Patents

Literature

63results about How to "Primary particle size is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

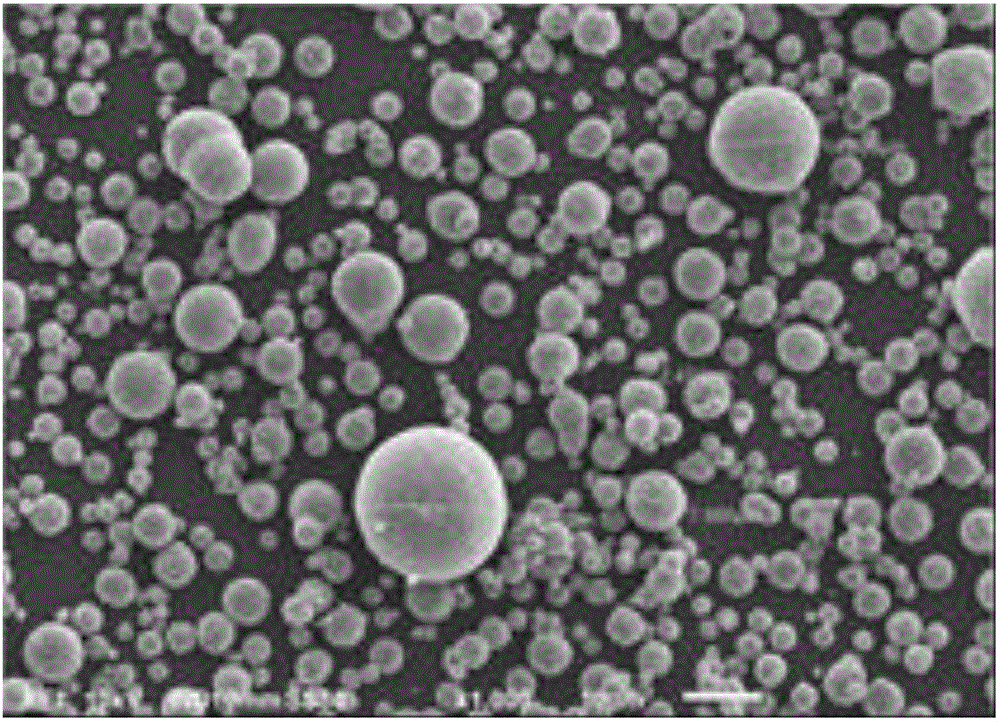

Layered lithium-nickel-based compound oxide powder and its production process

ActiveUS20050158546A1High bulk densityGood rate characteristicsElectrode thermal treatmentSolid electrolyte cellsLiquid mediumNickel compounds

