Patents

Literature

843results about "Fuse device manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

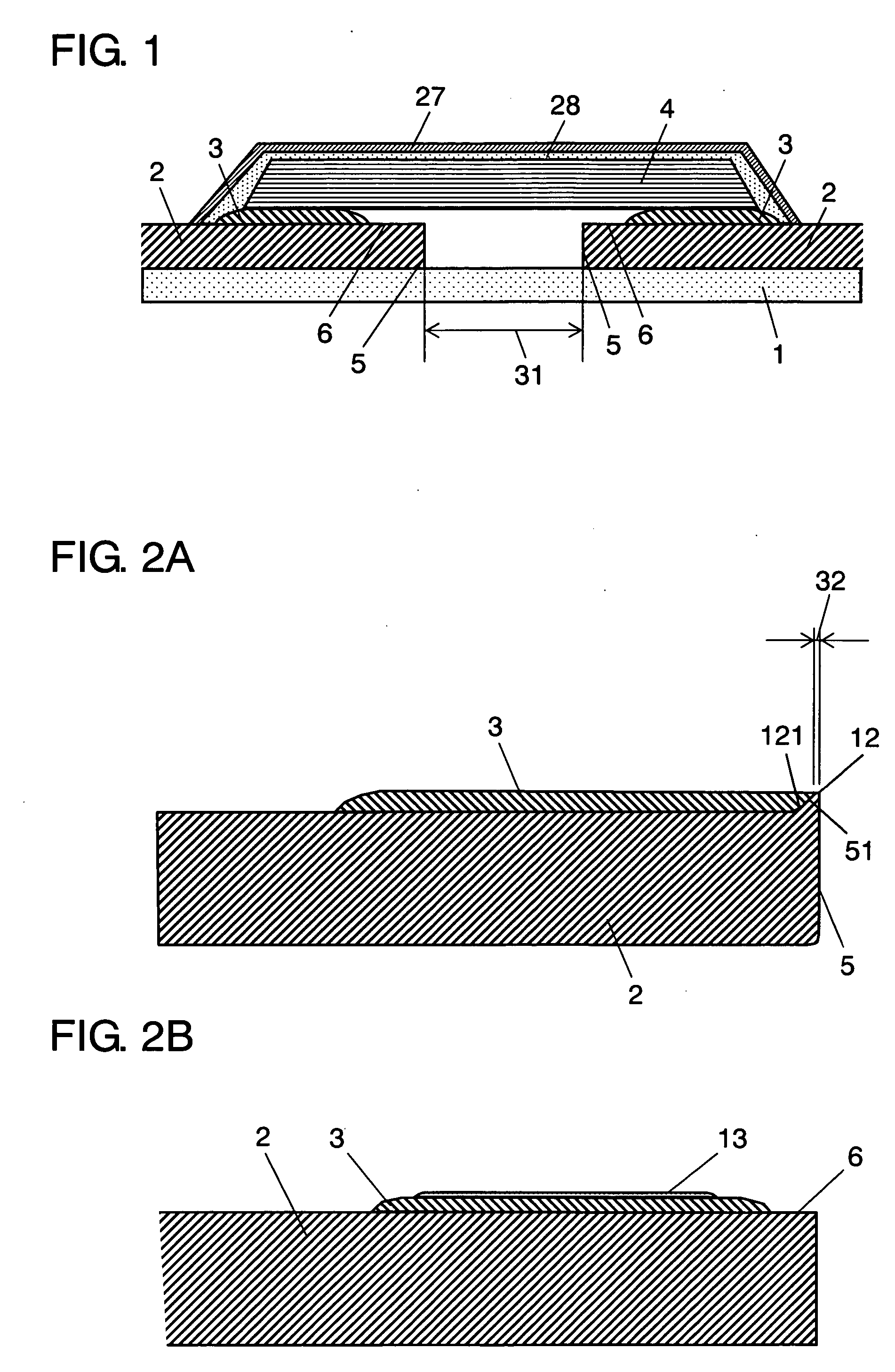

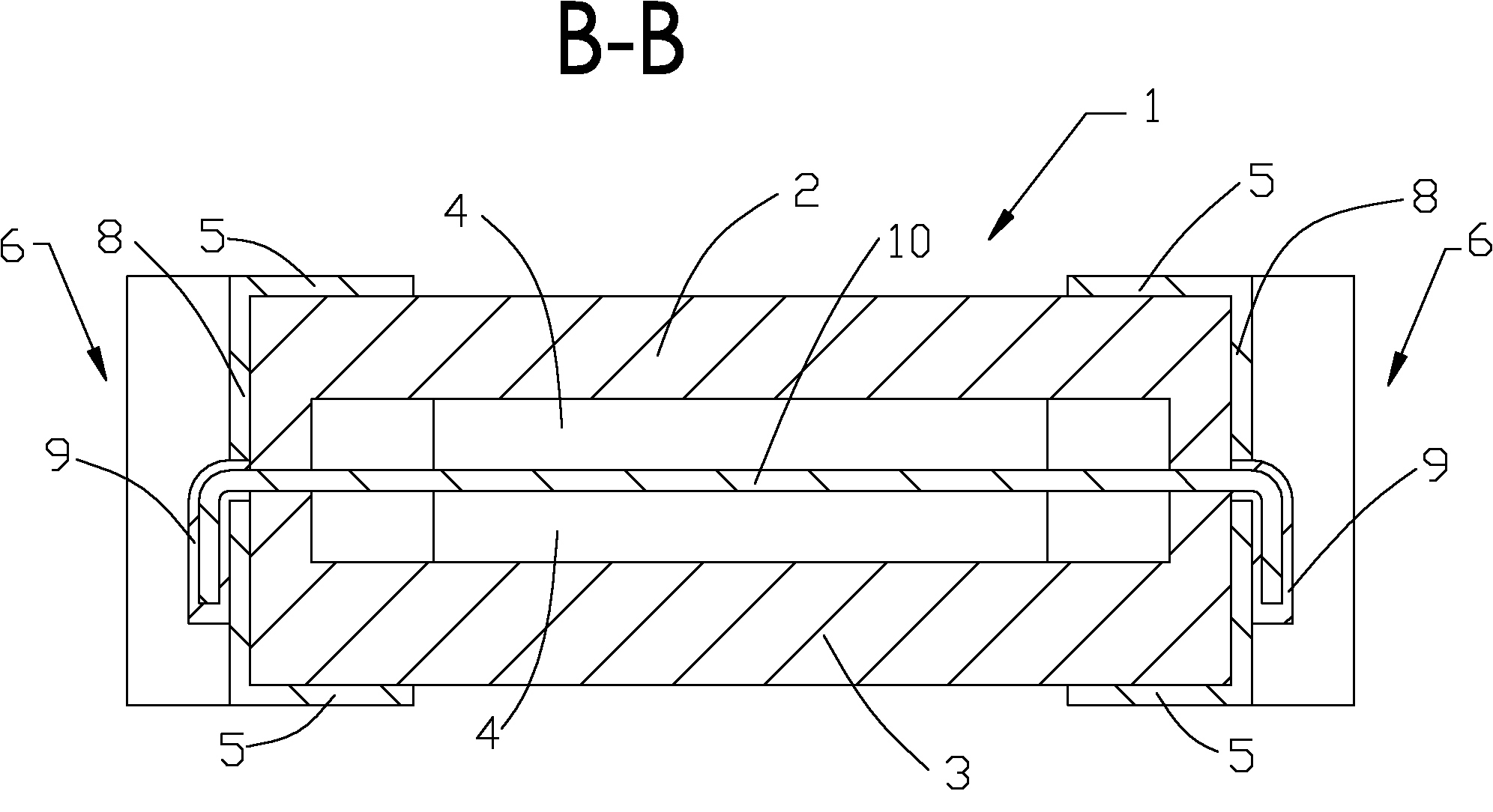

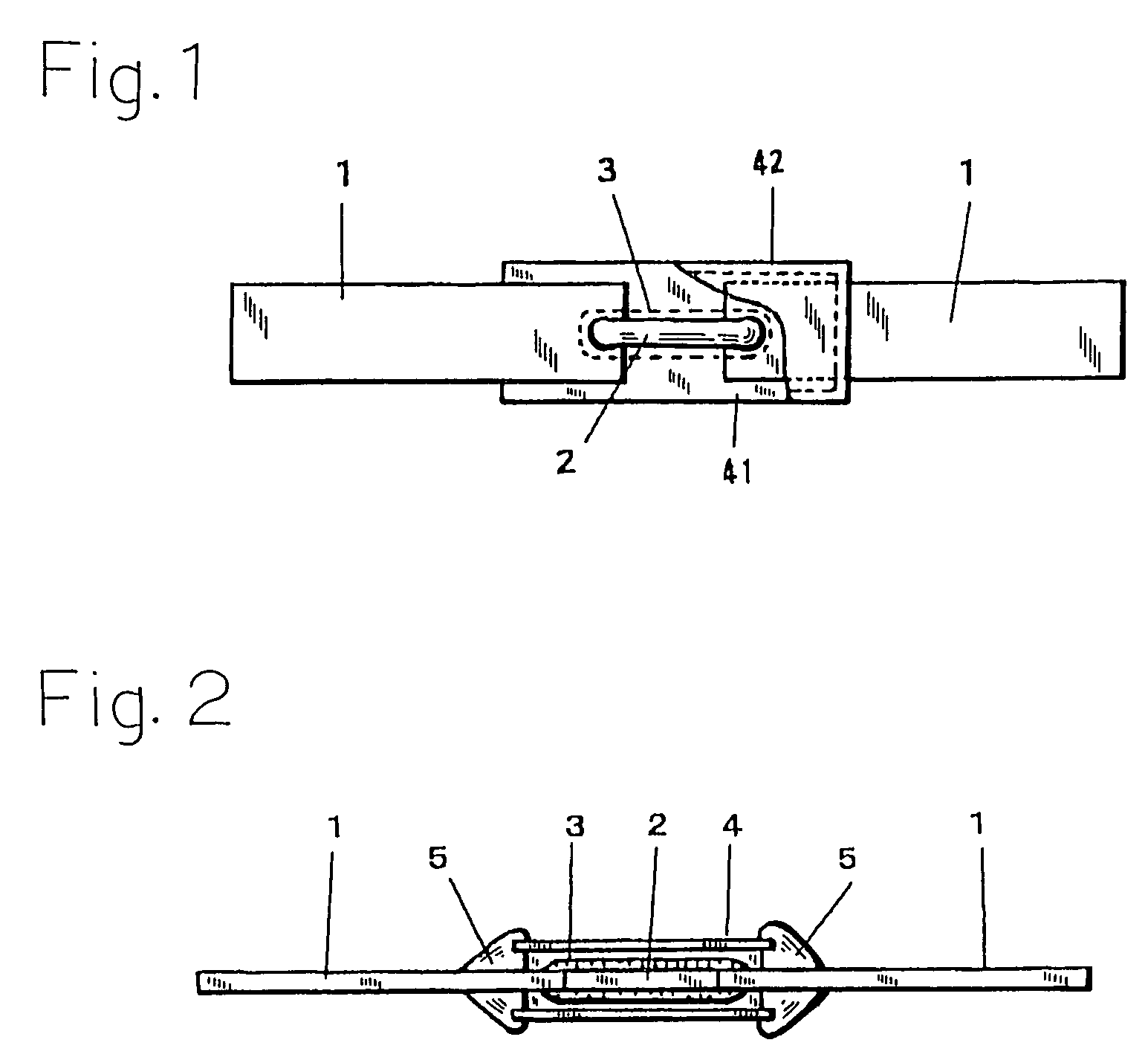

Membrane electrode unit for electrochemical equipment

InactiveUS20050014056A1Good design conceptOvercome disadvantagesCellsFuse device manufactureSpecial designEngineering

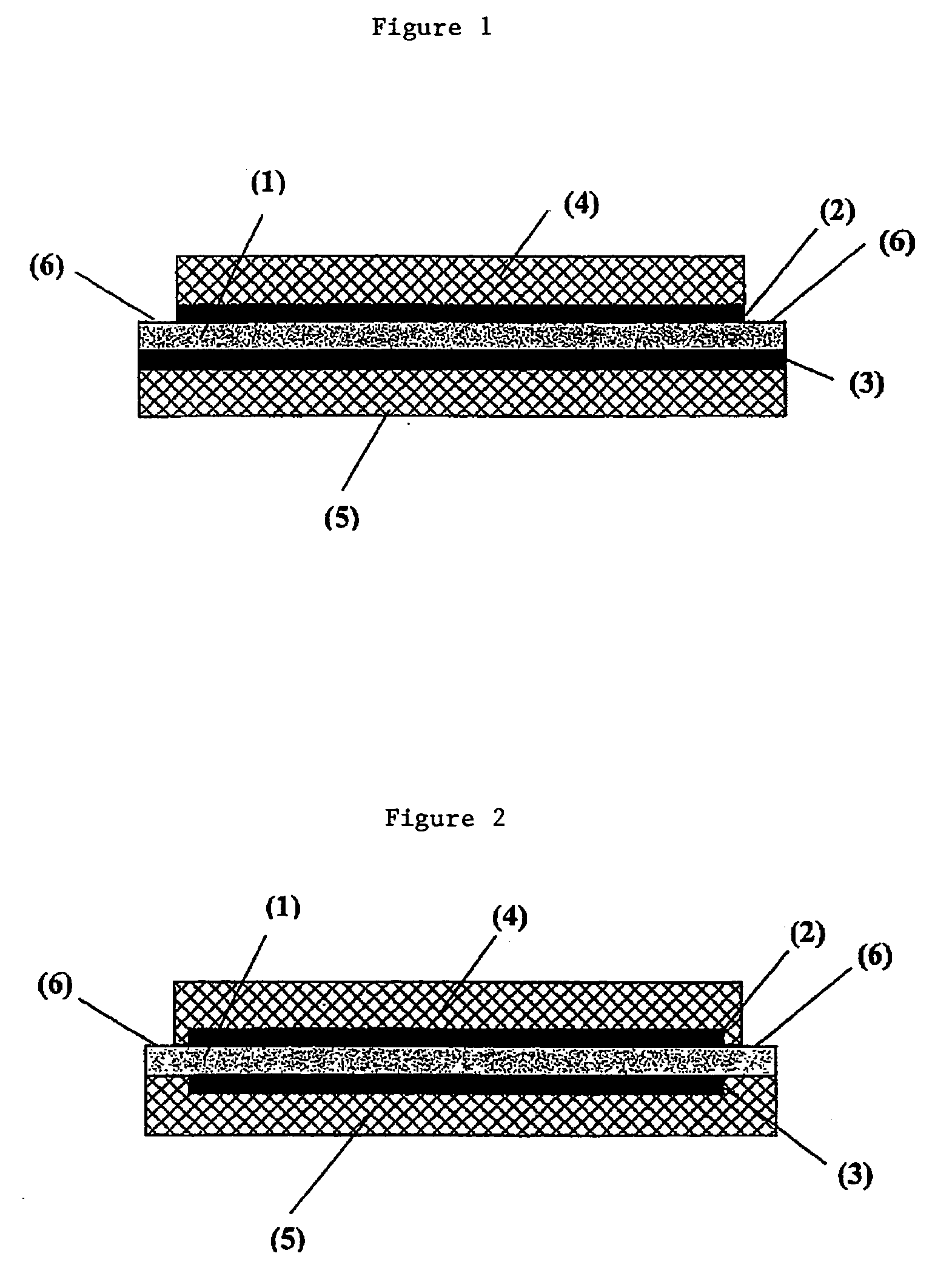

The invention concerns a membrane electrode unit (MEU) for electrochemical equipment, especially for membrane fuel cells. The membrane electrode unit has a “semi-coextensive” design and contains an ionically conductive membrane, two catalyst layers, and gas distributor substrates of different sizes on the front and back sides. The first gas distributor substrate has smaller surface dimensions than the ionically conductive membrane, while the second gas distributor substrate has the same area as the ionically conductive membrane. The membrane electrode unit has, because of its special design, a stable structure that can be handled well, and which exhibits advantages for sealing the reactive gases off from each other and in its electrical properties. In particular, the hydrogen penetration current is distinctly reduced. The membrane electrode unit is used in PEM fuel cells, direct methanol fuel cells, electrolyzers, and other electrochemical equipment.

Owner:UMICORE AG & CO KG

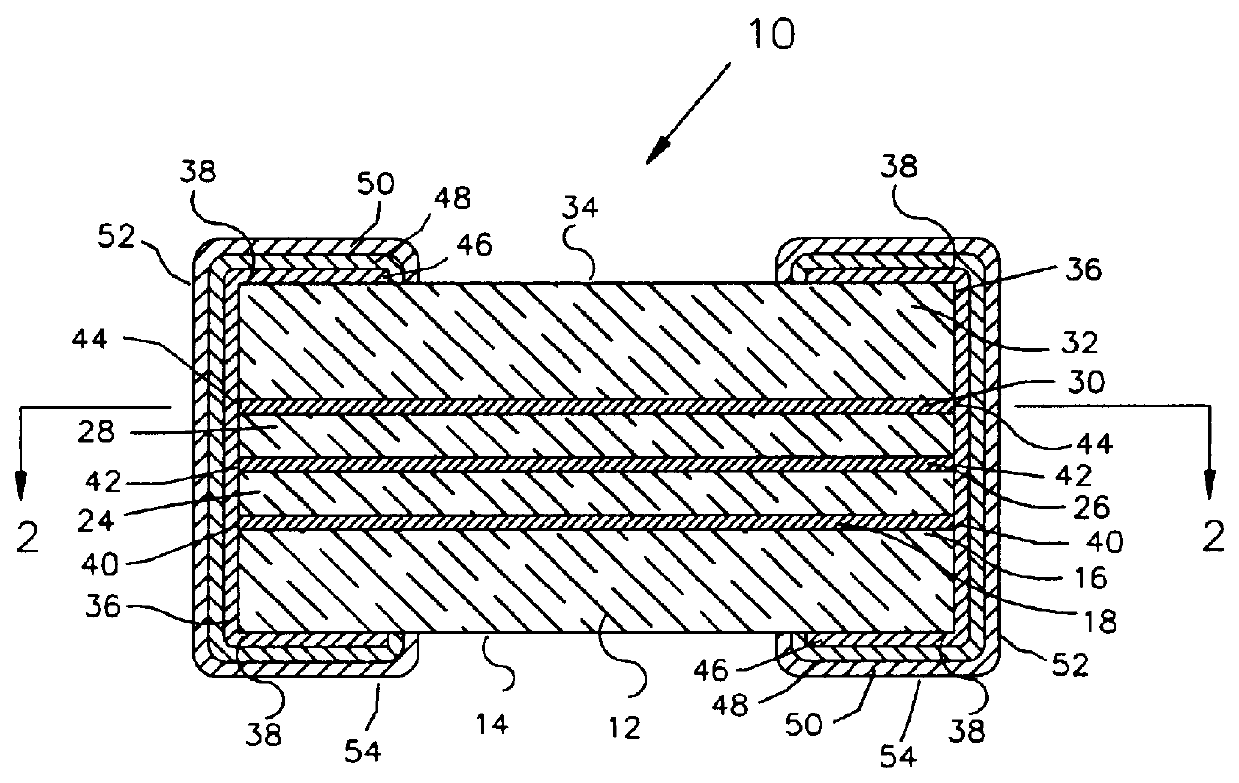

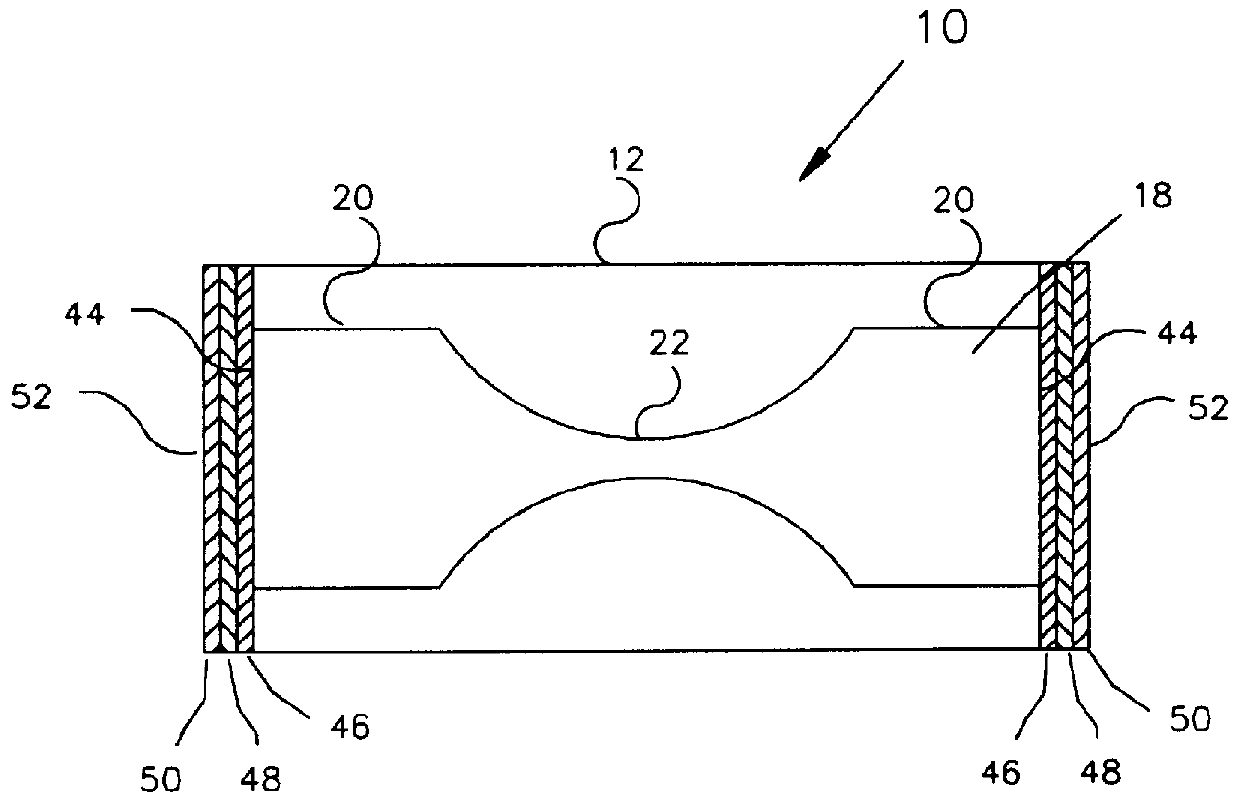

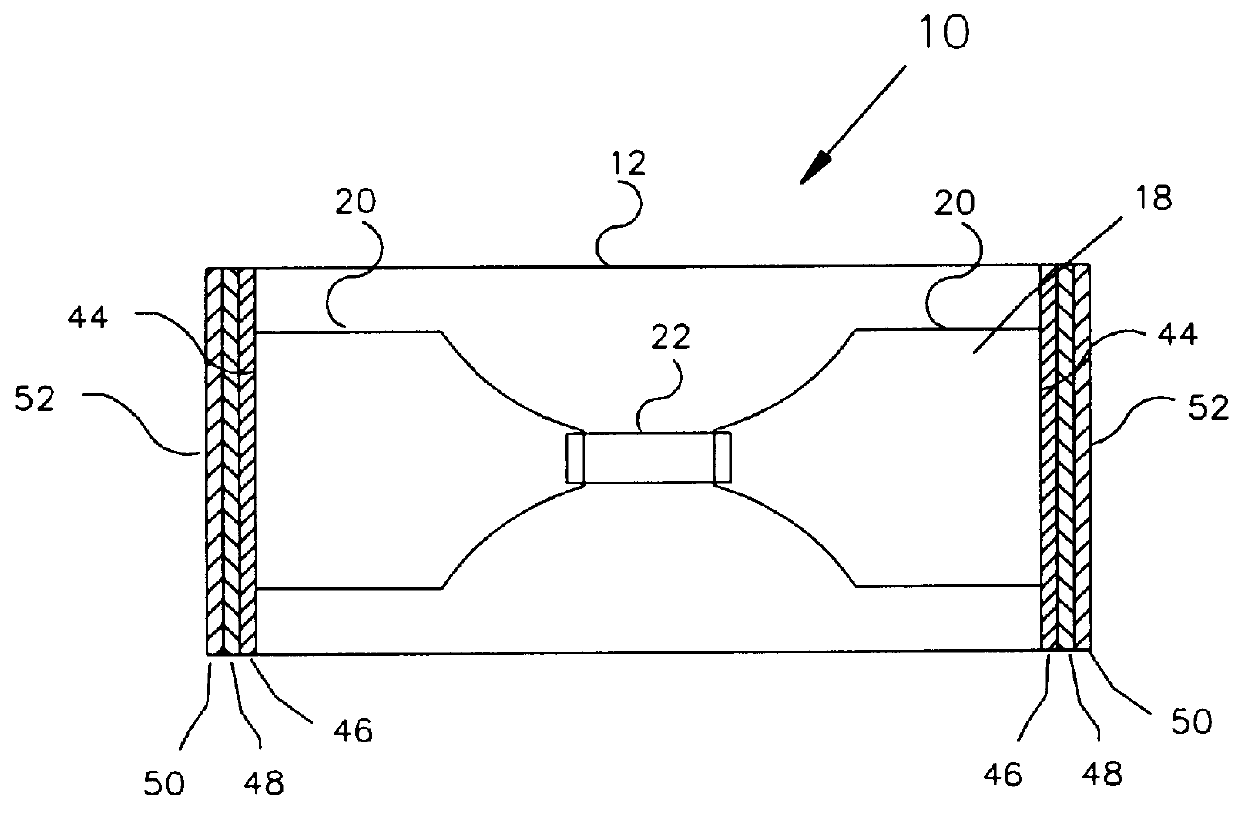

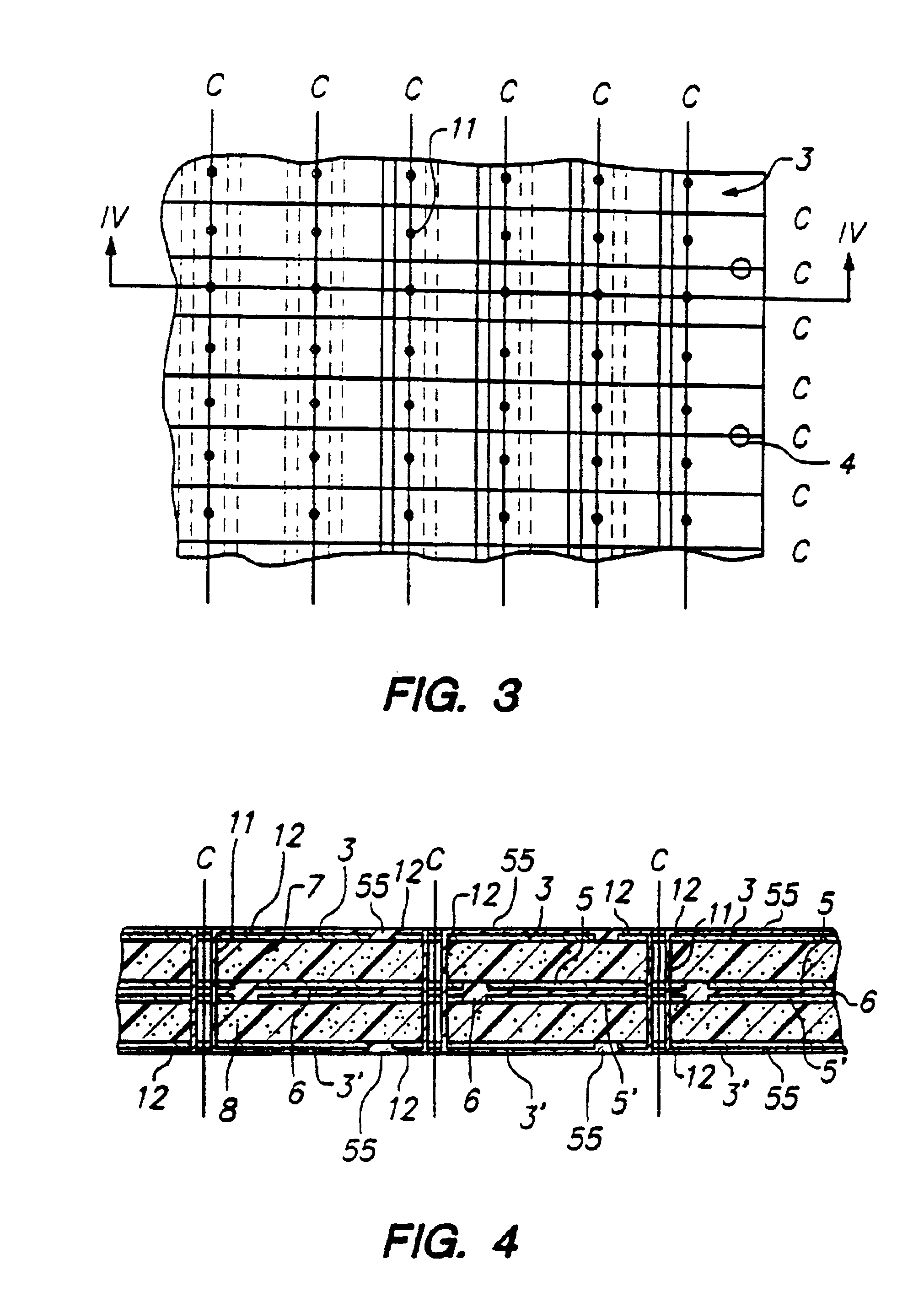

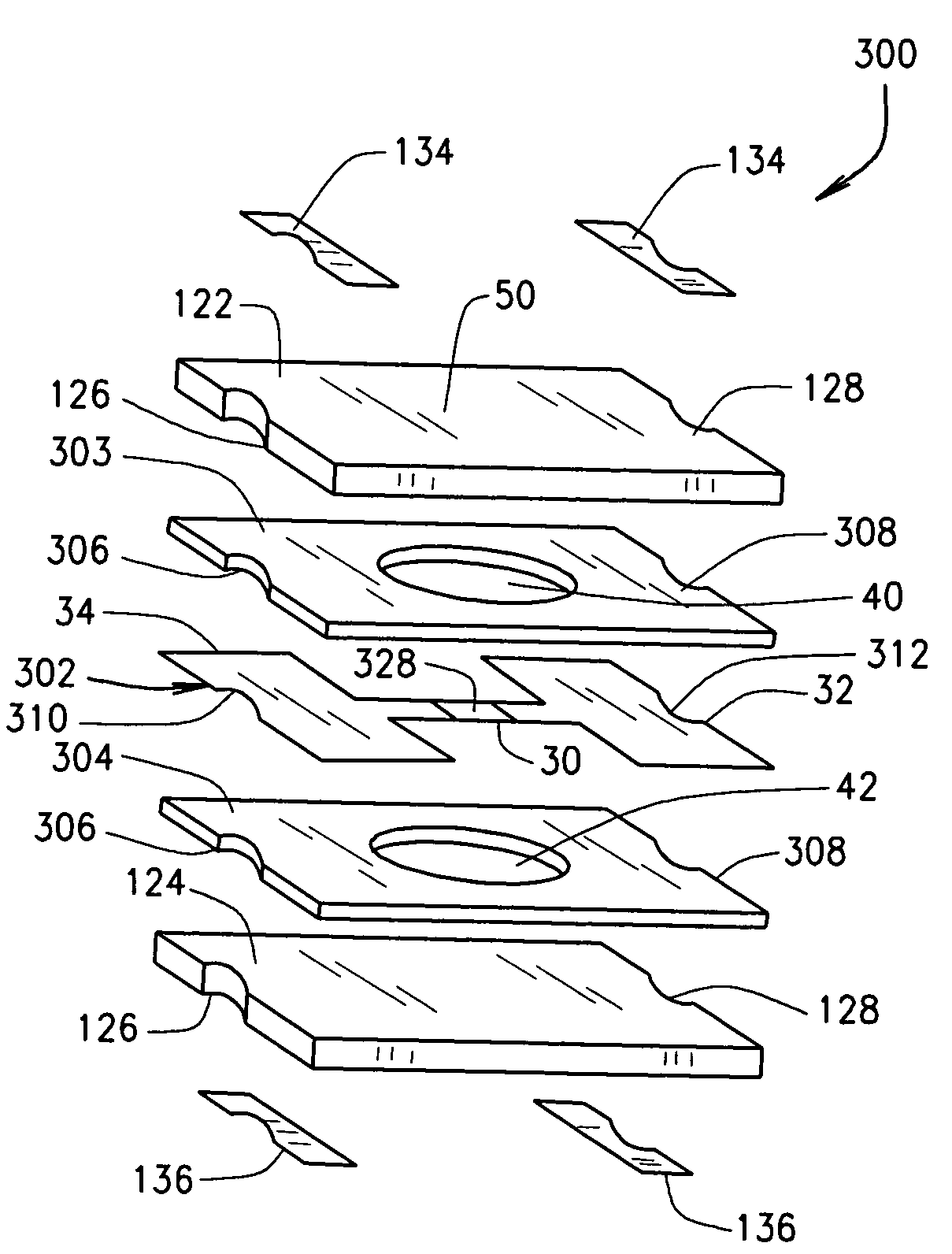

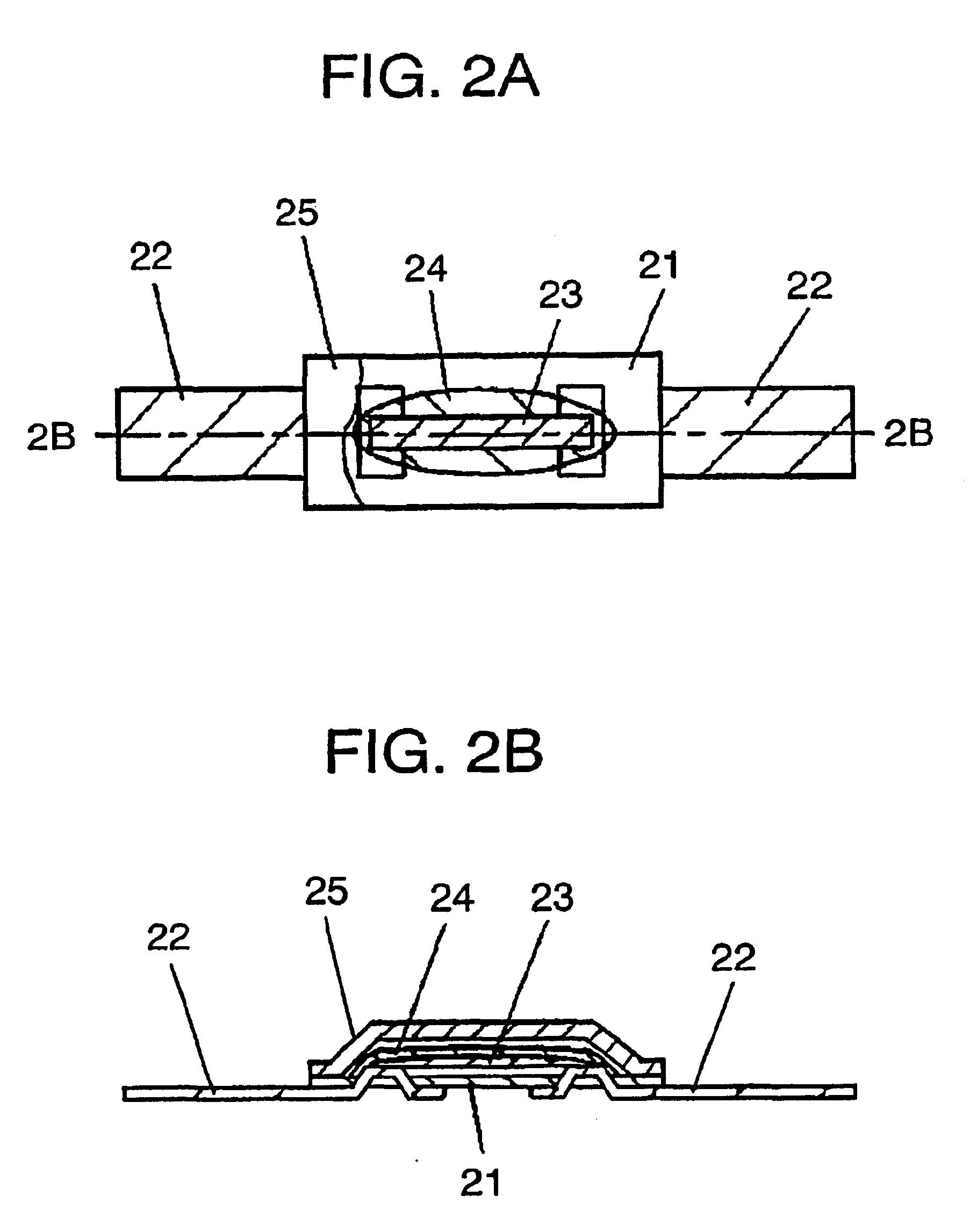

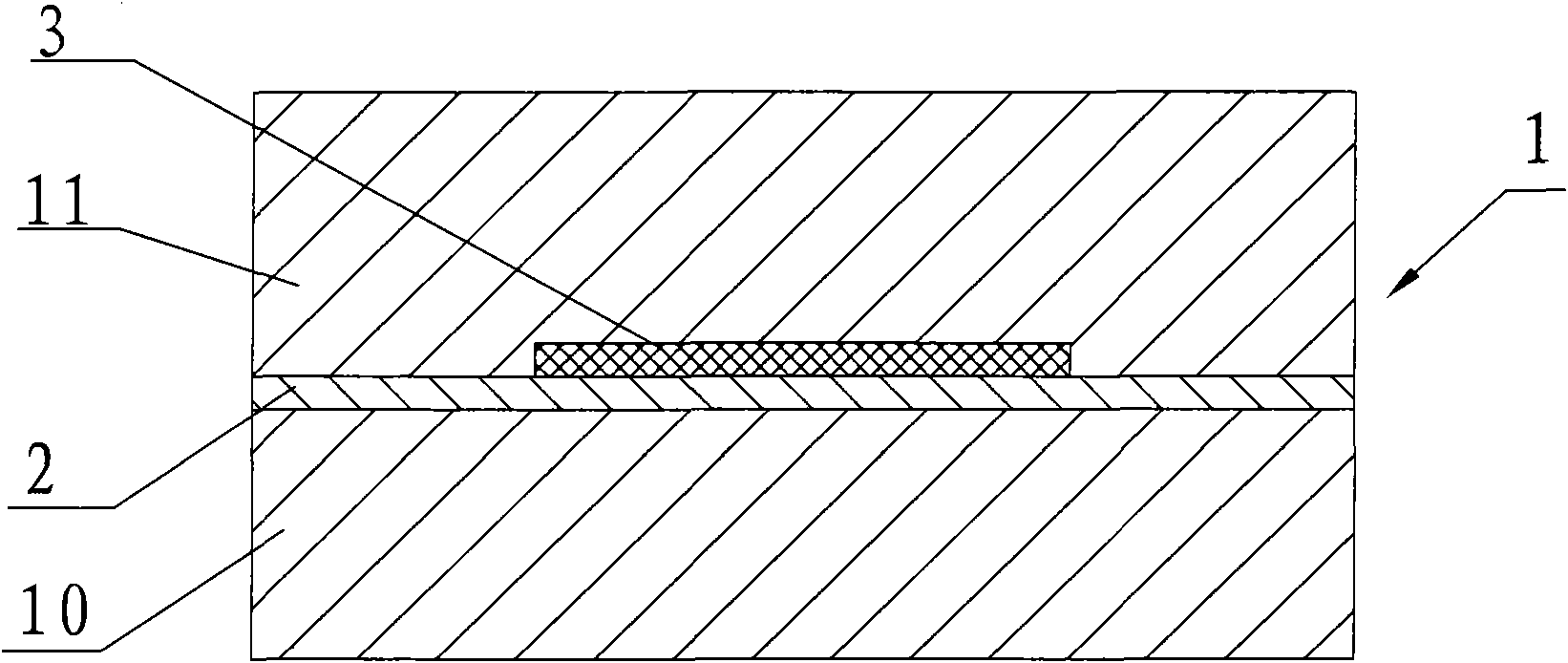

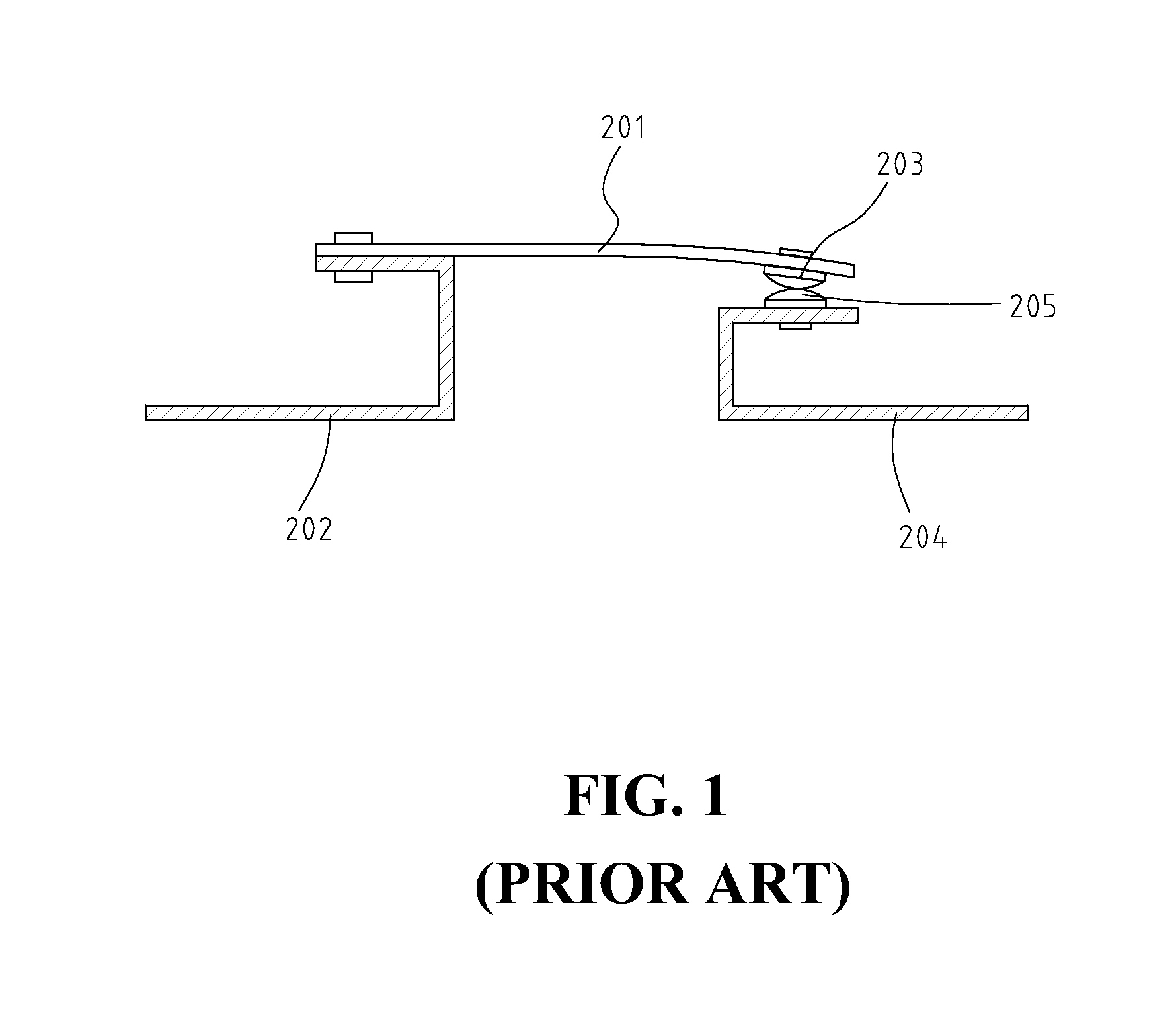

Low resistance polymer matrix fuse apparatus and method

InactiveUS20050141164A1Fuse device manufactureSemiconductor/solid-state device detailsContact padInsulation layer

A low resistance fuse apparatus and methods of manufacture includes a first intermediate insulation layer, a second intermediate insulation layer, and a free standing fuse element layer independently formed and fabricated from each of the first and second intermediate insulation layers, The fuse element layer includes first and second contact pads and a fusible link extending therebetween. The first and second intermediate insulation layers extend on opposite sides of the free standing fuse element layer and are laminated together with the fuse element layer therebetween.

