Patents

Literature

300results about How to "Precise punching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

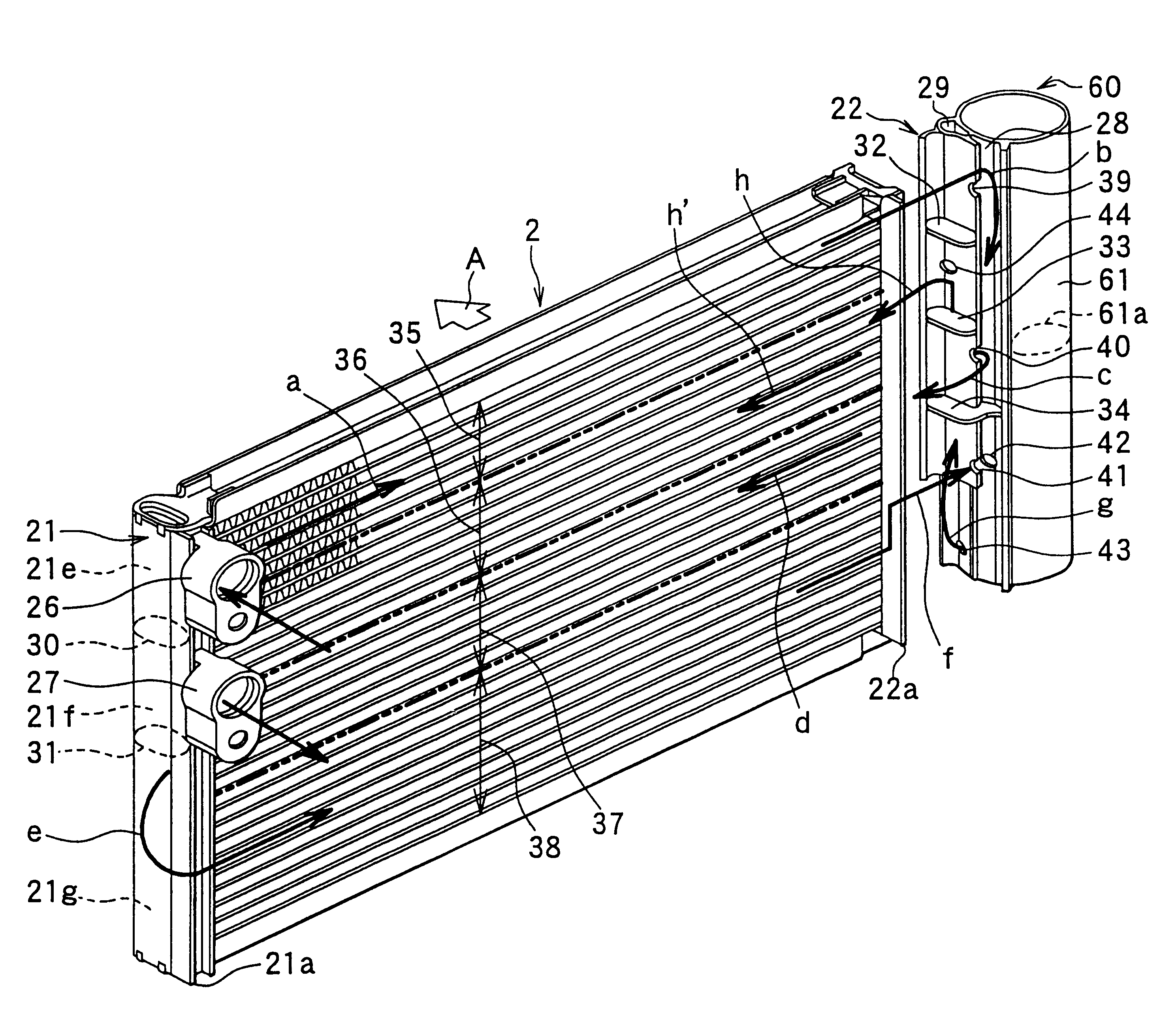

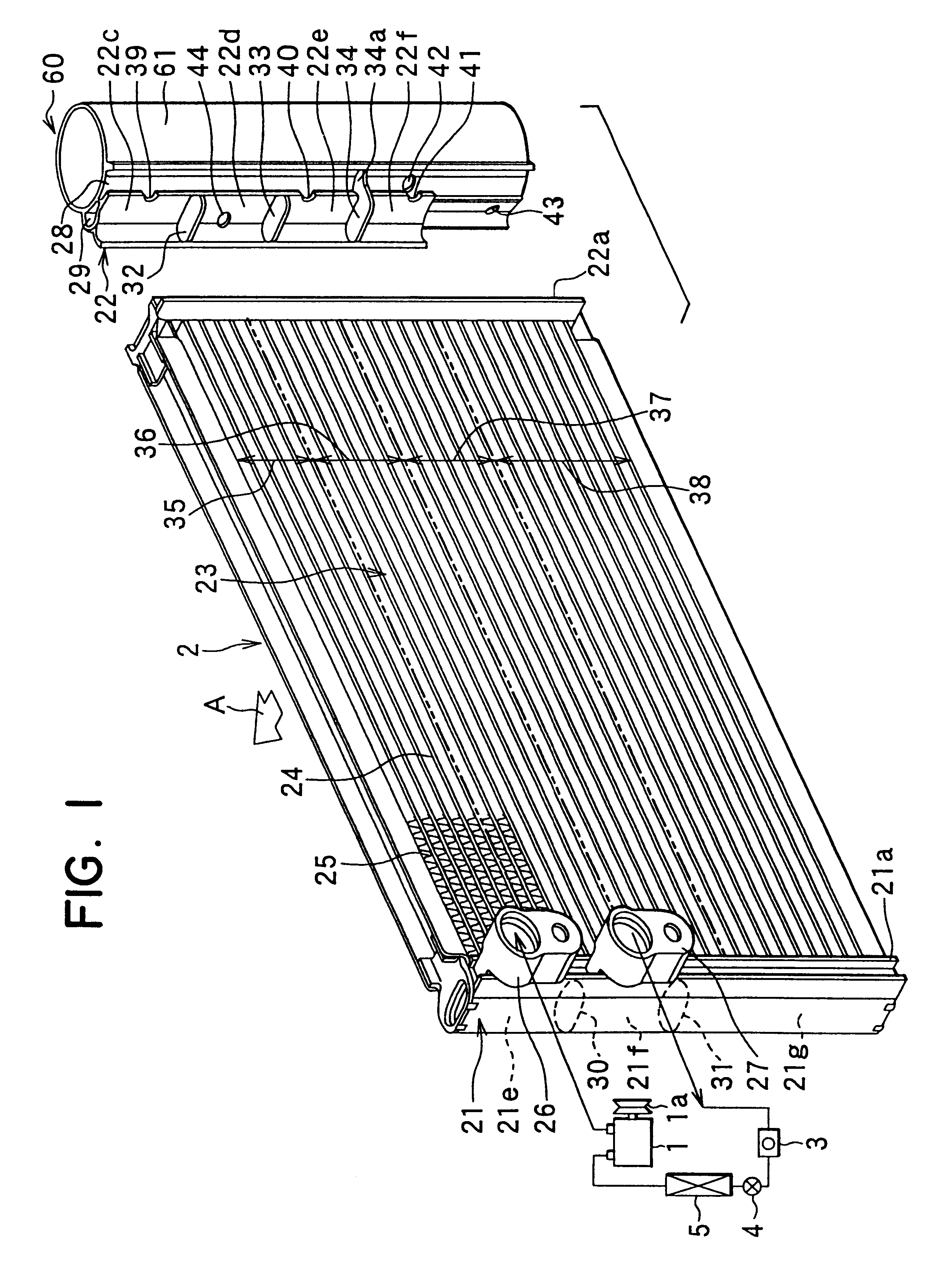

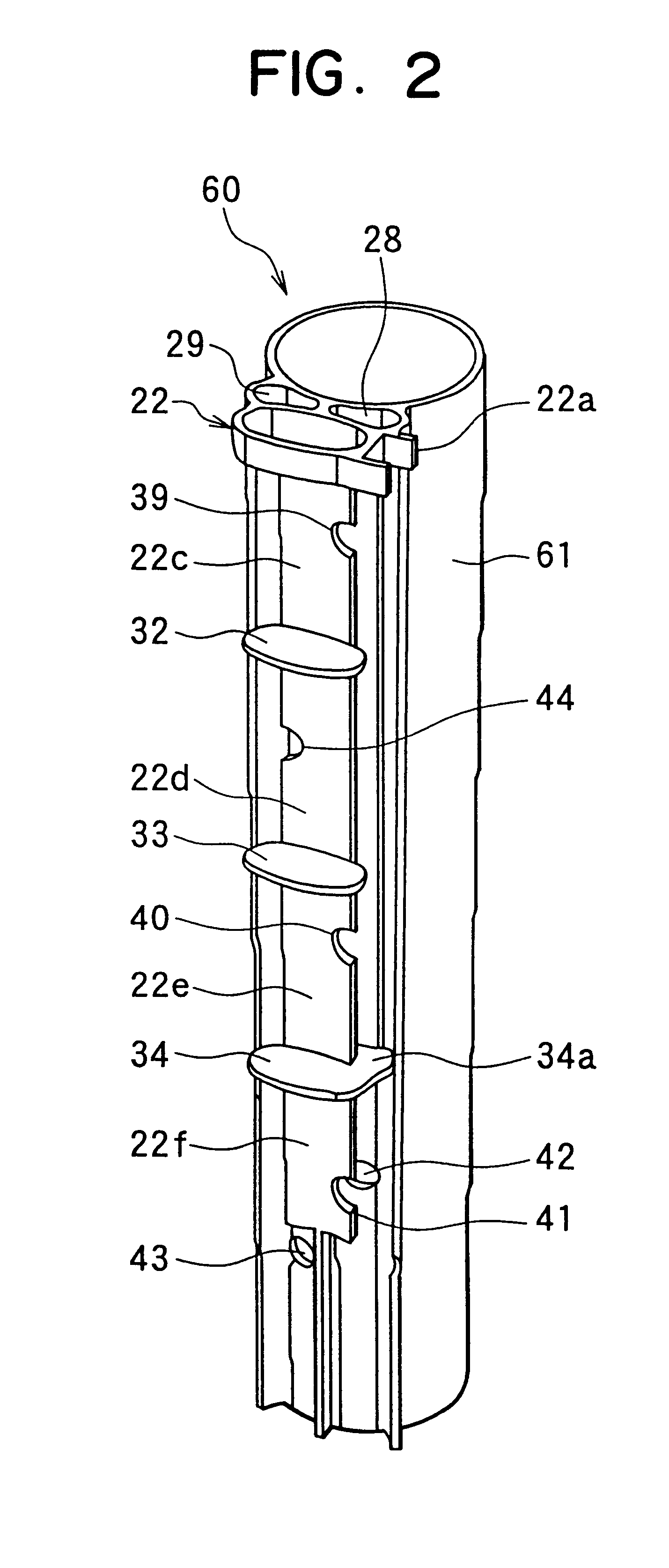

Receiver-integrated condenser

InactiveUS6397627B1Precise applicationPrecise punchingEvaporators/condensersClosure meansSuper coolingEngineering

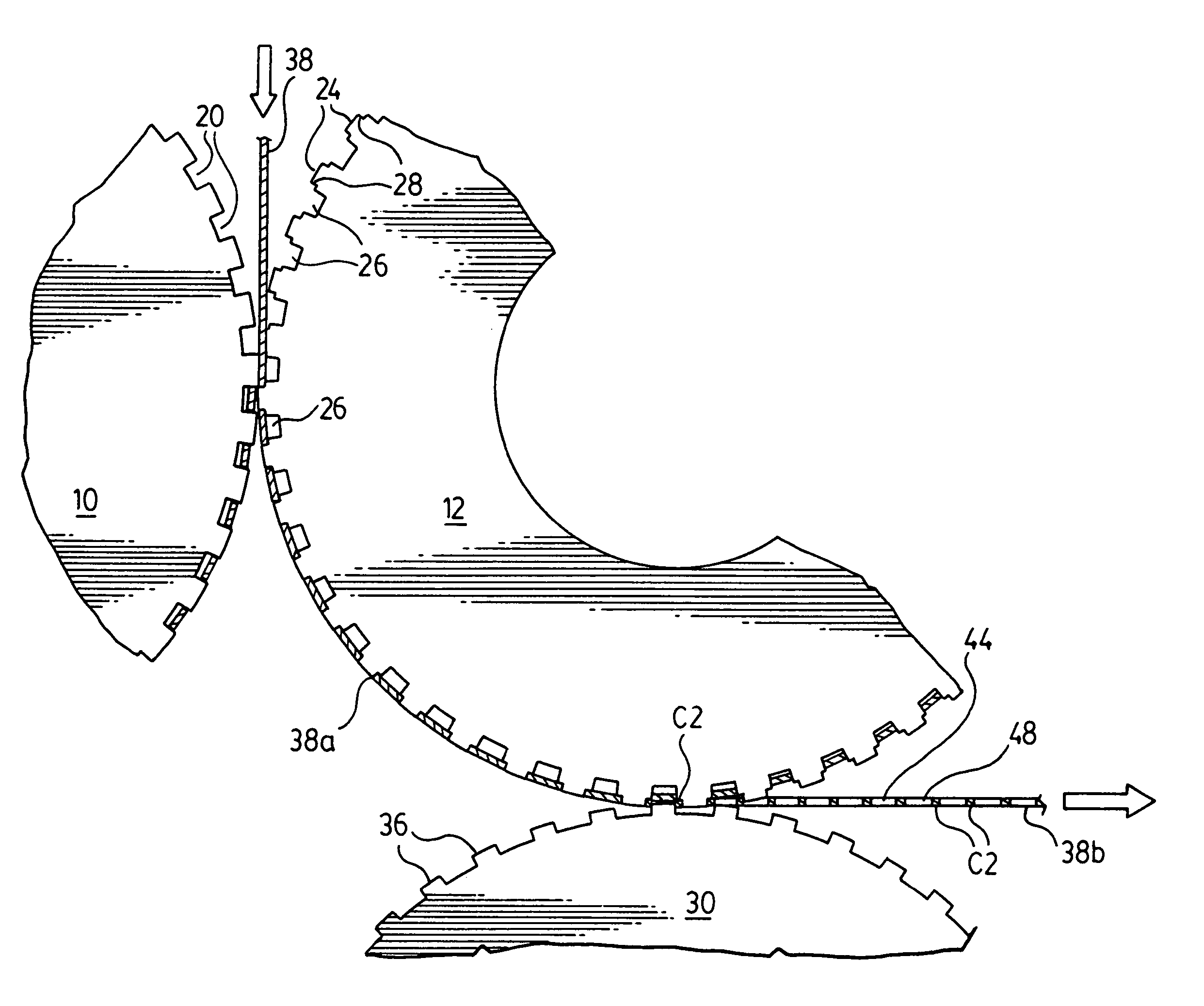

In a receiver-integrated condenser, a super-cooling portion for cooling liquid refrigerant from a receiving unit is disposed between first and second condensing portions in a core portion in a vertical direction. Therefore, in an engine-idling, even when high-temperature air having passed through the receiver-integrated condenser is introduced again toward an upstream air side of the receiver-integrated condenser through a lower side of the receiver-integrated condenser, the high-temperature air is not introduced toward the arrangement position of said super-cooling portion, because the super-cooling portion is positioned at an upper side from the second condensing portion. Thus, super-cooling performance of refrigerant in the super-cooling portion of the core portion is prevented from being decreased even in the engine idling.

