Patents

Literature

72results about How to "The ratio is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based epoxy zinc-rich primer

ActiveCN101104771AImprove construction efficiencyGood mechanical stabilityEmulsion paintsEpoxy resin coatingsChemistryCo solvent

This invention relates to a water-based epoxy zinc-rich priming paint. The water-based epoxy zinc-rich priming paint consists of two components, which is prepared by grinding, dispersing and other processes after the main base material of water-based epoxy resin and water-based epoxy curing agent are mixed with zinc powder, filler, additives, co-solvents, water and other ingredients. Safe and convenient in application, the water-based epoxy zinc-rich priming paint has no pollution to the environment and is harmless to the workers. Suitable for high-pressure airless spraying, the water-based epoxy zinc-rich priming panit is provided with high operation efficiency and a single 10-100um thick coating layer. The priming paint has advantages of fast drying, high mechanical strength of paint film, strong adhension and good anticorrosion performance. The priming paint can be used as an anticorrosion and protection layer of steel structure in ships, bridges and containers as well as priming paint of a workshop.

Owner:V ABC PAINTS MFG JIANGXI CO LTD

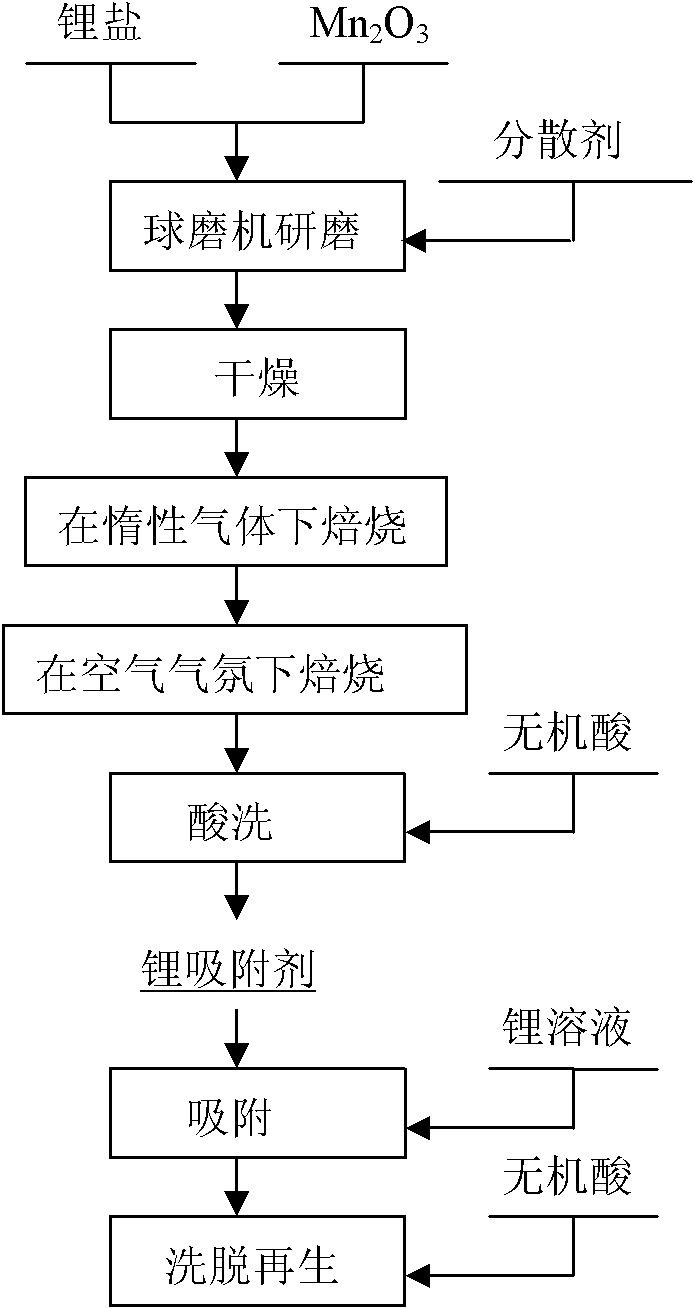

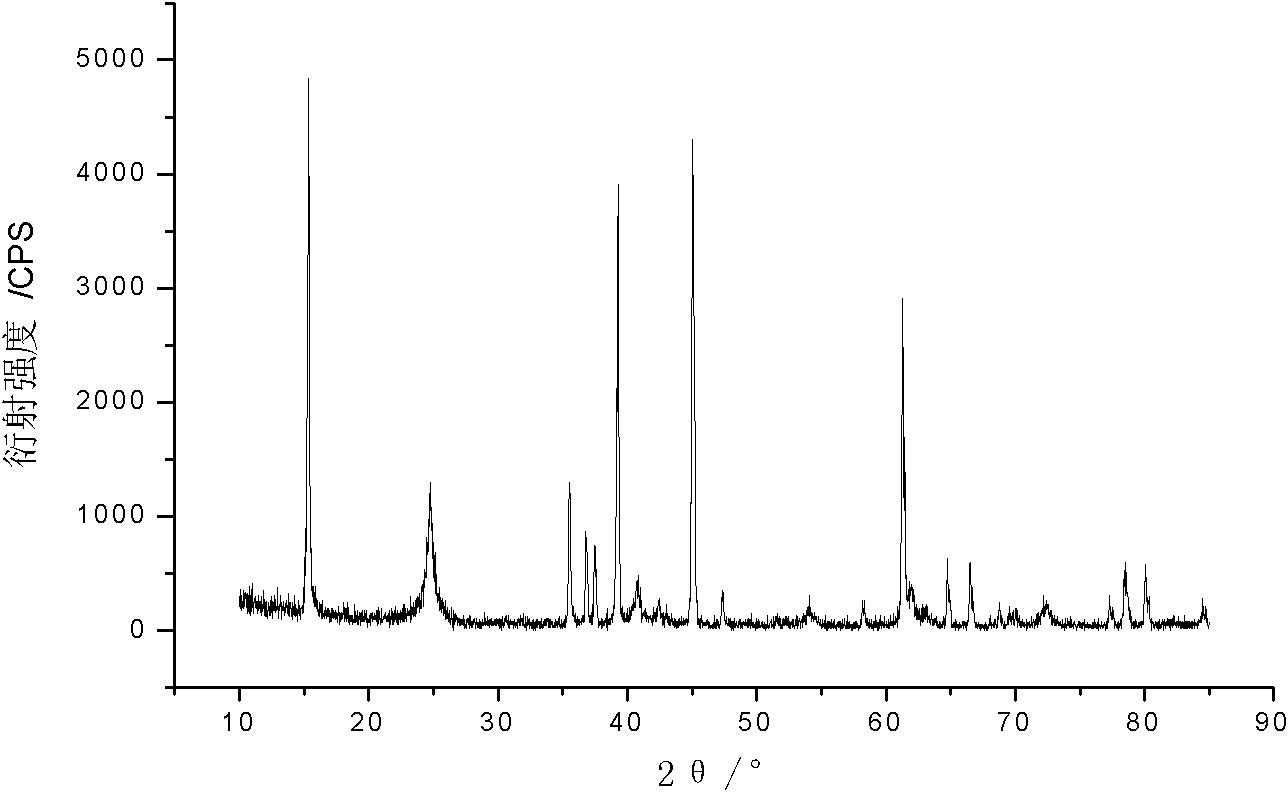

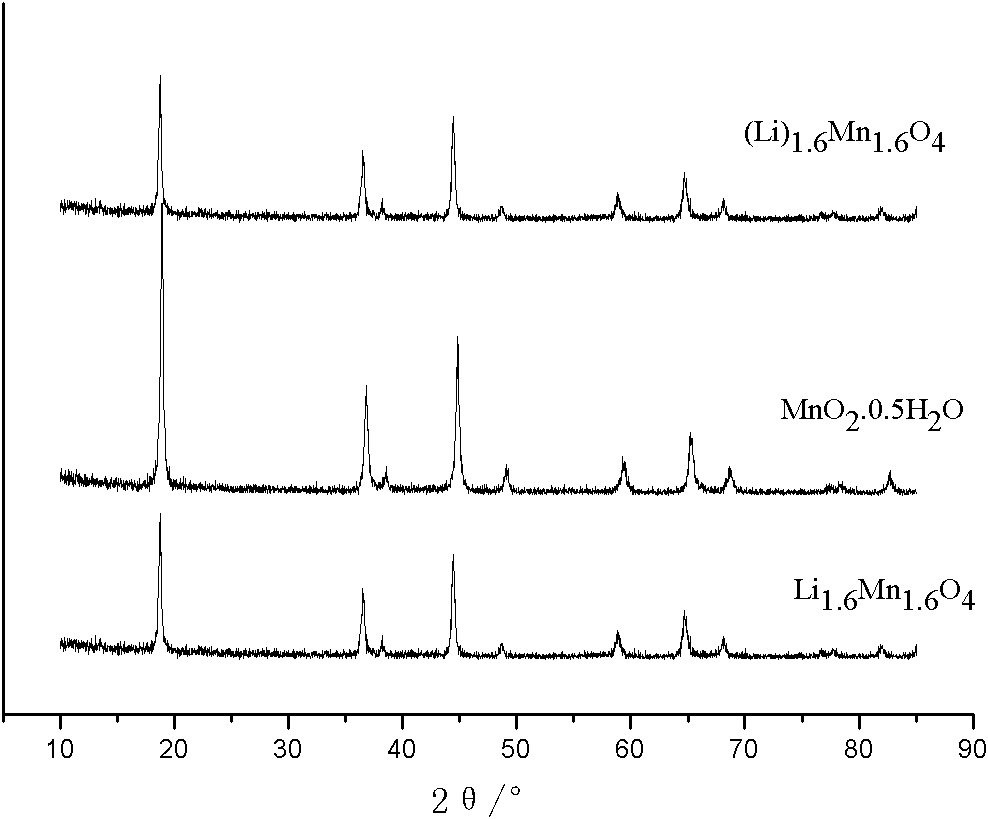

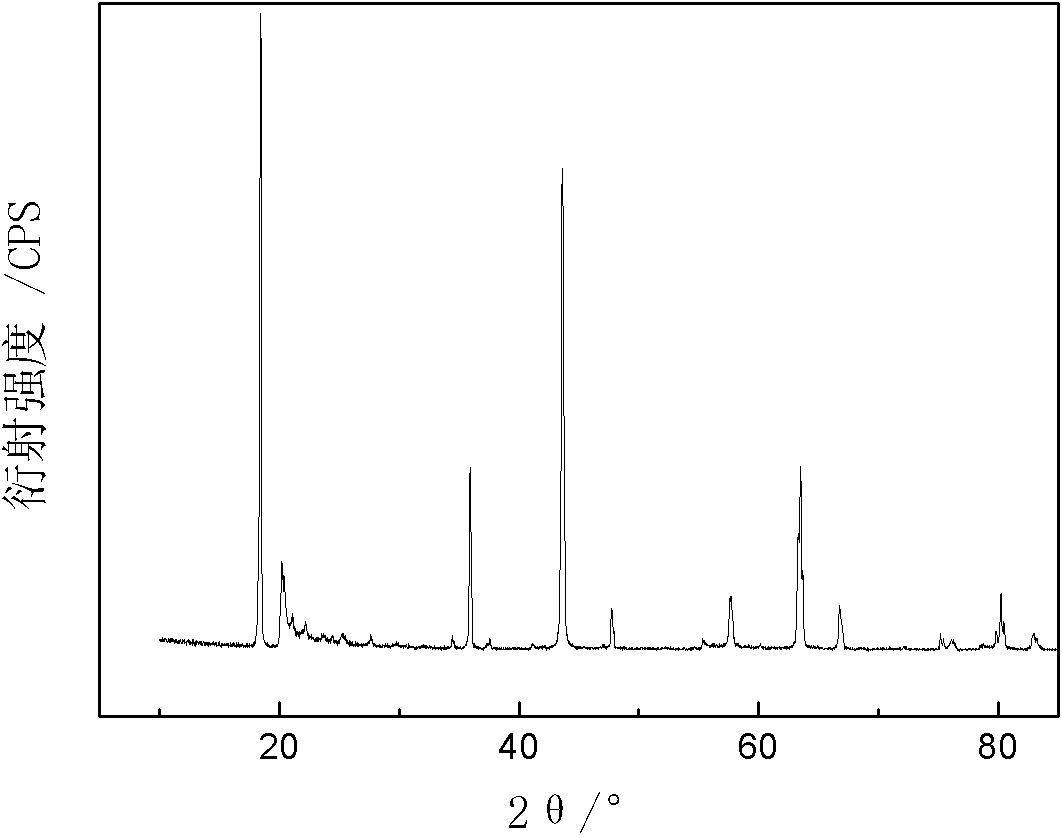

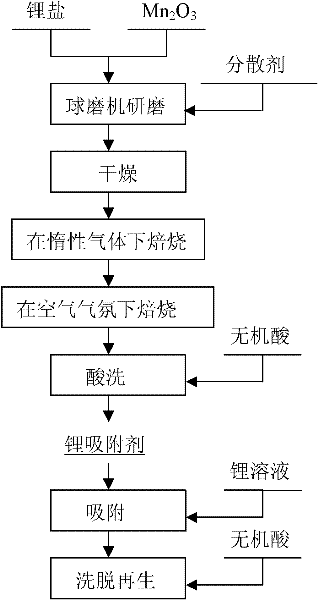

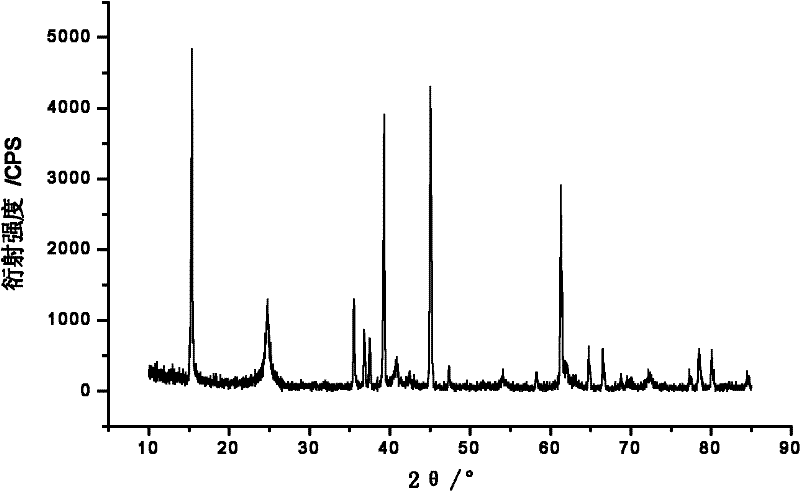

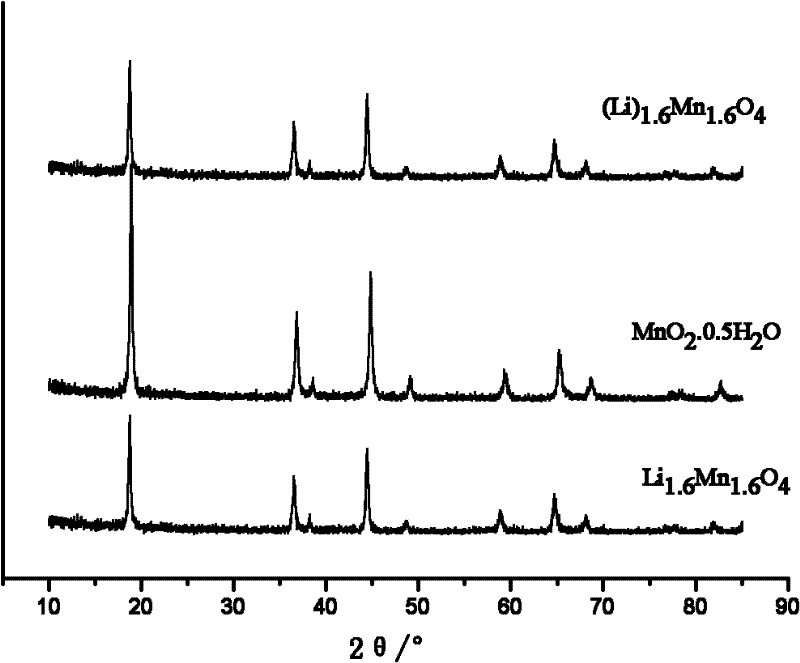

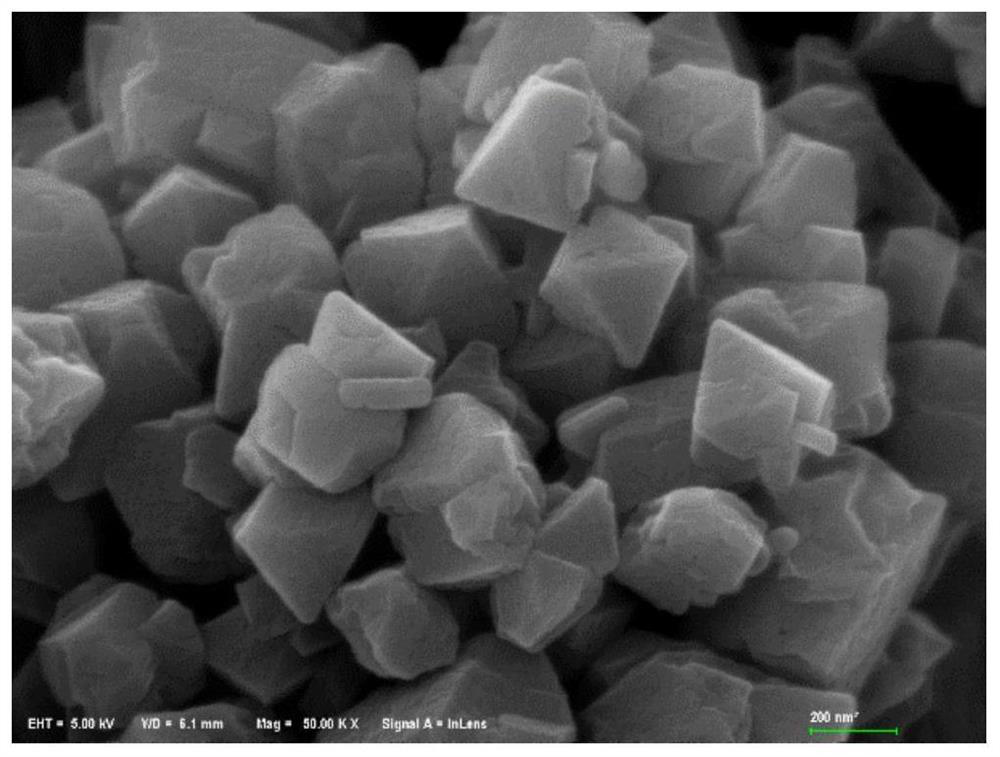

Manganese series lithium ion sieve adsorbent and preparation method of precursor thereof

ActiveCN101961634ALow priceThe ratio is easy to controlOther chemical processesManganese oxides/hydroxidesSorbentManganese

The invention discloses a method for preparing a manganese series lithium ion sieve adsorbent, and relates to a method for preparing an inorganic adsorbent for adsorbing lithium from liquid lithium resources such as brine of salt lake, seawater and the like. In the method, a cubic crystal ion sieve precursor Li1.6Mn1.6O4 is prepared from Mn2O3 and LiOH or Li2CO3 serving as raw materials by using two sections of solid-phase reactions, wherein the precursor also can be used as an anode material of a lithium ion battery. The precursor is acidized to obtain a lithium ion sieve adsorbent MnO2.0.5H2O (or expressed as H1.6Mn1.6O4), and the ion sieve is the lithium adsorbent which has high selectivity on lithium. The method has the advantages of simple and readily available raw materials, simple process, high adsorption capacity of the ion sieve, low cost, high purity of products and is easy to realize industrial production.