Owner:EATON INTELLIGENT POWER LIMITED

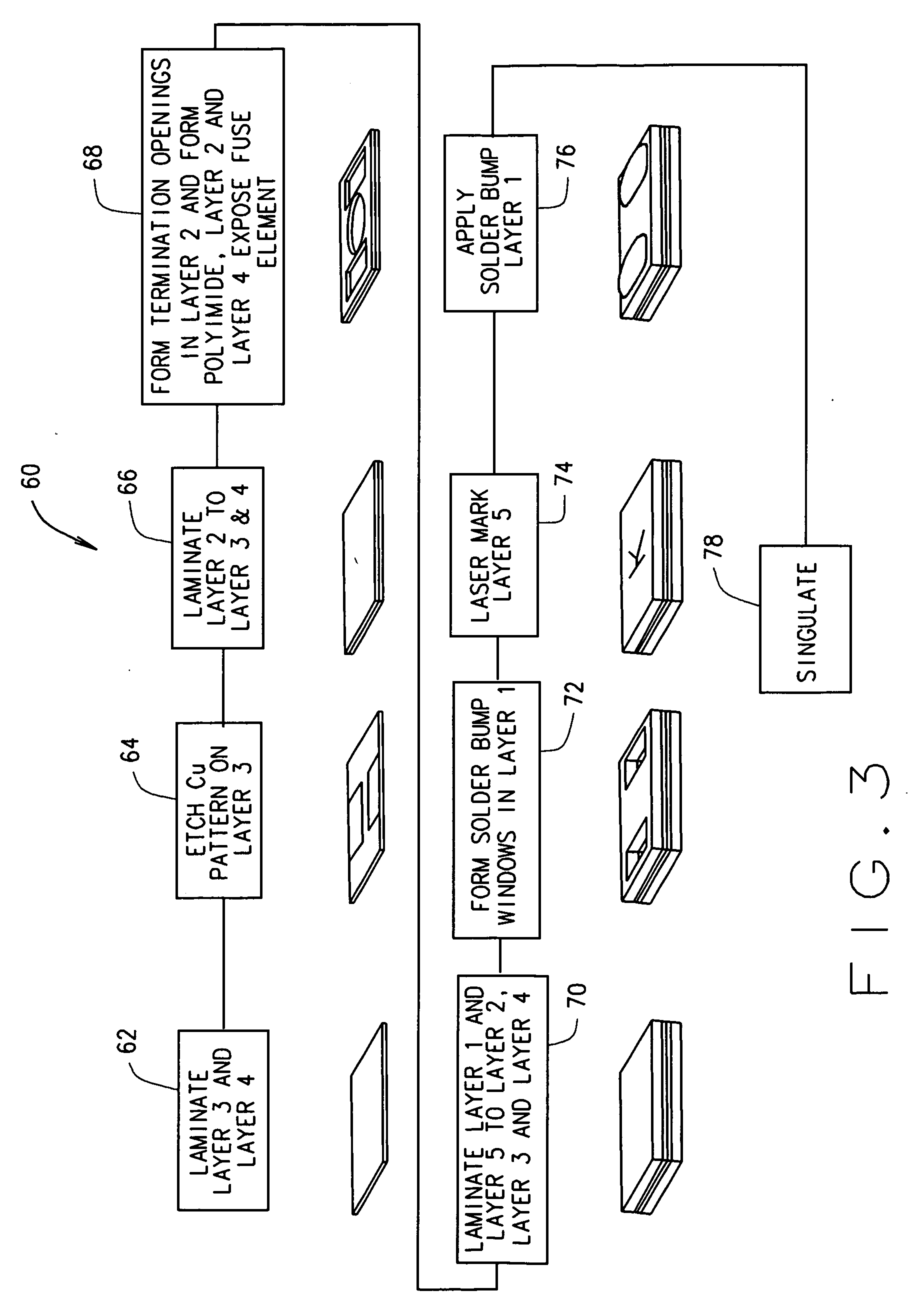

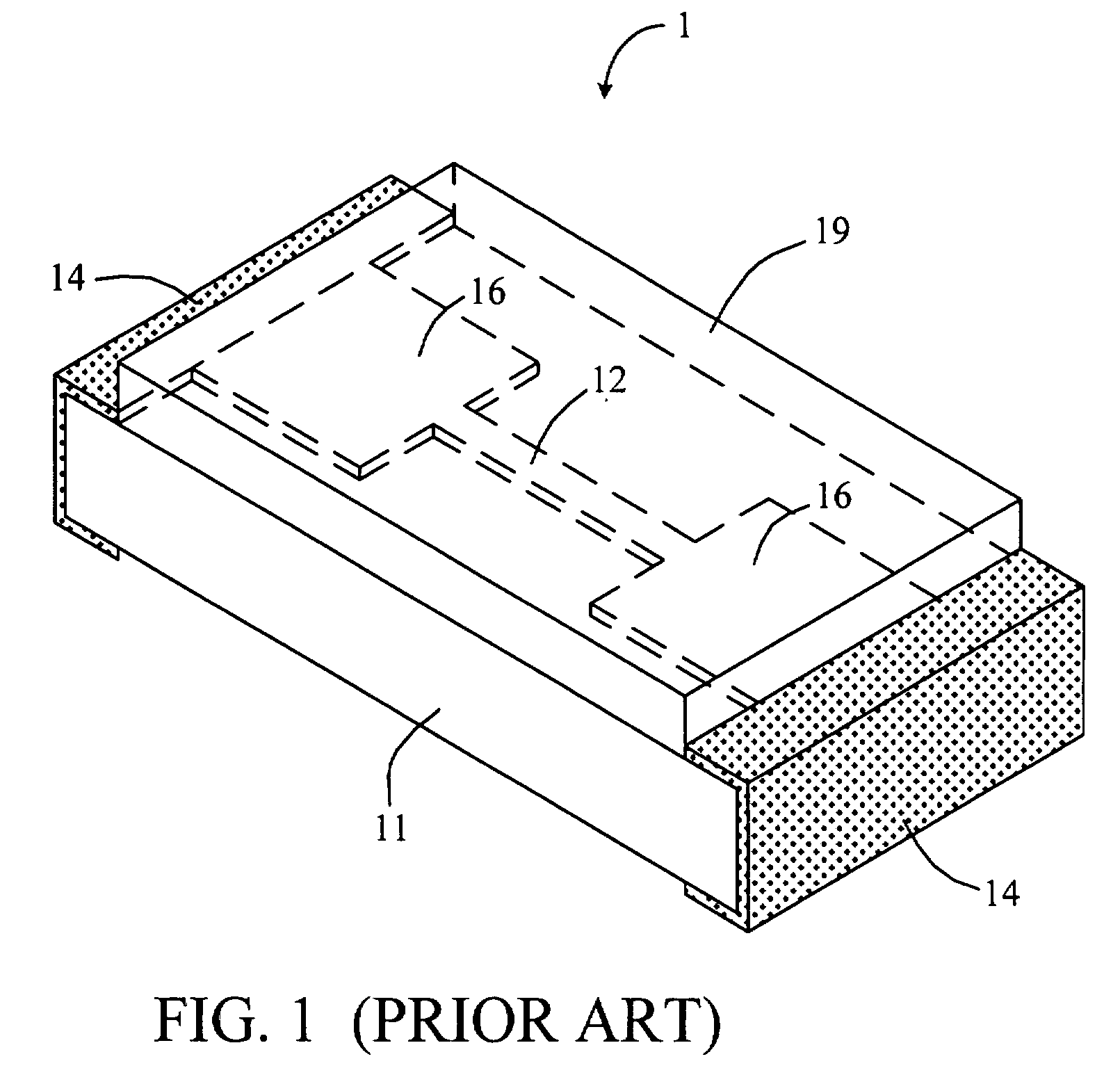

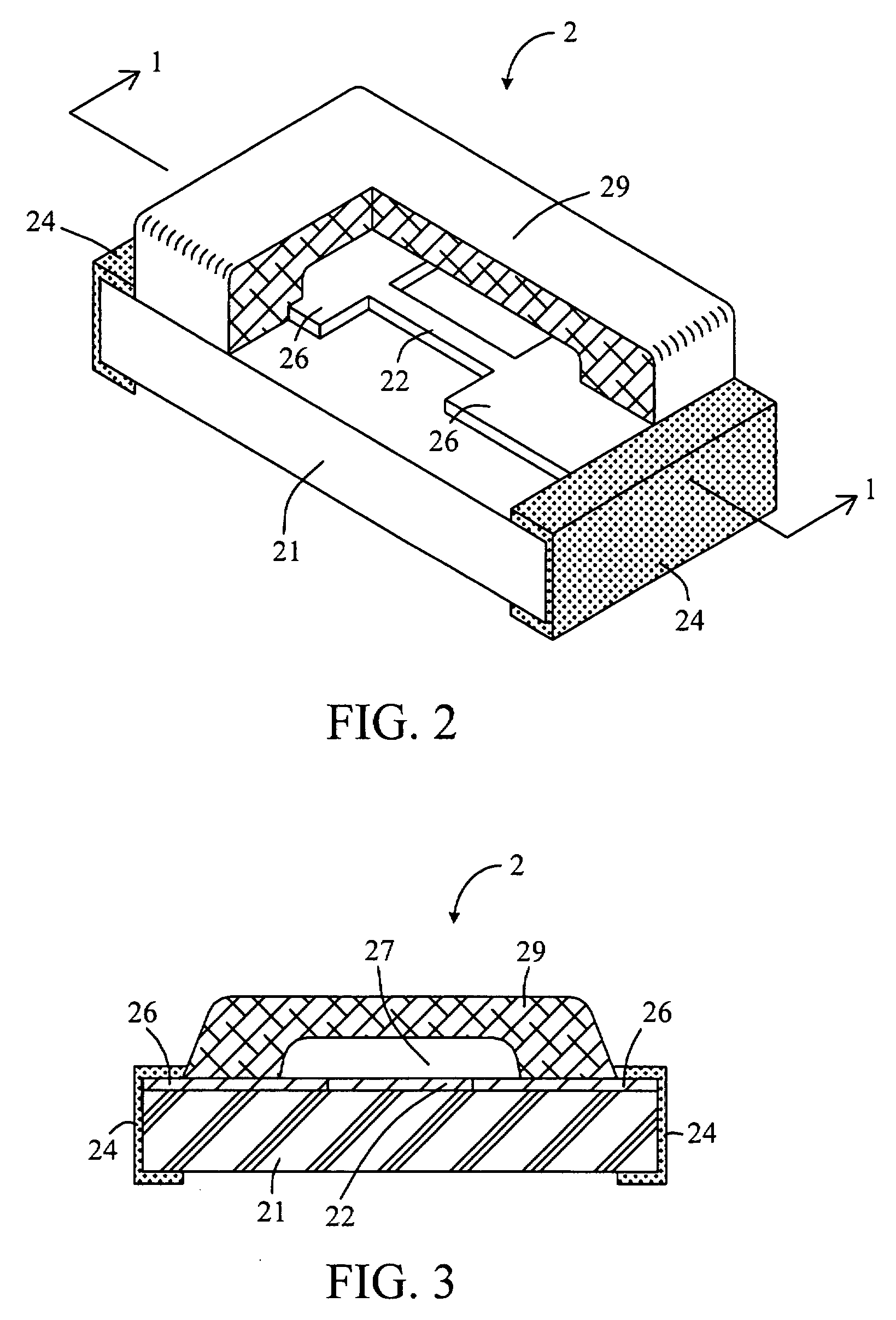

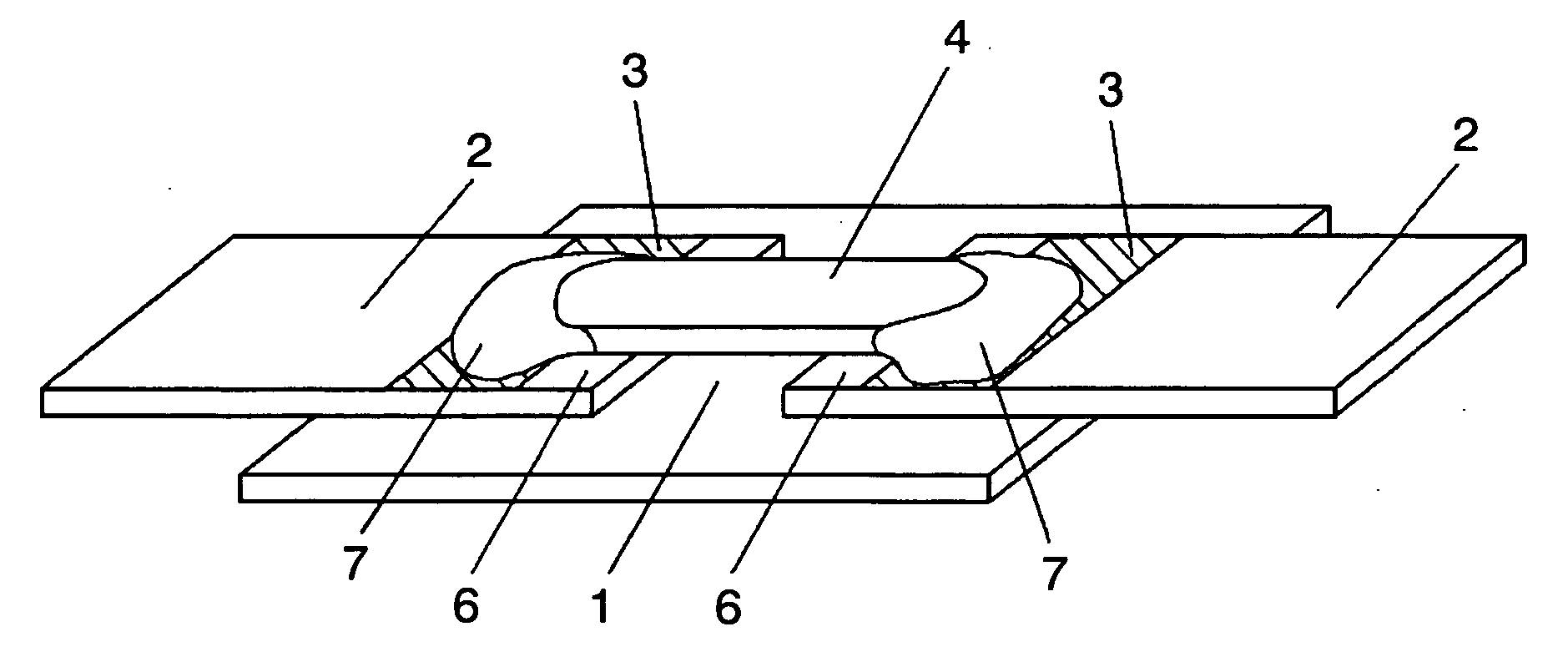

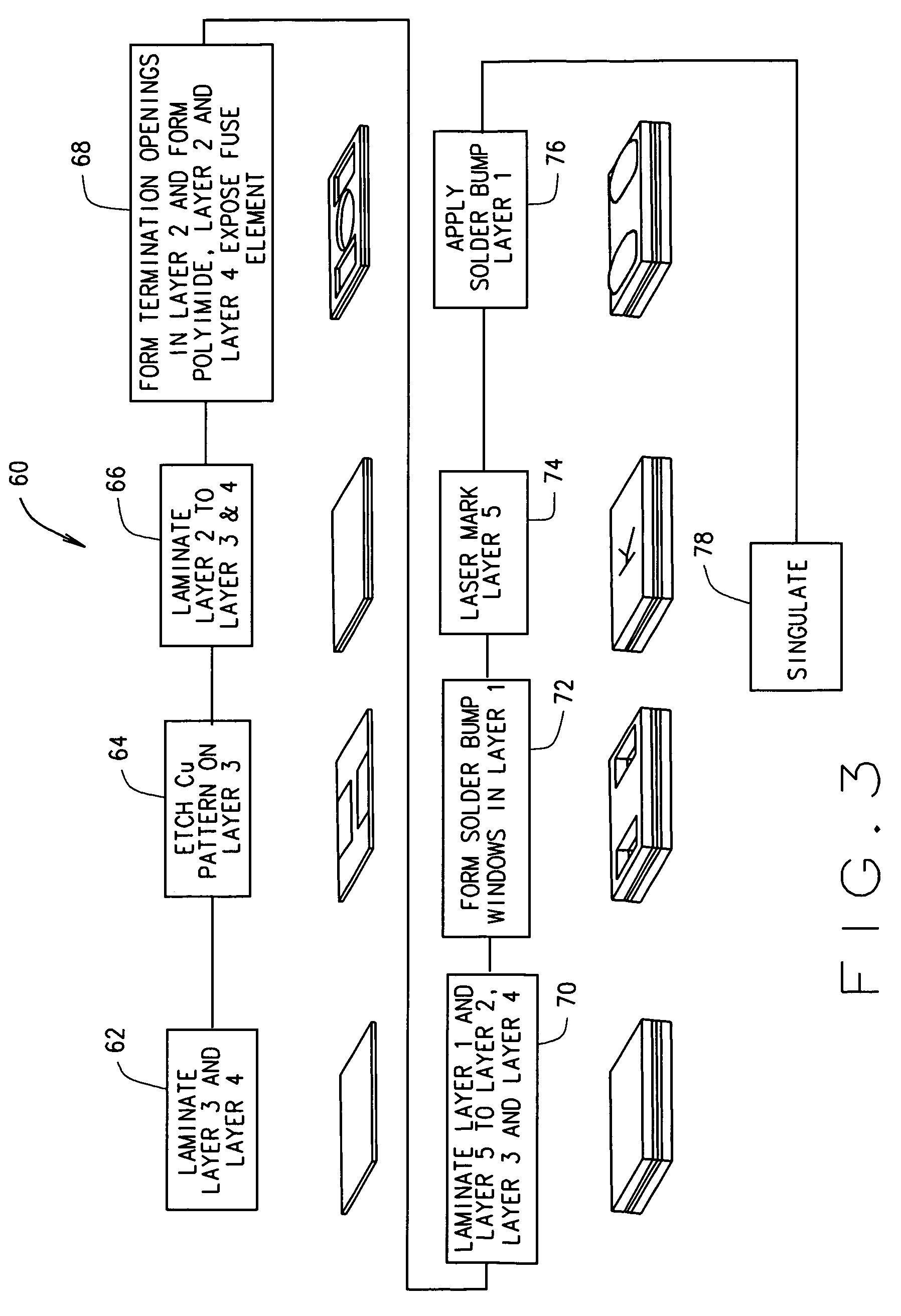

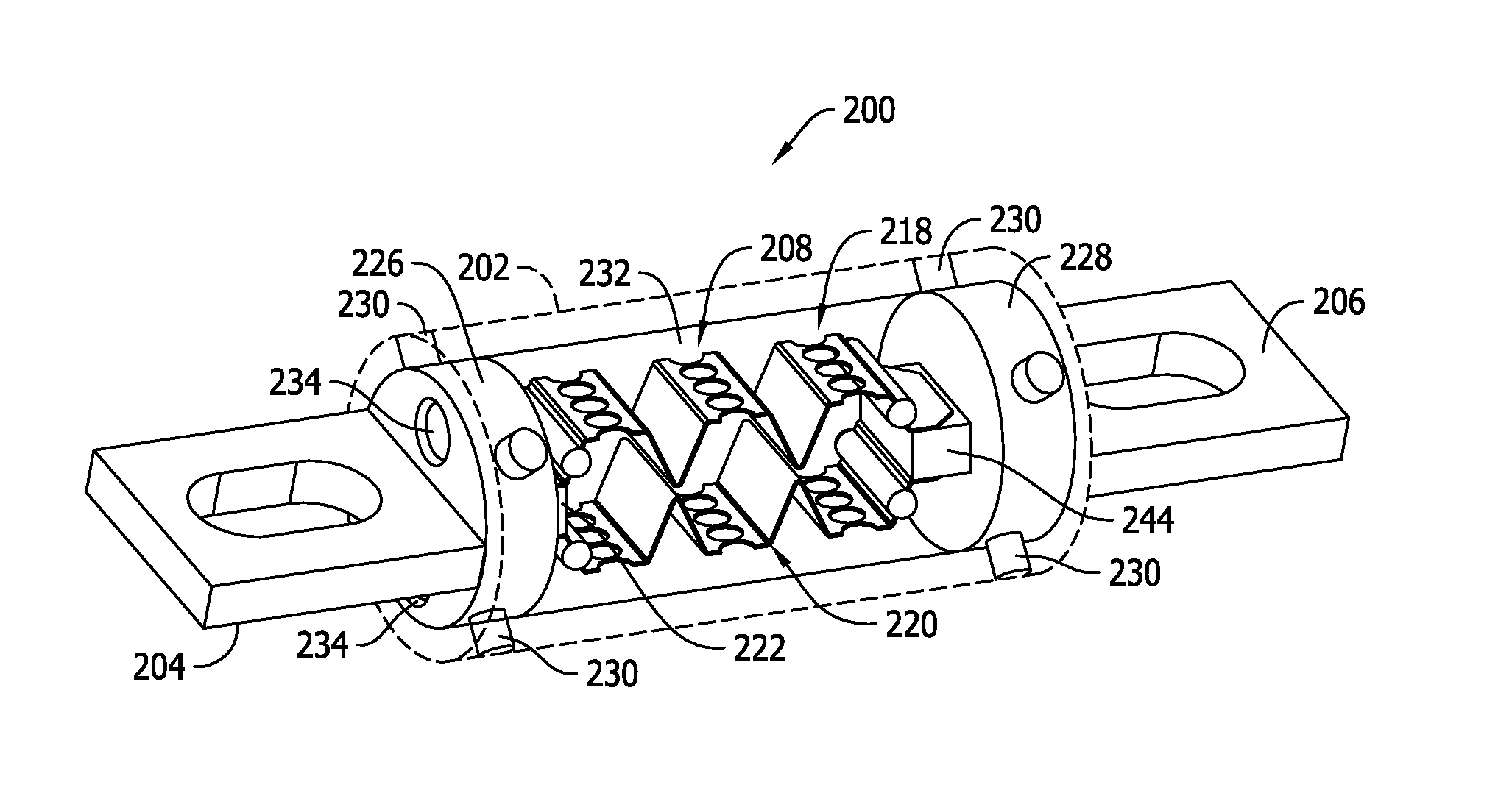

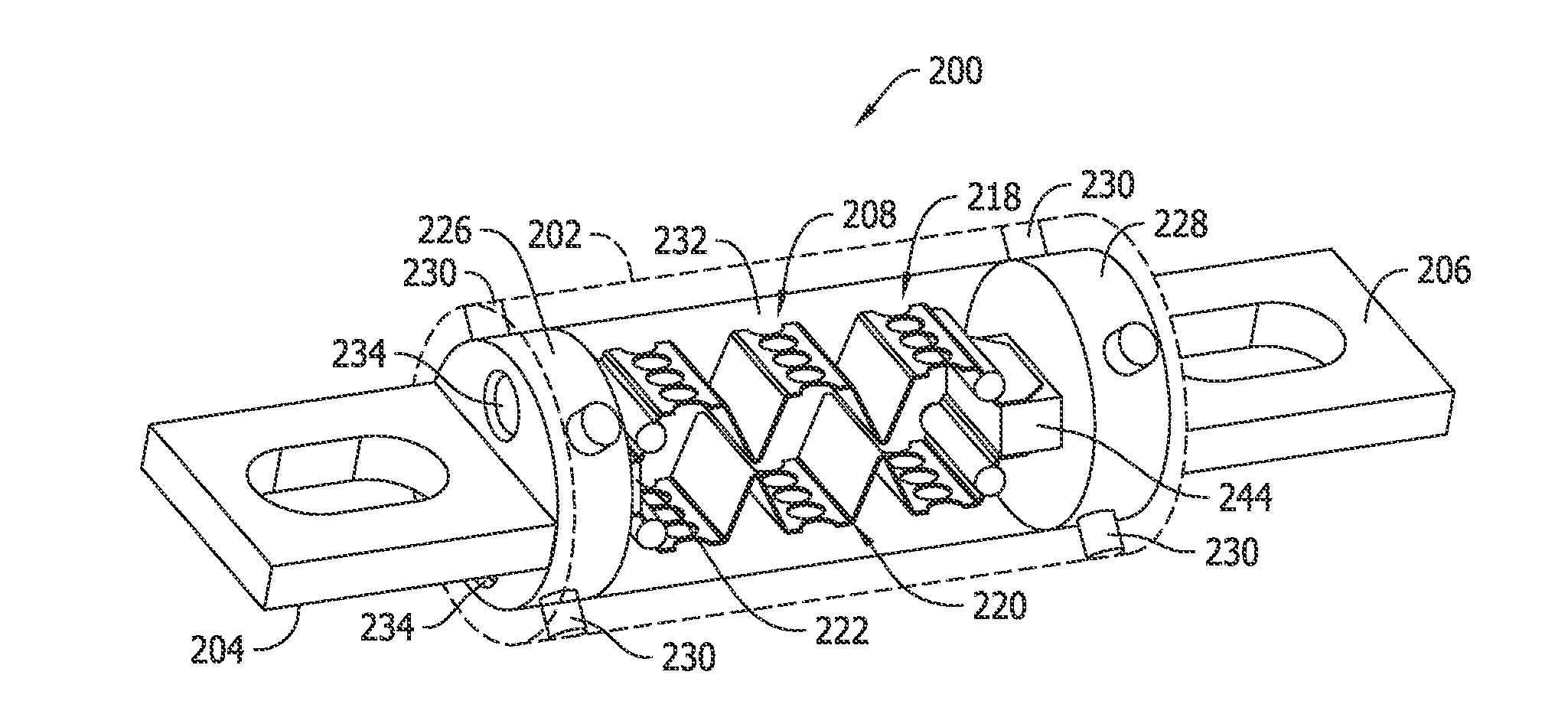

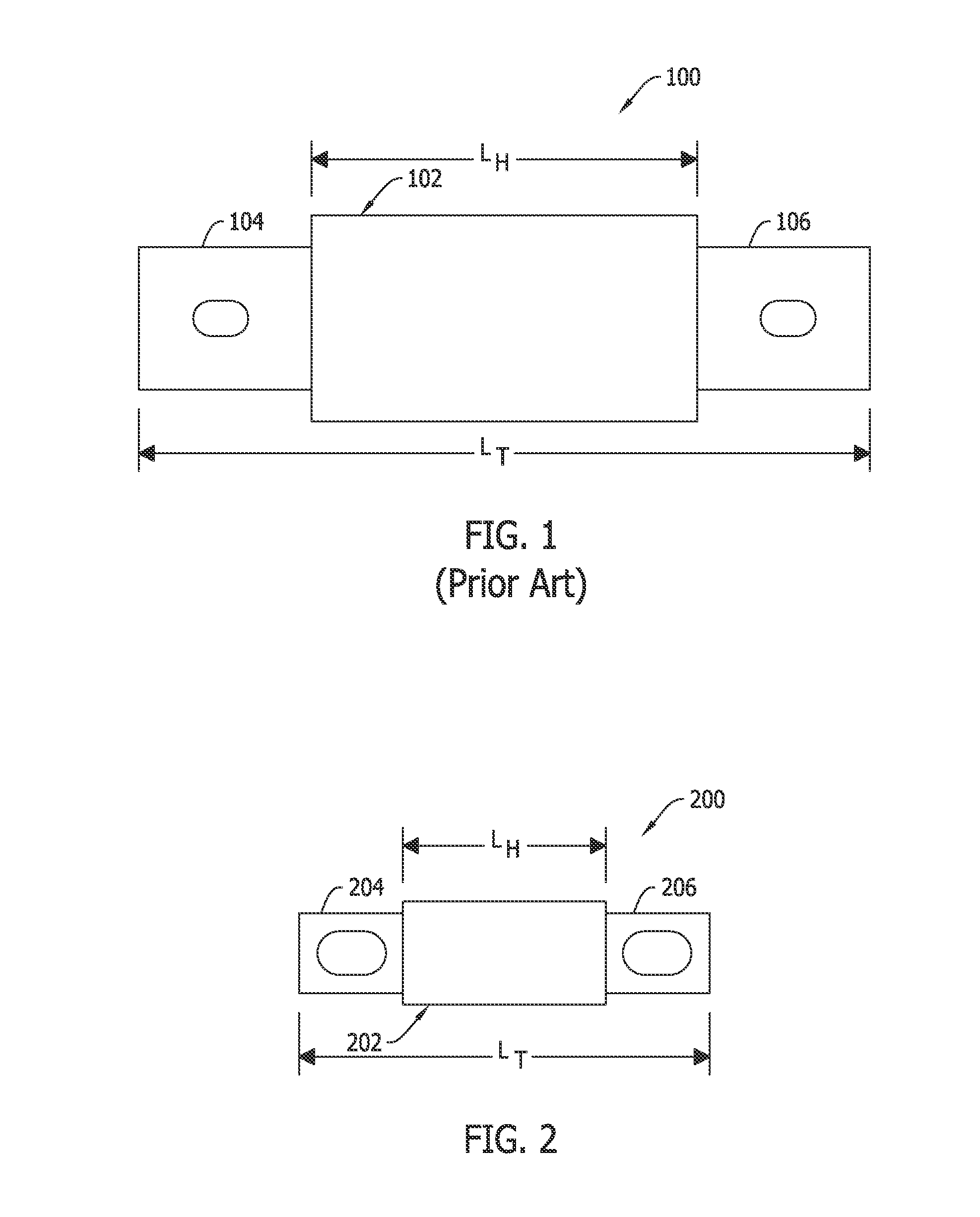

Multi-layer and multi-element monolithic surface mount fuse and method of making the same

InactiveUS6034589AHigh mechanical strengthImprove cycle performanceFuse device manufactureThermal switch detailsSurface mountingEngineering

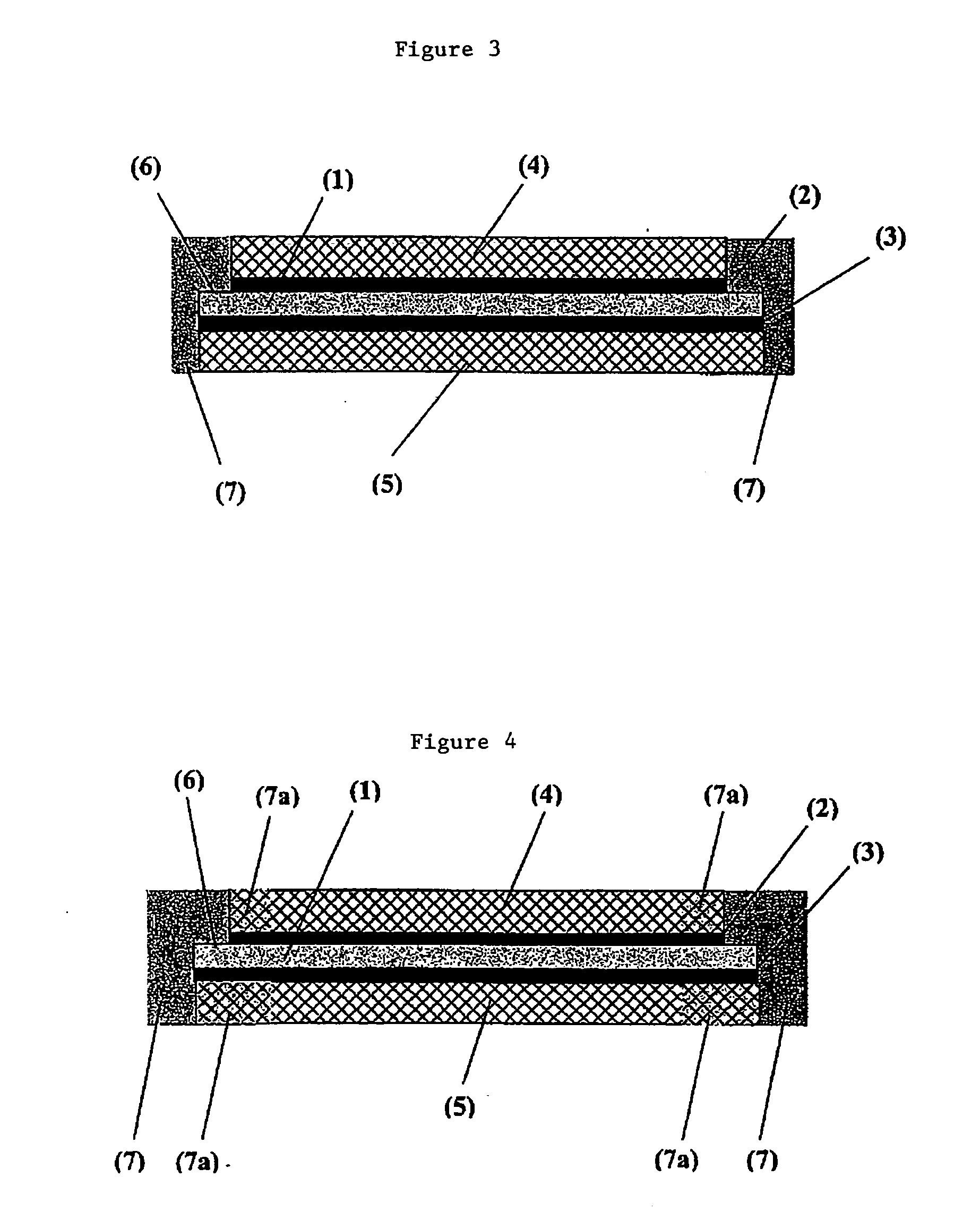

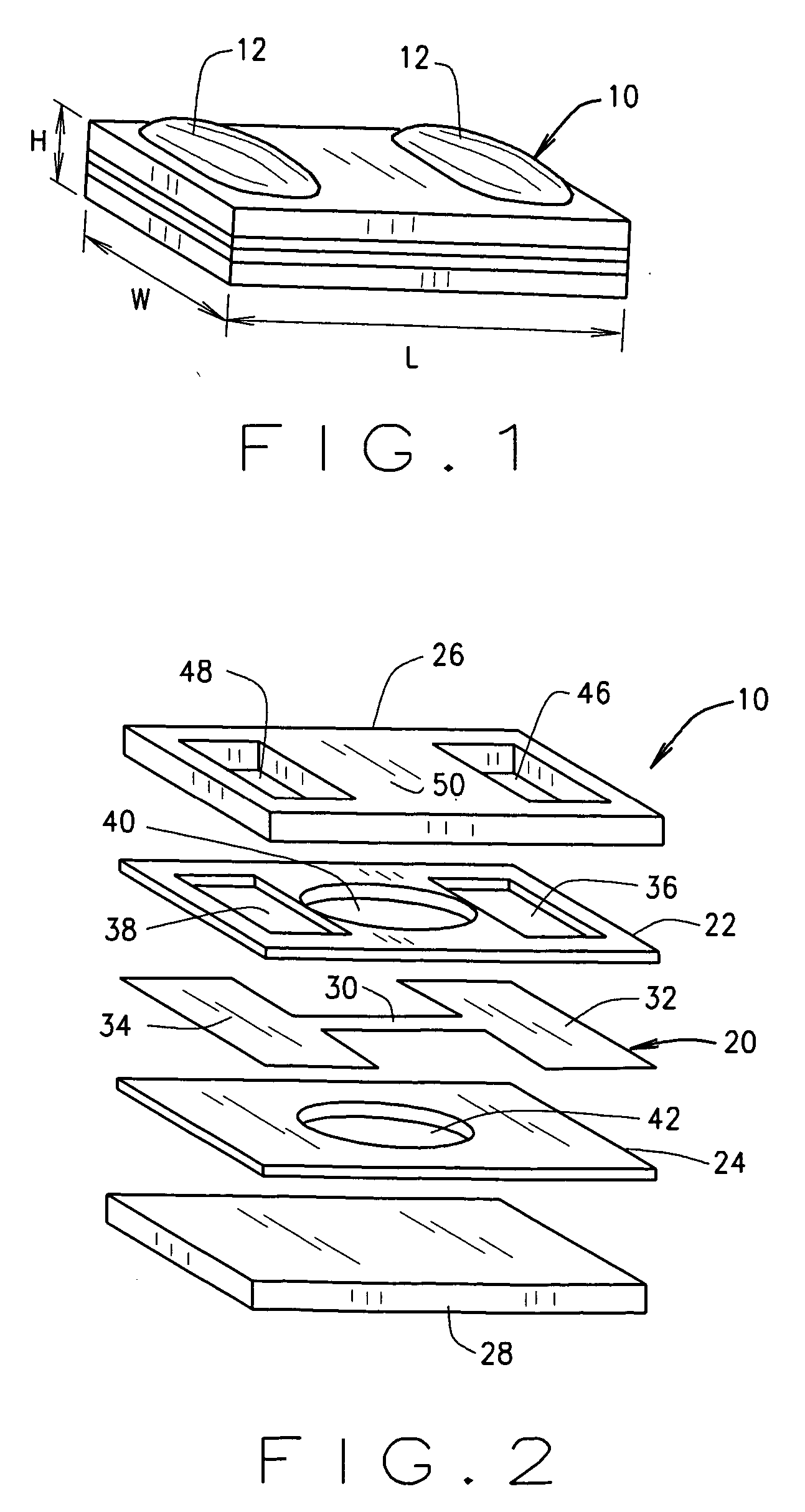

A surface mount fuse includes a plurality of substrate / arc suppressive layers, a plurality of fusible elements positioned between the substrate / arc suppressive layers and terminations connected to the ends of the fusible elements, such that the fusible elements are electrically connected in parallel. The surface mount fuse has greater amperage and voltage ratings than similarly sized conventional surface mount fuses. Additionally, the surface mount fuse has increased interrupt breaking capacity and superior mechanical properties.

