Patents

Literature

4015 results about "Stainless steel material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material Selection - Types of stainless steel. Austenitic stainless steel - A family of alloys containing chromium and nickel (and manganese and nitrogen when nickel levels are reduced), generally built around the type 302 chemistry of 18% Cr, 8% Ni, and balance mostly Fe.

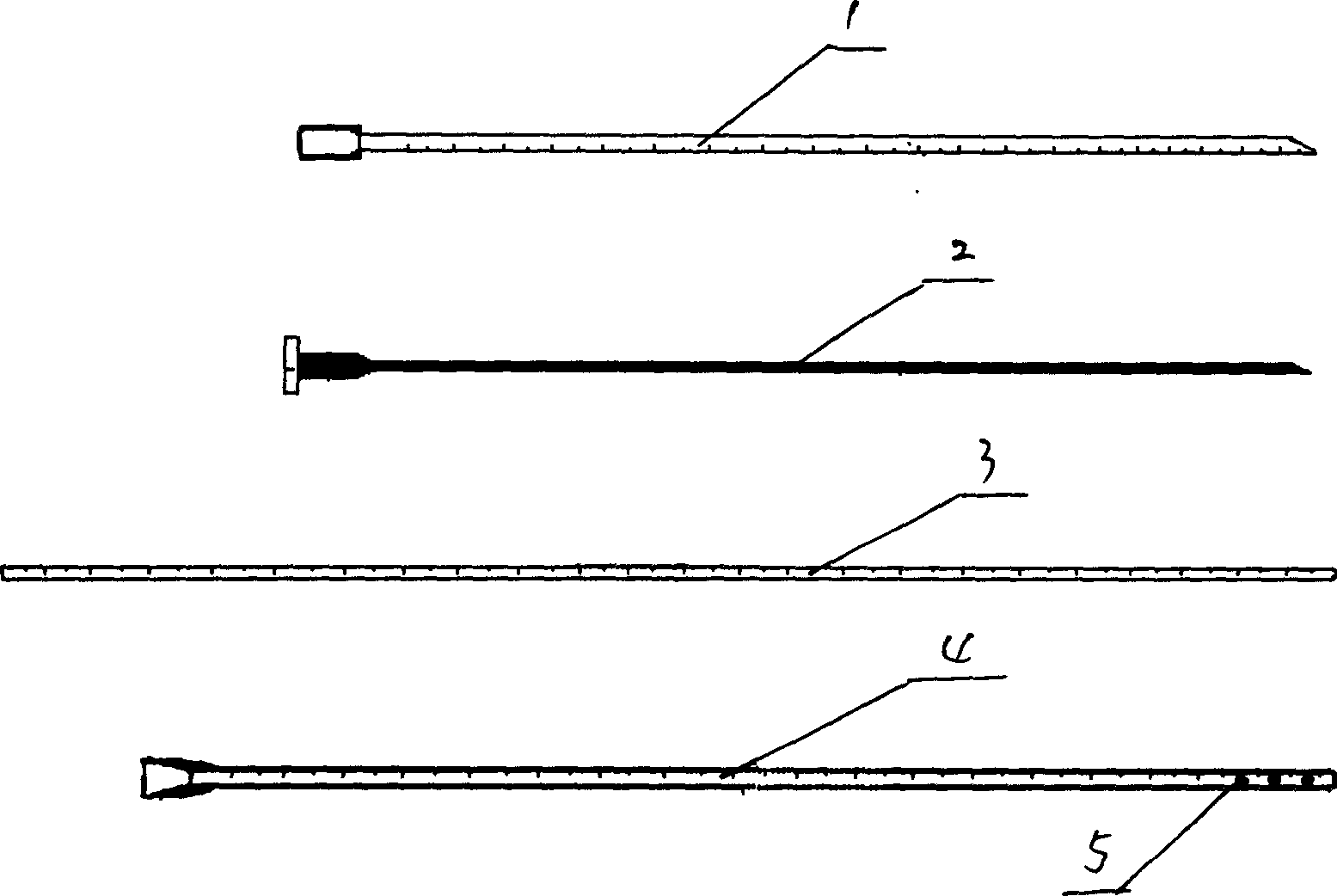

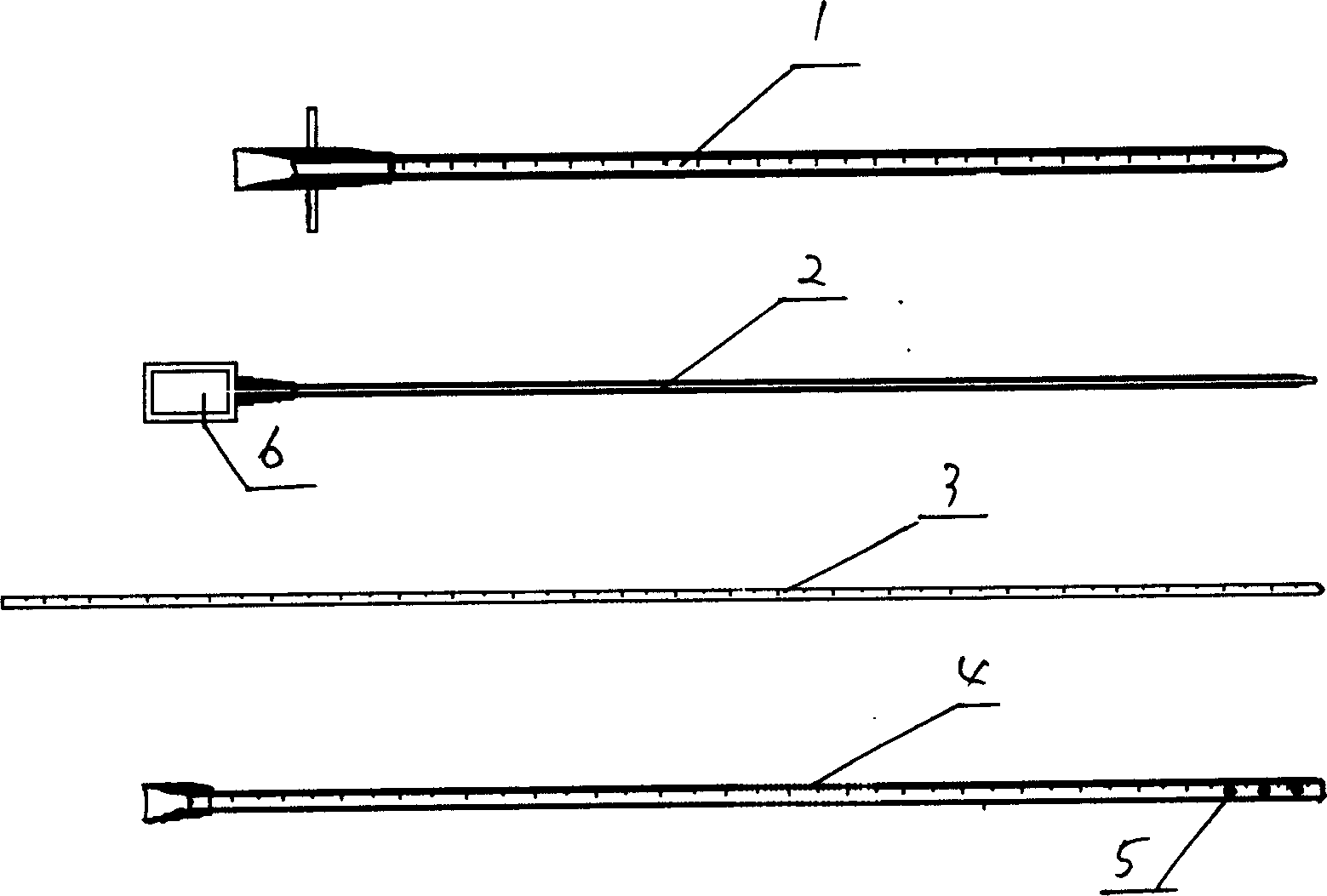

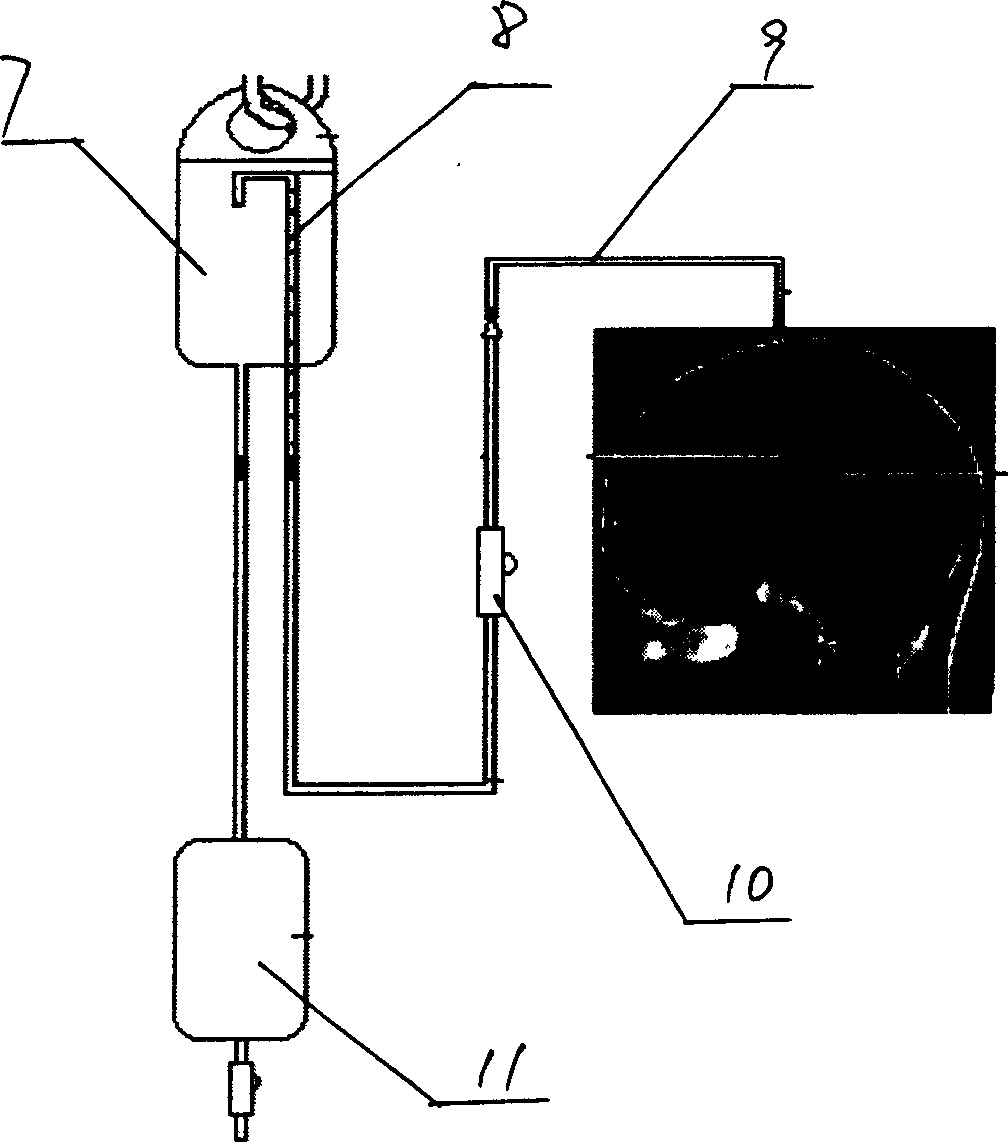

Cerebrospinal fluid puncturing drainer

The cerebrospinal fluid piercing drainer includes a piercing unit and an external draining unit. The piercing unit includes piercing needle, piercing sheath, guide wire and draining pipe. The piercing needle and the outside piercing sheath are made of stainless steel material and are used in piercing; the flexible guide wire of plastic-steel material with shape memory function is used in replacing the piercing needle; the draining pipe of soft silicone gel is used in replacing the piercing sheath and draining. During piercing, the piercing needle and the outside piercing sheath are first pierced into proper position, the piercing needle is then withdrawn and the guide wire is penetrated through the piercing sheath, and the piercing sheath is finally withdrawn and the draining pipe is fed along the guide wire to the cavity to be drained or fed to cerebral side room or even farther position under the monitoring with DSA. The draining pipe has external end connected to the draining unit.

