Patents

Literature

154results about How to "Increased accuracy level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

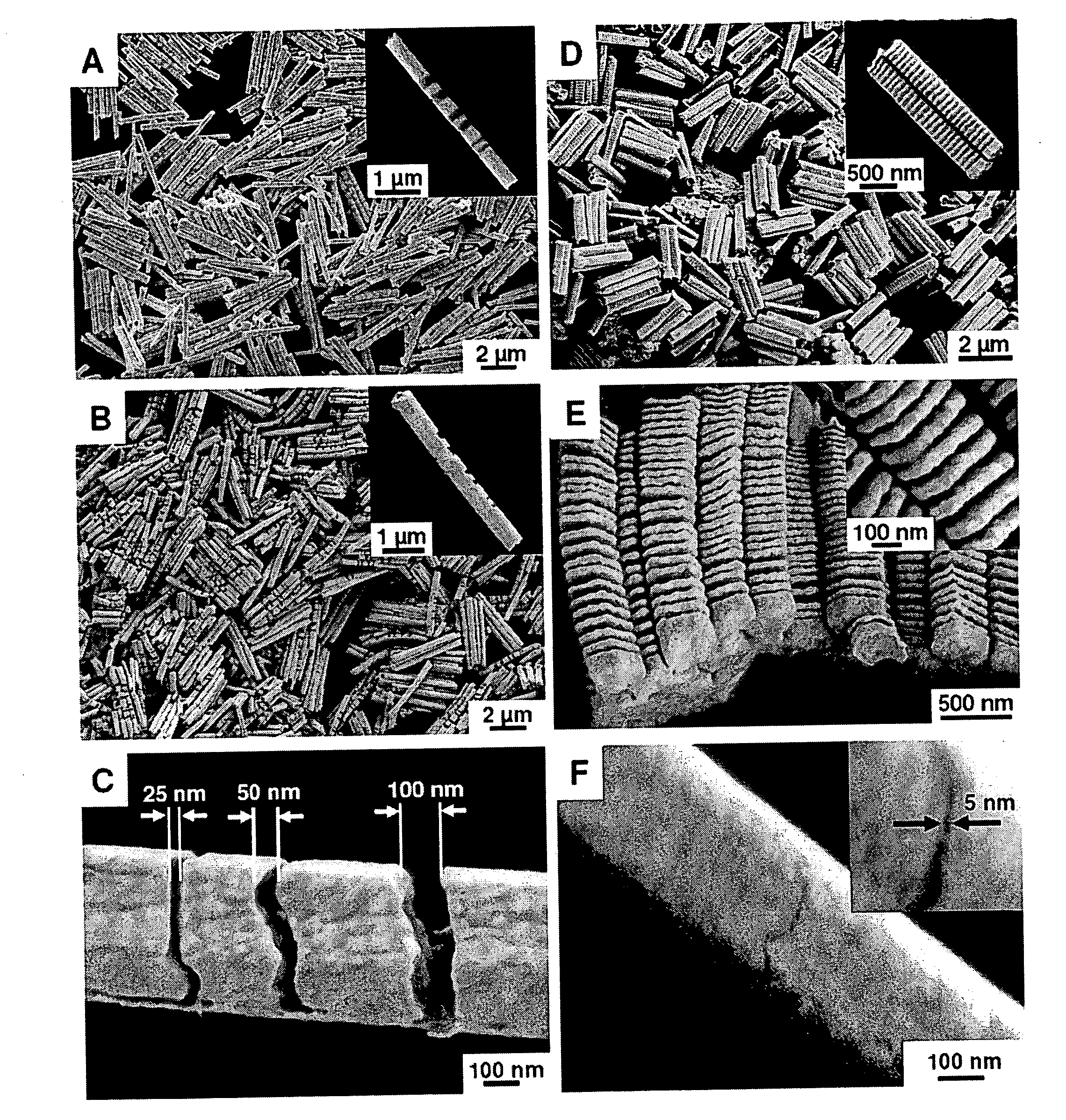

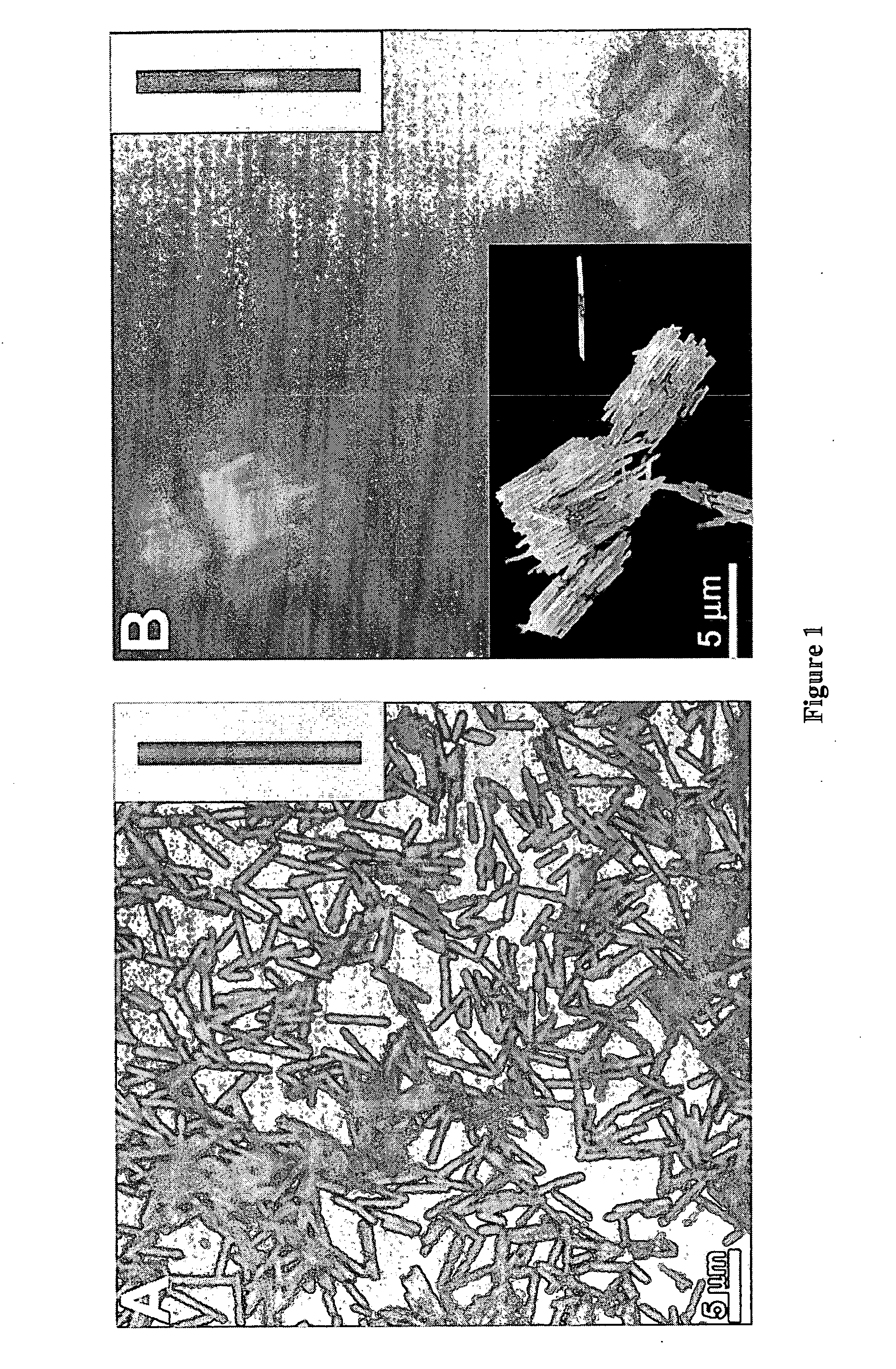

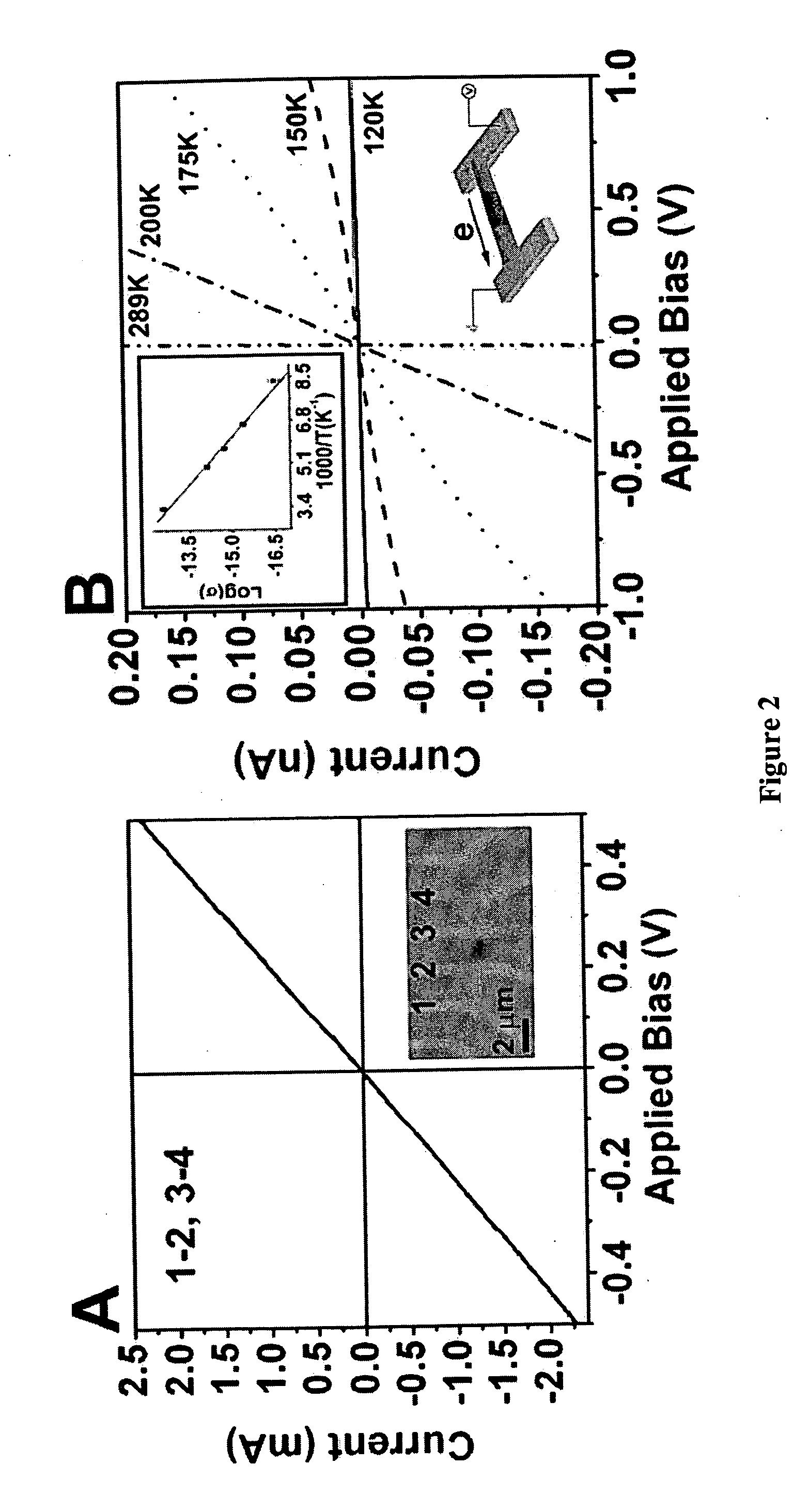

Multicomponent nanorods

InactiveUS20070077429A1Improve the level ofIncreased accuracy levelPaper/cardboard articlesDecorative surface effectsMultiple componentCompound (substance)

Owner:NORTHWESTERN UNIV

Apparatus

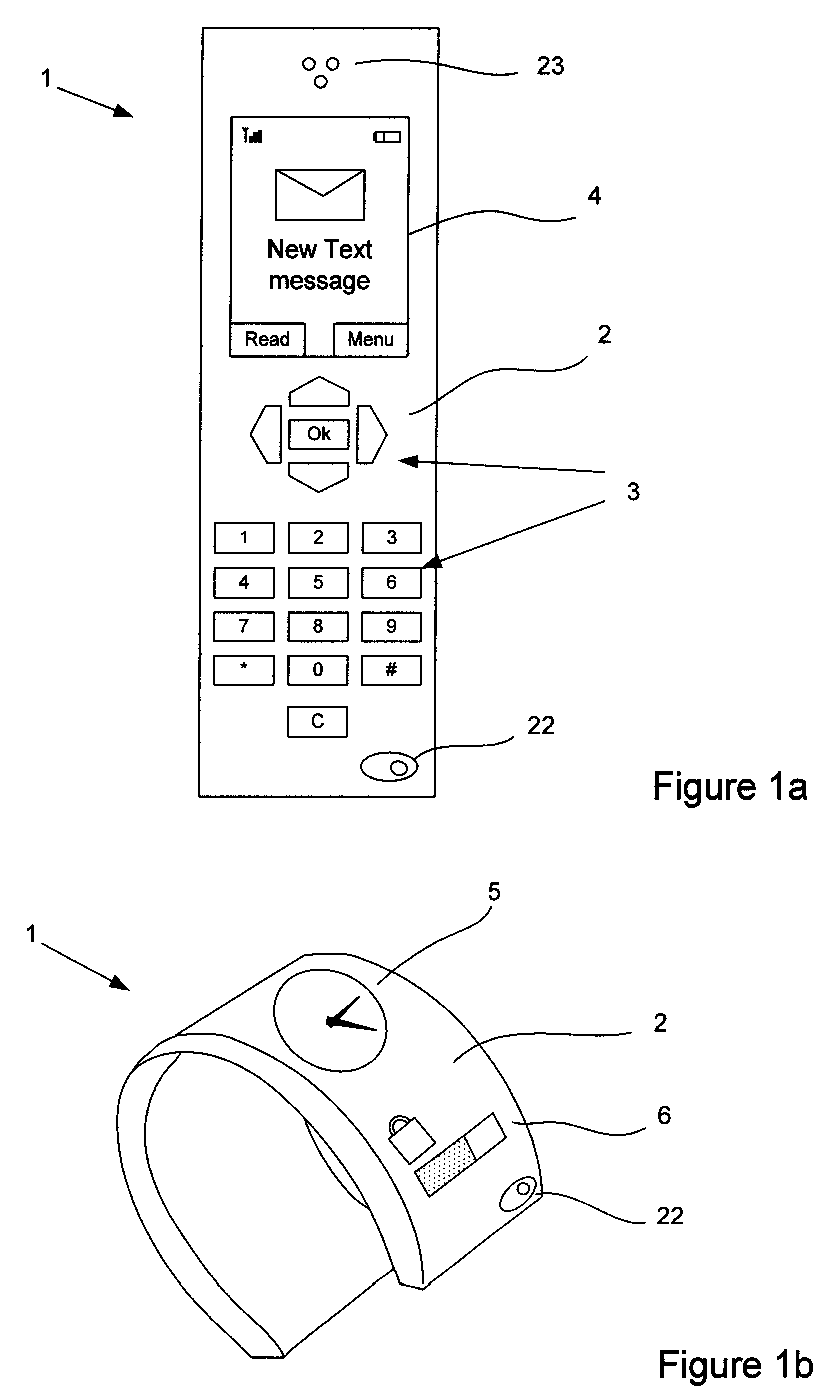

ActiveUS20090326833A1Improve matchIncreased accuracy levelError detection/correctionDigital computer detailsNanowireEngineering

An apparatus includes a deformable structure in which a neural network comprising a plurality of deformation sensors, e.g. nanowire sensors, and distributed in-situ processing circuits. The circuits generate a signal characterising features of the local deformation of the structure and / or a command signal corresponding to the detected deformation. The structure may be a wearable sleeve that conforms to deformations of a user's skin, part of an electronic device, such as a touch sensitive screen, or an object in itself. The apparatus can provide a user interface, wherein a command corresponding to a current shape of the structure is generated and acted upon by a integrated or remote device, or a device for monitoring a user's position or movement e.g. for replication by a robotic device. The apparatus may have machine learning capability to improve the matching of commands with determined shapes of the deformable structure.

Owner:NOKIA TECHNOLOGLES OY

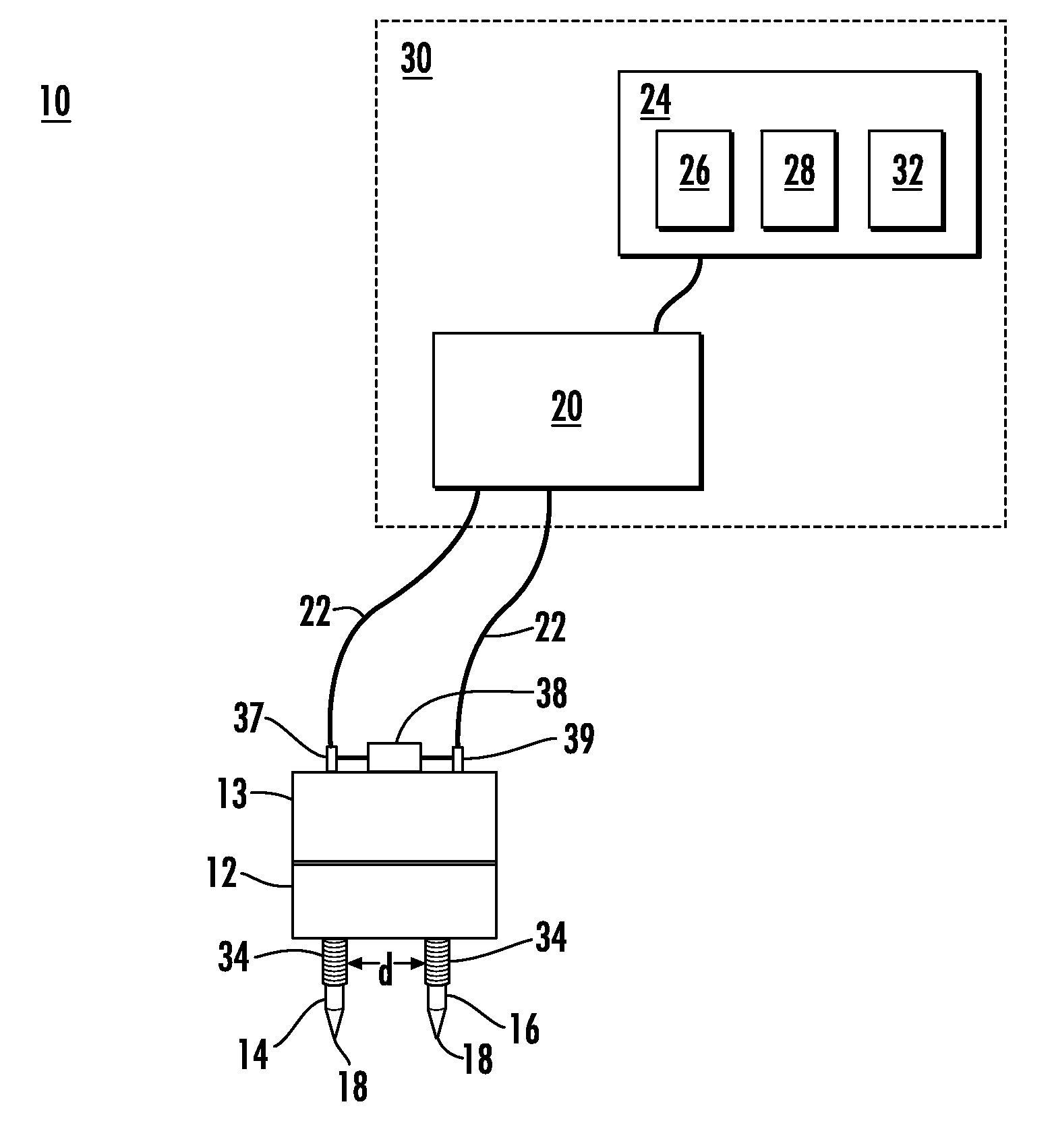

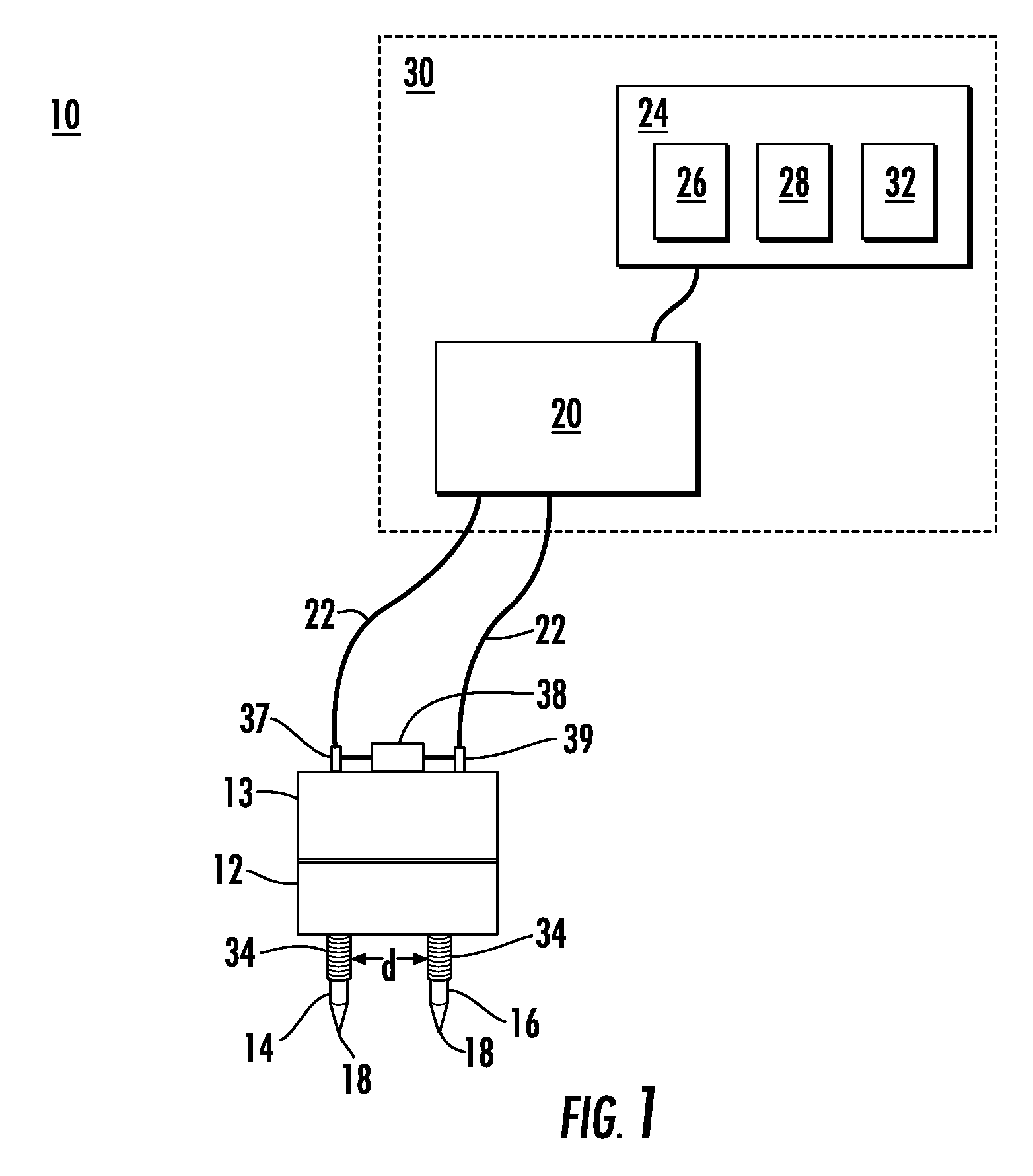

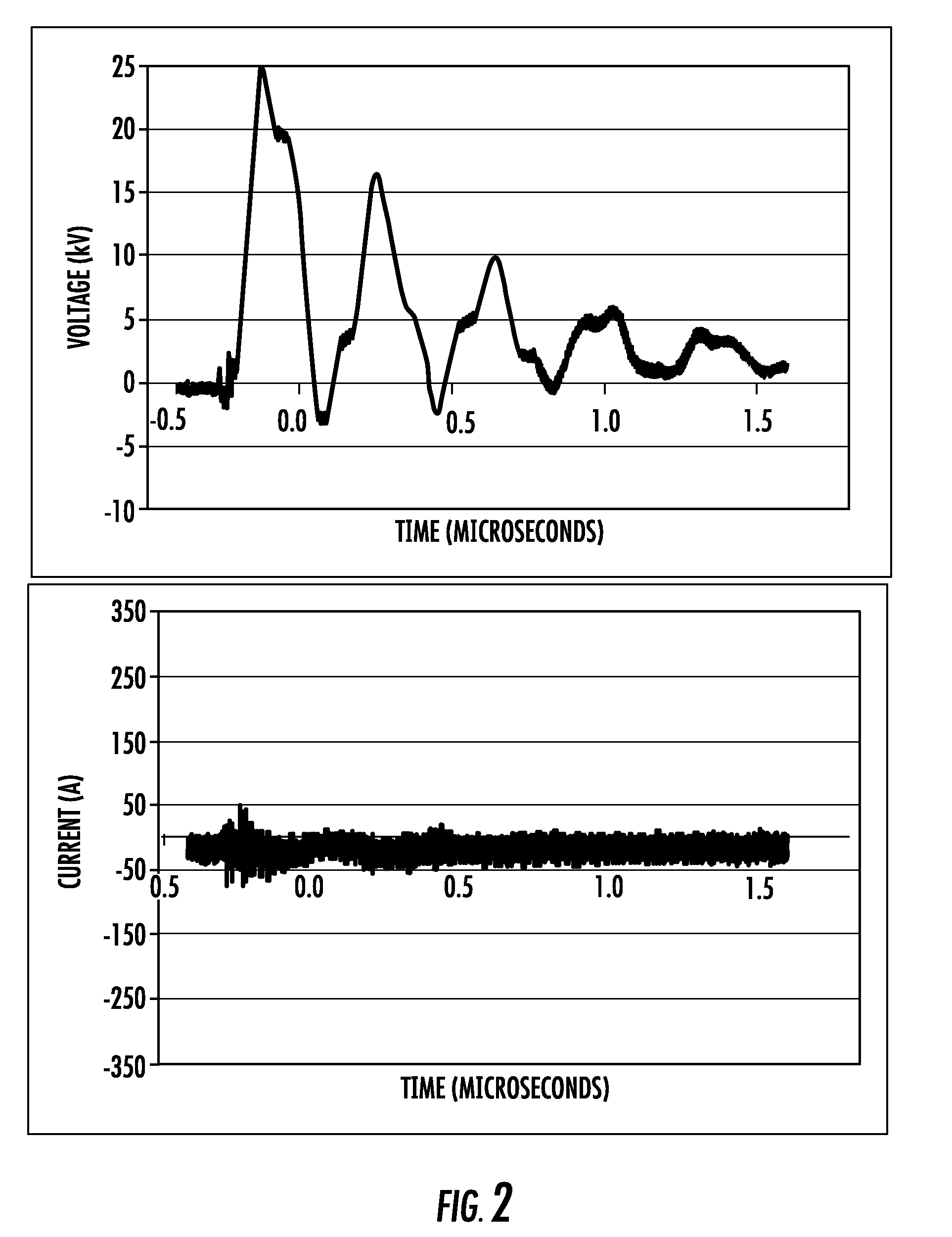

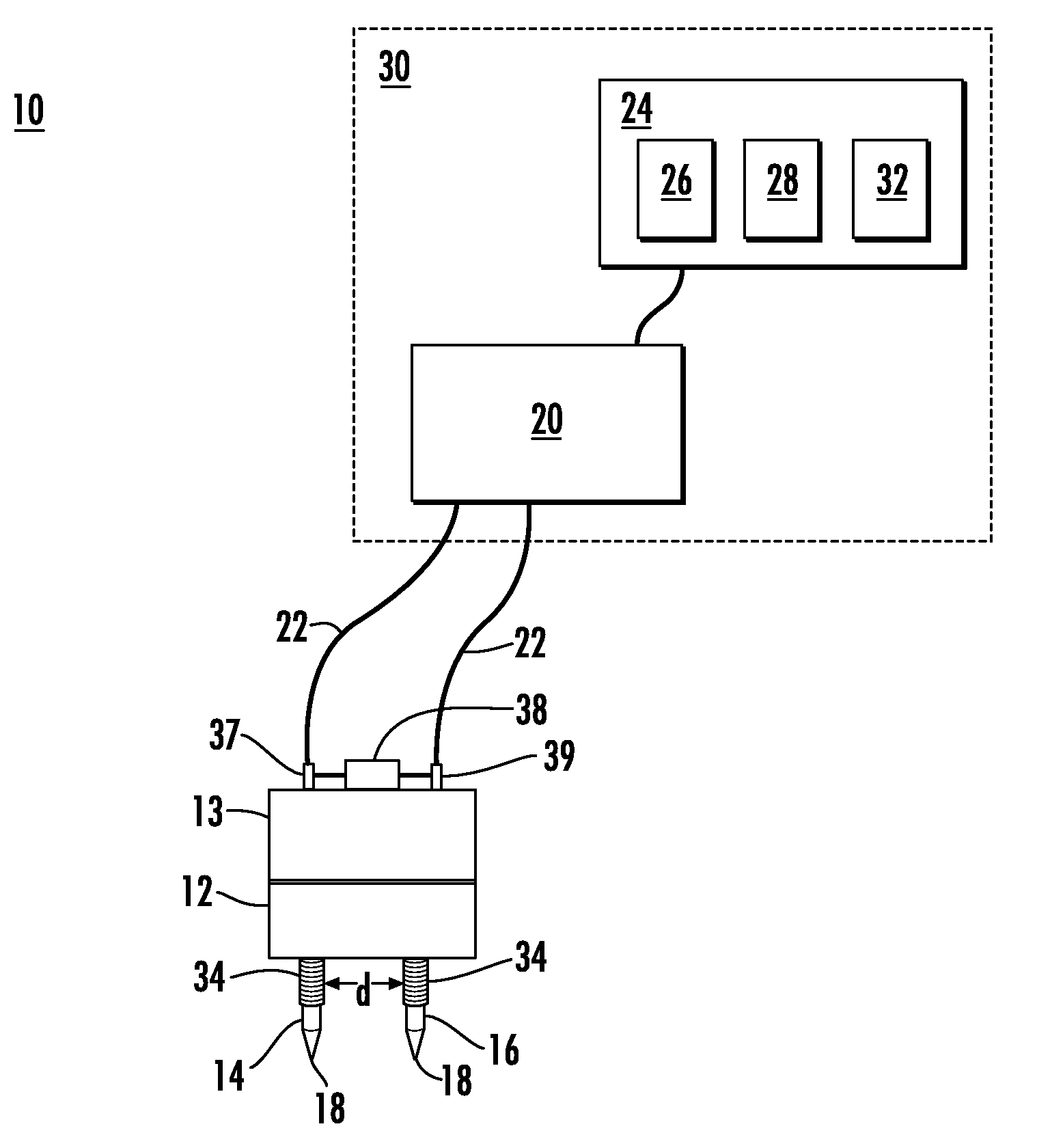

System and method for applying plasma sparks to tissue

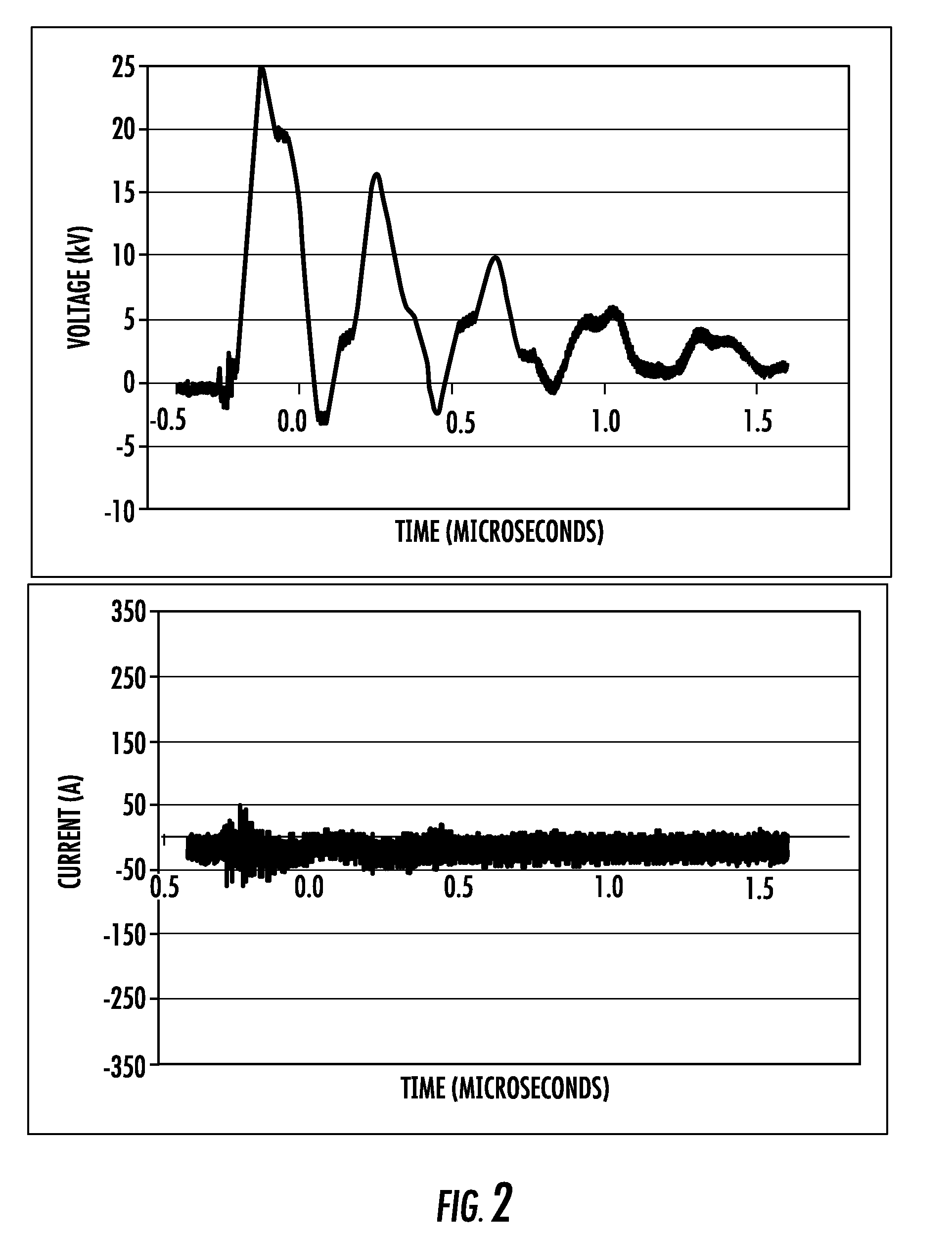

ActiveUS20100280513A1High currentMinimal collateral damageSurgical needlesSurgical instruments for heatingElectricityEngineering

A pulse delivery system for producing a spark in tissue is disclosed. The system can include at least two electrodes having sharp surface features, where the at least two electrodes are electrically isolated from one another. The sharp features of the electrodes can be separated by a distance of about 2 to 20 mm. The system can also include a pulse generator for delivering pulsed voltage differences between the at least two electrodes. The pulsed voltage differences can producing a voltage difference ranging from about 2.5 kV to about 35 kV for a duration of about 50 ns to 3 μs. The system can include a controller for determining whether the plurality of pulsed voltage differences produced a spark between the at least two electrodes. A method of producing a spark in tissue for both therapeutic and cosmetic, i.e., non-therapeutic, applications is also disclosed.