Owner:AEM COMPONENTS

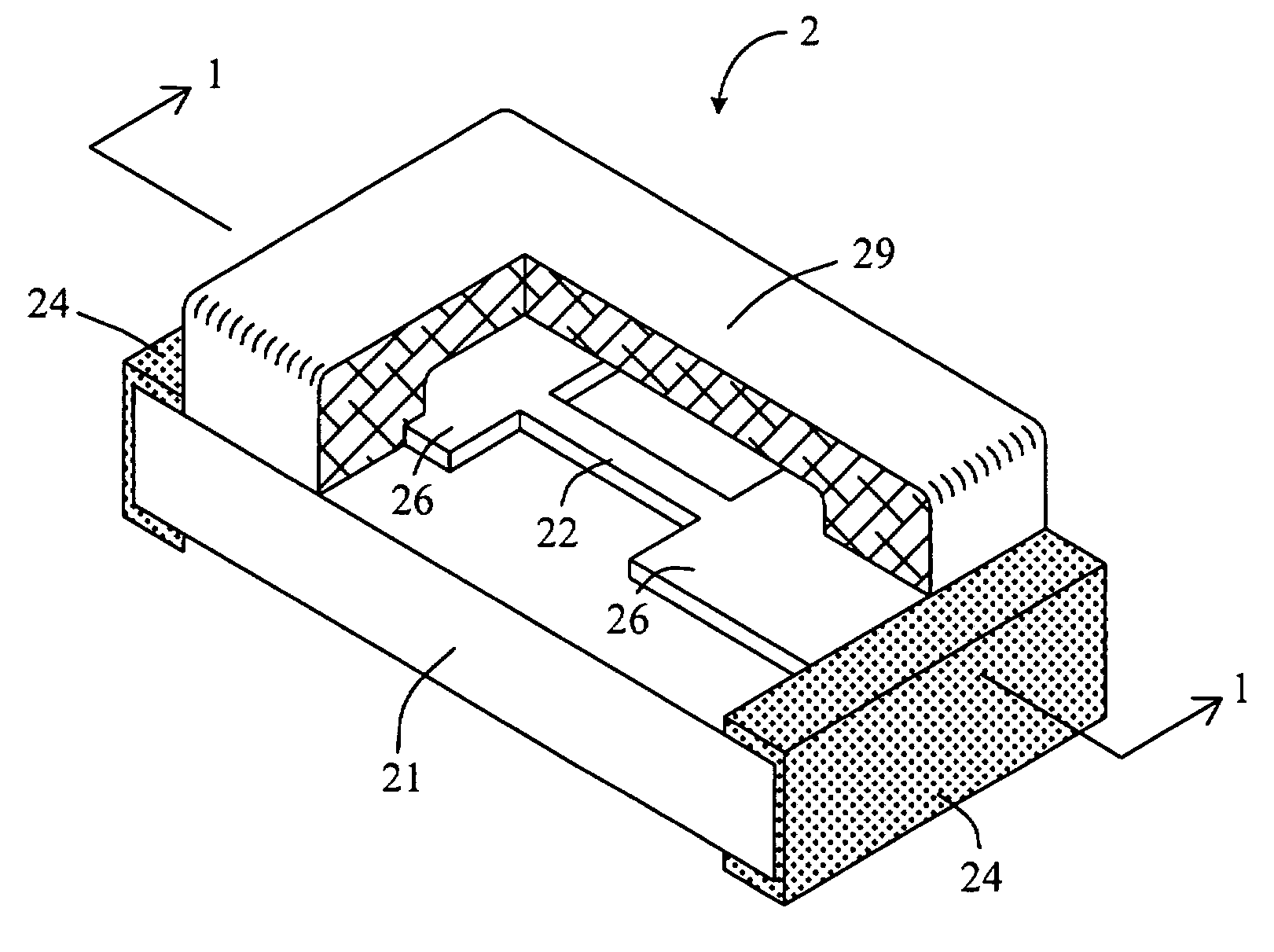

Chip-type fuse and method of manufacturing the same

InactiveUS20080191832A1Ensure long-term reliabilityLow costFuse device manufactureElectrical and Electronics engineeringFuse cutout

A chip-type fuse is based on an electrically insulating substrate and fusible element is disposed thereon. A protective layer is formed over the fusible element and adheres to the substrate around the fusible element so as to define a cavity between the protective layer and the fusible element. The cavity isolates the protective layer from direct contact with the fusible element so that the protective layer will not be melted or breached by the excessive heat and arc generated by the fusible element under overload condition. Further, the cavity can be hermetically sealed to enclose a gas of pressure less than one atmosphere. A thermally insulating layer and an arc suppressive layer may be incorporated to reduce the response time and arc intensity of the chip-type fuse respectively under overload condition. The method of manufacturing chip-type fuse, particularly the method of forming fusible element and cavity, is described too.

Owner:BESDON TECH CORP

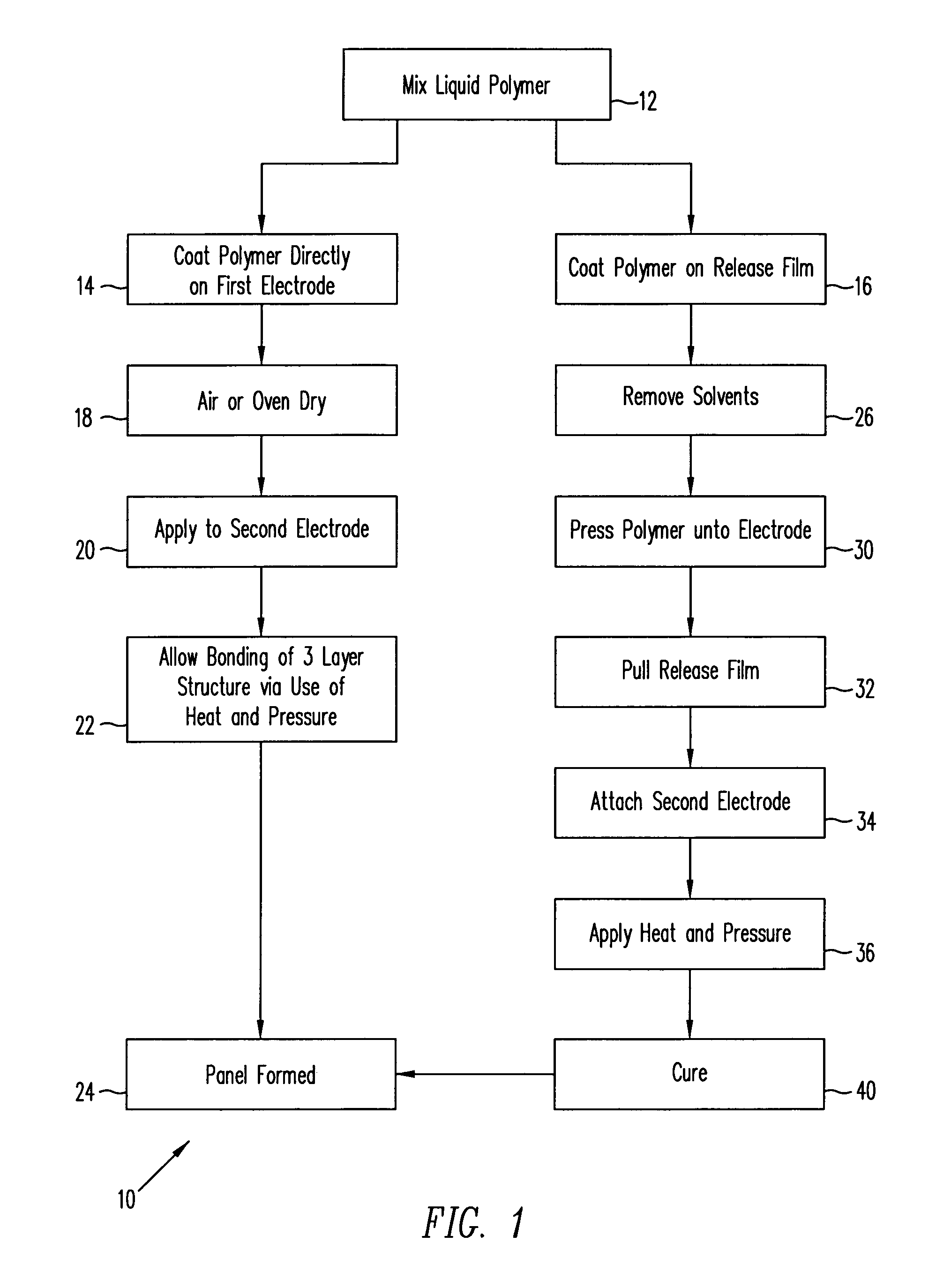

Method of manufacturing devices to protect election components

InactiveUS6981319B2Easy to customizeMake fastFuse device manufactureInsulating layers/substrates workingManufacturing technologyElectronic component

Devices capable of protecting electronic components during the occurrence of a disturbance event using printed circuit board manufacturing techniques. A three (3) layer structure is formed comprising a polymer-based formulation sandwiched between two electrode layers. The devices can be manufactured in panel form providing high quantities of devices which can be removed from the panel and applied directly to the component to be protected. Desired patterns can be formed on either one of the electrode layers by photo-etch techniques thereby providing a process that can be tailored to a large number of applications.

Owner:ELECTRONICS POLYMERS NEWCO

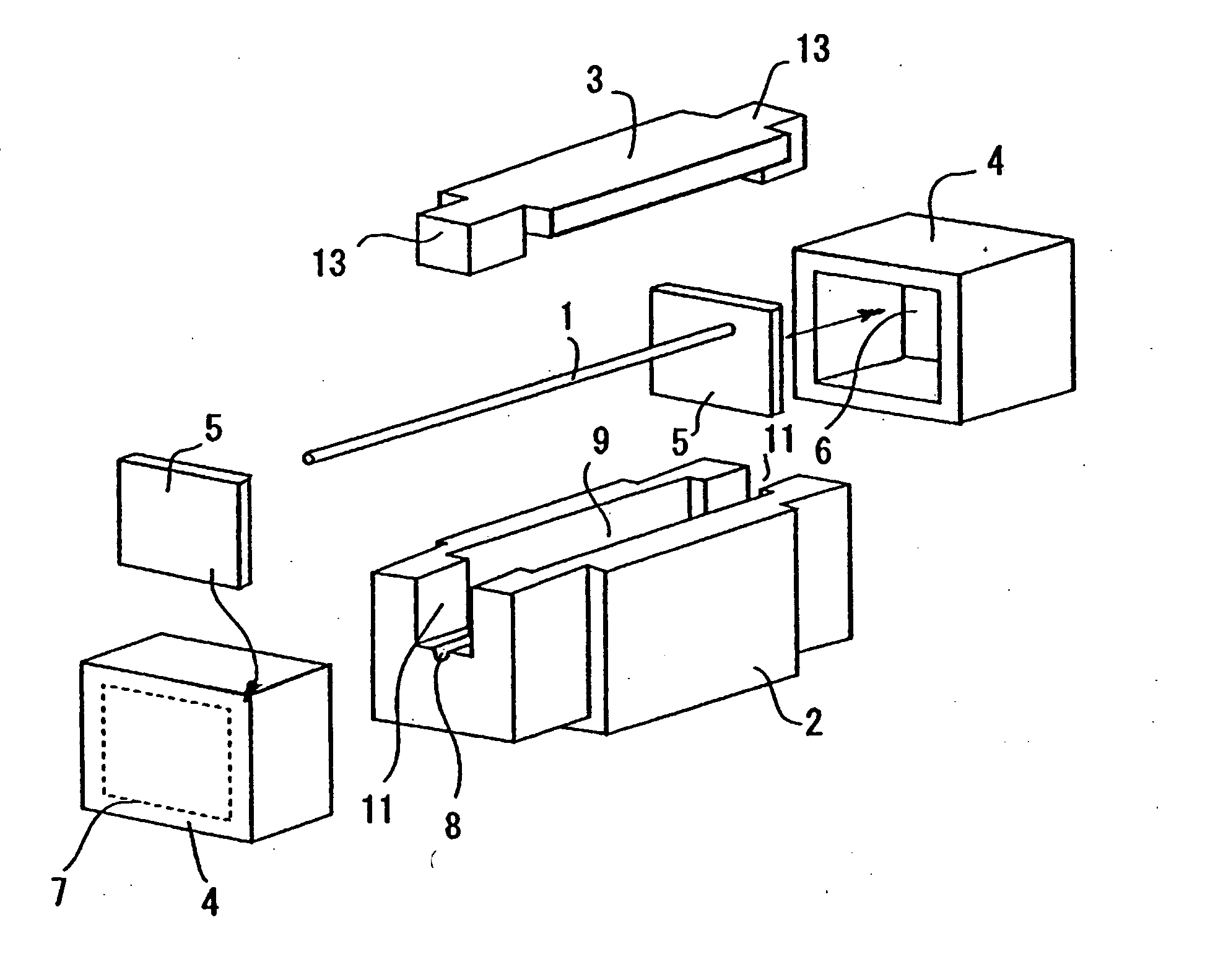

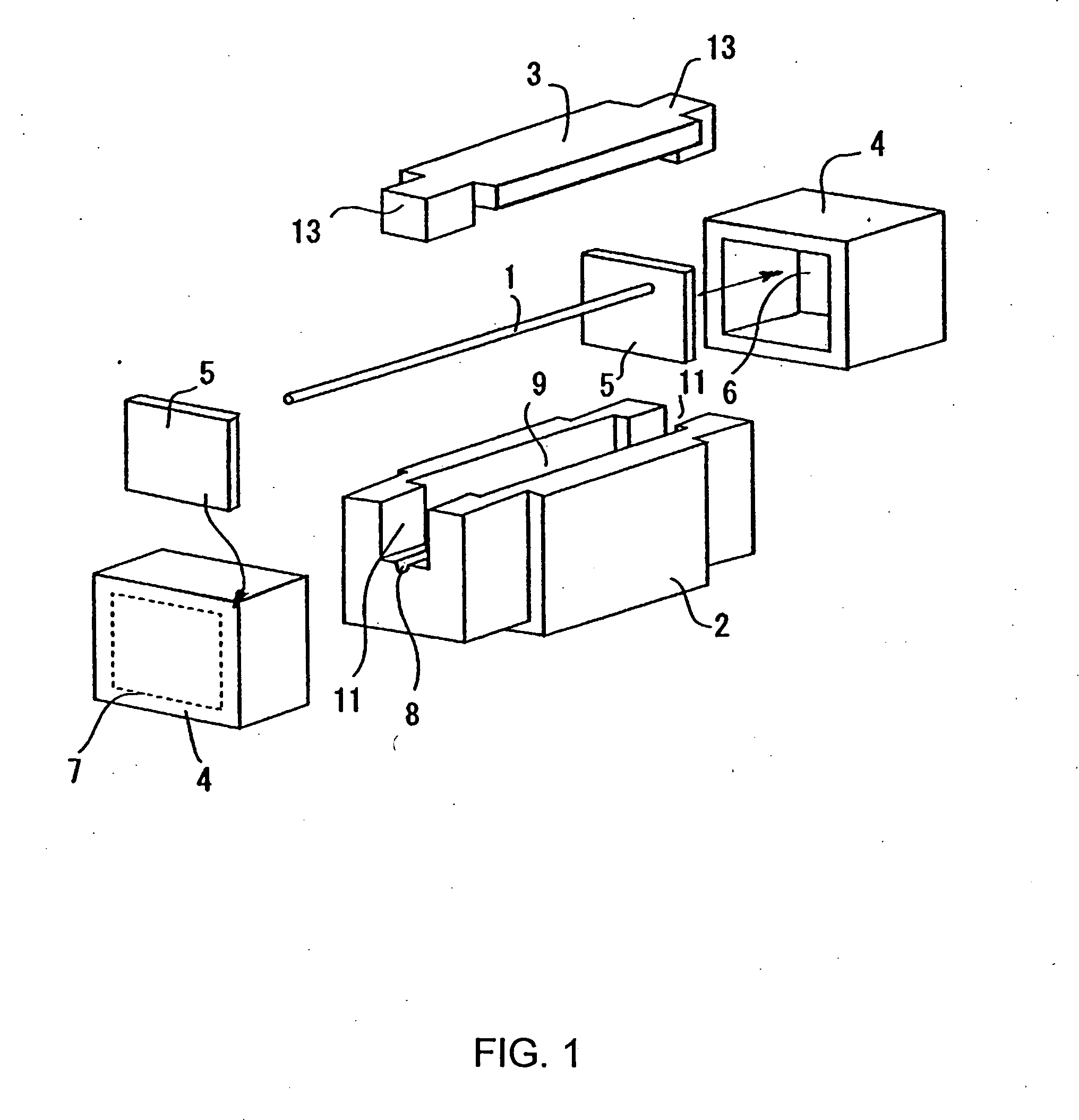

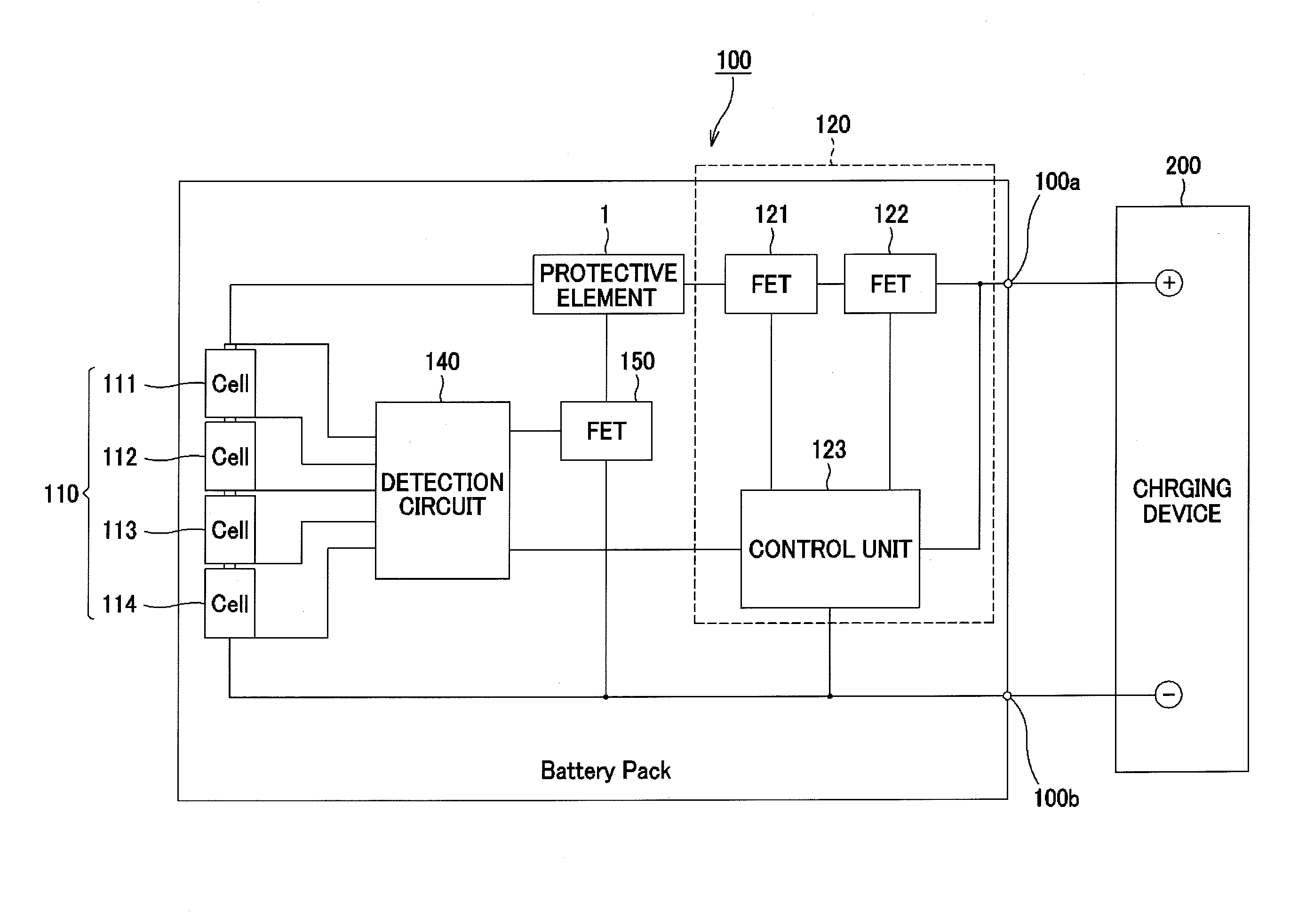

Fuse, battery pack using the fuse, and method of manufacturing the fuse

InactiveUS20050001710A1Fuse device manufactureHeating/cooling contact switchesEngineeringBattery pack

A fuse has a pair of lead terminals disposed on a substrate, an intermediate layers for welding formed on the surface of at least one of the lead terminals, and a fuse element. The fuse element is welded to the pair of lead terminals through the intermediate layer so as to span the same. Further, the intermediate layer is formed on at least one of the lead terminals except a face thereof opposing each other. Owing to this configuration, after the fuse has melted down, the melted fuse element is prevented from being spread out into the space between the opposing faces of the lead terminals and insulation therebetween is secured.

Owner:PANASONIC CORP

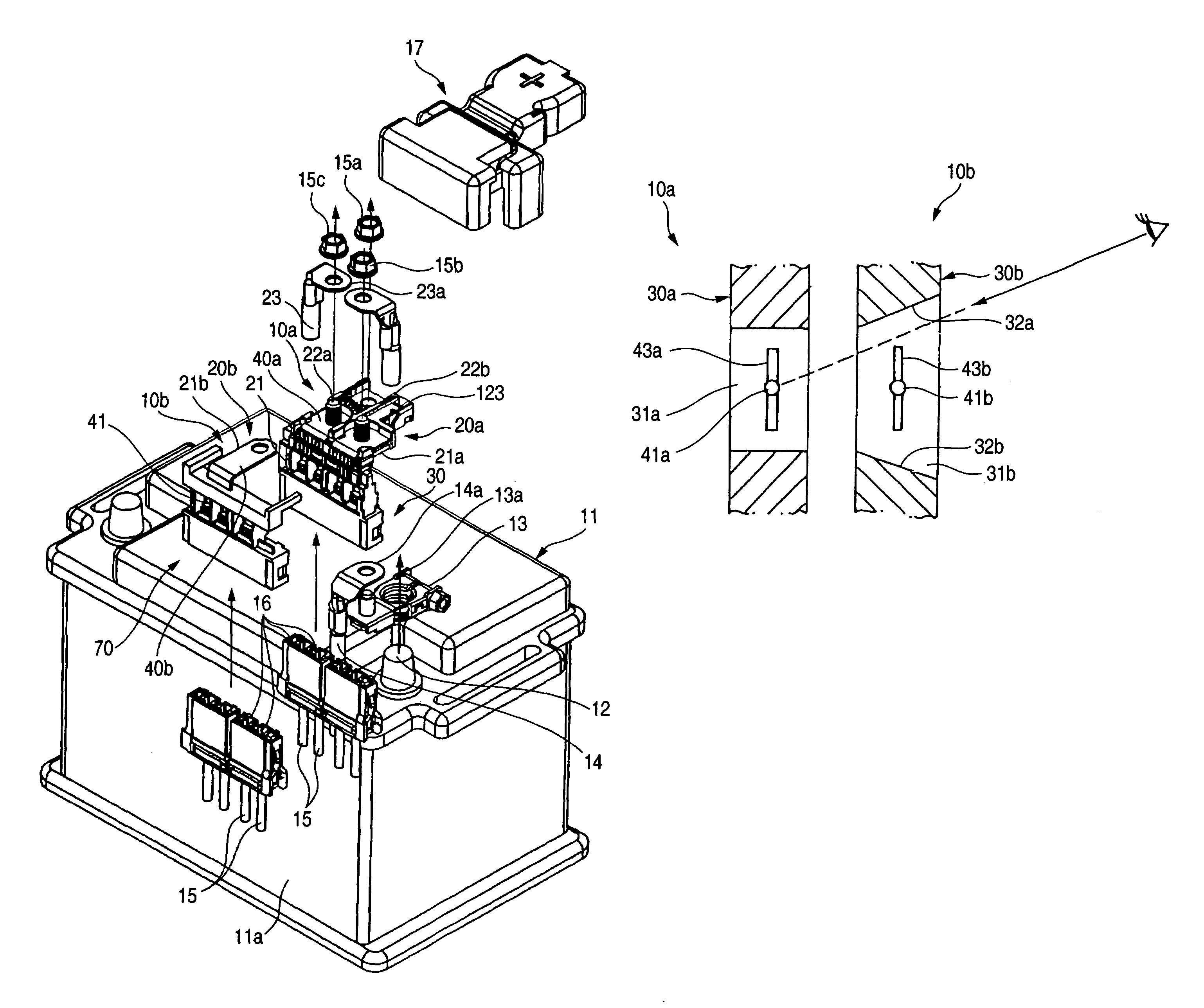

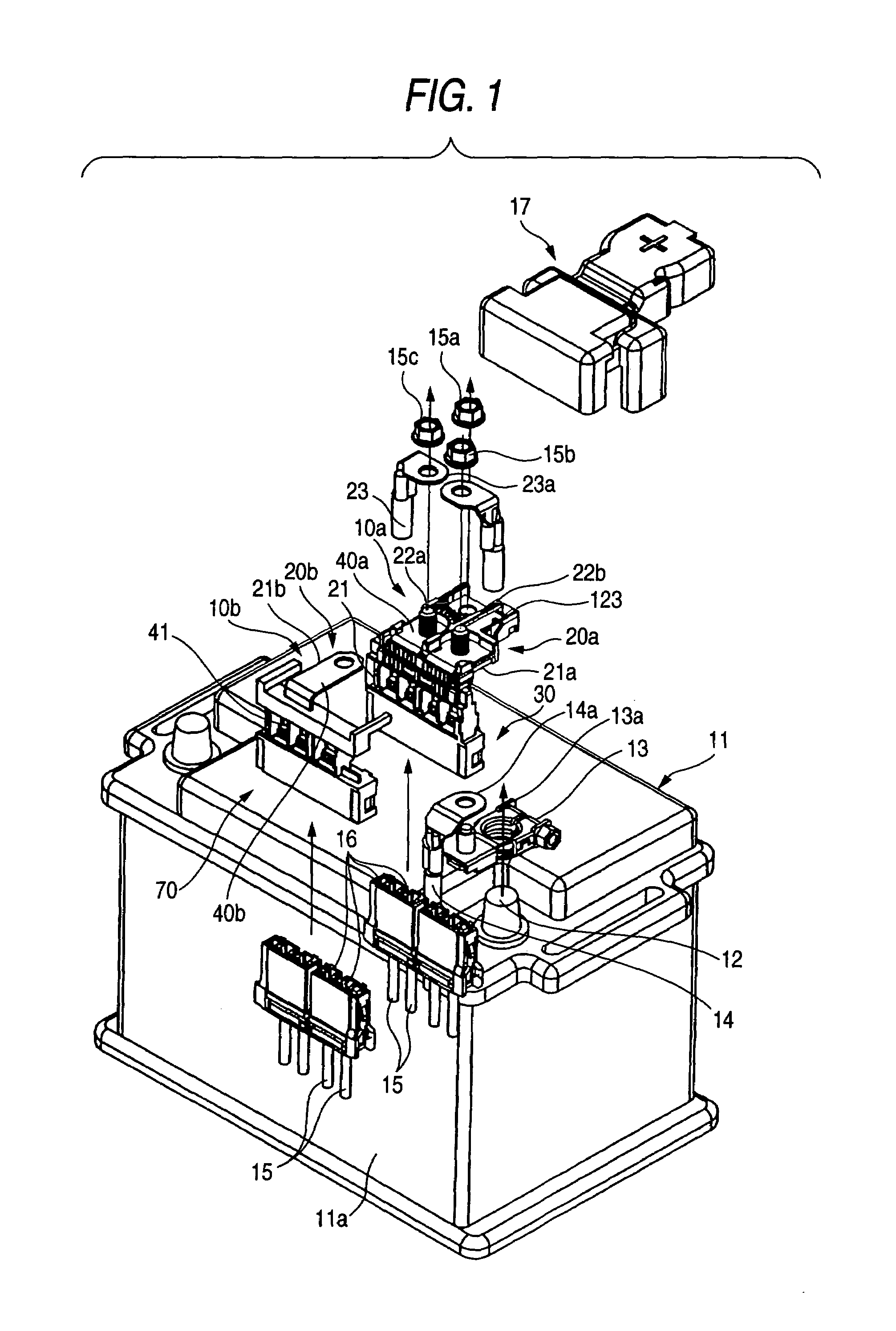

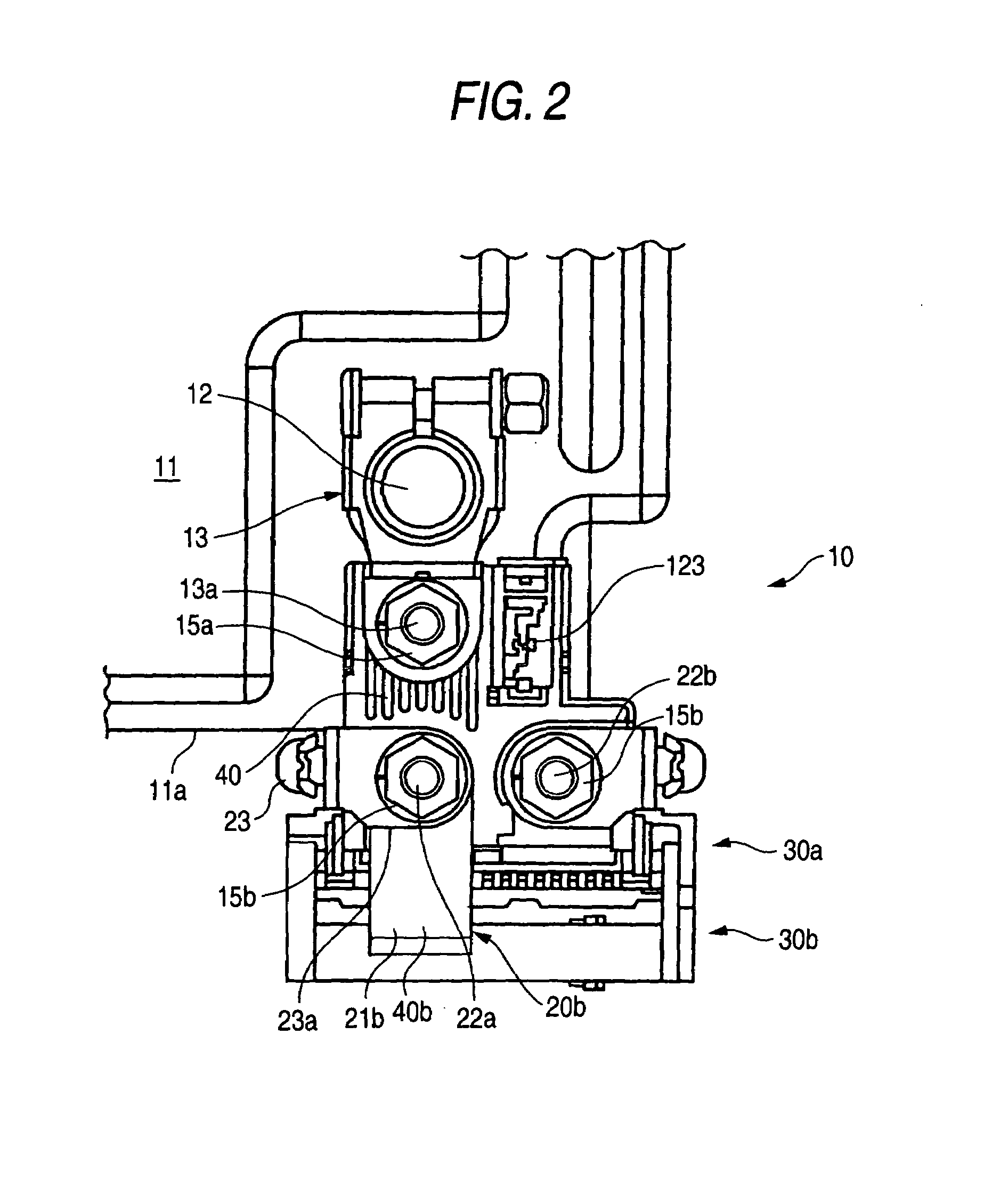

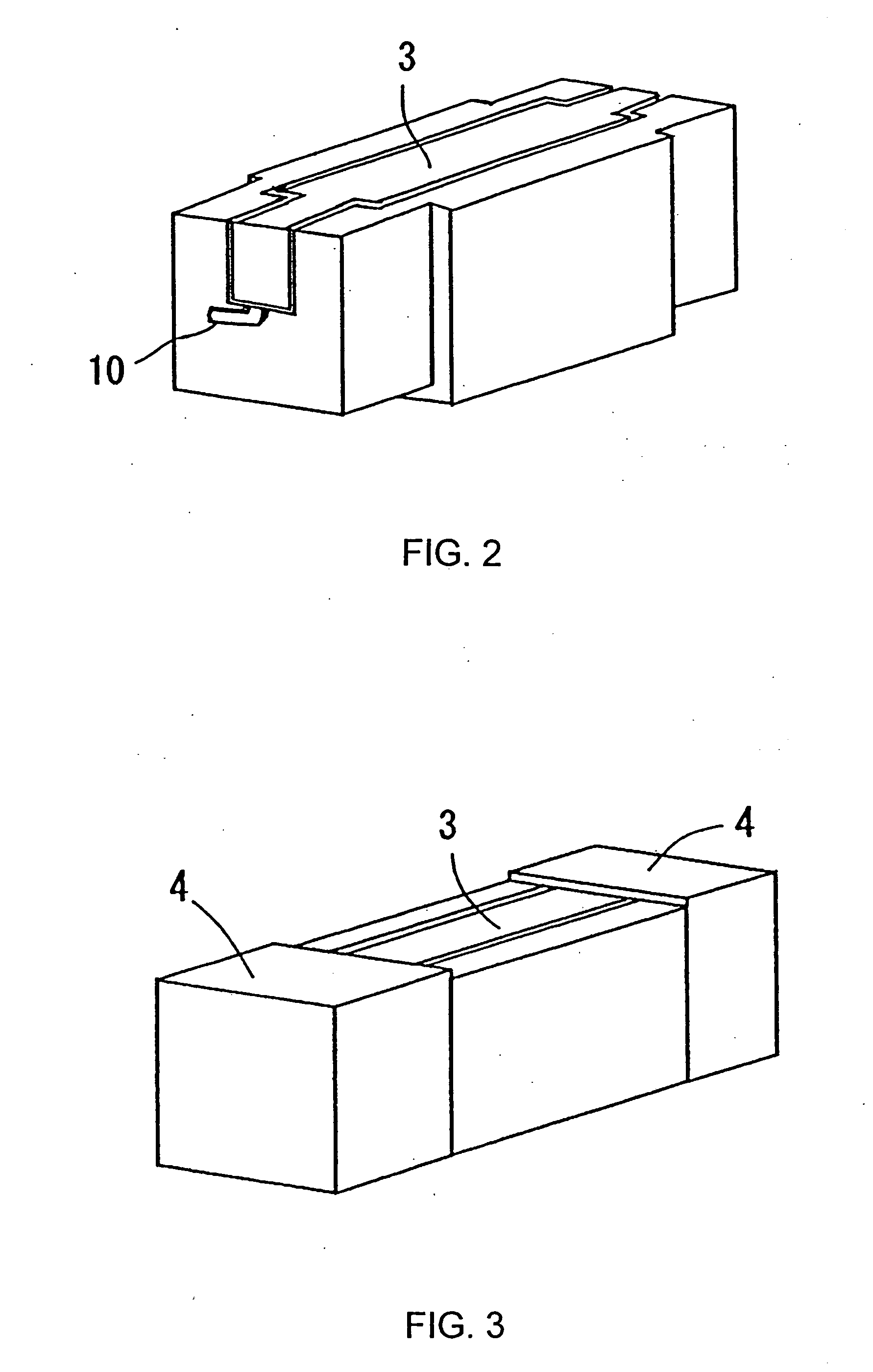

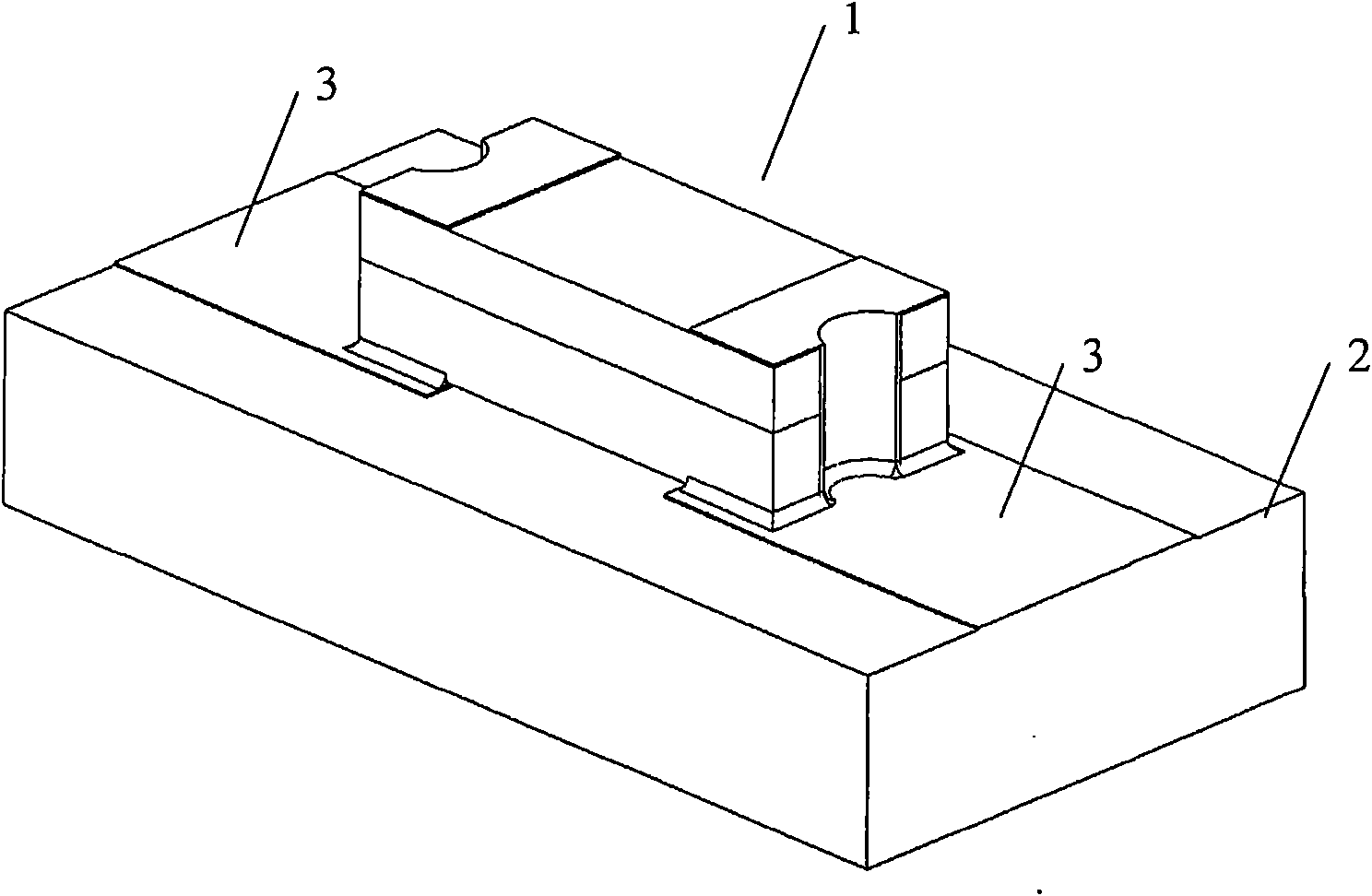

Fuse unit

ActiveUS7176780B2Easy to checkFuse device manufactureFuse disposition/arrangementEngineeringElectric wire

A fuse unit includes first and second fuse devices. Each of the fuse devices includes a attaching portion to be attached to a battery terminal of a battery, a housing provided on the attaching portion and having a cavity which is opened forward and backward of the housing, and a fuse body having a first end which is electrically connected to the battery terminal and a second end which is covered with the housing to form a wire connection part, the fuse body having a fusible portion which is disposed in the cavity. When the housings are superposed in a direction away from the battery, at least one of the housings and the fuse bodies are constructed so that the fusible portions are checked as viewed in a forward direction of the housings.

