Patents

Literature

298results about How to "Improve the first charge and discharge efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

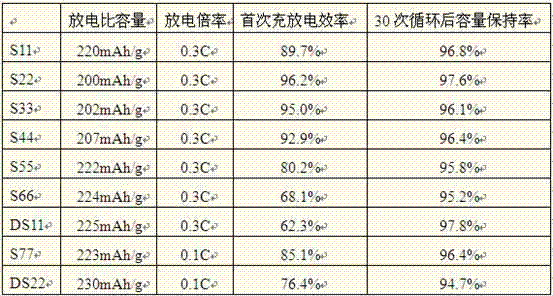

Silicon oxide/carbon cathode material of lithium ion battery and preparation method of material

ActiveCN103022446AHigh electrochemical activity and charge-discharge capabilityReduce volume expansion effectCell electrodesSilicon particleLithium electrode

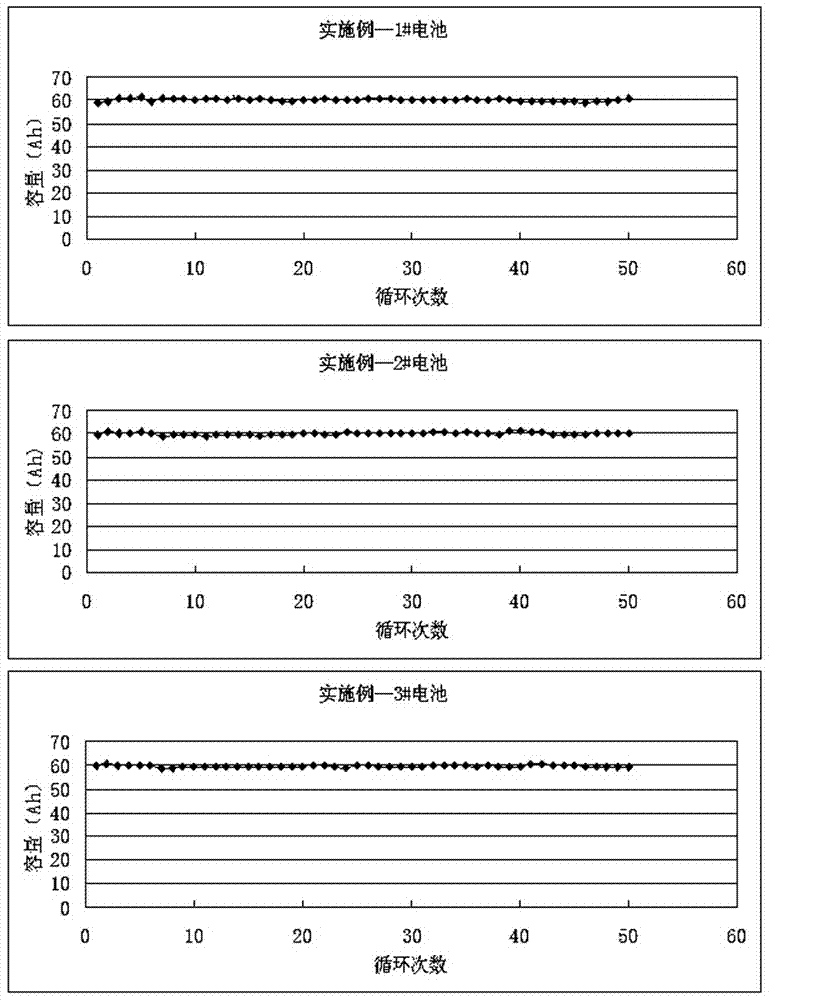

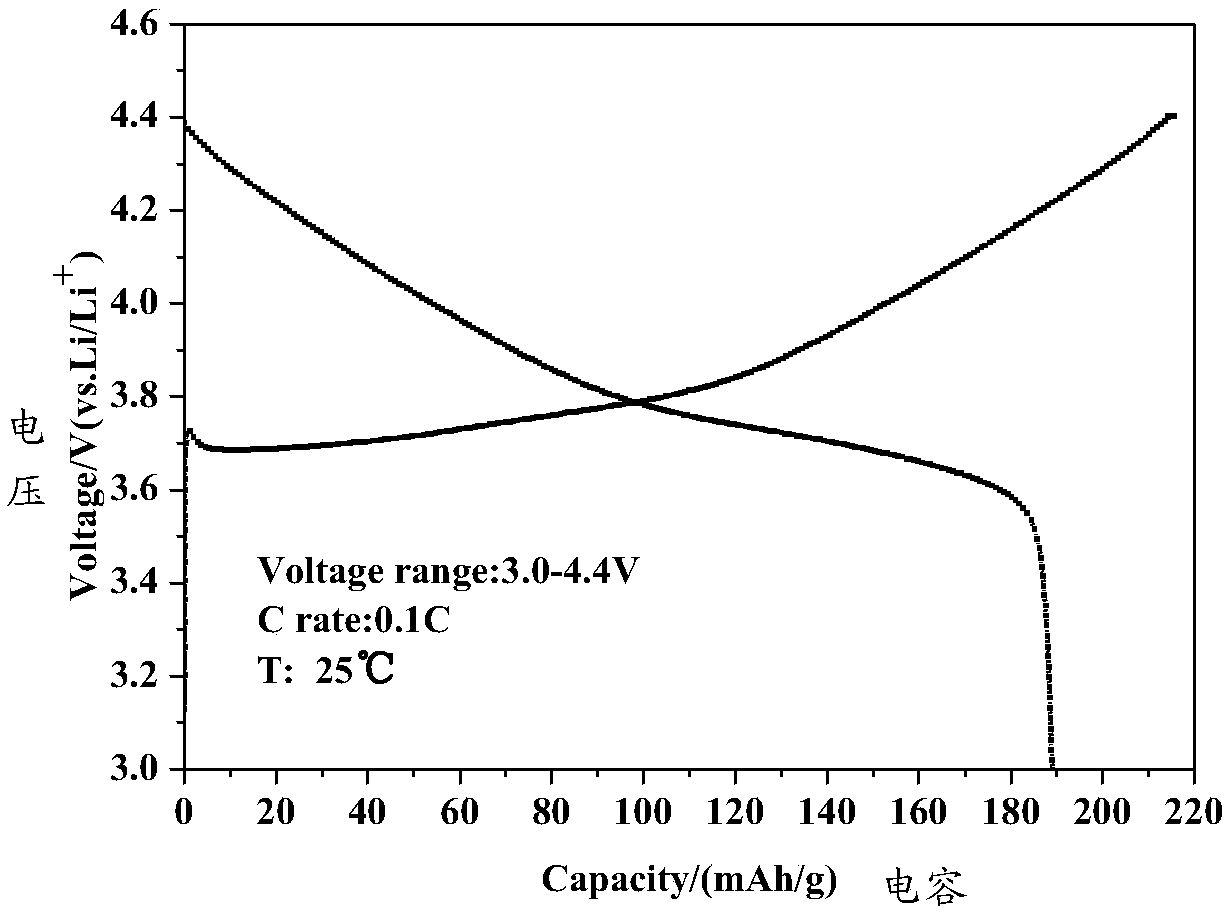

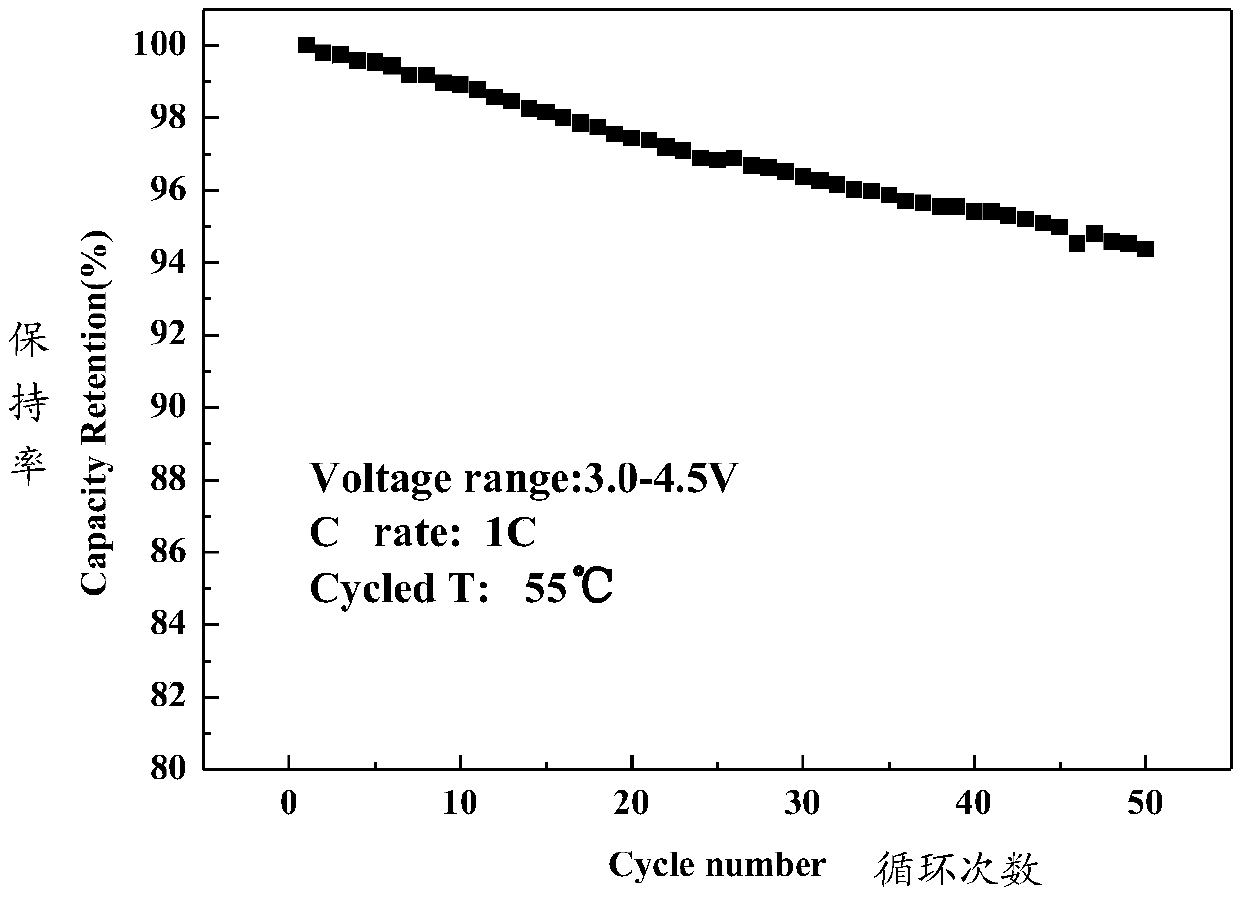

The invention discloses a silicon oxide / carbon cathode material of a lithium ion battery and a preparation method of the material. The silicon oxide / carbon cathode material is a three-layer compound material with a core-shell structure and takes a graphite material as an inner core, porous silicon oxide as a middle layer and organic pyrolytic carbon as an outermost covering layer; and the preparation method comprises a process of preparing porous SiOx and a carbon covering process. Compared with the prior art, active metal is added to reduce SiOx partially, the volume expansion effect of silicon particles is greatly reduced as the volume expansion effect of the silicon particles in the charging and discharging processes can be automatically absorbed by the obtained product structure, and the initial charging and discharging efficiency and the cycling stability are remarkably improved. The initial reversible specific capacity is larger than 600 mAh / g, the initial charging and discharging efficiency is higher than 88%, the capacity retention ratio is higher than 98% after the capacity is cycled for 50 times, the synthetic process is simple and easy to operate, the manufacturing cost is low, and the large-scale production is easy to realize.

