Forward multistage vertical multi-saw web combined continuous stone cutter

A technology of multiple saw blades and cutting machines, which is applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of low efficiency and slow cutting speed, so as to reduce waste, improve cutting efficiency, and increase feeding speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

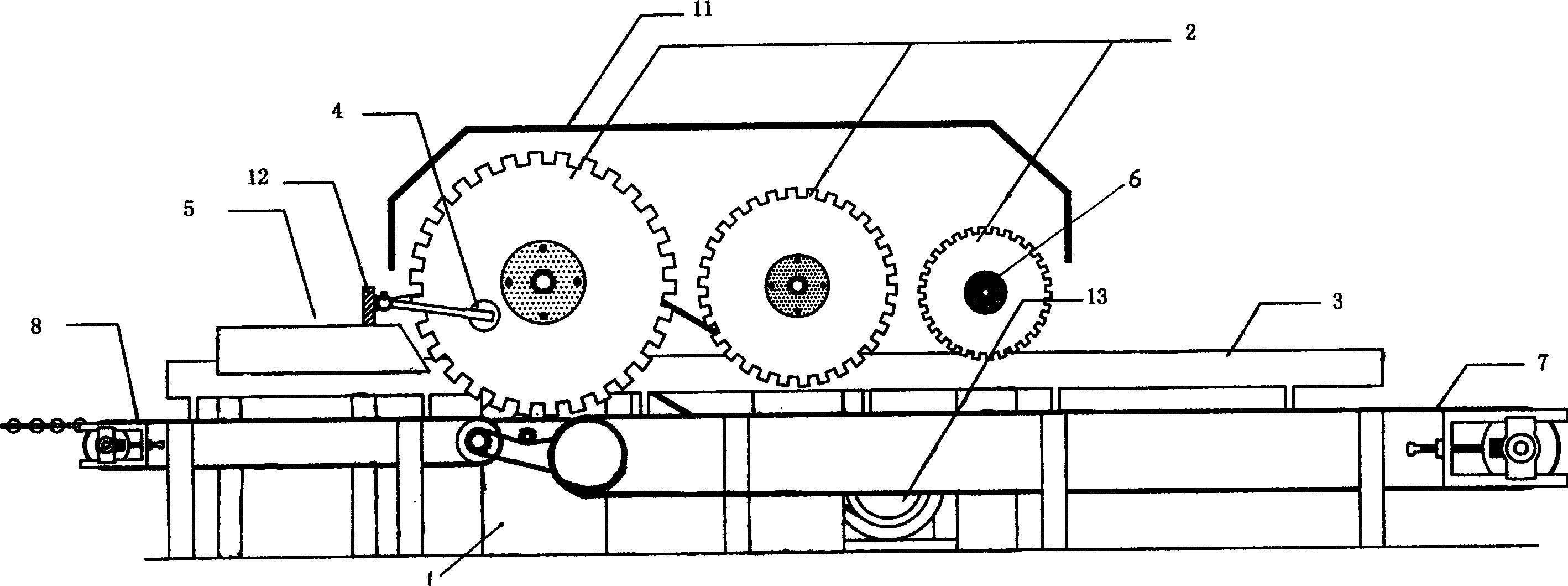

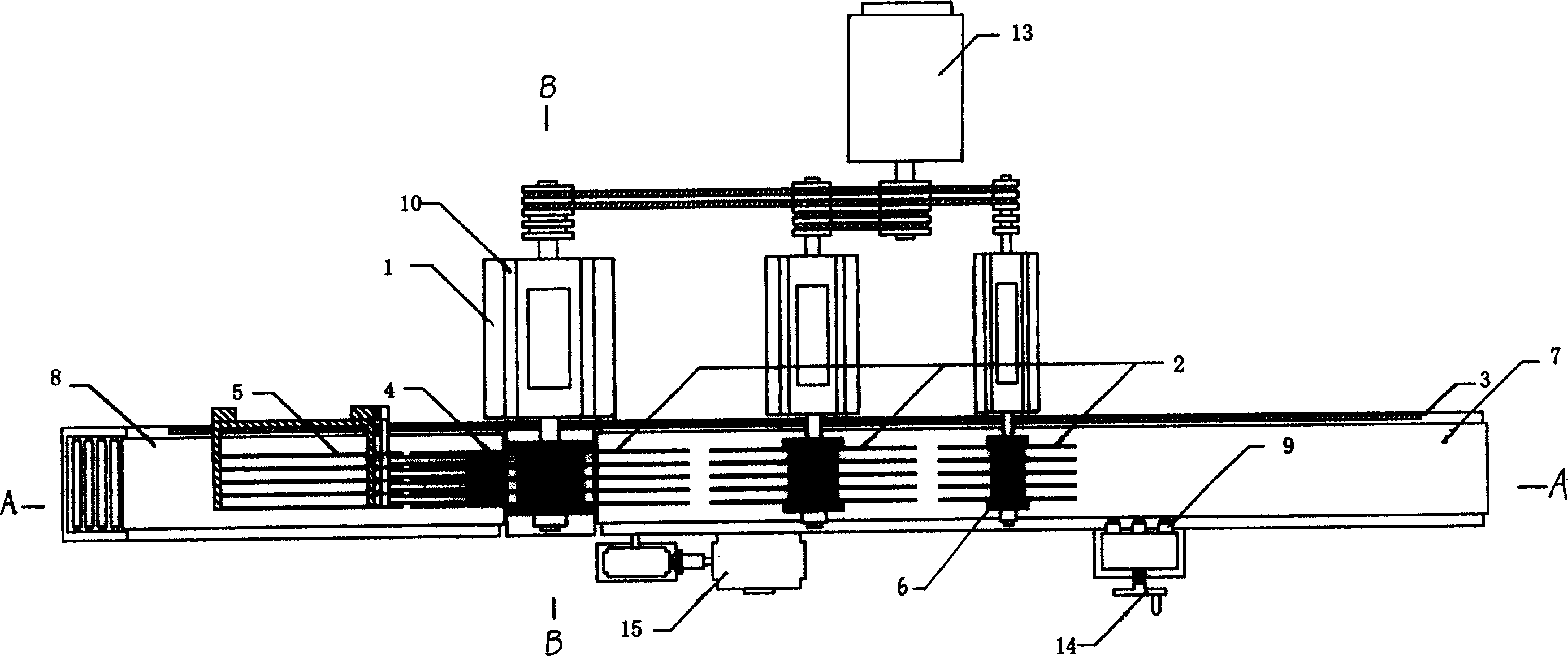

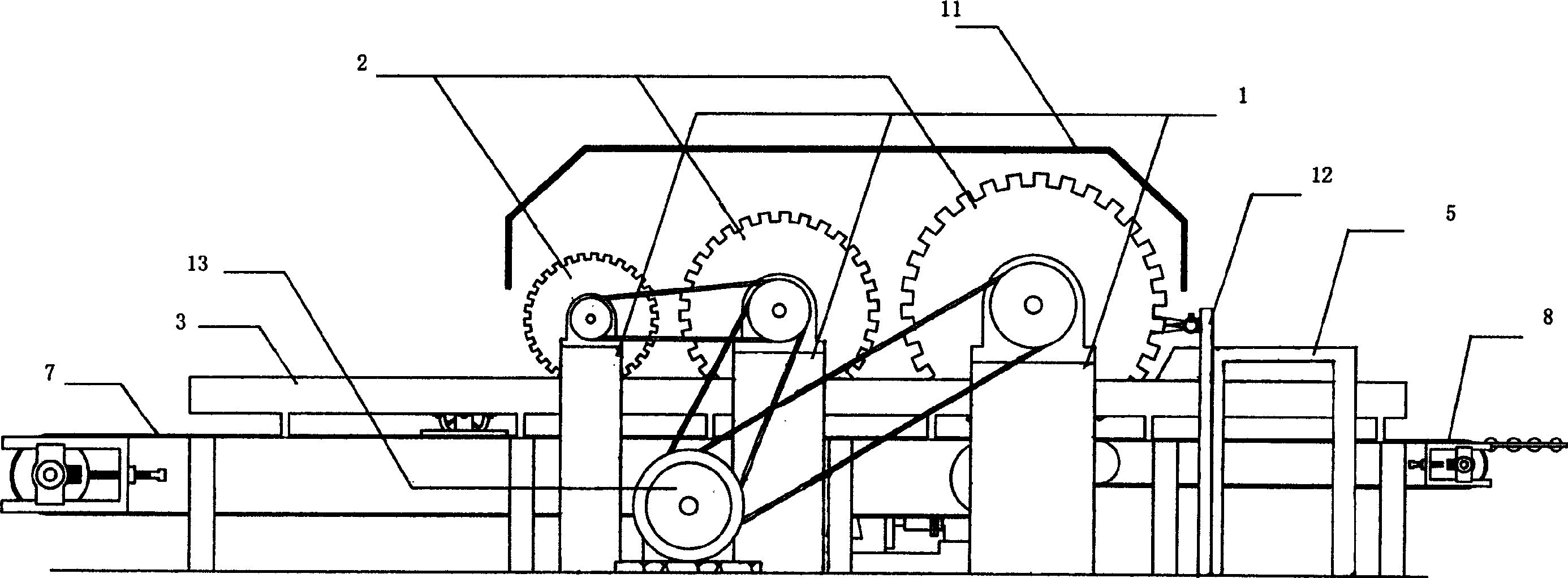

[0022] Such as Figure 1 to Figure 5 As shown, the conveyor belt for transporting stones is installed. The conveyor belt is divided into a front conveyor belt 7 and a rear conveyor belt 8. The conveying speed of the rear conveyor belt 8 is designed to be greater than the conveying speed of the front conveyor belt 7, so that the cut stone slabs can be sent away as soon as possible. Avoid clogging the conveyor belt. Front conveyer belt and rear conveyer belt can be driven with same motor 15, also can be designed to drive with different motors respectively for front and rear conveyer belt. When the front and rear conveyor belts are driven by the same motor, the diameter of the pulley of the rear conveyor belt can be designed to be smaller than the diameter of the pulley of the front conveyor belt. In order to meet the needs of various stone materials with different hardness, different feed rates and cutting depths, a speed control system can be set between the conveyor belt and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com