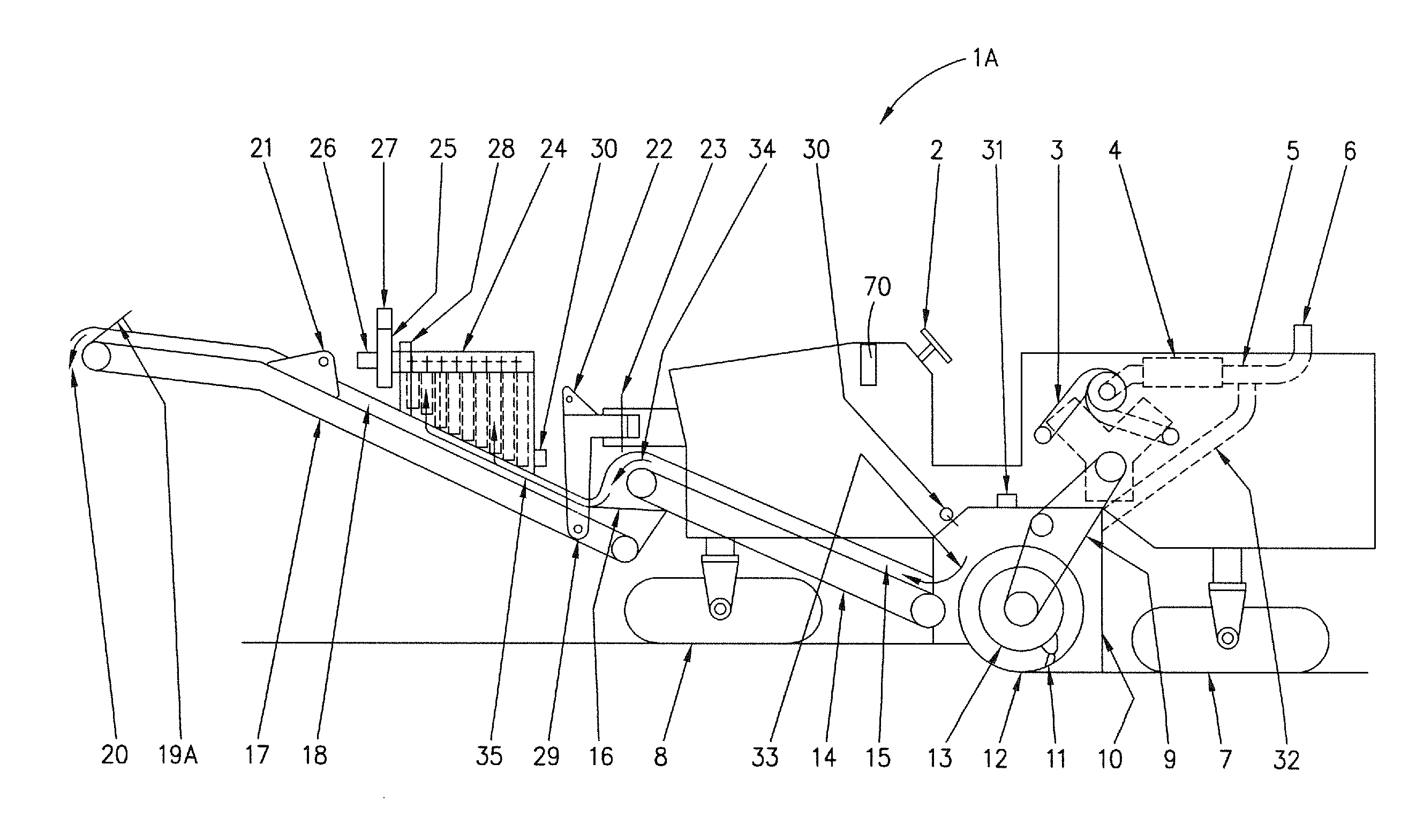

Method and apparatus for controlling dust emissions with temperature control

A working machine for use in milling the surface of a road includes a drive engine that produces engine exhaust gases. The working machine also includes a milling drum that is mounted for rotation against the surface of the road so as to generate milled material including dust from the road surface. The milling drum is contained within a milling chamber, and a spray assembly directs water into the milling chamber in such a manner that, during a period of rotation of the milling drum against the surface of the road, at least a portion of the water is converted to a vapor. A conduit is provided for conducting at least a portion of the engine exhaust gases into an enclosed space in communication with the milling chamber to raise the temperature of a gas stream therein containing vapor and dust from the milled material.

Owner:ROADTEC

Sputtering target containing zinc sulfide as major component, optical recording medium on which phase change optical disk protective film containing zinc sulfide as major component is formed by using the target, and method for manufacturing the sputtering target

ActiveUS7279211B2Reduce the impact of heatIncrease speedPigmenting treatmentCellsTectorial membraneRefractive index

Provided is a sputtering target and an optical recording medium having formed thereon a phase change optical disc protective film having zinc sulfide as its principal component employing such a target, as well as the manufacturing method thereof, characterized in that the sputtering target has zinc sulfide as its principal component, and is capable of adjusting the refractive index of a film containing conductive oxide in the range of 2.0 to 2.6. This sputtering target, and an optical recording medium having formed thereon a phase change optical disc protective film having zinc sulfide as its principal component employing such a target, is capable of reducing particles (dust emission) and nodules that arise during sputtering, has minimal variation in quality and is capable of improving mass productiveness, and in which the crystal grain is fine and has a high density of 90% or more.

