Patents

Literature

172 results about "STONE CUTTER" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

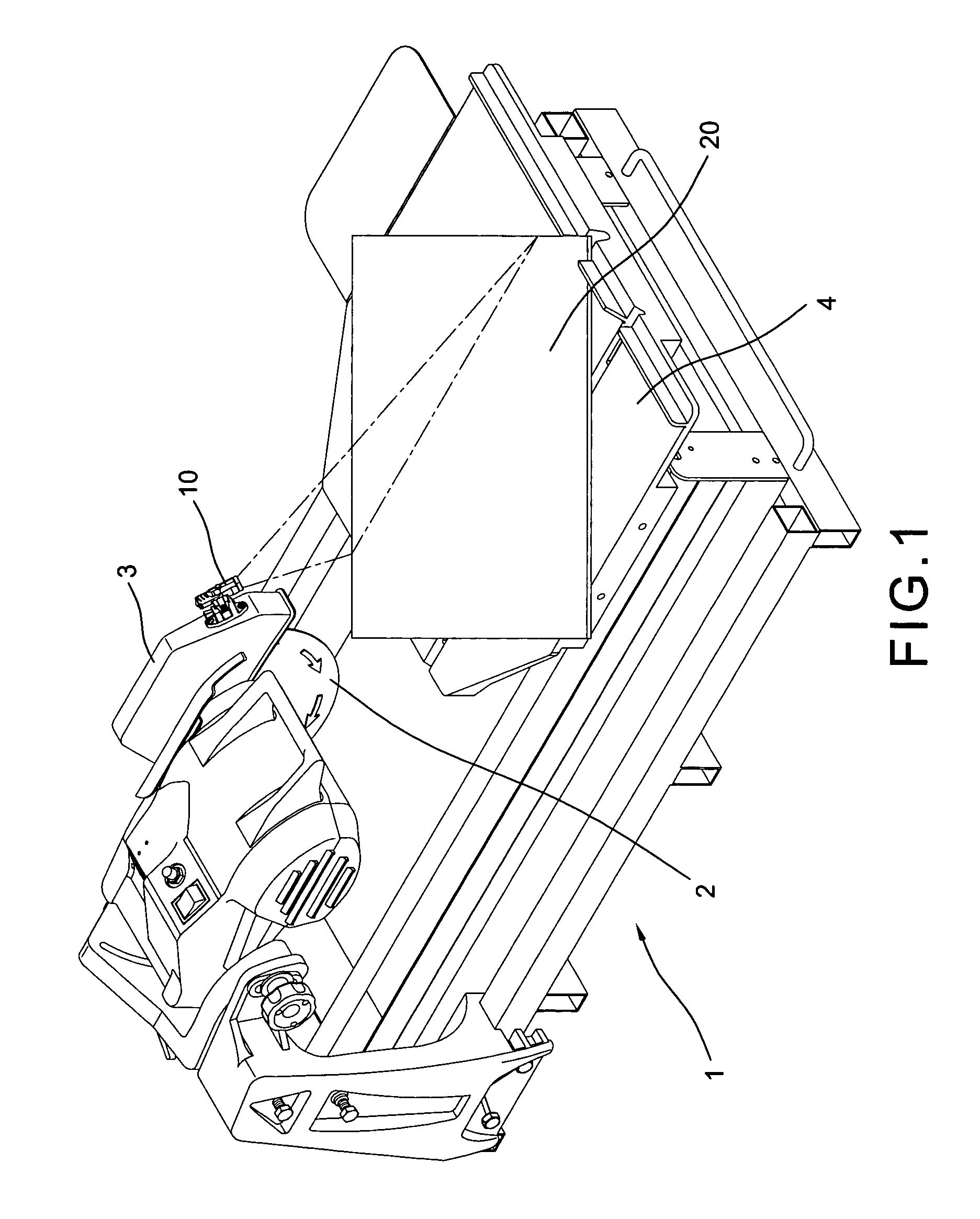

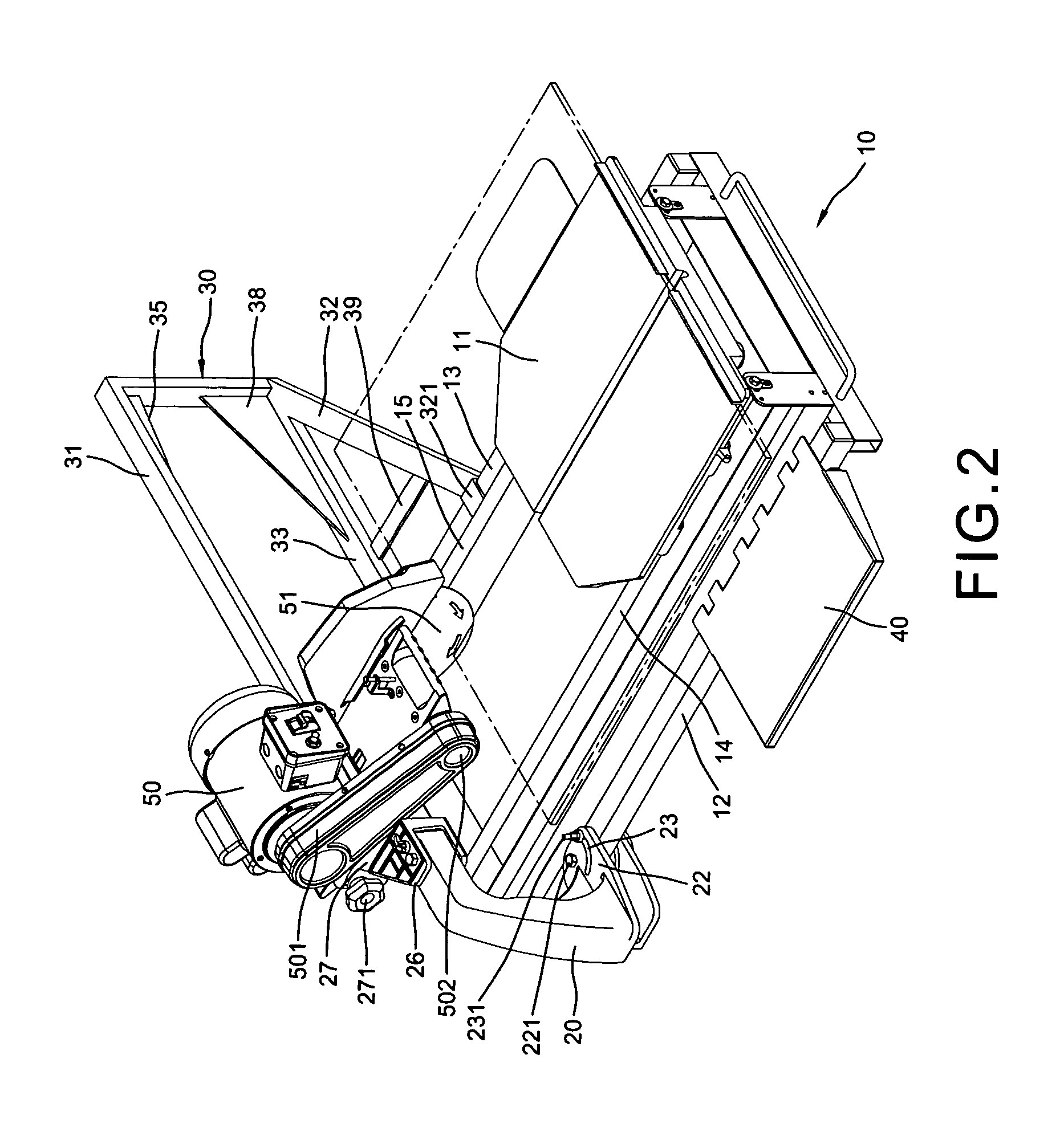

Laser light beam guiding device on a stone cutter

InactiveUS7066627B1Precise and rapid cutting activityPrecise and rapid activityMetal sawing accessoriesLighting elementsSTONE CUTTERLight beam

A laser light beam guiding device on a stone cutter includes a tubular main body pivoted to a lug of a seat which is secured to a front top of a blade guard of the stone cutter, a battery chamber in the main body controlled by a switch button on the top, a tubular sleeve on the rear portion of the main body and a laser projector rotatably engaged with the front end of the main body to emit the light beam on a working piece to decide a cutting line for the saw blade to follow up.

Owner:CHEN YUEH TING

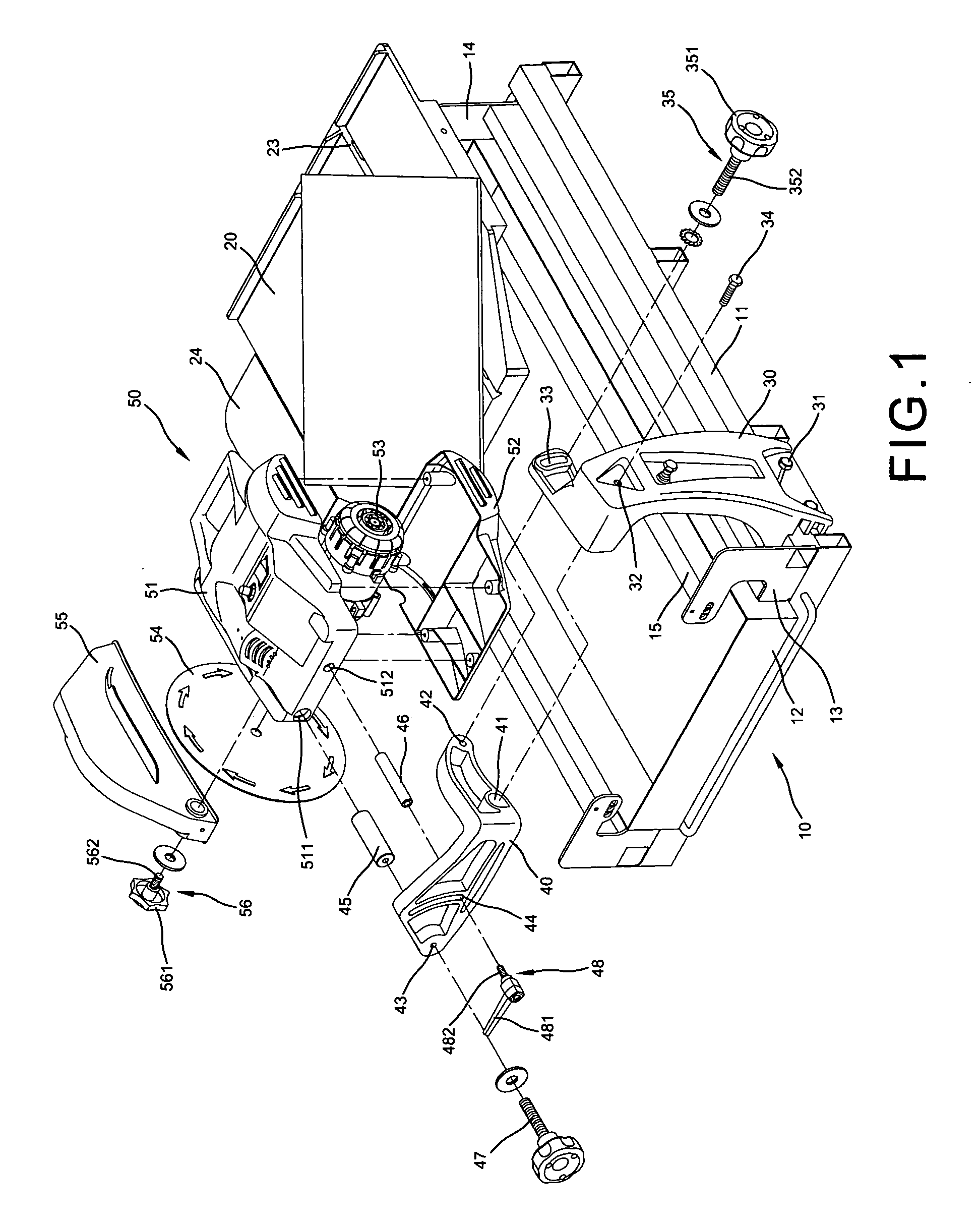

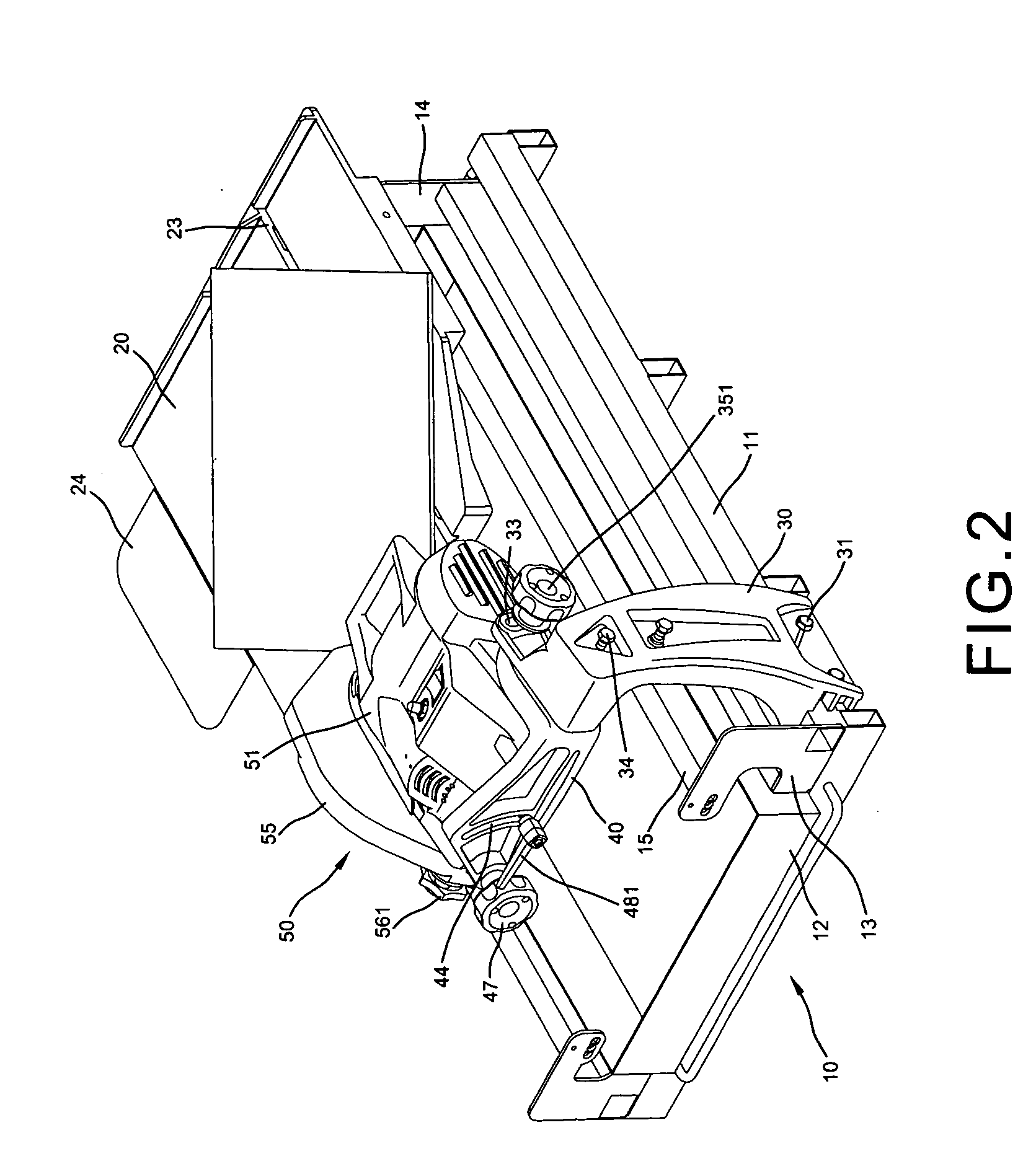

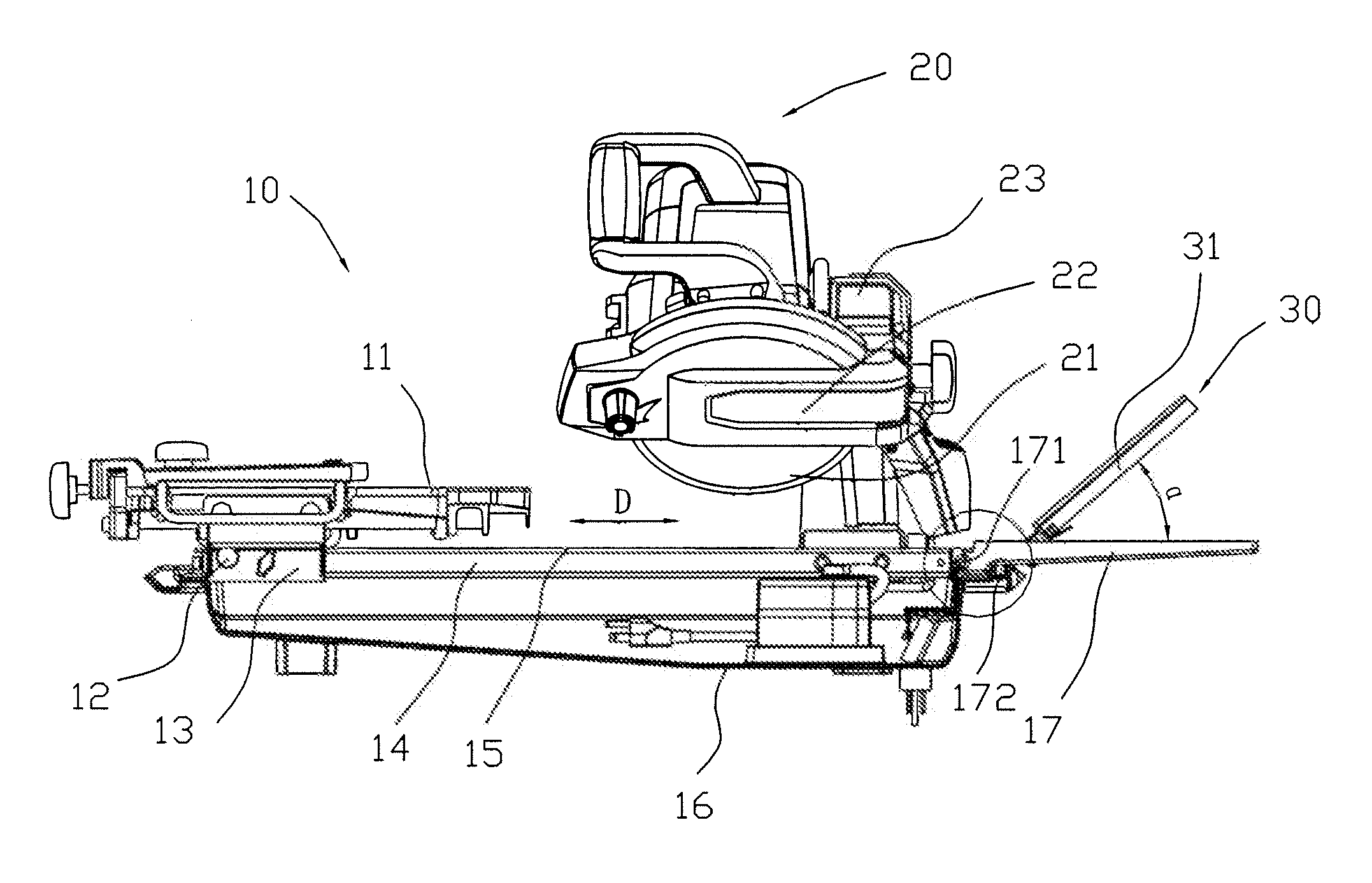

Blade angle adjustment device for a stone cutter

InactiveUS6932075B1Easy to adjustEasy to operatePortable power driven sawsMetal working apparatusSTONE CUTTERSlant angle

A blade angle adjustment device for a stone cutter includes a framed base having a working table slidably disposed on the base including a vertical cutting groove and a slant cutting groove in upper surface, a tool plate and a support arm respectively secured to a lateral side thereof, a L-shaped link having pair of screw holes in a longitudinal portion engaged with a screw hole and oblong hole on the top of the support arm and secured by a screw and a first swivel lock, a screw hole and an arcuate slot in a transverse portion respectively engaged with the front ends of a large and a small internally threaded large and small connection rods and secured by a second swivel lock and a handled screw, a motor protected by an upper housing and a lower housing which is connected to the rear end of the connection rods and a guarded circular blade connected to an axis of the motor so that slides the first swivel lock in the oblong hole to define the elevational angle for the cutting mechanism and slides the small connection rod to define the slant angle for the blade up to 45 degree.

Owner:TSAO WEN HAI

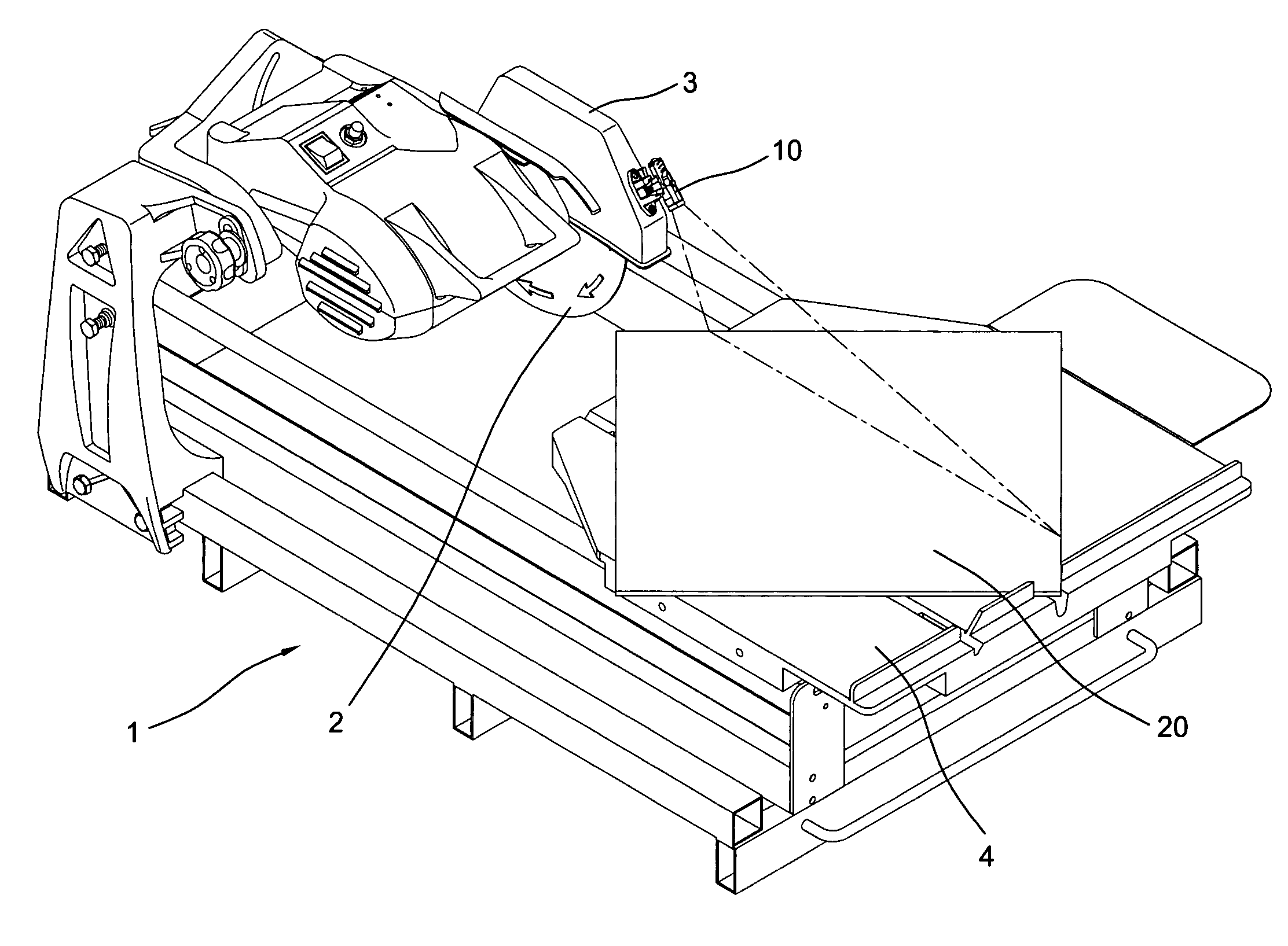

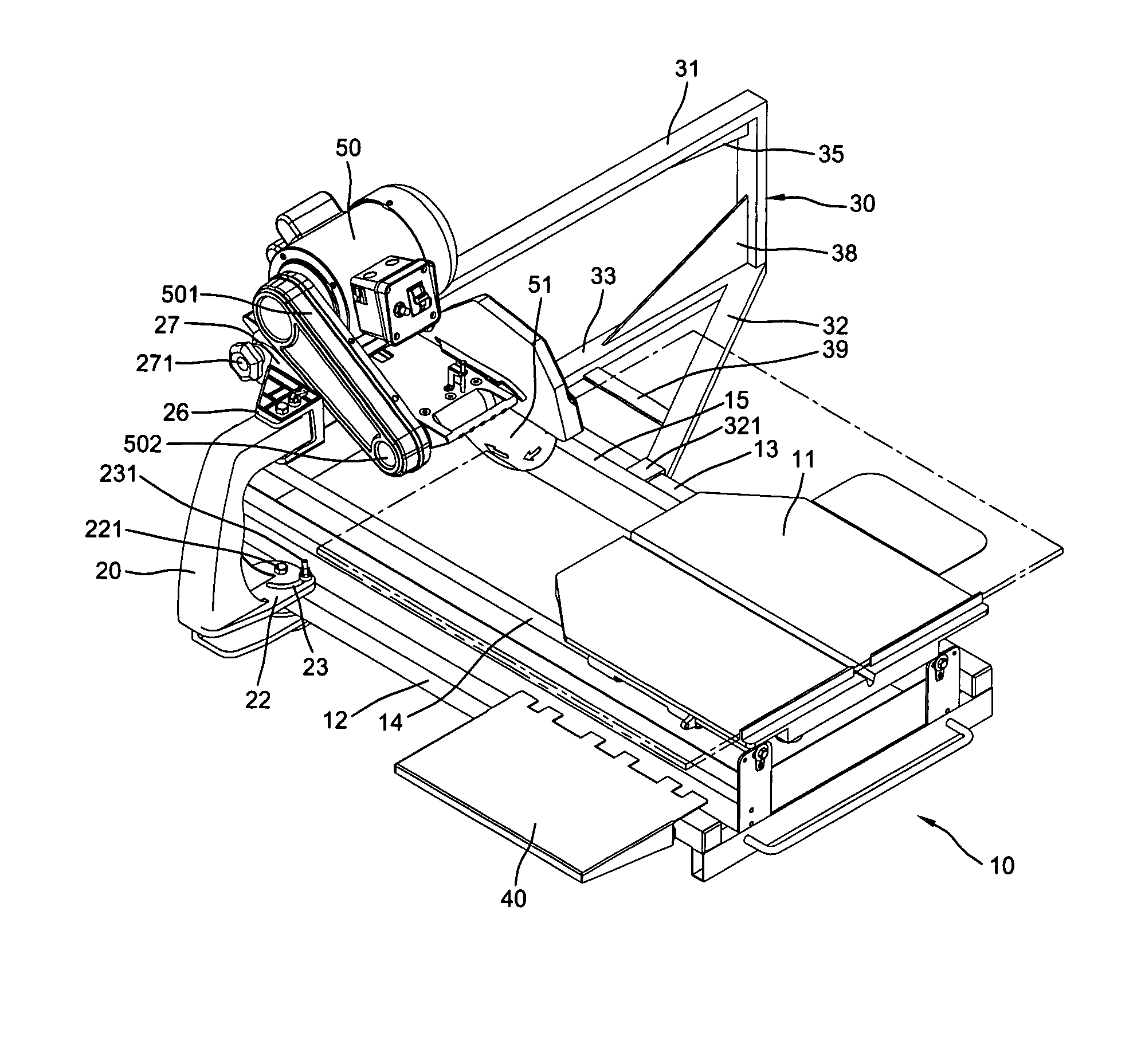

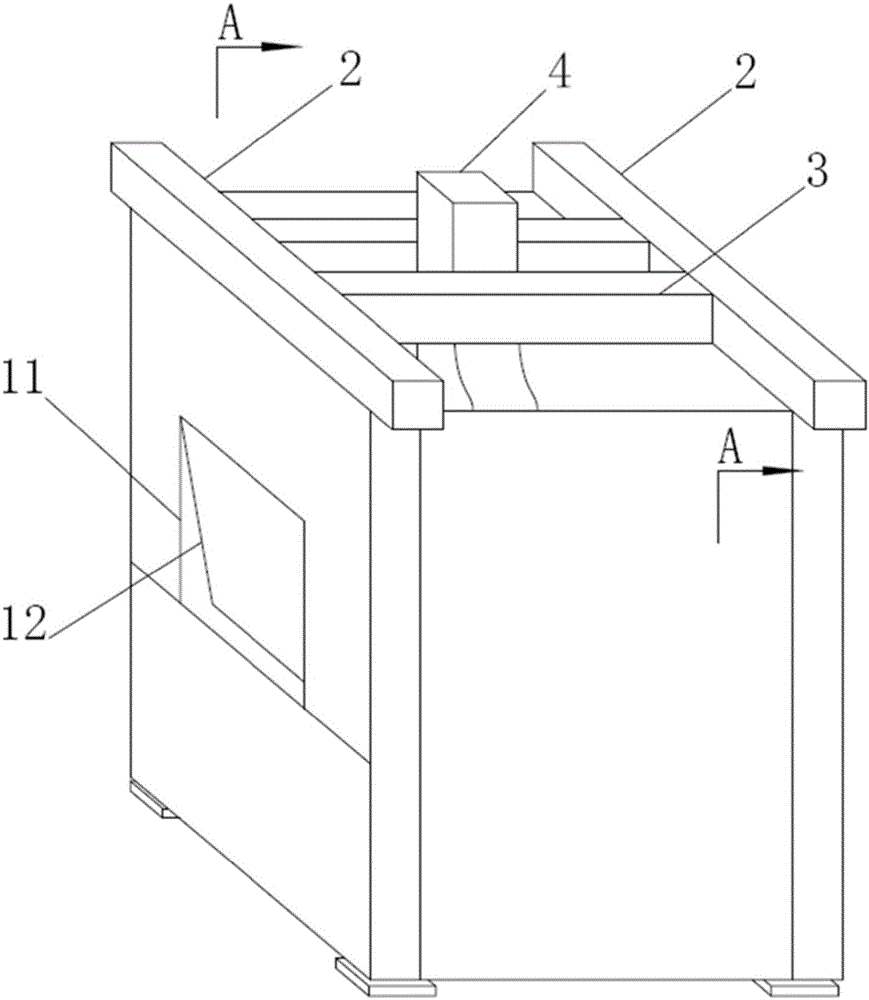

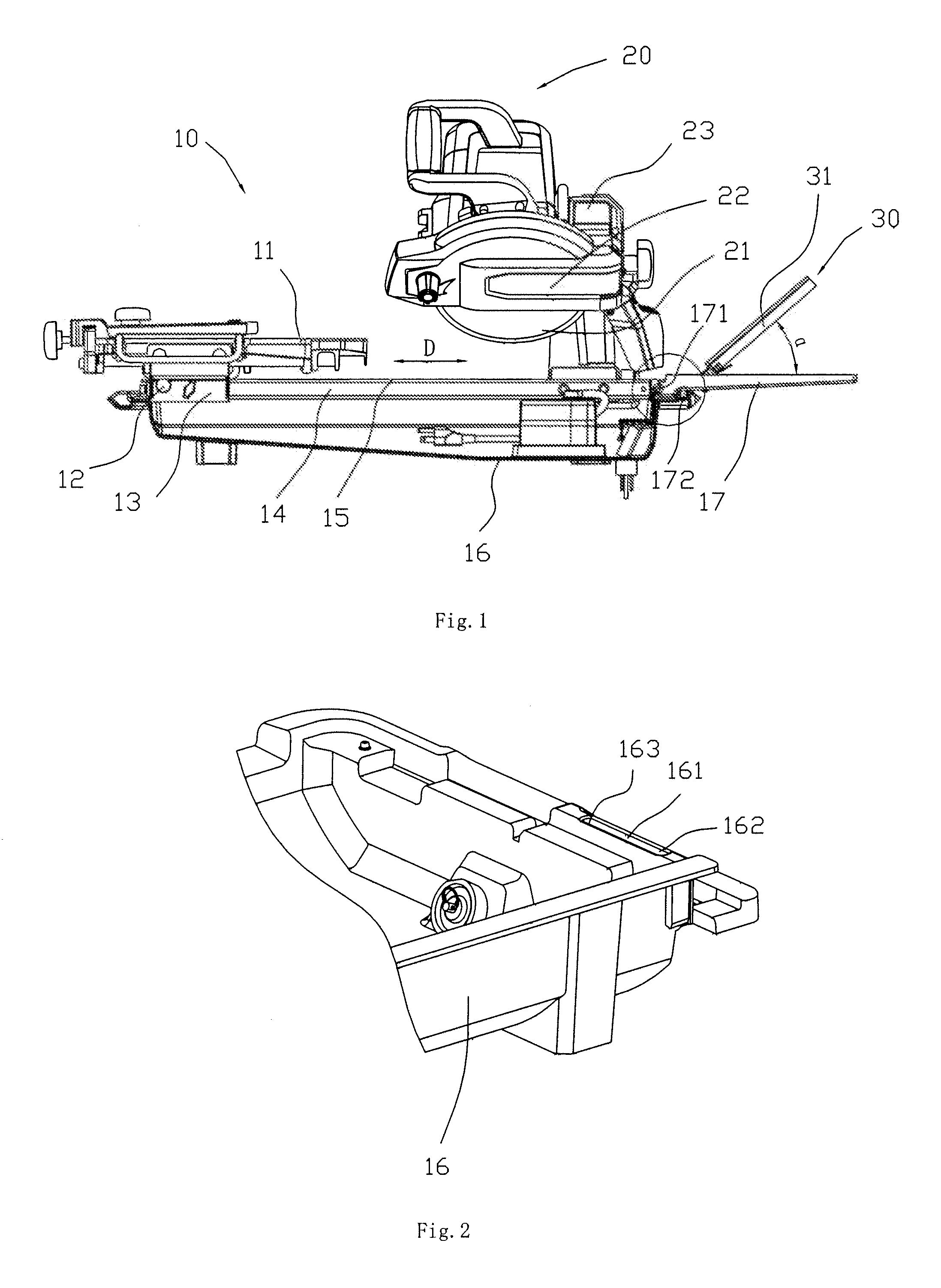

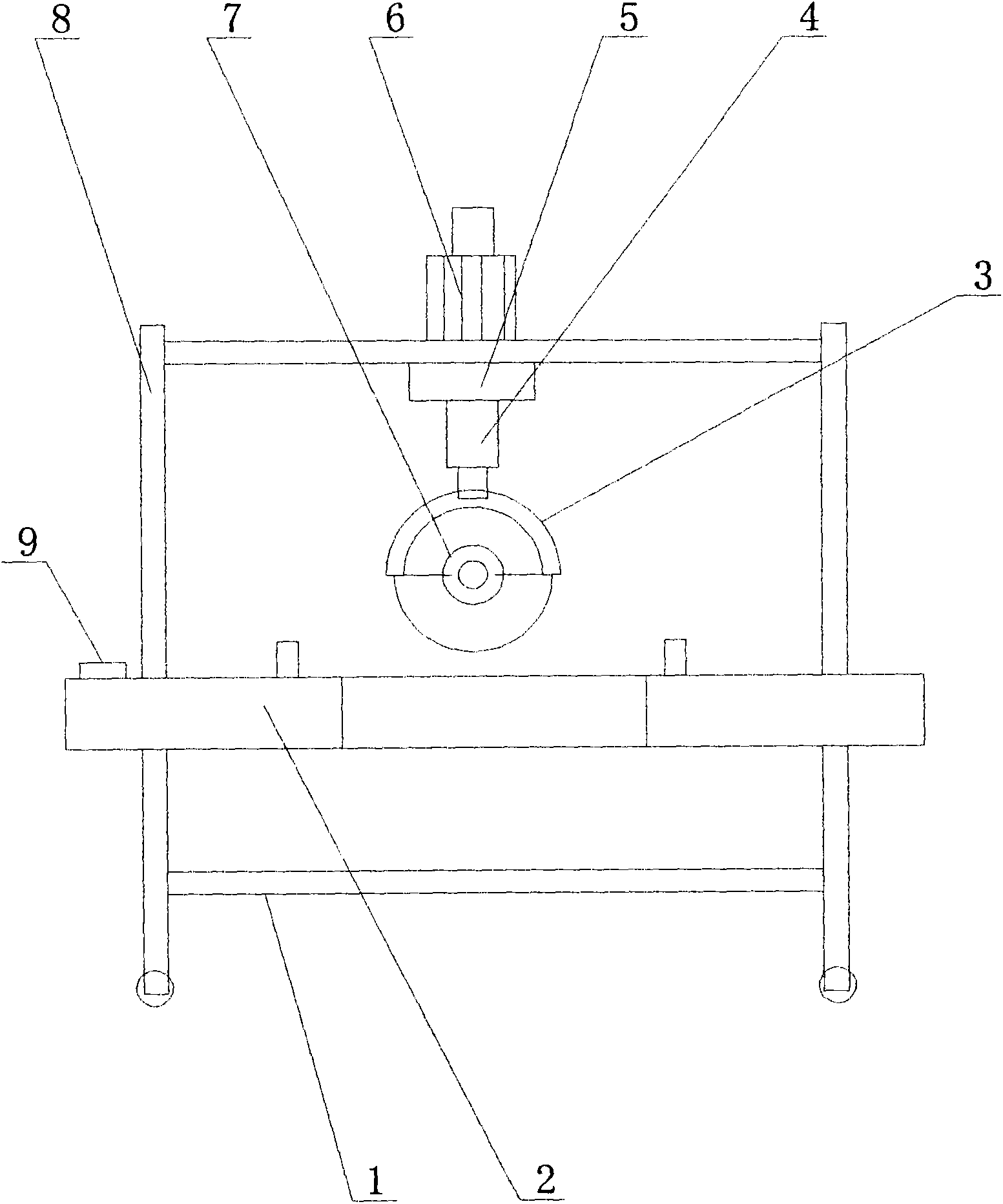

Portable stone cutter

InactiveUS6883511B1Increase volumeEasy to packMetal sawing devicesGang saw millsDrive shaftSTONE CUTTER

An improved portable stone cutter includes a base which is of a rectangular frame composed of a plurality of longitudinal bars, a pair of transverse bars and a pair sliding bars, a working table slidably secured to the sliding bars, a motor disposed on the front end of the frame and sustained by an arcuate support arm and a supplementary support arm which are releasably and rotatably secured to a pair of outmost longitudinal bars, a guarded circular saw blade connected to the motor and operated by the motor via a belt and a transmission shaft and a tool plate movably disposed to one of the outmost longitudinal bars. The feature is that the arcuate support arm and the supplementary support arm define a large space to permit a large piece of stone passing through the saw blade and both the supplementary support arm and the tool plate are removable to reduce the volume of the stone cutter to conveniently pack for transportation.