Owner:YAZAKI CORP

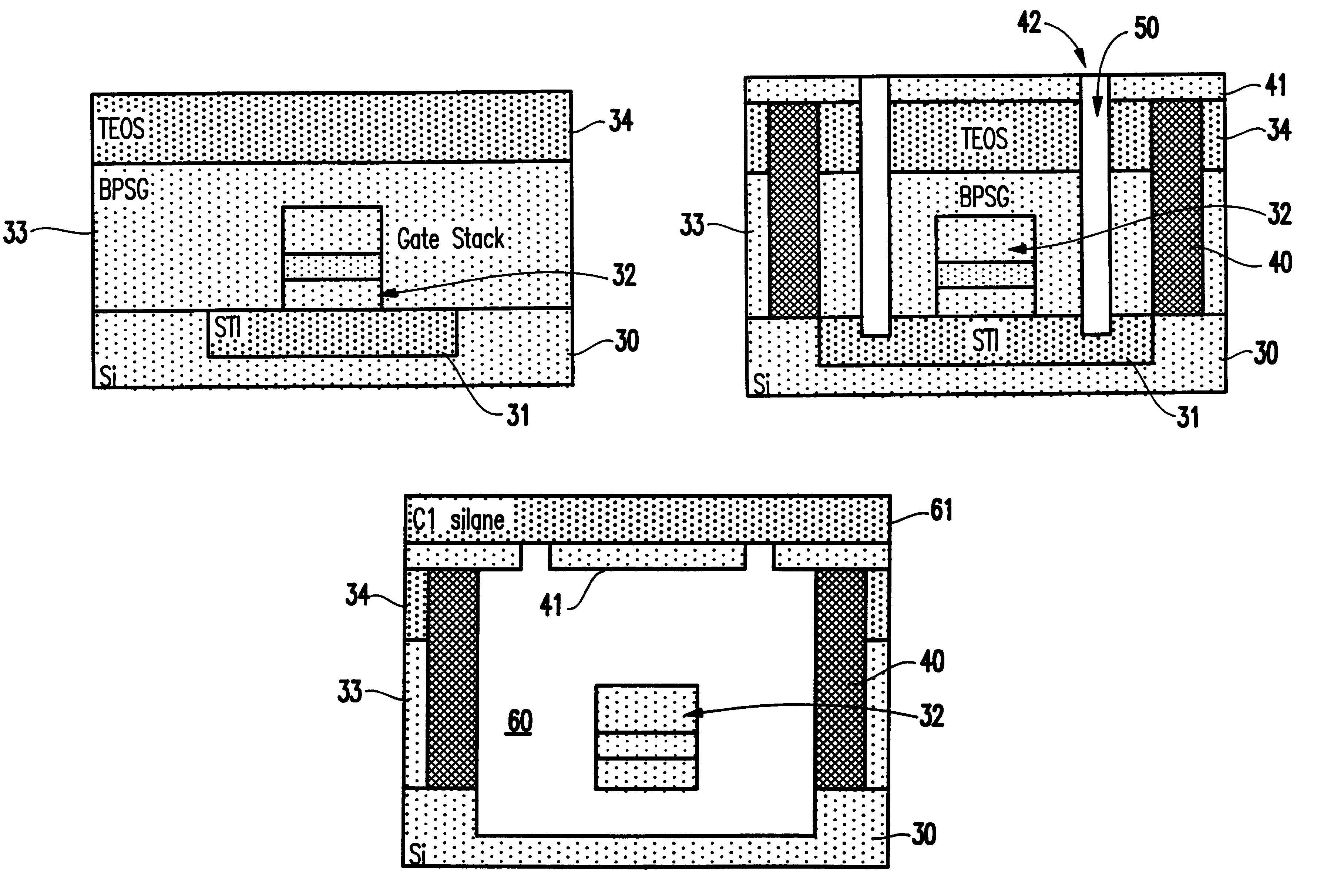

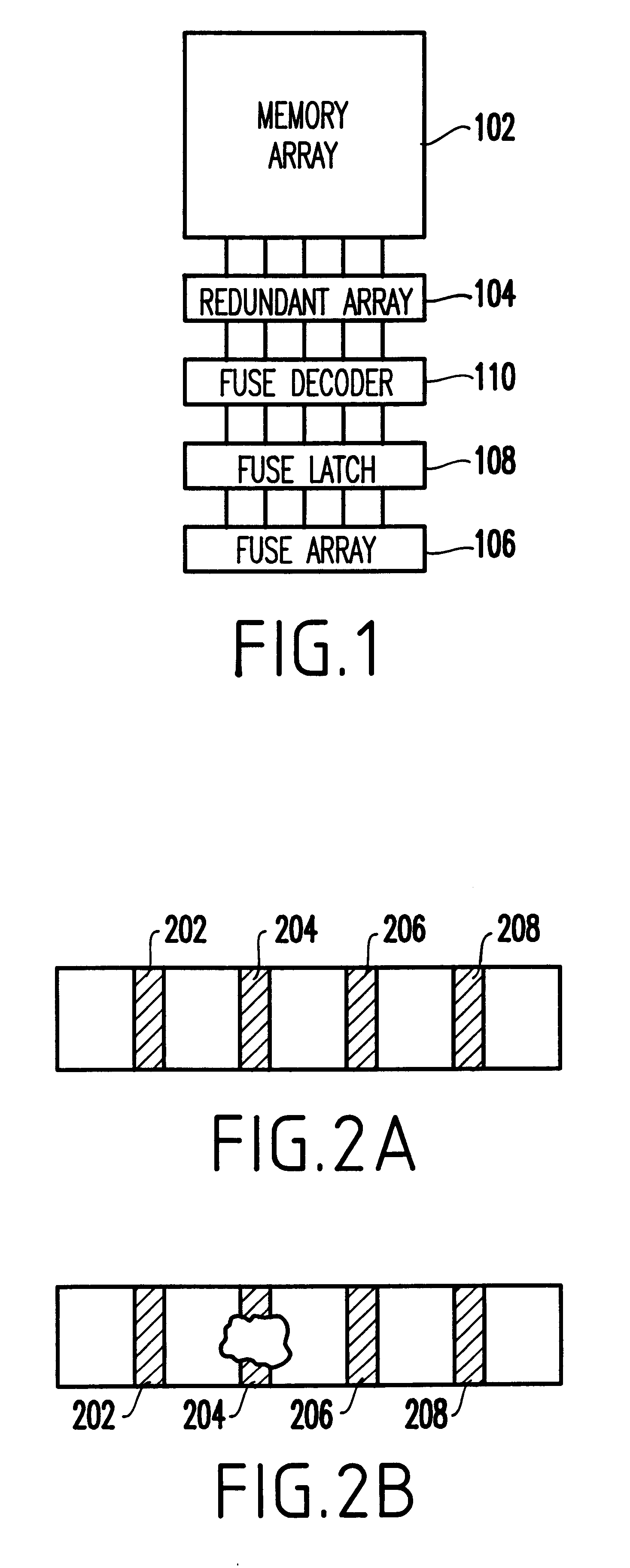

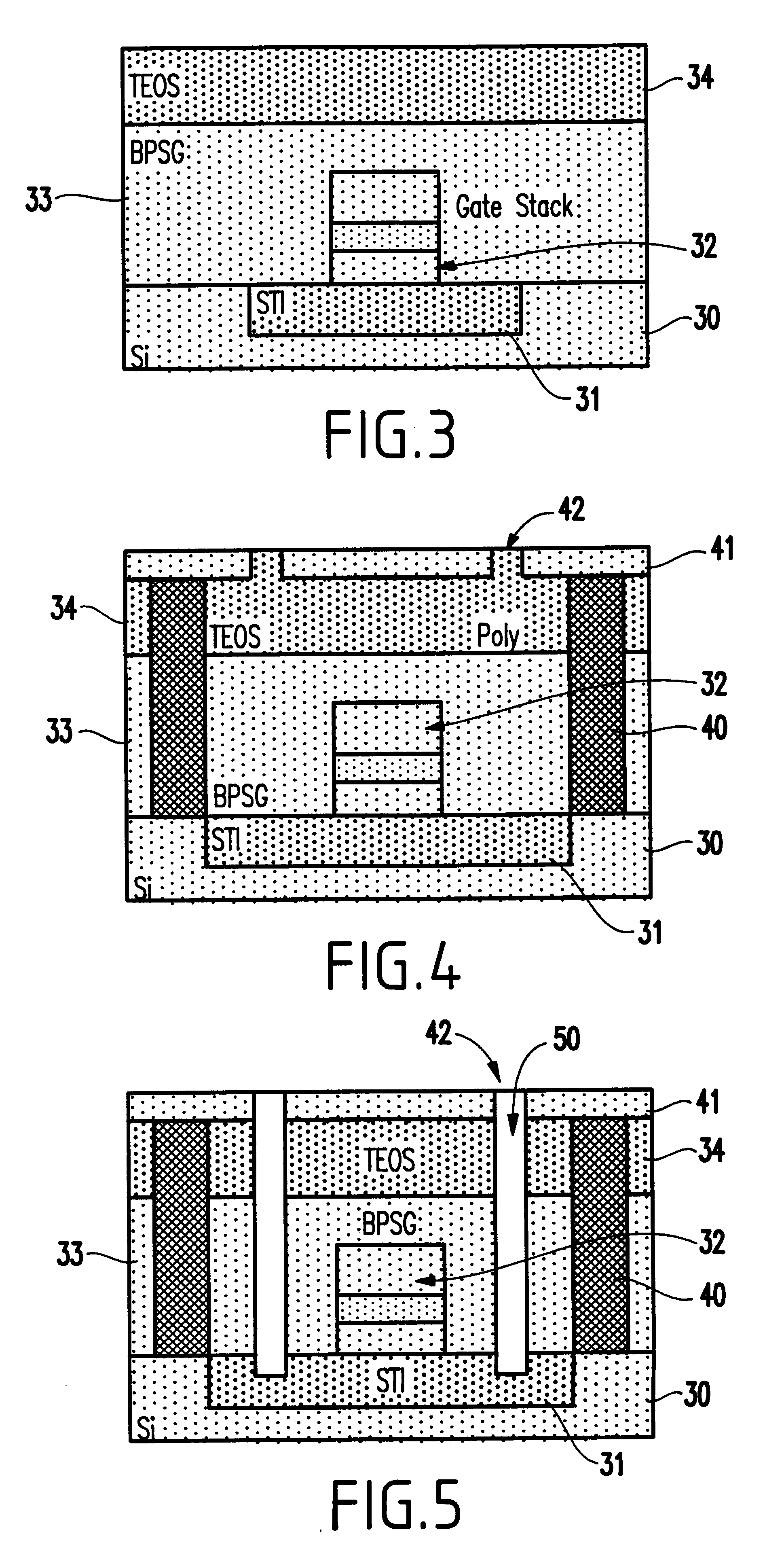

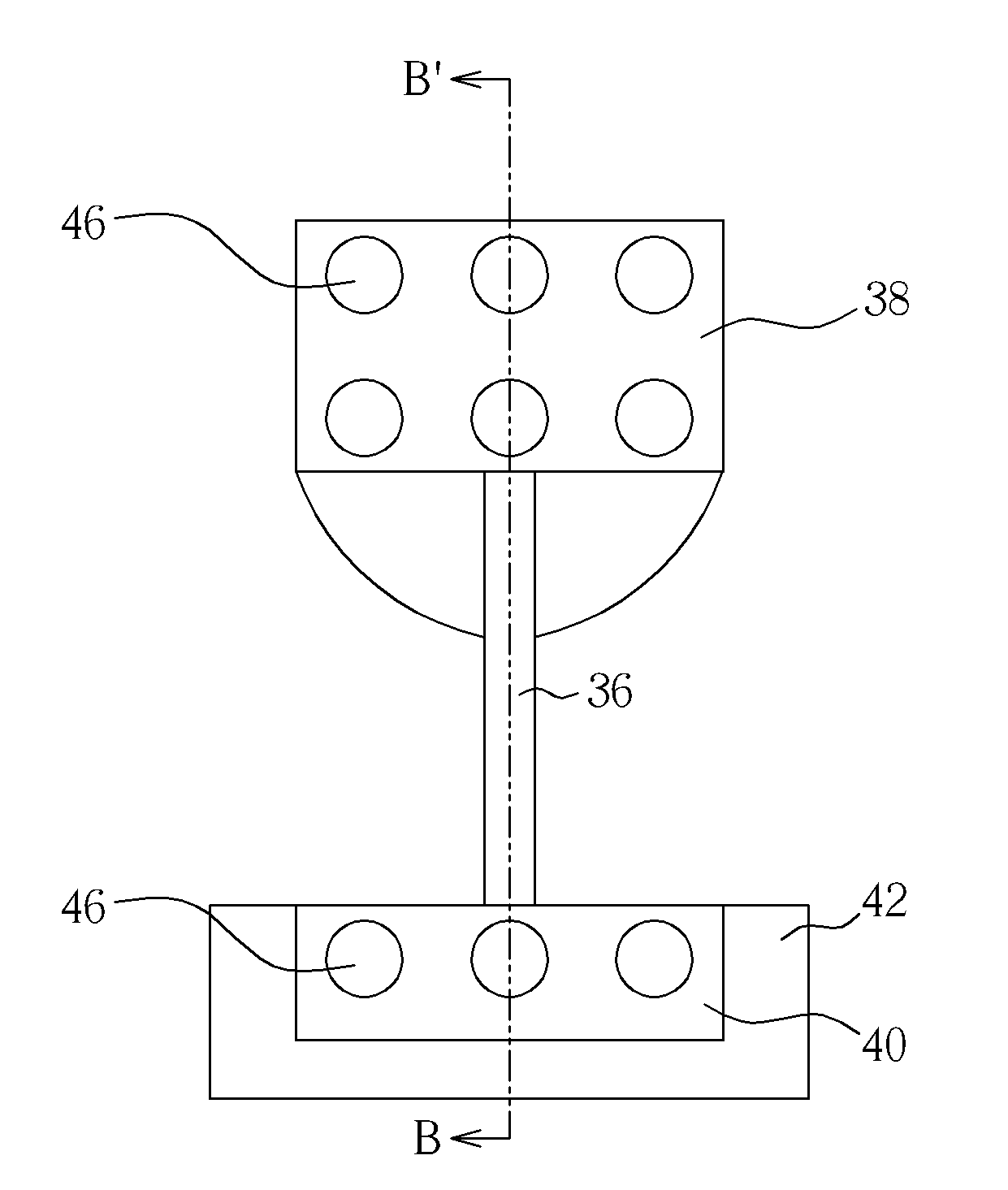

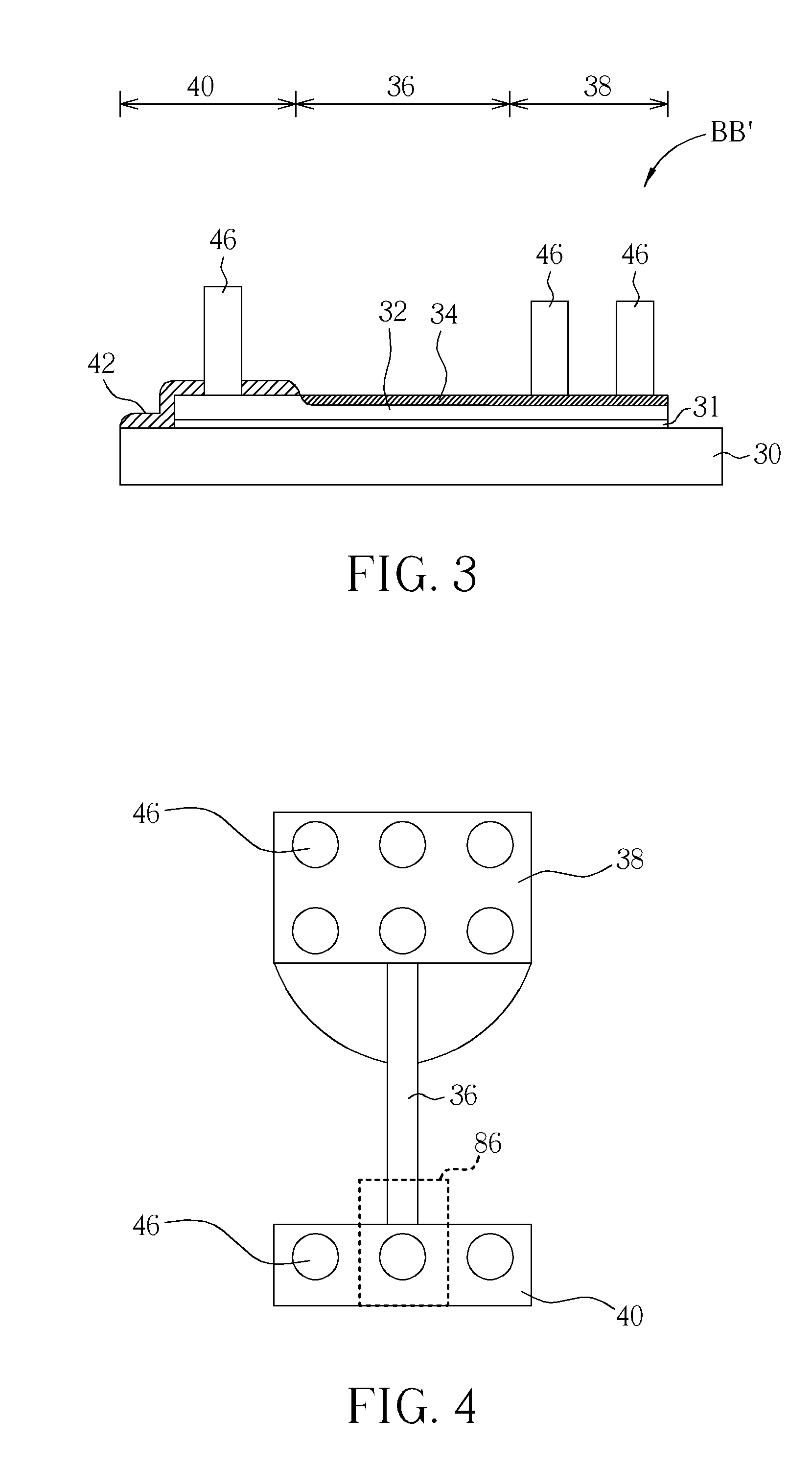

Manufacturing of cavity fuses on gate conductor level

A structure and method for making a cavity fuse over a gate conductor stack. The method includes providing a semiconductor substrate having a gate conductor stack over a shallow trench isolation region, forming oxide layers on the substrate about the gate conductor stack, etching electrical contact holes through the oxide layers to the substrate, filling the electrical contact holes with a first conductive material to establish electrical contact with the gate conductor stack, etching a pattern in an uppermost oxide layer of the oxide layers, depositing a conductive layer of a second conductive material over the oxide layers and the electrical contacts, planarizing the conductive layer whereby the conductive material remains only in the pattern, anisotropically etching the oxide layers to form at least one etching hole through the oxide layers to the shallow trench isolation region, and isotropically etching at least a portion of the oxide layers about the etching hole, whereby a cavity is formed beneath at least a portion of the conductive layer pattern, the gate conductor stack comprising a fuse.

Owner:INFINEON TECHNOLOGIES NORTH AMERICA CORPORATION +1

Electrical fuse structure and method for fabricating the same

InactiveUS20110074538A1Improve the bottleneckFuse device manufactureSemiconductor/solid-state device detailsSemiconductorSilicide

Owner:UNITED MICROELECTRONICS CORP +1

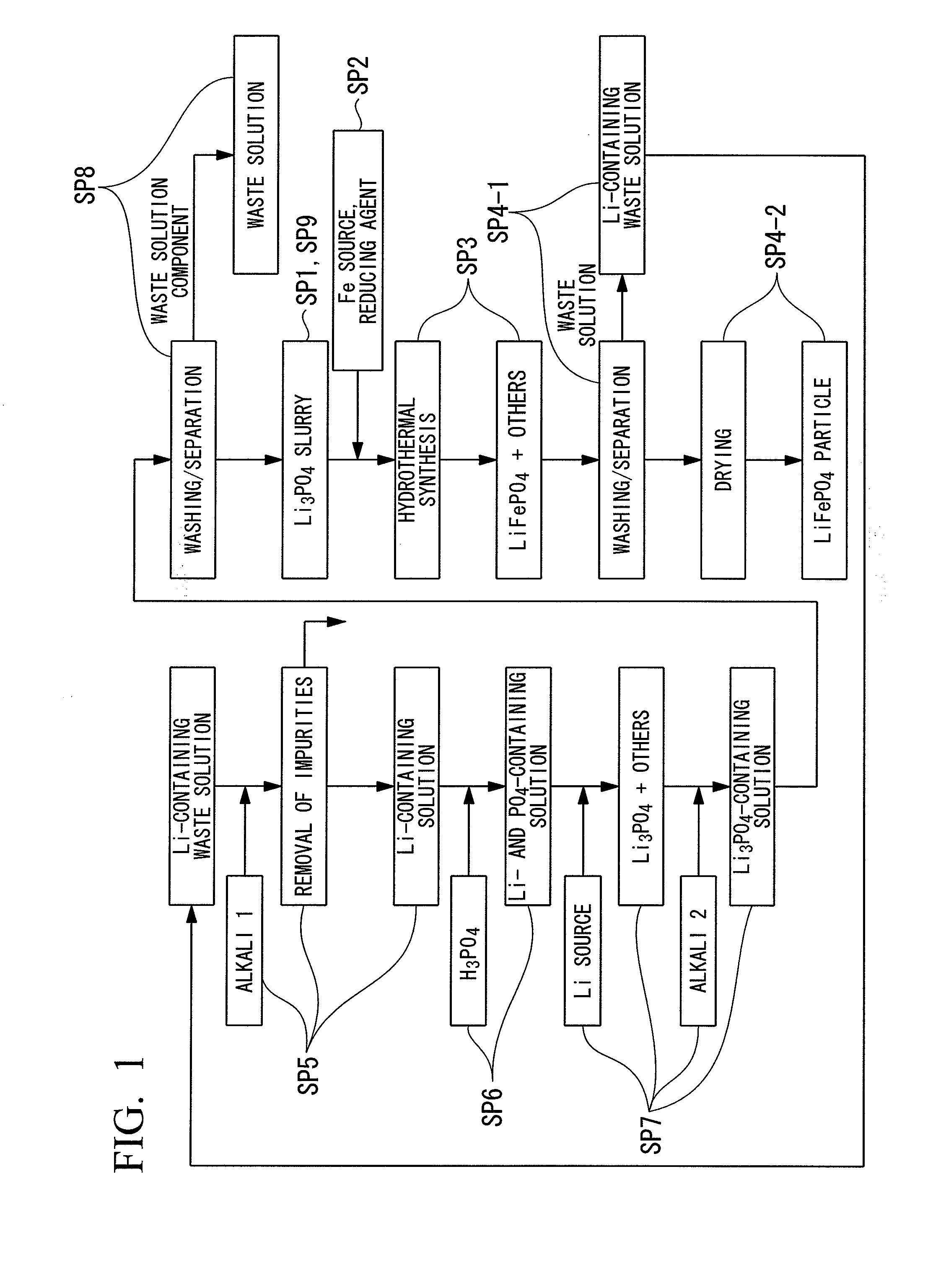

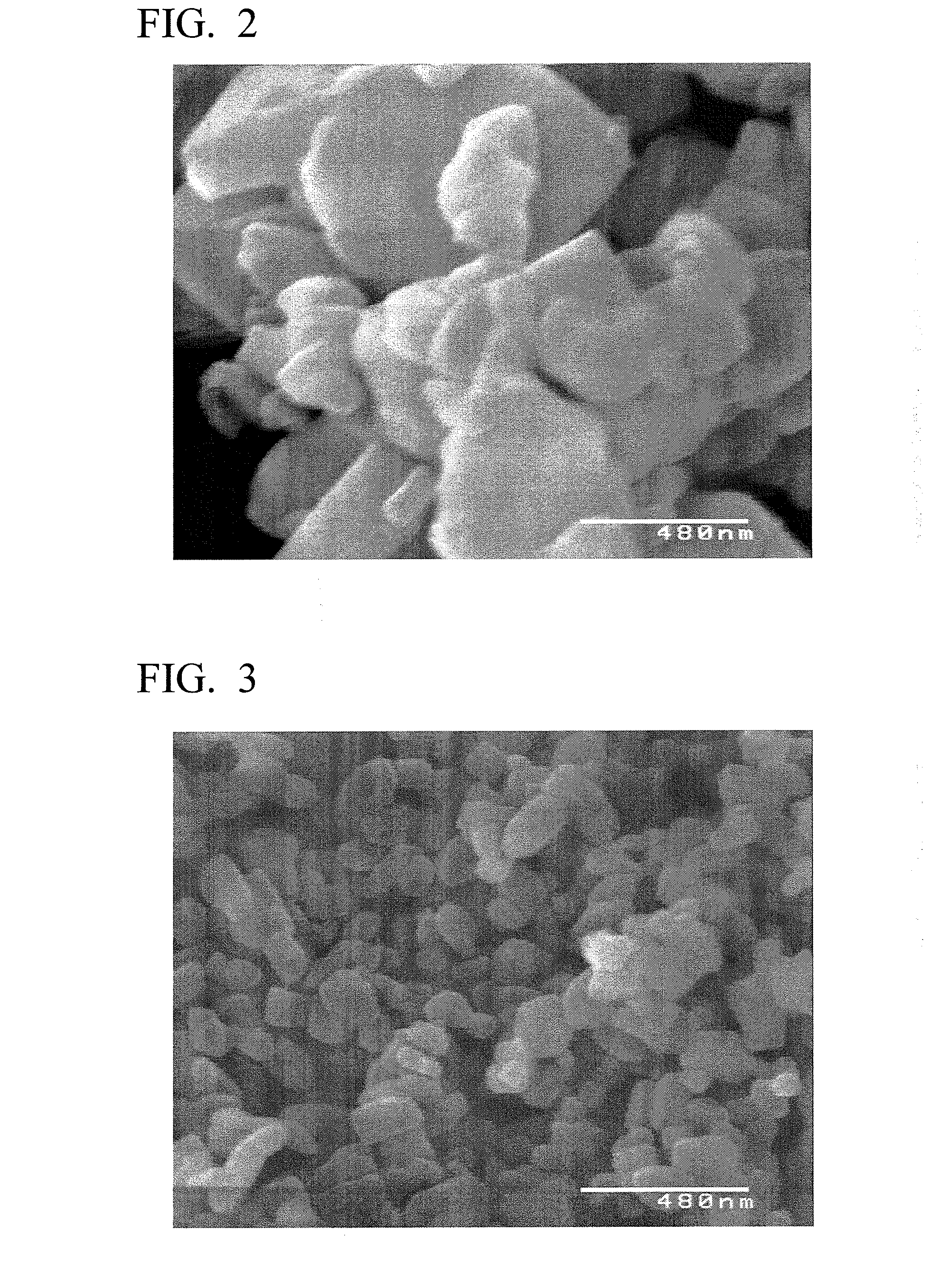

Method for producing cathode active material for lithium ion batteries, cathode active material for lithium ion batteries obtained by the production method, lithium ion battery electrode, and lithium ion battery

InactiveUS20110037019A1Improve reaction speedPrimary particle size is smallMaterial nanotechnologyFuse device manufacturePhosphoric acidLithium-ion battery

A method for producing a cathode active material for lithium ion batteries includes a step of synthesizing LiFePO4 by carrying out a hydrothermal reaction using an Li salt, a Fe salt, and a phosphoric acid source as raw materials. Elements Li and Fe in the Li and Fe salts are added to the reaction system in amounts excessively larger than the theoretical amounts required for the hydrothermal reaction. The synthesized LiFePO4 has an average primary particle size of equal to or larger than 30 nm and equal to or smaller than 100 nm.

Owner:SUMITOMO OSAKA CEMENT CO LTD

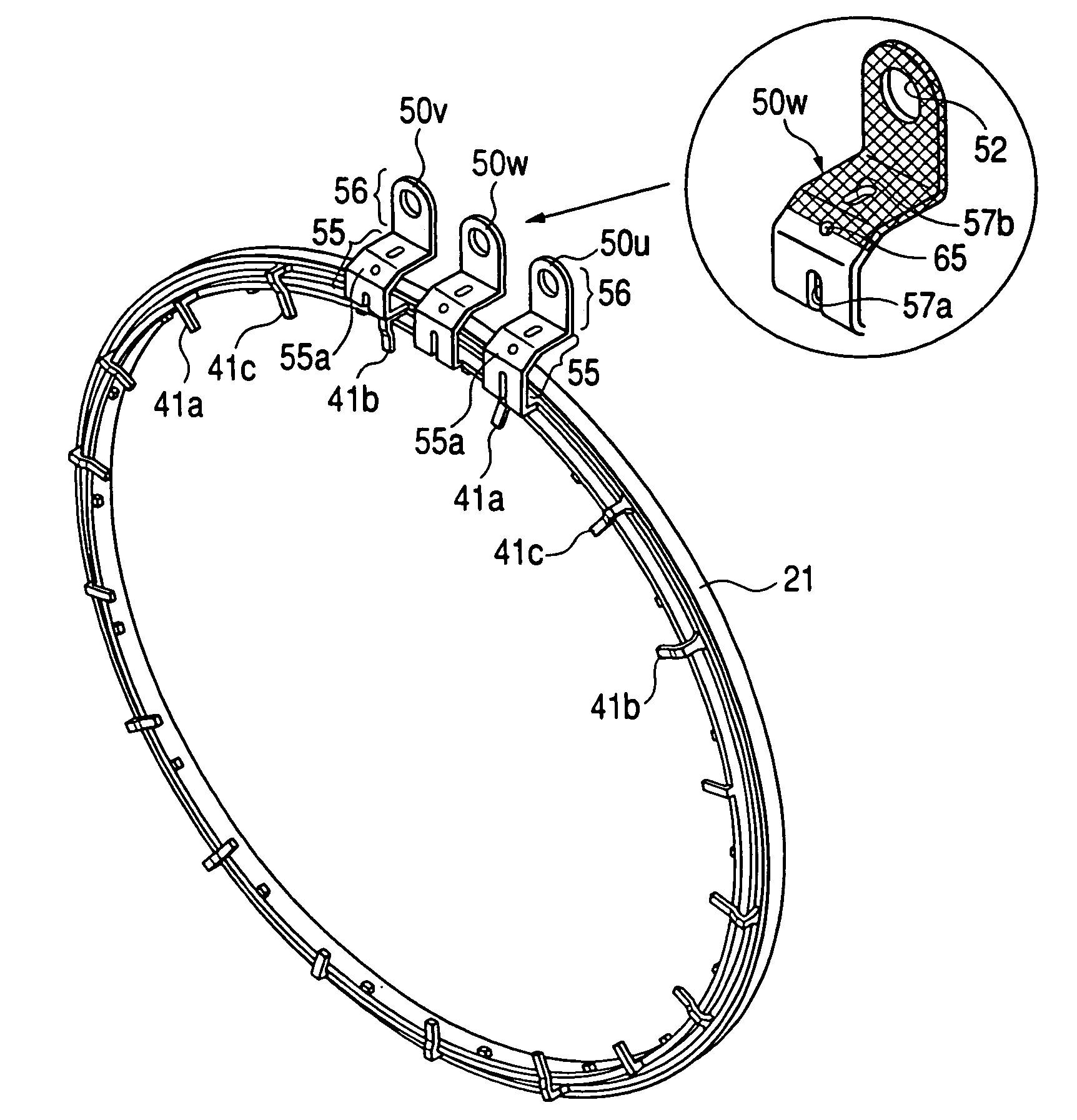

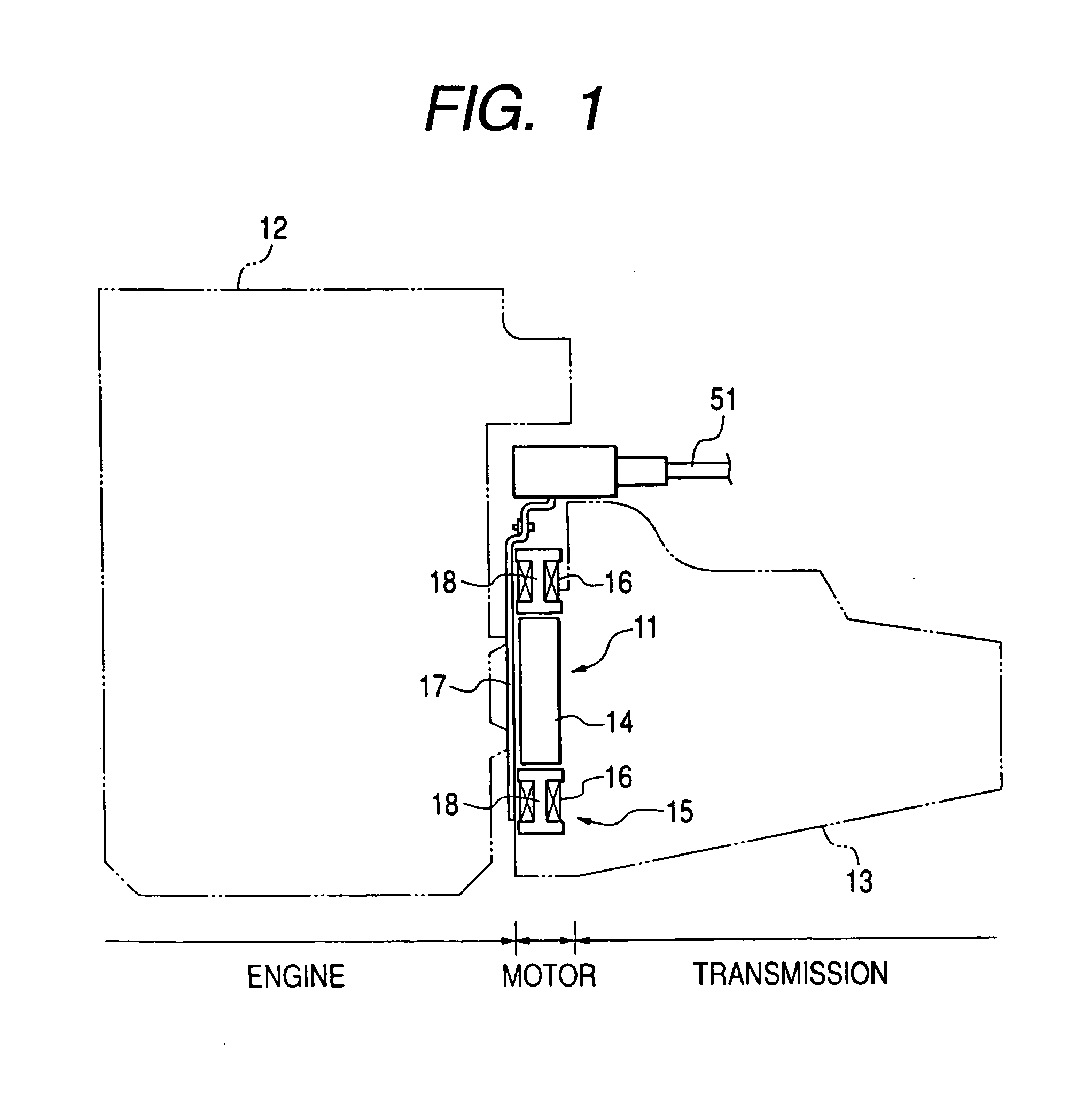

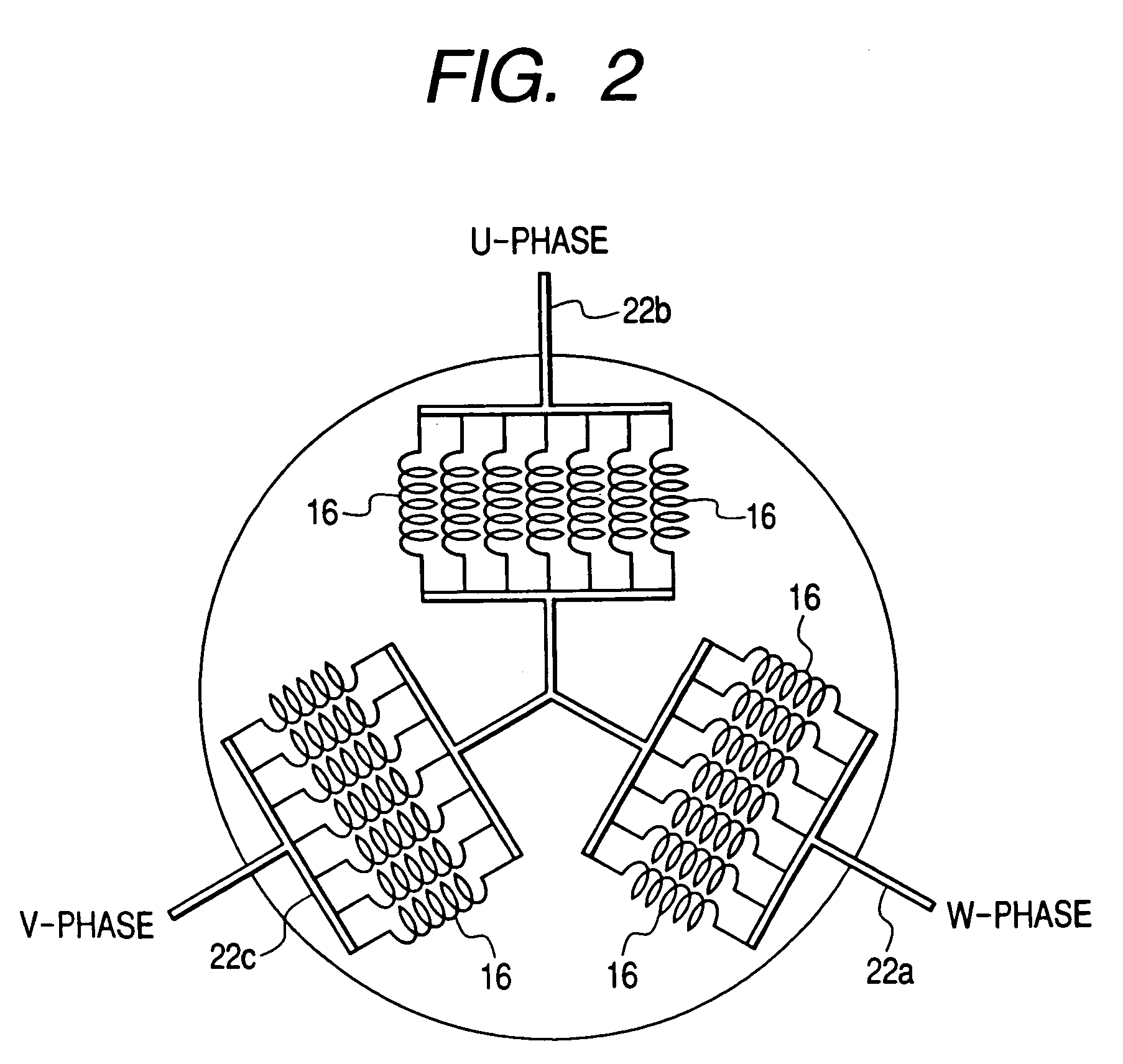

Method of producing bus bars for centralized power distribution unit

InactiveUS7219417B2Low costGood componentLine/current collector detailsWindingsStructural engineeringMechanical engineering

To produce bus bars, a conductive metal plate is stamped out into a plurality of strips simultaneously by press molding. Each strip has a tab having an L-shaped cross-section defined by a curved section and a distal end. The plurality of strips are bent in a thickness direction to obtain a plurality of rings, respectively. The rings are mutually different in diameter and have substantially the same center. The L-shaped tab of each of the rings is disposed such that the distal end of each tab is disposed substantially at a same distance from the center.