Owner:JX NIPPON MINING & METALS CORP

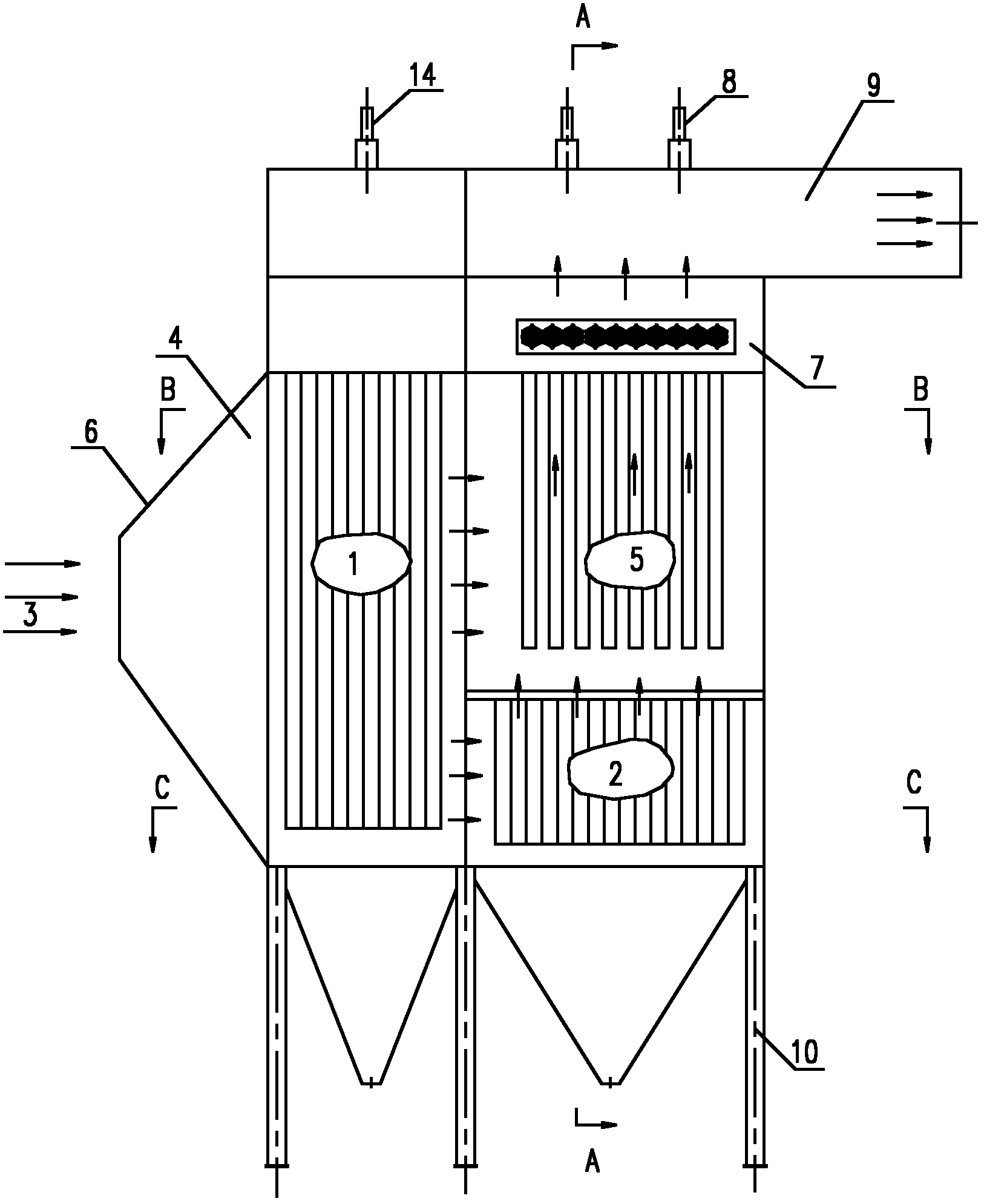

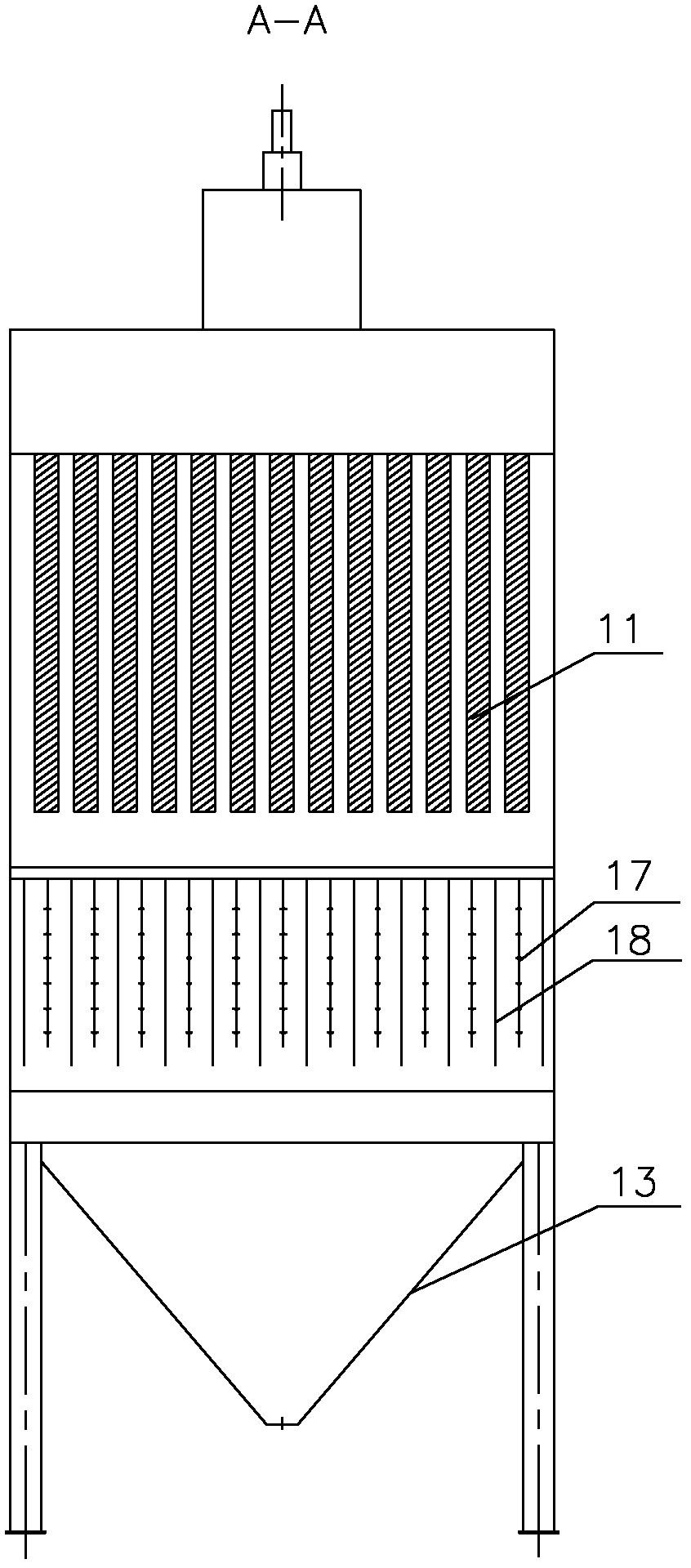

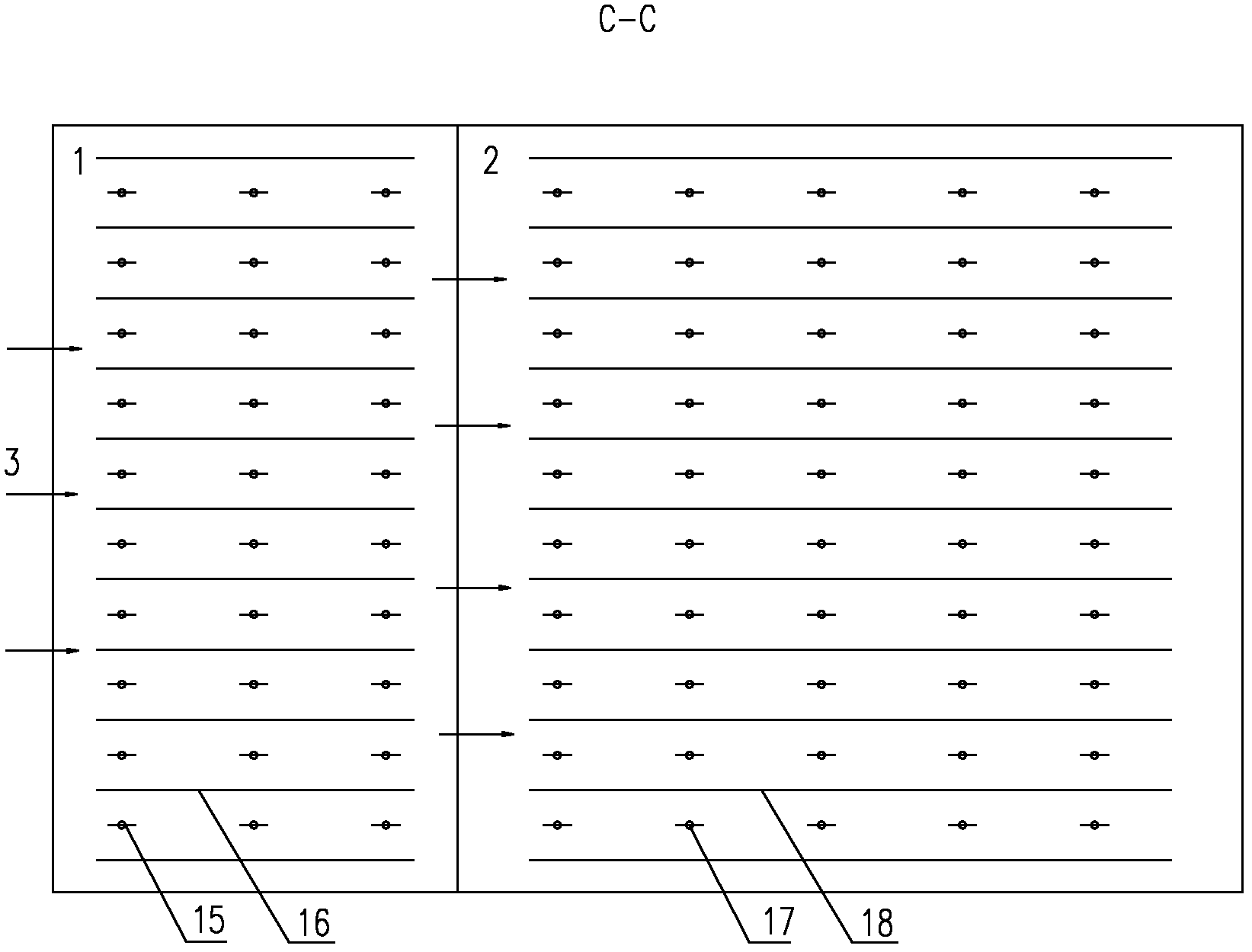

Electric-bag composite dust collector

ActiveCN102327724AIncrease the filtration speedReduce processingCombination devicesEngineeringDust emission

The invention discloses an electric-bag composite dust collector. The electric-bag composite dust collector comprises a composite dust collecting region in a housing, wherein the composite dust collecting region comprises an electric bag dust collecting region and a first electric field dust collecting region; the electric bag dust collecting region comprises a filter bag region and a second electric field dust collecting region; a filter bag dust collecting device is arranged in the filter bag region, and located on the upper end of the electric bag dust collecting region; an electric field dust collecting device is arranged in the second electric field dust collecting region, which is communicated with the filter bag region and located on the lower end of the electric bag dust collecting region; and an electric field dust collecting device is arranged in the first electric field dust collecting region, which is communicated with the electric bag dust collecting region and located onthe front end of the electric bag dust collecting region. In the electric-bag composite dust collector provided by the invention, the second electric field dust collecting region is arranged on the lower end of the electric bag dust collecting region, so that the dust can be recharged when a portion of smoke flows from the first electric field dust collecting region to the second electric field dust collecting region, thereby enhancing the dust charging strength. Additionally, the second electric field dust collecting region can effectively collect dust dropping from the filter bag region when the dust is removed, thereby reducing secondary dust emission, prolonging dust removal period, prolonging the service life of the filter bag, reducing the whole dust removing resistance, and improving the overall performance of the dust collector.

