Patents

Literature

904 results about "Puncturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

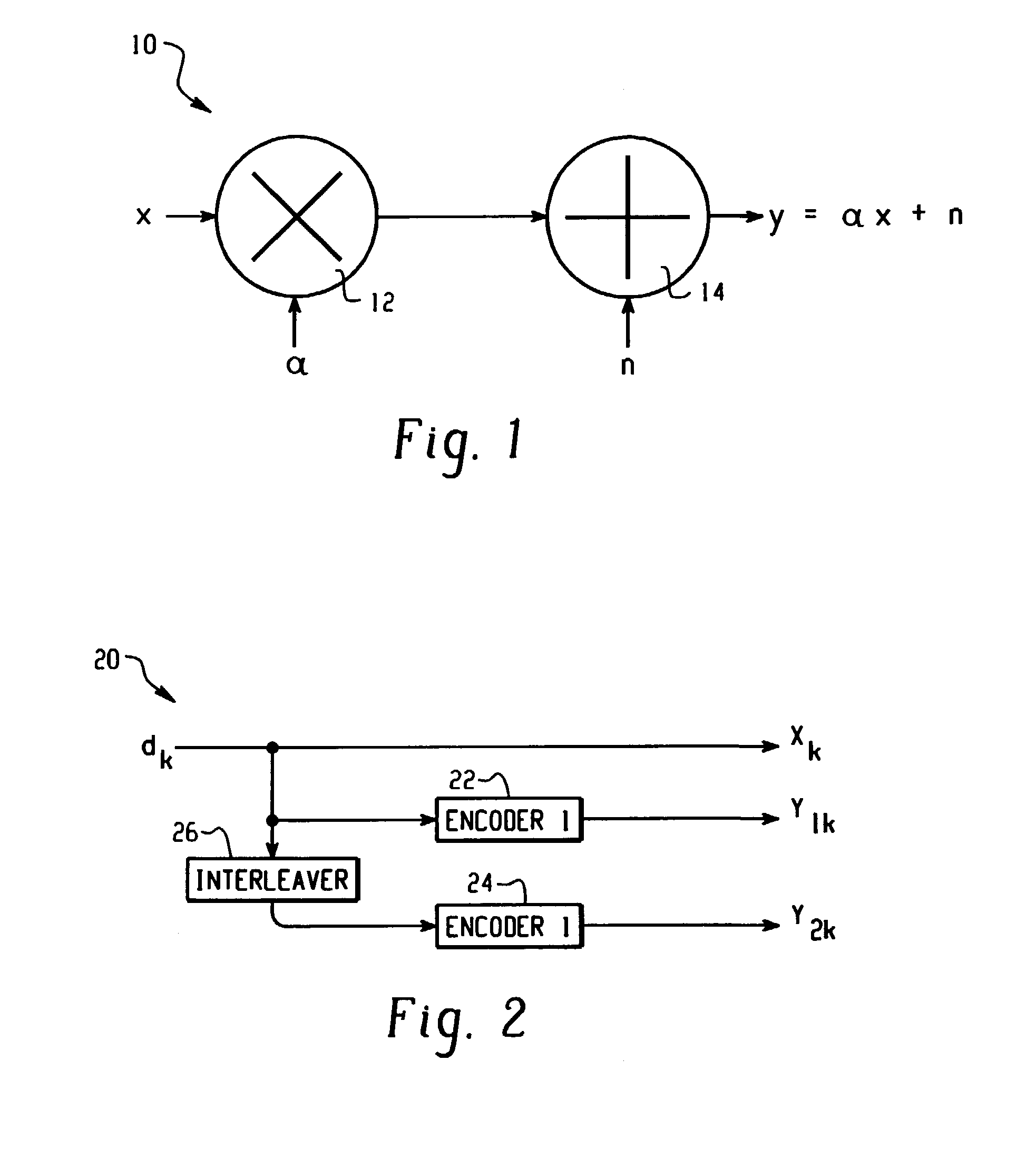

In coding theory, puncturing is the process of removing some of the parity bits after encoding with an error-correction code. This has the same effect as encoding with an error-correction code with a higher rate, or less redundancy. However, with puncturing the same decoder can be used regardless of how many bits have been punctured, thus puncturing considerably increases the flexibility of the system without significantly increasing its complexity.

