Patents

Literature

371results about How to "Avoid enrichment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

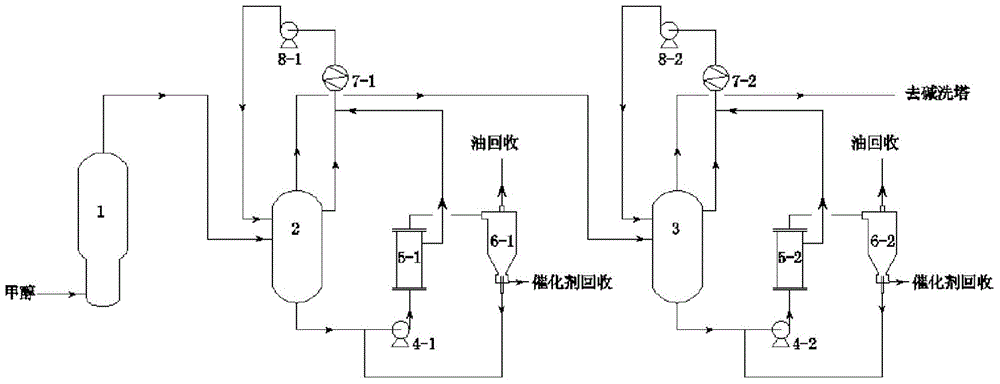

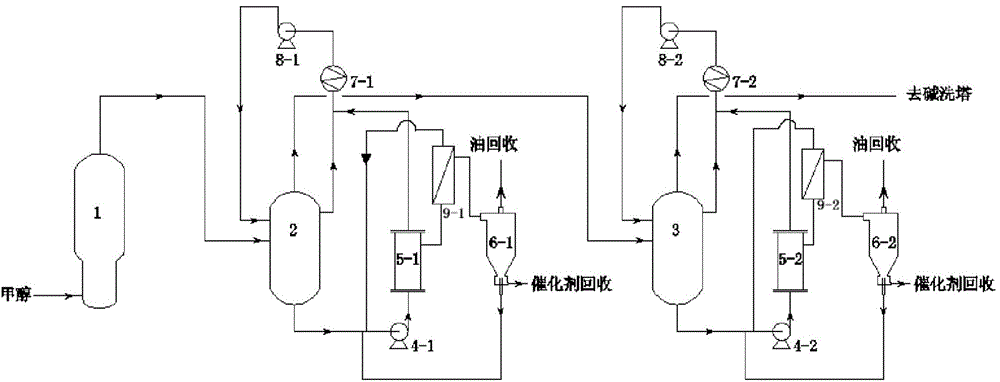

Solid and oil removal method and device for chilled water and washed water in MTO (methanol to olefin) process

ActiveCN103951098AEliminate enrichmentReduce the probability of forming large particlesHydrocarbon from oxygen organic compoundsMultistage water/sewage treatmentUF - UltrafiltrationChemistry

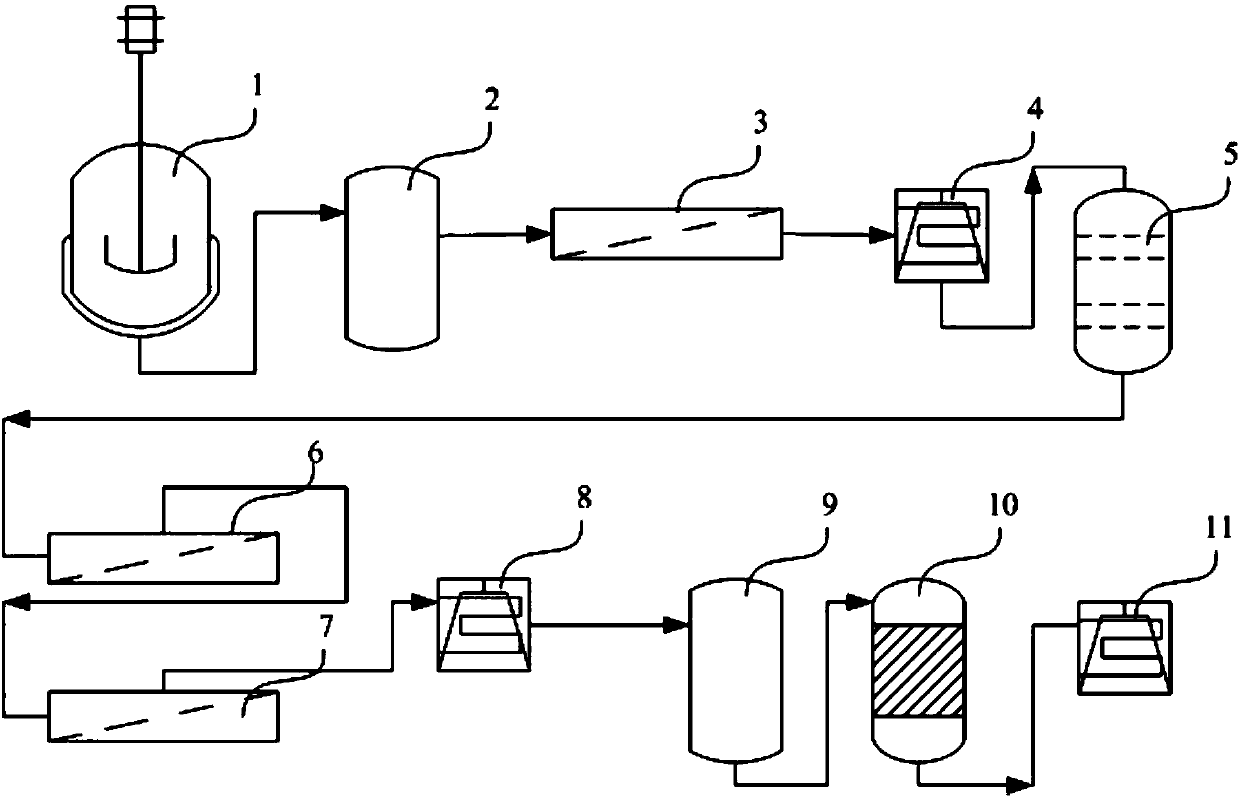

The invention relates to a solid and oil removal method and device for MTO (methanol to olefin) / MTP (methanol to propylene) chilled water and washed water. The method disclosed by the invention mainly comprises the following steps of carrying out ultrafiltration membrane separation on MTO / MTP chilled water, feeding an ultrafiltration membrane concentrated solution into a three-phase cyclone-separator separation system, and recovering a catalyst and oil; cooling ultrafiltration membrane permeated liquid, and feeding the obtained liquid back to a chilled water system to cyclically reuse; carrying out ultrafiltration membrane separation on MTO / MTP washed water, feeding an ultrafiltration membrane concentrated solution into the three-phase cyclone-separator separation system, and recovering a catalyst and oil; and cooling ultrafiltration membrane permeated liquid and feeding the obtained liquid back to a washed water system to cyclically reuse. The invention also provides a solid and oil removal device for MTO / MTP chilled water and washed water.

Owner:JIANGSU JIUWU HITECH

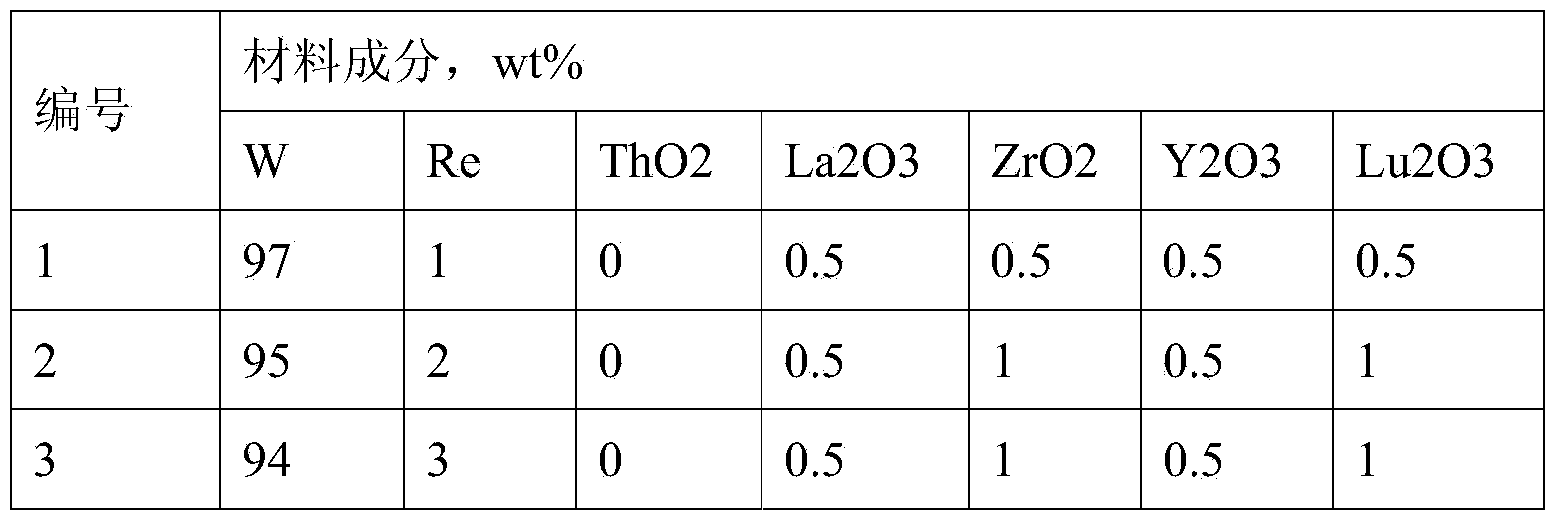

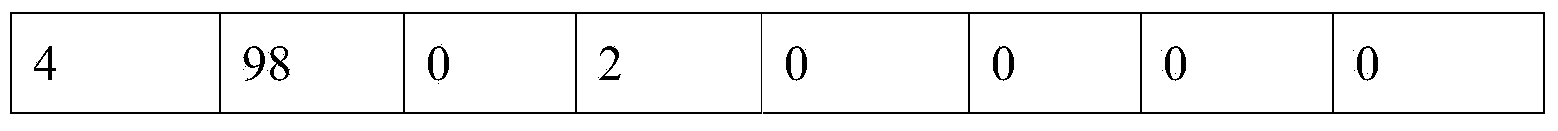

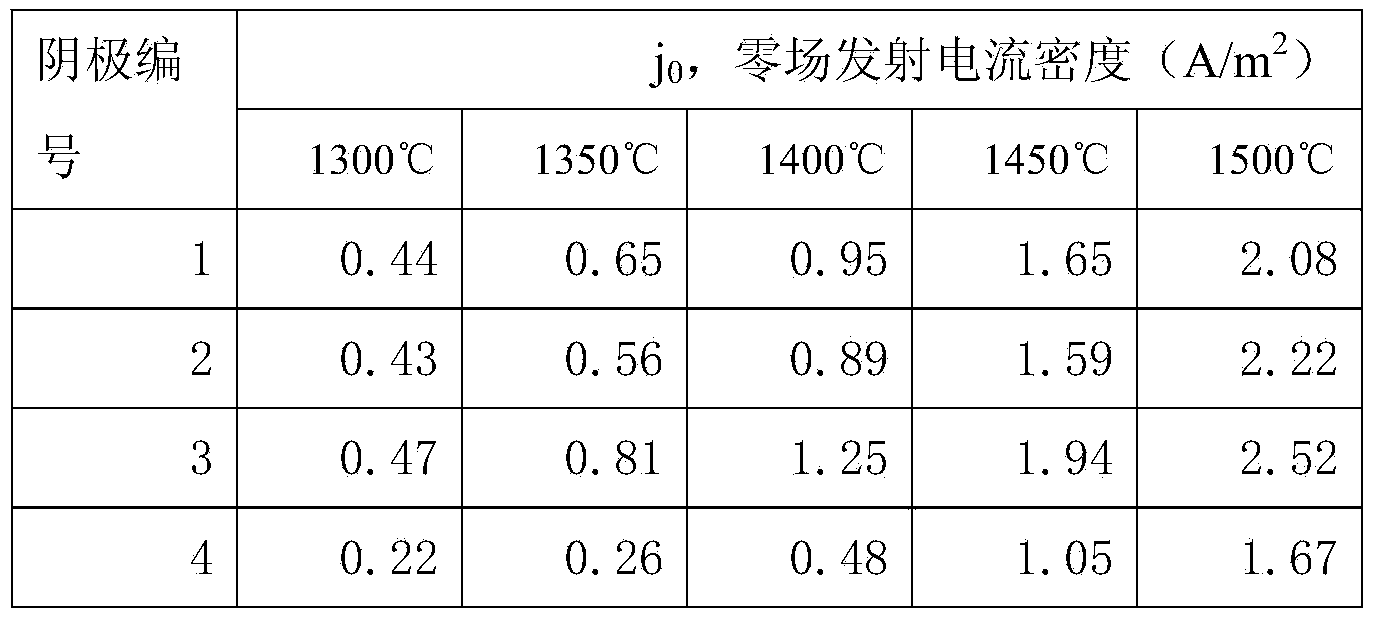

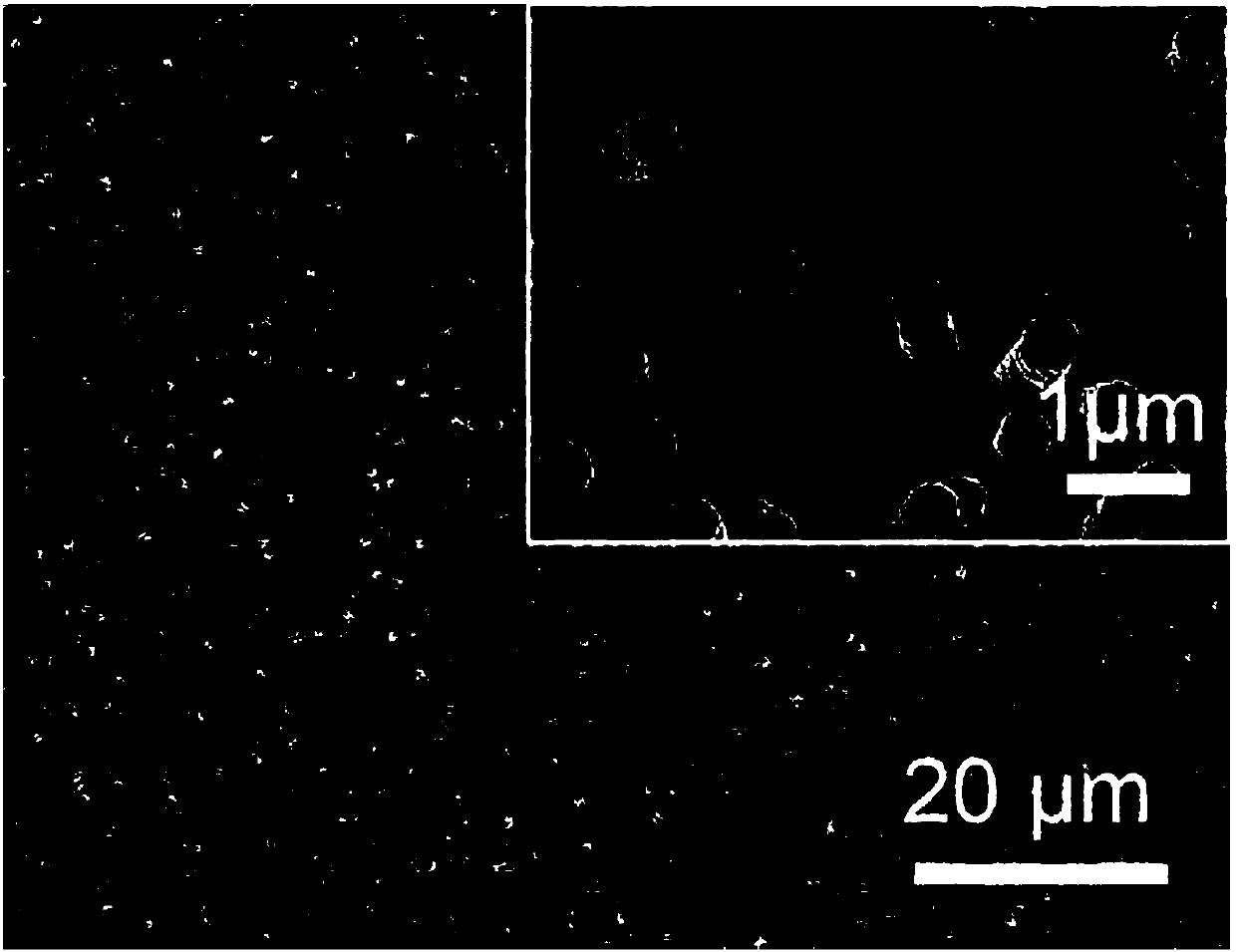

Non-radiative multi-component composite tungsten negative material for microwave oven magnetron and preparation process of negative material

InactiveCN103849804AImproved winding performanceWinding Performance GuaranteeTransit-tube cathodesRheniumLutetium

The invention discloses a non-radiative multi-component composite tungsten negative material for a microwave oven magnetron and a preparation process of the negative material. The tungsten cathode material comprises lanthanum oxide, zirconium oxide, yttrium oxide, lutetium oxide, rhenium and tungsten, wherein the mass percent of each rare-earth oxide in the tungsten electrode material is 0.5%-1.5%, the mass percent of the total rare-earth oxides in the tungsten electrode is 2%-3%, the mass percent of the alloy element rhenium in the tungsten electrode material is 1%-4%, and the tungsten accounts for the rest mass percent. The tungsten cathode material is non-radiative, excellent in thermal emission performance, excellent in high-temperature creep resistance, thermal shock resistance and sag resistance, and long in service life. The preparation method of the non-radiative multi-component composite tungsten cathode material for the microwave oven magnetron comprises the steps of solution preparation, drying, reducing, isostatic cool pressing, sintering, incipient fusion, medium-frequency induction annealing, press working, winding and mechanical straightening. The non-radiative multi-component composite tungsten negative material for the microwave oven magnetron is better in usability. When heated periodically for a long time at a high temperature, the multi-component composite tungsten wire produced by virtue of the process is capable of going through large deformational resistance, and has the sag resistance.