Owner:DENSO CORP

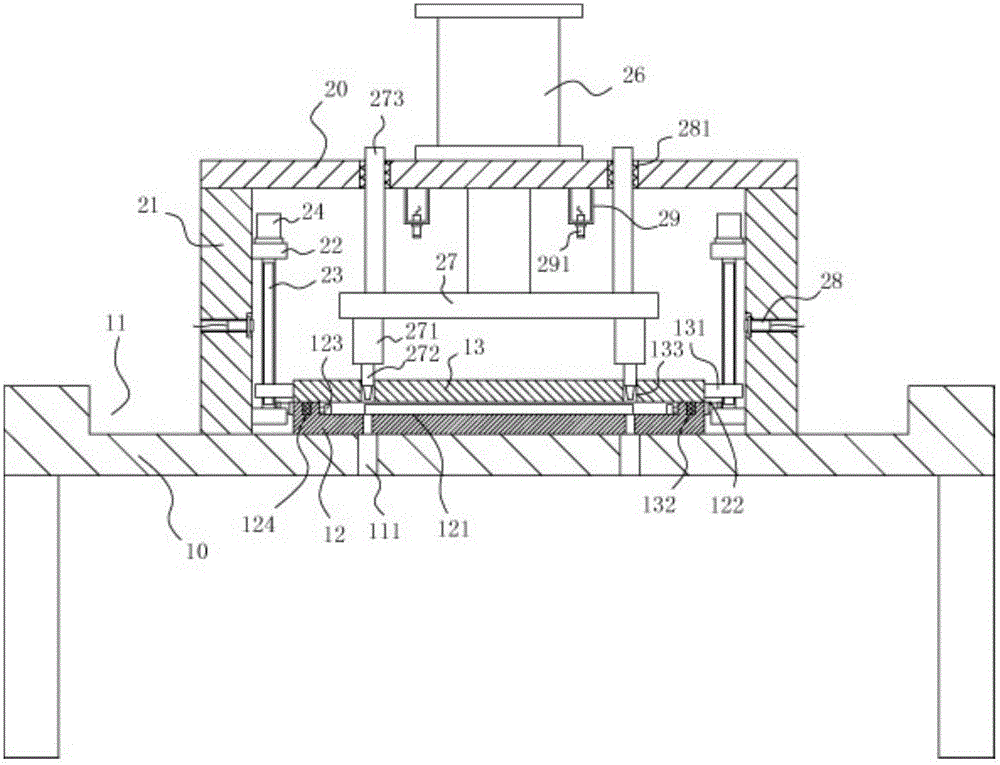

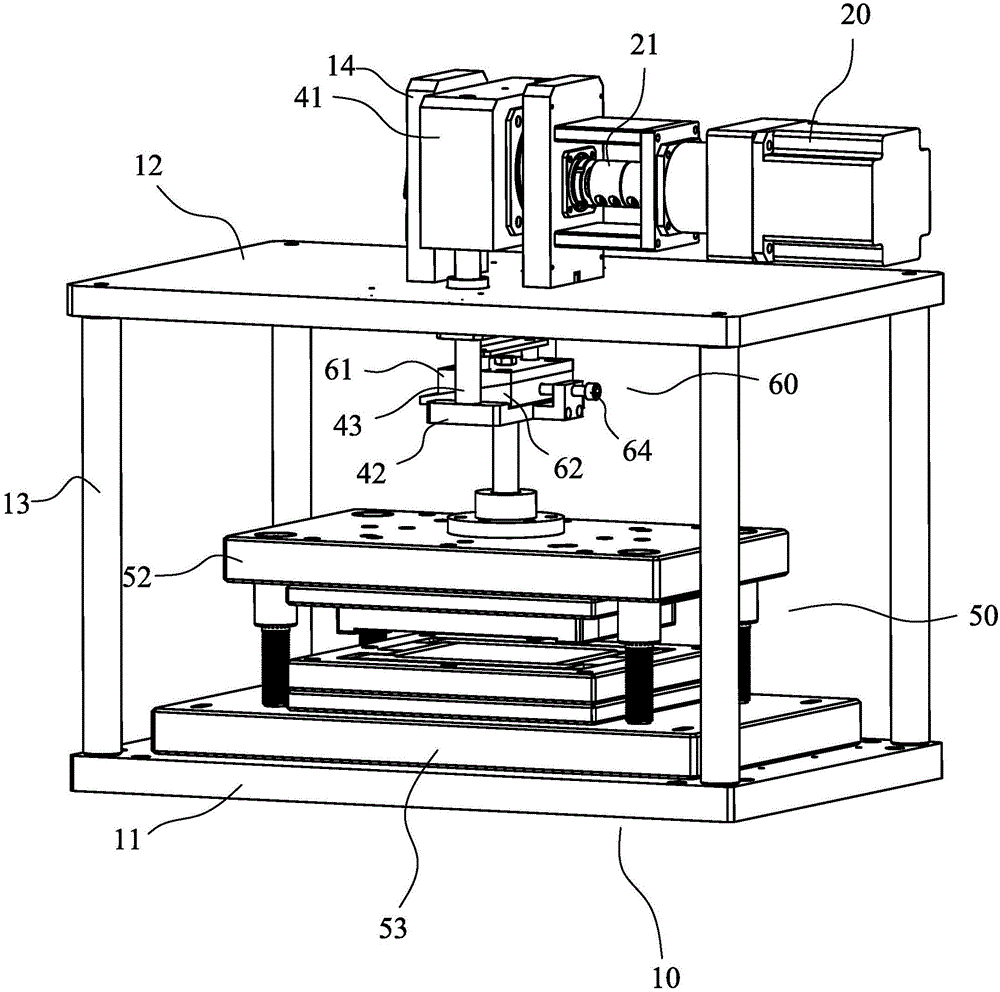

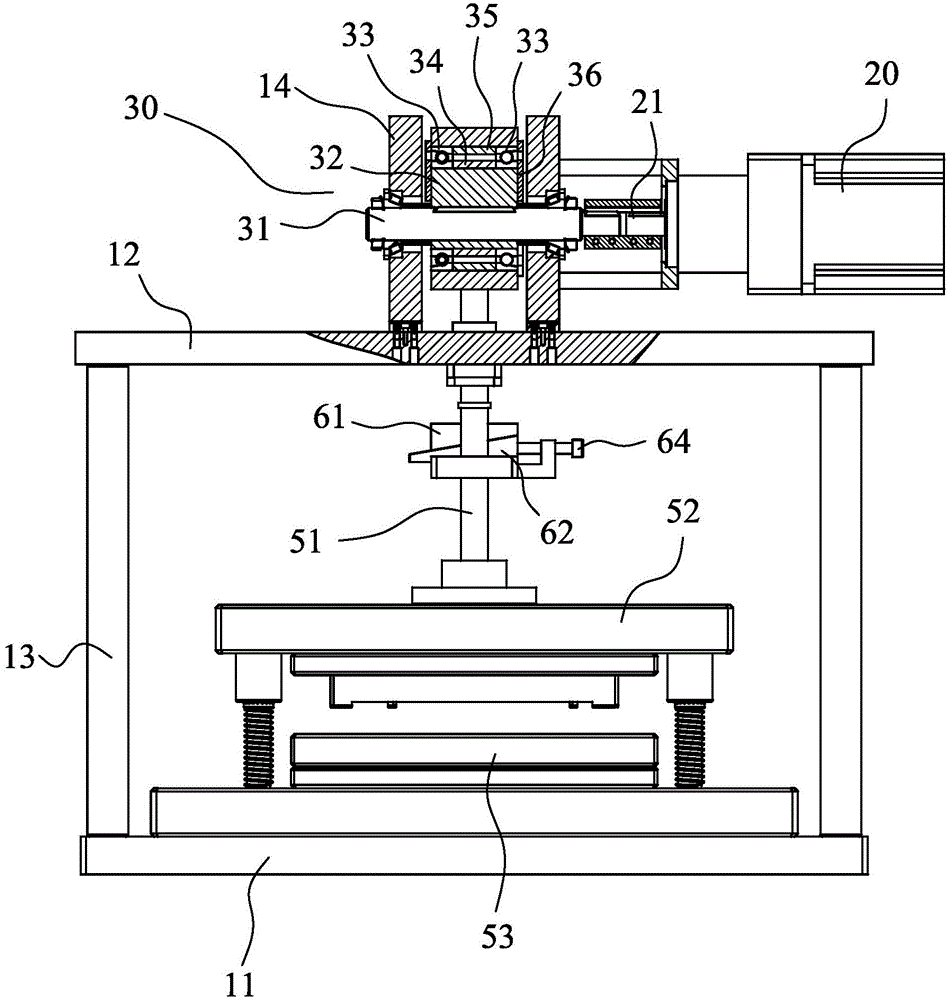

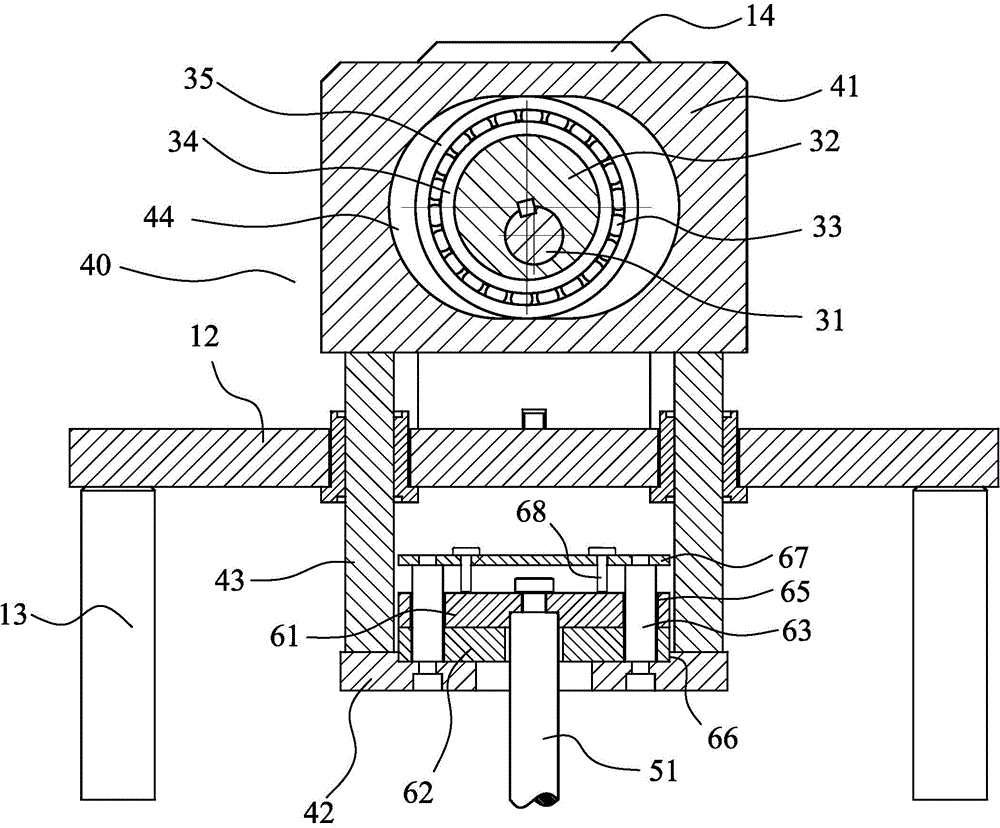

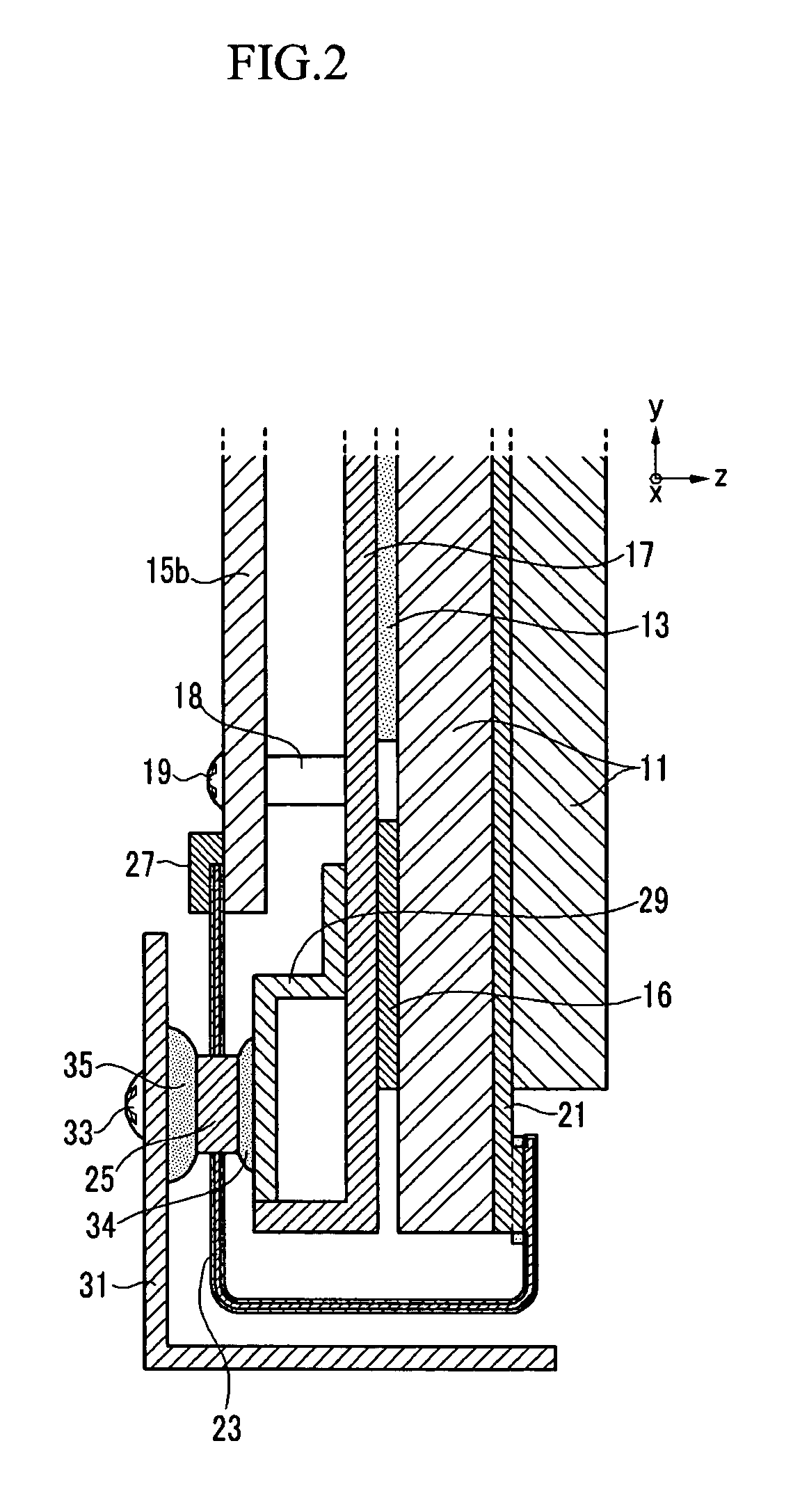

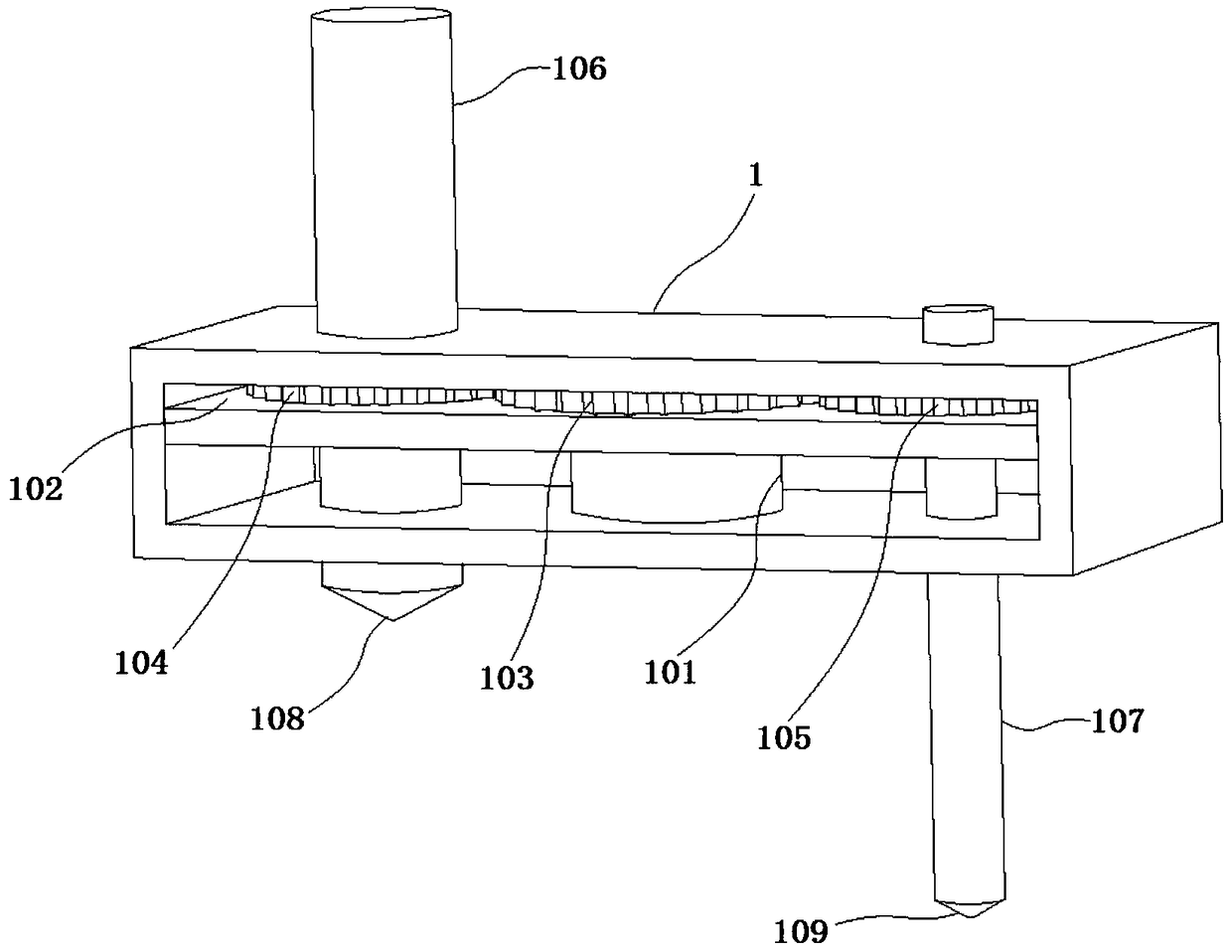

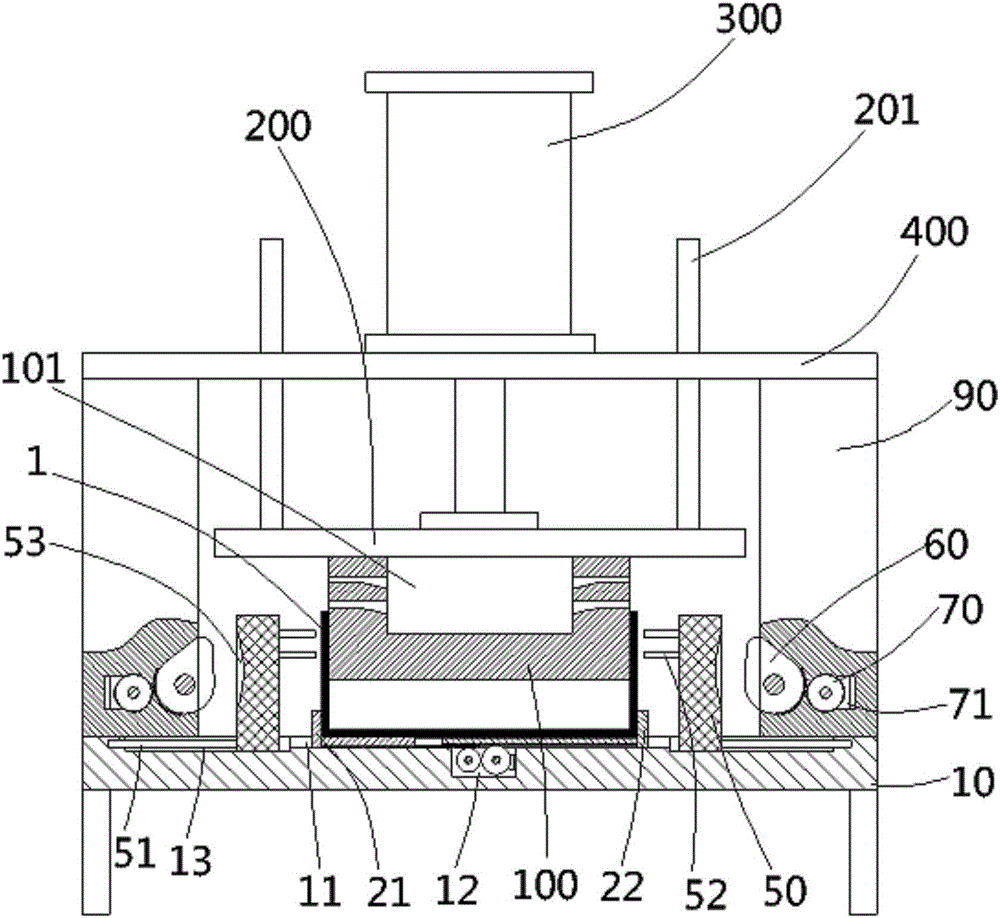

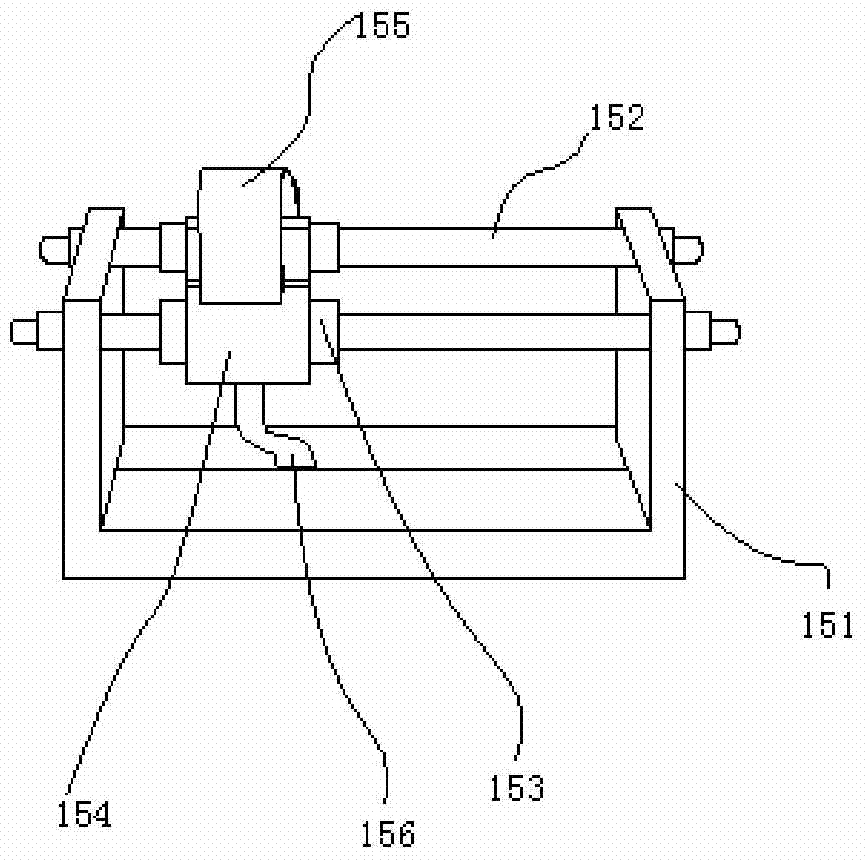

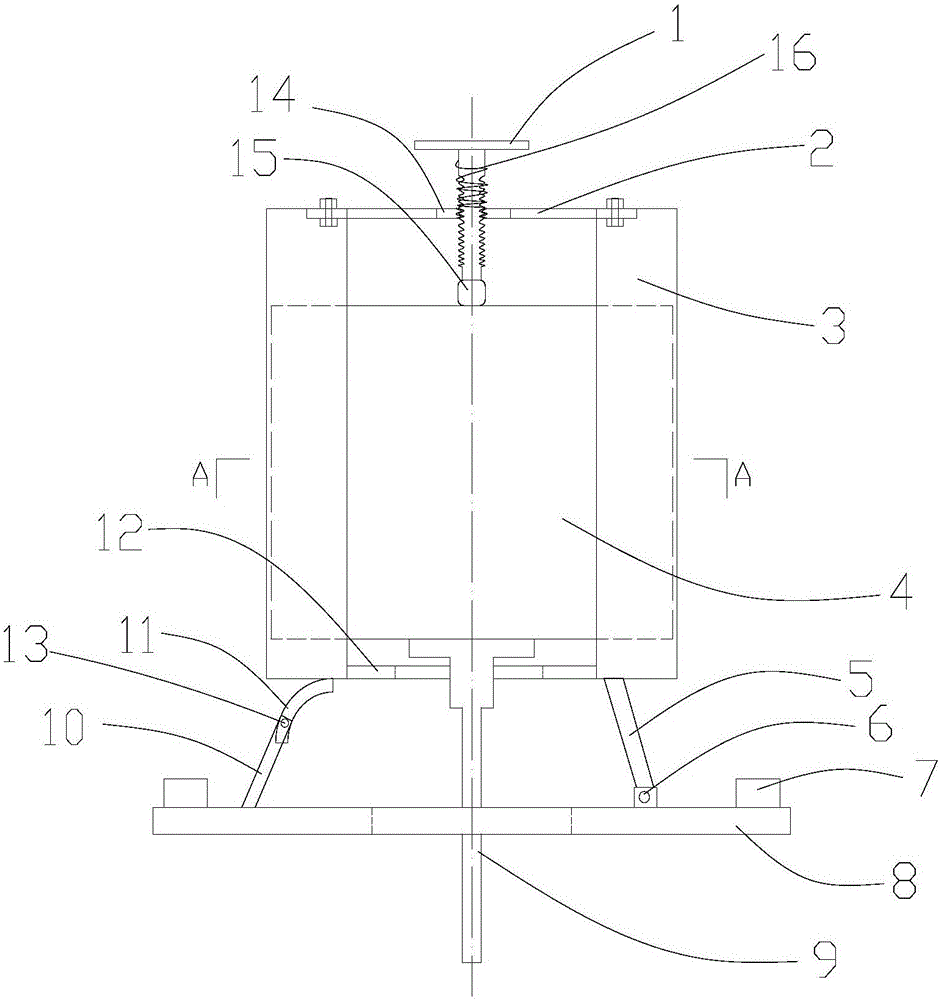

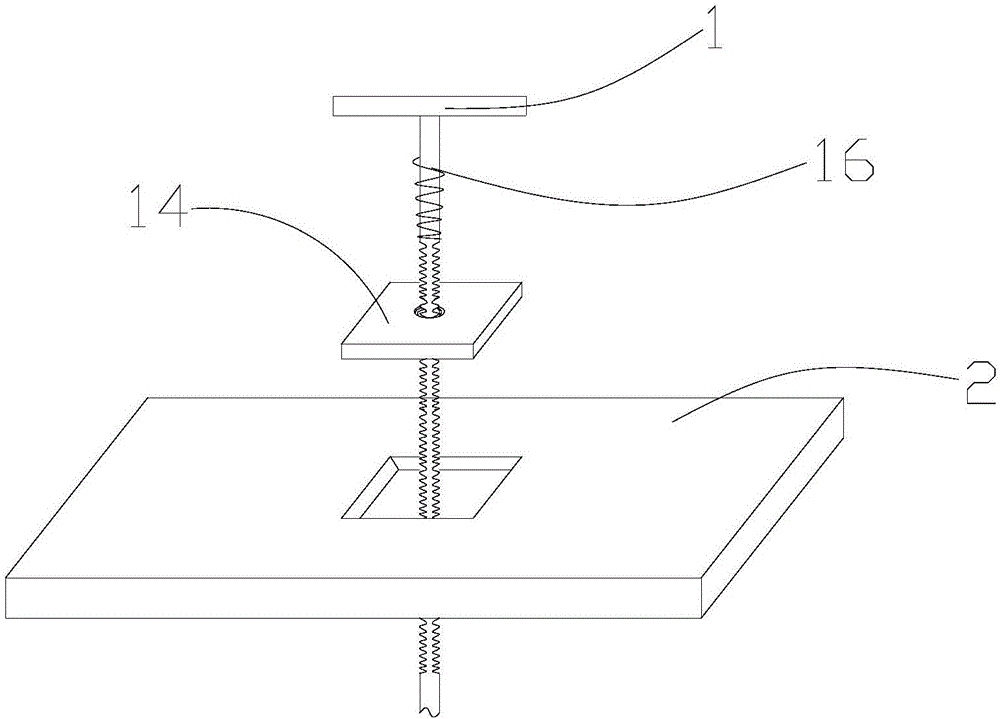

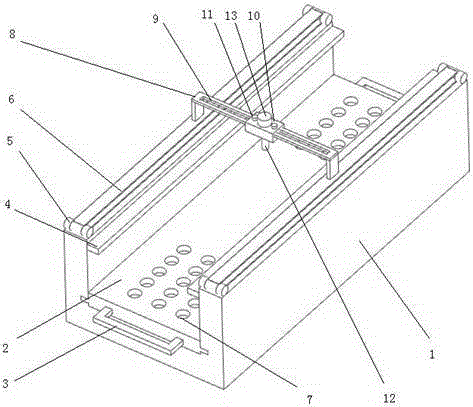

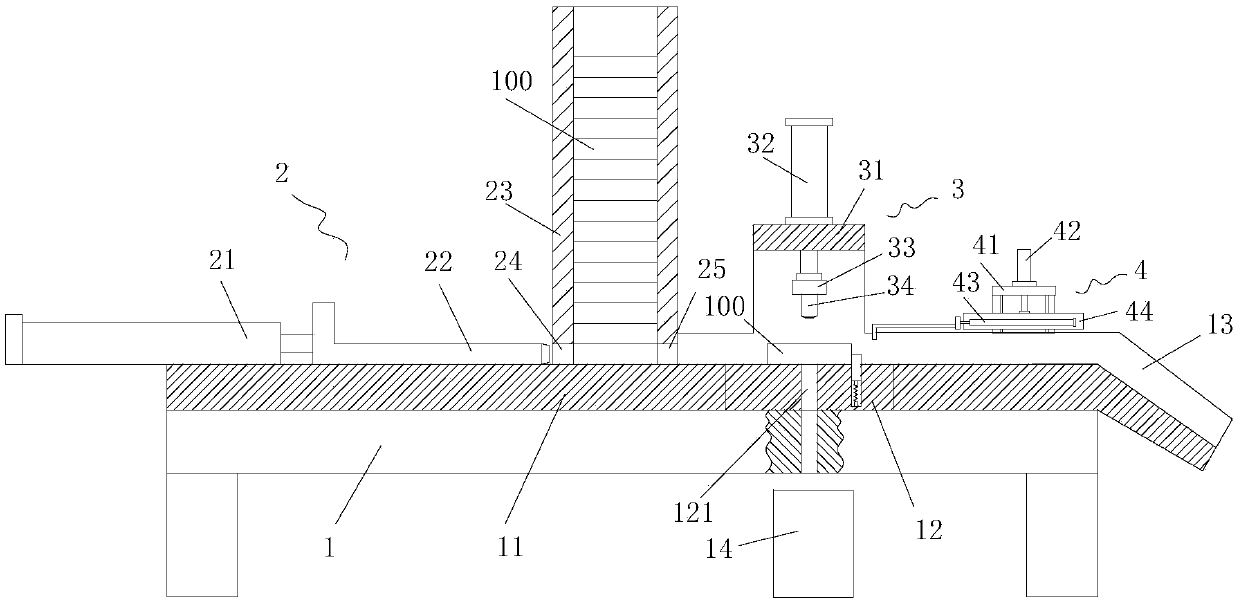

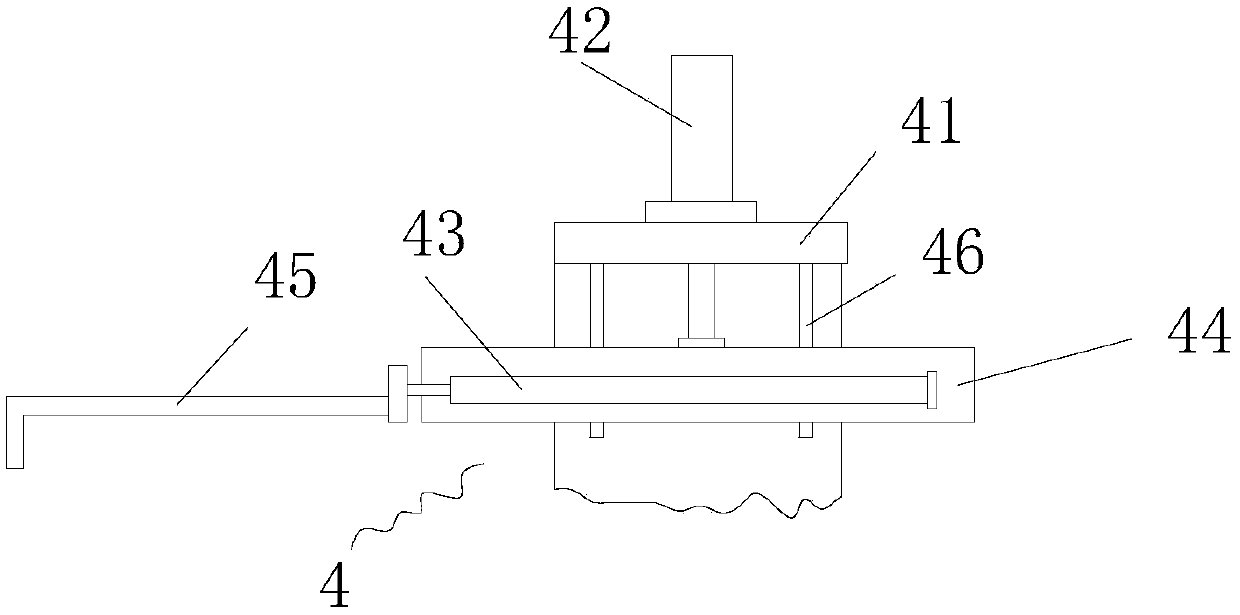

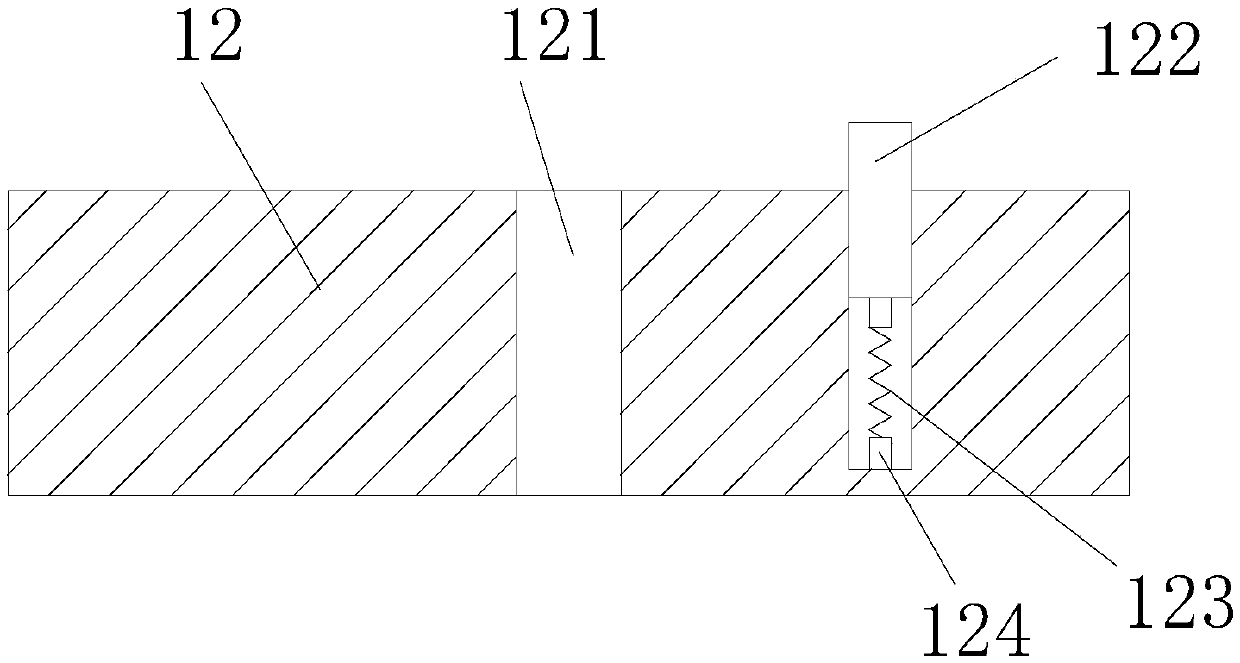

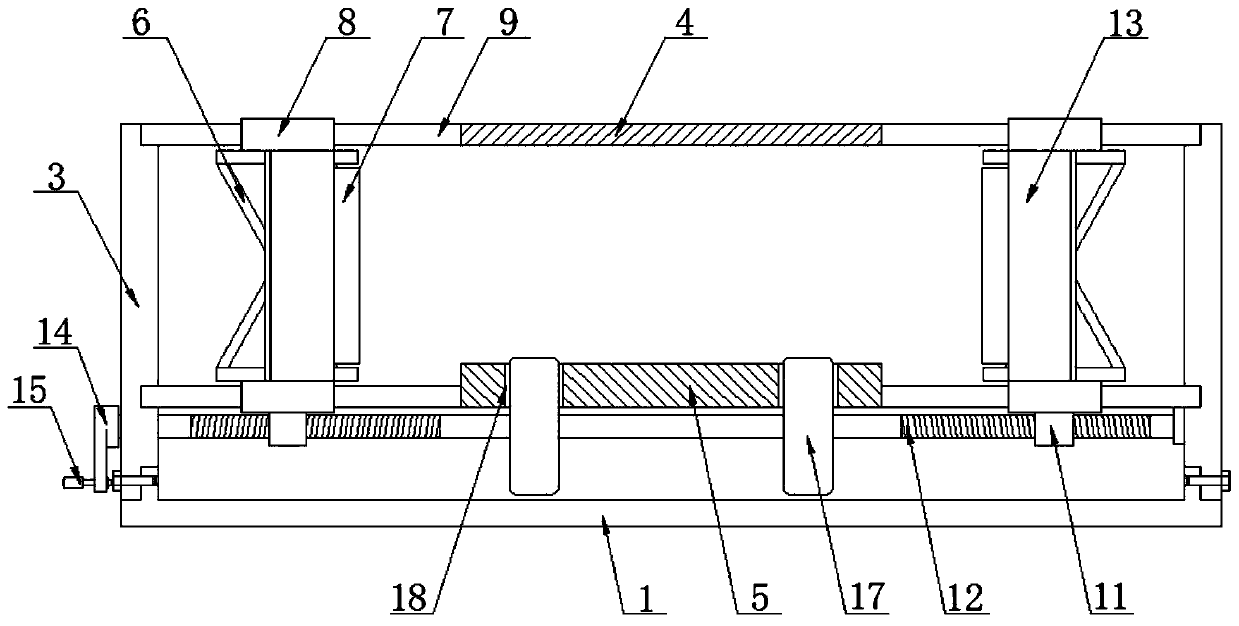

Steel plate punching clamping mechanism

ActiveCN105798107AStable clampingEasy to holdMetal-working feeding devicesPositioning devicesPunchingArchitectural engineering

The invention discloses a steel plate punching clamping mechanism. The steel plate punching clamping mechanism comprises a rack, a main groove is formed in the middle portion of the top face of the rack, a bottom containing block is fixed to the middle portion of the main groove, a containing groove is formed in the middle portion of the bottom containing block, and the four outer side walls of the bottom containing block are each provided with a pushing oil cylinder fixedly; a push rod of each pushing oil cylinder extends into the containing groove and is fixed to a corresponding clamping plate, and the clamping plates are parallel to the corresponding inner side walls of the containing groove; a main connecting support is fixed to the bottom face of the main groove, connecting plates are fixed to the upper portions and the lower portions of the inner side walls of two vertical supporting plates of the main connecting support, and the two ends of a transmission screw are hinged to the two connecting plates; one connecting plate is provided with a driving motor fixedly, an output shaft of the driving motor is a spline shaft, and the spline shaft is inserted into a corresponding spline hole formed in the end of the transmission screw in a sleeved manner; and an upper pressing plate is located above the bottom containing block, and adjusting fixing blocks are fixed to the two side walls of the upper pressing plate. The steel plate punching clamping mechanism is firm and convenient to clamp, accurate in punching and good in effect.