Owner:SUMITOMO WIRING SYST LTD +1

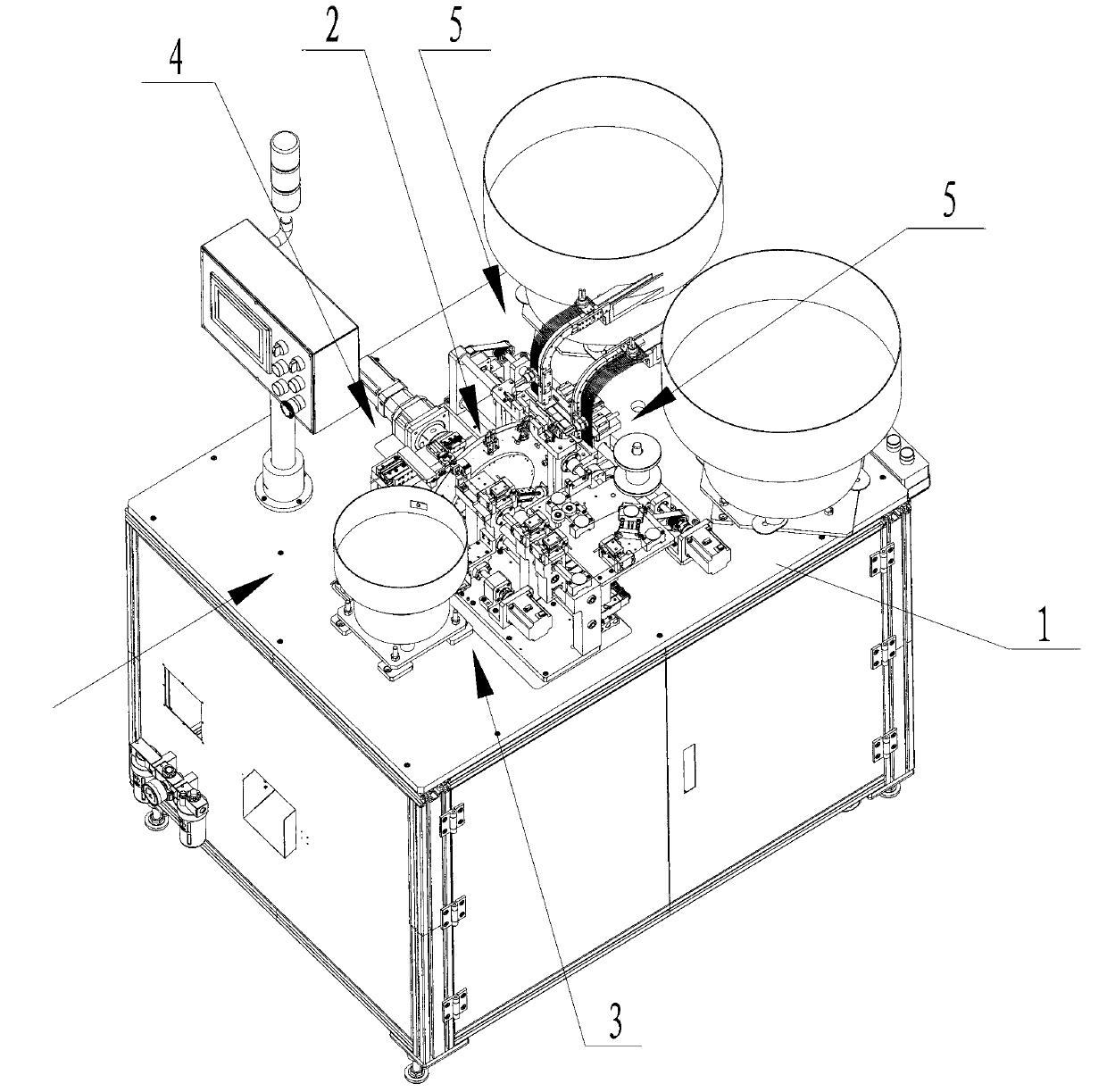

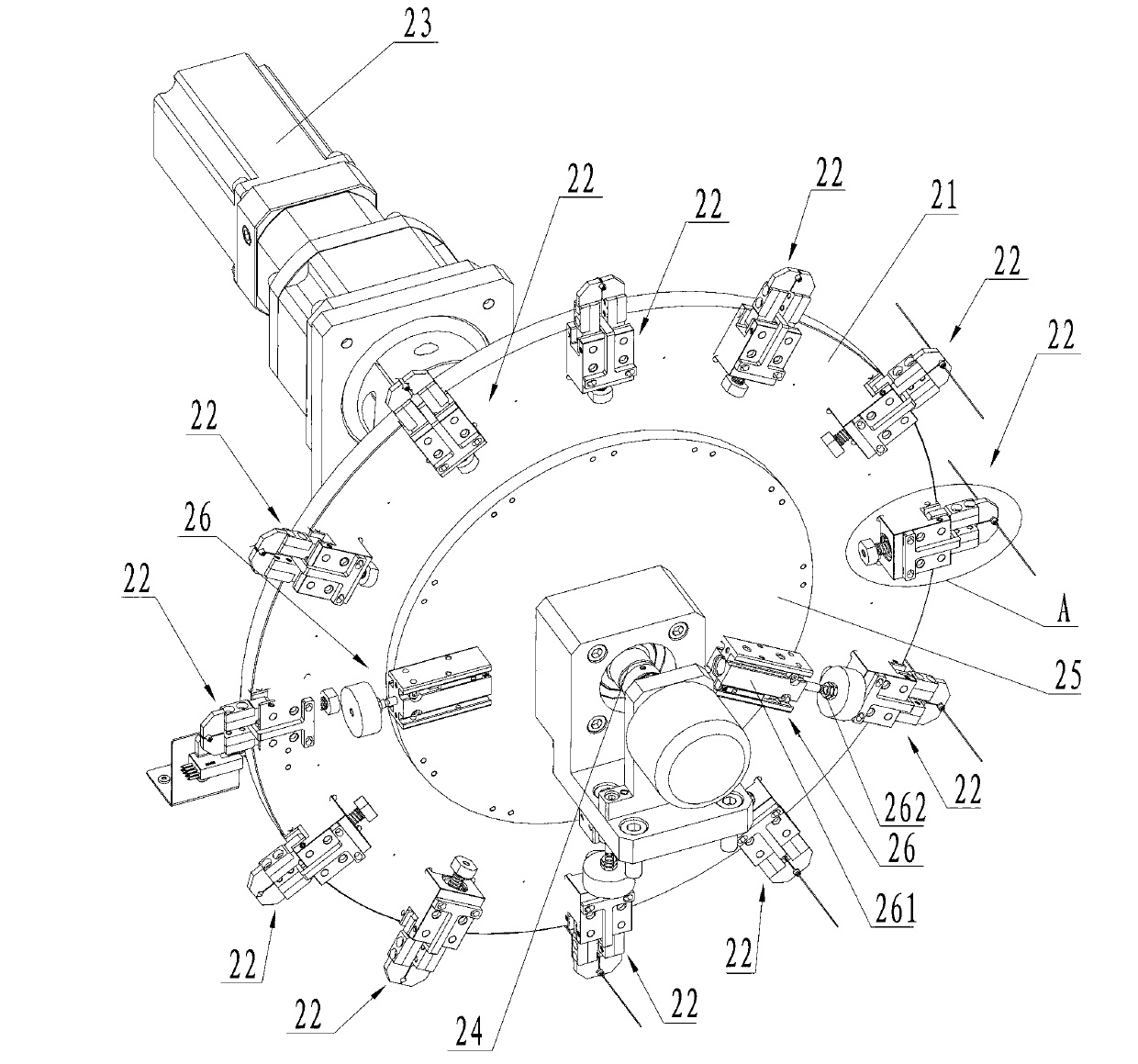

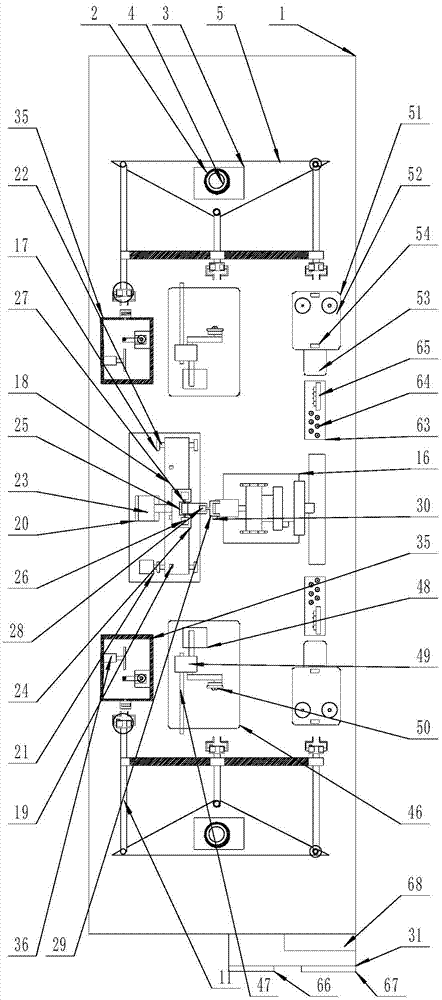

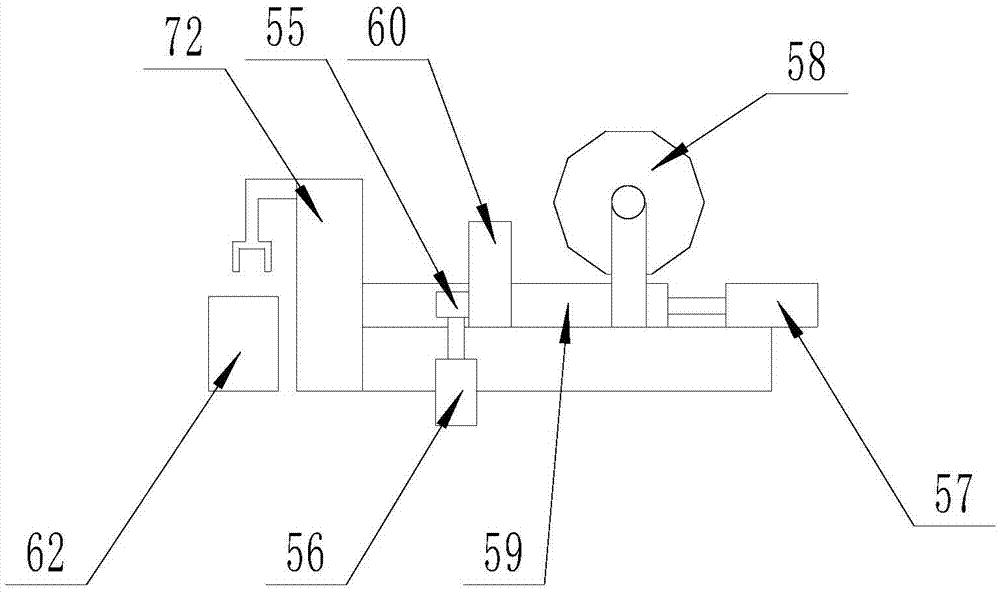

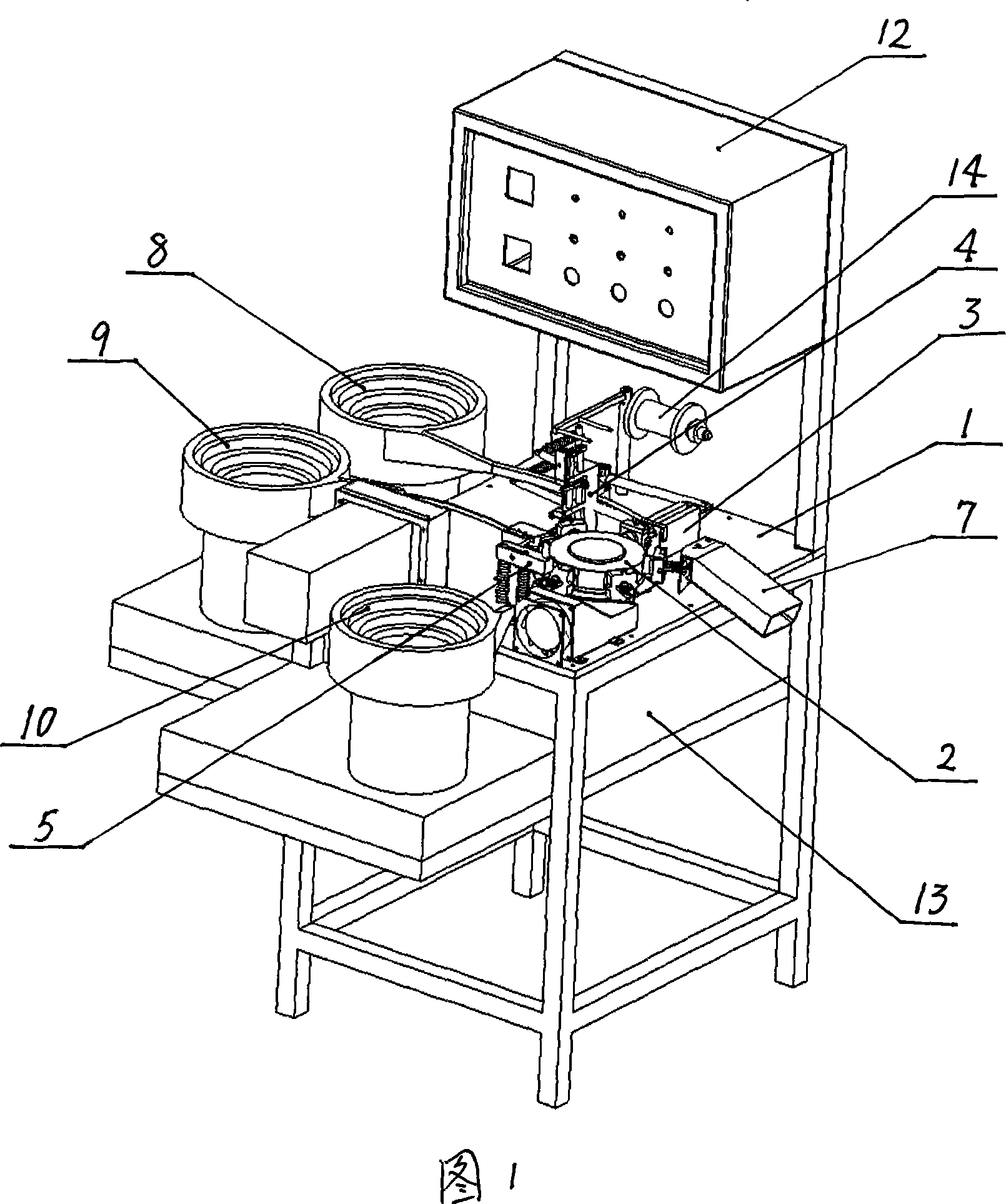

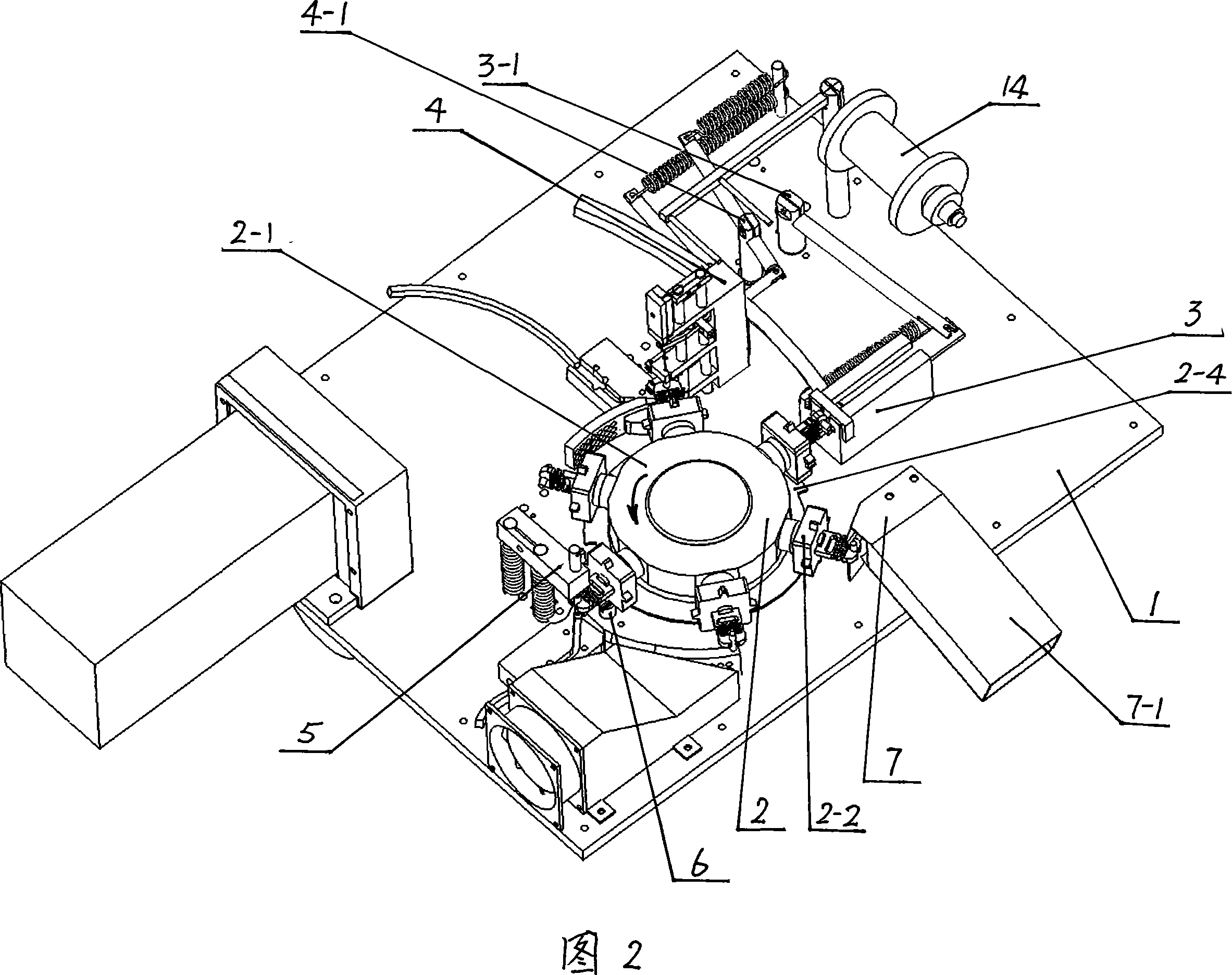

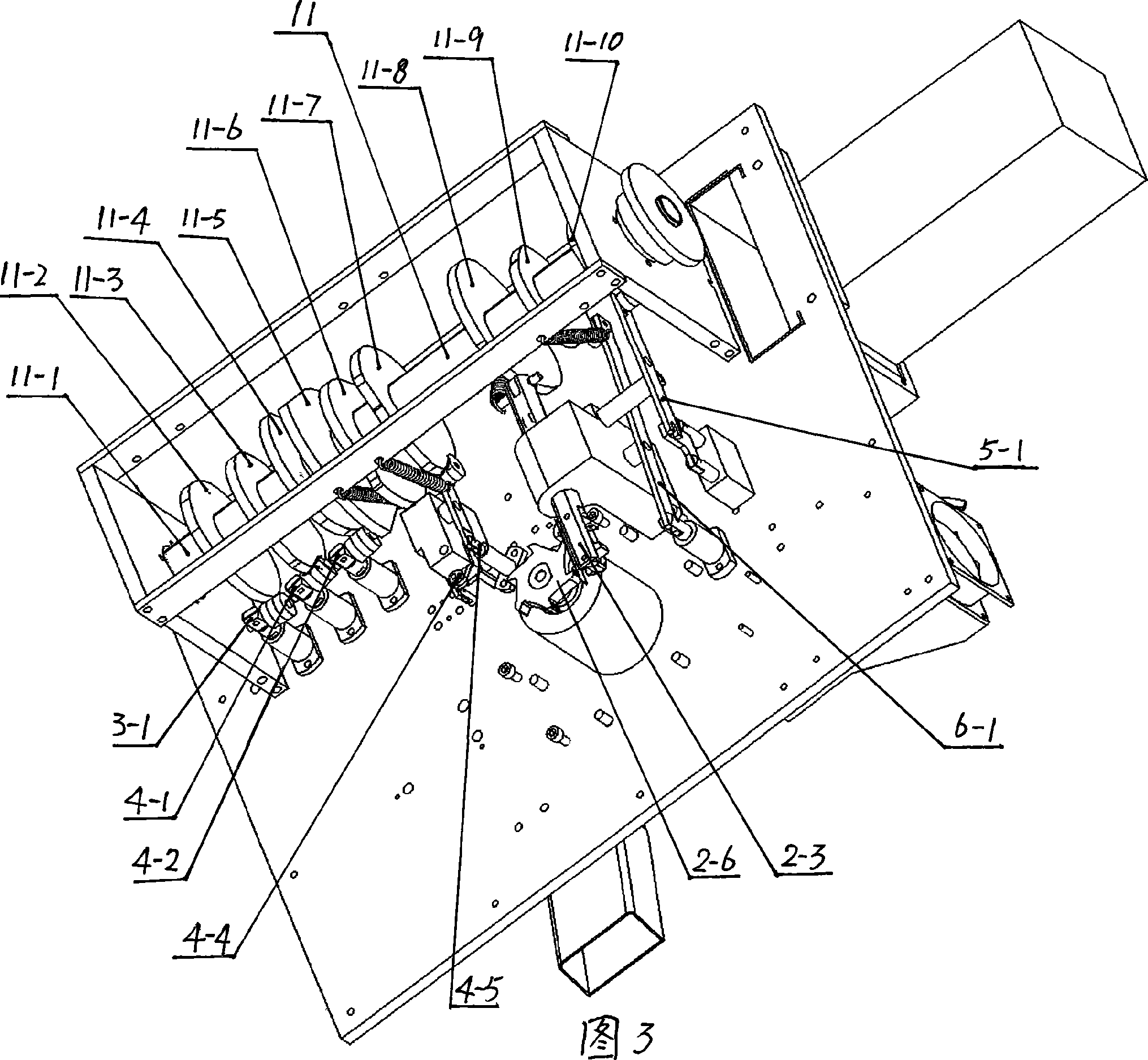

Automatic assembly machine for lead protective tube

ActiveCN103219202AImprove consistencyReduce labor intensityFuse device manufactureWire cuttingEngineering

The invention discloses an automatic assembly machine for a lead protective tube, wherein through the arrangement of a turntable type material clamping device, a tube body automatic material feeding device, an automatic wire feeding and cutting-off bending device, and an end cap automatic material feeding and pressing device, the production processes of tube body taking, fuse wire penetration, fuse wire cutting and bending, fuse wire penetration condition detection, end cap pressing and blanking can be automatically and sequentially completed, and finished products of the lead protective tube are obtained, so the assembly work of the lead protective tube can be automatically completed, the consistency of the finished products of the lead protective tube obtained through production is good, the production yield and the production efficiency are respectively and greatly improved, production personnel are greatly decreased, the work intensity of the production personnel is lowered, meanwhile, the production cost is reduced, and good practicality is realized.

Owner:SUZHOU MENGCHUAN AUTOMATION TECH

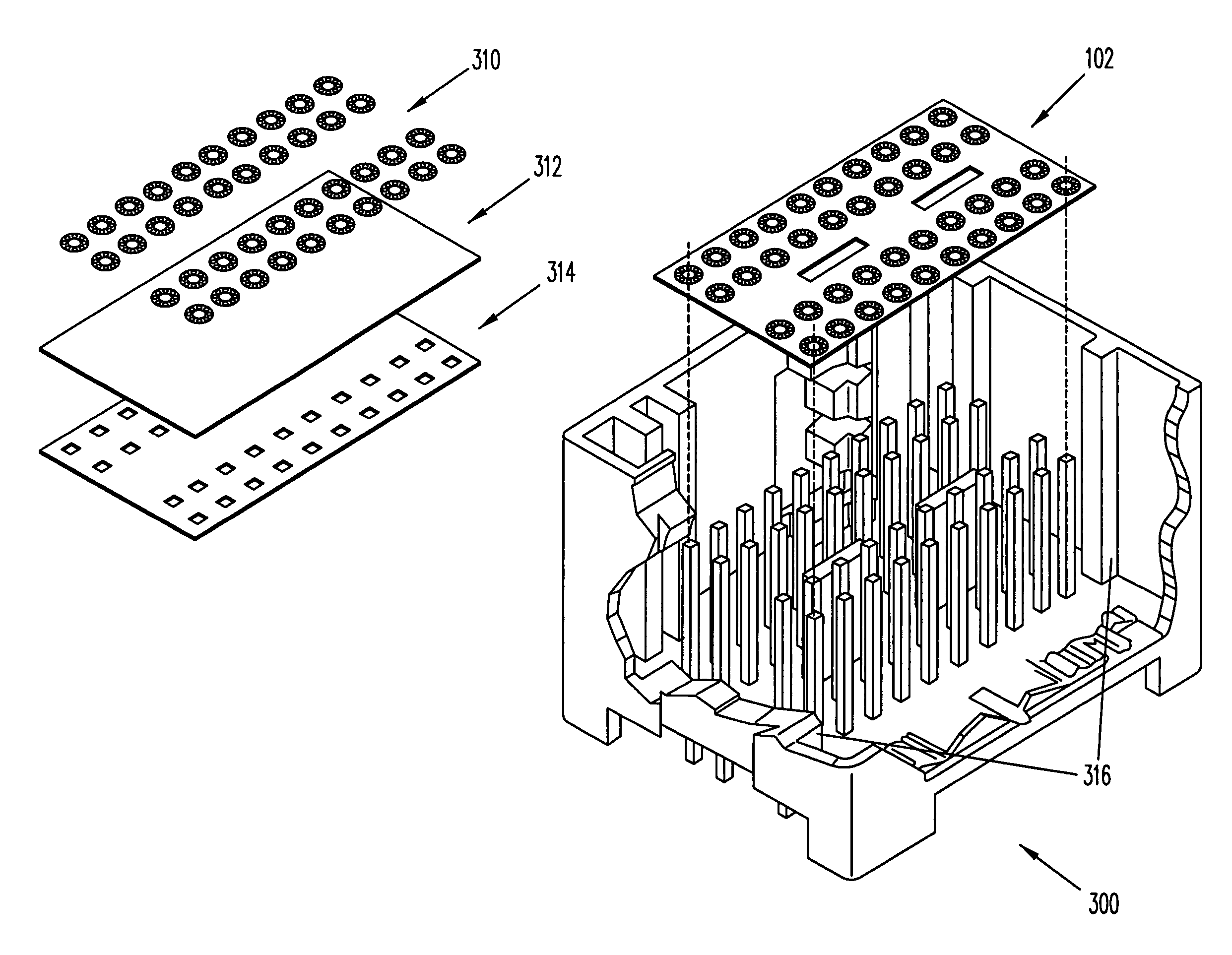

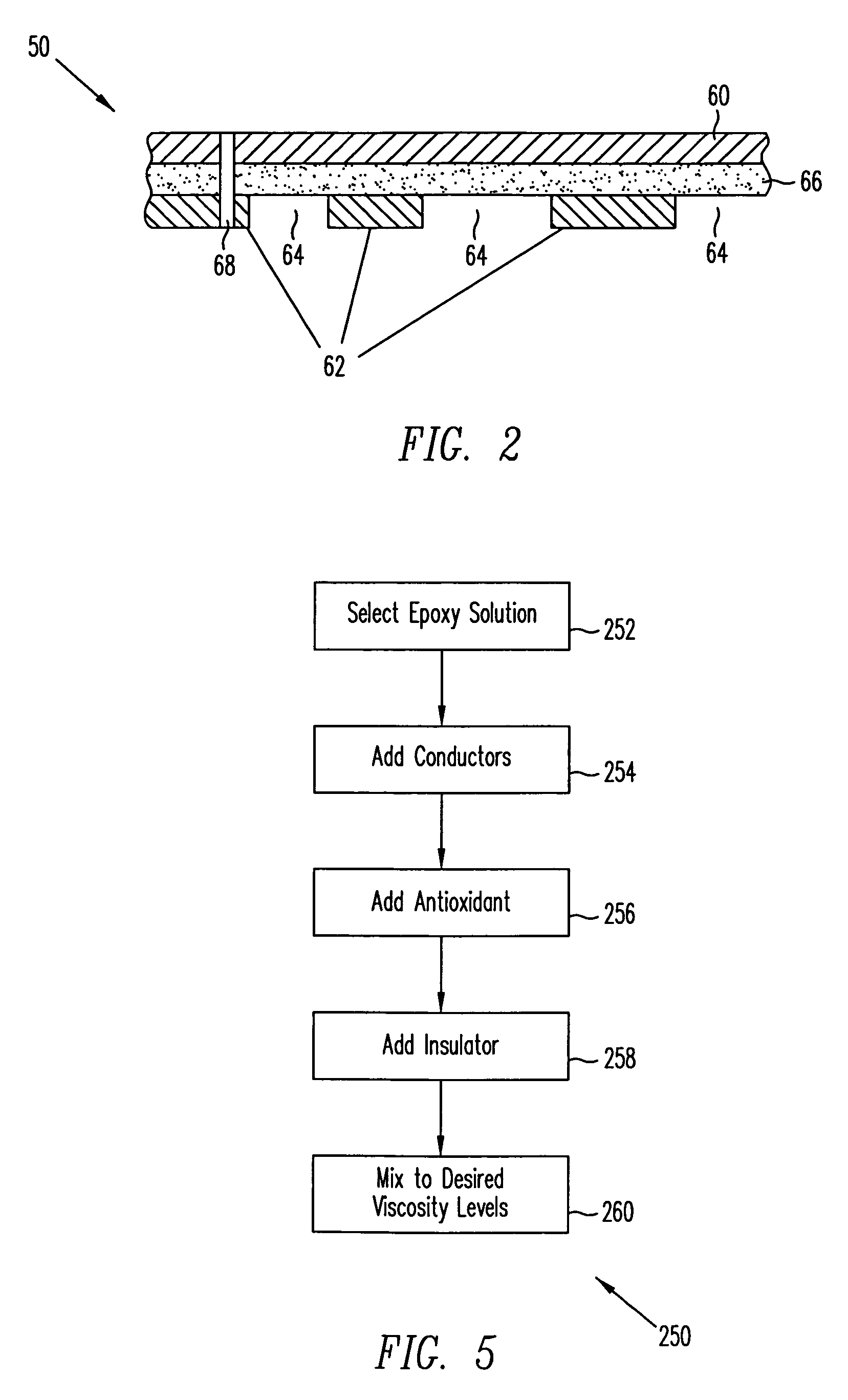

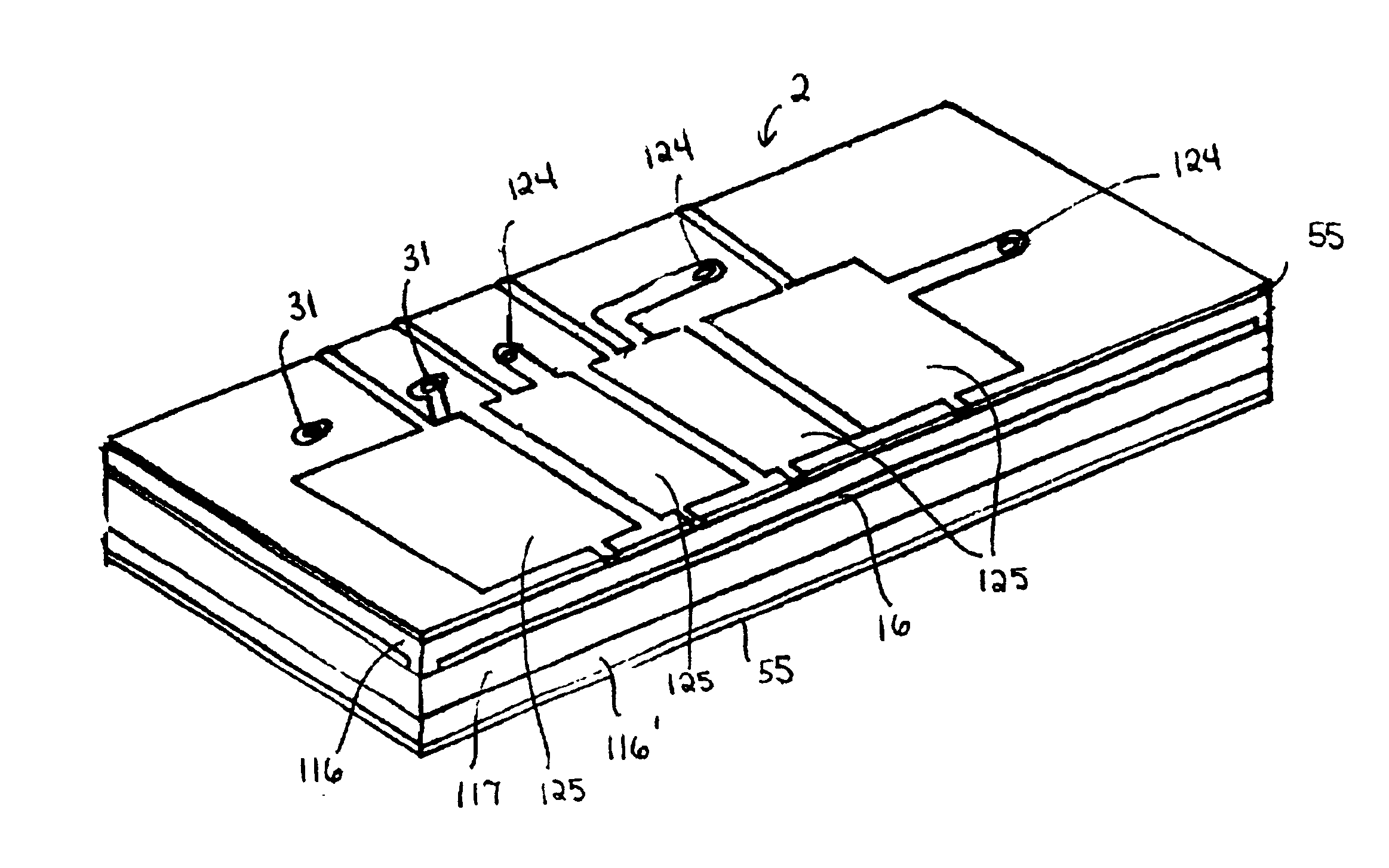

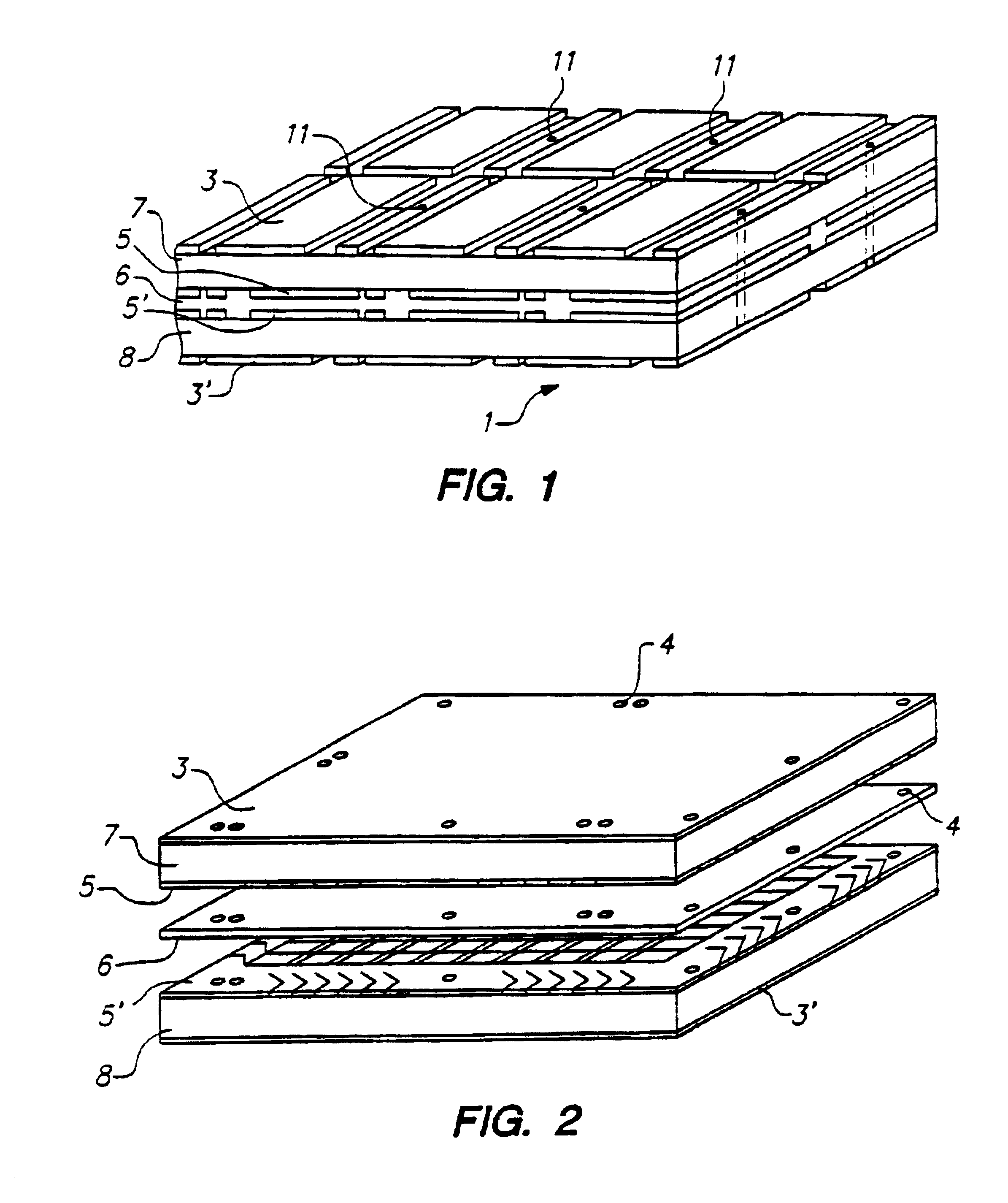

Process for manufacturing a composite polymeric circuit protection device

InactiveUS6854176B2Easy to buildInexpensively mass-producedResistor chip manufactureBatteries circuit arrangementsConductive polymerElectrical connection

A process for manufacturing a composite polymeric circuit protection device in which a polymeric assembly is provided and is then subdivided into individual devices (2). The assembly is made by providing first and second laminates (7,8), each of which includes a laminar polymer element having at least one conductive surface, providing a pattern on at least one of the conductive surfaces on one laminate, securing the laminates in a stack (1) in a desired configuration, at least one conductive surface of at least one of the laminates forming an external conductive surface (3) of the stack, and making a plurality of electrical connections (31,51) between a conductive surface of the first laminate and a conductive surface of the second laminate. The laminar polymer elements may be PTC conductive polymer compositions, so that the individual devices made by the process exhibit PTC behavior. Additional electrical components may be attached directly to the surface of the device or assembly.