Owner:CENT SOUTH UNIV +1

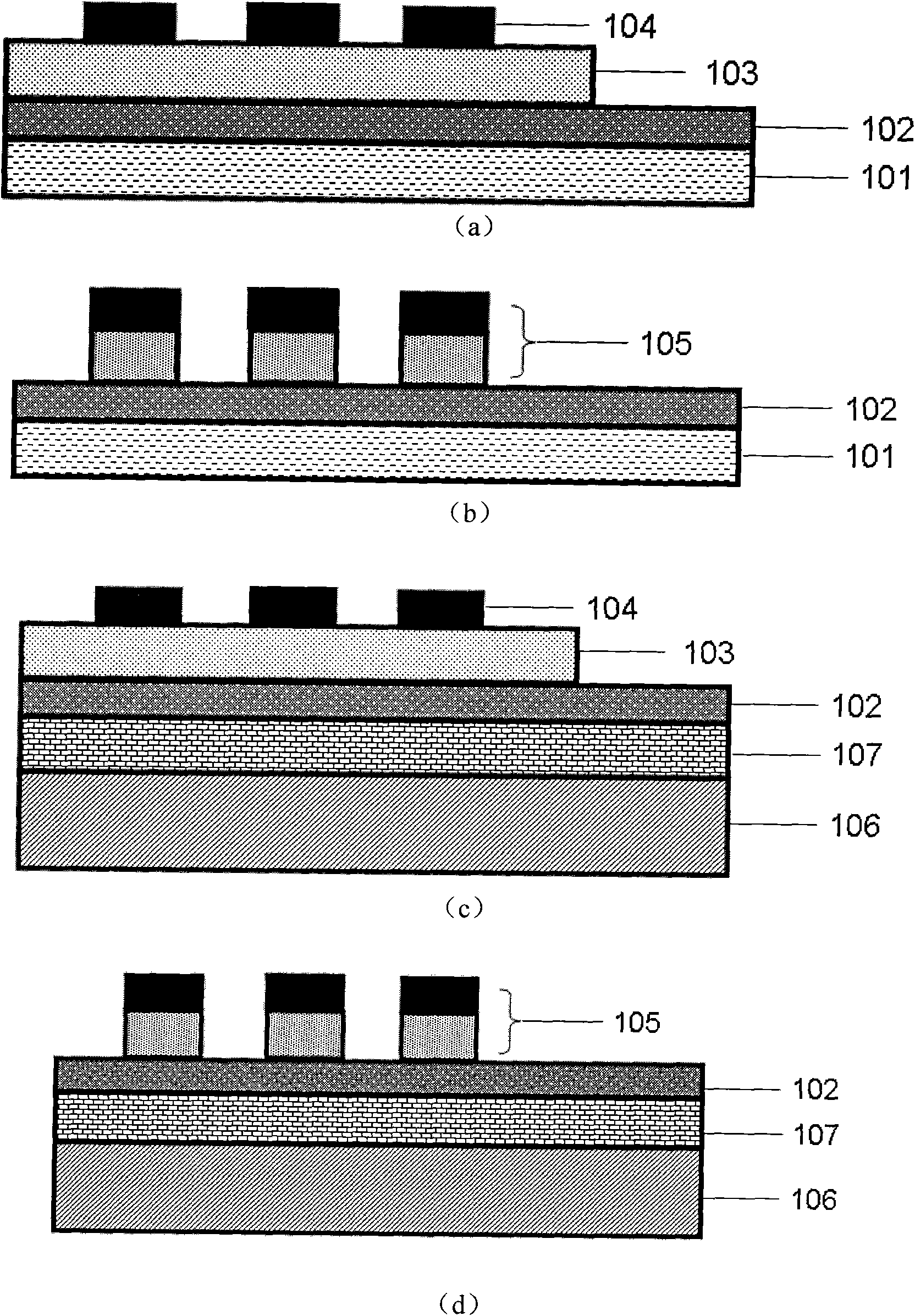

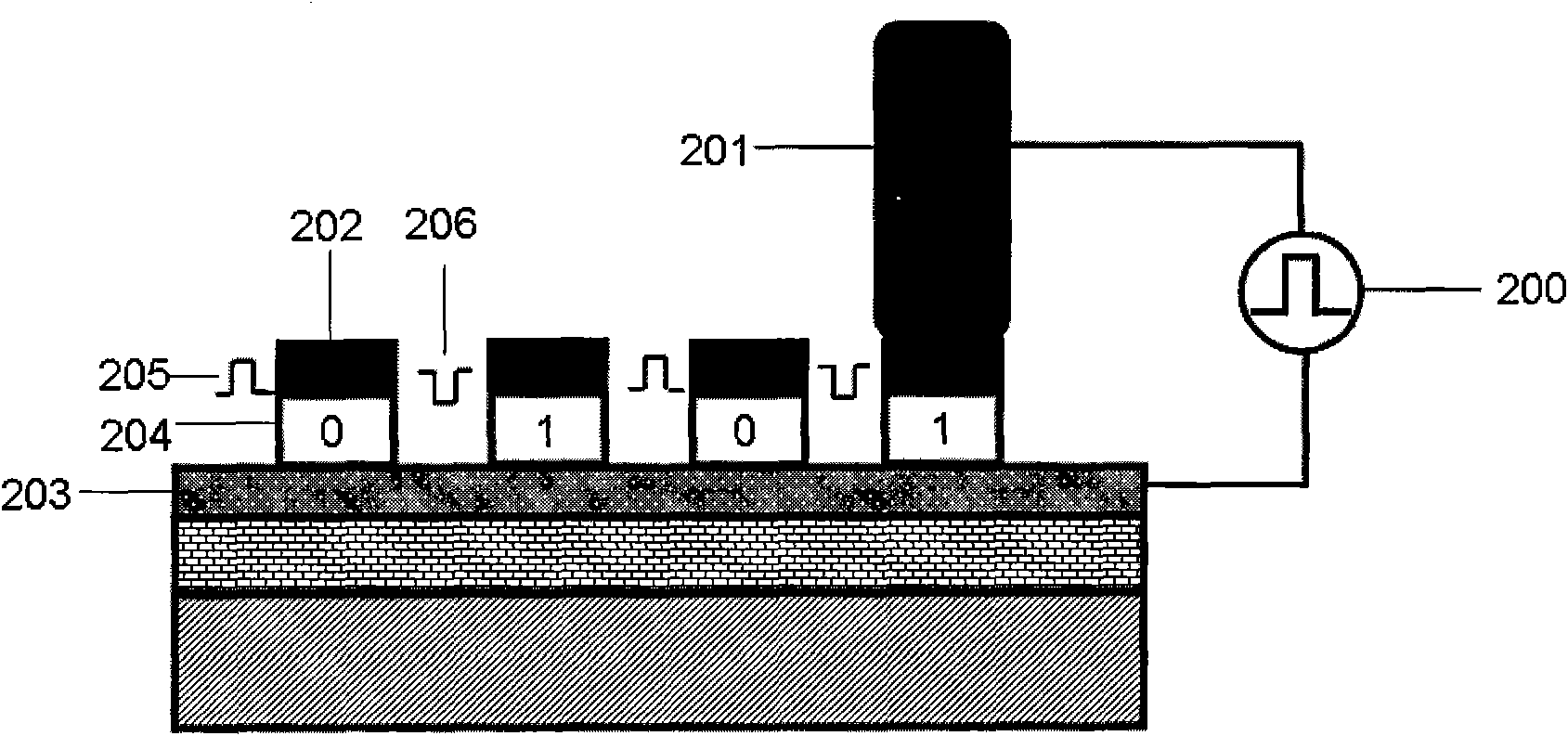

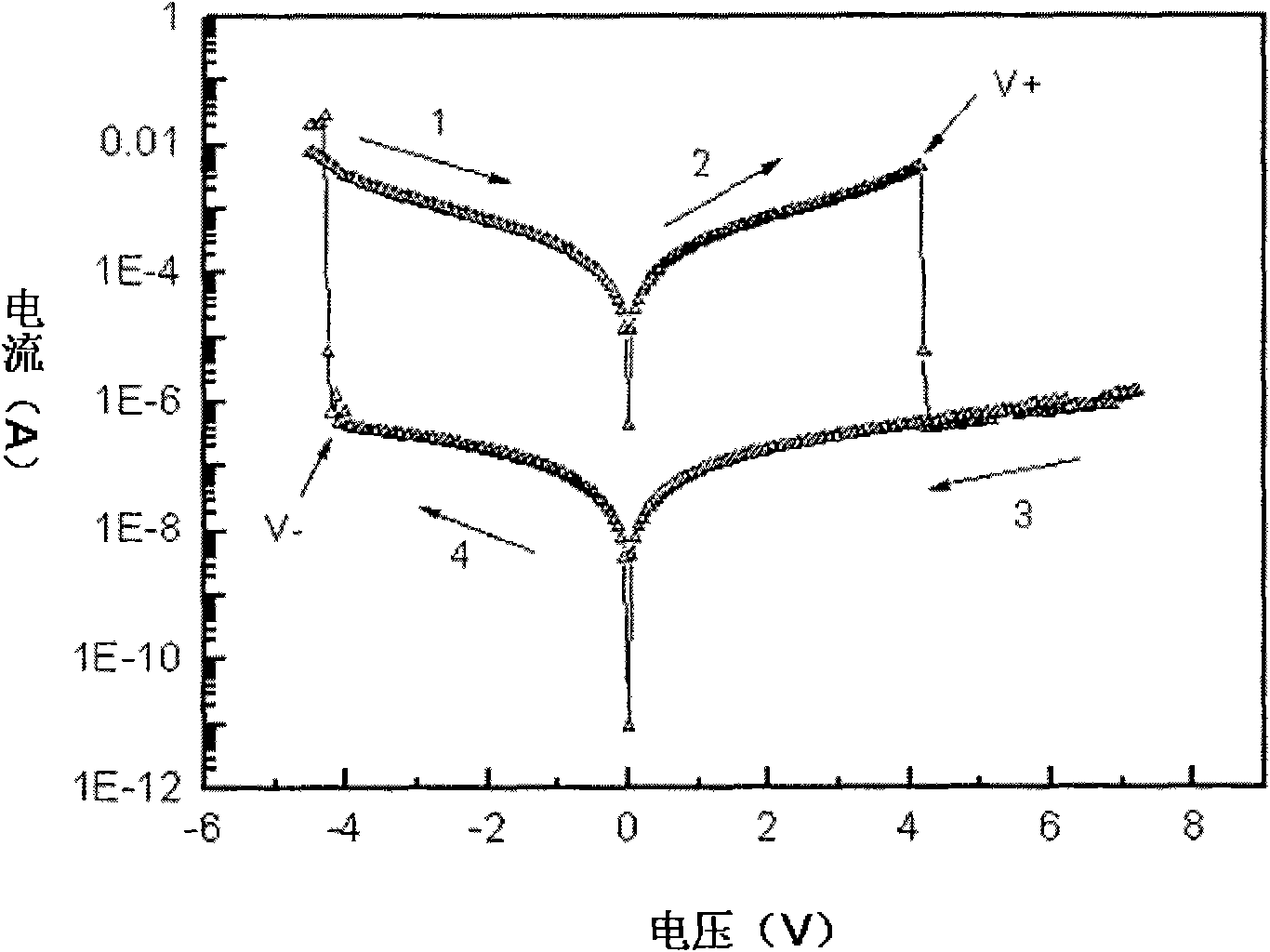

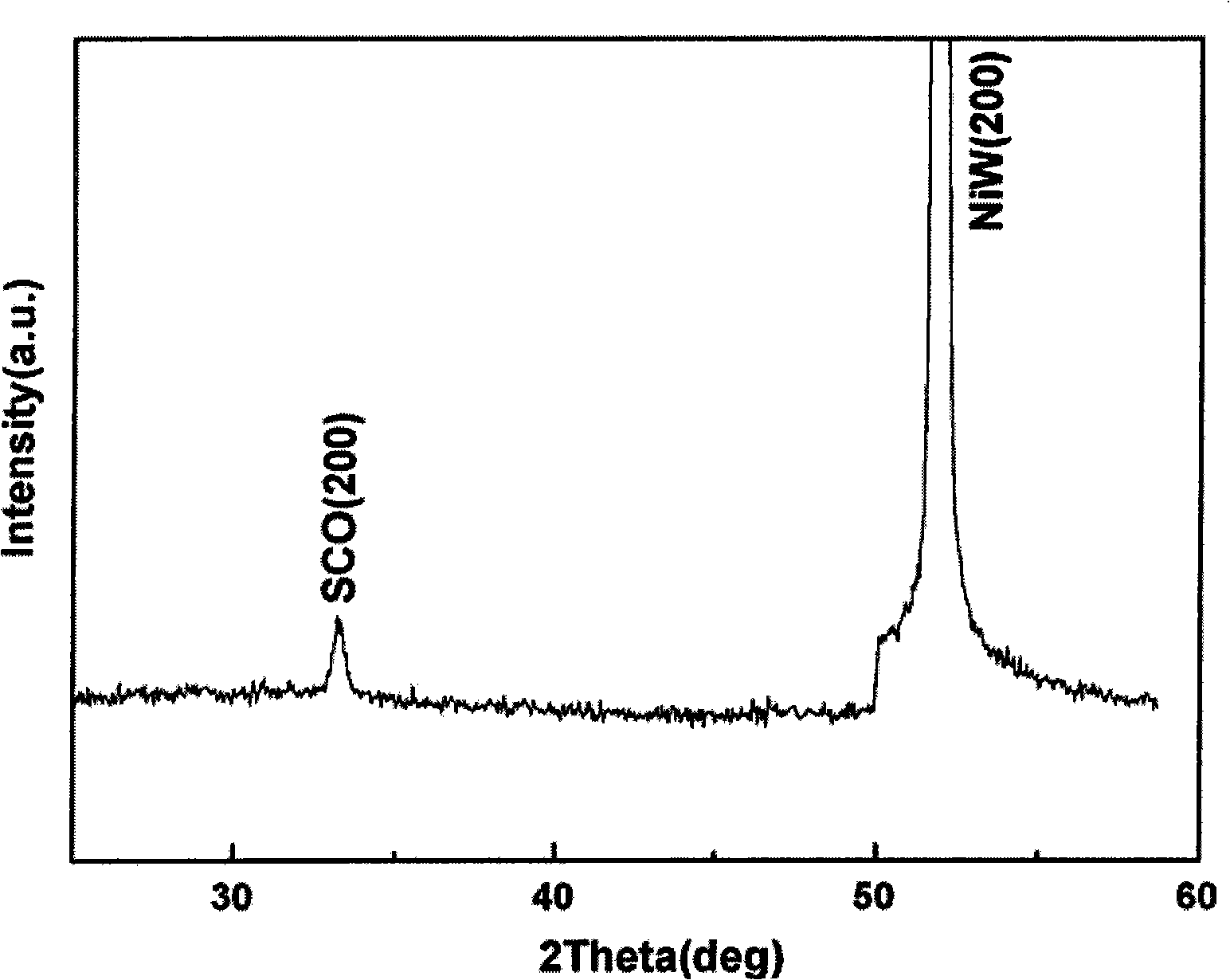

Resistive random access memory based on bismuth iron thin film system and manufacturing method thereof

ActiveCN101587936AHigh and low resistance state resistance value is stableWith magnetoelectric coupling effectElectrical apparatusDigital storageSputteringStatic random-access memory

The invention relates to a resistive random access memory based on bismuth iron thin film system and manufacturing method thereof. The memory comprises an insulating substrate (101) layer as the first layer, a lower electrode (102) as the second layer, a bismuth iron thin film (103) as the third layer, an upper electrode (104) as the fourth layer; the manufacturing method utilizes the method thermal evaporation or magnetron sputtering to grow the lower electrode on the insulating substrate layer, utilizes the method of magnetron sputtering, pulsed laser deposition or colloidal sol-gel to grow the bismuth iron thin film on the lower electrode, finally utilizes the method of thermal evaporation or magnetron sputtering to grow the upper electrode on the bismuth iron thin film, and utilizes the method of ultraviolet lithography, electron beam or ion beam etching to obtain the electrode pattern. The memory provided by the invention has excellent electroluminescent resistance effect and good stability, and has simple manufacturing method, low cost and is easy for manufacturing in large scale and commercial process.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

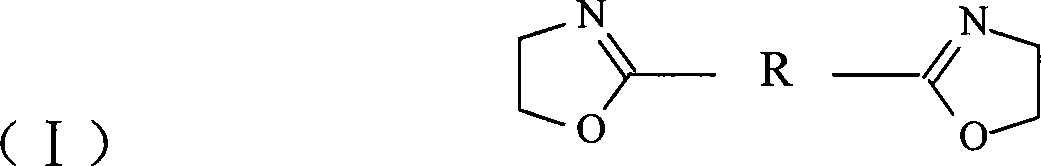

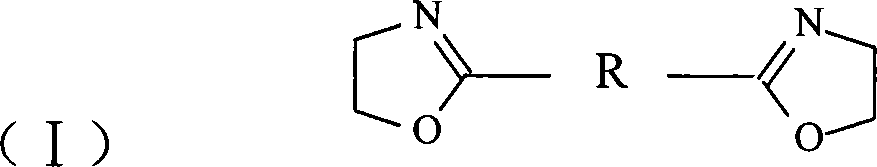

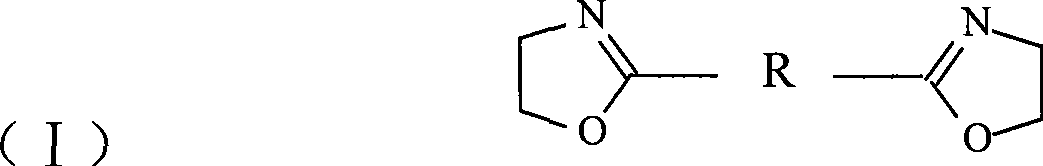

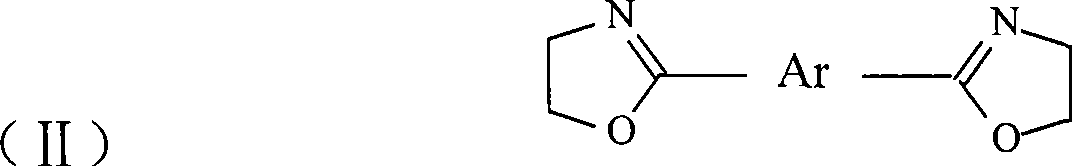

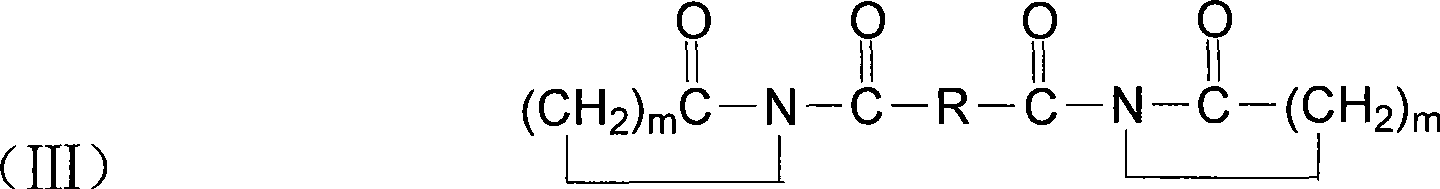

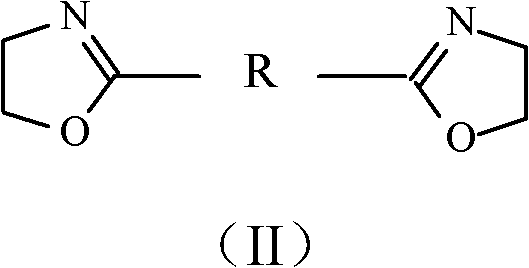

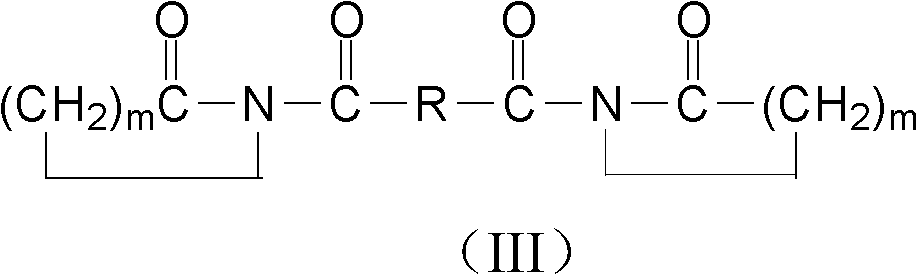

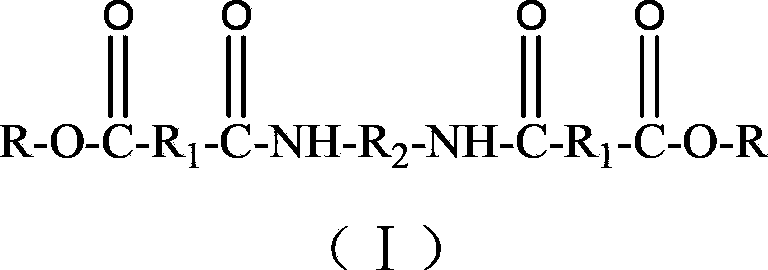

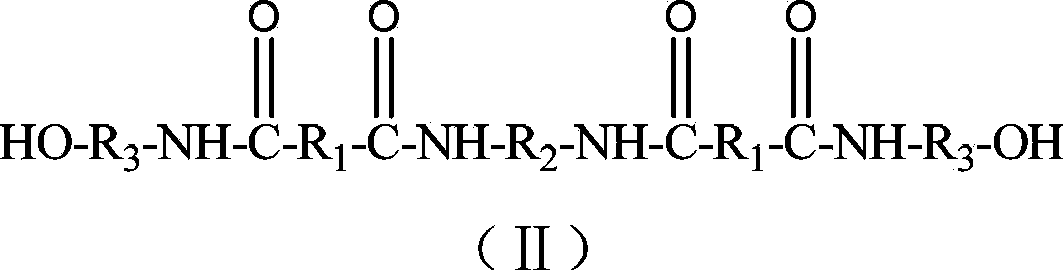

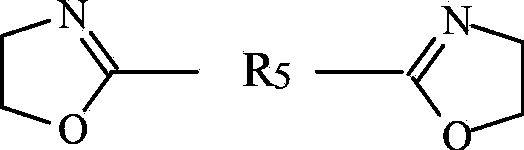

Prepn process of biodegradable polyamidoester

The present invention is preparation process of biodegradable polyamidoester. Dibasic alcohol and dibasic acid are first melt polycondensated to prepare low molecular weight polyester pre-polymer with number average molecular weight of 2000-9700 or inherent viscosity below 0.5; and the low molecular weight polyester pre-polymer is then melt and chain expanded with binary fatty oxazoline or binary aromatic oxazoline in the presence of chain expander to prepare biodegradable polyamidoester with number average molecular weight up to 39 KD and inherent viscosity up to 1.25 dL / g.

