Patents

Literature

2481 results about "Manganese salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sigma-Aldrich Online Catalog Product List: Manganese Salts

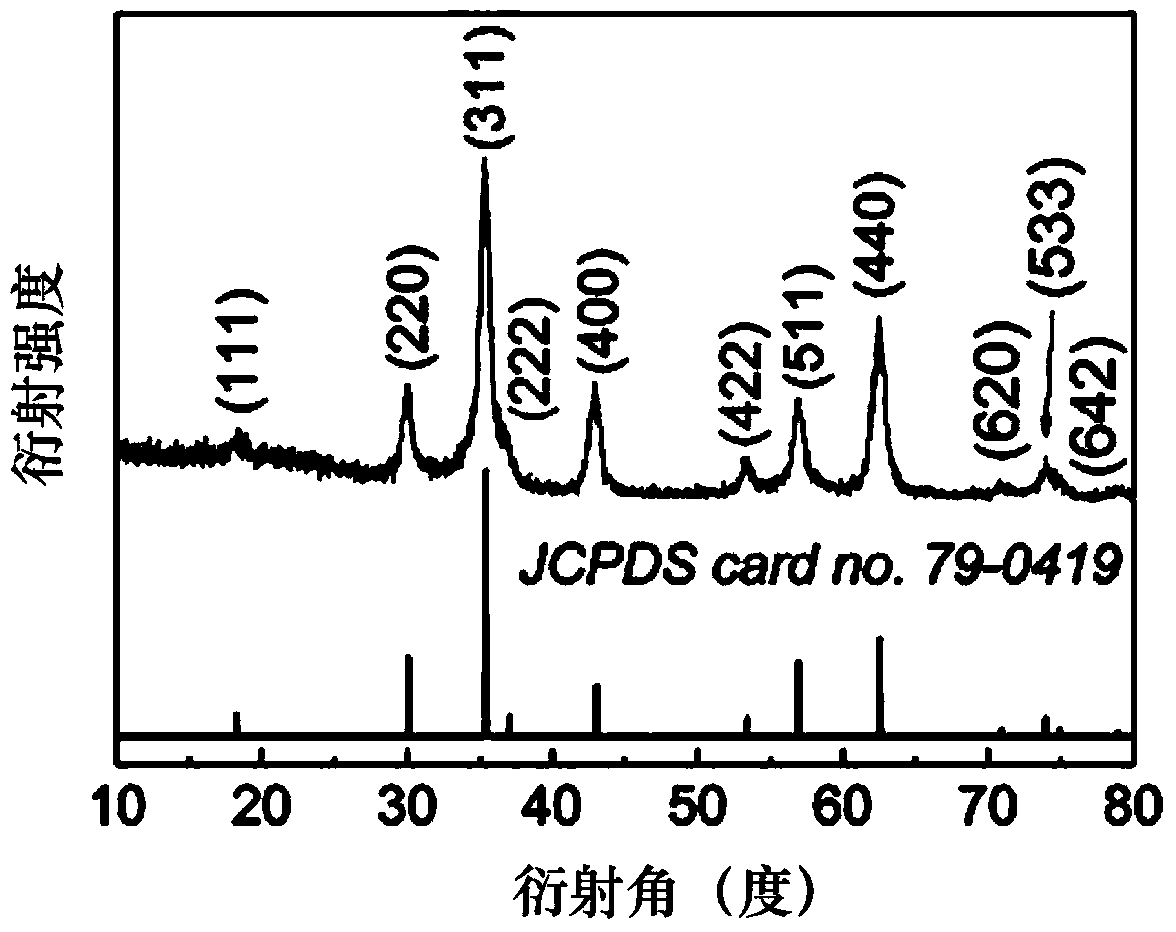

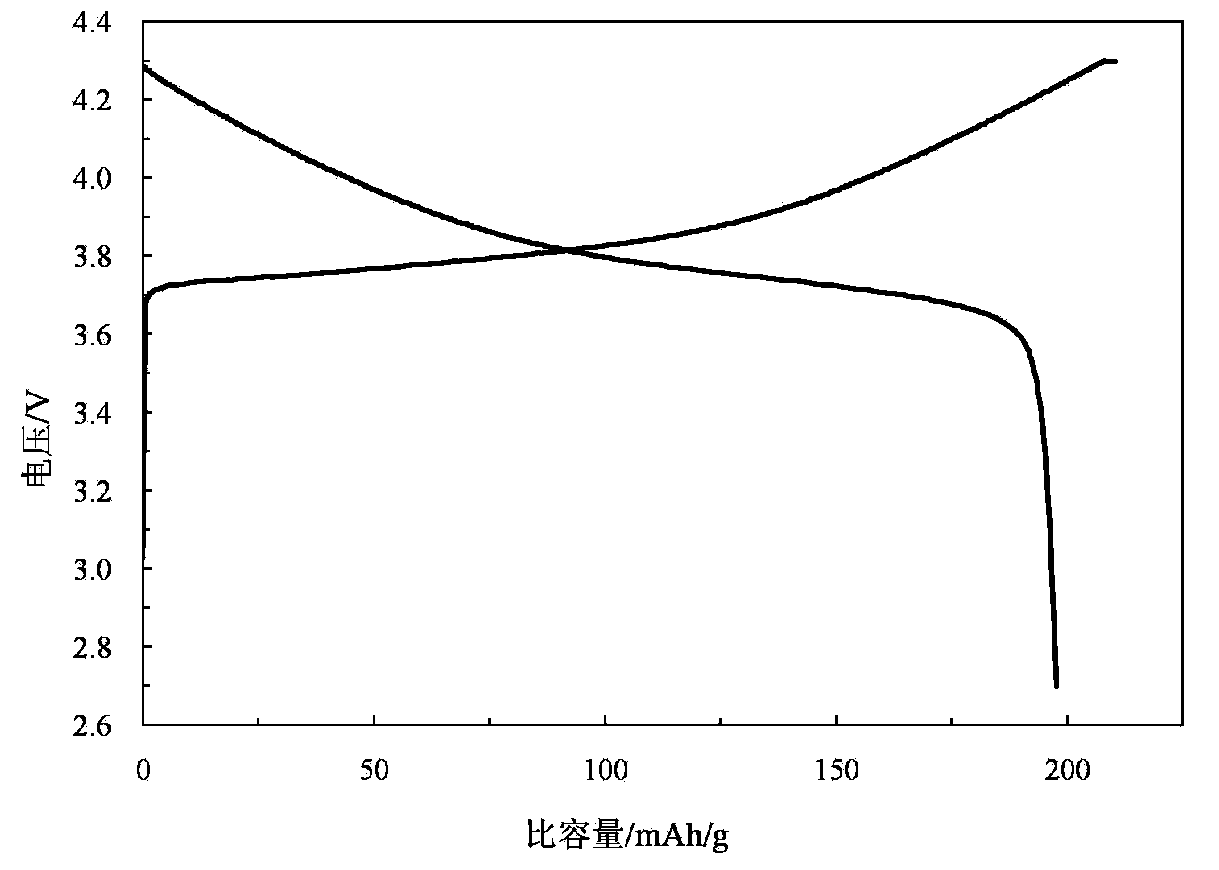

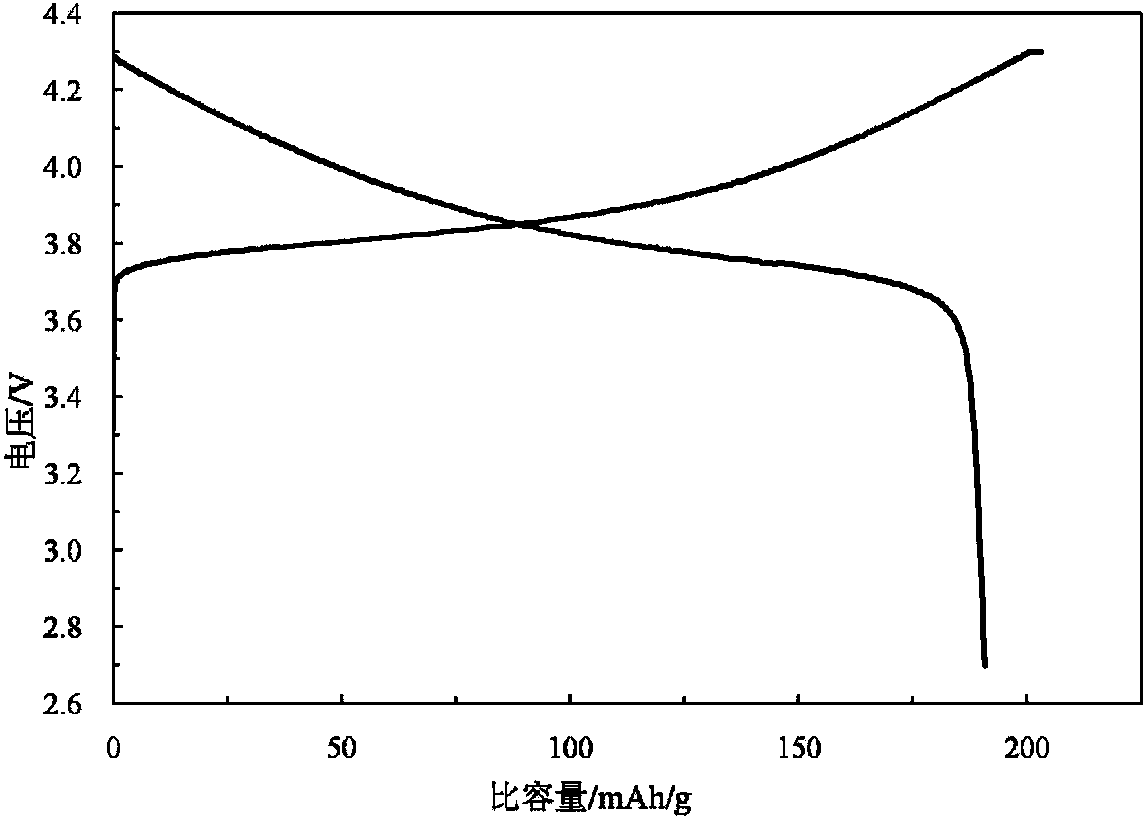

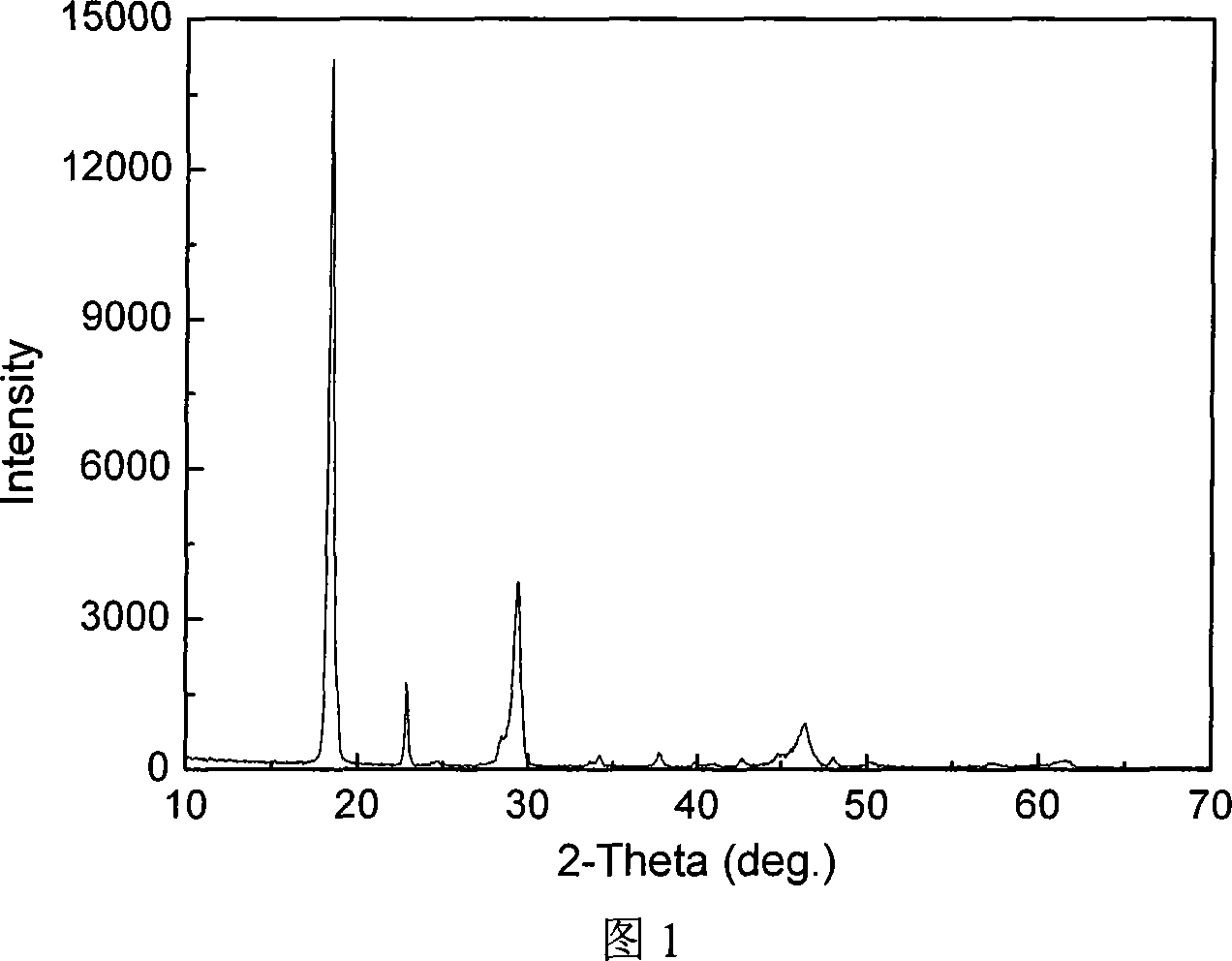

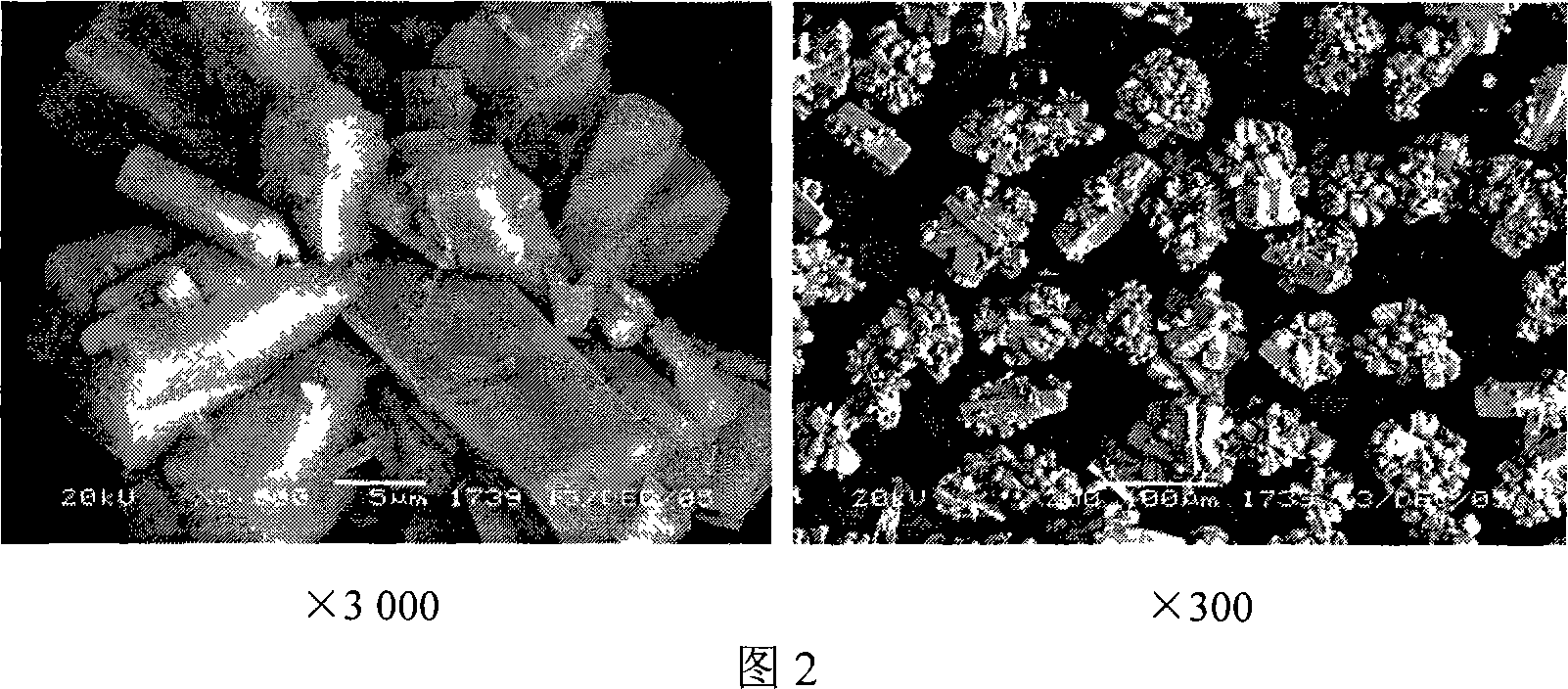

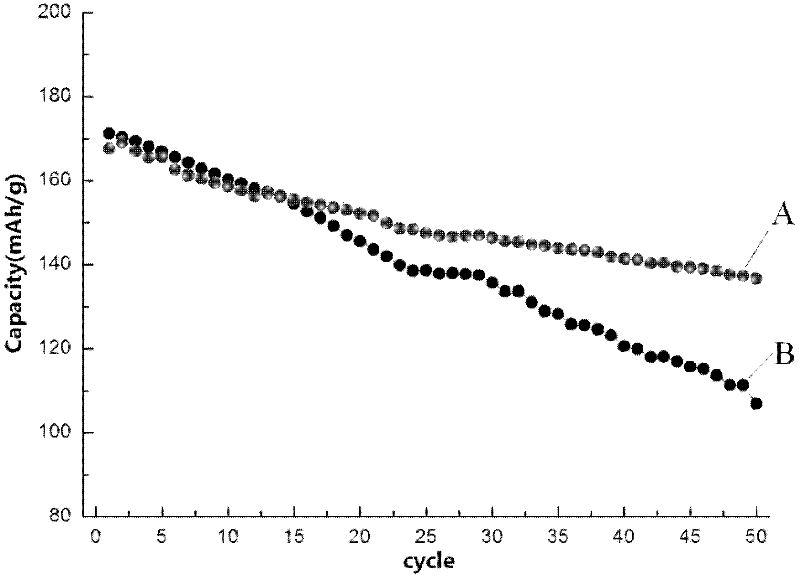

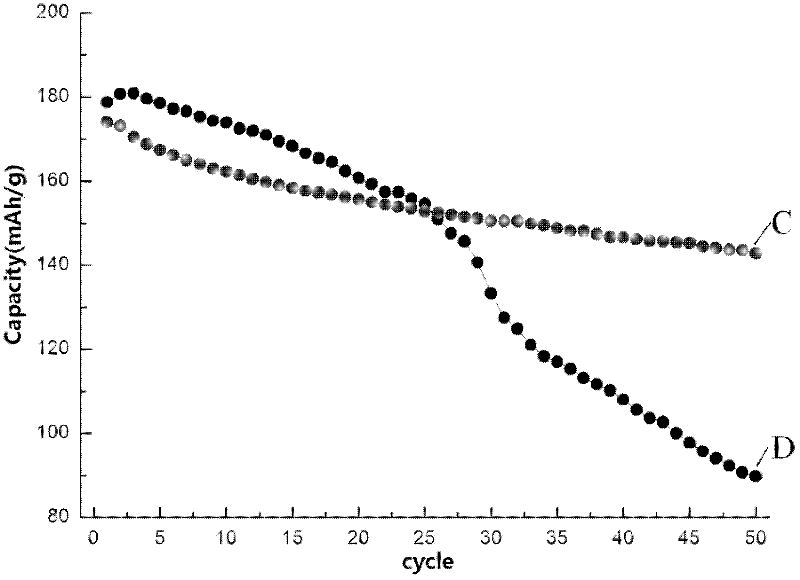

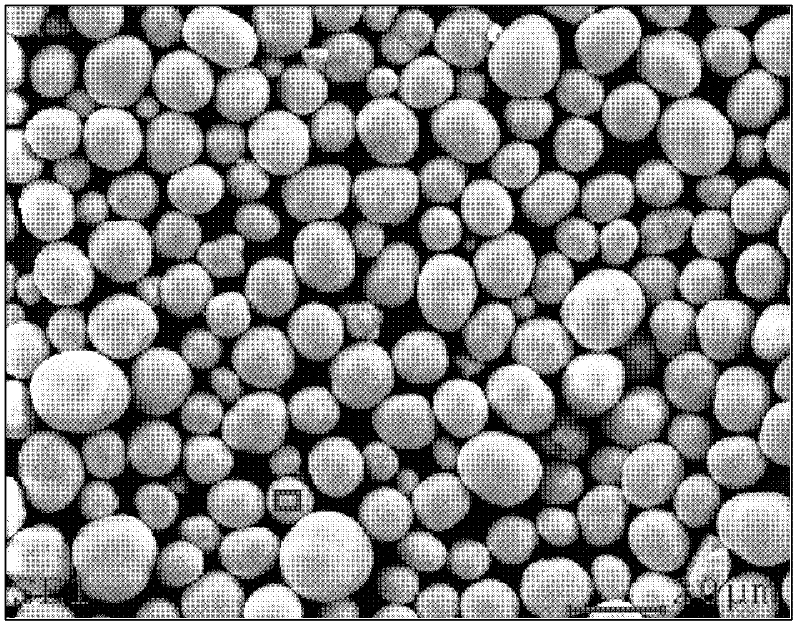

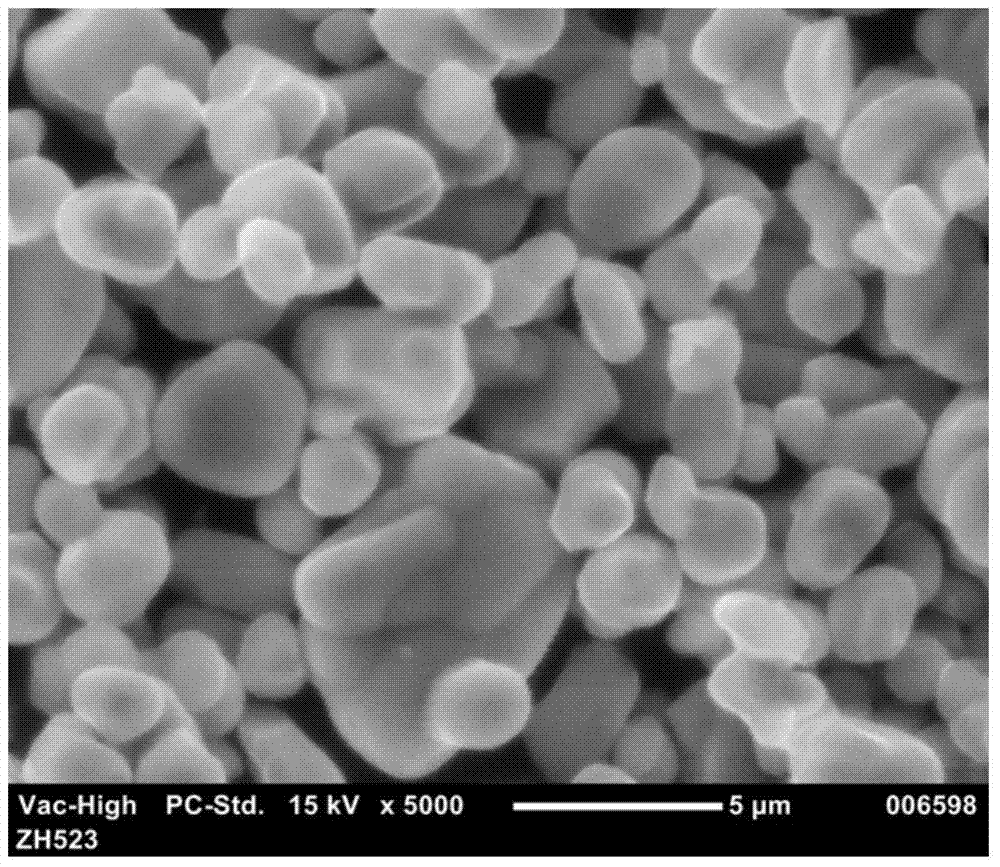

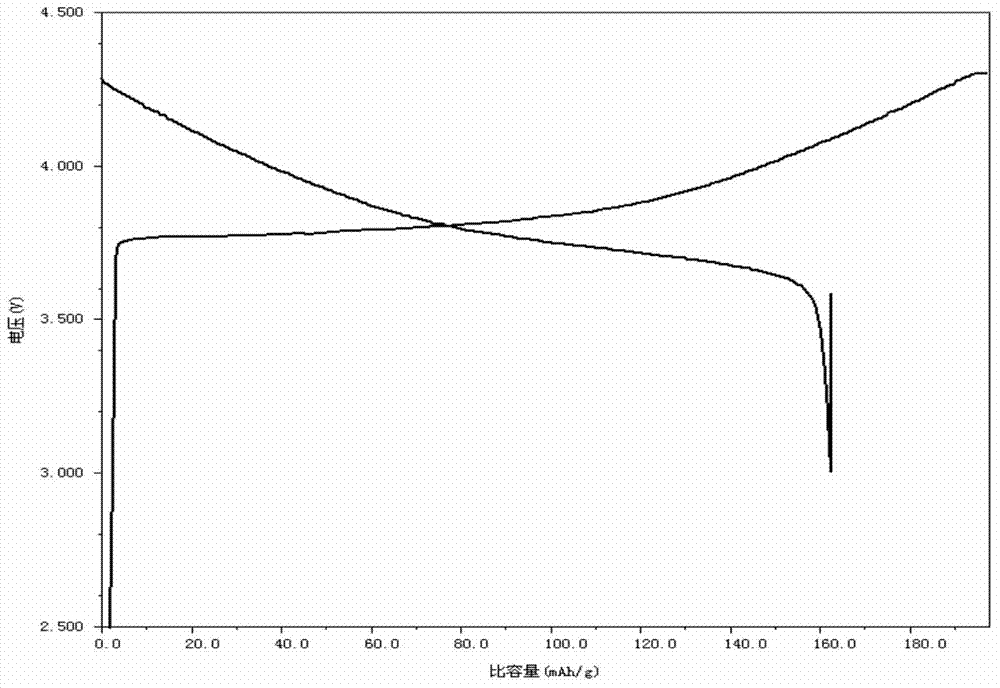

Process for preparing high density spherical nickel-cobalt lithium manganate as anode material of lithium ion cell

InactiveCN1622371AWell mixedImprove performanceElectrode manufacturing processesLithium compoundsNickel saltManganate