Owner:FUJIAN LONGKING

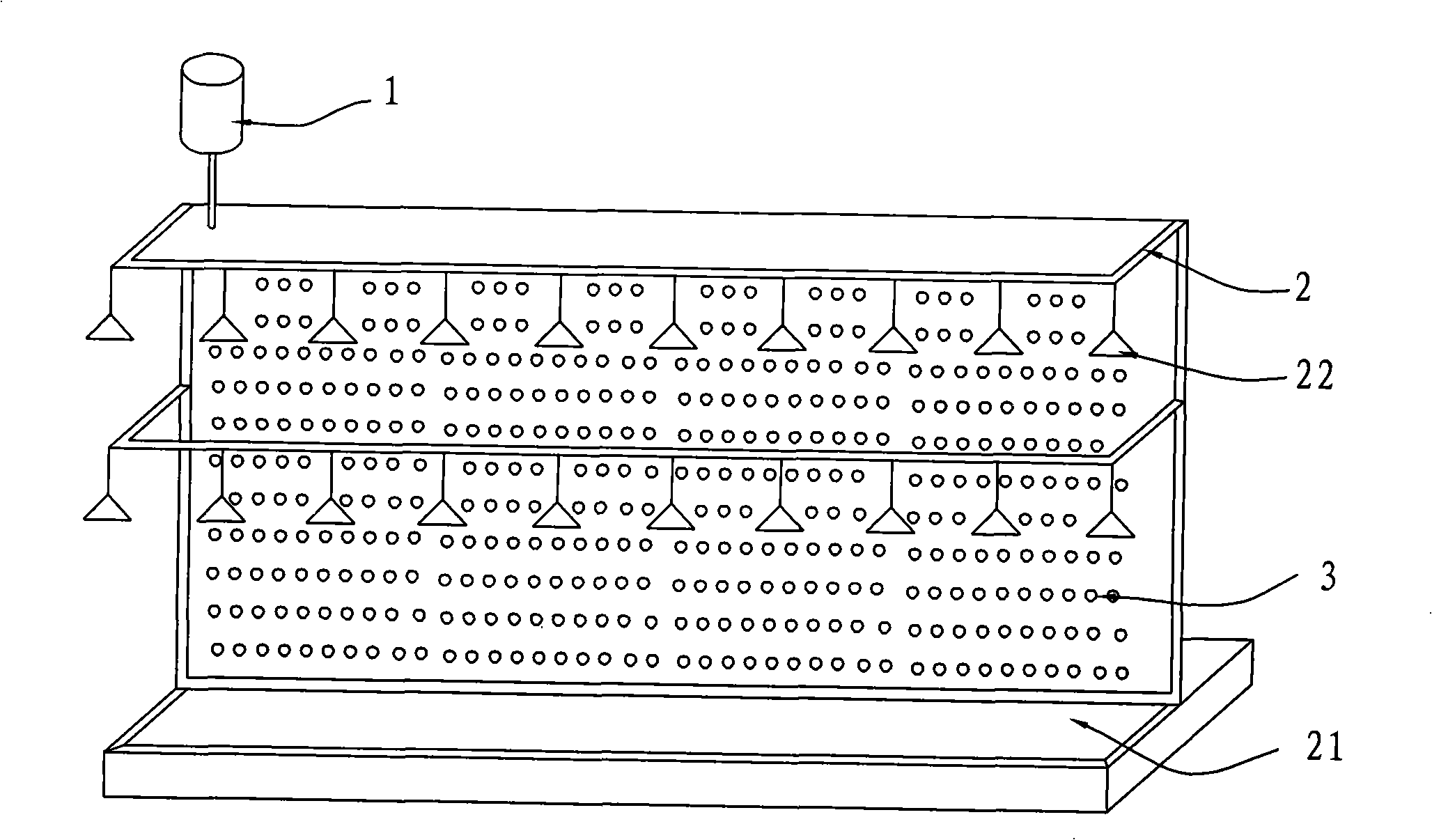

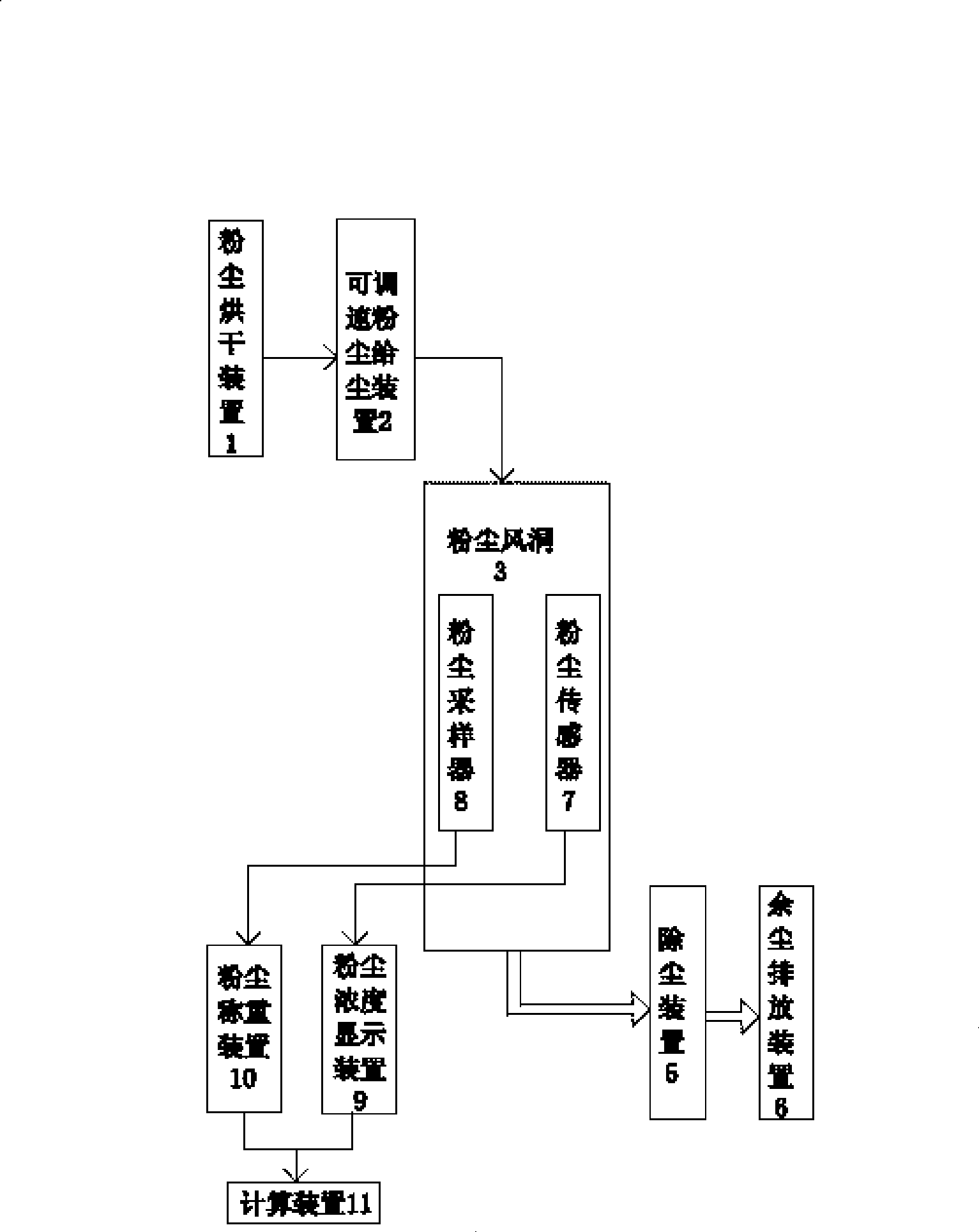

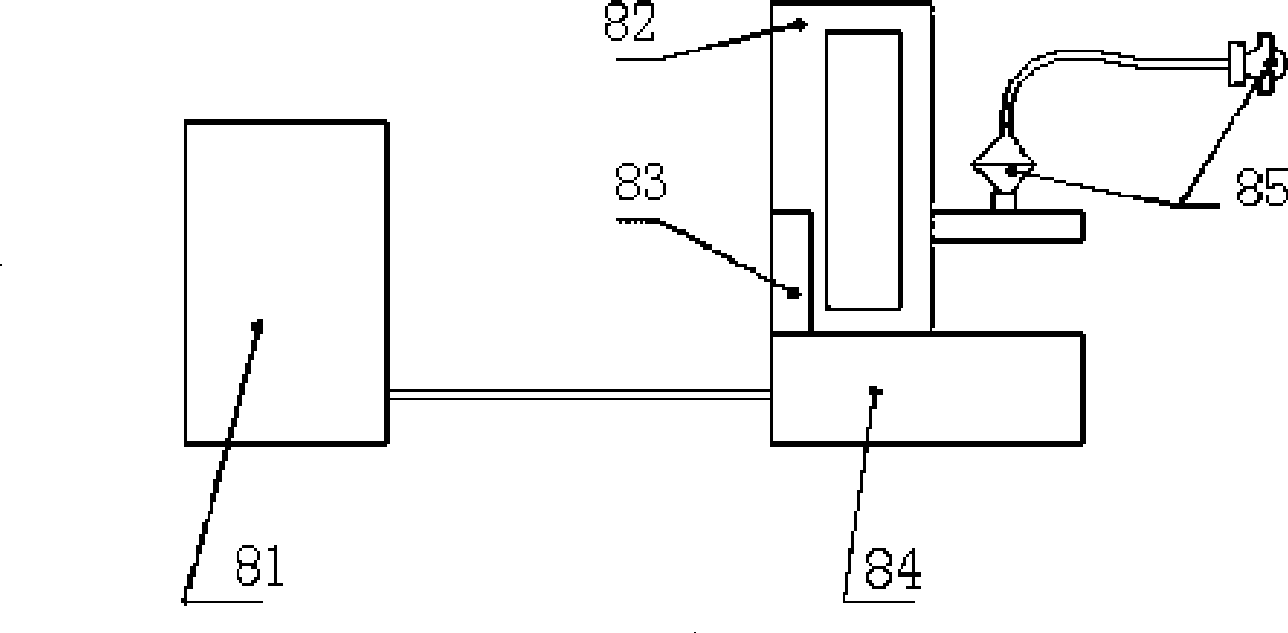

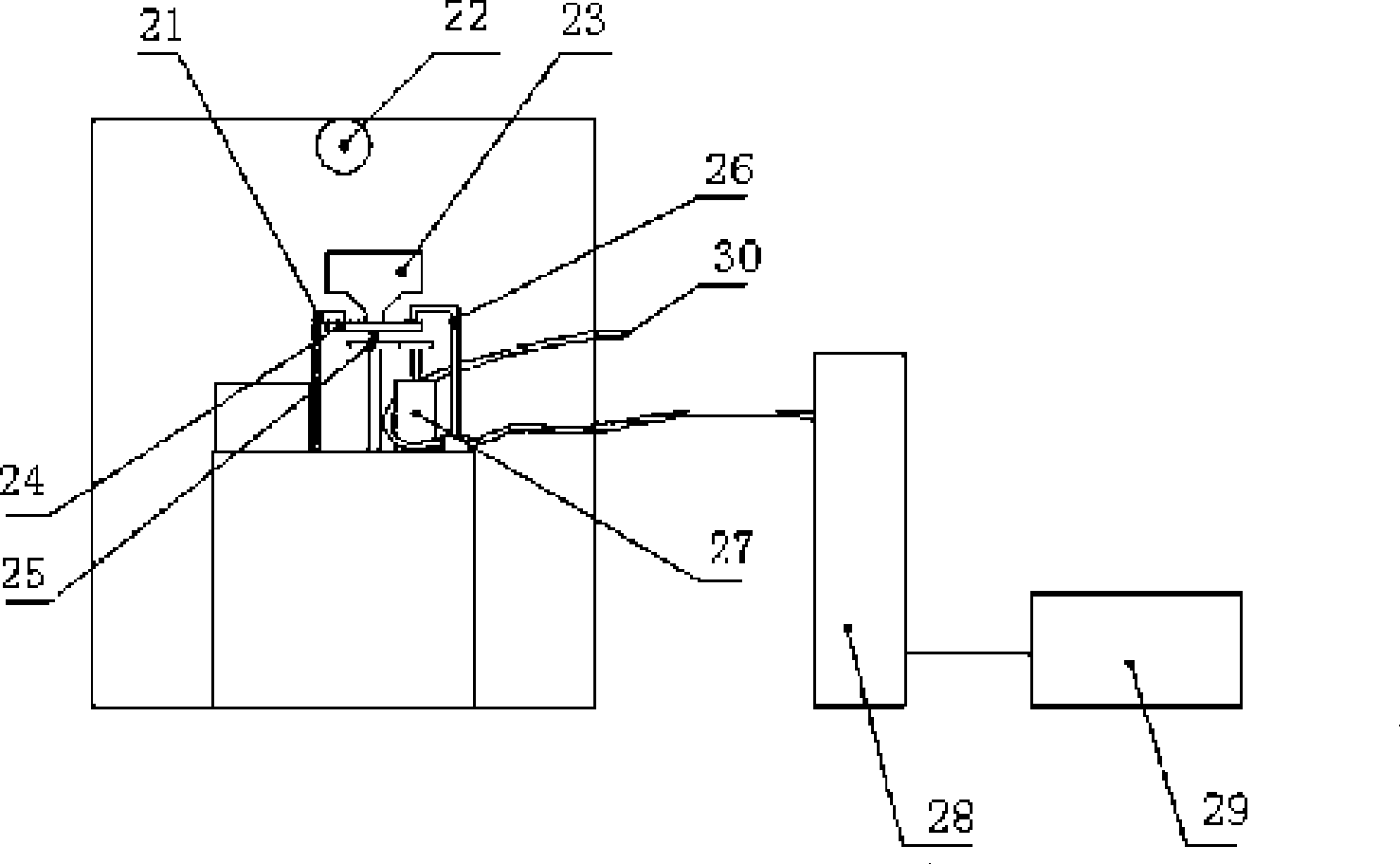

Wind tunnel test system of dust sensor

ActiveCN101504327AThe amount of dust is stableStable dustAerodynamic testingObservational errorDisplay device

The invention relates to a wind tunnel test system for a dust sensor, which comprises a dust drying device, a speed adjustable dust feed device connected with a dust output port of the dust drying device, and a dust wind tunnel. The dust wind tunnel comprises a wind inlet, a test section and a wind outlet; a dust output end of the speed adjustable dust feed device is arranged on the wind inlet of the dust wind tunnel; a dust sensor and a dust sampler are arranged in the test section of the dust wind tunnel parallelly; the wind outlet of the dust wind tunnel is connected with a dust removal device and a residual dust emission device in sequence; the dust sensor is connected with a dust concentration display device which displays a dust concentration value; dust sampled by the dust sampler is weighed through a dust weighing device to obtain the dust weight acquired in unit time; then, a corresponding dust concentration value can be calculated; and finally, the dust concentration value is compared with the dust concentration value displayed on the dust concentration display device, and a measurement error of the dust sensor can be calculated, thereby providing basis for trial manufacture, production and maintenance of the dust sensor.

Owner:JIANGSU SHINE TECH

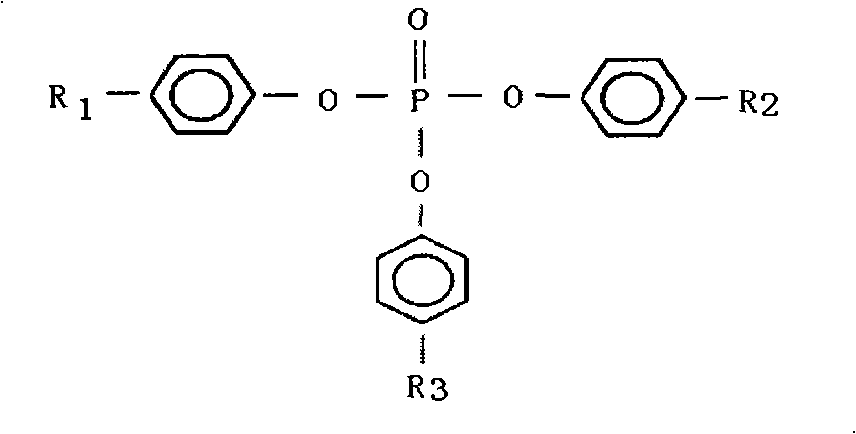

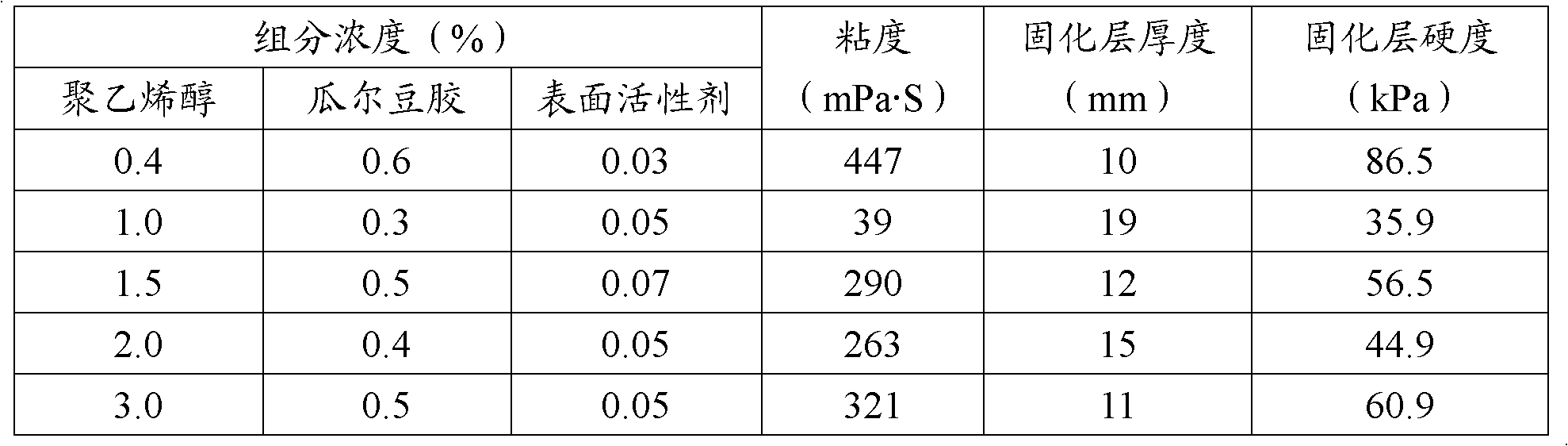

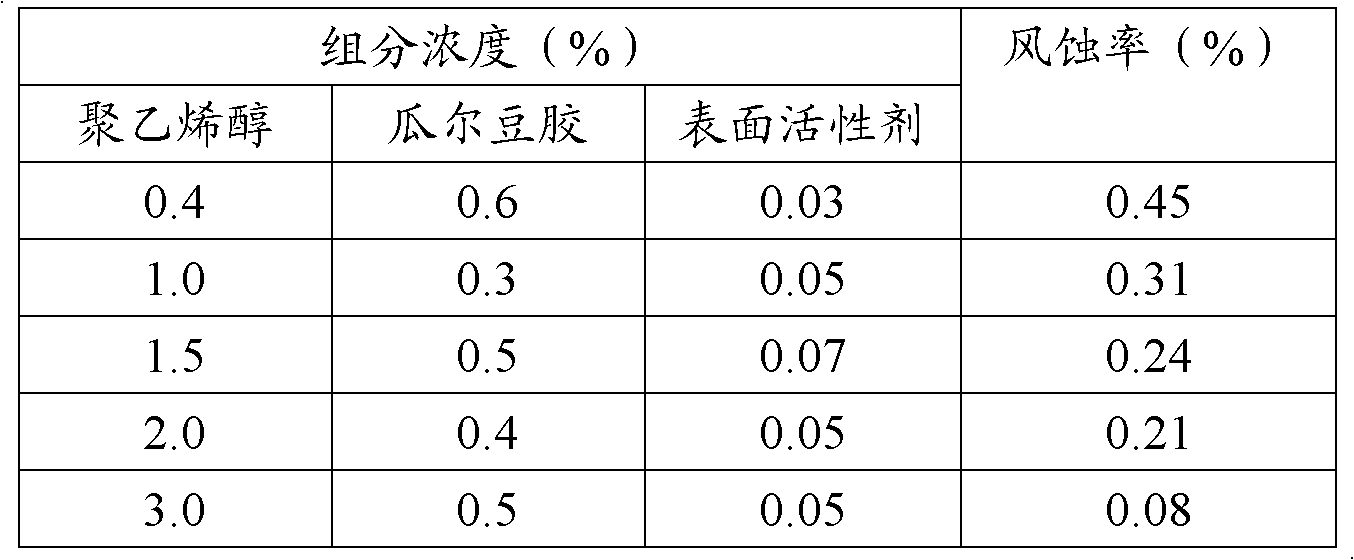

Phosphorus ore dust suppressant composition and preparation method thereof

ActiveCN102093846ADoes not affect processingDoes not affect transportation handlingOther chemical processesPolyvinyl alcoholPhosphate

The invention relates to a phosphorus ore dust suppressant composition and a preparation method thereof. The phosphorus ore dust suppressant composition comprises water-soluble polyvinyl alcohol, guar gum, microbicide, and water. The phosphorus ore dust suppressant provided by the invention can form a solidifying layer with certain strength and tenacity on the surface of phosphorus ore or powdered ore, which allows granular or powdered phosphorus ores to bond together, so as to effectively suppress dust emission of powder phosphate ores. The phosphorus ore dust can also be used for treatment of soil desertification and dust suppression at construction sites or dust suppression of other ores and can not pollute environment.