Owner:LITTELFUSE INC

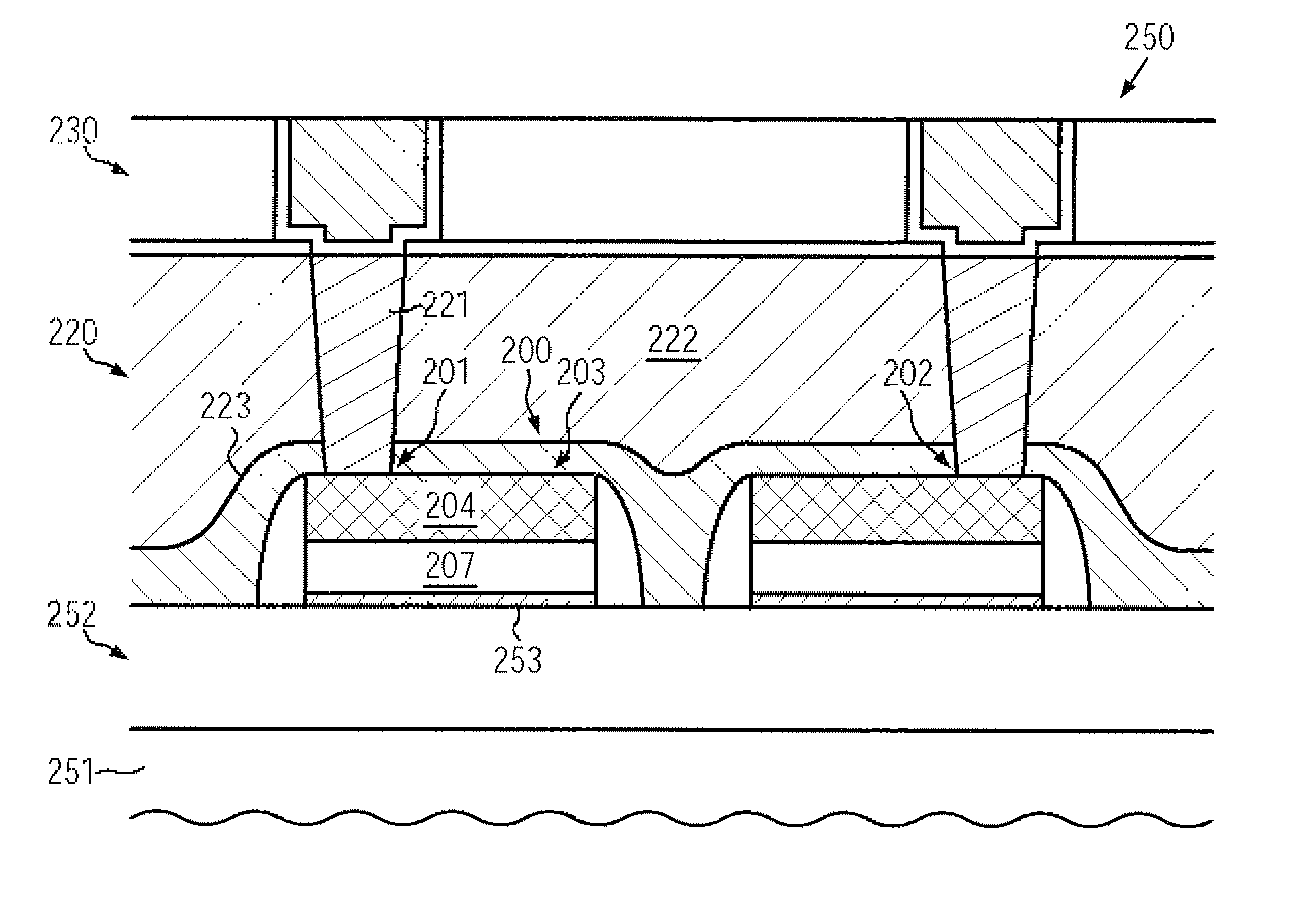

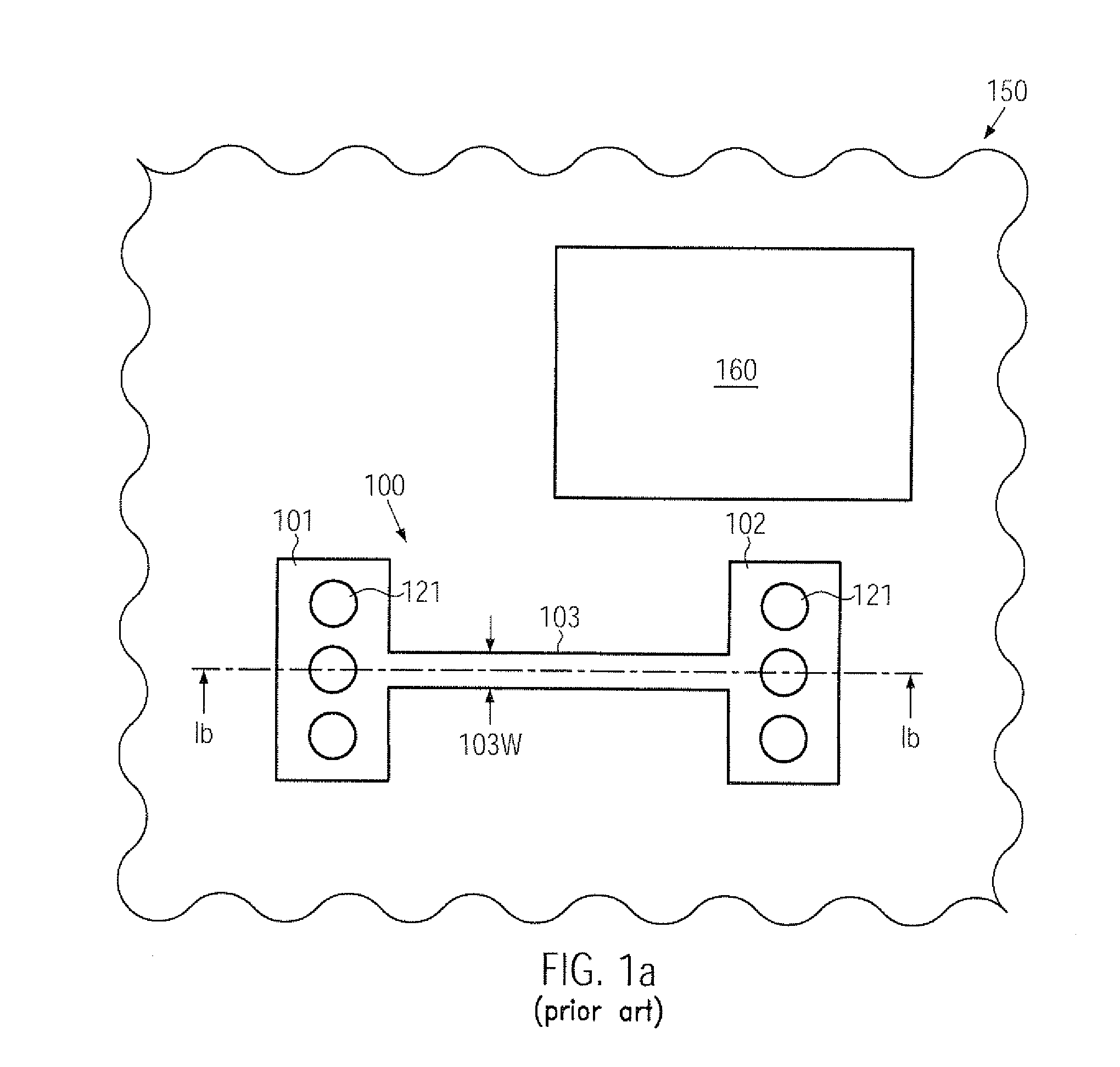

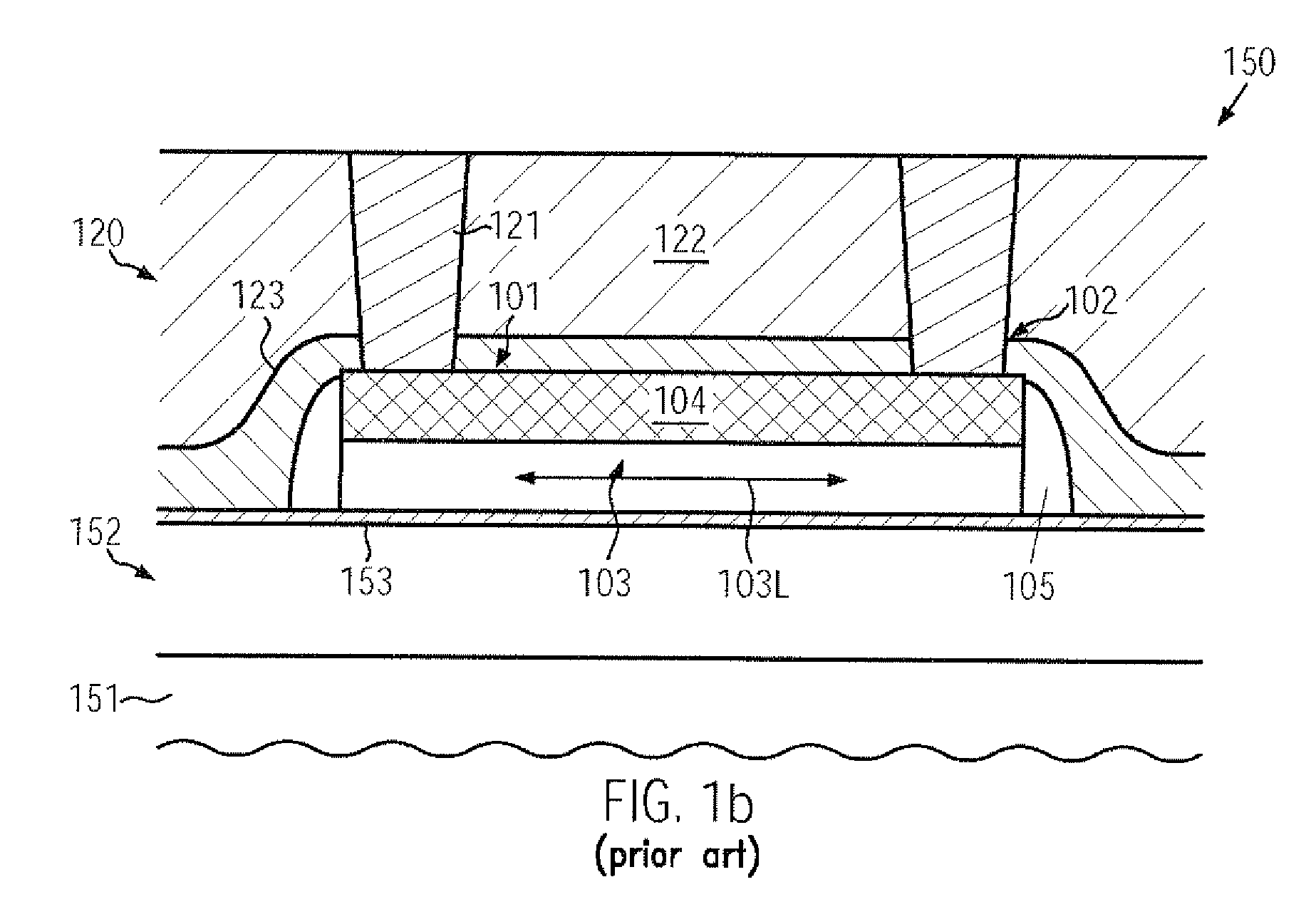

Low resistance polymer matrix fuse apparatus and method

InactiveUS7385475B2Fuse device manufactureSemiconductor/solid-state device detailsContact padInsulation layer

A low resistance fuse apparatus and methods of manufacture includes a first intermediate insulation layer, a second intermediate insulation layer, and a free standing fuse element layer independently formed and fabricated from each of the first and second intermediate insulation layers, The fuse element layer includes first and second contact pads and a fusible link extending therebetween. The first and second intermediate insulation layers extend on opposite sides of the free standing fuse element layer and are laminated together with the fuse element layer therebetween.

Owner:EATON INTELLIGENT POWER LTD

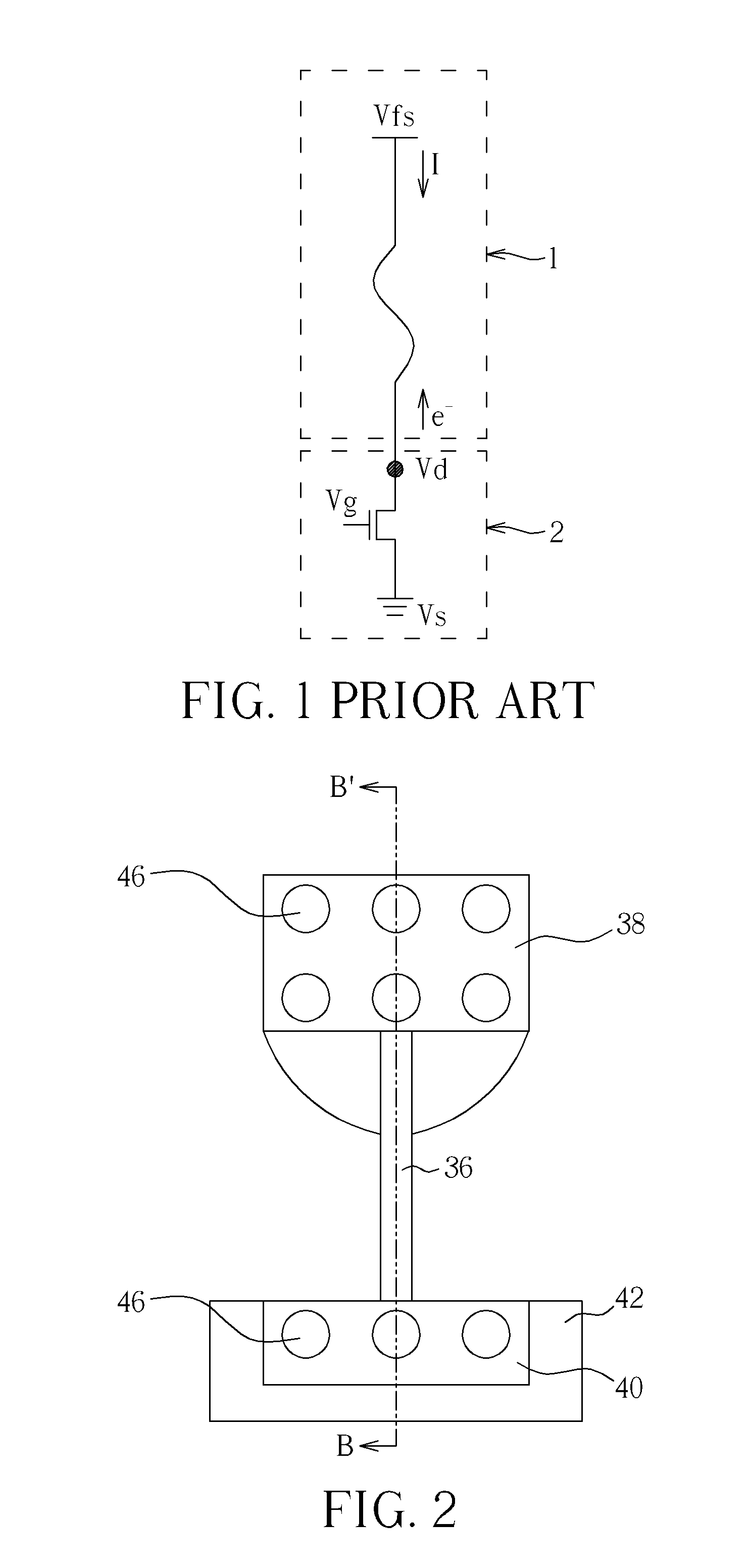

SEMICONDUCTOR DEVICE COMPRISING eFUSES OF ENHANCED PROGRAMMING EFFICIENCY

ActiveUS20100107403A1Increase current densityImprove toleranceFuse device manufactureSemiconductor/solid-state device detailsLinear configurationSemiconductor

In sophisticated integrated circuits, an electronic fuse may be formed such that an increased sensitivity to electromigration may be accomplished by including at least one region of increased current density. This may be accomplished by forming a corresponding fuse region as a non-linear configuration, wherein at corresponding connection portions of linear segments, the desired enhanced current crowding may occur during the application of the programming voltage. Hence, increased reliability and more space-efficient layout of the electronic fuses may be accomplished.

Owner:GLOBALFOUNDRIES US INC

Current fuse and method of making the current fuse

InactiveUS20050035841A1Fuse device manufactureWelding/cutting media/materialsHazardous substanceSolderability

In order to provide a current fuse with high solderability without containing harmful materials, solder chips containing 30 to 60 percent by weight of zinc, 0.1 to 2 percent by weight of copper, 0.1 to 1 percent by weight of nickel, and the remainder percent by weight being tin, or further containing 0.01 to 0.5 percent by weight of aluminum are inserted into the interior of the electrodes before pressing the electrodes into the ends of the substrate of the fuse, the exterior of the electrodes is heated to melt the solder chips, thereby connecting between the electrodes and the fuse wire.

Owner:KOA CORP

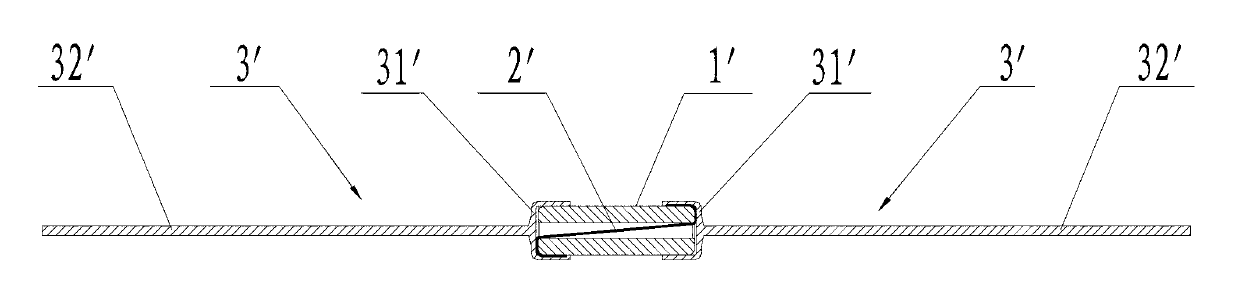

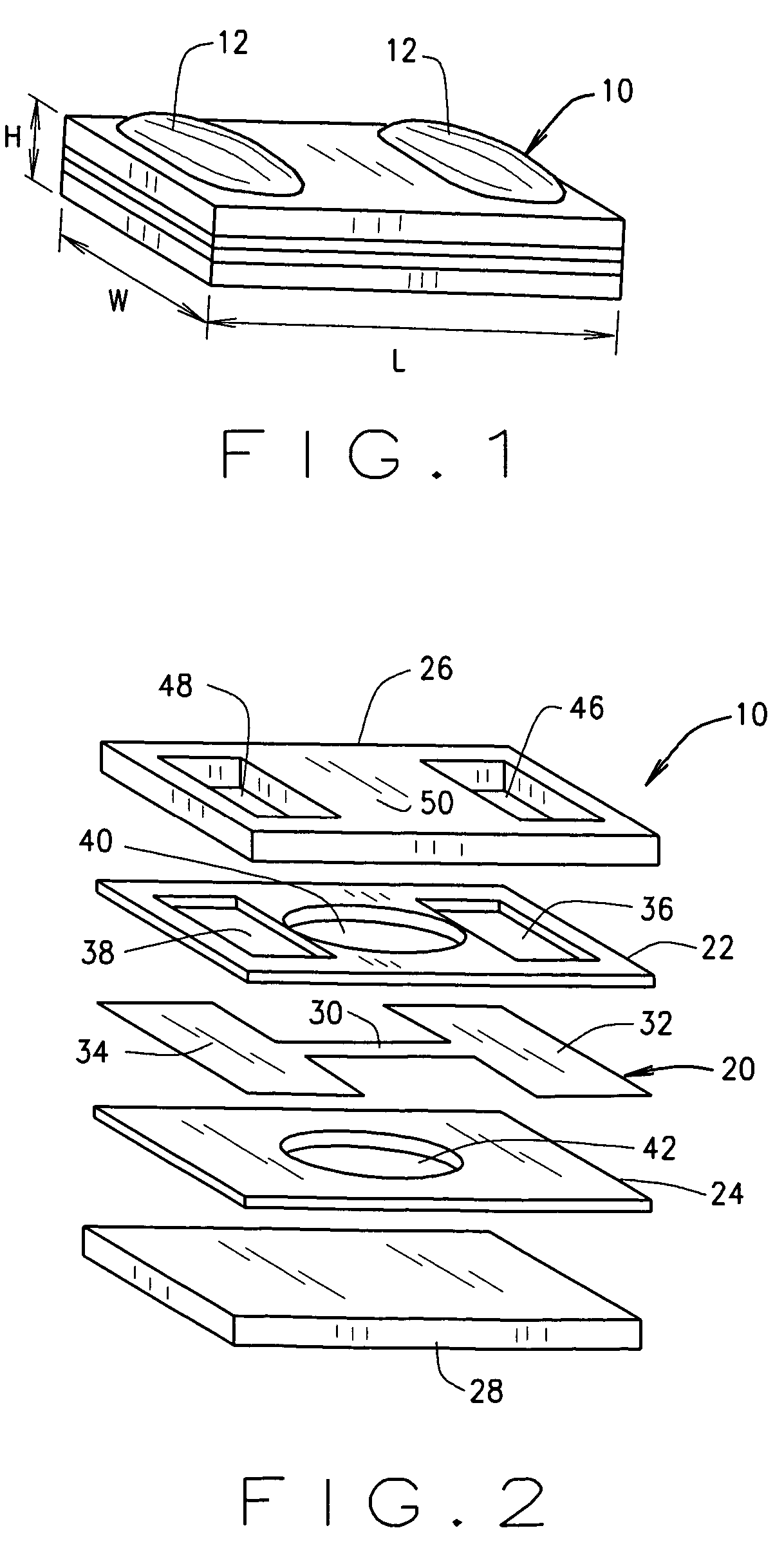

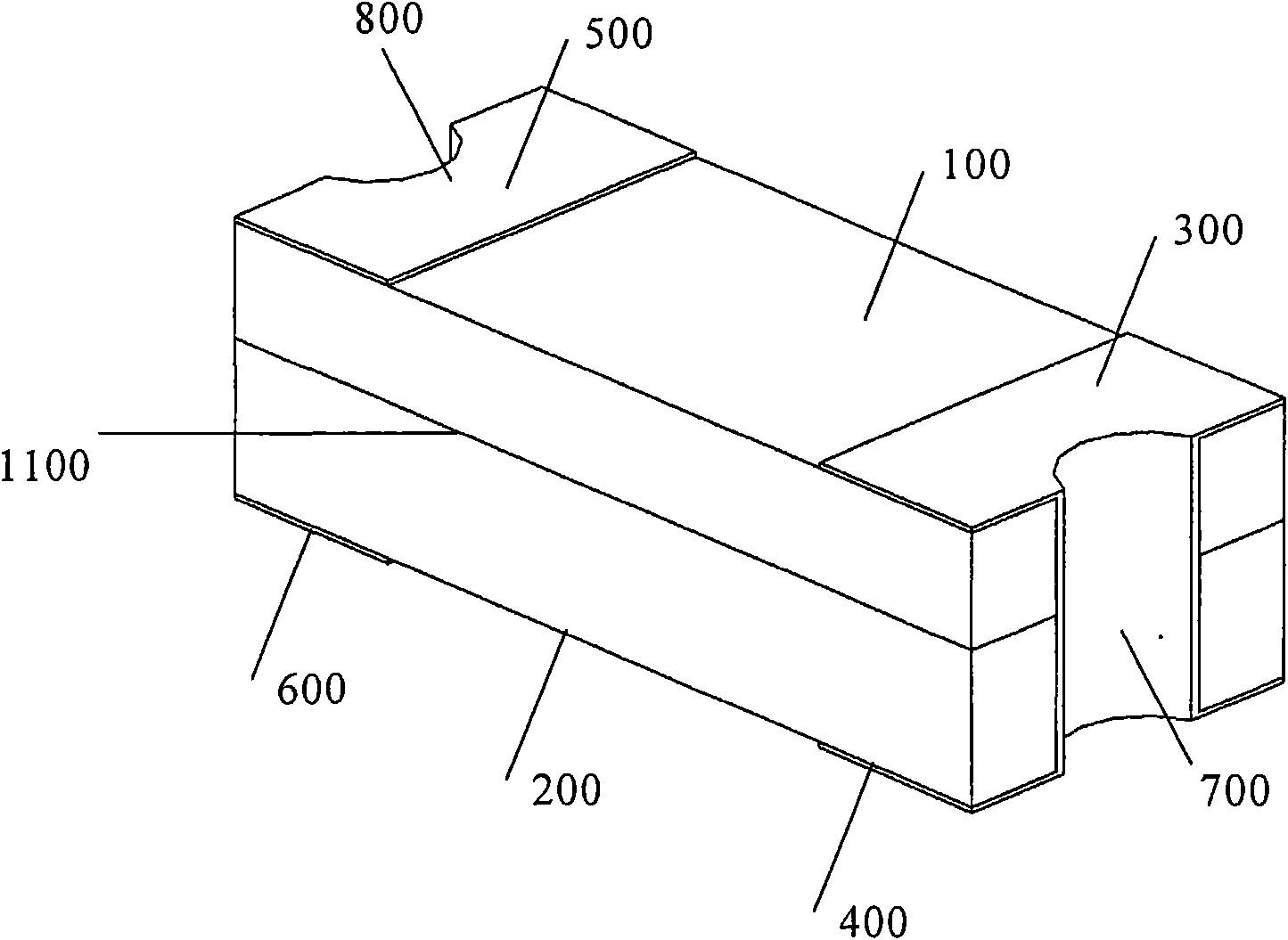

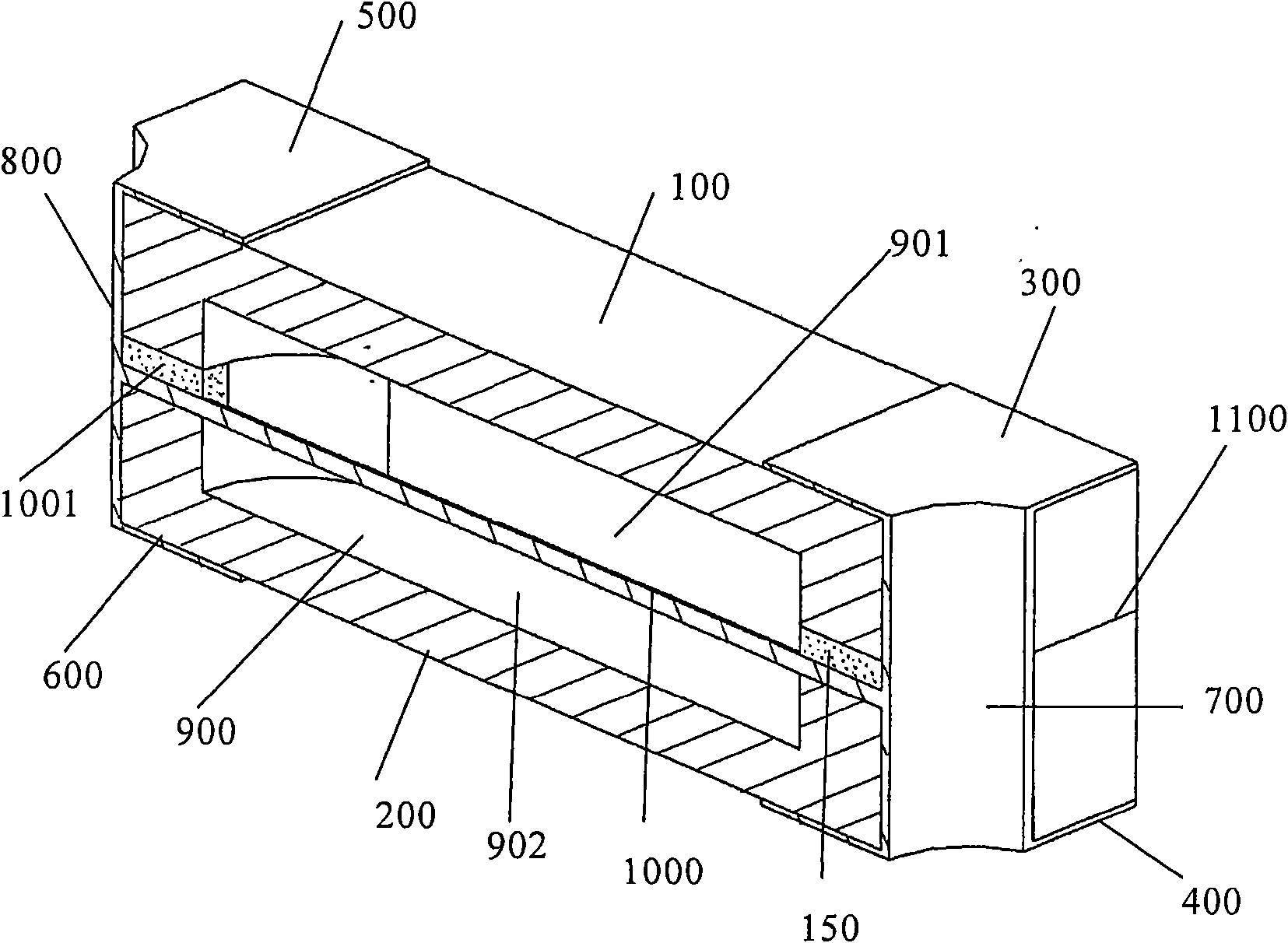

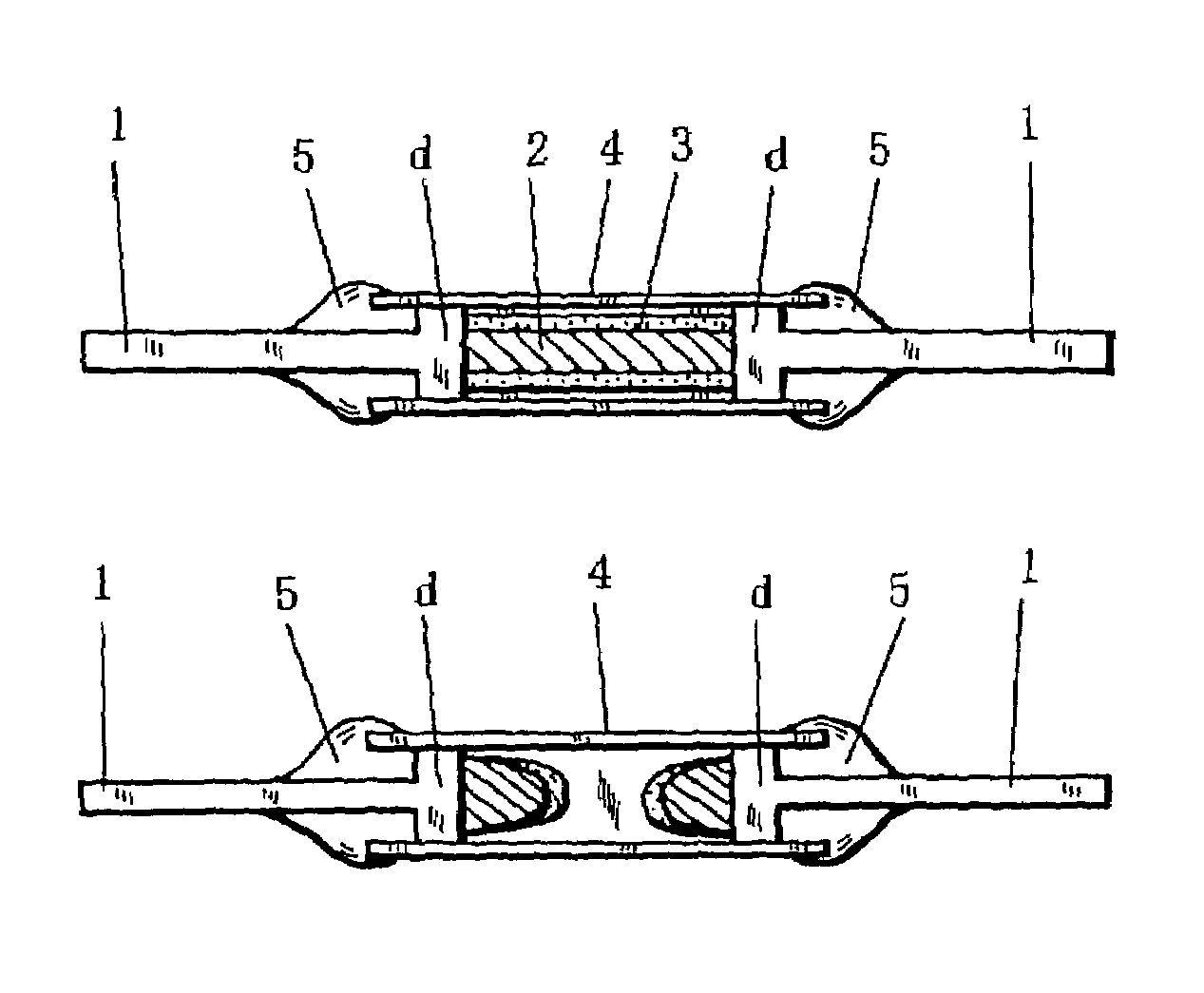

Surface mounting fuse protector and manufacturing method thereof

ActiveCN101567283AGuaranteed reliabilityGuaranteed SolderabilityFuse device manufactureBiochemical engineeringSurface mounting

The invention provides a surface mounting fuse protector and a manufacturing method thereof. The surface mounting fuse protector comprises an upper base plate, a lower base plate and a fuse wire, wherein one end of the outer side of the upper base plate is provided with a first end electrode, the other end of the same is provided with a second end electrode, and the middle of the inner side of the upper base plate is provided with a first recessed cavity; one end of the outer side of the lower base plate is provided with a third end electrode corresponding to the first end electrode, the other end of the same is provided with a fourth end electrode corresponding to the second end electrode, the middle of the inner side of the lower base plate is provided with a second recessed cavity corresponding to the first recessed cavity, and the first recessed cavity and the second recessed cavity together form a cavity; the fuse wire is clamped between the upper base plate and the lower base plate, a part of the fuse wire is suspended in the cavity, the first end electrode and the third end electrode are electrically connected with one end of the fuse wire, and the second end electrode and the fourth end electrode are electrically connected with the other end of the fuse wire. The wire suspending type surface mounting fuse protector reduces the heat transfer rate of the fuse wire at the periphery, is simple in structure and has the low stress of the fuse wire.

Owner:AEM COMPONENTS (SUZHOU) CO LTD

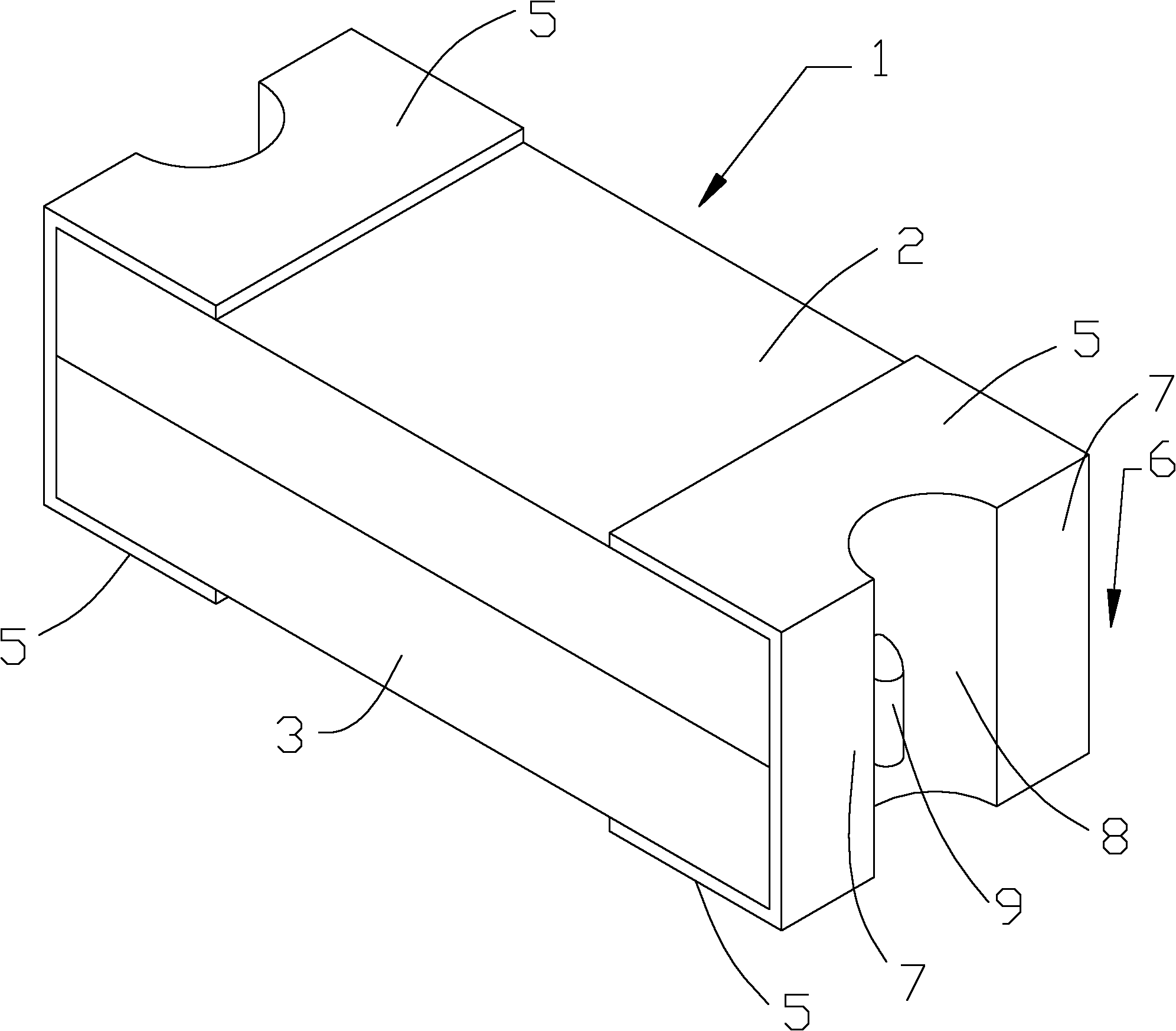

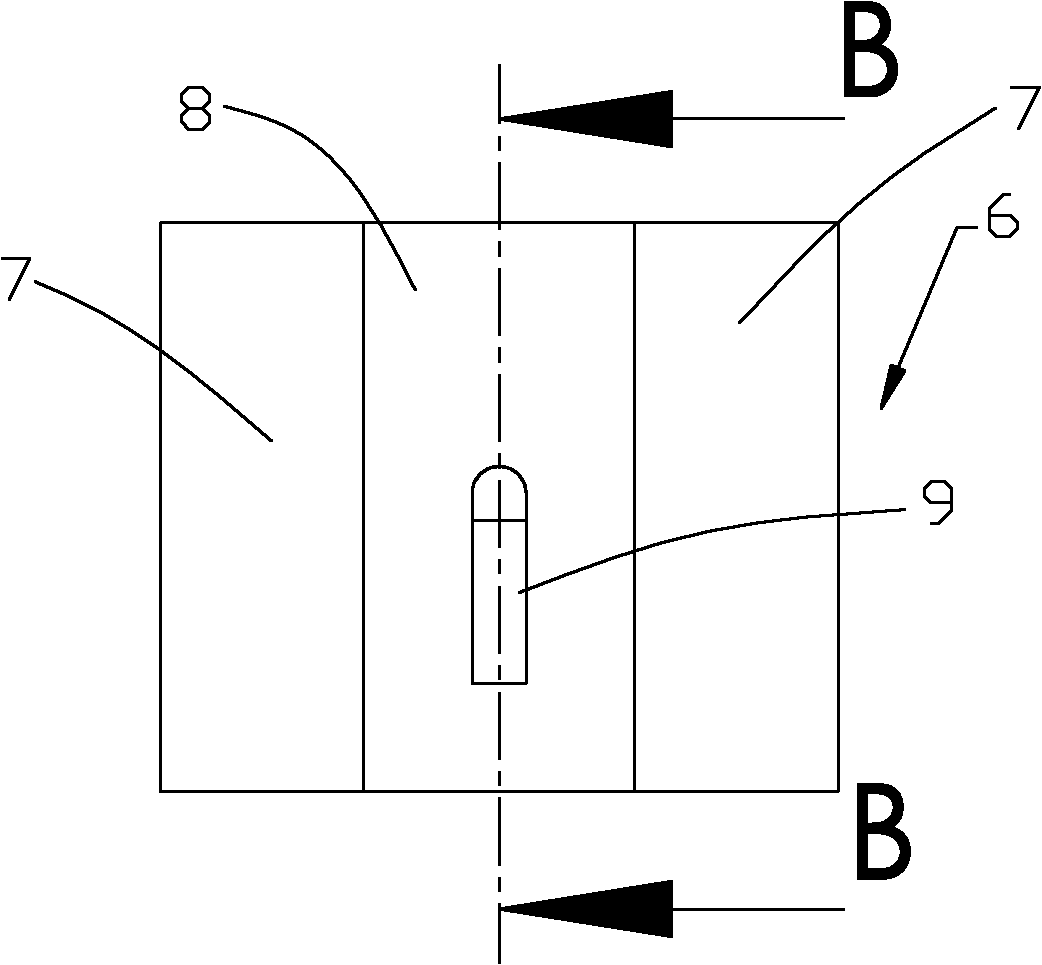

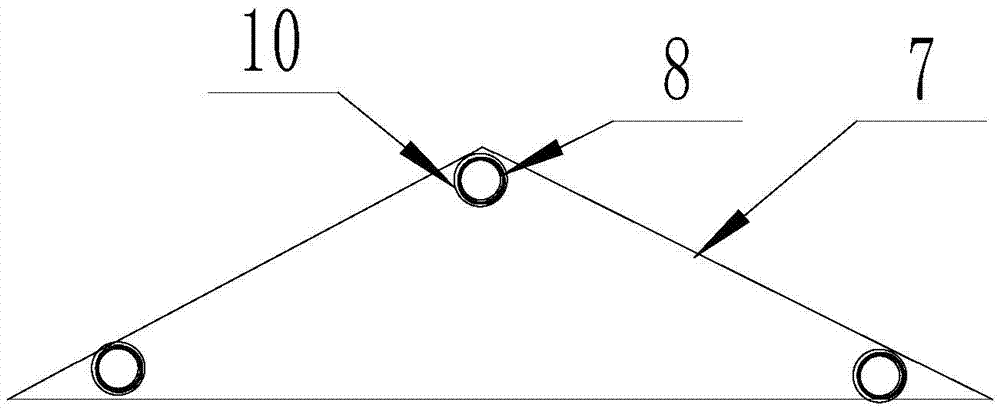

Suspended-fuse-wire-type surface-mount fuse and manufacturing method thereof

The invention discloses a suspended-fuse-wire-type surface-mount fuse and a manufacturing method thereof. In the fuse, an exposed end of a fuse wire is bent to be close to the end face of an insulator such that an end face electrode covers the total surface of the exposed bent end of the fuse wire; for a newly manufactured fuse, all of the bent end of the fuse wire is in contact with the end face electrode; when the fuse is under thermal shock, the fuse wire and the end face electrode can be ensured to be communicated with each under the condition that all the bent end of the fuse wire is ensured to be in contact with the end face electrode even though the fuse wire, the end face electrode and the insulator are subjected to harmomegathus difference, thus the reliability of the connection between the fuse wire and the end face electrode can be ensured; furthermore, if the bent end of the fuse wire, exposed out of the insulator, is totally arranged in the end face electrode in the fuse, the protection on the fuse and the prevention of flashover of a molten fuse wire on the end face during fuse melting are further ensured. A plurality of fuses are manufactured on a large substrate at the same time, and single fuses are separated in a cutting manner, thus the batch processing of the fuses is realized, and the production efficiency is improved; in addition, the end face electrodes of the manufactured fuses cover the whole end face and the bent end of the fuse wire, thus the weldability of the fuse on a PCB (Printed Circuit Board) is improved.