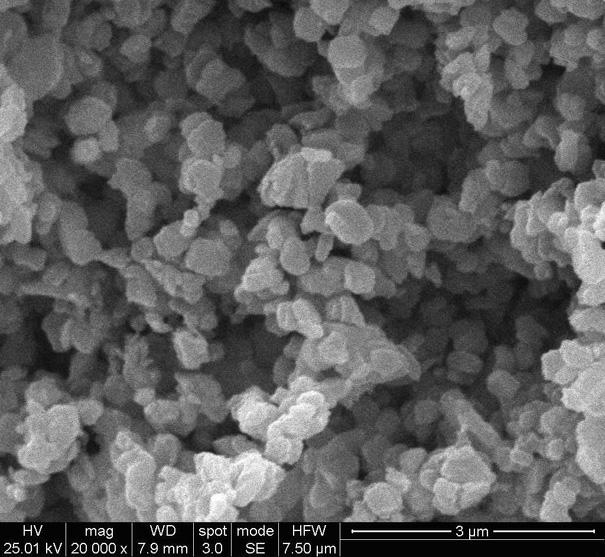

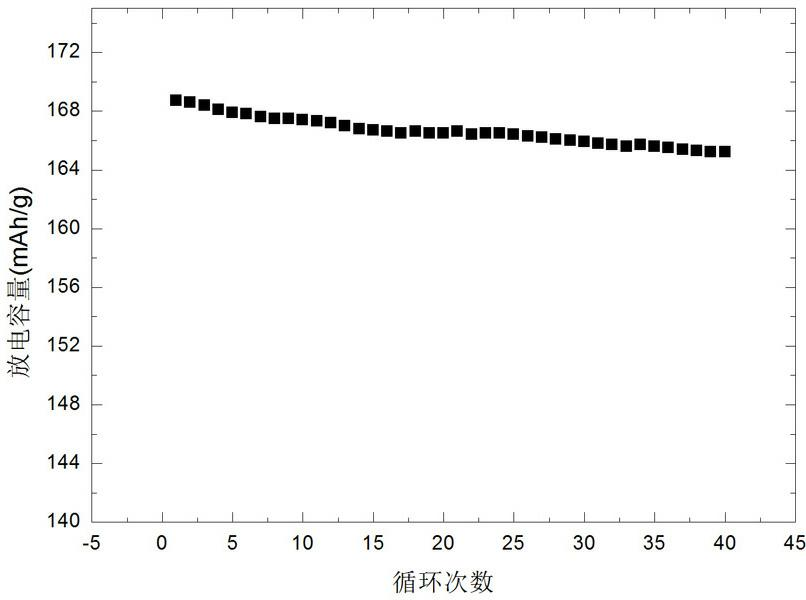

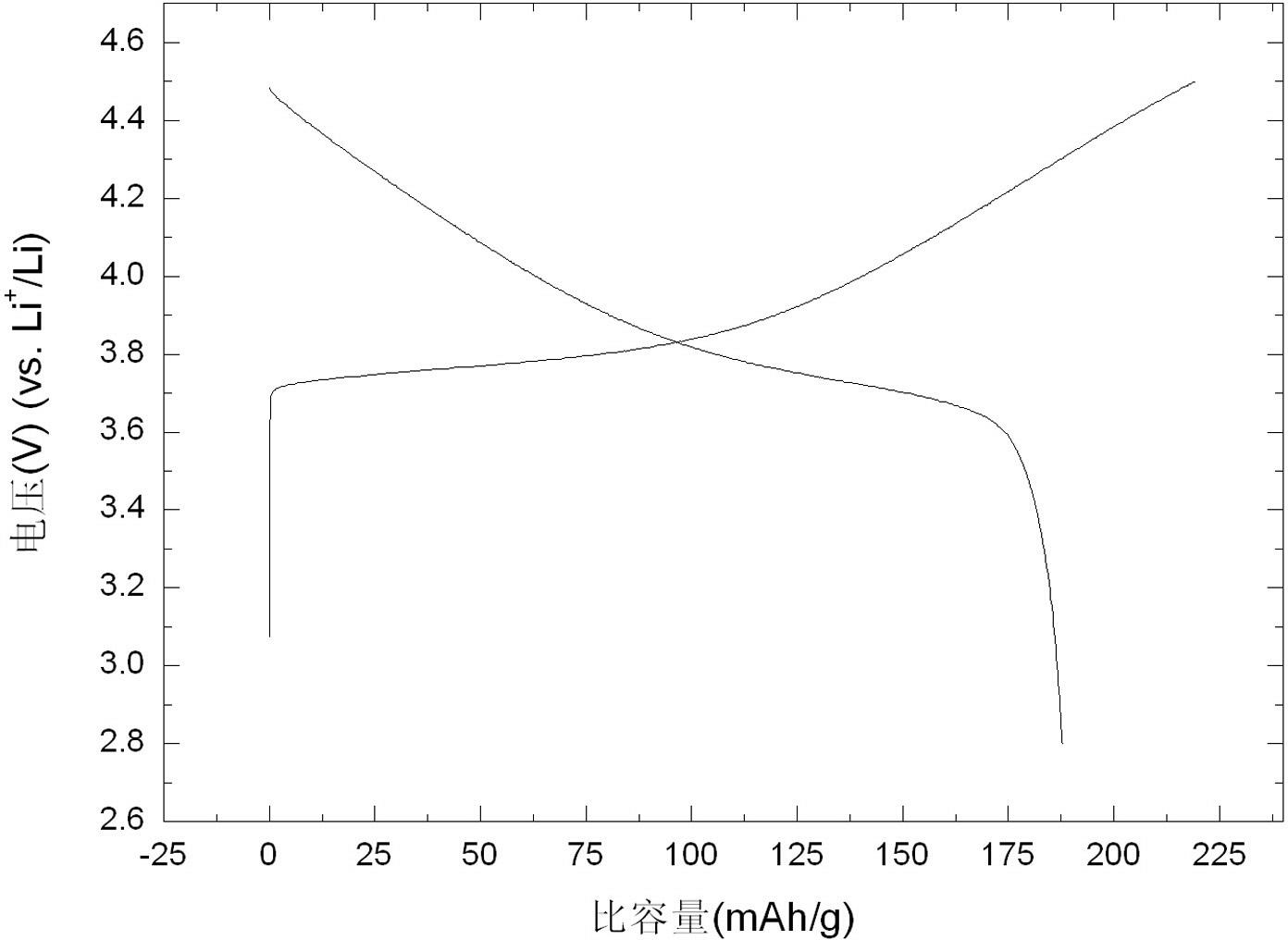

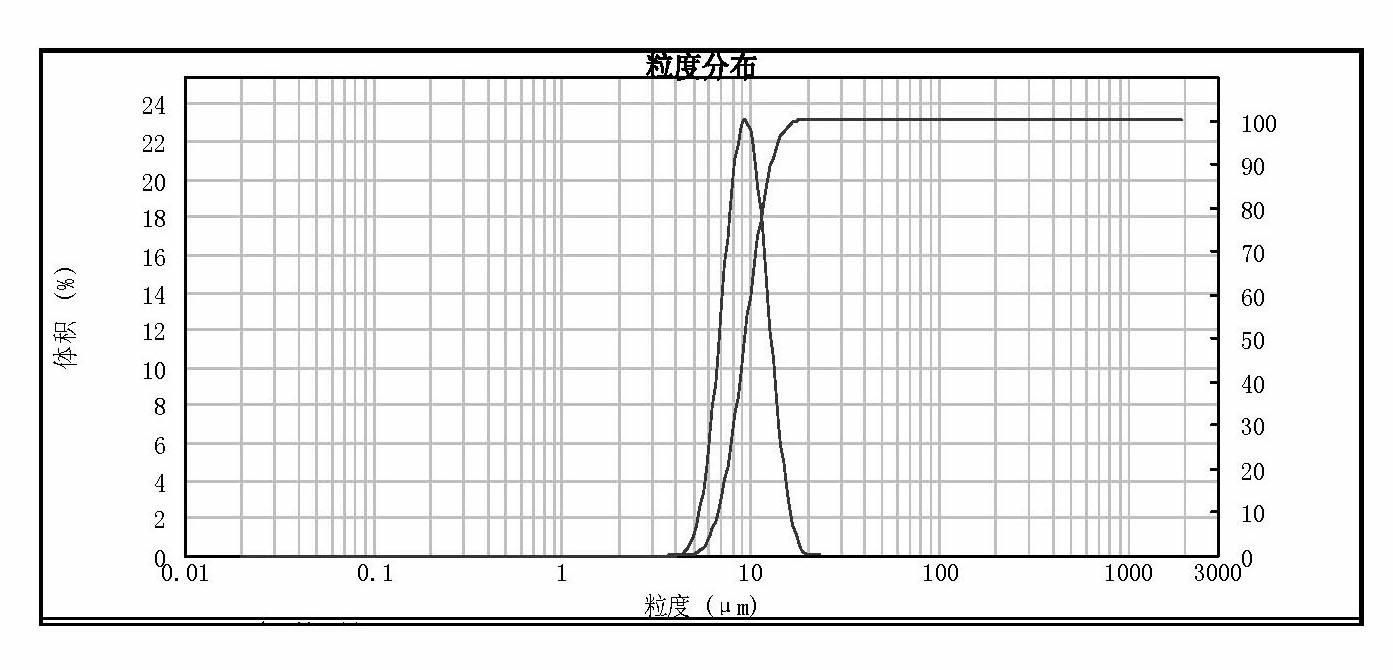

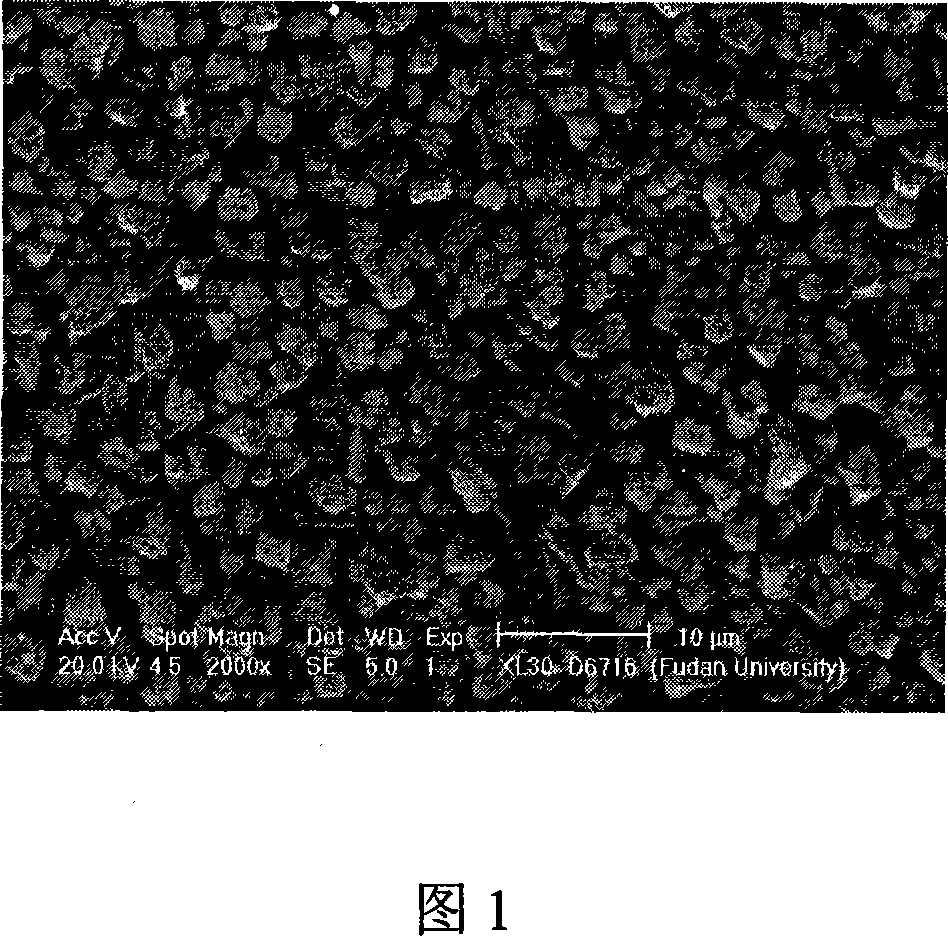

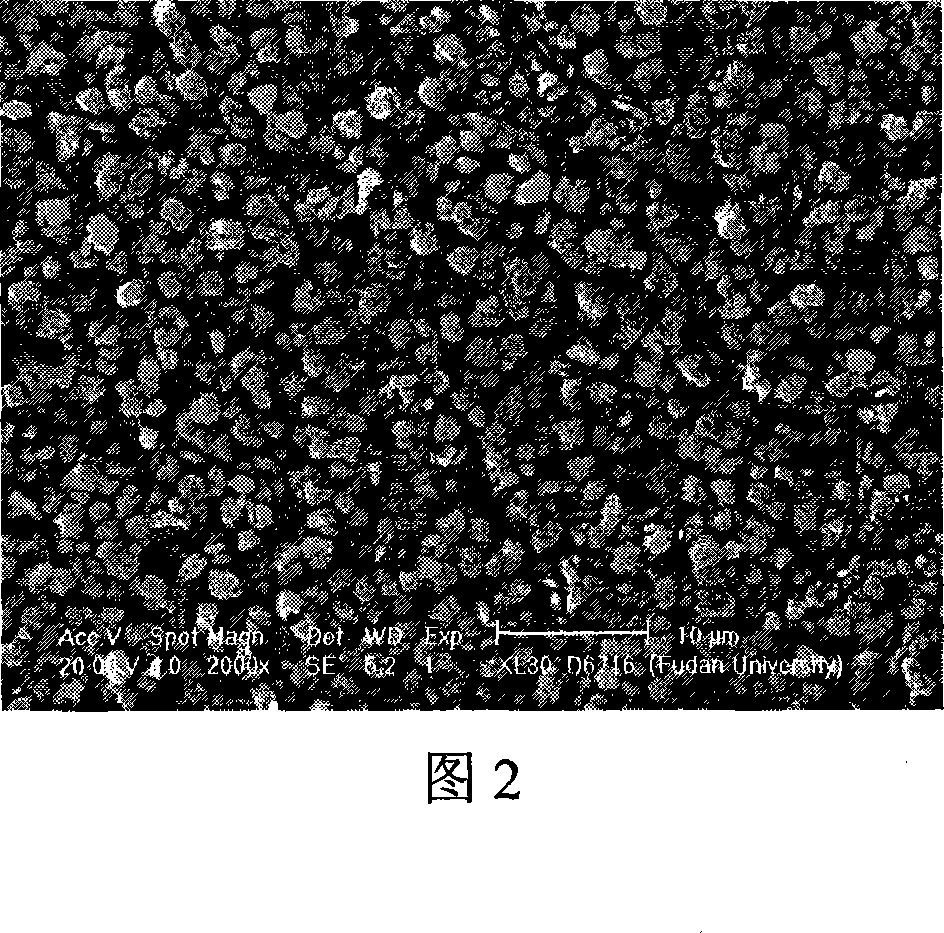

The present invention relates to energy source material technology, and is preparation process of high density spherical lithium nickel-cobalt-manganate as positive electrode material for lithium ion cell. The preparation process includes the reaction of nickel salt, cobalt salt, manganese salt, ammonium hydroxide and ammonian in water solution to synthesize spherical or spheroid precursor Ni1 / 3Co1 / 3Mn1 / 3 (OTHER)2, washing, drying and mixing with lithium carbonate; and high temperature treatment in the air at 750-950 deg.c for 8-48 hr to obtain spherical lithium nickel-cobalt-manganate. The spherical lithium nickel-cobalt-manganate has great bulk density reaching 2.25-2.50 g / cu cm after vibration densifying, average grain size of 3-7 microns, and reversible specific capacity up to 172-185 mA.hr / g.

Owner:TSINGHUA UNIV

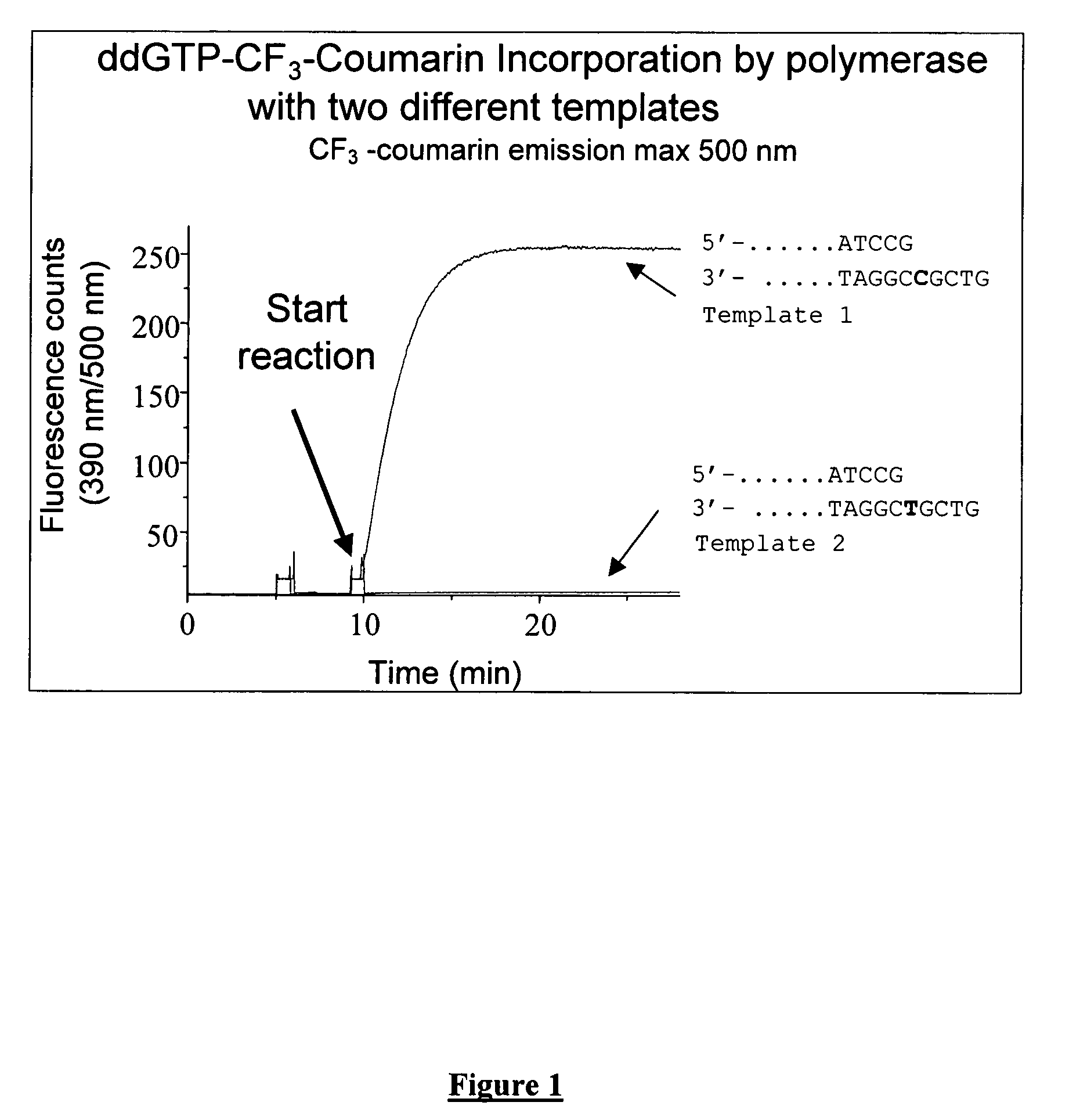

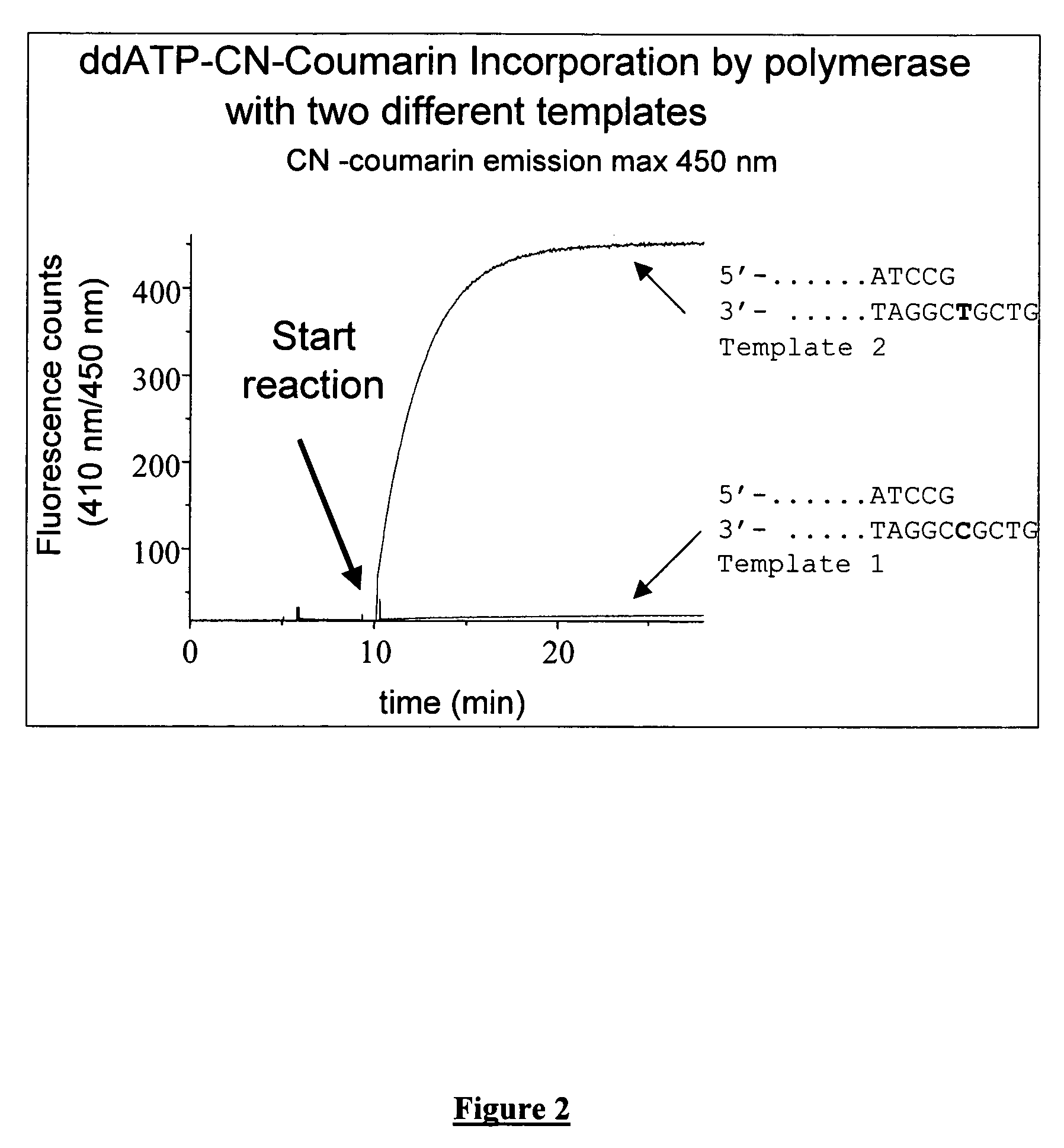

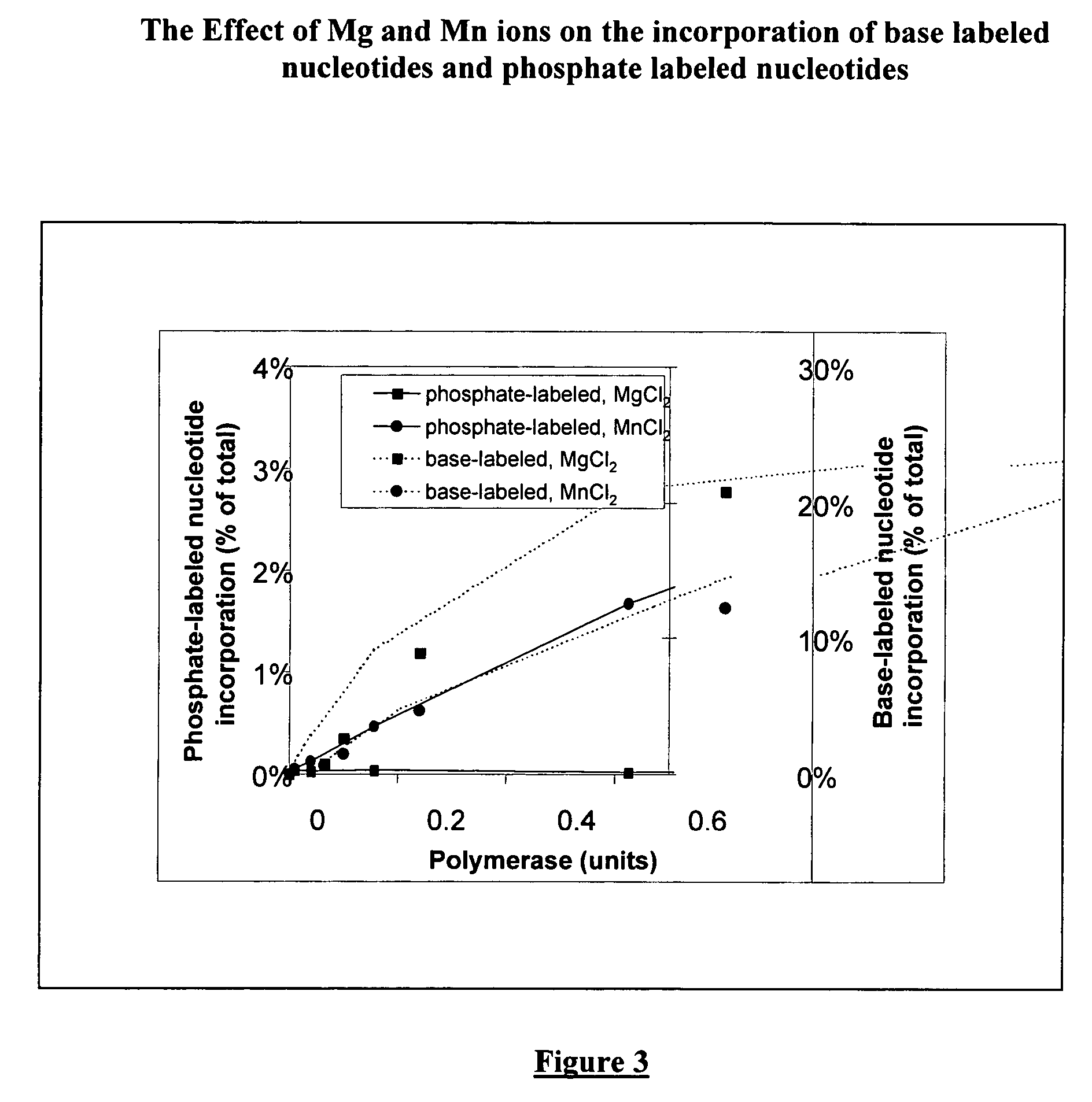

Terminal-phosphate-labeled nucleotides with new linkers

The present invention describes methods of using terminal-phosphate-labeled nucleotides in the presence of a manganese salt to enhance their substrate properties towards various enzymes. Particularly described are methods of detecting a nucleic acid in a sample, based on the use of terminal-phosphate-labeled nucleotides as substrates for nucleic acid polymerases, in the presence of a manganese salt. Further provided are manganese complexes of terminal-phosphate-labeled nucleotides as well as terminal-phosphate-labeled nucleotides with new linkers with enhanced substrate properties.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