Owner:TSAO WEN HAI

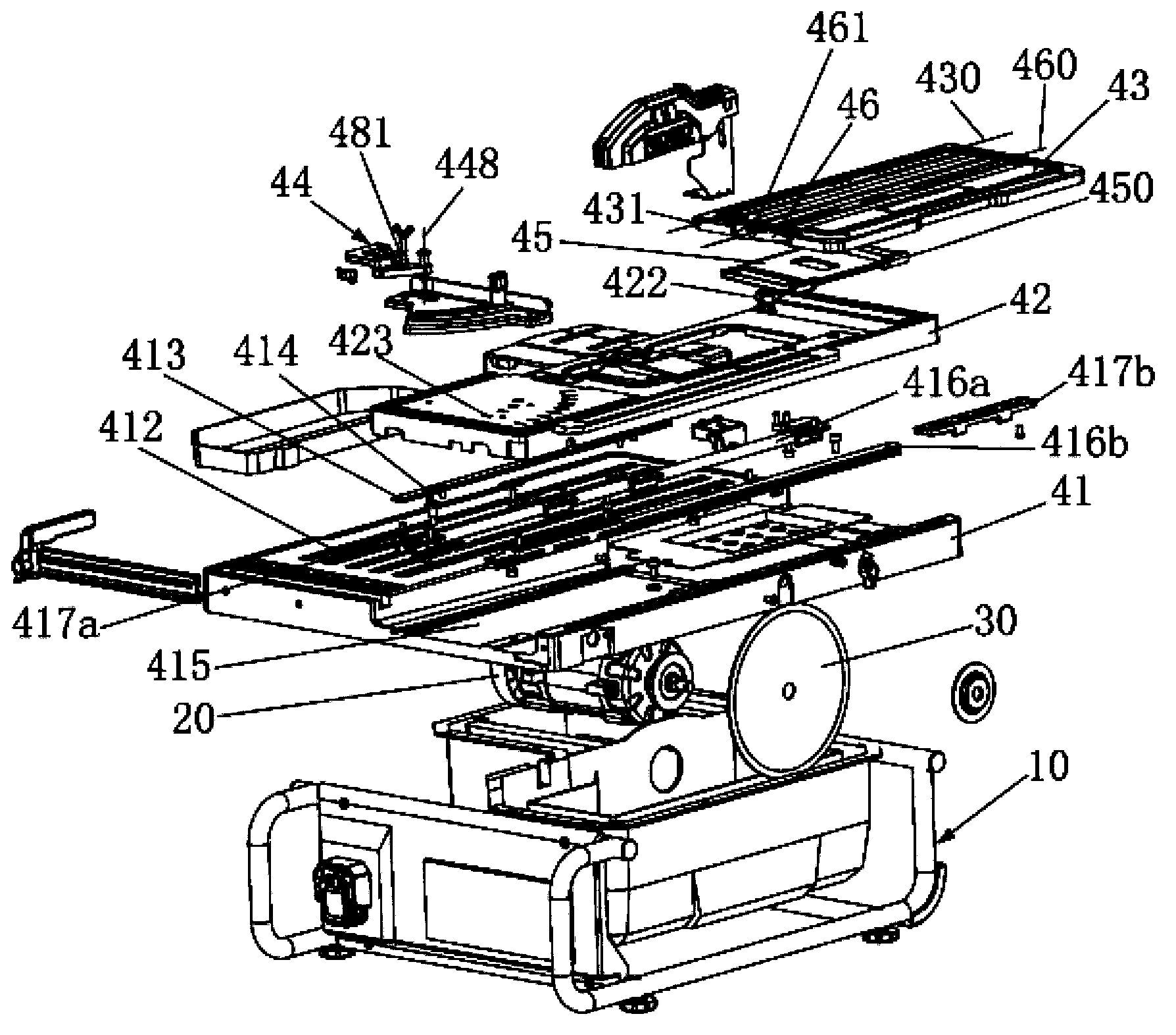

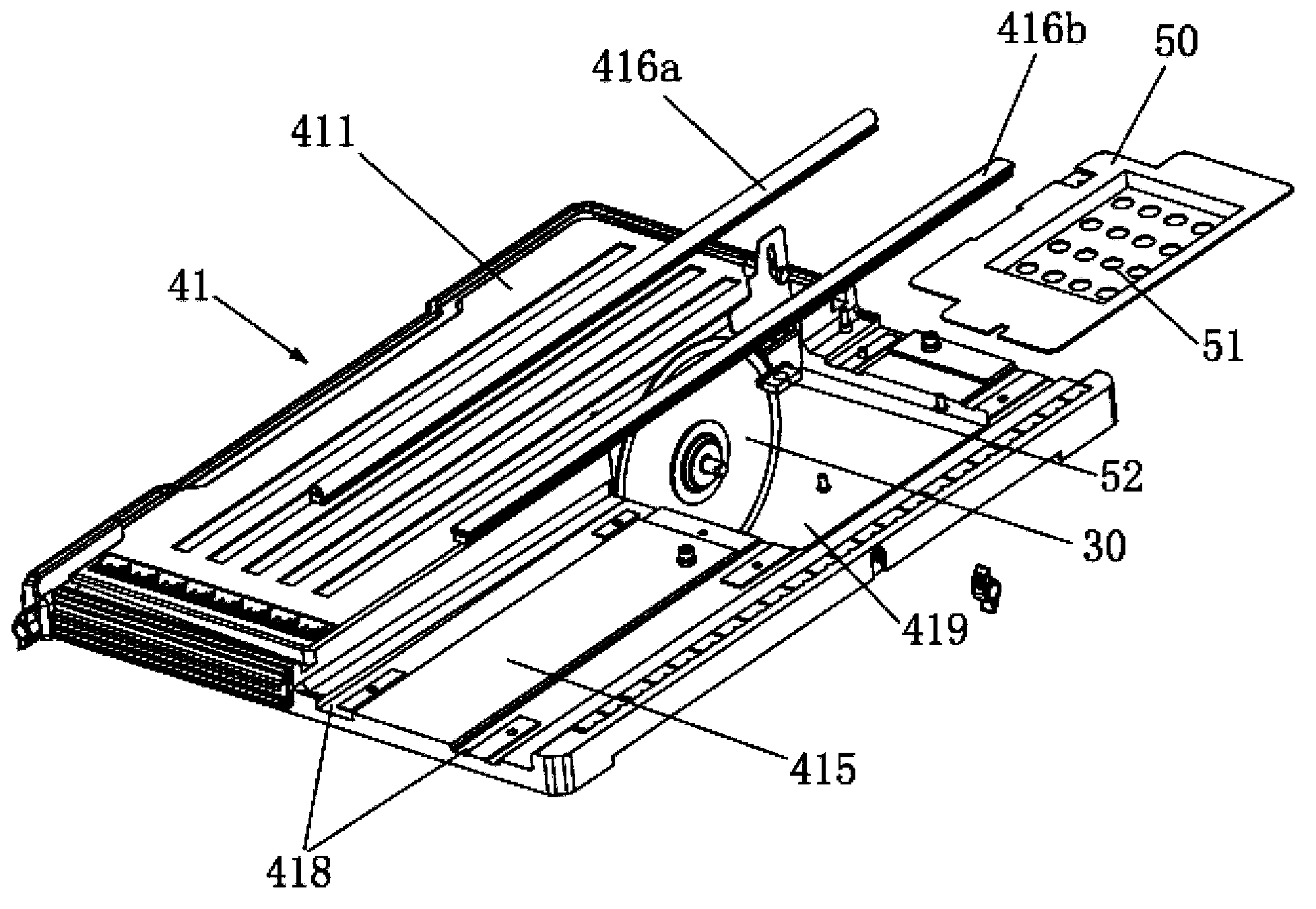

Stone cutter

ActiveCN104275749AReduce scratchesImprove straightnessWorking accessoriesStone-like material working toolsSTONE CUTTEREngineering

A tile cutting machine comprises a base, a motor accommodated in the base, a blade driven to rotate by the motor, and a working table supported on the base, wherein the working table comprises a fixed working table fixedly mounted to the base. A movable working table is slidably mounted to the fixed working table in a sliding direction parallel to a plane of the blade. The movable working table comprises a pivoting plate pivotally mounted to the movable working table about a pivoting axis parallel to the plane where the blade is located and a fence assembly mounted to the movable working table. The tile cutting machine can effectively enhance the ability to produce straight and / or square cuts.

Owner:NANJING CHERVON IND

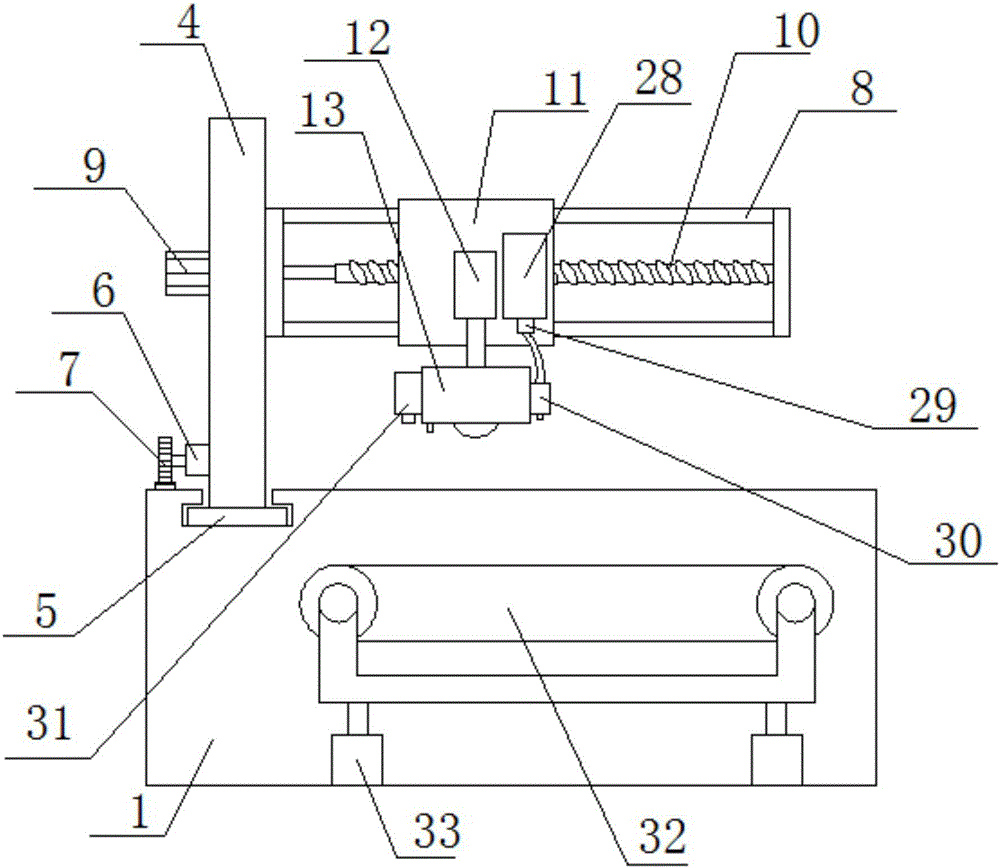

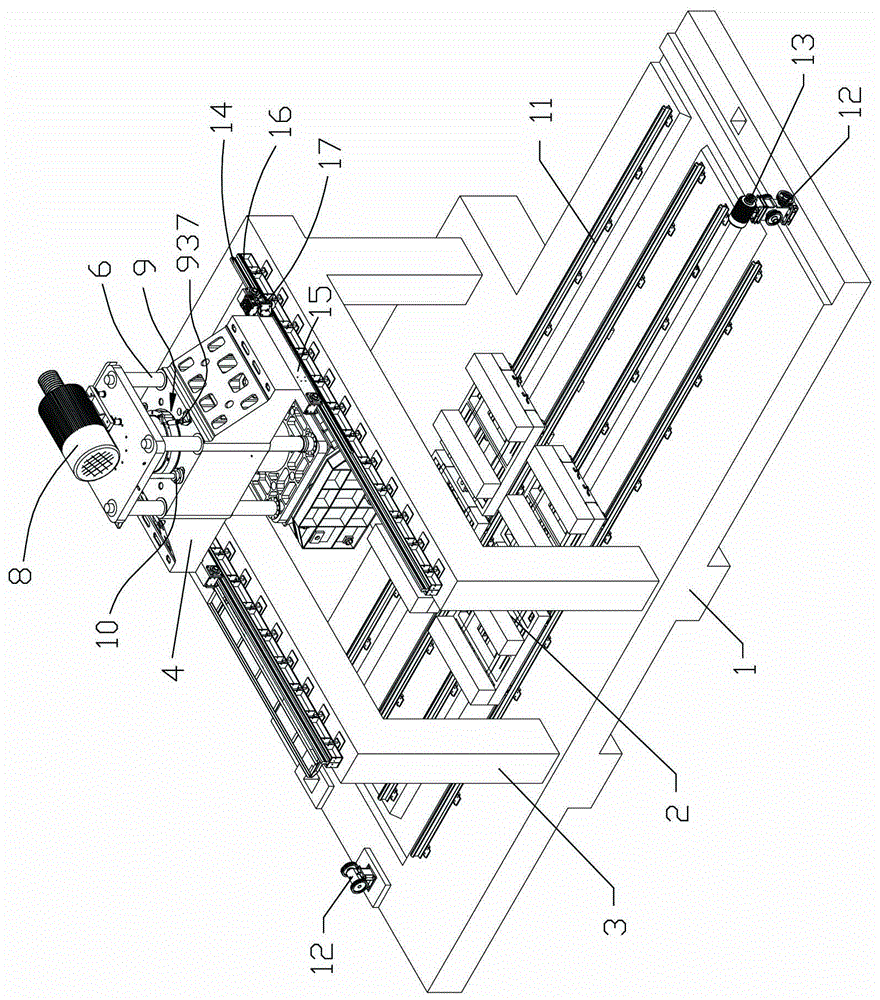

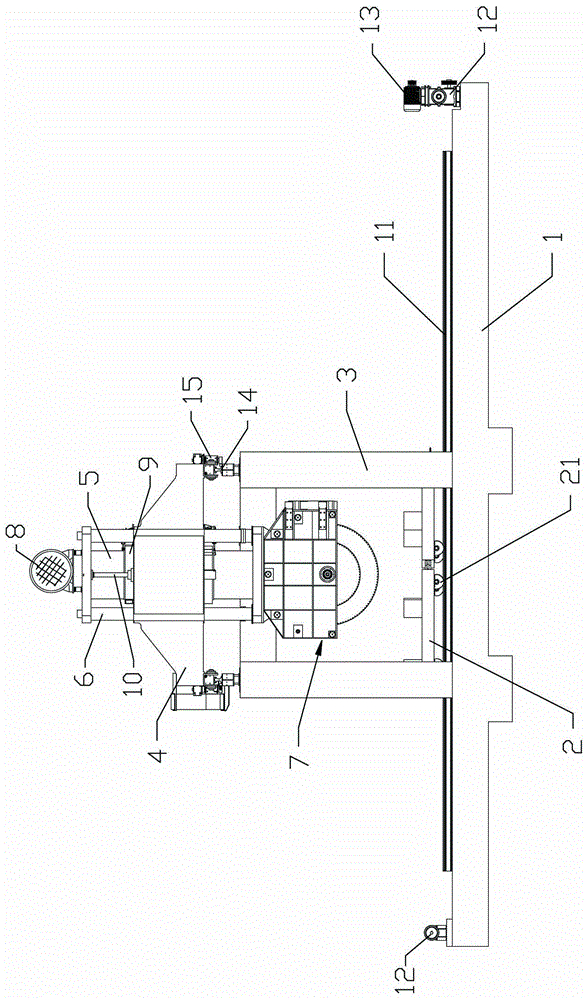

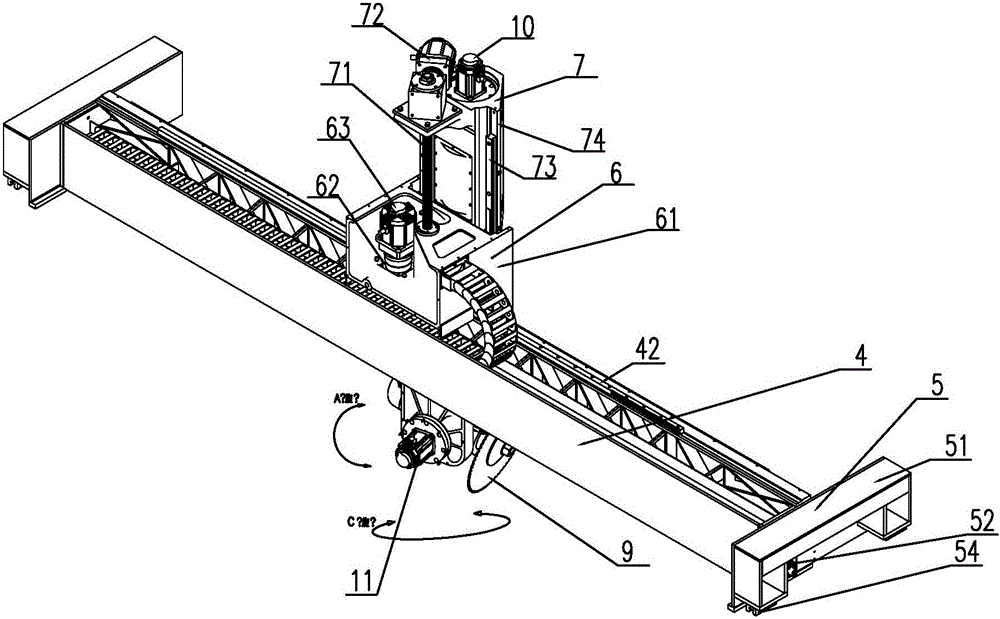

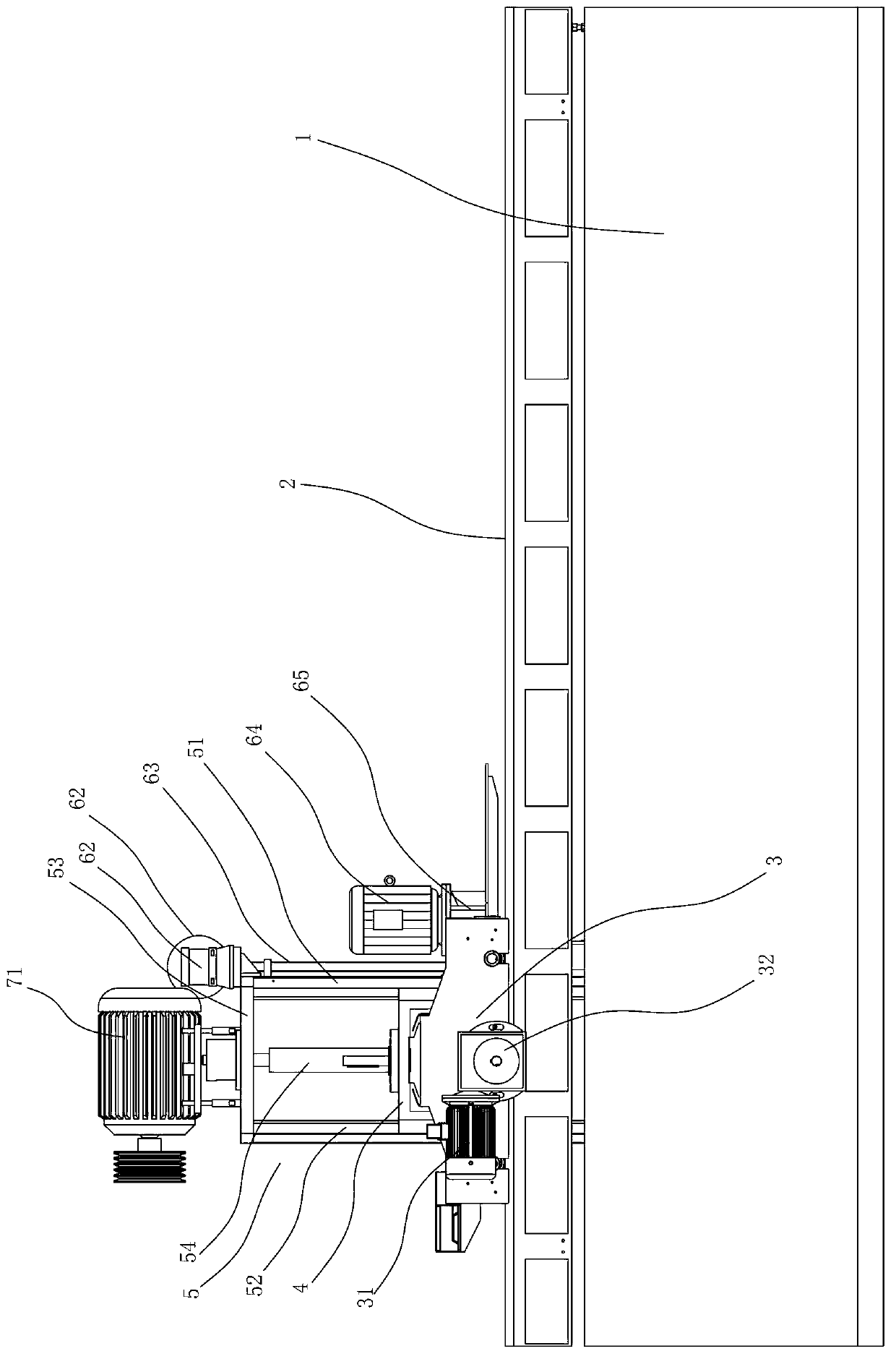

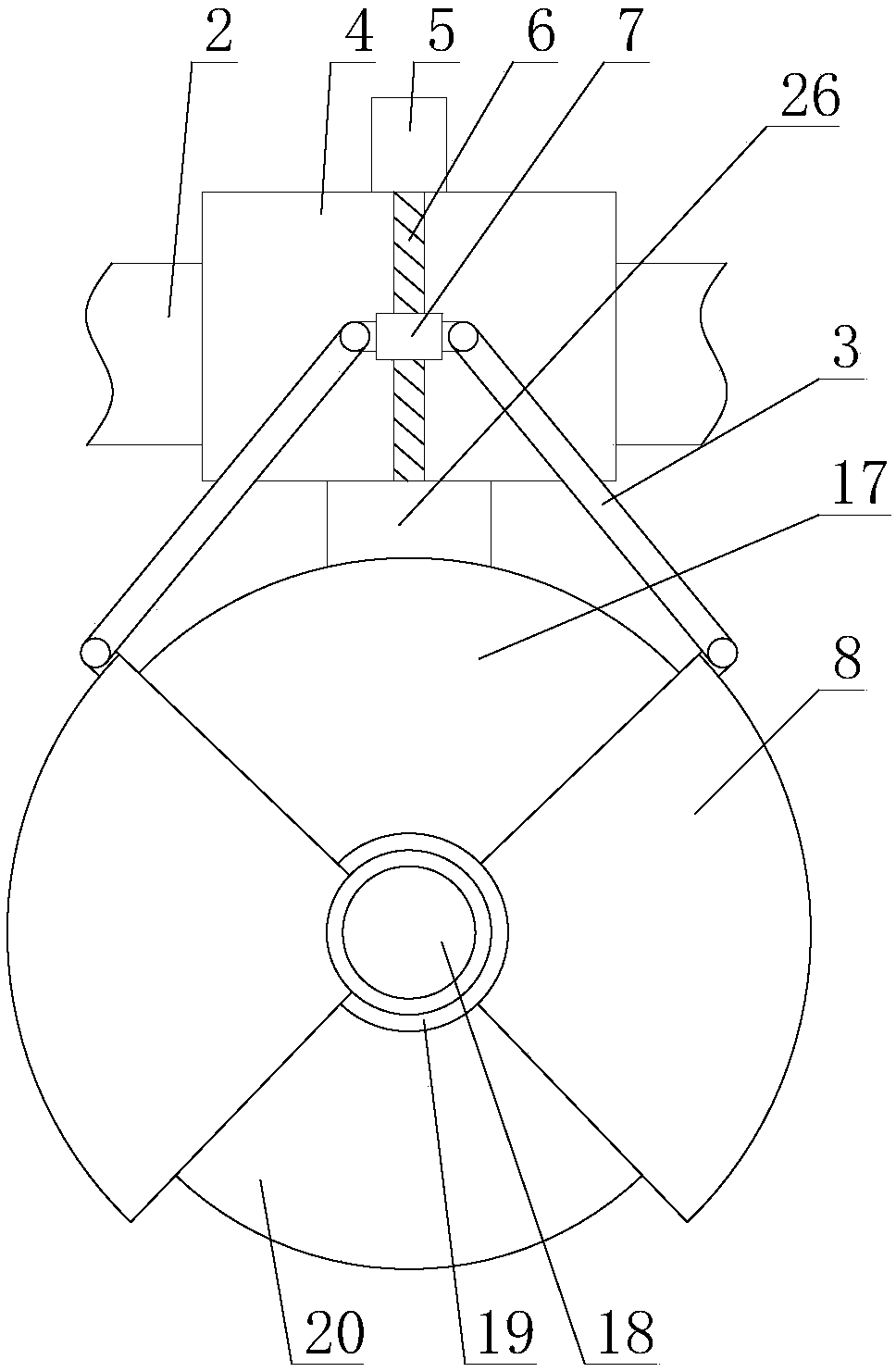

High-maneuverability stone cutting machine

ActiveCN106493862AImprove mobilityHigh feasibilityWorking accessoriesStone-like material working toolsSTONE CUTTERBall screw

The invention relates to a high-maneuverability stone cutting machine which comprises a base, a rack, a displacement mechanism, a travelling mechanism and a cutting mechanism. The displacement mechanism comprises a support rod, a slide block, a travelling motor and a circular gear. The travelling mechanism comprises a limit frame, a drive motor and a ball screw. The cutting mechanism comprises a support plate, a telescopic cylinder and a cutting assembly. The cutting assembly comprises a shell, a cutting motor, a first belt pulley, a second belt pulley, a first transmission shaft, a second transmission shaft, a clutch, a third belt pulley, a fourth belt pulley, a fifth belt pulley, a sixth belt pulley, a lifting motor, a connecting rod, a first saw blade and a second saw blade, wherein the cutting motor, the first belt pulley, the second belt pulley, the first transmission shaft, the second transmission shaft, the clutch, the third belt pulley, the fourth belt pulley, the fifth belt pulley, the sixth belt pulley, the lifting motor, the connecting rod, the first saw blade and the second saw blade are arranged in the shell. According to the high-maneuverability stone cutting machine, the displacement mechanism and the travelling mechanism are used in cooperation, the cutting mechanism can run at any position on the base and can conduct cutting with one saw blade when the clutch is separated and conduct cutting with the two saw blades when the clutch is united.

Owner:南通中煌工具有限公司

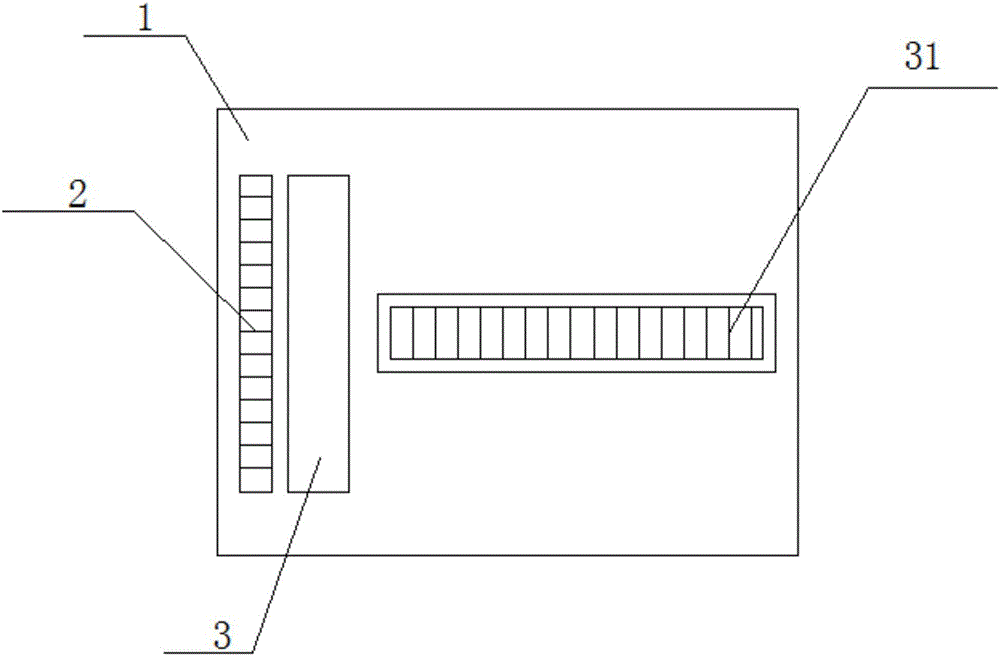

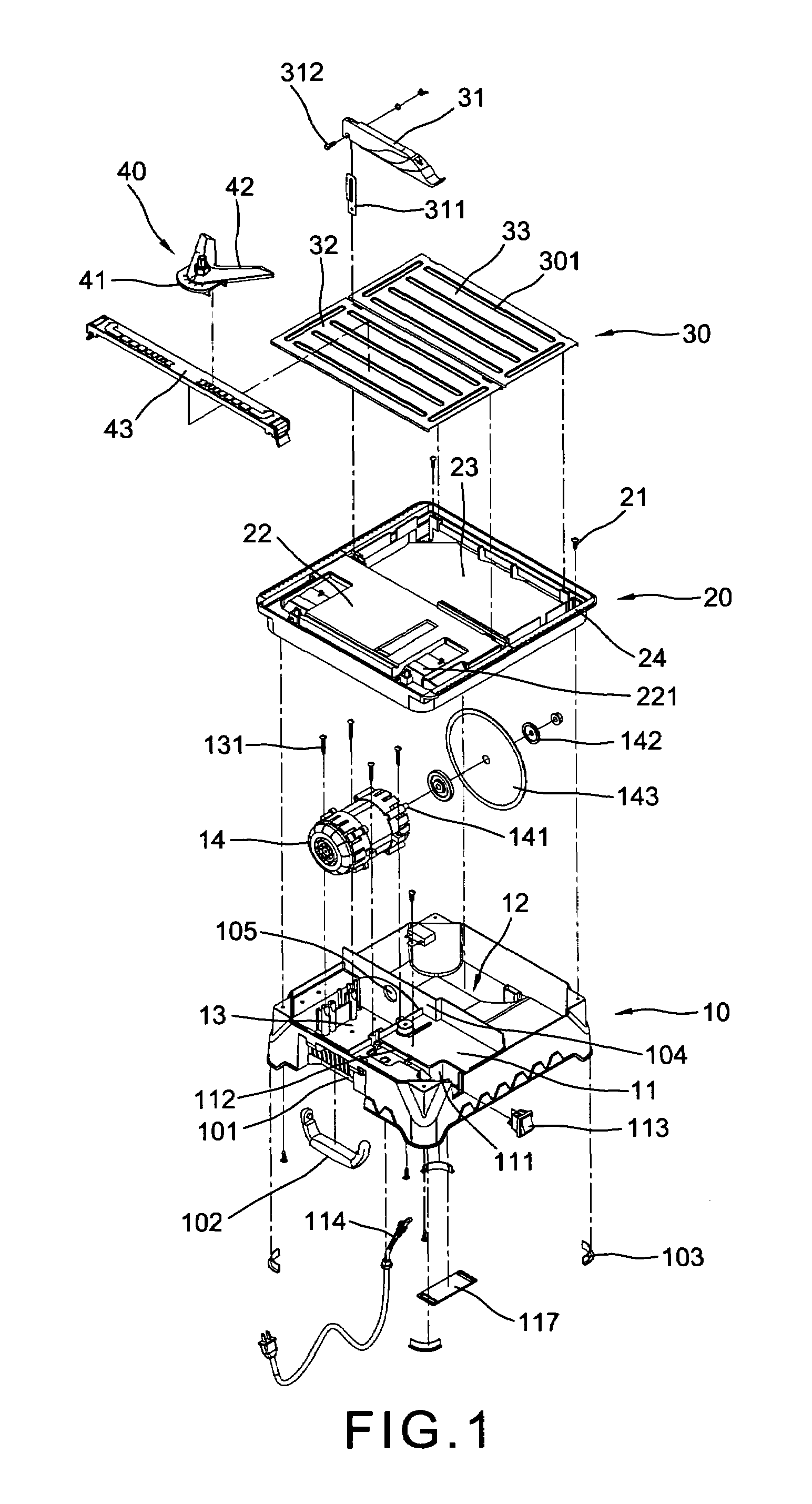

Structural improvement in a portable stone cutter

InactiveUS7028683B1Reduce measurementConvenience to workShearing machinesGang saw millsSTONE CUTTEREngineering

A structural improvement in a portable stone cutter includes a box like rectangular base being separated in the center by a partition into a water sink and motor compartment abutting a plain surface, to which a switch and piece of electric wire are disposed. The motor has an axis inserted into the water sink via a through hole in the partition and connected with a saw blade which is partially submerged in the water. A rectangular lid covering the top of the base includes a plate on the left side having a pair of stepped stopping surfaces spacedly formed on the top and an opening on the right side on the top of the water sink. A pair of first and second grille working plates respectively pivot to the middle and the right edge of the lid so that the working plates are capable of lifting and forming a certain angle relative to the plane surface of the lid. A dividing device together with a leant upon ruler slidably secured to the front and rear edge of the lid and a blade guide pivoted to a support plate on the top of the saw blade.