Owner:兰州天际环境保护有限公司 +1

Biomass cyclone dust removal burner

ActiveCN105864745AIncrease burn rateImprove combustion effectSolid fuel combustionAir/fuel supply for combustionCycloneCombustion chamber

The invention discloses a biomass cyclone dust removal burner. The biomass cyclone dust removal burner is characterized in that a cyclone dust removal burner is arranged at the upper part of a furnace body and at the lower end of a furnace body fire outlet, the cyclone dust removal burner divides the furnace body into a lower burning chamber and an upper burning chamber, a secondary air supply tube consistent with the spiral direction of the cyclone dust removal burner is arranged in the upper burning chamber, the cyclone dust removal burner consists of a concave barrel and S-shaped helical blades arranged outside the concave barrel, the head ends and the tail ends of the S-shaped helical blades are connected at intervals, and the helical angles of the S-shaped helical blades are 15-30 degrees. The biomass cyclone dust removal burner can keep dust particles formed after burning in the upper burning chamber and further enhances the wall-attaching dust collection effect under the centrifugal action, so that the burning effect, the dust removal performance and the fire purity of the burner are remarkably improved, the dust emission concentration is less than or equal to 5 mg / m<3>, the fume blackness reaches Ringelmann 0 grade, dust larger than 30 micrometers cannot overflow, a smoke-free and dust-free effect can be basically achieved, and the specifications of the biomass cyclone dust removal burner are higher than those of like products in the prior art.

Owner:郭征旭 +1

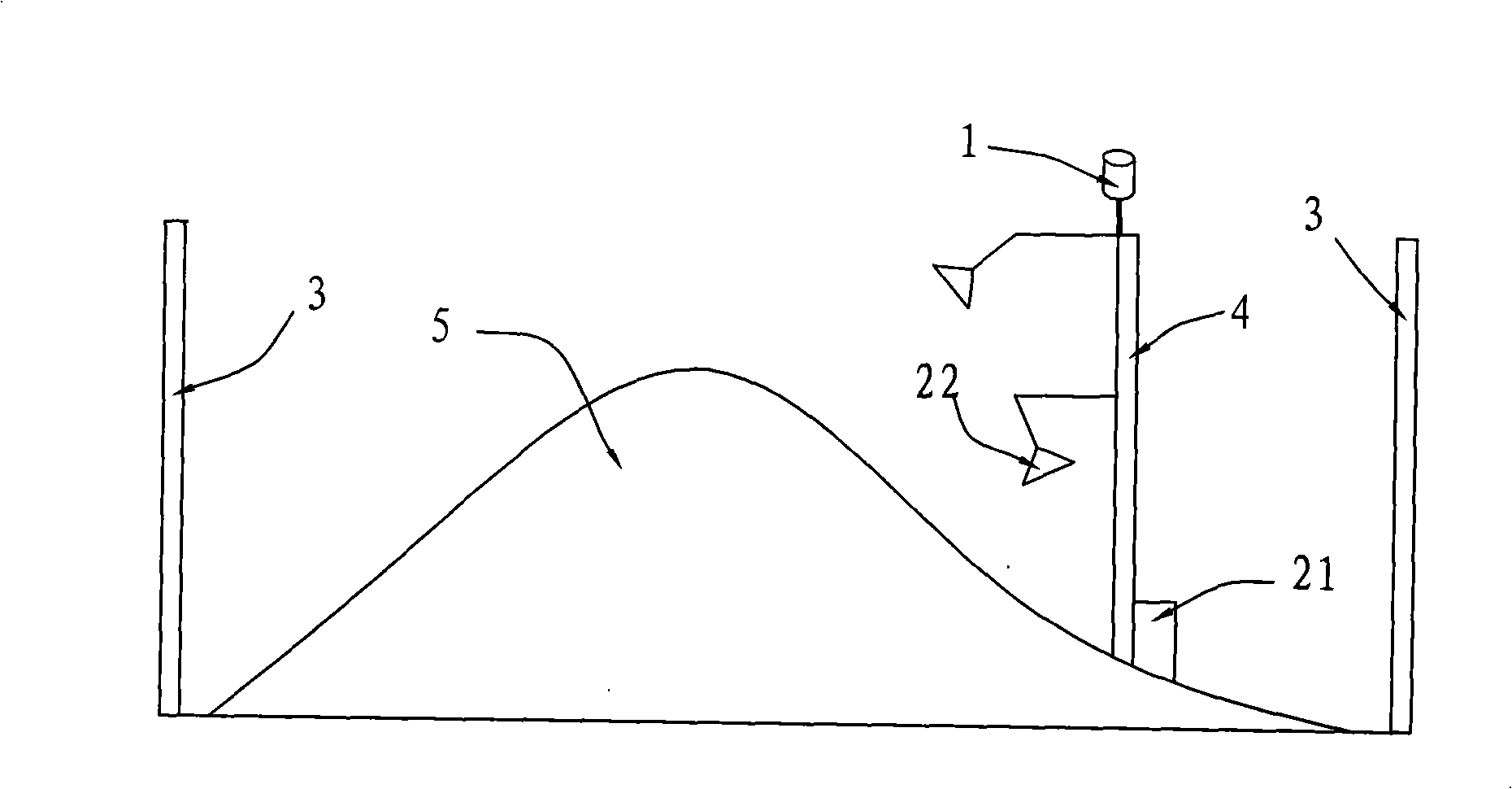

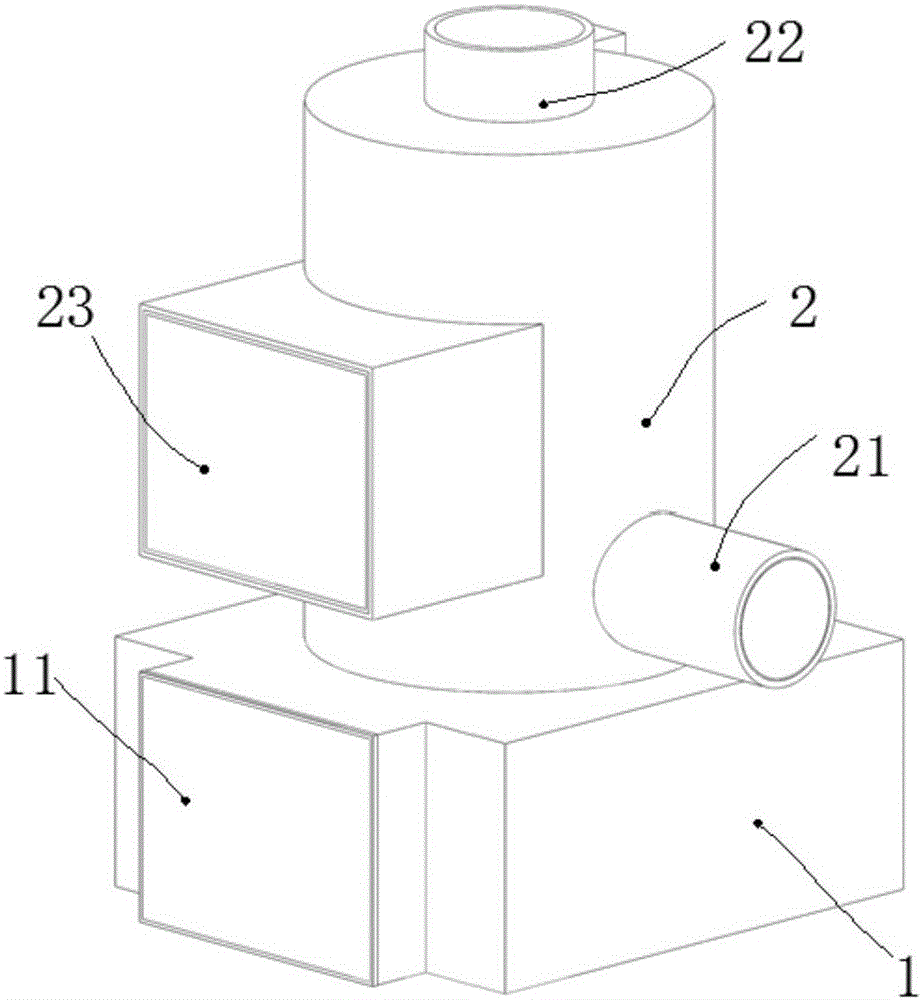

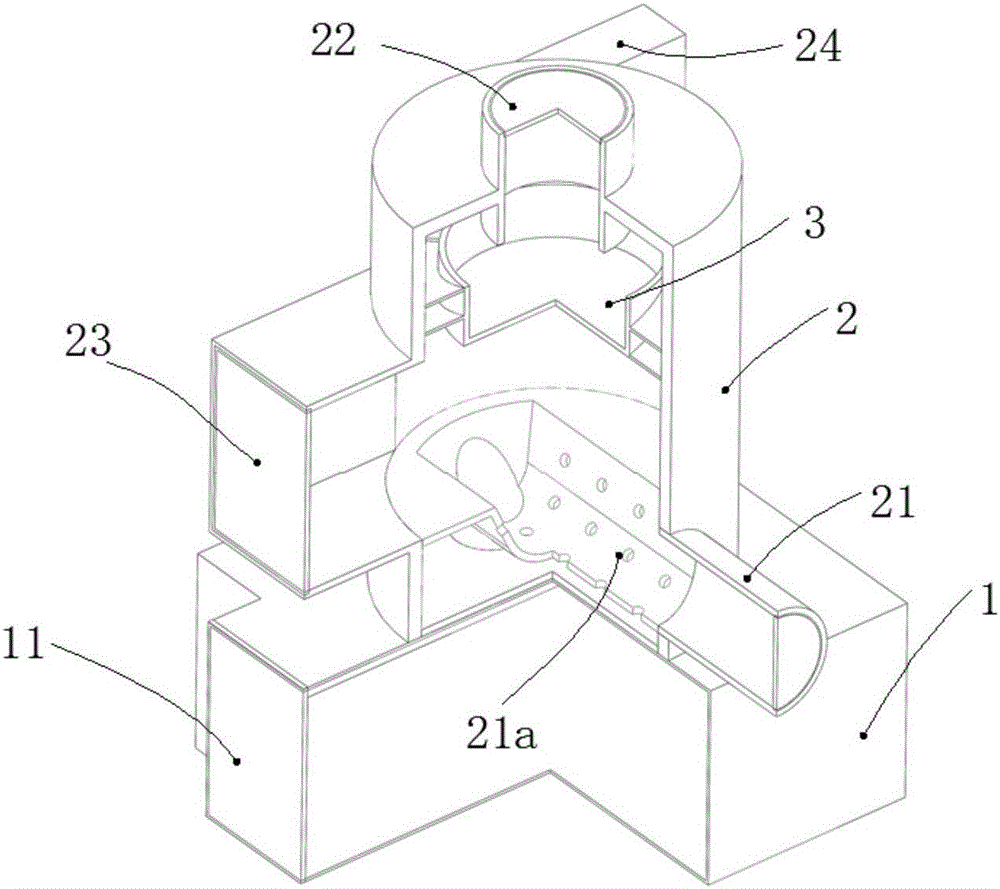

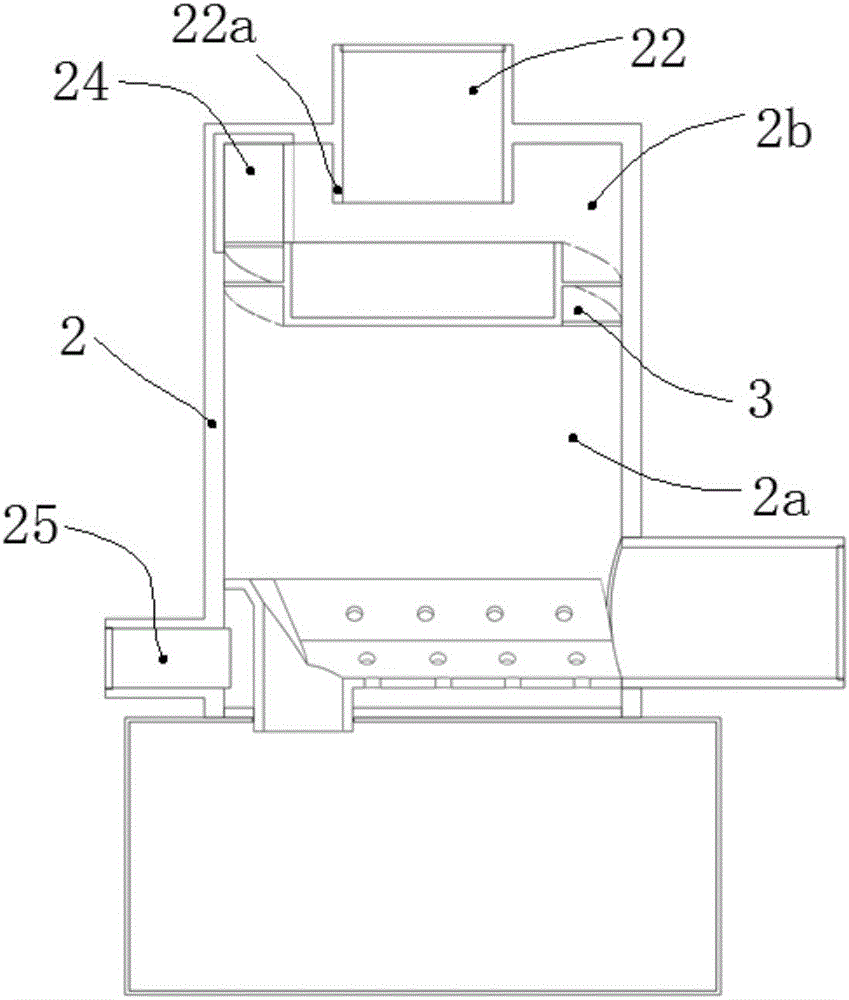

A slab continuous casting crystallizer protection slag automatically adding device

