Patents

Literature

168results about How to "Pollution is not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

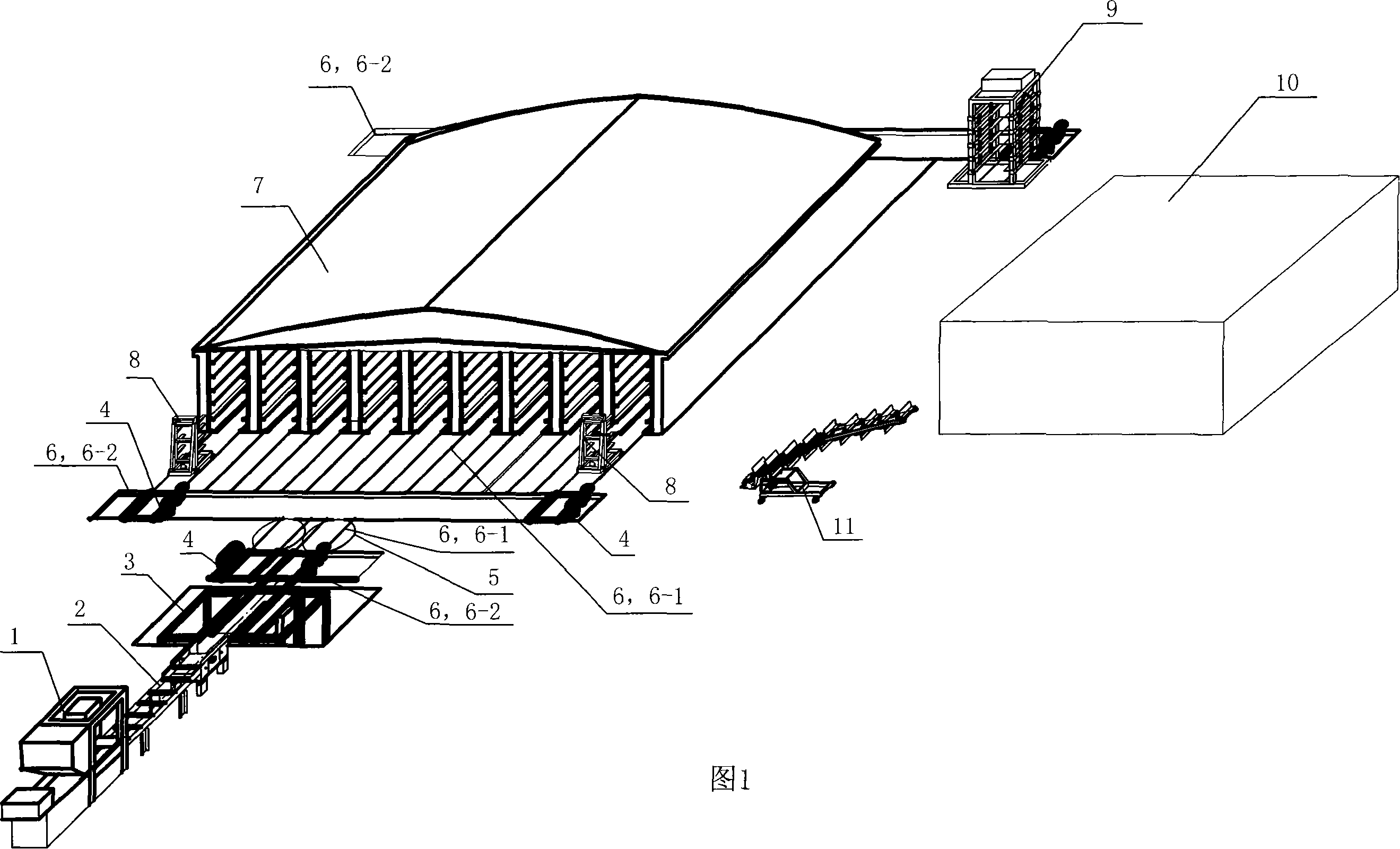

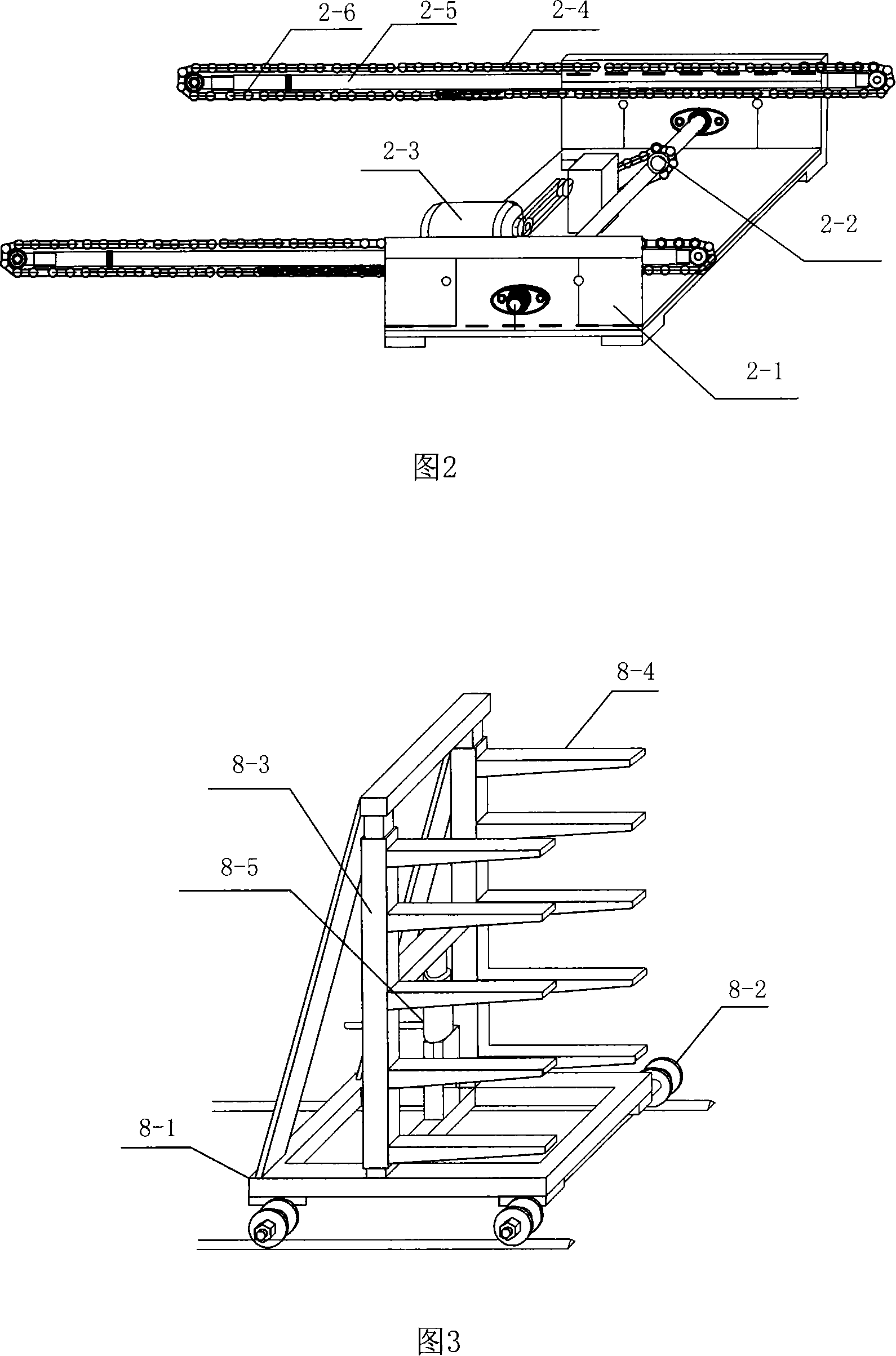

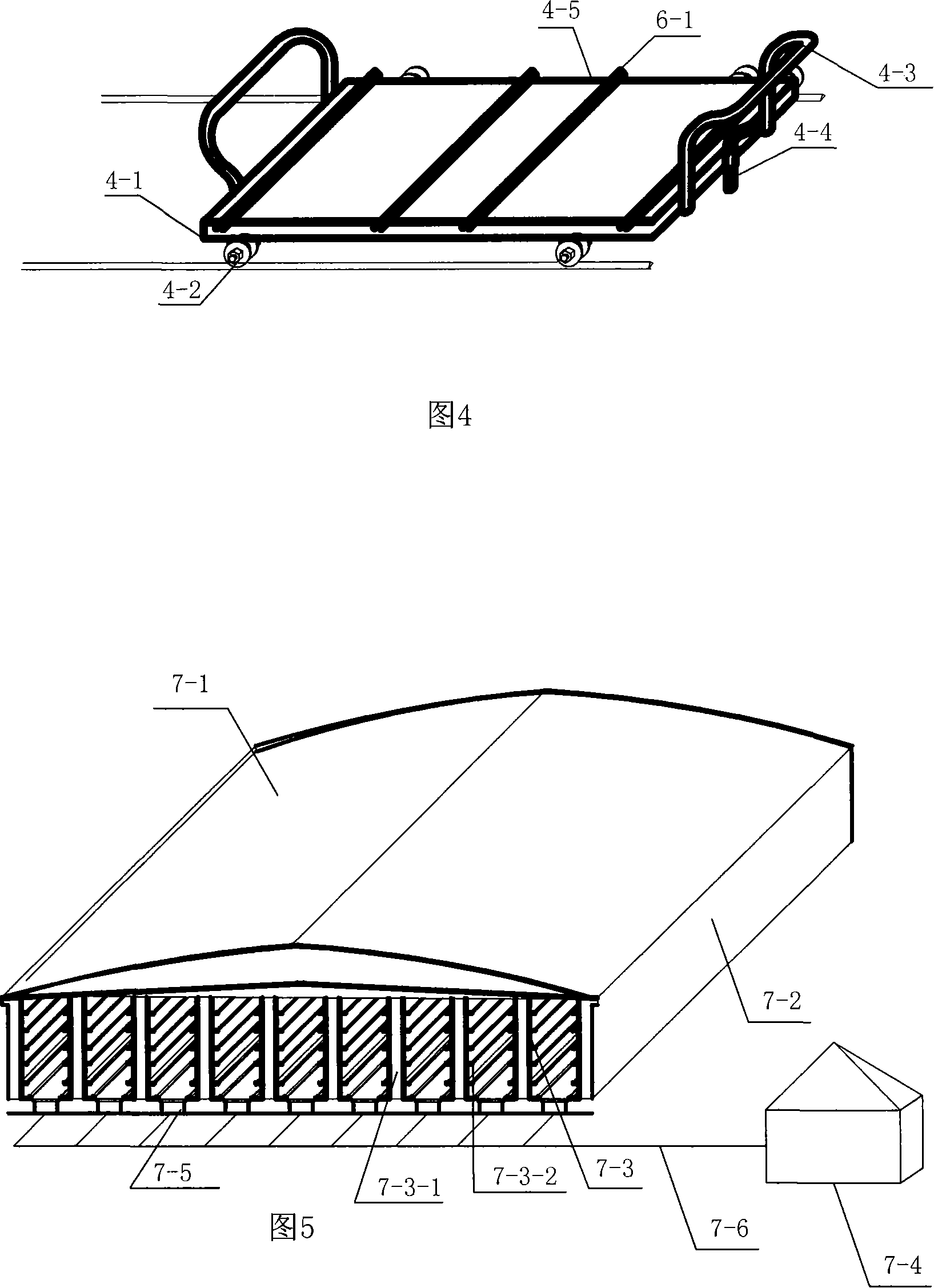

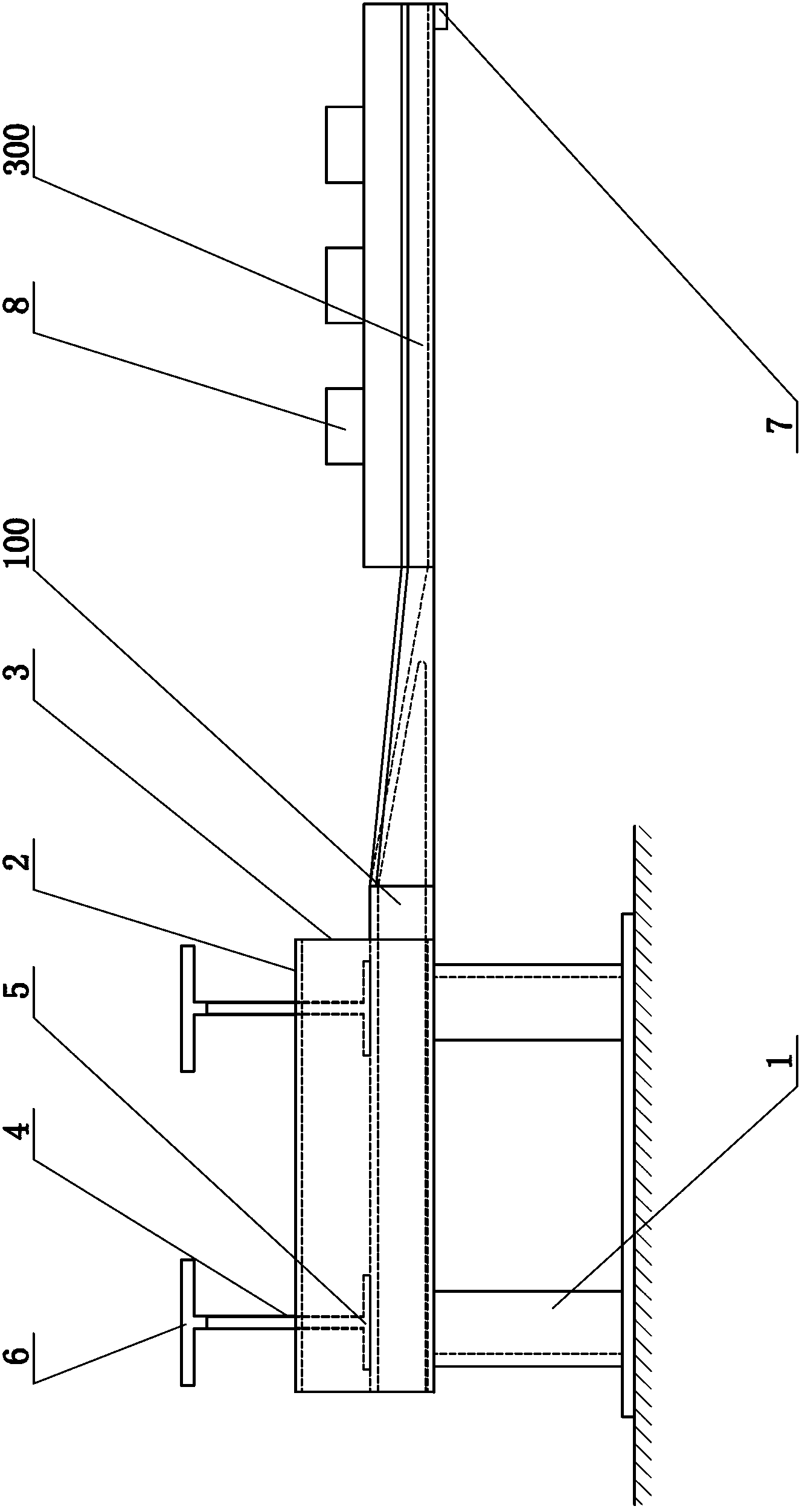

Fully-automatic building block forming machine mechanization production line

InactiveCN101148067ALess investmentSmall footprintDischarging arrangementCeramic shaping plantsEngineeringFully automatic

The semi-automatic mechanized brick producing line with automatic block forming machine includes one board feeding machine connected to one automatic block forming machine and one elevator, one rotary platform following the elevator and with fork lift tracks, one bogie on the bogie tracks perpendicular to the fork lift tracks, fork lift tracks stretching into the curing kiln, and one fork lift on the fork lift tracks and capable of returning to the elevator. The production line of the present invention has less investment, low power consumption, no pollution and other advantages, and is suitable for use in middle sized and small brick making enterprises.

Owner:袁森 +3

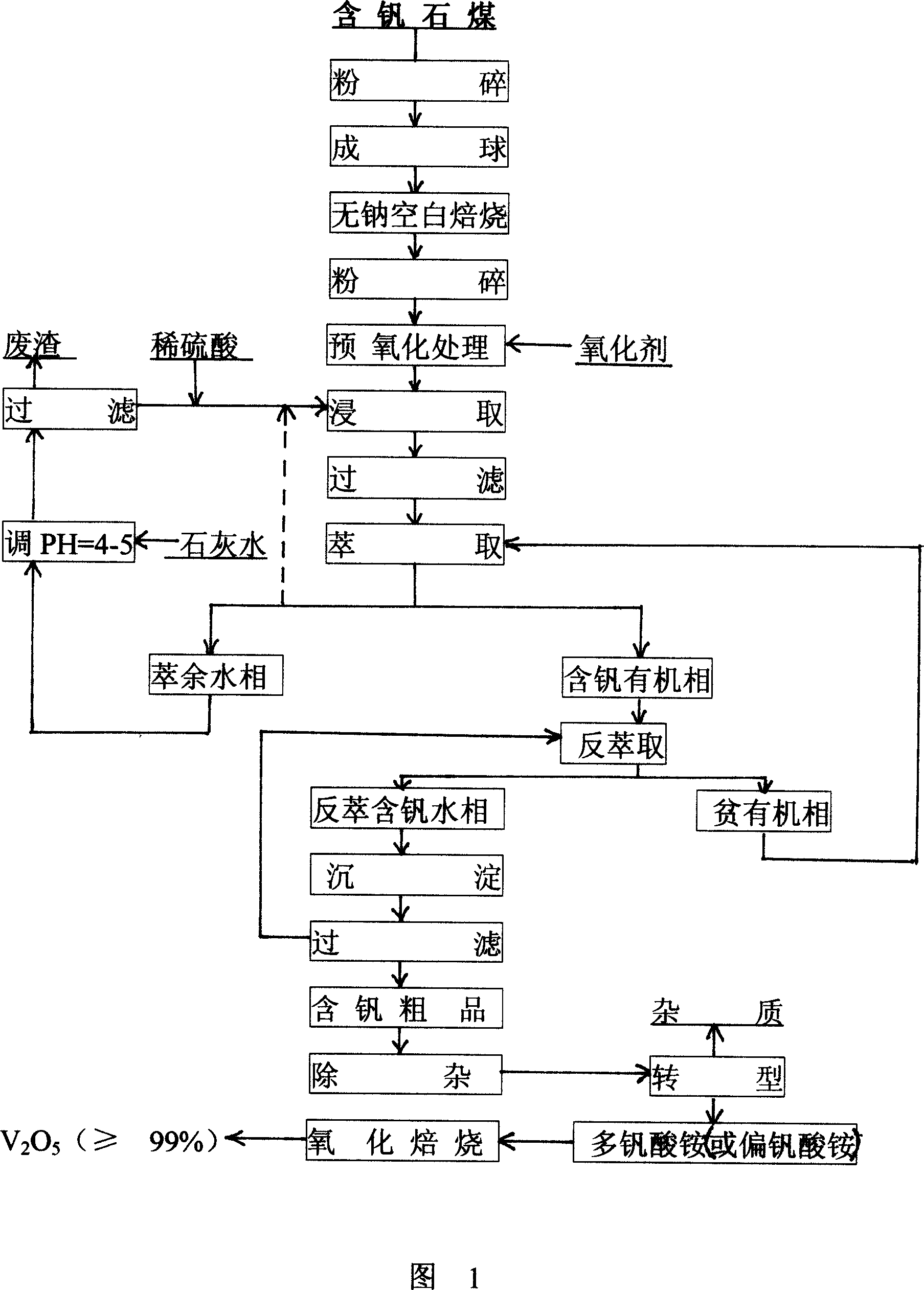

Process for producing vanadium pentoxide from vanadiferous coal stone

This invention relates to a new method for producing V2O5 with coal containing V stones aiming at providing a kind of coal with V stones to be Na-free spacing baked, pre-oxidized to be picked-up by diluted H2SO4 directly to get a V salt solution then to be extracted by TOA organic solvent to increase yield of V products and reduce cost of H2SO4 characterizing in crushing coal with V stones to spheres to be processed by Na-free spacing baking to get rid of carbon and crushed and added with oxidation agent for pre-oxidation process, adding diluted H2SO4 for leaching and filtering it, which is extracted to get V with water organic phase to be counter-extracted, heated, deposited and filtered to get rough products with V, and the final product V2O5 with the content of 99% is got after oxidizing and baking poly-V ammonium or ammonium metavanadate after being purified, and the rest solution after extraction is added with limewater and filtered to be recovered for leaching.

