Novel non-woven fabric handle ironing and edge sewing and transverse cutting all-in-one machine

A non-woven fabric and all-in-one machine technology, which is applied in the direction of paper/cardboard containers, containers, bag making, etc., can solve problems such as loss, disconnection of the handle from the bag, and loose connection of the handle of the handbag, etc., to achieve position reinforcement, Unwinding and loading is easy and convenient, and the effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

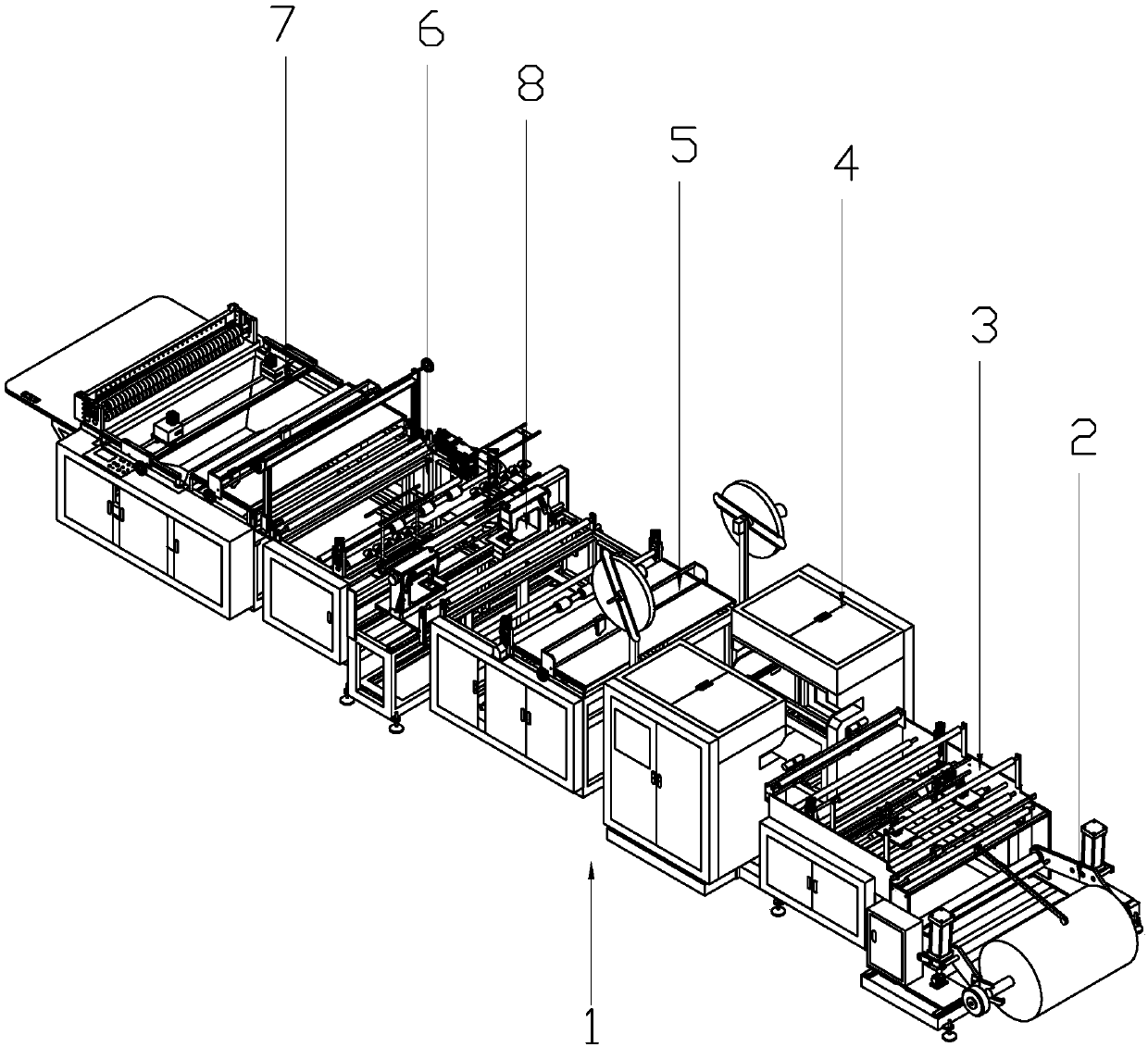

