Preparation method of negative material for low-temperature lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of complex process, high product cost, difficult control of preparation process, etc., and achieves simple preparation method, low cost, high-rate charging. Good discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

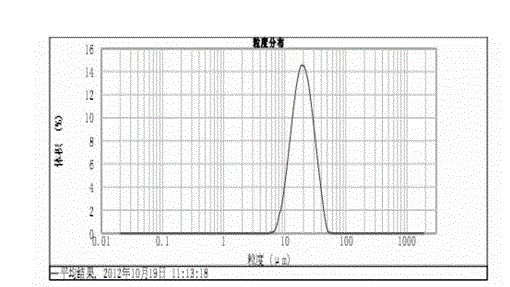

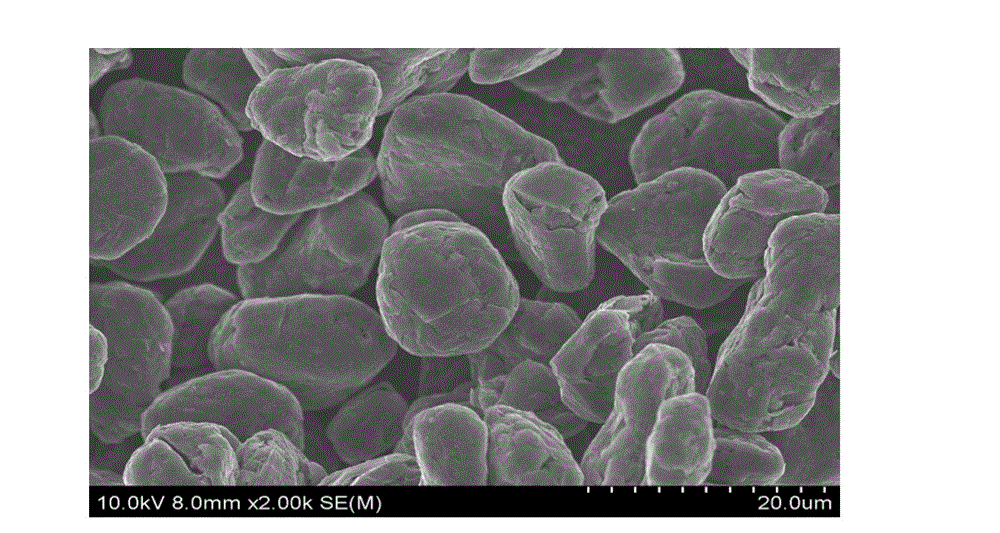

[0030] (1) Put 500g of large-grained natural graphite in a ball mill at a speed of 350 rpm, and grind for 1 hour. The natural graphite balls after ball milling are washed repeatedly, then dried, and passed through a 200-mesh sieve.

[0031] The raw material large particle graphite selected in the present invention has an average diameter of 15-70 μm, and the natural graphite after ball milling has an average particle diameter of 5-35 μm.

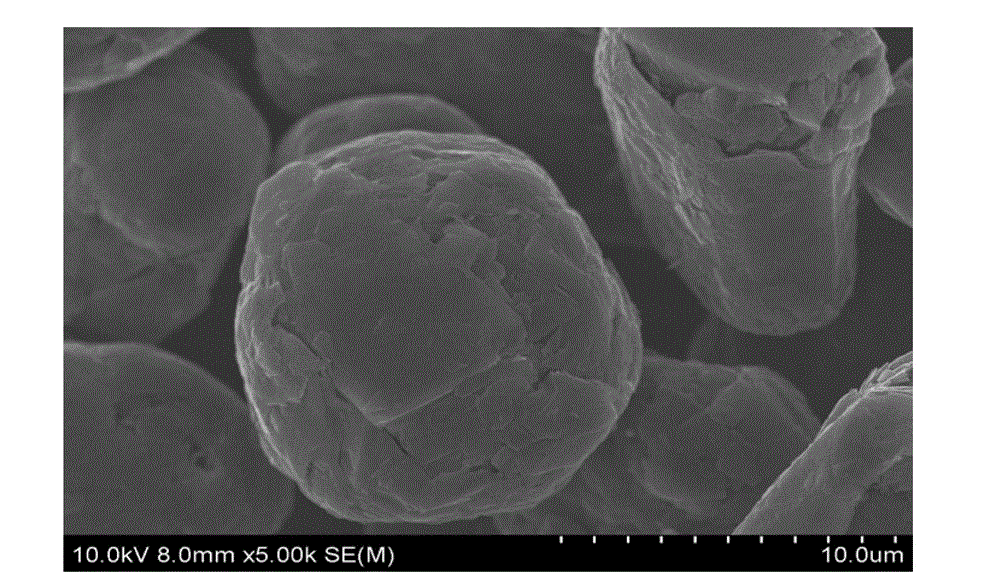

[0032] (2) Weigh 90g of graphite after ball milling in step (1) and 10g of soft carbon shell material, grind and mix for 2 hours, mix evenly, heat and stir at 200°C for 1 hour, cool and sieve.

[0033] The soft carbon shell material in the present invention is one or more of low-temperature asphalt, medium-temperature asphalt and high-temperature asphalt.

[0034] (3) Put the mixed modified natural graphite into the quartz boat, put it into the quartz tube, push the tube furnace with a program temperature controller to control the heating r...

Embodiment 2

[0042] (1) Put 500 g of large-grained natural graphite with an average diameter of 15-70 μm in a ball mill at a speed of 200 rpm, and grind for 3 hours. The ball-milled natural graphite balls are washed repeatedly, then dried, and passed through a 200-mesh sieve, wherein the ball-milled natural graphite has an average particle size of 5-35 μm.

[0043] (2) Weighing step (1) 200g of ball-milled graphite and 10g of soft carbon shell material were ground and mixed for 5 hours, then heated and stirred at 30°C for 2 hours, cooled and sieved.

[0044] (3) Put the mixed modified natural graphite into the quartz boat, put it into the quartz tube, push the tube furnace with a program temperature controller to control the heating rate of the system, and feed N 2 As a protective gas to prevent graphite from being oxidized by air, raise the temperature to 50°C at a rate of 6°C / min, keep it for 10 hours, then raise it to 1400°C at a rate of 30°C / min, hold it for 0.5h, and then heat it at 2...

Embodiment 3

[0051] (1) Put 500 g of large-grained natural graphite with an average diameter of 15-70 μm in a ball mill at a speed of 400 rpm, and grind for 0.5 h. The ball-milled natural graphite balls are washed repeatedly, then dried, and passed through a 200-mesh sieve, wherein the ball-milled natural graphite has an average particle size of 5-35 μm.

[0052] (2) Weighing step (1) 10g of ball-milled graphite and 10g of soft carbon shell material were ground and mixed for 1 hour, then heated and stirred at 400°C for 0.1 hour, cooled and sieved.

[0053] (3) Put the mixed modified natural graphite into the quartz boat, put it into the quartz tube, push the tube furnace with a program temperature controller to control the heating rate of the system, and feed N 2 As a protective gas to prevent graphite from being oxidized by air, raise the temperature to 500°C at a rate of 30°C / min, keep it for 0.15h, then raise it to 650°C at a rate of 2°C / min, hold it for 21h, and then heat it at 0.1°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com