Owner:CHEN YUEHTING

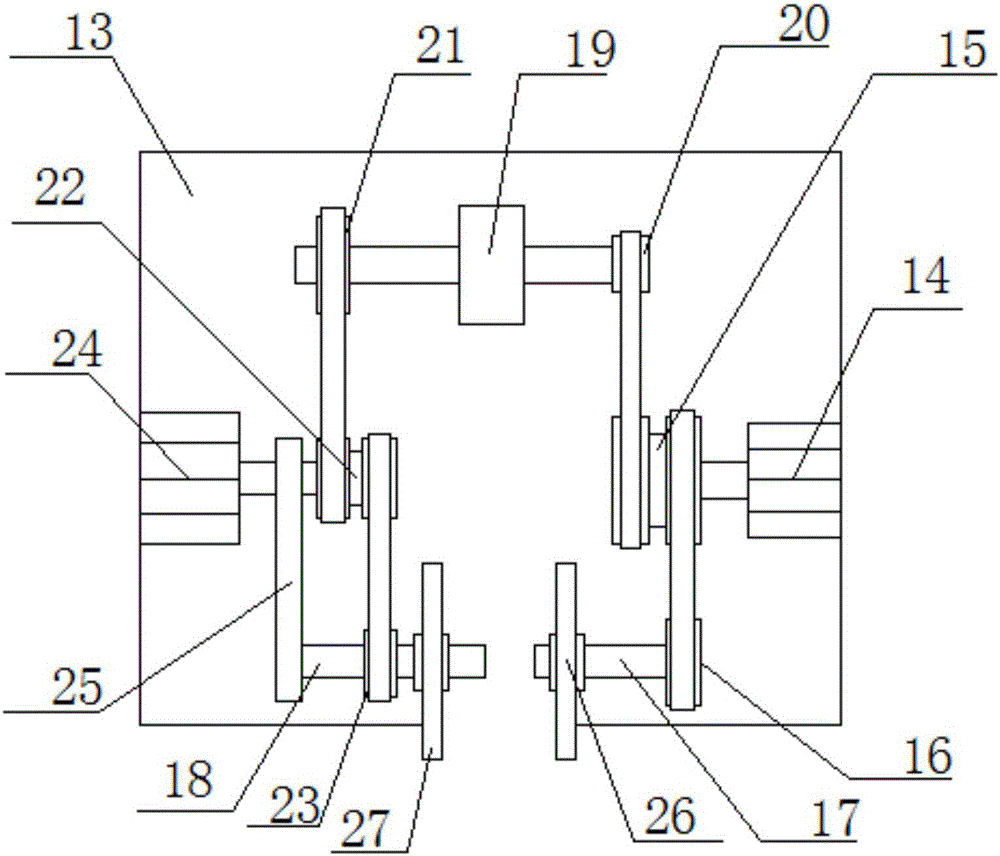

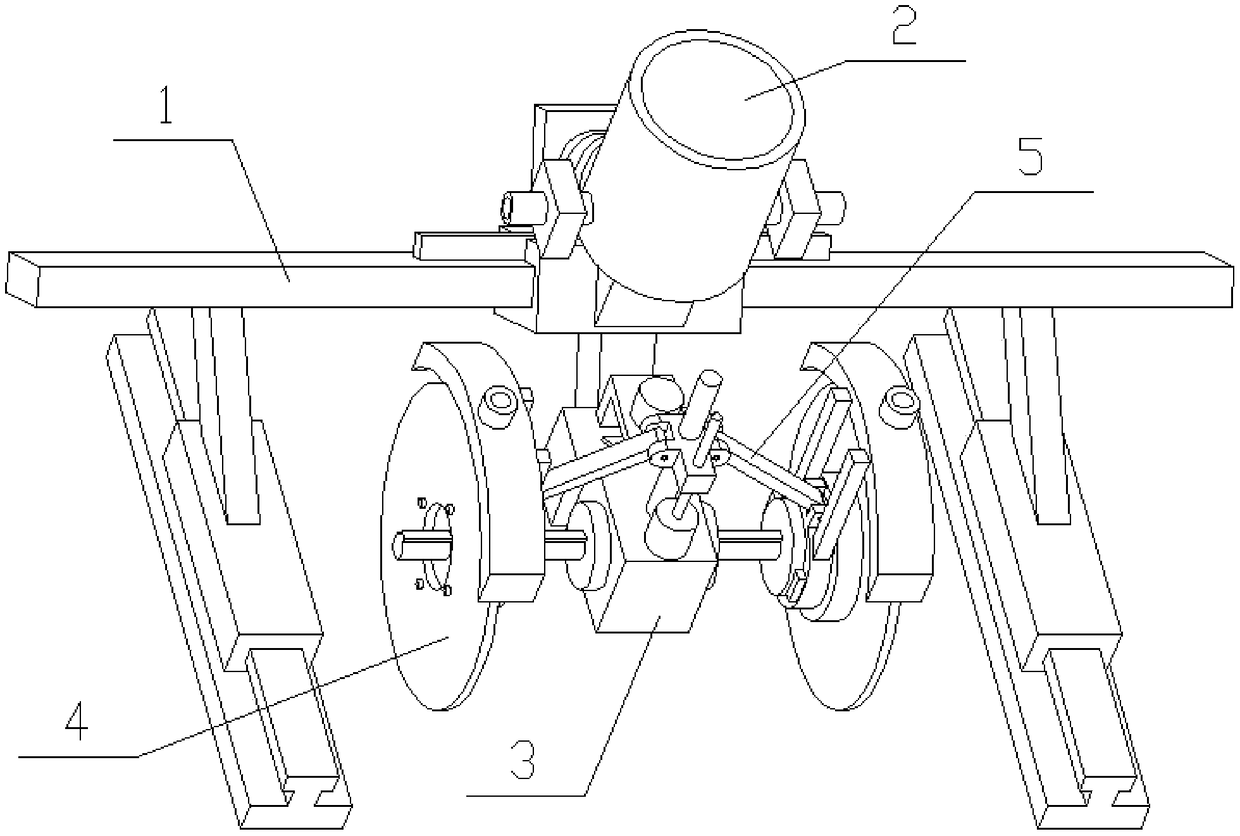

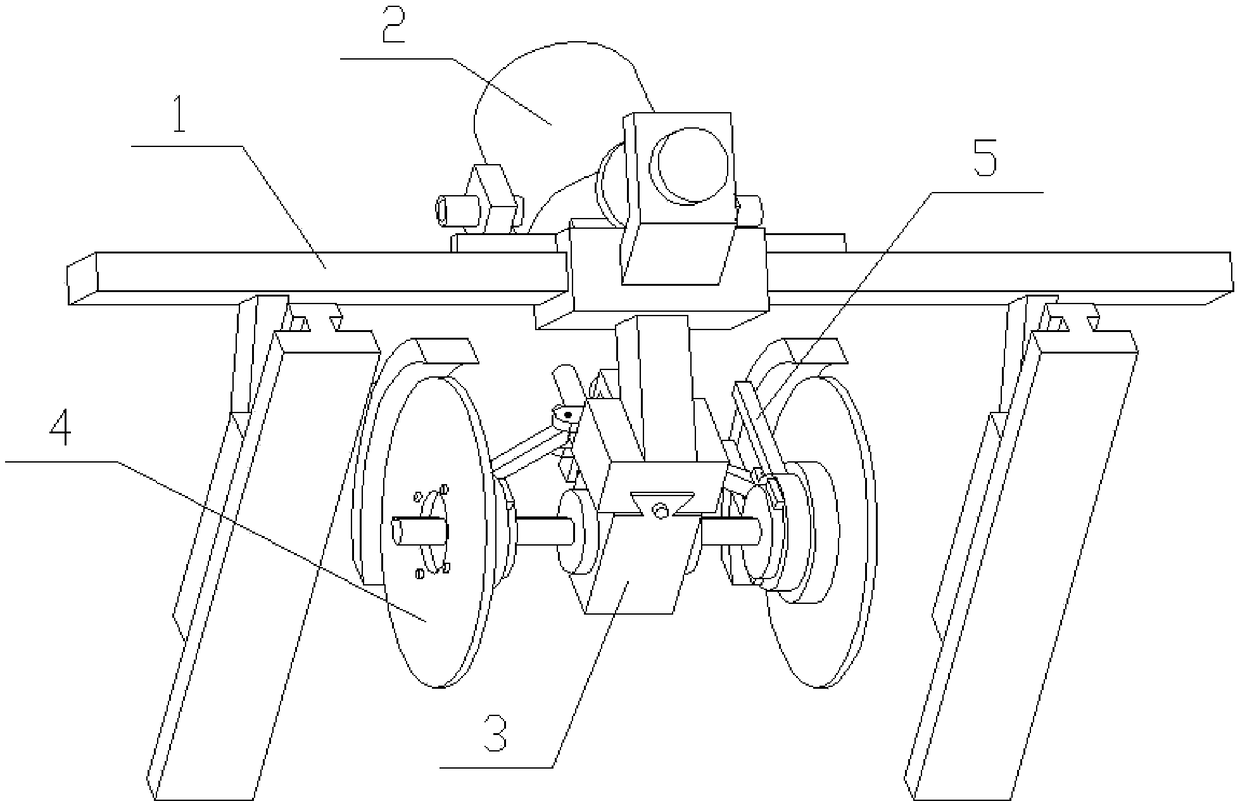

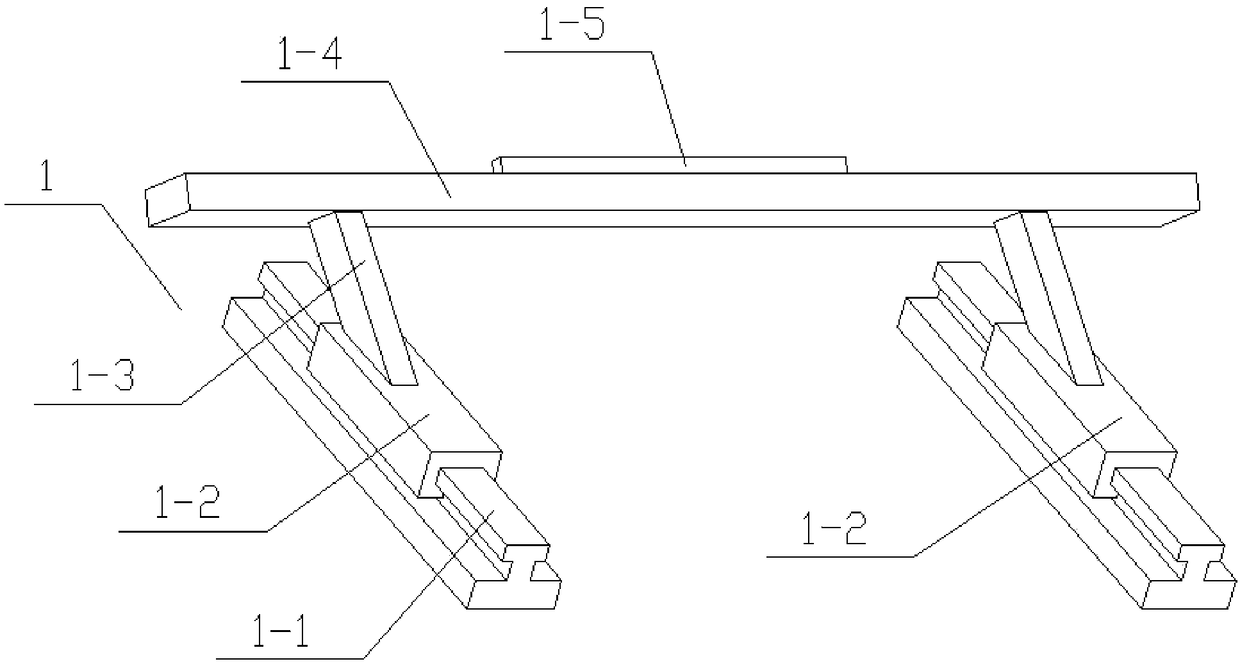

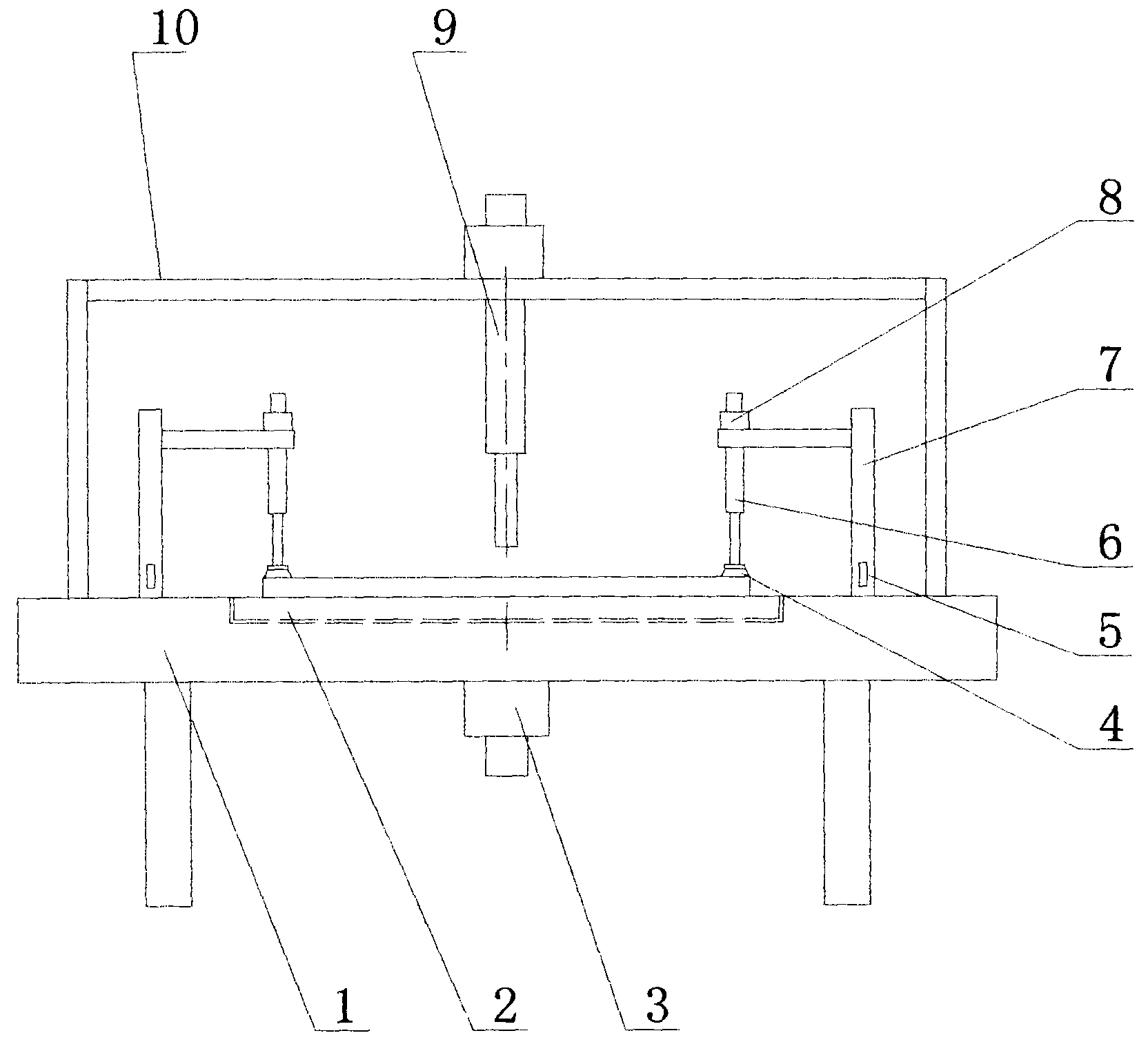

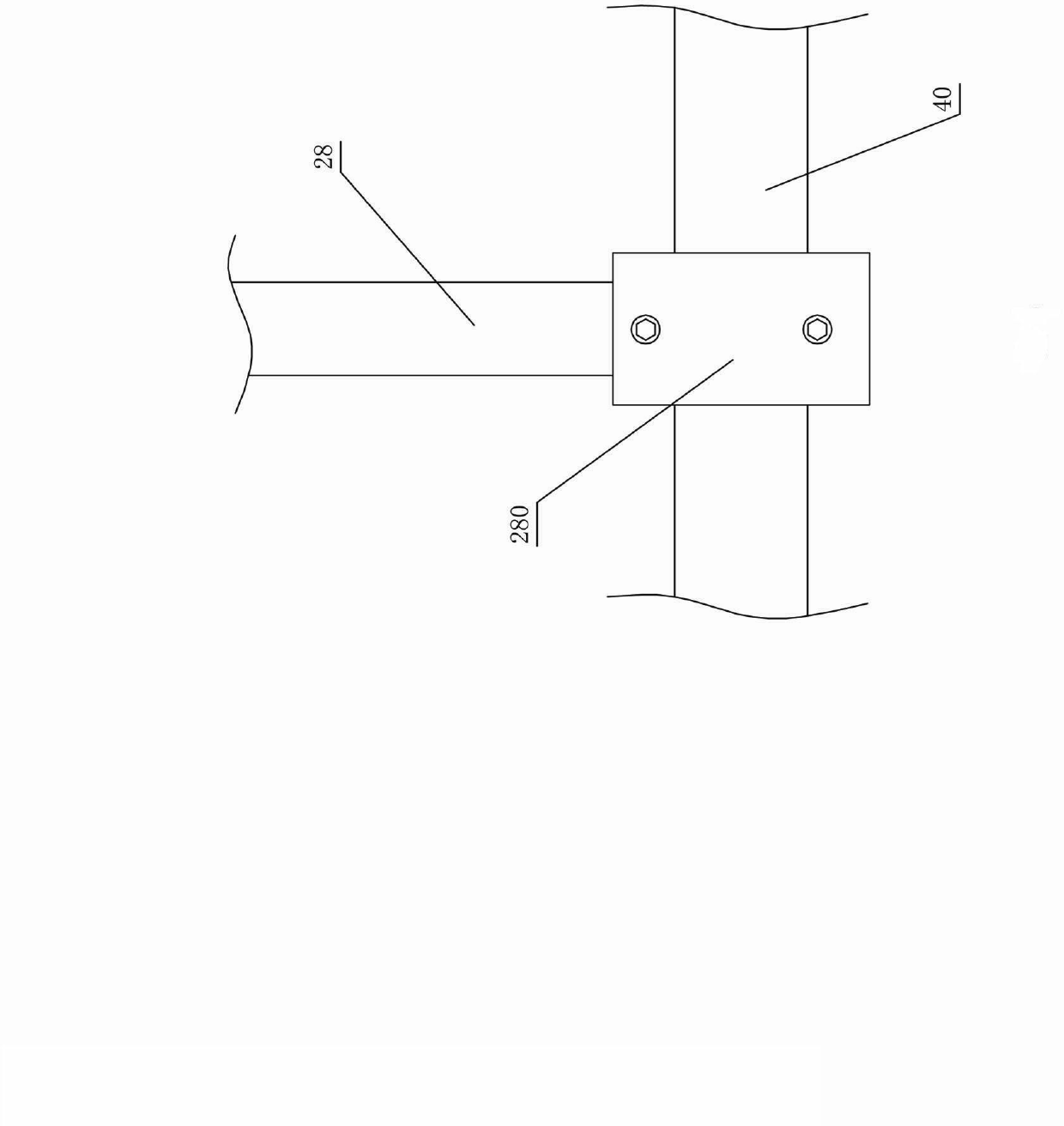

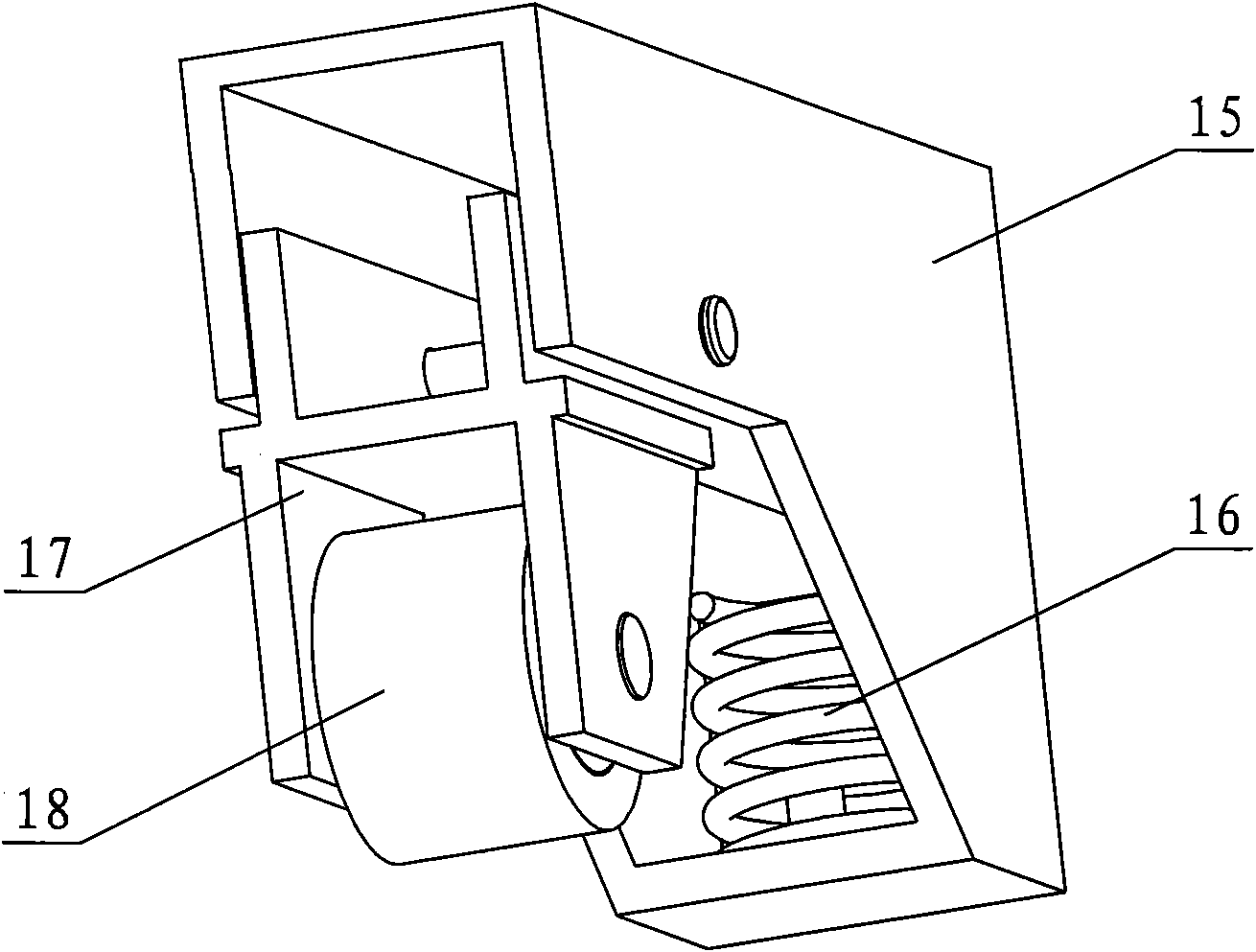

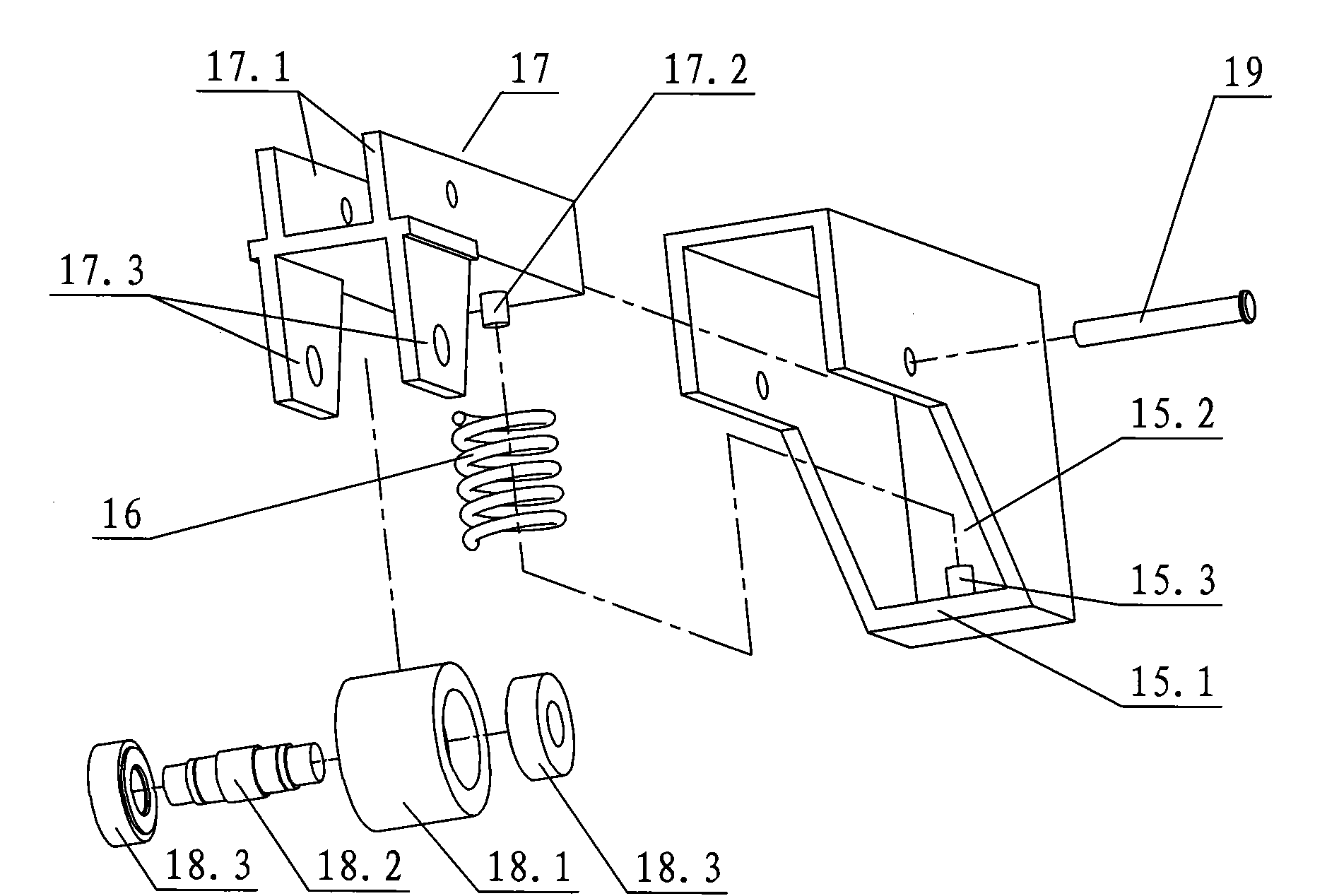

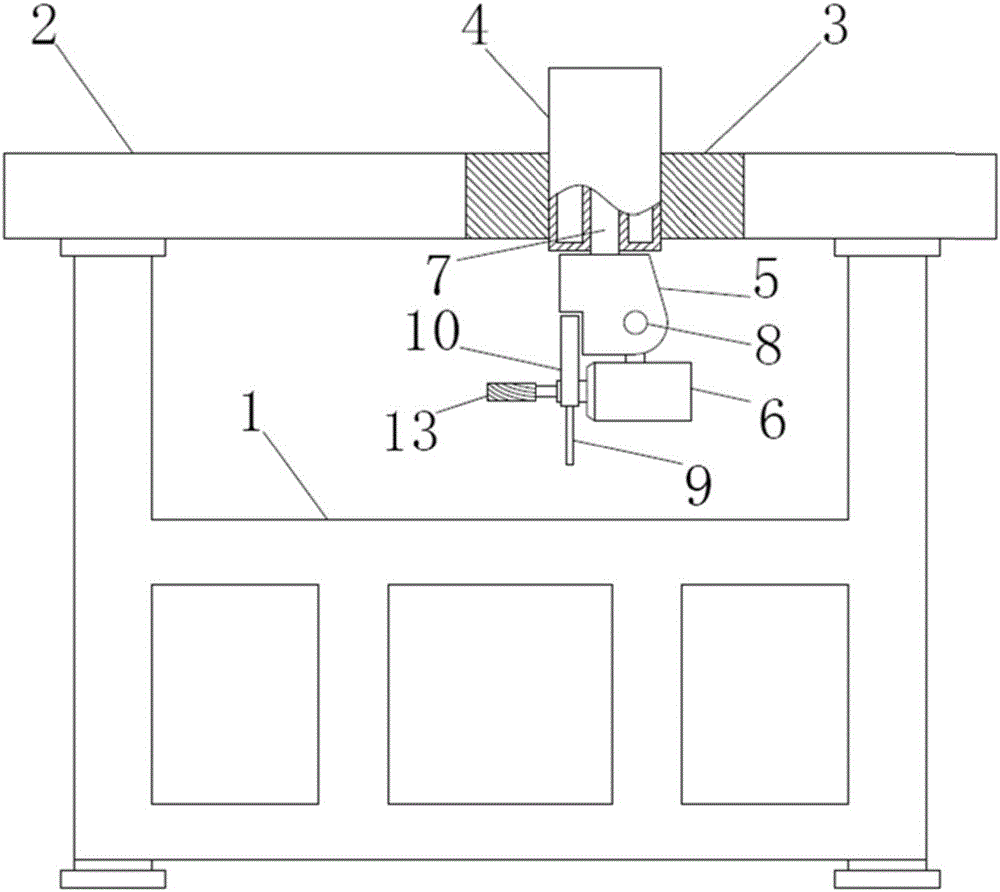

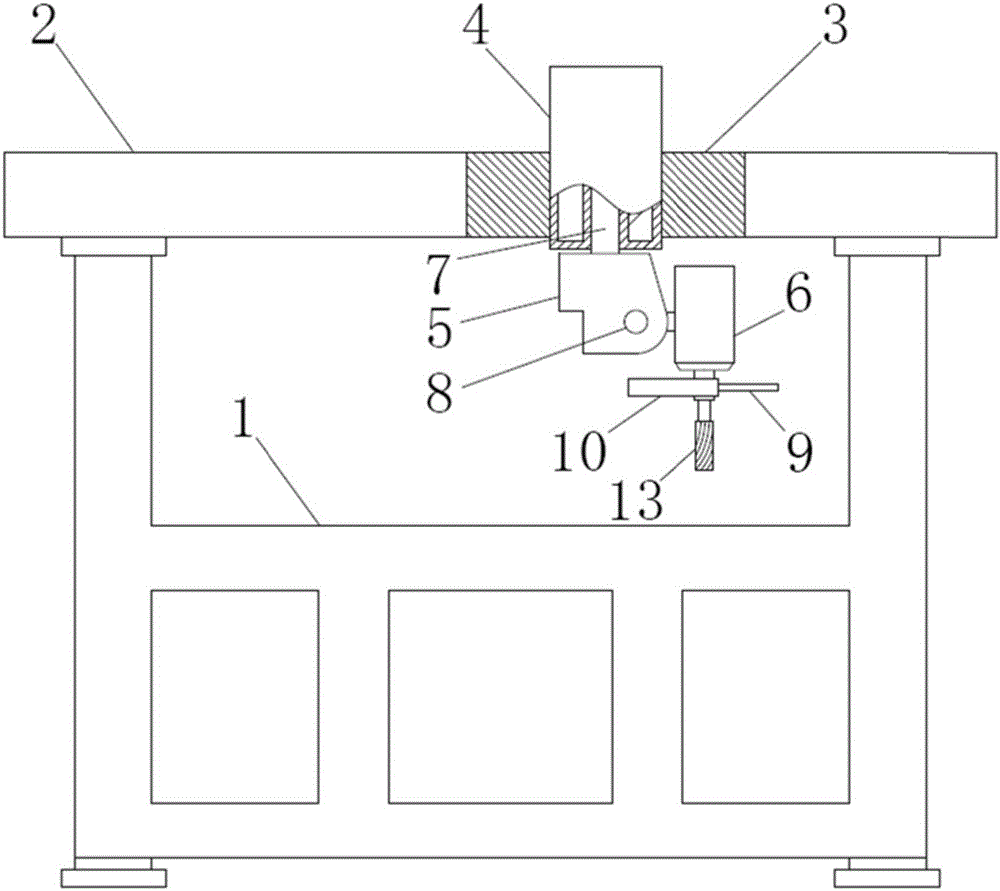

Gantry type stone cutter

ActiveCN105835233AWalking smoothlyAvoid shakingWorking accessoriesStone-like material working toolsSTONE CUTTEREngineering

The invention relates to a gantry type stone cutter. The gantry type stone cutter comprises a base, a trolley, two parallel support seats, a gantry frame, a lifting stand column, a combined sawing machine and a cutting motor, wherein a locking device sleeves the lifting stand column; the locking device comprises a locking base, an external-contacting brake and an internal-contacting brake; the external-contacting brake is assembled in the locking base; the internal-contacting brake is assembled between the inner side wall of the external-contacting brake and the outer side wall of the lifting stand column; the internal-contacting brake comprises a left internal-contacting brake and a right internal-contacting brake; the left internal-contacting brake and the right internal-contacting brake are combined to surround the outer side wall of the lifting stand column; an eccentric sleeve is arranged between the left internal-contacting brake and the right internal-contacting brake; the left internal-contacting brake and the right internal-contacting brake are articulated with the eccentric sleeve through a connection rod respectively; the eccentric sleeve rotates to enable the left and right internal-contacting brakes to be matched with the external-contacting brake so as to tightly hold and loosen the lifting stand column, so that the stability of the lifting stand column is improved; the swing of the lifting stand column in the high-load and high-vibration environment can be avoided, so that the cutting accuracy of the combined sawing machine is improved, and the service life of the combined sawing machine is prolonged.

Owner:QUANZHOU HAIENDE ELECTROMECHANICAL TECH DEV

Stone cutting machine

ActiveCN109291255AEasy to cutWorking accessoriesStone-like material working toolsSTONE CUTTERCircular saw

The invention relates to the field of stone processing, in particular to a stone cutting machine. The stone cutting machine is characterized in that two notches can be formed in stone at one time through cutting, and the distance between two circular saws can be adjusted; the height of the two circular saws can also be adjusted, so that cutting of the stone with different thicknesses is facilitated; and the left and right positions of the two circular saws can also be adjusted so that the positions of the two circular saws can be adjusted multiple times according to needs during use by a user,and the situations that different positions of the stone are cut by moving the thick and heavy stone are avoided. According to the stone cutting machine, a sliding seat is slidably connected to the upper end of a sliding frame, the sliding seat is in meshed transmission with the sliding frame, a middle seat is fixedly connected to the front end of the sliding seat, a cutting piece is fixedly connected to the middle seat, the middle end of a distance adjusting mechanism is connected with the middle seat in a sliding mode, the middle end of the distance adjusting mechanism also cooperates withthe middle seat through threads, and the left end and the right end of the distance adjusting mechanism are a rotationally connected with the left end and the right end of the cutting piece respectively.

Owner:邵东诺博建材有限公司

Stone cutting machine with fixing and limiting device

InactiveCN103753711AGuaranteed not to moveSimple structureWorking accessoriesStone-like material working toolsRotary stageSTONE CUTTER

The invention relates to the field of stone cutting equipment, in particular to a stone cutting machine with a fixing and limiting device. The stone cutting machine comprises an operation table provided with a lower frame, a sawing device is arranged on the lower frame, an inverted L-shaped support is arranged in the middle of each of the left side and the right side in the lower frame on the upper surface of the operation table, a telescopic cylinder is disposed at the outer end of a horizontal cross rod of each inverted L-shaped support, a servo motor is connected to the upper end of each telescopic cylinder, and a sucker is connected to a telescopic cylinder end at the lower end of each telescopic cylinder. A movable rotation table is embedded in the middle of the surface of the operation table 1, and a bottom motor which drives the movable rotation table to rotate is disposed in the middle of the bottom face of the operation table. The stone cutting machine with the fixing and limiting device is simple in structure and convenient to operate, a stone block can be fixed by the suckers on two sides of the operation table and is guaranteed against moving, and consequently operating efficiency and product yield are improved.