Owner:BEIJING UNIV OF CHEM TECH

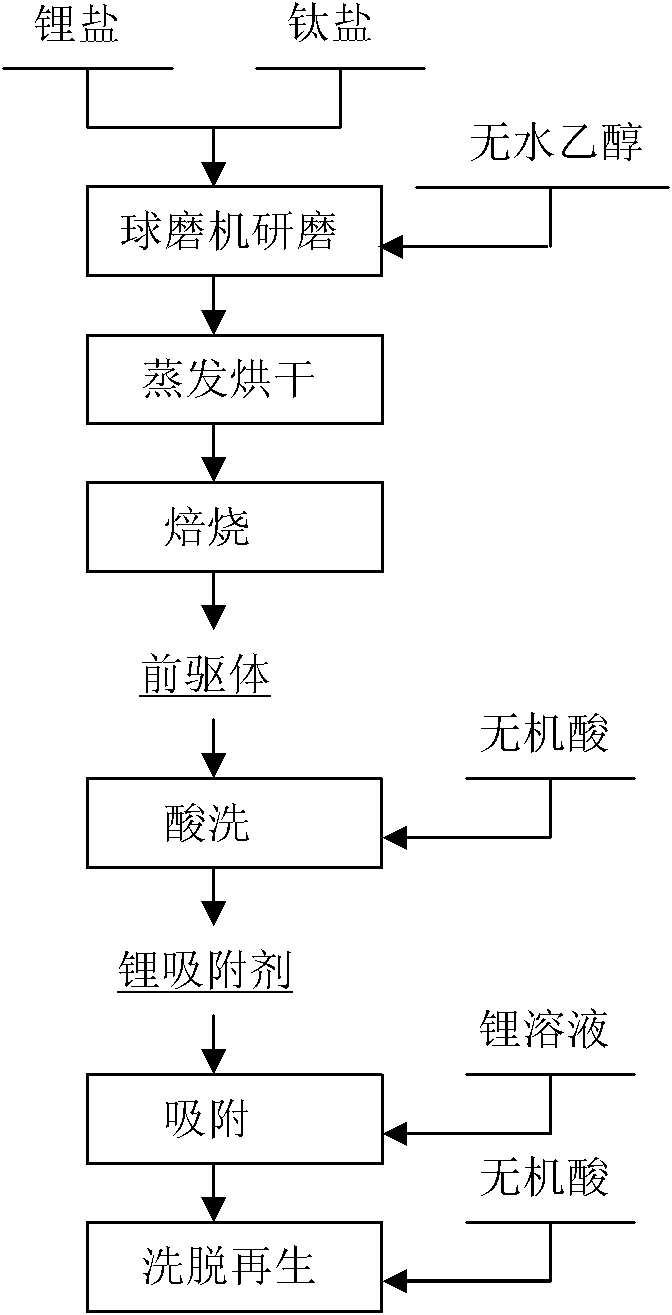

Lithium-titanium oxide type lithium ion sieve absorbent and method for preparing precursor thereof

InactiveCN101944600AWell mixedIncrease contact surfaceCell electrodesTitanium compoundsSalt lake brineTitanium oxide

The invention discloses a lithium-titanium oxide type lithium ion sieve absorbent and a method for preparing a precursor thereof, and relates to a method for preparing an inorganic absorbent for absorbing enriched lithium from salt lake brine, seawater and other liquid lithium resources. The method is characterized in that: titanium dioxide and lithium salt are taken as raw materials, ground by a ball grinder and dried so as to prepare a precursor Li2TiO3 of an ion sieve through a high-temperature solid-phase roasting method; and the lithium is eluted from the precursor Li2TiO3 by inorganic acid to prepare an ion sieve H2TiO3. The method has the advantage of simple technology, and the obtained ion sieve has the advantages of low solution loss and high adsorption capacity.

Owner:CENT SOUTH UNIV

Waterborne epoxy zinc-rich primer

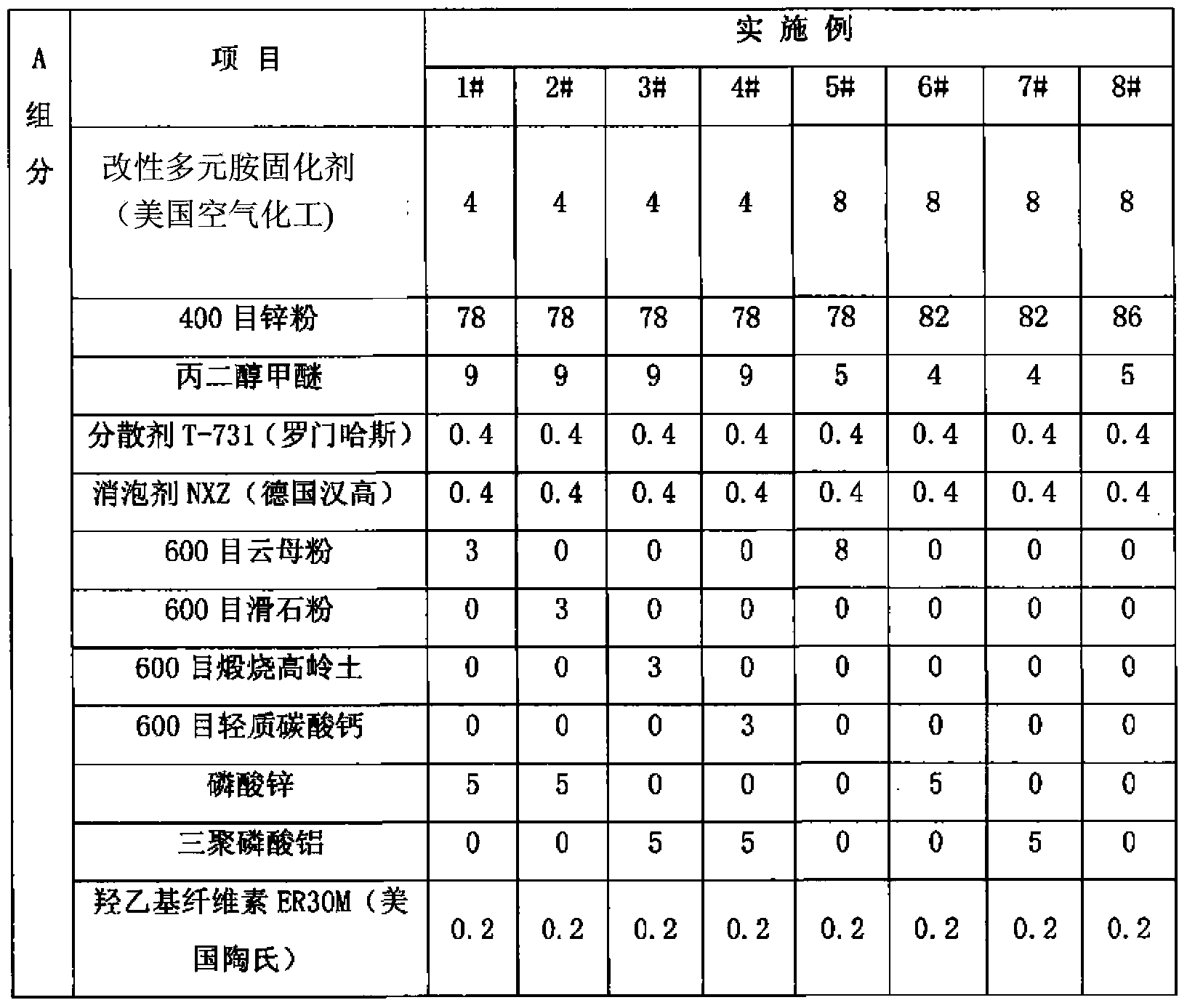

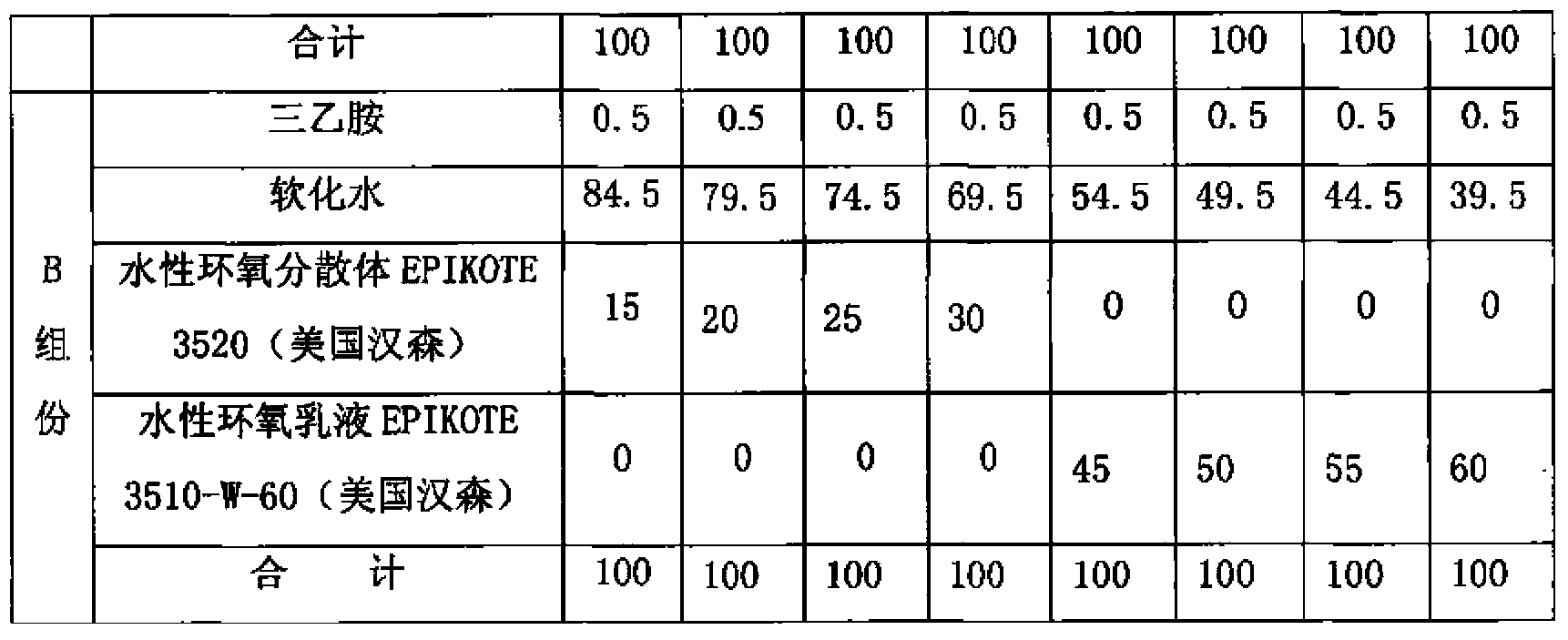

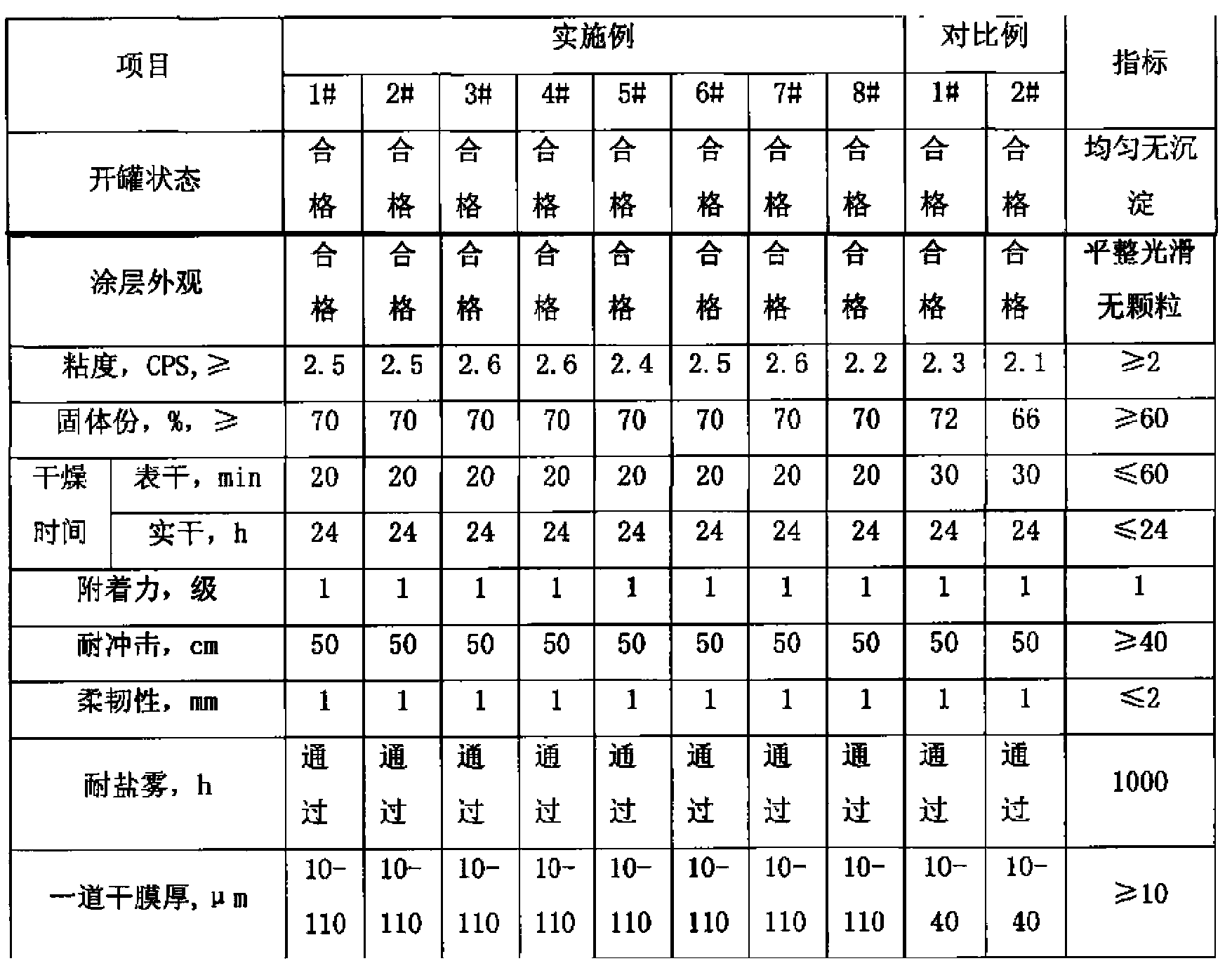

InactiveCN103409040AImprove rigidityHigh strengthAnti-corrosive paintsEpoxy resin coatingsEpoxySoftened water

The invention provides a waterborne epoxy zinc-rich primer. The waterborne epoxy zinc-rich primer is characterized by comprising component A and component B, wherein the component A comprises 3 to 10 wt% of a modified polyamine curing agent, 75 to 90 wt% of zinc dust, 2 to 10 wt% of a cosolvent, 0.1 to 2 wt% of an anti-settling thixotropic agent, 0.2 to 2 wt% of a dispersant and 0.2 to 20 wt% of an antifoaming agent, the zinc dust is nano-scale zinc dust, the component B comprises 14 to 60 wt% of a waterborne epoxy resin, 38 to 85 wt% of softened water and 0.2 to 2.0 wt% of a neutralizer, and a mass ratio of the component A to the component B is 100: 45.

Owner:张家港保税区金企鹅贸易有限公司

Method for preparing high molecular weight biodegradable polyester by combined chain extension

The invention relates to a method for preparing biodegradable polyester. Firstly, melt polycondensation is conducted through diol and dicarboxylic acid and a low molecular weight polyester prepolymer with number average molecular weight between 2, 000 and 20, 000 or intrinsic viscosity below 0.64dL / g is prepared; binary oxadiazoline and diacyl bis-caprolactamate are combined to extend chain, and chain extension is carried out at a certain temperature; and the biodegradable polyester is obtained. The number average molecular weight of polybutylene adipate (PBA) can reach up to 39, 000 and the intrinsic viscosity to 1.13dL / g. For poly (butylene succinate) (PBS) with relatively high melting point, the intrinsic viscosity after chain extension is up to 0.99dL / g.

Owner:BEIJING UNIV OF CHEM TECH

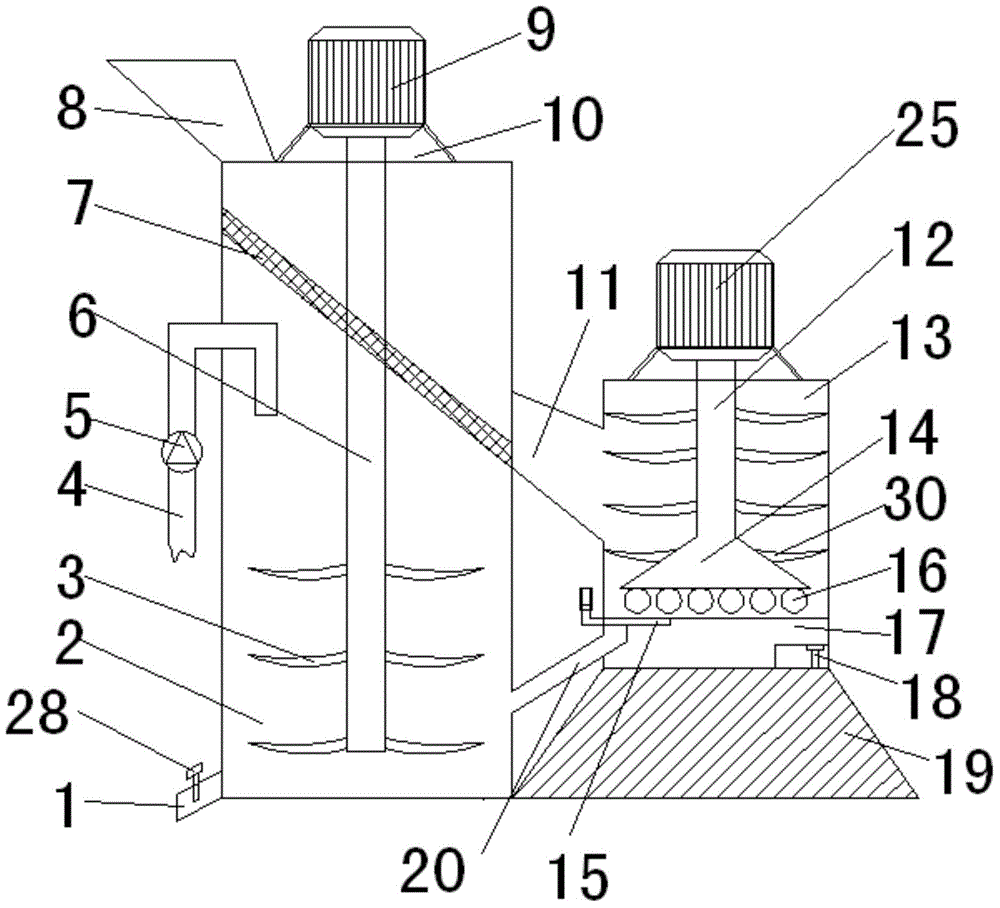

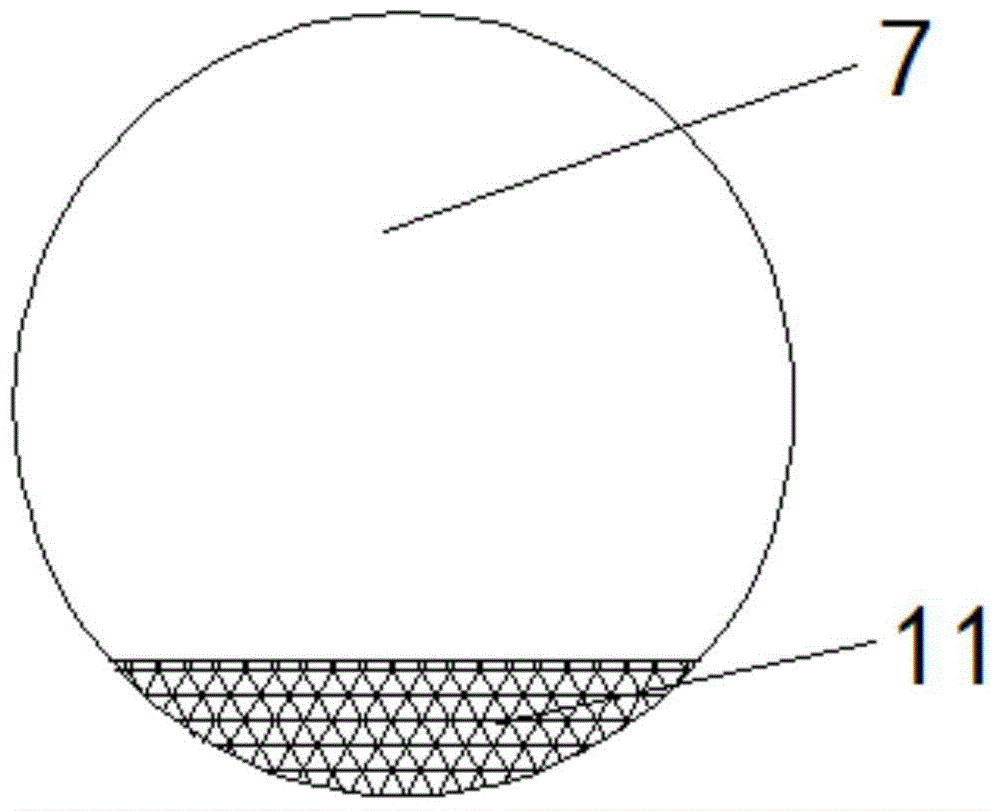

Medical and chemical crushing and stirring machine applicable to processing of paste

InactiveCN104785140AImprove the effectStir thoroughlyRotary stirring mixersGrain treatmentsEngineeringLarge particle

The invention discloses a medical and chemical crushing and stirring machine applicable to processing of paste. The crushing and stirring machine comprises a liquid outlet, a stirring box, stirring blades, a liquid inlet pipe, a gauge, a first center shaft, a filter net, a feeding port, a stirring motor, a residue discharging pipe, a second center shaft, a crushing box, a base plate, grinding balls, a lifting device and a base, wherein the stirring box and the crushing box are connected through the residue discharging pipe in the middle, the first center shaft connected with the stirring motor in a support at the top of the stirring box is arranged in the stirring box, the stirring blades are arranged at the bottom of the first center shaft, the feeding port, the liquid inlet pipe and the liquid outlet are also arranged on the stirring box, the second center shaft connected with a crushing motor in a support at the top of the crushing box is arranged in the crushing box, and the bottom of the second center shaft is connected with the base plate. The crushing and stirring machine is reasonable in design, convenient to use, capable of filtering, grinding and crushing larger particles of medicines and chemical raw materials and particularly applicable to production of pasty medicines and chemical raw materials.