A slab continuous casting crystallizer protection slag automatically adding device, pertaining to the field of continuous casting process equipment, includes a large hopper, electric valves, a feeding tube, a small hopper, a screw feeder, a two-dimensional movement mechanism and a base. The device uses gravity to fall material from height, so that the large hopper is far away from the crystallizer mouth, to increase storage amount and allow long time of continuous work; the small hopper with small size, the screw feeder and the two-dimensional motion mechanism are reasonably installed at the intermediate tanker flank nearby the crystallizer to avoid the obstruction to the observation and operation of workers because the device is mounted in front of the crystallizer; the precise control of the feed amount can be achieved by the screw feeder; the conveyer tube is totally enclosed, which avoids slag leakage and dust emission; orthogonal coordinate type two-dimensional motion mechanism can realize a larger area of protection slag uniform spreading, which adapts to different sizes of slabs and billet production; automatic uniform slag adding is achieved, billet surface quality can be improved and the labor intensity of workers is reduced.

Owner:CISDI ENG CO LTD +1

Novel dust-inhibiting and fire-retarding covering agent for coal, and preparation method thereof

InactiveCN102464971ALow costEasy to produceOther chemical processesSpontaneous combustionSocial benefits

The invention discloses a novel dust-inhibiting and fire-retarding covering agent for coal, and a preparation method thereof. The dust-inhibiting and fire-retarding covering agent comprises components of, by mass: 4-5% of a film forming agent, 10-12% of a curing agent, 2-3% of a film forming auxiliary agent, 1-3% of a penetrant, 1-3% of a fire retardant, and 74-82% of water. The preparation method of the dust-inhibiting and fire-retarding covering agent comprises steps that: the film forming agent is added and dissolved in water under a certain temperature; the temperature is controlled; the solution is continuously stirred, and the curing agent, the film forming auxiliary agent, the penetrant, and the fire retardant are orderly added to the solution while stirring; the mixture is stirred, until a reaction is sufficiently carried out. The novel dust-inhibiting and fire-retarding covering agent is sprayed onto the surface of coal under a normal temperature, and other equipments and conditions are not required. Within a short time, a flexible and compact continuous high-molecular covering membrane is formed, such that phenomena of dust emission and spontaneous combustion during transportation and stacking processes can be avoided. Therefore, coal economic loss and environmental pollution can be effectively reduced; and great economic benefits and social benefits of environmental protection are provided.

Owner:SHANDONG UNIV OF SCI & TECH

Mine field dust emission inhibitor and preparation method thereof

InactiveCN105062423ASuppress flyingReduce surface tensionOther chemical processesAnti freezingDust emission

The present invention discloses a mine field dust emission inhibitor and a preparation method thereof. The raw materials of the mine field dust emission inhibitor comprise a surfactant, a stabilizer, a wetting agent, an anti-freezing auxiliary agent, and water. During preparation, a proper amount of water is firstly added into a reaction kettle, and the surfactant and the stabilizer are added into the reaction kettle; after the surfacant and the stabilizer are sufficiently dissolved, the wetting agent is slowly added, and dissolved by stirring; then, the anti-freezing auxiliary agent is added; and finally, the residual water is added until determined concentration. According to the mine field dust emission inhibitor disclosed by the invention, the dust suppression principle of the mine field dust inhibitor is that the surfactant is utilized to form an isolating membrane on the contact surface of dust and air, and the isolating membrane has good water carrying property and adhesive property, so that the isolating membrane on the dust surface has stronger wettability and stability, and small-particle dust is aggregated into a large-particle solid, thereby achieving an ideal dust falling effect. and by adding a small amount of salt, the dust inhibitor has certain anti-freezing effect.

Owner:ANHUI ZHONGFA ENVIRONMENTAL PROTECTION TECH CO LTD

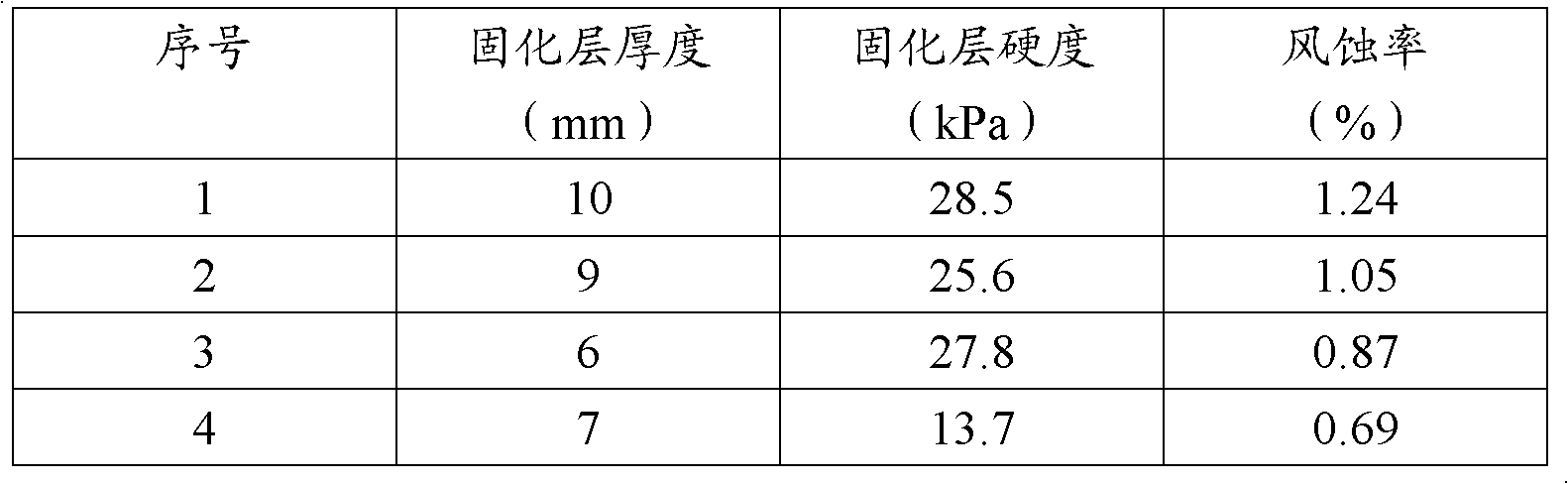

Stockyard dust emission inhibitor as well as preparation method and application thereof

InactiveCN106479277AHigh strengthQuality improvementLiquid surface applicatorsStarch dervative coatingsEmulsionPolyvinyl alcohol

The invention provides a stockyard dust emission inhibitor as well as a preparation method and an application thereof. The stockyard dust emission inhibitor is prepared from components forming the formula in parts by weight as follows: 5-20 parts of oxidized starch, 0.8-2.0 parts of modified cellulose, 2-10 parts of EVA emulsion, 0.6-0.8 parts of polyvinyl alcohol, 0.1-1 part of an emulsifier, 0.2-2 parts of a penetrant, 0.05-0.2 parts of a coalescing agent and the balance of water. The preparation method of the stockyard dust emission inhibitor comprises steps of preparing the oxidized starch, pretreating the raw materials, premixing the raw materials and mixing and stirring the raw materials. The dilution ratio and the spray times are determined according to the actual dust capacity, the dust emission inhibitor is diluted with water in a ratio of the dust emission inhibitor to water being 1:(10-20), then the solution is injected into high-pressure spray equipment and uniformly sprayed to the surfaces of stock piles in the dosage of 1.5 L / m<2> or higher, after the solution is dried, a polymer solidified layer with certain strength is formed on the stock surface, and stockyard dust emission inhibition is completed. The stockyard dust emission inhibitor is stable in quality, good in film-forming performance, high in solidified layer strength and wide in suitable material range, improves the environment after spray, can resist heavy weather and is long in spray cycle.

Owner:TANGSHAN JINSHA WATER TREATMENT COMPANY

Technique for crushing and water washing of aggregates on asphalt pavement of high-speed highway

InactiveCN101691732AImprove adhesionReduce pollutionRoads maintainenceEngineeringHigh pressure water

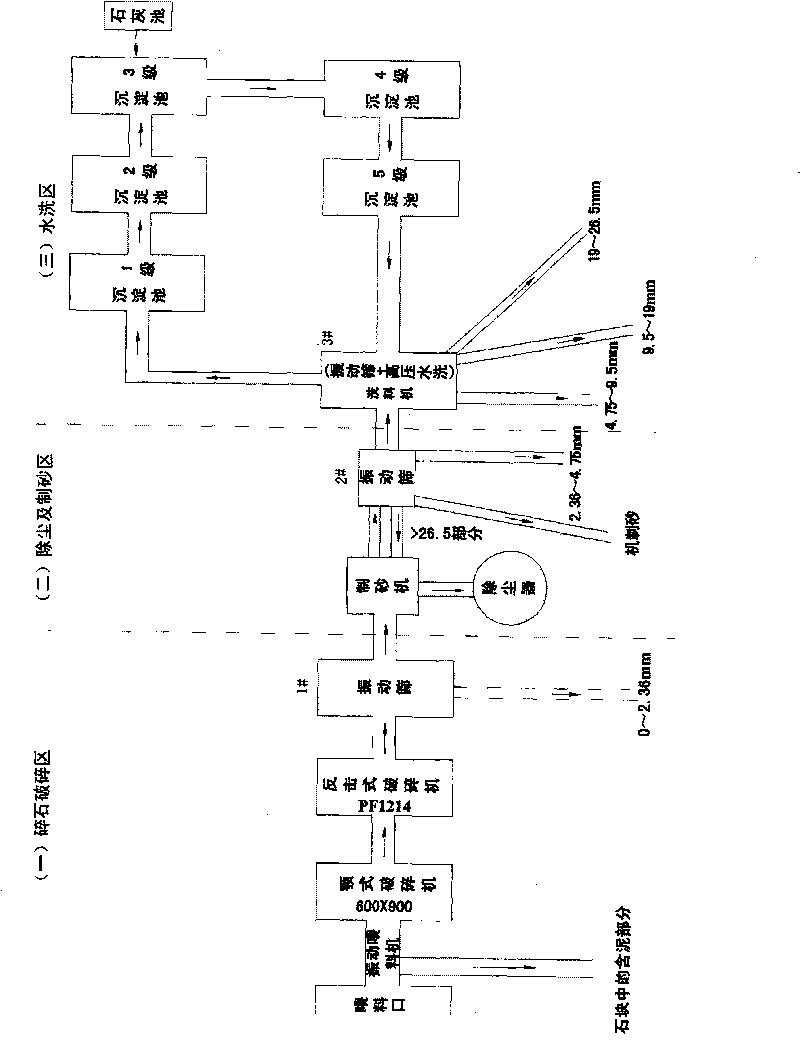

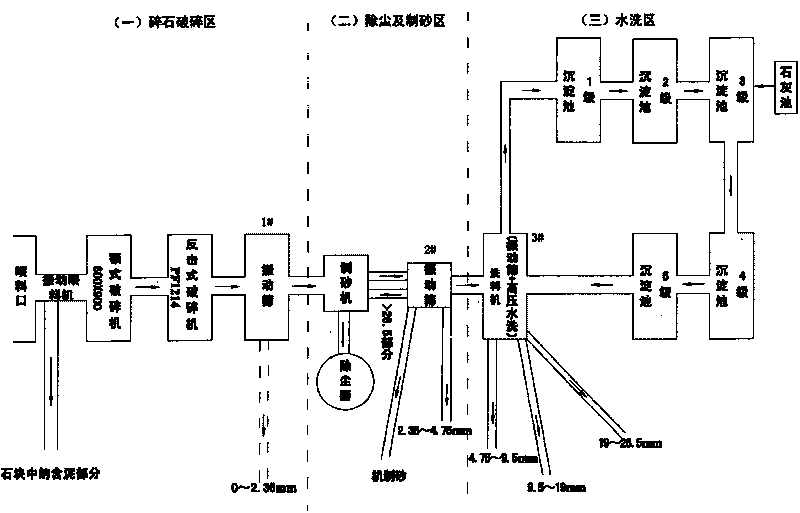

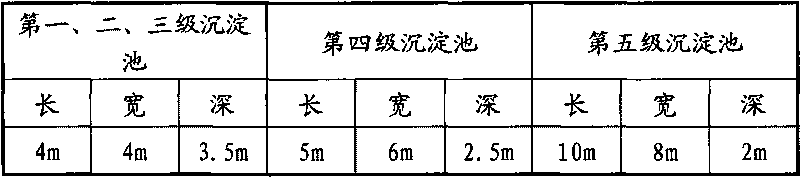

The invention relates to a technique for the crushing and the water washing of aggregates on an asphalt pavement of a high-speed highway, which comprises the following steps: selecting stone blocks at a feeding opening; crushing and sieving stone materials; manufacturing sand by a sand manufacturing machine and removing dust; washing coarse aggregates which are greater than 4.75mm by water; and flushing sewage, precipitating and recycling. By crushing three times, sieving four times, adopting the sand manufacturing machine to match with high-power dust removal equipment, arranging fan drum cloth at a discharge port of the sand manufacturing machine and arranging a water spraying facility for spraying water in a proper amount, the invention can effectively reduce dust emission and pollution to an ambient environment; the aggregates can be quickly and effectively washed in an omnibearing way by arranging a high-pressure water spraying pipe network above a vibration sieve, by washing the aggregates through limewater the surface cleanness and the surface alkalinity of the aggregates can be enhanced, and the adhesion property of asphalt is reinforced; and a five-level settling tank technology is adopted, flushing water is recycled, the cleanness of the used water is ensured, and water resources can be saved.