Owner:刘彪

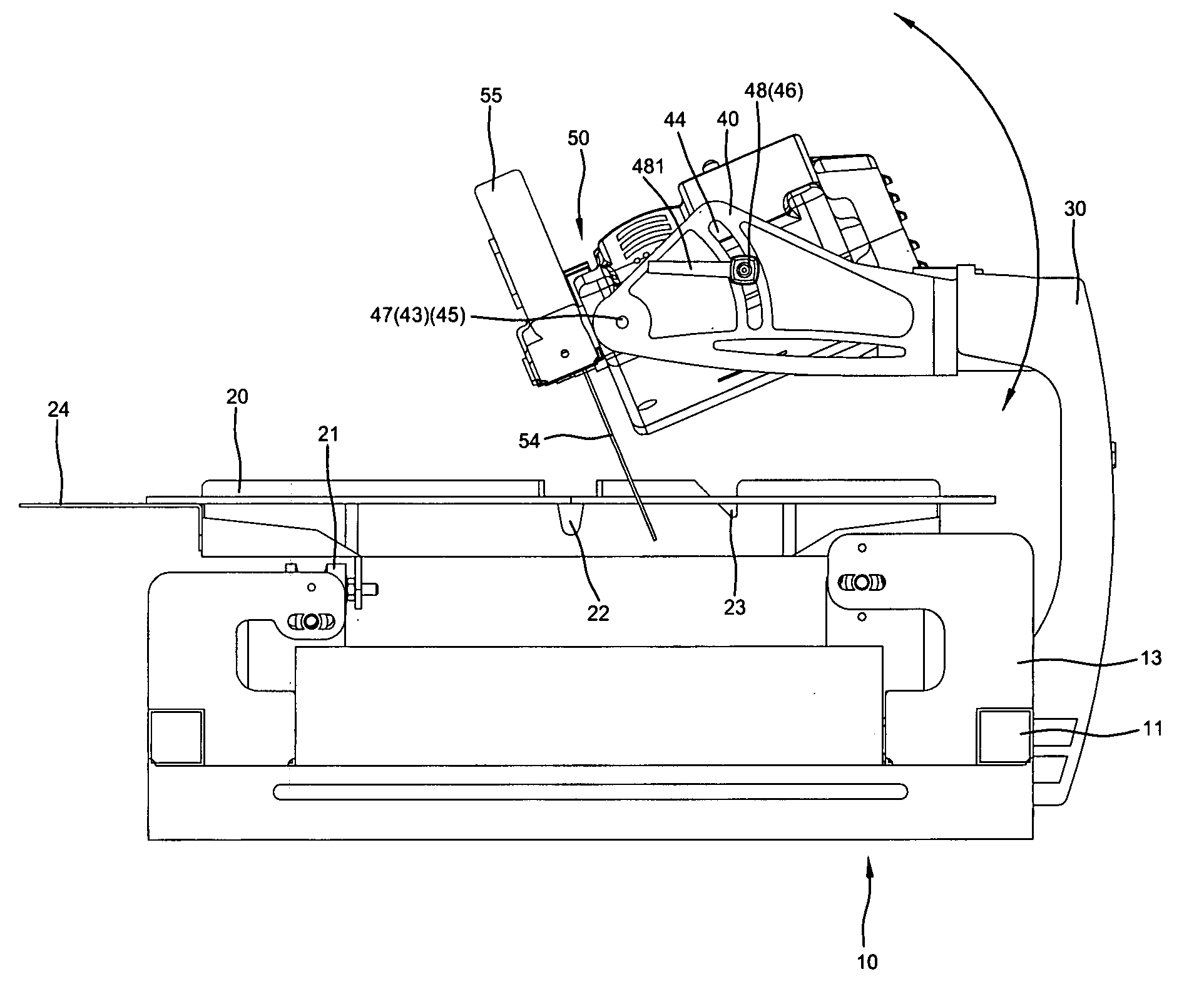

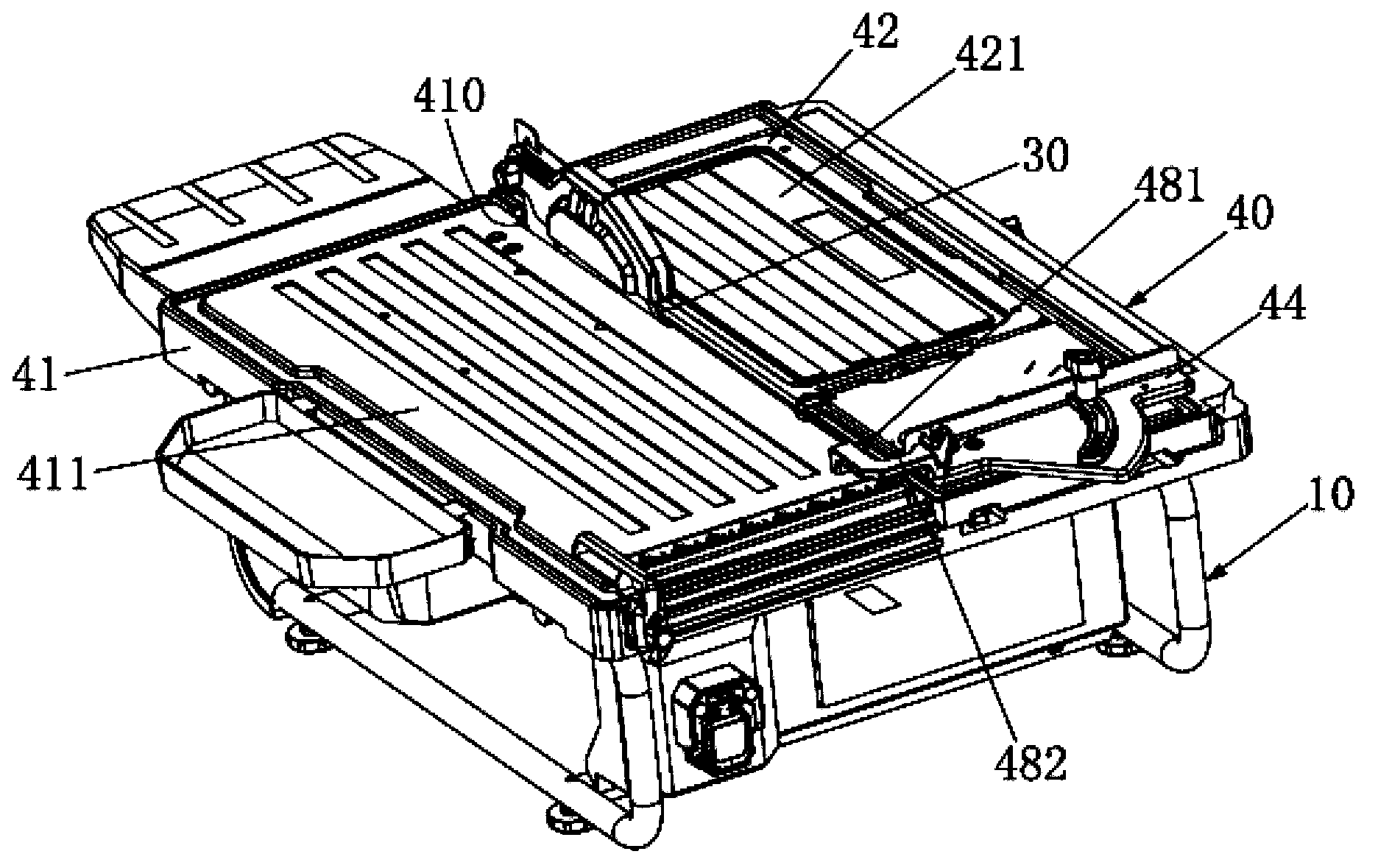

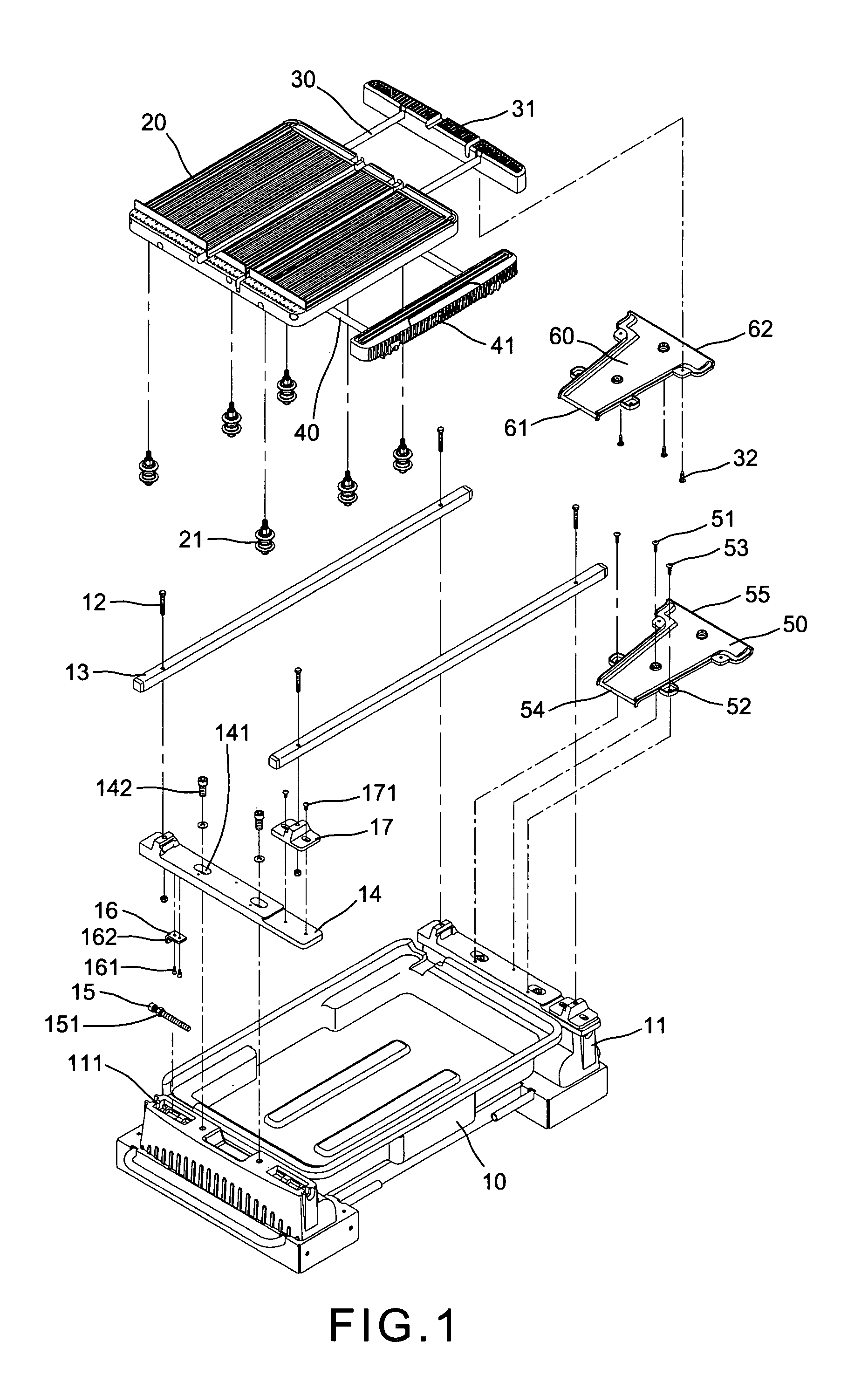

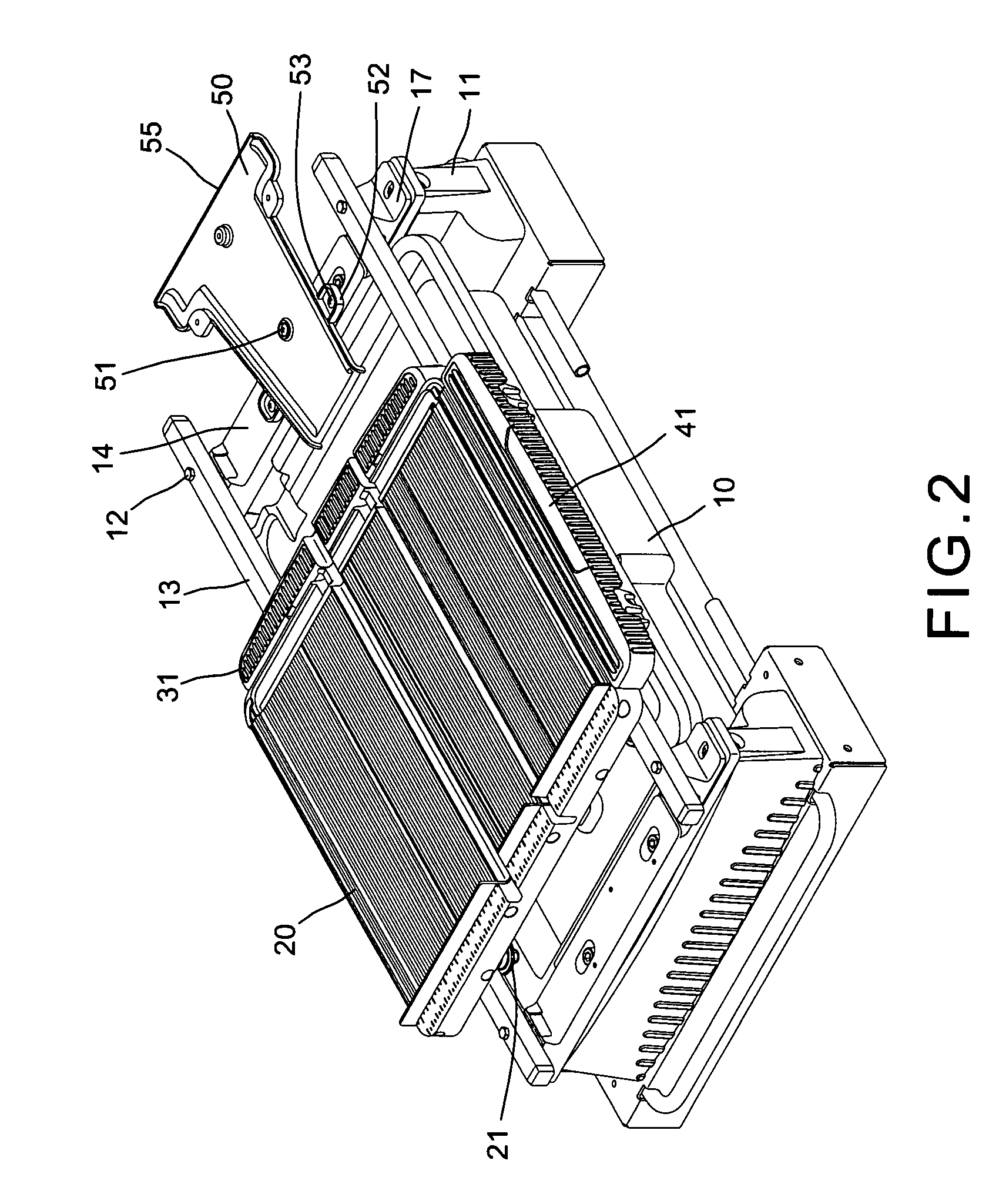

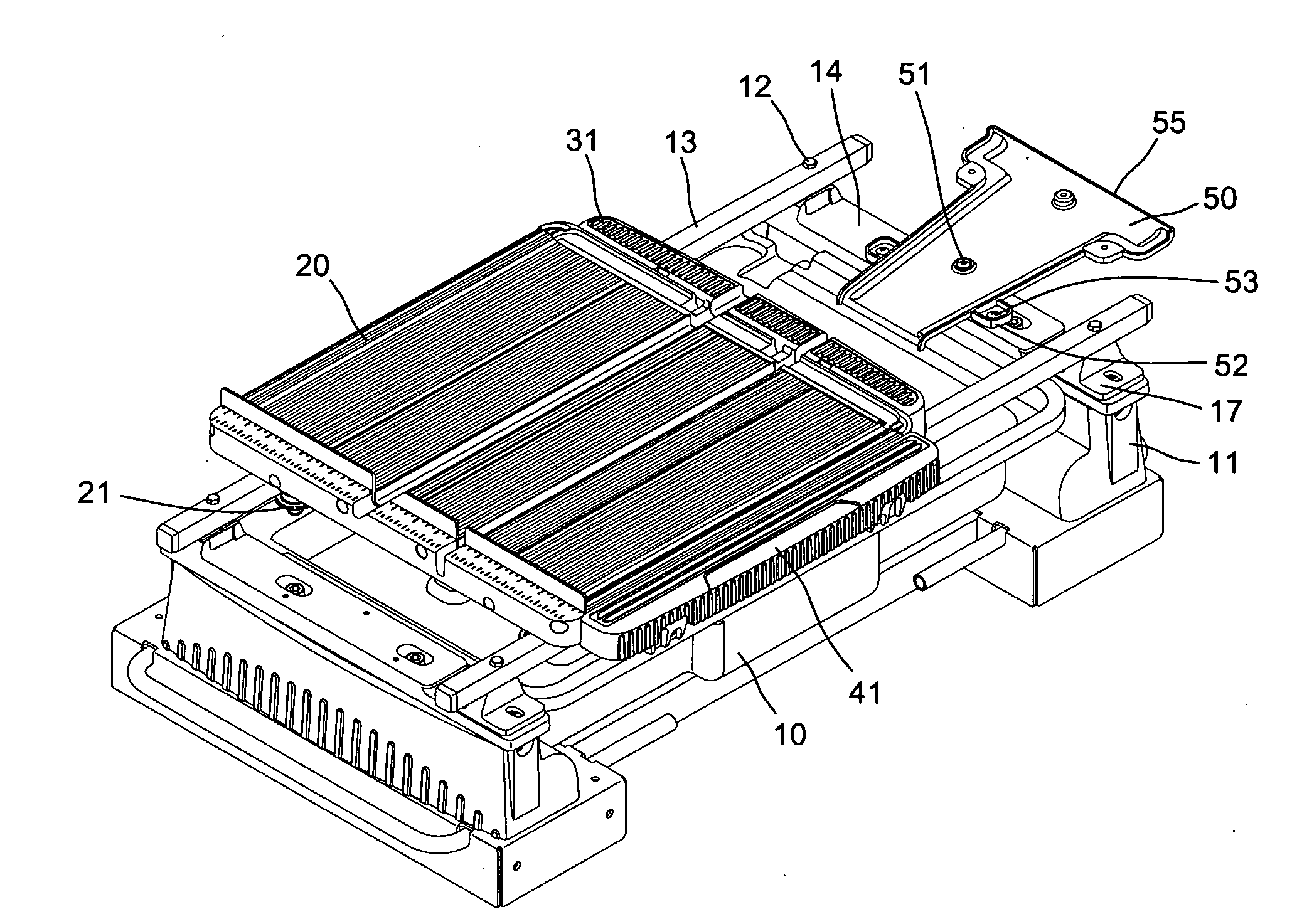

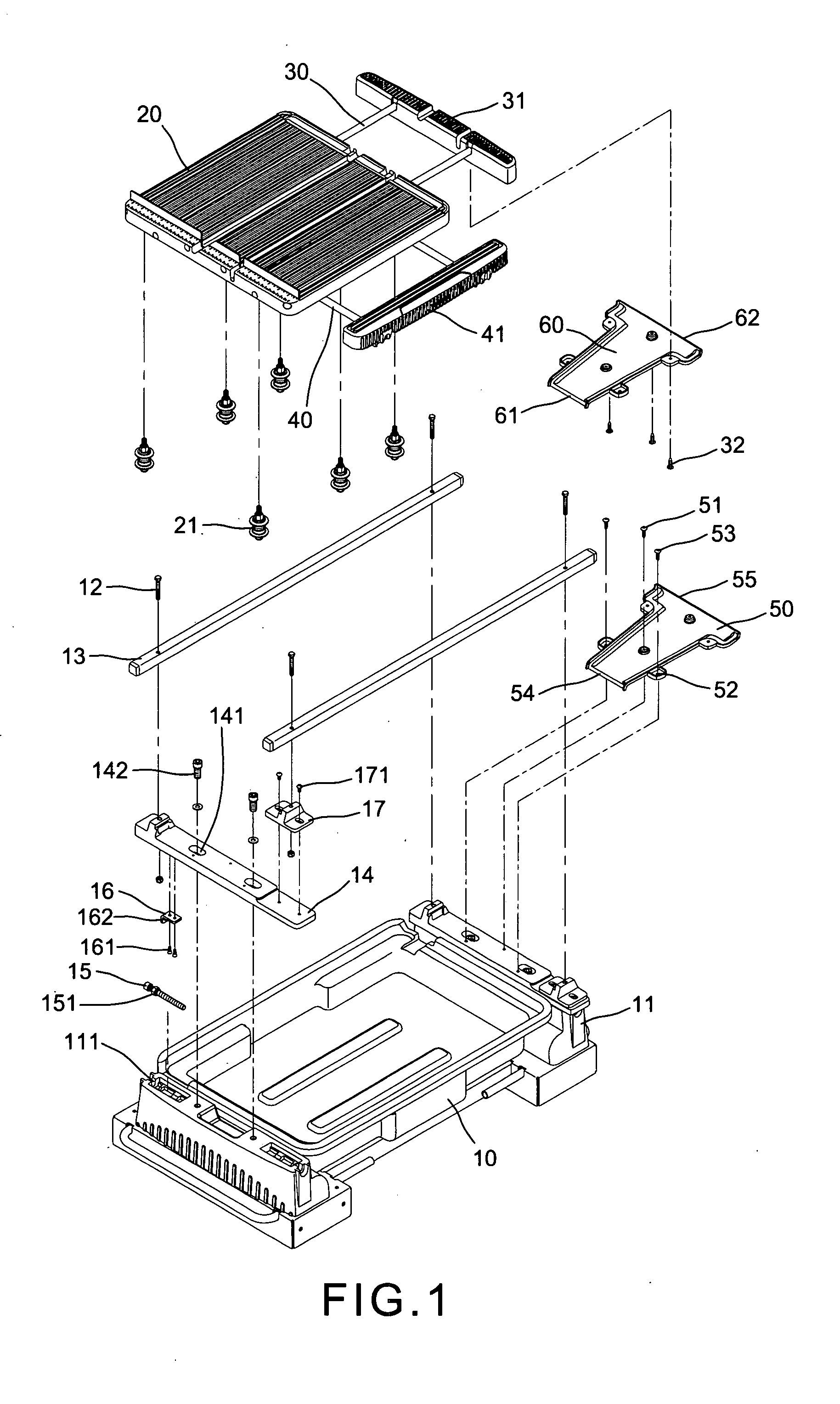

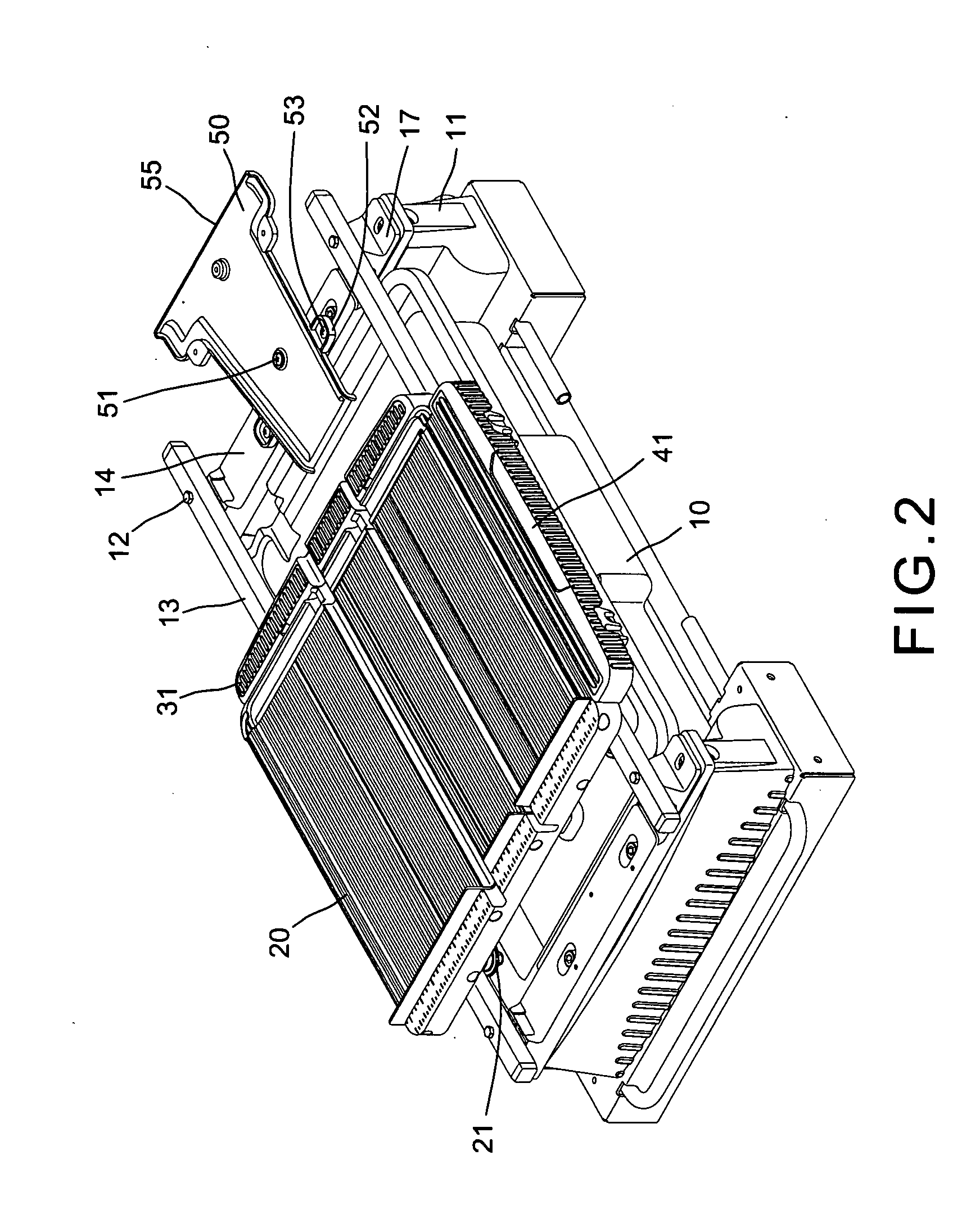

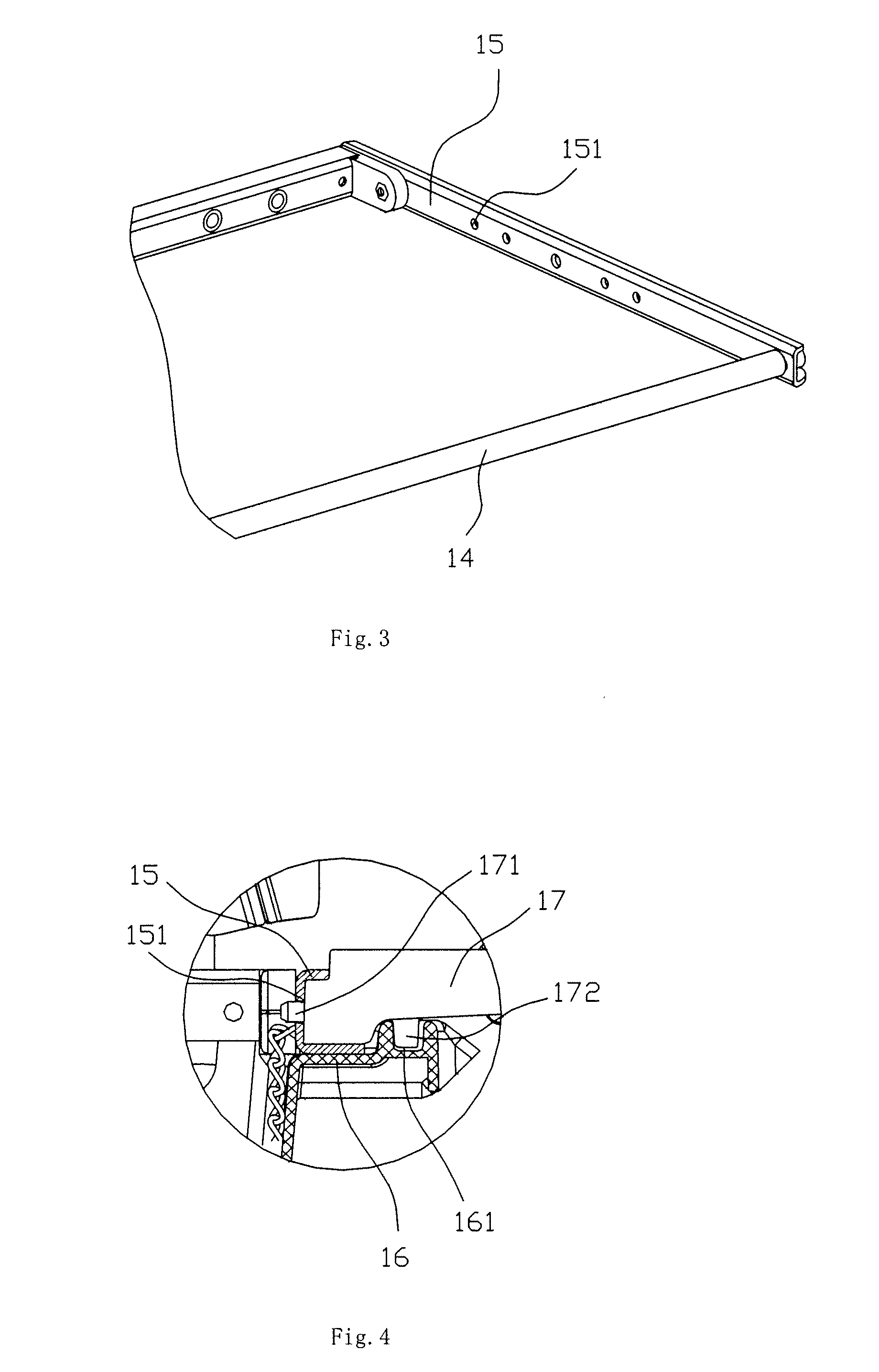

Platform minute adjustment, expansion and water collection devices

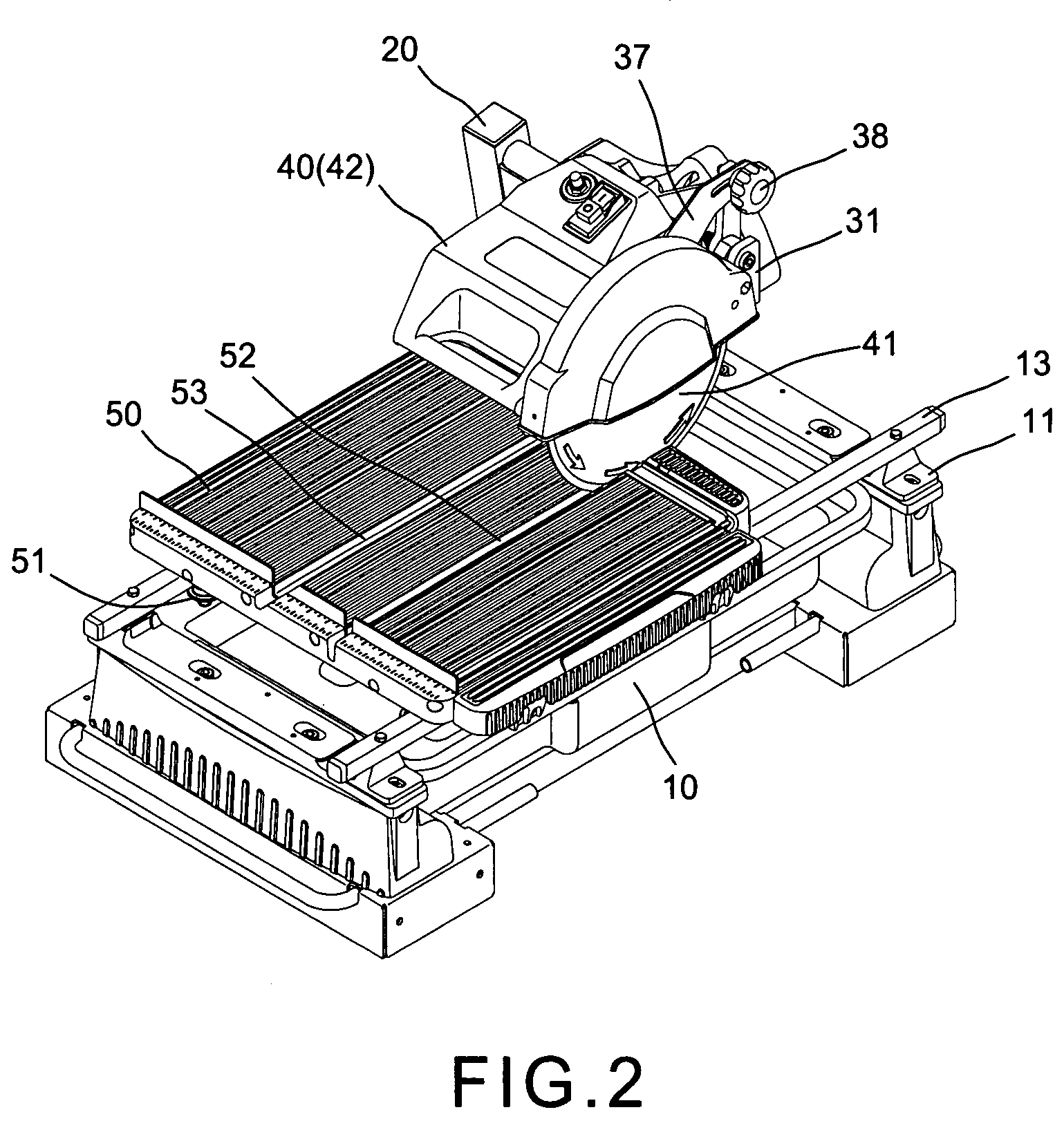

InactiveUS7406962B1Avoid distractionReduce water foamWorking accessoriesStone-like material working toolsSTONE CUTTERWater collection

A platform minute adjustment, expansion and collection device for a stone cutter includes a water tank supported by a pair of racks, a pair of guide rods spacedly bridged on the racks, a first water collection plate and a second water collection plate, both of which are slantly disposed to a front rack, a platform having a pair of rotors on the lower side thereof and slidably engaged on the inner sides of the guide rod. The platform has a pair of expansion plates for enlarging its size and for cutting a large-sized working piece, and two minute adjusting devices mounted on the tops of the racks for displacing the platform slightly, such that the sawdust may be stopped scattering all over the working place.