Owner:OLD DOMINION UNIVERSITY RESEARCH FOUNDATION

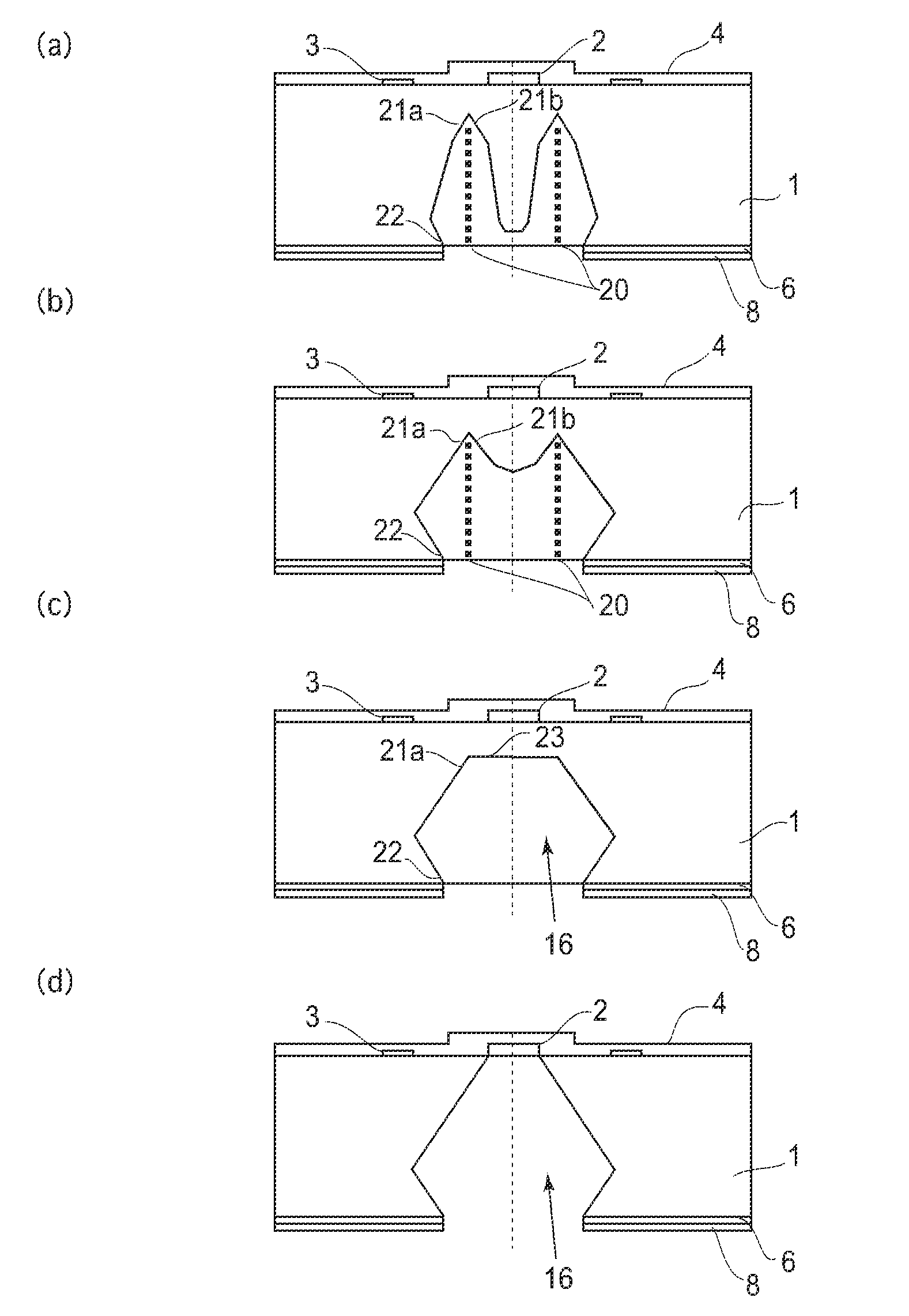

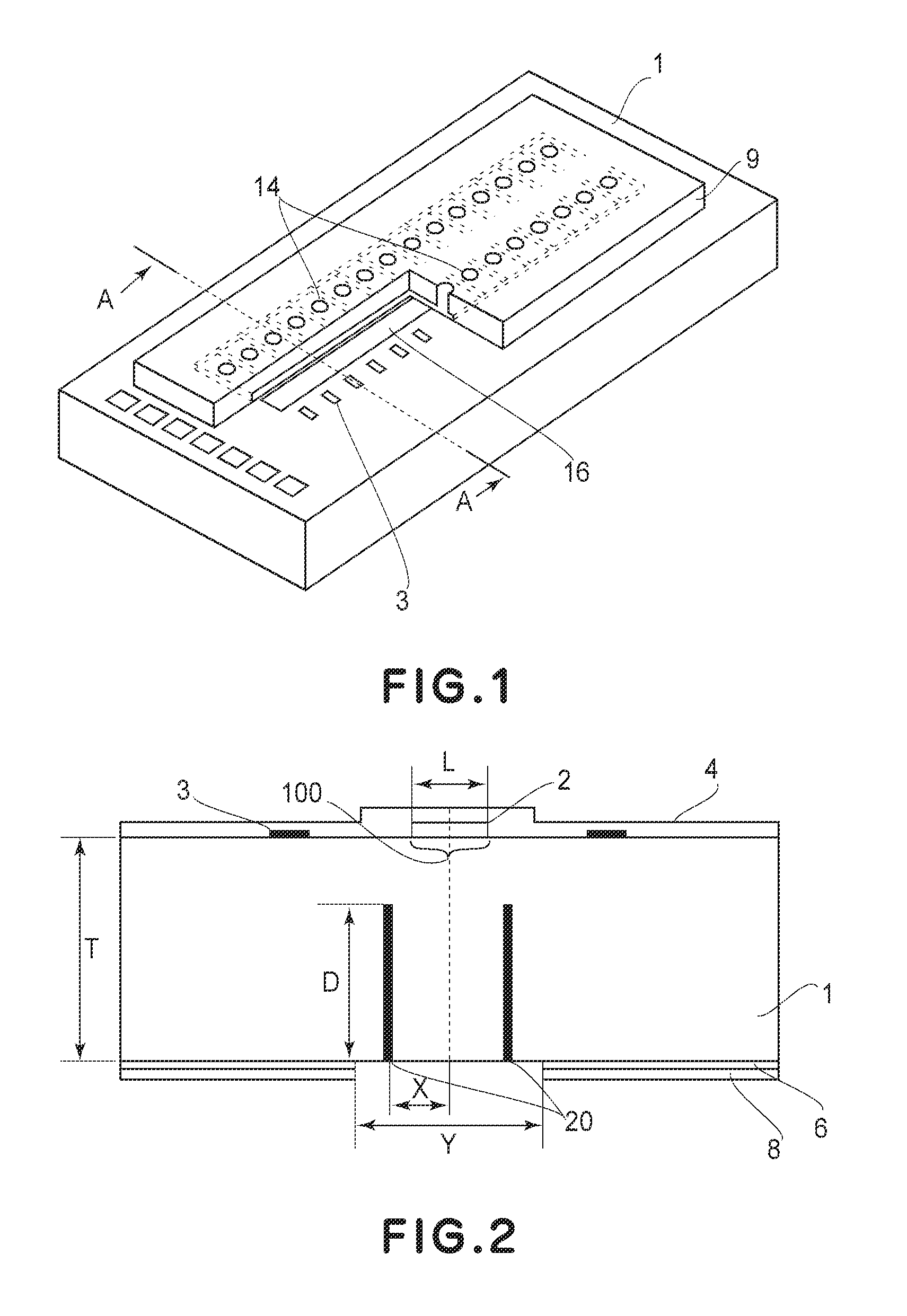

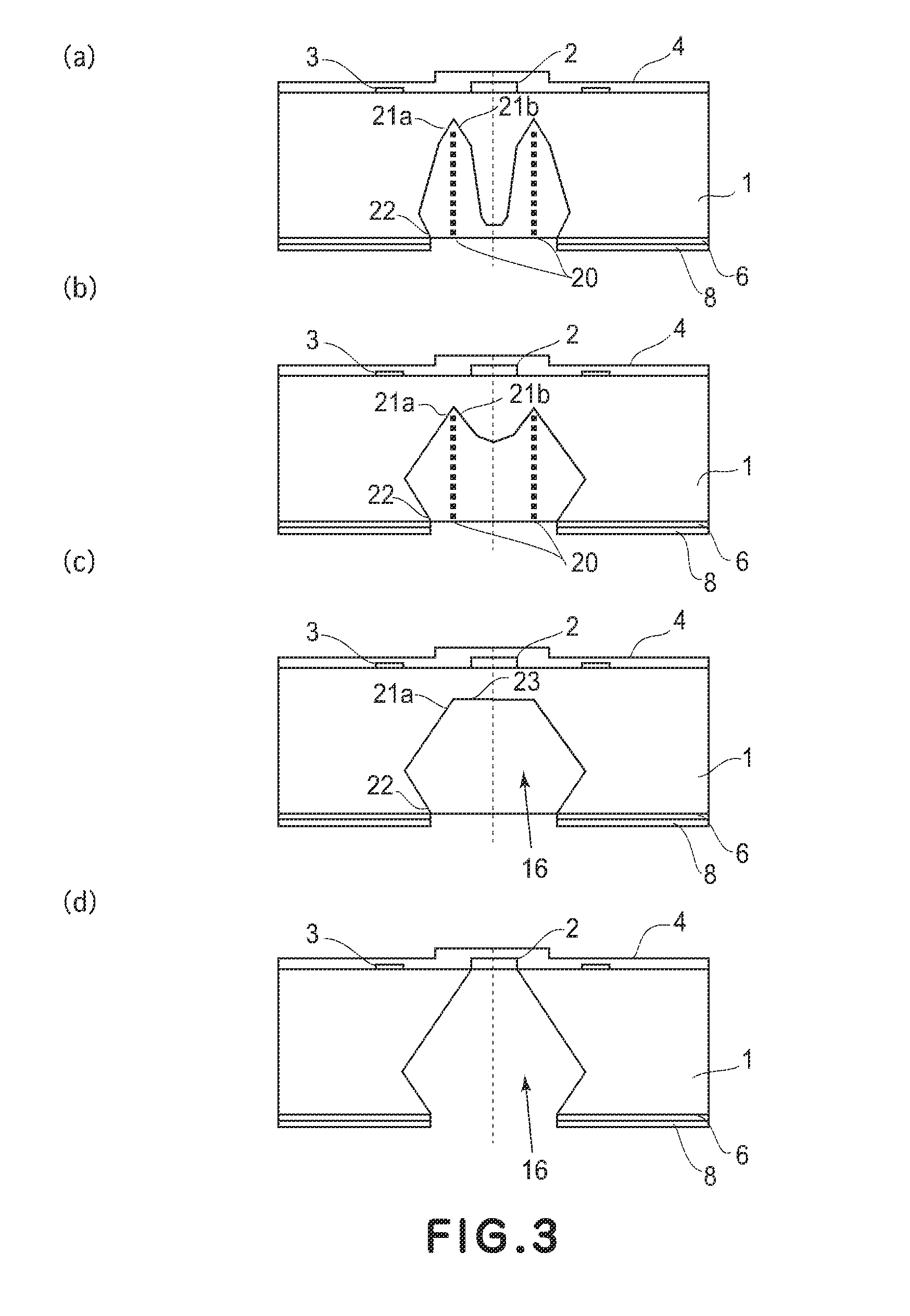

Manufacturing method for ink jet recording head chip, and manufacturing method for ink jet recording head

ActiveUS20070212890A1Improve efficiencyHigh precisionRecording apparatusSemiconductor/solid-state device manufacturingAnisotropic etchingCrystal anisotropy

A manufacturing method for a substrate for an ink jet head, including formation of an ink supply port in a silicon substrate, the method includes a step of forming, on one side of the substrate, an etching mask layer having an opening at a position corresponding ink supply port; a step of forming unpenetrated holes through the opening of the etching mask layer in at least two rows in a longitudinal direction of the opening; and a step of forming the ink supply port by crystal anisotropic etching of the substrate in the opening.

Owner:CANON KK

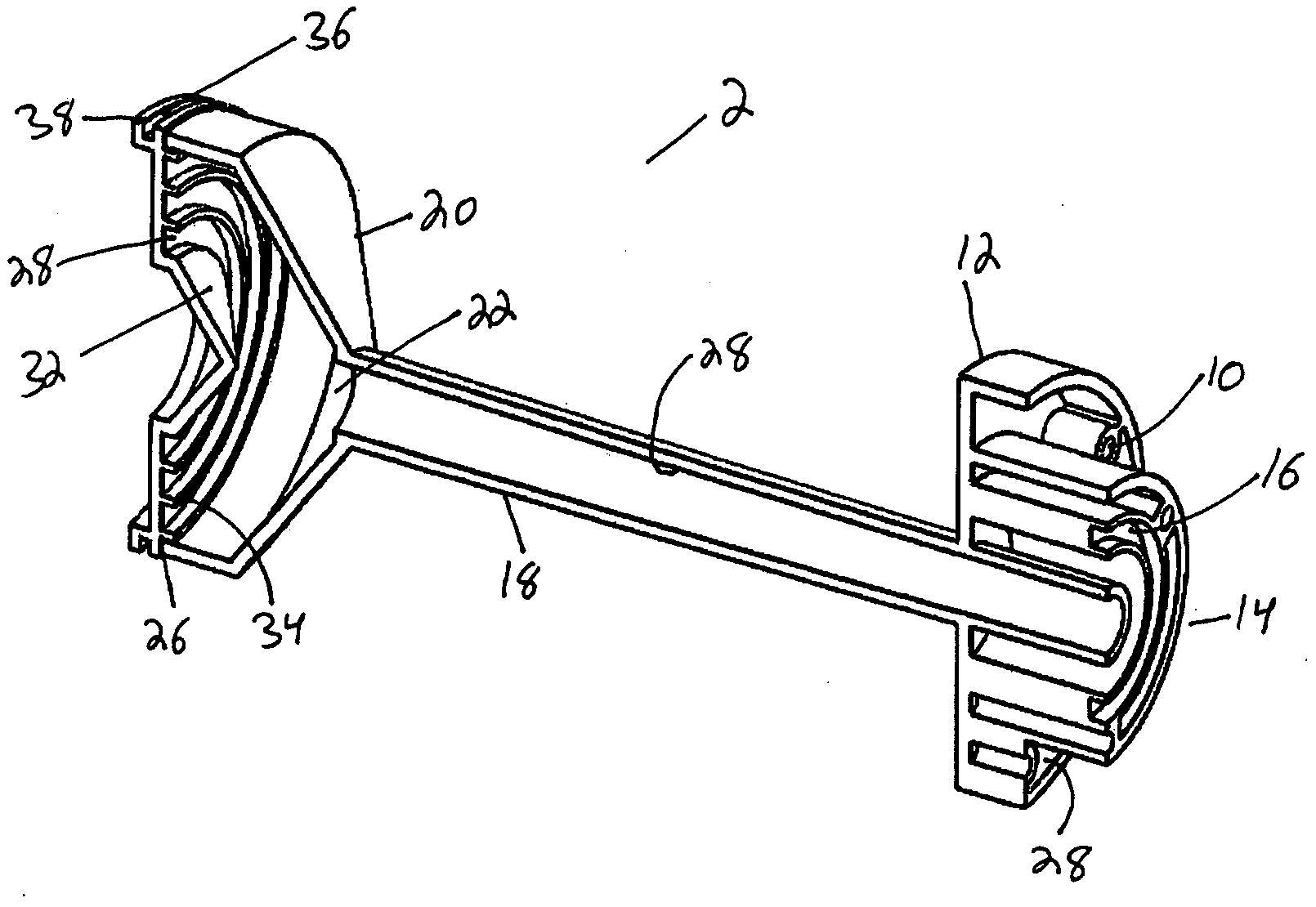

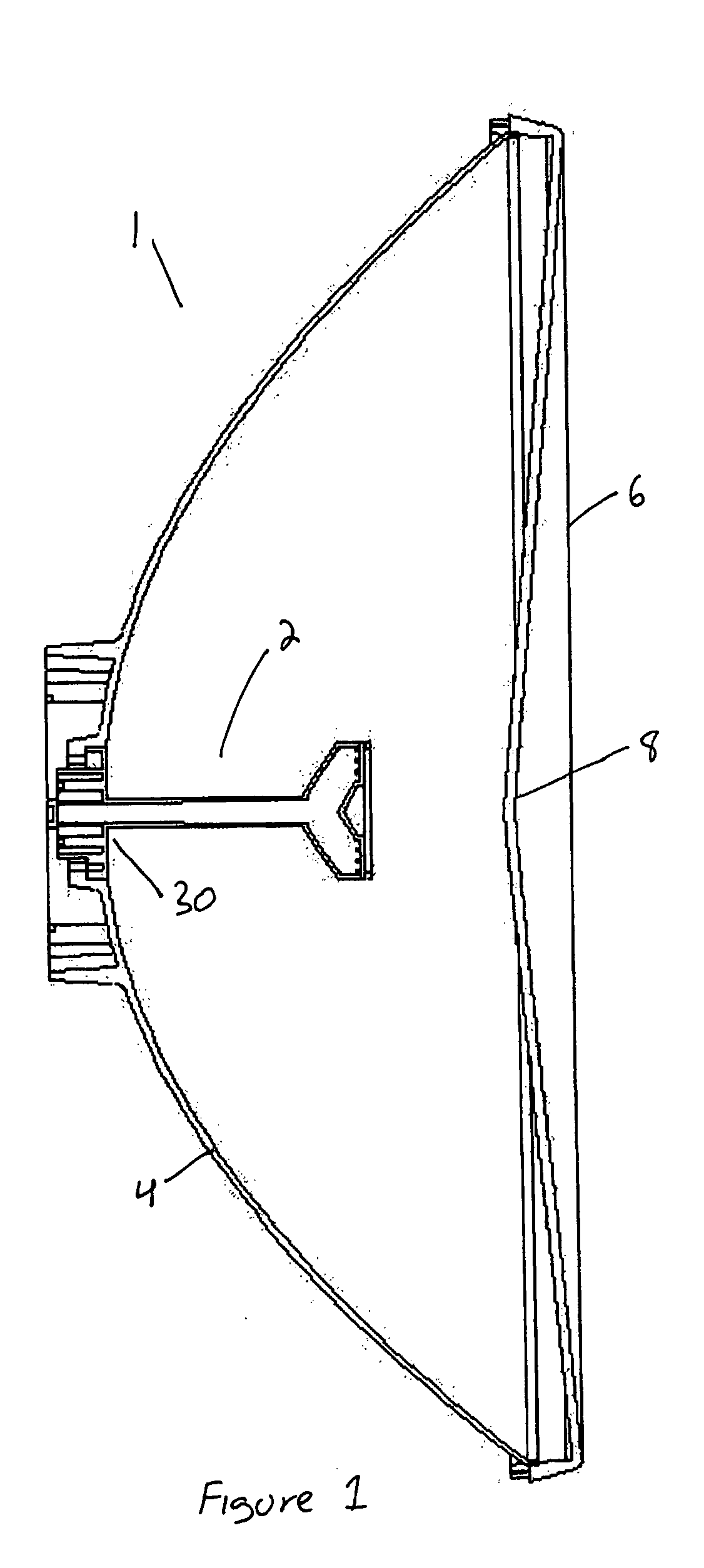

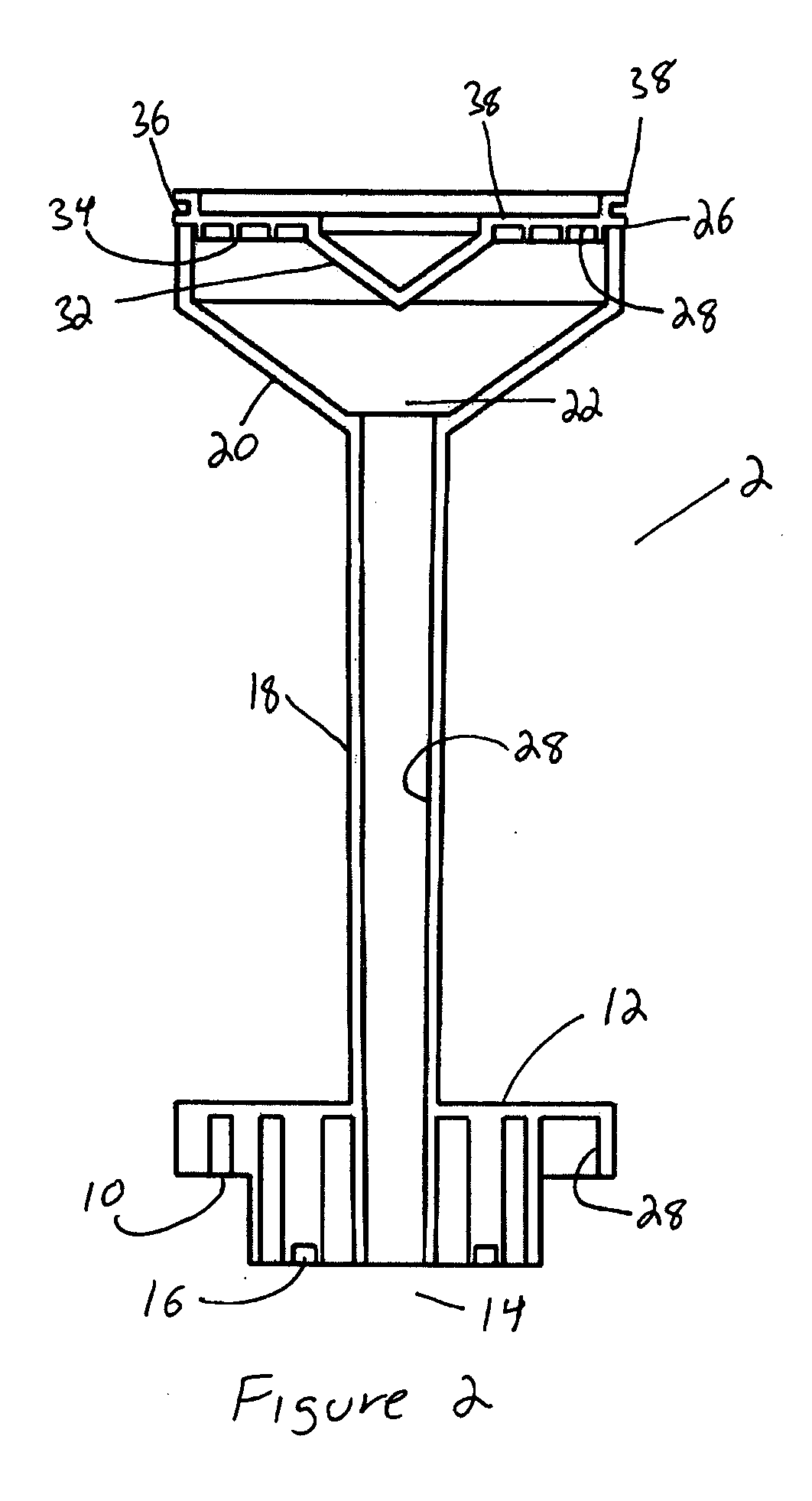

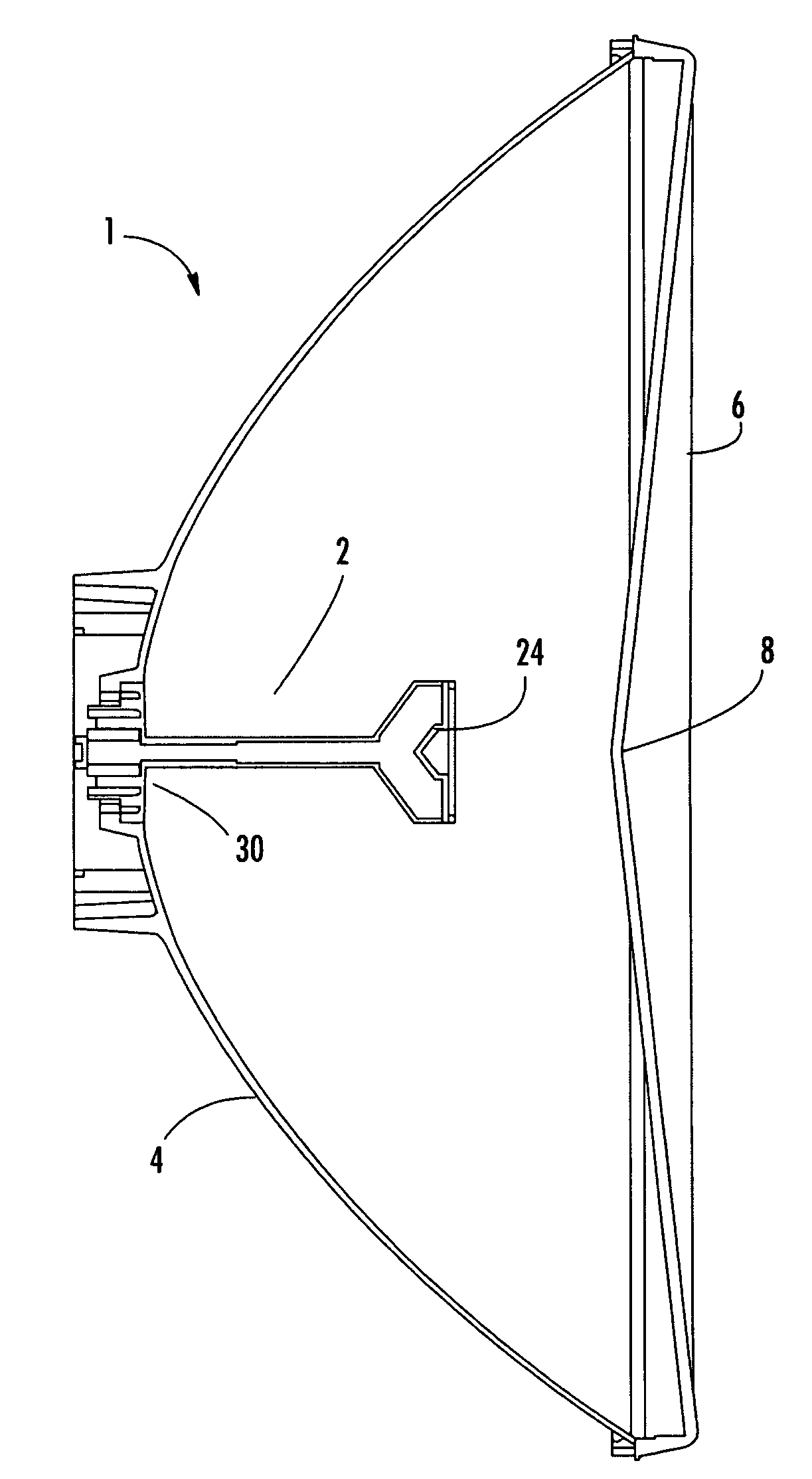

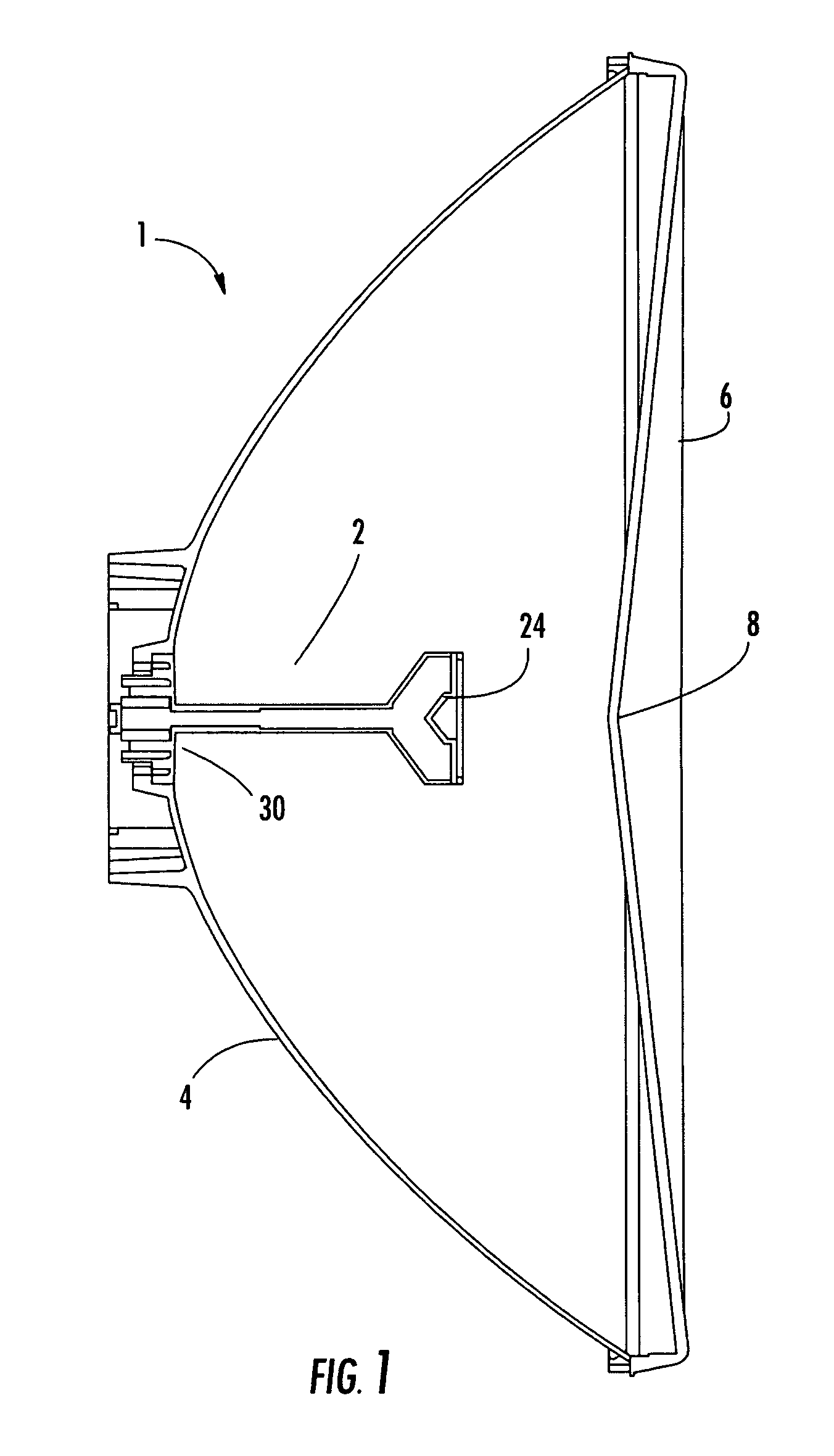

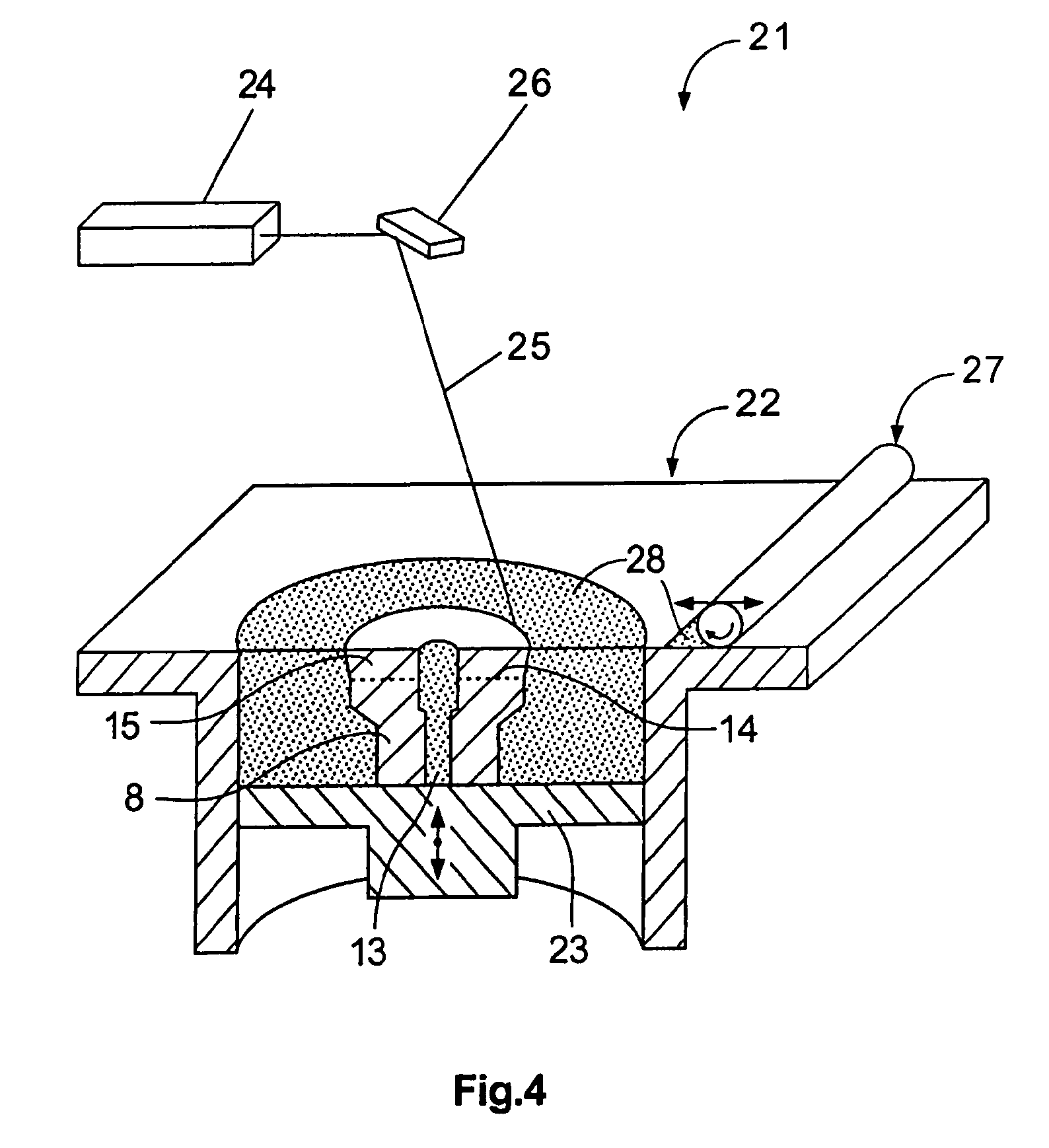

Reflector antenna with injection molded feed assembly

InactiveUS20050017916A1Improve wind loading characteristicMinimal degradationAntenna couplingsEngineeringInjection moulding

A reflector antenna with a self supported feed assembly that may be formed by injection molding. A waveguide portion of the feed assembly has a dielectric cone at a distal end that supports and retains a sub reflector, for example along a periphery of the sub reflector. A conductive surface coating on an internal surface of the waveguide and a bottom surface of the sub reflector creates surfaces with RF reflective and conductive properties. The return loss of the feed assembly is reduced due to a reduction of the thickness of the material forming the dielectric cone, compared to prior dielectric block designs and a soft boundary condition produced by dielectric coating of the waveguide which aids in reducing reflections to the vertex area of the reflector.