Owner:邓镇炎

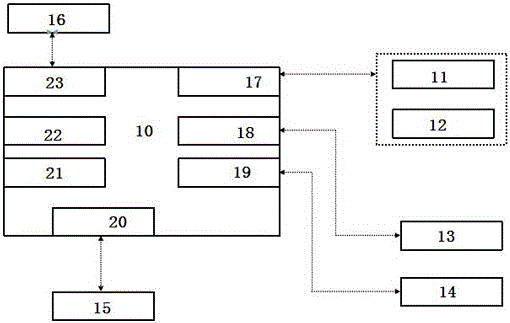

Full-automatic micro-fluidic chip fluorescence immune detection system and detection method implemented by same

ActiveCN107102131ANo need for manual sample additionReduce usageLaboratory glasswaresBiological testingFluorescenceControl system

The invention belongs to the field of immune detection and analysis, and particularly relates to a full-automatic micro-fluidic chip fluorescence immune detection system and a detection method implemented by the same. The full-automatic micro-fluidic chip fluorescence immune detection system comprises a shell and a main framework, and is characterized in that a chip card storage disc and a sample tube disc are fixed to the upper portion of the main framework, a centrifugal reaction disc is arranged between the chip card storage disc and the sample tube disc, and a filling system and a cleaning system are arranged between the centrifugal reaction disc and the sample tube disc; an optical detection system is arranged on the main framework and corresponds to the centrifugal reaction disc, a control system and motors are arranged inside the main framework, and the chip card storage disc, the centrifugal reaction disc, the sample tube disc and the filling system can be driven by the motors to rotate. The full-automatic micro-fluidic chip fluorescence immune detection system and the detection method have the advantage that requirements on full automation, multiple samples, high flux and quick detection can be fundamentally met by the full-automatic micro-fluidic chip fluorescence immune detection system.

Owner:沈阳优宁生物科技有限公司

Rubber tire tread and milling process thereof

The invention discloses a rubber tire tread and a milling process thereof. The rubber tire tread comprises the following components in parts by weight: 70-110 parts of natural rubber, 0-15 parts of styrene-butadiene rubber, 5-20 parts of tread rubber powder, 1.5-2.5 parts of stearic acid, 1-2 parts of sulfur powder, 2-18 parts of white carbon black, 12-15 parts of carbon block, 2-30 parts of aromatic oil, 1-8 parts of zinc oxide, 4-7 parts of an anti-aging agent, 1-4 parts of pine tar, 1-4 parts of an accelerating agent, 0.2-1 part of an anti-reversion agent and 2-5 parts of a binding agent. A three-section milling process is adopted, and the milling process can improve the abrasive resistance, tear resistance and chunking and chipping resistance of the tire tread.

Owner:SHANDONG YONGTAI CHEM GROUP

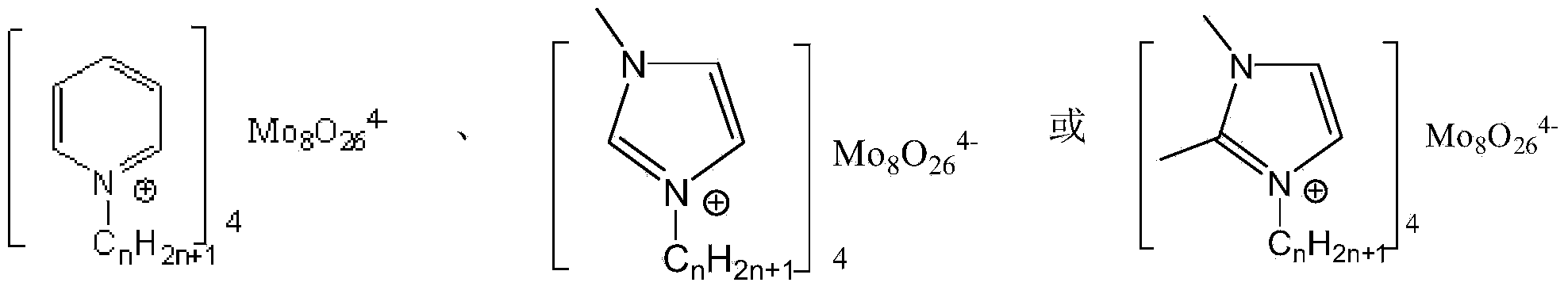

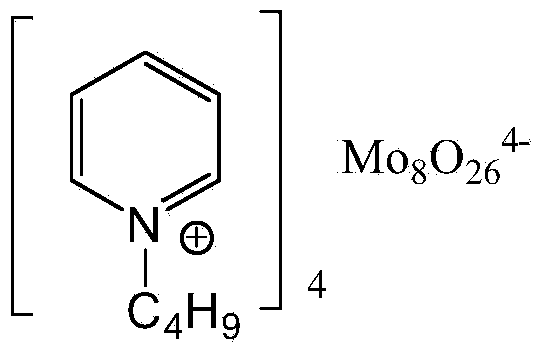

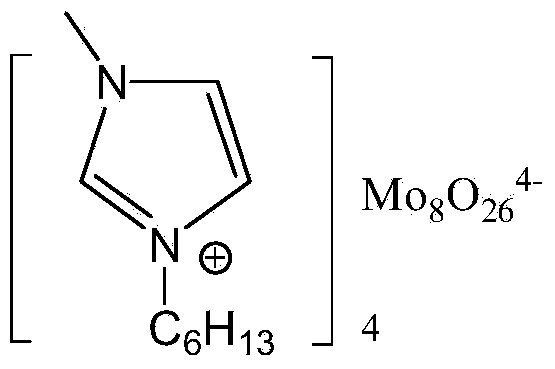

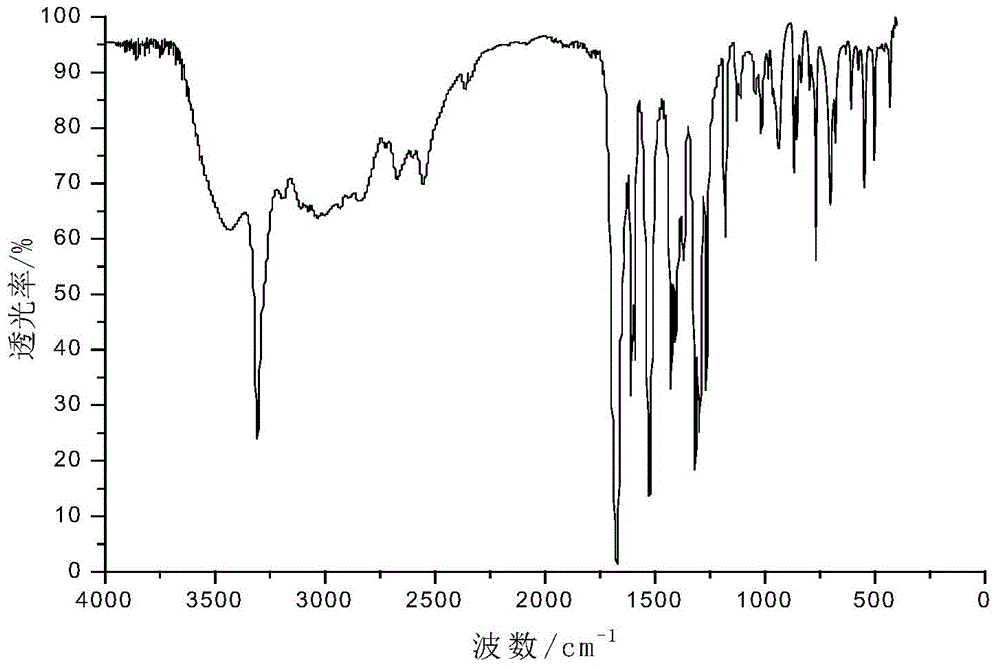

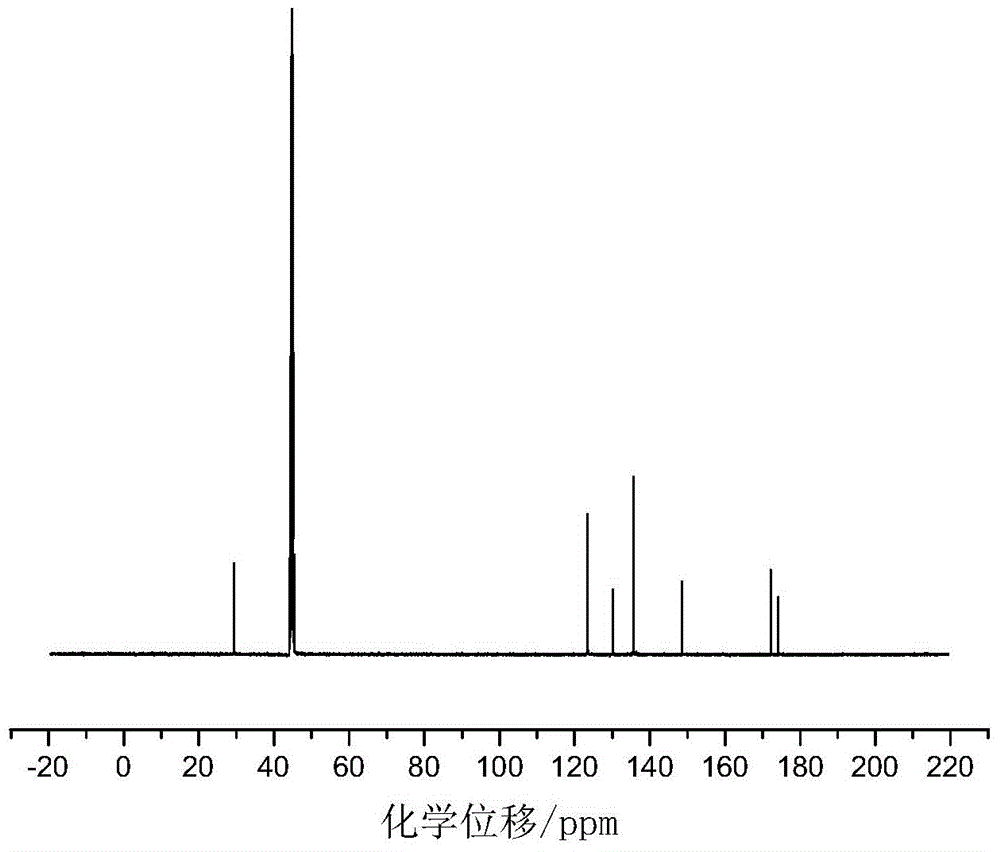

FCC (Fluid Catalytic Cracking) gasoline oxidation desulphurization method based on molybdenum polyoxometallate

ActiveCN103666536AReduce dosageHigh removal rateOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsRotary evaporatorIonic liquid

The invention relates to a FCC gasoline oxidation desulphurization method based on molybdenum polyoxometallate. A technical scheme used is as follows: molybdenum polyoxometallate based on Mo8O26 negative ions is used as a catalyst, and the catalyst, an ionic liquid, a hydrogen peroxide solution and FCC gasoline are mixed; desulphurization temperature is 40-70 DEG C, pressure is ordinary pressure, and desulphurization time is 0.5-1.5 hours; after reaction, reactant is cooled to room temperature, and is subjected to standing and layering, wherein the upper layer is the desulphurized FCC gasoline; measurement shows that primary desulfurization degree of the method to the FCC gasoline with initial sulphur content of about 114ppm is more than 95%, and the sulphur content can be reduced to be less than 10ppm; the ionic liquid and the catalyst at the lower layer can be recycled after being treated by evaporative dehydration through a rotary evaporator, back extraction so as to separate sulfone compounds, and drying under vacuum condition. In the method, catalyst dosage is low and desulfurization degree is high; moreover, the ionic liquid can be recycled, oil yield is high, cost is low, and environment pollution is prevented.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

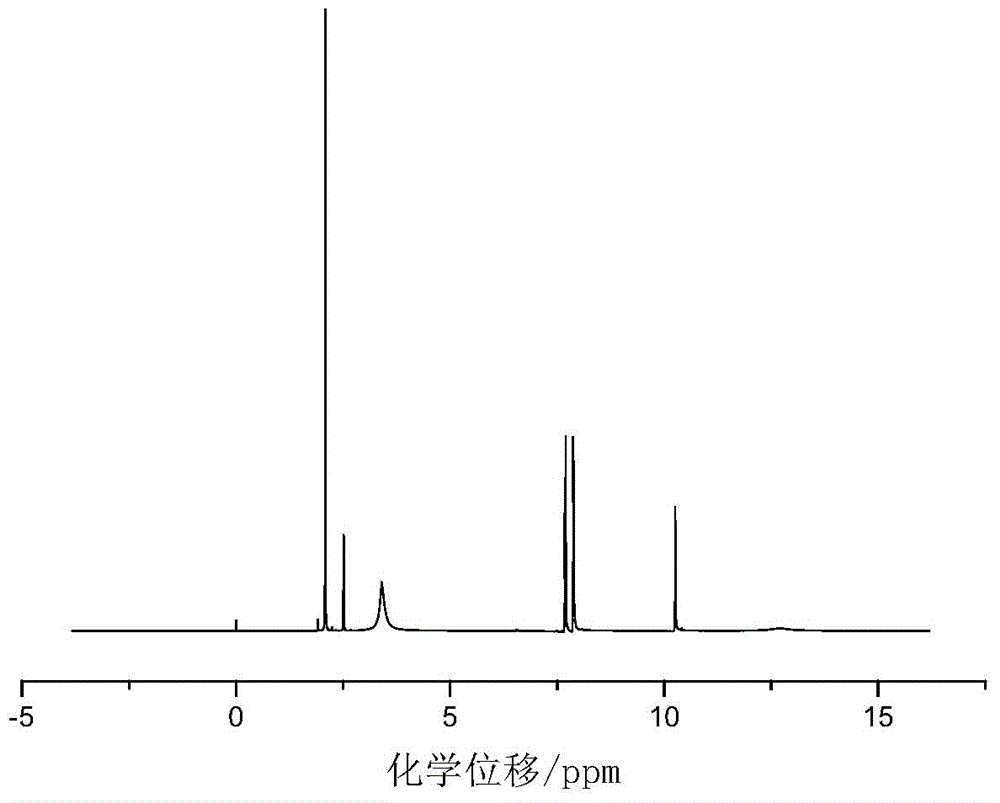

Reaction-type halogen-free flame retardant bis-(p-aminocarboxyphenyl)phenylphosphine oxide and synthetic method thereof

InactiveCN104945658APollution is notReduce production stepsGroup 5/15 element organic compoundsBenzoic acidDichlorophenylphosphine

The invention relates to reaction-type halogen-free flame retardant bis-(p-aminocarboxyphenyl)phenylphosphine oxide and its synthetic method and application and belongs to the field of preparation of a flame retardant. The synthetic method comprises the following steps: using glacial acetic acid as a solvent, adding para amino benzoic acid into glacial acetic acid, slowly dropwise adding dichlorophenylphosphine oxide into an acetic acid solution of para aminobenzoic acid, continuously stirring and reacting at 85-95 DEG C for 4-6 h, and absorbing hydrogen chloride discharged by the reaction by the use of aqueous alkali; and cooling a reaction product after the end of the reaction, carrying out suction filtration, washing and drying to obtain white powdery bis-(p-aminocarboxyphenyl)phenylphosphine oxide. The bis-(p-aminocarboxyphenyl)phenylphosphine oxide flame retardant has advantages of low toxicity, low smoke, innocuousness, high efficiency and the like, is a reactive flame retardant integrating a carbon source, an acid source and a gas source, and is applied in inherent flame retarding of nylon or thermoplastic polyester copolymer.