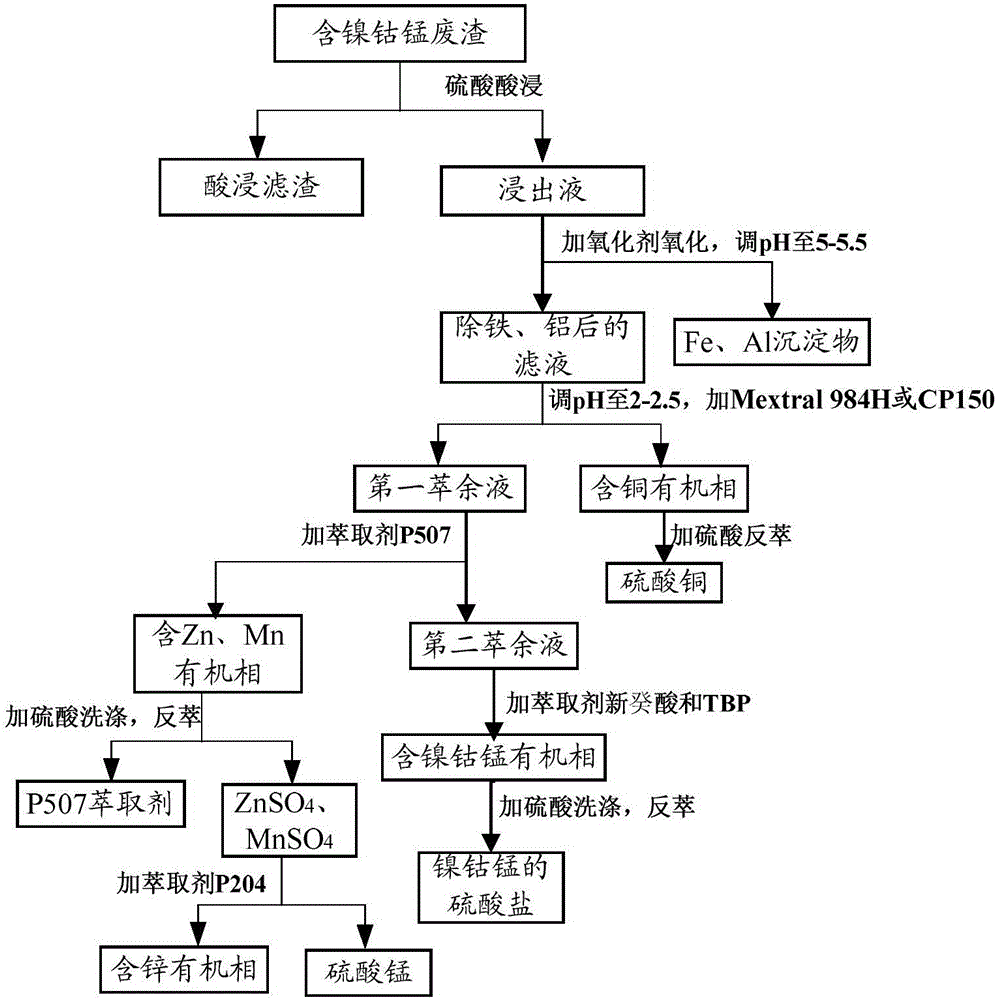

Method for recycling nickel, cobalt and manganese synchronously from waste residues containing nickel, cobalt and manganese

ActiveCN106319228AReduce separation costsSimple processProcess efficiency improvementManganeseCobalt

The invention discloses a method for recycling nickel, cobalt and manganese synchronously from a sulfuric acid leaching solution containing waste residues of nickel, cobalt and manganese. The method comprises the steps of firstly, removing iron and aluminum from the leaching solution through an oxidation and precipitation method; then, removing the element copper through extraction; then, extracting zinc; and finally, extracting nickel, cobalt and manganese synchronously with tributyl phosphate and saponified neodecanoic acid. By means of the method, nickel, cobalt and manganese in the leaching solution containing the waste residues of nickel, cobalt and manganese can be extracted and recycled synchronously; calcium and magnesium in a raw solution cannot exert an influence on the extraction process; separation cost for recycling the elements nickel, cobalt and manganese separately is lowered; and raw material cost for preparing a nickel-cobalt-manganese-salt ternary battery material is lowered.

Owner:JINGMEN GEM NEW MATERIAL

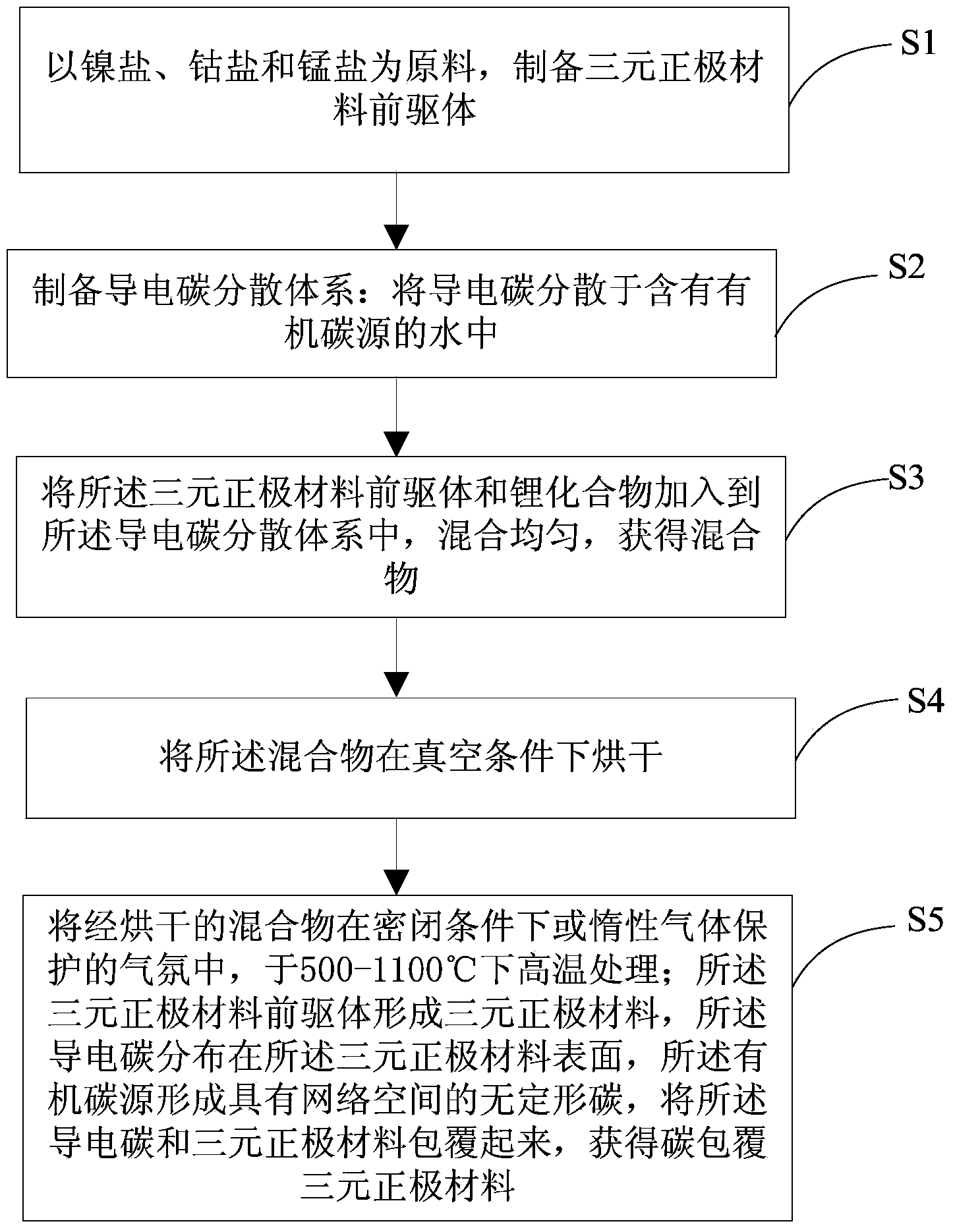

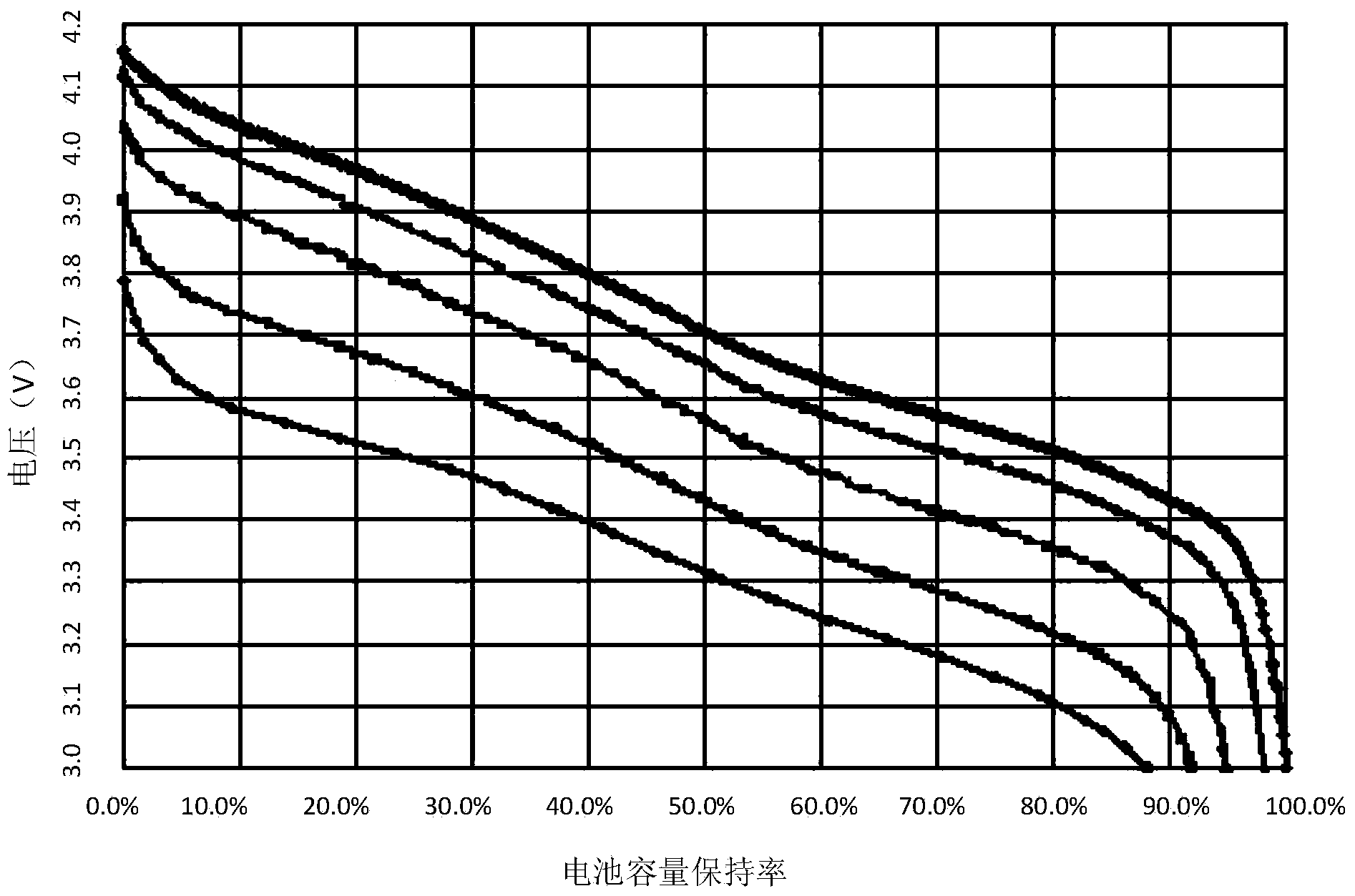

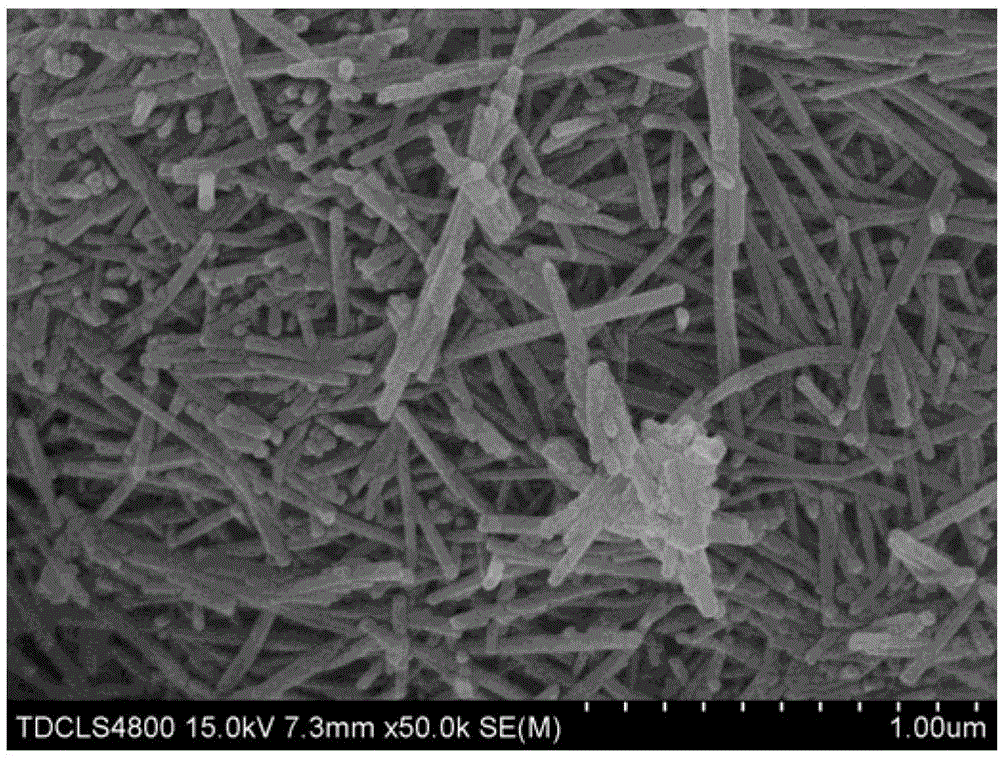

Carbon-coated ternary positive electrode material and preparation method thereof

ActiveCN103474628AImproved magnification performanceImprove conductivityCell electrodesNickel saltManganese

The invention discloses a carbon-coated ternary positive electrode material and a preparation method thereof. The preparation method comprises the following steps: S1, preparing a ternary positive electrode material precursor by taking nickel salt, cobalt salt and manganese salt as raw materials; S2, preparing a conductive carbon dispersion system, wherein conductive carbon is dispersed in water containing an organic carbon source; S3, adding the ternary positive electrode material precursor and a lithium compound into the conductive carbon dispersion system, and mixing uniformly to obtain a mixture; S4, drying the mixture under a vacuum condition; S5, carrying out high temperature treatment on the dried mixture under a closed condition or in an inert gas protection atmosphere so as to obtain the carbon-coated ternary positive electrode material. The carbon-coated ternary positive electrode material is uniform in coating, simple to operate, low in cost and high in efficiency; the conductive carbon and the ternary positive electrode material are simultaneously coated with network-shaped amorphous carbon which serves as a conductive medium or a channel of the conductive carbon and the ternary positive electrode material, thereby greatly improving the rate performance of the ternary positive electrode material.