Owner:COMMSCOPE TECH LLC

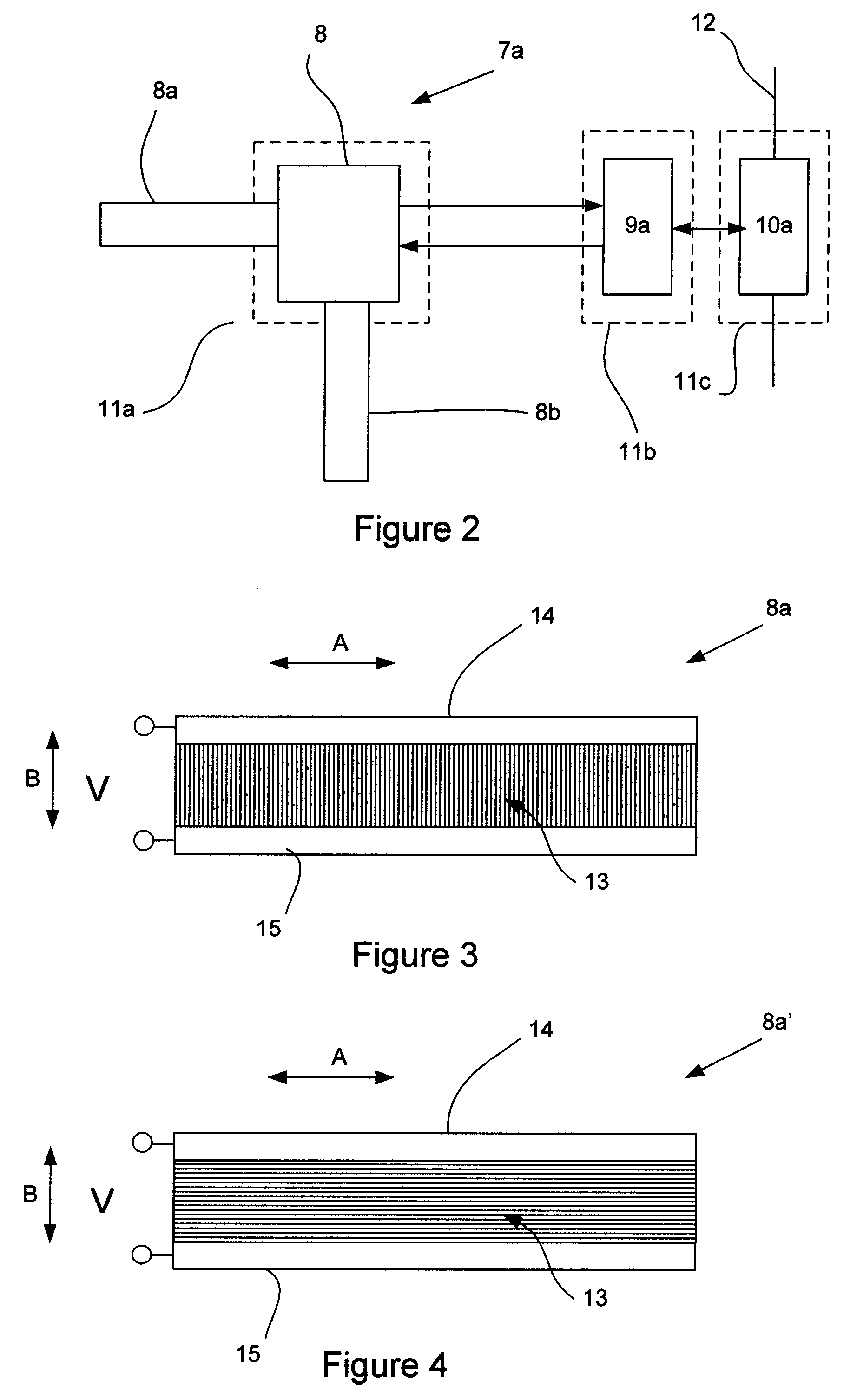

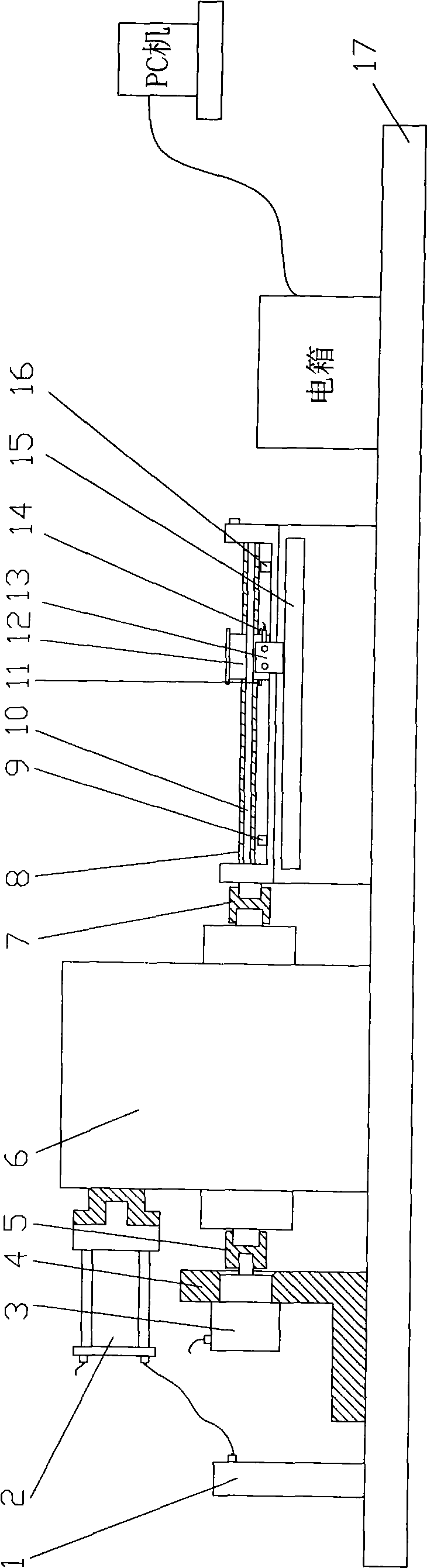

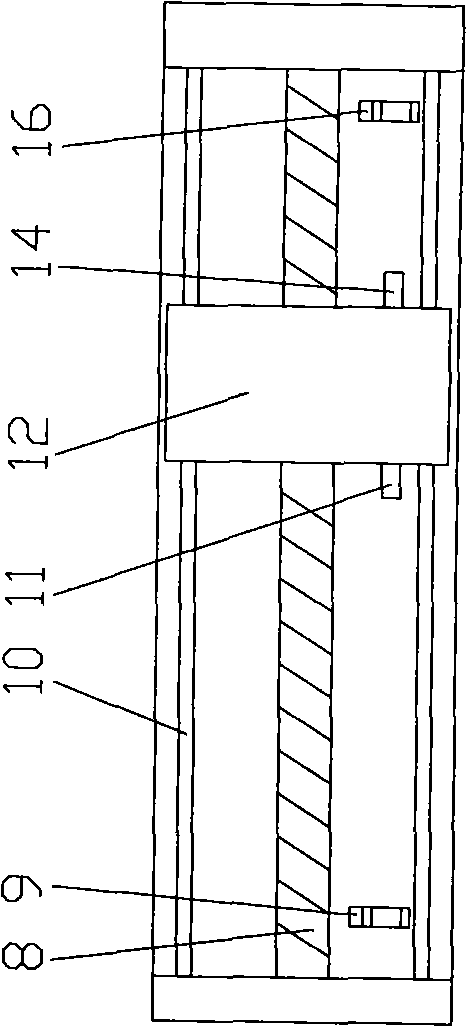

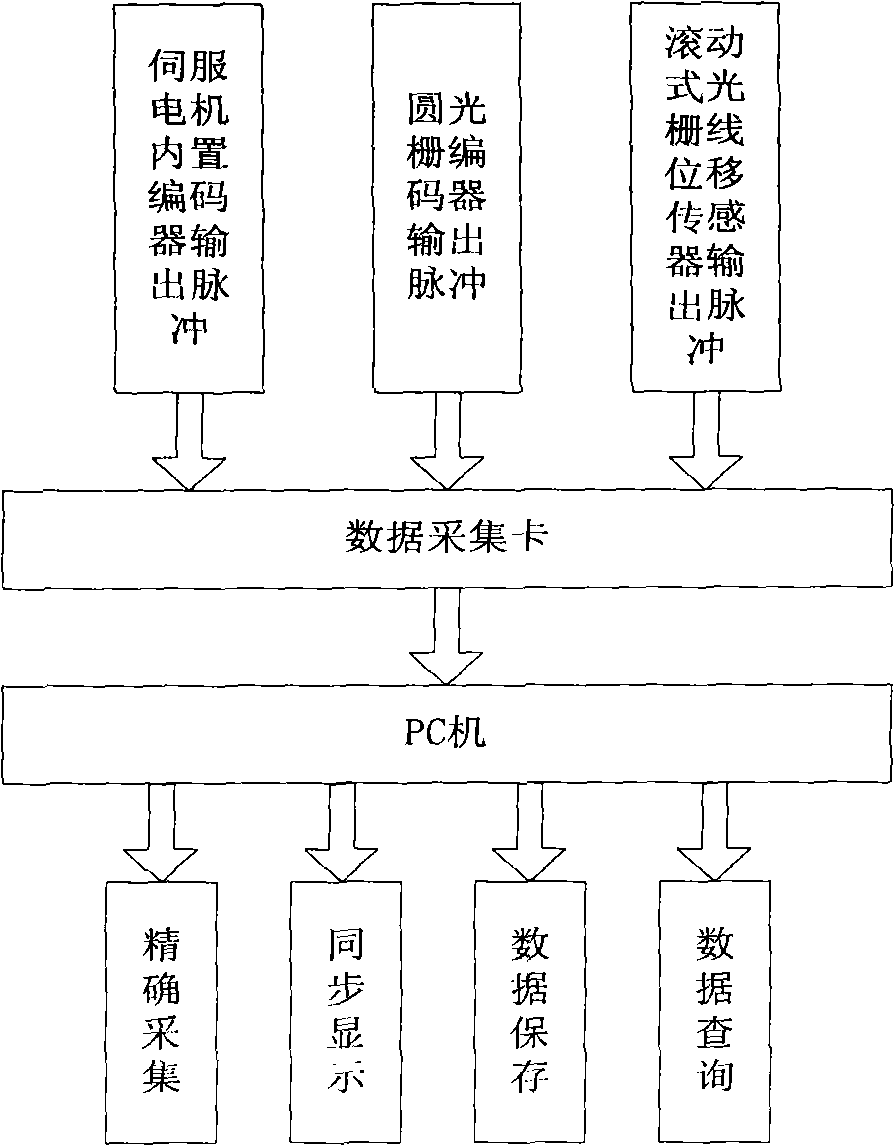

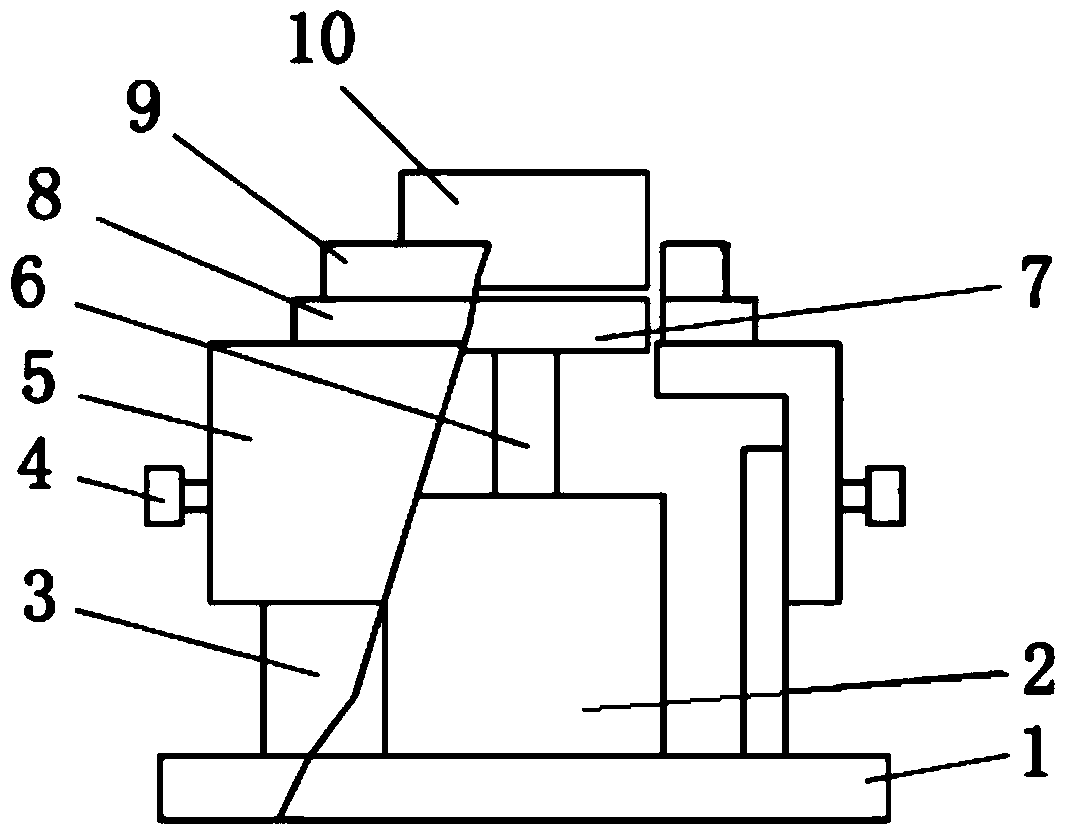

Multifunctional dynamic precision test system

InactiveCN101532912AIncreased accuracy levelImprove errorMachine part testingUsing optical meansGratingData acquisition

A multifunctional dynamic precision test system is characterized in that a servo motor is arranged, an output shaft of a speed reducer is connected with a rolling ball screw rod by a corrugated pipe coupling, a workbench capable of axially sliding along a straight line guide rail is fixedly connected with a nut of the rolling ball screw rod, and the workbench is supported by the straight line guide rail arranged at two sides of the rolling ball screw rod. each arranged measuring mechanism includes a built-in incremental encoder in the servo motor, circular grating encoder for measuring corner of the speed reducer, and a rolling type grating line displacement sensor for measuring displacement of the workbench. A multi-path signal data acquisition card is arranged, and detection signal of each measuring mechanism is synchronously displayed on a PC machine by the multi-path signal data acquisition card. The invention is used for researching theories such as whole system dynamic error, precision loss, error decomposition and affiliation of the dynamic system, and provides means for researching dynamic precision characteristic of dynamic system and related analysis.

Owner:HEFEI UNIV OF TECH

Reflector antenna with injection molded feed assembly

InactiveUS6985120B2Improve wind loading characteristicMinimal degradationAntenna couplingsEngineeringInjection moulding

Owner:COMMSCOPE TECH LLC

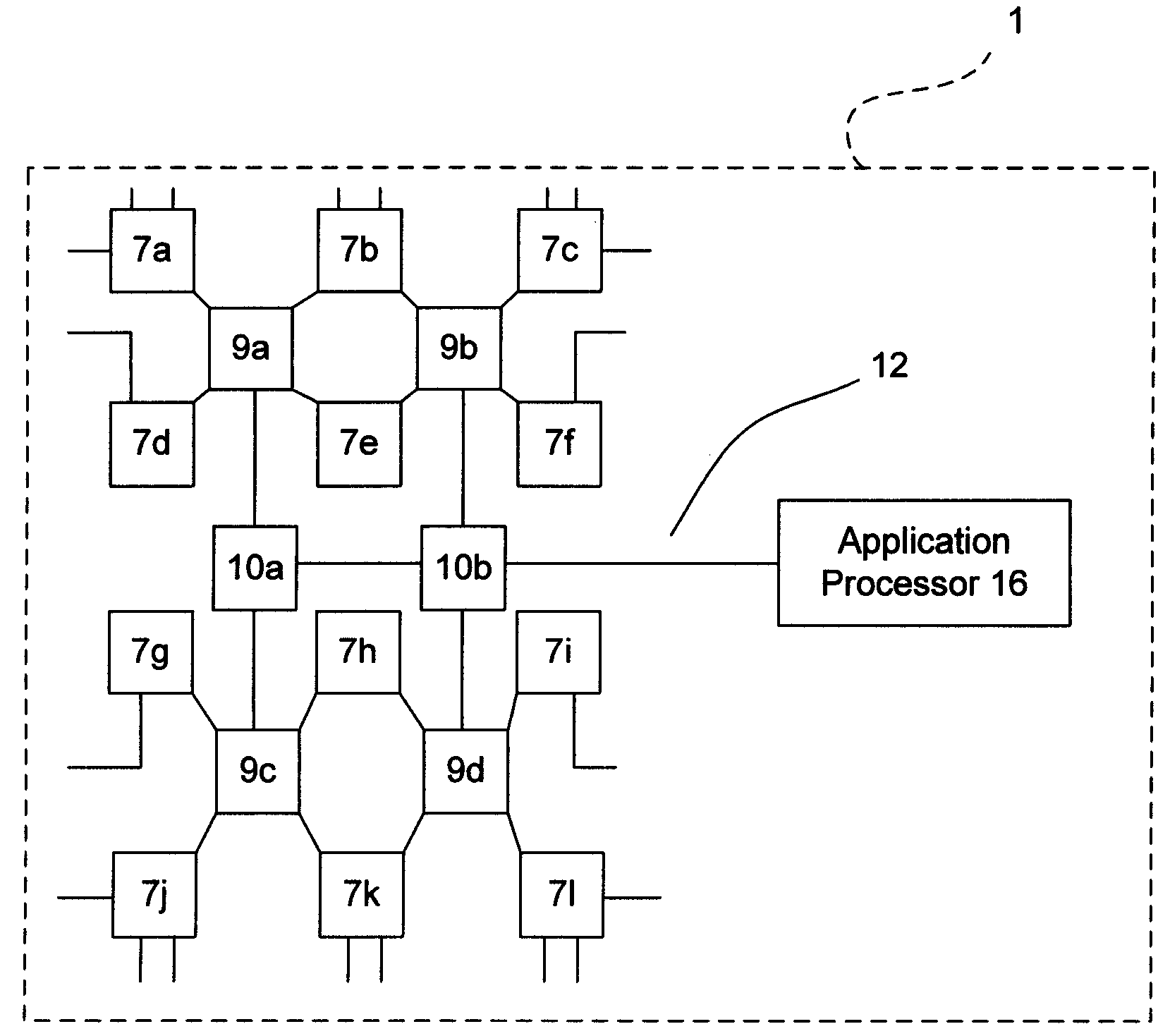

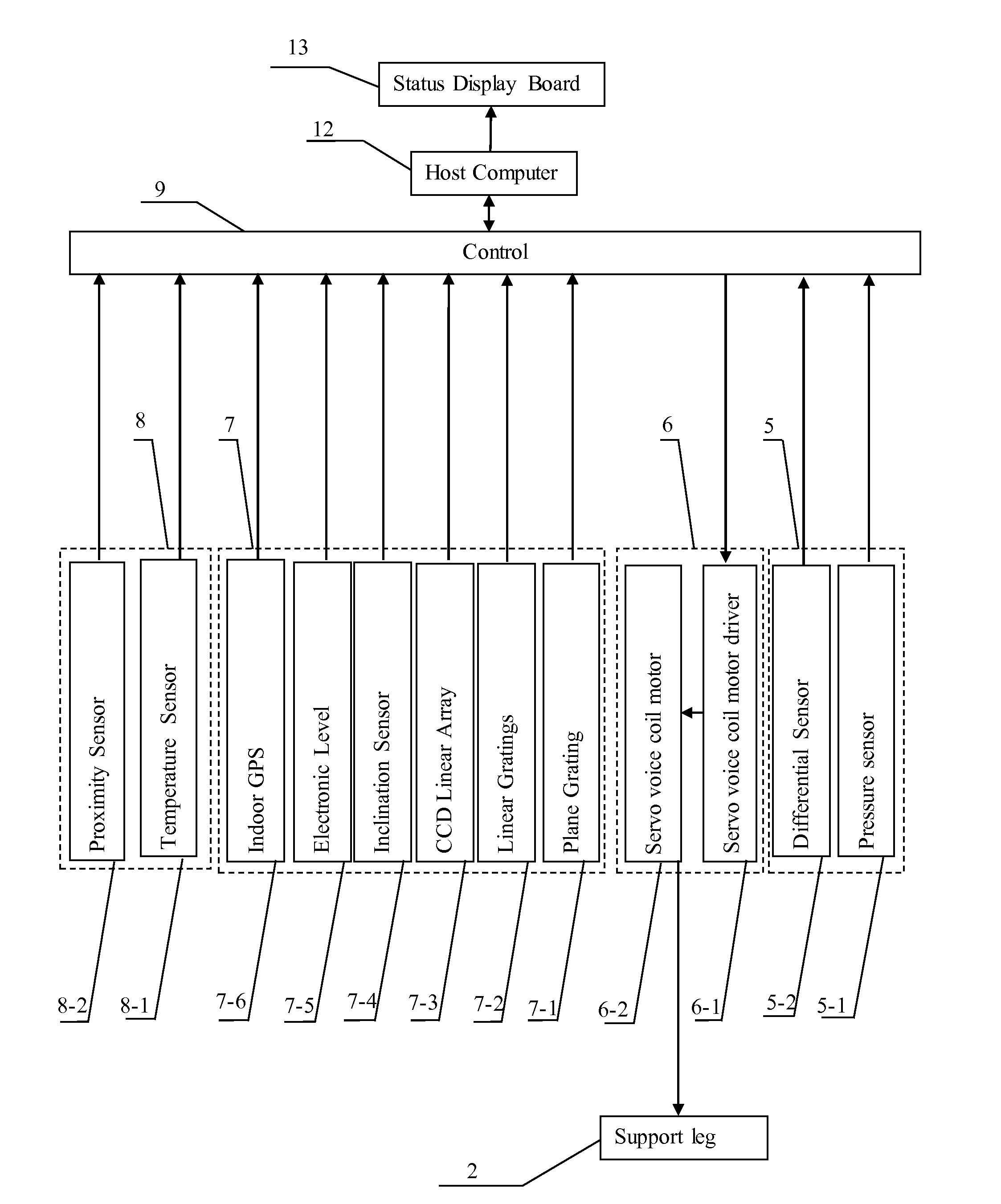

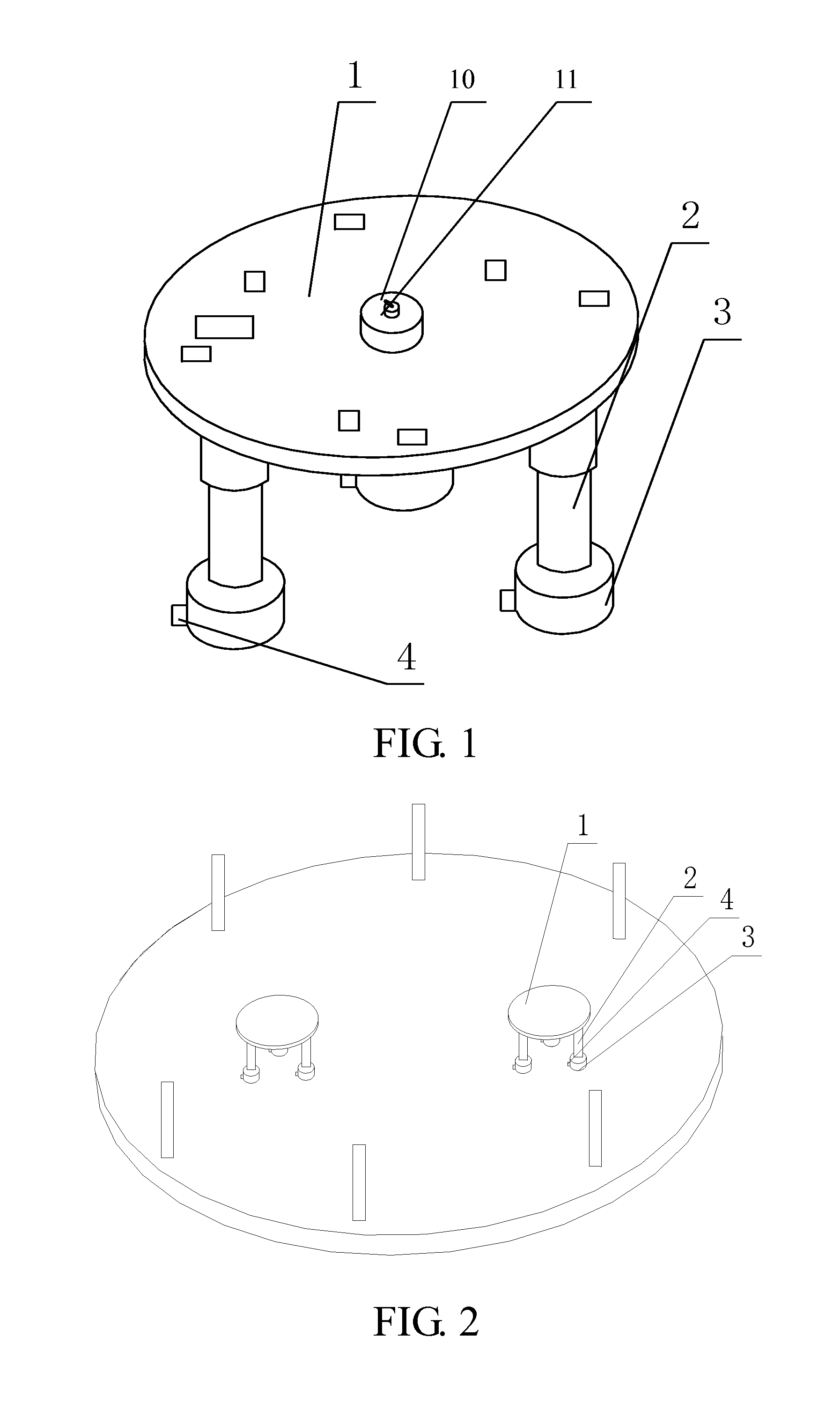

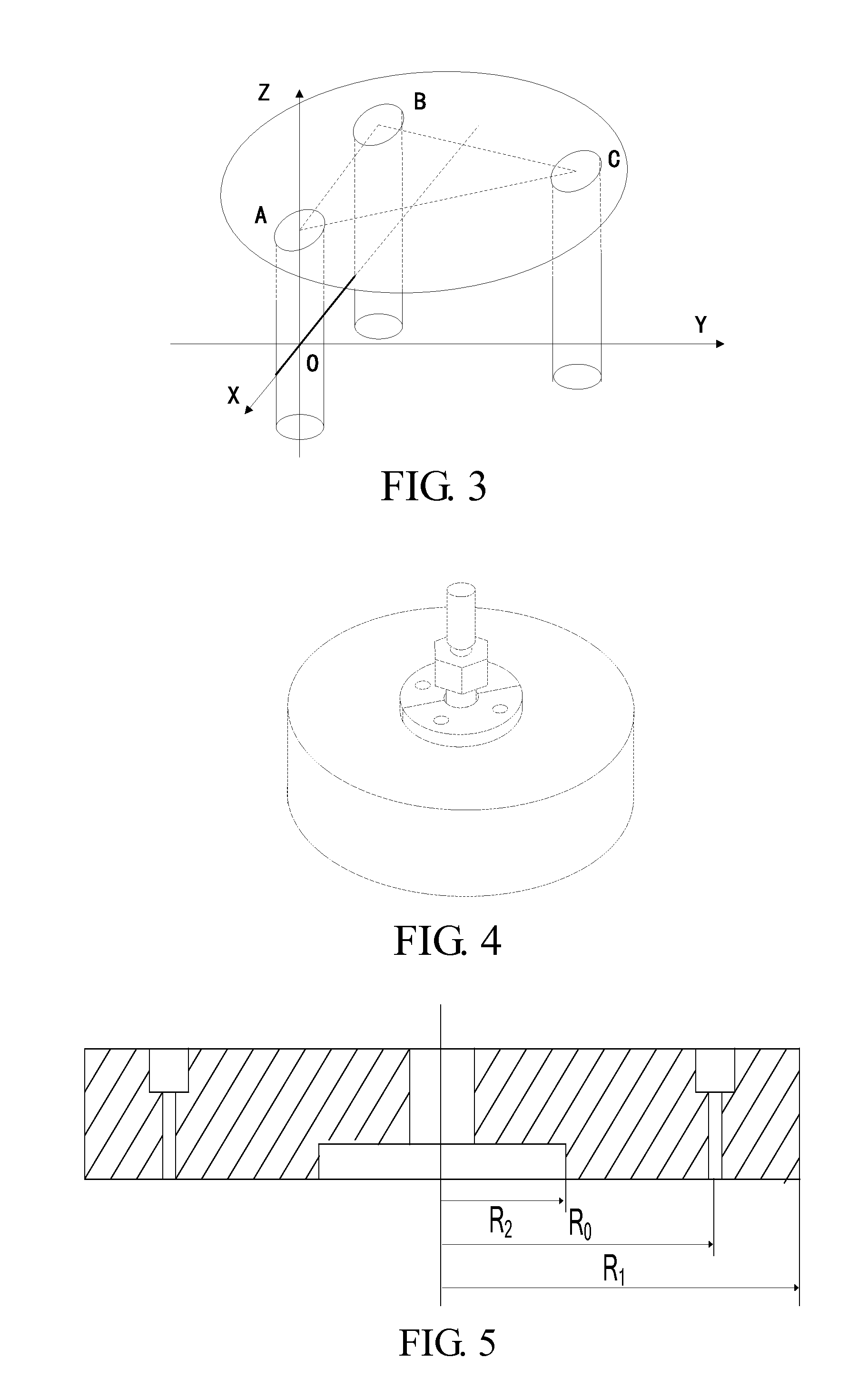

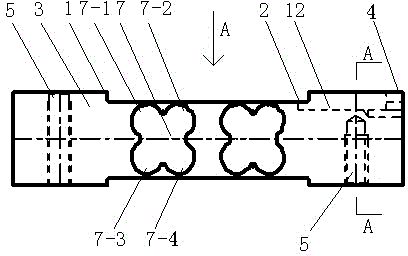

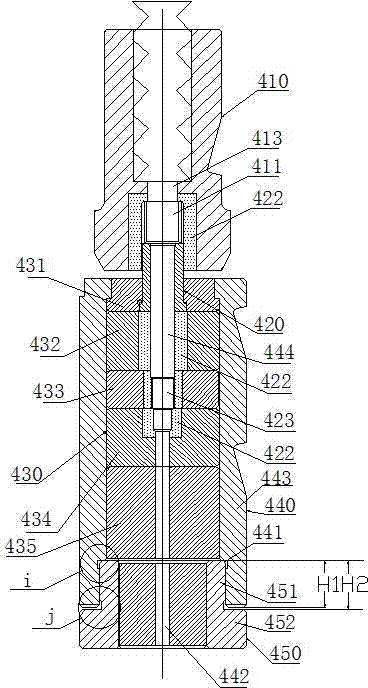

Measurement Control System for Multi-Shaft Supported Air Floatation Platform

ActiveUS20160124437A1Increased load-bearing capacityIncreased accuracy levelComputer controlStands/trestlesGratingProximity sensor

A measurement control system for a multi-shaft supported air floatation platform, the system comprising a load feedback unit (5), an execution unit (6), a position measurement unit (7), a safety protection unit (8), a controller (9), a rotating motor (10), and a linear light source 11; the load feedback unit comprises M pressure sensors (5-1) and four differential sensors (5-2); the execution unit comprises M servo voice coil motors (6-1) and M servo voice coil motor drivers (6-2); the position measurement unit comprises a plane grating (7-1), M linear gratings (7-2) a linear array CCD (7-3), a tilt sensor (7-4), M electronic levels (7-5), and an indoor GPS (7-6); the safety protection unit comprises 2M proximity sensors (8-1) and M temperature sensors (8-2); and the linear array CCD consists of no few then six CCDs. The system solves the problems of leveling limitations and narrow application range of existing supporting platforms.

Owner:HARBIN INST OF TECH

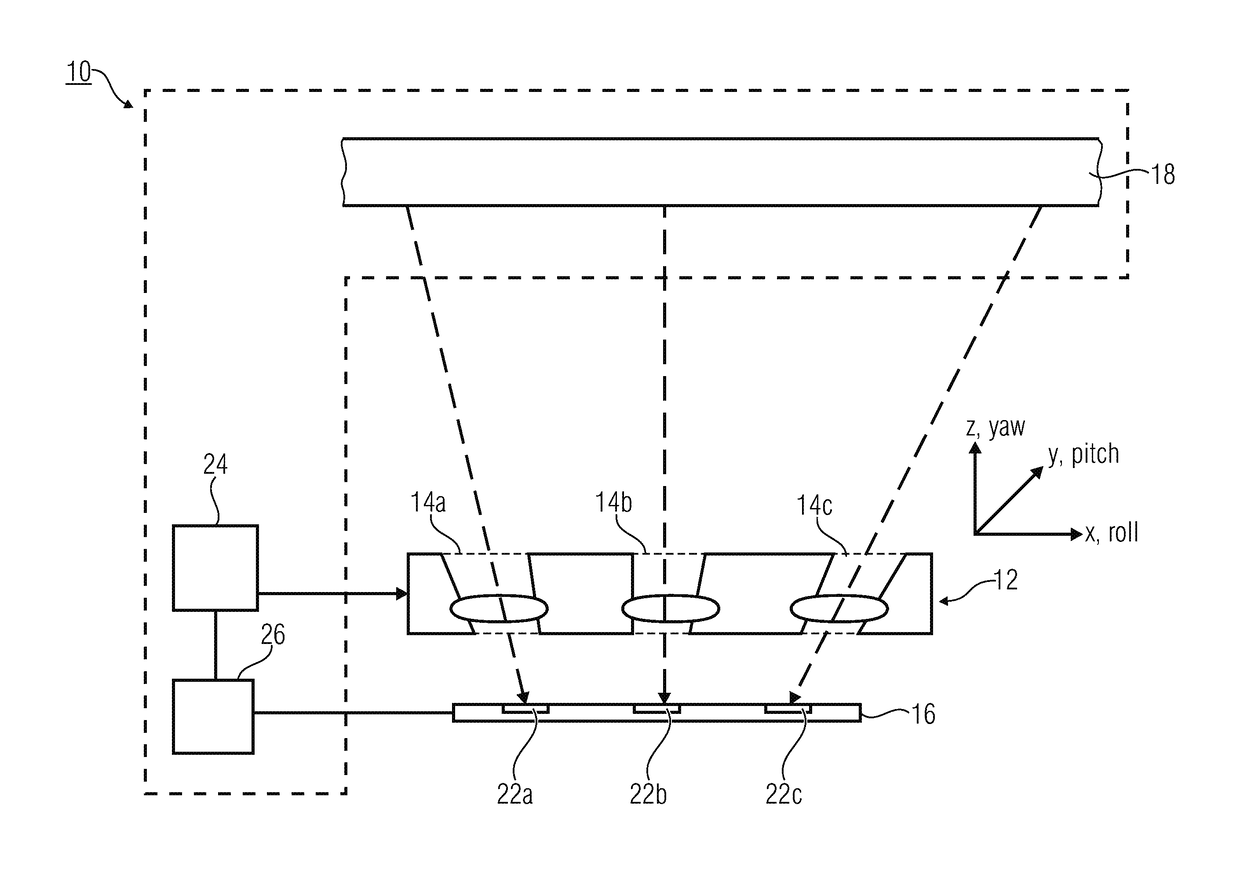

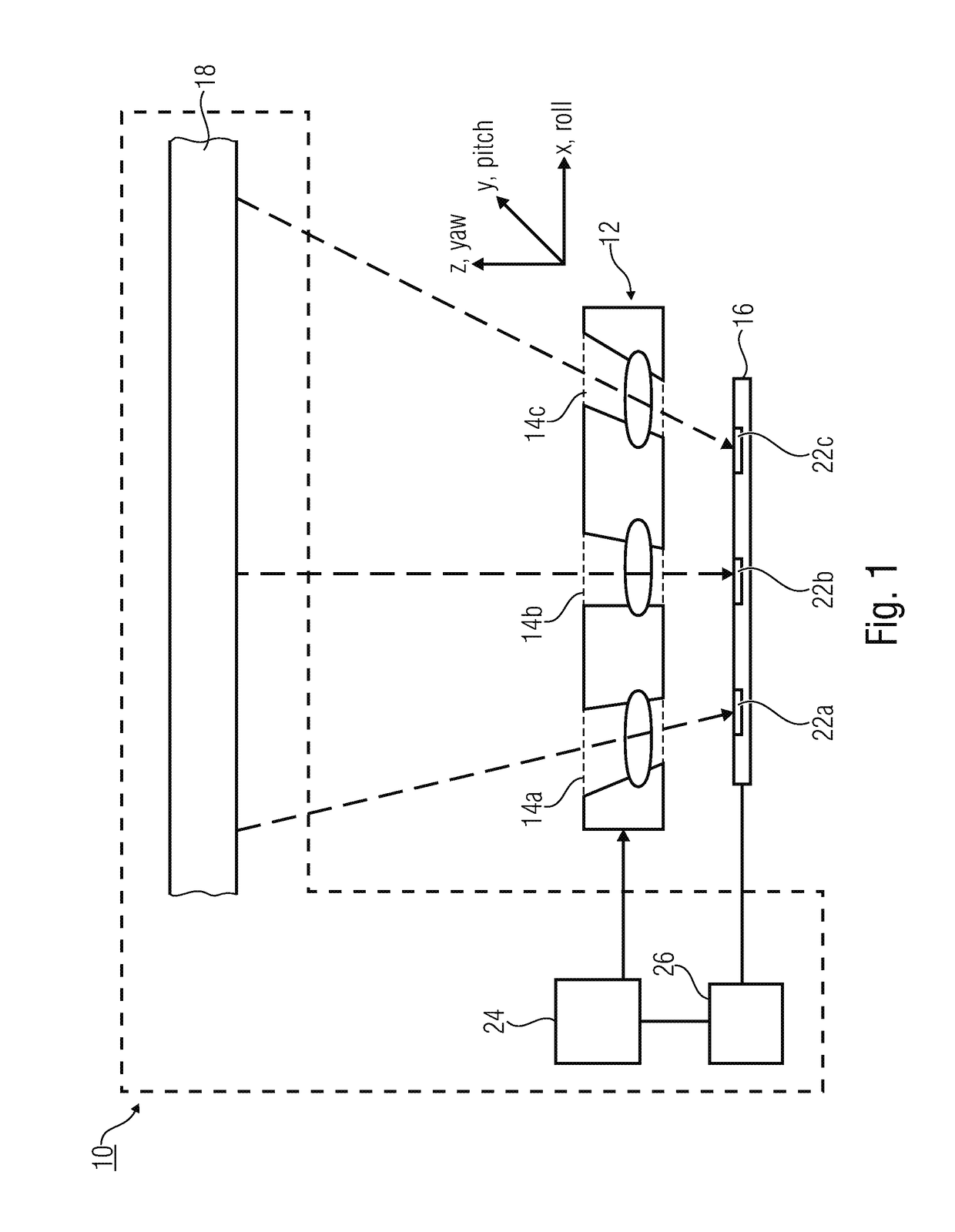

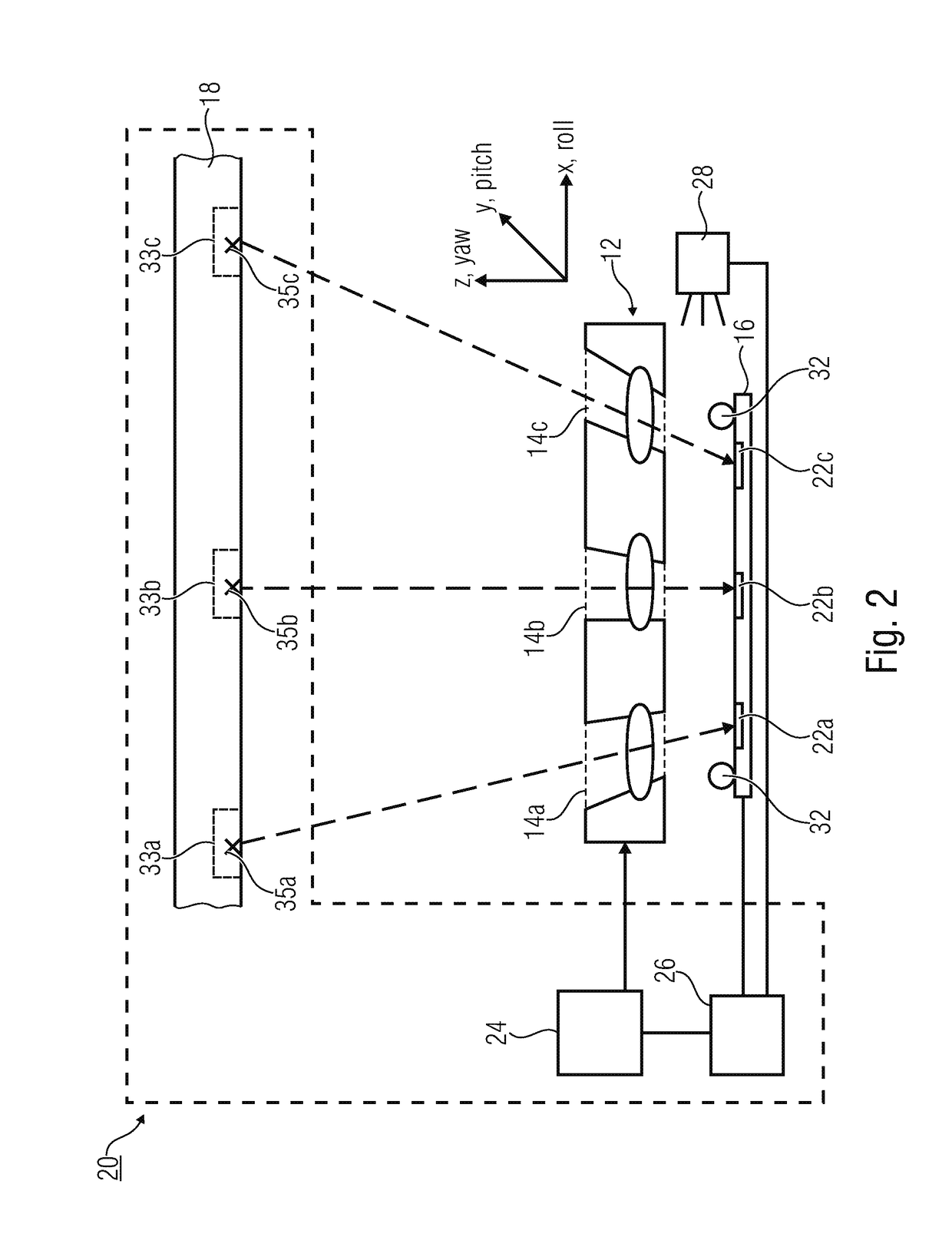

Device and method for relative positioning of multi-aperture optics comprising several optical channels in relation to an image sensor