Owner:CHENGDU GUANYU TECH

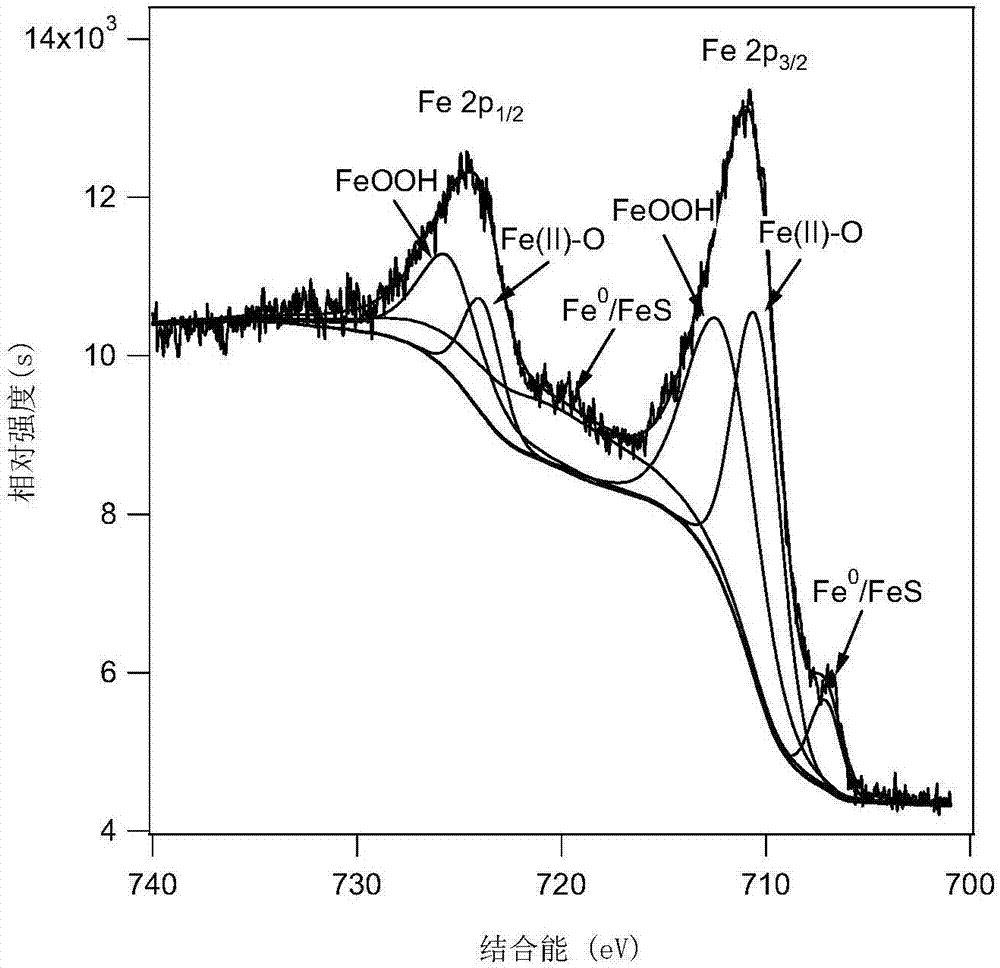

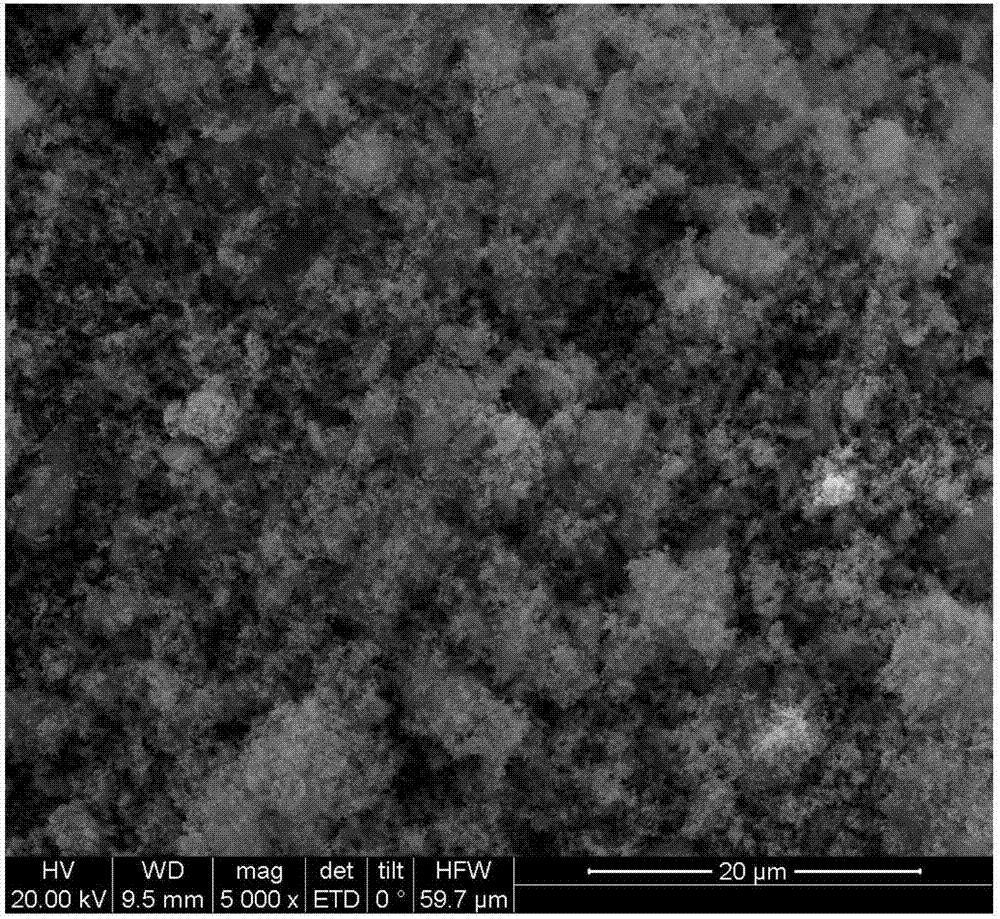

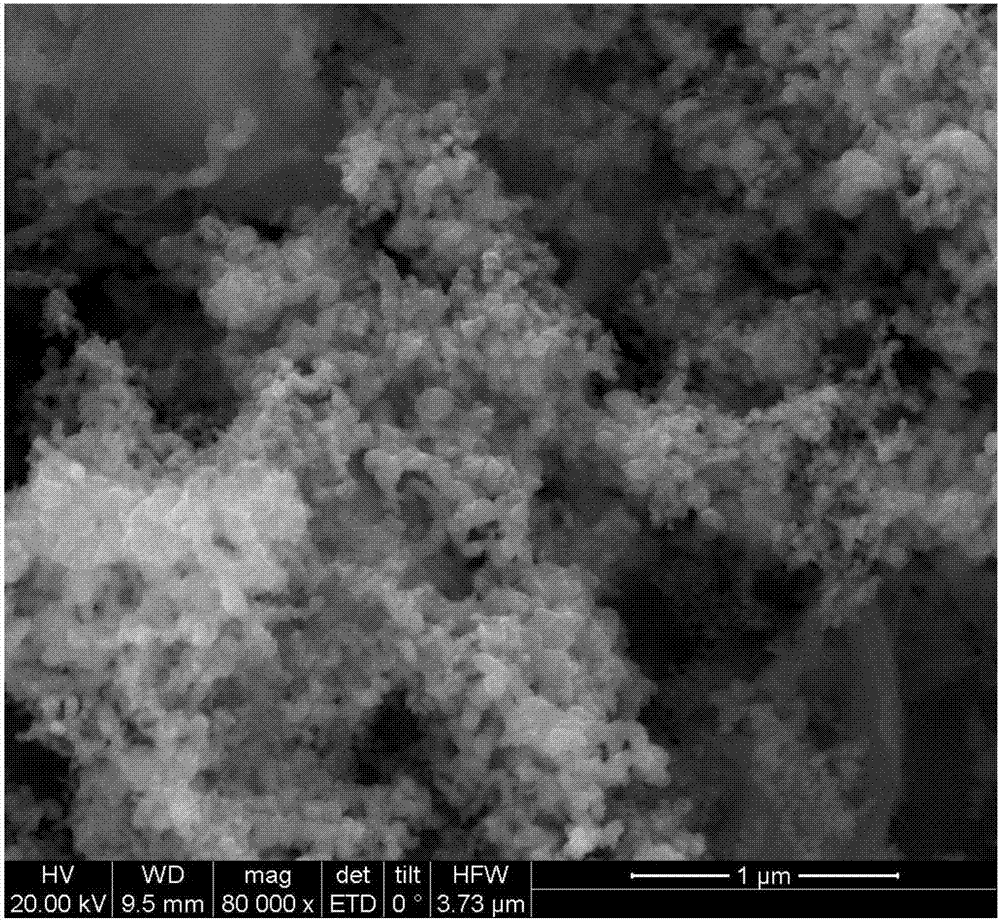

Bentonite-loaded sulfurized nanoscale zero-valent iron composite material and preparation method and application thereof

InactiveCN107081125AHigh reactivityFacilitates electron transferOther chemical processesWater contaminantsSodium BentoniteMass ratio

The invention relates to a bentonite-loaded sulfurized nanoscale zero-valent iron composite material and a preparation method and application thereof. According to the composite material, sulfurized modified nanoscale zero-valent iron is loaded on bentonite; the mass ratio of bentonite to total iron is (0.85-1.2):1, and the molar ratio of a sulfur element to total iron is (0.05-0.065):1. The bentonite-loaded sulfurized nanoscale zero-valent iron composite material is more stable and efficient, and is suitable for treatment of multiple pollutants; electron transfer on the surface of the nanoscale zero-valent iron can be accelerated through sulfurized modification and corrosion is promoted, thereby greatly improving the reaction activity of the material; furthermore, the sulfuration process is simple and is free of pollution; and the material is not easy to reunite when loaded on bentonite and the activity can be kept for a long period of time. The removal rate of the material on 4-nitrophenol within 2min reaches over 97.5%, and the removal rate on orange I is close to 100%.

Owner:山东大学深圳研究院 +1

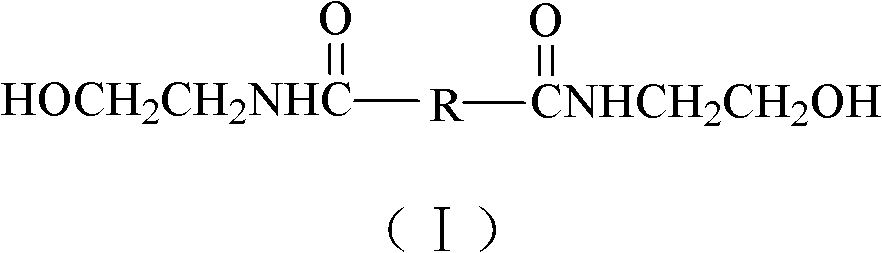

Preparation method for biodegradable aliphatic alternating polyester amide

The invention discloses a preparation method for biodegradable aliphatic alternating polyester amide. According to the preparation method, aliphatic dicarboxylic acid and diamide diol are subjected to melt phase polycondensation to prepare alternating polyester amide prepolymer with terminal carboxyl group and terminal hydroxy group; and diacyl di-lactam and a bisoxazoline chain extender are subjected to joint chain extension to prepare the biodegradable aliphatic alternating polyester amide with the intrinsic viscosity of 0.30-0.59dL / g. The preparation method disclosed by the invention has the characteristics of simple and convenient method, mild conditions, high efficiency and the like and can be used for preparing the biodegradable aliphatic alternating polyester amide with regular structure and favorable crystallinity.

Owner:BEIJING UNIV OF CHEM TECH

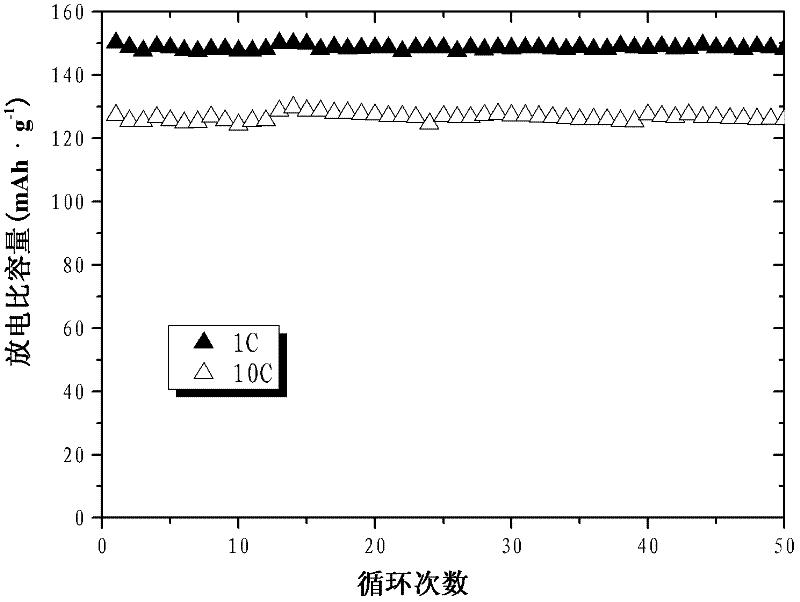

Synthesis method for lithium iron phosphate/carbon composite material

ActiveCN102332565AHigh crystallinityImprove electrochemical performanceCell electrodesCarbon compositesSucrose

The invention discloses a synthesis method for a lithium iron phosphate / carbon composite material. The synthesis method is characterized by comprising the following steps of: (1) uniformly mixing lithium phosphate, iron powder, iron phosphate, another lithium source and a carbonous conductive agent precursor, wherein the another lithium source is one or the combination of any of the following components: lithium carbonate, lithium oxalate, lithium acetate, lithium hydroxide and lithium nitrate, and the carbonous conductive agent precursor is one or the combination of any of the following components: glucose, sucrose, citric acid, starch, polyvinyl alcohol, stearic acid and lauric acid; (2) putting the raw material mixture obtained in the step (1) into a ball-milling container and performing full ball milling; and (3) putting the mixture subjected to the ball milling into nitrogen gas and baking the mixture at 600-800 DEG C to prepare the lithium iron phosphate / carbon composite material. The synthesis method is simple in process, and the synthesized lithium iron phosphate / carbon composite material is high in specific capacity and excellent in high-current and cycle performance.

Owner:ZHEJIANG UNIV OF TECH

Preparation method for anode material of red phosphorous cladding carbon nano tube composite ion battery

InactiveCN105098154AThe ratio is easy to controlSimple preparation processCell electrodesHigh ratePhosphate

The invention belongs to the field of a nano functional material and a new energy source, and relates to a preparation method for an anode material of a red phosphorous cladding carbon nano tube composite ion battery. The preparation method comprises the following steps of: mixing pretreated red phosphorous powder and a carbon nano tube according to a certain quality proportion; preparing to a uniform serous liquid with an appropriate amount of a grinding agent and transferring the uniform serous liquid to a ball grinding tank; carrying out anaerobic wet high-energy ball grinding, and thereby obtaining the anode material of the red phosphate cladding carbon nano tube ion battery, wherein effective ball grinding time is 2 to 6 hours. The core of the invention is that the simple and high-efficiency anaerobic wet high-energy ball grinding is adopted to further prepare the anode material of the red phosphate cladding carbon nano tube ion battery; red phosphate is uniformly coated on the surface of the carbon nano tube, a particular conductive network in the composite material is built by means of the carbon nano tube, the contact area of the red phosphate and the carbon nano tube is increased, and thus, the anode material of the composite ion battery has the advantages of high specific capacity, high rate performance and stable circularity; and moreover, the process is simple, the preparation quantity is large, and industrial production is easy to achieve.