Owner:深圳市威勒科技股份有限公司

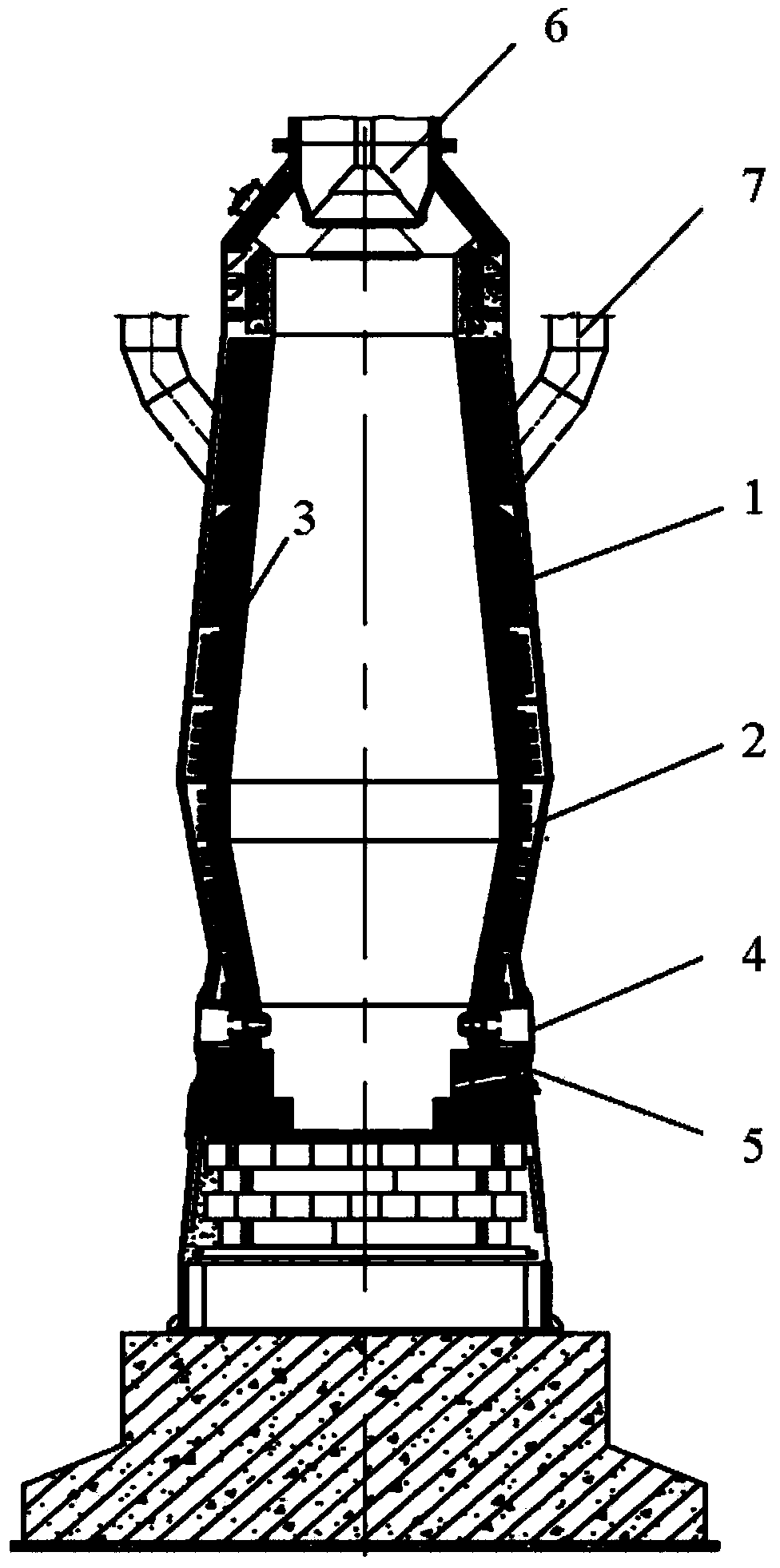

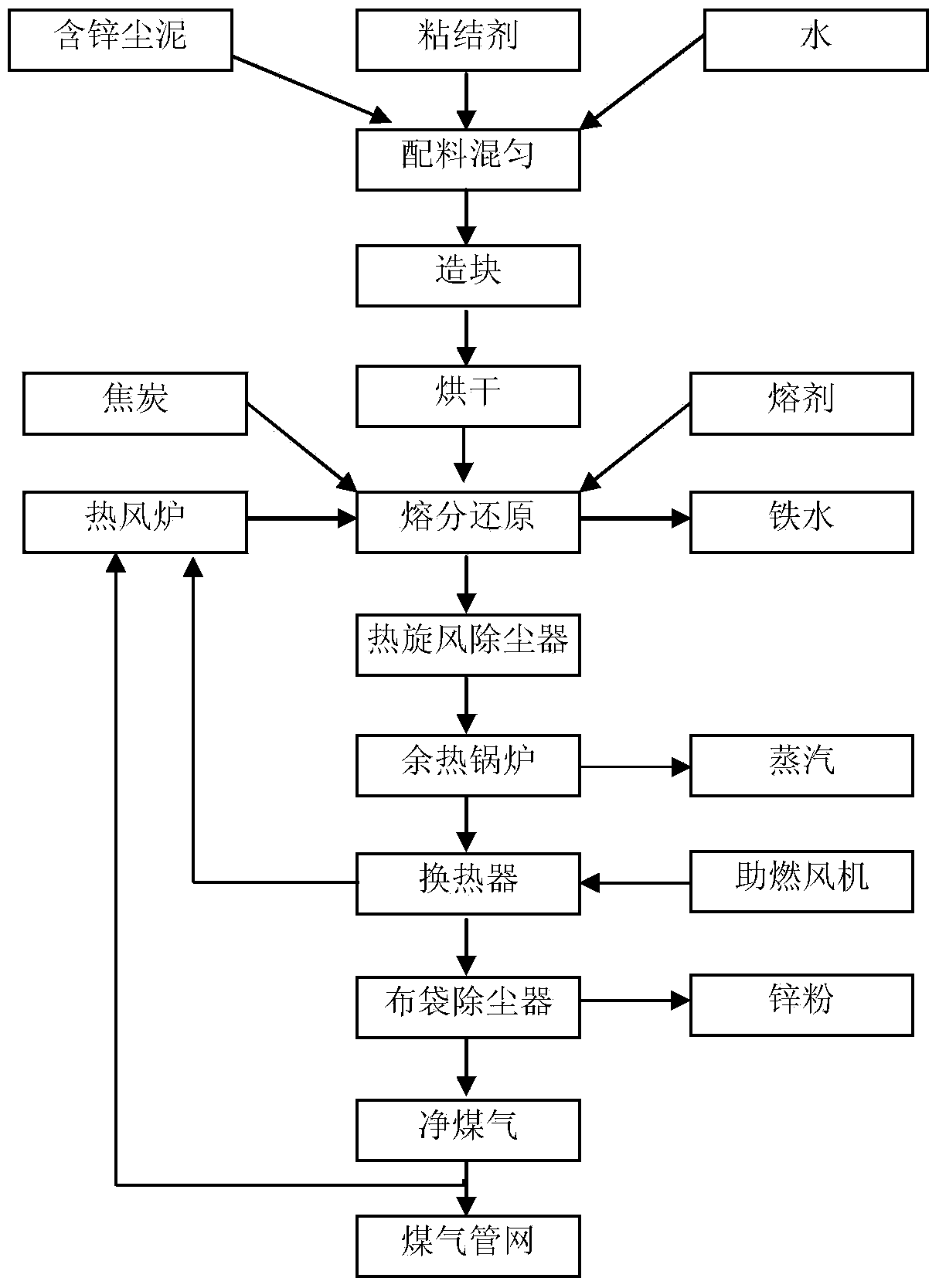

Method for producing molten iron and recovering zinc by utilizing zinc-containing dust or sludge in steelworks

The invention relates to a method for producing molten iron and recovering zinc by utilizing zinc-containing dust or sludge in steelworks. The method comprises the following steps of mixing dry zinc-containing dust or sludge in steelworks with binders and water uniformly to obtain a mixed raw material; forming the mixed raw material through cold bonding to obtain pellets or fragments of bricks; sending the pellets or fragments of bricks subjected to cold bonding to a dryer or a chain grate to be dried until the water content is not more than 1wt%; mixing the dried pellets or fragments of bricks with coke and a fluxing agent to undergo reduction smelting to obtain molten iron and zinc vapor; leading coal gas containing zinc vapor out, removing coarse grain dust by utilizing a thermal cyclone dust collector, recovering the sensible heat of the coal gas by utilizing a waste heat boiler, exchanging heat with a heat exchanger, and then carrying out fine dust collection by utilizing a bag-type dust collector to obtain high zinc dust. By adopting the method provided by the invention, the environment pollution caused by solid wastes such as metallurgical dust or sludge and the like in steelworks is reduced, and simultaneously, molten iron which can be directly used for steelmaking is generated, therefore, the method has better economic and social benefits.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

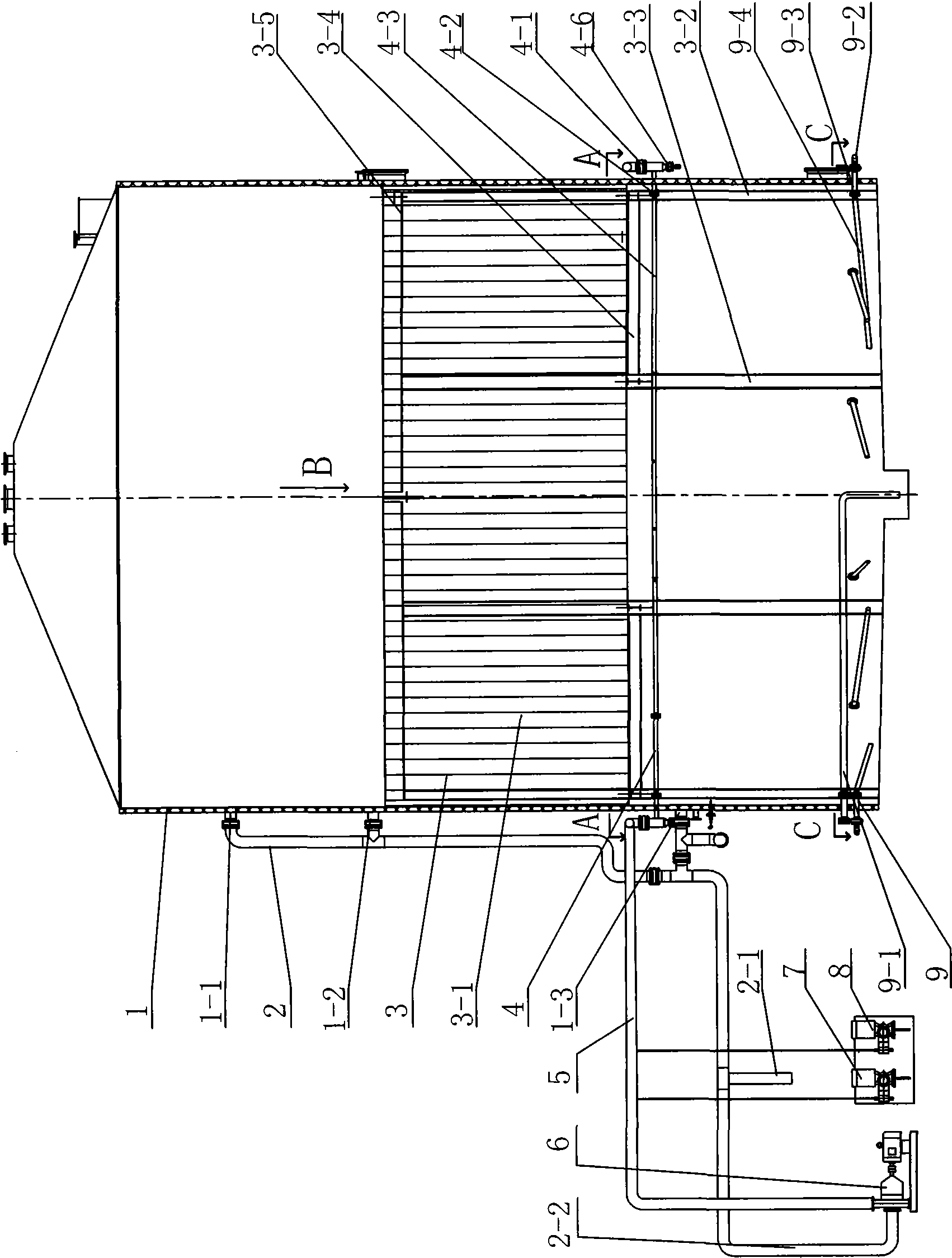

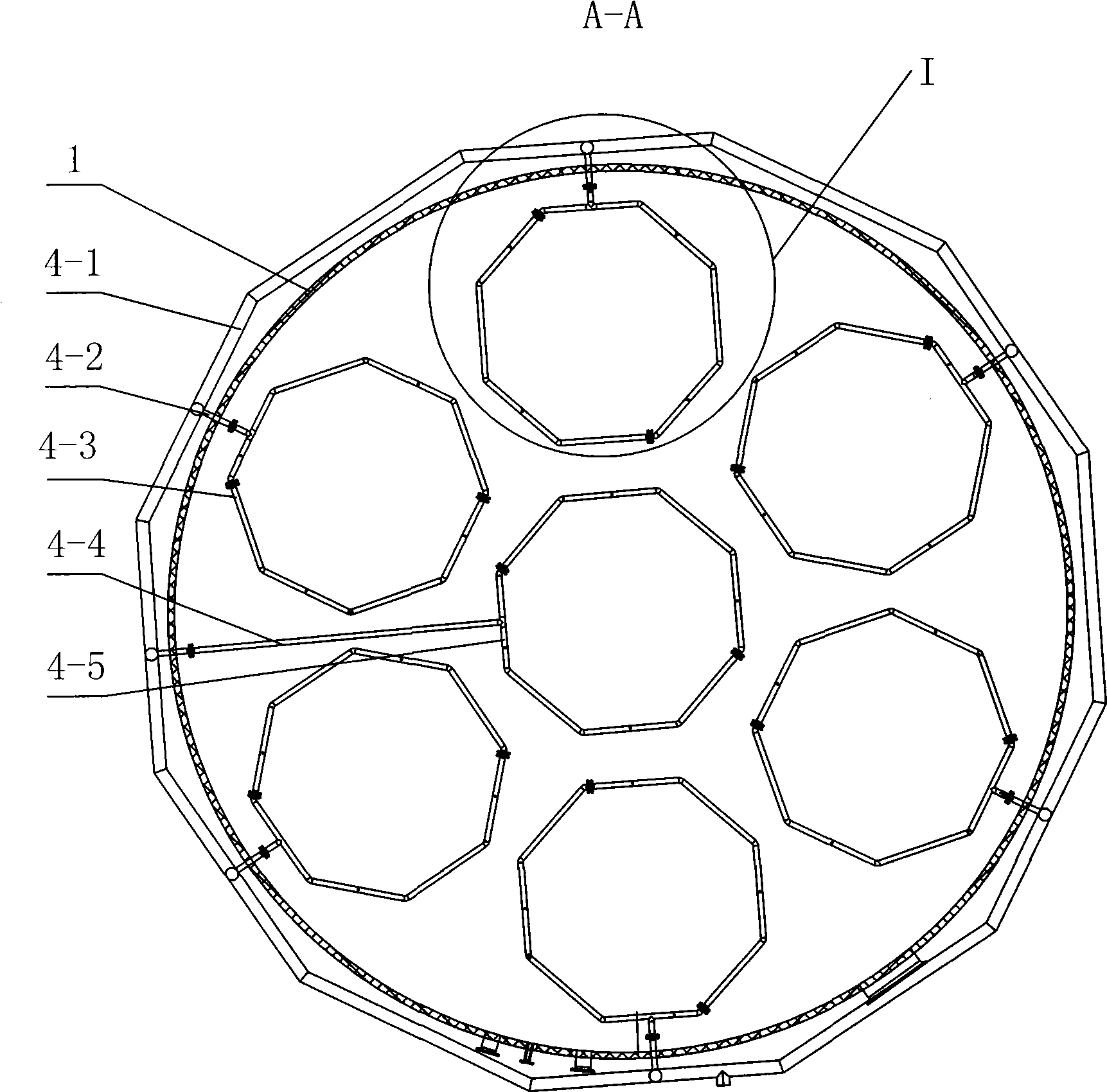

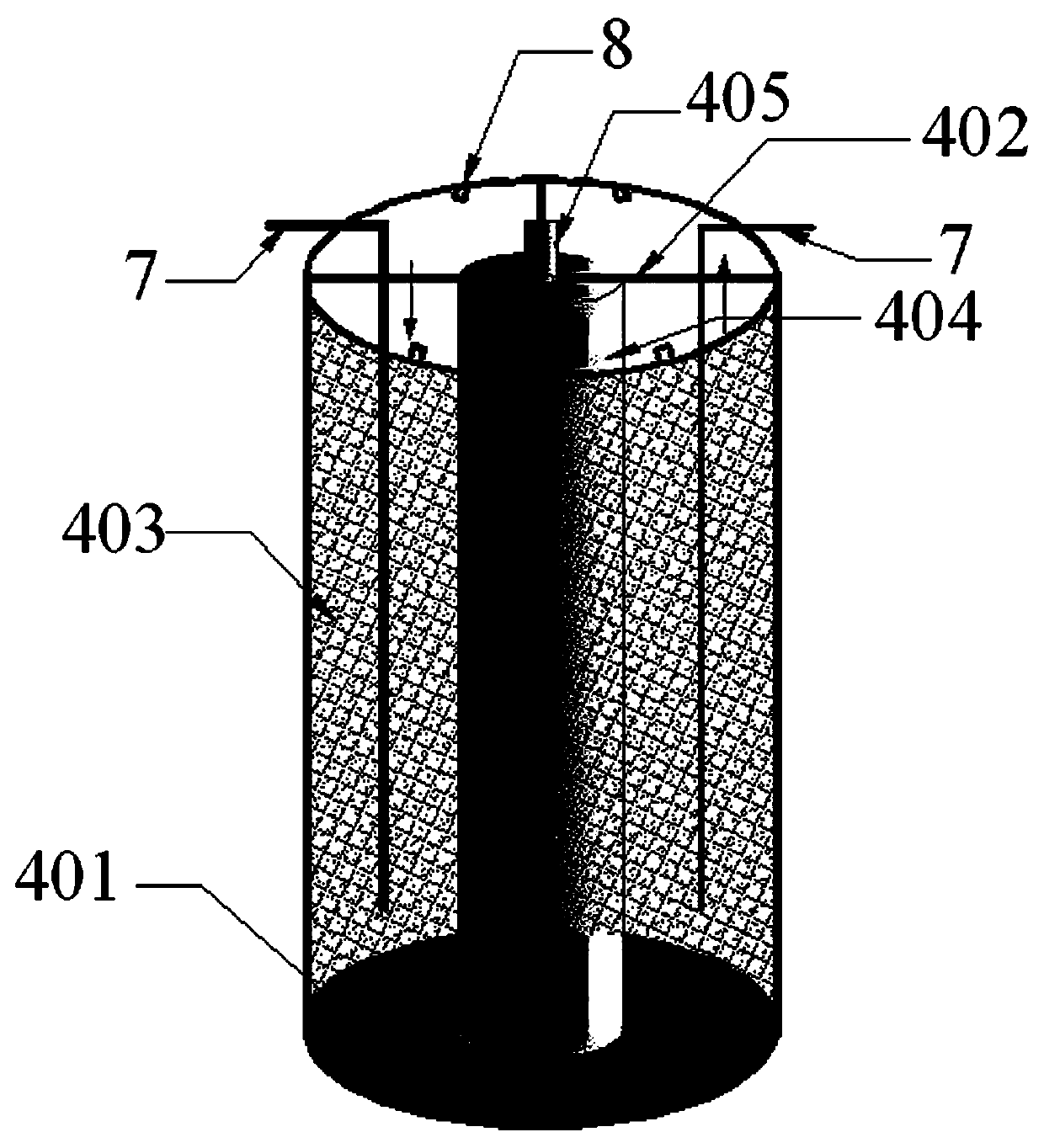

Anaerobic reactor

ActiveCN101497476ASolve easy blockageReduce foulingTreatment with anaerobic digestion processesAnaerobic reactorCirculating pump