ActiveUS20170111558A1High precisionIncrease precisionImage enhancementTelevision system detailsImage sensorImage area

A device for relative positioning of multi-aperture optics having several optical channels in relation to an image sensor includes a reference object, a positioning device, and a calculating device. The reference object is arranged such that the reference object is imaged onto one image region per channel in the optical channels by the multi-aperture optics. The positioning device is controllable to change a relative location between the multi-aperture optics and the image sensor. The calculating device is configured to determine actual positions of the reference object in at least three image regions in images of the reference object and to control the positioning device on the basis of a comparison of the actual positions with positions.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Method of optimizing dosage-dispensing processes, and dosage-dispensing device

ActiveUS20080173668A1Increased accuracy levelSuitable performanceOpening closed containersBottle/container closureComputer moduleCentral database

In the method of optimizing the dosage-dispensing process of a dosage-dispensing device, an examination takes place prior to a first dosage delivery, whether at least one flow parameter relating to the dosage-dispensing process is stored in the memory module of the dosage-dispensing unit. If a stored flow parameter is found to be present, said flow parameter is called up from the memory module. If no store flow parameter is present, a flow parameter is requested by the user by entering a request, a flow parameter is called up from a central database, or at least one flow parameter is determined by means of the first run of the dosage-dispensing process based on a default setting of the dosage-dispensing program. With the at least one flow parameter, the dosage-dispensing program is directly adapted, at least one run of the dosage-dispensing process is performed with the adapted dosage-dispensing program, and / or the at least one flow parameter is stored in the memory module. As a prerequisite for performing the method according to the invention, a dosage-dispensing device is required which comprises a drive device with a control- and regulation unit operable to execute a dosage-dispensing program, wherein a dosage-dispensing unit can be set in place in, and removed from, the drive device and wherein the dosage-dispensing unit is equipped with at least one memory module.

Owner:METTLER TOLEDO GMBH

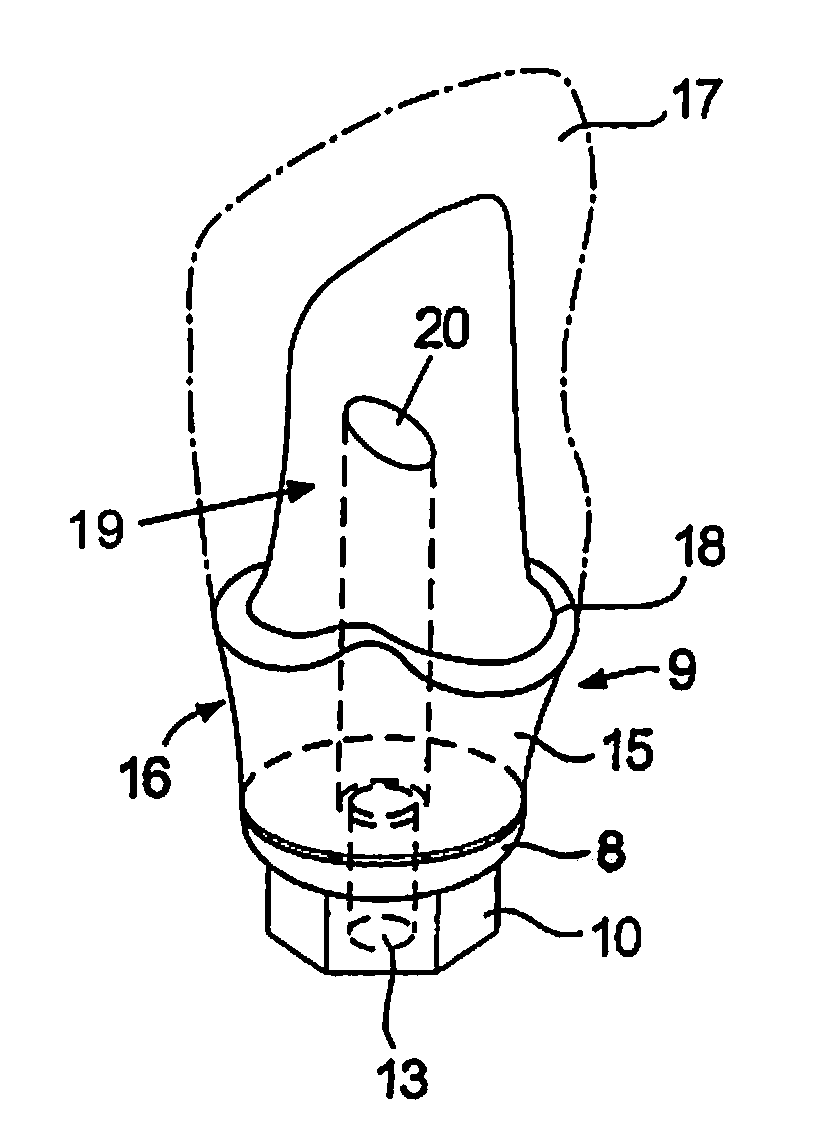

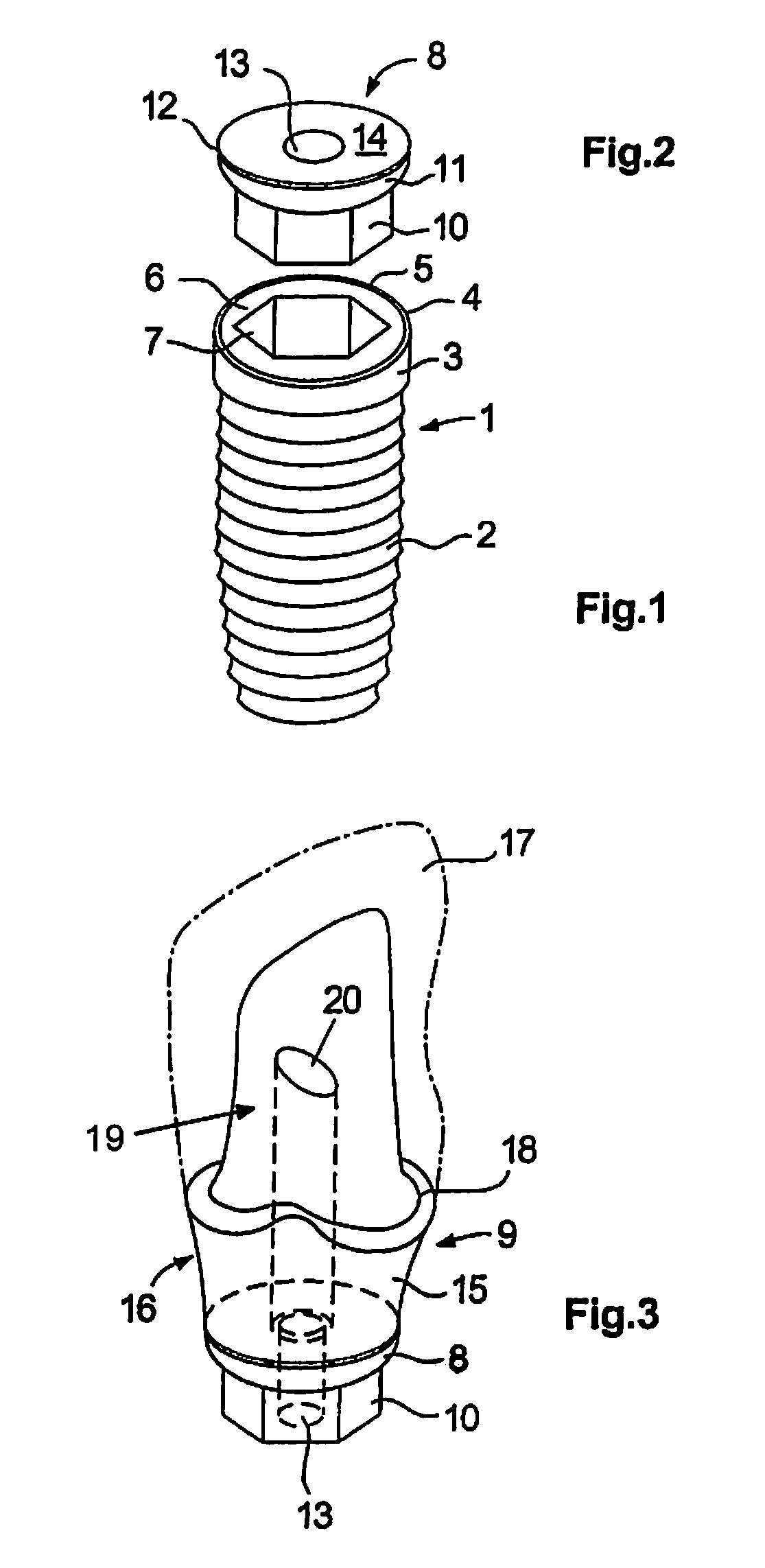

Method for manufacturing implant abutments for dental implants, and an implant abutment for a dental implant

ActiveUS8778443B2Improve aestheticsAvoid showingDental implantsImpression capsDental implantBiomedical engineering

The invention relates to a method for manufacturing implant abutments 9 for dental implants 1, wherein the implant abutment 9 comprises a prefabricated base member 8 for joining the implant abutment to the dental implant 1, and a customized main body 15. The aim of the invention is to simplify this method of manufacturing. To this end, the main body 15 is formed by sintering and / or melting powdery material onto the base member 8 using laser sintering and / or laser melting. The invention relates also to an implant abutment manufactured by such a method.

Owner:BEGO MEDICAL

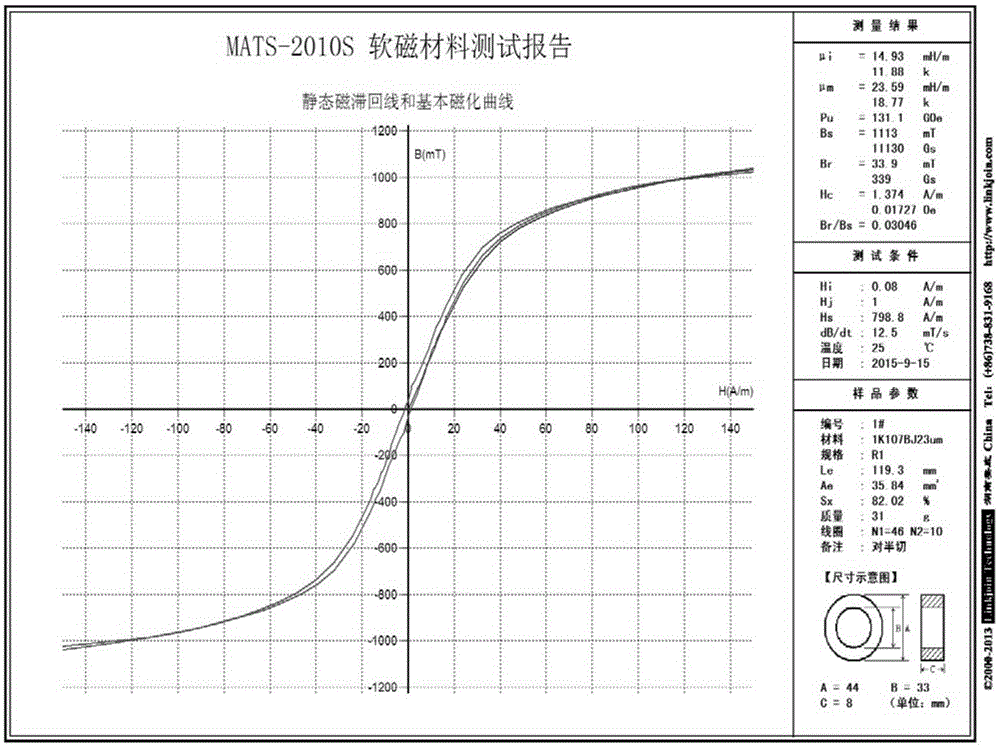

Method for precisely preparing nanocrystalline magnetic core with high magnetic permeability

ActiveCN105428053AImprove permeabilityIncreased accuracy levelMagnetic core manufactureEpoxyControl system

The invention provides a method for precisely preparing a nanocrystalline magnetic core with high magnetic permeability. The method comprises a step of nanocrystalline magnetic core curing and a step of nanocrystalline magnetic core cutting, wherein nanocrystalline magnetic core curing is realized by taking epoxy resin as varnish gum in a vacuum impregnation manner, particularly, a magnetic core and the varnish gum are preheated to 60-70 DEG C before impregnation, the epoxy resin varnish gum is mixed with acetone, then diluted and kept at the temperature for impregnation, the cured magnetic core has a clean and smooth surface, and the varnish gum can be kept in the magnetic core and doesn't overflow; the step of magnetic core cutting is implemented as follows: a grinding wheel machine cutting mechanism is adopted for cutting, meanwhile, a PLC (programmable logic controller) control system is adopted for controlling working feed, a self-made chemical corrosive agent is adopted for protecting a cutting site, and a tidy and smooth cutting surface of the magnetic core is guaranteed. The nanocrystalline magnetic core prepared with the method has the excellent characteristic that the magnetic permeability of the nanocrystalline magnetic core is 10 times higher than that of a conventional magnetic core and the nanocrystalline magnetic core has good temperature resistance and toughness.

Owner:FOSHAN CITY ZHONGYAN AMORPHOUS TECH

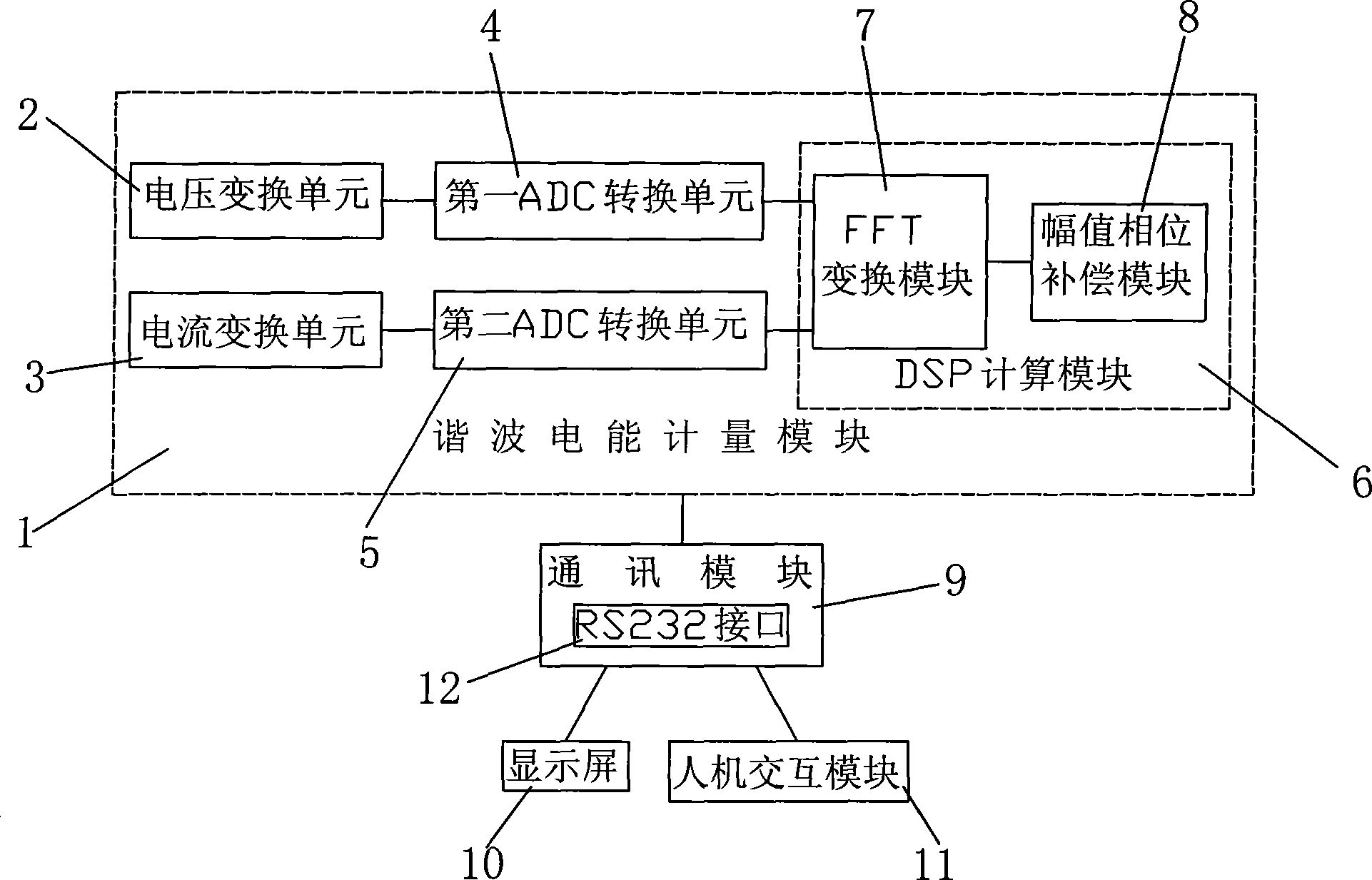

Three phase harmonic standard electric energy meter

ActiveCN101382588AIncreased accuracy levelImprove reliabilitySpectral/fourier analysisHarmonicRs 232 interface

A triphase harmonic standard electric energy meter comprises a harmonic electric energy measuring module which comprises a voltage conversion unit and a current conversion unit, wherein, the voltage conversion unit is connected with a first ADC conversion unit, the current conversion unit is connected with a second ADC conversion unit; the harmonic electric energy measuring module also comprises a DSP computing module which comprises an FFT conversion module used for computing the amplitude value and the phase position value of the harmonic output by the FFT conversion module so as to obtain a amplitude value phase position compensation module of each harmonic parameter. The triphase harmonic standard electric energy meter also comprises a communication module used for the communication of the harmonic electric energy measuring module with the outside, the communication module is connected with a display screen and a human-computer interaction module and comprises an RS232 interface used for being connected with the external control equipment. The invention provides a triphase harmonic standard electric energy meter used for carrying out calibration and detection to the harmonic electric energy meter.

Owner:NINGBO WEIJI ELECTRIC POWER TECH

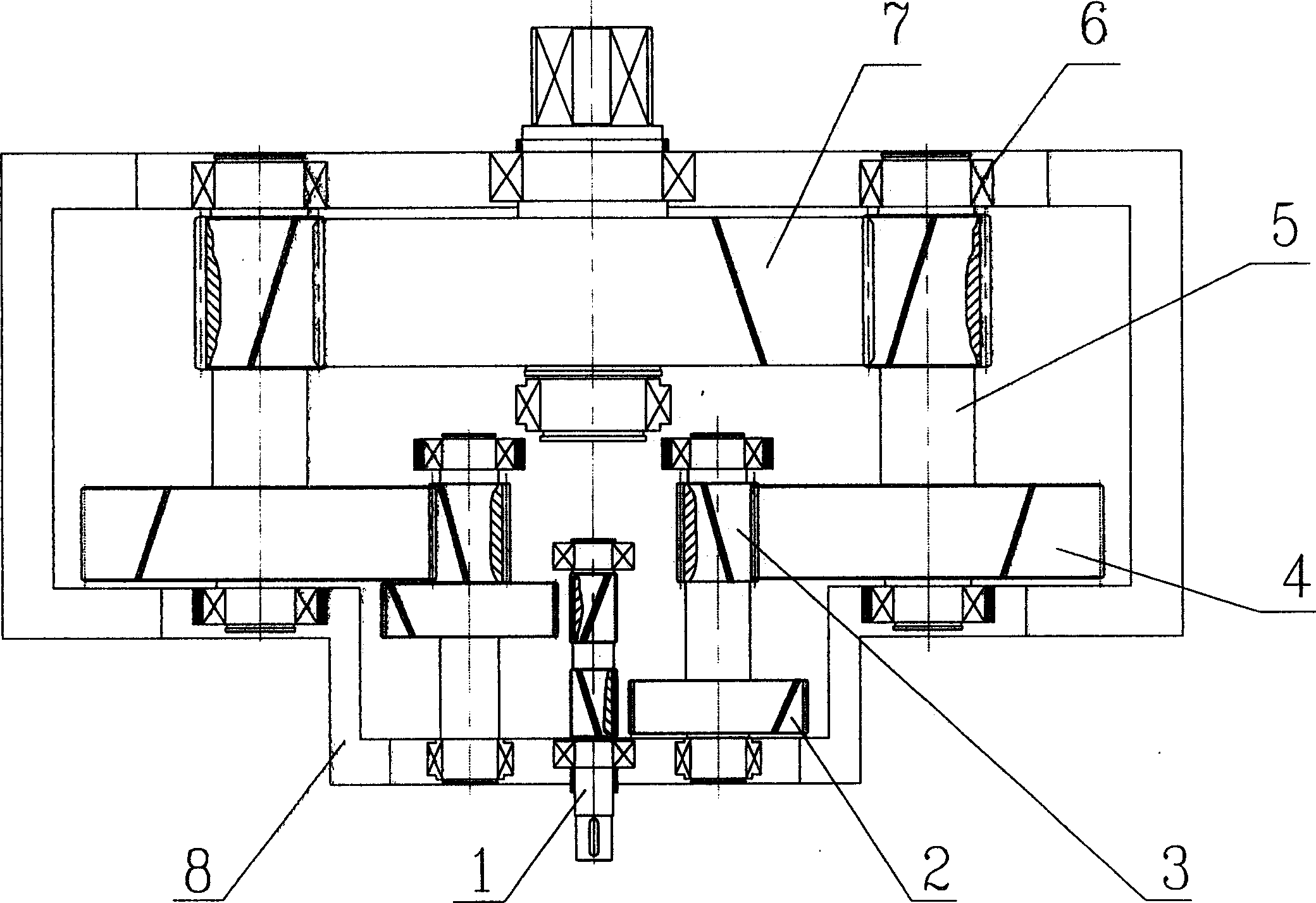

Multichannel digitized intelligent unbalance loading error correcting and weighing sensor and weighing method thereof

ActiveCN104374453AIngenious structural designMeet the requirements of eccentric load errorWeighing apparatus using elastically-deformable membersForce measurementLoad cellMechanical engineering

The invention relates to a multichannel digitized intelligent unbalance loading error correcting and weighing sensor and a weighing method thereof and belongs to the technical field of sensor structures. The multichannel digitized intelligent unbalance loading error correcting and weighing sensor comprises an elastic body which is composed of a cross beam in the middle, a left fixing portion and a right fixing portion, the left fixing portion and the right fixing portion are positioned at two ends of the elastic body, a mounting hole is formed in the left fixing portion, a mounting hole is formed in the lower surface of the right fixing portion, a groove used for placement of a circuit board is formed in the upper surface of the right fixing portion, multiple through holes penetrating the cross beam are formed inside the cross beam, positions, corresponding to the through holes, on the upper surface and the lower surface of the cross beam are strain areas, two resistance strain devices are arranged on each of the upper surface and the lower surface of the cross beam, each resistance strain device is composed of four resistance strain meters, the four resistance strain devices are welded with the circuit board through leads, the circuit board is in communication connection with an external display unit, and an anticorrosion processing layer coats each of the upper surface and the lower surface of the cross beam and the outer surface of the groove. The multichannel digitized intelligent unbalance loading error correcting and weighing sensor is needless of filing and adjusting, convenient to operate, time saving, labor saving and high in measuring accuracy.

Owner:YANTAI JUNJIE WEIGHING APP

Processing method for internally toothed annulus

The invention provides a processing method for an internally toothed annulus, which comprises the following steps: selecting a low-carbon steel tooth billet and carrying out rough lathing after the tooth billet is forged and normalizing treatment is performed; roughly machining the tooth billet into a tooth profile; conducting carburizing, quenching and high temperature tempering on the toothed part, and finally carrying out the shot peening; conducting finish machining on a datum plane; and conducting finish machining on the tooth profile through tooth grinding. The method solves the hardness problem of the toothed surface of the internally toothed annulus, adopts a low carbon steel material, carries out tough tooth punching before heating, and grinds the toothed part after cemented quenching; the hardness of the toothed surface can reach HRC 58 to 62, so as to thoroughly eliminate the pitting corrosion of the toothed surface and prolong the service lives of parts; as the tooth grinding process is carried out after heating, the precision of the toothed annulus can be above 6 grade; as the precision grade of the toothed part is improved after the tooth grinding process, the transmission of the toothed annulus becomes smoother; and as the tooth punching process is carried out before heating, the parts are low in hardness in the normalized condition, which provides convenience for tooth punching and improves the processing efficiency.