Owner:NANJING LIHAN CHEM CO LTD

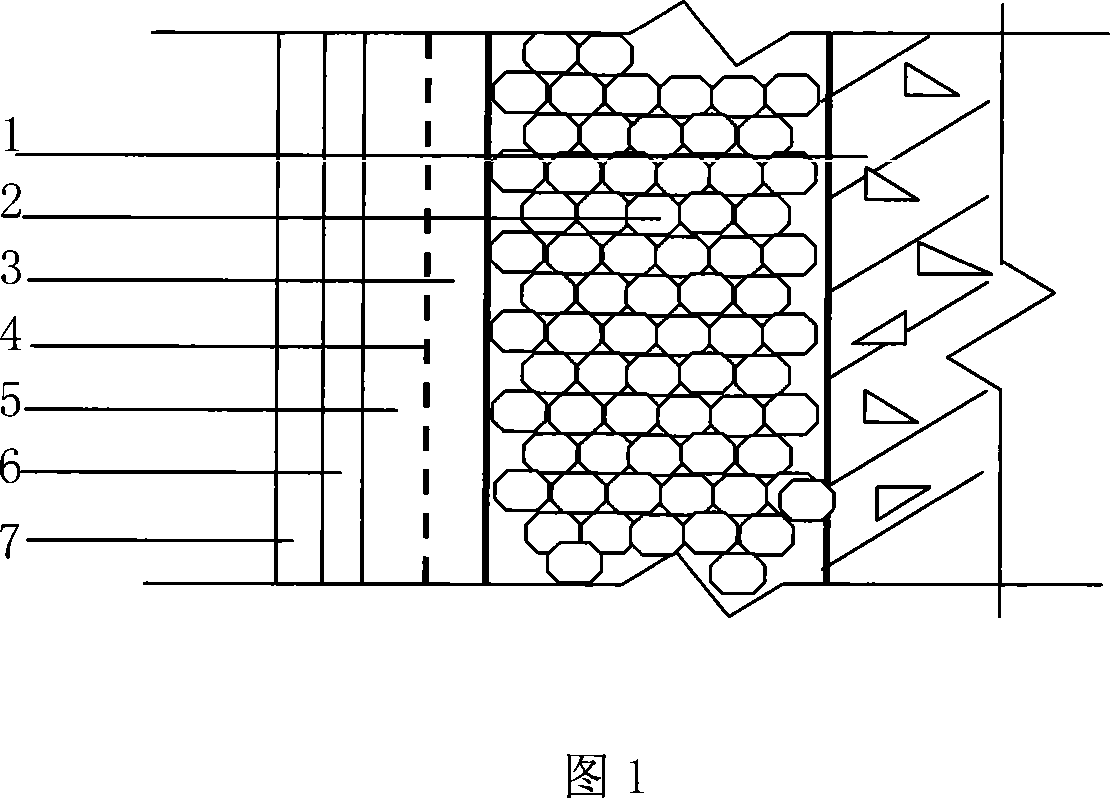

Rare-earth composite wall heat-insulating layer and heat-insulating layer material preparation method

InactiveCN101215858AHigh strengthImprove insulation effectCovering/liningsClimate change adaptationInfraredRare earth

The invention relates to a heat-insulating layer of a rare earth complex wall body and the manufacturing method of heat-insulating layer material, which belongs to the field of architectural materials. The invention is characterized in that the process for preparation comprises mixing rare earth rubber powder by weight ratio that rubber powder: water = 1:1 to 1.5, adding polyphenyl particles into material which is mixed, the proportion is that rubber powder: EPS particles = 1 kg: 8 L, continuously mixing for 5-10 min to make rare earth rubber powder EPS particle heat-insulating material, mixing rare earth trowel finish sand with water according to the proportion that rare earth trowel finish sand: water = 1: 1 into slurry, making rare earth trowel finish sand slurry, and brushing rare earth rubber powder EPS particle heat-insulating material, trowel finish sand slurry, standard net cloth, rare earth trowel finish sand slurry, flexible putty and face coat on the base layer of the wall body in turn. The invention has good heat-insulating property, strong binding power, high compression strength, good water resistance and flame proof, which is antiseptic, noncorrosive, nontoxic, tasteless and pollution-free, has the function of absorbing ultraviolet ray and infrared ray, and has quick coagulate speed, rapid increase of the strength of materials, and the construction procedure is rapid, timesaving and laborsaving.

Owner:包头市科强新型材料有限公司

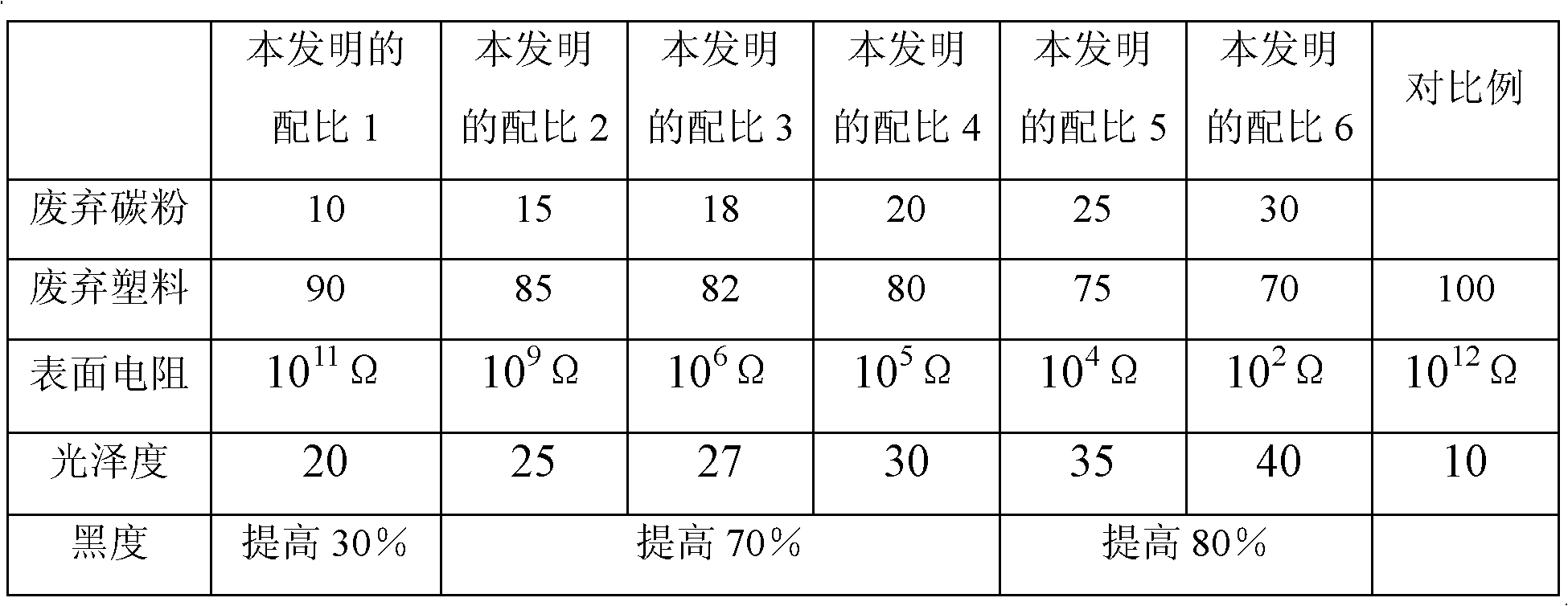

Recovery method and recovery device for waste carbon powder, and regenerated plastic thereof

InactiveCN102339006APollution is notCollect completelySievingDispersed particle filtrationRecovery methodFiltration

The invention discloses a recovery method and a recovery device for waste carbon powder, and regenerated plastic thereof. The recovery method for waste carbon powder comprises the steps of: conducting suction filtration to a raw material of waste carbon powder so as to remove impurities therein; pumping and filtering out the waste carbon powder with impurities removed, and collecting the powder for storage. The recovery device consists of an air duct, an air pumping mechanism connected to the air duct for pumping the carbon powder flow, a filtering mechanism arranged in front of the air duct for impurity filtration, an exhausting and powder filtering mechanism only able to exhaust air but unable to permeate carbon powder and a carbon powder storing mechanism that are positioned at the back of the air duct. The regenerated plastic is prepared by cooperation of the raw material of waste carbon powder recovered by the recovery method or the recovery device and waste plastic. The recovery method for waste carbon powder in the invention is simple and reliable, and has no environmental pollution. The recovery device for waste carbon powder in the invention has the advantages of simple structure, utility and convenience, high carbon powder recovery efficiency and no environmental pollution. Prepared by waste carbon powder, the regenerated plastic can have improved antistatic property or conductivity, and the plastic product can have better surface gloss.

Owner:ECO MATERIAL CHINA CORP

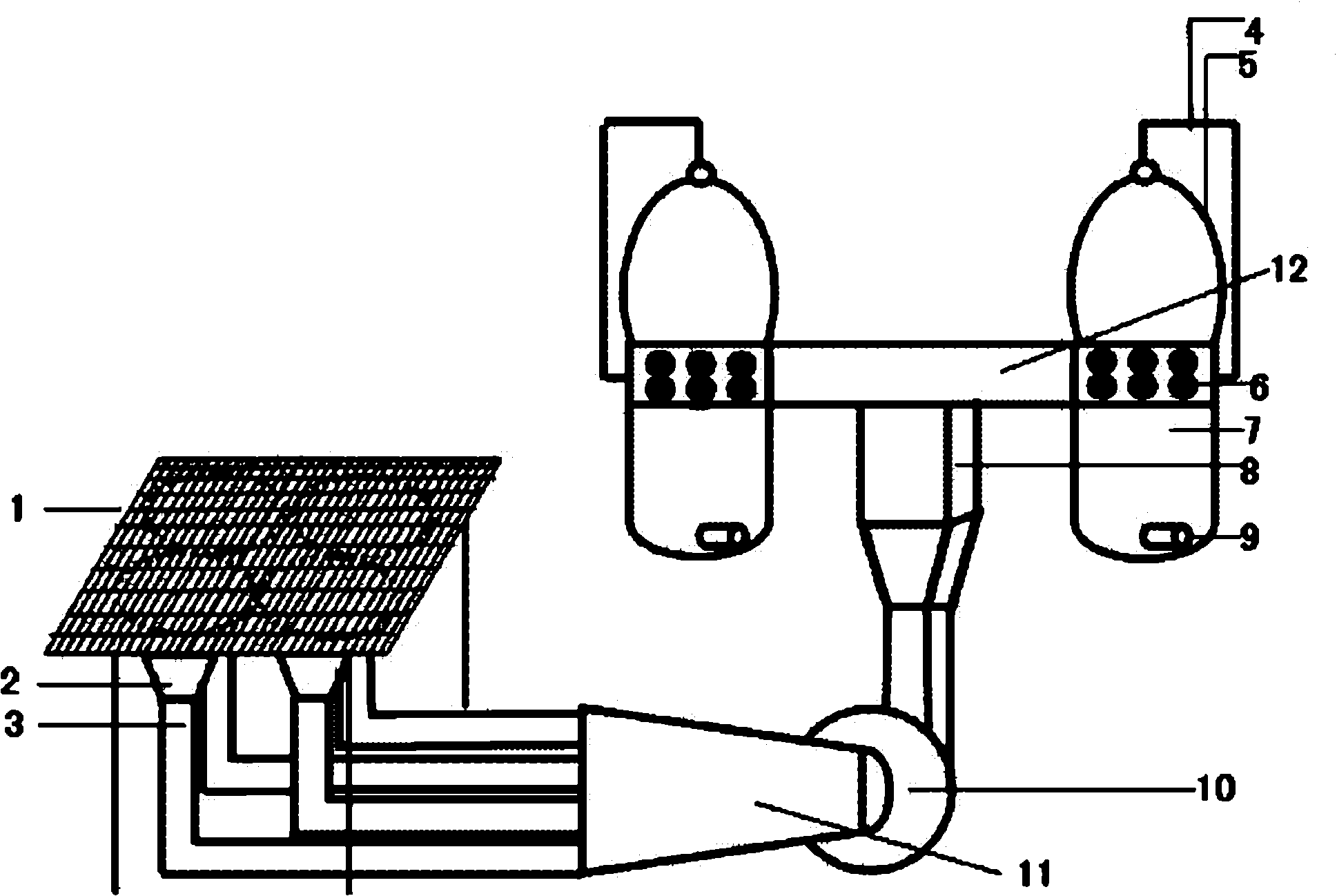

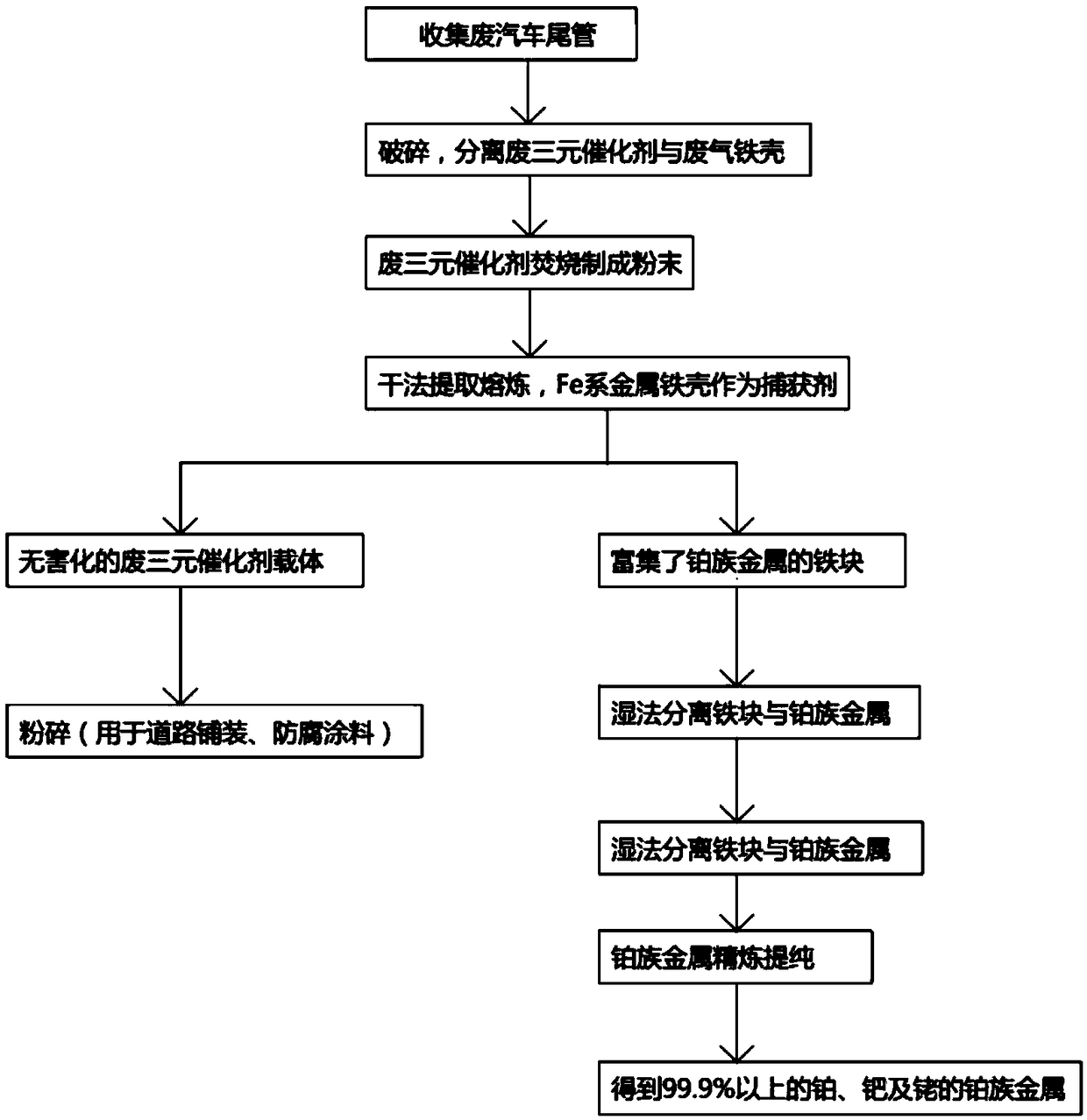

Comprehensive recovering and environmentally-friendly recycling method of wasted three-way catalyst

InactiveCN109338107APromote recycling levelsAccelerate the accumulation processProcess efficiency improvementElectric arc furnaceSeparation technology

The invention discloses a comprehensive recovering and environmentally-friendly recycling method of a wasted three-way catalyst. The method comprises the following steps: (1) collecting wasted automobile exhaust pipes containing the wasted three-way catalysts; crushing; and separating the wasted three-way catalysts and wasted iron housings; (2) incinerating the wasted three-way catalyst; and powdering; (3) extracting and melting the wasted three-way catalyst powder through an electric arc furnace in a dry manner; adding Fe serial iron block as a trapping agent; and extracting and separating platinum group metal enriched iron blocks and harmless wasted three-way catalyst carriers; (4) separating the iron blocks and platinum group metal from the platinum group metal enriched iron blocks; andseparating the platinum group metal by grades through a graded extracting and resin adsorbing type wet separation technology; and (5) refining and purifying the separated platinum group metal until the purity is more than 99.9%, thus obtaining the high-purity platinum group metal. According to the method, the precious metal recycling capacity is improved; the environmental pollution is reduced; and the environment is improved.

Owner:WUYI UNIV

Quenching process for heat treatment of high-chromium iron wear-resisting ball in water-based medium

InactiveCN103898296ANo pollution in the processPollution is notQuenching agentsHeat conservationChromium

The invention discloses a step and isothermal quenching process for heat treatment of a high-chromium iron wear-resisting ball in a water-based medium, which comprises the steps of heating the high-chromium iron wear-resisting ball to 850-1050 DEG C and preserving the temperature for 2-4h to realize austenitizing, putting the high-chromium iron wear-resisting ball into a 5-25% water-based quenching agent, taking out the high-chromium iron wear-resisting ball to be put into an isothermal oven at 220-300 DEG C for isothermality for 2-4h, and taking out the high-chromium iron wear-resisting ball and air cooling to the room temperature. In the heat treatment process of the wear-resisting ball, the water-based quenching medium is used, appropriate quenching speed is controlled by adding the water-based quenching medium at different cooling speeds and controlling the concentration of the quenching medium, the step quenching process and isothermal quenching process are used to ensure that the quenched wear-resisting ball has more ideal comprehensive effect than the wear-resisting balls which are produced by using common quenching media and quenching processes, and at the same time, the heat treatment cost of the wear-resisting ball can be reduced and the environmental conditions of the heat treatment can be improved.

Owner:BEIJING JATR NEW MATERIAL TECH

Outdoor large-cherry soil test fertilizer application method

An outdoor large-cherry soil test fertilizer application method comprises a step of soil nutrient detection, a step of fertilizer preparation amount calculation, and a step of fertilizer application, so the method reaches scientific and reasonable fertilizer application, and realizes the adjustment of measures according to local conditions, thereby the method has the advantages of no soil nutrient loss, imbalance, surface source pollution or soil acidification, proper fertilizer application, fruit quality improvement, no pollution, and no physiological diseases, and is especially suitable for the large-cherry fertilizer application.