Owner:何明利

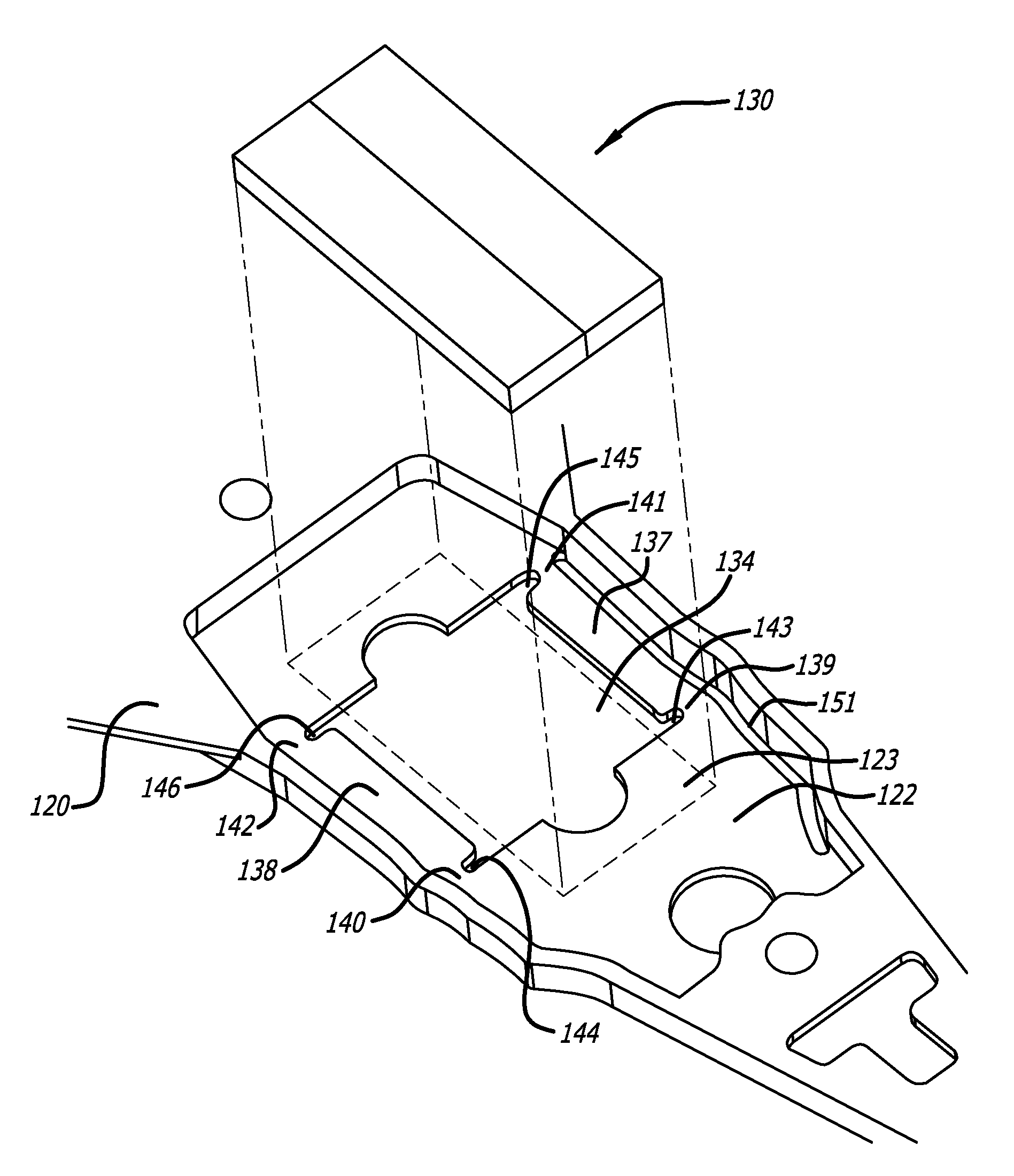

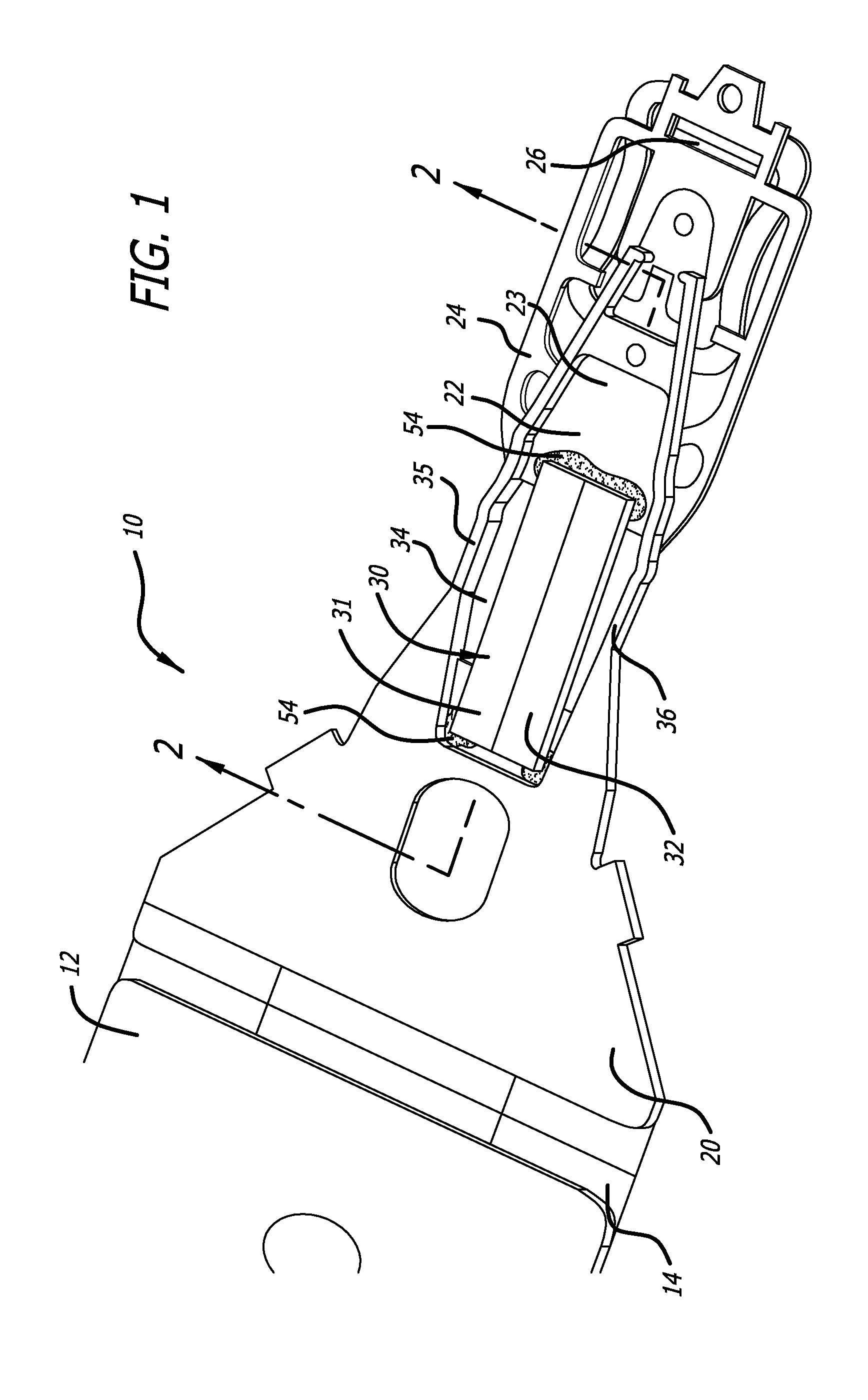

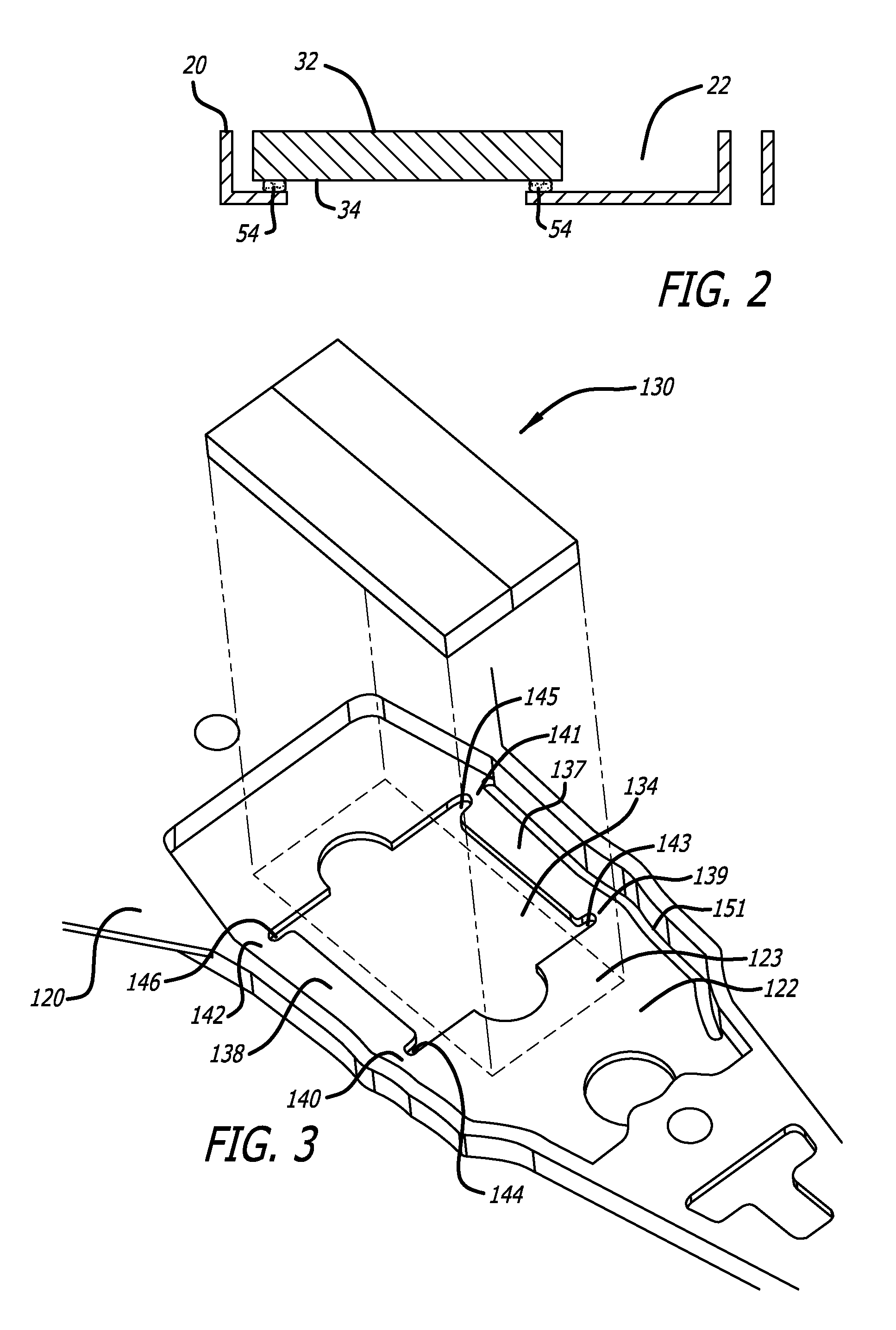

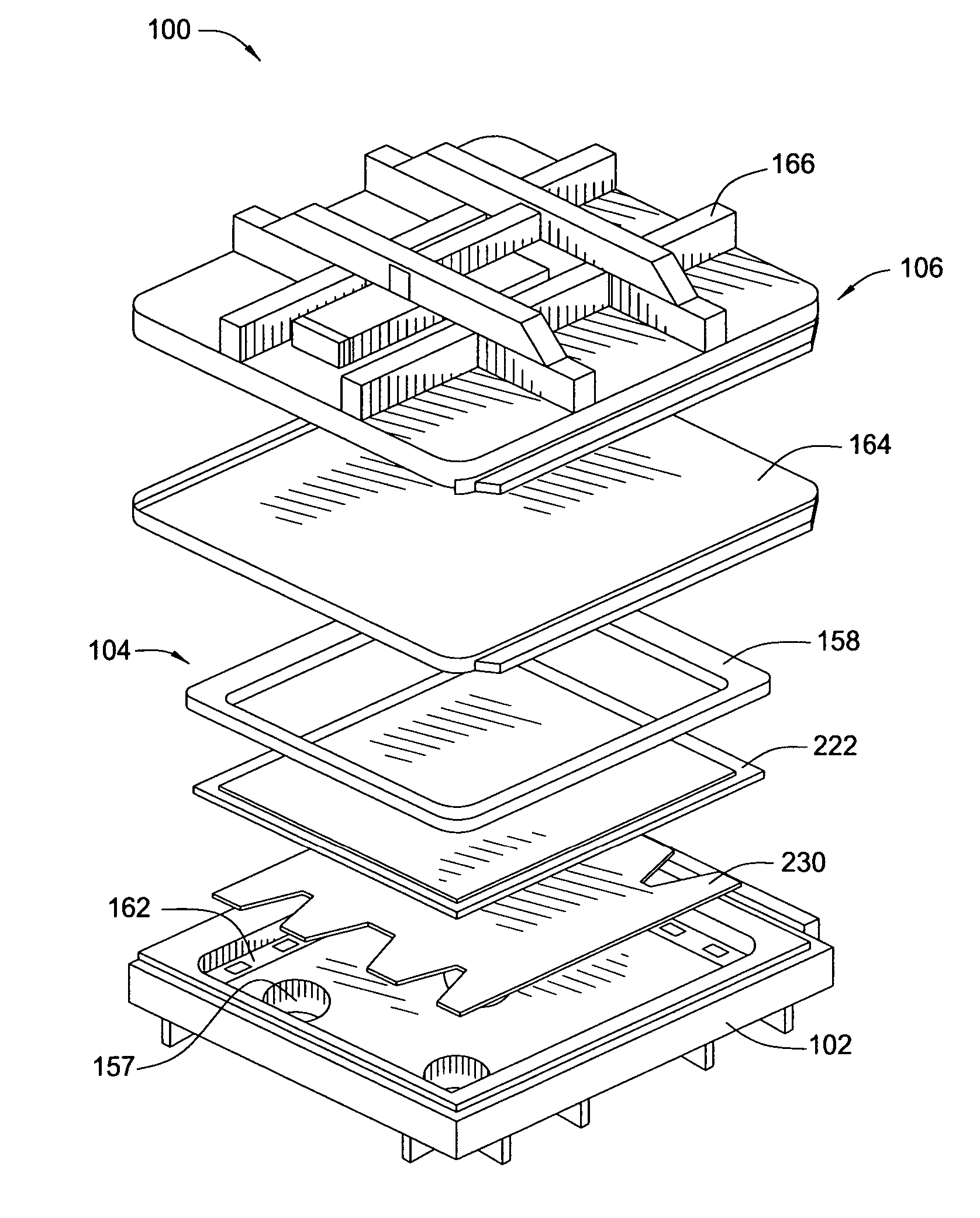

Low profile load beam with etched cavity for PZT microactuator

ActiveUS8149545B1Less windageImproves inertial balancingArm with actuatorsRecord information storageDual stageAtomic physics

A dual-stage actuator disk drive suspension load beam has a recessed cavity formed in it into which the microactuator motor is partially or completely placed. The cavity may be formed by partially etching the load beam during the same etching process that creates the load beam from a sheet of stainless steel material. The partially etched load beam having a cavity for the microactuator motor has the advantages of a lower profile, improved inertial balancing of the suspension, and increased sway resonant frequency.