Owner:SHENZHEN BETTERPOWER BATTERY

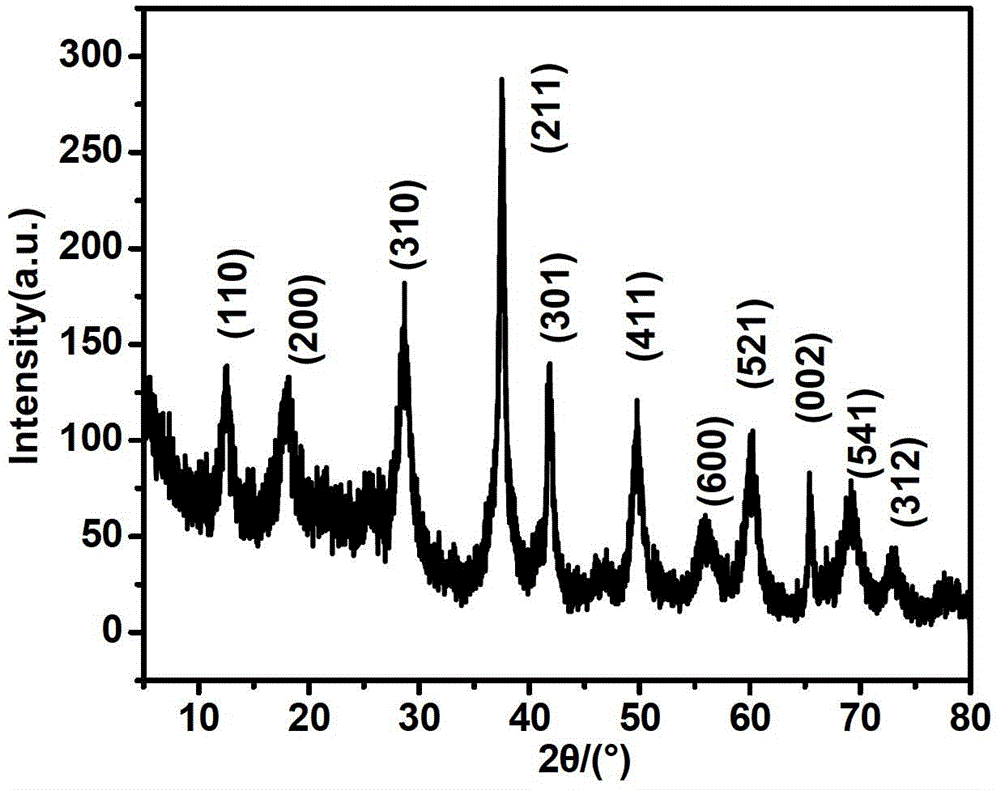

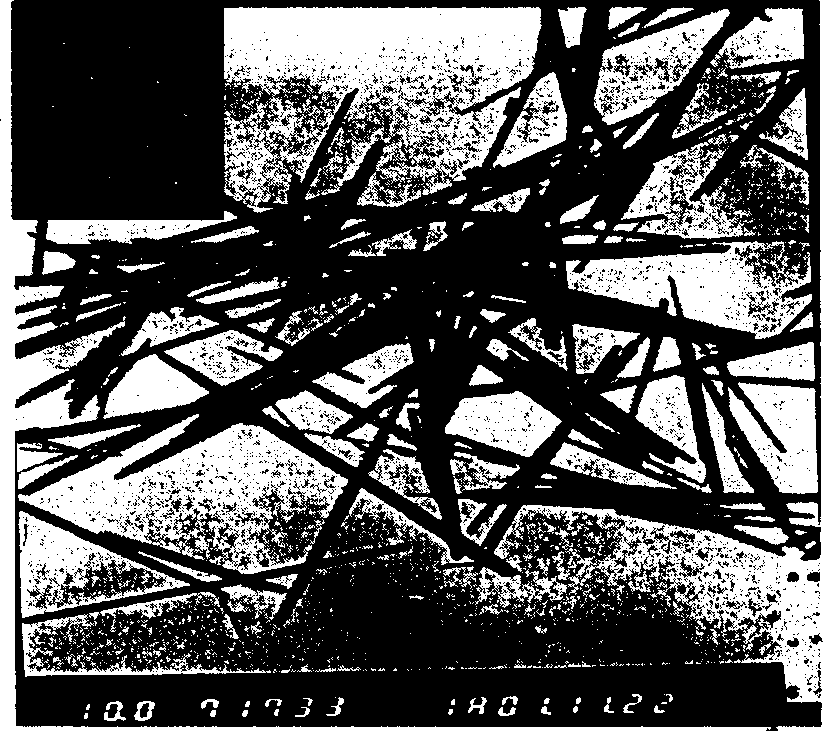

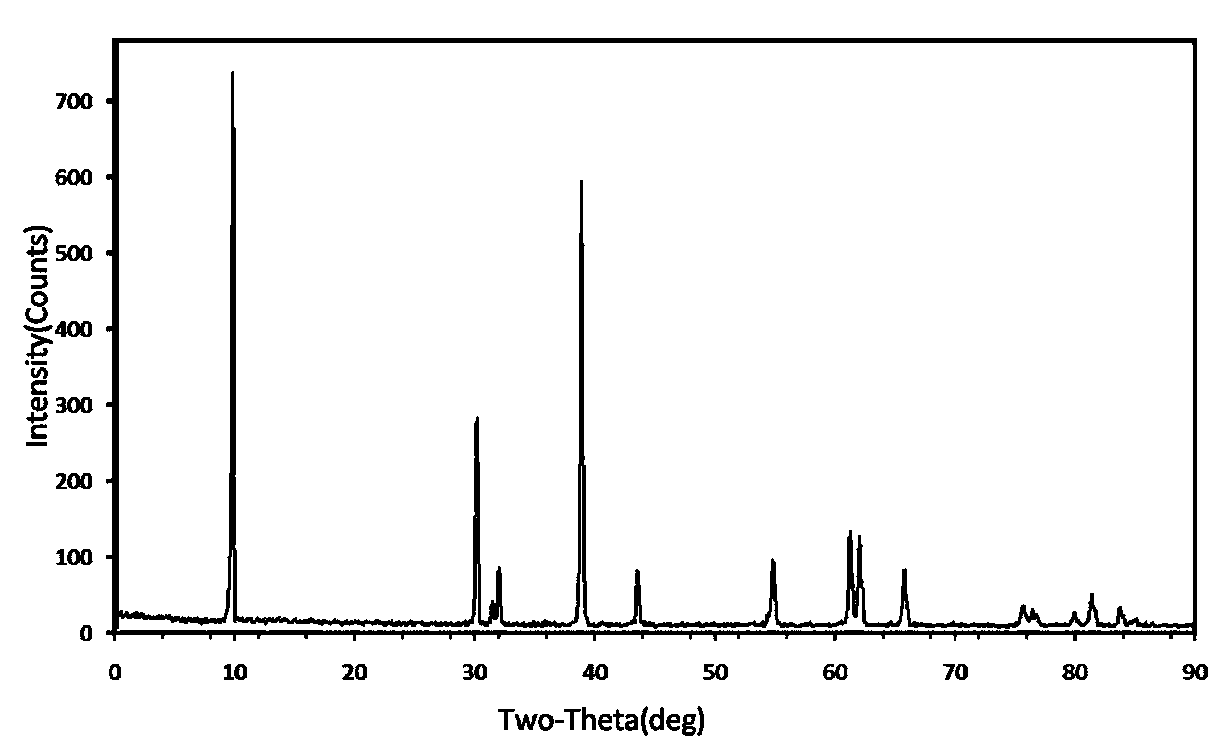

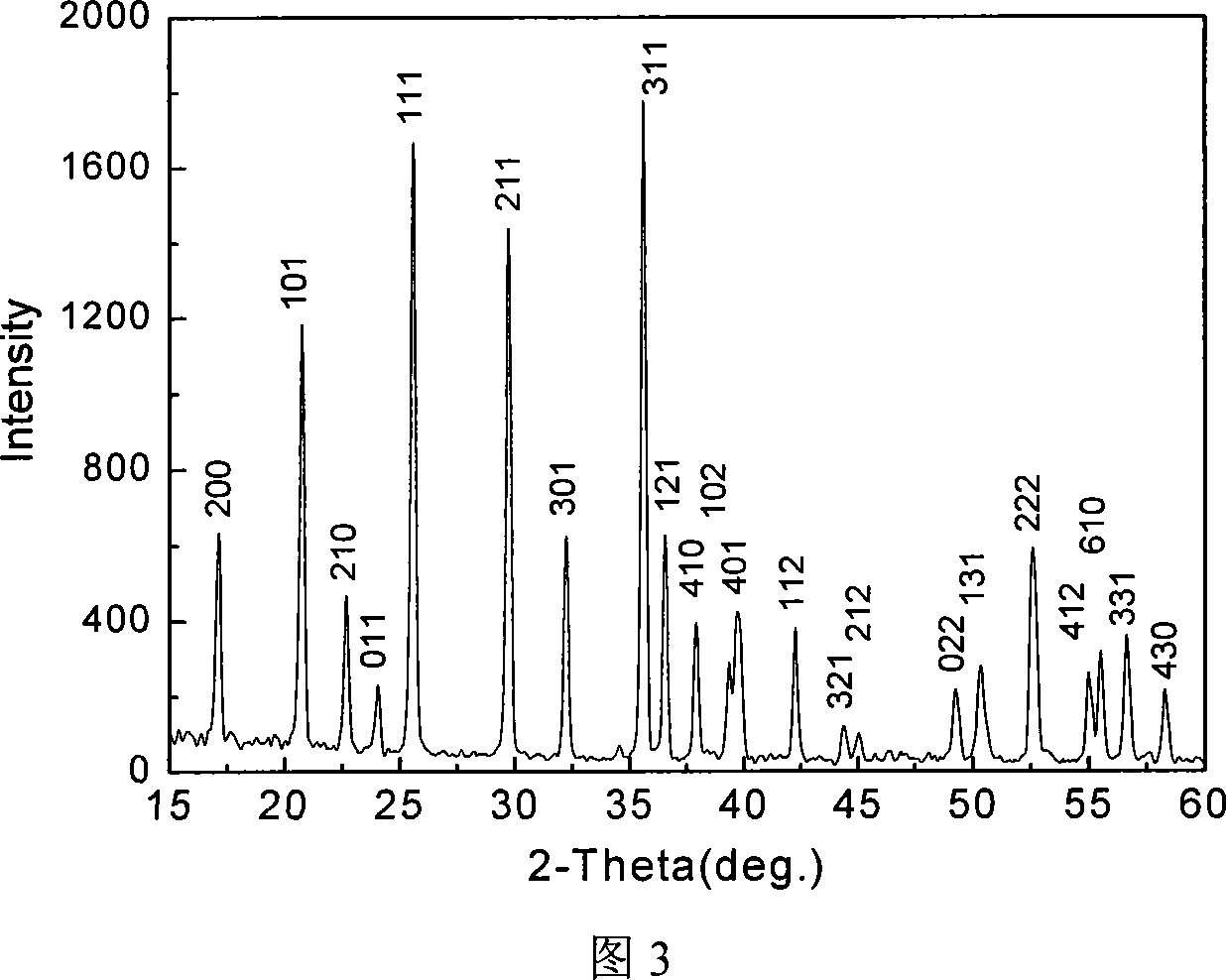

Preparation method for preparing manganese dioxides in various crystal forms

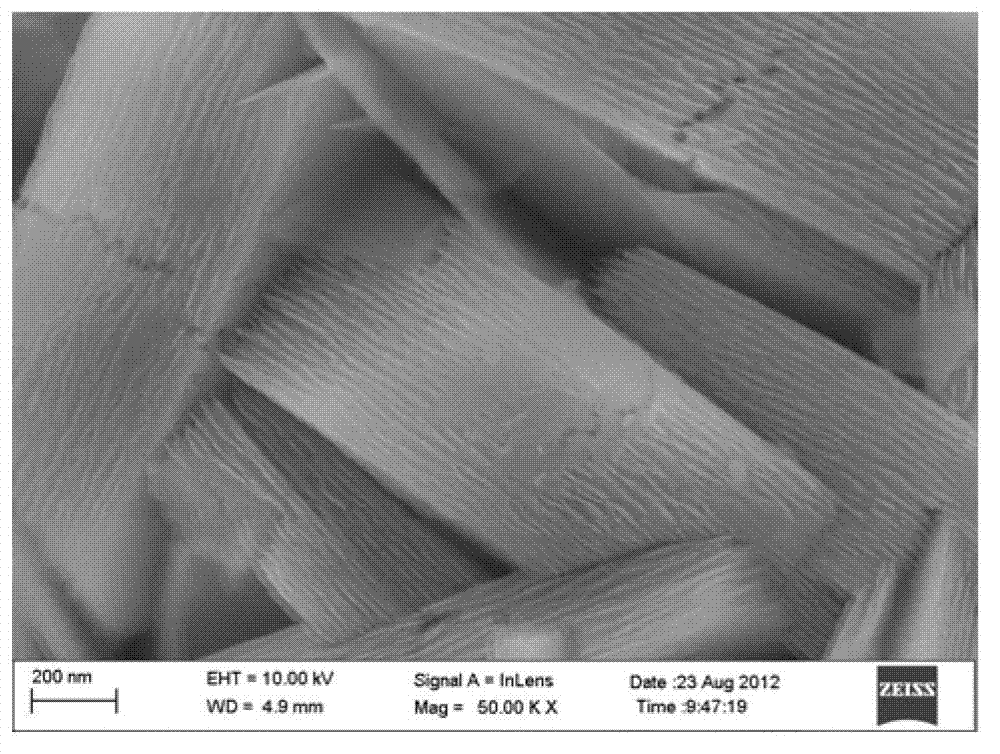

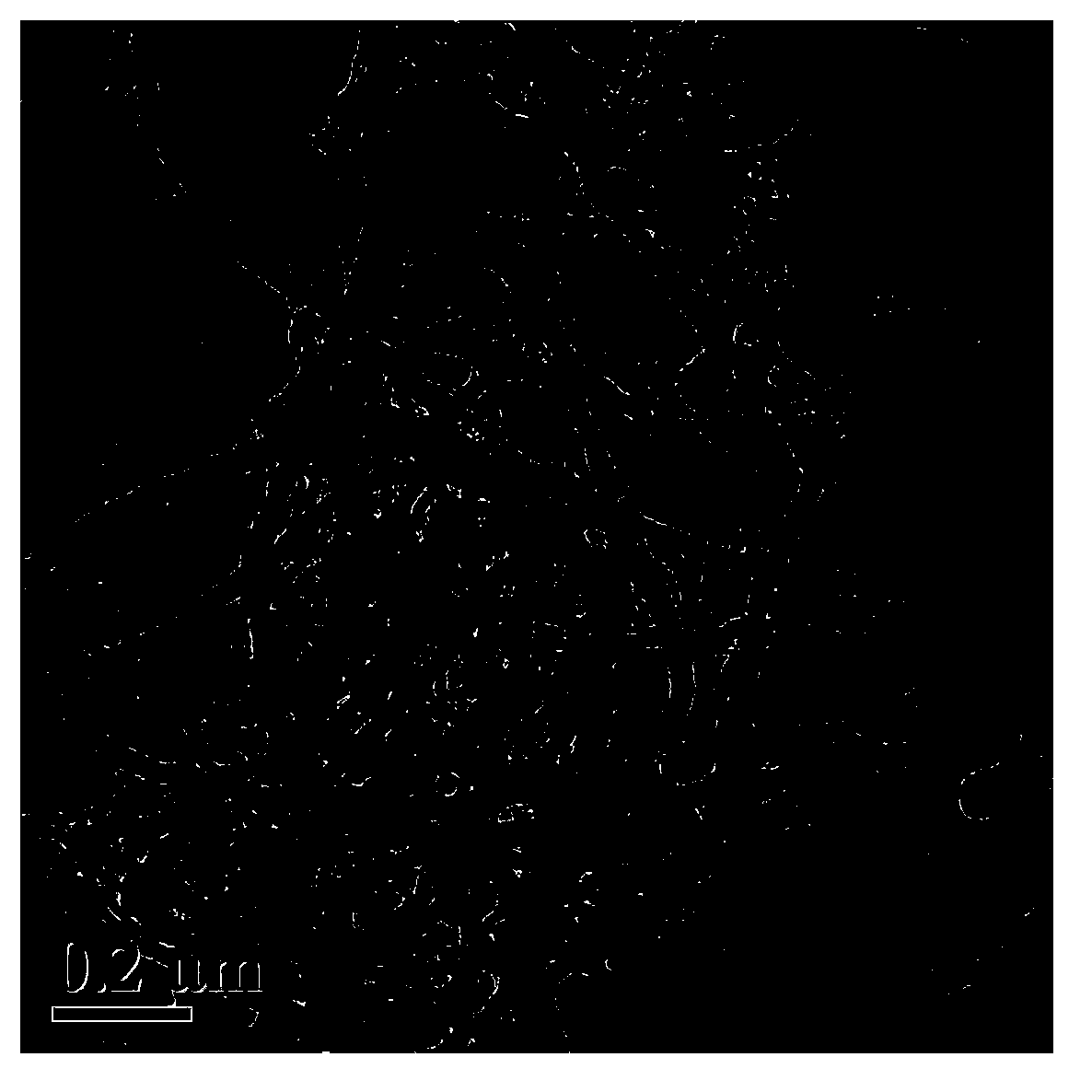

InactiveCN102910680ALow costThe experiment process is simpleElectrolytic capacitorsNanotechnologyFiberFlower like

The invention discloses a preparation method for preparing manganese dioxides in various crystal forms, comprising the following steps of: with divalent manganese salt as a reducing agent and potassium permanganate as an oxidant, adjusting the ratio of raw materials, and reacting in a reaction kettle at 160 DEG C for 1-12h to synthesize both one-dimensional alpha-MnO2 nano fibers and beta-MnO2 nano bars and gamma-MnO2 flower-like structures. The preparation method is simple in preparation process and low in cost; and the product can be used for the research in fields such as super capacitor direction, catalysis and the like.

Owner:TIANJIN UNIV

Lithium-nickel-cobalt-maganese containing composite oxide, material for positive electrode active material for lithium secondary battery, and methods for producing these

ActiveUS20060083989A1Large capacityExcels in charge-discharge cycle durabilityElectrode rolling/calenderingFluoride preparationManganeseOxygen

Coagulated particles of nickel-cobalt-manganese hydroxide wherein primary particles are coagulated to form secondary particles are synthesized by allowing an aqueous solution of a nickel-cobalt-manganese salt, an aqueous solution of an alkali-metal hydroxide, and an ammonium-ion donor to react under specific conditions; and a lithium-nickel-cobalt-manganese-containing composite oxide represented by a general formula, LipNixMn1-x-yCoyO2-qFq (where 0.98≦p≦1.07, 0.3≦x≦0.5, 0.1≦y≦0.38, and 0≦q≦0.05), which is a positive electrode active material for a lithium secondary cell having a wide usable voltage range, a charge-discharge cycle durability, a high capacity and high safety, is obtained by dry-blending coagulated particles of nickel-cobalt-manganese composite oxyhydroxide formed by making an oxidant to act on the coagulated particles with a lithium salt, and firing the mixture in an oxygen-containing atmosphere.

Owner:SUMITOMO CHEM CO LTD

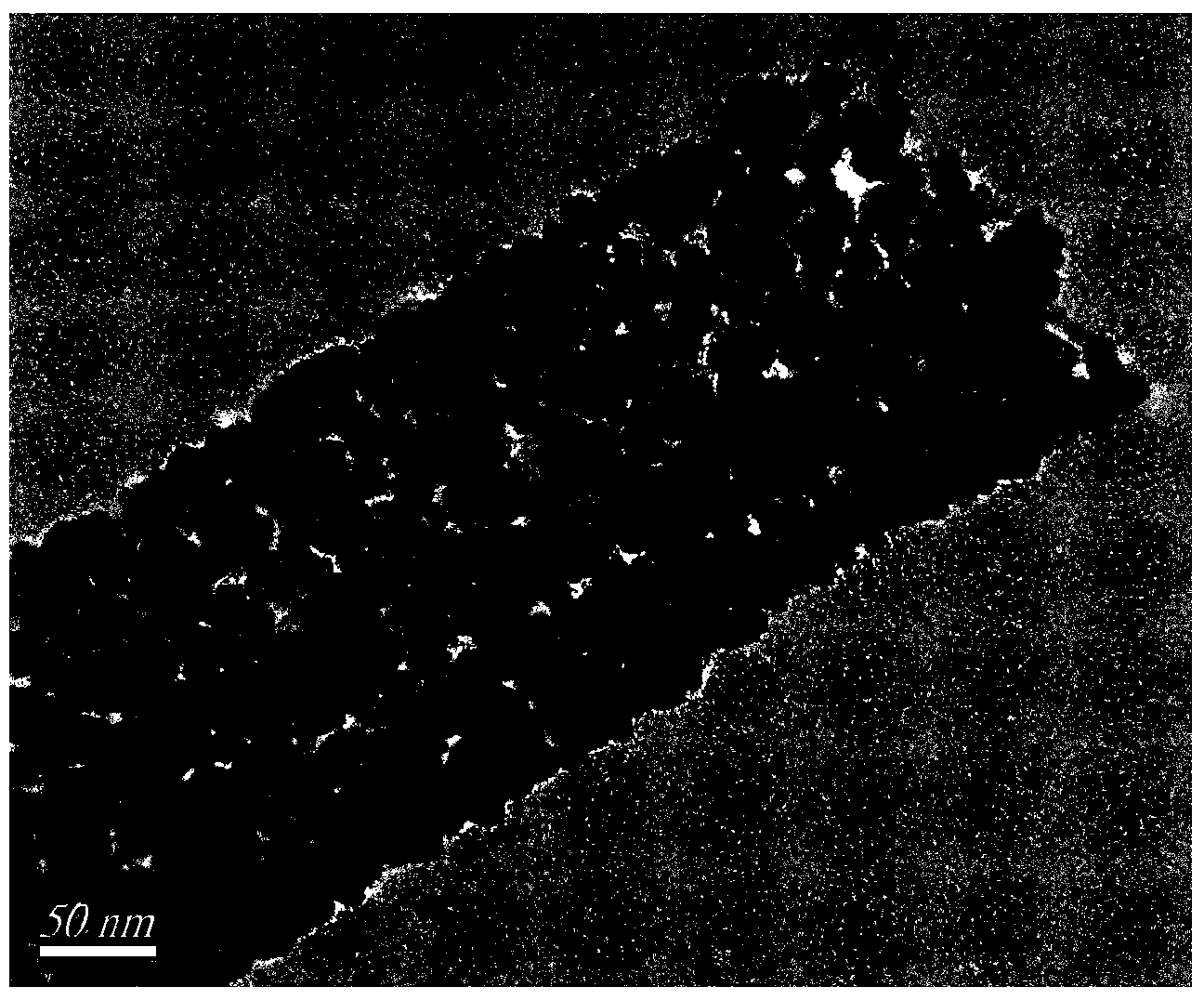

Preparation method of nano positive material for lithium ion battery

InactiveCN102386381AShort heat treatment timeReduce energy consumptionNanostructure manufactureCell electrodesNickel saltElectrical battery

The invention belongs to the field of preparation techniques of nanophase materials and green energy resources, and relates to a preparation method of a nano positive material LiNi1 / 3Mn1 / 3Co1 / 3O2 applied to a lithium ion battery. By using the method, the defects that the calcining temperature needed by a current synthetic material is high, the calcining time is long, the particle sizes of a product are not uniform, and the like, are mainly solved. The preparation method comprises the following steps: adding a certain amount of template agent in a mixed aqueous solution of a nickel salt, a manganese salt and a cobalt salt, and then, dripping a precipitant and a complexing agent into the obtained mixture to form a precipitate; subjecting the precipitate and the mixed aqueous solution to a high-pressure thermal reaction in a hydrothermal kettle, cleaning and baking the obtained product to be dry, so as to obtain a nickel manganese cobalt oxide; and finally, uniformly mixing the nickel manganese cobalt oxide with the lithium salt to prepare a final product by calcining and cooling. By using the preparation method, the product with favorable electrochemical performance can be obtained within a shorter calcining time; the energy consumption is decreased; and the preparation method has obvious economic benefit in the large-scale application of industrial synthesis.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +2

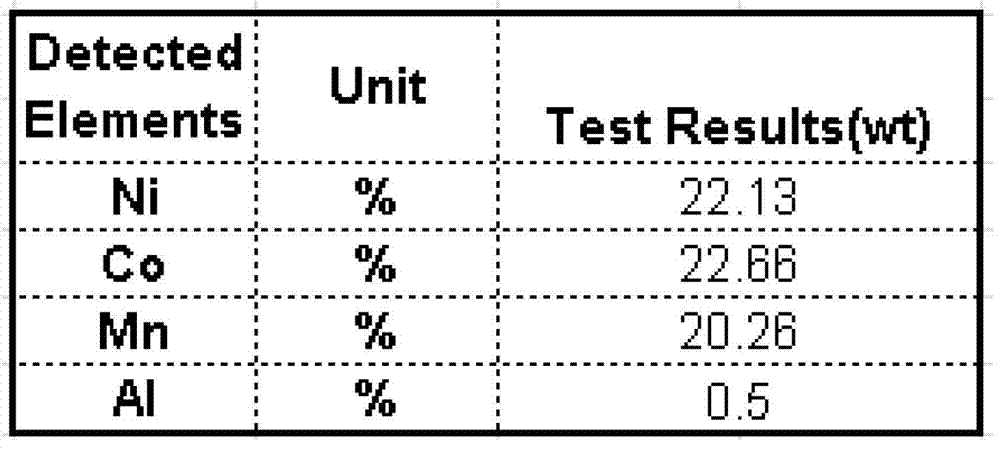

Method for preparing aluminum oxide coated modified lithium nickel cobalt manganese oxygen cathode material

ActiveCN103178258AAdvantages of preparation methodInhibition of agglomerationCell electrodesManganates/permanganatesLamellar crystalsReaction temperature

The invention discloses a method for preparing an aluminum oxide coated modified lithium nickel cobalt manganese oxygen cathode material. The method comprises the following steps of: (1) preparation of a precursor: mixing water-soluble metallic nickel salt, cobalt salt and manganese salt into a mixed solution, dripping the mixed solution, a precipitator and a morphological control agent into a reaction container, controlling the pH value and reaction temperature of a system, and performing filtering, washing and vacuum drying after reaction to obtain a (NixCoyMn1-x-y)(OH)2 precursor, wherein x, y and x+y are more than 0 and less than 1; (2) preparation of an aluminum oxide coated precursor: dispersing the (NixCoyMn1-x-y)(OH)2 precursor, water-soluble aluminum salt and a disperser into deionized water, stirring while heating until the disperser is hydrolyzed, filtering to obtain an Al(OH)3-coated (NixCoyMn1-x-y)(OH)2 precursor, roasting the precursor in a sintering furnace to obtain Al2O3-coated (NixCoyMn1-x-y)(OH)2 precursor powder; and (3) uniformly mixing the Al2O3-coated (NixCoyMn1-x-y)(OH)2 precursor powder with lithium salt powder, and calcinating at high temperature to obtain an aluminum oxide coated modified Li(NixCoyMn1-x-y)O2 cathode material with a lamellar crystal structure.

Owner:NINGDE AMPEREX TECH

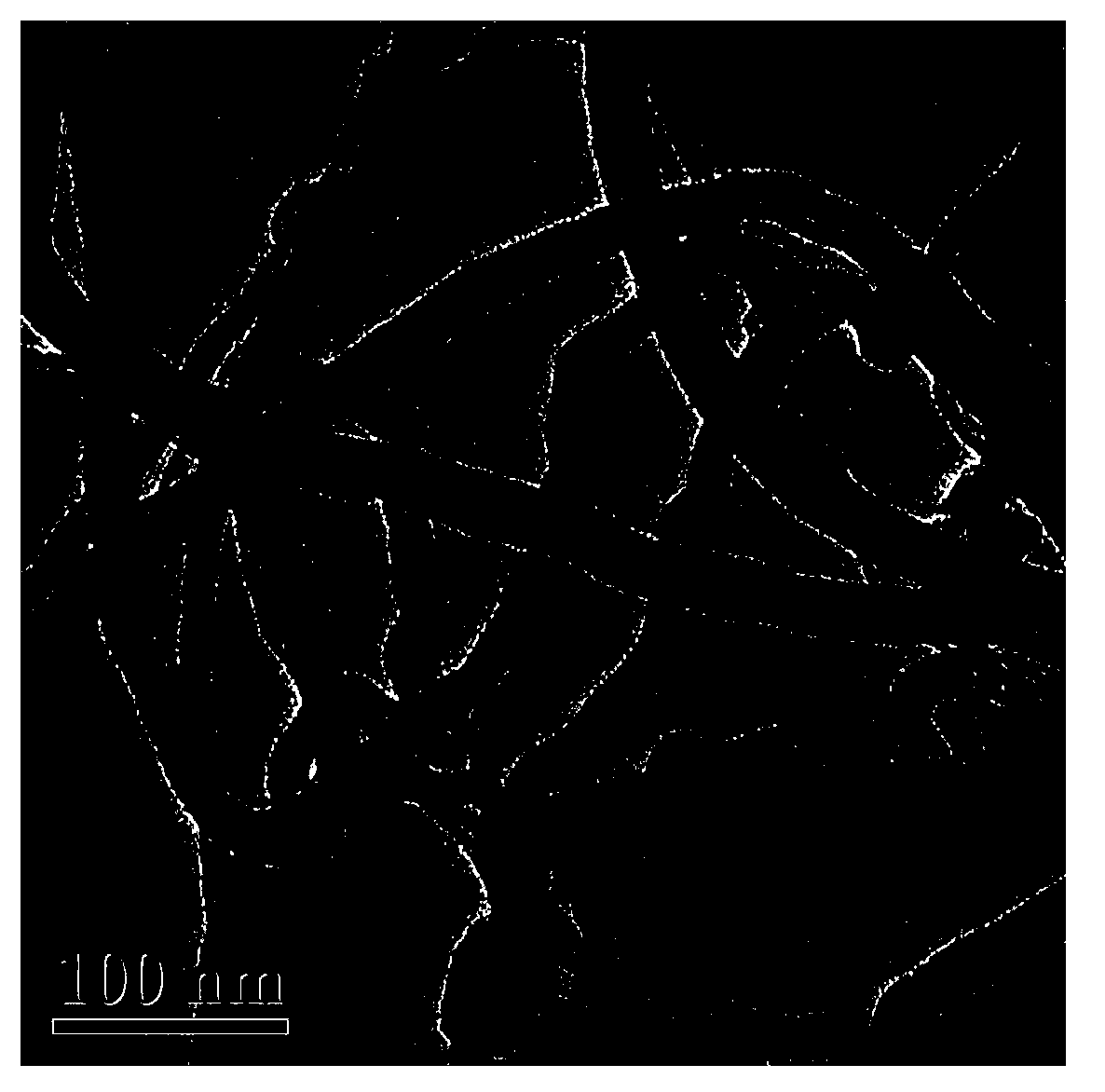

Preparation method of nano porous metal oxide/carbon lithium ion battery cathode material

ActiveCN104045116AImprove cycle performanceImprove conductivityMaterial nanotechnologyCell electrodesHigh energyManganese oxide

The invention provides a preparation method of a nano porous metal oxide / carbon lithium ion battery cathode material. The preparation method comprises the following steps: firstly, weighting ferric salt or manganese salt and carboxylate organic ligands, and putting into a high-pressure reaction kettle; and after a polar solvent is added and dissolved, carrying out a hydrothermal reaction for 10-72h at 100-180 DEG C to generate a transition metal coordination polymer precursor; and after the transition metal coordination polymer precursor is washed and dried, decomposing the precursor for 0.5-6h at a temperature of 300-600 DEG C in an inert atmosphere in a tube furnace, thus obtaining a nano porous metal oxide / carbon lithium ion battery cathode material containing iron oxides or manganese oxides. According to the preparation method, since the transition metal coordination polymer precursor which is structurally designable and controllable is used as a template-type precursor, a nano porous metal oxide / carbon lithium ion battery cathode material is obtained by using an in-situ thermal decomposition method. The method is simple in process, and the obtained products have the advantages of high electrical conductivity, high specific capacity, good cycle stability, excellent high-ratio discharge performance and high energy density.

Owner:JIANGSU UNIV

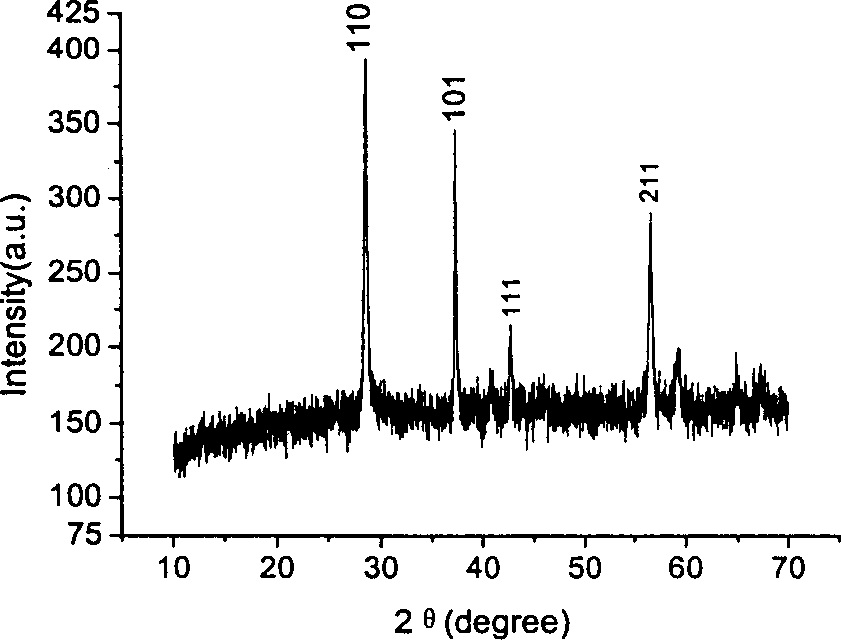

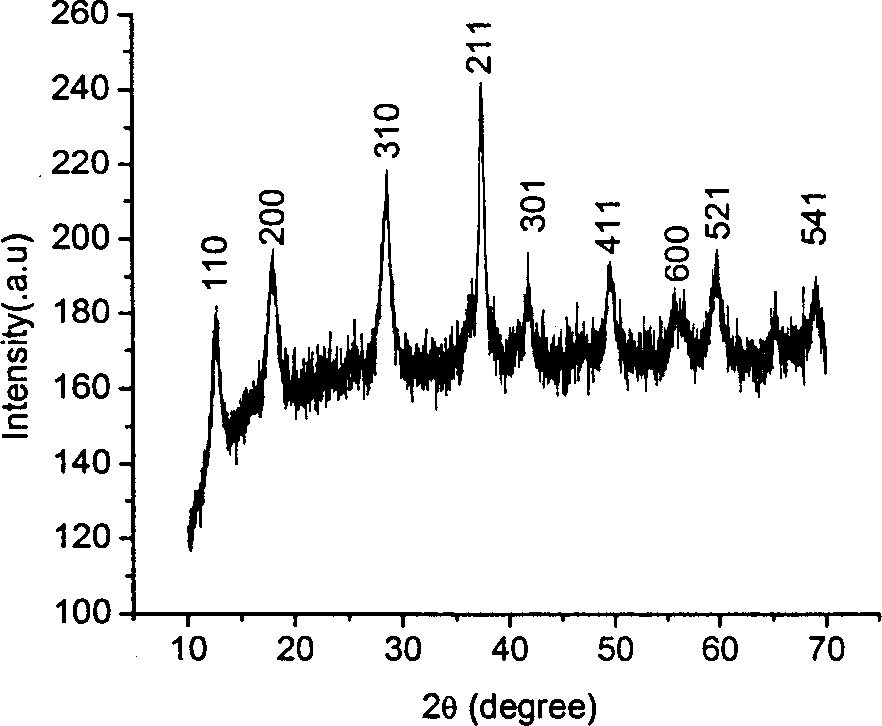

Process for synthesizing different crystal form one-dimensional single crystal mangnesium dioxide nano wire

InactiveCN1377832ALow costSimple processPolycrystalline material growthManganese oxides/hydroxidesNanowireManganese

The present invention relates to the preparation of nano material. One-dimensional monocrystalline nano manganese dioxide wire of different crystal form is synthesized selectively via controlling thetemperature, period and material control of the hydrothermal reaction of two-valent manganese salt and ammohnium persulfate as raw material and ammonium sulfate as additive at 100-220 deg.c inside one sealed reactor. The process may be widely used in basic theory research in lithium ion cell, molecular sieve and relevant fields.

Owner:TSINGHUA UNIV

Rare-earth doping modified lithium ion battery ternary positive electrode material and preparation method thereof

ActiveCN103855384AEase of industrial productionImprove charge and discharge efficiencyCell electrodesSecondary cellsCarbon compositesNickel salt

The invention relates to a rare-earth doping modified lithium ion battery ternary positive electrode material and a preparation method of the rare-earth doping modified lithium ion battery ternary positive electrode material. The chemical general formula of the material is as follows: LiNiaCo<1-a-b>MnbRxO2 / M, wherein a is more than 0 and less than 1, b is more than 0 and less than 1, (1-a-b) is more than 0 and less than 1, x is more than 0.005 and less than 0.1, R is one or more of rare-earth lanthanum, cerium, praseodymium and samarium, and M is a composite cladding layer of oxide of aluminum, titanium or magnesium and carbon. The soluble metal nickel salt, cobalt salt, manganese salt and rare-earth compound are mixed to prepare a mixed salt solution, the mixed salt solution is reacted with a mixed alkaline solution prepared by mixing NaOH and ammonium hydroxide, after the reaction solution is filtered, washed and dried, the obtained product is uniformly mixed with lithium salt powder to be ball milled, then the mixture is calcined at the high temperature and coated with the composite cladding layer of the aluminum, titanium or magnesium oxide and carbon, and finally the calcined mixture is calcined at a constant temperature to obtain the rare-earth doping modified lithium ion battery ternary positive electrode material. After doping the rare earth, the metal oxide and carbon composite cladding layer, which are cheap and easy to obtain, are adopted, so that the cycling performance and the rate performance can be improved, and the charging-discharging efficiency of the material also can be improved.