Owner:招远市农业技术推广中心

Method for one-step hydration synthesis of terpilenol by catalyzing turpentine through carbon-based solid acid

ActiveCN104529707AHigh activityEasy to recyclePhysical/chemical process catalystsOrganic compound preparationHydration reactionPtru catalyst

The invention provides a method for one-step hydration synthesis of terpilenol by catalyzing turpentine through carbon-based solid acid. The method is characterized in that the turpentine is used as the raw material, isopropyl alcohol or butyl alcohol or isobutyl alcohol is used as the solvent, and the terpilenol is formed by means of one-step hydration synthesis through the turpentine under the catalytic action of a carbon-based solid acid catalyst. The carbon-based solid acid is prepared through a lignin gel method and has the advantages of developed micropores and mesopores, high catalytic activity, easy separation, good thermostability, repeatable utilization, easy regeneration, low preparation cost and the like; since the carbon-based solid acid is used for catalyzing the turpentine to form the terpilenol by means of one-step hydration synthesis, the conversion rate of the turpentine is up to 95-98 percent, and the yield of the terpilenol is 35-42 percent; besides, in the production process, no liquid waste acid or waste water is produced, pollution to the environment is greatly relieved, and the requirement for green chemistry is met.

Owner:GUANGXI UNIV FOR NATITIES

Separation and purification method of beauveria bassiana

ActiveCN103571760AFast separation and purificationGrowth inhibitionFungiMicroorganism based processesPurification methodsCulture mediums

The invention relates to the technical field of identification, separation and purification application of beauveria bassiana strains, and discloses a separation and purification method of beauveria bassiana. By adopting the separation and purification method, a culture medium is scientifically optimized and improved; simple, quick and effective separation and purification of the beauveria bassiana are achieved by combining improvement of cultivation device coverings on the basis of the culture medium with a scientific formula. The method disclosed by the invention is simple and quick to operate, wide in samples applicable to separation and purification of the beauveria bassiana, low in operation cost and free of pollution on environment; the targets of separation and purification can be well achieved.

Owner:SOUTH CHINA AGRI UNIV

Gripper used for semiconductor laser chamber surface filming and bar loading device

InactiveCN1606204ANo mechanical damageGuaranteed uniformityLaser optical resonator constructionVicesMechanical engineeringSemiconductor

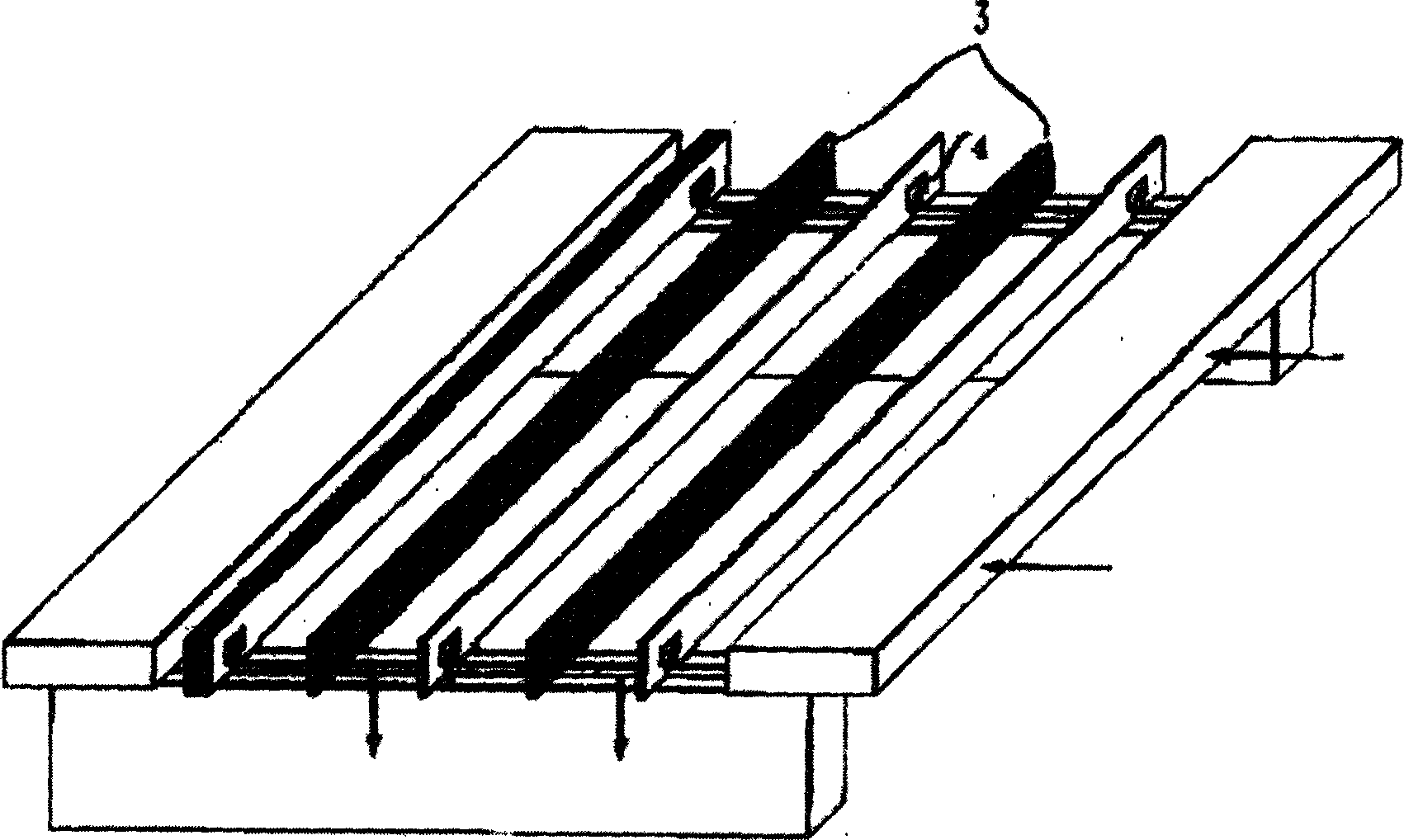

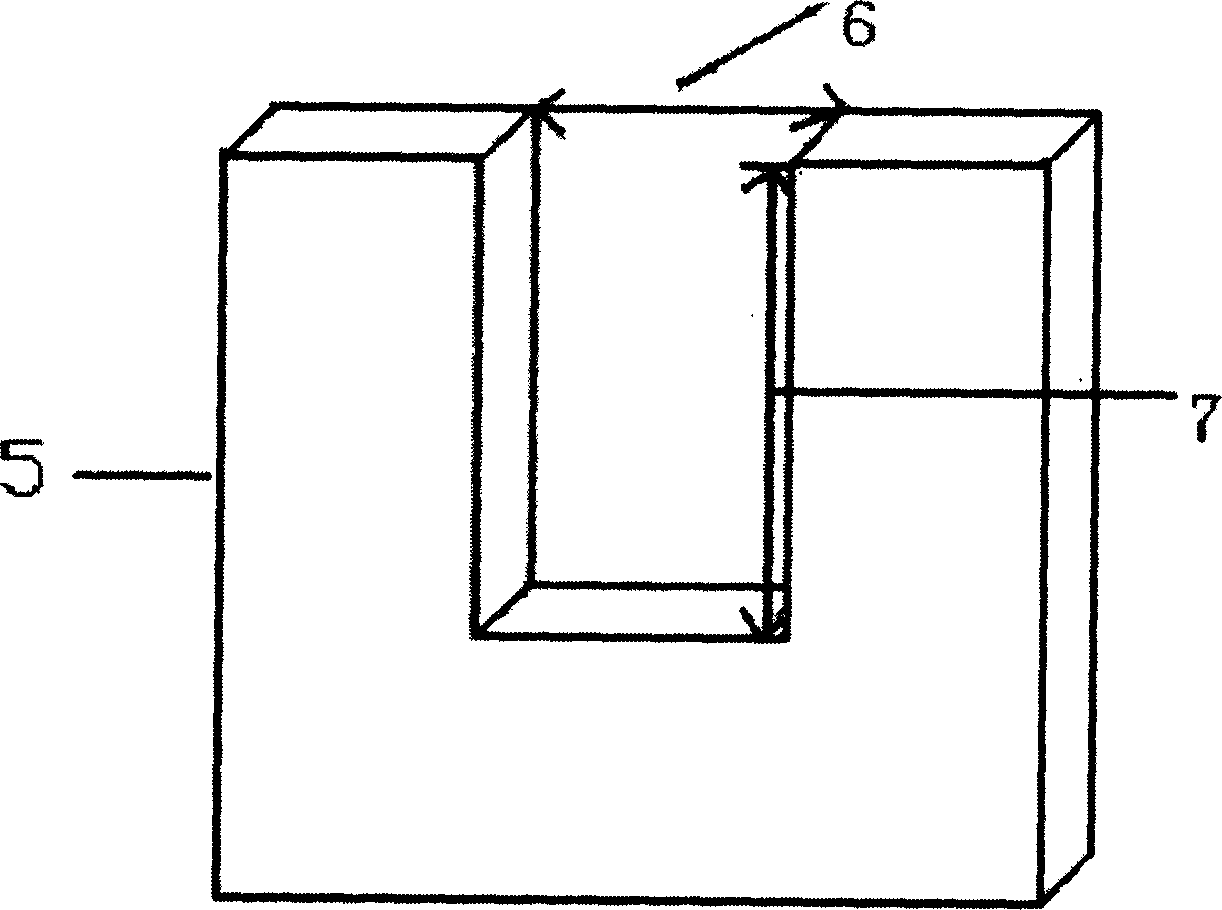

This invention provides a clamp used semiconductor laser cavity face coating composed of three parallel concave plates, a rectangular thin plate and a block for fixing and gripping. This invented strip installing device includes a vertical slide unit, a horizontal slide unit and a base, the vertical and slide units are same in structure all constituting a slide guide and a screw stem for adjusting the slide and a slide block.

Owner:BEIJING UNIV OF TECH

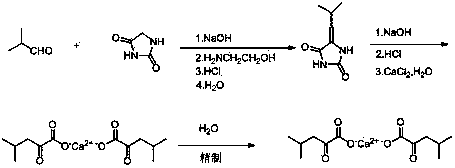

Environment-friendly technology for preparing ketoleucine calcium in aqueous phase

ActiveCN104058954AAvoid pollutionPollution is notCalcium/strontium/barium carbonatesOrganic compound preparationSolventHydrolysis

The invention relates to an environment-friendly technology for preparing ketoleucine calcium in an aqueous phase. Isobutylidene hydantoin and a calcium chloride aqueous solution serve as raw materials, and water serves as a solvent. The environment-friendly technology comprises the steps that heating reflux hydrolysis is carried out on the isobutylidene hydantoin in water and industrial liquid alkali, the calcium chloride aqueous solution is dropwise added, the mixed solution is filtered, filtered liquid is collected and cooled, hydrochloric acid acidification is carried out, vacuum nitrogen displacement is carried out, caustic soda liquid is added for alkalization, cooling is carried out, the calcium chloride aqueous solution is dropwise added, calcium salt is obtained, cooling is carried out, a crude product is obtained through filtering, the crude product is refined in purification water, and a ketoleucine calcium refined product is obtained. The environment-friendly technology for preparing the ketoleucine calcium in the aqueous phase has the advantages of being easy to operate, simple in steps, high in yield coefficient, good in product quality, environmentally friendly and the like. According to the environment-friendly technology for preparing the ketoleucine calcium in the aqueous phase, the environment-friendly water is adopted as the solvent completely, the requirement of green chemistry development is met, the pollution problem is solved from the source, and the environment-friendly technology is suitable for industrialized mass production.

Owner:SHAOXING MINSHENG PHARMA

Environmentally-friendly plant fiber packing material

InactiveCN101654890AWide variety of sourcesLow pricePulp beating methodsWood working apparatusFoaming agentPlant fibre

The invention relates to an environmentally-friendly plant fiber packing material, and belongs to the field of packing materials. The environmentally-friendly plant fiber packing material is preparedby the following steps: putting plant fibers of agricultural waste straws, wheat stalks, bean stalks, devil's rush herb, corn stalks and the like into a closed container, adding water containing one or more of fungi into the container to soak the plant fibers in the water to be degraded, and then sealing the container and shaking the container for 5 to 7 days; taking the plant fibers out and beating the plant fibers; preparing the plant fibers, adhesive, softener, mildew-proof agent, foaming agent and waterproof agent in a weight ratio of (50-70): (1-2): (0.5-1): (0.5-1): (1-2): (0.5-1); bulking the materials into granules through bulking equipment, and blowing the granules into different models according to the packing requirements; or directly pressing the prepared materials into different packing models on a hot press. The environmentally-friendly plant fiber packing material has the advantages that the material totally uses the plant fibers of the straws, wheat stalks, bean stalks,devil's rush herb, corn stalks and the like, so the source is wide, and the price is low; the production process has no three wastes and does not influence the environment; the product is in accordance with the requirements of environmentally-friendly packing materials on light weight, pressure resistance, seismic resistance, moisture prevention and water prevention; and after discarding, the packing material can be naturally degraded, so the packing material is favorable for environmental protection.

Owner:李小龙 +2

PVC water-proof coiled material

InactiveCN101498161ANo pollution in the processNo excessive phenomenon was foundRoof covering using flexible materialsProtective foundationWeather resistancePaper based

The invention relates to a PVC waterproof coil material which mainly comprises a buffer layer, a PVC material layer and a protective layer. The buffer layer and the PVC material layer are welded and jointed by PVC gaskets; and the protective layer is fixedly adhered to the PVC material layer in a point mode. The PVC waterproof coiled material has the characteristics of high tensile strength, large elongation, good weather resistance, wide range of the service temperature, and the like and the advantages of cold operation, simple and convenient construction, the reduction of environment pollution, the improvement on the labor conditions, and the like, not only makes up the defects of the yield and the performance of paper base asphalt felt, but also can effectively reinforce the impermeable performance of a waterproof layer of the coiled materials, prolong the waterproof durable time of the coiled materials, improve the integral quality of the waterproof layer, ensure that the waterproof layer has higher practical value in the building waterproof engineering and has wider application prospect.

Owner:王金军

Synthesis of poly lactic acid by microwave radiation melt polycondensation method

The invention discloses the synthesis of poly lactic acid by microwave radiation melt polycondensation method which comprises, (1) placing L-lactic acid on auxiliary reaction medium, increasing the system vacuum from 0.050-0.070 Mpa to 0.080-0.099Mpa, microwave radiating 30-50 min, obtaining prepolymer (OLLA), (2) charging catalyst into the prepolymer, microwave radiating 2-5 min under normal pressure, (3) under the condition of vacuum 0.085-0.1Mpa, microwave power 500-550W, radiating 25-50min, thus obtaining polylactic acid.

Owner:HARBIN INST OF TECH

Germination method for furred trichosanthes seed

The present invention discloses the germination method for furred trichosanthes seed. Trichosanthes seed is first taken out from mature fruit, washed, treated directly or air dried; then has its whole or two thirds of coat eliminated and soaked in warm water at 35-40 degc for 24 hr; and finally seeded in sand bed at the density of 5x20 cm to germinate in 7-10 days. After that, the seedling is transplanted into nutritive bag with humus soil and transplanted in field after the seedling grows to 3 or 4 euphyllas. The said method is simple, feasible, low in cost and environment friendly.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

