Patents

Literature

1373results about "Stationary drilling machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

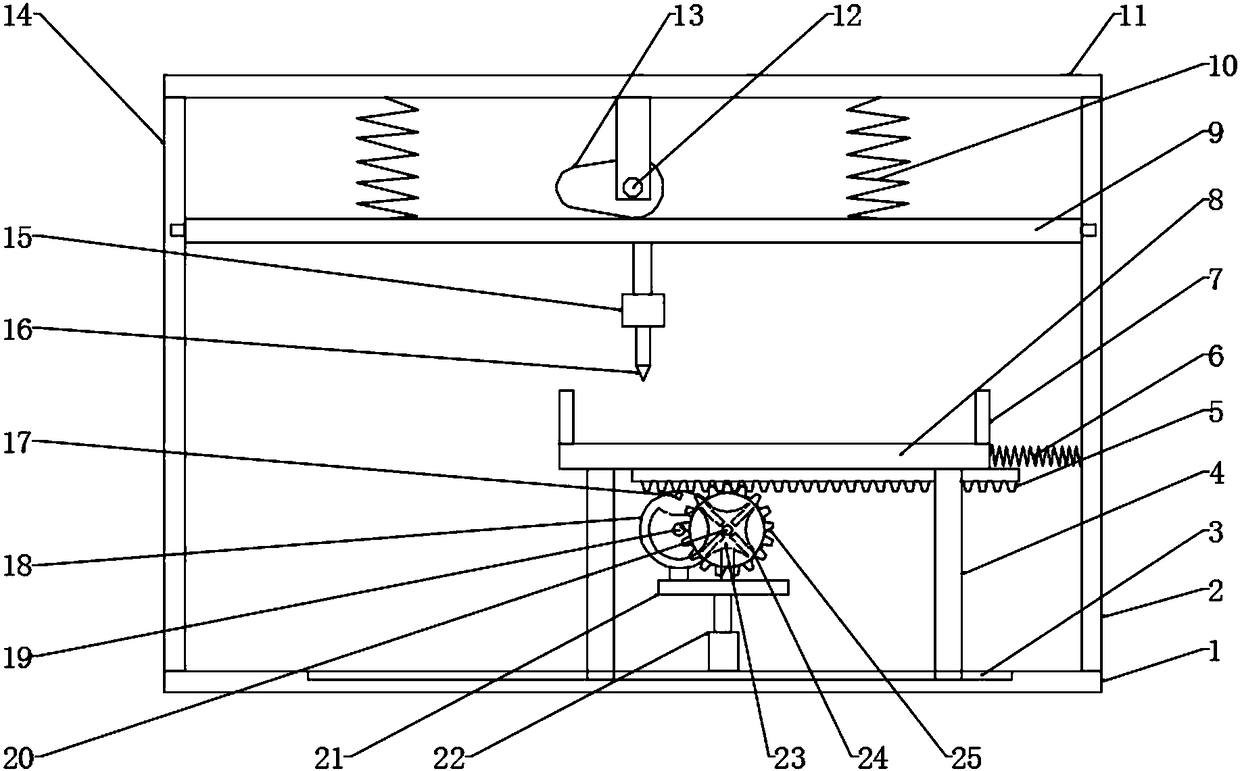

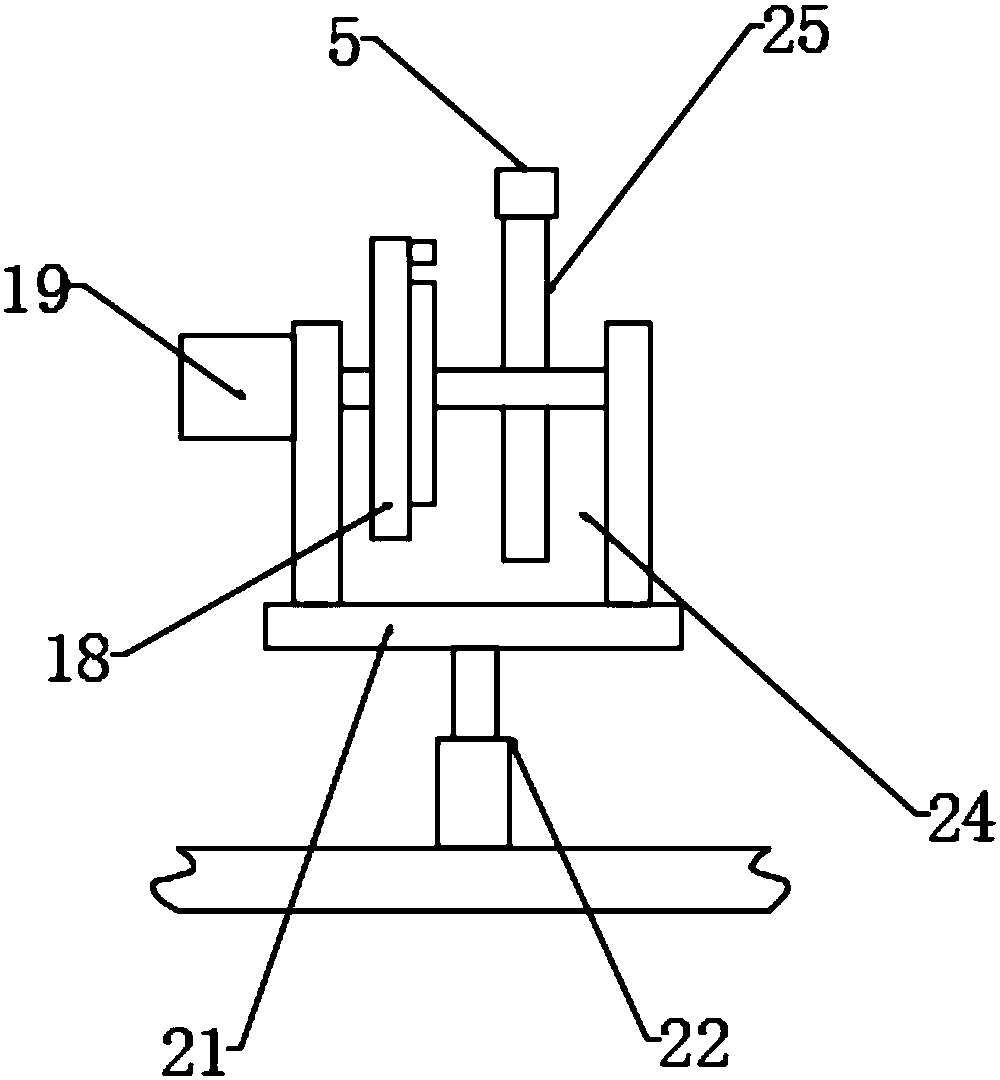

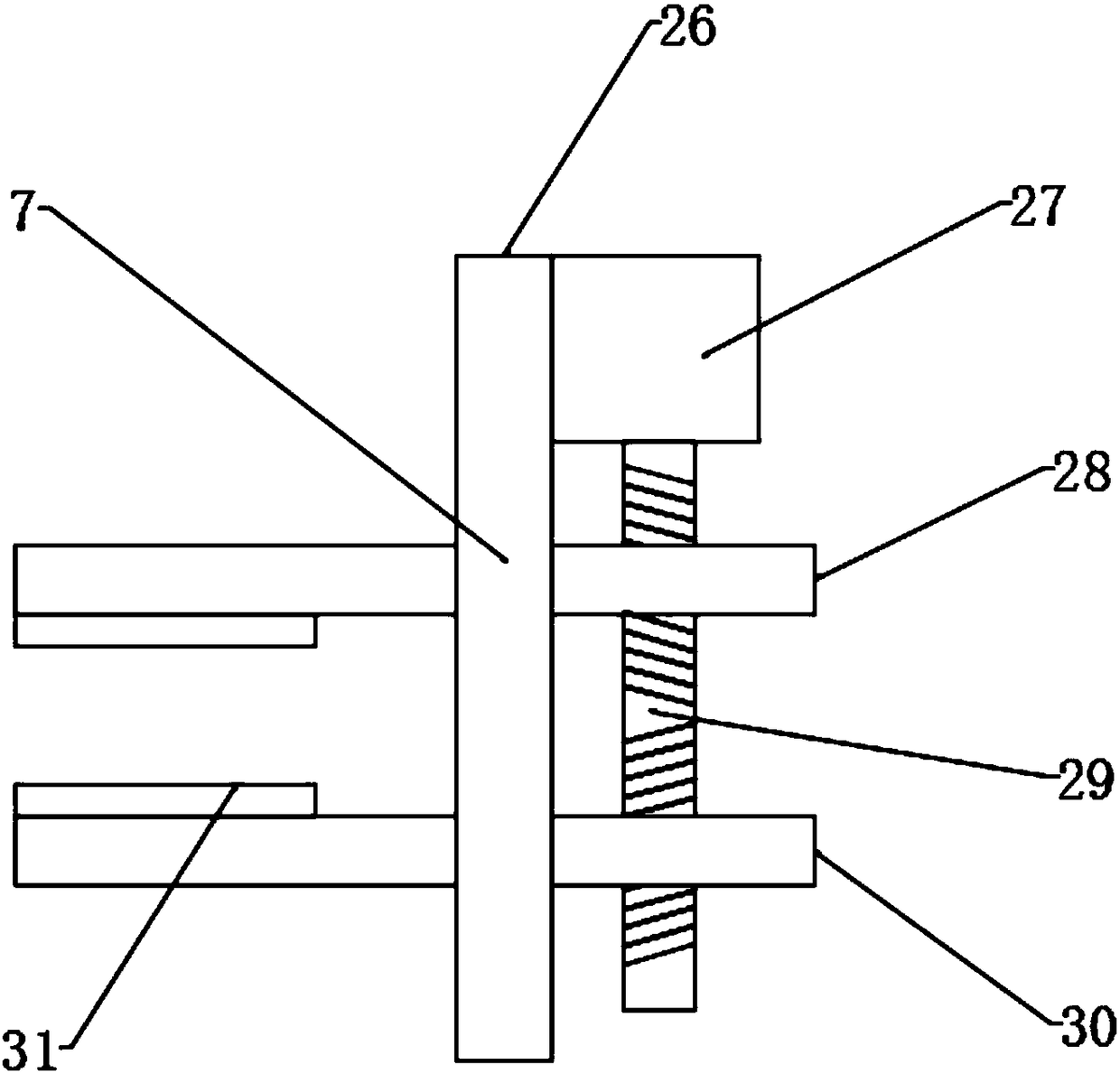

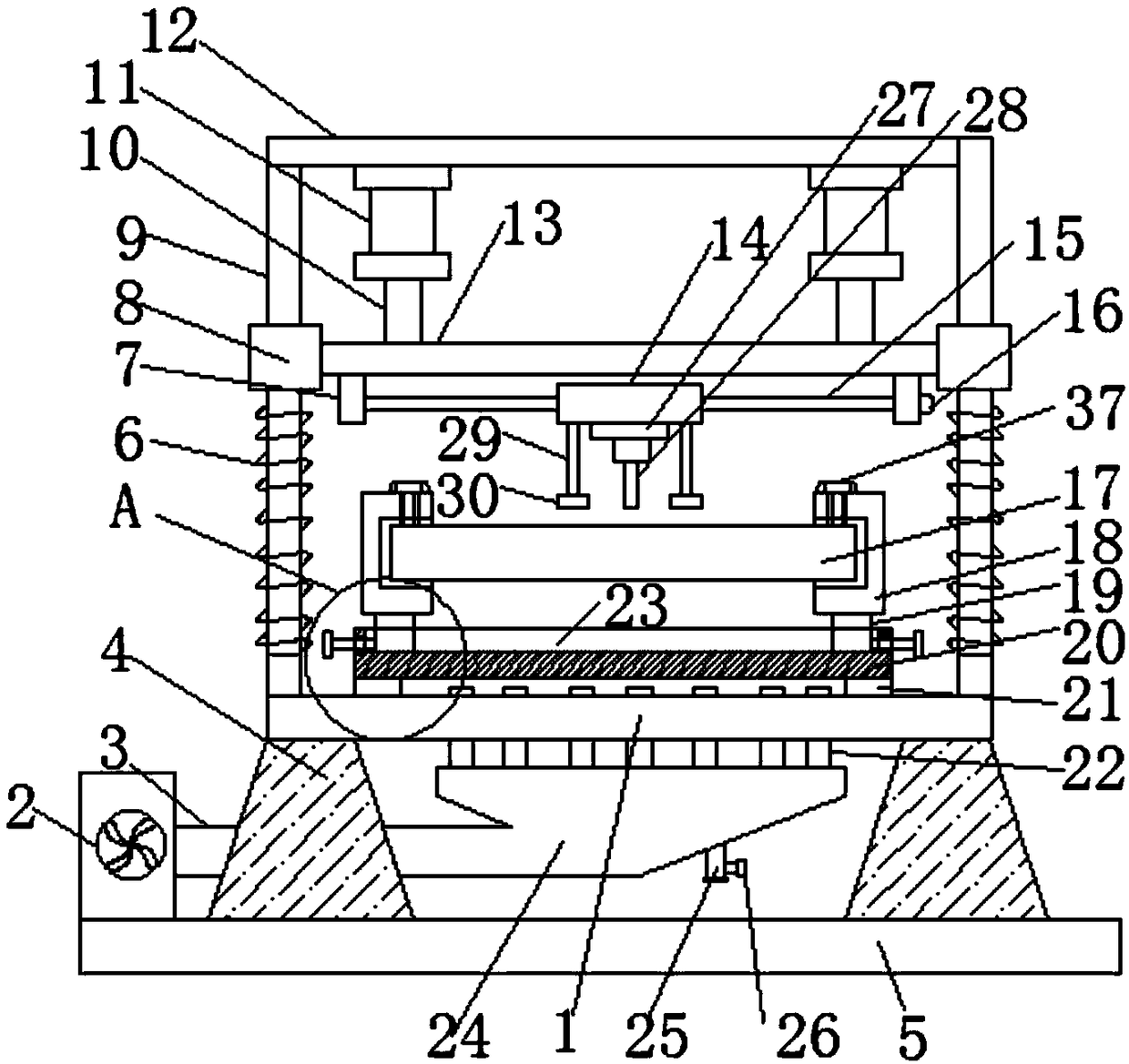

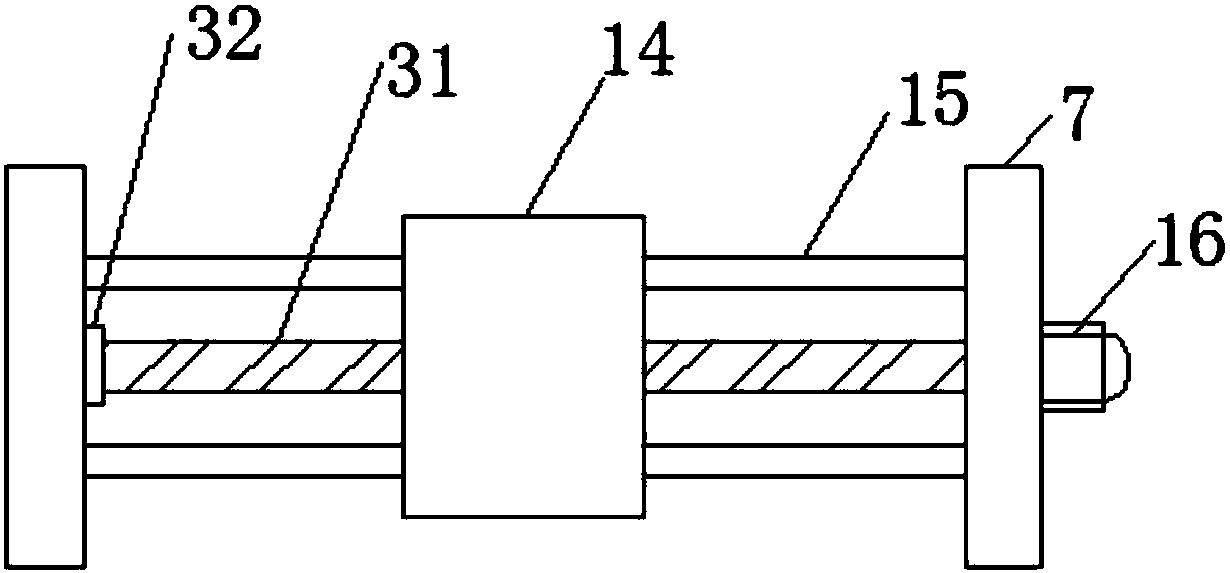

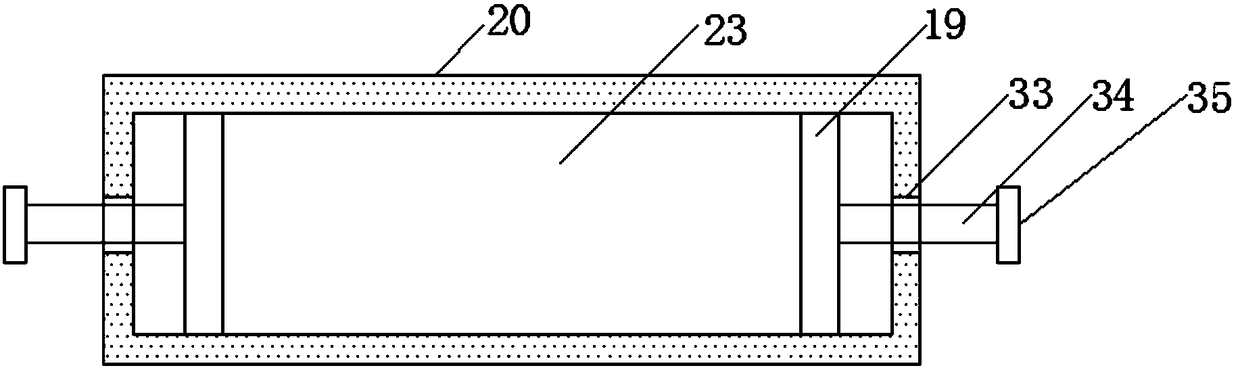

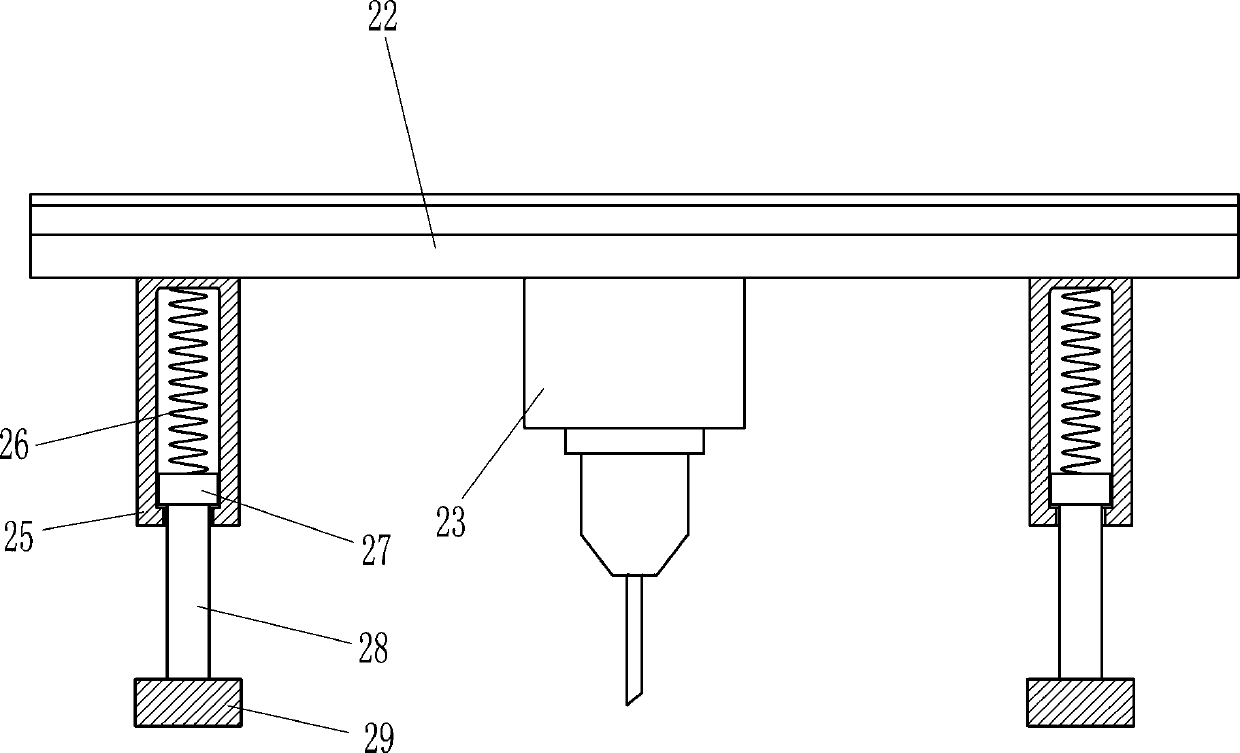

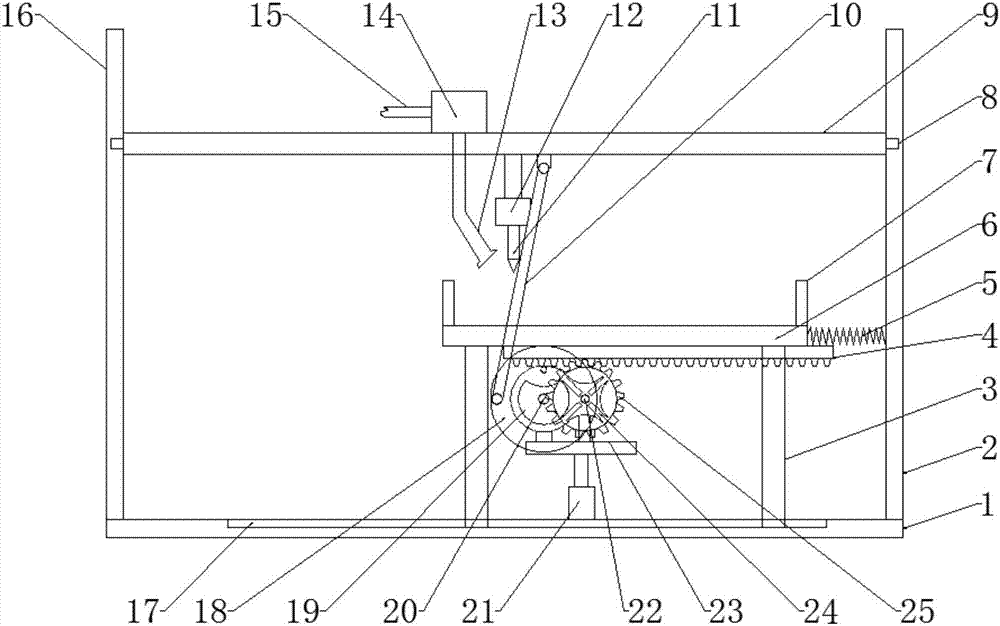

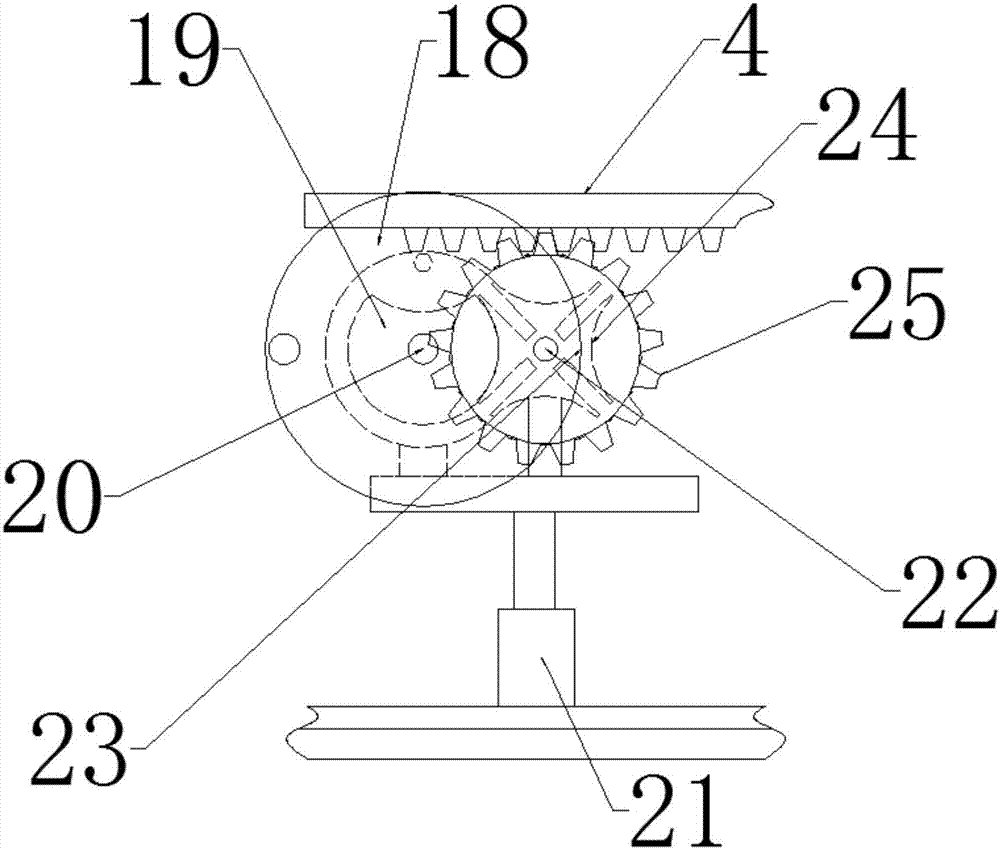

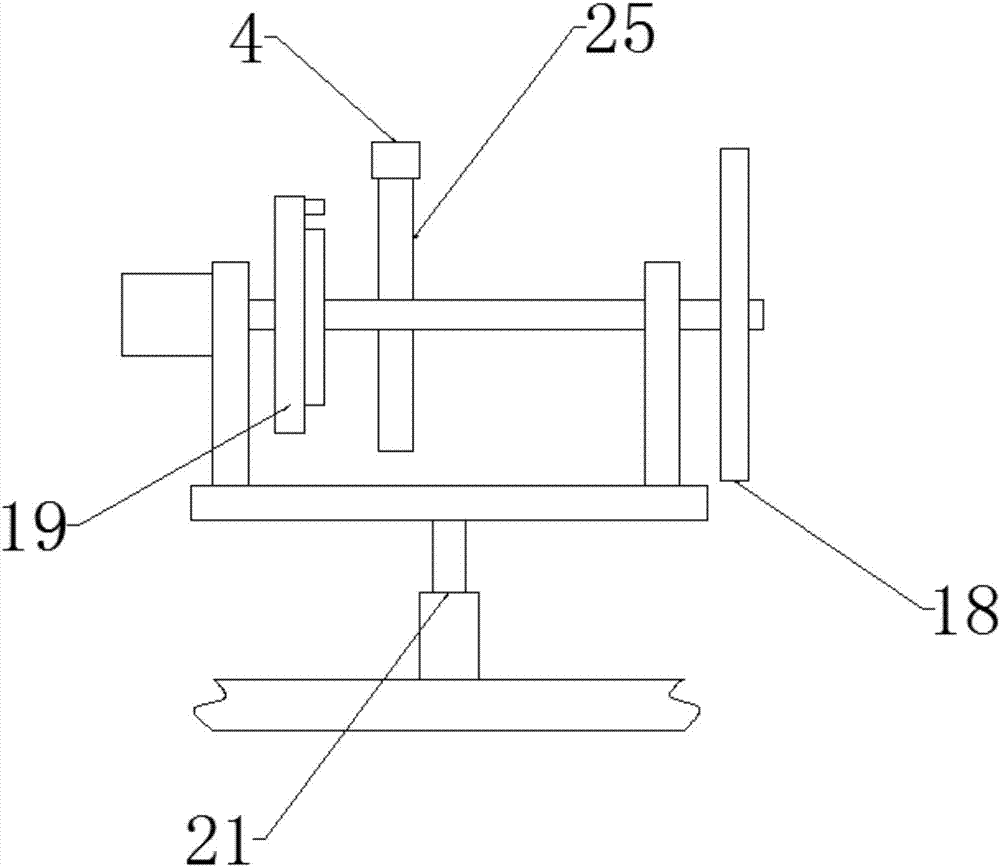

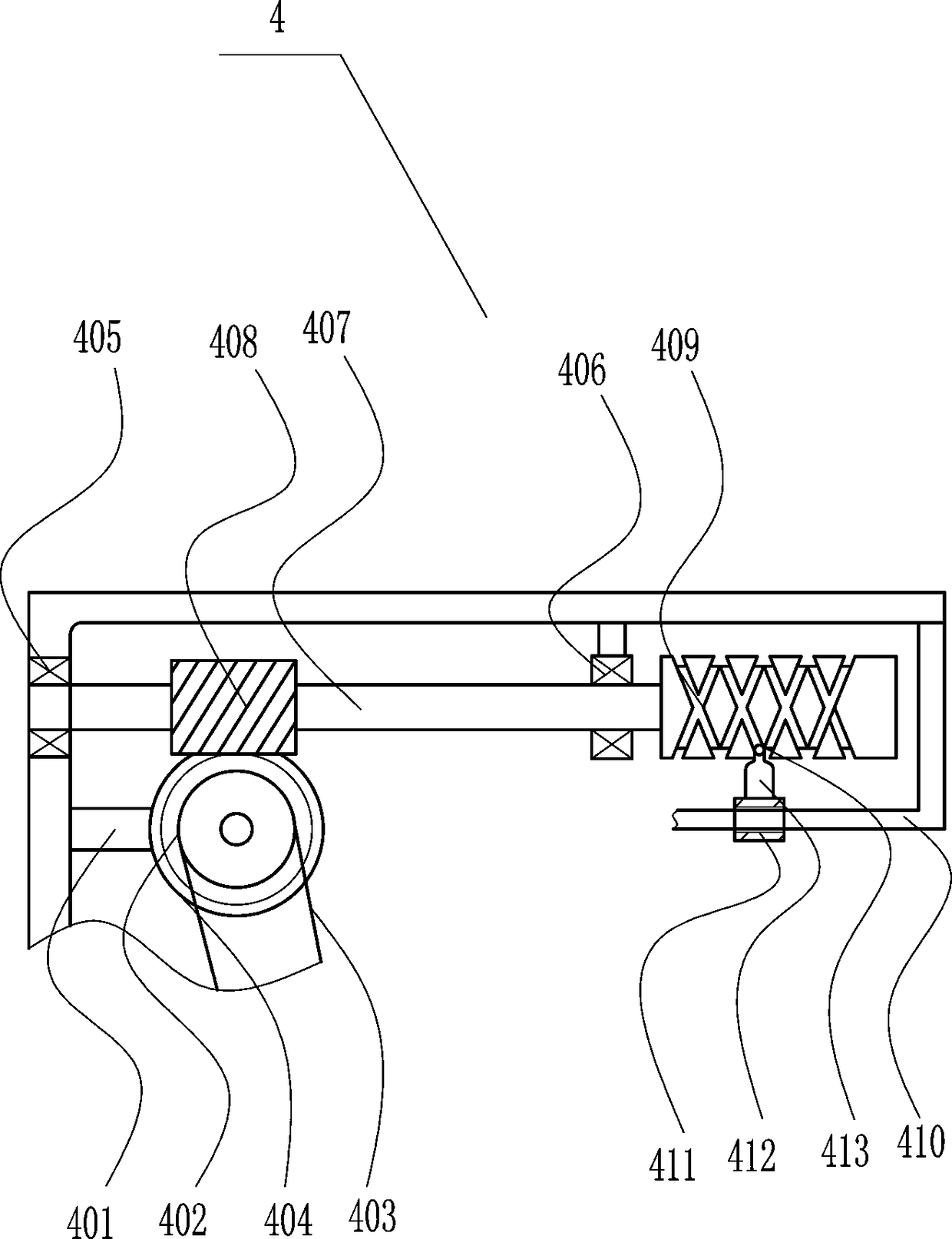

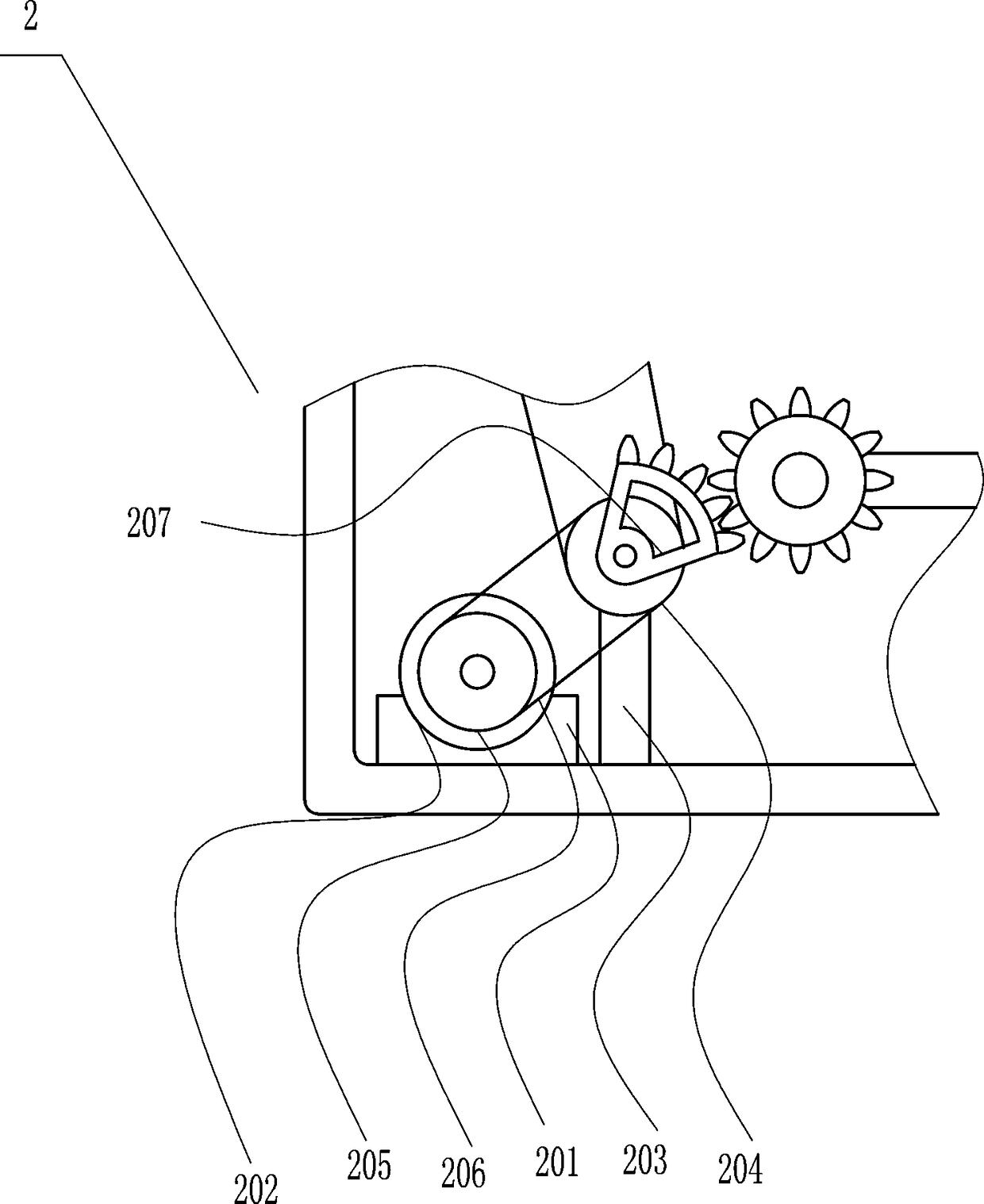

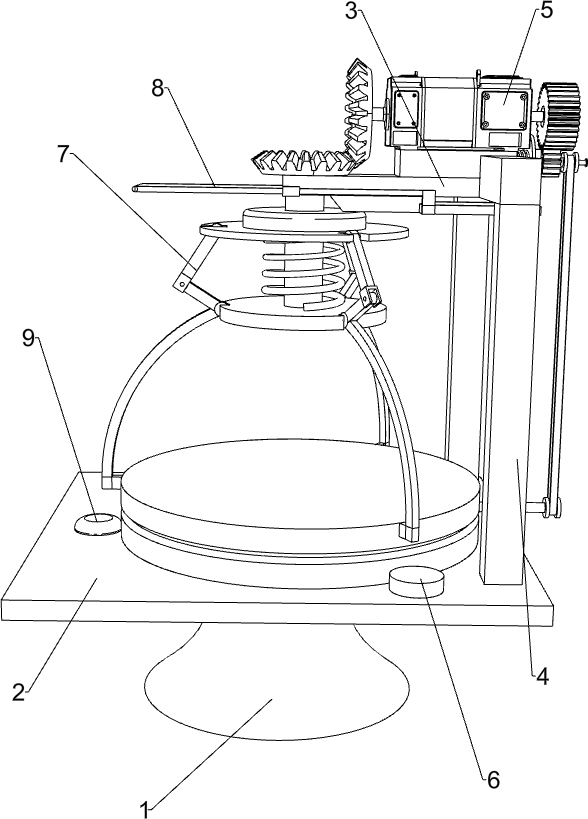

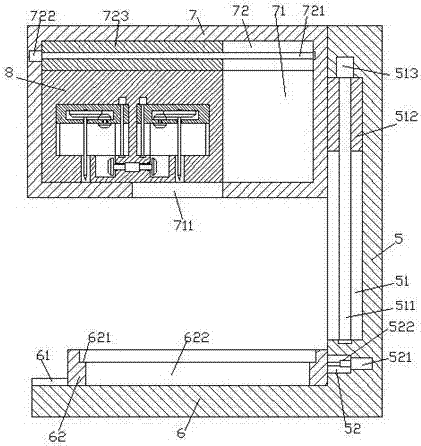

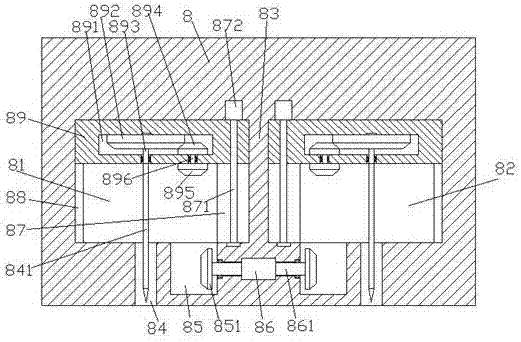

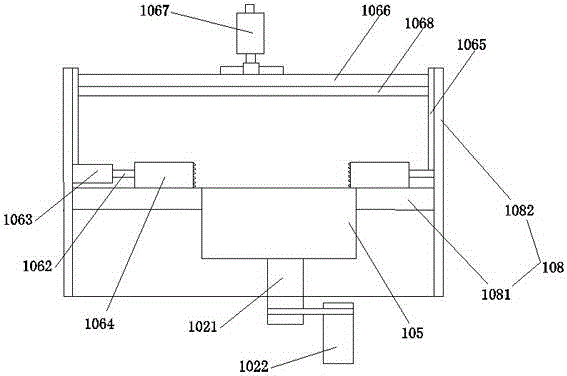

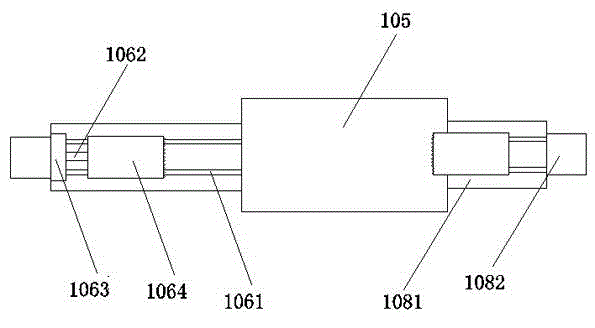

Highly efficient equidistant drilling equipment for furniture plates

InactiveCN108127460ASimple structureImprove drilling efficiencyStationary drilling machinesMetal working apparatusGear wheelSlide plate

