Cantilever manual punching machine for asymmetric deep groove square pipe

A deep groove square tube, asymmetric technology, used in perforation tools, metal processing equipment, manufacturing tools, etc., can solve the problems of poor precision and low efficiency, and achieve the effect of improving production efficiency and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

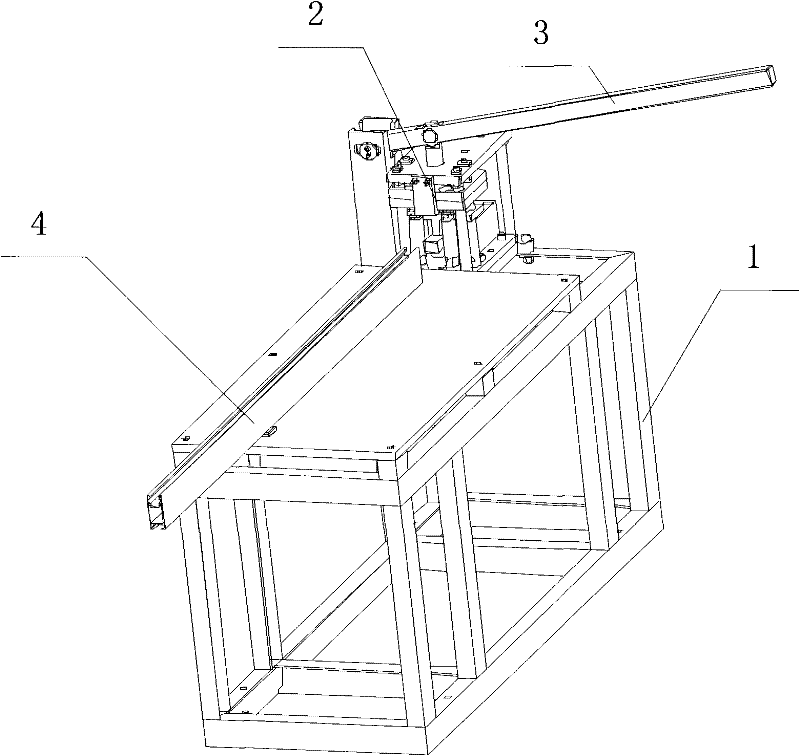

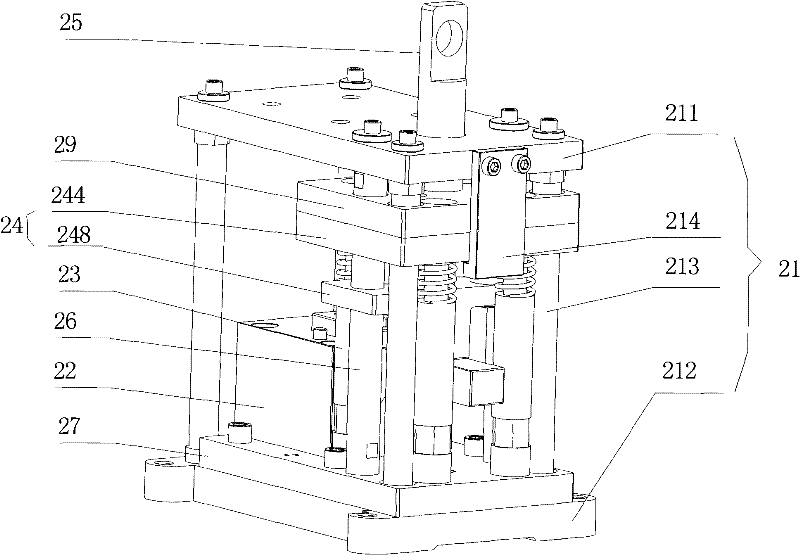

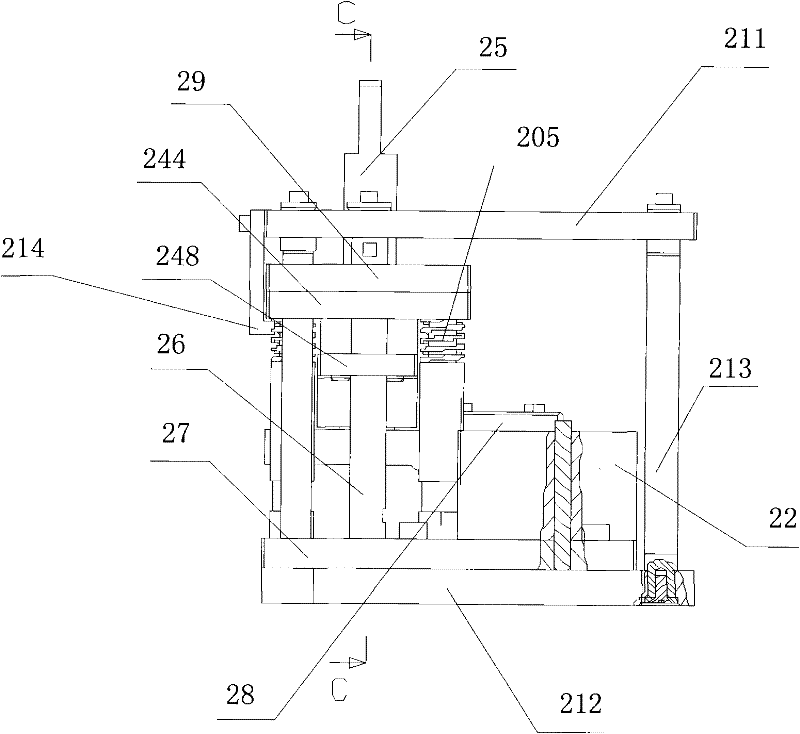

[0029] Such as figure 1 As shown, the deep groove square pipe manual punching machine of the present embodiment includes a frame 1 and a machine head 2 arranged on the frame. figure 2 A three-dimensional form of a handpiece structure used in this embodiment is shown. image 3 yes figure 2 Front view of the nose shown. Such as figure 2 and 3 As shown, the machine head 2 includes a machine head frame 21, a die 22, several spring assemblies 23, a punching assembly 24, a backing plate 29 and two guide posts (26).

[0030] The head frame 21 further includes a top plate 211 , a bottom plate 212 and a column 213 supported between the top plate 211 and the bottom plate 212 .

[0031] The die 22 is arranged in the head frame 21 and has a cantilever 221 extending in the horizontal direction for supporting the asymmetrical deep-groove square tube 4 to be punched. Also refer to Figure 4 and Figure 5 , the cantilever 221 is provided with the punching hole 221a that runs throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com