Gear shaft forming method and die adopted by same

A technology for gear shafts and molds, which is applied in the direction of manufacturing tools, mechanical equipment, engine components, etc., can solve the problems of low processing efficiency and low processing accuracy, and achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0025] Taking the processing of a gear shaft with a gear at one end and a spline at the other end as an example, the molding method of the present invention and the specific structure of the mold are described in detail, so as to facilitate the understanding of the molding method of the gear shaft of the present invention and the structure of the mold used.

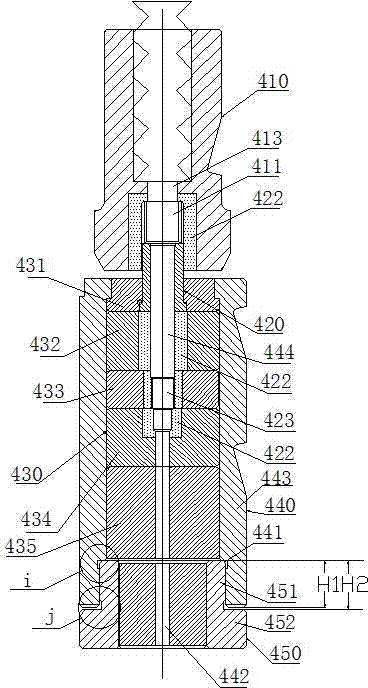

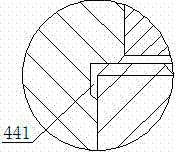

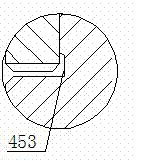

[0026] Such as figure 1 As shown, the upsetting mold for finally shaping the gear shaft of the present invention includes a die 410 , a main die 440 and a die cover 450 .

[0027] In the die 410, a die cavity 411 matching the outer surface shape of the gear cylinder of the gear shaft is provided, and a front rod hole 413 communicated with the die cavity 411 for the front rod to pass through;

[0028] In the main mold 440, a main mold cavity 444 matching the shaft portion of the gear shaft and the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com