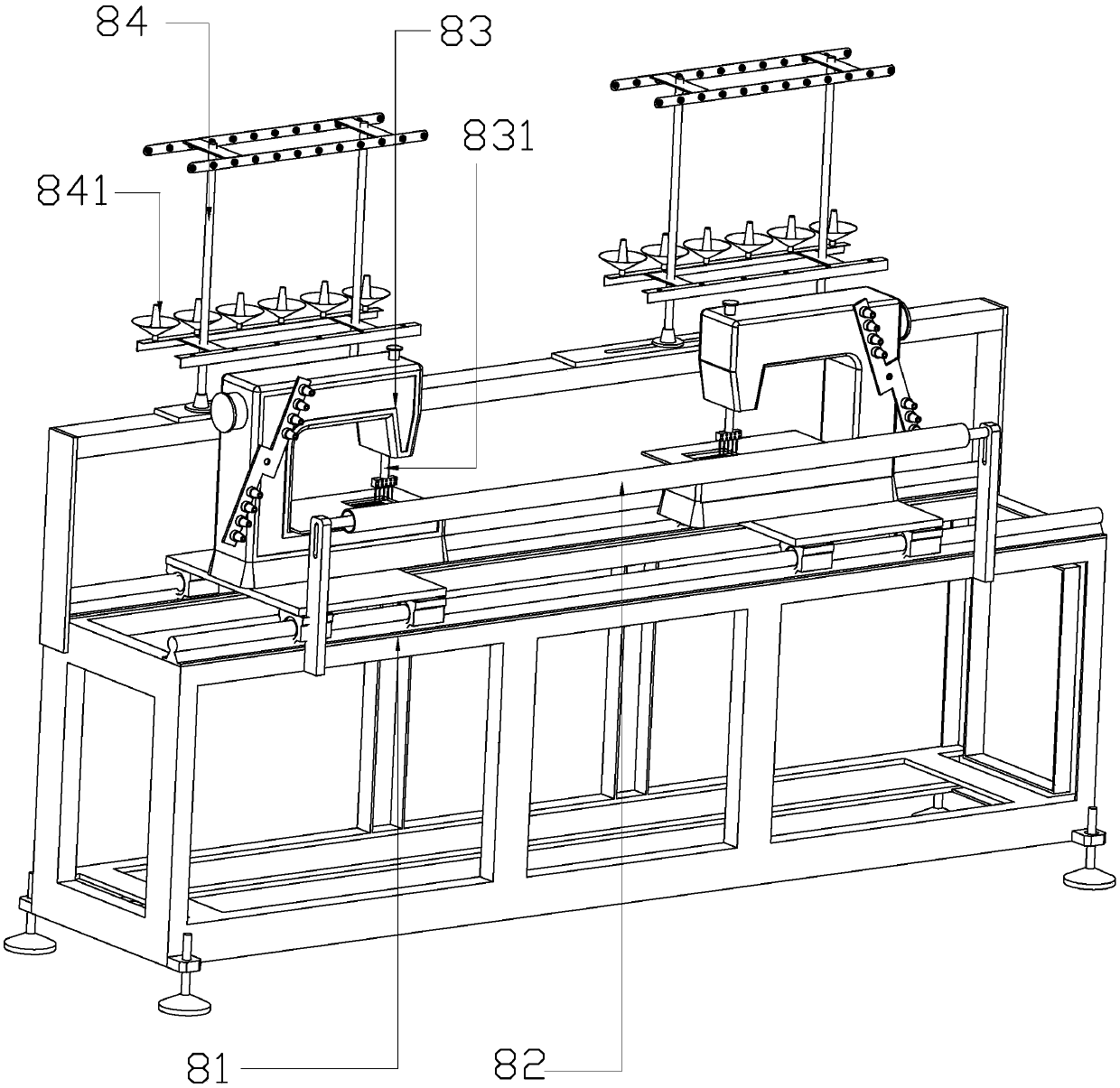

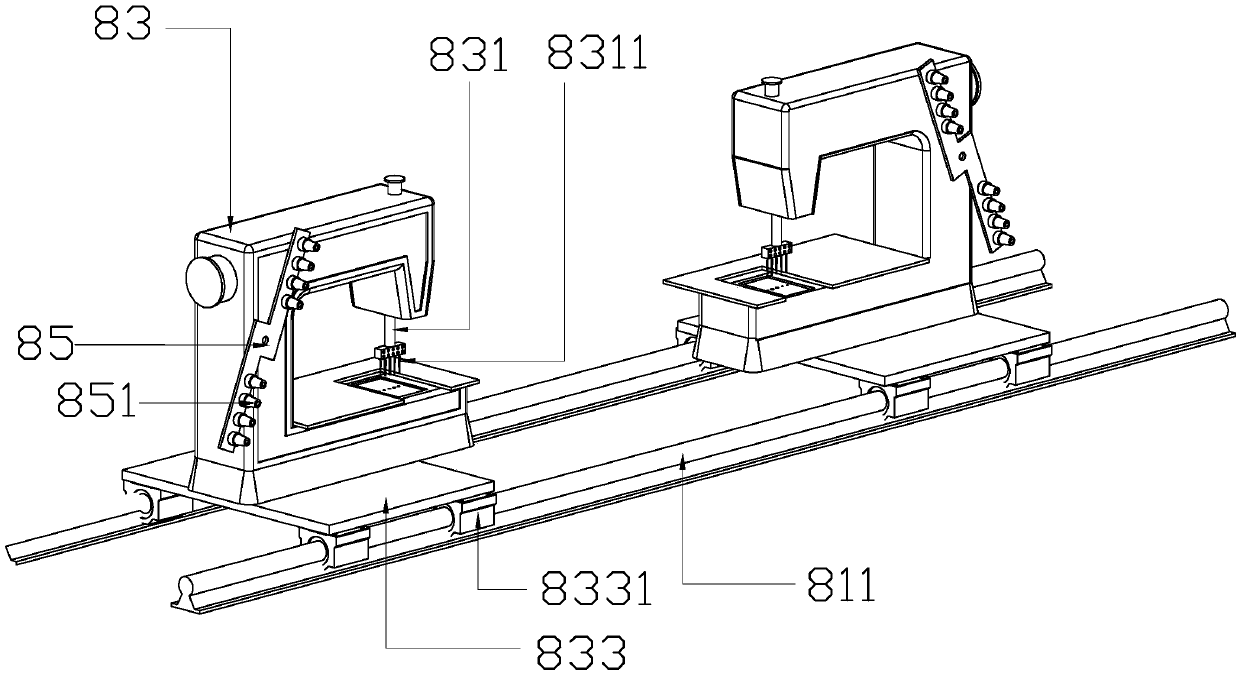

[0031] Such as Figure 1-Figure 11 As shown, a new type of non-woven fabric ironing and seaming cross-cutting machine includes its unit 1, and the unit 1 sequentially includes unwinding equipment 2, hemming equipment 3, ironing equipment 4, tracking equipment 5, and sewing traction. The device 6 and the cutting device 7 are characterized in that: the unit 1 also includes a hemming device 8 for hemming the material roll, and the hemming device 8 is arranged between the tracking device 5 and the sewing traction device 6, The hemming device 8 includes a sewing machine frame 81, a sewing roller 83 arranged on the sewing machine frame 81 for conveying the material roll 22, and a hemming mechanism that is arranged at both ends of the sewing machine frame 81 to hem the material roll 22 , the hemming mechanism includes a sewing motor 83 and a wire bracket 84, the wire bracket 84 is provided with at least two thread trays 841 loaded with sewing threads, and one end of the sewing motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com