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

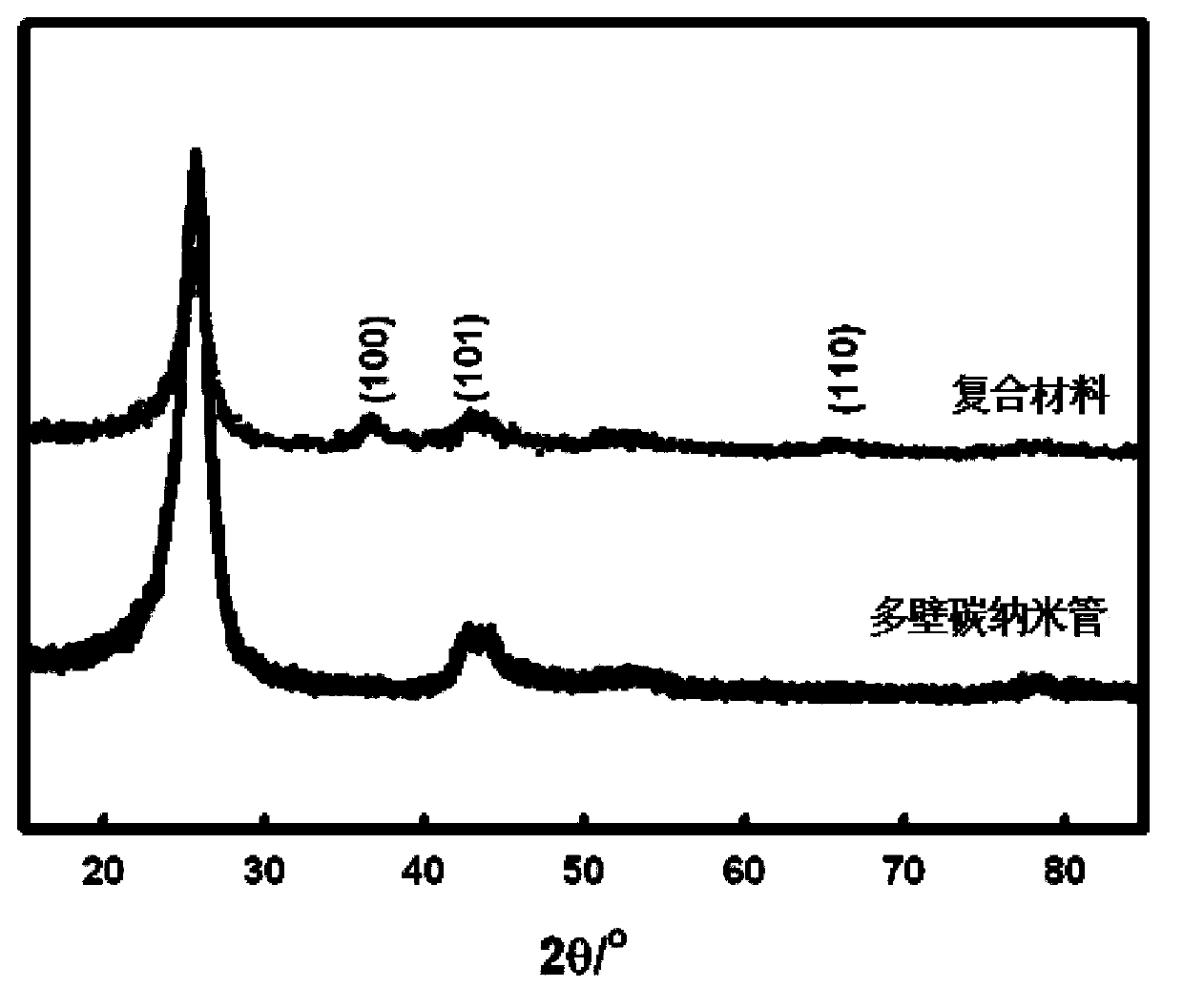

Manganese dioxide/carbon nanocomposite, and preparation method and application thereof

InactiveCN103972518AEasy to operateShort timeMaterial nanotechnologyHybrid capacitor electrodesFuel cellsSupercapacitor

The invention provides a manganese dioxide / carbon nanocomposite and a preparation method and application thereof. The preparation method comprises the following concrete steps: mixing an aqueous solution of permanganate, a carbon carrier and an aqueous solution of a divalent manganese salt; carrying out a reaction to produce a precipitate; and carrying out washing and drying so as to obtain the manganese dioxide / carbon nanocomposite. The preparation method has the advantages of easiness, rapidness, environment friendliness and easy realization of scale-up synthesis. The prepared manganese dioxide / carbon nanocomposite is applicable to a super-capacitor, a metal-air battery and a fuel battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

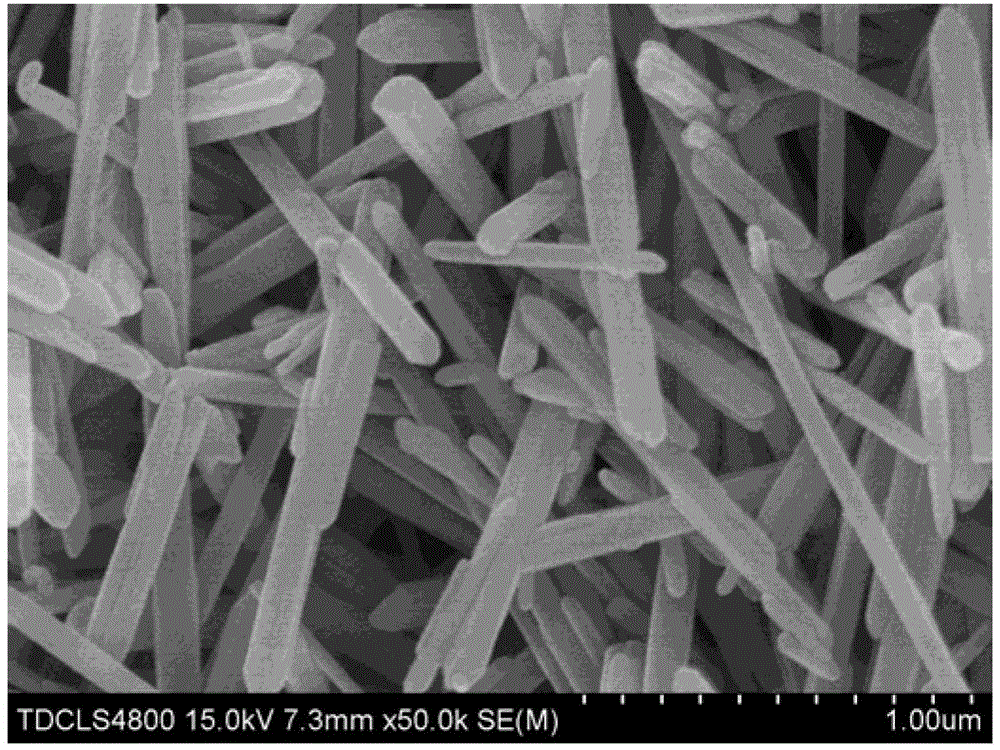

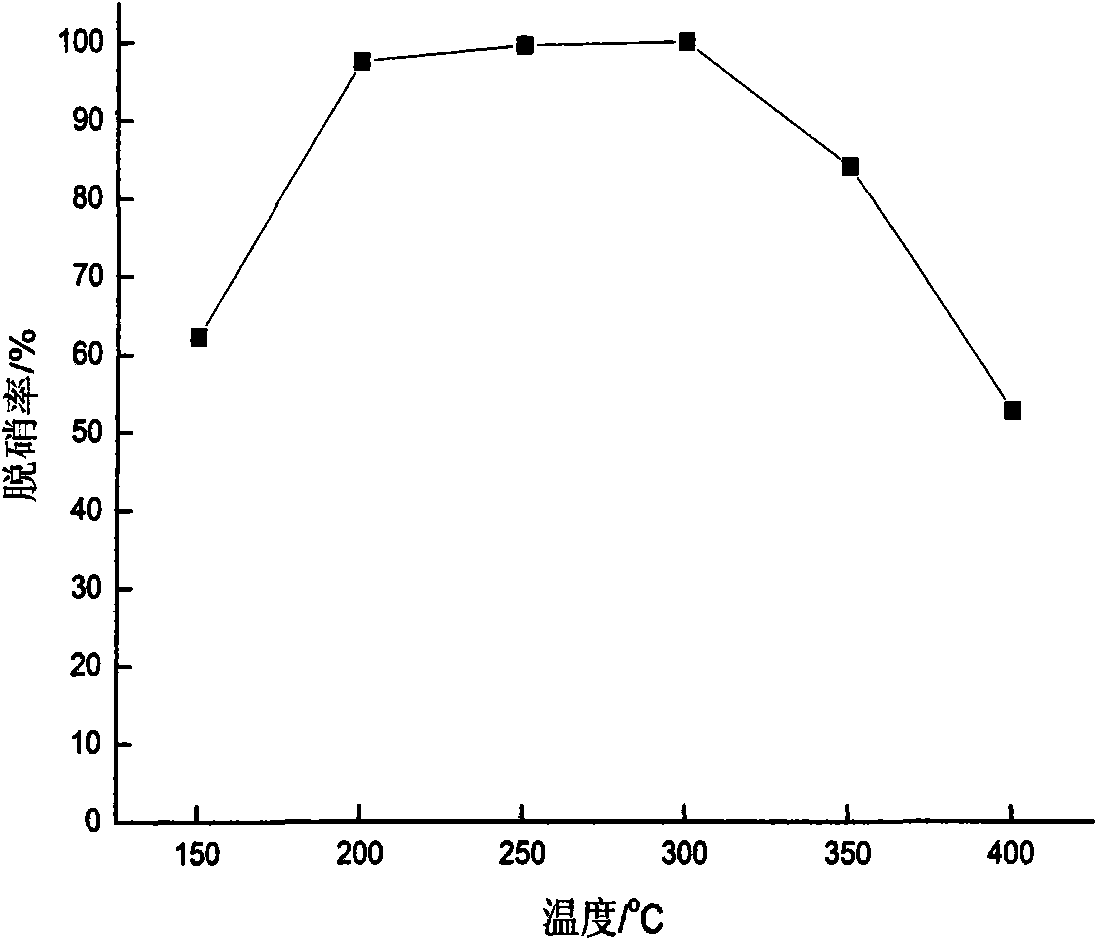

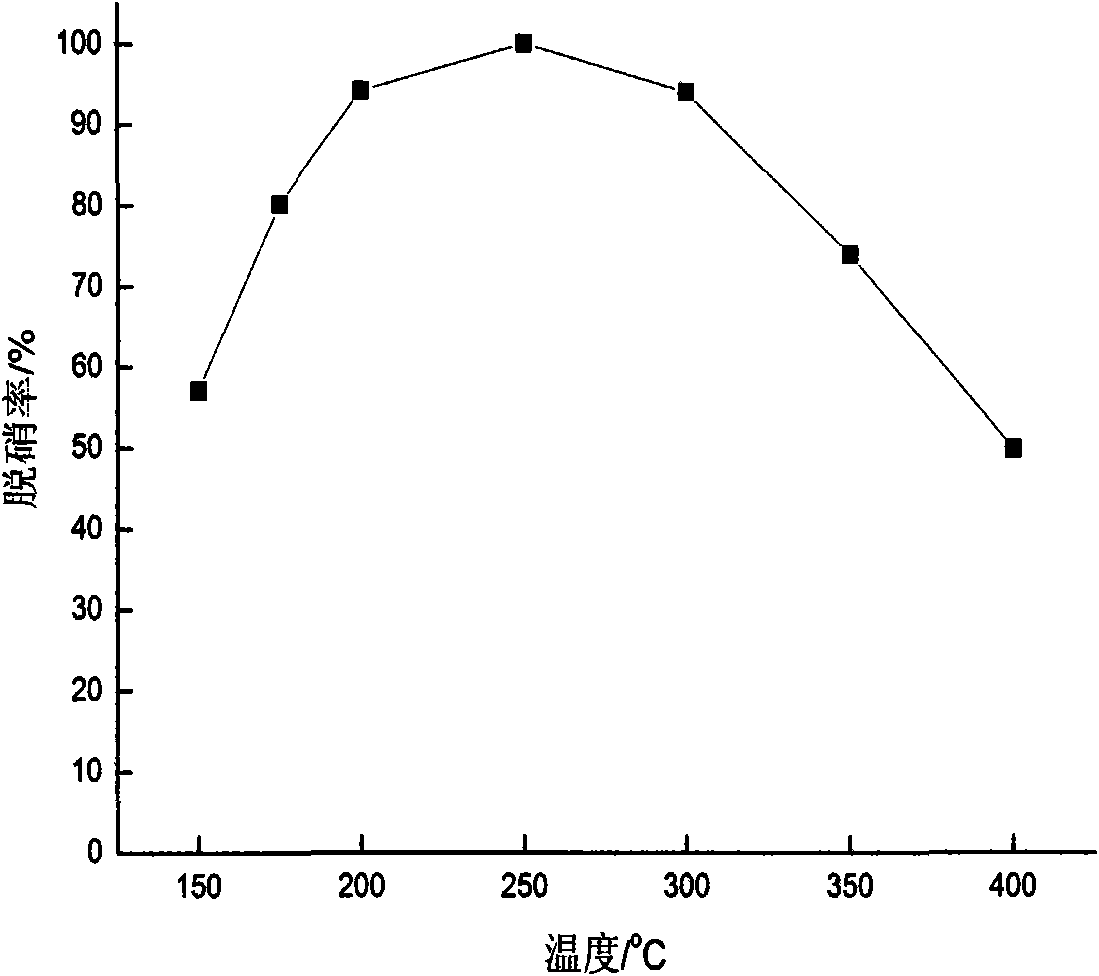

Low-temperature selective catalytic reduction denitration catalyst and preparation method thereof

ActiveCN101658787ALow costWide variety of sourcesDispersed particle separationCatalyst activation/preparationManganese oxideHigh activity

The invention discloses a low-temperature selective catalytic reduction denitration catalyst and a preparation method thereof, wherein the catalyst takes an attapulgite as a carrier to load nano-composite materials of manganese oxide nano-particles; the structure thereof is as follows: manganese oxide particles with the particle diameter of less than 20nm are loaded on the rod-shaped crystal surface of the attapulgite with the diameter of 40-50nm; one or more types from iron, copper and nickel are added as an additive; and calculated according to the mass percentage of manganese, the content of the manganese oxide in the catalyst is 0.1-20. The preparation method comprises the steps of: firstly extruding, drying and crushing the attapulgite clay, and then preparing attapulgite clay powderinto suspension liquid; adding acid solution to wash and remove carbonate impurities, adding manganese salt, and then adding alkali solution for stirring so as to lead the manganese ion to be hydrolyzed and precipitated and loaded onto the crystal surface of the attapulgite, and finally obtaining the product after centrifugal washing, dewatering, drying and calcinations. The catalyst takes ammoniaas a reducing agent, and has higher activity of catalyzing NH3 and reducing NO reaction within the scope of 120 DEG C to 350 DEG C.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

Modified lithium ion battery ternary positive electrode material and preparation method thereof

InactiveCN103855387ALower sintering temperatureHigh tap densityCell electrodesSecondary cellsAir atmosphereNickel salt

The invention relates to a modified lithium ion battery ternary positive electrode material and a preparation method of the modified lithium ion battery ternary positive electrode material. The chemical generation formula of the material is as follows: LiNiaCo<1-a-b>MnbBxO2 / TiO2, wherein a is more than 0 and less than 1, b is more than 0 and less than 1, (1-a-b) is more than 0 and less than 1, x is more than 0.005 and less than 0.1, and the TiO2 is a cladding layer. The soluble nickel salt, cobalt salt and manganese salt are prepared into a mixed salt solution, the mixed salt solution is reacted with a mixed alkaline solution prepared by mixing the NaOH and ammonium hydroxide, after being filtered, washed and dried, the reaction product is mixed with a boronic compound and roasted for 4h to 12h at the temperature of 300 to 800 DEG C under an air atmosphere, then the roasted product is ball milled with the lithium salt to be uniformly mixed together, the mixture is coated with titanium dioxide after being calcined at the high temperature to obtain the modified lithium ion battery ternary positive electrode material. The prepared boron doping modified ternary positive electrode material is high in specific capacity and good in cycling performance.

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

Method for preparing anode material of lithium ion battery in series of phosphate of olivine type

InactiveCN101049922AAchieve hybridEvenly distributedCell electrodesPhosphorus compoundsAluminium-ion batteryPhosphate

This invention relates to a method for preparing olivine-type phosphate-series lithium ion battery anode material. The method comprises: mixing one or more of ferrous salt solution, cobalt salt solution and manganese salt solution with oxalic acid or oxalate (precipitating agent) aqueous solution to obtain composite oxalate precursor, uniformly mixing with lithium source and phosphorus source by ball milling, and reacting in inert or weak-reductive atmosphere to obtain olivine-type phosphate-series lithium ion battery anode material. The method utilizes co-precipitation method for metal ion doping, and realizes molecular level uniform mixing among different ions. The obtained olivine-type phosphate-series lithium ion battery anode material has uniform chemical and physical compositions. The average particle size can be controlled within 0.3-10 mu.m. The first charge and discharge cycle specific capacity can reach 150 mAh / g at 0.1 C rate and room temperature. The livine-type phosphate-series lithium ion battery anode material has such advantages as high cycle performance and high charge / discharge performance.

Owner:CENT SOUTH UNIV

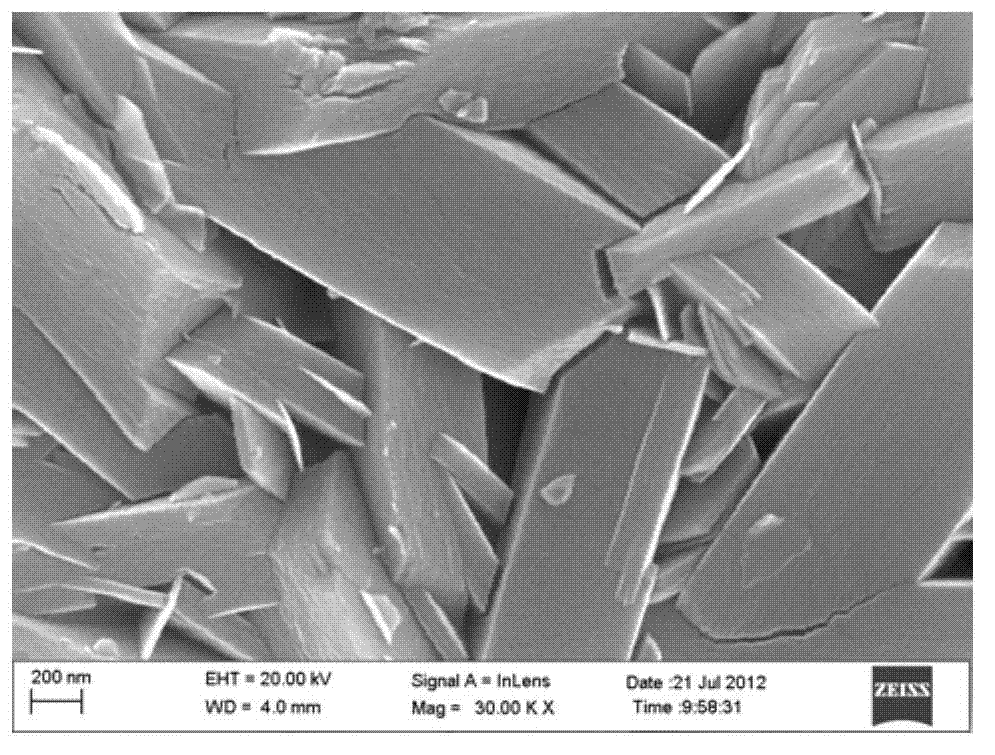

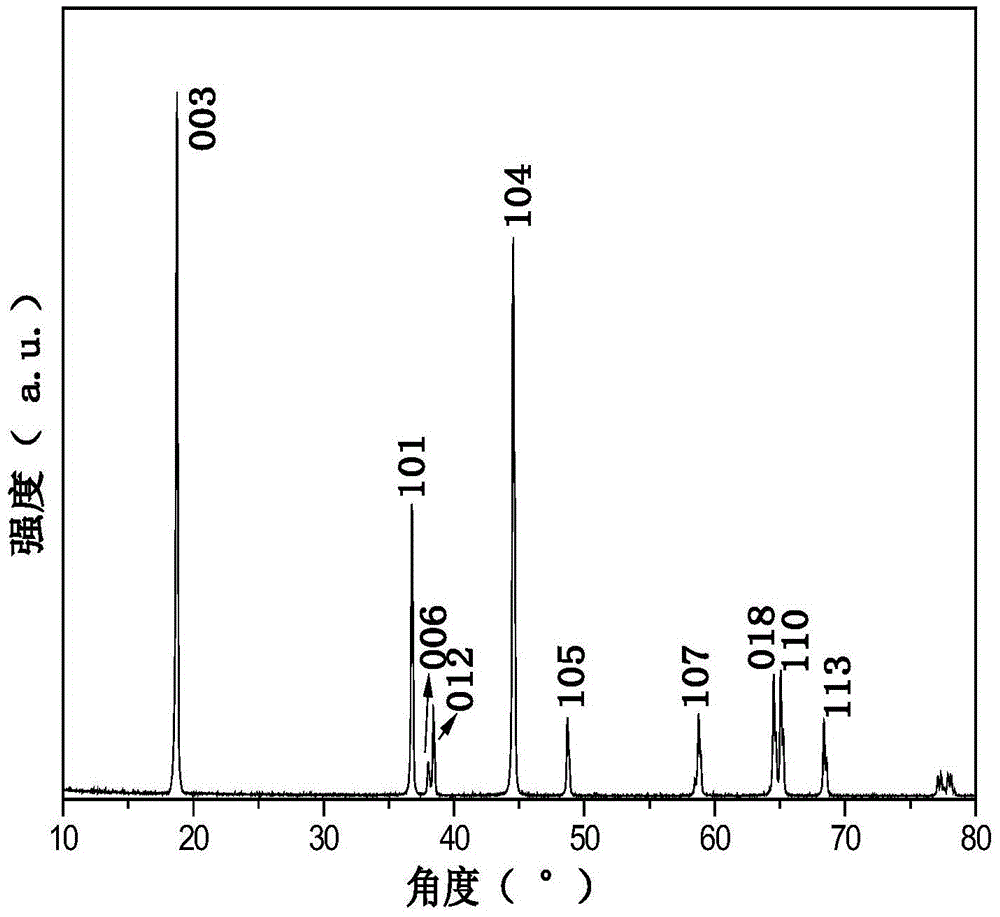

Preparation method of single-crystal Li(NiCoMn)O2 ternary cathode material

InactiveCN104868122AUniversalSimple preparation processCell electrodesNickel compoundsNickel saltHigh rate

The invention relates to a preparation method of a single-crystal Li(NiCoMn)O2 ternary cathode material, and belongs to the technical field of a manufacturing process for chemical electrode materials. The preparation method comprises the following steps: firstly, nickel salt, cobalt salt and manganese salt are dissolved in a deionized water and ethylene glycol mixed solution, the mixture is uniformly stirred, a surfactant is added, the mixed solution is clarified, a precipitant is added, the mixture is uniformly stirred and poured into a reactor, the reactor is arranged in a drying oven for a reaction, and then an obtained precursor and lithium salt are mixed, presintered and calcined to obtain a target product. The preparation method is simple and convenient to operate, the controllability of preparation parameters is high, the prepared ternary cathode material is a single-crystal material, particle sizes are concentrated at the submicron dimension, a fast conveying channel with the short path is provided for lithium ions, and contact of the material with an electrolyte is increased. The ternary cathode material has high specific capacity, high rate capability and high cycling stability, and meets the requirements of electronic products with high volume energy density.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method of lithium-ion battery cathode material coated aluminum

InactiveCN102299299ACoating process conditions are easy to controlImprove high temperature stabilityCell electrodesNickel saltElectrical battery

The invention relates to a method for preparing aluminum-coated anode materials of lithium-ion batteries, which is characterized in that: firstly, soluble nickel salts, cobalt salts, and manganese salts are formulated into salt solutions, and then mixed with ammonia-water-mixed sodium hydroxide or potassium hydroxide solutions React to form precursor particles, wash and dry; add water to the dried precursor particles to prepare a flowable slurry, stir, and add trivalent aluminum salt solution and sodium hydroxide or potassium hydroxide solution dropwise to the slurry at the same time , to obtain the precursor of nickel hydroxide cobalt manganese coated with aluminum; then mix the precursor with lithium source, and then sinter to obtain the positive electrode material of lithium ion battery coated with aluminum. The present invention has the following obvious advantages: raw materials are easy to obtain; coated The process conditions are easy to control, and it is easy to obtain a relatively uniform coating body; the prepared positive electrode material can make the lithium ion battery have superior high temperature stability and better cycle characteristics.

