Lithium sulfide/nano silicon carbon whole battery and preparation method and application thereof

A nano-silicon and lithium sulfide technology, applied in electrode manufacturing, secondary batteries, battery electrodes, etc., can solve the problems of poor first efficiency and cycle stability, easily damaged material structure, large irreversible capacity of batteries, etc. The process steps are concise, the removal of impurities is saved, and the operation is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

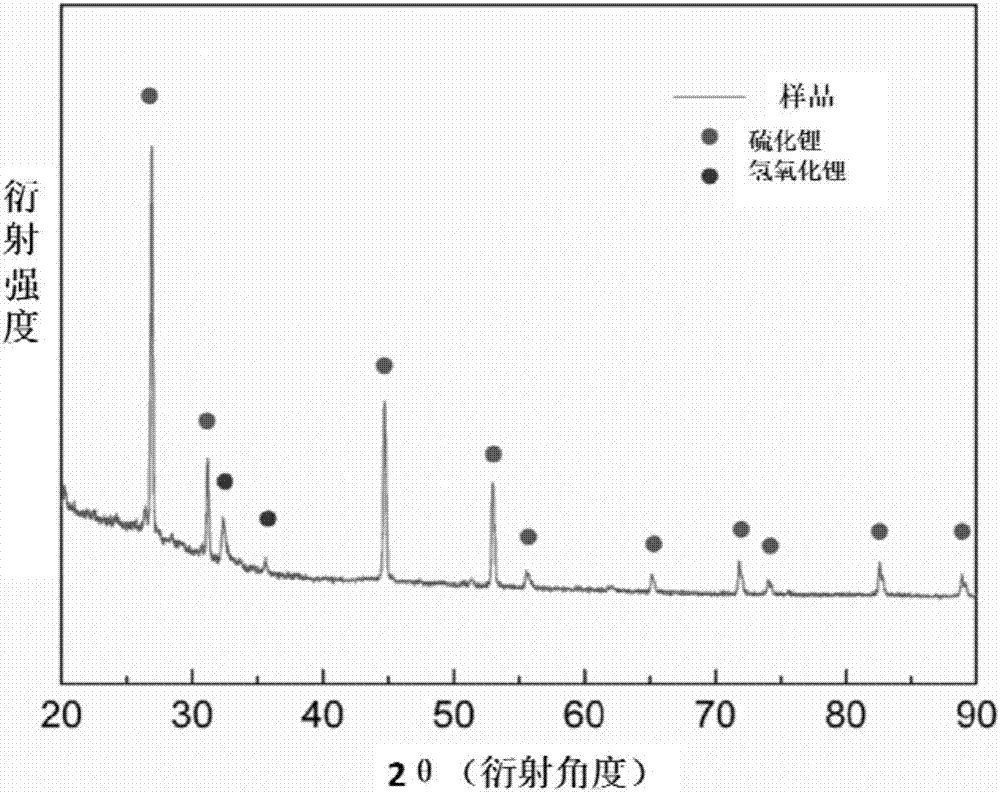

[0085] (1) The preparation of carbon-coated lithium sulfide cathode material, the specific steps are as follows:

[0086] (1) Disperse 16.7g of lithium sulfate in 200mL of deionized water, stir at a high speed of 1500r / min for 0.5h to obtain solution A;

[0087] (2) Dissolve 125g of sucrose in 200mL of deionized water, and stir at a high speed of 1500r / min for 0.5h to obtain a mixed solution B;

[0088] (3) Add the solution A prepared in step (1) to the solution B prepared in step (2), mix well to obtain a mixed solution C, and then carry out closed-loop spray drying of the mixed solution C to obtain a precursor Body D; wherein, the rotational speed of the centrifugal atomizer is 20000r / min during the closed cycle spray drying powder making, the inlet and outlet temperatures are 200°C and 100°C respectively, and the feed rate is 15mL / min;

[0089] (4) Place the precursor D prepared in step (3) in a tube furnace, feed nitrogen gas with a purity of 99.99%, and raise the tempera...

Embodiment 2

[0103] (1) The preparation of carbon-coated lithium sulfide cathode material, the specific steps are as follows:

[0104] (1) Disperse 16.7g of lithium sulfate in 200mL of deionized water, stir at a high speed of 1500r / min for 0.5h to obtain solution A;

[0105] (2) Dissolve 120g of asphalt in 200mL of tetrahydrofuran, and stir at a high speed of 1500r / min for 1h to obtain a mixed solution B;

[0106] (3) Add the solution A prepared in step (1) to the solution B prepared in step (2) and mix evenly to obtain a mixed solution C, and then carry out closed-loop spray drying of the mixed solution C to obtain a precursor D; Among them, the rotational speed of the centrifugal atomizer is 20000r / min, the inlet and outlet temperatures are 220°C and 100°C respectively, and the feed rate is 15mL / min during the closed cycle spray drying powder making;

[0107] (4) Place the precursor D prepared in step (3) in a tube furnace, feed in nitrogen gas with a purity of 99.99%, raise the temperatu...

Embodiment 3

[0121] (1) The preparation of carbon-coated lithium sulfide cathode material, the specific steps are as follows:

[0122] (1) Disperse 16.7g of lithium sulfate in 200mL of deionized water, stir at a high speed of 1500r / min for 0.5h to obtain solution A;

[0123] (2) Dissolve 120g polyvinyl alcohol (average molecular weight 20000) in 200mL deionized water, and stir at 60°C and 1500r / min at high speed for 1h to obtain mixed solution B;

[0124] (3) Add the solution A prepared in step (1) to the solution B prepared in step (2) and mix evenly to obtain a mixed solution C, and then carry out closed-loop spray drying of the mixed solution C to obtain a precursor D; Among them, the rotational speed of the centrifugal atomizer is 20000r / min, the inlet and outlet temperatures are 220°C and 100°C respectively, and the feed rate is 15mL / min during the closed cycle spray drying powder making;

[0125] (4) Place the precursor D prepared in step (3) in a tube furnace, feed nitrogen gas wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com