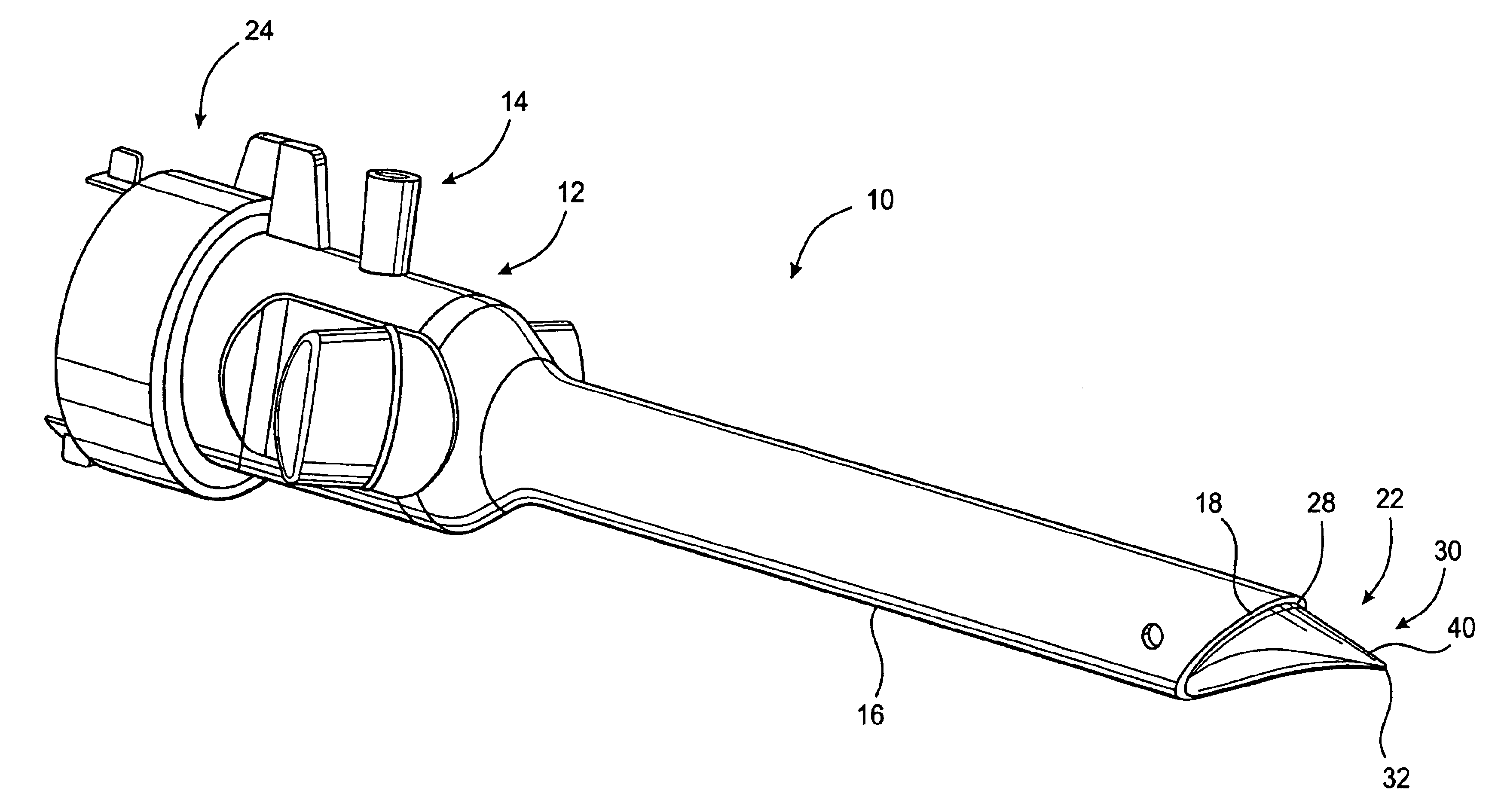

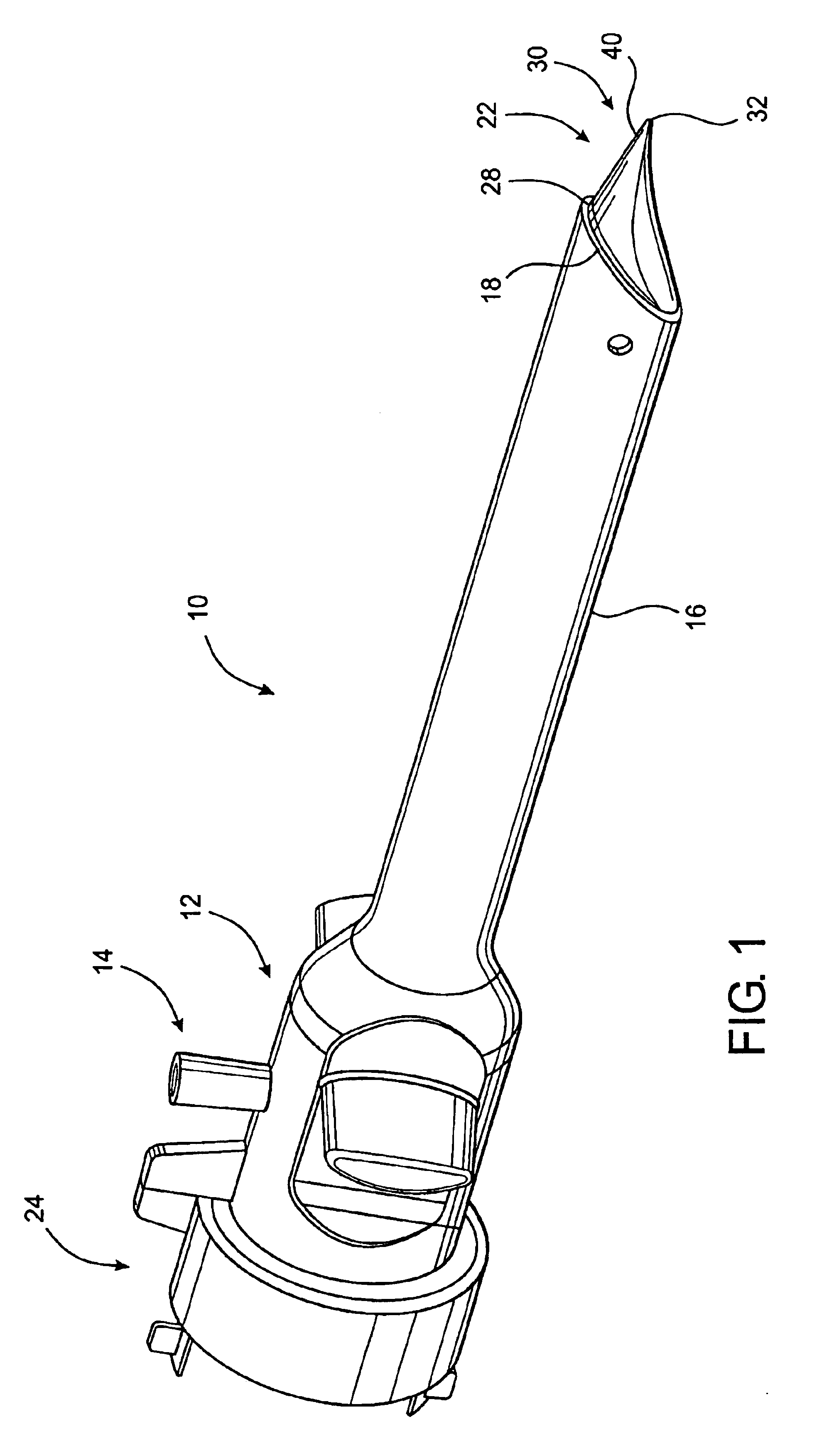

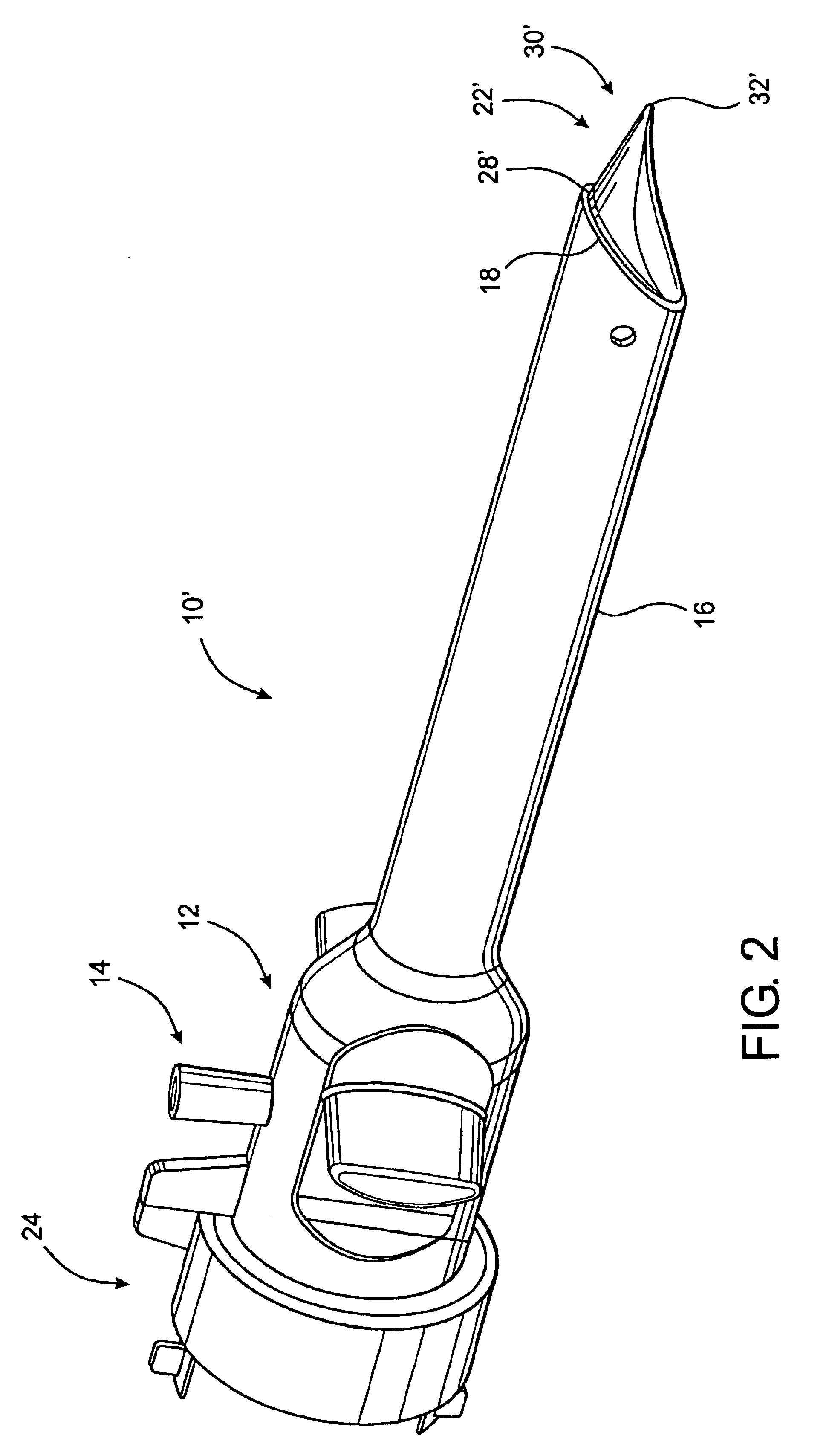

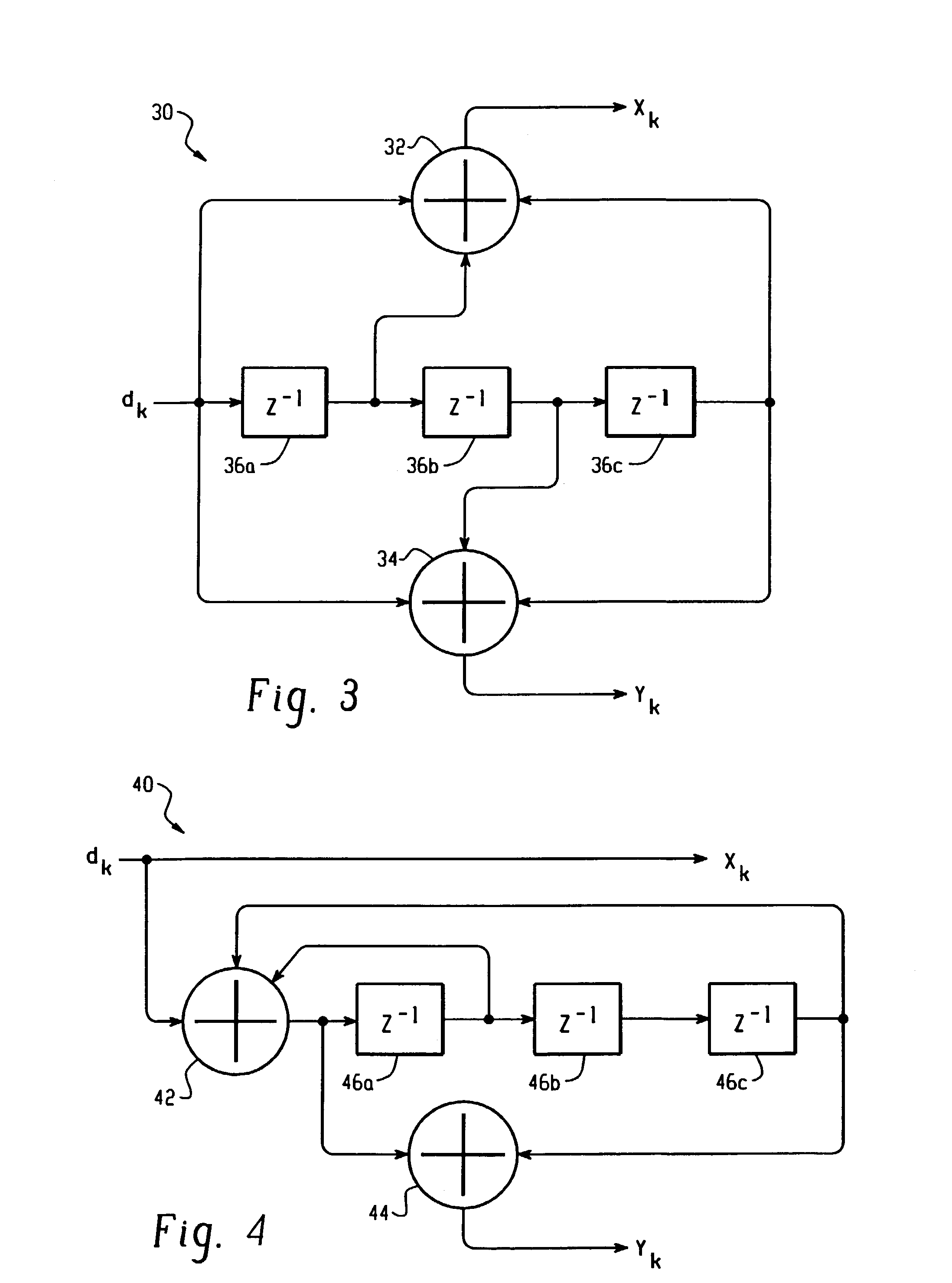

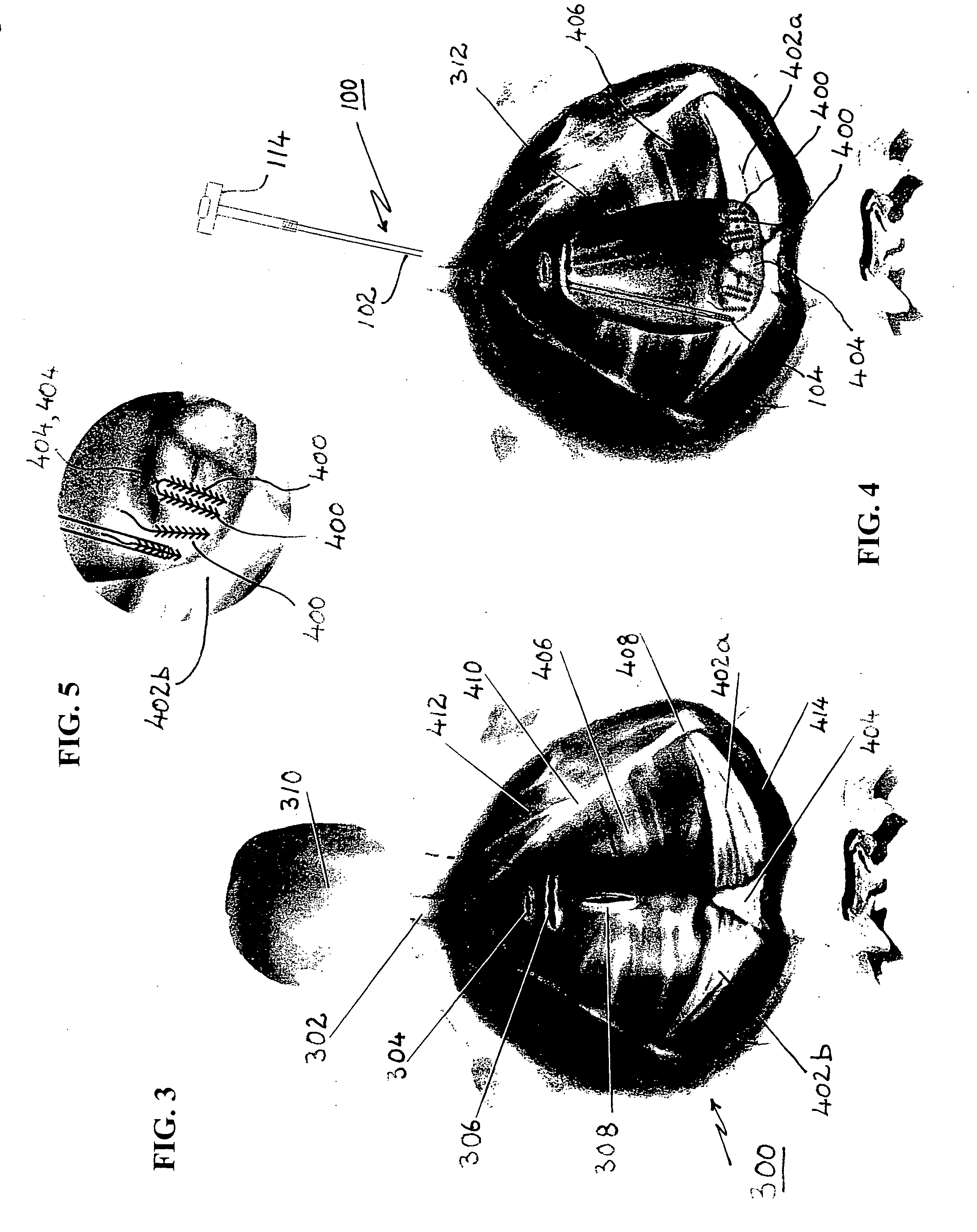

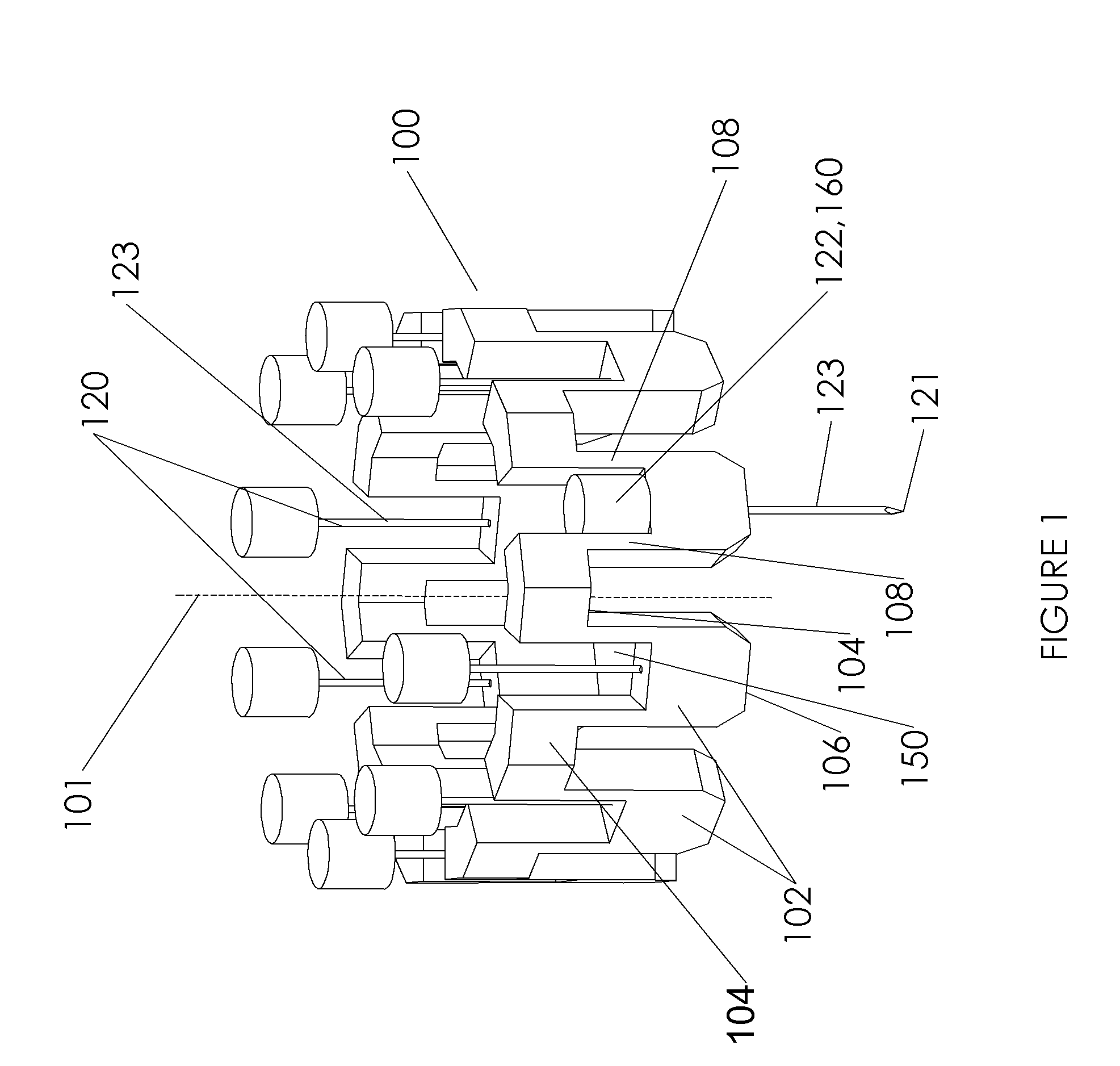

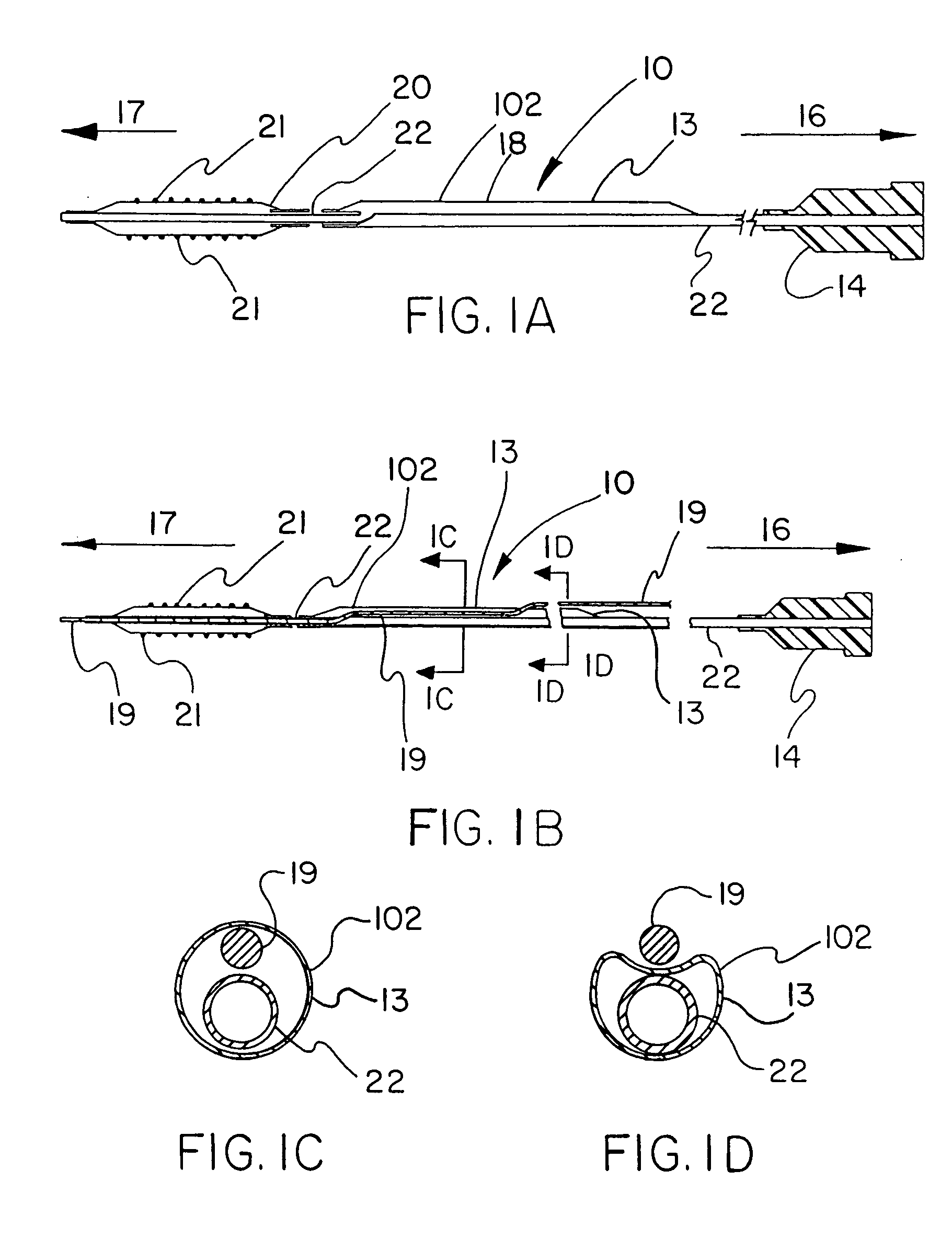

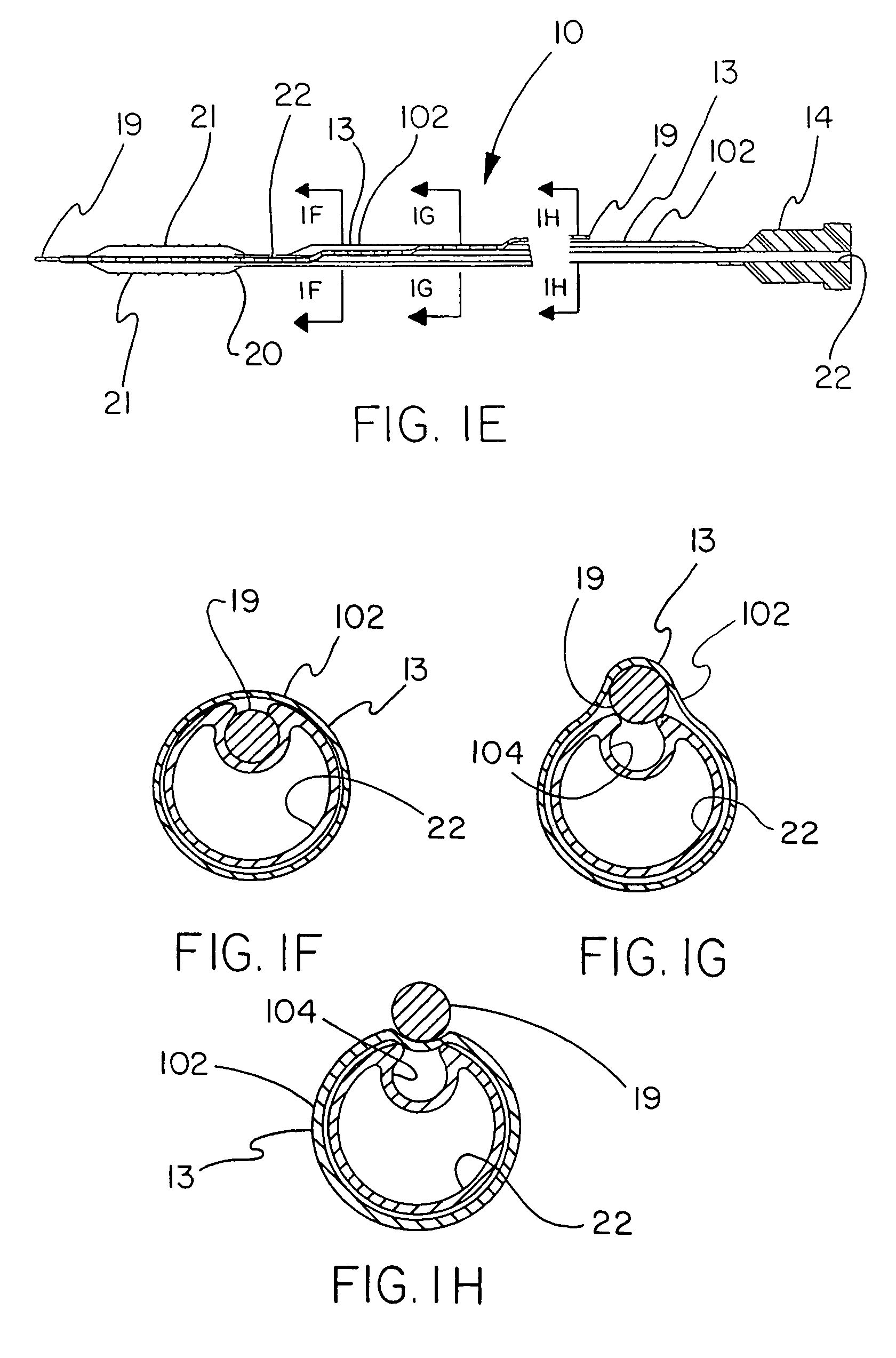

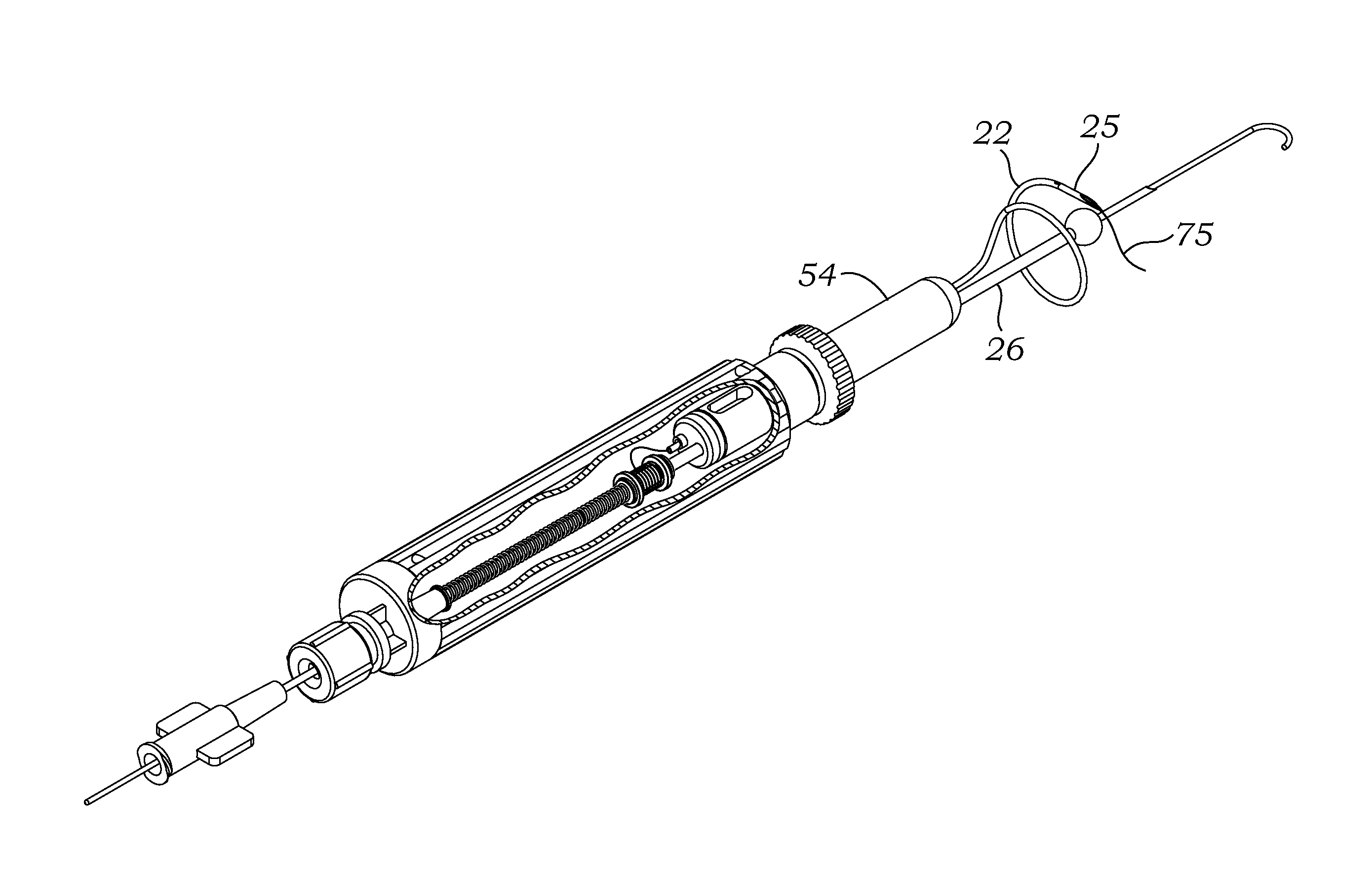

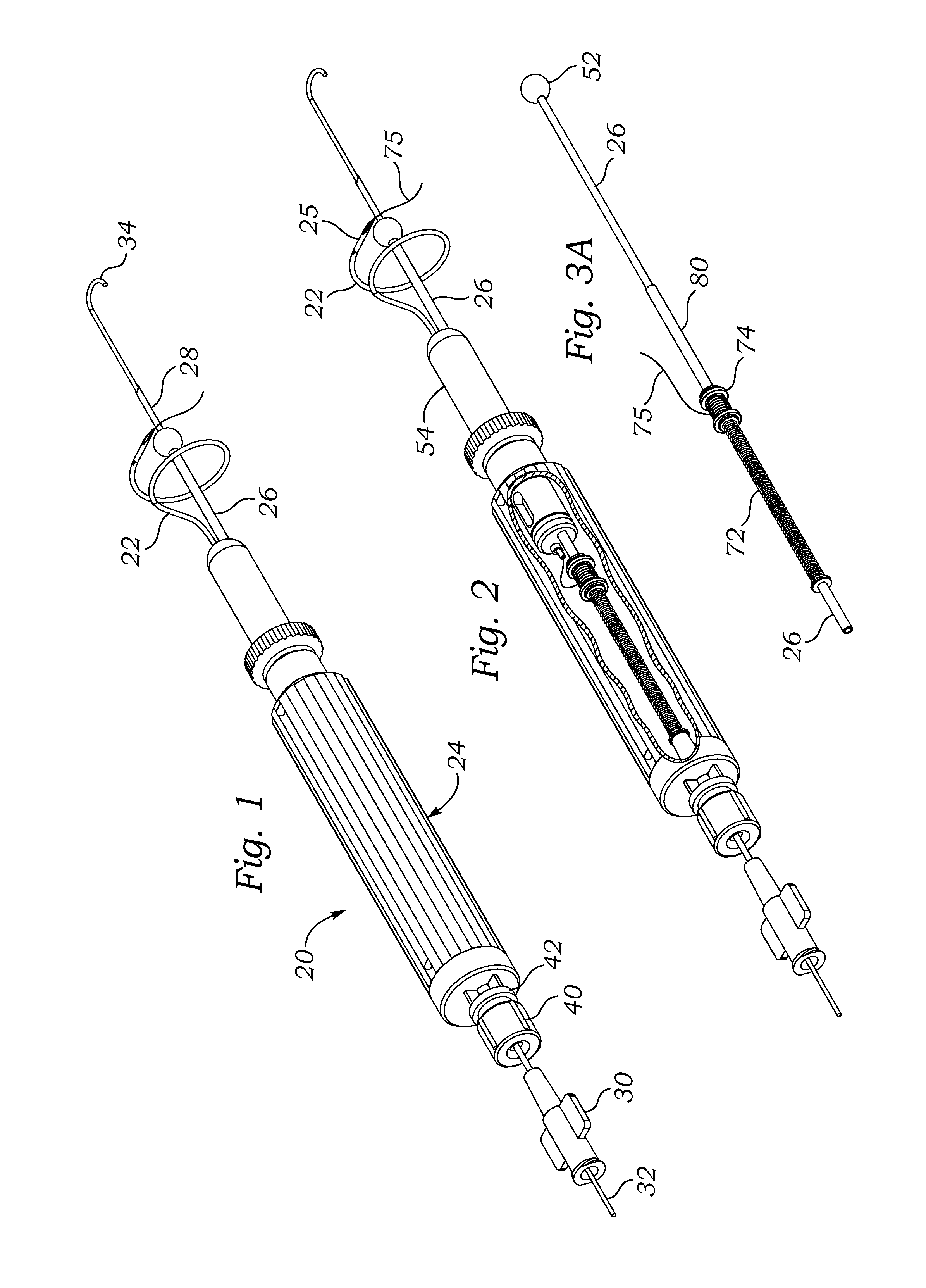

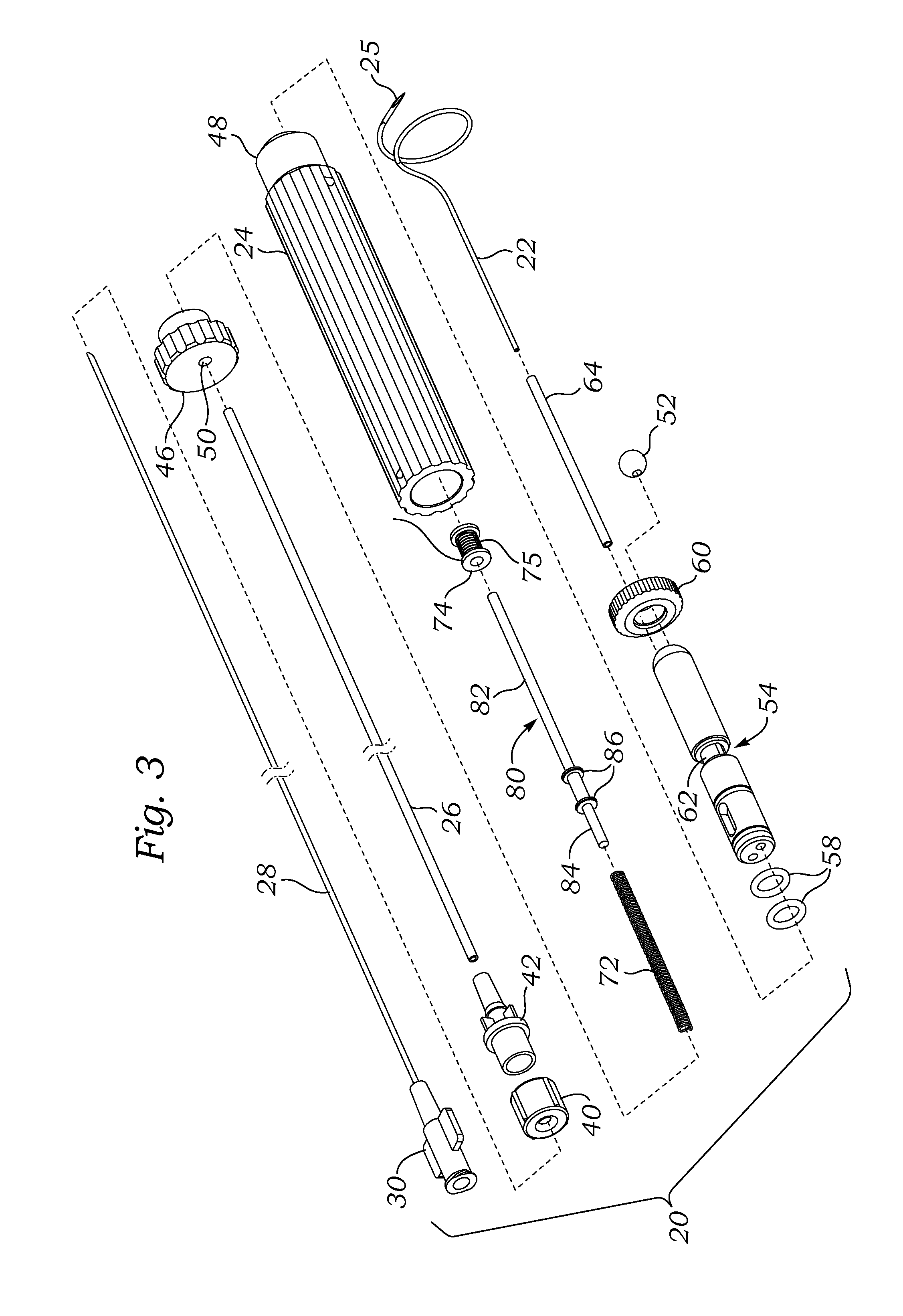

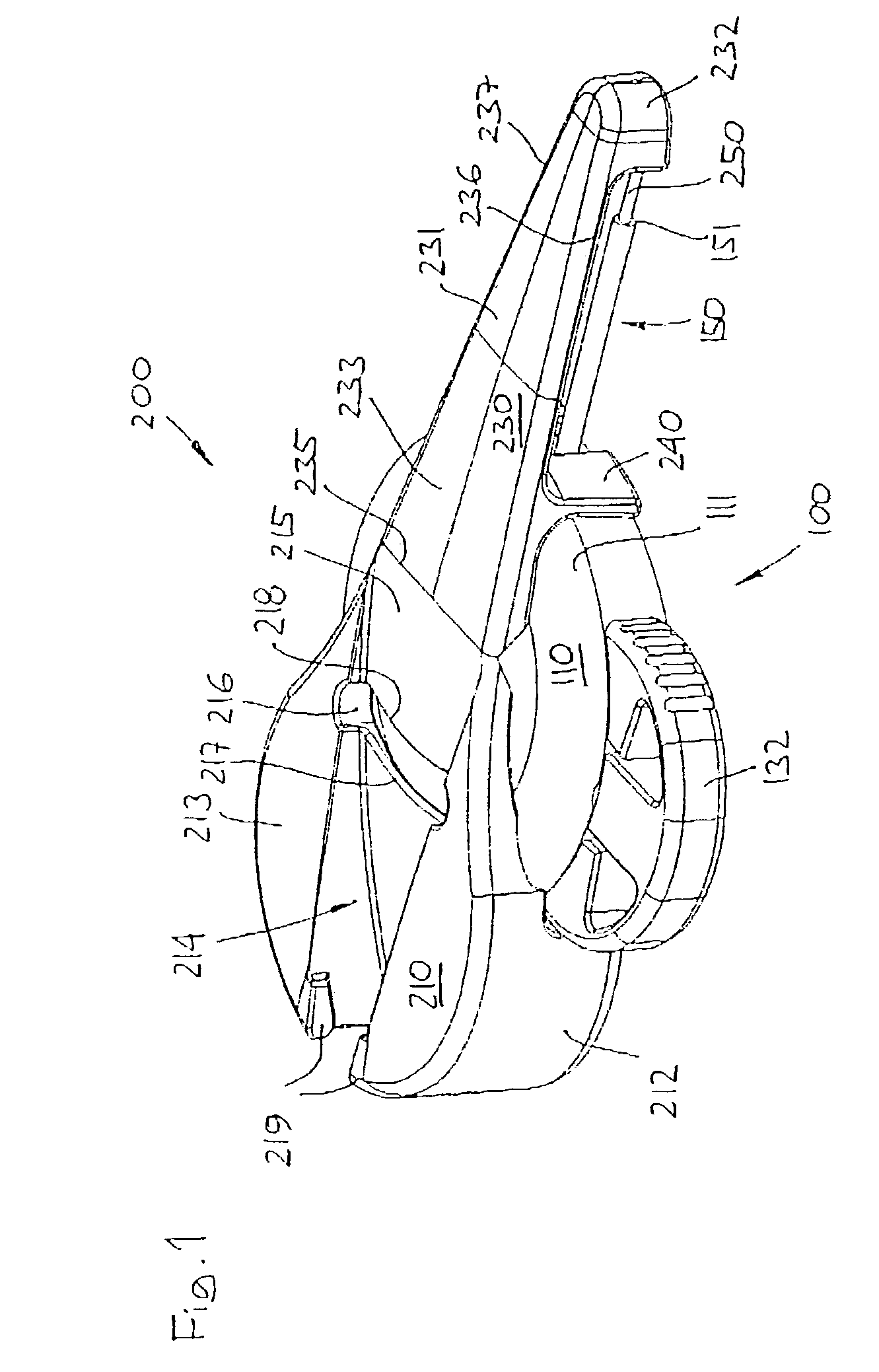

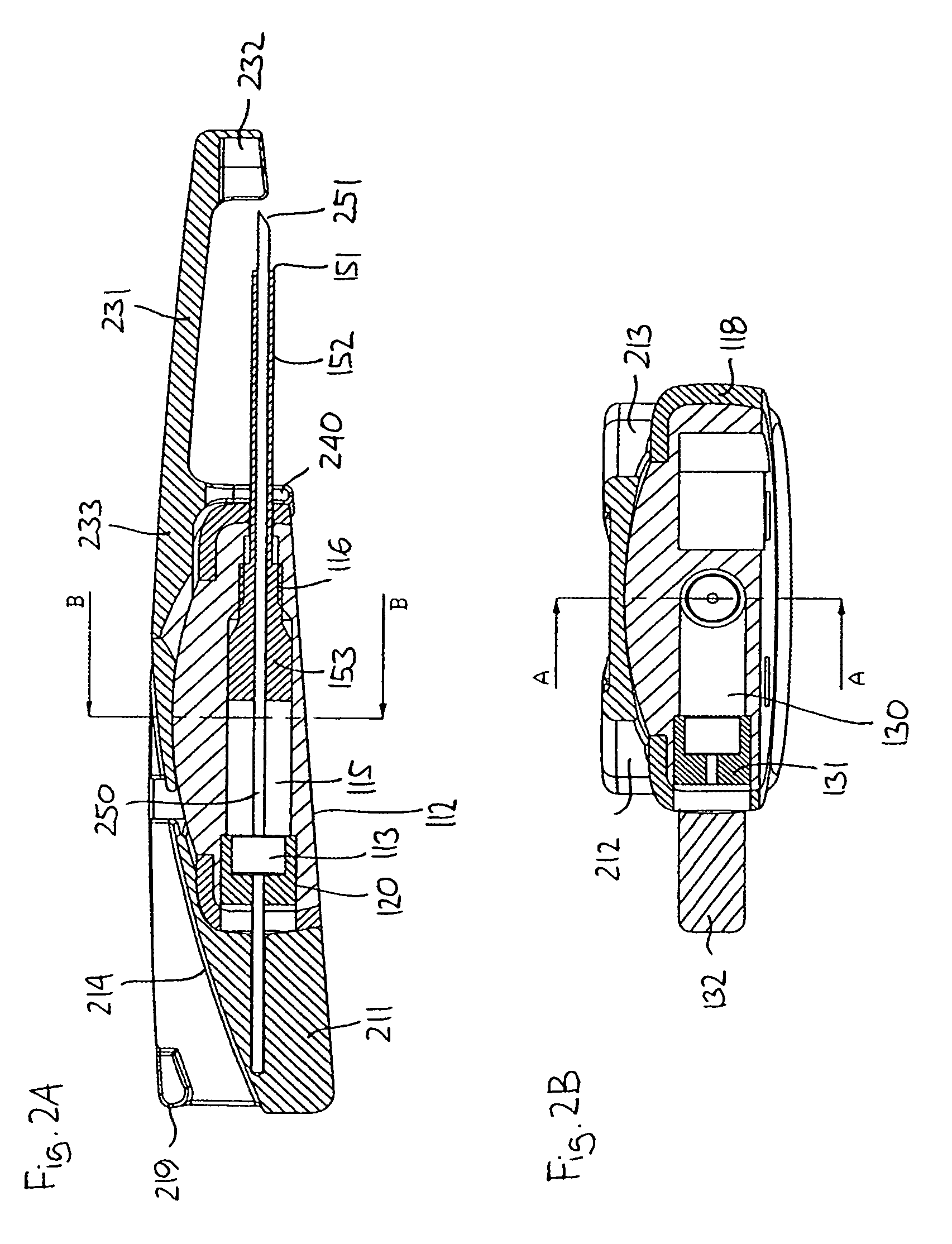

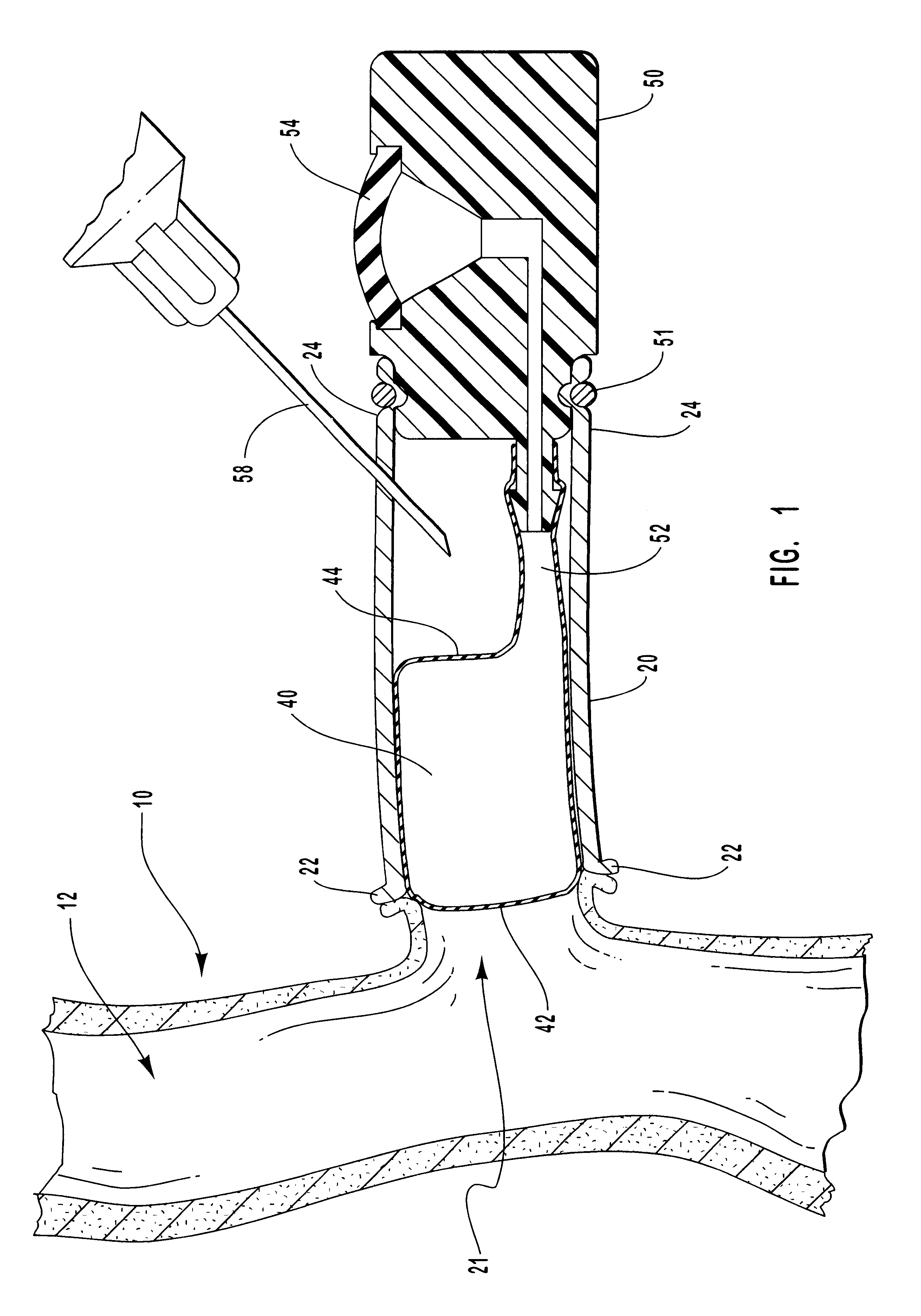

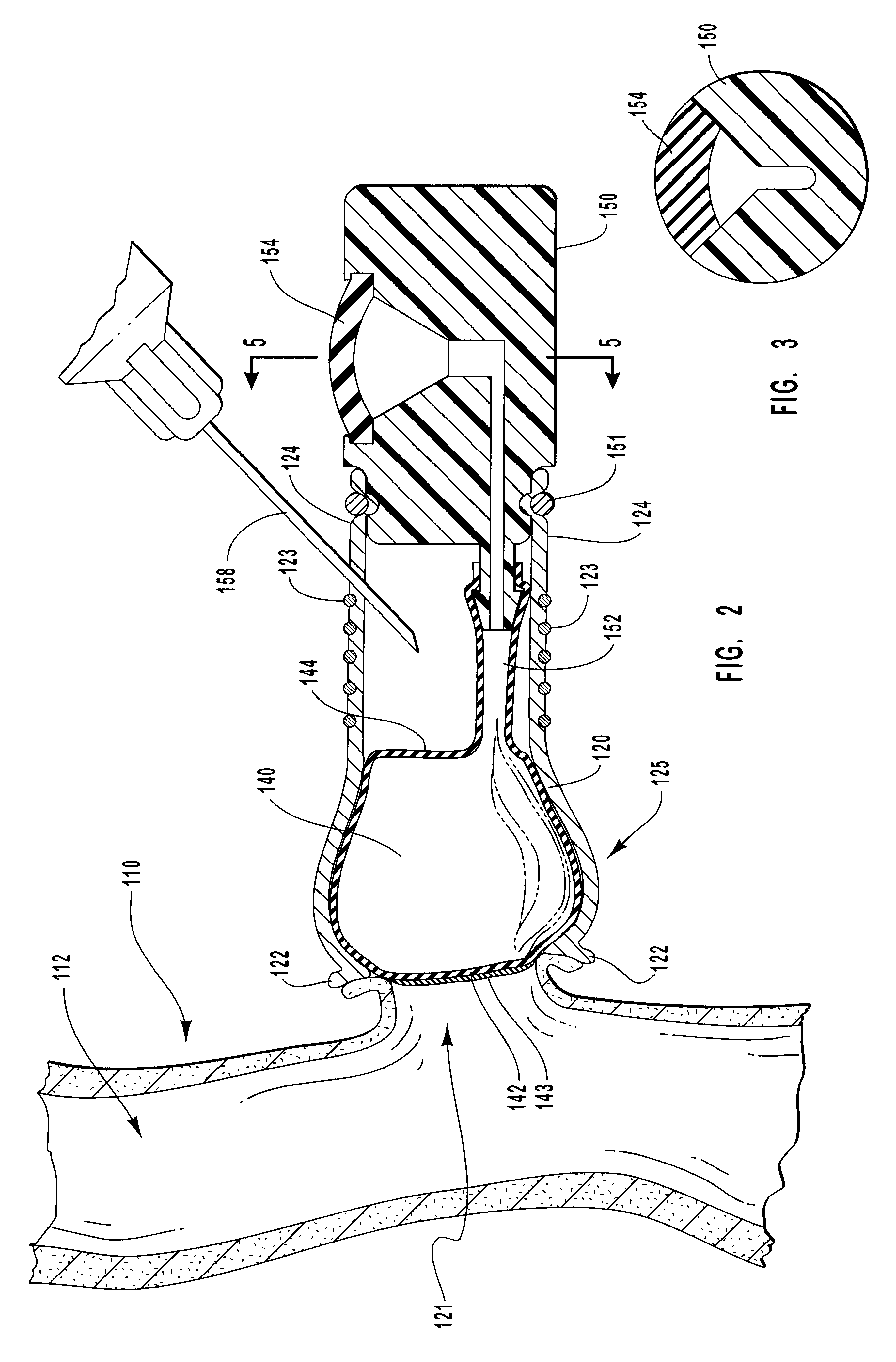

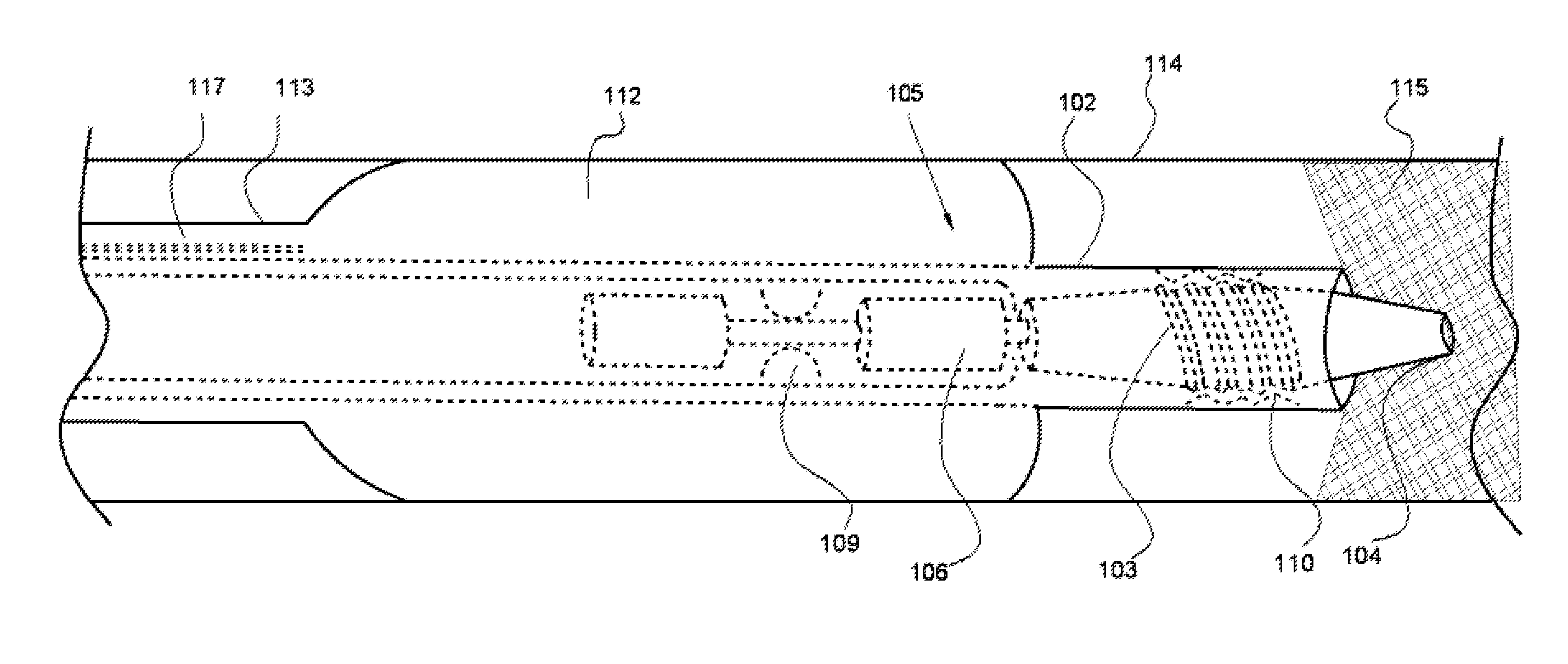

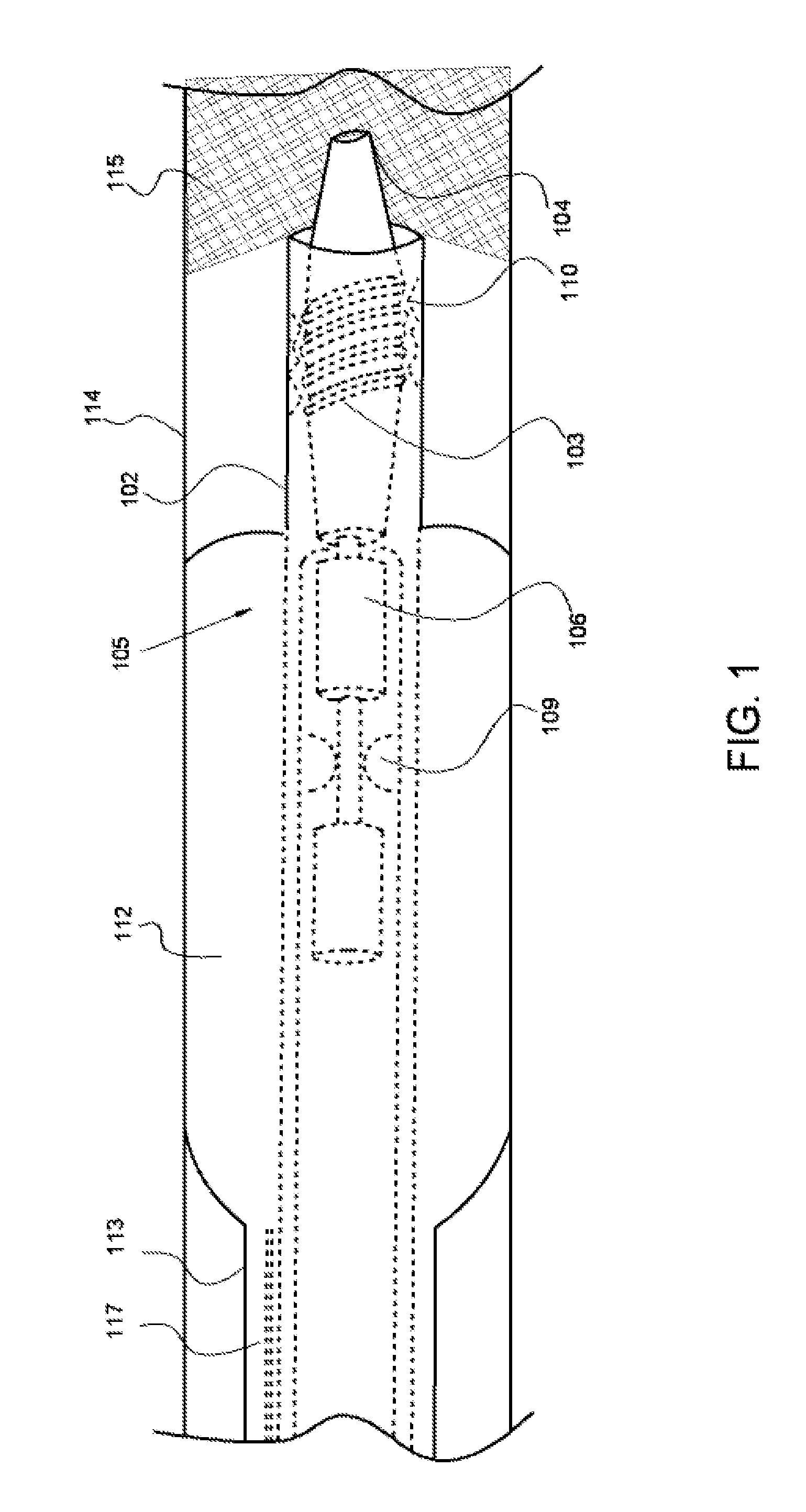

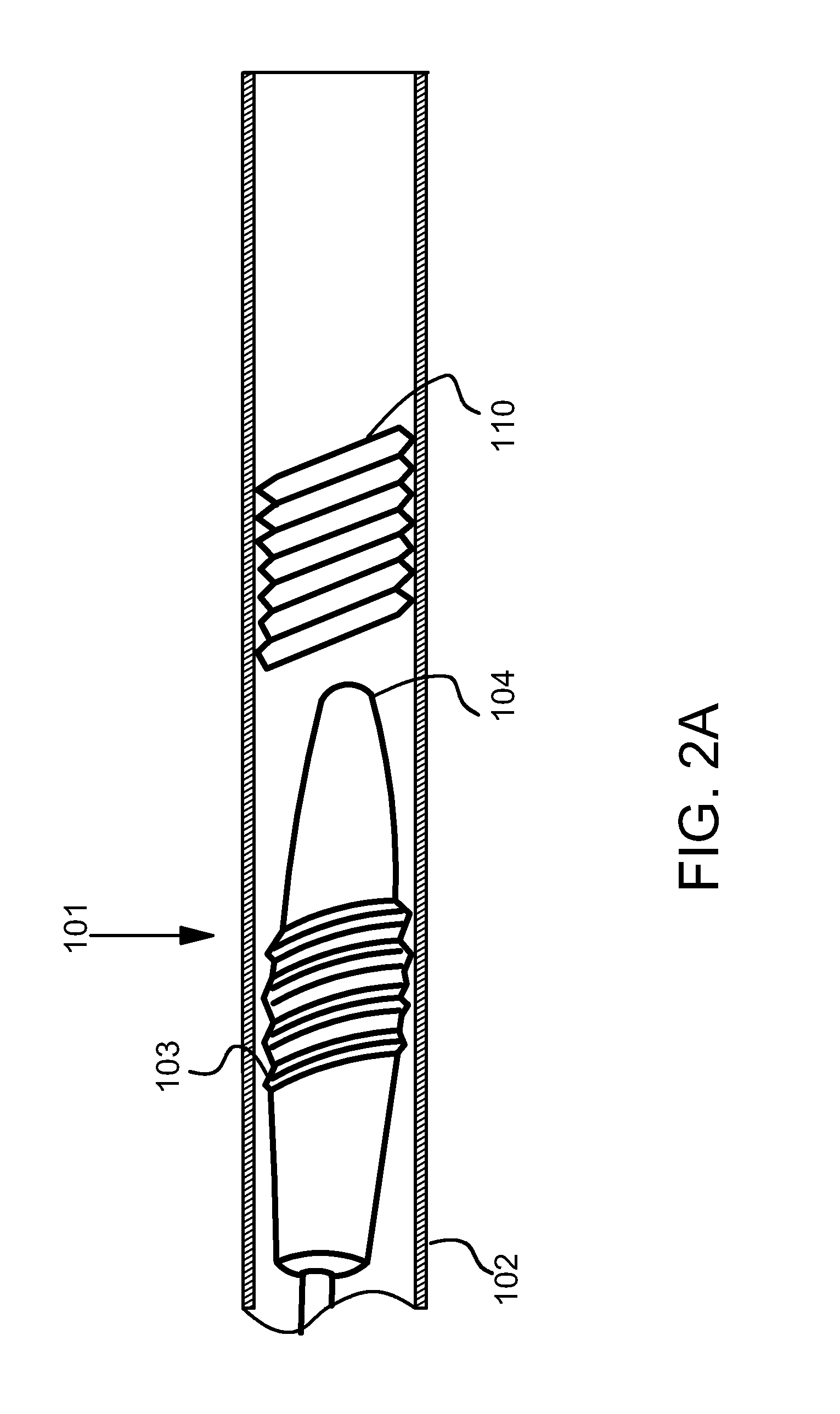

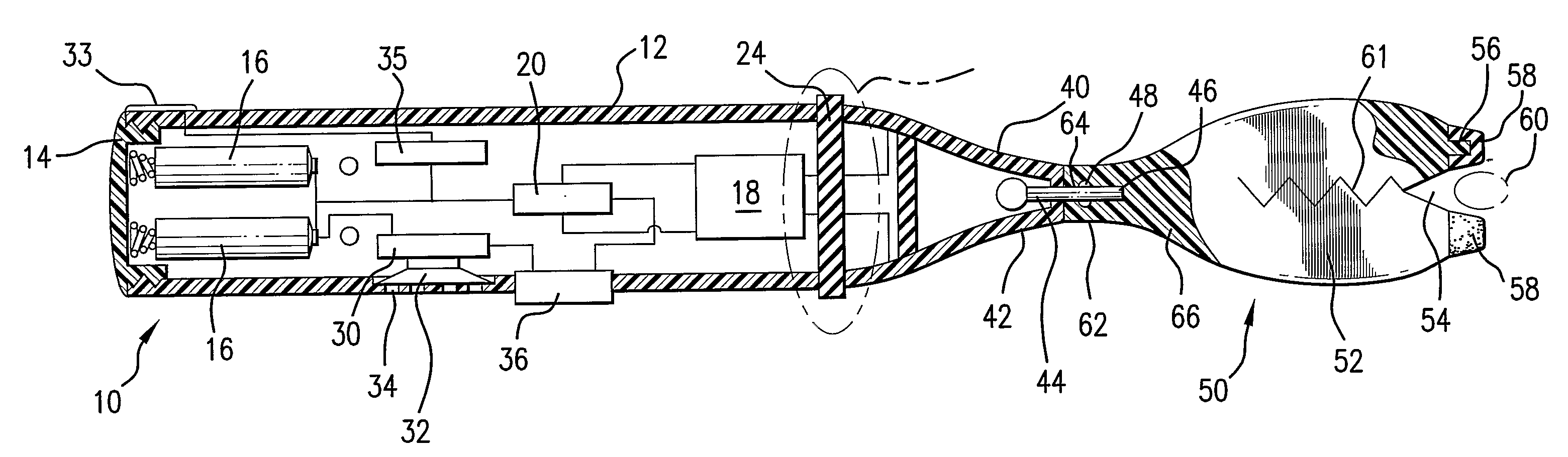

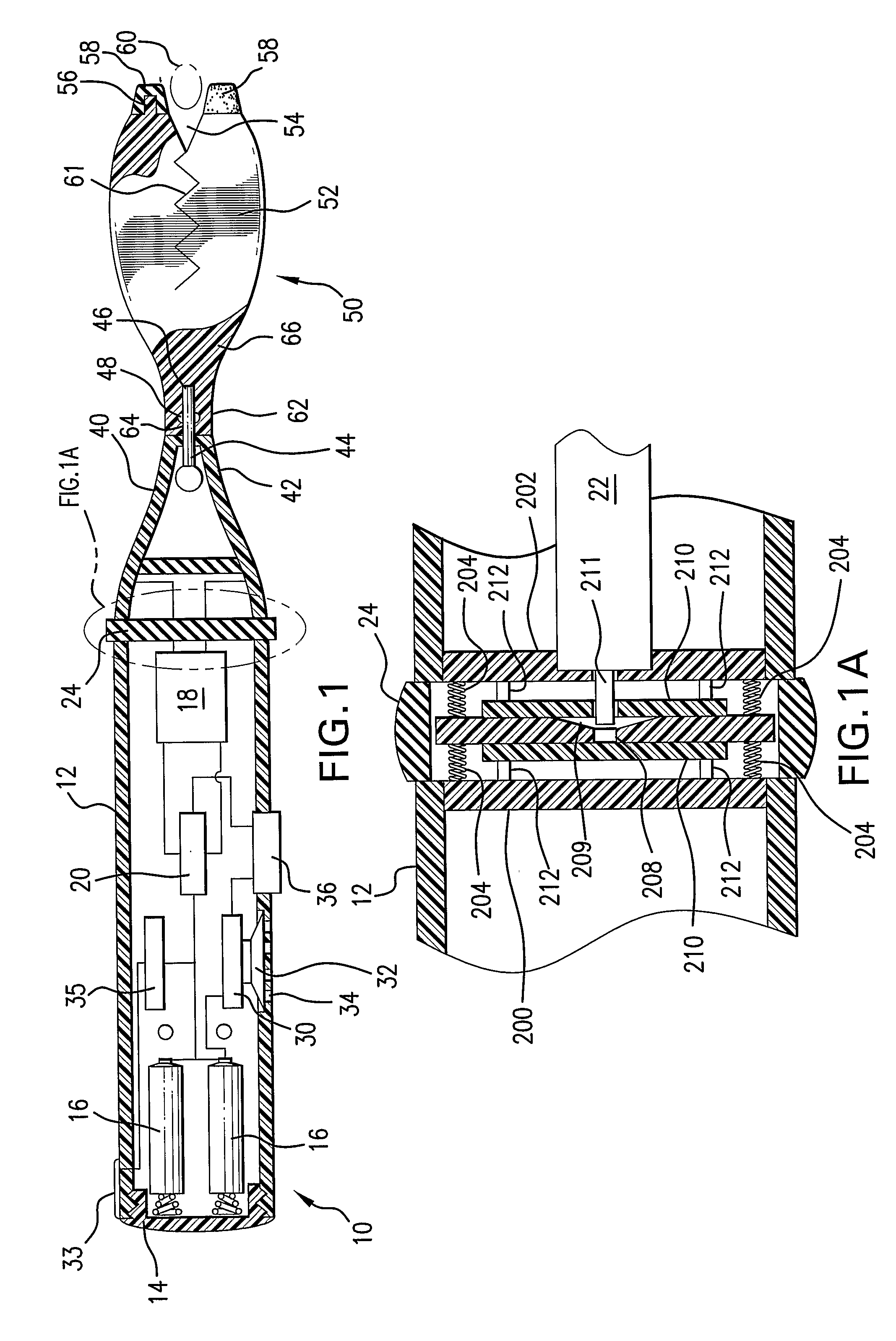

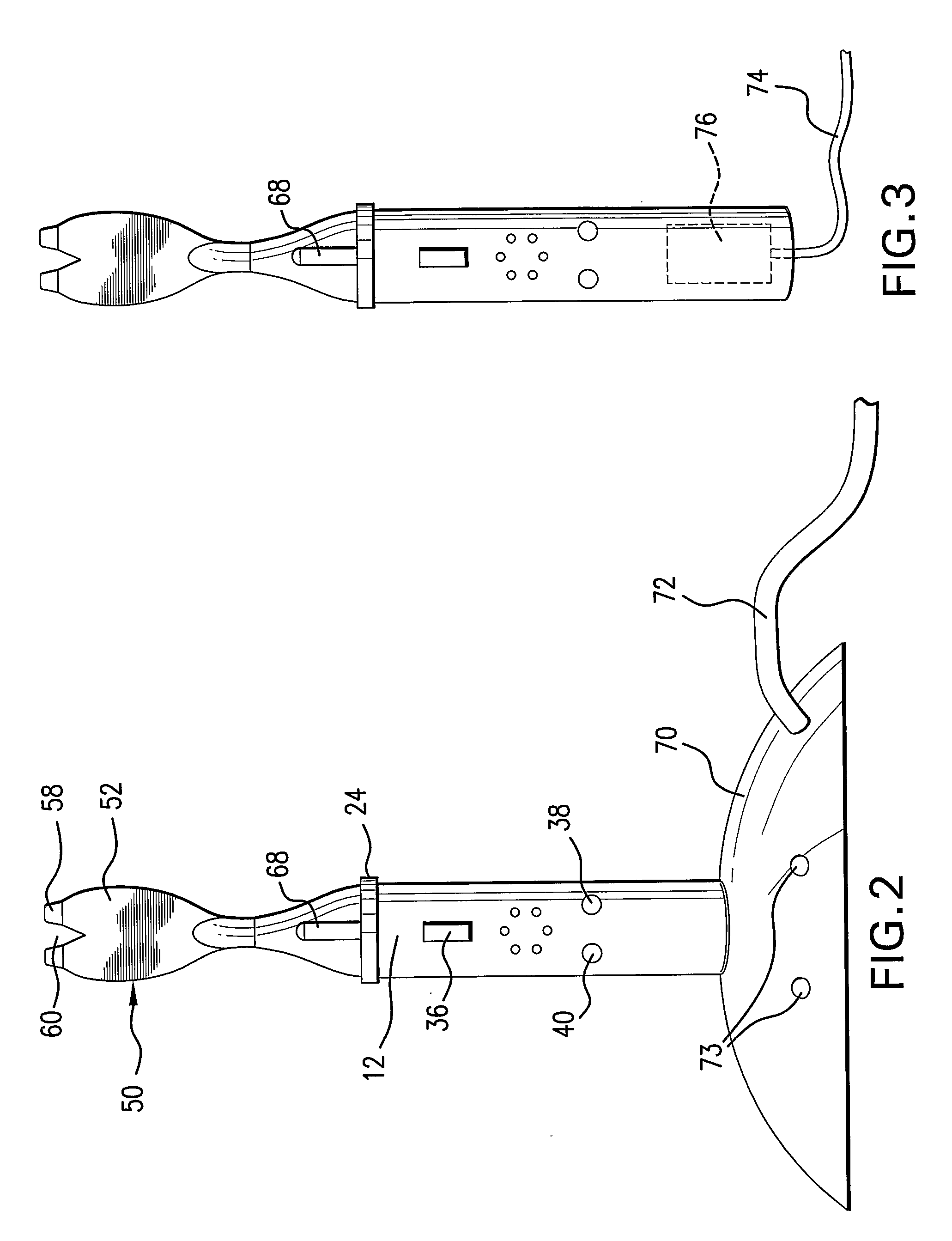

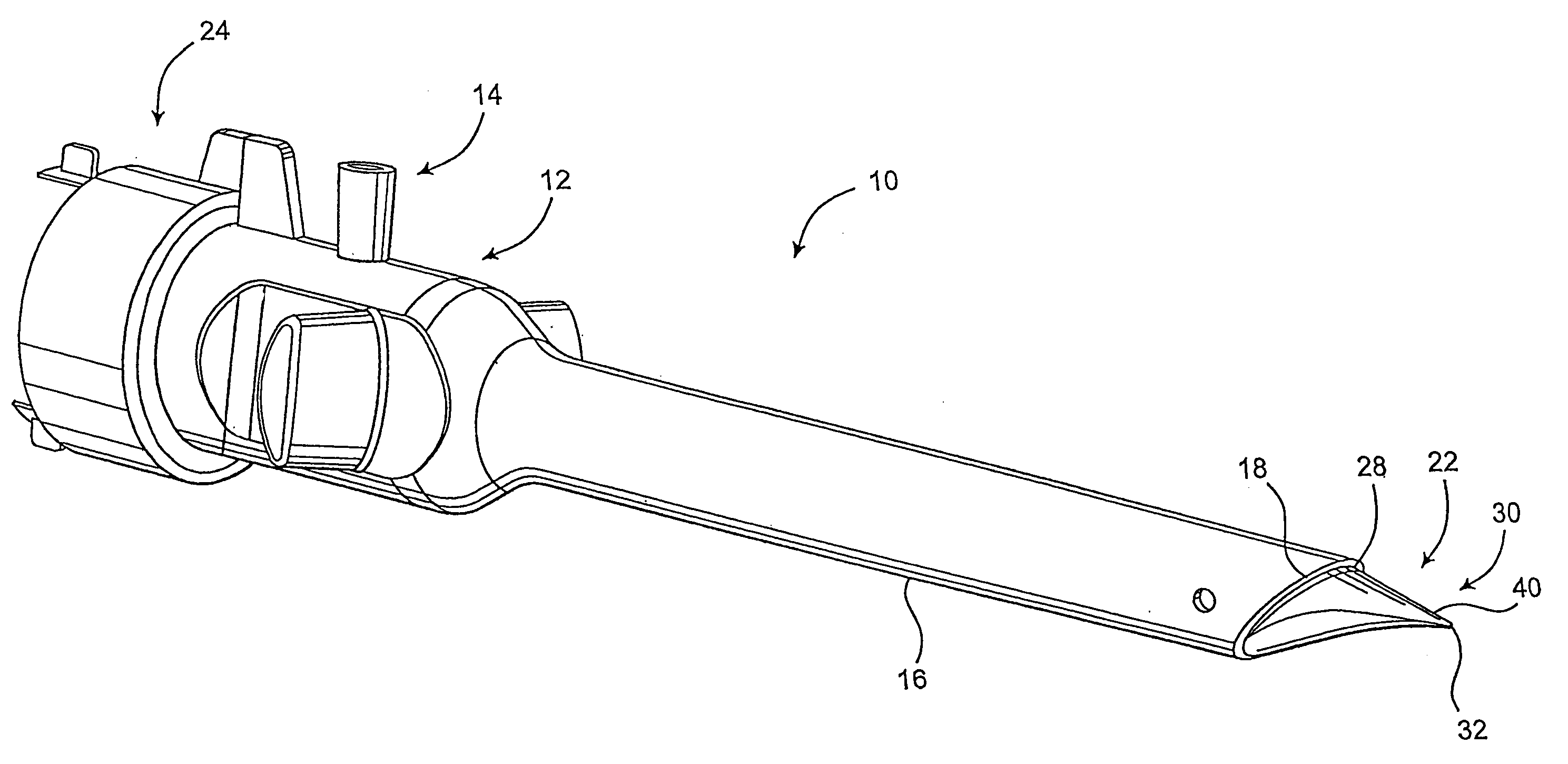

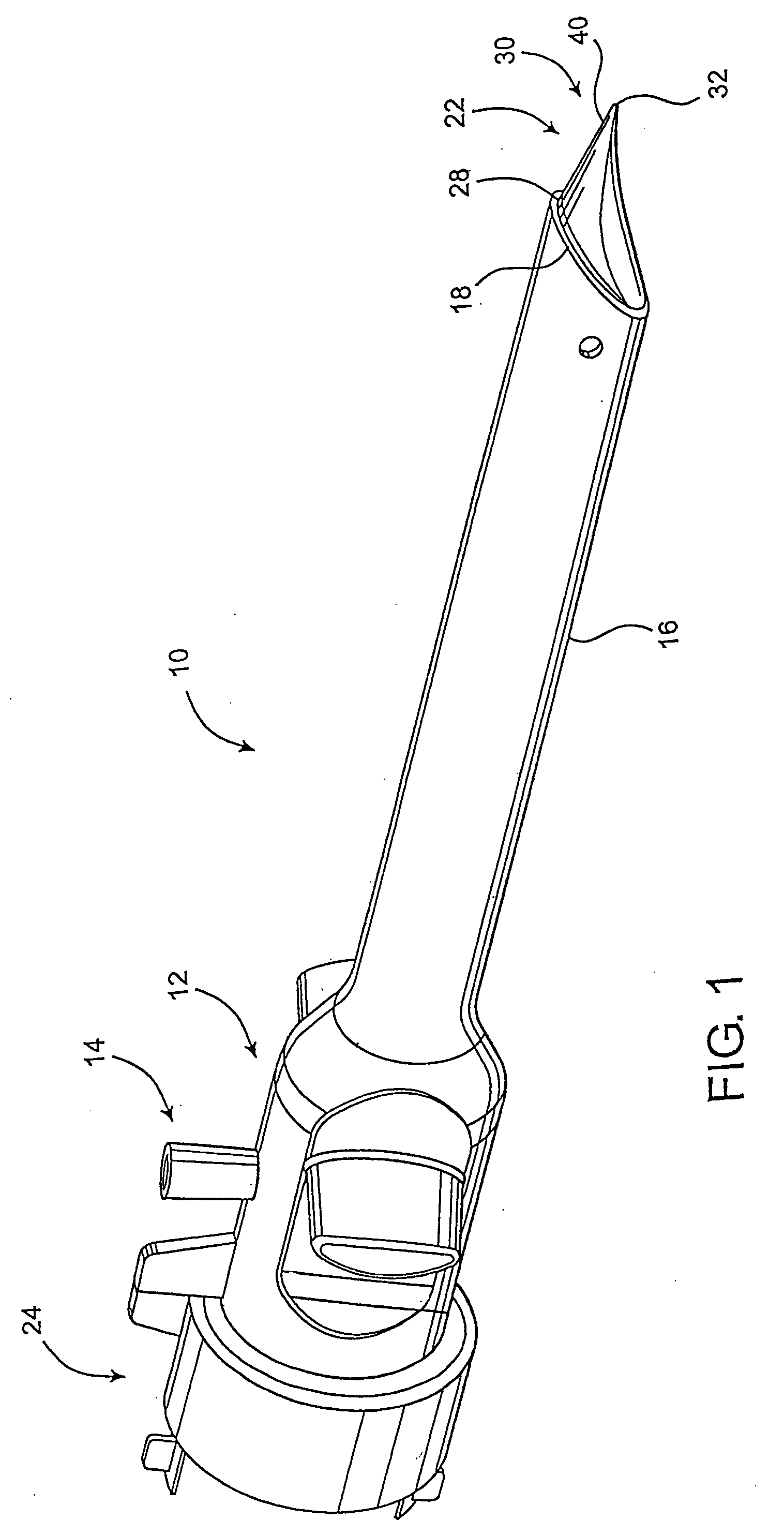

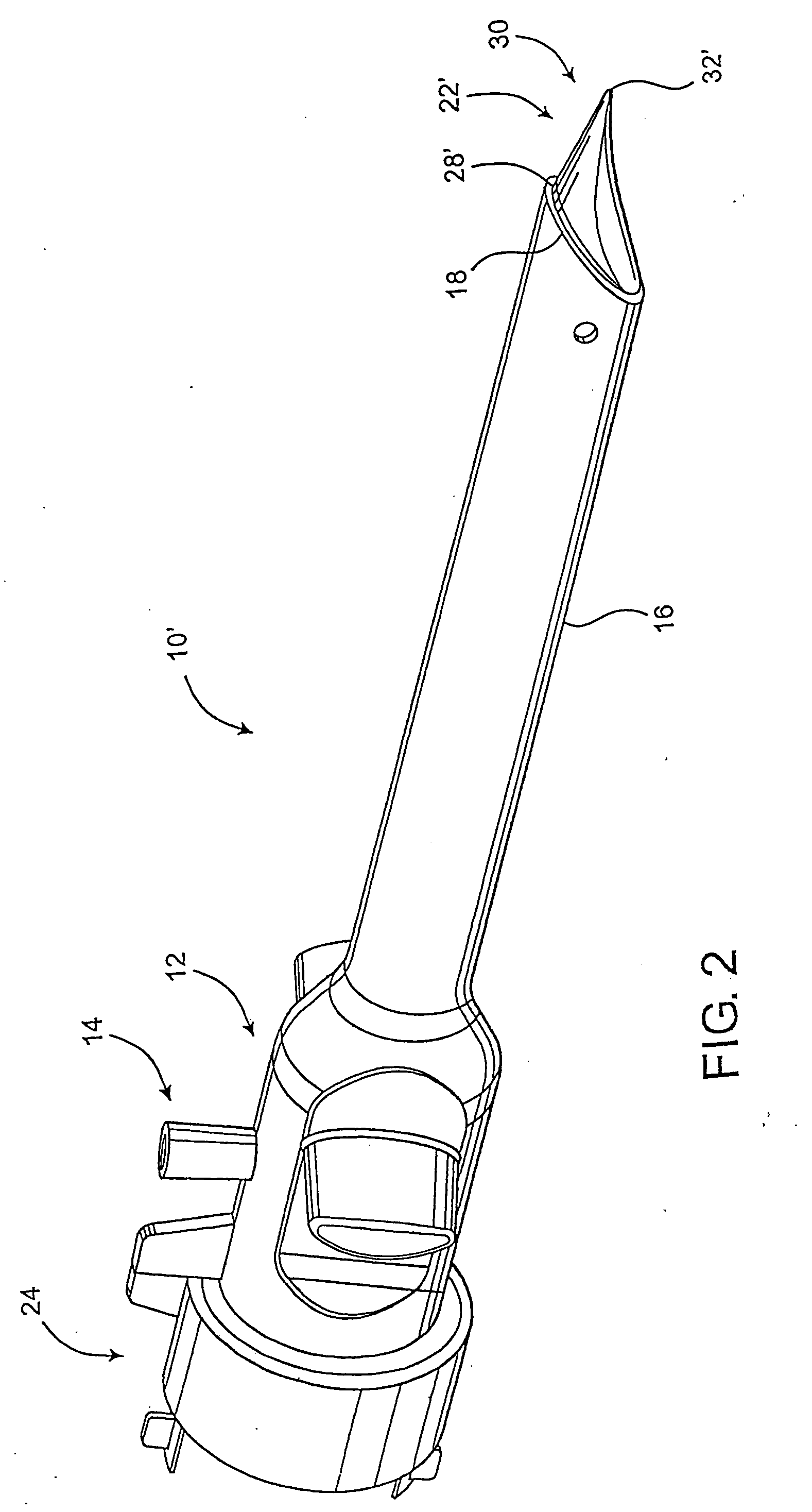

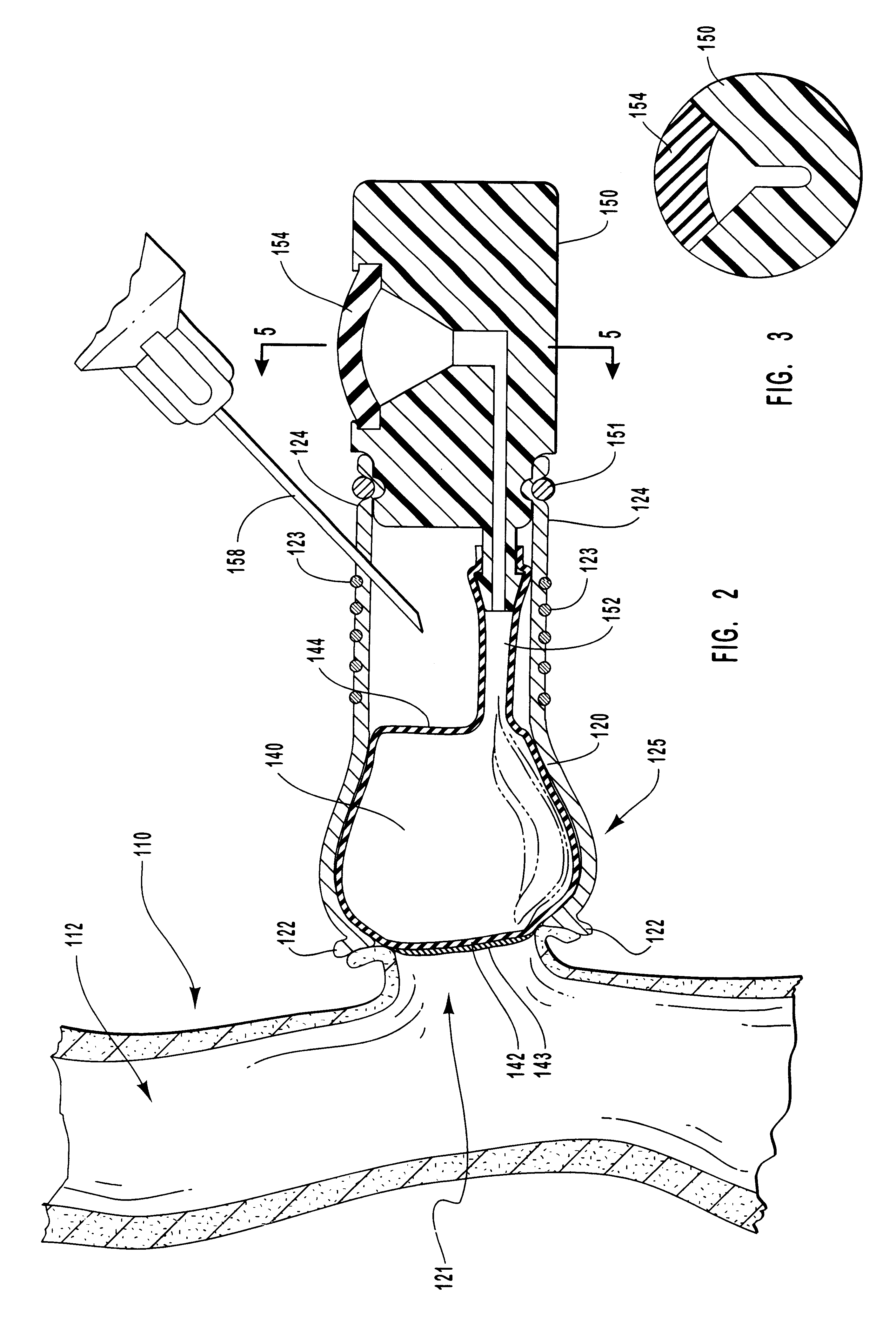

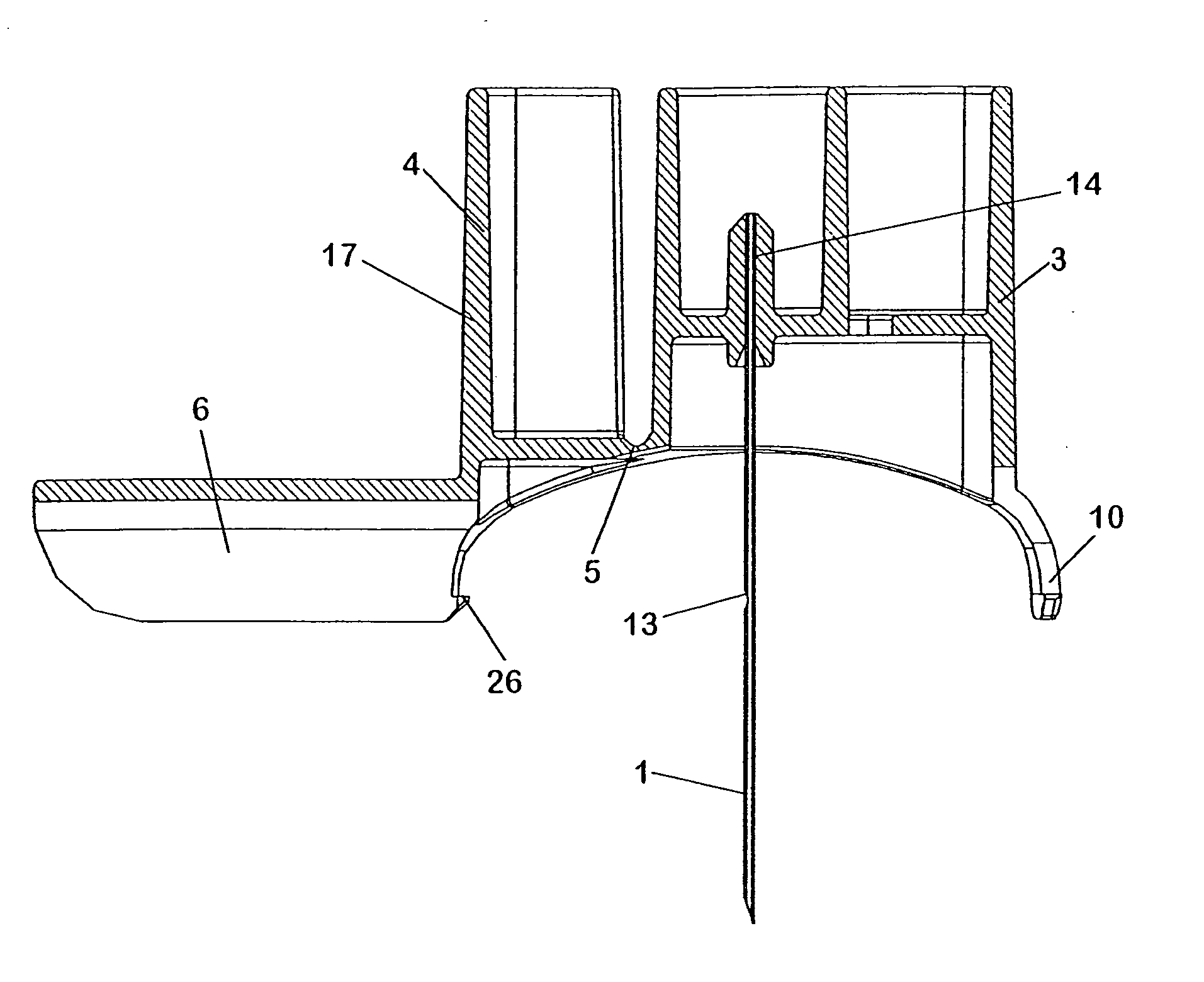

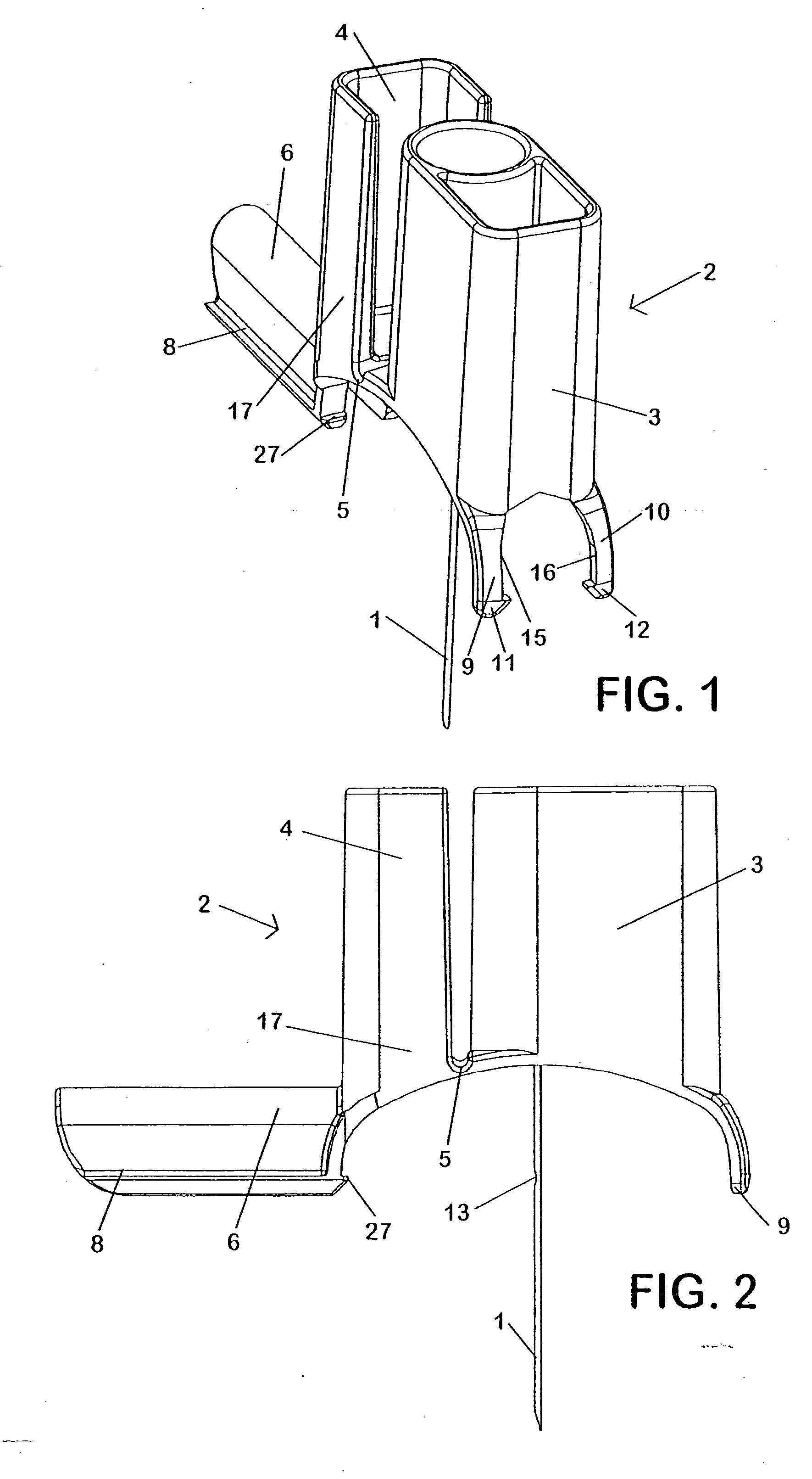

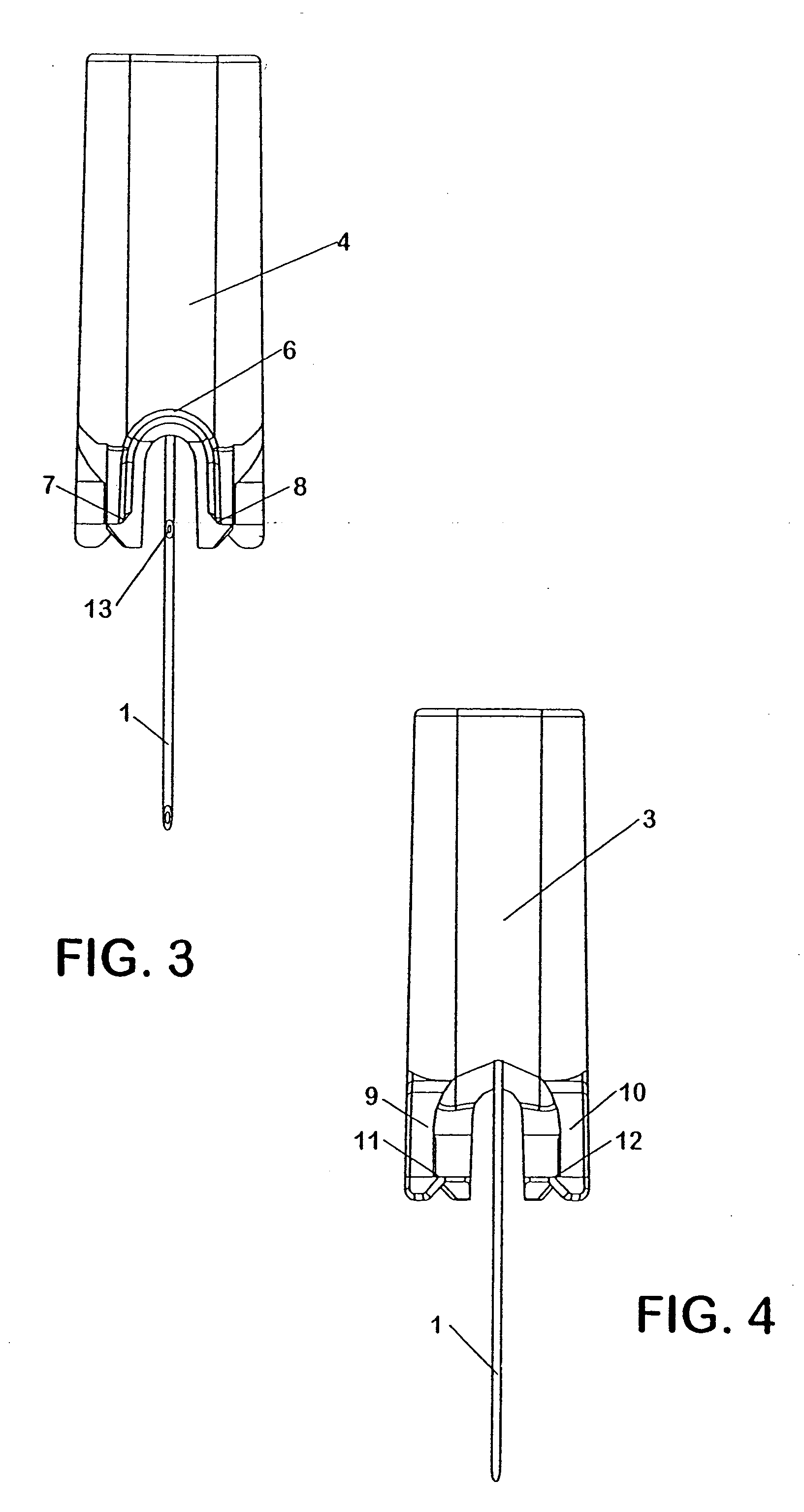

Penetrating tip for trocar assembly

InactiveUS6884253B1Facilitate of dilationFacilitate formationInfusion syringesSurgical needlesEngineeringBody tissue

A tissue penetrating instrument of the type used in the medical field and which may or may not be embodied in the form of an obturator associated with a trocar assembly, wherein the instrument includes an elongated shaft having a penetrating tip mounted on one end thereof. The penetrating tip includes a base secured to the one end of the shaft and a distal extremity spaced longitudinally outward from the base and formed into an apex which may be defined by a point or other configuration specifically structured to facilitate penetration or puncturing of bodily tissue. The apex may be substantially aligned with a linear extension of the central longitudinal axis of the shaft or alternatively, may be spaced laterally outward or off-set from the central longitudinal axis of the shaft. The penetrating tip further includes an exterior surface extending continuously between the apex and the base and configured to facilitate puncturing of the tissue and an enlargement of an access opening formed in the tissue, in a manner which facilitates separation of the tissue and minimizes cutting, severing or otherwise damaging the contiguous bodily tissue surrounding the access opening.