Owner:JIANGXI GANYUE EXPRESSWAY +2

Dry-type flue gas desulphurization, denitration and dedusting integrated device and method

InactiveCN101983755ASimple process controlSmall footprintDispersed particle separationAir quality improvementFlue gasSewage

The invention discloses a dry-type flue gas desulphurization, denitration and dedusting integrated device and method. The integrated device comprises a flue gas guide device, a reactor, a dedusting device, a draught fan and a funnel which are sequentially connected, as well as a circulation dust fluidization cabin, a humidifying digester, a denitration additive storage bin and a desulphurization absorbent storage bin. The circulation dust fluidization bin is arranged at the bottom of the dedusting device, the output end of the circulation dust fluidization bin is connected with the input end of the humidifying digester, and the output end of the desulphurization absorbent storage bin is also connected with the input end of the humidifying digester. The output end of the denitration additive storage bin is connected with at least one of the input end of the humidifying digester and the flue gas guide device. The invention has the advantages of simple process, small occupation, low one-time investment and low operating cost, the SO2 removing efficiency is 80 to 95%, the NOx removing efficiency is 40 to 65%, and the dust emission concentration is less than 50 mg / Nm<3>. The desulphurization and denitration efficiency of the invention can meet the requirement of environmental protection, the running resistance of the device is low, and no sewage generates during the desulphurization and denitration processes. The final product is dry powder and can not cause any secondary pollution, the flue gas can be directly discharged without the need of heat exchange, and the added denitration additive has the synergistic effect with the absorbent to strengthen the removing of the SO2, thereby enhancing the desulphurization efficiency.

Owner:浙江菲达脱硫工程有限公司 +1

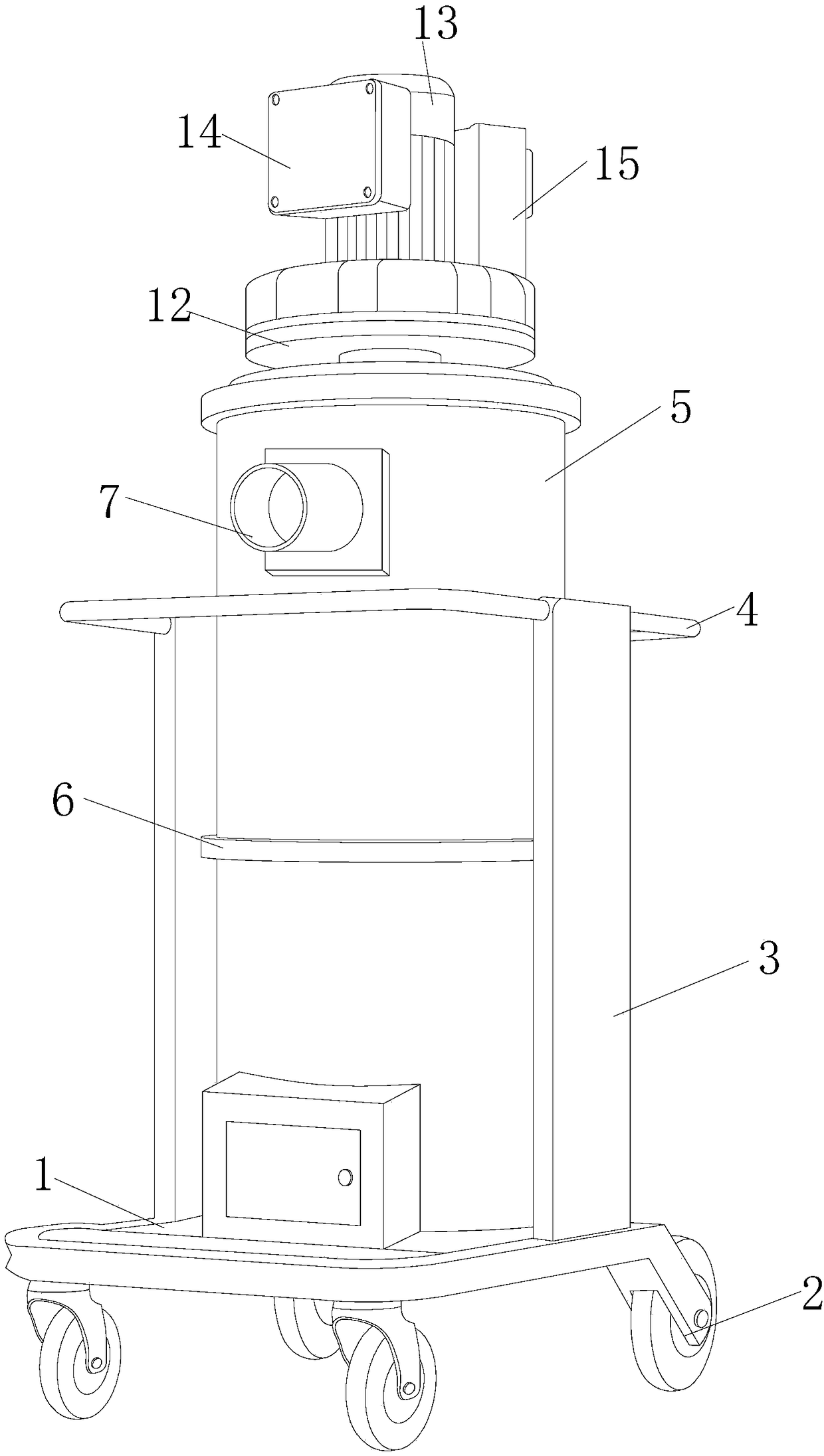

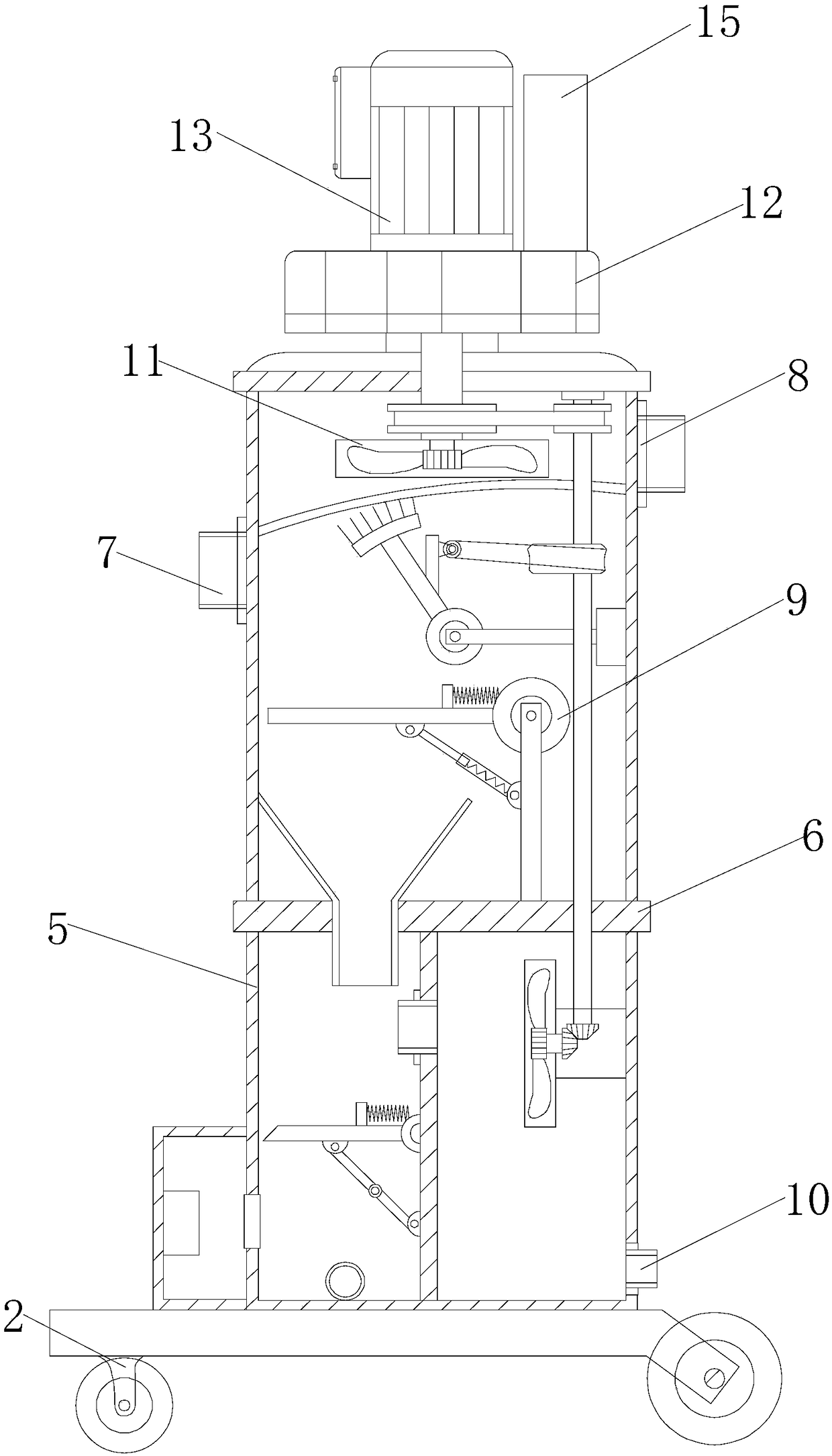

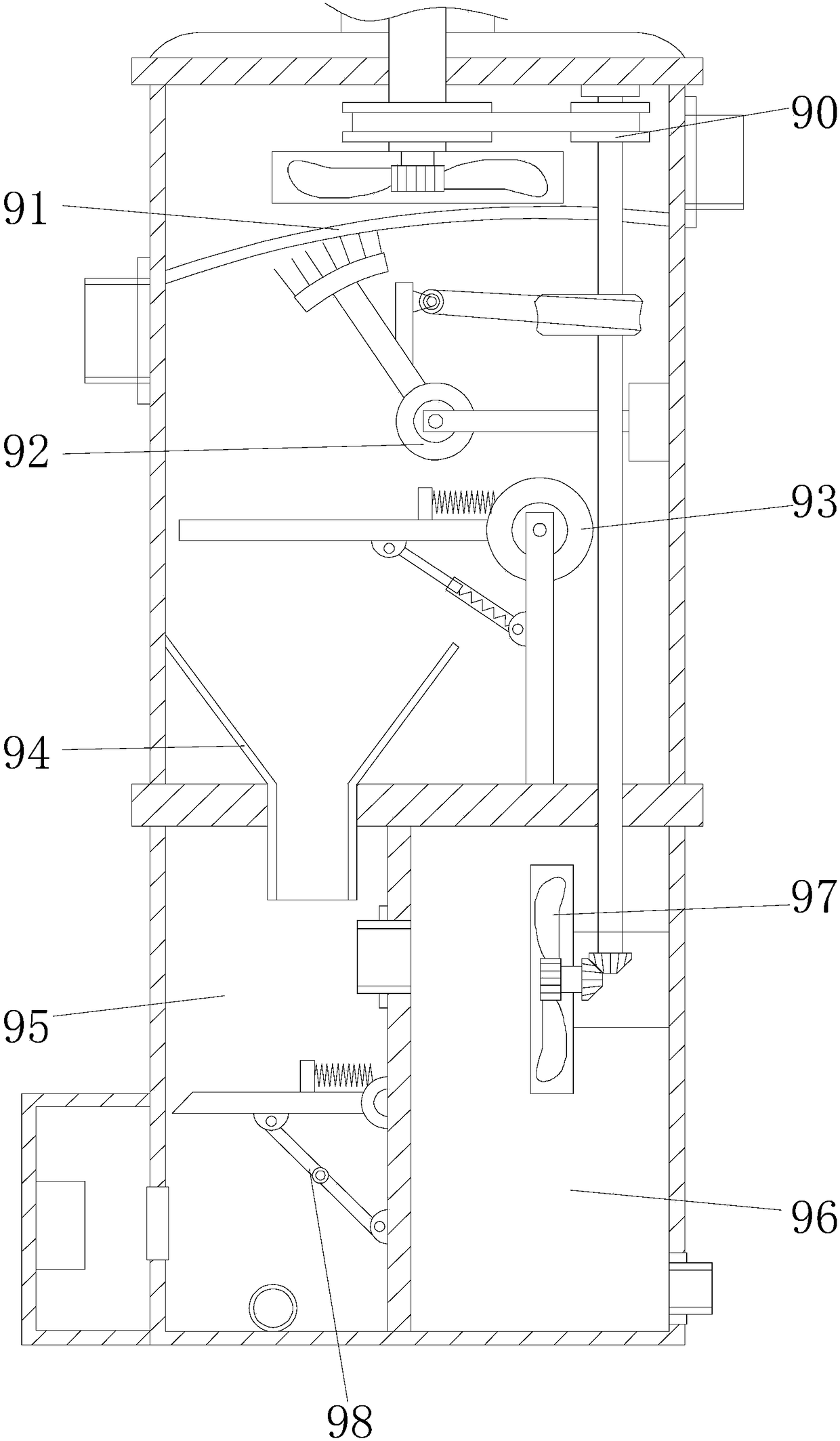

Environmental-protection air cleaning equipment used for hardware production workshop