Owner:BTR NEW MATERIAL GRP CO LTD

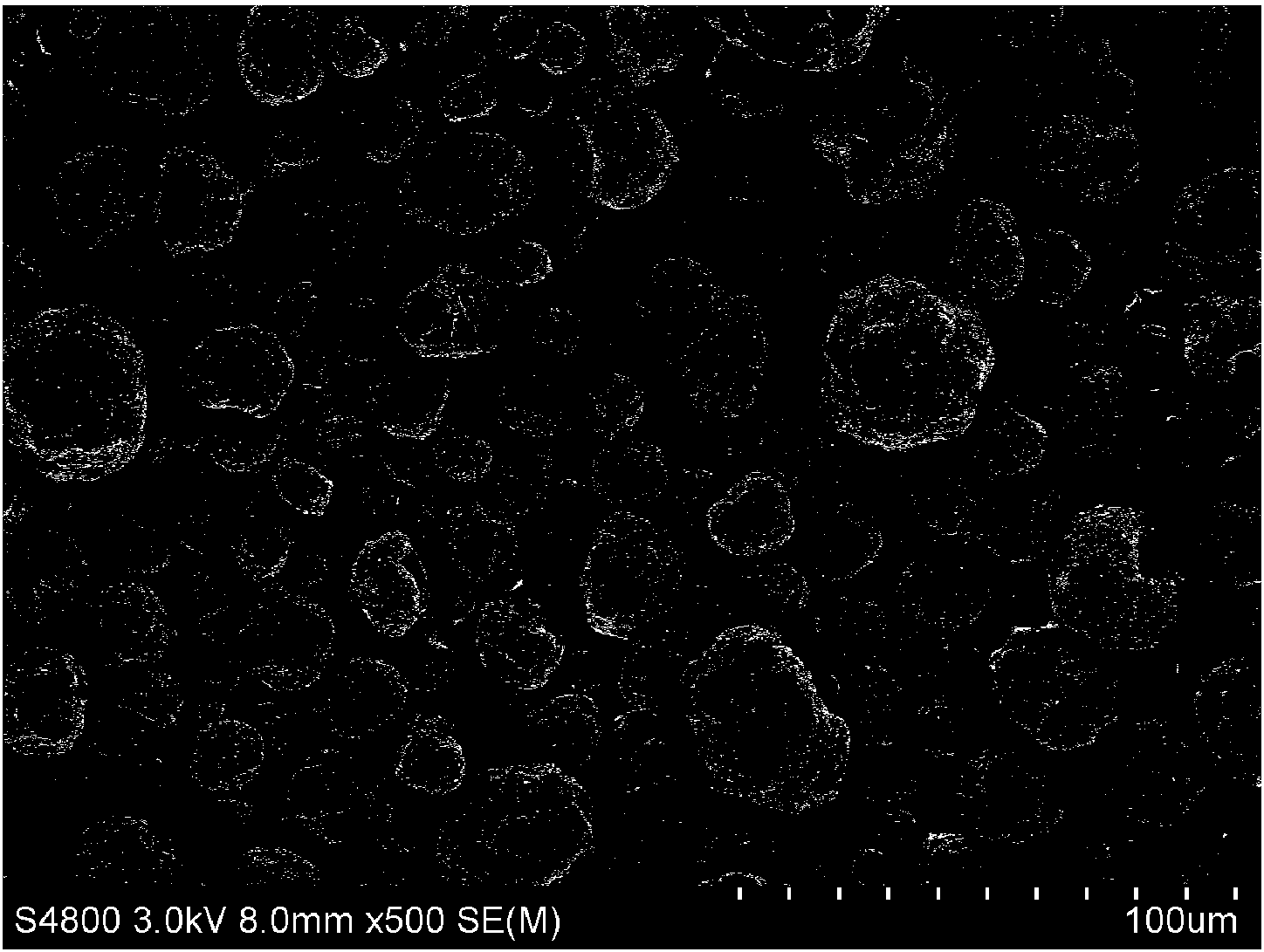

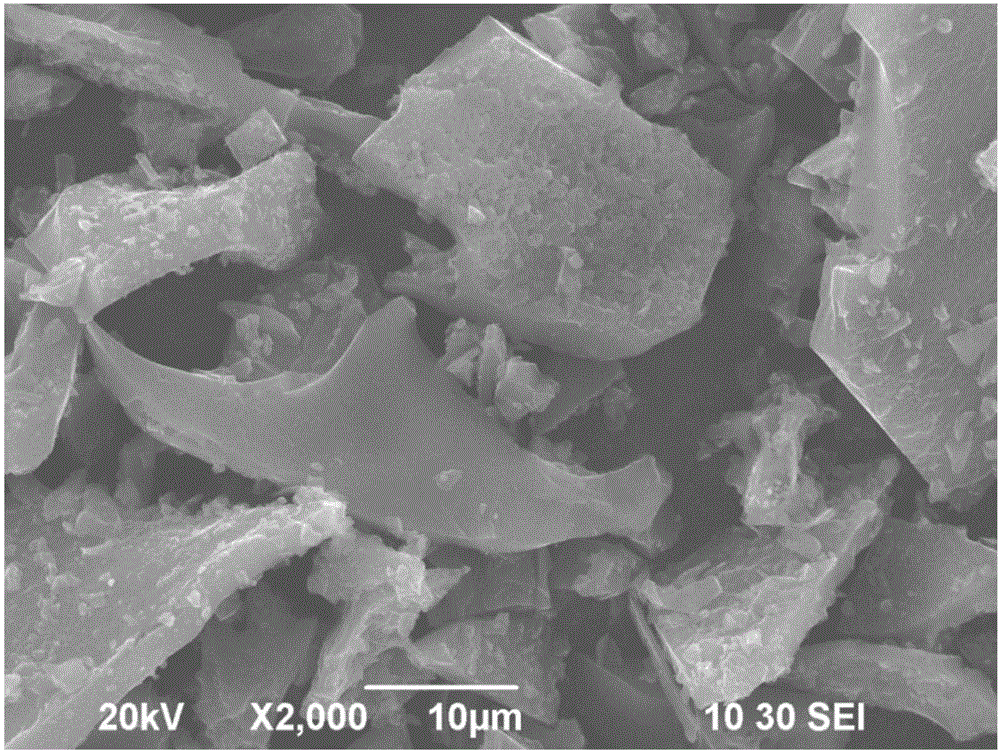

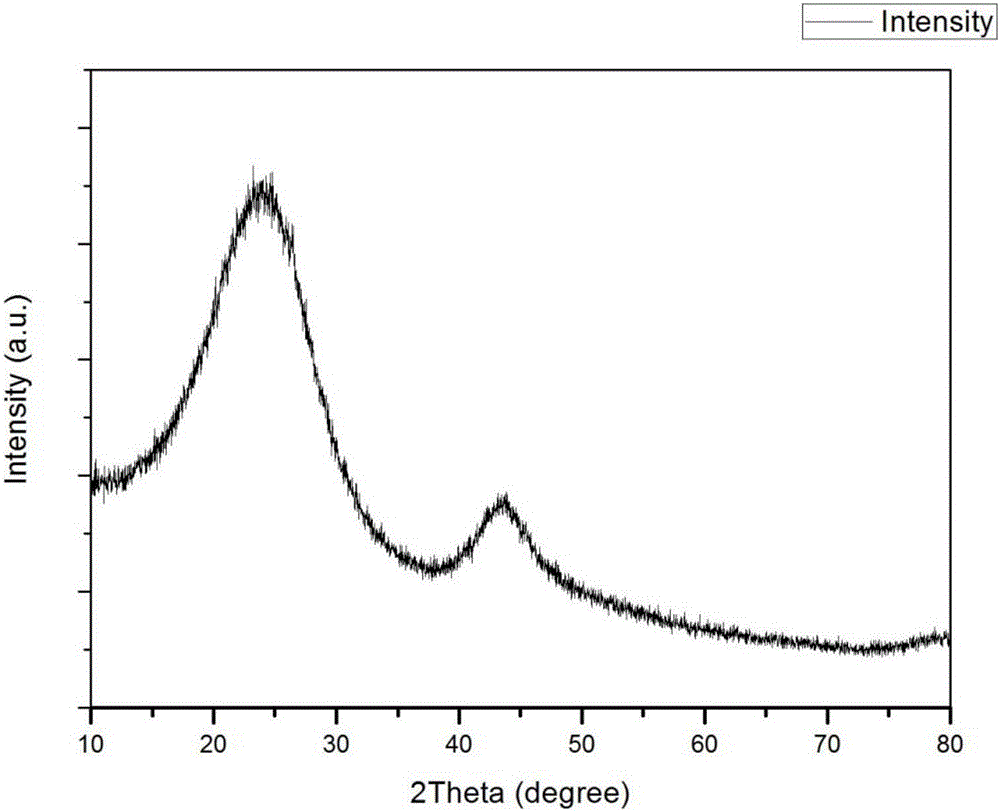

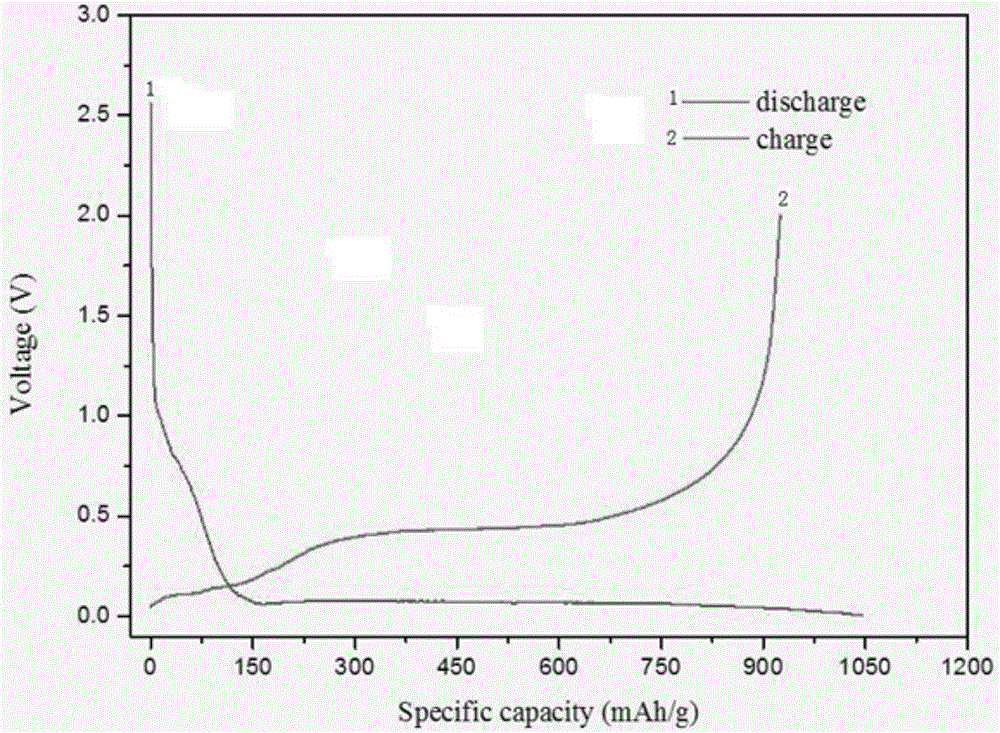

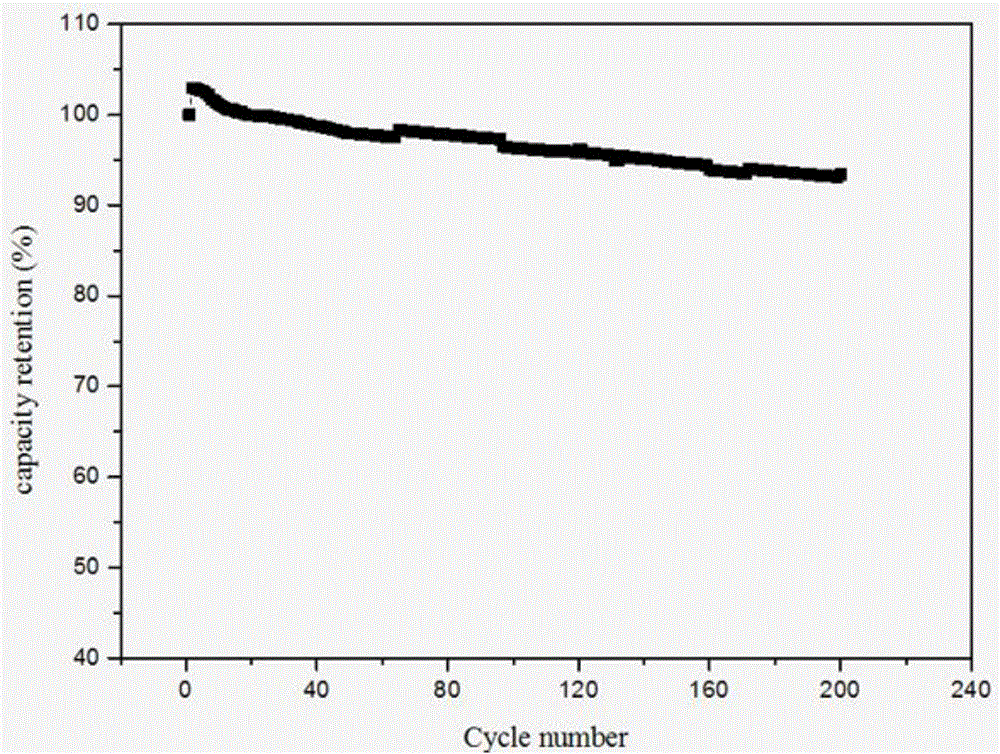

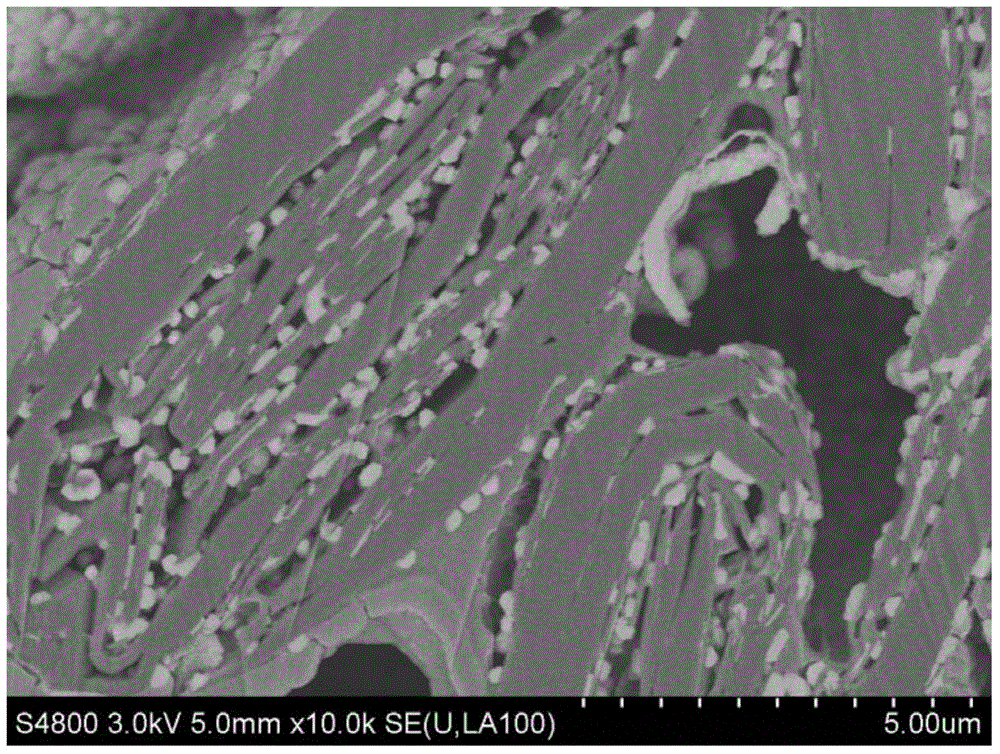

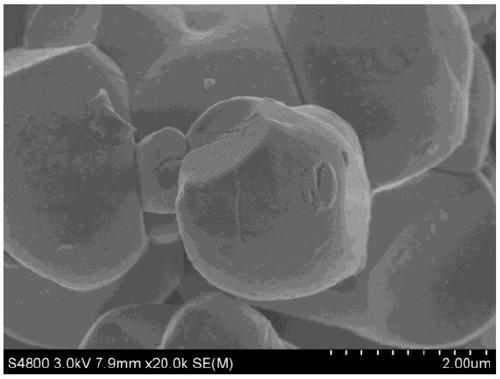

Biomass hard carbon negative electrode material for sodium ion battery, preparing method and sodium ion battery

ActiveCN106299365AImprove the first charge and discharge efficiencyImprove electrochemical performanceNon-aqueous electrolyte accumulatorsCell electrodesSodium-ion batteryLithium-ion battery

The invention relates to a biomass hard carbon negative electrode material for a sodium ion battery, a preparing method and the sodium ion battery and belongs to the technical field of sodium ion energy storage equipment. The biomass hard carbon negative electrode material is prepared through the method including the following steps that firstly, a biomass raw material is smashed, and precursor particles are obtained; secondly, in a protection atmosphere, the precursor particles are heated to 400-600 DEG C to be pre-sintered for 1.5-2.5 h, then cooled to the room temperature along with a furnace, then heated to 800-1600 DEG C to be sintered for 2-5 h and cooled, and an intermediate is obtained; thirdly, the intermediate is put into an alkali solution to be soaked, taken out, then put into an acid solution to be soaked, then washed with water to be neutral and dried, and a purified product is obtained; fourthly, the purified product is subjected to microwave vacuum activation for 3-15 s at the power of 1000-2000 W, and then the biomass hard carbon negative electrode material is obtained. The first-time charging and discharging efficiency of the obtained biomass hard carbon negative electrode material reaches up to 90% or above, the circulation stability is good, the reversible specific capacity is 300 mAh / g or above, and the biomass hard carbon negative electrode material has a good electrochemical property.

Owner:浙江瓦司特钠科技有限公司

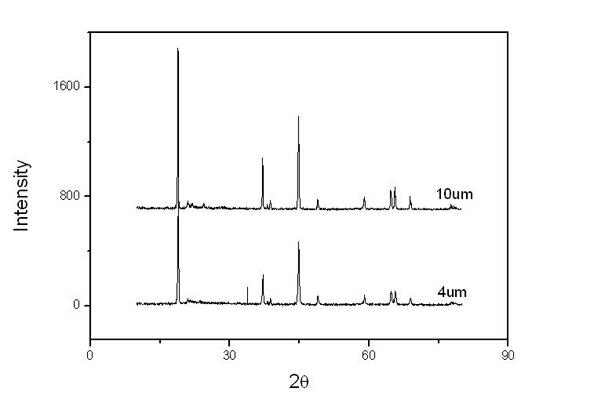

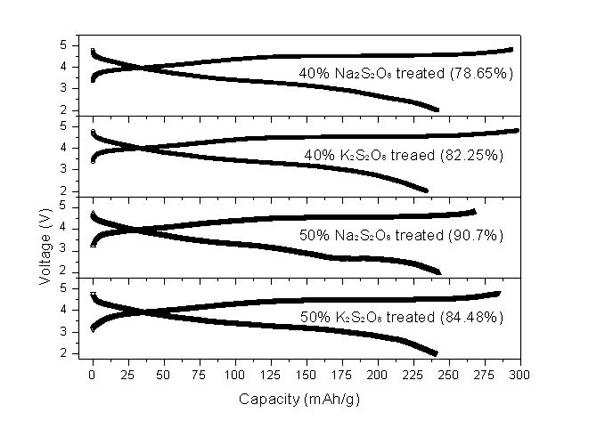

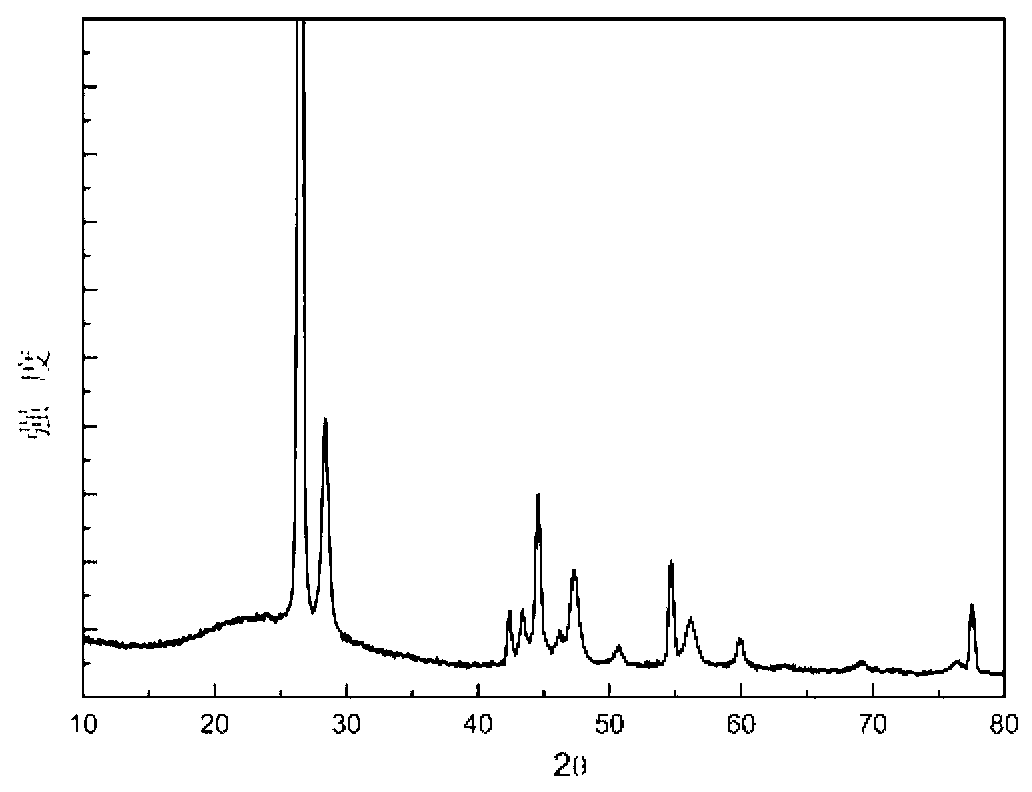

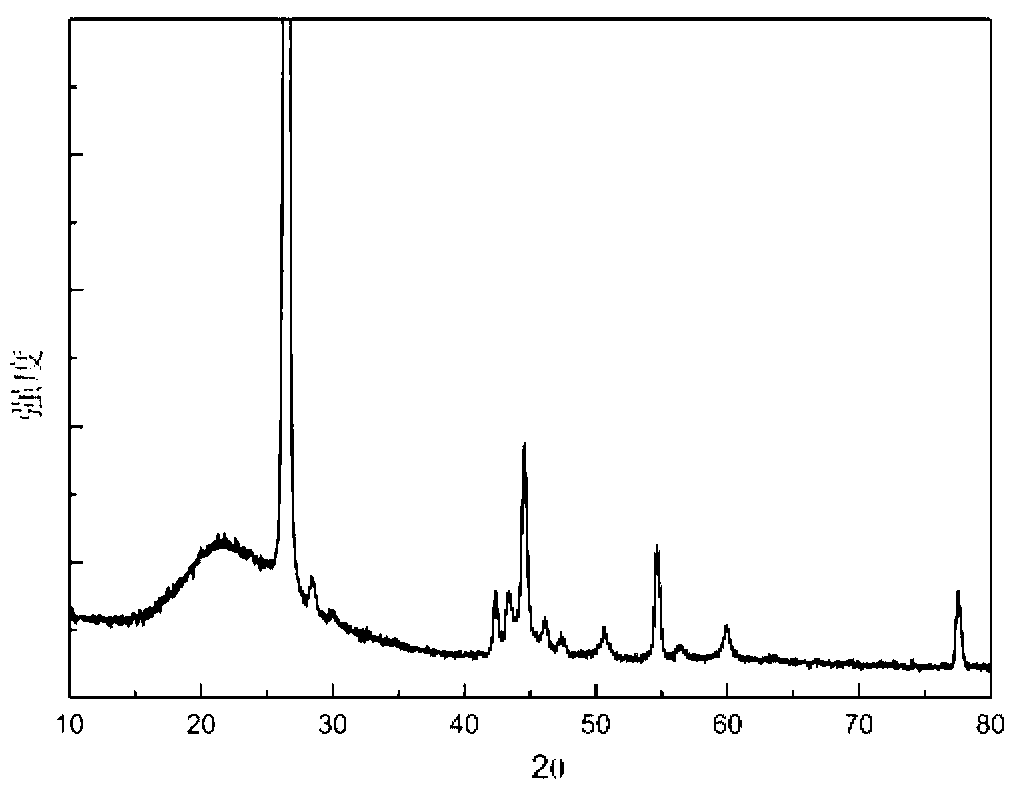

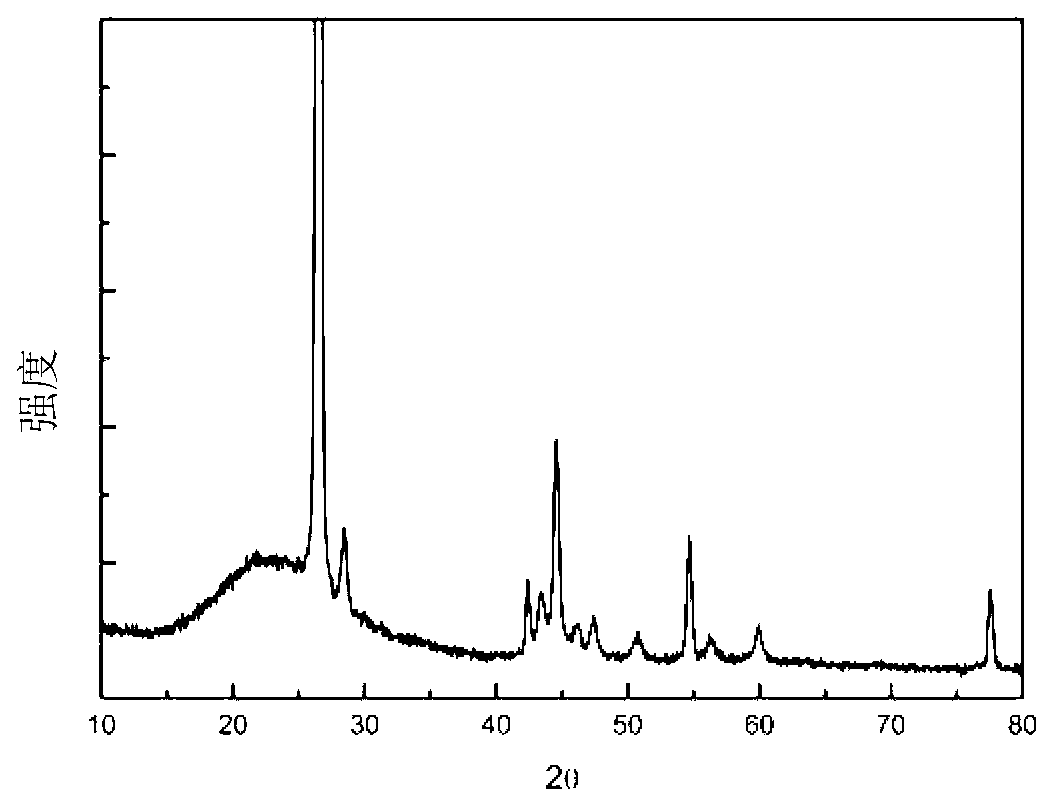

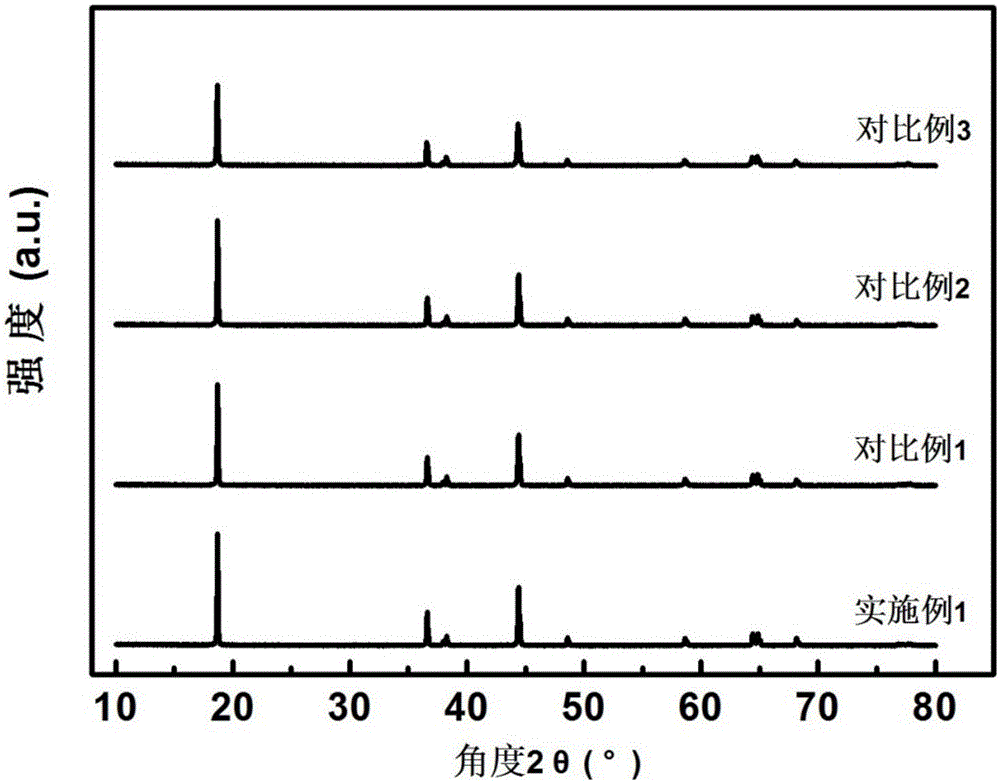

Synthesis and surface modification method of lithium excessive laminar oxide anode material

The invention relates to a synthesis and surface modification method of a lithium rich anode material Li1+xM1-xO2 (M is one or more of Ni, Co and Mn, and X is more than or equal to 0 and less than or equal to 1 / 3) for a lithium ion battery. The method comprises the following steps of: synthesizing a precursor by using a carbonate precipitation method, mixing the precursor and a lithium salt, and calcining for 2 to 20 hours at the temperature of between 800 and 1,100 EG C to obtain a lithium rich material, wherein the prepared lithium rich material has controllable particle size and higher reversible capacity; and dissolving persulfate or sulfate in an amount which is 5 to 80 mass percent of the lithium rich material into deionized water, adding the lithium rich material, stirring for 2 to 100 hours at the temperature of between 25 and 80 DEG C, heating the materials to the temperature of between 100 and 500 DEG C in a muffle furnace, calcining the materials for 2 to 20 hours, fully filtering the obtained materials, and washing off impurities to obtain the surface modified anode material Li1+x-yM1-xO2. The synthesized lithium rich material has controllable particle size; the first charge / discharge efficiency of the lithium rich material and the discharge specific capacity and the cyclical stability under high magnification can be improved; and the method is simple, low in cost, convenient for operation and suitable for industrialized production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

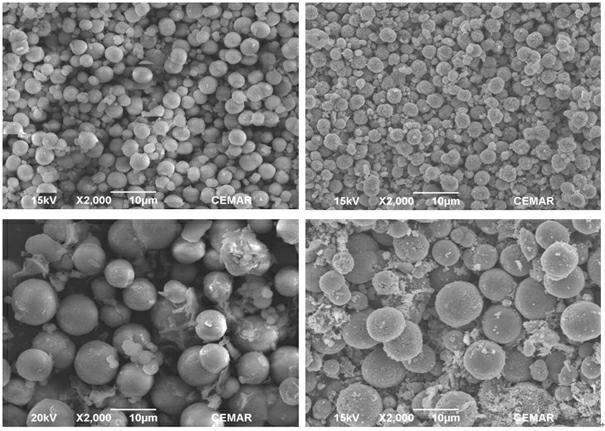

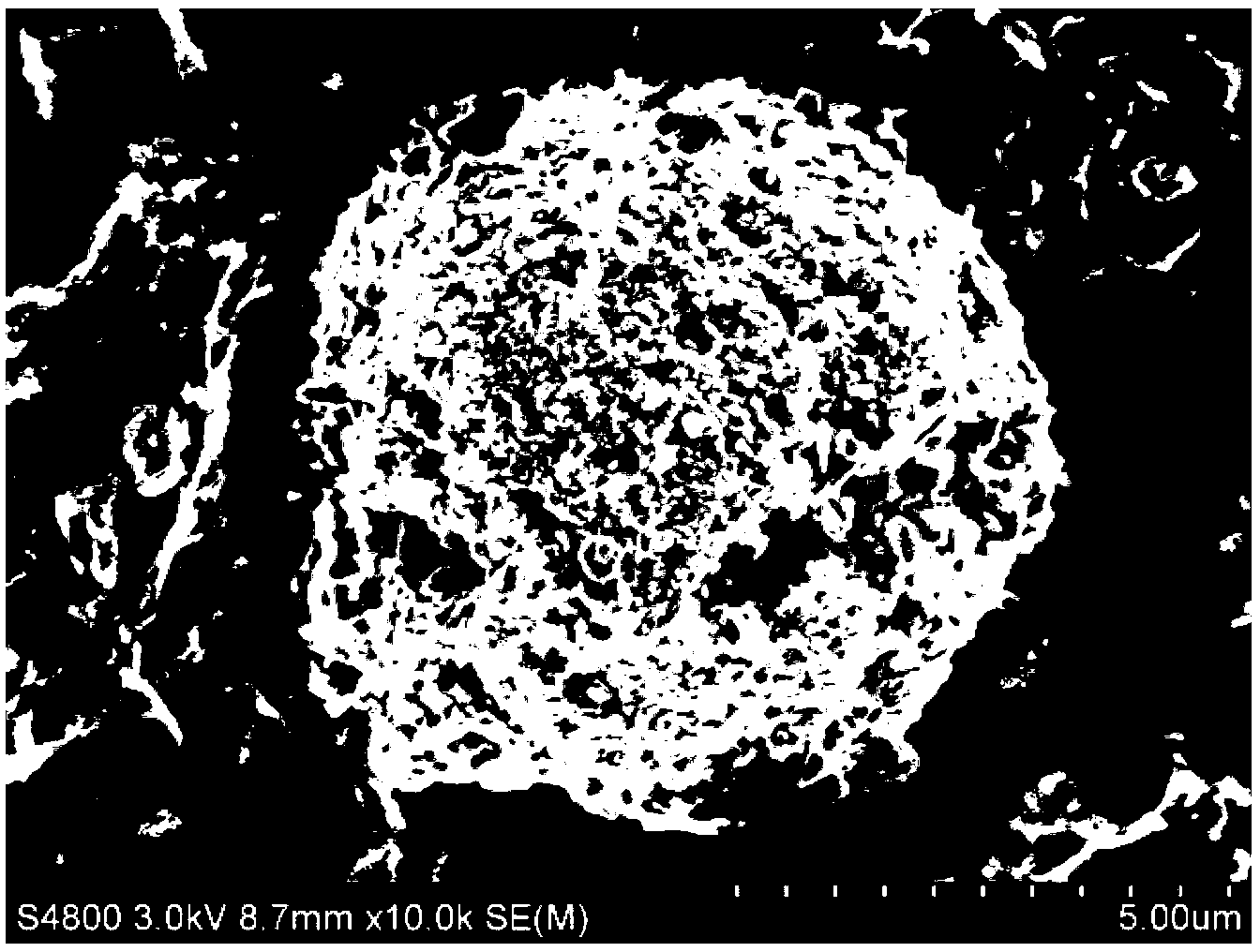

Preparation and application of lithium battery silicon-carbon composite material taking synthetic graphite as carrier

ActiveCN103346305AImprove integrity and compactnessSmall apertureCell electrodesCarbon sourceCarbon composites

The invention provides preparation and application of a lithium battery silicon-carbon composite material taking synthetic graphite as a carrier. The preparation method comprises the following steps of: dissolving nanometer silicon and synthetic graphite in a dispersant to obtain a uniform dispersion liquid, adding an organic carbon source, stirring uniformly to obtain a mixed liquid, feeding the mixed liquid into a closed circulation spray dryer to prepare composite precursor powder, pre-sintering for 3-10 hours at the temperature of 300-700 DEG C to obtain a silicon-carbon composite material subjected to primary carbon cladding; and further dissolving the silicon-carbon composite material subjected to primary carbon cladding with the organic carbon source in a dispersant, stirring to obtain a uniform mixed liquid, feeding the uniform mixed liquid into a second closed circulation spray dryer to prepare composite powder, and heating the powder for 6-18 hours at the temperature of 700-1000 DEG C, so as to obtain the lithium battery silicon-carbon composite material taking synthetic graphite as a carrier. The lithium battery silicon-carbon composite material prepared by the invention shows such excellent electrochemical properties as high first charge-discharge efficiency, high specific capacity and good cycle performance after being applied to a lithium battery.