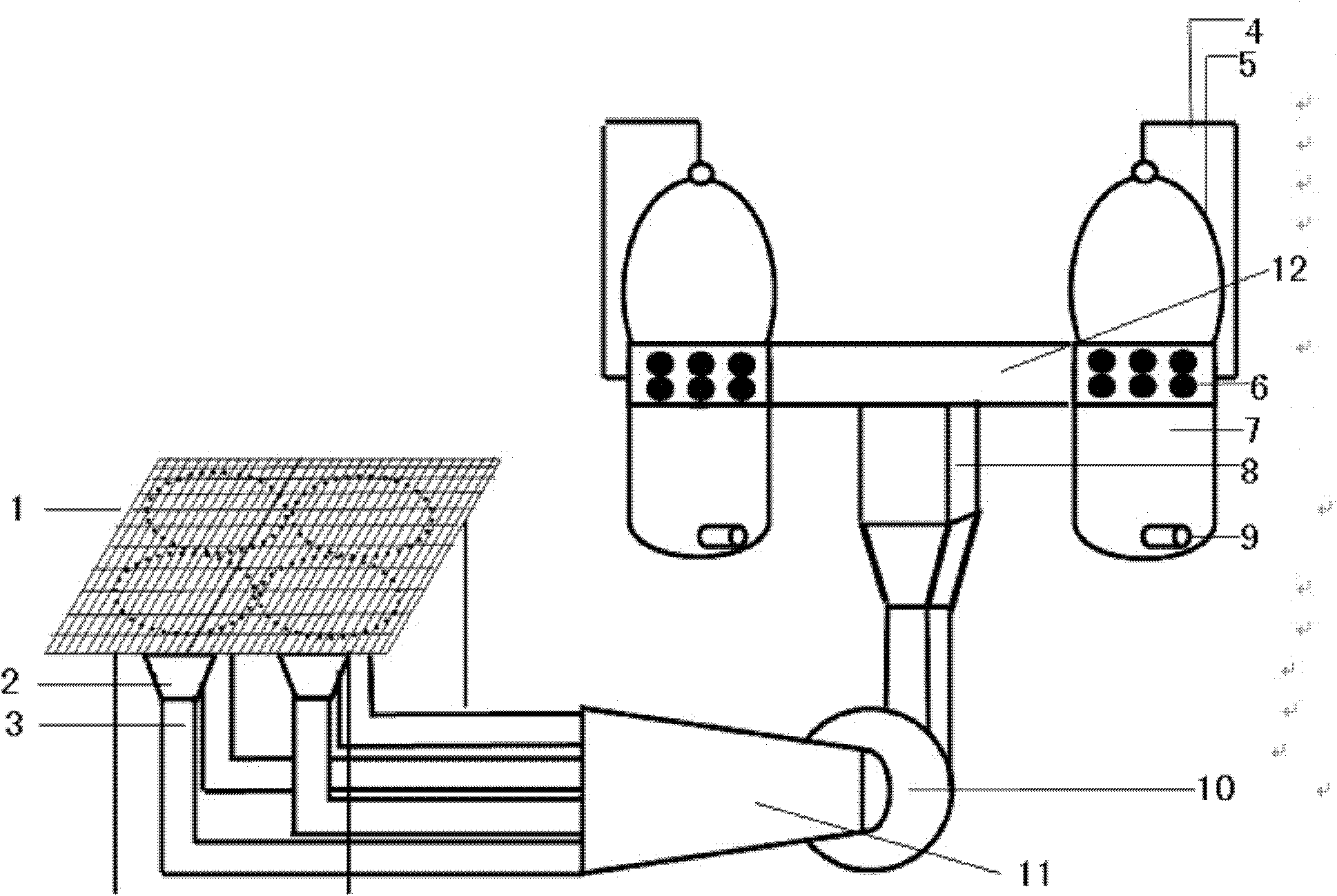

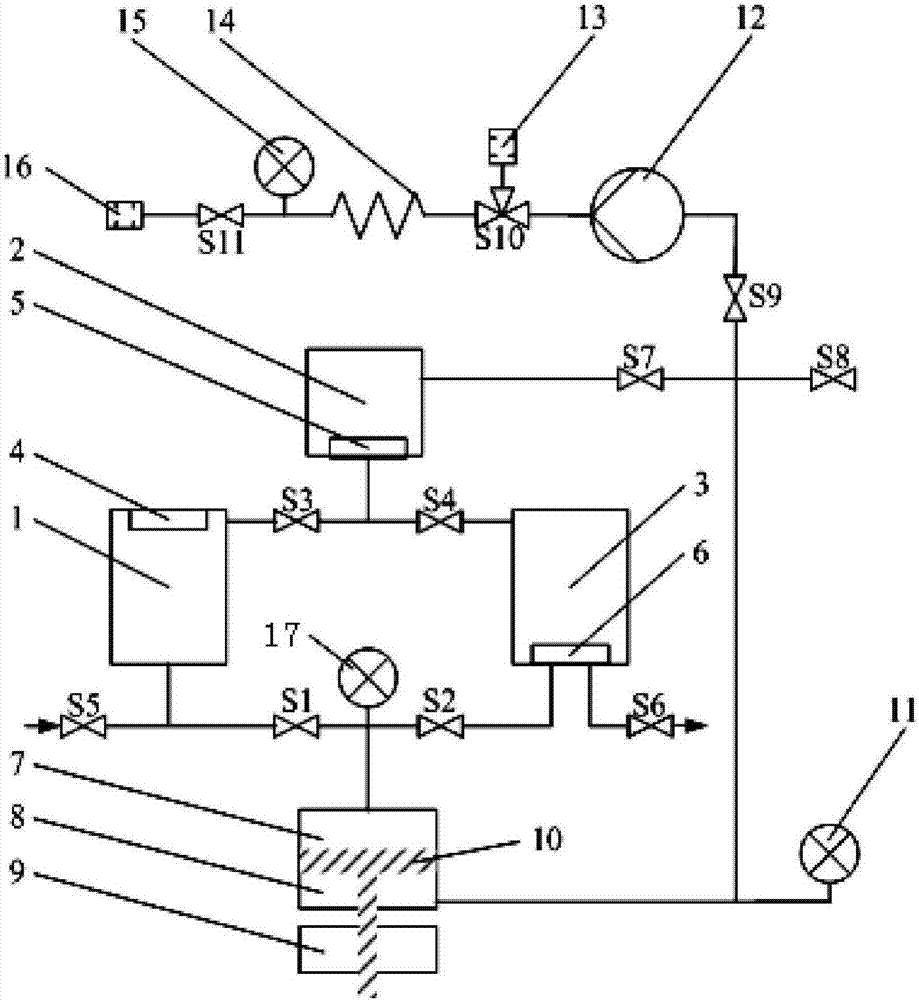

High-concentration vacuum oil-gas separation device and method for online monitoring transformer oil

ActiveCN107247108AFacilitate real-time online analysisShort degassing timeComponent separationAir quality improvementAir pumpDrive motor

The invention relates to a high-concentration vacuum oil-gas separation device and method for online monitoring transformer oil. The high-concentration vacuum oil-gas separation device is provided with a quantification chamber, a gas well, an oil well, a degassing chamber, a gas collection chamber, a quantification pipe, an anti-vacuum gas pump, a driving motor and oil and gas pipelines, wherein a gas path part of a vacuum degassing machine is formed by the gas collection chamber, the anti-vacuum gas pump and the quantification pipe; the lower end of the quantification chamber is connected with an oil outlet of a transformer oil tank and the degassing chamber respectively and the upper end of the quantification chamber is connected with the gas well; the upper end of the gas well is connected with the gas collection chamber through a gas pipeline and the lower end of the gas well is connected to the upper end of the quantification chamber and the upper end of the oil well; the lower end of the oil well is connected with the degassing chamber and an oil inlet of the transformer oil tank through two branch pipelines respectively; the degassing chamber and the gas collection chamber are separated through a piston and the driving motor is connected with the piston; a gas inlet of the anti-vacuum gas pump is connected with the gas collection chamber and a gas outlet of the anti-vacuum gas pump is connected with the quantification pipe. According to the high-concentration vacuum oil-gas separation device and method provided by the invention, degassing is finished by adopting a vacuum degassing principle and real-time online analysis of dissolved gas in the transformer oil is facilitated; a manner of degassing and collecting gas for a plurality of times is adopted, so that the degassing efficiency is high and the repeatability is good.

Owner:SIFANG-TBEA INTELLIGENT ELECTRICAL CO LTD

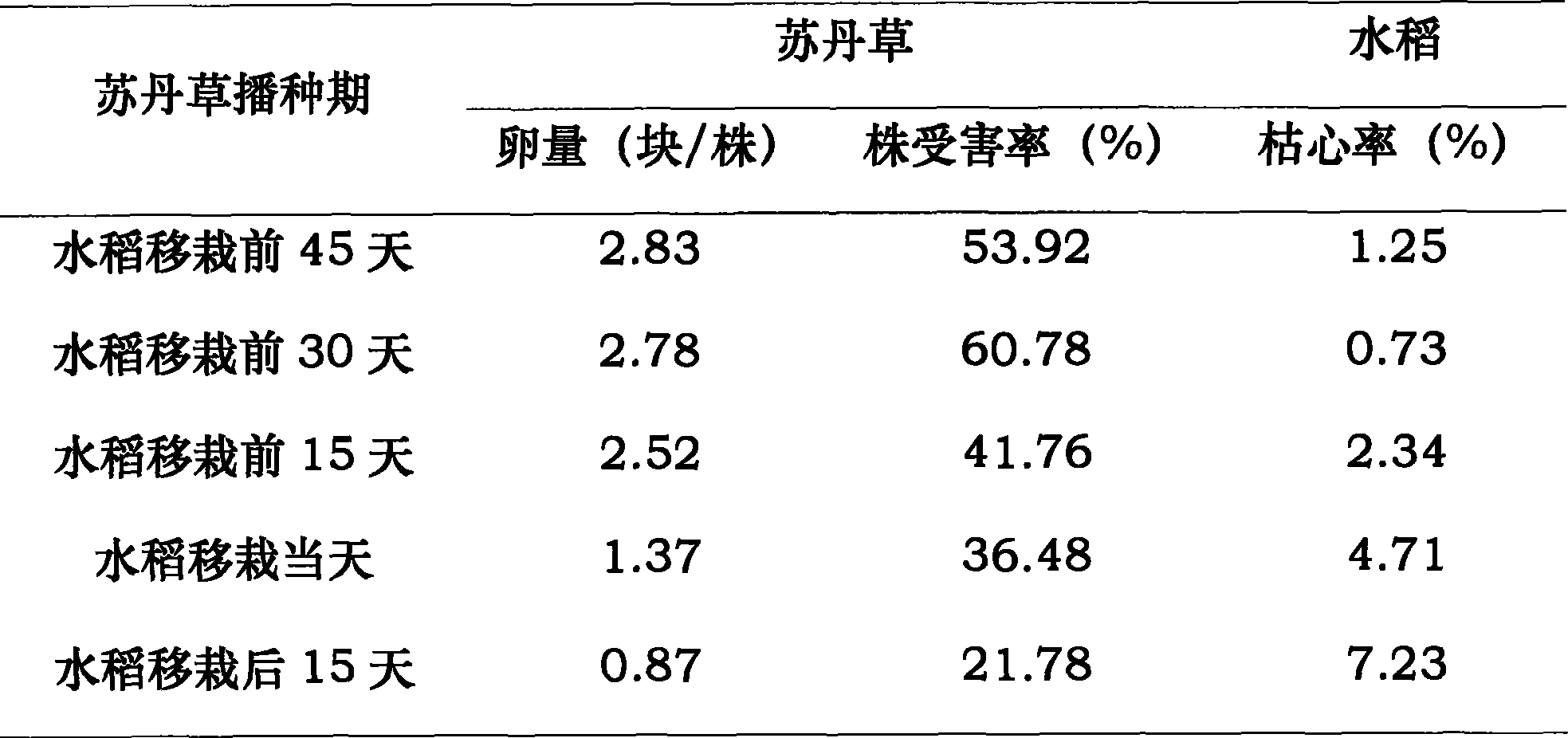

Plant for trapping and killing Phralidid caterpillar as well as using method

InactiveCN101496510AStrong ability to seduceGood lure effectInsect catchers and killersRice cultivationCaterpillarCrop

The invention provides a plant for luring and killing stem borers, and a using method thereof. The method comprises the following steps: Sudan grass is planted around mainly planted crops or is planted alternately with the mainly planted crops; the stem borers are lured into laying eggs or staying on the Sudan grass by utilizing the special luring capability of the Sudan grass to the stem borers; and then the Sudan grass is intensively removed or the stem borers on the Sudan grass are directly killed so as to control the harm of the stem borers to the mainly planted crops. The method has the characteristics of labor conservation, time conservation, simple operation, no environmental pollution and the like.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