The invention relates to an anaerobic reactor. The anaerobic reactor comprises a cylinder body, a water inlet pipe, a water outlet pipe, a filling device on the middle part of the water outlet pipe, a water distribution device at the bottom of the filling device and a sludge discharge device at the bottom of the water distribution device; the water distribution device comprises a water distribution main pipe and more than four closed annular water distribution branch pipes; water outlet holes of the water distribution branch pipes are alternately arranged along more than three concentric circumferences; the cylinder body is positioned on the upper part of the filling device; the lower part of each water distribution branch pipe is provided with more than two water outlets; the water outlets are connected with the water outlet pipe; a reflowing pipe of the water outlet pipe is mixed with the water inlet pipe by a circulating pump and is communicated with the water distribution main pipe; a first medicating device and a second medicating device are communicated with the water inlet pipe respectively through connecting pipes; the filling device comprises a filling rack, a membrane hanging rack and a zonal biomembrane strip; the biomembrane strip is hung on the membrane hanging rack; and the sludge discharge device comprises a sludge discharge main pipe and six sludge discharge branch pipes arranged in length alternation along radial direction. The anaerobic reactor has the characteristics of reasonable water distribution, compact structure and stable operation of the reactor.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

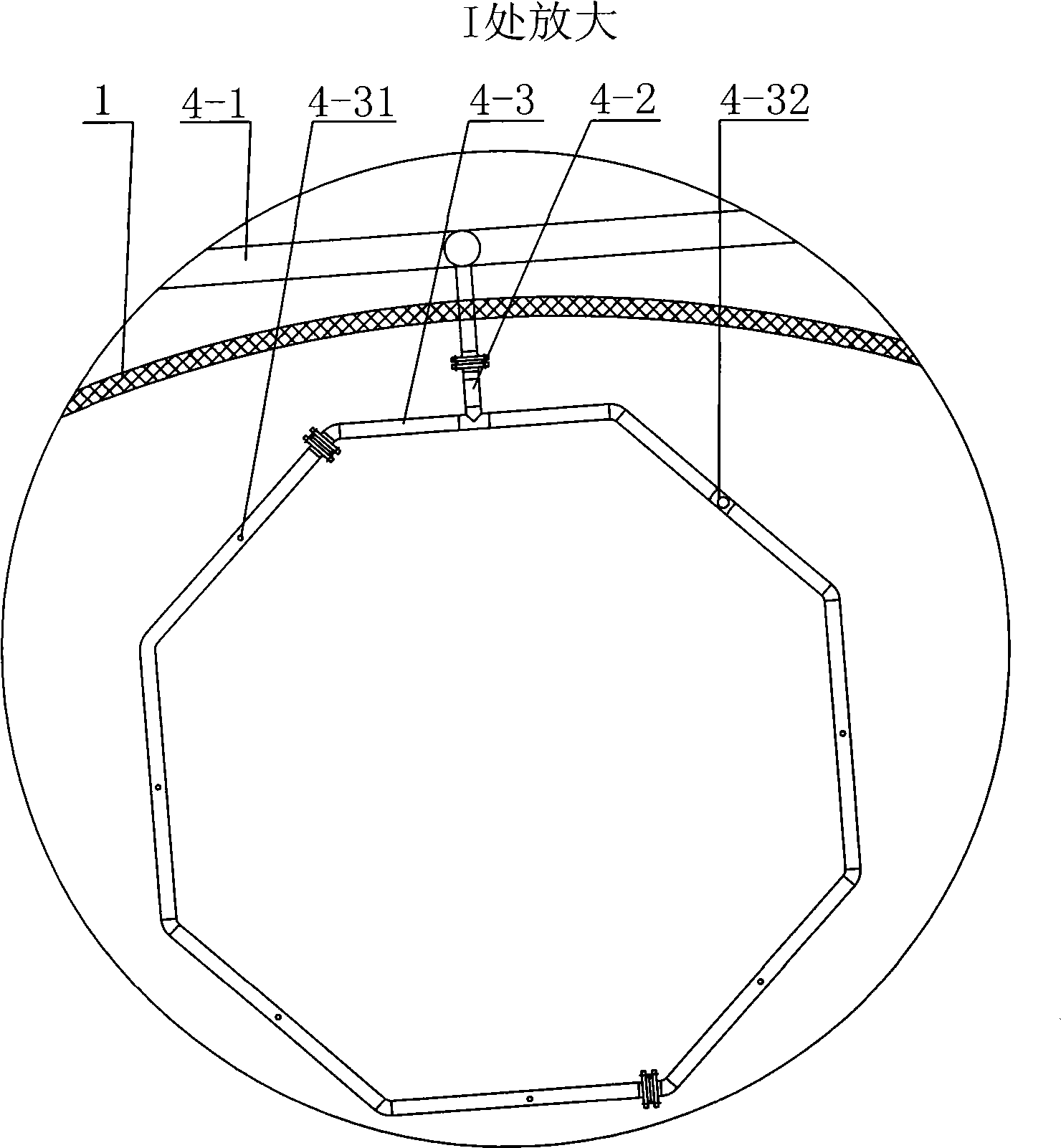

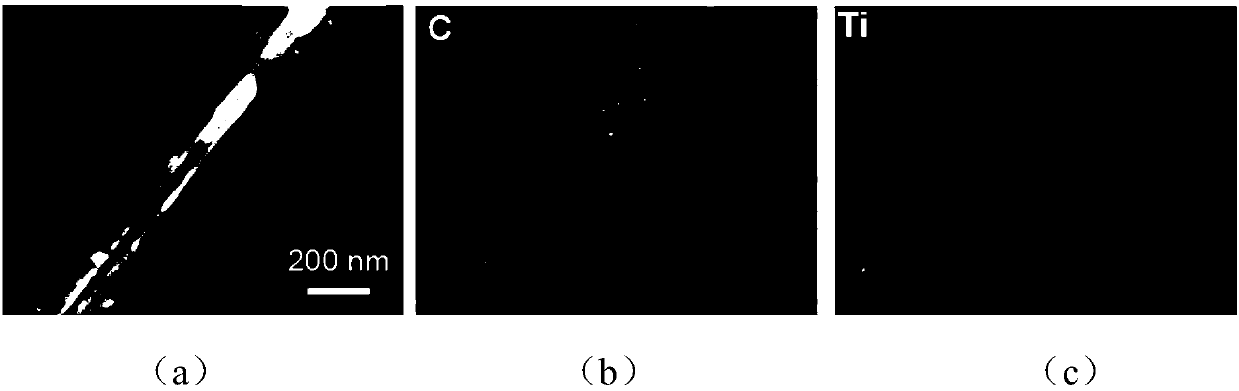

Efficient lithium metal composite material and preparation method thereof, applications of efficient lithium metal composite material as negative electrode

ActiveCN107732170AGood adsorption of molten lithiumAvoid enrichmentMaterial nanotechnologyNegative electrodesLithium iron phosphateLithium metal

The invention discloses an efficient lithium metal composite material and a preparation method thereof, applications of the efficient lithium metal composite material as a negative electrode. According to the preparation method, a reaction is performed for 1-5 h through a chemical vapor deposition method to synthesize a TiC / C three-dimensional porous skeleton layer, and the efficient lithium metalcomposite material is prepared through a melting lithium infiltration method by using the TiC / C three-dimensional porous skeleton layer as a carrier. According to the present invention, the efficientlithium metal composite material comprises a Ti6Al4V substrate, a TiC / C three-dimensional porous skeleton layer growing on the substrate, and a lithium metal phase adsorbed in the skeleton layer, wherein the TiC / C three-dimensional porous skeleton layer comprises titanium carbide nano-tubes and amorphous carbon wrapping on the titanium carbide nano-tubes; and the efficient lithium metal compositematerial has characteristics of high coulombic efficiency, significant inhibition of dendrite growth, and the like, and the energy density and the cycle stability of the whole battery can be significantly improved when the efficient lithium metal composite material is matched with lithium iron phosphate or sulfur positive electrode materials.

Owner:ZHEJIANG UNIV

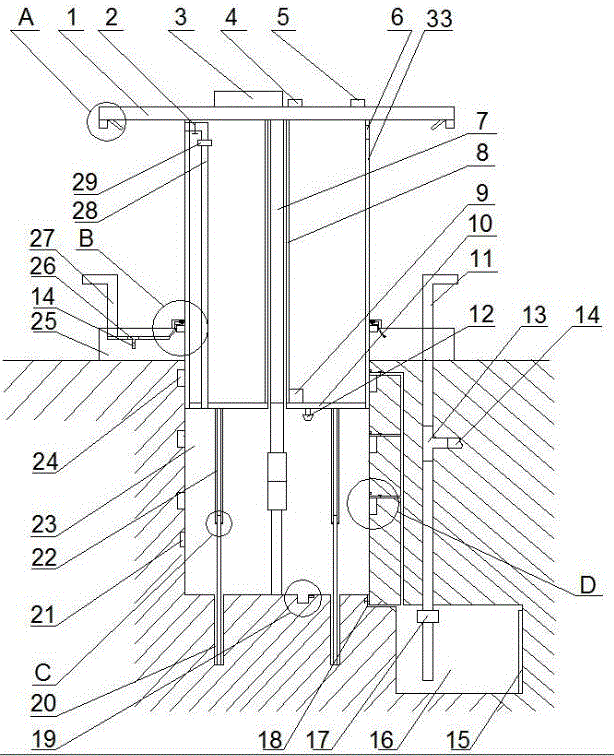

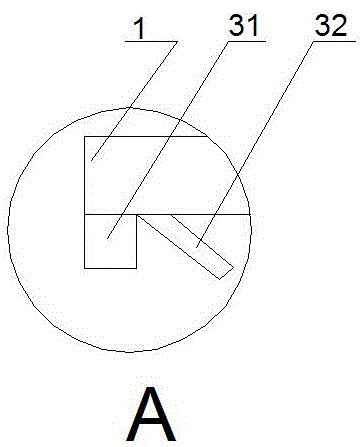

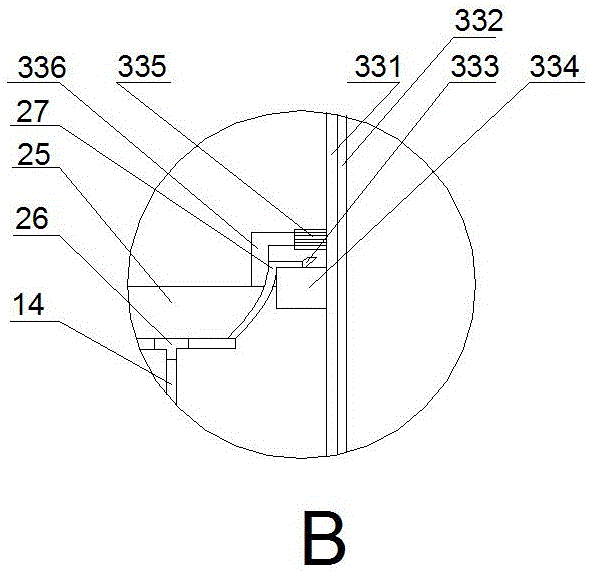

Outdoor display device of ideologies and politics

InactiveCN106846976AAvoid erosionAvoid damageCleaning using toolsCleaning using gasesAutomatic controlProtection mechanism

The invention provides an outdoor display device of ideologies and politics. The device comprises a base, a groove formed in the base, a display mechanism arranged in the groove, a retracting mechanism arranged between the display mechanism and the groove for lifting the displaying mechanism in the groove, and a water drainage mechanism arranged at the periphery wall of the groove. According to the outdoor display device of ideologies and politics, the lifting mode is used for administering self-protection measures during the occurrence of severe convection weather to retract the device into the groove to lower the height. At the same time, a sealed display structure is used for preventing the phenomenon that stagnant water enters the display mechanism, and combined with the inclined ring groove and the ring water seal, the display mechanism can not only retract freely in the groove, but also achieve the automatic water drainage. An emergency protection mechanism is used for implementing further self-protection during the occurrence of severe convection weather to guarantee that the device can achieve intelligent and automatic control after being inducted for once, the personnel maintenance is reduced, and reconstruction investment for the damages caused by the severe convection weather can be lowered.

Owner:裴天锋

Preparation method of TC17 titanium alloy flat square section bar

ActiveCN103143660ARefining as-cast structureAddressing inhomogeneityMetal-working apparatusIngotWork in process

The invention provides a preparation method of a TC17 titanium alloy flat square section bar. The preparation method comprises the following steps that (1) a riser and an ingot bottom of a TC17 titanium alloy cast ingot are cut off, and surface defects are removed; (2) billet forging is performed on the TC17 titanium alloy cast ingot, and primary forging stocks are obtained; (3) first middle forging is performed on the primary forging stocks, and first middle forging stocks are obtained; (4) second middle forging is performed on the first middle forging stocks, and second middle forging stocks are obtained; (5) sawing is performed on the second middle forging stocks, then forming forging is performed, and a semi-finished flat square section bar is obtained; and (6) heat treatment is performed on the semi-finished flat square section bar, and the TC17 titanium alloy flat square section bar with the length of 850 mm to 1600 mm, the width of 132 mm and the thickness of 65 mm to 100 mm is obtained. The preparation method has the advantages of integral technical scheme, strong process controllability, uniformity in product texture and shape, excellent overall performance, high batch stability and high yield and is suitable for large-scale industrial production.

Owner:WESTERN TITANIUM TECH

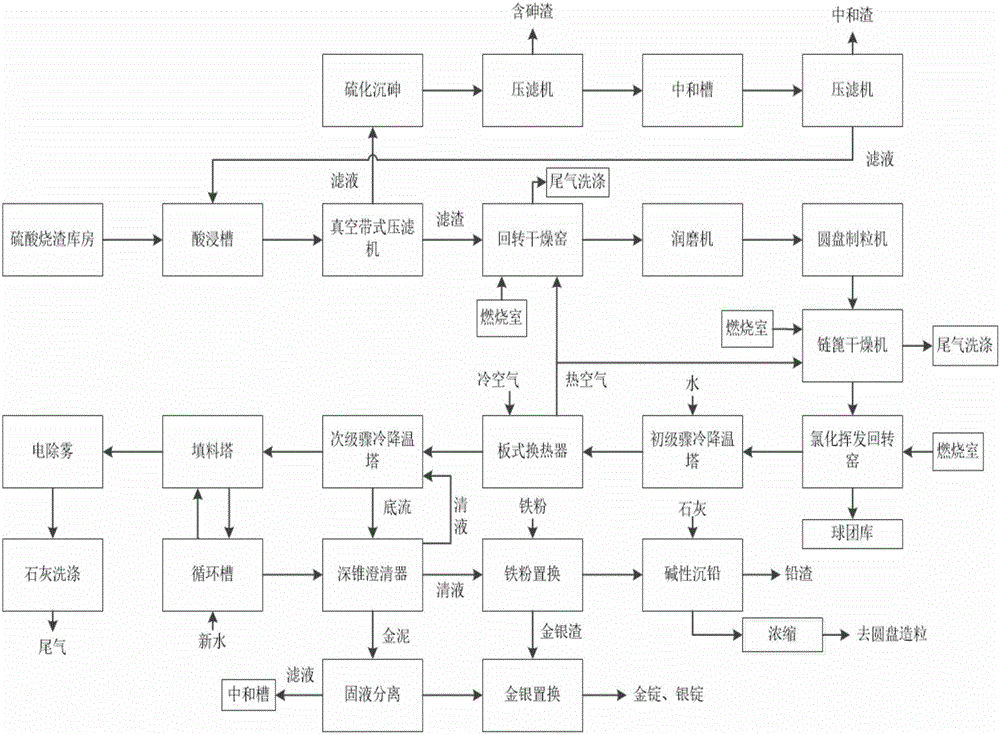

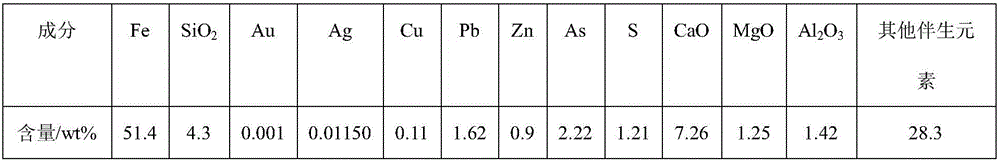

Chlorination-extraction process of gold in arsenic-containing sulphuric acid slag and comprehensive utilization method of gas heat

ActiveCN106086434AReduce system power consumptionSolve the blockage of the pipeProcess efficiency improvementWet grindingElectrostatic precipitator

The invention relates to a method for chlorinating and extracting gold in arsenic-containing sulphuric acid slag and comprehensively utilizing gas heat. The method comprises the following specific steps of (1) acid leaching and arsenic sulfide precipitation; (2) drying, wet-grinding, pelletizing, drying and chloridizing volatilization; (3) primary quench cooling, heat exchanging, secondary quenching and electrostatic precipitation; and (4) dust scrubbing, chloride leaching of gold, gold reducing, silver extraction by ammonia leaching and silver reducing. An acid leaching and arsenic precipitation technology is adopted, and arsenic is first separated from raw materials, so that the influence of arsenic on a follow-up system is eliminated. The arsenic sulfide precipitation technology realizes enrichment of arsenic in water and recycling of water. The primary quench cooling technology is adopted, so that the temperature of dust-laden gas is higher than that of a softening point of dust, and relatively high liquidity is obtained. An iron powder replacement technology is adopted, so that gold and silver enriched in recycling process water are recycled. Lead and zinc in the process water are recycled through alkaline lead and zinc precipitation, so that the problem that a pipeline is blocked with soluble salt is solved.