Owner:MAGNECOMP

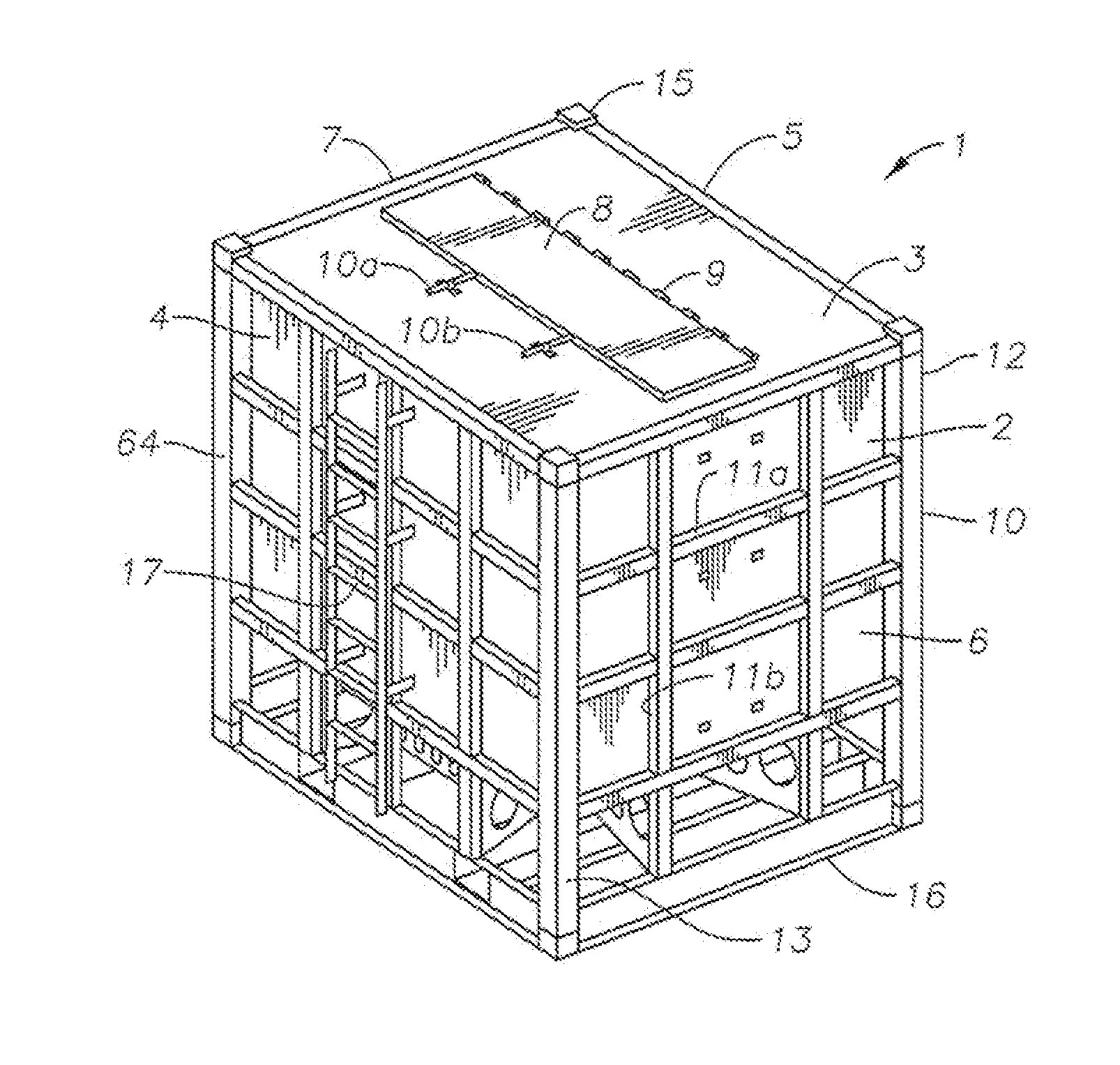

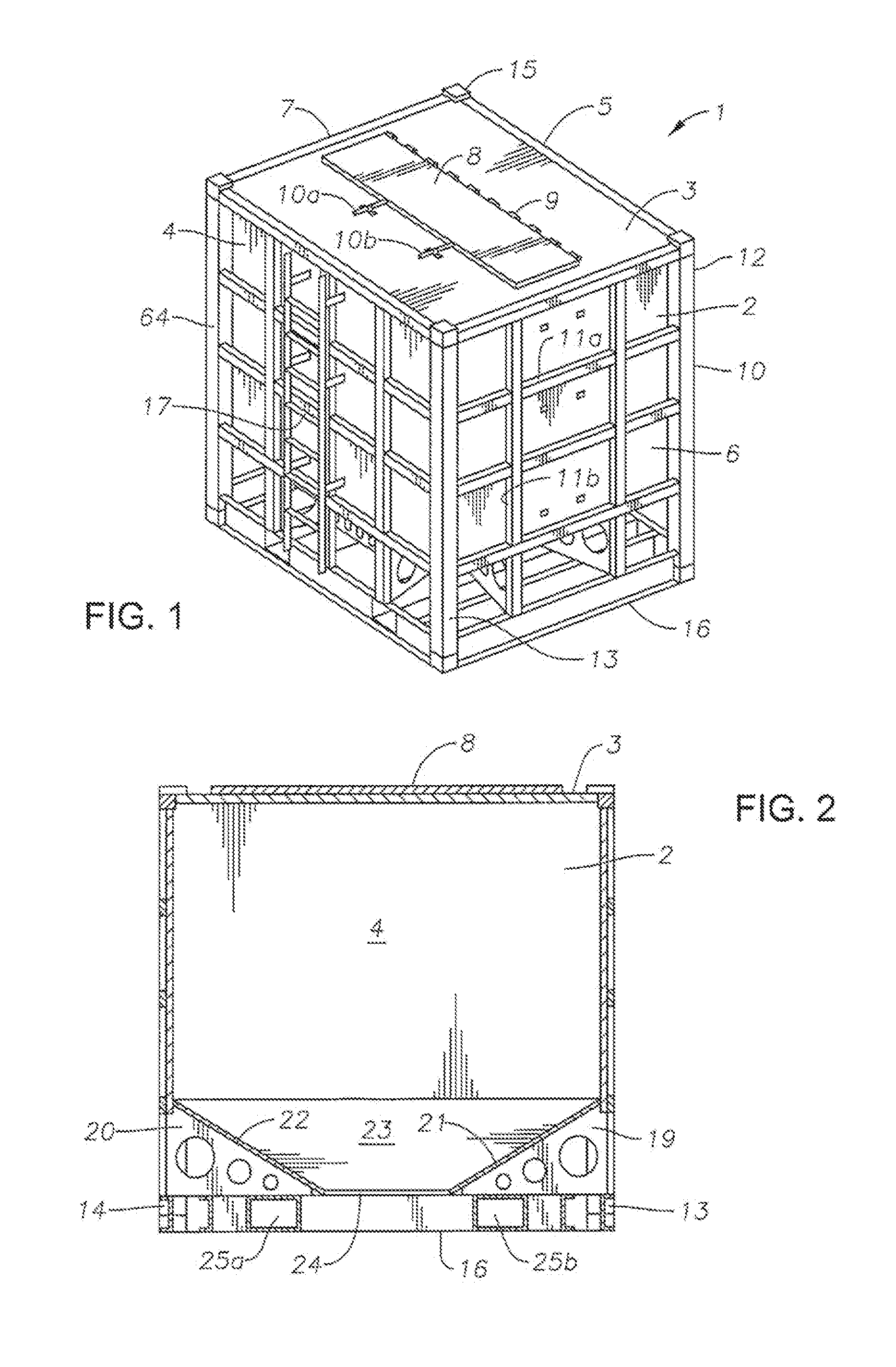

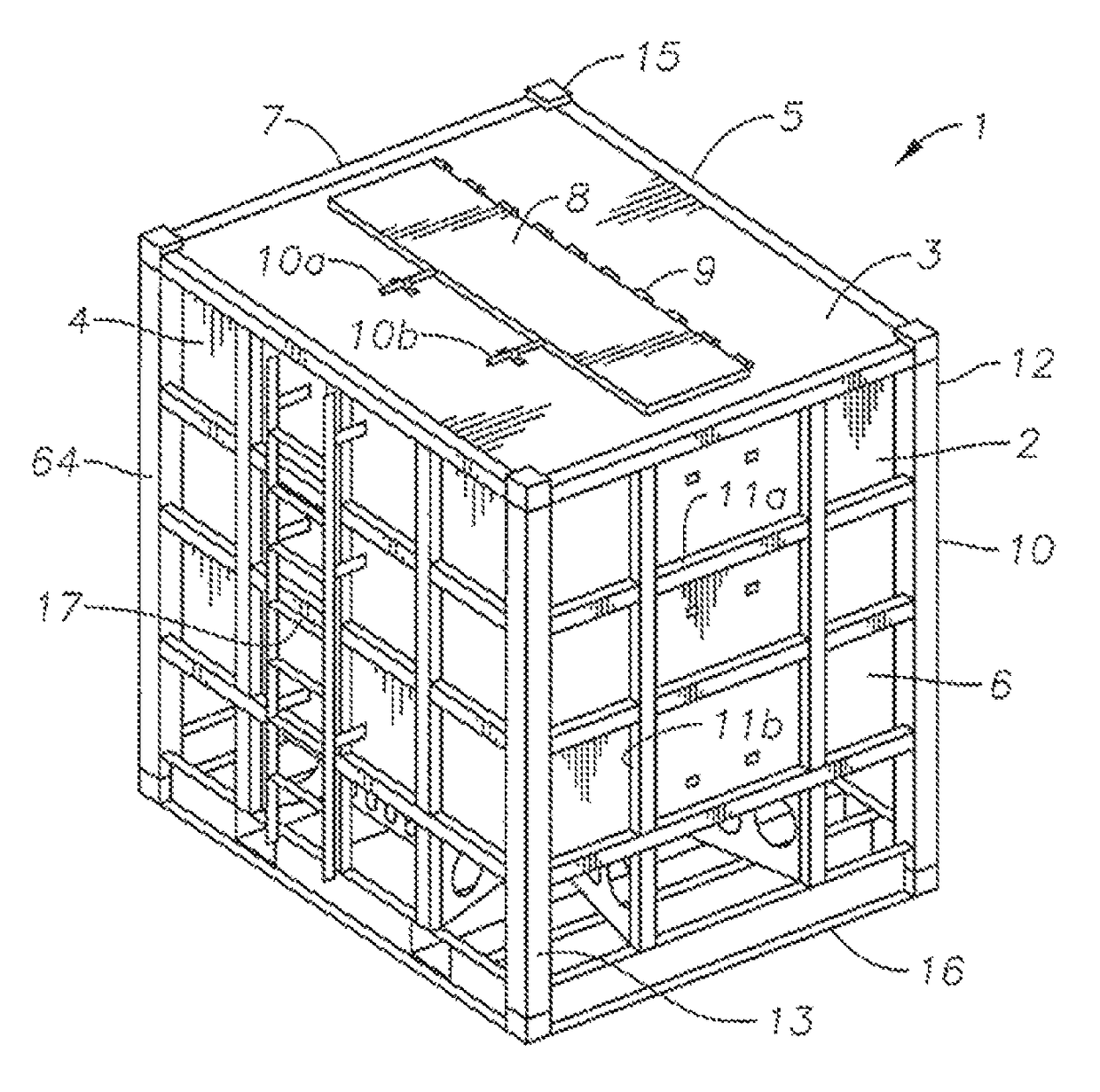

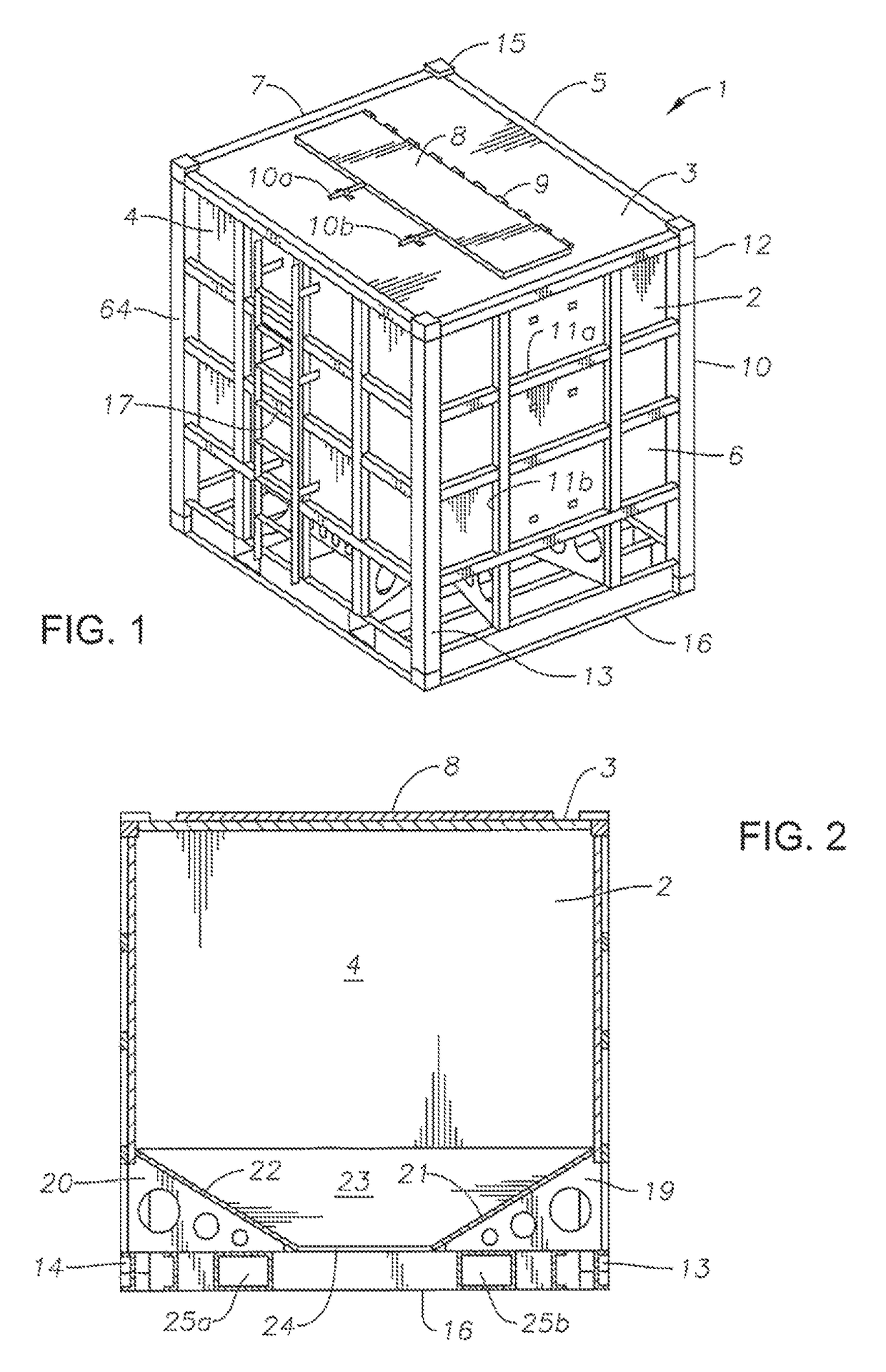

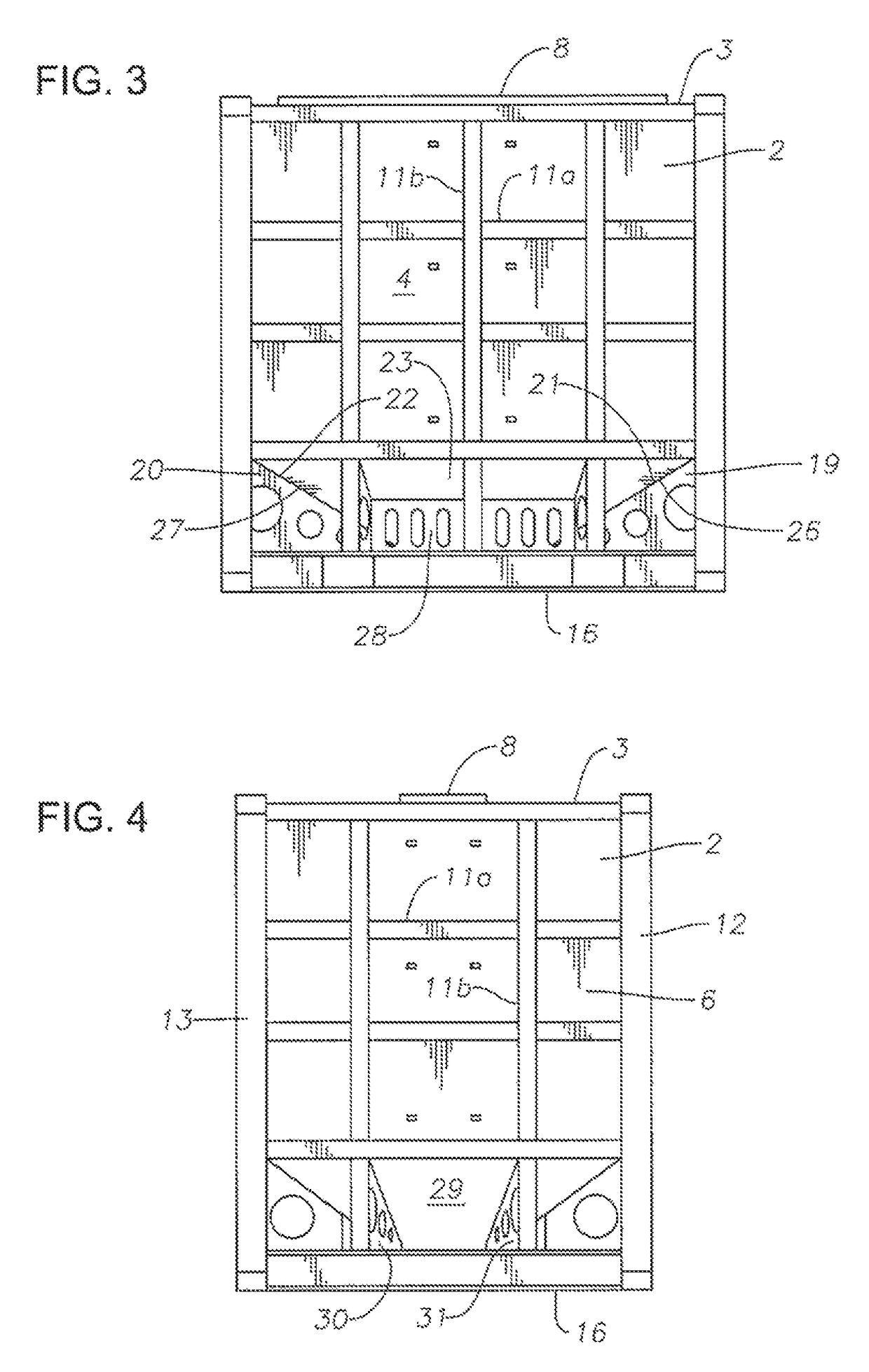

Apparatus for the transport and storage of proppant

ActiveUS20150284194A1Facilitating ability to quickly and inexpensively off-load proppantImprove velocity and turn-around and revenue-generating capacityConveyorsLarge containersEngineeringStainless steel material

An apparatus for the transport and storage of proppant has a container with a top wall, a pair of end walls and a pair of side walls. The pair of side walls extend between the pair of end walls. The container has a bottom discharge opening. The container includes a funnel extending from the pair of side walls and from the pair of and walls toward the bottom discharge opening. The funnel has sides extending in an angle of greater than 25° with respect to horizontal. The funnel includes a pair of side plates extending respectively from the pair of side walls toward the bottom discharge opening and a pair of end plates extending respectively from the pair of end walls toward the bottom discharge opening. Each of the side plates and the end plates is formed of a stainless steel material.