Owner:NANJING JINXIN TRANSMISSION EQUIP

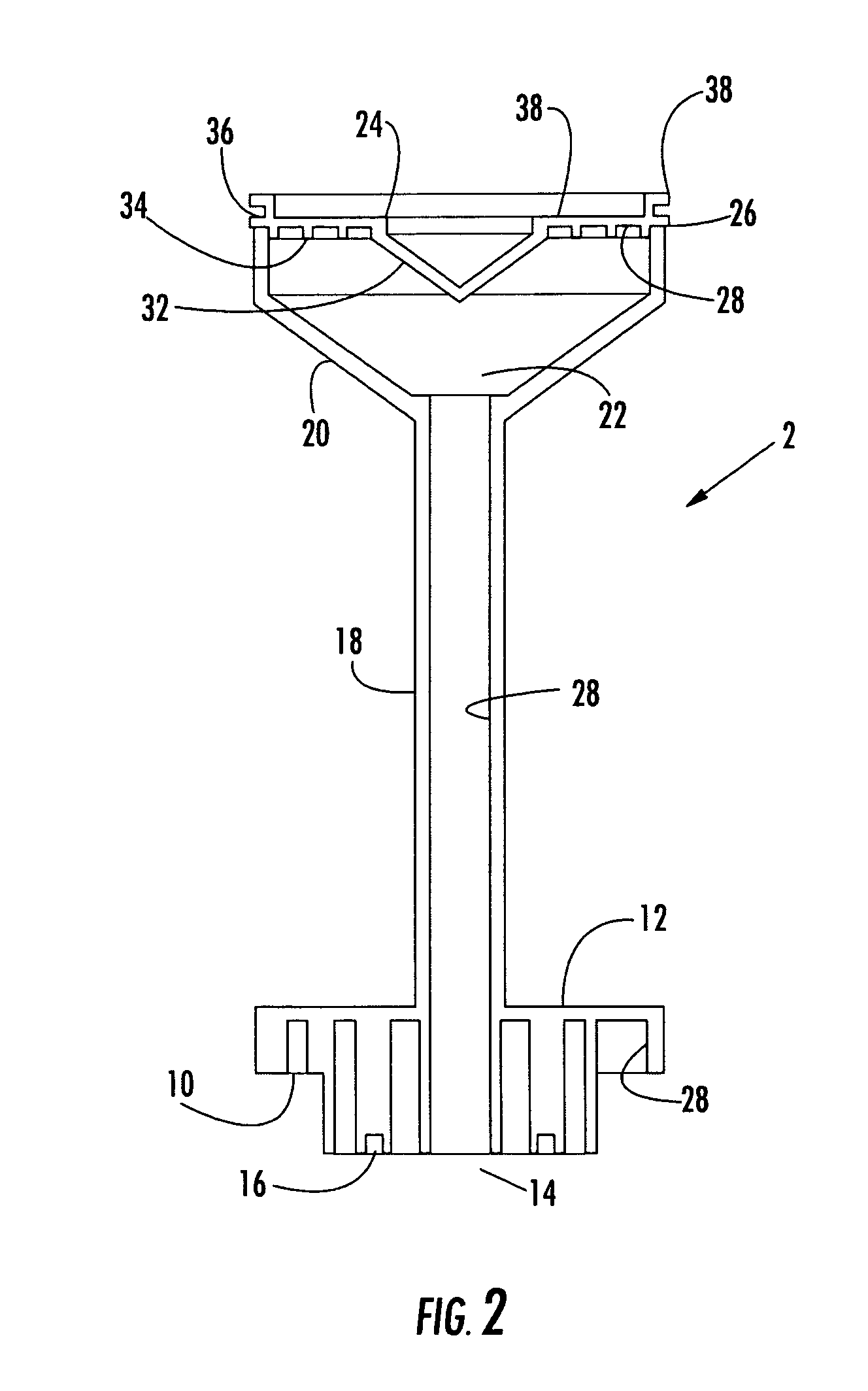

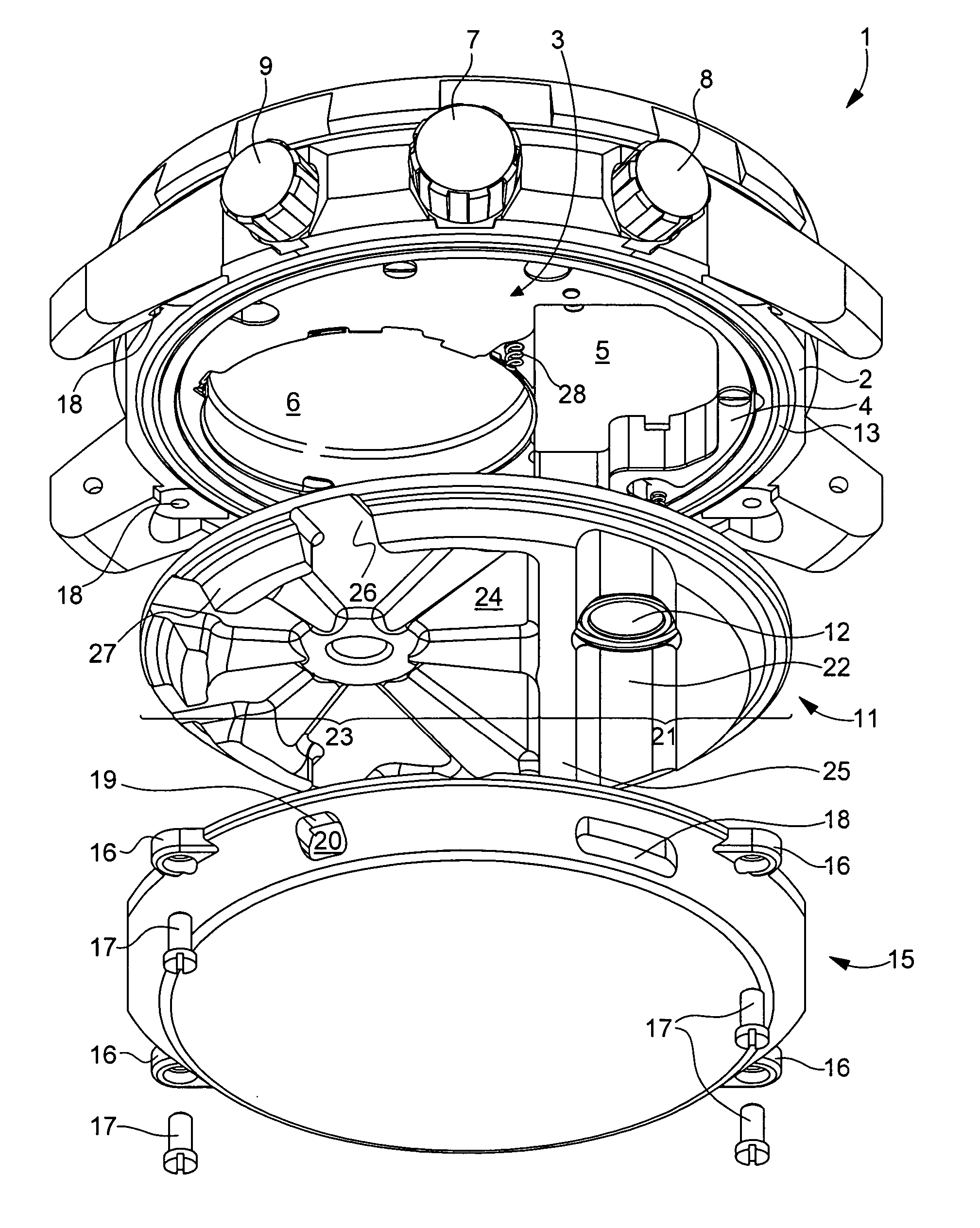

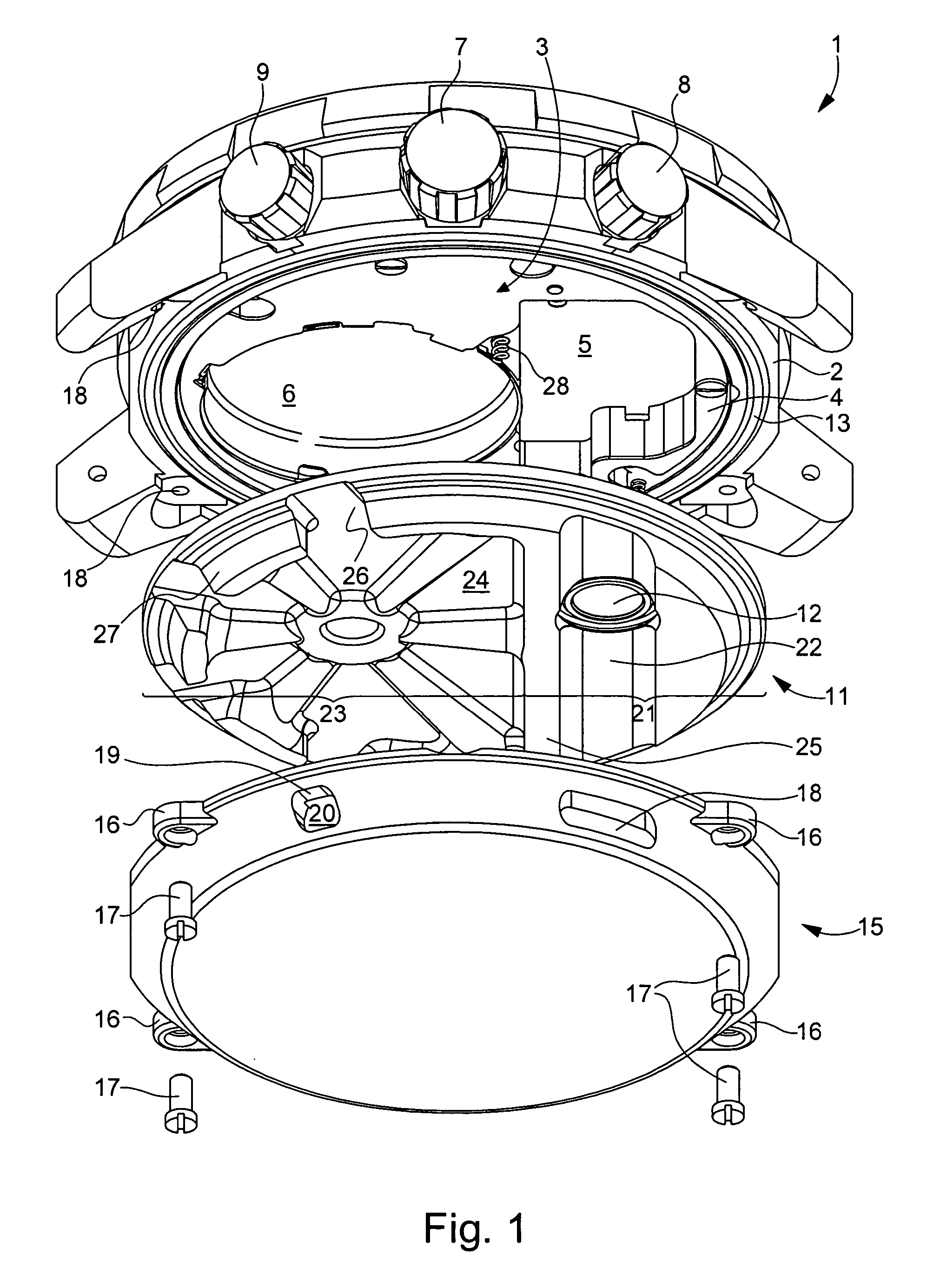

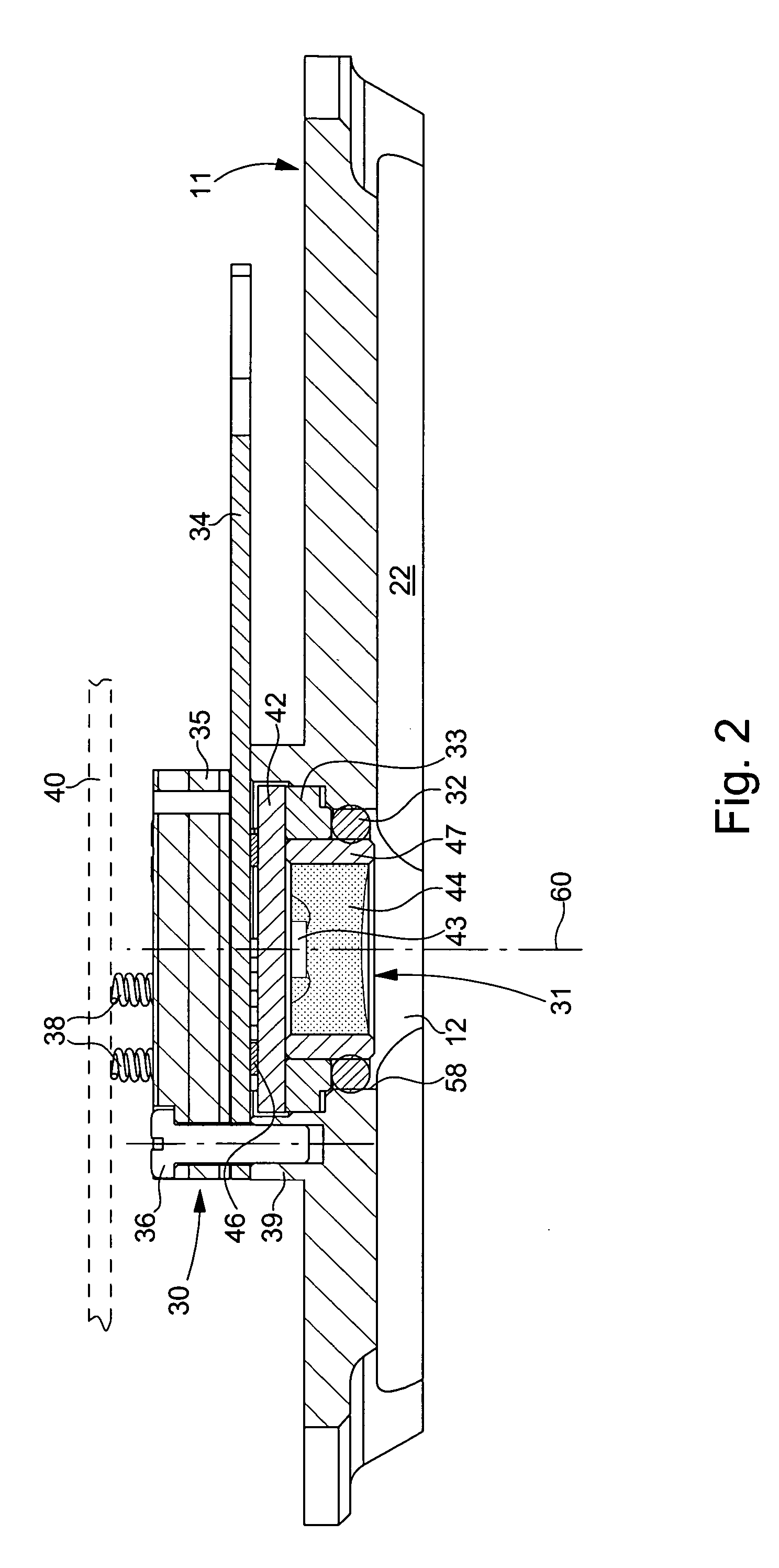

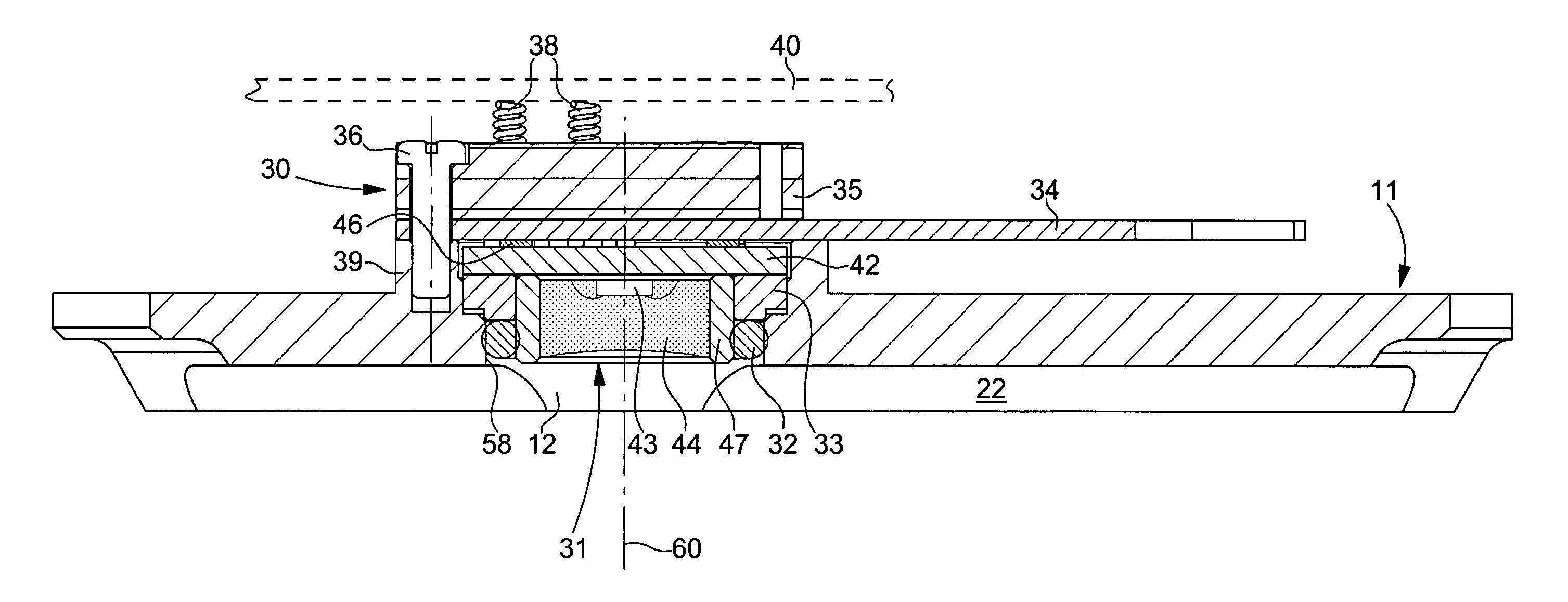

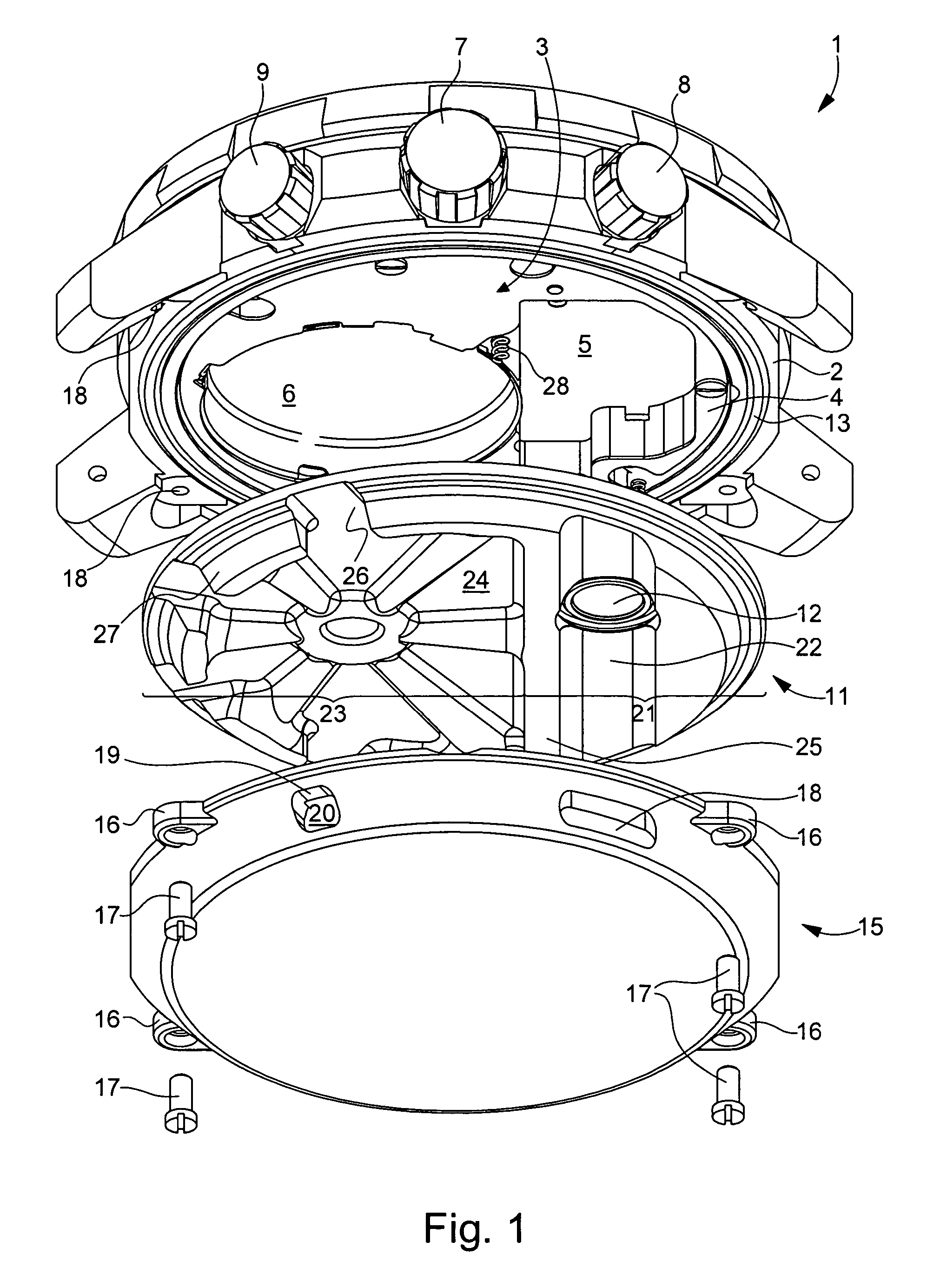

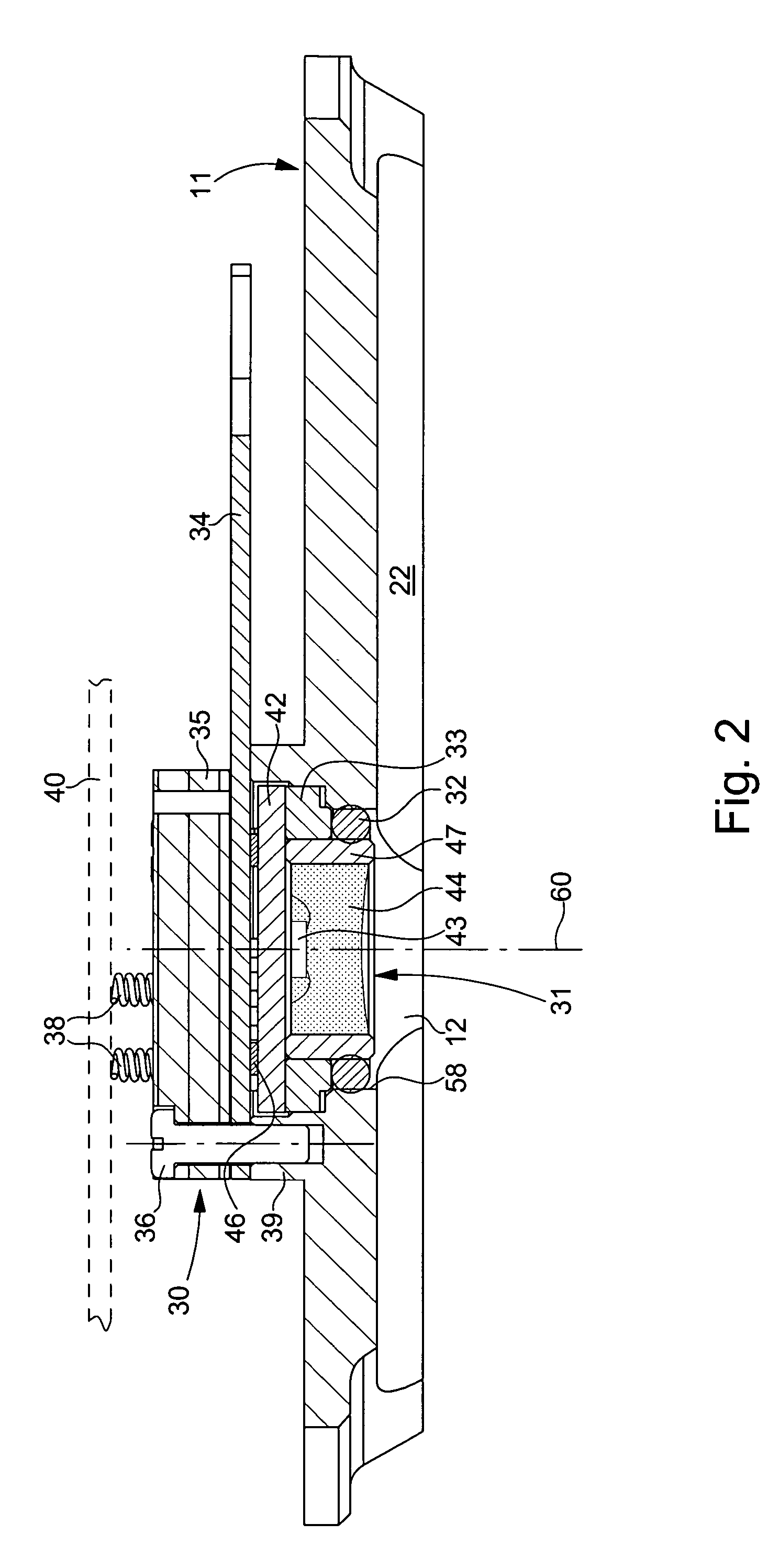

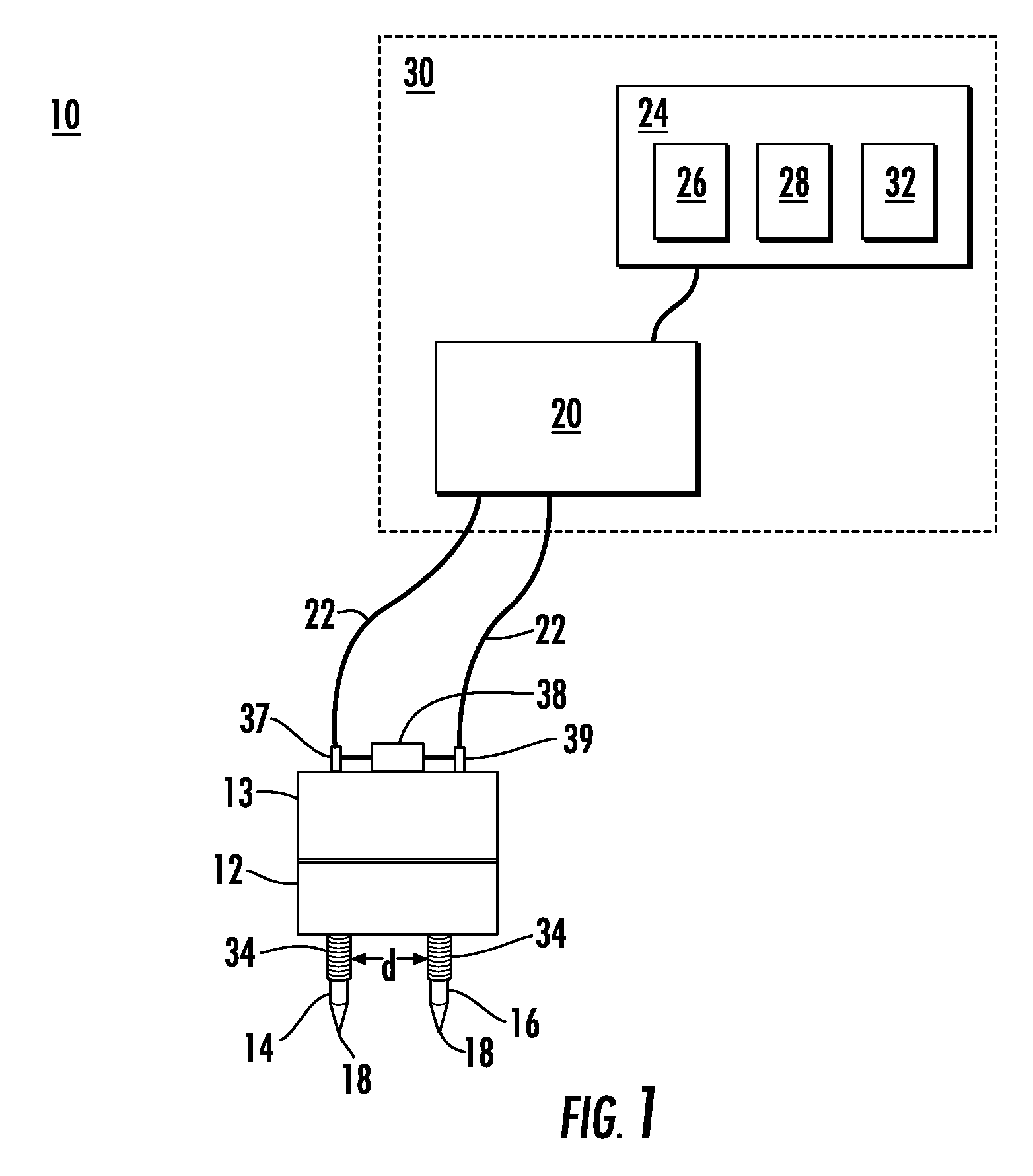

Watch including a pressure sensor

ActiveUS20060133213A1Precise positioningFacilitate assemblyTime indicationTime-pieces with integrated devicesSensor holderEngineering

The invention concerns a device for mounting a pressure sensor simply and precisely on the back cover (11) of a diver's watch or altimeter watch. The pressure sensor (31) is driven into an intermediate ring (33) forming part of a sensor module (30) which further includes an additional PCB (34), a sensor support (35) and connecting elements (38) between the additional PCB (34) and a main PCB of the watch. To ensure very precise positioning relative to the back cover, the intermediate ring (33) includes feet (35) that engage in holes in the additional PCB and in the sensor support. A sealing gasket (32) is radially compressed between the wall of the orifice (12) of the back cover and a tubular casing (47) of the pressure sensor. The back cover (11) is covered externally by a perforated cover.

Owner:ETA SA MFG HORLOGERE SUISSE

Watch including a pressure sensor

ActiveUS7123549B2Increased accuracy levelSimple methodTime indicationTime-pieces with integrated devicesPressure sensorAltimeter

The invention concerns a device for mounting a pressure sensor simply and precisely on the back cover (11) of a diver's watch or altimeter watch. The pressure sensor (31) is driven into an intermediate ring (33) forming part of a sensor module (30) which further includes an additional PCB (34), a sensor support (35) and connecting elements (38) between the additional PCB (34) and a main PCB of the watch. To ensure very precise positioning relative to the back cover, the intermediate ring (33) includes feet (35) that engage in holes in the additional PCB and in the sensor support. A sealing gasket (32) is radially compressed between the wall of the orifice (12) of the back cover and a tubular casing (47) of the pressure sensor. The back cover (11) is covered externally by a perforated cover.

Owner:ETA SA MFG HORLOGERE SUISSE

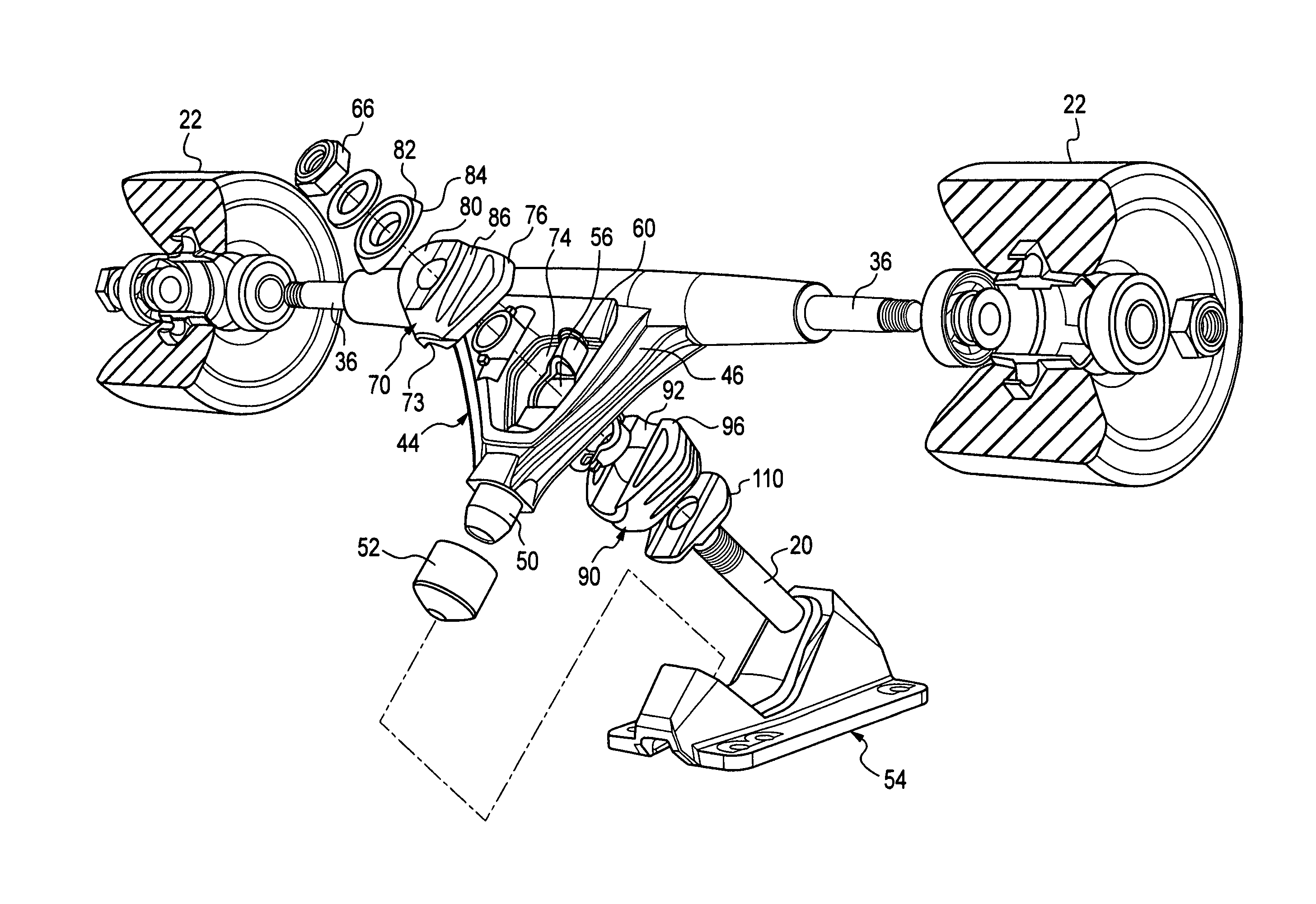

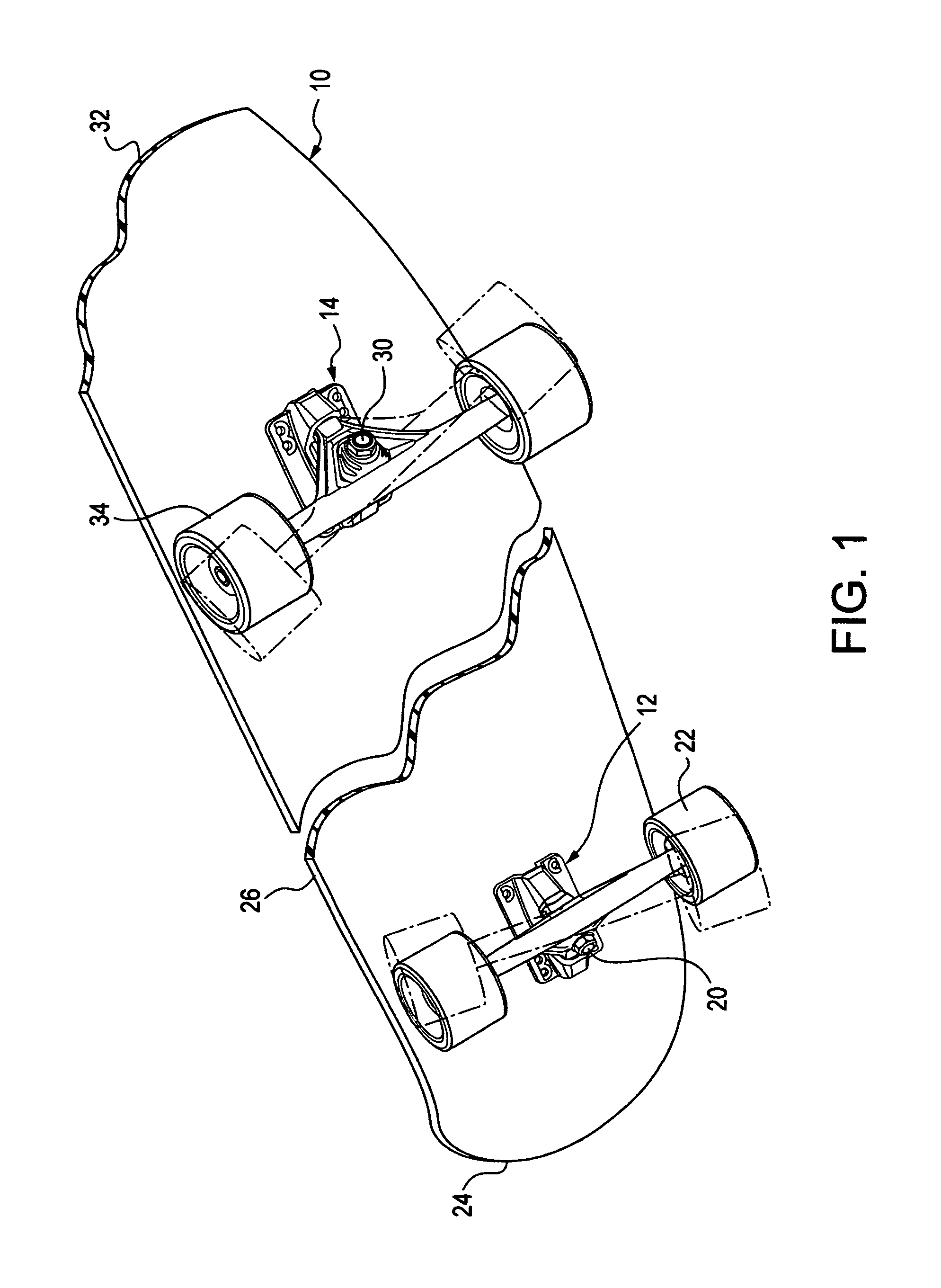

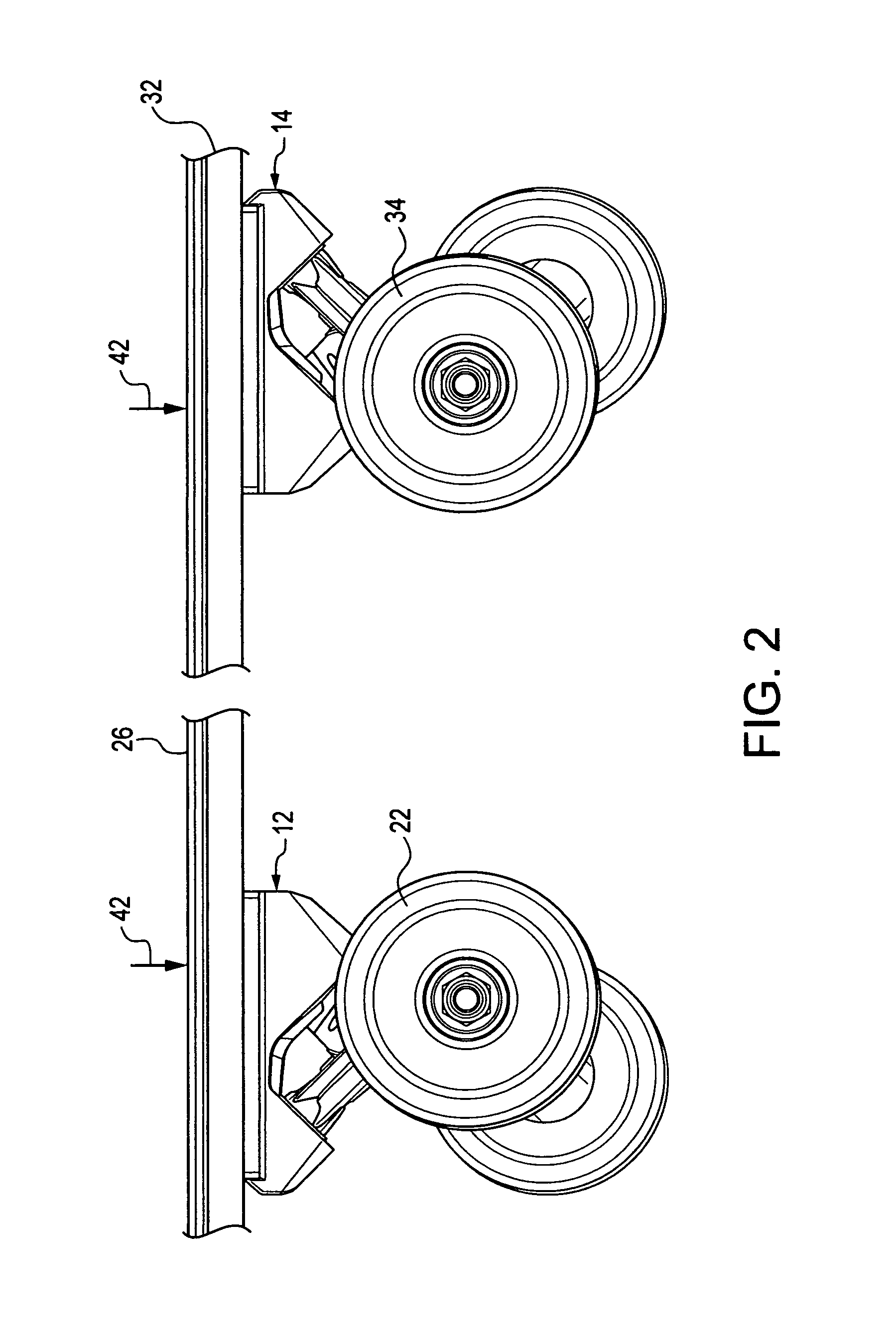

Truck and wheel bearing assembly

ActiveUS8783699B2Provide controlSmoothly and predictably resistHubsBearing componentsSteering controlBearing surface

An improved skateboard or roller-skate truck and wheel bearing assembly is disclosed containing an axle bearing yoke, base, grommet, and wheel and bearing combination which delivers improved steering precision, steering control, and wheel alignment. A grommet in the truck includes a bearing surface on a face which engages a bearing member in the yoke and restricts arcuate movements of the yoke and wheels. The contours of the grommet are also unique and contribute to steering control. The wheel and bearing combination incorporates paired bearing casings with bell-shaped members in their ends which meet each other inside a wheel of the board or skate and self-adjust to accommodate imperfections in the bearing seat levelness, bearing seat spacing, axle diameter and axle straightness.

Owner:GESMER DANIEL JON

Gear shaft forming method and die adopted by same

ActiveCN103192020AImprove straightnessIncreased accuracy levelForging/hammering/pressing machinesEngine componentsGear wheelGear tooth

The invention aims at the defects of low processing efficiency and low machining precision when a gear shaft is upset in the prior art, and provides a gear shaft forming method and die adopted by the same. The die comprises a stamping die and a main die, wherein a stamping die cavity matched with the outer surface shape of a gear of the gear shaft is formed in the stamping die; a main die cavity matched with the outer surfaces of a shaft lever part and a spline part of the gear shaft is formed in the main die; the upper end of the stamping die cavity is coaxially communicated with a front bar beating hole; and the lower end of the main die cavity is coaxially communicated with a rear bar beating hole. During the upsetting, a reverse strong beam is used for forming the gear in the stamping die cavity and forming the spline and the shaft lever in the main die cavity. With the adoption of the method and the die, not only can the gear teeth and the spline be formed once, but also the obtained gear shaft has high grades in straightness and precision, and the production efficiency is also improved.