Owner:CHEN YUEHTING

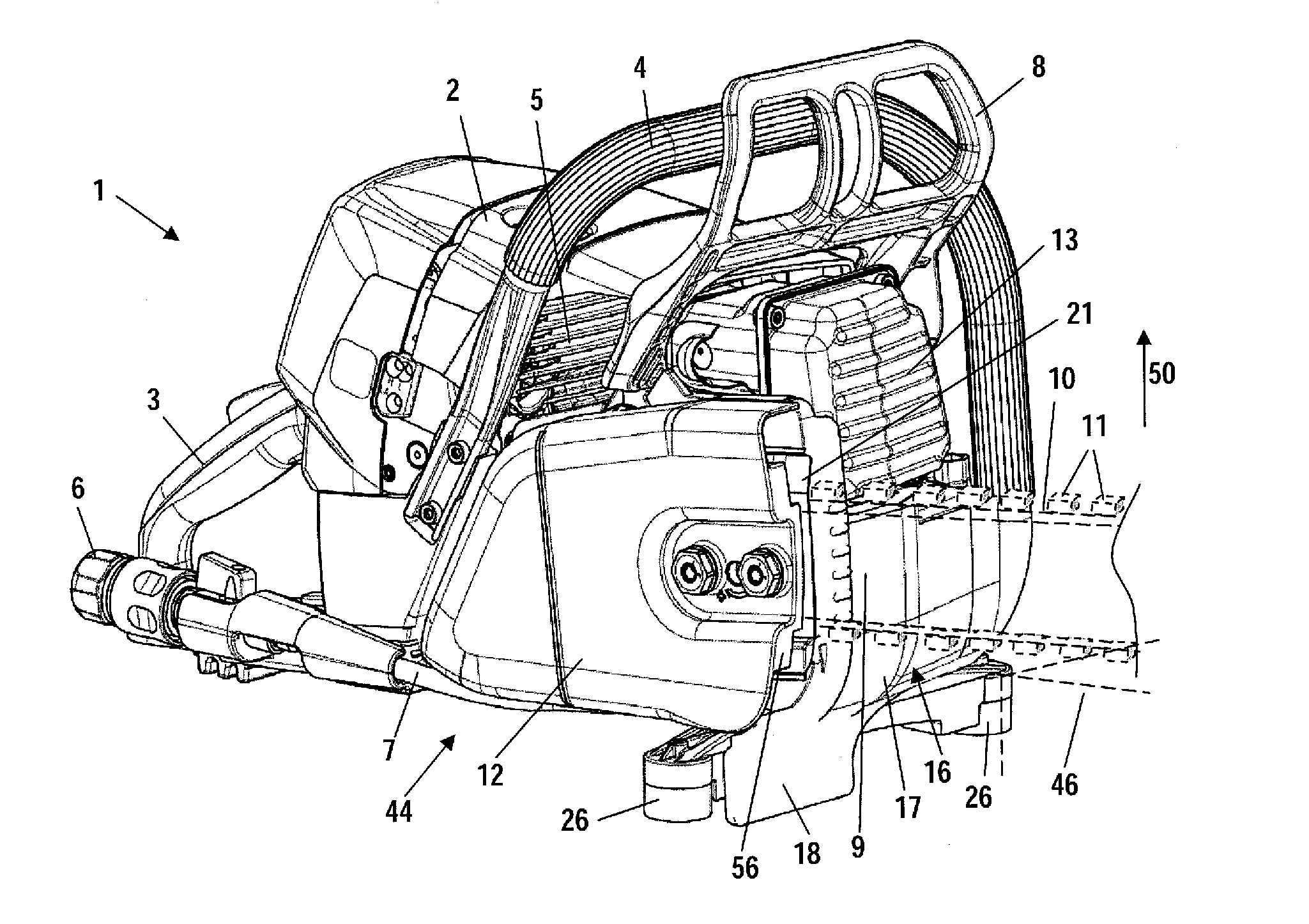

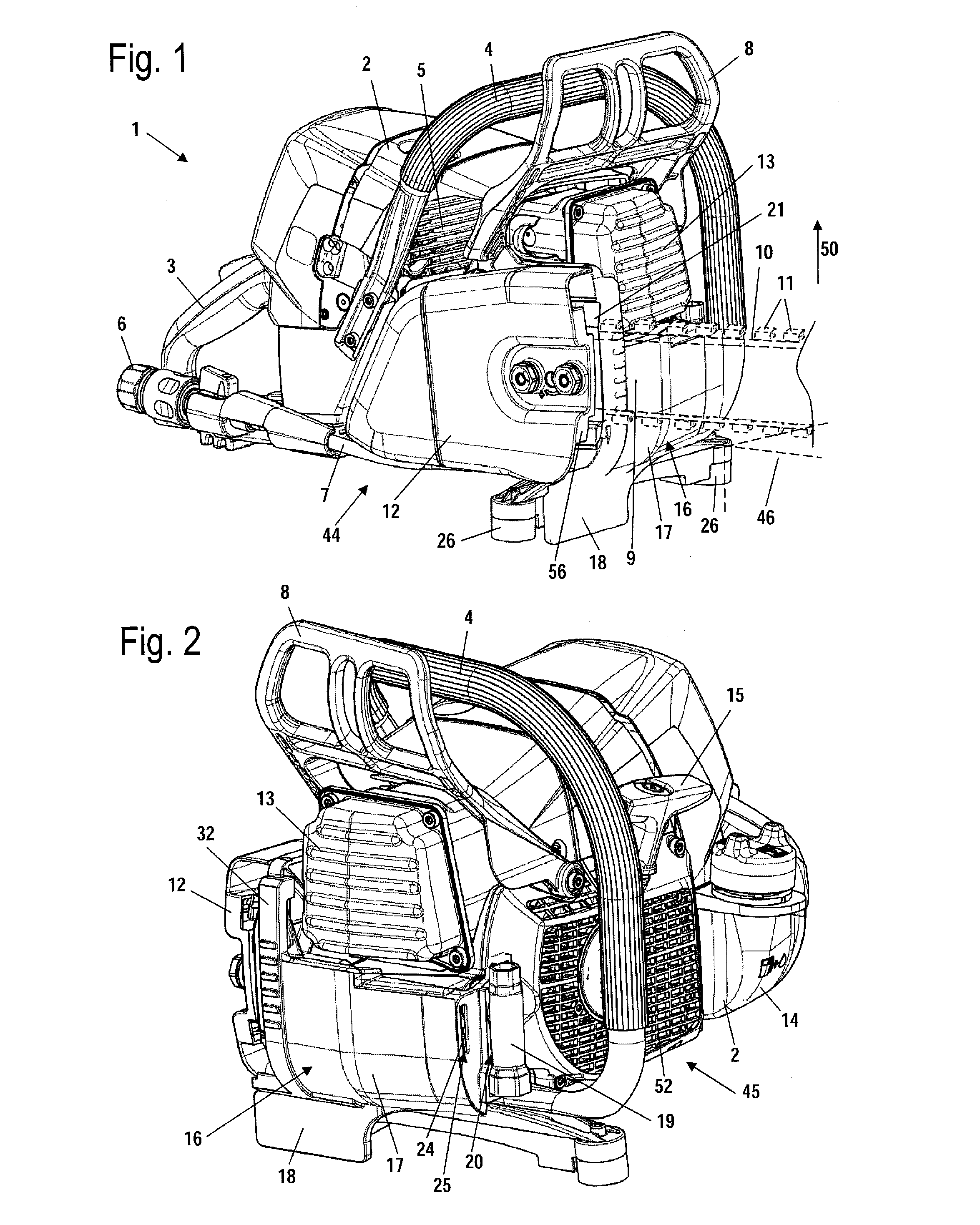

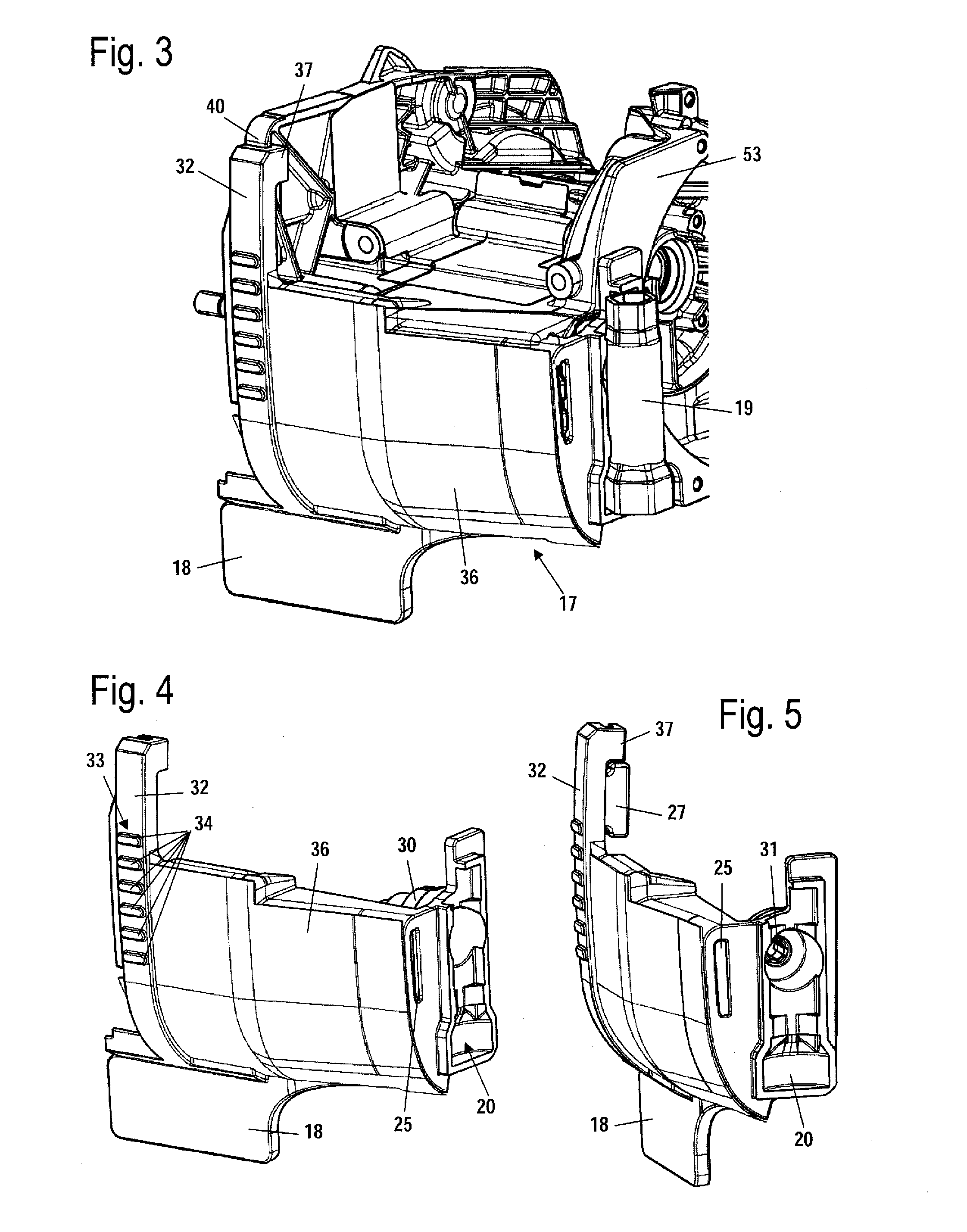

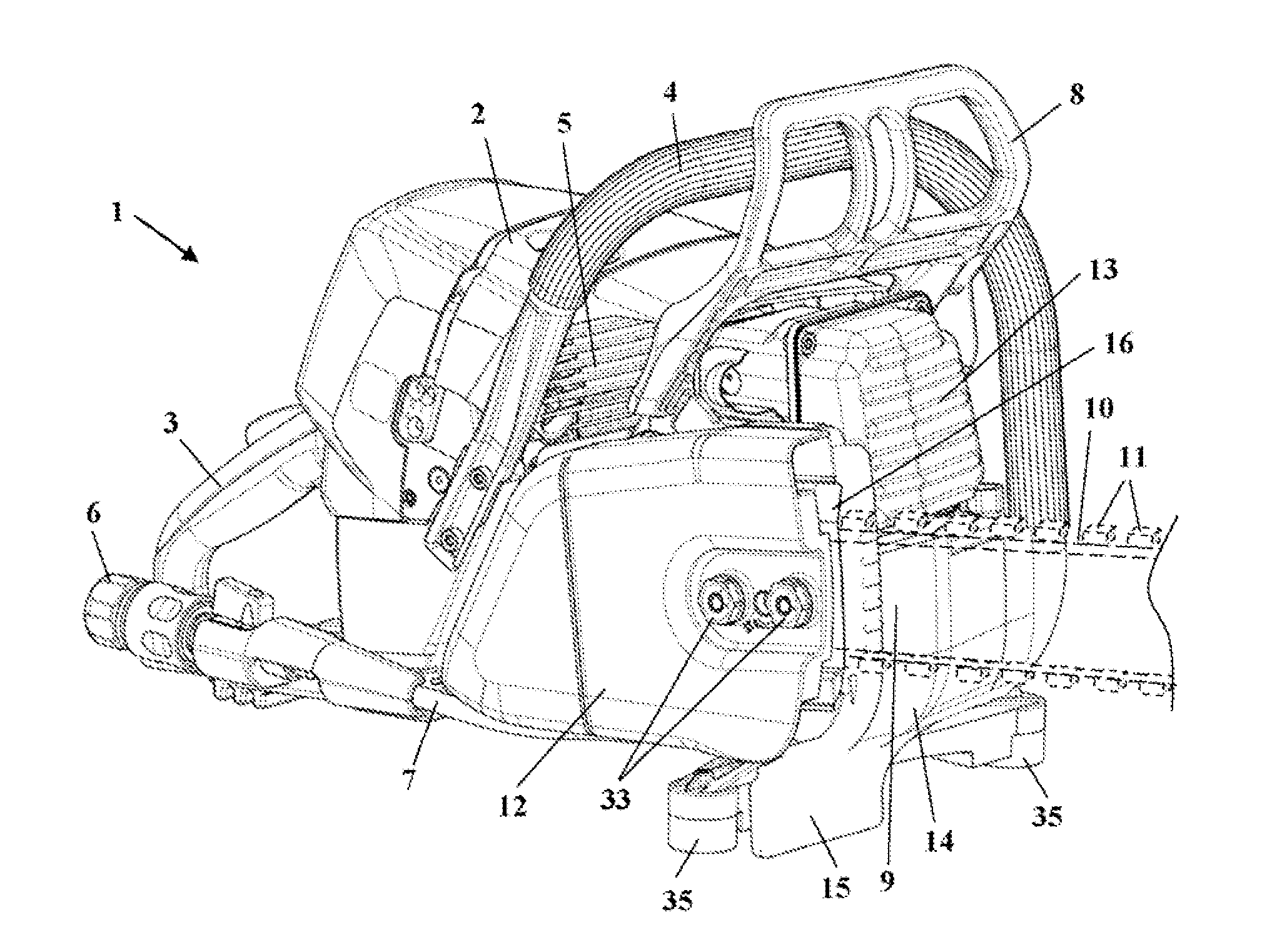

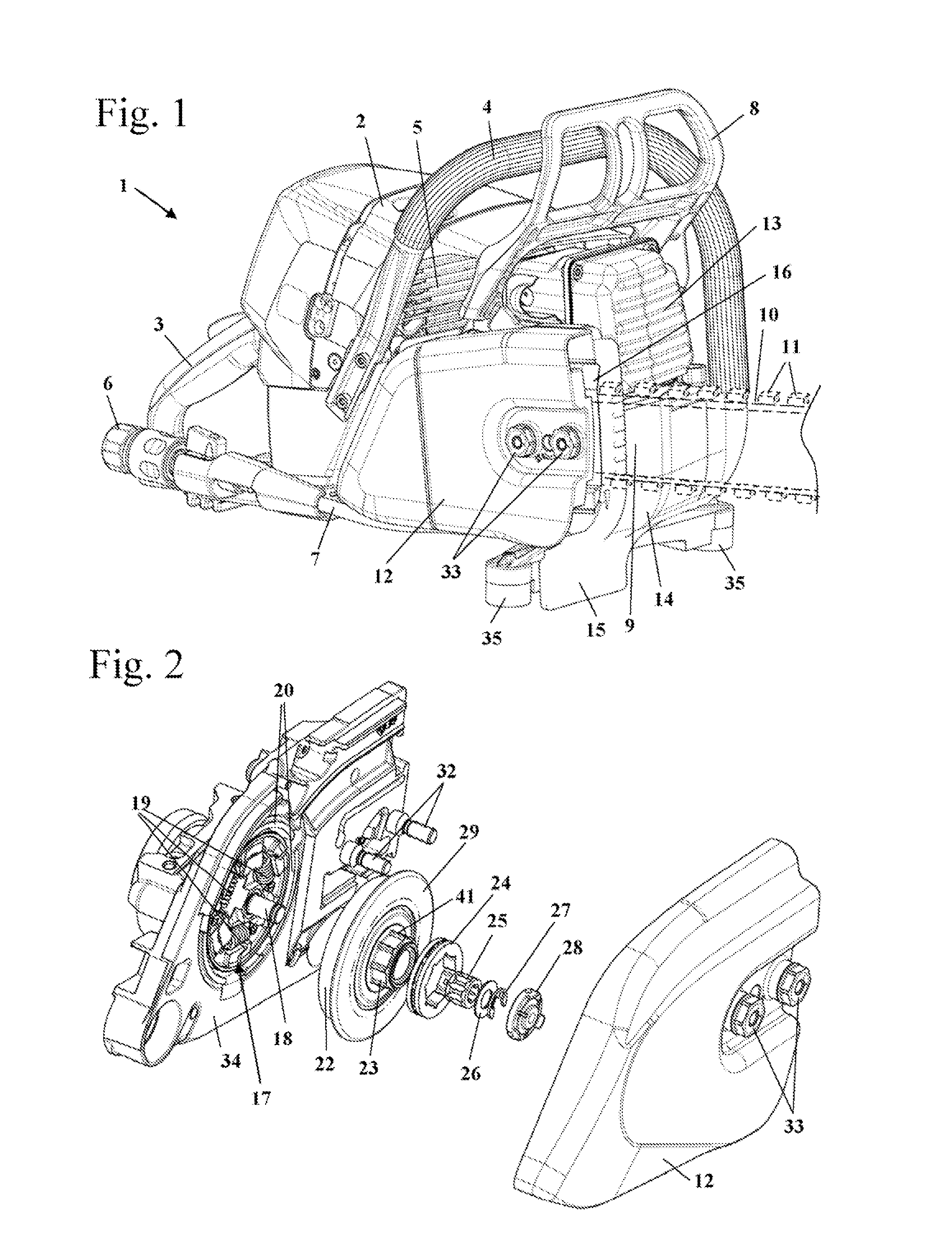

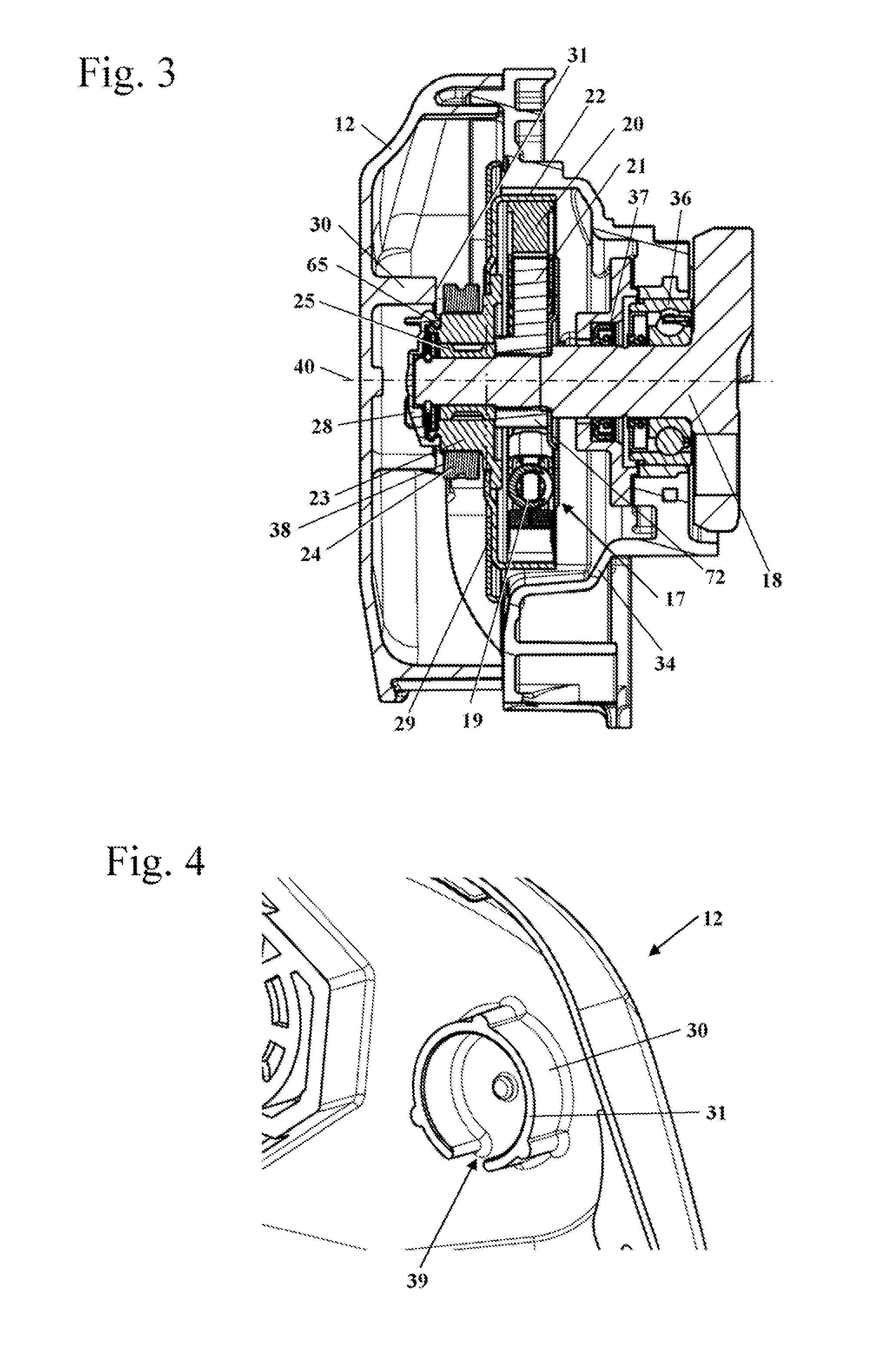

Handheld work apparatus having a guard

InactiveUS20130091715A1Robust constructionReduce weightMetal sawing devicesMetal sawing accessoriesSTONE CUTTERMetallic materials

A handheld work apparatus such as a stone cutter (1) having a housing (2) in which a drive motor (5) is arranged. The work apparatus has a tool driven by the drive motor (5) for cutting mineral or metallic materials. The housing (2) has a housing front end (16) facing the workpiece to be cut and arranged adjacent to the workpiece. The tool projects beyond the housing front end (16). In order to avoid damage on the housing front end (16), it is provided that an elastic guard (17, 47), which extends over at least 50% of the width (b) of the housing front end (16), is arranged on the housing front end (16).

Owner:ANDREAS STIHL AG & CO KG

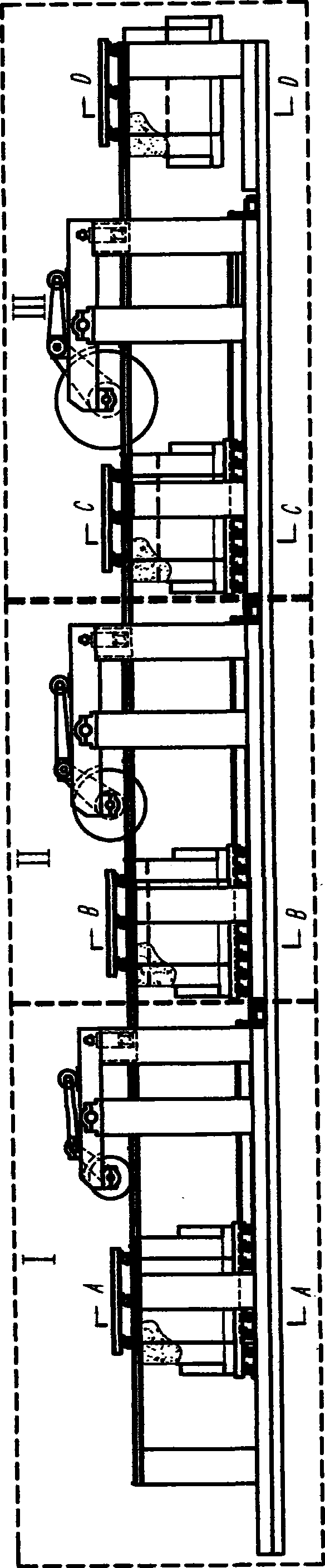

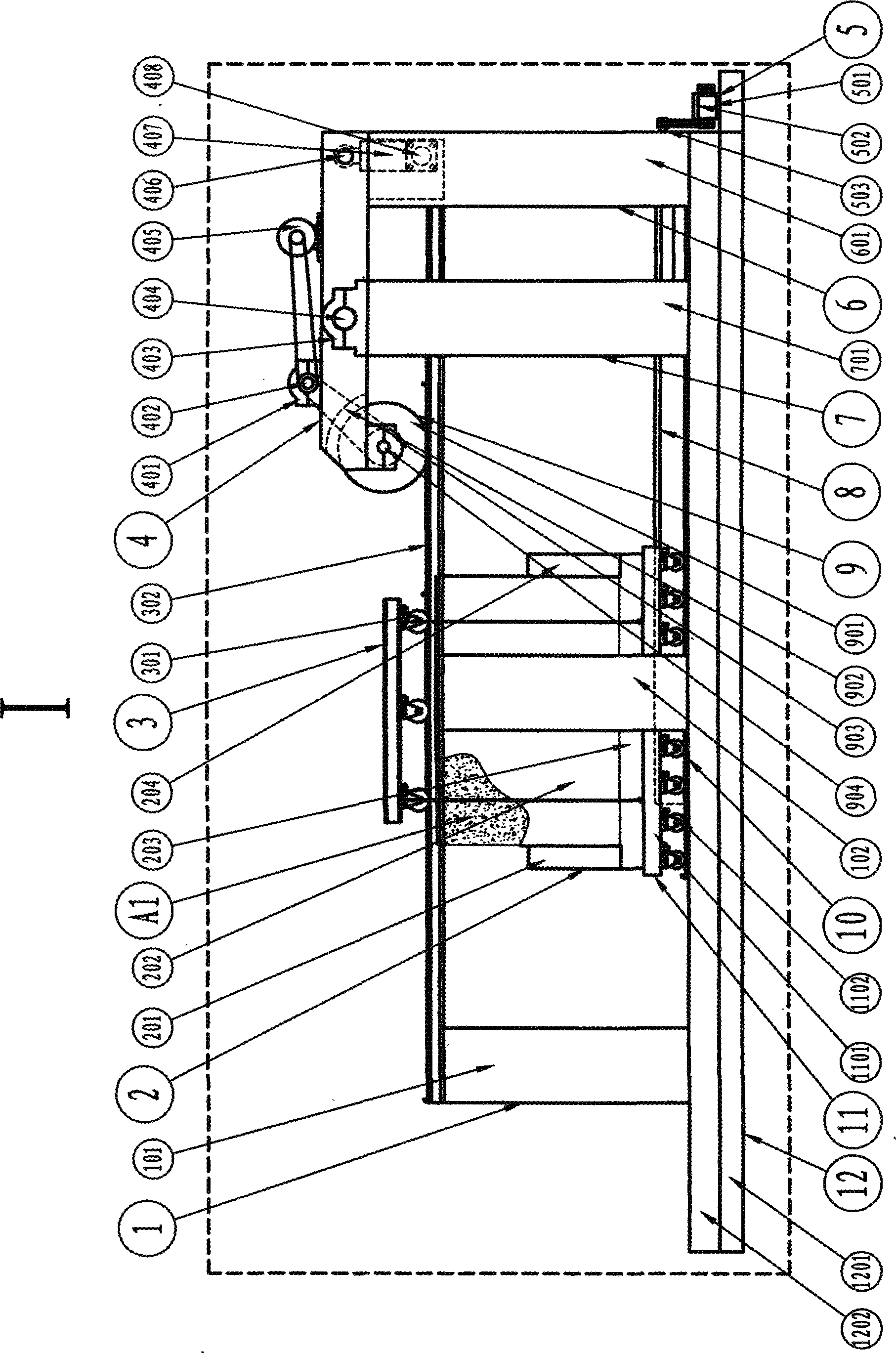

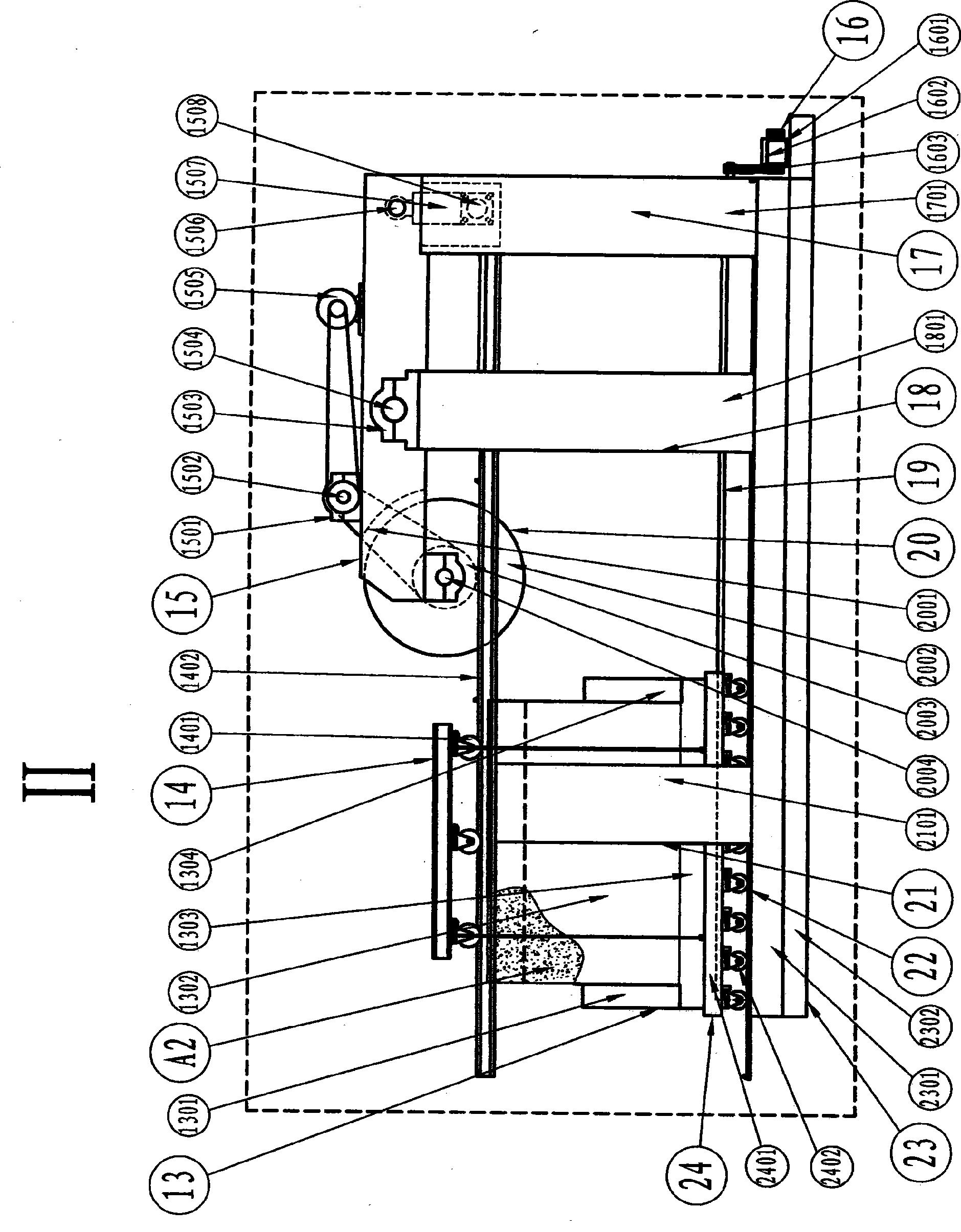

Multi-cutter swivel stone material multi-machine cutoff production line

InactiveCN101508148AReduce consumptionLow costWorking accessoriesStone-like material working toolsProduction lineMulti machine

The invention relates to a processing production line for stone, in particular to a multi-machine combined cutting production line for multi-cutter pivot stone. The production line is characterized in that a plurality of multi-cutter pivot stone cutting machine sets in-line arrangement are arranged on a baseframe assembly to form a plurality of processing districts; each cutting machine set comprises an overhead crane assembly, a fixture assembly, a cutter shaft assembly, a cutter shaft frame assembly, a stroke transmission assembly, a flat guide assembly and a stroke slider assembly, and the stroke slider assembly is in transmission connection with the stroke transmission assembly to realize horizontal cutting and reciprocating motion for a stone workpiece; the fixture assembly clamps the workpiece and is lifted on an overhead crane, the overhead crane is arranged on a wheeltrack of a support column, and a cutter shaft frame is a lever hydraulic lifting transmission structure and is also arranged on the support column to realize depth cutting up and down; and the cutter shaft frame is provided with the cutter shaft assembly which adopts a pivot installing mode, and the cutter shaft assembly is provided with a plurality of saw blades so as to realize the multi-cutter cutting for the stone to be processed at the same time. Continuous processing is carried out on the whole production line so as to improve the production efficiency and the management efficiency greatly.

Owner:陈正枢

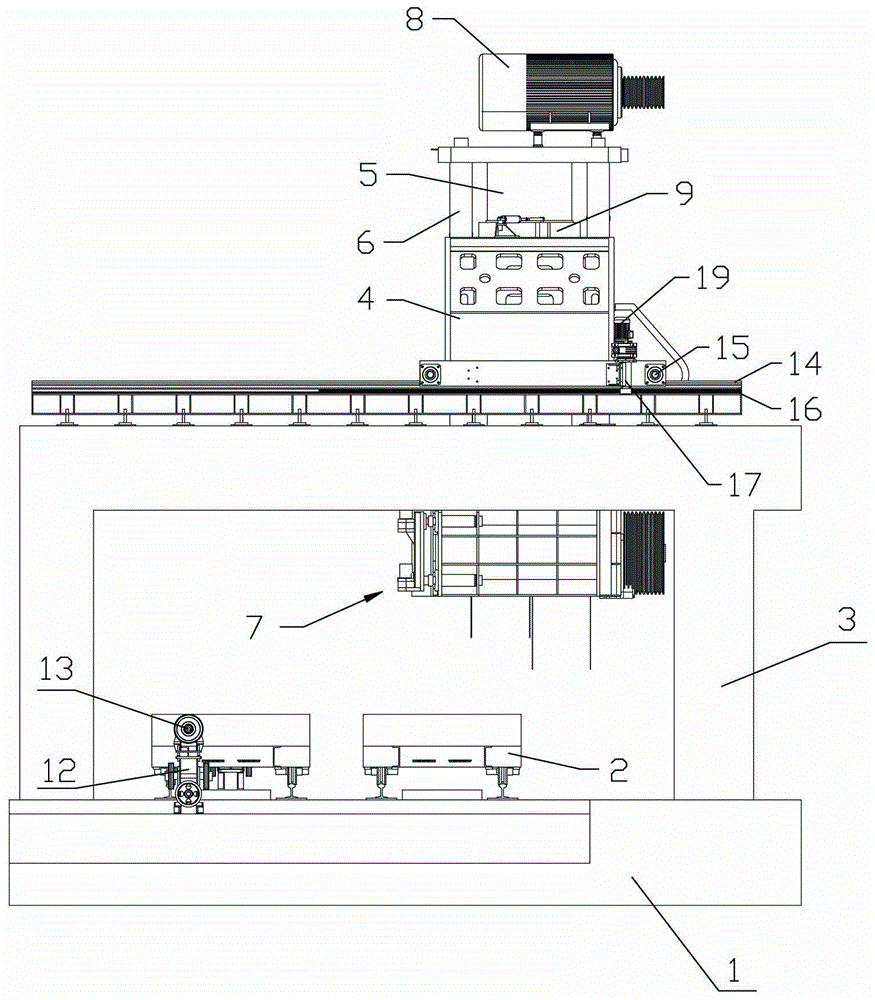

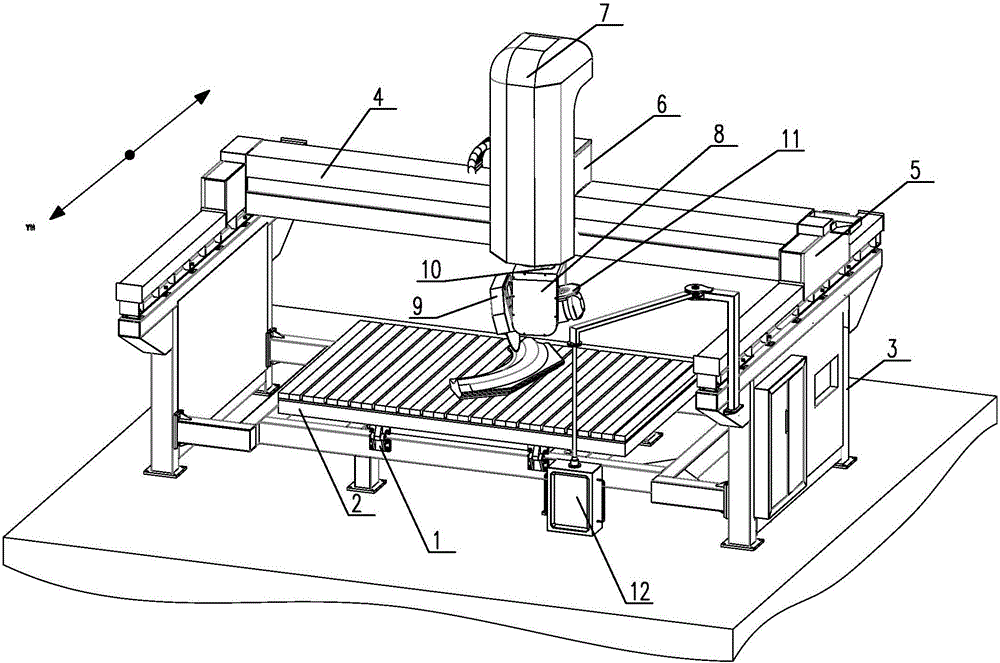

Numerical control five-shaft motion bridge type stone cutter

InactiveCN104985707AImprove efficiencyGuaranteed uptimeWorking accessoriesStone-like material working toolsLine shaftNumerical control

The invention relates to the stone processing machinery technical field, and especially relates to a stone multidimensional space heterotype curved surface processing five-shaft motion bridge type stone cutter comprising a pedestal, a work table, a side frame, a crossbeam, a vertical travel mechanism, a transverse travel mechanism, a lifting cutting mechanism, a cutting link seat, a cutter device, a C-shaft rotary drive mechanism, an A-shaft rotary drive mechanism, and a pc industrial control box; the vertical travel mechanism, the transverse travel mechanism, the lifting cutting mechanism, the C-shaft rotary drive mechanism, and the A-shaft rotary drive mechanism, are respectively connected with the pc industrial control box, and the cutter can be controlled on three linear shafts (X,Y and Z) and the two rotary shafts (A and C). the five-shaft motion bridge type stone cutter has five-shaft motion, real time linear, arc interpolation functions, can realize complex pentahedron curved surface processing, is mainly applied to multidimensional space heterotype curved surface stone decoration elaboration processing, thus doubling efficiency; the five-shaft motion bridge type stone cutter is stable in operation, and can reduce production and equipment maintenance cost.