Owner:TELEFLEX MEDICAL INC

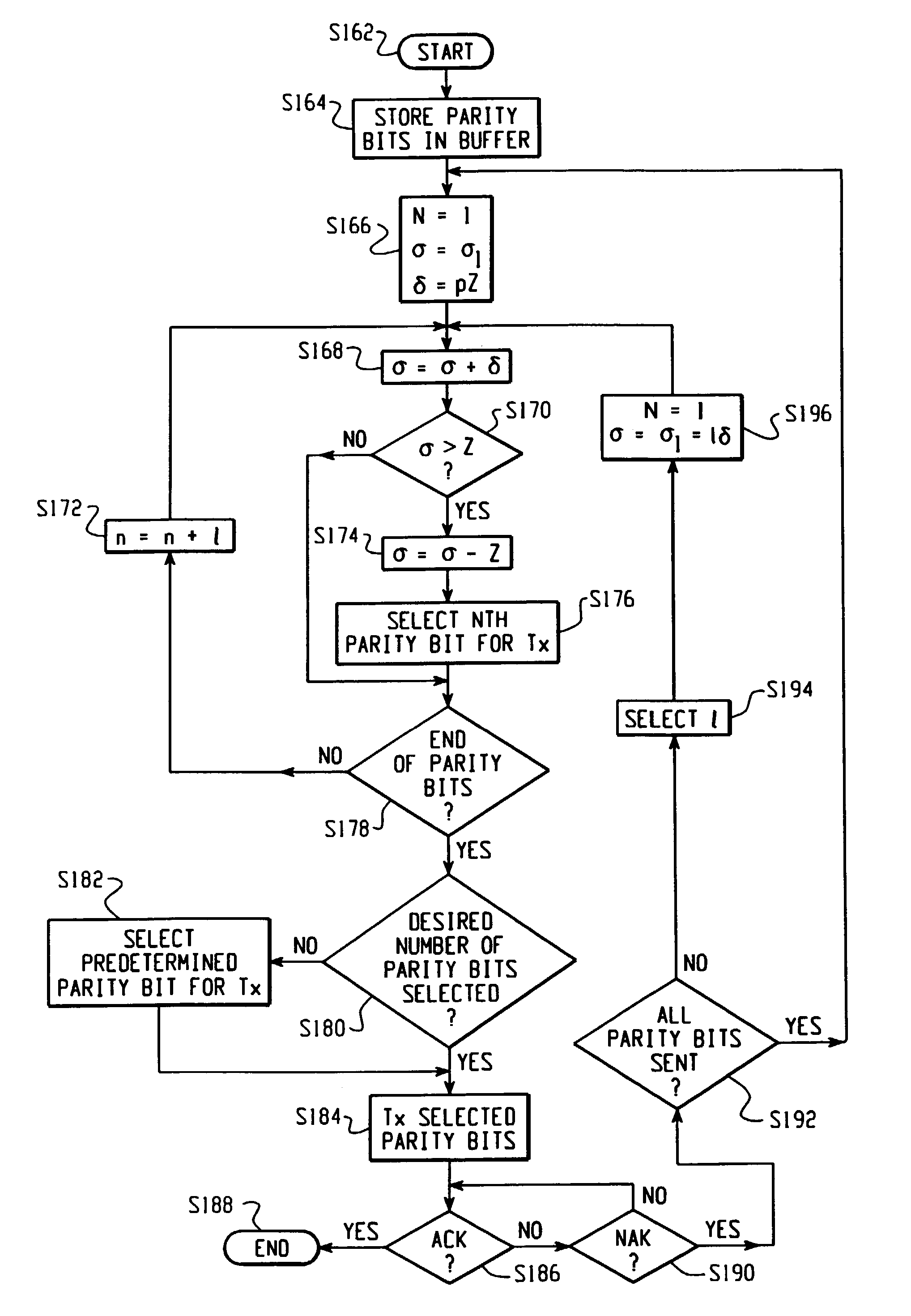

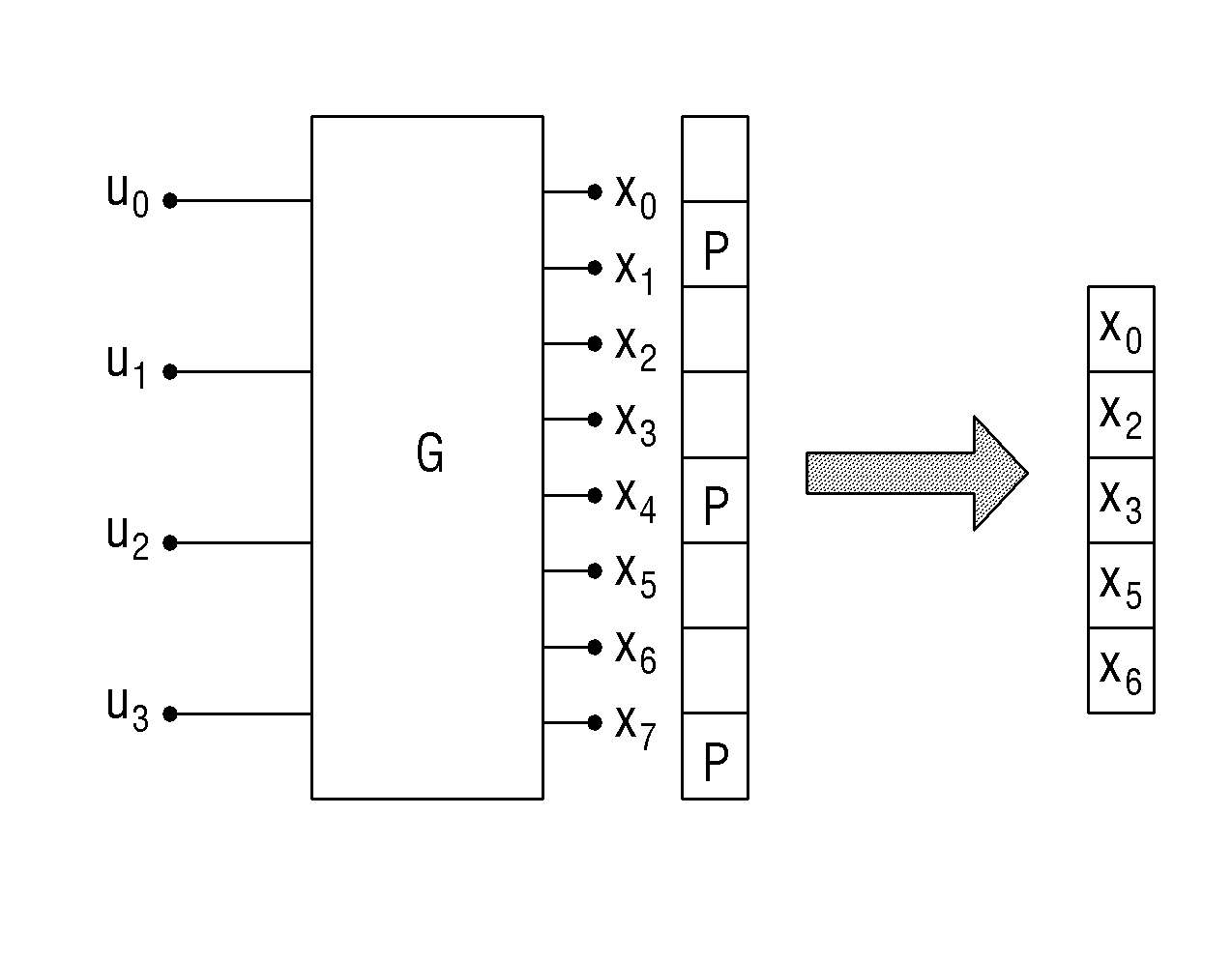

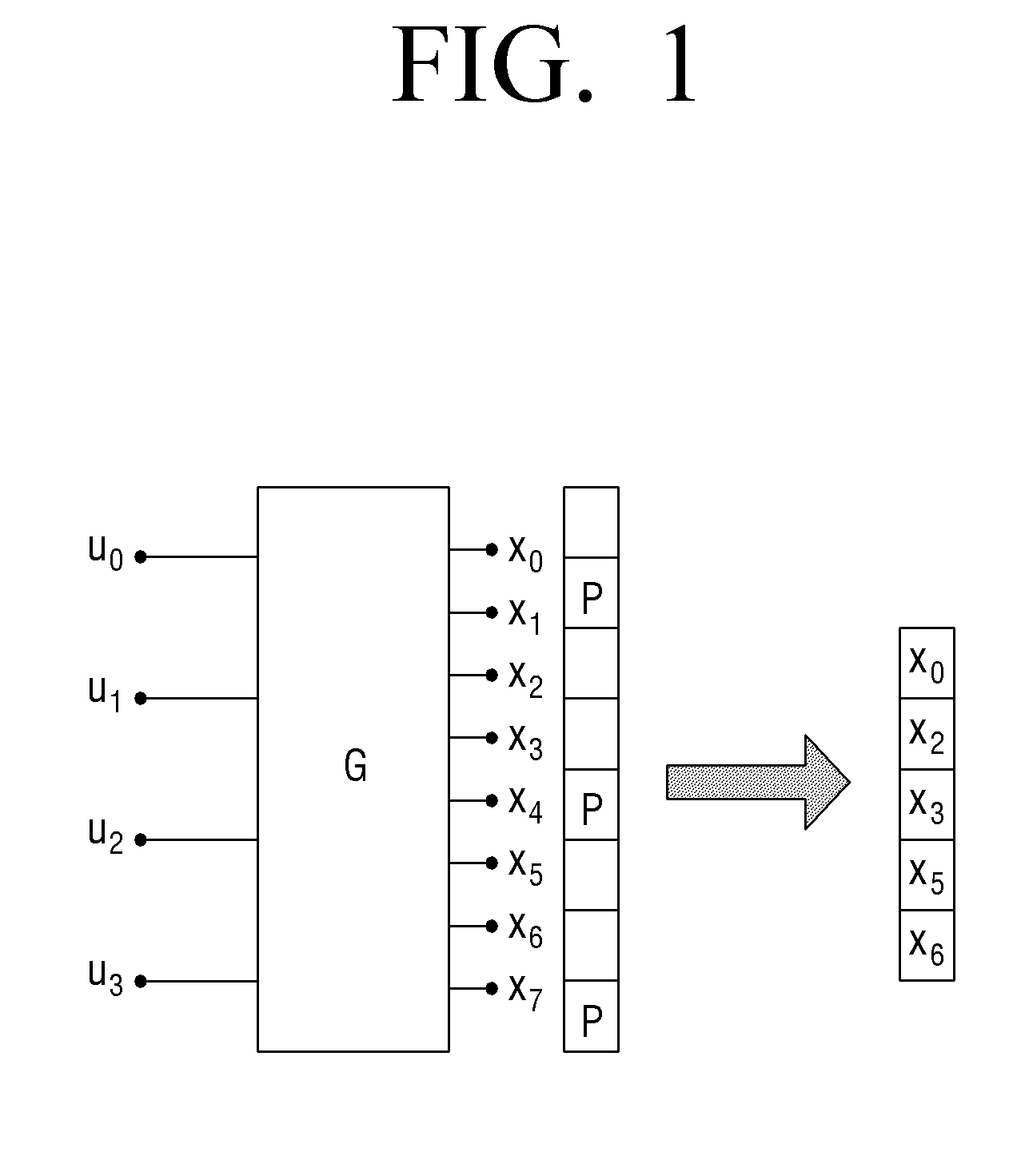

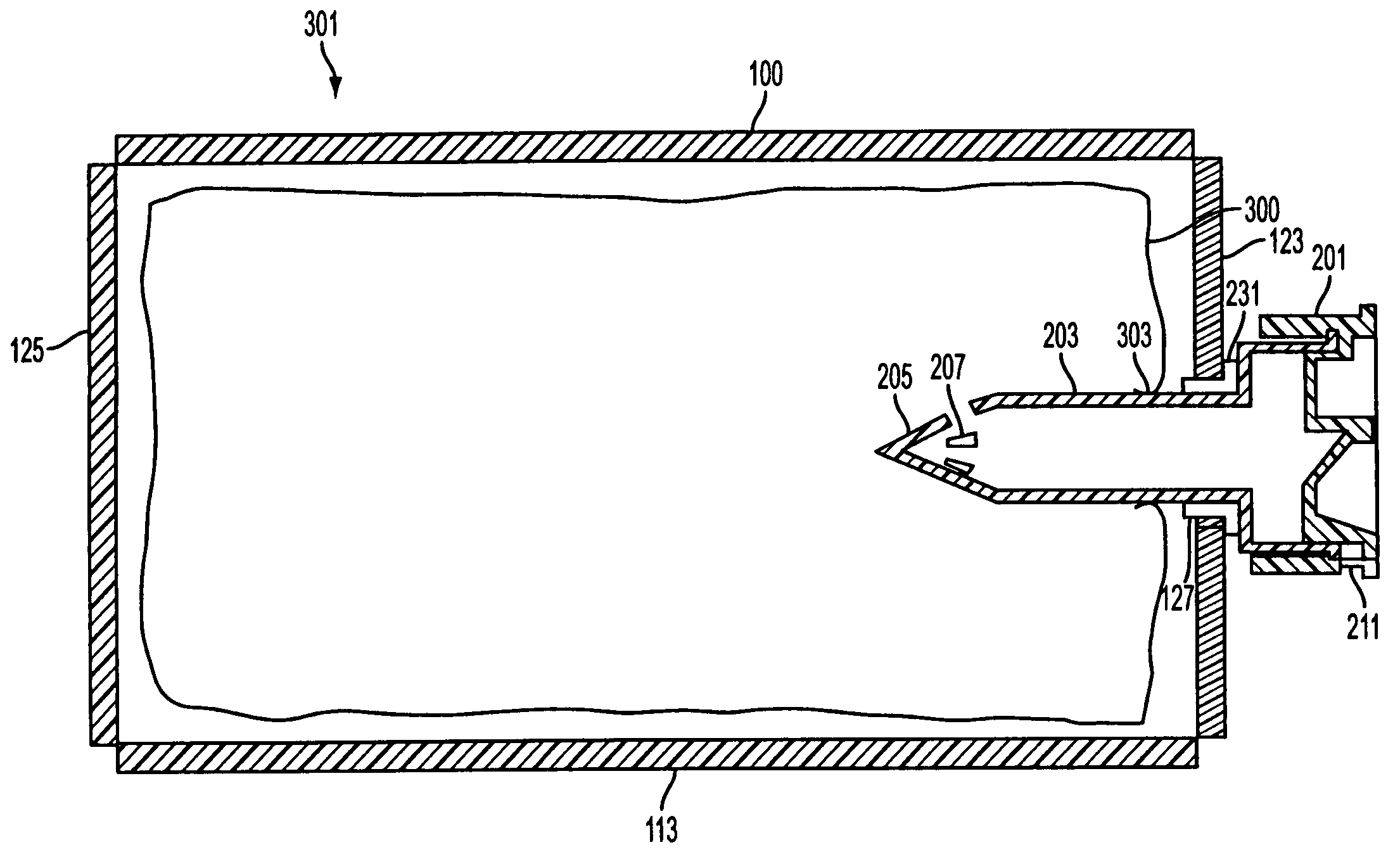

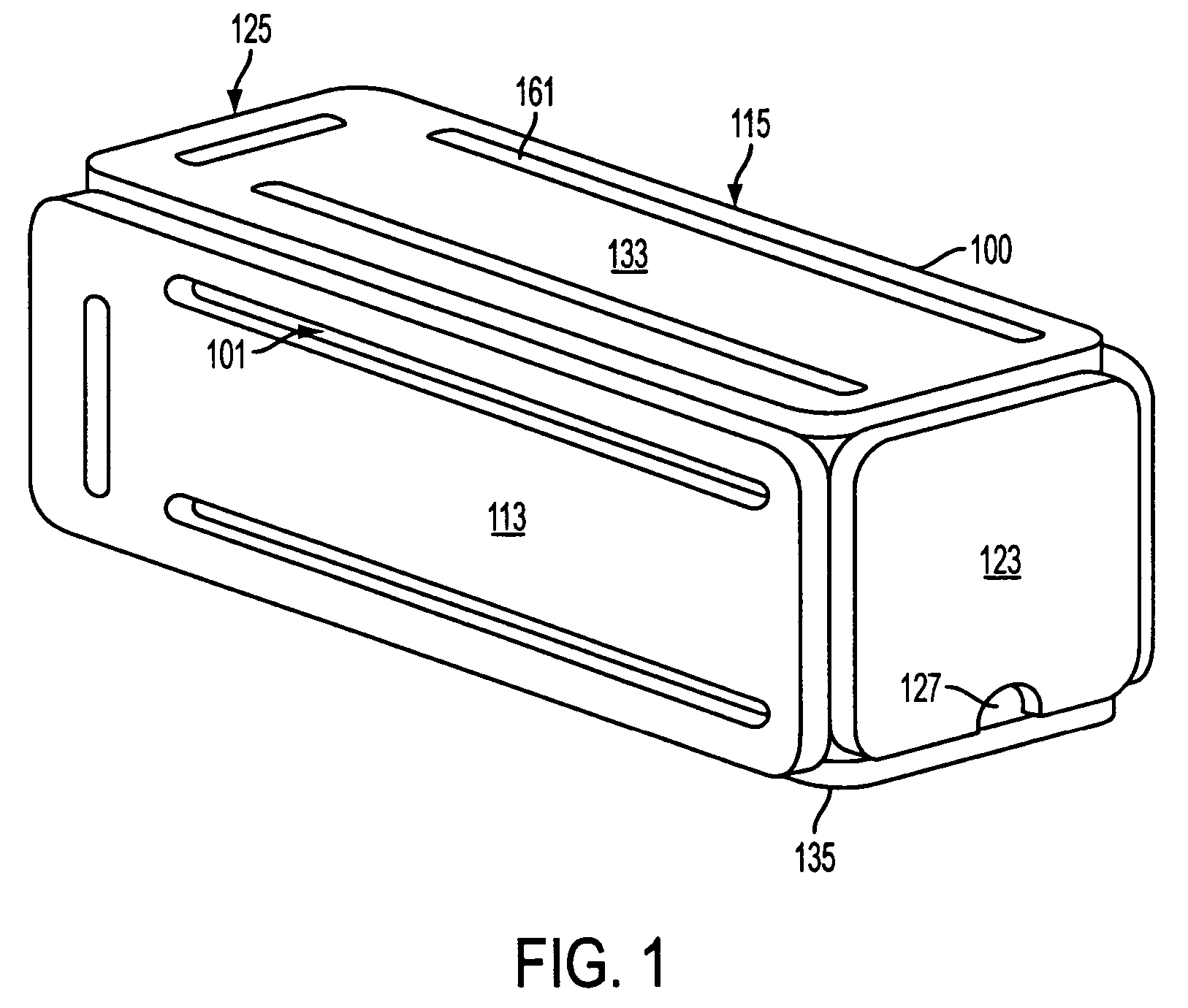

Hybrid automatic repeat request system and method

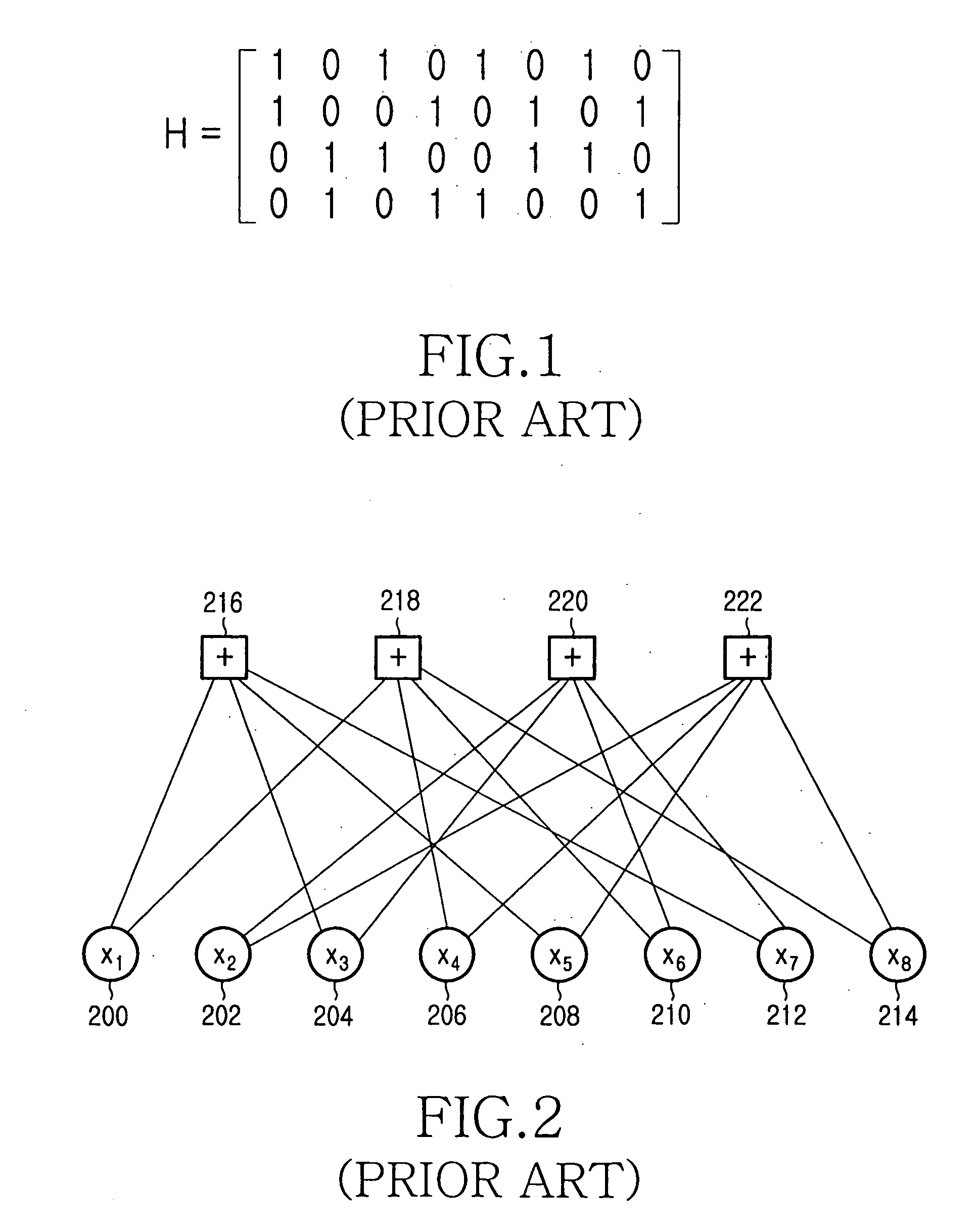

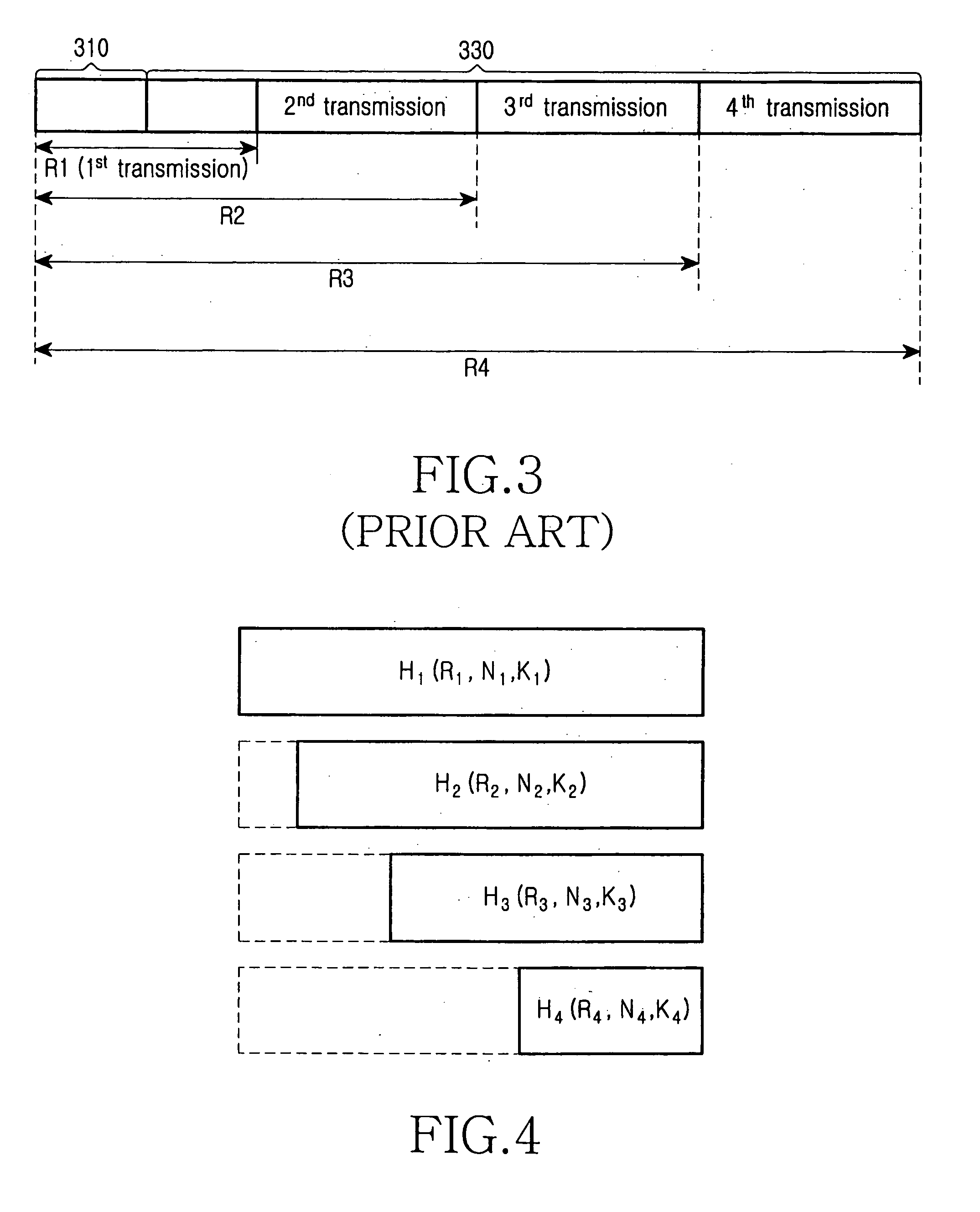

InactiveUS7000174B2Uniform puncturingError prevention/detection by using return channelTransmission systemsTheoretical computer scienceLow density

A data communication method and system for uniform arbitrary puncturing of parity bits generated by an encoder. The parity bits are stored in a buffer, and an a-bit accumulator is incremented to a predetermined initial value. For each parity bit in the buffer, the following steps are performed: the accumulator is incremented by a predetermined increment value, and if the accumulator overflows, the parity bit is selected for transmission. The predetermined initial value and the predetermined increment value are selected to achieve a desired amount of puncturing. In a further hybrid automatic repeat request (HARQ) communication method and system, the parity bits are generated by a low density parity check (LDPC) coder.

Owner:MALIKIE INNOVATIONS LTD

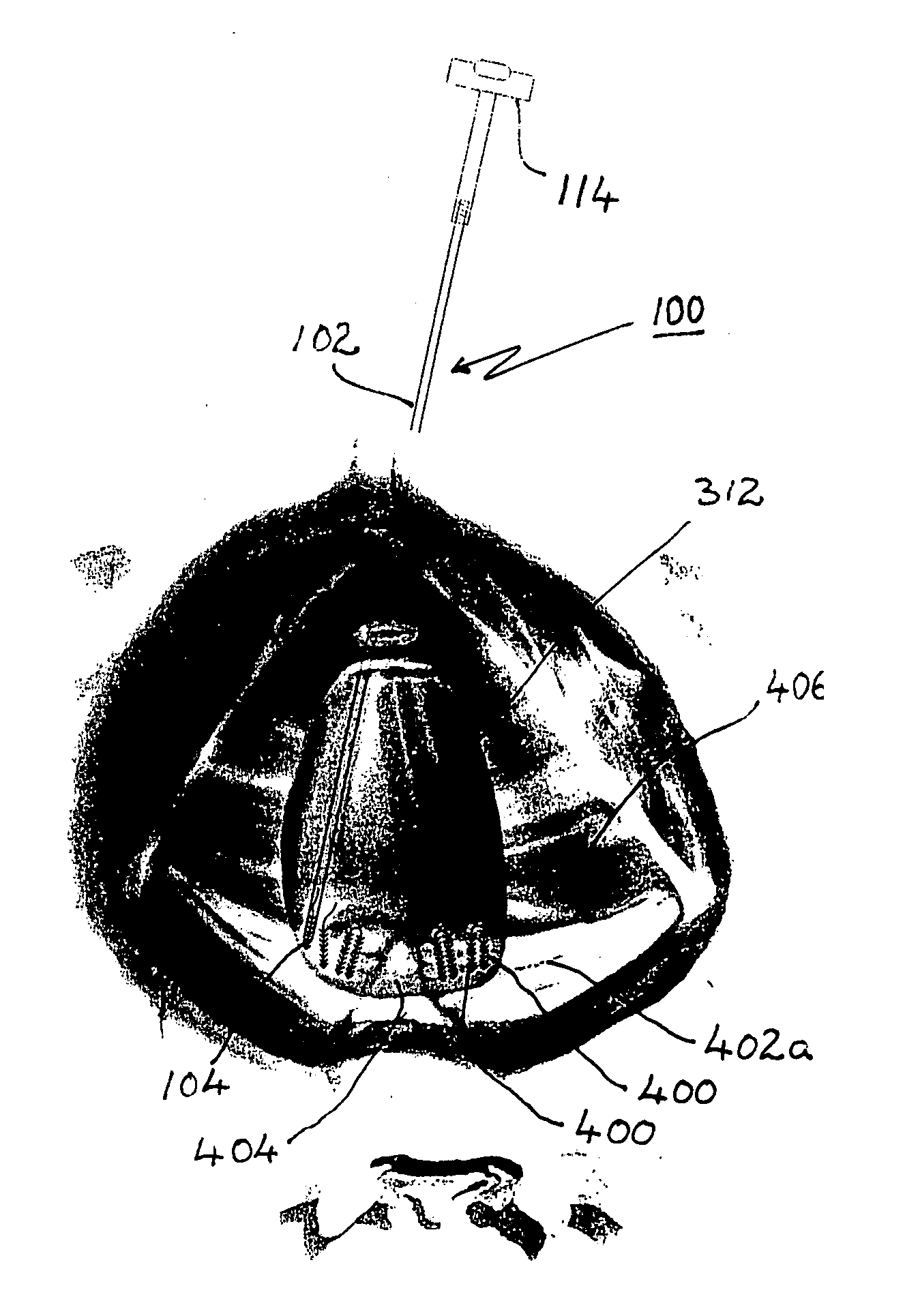

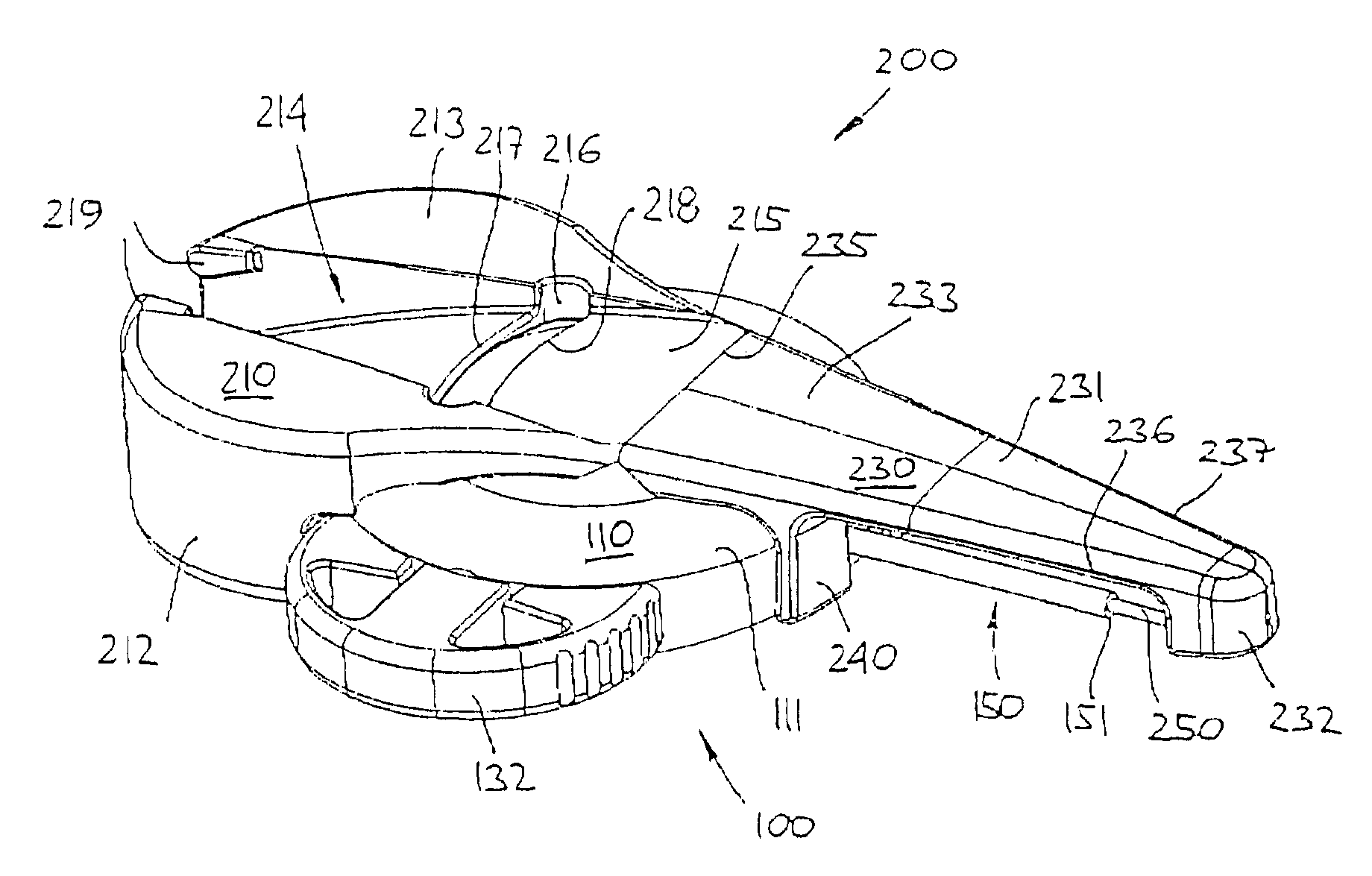

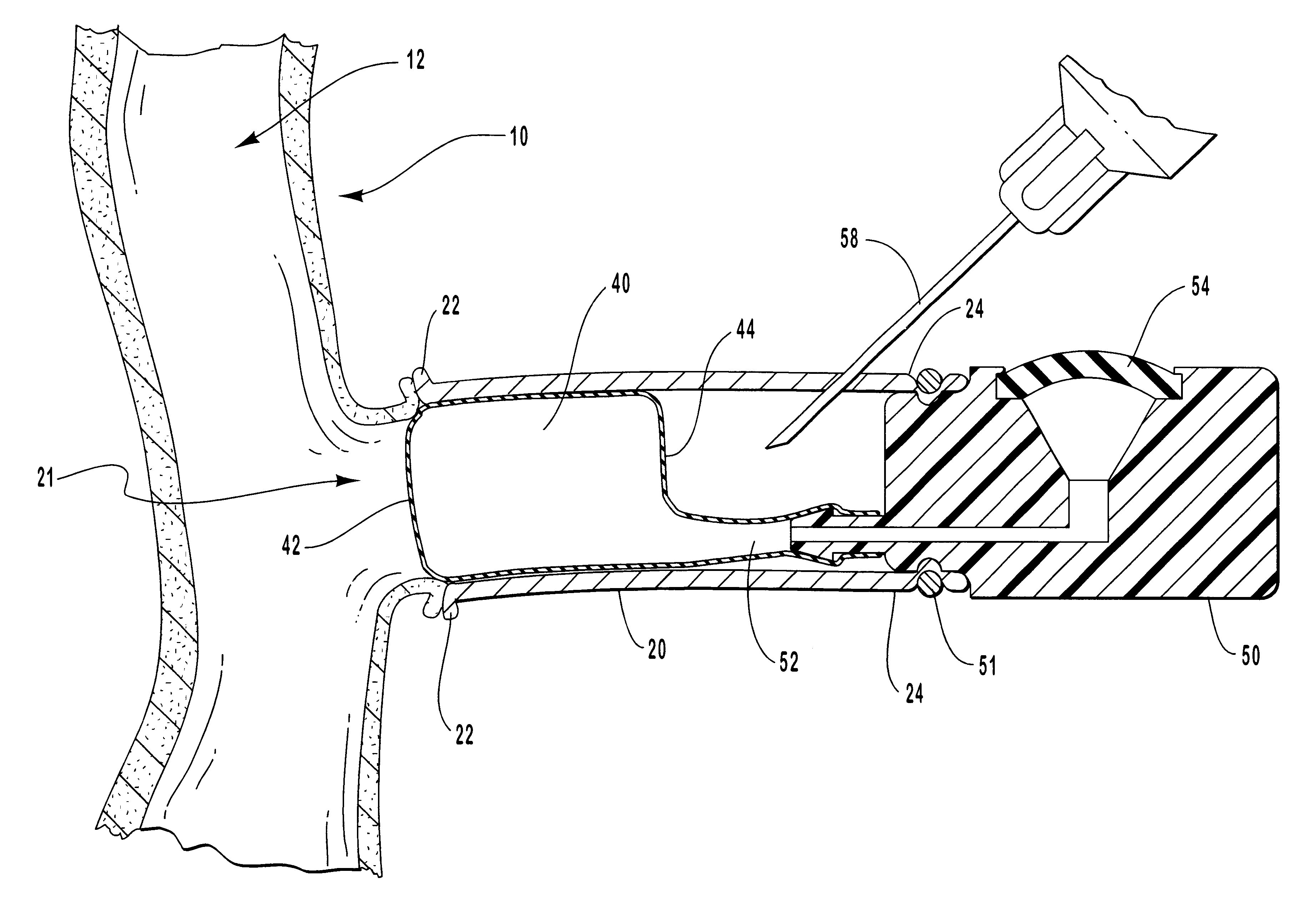

Apparatus and method for incision-free vaginal prolapse repair

InactiveUS20050199249A1Simple, minimally invasive and inexpensiveQuick fixSuture equipmentsBed wetting preventionVaginal ProlapsesDistressing

In a preferred application, e.g., the repair of vaginal prolapse after relocation of the vagina and any organs displaced by the prolapse, corrective surgery is initiated by applying a hollow tubular element, formed to forcibly insert a barbed anchor attached to a distal end of a first length of suture, without any incision, from the inside of the vagina through the vaginal wall (the supported tissue) into selected support tissue within a patient's pelvis. This involves puncturing and thus locally severe physical distressing of both the supported tissue and the support tissue. The barbed anchor is left in the support tissue as the tubular element is then withdrawn from the support tissue and out of the vagina, leaving the proximate end portion of the suture extending through the vaginal wall into the vagina. A second such anchor, with a second length of suture attached thereto, is similarly inserted adjacent to the first anchor. The proximate end portions of the sutures are tied to each other inside the vagina, to thereby secure the vaginal wall to the support tissue with corresponding punctures formed in each by the insertions of the two anchors being thereby held in respective, precisely aligned, intimate contact during healing. This results in a pair of fused scars that cooperate to permanently bond the vaginal wall locally to the support tissue. If the sutures and / or the anchors are made of absorbable material they will all eventually disappear and the fused scars will provide the permanent bonding. If the anchors are made of non-absorbable material they may remain where located. A plurality of such paired fused-scar bonds may be generated, at the surgeon's discretion, to ensure adequate support for the repaired vagina. The apparatus and method can be readily adapted to similarly effect deliberate, local, beneficial bonding between other adjacent living tissues in a patient.

Owner:KARRAM MICKEY M

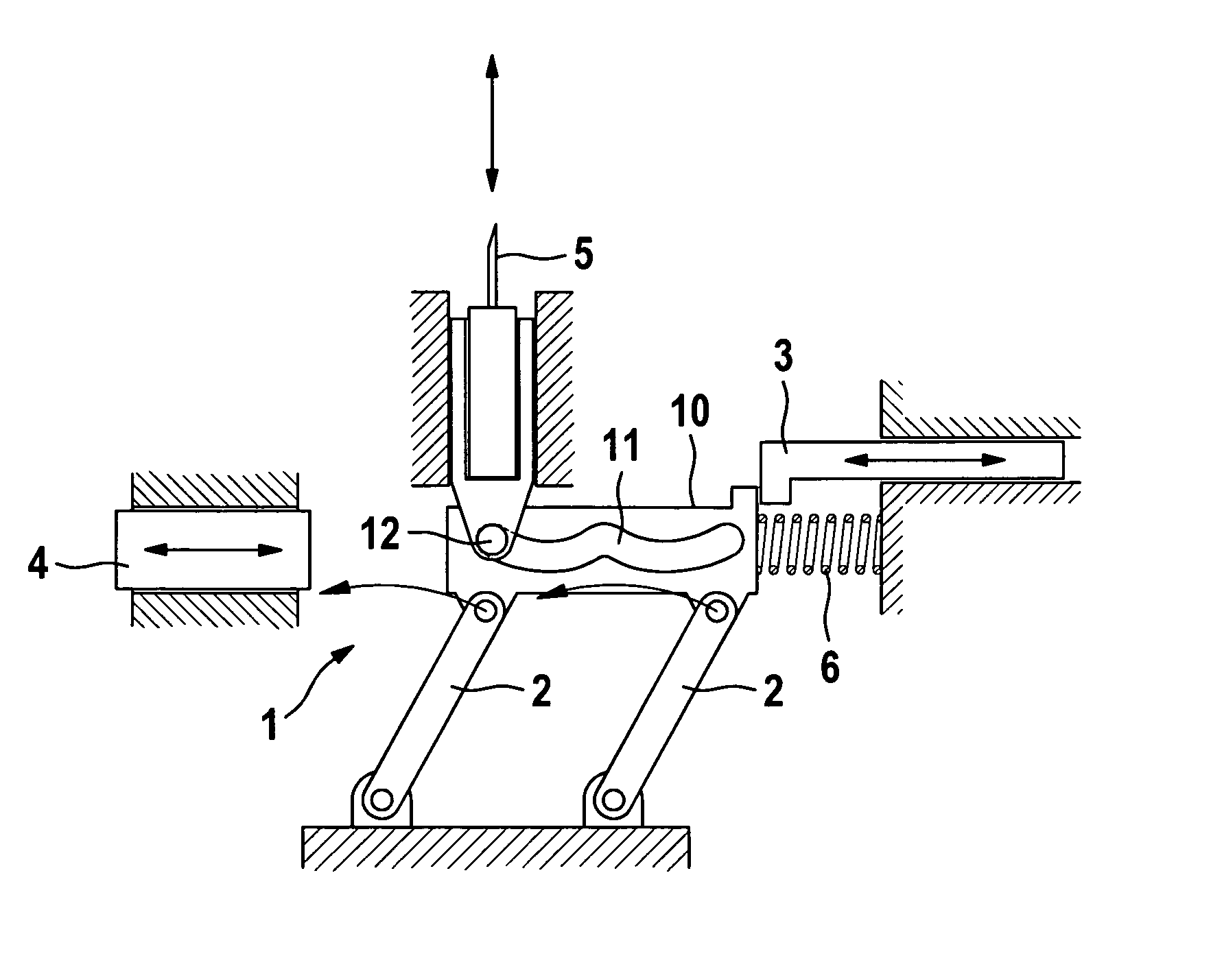

Puncturing System For Collecting Body Fluid Sample

InactiveUS20080262388A1Avoid oscillationMicrosampler puncturing systems may be improvedSensorsPackagingPuncturingSample collection

The invention relates to a microsampler puncturing system for collecting a body fluid from a body part, comprising a sample collection unit having a piercing element, and a puncturing instrument having a drive, by which a sample collection unit is movable on a movement path for piercing the piercing element into the skin of the body part and withdraw it again by means of a piercing and retraction movement, a setting device for setting the puncturing depth of the piercing wound to be generated, and a control device for controlling the piercing and retraction movement having the following sequentially executed movement phases: a forward phase (V), in which the piercing element is pierced up to a defined puncturing depth (dm), a retraction phase (R1), in which the piercing element is partially retracted by a retraction distance (Δd) and is decelerated toward the end of the retraction phase (R1), so that it remains projecting into the skin at a defined residual puncturing depth (dr), and a collecting phase (S), in which the piercing element projects into the skin and a body fluid sample is absorbed by the sample collection unit. The setting device is adapted for the defined puncturing depth is settable independently of the chronological mean <dr> of the defined residual puncturing depth (dr), with reference to the collecting phase.