Owner:SANDBOX ENTERPRISES LLC

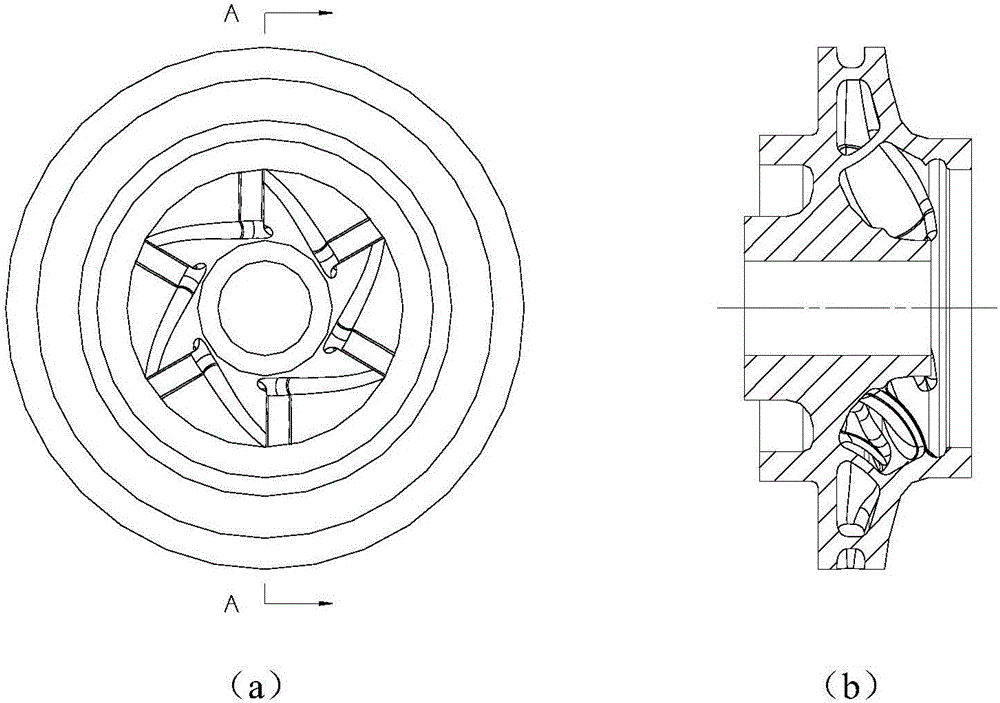

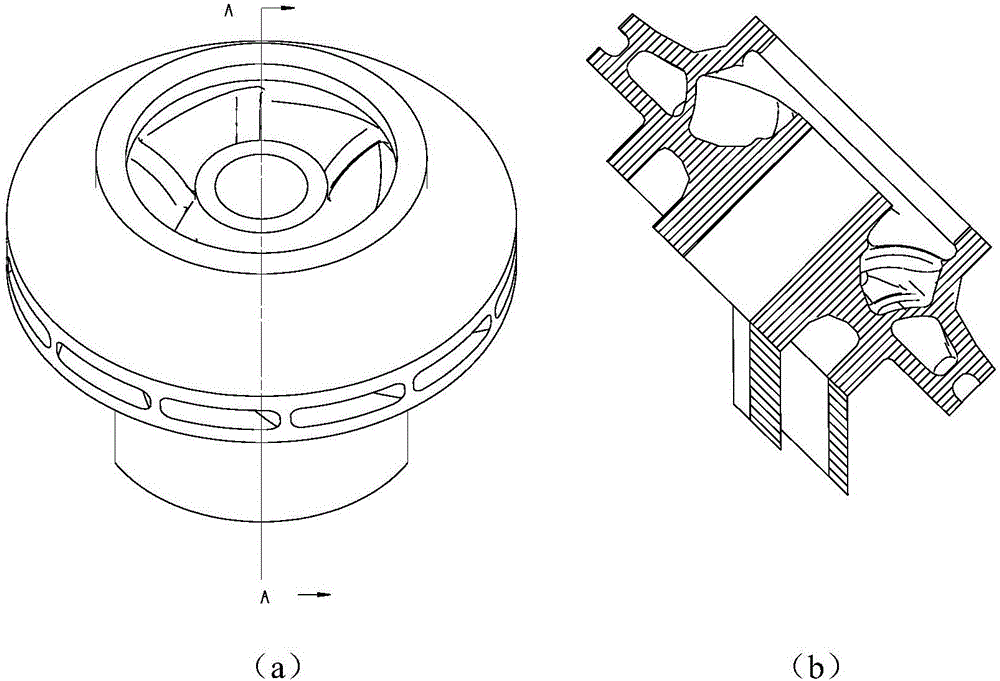

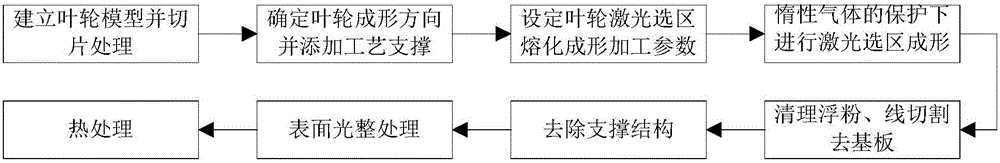

Integral manufacturing method of S-04/S-08 high-strength stainless steel three-dimensional flow shrouded impeller

ActiveCN106077643AShorten the manufacturing cycleCompact structureAdditive manufacturing apparatusEngine manufactureMaterials scienceAustenitic stainless steel

The invention provides an integral manufacturing method of an S-04 / S-08 high-strength stainless steel three-dimensional flow shrouded impeller. The integral manufacturing method comprises the steps of firstly, establishing an impeller three-dimensional model, and carrying out slicing treatment; determining the forming direction and support adding positions according to structural characteristics of the impeller; setting parameters of a laser selective melting forming processing technology according to characteristics of a high-strength stainless steel material; forming under protection of an inert gas; after forming, cleaning floating powder, removing a base plate through linear cutting, and removing supports; and finally, carrying out follow-up treatment such as surface treatment and thermal treatment on the impeller. According to the integral manufacturing method, complex cutters or fixtures do not need to be designed, materials can be directly added for part manufacturing only through the three-dimensional model of the impeller, the manufacturing cycle is greatly shortened, and the integral manufacturing method is applicable to trial manufacturing and middle and small-batch production in the development stage.

Owner:XIAN SPACE ENGINE CO LTD

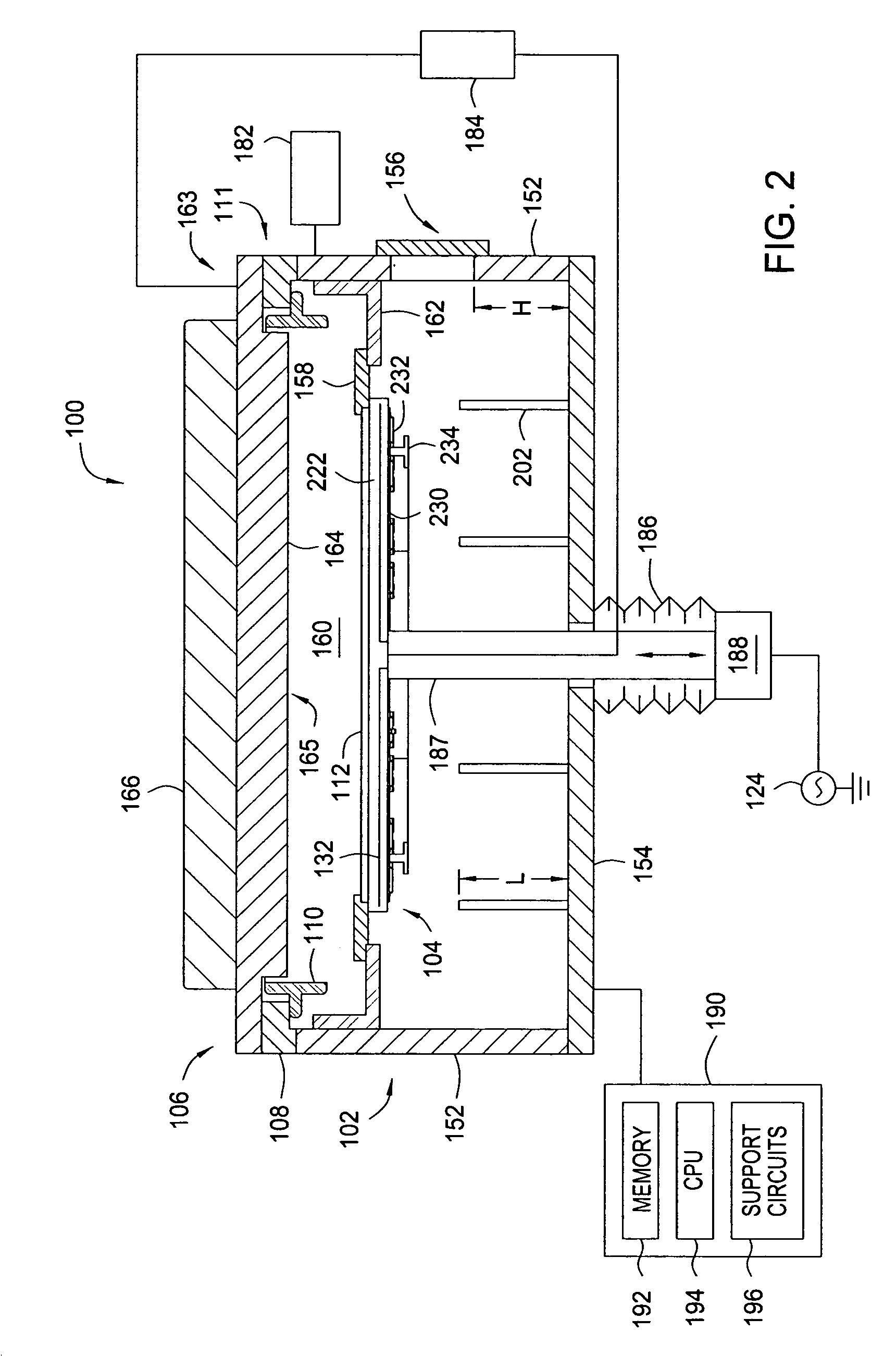

Heating and cooling of substrate support

ActiveUS20070029642A1Increase temperatureReduce the temperatureDrying solid materials with heatMuffle furnacesCooling channelMaterials science

A substrate support assembly and method for controlling the temperature of a substrate within a process chamber are provided. A substrate support assembly includes an thermally conductive body comprising a stainless steel material, a substrate support surface on the surface of the thermally conductive body and adapted to support a large area substrate thereon, one or more heating elements embedded within the thermally conductive body, a cooling plate positioned below the thermally conductive body, a base support structure comprising a stainless steel material, positioned below the cooling plate and adapted to structurally support the thermally conductive body, and one or more cooling channels adapted to be supported by the base support structure and positioned between the cooling plate and the base support structure. A process chamber comprising the substrate support assembly of the invention is also provided.

Owner:APPLIED MATERIALS INC

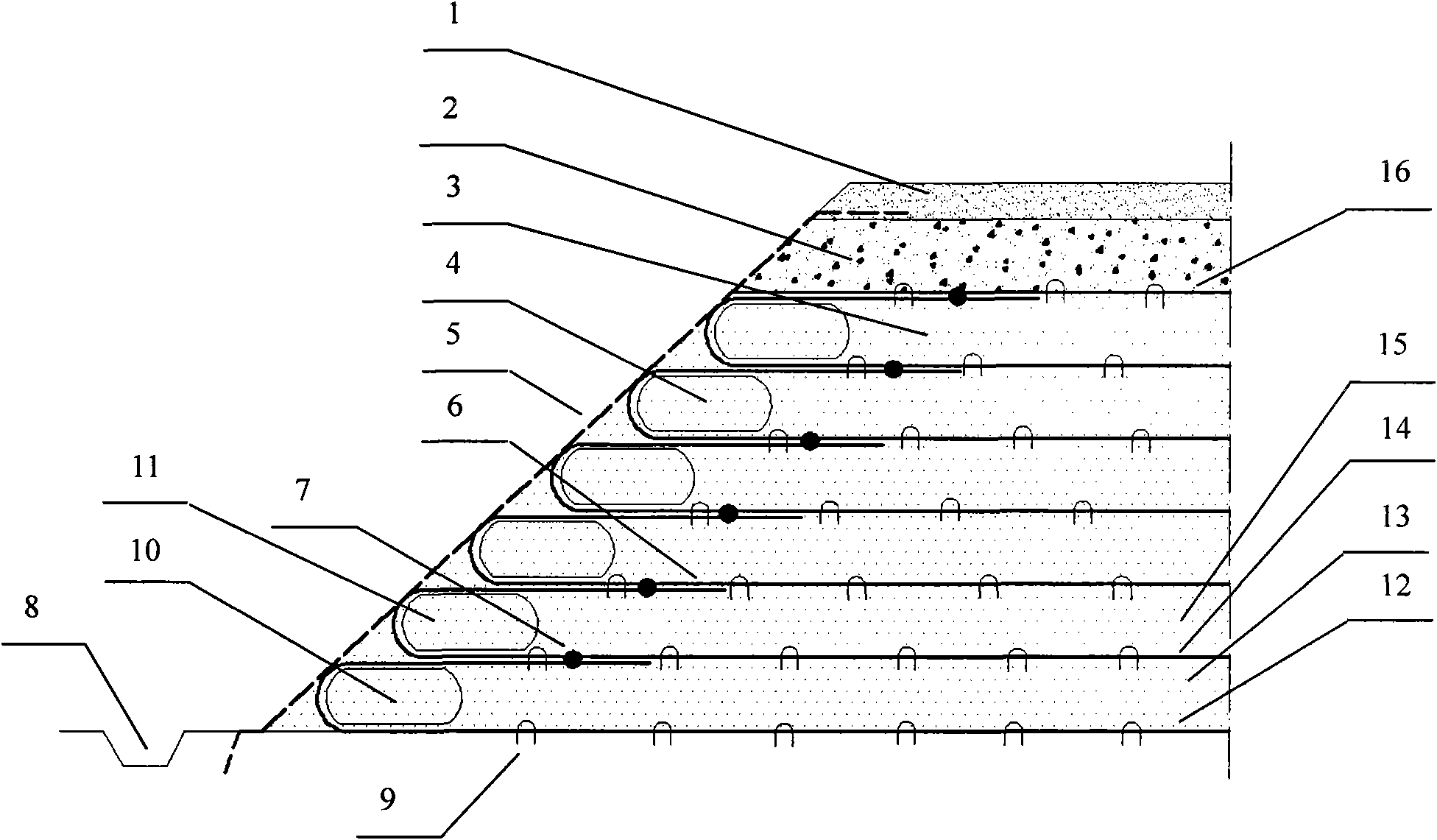

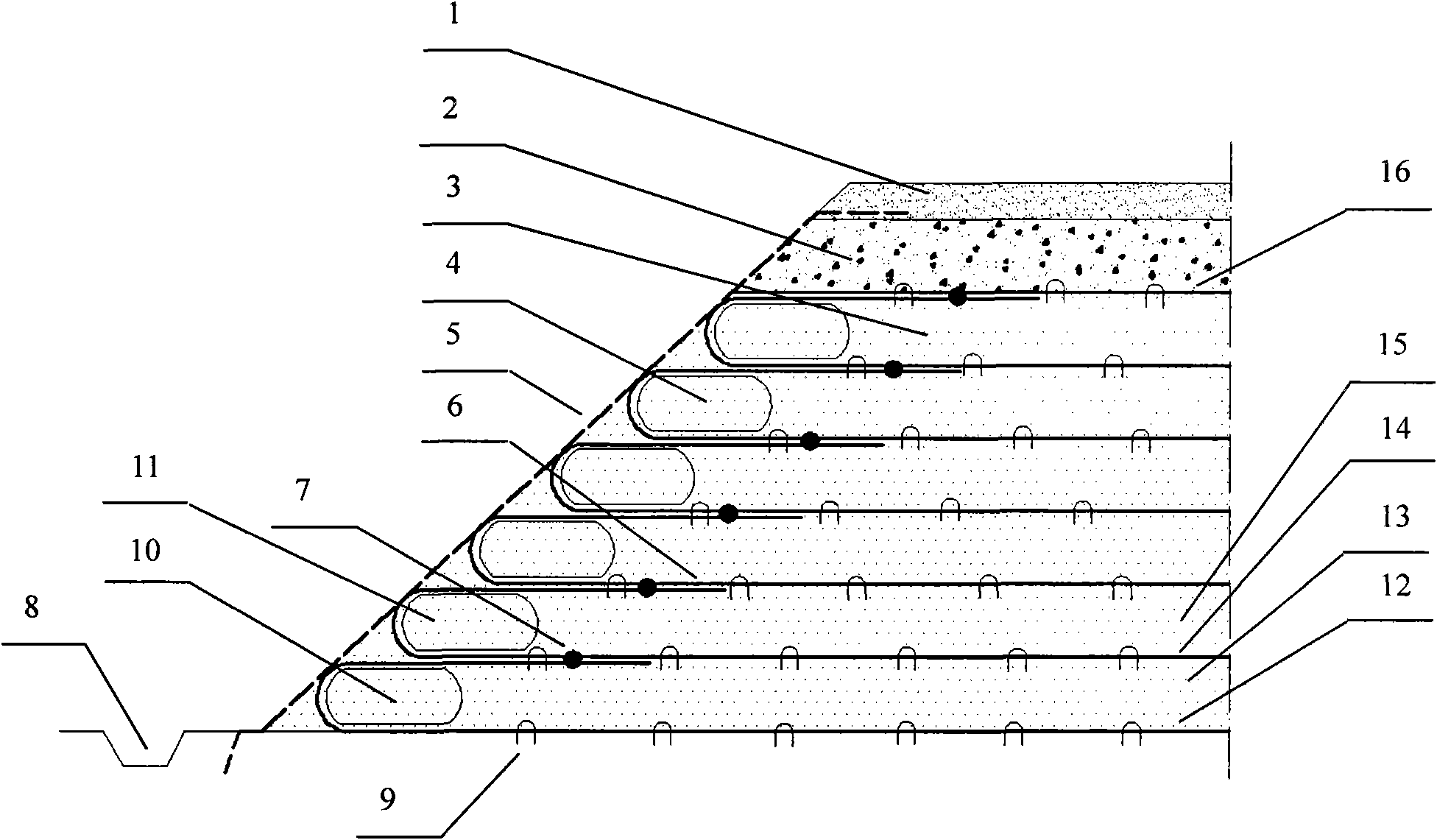

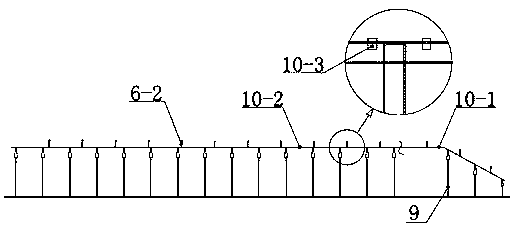

Method for improving and protecting collapsible loess slope project

InactiveCN101851928ARealize comprehensive utilizationFix stability issuesExcavationsCalcium in biologyGeogrid