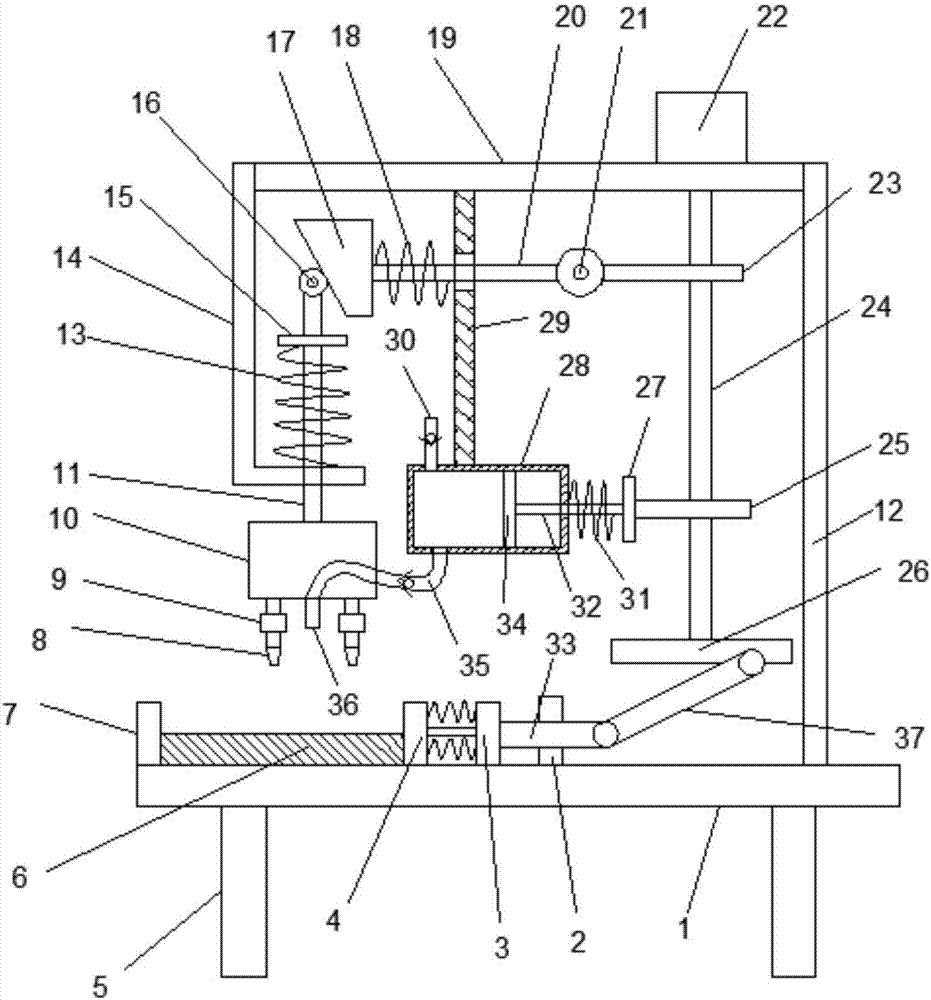

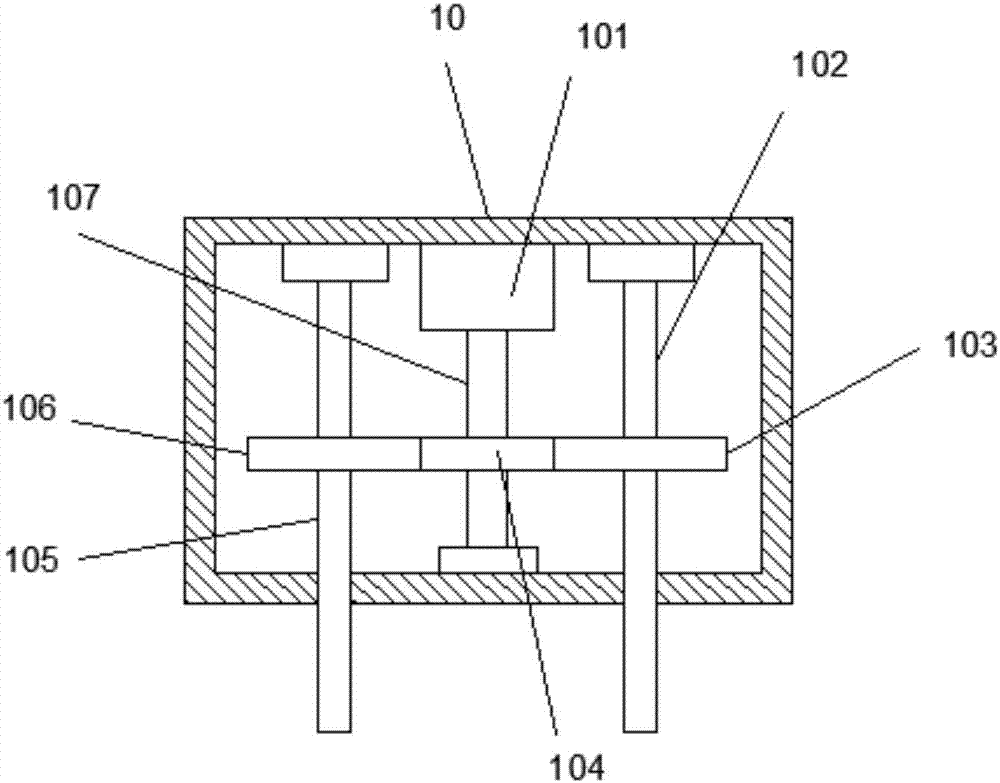

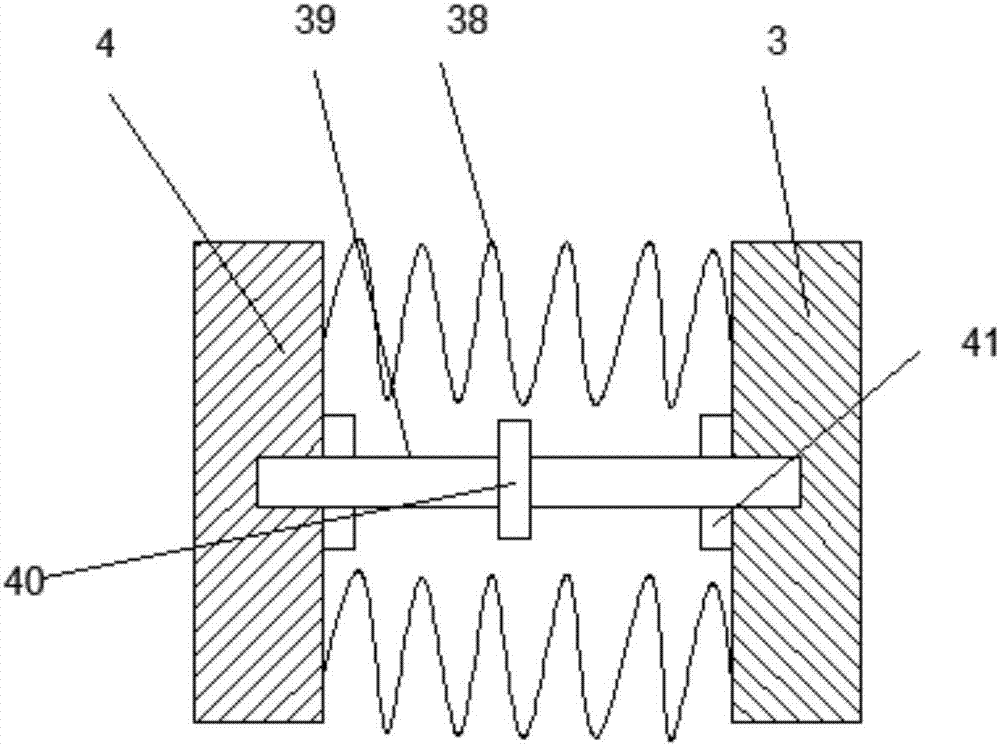

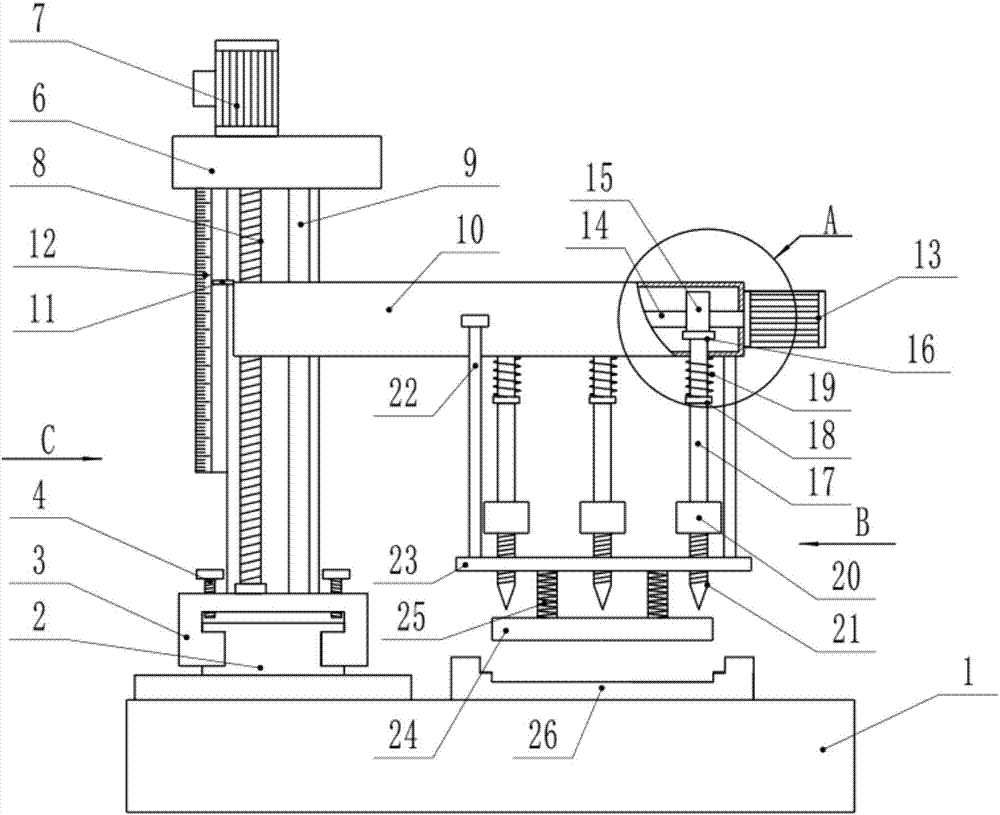

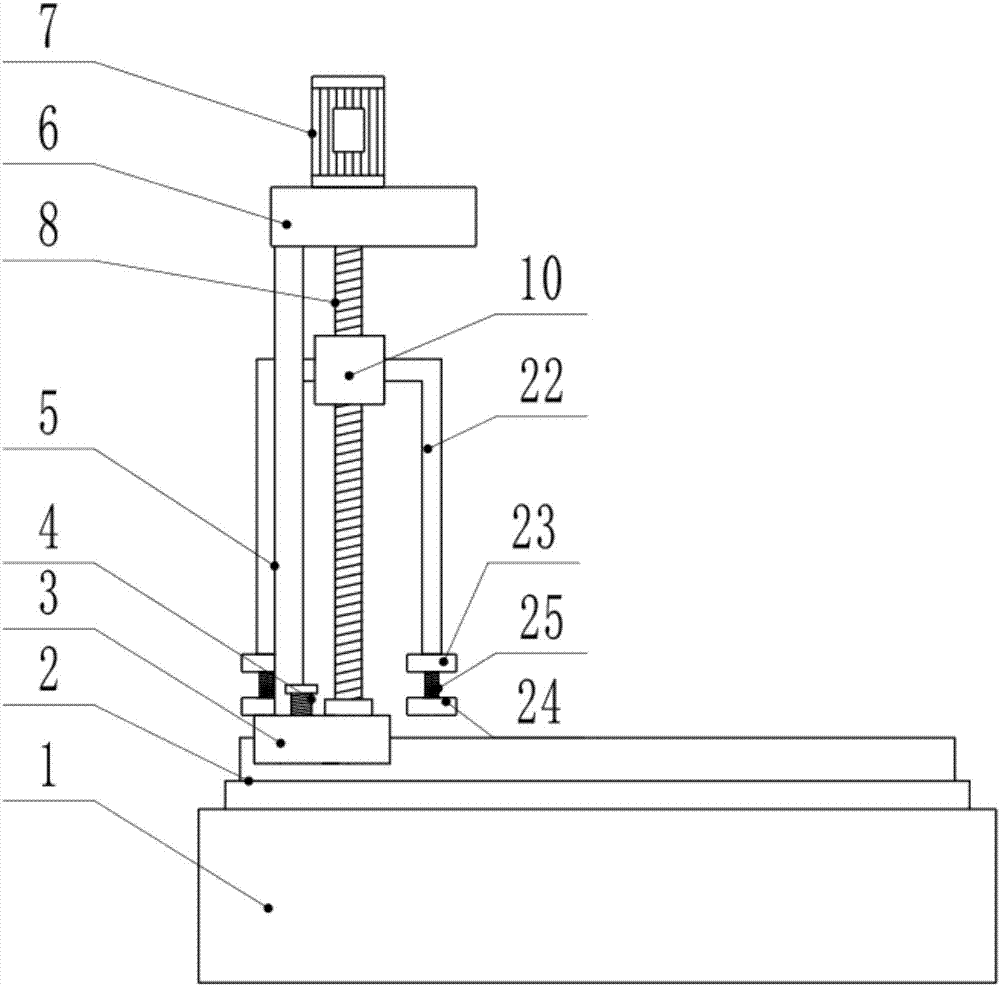

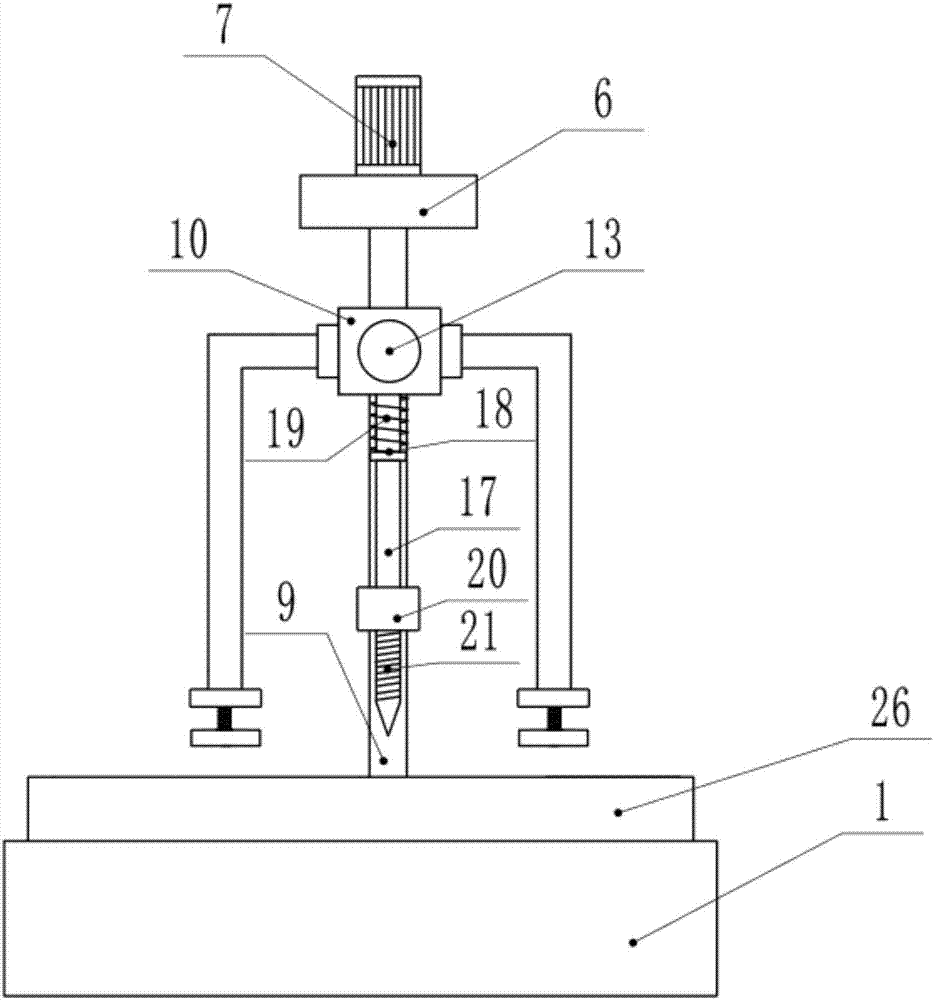

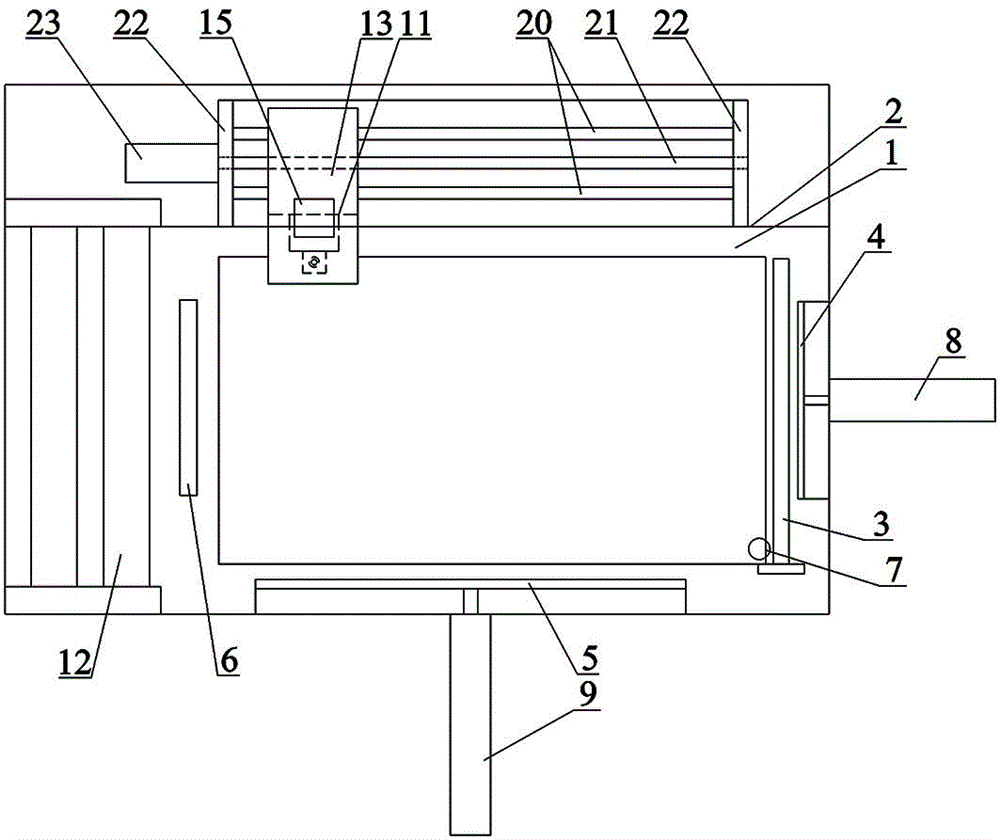

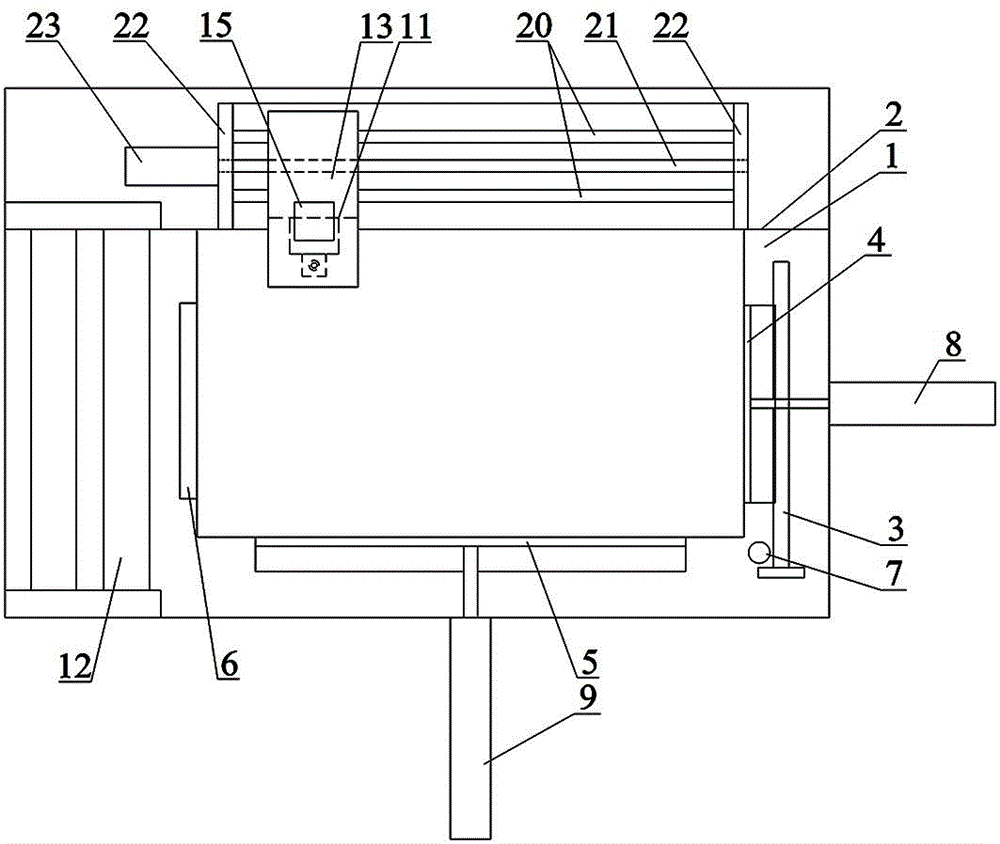

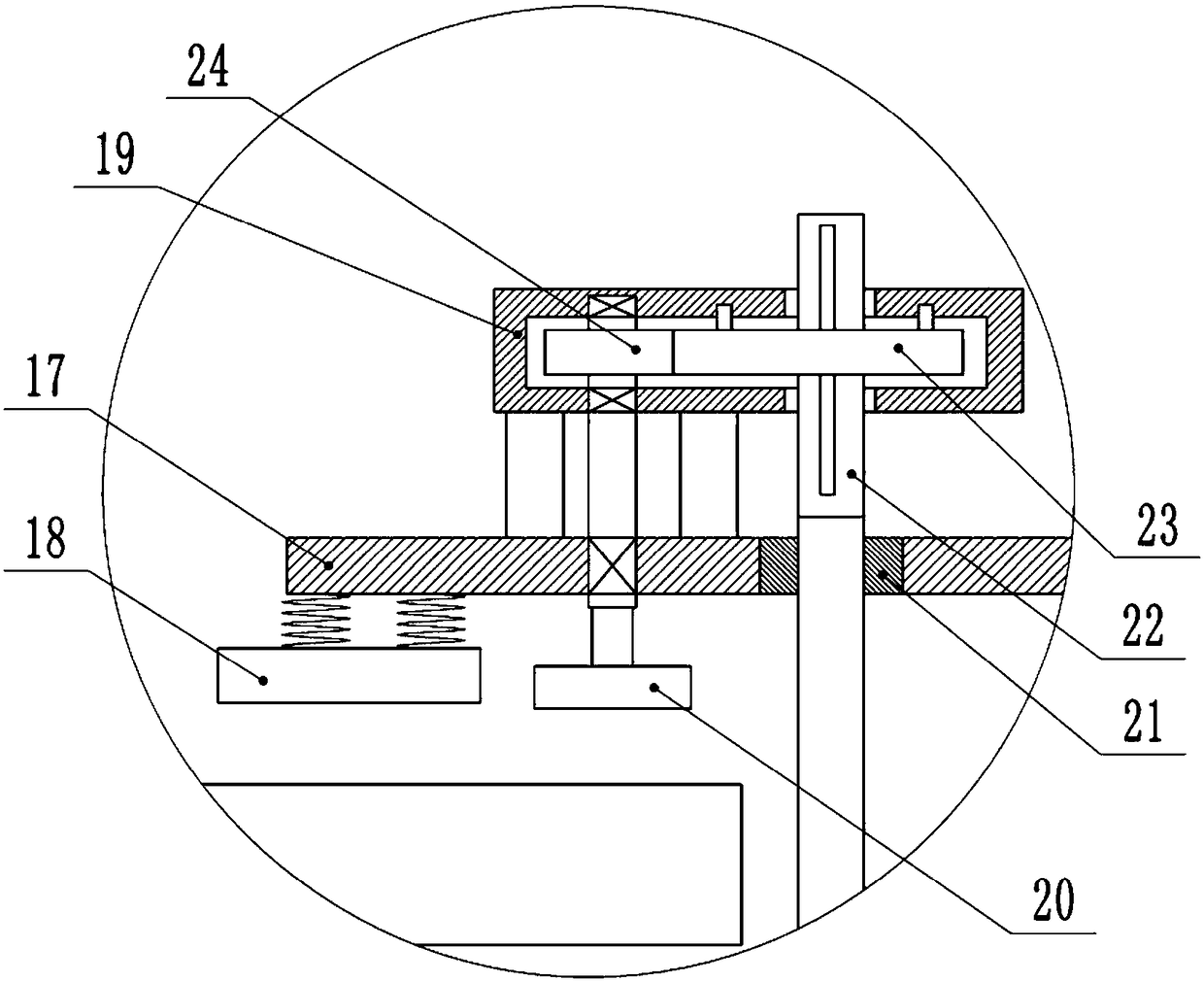

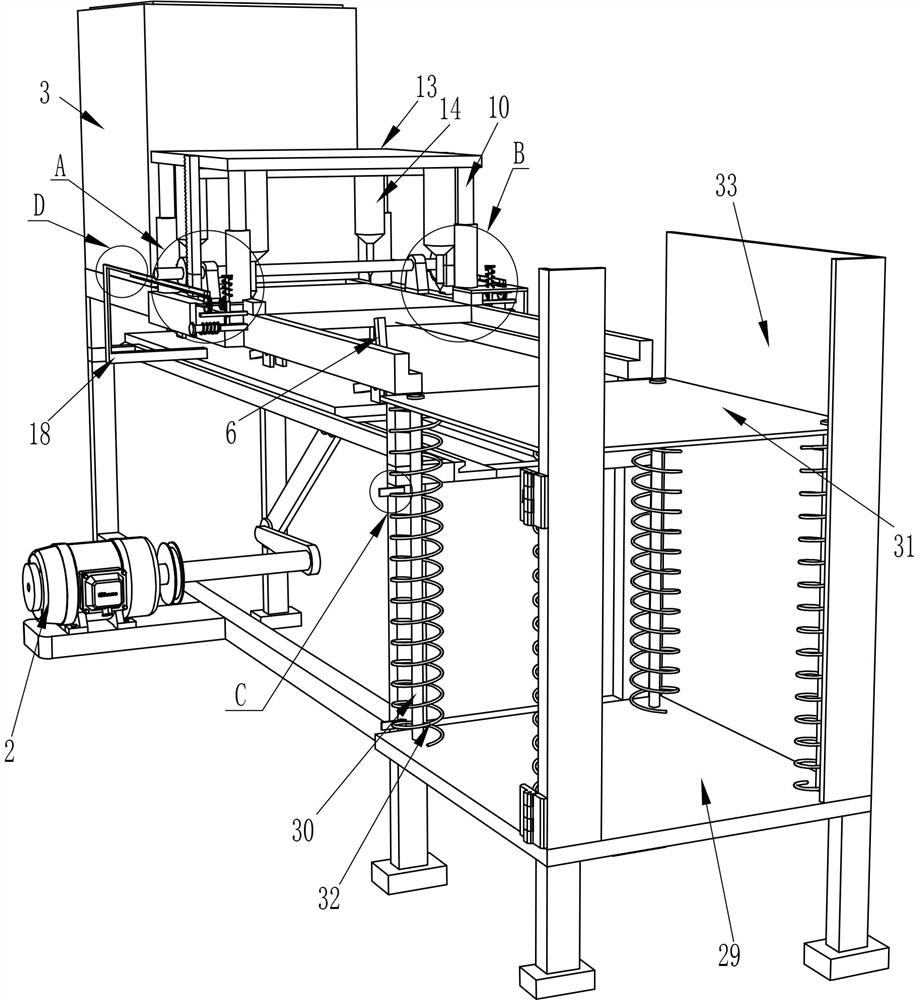

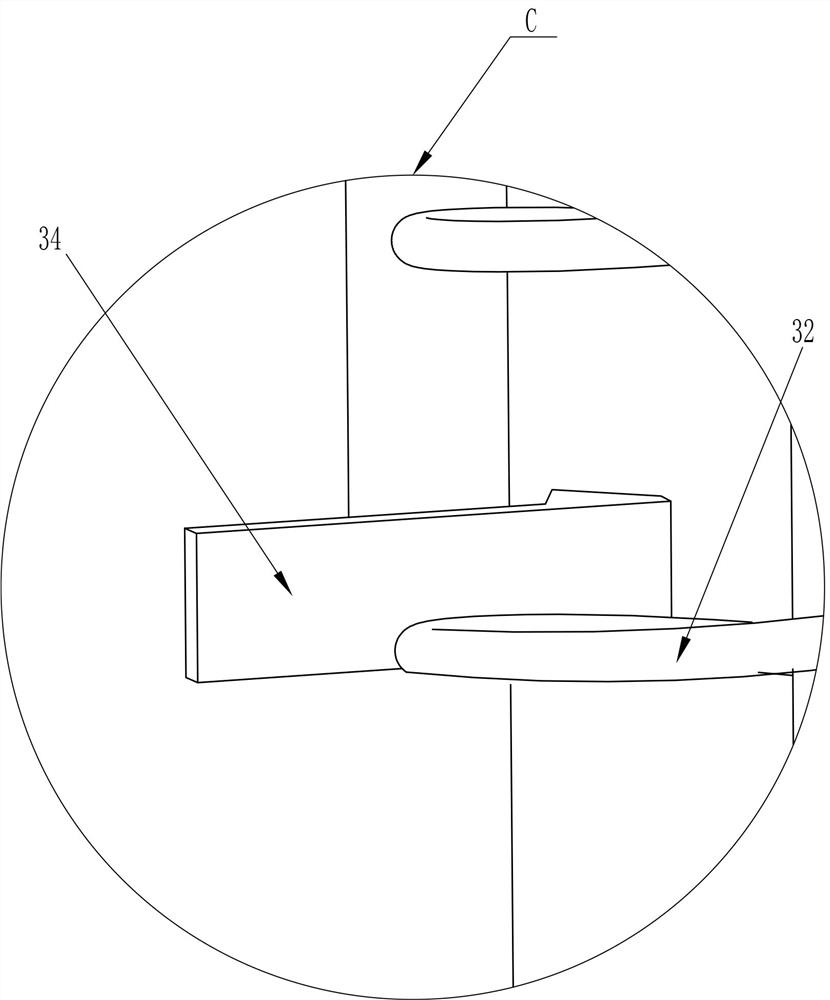

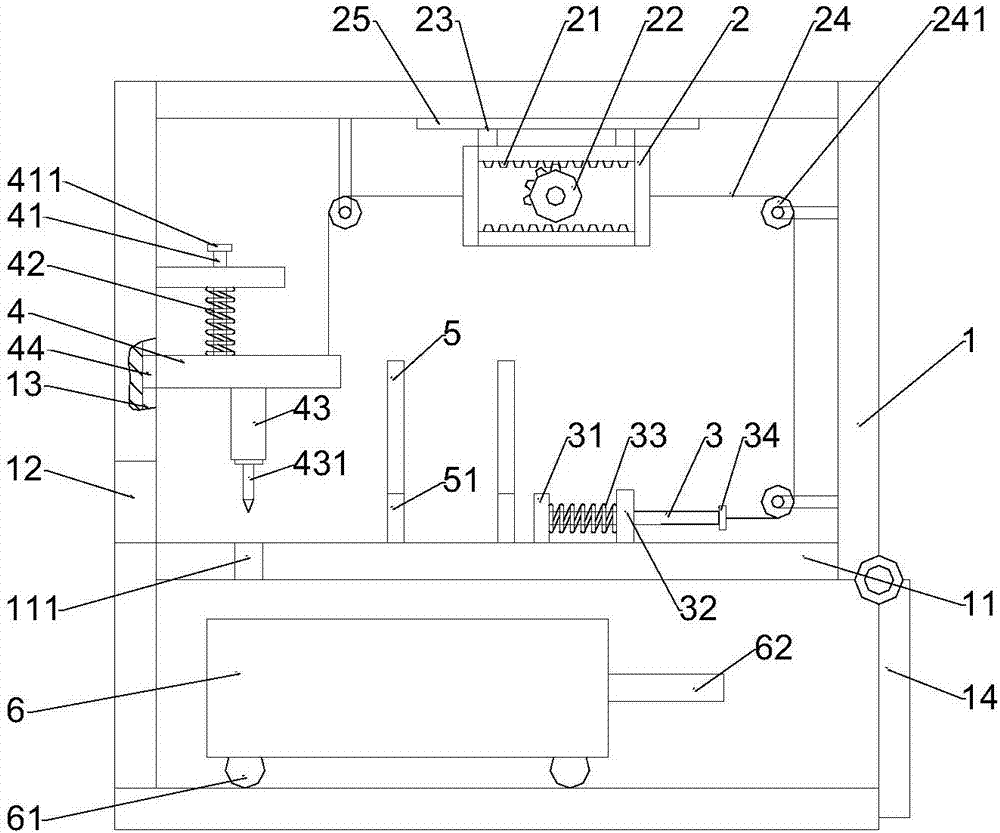

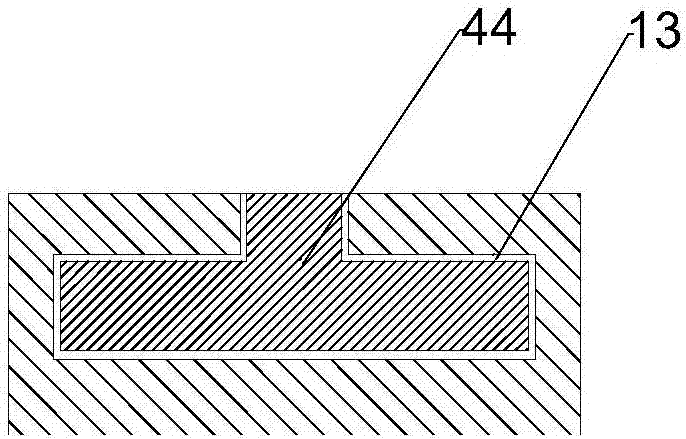

The invention discloses highly efficient equidistant drilling equipment for furniture plates. The equipment comprises a base plate, a left side plate, a right side plate, a top plate, a worktable, support legs, a first spring, a power mechanism, clamping devices, a sliding plate and a mounting plate. A third motor, a cam, a fourth motor and a drill bit are mounted on the lower portion of the mounting plate. The arranged power mechanism includes a first electric push rod, a first motor, a driving plate, a driven sheave, a gear and a rack. Through cooperation of the components above to drive theworktable to intermittently and equidistantly move to the left, equidistant drilling is achieved. The arranged clamping device comprises a second motor, a bidirectional lead screw, a vertical plate,an upper clamping plate and a lower clamping plate and can clamp or loose the plates, and clamping is convenient, fast and reliable. The cam and second springs are arranged and cooperate with each other to drive the sliding plate to move up and down, and the sliding plate drives the fourth motor and the drill bit to move up and down, so that drilling is performed on the plates. The equipment is simple in structure, convenient and fast and high in drilling efficiency.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

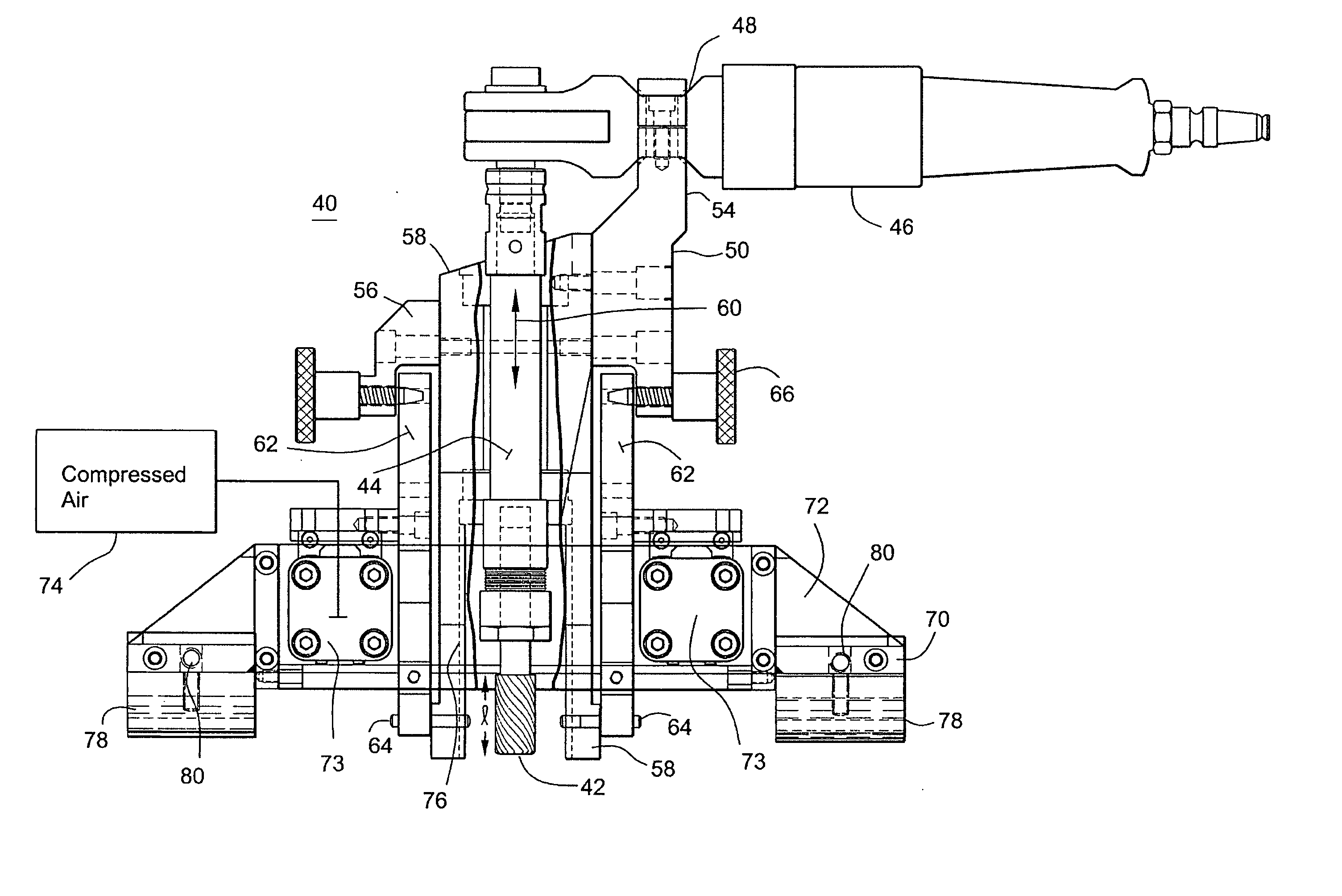

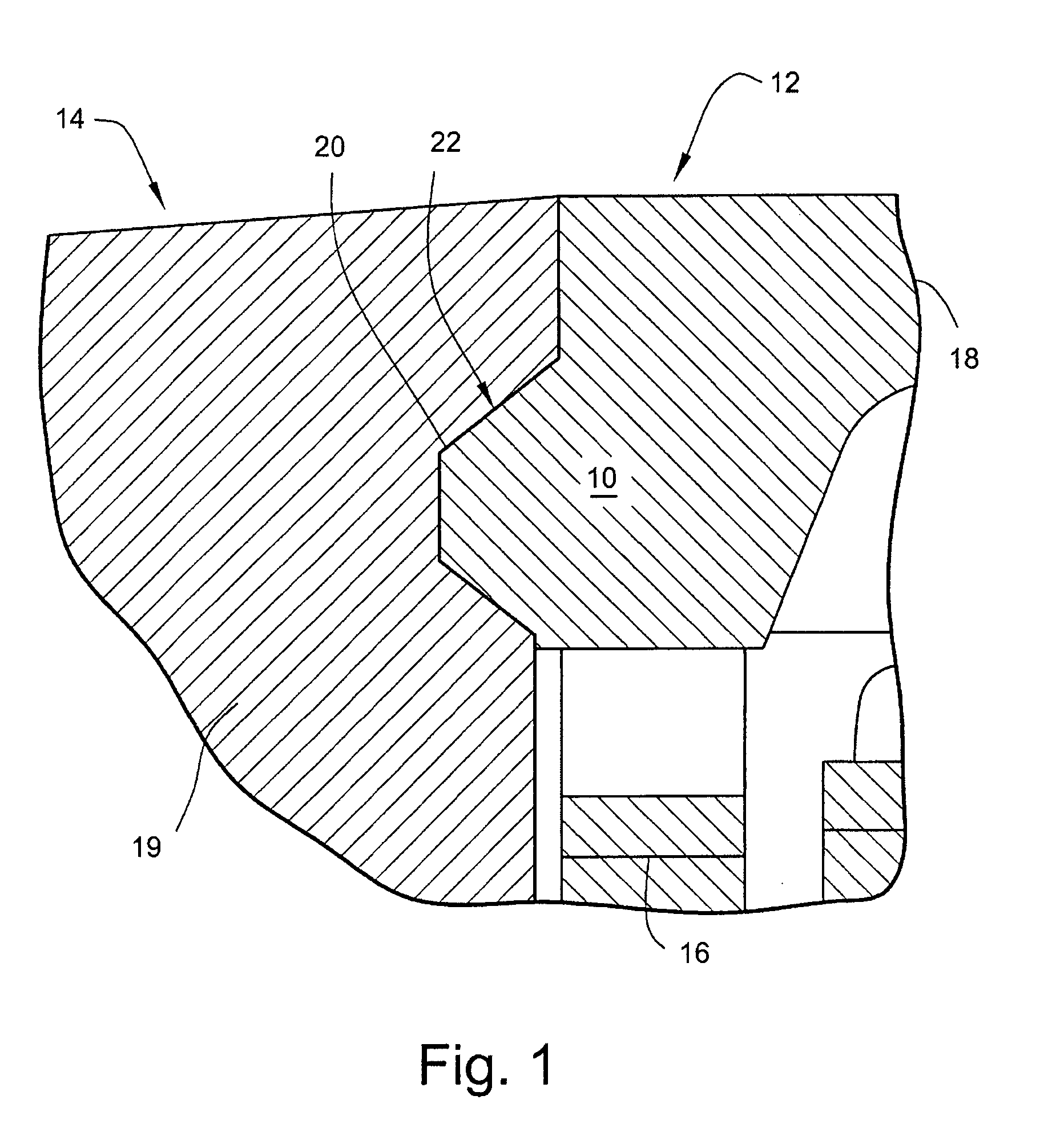

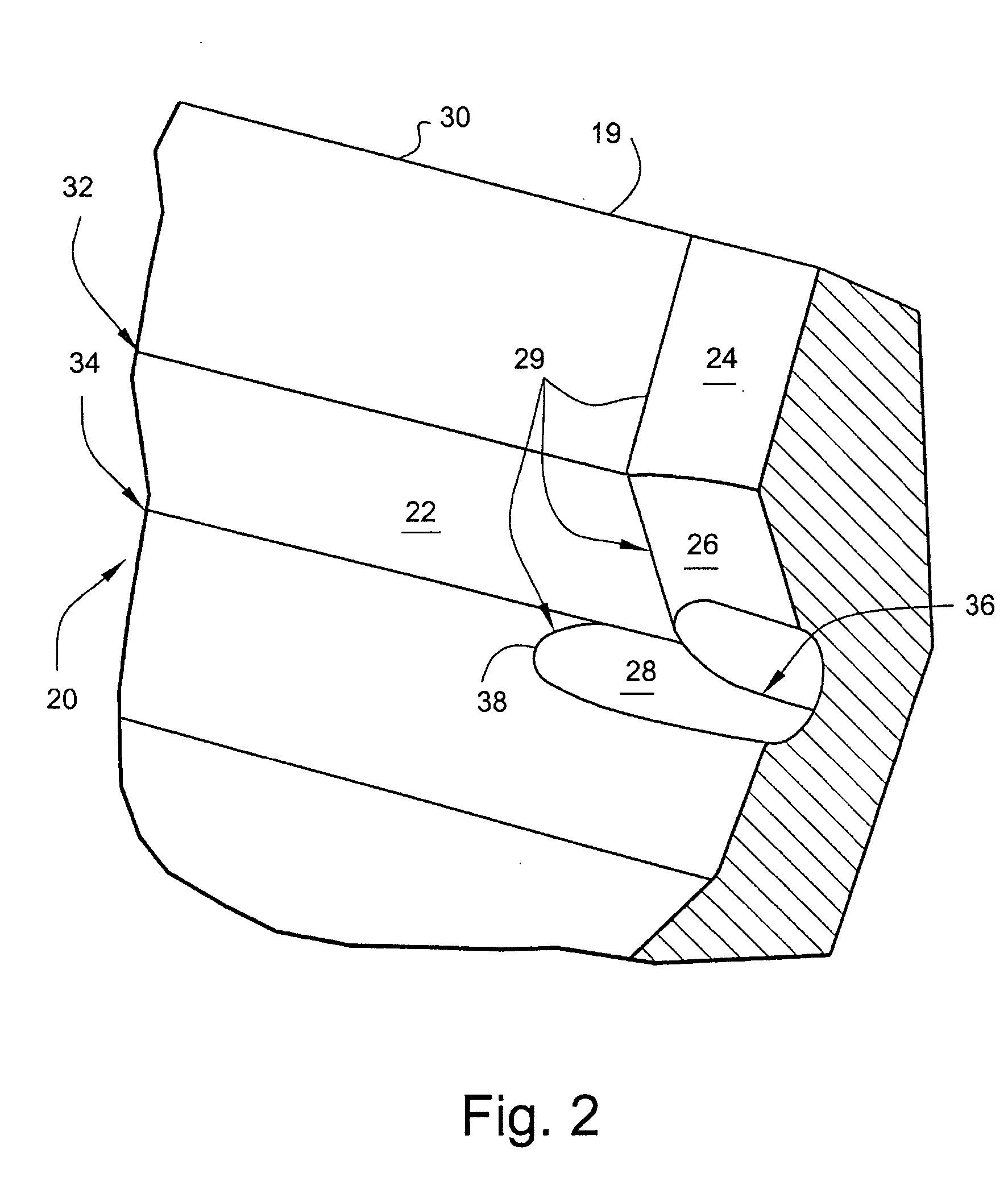

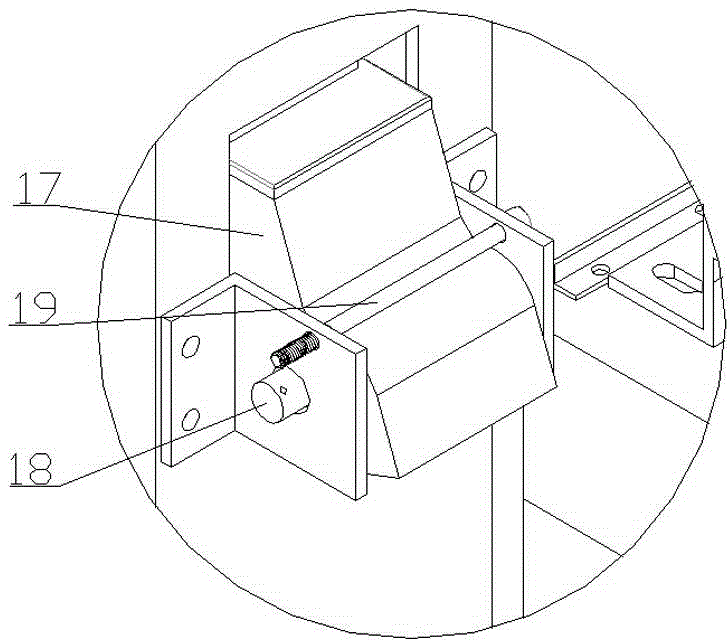

Machining tool and method for repair of rotor teeth in a generator

A machine cutter including a cutting bit positionable in a slot of a machine; a drive shaft rotatably driving the bit; a bracket having a plurality of angular positions for supporting and pivoting the bit wherein bit pivots about a pivot point on the bracket proximate to the bit, and a frame supporting the bracket on a slidable support providing linear movement to the bit.

Owner:GENERAL ELECTRIC CO

Self-cleaning type building timber equally-spaced punching device

InactiveCN107186825AReasonable structureInnovative designStationary drilling machinesBark-zones/chip/dust/waste removalPunchingDrive wheel

The invention discloses a self-cleaning equidistant punching device for building timber, which comprises a workbench, a support frame is connected to the upper end of the right side of the workbench, a top plate is connected to the left side of the upper end of the support frame, and a driving motor is arranged on the right side of the top plate to drive The lower end of the motor is connected to the drive shaft, the middle part of the upper end of the drive shaft is connected to the first cam, the left end of the first cam is in contact with the roller, the left end of the roller is connected to the push rod, the left end of the push rod is connected to the push block, and the left lower end of the push block contacts There is a pulley, the lower end of the pulley is connected with a lifting rod, the middle part of the upper end of the lifting rod is connected with a limit plate, the lower