Owner:宁夏远高绿色科技建筑有限公司

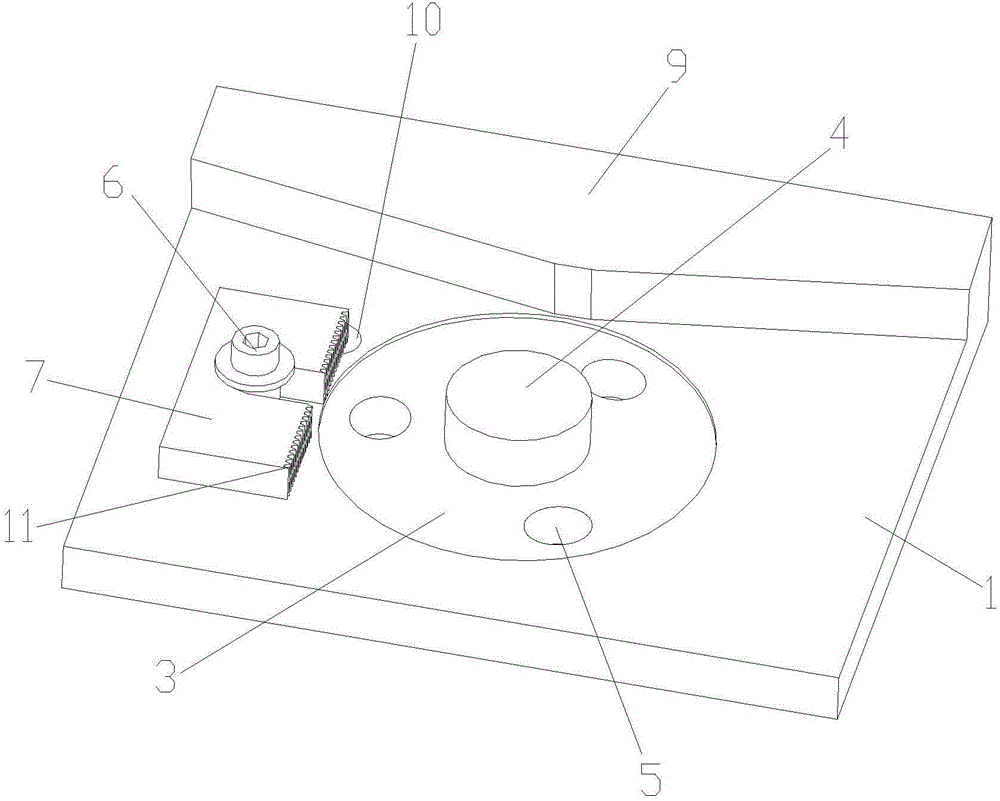

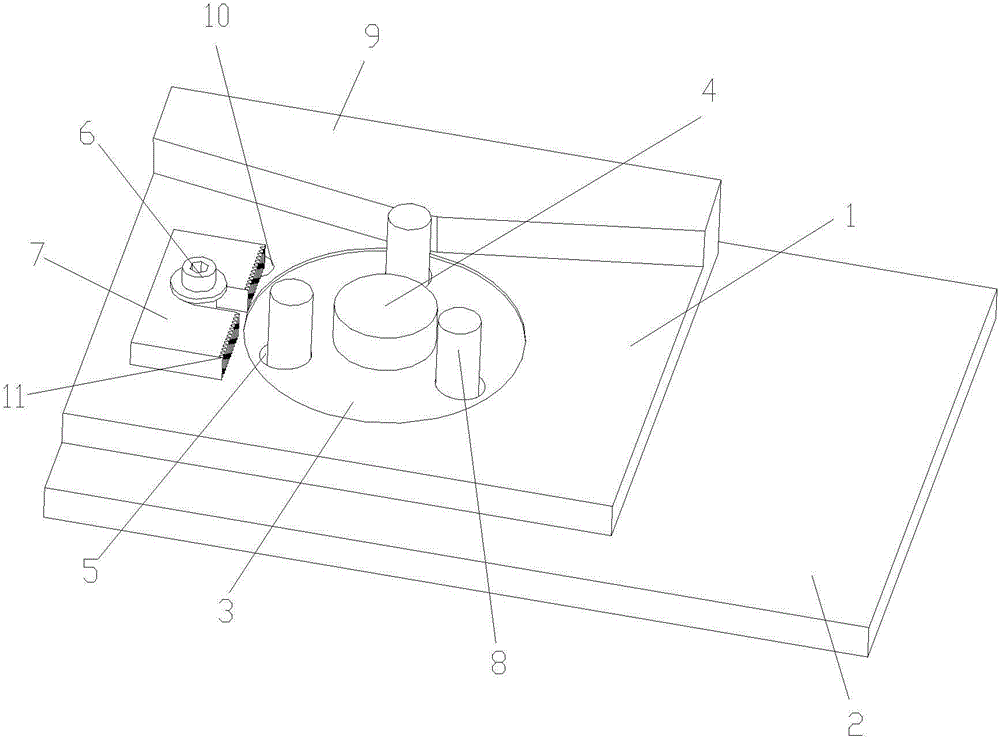

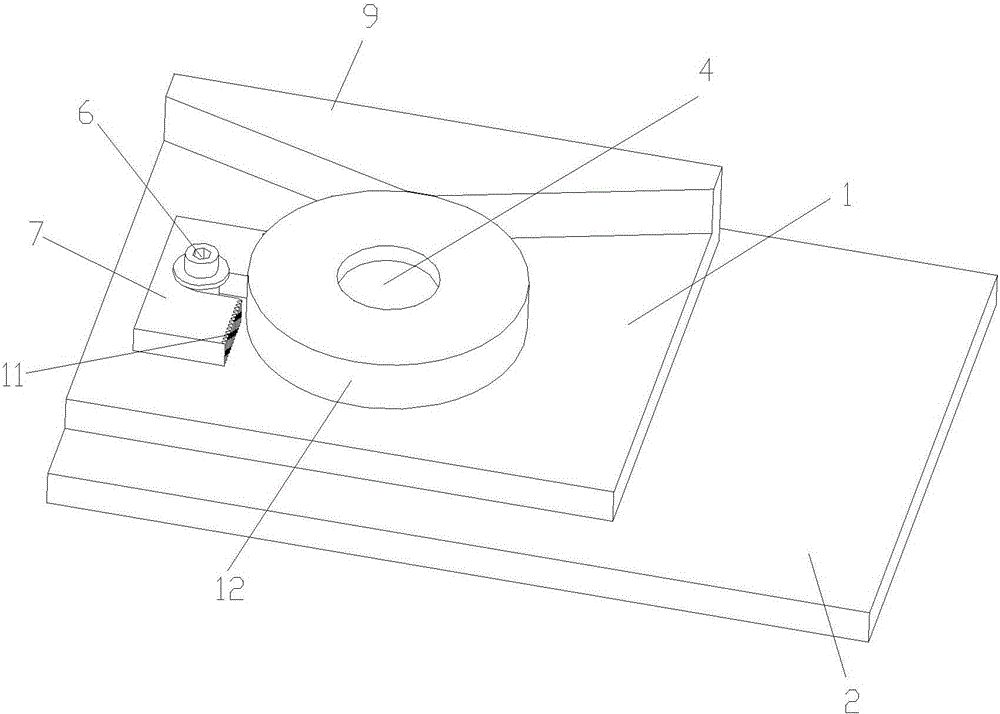

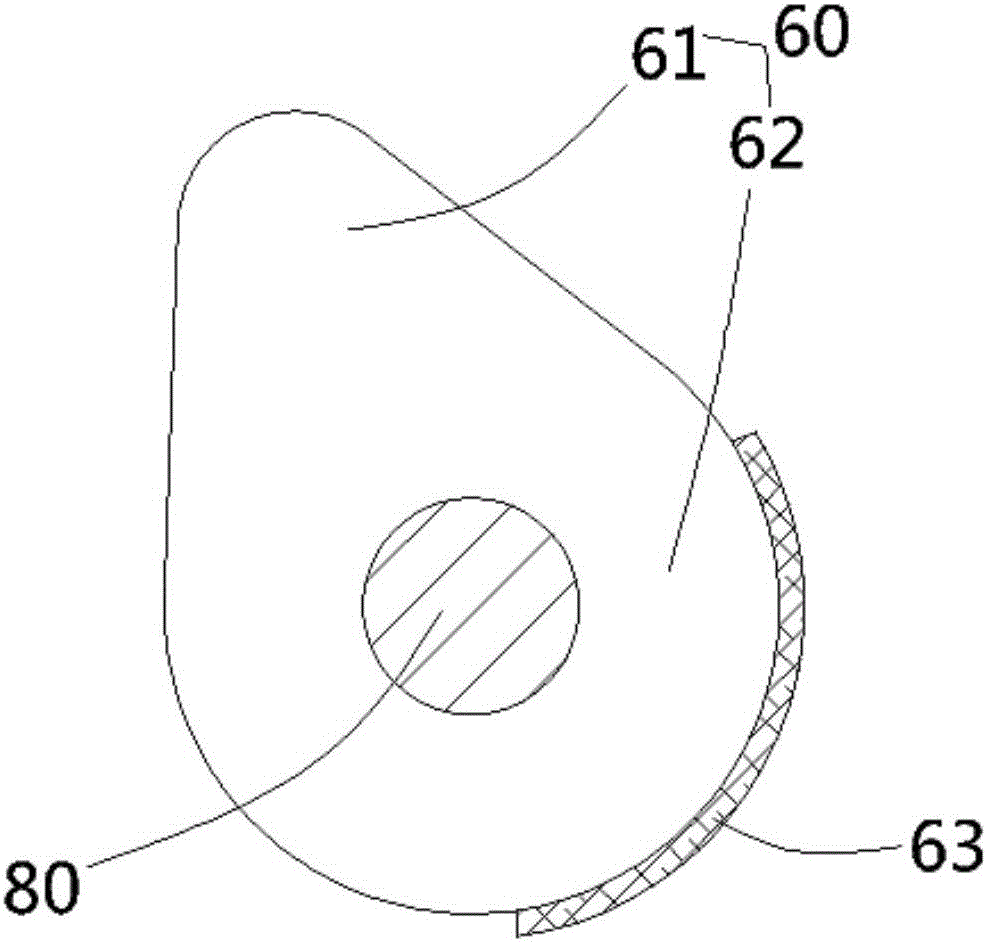

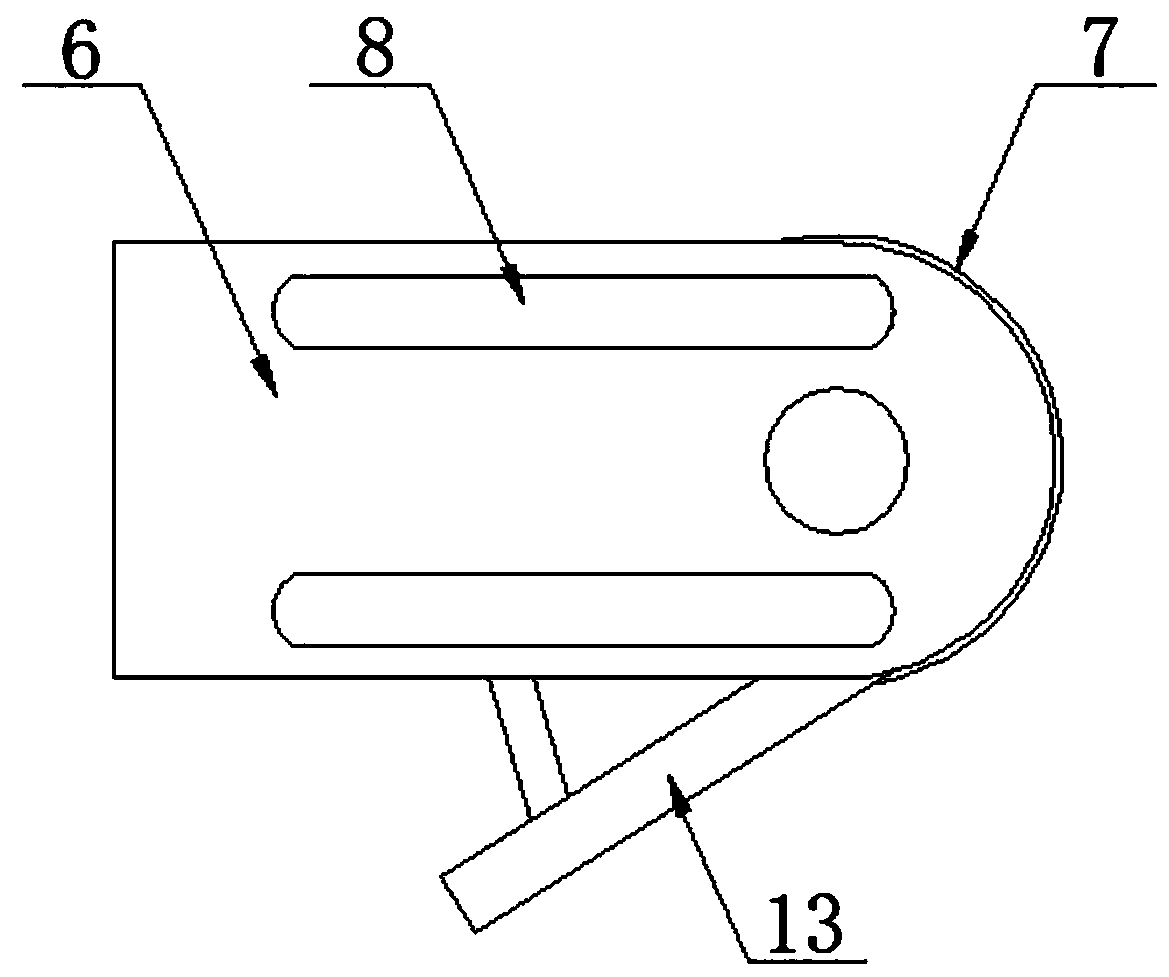

Disc punching clamp

InactiveCN104400492APrecise punchingQuick pick and placeWork clamping meansPositioning apparatusPush outEngineering

The invention discloses a disc punching clamp which comprises a base and a jacking rod base, wherein a disc slot is arranged in the base; a positioning pillar is arranged at the center of the disc slot; jacking rod holes are uniformly distributed in the disc slot; a clamping block is arranged on one side of the disc slot; the clamping block is connected through a bolt and takes the bolt as a rotating center; a baffle is arranged at one end of the base; jacking rods matched with the jacking rod holes in the disc slot are arranged on the jacking rod base. According to the disc punching clamp, the positioning pillar is arranged at the center of the disc slot, the clamping block which is connected through the bolt and takes the bolt as the rotating center is arranged on one side of the disc slot, a to-be-processed disc slot is fixedly arranged on the positioning pillar, the clamping block is rotated and adjusted and is clamped on a disc, the baffle on one side is resisted against the disc, the disc is fixed and then is punched, and the jacking rod base is inserted into the jacking rod holes so as to push out the disc after being punched, so that the accurate punching for the disc is realized, the quick fetching of the disc is realized and the product quality and the working efficiency are increased.

Owner:SUZHOU FUMAI PRECISION MACHINERY

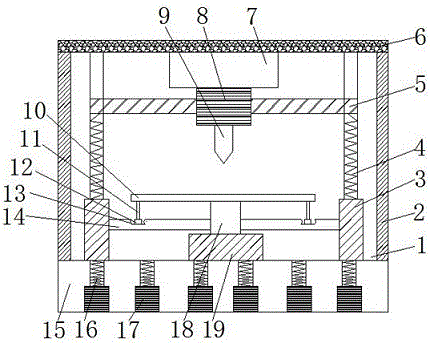

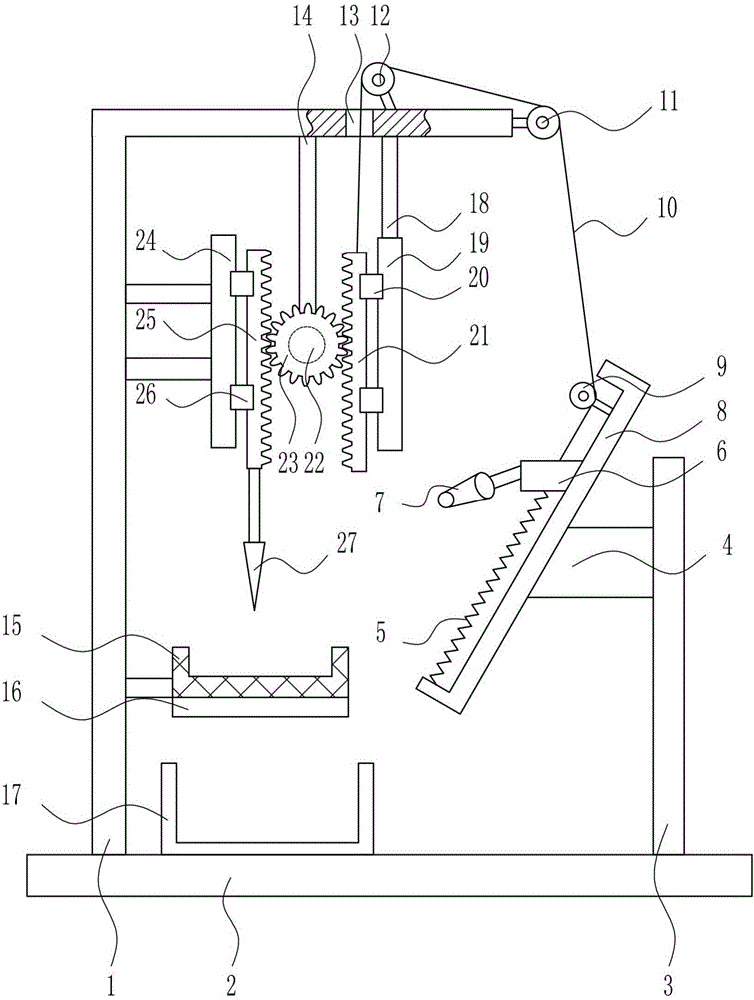

Perforating machine for auto parts

ActiveCN105946041AAvoid offsetEasy to punchPerforating toolsMetal working apparatusSlide plateEngineering

The invention discloses a perforating machine for auto parts. The perforating machine comprises a main body and a base. The two sides of the main body are fixedly connected with supports correspondingly. A top plate is mounted at the tops of the supports. A sliding seat is movably connected with the bottom of the top plate. An electric extensible rod is connected with the bottom of the sliding seat. A sliding plate penetrates through an inner chamber of the electric extensible rod. The bottoms of the two sides of the sliding plate are connected with springs correspondingly. First support plates are mounted at the bottoms of the springs correspondingly. A second support plate is connected with one sides of the first support plates. Arc-shaped slide grooves are formed in the top of the second support plate. Sliding blocks are arranged in inner chambers of the arc-shaped slide grooves correspondingly. Connection rods are connected with the tops of the sliding blocks. A holding plate is mounted at the tops of the connection rods. The bottom of the holding plate is movably connected with a rotary shaft. A rotary motor is connected with the bottom of the rotary shaft. According to the perforating machine for the auto parts, the holding plate is driven to slide in the arc-shaped slide grooves by the rotary motor and the rotary shaft, multidirectional perforating to the auto parts is facilitated, a perforating device can be driven to move by the sliding seat, and perforating positions can be conveniently adjusted.

Owner:WUXI GUOSONG ENVIRONMENTAL PROTECTION MACHINERY

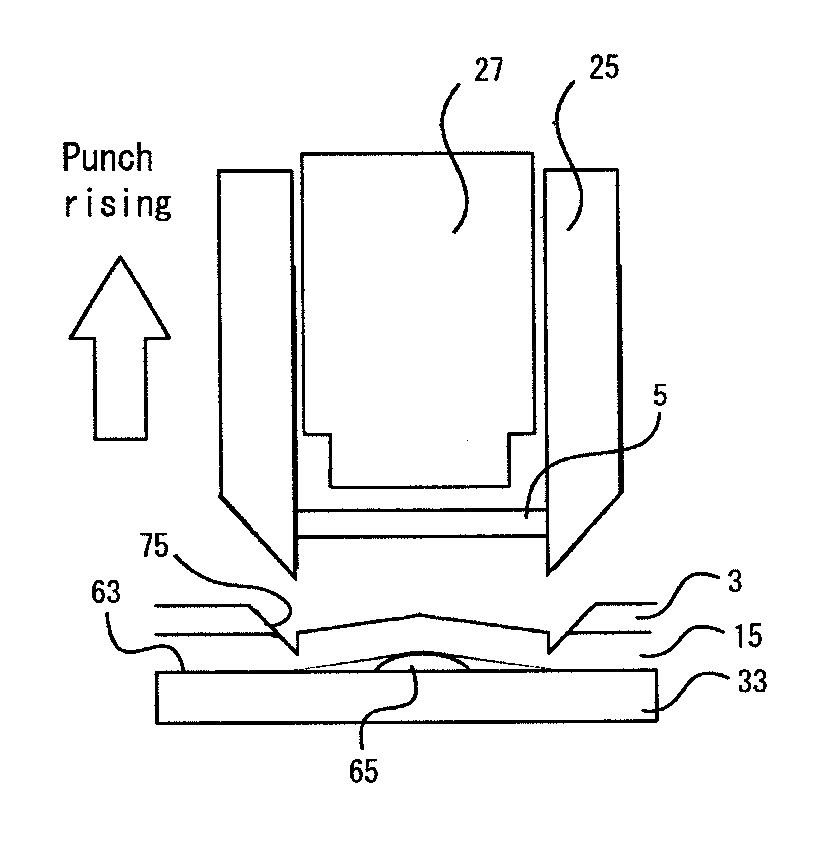

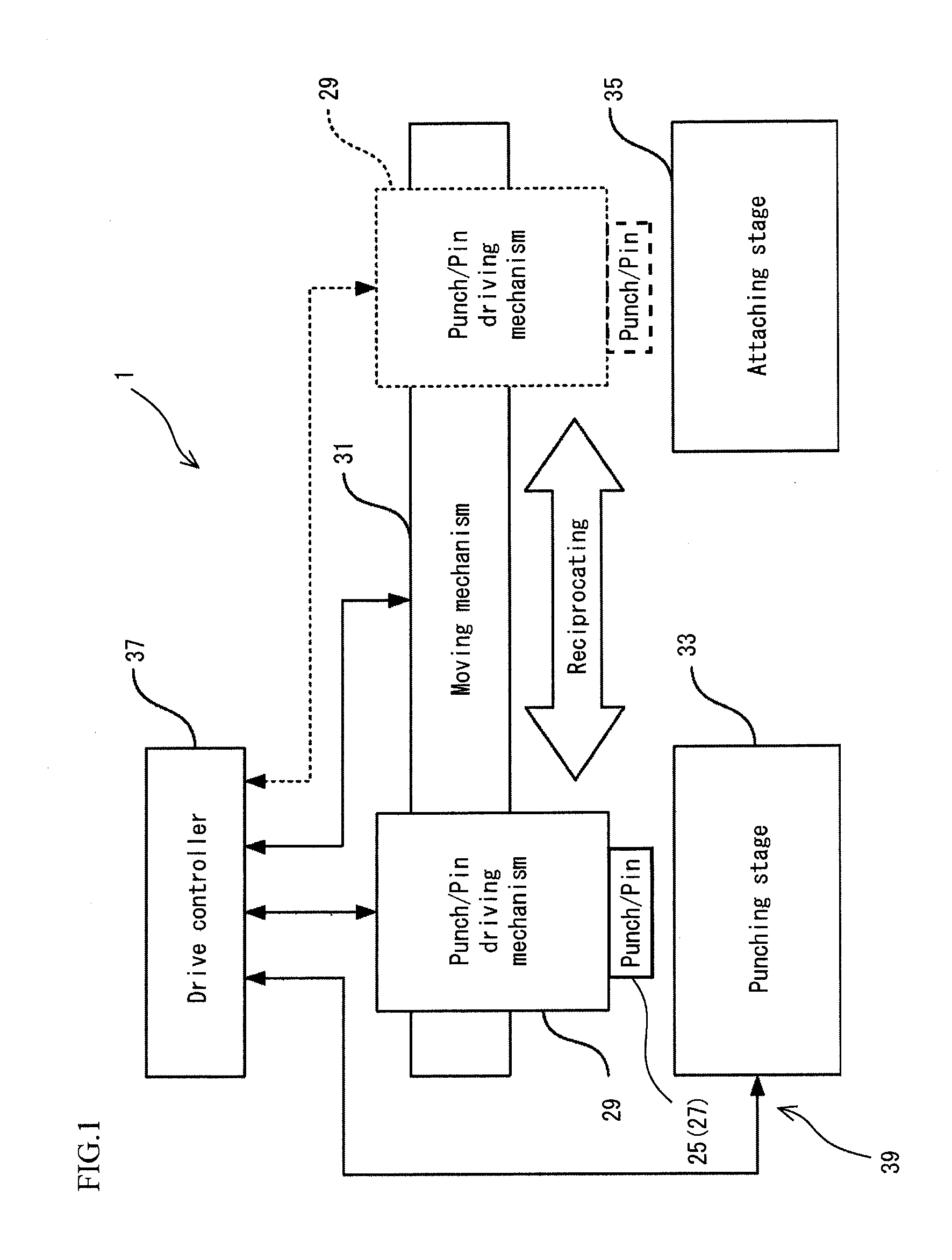

Method of punching damper with use of hollow punch, punching apparatus for the method, and attaching apparatus with the punching apparatus

ActiveUS20130047807A1Easy to separateAccurately heldMetal sawing devicesShearing machinesSupport surfaceShock absorber

A method punches a damper out from a damper material that is detachably attached on a flexible exfoliative member through an attaching surface of the damper material with use of a hollow punch. The method includes steps of setting the damper material on a supporting surface, positioning a projection part between the exfoliative member and the supporting surface, and punching the damper out from the damper material by cutting the damper material around the projection part by the hollow punch without punching the exfoliative member.

Owner:NHK SPRING CO LTD

Lithium battery electrode piece cutting and forming machine and cutting trimming device thereof

ActiveCN104668331AAccurate punchingExtended service lifeShaping toolsElectrode manufacturing processesEngineeringDrive shaft