The invention relates to a method for improving and protecting a collapsible loess slope project, which is characterized in that: the loess slope project is protected by adopting improved loess (3), gunny bags (4), a protective net (5), a geogrid (6) and a drainage ditch (8), wherein the improved loess is prepared by stirring and blending lime, fly ash and loess in a volume ratio, the total volume of the lime and fly ash accounts for no less than 30 percent of the volume of the admixture, the SiO2 and Al2O3 total content of the fly ash is no less than 75 percent, and the lime is calcium quicklime or calcium hydrated lime; the geogrid (6) is high-density polyethylene uniaxial geogrid; the gunny bags (4) are jute gunny bags; and the protective net (5) is made of a flexible stainless steel material. The method has the advantages of stabilizing the slope, solving the stability problem of the fill slope, realizing waste utilization, afforesting the environment and preventing soil erosion by improving the structural protective system consisting of the loess and geogrid; and the method is suitable for improving the collapsible loess project in civil engineering and can be used for projects such as highway embankment filling, building foundation improvement, retaining wall reinforcement and the like.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

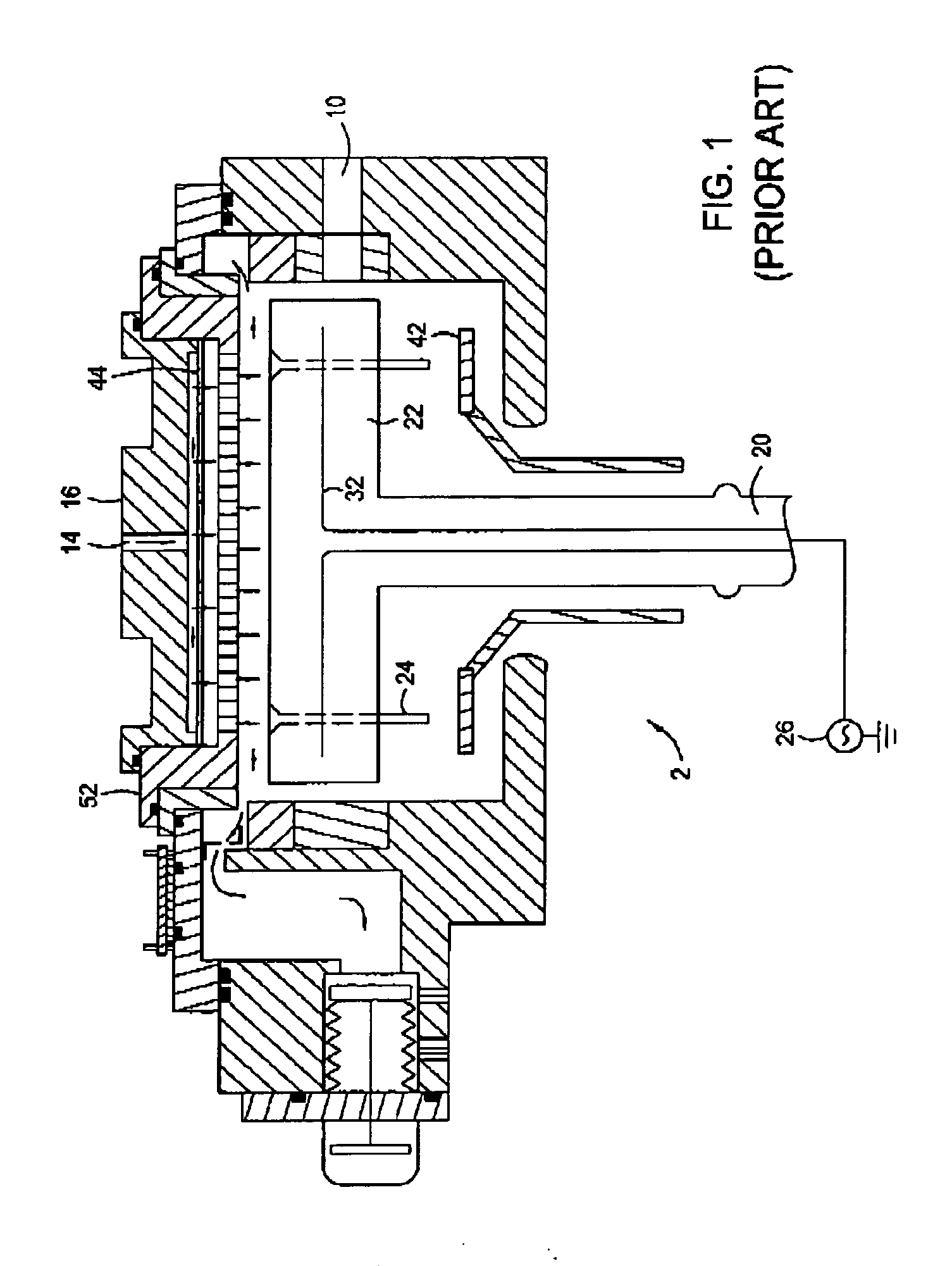

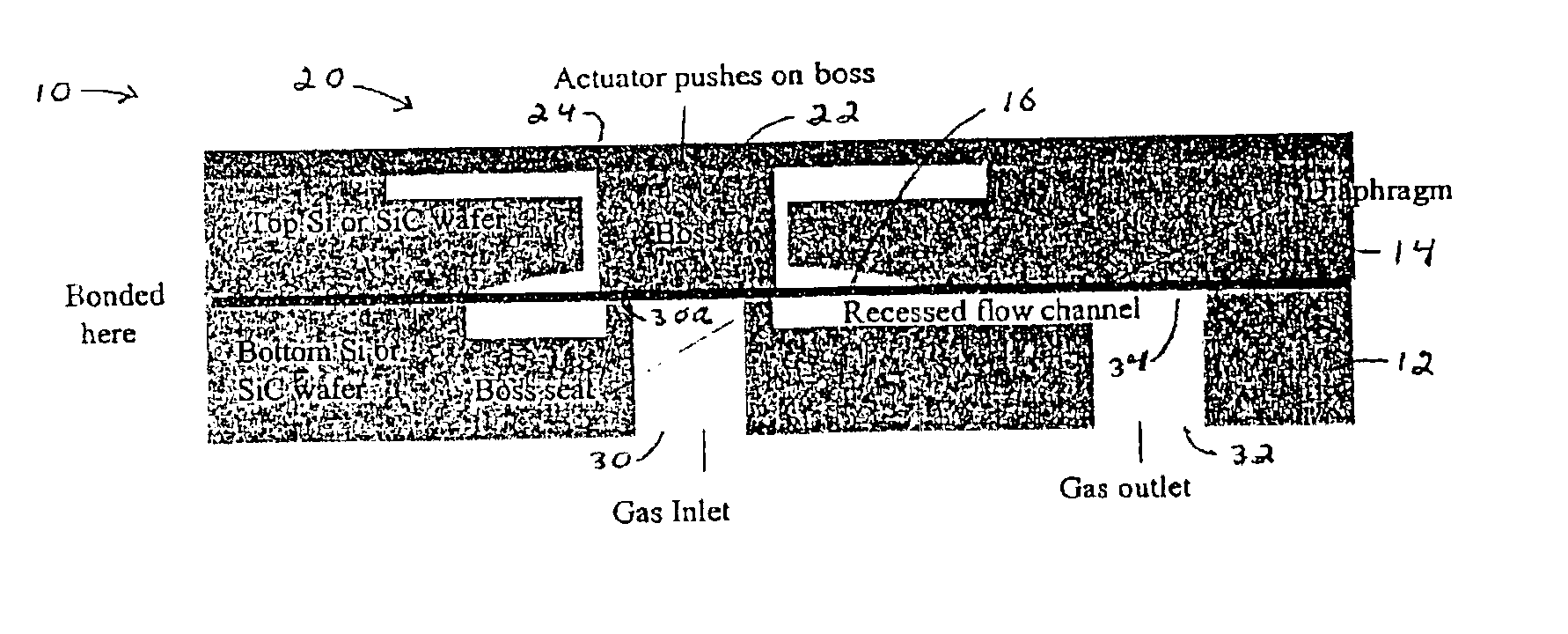

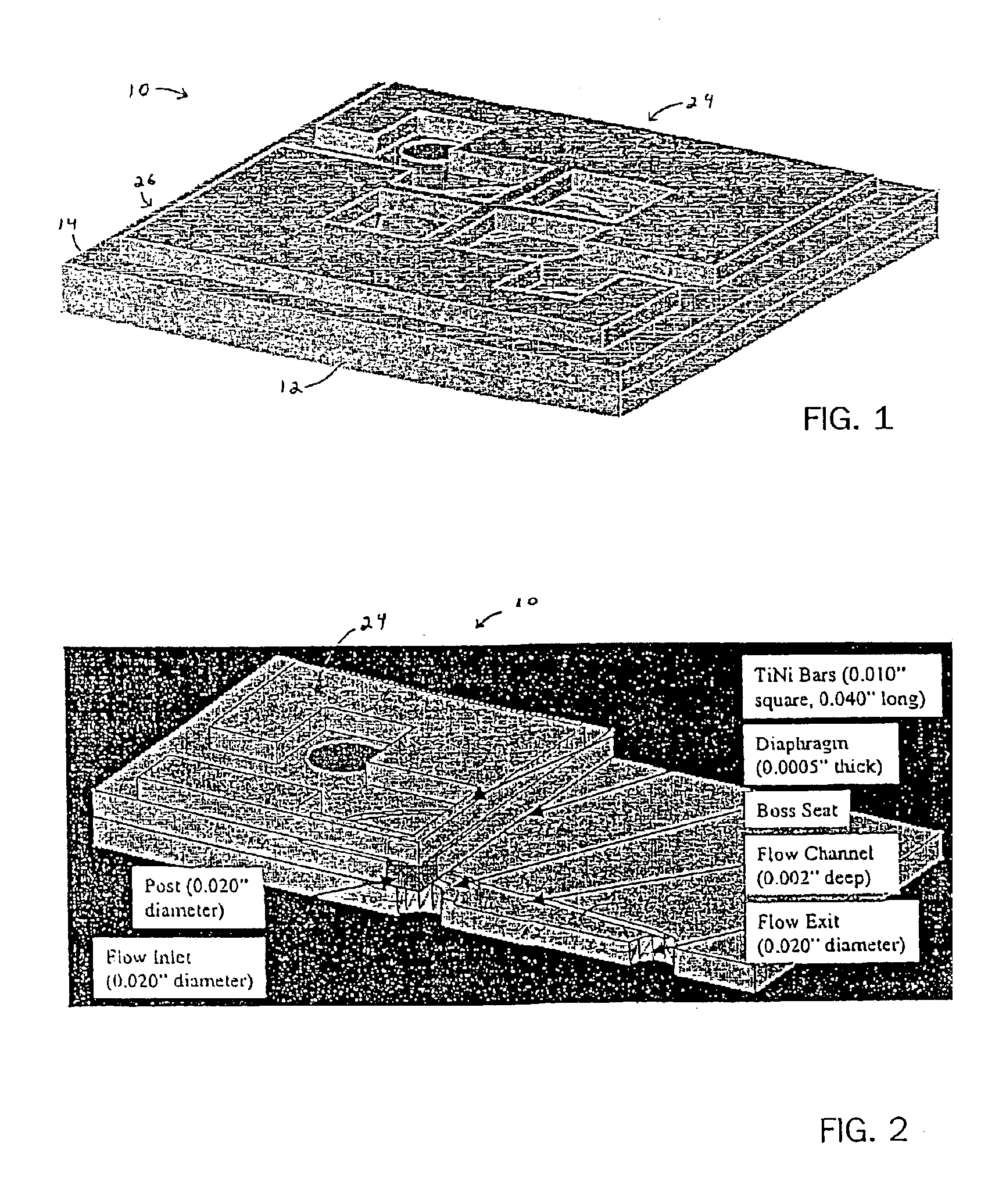

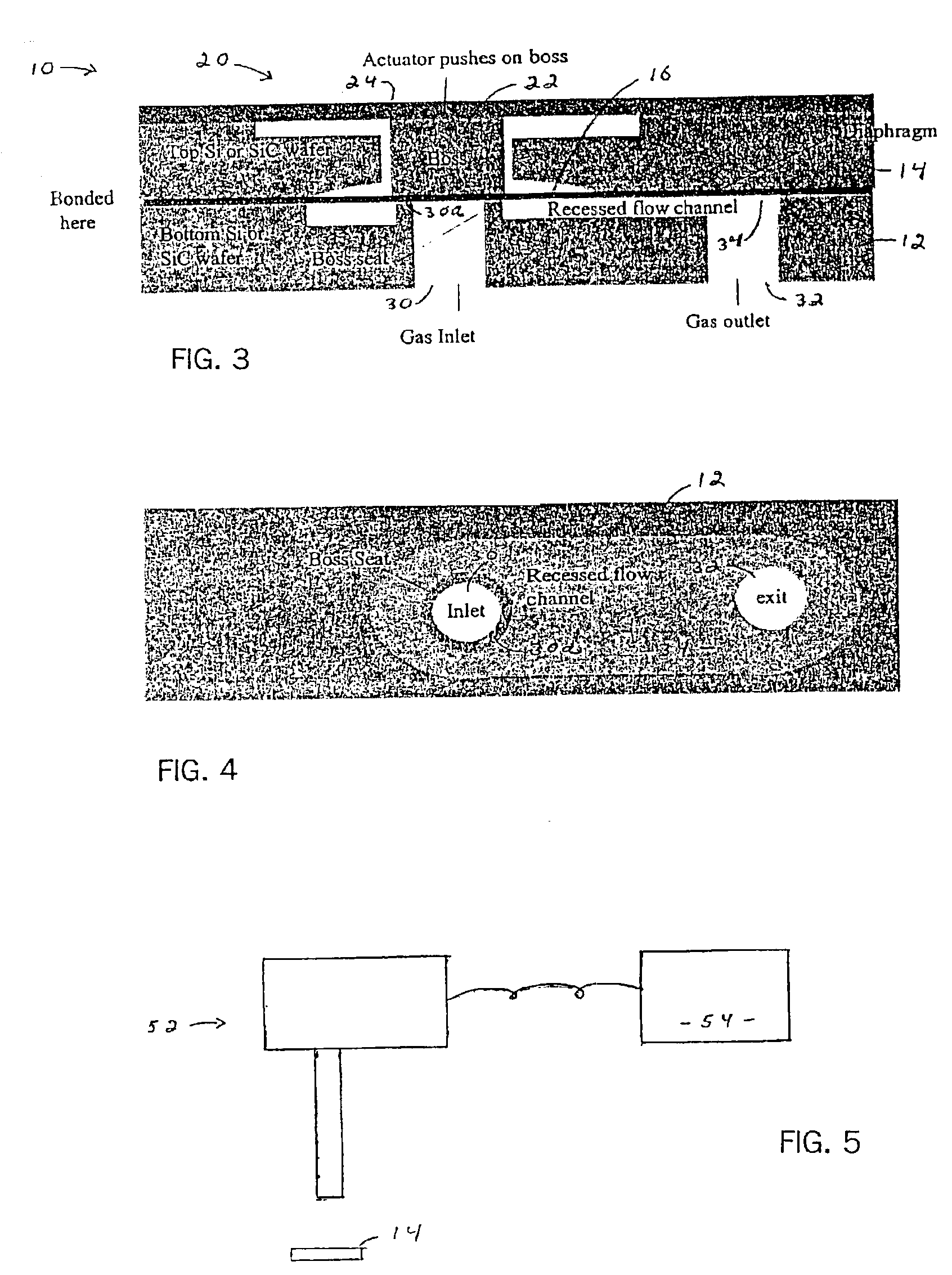

Microelectromechanical high pressure gas microvalve

InactiveUS6883774B2Effectively and reliably workDiaphragm valvesOperating means/releasing devices for valvesEngineeringHigh pressure