Owner:深圳市天骄科技开发有限公司

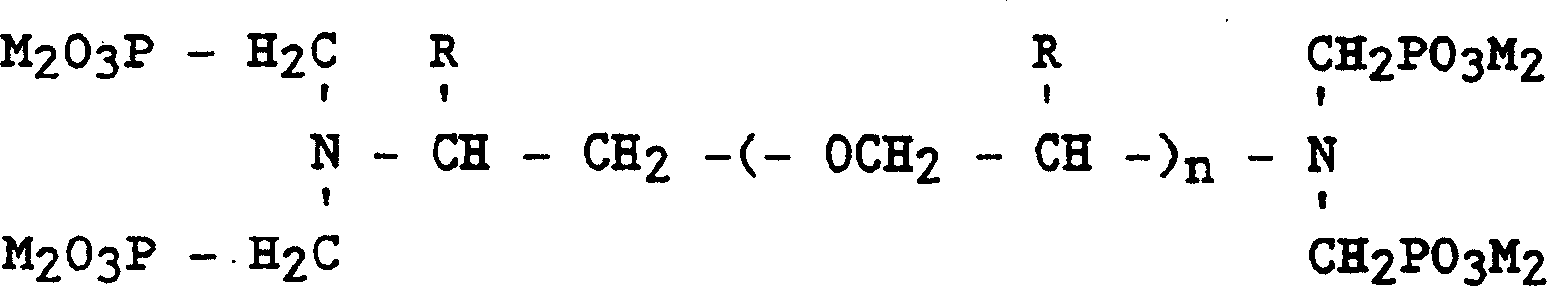

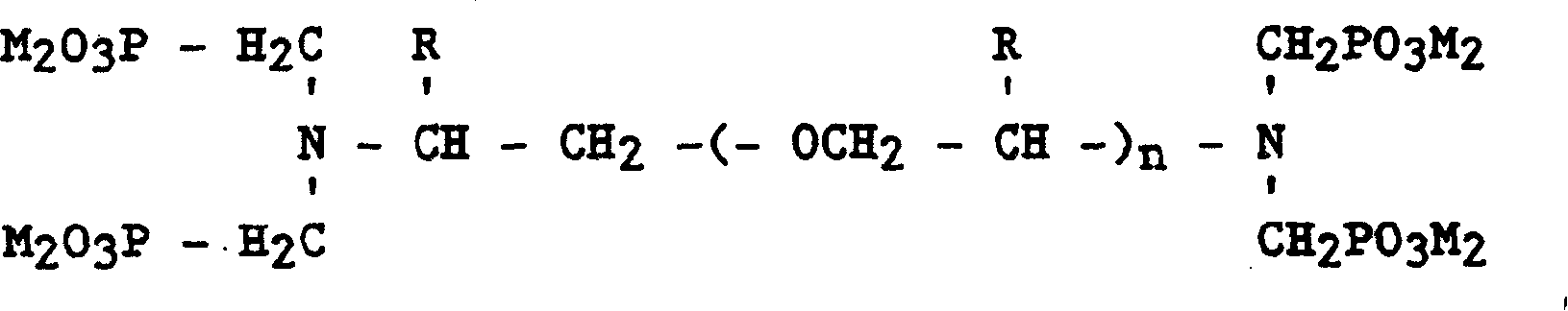

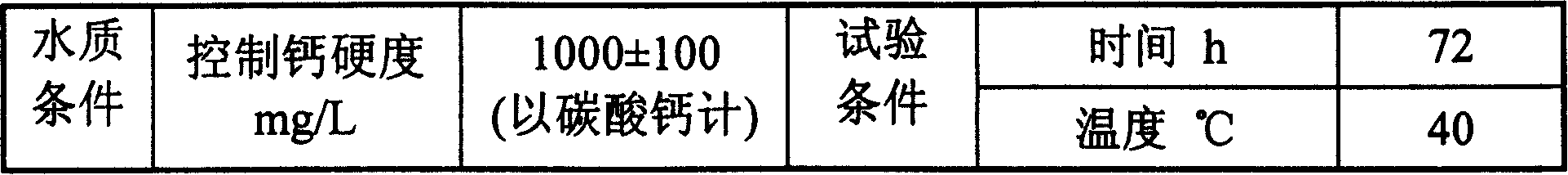

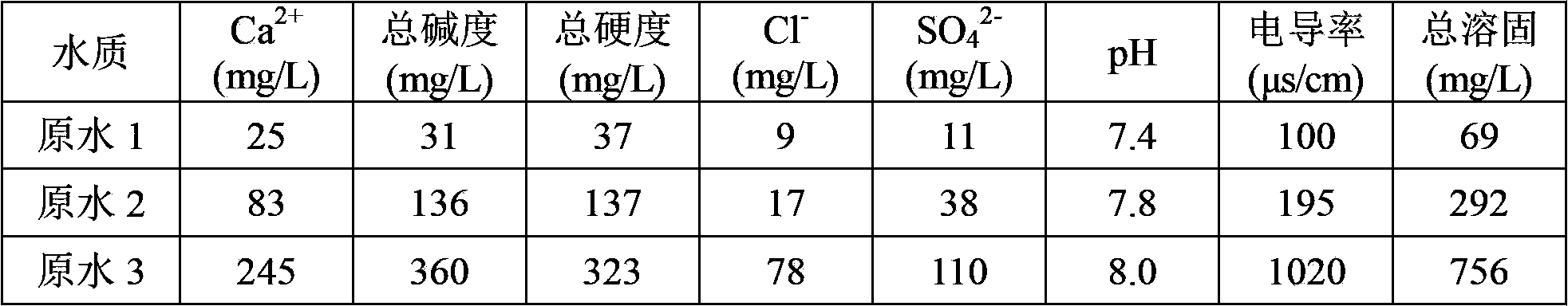

Dirty blocking inhibitor and application in water treatment thereof

ActiveCN101172719AGood dispersionGood corrosion inhibition effectScale removal and water softeningSludgeWater quality

The invention provides anti-sludge inhibiter and the application method thereof. The inhibiter comprises multi-amino multi-ether methene phosphonic acid, poly-aspartic acid and acrylic polymer which comprises sulfonic groups, and at least one of other organic phosphonic acid, as well as zinc salt, inorganic acid, manganese salt and copper inhibiter. The inhibiter is applicable to the water quality with high rigidity, high alkaline and high salt. The sum of the rigidity the calcium and total alkalinity in water reaches 1500mg per liter, wherein, the inhibiter has excellent anti-sludge and corrosion inhibition effect when the rigidity of the calcium (counting in accordance with calcium carbonate ) is 1000mg per liter. The invention can be used in the circulated cooling water system of the industries such as petroleum chemical, as well as power and paper making plant. The invention can also be used in the water treatment process of poor water quality conditions such as seawater desalination and reverse osmosis.

Owner:CHINA PETROLEUM & CHEM CORP +1

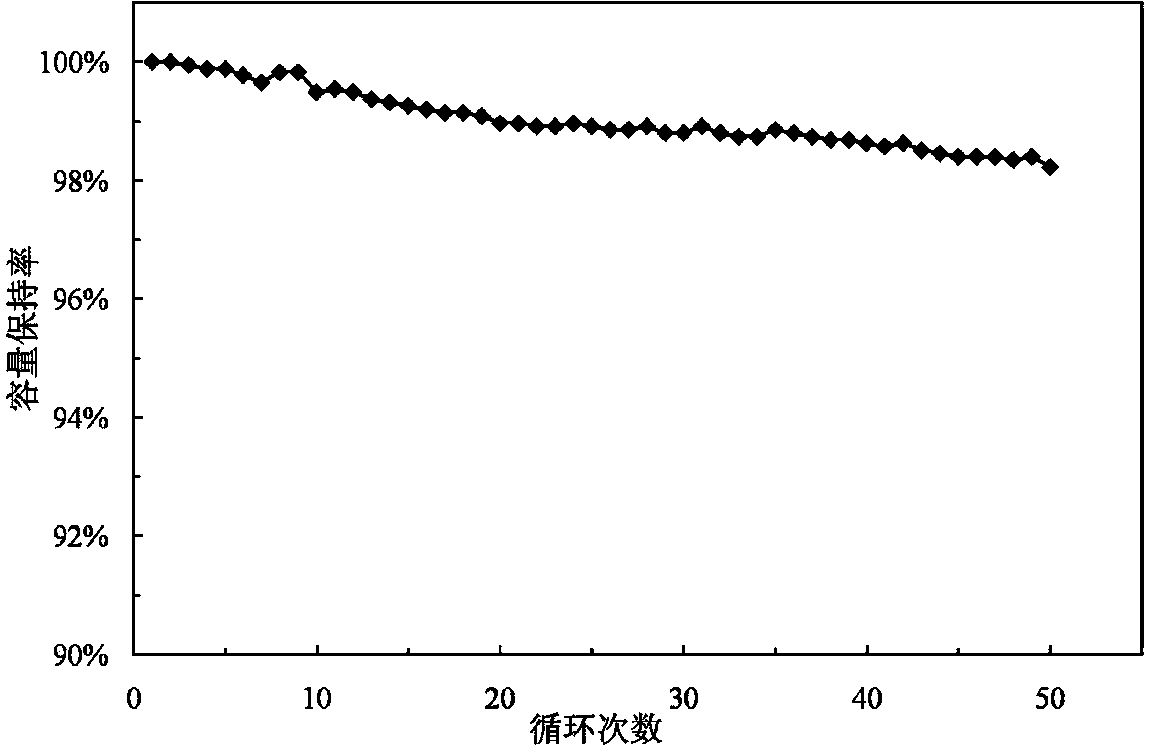

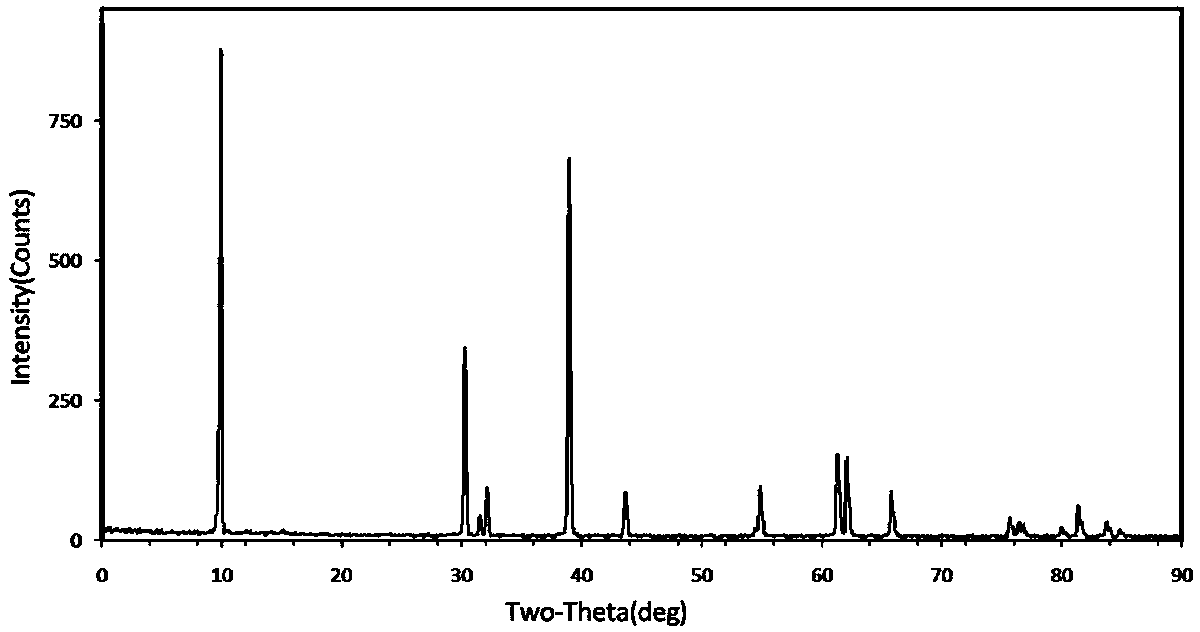

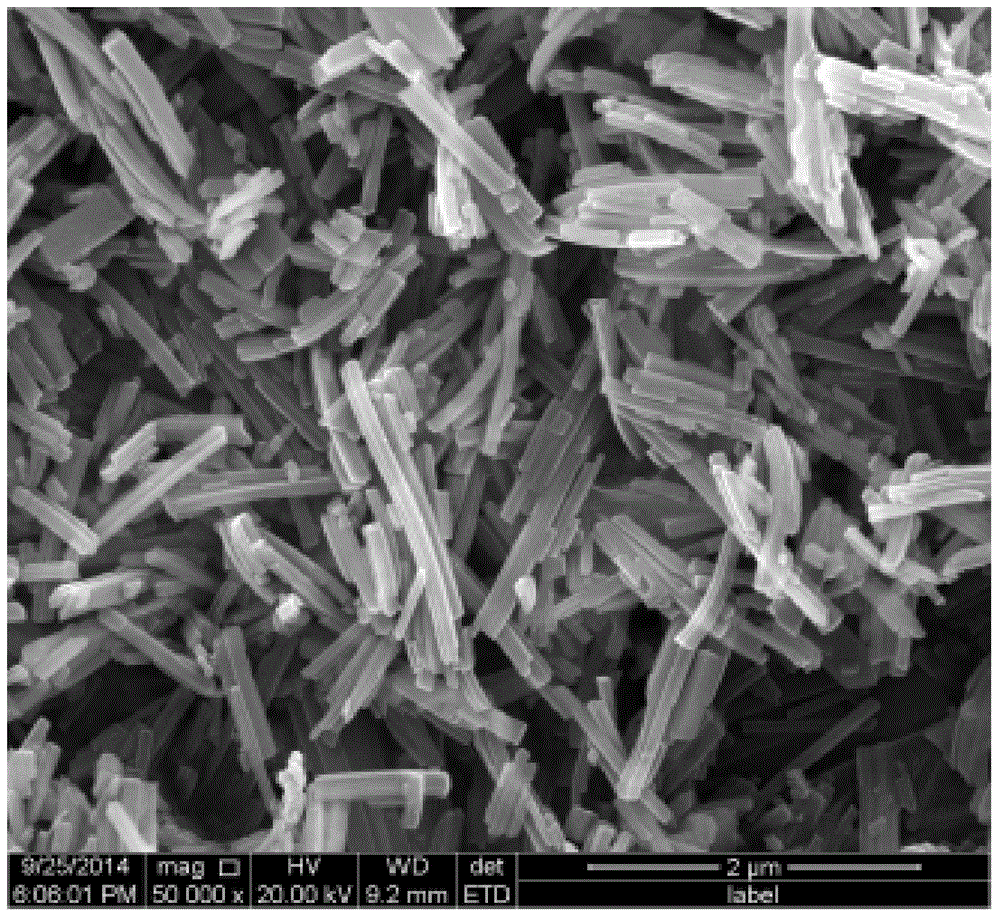

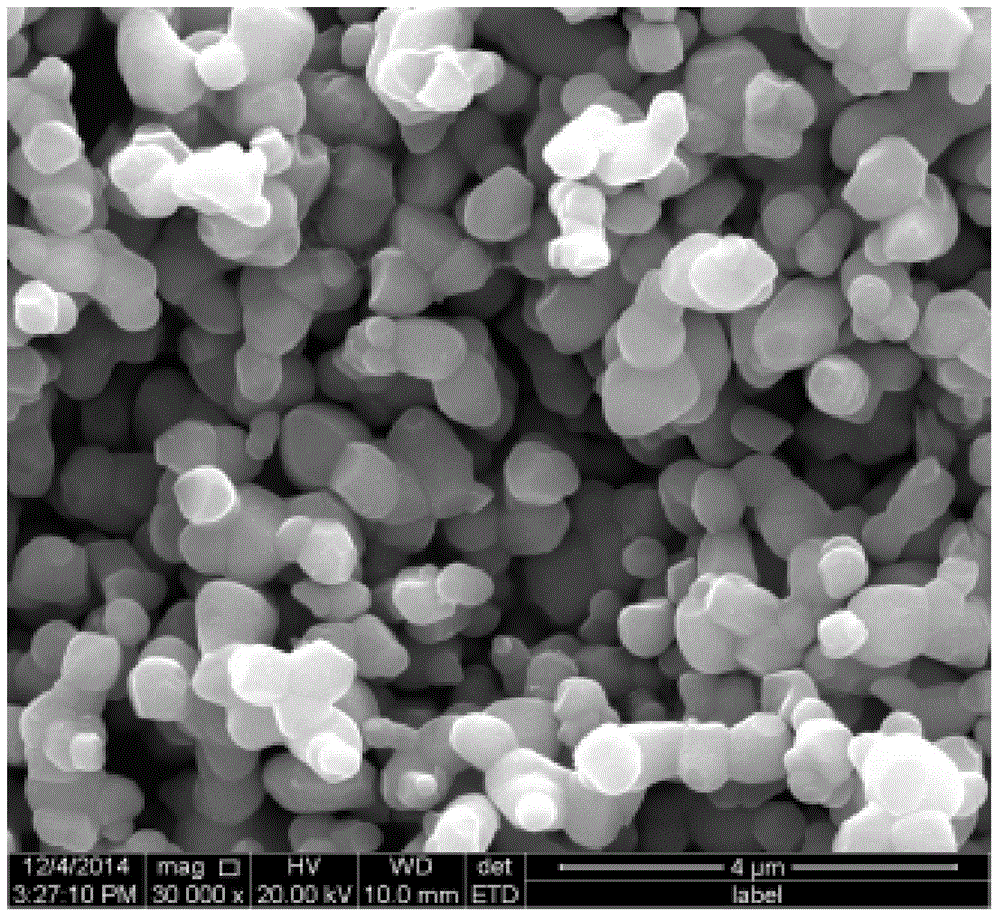

Preparation method of high density nickel cobalt lithium manganate positive electrode material

The invention discloses a preparation method of a high density nickel cobalt lithium manganate positive electrode material, LiNixCoyMnzO2. The preparation method comprises the following steps: firstly, mixing a nickel salt solution, a cobalt salt solution and a manganese salt solution according to a certain mol ratio, adding the mixed solution, a complexing agent solution and a precipitant solution together to a stirring reaction kettle with a base solution, fully reacting, carrying out solid-liquid separation, and washing and drying to obtain a globular nickel cobalt manganese oxyhydroxide precursor; calcining the precursor at the temperature of 350-900 DEG C for 2-20 hours to obtain a globular nickel cobalt manganese oxide precursor, and smashing the globular nickel cobalt manganese oxide precursor at high speed to obtain a mono-crystalline nickel cobalt manganese oxide precursor; mixing a lithium source and the mono-crystalline precursor according to a certain mol ratio, calcining at the temperature of 700-980 DEG C for 2-20 hours, and smashing and classing to obtain the mono-crystalline nickel cobalt lithium manganate positive electrode material. The preparation method provided by the invention has the advantages that the compacted density of the prepared nickel cobalt lithium manganate material is large, the specific capacity is high, the rate property and consistency are good, the preparation method is simple, and the preparation process is easy to control and operate.