ActiveCN108159818AImprove environmental performanceAvoid wastingCombination devicesGas treatmentElectricityAir cleaning

The invention discloses environmental-protection air cleaning equipment used for a hardware production workshop. The environmental-protection air cleaning equipment comprises a movable sweeping board,universal wheels, a support plate rack, a fixed rod frame, an air cleaning cylinder, a separation plate, an air-inlet pipe, an air-outlet pipe, a multiple screening processing apparatus, a dust-emission pipe, a turbine air-exhaust fan, a turbine air-exhaust apparatus, a servo motor, an electricity-connection box, and a distribution box. The movable sweeping board is in a rectangular stricture, the universal wheels are arranged at four ends below the movable sweeping board, and connected through screws in a spiral mode. The multiple screening processing apparatus can separate iron filings, metal shreds and dust collected during an air cleaning process, air purifying is realized, resource can be reutilized and classified for recovery, resource waste can be prevented, the utilization rate ofthe resource is increased, and the environmental-protection air cleaning equipment can effectively enhance the environmental protection performance for the air cleaning equipment.

Owner:万腾钣金(深圳)有限公司

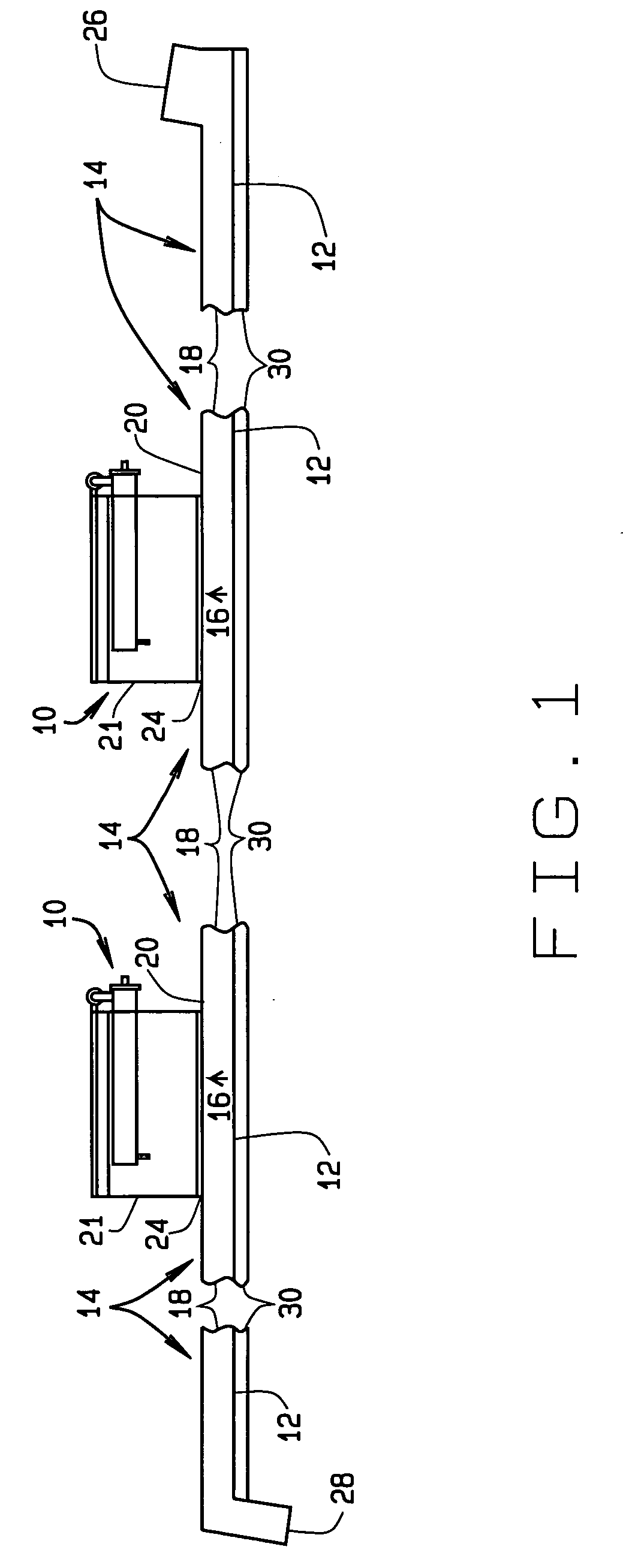

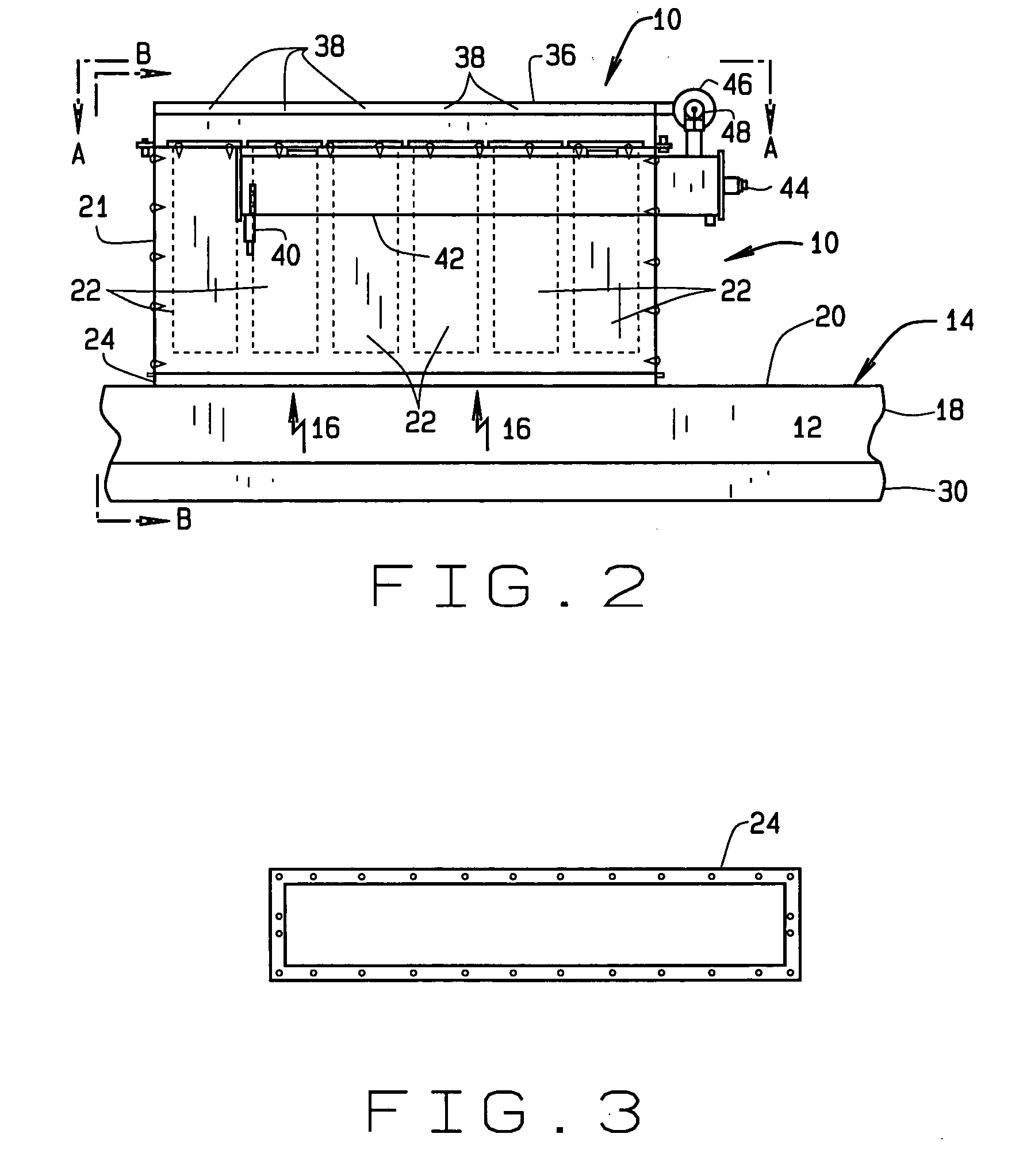

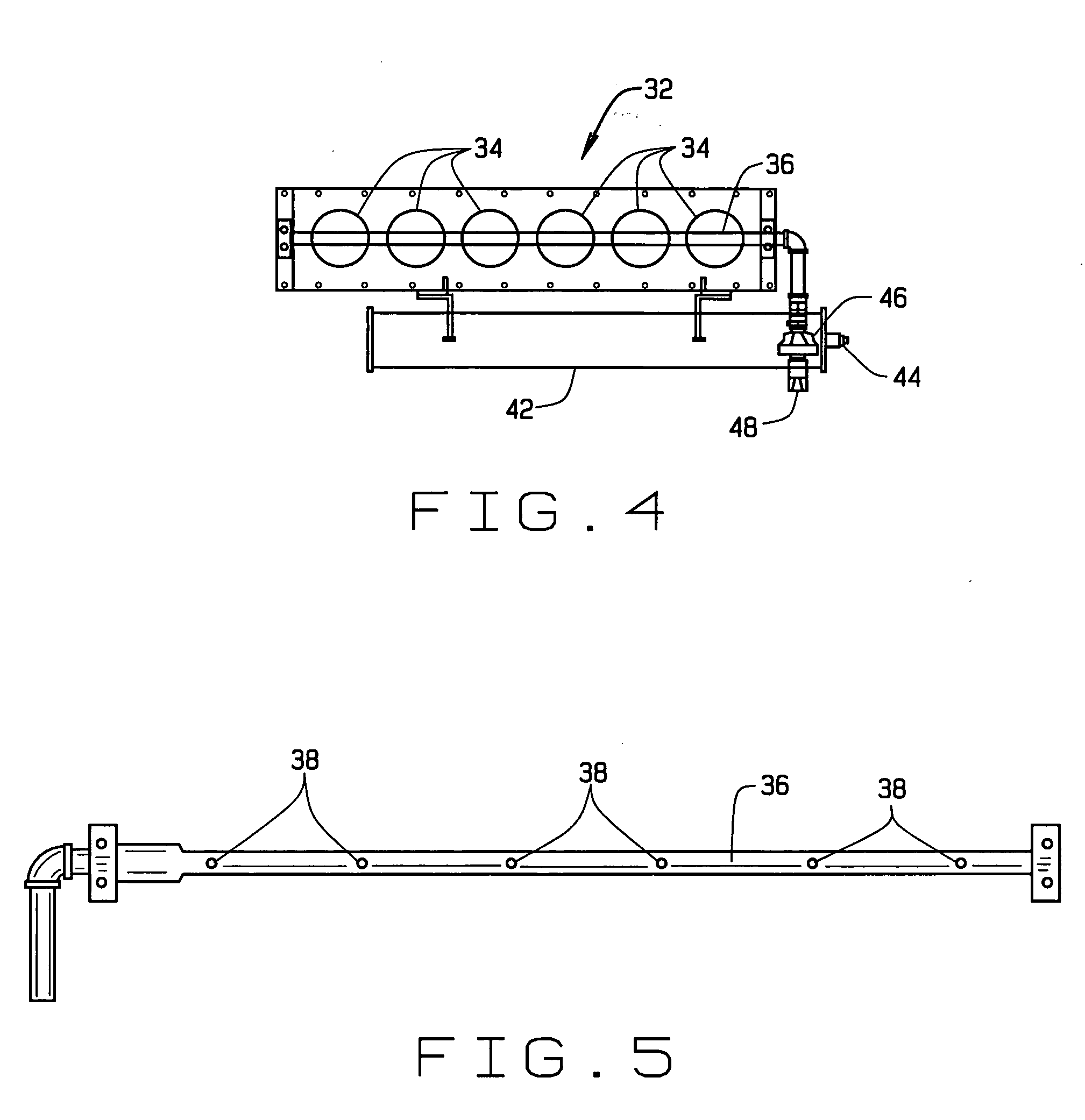