Owner:中国有色桂林矿产地质研究院有限公司

Negative pole piece and lithium-ion battery

ActiveCN105742613AImprove charging effectGood inner dynamicsCell electrodesSecondary cellsElectrical batteryPole piece

The invention relates to a negative pole piece, which comprises a negative pole current collector and a negative pole film layer, wherein the negative pole film layer is arranged on the negative pole current collector and comprises at least two negative pole active material layers; and the at least two negative pole active material layers are sequentially arranged on the negative pole current collector from the inside to the outside according to the lithium-ion dynamic property decreasing order of the negative pole active material layers. The invention particularly relates to the negative pole film layer of which the negative pole active material is a graphite / hard carbon and / or silicon material composite material. The graphite is compounded with the hard carbon and / or silicon material, and a multi-layer gradient of which the lithium-ion dynamic property is sequentially increased from the outside to the inside is formed, so that the negative pole piece has the effects of simultaneously improving the charging capability and increasing the energy density.

Owner:NINGDE AMPEREX TECH

Silicon-carbon composite negative pole material preparation method and lithium ion battery

ActiveCN106257716AEvenly dispersedAvoid direct contactNegative electrodesSecondary cellsCarbon compositesElectric capacity

The invention relates to a silicon-carbon composite negative pole material preparation method and a lithium ion battery. The preparation method comprises putting nanometer silicon and graphite micro-powder into a ball mill, carrying out ball milling uniform dispersion in an organic solvent environment, carrying out vacuum drying, putting the dried mixture and asphalt into a cone-type mixer, carrying out coarse mixing, putting the mixed powder subjected to coarse mixing into a mechanical fusion machine, carrying out mechanical fusion, carrying out heat treatment in an inert gas protective atmosphere and carrying out cooling to obtain the silicon-carbon composite negative pole material. The preparation method carries out asphalt softening coating on nanometer silicon so that silicon particle and electrolyte direct contact is avoided, a capacity reduction rate is delayed, a lithium ion diffusion path is shortened, an electrode material electron conduction loss is avoided, and first charge-discharge efficiency, a charge-discharge electric capacity and cycle performances are improved. Before coating, nanometer silicon is dispersed through graphite micro-powder so that it is avoided that in asphalt coating, nanometer silicon aggregation causes local capacity excess and nanometer silicon is uniformly dispersed.

Owner:浙江超恒动力科技有限公司

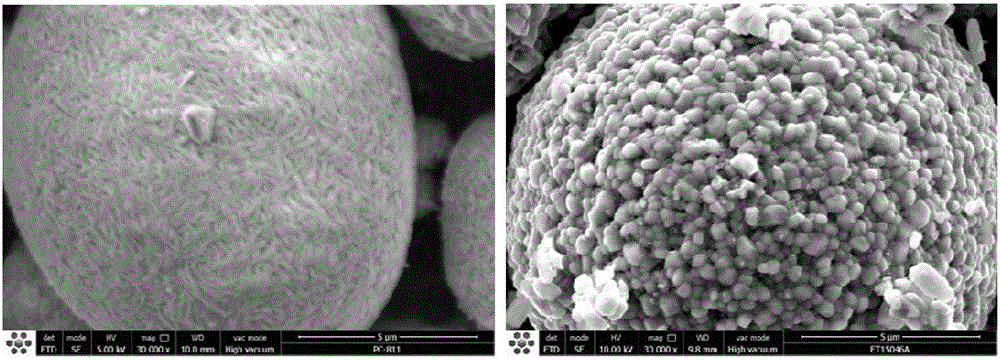

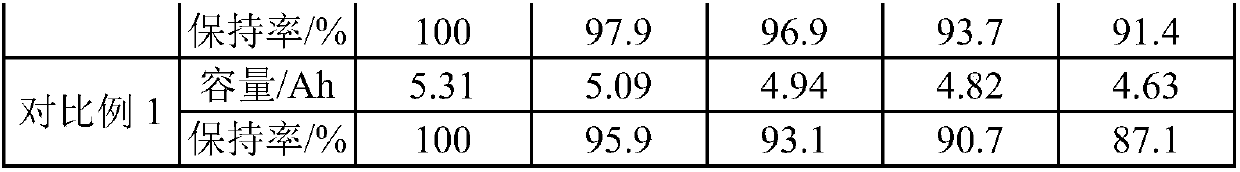

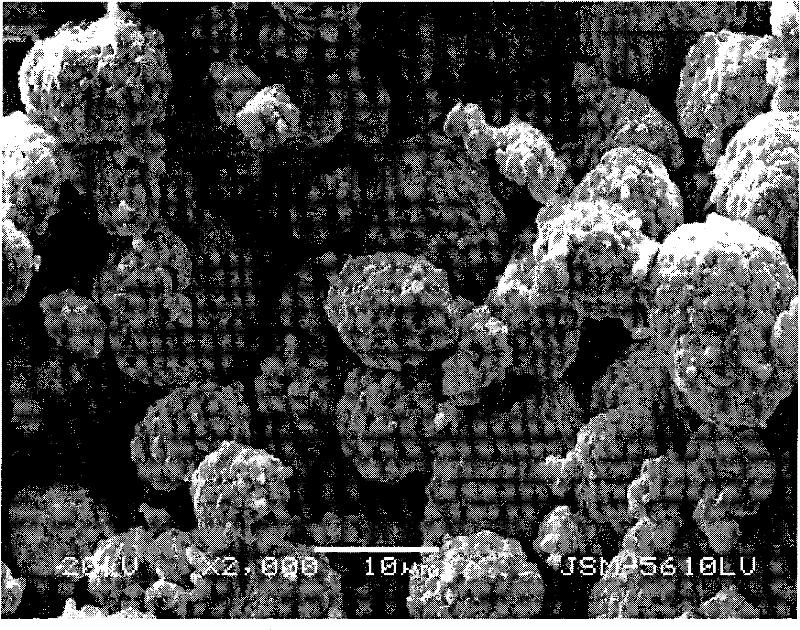

Polycrystal high-nickel positive electrode material used for lithium ion battery and preparation method for polycrystal high-nickel positive electrode material

InactiveCN105958062AExtended storage timeReduce lithiumCell electrodesSecondary cellsSodium-ion batteryLithium-ion battery

Disclosed is a polycrystal high-nickel positive electrode material used for a lithium ion battery. The polycrystal high-nickel positive electrode material comprises a base material with a layered structure and a coating layer which is arranged outside the base material and has a spinel structure; the general formula of the base material is LiNi<1-x-y>Co<x>M<y>O<2>, wherein M is at least one kind of Mn and Al; the coating layer is lithium manganese oxide; the mass percentage of the total impurity lithium on the surface of the base material is less than 0.085% based on the total mass percentage of the base material; the preparation method for the positive electrode material comprises the following steps of weighing Ni<1-x-y>Co<x>M<y>(OH)<2>, and mixing with a lithium source, then carrying out thermal treatment, cooling, crushing and sieving to obtain the base material; measuring the content of the residual impurity Li<2>CO<3> and LiOH on the surface of the base material, adding into the metal Mn compound according to the measurement result, and carrying out low-temperature thermal treatment in an oxygen atmosphere to obtain the polycrystal high-nickel positive electrode material used for the lithium ion battery. The polycrystal high-nickel positive electrode material provided by the invention has the advantages of low material alkalinity, low inflatable degree, excellent processing property and cycling performance, and the like.

Owner:HUNAN SHANSHAN NEW ENERGY CO LTD

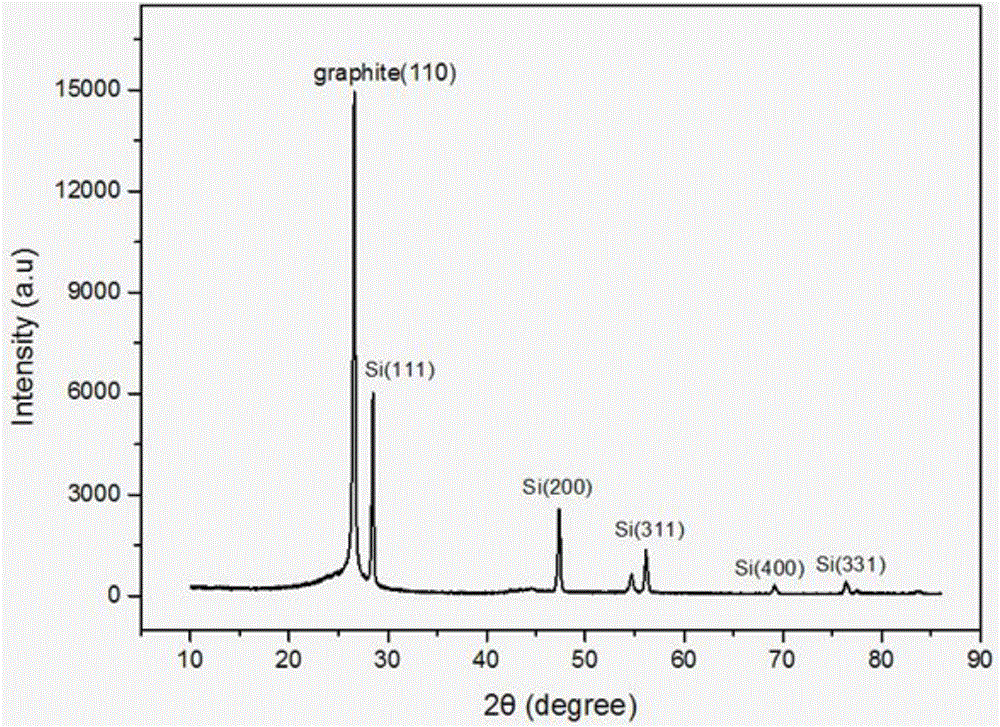

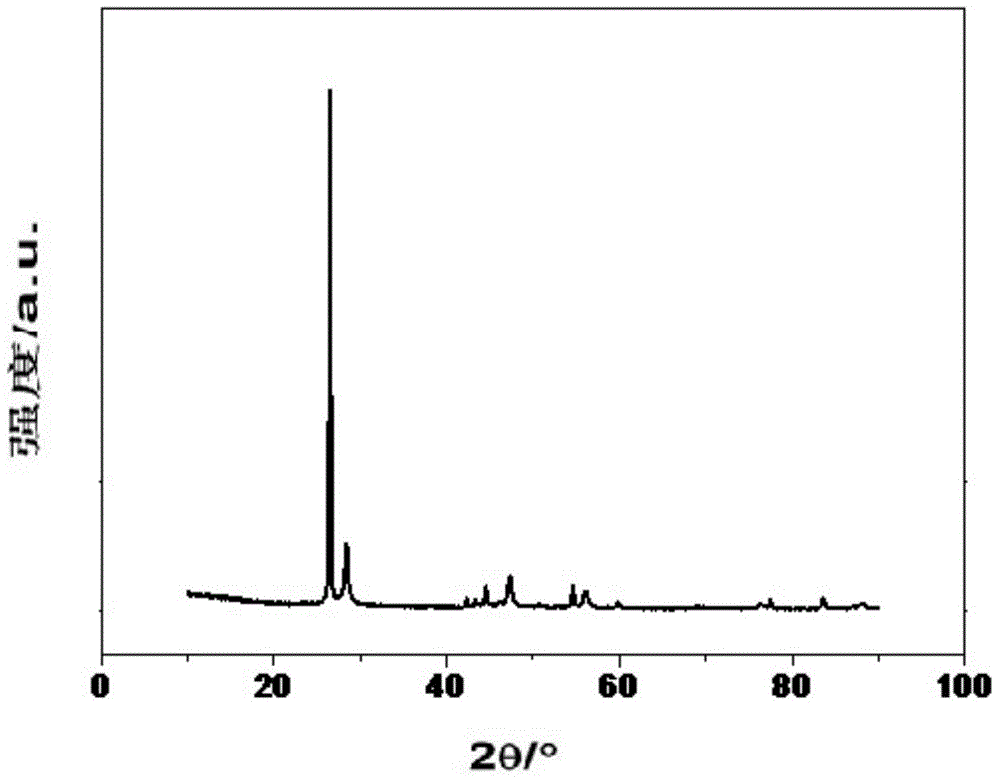

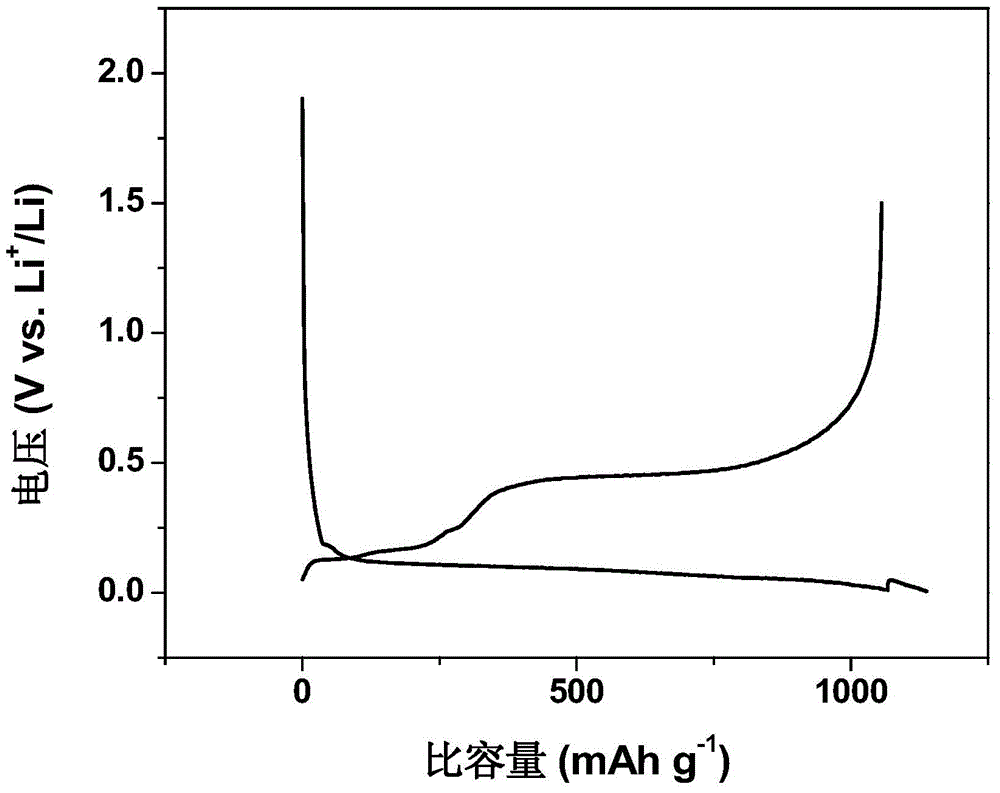

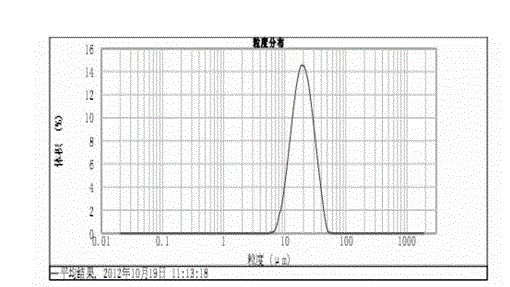

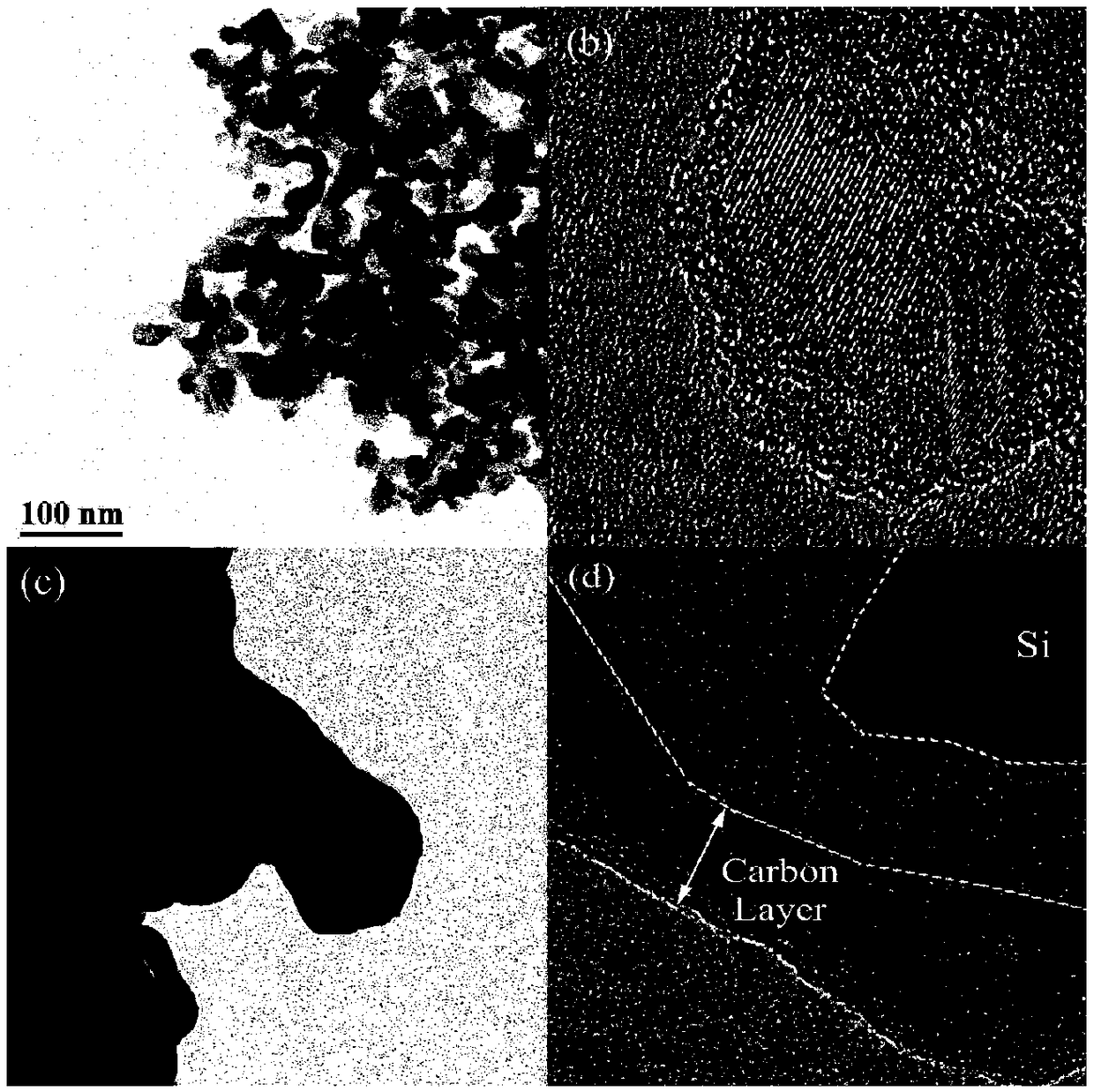

Nano silicon composite negative electrode material for lithium ion battery, preparation method and lithium ion battery

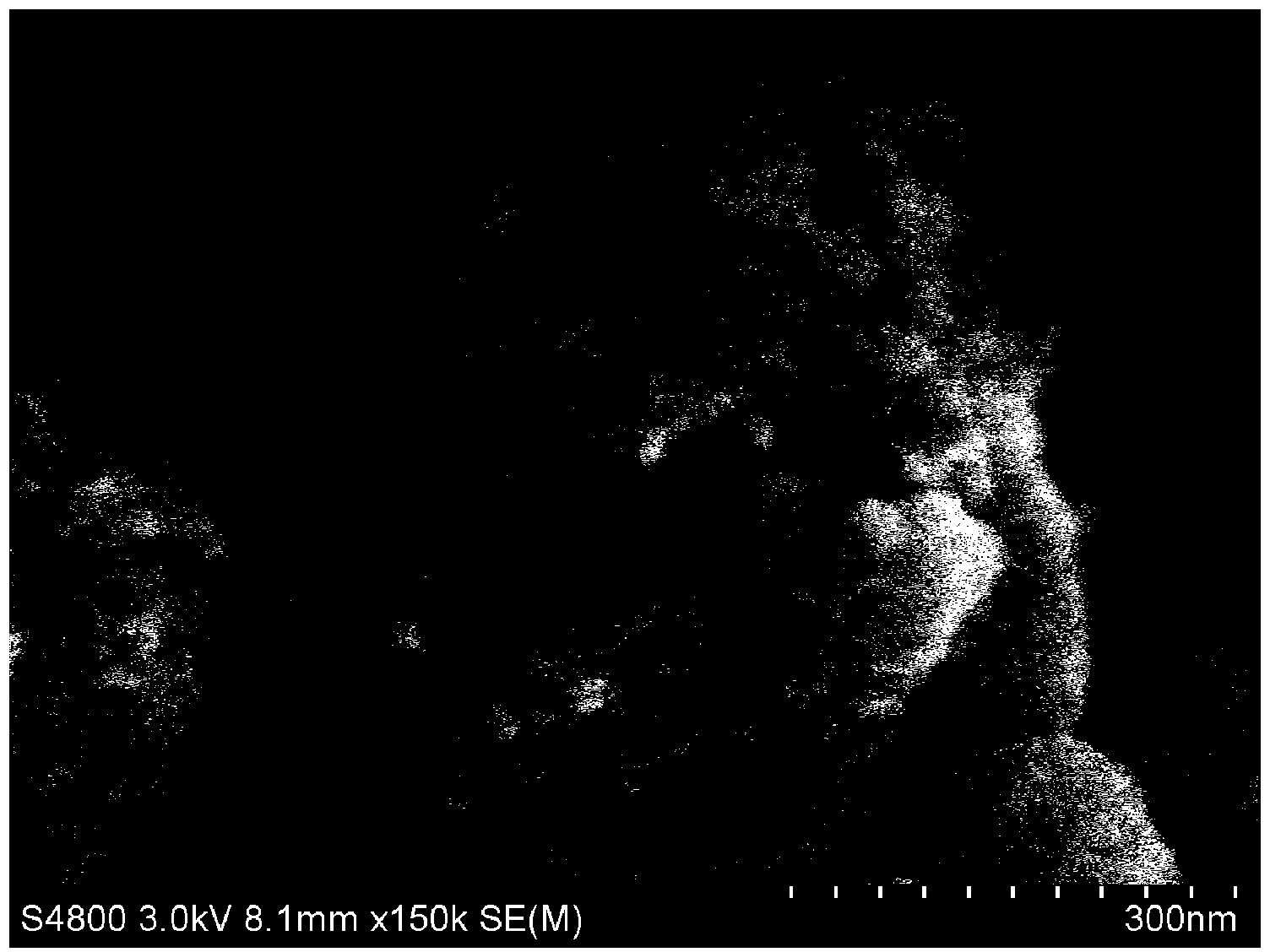

InactiveCN104577084AHigh specific capacityImprove the first charge and discharge efficiencyMaterial nanotechnologyElectrode thermal treatmentNano siliconGas phase

The invention discloses a nano silicon composite negative electrode material, which comprises graphite matrix and a nano silicon material which is evenly deposited in the graphite matrix, wherein the nano silicon composite negative electrode material is prepared by chemical vapor deposition of nano silicon particles in hollow graphite with a silicon source. The nano silicon composite negative electrode material disclosed by the invention has the characteristics of high specific capacity (greater than 1,000mAh / g), high initial charge-discharge efficiency (greater than 93%) and high conductivity. The preparation method disclosed by the invention is simple to operate, easy to control, low in production cost and suitable for industrial production.

