Method for dynamically dissolving and preparing nitratine ore leaching solution

A technology of leaching solution and sodium saltpeter, which is applied in the field of dynamic dissolution and preparation of leaching solution of sodium saltpeter ore, can solve the problems of low extraction efficiency of leaching solution, low resource recovery rate, no disclosure, etc., so as to improve the utilization rate of resources. , High leaching yield, no emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

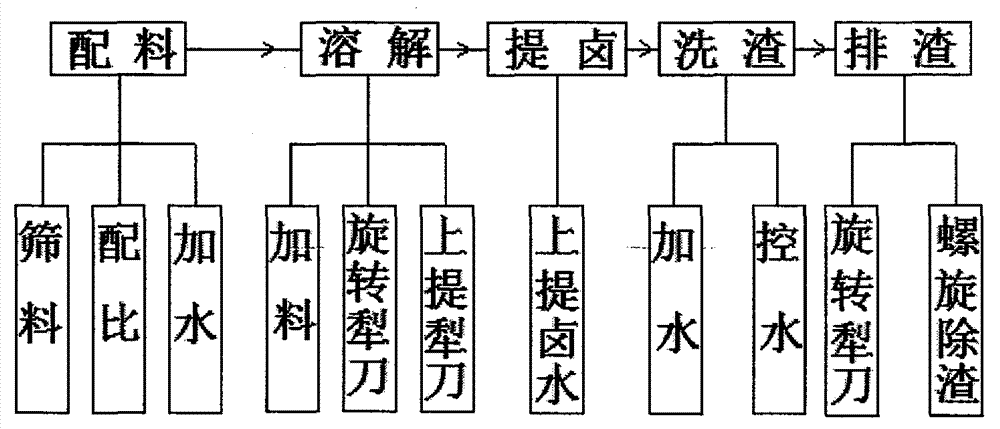

Method used

Image

Examples

Embodiment 1

[0022] Example 1: The average ore grade is 4.58%, the initial water addition is 100kg, the dynamic and continuous cumulative feeding reaches 700kg, the dynamic and continuous water addition totals 165 liters of water, the amount of concentrated brine extracted is 90 liters, the concentration of concentrated brine is 139.52 grams per liter, and the amount of flushing dilute brine is 700 liters , the concentration of light brine is 8.16 g / L, the water content of slag is 11.23%, and the content of slag is 1.57%.

Embodiment 2

[0023] Example 2: The average ore grade is 4.47%, the initial water addition is 112.5 kg, the dynamic and continuous cumulative feeding reaches 700 kg, the dynamic and continuous water addition totals 235 liters of water, the amount of concentrated brine extracted is 165 liters, the concentration of concentrated brine is 120.99 grams per liter, and the flushing concentration is 14.00 grams per liter The volume of fresh brine is 700 liters, the flushing concentration is 7.59 grams per liter, the volume of fresh brine is 650 liters, the water content of slag is 10.95%, and the content of slag slag is 0.89%.

Embodiment 3

[0024] Example 3: The average ore grade is 4.74%, the initial water addition is 200 kg, the dynamic and continuous cumulative feeding is up to 1000 kg, the total dynamic and continuous water addition is 340 liters of water, the extraction of concentrated brine is 265 liters, the concentration of concentrated brine is 120.99 grams per liter, and the amount of flushing light brine is 250 liters, the concentration of light brine is 16.32 g / liter, the moisture content of slag is 9.12%, and the content of slag slag is 1.76%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com