Owner:浙江鼎盛汽车紧固件有限公司

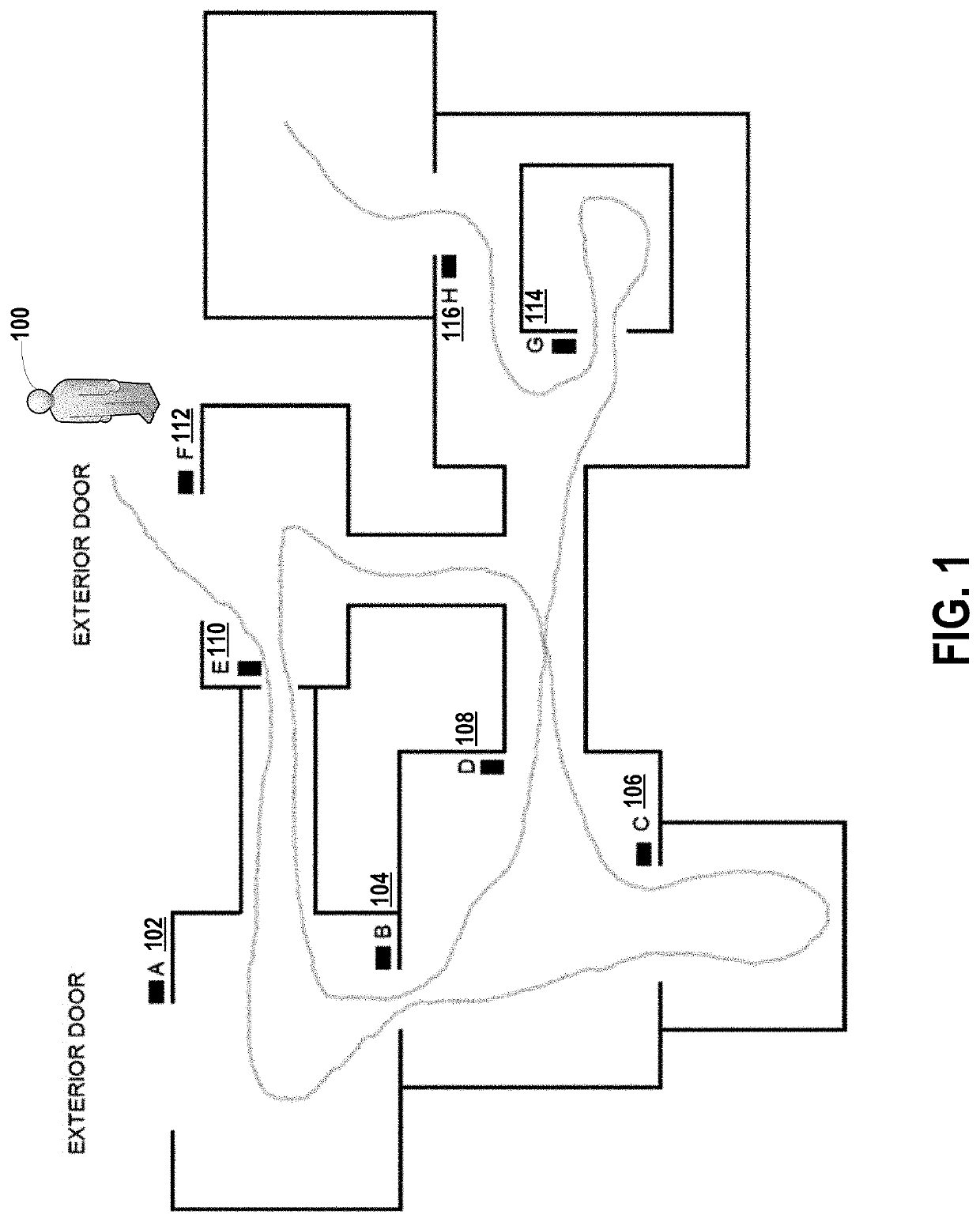

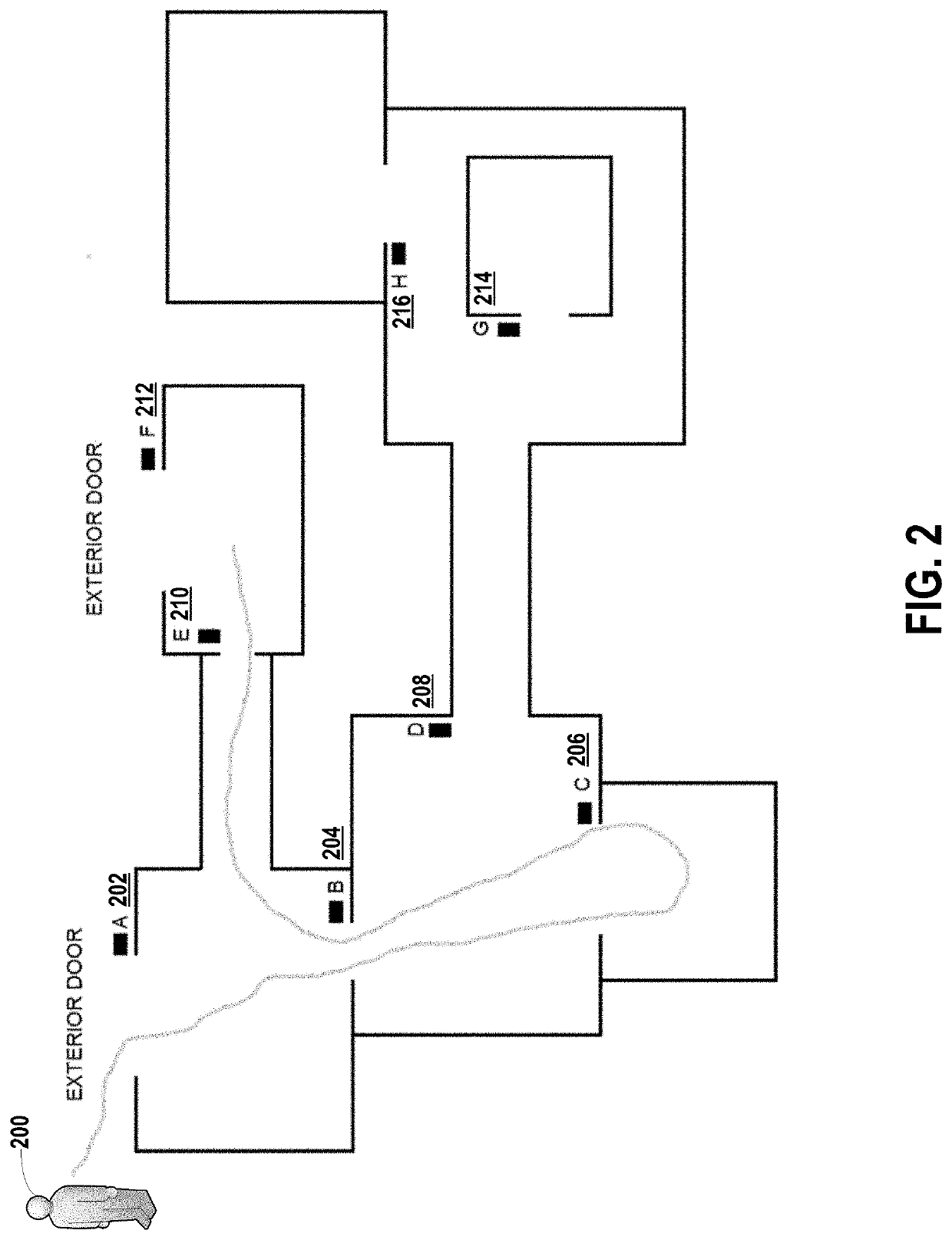

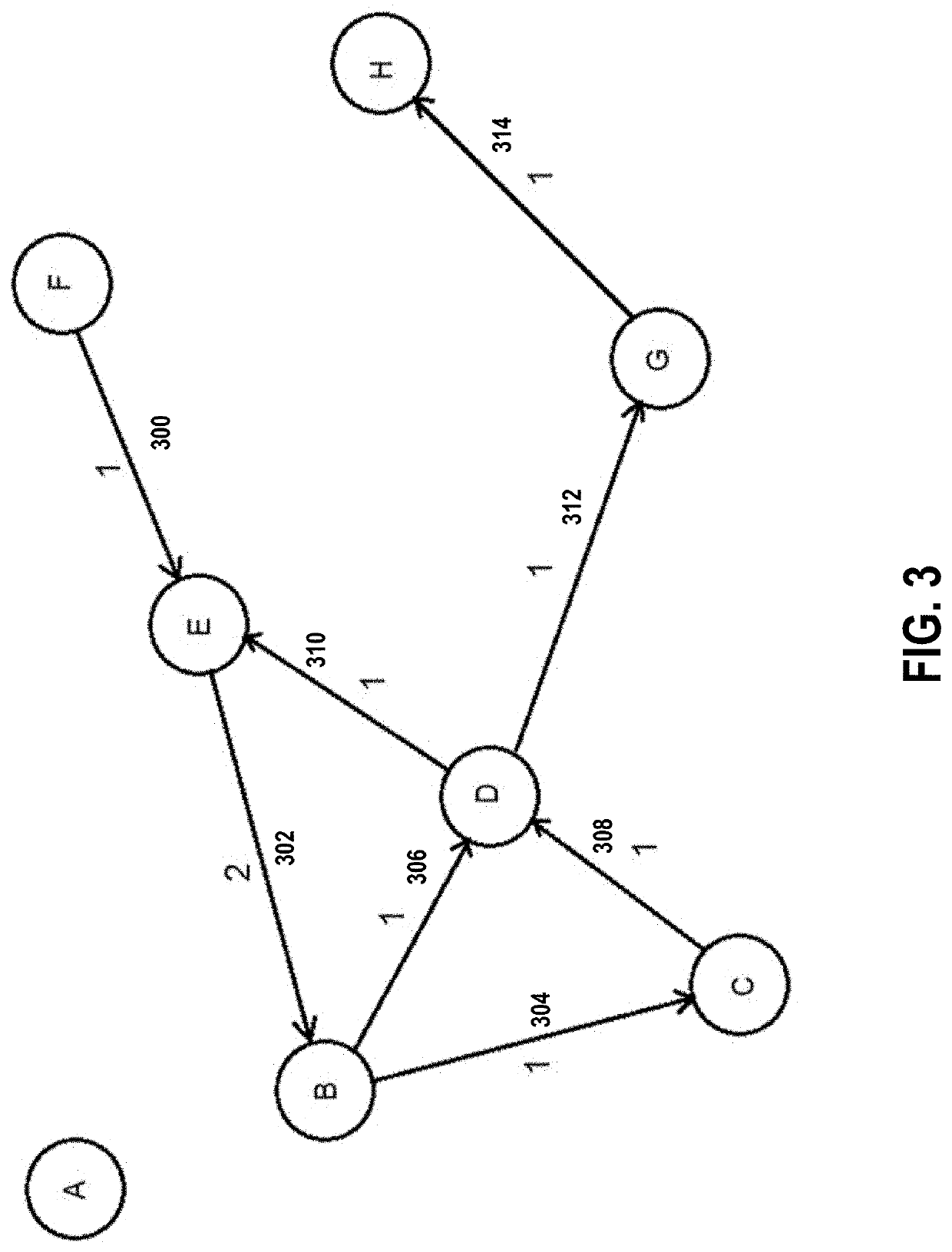

Systems and methods for physical access control

InactiveUS20210112064A1Improve accuracyReduce computation processingIndividual entry/exit registersTransmissionComputer visionCartography

A system and methods for interpreting a user's movement through space as a passive behavioural biometric is described. Using patterns of user's movement through space, the system detects anomalies in user movement, provides or restricts access to a restricted space without adding extra friction to the user, and generates risk events. An adjacency matrix (i.e., footprint) is generated by analyzing a user's movement through space and creating a weighted directed graph for the user. Anomalies are detected by comparing a user's footprint against the same user's earlier footprint, or the footprints of other users within a group, or the footprints of all other uses in the system.

Owner:BIOCONNECT INC

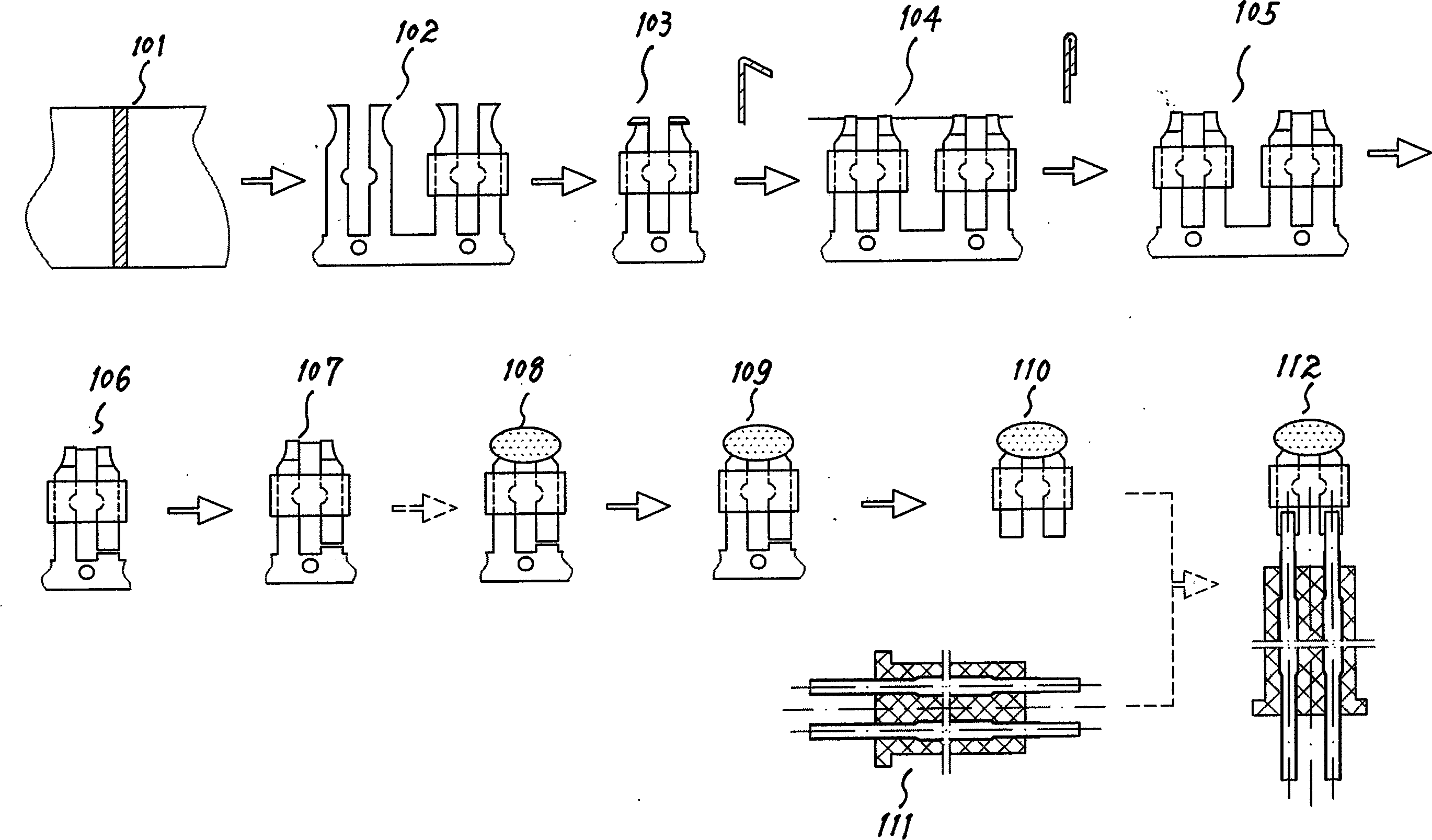

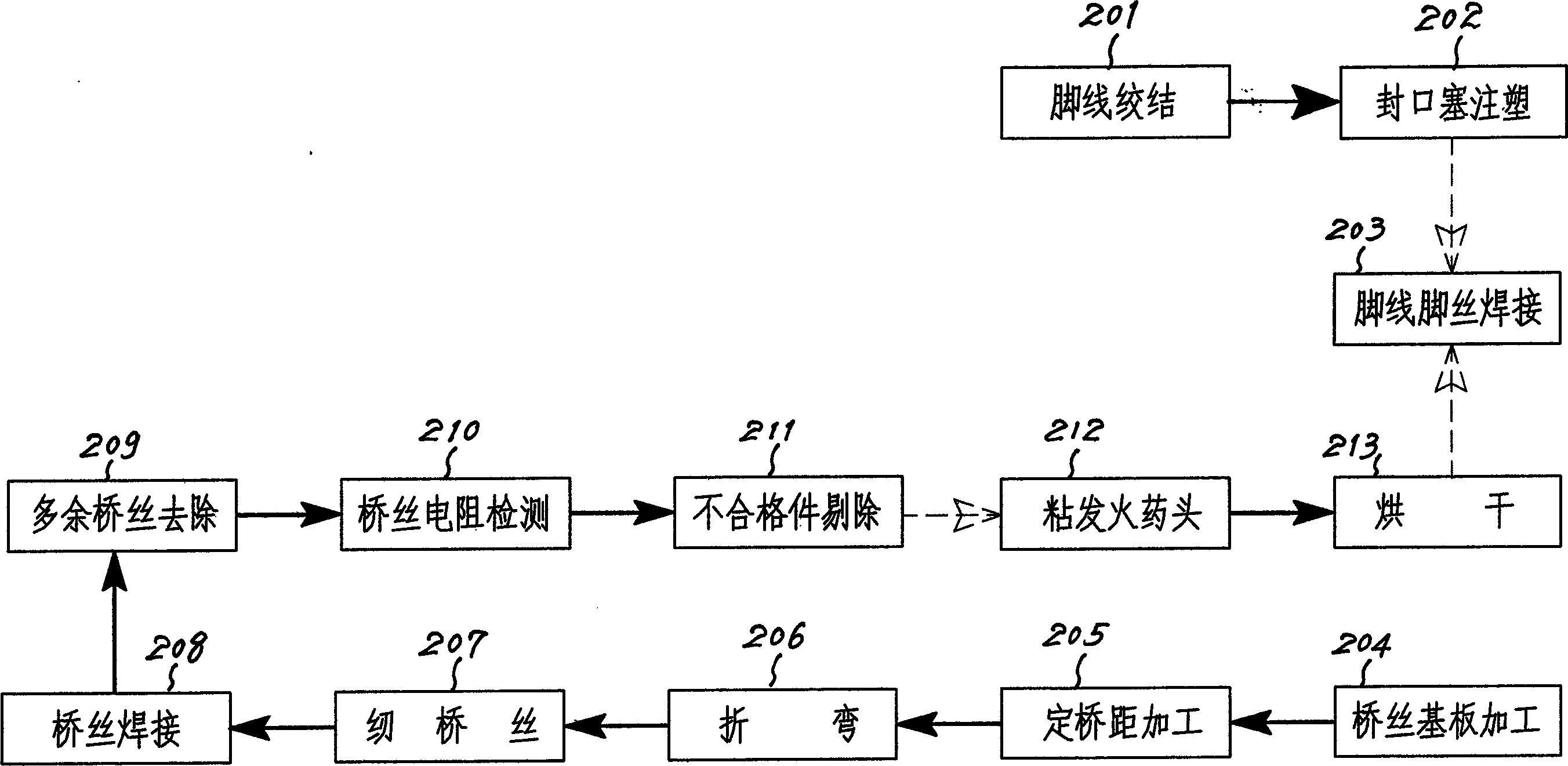

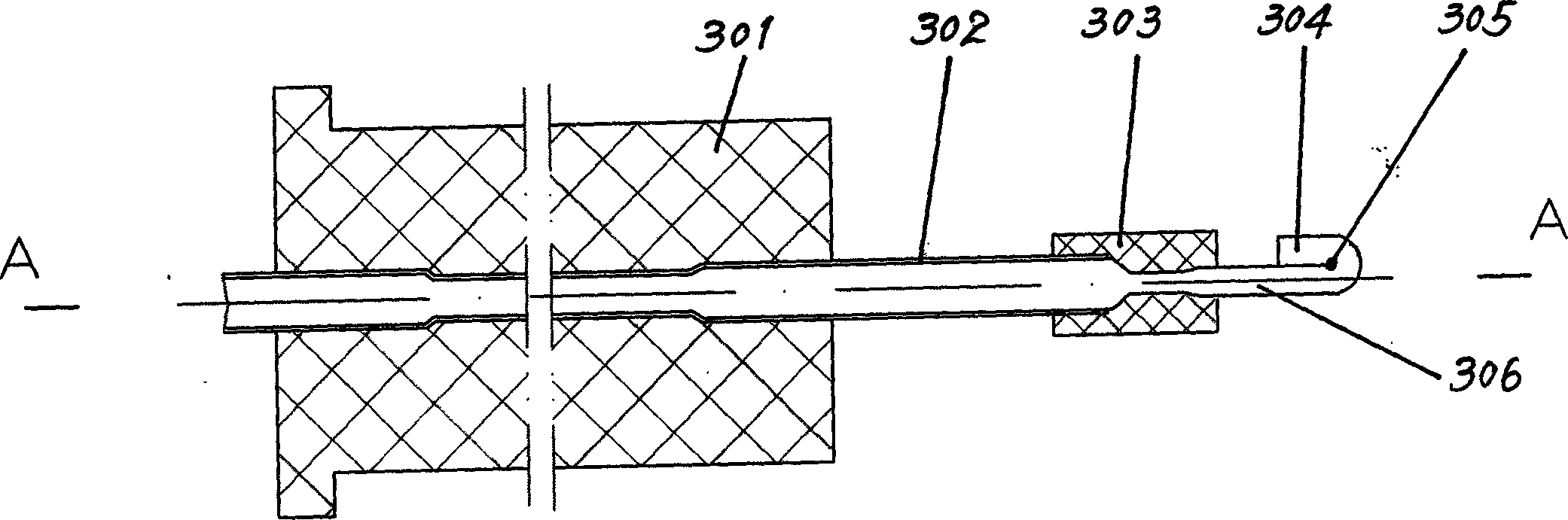

Electric detonator initiator

The electric detonator initiator includes bridge filaments, pin wires, span determinator and sealing plug. The pin wires are integral with the base board for the bridge filaments, and each piece of pin wires is formed with one section of pin wire from the sealing plug to the bridge filament welding end and is variable flat cross section structure. The pin wires have their flat parts inside sealing plug, span determinator and welding end. Both the sealing plug and the span determinator are linked structure with several parts. The present invention has simple production process, and the electric detonator initiator has small dispersion of bridge filaments and high side rigidity.

Owner:顾杨

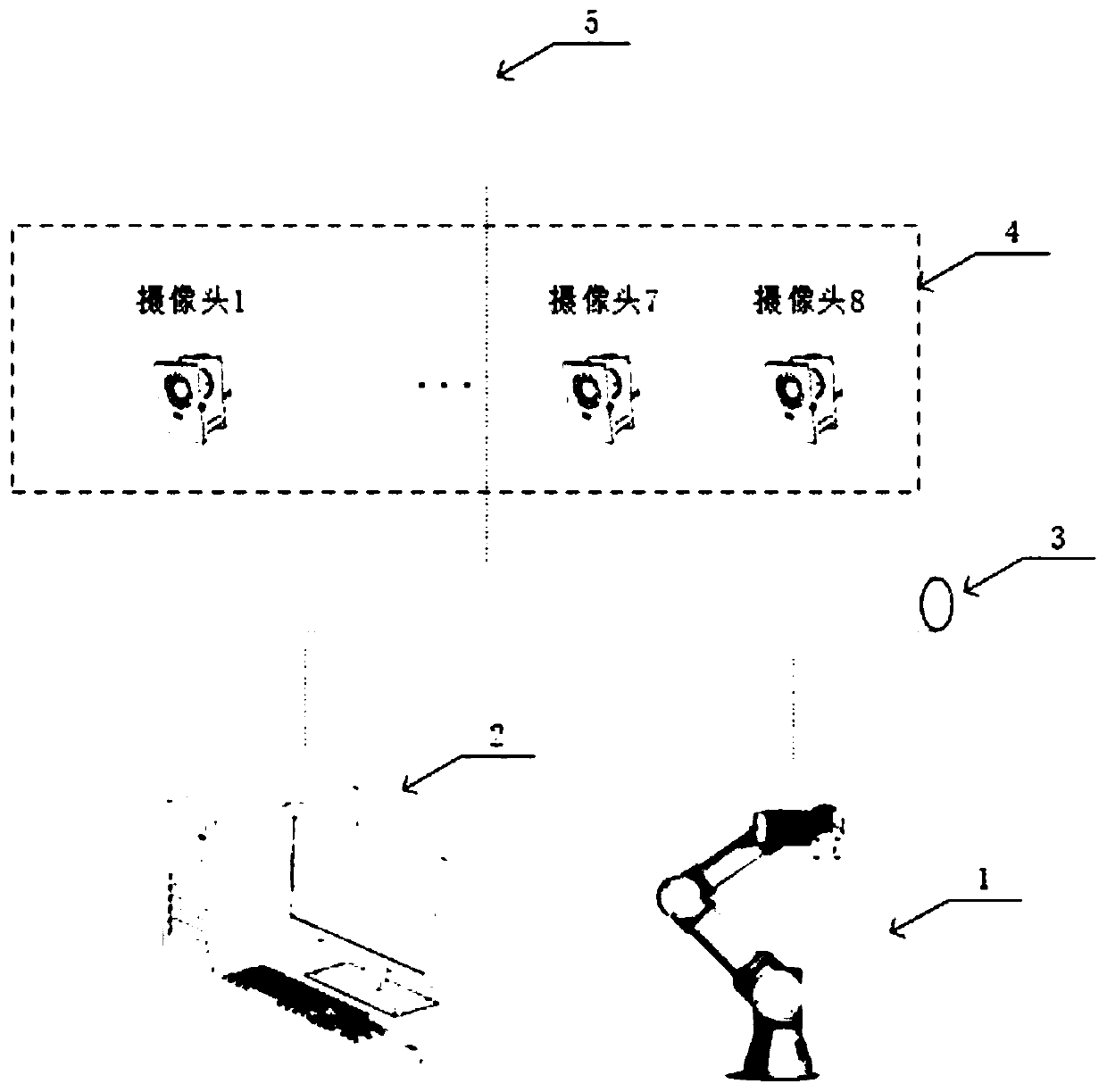

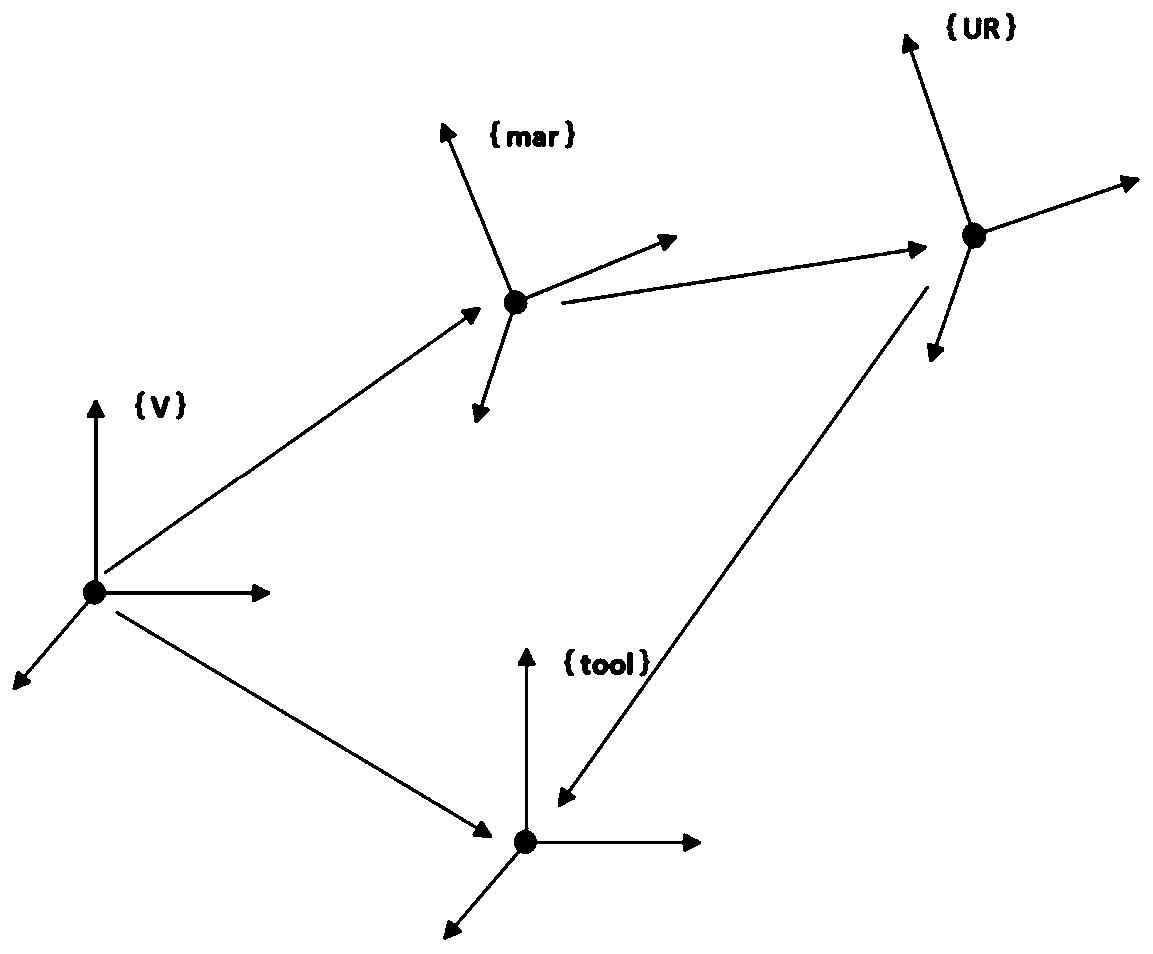

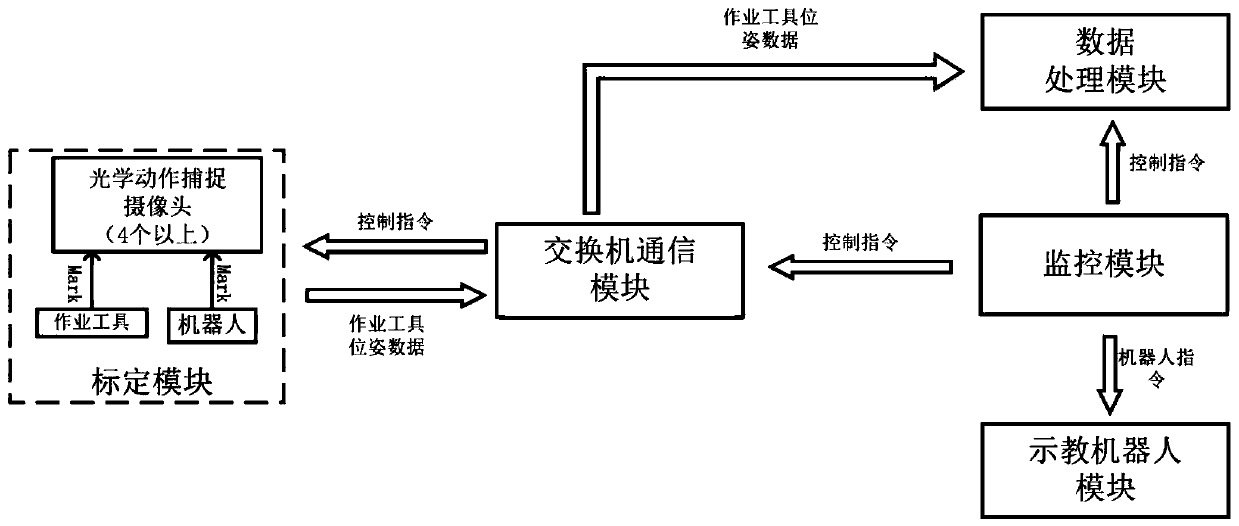

Teaching robot data acquisition system based on optical motion capturing

ActiveCN109848964AEnsure safetyEfficient and smooth captureProgramme-controlled manipulatorReal time acquisitionData processing

The invention discloses a teaching robot data acquisition system based on optical motion capturing. Modules are mainly divided into a calibration module, a switch communication module, a data processing module, a monitoring module and a teaching robot module, wherein the data processing module sends an acquisition command to the calibration module through the switch communication module to obtainteaching motion data, the teaching motion data are poses, of operation tools in the teaching motion process, acquired by the calibration module, the data processing module is used for acquiring the poses of the operation tools, carrying out coordinate transformation and generating a motion command which can be executed by a robot, the motion command is sent to the robot module through WiFi, the monitoring module is used for sending a control command to each module and monitoring the whole system so as to enable the teaching robot to complete the same actions as the teaching actions, and then teaching is realized. According to the teaching robot data acquisition system, an optical motion capturing system is adopted for real-time acquisition, compared with the prior art, the teaching robot data acquisition system has good the remote control performance, the acquired data are highly precise, and the stability of teaching is realized.