Owner:AEM COMPONENTS

Novel protective tube welding mechanical device

InactiveCN105448605AControllable distanceIncrease productivityFuse device manufactureEngineeringElectrical bonding

Owner:徐海慧

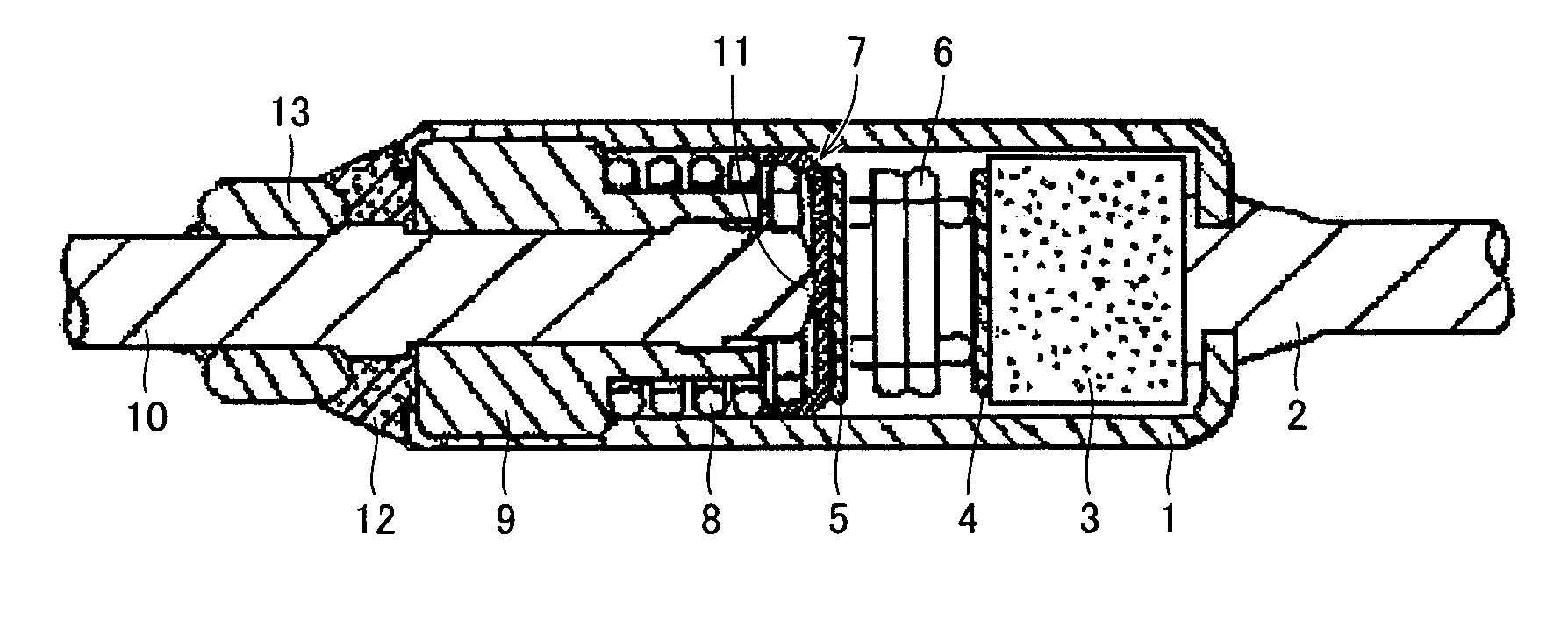

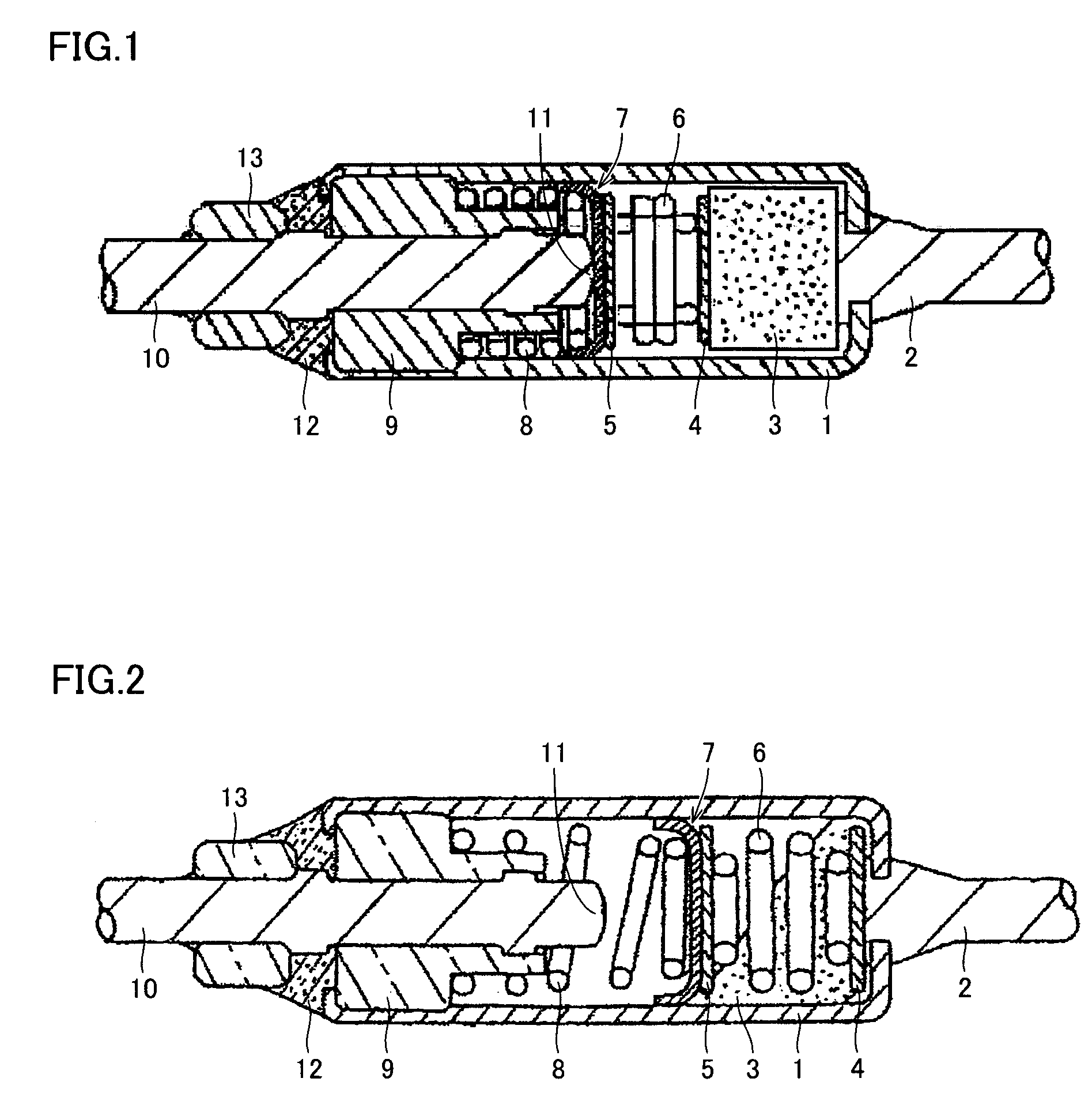

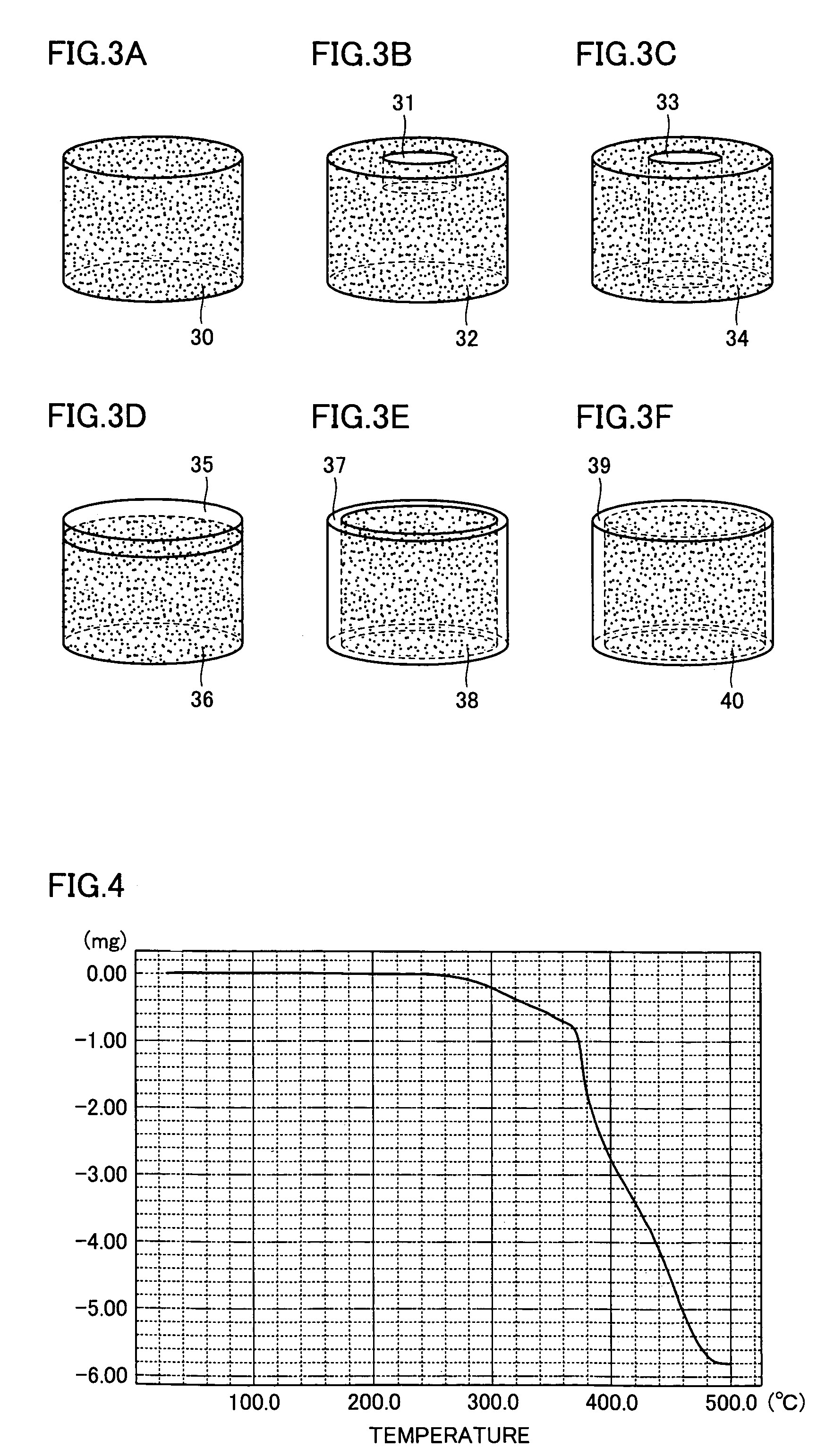

Thermal pellet incorporated thermal fuse and method of producing thermal pellet

ActiveUS7323966B2Improve featuresReduce deliquescenceFuse device manufactureHeating/cooling contact switchesHeat deflection temperatureHot melt

A thermal fuse incorporating a thermal pellet has its operating temperature, or heat distortion temperature, adjusted and the thermosensitive material of the pellet avoids deformation, modification or similar deficiency if it is exposed to a severe external environment. The inexpensive thermal fuse provides a wider range from which an operating temperature can be selected, improved insulation resistance after operation, faster response speed in operation, and enhanced strength of the thermal pellet. The thermosensitive material is formed of a thermoplastic resin corresponding to a high molecular weight substance. The thermal pellet's heat distortion temperature is adjusted by a temperature setting method. An enclosure of the fuse has a metal casing with a spring member's strong and weak compression springs both accommodated therein and hermetically sealed.

Owner:SCHOTT JAPAN CORP

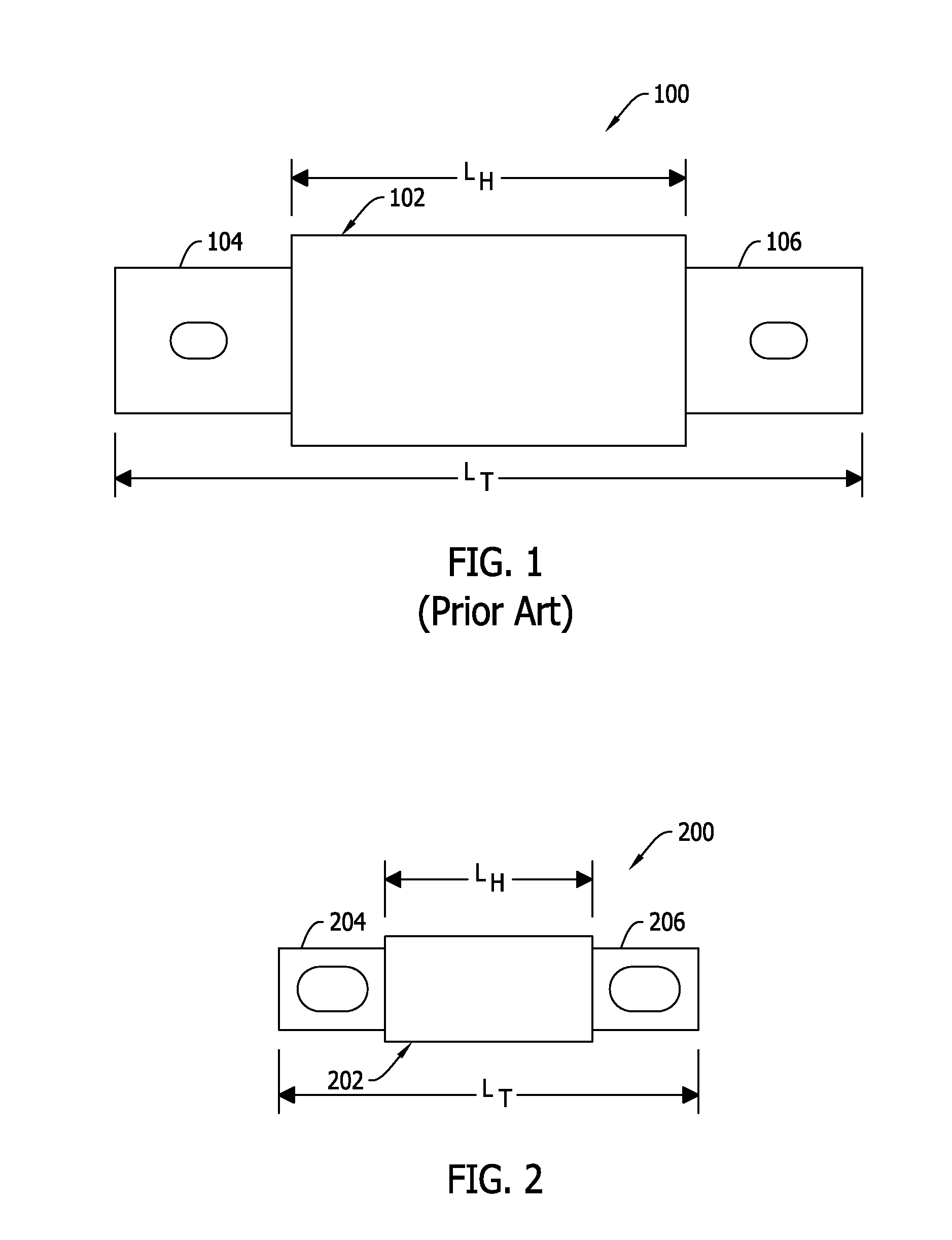

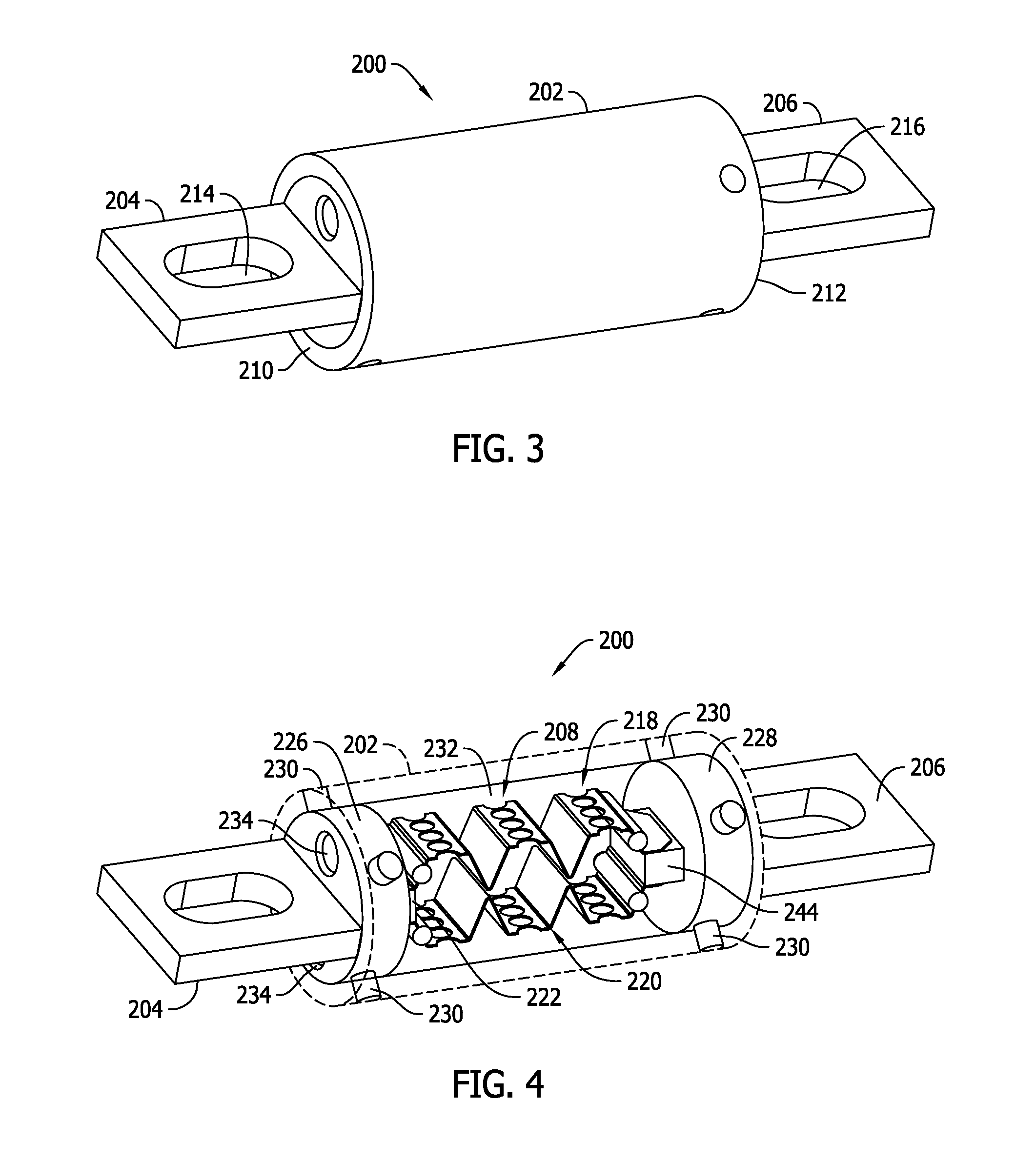

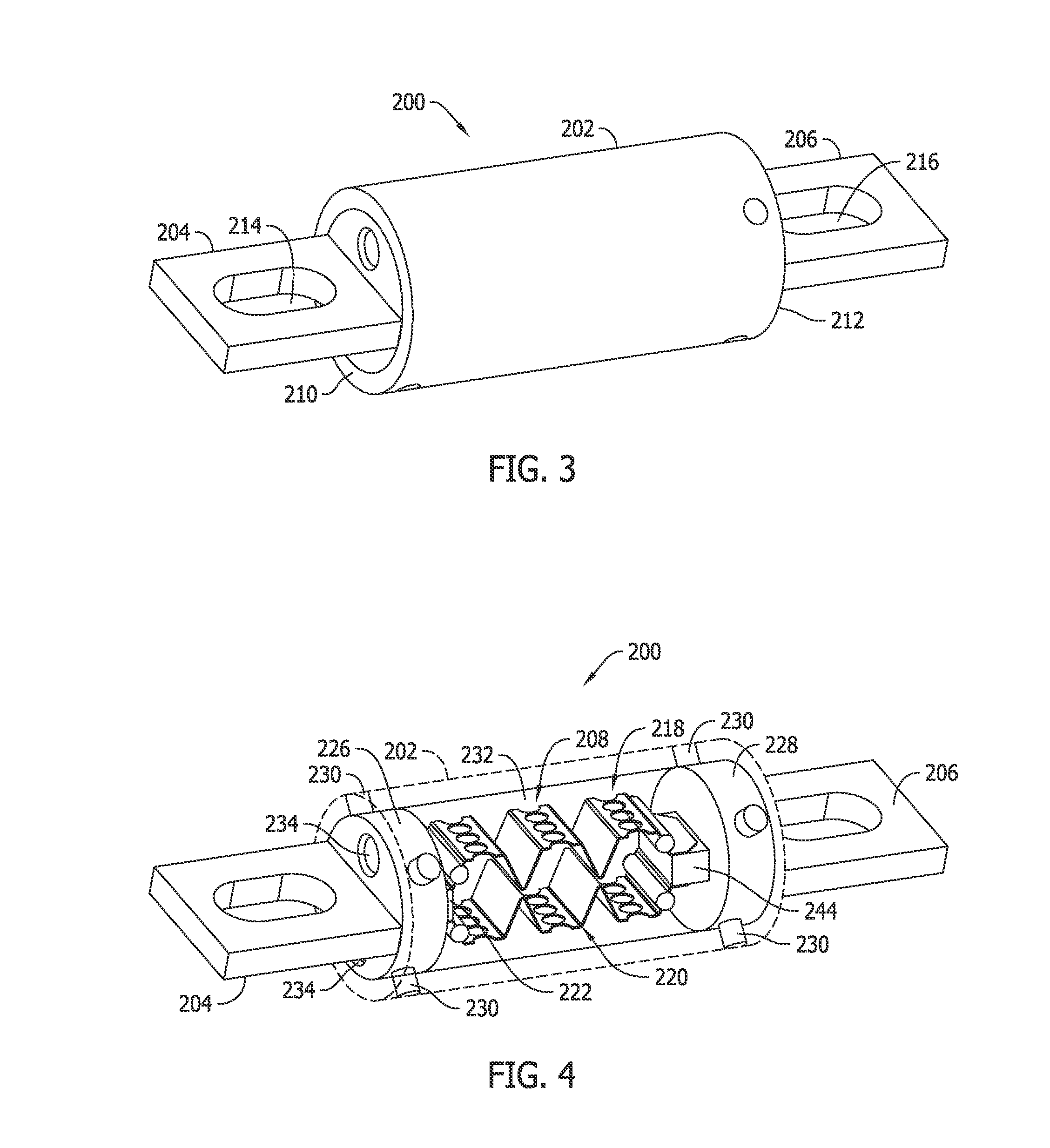

Compact high voltage power fuse and methods of manufacture

A high voltage power fuse having a dramatically reduced size facilitated by silicated filler material, a formed fuse element geometry, arc barrier materials and single piece terminal fabrications. Methods of manufacture are also disclosed.

Owner:EATON INTELLIGENT POWER LIMITED

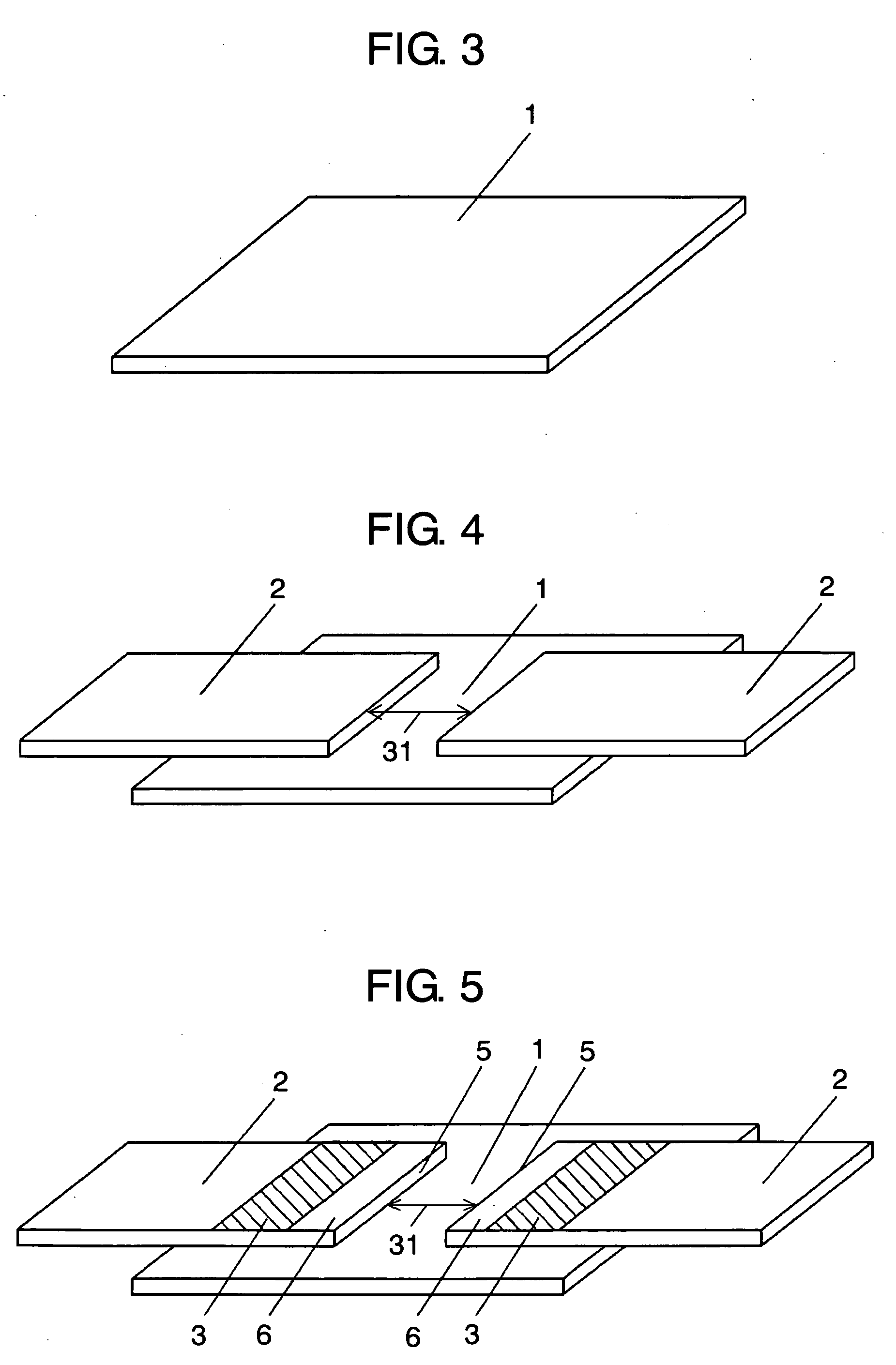

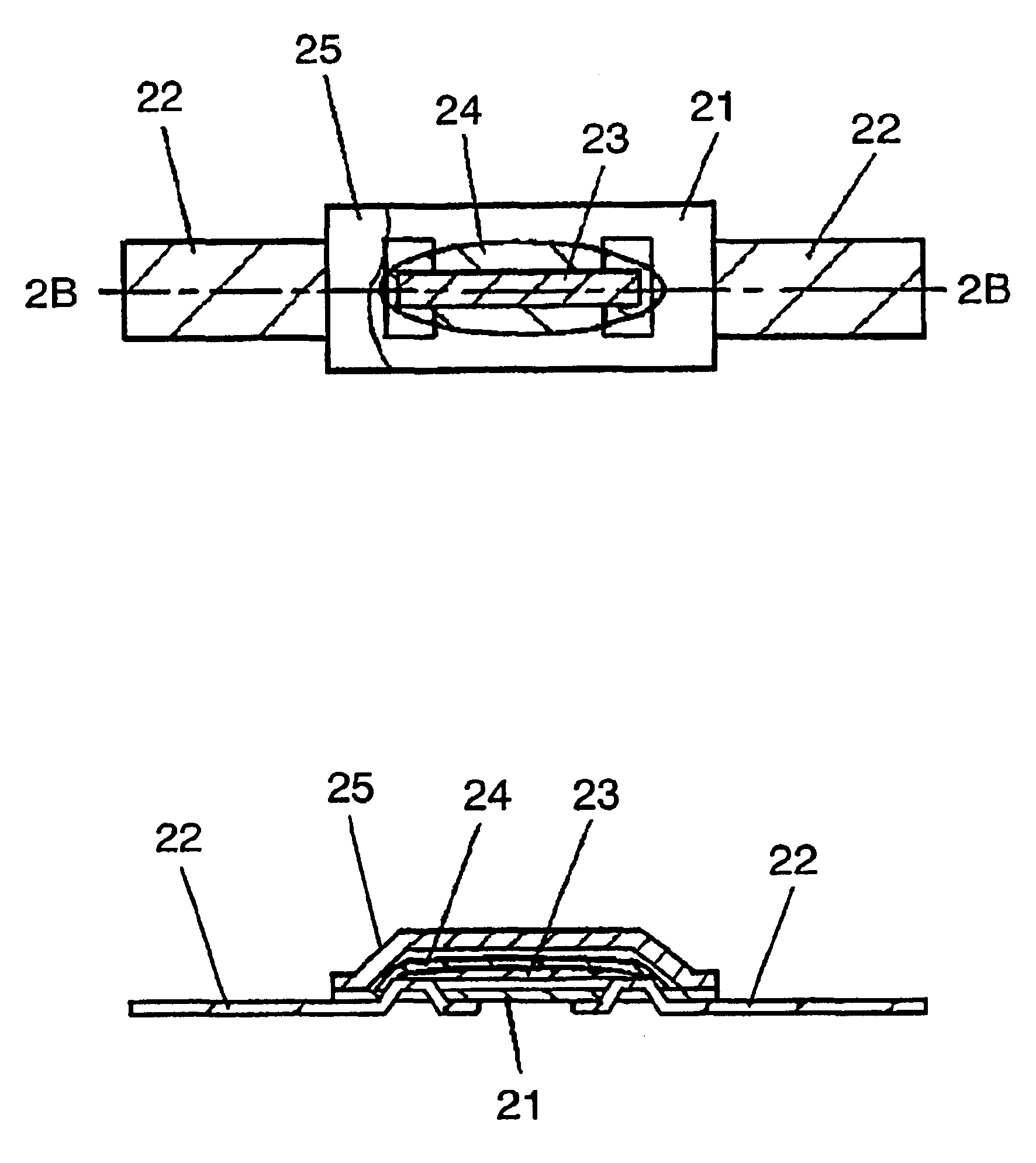

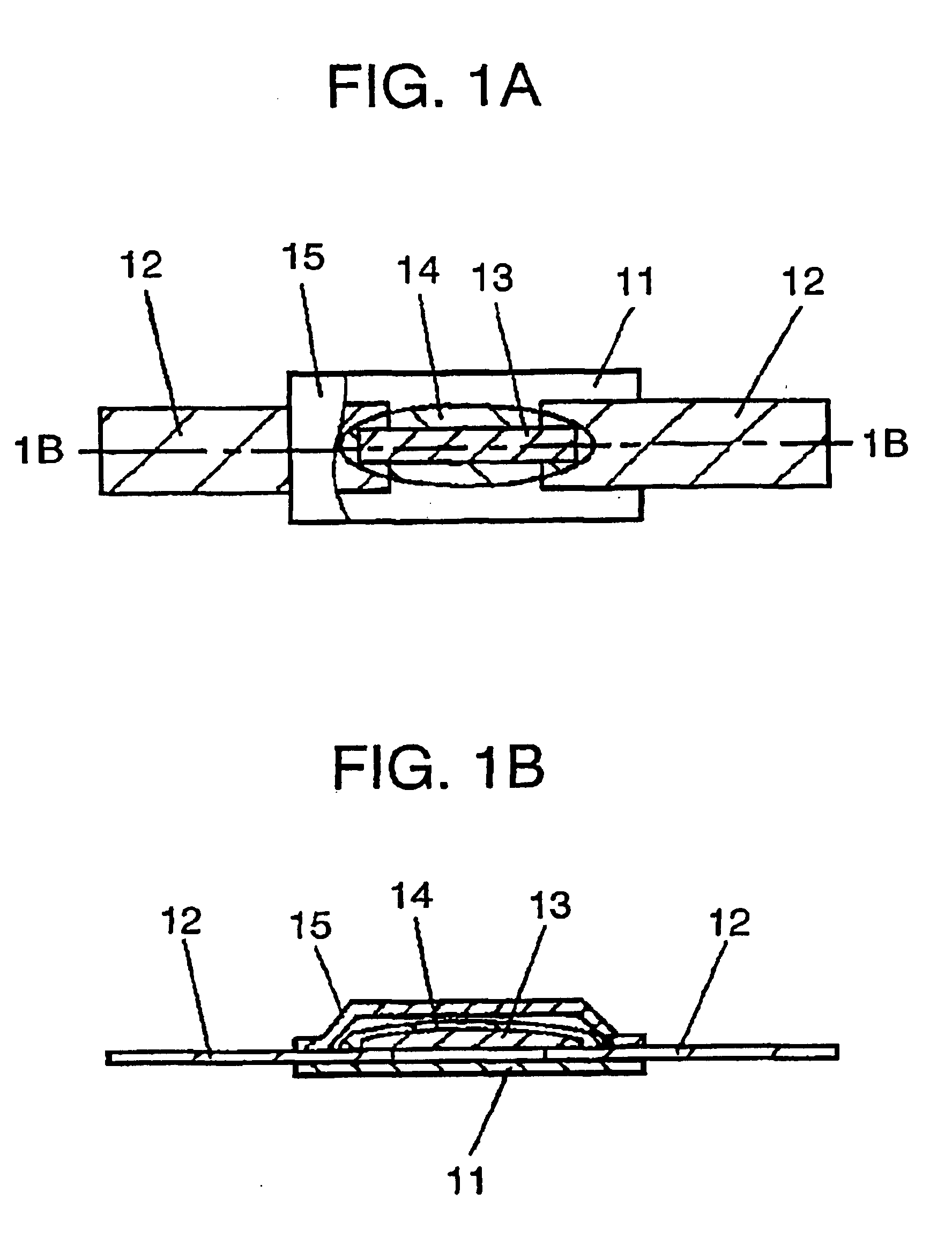

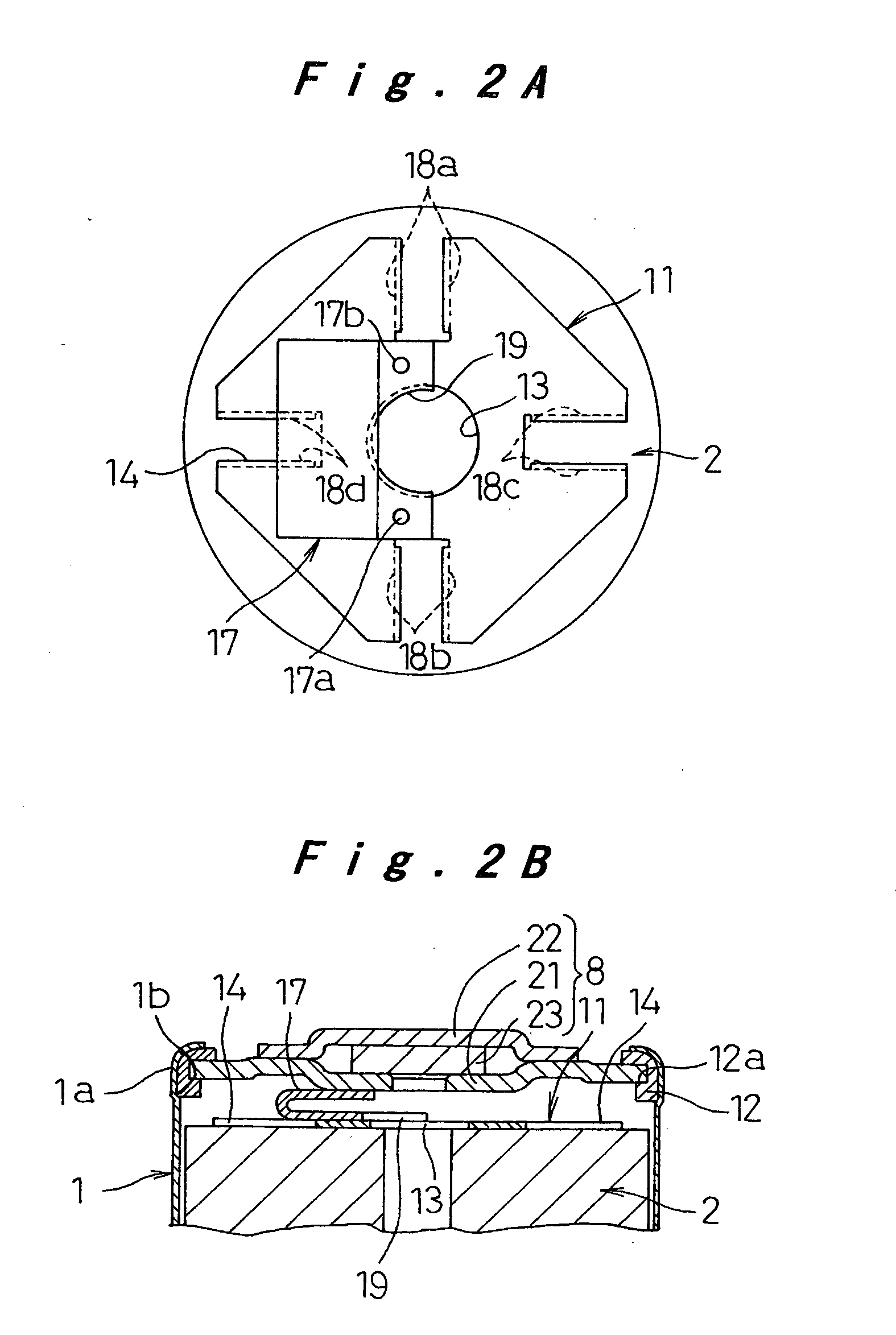

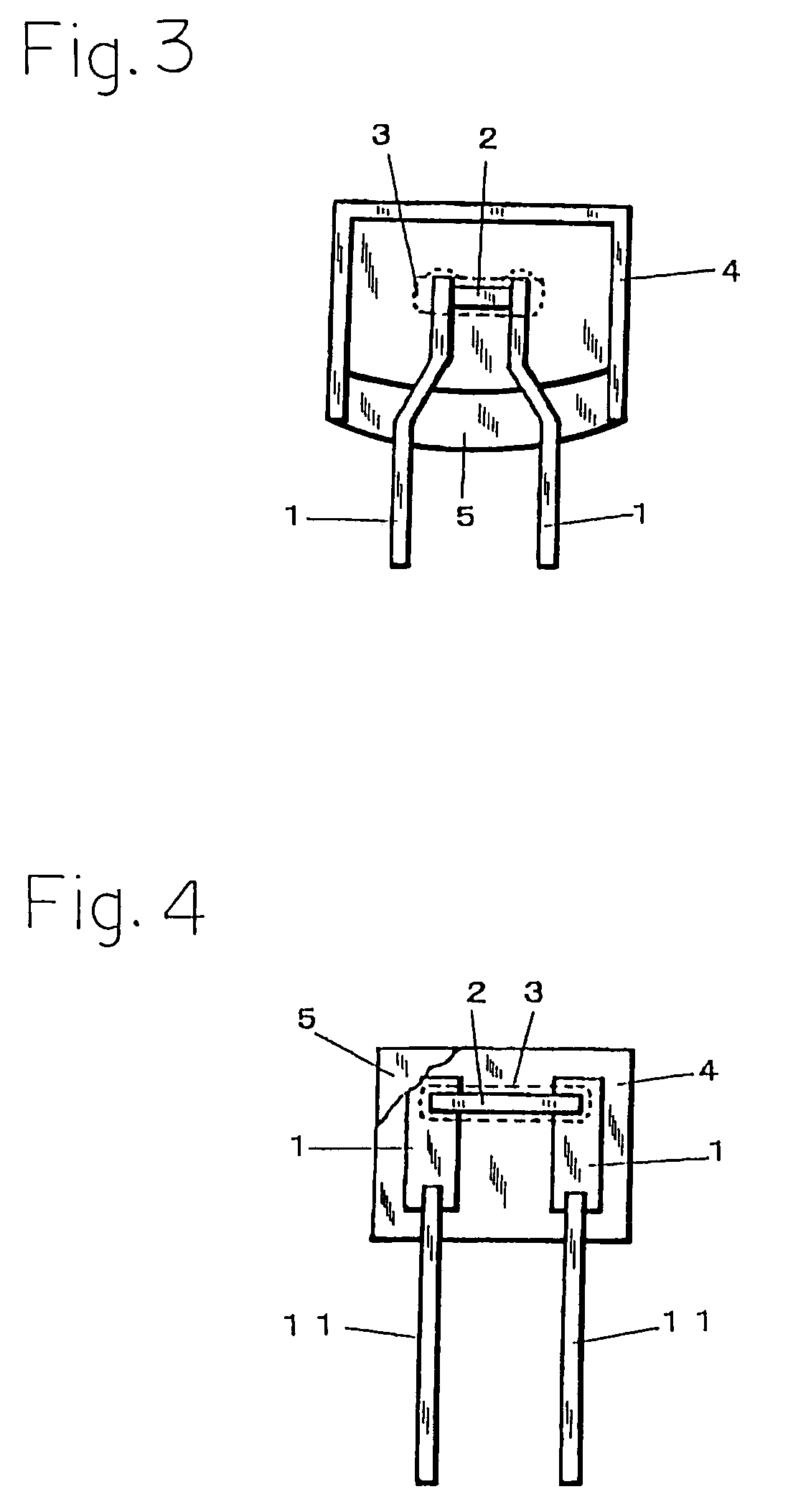

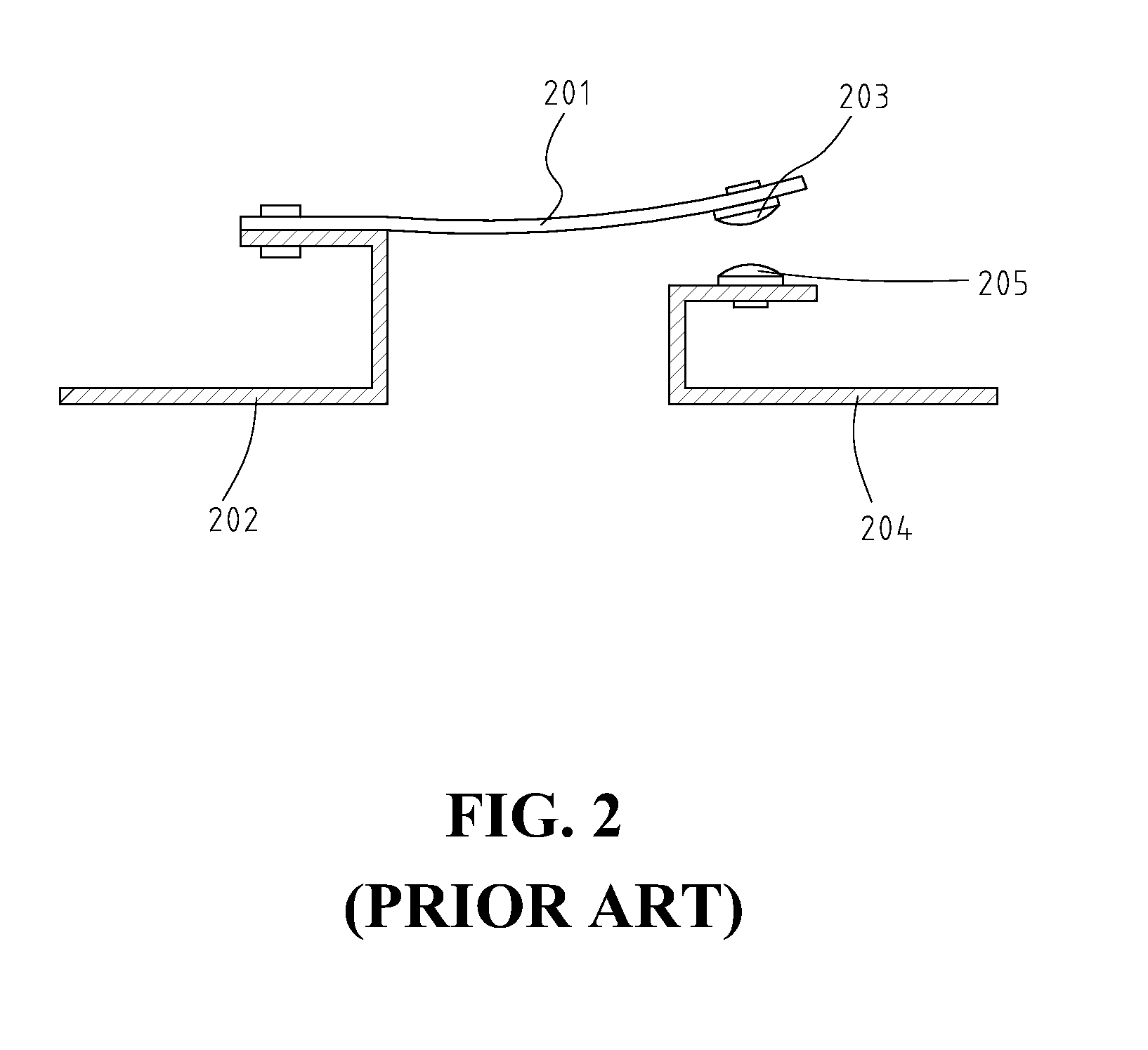

Thermal fuse

InactiveUS6838971B2Inspection is accurateEasy to distinguishFuse device manufactureHeating/cooling contact switchesGardner color scaleImaging processing

Quantity of flux coated on fusible alloy of a thermal fuse disclosed can be inspected accurately by an image processing method. The thermal fuse comprises:(a) first insulation film 11 coupled with a pair of metal terminals 12; (b) fusible alloy 13 coupled between ends of the metal terminals 12, being placed above first insulation film 11; (c) flux 14 coated on fusible alloy 13; and(d) second insulation film 15 disposed on first insulation film 11 so that an internal space is formed, being placed above fusible alloy 13, wherein at least either of first insulation film 11 or second insulation film 15 is transparent or translucent, and flux 14 has the Gardner color scale from 4 to 16.

