Method for preparing high temperature superconduction coating conductor buffer layer using polymer auxiliary deposition

A polymer-assisted, high-temperature superconducting technology, applied in the usage of superconducting elements, superconducting/high-conducting conductors, manufacturing/processing of superconducting devices, etc., can solve the problem of high cost, complicated system of physical vapor deposition method, and unsuitability for industrial production and other problems, to achieve the effect of easy operation and control, smooth and compact surface, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

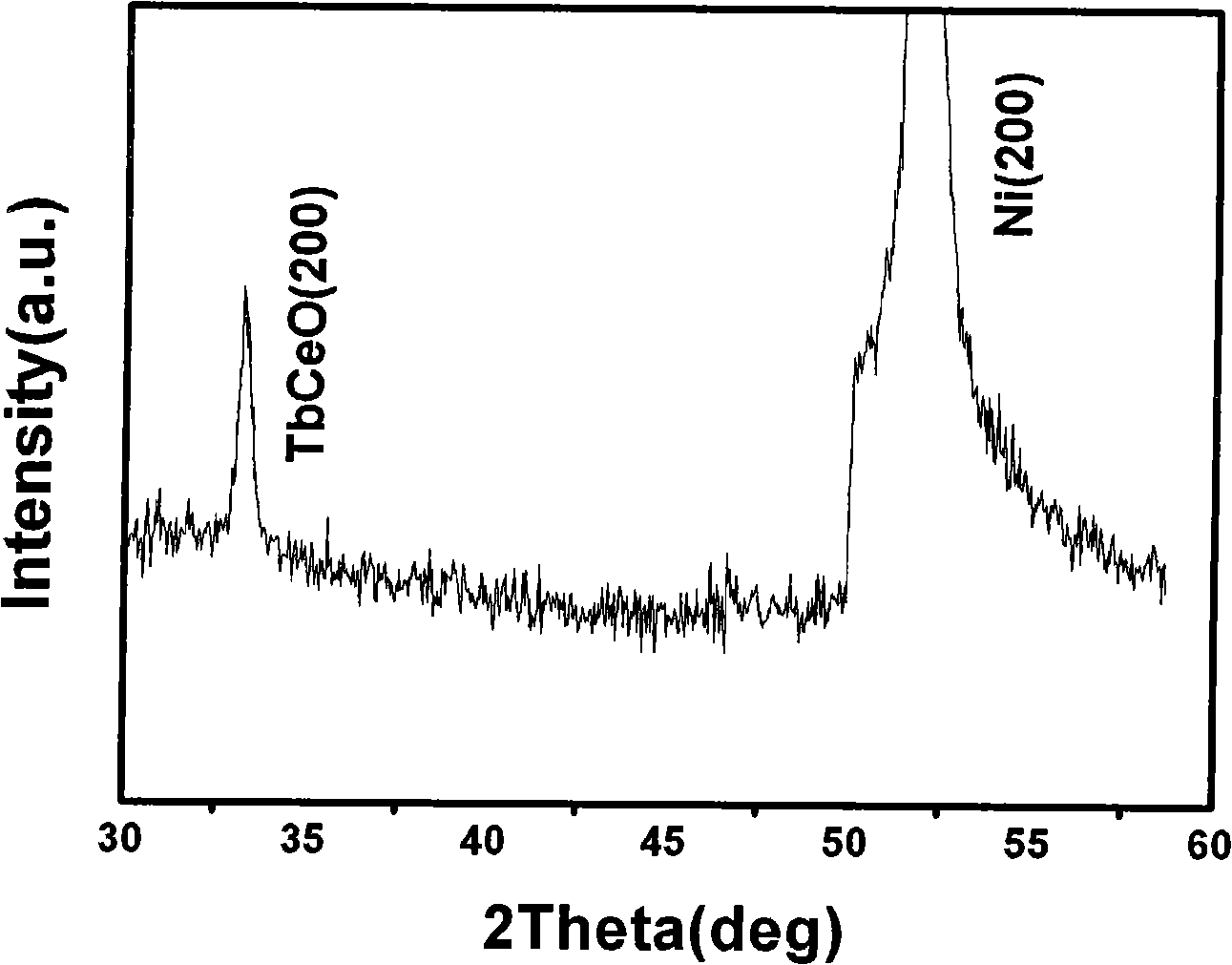

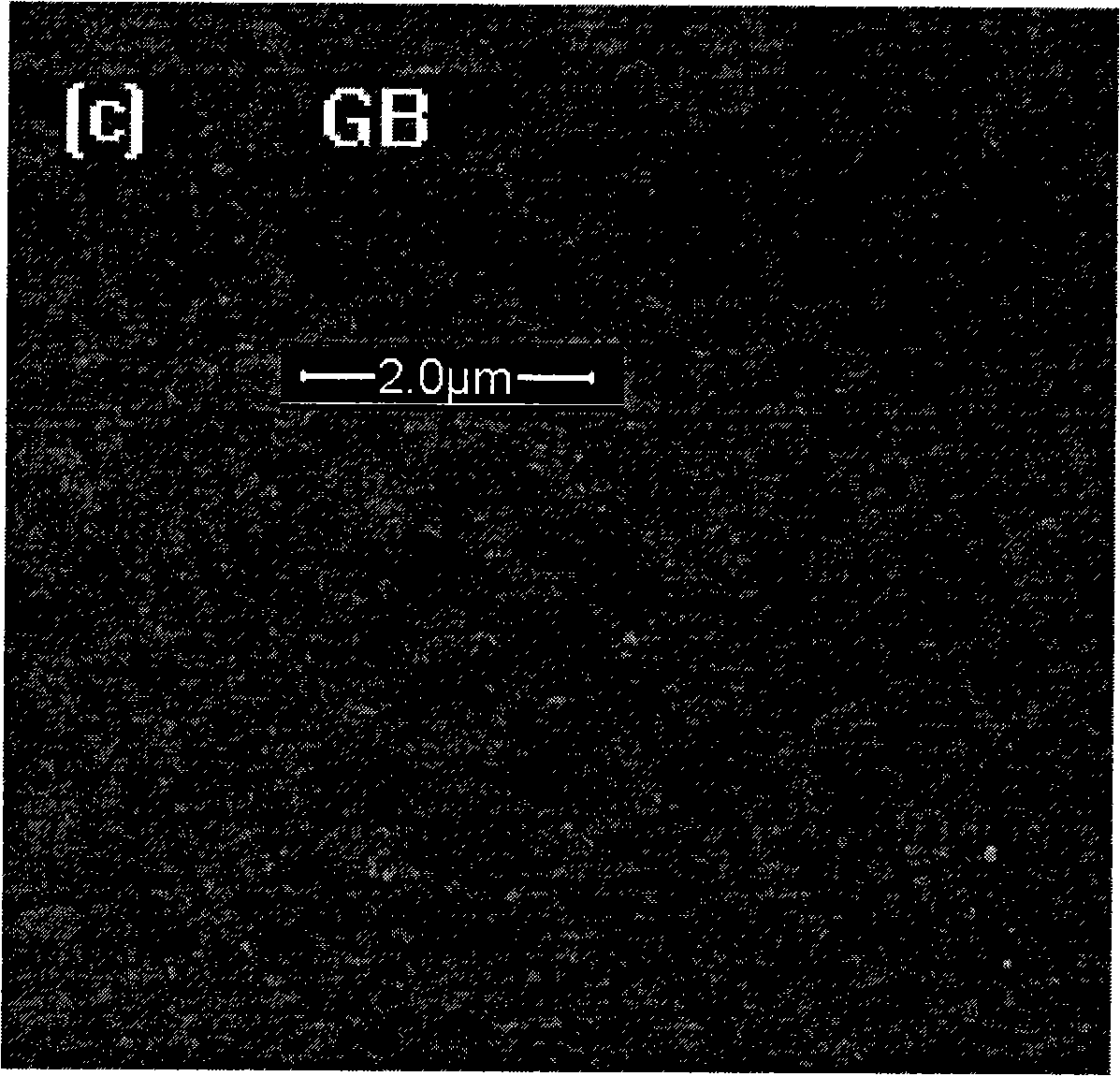

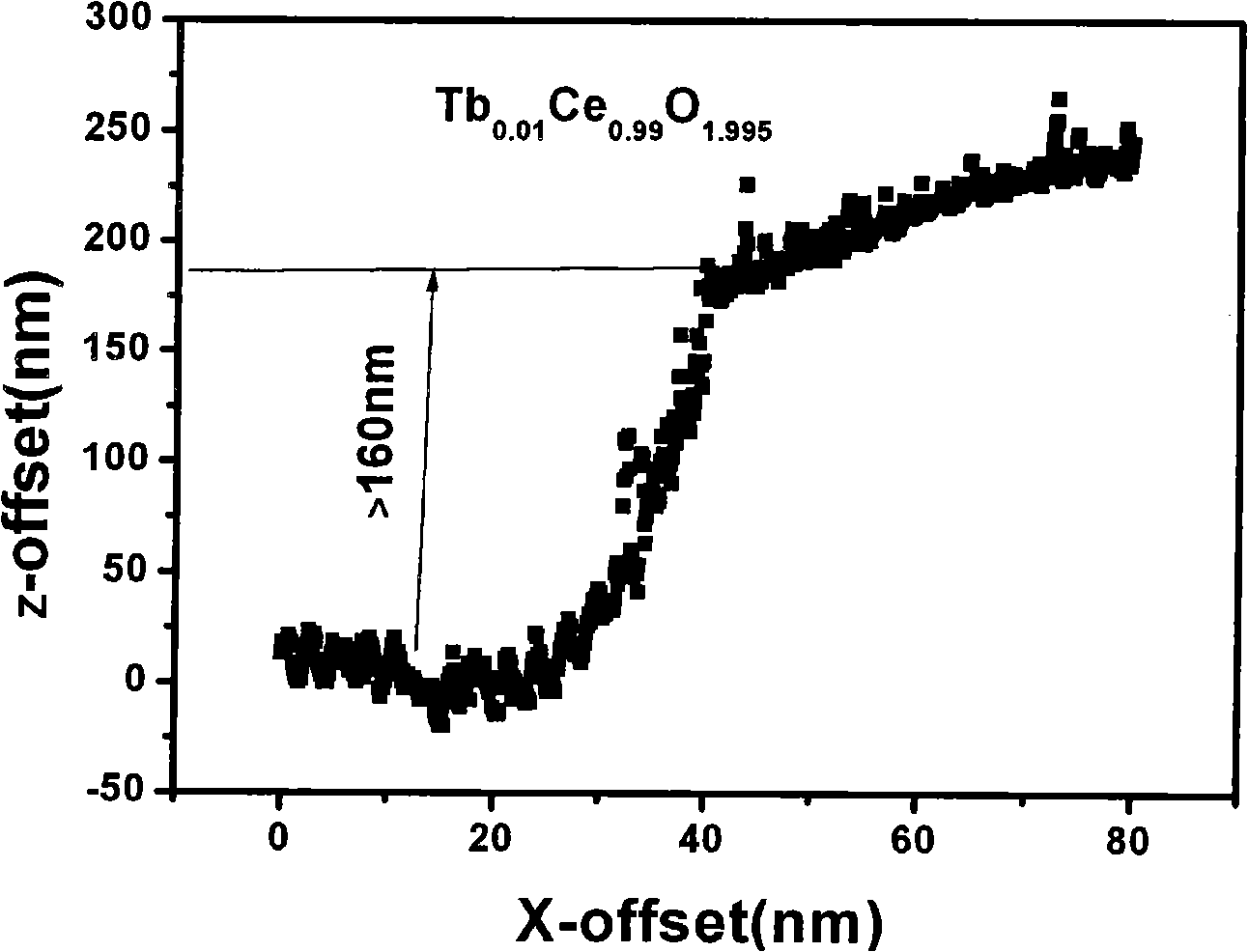

[0026] A kind of specific embodiment of the present invention is:

[0027] a. Preparation of anhydrous solution: Dissolve terbium acetate and cerium acetylacetonate in acetic acid according to the ratio of cations, namely terbium (Tb): cerium (Ce) = 0.01: 0.99, to form an anhydrous solution.

[0028] b. Colloid preparation: Add polyvinyl butyral (PVB) to the anhydrous solution in step a to form a colloid with good film-forming properties.

[0029] c. Colloid coating and drying: the colloid prepared in step b is coated on the Ni alloy substrate, and then dried at 200°C.