Owner:HUNAN SOUNDDON NEW ENERGY

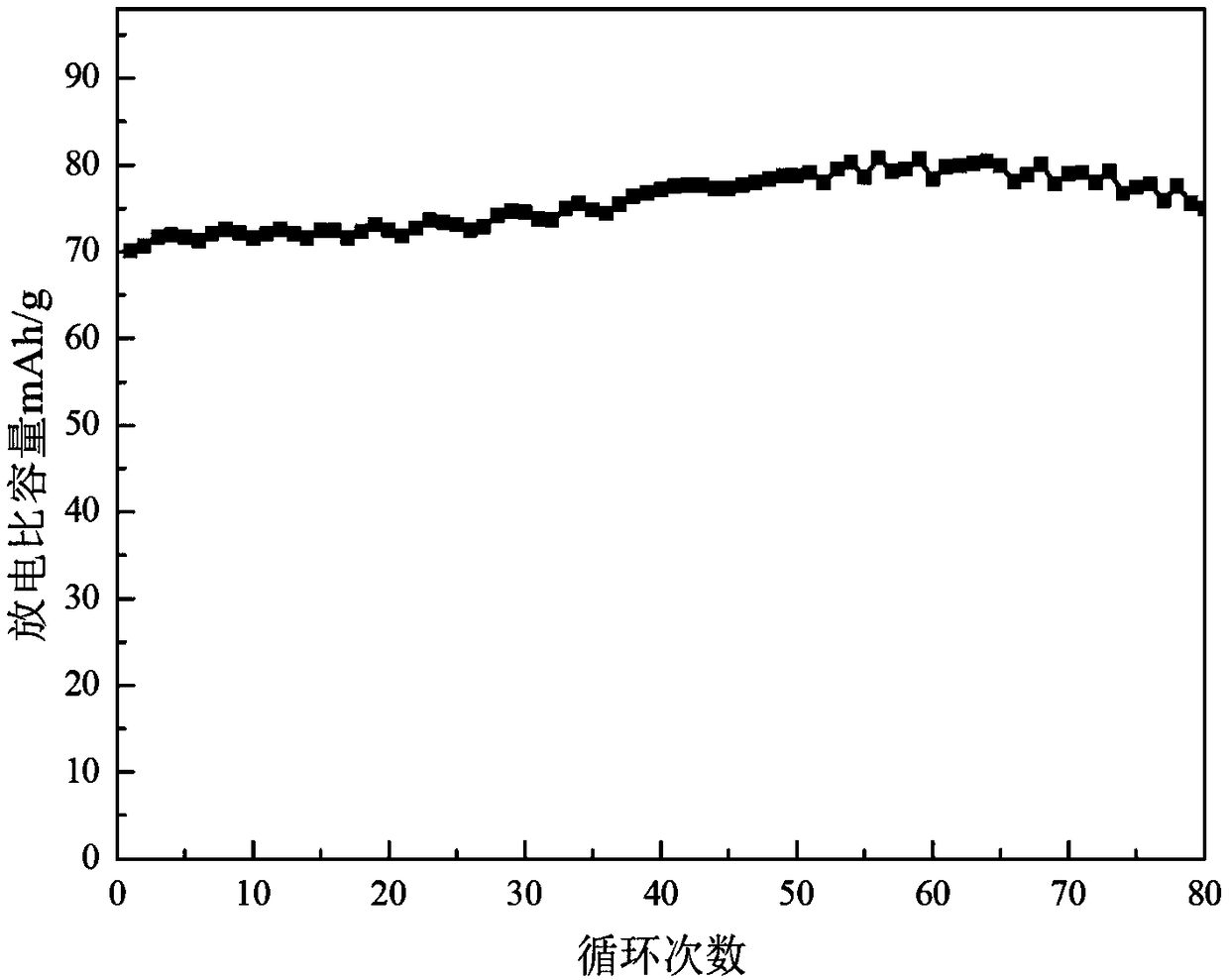

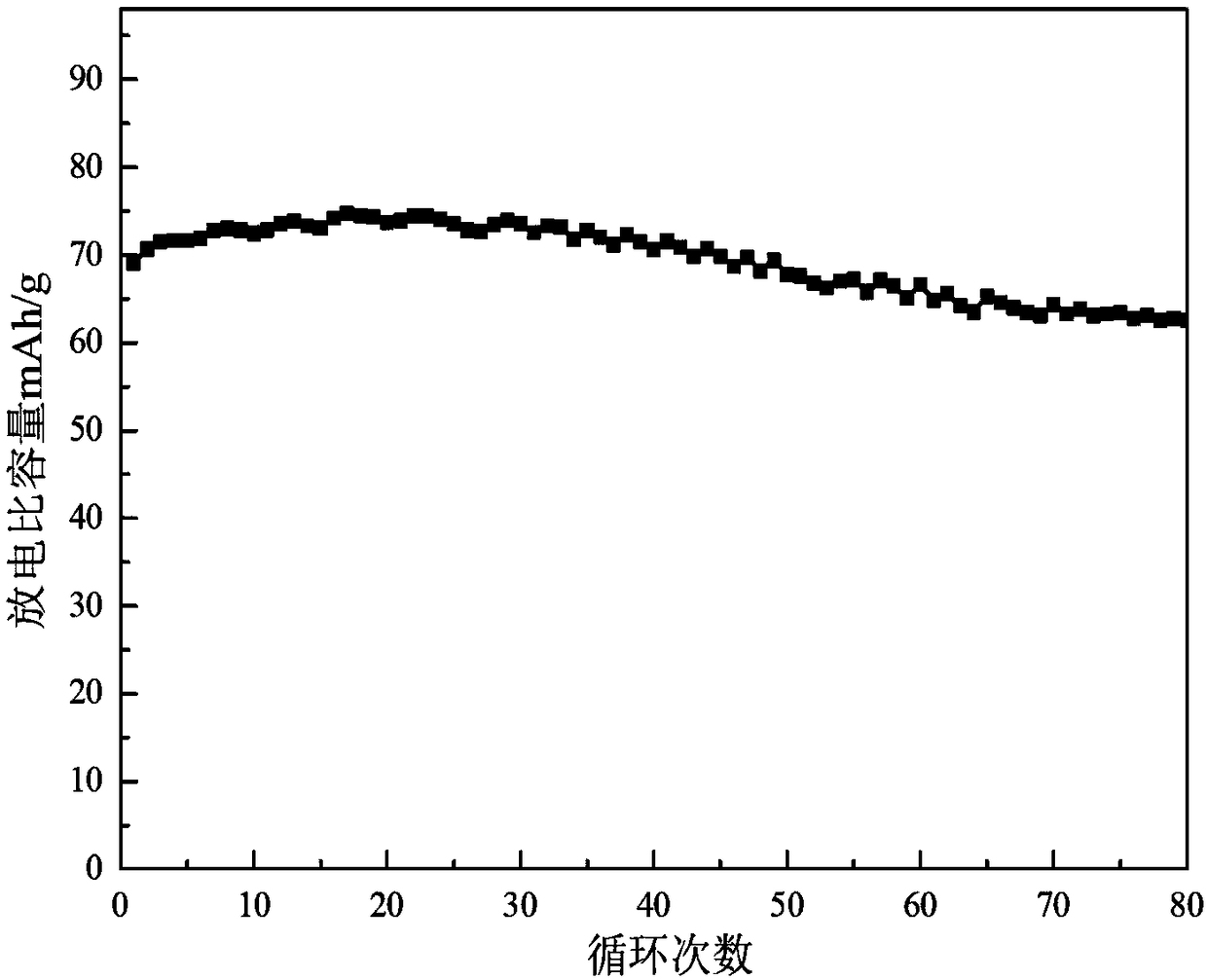

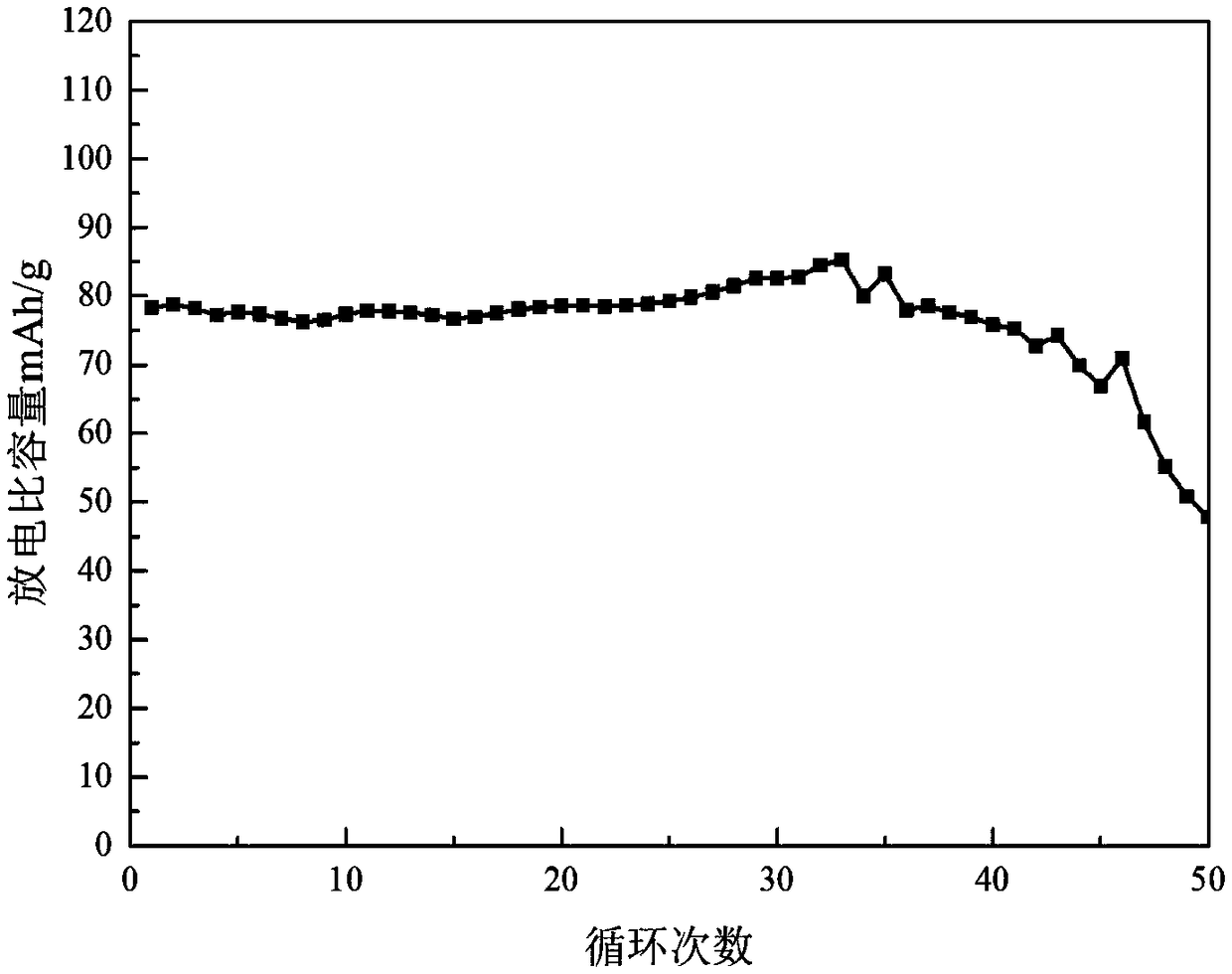

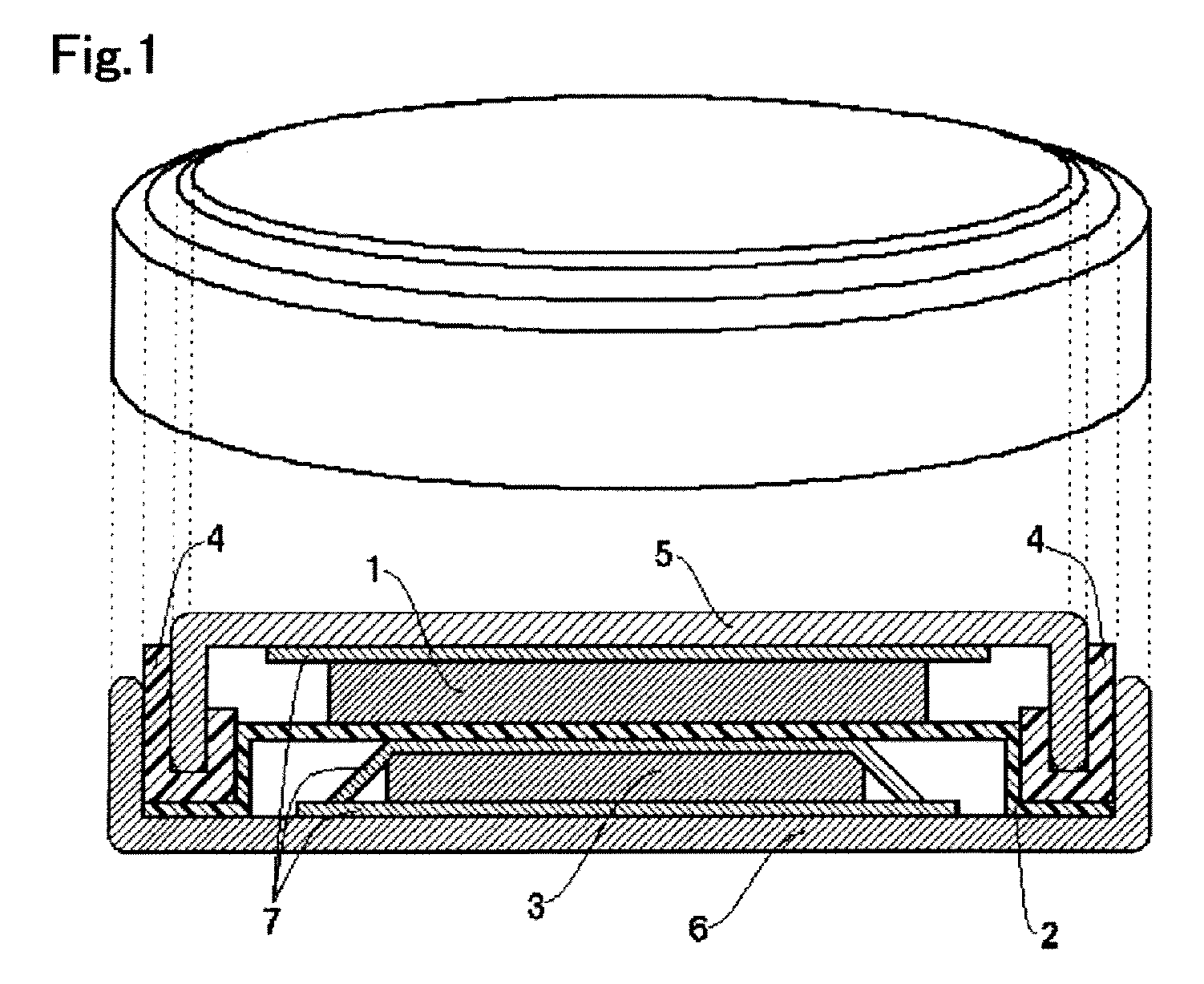

Aqueous zinc ion battery

InactiveCN108807910APromote circulationSimple preparation processFinal product manufactureSecondary cellsElectrical batteryZinc ion

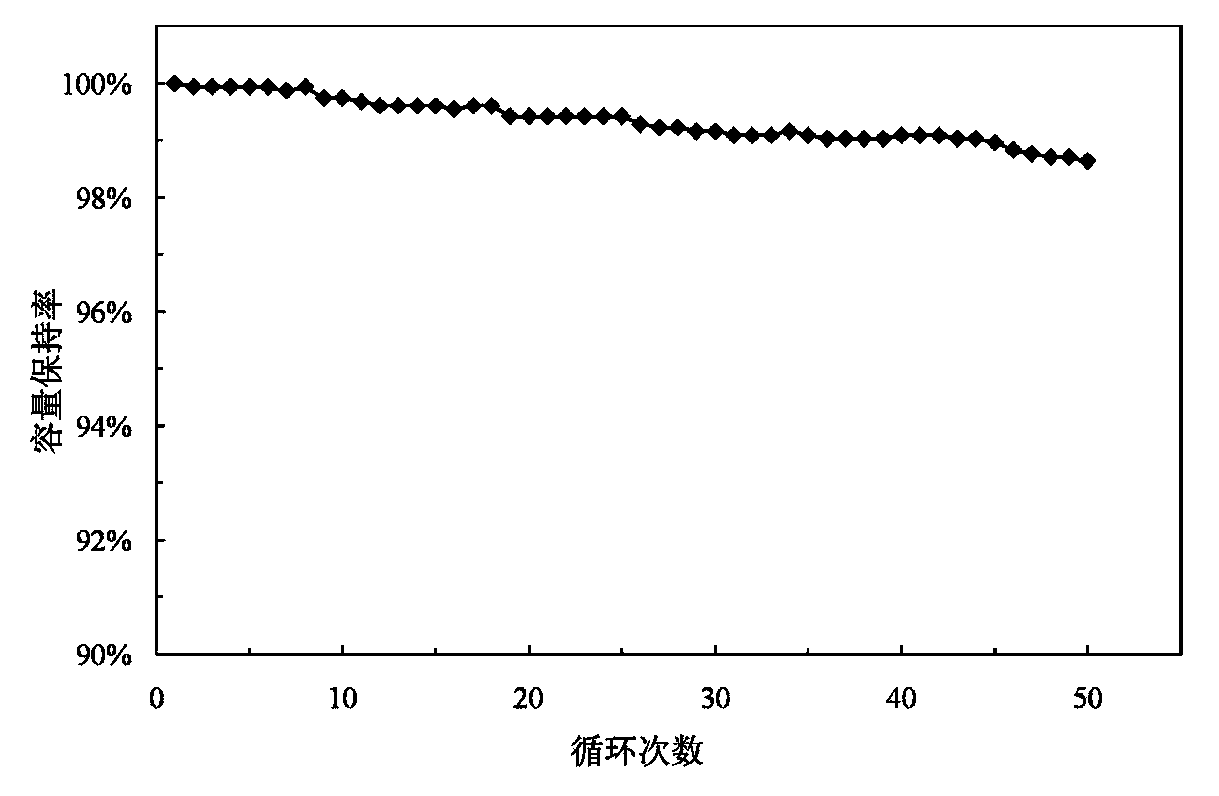

The invention belongs to the technical field of batteries, and particularly relates to an aqueous zinc ion battery. The aqueous zinc ion battery comprises an anode, a cathode, an electrolyte and a diaphragm, wherein the diaphragm is arranged between the anode and the cathode; the cathode is a graphene-assisted zinc cathode; the electrolyte comprises a solvent and a solute, the solvent is water, and the solute comprises soluble zinc salt and manganese salt. Compared with the prior art, the aqueous zinc ion battery has the advantages that the graphene-assisted zinc cathode is applied to the aqueous zinc ion battery system; by adopting the graphene with excellent property and stable structure, the stability and conductivity of the zinc cathode are enhanced, so that the cycle property of the graphene-assisted zinc cathode is enhanced; especially, by adding the trace manganese salt and the corrosion inhibitor into the electrolyte, the problems of zinc corrosion, passivating and the like canbe effectively relieved; the cycle life of the graphene-assisted zinc cathode is further prolonged.

Owner:SHENZHEN CITY THROUGH SCI & TECH OF NEW ENERGY CO LTD

Method for preparing lithium-enriched lithium manganese oxide solid solution cathode material

ActiveCN102544475AFlexible adjustment ratioHomogeneous coprecipitationCell electrodesOXALIC ACID DIHYDRATENickel salt

The invention relates to a method for preparing a lithium-enriched lithium manganese oxide solid solution cathode material. The method comprises the following steps of: adding a mixed aqueous solution of nickel salt, cobalt salt and manganese salt into an oxalic acid or oxalate aqueous solution by an oxalate coprecipitation high-temperature solid state method, and stirring and reacting to generate nickel, cobalt and manganese oxalate coprecipitation; performing solid and liquid separation, washing and drying to obtain a nickel, cobalt and manganese oxalate precursor; and mixing and grinding the precursor and lithium salt, drying, baking at high temperature in an air atmosphere, and thus obtaining the lithium-enriched lithium manganese oxide solid solution cathode material. During preparation of the precursor, the proportion of the nickel salt, the cobalt salt and the manganese salt is adjusted, so that the constituents of the lithium-enriched lithium manganese oxide solid solution cathode material can be adjusted flexibly. The preparation method is suitable for large-scale, economic, stable and reliable production of the lithium-enriched lithium manganese oxide solid solution cathode material, has obvious advantages, and is high in practical value.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Phosphorus-free composite scale and corrosion inhibitor, applications thereof, and processing method for circulating water

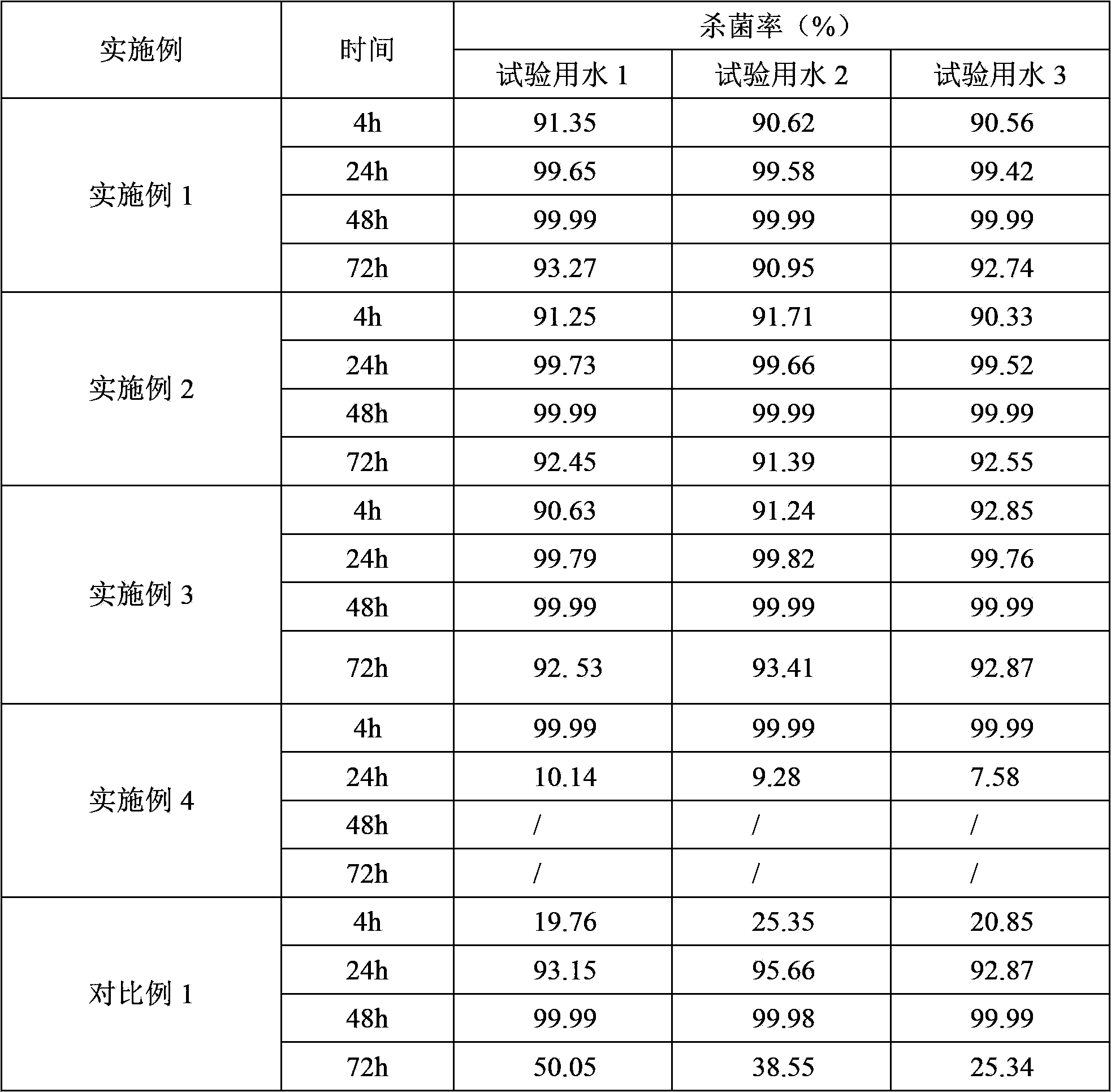

ActiveCN103771596AImprove toleranceGood synergyScale removal and water softeningWater/sewage treatment using germicide/oligodynamic-processIsothiazolinoneManganese

The invention discloses a phosphorus-free composite scale and corrosion inhibitor, applications thereof, and a processing method for circulating water. The phosphorus-free composite scale and corrosion inhibitor comprises dispersants, phosphorus-free corrosion inhibitors and manganese salts. The weight ratio of the dispersants, the phosphorus-free corrosion inhibitors and the manganese salts is 1:0.5-50:0.025-0.5, wherein the weight of the manganese salts is in terms of manganese ions. The phosphorus-free composite scale and corrosion inhibitor has good synergistic effects with non-oxidation-type bactericides, especially isothiazolinone, and can raise the bactericidal effects of the non-oxidation-type bactericides obviously, the bactericidal speed is rapid and the drug effect time is long. The phosphorus-free composite scale and corrosion inhibitor is environmentally friendly, has phosphorus-free and nitrogen-free characteristics, meets green environmental protection requirements, and reduces environmental burden. The phosphorus-free composite scale and corrosion inhibitor has a wide water quality adaptation range, and is easy to be popularized and applied.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high-tap spherical ternary cathode material precursor

InactiveCN102280619AImprove physicsImprove electrochemical performanceCell electrodesNickel saltManganese

The present invention discloses a high -vibration -shaped triggea orthopedic material preparation method. Put nickel salt, cobalt salt, manganese salt and alkaline aquatic solution, complexing agent in the reactor.Synthetic spherical or spherical ternary orthopedic material front -drive body, chemical formula is NIXCOYMNZ (OH) 2,0.5 ≤ x ≤1,0≤y ≤ 0.5, 0 ≤Z ≤ 0.5, x+y+z = 1, add alkaline pH pHSurface treatment, washing dry and drying the three -yuan positive electrode material front drive body.The present invention improves the processing performance of ternary positive electrode materials, vibrating density, overcoming material capacity and stability defects. By controlling the appearance and particle size of the front -drive body, the materialization performance of the three yuan positive pole material is achieved, and the stability of the material is improved.

Owner:XIAMEN TUNGSTEN

Preparing method of lithium ionic cell 5V anode material spherical LiNi*Mn*O*

InactiveCN101335348AImprove electrochemical performanceSimple processElectrode manufacturing processesLithium compoundsNickel saltHigh energy

The invention relates to a preparation method of 5V level anode material of a lithium ion battery, namely, ball LiNi0.5Mn1.5O4, and pertains to the energy material and novel material preparation technology field. The method includes the steps that: a liquid mixture of manganese salt and nickel salt which is prepared according to a molar ration of 3:1, reacts with dissoluble carbonate or bicarbonate water solution and ammonia or ethylene diamine water solution to obtain ball MnCO3-NiCO3, processes of centrifugal separation, washing and drying are carried out, ball Mn2O3-Ni2O3 powder is obtained by heat treatment at 400 DEG C to 600 DEG C, the ball Mn2O3-Ni2O3 powder is mixed with lithium salt compound, ball LiNi0.5Mn1.5O4 is obtained by heat treatment at 700 DEG C to 900 DEG C. The LiNi0.5Mn1.5O4 anode material obtained by the method has high purity and relatively high specific capacity; the product grain is a ball shape, with high tap density which can reach 2.2 to 2.5 g question mark cm <-3>; the ball grain can provide a beneficial condition to the further carrying out of surface coating and to the improvement of the cycle stability of the material, and has great practical value in the field of high energy density and high power lithium ion battery.

Owner:TSINGHUA UNIV

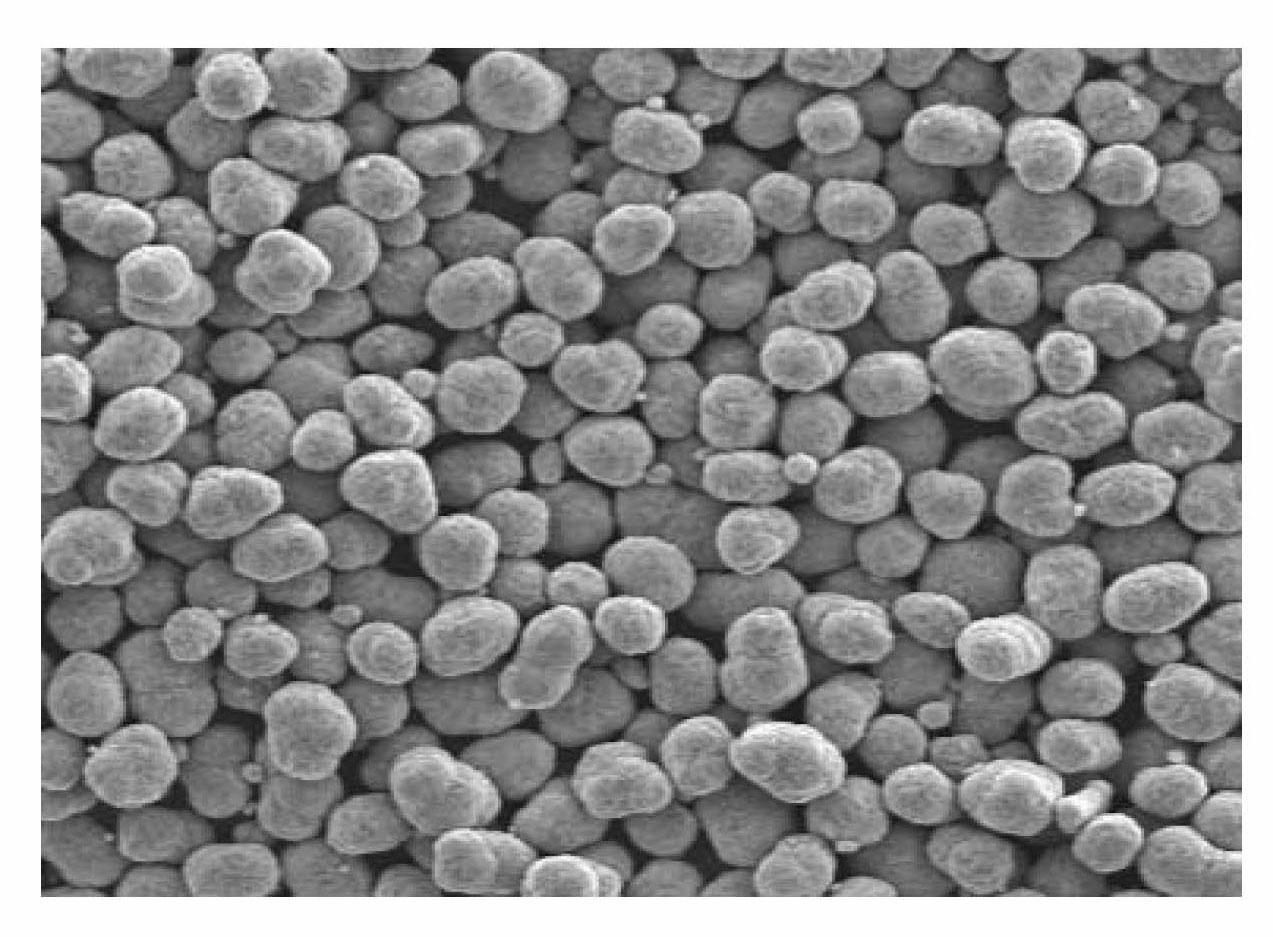

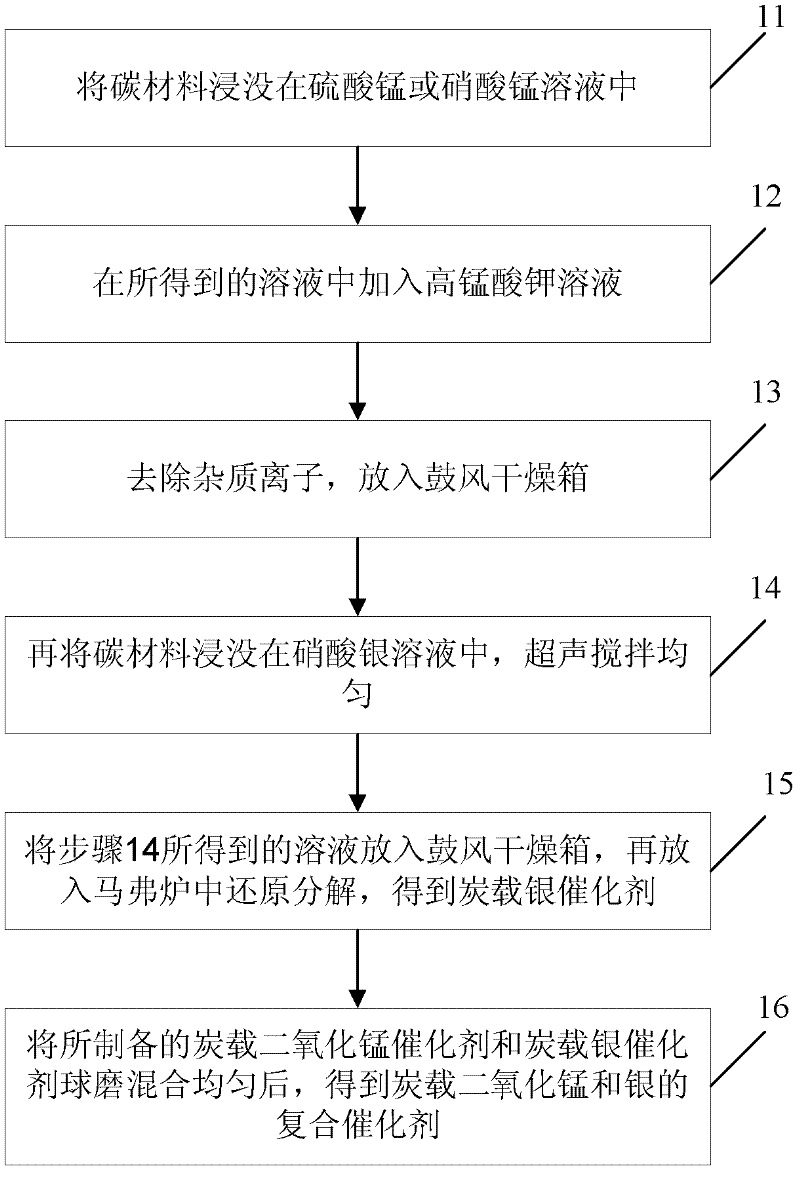

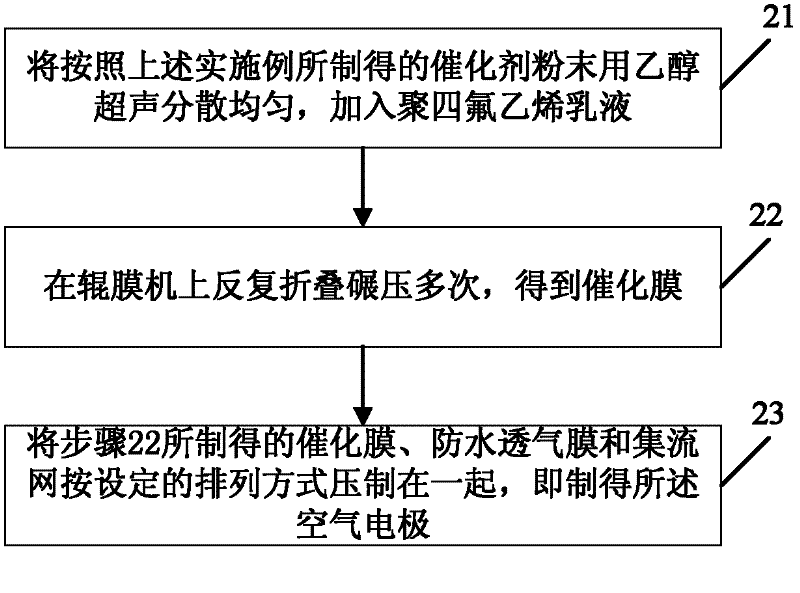

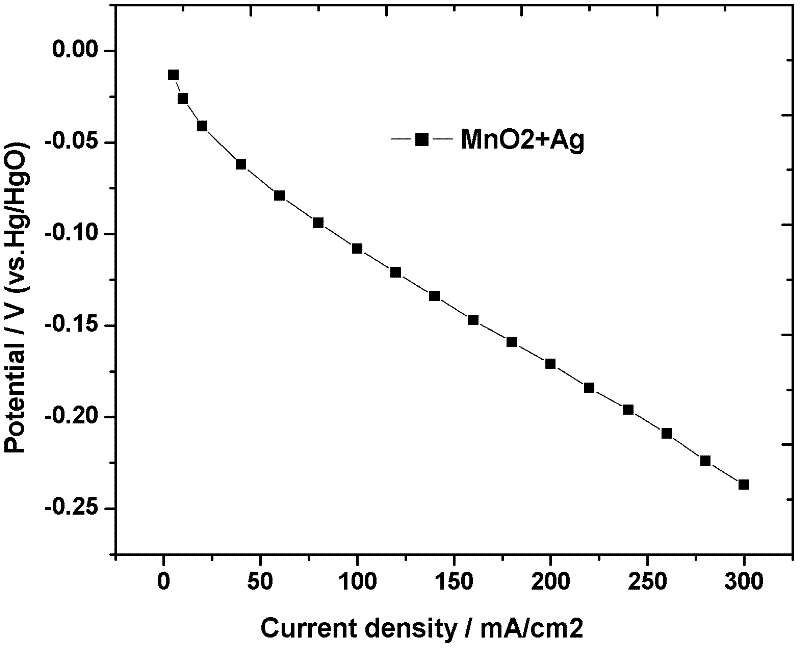

Catalyst for air electrode, air electrode and preparation methods

InactiveCN102306808AHigh catalytic activityImprove performanceCell electrodesMetal/metal-oxides/metal-hydroxide catalystsClark electrodeManganese salt

The embodiment of the invention discloses a catalyst for an air electrode, an air electrode and preparation methods for the catalyst and the air electrode. The catalyst for the air electrode takes a manganese salt and silver salt as raw materials, takes a carbon material as a carrier and has a chemical expression of (MnO2+Ag) / C, wherein the content ratio of each component is MnO2:Ag:C of 2:1:17. The air electrode is obtained by pressing a catalytic film made from the catalyst, a waterproof breathable film and a grid in a set arrangement way. The catalyst for the air electrode has high catalytic activity, so that the performance of the prepared air electrode is greatly improved; and the preparation methods have simple processes, and are relatively lower in production cost.