Owner:FUJIAN JINJIANG SHENGDA MACHINERY

Cutting chain for a hand-operated implement and hand-operated implement

InactiveUS20130269673A1Small volumeEngage with obstructionMetal sawing devicesChain sawsSTONE CUTTEREngineering

Owner:ANDREAS STIHL AG & CO KG

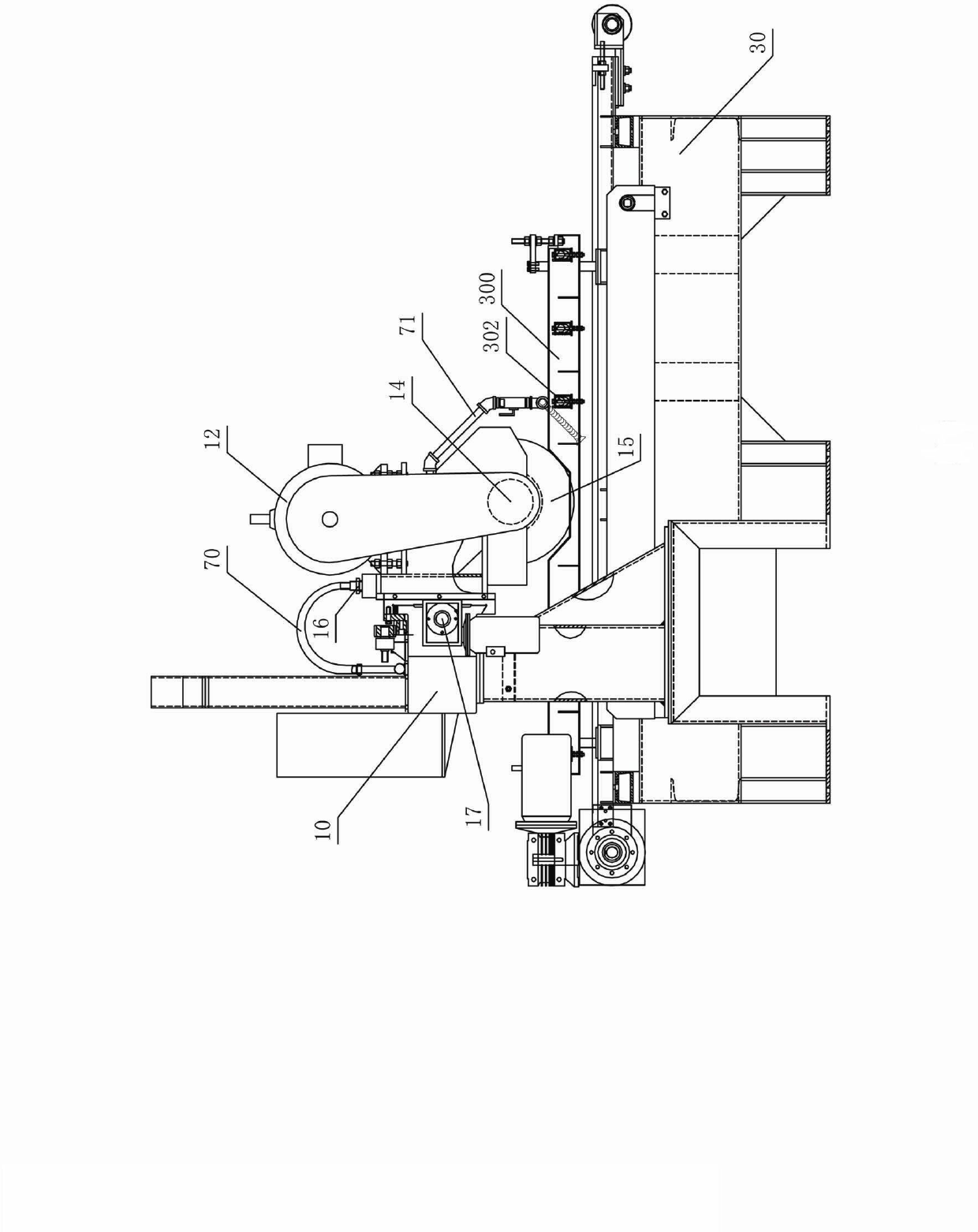

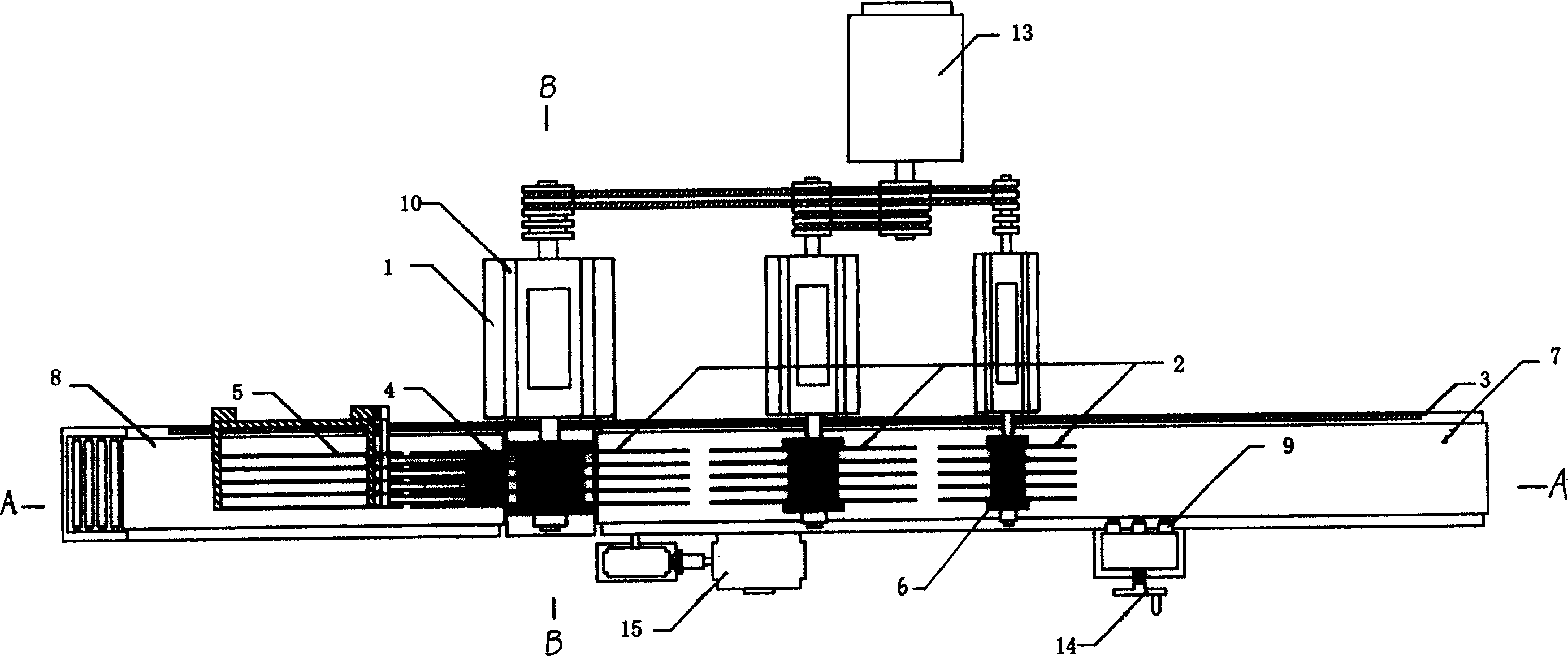

Stone cutting processing production line

ActiveCN102581964AVarious sizesMeet needsWorking accessoriesStone-like material working toolsProduction lineReduction drive

The invention relates to a stone cutting processing production line which comprises a stone conveying mechanism, a stone cutting mechanism and a dust removal cooling mechanism. The stone cutting mechanism comprises a longitudinal cutting assembly and a transverse cutting assembly which are arranged back and forth. The transverse cutting assembly comprises a transverse bracket and two groups of transverse cutting components which are arranged side by side. The longitudinal cutting assembly comprises a longitudinal bracket and three groups of longitudinal cutting components which are arranged side by side. Each group of longitudinal cutting component comprises a saw blade motor, a speed reducer, a cutting shaft and a longitudinal cutting saw blade arranged on the cutting shaft. The cutting shafts are in drive connection with output shafts of the corresponding saw blade motors by the corresponding speed reducers. The three groups of longitudinal cutting components are all arranged on the longitudinal bracket in an up-and-down adjustable mode and each group of longitudinal cutting component is positioned above the stone conveying mechanism in a left-and-right adjustable mode. On the stone cutting processing production line, the cutting is respectively carried out in the longitudinal and transverse directions, the operation is carried out in a production line mode, and both the longitudinal cutting saw blades and the transverse cutting saw blades are used for carrying out cutting processing back and forth, so that the cutting efficiency is greatly improved.

Owner:福建海龙机械有限公司

Process for manufacturing ultra-thin stone honeycombed sheet for fire surface

InactiveCN101318396AEasy to prepareLow costLamination ancillary operationsLaminationBurn treatmentSTONE CUTTER

The invention relates to a manufacturing method of a burning surface ultrathin stone honeycomb plate. The manufacture steps include that: 1) a natural stone slab is fetched, burning treatment is carried out on the front and the back surfaces of the natural stone slab to form burning surfaces; 2) a stone glue is coated on the surrounding of the front and the back burning surfaces; two stone transition backing boards are respectively stuck on the front and the back burning surfaces; the three stones form a whole after being spliced; 3) a stone cutter is adopted to cut the combined body of the three stones into two halves along the central position of the thickness of the natural stone slab to form two natural stone composition boards provided with the backing boards; 4) the cutting surface of the composition boards is processed to lead the natural stone slab to reach the designed thickness for forming a ultrathin natural stone slab; 5) a stone compound glue is coated on the back of the burning surface, a honeycomb plate or a foaming plate is stuck, the natural stone slab is taken out after being pressurized and solidified under normal temperature to lead the ultrathin natural stone slab to become the ultrathin natural stone slab that one surface of which is spliced with the transition backing board and the other surface with the honeycomb plate or the foaming plate by the glue; 6) a cutting device is adopted to cut off the surroundings of the ultrathin natural stone slab the two surfaces of which are respectively provided with the transition backing board and the honeycomb plate or the foaming plate, thus leading the transition backing board to separate from the natural stone slab. The finished product has the good properties of high intensity, impact resistance, heat preservation, heat insulation, water resistance, anti-shaking and high application value.

Owner:福州盛山超薄石材有限公司

Bridge type stone cutter with polishing function

ActiveCN103128860AWith cutting functionReduce the handling processGrinding machinesStone-like material working toolsSTONE CUTTERBridge type

A bridge type stone cutter with a polishing function comprises a crossbeam, two longitudinal beams, a moving seat, a lifting frame, a worktable and a cutting device. The cutting device is arranged on the lifting frame, a longitudinal moving mechanism is arranged among the crossbeam and the longitudinal beams, a transverse moving mechanism is arranged between the moving seat and the crossbeam, and a lifting moving mechanism is arranged between the lifting frame and the moving seat. The bridge type stone cutter is characterized by further comprising a polishing device, the polishing device is arranged on the lifting frame and comprises a spindle box, a spindle, a main motor, an abrasive disc and a vertical moving mechanism, the spindle box is arranged on the lifting frame in such a manner that the spindle box can vertically move up and down on the lifting frame, the spindle is vertically arranged on the spindle box, the main motor is arranged on the spindle box and is connected with the spindle to drive the spindle to rotate, the abrasive disc is arranged at the lower end of the spindle, and the vertical moving mechanism is connected with the spindle box to drive the spindle box to vertically move. The bridge type stone cutter has the advantages that a cutting function is integrated with the polishing function, a procedure for shifting stone between cutting equipment and polishing equipment and a procedure for clamping the stone are omitted, the stone processing efficiency is improved, and the labor cost is saved.