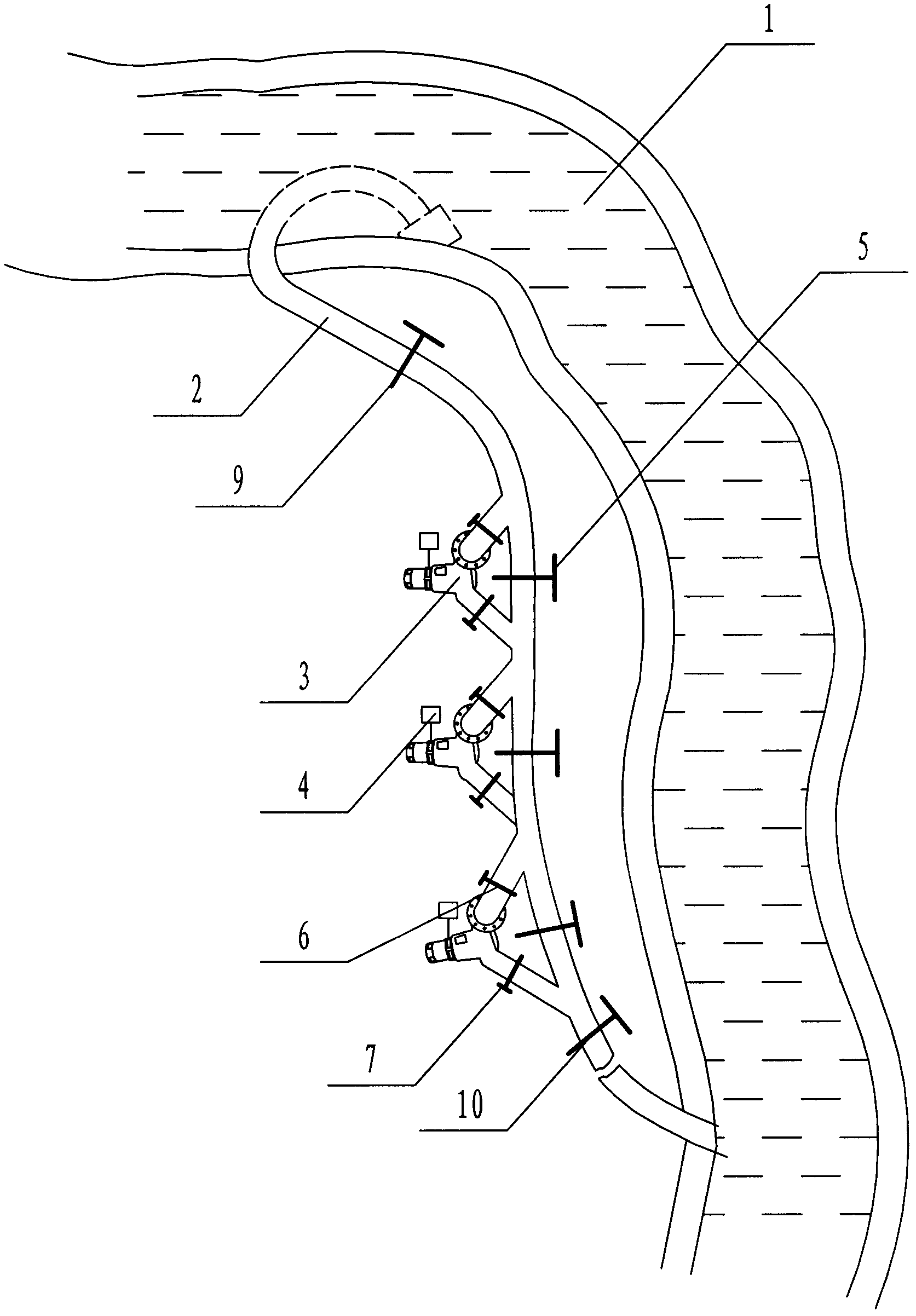

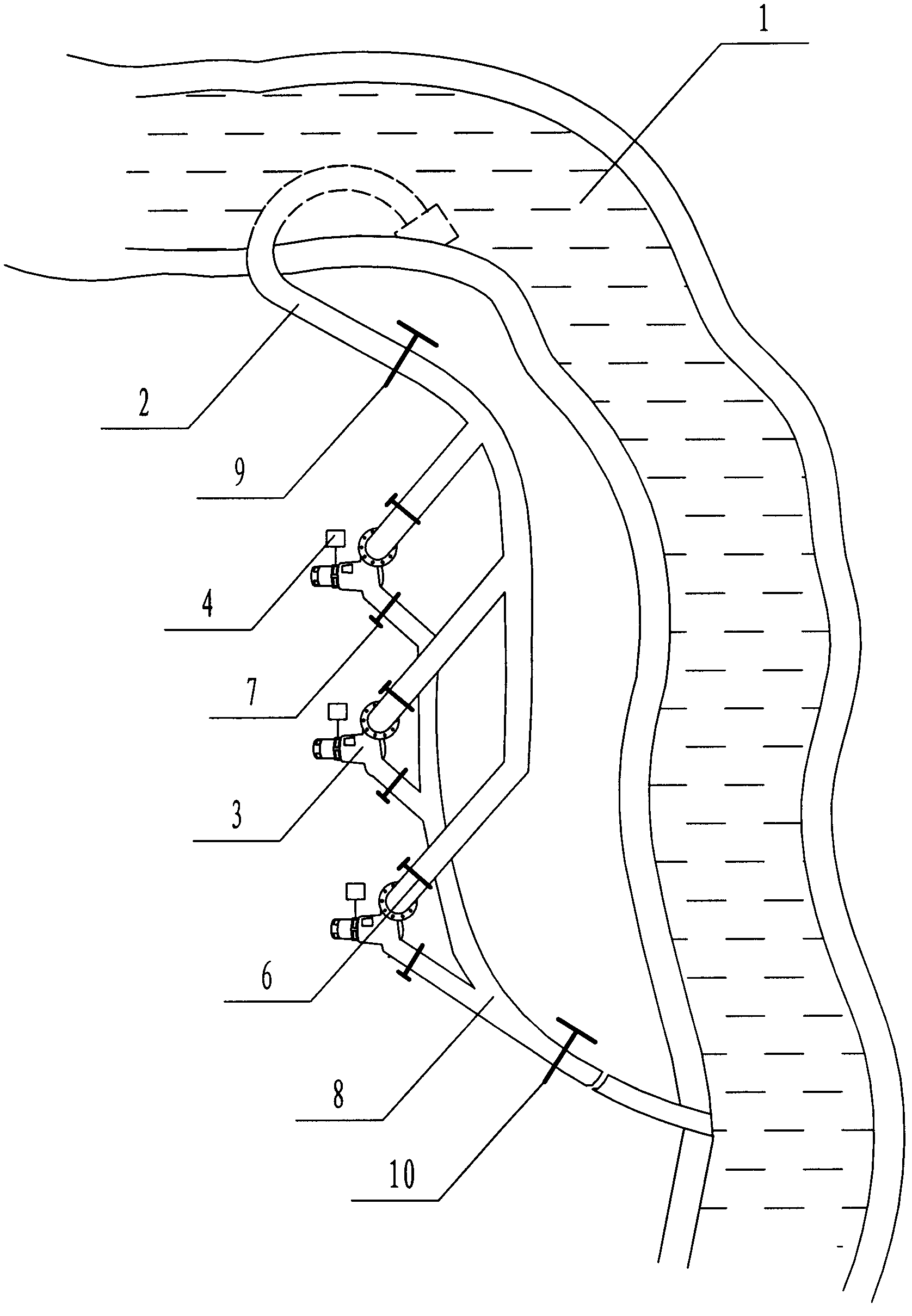

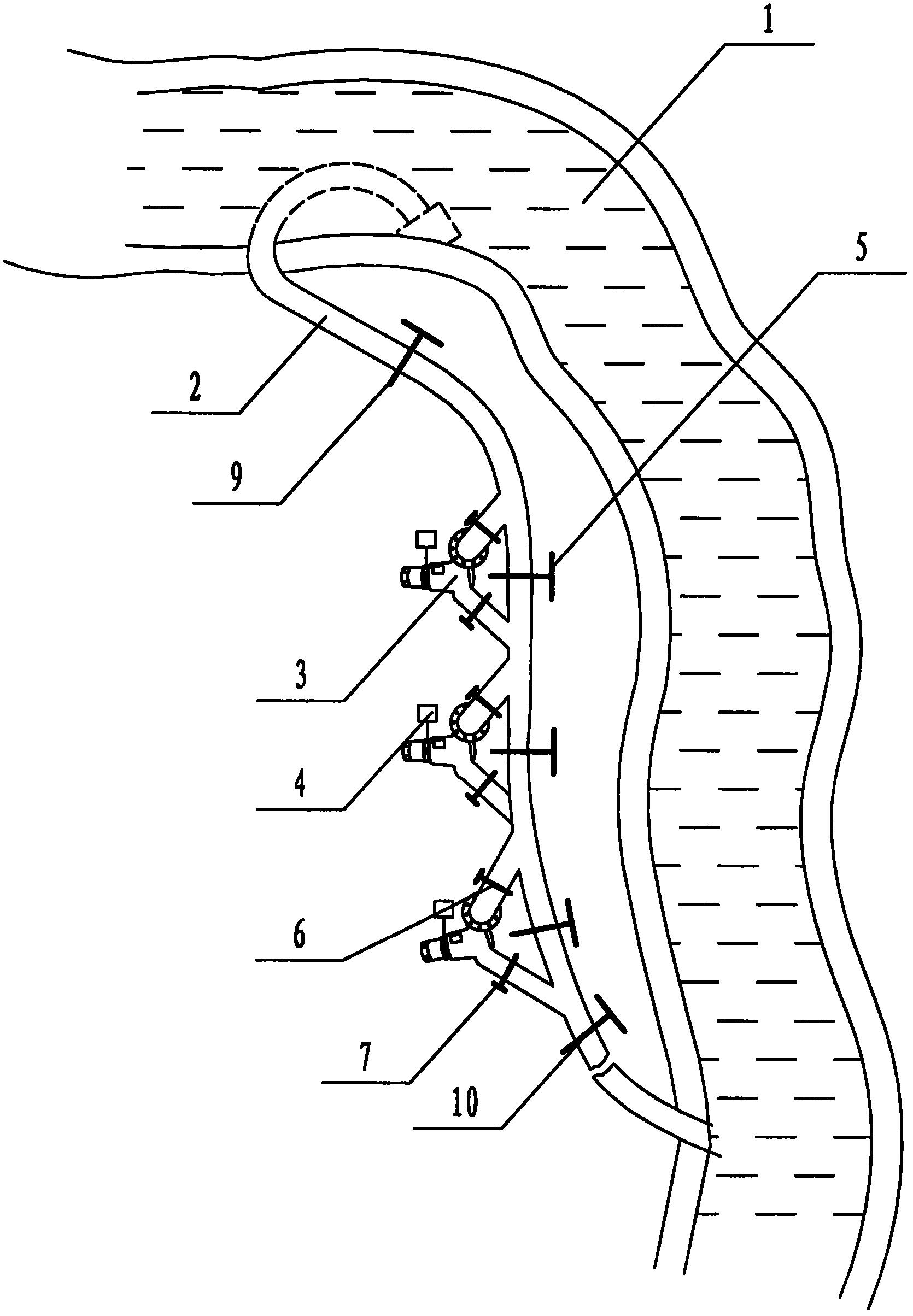

Hydrocone type multi-stage hydroelectric generation method

InactiveCN102635485ALow costImprove layout flexibilityHydro energy generationMachines/enginesPipeflowControl system

The invention provides a hydrocone type multi-stage hydroelectric generation method and belongs to the technical field of hydroelectric generation. The method comprises the following steps of: firstly, selecting one section of river basin with a flow fall, installing a water inlet end of a siphonage pipeline on the upper end of water area of the flow fall section, laying the siphonage pipeline along the flow fall section, intruding a water outlet end of the siphonage pipeline into the lower end of water area of the flow fall section or other discharge regions; and arranging one or more water-turbine generator sets in a pipe section where the flow pressure difference of the siphonage pipeline reaches the requirement of the rotating speed of the water-turbine generator sets, wherein each water-turbine generator set is connected with a parallel operation control system. The method provided by the invention has the advantages of low engineering cost, little limit to regions, no need of building a dam on a river, large flexibility in arranging the generator sets, no damage and pollution to environments, lower operation cost, stable flow speed, and more suitability of being built in the river basin with the flow fall. The water outlet end of the siphonage pipeline can be used for supplementing a water source for a lake and a reservoir, can also be used for supplementing water for a water-deficient area, a dry river and a farmland, and plays a role in improving environment and farmland soil.

Owner:王宝民 +1

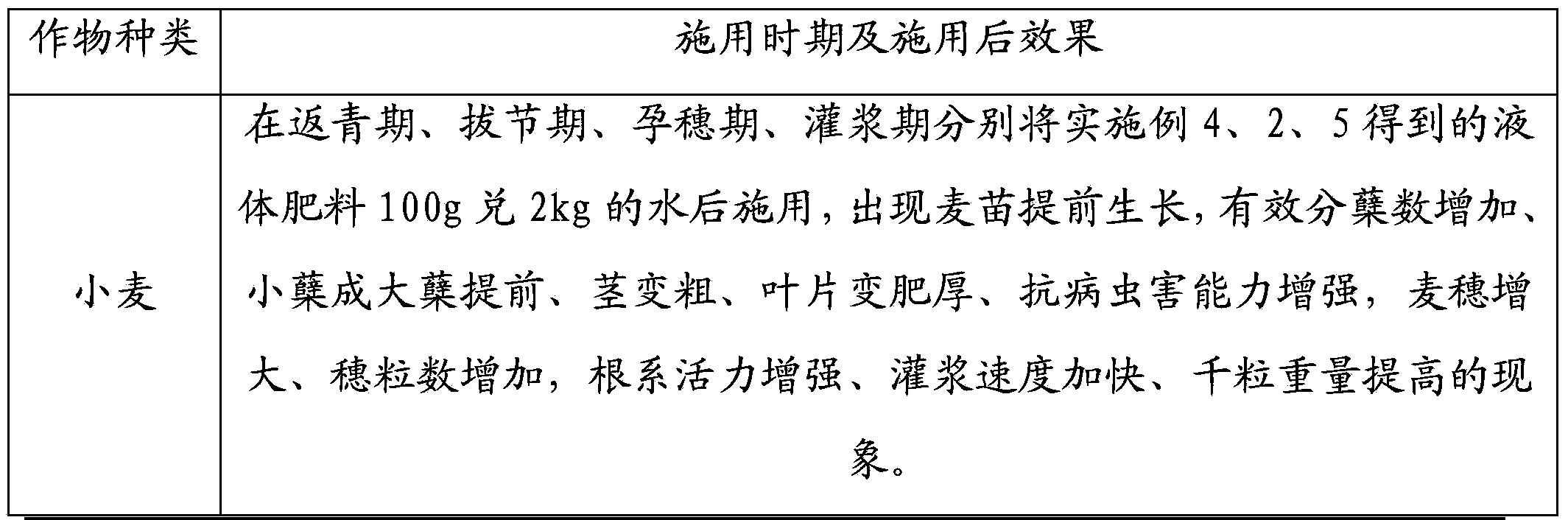

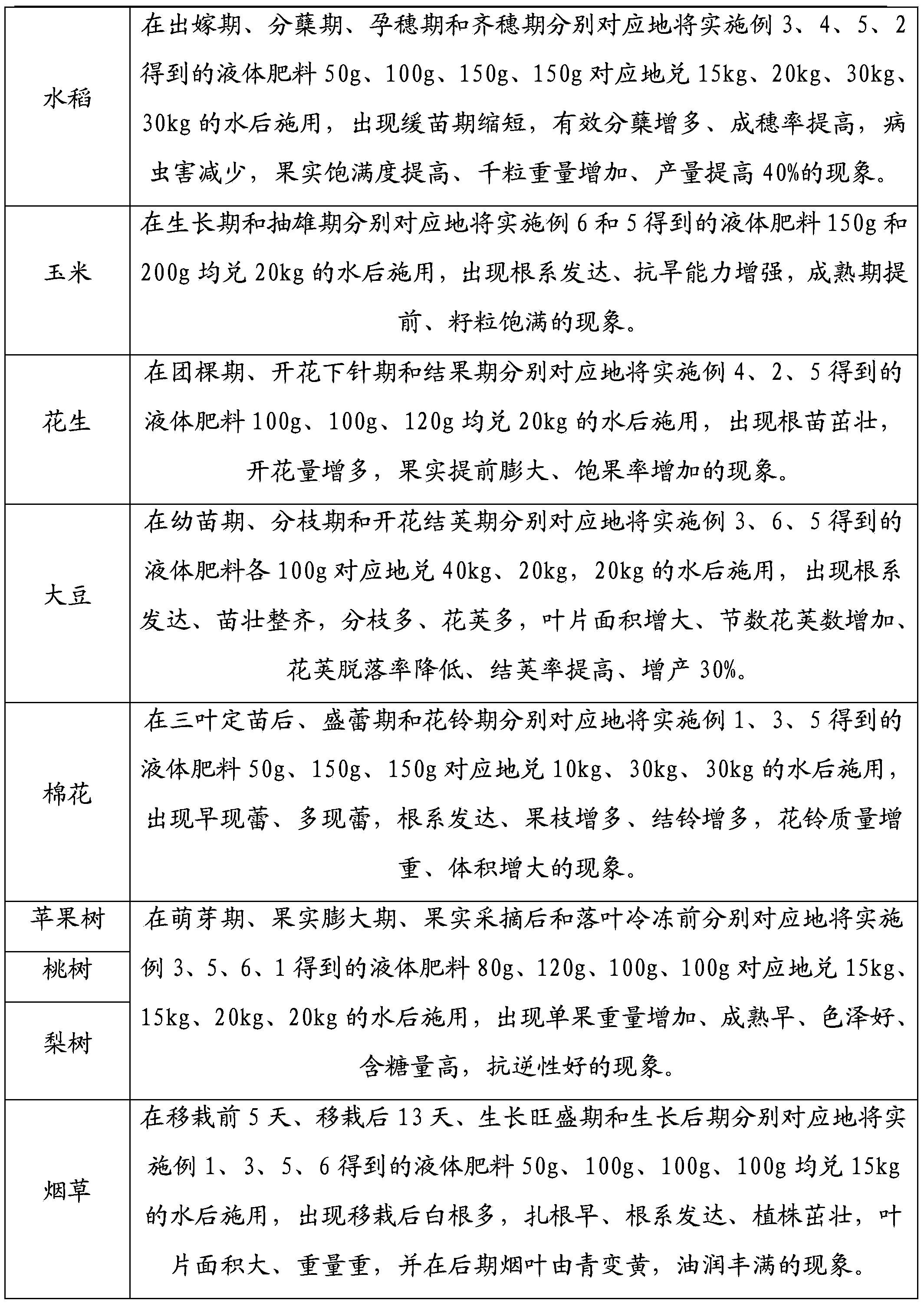

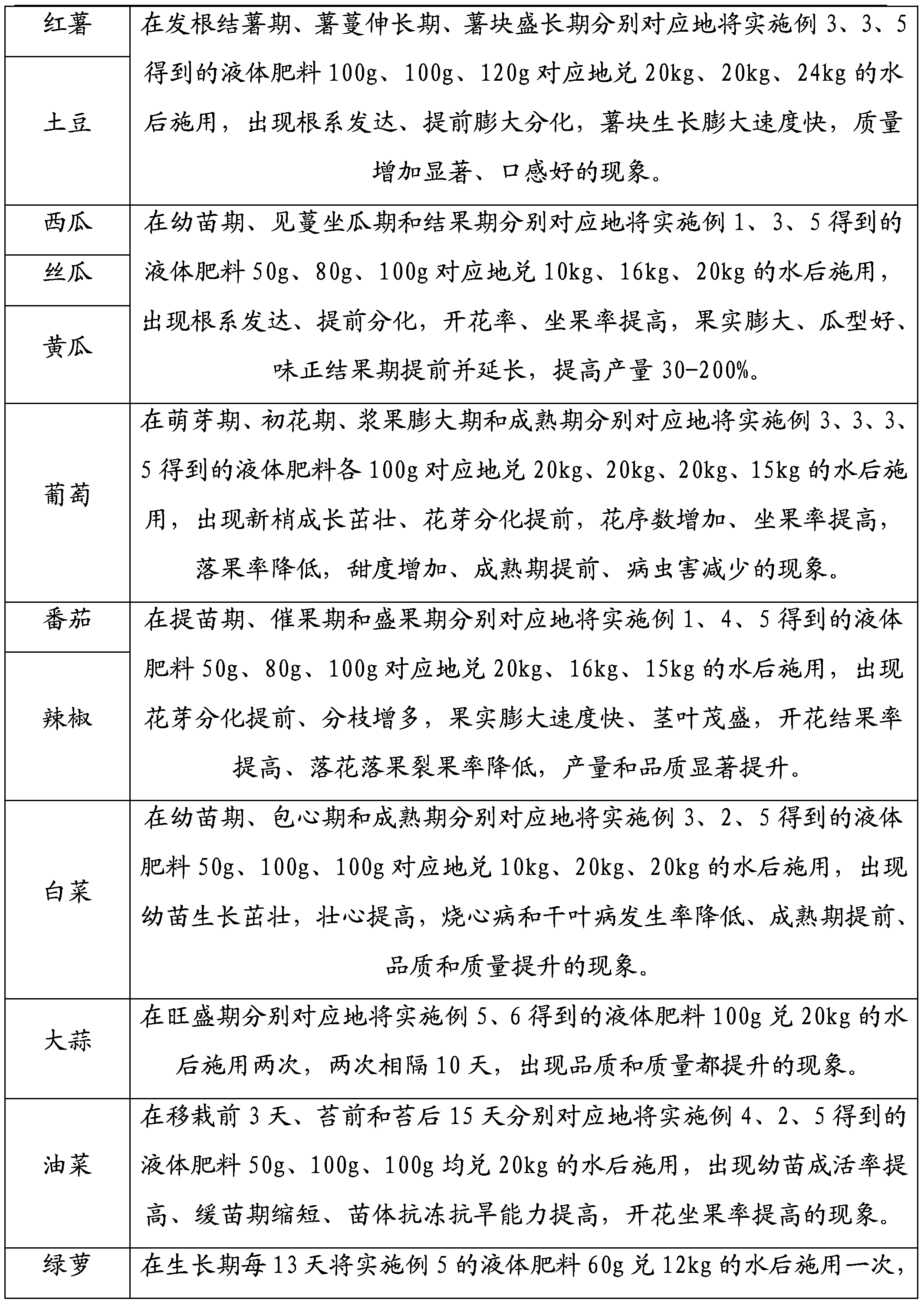

Preparation method of all-nutrition type liquid fertilizer

The invention discloses a preparation method of an all-nutrition type liquid fertilizer. The preparation method comprises the following steps: using 25-35 parts of humic acid, 1-2 parts of zinc sulfate and 0.5-1 part of copper sulfate to prepare a solution A, adding 48-72 parts of water into 6-9 parts of ferrous sulfate and 3-6 parts of ethylenediaminetetraacetic acid to prepare a solution B, using 3-6 parts of boric acid, 1.5-3 parts of manganese sulfate, 3-6 parts of magnesium sulfate, 51-60 parts of potassium dihydrogen phosphate and 4.5-7.5 parts of glacial acetic acid to prepare a liquid C; mixing the solution A, the solution B and the solution C in proportion and adding urea and ammonium dihydrogen phosphate at the same time, and stirring to form a uniform solution; and regulating the pH value to 3.5-5 by using the humic acid and filtering to finally obtain the all-nutrition type liquid fertilizer. The method disclosed by the invention has the characteristics of simple process, suitability for large-scale industrial production, low equipment requirements, capability of enhancing stress resistance of crops, no toxicity, no harm, no environmental pollution and no soil hardening.

Owner:天津坂结土壤肥料技术开发有限公司

Preparation of urban sculpture material from construction waste and method for preparing urban sculpture from urban sculpture material

InactiveCN106904918ASave resourcesLow costSolid waste managementOrnamental structuresSodium silicateScrap

The invention relates to preparation of an urban sculpture material from construction waste and a method for preparing an urban sculpture from the urban sculpture material. The urban sculpture material comprises the following raw materials by weight: solid construction waste, water, aluminoferrite cement, nanometer nickel borate whiskers, boiler fly ash beads, perlite particles, expanded polystyrene particles, basalt fiber, sodium silicate, anhydrous calcium sulfate, calcium lignin sulphonate, isobutyltriethoxysilane, gypsum powder, 107 glue and an accelerator. The sculpturing method comprises the following successive steps: preparing a bearing framework for the sculpture; preparing a surface coating layer; crushing construction waste into particles by using a pulverizer and a grinder; adding the crushed construction waste particles into an agitator; adding the rest raw materials into the agitator and a mixer and carrying out mixing under stirring so as to obtain a wet mixed material; coating the coating layer with the wet mixed material so as to form a basic contour layer of the sculpture; leaving a wet mixed material inlet in the top of the sculpture in advance; when the sculpture is placed at a set position, injecting the wet mixed material into a cavity in the sculpture; and then treating the surface of the sculpture.