Owner:BTR NEW MATERIAL GRP CO LTD

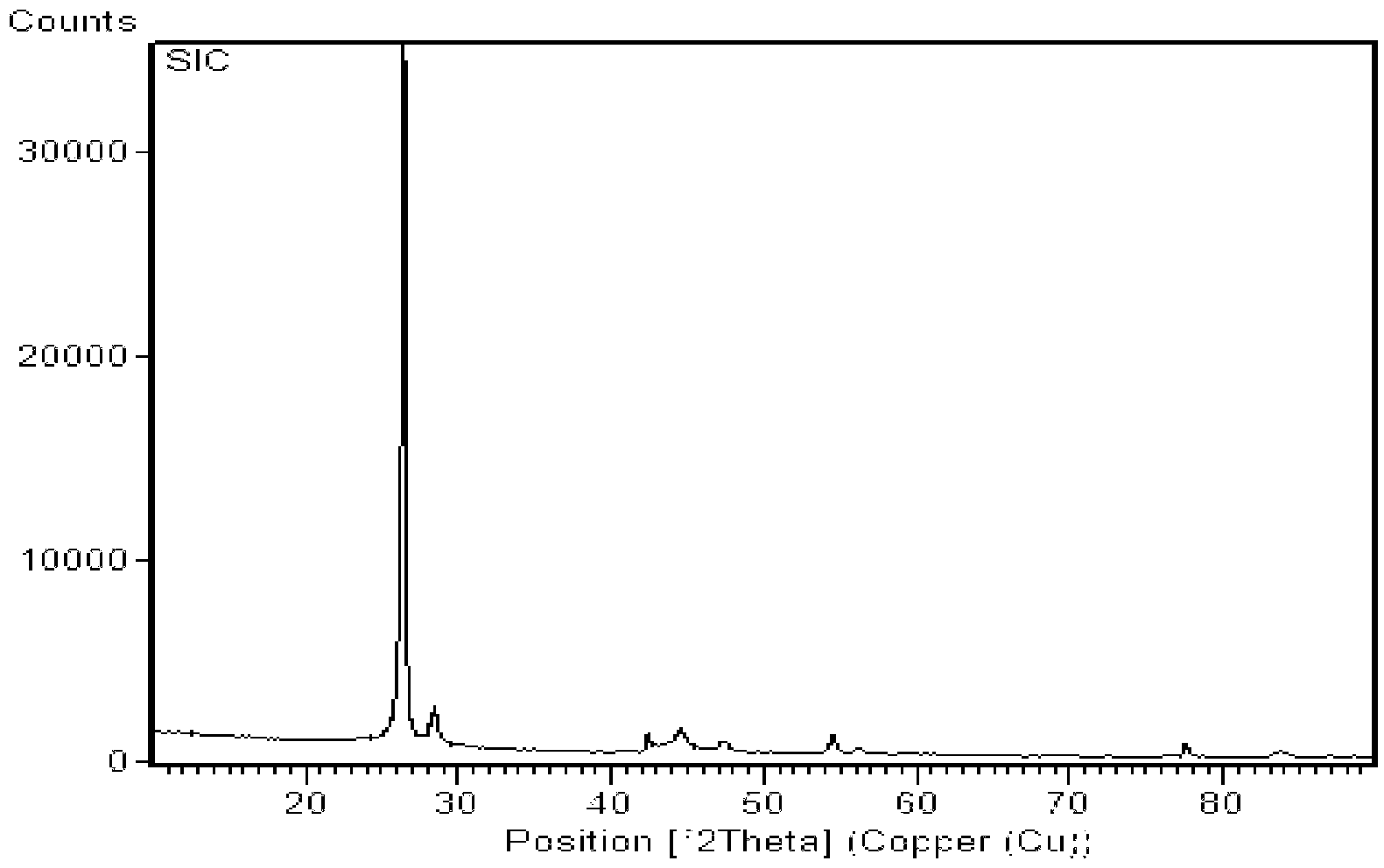

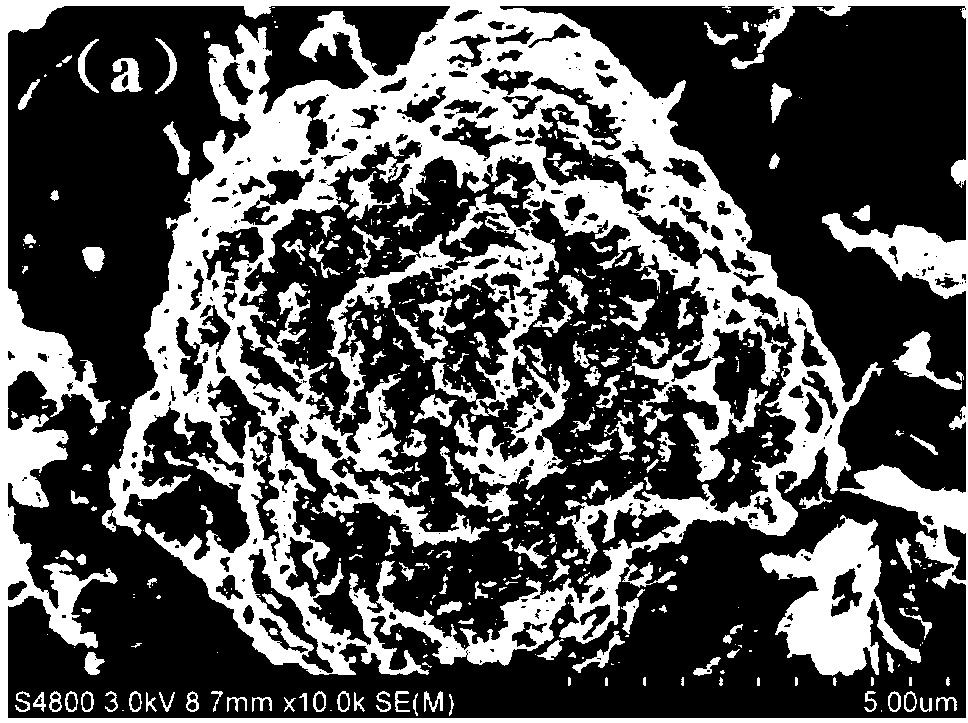

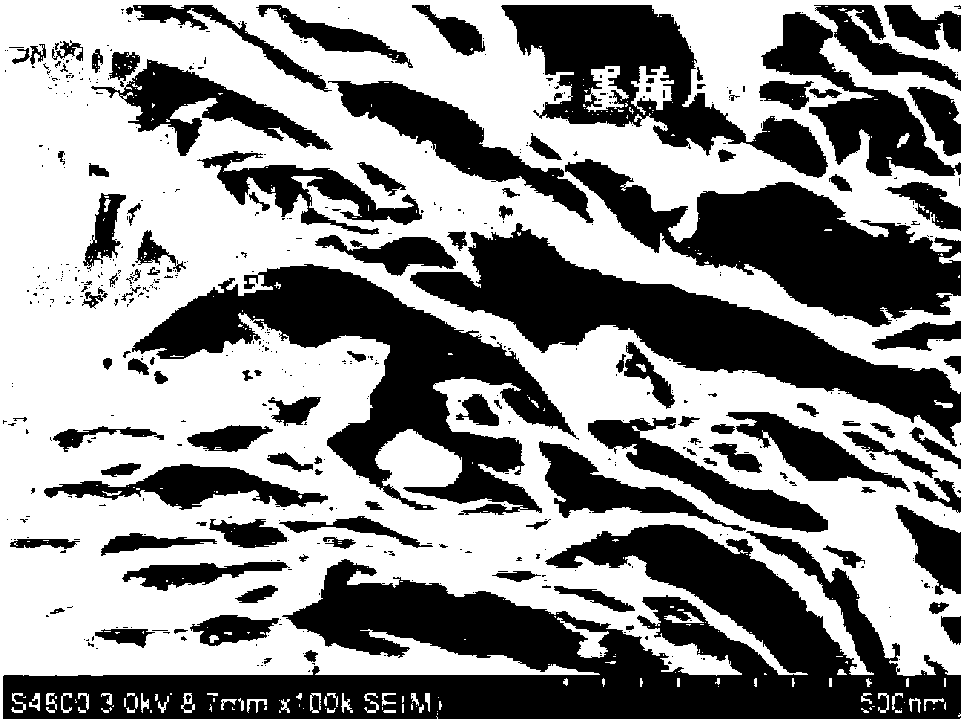

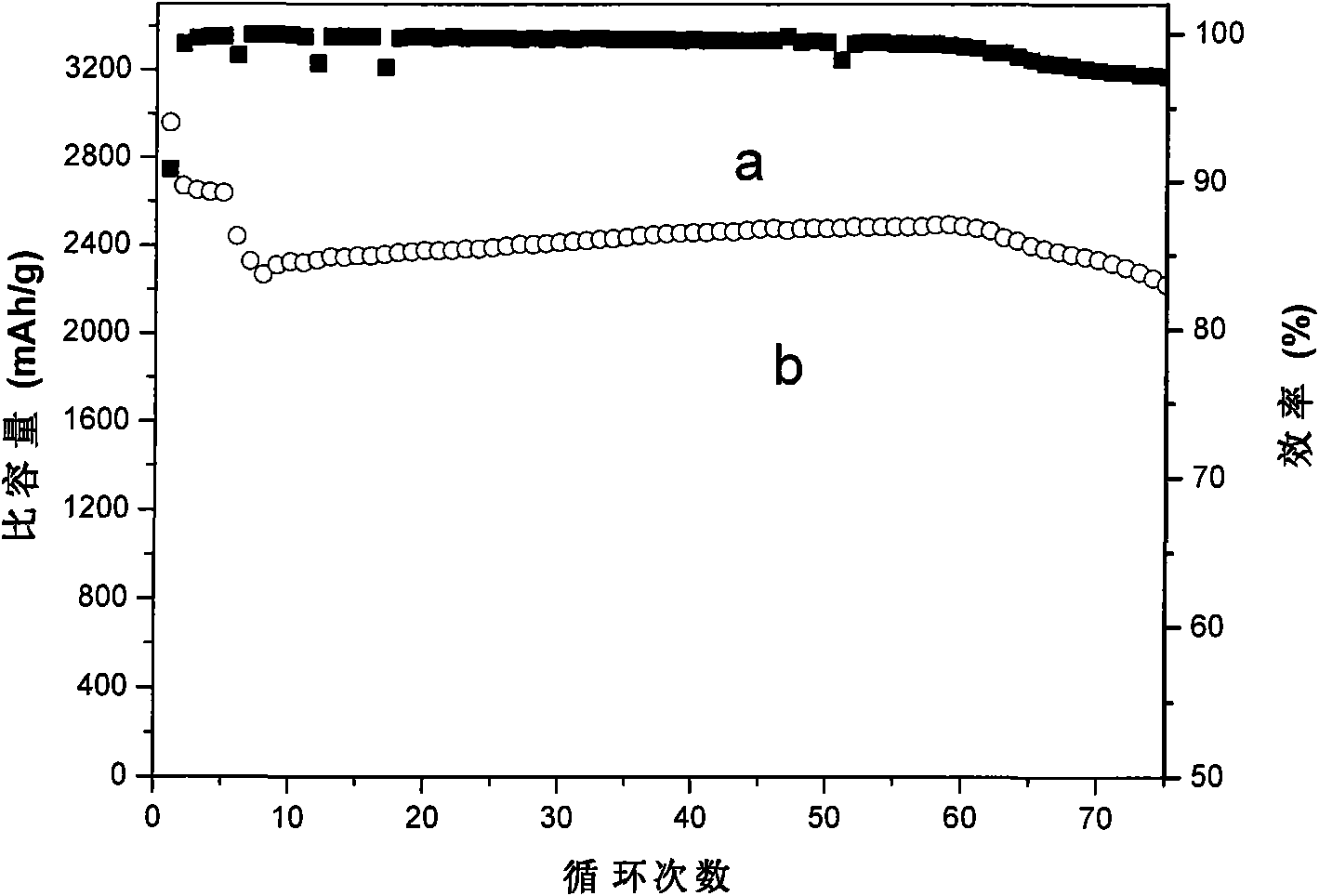

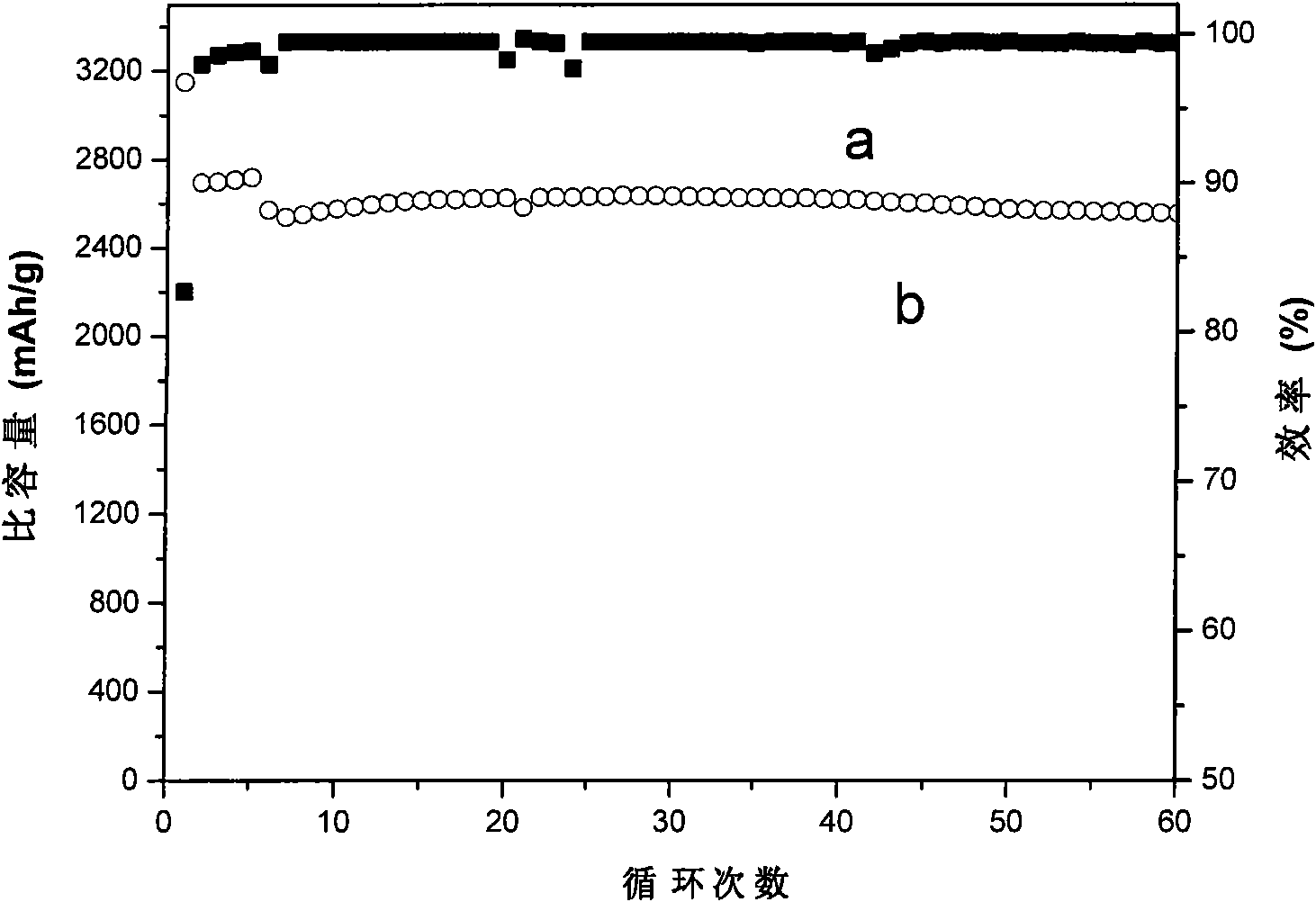

Monox/carbon composite material as well as preparation method and use thereof

InactiveCN103311526AGood electrical contactShorten the diffusion pathCell electrodesSecondary cellsCarbon compositesGraphite

The invention relates to a monox / carbon composite material, comprising monox / graphene particles, organic matter pyrolysis carbon and graphite powder, wherein monox particles are adhered to the surface of a grapheme sheet; the organic matter pyrolysis carbon coats the monox / graphene particles, and then is compounded with graphite. The preparation method of the monox / carbon composite material comprises the steps of: mixing monox particles with graphene to obtain the monox / graphene particles; coating organic carbon by obtained monox / graphene particles, thereby obtaining the monox / graphene material coated by the organic matter pyrolysis carbon; and mixing the obtained monox / graphene material coated by the organic matter pyrolysis carbon with the graphite powder, so as to obtain the monox / carbon composite material. The monox / carbon composite material is used as a lithium ion battery cathode material. Thus, the monox / carbon composite material has the characteristics of high first charge and discharge efficiency, excellent cycle performance and power charge and discharge properties, and low volume expansion effect.

Owner:BTR NEW MATERIAL GRP CO LTD

Preparation method of negative material for low-temperature lithium ion battery

ActiveCN103151497AWide variety of sourcesImprove the first charge and discharge efficiencyGraphiteCell electrodesHigh rateLithium-ion battery

The invented relates to a preparation method of a negative material for a low-temperature lithium ion battery. The preparation method comprises the steps of: carrying out ball-milling and refining treatment on natural graphite by adopting a ball mill, afterwards carrying out soft carbon coating for modification, then carrying out hard carbon coating, and finally curing and carbonizing the natural graphite modified by the soft-hard carbon double-layer coating to obtain final modified natural graphite. The preparation method provided by the invention is simple and convenient, low in cost, wide in raw material sources and easy to realize the industrial production; and the prepared negative material for the low-temperature lithium ion battery is high in first charging and discharging efficiency, and good in low-temperature performance and high-rate charging and discharging performance, and can satisfy the actual needs of people.