Owner:ZHEJIANG UNIV OF TECH

Hard tooth face sugar press used reducer and hard tooth face processing method

InactiveCN1908461AExtended service lifeReduce weightToothed gearingsSolid state diffusion coatingCarbon layerEngineering

The invention relates to a speed reducer of sugar maker with rigid tooth surface, and relative rigid tooth surface treatment, wherein it comprises: the I gear axle, I large gear, II gear axle, II large axle, III gear axle, and III large gear are made from high-strength alloy steel; the rigidity of tooth surface is HRC58-62; the treatment comprises: machining the blank, and rolling tooth on it; immerging carbon, checking the depth of carbon layer and the metal structure, quenching, and tempering at low temperature to form the rigid tooth surface; then strengthening the tooth root, and refining it; abrading the tooth to form high-accuracy rigid tooth surface, whose accuracy level is not lower than six level of ISO1328 standard. And the invention has the advantages that: since all gears have rigid tooth surfaces, the abrasion resistance and load ability of gear are improved to reduce or avoid point corrosion, and prolong the service life, reduce the weight and reduce the volume.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

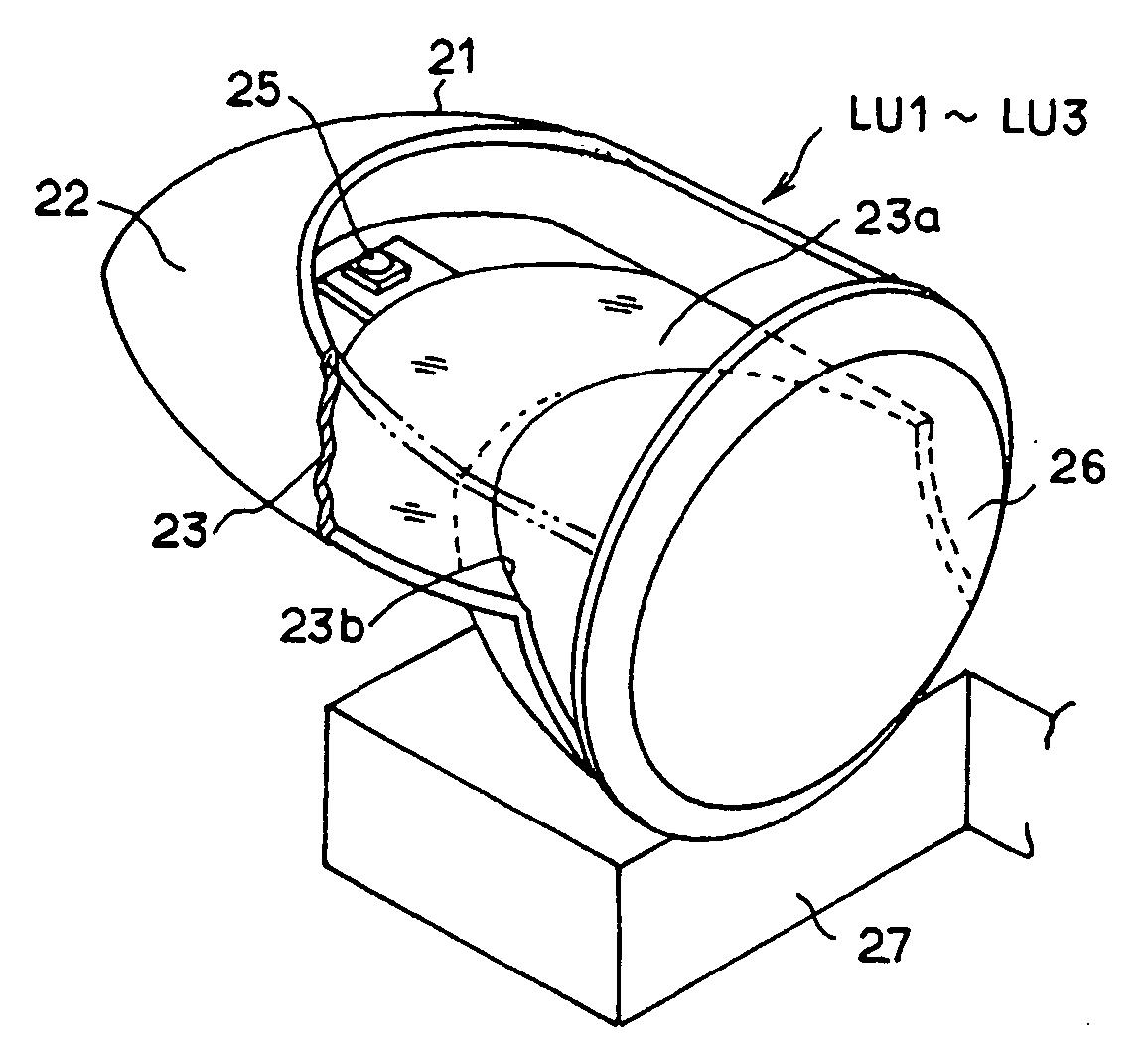

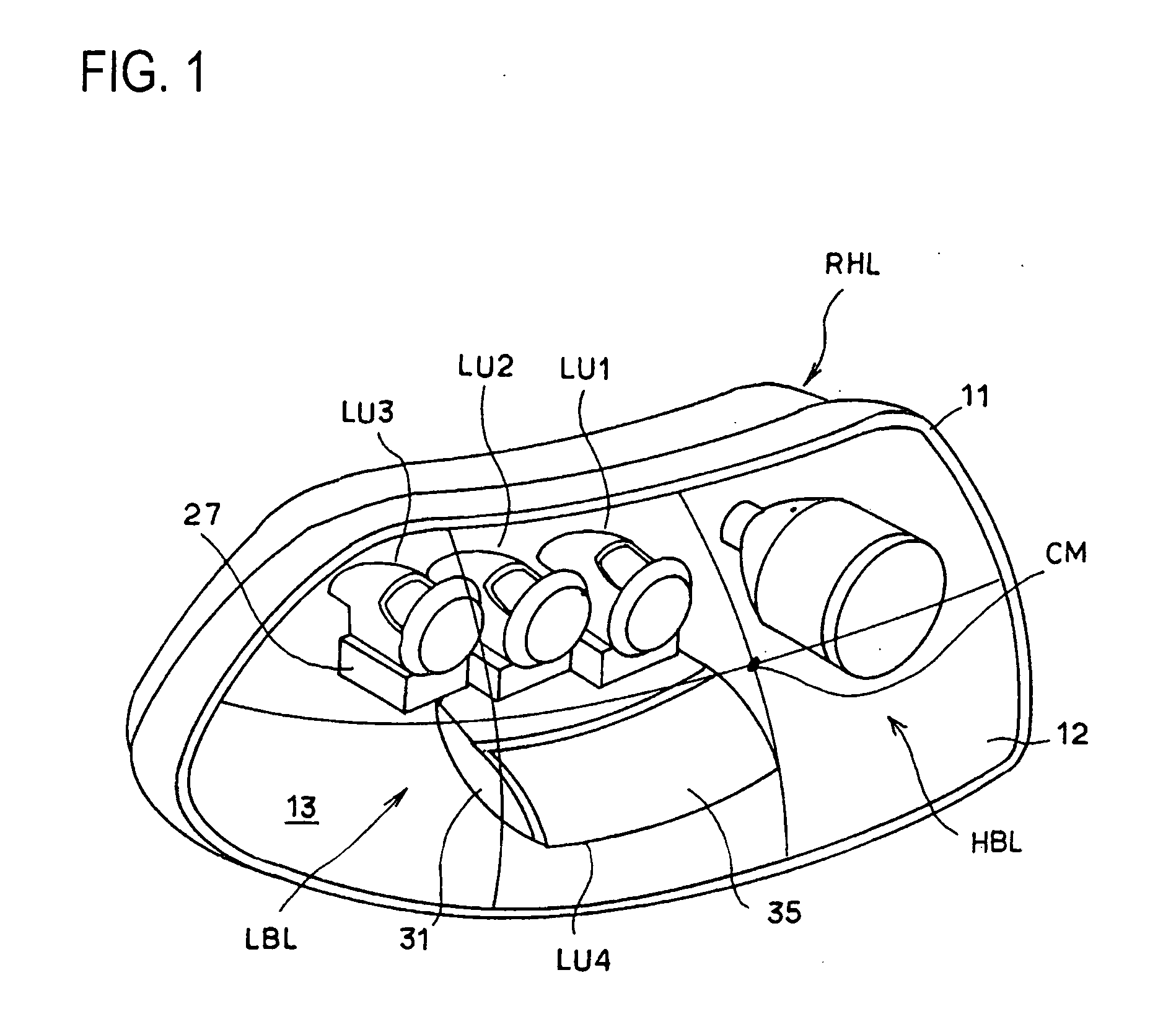

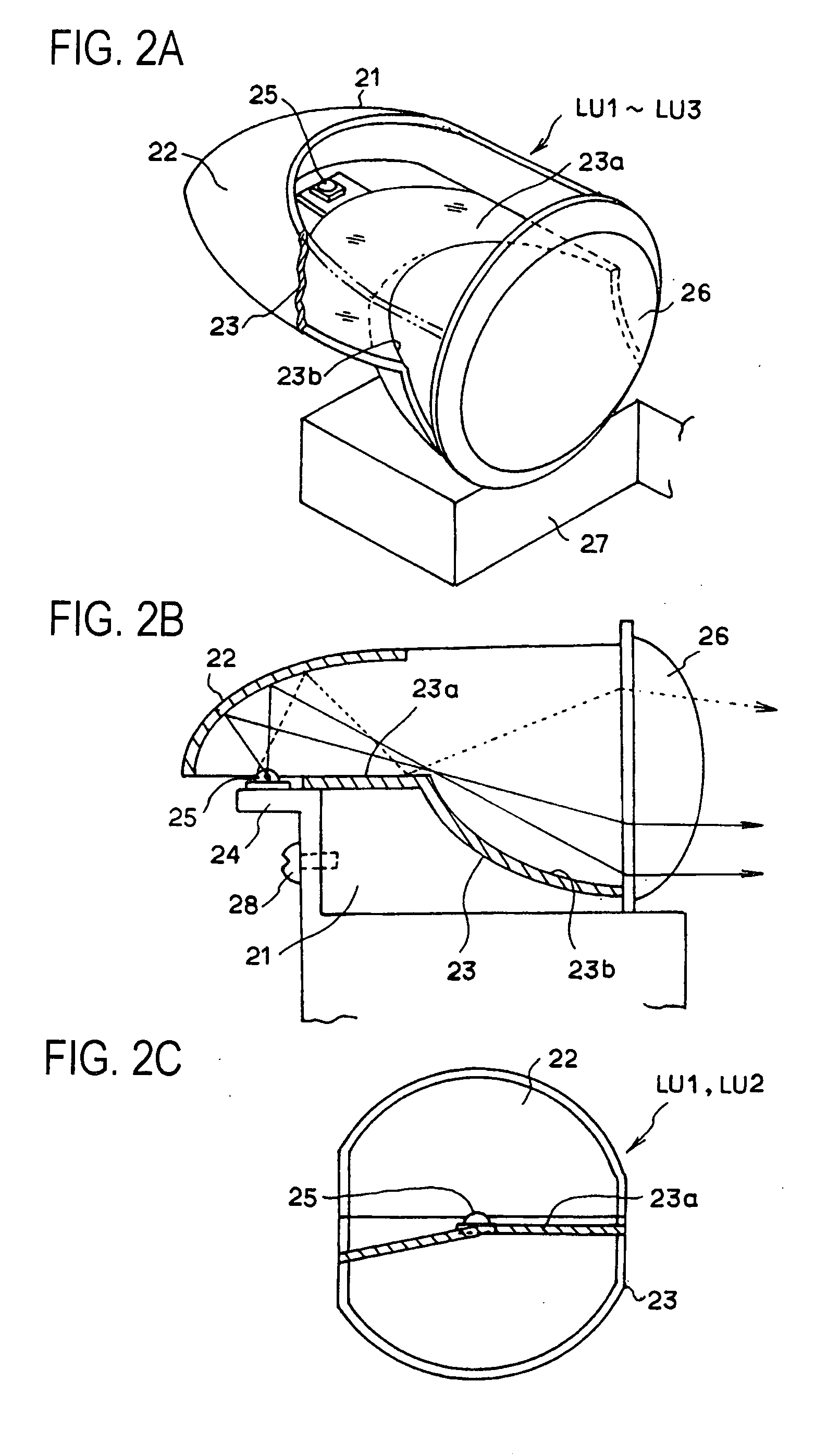

Vehicular headlamp

InactiveUS20070165416A1High precisionIncreased accuracy levelVehicle headlampsPoint-like light sourceHot zoneLight beam

In a headlamp providing a predetermined light distribution pattern by combining illumination light beams that are respectively emitted from a plurality of light source units LU1 to LU4 each of which using a light emitting element as the light source, at least one of the plurality of light source units being a light source unit that forms a hot zone in the light distribution pattern, the lamp center being provided within a light emission area of the light source unit LU1 that forms the hot zone, and a center mark CM that indicates the lamp center being provided on the front cover of the lamp.

Owner:ZF FRIEDRICHSHAFEN AG +1

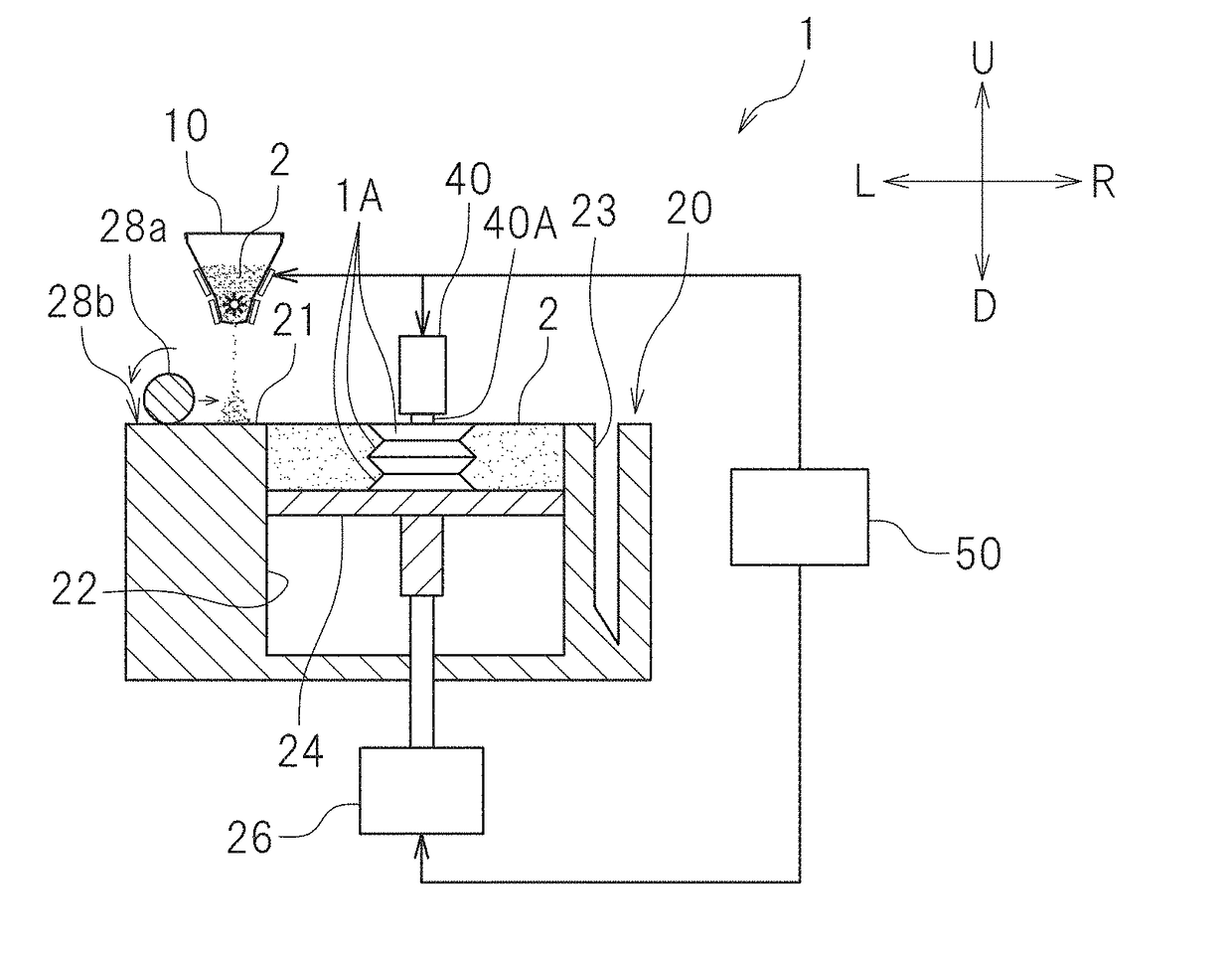

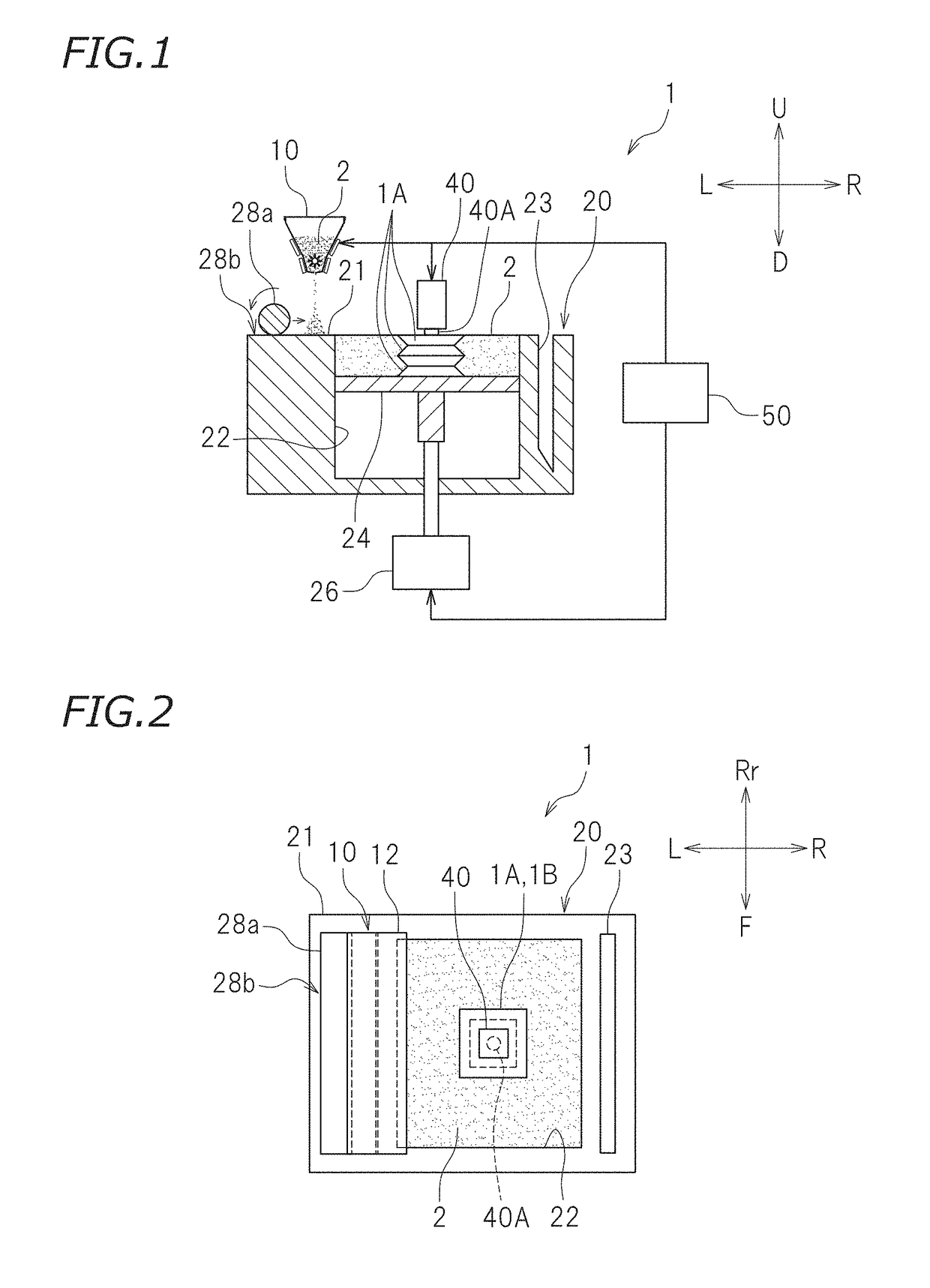

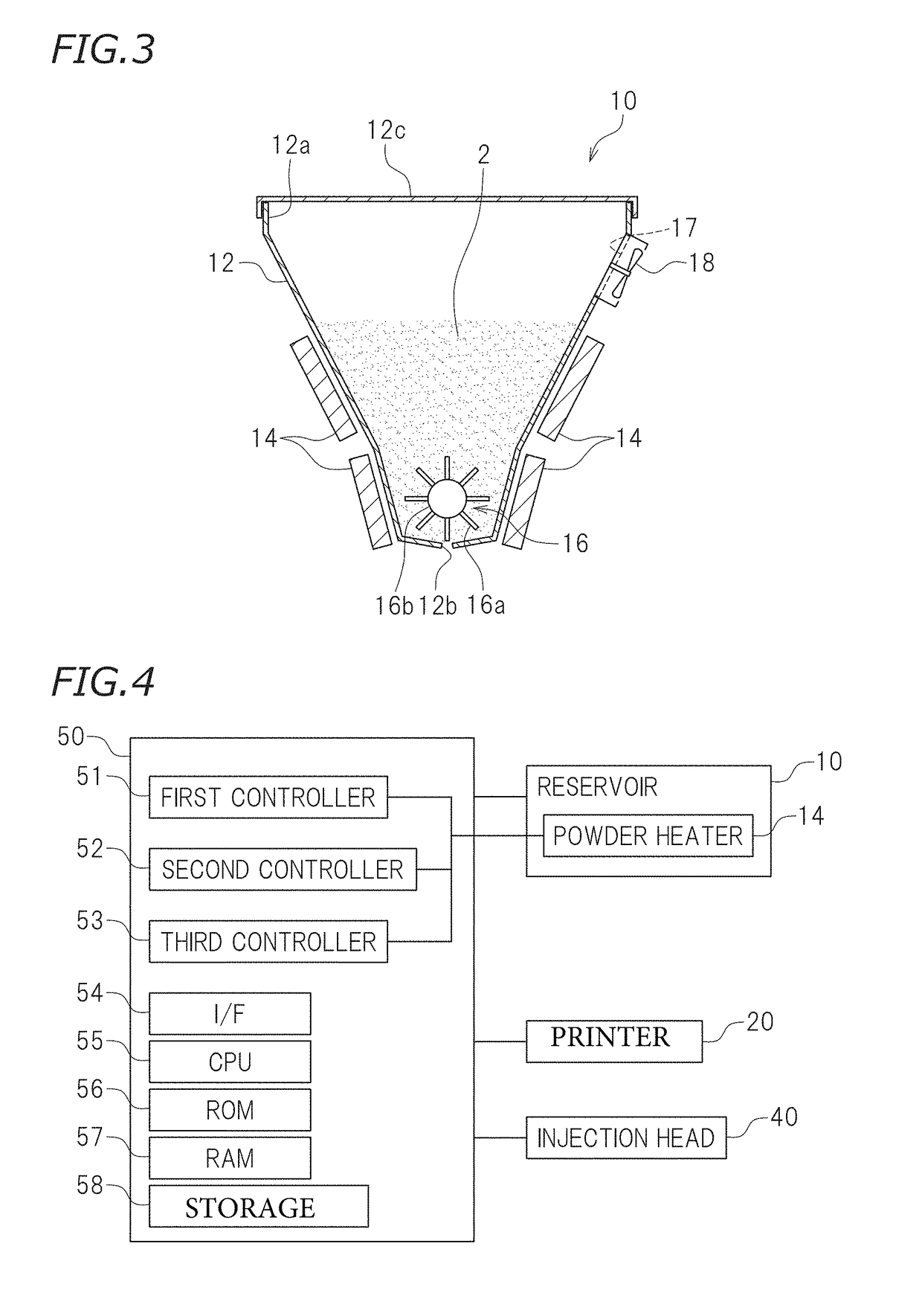

Three-dimensional printing device

InactiveUS20180229428A1Increased accuracy levelImprove liquidityManufacturing enclosuresTransportation and packagingEngineering3 dimensional printing

A three-dimensional printing device includes a reservoir that stores a powdery material, a powder heater provided in the reservoir and capable of heating the powdery material, a printing table that allows the powdery material to be put thereon, an injection head that injects a curing liquid binding the powdery material, and a conveyor that moves the printing table and the injection head with respect to each other.

Owner:ROLAND DG CORP

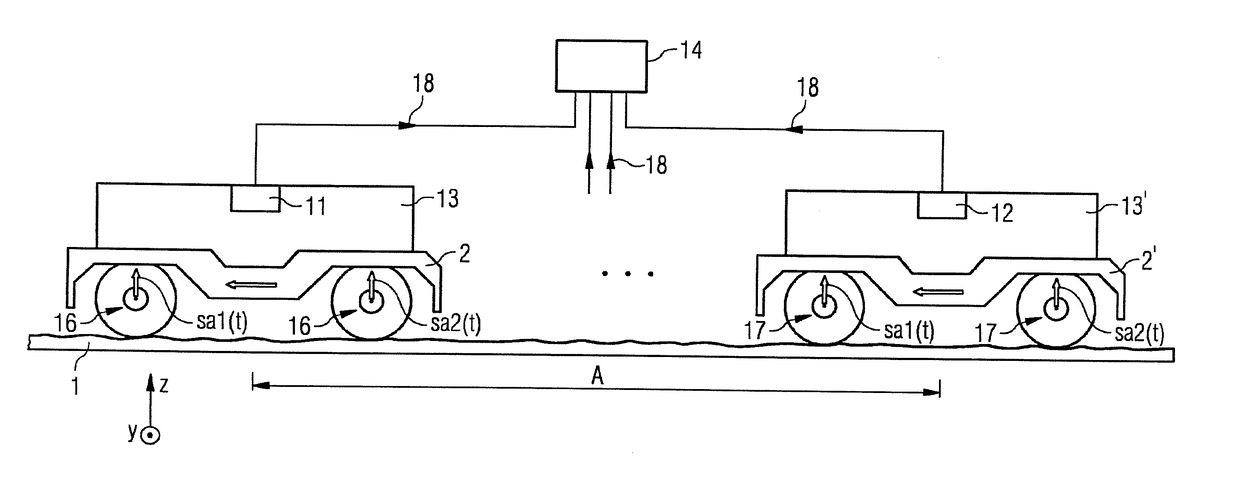

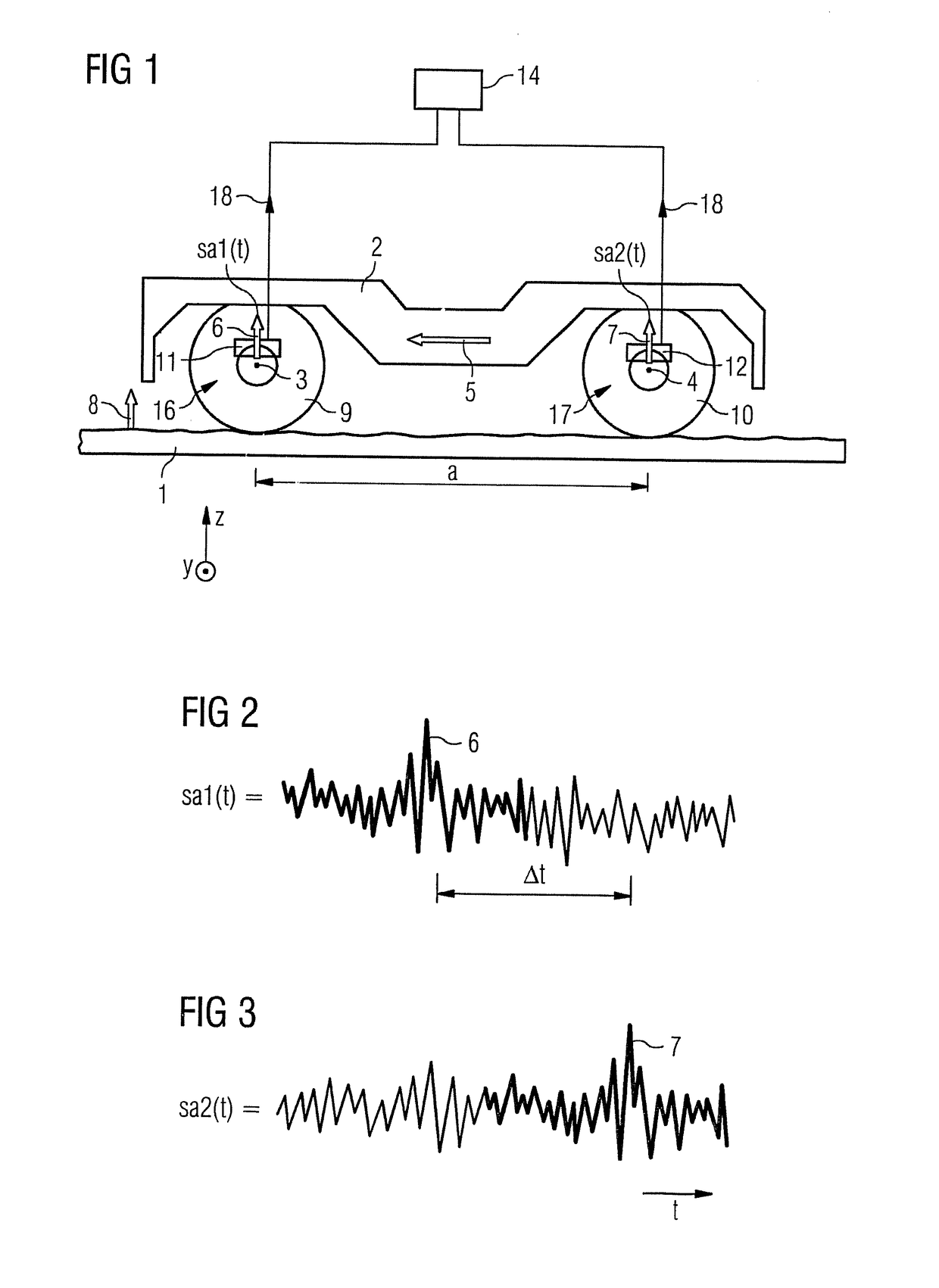

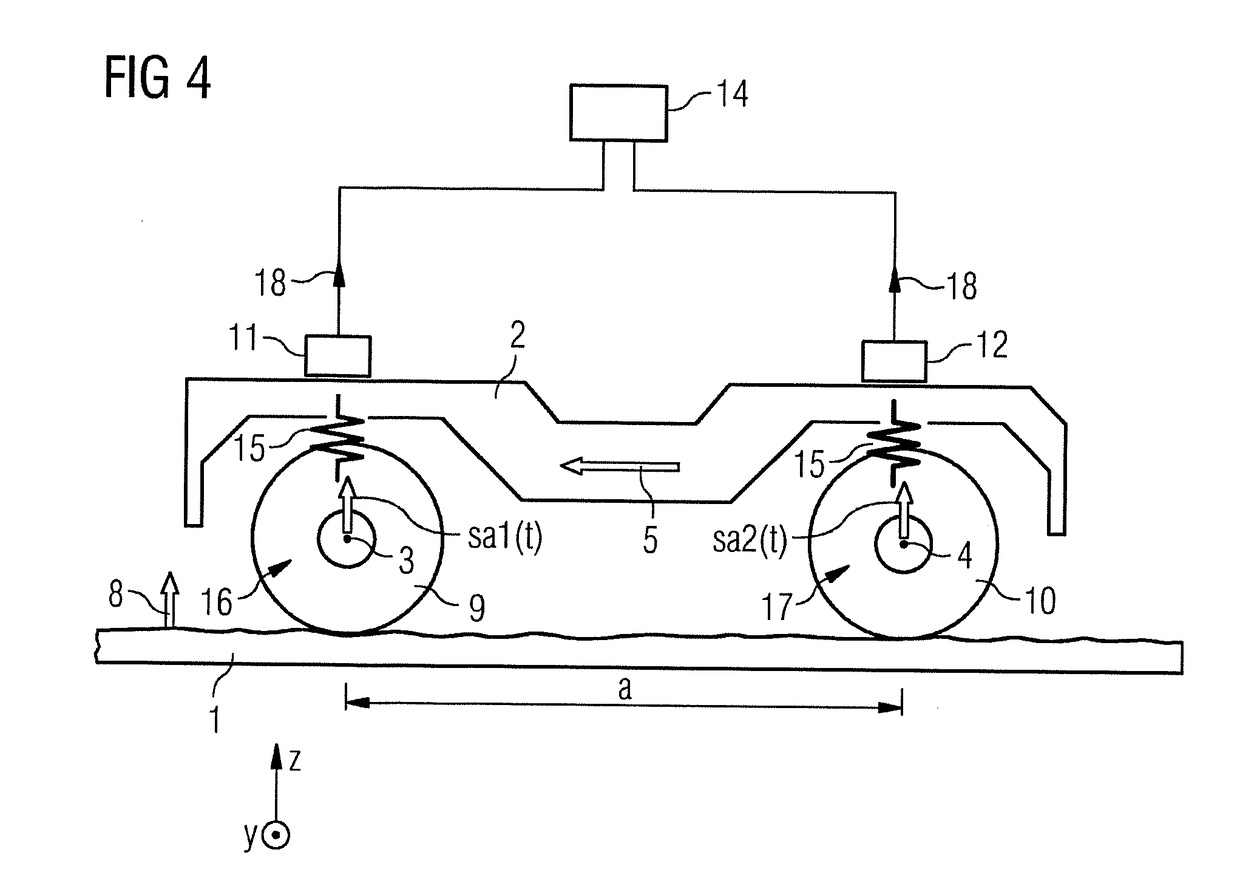

Method And Device For Determining Absolute Speed Of A Rail Vehicle

InactiveUS20170212142A1Improve accuracyAbsolute speed can be easily and accuratelyAcceleration measurementDevices using time traversedSignal processingTransfer function

A method for determining absolute speed of a rail vehicle including onboard sensor devices and a signal processor, wherein the method includes the steps of detecting irregularities in the rail respectively on one front wheel set via a first sensor device and at least on a subsequent wheel set via another sensor device, and transmitting the sensor signals produced by the sensor devices to a signal processor configured to determine the absolute speed by analyzing the supplied sensor signals, where an estimation of the transfer function between a sensor is used, and where an FIR filter can, in this case, optimally reproduce the signal of one sensor via the signal of the other sensor in which the smallest square of the error is formed such that the time offset between both signals can be determined, from which the speed can be determined at a known distance of the sensor.