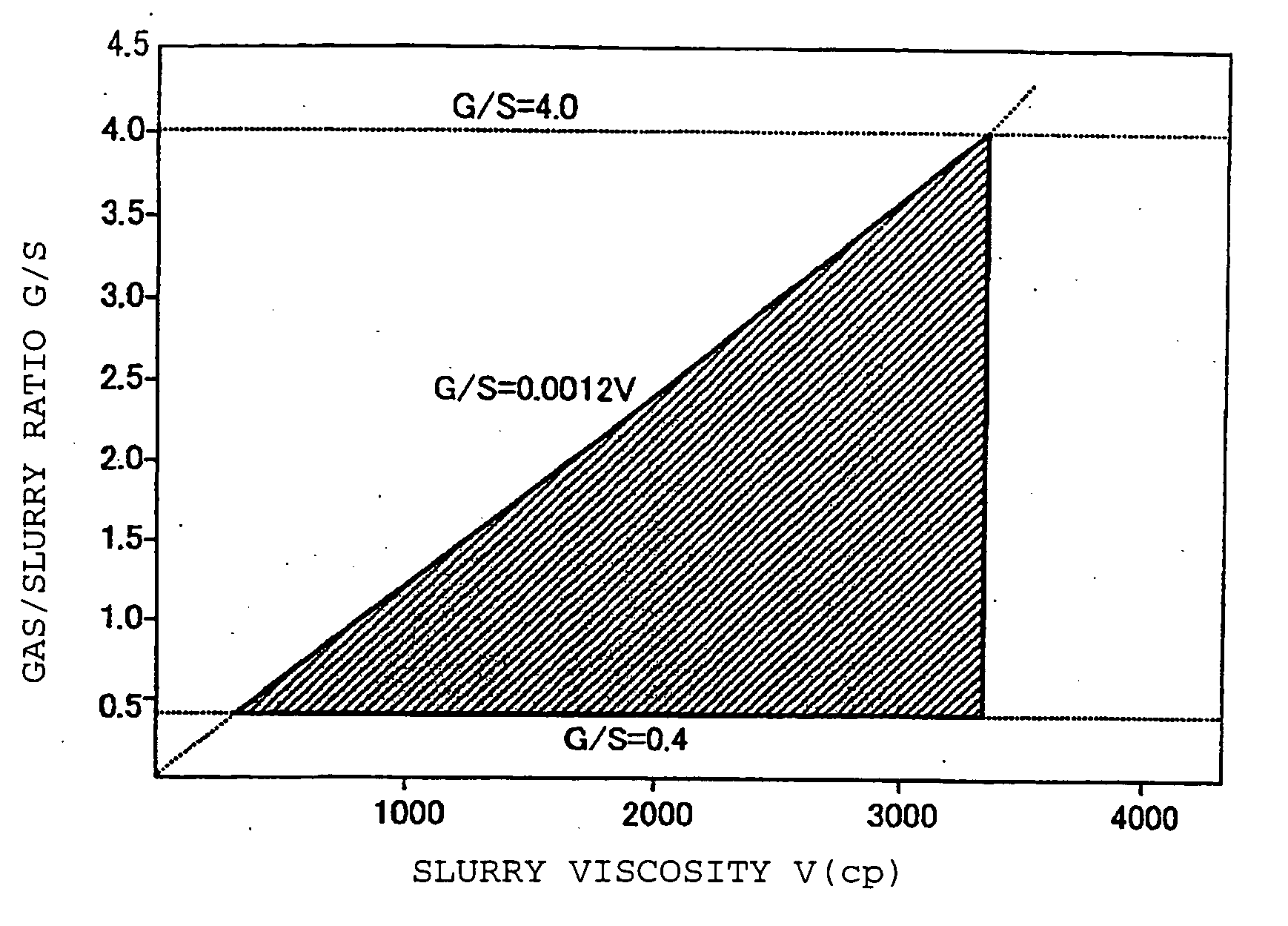

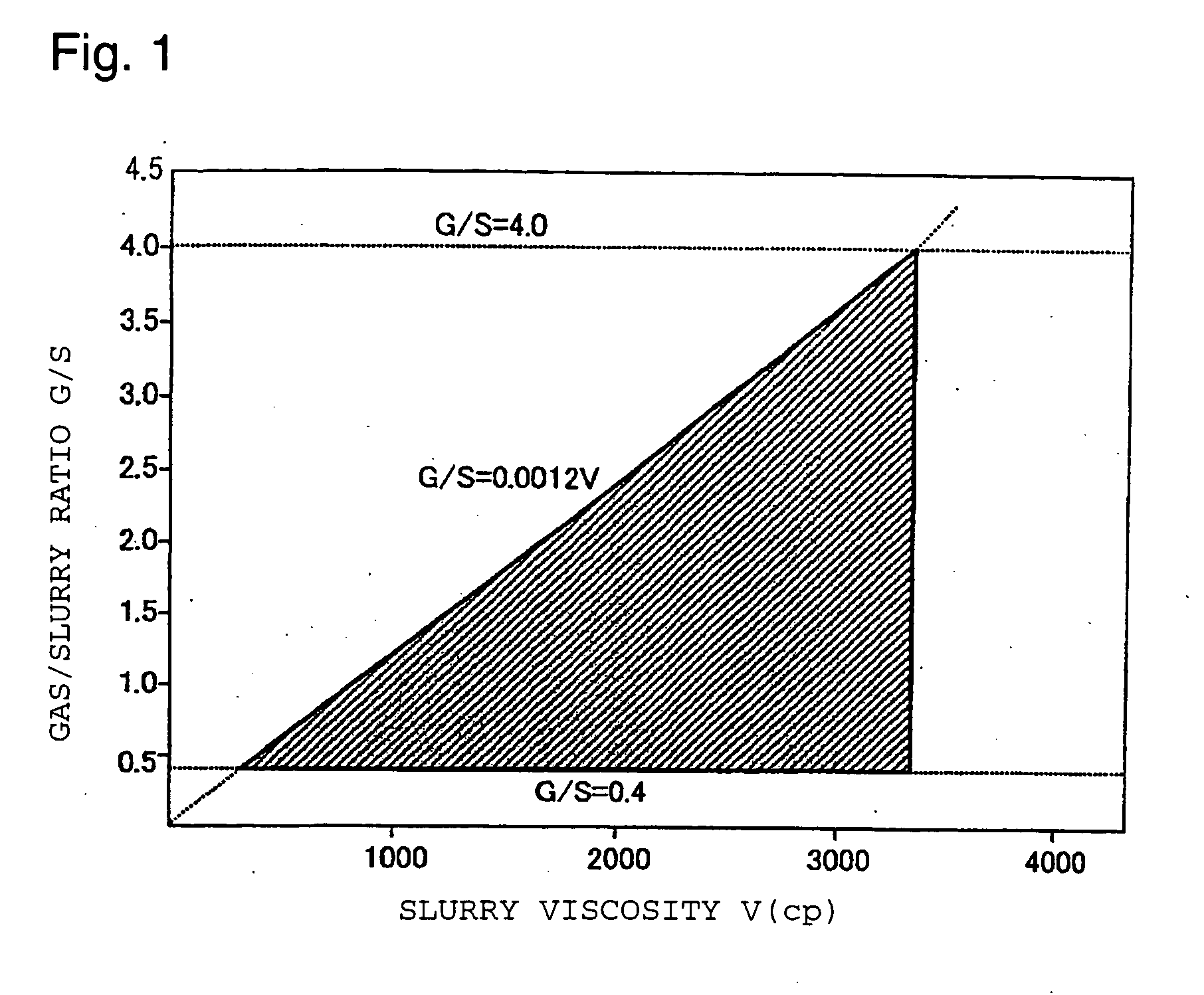

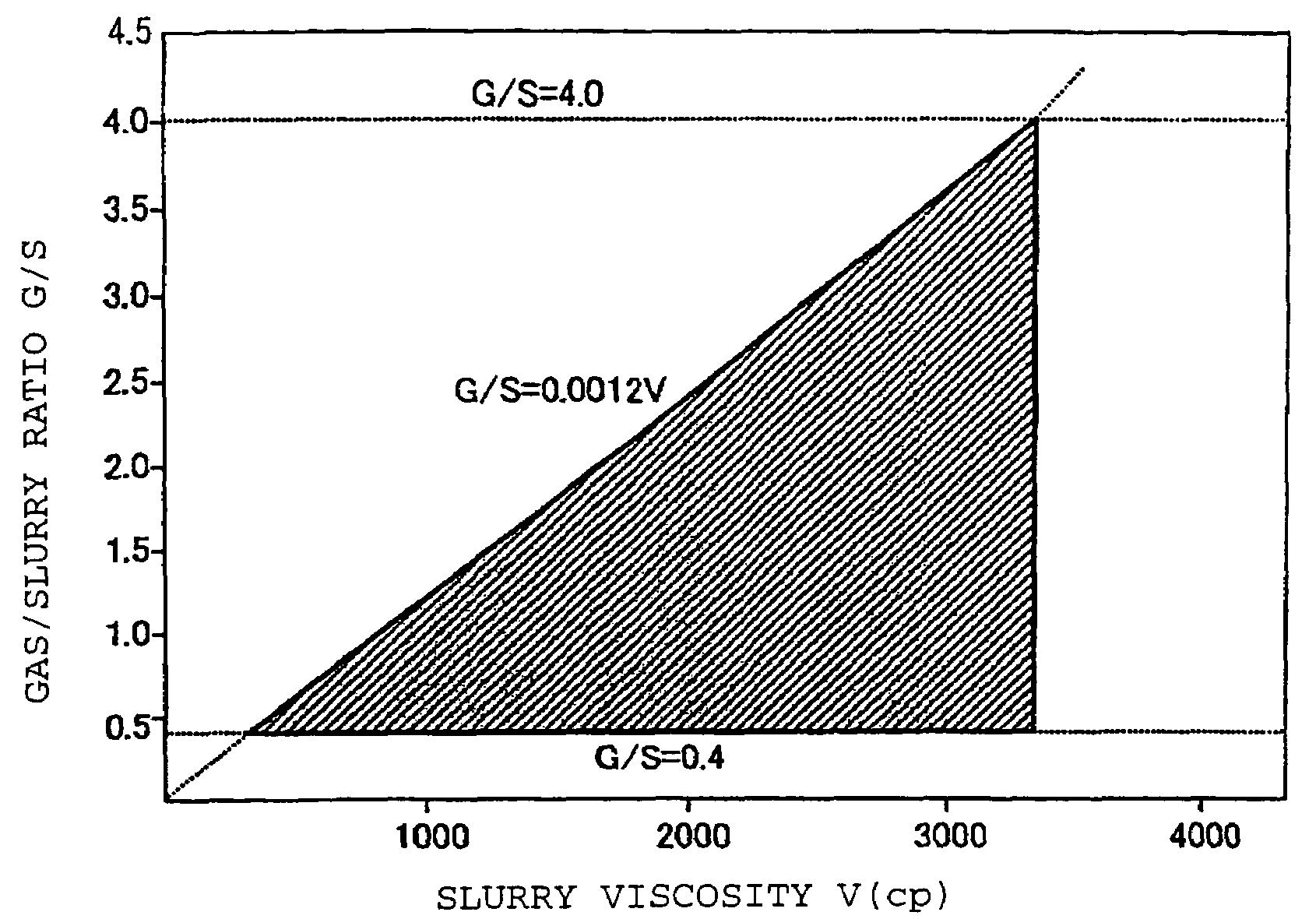

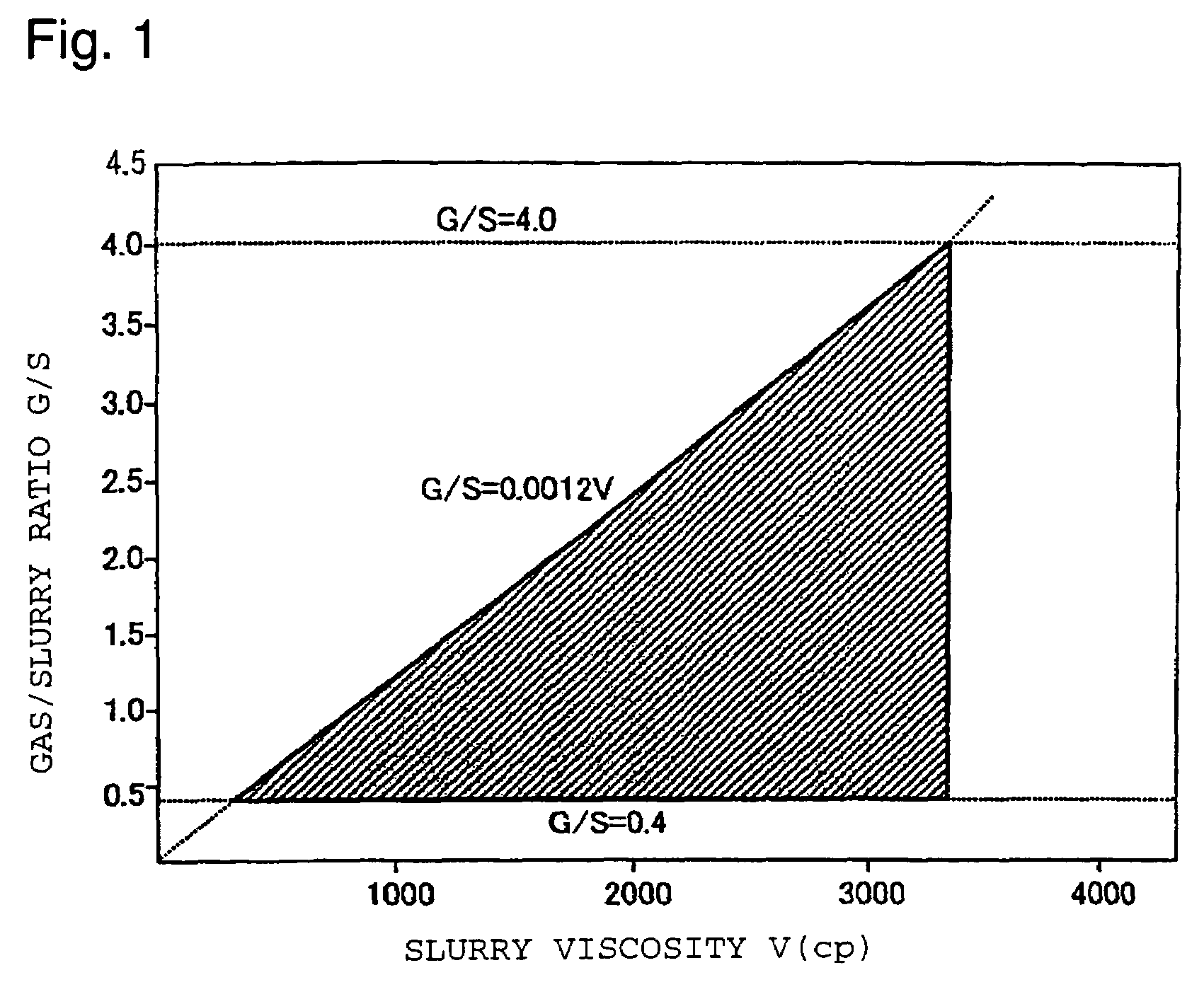

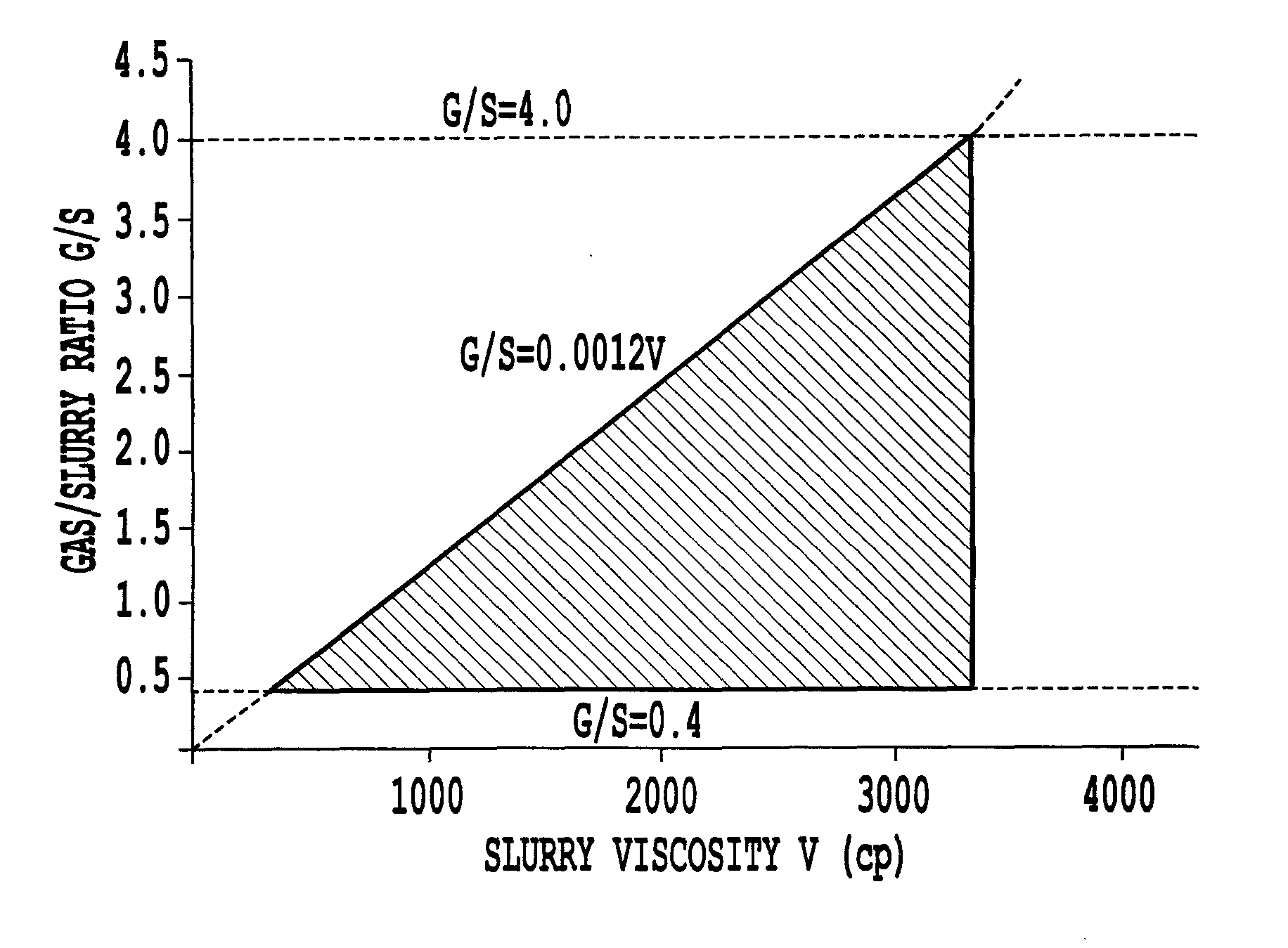

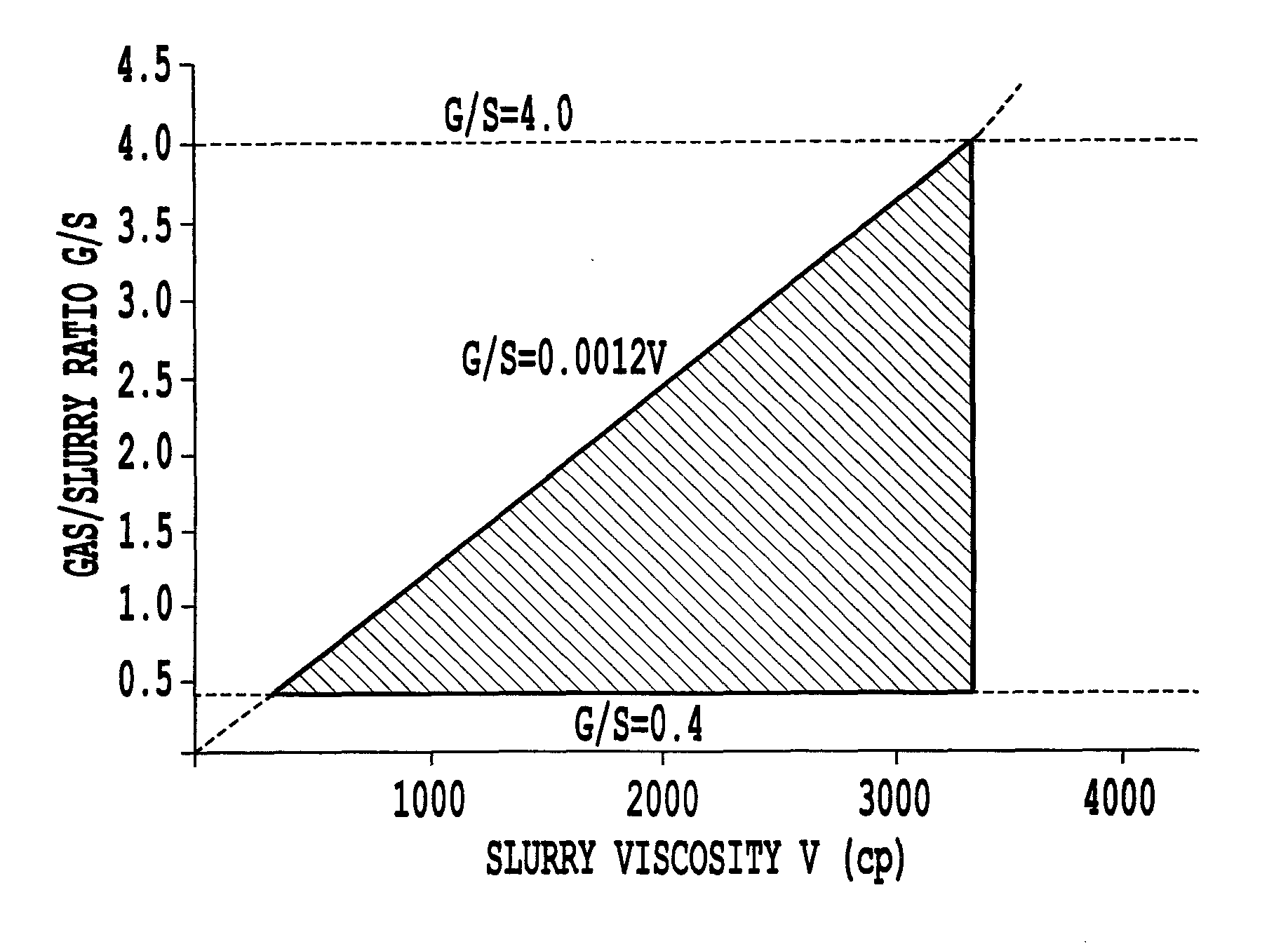

A layered lithium-nickel-based compound oxide powder for a positive electrode material for a high density lithium secondary cell, capable of providing a lithium secondary cell having a high capacity and excellent in the rate characteristics also, is provided. A layered lithium-nickel-based compound oxide powder for a positive electrode material for a lithium secondary cell, characterized in that the bulk density is at least 2.0 g / cc, the average primary particle size B is from 0.1 to 1 μm, the median diameter A of the secondary particles is from 9 to 20 μm, and the ratio A / B of the median diameter A of the secondary particles to the average primary particle size B, is within a range of from 10 to 200. In production of a layered lithium-nickel-based compound oxide powder, which comprises spray drying a slurry having a nickel compound and a transition metal element compound capable of substituting lithium other than nickel, dispersed in a liquid medium, followed by mixing with a lithium compound, and firing the mixture, the spray drying is carried out under conditions of 0.4≦G / S≦4 and G / S≦0.0012 V, when the slurry viscosity at the time of the spray drying is represented by V (cp), the slurry supply amount is represented by S (g / min) and the gas supply amount is represented by G (L / min).