Owner:WUXI DONGHENGNEWENERGYTECHNOLOGYCO LTD

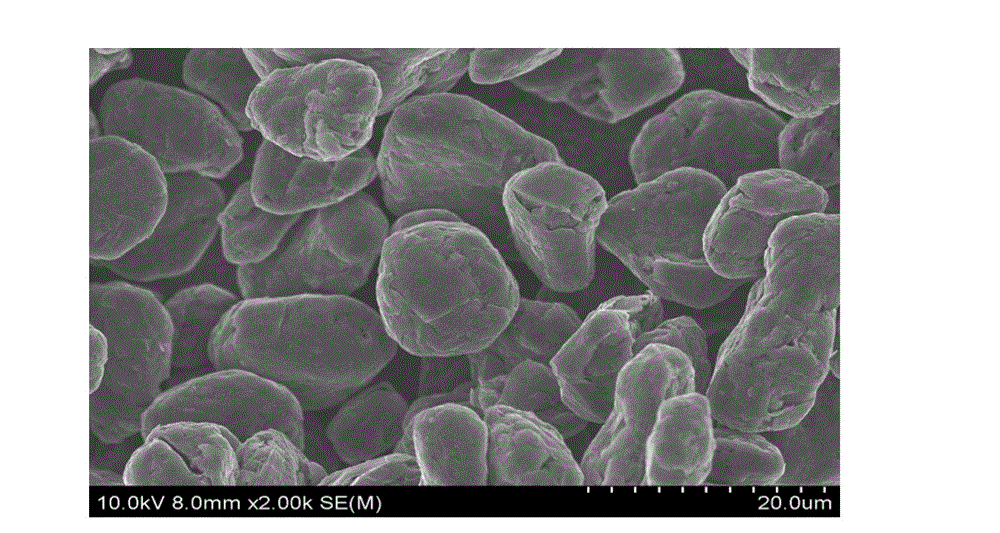

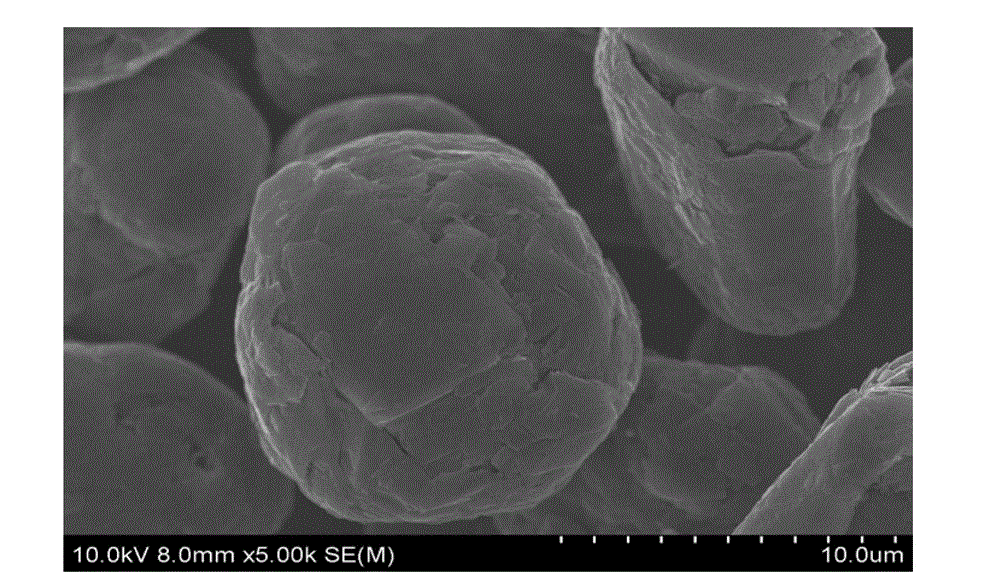

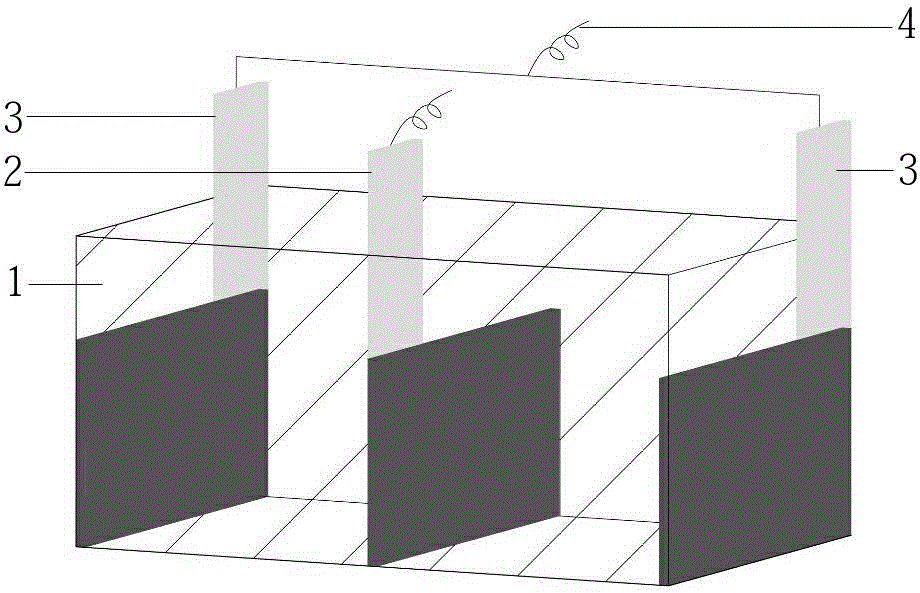

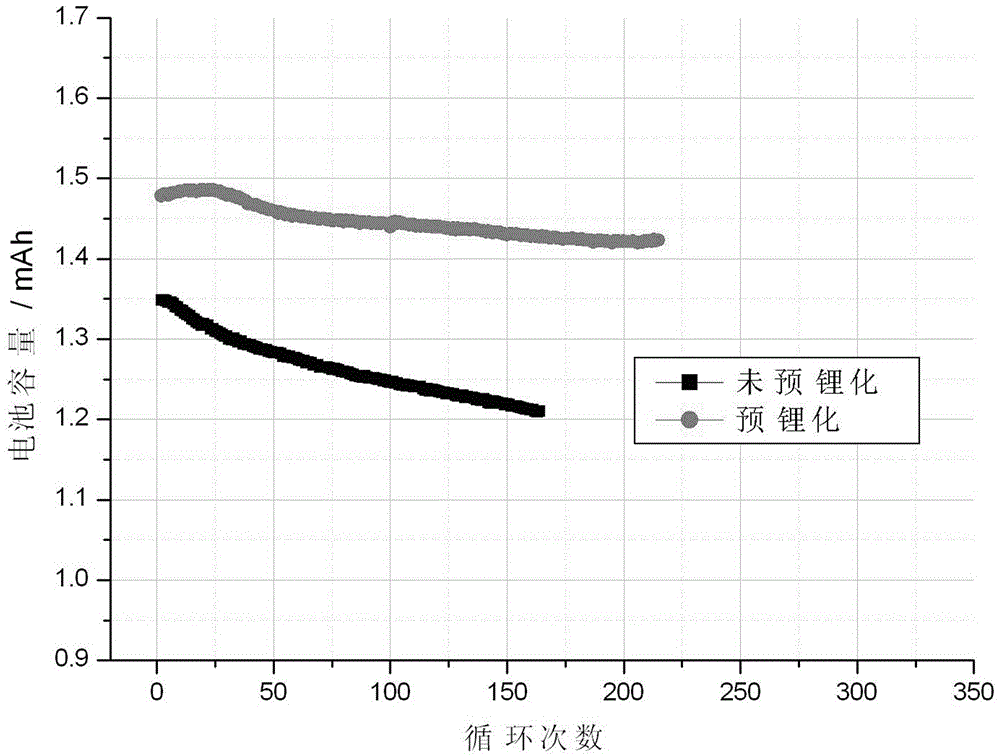

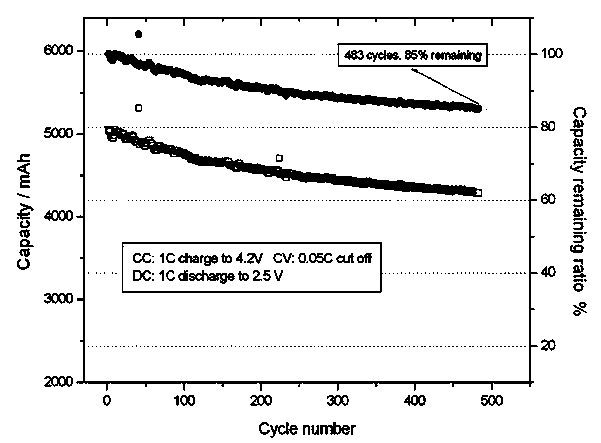

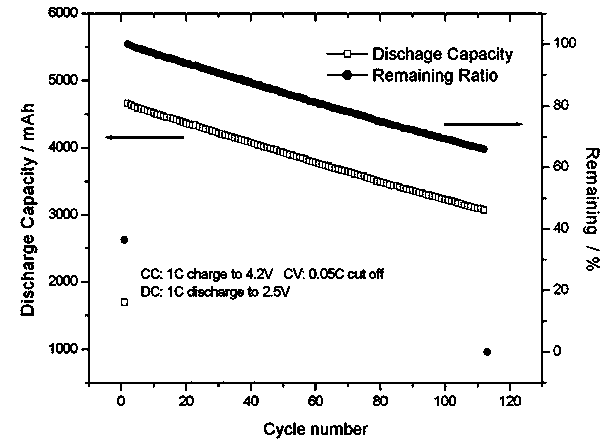

Pre-lithiation treatment process and device of silicon-based negative electrode

ActiveCN105470465ASolve the problem of low charging and discharging efficiency for the first timeImprove the first charge and discharge efficiencyCell electrodesFinal product manufactureLithiumPower flow

The invention provides a pre-lithiation treatment process of a silicon-based negative electrode. The pre-lithiation treatment process comprises the steps of paste uniformization, coating, metal lithium electrodeposition by a two-step constant-current pulse deposition method, DMC soaking, drying and the like. The invention simultaneously provides a pre-lithiation treatment device of the silicon-based negative electrode. The pre-lithiation treatment device comprises an electrolytic groove, a working electrode, two pieces of counter electrodes and a wire. With the adoption of the pre-lithiation treatment process and device, the initial charging and discharging efficiency of a silicon-carbon negative electrode can be effectively improved, and the cycle lifetime of the silicon-carbon negative electrode can be prolonged.

Owner:WANXIANG 123 CO LTD

Surface modified lithium ion battery anode material and preparation method thereof

InactiveCN104600282AImprove the first charge and discharge efficiencyImprove cycle lifeCell electrodesOxide coatingSurface modification

The invention discloses a surface modified lithium ion battery anode material and a preparation method thereof. The preparation method comprises the following steps: (1) fully mixing a lithium ion battery anode material with one or more types of metal acetates; (2) heating the mixture obtained in the step (1) to a temperature 1 to ensure that the low-melting-point acetate in the mixture reaches a molten or co-molten state, and complete infiltration and complete coating are realized on the surface of the anode material; and (3) further heating to a temperature 2 to ensure that the metal acetate coating layer on the surface of the anode material is decomposed into a metal oxide coating layer and metal ions are diffused to the inside of the material to form a doped modified layer, thereby obtaining the surface modified lithium ion battery anode material. According to the preparation method disclosed by the invention, the melting and uniform coating of the metal acetates on the surface of the anode material are realized, the metal acetate coating layer is decomposed and converted into the oxide coating layer and is diffused to form the surface doped modified layer, the process is simple, the cost is relatively low, and the operation is convenient.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

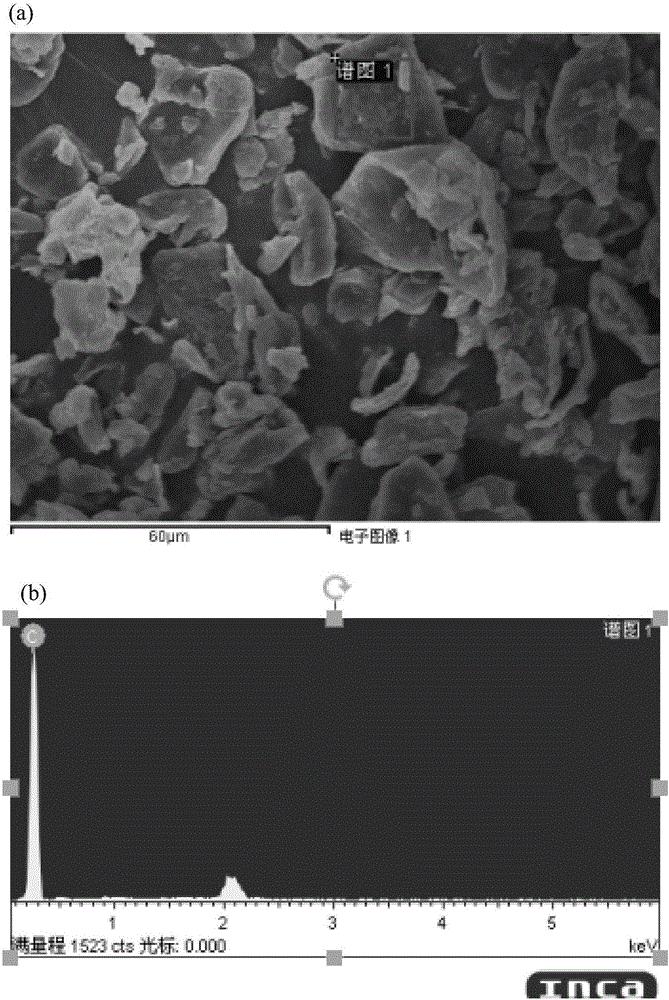

Preparation method of lithium ion battery porous silicon carbon composite negative material

InactiveCN102709565AInhibition of volume changeSmall volume changeCell electrodesAcid etchingCarbon composites

The invention puts forwards a preparation method of a lithium ion battery porous silicon carbon composite negative material. The prepared porous silicon carbon composite material simultaneously has the characteristics of high capacity and excellent circulating stability. Micron silicon and nanometer aluminum powder are promoted to be compounded by utilizing a high-energy ball milling method, a porous silicon material can be formed through acid etching, and through a porous structure, the volume change of silicon in the discharging process is relieved to a great extent. Meanwhile, the stress generated by the volume change of the silicon can be effectively buffered through taking graphite as a dispersion matrix and in combination with a secondary surface amorphous carbon coating technology of the composite material, so that the circulating stability of the material is improved. The preparation method of the material has the advantages of simplicity, low cost and easiness in industrial production.

Owner:力芯(青岛)新能源材料有限公司

Quick formation method for lithium ion battery adapting to various cathode material systems

ActiveCN102760908AImprove the first charge and discharge efficiencyImprove cycle performanceFinal product manufactureSecondary cells charging/dischargingElectrical batteryThree stage

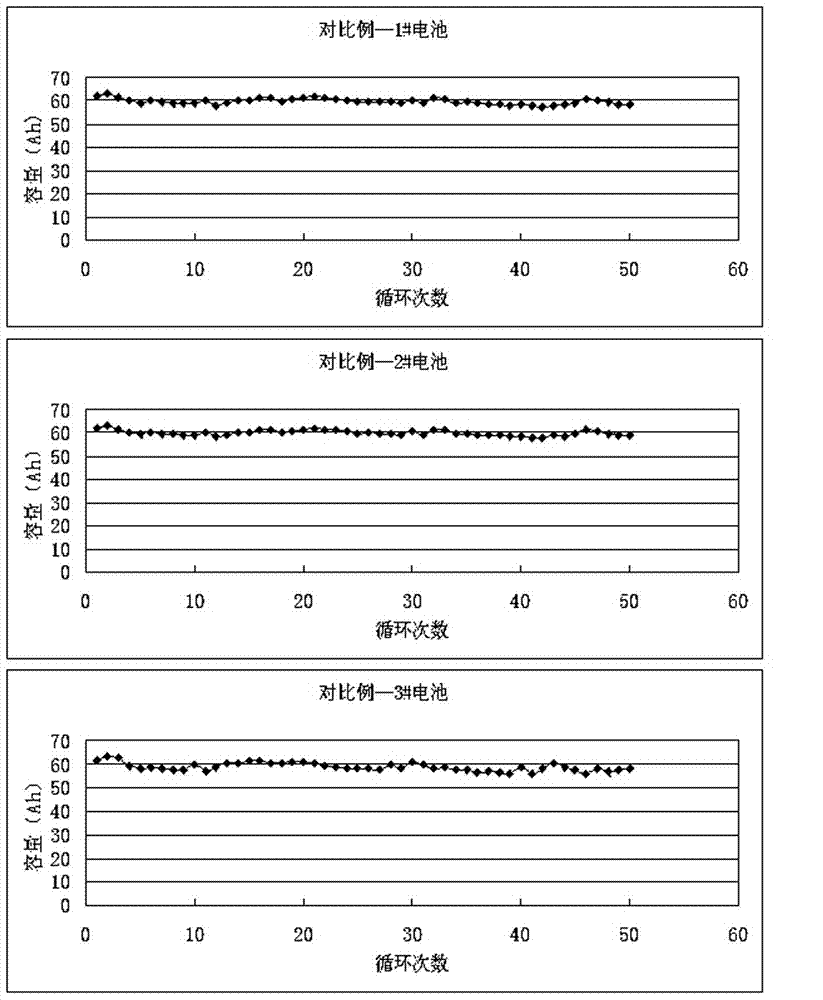

The invention provides a quick formation method for a lithium ion battery adapting to various cathode material systems. The formation method is divided into three stages, and in each stage, constant-current charging of the battery is realized through different currents, and the upper-limit cut-off voltage of each stage is controlled as the end condition. Currents selected in each stage gradually increase in a stepped manner, so that an SEI (Solid Electrolyte Interphase) film can be slowly and uniformly produced on the surface of a graphite negative pole; and selected upper-limit cut-off voltages are in different ranges respectively according to different cathode material systems, so that the SEI film can be effectively produced while the excessive lithium ion consumption is avoided. Besides, after each stage finishes, a certain standing time is set, so that the SEI films formed in each stage can be in steady states as far as possible According to the invention, not only is the production efficiency of the formation procedure improved, but also the quality of the SEI films in the formation process is guaranteed, and further, the comprehensive electrochemical performance of the lithium ion battery is improved.

Owner:NINGBO SHIJIE NEW ENERGY TECH

Lithium ion secondary cell

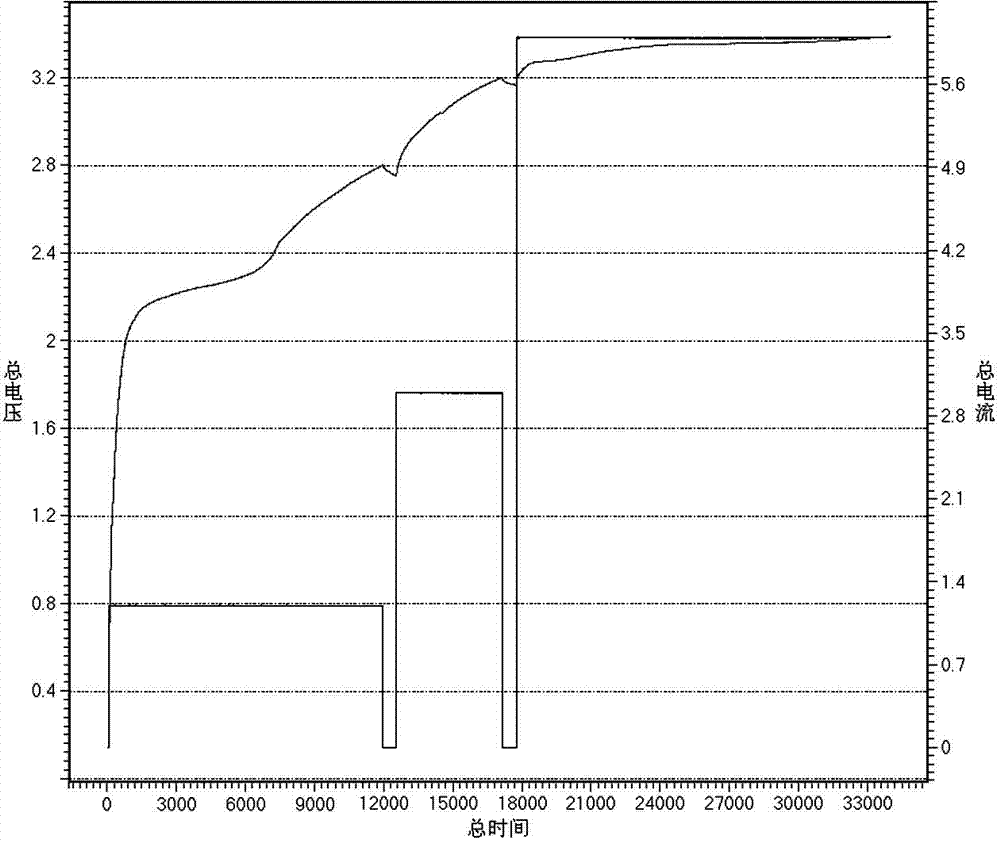

ActiveCN105304936AEasy to embedImprove the first charge and discharge efficiencyCell electrodesSecondary cellsFast chargingPhysical chemistry

The invention provides a lithium ion secondary cell, in particular a long-life fast-charging cell. The long-life fast-charging cell comprises a positive electrode material, a negative electrode material, a diaphragm and a nonaqueous electrolyte, wherein the active substance of the negative electrode material comprises at least one of hard carbon and soft carbon; the nonaqueous electrolyte contains a film-forming additive and a lithium salt; the film-forming additive comprises vinylene carbonate; and the lithium salt comprises lithium difluorosulfonylimide. Due to excellent performance, the long-life fast-charging cell has broad market prospects.

Owner:微宏先进材料公司

Silicon-carbon composite anode material, preparation method thereof and lithium ion battery

InactiveCN104103807ANot prone to the problem of electrochemical agglomerationReduce the effects of volume expansionMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

An embodiment of the invention provides a silicon-carbon composite anode material which includes a shell and an active and conductive material which is accommodated in the shell. The active and conductive material includes a silicon nano-material, a graphite material and carbon nano-tubes, wherein the silicon nano-material, the graphite material and the carbon nano-tubes are blended according to a weight ratio of 10-30:15-35:1-5. The shell is a cracked carbon layer. The silicon nano-material is silicon nano-sheets or silicon nano-belts with a length-width size being 50-5000 nm and a thickness being 10-500 nm. Surfaces of the silicon nano-sheets or silicon nano-belts are provided with Si-N-Si composite layers and Si-N-C composite layer. The silicon-carbon composite anode material is high in reversible capacity, is high in first-time charging-discharging efficiency, is good in circulating performance, can finally increasing a system capacity of a lithium ion battery and prolongs a cyclic service life of the lithium ion battery. The embodiment of the invention also provides a preparation method of the silicon-carbon composite anode material and the lithium ion battery containing the silicon-carbon composite anode material.