[0030] Thermal decomposition treatment before sintering: put the colloid-coated substrate in a sintering furnace, slowly increase the temperature of the furnace from room temperature to 210°C, and then rise to 290°C at a rate of 0.15°C / min, and keep the temperature for 20 minutes.

[0031]d. Sintering phase formation: put the thermally decomposed substrate into the sintering furnace, rapidly raise the furnace...

Embodiment 2

[0033] The preparation method of this example consists of the following steps in turn:

[0034] a. Preparation of anhydrous solution: dissolving praseodymium propanol and cerium acetylacetonate in methanol at a ratio of cation ratio Pr:Ce=0.1:0.9 to form an anhydrous solution.

[0035] b. Colloid preparation: Add polyethylene glycol (PEG) to the anhydrous solution in step a to form a colloid with good film-forming properties.

[0036] c. Colloid coating and drying: Coating the colloid prepared in step b on the Ni alloy substrate, and drying at 100°C.

[0037] Thermal decomposition treatment before sintering: place the colloid-coated substrate in a sintering furnace, slowly increase the temperature of the furnace from room temperature to 200°C, and increase it to 280°C at a speed of 0.1°C / min, and keep it warm for 15 minutes .

[0038] d. Sintering phase formation: put the thermally decomposed substrate into the sintering furnace, rapidly raise the furnace temperature to 850°...

Embodiment 3

[0040] The preparation method of this example consists of the following steps in turn:

[0041] a. Preparation of anhydrous solution: Dysprosium acetylacetonate and cerium acetylacetonate were dissolved in ethylene glycol methyl ether according to the ratio of cations Dy:Ce=0.3:0.7 to form an anhydrous solution.

[0042] b. Colloid preparation: Add polyvinylpyrrolidone (PVP) to the anhydrous solution in step a to form a colloid with good film-forming properties.

[0043] c. Colloid coating and drying: the colloid prepared in step b is coated on the Ni alloy substrate, and then dried at 150°C.

[0044] Thermal decomposition treatment before sintering: place the colloid-coated substrate in a sintering furnace, slowly increase the temperature of the furnace from room temperature to 215°C, and rise to 350°C at a speed of 0.5°C / min, and keep it for 18 minutes .

[0045] d. Sintering phase formation: put the thermally decomposed substrate into the sintering furnace, rapidly raise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com