Owner:TIANJIN POLYTECHNIC UNIV

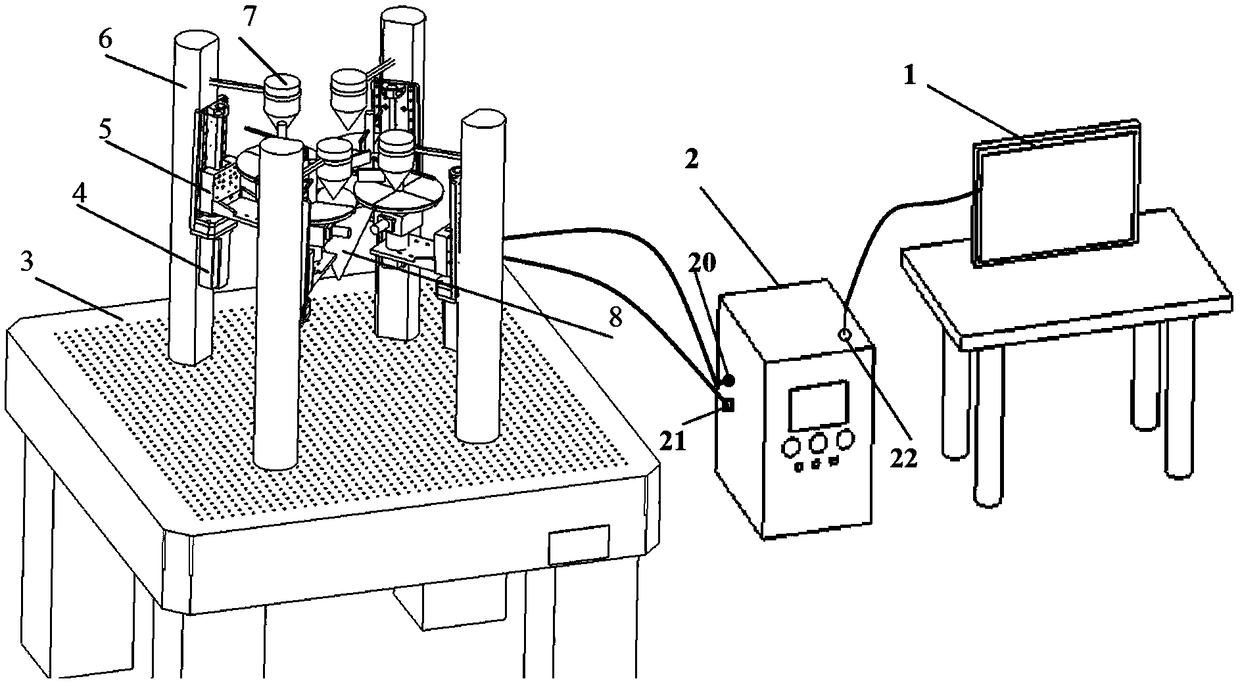

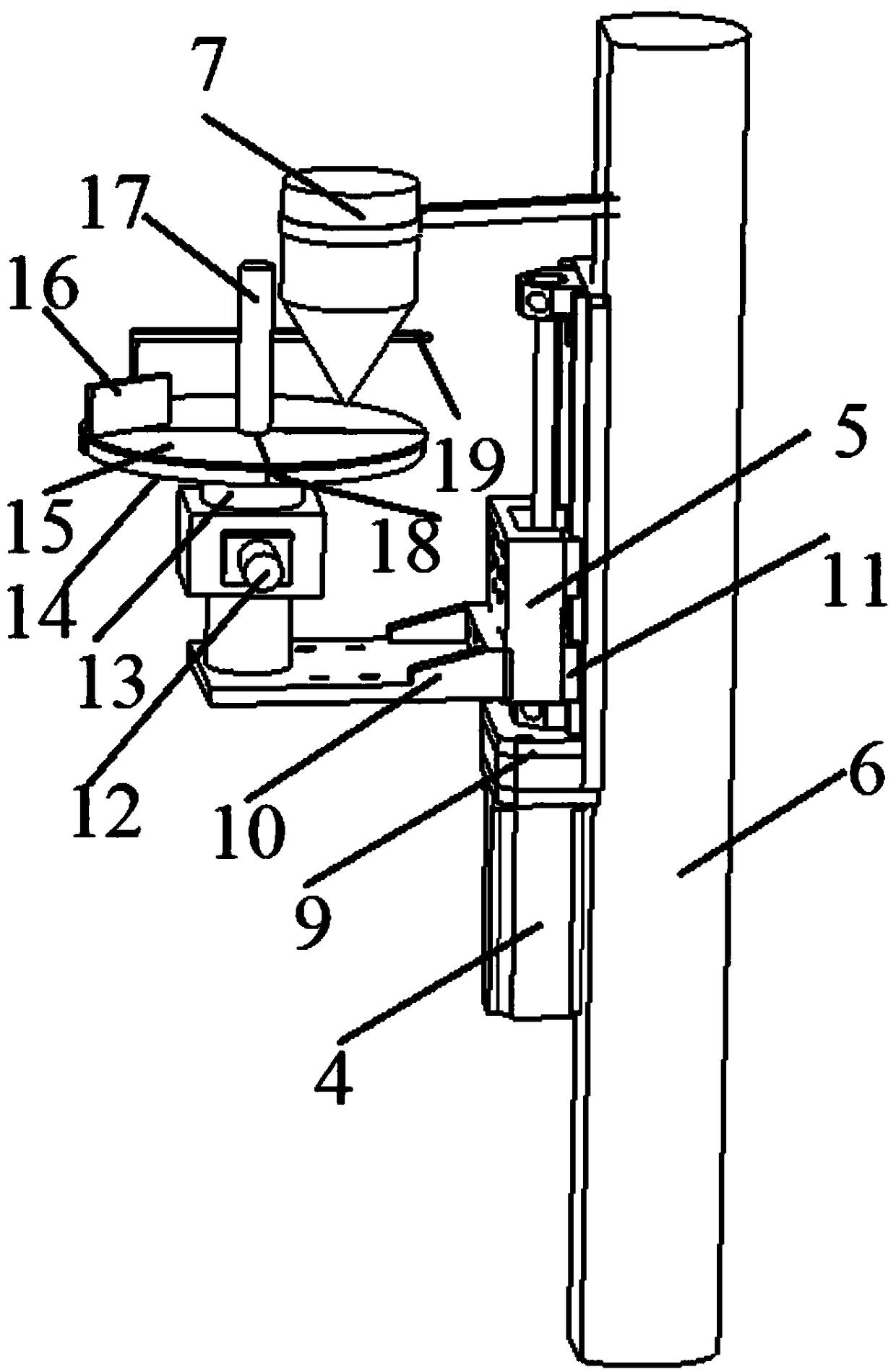

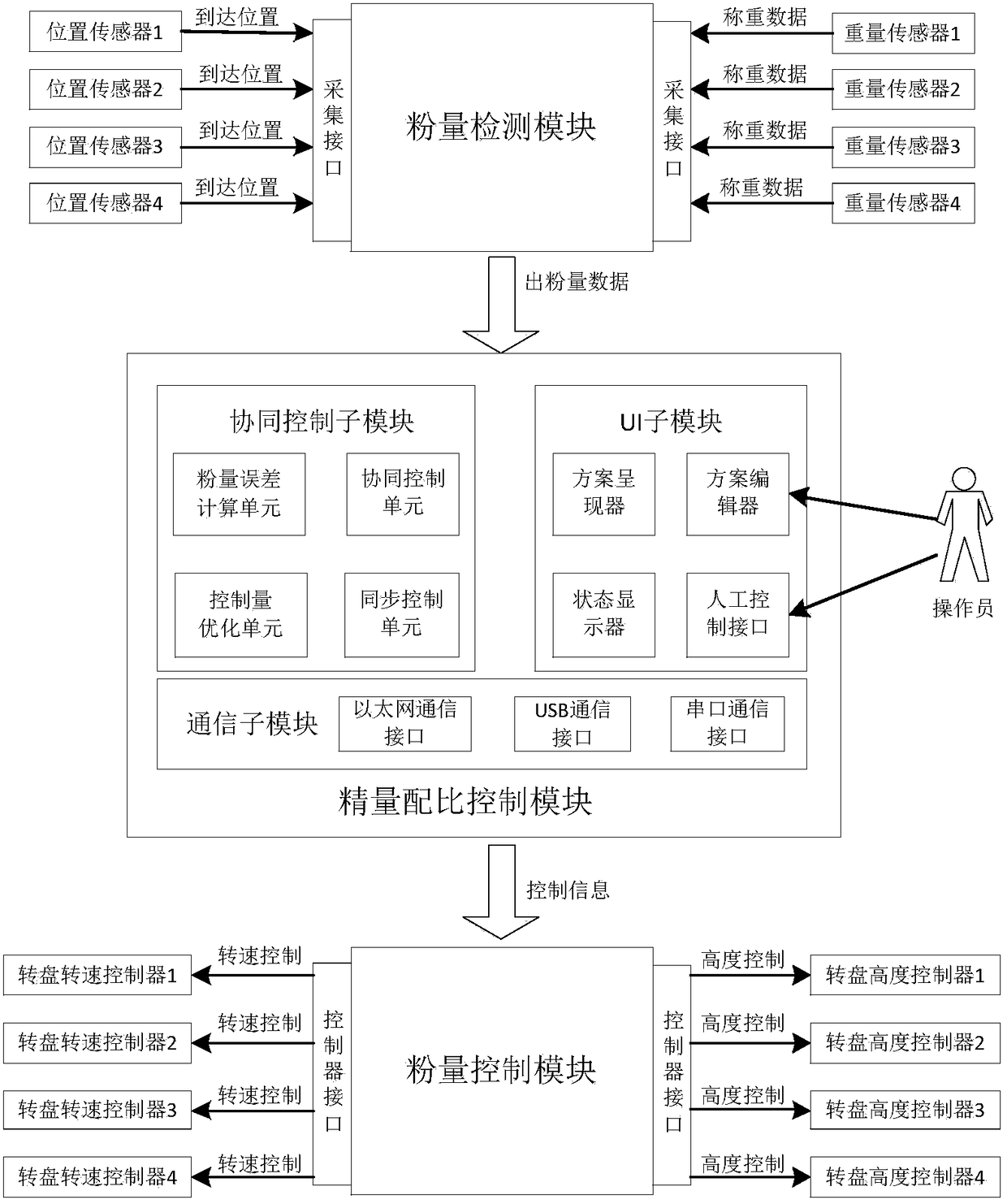

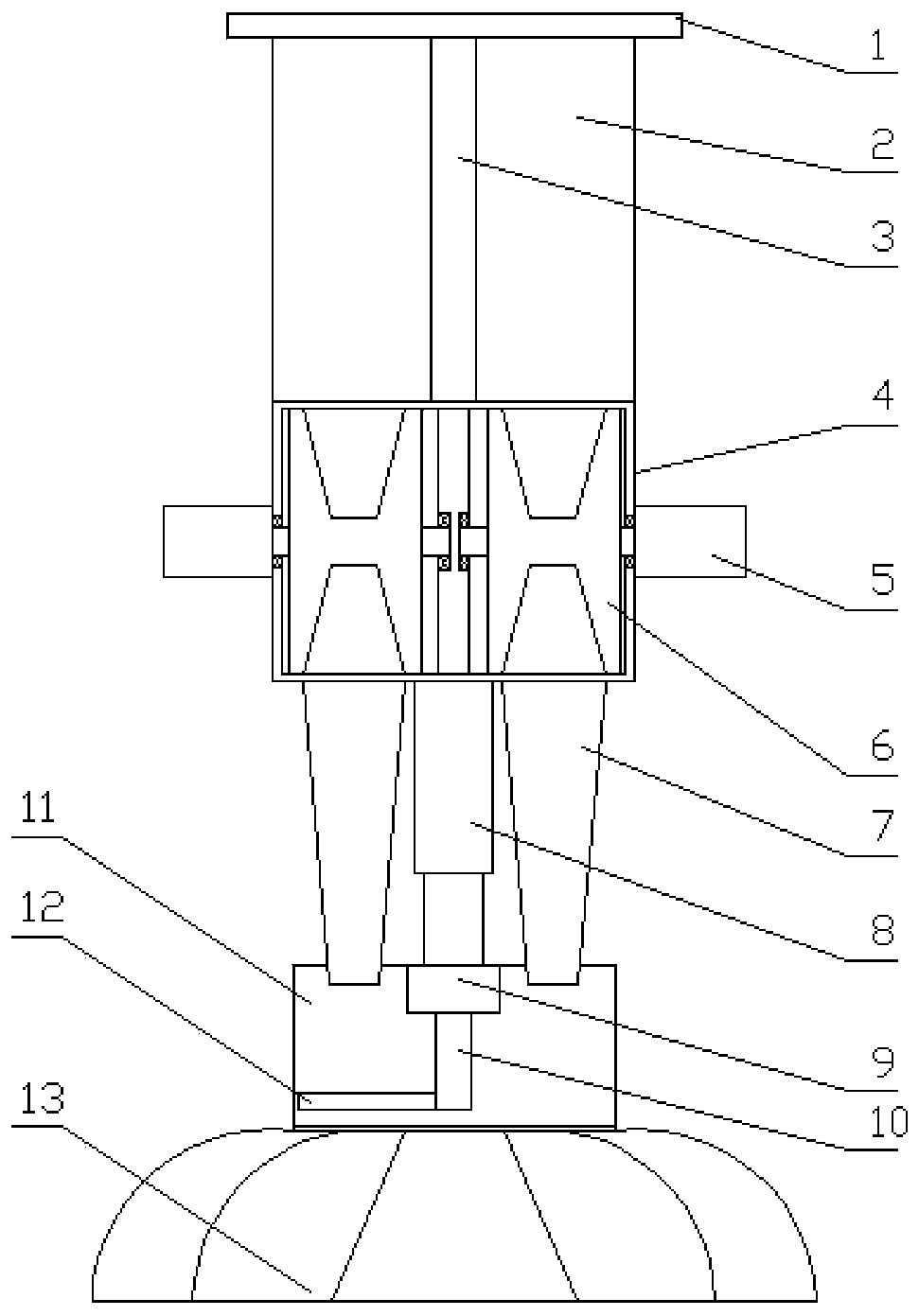

Precise proportioning powder feeding system and powder outlet amount and proportioning amount dynamic control method

ActiveCN108189406ARealize collaborative workThe ratio is easy to controlAdditive manufacturing apparatusManufacturing material handlingMulti materialLaser processing

The invention relates to a precise proportioning powder feeding system and a powder outlet amount and proportioning amount dynamic control and detection method, and belongs to the field of synchronouspowder feeders in additive manufacturing and laser manufacturing. The system consists of a control computer, a control cabinet, powder feeders, powder amount detecting modules, powder amount controlmodules and a precise proportioning control module, wherein the powder feeders store and hold powder and convey the powder to a laser machining area; the powder amount detecting modules acquire precise powder amount output by the powder feeders in real time, and transmit powder amount data to the precise proportioning control module; and the powder amount control modules control the powder amountoutput by the powder feeders in real time, receive control information of the precise proportioning control module, and regulate the power outlet amount in real time. The precise proportioning controlmodule controls the powder feeding amount and the powder feeding proportioning amount dynamically in real time to achieve precise proportioning control. The precise proportioning powder feeding system and the powder outlet amount and proportioning amount dynamic control and detection method support mixed powder feeding of a plurality of materials, ensure precise proportioning control of various materials, and effectively improve the powder feeding precision, the continuity, the stability and the controllability.

Owner:JILIN UNIV

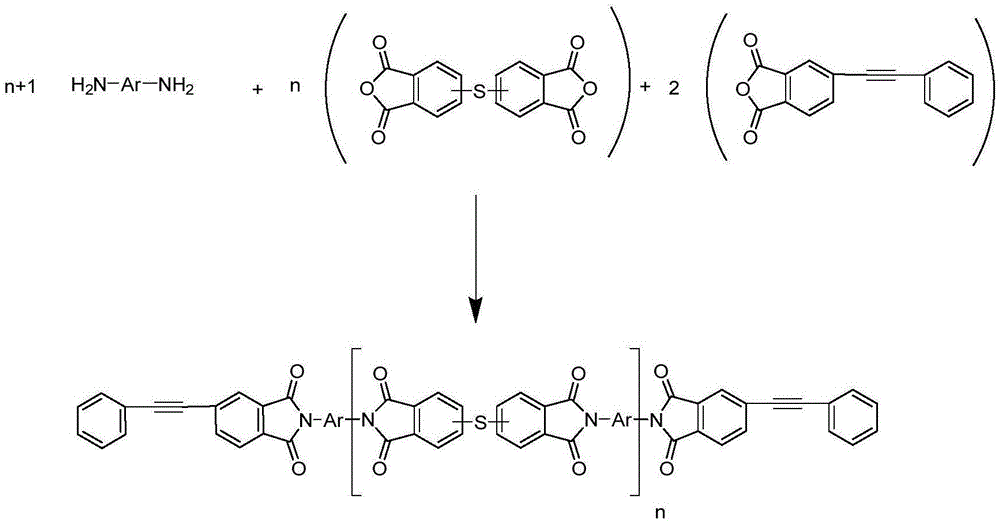

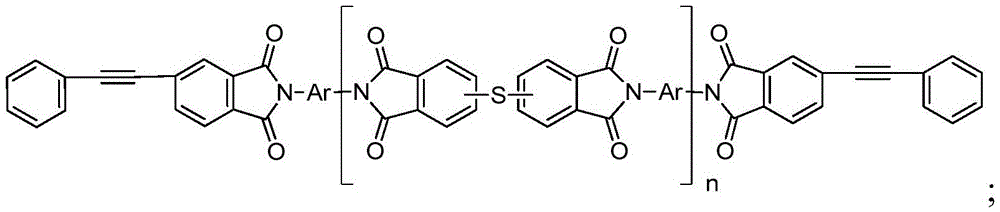

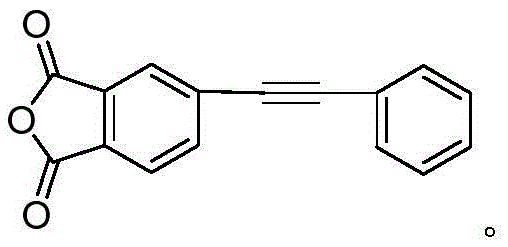

Low-viscosity thermosetting polyimide resin and preparation method and application thereof

The invention relates to low-viscosity thermosetting polyimide resin and a preparation method thereof. The method comprises the following steps that diamine monomers and mixed thioether dianhydride are added to organic solvent to be reacted for 4-6 h; an end capping agent is added to be reacted continuously for 8-12 h; a water removing agent is added, the temperature of a reaction system rises to 175-185 DEG C, reflux is conducted for 1-3 h, and the water removing agent and water in the system are removed through distillation; the temperature rises continuously to 190-210 DEG C, and a reflux condensation reaction is conducted for 1-3 h; the reaction system is cooled and poured into precipitator, filtration, cleaning and drying are conducted, and the low-viscosity thermosetting polyimide resin is obtained. The invention further relates to application of the low-viscosity thermosetting polyimide resin in thin films or engineering plastics or composites. Due to the fact that -S- and -O- flexible units are introduced into a main chain of the low-viscosity thermosetting polyimide resin, and the main chain contains asymmetric and non-coplanar structural units, the low melt viscosity, good dissolving property and high vitrification transition temperature are achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