Owner:HUAWEI TECH CO LTD

Method for preparing silicon-carbon composite anode and lithium ion battery

ActiveCN104681797APromote circulationSimple preparation processCell electrodesSecondary cellsCarbon compositesCyclic process

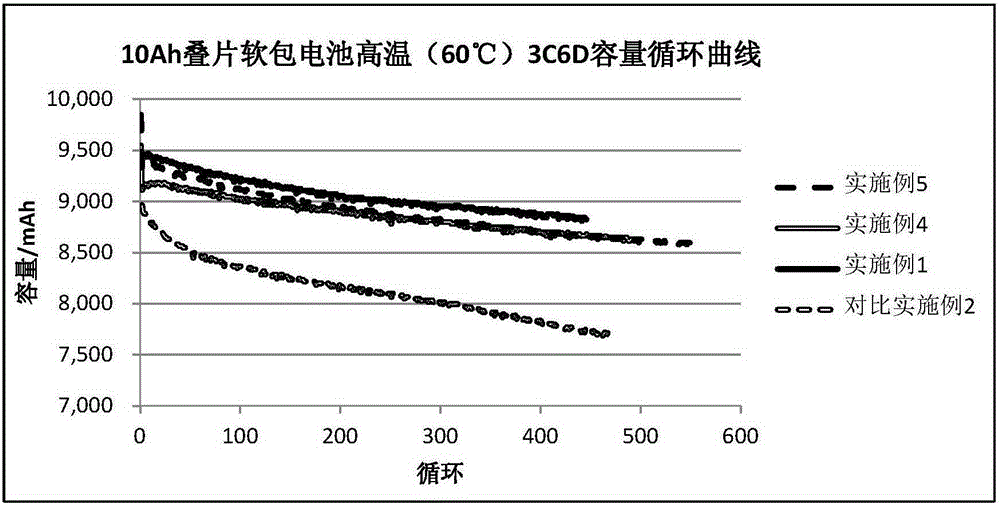

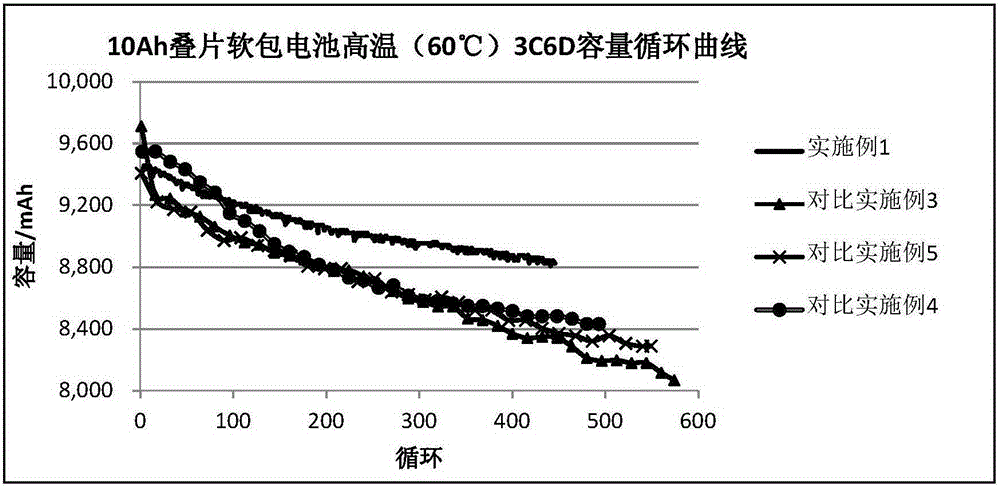

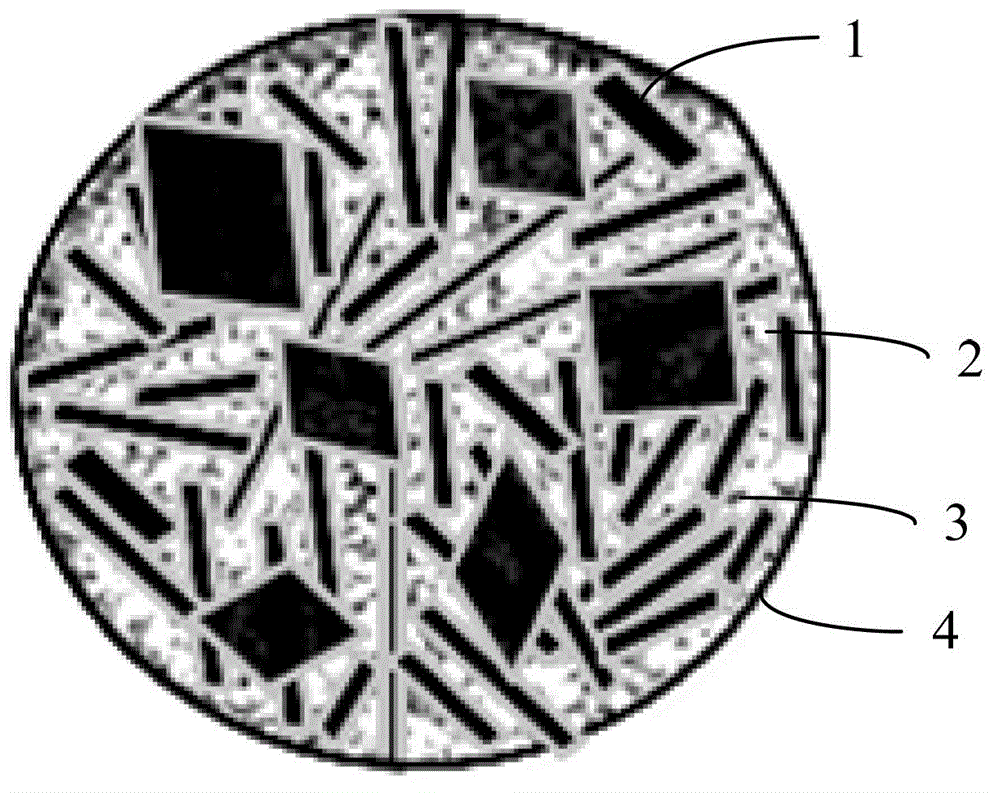

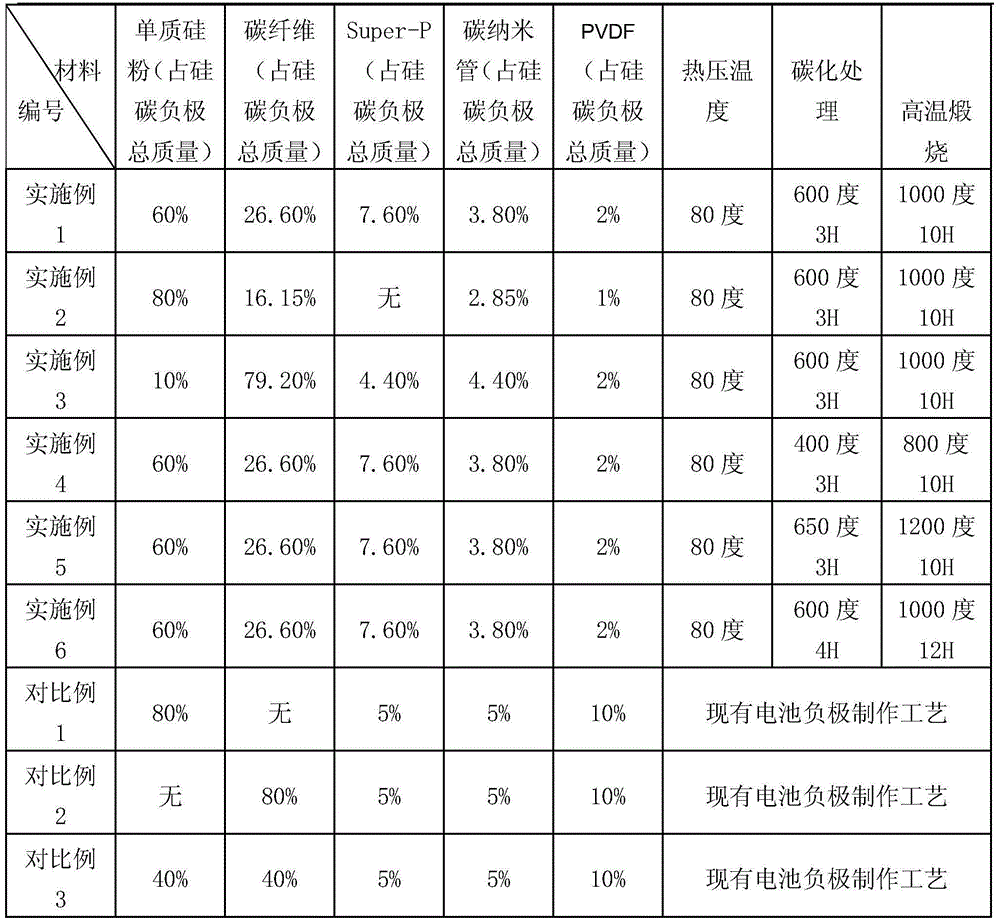

The invention discloses a silicon-carbon composite anode comprising a silicon source and a carbon source, wherein silicon source is monatomic silicon, the particle size distribution is 100 nm to 80 microns, and the mass of the silicon source accounts for 10-80% of the total mass of the silicon-carbon composite anode; the carbon source comprises a carbon anode material and a conductive agent, the carbon anode material is one or more of carbon fiber, graphite and mesocarbon microbead, and the mass of the carbon anode material accounts for 10-90% of the total mass of the carbon source. According to the silicon-carbon composite anode disclosed by the invention, one-step coating forming, hot pressing flaking, carbonization treatment and high-temperature calcination are carried out on anode slurry prepared by mixing the silicon source with the carbon source, so as to guarantee that the silicon material is effectively dispersed in a carbon skeleton, the prepared silicon-carbon anode can effectively relieve the volume expansion of the silicon material in charging and discharging processes in a circulation process and guarantee excellent cycle performance of the battery; the silicon-carbon composite anode is prepared by one-step coating forming, and no current collector is needed, so that the production process is simplified and the battery is guaranteed to have high energy density; meanwhile, the invention further provides a lithium ion battery containing the silicon-carbon composite anode.

Owner:江苏中兴派能电池有限公司

Graphite silicon-based composite anode material and preparation method thereof

InactiveCN104362307ASmall granularityHigh specific surface energyCell electrodesSecondary cellsCarbon compositesHigh carbon

The invention relates to a graphite silicon-based composite anode material for a lithium ion battery and a preparation method thereof. The graphite silicon-based composite anode material comprises a nano-silicon cracked carbon composite material, graphite and a carbon material coating layer. The preparation method comprises the following steps: firstly, nano-silicon is obtained by a high-energy wet mechanical milling method; secondly, nano-silicon and a polymer with high carbon residue are compounded by dispersion polymerization so as to form a polymer / nano-silicon composite microsphere emulsion with nano-silicon inlaid in polymeric microspheres; thirdly, the microsphere emulsion and graphite are compounded; and finally, solid-phase coating is carried out by the use of an organic carbon source, and heat treatment is conducted to obtain the graphite silicon-based composite anode material for a lithium ion battery. By the above method, the problem that nano-silicon is liable to agglomeration, especially agglomeration of nano-silicon from a liquid disperse state to a dry state, due to low granularity and high specific surface energy is solved. The anode material has characteristics of high specific capacity (greater than 550mAh / g), high initial charge discharge efficiency (greater than 80%) and high conductivity.

Owner:南京毕汉特威高分子材料有限公司

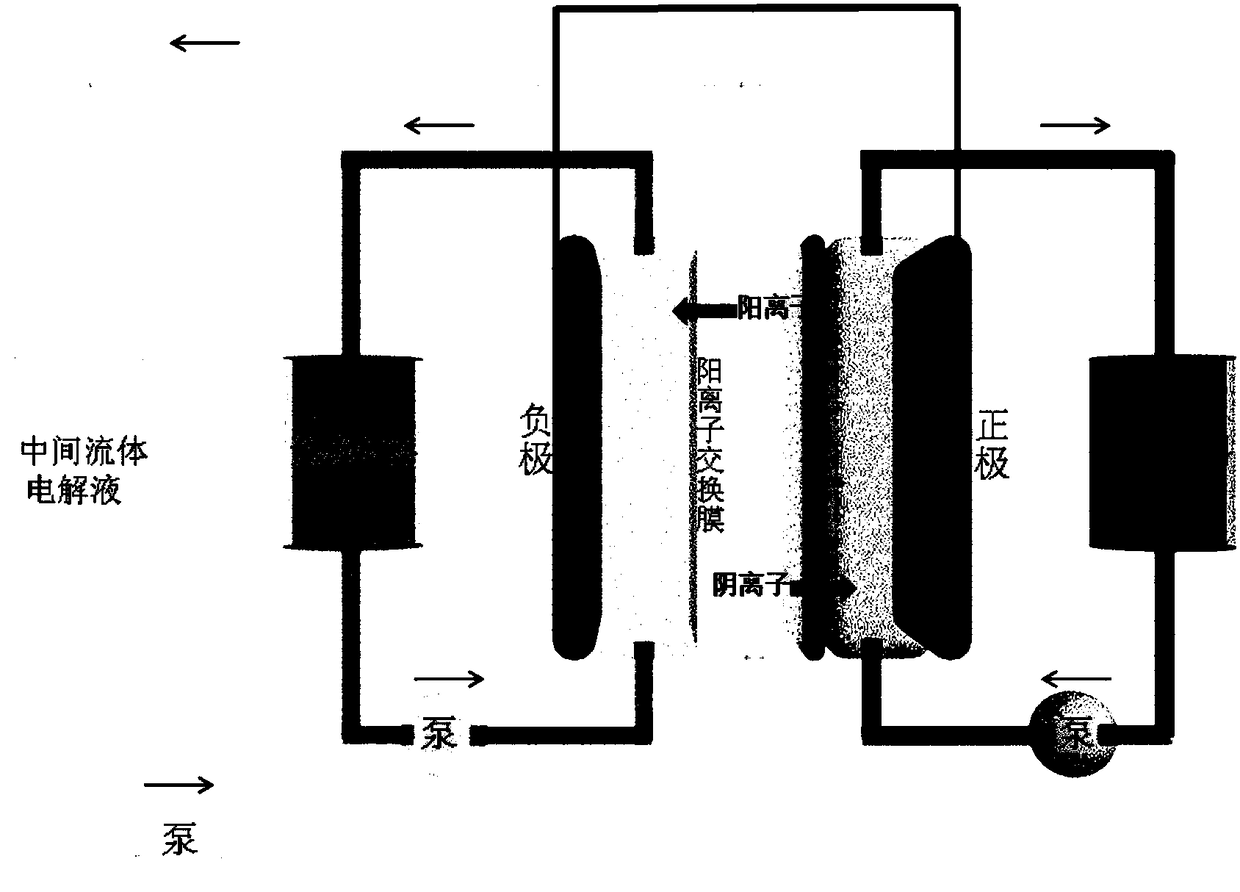

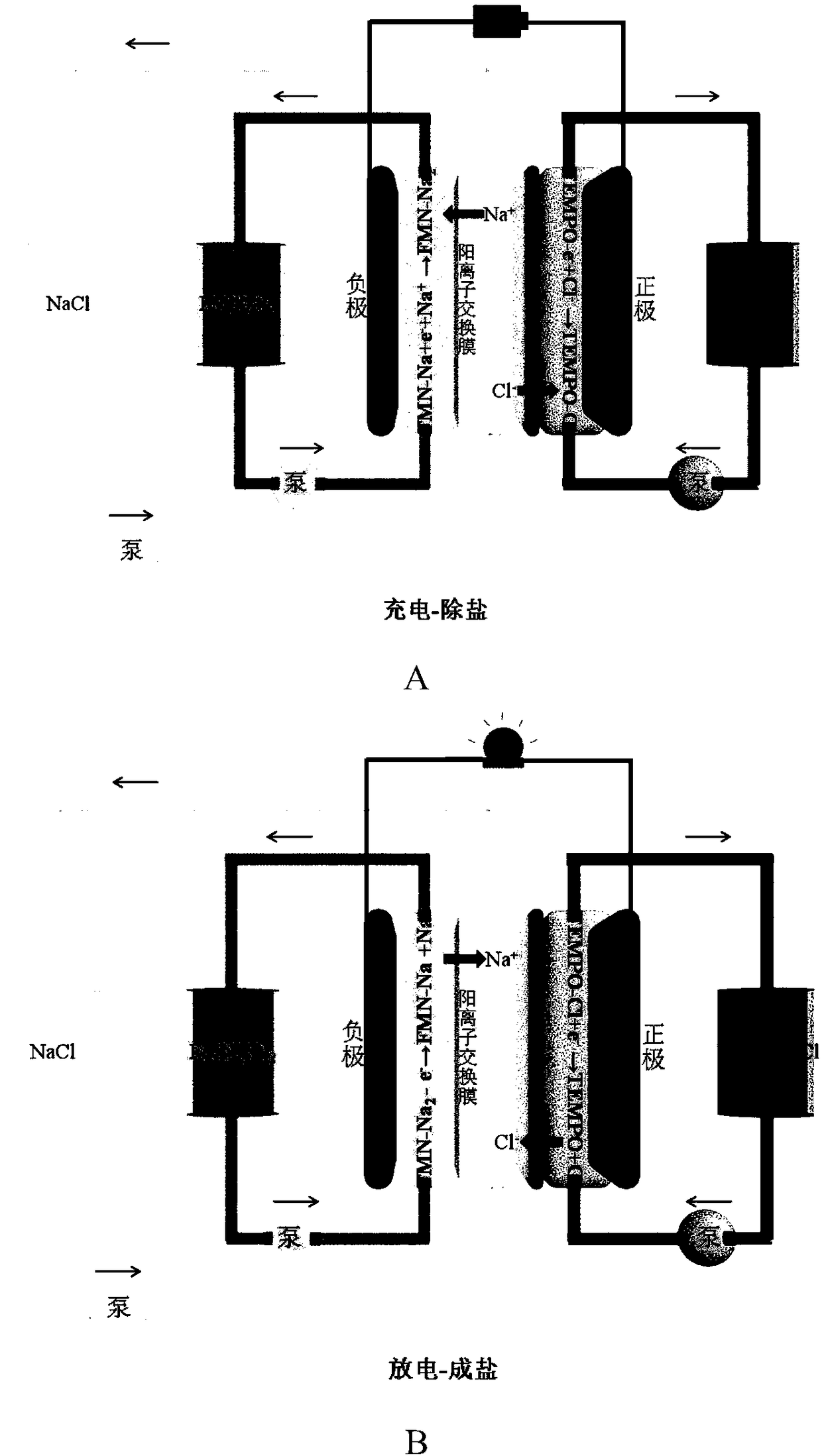

Method for removing salt by using fluid battery and application thereof

ActiveCN108483573AImprove electrochemical performanceImprove the first charge and discharge efficiencyWater/sewage treatment by ion-exchangeWater/sewage treatment using germicide/oligodynamic-processIon-exchange membranesSeawater

The invention discloses a method for removing salt by using a fluid battery and application thereof. According to the method, salt removal is performed by a salt-removing fluid battery device, whereinthe salt-removing fluid battery device uses a positive active material as a positive electrode of the fluid battery, a negative active material as a negative electrode of the fluid battery and a saltsolution as an intermediate fluid electrolyte of the fluid battery. According to the invention, organic or inorganic active materials are used as the positive and negative electrode materials of thefluid battery, a salt-removing fluid battery is built in a fixed order, and the salt removing purpose is achieved through charging and discharging; during charging, through respective redox reactionsof the organic active positive and negative electrode materials, under an interfacial effect of an ion exchange membrane, electrodialysis is coupled to remove anions and cations in the salt solution,so that the purposes of removing the salt and removing other ions are achieved. The salt-removing fluid battery used in the invention is simple, low in cost and environment-friendly, shows excellent electrochemical performance, good cycle stability and salt removing capacity, and is applicable to the field of seawater salt removal and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Positive electrode material with improved first discharge capacity and preparation method thereof

InactiveCN111162249ASimple preparation processEase of industrial productionCell electrodesSecondary cellsDischarge efficiencyPhysical chemistry

The invention provides a positive electrode material with improved first discharge capacity and a preparation method of the positive electrode material. The positive electrode material is prepared from a positive electrode material matrix, a lithium source and a coating agent. The first discharge capacity is improved by improving the first charge-discharge efficiency and the first-week charge capacity, and the cycle performance of the positive electrode material is effectively improved. The preparation method provided by the invention adopts a solid-phase method, is simple in preparation process and is beneficial to industrial production.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

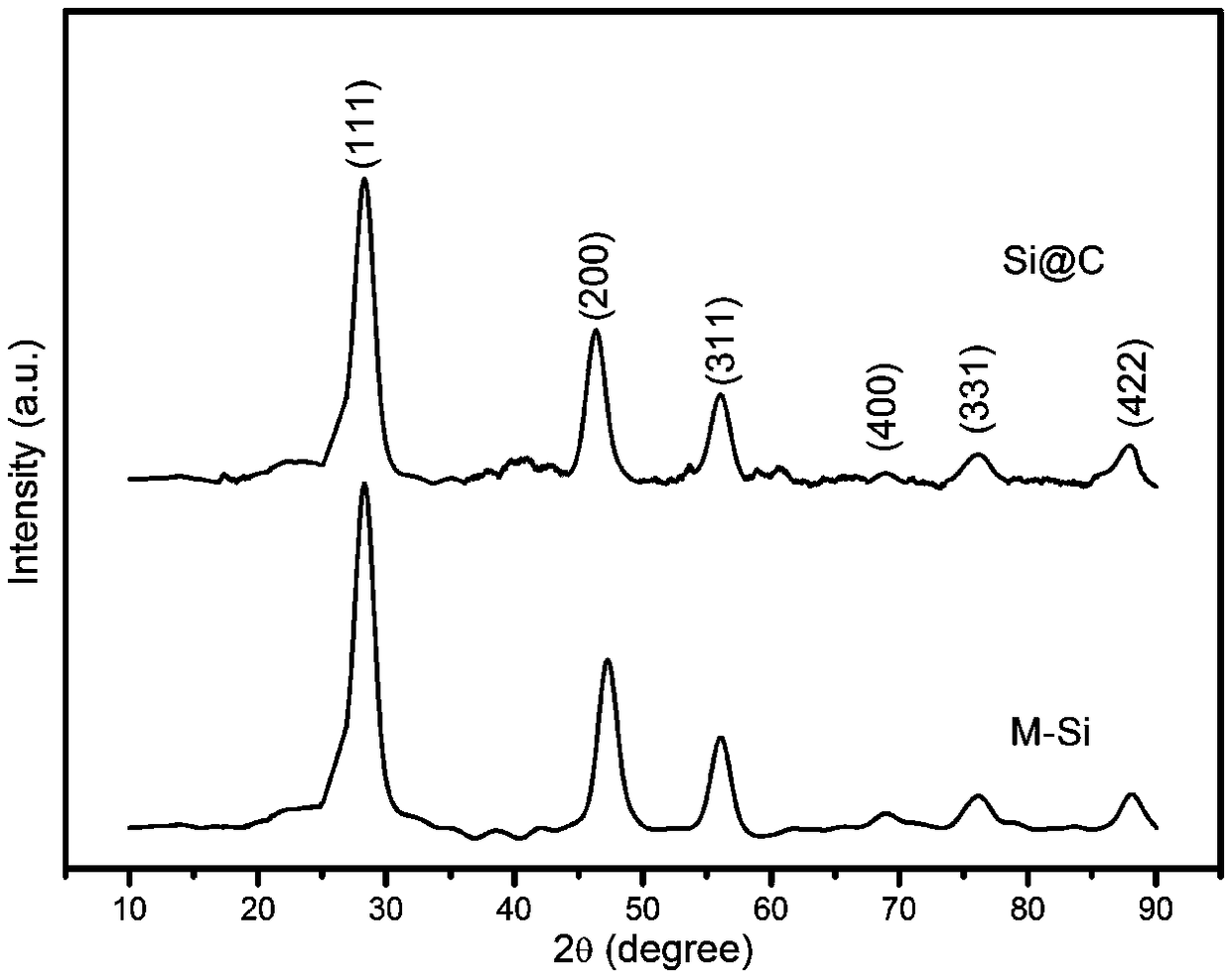

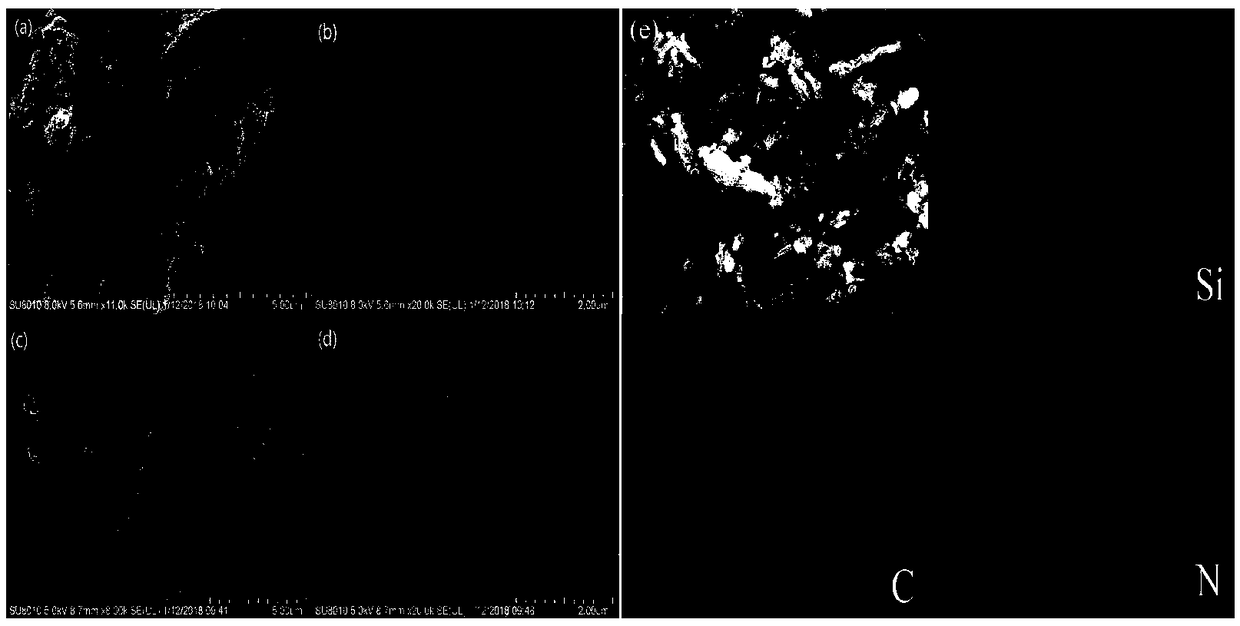

Silicon @ carbon composite material with egg yolk shell structure and preparation and application thereof