Owner:福建省南安市巨轮机械有限公司

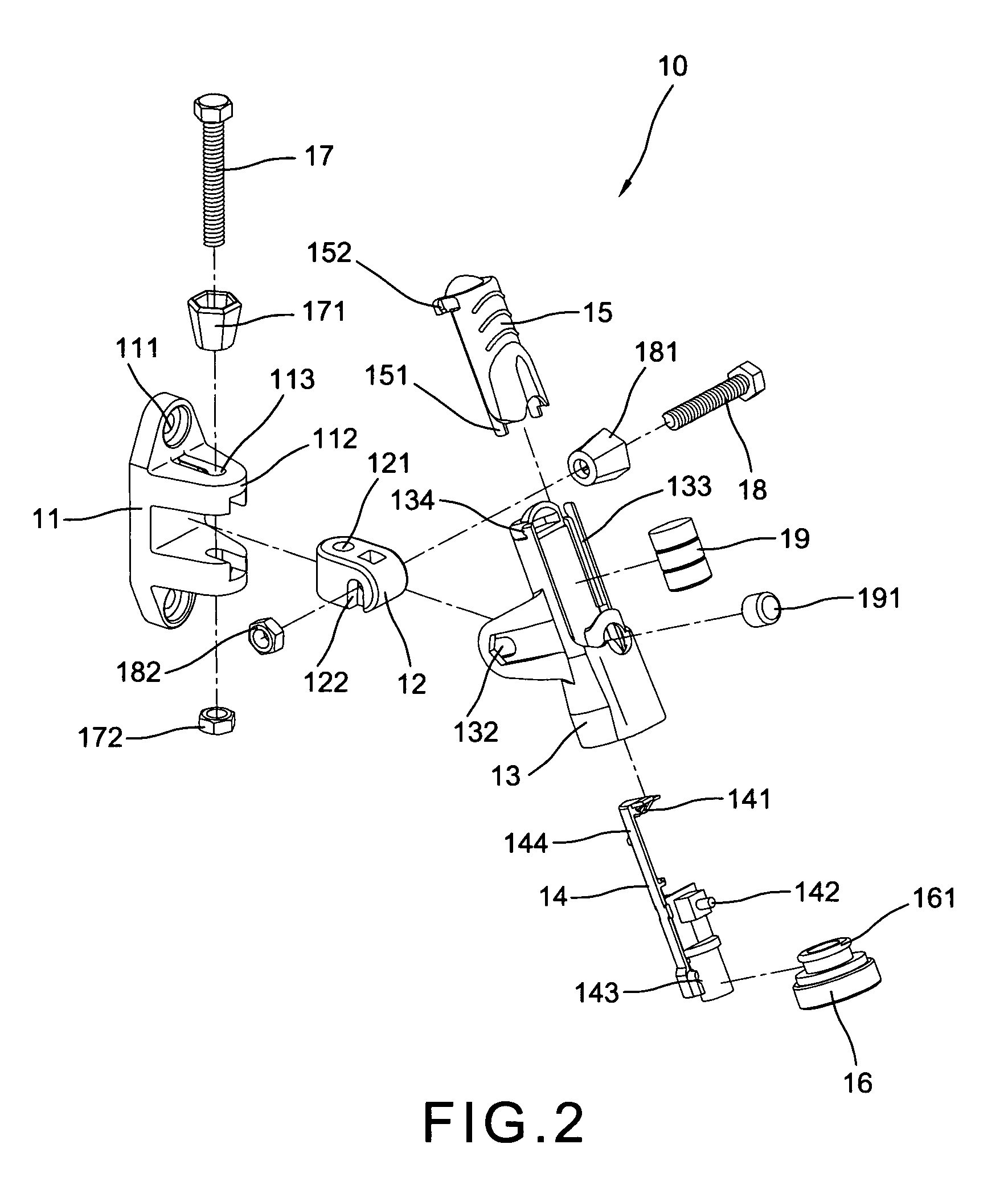

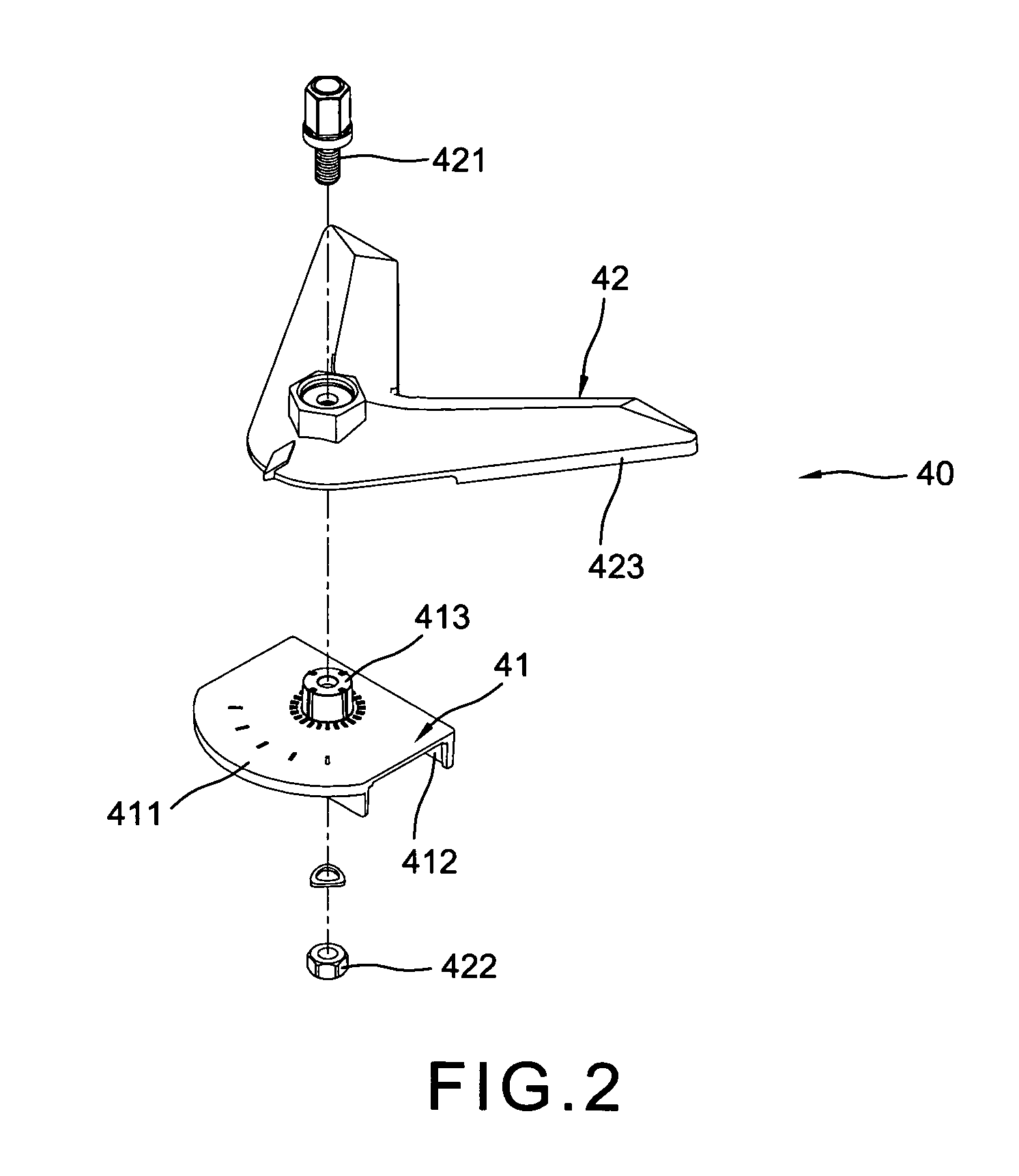

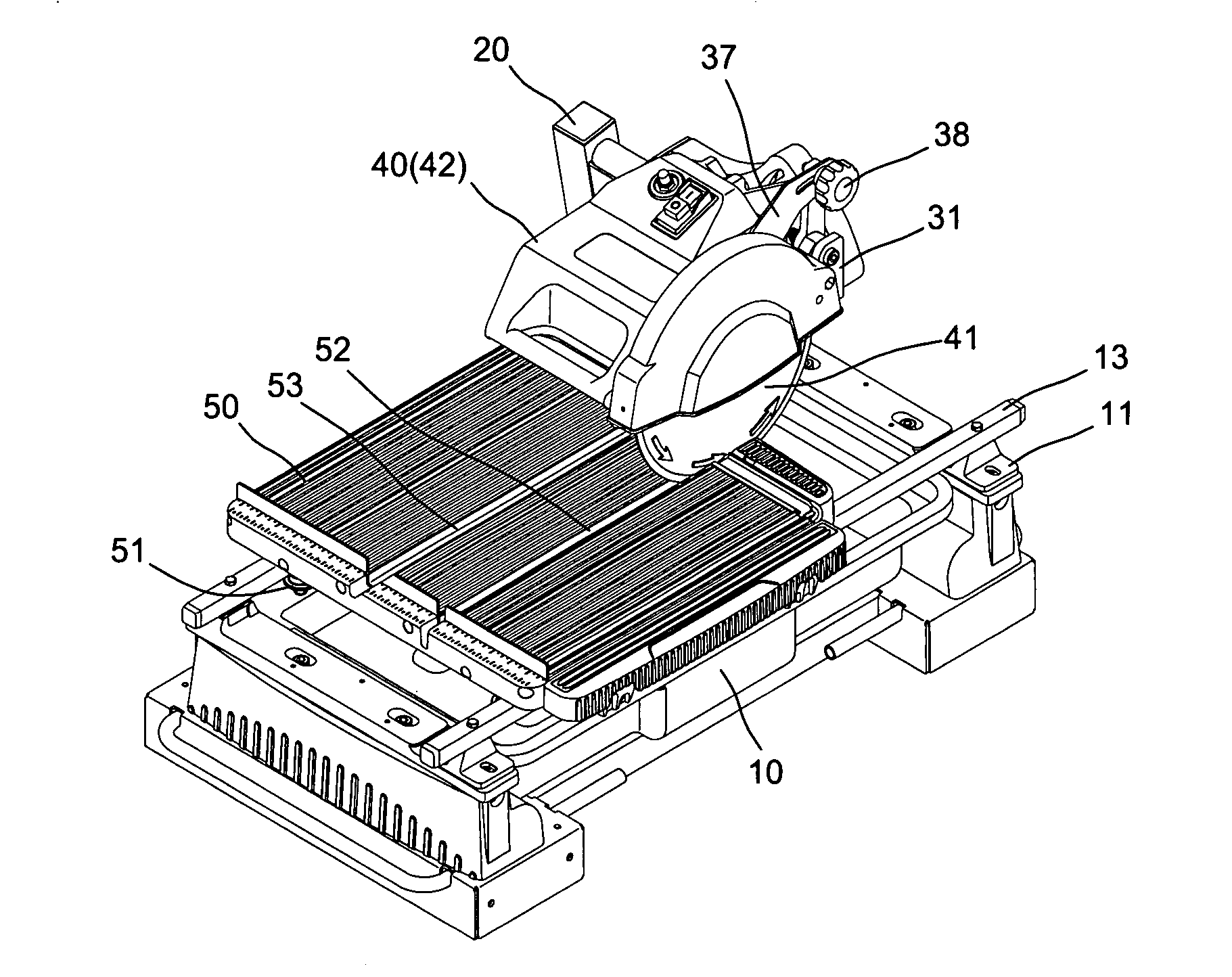

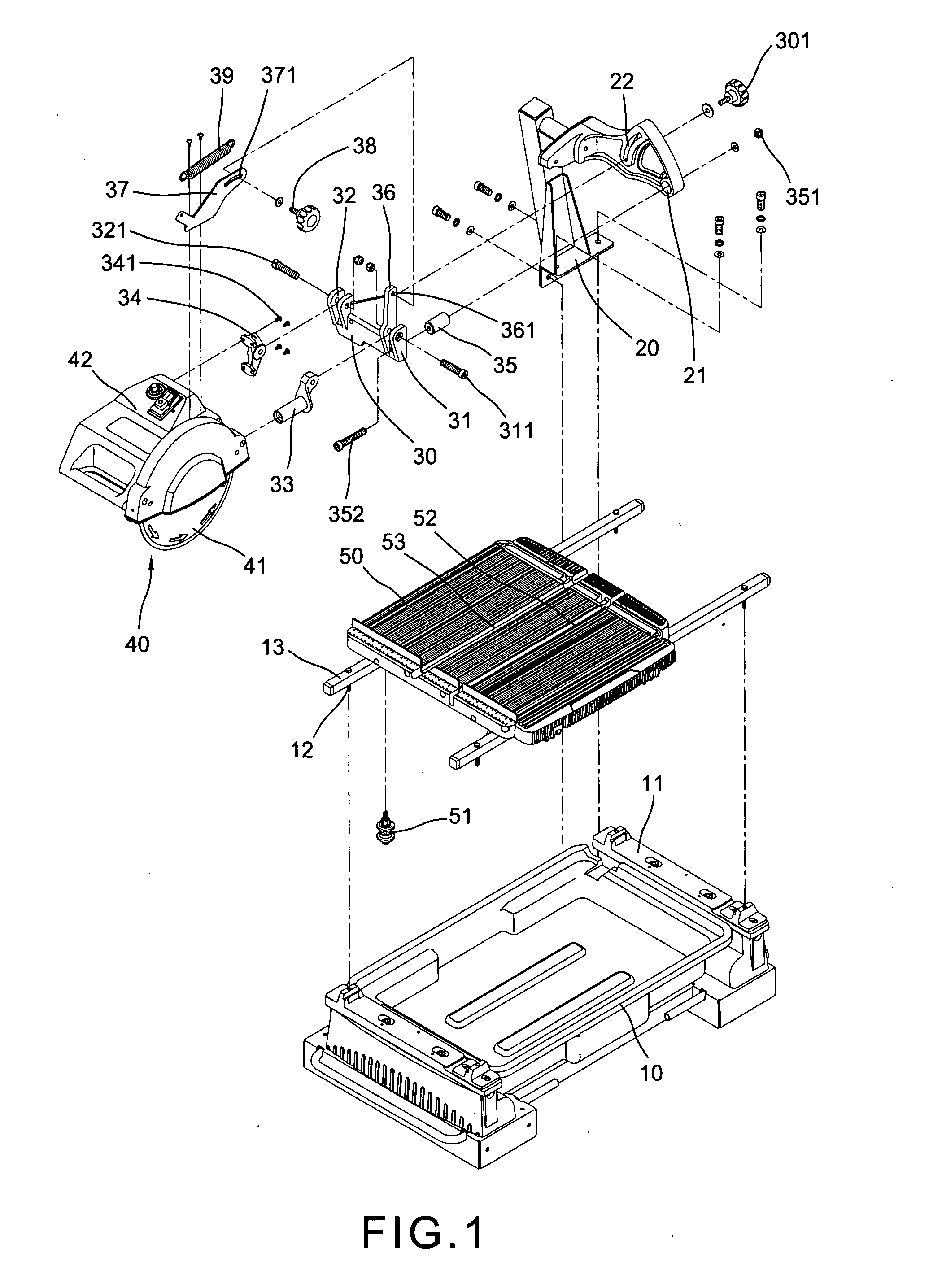

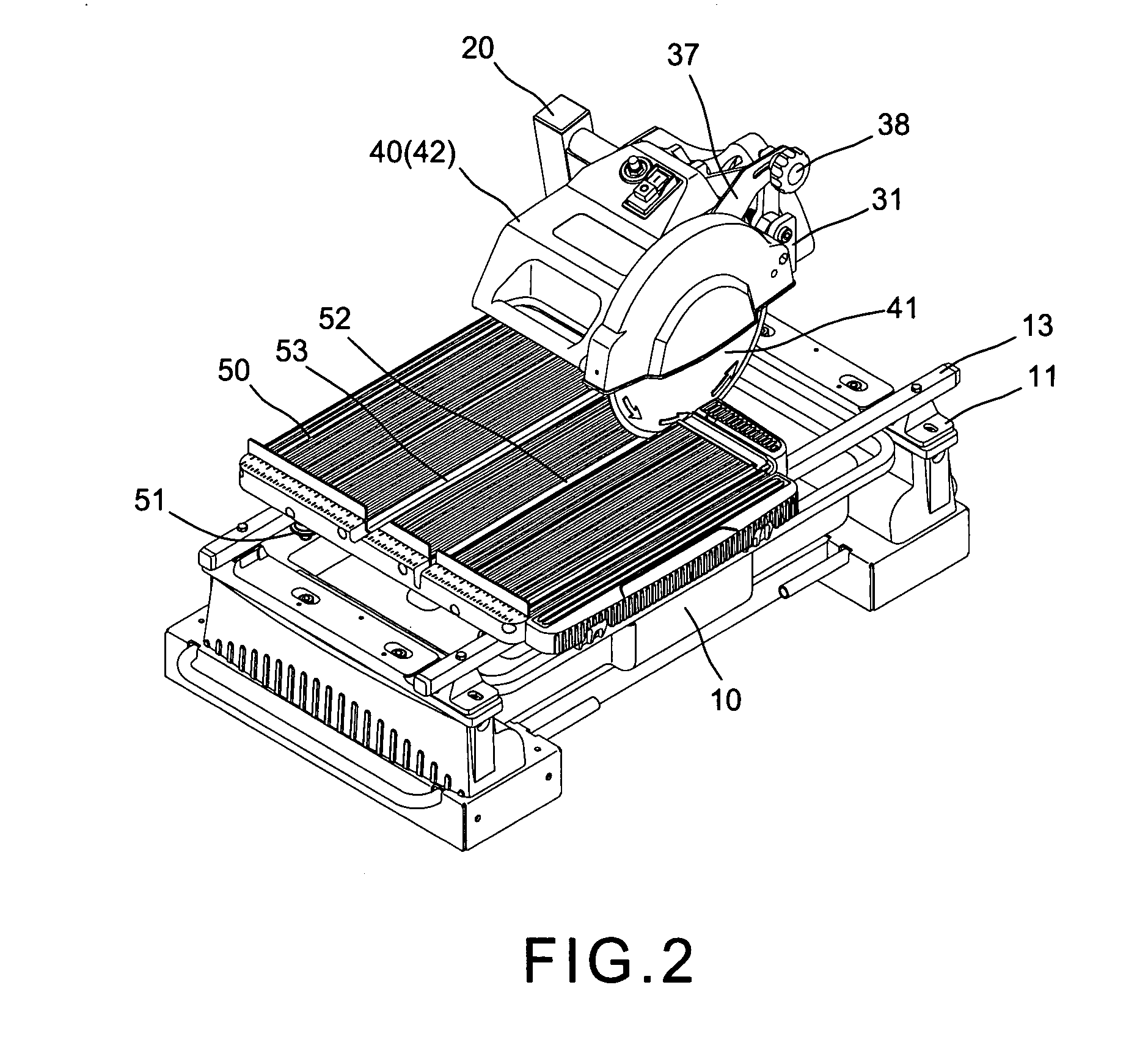

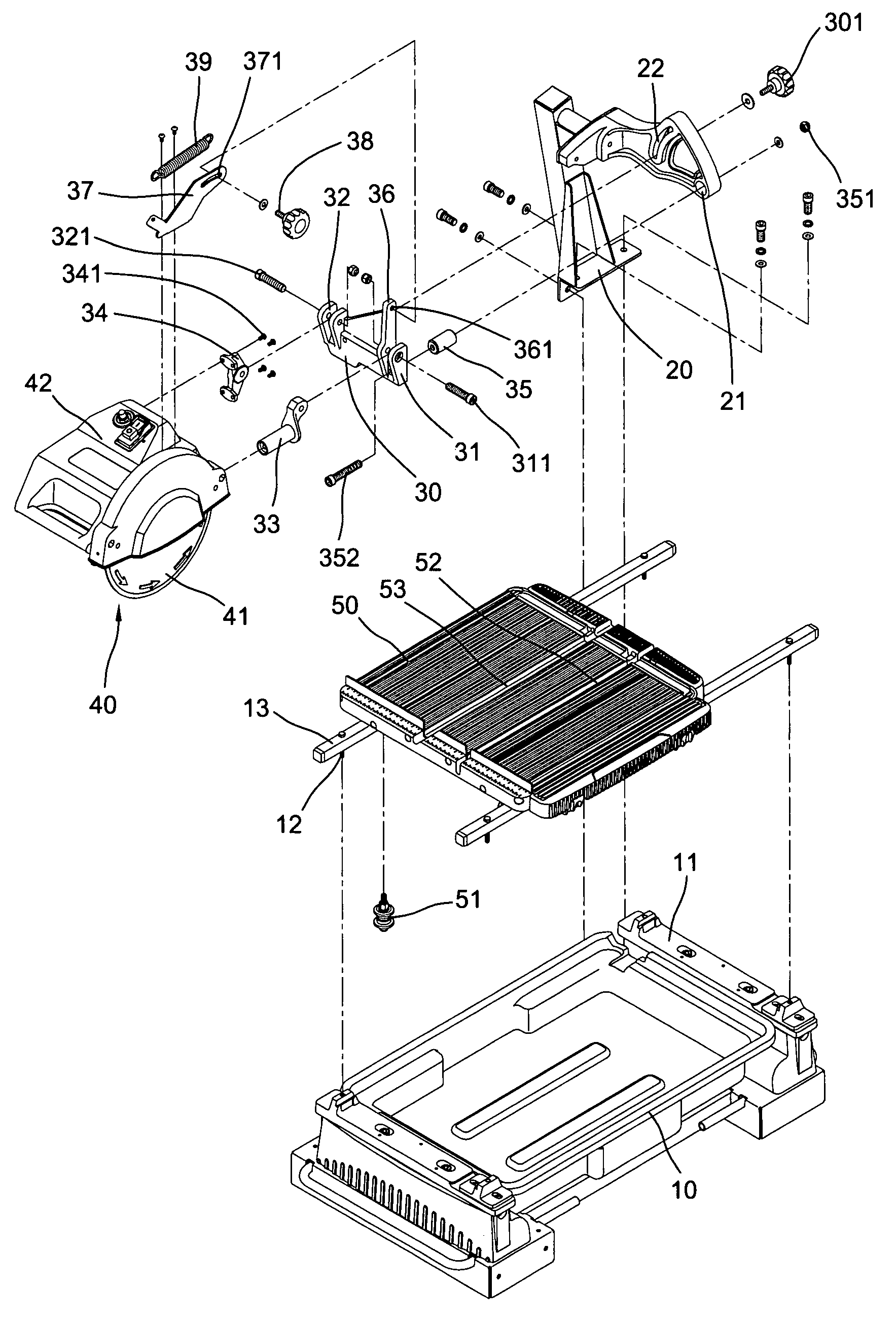

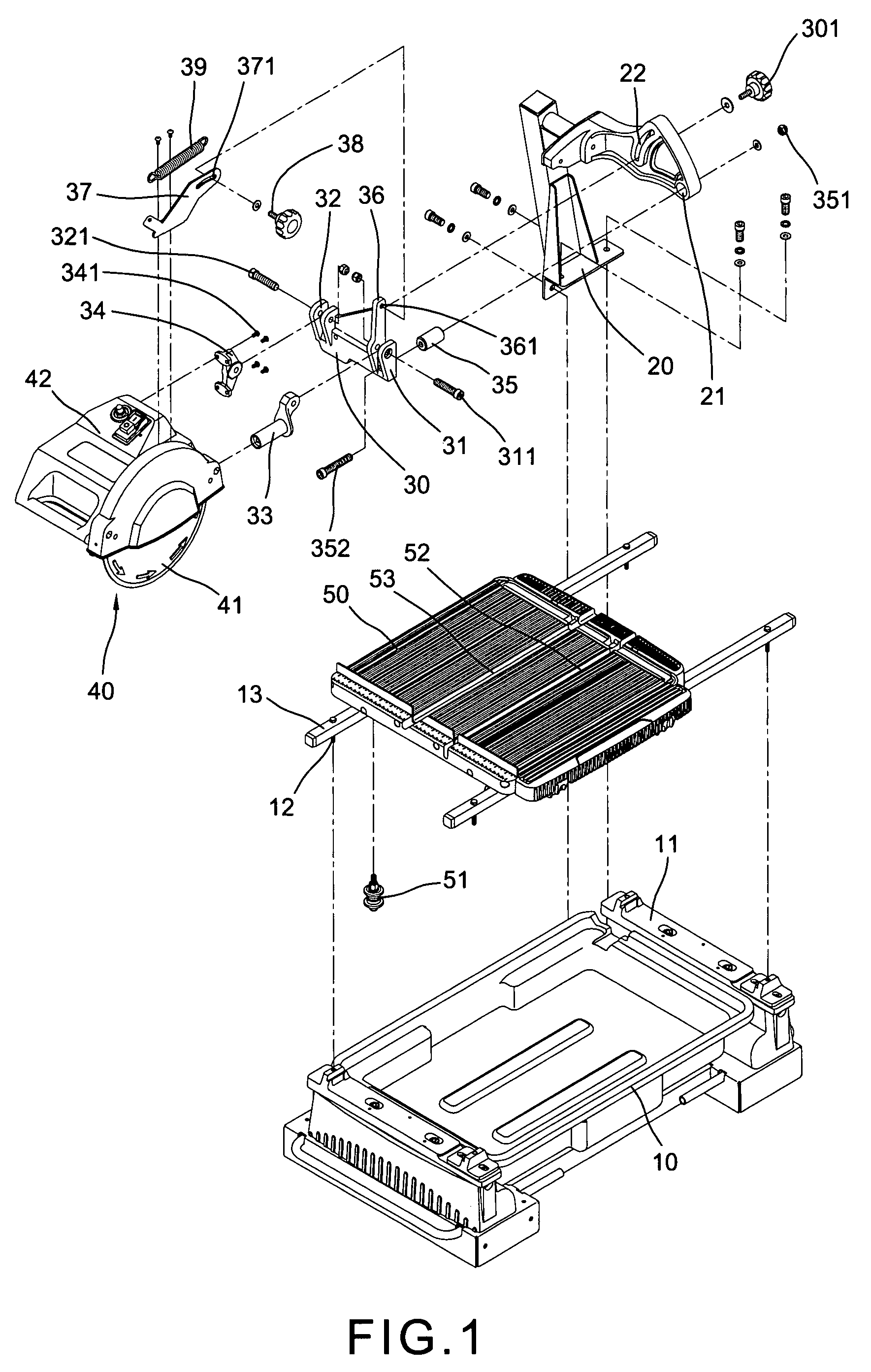

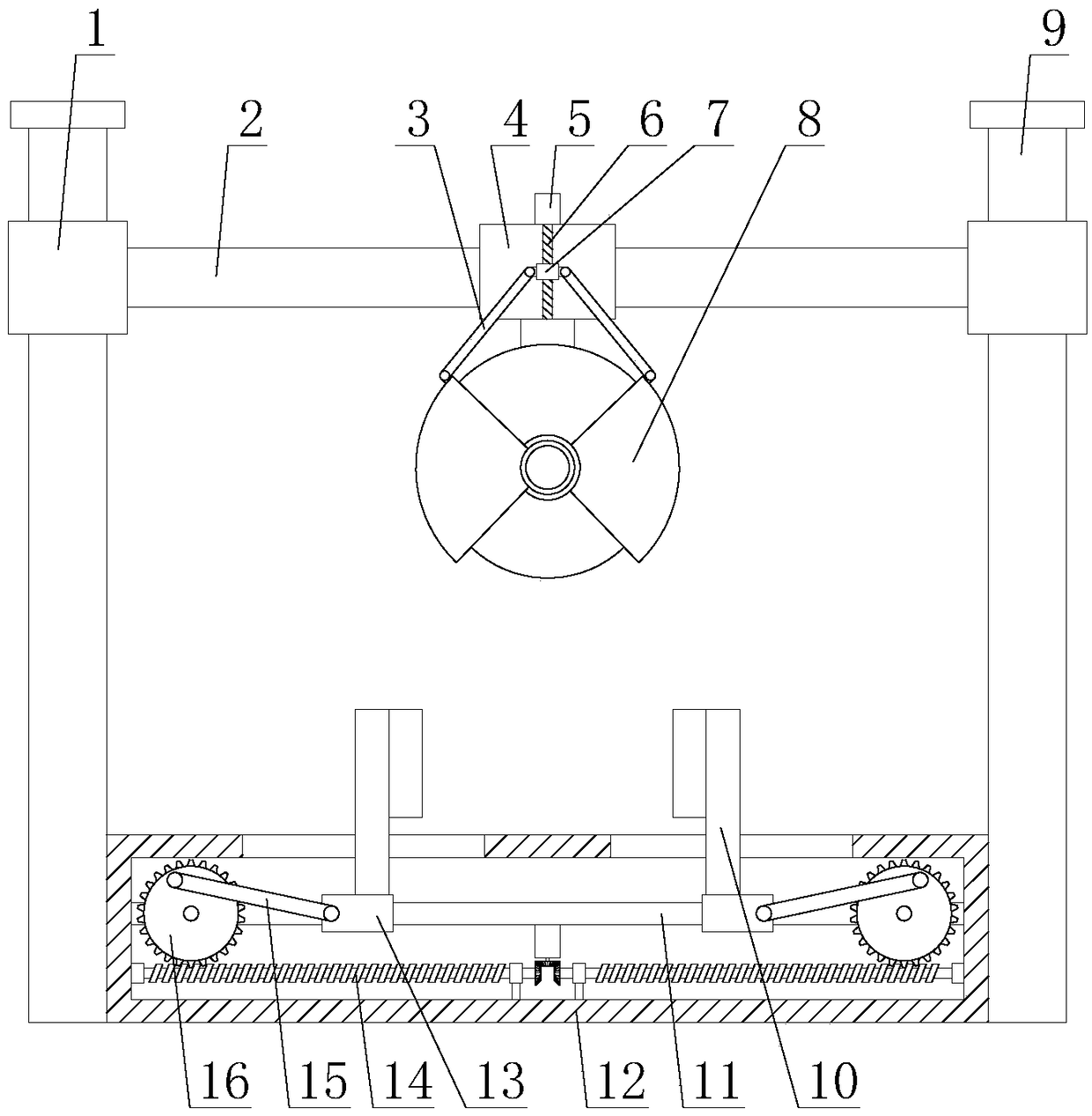

Cutting angle adjustment device for a stone cutter

A cutting angle adjustment device for a stone cutter includes a rectangular water sink, an inverse L-shaped support arm anchored to a lateral side of the sink, a stone cutter adjustably connected to the support arm through a coupling assembly, a pair of guide rods parallel disposed to a pair of rack on front and rear ends of the sink, a platform having two alignments of rotors symmetrically arranged and slidably engaging with the inner sides of the pair of guide rods, a vertical cutting slit and a slant cutting slit parallel formed in the upper surface thereof. Thereby, a saw blade has been adjusted vertically and / or slantly relative to the top of the platform to conduct a vertical or slant cutting and a shallow or deep cutting of the working pieces.

Owner:CHEN YUEHTING +1

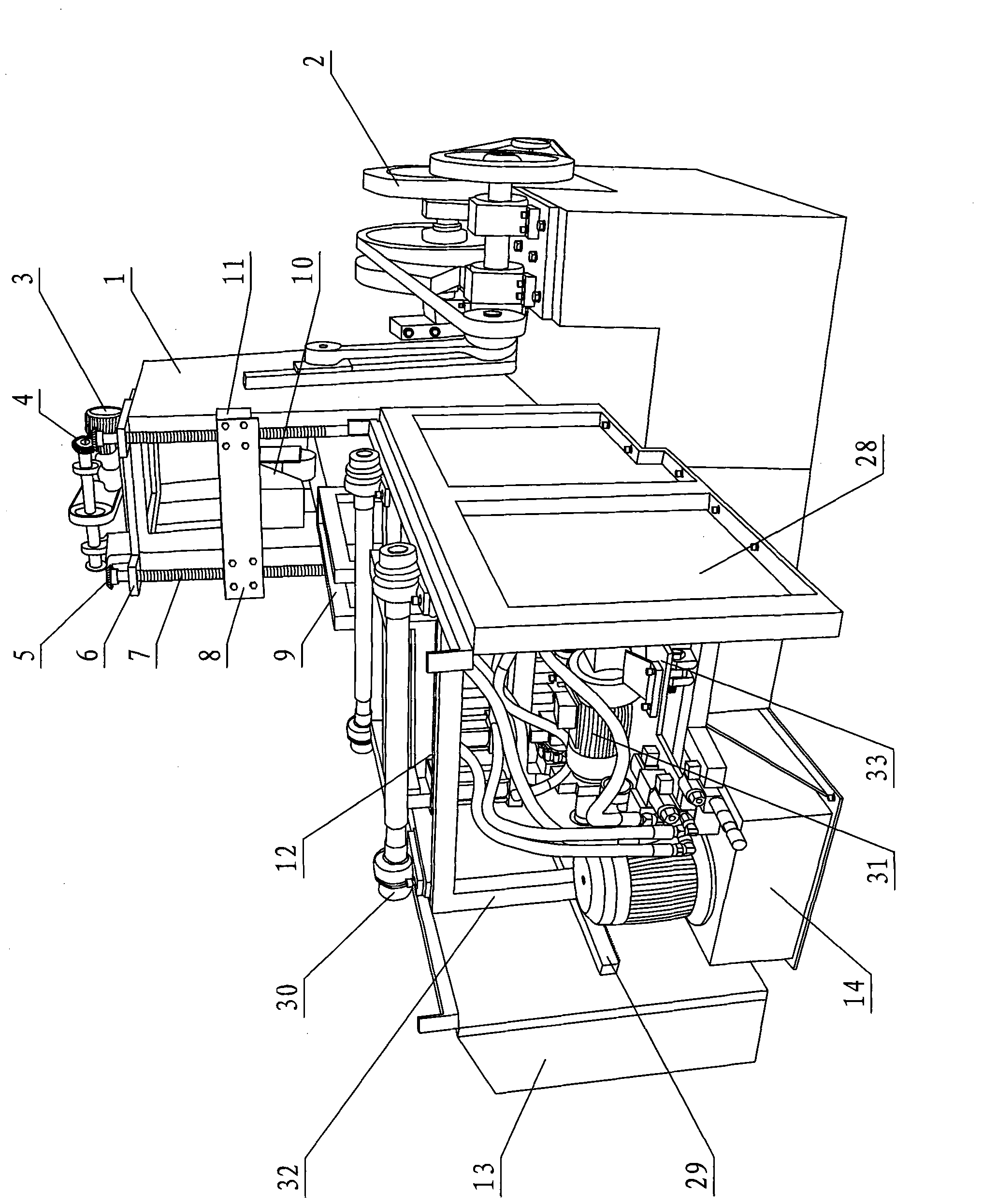

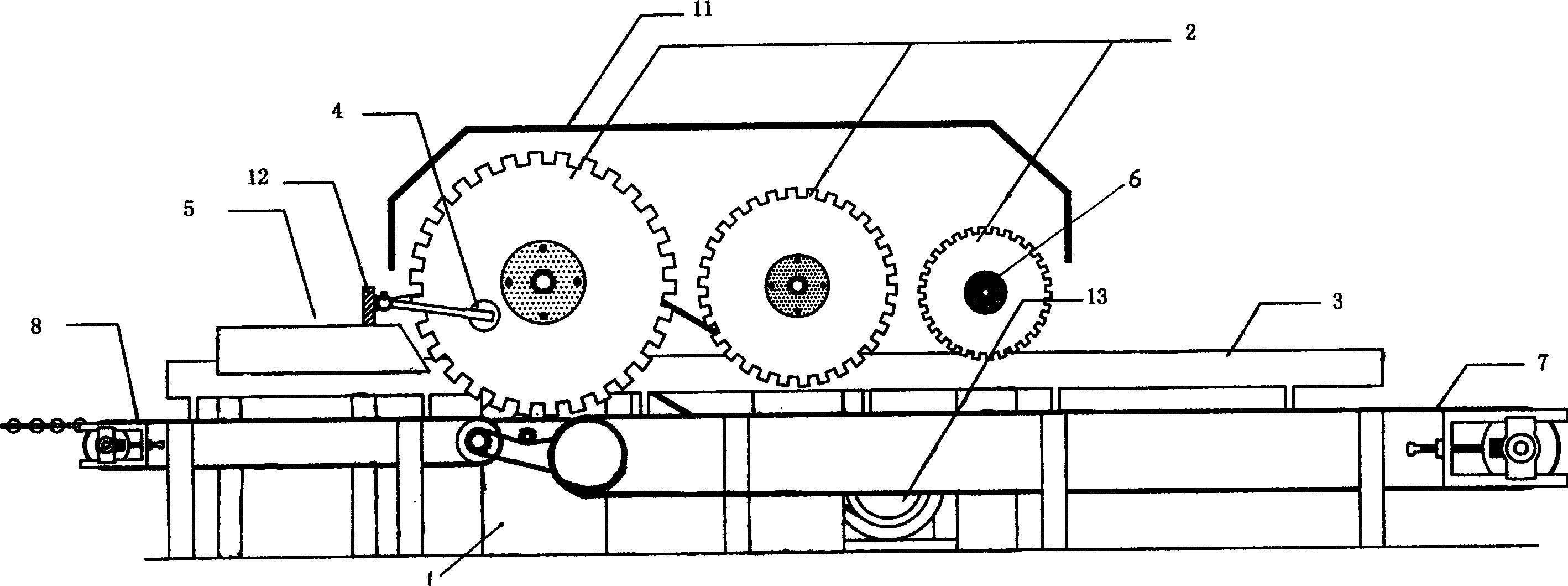

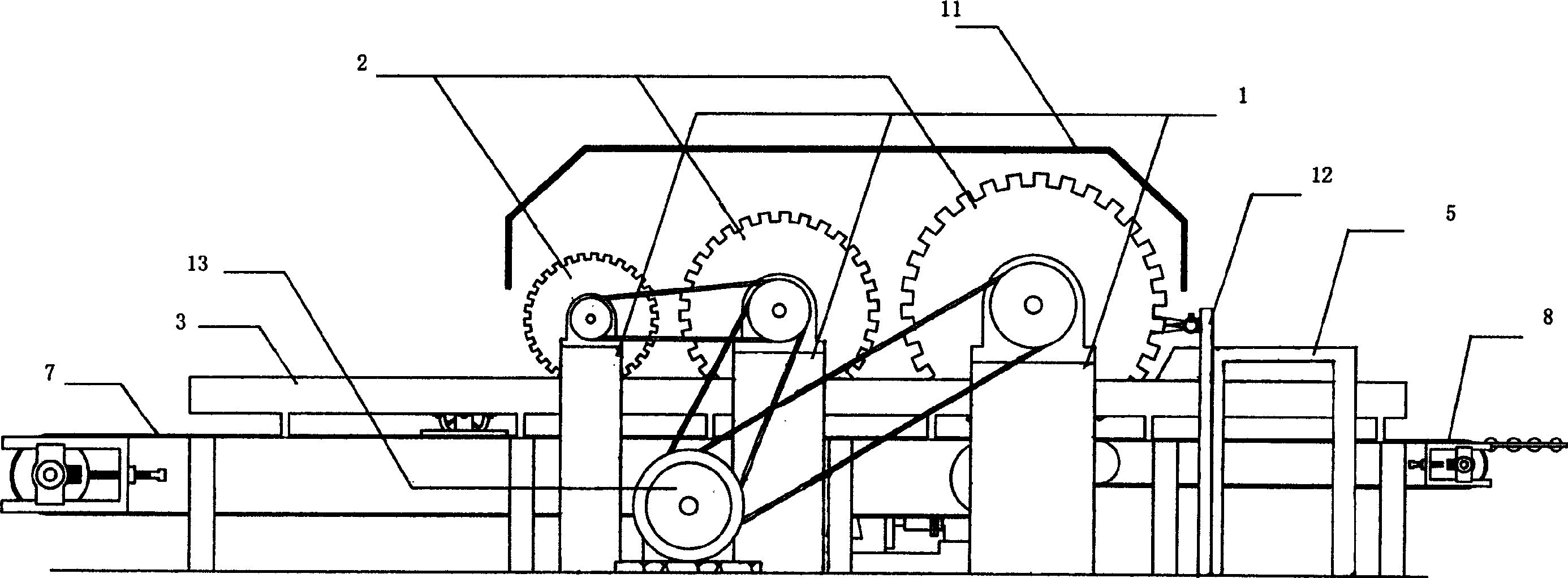

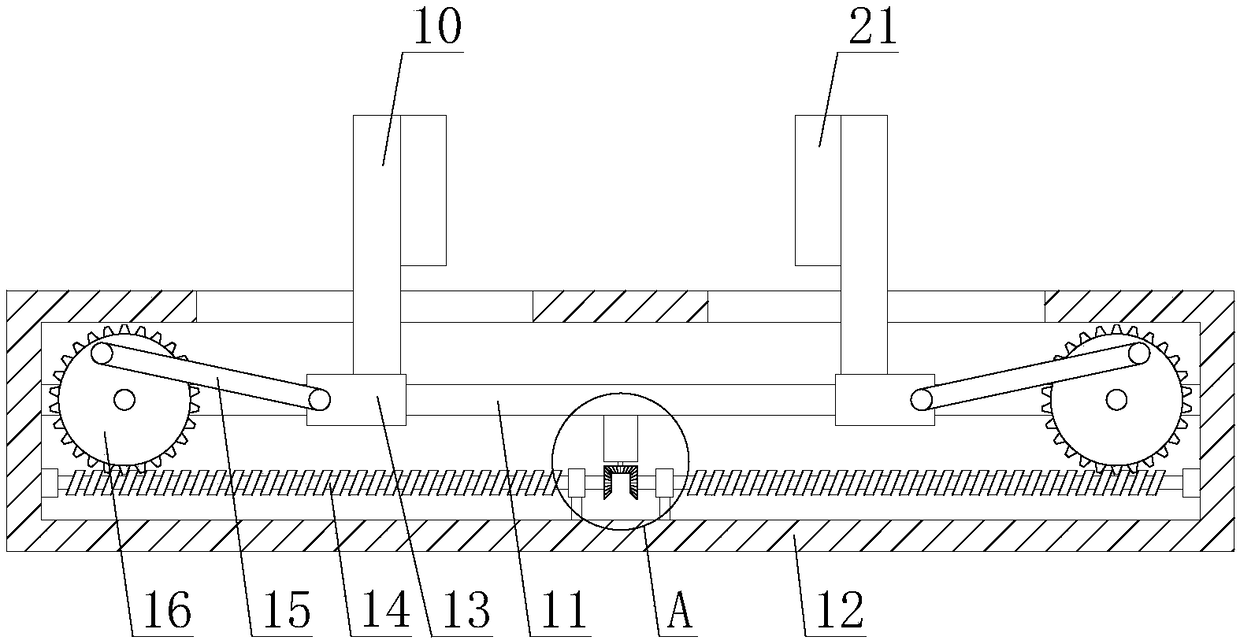

Feeding structure for stone cutter

InactiveCN101941251AStable speedLarge thrustWorking accessoriesStone-like material working toolsSTONE CUTTERGear wheel

The invention relates to a feeding structure for a stone cutter, which comprises a feeding mechanism, wherein the feeding mechanism is arranged at the rear part of the machine frame and can move back and forth; a bearing part for placing stones is arranged in front of the feeding mechanism; a blanking part is arranged in front of the bearing part; the blanking part is connected with a main driving mechanism in a transmission mode; the rear part of the machine frame is transversely provided with a rack; the feeding mechanism is provided with a forward gear and a backward gear, the forward gear is driven by a forward motor, and the backward gear is driven by a backward motor; and the forward gear and the backward gear are respectively connected with a front lifting mechanism and a rear lifting mechanism, so that the forward gear and the backward gear meshes with or disengage from the rack through the lifting motion. The forward and backward motions of the feeding mechanism in the invention are respectively controlled by the forward motor and the backward motor, so that the forward and backward motions of the feeding mechanism have two different speeds. Meanwhile, the forward gear and the backward gear respectively mesh with the rack fixed on the machine frame, so the forward and backward motions do not interfere with each other. The invention has the advantages of simple and reasonable structure, low cost and smooth operation, and the feeding mechanism has the advantages of high thrust force and fast backward speed.

Owner:佛山市顺德区悍天睿数控机械有限公司

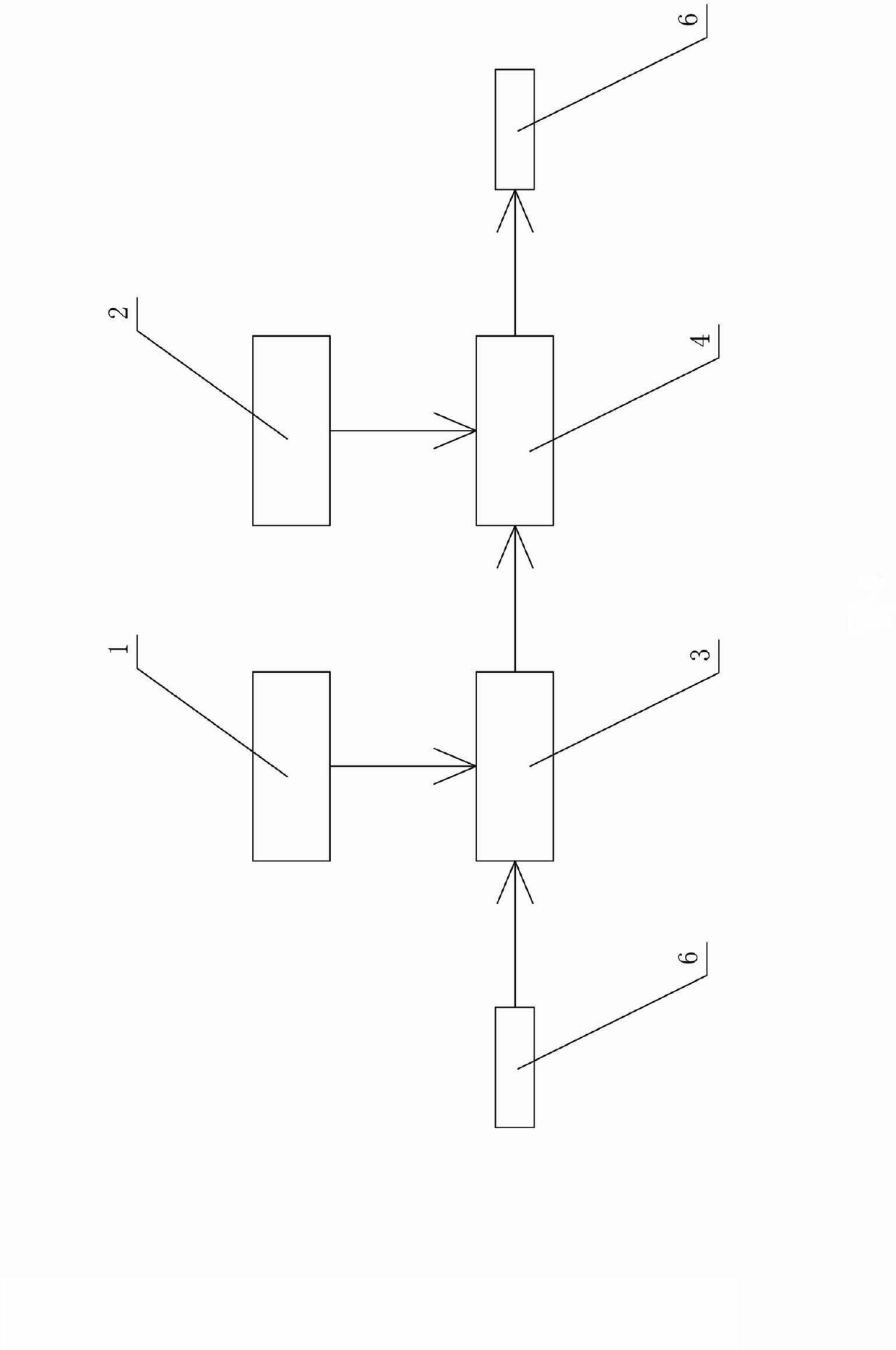

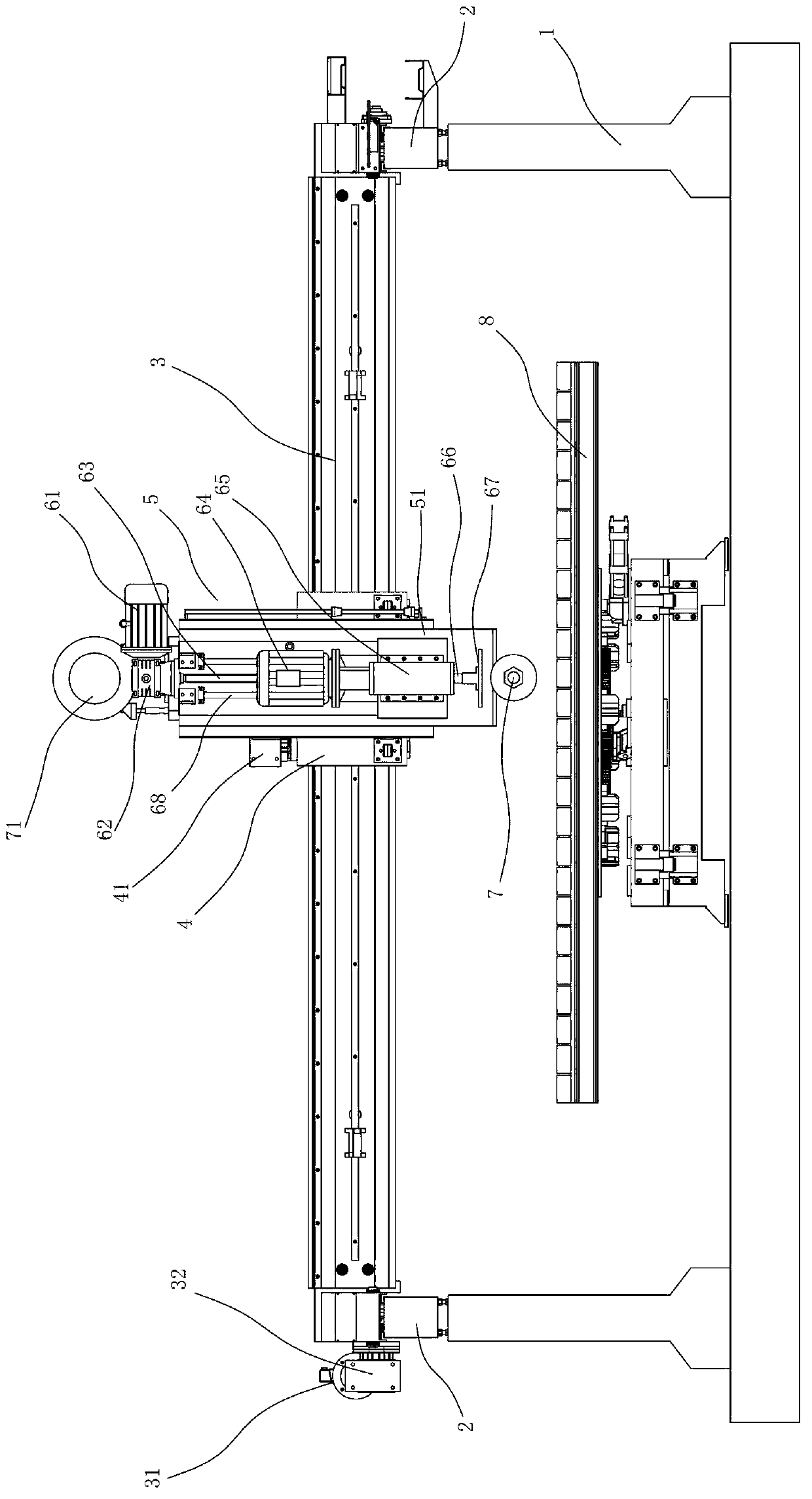

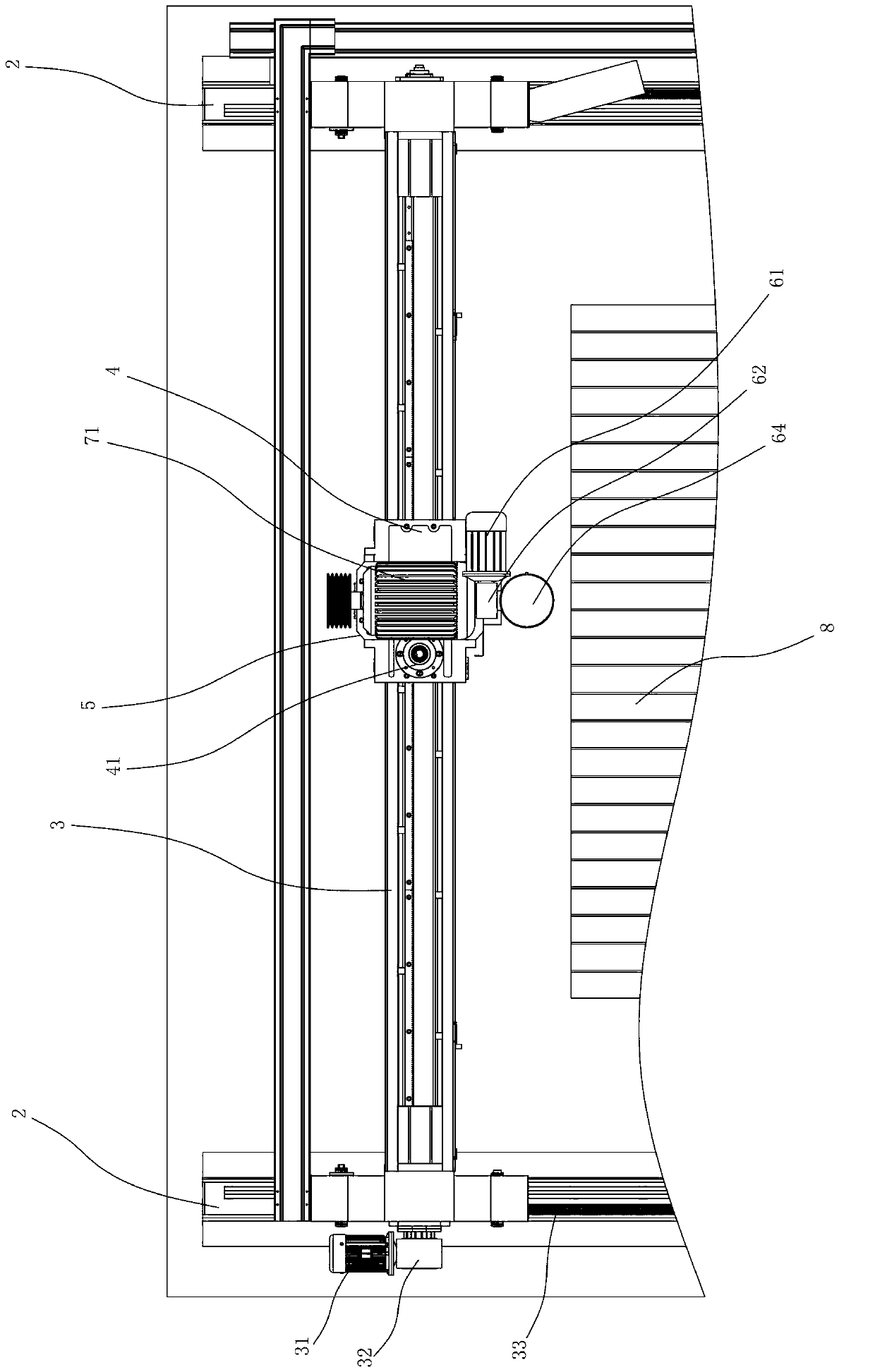

Forward multistage vertical multi-saw web combined continuous stone cutter

InactiveCN1597287AFast feedingCutting stabilityStone-like material working toolsSTONE CUTTEREngineering

Owner:熊敏

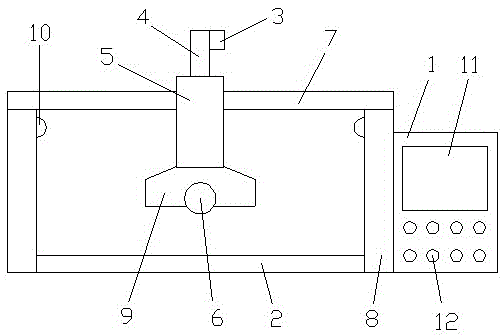

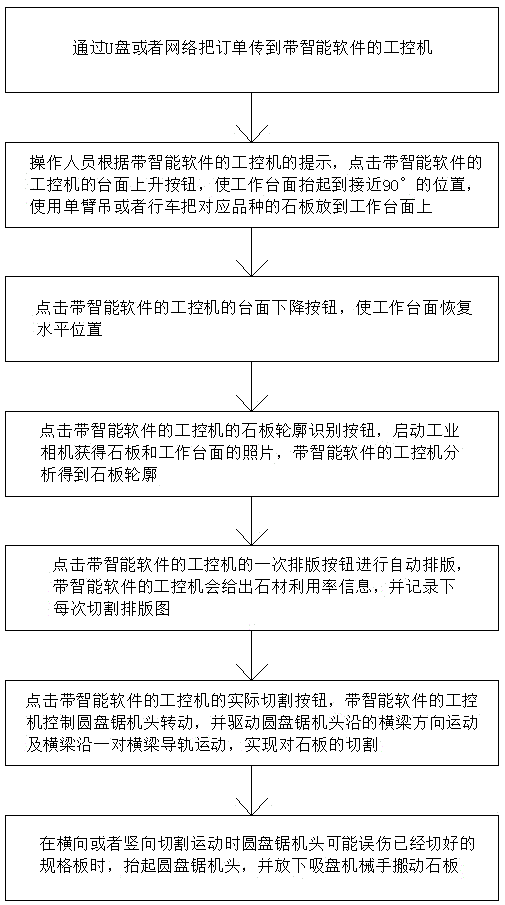

Intelligent stone cutting robot and cutting method thereof

ActiveCN105538518AGuaranteed utilizationIncrease profitWorking accessoriesStone-like material working toolsMachine visionBridge type

The invention discloses an intelligent stone cutting robot and a cutting method thereof. The intelligent stone cutting robot comprises an industrial control machine with intelligent software, a work table, an industrial camera, a camera fixing support, a base, a disk saw machine head, a cross beam, a pair of cross beam guide rails, a suction cup manipulator and an auxiliary light source, wherein the industrial control machine with the intelligent software is arranged on one side of the work table; the cross beam guide rails are arranged on two sides of the work table, the cross beam is arranged on the cross bean guide rails, the base is arranged on the cross beam, the disk saw machine head is arranged at the bottom of the base, and the suction cup manipulator is arranged at the bottom of the base; the industrial camera is arranged on the camera fixing support; the industrial camera is connected with the industrial control machine with the intelligent software; the auxiliary light source is arranged above the work table. Machine vision and robot technologies are introduced and combined with a production process management concept, traditional machines are improved and upgraded, a set of intelligent equipment is increased and is abutted against an original machine, accordingly, the original machine is converted into an intelligent infrared bridge type stone cutting robot, dependence on workers is reduced, the cutting efficiency is improved, and the stone utilization rate is increased.

Owner:李谋遵

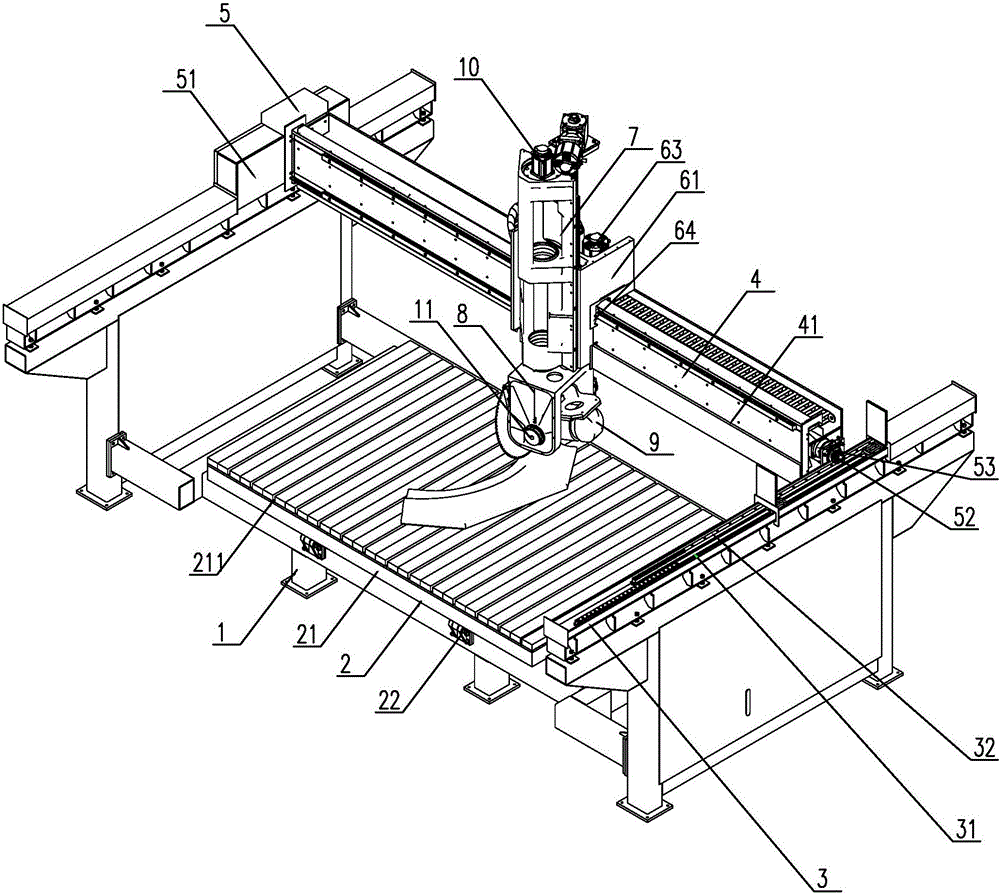

Five-axis numerically controlled stone cutting machine

ActiveCN105751382ADrive precisionDrive stabilityWorking accessoriesStone-like material working toolsSTONE CUTTERMachine tool

The invention relates to the technical field of numerically controlled machine tools and provides a five-axis numerically controlled stone cutting machine. The five-axis numerically controlled stone cutting machine comprises an operation platform, a two-arm longitudinal beam, a two-arm transverse beam, a lifting rotary frame, a turnover frame and a cutting head. The cutting head is capable of swinging around a horizontal rotary shaft relative to the turnover frame; the turnover frame is capable of rotating around a vertical rotary shaft and moving up and down along the vertical rotary shaft relative to the lifting rotary frame; the lifting rotary frame is capable of moving leftward and rightward on the two-arm transverse beam; the two-arm transverse beam is capable of moving forward and backward on the two-arm longitudinal beam. The five-axis numerically controlled stone cutting machine has the advantage that by structural combination of the longitudinal beam, the transverse beam, the lifting rotary frame and the turnover frame, the cutting head is capable of moving vertically, transversely and longitudinally and rotating around the vertical shaft and the horizontal shaft respectively, so that free variation of operation angles and distances is realized.