Owner:SIEMENS MOBILITY AUSTRIA GMBH

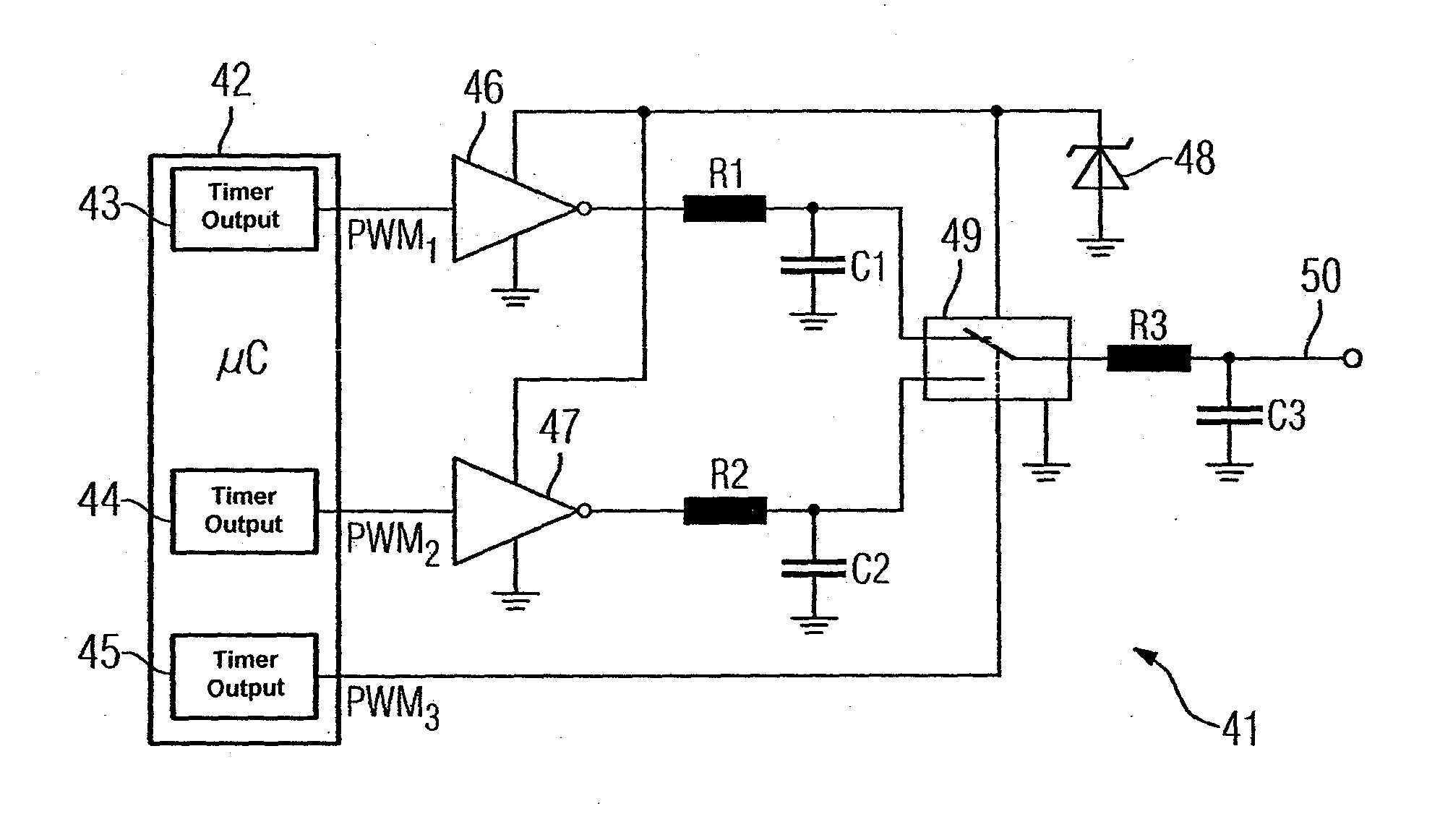

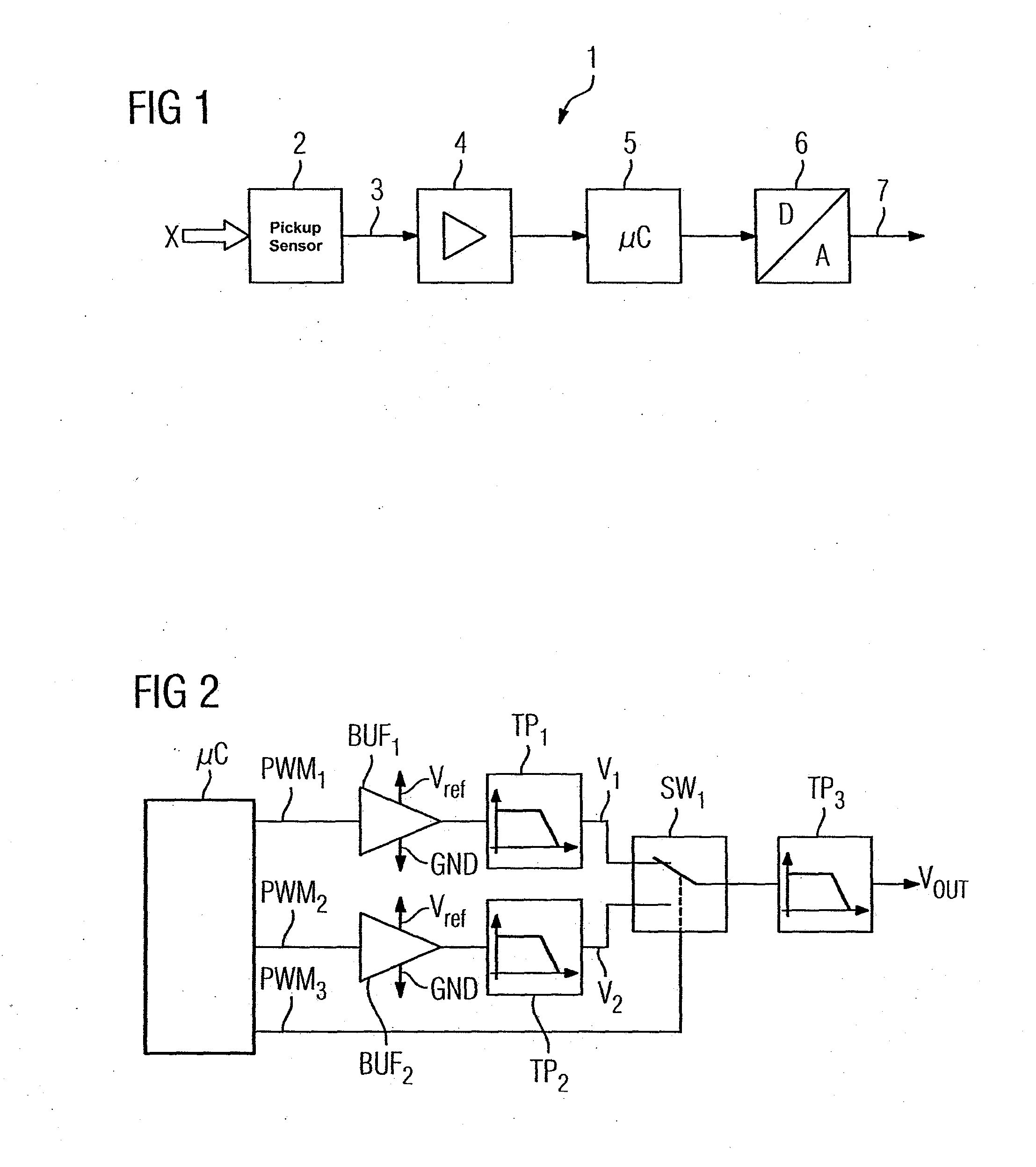

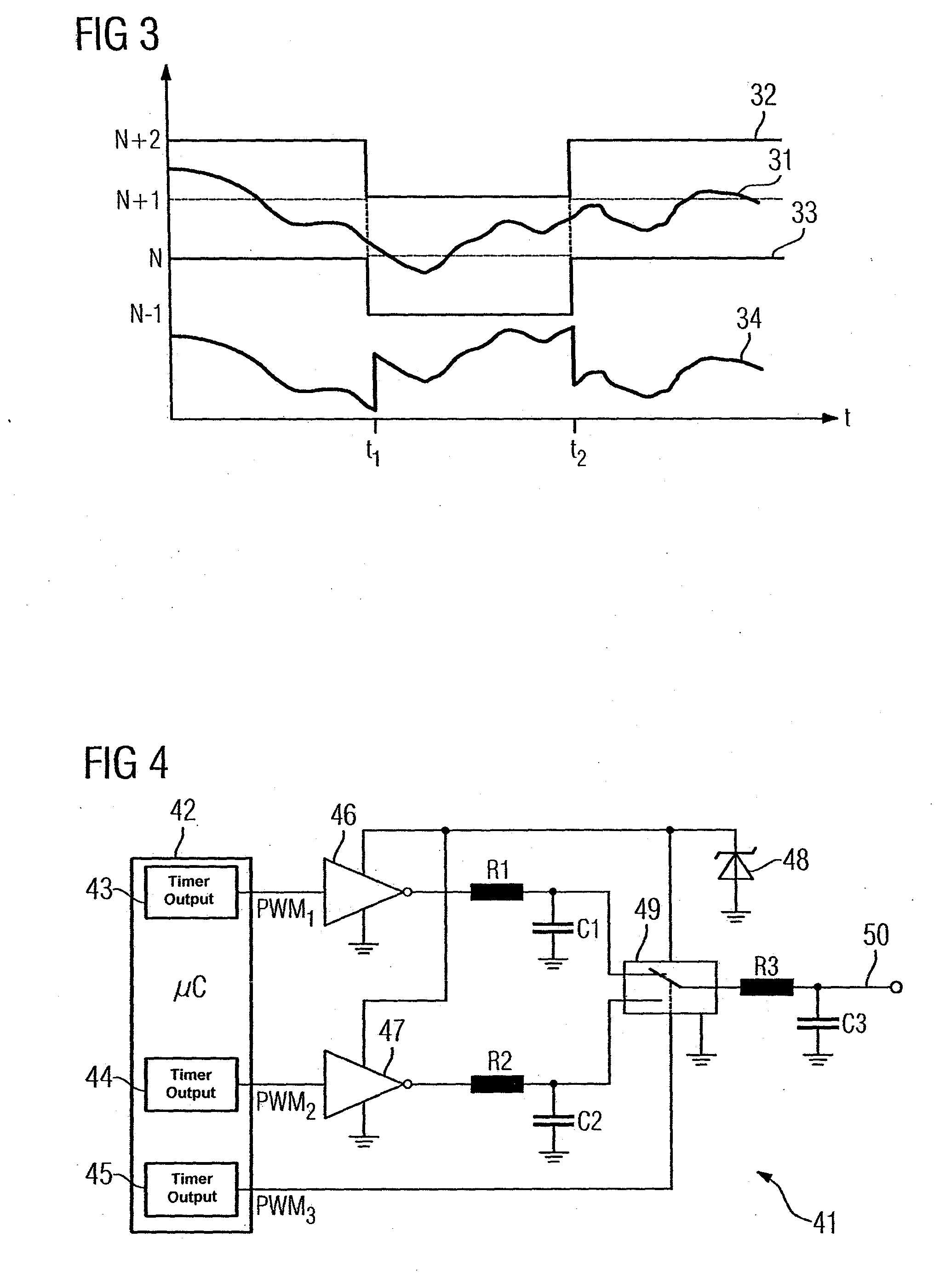

Field Device Having an Analog Output

InactiveUS20100302085A1Reduce power consumptionLarge dynamic rangeElectric signal transmission systemsAltering/correcting law of variationLow-pass filterTransducer

A field device having an analog output, i.e., a measuring transducer, for process instrumentation having a 4-20 mA interface as the analog output. For digital-to-analog conversion, a digital value is split into a digital coarse portion and a digital fine portion. Depending on the digital coarse portion, a first analog signal is generated using a pulse width modulator having a downstream mounted low path filter and a signal above the analog output signal, and a second output signal using a pulse width modulator also having a downstream mounted low path filter with a signal below the analog output signal. The analog signals are supplied to a third pulse width modulator controlled with the digital fine portion, where a low-pass filter (TP3) is downstream mounted. As a result, an analog output signal is provided having a high resolution and good dynamic properties. In addition, the field device is provided with a digital-to-analog converter that can be produced having minimal complexity.

Owner:SIEMENS AG

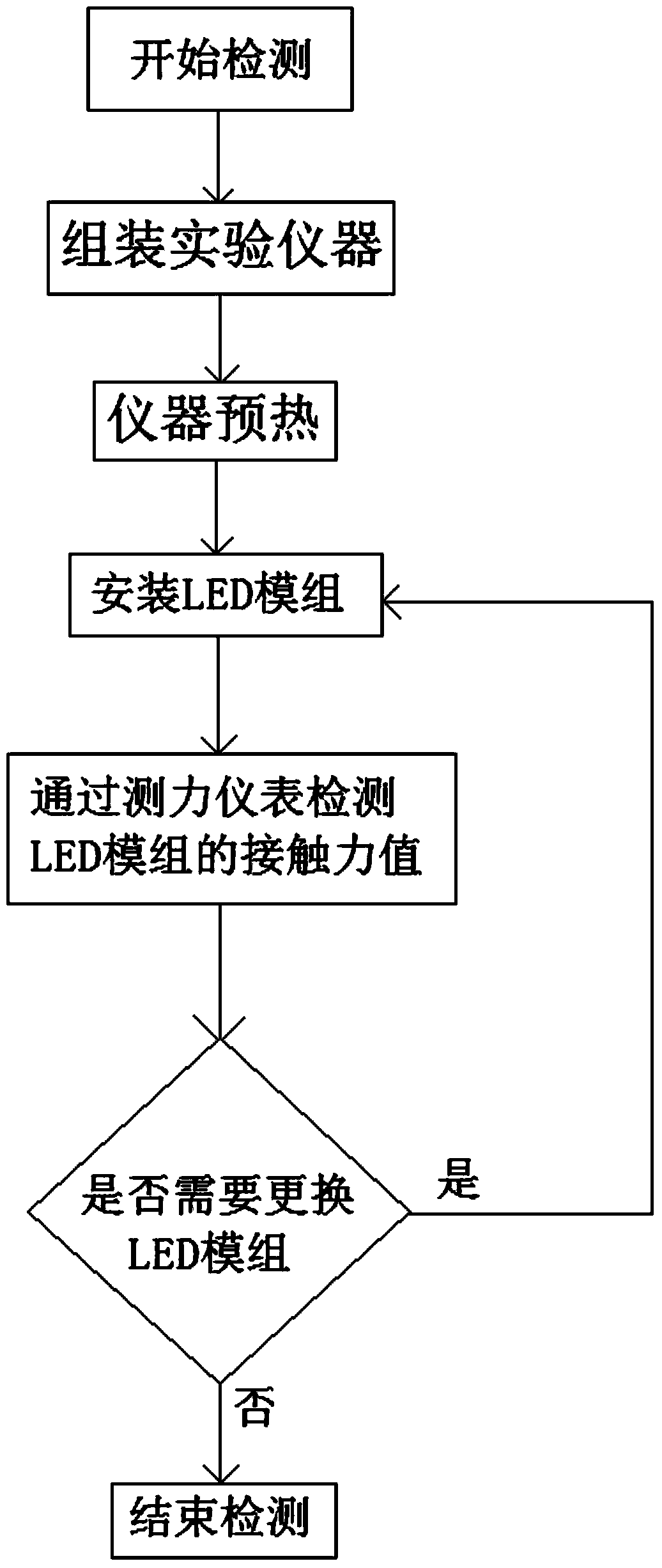

LED (Light Emitting Diode) module contact force testing device and method

InactiveCN104344920AScientific and reasonable structureIncreased accuracy levelApparatus for force/torque/work measurementEngineeringContact force

The invention relates to an LED (Light Emitting Diode) module contact force testing device and method. The testing device comprises a base, a force sensor, a supporting frame, a module installation seat, a force transmission shaft, a contact plate and an adapting seat, wherein the force sensor and the lower end of the supporting frame are respectively fixed with the base, and the supporting frame is arranged on the outer side of the force sensor in an enclosed manner; the two ends of the force transmission shaft which is vertically arranged are respectively connected with the force sensor and the contact plate; the module installation seat is arranged on the outer side of the supporting frame, the adapting seat is arranged on the module installation seat, and the upper surface of the adapting seat and the upper surface of the contact plate are at the same level; an LED module to be tested is arranged in the adapting seat, the lower surface of the LED module to be tested is in contact with the upper surface of the contact plate, the contact force of the LED module to be tested is measured through the contact plate, and the contact force is transmitted to the force sensor through the force transmission shaft. The indicating value relative error and the repeatability of the testing device are superior to 0.3 percent, the testing device is applicable to testing of modules with different specifications, the testing device is light, ingenious and convenient to carry, and the testing device can be widely used for testing the contact force of various LED modules.

Owner:NAT INST OF METROLOGY CHINA +1

System and method for applying plasma sparks to tissue

ActiveUS8709006B2Increased accuracy levelPromote generationSurgical needlesSurgical instruments for heatingElectricityEngineering

A pulse delivery system for producing a spark in tissue is disclosed. The system can include at least two electrodes having sharp surface features, where the at least two electrodes are electrically isolated from one another. The sharp features of the electrodes can be separated by a distance of about 2 to 20 mm. The system can also include a pulse generator for delivering pulsed voltage differences between the at least two electrodes. The pulsed voltage differences can producing a voltage difference ranging from about 2.5 kV to about 35 kV for a duration of about 50 ns to 3 μs. The system can include a controller for determining whether the plurality of pulsed voltage differences produced a spark between the at least two electrodes. A method of producing a spark in tissue for both therapeutic and cosmetic, i.e., non-therapeutic, applications is also disclosed.

Owner:OLD DOMINION UNIVERSITY RESEARCH FOUNDATION

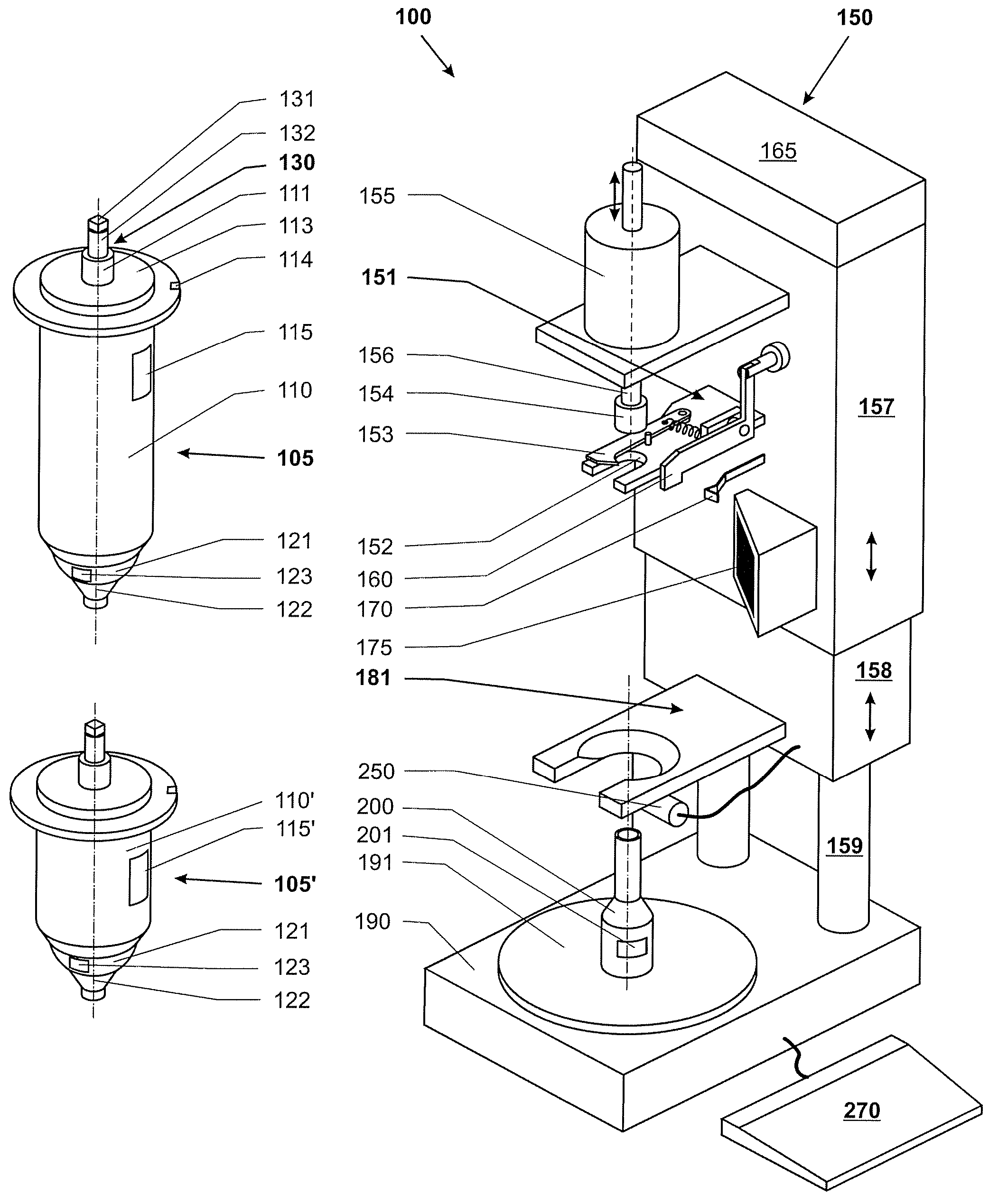

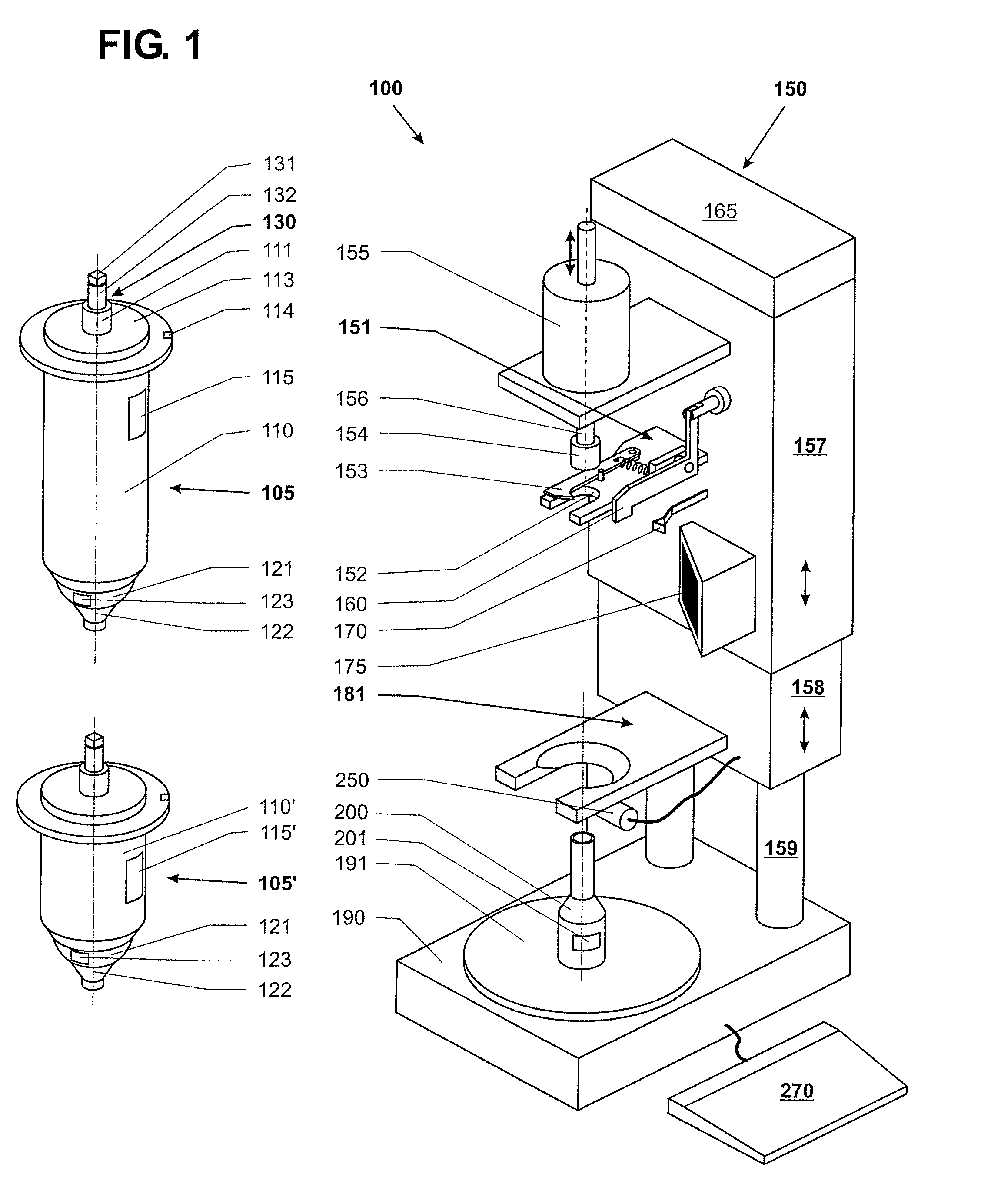

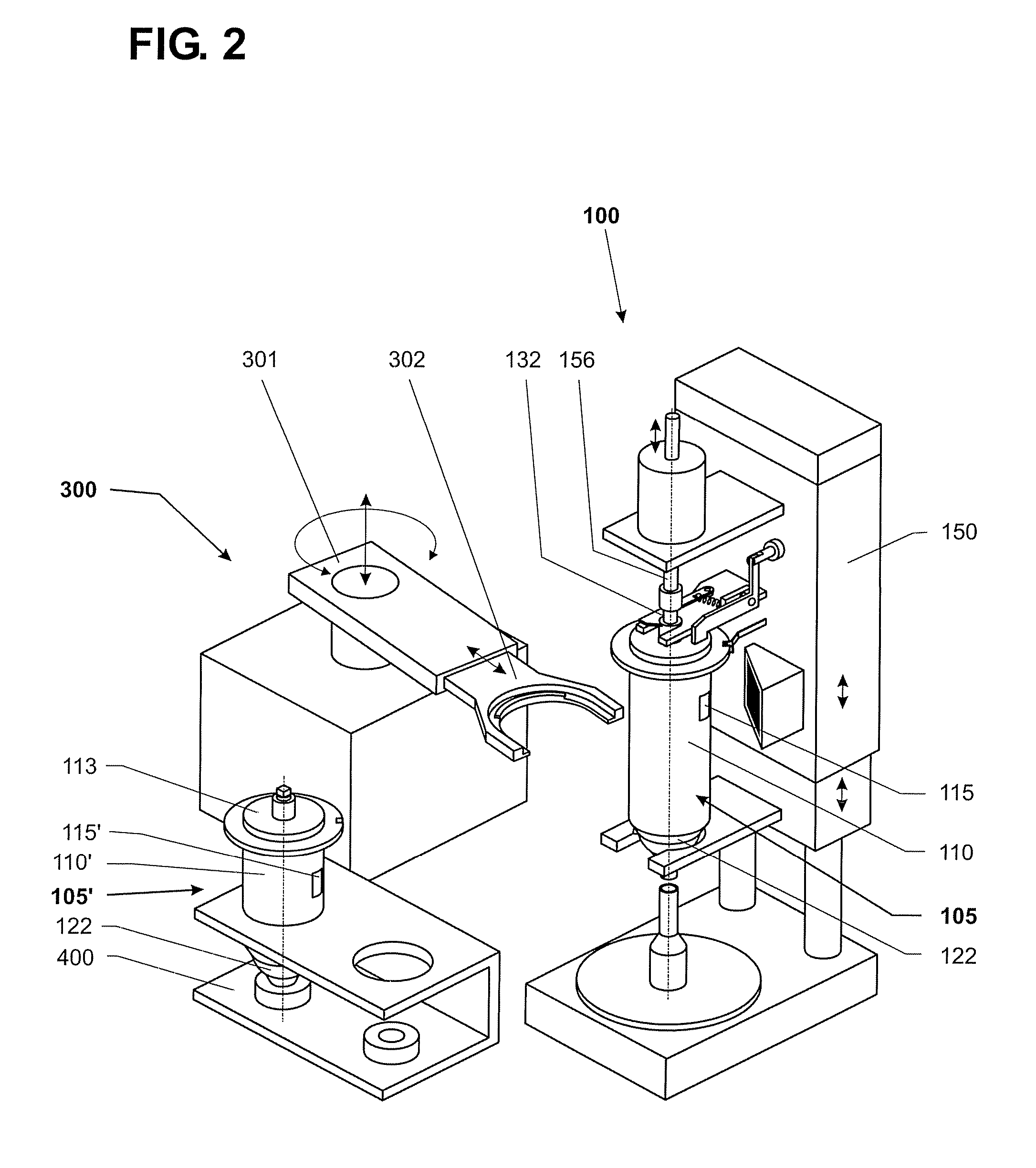

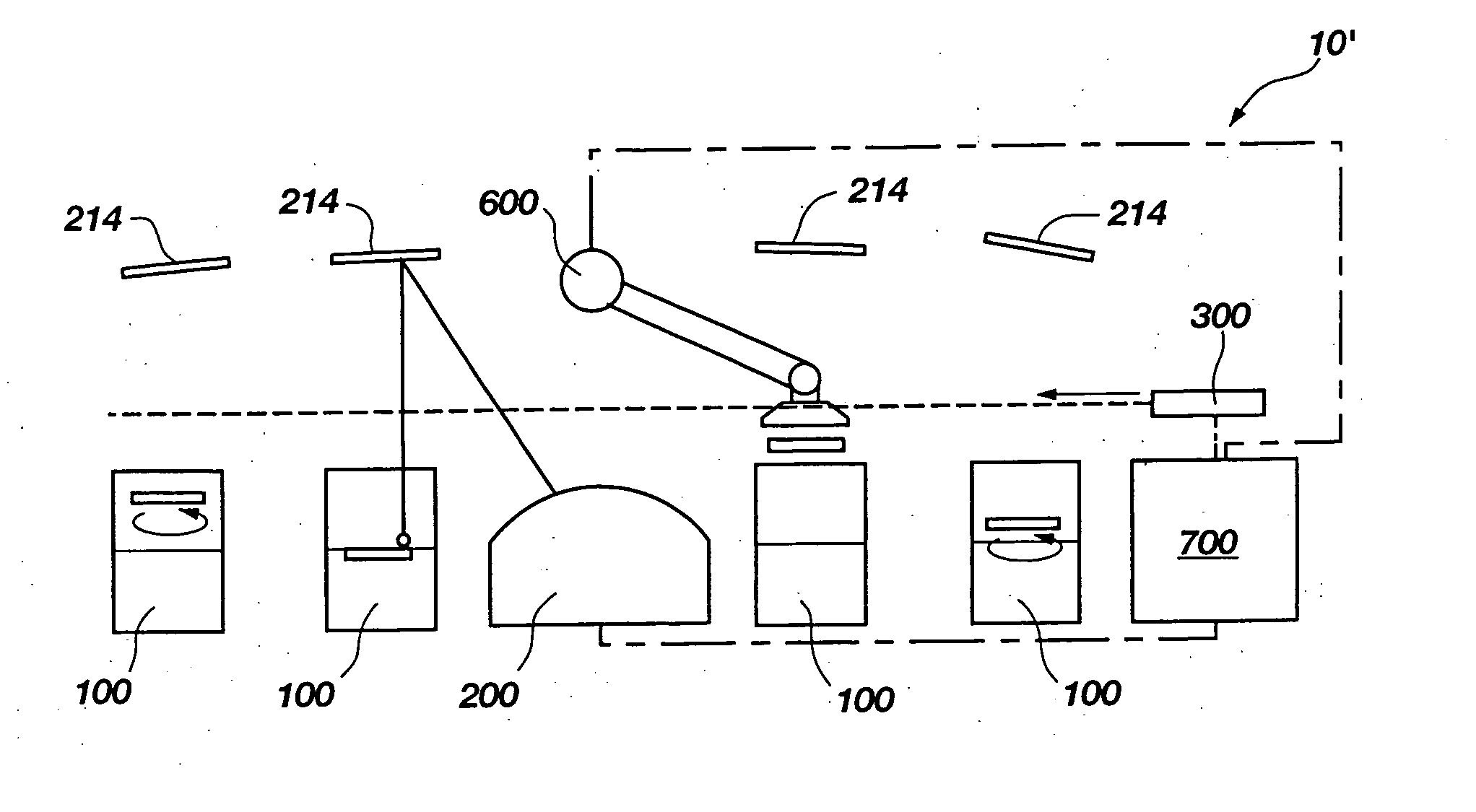

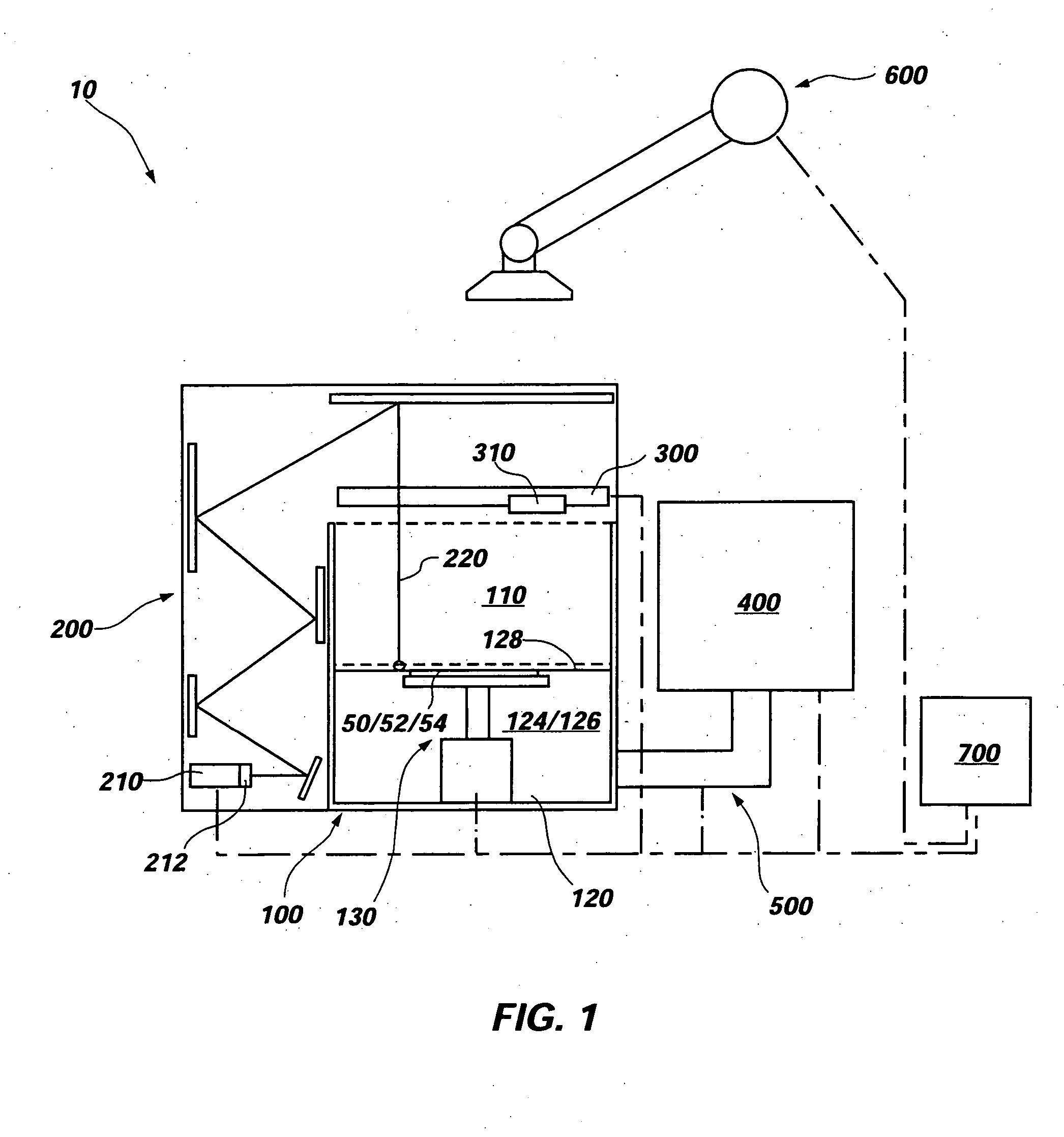

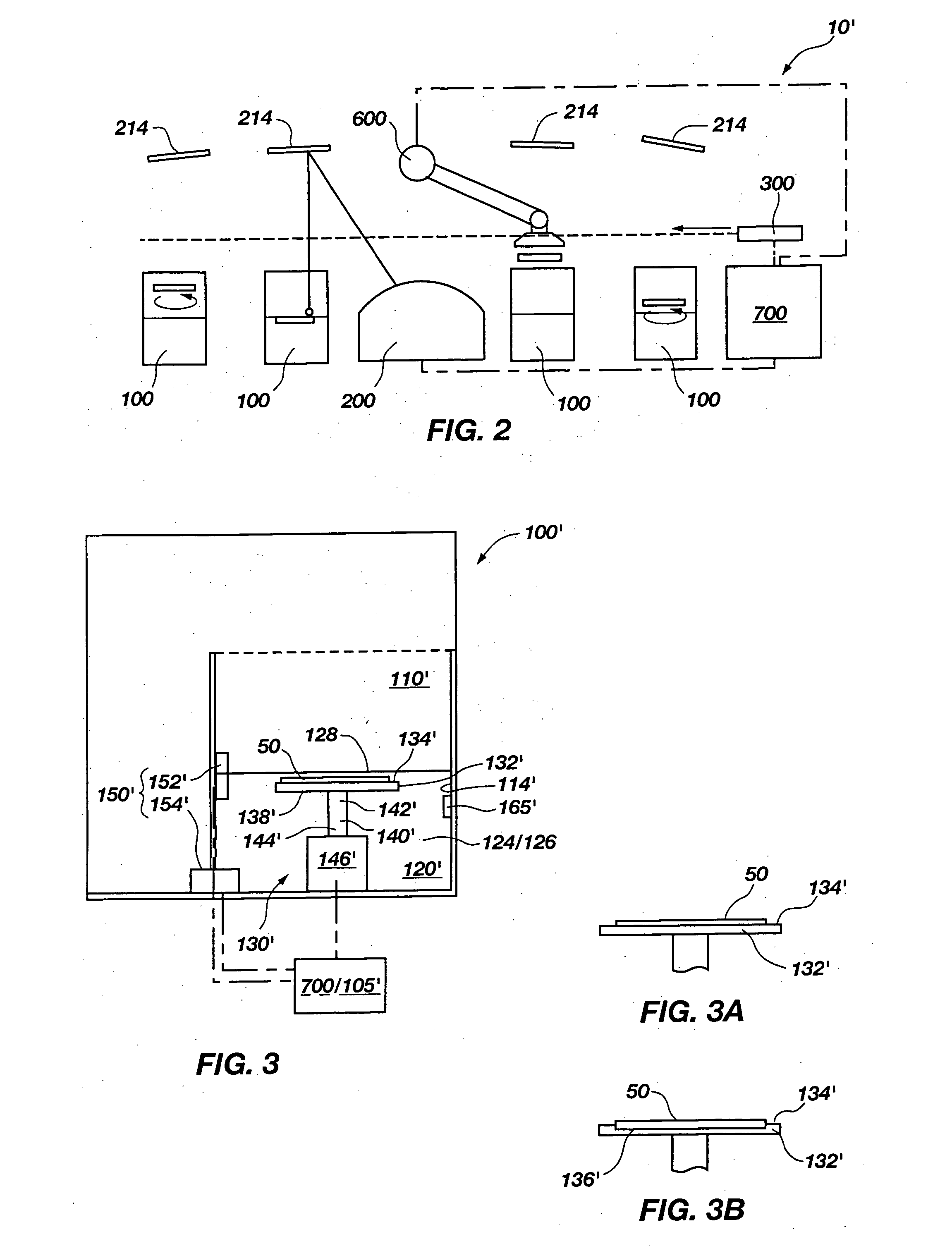

Machine vision systems for use with programmable material consolidation apparatus and systems

InactiveUS20050049751A1Increased accuracy levelProgramme controlAdditive manufacturing apparatusHandling systemSemiconductor

A programmed material consolidation apparatus includes at least one fabrication site and a material consolidation system associated with the at least one fabrication site. The at least one fabrication site may be configured to receive one or more fabrication substrates, such as semiconductor substrates. A machine vision system with a translatable or locationally fixed camera may be associated with the at least one fabrication site and the material consolidation system. A cleaning component may also be associated with the at least one fabrication site. The cleaning component may share one or more elements with the at least one fabrication site, or may be separate therefrom. The programmed material consolidation apparatus may also include a substrate handling system, which places fabrication substrates at appropriate locations of the programmed material consolidation apparatus.

Owner:MICRON TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com