Owner:BEIJING CHANGLI UNION ENERGY TECH CO

Triple cationic phosphorizing fluid containing calcium, zinc and manganese for steel plate and zinc-coated plate treatment

InactiveCN101029386AMeet the protection requirementsGood alkali resistanceMetallic material coating processesPhosphateManganese

A phosphorizing liquid contains calcium, zinc and manganese triple cation for steel plate and zinc-plated plate treatment consists of calcium salt 5-60g, manganese salt 0.5-10g, zinc salt 2-35g, phosphate 5-20g, nitrate 5-30g and improver 0.5-10g. It hasn't Cr6+ and heavy metal ion Ni2+ and no environmental pollution, and it can be used with cathode electrophoresis. It's simple, cheap, has excellent alkali-resistance and homogeneous crystal grain.

Owner:HUNAN UNIV

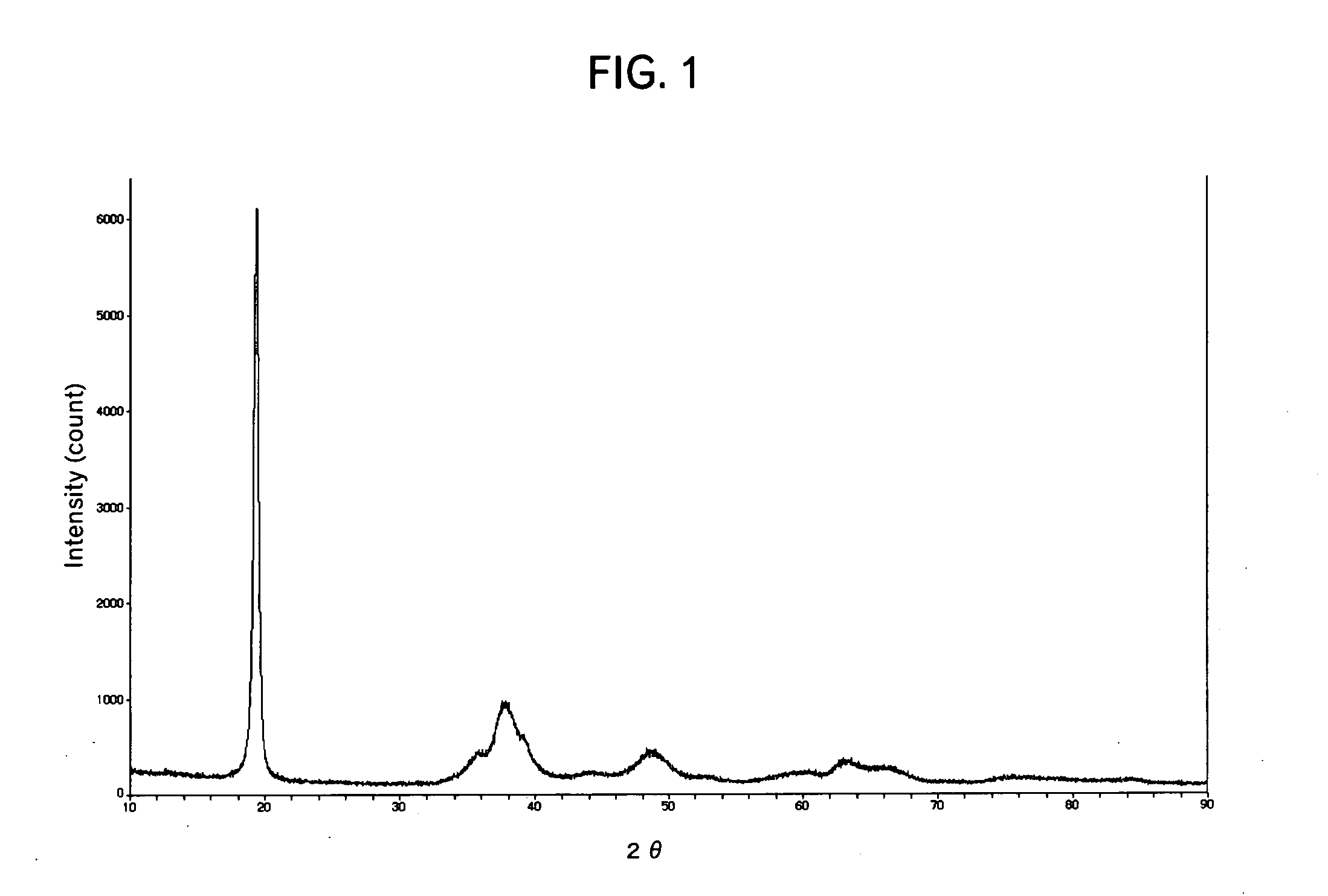

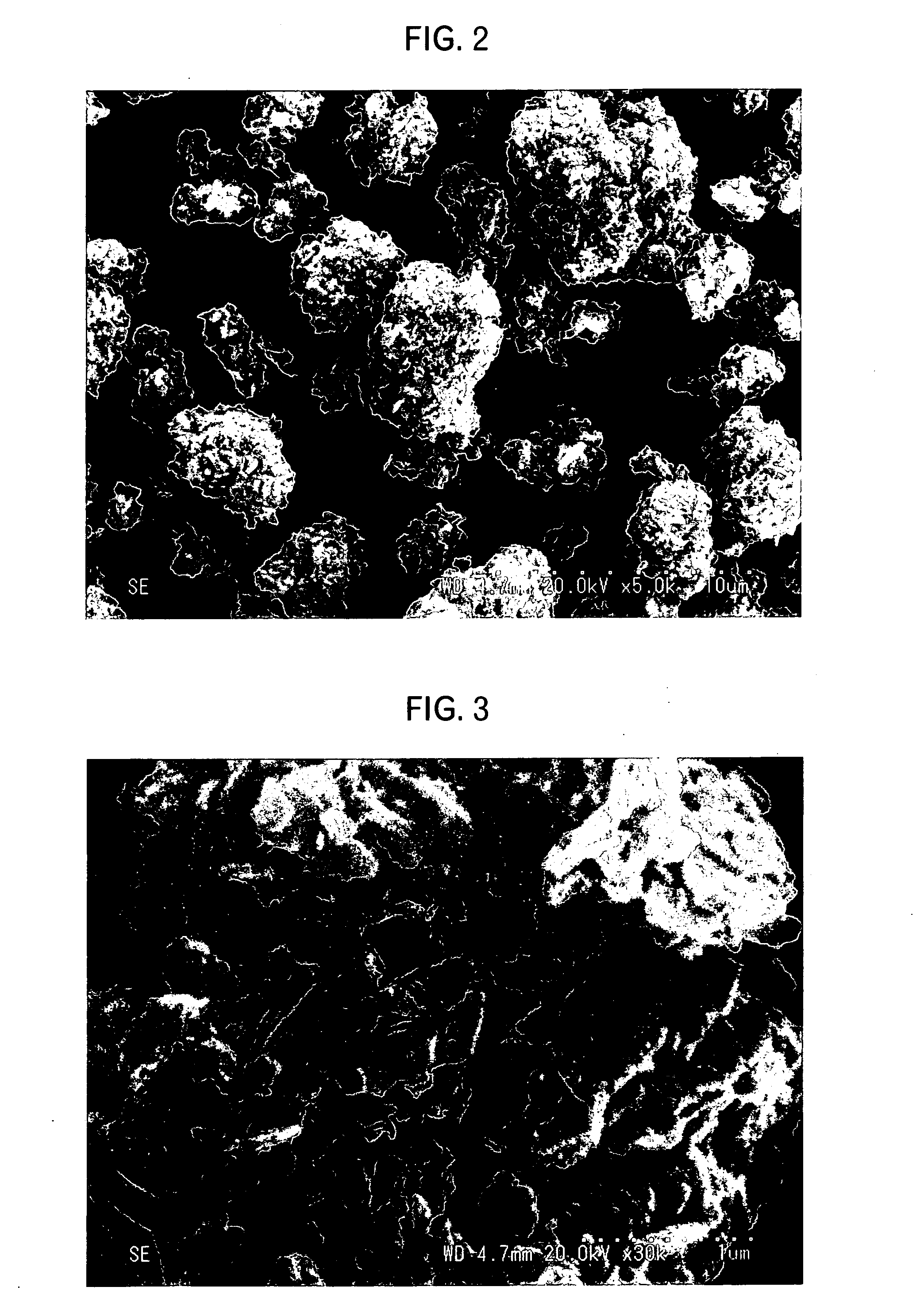

Cathode active material for a nonaqueous electrolyte secondary battery and manufacturing method thereof, and a nonaqueous electrolyte secondary battery that uses cathode active material

ActiveUS20080311473A1Improve discharge capacityExcellent cycle characteristicsFinal product manufacturePositive electrodesManganeseSlurry

The present invention provides a cathode active material that makes possible a high capacity nonaqueous electrolyte secondary battery that has excellent discharge load characteristics that provide both good cycle characteristics and thermal stability. The cathode active material comprises a lithium nickel composite oxide having the compositional formula LiNi1−aMaO2 (where, M is at least one kind of element that is selected from among a transitional metal other than Ni, a group 2 element, and group 13 element, and 0.01≦a≦0.5) to which fine lithium manganese composite oxide particle adhere to the surface thereof. This lithium nickel composite oxide is obtained by adding manganese salt solution to a lithium nickel composite oxide slurry, causing manganese hydroxide that contains lithium to adhere to the surface of the lithium nickel composite oxide particles, and then baking that lithium nickel composite oxide.

Owner:SUMITOMO METAL MINING CO LTD +1

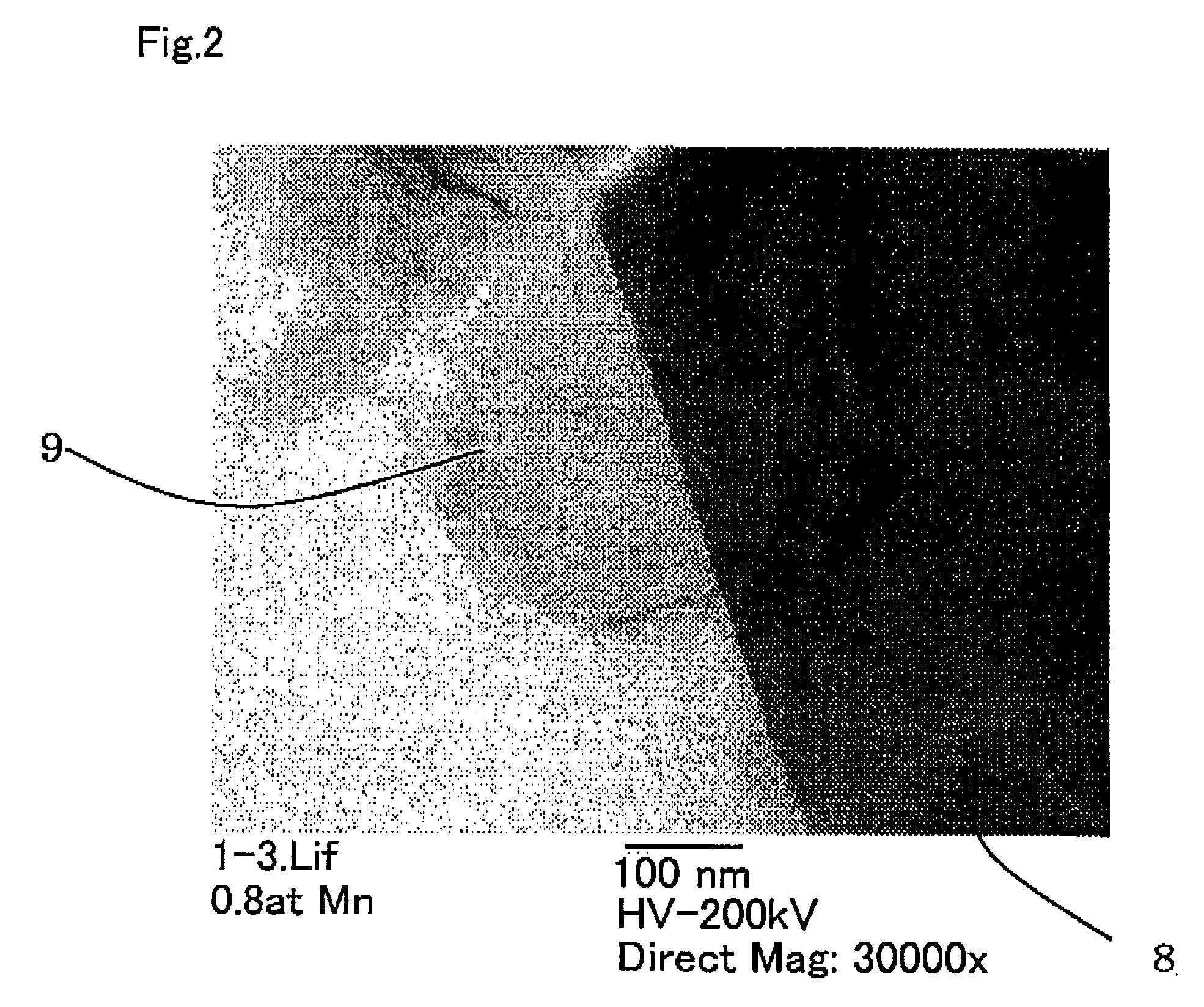

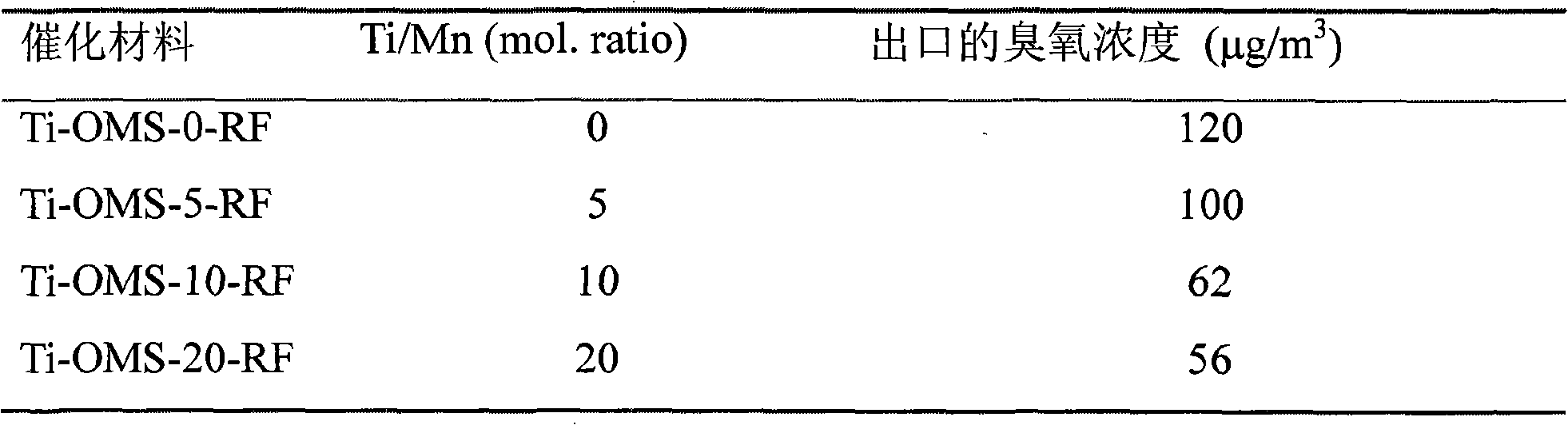

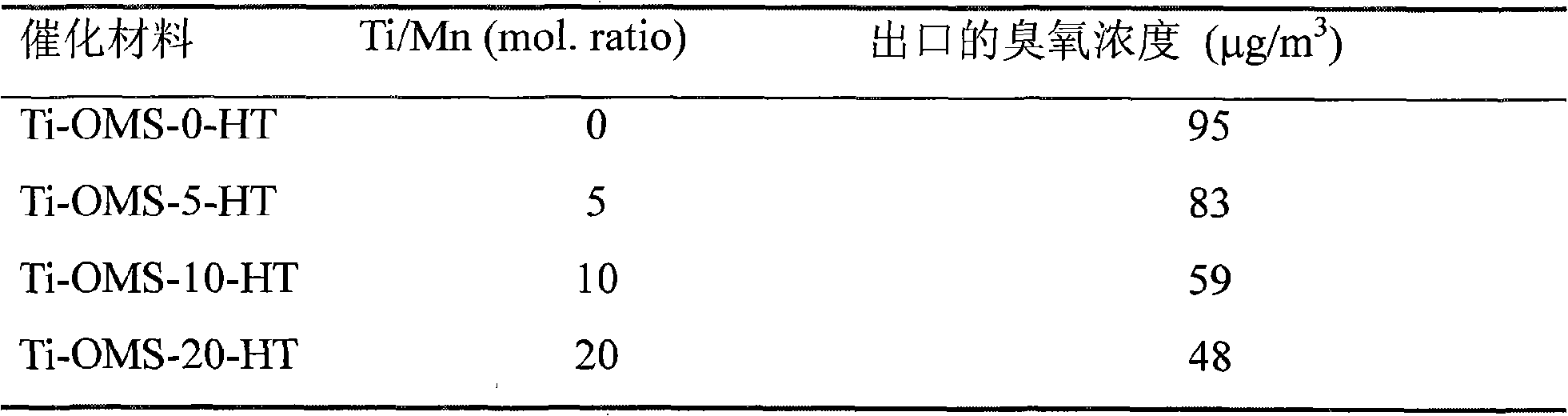

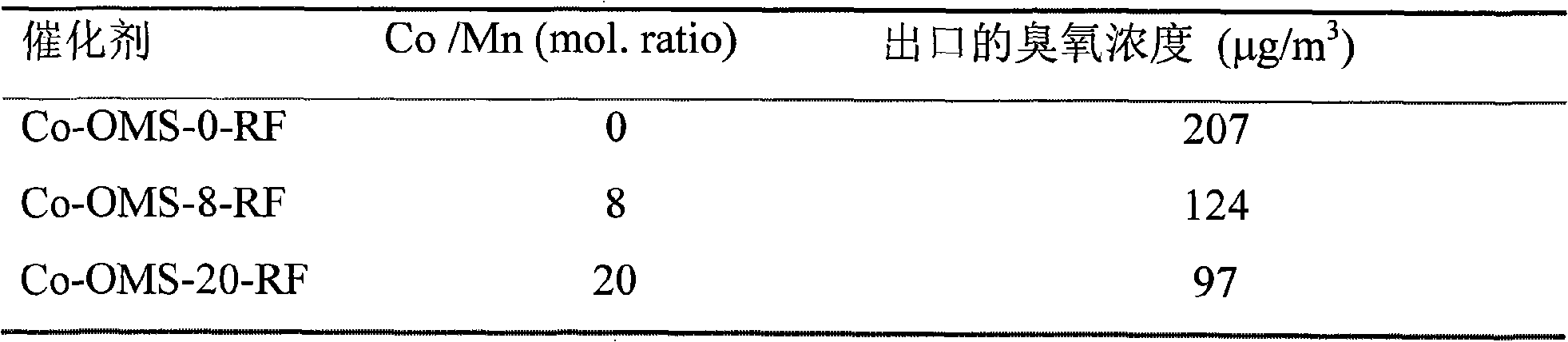

Room-temperature decomposition ozone catalysis material and preparation method thereof

InactiveCN101357331AImprove moisture resistanceImprove processing efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAir volumeDecomposition

The invention discloses a manganese oxide molecular sieve-doped monolithic catalyst for decomposing ozone (O3) at room temperature and a preparation method thereof, which relates to the fields of catalysis and environmental protection. The preparation method is characterized in that a ceramic honeycomb monolithic type or porous foam metal carrier is adopted, and the manganese oxide molecular sieve doped with cobalt or titanium is taken as an active component. The manganese oxide molecular sieve doped with the cobalt or titanium is characterized in that: 1) the manganese oxide molecular sieve has Hollandite-typed manganese oxide octahedral molecular sieves (OMS-2) structure, the pore size is about 0.46nm multiplied by 0.46nm; 2) cobalt or titanium ions are introduced on a framework of the Hollandite-typed manganese oxide octahedral molecular sieves to form the manganese oxide molecular sieve doped with cobalt or titanium. An ozone decomposition catalyst is prepared by an oxidation reduction-refluxing method or an oxidation reduction-hydrothermal synthesis method, namely, the solution with manganese salt and cobalt salt or titanium salt is added with a strong oxidizer to synthesize the ozone decomposition catalyst by refluxing at the temperature of 90-200 DEG or hydrothermal process for more than 12 hours. The monolithic catalyst is characterized in that the input of additional energy sources such as light, heat, electricity, and the like, is unnecessary, and the ozone can be stably decomposed into oxygen under the conditions of normal temperature, normal humidity and large air volume.

Owner:李永刚

Low temperature CO oxidation non-noble metal catalyst

InactiveCN101143321AHave substantive characteristicsLow costCatalyst carriersDispersed particle separationNickel saltIron salts

The invention provides an oxidation catalyst to purify CO in room temperature, which is prepared in coprecipitation method or deposition-precipitation method. The catalyst consists of non precious metal active components and carrier, wherein the loading of the active components is 5 to 80 percent of the conversion value of metal element. The active components come from cobalt salt liquid, iron salt liquid, nickel salt liquid, manganese salt liquid, copper salt liquid, zinc salt liquid, tin salt liquid and cerium salt liquid. The carrier comes from alumina, silica, molecular sieve, honeycomb ceramics, wire fence, cobalt oxide, iron oxide, manganese oxide, copper oxide, zinc oxide, tin oxide and cerium oxide. The precipitant is Na2CO3, K2CO3, sodium hydroxide, urea or ammonia. The catalyst preparation solution needs to be fully stirred for 1 to 8 hours and the retrogradation duration is 1 to 16 hours. The dried solution needs to be treated in in-situ remediation in air, oxygen, and hydrogen or nitrogen atmosphere in temperature from 100 to 500 degrees centigrade. The catalyst disuses precious metal as active component, so the cost is low and the preparation process is simple.

Owner:NO 63971 TROOPS PLA

High density cobalt-manganese coprecipitated nickel hydroxide and process for its production

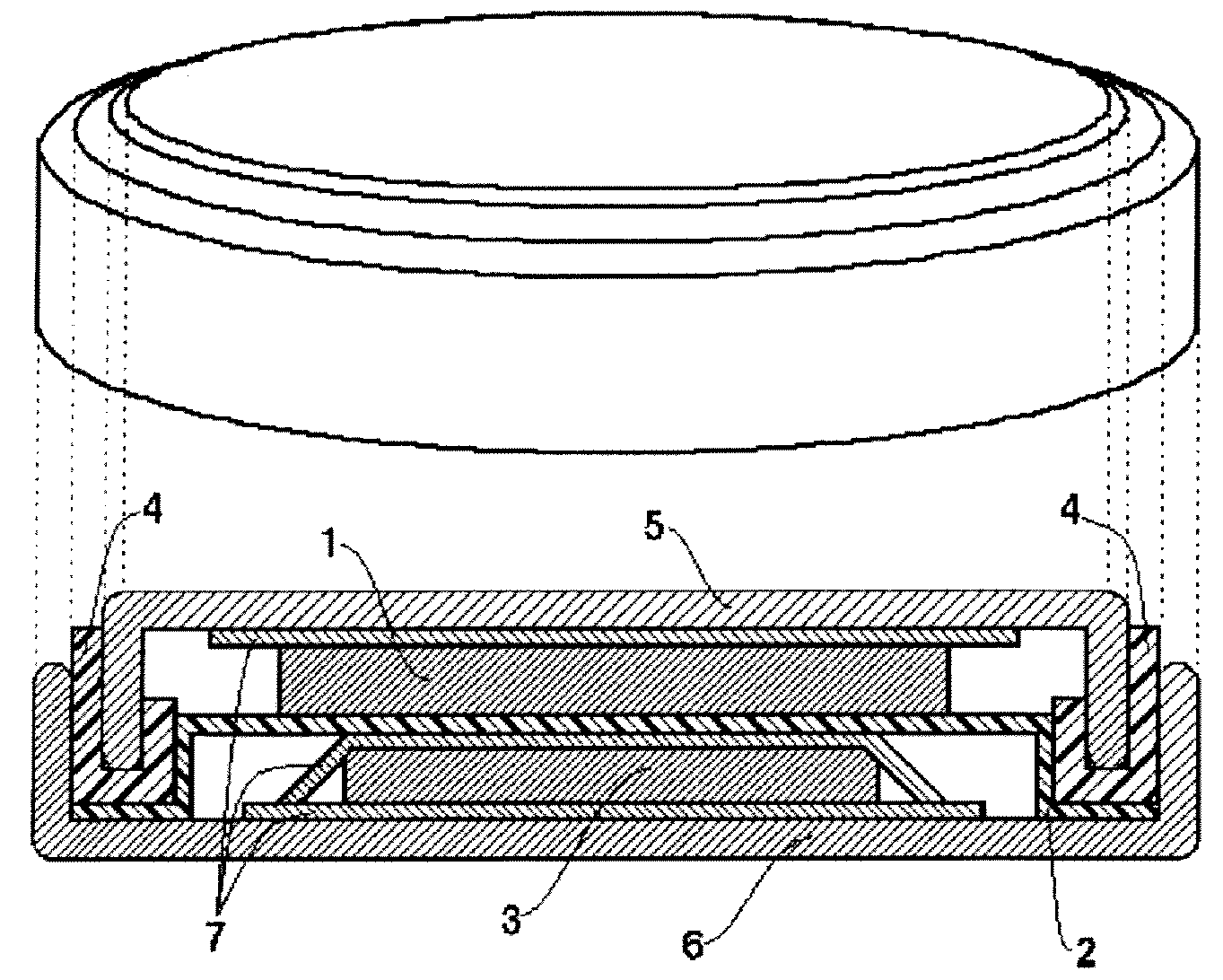

The present invention provides high density cobalt-manganese coprecipitated nickel hydroxide, particularly having a tapping density of 1.5 g / cc or greater, and a process for its production characterized by continuous supply of an aqueous solution of a nickel salt which contains a cobalt salt and a manganese salt, of a complexing agent and of an alkali metal hydroxide, into a reactor either in an inert gas atmosphere or in the presence of a reducing agent, continuous crystal growth and continuous removal.

Owner:TANAKA CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com