A microvalve and a method of forming a microvalve. The microvalve comprises first and second layers, a diaphragm member and a switching means. The first and second layers are secured together to form a valve body that forms an inlet opening for receiving fluid, an outlet opening for conducting fluid from the valve body, and a flow channel for conducting fluid from the inlet to the outlet. The diaphragm is disposed between the layers, and is movable between open and closed positions. In these position, the diaphragm, respectively, allows and blocks the flow of fluid from the inlet to the flow channel. The diaphragm is biased to the closed position, and moves from the closed position to the open position when the pressure of fluid in the inlet reaches a preset value. The switching means is connected to the valve body for moving the diaphragm to the closed position against the pressure of fluid in the inlet. Preferably, the microvalve is constructed out of SiC and stainless steel materials, allowing the microvalve to be used in a harsh environment.

Owner:LOCKHEED MARTIN CORP

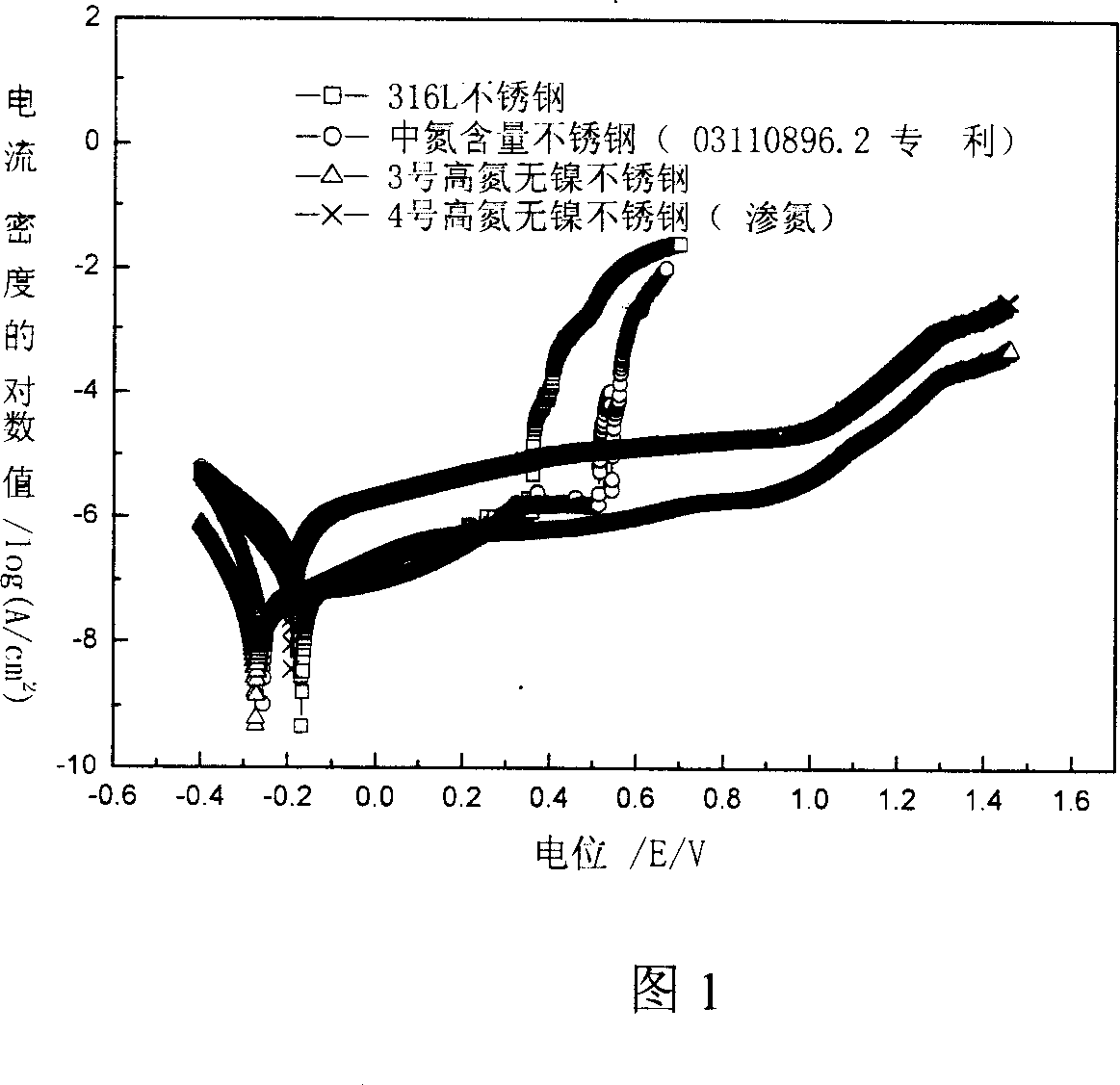

Medical free nickel high nitrogen stainless steel material and preparation and application thereof

InactiveCN101077425AImprove wear resistanceImprove corrosion resistanceProsthesisChemical compositionMedical equipment

The present invention relates to medical stainless steel implant material, and is especially one kind of medical no-nickel stainless steel material. Chemically, the medical no-nickel stainless steel material includes Cr 17-24 wt%, Mn 12-20 wt%, Mo 1-3 wt%, Cu 0.5-1.0 wt%, N 0.71-1.20 wt%, C not more than 0.03 wt% and Fe for the rest. The medical no-nickel stainless steel material containing no toxic Ni element may be used in surgical implant, medical equipment, food appliance, ornament and other product contacting direct to human body, and may be also used in chemical, environment protecting and other fields.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Manufacturing process of pump body casting of super duplex stainless steel centrifugal pump

InactiveCN102626769AReduce manufacturing costReduce maintenance costsFoundry mouldsFoundry coresFuranTemperature control

The invention provides a manufacturing process of a pump body casting of a super duplex stainless steel centrifugal pump. The manufacturing process comprises steps of sand mould prefabricating, material smelting, casting, sand shakeout and heat treatment, wherein a runner core in a sand mould is composed of chromite furan resin sand of which the outer layer is filled with quartz furan resin sand;in material smelting, super duplex stainless steel material ZG00Cr25Ni7Mo4N is used, the chemical composition, ferrite content and PREN (Pitting Resistance Equivalent) value of molten steel are undercontrol and the casting temperature is from 1540 DEG C to1560 DEG C; after sand shakeout, forced air cooling is carried out, spray cooling is further carried out on the thick and large part of the casting, and after a casting system and a dead head are removed, the heat treatment is carried out. The pump body casting of a super duplex stainless steel centrifugal pump, which is manufactured by using the manufacturing method, has the advantages that the manufacturing and maintenance cost is reduced, abrasion resistance and pitting resistance are improved and the service life is prolonged.