Owner:MITSUBISHI CHEM CORP

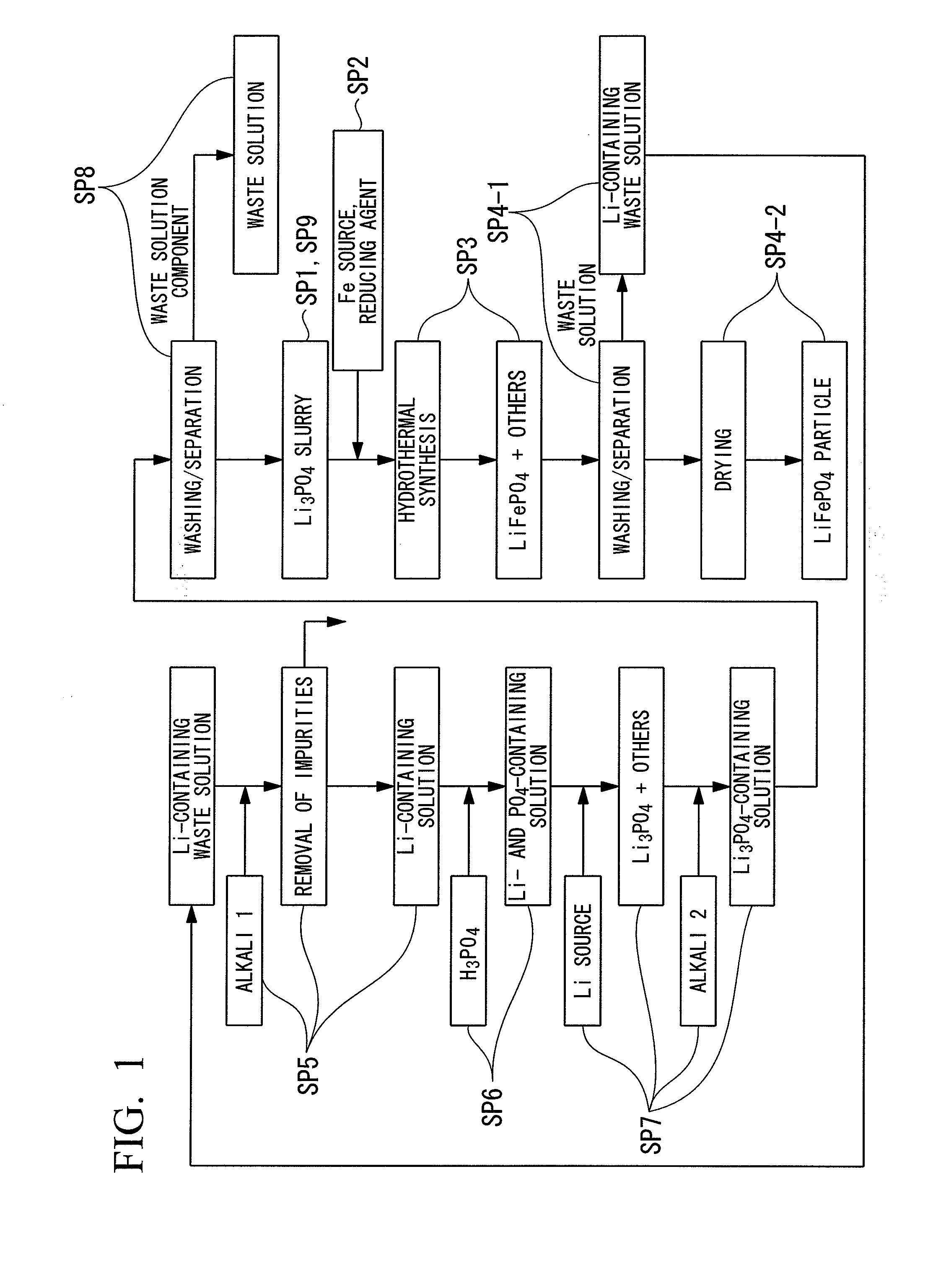

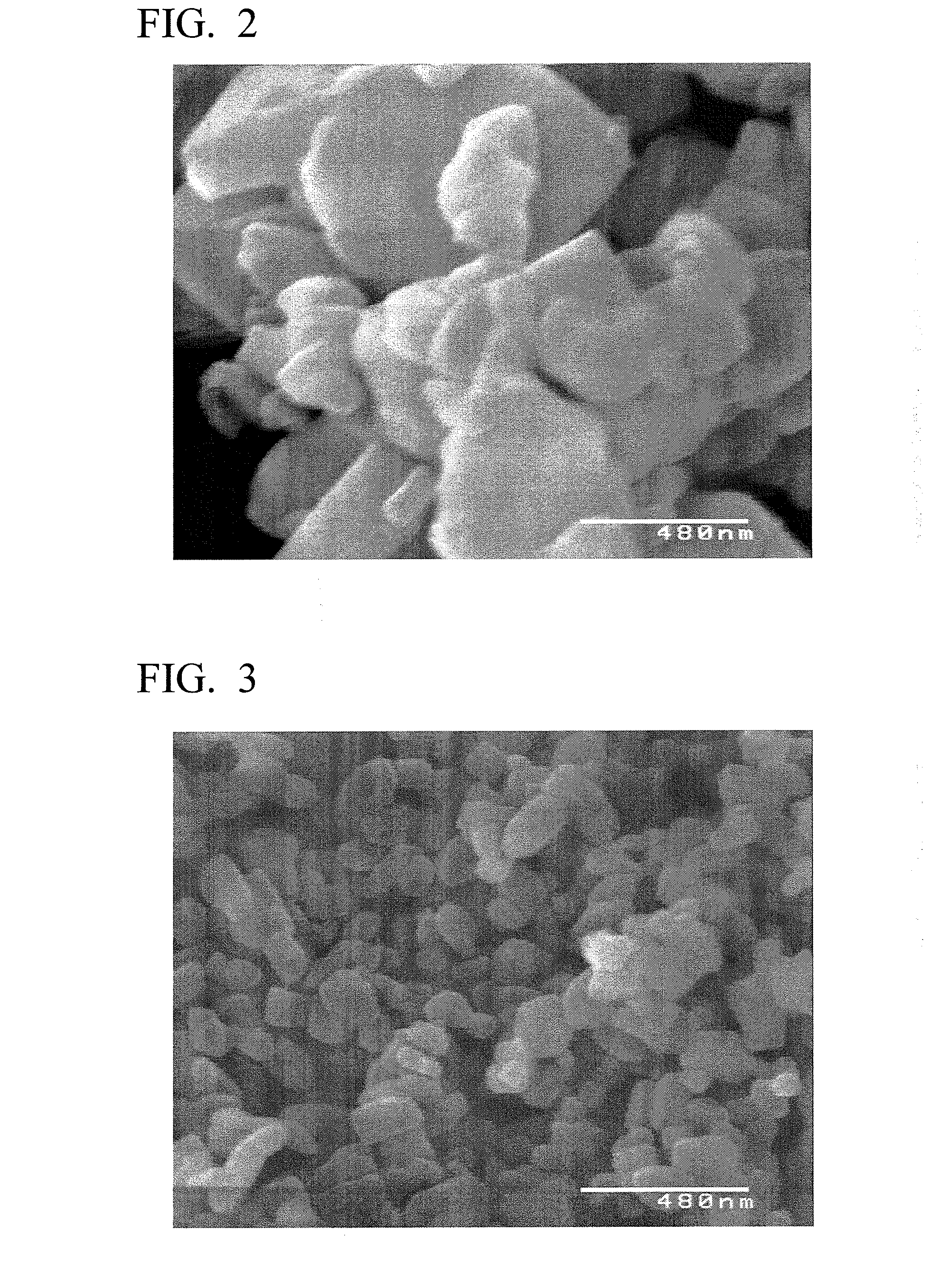

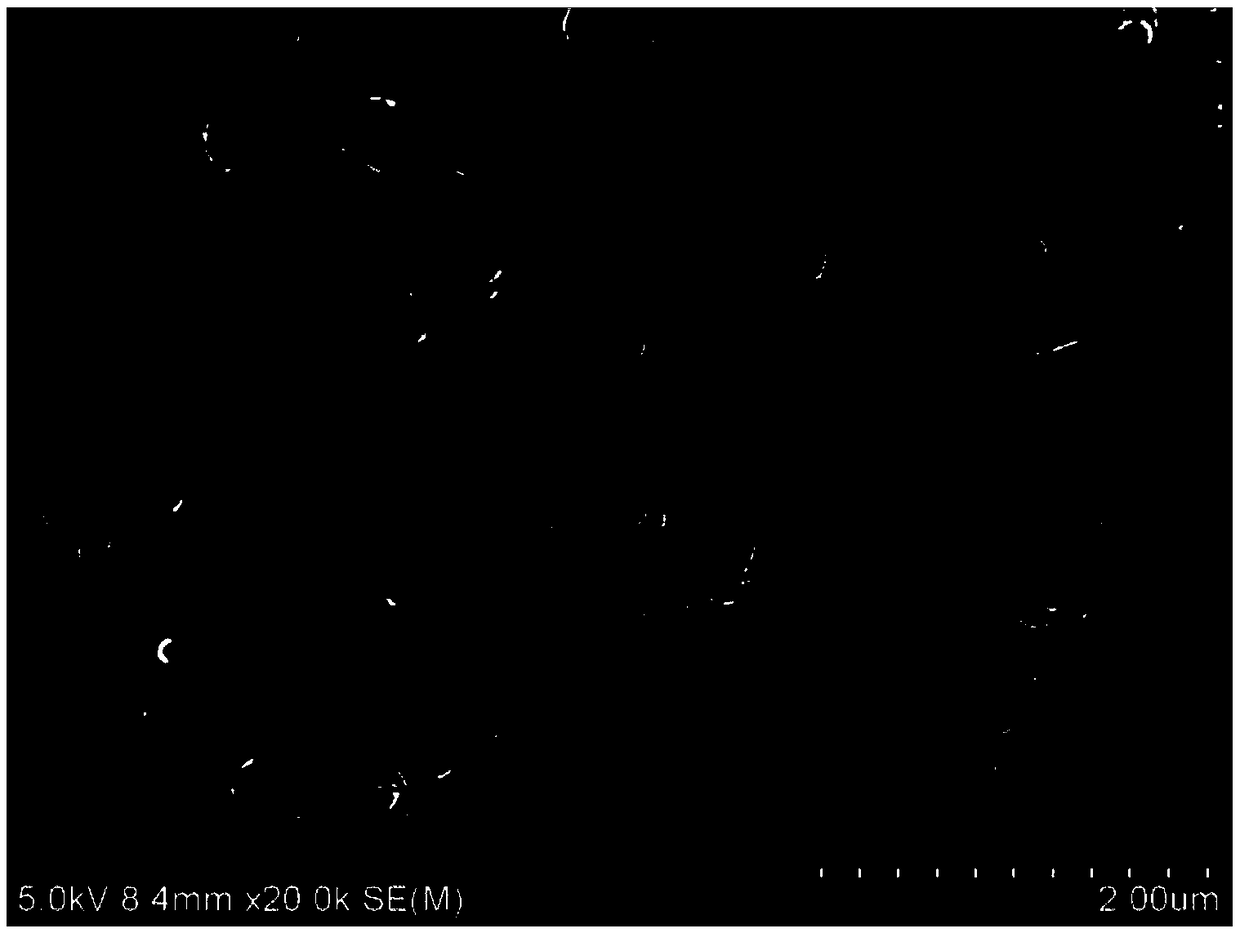

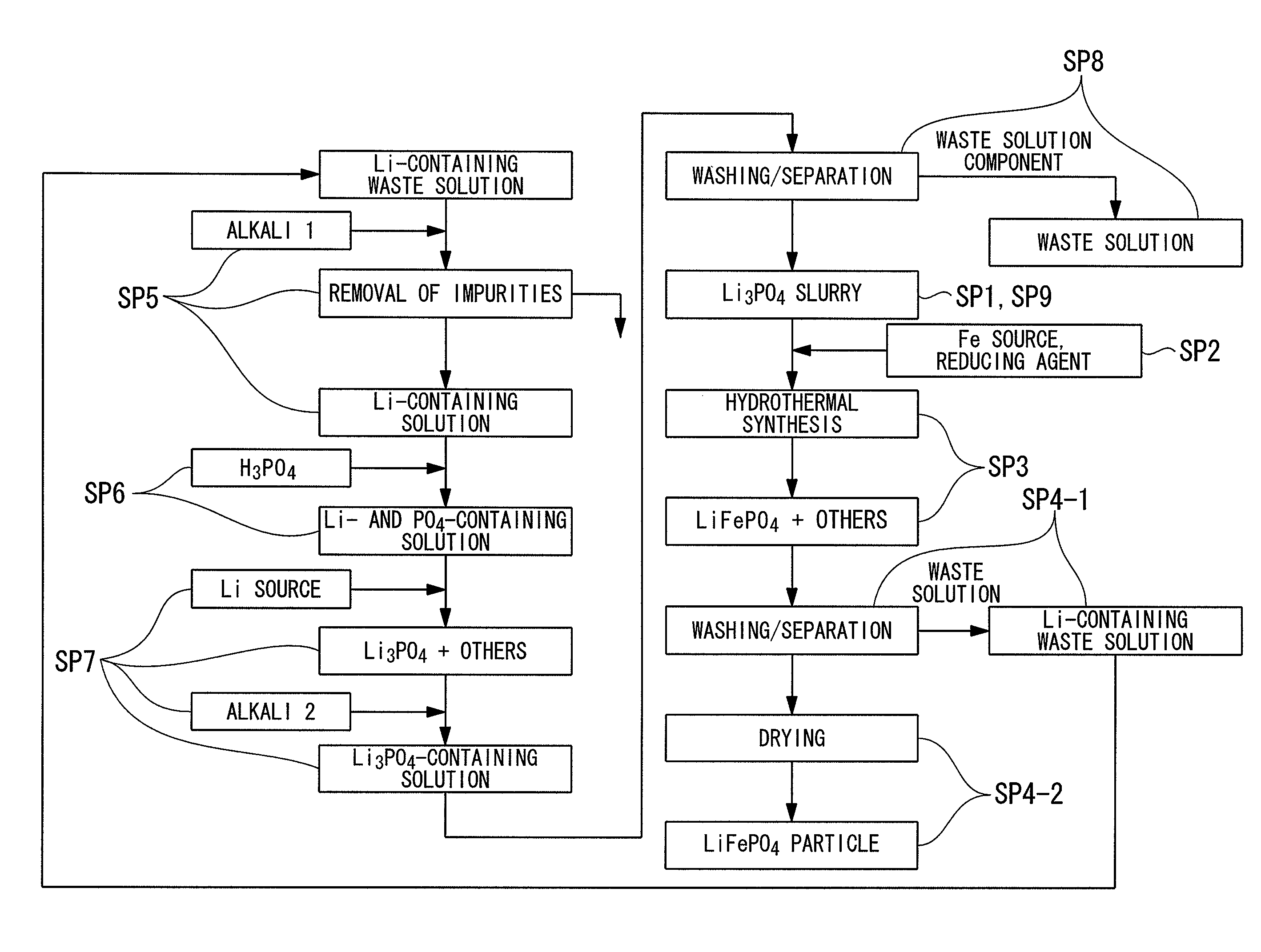

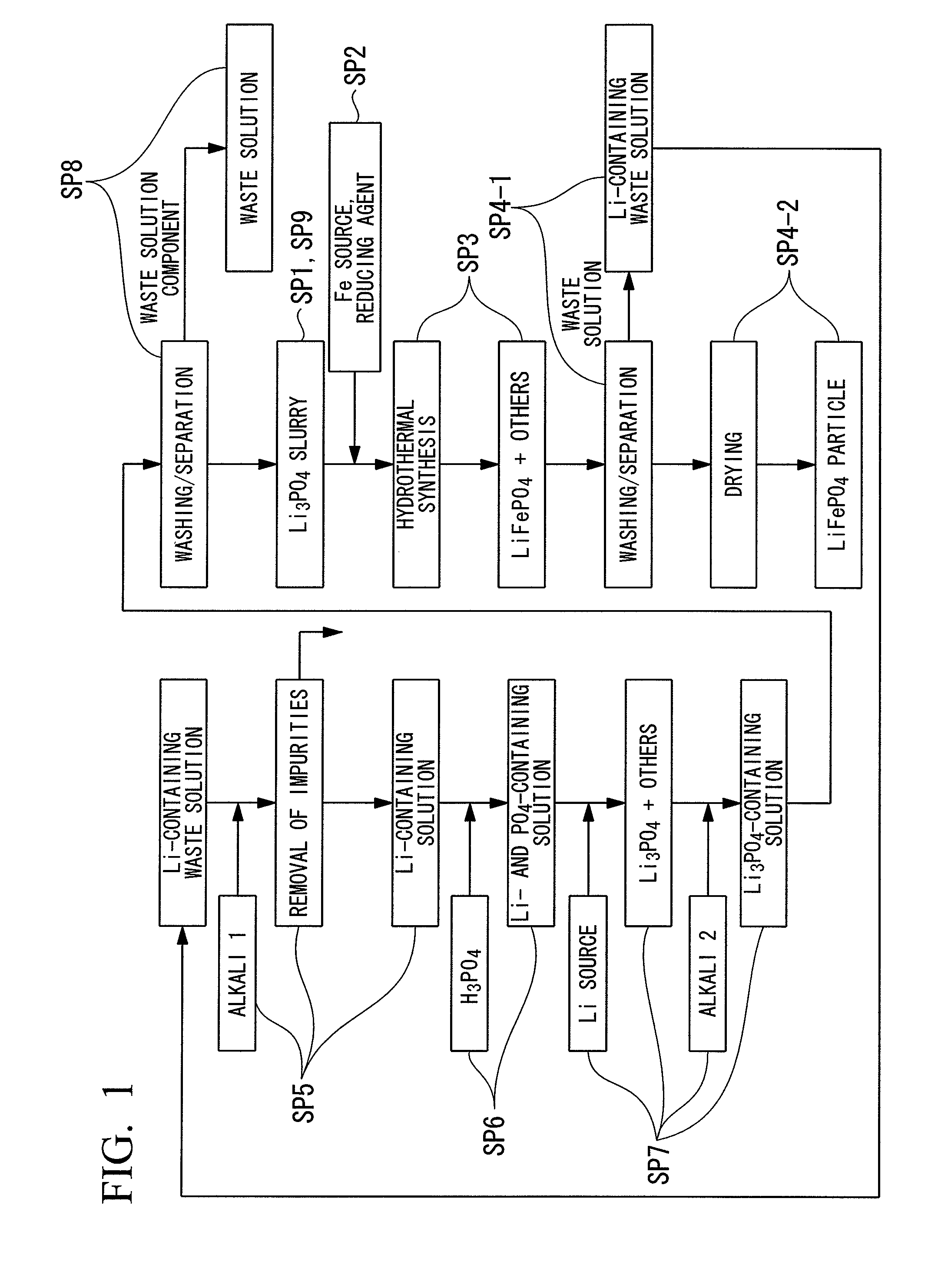

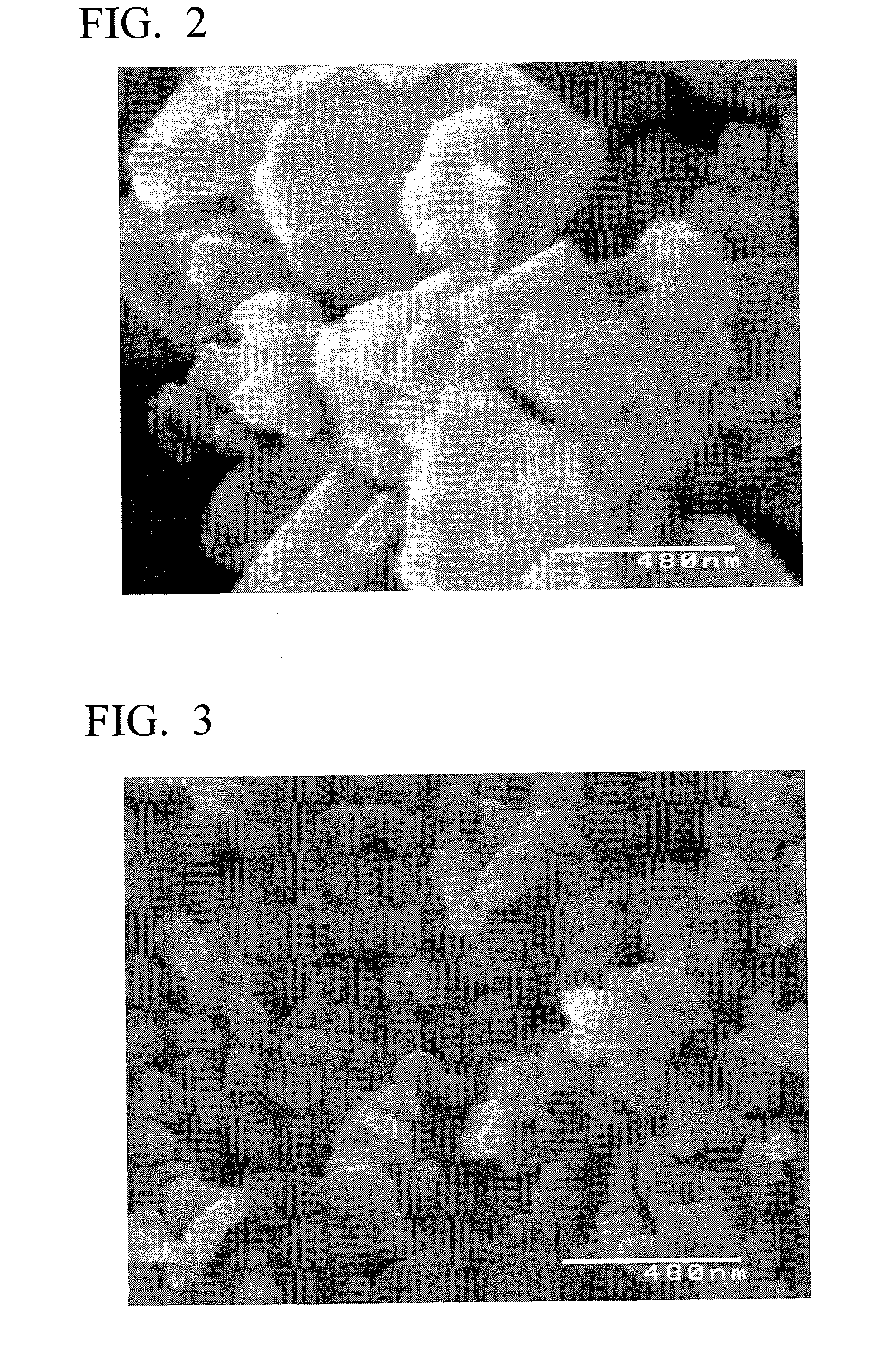

Method for producing cathode active material for lithium ion batteries, cathode active material for lithium ion batteries obtained by the production method, lithium ion battery electrode, and lithium ion battery

InactiveUS20110037019A1Improve reaction speedPrimary particle size is smallMaterial nanotechnologyFuse device manufacturePhosphoric acidLithium-ion battery

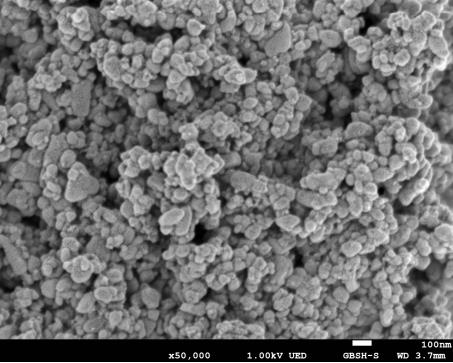

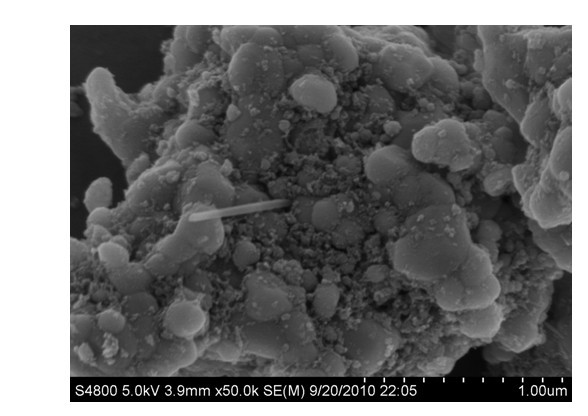

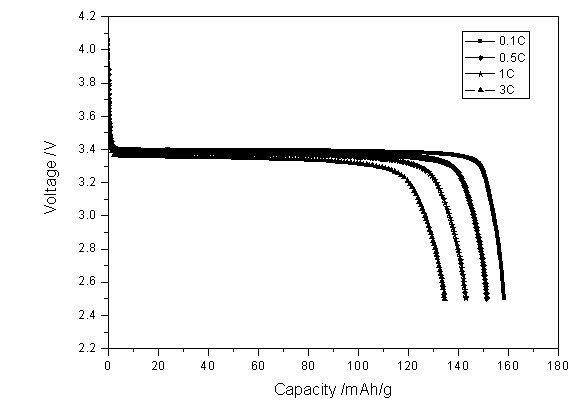

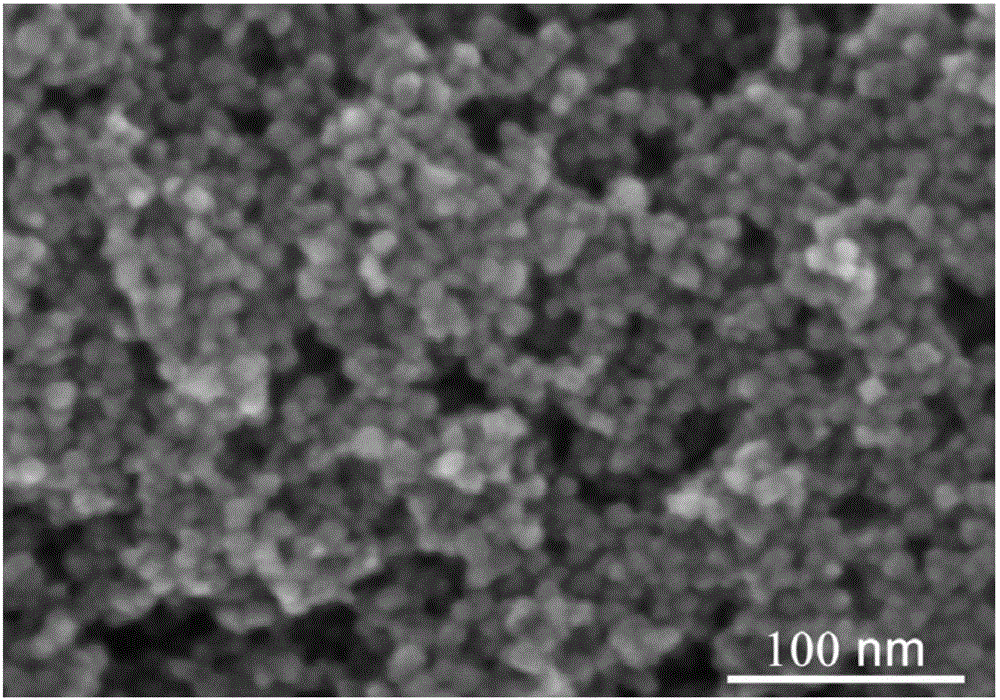

A method for producing a cathode active material for lithium ion batteries includes a step of synthesizing LiFePO4 by carrying out a hydrothermal reaction using an Li salt, a Fe salt, and a phosphoric acid source as raw materials. Elements Li and Fe in the Li and Fe salts are added to the reaction system in amounts excessively larger than the theoretical amounts required for the hydrothermal reaction. The synthesized LiFePO4 has an average primary particle size of equal to or larger than 30 nm and equal to or smaller than 100 nm.

