Preparation method of nickel-cobalt-manganese precursor particles

A precursor, nickel-cobalt-manganese technology, which is used in the preparation of nickel-cobalt-manganese precursor particles and the preparation of nickel-cobalt-manganese precursor particles by liquid phase gradient doping can solve the problem of reducing product stability, backward doping methods, and doping Element enrichment and other issues, to achieve the effect of eliminating doping element enrichment, ensuring uniform gradient distribution, and controllable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The embodiment of the present invention proposes a method for preparing nickel-cobalt-manganese precursor particles, including the following steps:

[0047] Step 1: soluble nickel salt, soluble cobalt salt, soluble manganese salt and soluble salt doped with metal T are formulated into nickel-cobalt solution, nickel-manganese solution and nickel-T solution; the concentration of the nickel-cobalt solution is greater than that of the nickel-manganese solution, The concentration of the nickel manganese solution is greater than the nickel T solution;

[0048] Step 2: After mixing the nickel-cobalt solution and the nickel-manganese solution, add a complexing agent, adjust the pH value of the solution to 9-11.5, then add the nickel T solution, and react under an inert atmosphere to obtain the nickel-cobalt-manganese precursor particles .

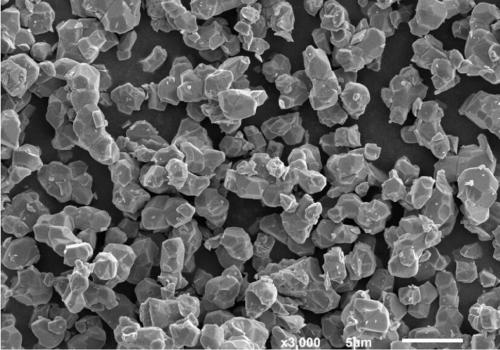

[0049] The particle size characterization instrument of the nickel-cobalt-manganese precursor particles is a laser particle size analyzer....

Embodiment 1

[0057] Nickel sulfate is made into nickel-cobalt sulfate solution, nickel-manganese sulfate solution and nickel-aluminum sulfate solution in proportion with cobalt sulfate, manganese sulfate and aluminum sulfate respectively; Wherein the concentration of nickel-cobalt sulfate solution is 50g / L, the concentration of nickel sulfate and cobalt sulfate The mass ratio is 5:0.6; the concentration of nickel-manganese sulfate solution is 32g / L, and the mass ratio of nickel sulfate and manganese sulfate is 2.5:0.4; the concentration of nickel-aluminum sulfate solution is 6g / L, and the mass ratio of nickel sulfate and aluminum sulfate is 0.5:0.007.

