Process for producing vanadium pentoxide from vanadiferous coal stone

A technology of vanadium pentoxide and vanadium-containing stone coal, applied in the direction of vanadium oxide, etc., can solve the problems of low product yield, high acid consumption, immature process conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

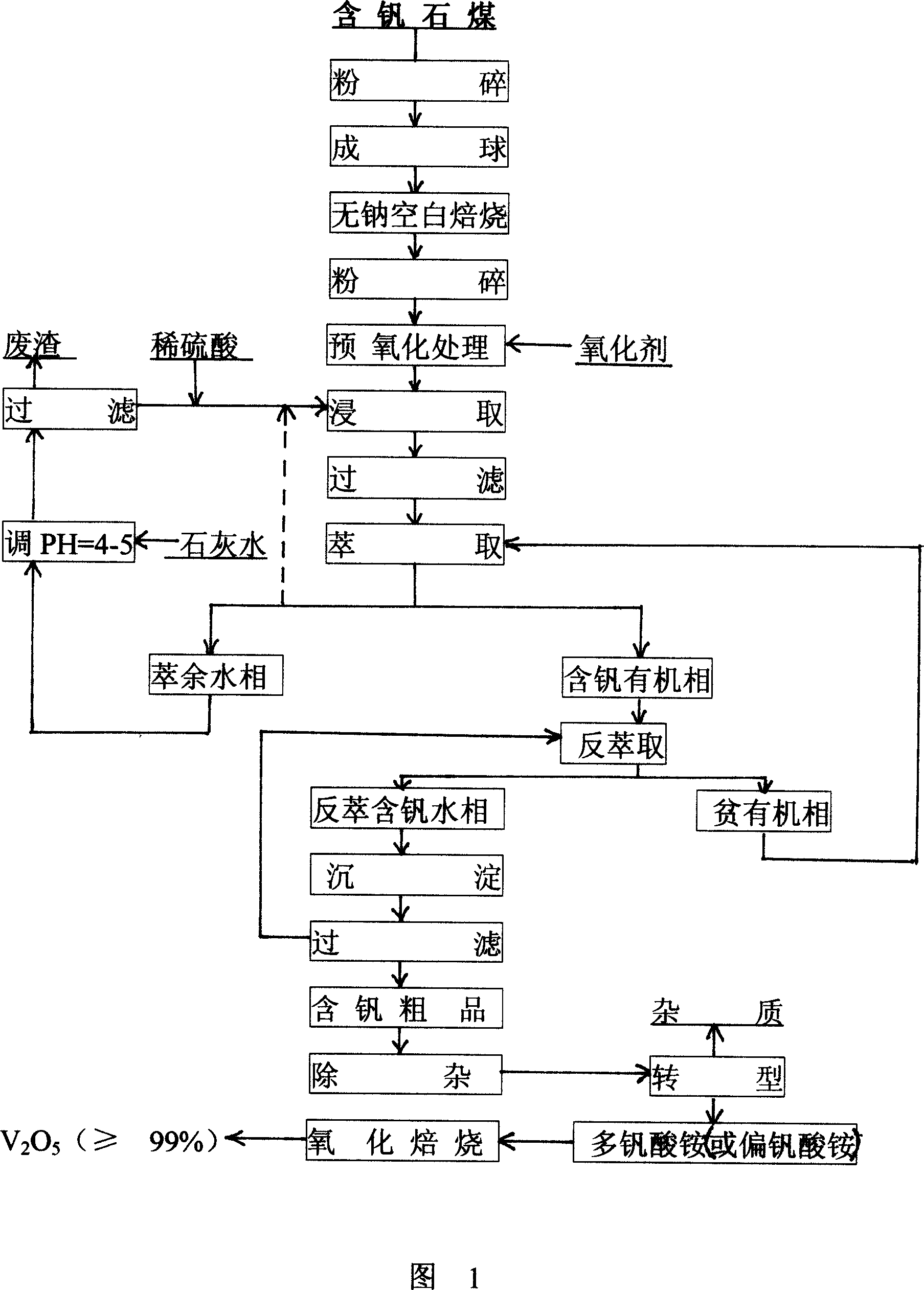

[0009] The present invention is described in further detail now in conjunction with accompanying drawing. Referring to Fig. 1, the present invention firstly crushes the stone coal into balls, then puts it in a flat kiln type converter for decarburization at a temperature of 600-800°C for 3-8 hours, and then discharges the material, after roasting and decarburizing The stone coal is crushed again, and 6-20% oxidant solution is evenly mixed into the crushed material for heating and oxidation treatment. The oxidation time is 0.5-4 hours. The oxidant used can be: potassium permanganate, sodium chlorate, potassium chlorate , hydrogen peroxide, oxyacids, etc. Taking potassium permanganate as an example, the reaction equation is as follows:

[0010]

[0011] 2V 2 o 3 +O 2 = 4VO 2

[0012] 4VO 2 +O2=2V 2 o 5

[0013] After the pre-oxidation process, the vanadium in the stone coal is fully transformed into vanadium pentoxide, and then it can quickly react with dilute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com