Preparation method of nano porous metal oxide/carbon lithium ion battery cathode material

A lithium-ion battery, nanoporous technology, applied in the field of electrochemistry, can solve the problems that limit the practical application of porous transition metal oxide/carbon composite materials, reduce the porosity of composite materials, and uncontrollable reaction process, etc., and achieve excellent high-rate discharge performance, inhibition of dissolution loss, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh ferrous ammonium sulfate and aminotriacetic acid at a molar ratio (1-3):1, put them into a high-pressure reactor, then add distilled water to vigorously stir and dissolve, and obtain a concentration of ferrous ammonium sulfate of 0.05mmol / mL~0.6 mmol / mL solution. Heating at 100-180°C for 10-72 hours, cooling naturally to obtain a blue-white one-dimensional nanoribbon iron-based complex Fe-NTA, which is centrifuged, washed, and vacuum-dried. Put the obtained iron-based complex Fe-NTA into a tube furnace with nitrogen or argon, and thermally decompose it at 300-600°C for 0.5-6h, with a heating rate of 2-10°C / min, to obtain a one-dimensional nanoribbon porous nano-Fe 3 o 4 / C composite anode material.

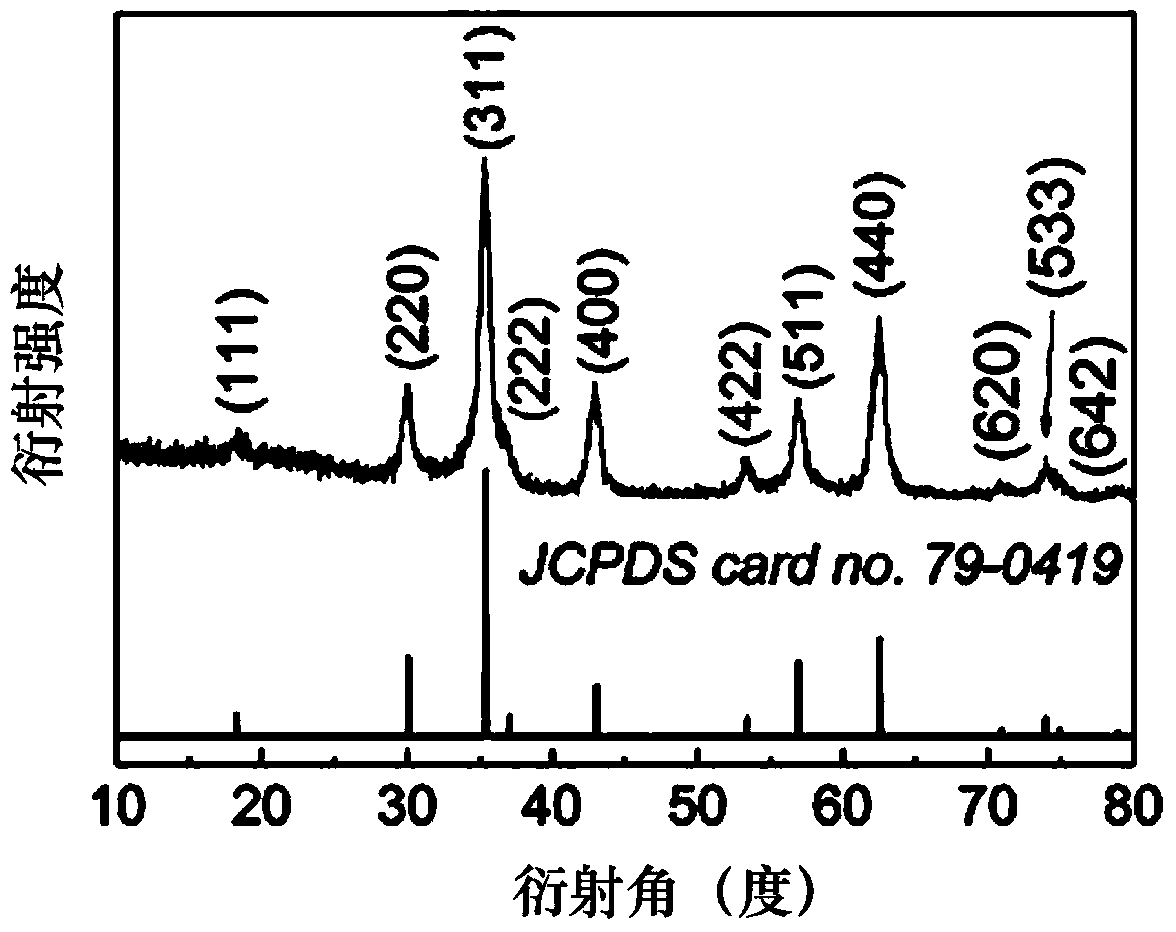

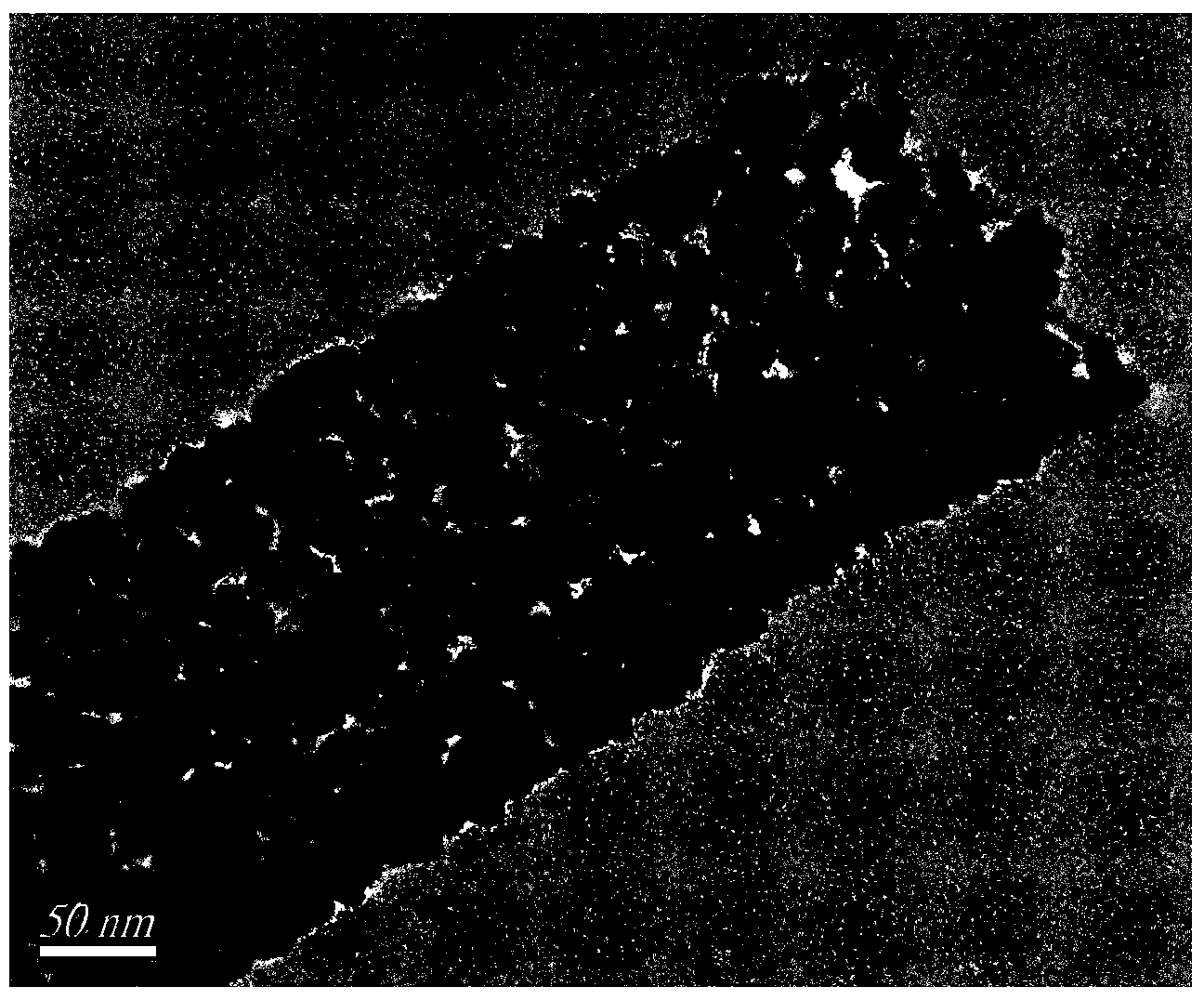

[0040] The resulting product was analyzed by X-ray diffraction as follows: figure 1 The diffraction pattern shown shows that the product is Fe 3 o 4 , without any impurity phase; the scanning electron microscope picture is as follows figure 2 Shown, showing Fe...

Embodiment 2

[0043] Ferrous ammonium sulfate is replaced by ferrous chloride in embodiment 1, other is the same as embodiment 1, obtains one-dimensional nanoribbon shape porous Fe 3 o 4 / C composite negative electrode material, under the current density of 100 mA / g, the charge and discharge test results in the first three weeks are as follows: Figure 6 shown. The charge and discharge capacities in the first three weeks were 1162 / 1789, 1180 / 1336, and 1140 / 1310 mAh / g, respectively.

Embodiment 3

[0045] Ferrous ammonium sulfate is replaced by ferrous sulfate in embodiment 1, and other is the same as embodiment 1, obtains one-dimensional nanoribbon-shaped porous Fe 3 o 4 / C composite negative electrode material, under the current density of 100 mA / g, the charge and discharge test results in the first three weeks are as follows: Figure 7 shown. The charge and discharge capacities in the first three weeks were 1239 / 1863, 1245 / 1371, and 1252 / 1357 mAh / g, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com