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

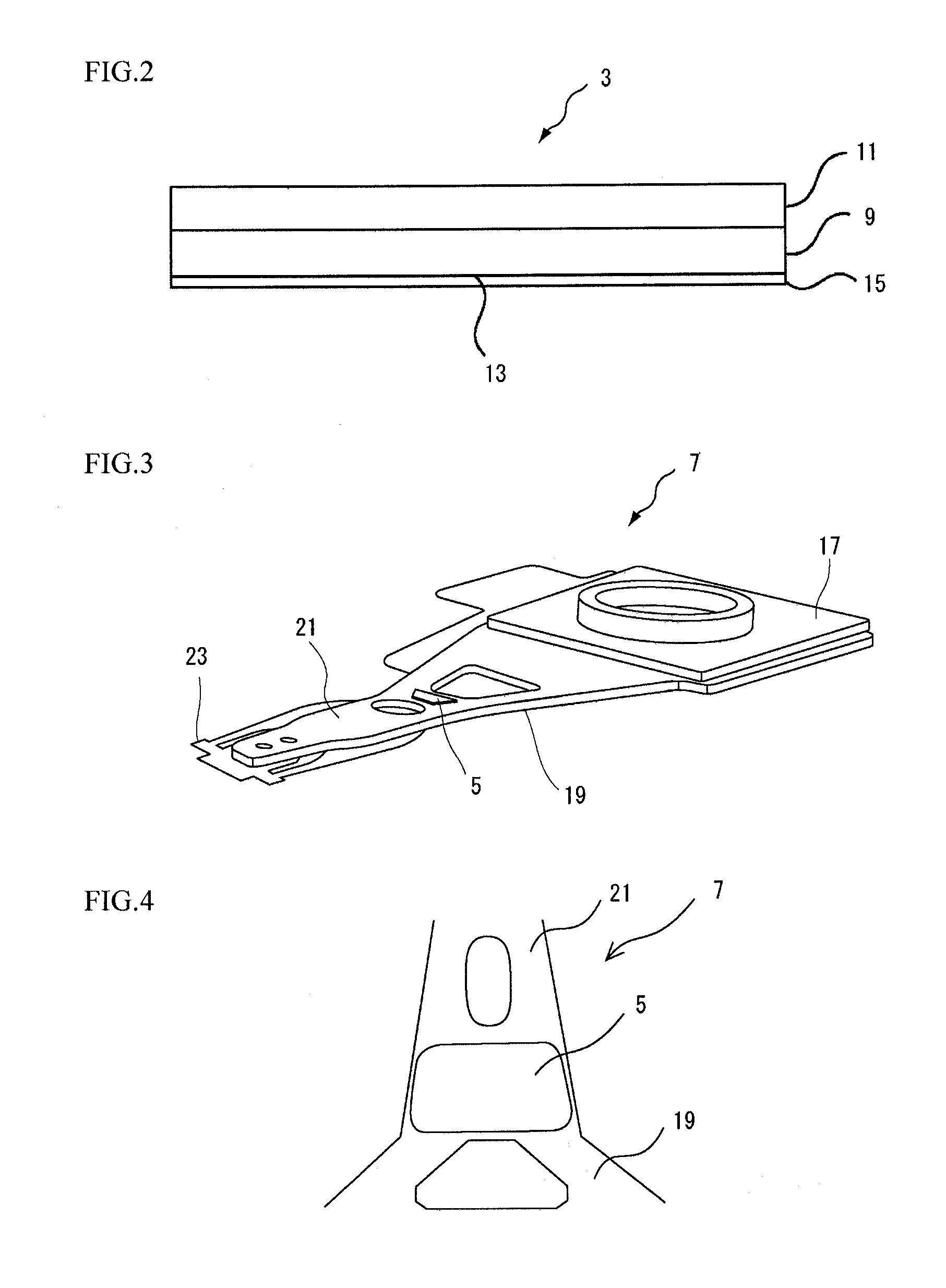

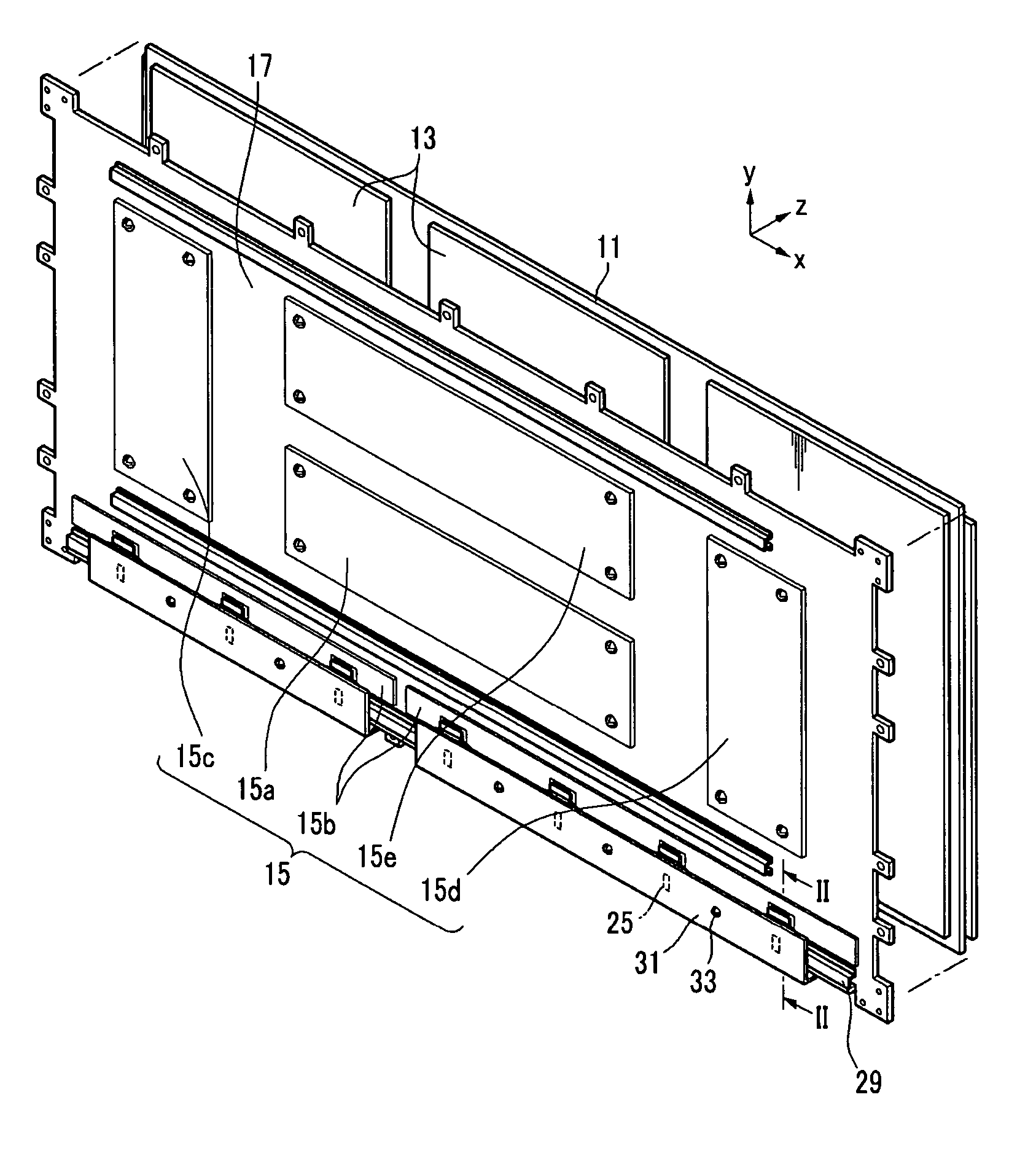

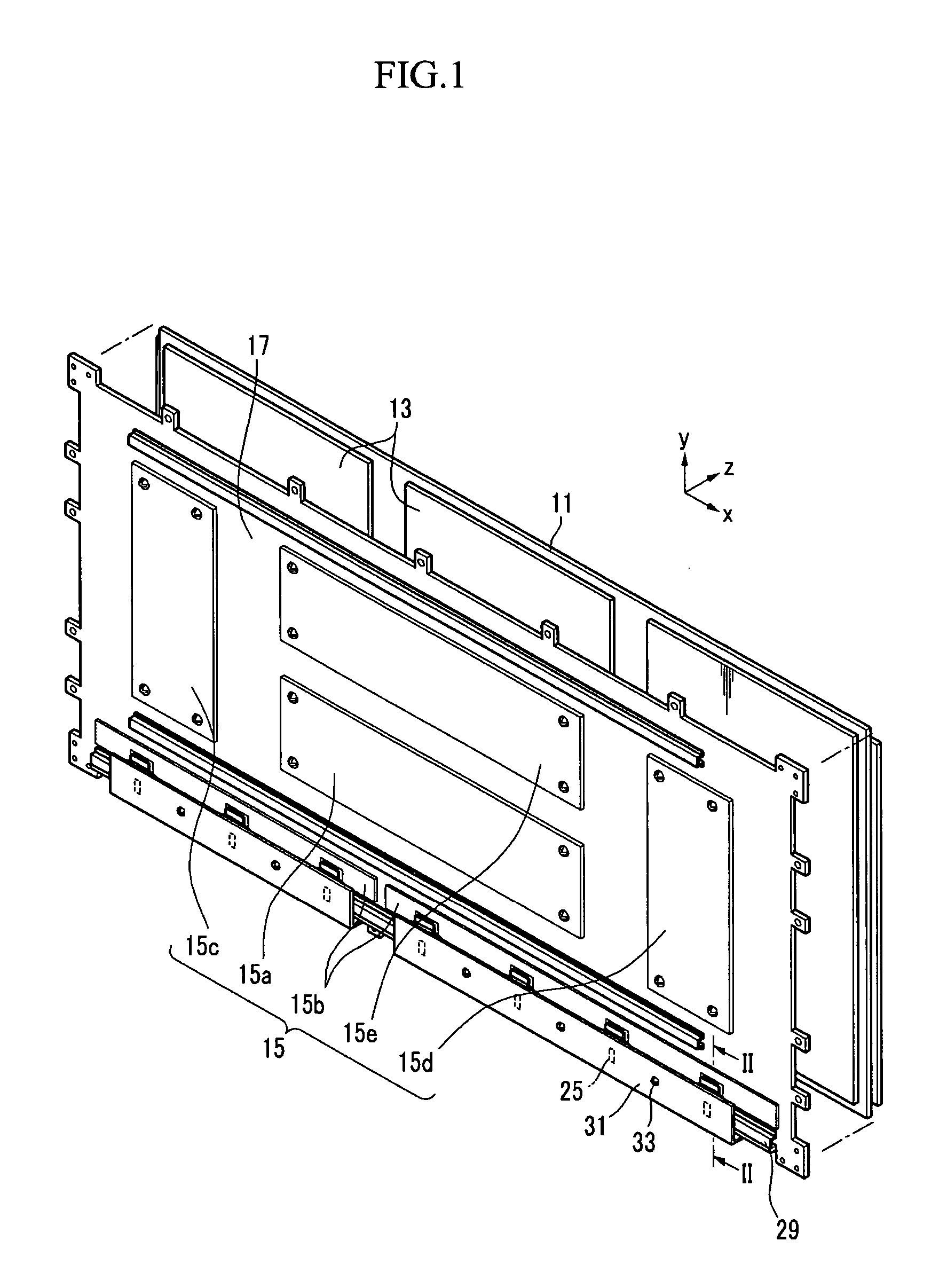

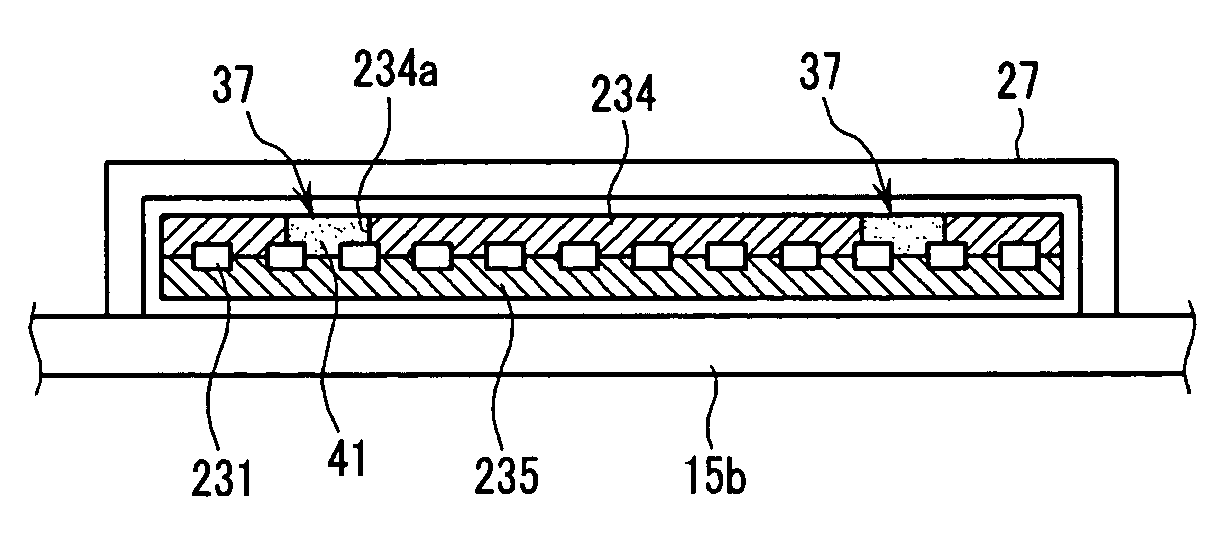

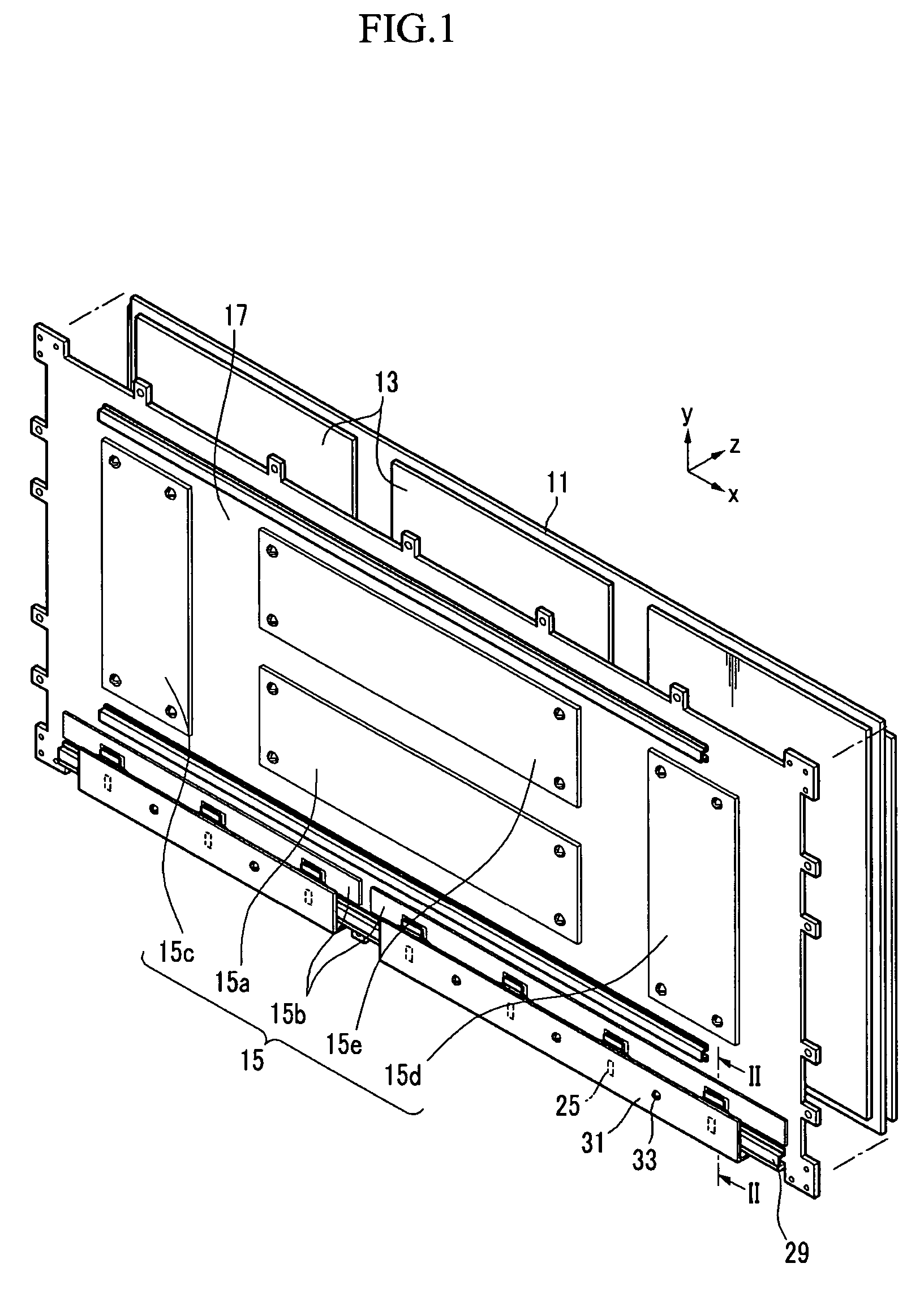

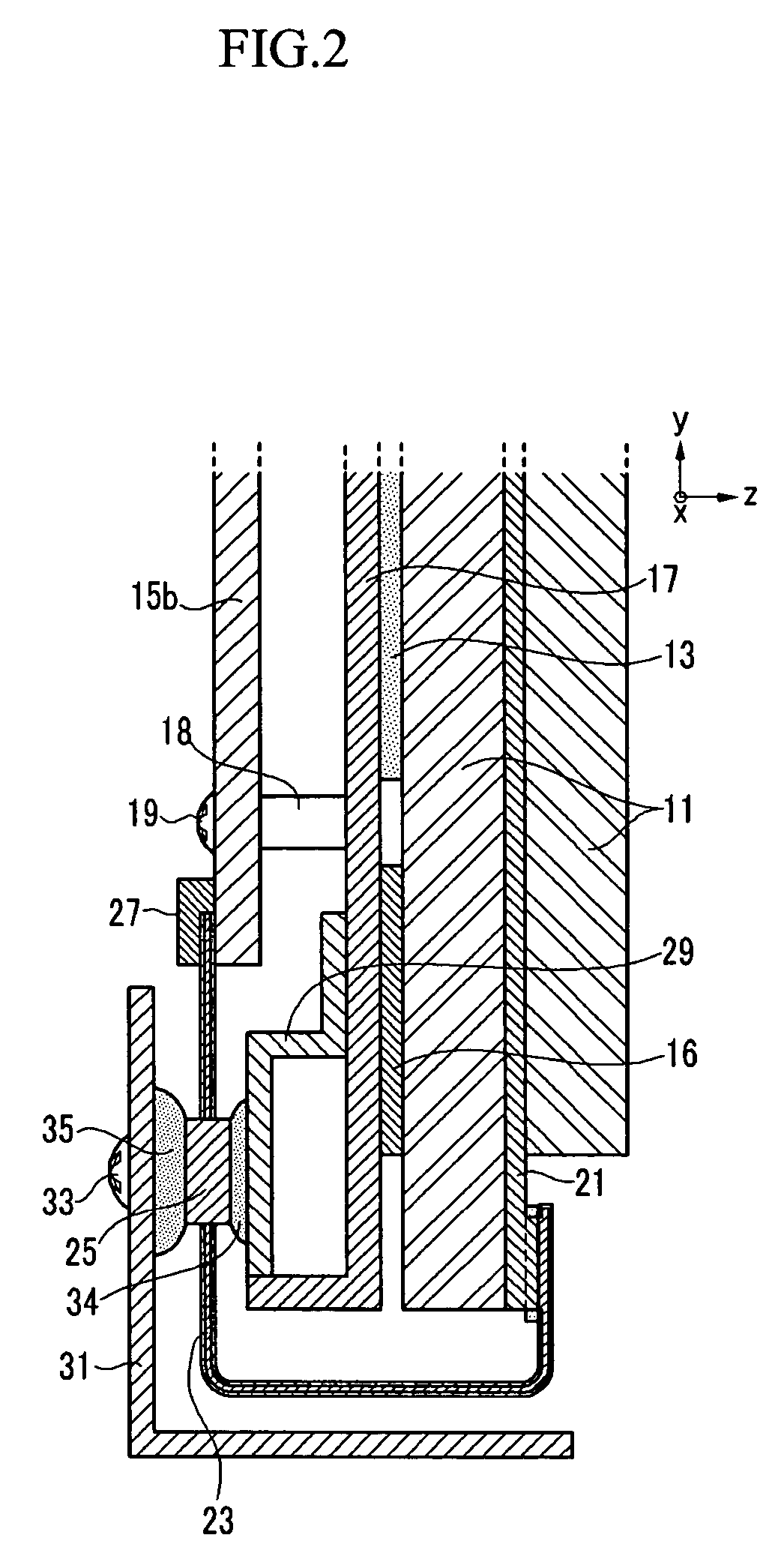

Tape carrier package on reel and plasma display device using the same

InactiveUS20060132692A1Precise punchingAvoid misalignmentPrinted circuit aspectsGas discharge connecting/feedingPrinted circuit boardPlasma display

A Tape Carrier Package (TCP) that is attachable to and detachable from a connector of a Printed circuit Board Assembly (PBA) of a plasma display apparatus that includes a plurality of electrodes, and a plasma display device including the same. The TCP includes an input portion that is attachable to and detachable from the PBA, an output portion that is attachable to and detachable from one of the plurality of electrodes of the plasma display apparatus, and at least one alignment mark, at least a portion of the alignment mark corresponding to or abutting an edge of the input portion.

Owner:SAMSUNG SDI CO LTD

Accurate key punching device for hardware manufacturing

ActiveCN106112066AFresh airSave materialPositioning apparatusBoring/drilling componentsScrapEngineering

The invention relates to a key punching device, and particularly relates to an accurate key punching device for hardware manufacturing. The technical problem to be solved by the invention is to provide an accurate key punching device for hardware manufacturing, which is accurate in punching. In order to solve the abovementioned technical problem, the invention provides an accurate key punching device for hardware manufacturing. The accurate key punching device for hardware manufacturing comprises a left support frame, a bottom plate, a right support frame, a support seat, a spring, a first slide block, a fan, a first slide rail, a first fixed pulley, a stay wire, a second fixed pulley, a third fixed pulley and the like, wherein a screen groove is arranged below the right side in the left support frame, an electromagnet is arranged at the bottom of the screen groove, a third slide rail is arranged above the right side in the left support frame, a third slide block is arranged on the third slide rail, and a second rack is arranged on the third slide block. The accurate key punching device for hardware manufacturing, which is disclosed by the invention, achieves the purpose of accurate key punching for hardware manufacturing. According to the device, a key is fixed by virtue of the electromagnet, and scraps generated by punching are blown away by virtue of the fan, so that the punching is clearer.

Owner:浙江三行电气科技有限公司

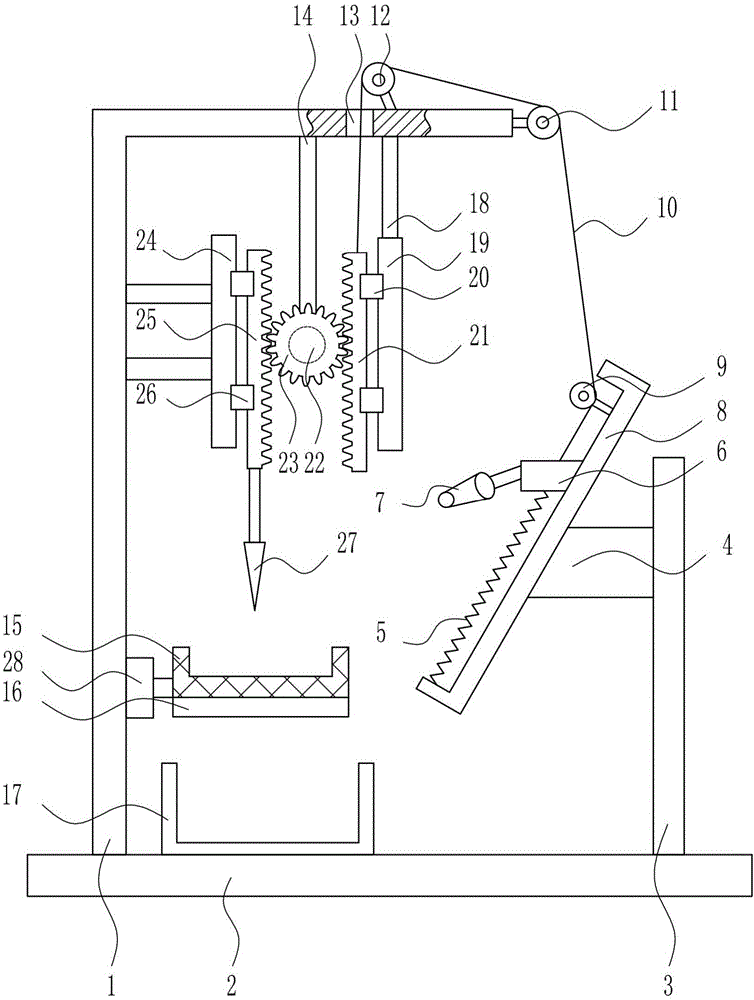

Perforating equipment for garment production

InactiveCN108943123AAvoid not only time-consuming and laboriousAvoid the problem that the punch is easy to be placed incorrectlyMetal working apparatusPunchingGear wheel

The invention discloses perforating equipment for garment production and relates to the technical field of garment production equipment. The perforating equipment for the garment production comprisesa box body. A motor is fixedly connected to one surface of the box body. A first cavity is formed inside the box body. A first gear is fixedly connected to one end of the output shaft of the motor. Asecond gear and a third gear are meshed with the circumferential side face of the first gear correspondingly. A first screw rod is in threaded connection with the position of the axis of the second gear. A second screw rod is in threaded connection with the position of the axis of the third gear. According to the perforating equipment for the garment production, through cooperation of a driving device and the screw rods, different punching pins can be automatically switched, and perforation work is conducted on garments; manpower resource is saved; the situation that replacement of perforationpins is conducted through midway labor pause is avoided; the operation is simple and convenient to conduct; diversity of buttonhole perforation is achieved; by means of a compressing mechanism, compressing and fixing effects are provided for the garments, and in addition, the function of tensioning the garments is also provided; movement of the garments because of force application when perforated is avoided; perforation accuracy is guaranteed; and the perforation efficiency of the garments is improved.

Owner:安徽省鼎立服饰有限公司

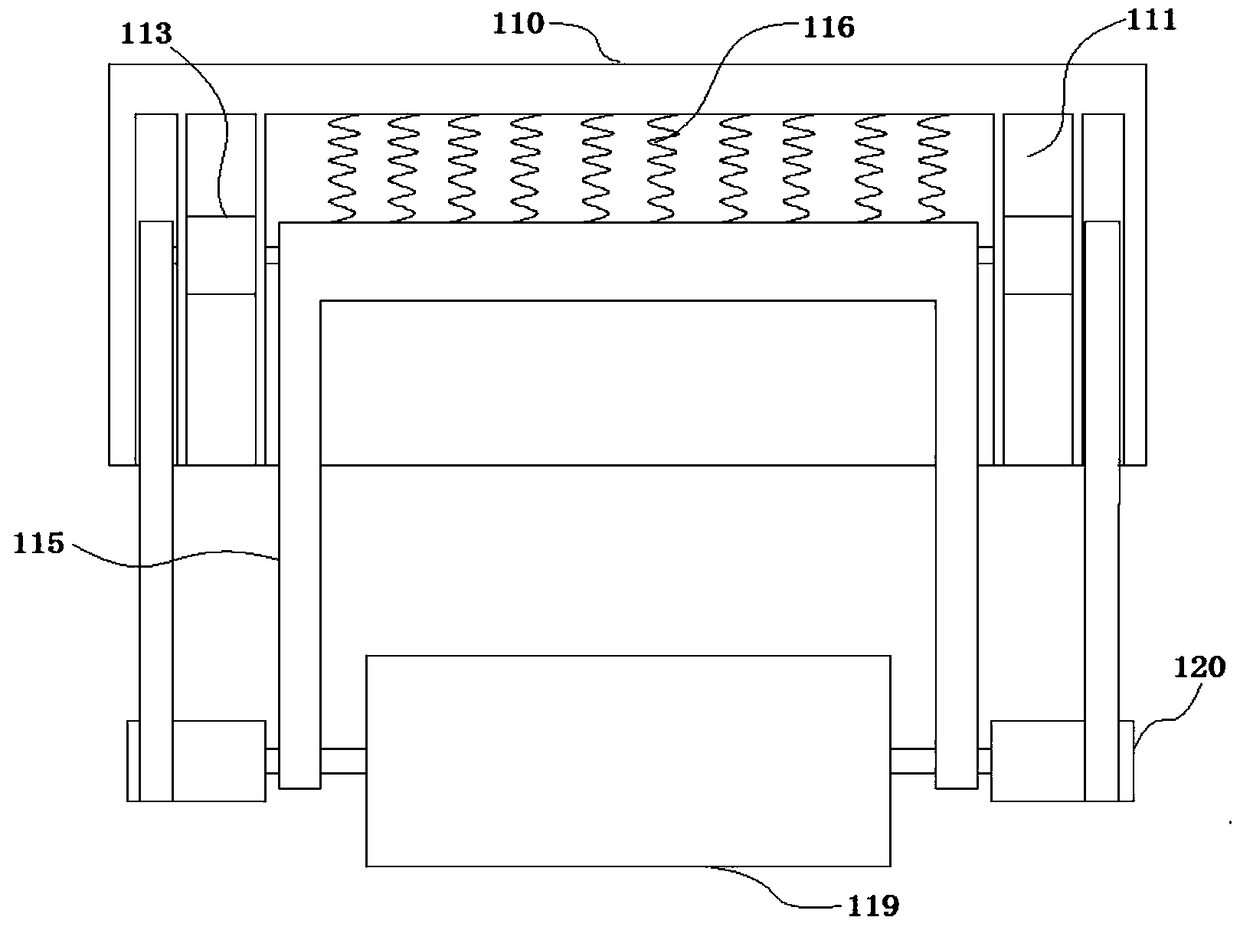

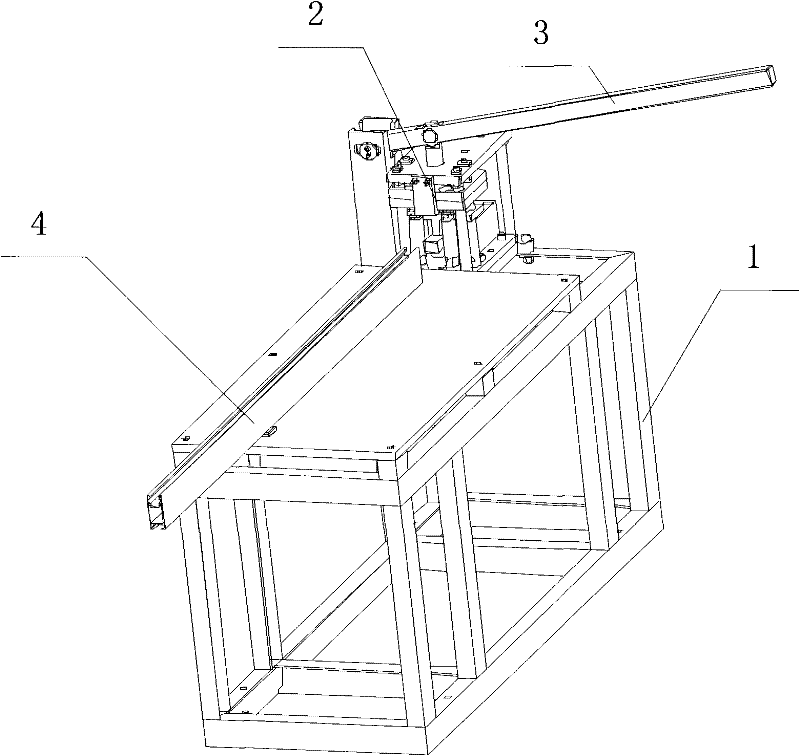

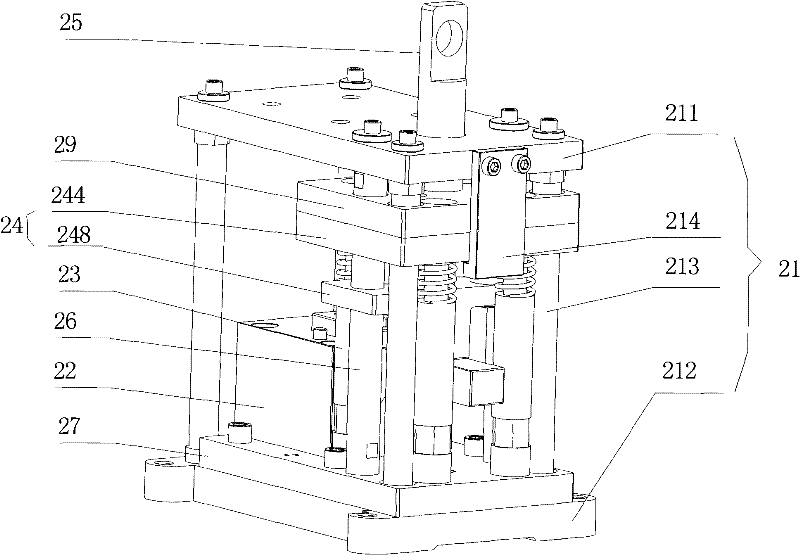

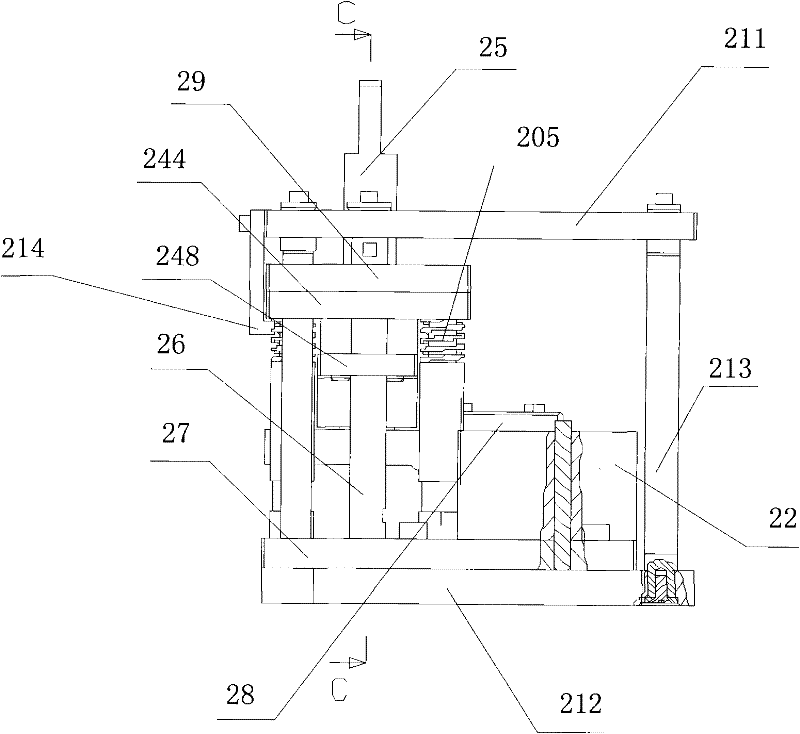

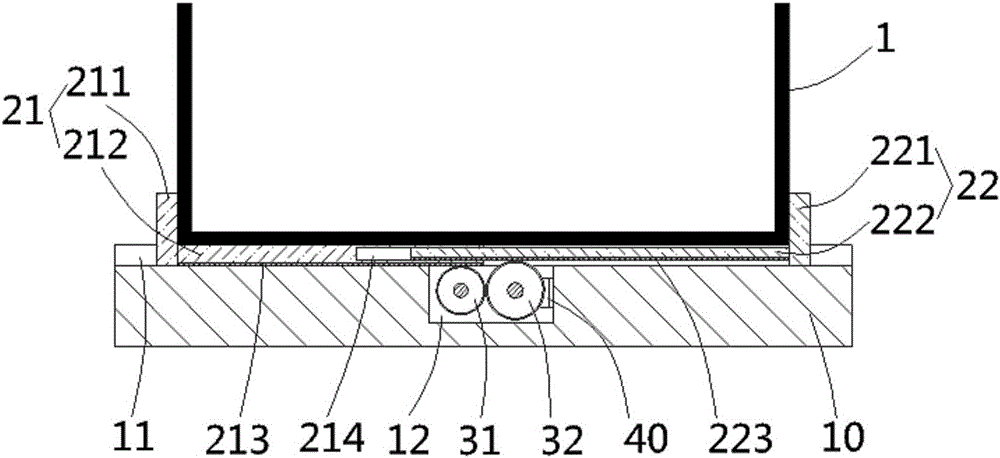

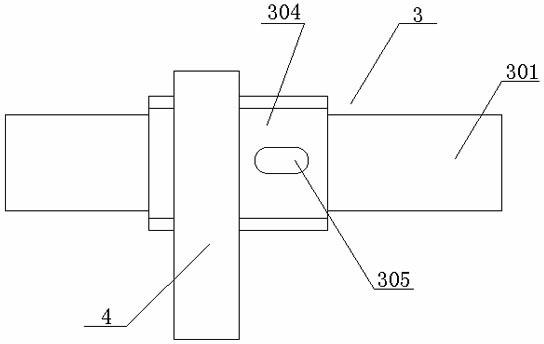

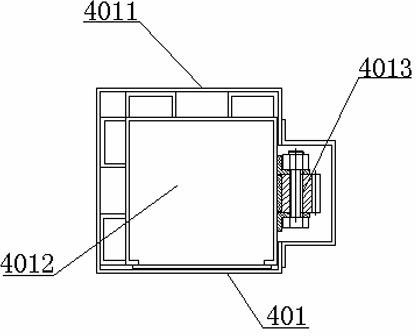

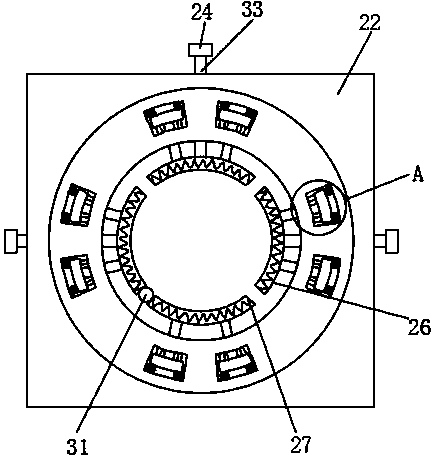

Cantilever manual punching machine for asymmetric deep groove square pipe

The invention provides a cantilever manual punching machine for an asymmetric deep groove square pipe. The punching machine comprises a frame (1) and a machine head (2) arranged on the frame, wherein the machine head (2) comprises a machine head frame (21), a female die (22), a plurality of elastic components (23), a punching component (24), a die handle (25), a padding plate (29) and two guide columns (26). The cantilever manual punching machine can be used for conveniently and precisely punching the pipe wall of the asymmetric deep groove square pipe on the basis of the cooperation of the punching component (24) containing a male die, the female die (22) with a cantilever and the guide columns (26).