end of the limit plate is connected with a second spring, the lower end of the lifting rod is connected with a driving box, the middle part of the lower end of the drive shaft is connected with a second cam, and the bottom of the drive shaft The end is connected with a driving wheel, and the middle part of the driving wheel is connected with a crank. The present invention realizes the efficient punching effect on wood pieces, improves the working efficiency of wood punching, and at the same time avoids the accumulation of sawdust on the wood pieces, thereby increasing the processing quality of the wood pieces.

Owner:阮霞伟

Building wood drilling device with porous continuously-punching function

The invention discloses a construction wood drilling device with multi-hole continuous punching function, comprising a platform, a slide rail, a slider, a lifting motor, a screw rod, a lifting platform, a driving motor, a cam, a drilling motor, a drill bit and a drilling platform , a lifting motor is fixedly installed on the cover plate, the output shaft of the lifting motor is vertically downward and is connected with a screw rod, several groups of cams are fixedly installed on the rotating shaft, the top block is matched with the cam, and the connecting A drilling motor is fixedly installed at the lower end of the rod, and a drill bit is fixedly installed on the output shaft of the drilling motor; the lifting work of the lifting platform is realized through the threaded cooperation between the screw rod and the lifting platform, and the working of the lifting motor, so as to meet the needs of different thicknesses of wood. Drilling work improves the versatility of the drilling machine; multiple sets of drill bits are set in the device, which can perform multi-hole continuous punching work at the same time. Compared with manual drilling in sequence, the work efficiency is high and the distance between holes can be effectively controlled, improving Drilling accuracy.

Owner:张志航

Building panel drilling device with waste recycling function

InactiveCN108189158AReduce pollutionStationary drilling machinesBark-zones/chip/dust/waste removalHydraulic cylinderPiston rod

The invention discloses a building panel drilling device with a waste recycling function. The building panel drilling device comprises a supporting platform. Hydraulic cylinder devices are arranged atthe left end and the right end below a beam plate. Piston rods are arranged below the hydraulic cylinder devices. A lifting plate is fixedly welded to the lower portions of the left piston rod and the right piston rod. Sleeve bases which are in cup joint to a front stand column and a rear stand column are arranged on the left side wall and the right side wall of the lifting plate. Fixing tables are arranged at the left end and the right end below the lifting plate. A material collecting hopper is arranged below the supporting platform. Waste suction pipes are evenly arranged above the material collecting hopper and penetrate the upper end face of the supporting platform. A dust suction device is fixedly arranged at the left end above the supporting base, and the right side of the dust suction device is connected with the material collecting hoper through a dust guiding pipe. According to the building panel drilling device with the waste recycling function, the dust suction device canbe started in the drilling process for collecting dust waste in the drilling process into the material collecting hopper through the waste suction pipes, and accordingly environment pollution in the work process is reduced.