Owner:SUMITOMO OSAKA CEMENT CO LTD

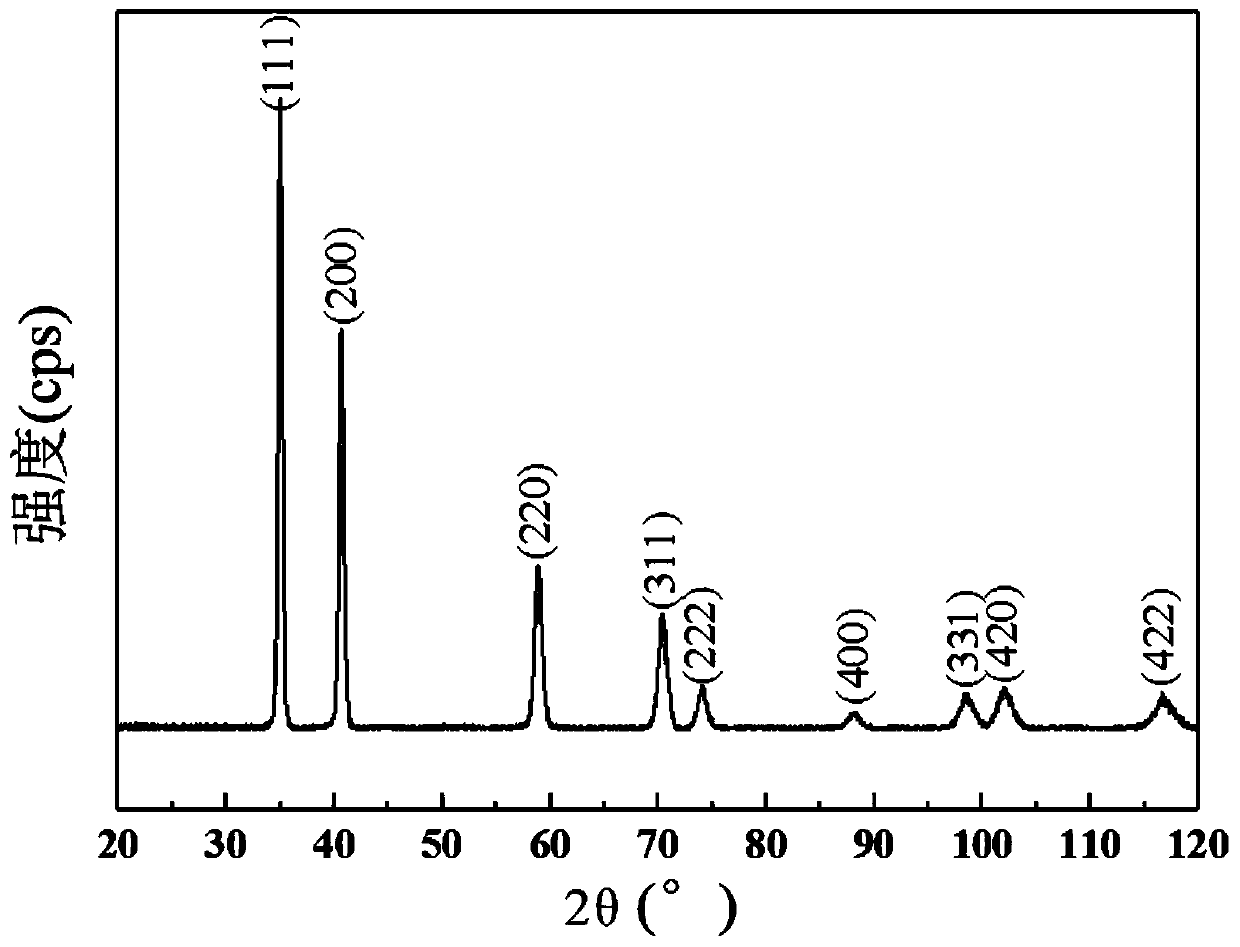

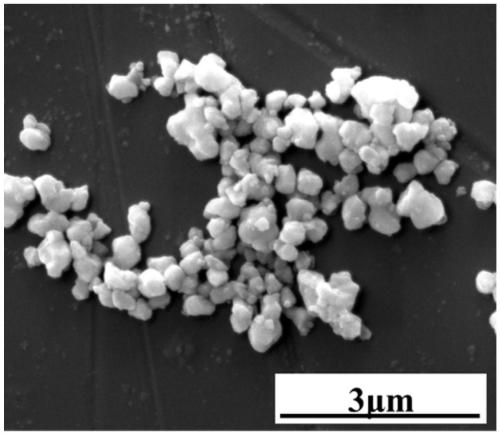

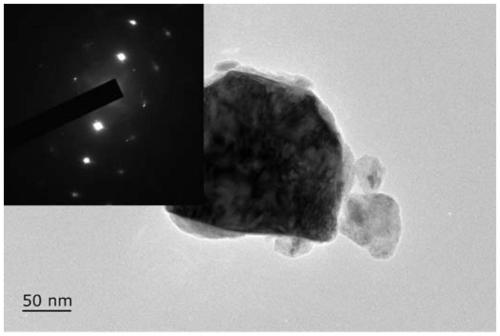

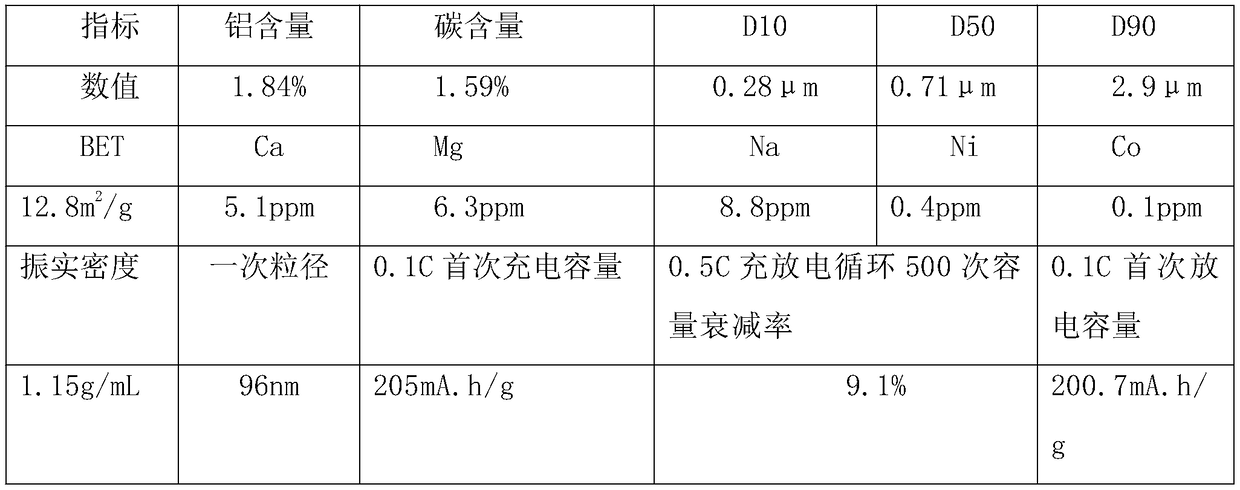

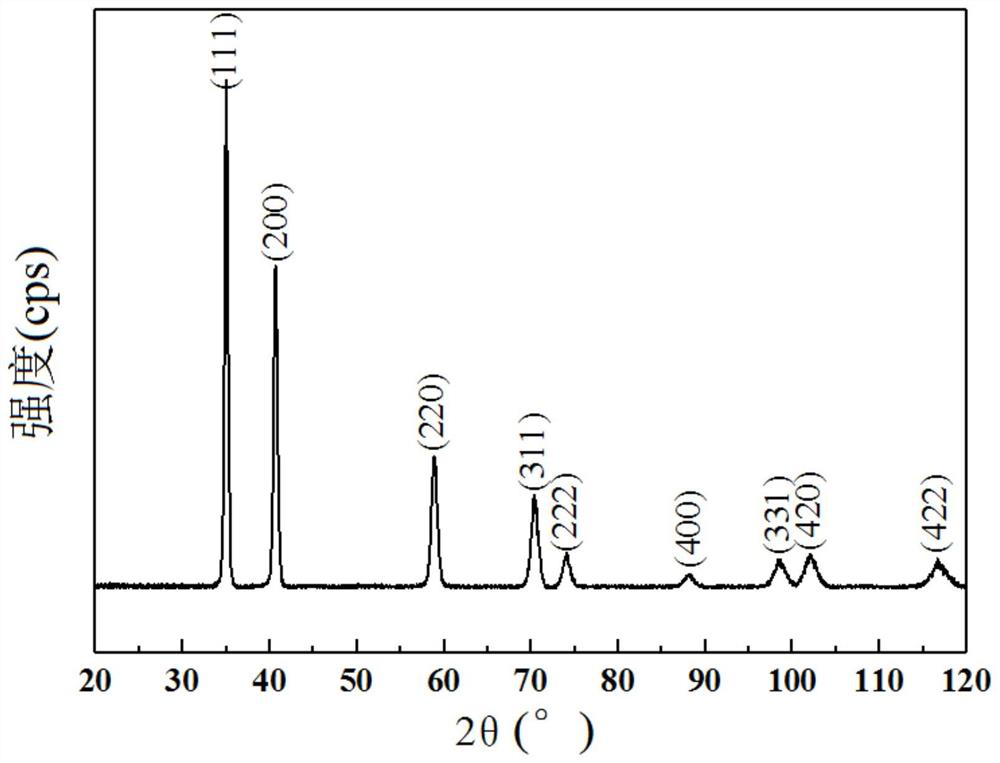

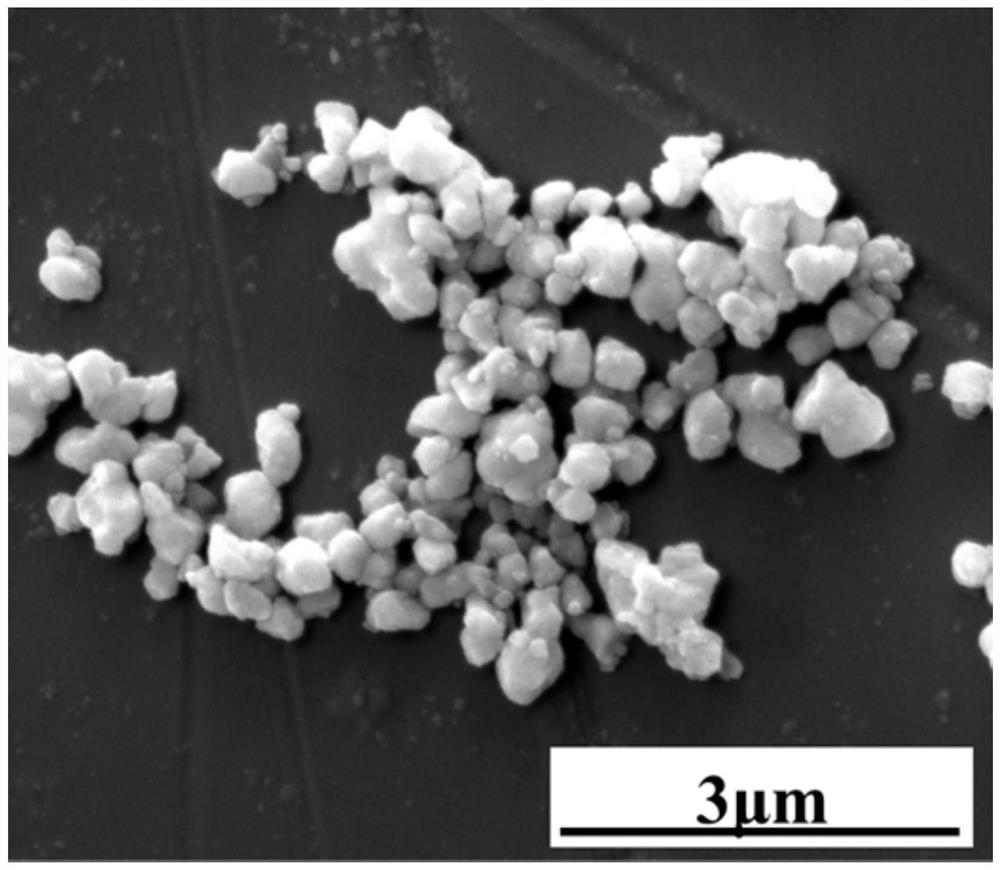

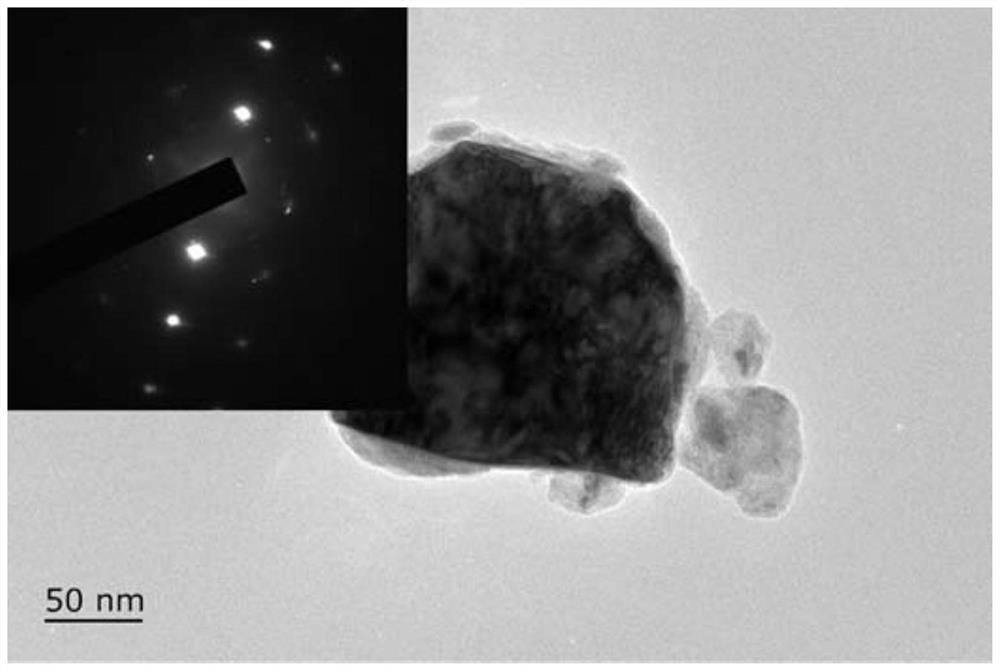

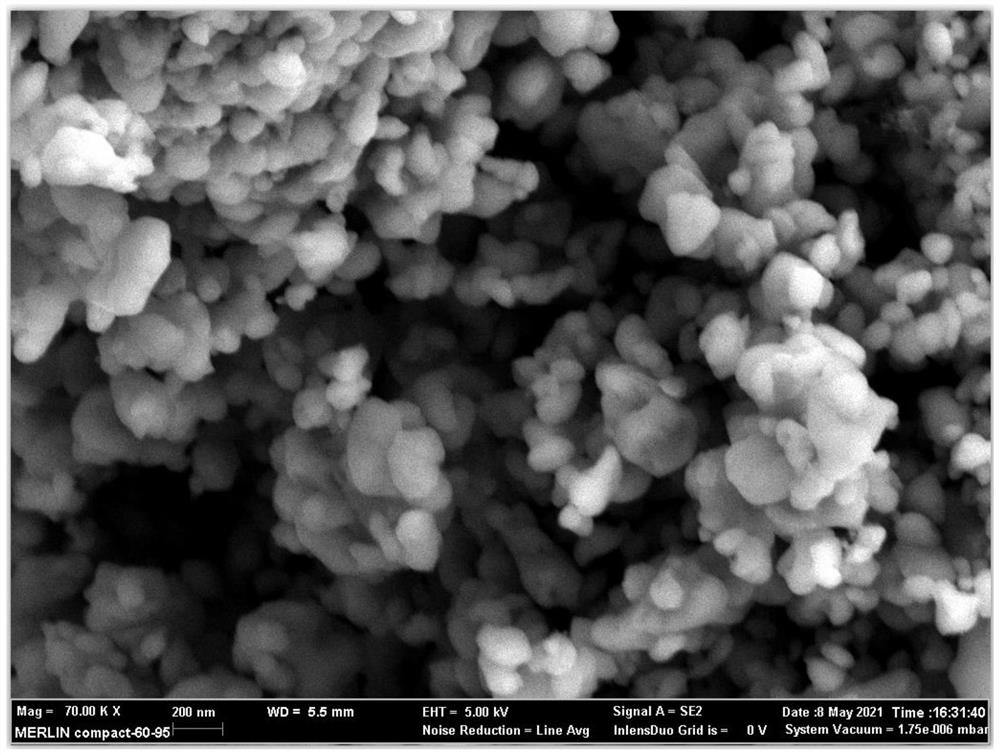

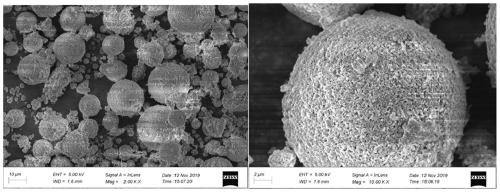

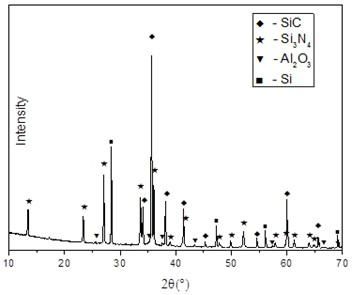

High-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder and preparation method thereof

ActiveCN110330341APrimary particle size is smallCalcination temperature is lowTransition metal carbidesGranularity

The invention discloses high-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder and a preparation method thereof, belongs to the technical field of super-hard ceramic materials, and particularly relates to the preparation method of the high-entropy ceramic powder. The invention aims to solve the problems of high oxygen content, high residual carbon content, low purity, large particle size and poor sphericity of a multi-component carbide high-entropy ceramic material prepared with the prior method. The chemical formula of the high-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder is (Hfx1Nbx3Tax4Tix2Mx5)C. The method comprises the following steps: 1, weighing materials; 2, mixing; and 3, calcining. The high-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder prepared in the invention has the advantages of small particle size, low oxygen content and low free carbon content. The high-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder can be obtained in the invention.

Owner:HARBIN INST OF TECH

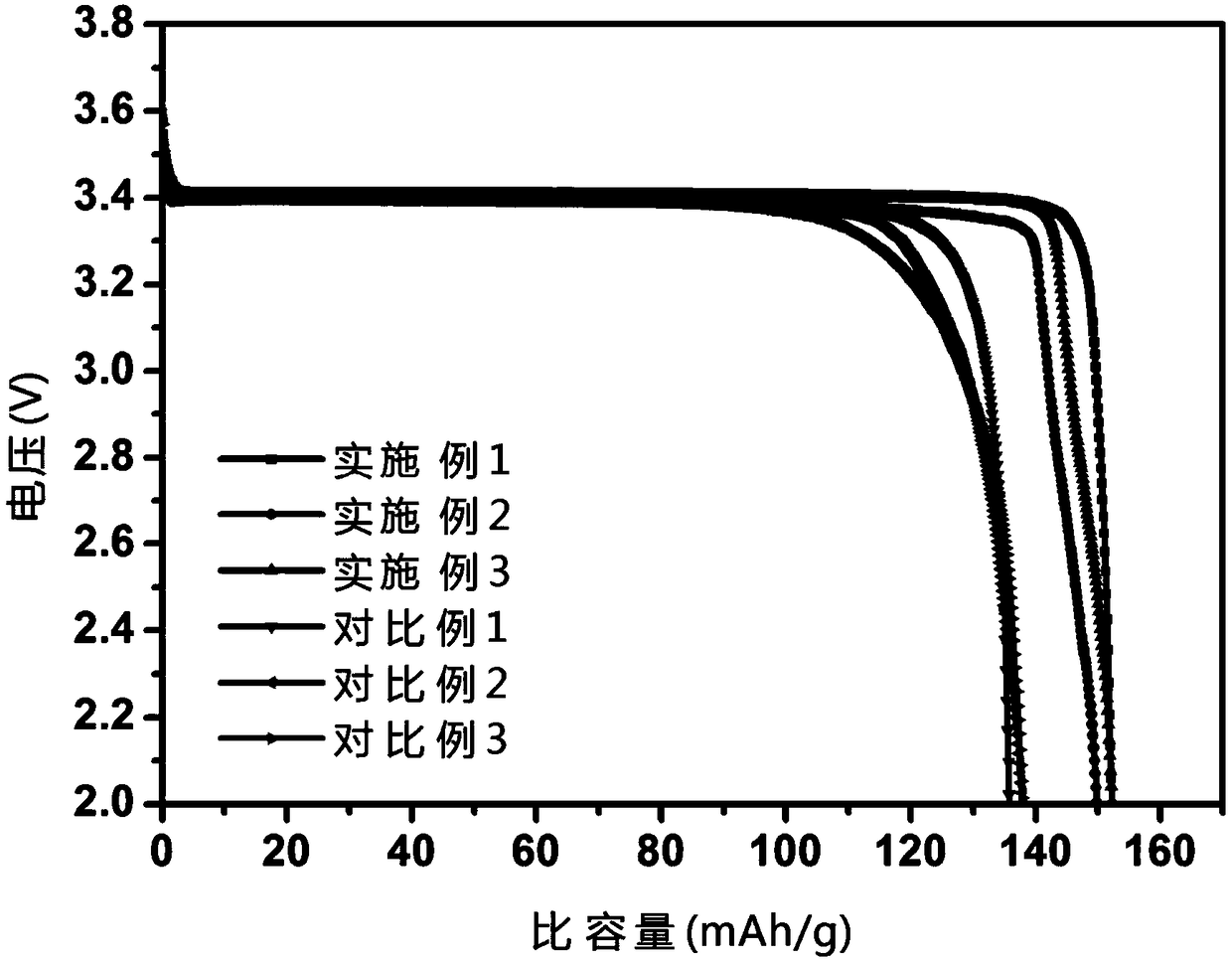

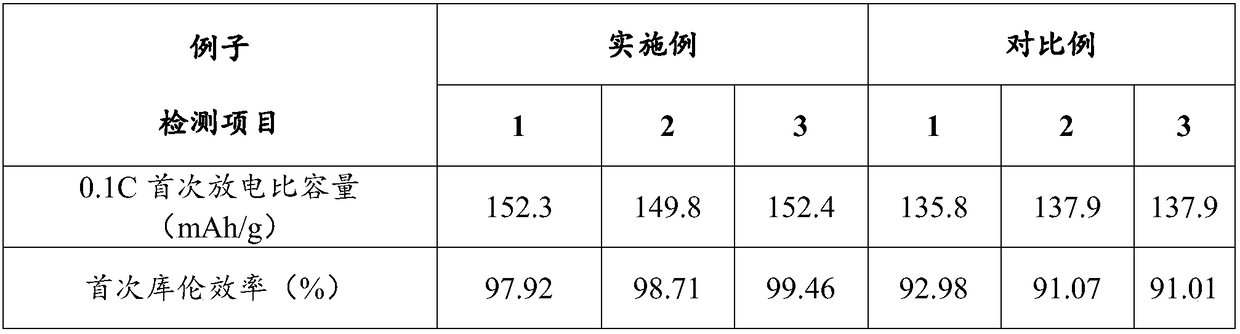

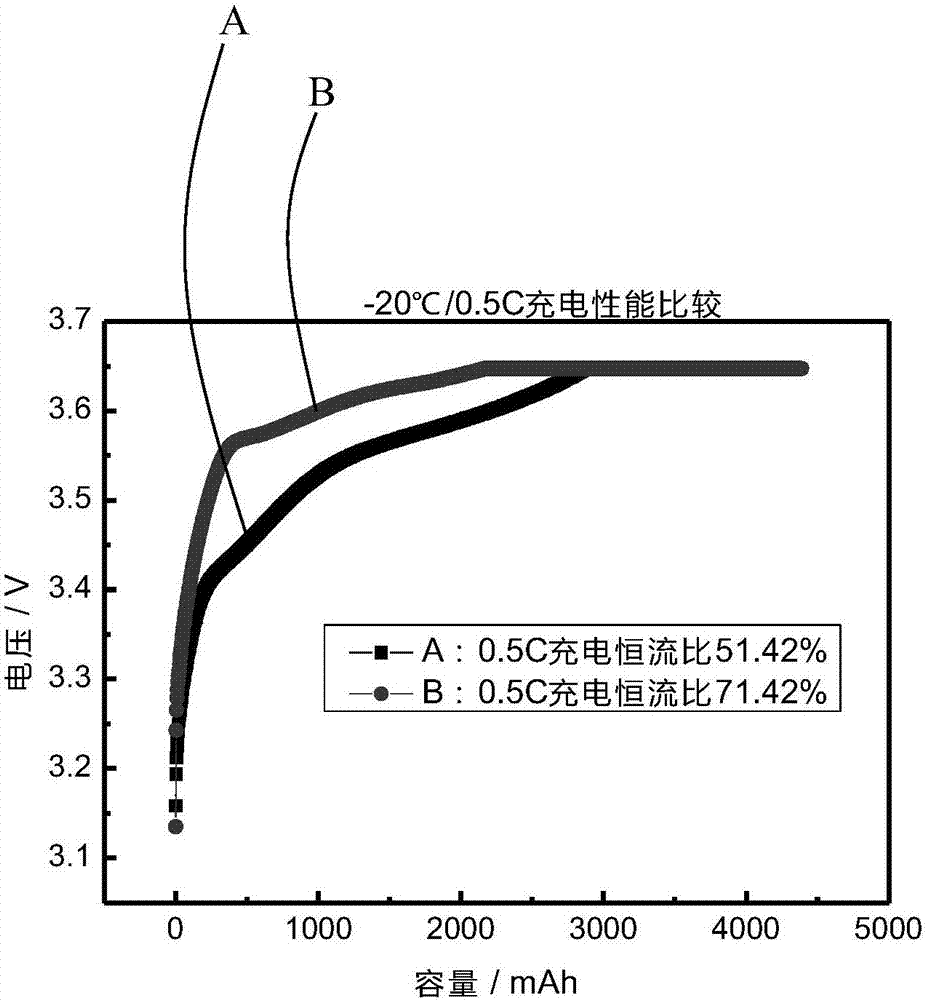

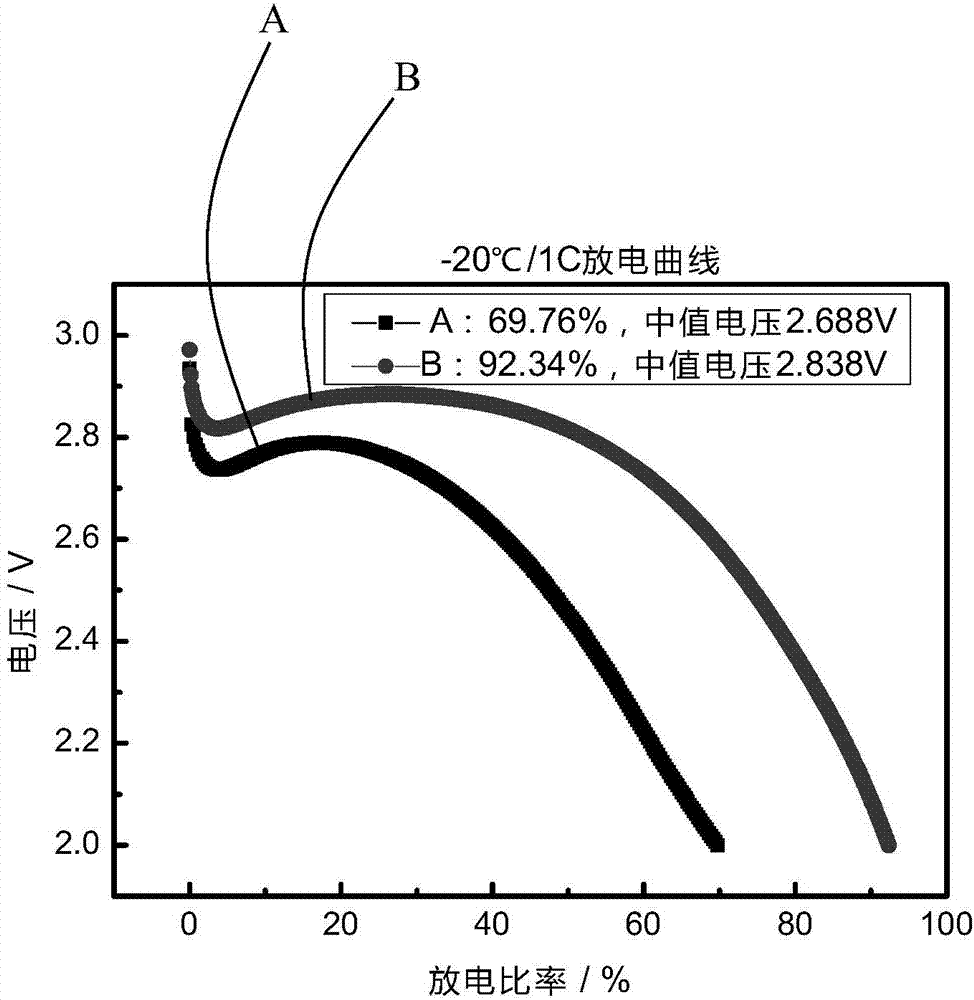

Preparation method of lithium manganese iron phosphate positive electrode material