Owner:HARBIN UNIV

Preparation method for artificial bone scaffold capable of loading drugs according to layers and quantity

InactiveCN105749337ARelieve painReduce or avoid secondary infectionProsthesisDrugCalcium phosphate cement

The invention provides a preparation method for an artificial bone scaffold capable of loading drugs according to layers and quantity.The method comprises the steps that a rapid molding method through a biological three-dimensional extrusion molding machine is adopted, different drugs and calcium phosphate cement are mixed and embedded, an artificial bone scaffold three-dimensional CAD model is processed by means of a computer, bio-adhesive and mixed powder are mixed to be uniform to be put into the biological three-dimensional extrusion molding machine, and a bone scaffold mold which accords with bone porosity of an individual patient, has the anti-infection characteristic and is good in biocompatibility is obtained through extrusion molding.According to the preparation method for the artificial bone scaffold, the different drugs can be selectively sprayed on the specific portions of an artificial bone according to needs of the patients; by means of the arrangement of different gradients for different drugs, various drugs with different contents can be loaded on different portions of the same drug-loading artificial bone scaffold, and complex local drug combined application is formed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

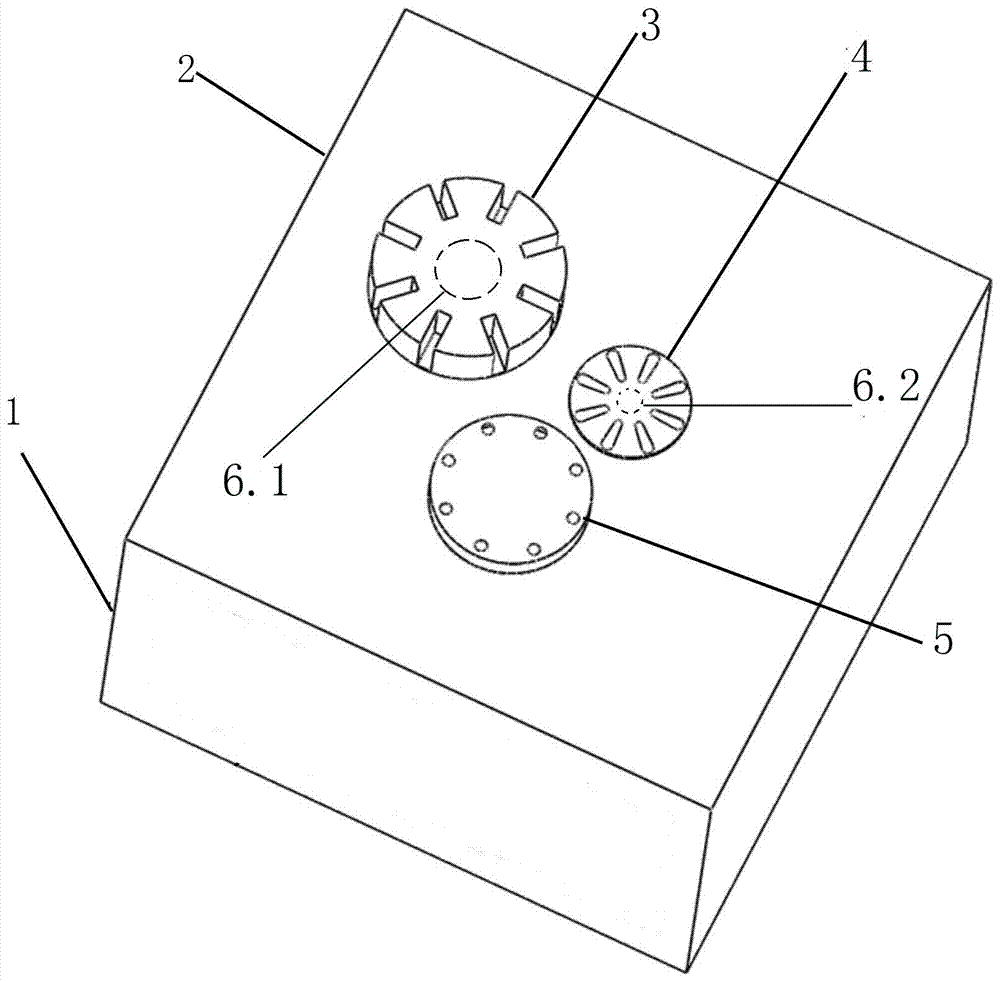

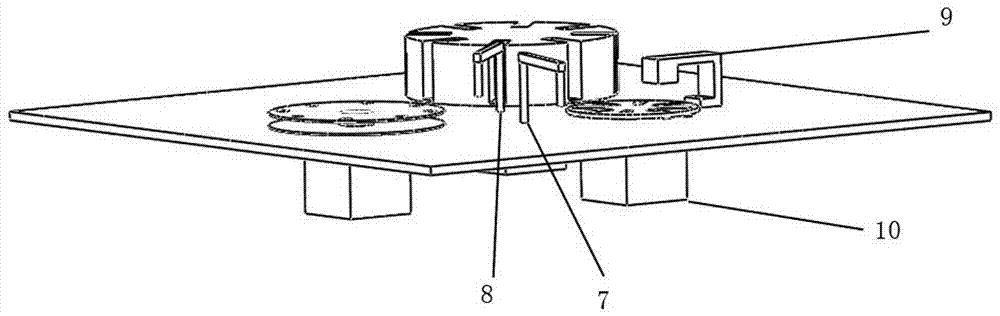

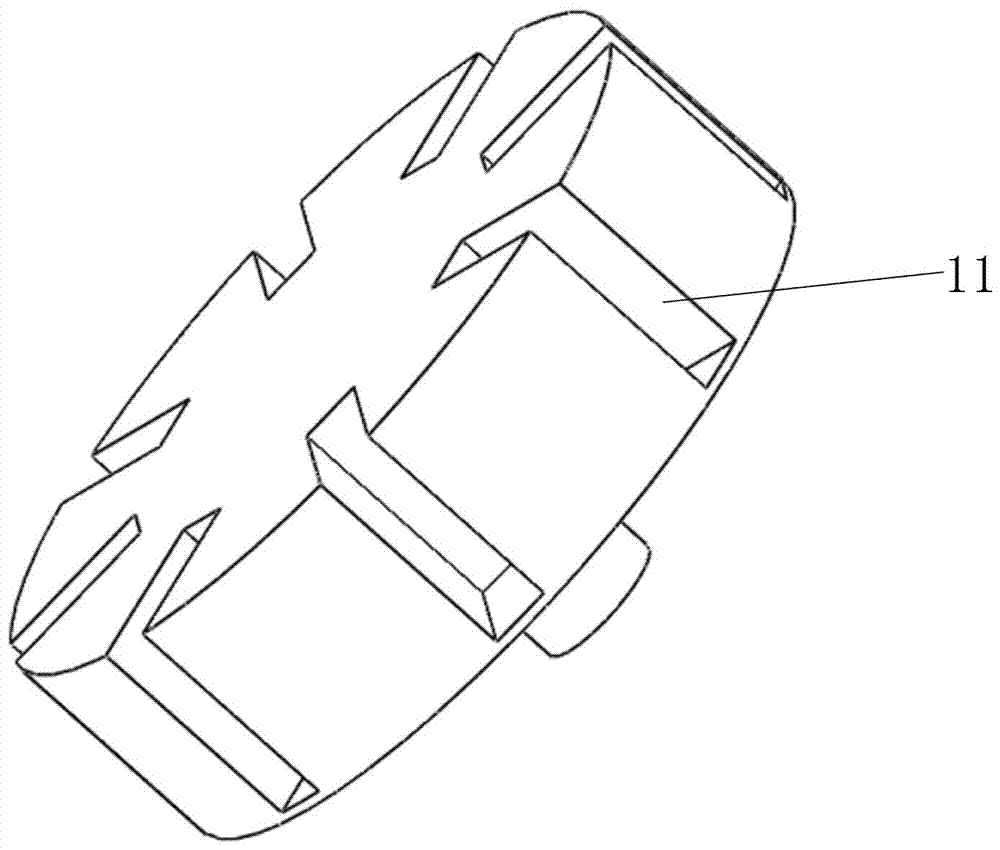

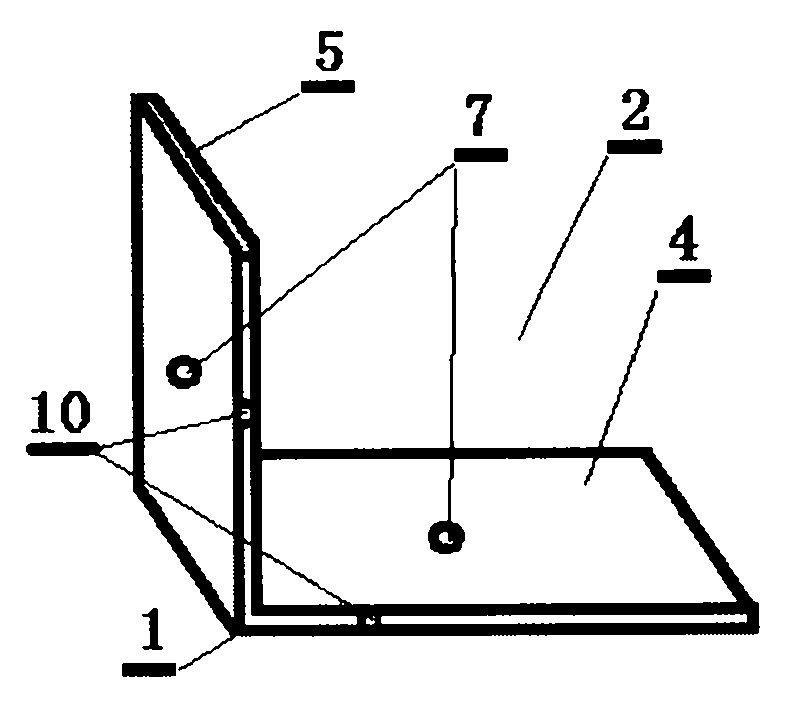

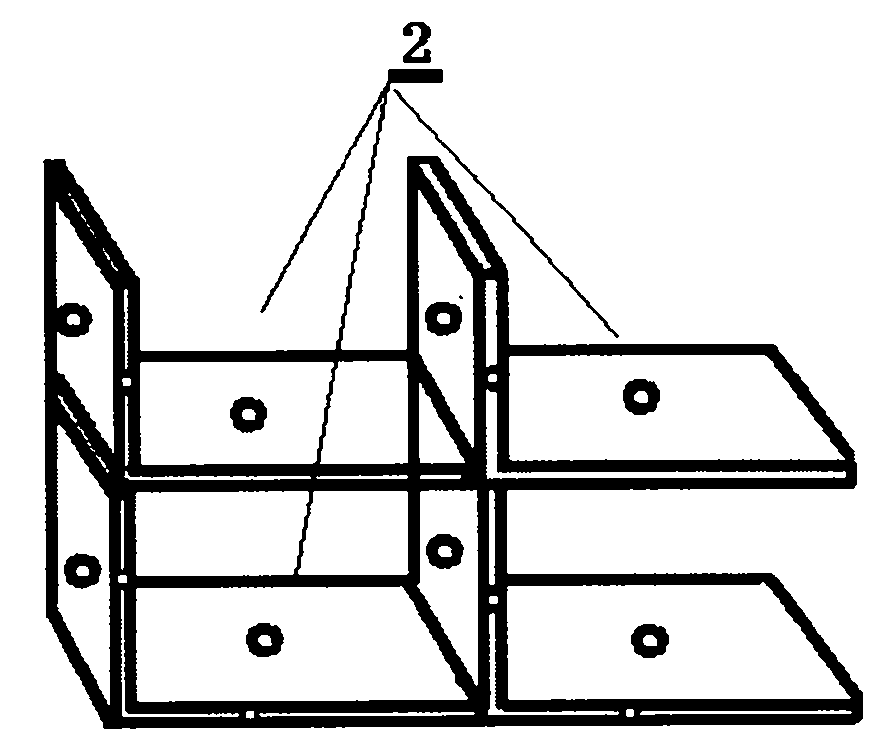

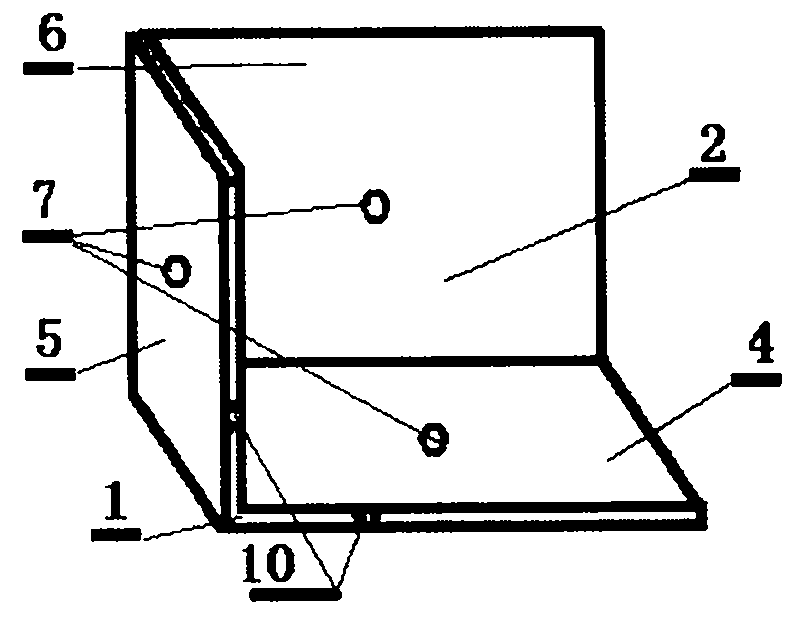

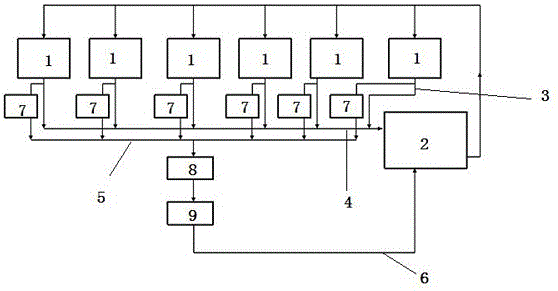

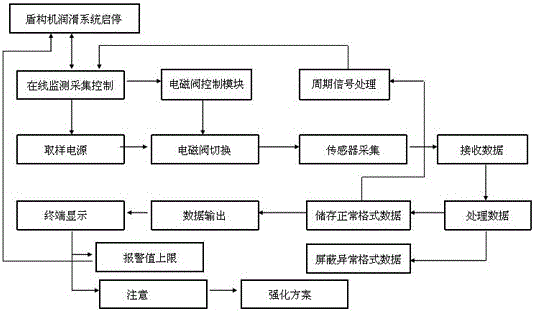

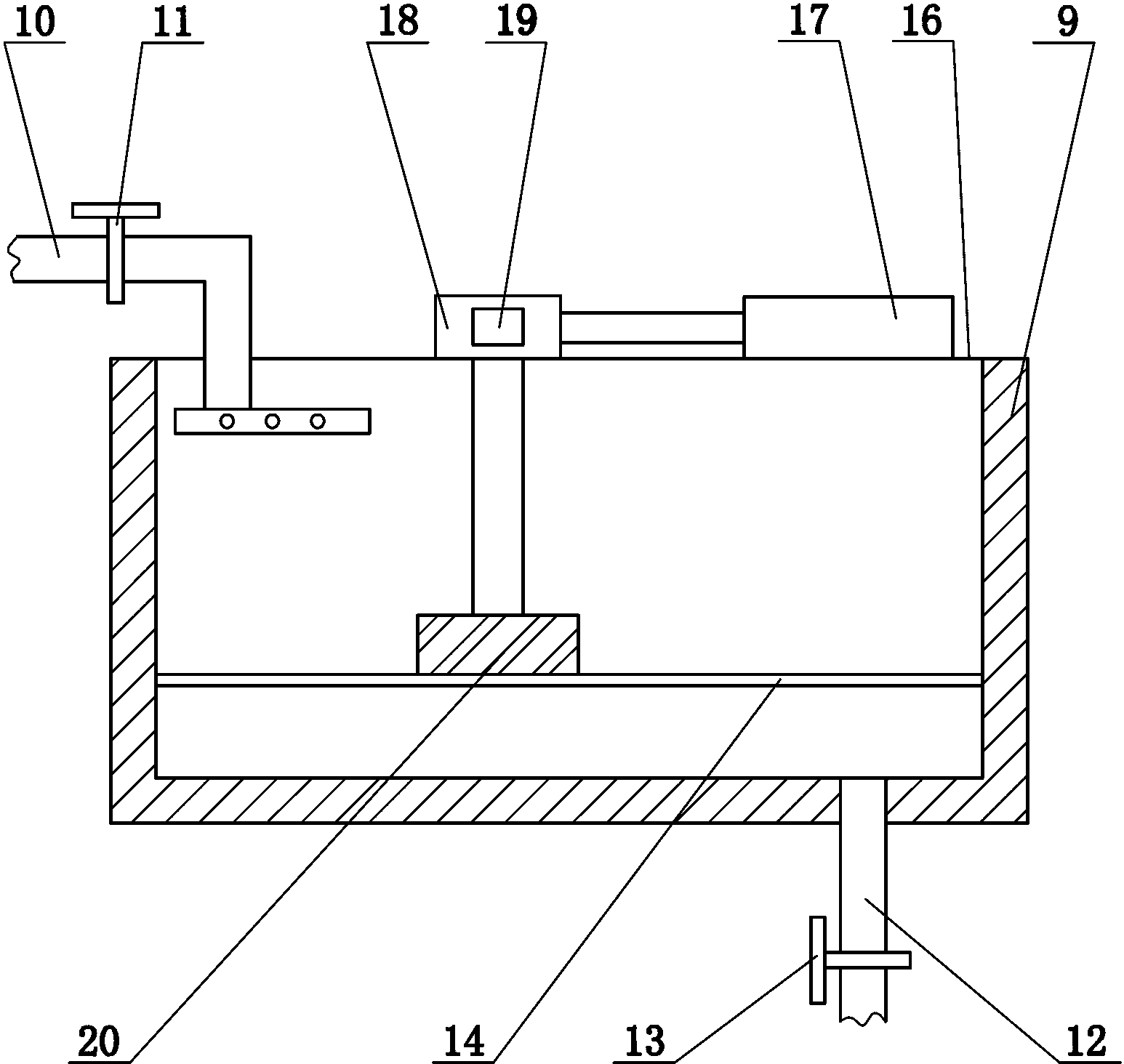

Shield TBM oil liquid state on-line automatic monitoring system

InactiveCN106525141AReal-time monitoring of moisture contentReal-time monitoring of viscosity changesMeasurement devicesLiquid stateSolenoid valve

The invention belongs to the technical field of shield machine lubrication condition monitoring, and proposes a shield TBM oil liquid state on-line automatic monitoring system. The proposed shield TBM oil liquid state on-line automatic monitoring system includes a planetary gear oil tank (1), a main bearing gear main oil tank (2) and an on-line monitoring acquisition control part (9); the on-line monitoring acquisition control part (9) has a plurality of solenoid valves (7); the plurality of solenoid valves (7) and a plurality of planetary gear oil tanks in a shield machine gear oil lubrication system are in one-to-one correspondence; the plurality of solenoid valves are cyclically opened in an on-line monitoring period, and only one is in a normally open state; the on-line automatic monitoring system is also provided with an oil liquid monitoring loop (5); the other ends of the plurality of solenoid valves (7) communicate with the oil liquid monitoring loop (5); and the oil liquid monitoring loop (5) is connected with the on-line monitoring acquisition control part (9). The shield TBM oil liquid state on-line automatic monitoring system provided by the invention ensures reliable lubrication of equipment and safe operation of a shield machine.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