Owner:CHENZHOU YANGTAO CHEM

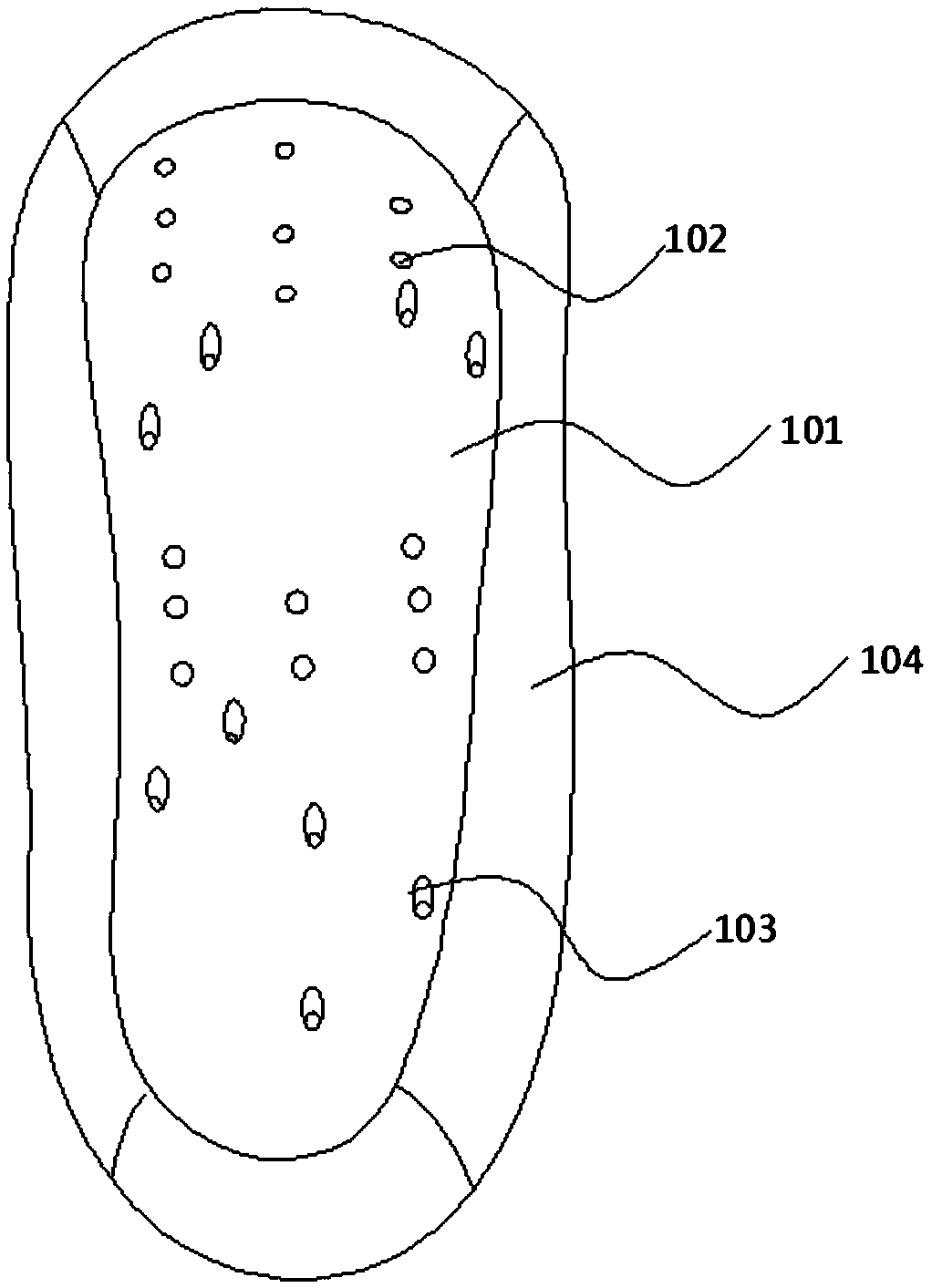

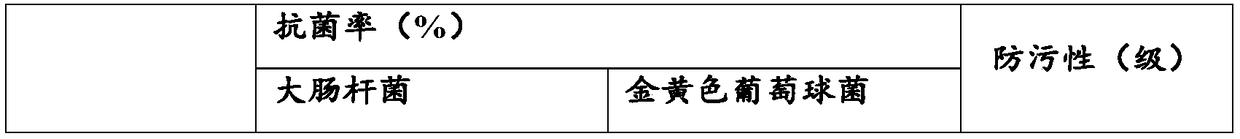

Corrective anti-bacterial grapheme self-cleaning insole and preparation method thereof

InactiveCN109232853AImprove mechanical propertiesImprove microcirculationInsolesAir quality improvementMechanical propertyPollution

The invention provides a corrective anti-bacterial grapheme self-cleaning insole and a preparation method thereof, which relates to the technical field of insoles. The insole is mainly prepared from the following raw materials in parts by weight: 80-100 parts of polyether polyol, 45-65 parts of isocyanate, 2-10 parts of a chain extender, 0.1-0.5 parts of a tin catalyst, 0.3-0.8 parts of an amine catalyst and 0.5-2 parts of a self-cleaning material, wherein the nano-antibacterial self-cleaning material comprises nano-silver, nano-TiO2 and graphene; the nano-silver and the nano-TiO2 respectivelygrow on a graphene slice layer in situ; the technical problem that an adverse effect is caused on the health of feet as the environment of shoes is closed, bacteria are bred easily, and pollutants are easily enriched is solved. The insole provided by the invention not only has excellent mechanical property, but also has excellent functions of preventing pollution, clearing damp and air ventilation; in addition, the insole has the advantages of realizing effective bacteria resistance and bacteria inhibition, avoiding enrichment of the pollutants and promoting the health of the feet.

Owner:权健自然医学科技发展有限公司

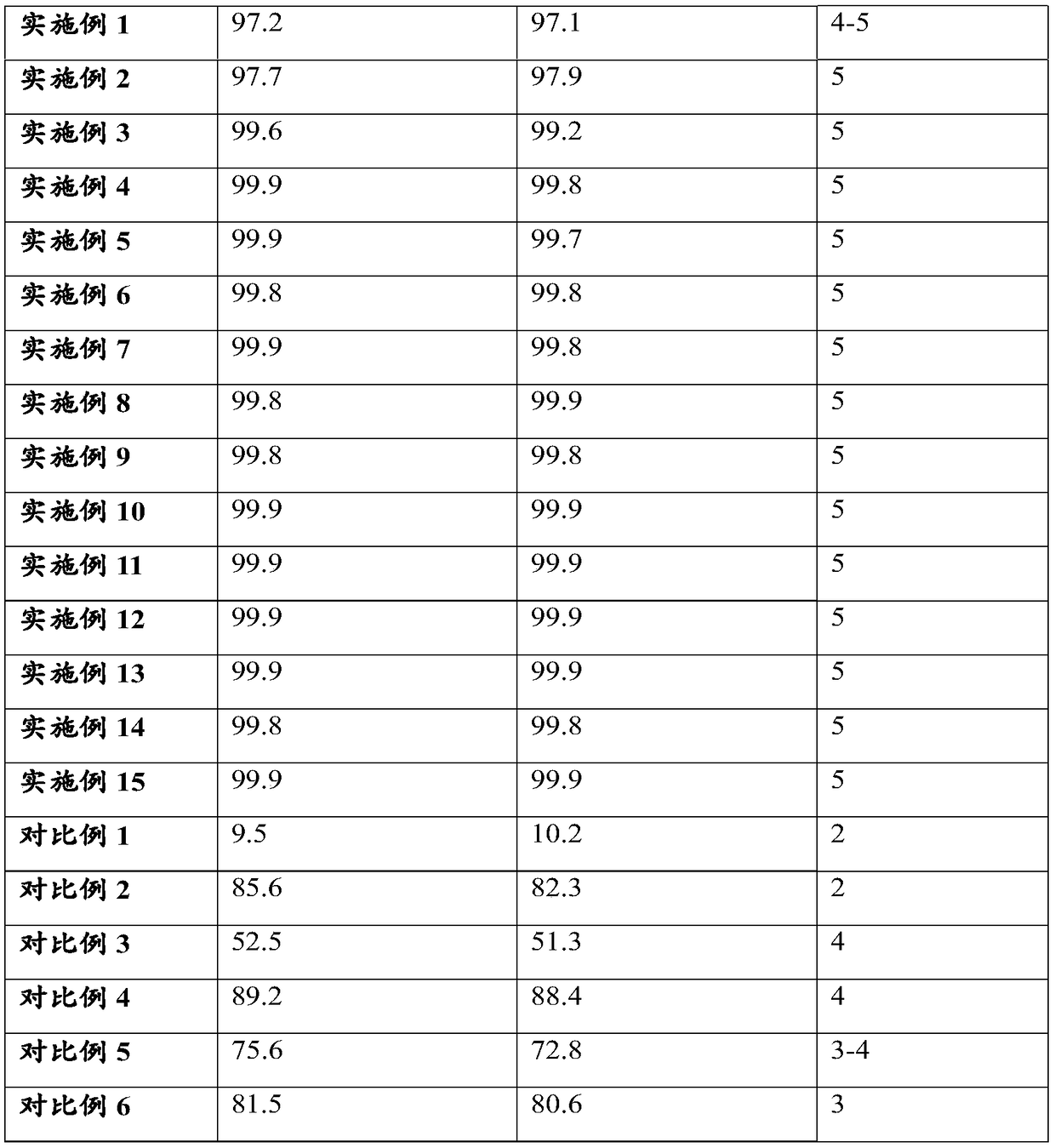

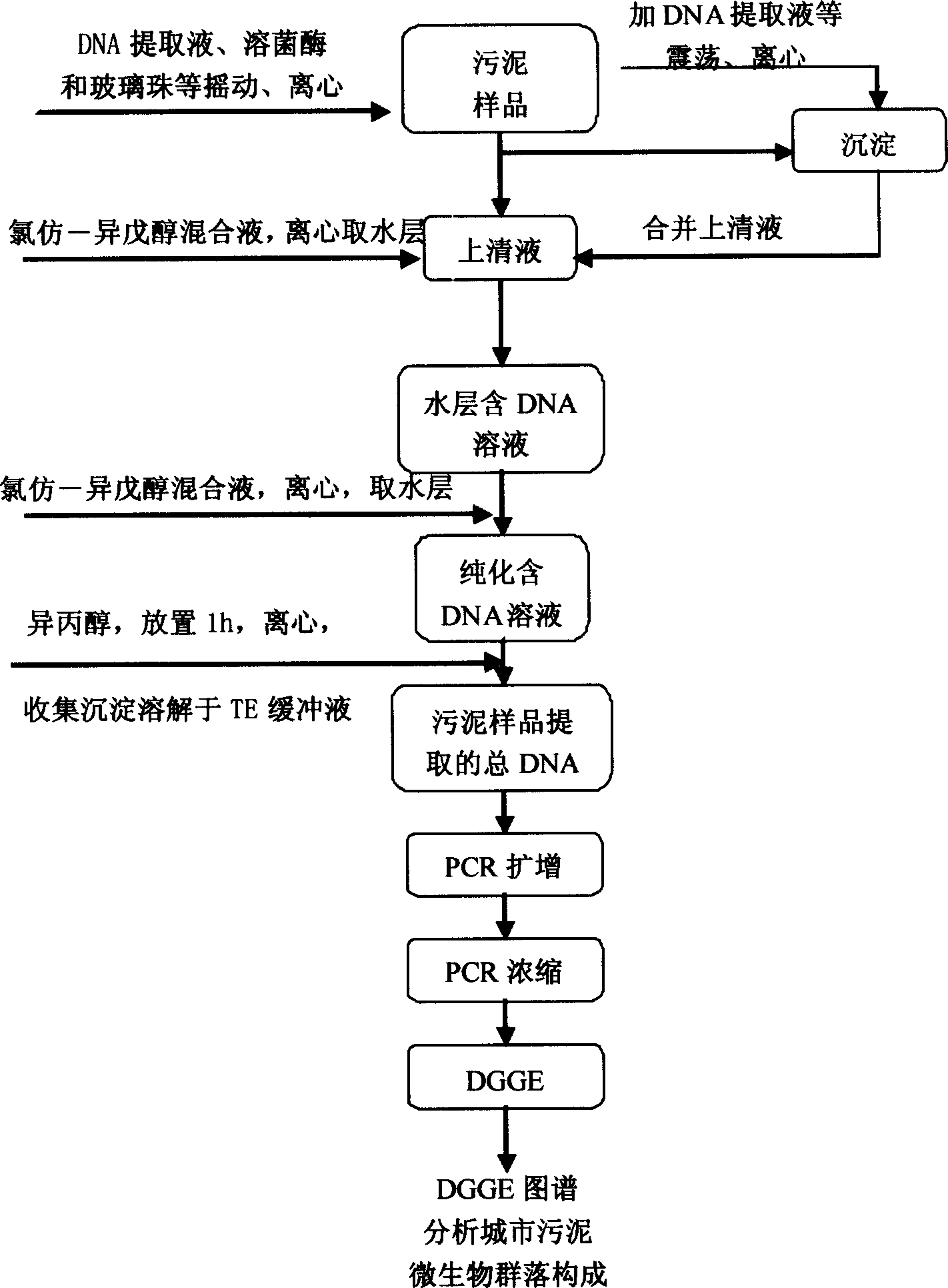

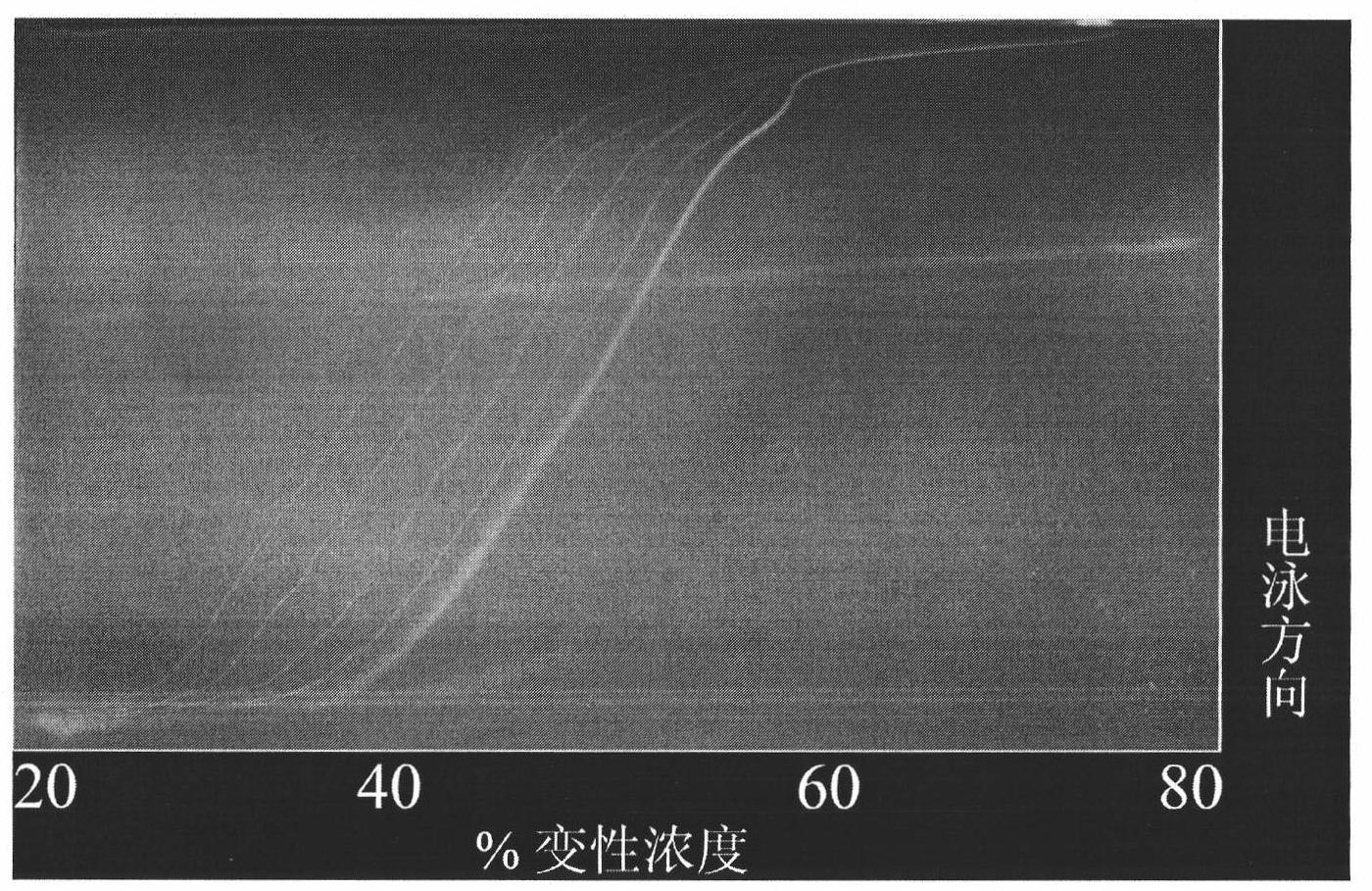

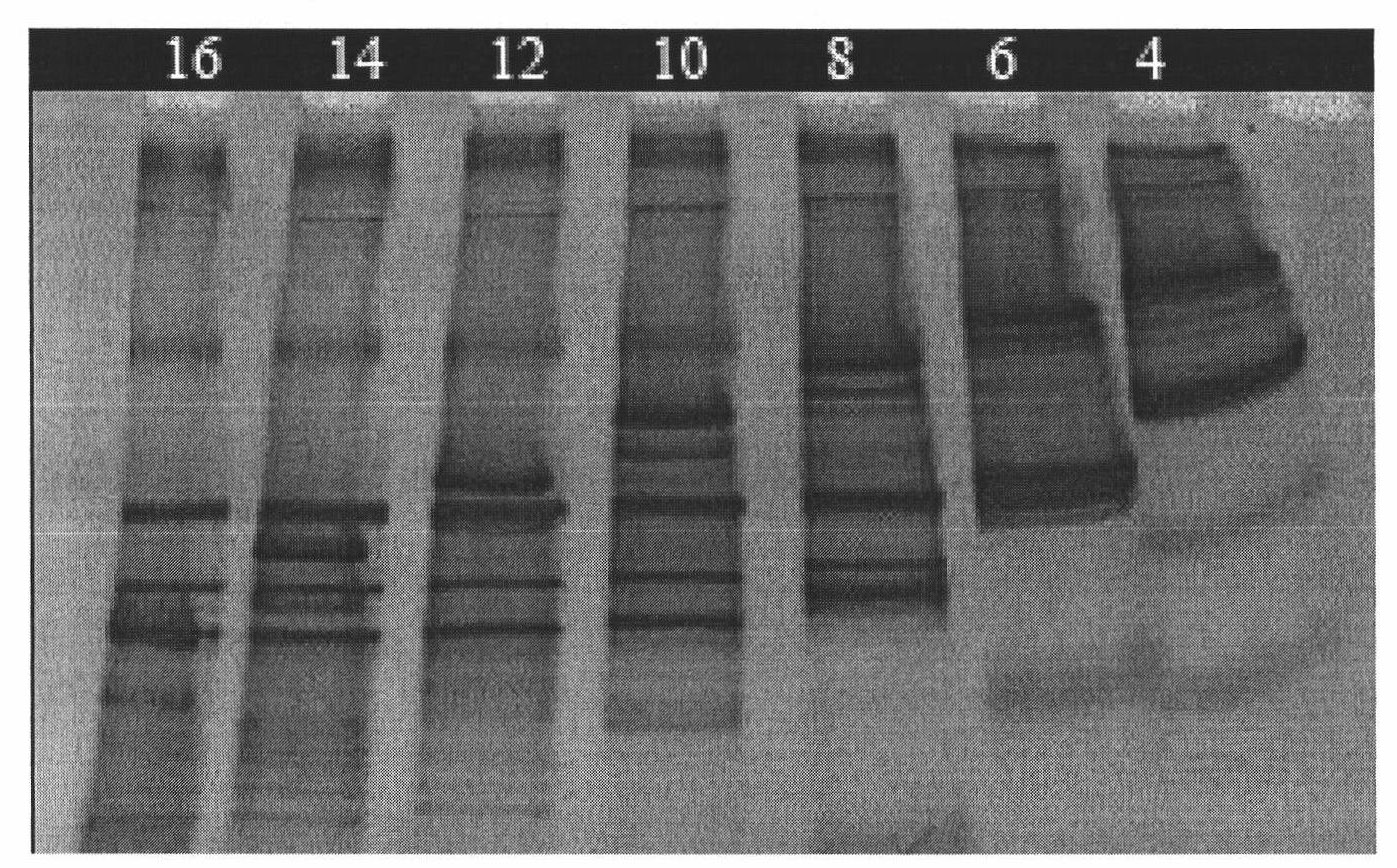

Method for analyzing sludge microbiological community configuration in urban sewage plant

InactiveCN1584051AAvoid screeningAvoid enrichmentMicrobiological testing/measurementMicroorganismDNA extraction

A method for analyzing sludge microbiocoenosis construction of municiple sewage plant relating PCR-DGGE technology analytical method for sludge microbiocoenosis construction of municiple sewage plant is disclose. It includes: DNA extracting, PCR amplifying, PCR product concentrating, DGGE electrophoretic separating to obtain DGGE map. It is characterized by two DNA extracting to obtain general DNA, taking 2-5g sludge sample, sludge DNA extracting by DNA extract, adding DNA extract etc. centrifugal collecting supernatant fluid in sediment, adding mixed liquor of chloroform and isopentanol, centrifugal pooling, DGGE electrophoretic separating by denaturing gradient 30%-60% polyacrylamide gel to obtain DGGE map. It achieves time saving and low cost.