PendingCN113929073ARealize NanoizationAchieve primary particle sizeSecondary cellsPositive electrodesLithium iron phosphatePhysical chemistry

The invention discloses a method for preparing lithium manganese iron phosphate by a solid phase method. The preparation method comprises the following steps: weighing a certain amount of a manganese source and an iron source according to a molar ratio of 7:3, weighing a lithium source, a phosphorus source, a carbon source and a dopant according to a certain stoichiometric ratio, adding pure water, carrying out ball milling and sanding, controlling the sanding particle size D50 to be less than or equal to 300 nm, and carrying out spray drying to obtain brown precursor powder; and sintering the precursor under the protection of a nitrogen atmosphere, controlling the sintering temperature to be 600-700 DEG C, then performing crushing and screening, and removing iron to obtain the lithium manganese iron phosphate positive electrode material. The lithium manganese iron phosphate prepared by the method is simple in process and easy to control in process, compared with existing lithium iron phosphate and ternary materials, the lithium manganese iron phosphate is lower in cost and higher in voltage platform, and meanwhile, the obtained lithium manganese iron phosphate has good electrical performance and cycle performance.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

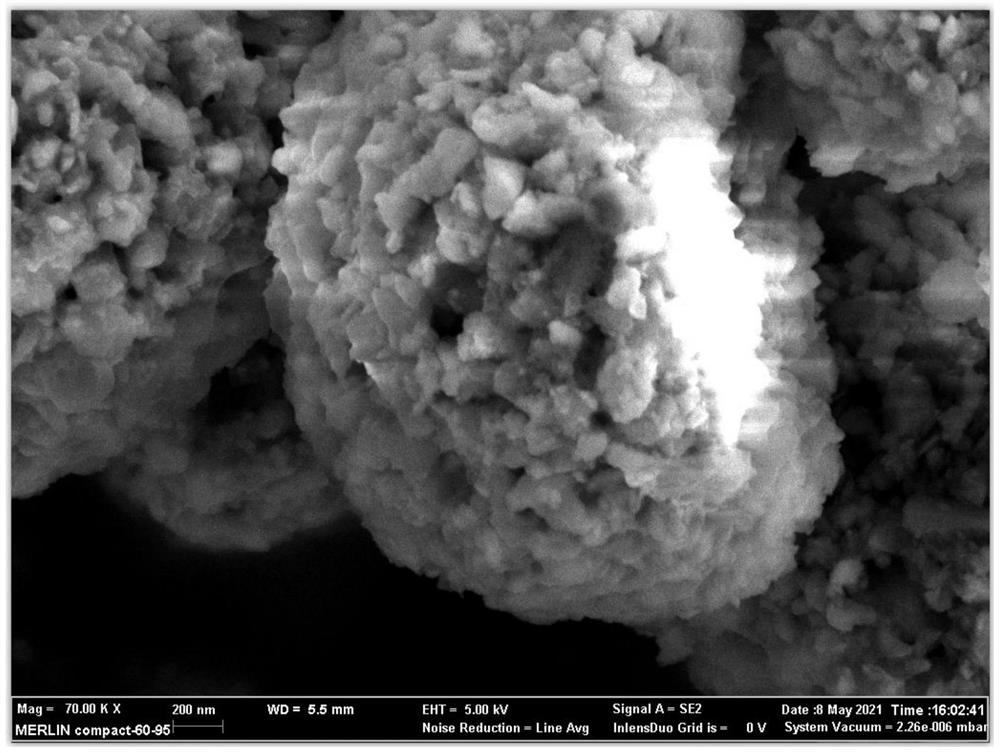

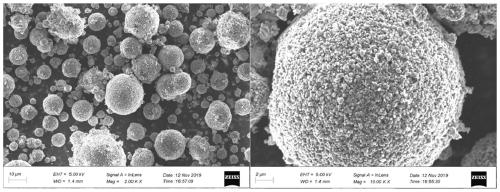

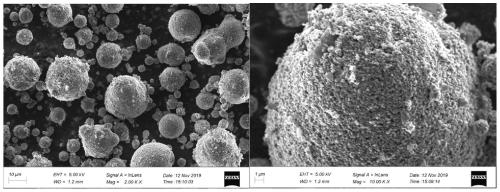

Microspheres prepared from composition containing zirconium oxide and preparation method of microspheres

The invention relates to composite zirconium oxide microspheres and a preparation method thereof. The microspheres are prepared from yttrium oxide as a stabilizer of a zirconium oxide material. The microspheres comprises a doped system of third components including one or more of alumina, cerium oxide, copper oxide, magnesia, calcium oxide and silica, wherein the content of the yttrium oxide in the zirconium oxide is 0.1-8mol% while the total doping amount of the alumina, the cerium oxide, the copper oxide, the magnesia, the calcium oxide and the silica is 0-30wt%. According to the method, sediment dry gel is molded and further sintered to finish preparation of the composite zirconium oxide ceramic microspheres. The preparation method is simple in production technology, relatively low in cost, and applicable to industrialization. A lot of energy sources are saved for industrialization of the zirconium oxide ceramic microspheres. Meanwhile, the prepared ceramic microspheres disclosed by the invention have the characteristics of large density, durability, stability and the like.

Owner:YAAN YUANCHUANG CERAMIC

Layered lithium-nickel-based compound oxide powder and its production process

ActiveUS7309543B2Improve featuresIncrease in sizeElectrode thermal treatmentSolid electrolyte cellsLiquid mediumNickel compounds

Owner:MITSUBISHI CHEM CORP

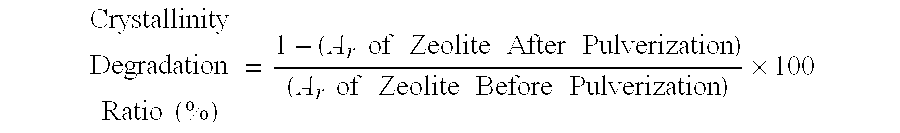

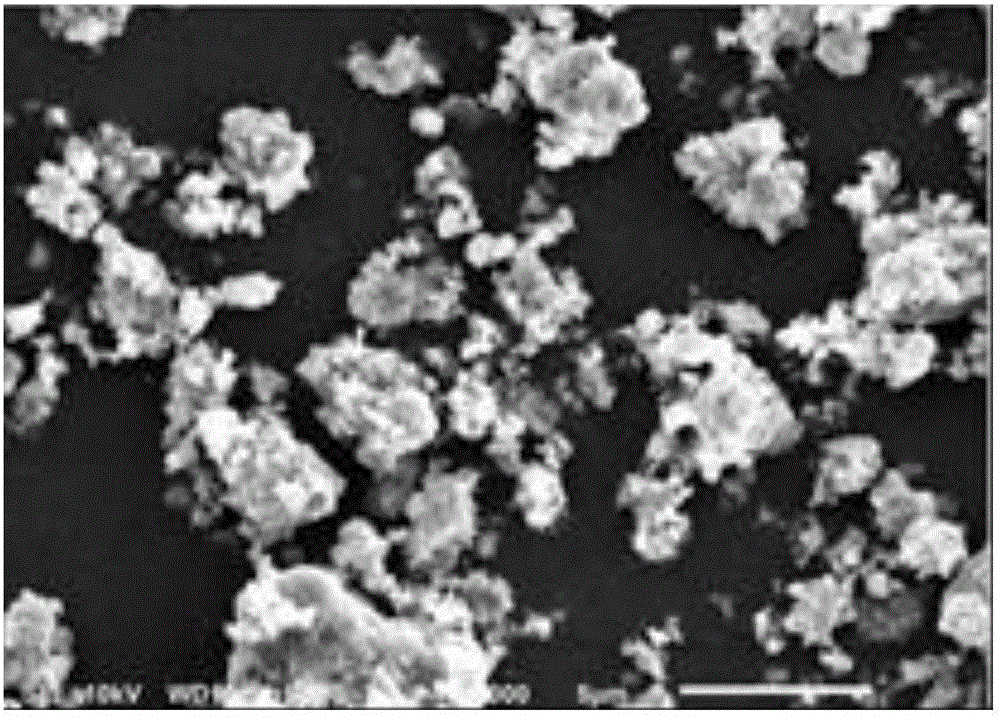

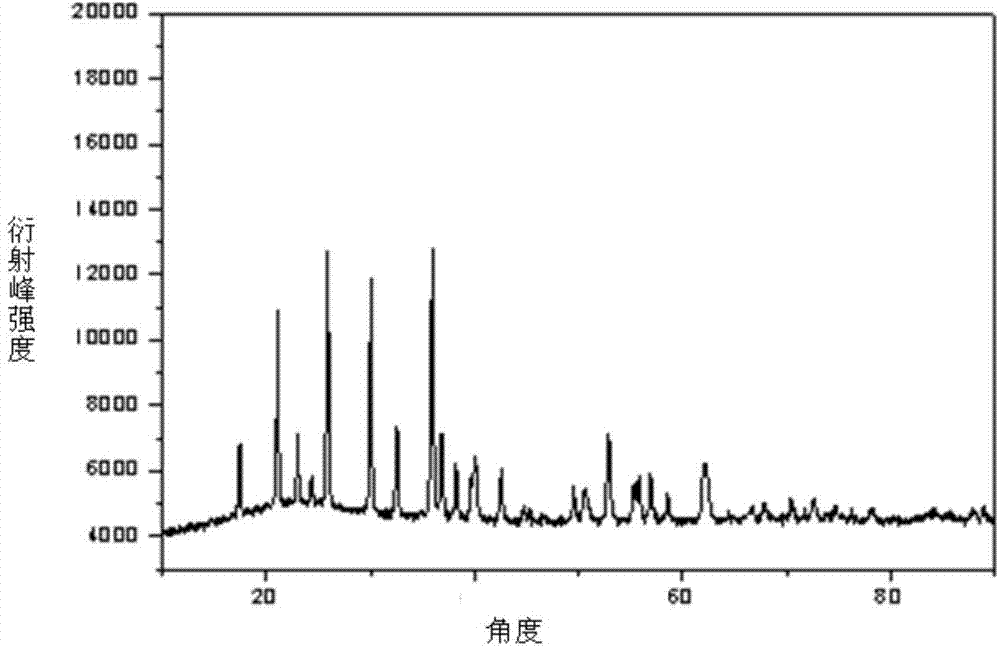

Fine zeolite particle

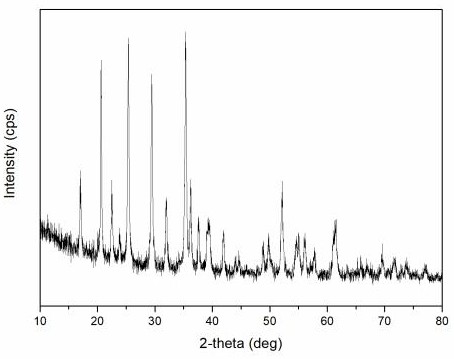

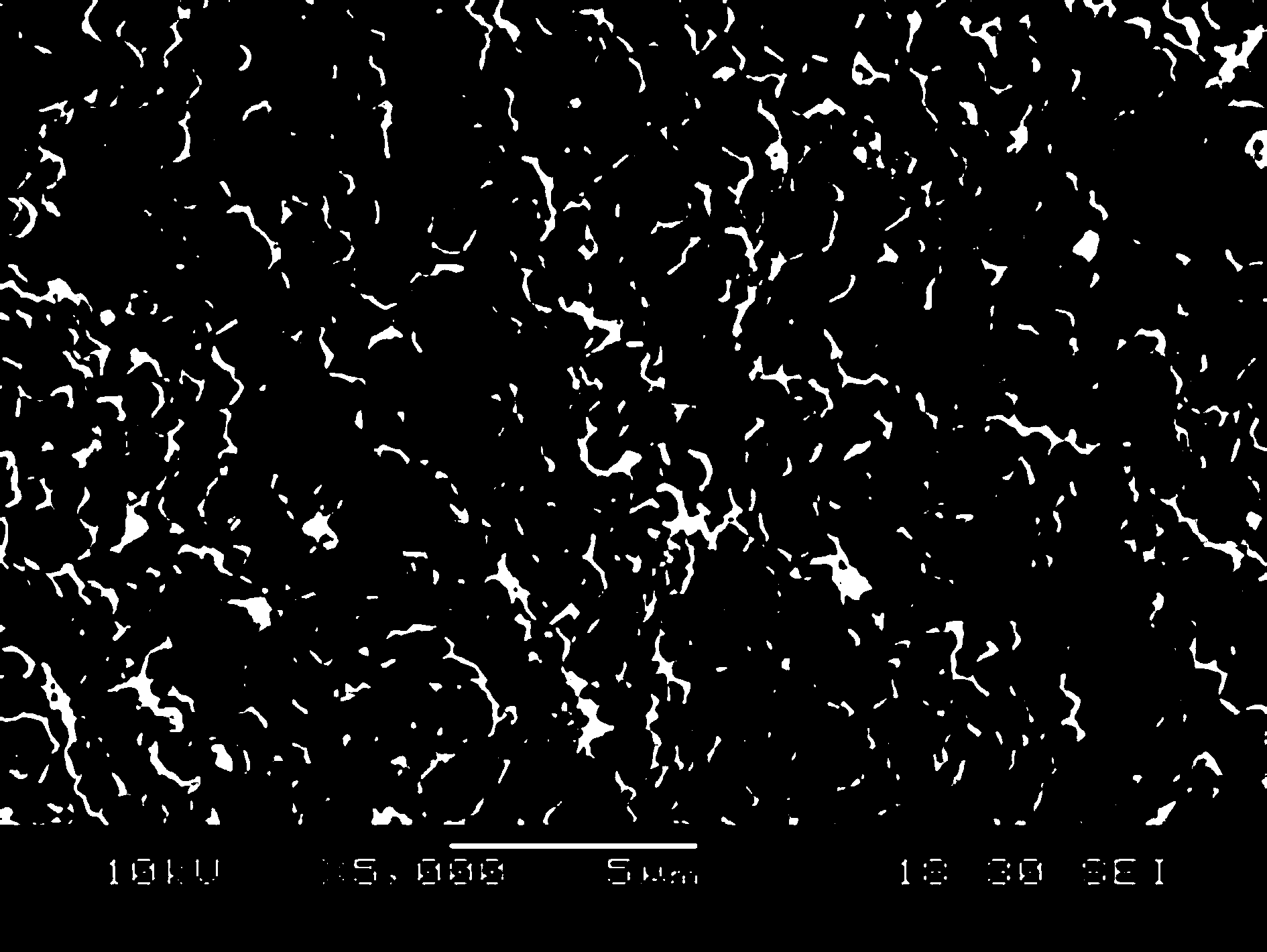

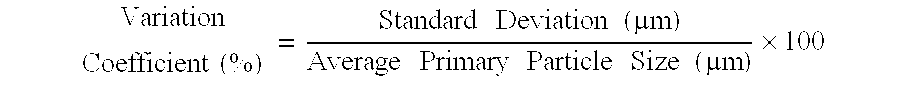

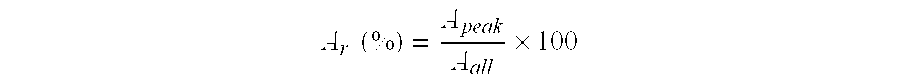

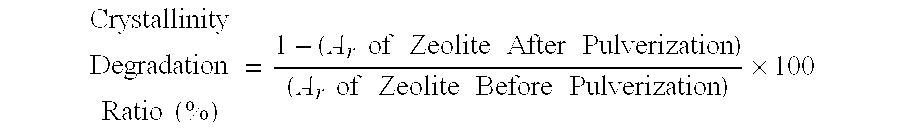

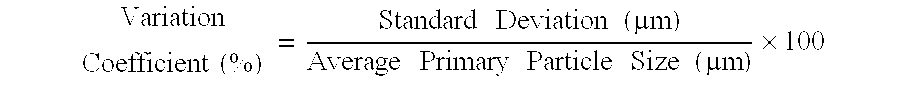

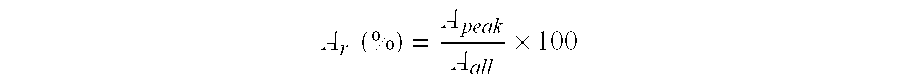

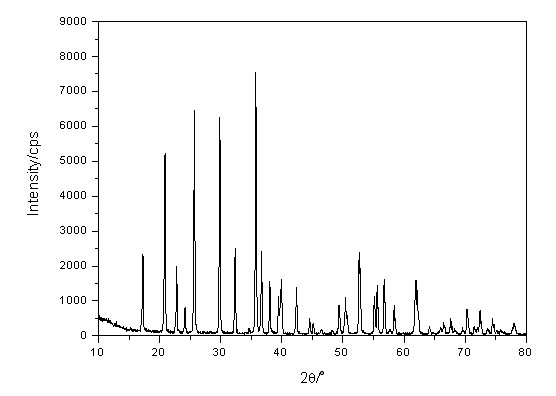

InactiveUS20040018146A1Increase cation exchange capacityGood decontamination effectInorganic/elemental detergent compounding agentsAluminium compoundsX-rayOxygen

A fine A-type zeolite particle having an average primary particle size of 0.1 mum or less and a variation coefficient of 90% or less, wherein a ratio of a peak area above a background level to all peak are in the range of 2theta=20° to 40° in a powder X-ray diffraction spectrum of said fine A-type zeolite particle is 30% or more; a process for preparing the fine A-type zeolite particle, comprising reacting a silica source with an aluminum source in the presence of an organic compound having an oxygen-containing functional group and a molecular weight of 100 or more; and a detergent composition comprising a surfactant and the fine A-type zeolite particle. The fine zeolite particle is suitably used for detergent builders, water treatment agent, fillers for paper, resin fillers, oxygen-nitrogen separating agents, adsorbents, catalyst carriers, soil improvers for gardening, polishing agents, and the like.

Owner:KAO CORP

Fine zeolite particle

InactiveUS6773693B2Crystal growth can be suppressedElution of Al (Al ion) can be suppressedInorganic/elemental detergent compounding agentsAluminium compoundsX-rayLotion

A fine A-type zeolite particle having an average primary particle size of 0.1 mum or less and a variation coefficient of 90% or less, wherein a ratio of a peak area above a background level to all peak are in the range of 2theta=20° to 40° in a powder X-ray diffraction spectrum of said fine A-type zeolite particle is 30% or more; a process for preparing the fine A-type zeolite particle, comprising reacting a silica source with an aluminum source in the presence of an organic compound having an oxygen-containing functional group and a molecular weight of 100 or more; and a detergent composition comprising a surfactant and the fine A-type zeolite particle. The fine zeolite particle is suitably used for detergent builders, water treatment agents, fillers for paper, resin fillers, oxygen-nitrogen separating agents, adsorbents, catalyst carriers, soil improvers for gardening, polishing agents, and the like.

Owner:KAO CORP

Use of fly ash from burning city domestic garbage

InactiveCN1810894AImprove securityReduce leaching concentrationPigment treatment with non-polymer organic compoundsActive agentEnvironmental engineering

The present invention relates to new use of fly ash from burning city domestic garbage, and the fly ash is used as stuffing for polymer material after being activated with surfactant in a dry process. Fly ash is first crushed to 500-1200 mesh and stoved, and then mixed with surfactant in the ratio of 100 to 1-5 inside a ball mill through grinding for 5-30 min, with the modified fly ash being preserved hermetically. The modified fly ash in 10-15 wt% is added into polypropylene base material to produce product reaching relevant standard. The present invention has wide material source, low cost, no secondary pollution caused by the activation treatment and excellent market foreground.