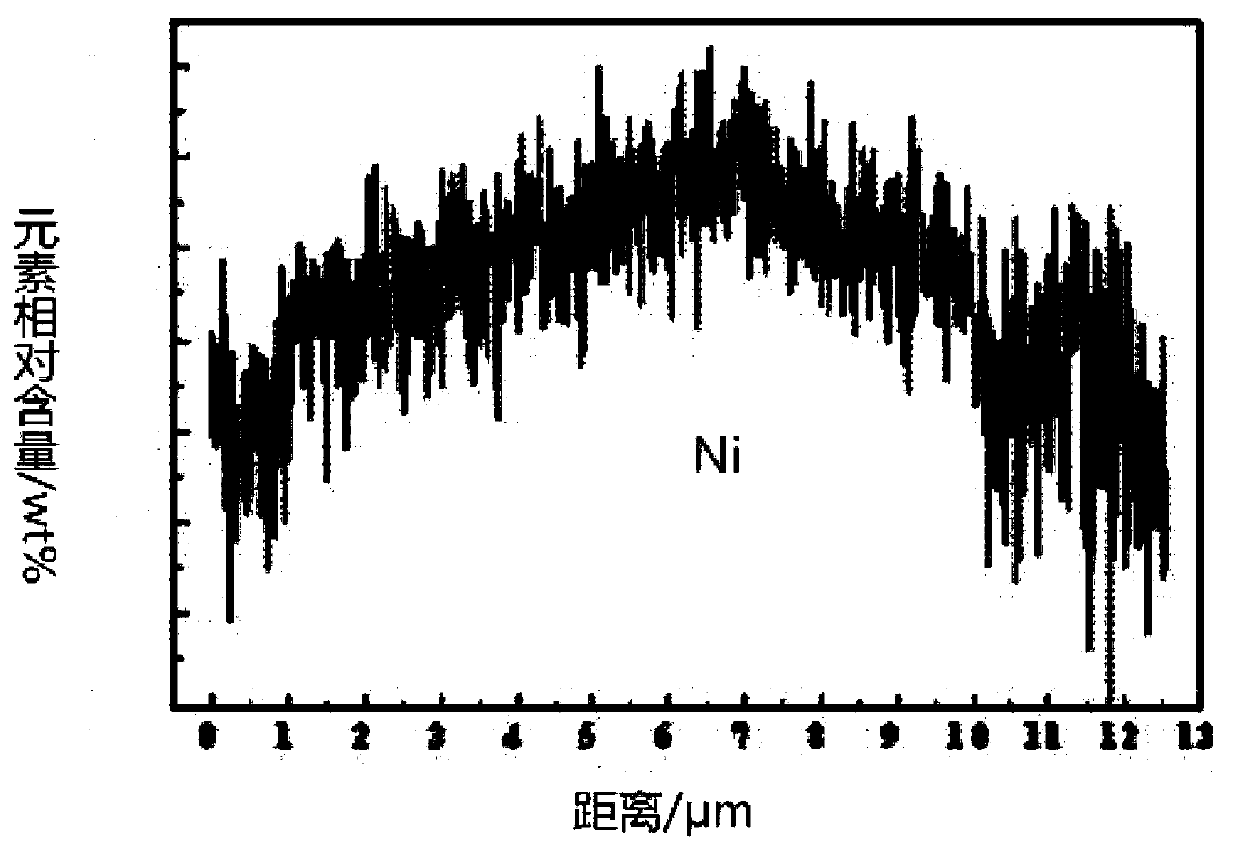

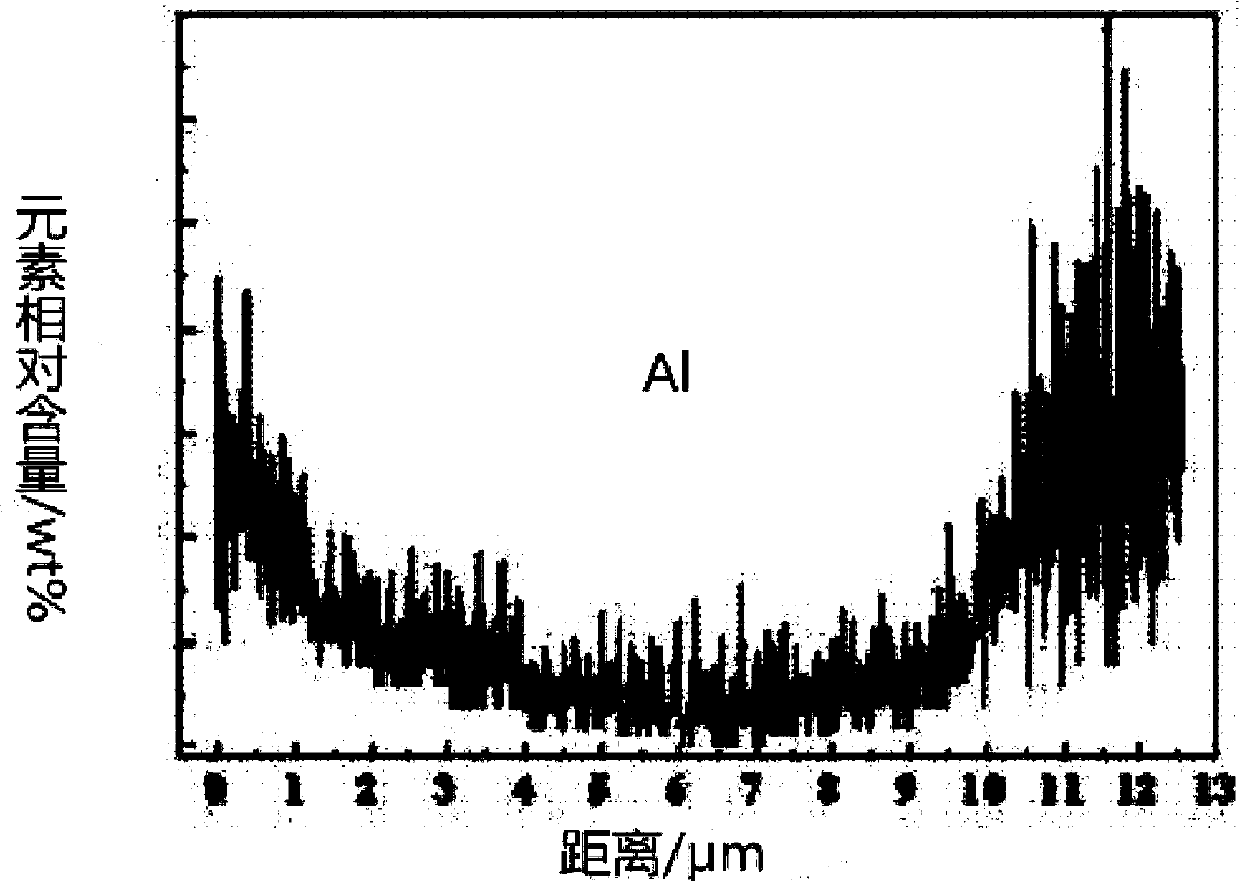

[0058] The nickel-cobalt sulfate solution was added to the reactor with a flow rate of 350L / h and the nickel-manganese sulfate solution was added to the reactor with a flow rate of 280L / h, and then the pyridinium propanesulfonate solution with a concentration of 9g / L was added at a flow rate of 10L / h. A sodium hydroxide solution with a conc...

Embodiment 2

[0064] Nickel sulfate is made into nickel-cobalt sulfate solution, nickel-manganese sulfate solution and nickel-aluminum sulfate solution in proportion with cobalt sulfate, manganese sulfate and aluminum sulfate respectively; Wherein the concentration of nickel-cobalt sulfate solution is 50g / L, the concentration of nickel sulfate and cobalt sulfate The mass ratio is 5:0.6; the concentration of nickel manganese sulfate solution is 32g / L, the mass ratio of nickel sulfate to manganese sulfate is 2.5:0.4; the concentration of nickel aluminum sulfate solution is 6g / L, the mass ratio of nickel sulfate to aluminum sulfate is 0.5:0.007.

[0065] The nickel-cobalt sulfate solution was added to the reactor with a flow rate of 350L / h and the nickel-manganese sulfate solution was added to the reactor with a flow rate of 280L / h, and then the pyridinium propanesulfonate solution with a concentration of 1g / L was added at a flow rate of 10L / h. A sodium hydroxide solution with a concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com