Owner:遵义拓特铸锻有限公司

Conductor rail

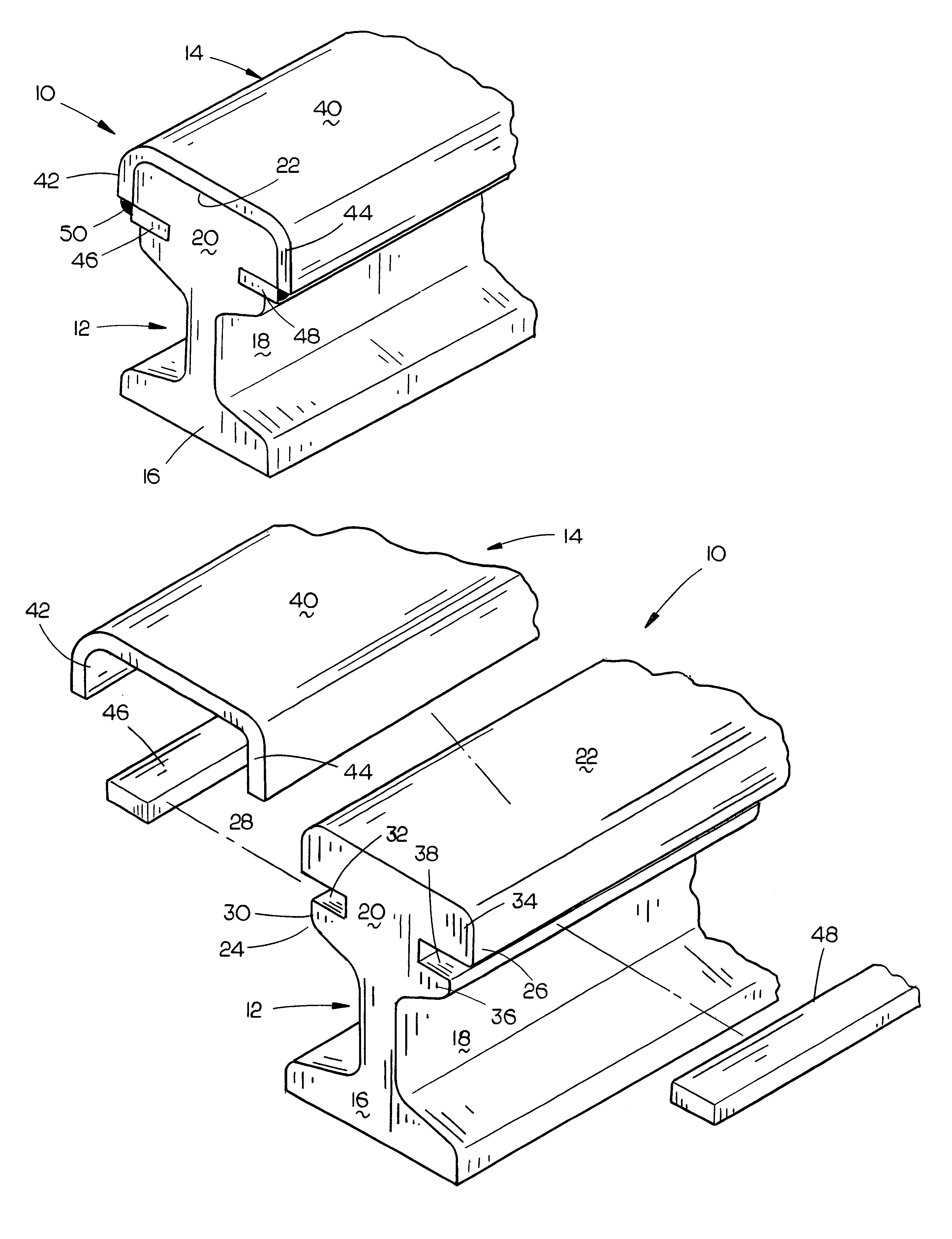

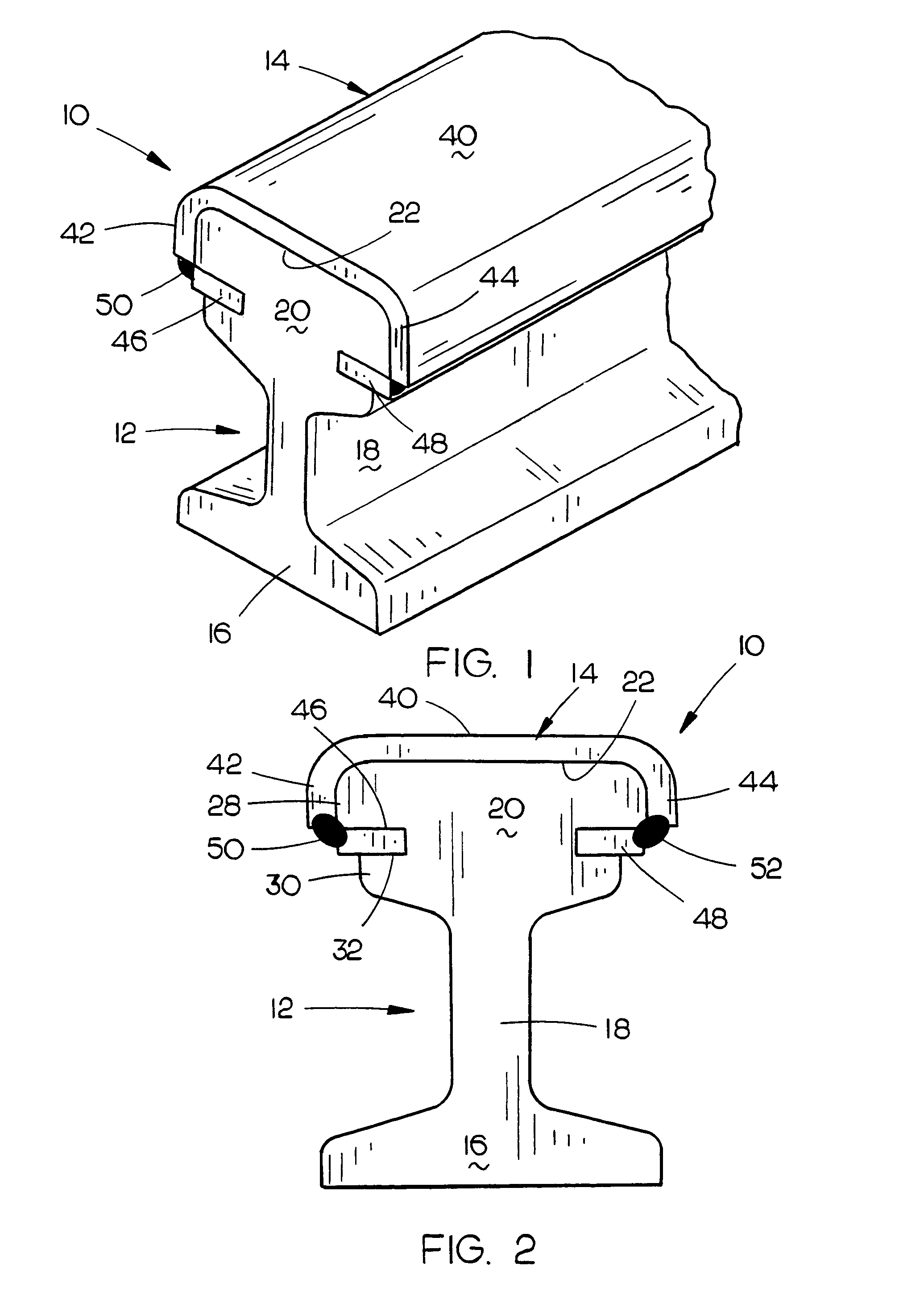

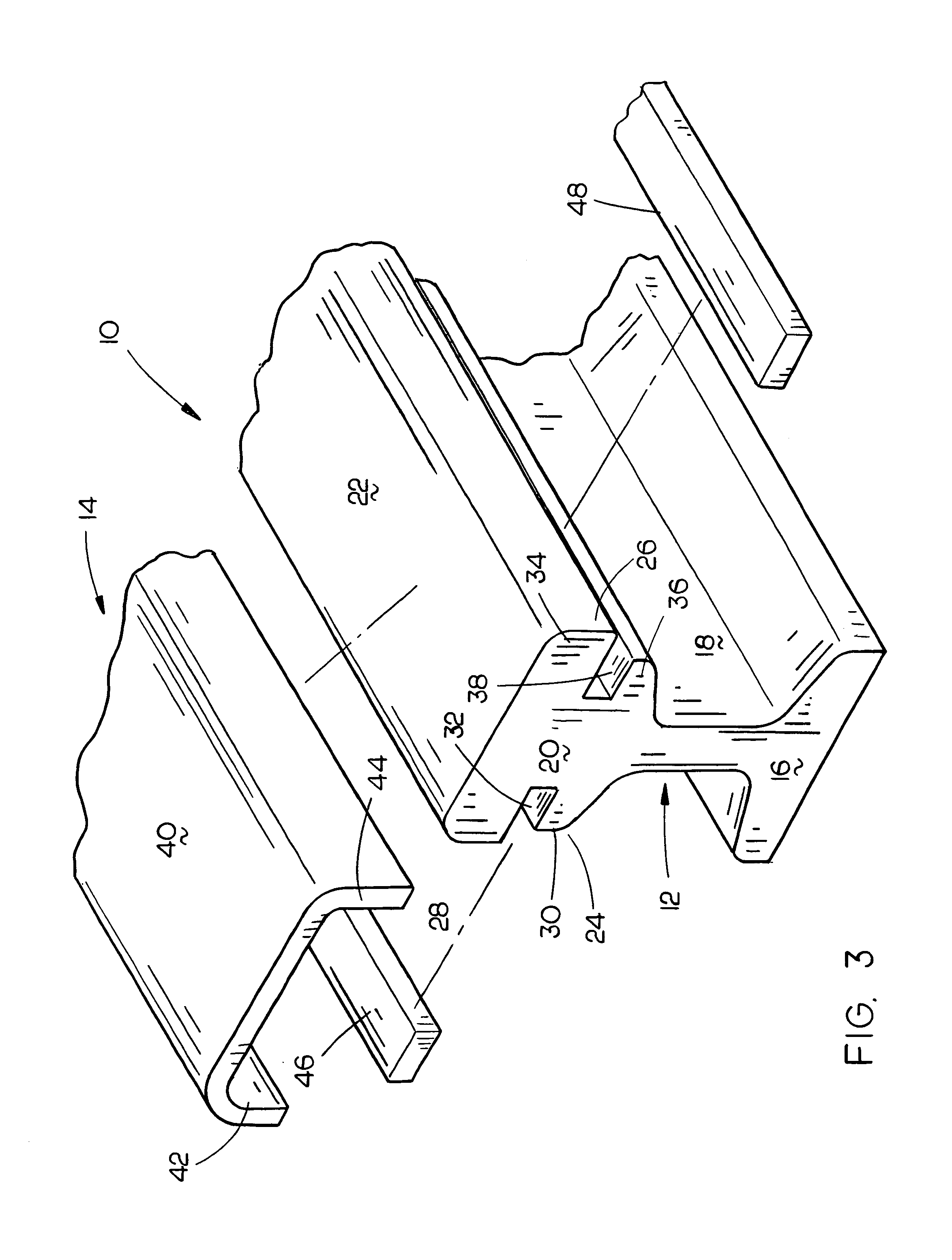

ActiveUS6983834B1Easy to assembleSatisfactory performancePower railsStainless steel materialAluminium

A conductor rail comprising a main body having a facing cap mounted thereon. The main body is comprised of aluminum while the facing cap is comprised of a stainless steel material. The main body of the conductor rail has a head portion which has channels extending into the opposite sides thereof. The facing cap comprises a top portion which is positioned upon the upper part of the head portion and which has side portions welded to plate members positioned in the channels.

Owner:CONDUCTIX

Manual odor removal structure

InactiveUS20100042113A1Increase surface areaHigh appearance requirementsSurgeryDetergent mixture composition preparationPunch pressOrganic matter

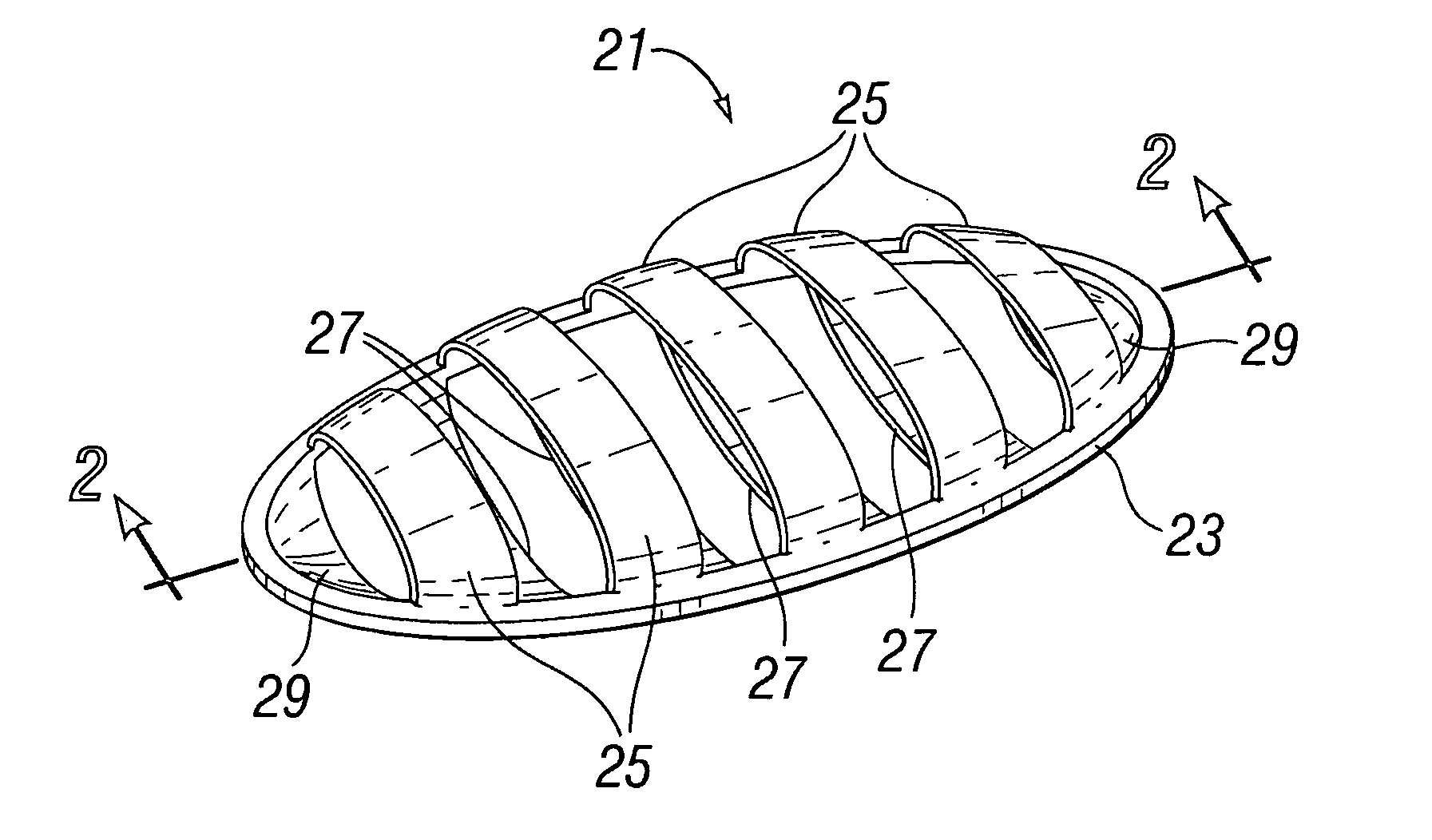

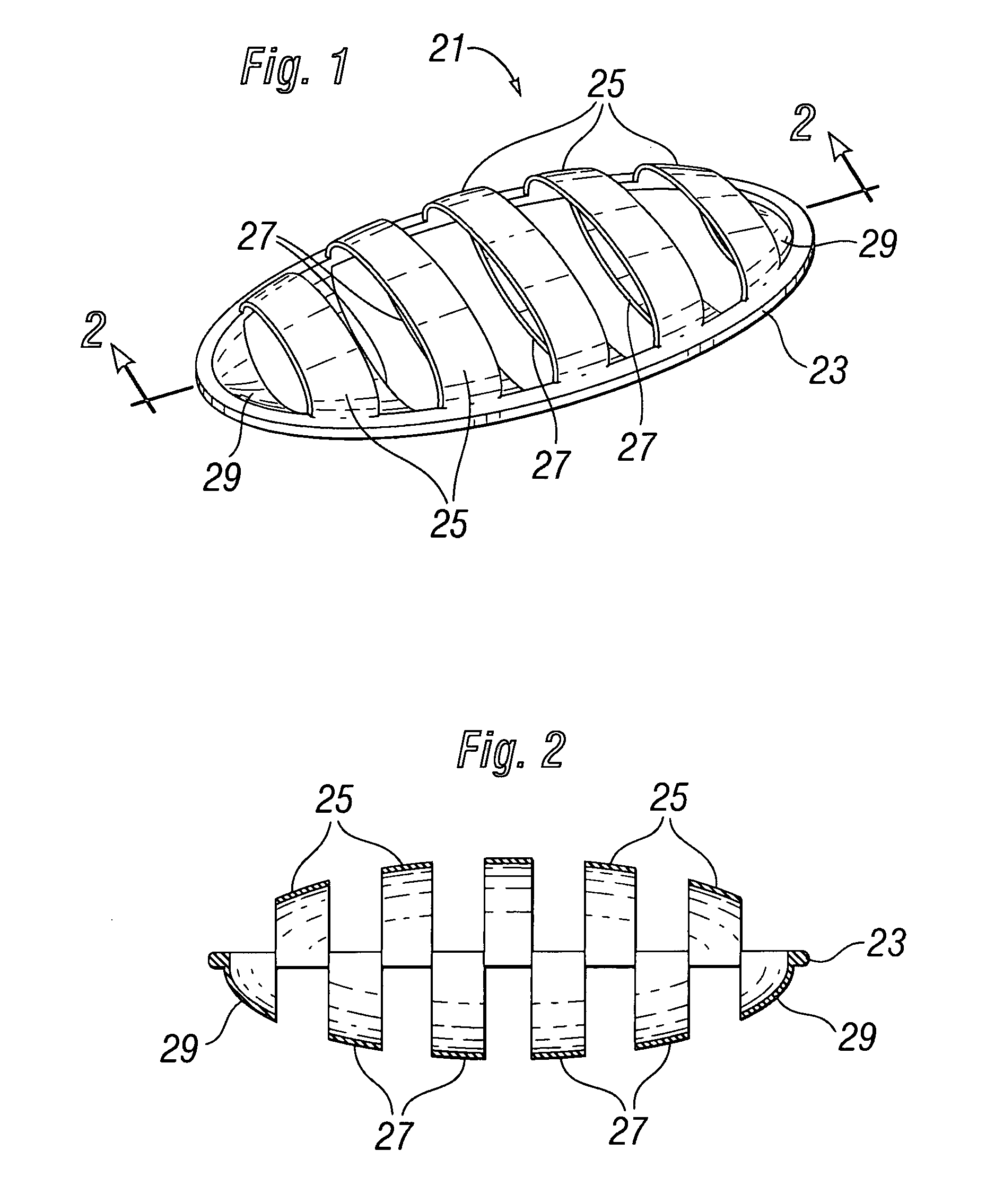

A volumetric stainless steel structure is provided by punch pressing a single blank and results in a volumetric presentation of alternating bands of stainless steel material. The spacing of the bands is sufficient to provide (1) an interruption in the surface to surface contact which might entrap organic species and (2) a space which allows the epidermis to be scrubbed, manipulated and massaged by the rounded edge of the bands as the hands manipulate it in a way similar the manipulation of soap. Further, the alternating bands provide internal surface area, in the form of the inside of the bands which are protruding, for additional adsorptive area.

Owner:DAKA RESEARCH INC

Molybdenum copper and stainless steel argon tungsten argon arc welding process

InactiveCN101284330AReduce temperature differenceReduce welding stressArc welding apparatusWelding/soldering/cutting articlesSurface cleaningAlloy

The invention discloses an argon tungsten arc process of molybdenum copper and a dissimilar stainless steel material. The method comprises the steps of cleaning the surface of the molybdenum copper and the surface of the stainless steel, which are to be connected, and the surface the Cr-Ni alloy system welding wire used for filling before welding; preheating by using a tungsten electrode argon arc inclining to the molybdenum copper first after arc starting; adopting pure argon protection; keeping down the argon arc to control heat distribution and to conduct filler rod argon tungsten-arc welding. The method has the advantages of convenient operation and strong applicability. Furthermore, the obtained welding joint of the molybdenum copper and the stainless steel has higher strength and stable property, and can be widely used for welding the molybdenum copper and the stainless steel and other dissimilar materials, thus being worth popularization and application.