Owner:冯瑞芳

Batten board punching equipment

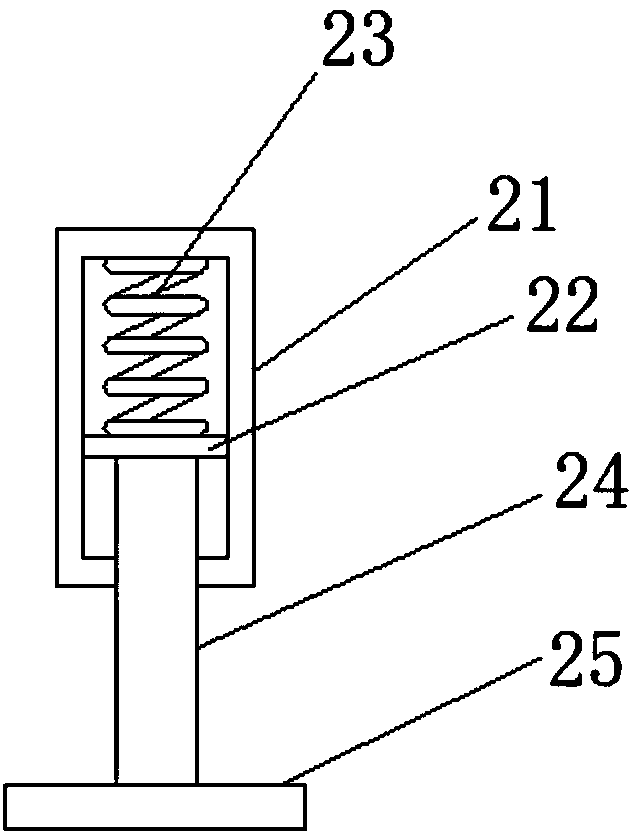

InactiveCN109910113AReduce fatigueReduce labor intensityStationary drilling machinesPunchingEngineering

The invention relates to punching equipment, in particular to batten board punching equipment. According to technical problems to be solved, the batten board punching equipment can reduce fatigue andthe labor strength. According to the technical scheme, the batten board punching equipment comprises a base, a first machine frame, a mounting board, a motor, a cam, a first belt wheel and the like; and the first machine frame is mounted at the top of the base, and the mounting board is connected between the lower parts of the left side and the right side of the interior of the first machine frame. According to the batten board punching equipment, the position of an electric frill can be adjusted through a fastening mechanism, and therefore, a user can conveniently punch different positions ofa batten board; the batten board can be conveyed to the left through continuous anticlockwise rotation of a bracket; and the batten board can be punched continuously through continuous moving up anddown of the electric drill, therefore, the user is not required to punch the batten board by holding the electric drill, so that fatigue of the user is reduced, the batten board is punched without using hands and feet of the user, and thus, the labor strength of the user can be reduced.

Owner:太和县森之源木业有限公司

Full-automatic effective drilling machine for furniture panel

ActiveCN104875243AReduce labor intensityShorten the timeStationary drilling machinesEngineeringUltimate tensile strength

The invention belongs to the technical field of panel processing and discloses a full-automatic effective drilling machine for a furniture panel. The full-automatic effective drilling machine for the furniture panel is used for solving the problems that an existing panel drilling device is large in labor intensity and low in production efficiency due to discontinuous production. The full-automatic effective drilling machine for the furniture panel comprises a main stand, the main stand is provided with a feed cabin for holding a workpiece to be processed, the main stand before the feed cabin is provided with a push cylinder for pushing the workpiece to be processed, the main stand behind the feed cabin is provided with a drilling device for drilling the lateral surface of the workpiece to be processed, and the main stand at one side of the feed cabin is provided with a transverse push cylinder for pushing out the processed workpiece; the main stand at the other side of the feed cabin is provided with a storage device for recycling the processed workpiece, and the transverse push cylinder and storage device are respectively located at two sides of the feed cabin.

Owner:QUANYOU FURNITURE

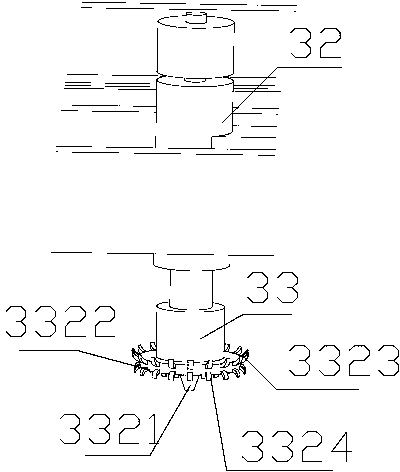

Plate punching device capable of automatically replacing drill bits

InactiveCN106976131ARealize automatic controlSimple structureStationary drilling machinesPunchingEngineering

The invention discloses a plate punching device capable of automatically replacing drill bits. The device comprises a frame body, a cross beam and a punching assembly; the frame body includes a base, and stand columns fixed on the left and right sides of the top of the base; first cavities are arranged in the punching assembly in a bilateral symmetry manner; a second cavity is formed at the part, above the first cavities, in the wall body of the punching assembly; guide grooves arranged in a manner of extending up and down are respectively formed in the inner side walls of the first cavities on the left and right sides; transmission cavities are formed in the parts, above the guide grooves, in the wall body of the punching assembly; first rotating shafts arranged in a manner of extending up and down are arranged on the sides, far away from the guide grooves, of the first cavities; the top extension sections of the first rotating shafts penetrate through the inner top walls of the first cavities and extend into the second cavity; first bevel gears are fixedly arranged on the outer surfaces of the parts, positioned at the bottoms of the first cavities, of the first rotating shafts; a second rotating shaft is arranged in the center position of the inner wall of the second cavity; and the top of the second rotating shaft is connected with a first motor in a matched manner. The device is simple in structure, reasonable in design and convenient to operate, improves the punching efficiency, and is stable in operation and high in precision.

Owner:佛山市南海区澳宏家具有限公司

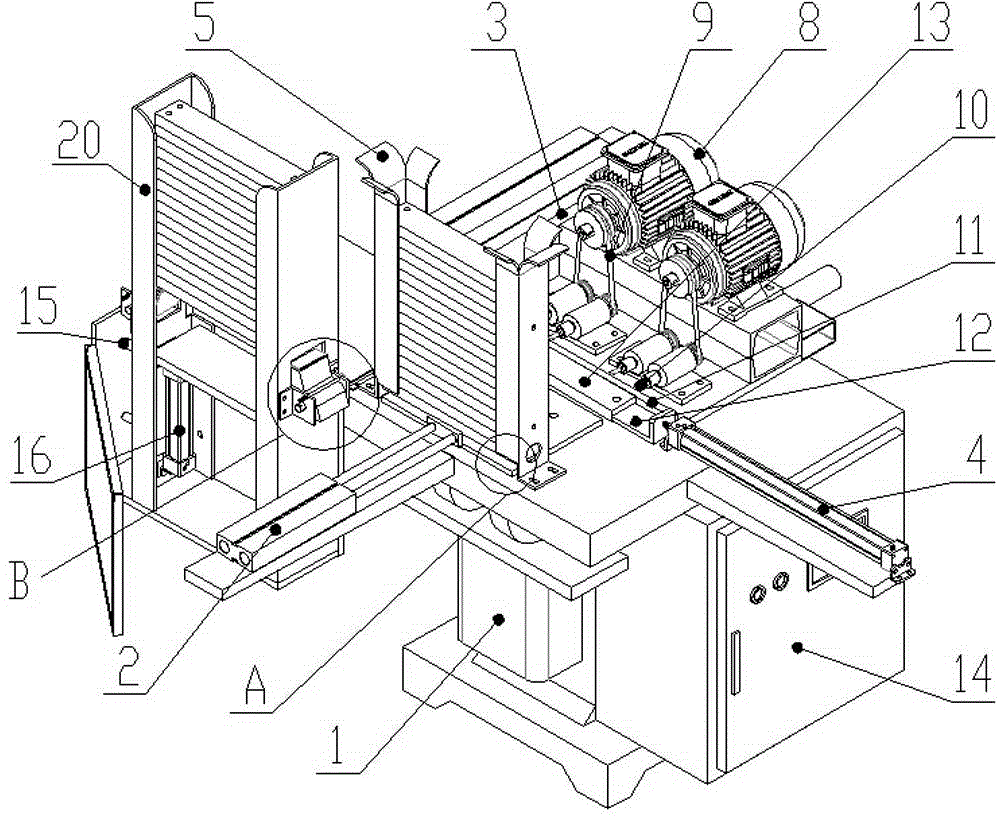

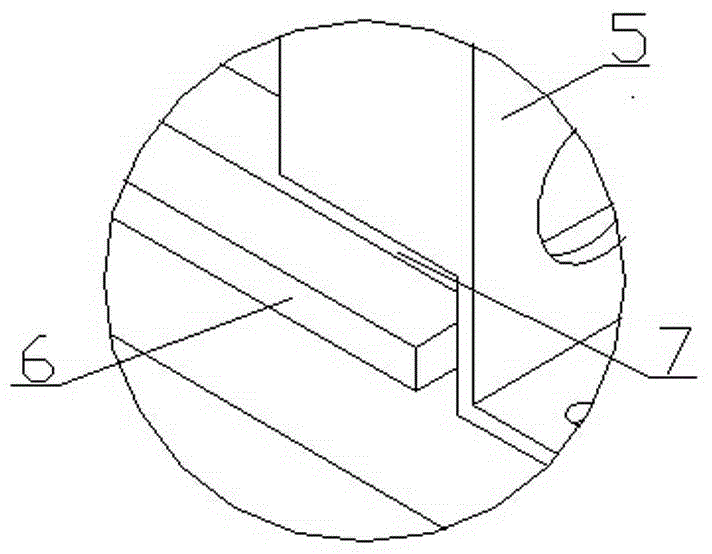

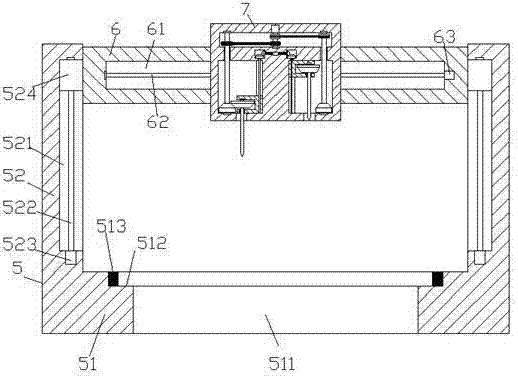

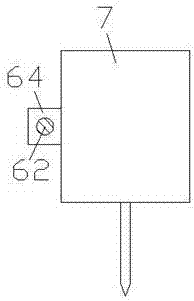

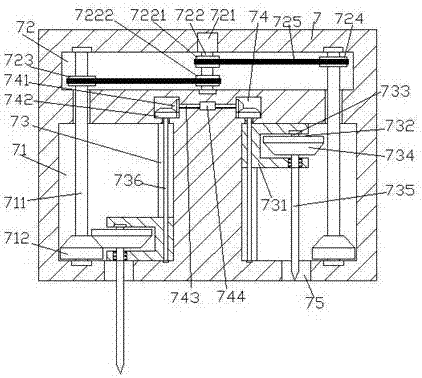

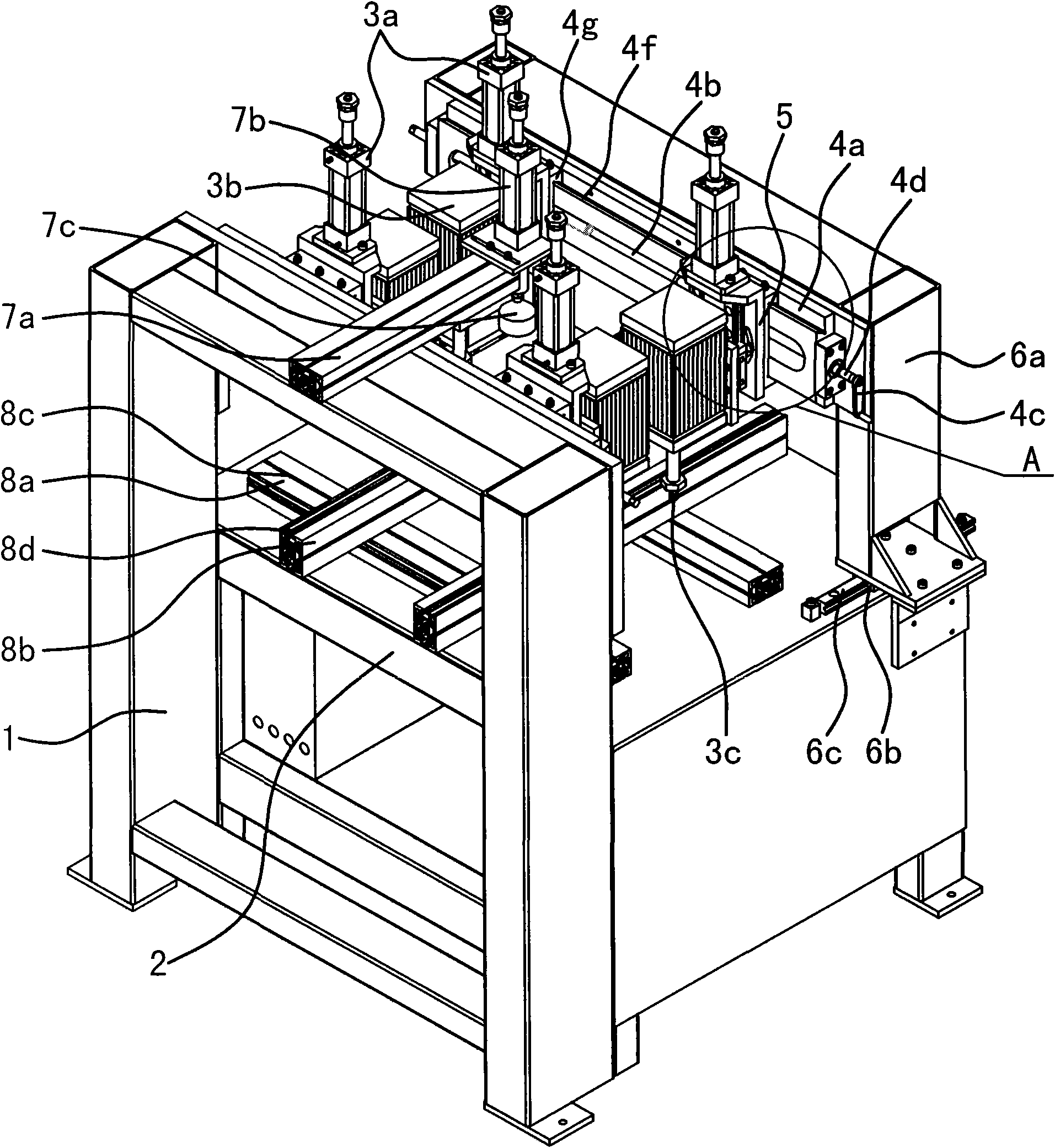

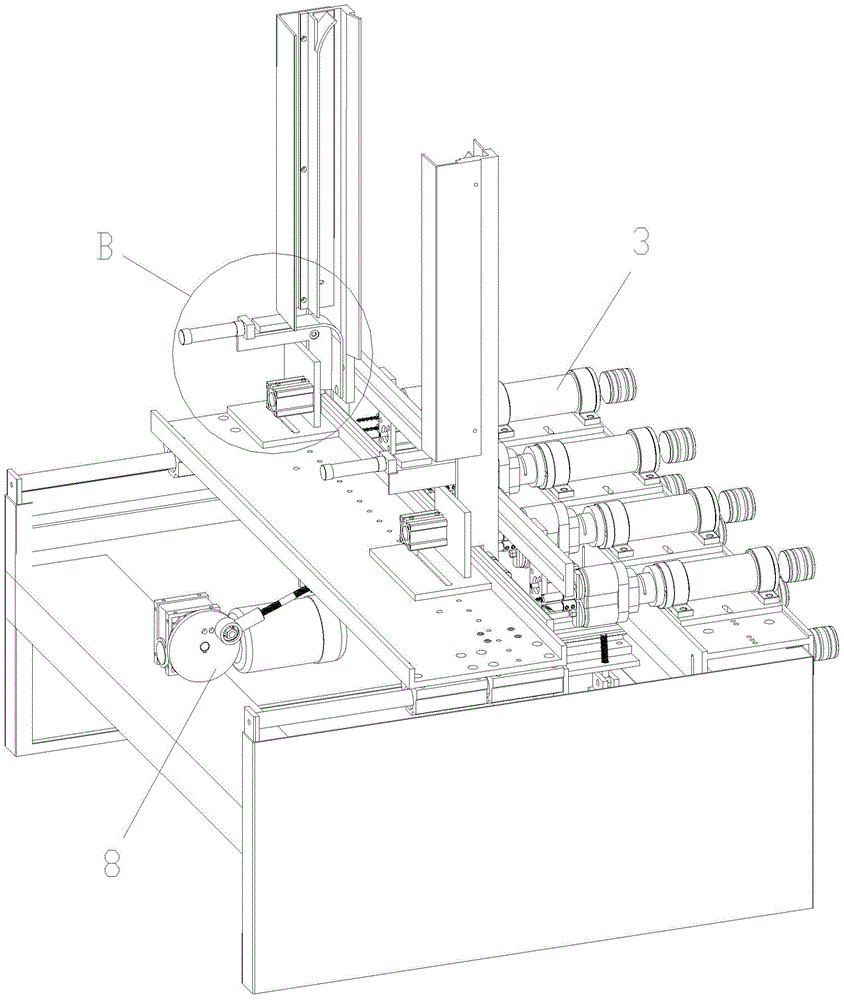

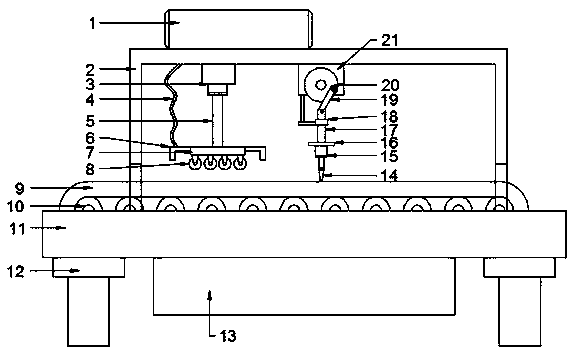

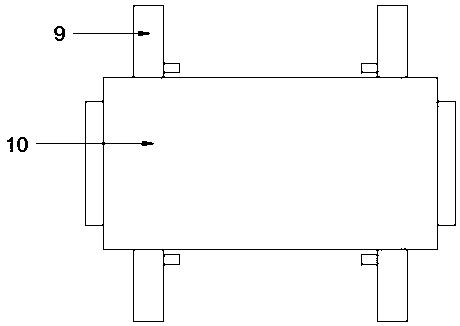

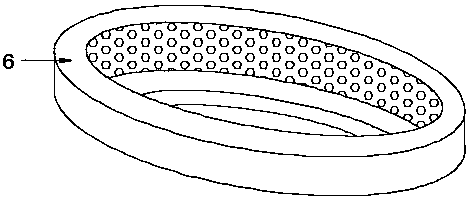

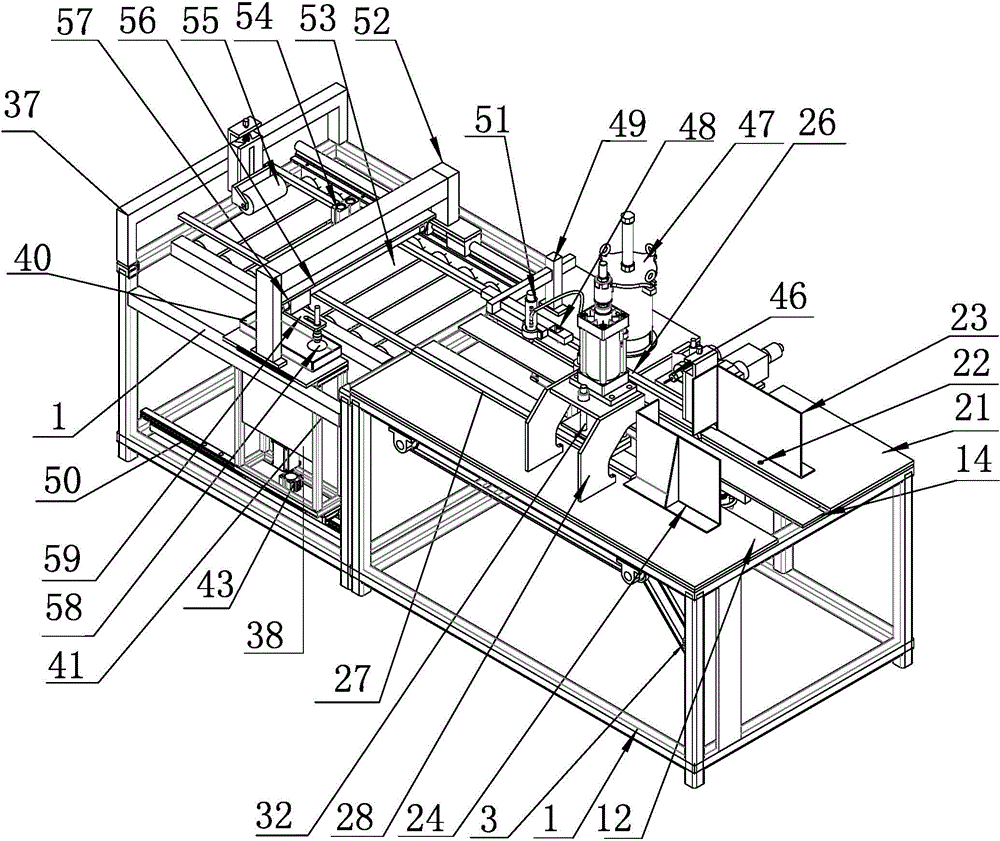

Full-automatic porous plate machining device and machining method thereof

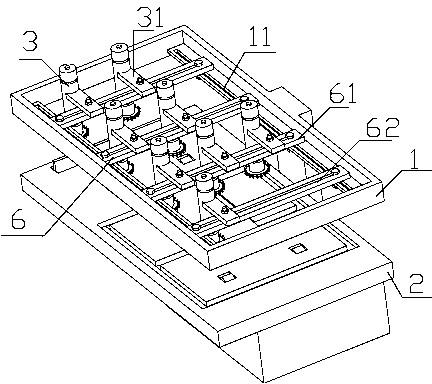

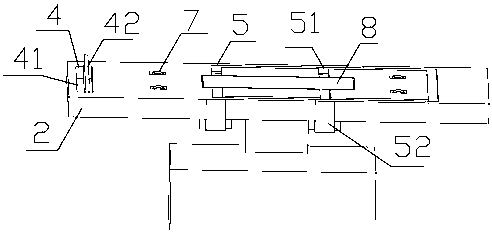

ActiveCN104626282AHigh degree of automationHigh positioning accuracyStationary drilling machinesProgrammable logic controllerEngineering

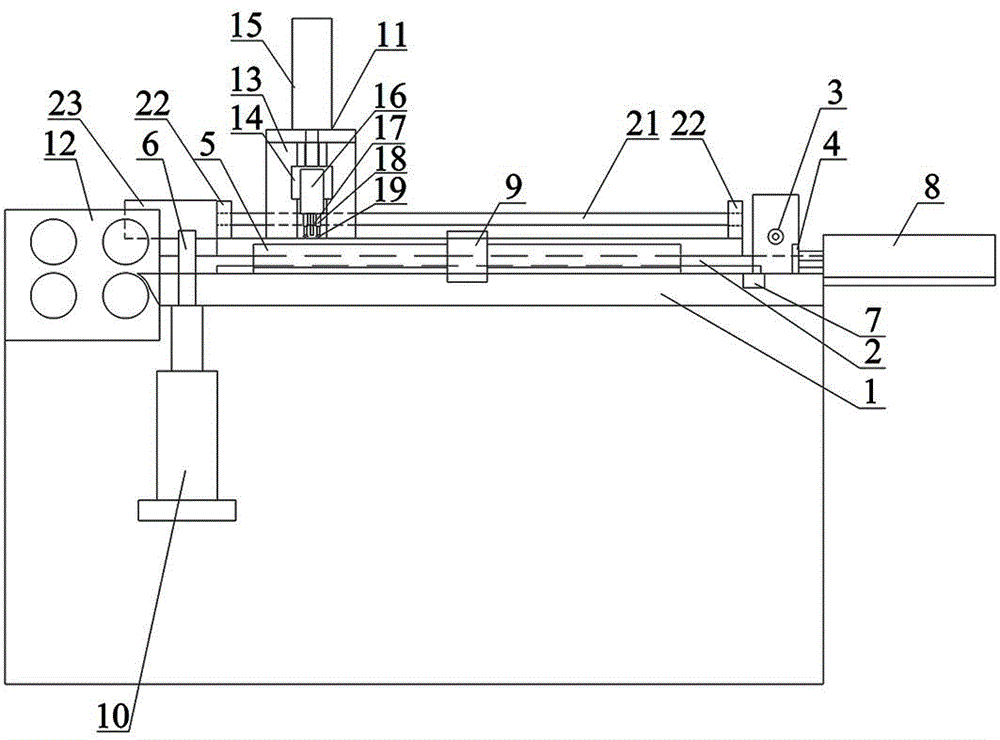

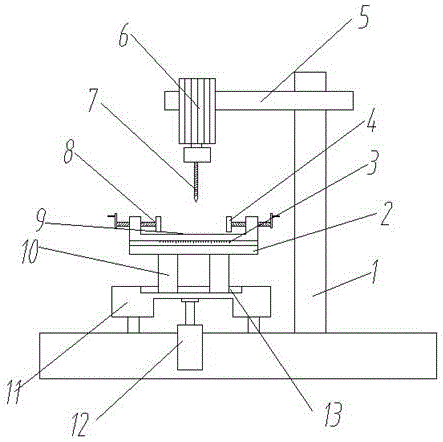

The invention discloses a full-automatic porous plate machining device. The device comprises a worktable (1) and a PLC (programmable logic controller), wherein a rear side stop surface (2), a left ejector plate (4), a backward ejector plate (5) and a left-side limiting plate (6), which are used for positioning plates, are formed on the worktable (1); the left ejector plate (4) and the backward ejector plate (5) are driven to horizontally move by virtue of a cylinder; the left-side limiting plate (6) is driven to vertically move by virtue of a cylinder; and a drilling machine (11) is driven to slide along a horizontal guide rail (20) by virtue of a stepping motor. The device disclosed by the invention has the beneficial effects that when wood plates are subjected to one-step feeding, three operating steps of positioning, drilling and discharging can be controlled by the PLC to be automatically finished, the degree of automation is high, the machining efficiency and yield are improved, the product specification is unified, and the machining quality is high; and moreover, sequential drilling at multiple stations can be realized, the drilling positions can be adjusted by virtue of setting, and the device can be applied to machining of plates with different drilling positions and is wide in application range.

Owner:浙江西宇电气有限公司

Board punching device

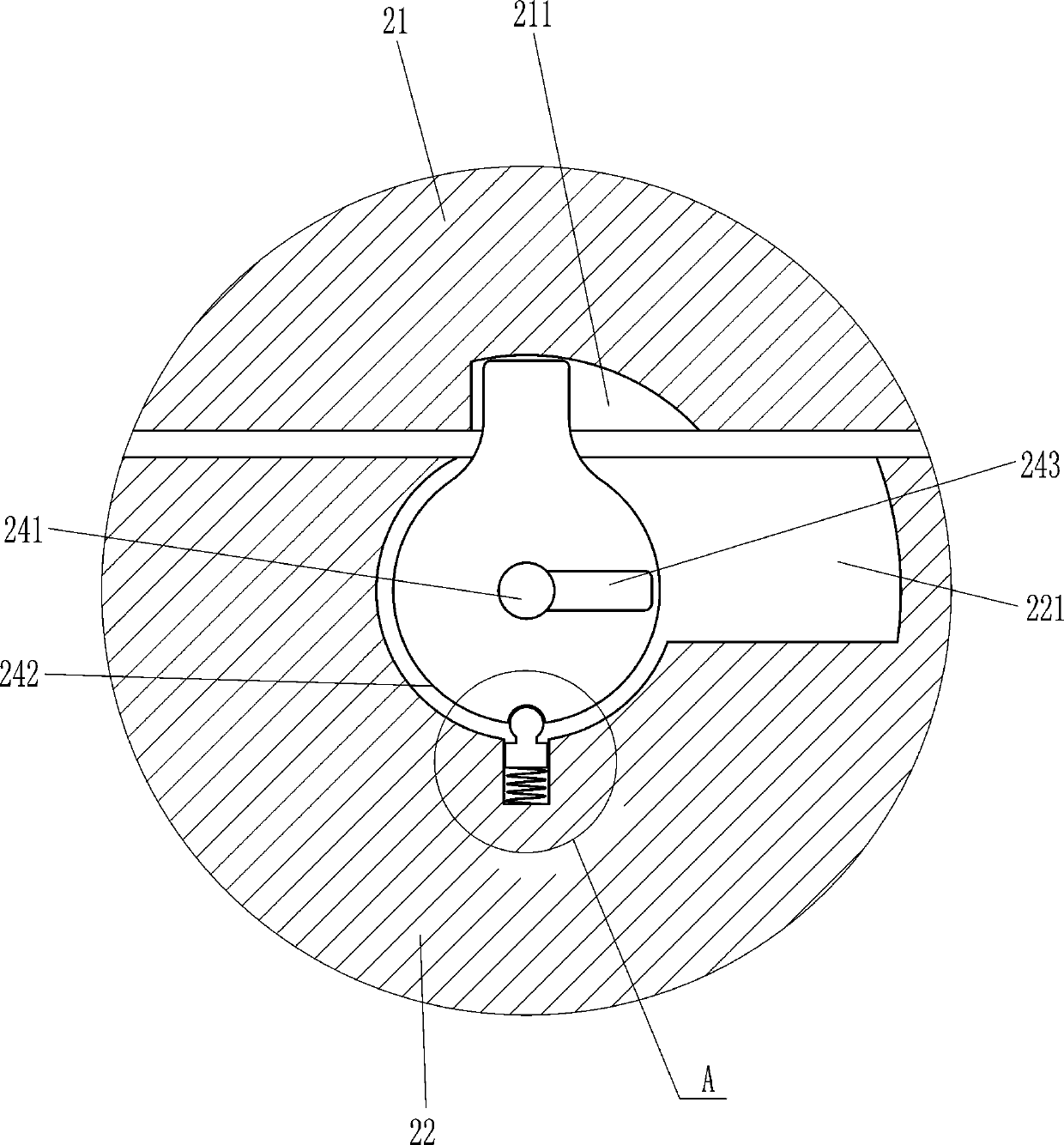

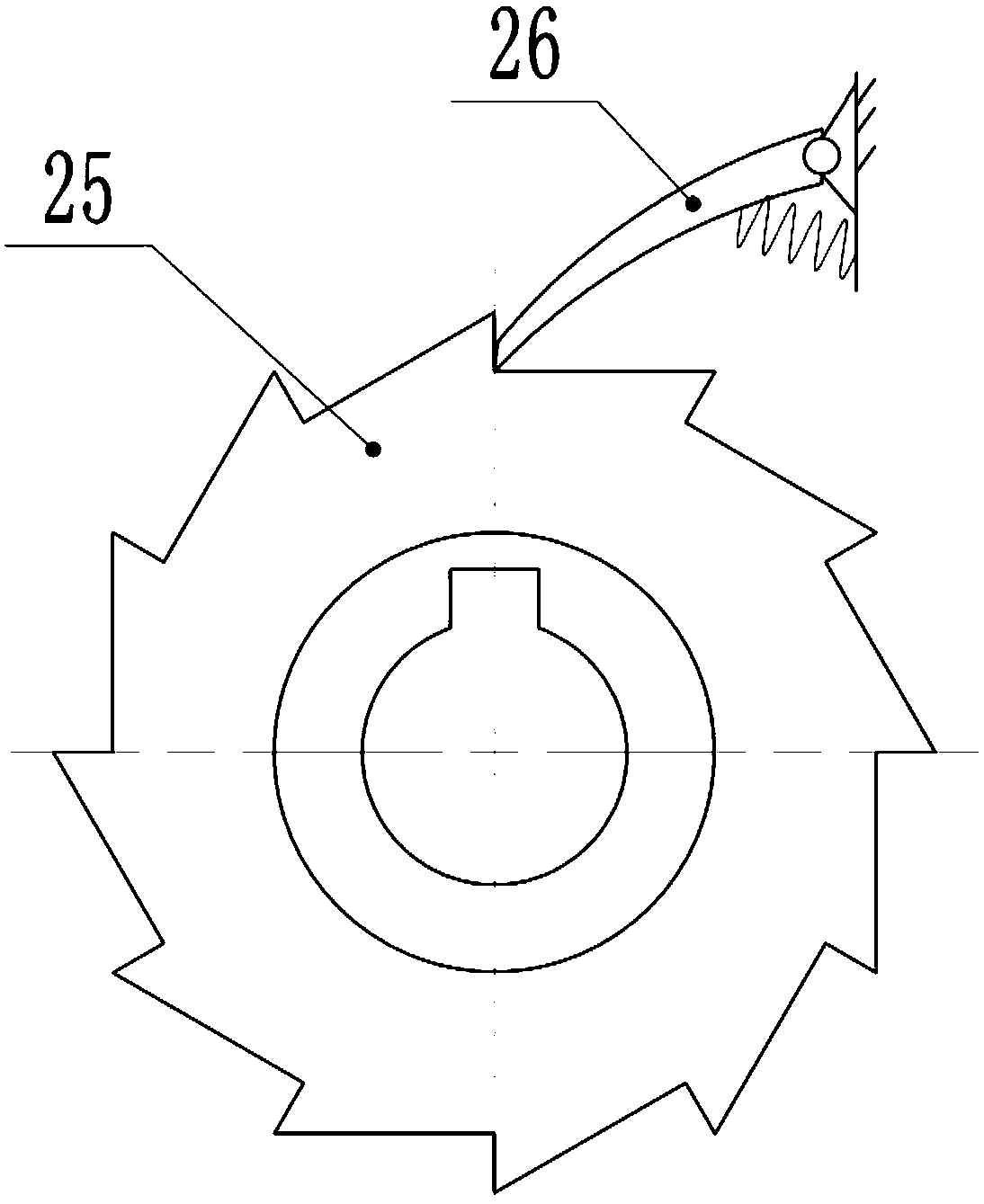

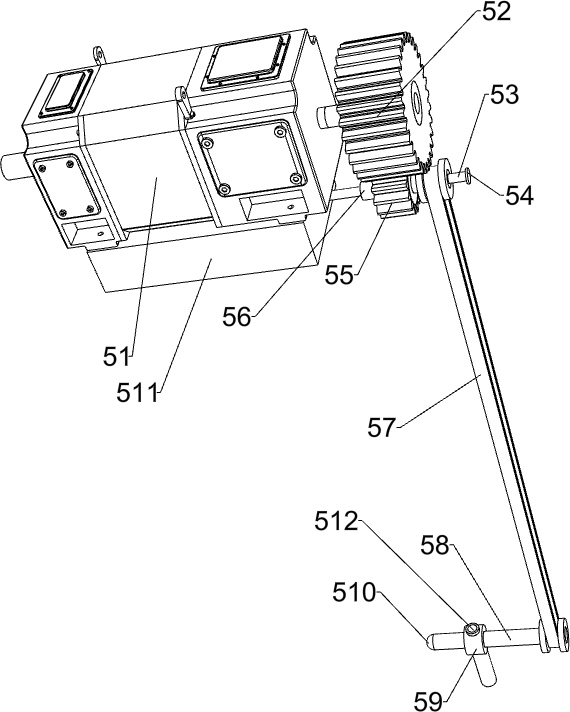

PendingCN108638225AEvenly punchedRealize Angle SwitchingEdge grinding machinesGrinding carriagesPunchingGear wheel