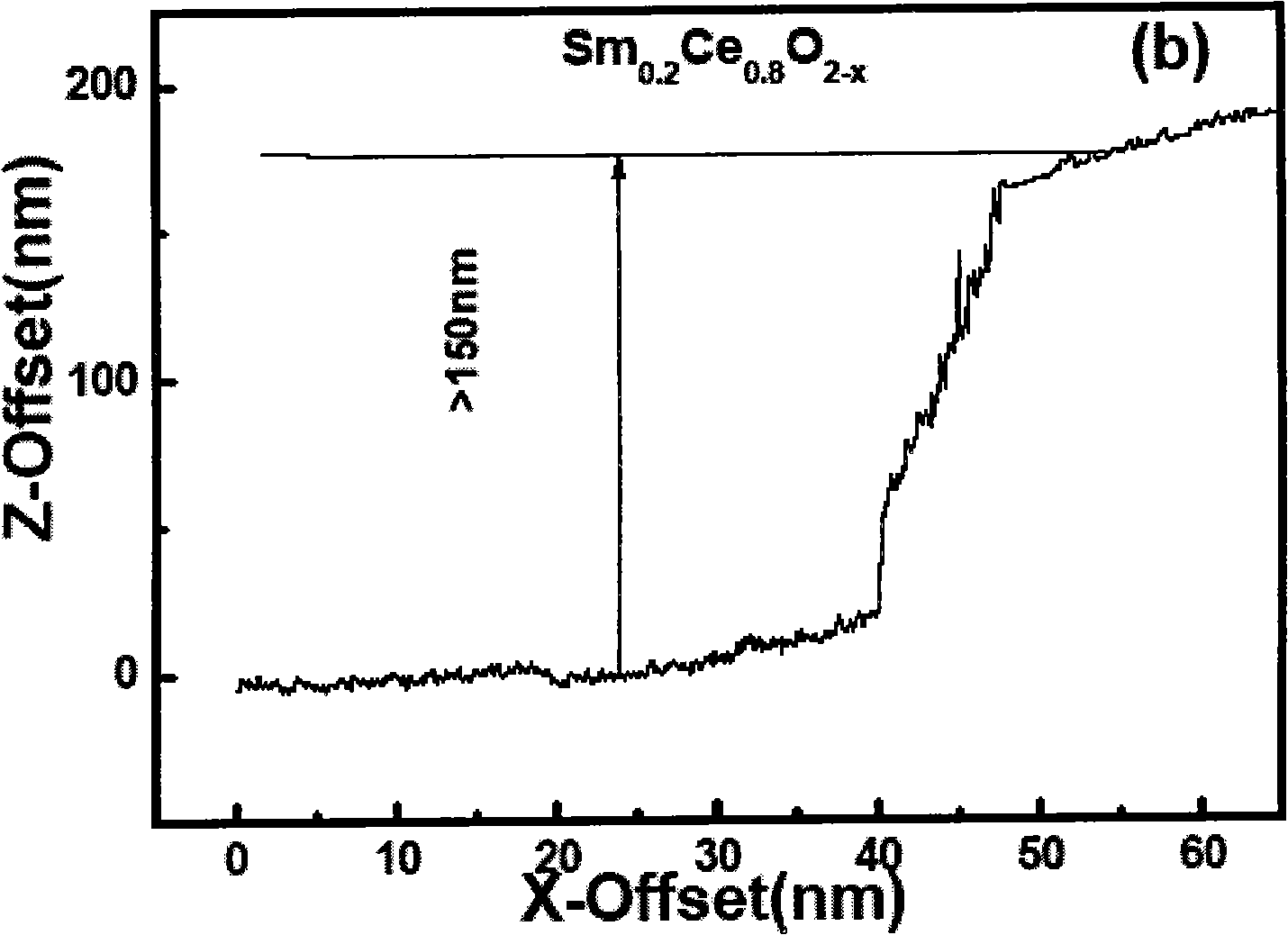

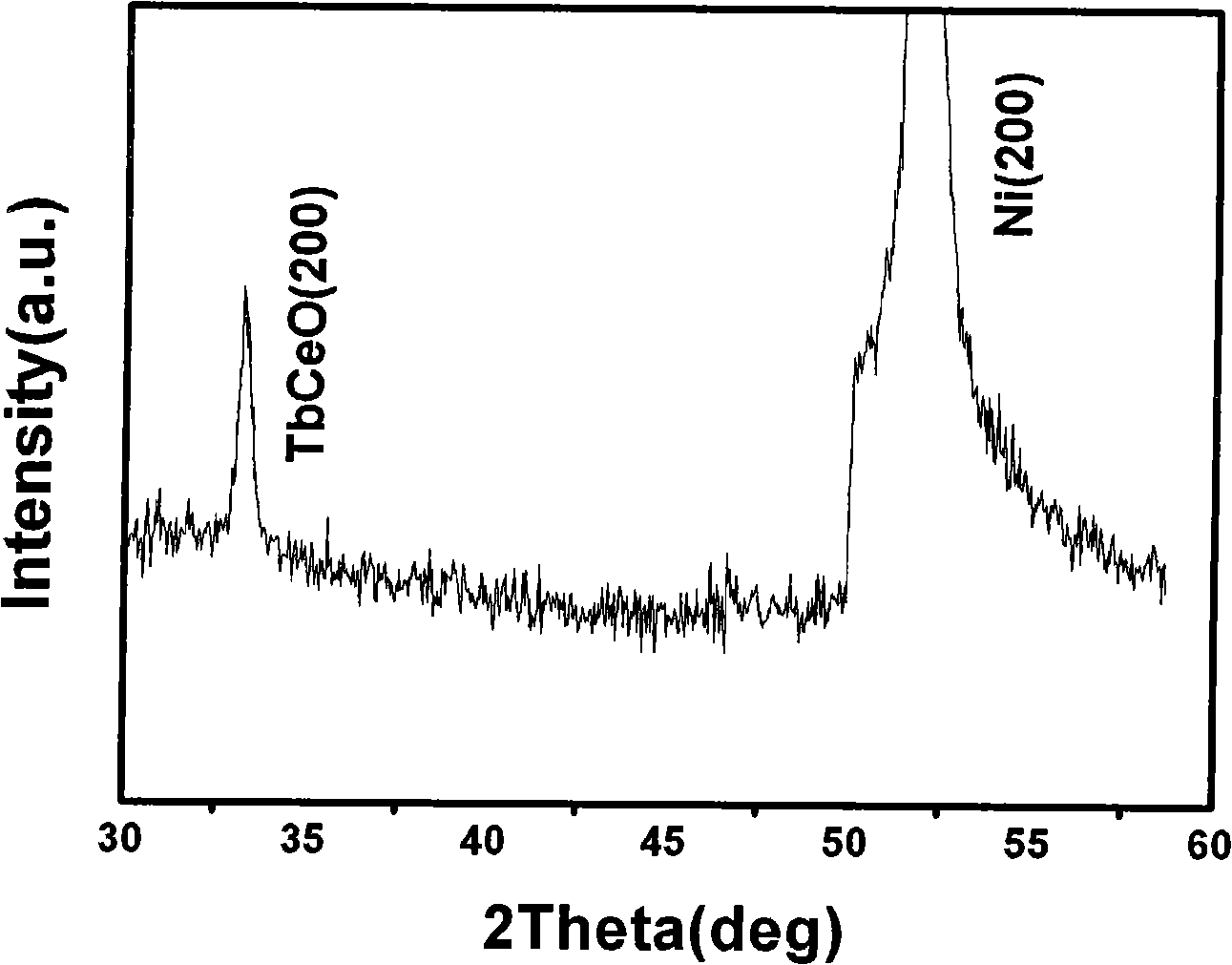

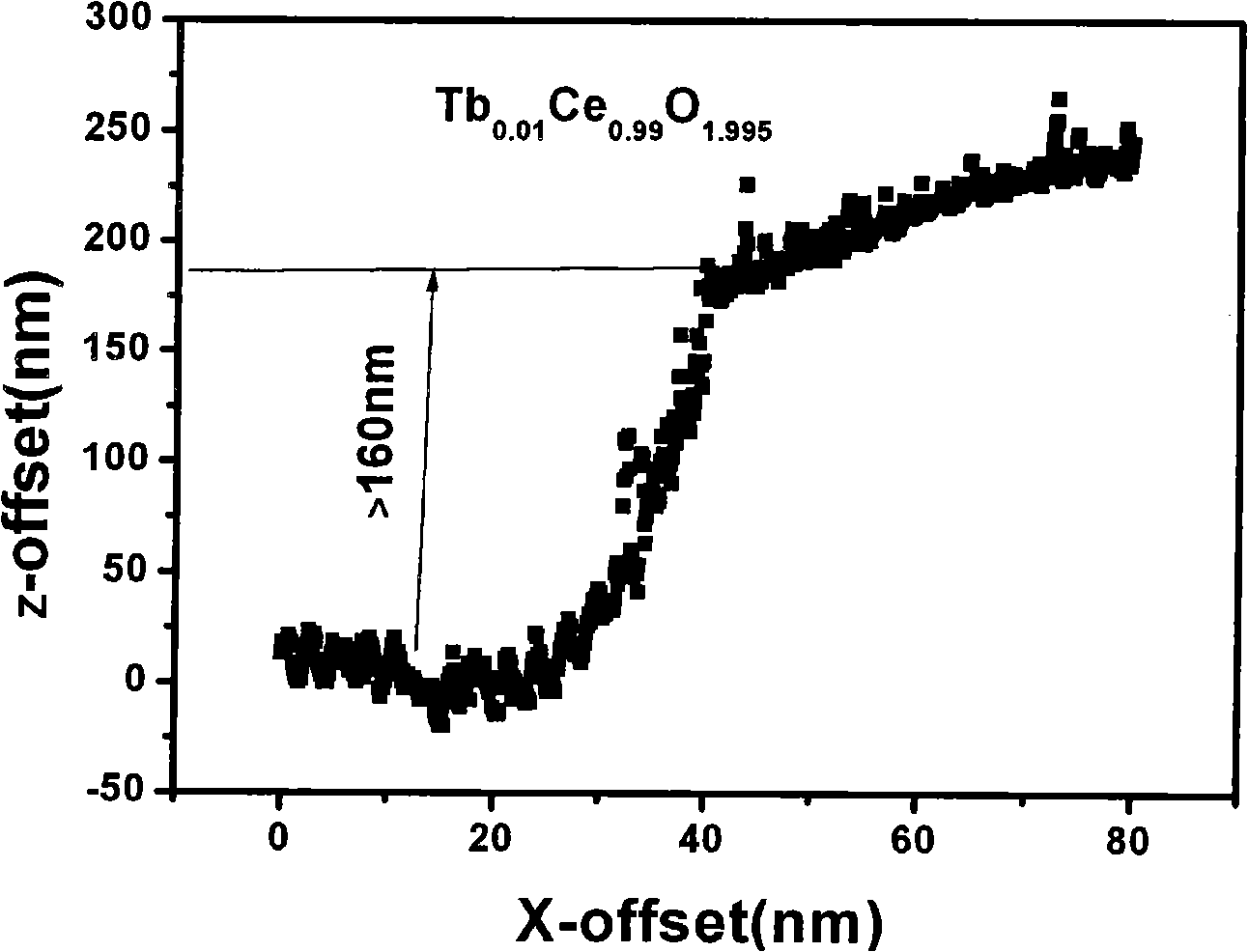

Method for preparing high temperature superconduction coating conductor buffer layer using polymer auxiliary azotate deposition

InactiveCN101281805AImprove textureFlat and dense surfaceSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentElectrical conductorCerium nitrate

The present invention provides a method for producing the buffer layer of a conductor coated with high temperature superconducting coating by means of macromolecule assisted nitrate deposition, a. producing a waterless weigh rare earth nitrate or zirconium nitrate and cerous cerium nitrate at an ionic ratio of rare-earth or zirconium: cerium as x:1-x (0.01<=x<=0.5), and dissolve the elements in N,N-dimethyl formamide to form a waterless solution; b. preparing colloid: add polyacrylic acid or polymethacrylic acid to the waterless solution prepared in step a; c. coating the colloid and drying: coat the colloid prepared in step b on a substrate and the dry the substrate. d. sintering: load the dry substrate into a sintering oven, heat up to 850-1150 DEG C at 5-100 DEG C / min speed, hold for 0.25-2h, and then drop the oven temperature to room temperature. The method is characterized in simple process, easy operation control, low cost, and free of environment pollution; the single-layer cerium oxide buffer layer obtained can be in thickness up to 150-200nm.

Owner:SOUTHWEST JIAOTONG UNIV

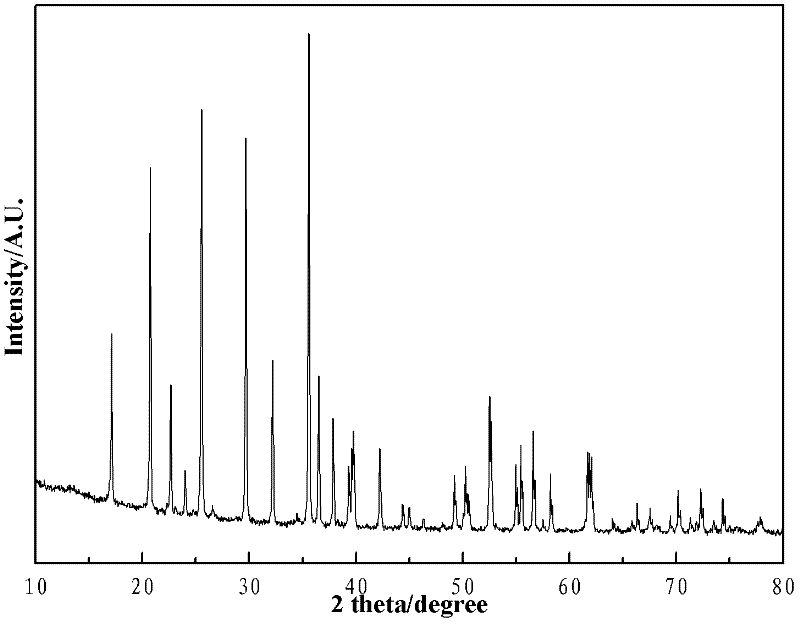

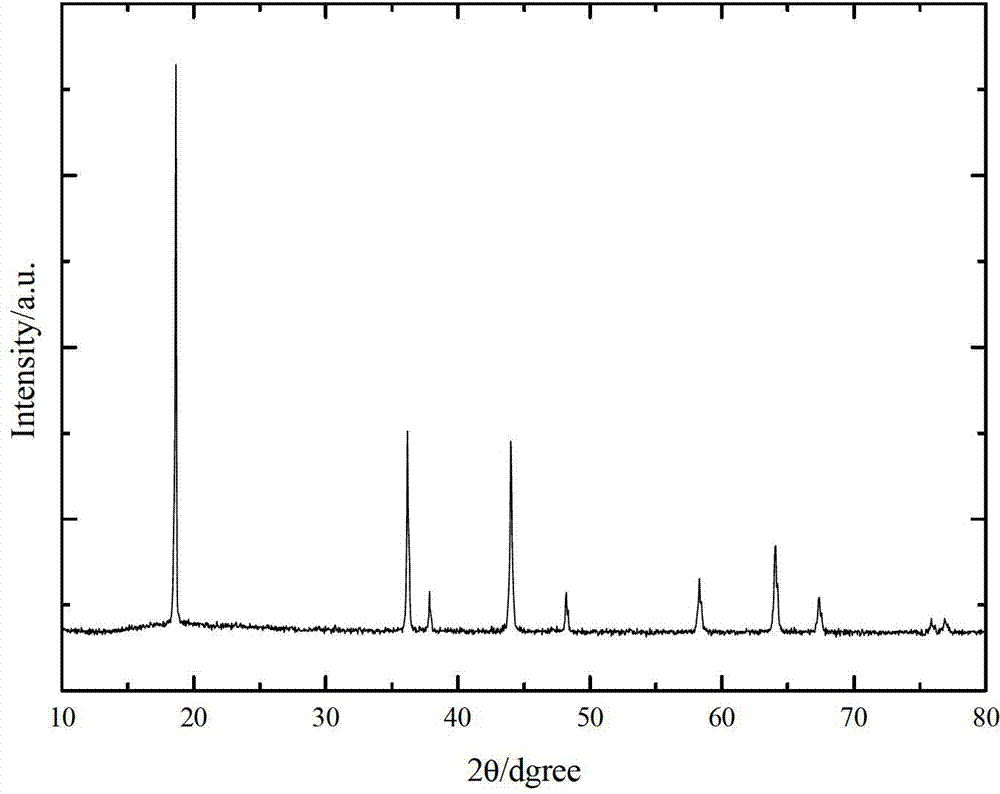

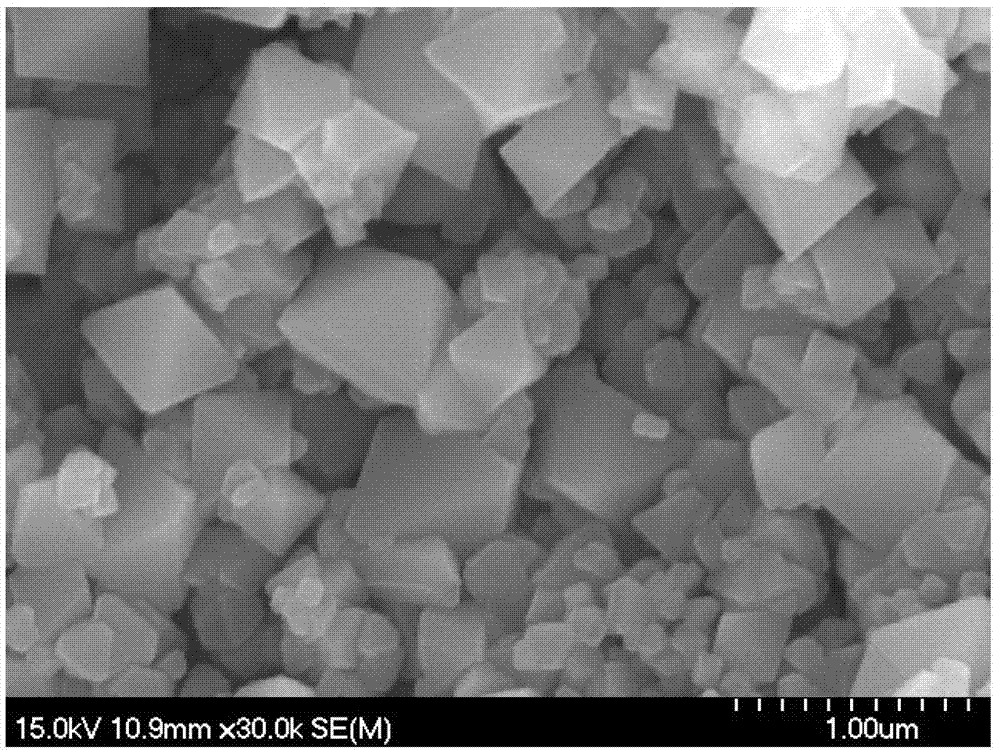

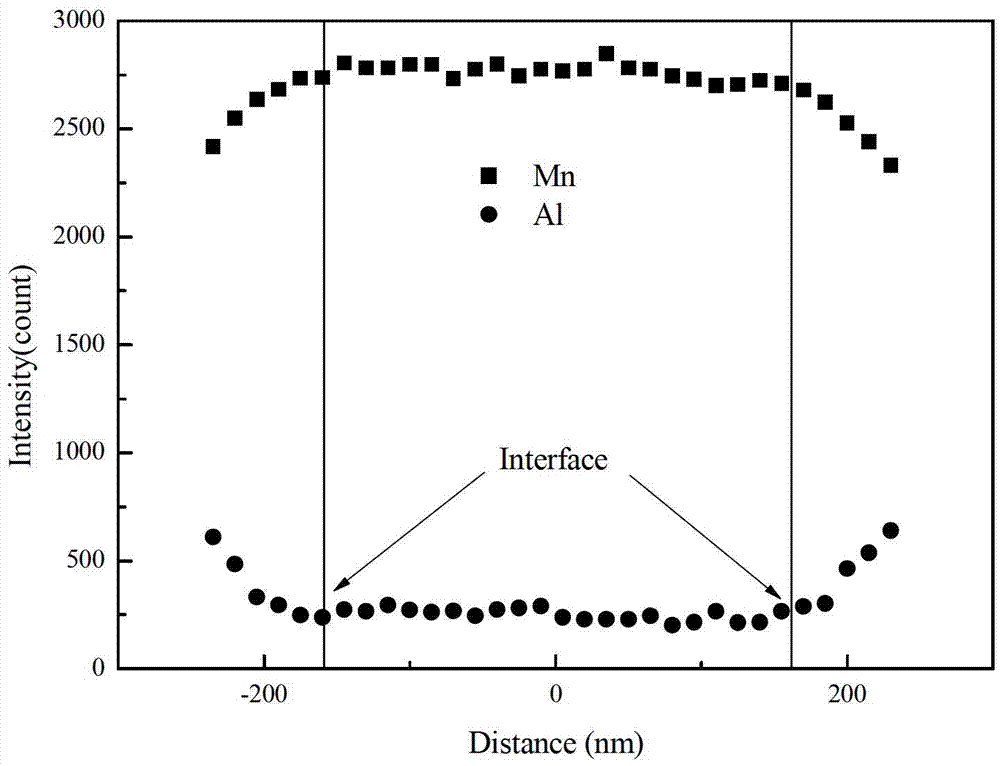

Modified lithium manganate material, and preparation method and application thereof

ActiveCN103035904ADissolution inhibitionMaintain capacity performanceCell electrodesManganateCore shell

The invention discloses a modified lithium manganate material, and a preparation method and application thereof. The modified lithium manganate material adopts a core-shell structure taking LiMn204 as a core and LiMn2-xMxO4-delta as a coating layer, wherein M is one of Al, Ti, Ce, Co and Ni, the value of x ranges from 0.05 to 0.5, and delta ranges from 0.01-0.1. The modified lithium manganate material is prepared by co-precipitation coating, hydro-thermal reaction and high-temperature heat treatment, and used as the cathode material of a lithium ion battery. The preparation process is simple and feasible, the components and the proportion of the raw materials are easy to control, the stability from batch to batch is good, the cost is low, and the synthesized lithium manganate material is high in specific capacity, high in current and excellent in cycle performance, and is expected to be applied in the field of power cells.

Owner:嘉善县国创新能源研究院

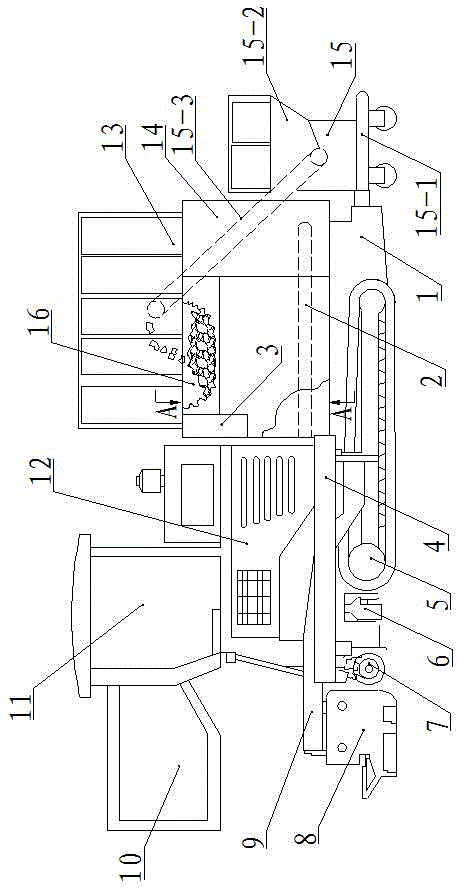

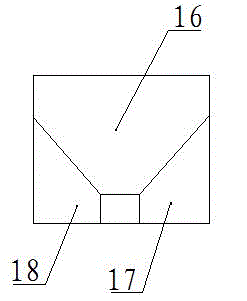

Cold-stirring and cold-paving all-in-one machine

ActiveCN102912712AReduced horizontal seamsImprove pre-compactionRoads maintainenceRoad surfaceEngineering

The invention relates to a cold-stirring and cold-paving all-in-one machine for paving an asphalt or concrete pavement. The cold-stirring and cold-paving all-in-one machine comprises a stander, a power assembly arranged on the rear part of the upper side of the stander and a traveling mechanism which is arranged on the lower side of the stander and is connected with the power assembly; an aggregate bin, an emulsified asphalt storage device and a water storage device are arranged on the front part of the upper side of the stander; a cement storage device is arranged on the rear side of the aggregate bin; a transmission auxiliary device is arranged on the front side of the aggregate bin; a steering room is arranged on the upper side of the power assembly; an asphalt scattering tank is arranged on the rear side of the steering room; a stirring device is arranged between the power assembly and the stander; an ironing plate is arranged at the rear end of the stander; a helical material divider and an asphalt scattering device are sequentially arranged between the ironing plate and the rear end of the traveling mechanism; and a feeding device is arranged at the front end of the stander. The cold-stirring and cold-paving all-in-one machine can realize cold-stirring and cold-paving continuous construction, so that transverse seams are reduced, and the construction quality and the construction efficiency are improved; and the cold-stirring and cold-paving all-in-one machine has functions of continuously supplying, stirring and paving the materials, is rational in design and simple in structure and has the advantage of convenience in use and transferring.

Owner:河南万里交通科技集团股份有限公司

Preparation method for epoxy-organic silicon resin modified polyurethane-acrylate water-dispersion and water-based epoxy zinc-rich primer paint

InactiveCN105218752AGood weather resistanceHigh mechanical strengthAnti-corrosive paintsWater basedEthylenediamine

The invention discloses a preparation method for an epoxy-organic silicon resin modified polyurethane-acrylate water-dispersion. The method comprises the following steps: firstly subjecting a silane coupling agent and epoxy resin to reaction so as to obtain a component A; then adding polycarbonate polyol and isophorone diisocyanate and carrying out reaction, then adding diethylene glycol, trimethylolpropane, dimethylolpropionic acid, acetone and a catalyst, continuing reaction, then dropwise adding methyl methacrylate and hydroxyethyl acrylate, then adding triethylamine and deionized water under stirring, and adding ethylenediamine and carrying out chain extension so as to obtain a prepolymer; and finally, adding the acetone of azodiisobutyronitrile and initiating polymerization reaction of an acrylic monomer so as to obtain the water-dispersion. The water-based epoxy zinc-rich primer paint prepared in the invention has tough paint film, high mechanical strength, good adhesive force to a substrate and excellent anticorrosion performance, facilitates to matching with a finish paint, is free of flash erosion, and has strong market potential.