Owner:TONGJI UNIV

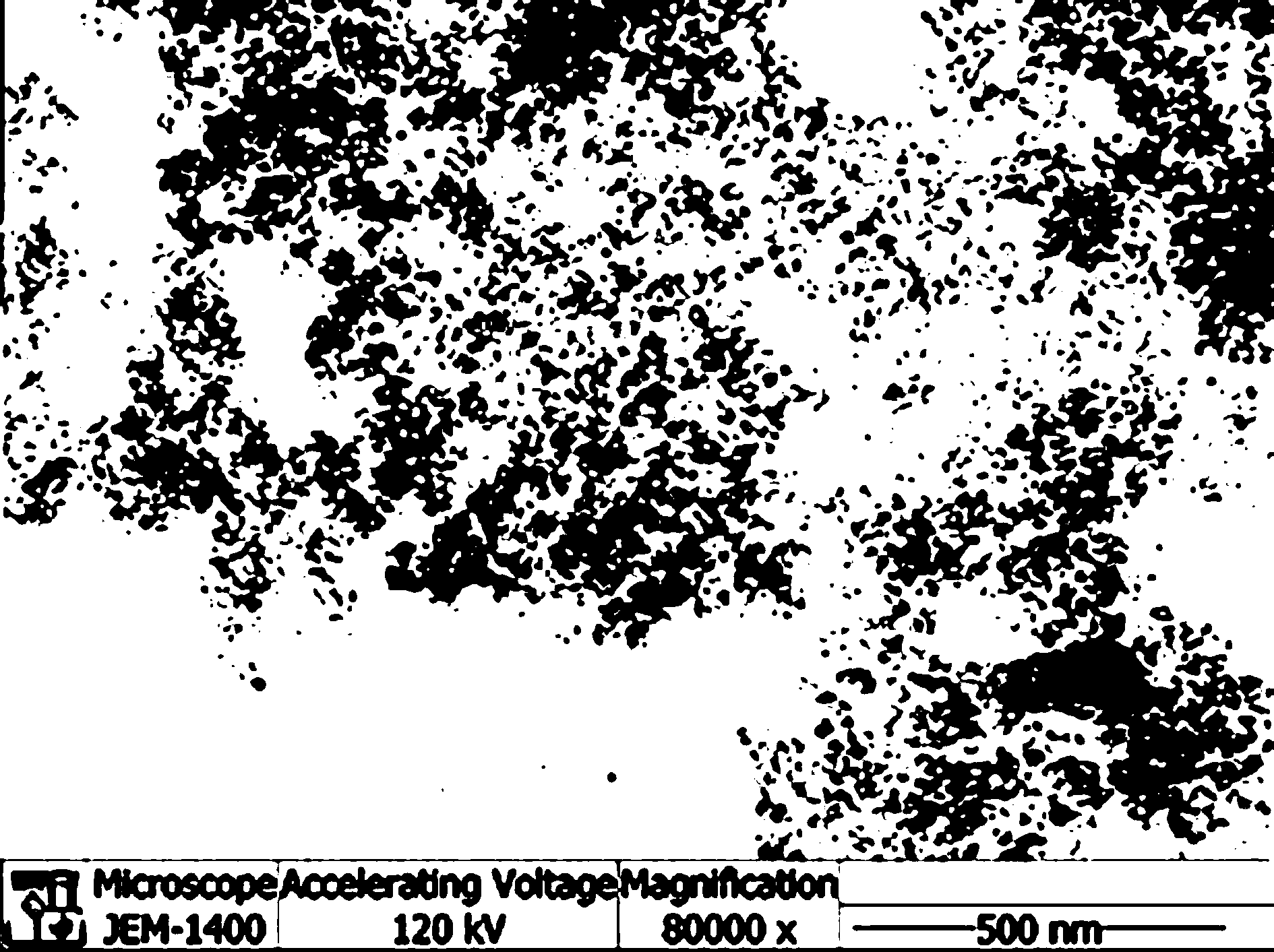

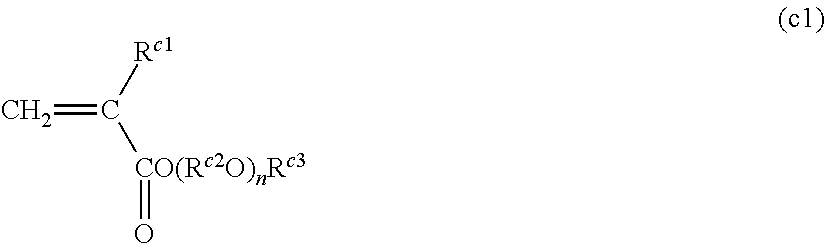

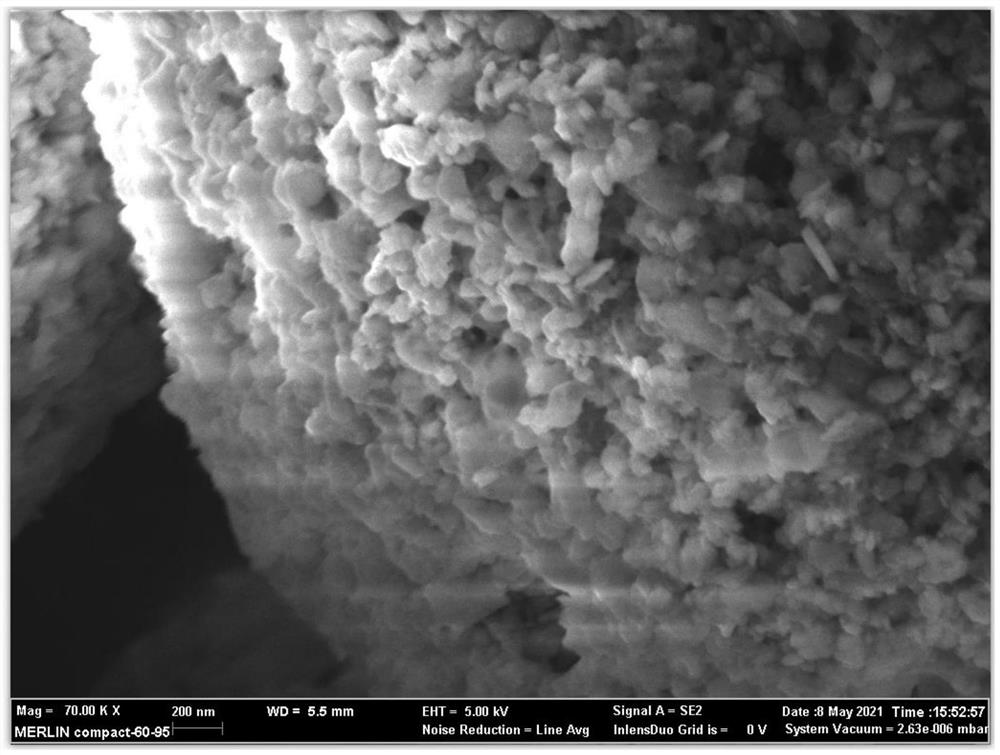

Preparation method of lithium iron phosphate/double carbon layer coated composite material

InactiveCN106848222AGood size controlPrimary particle size is smallCell electrodesCarbon layerSolvent

The invention provides a preparation method of a lithium iron phosphate / double carbon layer coated composite material. The preparation method comprises the following steps of: S1, preparing an iron source, a phosphorus source and a lithium source in a certain ratio of amount of substance, adding a reducing agent to stir, then adding mesoporous carbon, and performing ultrasonic stirring; S2, transferring a mixed liquid prepared in the S1 to a reaction kettle, performing a hydrothermal reaction, reducing the temperature to room temperature after reaction, and washing, blowing and drying the reaction product to obtain a composite material; S3, putting the composite material in a tubular furnace for first time high-temperature calcining, cooling the composite material and taking out the same, and washing and drying the same; and S4, dissolving an additive in absolute ethyl alcohol, adding the composite material prepared in the S3, stirring the mixture to prepare a second mixed liquid, putting the second mixed liquid in an oven to be dried, fully evaporating a solvent, putting the obtained product under protection of inert gas for second time high-temperature calcining, and cooling, washing and drying the product to obtain the secondarily granulated lithium iron phosphate / double carbon layer coated composite material.

Owner:OPTIMUM BATTERY CO LTD

Layered lithium-nickel-based compound oxide powder and its prodution process

InactiveUS20080182169A1Improve featuresIncrease in sizeElectrode thermal treatmentCobalt compoundsLiquid mediumNickel compounds

A layered lithium-nickel-based compound oxide powder for a positive electrode material for a high density lithium secondary cell, capable of providing a lithium secondary cell having a high capacity and excellent in the rate characteristics also, is provided.A layered lithium-nickel-based compound oxide powder for a positive electrode material for a lithium secondary cell, characterized in that the bulk density is at least 2.0 g / cc, the average primary particle size B is from 0.1 to 1 μm, the median diameter A of the secondary particles is from 9 to 20 μm, and the ratio A / B of the median diameter A of the secondary particles to the average primary particle size B, is within a range of from 10 to 200. In production of a layered lithium-nickel-based compound oxide powder, which comprises spray drying a slurry having a nickel compound and a transition metal element compound capable of substituting lithium other than nickel, dispersed in a liquid medium, followed by mixing with a lithium compound, and firing the mixture, the spray drying is carried out under conditions of 0.4≦G / S≦4 and G / S≦0.0012V, when the slurry viscosity at the time of the spray drying is represented by V (cp), the slurry supply amount is represented by S (g / min) and the gas supply amount is represented by G (L / min).

Owner:MITSUBISHI CHEM CORP

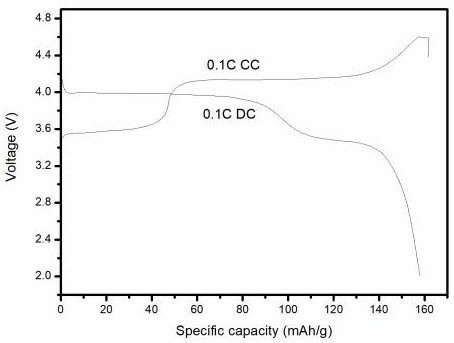

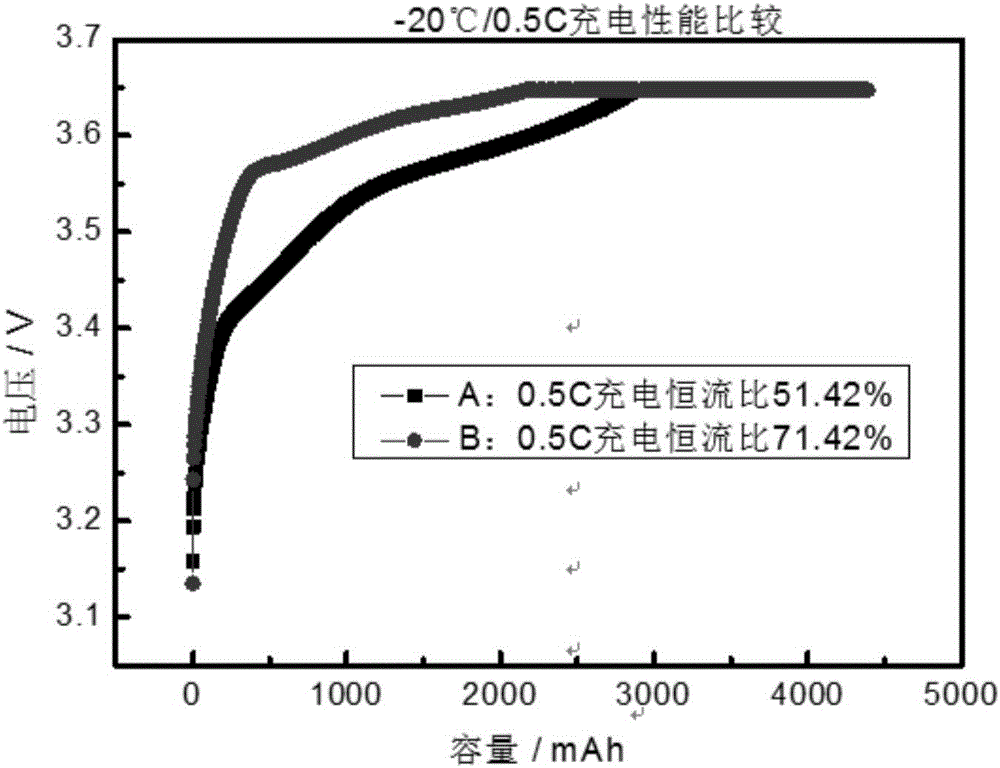

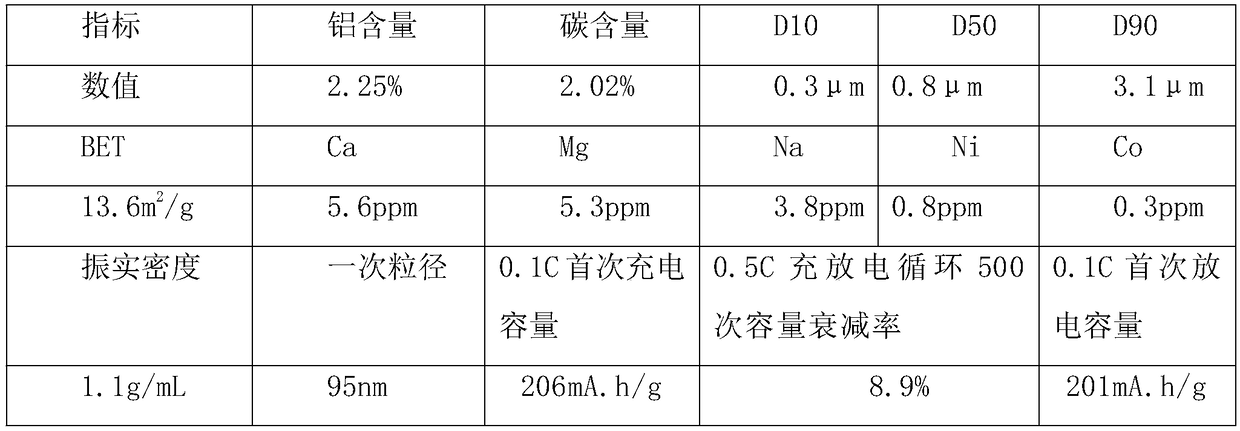

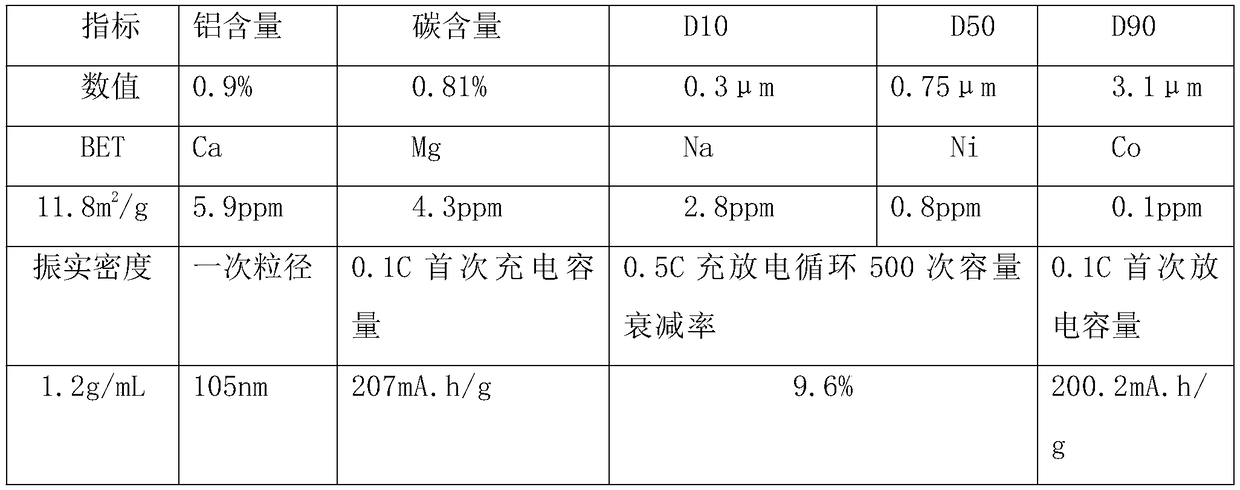

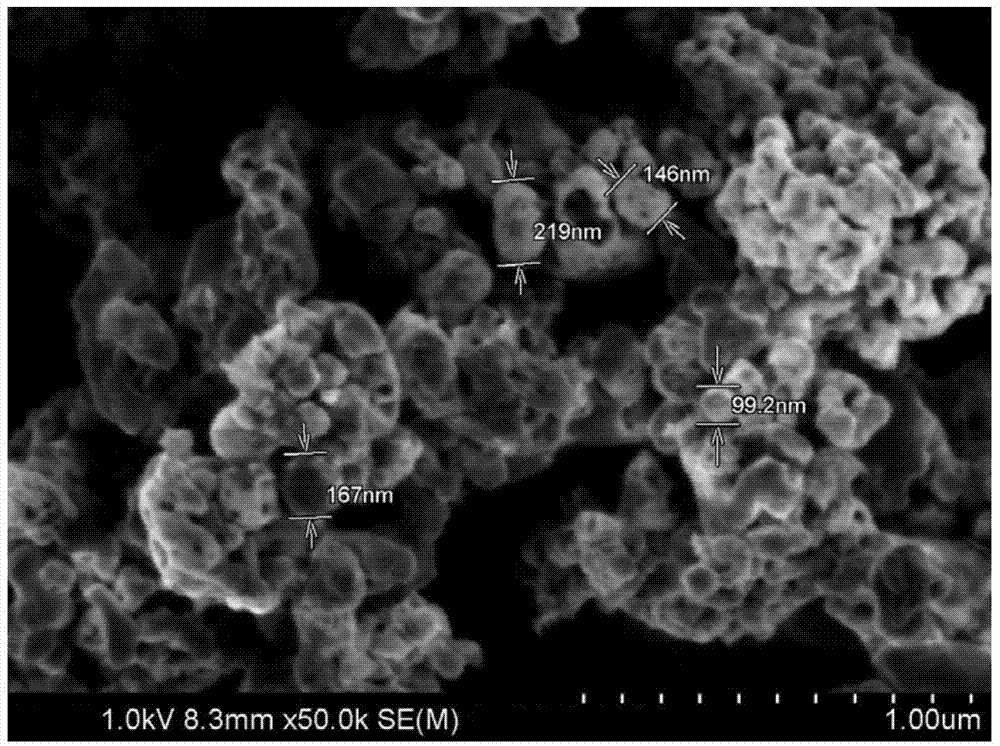

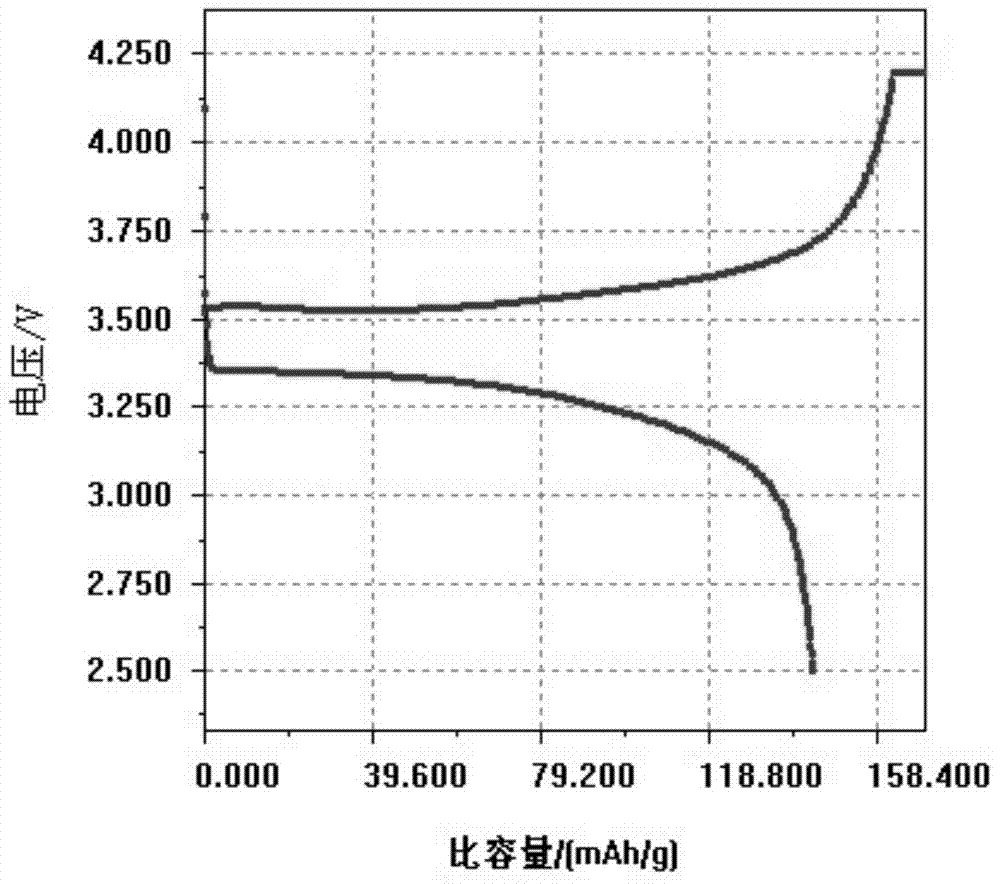

Method for synthesizing lithium iron phosphate anode material at low cost

ActiveCN101973539ALow costPrimary particle size is smallPhosphorus compoundsPhosphatePhosphoric acid

The invention discloses a method for synthesizing lithium iron phosphate anode material at low cost, which belongs to the technical field of energy materials. The method comprises the following steps: preparing a solution containing equimolar Li+ and H2PO4- from lithium salt and phosphoric acid directly; adding an iron source, an organic carbon source and an inorganic carbon source into the solution, and grinding the mixture in a stirring ball mill to obtain precursor slurry; spraying the precursor slurry, drying and granulating to obtain spherical precursor powder; and sintering the precursor powder in a rotary furnace under the protection of inert gas, and naturally cooling to the room temperature to obtain the product. As the solution containing equimolar Li+ and H2PO4- is directly prepared, the steps of reaction, purification, re-crystallization, drying and the like during the manufacturing of lithium dihydrogen phosphate are saved, and the cost of the raw materials is reduced by over 20%. Moreover, by adopting of a joint cladding means combining organic carbon and inorganic carbon, the method reduces the primary particle size (about 200 nm) of the lithium iron phosphate powder, improves the conductivity of the material and greatly enhances the electrochemical performance of the product.