Owner:ROCHE DIABETES CARE INC

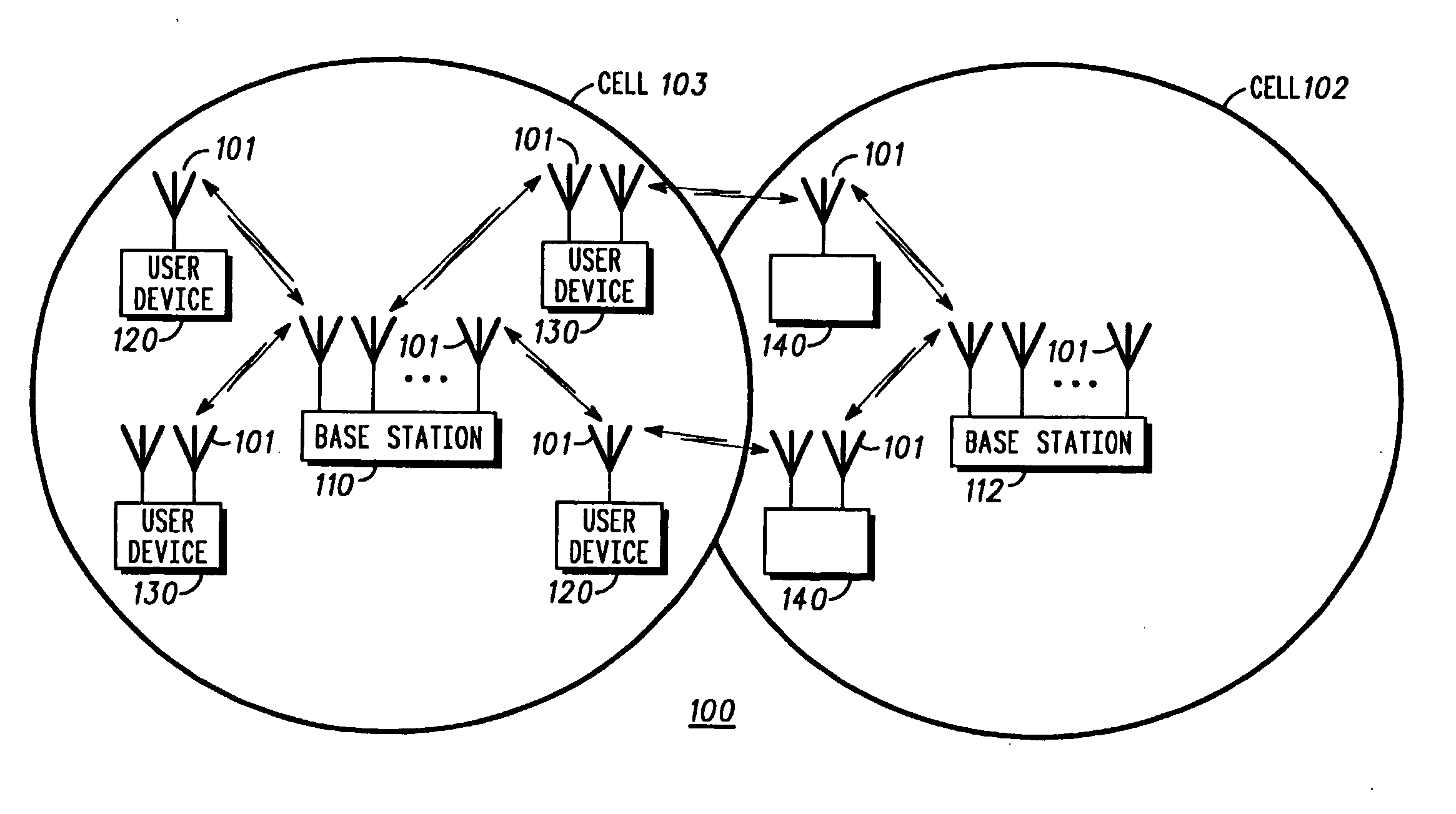

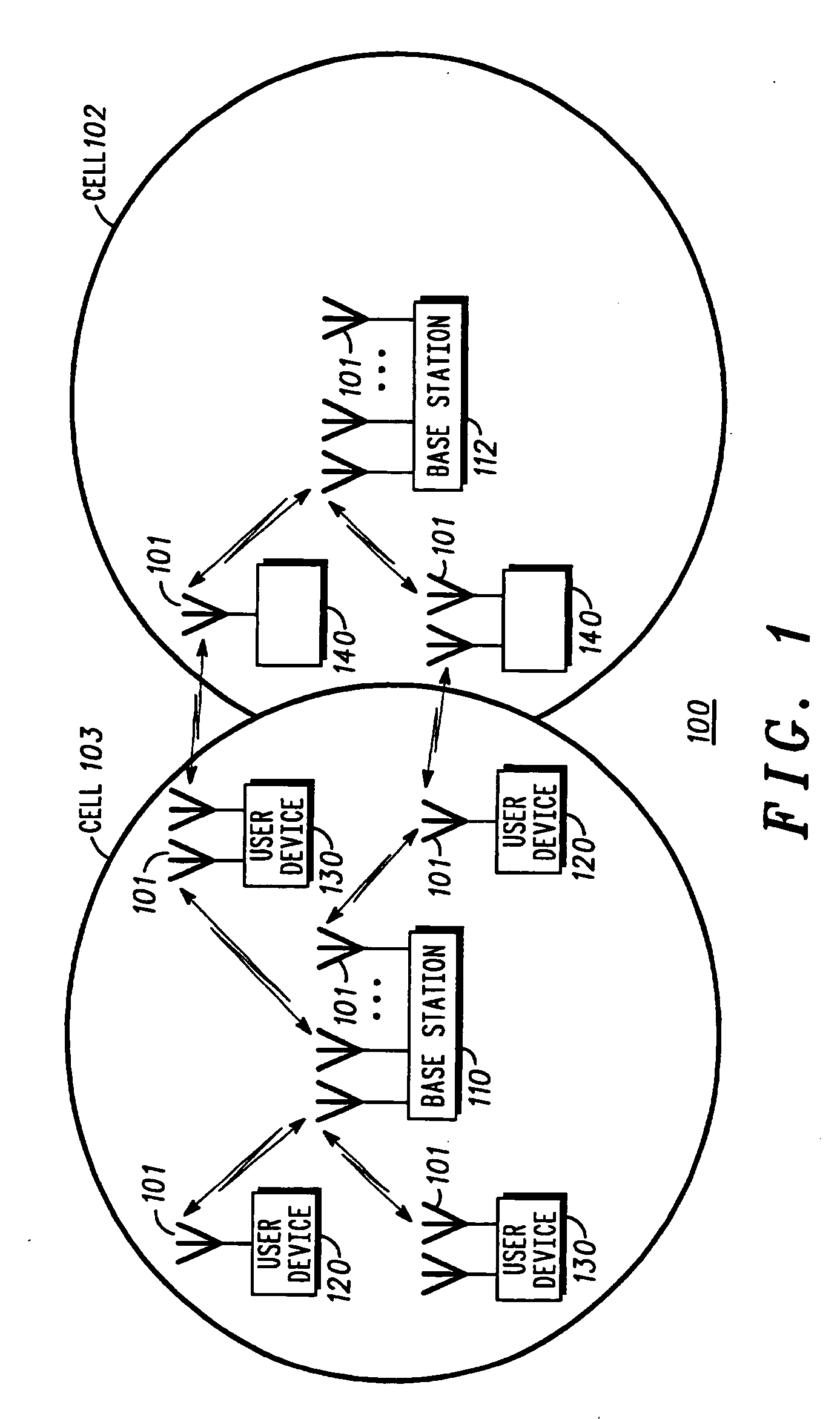

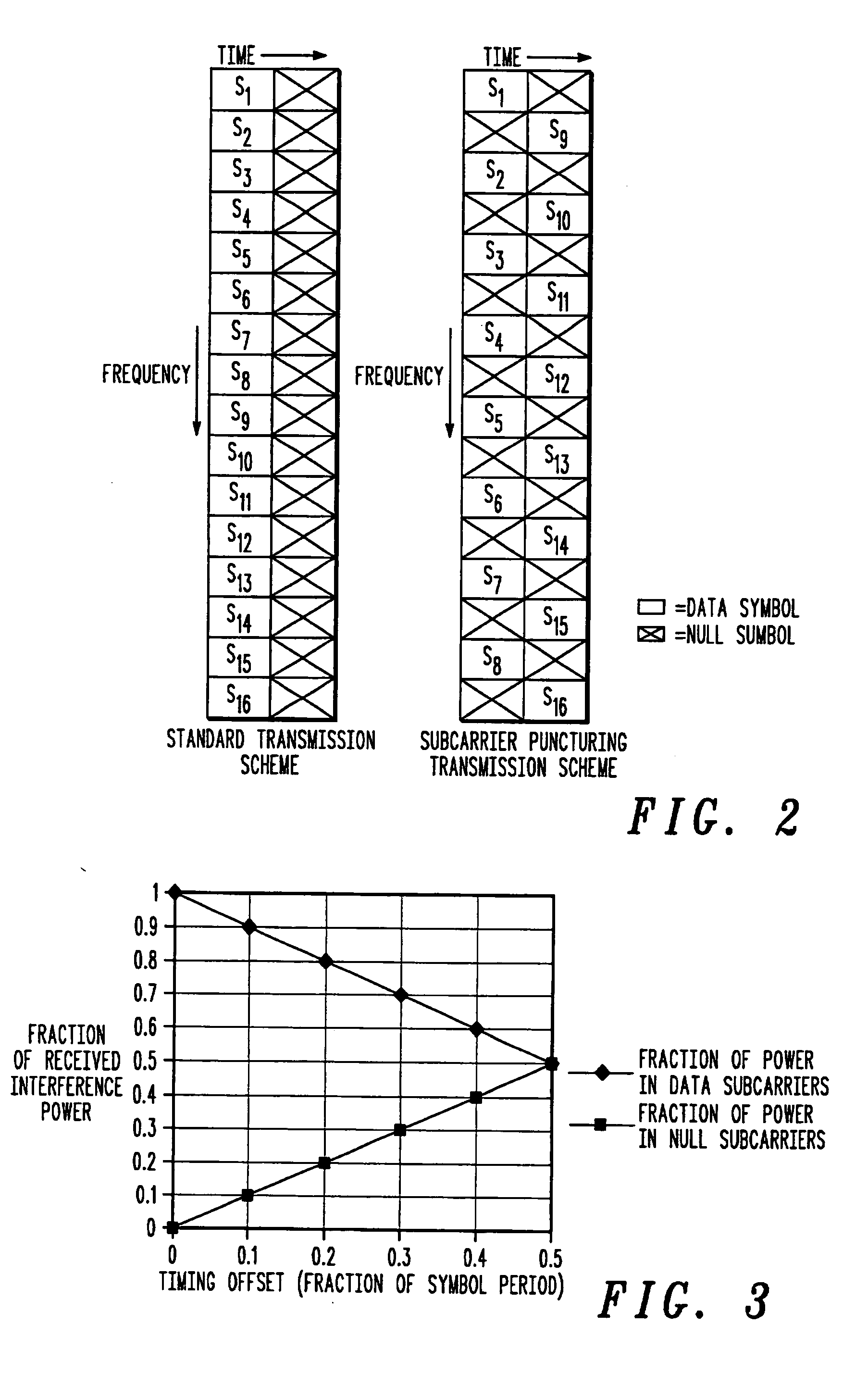

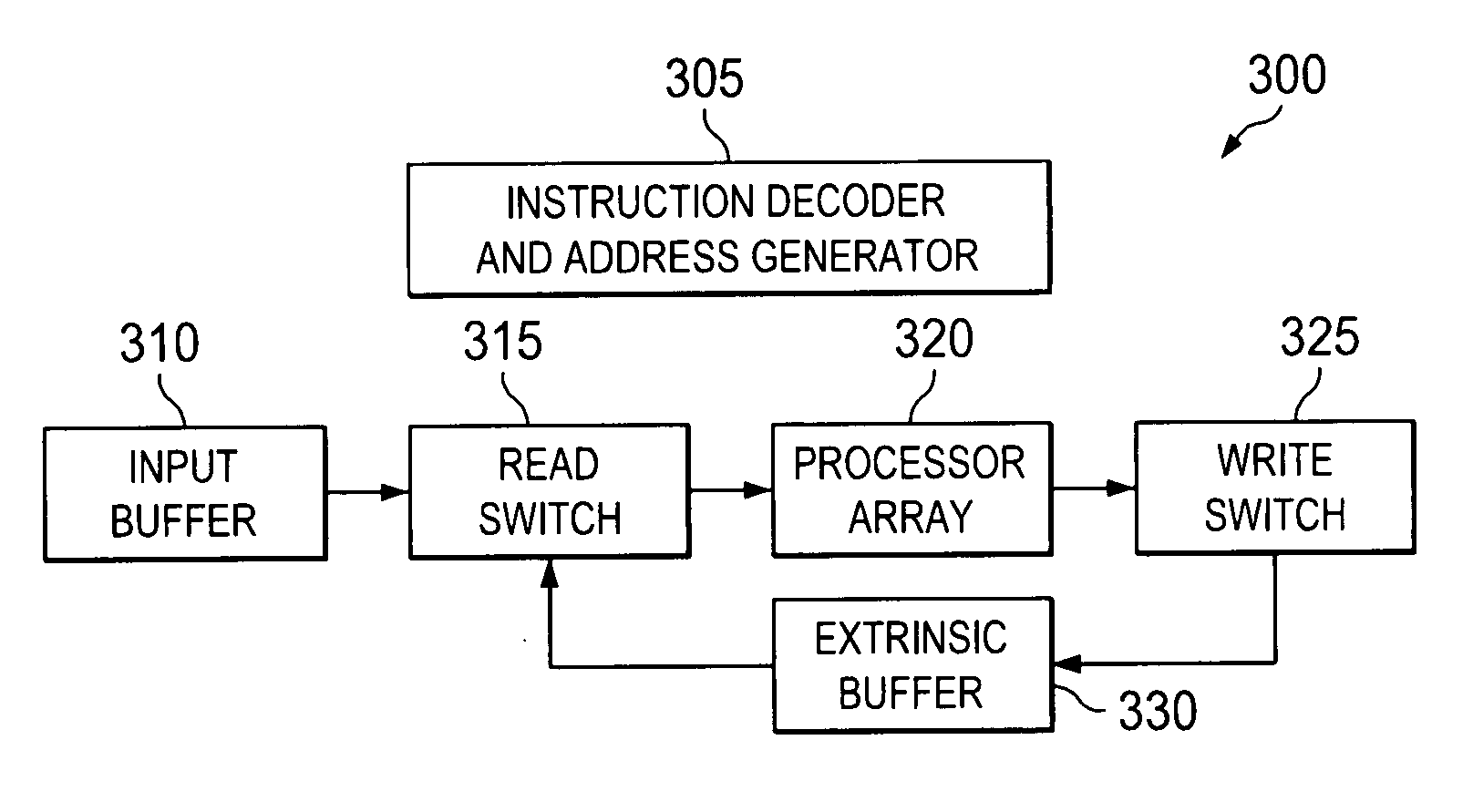

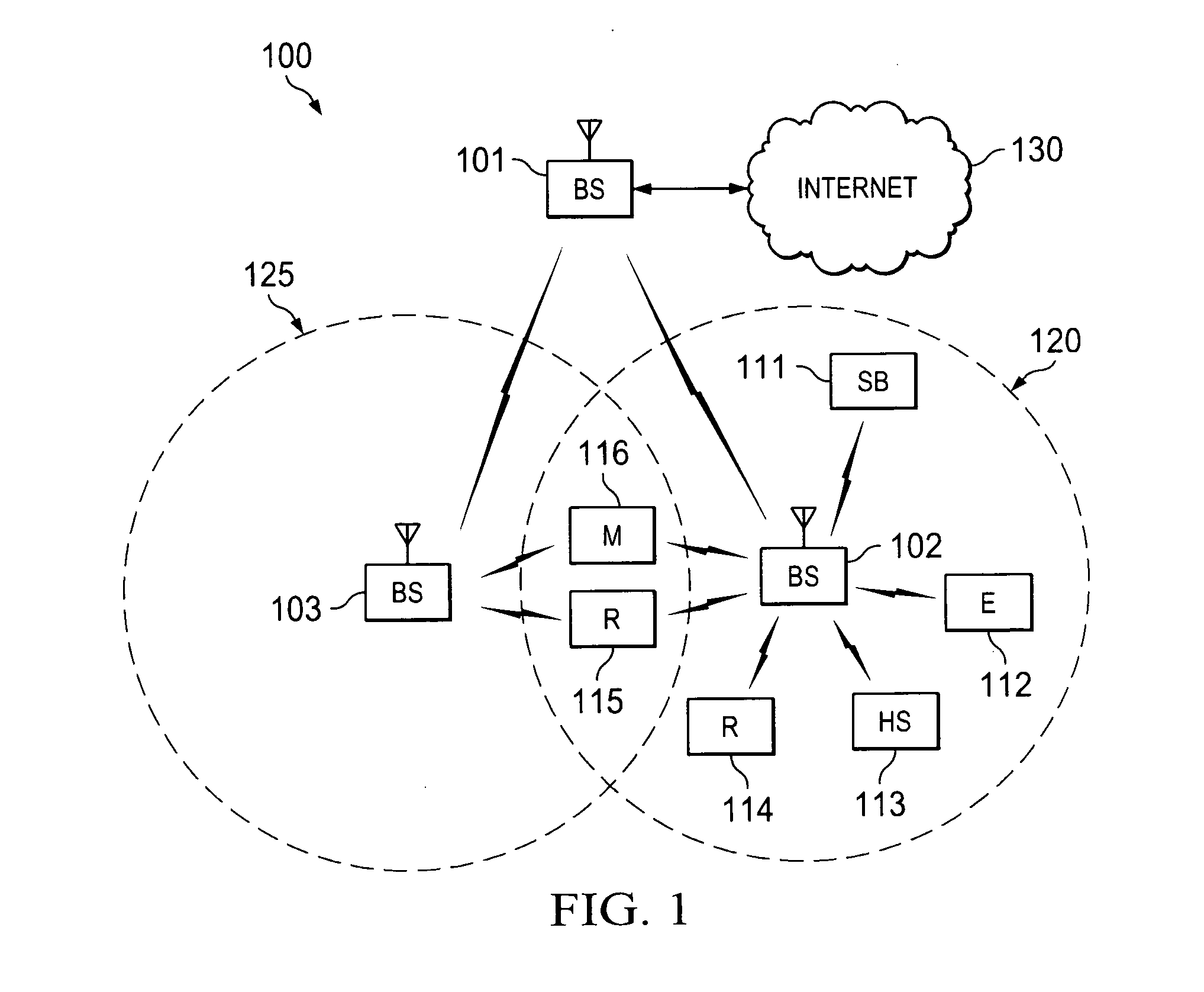

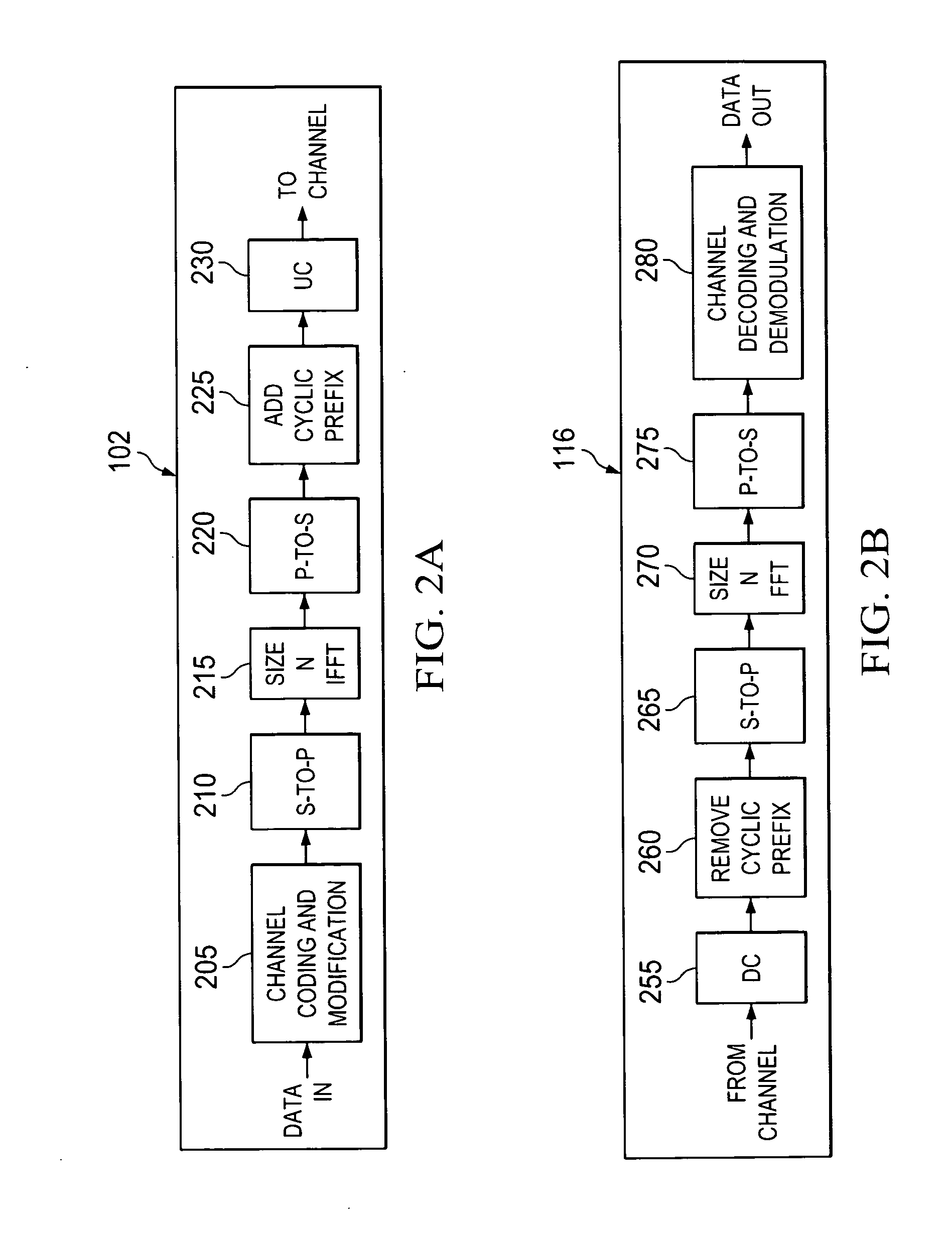

Method and system for interference averaging in a wireless communication system

A family of methods for interference averaging in multicarrier systems, such as orthogonal frequency division multiplexing (OFDM) systems. The methods can provide interference averaging in situations where an interfering co-channel is either partially or fully loaded. For partially loaded systems, subcarrier puncturing, frequency domain repetition, time domain repetition, and hybrid time-frequency repetition schemes are provided. For systems using adaptive modulation / coding rates, lower rates and transmit power can be selected in order to perform interference averaging in time-spread and frequency-spread OFDM schemes. In systems with downlink power control, frequency domain mixing can be used to perform interference averaging.