The invention belongs to the technical field of wood processing equipment, and particularly discloses a board punching device. The board punching device comprises a machine frame. A rotary table is arranged on the machine frame, a punching mechanism and a power mechanism are arranged on the upper portion of the machine frame, and the power mechanism drives the punching mechanism to ascend and descend. A crank and sliding block mechanism is arranged on the machine frame, a push rod which is fixedly connected with a sliding block is connected to the machine frame in a sliding mode, and an intermittent mechanism which drives the rotary table to conduct one-way intermittent rotation is connected between the push rod and the rotary table. A clamping mechanism is further arranged on the machineframe, and comprises a supporting rod. Two supporting plates are connected to the supporting rod in a sliding mode. A two-way lead screw is connected to the machine frame in a rotating mode, the two supporting plates are matched with the two-way lead screw through nuts, and the two-way lead screw and the push rod are connected through a gear and rack pair. Clamping plates and polishing discs are arranged on the inner sides of the two supporting plates, and transmission mechanisms which are used for driving the polishing discs to rotate are connected between the polishing discs and the two-waylead screw. By the adoption of the scheme, automatic rotation and clamping of a board are achieved in the drilling process, the working efficiency is high, and the labor intensity of workers is reduced.

Owner:重庆哲骁装饰工程有限公司

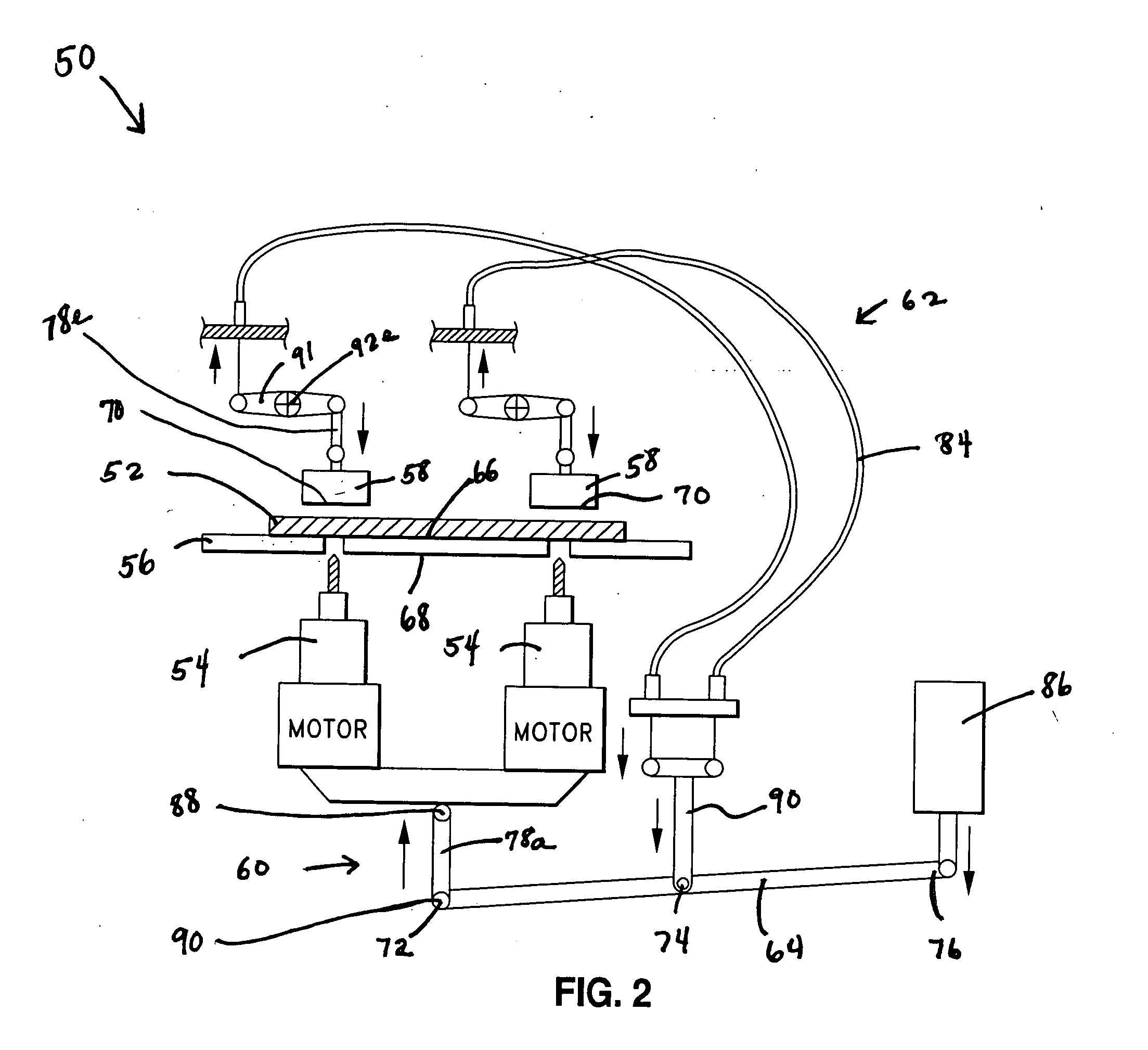

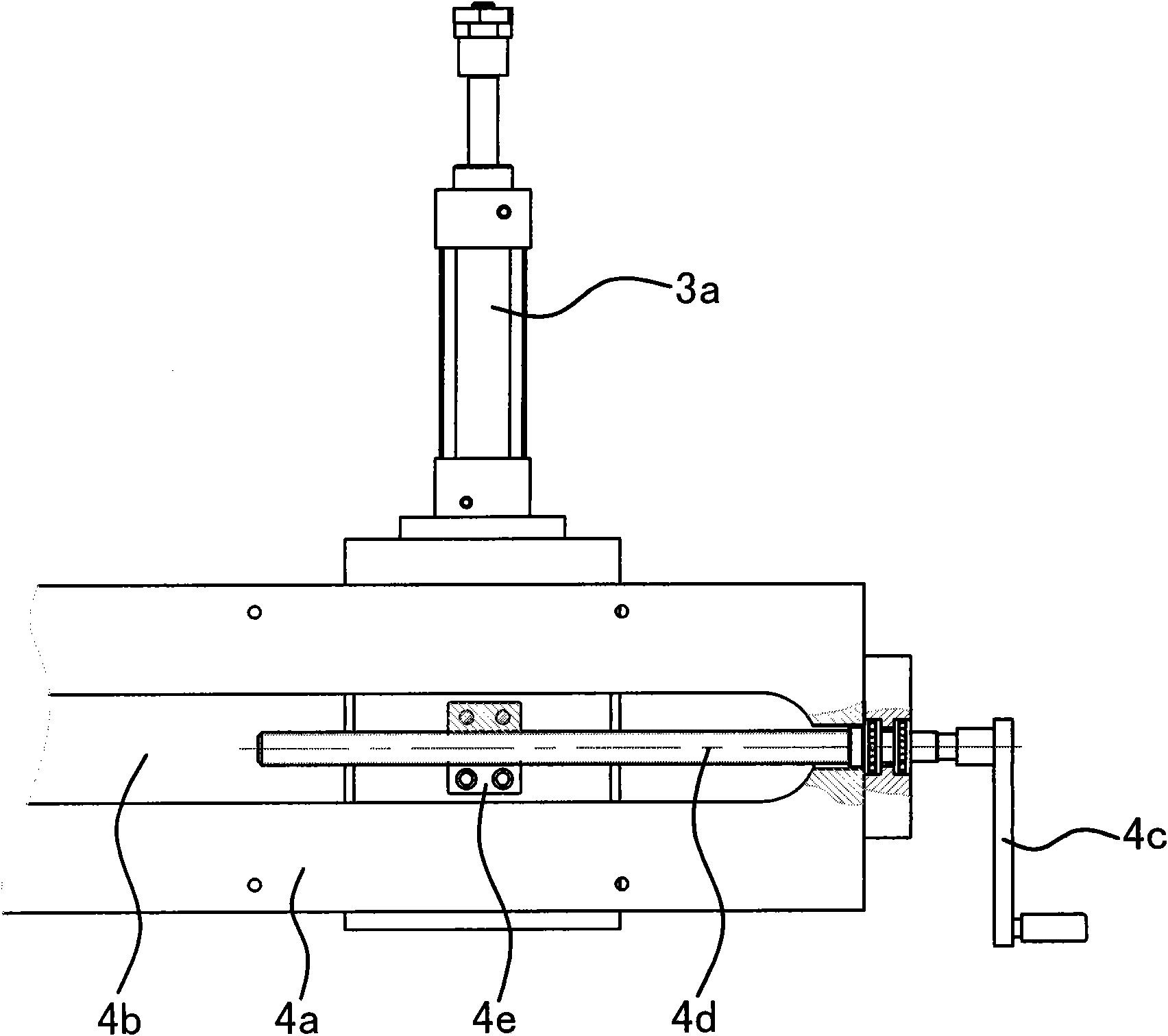

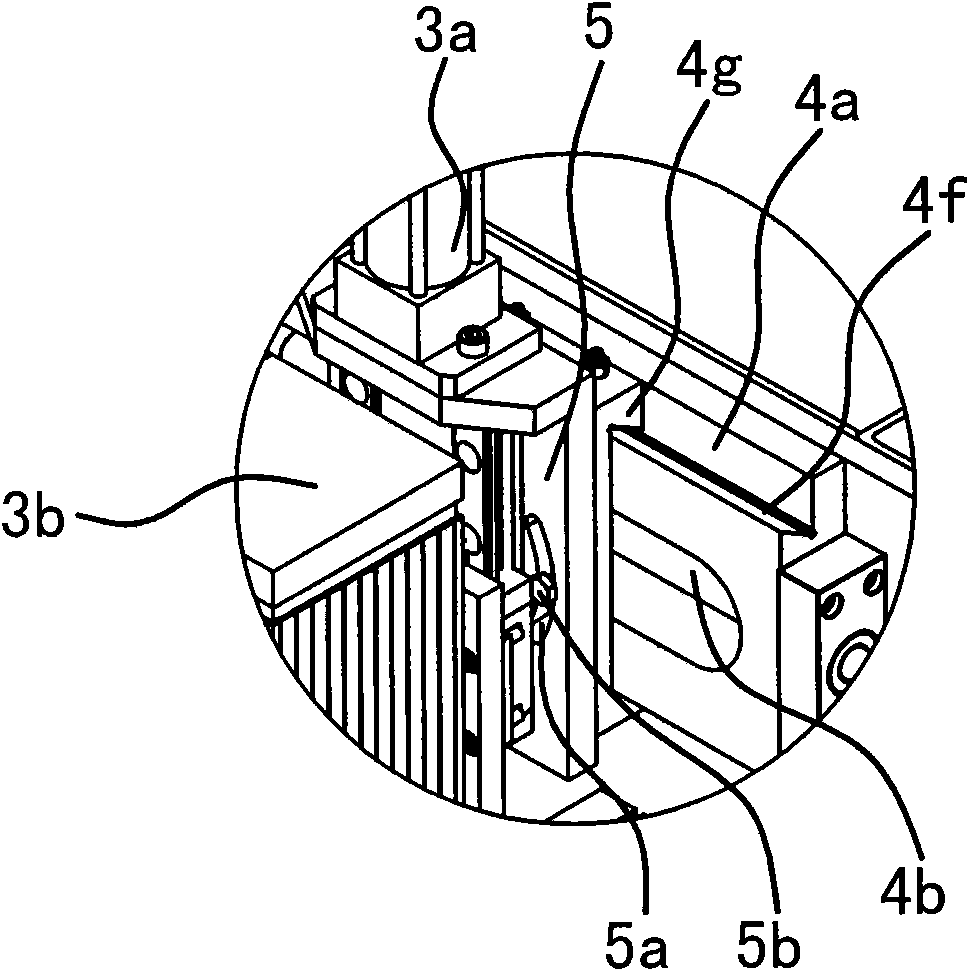

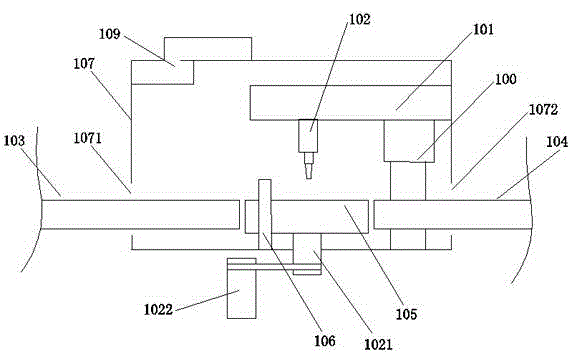

Line boring machine

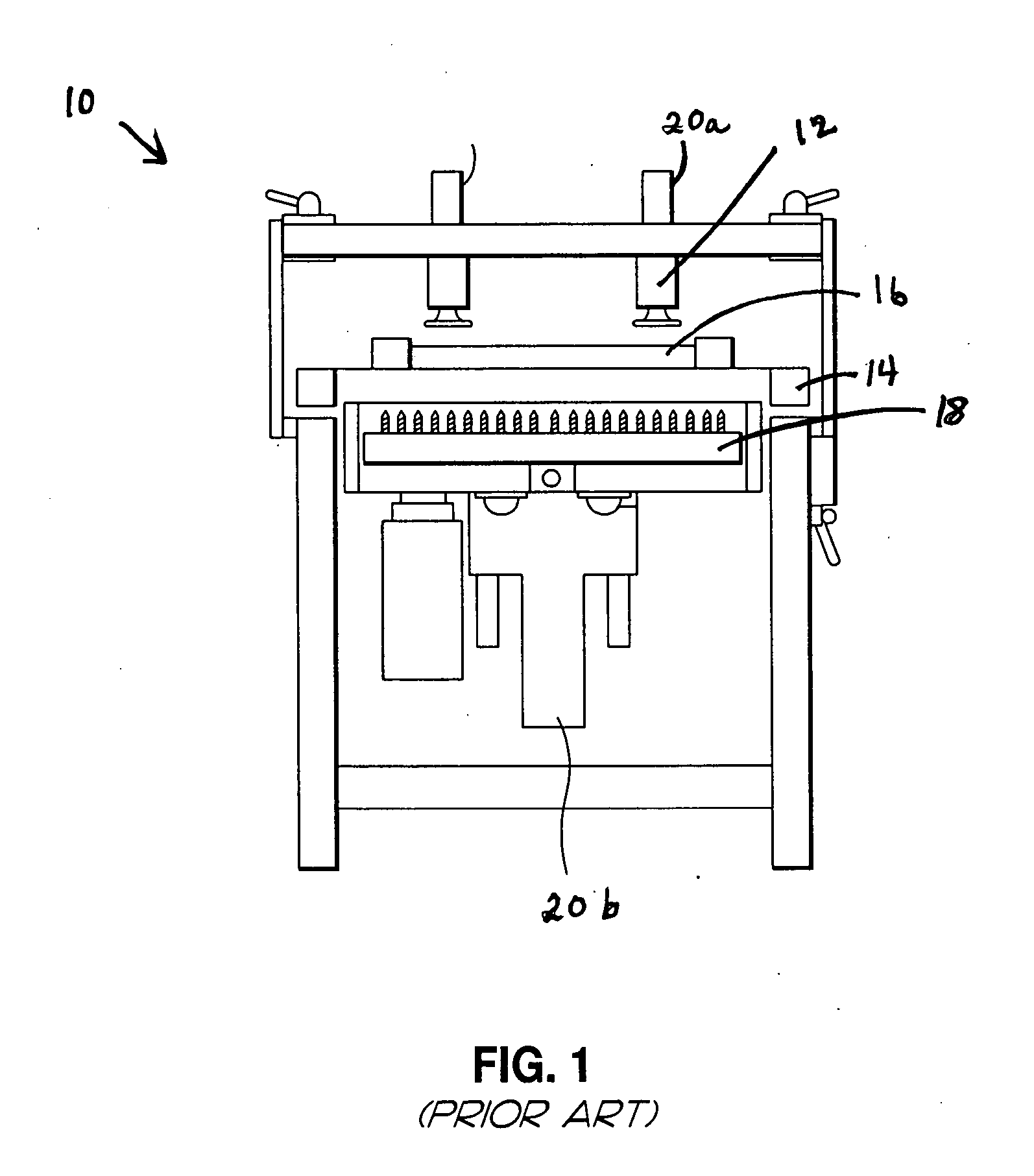

ActiveUS20050013673A1Stationary drilling machinesDrilling/boring measurement devicesEngineeringMechanical engineering

An up modifier is provided which includes a bed, a modifier, a clamp, a modifier linkage system, a clamp linkage system, and a lever. The modifier is disposed below the bed and is vertically traversable thereunder. The clamp is disposed above the bed and is vertically traversable thereabove. The lever defines a modifier pivot, clamp pivot and a pedal portion. The clamp pivot is interposed between the modifier pivot and the pedal portion. The clamp pivot is vertically traversable, and the modifier pivot and the pedal portion are pivotable about the clamp pivot. The modifier linkage system is attached to the modifier and the lever at the modifier pivot, and the clamp linkage system is attached to the clamp and the lever at the clamp pivot.

Owner:TUCKER BRADLEY J

Wood block drilling machine for wooden toy

ActiveCN112045784AAchieve push leftAchieve fixationStationary drilling machinesElectric machineryWorkbench

The invention relates to a drilling machine, and particularly relates to a wood block drilling machine for a wooden toy. The wood block drilling machine for the wooden toy can efficiently drill holesand can automatically push and fix wood blocks. The wood block drilling machine for the wooden toy comprises a workbench, a drilling mechanism, a feeding mechanism and a pressing material returning mechanism, wherein a motor is arranged at the top of the workbench; the drilling mechanism is arranged on the workbench; the feeding mechanism is arranged on the workbench; and the pressing material returning mechanism is arranged on the workbench. According to the wood block drilling machine for the wooden toy, the holes are drilled in the wood blocks through the drilling mechanism, then the wood blocks are pushed leftwards and fixed under the cooperation of the feeding mechanism and the pressing material returning mechanism, and therefore the holes can be stably and rapidly drilled in the woodblocks; and the wood blocks are placed between the workbench and a limiting block, and therefore a second pushing block can automatically push the wood blocks forwards under the action of a fifth spring, and convenience is provided for people.

Owner:李拥政

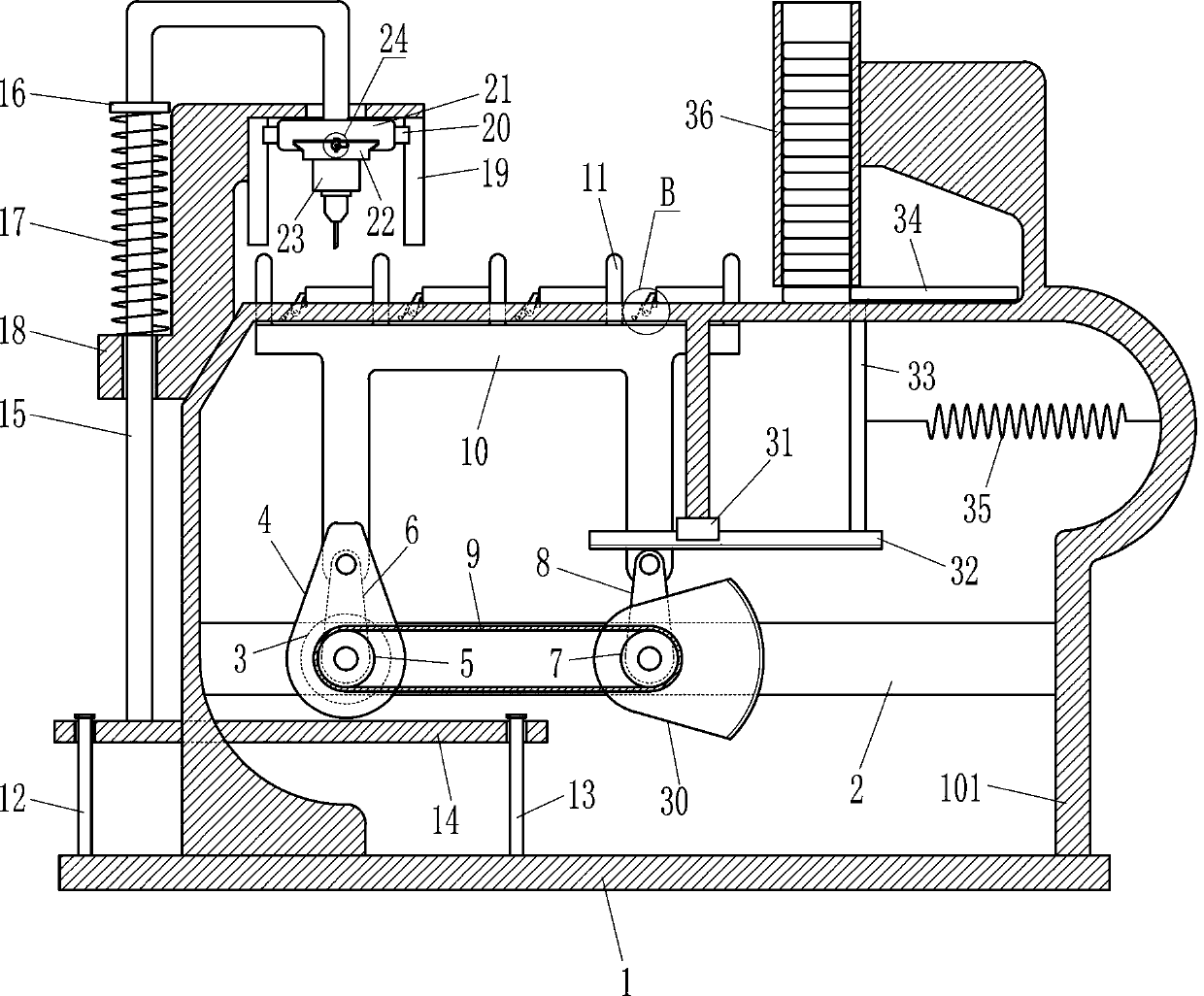

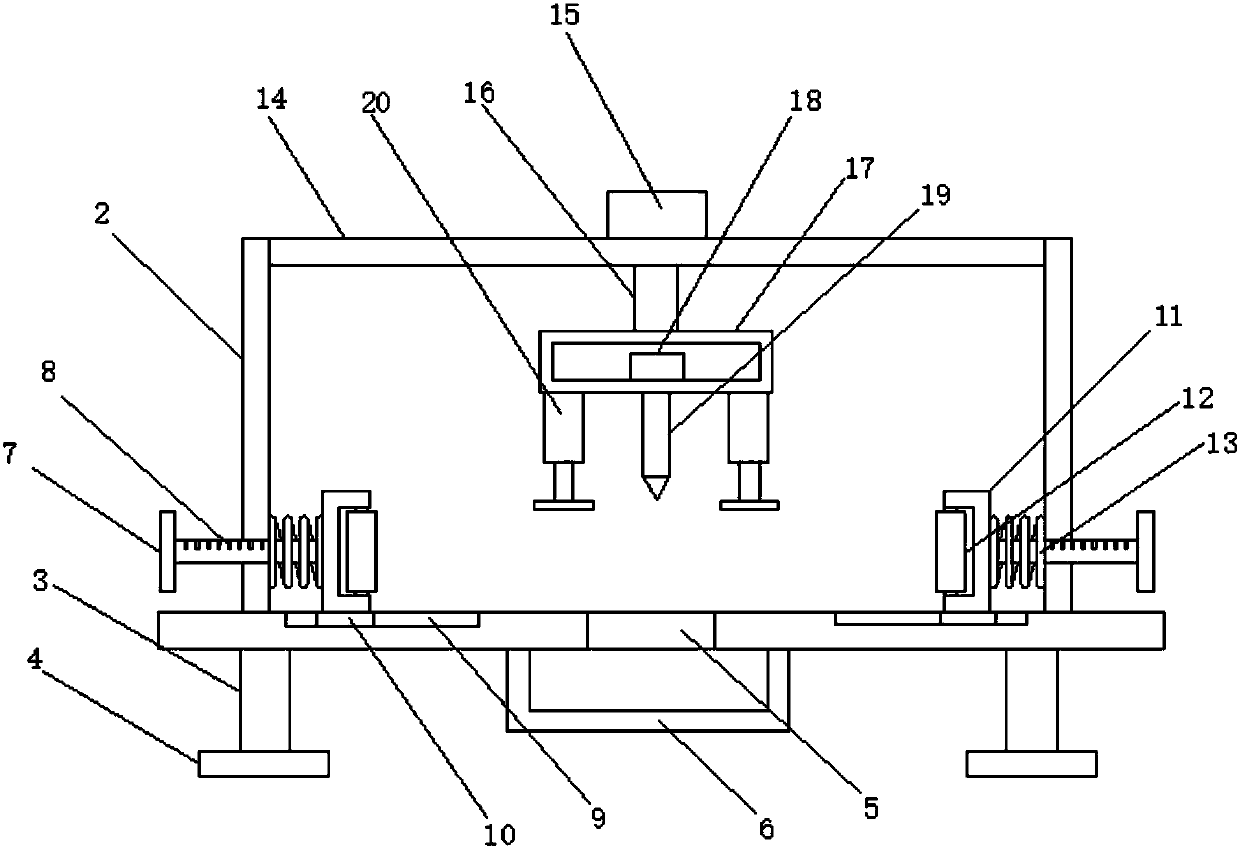

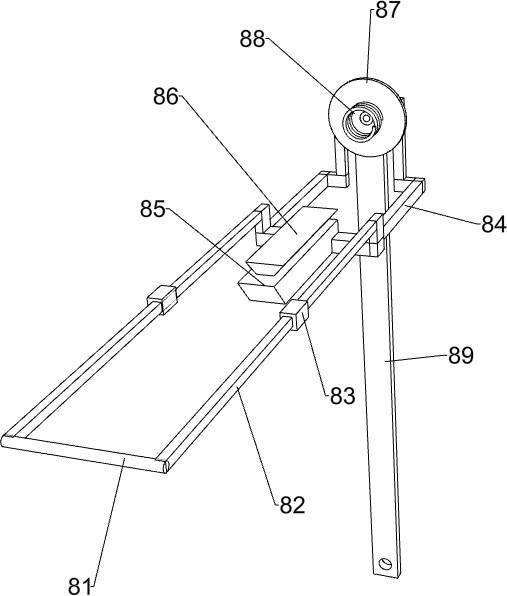

Equal-distance and efficient hole drilling device for building wood

InactiveCN107234678ASimple structureEasy to operateStationary drilling machinesBark-zones/chip/dust/waste removalMotor driveArchitectural engineering

The invention discloses an equidistant high-efficiency drilling device for building timber, comprising a bottom plate, a left side plate is fixed on the upper left part of the bottom plate, a right side plate is fixed on the upper right part of the bottom plate, a workbench is arranged above the bottom plate, and the workbench and the bottom plate Sliding connection, a power mechanism is provided under the worktable, clamping devices are provided on both sides of the upper part of the worktable, a mounting plate is slidably connected between the left side plate and the right side plate, and a second motor is fixed in the middle of the bottom of the mounting plate. The second motor drives and connects the drill bit, and a dust-absorbing device is installed on the mounting plate. The present invention is provided with a power mechanism, which includes a first electric push rod, a first motor, an active dial, a driven sheave, a gear, a rack and The disc, through the cooperation of the above components, realizes equidistant drilling, high drilling efficiency, equipped with a clamping device, which can clamp or loosen the board, easy to operate, reliable clamping, equipped with a vacuum device to avoid dust in the working area Scattered, the working environment is extremely poor, affecting the health of the staff.