Owner:ZHEJIANG RICHPOWER TECH

Preparation method of metallic oxide with photocatalytic activity

InactiveCN106179346APrimary particle size is smallSmall height specific surface areaMetal/metal-oxides/metal-hydroxide catalystsThermal insulationHigh pressure

The invention relates to the technical field of photocatalytic materials, in particular to a preparation method of a metallic oxide with photocatalytic activity. The method comprises the following steps that 1, a metal precursor corresponding to the metallic oxide is obtained, a liquid-phase medium is added according to the condition that the mass ratio of the metal precursor to the liquid-phase medium is 1:(5-40), stirring and mixing are conducted, and a dispersion liquid is obtained; 2, the dispersion liquid is transferred into a high-pressure closed container, a thermal insulation reaction is conducted for 2 h to 24 h under the temperature condition of 120 DEG C to 200 DEG C, and a reaction product is obtained; 3, solid-liquid separation, cleaning and drying are conducted on the reaction product, and the metallic oxide is obtained. According to the method for preparing the metallic oxide with the photocatalytic activity through low temperature, the metallic oxide is small in primary particle size and high in specific surface area, and doped ions are easy to introduce.

Owner:深圳市尤佳环境科技有限公司

Fine pigment composition and manufacturing method thereof

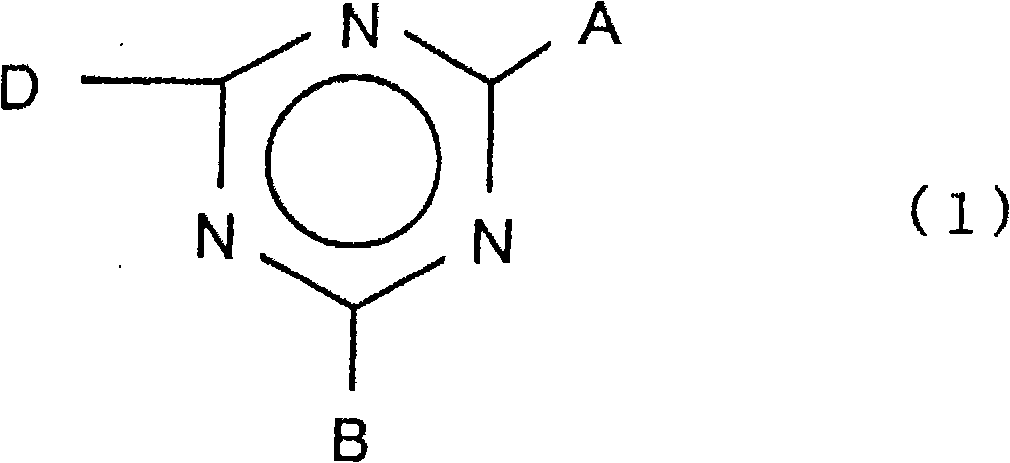

ActiveCN101987925APrimary particle size is smallPrevent agglutinationReactive dyesAnthracene dyesTriazineAgglutination

The present invention provides a fine pigment composition which comprises organic pigment with extraordinarily small particle diameter and has remarkably restrained agglutination. The invention also provides a manufacturing method which can easily prepare the fine pigment composition. The fine pigment composition comprises triazine represented by a formula (1) and the organic pigment. In the formula (1), A represents an acid group or a base group; B represents -OH, -Cl, an acid group or a base group; and D represents -H, -Cl, -OH or aromatic amine residues.

Owner:SANYO COLOR WORKS

A preparation method of lithium iron phosphate

ActiveCN109192936AImprove processing performanceReduce overall energy consumptionCell electrodesSecondary cellsSolventChemistry

The invention provides a preparation method of a lithium iron phosphate positive electrode active material, comprising: (1) firstly mixing a lithium source, an iron source and a doped element source,then sequentially adding a phosphorus source and a carbon source, uniformly mixing to obtain a mixed material; the mixture is placed in a double-cone dryer under solvent-free conditions, and the mixture is dried in a temperature range of 150 DEG C to 400 DEG C, and that heat preservation is performed for 8-12h to obtain dry material, crushing and refine that dry material by adopting a jet mill toobtain powder particles having a primary particle size of 100-200 nm; 2, sintering that powder particle to obtain a primary sintering material under a protective atmosphere, and crushing and refine the primary sintering material by a gas flow crusher to obtain a lithium iron phosphate positive electrode active material. The preparation method comprises the following steps of: adding raw materialsrequired for synthesizing lithium iron phosphate in a certain order without using a solvent; and sintering the raw materials in one step to obtain an end product with uniform size and excellent performance. The preparation method has the advantages of simple process, low energy consumption and environment friendliness.

Owner:SHENZHEN DYNANONIC

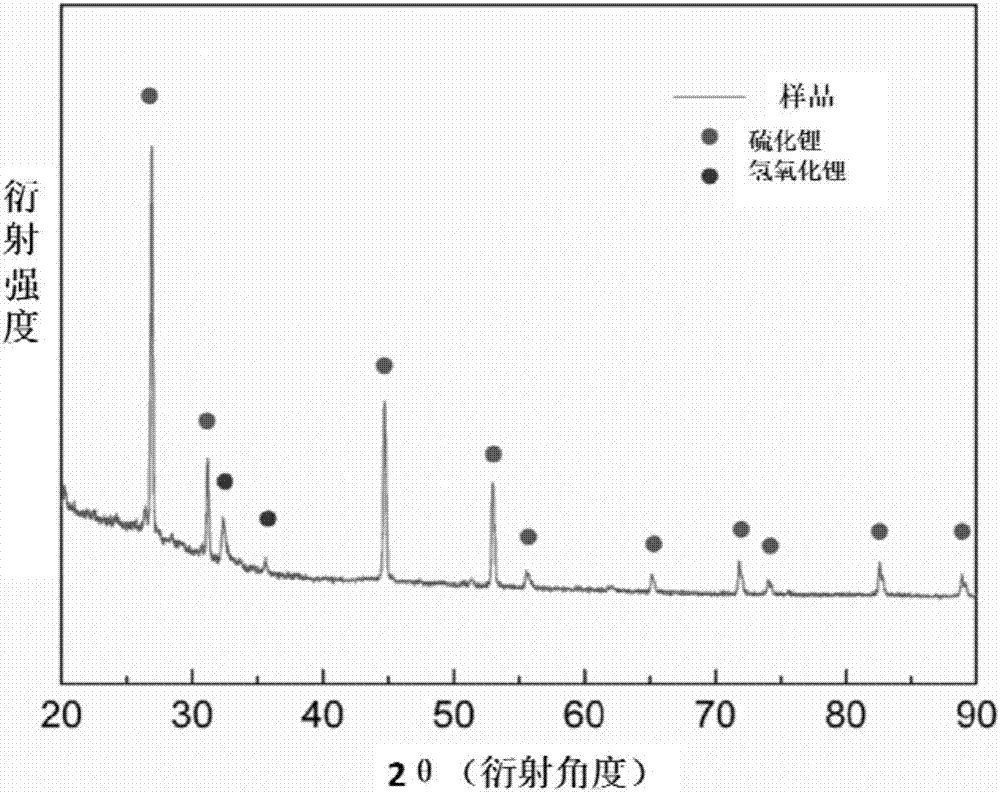

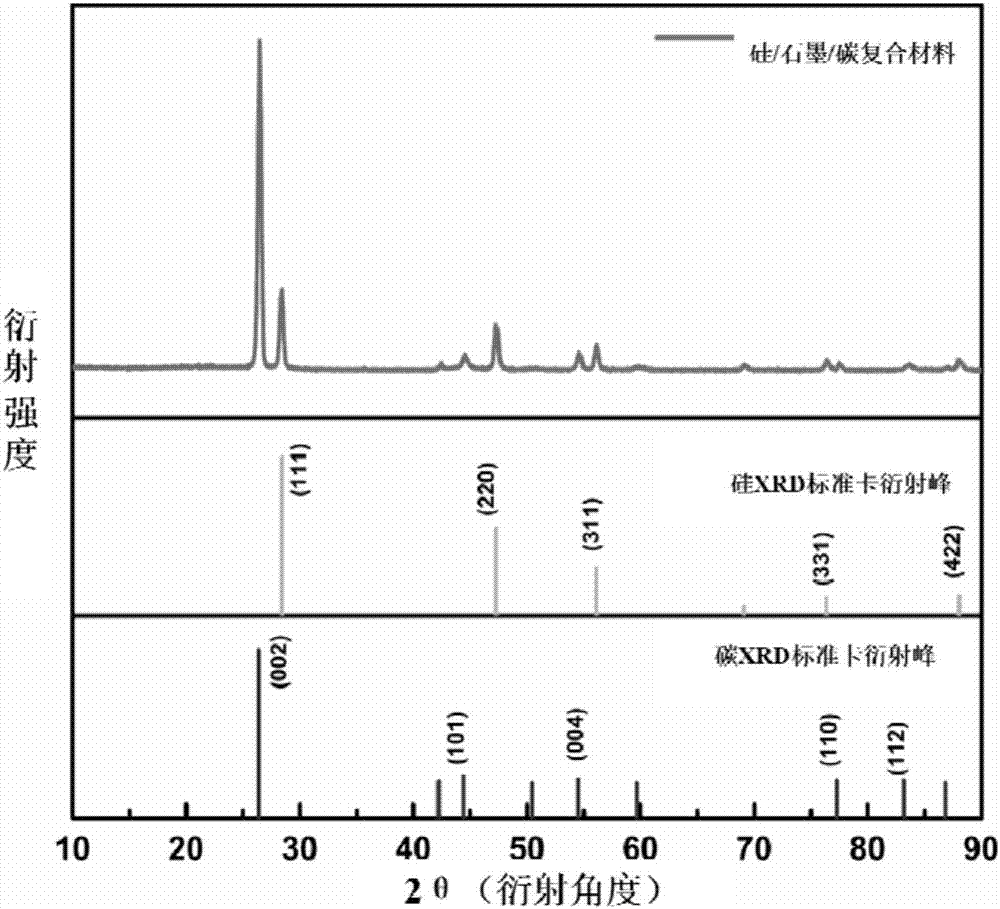

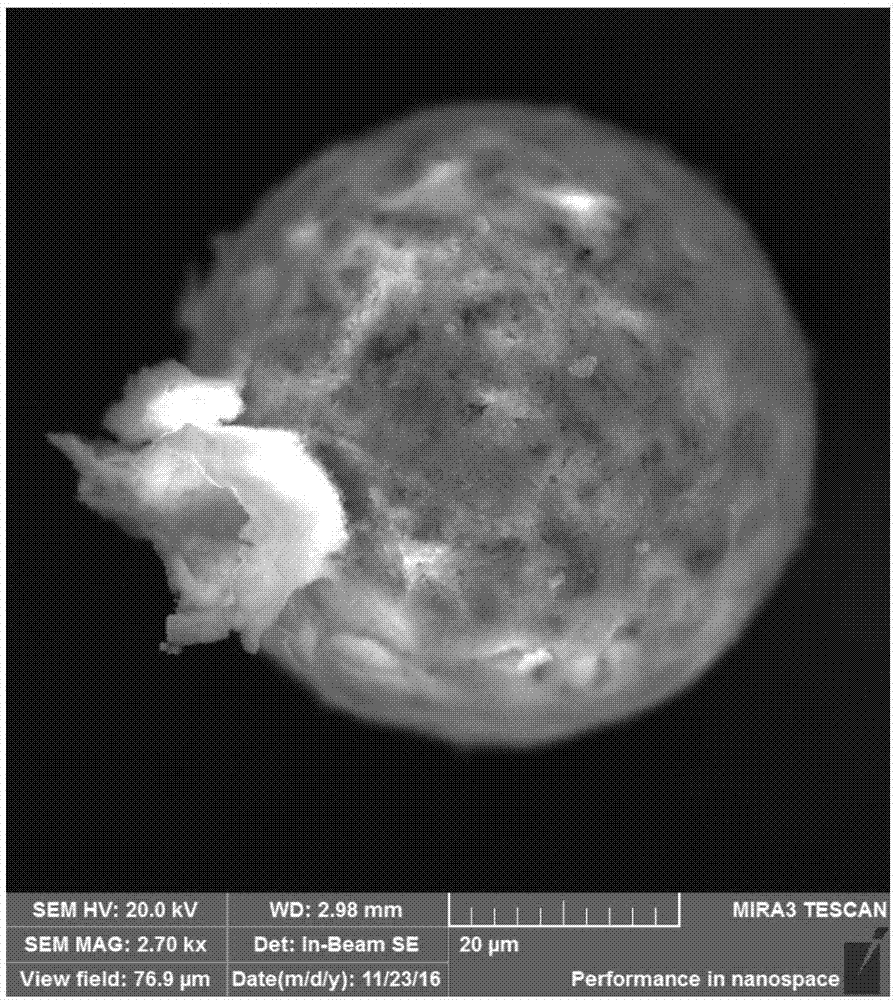

Lithium sulfide/nano silicon carbon whole battery and preparation method and application thereof

InactiveCN107275571AEvenly dispersedSimple stepsElectrode thermal treatmentFinal product manufactureCarbon compositesCarbon coated

The invention discloses a lithium sulfide / nano silicon carbon whole battery and a preparation method and application thereof. The preparation method includes following steps: dispersing lithium sulfate into water, dispersing an organic carbon source into an organic solvent, drying and granulating to prepare a composite precursor after sufficient mixing, and calcining at high temperature to obtain a carbon coated lithium sulfide composite anode material; respectively dispersing nano silicon, the organic carbon source and artificial graphite into the organic solvent, drying and granulating after sufficient mixing, and calcining at high temperature to obtain a carbon coated silicon carbon composite cathode material; assembling the carbon coated lithium sulfide composite anode material and the carbon coated silicon carbon composite cathode material to obtain the lithium sulfide / nano silicon carbon whole battery. The preparation method is simple in preparation process, simple and convenient to operate and suitable for large-scale production; the whole battery prepared by the method has the advantages of high first-time charging and discharging efficiency, high specific capacity and good circulating performance, can meet needs of high-capacity electronic equipment and is suitable for electromobiles or portable electronic products.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for producing cathode active material for lithium ion batteries, cathode active material for lithium ion batteries obtained by the production method, lithium ion battery electrode, and lithium ion battery

InactiveUS8460573B2Improve reaction speedPrimary particle size is smallMaterial nanotechnologyFuse device manufacturePhosphoric acidLithium-ion battery

A method for producing a cathode active material for lithium ion batteries includes a step of synthesizing LiFePO4 by carrying out a hydrothermal reaction using an Li salt, a Fe salt, and a phosphoric acid source as raw materials. Elements Li and Fe in the Li and Fe salts are added to the reaction system in amounts excessively larger than the theoretical amounts required for the hydrothermal reaction. The synthesized LiFePO4 has an average primary particle size of equal to or larger than 30 nm and equal to or smaller than 100 nm.

Owner:SUMITOMO OSAKA CEMENT CO LTD

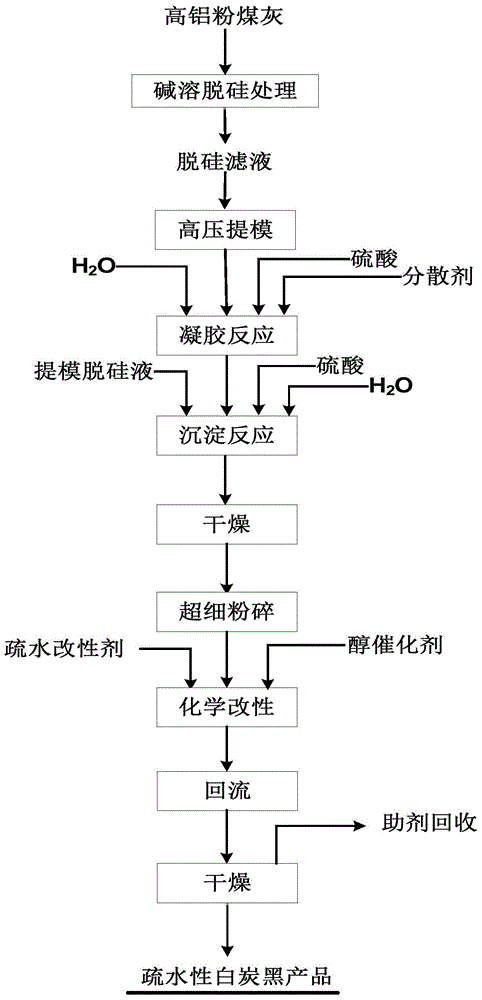

Method for preparing hydrophobic white carbon black by using high-alumina fly ash

The invention discloses a method for preparing hydrophobic white carbon black by using high-alumina fly ash. The method comprises the following steps of carrying out pressure mould lifting and refining treatment on a desilication solution obtained by carrying out alkali dissolution desilication reaction on high-alumina fly ash as a raw material and an alkaline solution; adding a mould lifting desilication solution and a sulfuric acid solution into a bottom alkaline solution prepared from the mould lifting desilication solution, carrying out a sectional acidification reaction including two-stage heating and two-step cocurrent flow precipitation method reaction until the pH value is reduced, and stopping curing reaction, wherein the Na2O concentration of the bottom alkaline solution is 0.080-0.090mol / L, and a dispersant is added into the bottom alkaline solution; filtering, washing, pulping, drying and smashing to obtain a hydrophobic nanometer silicon dioxide masterbatch; dropwise adding methylsilicone oil, a trimethylchlorosilane modifier and an alcohol catalyst which have different characteristics into the masterbatch, carrying out grafting reaction and reflux reaction, and drying to obtain the hydrophobic white carbon black. By using the method, the pore volume of the hydrophobic white carbon black is increased, the regrinding process flow is simplified, and the production cost of the hydrophobic white carbon black produced by using the traditional sulfuric acid method is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