Owner:PANASONIC CORP

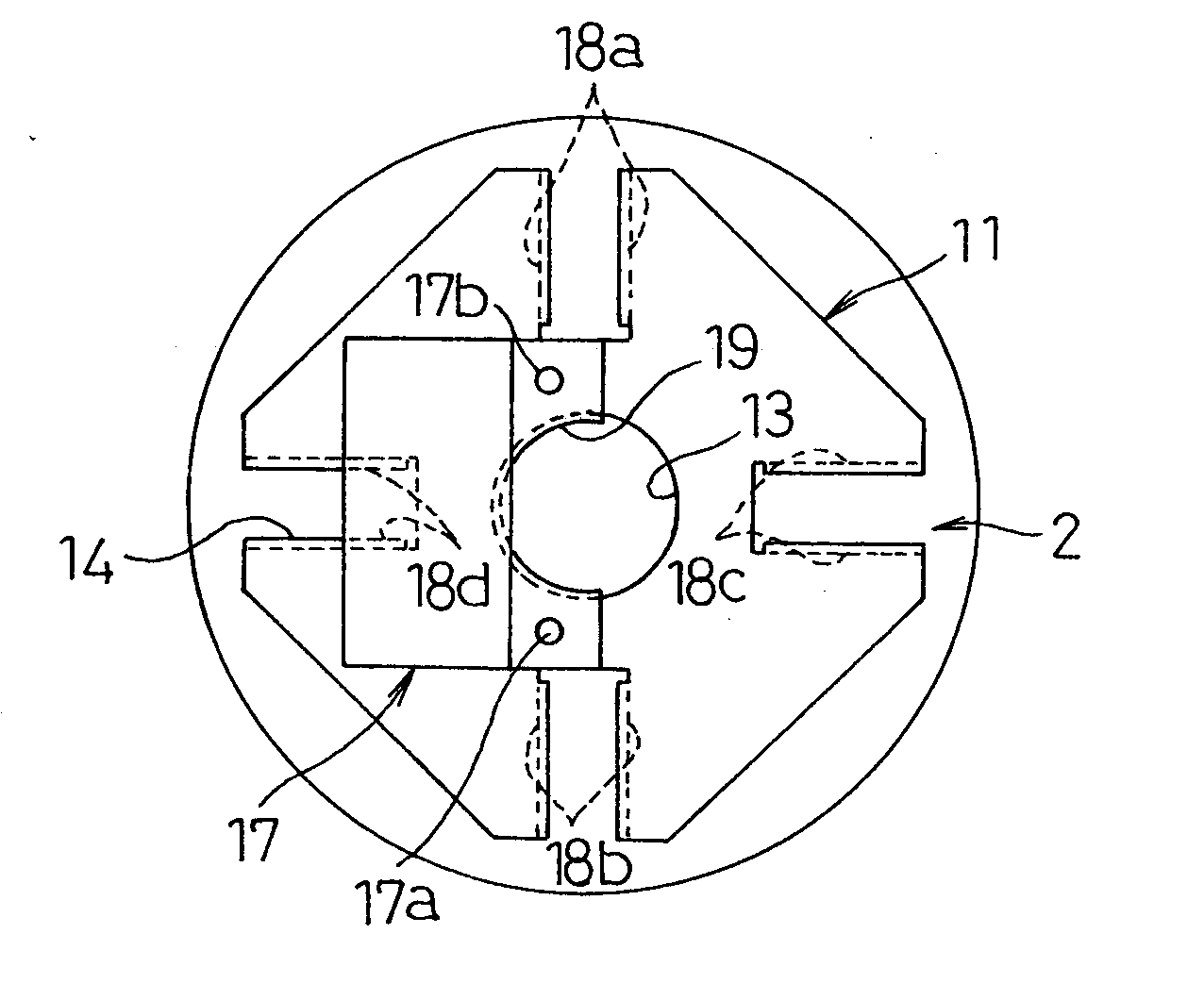

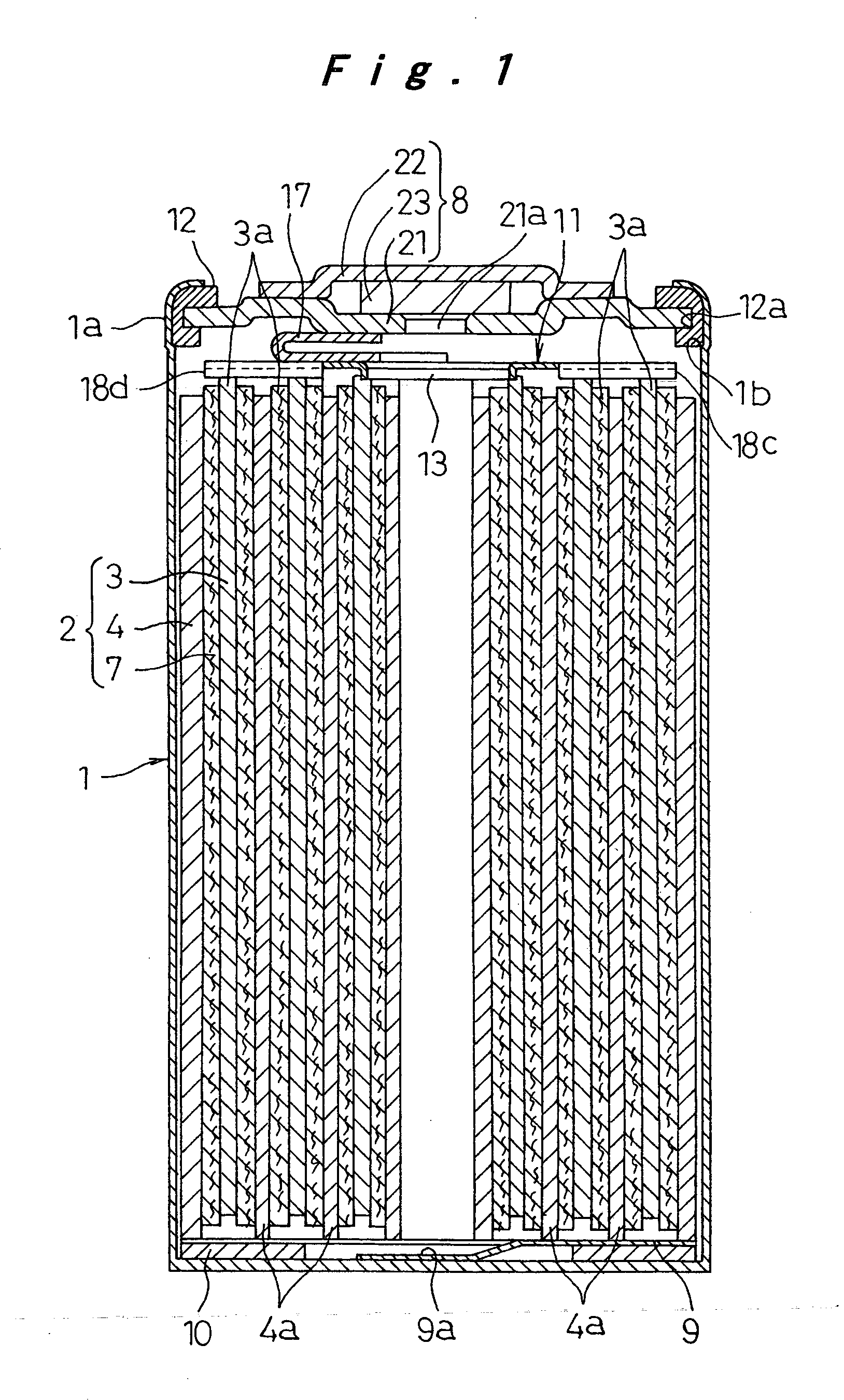

Battery and method for manufacturing the same

InactiveUS20050147878A1Lower internal resistanceEasy to makeFuse device manufactureFinal product manufactureInternal resistanceElectrical polarity

A battery having a collecting structure that can reduce internal resistance of the battery and a structure that allows easy manufacturing of the battery by the following processes is provided. An enlarged portion is formed near an opening end of a battery case and a supporting ledge is provided on the inner surface of the lower end of the enlarged portion. A collector of one polarity is bonded to an electrode plate group. A connection lead is bonded to the collector at one end and is bonded to a lower surface of a sealing member at the other end. An insulation gasket is mounted to a peripheral edge portion of the sealing member from a side opposite to the collector. The peripheral edge portion of the sealing member is supported by the supporting ledge with the insulation gasket interposed therebetween. Then, the peripheral edge portion of the sealing member is horizontally fastened and securely held via the insulation gasket by caulking the opening end of the battery case and performing a process for reducing the diameter of the enlarged portion.

Owner:PANASONIC CORP

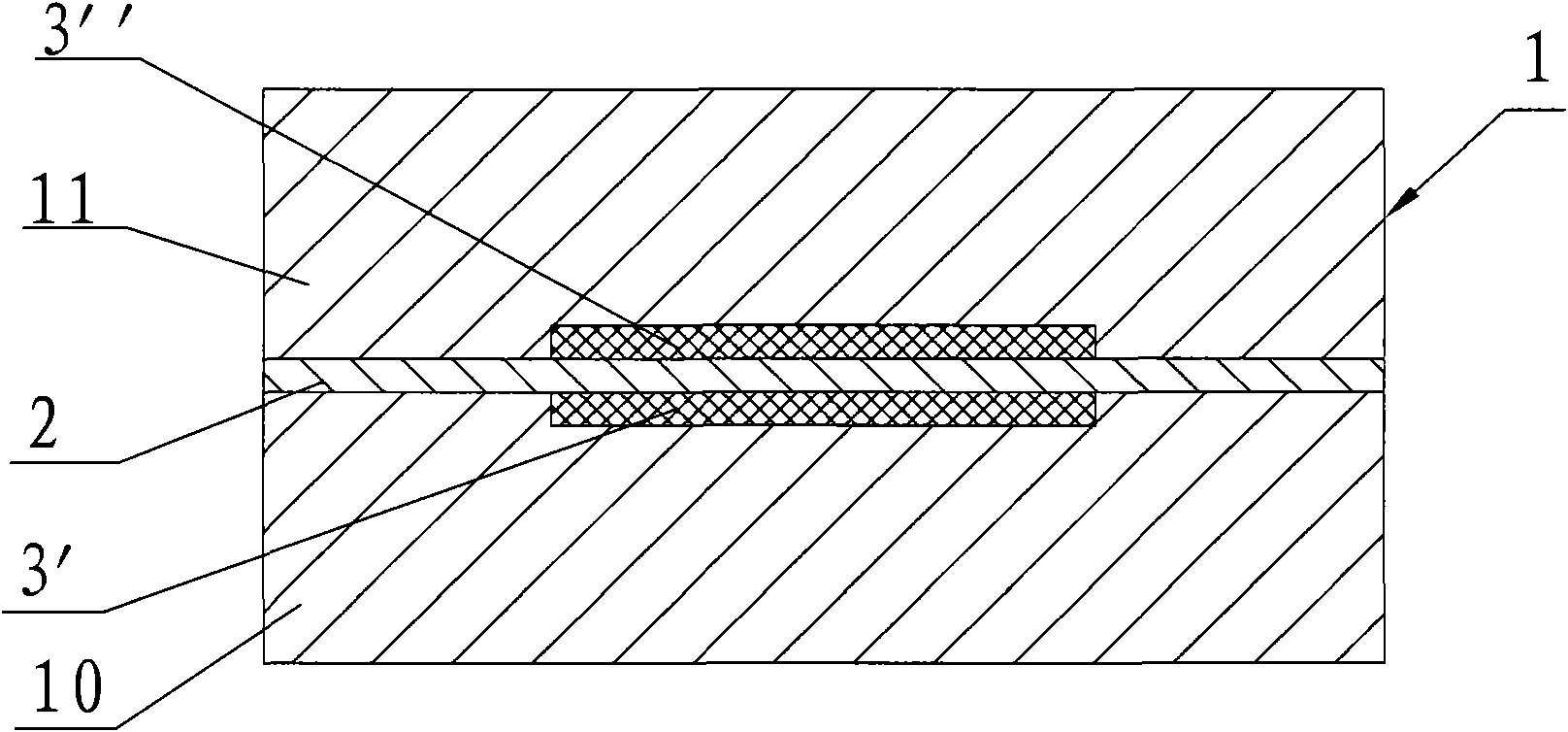

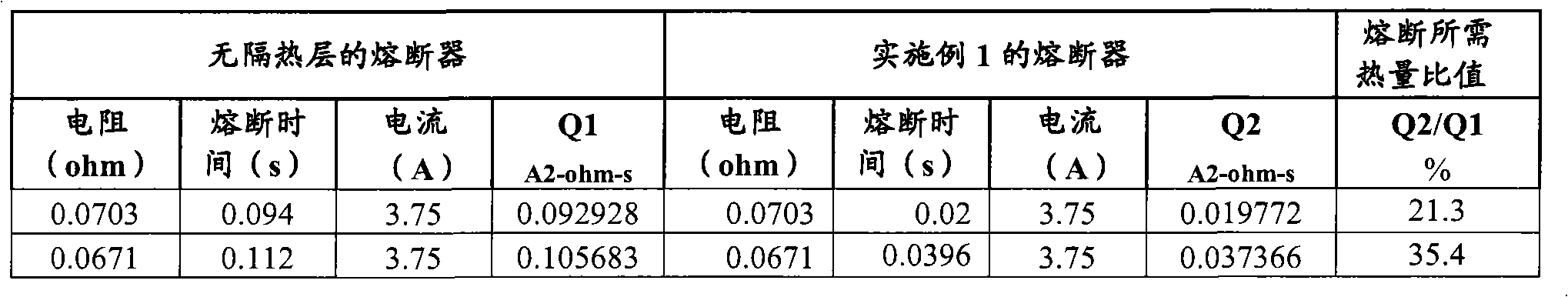

Fuse with built-in thermal-protective coating and manufacture process thereof

ActiveCN102013368AReduce heat transferLower resistanceFuse device manufactureCeramic compositeElectrical conductor

The invention relates to a fuse and a production process thereof, wherein the fuse comprises a glass-ceramic substrate, a fusible metallic conductor built in the glass-ceramic substrate, a thermal-protective coating arranged on at least one face of the fusible metallic conductor, and a terminal electrode arranged on the glass-ceramic substrate, and the thermal-protective coating is made of a porous glass-ceramic composite material. In the manufacture process, an ultraviolet curing technology is utilized, and the fuse is produced through low temperature cofiring after UV (ultraviolet) curing. The thermal-protective coating has low heat conductivity, so that the radiating of the metallic conductor is effectively reduced, and the required resistance is much smaller at the fuse demand of certain current intensity. The manufacture process provided by the invention is simple, each coating of the fuse is combined compactly, and the fuse has outstanding arc extinction performance and higher stability. The surface- mounted fuse in the structure not only has high reliable fusing property, but also has the characteristics of low resistance and low power consumption, therefore the energy consumption in the circuit can be reduced, energy sources are saved, and the fuse can be widely used in the circuit protection of mini portable electronic products.

Owner:AEM COMPONENTS (SUZHOU) CO LTD

Alloy type thermal fuse and wire member for a thermal fuse element

InactiveUS7042327B2Improve tensile propertiesEasy to thinFuse device manufactureHeating/cooling contact switchesHot meltOperating temperature range

An alloy type thermal fuse is provided in which a ternary Sn—In—Bi alloy is used, the operating temperature belongs to the range of 130 to 170° C., the overload characteristic and the dielectric breakdown characteristic are excellent, the insulation stability after an operation can be sufficiently ensured, and thinning of a fuse element can be easily realized. A fuse element having an alloy composition in which Sn is larger than 43% and 70% or smaller, In is 0.5% or higher and 10% or lower, and a balance is Bi is used.

Owner:UCHIHASHI ESTEC

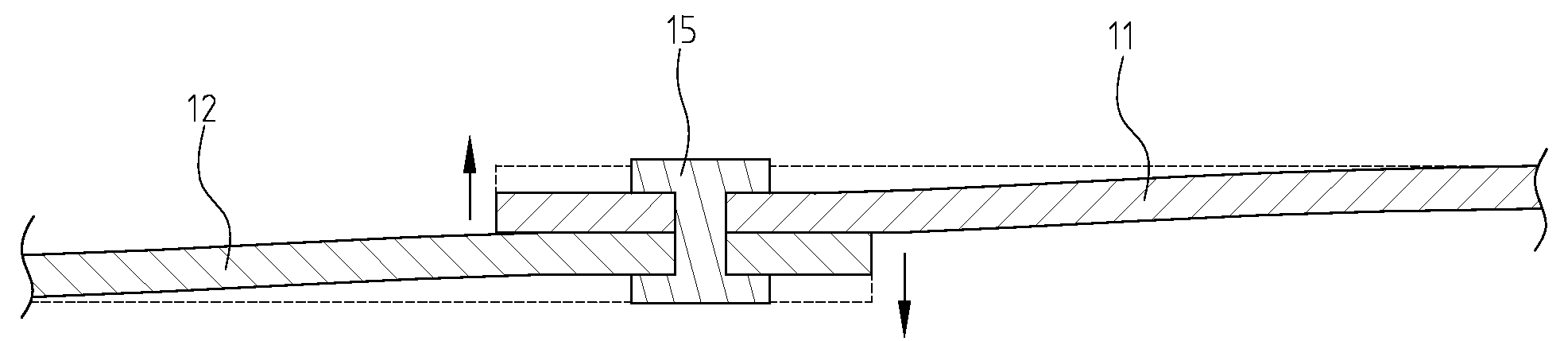

Temperature Fuse Protection Device

InactiveUS20080117016A1Unstable operationSolution to short lifeFuse device manufactureHeating/cooling contact switchesElectricityHot melt

A temperature fuse protection device uses a hot melt metal to rivet for connecting two terminals in the circuit that are separated for making the two terminals electrically-connected and the circuit complete. There is a spacing in between the two free ends of the two terminals when no external force is being imposed. When an electric overloading or high circuit temperature event occurs, the hot melt metal would be heated to melt and break, which would then make the free ends of the two terminals to be disconnected, and therefore, the circuit will be at “OFF” status.

Owner:YU TSUNG MOU

Fuse threading weld capper

InactiveCN101030504AOvercome longevityOvercome efficiencyFuse device manufactureProcess equipmentEngineering

The invention is concerned with a kind of process equipment for produce production, especially a kind of wire feeding welding machine with fuse for fusible core. The worktable fixed on the frame has turning plate frame with at least four tasks and the task has movable clamp extended among the radial direction, and at the corresponding position to each task, there are tube push framework, wire feeding welding upper cap framework, welding down cap framework, location framework and stuff-accepting framework on the surface of worktable. Except the stuff-accepting framework, each of the aforesaid framework drives by each cam and drive pole under the worktable. The tube push framework connects with tube feeding equipment, and the wire feeding welding upper cap framework connects with upper cap feeding equipment, the welding down cap framework connects with down cap feeding equipment. The worktable and / or turning plate has equipment that keeps clamp moving. The drive axis drives by motor, the feeding equipment, heating equipment and motor of the tube, upper cap and down cap monitors by power control equipment.

Owner:李风雷

Metal fuse structure for improved programming capability

InactiveUS20130214894A1More controlled and predictable final resistanceFuse device manufactureSemiconductor/solid-state device detailsElectrical resistance and conductanceElectrical conductor

Structure providing more reliable fuse blow location, and method of making the same. A vertical metal fuse blow structure has, prior to fuse blow, an intentionally damaged portion of the fuse conductor. The damaged portion helps the fuse blow in a known location, thereby decreasing the resistance variability in post-blow circuits. At the same time, prior to fuse blow, the fuse structure is able to operate normally. The damaged portion of the fuse conductor is made by forming an opening in a cap layer above a portion of the fuse conductor, and etching the fuse conductor. Preferably, the opening is aligned such that the damaged portion is on the top corner of the fuse conductor. A cavity can be formed in the insulator adjacent to the damaged fuse conductor. The damaged fuse structure having a cavity can be easily incorporated in a process of making integrated circuits having air gaps.

Owner:GLOBALFOUNDRIES INC

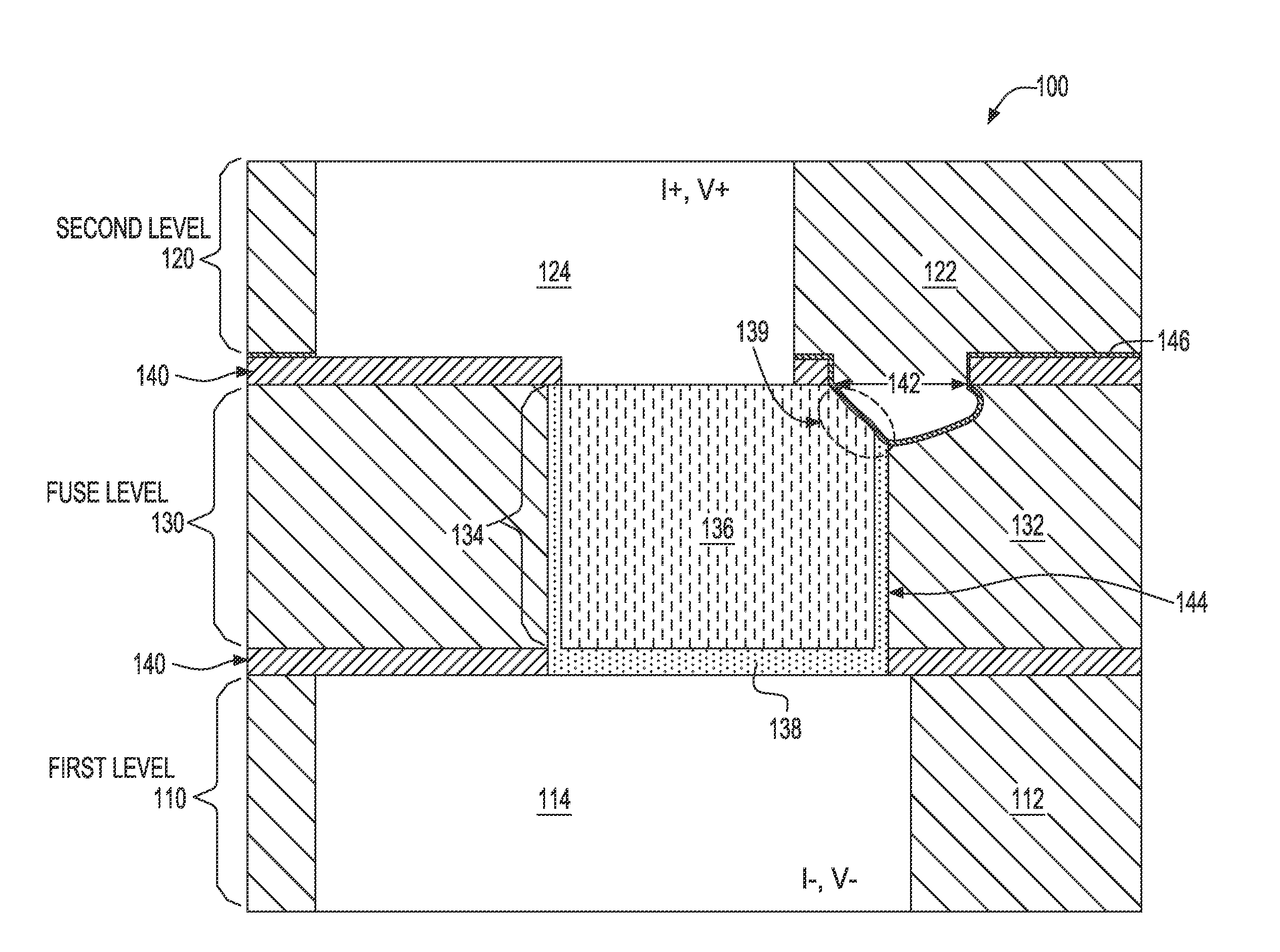

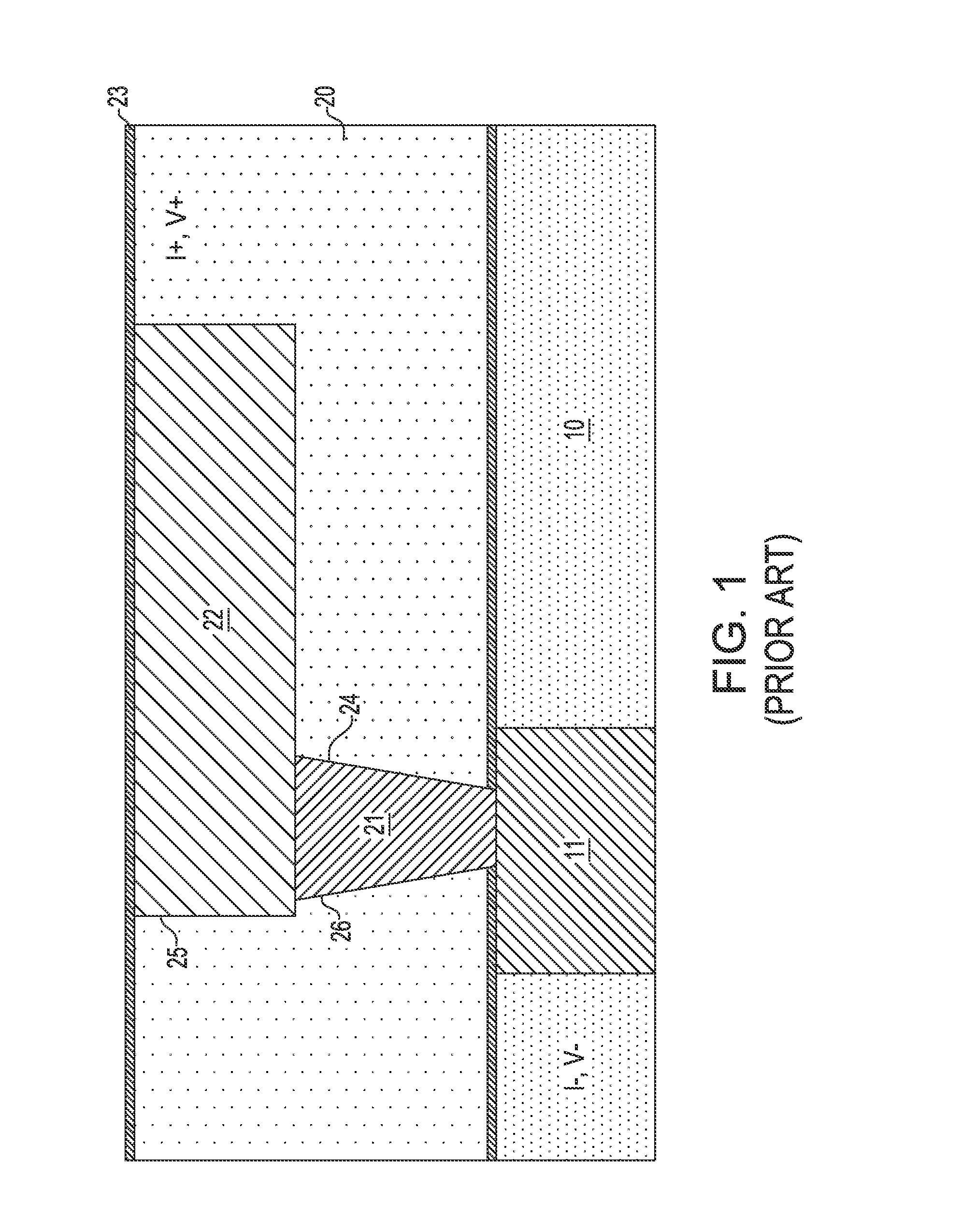

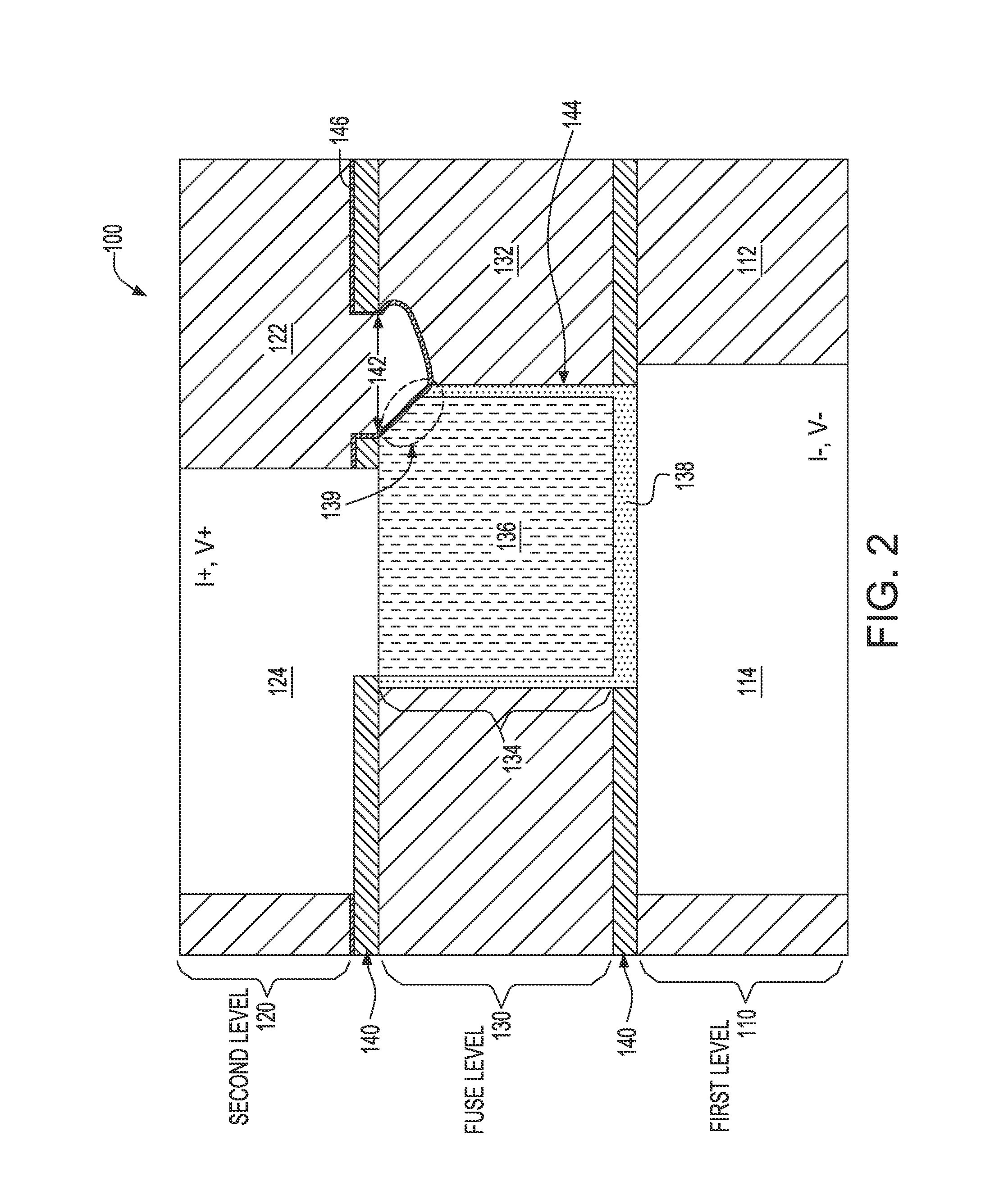

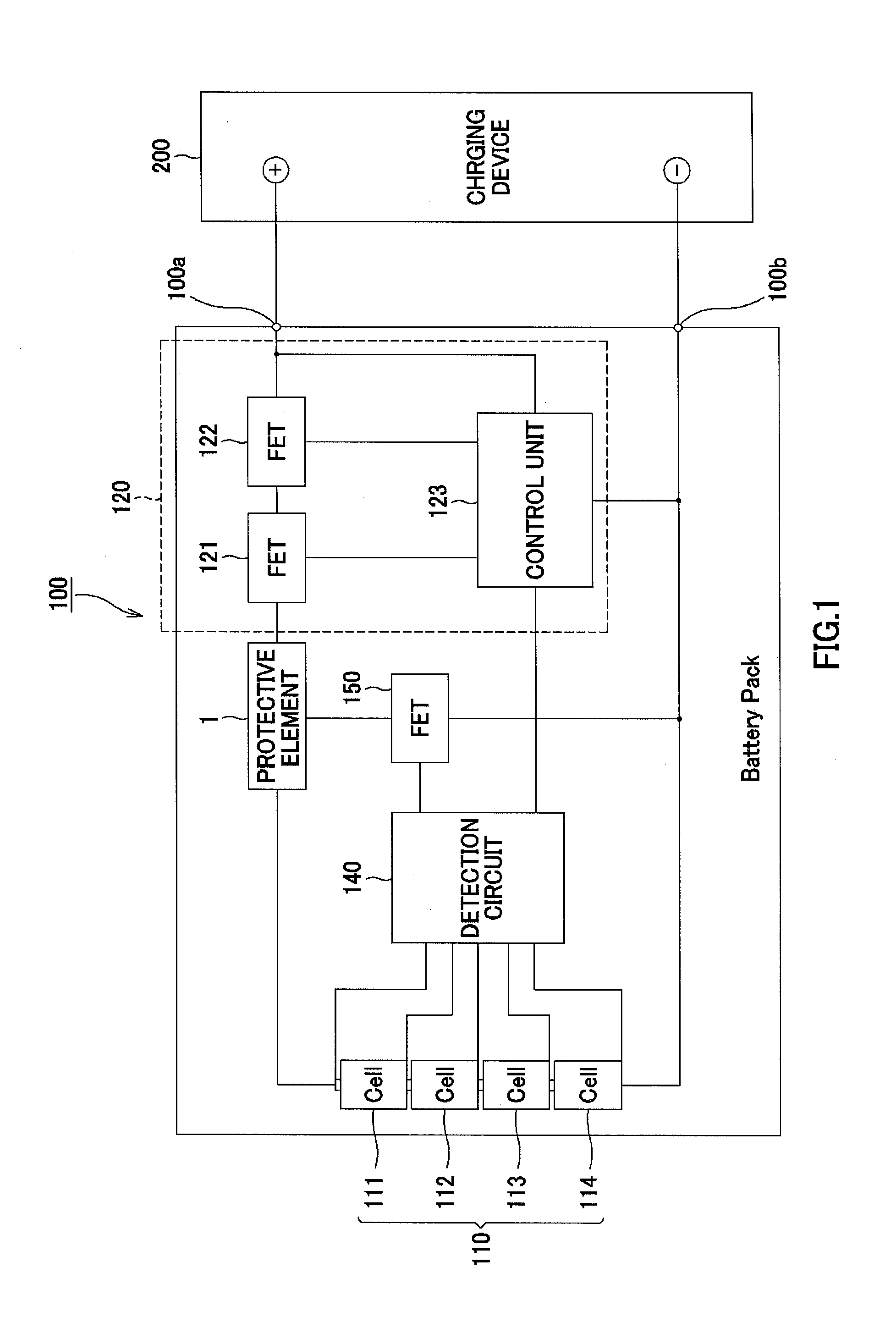

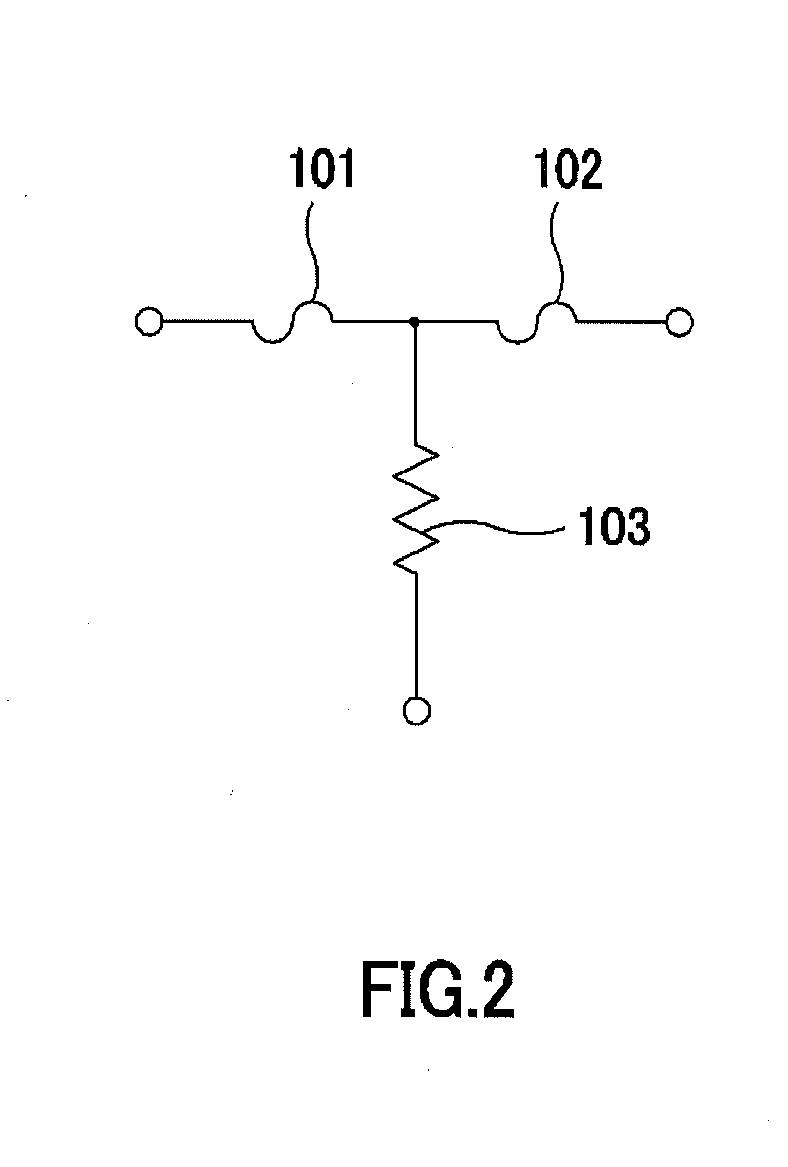

Protective element, protective element fabrication method, and battery module in which protective element is embedded

ActiveUS20140340046A1Reliable blowoutReduce the overall heightFuse device manufactureContact member assembly/disassemblyPower flowComputer module

A protective element including a substrate having a first insulating member and a concave portion formed thereon, a heating body layered on the concave portion of the substrate, a second insulating member layered on the substrate so as to cover at least covering the heating body, first and second electrodes layered on a surface of the substrate on which the second insulating member is layered, a heating body electrode layered on the second insulating member so as to be superimposed with the heating body, and electrically connected to a current path between the first and the second electrodes as well as onto and the heating body, and a low-melting point metal layered from the heating body electrode toward the first and the second electrodes configured to cause a blowout of the current path between the first and the second electrodes by heating.

Owner:DEXERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com