Owner:TONGJI UNIV

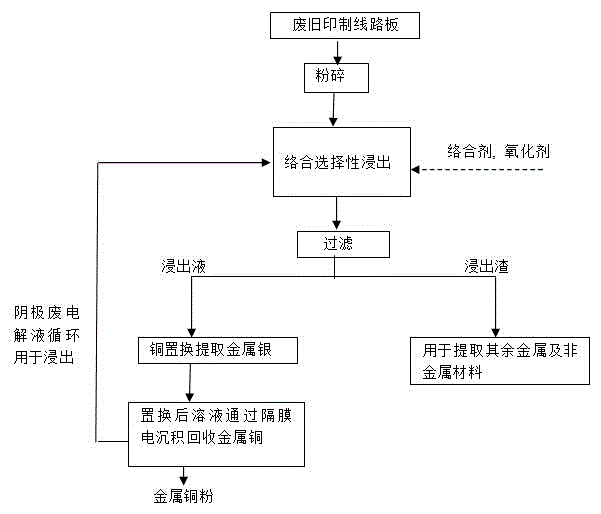

Method for extracting metallic silver from waste circuit board

InactiveCN104988317ASelect strong leachingAvoid emissionsPhotography auxillary processesProcess efficiency improvementEnvironmental geologyOxidizing agent

The invention discloses a method for extracting metallic silver from a waste circuit board. The method comprises the steps that after the waste circuit board is smashed into crushed materials, the crushed materials are placed into an extracting solution of a leaching reactor to be subjected to selective leaching reaction, wherein the extracting solution is formed by a complexing agent and an oxidizing agent; a copper sheet is added to an obtained leaching solution to be subjected to replacement reaction, and the metallic silver is prepared. The technology is simple, the cost is low, the metallic silver in the circuit board can be subjected to complexing leaching in a selective mode, it is avoided that strong acid is in use, and the environment-protected and resource-recovered processing on the metallic silver of the waste circuit board is achieved.

Owner:CHINA NAT ELECTRIC APP RES INST +1

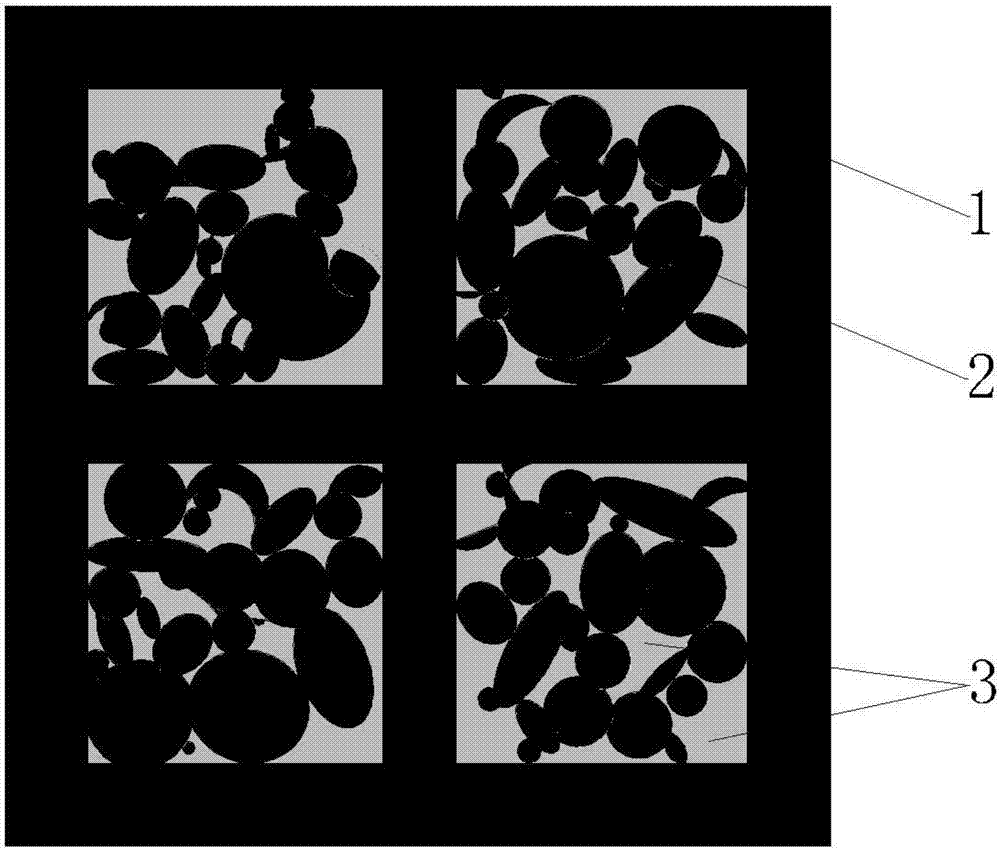

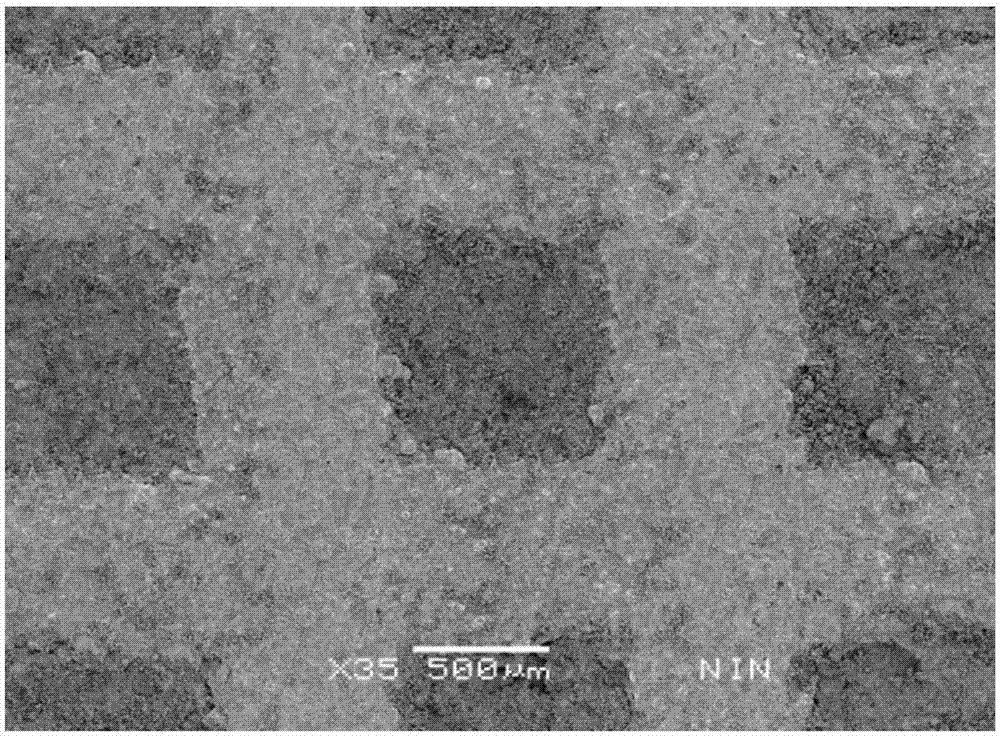

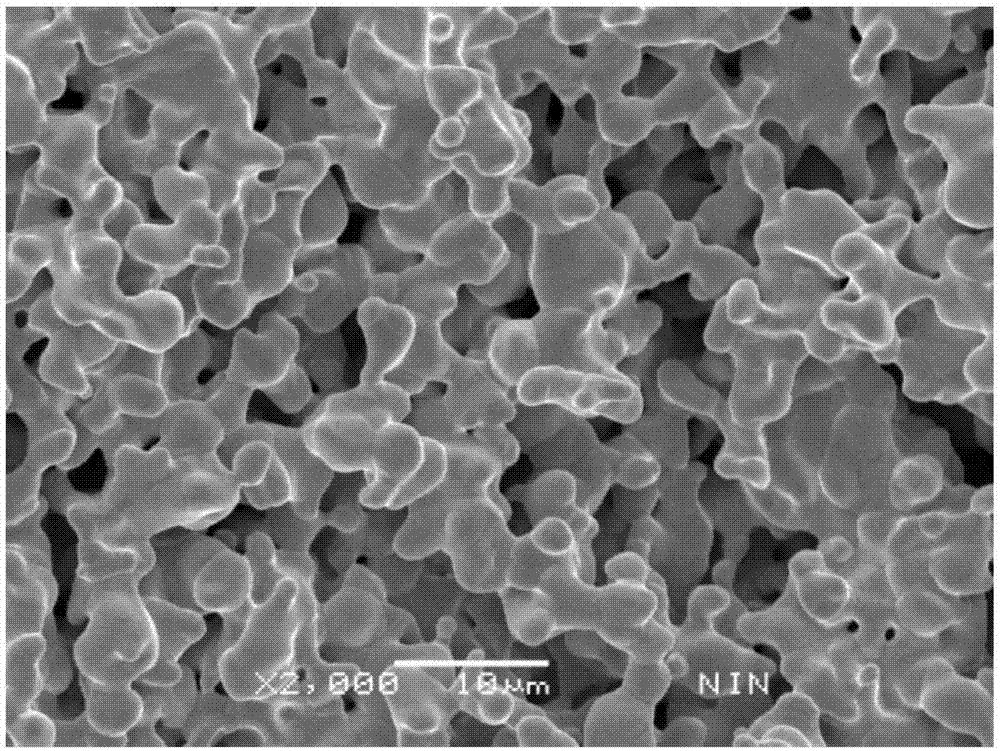

Tungsten-copper composite material and preparation method thereof

InactiveCN107498047AHigh strengthImprove anti-ablation performanceAdditive manufacturing apparatusIncreasing energy efficiencyHigh energyCopper

The invention provides a tungsten-copper composite material. The tungsten-copper composite material comprises a tungsten framework, tungsten porous bodies and a copper filling phase. The tungsten framework has a porous three-dimensional dot matrix structure. The tungsten porous bodies fill the pores of the tungsten framework. Pores are arranged between the tungsten porous bodies and the tungsten framework. The copper filling phase fills the pores of the tungsten porous bodies and the pores between the tungsten porous bodies and the tungsten framework. The composite structure formed by the tungsten porous bodies and the tungsten framework improves the strength of the tungsten-copper composite material. The copper filling phase is uniformly distributed in the pores of the tungsten porous bodies and the pores between the tungsten porous bodies and the tungsten framework, so that the anti-ablation performance of the tungsten-copper composite material is enhanced. The invention also provides a preparation method of the tungsten-copper composite material. The preparation method comprises the following steps of: firstly, preparing the tungsten framework by means of a method of fusion forming in a high energy bundle selecting region; then filling tungsten powder into the tungsten framework to form the tungsten porous bodies by means of an isostatic cool pressing method and a high-temperature sintering process; and then combining with a copper infiltration method to prepare the copper filling phase. The method is high in precision and efficient and reliable.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

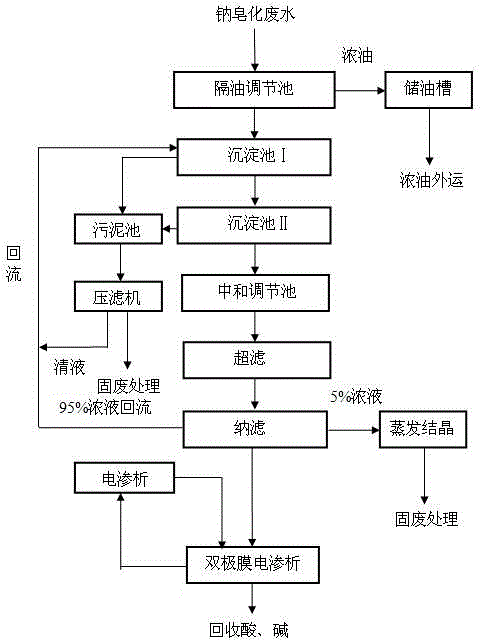

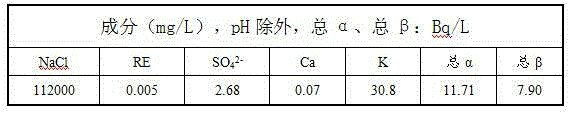

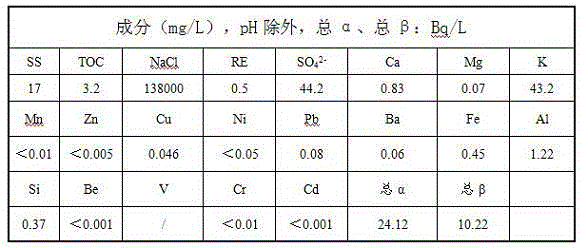

Acid and alkali resource recovery process technology from sodium saponification waste water

InactiveCN104591459AAchieving zero emissionsRealize high-content sodium chloride acid-base resourceFatty/oily/floating substances removal devicesWaste water treatment from metallurgical processHigh sodiumResource recovery

The invention relates to an acid and alkali resource recovery process technology from sodium saponification waste water discharged in a rare earth separating and manufacturing process. The acid and alkali resource recovery process technology of the invention mainly comprises three steps, including pre-treating of the waste water, treating by a membrane process and recycling of acids and alkalis. According to the process of the invention, acids and alkalis needed in the rare earth separating process can be produced from the sodium saponification waste water with high sodium chloride content, so as to effectively realize the purpose of zero release and acid and alkali resource recovery after treatment of the waste water.

Owner:蓝星工程有限公司

Natural plant growth promoter

InactiveCN105918364APromote plant growthAvoid enrichment in plantsBiocidePlant growth regulatorsPeanut hullNutrient content

The invention belongs to the field of plant growth control, and particularly relates to a natural plant growth promoter. The natural plant growth promoter comprises 5-6% of chitosan quaternary ammonium salt, 15-20% of semen coicis water extract, 4-8% of lotus seed hull submicron powder, 10-15% of banana peel, 10-12% of coconut shell submicron powder, 8-10% of peanut shell submicron powder, 0.1-0.4% of tender leaves of Chinese toon juice and the balance water. The natural plant growth promoter has slow release effects, ethylene gas can be slowly released, plant growth can be controlled, the natural plant growth promoter is rich in nutritional components needed by plant growth, the nutritional components include N, P, K and the like, plant growth is promoted, heavy metals in water and soil can be effectively removed and are not easily enriched in plants, and natural, organic and pollution-free crops can be planted.

Owner:DR ECO PINGTAN BIOTECH CO LTD

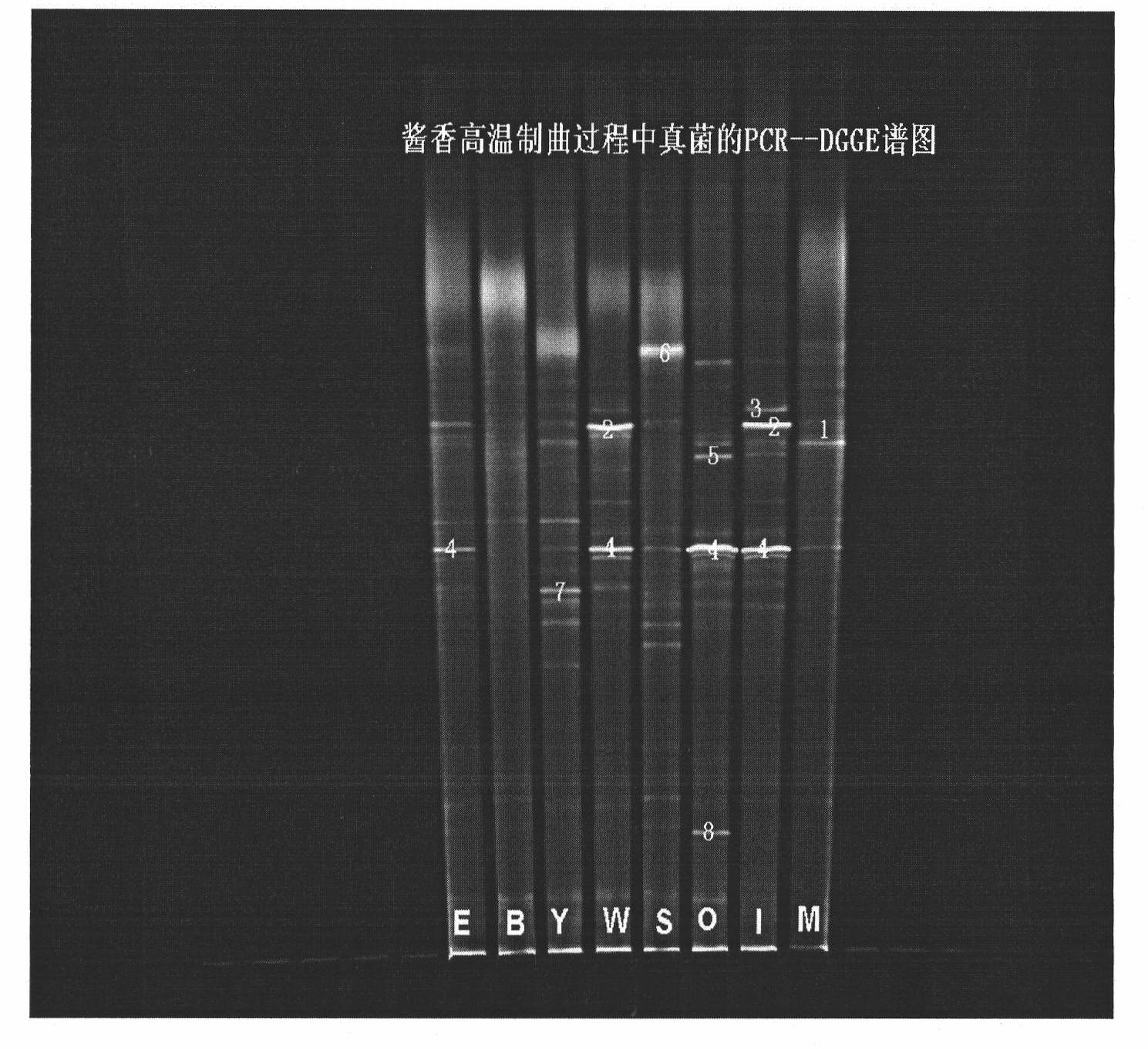

Method for identifying Maotai-flavor Daqu liquor

InactiveCN102071249AAvoid screeningAvoid enrichmentMicrobiological testing/measurementMicroorganism based processesMicroorganismMicrobiology