ActiveCN109256535AAvoid direct contactShorten the diffusion pathMaterial nanotechnologyCell electrodesCarbon compositesAluminium hydroxide

The invention belongs to the field of battery negative electrode materials, and particularly discloses a preparation method of silicon @ carbon composite material with egg yolk shell structure, whichis characterized in that the preparation method comprises the following steps: step 1) mesoporous nano SiOX, molten salt and magnesium powder are mixed and calcined to obtain mesoporous nano silicon;2) mesoporous nano-silicon powder, the surfactant and the aluminum salt prepared in the step 1) are added into a solution at a pH value of 2, and the mesoporous nano-silicon powder, the surfactant andthe aluminum salt are added into the solution at a pH value of 2; 7, coat aluminum hydroxide colloid on that surface of nano silicon to obtain silicon / aluminum hydroxide colloid composite material; 3) silicon / aluminum hydroxide colloidal composite material is mixed with an organic carbon source, carbon is coated on the surface of the silicon / aluminum hydroxide colloidal composite material, and then the silicon / aluminum hydroxide colloidal / carbon composite material is acuquried by carbonizing operation; 4) aluminum hydroxide colloid of the material obtained in the step 3) is removed by using an acid solution and / or an alkali solution to prepare the silicon @ carbon composite material with the egg yolk shell structure. The invention can stably prepare the silicon @ carbon composite materialwith the egg yolk shell structure, and the material has excellent electrical performance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

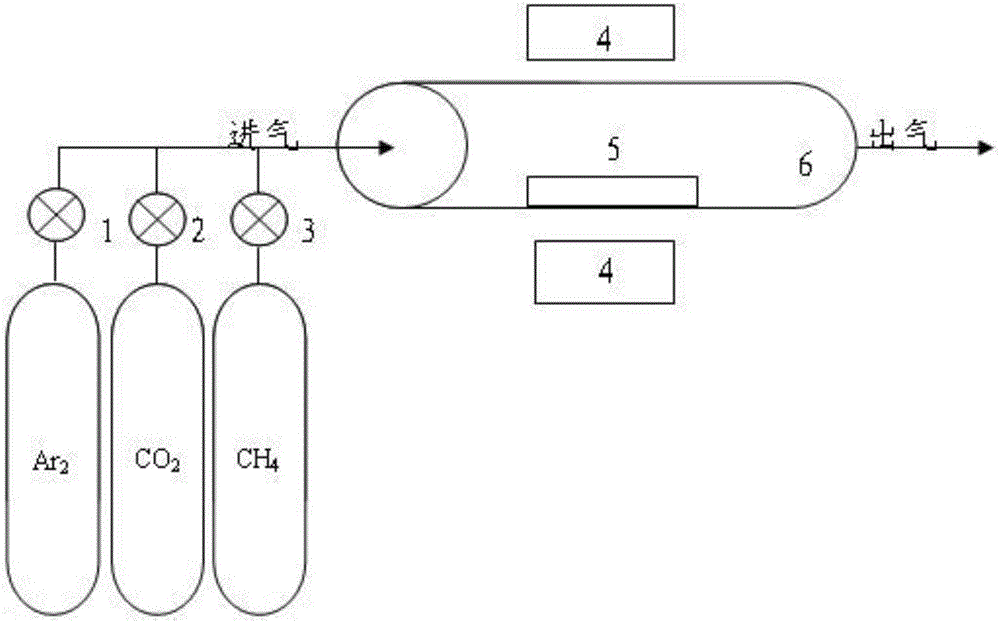

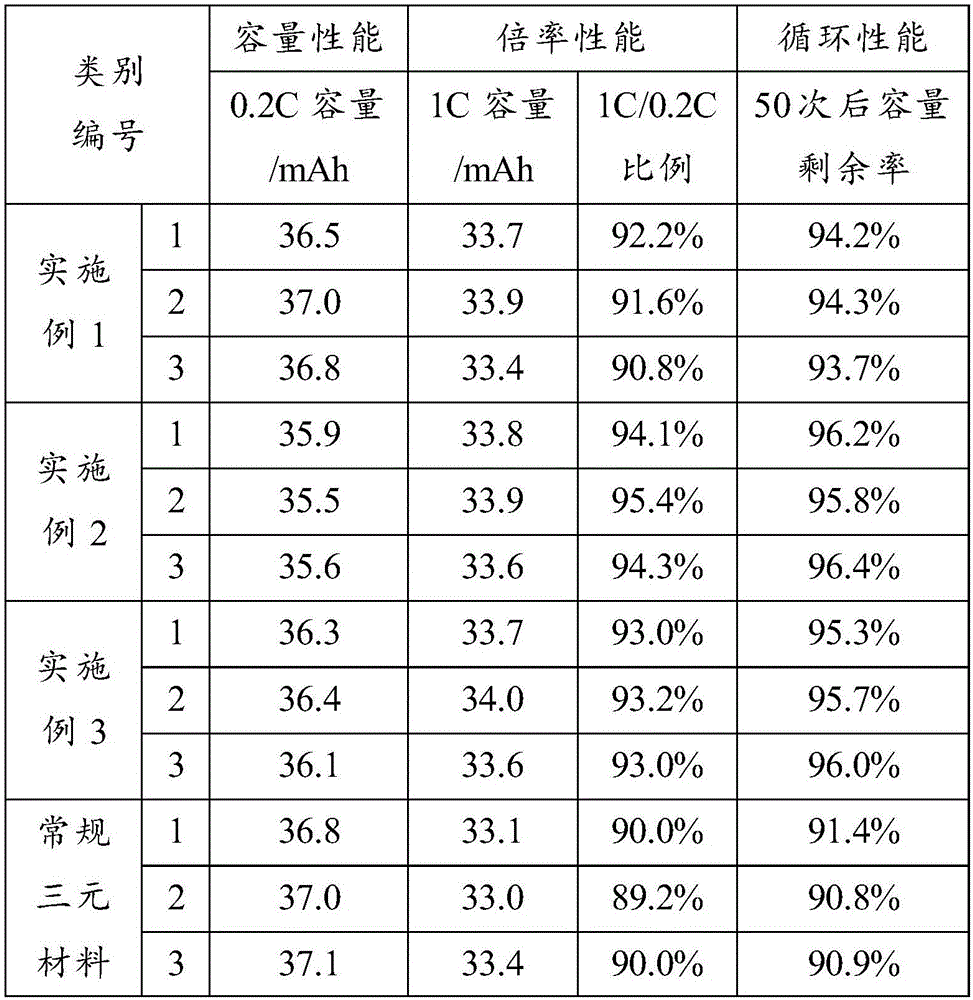

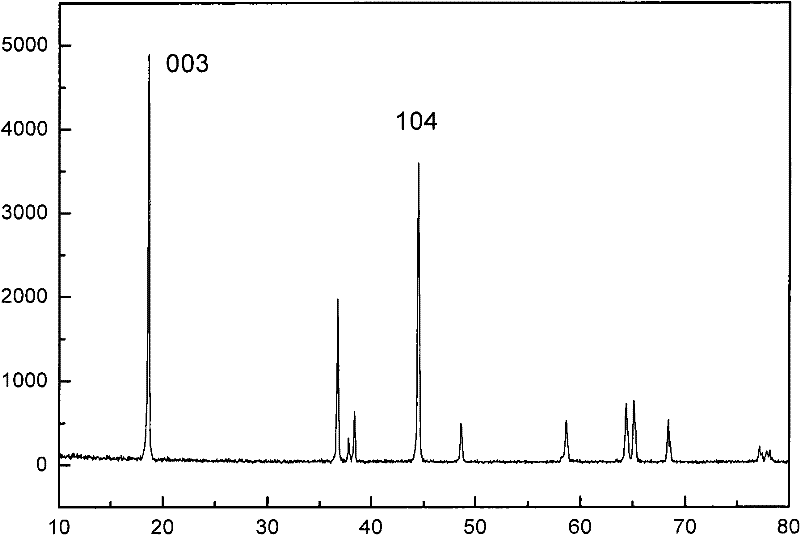

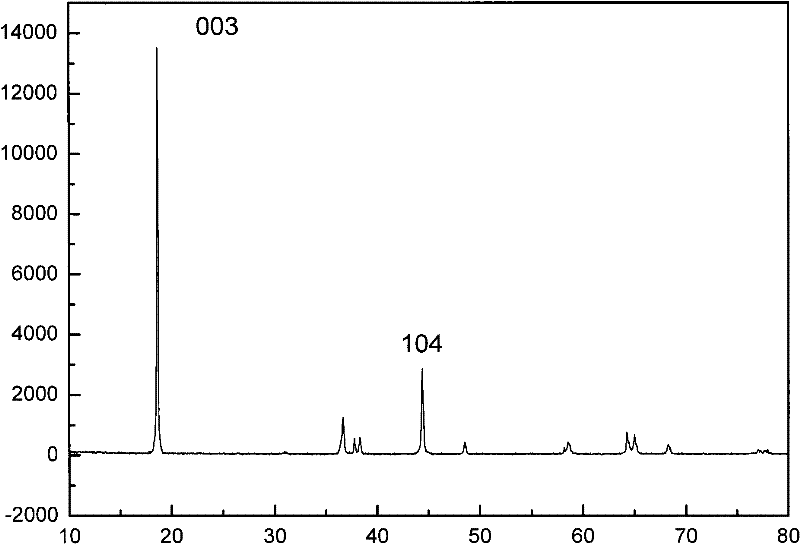

Modification method of lithium nickelate, cobaltate and manganate ternary material

ActiveCN106450217ASimple processReduce shufflingCell electrodesSecondary cellsCarbon coatingCarbon source

The invention provides a modification method of a lithium nickelate, cobaltate and manganate ternary material. The method comprises the step that after a lithium nickelate, cobaltate and manganate material is subjected to vapor phase deposition under the conditions of carbon source gas and protective gas, a carbon-coated modified lithium nickelate, cobaltate and manganate material is obtained. The modification method provided by the invention has the benefits that carbon deposits on the surface of the lithium nickelate, cobaltate and manganate ternary material through a vapor phase deposition method, so that carbon coating is realized; by adopting simpler processes, with the aid of the protective gas, the ternary material is carbon-coated, so that the problem of lithium nickelate reduction in the coating process of a traditional ternary material is effectively solved, and the coating of a carbon layer on the surface of the ternary material is realized; through the lithium nickelate, cobaltate and manganate ternary material coating carbon, the first-time charging and discharging efficiencies are improved, the lithium ion diffusion coefficients and the electronic conductivity of the material are improved, and the electrochemical performance of the NCM material is improved. According to the modification method provided by the invention, equipment is relatively simple, the process is less, and the structure is controllable; the material has higher battery capacity, cycle performance and rate capability.

Owner:GREE ELECTRIC APPLIANCES INC

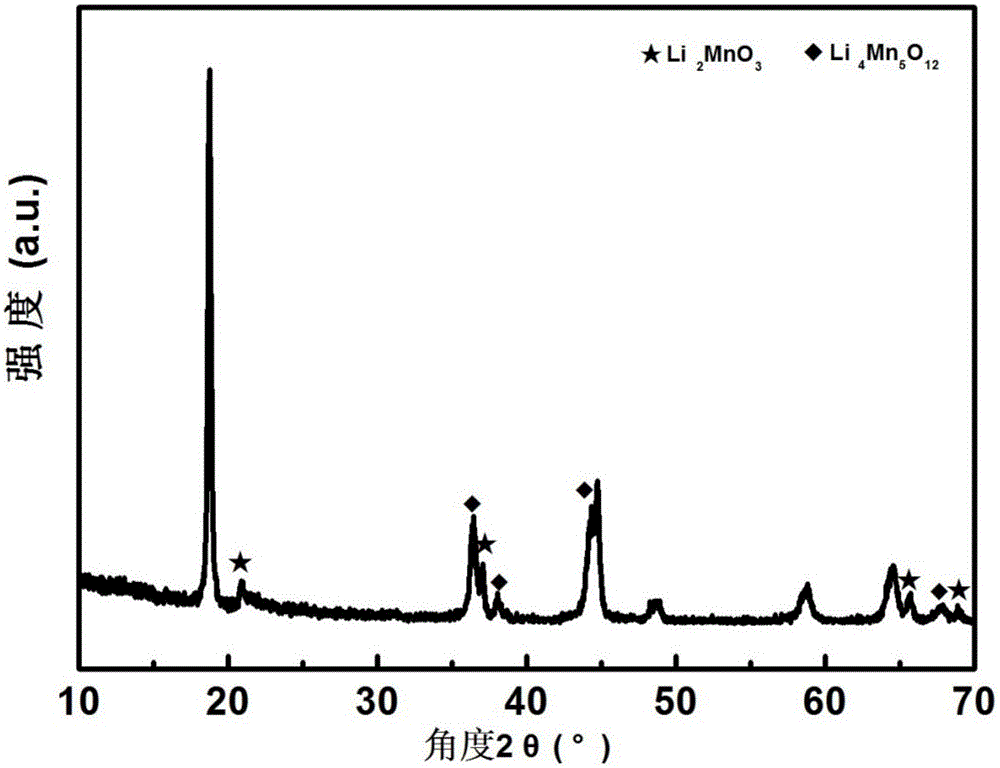

Positive electrode material of lithium cell, preparation method of positive electrode material and lithium cell

InactiveCN102683666AImprove cycle performanceImprove the first charge and discharge efficiencyCell electrodesSecondary cellsLithiumSolid solution

The invention provides a positive electrode material of a lithium cell. The positive electrode material is characterized by comprising a layered composite solid solution and SnO2 dispersed in the layered composite solid solution; the layered composite solid solution is xLi2MnO3*yLiMO2, wherein the M is selected from one or more of Mn, Ni, Co, Cr, Ti and Al, the x and the y are mole contents, and (2x+y) / (x+y) is larger than or equal to 1.2 and also smaller than or equal to 1.6; and in the layered composite solid solution, the content of the Mn is not less than 50% based on the total mole content of the Mn and the M. The invention further provides a preparation method of the positive electrode material of the lithium cell, and the lithium cell utilizing the positive electrode material. A cell prepared from the positive electrode material disclosed by the invention has high cycle performance and high first charge and discharge efficiency simultaneously.

Owner:BYD CO LTD

Flexible package lithium ion battery silicon negative pole and manufacturing method thereof

ActiveCN104282881AImprove the first charge and discharge efficiencyImprove cycle stabilityCell electrodesSecondary cellsIonSolvent

The invention relates to a flexible package lithium ion battery silicon negative pole. The flexible package lithium ion battery silicon negative pole consists of a current collector and an active substance layer coating the surface of the current collector, wherein the active substance layer consists of the following substances in percentage by mass: 10-92 percent of silicon-carbon composite material, 2-70 percent of a conductive agent and 5-20 percent of an adhesive; the adhesive refers to polyimide; the porosity of the active substance layer is 30-65 percent, and the compaction density is 1.1-2.0g / cm<3>. Polyimide is dispersed by adopting a proper solvent, and the adhesive subjected to high-temperature polyacylation treatment has extremely high adhesive force, so that the prepared silicon negative pole piece has ultra-strong tension stress, the structure is kept stable in the repeated lithium-ion embedding and separating process, the first charge-discharge efficiency of the silicon negative pole can be obviously improved, and the cycling stability is improved.