Owner:JIANGSU LONGSHENG POLYMER MATERIAL TECH CO LTD

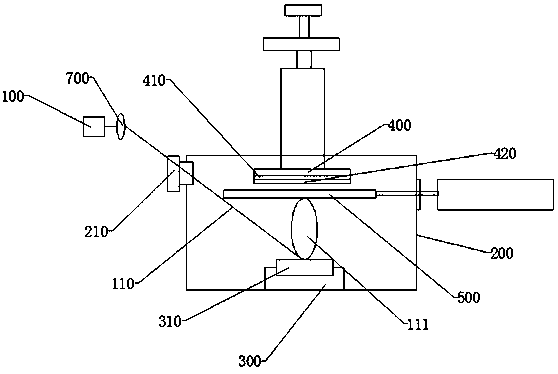

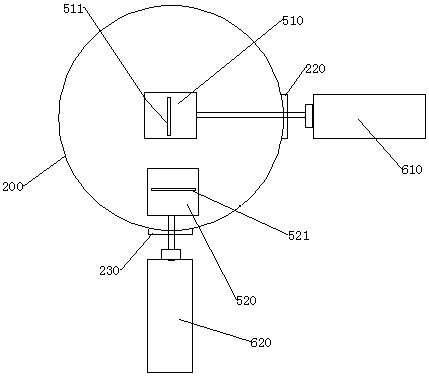

Ratio-controllable large-area and high-throughput composite film synthesis device and method

PendingCN109355621AIncrease the areaEasy to measureVacuum evaporation coatingSputtering coatingComposite filmStop time

The invention provides a ratio-controllable large-area and high-throughput composite film synthesis device and method. The synthesis device is provided with a movable substrate frame; a baffle plate for shielding part of the area of a mask is arranged between the substrate frame and a target; in the film synthesis process, the baffle plate is used for covering part of mask holes, and the substrateframe is shifted to adjust relative positions and moving speeds of the substrate frame and the target, so that the stop time of plume centers in each mask hole is adjusted, the thickness of compositefilm samples corresponding to each mask hole can be controlled, and the defect of nonuniform film plating on high-throughput PLDs is overcome; and through control of the stop time ratio of the plumecenters when depositing different materials in each mask hole, the ratio among the different materials deposited in the substrate samples corresponding to each mask hole is adjusted to achieve the ratio controllability.

Owner:SHENZHEN ARRAYED MATERIALS TECH CO LTD

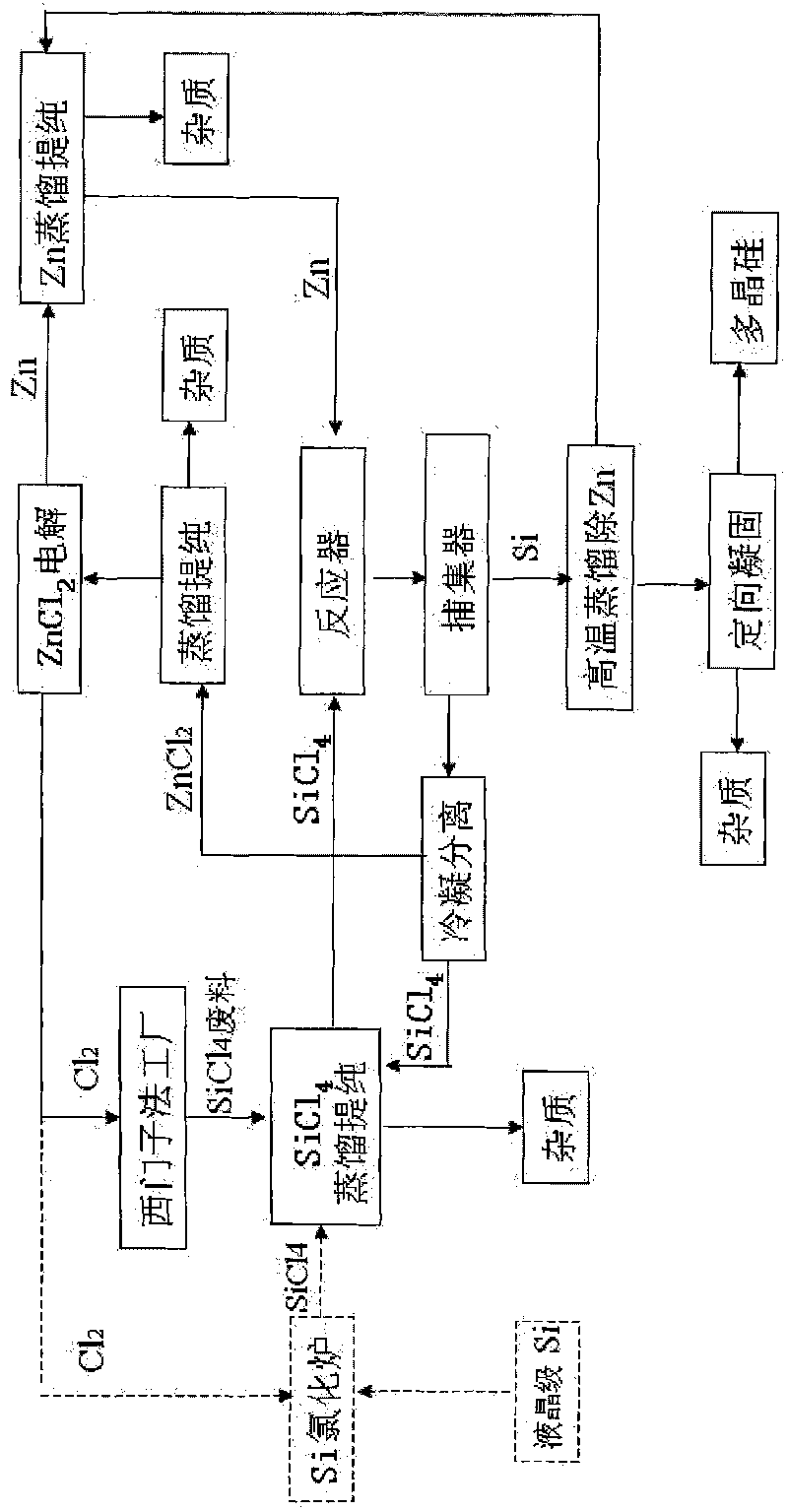

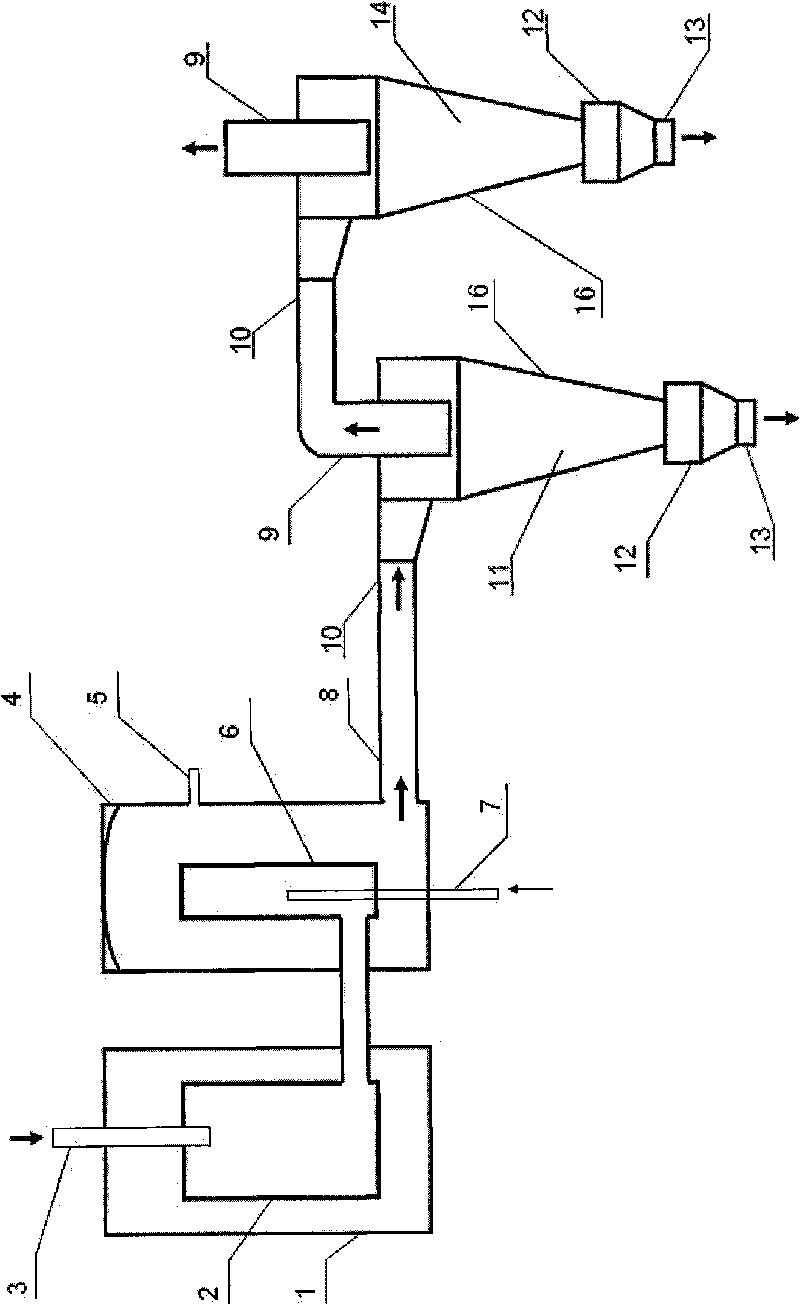

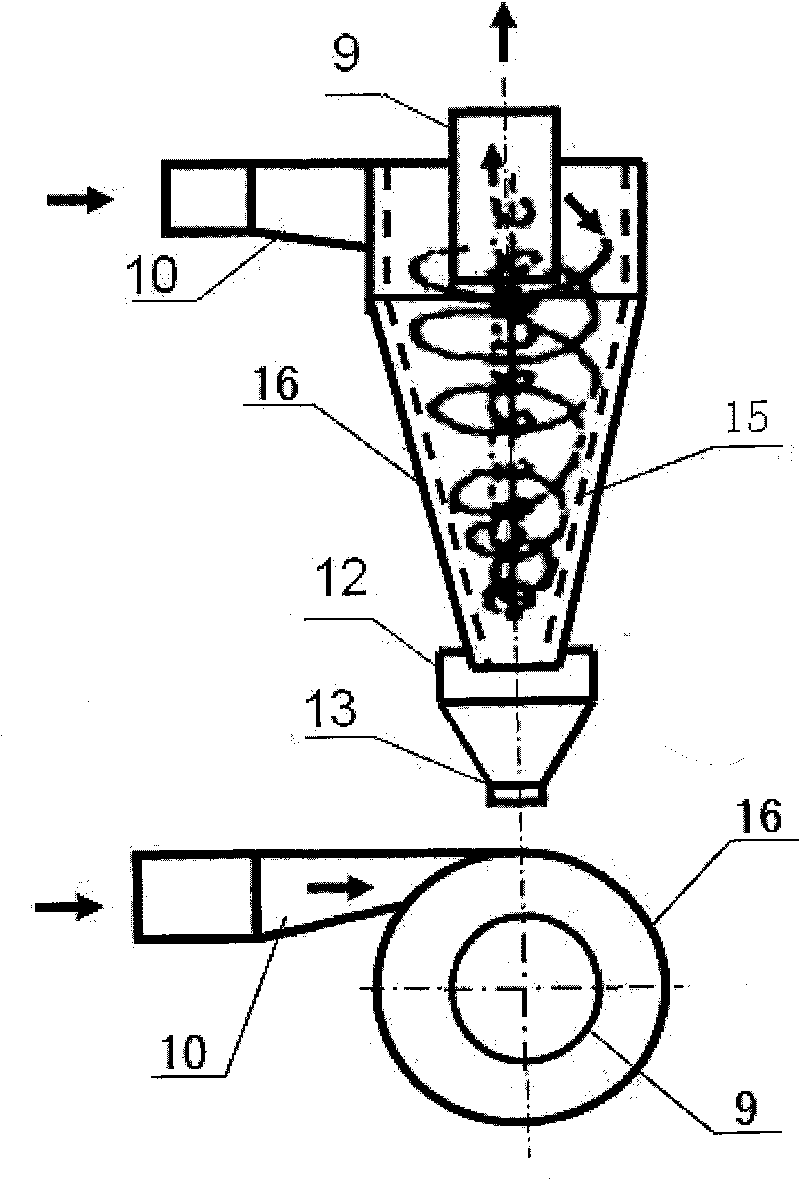

Preparation method and device for solar-grade polycrystalline silicon

InactiveCN101759187ASignificant progressAchieve recyclingPolycrystalline material growthSilicon compoundsDistillationSilicon tetrachloride

The invention relates to a preparation method and a device for solar-grade polycrystalline silicon. The preparation device is formed by a reactor and a catcher. The reactor is formed by a reducing agent storage chamber and a reaction chamber. The catcher is formed by a first-stage catcher and a second-stage catcher. Liquid zinc reacts with 7N-grade silicon tetrachloride gas under 650-900 DEG C. The product is brought to the catcher. The collected polycrystalline silicon is distilled in vacuum and is directionally solidified to obtain 6N-grage solar polycrystalline silicon. SiCl4 in waste gas is returned and recycled. After ZnCl2 is distilled and purified, the ZnCl2 is electrolyzed to obtain Zn and chlorine which are returned and recycled. The main raw material of the method is 7N-grade silicon tetrachloride obtained from waste silicon tetrachloride or metallurgical-grade silicon tetrachloride in Siemens process through distillation and purification, the production cost is low and the pollution problem caused by the Siemens process is solved.

Owner:SHENYANG JINBO NEW TECH IND +1

Method for preparing high temperature superconduction coating conductor buffer layer using polymer auxiliary deposition

InactiveCN101281806AImprove textureFlat and dense surfaceSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentElectrical conductorPolyvinyl alcohol

A method for producing the buffer layer of a conductor coated with high temperature superconducting coating by means of macromolecule assisted deposition, which comprises: a. preparing waterless: weigh rare-earth acetate, or rare-earth propoxide, or rare-earth acetylacetonate, or zirconium propoxide, or zirconium n-butoxide and cerium acetylacetonate at an ionic ratio of rare-earth or zirconium: cerium as x:1-x (0.01<=x<=0.5), dissolve the compound in an organic solvent to form a waterless; b. preparing colloid: add polyvinyl butyral, or polyethylene glycol, or polyvinyl pyrrolidone, or polyvinyl alcohol, or polyoxyethylene to the waterless solution to form colloid; c. coating the colloid and drying: coat the colloid on a substrate and then dry the substrate; d. sintering: load the substrate into a sintering oven, heat up to 850-1150 DEG C at 5-100DEG C / min, hold for 0.25-2h, and drop the temperature at 1-2 DEG C / min to room temperature. The method is characterized in simple process, easy operation control, low cost, and free of environment pollution; the single-layer cerium oxide buffer layer obtained can be in critical thickness of 150-200nm.

Owner:SOUTHWEST JIAOTONG UNIV

Biodegradable alternate poly tetraamide diester preparation method

InactiveCN103881085AImprove thermal performanceRealize hybrid chain extensionPolymer scienceCrystallinity

The invention relates to a biodegradable alternate poly tetraamide diester preparation method, and belongs to the technical field of polyamide esters. The preparation method comprises that: an aliphatic diamine and a dicarboxylic acid ester are subjected to a reaction to prepare a diamide diester, the diamide diester reacts with alcohol amine to obtain tetraamide diol, the tetraamide diol and a dicarboxylic acid are subjected to condensation polymerization to prepare an alternate poly tetraamide diester prepolymer, and chain extenders such as bisoxazoline and diacyl di-lactam are adopted to carry out chain extension on the prepolymer to prepare the biodegradable alternate poly tetraamide diester with the 30 DEG C intrinsic viscosity of 0.26-0.45 dL / g. The biodegradable alternate poly tetraamide diester has characteristics of regular structure, good crystallinity, high melting point, good thermal property, good mechanical property, and green and pollution-free synthesis route.

Owner:BEIJING UNIV OF CHEM TECH

Cleaning agent and preparation method and application thereof

ActiveCN105176699ARemove completely and quicklyFree from harmInorganic/elemental detergent compounding agentsSurface-active detergent compositionsSolventCleansing Agents

The invention relates to a cleaning agent and a preparation method and application thereof, and belongs to the field of resource environment waste disposal. The cleaning agent is characterized by being prepared by adopting and sequentially mixing surface active agents such as sodium dodecyl sulfate and polyoxyethylene fatty alcohol sodium sulfate which have the effects of permeating, foaming and emulsifying, acid-alkali agents such as sodium hydroxide, potassium hydroxide and barium hydroxide which have the effect of regulating the acidity and alkalinity, moisturizing agents such as ethylene glycol and propylene glycol which have the effect of keeping the humidity and solvent such as isopropyl alcohol, ethyl alcohol and propylene glycol monomethyl ether which have the effect of dissolving. The cleaning agent and the preparation and application thereof have the advantages that the cleaning agent is sprayed to solid matter to be permeated and dissolved for 5-10 min and then smeared with a cleaning cloth, and advertising stickers, ink marks, pressure-sensitive adhesive marks, mark pen writing and the like on the surface of the solid matter can be quickly and conveniently removed.

Owner:KUNMING UNIV OF SCI & TECH

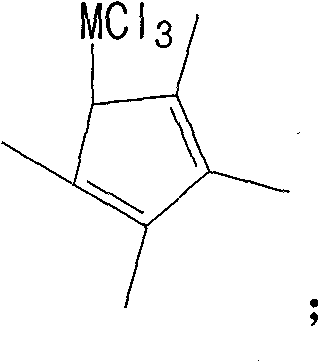

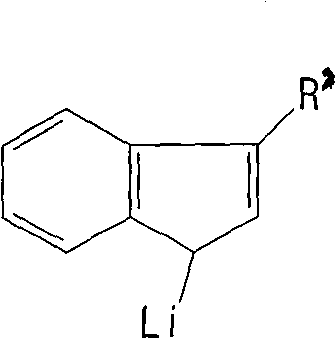

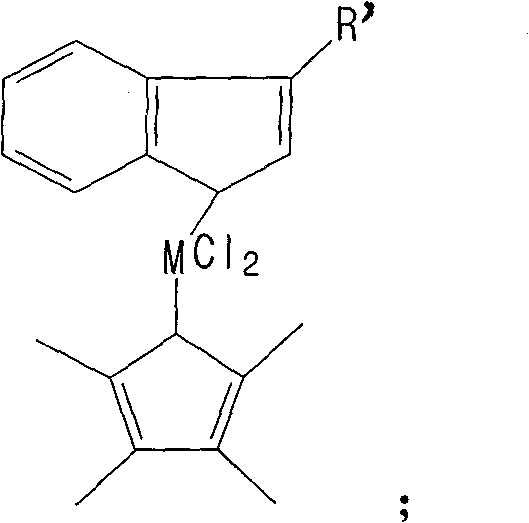

Method for preparing metallocene catalyst and application thereof in ethylene propylene rubber production

The invention discloses a preparation method of metallocene catalyst and an application in the production of ethylen-propylene rubber, wherein the preparation method comprises at 0-30 DEG C, under nitrogen gas protection, reacting tetramethyl cyclopentadienyl lithium with MCI4 at a mol ratio of 1 / 2 to prepare (C9H13) MCI3, at 0 to 30 DEG C, under nitrogen gas protection, reacting substituted undenyl ligand and (C9H13) MCI3 at a mol ratio of 1 / 1, to obtain [(C9H6R)(C9H13)]MCI2. The catalyst synthesis method has simple process, high yield, strong operability and benefit for industrial production. In the presence of a metallocene compound catalyst and a catalyst promoter as methylaluminoxane, ethane and propone can be used as main materials to be polymerized for 1-5h in toluene solution at 30 to 70 DEG C and under 1-10kg / cm2 pressure to prepare ethylen-propylene rubber, with simple polymerization process, low catalyst consumption and low production cost. Compared with the prior art, the invention reduces the pollution of vanadium catalyst, protects environment and develops a new route for ethylen-propylene rubber production.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