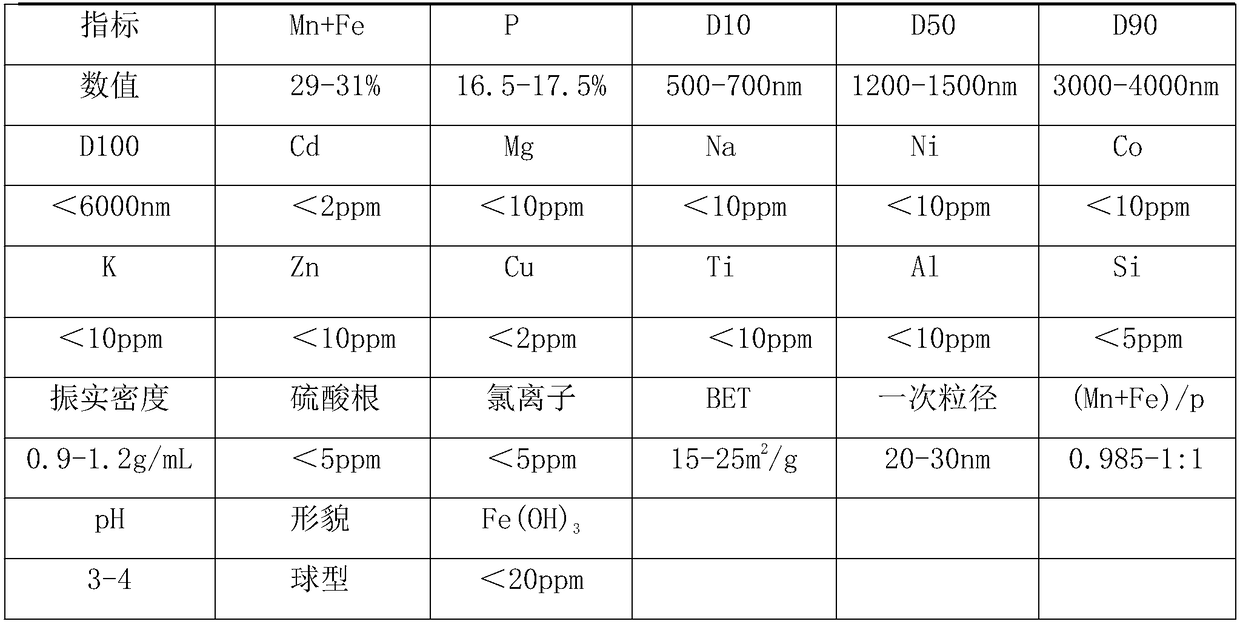

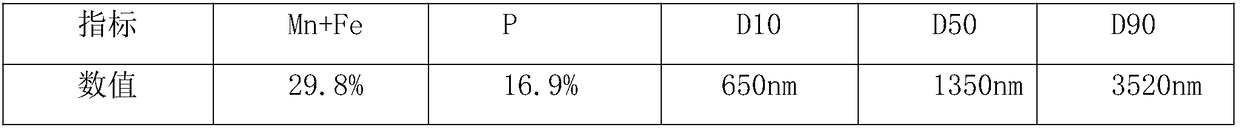

Preparing method of wrapping type phosphate ferromanganese

The invention discloses a preparing method of wrapping type phosphate ferromanganese. The method includes the steps of adding phosphoric acid to ferromanganese powder, conducting a stirring reaction until the ferromanganese powder is incompletely dissolved, conducting filtering, adding filtrate to hydrogen peroxide, starting to raise the temperature after adding is completed, conducting a stirringreaction to obtain ferric phosphate slurry, adding sodium dodecyl benzene sulfonate and then manganese carbonate, making manganese carbonate completely dissolved, continuing to add hydrogen peroxide,conducting filtering to obtain mother liquor and filter residues, adding the filter residues to pure water to be washed, drying the washed filter residues in a microwave dryer until the water contentis lower than 1%, and conducting screening, electromagnetic ferric removing and material mixing to obtain the wrapping type phosphate ferromanganese. The method is simple in process, low in cost andsmall in wastewater discharge amount, the phosphate ferromanganese material with ferric phosphate wrapped by manganese carbonate is obtained, the primary particle size is small, the shape is a spherical shape, the tap density is high, the specific surface is small, the size distribution is uniform, and the content of sulfate radicals and chloridion is low.

Owner:SICHUAN LOMON PHOSPHORUS CHEM

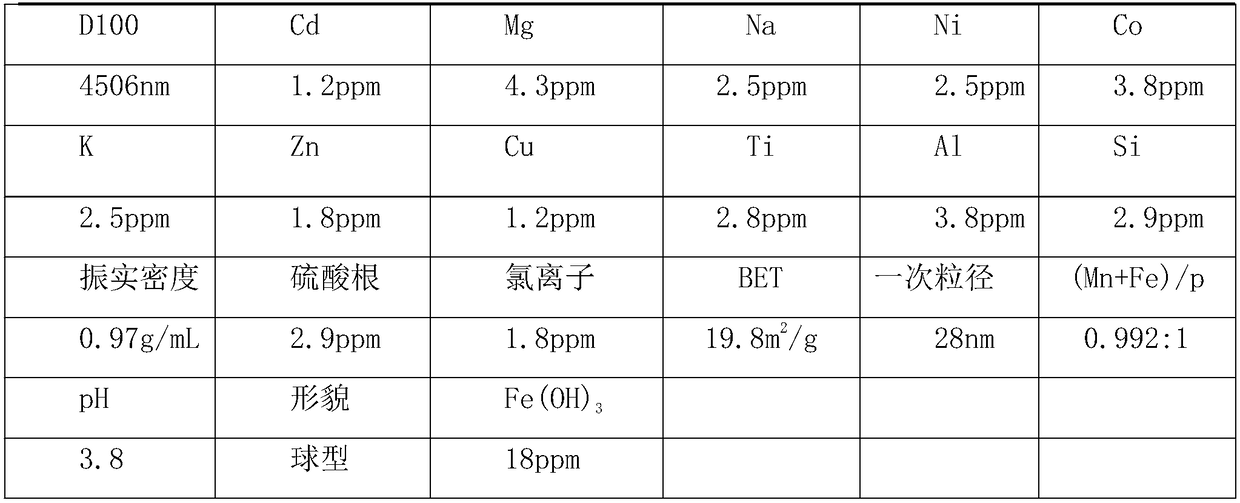

Production method for fine organic pigment

ActiveUS20160090483A1Improve propertyPrimary particle size is smallMonoazo dyesDisazo dyesSolventWater soluble

The present invention provides the following process for producing a fine organic pigment which is capable of producing the fine organic pigment that has a very small primary particle size and is excellent in filtering property even in a cleaning step, and a fine organic pigment produced by the process; a process for producing a dispersion using the fine organic pigment, and a dispersion produced by the process; and a process for producing an ink using the dispersion. The present invention relates to [1] a process for producing a fine organic pigment, including steps 1 and 2: step 1: kneading a mixture prepared by compounding a raw material organic pigment, a water-soluble inorganic salt, a water-soluble organic solvent and a compound represented by the following formula (1) with each other, the compound being compounded in an amount of not less than 0.8 part by mass and not more than 18.0 parts by mass on the basis of 100 parts by mass of the raw material organic pigment: R1O(PO)m(EO)nA (1); and step 2: subjecting the mixture obtained in the step 1 to cleaning treatment with an aqueous solvent and then to filtration, [2] a fine organic pigment produced by the process according to the above aspect [1], [3] a dispersion produced using the fine organic pigment according to the above aspect [2], [4] a process for producing a paste of a fine organic pigment, including the above step 1 and 2, [5] a process for producing a dispersion, including step 3 of subjecting the paste of the fine organic pigment produced by the process according to the above aspect [4], an organic solvent and water to dispersing treatment, and [6] a process for producing an ink, including step 4 of mixing the dispersion produced by the process according to the above aspect [5] with at least one material selected from the group consisting of water and an organic solvent.

Owner:KAO CORP

Preparation method of lithium iron phosphate composite coated by double carbon layers

InactiveCN107170964APrimary particle size is smallEvenly distributedCell electrodesLi-accumulatorsCarbon dopedChemistry

The invention discloses a preparation method of a lithium iron phosphate composite coated by double carbon layers. The preparation method comprises the following steps: step 1, evenly mixing an iron source, a phosphorus source and a lithium source at certain molar ratio into an ethanol solution to form a mixed solution, then adding and dissolving a carbon source into the mixed solution to form a first mixture, then adding an ordered mesoporous carbon into the first mixture, conducting ultrasonic treatment for a first preset time at the room temperature to form a second mixture; step 2, putting the second mixture into a container, conducting a hydrothermal reaction for a second preset time at a first preset temperature, cooling to form a third mixture, washing and drying the third mixture to prepare a carbon doped lithium iron phosphate composite; step 3, putting the carbon doped lithium iron phosphate composite into a container under the protection of nitrogen gas, calcining for a third preset time at a second preset temperature, cooling, taking out, alternatively washing with the deionized water and absolute ethyl alcohol sequentially for a plurality of times, and drying to obtain the lithium iron phosphate composite coated by the double carbon layers.

Owner:JIANGSU ENE CARBON ENERGY TECH CO LTD

Preparation method of lithium iron borate

The invention discloses a preparation method of lithium iron borate. The preparation method comprises the following steps: mixing a lithium borohydride solution with a ferric nitrate solution and pouring a mixed solution into a sealed high-pressure reactor, carrying out hydrothermal reaction and then decompressing; absorbing the exported gas with ferric hydroxide slurry, adding aluminum citrate, uniformly stirring and mixing and then carrying out spray drying to obtain a dry material; sintering the dry material in an inert atmosphere, cooling to a temperature below 60 DEG C and discharging toobtain a calcined material; carrying out fluid energy milling on the obtained calcined material by using nitrogen, screening, removing iron and carrying out vacuum packaging to obtain a cathode material of the lithium iron borate. According to the preparation method of the lithium iron borate, disclosed by the invention, amorphous lithium iron borate is prepared by using the hydrothermal method, is coated with alumina citrate and is then calcined at high temperature to obtain the lithium iron borate coated with alumina and carbon; the lithium iron borate has the advantages of small primary particle size, good stability and good electrochemical property.

Owner:临汾市中贝新材料有限公司

Water-based nano pigment dispersion

PendingCN114133792AAvoid reunionImprove performanceChemical industryPigment pastesPigment dispersionEnvironmental engineering

The invention provides a water-based nano pigment dispersion, and belongs to the field of pigments. The invention provides a water-based nano pigment dispersion. A preparation method of the water-based nano pigment dispersion comprises the following steps: step 1, preparing nano-scale pigment particles with uniform particle size; 2, hydrophilic groups are introduced to the surfaces of the nano-scale pigment particles through a diazonium salt coupling method, and modified nano-scale pigment particles are obtained; and step 3, adjusting the pH value of the modified nano pigment particles to 7-9 by using a pH regulator, washing, percolating, desalting, concentrating and removing impurities to obtain the water-based nano dispersion. According to the method, a process integration mode is adopted, pigment refinement and subsequent diazotization modification are linked, the phenomenon of pigment agglomeration possibly caused by step-by-step operation in a common mode is avoided, the more uniform water-based nano pigment is obtained, the primary particle size is reduced to about 50nm, and the pigment performance is greatly improved.

Owner:FUDAN UNIV +1

A high-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder and its preparation method

ActiveCN110330341BPrimary particle size is smallCalcination temperature is lowTransition metal carbidesCarbide

A method for preparing high-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder, the invention belongs to the technical field of superhard ceramic materials, and in particular relates to a method for preparing high-entropy ceramic powder. The purpose of the present invention is to solve the problems of high oxygen content and residual carbon content, low purity, large particle size and poor sphericity in the multi-component carbide high-entropy ceramic material prepared by the existing method. The chemical formula of high-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder is (Hf x1 Nb x3 Ta x4 Ti x2 m x5 ) C. Methods: 1. Weighing; 2. Mixing; 3. Calcining. The high-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder prepared by the invention has the advantages of small particle size, low oxygen content and low free carbon content. The invention can obtain a high-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder.

Owner:HARBIN INST OF TECH

Modified polytetrafluoroethylene fine powder and its manufacturing method, and electric wire and tube using it

ActiveUS20180037689A1Sufficiently sinteredShort sintering timePlastic/resin/waxes insulatorsInsulated cablesHexafluoropropylenePTFE - Polytetrafluoroethylene

To optimize the primary particle size of a modified PTFE fine powder to shorten the sintering time during the extrusion molding.A modified polytetrafluoroethylene fine powder which is a fine powder of a non-melt-processable modified polytetrafluoroethylene comprising units derived from tetrafluoroethylene, units derived from hexafluoropropylene, units derived from a perfluoro(alkyl vinyl ether) represented by CF2═CFO—CnF2n+1 (n is an integer of from 1 to 6) and units derived from a (perfluoalkyl)ethylene represented by CH2═CH—CmF2m+1 (m is an integer of from 3 to 7).

Owner:AGC CHEM EURO LTD +1

Preparation method of sodium vanadium phosphate type sodium battery positive electrode material

PendingCN114335529AGood dispersionPrimary particle size is small and uniformCell electrodesSecondary cellsSodium phosphatesElectrical battery

The invention discloses a preparation method of a sodium vanadium phosphate type sodium battery positive electrode material. The method comprises the following steps: dissolving vanadium trichloride, ferric trichloride and phosphorous acid in anhydrous alcohol, then adding an ammonia gas-alcohol solution, then pouring into a hydrothermal reaction kettle, then introducing nitrogen, discharging air in the hydrothermal reaction kettle, then heating, reacting at high temperature and high pressure, and filtering the obtained slurry to obtain a solid and filtrate; adding hydrogen peroxide into the obtained solid for slurrying, then reacting, and filtering and washing the obtained solid particles to obtain a ferrovanadium phosphorus precipitate; adding a sodium phosphate solution and ammonium dihydrogen phosphate into the ferrovanadium phosphorus precipitate, then adding a dispersing agent, stirring and slurrying, and carrying out spray drying to obtain a spray-dried material; and calcining the obtained dried material, keeping the calcining process in a nitrogen atmosphere, and then screening to remove iron, thereby obtaining the sodium ion battery material. The sodium vanadium phosphate type sodium battery positive electrode material is small in primary particle size, good in rate capability, high in capacity, simple to prepare and low in cost.

Owner:SICHUAN LOMON PHOSPHORUS CHEM

Preparation method of high-power lithium iron phosphate material

The invention relates to a preparation method of a high-power lithium iron phosphate material. The preparation method comprises the following steps: 1. preparing a liquid-phase rapid gel forming precursor: (1) stirring a soluble lithium-source compound, an iron-source compound and a phosphorus-source compound to form a mixed solution; adding a dispersing agent into the mixed solution, adding ammonia water into a stirrer, and forming a jelly mixture in the stirrer; (2) drying the jelly mixture in the step 1 (1) to obtain the precursor; 2. pre-sintering and granulating the precursor; 3. carrying out the high-temperature heat treatment on the material. The lithium iron phosphate precursor synthesized in the liquid phase has the characteristic of small primary particle size, various raw materials are uniformly mixed on the molecular level, and various liquid-phase process parameters are controlled, so that the quality stability of the material in a same batch and among different batches can be realized; solvent evaporation is not needed, the material production cost is lowered, and the method is extremely suitable for industrial production of the material.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Preparation method of high-activity lithium carbonate

InactiveCN111422889AHigh activityHigh sphericityNanotechnologyLithium carbonates/bicarbonatesLithium carbonatePhysical chemistry

The invention discloses a preparation method of high-activity lithium carbonate. The preparation method comprises adding a lithium solution, an alkali solution and an ammonium bicarbonate solution into a reaction kettle in a convection manner, adding a base solution into the reaction kettle, after the reaction is finished, filtering and washing until the conductivity of washing water is less thanor equal to 100 [mu]S / cm, then drying by adopting microwave, introducing carbon dioxide gas for activation in the drying process, stopping drying until the mass fraction of free water of the materialis less than or equal to 1%, screening, removing iron, and packaging to obtain the high-activity lithium carbonate. The purified lithium salt solution, ammonium bicarbonate and alkaline solution are added into the reaction kettle at a certain flow rate to react, the reaction temperature, the pH value and the CO3<2-> concentration are controlled so that the battery-grade lithium carbonate with highactivity, small primary particle size and high sphericity is obtained, and carbon dioxide is adopted to activate the surface of the lithium carbonate in the microwave drying process, so that the activity of the lithium carbonate is further improved, and the high-activity lithium carbonate is obtained through screening and iron removal.

Owner:蒋央芳

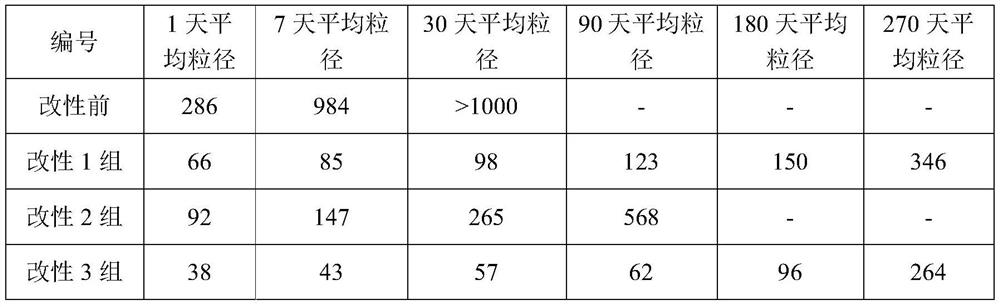

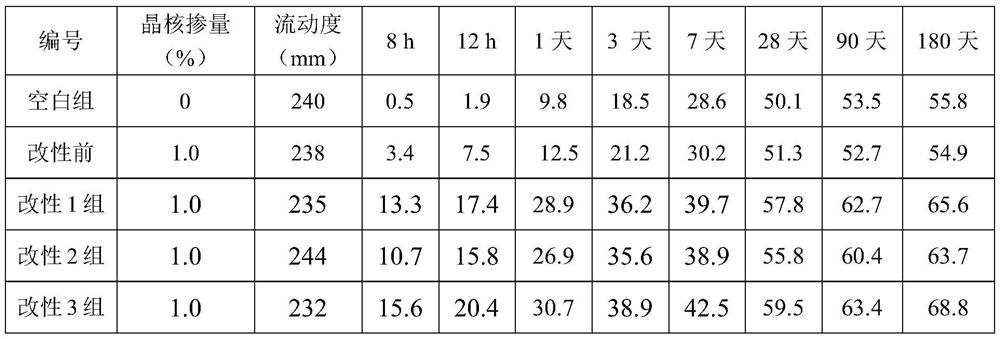

A kind of alcohol amine modified calcium silicate hydrate nano crystal nucleus early strength agent and preparation method thereof

ActiveCN111253107BIncrease the average molecular chain lengthStable dispersion stabilityCalcium silicateSimple Organic Compounds

The invention discloses an alcohol amine-modified calcium silicate hydrate nano crystal nucleus early strength agent, which is prepared from a reaction stock solution, a reaction bottom liquid and a dispersion stabilization liquid, and the reaction stock solution includes the following components: soluble calcium salt and Soluble silicon salt; the reaction bottom liquid includes the following components: polycarboxylate superplasticizer; the dispersion stabilization liquid includes the following components: soluble alkanolamine organic matter and soluble aluminum salt. The alcohol amine modified calcium silicate hydrate nano crystal nucleus early strength agent solves the problem of long-term dispersion stability of the calcium silicate hydrate crystal nucleus suspension, and its initial particle size is small, the dispersion stability time is long, and it is durable to storage. The preparation process and application method are simple, and the effect of improving the strength of cement-based materials in the early stage and later stage is remarkable, and the performance is excellent. The invention also discloses a preparation method of the alcohol amine modified calcium silicate hydrate nano crystal nucleus accelerator.

Owner:WUHAN UNIV OF TECH

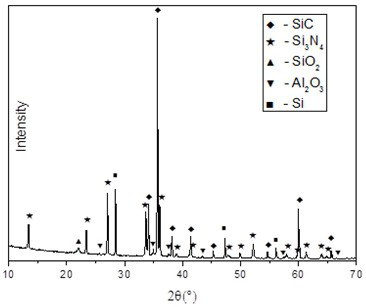

Catalyst carrier for cracking of biological tar, catalyst and preparation method

ActiveCN113117716AImprove high temperature strengthImprove high temperature stabilityCatalyst carriersCatalyst activation/preparationPtru catalystSilicon oxide

The invention discloses a catalyst carrier for biological tar cracking, a catalyst and a preparation method. The catalyst carrier for biological tar cracking takes a silicon carbide-silicon nitride composite material as a matrix, silicon oxide is distributed on the matrix, and the preparation method comprises the following steps: firstly, preparing the silicon carbide-silicon nitride composite material; then making the composite material contact with oxygen-containing gas for treatment, and conducting cooling to obtain a carrier intermediate A; and conducting mixing with an alkaline solution or a hydrofluoric acid solution, conducting washing, carrying out low-temperature heat treatment, and carrying out high-temperature heat treatment to obtain the biological tar cracking catalyst carrier. The invention also provides the catalyst adopting the carrier. The catalyst for biological tar cracking is good in wear resistance, high in activity, high in microwave absorption rate, good in thermal shock resistance and high in water resistance at high temperature, and the preparation method is simple, low in cost, resistant to sintering and carbon deposition and capable of being recycled for a long time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com