Owner:HUNAN XINMEIGE INNOVATORY DECORATIVE MATERIAL

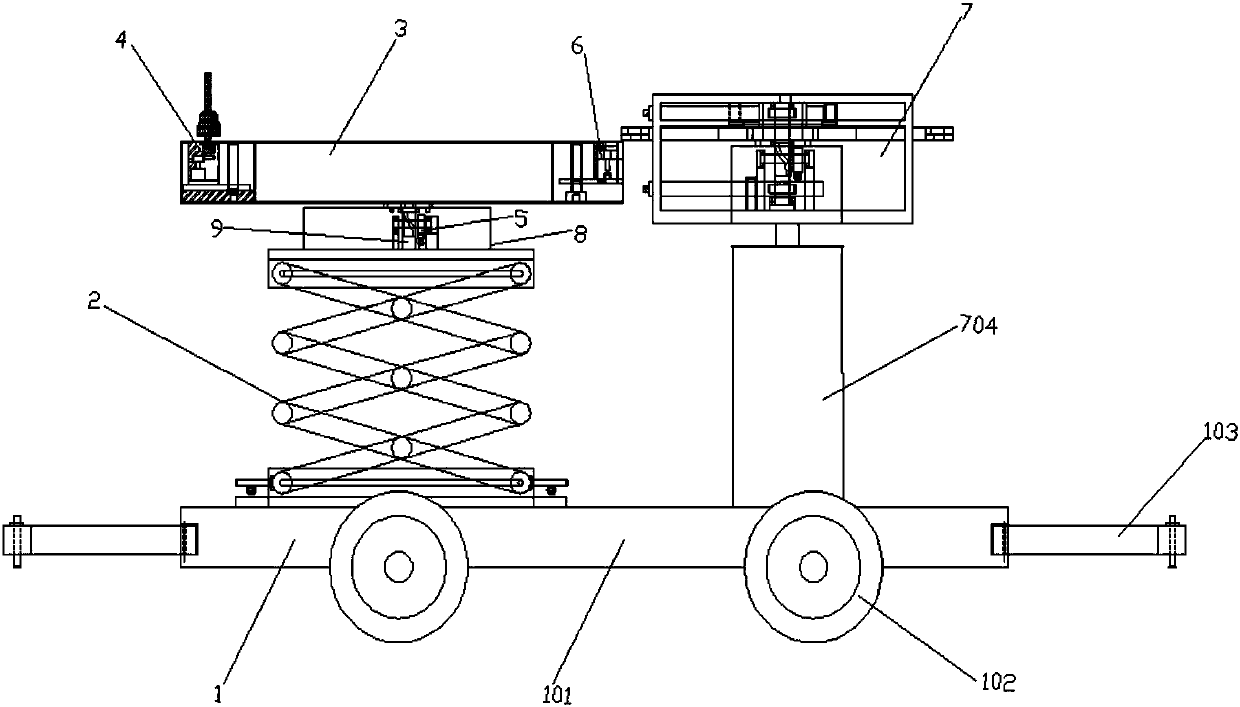

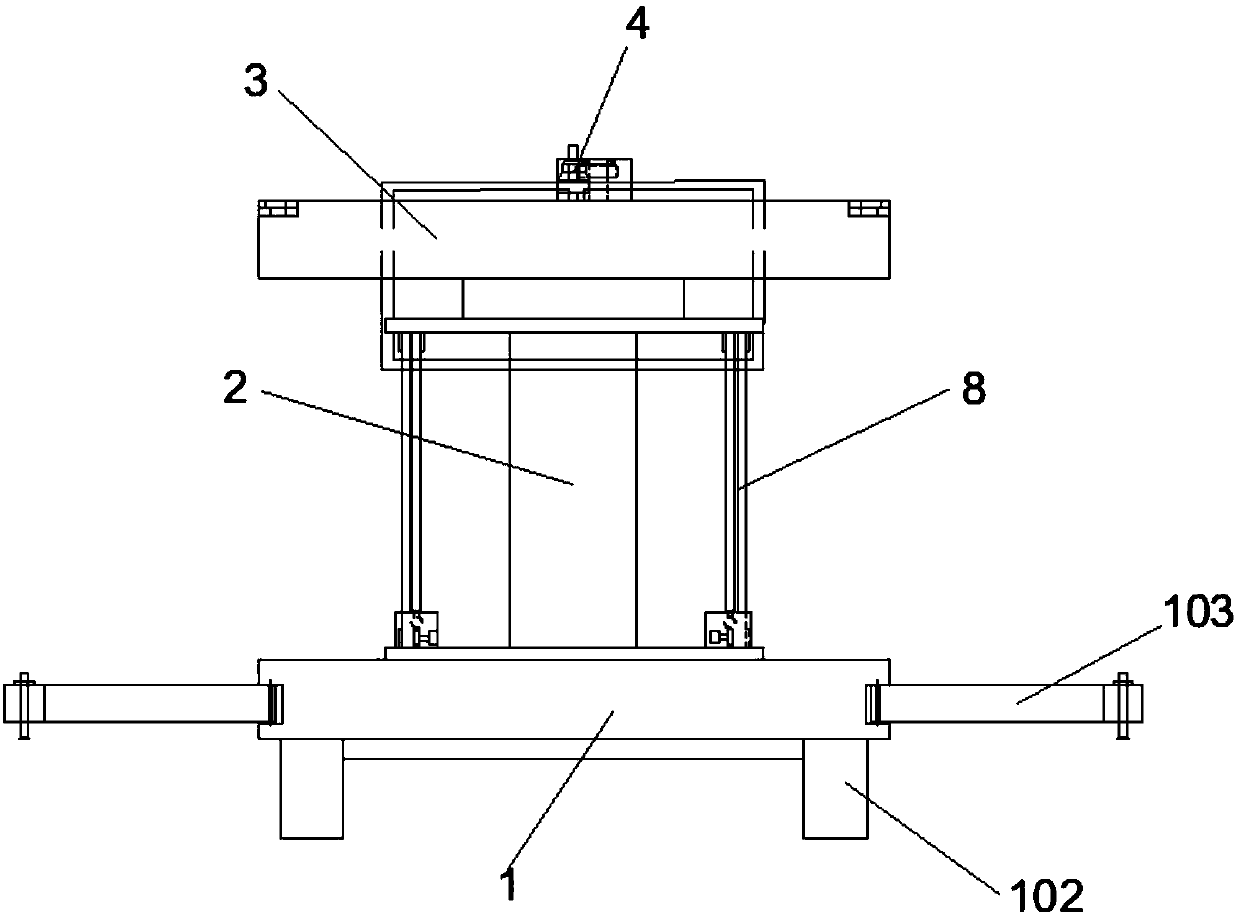

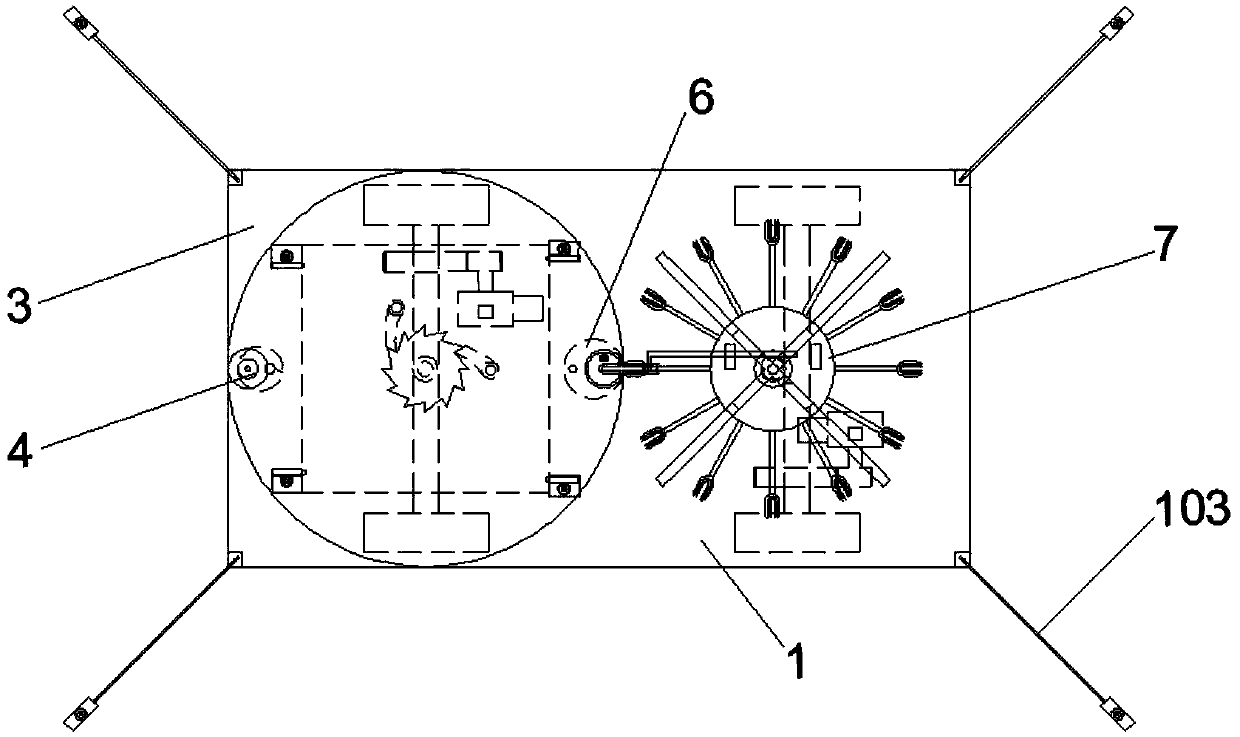

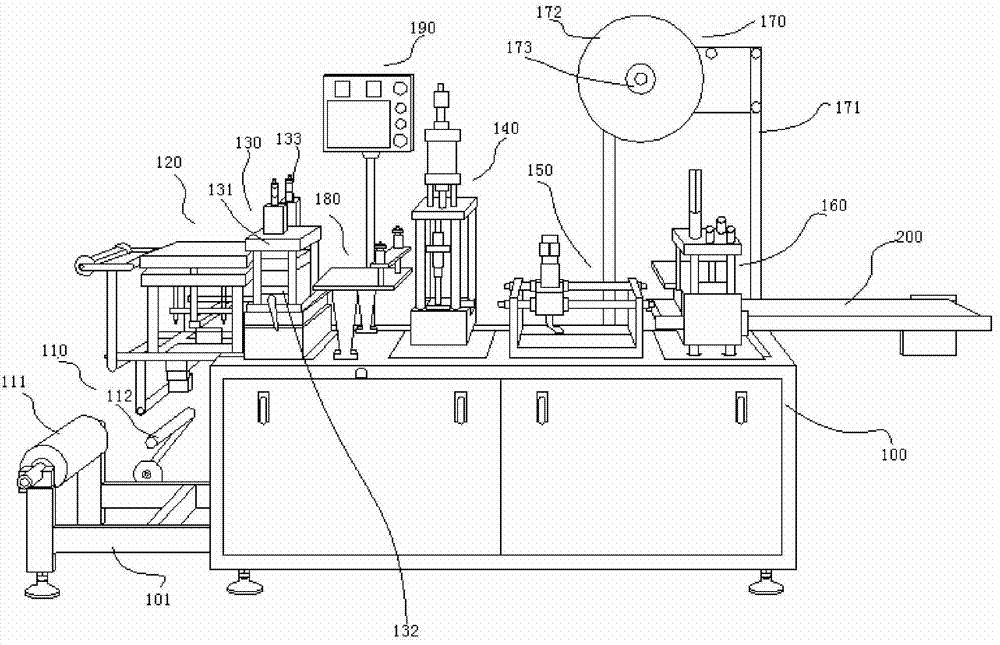

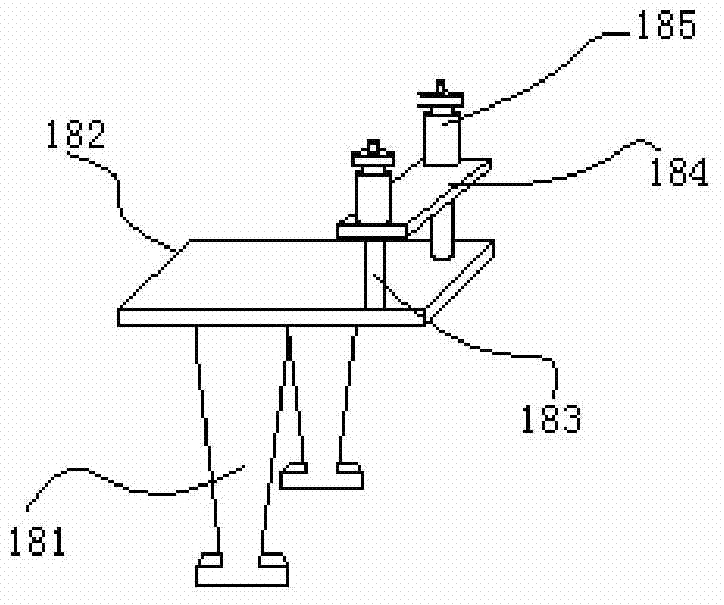

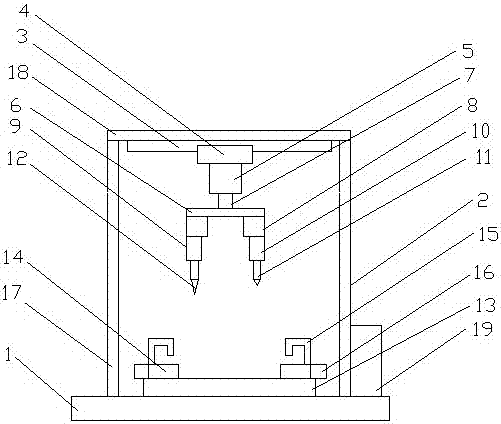

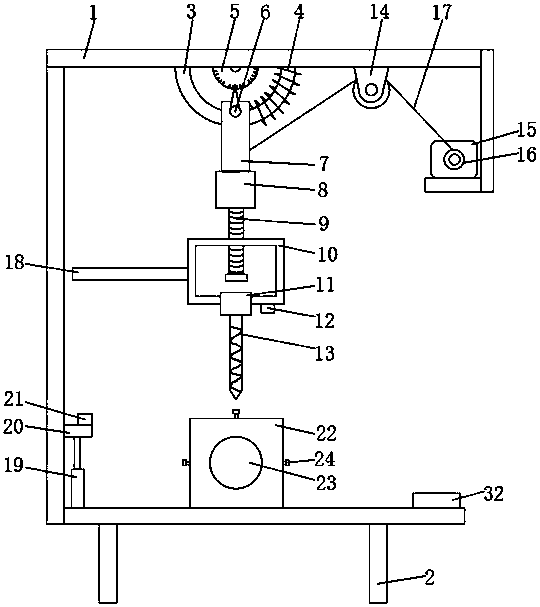

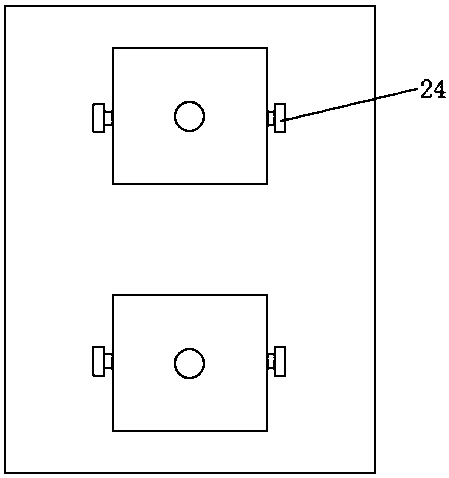

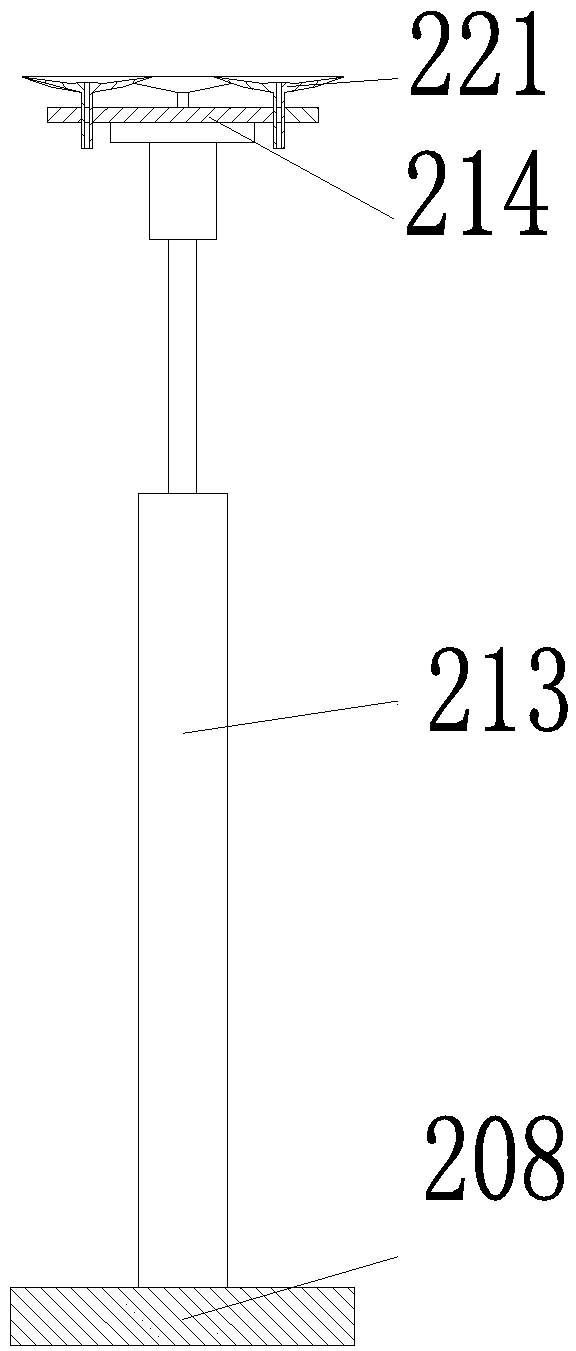

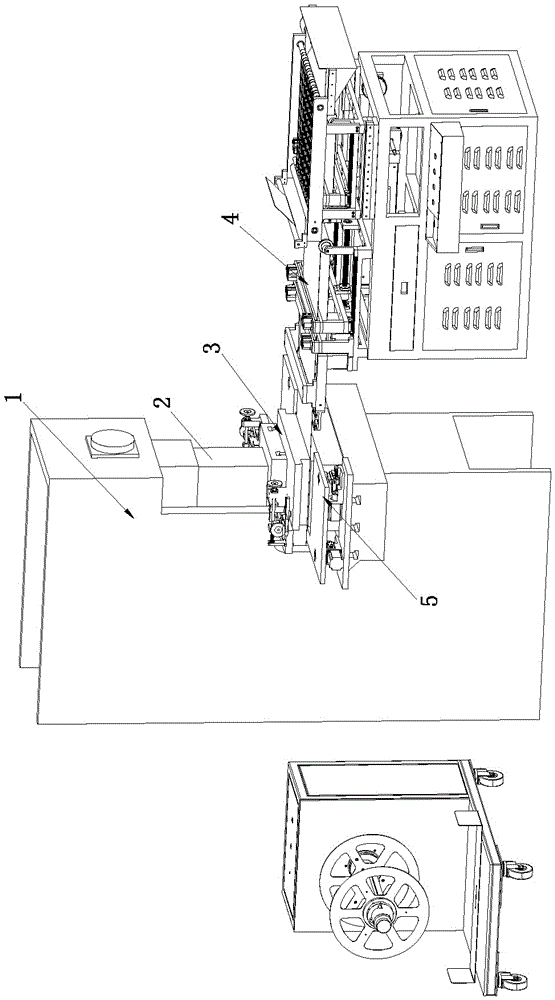

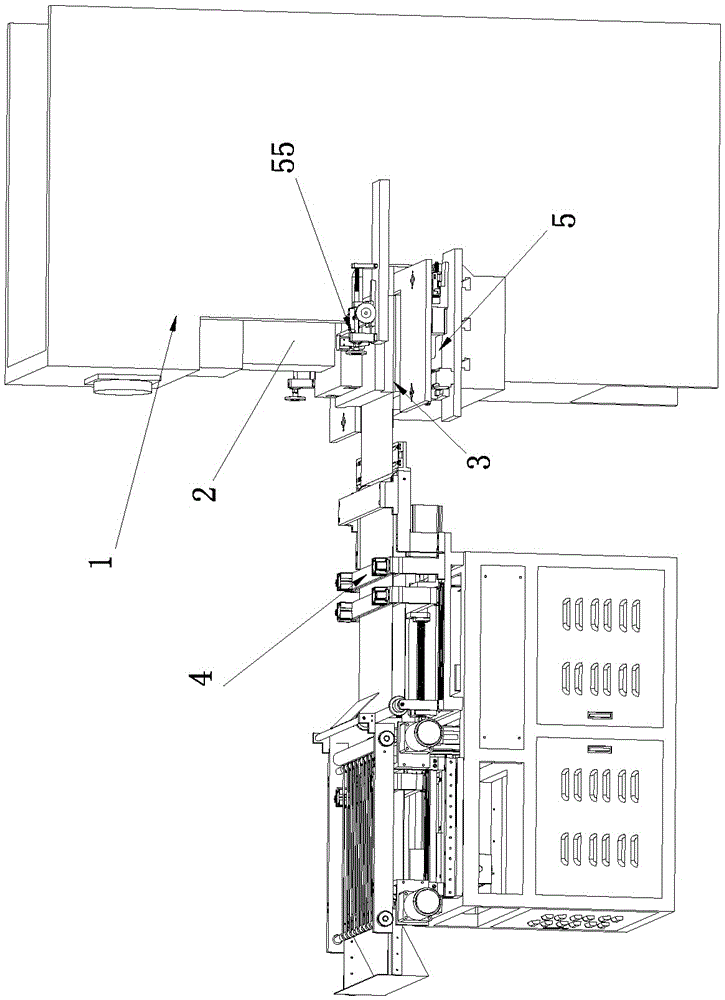

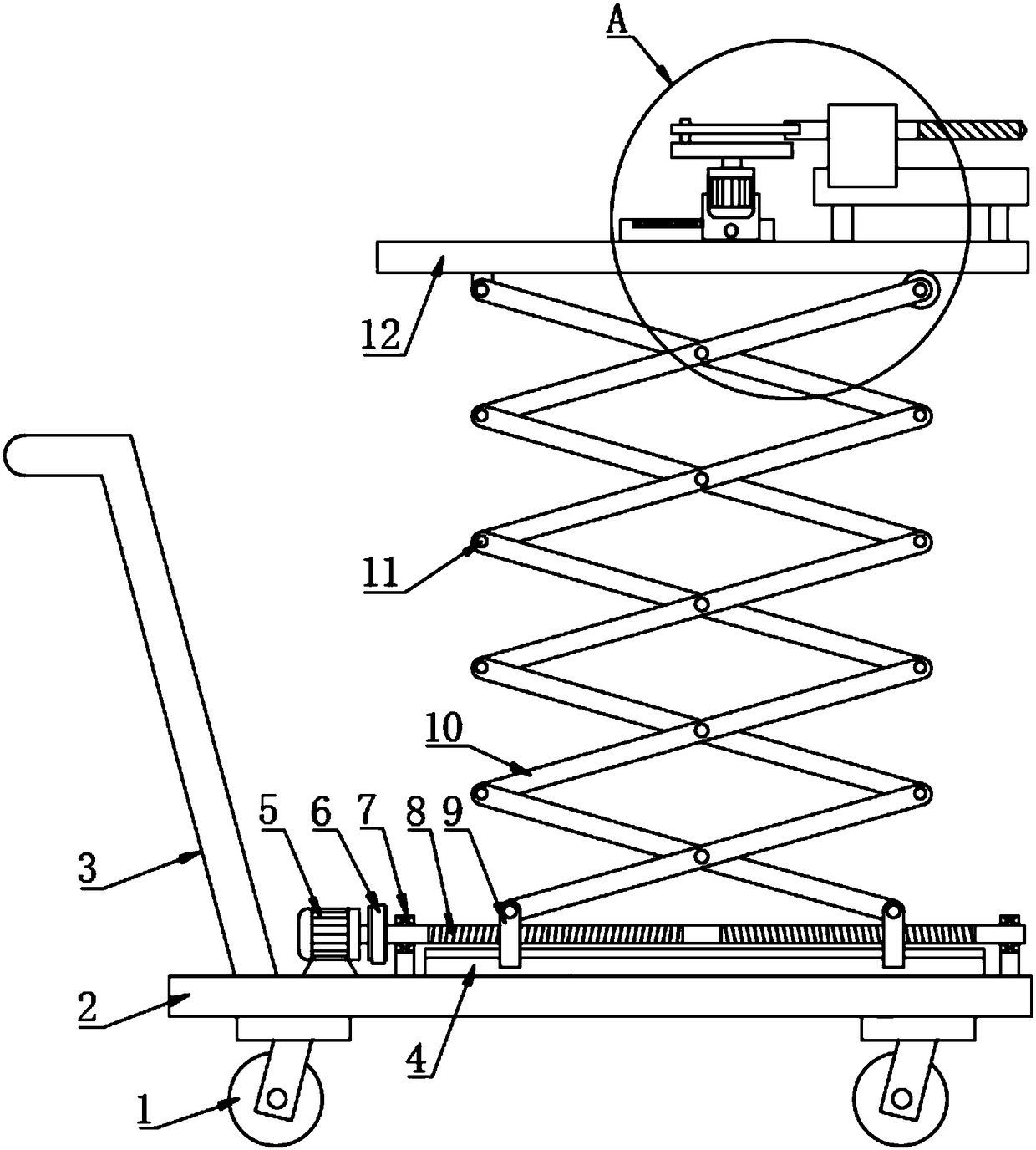

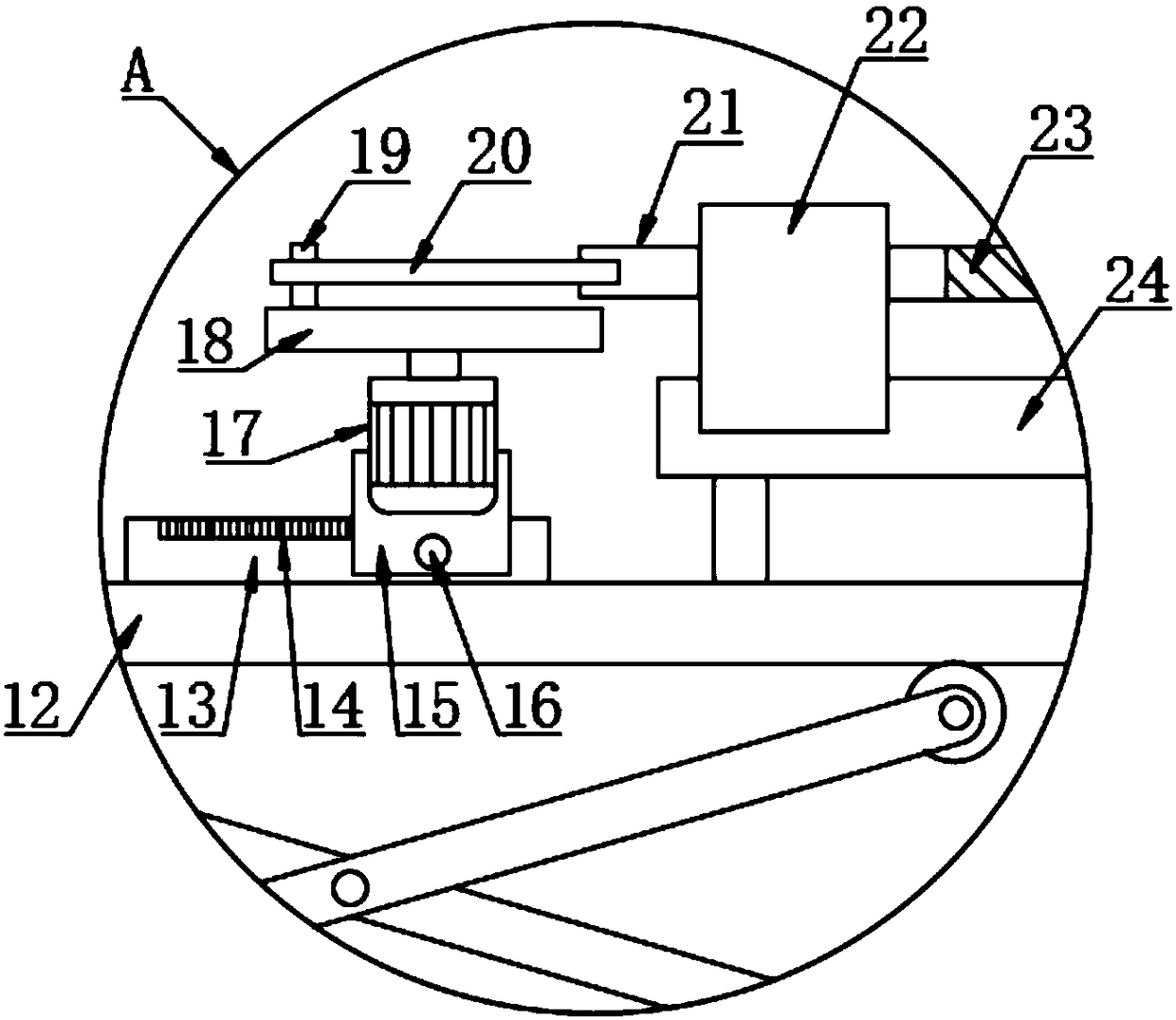

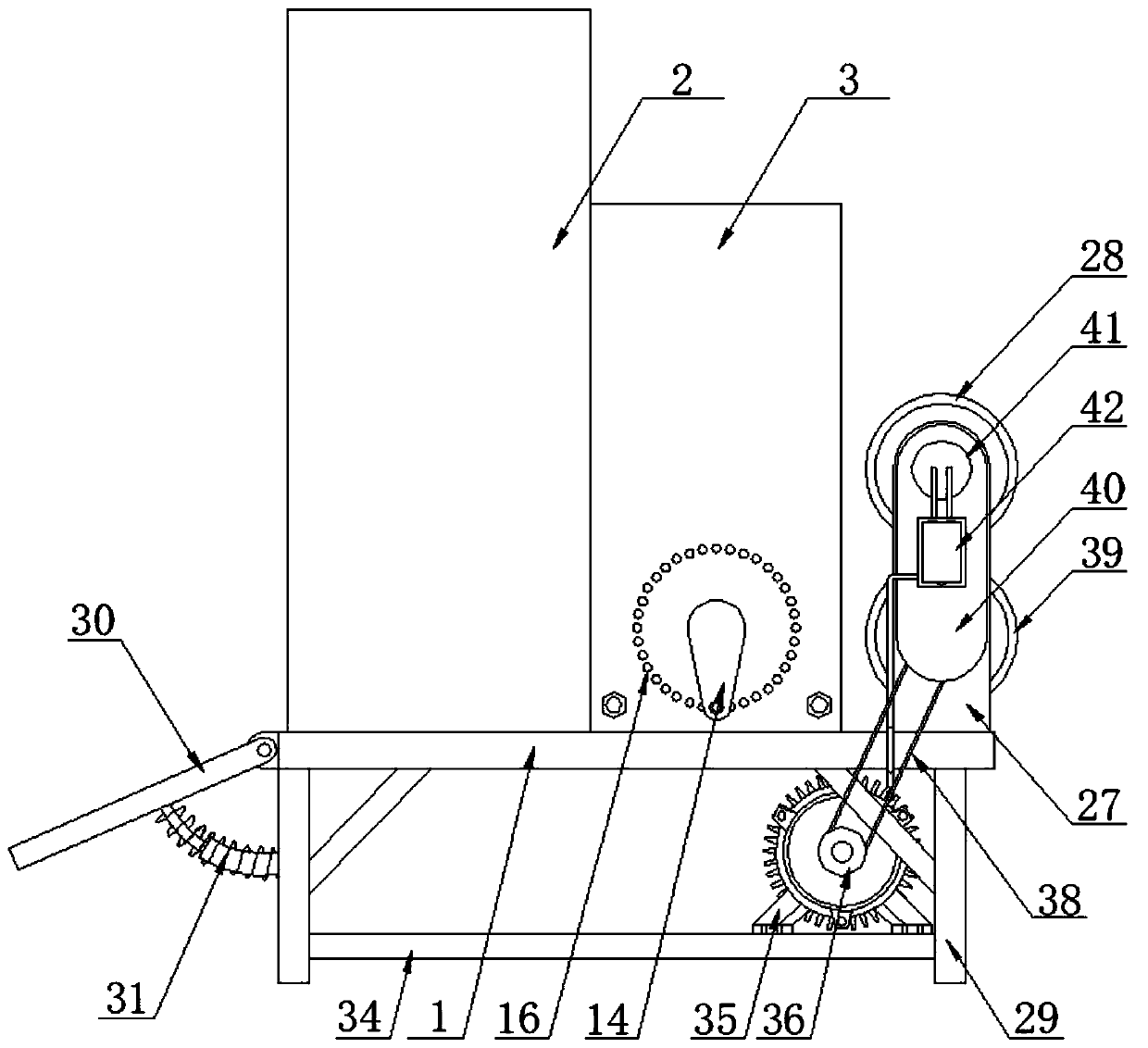

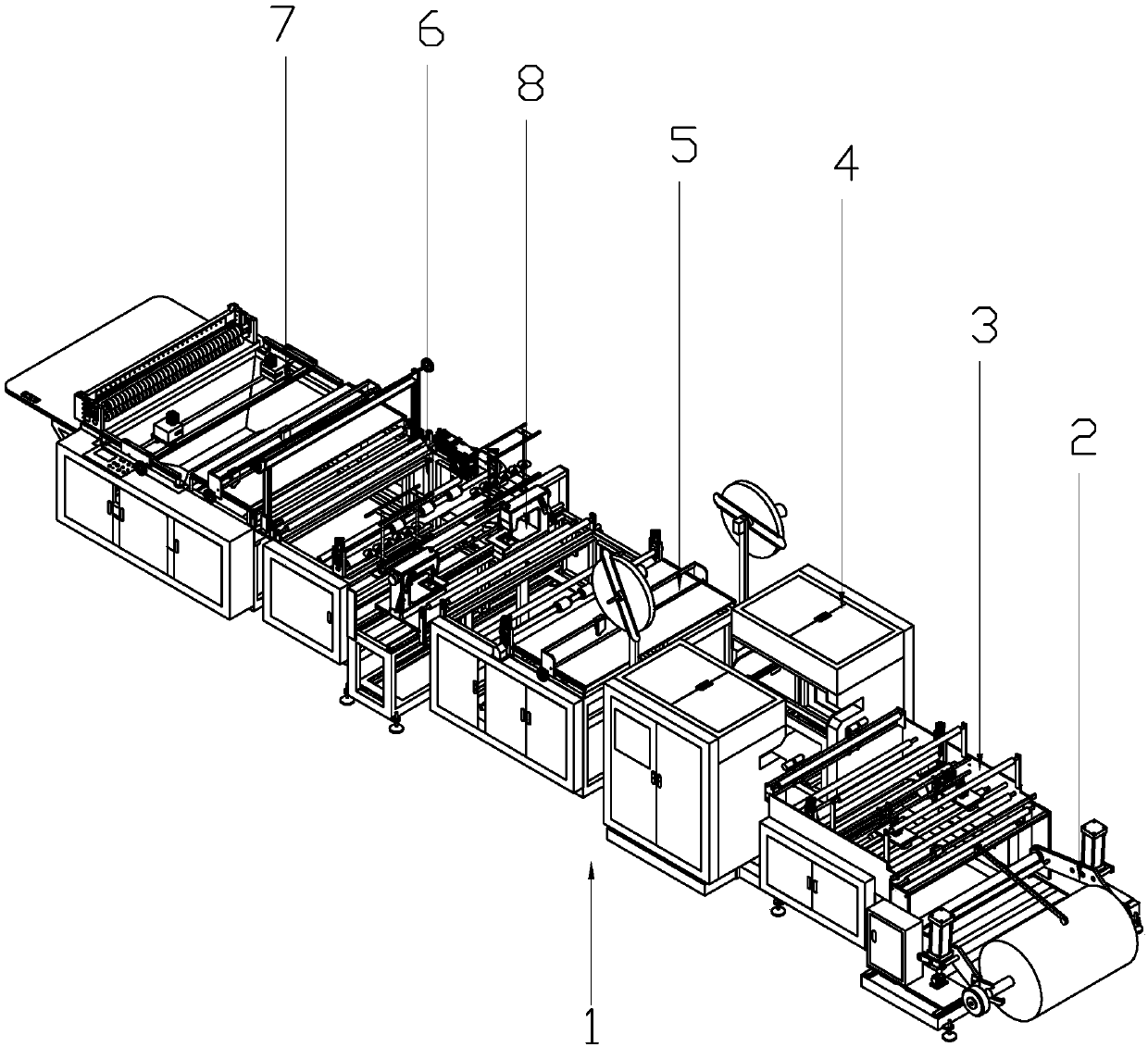

Automatic material fetching, hole punching and fastening machine for ceiling

PendingCN107738364AHigh degree of automationPrecise punchingWorking accessoriesMetal working apparatusIntermittent motionEngineering

The invention relates to an automatic material fetching, hole punching and fastening machine for a ceiling. The automatic material fetching, hole punching and fastening machine for the ceiling aims tosolve the technical problem that at present, when a hole is punched in the ceiling, full-automatic operation cannot be achieved, manual operation is needed, the risk is high, and efficiency is low. The automatic material fetching, hole punching and fastening machine for the ceiling comprises a bearing trolley, a fixed type scissor fork lifting ladder, a round rotatable platform, an ascendable hole punching mechanism, a first intermittent motion mechanism, an ascendable expansion screw screwing mechanism, a multiple-wrench rotation type material reloading machine, a shell, a fixing shaft, a plurality of bearings and a plurality of supporting frames. The automatic material fetching, hole punching and fastening machine for the ceiling has the beneficial effects that the automatic material fetching, hole punching and fastening machine for the ceiling is higher in automation degree and capable of replacing workers to accurately punch the hole in the ceiling and greatly saving labor and material sources, brings convenience to indoor decoration and architectural design work, greatly improves the hole punching efficiency and guarantees the safety of the whole operation process.