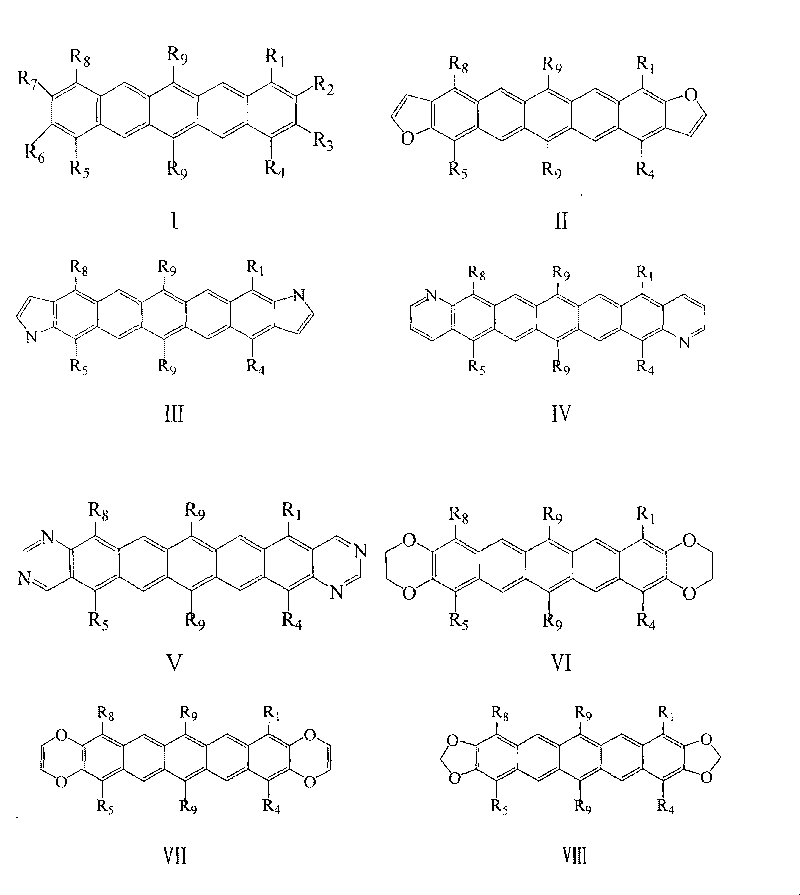

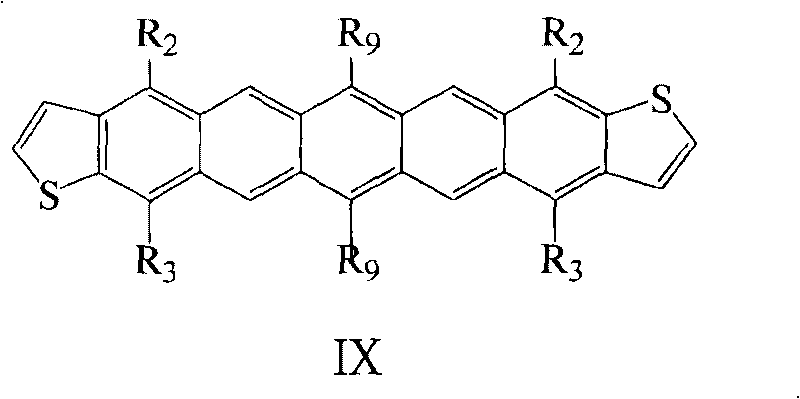

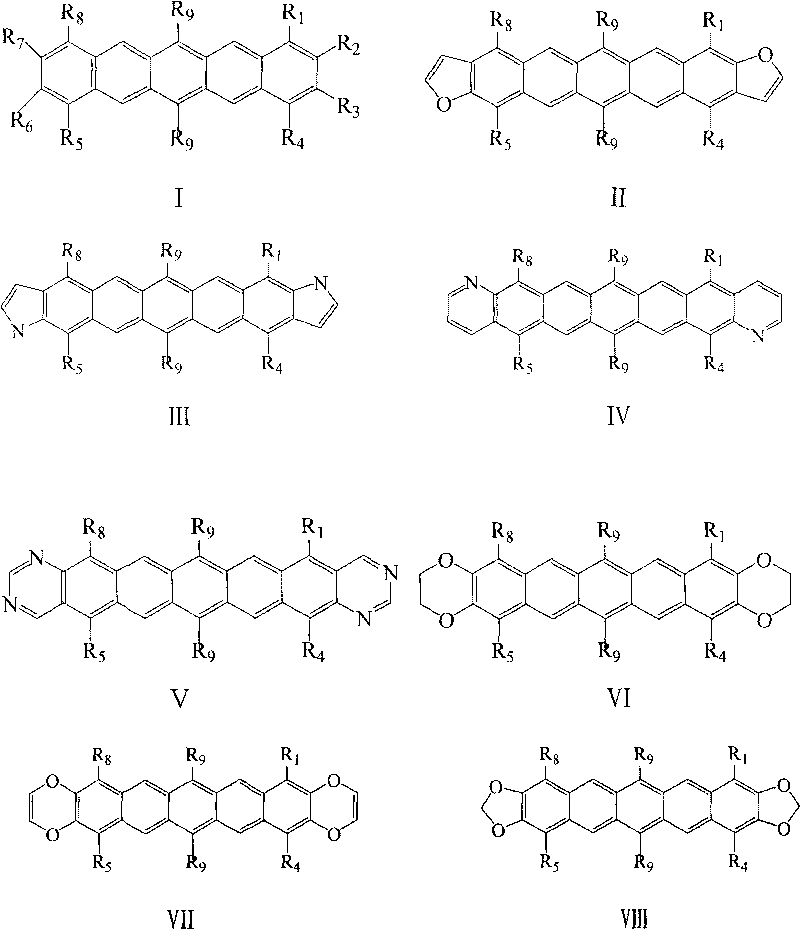

Inorganic-pentacene like substance compound semiconductor material and preparation method thereof

InactiveCN101752499AThe ratio is easy to controlSimple processSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsOrganic solvent

The invention discloses an inorganic-pentacene like substance compound semiconductor material and a preparation method thereof. Pure pentacene and derivative thereof are applied on parts, which have small current intensity and low start and reduction potential when at the lower potential, of electronic devices. The inorganic-pentacene like substance compound semiconductor material prepared by the invention consists of pentacene like substance and inorganic material according to the molar ratio of 10:1-1:10. The invention removes organic solvent by dissolving the pentacene like substance into the organic solvent, adding the inorganic material according to the molar ratio of 10:1-1:10, sealing and dispersing for 0.5 to 10 hours, and then obtains the inorganic-pentacene like substance compound semiconductor material. The invention provides the compound semiconductor material which has both the advantages of n type semiconductors and p type semiconductors, has simple preparation method and low cost.

Owner:BEIJING UNIV OF CHEM TECH +1

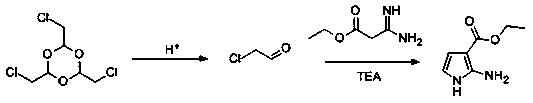

Continuous preparation method for 2-aminopyrrolyl-3-ethyl carboxylate

The invention provides a continuous preparation method for 2-aminopyrrolyl-3-ethyl carboxylate. The preparation method comprises the steps: continuously feeding a trichloroacetaldehyde solution to a first continuous reactor to carry out continuous acid catalyzed depolymerization on trichloroacetaldehyde, so as to a chloroacetaldehyde solution; and continuously feeding a 3-amino-3-imidoethyl propionate solution, an alkali solution and the chloroacetaldehyde solution to a second continuous reactor for a condensation reaction, thereby obtaining the 2-aminopyrrolyl-3-ethyl carboxylate. According to the continuous process, the restriction to anhydrous chloroacetaldehyde is broken through, the anhydrous chloroacetaldehyde is prepared by a continuous reaction, the reaction speed is higher than that of batches, and the yield is higher; and when the prepared chloroacetaldehyde solution is directly applied to the condensation reaction of next step, the material proportioning ratio is more controllable, the front and rear two steps can be compatible, and thus, the yield of the 2-aminopyrrolyl-3-ethyl carboxylate is globally increased. In addition, due to the continuous process, a scaling effect of the batches is avoided, and high yield during industrial application is also guaranteed.

Owner:ASYMCHEM LIFE SCI TIANJIN

Manganese series lithium ion sieve adsorbent and preparation method of precursor thereof

ActiveCN101961634BLow priceThe ratio is easy to controlOther chemical processesManganese oxides/hydroxidesSorbentManganese

Owner:CENT SOUTH UNIV +1

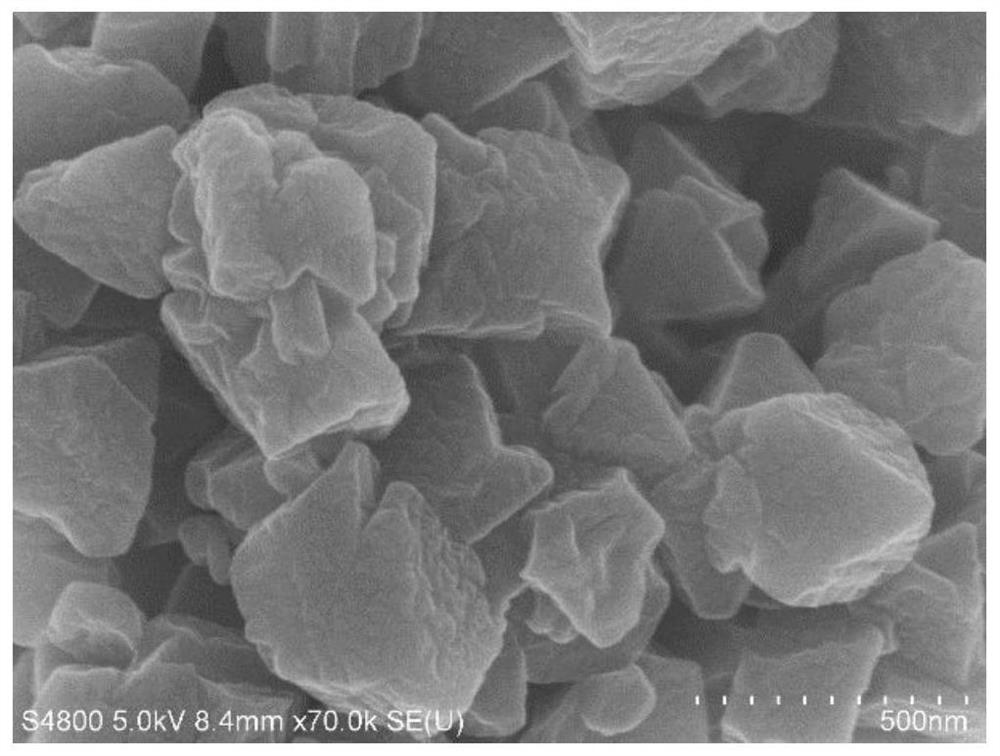

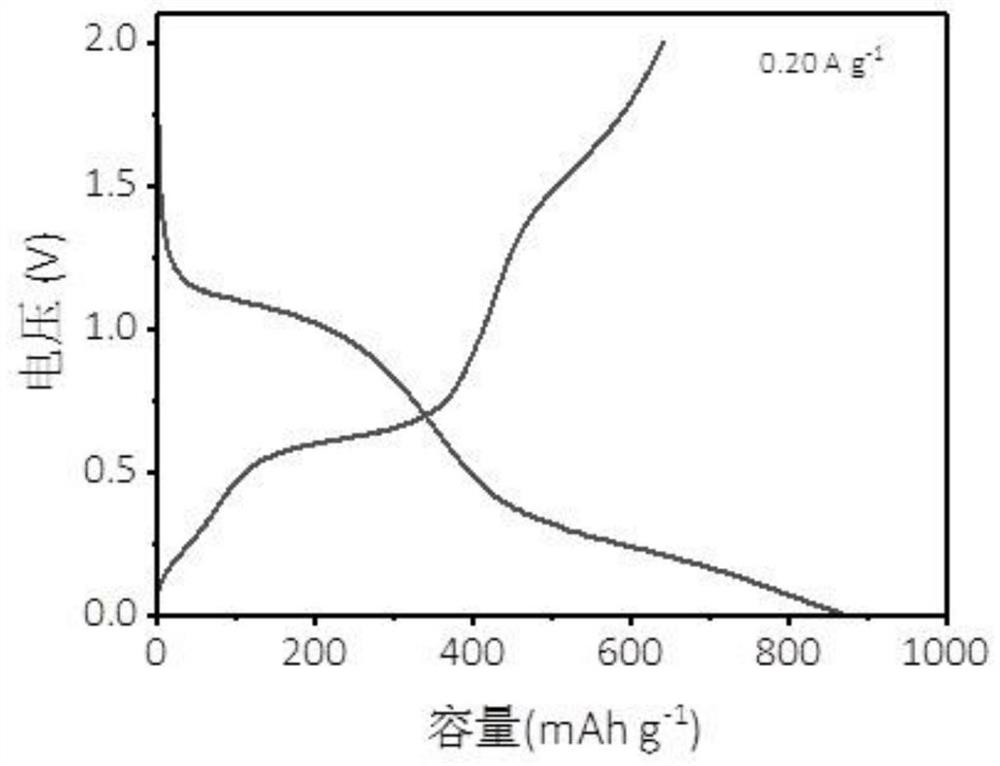

High-capacity/high-first-effect red phosphorus-molecular sieve template carbon composite negative electrode material as well as preparation method and application thereof

PendingCN112054177AInhibit sheddingImprove Capacitive PerformanceNegative electrodesSecondary cellsCarbon compositesElectrical battery

The invention provides a high-capacity / high-first-effect red phosphorus-molecular sieve template carbon composite negative electrode material and a preparation method thereof. The composite negative electrode material comprises nano-dispersed red phosphorus and molecular sieve template carbon, and the molecular sieve template carbon is used as a porous carrier of electrochemically active red phosphorus and has a high specific surface area and a large pore volume. The composite negative electrode material is prepared from the following raw materials in parts by weight: 30-90 parts of red phosphorus; and 10-70 parts of molecular sieve template carbon. The red phosphorus -molecular sieve template carbon composite material provided by the invention is mainly used as a negative electrode material of a sodium ion battery or a potassium ion battery, and has high charge-discharge specific capacity and high first effect. In addition, the material also has good cycling stability. Therefore, thesodium / potassium ion battery disclosed by the invention has a good application prospect in the fields of renewable energy consumption, peak load shifting, distributed energy storage power stations andother large-scale energy storage.

Owner:WUHAN UNIV OF TECH

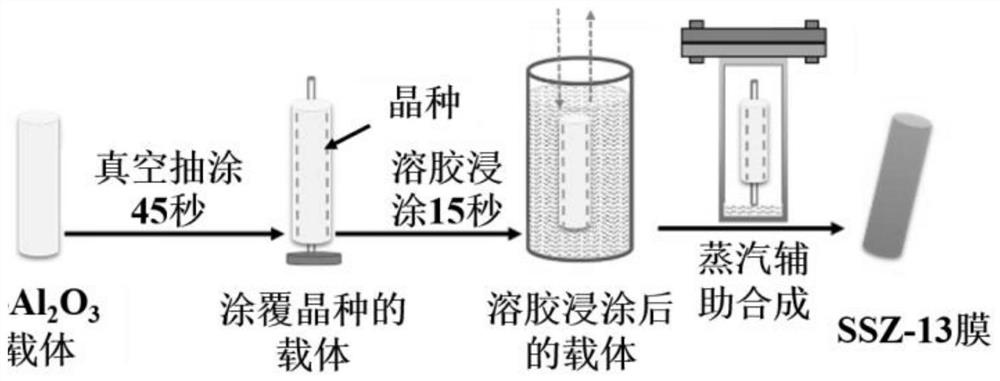

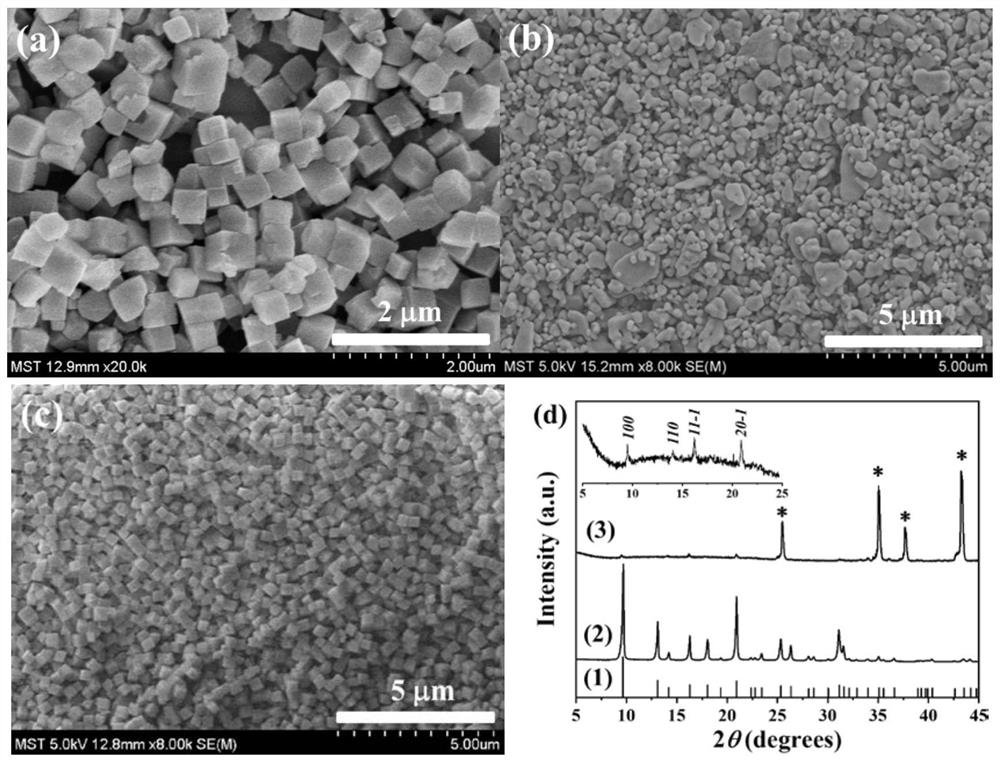

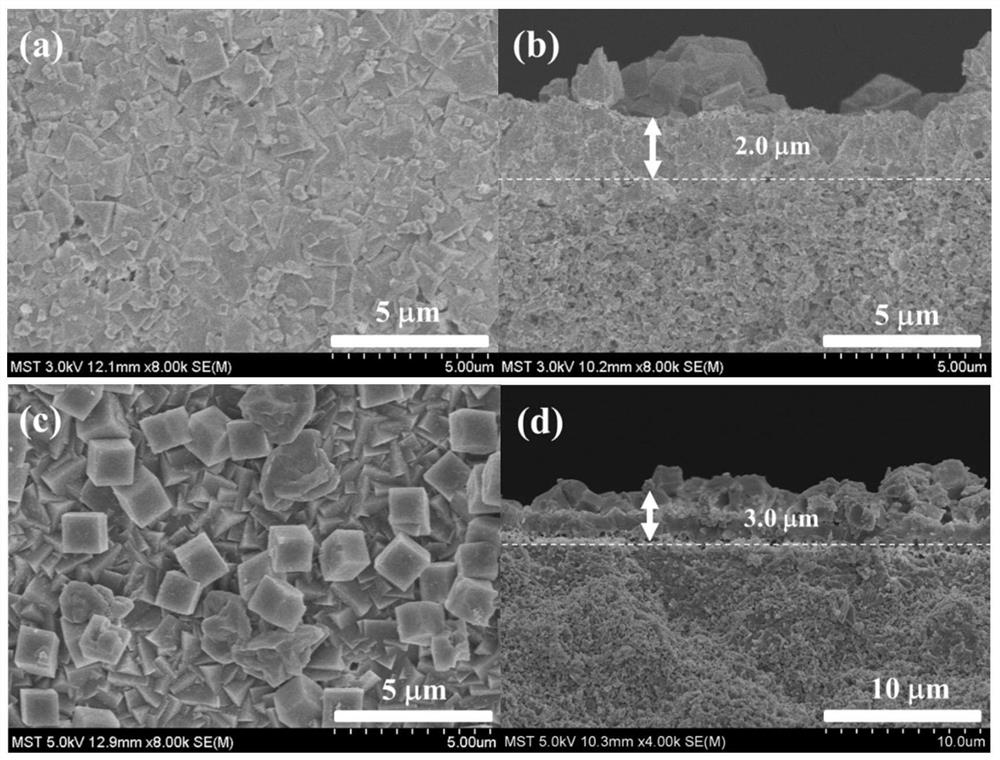

Method for preparing SSZ-13 molecular sieve membrane through steam-assisted conversion

ActiveCN112645344AImprove synthesis reproducibilityGuaranteed compactnessCrystalline aluminosilicate zeolitesMolecular-sieve compoundsMolecular sieveSeed crystal

The invention discloses a method for preparing an SSZ-13 molecular sieve membrane through steam-assisted conversion. The method comprises the following steps: (1) preparing a SSZ-13 molecular sieve seed crystal; (2) pretreating a porous support, namely coating a porous support with a crystal seed layerhaving a density of 1-300 [ mu ] g / cm<2> ; and (3) preparing a SSZ-13 molecular sieve membrane, namely adding a small amount of synthetic sol without contacting with the pretreated support, heating the sol, vaporizing and transferring heat, and matching with a small amount of structure directing agent and water to pre-coat the sol to perform crystallization, thereby forming the molecular sieve membrane. According to the invention, more than 90% of synthetic sol can be saved through steam-assisted conversion, the synthesis operation process is safe, and the discharge of reaction waste liquid is reduced. The method is economical, safe and environment-friendly, and the prepared membrane is excellent in performance and can be applied to industrial preparation of the molecular sieve membrane.

Owner:NANJING UNIV OF TECH

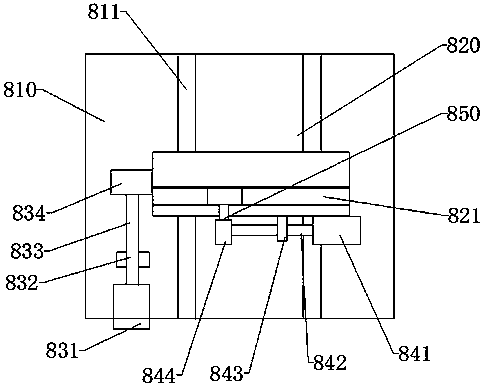

Livestock-raising automatic feeder

PendingCN110771531AThe ratio is easy to controlReduce labor intensityTransportation and packagingMixer accessoriesAgricultural scienceCrop livestock

The invention discloses a livestock-raising automatic feeder which comprises multiple bins for feeding. A feed distributing component for quantitatively distributing feed is arranged below the bins and comprises at least two feed distributing devices arranged side by side and assembled together, an inlet of each feed distributing device is communicated with an outlet of one bin in a one-to-one corresponding manner, a feed mixing device for well stirring the feed is arranged below the feed distributing component, an inlet of the feed mixing device is communicated with outlets of all feed distributing devices, and a tray for containing the feed flowing out of the feed mixing device is arranged below the same. Feed different in type is regularly and quantitatively discharged into the feed mixing device for mixing and then discharged into the tray through the feed distributing devices, the whole charging process is simple, and feed proportion is easy to control, so that labor intensity ofworkers is relieved effectively, and the livestock-raising automatic feeder is simple in operation, high in working efficiency and practicability and worthy of popularization.

Owner:太原动物园

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com