Owner:唐山市洪志机械设备制造有限公司

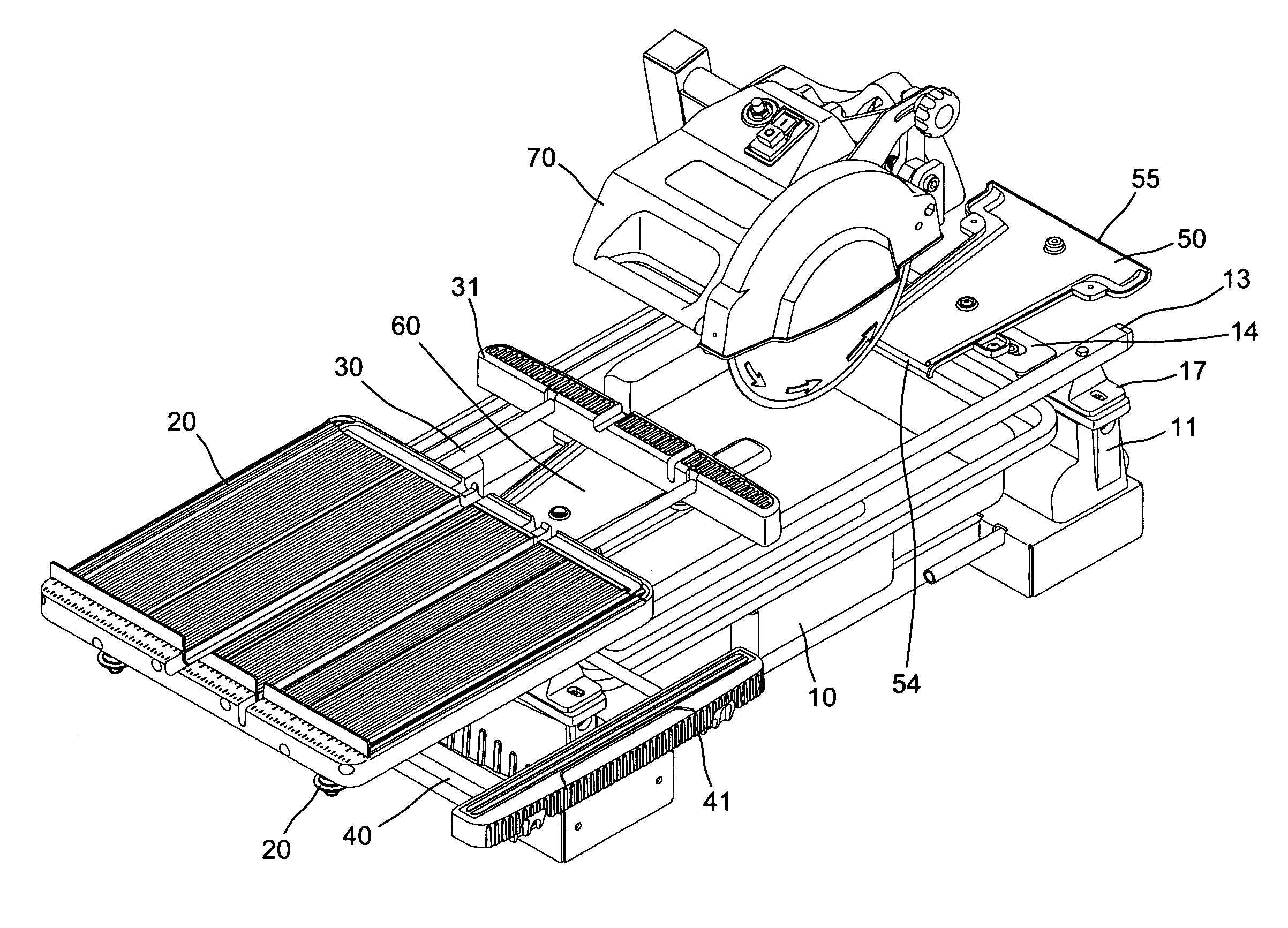

Platform minute adjustment, expansion and water collection devices

InactiveUS20080173294A1Improve cutting accuracyWorking accessoriesStone-like material working toolsSTONE CUTTEREngineering

A platform minute adjustment, expansion and collection device for a stone cutter includes a water tank supported by a pair of racks, a pair of guide rods spacedly bridged on the racks, a first water collection plate and a second water collection plate, both of which are slantly disposed to a front rack, a platform having a pair of rotors on the lower side thereof and slidably engaged on the inner sides of the guide rod. The platform has a pair of expansion plates for enlarging its size and for cutting a large-sized working piece, and two minute adjusting devices mounted on the tops of the racks for displacing the platform slightly, such that the sawdust may be stopped scattering all over the working place.

Owner:CHEN YUEHTING

Cutting angle adjustment device for a stone cutter

InactiveUS7552725B2Easy to adjustThe result is accurateGuide fencesShearing machinesCouplingSTONE CUTTER

A cutting angle adjustment device for a stone cutter includes a rectangular water sink, an inverse L-shaped support arm anchored to a lateral side of the sink, a stone cutter adjustably connected to the support arm through a coupling assembly, a pair of guide rods parallel disposed to a pair of rack on front and rear ends of the sink, a platform having two rotors aligned to each other and symmetrically arranged and slidably engaged with the inner sides of the guide rods, a vertical cutting slit and a slant cutting slit parallel formed in the upper surface thereof. Thereby, a saw blade is adjusted vertically and / or slantly relative to the top of the platform to conduct a vertical or slant cutting and a shallow or deep cutting of the workpiece.

Owner:CHEN YUEHTING +1

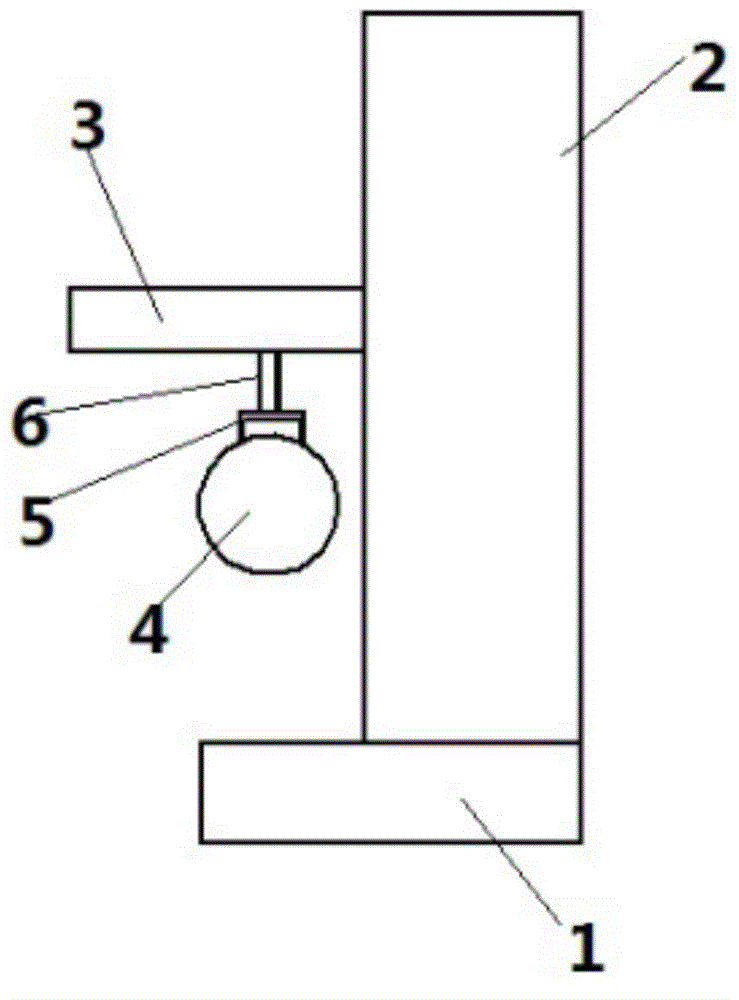

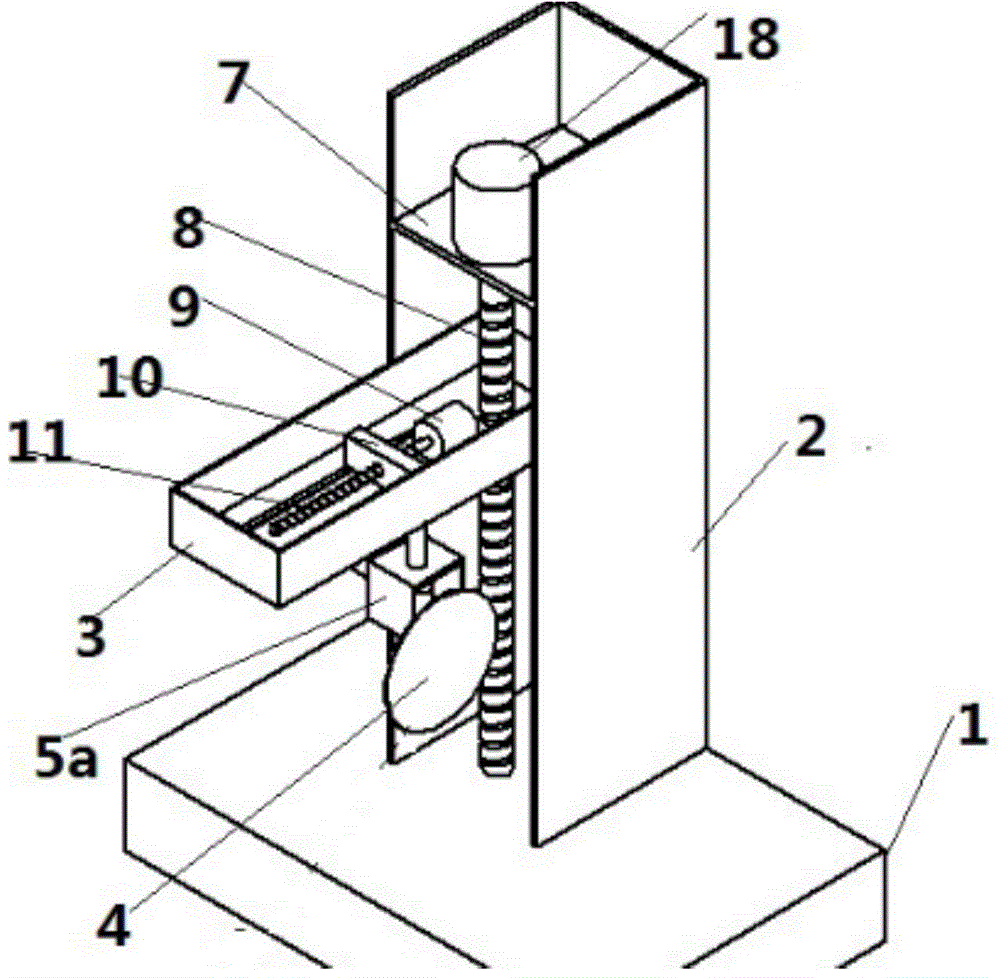

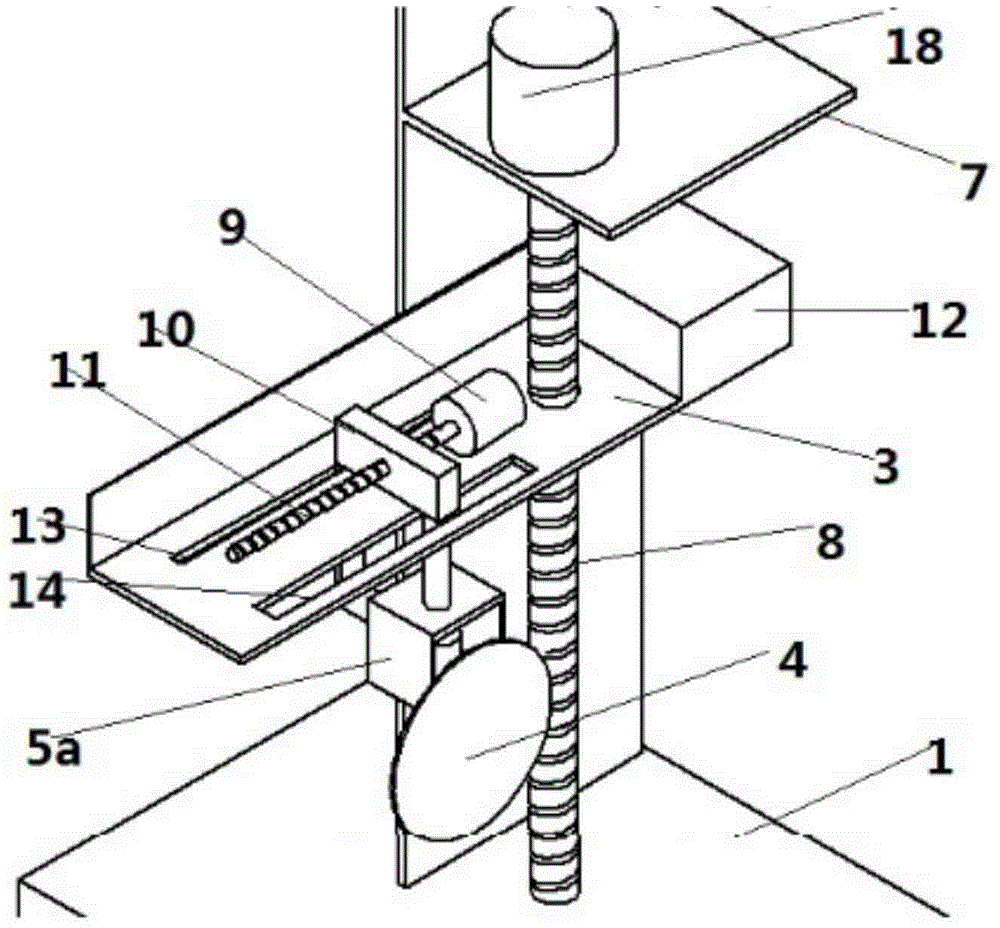

Computer numerical control profiling stone cutting machine capable of enabling cutter to rotate freely

InactiveCN103600425AEasy to controlVarious cutting methodsStone-like material working toolsNumerical controlFree rotation

A computer numerical control profiling stone cutting machine capable of enabling a cutter to rotate freely is mainly composed of a base, a vertical supporting column, a horizontal movement mechanism and the cutter, the cutter can move in the vertical direction, can move in the horizontal direction and can freely rotate in a horizontal plane, meanwhile, the cutter is driven to move vertically and move left and right through screw rods and nuts, more precise control is achieved, the movement of the cutter in all directions is achieved through numerical control, and the computer numerical control profiling stone cutting machine has the advantages of being precise in cutting, having diversified cutting methods, being easy to operate, simple in manufacturing, low in price and strong in practicality and the like.

Owner:青岛中科菲力工程技术研发有限公司

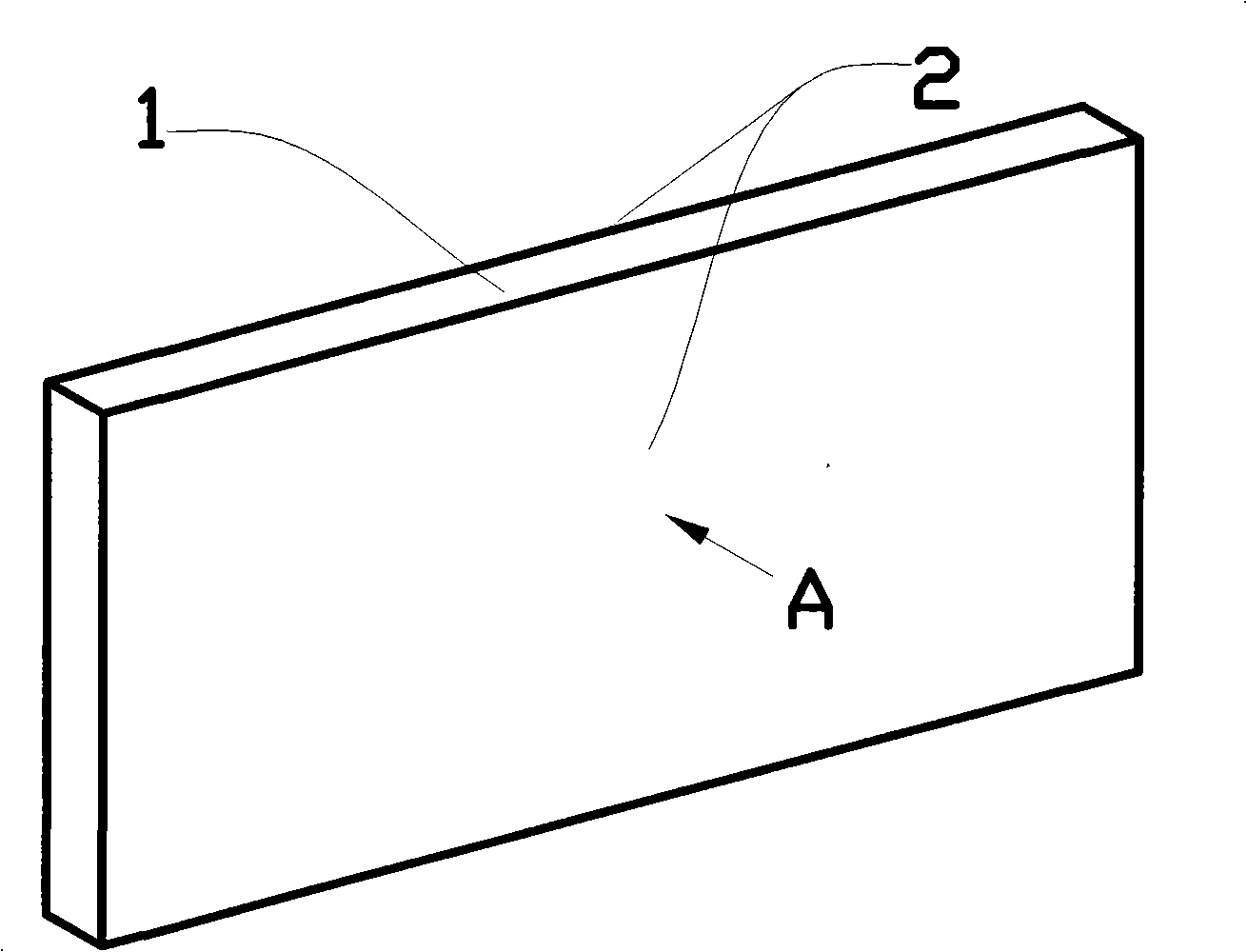

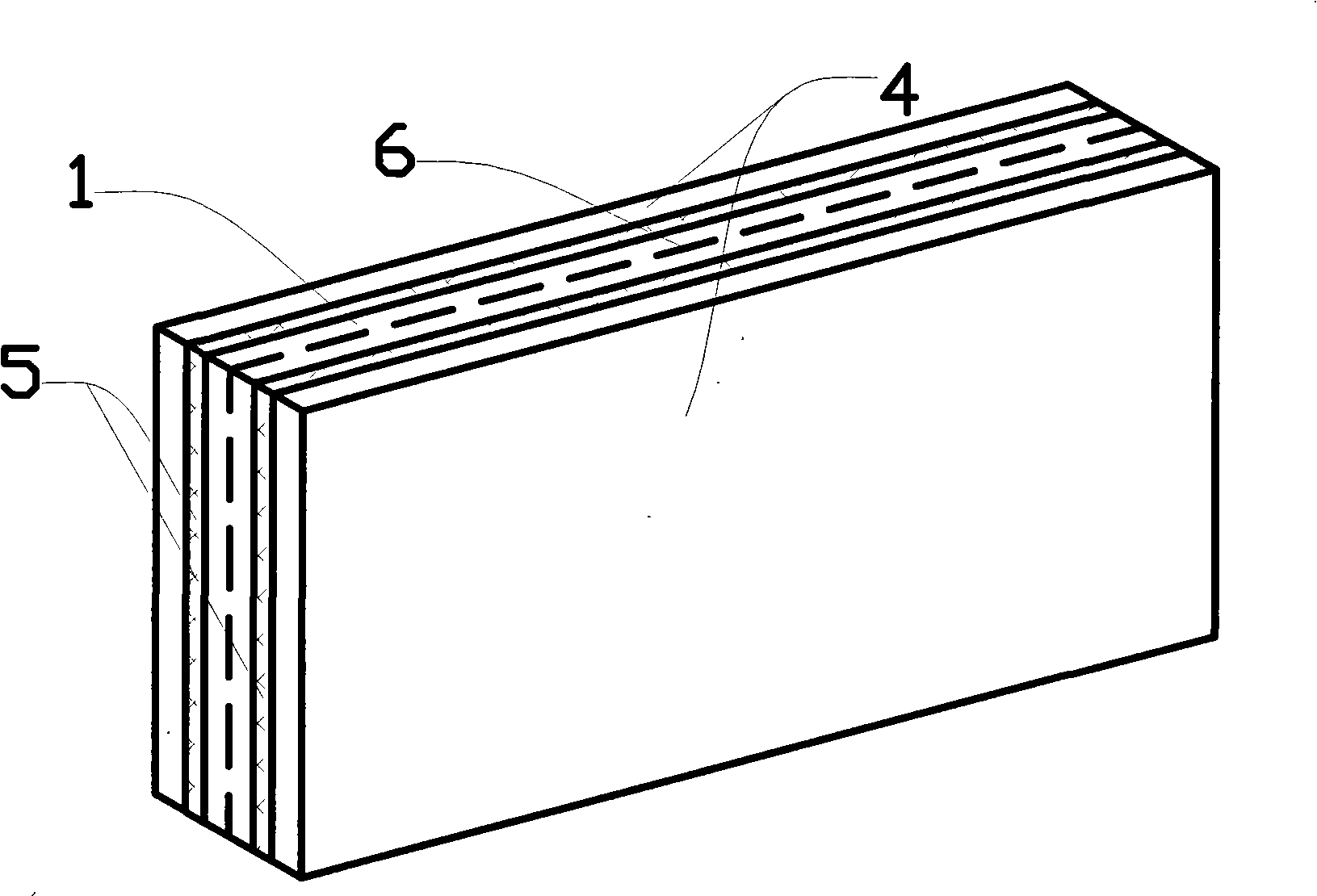

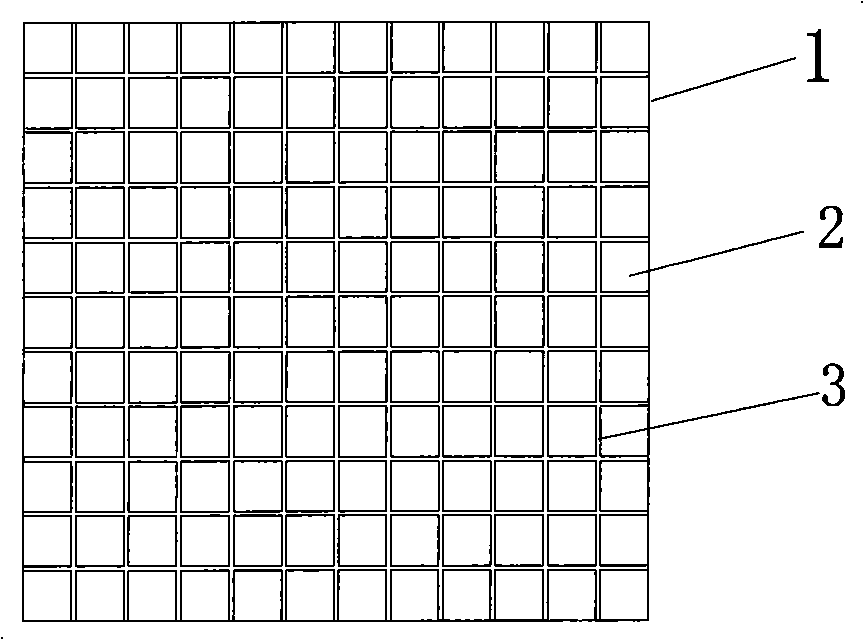

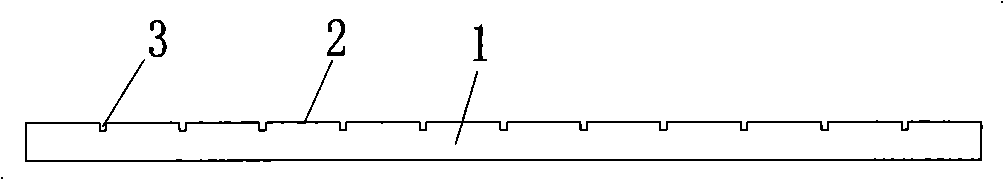

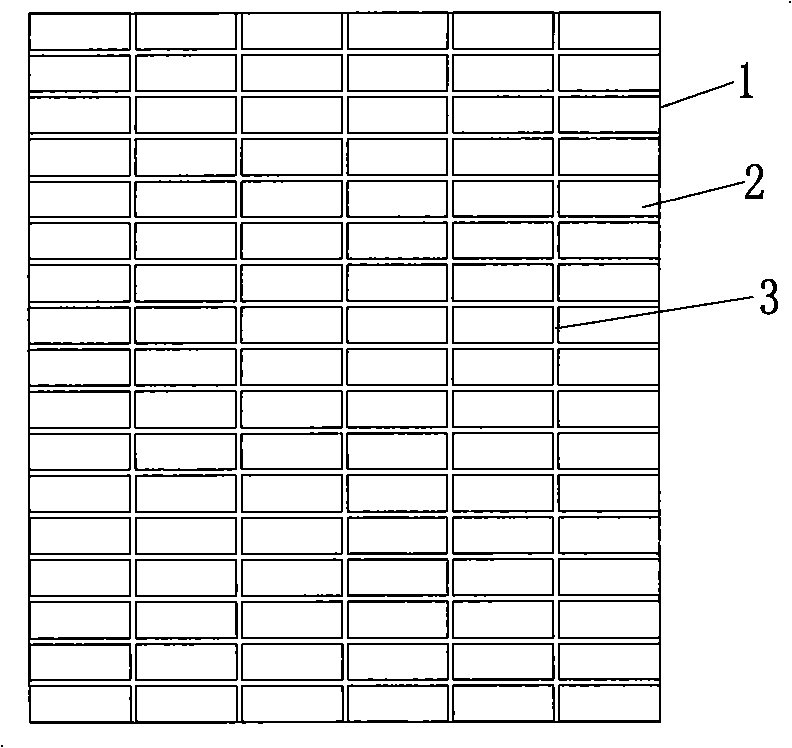

Stone mosaic brick and method for making same

The invention discloses a stone mosaic brick and a manufacturing method thereof, and relates to a stone. A stone mosaic brick which not only is simple in manufacturing technique, low in manufacturing cost, capable of employing the mounting manners like paving or dry-hanging and can realize large-scale production and mass production, but also can achieve the mosaic effect after the paving or the dry-hanging, and a manufacturing method thereof are provided. The stone mosaic brick is stone brick, a scratch slot, which is a mosaic pattern particle scratch slot, is provided on the surface of the stone brick. The mosaic pattern is provided on the stone brick in accordance with design requirement; by using a stone cutting machine, the scratch slot is scratched in terms of the mosaic pattern on the stone brick provided with the mosaic brick, namely, the stone mosaic brick is obtained. The stone brick can be natural stone brick or stone composite board brick.

Owner:厦门捷报进出口有限公司

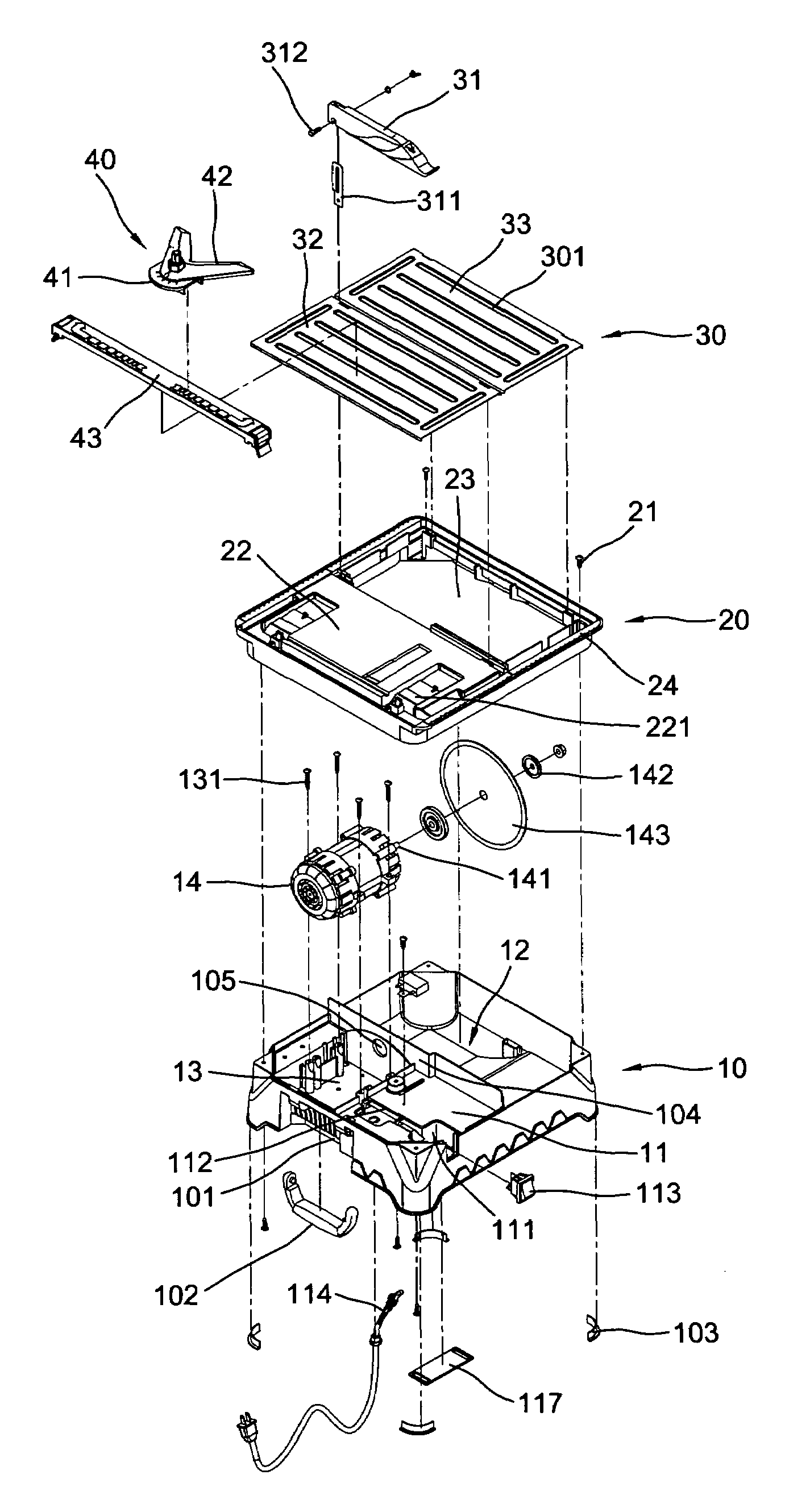

Cutting machine for stone materials

ActiveUS20110232620A1Reduce weightReduce material usageWorking accessoriesMetal working apparatusSTONE CUTTERSlope angle

The present invention provides a cutting machine for stone materials having a power head part, a bedplate, a frame for supporting the bedplate and a basin disposed under the frame. The present invention may also have an expanded basin disposed outside of the basin and a water-retaining device with an upward slope angle may be arranged on the expanded basin to block splashed muddy water in a multi-directional manner during a cutting operation.

Owner:CHERVON HK LTD WANCHAI

Stone cutting machine

InactiveCN108638350AReduce maintenance costsHigh precisionWorking accessoriesStone-like material working toolsSTONE CUTTERGear wheel

The invention relates to a stone cutting machine. The stone cutting machine comprises a base, a guide rod, a moving module, two lifting modules and two brackets, and further comprises a fixing mechanism and a cutting mechanism; the cutting mechanism comprises a first driving module, a reinforcing rod, a blade, a first protective cover, a connecting shaft, two first transmission rods, two second protective covers and two connecting sleeves; and the fixing mechanism comprises a support rod, a second driving module, two transmission modules, two moving sleeves, two clamping rods, two second transmission rods and two first gears. In the stone cutting machine, as the cutting mechanism drives the two second protective covers to rotate around the connecting shaft, under the protecting effect of the first protective cover and the two second protective covers on the blade, the damage probability of the blade is reduced; and the fixing mechanism drives the two clamping rods to move, so that thestone stability is improved under the effect of the clamping rods, and the precision of the stone cutting machine is improved.

Owner:永春福源建材科技有限公司

Stone cutter with rotary saw bit

InactiveCN103770222AEasy to cutCut fitStone-like material working toolsProgrammable logic controllerSTONE CUTTER

The invention relates to the field of stone cutting equipment, in particular to a stone cutter with a rotary saw bit. The stone cutter with the rotary saw bit comprises a worktable which is installed on a bottom support, and a lower frame upper support is arranged on the worktable; a rotary disc is arranged at the middle part of the bottom surface of a horizontal beam of the lower frame upper support, a telescopic cylinder is arranged at the middle part of the bottom surface of the rotary disc and the telescopic cylinder is connected with a saw bit; a servo motor is arranged at the middle part of the upper surface of the horizontal beam of the lower frame upper support and the servo motor is connected with the rotary disc. Since the saw bit with the rotary disc is adopted and the direction of the saw bit is controlled through a PLC (Programmable Logic Controller) on the worktable, the cutting is facilitated; the cutting speed is fast, the stone cutter is convenient and practical, the working efficiency is improved, the production cost is reduced and the stone cutter is applicable to the cutting of stones with complex shapes.

Owner:刘懿

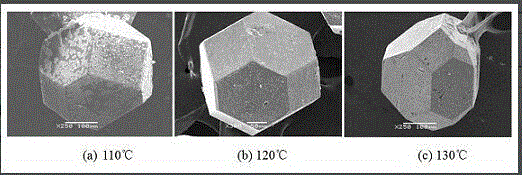

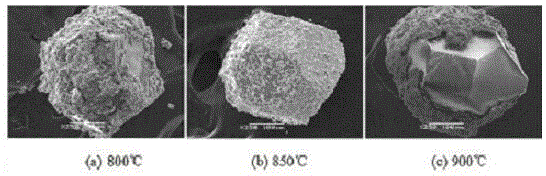

Novel composite coating of diamond applied to stone cutter

ActiveCN105177540ASimple methodLow costLiquid/solution decomposition chemical coatingSTONE CUTTEREconomic benefits

The invention provides a preparing technology of a surface hydrothermal composite titanizing and tungsten plating metal layer of the diamond applied to a stone cutter, and belongs to the technical field of diamond surface plating metal layer film preparing. The low-temperature pressure plating and high-temperature thermal treatment technology is achieved, the continuity and uniformity of an obtained film are good, the shape is regular, the thickness is controllable, the strength of the diamond is improved, and the anti-corrosion capability and bonding performance under the high temperature are improved. The service life of the manfuactured cutter during stone cutting is greatly prolonged, the efficiency of the manufactured cutter during stone cutting is greatly improved, and economic benefits are obvious. The preparing method is simple and low in cost, and large-scale production is easy to achieve. Thus, the technology method has very wide application prospects.

Owner:SHANDONG JIANZHU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com