Owner:SHANXI UNIV

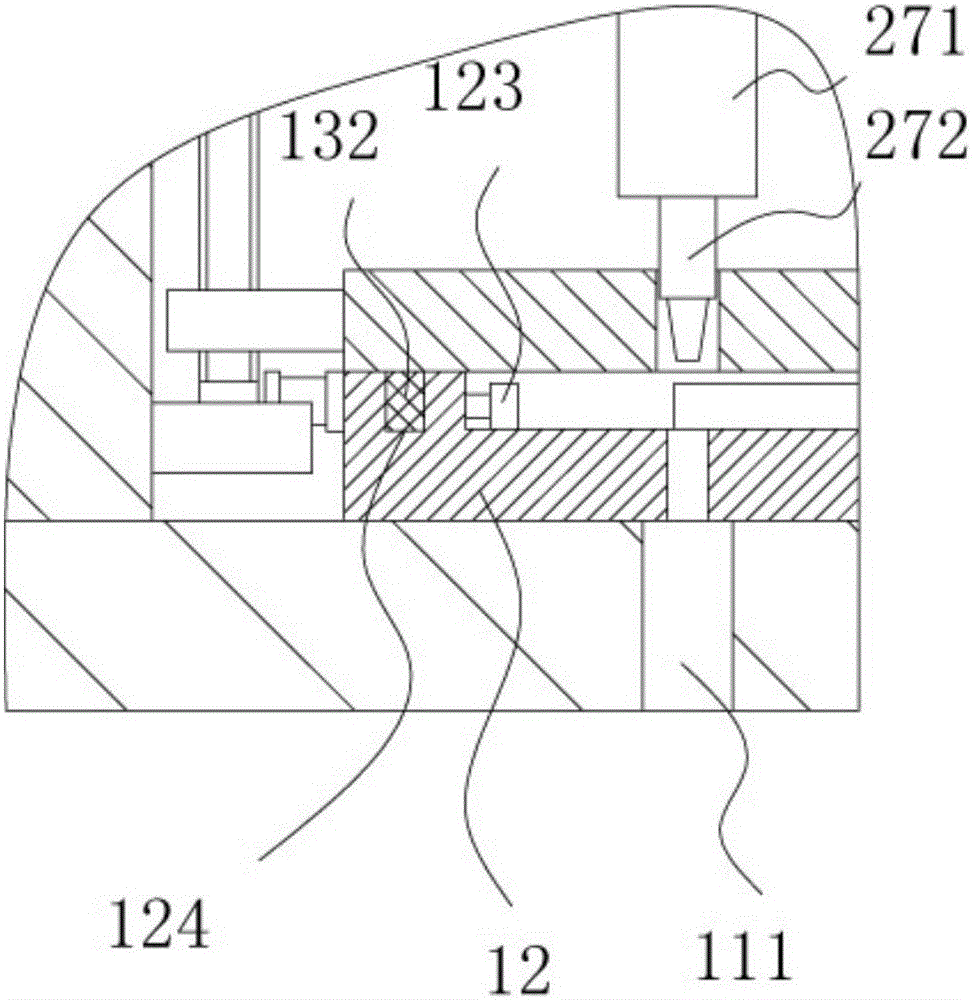

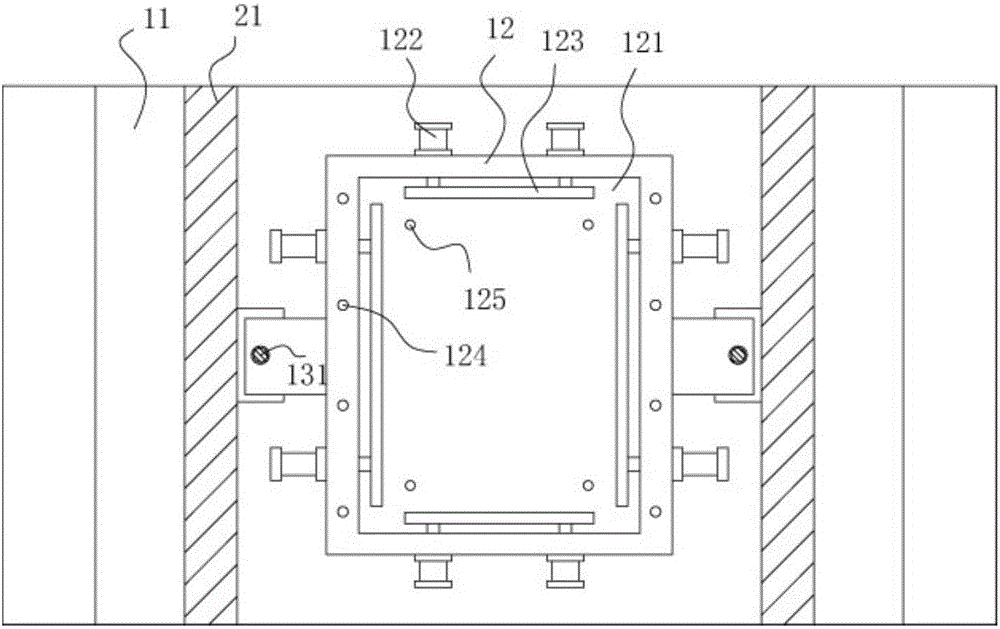

Mechanism for punching side wall of firefighting main machine shell

InactiveCN106216488AFirmly clampedPrecise punchingMetal-working feeding devicesPositioning devicesCamEngineering

The invention discloses a mechanism for punching the side wall of a firefighting main machine shell. The mechanism comprises a rack; an inserting groove is formed in the middle of the top surface of the rack; a first clamping plate and a second clamping plate which are both in L shapes and are arranged oppositely are inserted into the inserting groove in a sleeved mode and correspond to the edge parts of the two sides of a to-be-machined shell correspondingly; slide grooves are formed in the positions, on the two sides of the inserting groove, of the top surface of the rack; punching plates are inserted in the slide grooves in a sleeved mode; punching heads are formed in the positions, facing the upper end of the side wall of the to-be-machine shell, of the punching plates; impact cams are arranged on the side, back onto the punching heads, of the punching plates; transmission gear rings are formed in the arc-shaped walls, opposite to convex parts, of the impact cams and are connected with rotary gears in an engaged mode; a middle supporting block is inserted into the to-be-machined shell in a sleeved mode; a blanking groove is formed in the middle of the middle supporting block; and impact through holes corresponding to the punching heads of the punching plates are formed in the left side wall and the right side wall of the blanking groove. By means of the mechanism, the firefighting main machine shell can be firmly clamped and fixed, and the punching efficiency is high.

Owner:绍兴柯桥远达纺织有限公司

Forming and punching device

InactiveCN103659894AImprove work efficiencyReduce manufacturing costMetal working apparatusPunchingEngineering

The invention discloses a forming and punching device. The forming and punching device comprises an objective table. A first rolling and shaking device, a heating device, a forming die, a hole punching device, a mechanical clamping piece device, a punching device and a second rolling and shaking device are sequentially arranged on the objective table. A control device is also arranged on the objective table. The control device is respectively connected with the heating device, the forming die, the hole punching device, the mechanical clamping piece device, the punching device and the second rolling and shaking device. According to the forming and punching device, forming and punching of plastic goods can be integrated, working efficiency is greatly improved, and the production cost is reduced.

Owner:SHANGHAI LONGLIAN PACKAGING MATERIALS

Adjustable wood board punching machine provided with different drilling bits

InactiveCN107097300APrecise positioningPrecise punchingStationary drilling machinesPunchingDrill bit

The invention discloses an adjustable wood board punching machine provided with different drilling bits. The punching machine includes a work bench and a machine frame which is fixedly connected thereon. A slide rail is horizontally installed on the machine frame. A fixing base is slidingly connected into the slide rail. A rotating apparatus is fixedly connected to the lower end of the fixing base. A disc body is arranged on the lower end of the rotating apparatus. A plurality of air cylinders are uniformly installed on the lower end surface of the disc body. A telescopic shaft is stretched out from each air cylinder downwardly. The telescopic shaft includes a fixed shaft and a movable shaft. A plurality of drilling bits, in different sizes, are respectively mounted on the lower ends of the movable shafts. A punching bench is arranged under the slide rail. Two guide rails are symmetrically installed on the punching bench. The sliding directions of the guide rails are vertical to the sliding direction of the slide rail. By means of the structure, the punching machine can satisfy punching demands with different sizes by adjustably using drilling bits in different sizes.

Owner:无锡凯皓科技有限公司

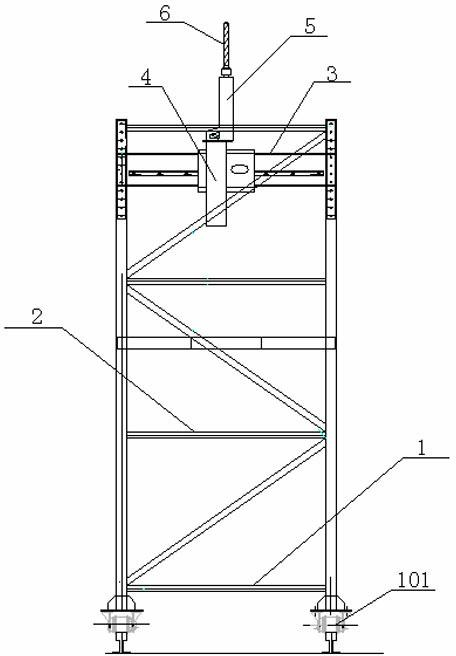

Tunnel drilling machine

ActiveCN102654021ALight weightReduce weightConstructionsDerricks/mastsEngineeringMechanical engineering

The invention discloses a tunnel drilling machine, relating to a drilling device at the top of a tunnel. The tunnel drilling machine mainly comprises a base, a frame, a transverse guide mechanism, a longitudinal feed mechanism, a drilling rod and a power mechanism for driving the drilling rod, wherein the longitudinal feed mechanism is arranged on the frame through the transverse guide mechanism, the drilling rod and the power mechanism are arranged at the top of the longitudinal feed mechanism, and the drilling rod can move in the vertical direction through the longitudinal feed mechanism. The tunnel drilling machine is lighter in weight and convenient to mount and detach in the tunnel, can be arranged on a track at any time for construction, and can be evacuated from a track area at any time so as to make a room for the track to facilitate the construction of other construction parties. During drilling, the horizontal part is connected with the vertical part through a gear, thus the drilling precision is higher.

Owner:THE 1ST ENG CO LTD OF CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP

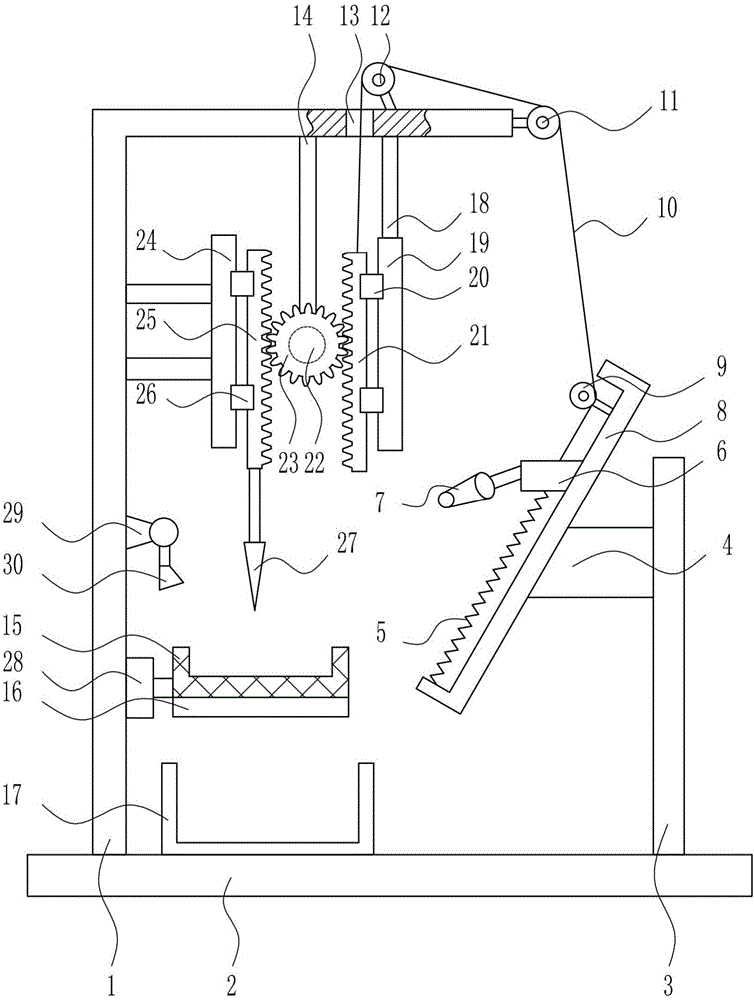

Orthopedics department positioning and punching device

InactiveCN108420502AAids in post-recoveryPrevent tamperingInstruments for stereotaxic surgeryBone drill guidesTemperature controlPunching

The invention discloses an orthopedics department positioning and punching device, comprising a body, wherein the inner top wall of the body is fixedly connected with an arc-shaped slide bar, one sideof the arc-shaped slide bar is provided with a rotation device, the middle of the arc-shaped slide bar is connected with a rotary block, a first spring sleeves the arc-shaped slide bar located between one side wall of the rotary block and the inner top wall of the body, and the inner top wall of the body is further fixedly connected with an angle scale. The orthopedics department positioning andpunching device has the advantage that an infrared sighting device is arranged to sight and punch an affected part, thus realizing accurate punching; the device can incline by a certain angle throughthe rotation device to punch the affected part, thus solving the problem that sometimes two or three holes are needed to meet the treatment need, reducing the workload, and facilitating later restoration of a patient; a fixing device is arranged to avoid involuntary movement of the patient due to pain or nervousness caused by punching, thus reducing punching difficulty; the temperature of a fixedpart is controlled to create a good hospital environment for the patient.

Owner:赵训明

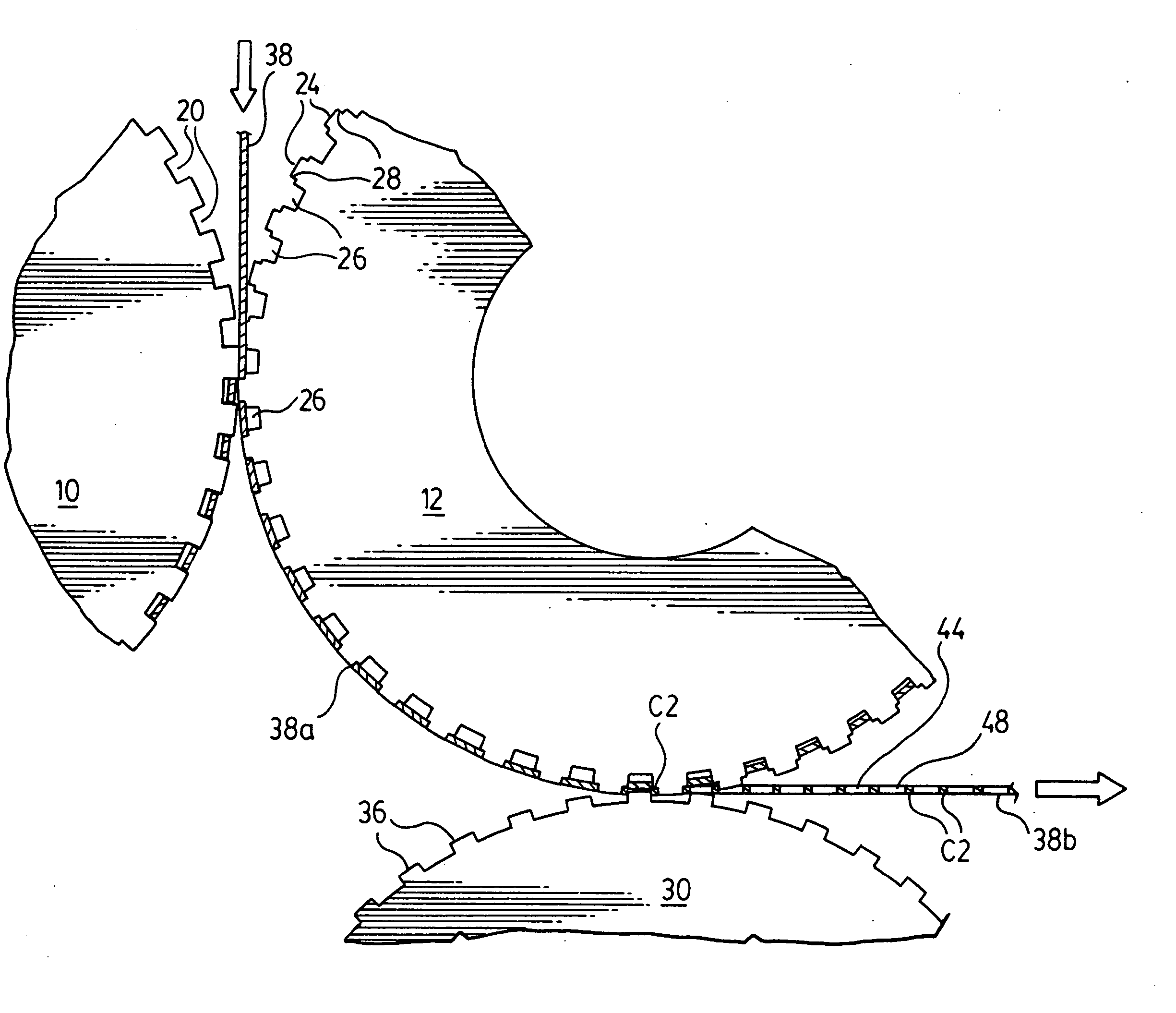

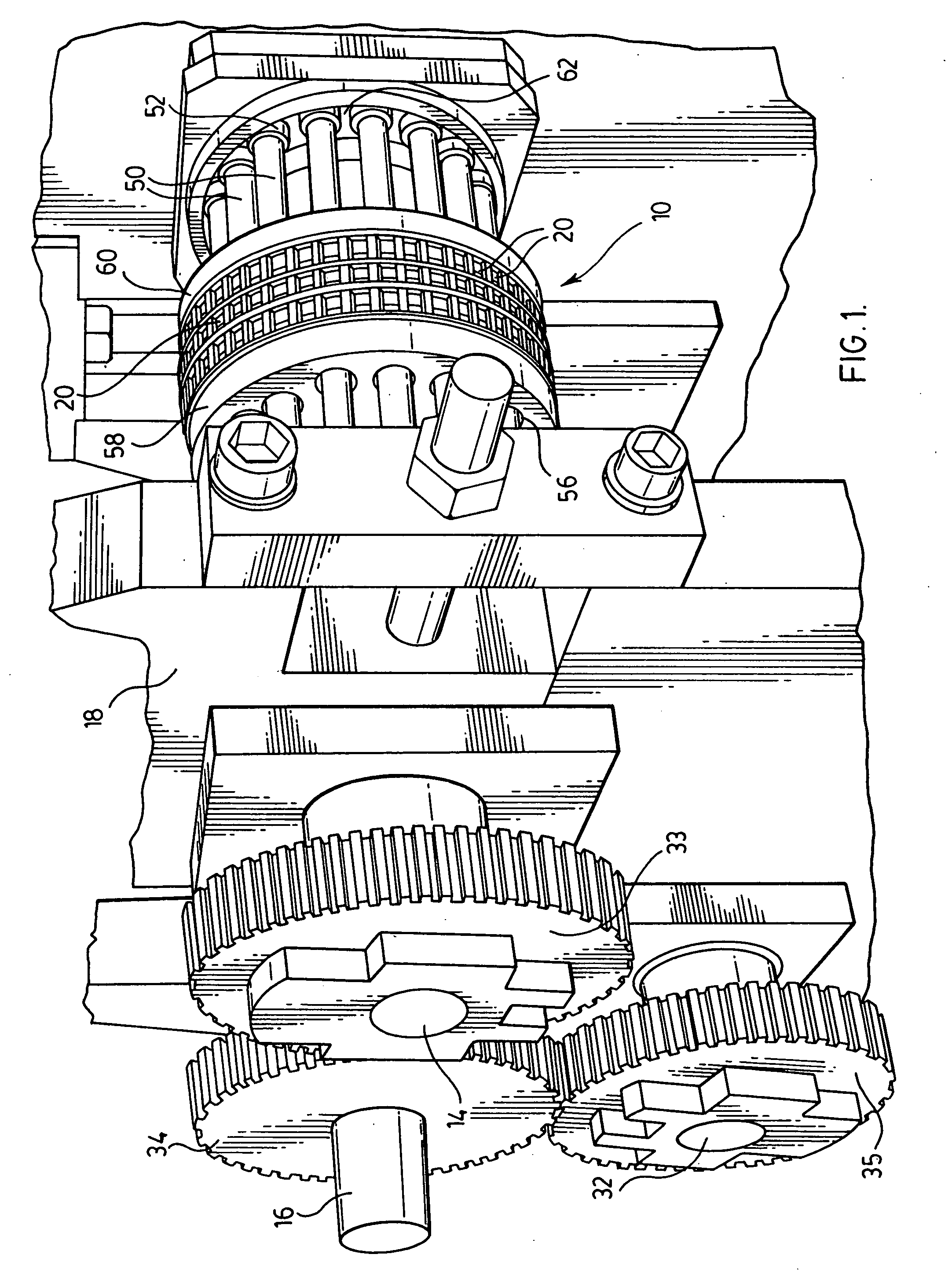

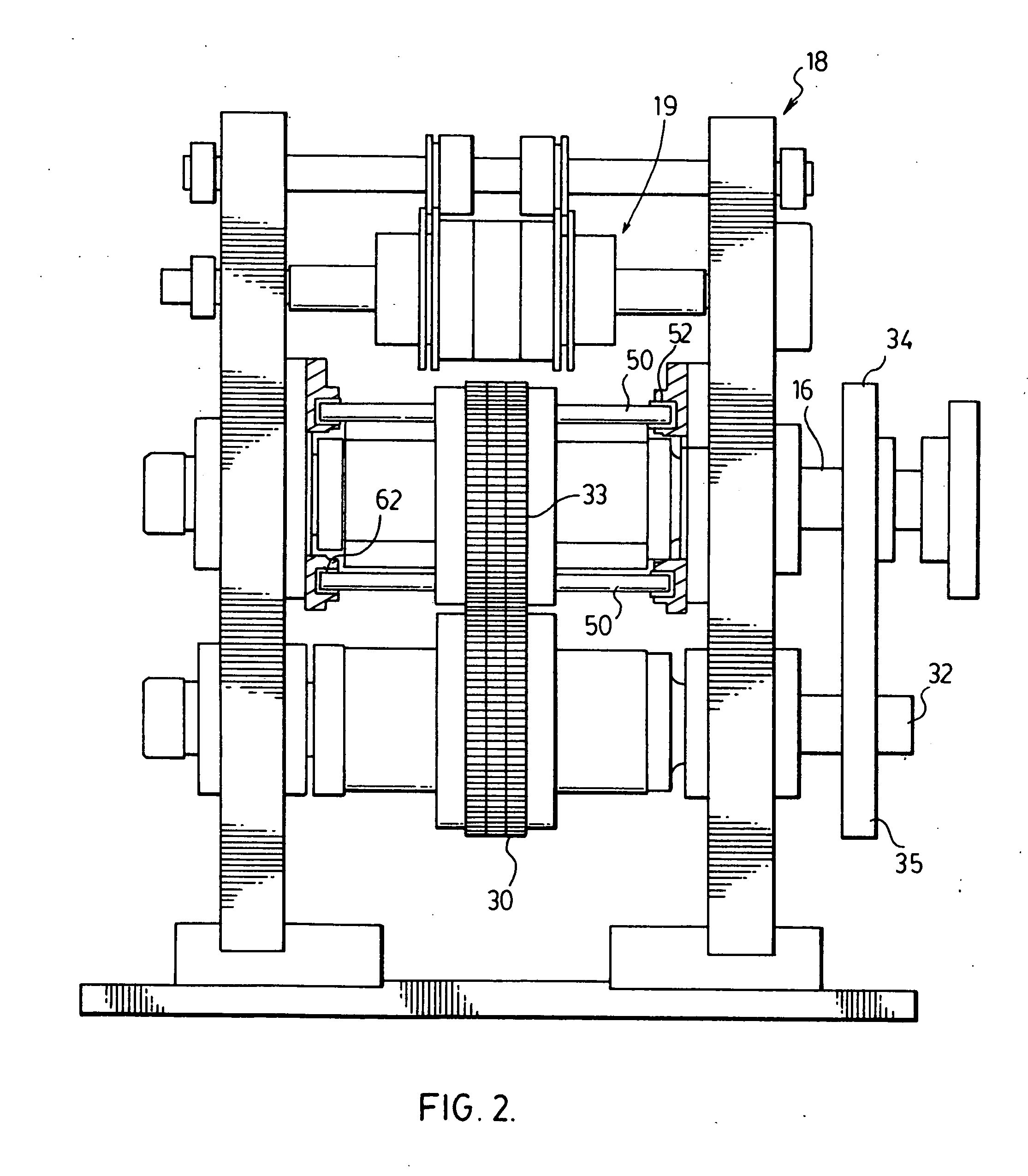

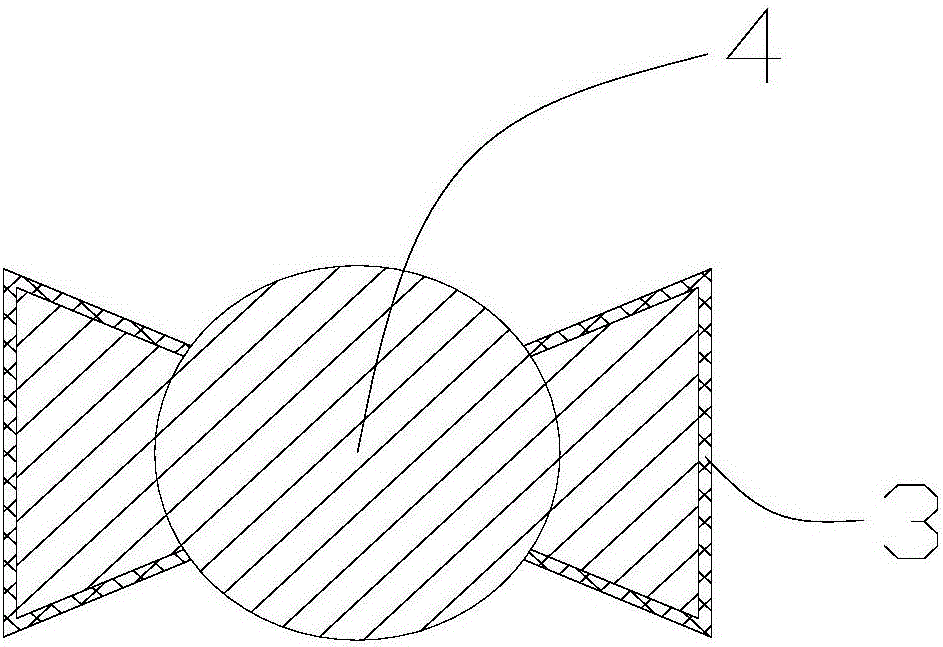

Continuous rotary hole punching method and apparatus

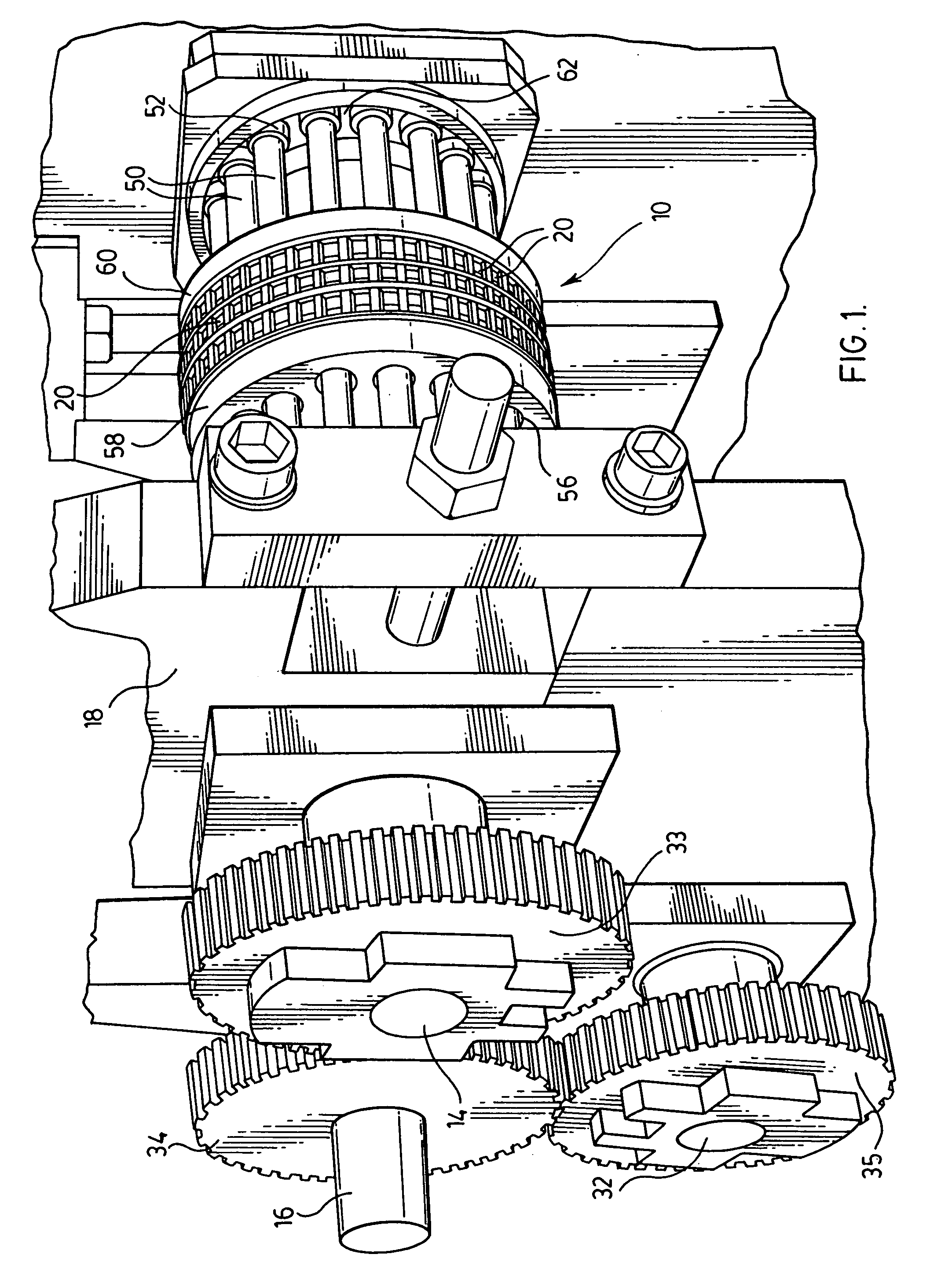

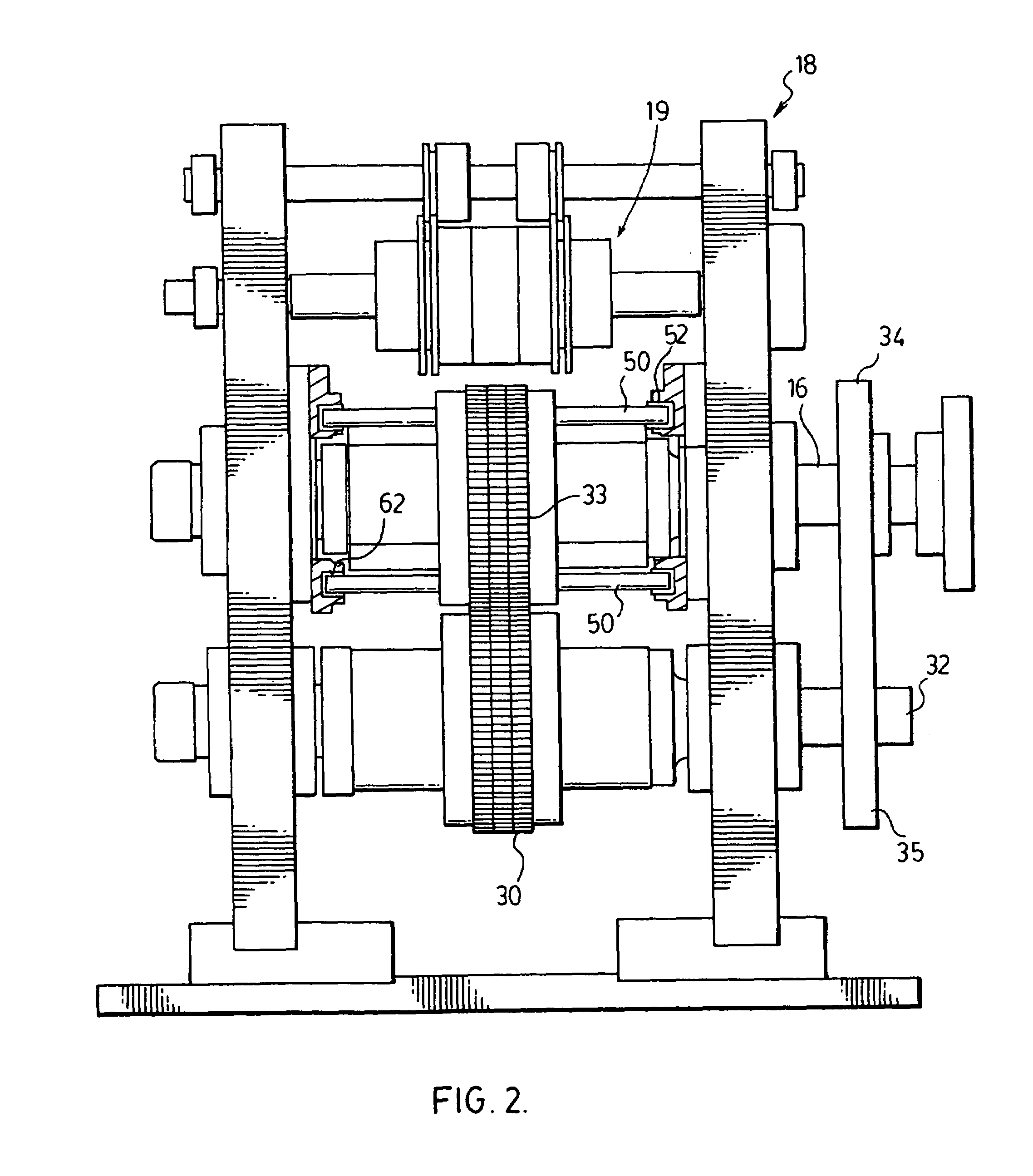

ActiveUS7066066B2Positive ejection of waste materialHigh speed productionBox making operationsPaper-makingPunchingStamping process

A method and apparatus for continuous, high-speed production of punched strip having an array of high-tolerance closely-spaced holes with positive ejection of waste punch-out material. A first pair of opposed rotary dies, one a female die and the other a male / female die, punches a first set of holes in a strip fed continuously between the dies, and a second pair of opposed rotary dies, one the male / female die and the other a male die, punches a second set of holes in the strip between the first set of holes, the strip being wrapped about the common male / female die during punching of the first and second sets of holes to continuously index the strip with the two opposed pairs of rotary dies to ensure production of the high-tolerance closely-spaced holes. A plurality of angular segments mounted in an annulus formed in proximity to the perimeter of the dies adapted for controlled radial travel of the angular segments during rotation of the dies, each angular segment having at least one ejector pin for radial reciprocal travel in a die recess, ejects punch-out material from the recess.