Owner:MOTOROLA SOLUTIONS INC

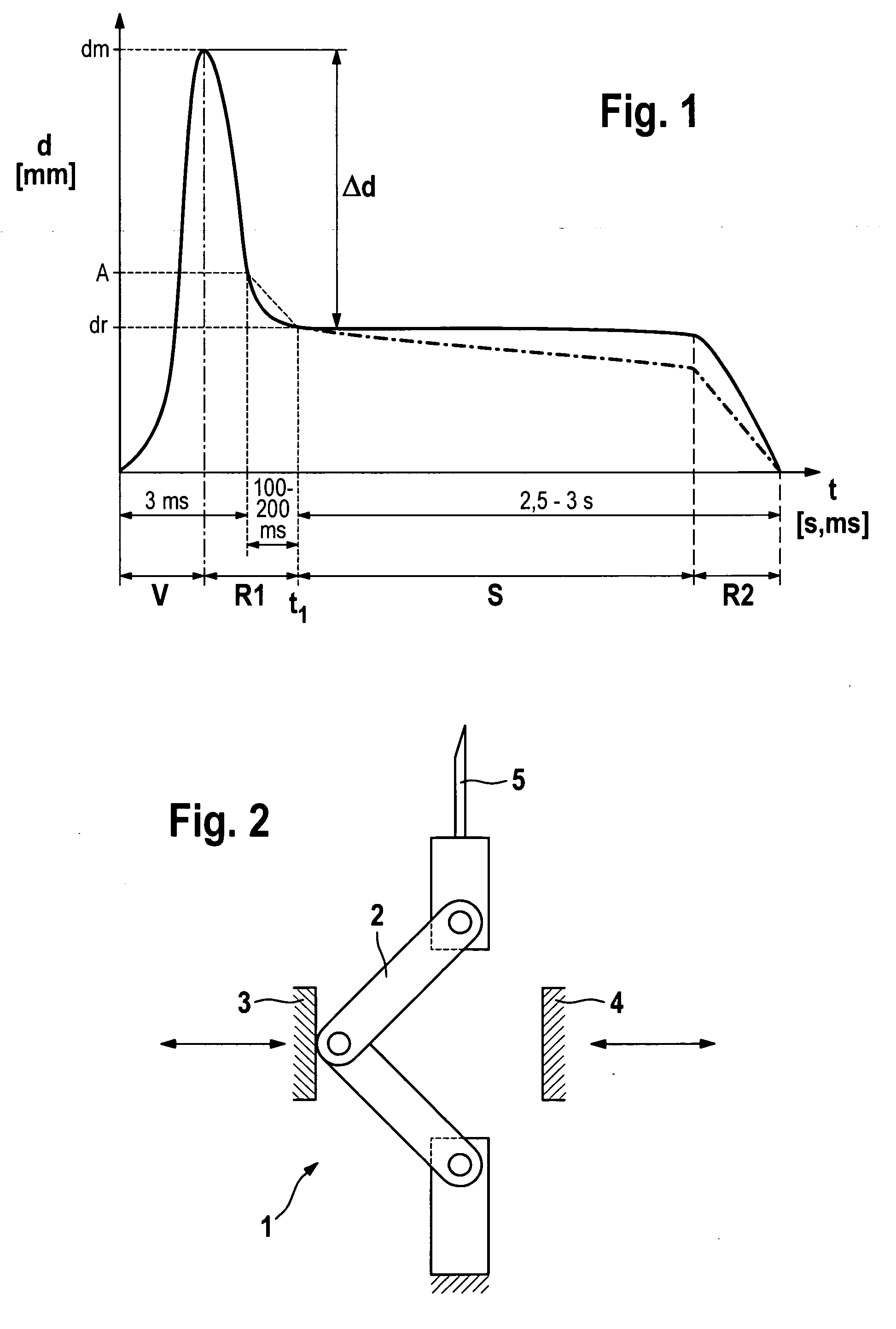

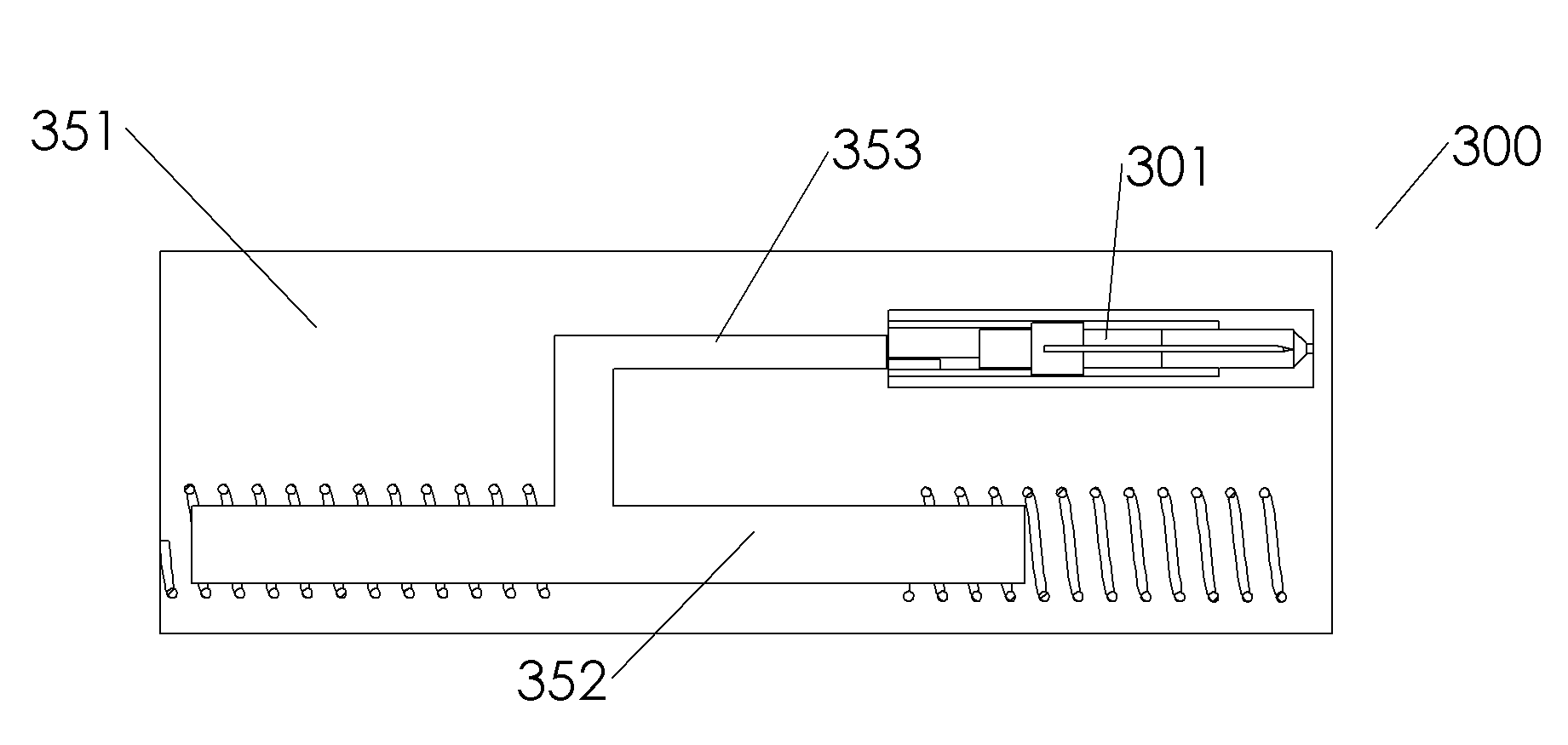

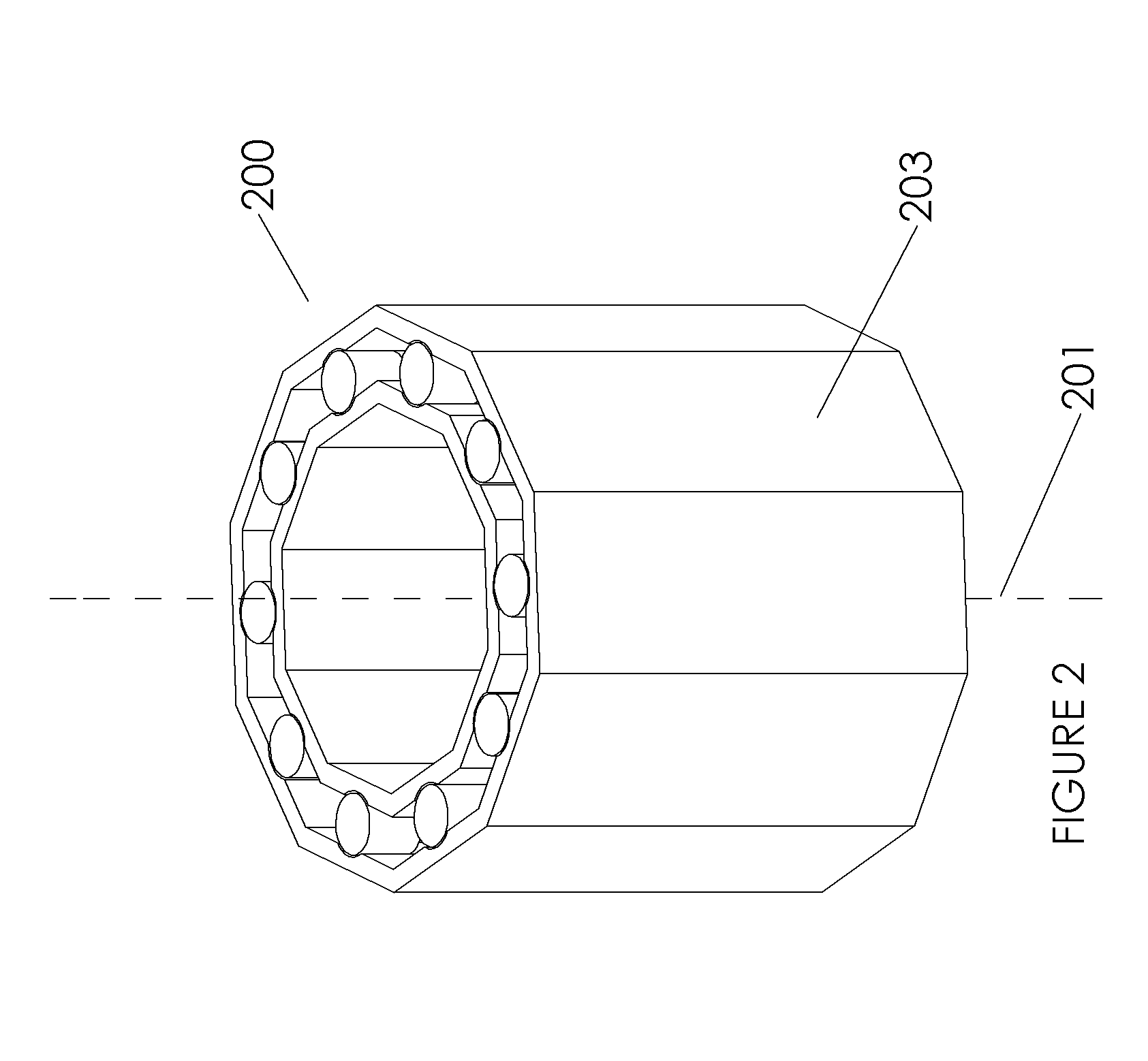

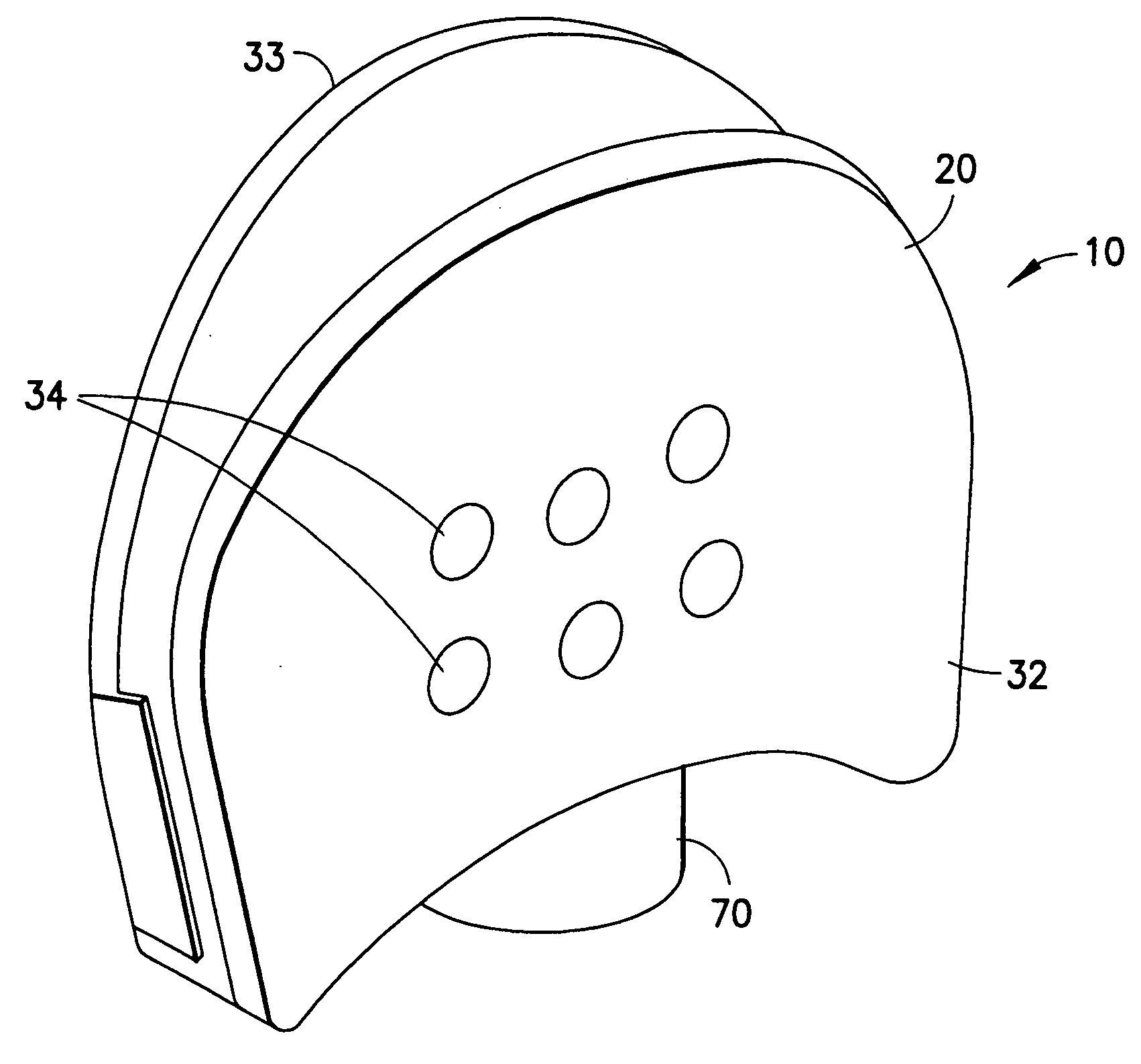

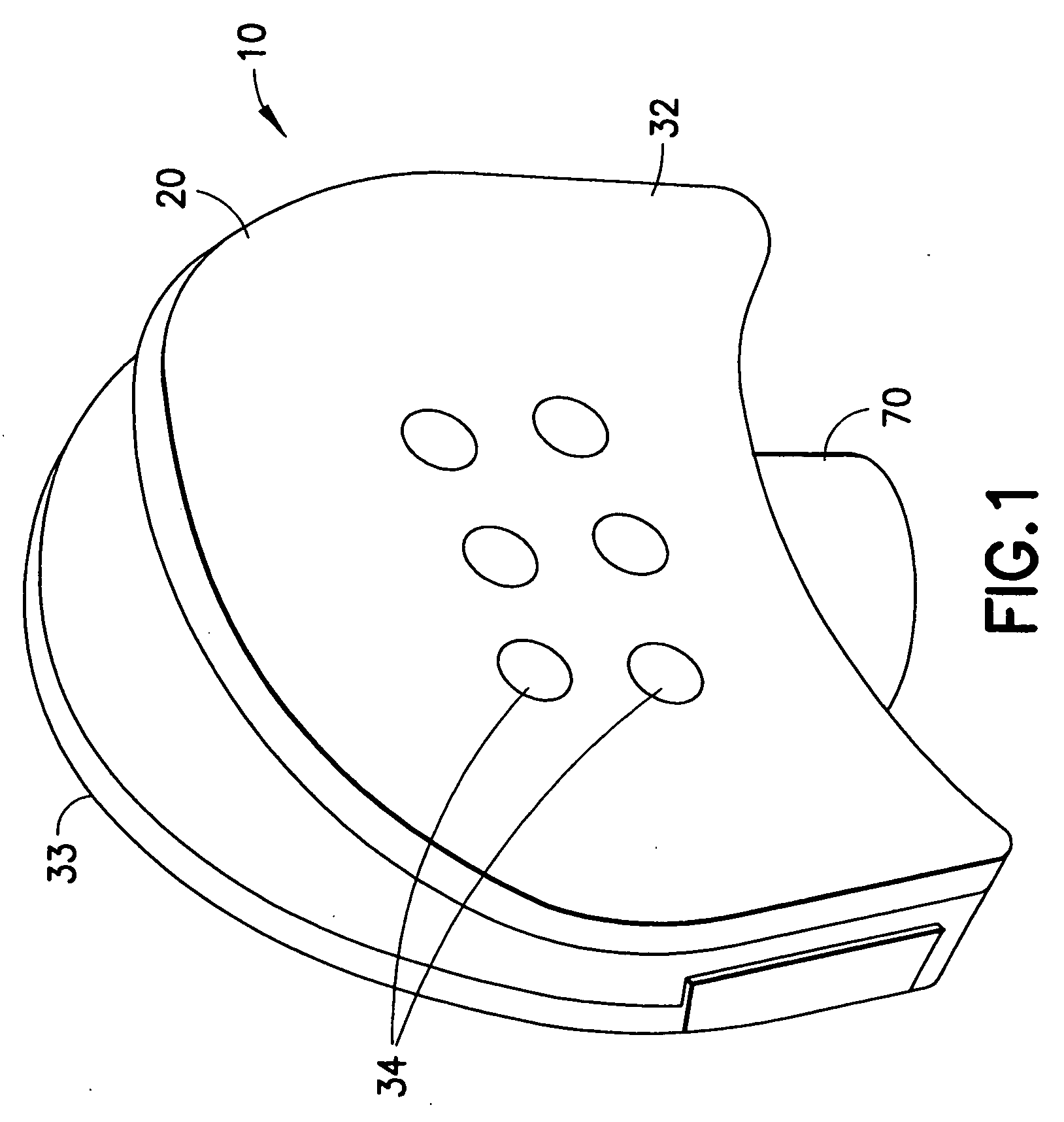

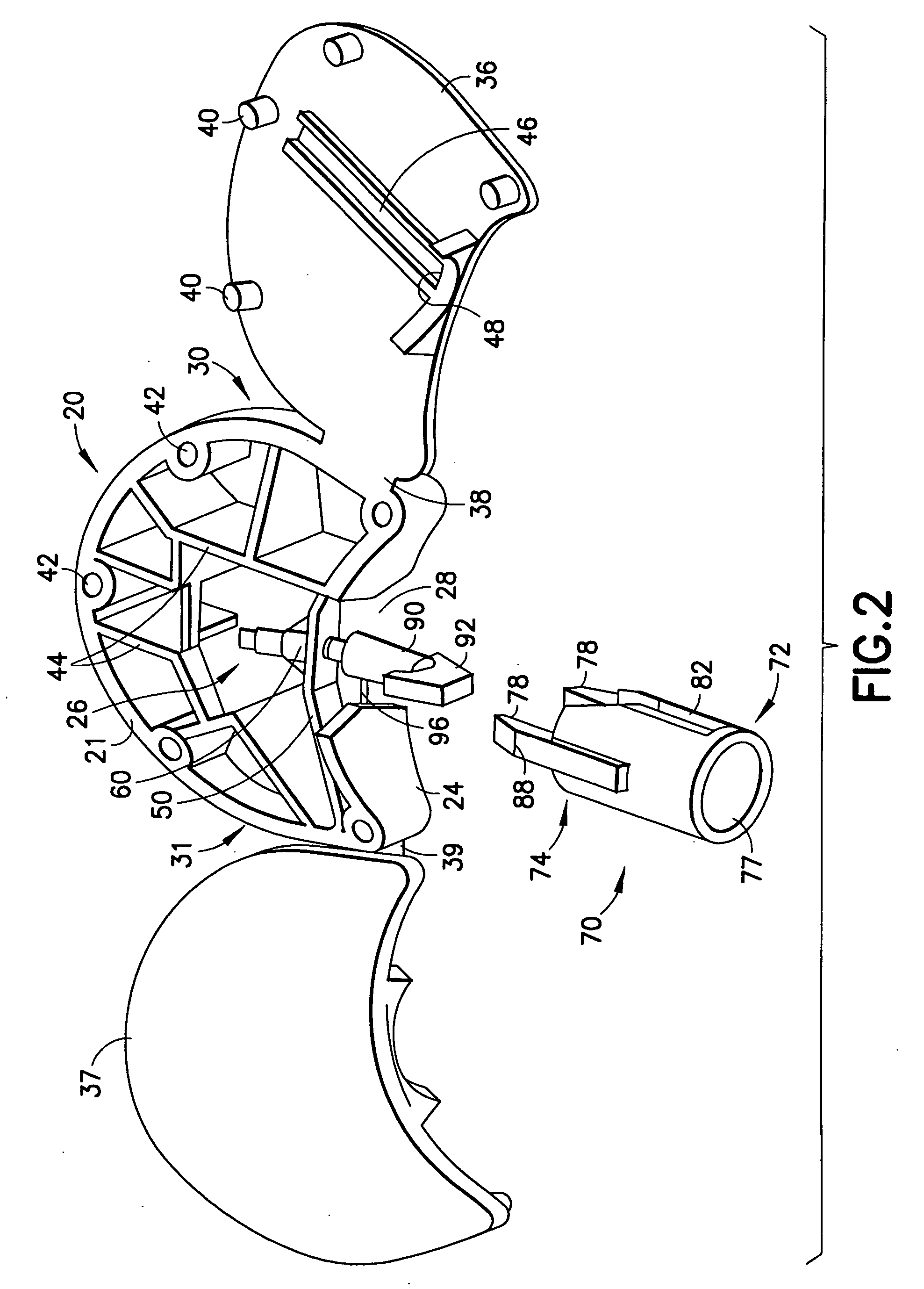

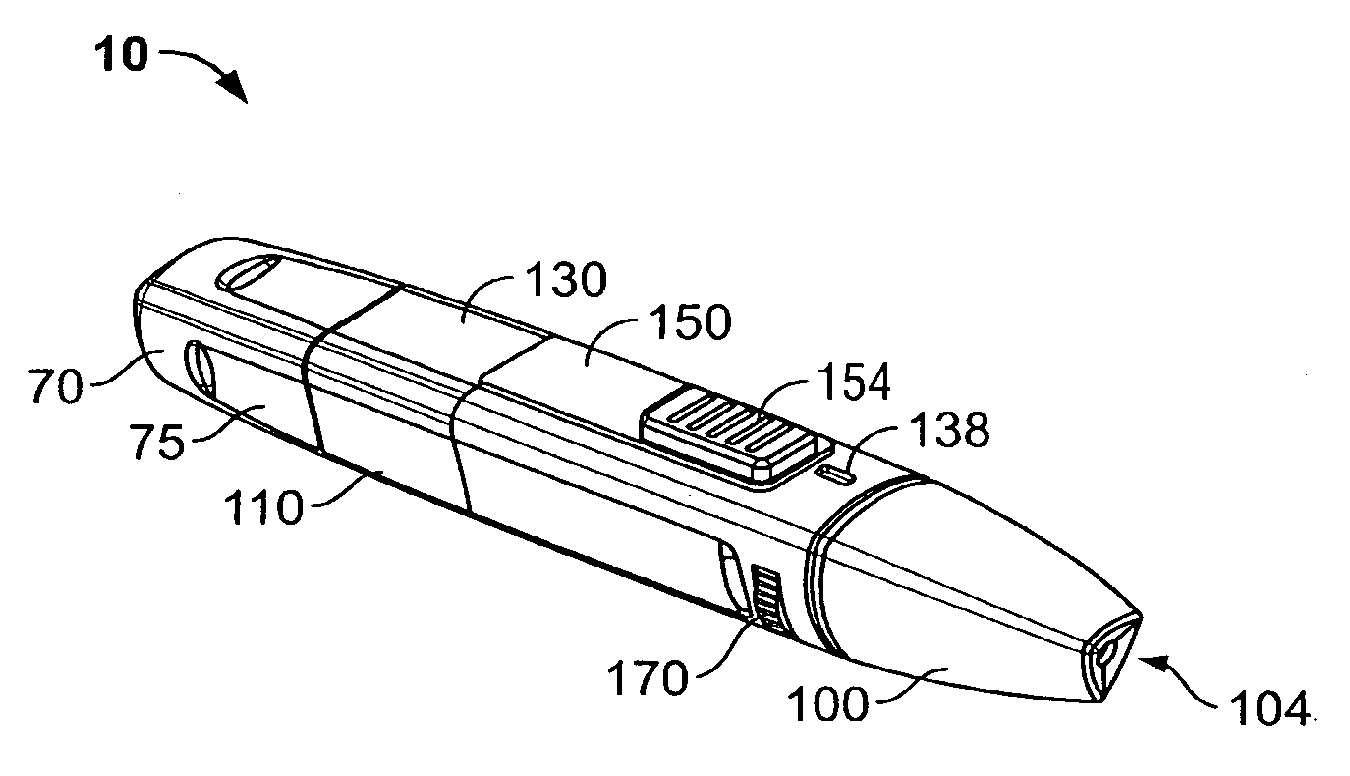

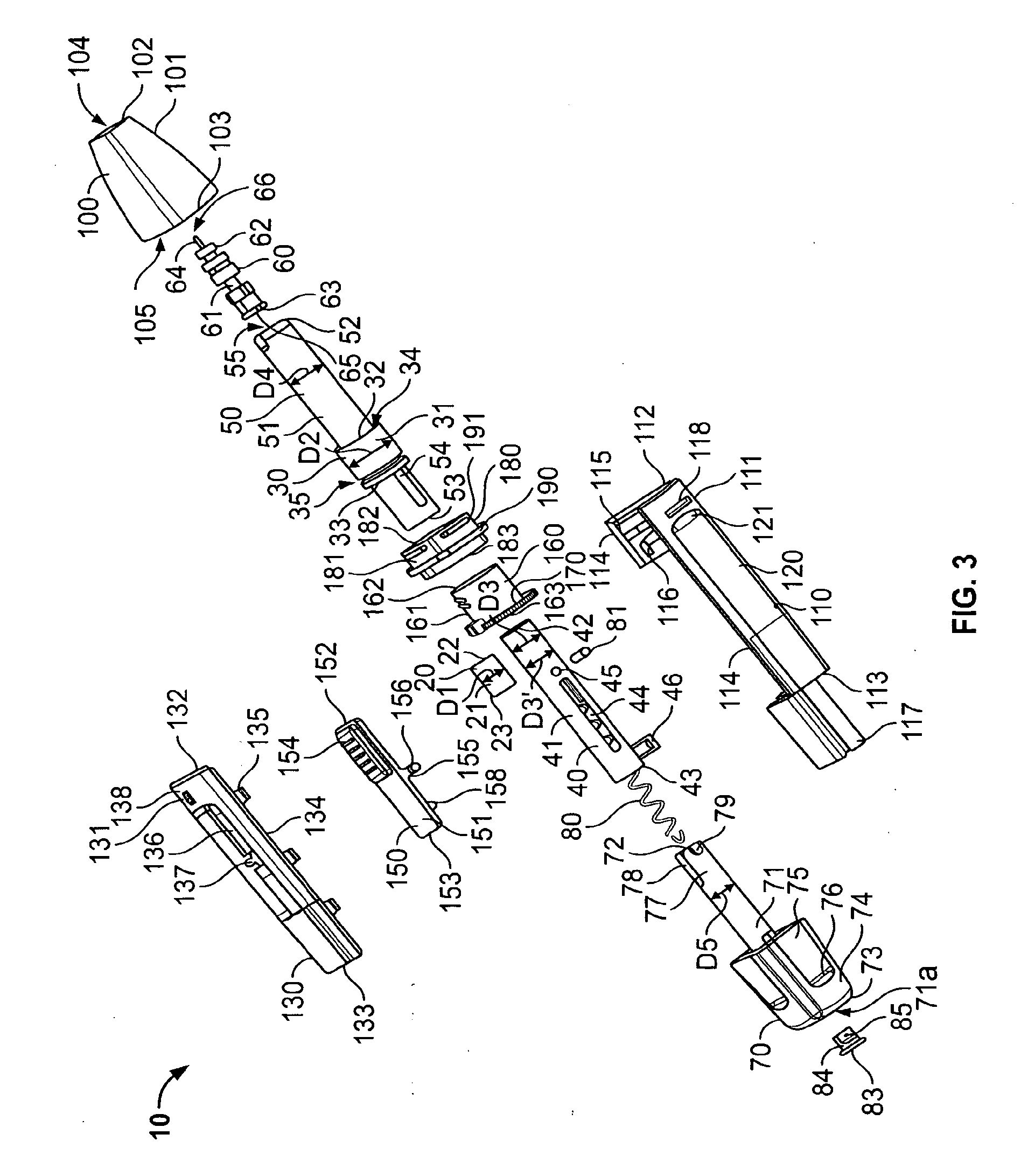

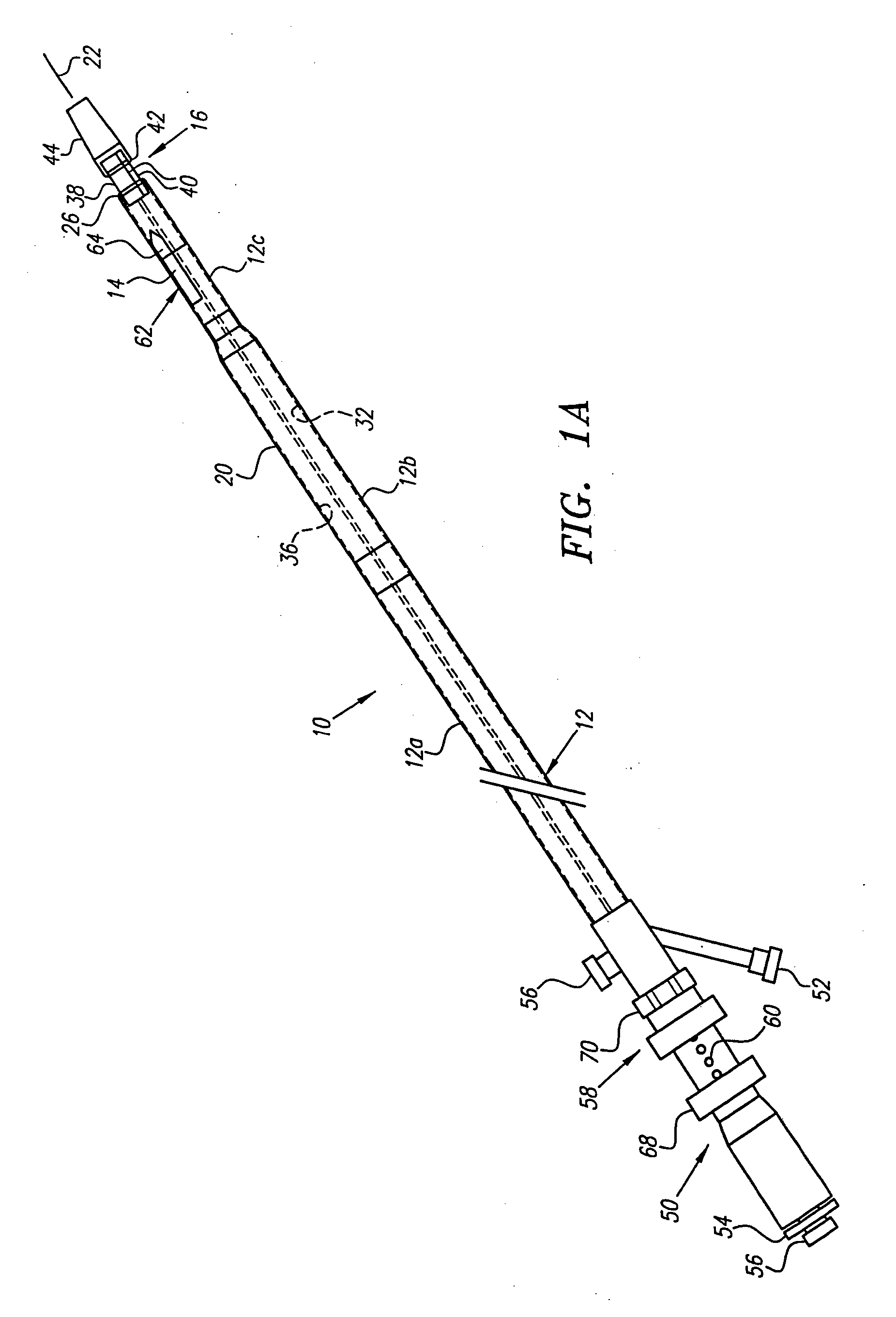

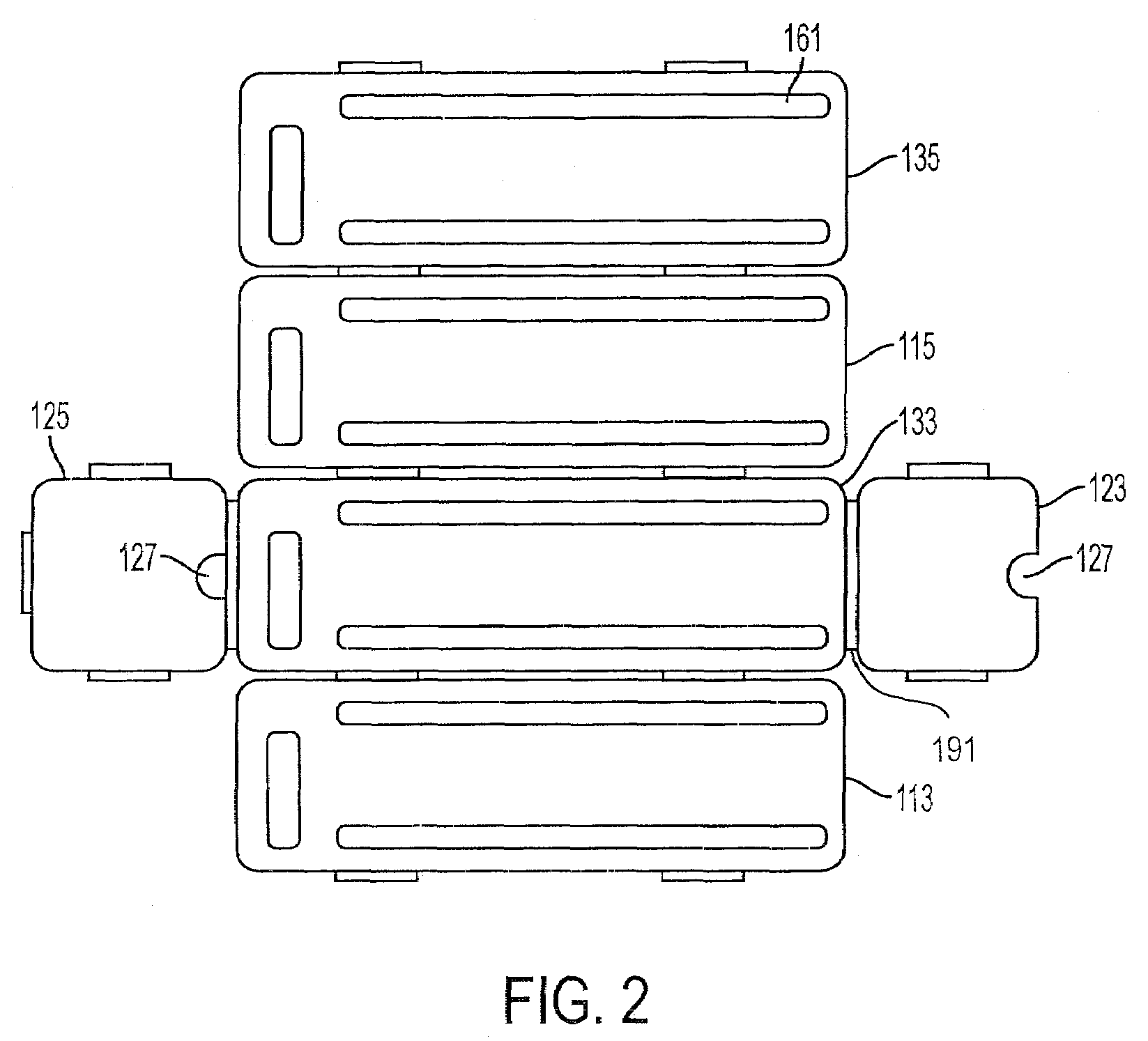

Lancet Cartridges and Lancing Devices

ActiveUS20080109024A1Shorten the counting processLow opportunityCatheterDiagnostic recording/measuringEngineeringPuncturing

A lancet cartridge has a U-shaped support with a pair of anchor portions, a base portion, and a pair of deformable leg portions connecting the anchor portions to the base portion. The pair of deformable leg portions change shape from an initial shape to an extended shape in response to an external applied force and recover to a retracted shape upon removal of the force. The lancet cartridge also has a lancet having a tip end, an opposing base end, and an axis extending between the tip end and the base end. A portion of the lancet is disposed between the pair of deformable leg portions of the U-shaped support. The lancet is movable between a starting position, an extended puncturing position, and an ending position along the axis of the lancet in a path defined by the U-shaped support. When the lancet is in the starting position, the tip end of the lancet is disposed at least partially through the base portion of the U-shaped support, and the U-shaped support is in the initial shape. When the lancet is in the extended puncturing position, the tip end of the lancet is extended through the base of the U-shaped support, and the U-shaped support is in the extended shape. When the U-shaped support recovers to its retracted shape upon removal of the force, the lancet is retracted to the end position.

Owner:AGAMATRIX INC

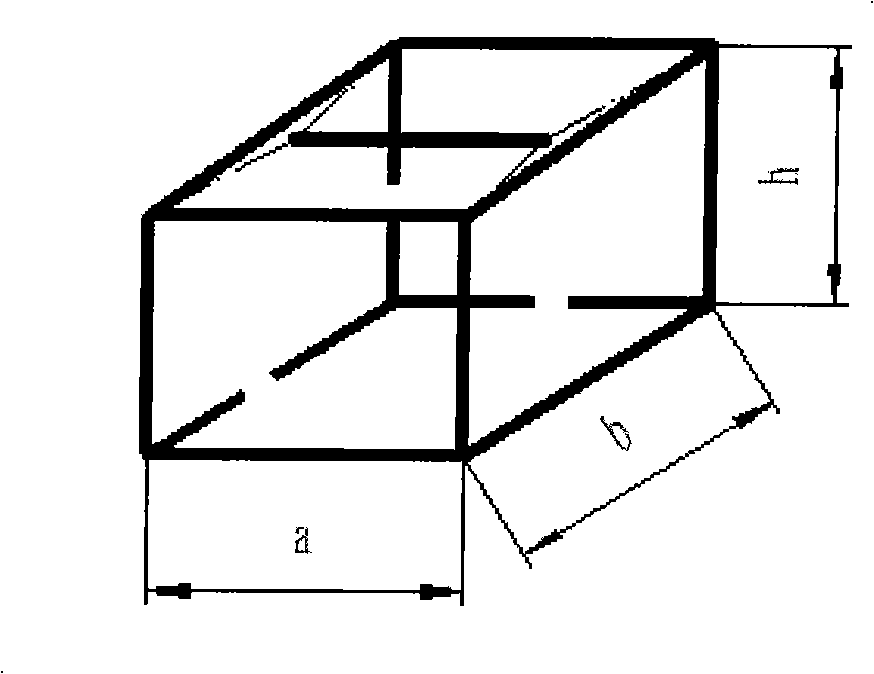

Interleaving and puncturing apparatus and method thereof

ActiveUS20150333769A1Code conversionError correction/detection using interleaving techniquesWrite bitComputer science

An apparatus and method for interleaving and puncturing are provided. The apparatus includes: an interleaver formed of a plurality of columns and rows, configured to perform interleaving by writing bits input to the interleaver in the plurality of columns and reading the bits from each row of the plurality of columns in which the bits are written; and a puncturer configured to puncture a predetermined number of bits among the bits read from the interleaver.

Owner:SAMSUNG ELECTRONICS CO LTD +1

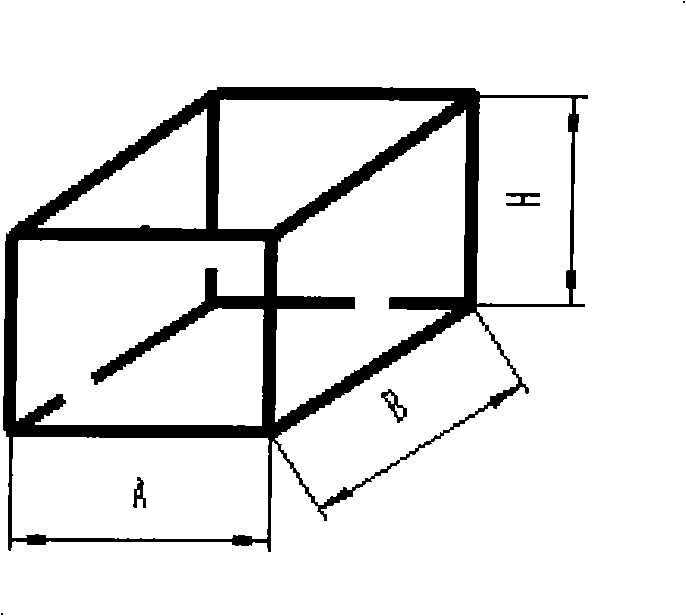

Transmitting apparatus and puncturing method thereof

InactiveUS20150082118A1Improve decoding performanceError correction/detection using multiple parity bitsCode conversionLow-density parity-check codeLow density

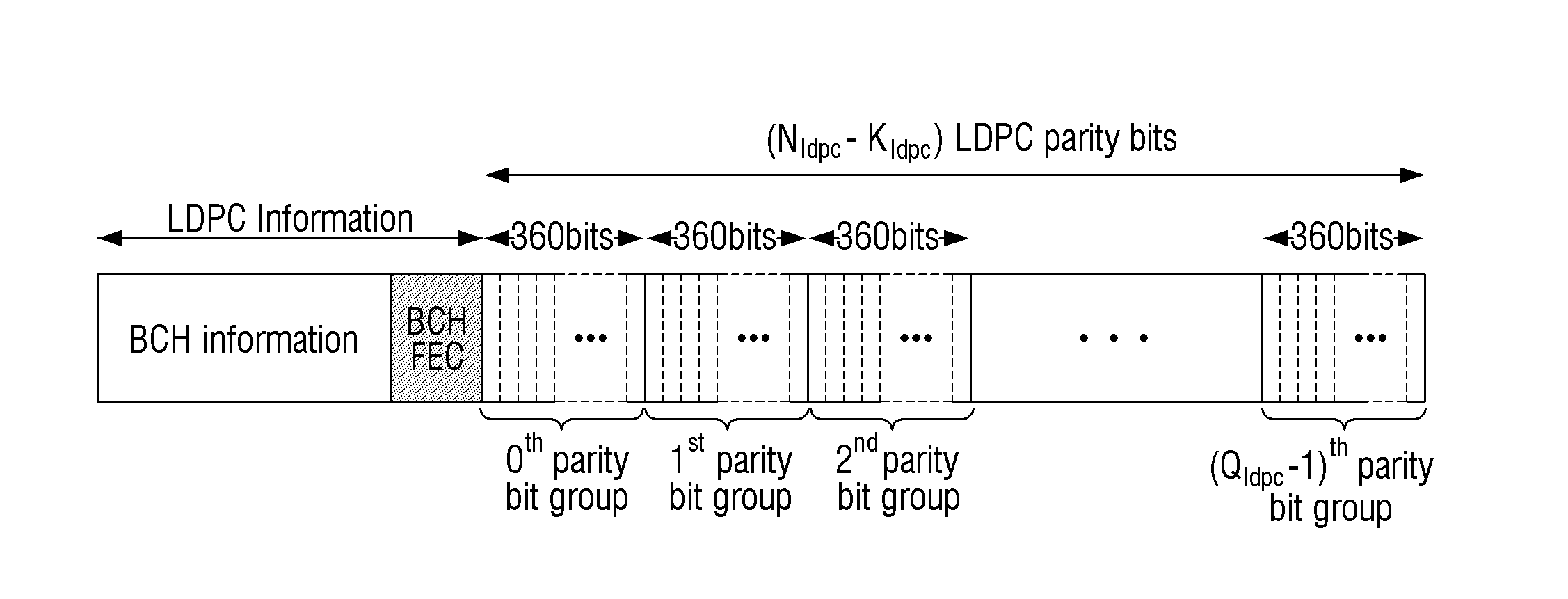

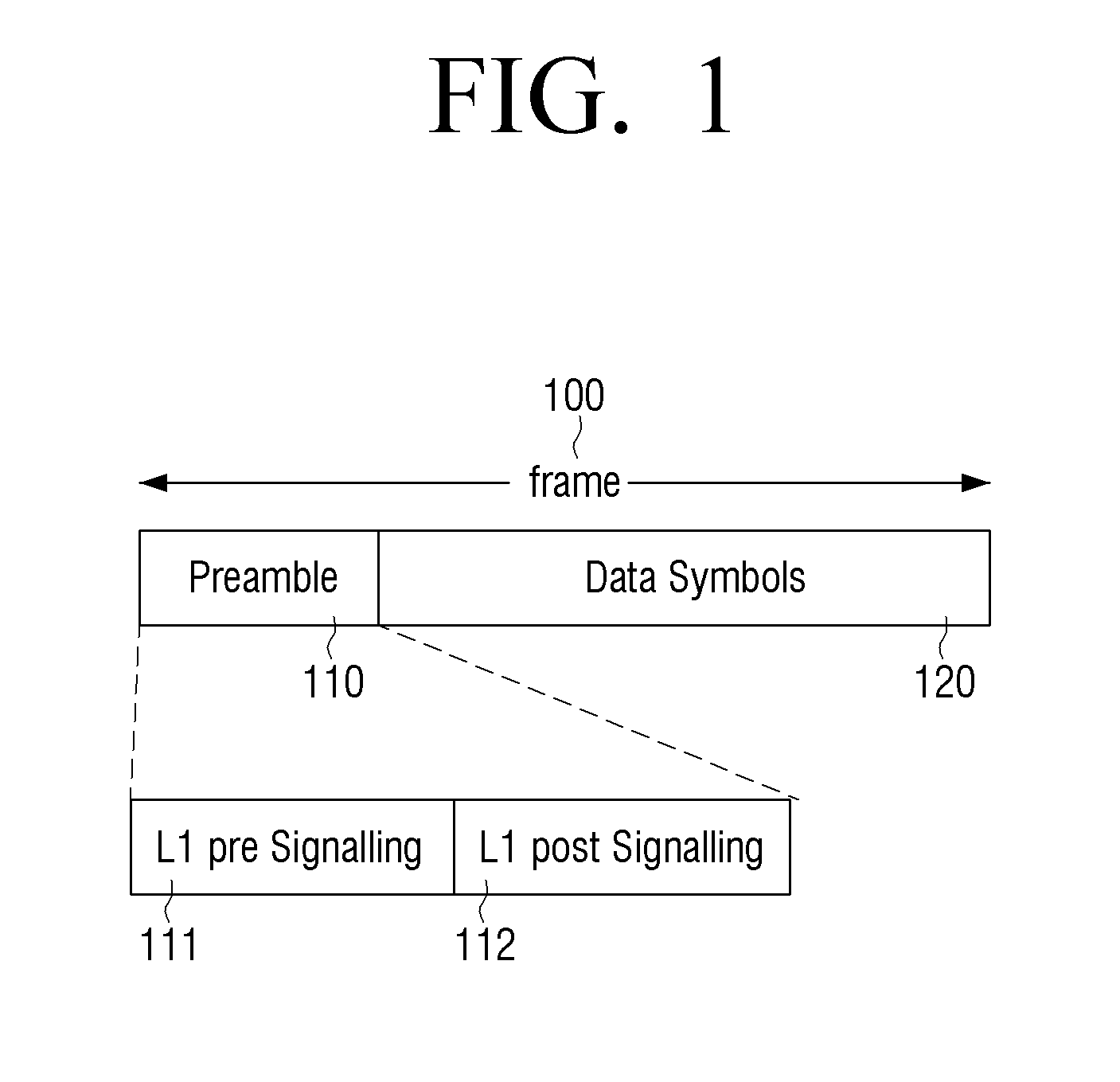

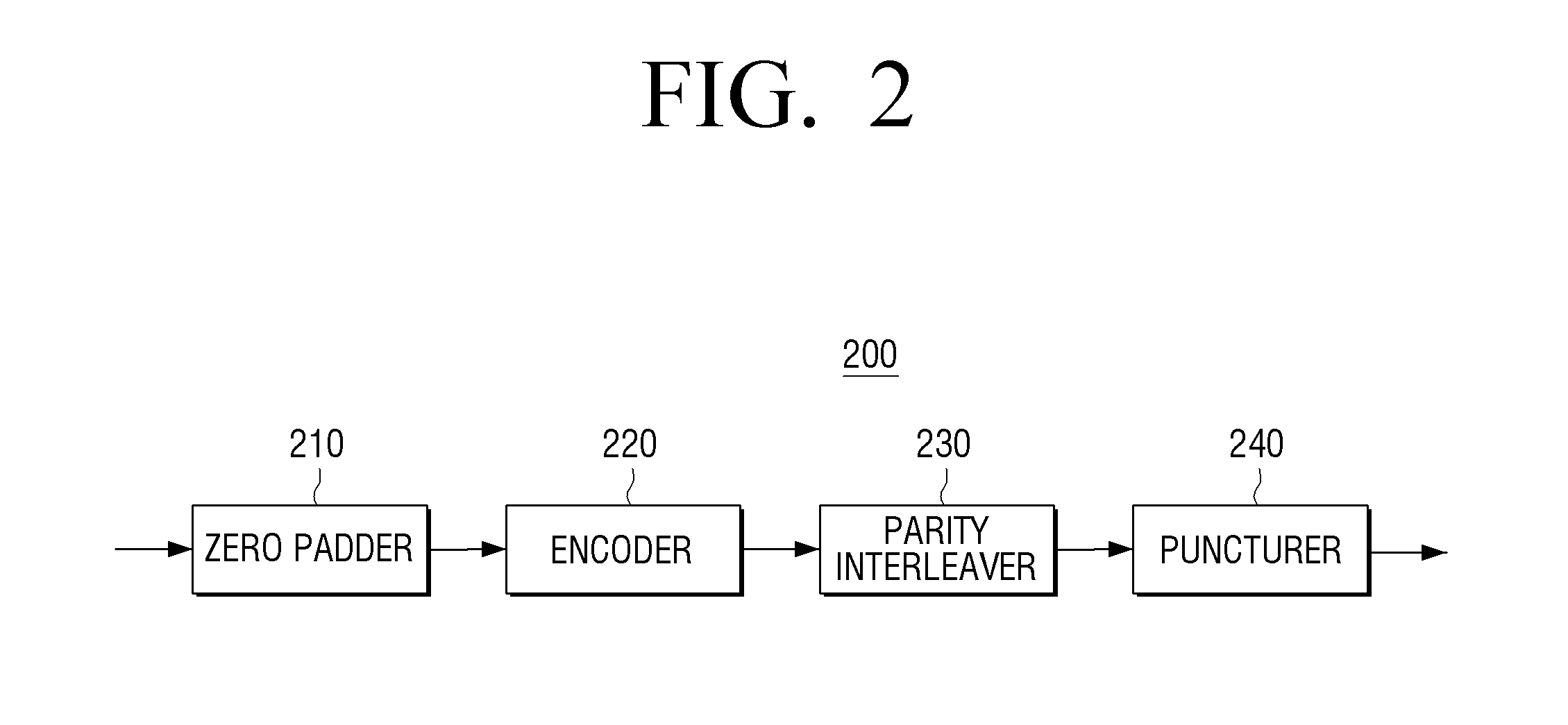

Provided are a transmitting apparatus, a receiving apparatus and methods of puncturing and depuncturing of parity bits. The transmitting apparatus includes: a zero padder configured to pad at least one zero bit to input bits; an encoder configured to generate a Low Density Parity Check (LDPC) codeword by performing LDPC encoding with respect to the bits to which the at least one zero bit is padded; a parity interleaver configured to interleave LDPC parity bits constituting the LDPC codeword; and a puncturer configured to puncture at least a part of the interleaved LDPC parity bits based on a pre-set puncturing pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

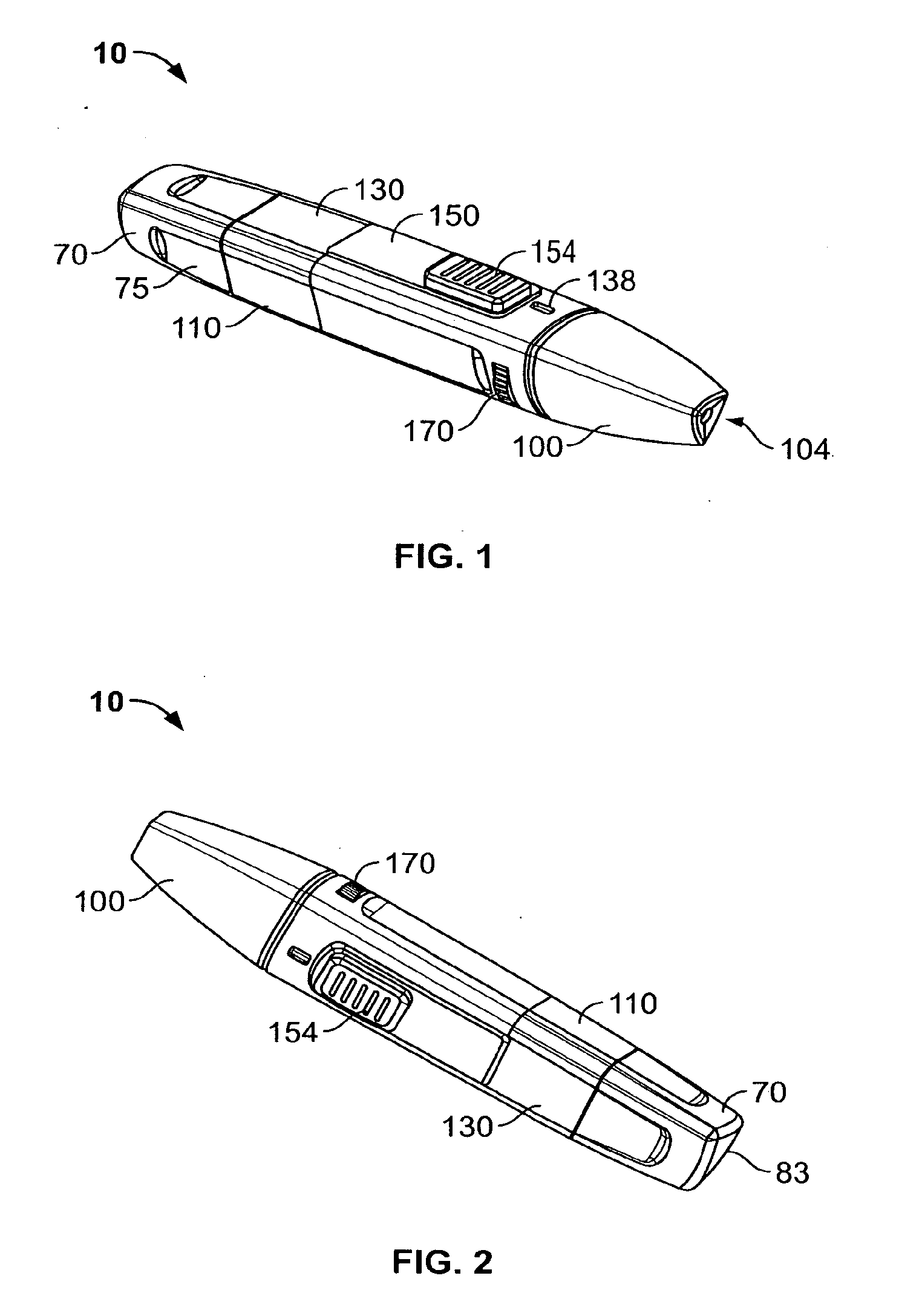

Finger activated lancet device

ActiveUS20060264997A1Easy to manufactureEasy to assembleCatheterDiagnostic recording/measuringEngineeringActuator

A lancet device includes a housing with a cantilever spring extending therein and defining a lancet having a puncturing end on the cantilever spring. An actuator extends within the housing through an opening at the forward end. The actuator includes an interfering engagement with the cantilever spring. Movement of the actuator into the housing through the forward end pivots the cantilever spring against its relaxed condition and then releases the engagement with the cantilever spring, thereby permitting the cantilever spring to pivot the lancet structure to an extended position with the puncturing end extending through the forward opening, and to return to the relaxed condition retracting the puncturing end back within the housing.

Owner:BECTON DICKINSON & CO

Puncturable catheter

Owner:WL GORE & ASSOC INC

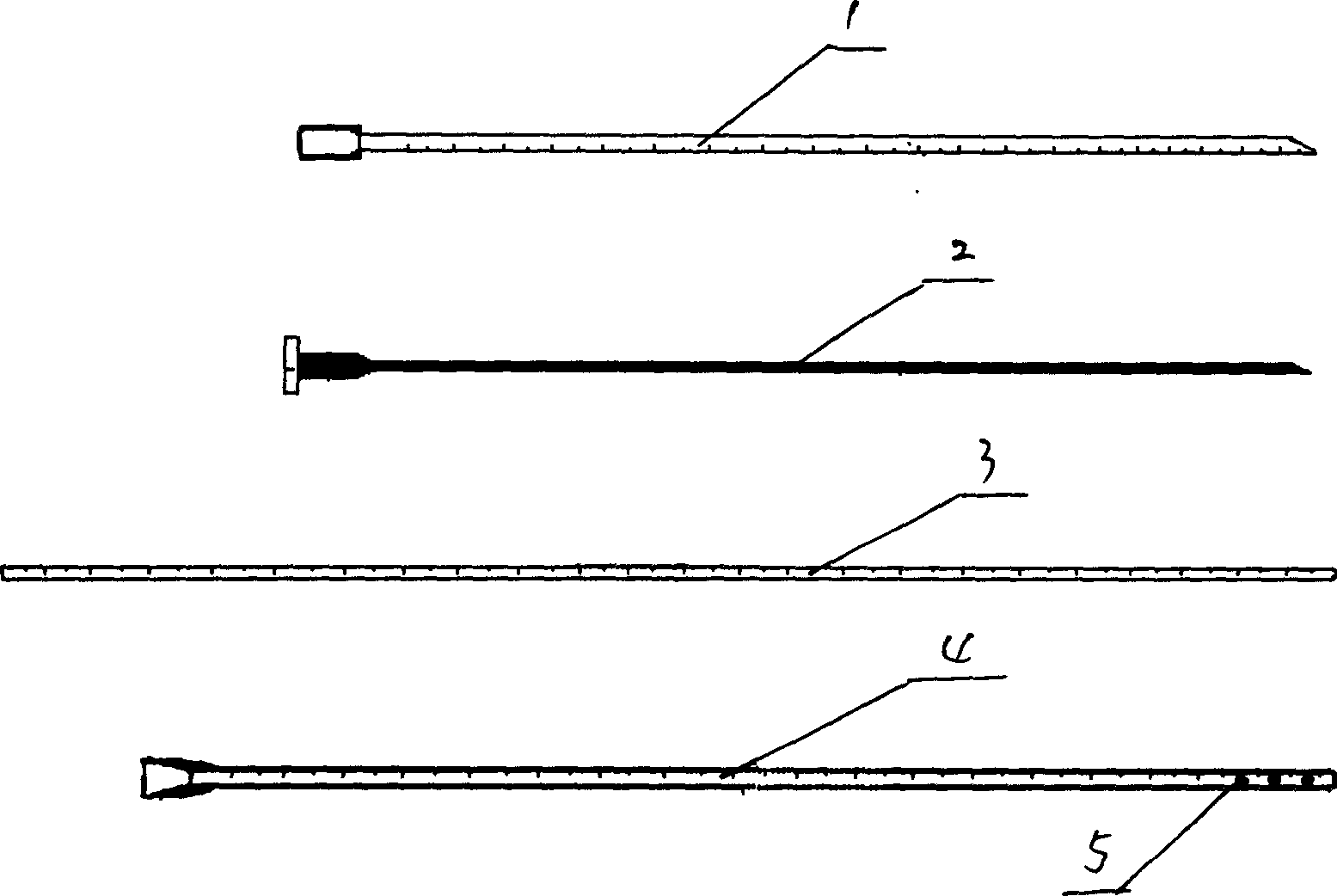

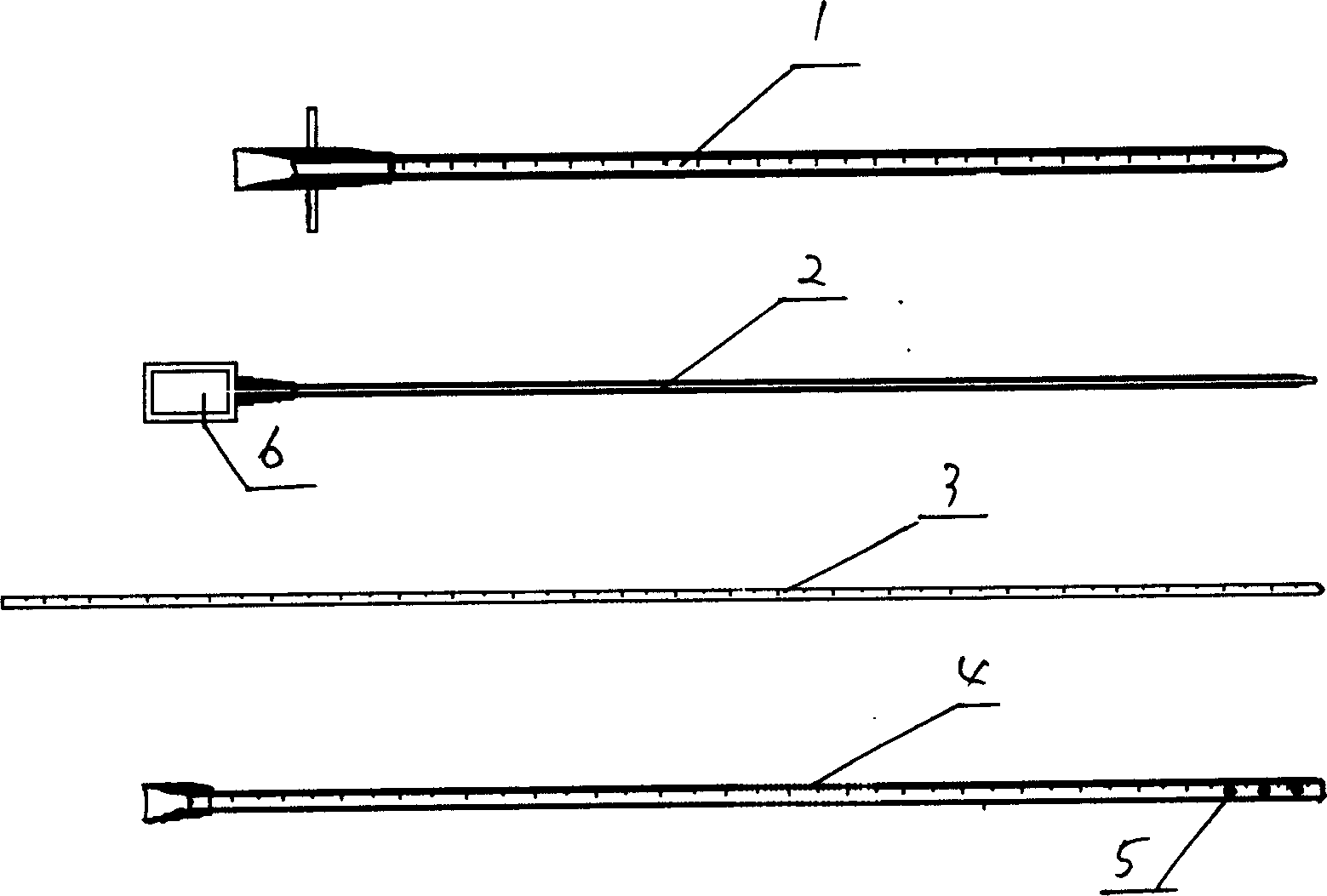

Cerebrospinal fluid puncturing drainer

The cerebrospinal fluid piercing drainer includes a piercing unit and an external draining unit. The piercing unit includes piercing needle, piercing sheath, guide wire and draining pipe. The piercing needle and the outside piercing sheath are made of stainless steel material and are used in piercing; the flexible guide wire of plastic-steel material with shape memory function is used in replacing the piercing needle; the draining pipe of soft silicone gel is used in replacing the piercing sheath and draining. During piercing, the piercing needle and the outside piercing sheath are first pierced into proper position, the piercing needle is then withdrawn and the guide wire is penetrated through the piercing sheath, and the piercing sheath is finally withdrawn and the draining pipe is fed along the guide wire to the cavity to be drained or fed to cerebral side room or even farther position under the monitoring with DSA. The draining pipe has external end connected to the draining unit.