Owner:杜鑫

Plank drilling device for furniture product

InactiveCN108115770AGuaranteed to move in a straight linePrevent tamperingStationary drilling machinesBark-zones/chip/dust/waste removalDrive motorEngineering

The invention discloses a plank drilling device for a furniture product. The plank drilling device comprises a working table and two side plates, a top plate is arranged at the top end of the side plate, a plurality of support columns are arranged on the lower end face of the working table, a bottom plate is arranged at the bottom end of the support column, two symmetric mounting racks are arranged on the upper end face of the working table, a positioning press roll is arranged on the mounting rack, an adjusting screw rod is arranged on each of the two side plates, scales are further arrangedon the adjusting screw rod, one side of the mounting rack is connected with the side plate through a reset spring, an air cylinder is arranged on the top plate, a pneumatic push rod is arranged at thelower end of the air cylinder, an outer frame is fixedly connected at the bottom end of the pneumatic push rod, a drill bit is installed on the lower end face of the outer frame, the upper end of thedrill bit is connected with a drive motor arranged in the outer frame, and compressing devices are symmetrically arranged on the two sides of the lower end of the outer frame. The plank drilling device is simple in structure, the drilling accuracy is higher, the efficiency is higher, the plank drilling device can continuously drill by being adaptive to planks of different widths, the operation issimple and convenient, and the practicality is stronger.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

Drilling machine for furniture board material

ActiveCN104339423AEasy and effective removalProtection cleanStationary drilling machinesBark-zones/chip/dust/waste removalEngineeringDrilling machines

The invention relates to the field of furniture processing equipment, and particularly relates to a drilling machine for a furniture board material. The invention is realized by the following technical scheme: the drilling machine for the furniture board material comprises a drilling device, a lower-site machine platform, an upper-site machine platform, a sliding device and a clearing device, wherein the lower-site machine platform is used for placing a board material; the upper-site machine platform is parallel to the lower-site machine platform, arranged above the lower-site machine platform and connected with the drilling device; the sliding device is connected with the drilling device so that the drilling device can move along X axis and Y axis on the plane of the upper-site machine platform, and the clearing device is arranged on the lower-site machine platform and used for clearing board material scraps. The invention aims to provide the drilling machine for the furniture board material, the drilling device can be arranged flexibly, a plurality of holes of the board material are drilled once only at preset positions, the drilling machine also has the function of clearing the scraps, and the cleanness of the processing environment is improved.

Owner:ZHEJIANG BOTAI FURNITURE

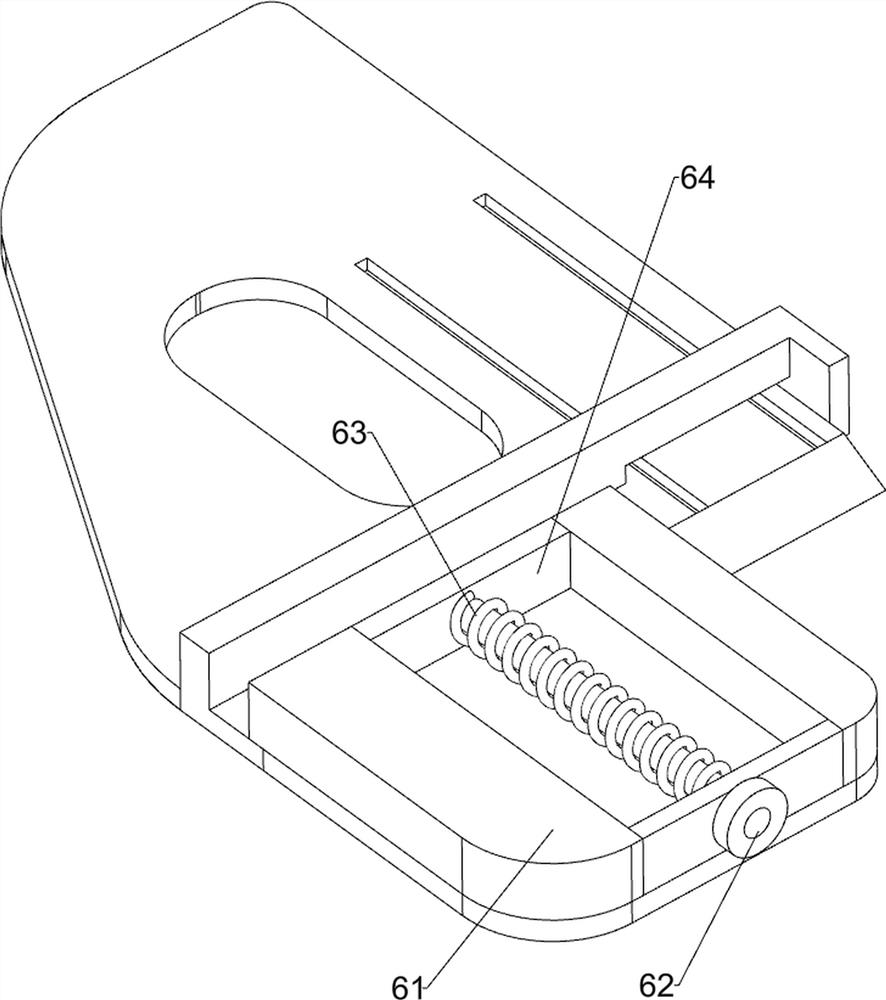

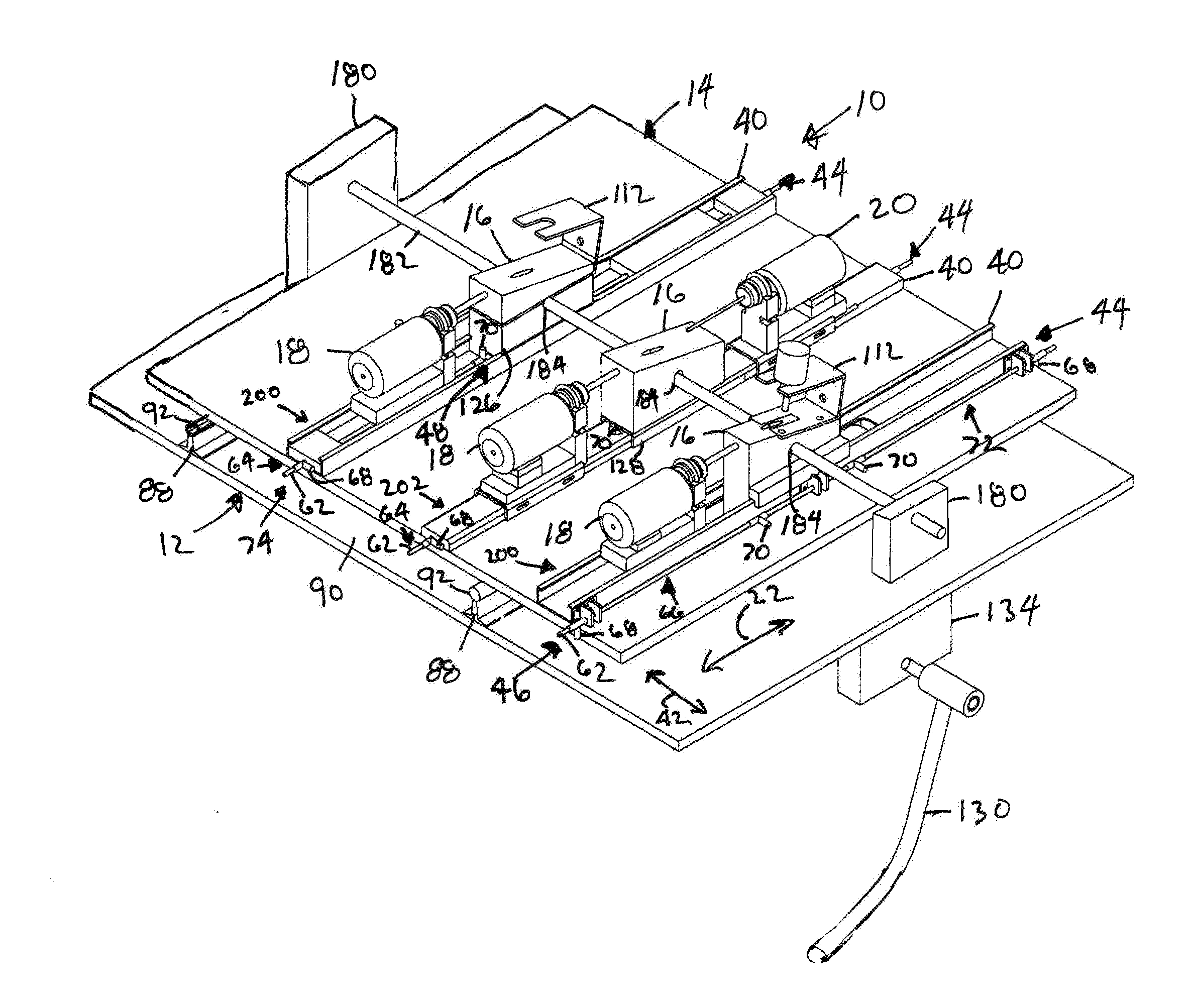

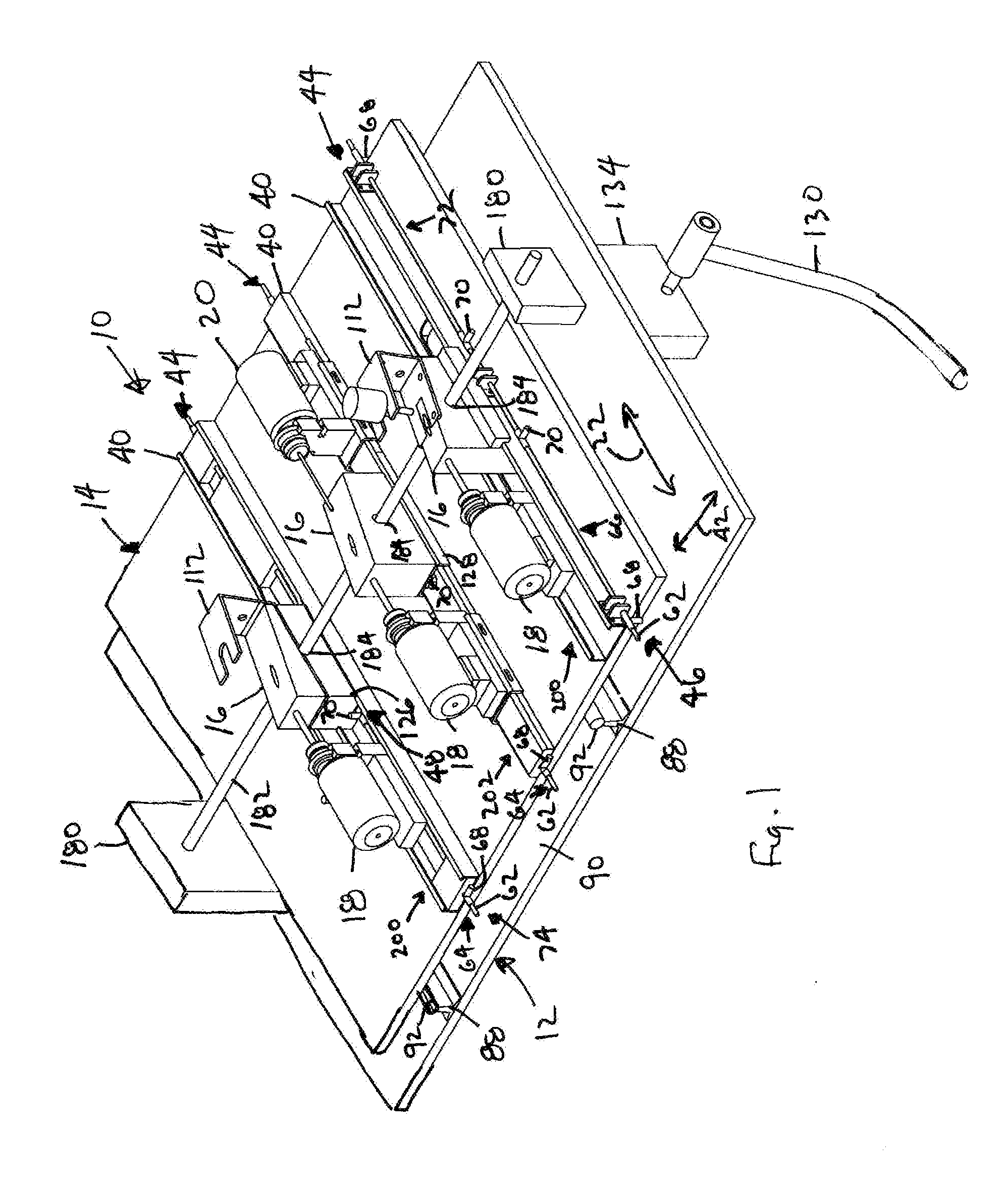

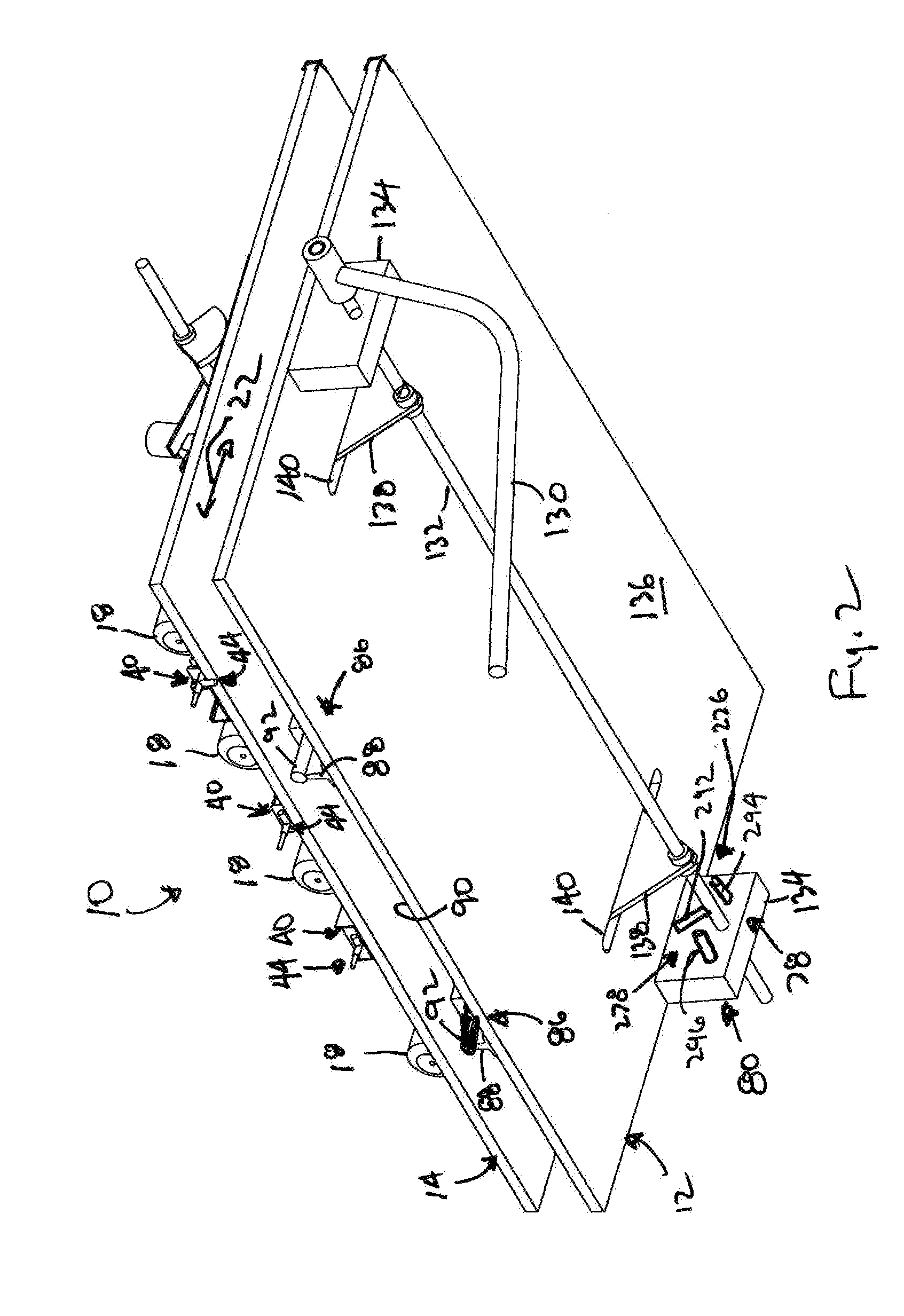

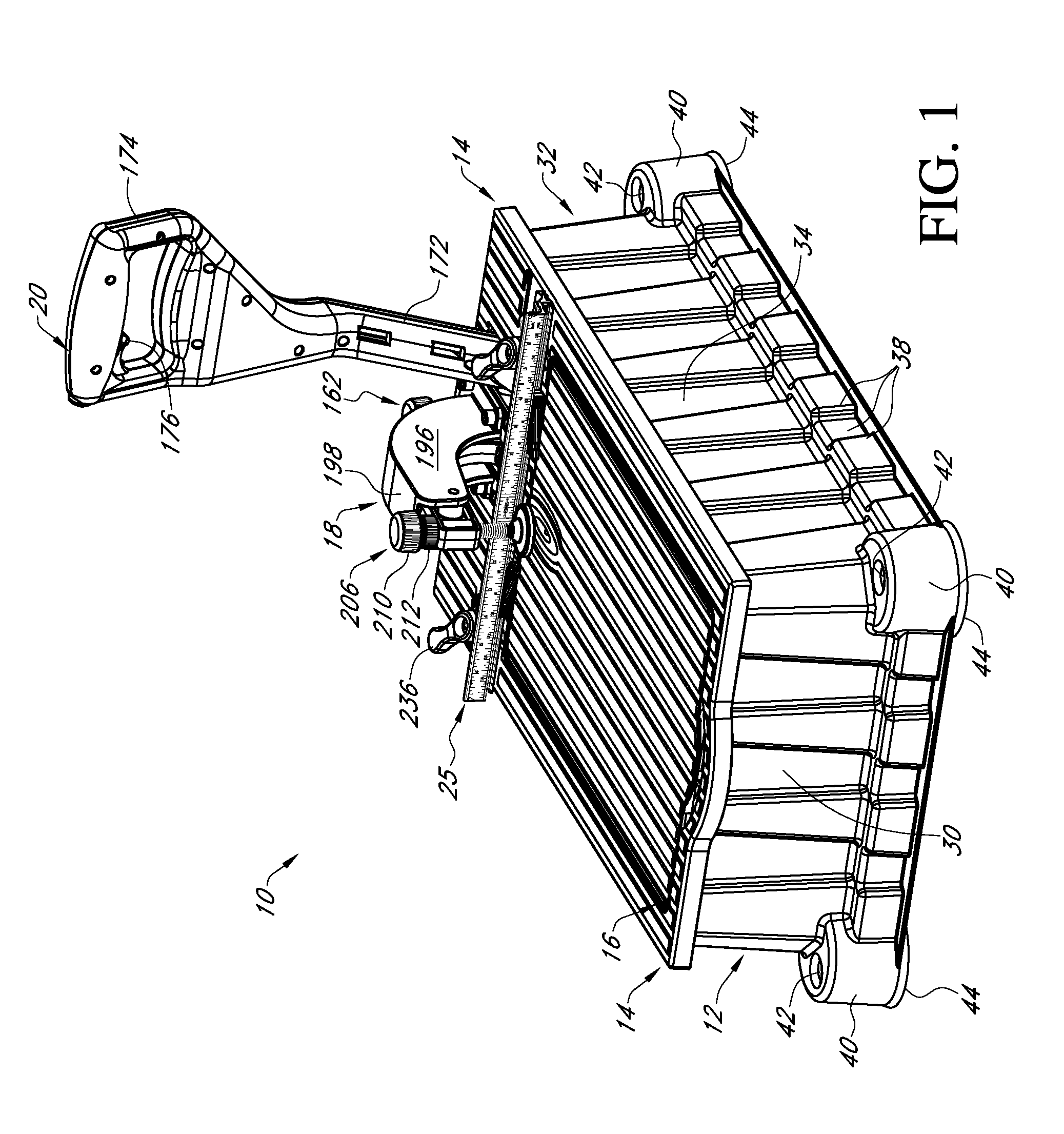

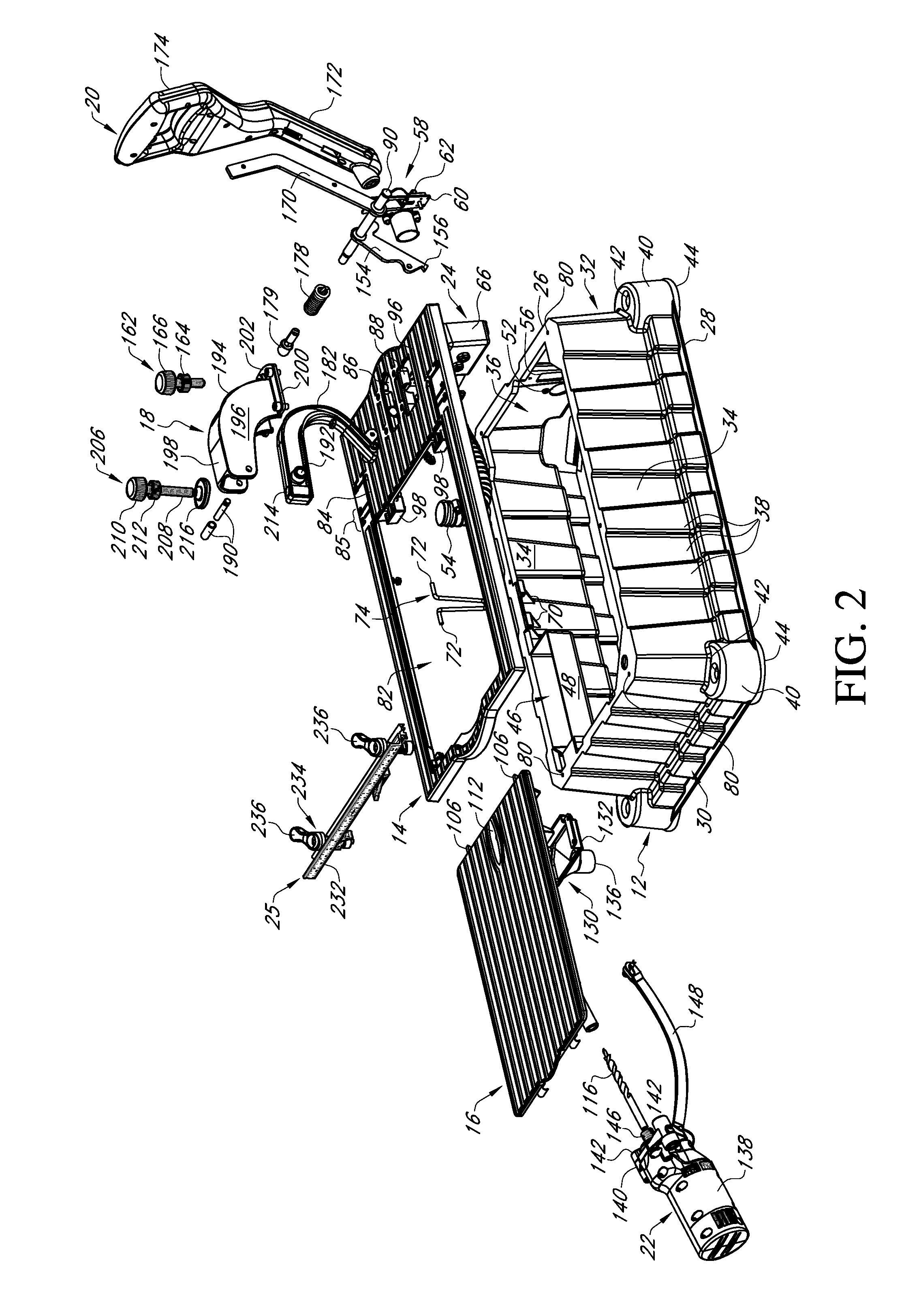

Adjustable Pocket Hole Apparatus

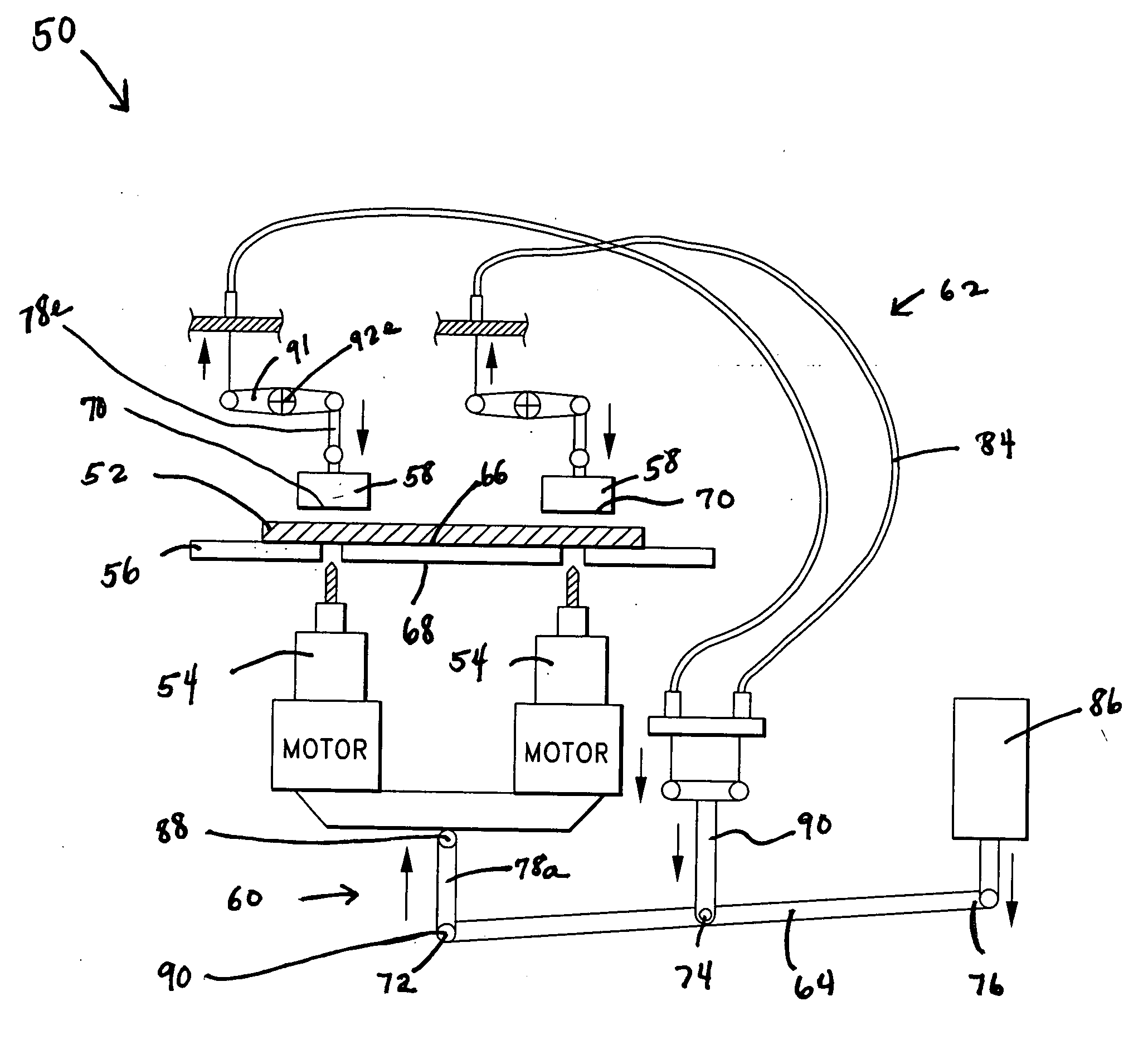

InactiveUS20110150587A1Permit adjustmentDrilling/boring measurement devicesStationary drilling machinesReciprocating motionEngineering