Owner:TBS USA INC

Steel pipe automatic drilling robot

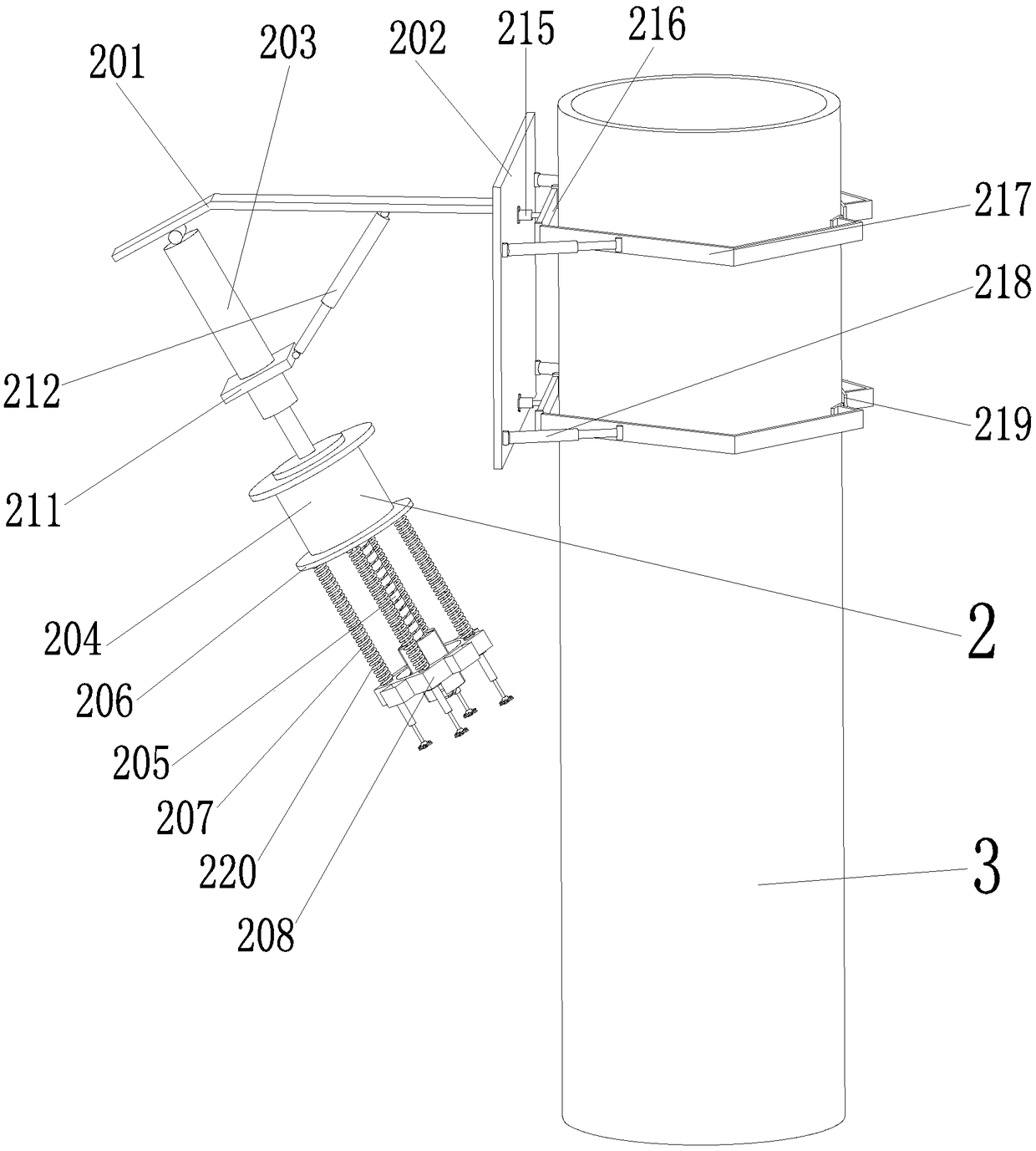

ActiveCN108941695AReduce labor intensitySolve the inconvenience of manual operationWork benchesPortable drilling machinesMotor driveSteel tube

The invention relates to a steel pipe automatic drilling robot. The steel pipe automatic drilling robot comprises an execution mechanism and a steel pipe body; the execution mechanism butts against the outer wall of the steel pipe body; the steel pipe body is of a hollow cylinder structure; an execution cylinder drives an inclined hole drill bit, mounted on an output shaft of a drilling driving motor, to drill and feed through extension control; the drilling driving motor drives the inclined hole drill bit to rotate for drilling; an adjusting cylinder drives the execution cylinder to perform an arc motion through extension control to achieve the effect of adjusting the drilling angle; and an auxiliary spring cooperates with an auxiliary extension rod to fix a positioning plate and to achieve a damping effect during drilling. The steel pipe automatic drilling robot can solve the problems of inconvenience for manual operation in multi-angle drilling, time and manpower waste, instable drilling, easy deflection of inclined holes, influence on the drilling quality and use, incapability of drilling holes on the same steel pipe by multiple angles through traditional drilling machinery, and the like.

Owner:安徽天康特种钢管有限公司

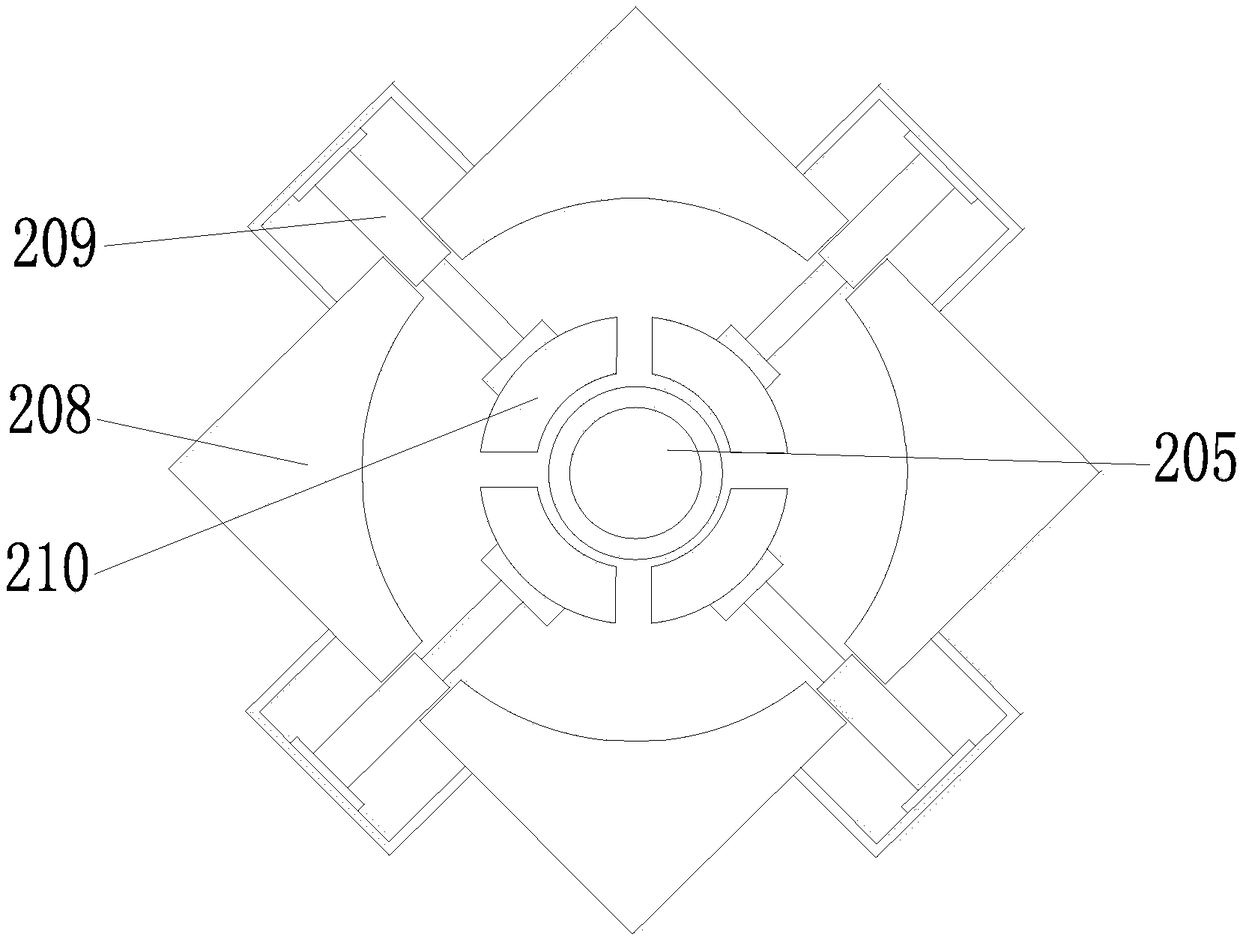

Alignment punch press system

ActiveCN105538410ARealize automatic alignmentReduce labor costsMetal working apparatusPunch pressFlexible circuits

The invention relates to the technical field of flexible circuit board production equipment, in particular to an alignment punch press system. The system comprises a punching device and a four-axis automatic alignment platform, wherein the punching device is provided with a puncher pin for punching, the four-axis automatic alignment platform comprises a bottom plate, a CCD camera assembly, a computer control assembly and an operation table used for adjusting material positions, the bottom plate is arranged on the punching device, a punching station is arranged between the puncher pin and the operation table, four groups of X-Y-theta alignment units used for driving the operation table to achieve X-Y-axis horizontal movement and rotation are arranged between the bottom plate and the operation table, the four groups of X-Y-theta alignment units are distributed on the bottom plate in a rectangular shape, rotary shafts of the four groups of X-Y-theta alignment units are rotationally connected with the operation table, the CCD camera assembly and at least three groups of X-Y-theta alignment units are connected with the computer control assembly through electric signals, and the CCD camera assembly shoots materials on the operation table. The punch press system is high in alignment efficiency and accuracy and improves punching quality and punching efficiency.

Owner:SHENZHEN VILITY AUTOMATION EQUIP

Continuous rotary hole punching method and apparatus

ActiveUS20050199110A1High speed productionPositive ejection of waste materialBox making operationsPaper-makingPunchingEngineering

A method and apparatus for continuous, high-speed production of punched strip having an array of high-tolerance closely-spaced holes with positive ejection of waste punch-out material. A first pair of opposed rotary dies, one a female die and the other a male / female die, punches a first set of holes in a strip fed continuously between the dies, and a second pair of opposed rotary dies, one the male / female die and the other a male die, punches a second set of holes in the strip between the first set of holes, the strip being wrapped about the common male / female die during punching of the first and second sets of holes to continuously index the strip with the two opposed pairs of rotary dies to ensure production of the high-tolerance closely-spaced holes. A plurality of angular segments mounted in an annulus formed in proximity to the perimeter of the dies adapted for controlled radial travel of the angular segments during rotation of the dies, each angular segment having at least one ejector pin for radial reciprocal travel in a die recess, ejects punch-out material from the recess.

Owner:TBS USA INC

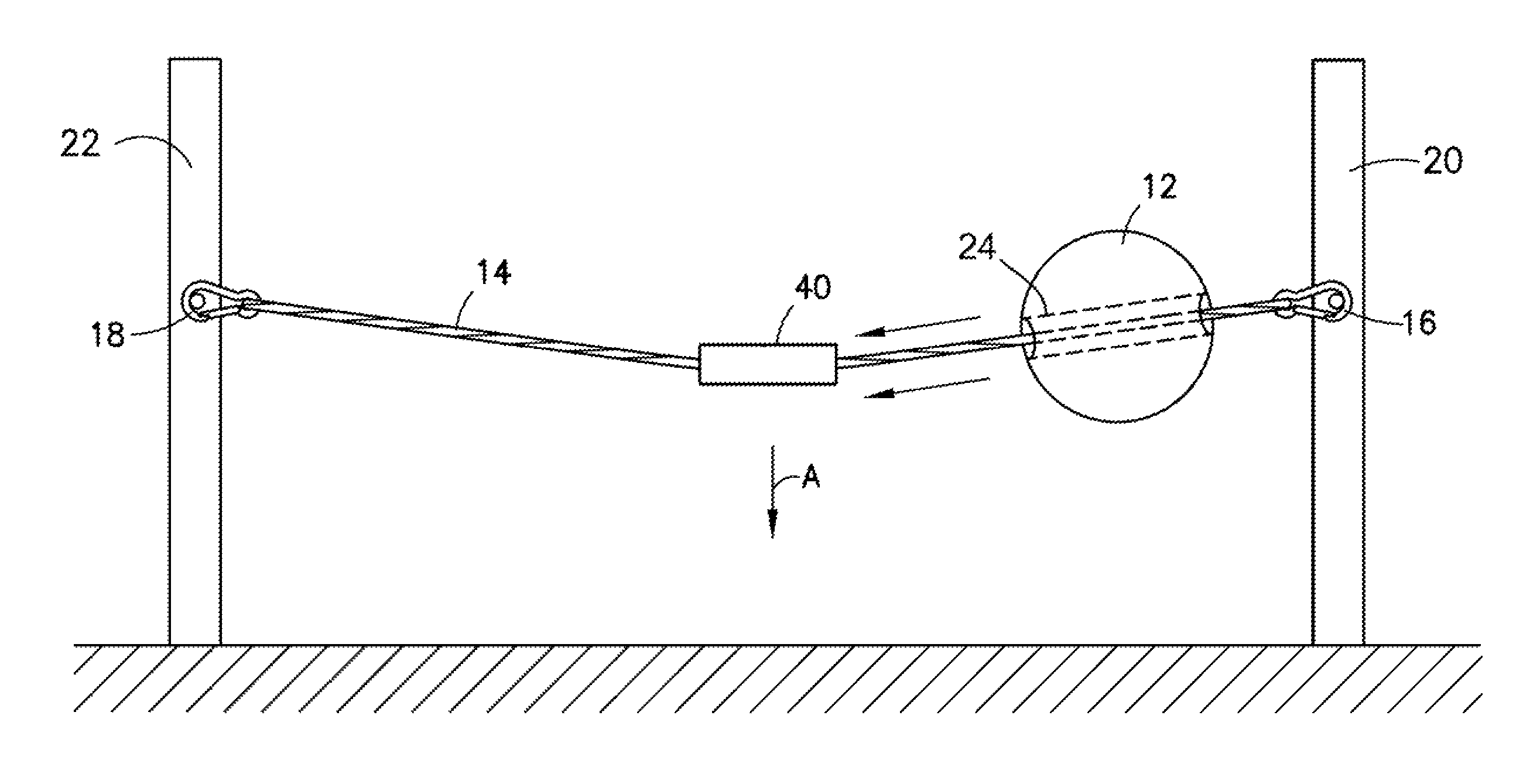

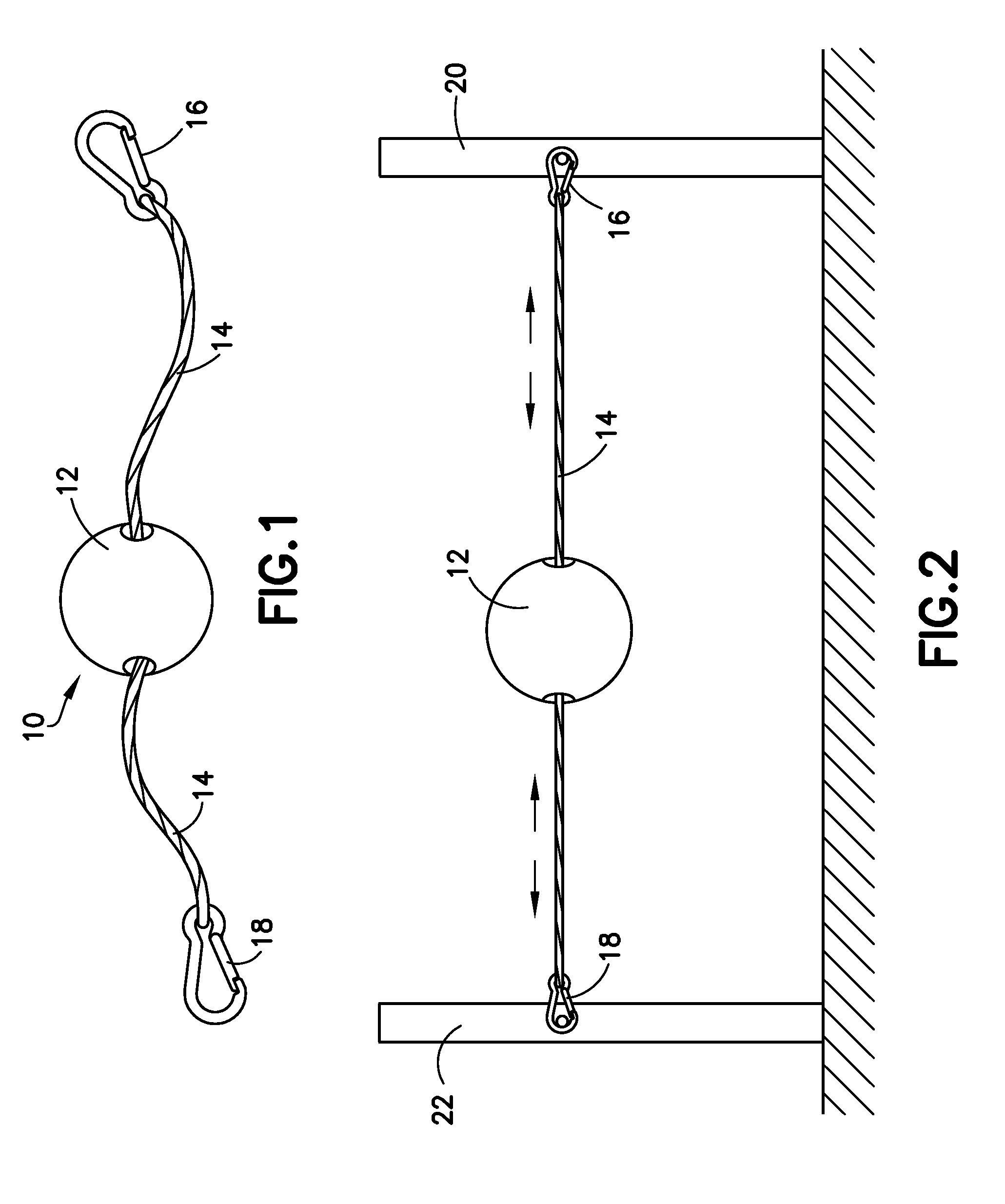

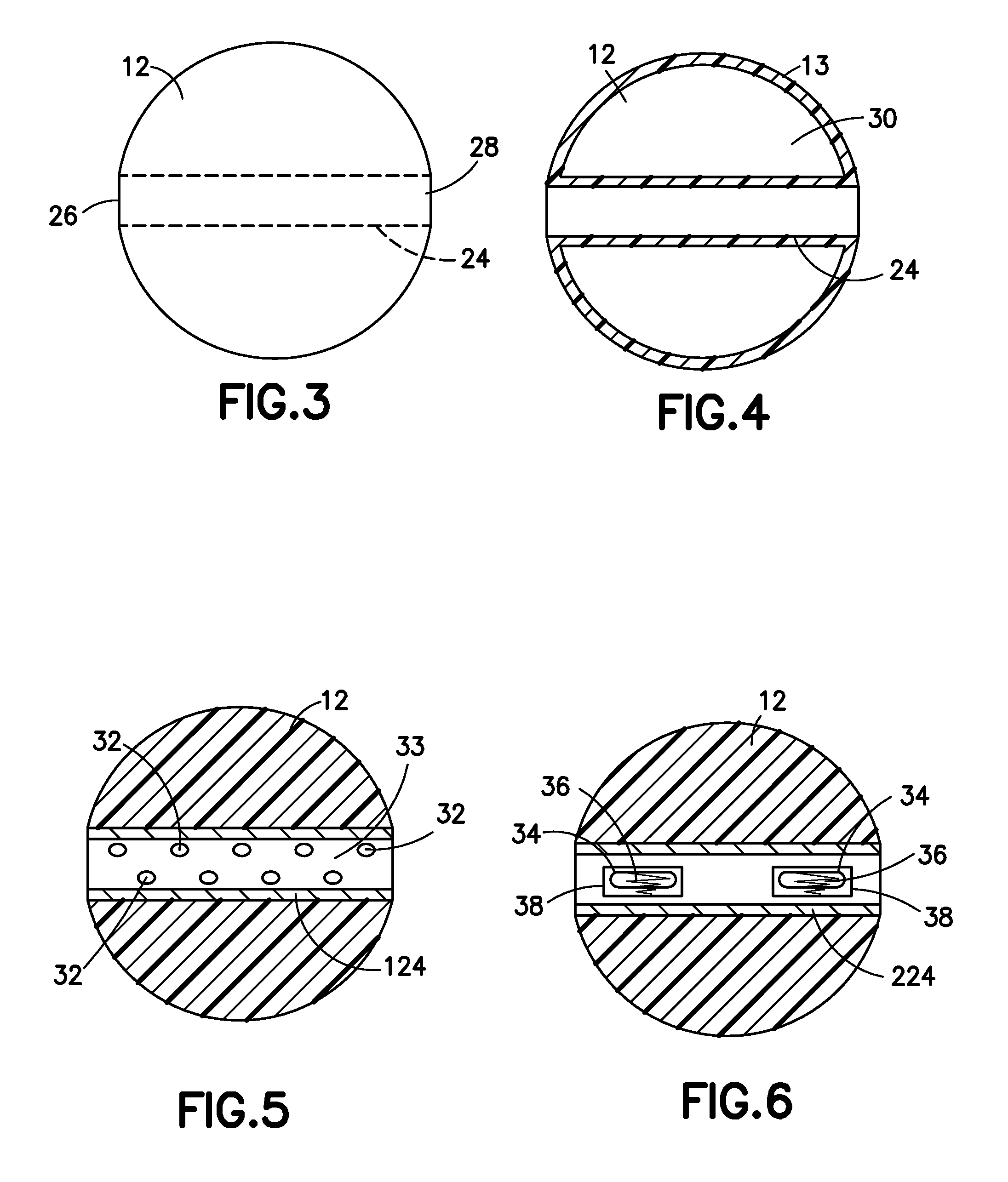

Punching bag and suspension system

InactiveUS9114298B2Advanced footworkPrecise punchingBall sportsMuscle exercising devicesPunchingRange of motion

A punching bag and suspension system is a boxing training device that is oriented horizontally, which permits the punching bag to move vertically, horizontally, diagonally, as well as in 360 degree range of motion. The punching bag has a plastic or metal cylindrical tube running through its core. The tube contains an opening on both sides extending to the outer circumference of the punching bag. These openings allow the tube, and therefore the punching bag, to slide along a suspension member. At the center of the suspension member there is a weight that through gravitational pull, creates an orientation and return point for the punching bag.

Owner:ENERGY EQUITY

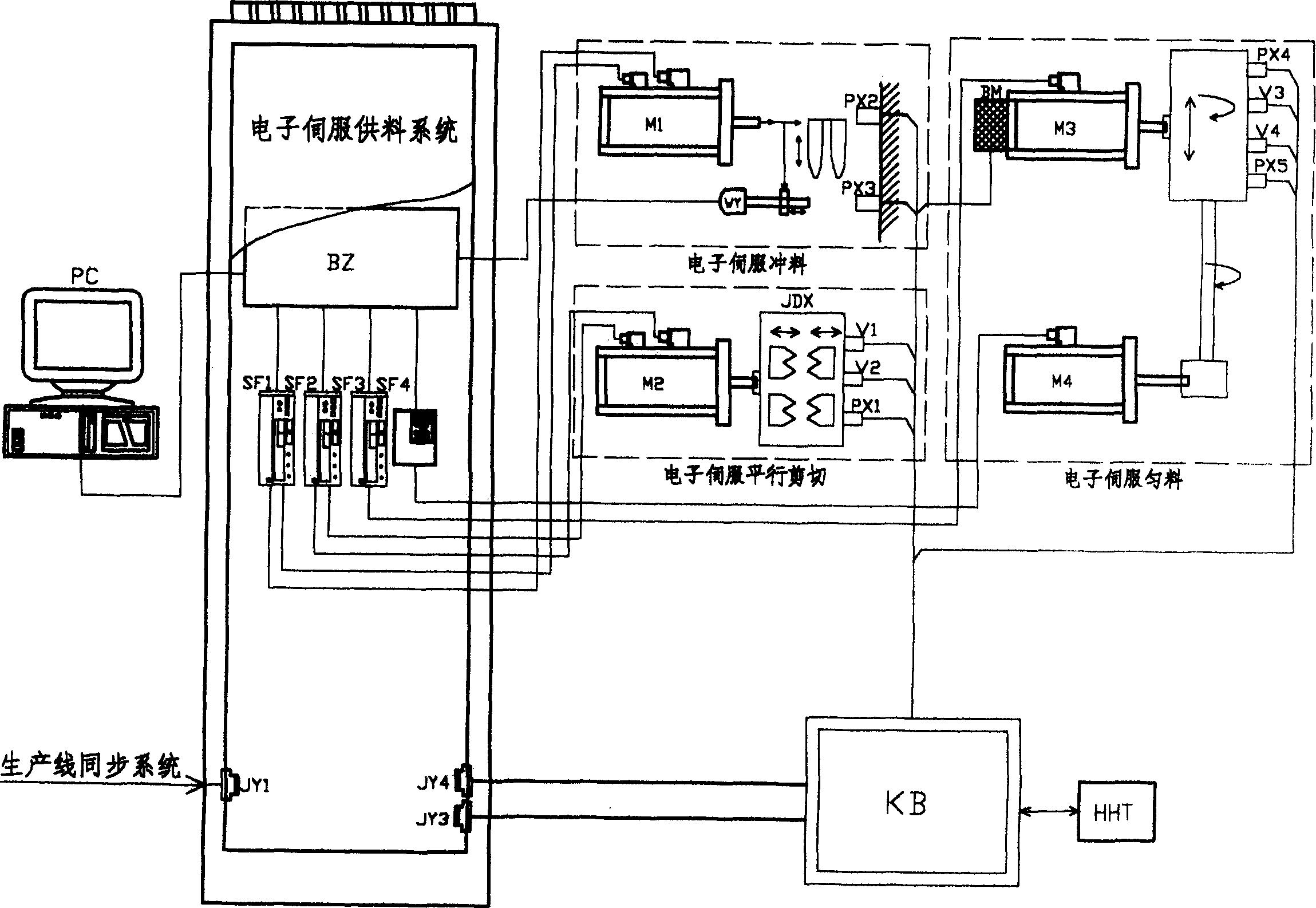

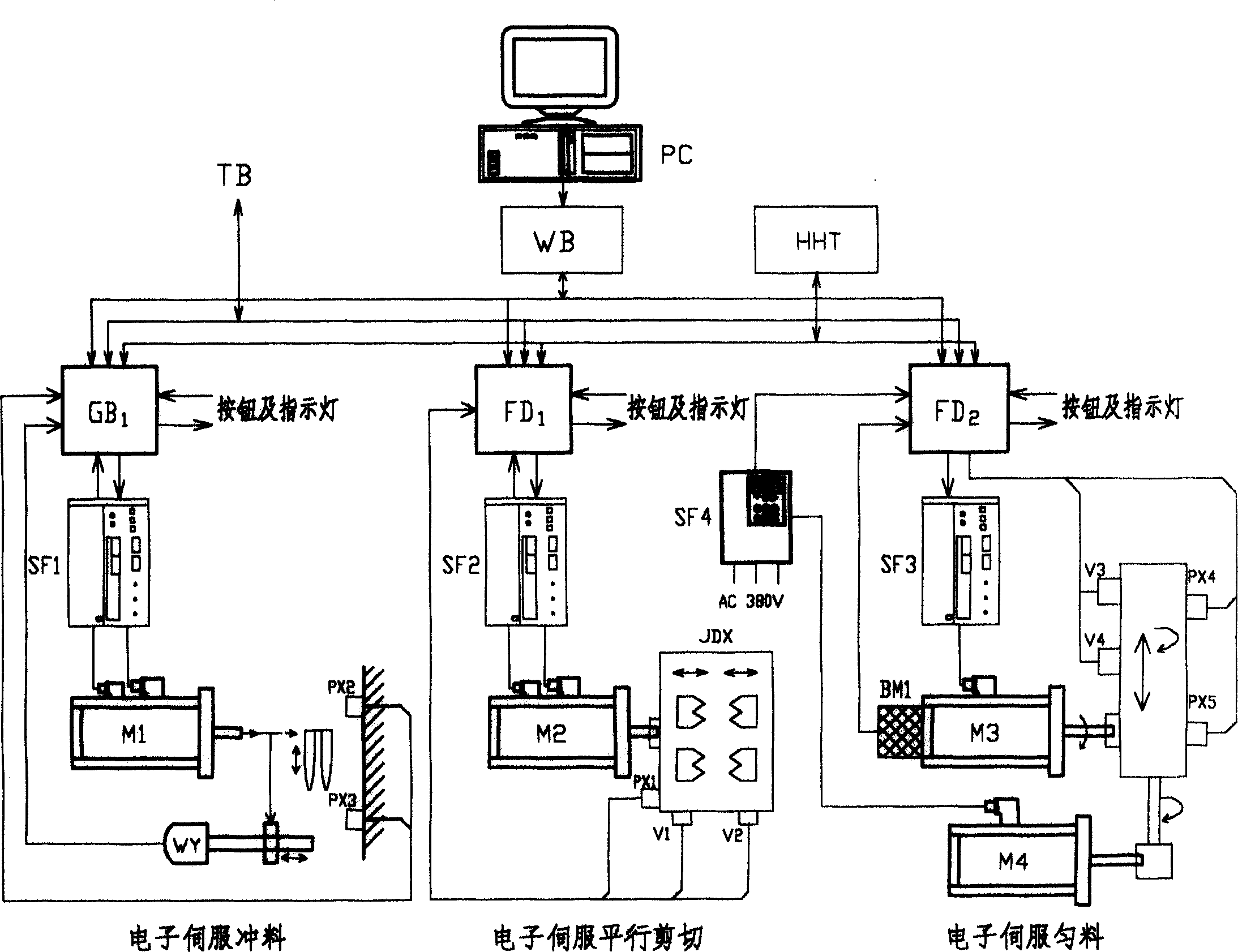

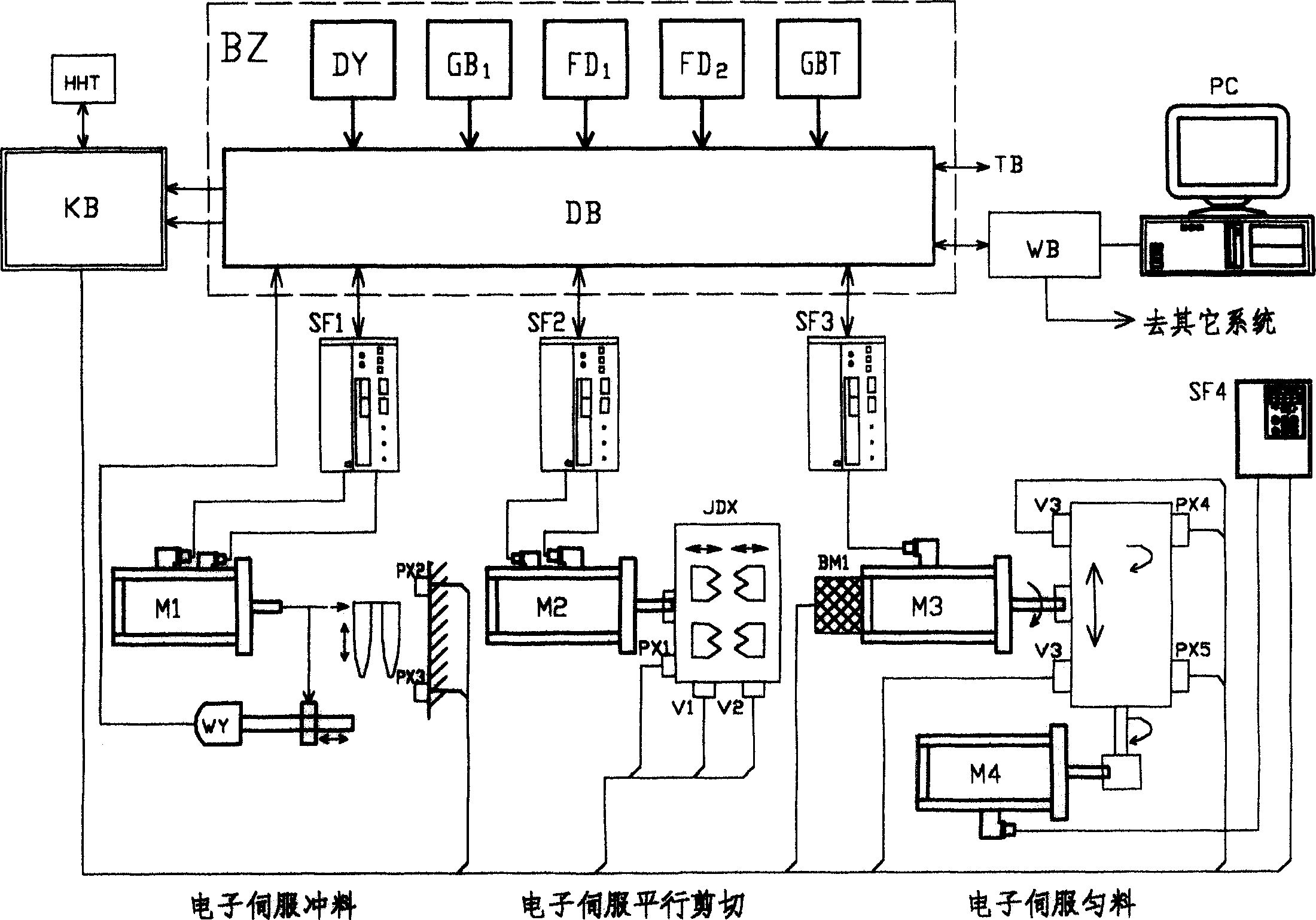

Electron servo feed system

An electronic servo feeding system is composed of an electronic servo punching unit, an electronic servo parallel shearing unit, and an electronic servo homogenizing system. Under the action of computer, the intelligent control is applied to the electronic feeding system. Its advantages are simple structure, correct and reliable operations, and high rate of qualified products.