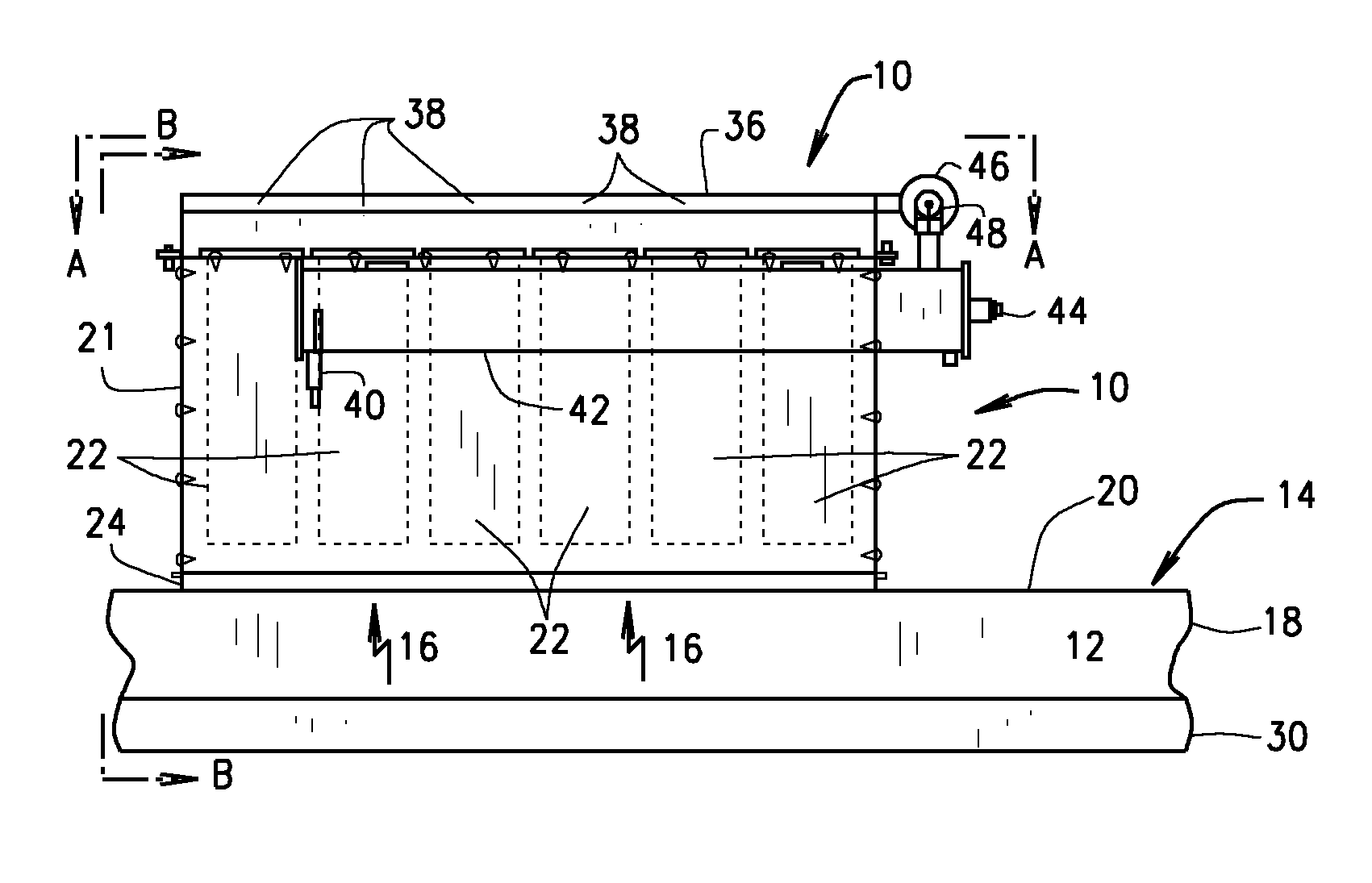

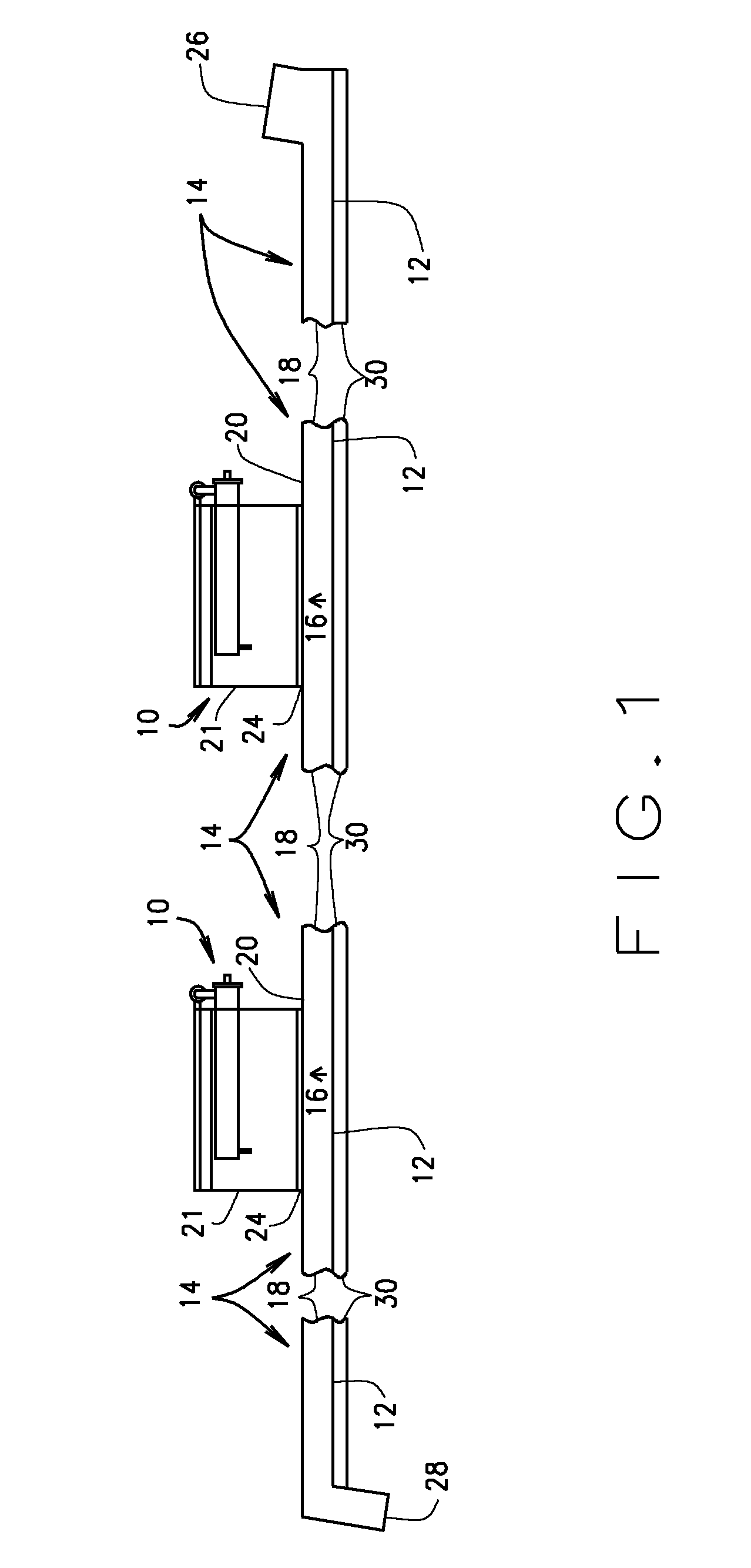

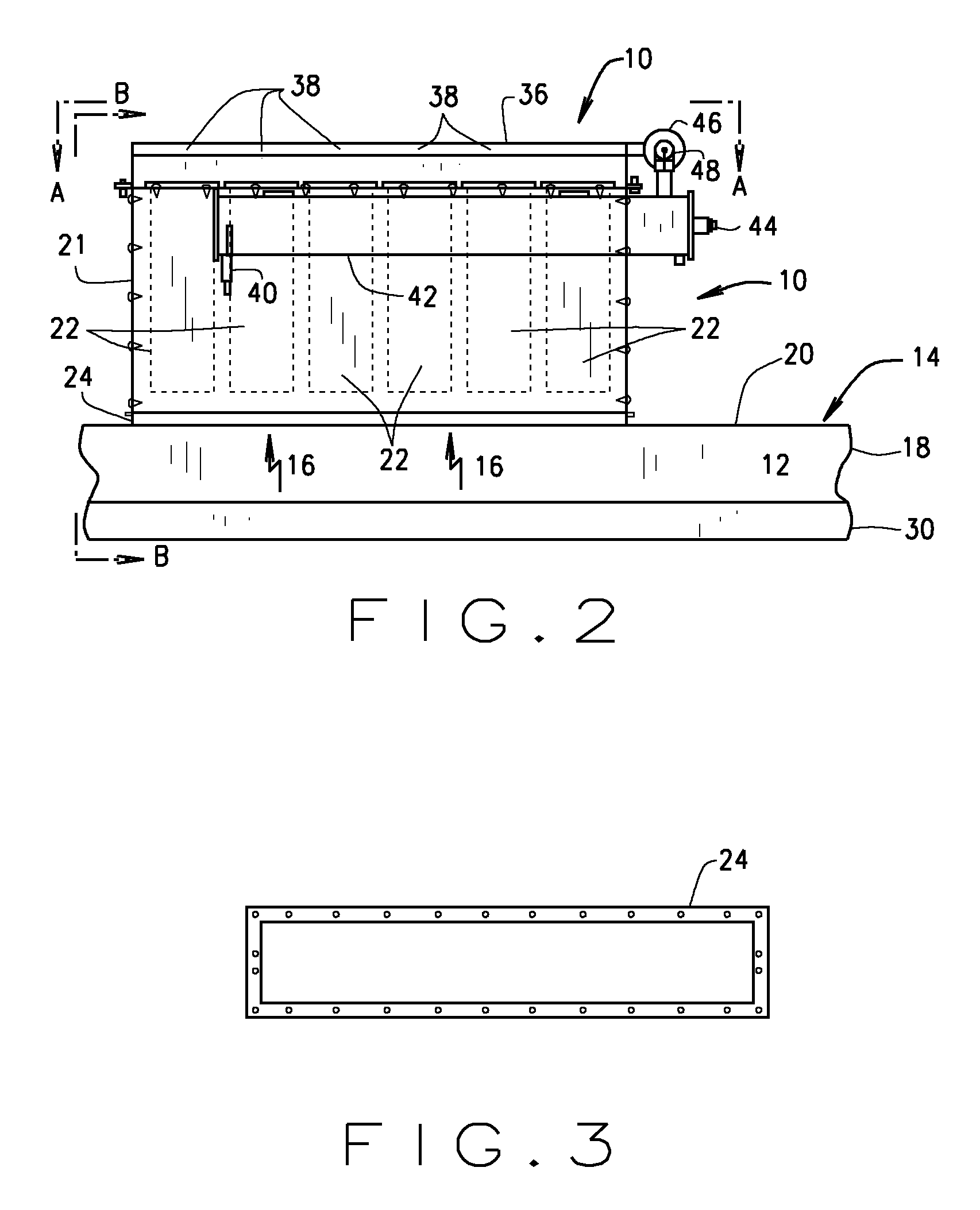

Methods and apparatus for air conveyor dust emission control

InactiveUS20060093444A1Easy to installDispersed particle filtrationBulk conveyorsEngineeringDust emission

A collector assembly is configured to vent dust-laden air through at least one filter in one direction using pressure in an air conveyor, whereby dust collects on one side of the filter or filters. The collector assembly is further configured to pulse compressed air through the filter or filters in an opposite direction to dislodge the collected dust into the air conveyor without the dislodged dust entering the atmosphere around the air conveyor.

Owner:BHA ALTAIR

Methods and apparatus for air conveyor dust emission control

InactiveUS7407346B2Easy to installDispersed particle filtrationBulk conveyorsEngineeringDust emission

A collector assembly is configured to vent dust-laden air through at least one filter in one direction using pressure in an air conveyor, whereby dust collects on one side of the filter or filters. The collector assembly is further configured to pulse compressed air through the filter or filters in an opposite direction to dislodge the collected dust into the air conveyor without the dislodged dust entering the atmosphere around the air conveyor.

Owner:BHA ALTAIR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com