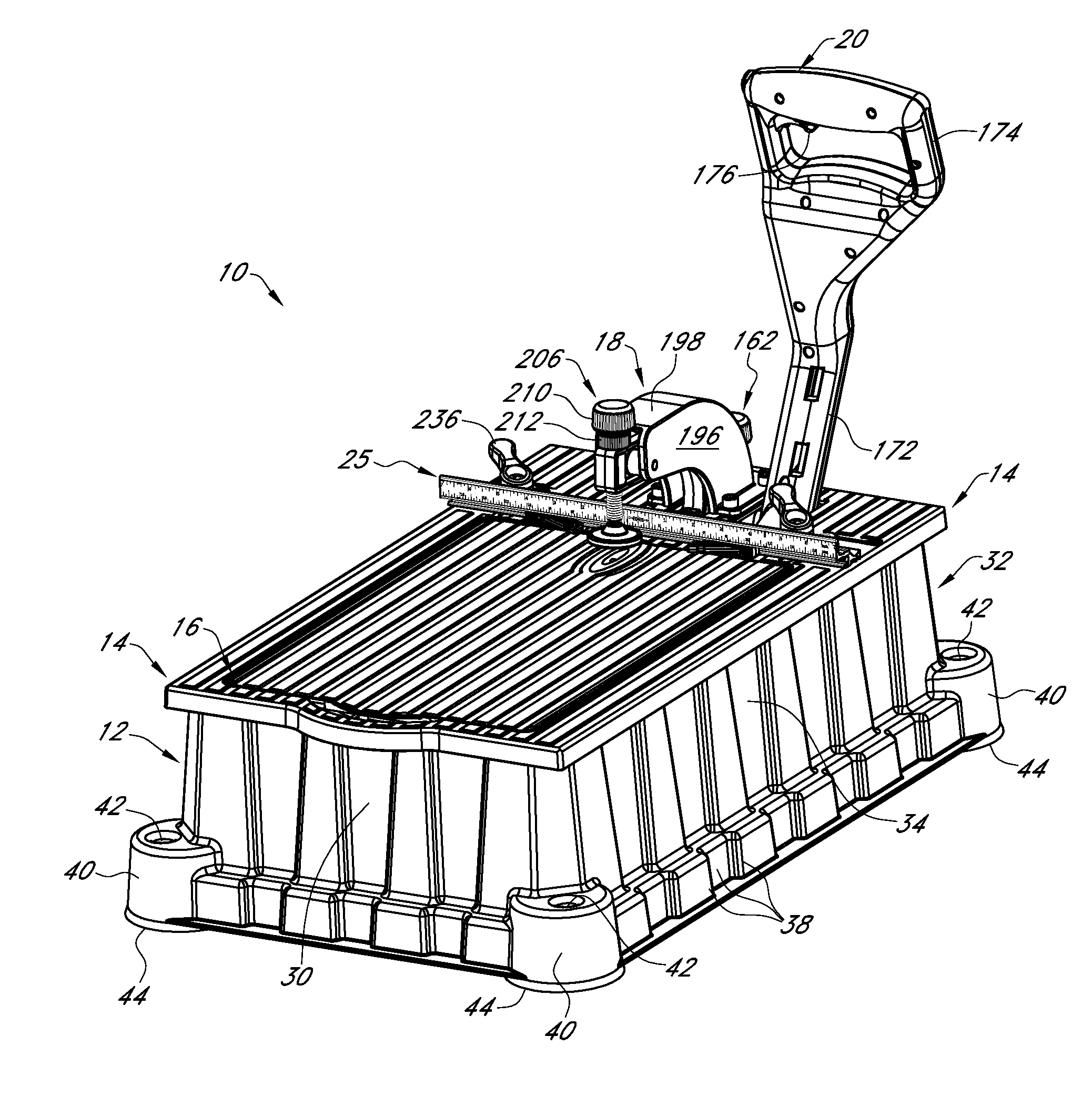

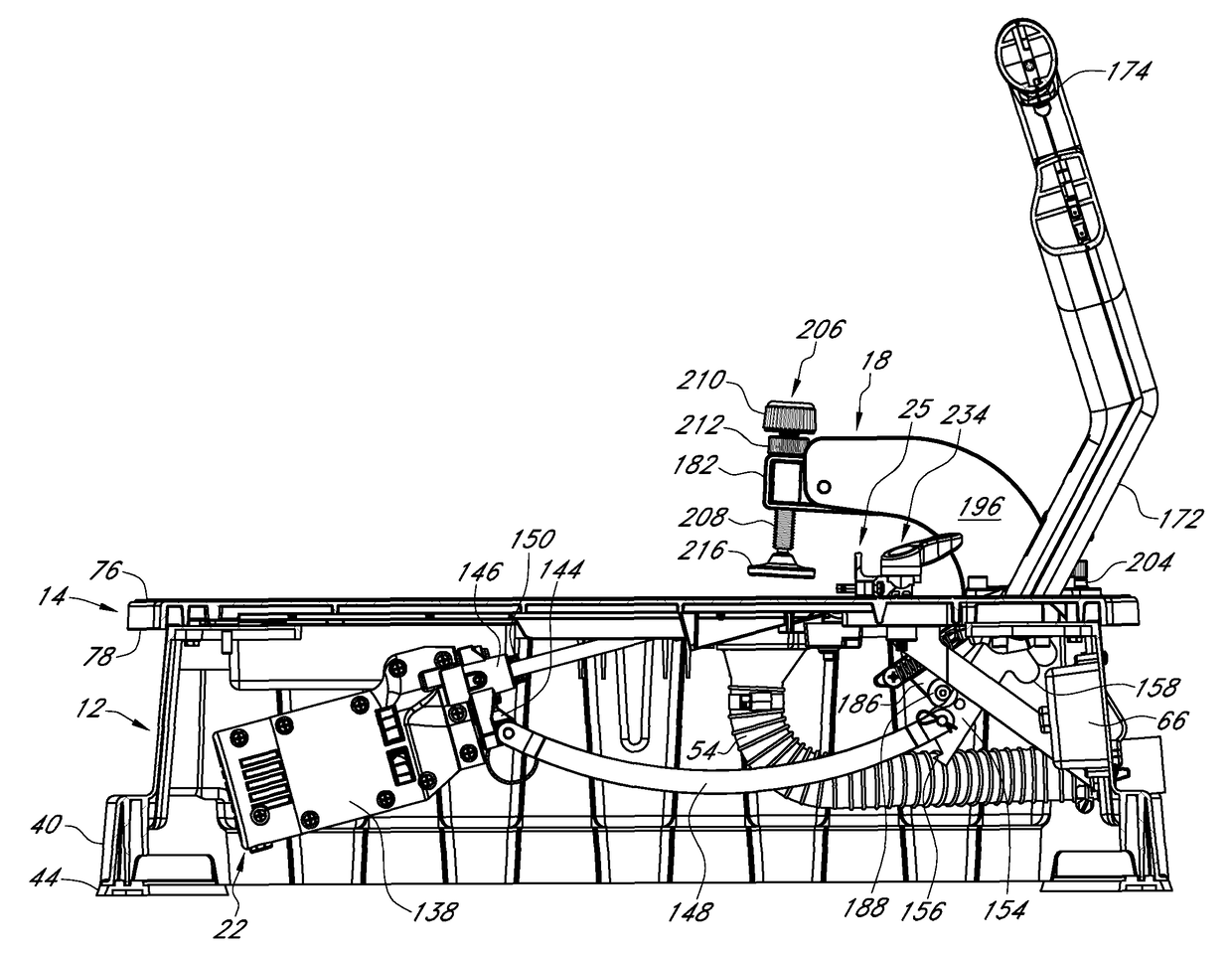

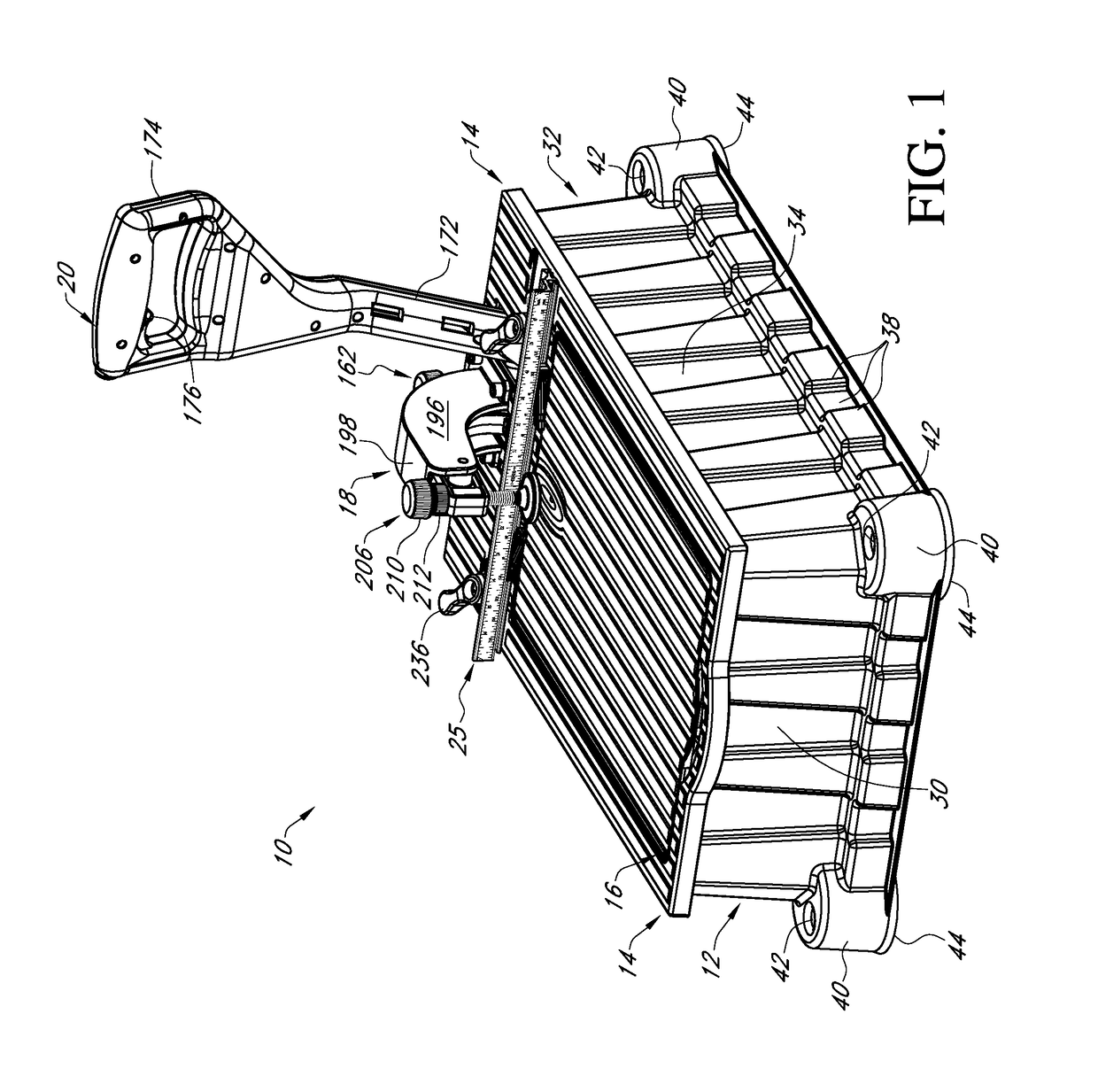

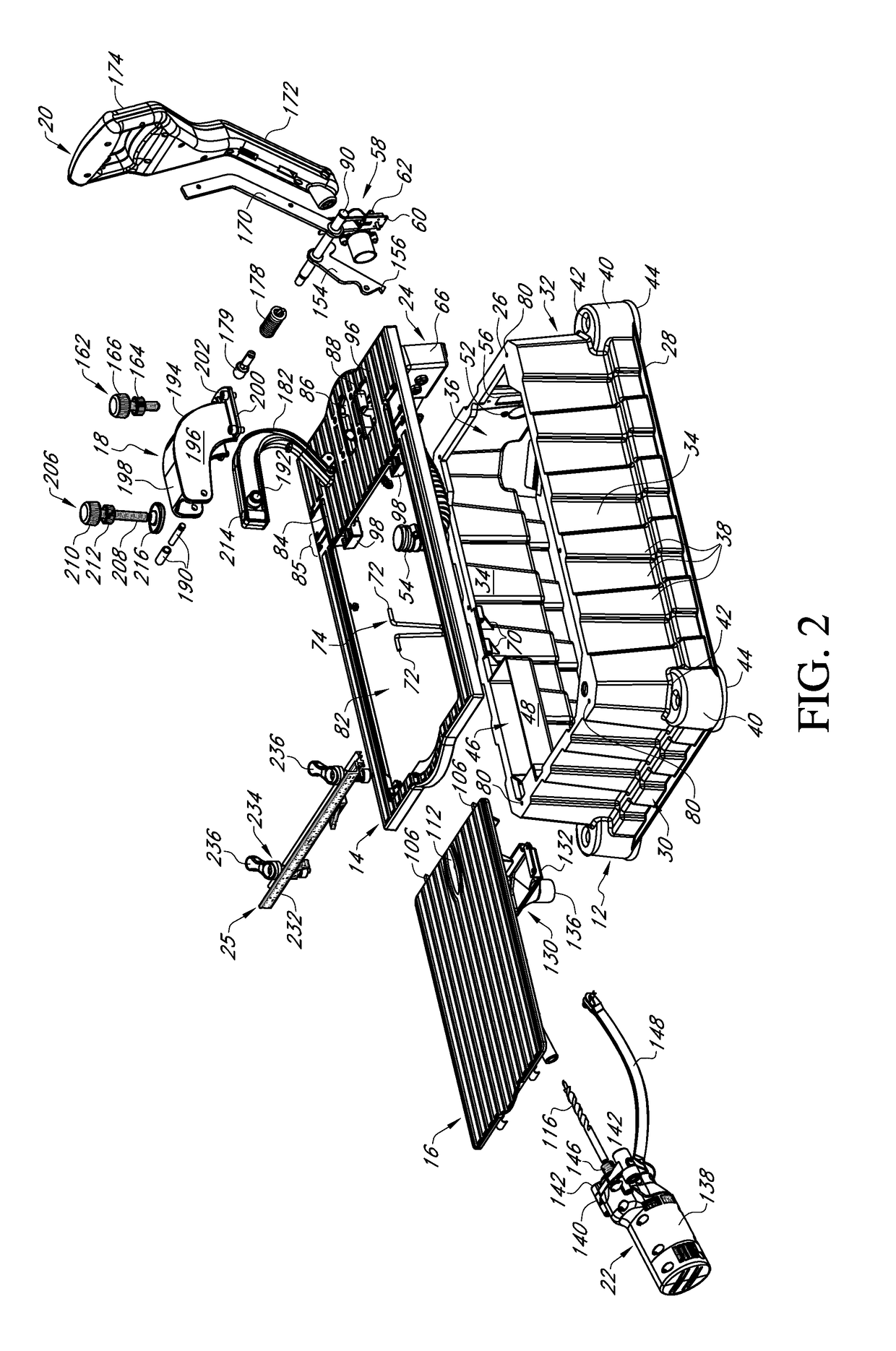

In the pocket hole apparatus of the present invention, a table reciprocates linearly relative to a base. An anvil is fixed relative to the base and holds the workpiece on a sloped top surface at the desired angle for the pocket hole. A drill spindle with a drill bit is fixed relative to the table. After the workpiece is mounted to the anvil, the table is moved to drill the pocket hole. Optionally, a second spindle on the opposite side of the anvil predrills the pocket hole when the table is first moved to a predrill position. The spindle is enabled or disabled by latching mechanism. The spindle is mounted to a rail that is slidably mounted to the table so that the rail can slide perpendicularly thereby adjusting the spacing between pocket holes.

Owner:STUKULS ALFRED

Seat drilling machine

InactiveCN101570029AFreely adjust the travel distanceImprove work efficiencyStationary drilling machinesBatch processingEngineering

The invention provides a seat drilling machine, and belongs to the field of a woodworking machine tool. The seat drilling machine solves the technical problems of multiple clamping and positioning, complicated operation, low dimension precision of holes, low working efficiency, difficult batch processing and the like existing in the existing drilling technique. The seat drilling machine comprises a machine tool rack and a workstation; wherein, the workstation is fixed on the machine tool rack to place working pieces. The seat drilling machine is characterized in that a drilling equipment is arranged above the workstation, and comprises a driving air cylinder which is vertically arranged; a piston rod of the driving air cylinder is fixedly connected with a motor which is vertically arranged; an output shaft of the motor is connected with a drill bit; a transversal adjusting mechanism enabling the driving air cylinder to horizontally and transversally move is arranged between the driving air cylinder and the workstation. The seat drilling machine can drill a plurality of holes by clamping once, the dimension precision is high, and the working efficiency is high.

Owner:TAIZHOU EVOK MASCH CO LTD

Wood slotting device capable of achieving automatic discharge

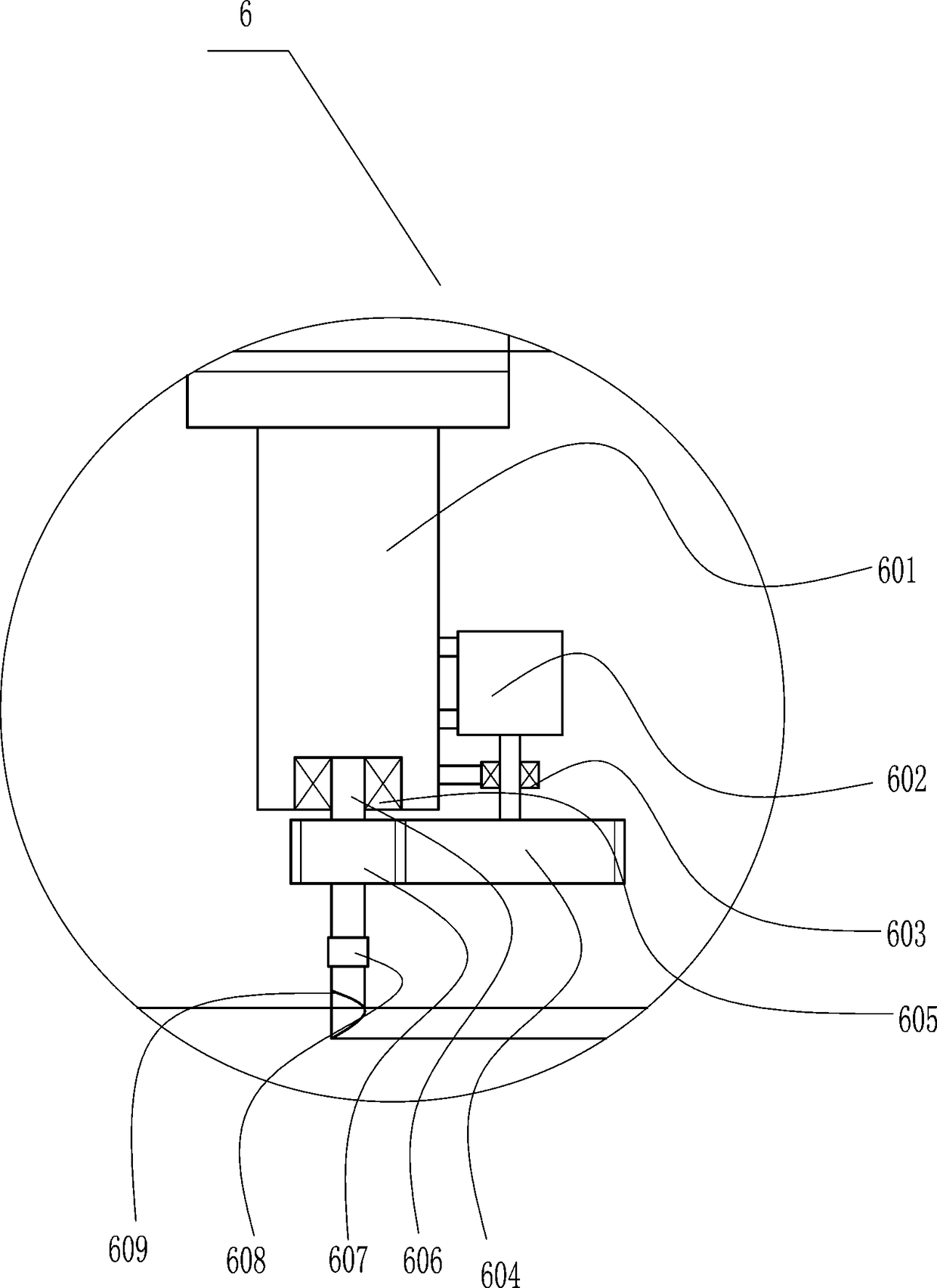

ActiveCN108162101APlay the role of cuttingReach the function of feeding switchStationary drilling machinesWood mortising machinesEngineeringCam

The invention relates to a slotting device, particularly to a wood slotting device capable of achieving automatic discharge, and provides the wood slotting device capable of achieving automatic discharge, which utilizes machinery to replace manual work. The wood slotting device capable of achieving automatic discharge provided to solve the technical problem comprises a rack, a driving device, a conveying device, a cam device, a discharge device, and the like, wherein the driving device is arranged on the rack; the conveying device is arranged on the right side of the driving device; the cam device is arranged above the driving device; the discharge device is arranged below the cam device; a slotting device is arranged below the cam device; and a switch device is arranged below the right side of the discharge device. According to the wood slotting device, an automatic slotting function is achieved, an automatic conveying function is achieved, and the wood slotting device has the characteristics that the slotting speed is high, operation is convenient, manufacturing is simple, manufacturing cost is low, popularization is facilitated, and the like.

Owner:成都千川门窗有限公司

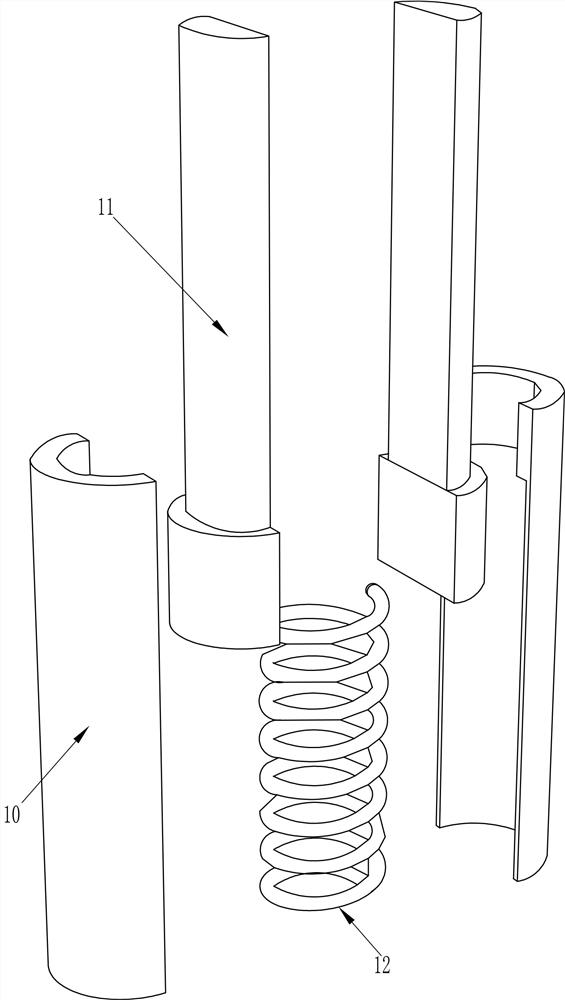

Bamboo stick clamping and drilling equipment for bamboo straw manufacturing

InactiveCN111168790AImprove processing efficiencyImprove yieldStationary drilling machinesCane mechanical workingWood machiningProcess engineering

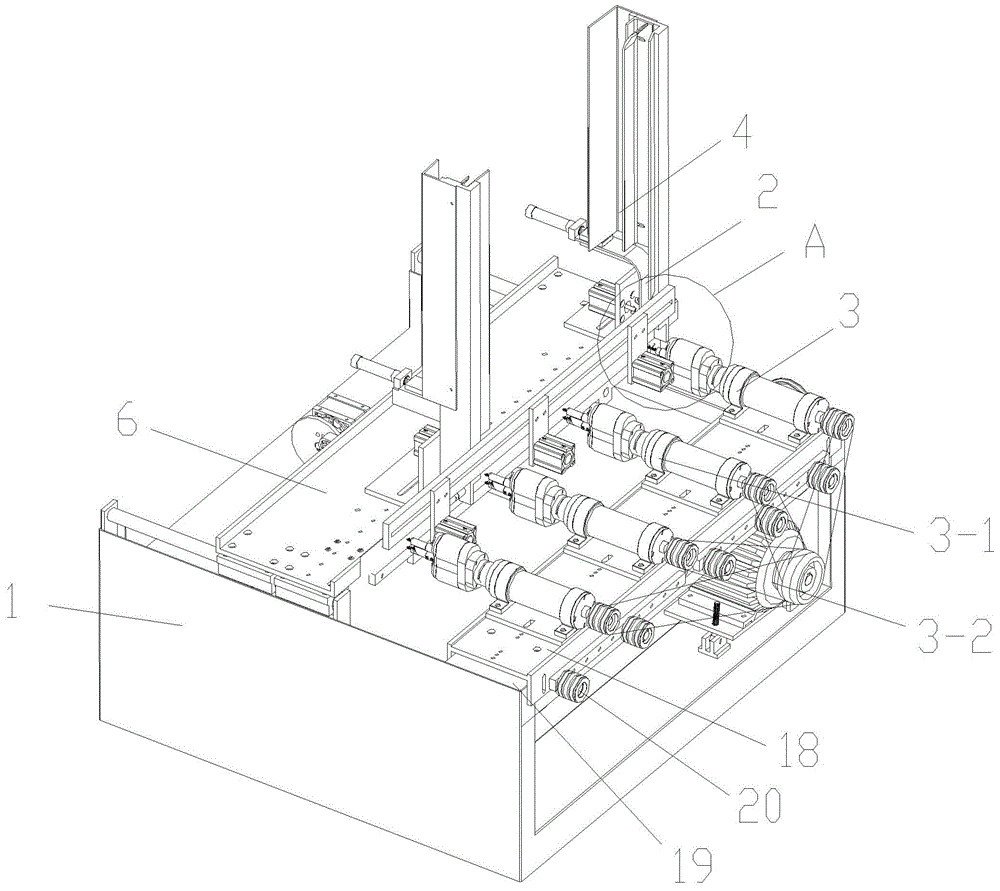

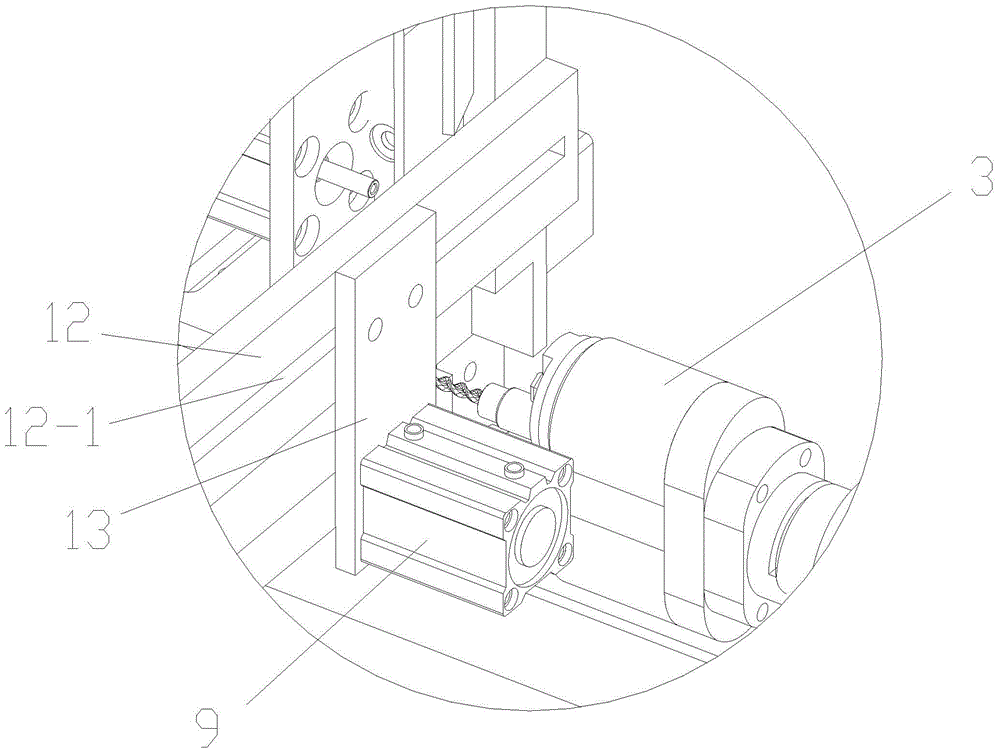

The invention relates to the technical field of bamboo and wood machining, in particular to bamboo stick clamping and drilling equipment for bamboo straw manufacturing. The equipment comprises a conveying device, a clamping device and a drilling device which are arranged on a rack, wherein the conveying device is arranged on one side of the clamping device and used for conveying a bamboo stick tothe clamping device, and the drilling device is used for drilling the bamboo stick clamped by the clamping device. According to the bamboo stick clamping and drilling equipment for bamboo straw manufacturing, the machining efficiency of the bamboo straw is greatly improved, and the equipment is simple in mechanism and easy to disassemble and maintain; the formed bamboo stick can be directly drilled, and compared with a traditional bamboo straw manufacturing mode, the efficiency is higher; and through the straightening and fixing effect of a taper sleeve and a clamping roller on the bamboo stick, the bamboo stick is always in a rotating state in the drilling process, it is guaranteed that a drill bit advances straightly in the bamboo stick, the problem that the drill bit drills through thebamboo stick due to the insufficient straightness of the bamboo stick or the structure of a sunny side and a nightside is avoided, and the yield of bamboo straw machining is greatly increased.

Owner:邵武市意创机械有限公司

Cutting board slotting equipment

InactiveCN111605005ATo achieve the effect of slottingSave human effortStationary drilling machinesWood mortising machinesWorkbenchIndustrial engineering

The invention relates to slotting equipment, in particular to cutting board slotting equipment, and aims at solving the technical problem about how to design cutting board slotting equipment simple inoperation and capable of improving work efficiency and saving manpower. The cutting board slotting equipment is provided and comprises a landing leg with the top connected with a workbench, a supportconnected to one side of the top of the workbench, and a slotting assembly, wherein the top of the support is connected with a transverse plate, and the slotting assembly is arranged between the transverse plate and the support. The slotting assembly is used for slotting a cutting board, and accordingly the effect of cutting board slotting is achieved. The slotting assembly is assisted in runningand rotating the cutting board through cooperation of a clamping assembly and a downward pressing assembly, manual cutting board rotation is not needed, and manpower is effectively saved.