Owner:SHANDONG SANJIN GLASS MASCH CO LTD

Holding-free electric hand drill

ActiveCN106112061APrecise punchingPortable grinding machinesPortable drilling machinesSpherical jointScrew thread

The invention discloses a holding-free electric hand drill. The holding-free electric hand drill comprises a sliding part, an angle adjusting device and a fixing suction cup, wherein the sliding part comprises a hand screw, a dovetail groove transverse connecting piece, dovetail grooves, a motor and a spherical joint; left and right sides of the motor are connected with dovetail sliders matched with the dovetail grooves, and the lower side of the motor is connected with a drill bit or grinding wheel; a rhombic hole is formed in the middle of the dovetail groove transverse connecting piece, a movable fixing nut is arranged in the hole, the external thread of the hand screw is matched with the movable nut, and the hand screw rotationally penetrates the nut and is connected to the spherical joint at the top end of the motor; the angle adjusting device comprises a movable fixing structure arranged on one sides of the bottom ends of the dovetail grooves and an angle adjusting structure arranged on the other sides. The holding-free electric hand drill has the following advantages: 1, the holding-free electric hand drill is convenient and flexible, is suitable for various working conditions and drill holes precisely; 2, the holding-free electric hand drill is widely applied and can be applied to a condition under which a bench drill cannot be used; 3, the holding-free electric hand drill is free of holding and can perform drilling without hand holding; 4, the holding-free electric hand drill can drill oblique holes at fixed angles.

Owner:山东临港智能制造产业园有限公司

Full-automatic punching die

InactiveCN105268828APrecise punchingRealize continuous punchingPerforating toolsMetal working apparatusPunchingElectric machinery

The invention discloses a full-automatic punching die. The section of a bottom frame of the full-automatic punching die is U-shaped; inner walls of two side ends of the bottom frame are provided with guide rails; two ends of a pulling plate are clamped into the guide rails; the upper parts of the two side ends of the bottom frame are each provided with a pair of primary motors; two transmission belts are respectively arranged on rotary shafts of corresponding primary motors; two side bottom ends of a bracket are fixed on the corresponding transmission belts; two groups of fixing holes are formed in the pulling plate; each group of fixing holes comprises at least two rows of fixing holes; a guide rail slot is formed in the bracket; a movable bracket is arranged on the bracket in a sleeving mode; the bottom of the movable bracket is provided with a punch; the movable bracket is provided with a movable motor; a rotary shaft of the movable motor penetrates through the movable bracket to the guide rail slot; a limiting part is arranged at each of two sides of the movable motor; and the limiting parts penetrate through the movable bracket to the guide rail slot. According to the full-automatic punching die provided by the invention, full-automatic movement of punching equipment is realized by virtue of the corresponding structures, so that precise punching and positioning are guaranteed, and punching effect is good.

Owner:滁州市成业机械制造股份有限公司

Lifting type wall boring device capable of adjusting boring depth

The invention discloses a lifting type wall boring device capable of adjusting boring depth, which comprises a base; the top part of the base is provided with front and back slide rails; the upper part of every slide rail is glidingly connected with left and right moving bases, upper parts of the moving bases are hinged with struts, left and right struts are intersected; the bottom end of the strut at the upper part is hinged with the top end of the strut at the lower part through a link rod, the upper part of the strut is provided with a top plate; the top part of the base is further fixedlyprovided with a first reducing motor, and a motor shaft at the right end of the first reducing motor is connected to the left end of the front side screw; the top part of the top plate is fixedly provided with a second slide rail through a bracket, the upper part of the second slide rail is glidingly connected with an electric drill, and the right side of the electric drill is connected with a drill bit. The boring height is adjustable, thus the trouble and risk of manually combining along with the electric drill are avoided; the boring depth can be adjusted in advance, thereby boring holes with different depths conveniently; the boring is more accurate.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

Tape carrier package on reel and plasma display device using the same

InactiveUS7656089B2Precise punchingAvoid misalignmentPrinted circuit aspectsGas discharge connecting/feedingDisplay deviceEngineering

A Tape Carrier Package (TCP) that is attachable to and detachable from a connector of a Printed circuit Board Assembly (PBA) of a plasma display apparatus that includes a plurality of electrodes, and a plasma display device including the same. The TCP includes an input portion that is attachable to and detachable from the PBA, an output portion that is attachable to and detachable from one of the plurality of electrodes of the plasma display apparatus, and at least one alignment mark, at least a portion of the alignment mark corresponding to or abutting an edge of the input portion.

Owner:SAMSUNG SDI CO LTD

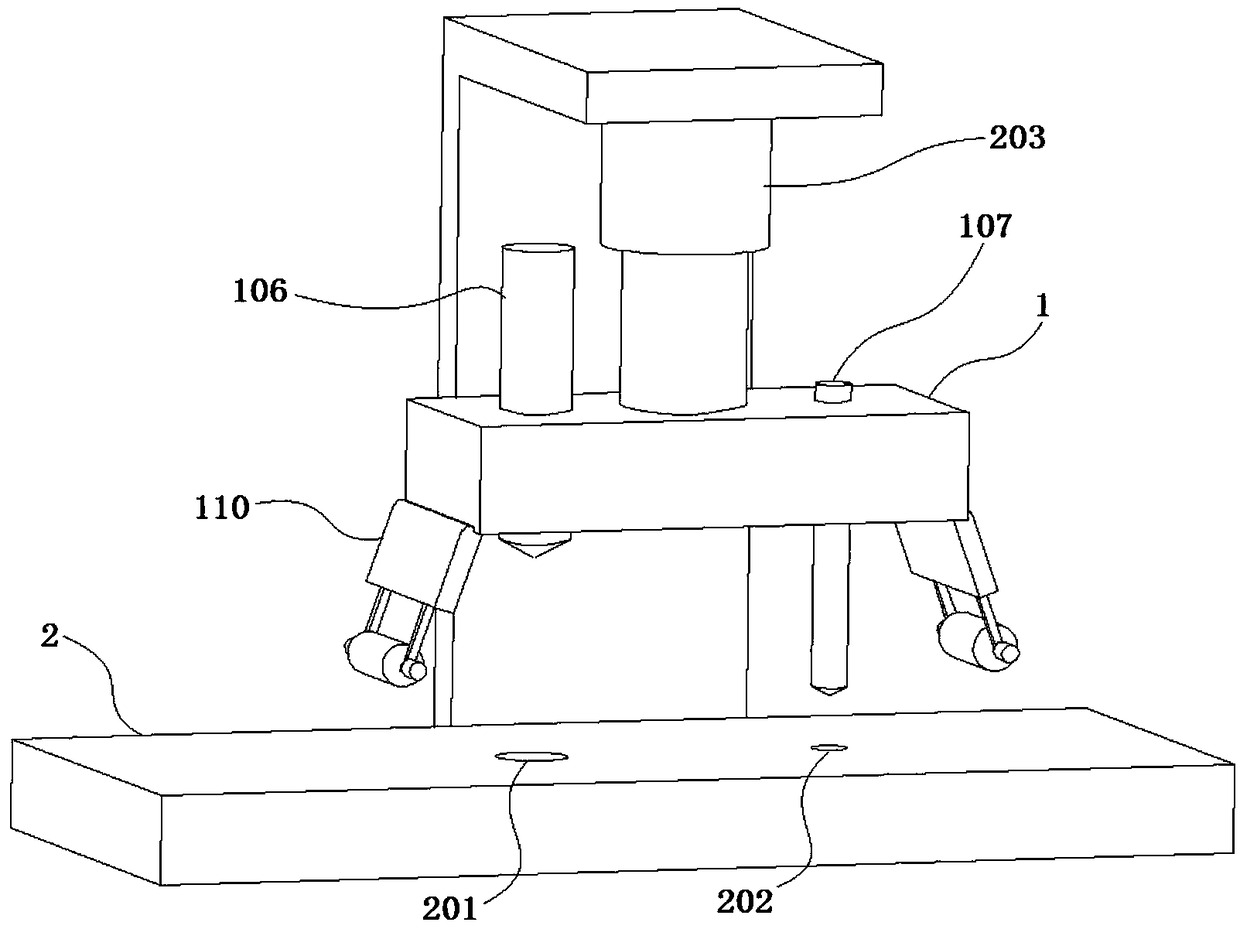

Chain plate precise punching equipment

PendingCN109622733APrecise punchingAchieve positioningMetal-working feeding devicesStripping-off devicesPunching

The invention discloses chain plate precise punching equipment. The chain plate precise punching equipment comprises a worktable; a feeding channel, a punching base and an unloading channel are mounted on the upper end surface of the worktable in sequence from left to right; a chain plate feeding mechanism is mounted above the worktable corresponding to the feeding channel; a punching mechanism ismounted above the worktable corresponding to the punching base; and a chain plate unloading mechanism is mounted above the worktable corresponding to the unloading channel. The chain plate precise punching equipment is reasonable in structural arrangement, stacks chain plates in a storage bin, can realize precise punching of the chain plates through cooperation among the chain plate feeding mechanism, the punching mechanism and the chain plate unloading mechanism to achieve high working efficiency, and can realize positioning of the chain plates through cooperation between a positioning baffle plate and a feeding push plate to achieve precise punching.

Owner:江阴市尚泰起重设备有限公司

Adjustable guide plate device used for strip steel shear equipment and operation method of adjustable guide plate device

InactiveCN110695183AEasy to navigateExtended service lifeShaping toolsMetal-working feeding devicesStrip steelSlide plate

The invention discloses an adjustable guide plate device used for strip steel shear equipment and an operation method of the adjustable guide plate device. The adjustable guide plate device comprisesa workbench. The left side of the top of the workbench is fixedly connected with a shear box. The positions, located on the right side of the shear box, of the front side and the rear side of the workbench are fixedly connected with side plates. A first sliding plate and a second sliding plate are fixedly connected between the two side plates in sequence from top to bottom. The invention relates to the technical field of strip steel shear equipment. According to the adjustable guide plate device used for the strip steel shear equipment and the operation method of the adjustable guide plate device, inclined guide plates are arranged to be used in cooperation with guide wheels, strip steel can be guided rapidly and conveniently, the strip steel is kept at the middle position to enter the shear box, the problem that the strip steel shifts, stress of the shear structure in the shear box is not uniform, and then loosening happens after long-time work can be avoided, and the service life ofthe shear equipment can be prolonged; and a bidirectional screw and threaded sleeves are used in cooperation with scale lines, the distance between the two guide wheels can be adjusted, the guide requirements of strip steel of different widths can be met, and use is convenient.

Owner:杭州新融方科技有限公司

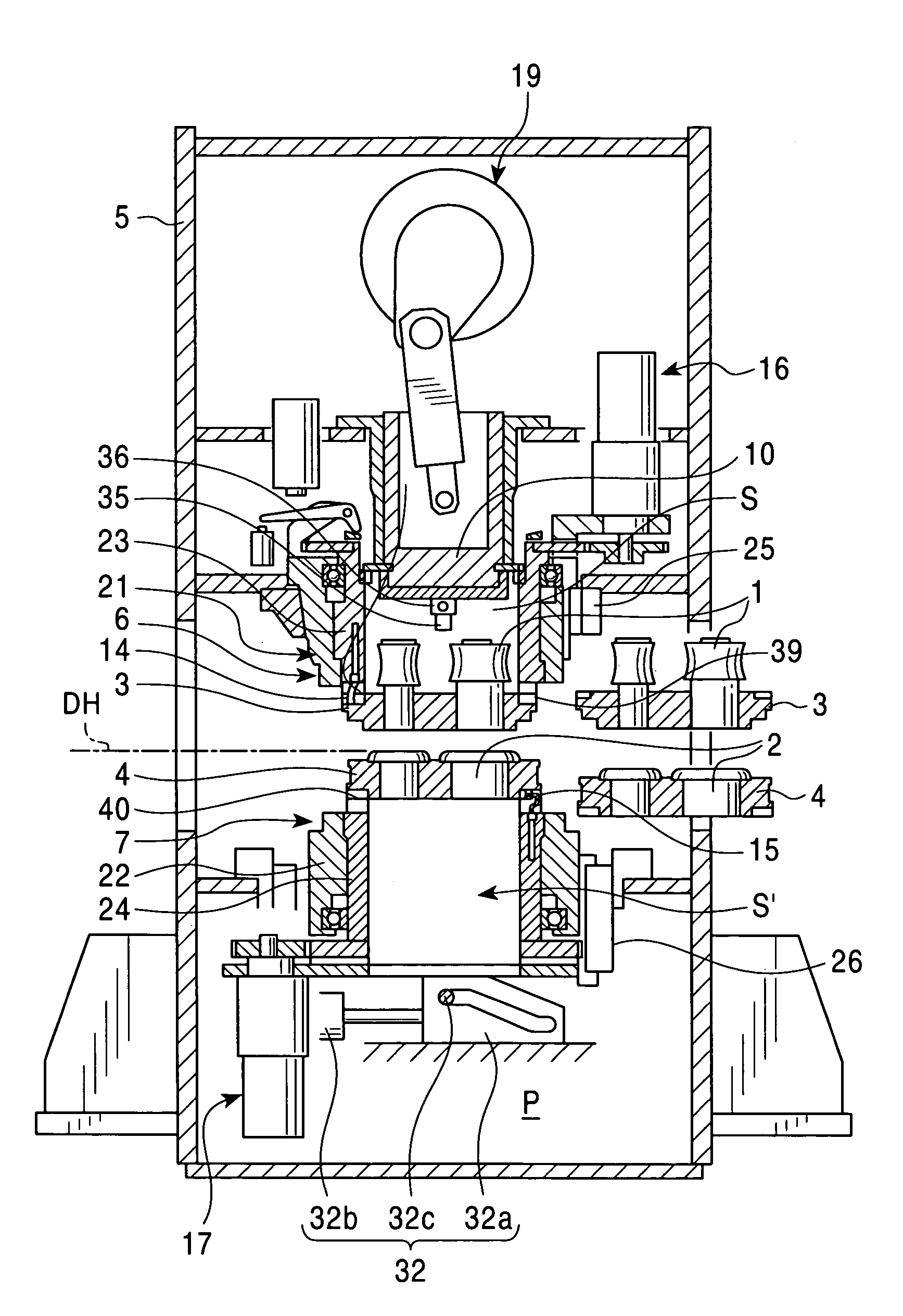

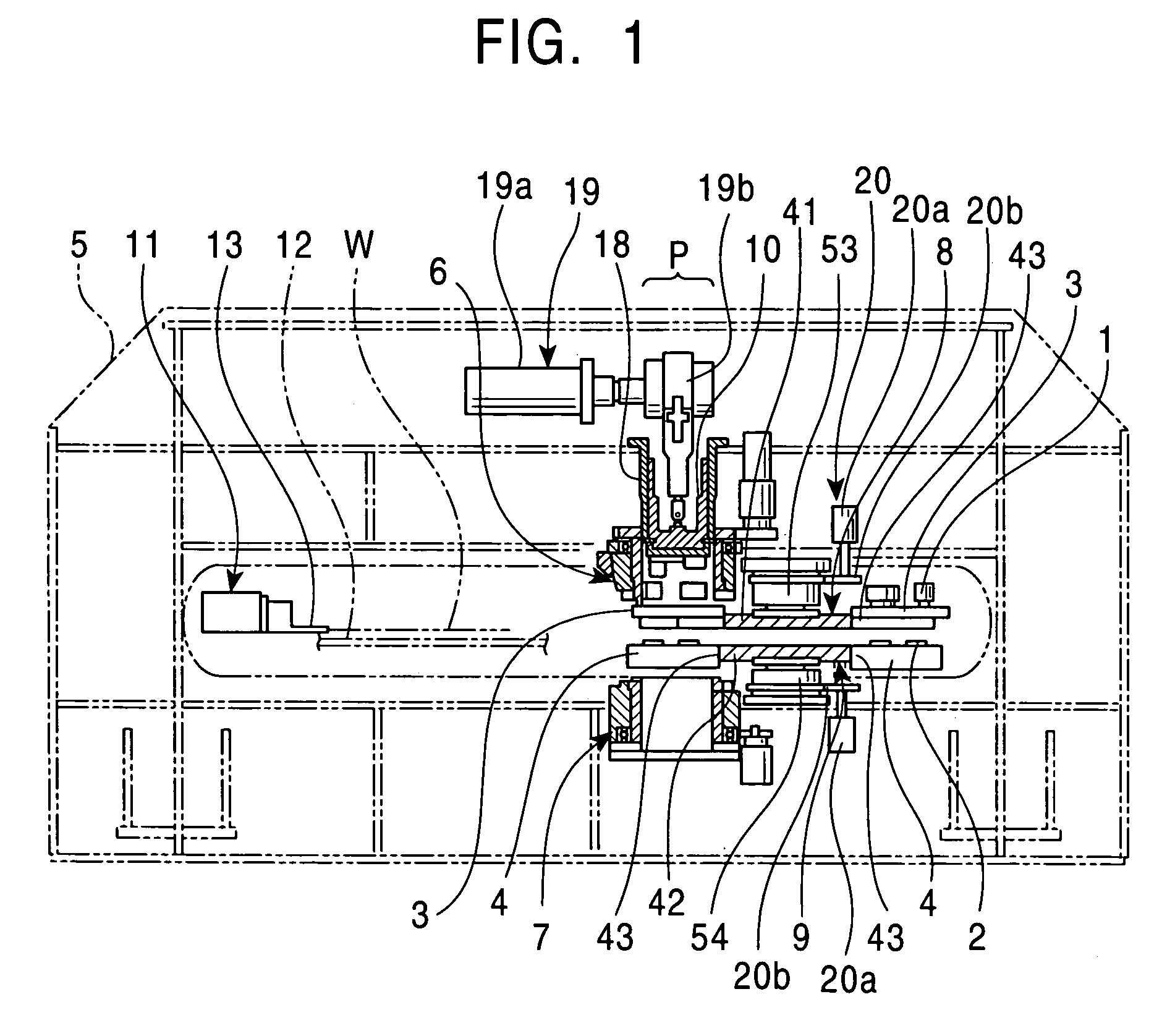

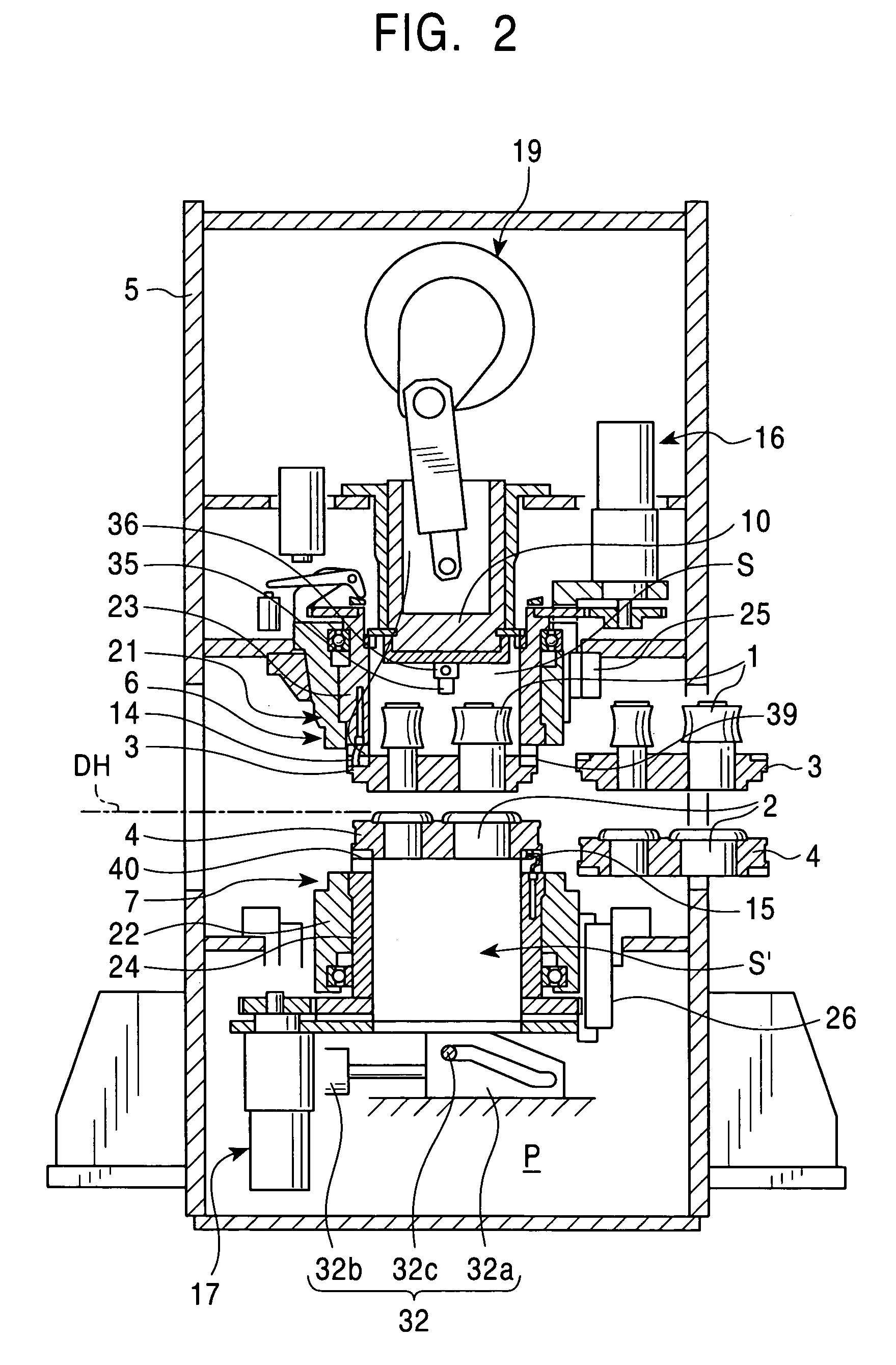

Punch press

InactiveUS7461579B2Easy to replacePrecise punchingShaping toolsMetal working apparatusEngineeringPunch press

The present invention provides a punch press which enables cartridges to be easily replaced so that the replacement of the cartridges allows the use of a large number of tools, which enables tools in the cartridges to be quickly indexed, and which allows the accuracy of punching to be easily improved. Cartridges 3, 4 are used which hold tools 1, 2, respectively. Cartridge holders 6, 7 are provided which hold the cartridges 3, 4, respectively, that are supported by a punch frame 5 and located at a press position P. A ram 10 is provided above the cartridge means holders 6, 7. The cartridge holders 6, 7 have cartridge clamps 14, 15, respectively, removably holding the corresponding cartridges 3, 4. The cartridge holders 6, 7 have cartridge rotating mechanisms 16, 17, respectively, that rotate the held cartridges 3, 4 in order to index any of the tools 1, 2. The cartridge holders 6, 7 fix the cartridges 3, 4 during punching so that the cartridges cannot be moved in a vertical direction.

Owner:MURATA MASCH LTD

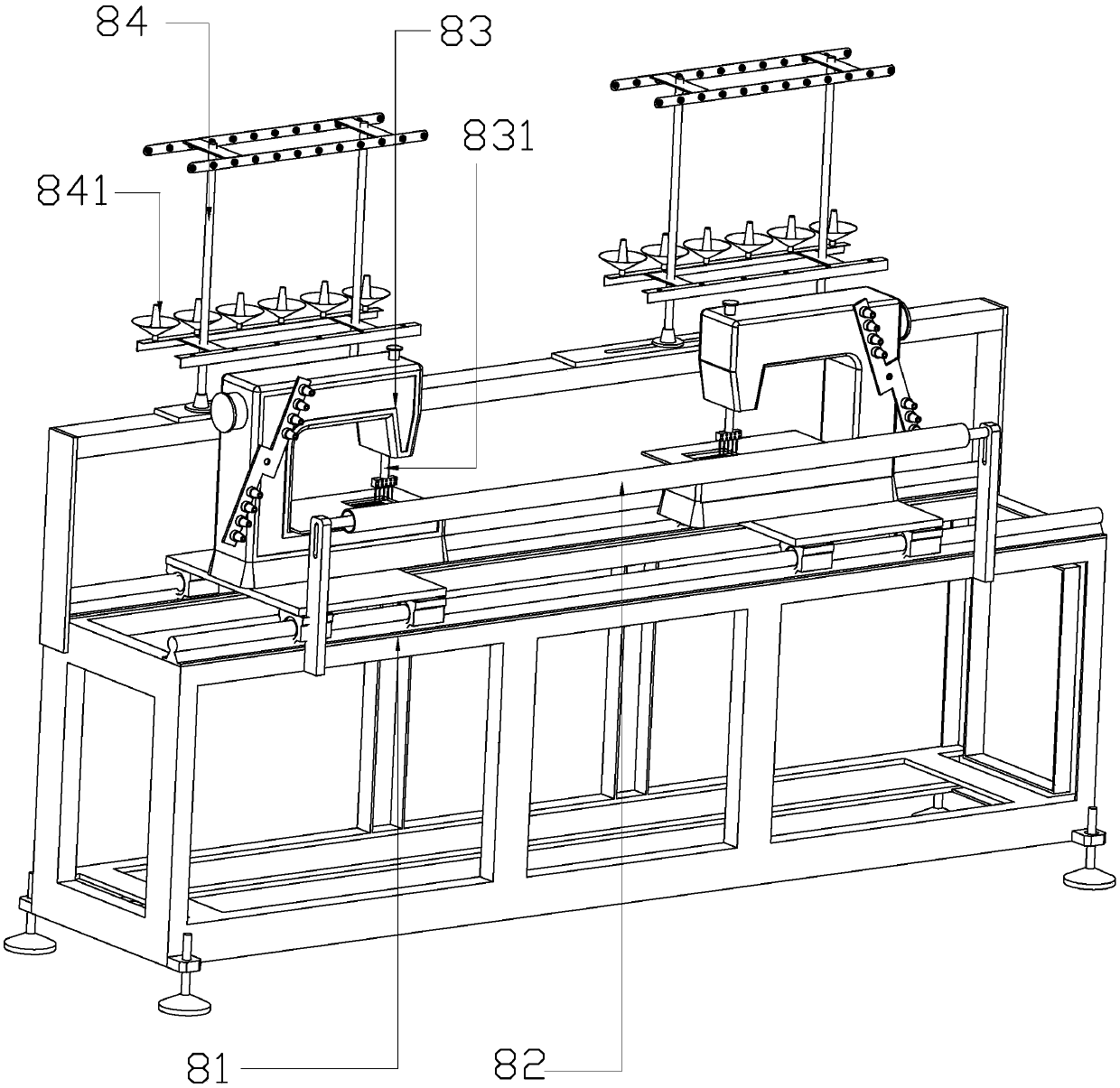

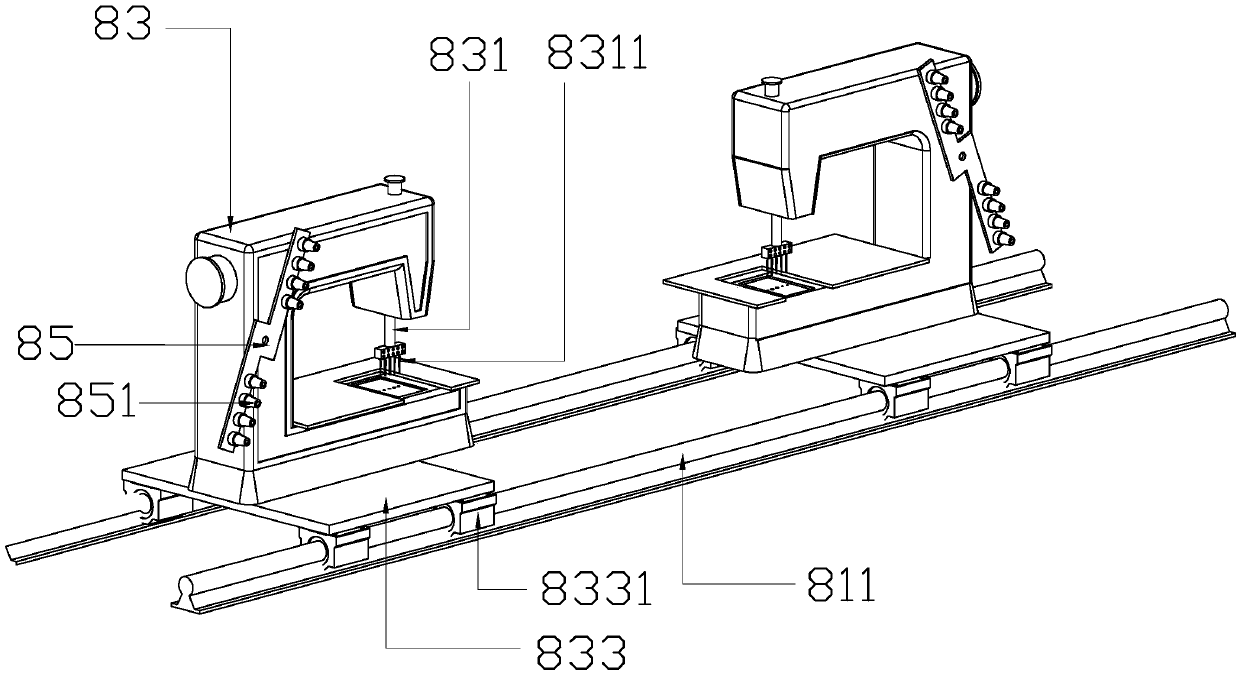

Novel non-woven fabric handle ironing and edge sewing and transverse cutting all-in-one machine

The invention relates to a novel non-woven fabric handle ironing and edge sewing and transverse cutting all-in-one machine which comprises a unit; the unit sequentially comprises unwinding equipment,folding equipment, handle ironing equipment, tracking equipment, edge sewing equipment, sewing traction equipment and cutting equipment. The novel non-woven fabric handle ironing and edge sewing and transverse cutting all-in-one machine has the beneficial effects that the bidirectional edge sewing equipment is provided for further reinforcing the position of a hand-held handle after ultrasonic handle ironing, simultaneous multiple-row edge sewing as required is realized by adjusting the needle number of edge sewing needles; handbags of different sizes are conveniently machined through a base adjusting device between a sewing motor and a sewing machine frame; unwinding and feeding are easier and more convenient by improving the unwinding equipment; and finally a positioning cloth pressing mechanism is combined with a punching mechanism and a cutter mechanism, so that integrated positioning, punching and cutting is realized, and the precision and efficiency of punching are greatly improved.

Owner:RUIAN XINDA PACKING MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com