Owner:贵州国台酒业集团股份有限公司

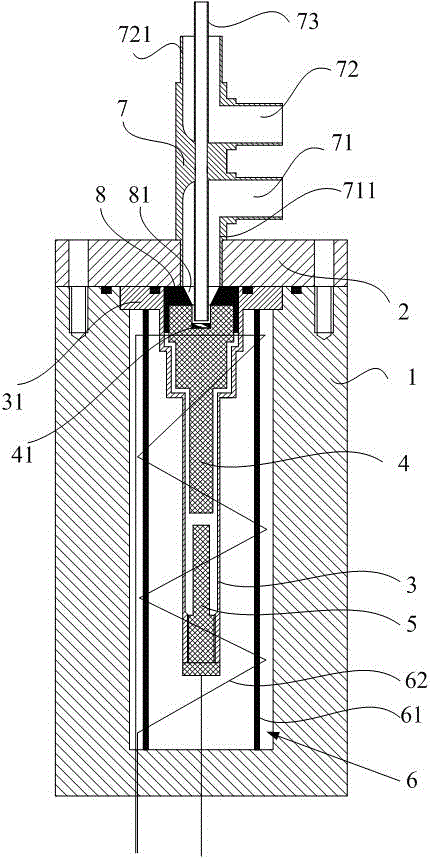

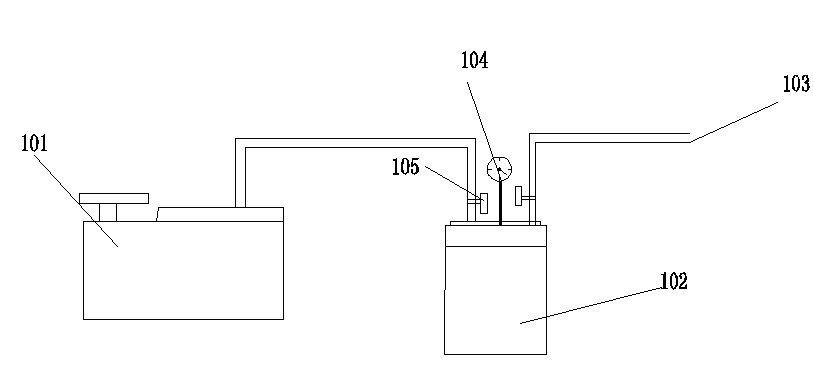

Nitrogen dioxide standard gas generating device and method

InactiveCN104445110AStable and reliable penetration rateAvoid enrichmentNitrogen dioxideGas pipelineElectric heating

The invention provides a nitrogen dioxide standard gas generating device and method. The nitrogen dioxide standard gas generating device comprises an outer barrel, a cover plate, a heat-conducting sleeve, a nitrogen dioxide permeation tube, a temperature sensor, an electric heating device and a gas channel nipple, wherein the heat-conducting sleeve and the electric heating device are located in the outer barrel; the temperature sensor and the nitrogen dioxide permeation tube are arranged in the heat-conducting sleeve; the nitrogen dioxide permeation tube is provided with a permeable membrane; a sealing ring is arranged between the nitrogen dioxide permeation tube and a cover plate; a through hole is formed in the sealing ring and opposite to the permeable membrane; the gas channel nipple comprises a carrier gas pipeline, a dilution pipeline and a standard gas pipeline; the carrier gas pipeline is provided with a first elbow, while the dilution pipeline is provided with a second elbow; the first elbow and the second elbow are arranged back on to each other; the standard gas pipeline penetrates through the first elbow and the second elbow; one port of the standard gas pipeline extends out of the first elbow and is inserted into the through hole and located on one side of the permeable membrane. The distribution difficulty of the nitrogen dioxide standard gas is reduced and the detection accuracy and stability of the detection equipment are improved.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI +1

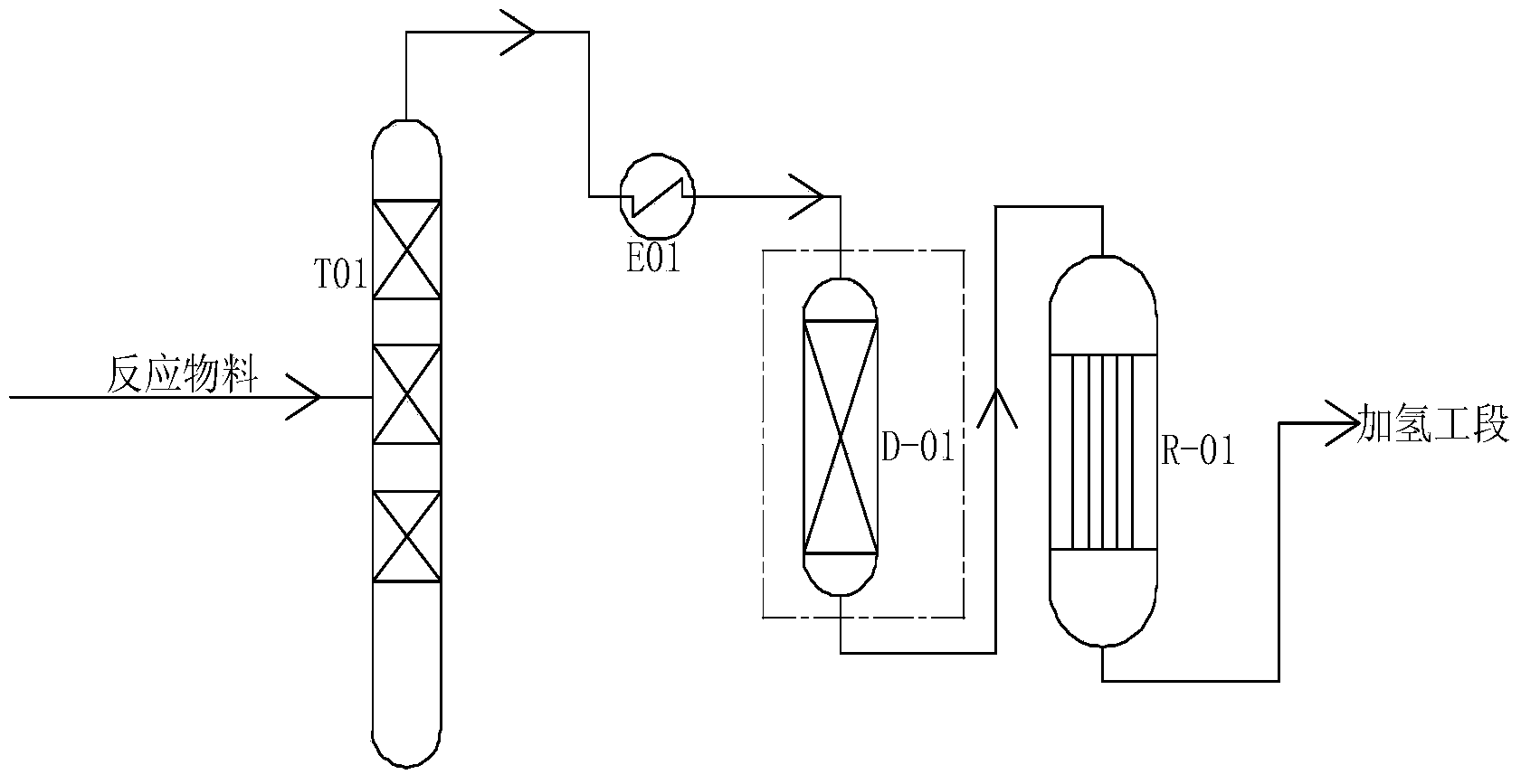

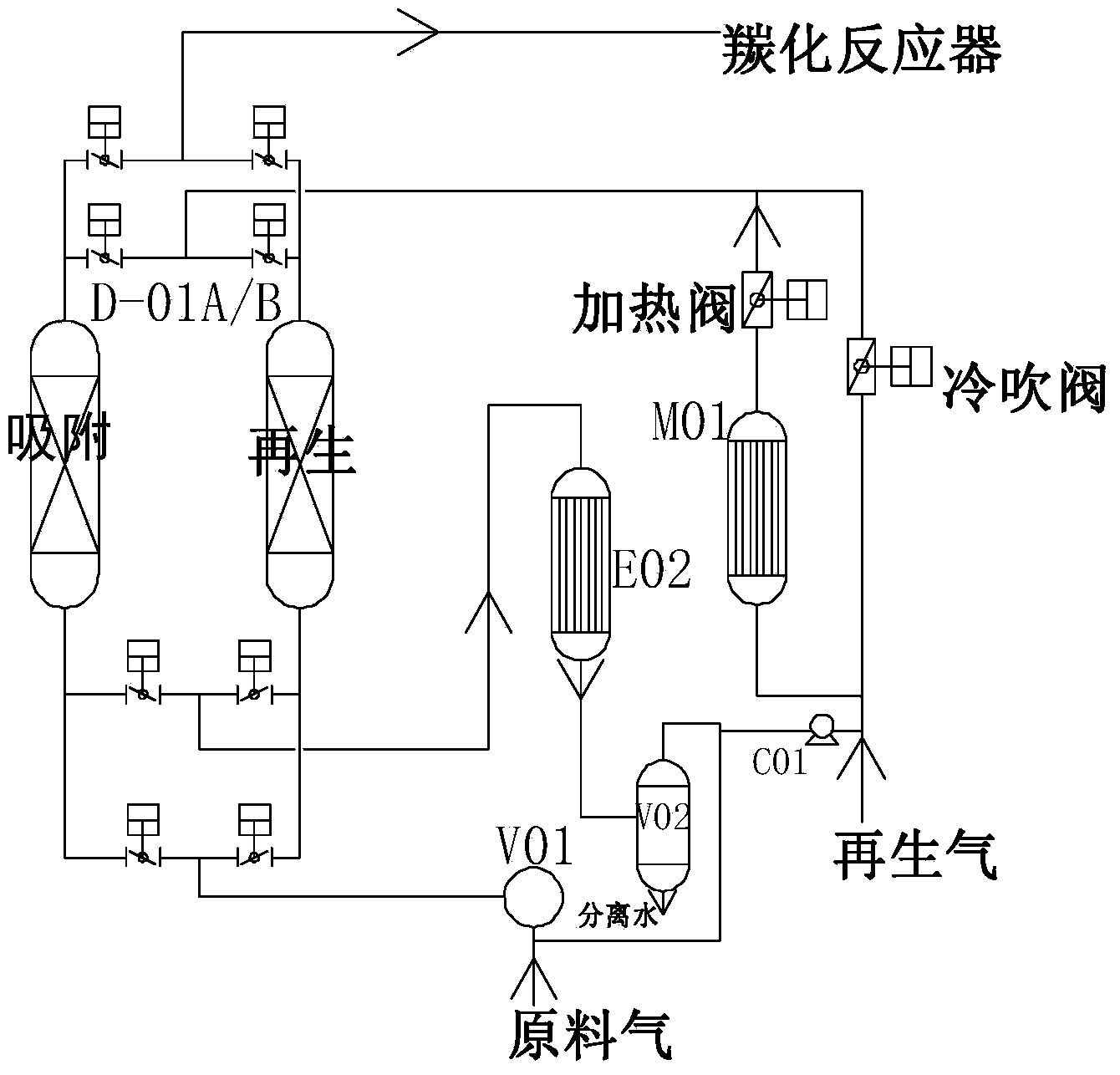

Method and device for producing and synthesizing ethylene glycol by using coal as raw material

ActiveCN103483150AAvoid enrichmentImprove the premium rateOrganic compound preparationHydroxy compound preparationChemistryCorrosion

The invention relates to a method for producing and synthesizing ethylene glycol by using coal as a raw material, which comprises an oxidation and esterification procedure, a carbonylation procedure and a procedure of ethylene glycol preparation through dimethyl oxalate hydrogenation, and further comprises a drying and purifying apparatus, wherein the drying and purifying apparatus is used for drying saturated water in process gas coming out from an oxidation and esterification tower before the process gas enters a carbonylation reactor. The method avoids enrichment of methyl nitrite (MN) in the process gas in an adsorption tower in the regeneration process and harmful emission of regeneration gas, avoids apparatus corrosion caused by oxalic acid formed by hydrolysis of the carbonylation reaction product dimethyl oxalate (DMO), provides a guarantee for long-period operation of the apparatus and improves the high-quality product rate of the final product ethylene glycol.

Owner:PUJING CHEM IND SHA

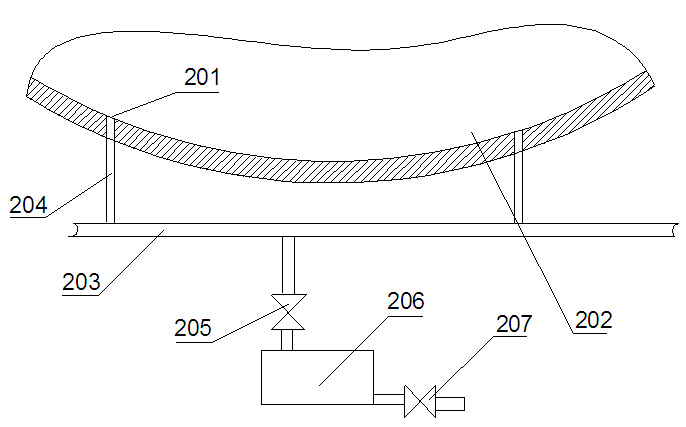

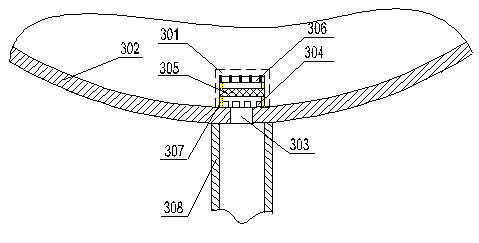

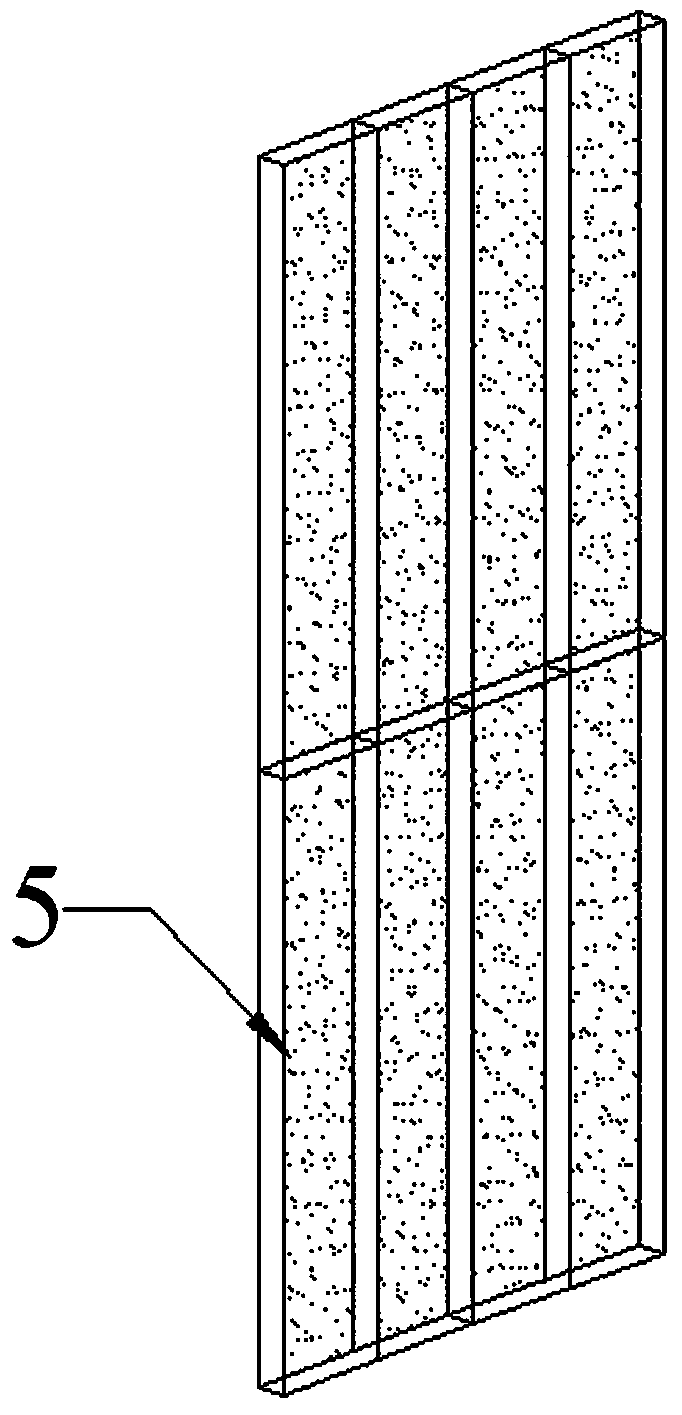

Vacuumizing method for producing large-sized composite material member and composite air extracting layer

The invention discloses a vacuumizing method for producing a large-sized composite material member and a composite air extracting layer. At an air extract port of a die used by a vacuum pouring process, the continuous air extraction is always carried out on a die cavity system in the vacuum pouring process through an air extraction system with the composite air extracting layer, thereby ensuring that resin can be completely wetted in glass fiber cloth, avoiding the phenomenon that fiber filament is dried in a local area and effectively ensuring the appearance and the quality of products. The air extraction system at least comprises a pressure-adjusting pump, an air extraction pipeline, an air extraction port and the composite air extracting layer. The composite air extracting layer at least comprises an air leading and glue-absorbing material, a micropore ventilated membrane, an air leading supporting material and a sealing material.

Owner:TIANJIN CRRC WIND POWER BLADE ENG CO LTD

Die casting aluminum alloy and preparation method thereof

The invention provides a die casting aluminum alloy which comprises the following components in percentage by weight: 0.3%-1% of Mg, 1%-5% of Si, 0.03%-0.7% of Sr, 0.3%-1.5% of Mn and the balance of Al. The invention also provides a preparation method of the die casting aluminum alloy. A film obtained after the die casting aluminum alloy is subjected to anodic oxidation is uniform in color and good in texture. In addition, the mechanical property of the die casting aluminum alloy provided by the invention can meet the requirement.

Owner:BYD CO LTD

Ecological dustproof type seawater sea-sand anti-corrosion marine concrete and preparation method thereof

The invention discloses an ecological dustproof type seawater sea-sand anti-corrosion marine concrete and a preparation method thereof. The concrete comprises the following raw materials: cement, silica fume, coal ash beads, blast furnace slag powder, corroding ion inhibitors, sea sand, steel fibers, a water reducing agent and seawater. The preparation method comprises the following steps: mixingcement, silica fume, coal ash beads, blast furnace slag powder, corroding ion inhibitors and steel fibers and then uniformly stirring with a stirrer; adding sea sand and continuing to uniformly stir;adding seawater and the water reducing agent; mechanically stirring till uniformly stirring, thereby acquiring a concrete slurry; pouring and then removing a mold and maintaining for 48h at 80 DEG C under the condition of humidity of 95%, thereby acquiring the marine concrete. The concrete disclosed by the invention has the advantages of high curing rate of chloride ions, excellent working performances, high durability, lower cost, locally acquired raw materials, short construction period and suitability for popularization and application.