Owner:何明利

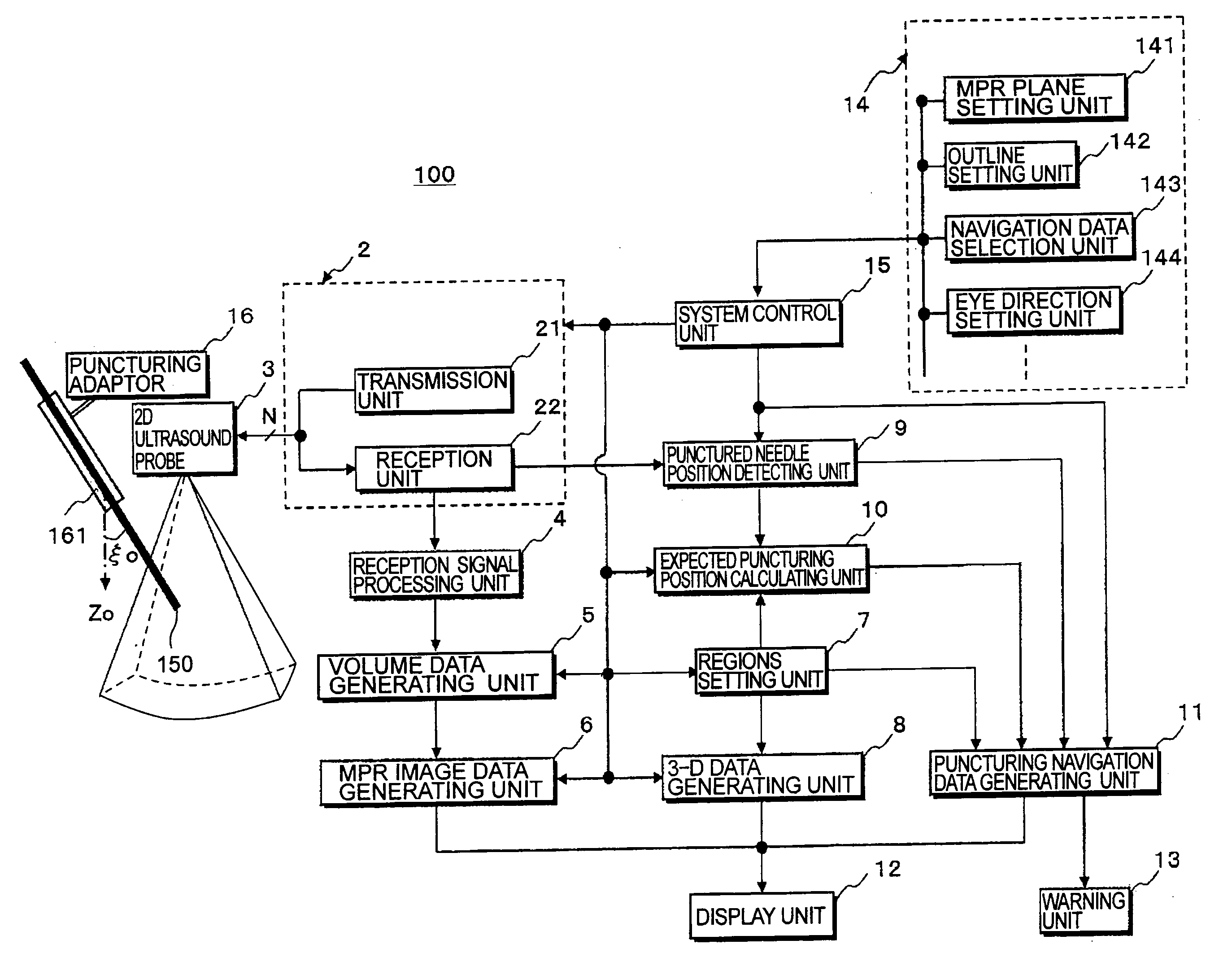

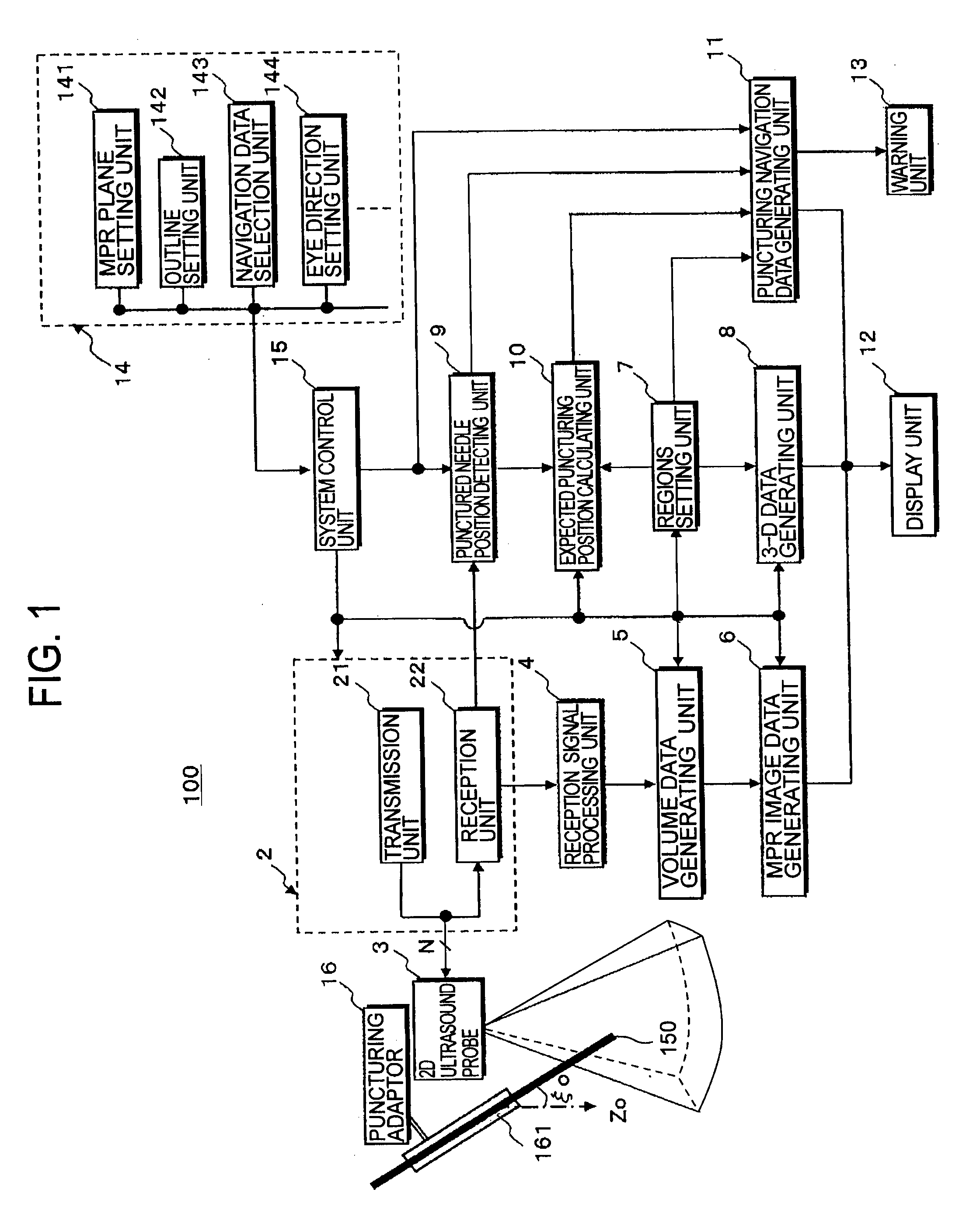

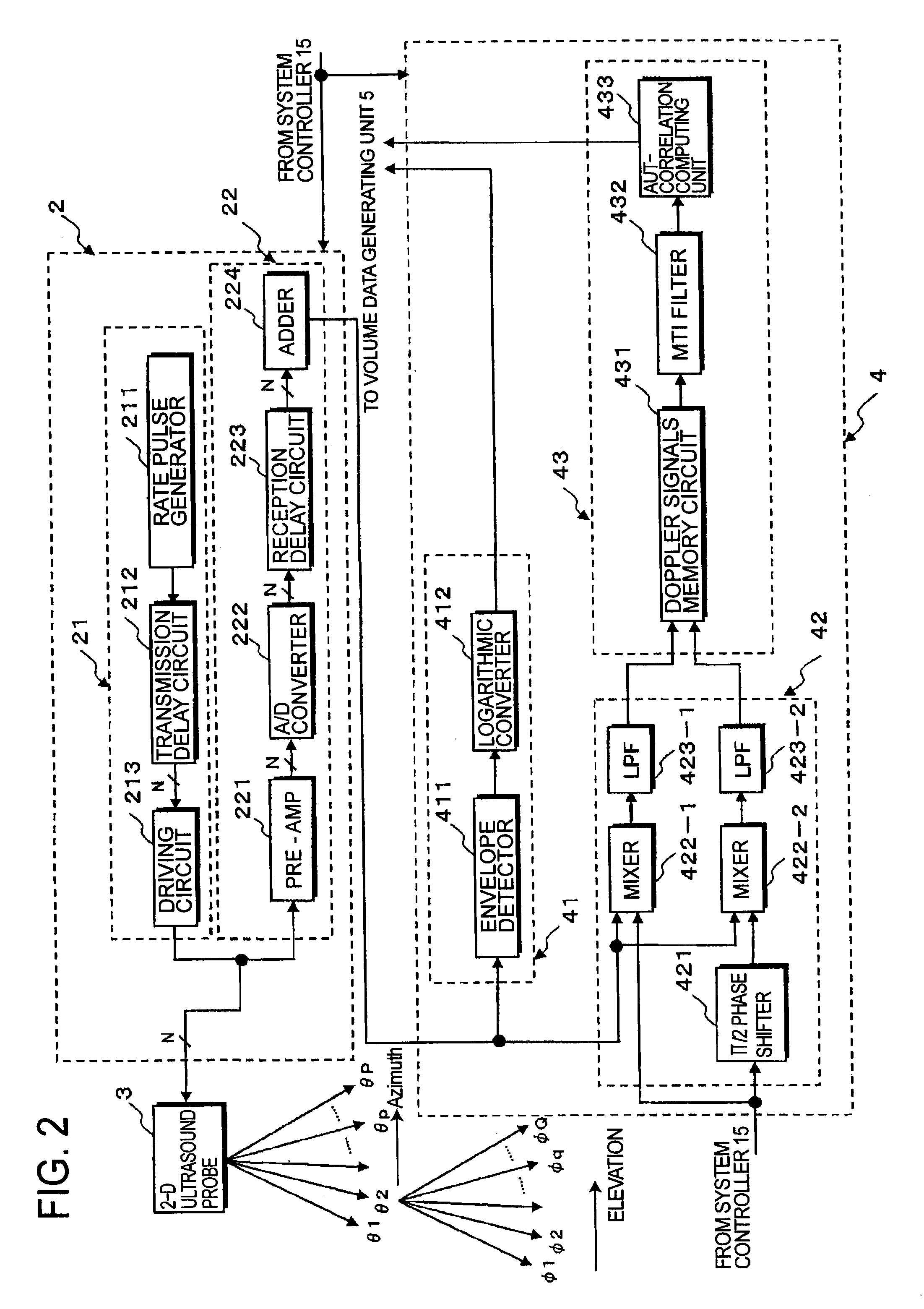

Imaging diagnosis apparatus having needling navigation control system and a needling navigation controlling method

InactiveUS20090137907A1Safe and accurateAccurately and safely insertUltrasonic/sonic/infrasonic diagnosticsSurgical needlesTip positionOrgan region

An ultrasound imaging diagnosis apparatus and a method for supporting safe and exact puncturing operation into a target region in a living body of a patient are provided. In the ultrasound imaging diagnosis apparatus, a regions setting unit sets a target tumor region for puncturing and blood vessel regions and organ region that are located near the tumor region based on the volume data acquired by 3-D scans on the object. To avoid insertions into the blood vessel regions and organ region, a puncturing needle position detecting unit detects the tip position and the inserting direction of the puncturing needle at just before and during insertion into the object. An expected inserting position calculating unit calculates an expected inserting position and an insertion error region to the tumor region based on the tip position data, inserting direction data and characteristic data of the puncturing needle. A puncturing navigation data generating unit generates a puncturing navigation data by composing the tumor region data, the organ region and blood vessel regions data, and the data relating to the expected inserting position and the insertion error region.

Owner:TOSHIBA MEDICAL SYST CORP

Surgical Puncture Cinch and Closure System

A system for forming a purse string suture, including a suture applicator having a proximal handle having a suture spool mounted thereon or in an internal chamber. A length of suture is partly wound on the spool, and a hollow suture needle extends from a distal end of the handle and contains a free end of the length of suture. The suture needle projects distally from the handle in a helical shape and terminates in a sharp distal tip with an opening in one side close to the distal tip. The free end of the length of suture may extend out of the distal tip and back into the hollow suture needle through the opening. The suture needle may have a deflection segment adjacent the distal tip that is more flexible than the rest of the helical distal portion of the suture needle. A linear hollow pivot shaft extends from a distal end of the handle substantially along an axis of the helical distal portion of the suture needle. The pivot shaft has a blunt tip with a substantially larger radial profile than the shaft to prevent puncturing tissue.

Owner:EDWARDS LIFESCIENCES CORP

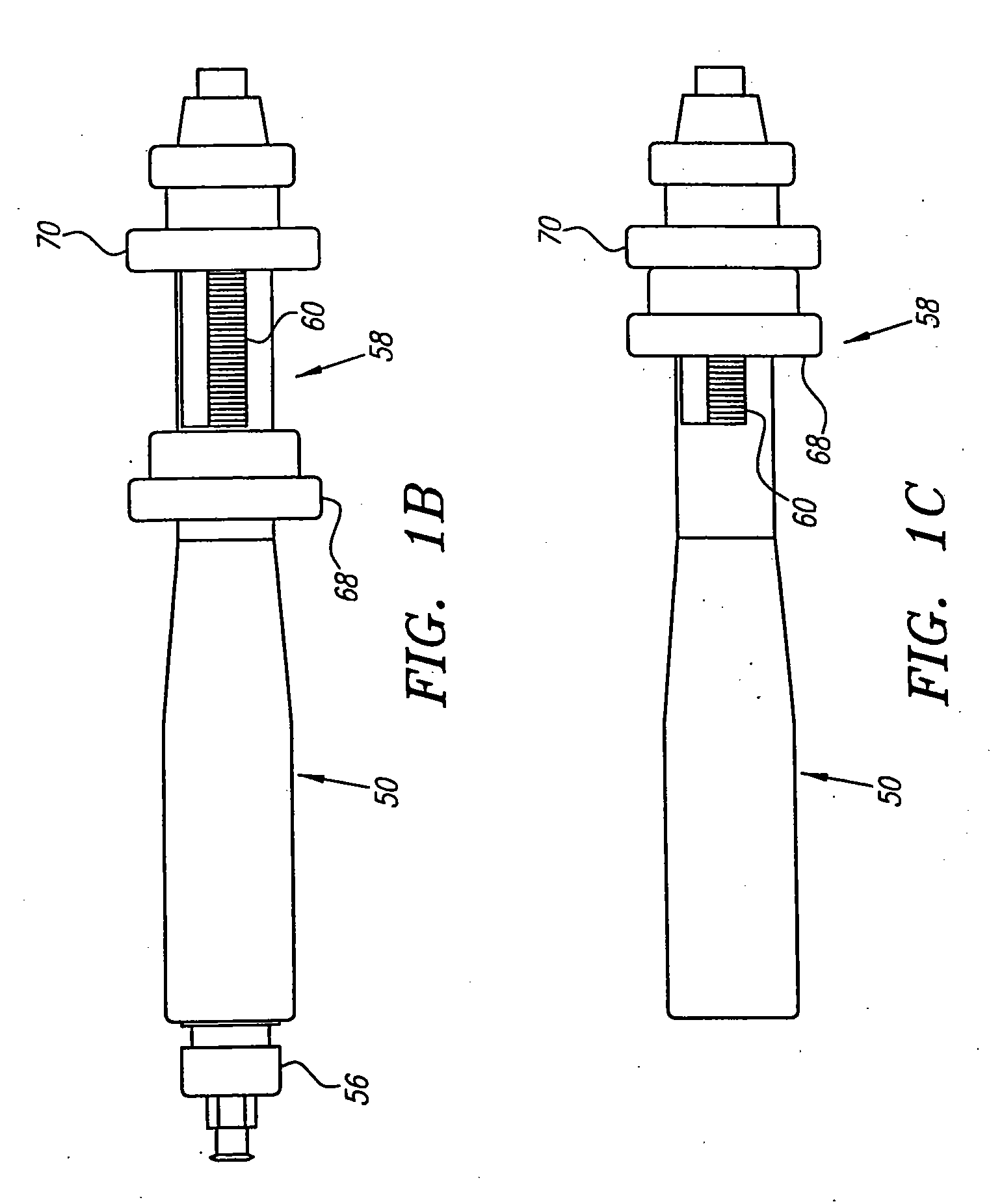

Infusion device with needle shield

InactiveUS7147623B2High protection levelSimple and cost-effectiveGuide needlesInfusion syringesMedication infusionSyringe needle

The invention relates to a medication infusion set of the type having a flexible cannula adapted for subcutaneous placement, in combination with an insertion, or puncturing, device comprising an insertion needle extending through the cannula and beyond the outer tip thereof, the insertion device further comprising a shield adapted to cover the insertion needle when the latter is withdrawn from the cannula. More specifically, the invention provides a fully integrated shield member having a position in which it covers the cannula and the needle when the insertion device is connected to the housing, a position allowing the cannula to be inserted when the insertion device is connected to the housing, and a position in which the shield covers the needle and the outer tip thereof when the insertion device has been removed from the housing. By this arrangement the need for a separate cover to protect the needle prior to use can be dispensed with.

Owner:UNOMEDICAL AS

Lancet device and method

A lancet device (10) having an internal magnet (20) and the forces emanating therefrom driving and retracting a collar (30) and a lancet (60). The device has a steady state condition (SS) wherein the device is at rest and in equilibrium. The device can be armed and activated to puncture. Once puncturing has occurred the device returns to a steady state condition.A lancet method involves positioning both a magnet (20) and a member (30) capable of being affected thereby with a lancet (60) in communications with one of either the magnet or the member, positioning either the member (30) or the magnet (20) to an armed position wherein the magnetic forces from the magnetic affect the member, and releasing the one of either the member or the magnet from the armed position permitting movement between the member and magnet by at least, in part, the magnetic forces, resulting in the movement of the lancet from a withdrawn position to the piercing position.

Owner:VIROTEK LLC

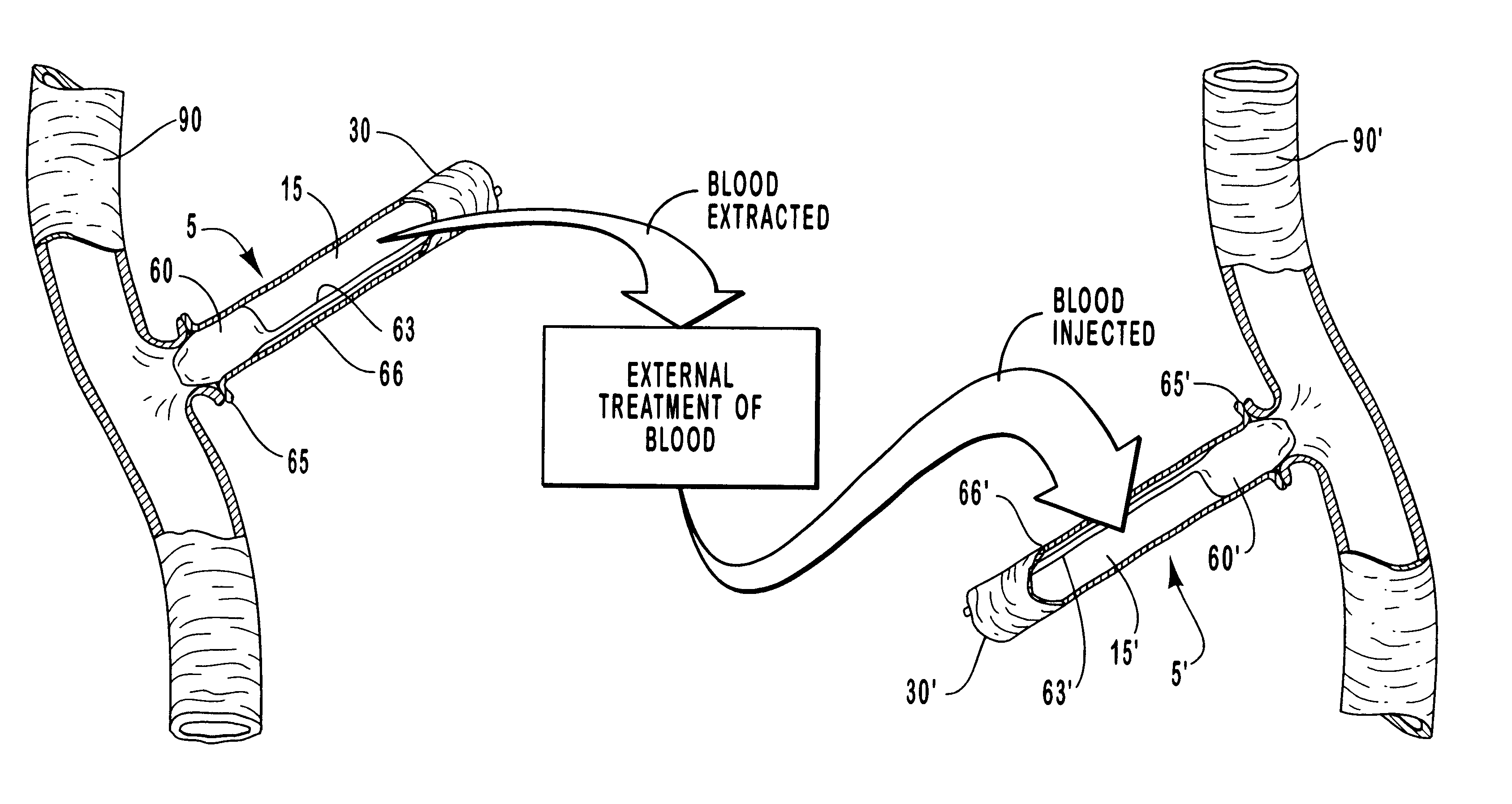

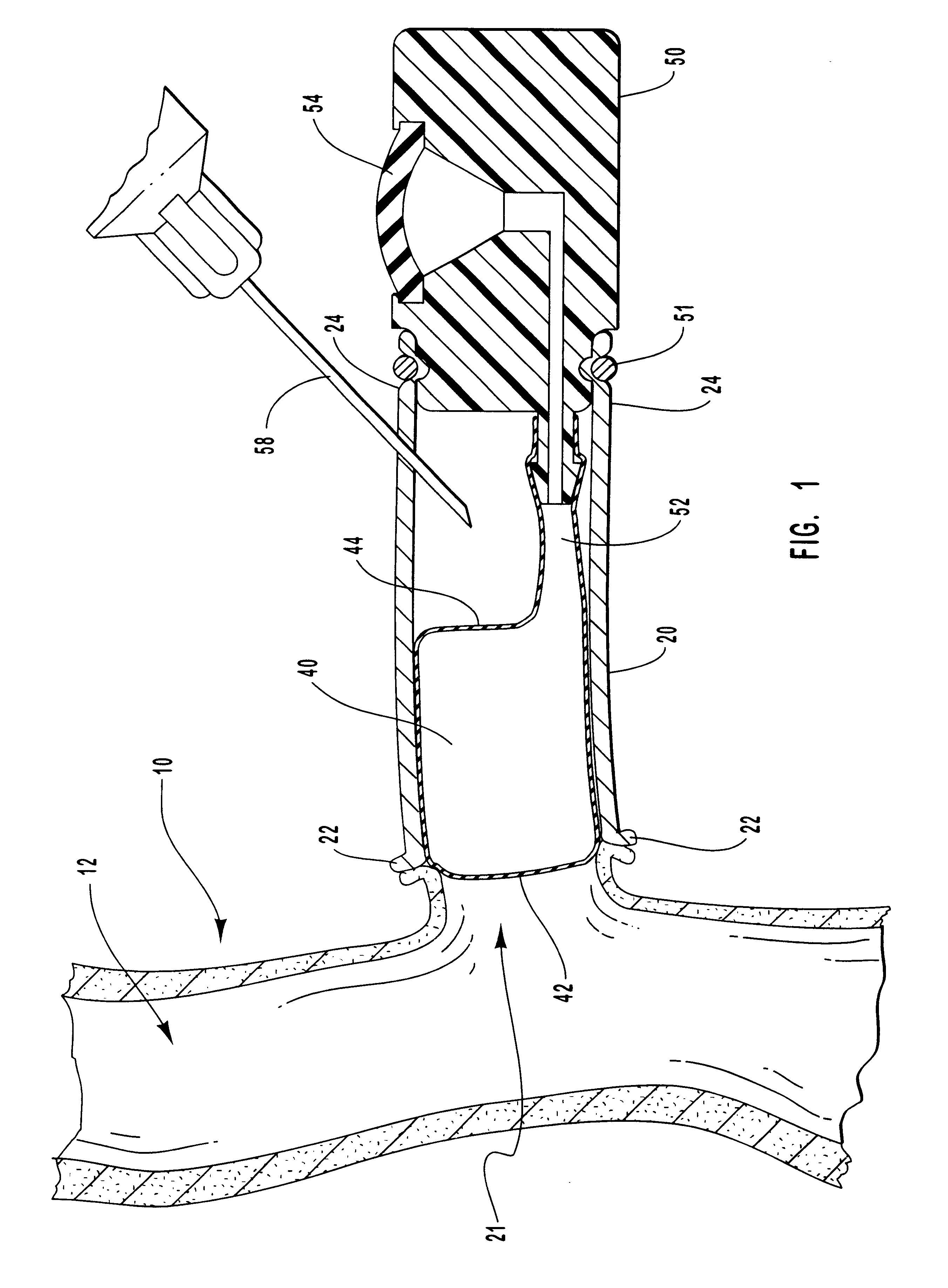

Vascular access devices and systems

InactiveUS6656151B1Vascular deterioration can be seriously acceleratedReduces and even avoids errorStentsBalloon catheterVascular Access DevicesBlood Vessel Tissue

Vascular access systems and devices for facilitating repeated access to a blood vessel. These systems and devices can be used in external treatment of blood, such as dialysis, and in intra-venous administration of medicines, such as heparin, for extended periods of time, while avoiding deleterious effects such as those derived from repeated puncturing of the blood vessel tissues or exposure of such tissues to abnormal fluid flows. The vascular access systems comprise an anastomosis graft vessel, an occlusal balloon, and a port device for accessing the occlusal balloon. Occlusal balloons can be self-contained, they can rely on osmosis, and they can serve as the support of an agent to which the blood stream is exposed, either by transport or by mere contact. In addition, occlusal balloons can adopt a distended and a collapsed configuration, the latter allowing for blood flow through the anastomosis graft vessel.

Owner:VITAL ACCESS CORP

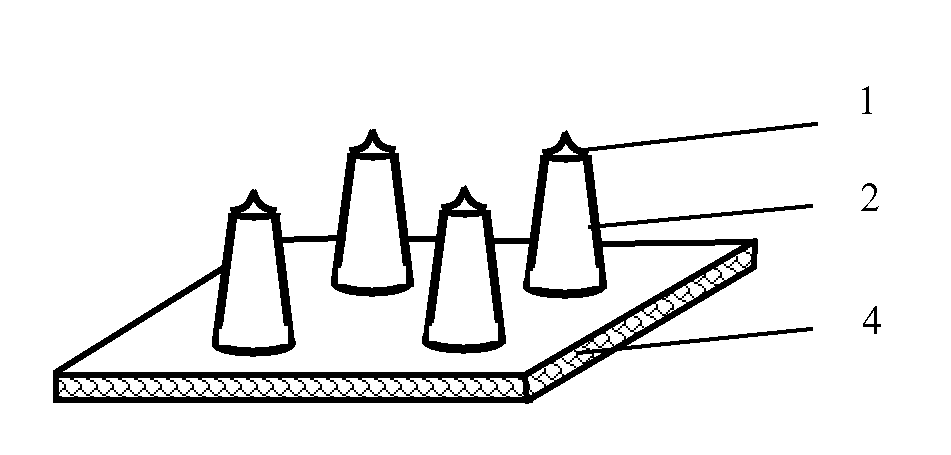

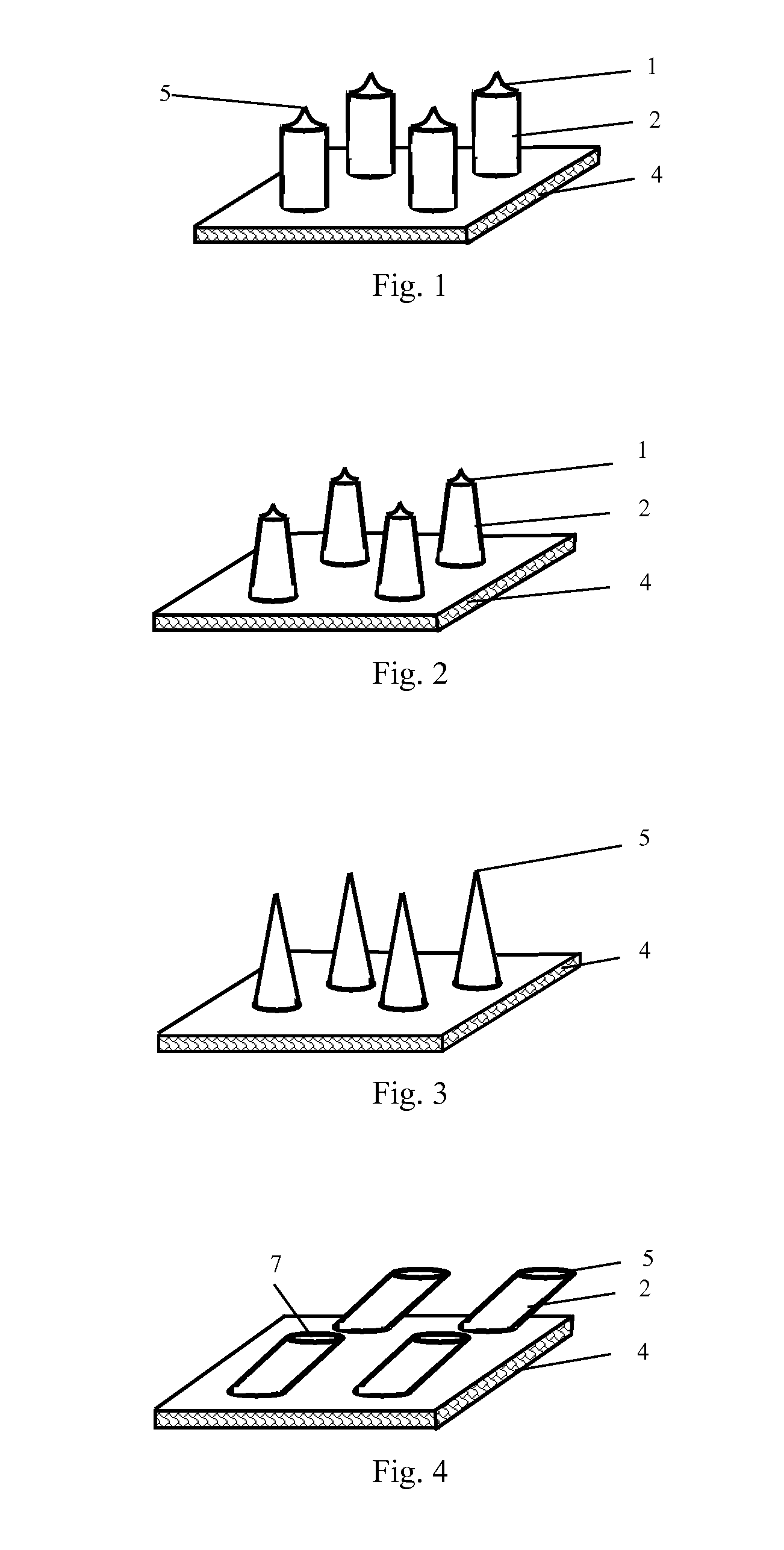

Microneedle array chip, device and patch for transdermal drug delivery utilizing the same, and preparation method therof

InactiveUS20110237925A1Easy to punctureEasy to adjustElectrolysis componentsDecorative surface effectsAcute angleTherapeutic effect

The invention discloses a microneedle array chip comprising metal microneedles and a substrate, wherein the microneedle consists of a needle head with a tip at its top, a needle bar and a needle seat, and is fixed onto the substrate via the needle seat; and the needle bar of the metal microneedle, having a cylindrical or conical shape, is inclined toward the substrate at a preset angle, and the needle head has a conical shape, or the upper surface of the tip is an oval plane or oval ring plane parallel to the substrate or inclined toward it at a preset acute angle. The metal microneedles in the microneedle array chip of the invention have firm structures to avoid fracture, and have sharp tips to facilitate puncturing. The maximal puncturing depth of the microneedles is easy to adjust and control. The microneedles in the array have good uniformity, and are safe and reliable to use. The hollow microneedles, like conventional syringe needles, have lateral openings, and thus can effectively avoid the blockage of the infusion poles by skin, thereby facilitating rapid diffusion and absorption of drugs, and resulting in significant therapeutic effects.

Owner:TSINGHUA UNIV

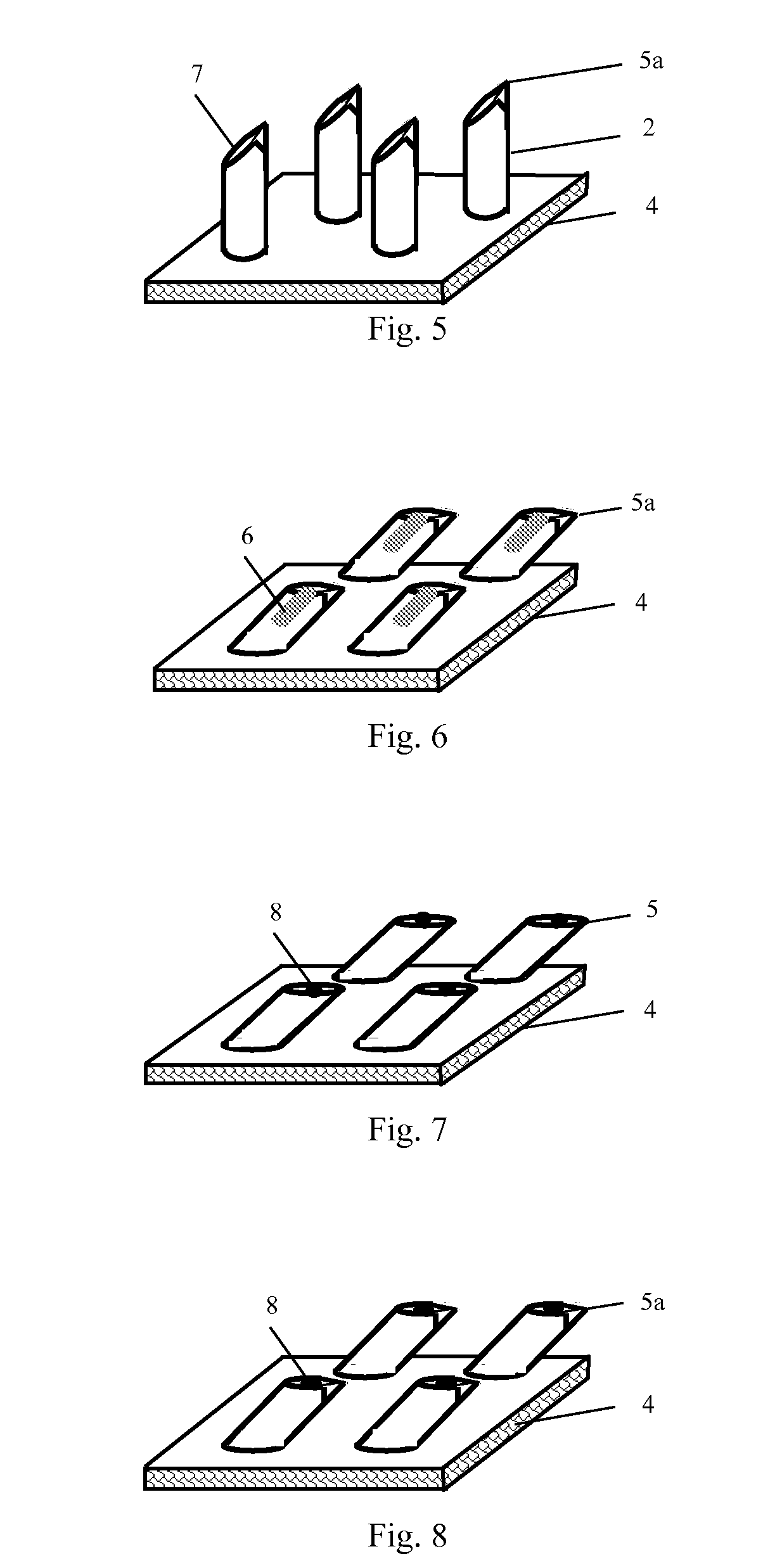

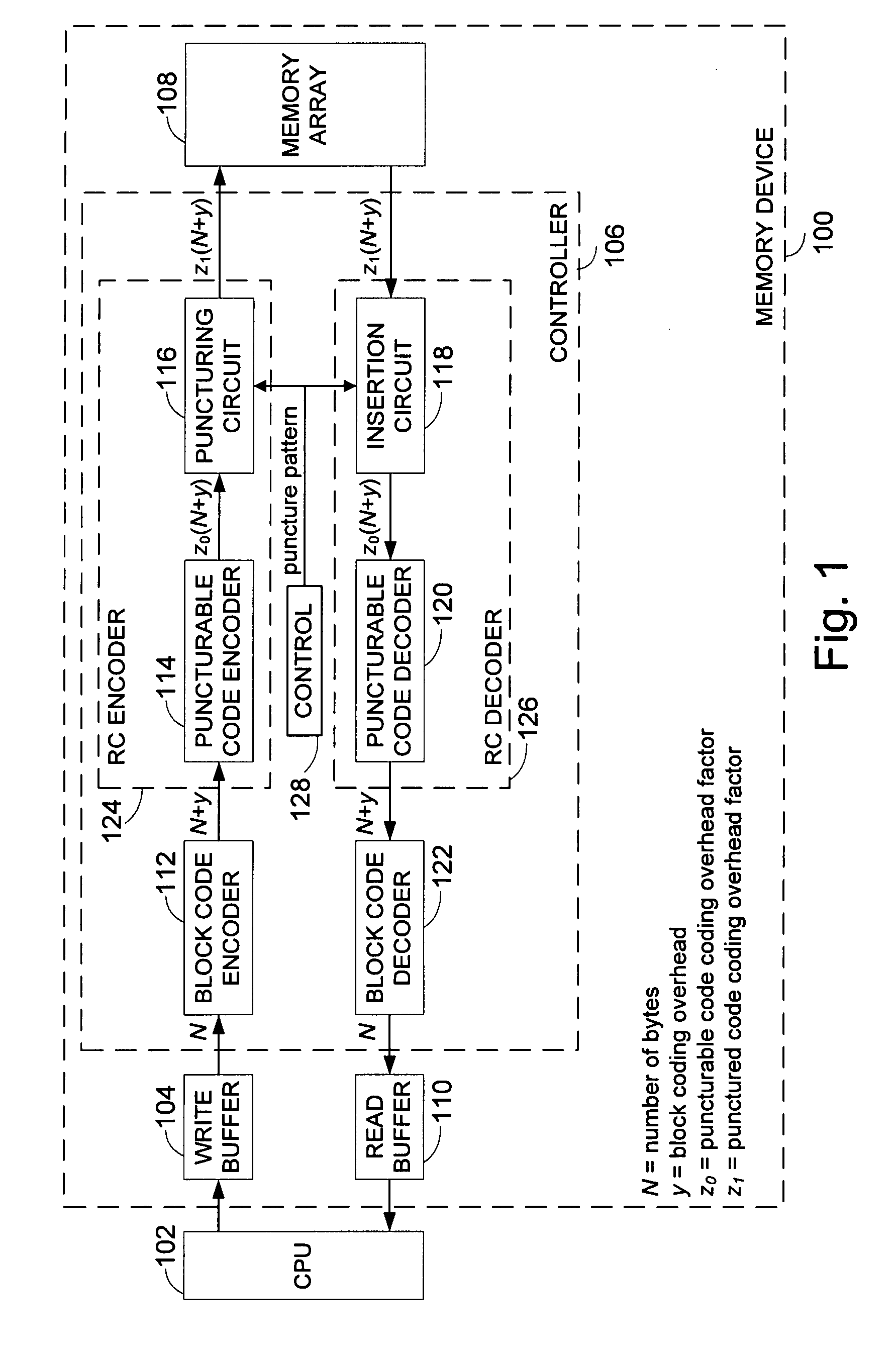

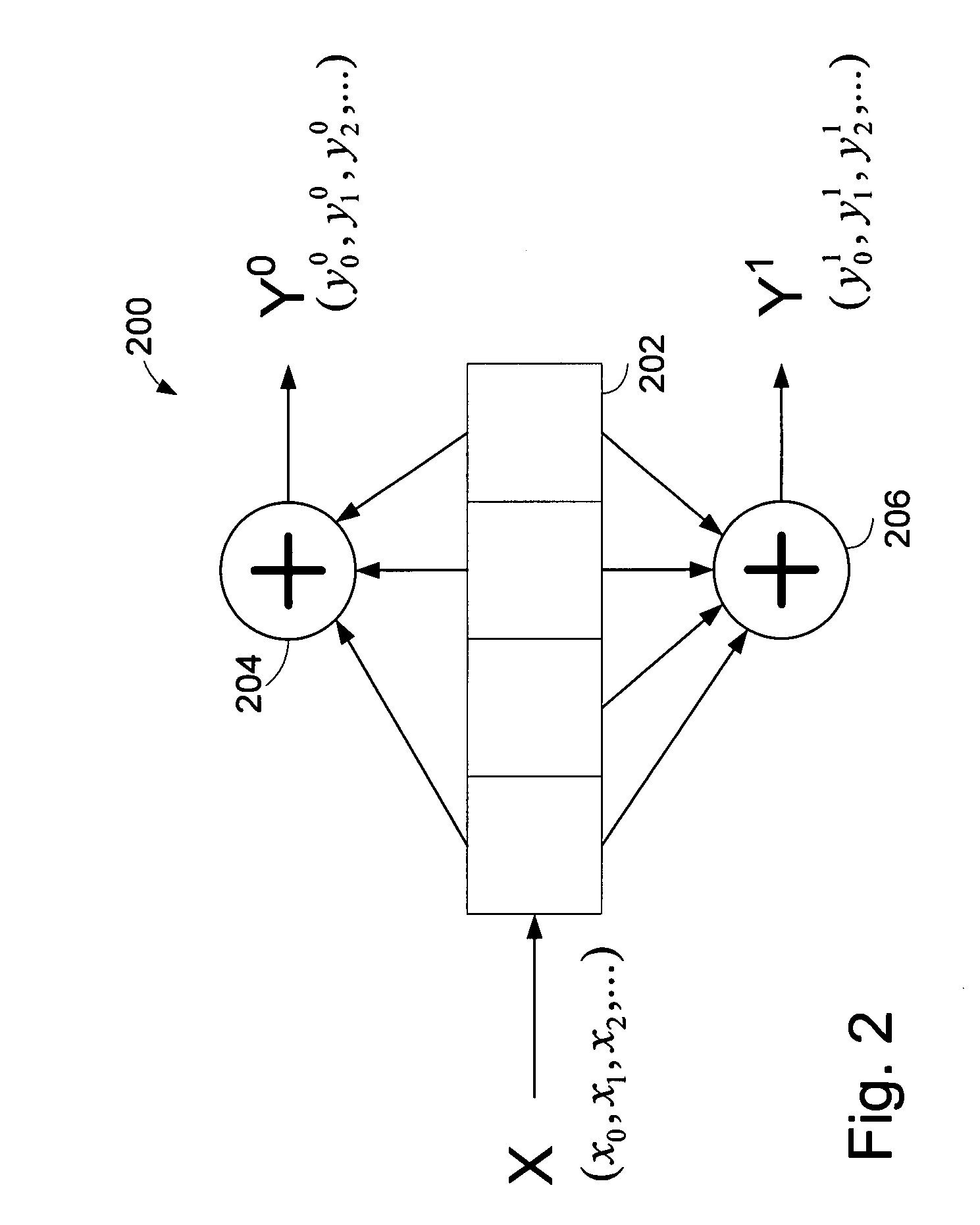

Memory controller supporting rate-compatible punctured codes

ActiveUS20090132889A1Error correction/detection using convolutional codesFault responseBlock codeConvolutional code

Apparatus and methods store data in a non-volatile solid state memory device according to a rate-compatible code, such as a rate-compatible convolutional code (RPCC). An example of such a memory device is a flash memory device. Data can initially be block encoded for error correction and detection. The block-coded data can be further convolutionally encoded. Convolutional-coded data can be punctured and stored in the memory device. The puncturing decreases the amount of memory used to store the data. Depending on conditions, the amount of puncturing can vary from no puncturing to a relatively high amount of puncturing to vary the amount of additional error correction provided and memory used. The punctured data can be decoded when data is to be read from the memory device.