Owner:WANXIANG 123 CO LTD

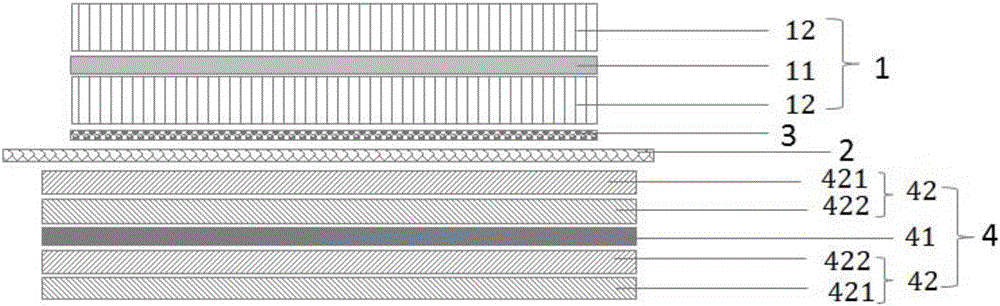

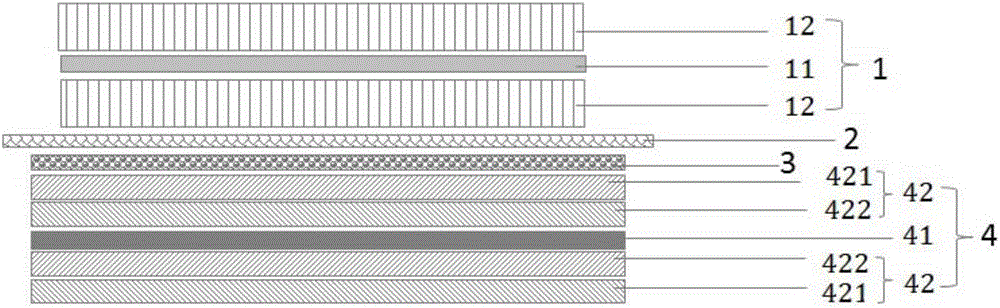

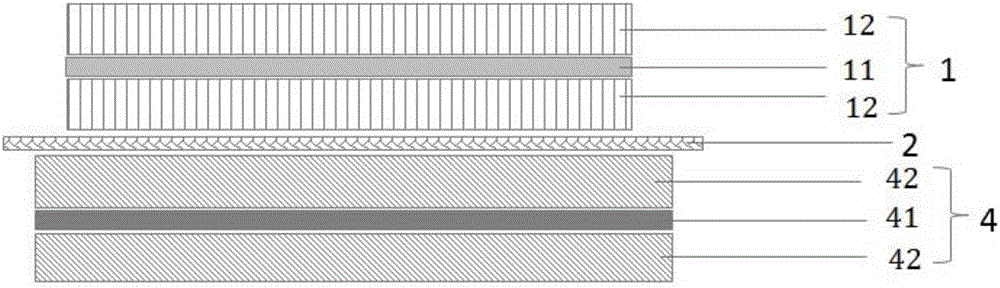

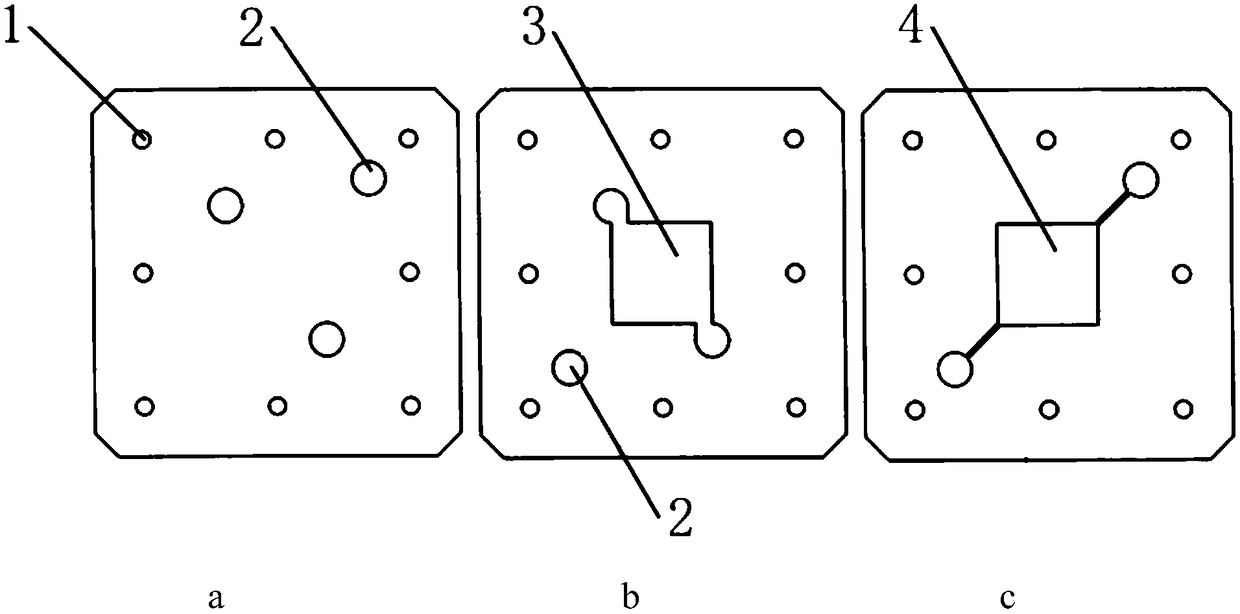

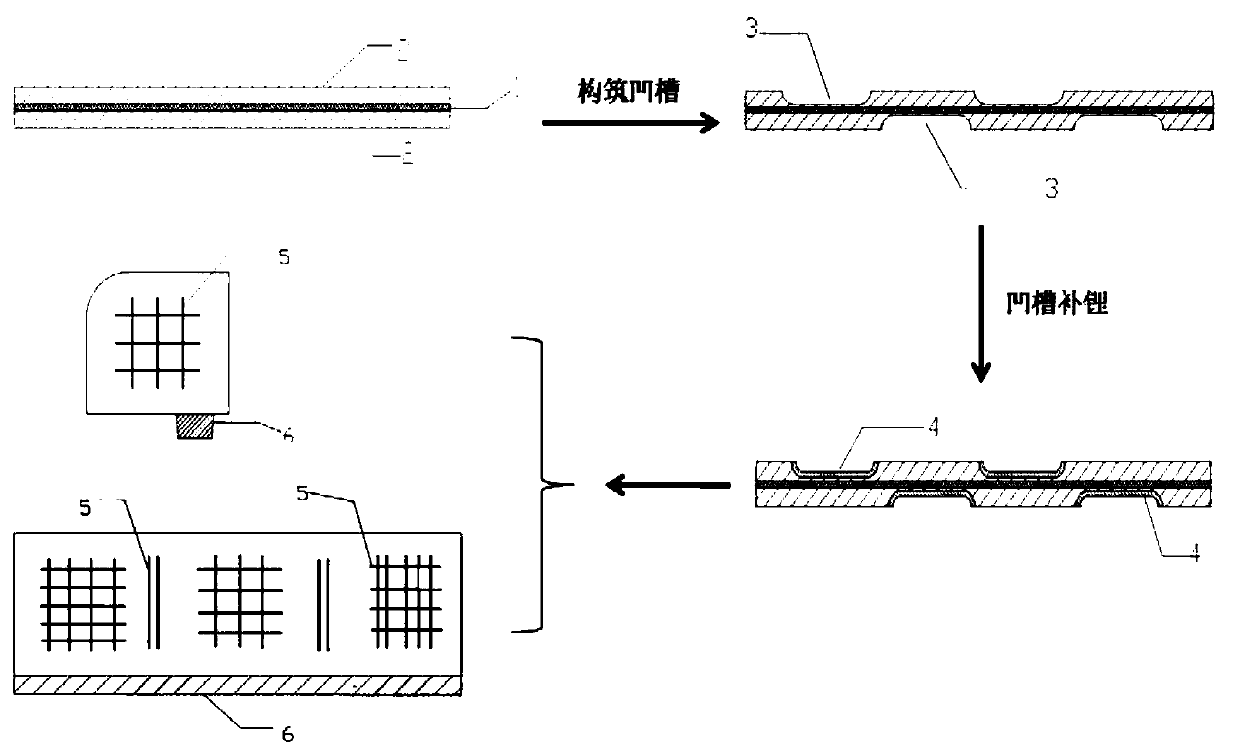

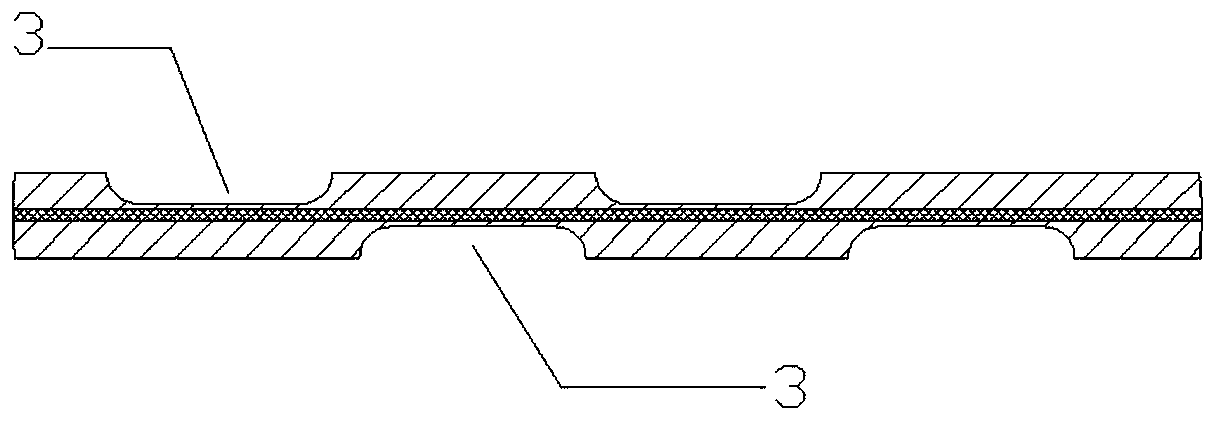

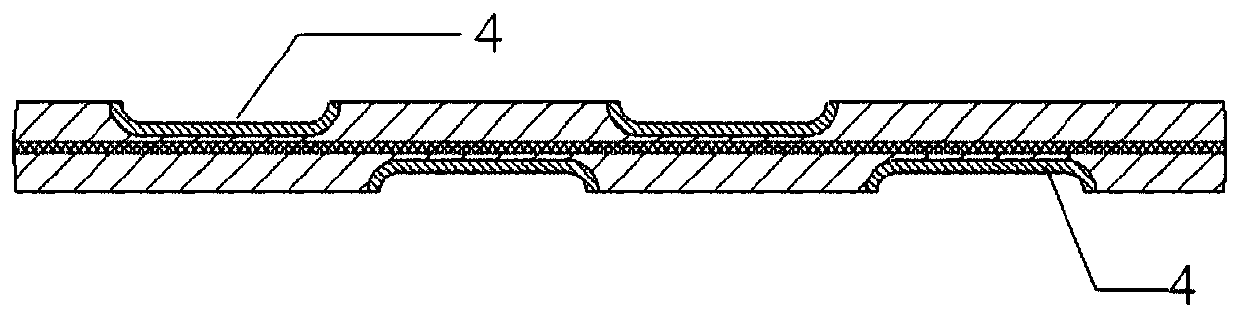

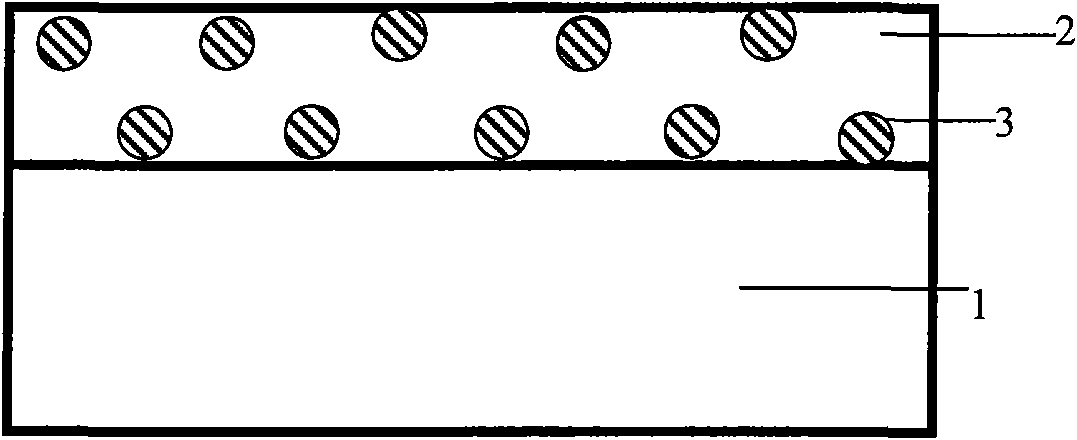

Lithium ion battery anode lithium supplement pole piece and preparation method thereof

InactiveCN109786662AImprove mass energy densityImprove the first charge and discharge efficiencyFinal product manufactureSecondary cellsLithiumPole piece

The invention relates to a lithium ion battery anode lithium supplement pole piece and a preparation method thereof. The lithium ion battery anode lithium supplementary pole piece comprises a currentcollector (1), active material coating layers (2) which are attached on upper and lower surfaces of the current collector (1), microstructure grooves (3) which are set on a single side or double sidesof the surfaces of the active material coating layers (2), and lithium supplement layers (4) which cover the surfaces of the microstructure grooves (3). According to the lithium ion battery anode lithium supplement pole piece and the preparation method, consumption of lithium in an application process of the battery can be effectively supplemented, a first effect is improved, relatively much space and many channels for soaking of electrolyte are provided, and circulation service life and stability of the battery are greatly improved.

Owner:湖北锂诺新能源科技有限公司

Cathode of lithium-ion secondary battery, preparation method and lithium-ion secondary battery

InactiveCN101640261AIncrease sputtering powerHigh charge and discharge capacityElectrode manufacturing processesVacuum evaporation coatingCapacitanceSputtering

The invention provides a cathode of a lithium-ion secondary battery, which comprises a current collector and a cathode material layer covered on the current collector. The cathode material layer is prepared by adopting magnetron sputtering technology under the sputtering power of 1,000 to 5,000 W. By greatly improving the target sputtering power of magnetron sputtering, the prepared lithium-ion secondary battery has high charge / discharge capacitance and excellent cycle performance, and improves the production efficiency of the material, has simple manufacturing process and operation and good electrochemical performance, and greatly improves the primary charge / discharge efficiency and the discharge capacity compared with the reported silicon-based film cathode material.

Owner:CITIC GUOAN MENGGULI NEW ENERGY TECH

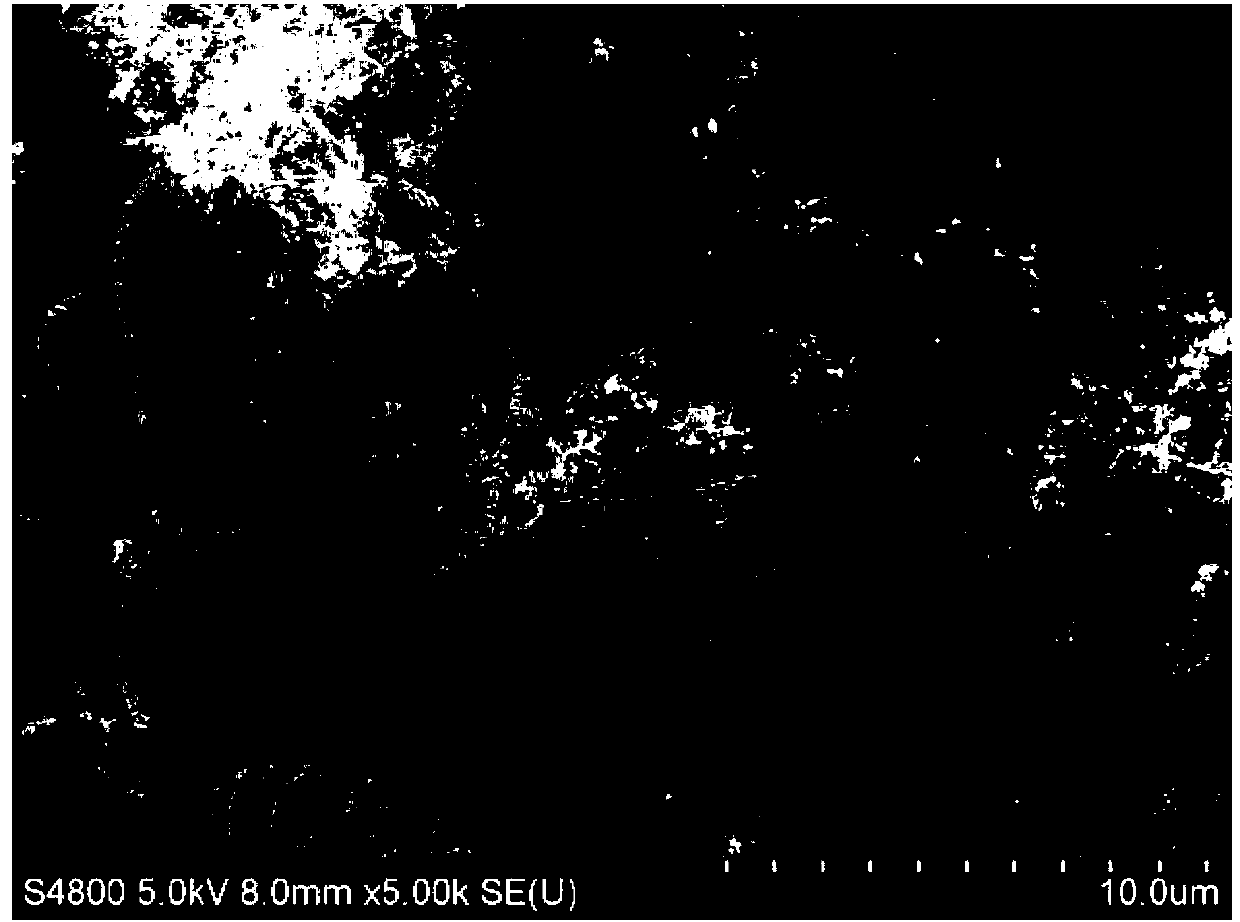

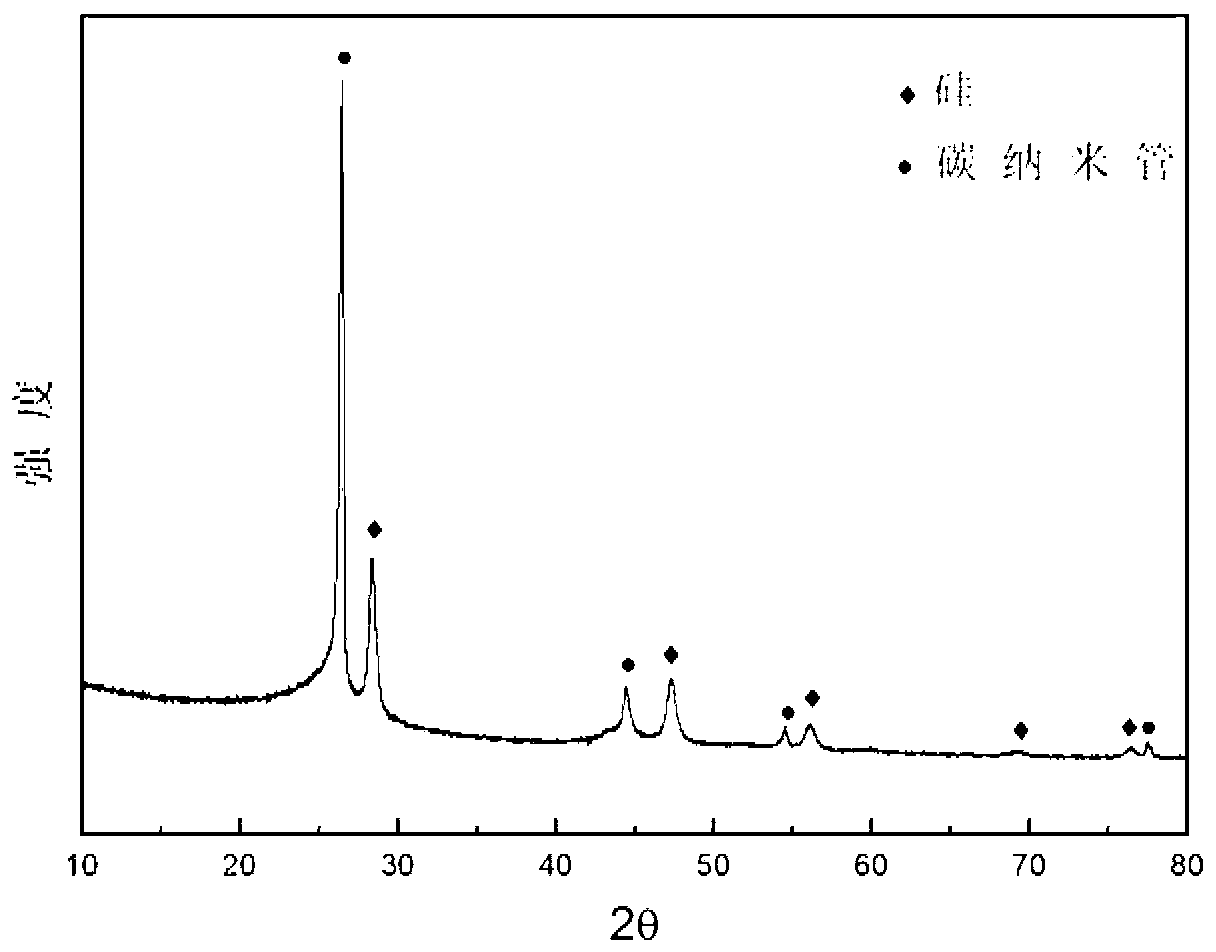

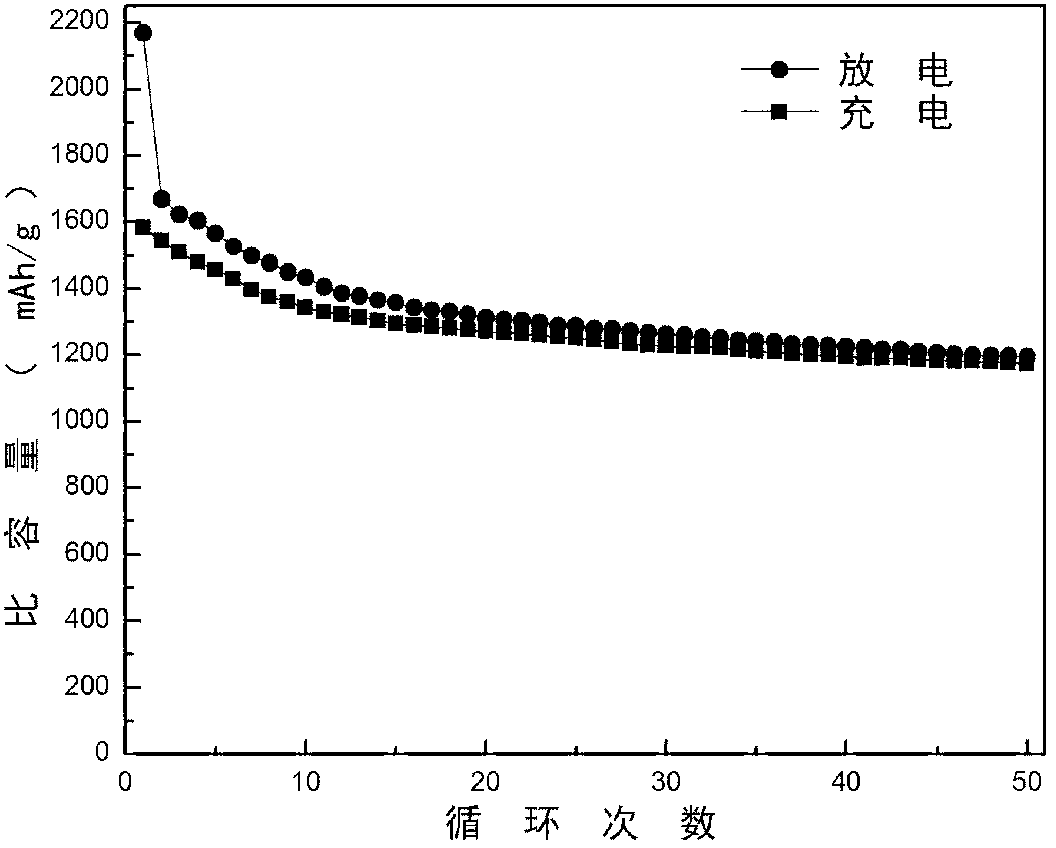

Lithium battery silicon-carbon nanotube composite cathode material as well as preparation method and application thereof

InactiveCN103346302ASolution volumeSolve efficiency problemsMaterial nanotechnologyCell electrodesCarbon nanotubeSlurry

The invention discloses a lithium battery silicon-carbon nanotube composite cathode material as well as a preparation method and application of the lithium battery silicon-carbon nanotube composite cathode material. The preparation method of the lithium battery silicon-carbon nanotube composite cathode material comprises the following steps of: mixing and uniformly stirring an organic carbon source and nanometer silicon based on the mass ratio of (0.4-9): 1, adding a catalyst to obtain mixed slurry, drying by a closed circulation spray dryer to obtain a precursor, insulating the precursor for 1-5 hours at the temperature of 300-700 DEG C to obtain a sample, feeding the sample in a tube furnace, increasing the temperature to 500-900 DEG C under the mixed gas of gaseous organic carbon source and N2 and Ar2, and naturally cooling to obtain the lithium battery silicon-carbon nanotube composite cathode material. The lithium battery silicon-carbon nanotube composite cathode material has excellent electrochemical properties, high first charge-discharge efficiency up to more than 2000mAh / g, reversible specific capacity of about 1100mAh / g after cycle of 50 weeks, and good specific capacity and cycle performance, and the problems of low first efficiency, large irreversible capacity loss and poor conductivity of silicon when being used to prepare a lithium ion battery cathode are successfully solved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

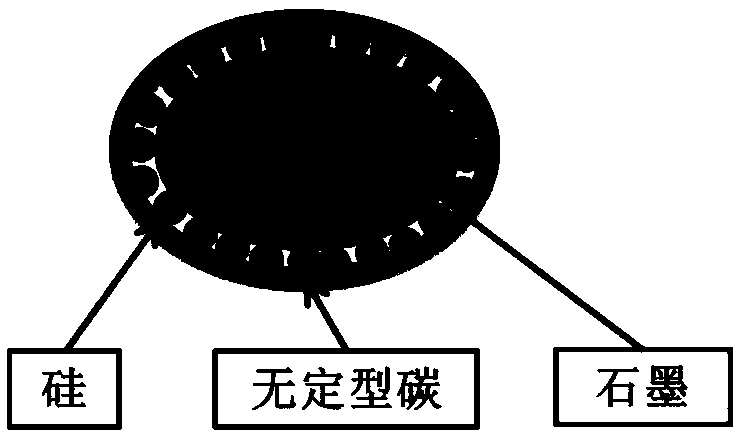

Preparation method of silicon-carbon anode material and lithium ion battery

The invention discloses a preparation method of a silicon-carbon anode material and a lithium ion battery. The preparation method includes: mixing nano-silicon with graphite solid phase, sieving the mixture, mixing the mixture with an amorphous carbon precursor solid phase, sieving the mixture, performing vibrating shaping, and sintering the product to obtain the silicon-carbon anode material. Bymeans of sieving, the graphite, nano-silicon and amorphous carbon precursor are dispersed, so that the surface of graphite can be uniformly coated with the nano-silicon and the surface of nano-siliconcan be uniformly coated with the amorphous carbon precursor; through the vibrating shaping, surface-to-surface contact between the amorphous carbon precursor and the nano-silicon and between the nano-silicon and the graphite is achieved without existence of a gap; through the sintering step, a volatile substance can be slowly volatilized from interior to exterior, so that a problem of forming pores since a huge gas pressure is generated from the volatile substance can be avoided. The silicon-carbon anode material, when being used for producing the lithium ion battery, shows excellent electrochemical cyclic stability.

Owner:湖北融通高科先进材料集团股份有限公司

Aluminum fluoride/silver double-coated lithium nickel cobalt manganese oxide positive electrode material and preparation method thereof

ActiveCN107591532AImprove cooling effectImprove conductivityCell electrodesDischarge efficiencyAluminum fluoride

The invention relates to an aluminum fluoride / silver double-coated lithium nickel cobalt manganese oxide positive electrode material and a preparation method thereof and belongs to the technical fieldof positive electrode materials for lithium-ion batteries. The aluminum fluoride / silver double-coated lithium nickel cobalt manganese oxide positive electrode material has a core-shell structure; a core is lithium nickel cobalt manganese oxide LiNixCoyMn(1-x-y)O2, wherein x smaller than or equal to 1.0 and greater than or equal to 0.5 and y is smaller than or equal to 0.23 and greater than or equal to 0; and a shell of the core-shell structure comprises an inner shell and an outer shell, wherein the inner shell is aluminum fluoride and the outer shell is silver. The aluminum fluoride / silver double-coated lithium nickel cobalt manganese oxide positive electrode material has excellent cycle performance, high initial charge-discharge efficiency and excellent safety performance.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Positive active material and preparation method thereof

ActiveCN102237510AImprove charge and discharge efficiencyImprove cycle performanceCell electrodesComposite oxideChemistry

The invention belongs to the technical field of lithium ion batteries and in particular discloses a positive active material and a preparation method thereof. The positive active material comprises ternary composite oxides, the general formula of the ternary composite oxides is LiaNibCocMndMeO2, wherein M is a doped chemical element, a is more than or equal to 0.97 and less than or equal to1.06, b+c+d+e=1 and e / d is more than or equal to 0.05 and less than or equal to 0.15. The preparation method for the positive active material comprises the following steps: carrying out step S: adding a solution A and a solution C to a base solution for depositing in parallel, and adding a solution B and the solution C to the base solution for depositing in parallel; repeating the step S, then carrying out aging and finally sintering with a lithium source to obtain the positive active material. The element-doped ternary material provided by the invention is improved greatly in the first charge-discharge efficiency and the cycle performance. The preparation method of the positive active material is simple and practicable and is applied to mass production.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com