Owner:HOHAI UNIV

Lead-carbon battery negative plate

ActiveCN105140466ARapid response to large currentIncrease migration rateLead-acid accumulator electrodesIonHumic acid

The invention discloses a lead-carbon negative plate. Common negative lead paste coats lead-calcium grid alloy; negative lead paste with high carbon content coats two surfaces of a pole plate; and the lead-carbon negative plate is obtained by curing and drying, wherein the negative lead paste with high carbon content is prepared from the following raw materials in parts by weight: 100 parts of lead powder, 0.5-1 part of a carbon material A, 5-20 parts of a carbon material B, 0.1-1.5 parts of barium sulfate, 0.1-0.5 part of sodium lignosulphonate, 0.1-0.5 part of humic acid, 0.1-0.5 part of a staple fiber, 0-20 parts of water and 4-8 parts of 1.0-1.4g / cm<3> sulfuric acid. According to the lead-carbon negative plate, a hierarchical pore structure carbon material coats the outer layer of the negative plate; the capacitance characteristics of the carbon material are kept; the migration rate of ions in electrolyte is improved; the high-current discharge performance is improved; irreversible sulfation is inhibited; and the cycle life of a battery high-rate partial state of charging (HRPSoC) is prolonged.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

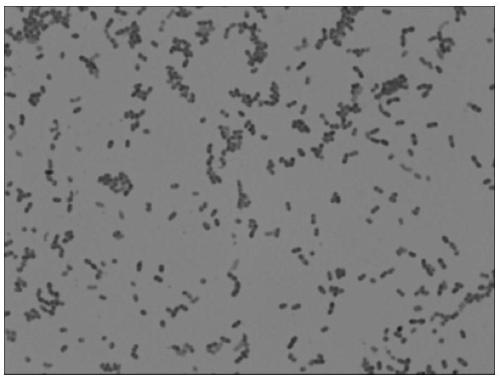

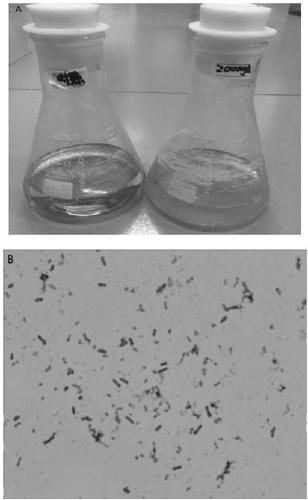

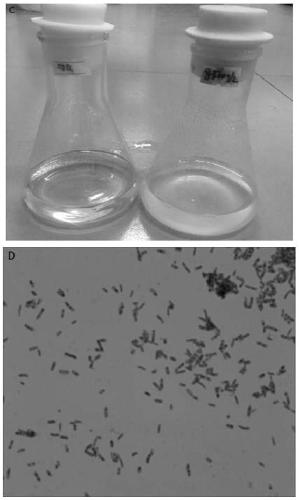

Cupriavidus, cupriavidus preparation, and application of cupriavidus preparation in heavy metal contaminated soil remediation

ActiveCN109055258AWell toleratedReduce cadmium contentBacteriaContaminated soil reclamationFertilizerSoil acidification

The invention discloses cupriavidus, a cupriavidus preparation, and application of the cupriavidus preparation in heavy metal contaminated soil remediation. The cupriavidus sp. is resistant to heavy metal ions, and capable of adsorbing the heavy metal ions, increasing pH of the soil water phase micro-environment and producing struvite with a nitrogen and phosphorus slow controlled-release fertilizer function; when the cupriavidus is used for heavy metal contaminated soil remediation, in particular to cadmium contaminated soil remediation, cadmium ions in soil can be fixed through adsorption and deposition, the bioavailability of soil cadmium is reduced, the soil fertility can be improved, and the technical problems such as soil acidification are solved.

Owner:XIANGTAN UNIV

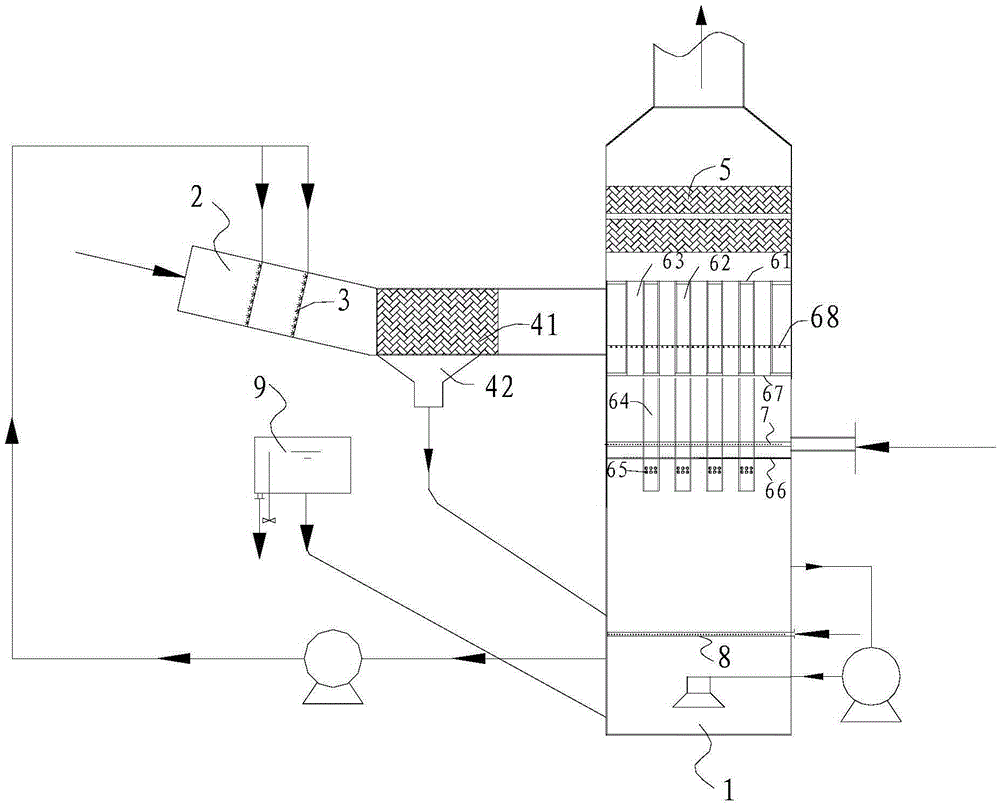

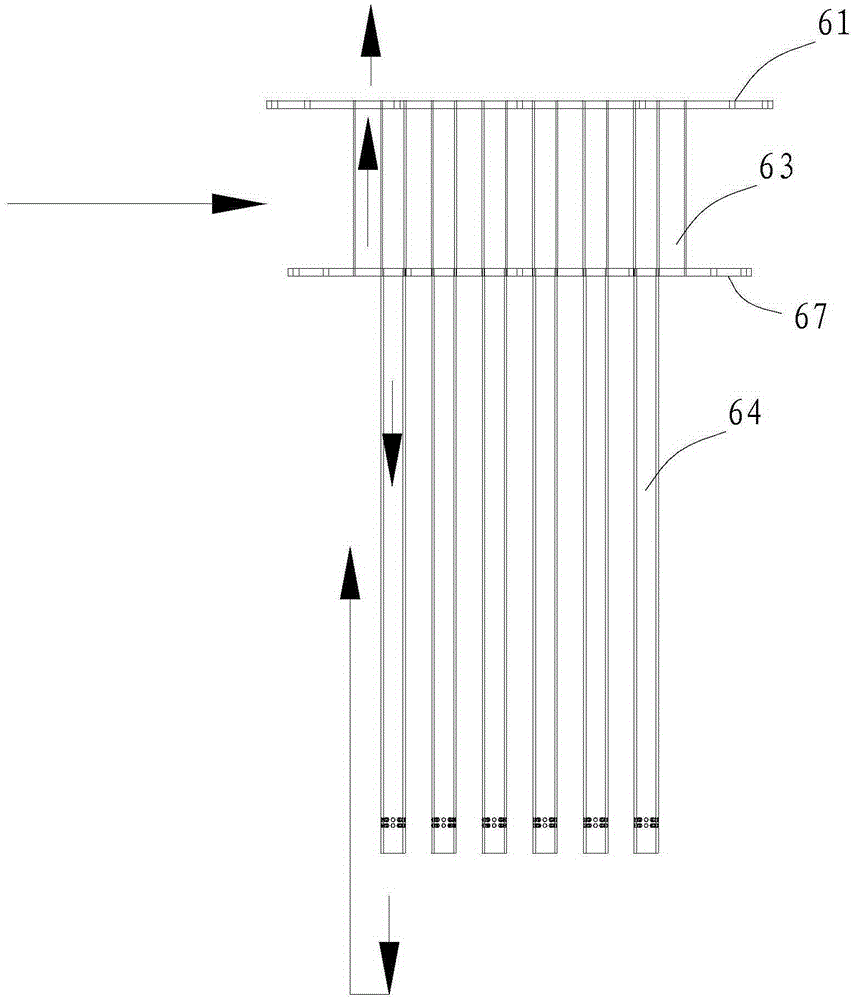

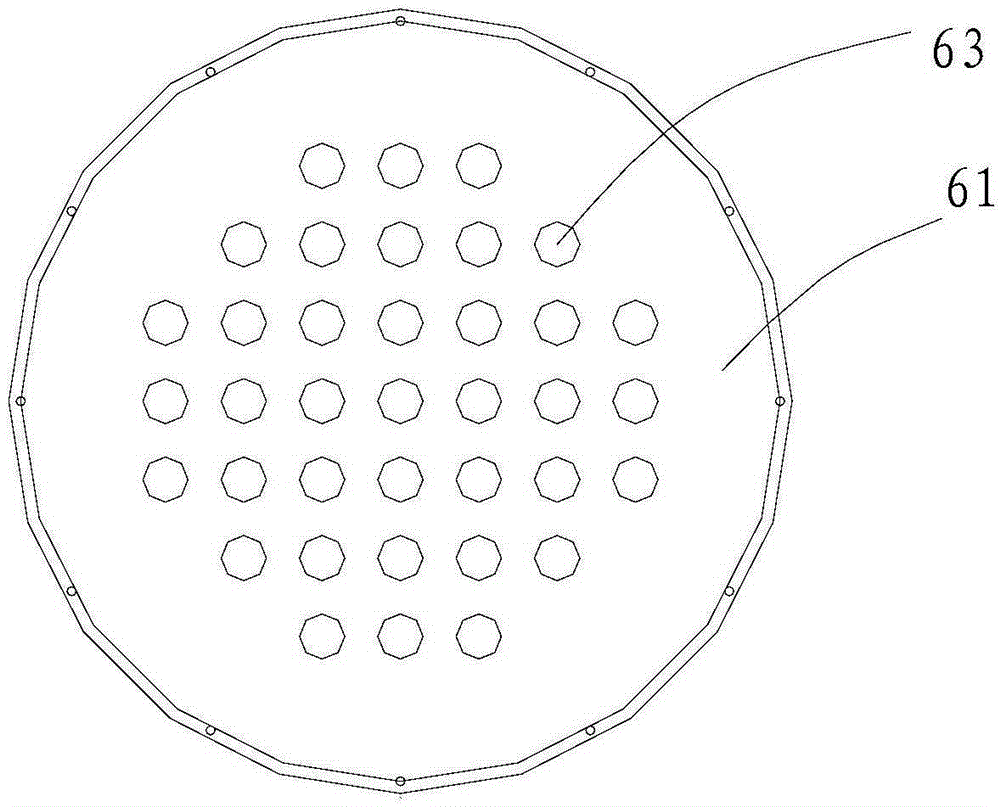

Bubble tower and method for wet flue gas desulphurization

ActiveCN105381703AImprove desulfurization efficiencySmall volumeCombination devicesGas treatmentFlue gasProcess engineering

The invention discloses a bubble tower and method for wet flue gas desulphurization. The bubble tower comprises an absorbing tower, a bubbling mechanism is arranged in the absorbing tower, the bubbling mechanism is connected to an inlet flue, a humidifying spray mechanism and a dust pre-removal mechanism are orderly arranged in the inlet flue along a flue gas flow direction, the bubbling mechanism comprises a sealed flue gas inlet zone formed from an upper separation plate, a lower separation plate and inner walls of the absorbing tower, the sealed flue gas inlet zone is communicated with the inlet flue, the bubble tower also comprises several vertical bubbling pipes, the upper ends of the bubbling pipes go through the lower separation plate and are communicated with the flue gas inlet zone, the lower ends of the bubbling pipes stretch into the tower bottom, the bubble tower also comprises several vertical flue gas discharge pipes, the flue gas discharge pipes go through the upper separation plate and the lower separation plate, the flue gas discharge pipes and the bubbling pipes are staggered, the bubble tower comprises a flushing pipe network, the flushing pipe network is arranged in the flue gas inlet zone and is located above inlets of the bubbling pipes, and the flushing pipe network is provided with several atomizing nozzles. The bubble tower and method are used for wet flue gas desulphurization and mainly solve the problem that the existing bubble tower easily produces scale in the bubbling pipes so that the bubbling pipes are blocked and bubbling tower normal operation is influenced.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Device and method for in-situ remediation of fluoride-polluted soil

The invention discloses a device and method for in-situ remediation of fluoride-polluted soil, which can adopt a permeable reactive barrier in combination with an electrodynamics technology to performin-situ remediation on fluoride-polluted soil. The remediation method comprises the steps of performing physicochemical property measurement on soil, performing fluorine elution on the surface of thesoil using a soil eluent, laying an electrode capable of being repaired in situ, constructing an electrolyte continuous cycle loop between an electrolysis chamber and an electrolyte storage tank of the in situ electrode, and applying a direct-current electric field between the anode and cathode with a low-pressure pulsed power supply. Fluorinion carrying negative charge moves towards an anode chamber through electromigration under the action of the electric field and is adsorbed by a permeable reactive barrier in the anode chamber, meanwhile, fluorine, in the form of fluoride or other solubleions, moves towards a cathode chamber through electrodialysis and is adsorbed by a permeable reactive barrier in the cathode chamber, after the remediation is completed, the electrode is taken out, thereby completing the removal and remediation of fluorine pollutants in the soil.

Owner:HENAN UNIV OF SCI & TECH

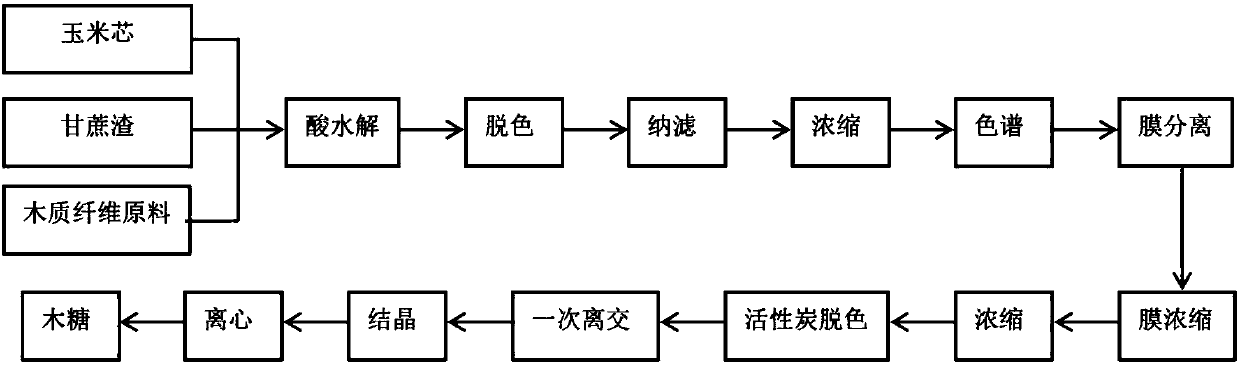

Production method and device for xylose

PendingCN107893132ARealize green and energy-saving manufacturingAvoid enrichmentXylose productionFiberActivated carbon

The invention provides a production method for xylose, wherein corncobs, bagasse or other wood fibers are used as raw materials in the method. The method comprises the steps: 1) carrying out acid hydrolysis to obtain a xylose-containing solution; 2) carrying out activated carbon decoloration to obtain a decolorized solution; 3) making the decolorized solution enter a nanofiltration membrane recovery system, and recycling a clear liquid for next acid hydrolysis of a raw material; 4) increasing the concentration of xylose in the obtained concentrated solution, carrying out primary evaporation concentration, then, entering a chromatographic system to carry out impurity removal and desalination to obtain a chromatographic eluent; and 5) carrying out nanofiltration membrane decoloration, membrane concentration, secondary evaporation concentration, activated carbon decoloration, ion exchange, vacuum concentration and crystal centrifugation to obtain a high-quality xylose crystal.

Owner:JIANGSU JIUWU HITECH

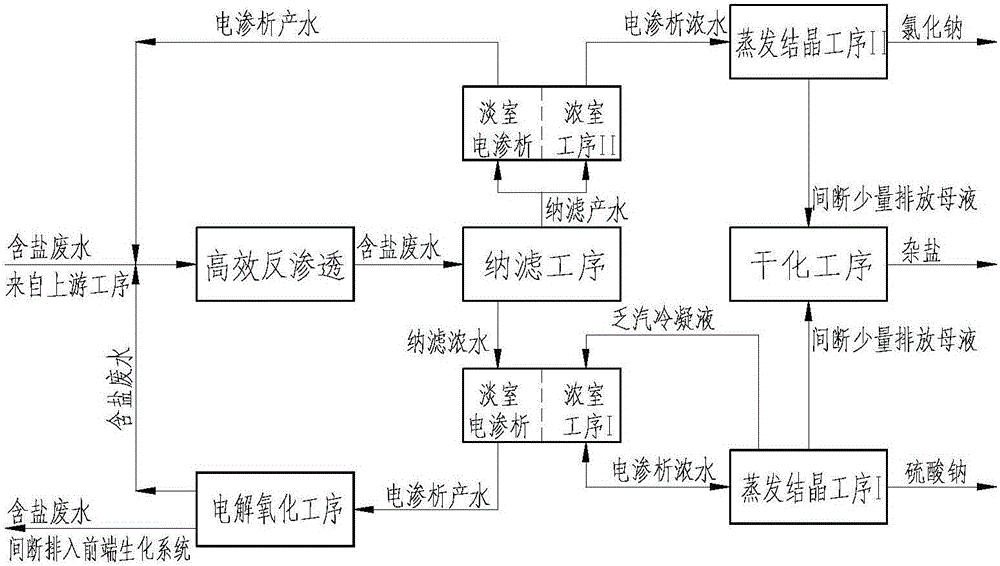

Method for separating organic matter impurities from brine waste of coal chemical industry and separating salt by utilizing membrane method

InactiveCN106830481AAchieve separationAvoid disadvantages such as low purityWater treatment parameter controlMultistage water/sewage treatmentReverse osmosisWater quality

The invention discloses a method for separating organic matter impurities from brine waste of a coal chemical industry and separating salt by utilizing a membrane method. The method comprises the following steps: (1) efficient reverse osmosis process; (2) nanofiltration process; (3) electroosmosis process I; (4) evaporative crystallization process I; (5) electrolytic oxidation process; (6) electroosmosis process II; and (7) evaporative crystallization process II. The invention abandons the traditional scheme for separating the salt in the manner of high-quality crystal separation through freezing crystallization or thermal method at the rear end and adopts a nanofiltration membrane process for separating the salt. The selective permeability of the nanofiltration membrane for ions under different valence states is utilized to separate the two main components, namely, sodium chloride and sodium sulfate in the waste water. The defects that the water quality change cannot be coped with and the product purity is low in the traditional salt niter separation hot-process crystallizing scheme can be overcome.