Owner:MICRON TECH INC

System and Method for the Treatment of Occluded Vessels

InactiveUS20110208222A1Prevent life threatening embolizationsIncrease successCannulasExcision instrumentsCatheterThree vessels

A system for treating an occlusive region of a blood vessel comprises: a catheter outer tube forming a lumen for inflation of a centering balloon; a catheter inner tube lined with either internal spiral threads or point slots to assist controlled guidewire movement; and a rotatable guidewire that may be solid or hollow. The guidewire comprises a rotatable body and a proximal shaft. The rotatable body has two components: a distal rotating head and a proximal rotating shaft, wherein these components are of equal length and the rotating shaft resides within the proximal shaft. Linear force applied to the proximal shaft will result in the rotational guidewire tip puncturing cutting through an occlusion. In an alternative embodiment, the guidewire rotatable body comprises two mechanical rings and a compression spring, wherein when the spring is released via depression of a button, the guidewire tip drills through an occlusion.

Owner:LJAHNICKY BORIS +1

Trilaminar co-extrusion thermal contraction resin film, manufacturing method and application method thereof

InactiveCN101318392AReduce pollutionReduce packaging costsWrappers shrinkageSynthetic resin layered productsThermal contractionPuncturing

The invention discloses a three-layer coextrusion heat shrinkage resin film, a production method and an application method. The-three layer coextrusion heat shrinkage resin film is produced by taking PE(LDPE, HPPE, LLDPE, mPE), EVA, PP, PA and EVOH resins as the main materials which are matched with a functional master batch and adopting a production method of one-step huffing. The largest transverse and longitudinal shrinking rates of the product can reach 60 percent and 85 percent; the largest shrinking force of the product can reach 2.0N / cm. The shrinking rate and the shrinking force of the product can be controlled and adjusted by controlling various technical parameters to lead a package to be firm and endurable. The packaged objects are pertinently led to reach the anti-rust, anti static, illumination-resistance, anti-aging, anti-puncturing, anti-low-temperature, anti-isolation, anti-bacteria and anti-degradation effects and the like by adjusting the material composition and mixture ratio of each layer. The three-layer coextrusion heat shrinkage resin film is used for replacing the traditional paper box wrappage to reduce the packaging cost. The mechanical properties are good, the pertinence is strong, the materials are saved; when the three-layer coextrusion heat shrinkage resin film is used, the shrinking temperature is low, the power is saved and the packaging cost is saved, thus effectively reducing the production cost and having extremely high application value.

Owner:大连华诺塑胶科技有限公司

Apparatus and Method for Reducing Pain During Skin Puncturing Procedures

ActiveUS20080255483A1Easily and inexpensively utilizedFree from painTooth pluggers/hammersSurgeryInjection siteHand held

A handheld instrument for minimizing pain during administration by injection of a liquid, such as, an anesthetic that has a main body, a vibration unit mounted in the main body when initiated to cause the main body to vibrate, and a detachable tip cantilever mounted on the main body to vibrate with it, the tip having a free end characterized by a bifurcation to form two spaced projections defining a space between them, whereby the spaced projections can be placed in proximity to, adjacent to and bracketing a preselected injection site on a human or animal and the tissue at said preselected injection site and vibrated while an injection is given.

Owner:BING INNOVATIONS

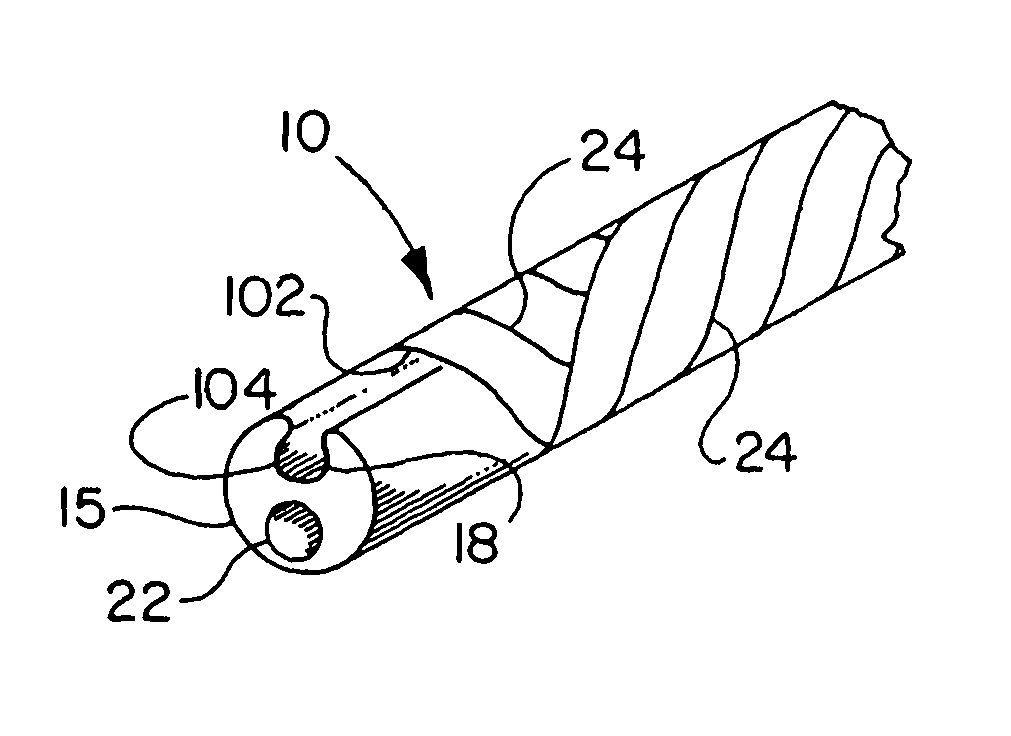

Penetrating tip for trocar assembly

InactiveUS20050251190A1Easy to separateMinimize damageCannulasSurgical needlesEngineeringBody tissue

A tissue penetrating instrument of the type used in the medical field and which may or may not be embodied in the form of an obturator associated with a trocar assembly, wherein the instrument includes an elongated shaft having a penetrating tip mounted on one end thereof. The penetrating tip includes a base secured to the one end of the shaft and a distal extremity spaced longitudinally outward from the base and formed into an apex which may be defined by a point or other configuration specifically structured to facilitate penetration or puncturing of bodily tissue. The apex may be substantially aligned with a linear extension of the central longitudinal axis of the shaft or alternatively, may be spaced laterally outward or off-set from the central longitudinal axis of the shaft. The penetrating tip further includes an exterior surface extending continuously between the apex and the base and configured to facilitate puncturing of the tissue and an enlargement of an access opening formed in the tissue, in a manner which facilitates separation of the tissue and minimizes cutting, severing or otherwise damaging the contiguous bodily tissue surrounding the access opening.

Owner:TELEFLEX MEDICAL INC

Methods for external treatment of blood

InactiveUS6595941B1Avoid harmful effectsImprove accessibilityStentsBalloon catheterBlood Vessel TissueBlood processing

Vascular access systems, devices and methods for facilitating repeated access to a blood vessel. These systems, devices and methods can be used in external blood treatment, such as dialysis, and in intra-venous administration of medicines, such as heparin, for extended periods of time, while avoiding deleterious effects such as those derived from repeated puncturing of the blood vessel tissues or exposure of such tissues to abnormal fluid flows. The vascular access systems comprise an anastomosis graft vessel, an occlusal device, such as an occlusal balloon, and a port device for accessing the occlusal device. Occlusal devices can be self-contained, they can rely on osmosis, and they can serve as the support of an agent to which the blood stream is exposed, either by transport or by mere contact. In addition, occlusal devices can adopt a distended and a collapsed configuration, the latter allowing for blood flow through the anastomosis graft vessel.

Owner:VITAL ACCESS CORP

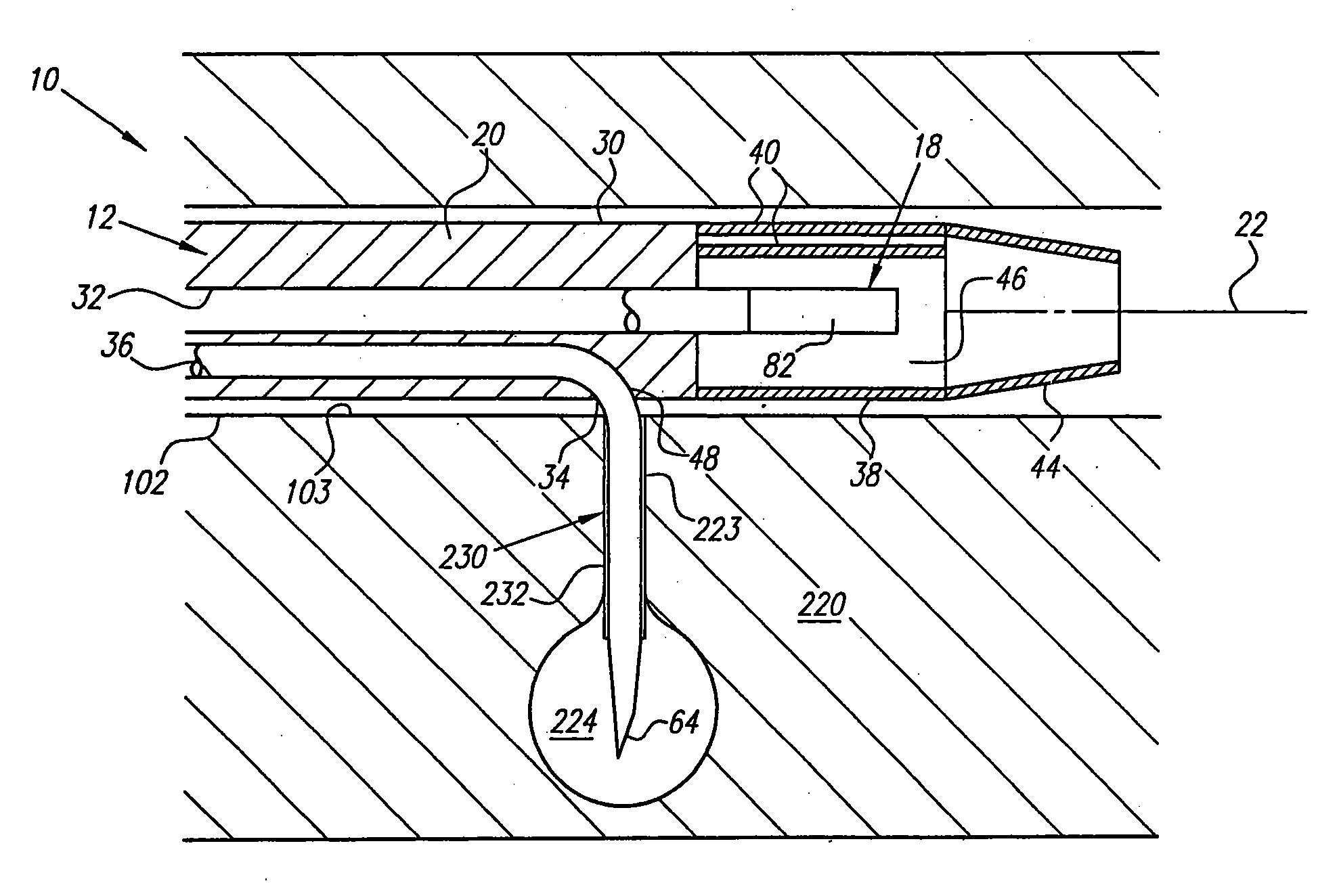

Systems and Methods for Delivering Drugs to Selected Locations Within the Body

InactiveUS20070021730A1Avoid MisdeliveryMaximum precisionCannulasDiagnosticsDistal portionBlood vessel

A transvascular system (10) for delivering a drug to a tissue region from a blood vessel, such as a coronary vein, includes a catheter (12) having a distal portion (26) with puncturing (14), orientation (16), drug delivery (62), and imaging elements (18). The puncturing element (14) is deployable for penetrating the vessel wall to access the tissue region. The orientation element (16), e.g. a “cage” including a plurality of struts (38) (40) and / or a radiopaque marker, has a predetermined relationship with the puncturing element (14), the imaging element (18) detecting the location of the orientation element (16) with respect to the tissue region to orient the puncturing element. The catheter (12) is percutaneously introducing into the vessel, the puncturing element (14) is oriented towards the tissue region, the puncturing element (14) is deployed to access the tissue region, and the drug is delivered to the tissue region. An ablation device (230) may also be deployed to create a cavity or fluid reservoir in the tissue region for receiving the drug therein, or an indwelling catheter (214) may be advanced into and left in the tissue region.

Owner:MEDTRONIC VASCULAR INC

Medical puncturing device

The invention relates to a medical puncturing device comprising a rigid needle being at one end adapted for facilitating the puncturing and comprising at the opposite end a hub, the hub comprising a handle part and a shield part being pivotable in relation to the handle part and further comprising locking means on the shield part and the handle part, the locking means being adapted to interlock the shield and the handle part in a pivoted position of the shield part where the rigid needle is covered by this.

Owner:UNOMEDICAL AS

Apparatus and method for encoding/decoding block low density parity check codes having variable coding rate

ActiveUS20070089025A1Minimized coding complexityError prevention/detection by using return channelError correction/detection using multiple parity bitsPattern matchingTheoretical computer science

A method for encoding a rate-compatible block Low Density Parity Check (LDPC) code. The method includes designing specific LDPC codes for a predetermined number of coding rates, and generating a pruning pattern by comparing information node degrees of the predetermined number of LDPC codes; matching check node degrees of the predetermined number of LDPC codes; generating a predetermined number of puncturing patterns according to the check node degree when the matched check node degree is calculated; determining whether a first condition given for the generated puncturing patterns is satisfied; and determining the generated puncturing patterns as rate-compatible puncturing patterns when the puncturing patterns satisfy the first condition.

Owner:SAMSUNG ELECTRONICS CO LTD

Container adapted to hold and dispense bagged fluids

Owner:INT PACKAGING INNOVATIONS

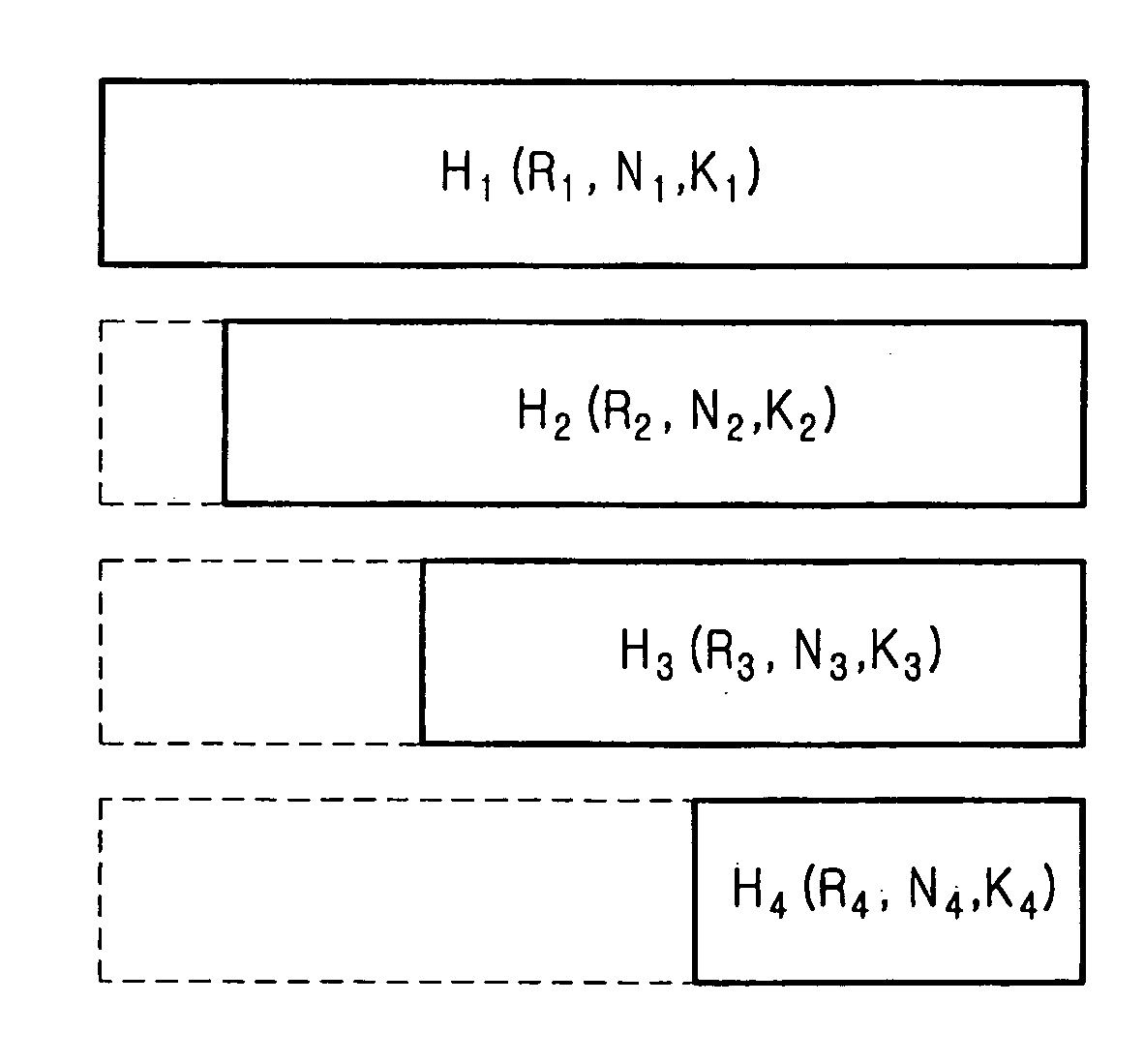

System and method for structured LDPC code family with fixed code length and no puncturing

InactiveUS20110047433A1Low parityHigh bit rateError correction/detection using multiple parity bitsCode conversionTheoretical computer scienceLow density

A family of low density parity check (LDPC) codes is generated based on a mother code having a highest code rate. The low density parity check (LDPC) codes include a codeword size of at least 1344. The LDPC codes also include a plurality of parity bits in a lower triangular form. The mother code is constructed by: selecting m number of rows and n number of columns; setting maximum column weights and row weights; designing a protograph matrix based on the set column weights and row weights and selected m and n; and selecting circulant blocks based on the protograph matrix.

Owner:SAMSUNG ELECTRONICS CO LTD

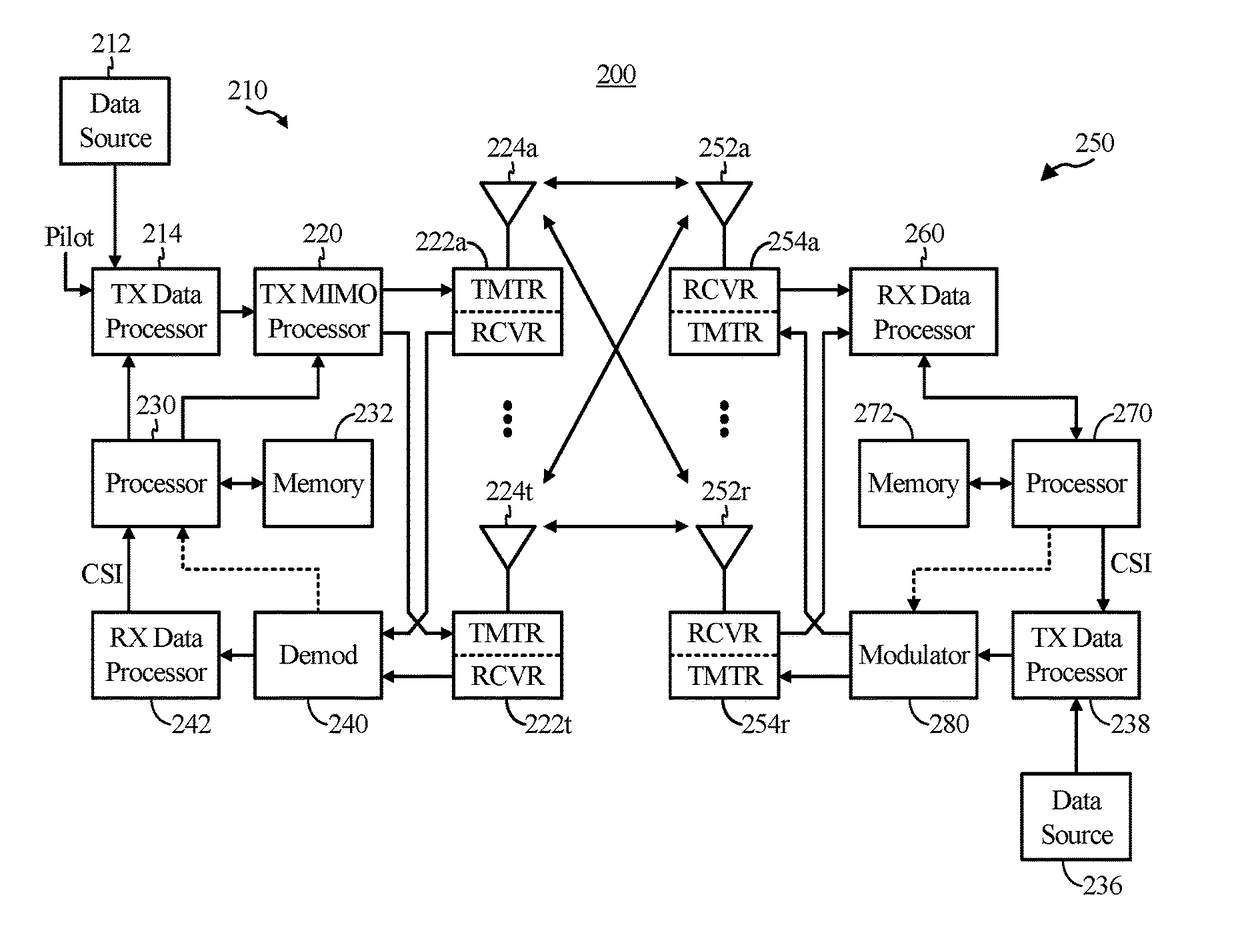

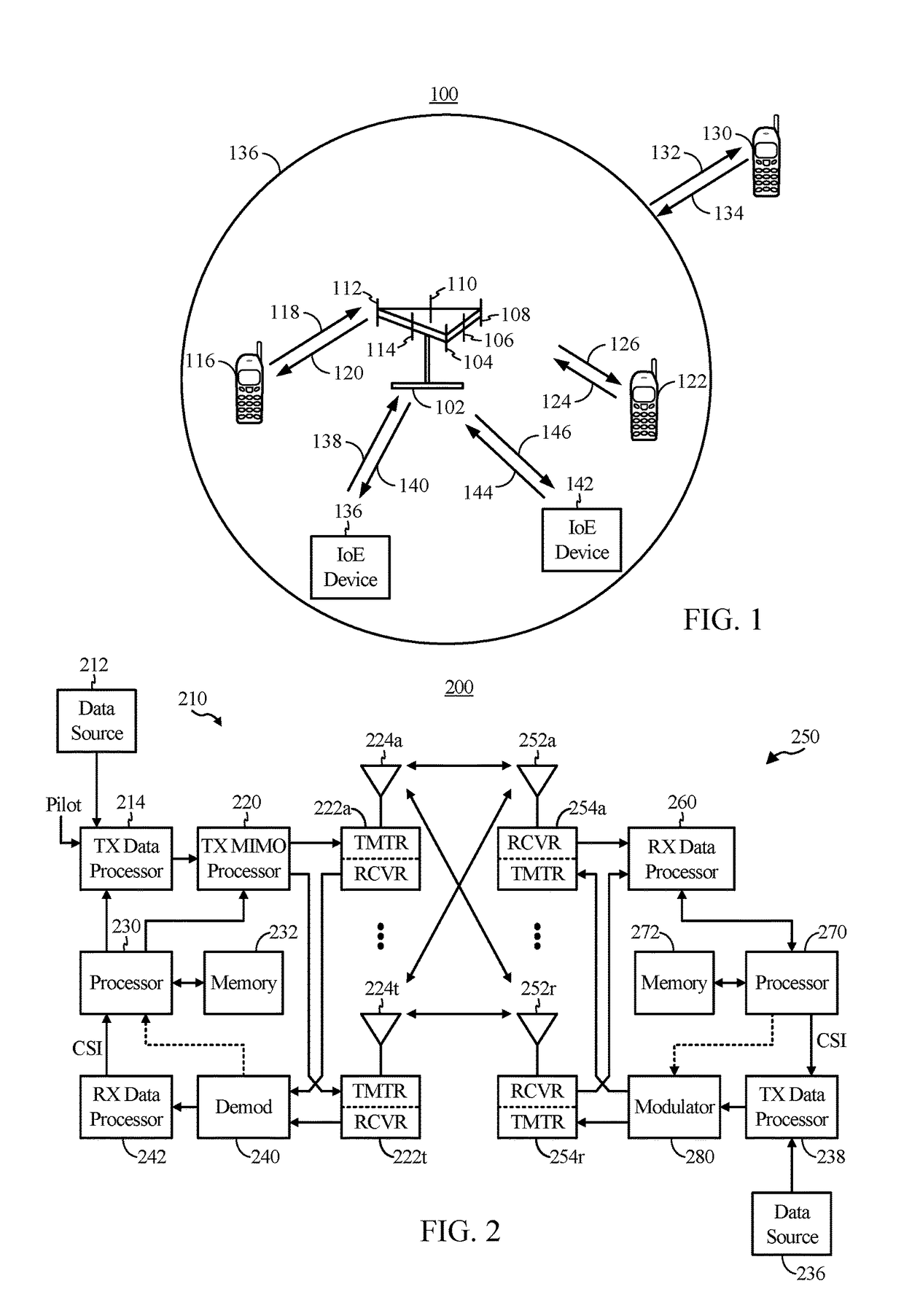

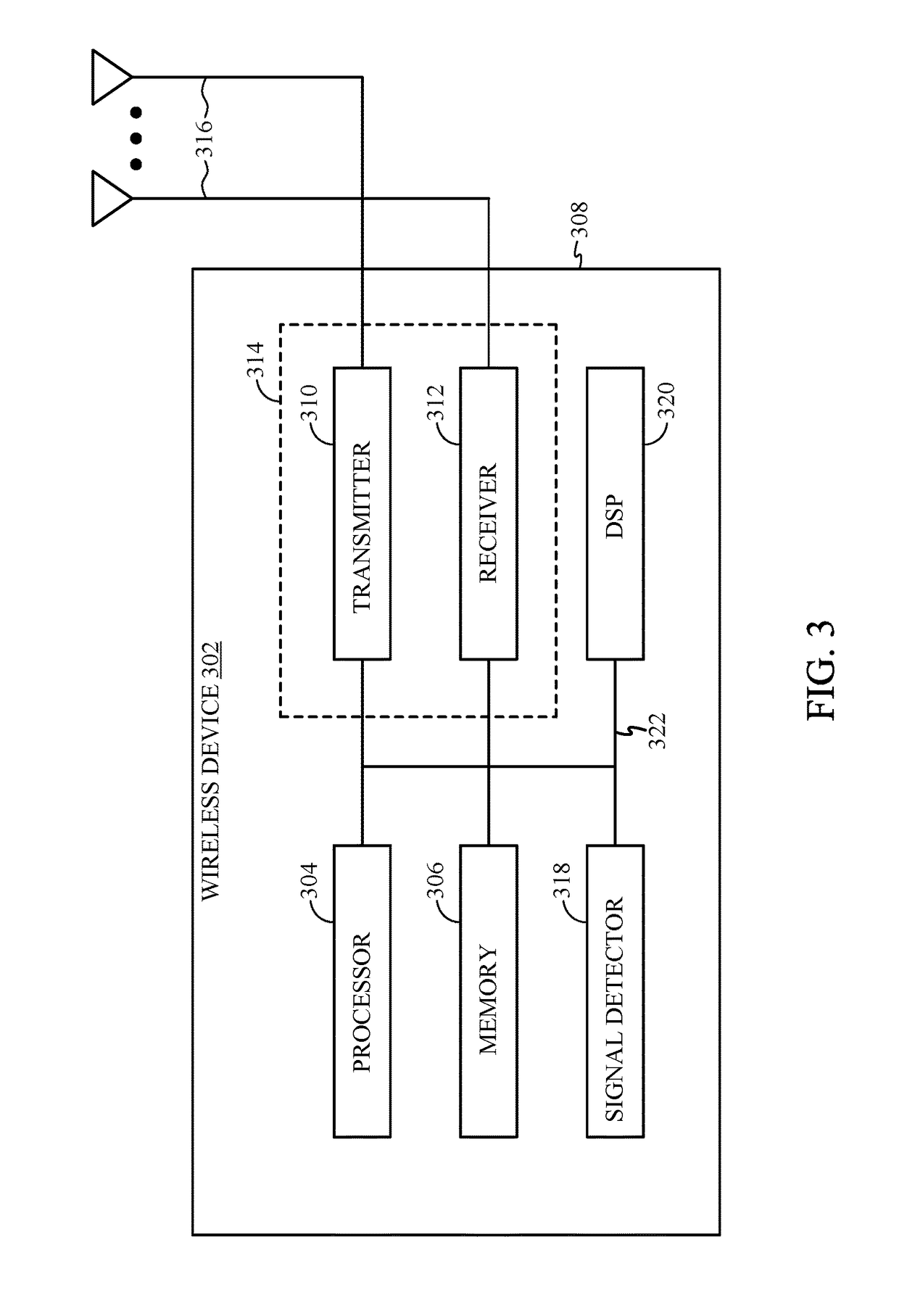

Puncturing for structured low density parity check (LDPC) codes

ActiveUS20170141798A1Facilitate communicationError preventionError correction/detection using LDPC codesTheoretical computer scienceLow density

Certain aspects of the present disclosure generally relate to techniques for puncturing of structured low density parity check (LDPC) codes. A method for wireless communications by wireless node is provided. The method generally includes encoding a set of information bits based on a LDPC code to produce a code word, the LDPC code defined by a matrix having a first number of variable nodes and a second number of check nodes, puncturing the code word to produce a punctured code word, wherein the puncturing is performed according to a first puncturing pattern designed to puncture bits corresponding to one or more of the variable nodes having a certain degree of connectivity to the check nodes, and transmitting the punctured code word

Owner:QUALCOMM INC

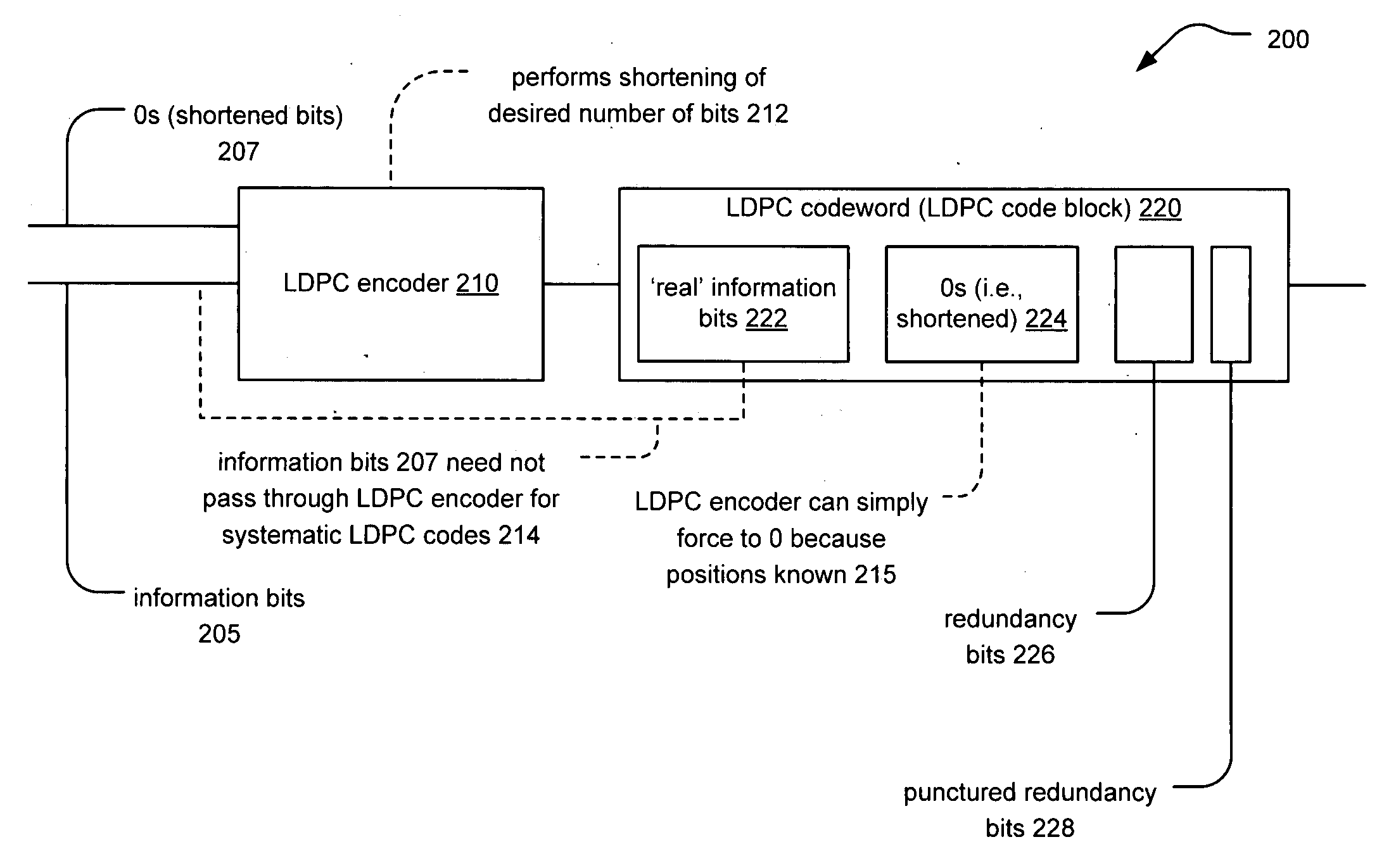

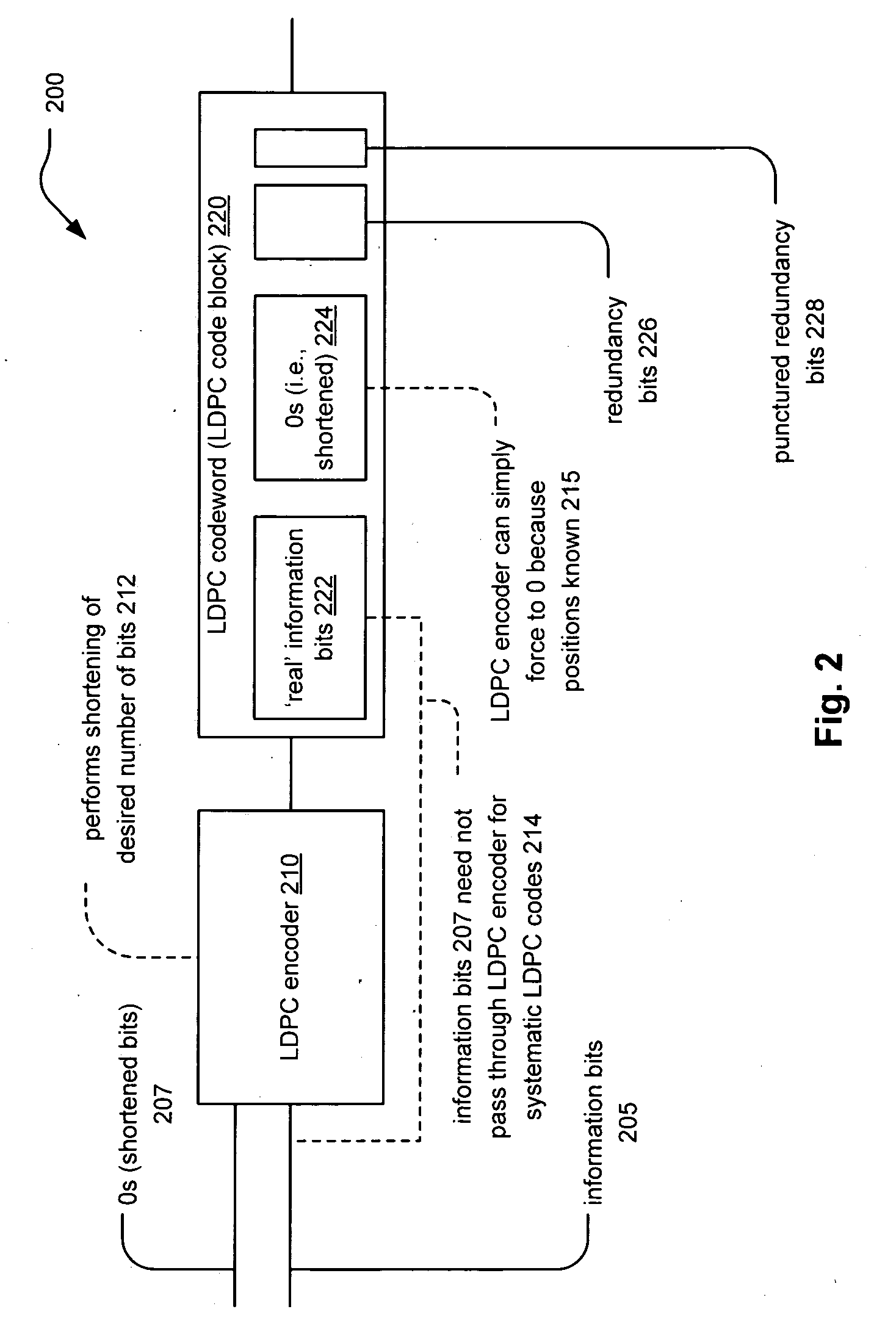

LDPC (low density parity check) code size adjustment by shortening and puncturing

LDPC (Low Density Parity Check) code size adjustment by shortening and puncturing. A variety of LDPC coded signals may be generated from an initial LDPC code using selected shortening and puncturing. Using LDPC code size adjustment approach, a single communication device whose hardware design is capable of processing the original LDPC code is also capable to process the various other LDPC codes constructed from the original LDPC code after undergoing appropriate shortening and puncturing. This provides significant design simplification and reduction in complexity because the same hardware can be implemented to accommodate the various LDPC codes generated from the original LDPC code. Therefore, a multi-LDPC code capable communication device can be implemented that is capable to process several of the generated LDPC codes. This approach allows for great flexibility in the LDPC code design, in that, the original code rate can be maintained after performing the shortening and puncturing.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com