Owner:南京科信磁业有限公司

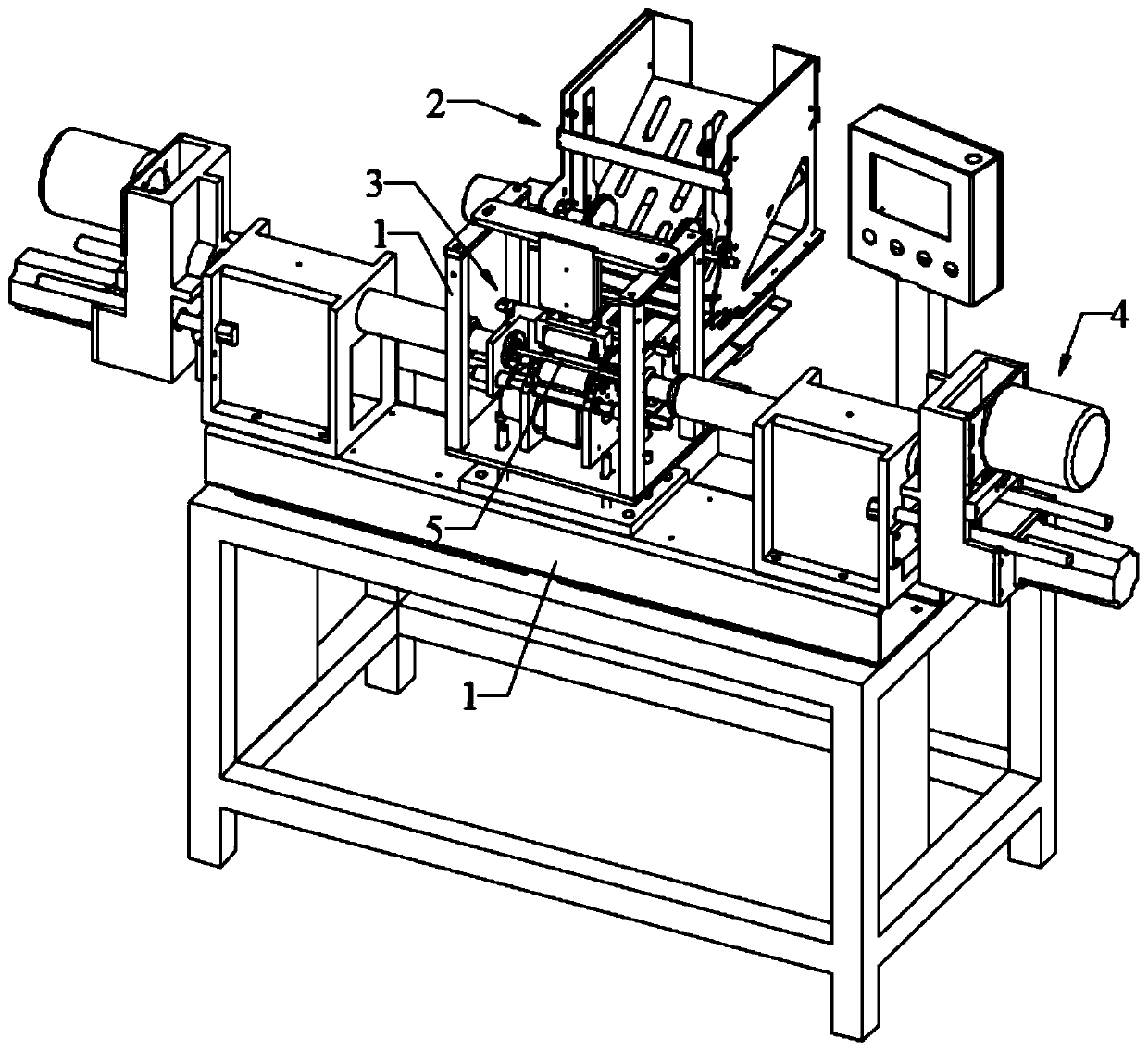

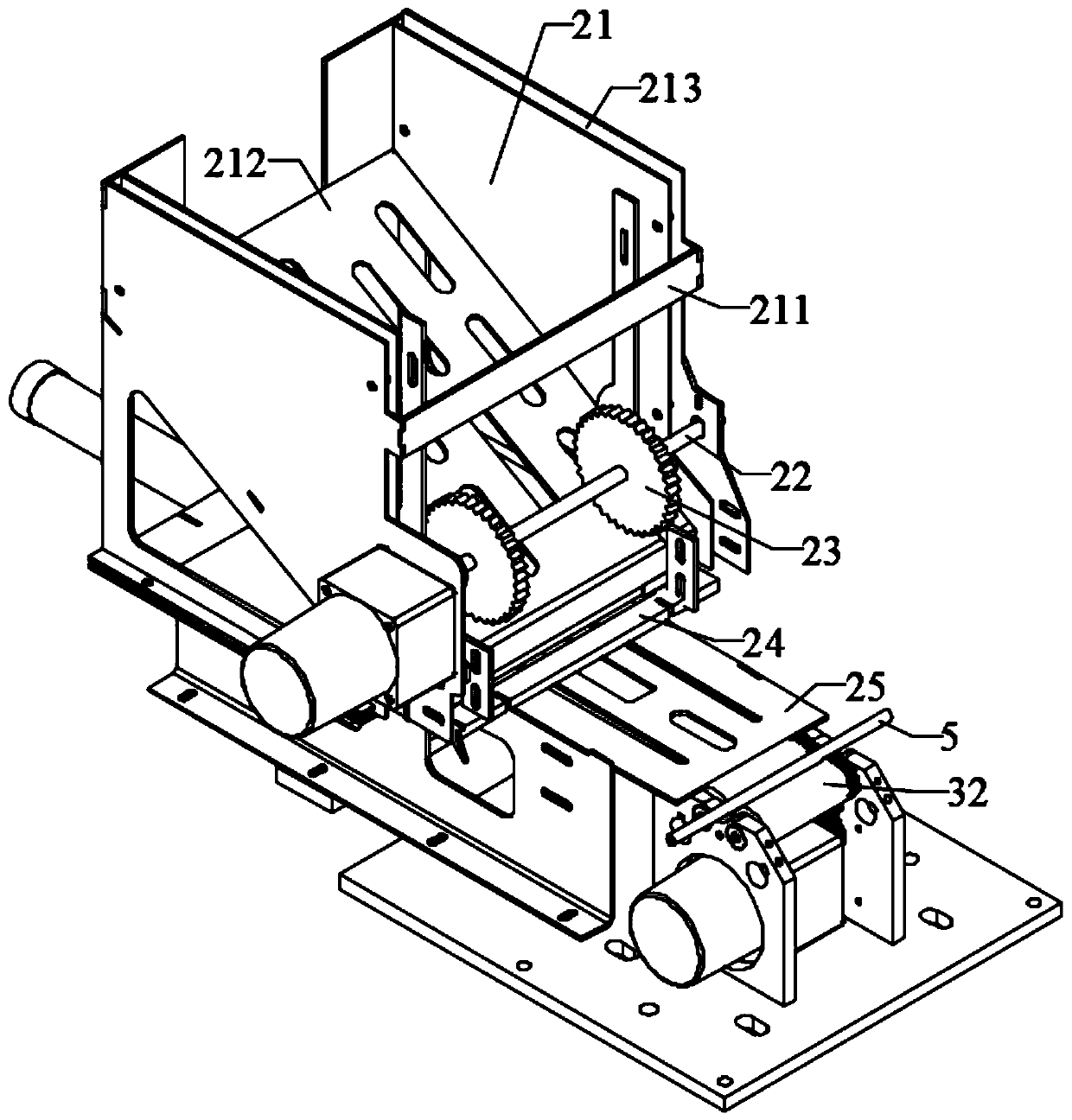

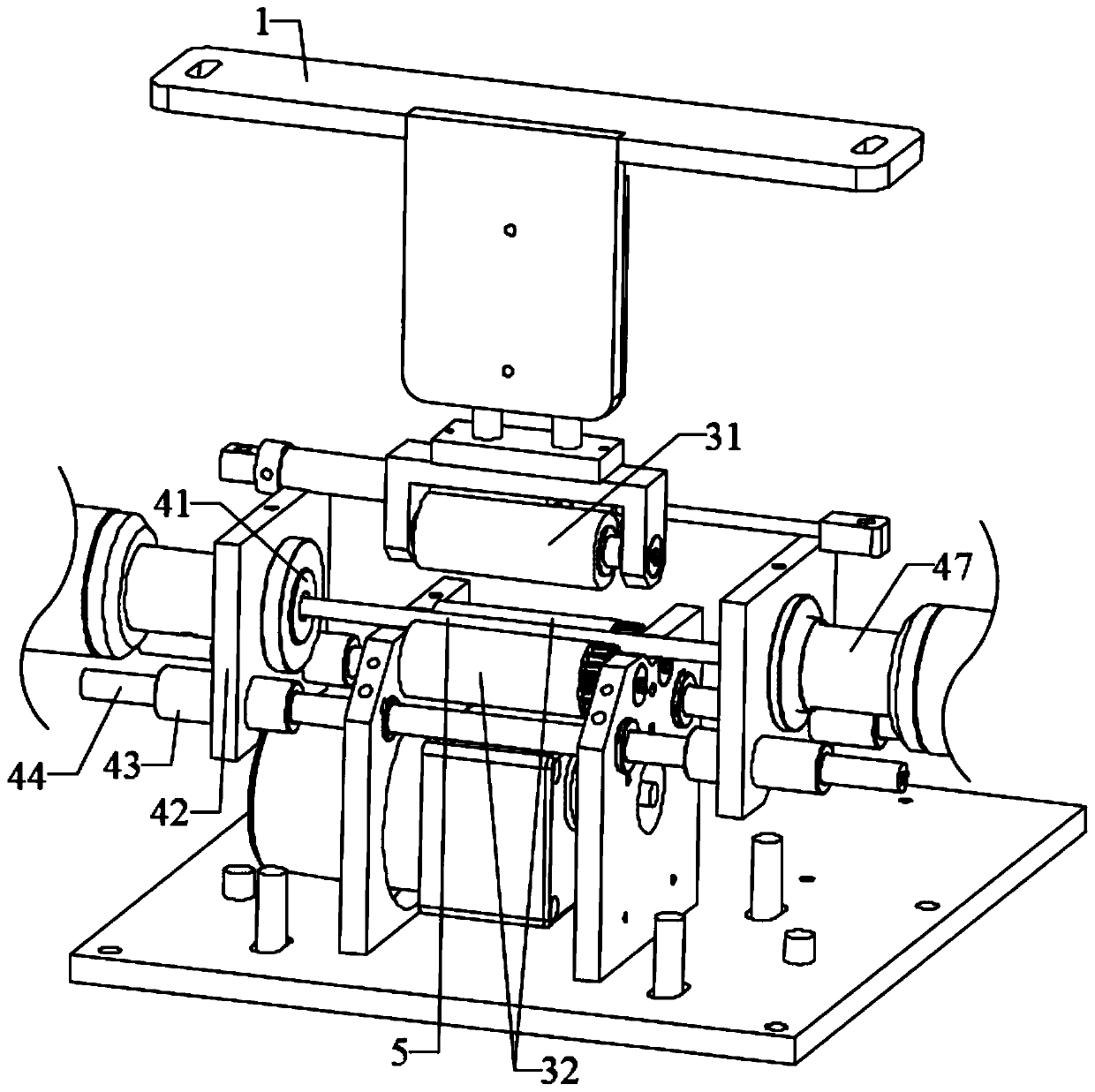

Drilling equipment used before assembling of storage cabinet

ActiveCN111673841AUniform sizeDeep unityStationary drilling machinesMulti-purpose machinesGear wheelElectric machinery

The invention relates to drilling equipment, in particular to drilling equipment used before assembling of a storage cabinet. The technical problem to be solved is to how to provide the drilling equipment used before assembling of the storage cabinet, in which a storage cabinet wood board needing to be drilled can be automatically and intermittently replaced, the storage cabinet wood board can beautomatically drilled, and the drilled wood board can be automatically stored. The drilling equipment used before assembling of the storage cabinet comprises a rack, a motor, a discharging box, a sliding plate and the like; and the motor is installed in the middle of the lower portion of the rack through bolts, the discharging box used for storing plates is installed between the tops of the rack,and the sliding plate is arranged on the upper portion of the rack in a sliding mode and located below the discharging box. Through the motor, the sliding plate, an L-shaped push rod, a first connecting rod and the like, a plate needing to be drilled can be automatically replaced, the plate can be transported, and the fixed position of the plate can be drilled through a transmission mechanism, a sector gear, a first rotating shaft, a placing plate, an electric drill and the like.

Owner:TRANTEX PROD CO LTD

Full-automatic plate material drilling machine

A full-automatic plate material drilling machine comprises a machine frame, the machine frame is provided with a positioning frame for fixing a plate material and a drilling machine for drilling the plate material, the positioning frame is provided with a positioning groove for making the plate material placed longitudinally and positioned, the bottom of the positioning groove is provided with discharge ports, each discharge port is provided with a supporting limit block, and each supporting limit block is arranged on a first gas cylinder; the top of the positioning groove is connected with a feeding device, the feeding device comprises a placing frame, the placing frame is provided with a groove body for making the plate material transversely placed, the groove body is vertically arranged, the bottom of the groove body is provided with a supporting seat, the side edge of the bottom of the groove body is provided with a plate material outlet, and the supporting seat is provided with a second gas cylinder for pushing the plate material out of the plate material outlet; a guide channel is arranged between the plate material outlet and the top of the positioning groove.

Owner:恒达传动禹城有限公司

Bamboo chip trepanning and grinding integrated automation device

InactiveCN108312025ARealize transmission grindingImprove grinding efficiencyStationary drilling machinesCane mechanical workingHydraulic cylinderArchitectural engineering

The invention discloses a bamboo chip trepanning and grinding integrated automation device. The bamboo chip trepanning and grinding integrated automation device comprises grinding rollers, a workbenchand a drill bit. A conveying belt is arranged at the upper end of the workbench. In cooperation with the conveying belt, the upper end of the workbench is provided with a cavity. The conveying belt is provided with a baffle. A fixing cover is fixed to the upper end of the workbench. The four grinding rollers are arranged and are distributed on a first fixing plate in an array manner. A dust suction cover is fixed to the outer side of the first fixing plate, and the upper end of the first fixing plate is fixed to a push rod. The push rod is fixed to a hydraulic cylinder, and the drill bit is fixed to an output shaft of a first motor. The bamboo chip trepanning and grinding integrated automation device is high in grinding efficiency and quality; and meanwhile, in the grinding process, the dust suction cover can suck away fine dust generated during grinding

Owner:安吉森虎机械有限公司

Furniture wood drilling device capable of drilling continuously

InactiveCN107263618AAchieve continuous drillingGuaranteed continuityStationary drilling machinesBark-zones/chip/dust/waste removalEngineeringWood flour

The invention discloses a furniture wood drilling device capable of drilling continuously. The furniture wood drilling device comprises a frame body; the middle lower portion of an inner cavity of the frame body is provided with a partition plate; the upper portion of the right side of the inner cavity of the frame body is provided with a movable frame, steel wires are connected to the left side and the right side of the movable frame correspondingly, and the steel wire on the right side is connected with a transverse push rod through a right-side guide wheel; the left side of the transverse push rod is provided with a wood storing frame, ejection openings are symmetrically formed in the two sides of the bottom of the wood storing frame, and the length of the ejection openings is the same as that of the push plate; the steel wire on the left side of the movable frame is connected with a moving seat through a left-side guide wheel, and a drilling mechanism is installed at the bottom of the moving seat; and the partition plate is provided with a discharging hole, and a wood flour collecting frame is arranged below the discharging hole. Through the furniture wood drilling device, continuous drilling operation can be conducted on a plurality of pieces of wood, the wood drilling efficiency is improved, and meanwhile, the drilling device is ingenious in design, easy to operate and worth of application and popularization.

Owner:佛山市顺德区渝鸿塑料制品有限公司

Adjustable timber drilling device

InactiveCN107433640APrecise positioningStable clampingStationary drilling machinesDrill bitIndustrial engineering

The invention discloses an adjustable wood drilling device, which comprises a base, on which a support rod and a crossbeam are arranged, the crossbeam is arranged on the support rod, a drilling motor and a drill bit are arranged on the crossbeam; a wood placing mechanism is arranged on the base , the wood placement mechanism includes a lifting platform and a workbench. The lifting platform is connected to the base through a cylinder and a guide rod to realize the lifting of the lifting platform; the working platform is connected to the chute on the lifting platform through a slider, and the A locking mechanism is arranged between them; a placing groove is arranged on the workbench, and a clamping device is arranged on the side wall of the placing groove. The invention can locate accurately, clamp stably, and ensure the accuracy of drilling. At the same time, the lifting seat can be driven up and down by setting the cylinder, so that drilling can be performed, manual operation is avoided, and the quality of drilling is improved. The table can be moved on the lifting table, and the scale line is set on the workbench, which can accurately move the wood to be processed and improve the processing efficiency.

Owner:南京淳飞怿建筑科技有限公司

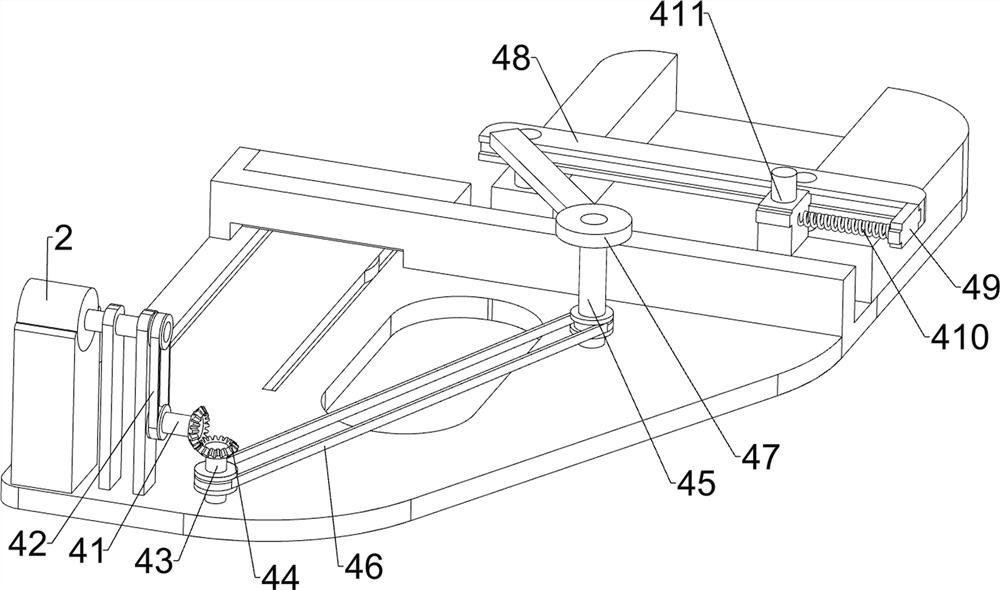

Cam lock fence system and method of use

ActiveUS20140363245A1Quick and durable and easy and accurate mannerDrilling/boring measurement devicesThread cutting machinesCamMechanical engineering

A cam lock connected with a fence assembly includes a handle portion, a top carrier and a bottom carrier connected by a threaded shaft. The handle portion and top carrier are positioned above the fence assembly and a work table or surface; wherein the bottom carrier is positioned below the fence assembly and work table or surface. The top carrier and bottom carrier both have a pair of alignment arms with a space positioned therebetween, the alignment arms of the top carrier nest with the alignment arms of the bottom carrier. The handle portion and top carrier both have cam surfaces that engage one another such that when the handle portion is rotated around the axis of the threaded shaft the handle portion is raised or lowered thereby raising or lowering the bottom carrier, thereby locking or unlocking the fence assembly in a quick, durable, easy and accurate manner.

Owner:KREG ENTERPRISES

Punching device for building decorative board

InactiveCN107097302ARealize automatic controlEnable connectivityStationary drilling machinesWood working safety devicesPunchingArchitectural engineering

The invention discloses a punching device for a building decorative board. The punching device comprises a rack composed of a base and a vertical frame and a switching mechanism arranged in the rack. A switching cavity is formed in the switching mechanism. A first sliding groove is formed in the inner top wall of the switching cavity in a left-right extending manner. A first threaded rod is arranged in the first sliding groove in a left-right extending manner. A first sliding block is connected to the first threaded rod in a threaded fit manner. A through groove with the top communicating with the switching cavity is formed in the middle position of the end of the bottom of the switching mechanism. A punching operation mechanism with the top fixedly connected with the bottom end of the first sliding block is arranged in the switching cavity. A first sliding cavity and a second sliding cavity are symmetrically arranged in the left side and the right side of the punching operation mechanism. A partition is arranged between the first sliding cavity and the second sliding cavity. A second sliding groove is formed in the each of the inner walls of the sides, close to the partition, of the first sliding cavity and the second sliding cavity. A third sliding groove is formed in each of the inner walls of the sides, far away from the partition, of the first sliding cavity and the second sliding cavity. The punching device is simple in structure, convenient to operate, high in safety, fast in maintenance speed and capable of improving the punching efficiency and the punching accuracy.

Owner:广东易享家科技有限公司

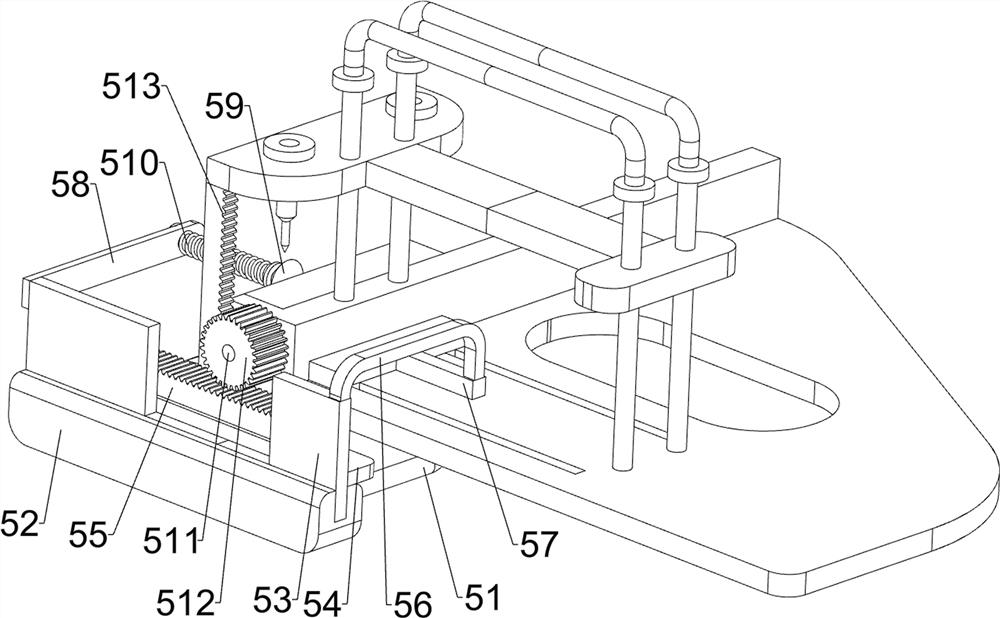

Pocket hole drilling machine

A pocket hole drilling machine is presented. The pocket hole drilling machine has a cabinet made of a molded unitary monolithic piece. A monolithic top plate is connected to the cabinet with an opening in the middle for an insert plate which is positioned therein. A handle extends above the top plated as does a clamping assembly however actuating mechanics of the device move within the cabinet, thereby improving safety by eliminating pinchpoints. An adjustable fence assembly having cam locks connected thereto is also connected to the top plate. This arrangement provides a low cost, safe and efficient pocket hole drilling machine.

Owner:KREG ENTERPRISES

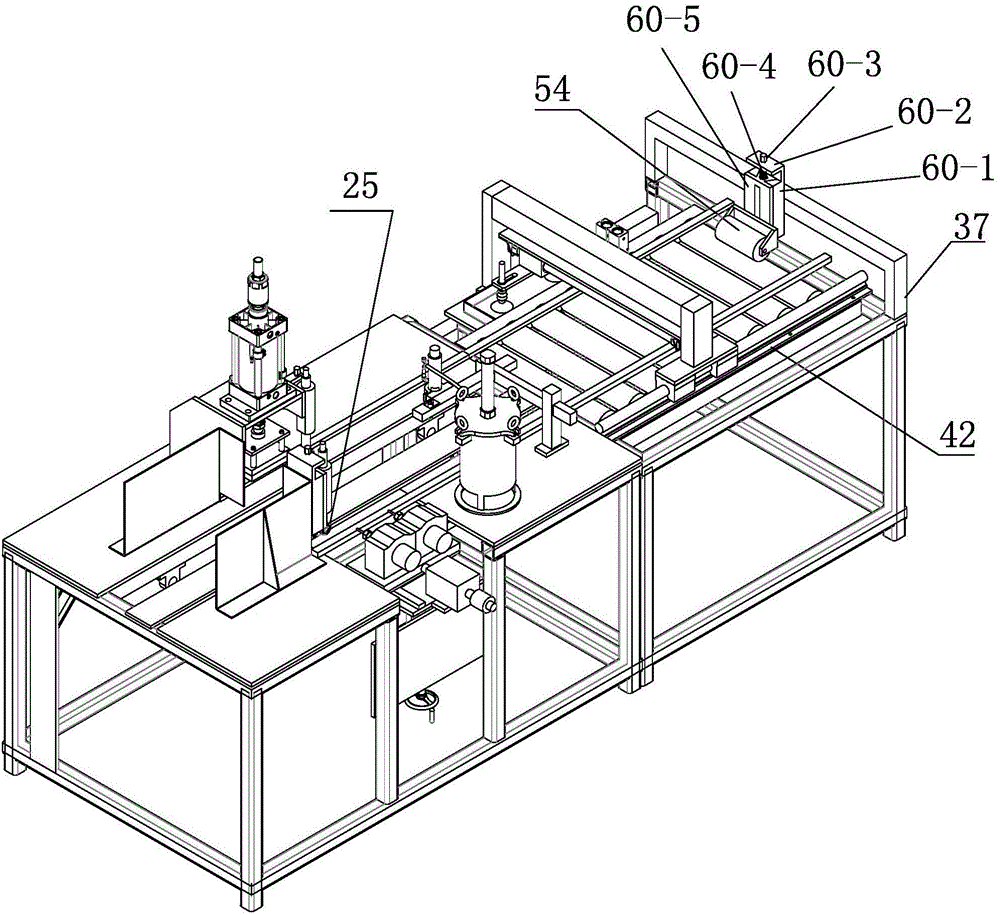

Automatic branding, drilling and labelling machine

InactiveCN104385420AContinuous brandingContinuous drillingBranding equipmentStationary drilling machinesButt jointWorkbench

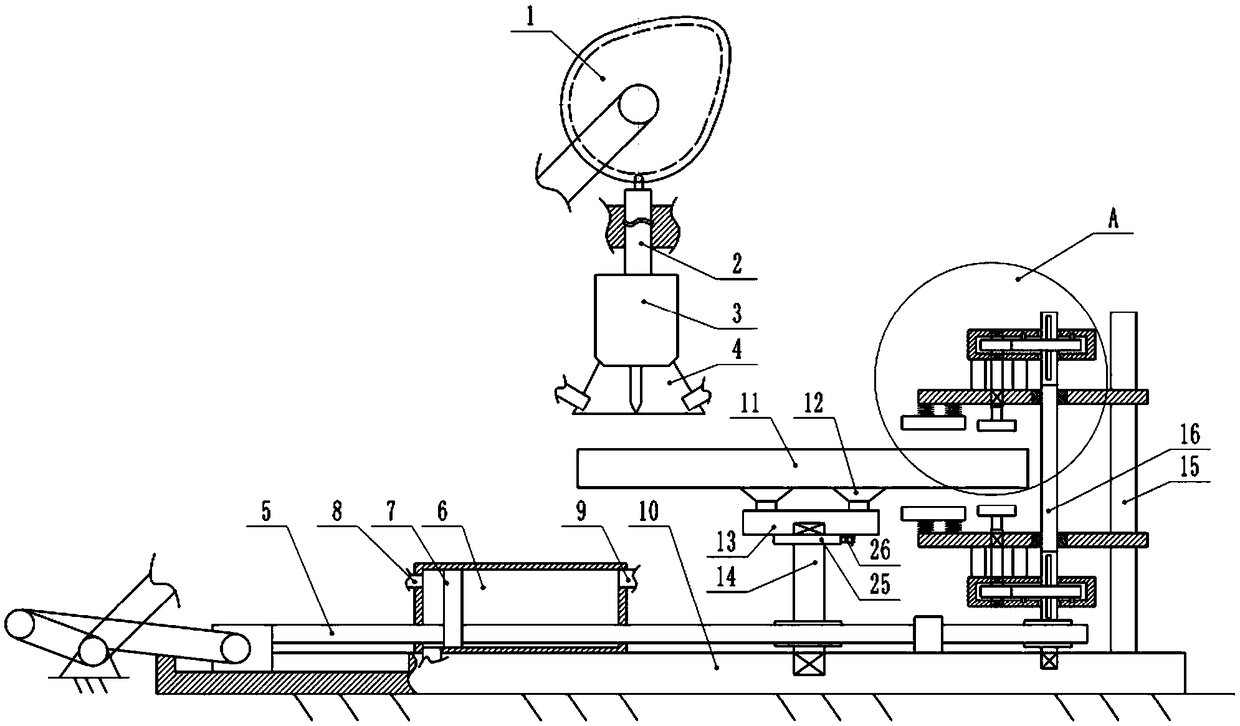

The invention relates to an automatic branding, drilling and labelling machine, which can be used for sequentially finishing the procedures of conveying, branding, drilling, glue dripping, labelling and the like, can be used for machining products of various specifications and has the characteristics of high working efficiency, convenience in adjustment, and the like. According to the technical scheme, the automatic branding, drilling and labelling machine comprises a front half part and a back half part, wherein the front half part comprises a feeding mechanism arranged on the front segment of a frame, a fixed workbench arranged on the left side of the feeding mechanism, and a movable workbench arranged on the right side of the feeding mechanism; a hand drill hole lifting mechanism and a glue dripping mechanism are arranged on the fixed workbench; a branding mechanism is arranged on the movable workbench; the back half part comprises a drum group arranged on the back segment of the frame, a labelling device arranged above the drum group, a label lifting mechanism arranged on the right side of the drum group, and a label pressing mechanism arranged at the back end of the drum group; the front end of the drum group is in butt joint with the back end of the feeding mechanism.

Owner:ZHEJIANG TIANZHU IND & TRADE

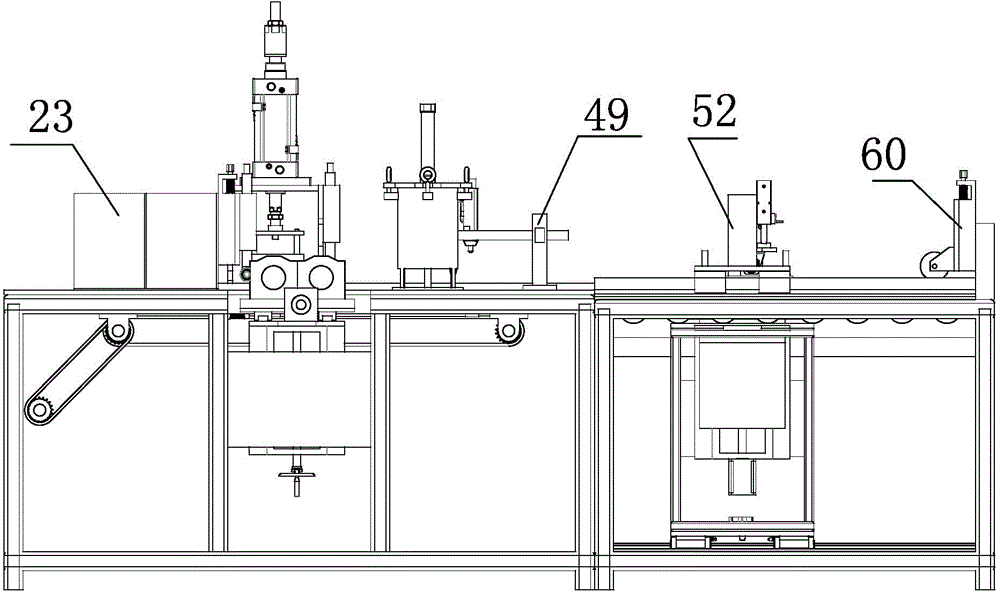

High-efficient punching equipment for producing chairs

ActiveCN104308910APrecise punchingQuick punchStationary drilling machinesBark-zones/chip/dust/waste removalPunchingEngineering

The invention belongs to the field of chair processing and relates to high-efficient punching equipment for producing chairs. The high-efficient punching equipment comprises a rack, a punching device arranged on the rack, a lifting device for driving the rack to lift, an inputting rail and an outputting rail, wherein the inputting rail and the outputting rail are arranged below the punching device; a punching table is arranged between the inputting rail and the outputting rail and is arranged right below the punching device; clamping devices are arranged at two opposite sides of the punching table; a protective hood is arranged outside the rack and is provided with a front passing hole and a rear passing hole; the inputting rail can enter from the front passing hole; the outputting rail can enter from the rear passing hole. The high-efficient punching equipment can accurately and fast punch a chair back or a chair pad, harm to bodies, caused by chippings and dust, can be avoided, a punching part can be relatively sealed, the chippings and the dust can be collected, thus being relatively environmentally-friendly.

Owner:ZHEJIANG ANJI HUIYE FURNITURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com