Owner:EAST CHINA ENG SCI & TECH

A preparation method of high-performance sintered Nd-Fe-B permanent magnet material

InactiveCN109192493AStrong combinationFacilitate grain boundary diffusion processInductances/transformers/magnets manufactureMagnetic materialsAlloy elementRare-earth element

The invention relates to a preparation method of a high-performance sintered Nd-Fe-B permanent magnet material, belonging to the field of rare earth permanent magnet material. The quaternary and abovequaternary rare earth alloy films are deposited on the surface of pretreated Nd-Fe-B magnet by magnetron sputtering. The homogenization, grain boundary diffusion and low temperature tempering are used as diffusion sources to improve the boundary structure of the magnet, so that the coercivity of the magnet is greatly increased and the remanence is kept basically unchanged. The composition of thequaternary and above quaternary rare earth alloy film is LRE 100-X-Y-ZHRExMyAlz (1 <= x <= 40, 1 <= y <= 20, 1 <= z <= 20), wherein LRE is one or more of the light rare earth elements such as Y, La, Ce, Pr, Nd, HRE is one or more of the heavy rare earth elements such as Tb, Dy, Ho, and M is one or more of the alloy elements such as Cu, Fe, Co, Ga, Zr, Zn, Mn, and Mg. The rare earth alloy thin filmprepared by the invention is uniform, compact and strong in adhesion as diffusion source, the quantity is continuously controllable, and the consistency of magnetic properties of the magnet after diffusion treatment is good; It can reduce the amount of rare earth and is suitable for industrial production.

Owner:UNIV OF SCI & TECH BEIJING

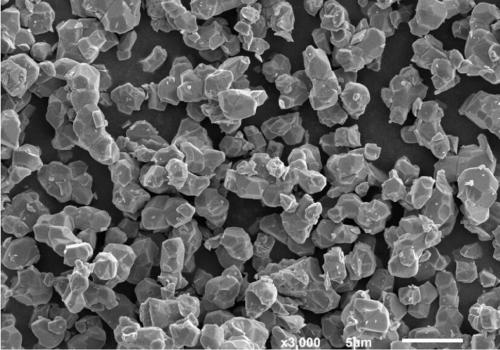

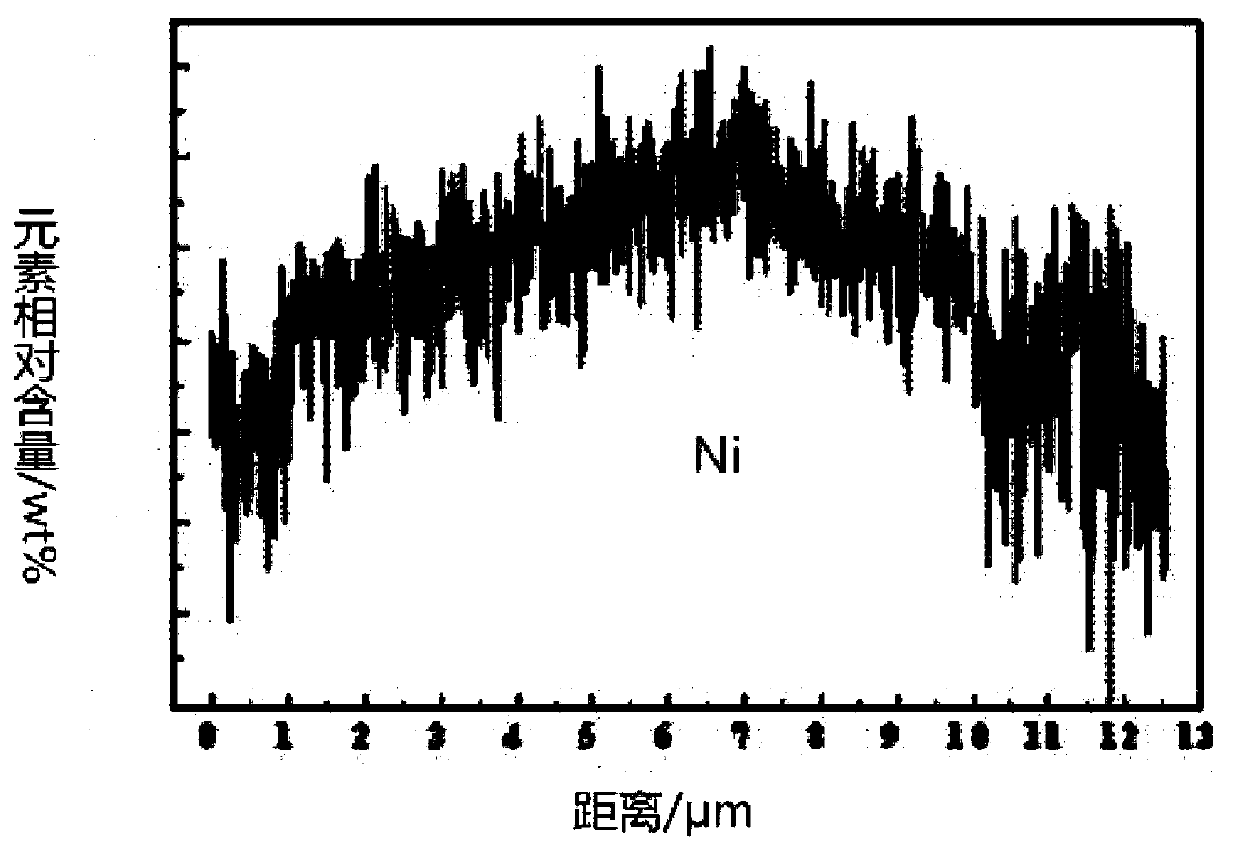

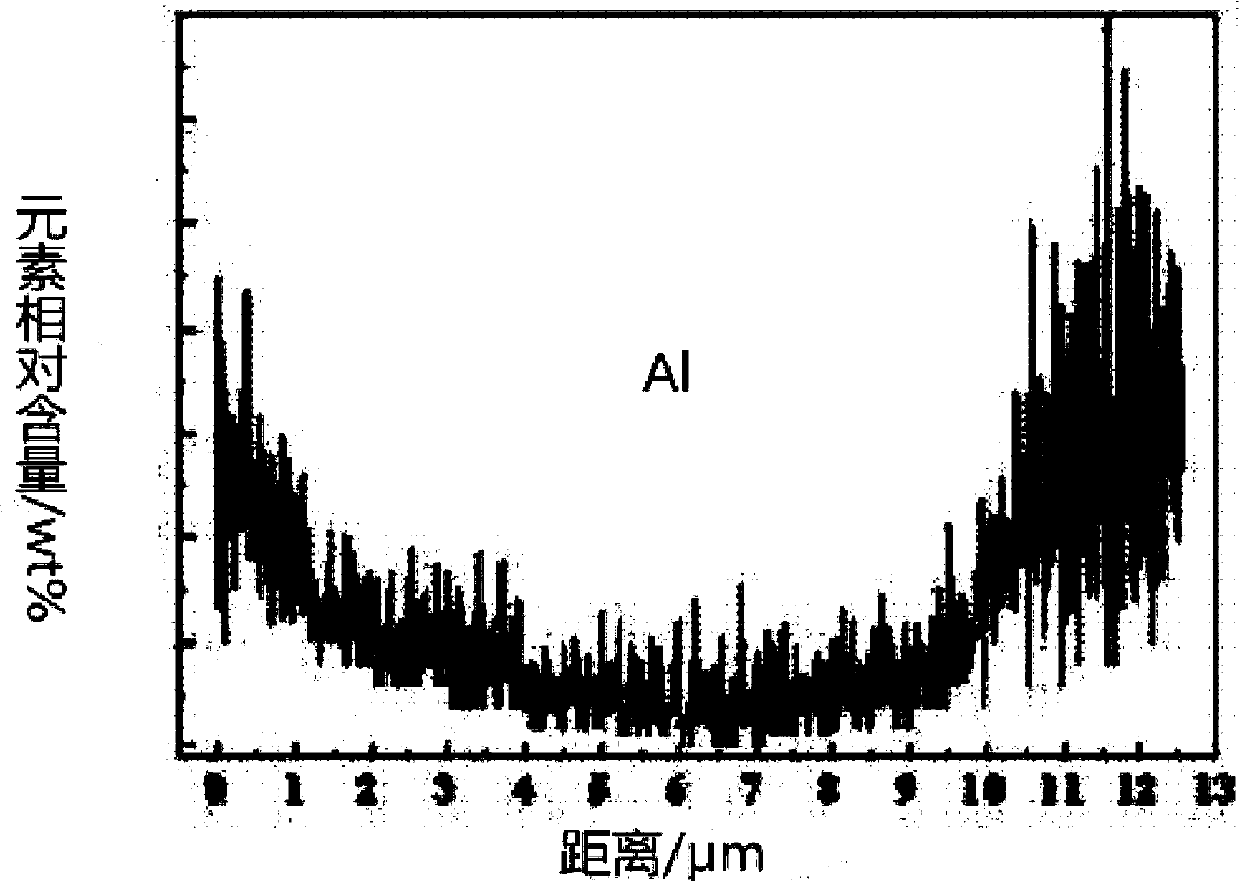

Preparation method of nickel-cobalt-manganese precursor particles

ActiveCN110190241AReduce contentIncrease contentElectrode manufacturing processesSecondary cellsNickel saltManganese

The invention relates to a preparation method of a nickel-cobalt-manganese precursor, which specifically includes the following steps: preparing nickel-cobalt solution, nickel-manganese solution and nickel-T solution by mixing soluble nickel salt with soluble cobalt salt, soluble manganese salt and soluble salt doped with metal T respectively, wherein the concentration of the nickel-cobalt solution is higher than that of the nickel-manganese solution, and the concentration of the nickel-manganese solution is higher than that of the nickel-T solution; mixing the nickel-cobalt solution with thenickel-manganese solution and adding a complexing agent to obtain a mixed solution, and adjusting the pH value of the mixed solution to 9-11.5 by adding alkali solution; and adding the nickel-T solution to the mixed solution for reaction in an inert atmosphere to obtain nickel-cobalt-manganese precursor particles with uniform size, high purity and stable chemical performance. The prepared nickel-cobalt-manganese precursor particles show a gradient decrease in the relative content of nickel element and a gradient increase in the relative content of doped element from the core to the surface.

Owner:HUNAN ZOOMWE NEW ENERGY TECH CO LTD

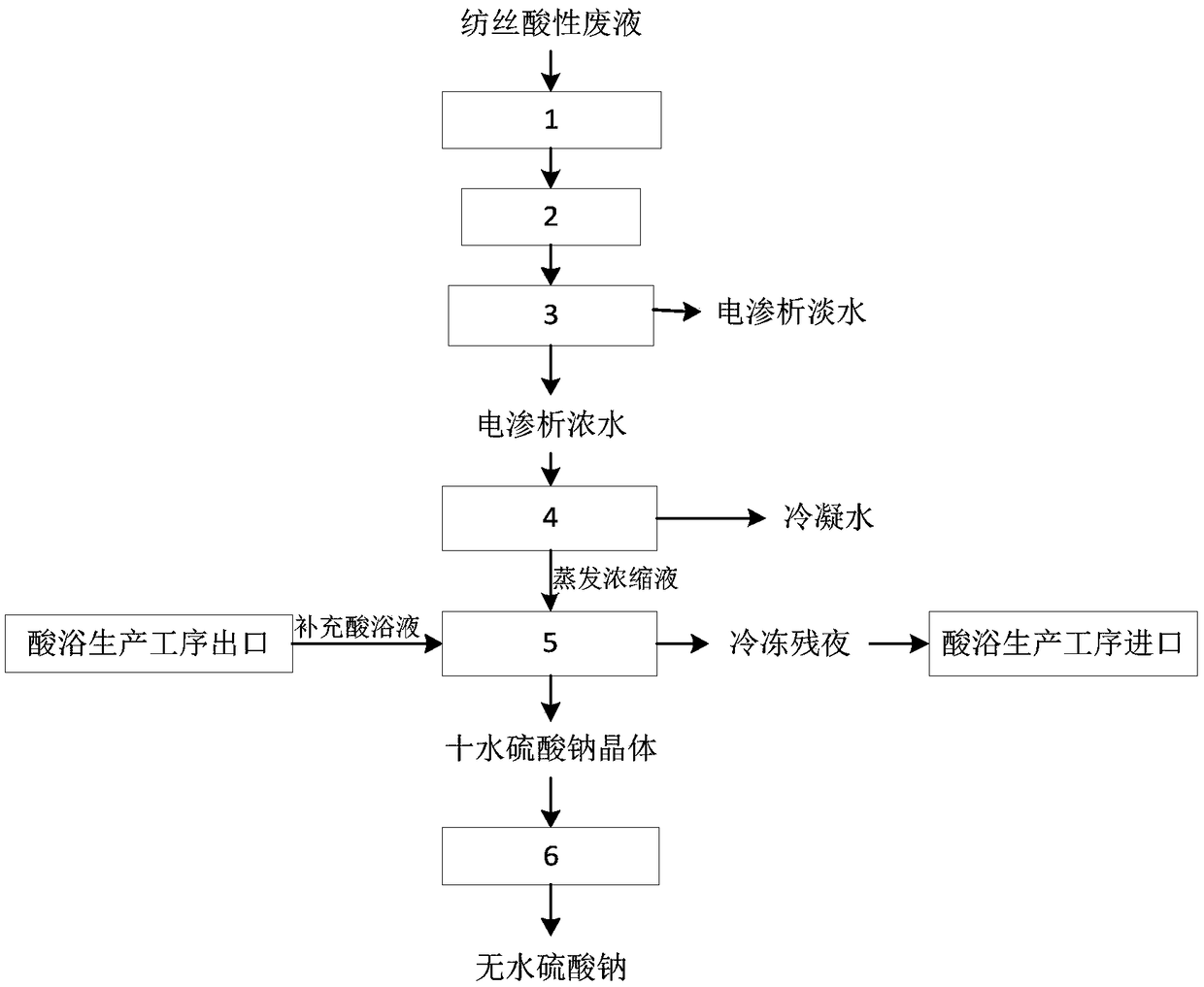

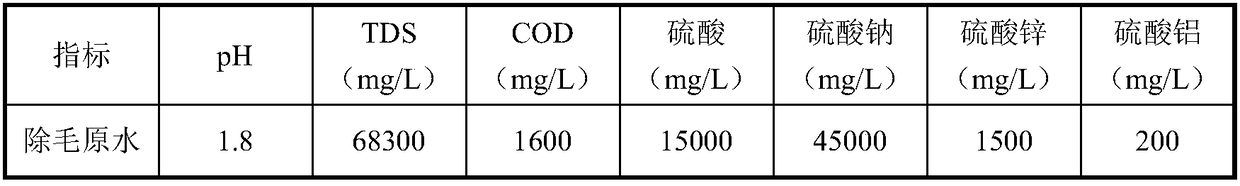

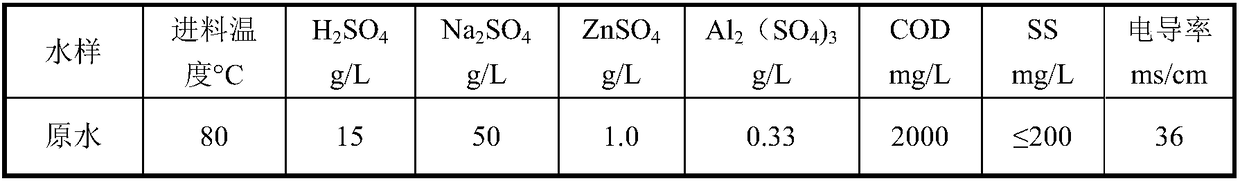

Method and device for progressively recovering and circularly applying viscose fiber spinning acid waste liquid

InactiveCN109457325AAchieve balanceSolve the reuse problemArtificial filament recoveryArtificial filaments from viscoseLiquid wasteResource utilization

The invention discloses a method and a device for progressively recovering and circularly applying viscose fiber spinning acid waste liquid. The method comprises the following steps of (1), carrying out cooling and heat interchange on spinning acid waste liquid from a viscose fiber industry, and then removing a solid insoluble substance in the waste liquid by adopting a precision filter; (2), carrying out electrodialysis on the waste liquid treated in step (1), removing an organic substance in waste water, and carrying out evaporation concentration treatment on thick water subjected to the electrodialysis, so that a concentrated solution with a saline mass concentration of 30% to 50% is obtained; (3), recycling a sodium sulfate decahydrate crystal in the concentrated solution obtained in the step (2) by adopting a freezing crystallization way, and recycling freezing residual liquid in an acid bath device in a spinning production process; and (4), refining the sodium sulfate decahydratecrystal recycled in the step (3) to obtain anhydrous sodium sulfate. By using the method, the balancing of sodium sulfate in a system is realized; the resource utilization and the near zero emissionof viscose fiber spinning waste water are realized; and an organic substance is prevented from being enriched in the system.

Owner:JIANGSU NJU ENVIRONMENTAL TECH

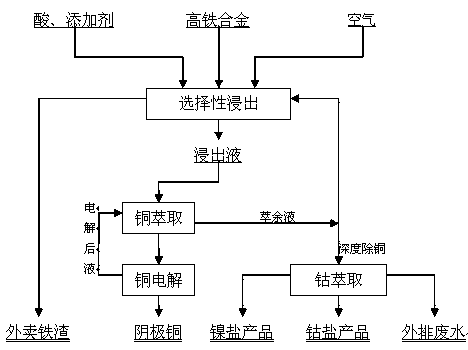

Process for recovering valuable metals from high-iron alloys

The invention discloses a process for recovering valuable metals from high-iron alloys. The process comprises the following steps: 1) the selective leaching of copper, cobalt and nickel: carrying out a leaching reaction on a crushed high-iron alloy by using a sulfuric acid-hydrochloric acid mixed solution with an acid concentration of 0.3-5 mol / L, wherein through the reasonable control over the selected liquid-solid ratio of 5:1-30:1 and the addition of an additive which can be ammonia salts, manganese salts, chloride and the like, Cu, Co and Ni in the alloy can come into the solution in an ion state, Fe in the alloy precipitates in a form of hematite or goethite, and the content of Fe<2+> and Fe<3+> in the obtained leaching liquid is less than 0.1g / L; 2) the selective extraction of copper: feeding the solution into a copper extraction system, and extracting copper by using hydroxamic copper extraction agents or commercially available other copper extraction agents, so that copper is separated and purified; 3) the electrolytic deposition of copper: carrying out reverse extraction on a copper-loaded extraction agent by using electrodeposition liquid, and carrying out electrodeposition so as to obtain a standard cathode copper plate; and 4) the separation and recovery of a solution containing nickel and cobalt. According to the process, the process flow can be greatly shortened and the production costs of copper and cobalt are greatly reduced.

Owner:TIANJIN MAOLIAN SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com