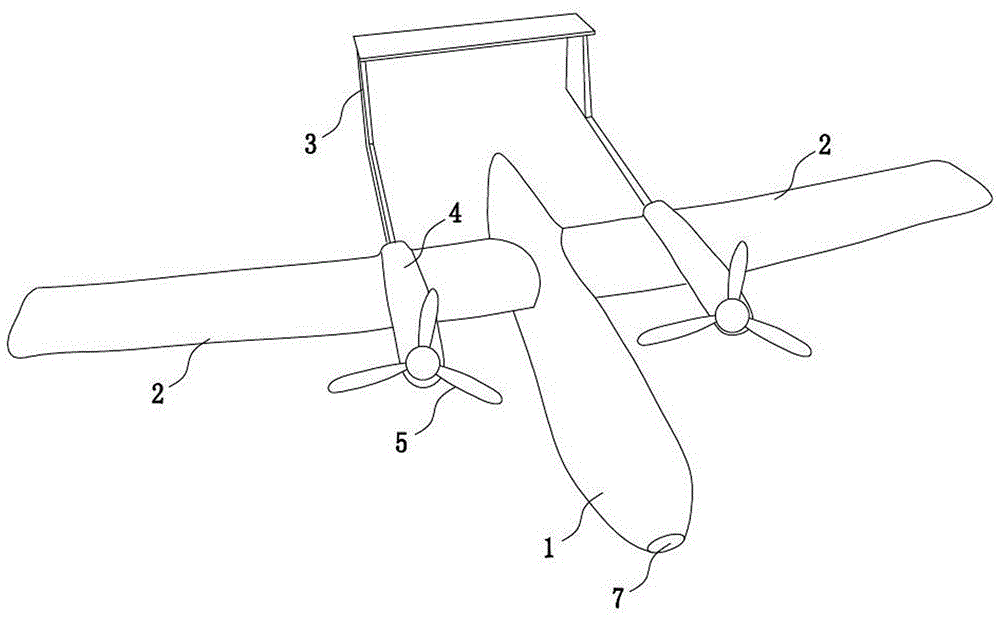

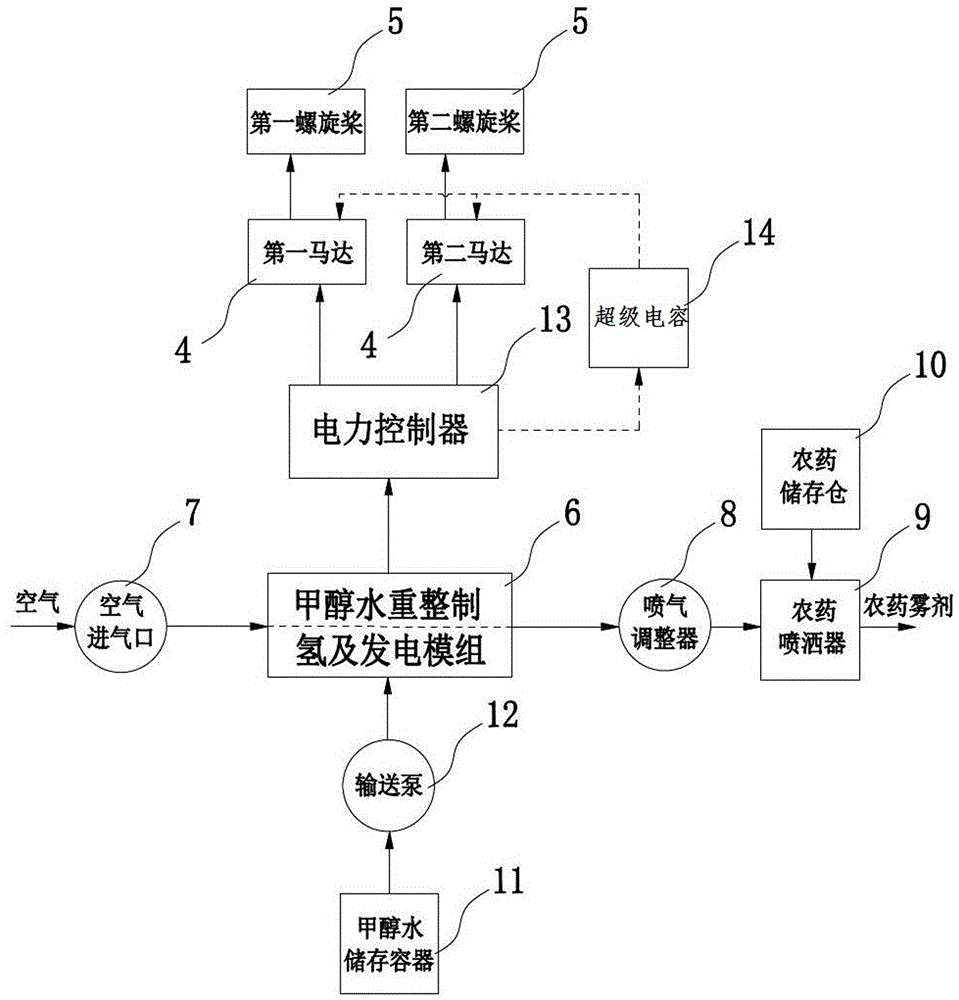

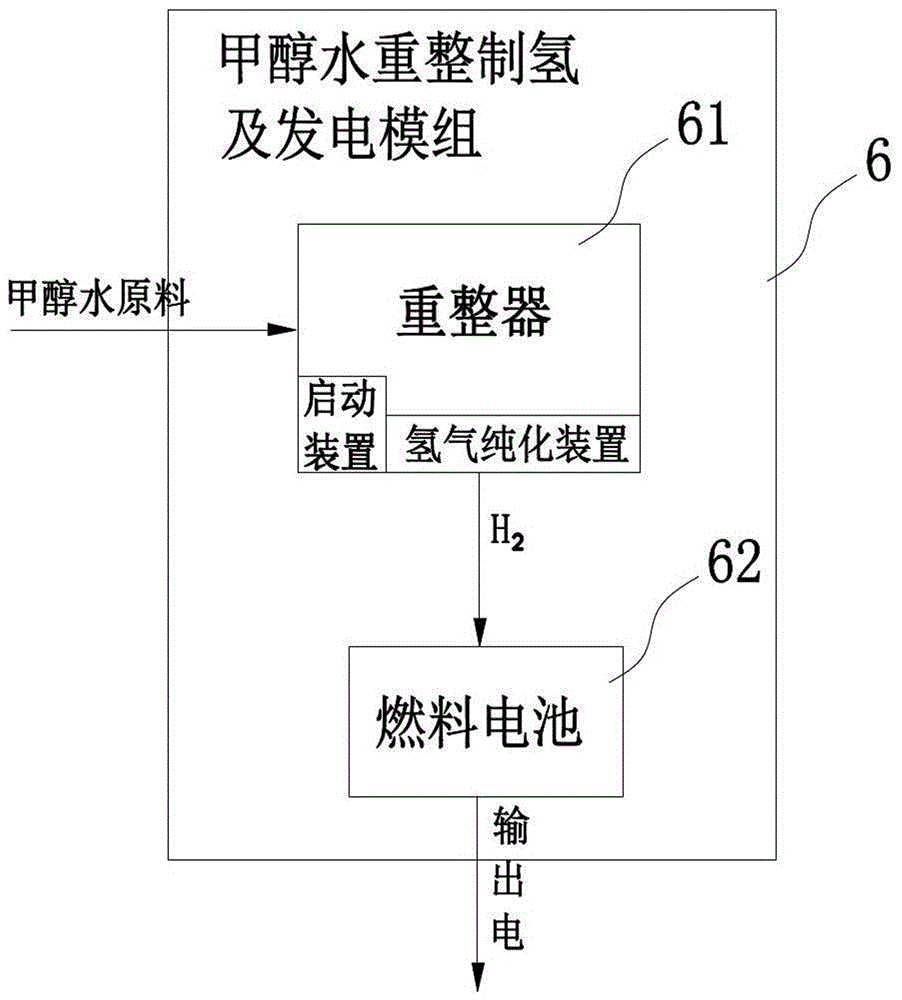

Fixed-wing unmanned aerial vehicle used for insecticide spraying and method for insecticide spraying

InactiveCN106516114ALight weightLow priceFuel cell heat exchangeEfficient propulsion technologiesCapacitanceFixed wing

The invention discloses a fixed-wing unmanned aerial vehicle used for insecticide spraying. The fixed-wing unmanned aerial vehicle comprises a vehicle body, wings and a tail wing, wherein the wings and the tail wing are mounted on the vehicle body, and vehicle motors and propellers are arranged on the wings. The vehicle body is provided with methanol and water reforming hydrogen making and electricity generating modules, an air inlet, an air injection adjuster, an insecticide sprayer, an insecticide storage cabin, a methanol and water storage container, delivering pumps, an electric power controller and a super capacitor, wherein a reformer and a fuel battery are integrated in each methanol and water reforming hydrogen making and electricity generating module. The air inlet is used for inputting outside air, and the input outside air passes through the fuel batteries and the air injection adjuster sequentially and then is output from the insecticide sprayer. The super capacitor is used for electricity supply when the fixed-wing unmanned aerial vehicle is started and supplies electricity to the vehicle motors when the real-time power of the vehicle motors is increased rapidly. According to the fixed-wing unmanned aerial vehicle used for insecticide spraying and a method for insecticide spraying, the capacity usage ratio and conversion rate are high, the volume of carried insecticide is large, the outside air used by the methanol and water reforming hydrogen making and electricity generating modules can be utilized to spray insecticide, operating cost is low, and environment is not polluted.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

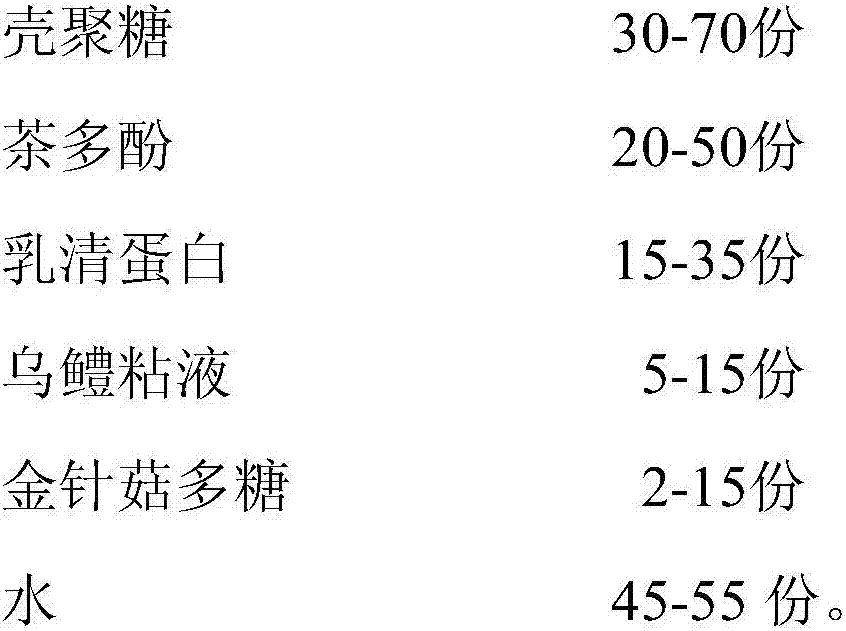

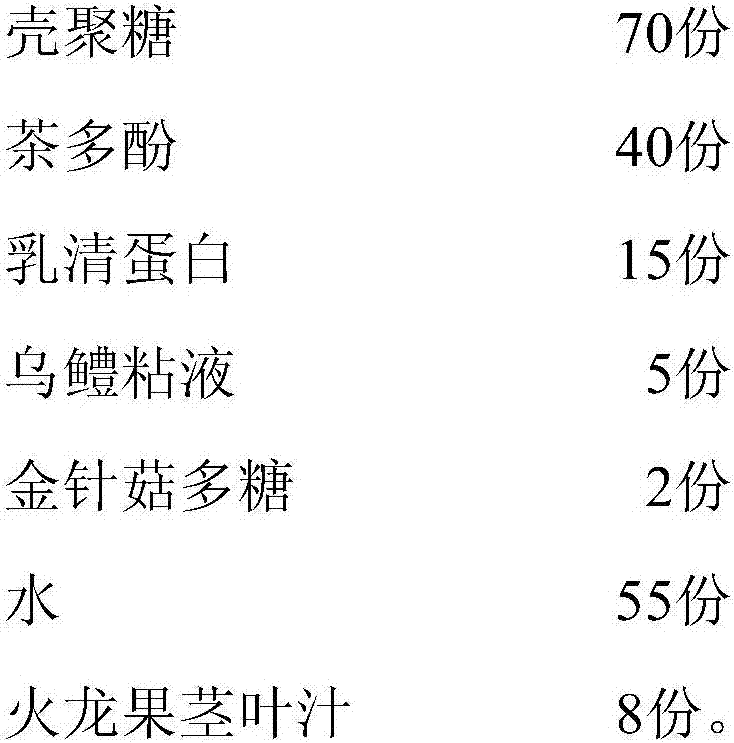

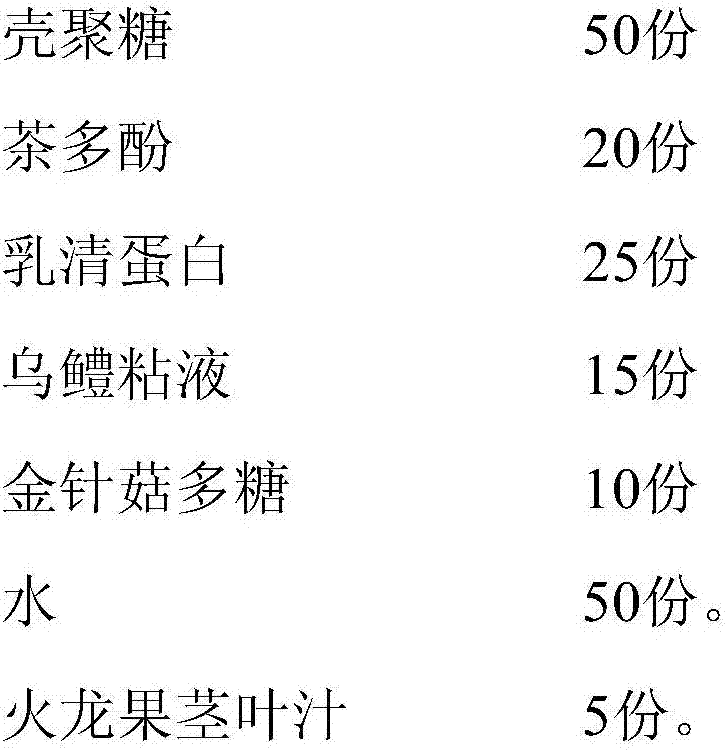

Novel fish paste preservative as well as preparation method and application thereof

InactiveCN107439667ASimpleAbundant resourcesMeat/fish preservation using chemicalsUltra high pressure food processesMushroomChemistry

The invention belongs to the technical field of meat product preservation methods and discloses a novel fish paste preservative as well as a preparation method and application thereof. The preservative comprises the following raw material substances in parts by weight: 30-70 parts of chitosan, 20-50 parts of tea polyphenol, 15-35 parts of whey protein, 5-15 parts of snakehead mucus, 2-15 parts of needle mushroom polysaccharide and 45-55 parts of water; and the preservative also can comprise 5-10 parts of pitaya stem and leaf juice. The preparation method comprises the following steps: uniformly mixing chitosan, tea polyphenol, whey protein, snakehead mucus, needle mushroom polysaccharide and water by virtue of ultrasonic treatment of ultrasonic waves, carrying out ultra high pressure treatment on the uniformly mixed liquid, and uniformly mixing the solution in combination with micro-jet high pressure homogenization treatment, thereby obtaining the novel fish paste preservative.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

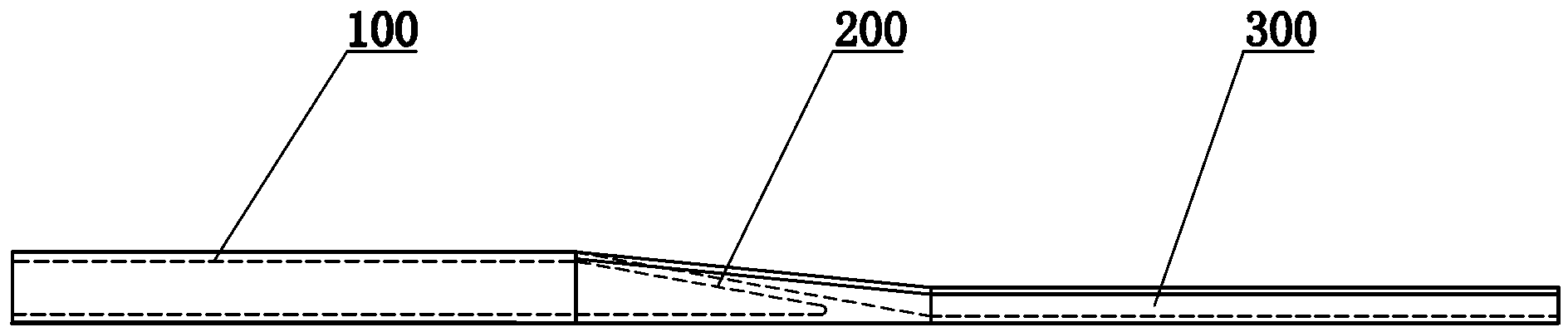

Preparation method of reaction sintered silicon carbide cantilever paddle

The invention discloses a preparation method of reaction sintered silicon carbide cantilever paddle, and belongs to the technical field of silicon carbide cantilever paddle. The preparation method comprises the steps as follows: preparing an extrusion forming mould of a silicon carbide cantilever paddle fixing region; extruding a pipe blank in the fixing region and segmentally cutting the pipe blank; drying the cut pipe blanks in the fixing region; preparing ramming forming moulds of a silicon carbide cantilever paddle transition region and a load region; preparing integral blank bodies in the transition region and the load region; drying the integral blank bodies in the transition region and the load region; trimming biscuits; bonding the pipe blanks in the fixing region with the integral blank bodies in the transition region and the load region to finish preparation of a blank body of the silicon carbide cantilever paddle; sintering. Compared with a conventional slip casting process, for the method disclosed by the invention, the blank body forming rate is increased and the preparation cost is saved through using a bonding combination structure; the process is simple, the finished product rate is high, and the prepared silicon carbide cantilever paddle is high in strength, pore-free, good in heat conductivity, resistant to acid and base corrosion, pollution-free at a high temperature, deformation-free, large in load capacity and long in service life.

Owner:WEIFANG HUAMEI FINE TECHN CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com