Owner:SHANDONG UNIV

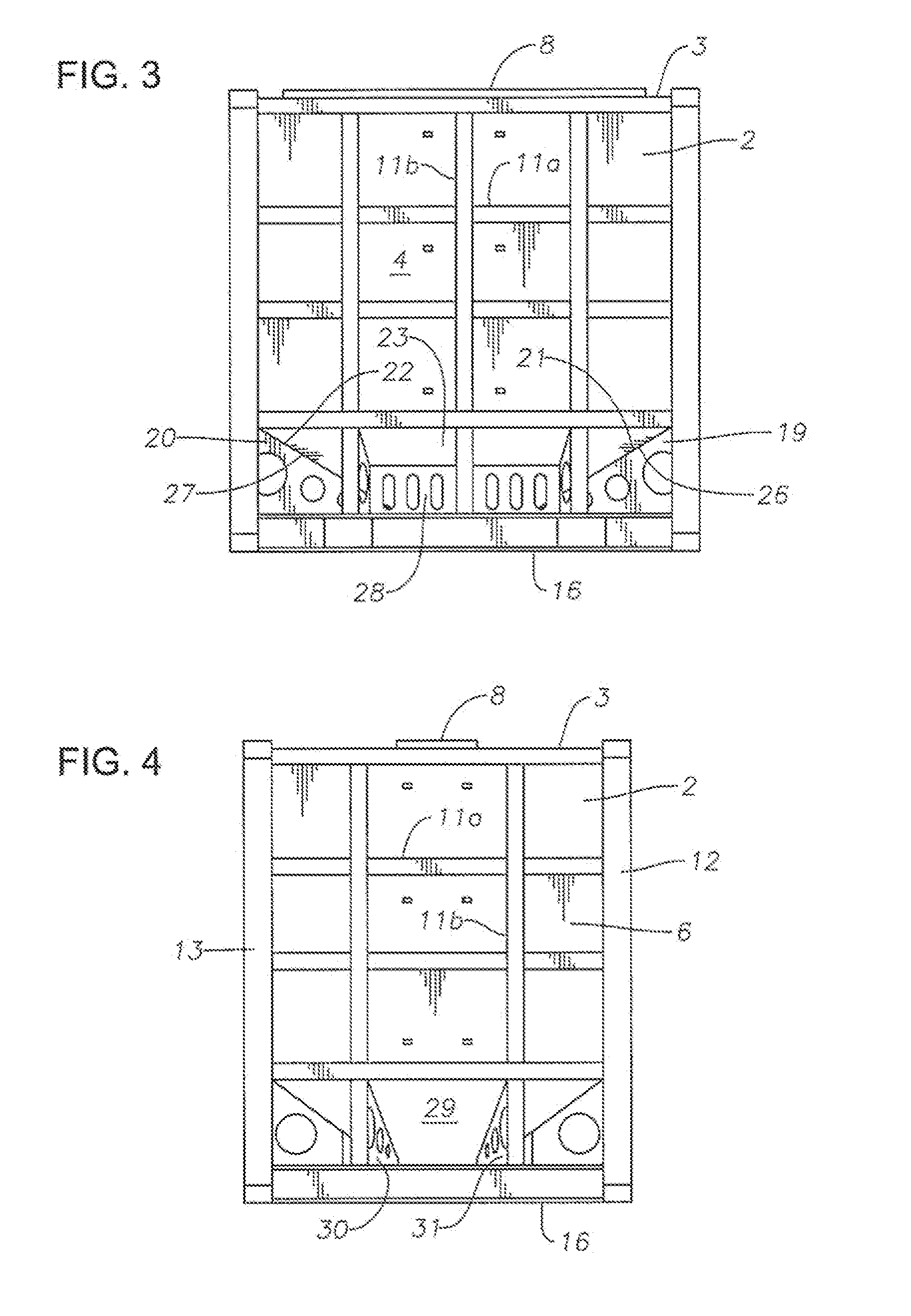

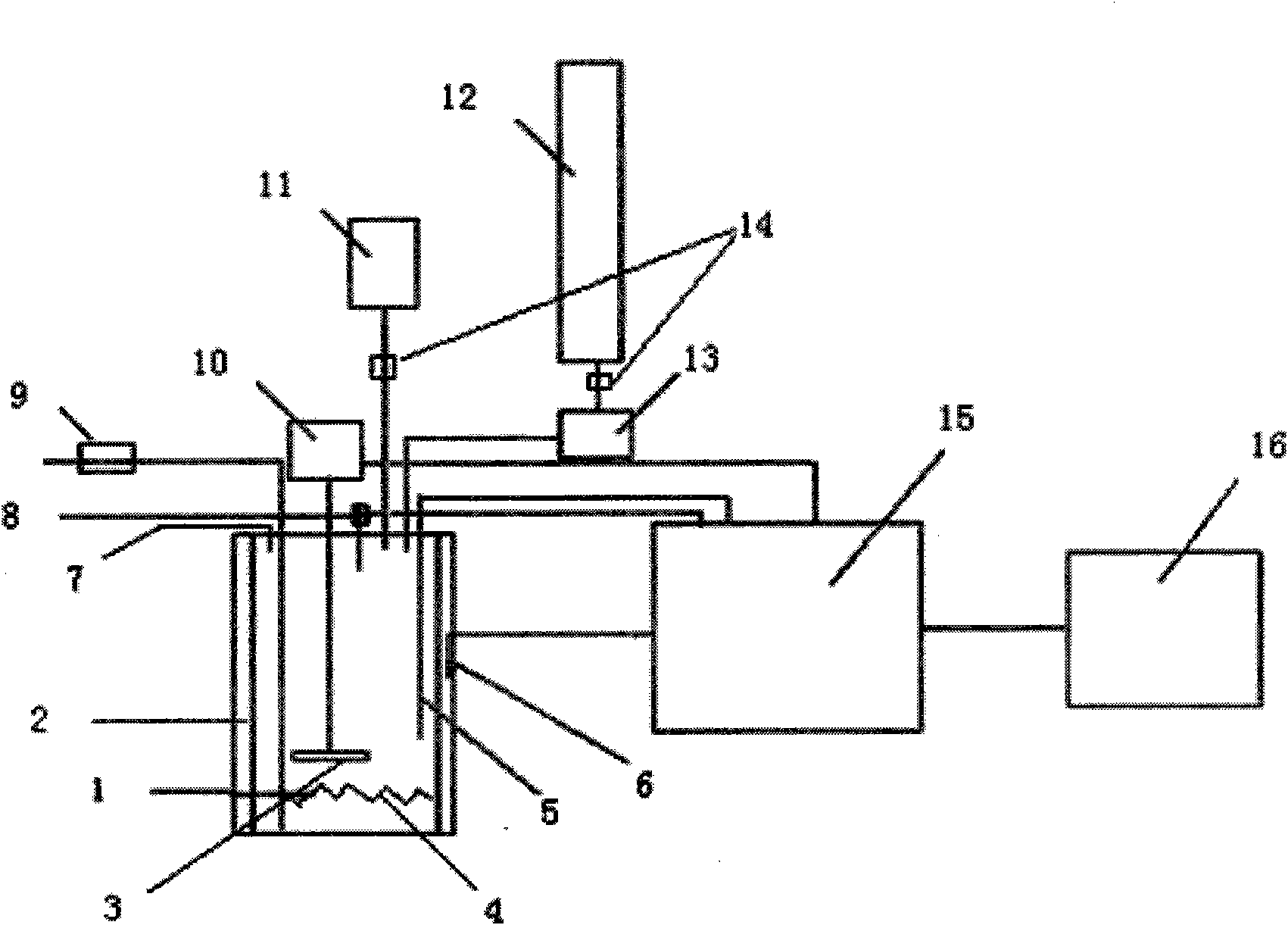

Multi-functional chemical engineering experiment device

InactiveCN101658780AWide range of usesEasy to installChemical/physical/physico-chemical stationary reactorsEducational modelsApplicability domainChemical reaction

The invention belongs to the technical field experimental instruments, which relates to a multi-functional reaction device used for chemical engineering experiment. The multi-functional chemical engineering experiment device comprises a chemical reaction kettle, a control system and a feeding and discharging and metering system of reaction materials. The chemical reaction kettle adopts a double-layer high-transparent visible kettle body. An upper kettle cover and a lower kettle cover are made of stainless steel materials. The double-layer kettle body adopts conduction oil with high degree of transparency to heat, and the agitation is carried out by adopting strong magnetic force under static sealing. The control system comprises an in-kettle temperature measuring device, a kettle sleeve temperature measuring device, an in-kettle pressure measuring and transmitting device, a motor rotation speed measuring and transmitting device. The control system is connected with a control panel, andcan be connected with a computer to realize remote operation. The feeding and discharging and metering system of reaction materials comprises a feeding and metering system and a backflow separating and metering system of liquid and gaseous reaction materials. The multi-functional chemical engineering experiment device adopts a clasp or bolt connecting structure, wherein clasps and bolts are standardized and general and can be interchanged. The components can be added or cut voluntarily according to the change of the technique. The invention can be applied widely.

Owner:NANJING COLLEGE OF CHEM TECH

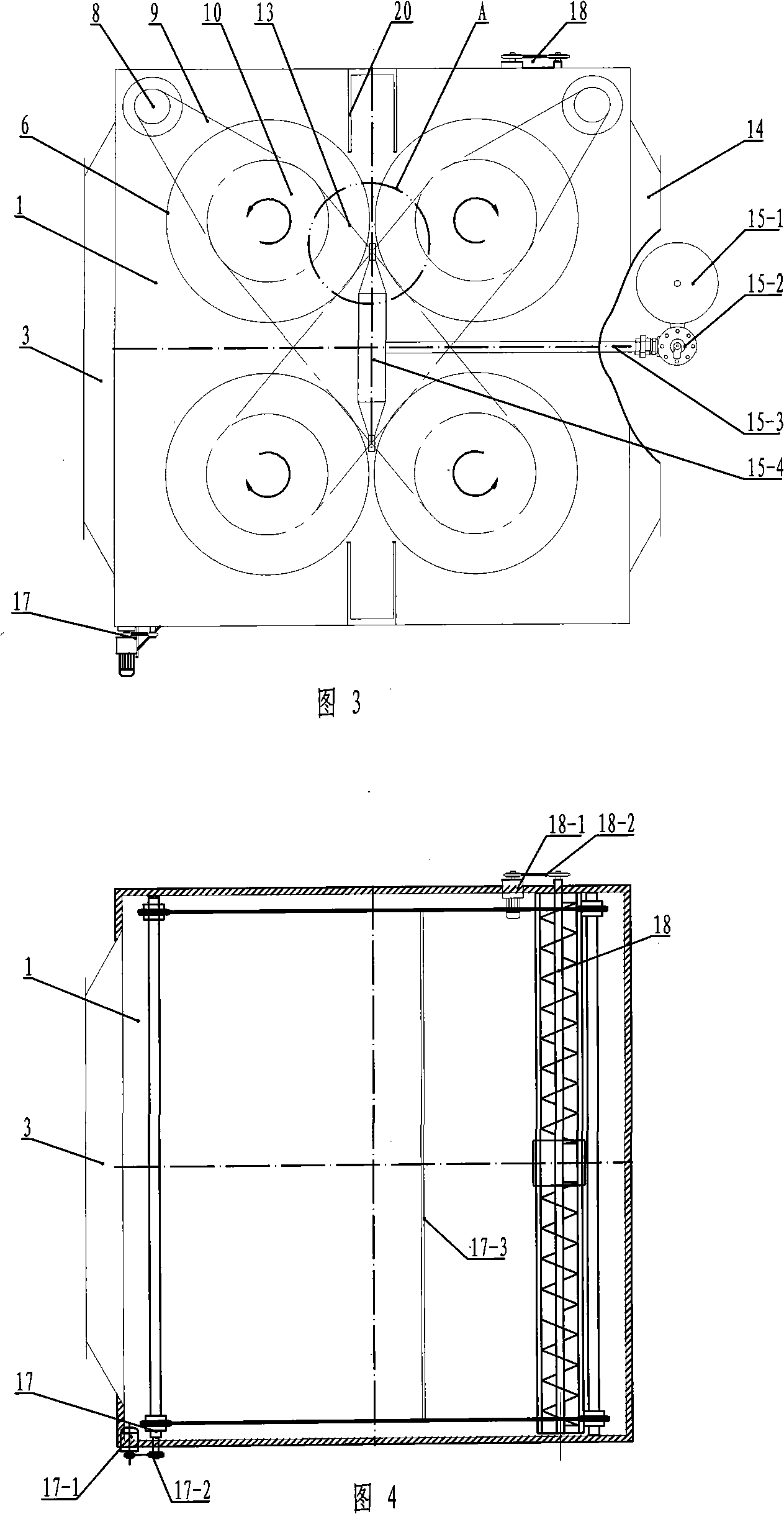

Rotating filter cartridge type air dust remover

InactiveCN101264406AEfficient removalConstant dust removal effectDispersed particle filtrationHigh humidityChain type

The invention discloses a rotary drum type dust remover, comprising a housing, a plurality of filter cylinders arranged in the intracavity of the housing for isolating dust, a main motor for driving filter cylinders, an impulse sweep system for cleaning the deposit dust on the surface of the filter cylinder, a chain typed scraper chain conveyor for cleaning dust, a spiral ash transportor and a dust discharge valve. The dust remover has the advantages of low dust concentration requirement for the air to be purified, ability to remove dust in various environments, and stable dust removal efficiency; and high temperature resistance, high humidity resistance, acid and alkaline corrosion resistance, electrostatic prevention as the filtered cloth material is stainless steel material; and ability to be used independently, also to be used multi-parallelly, and to select the number of single machine in an unit according to different discharge standard.

Owner:JIANGSU HUAZHENG ENVIRONMENTAL PROTECTION TECH CO LTD

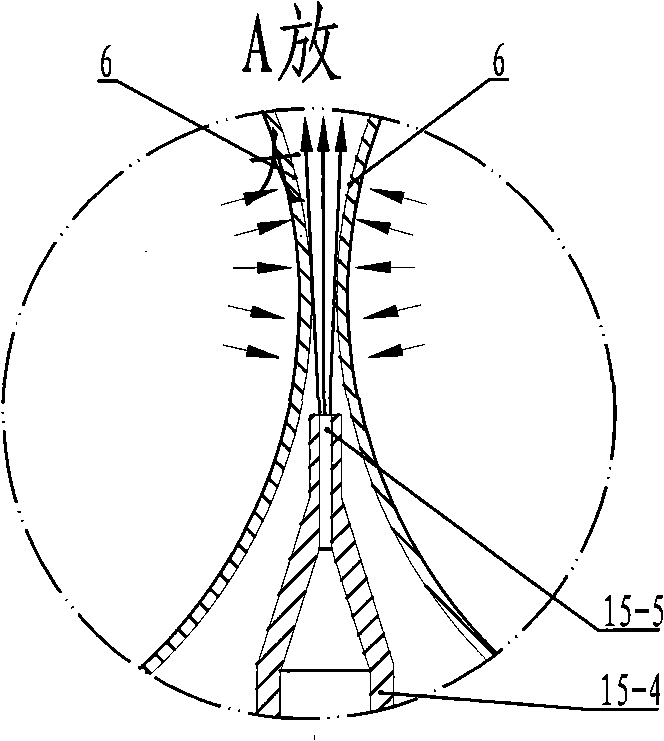

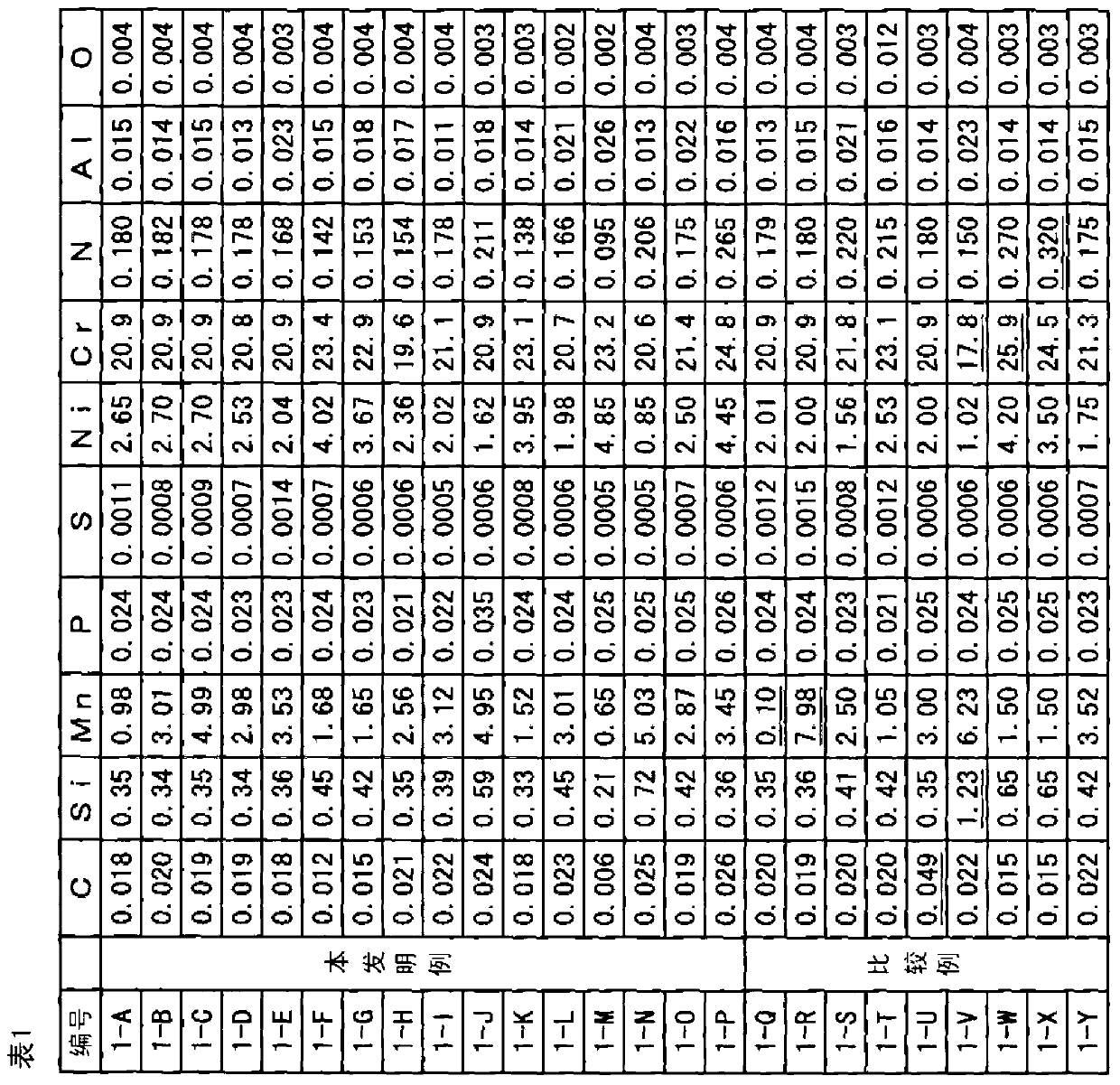

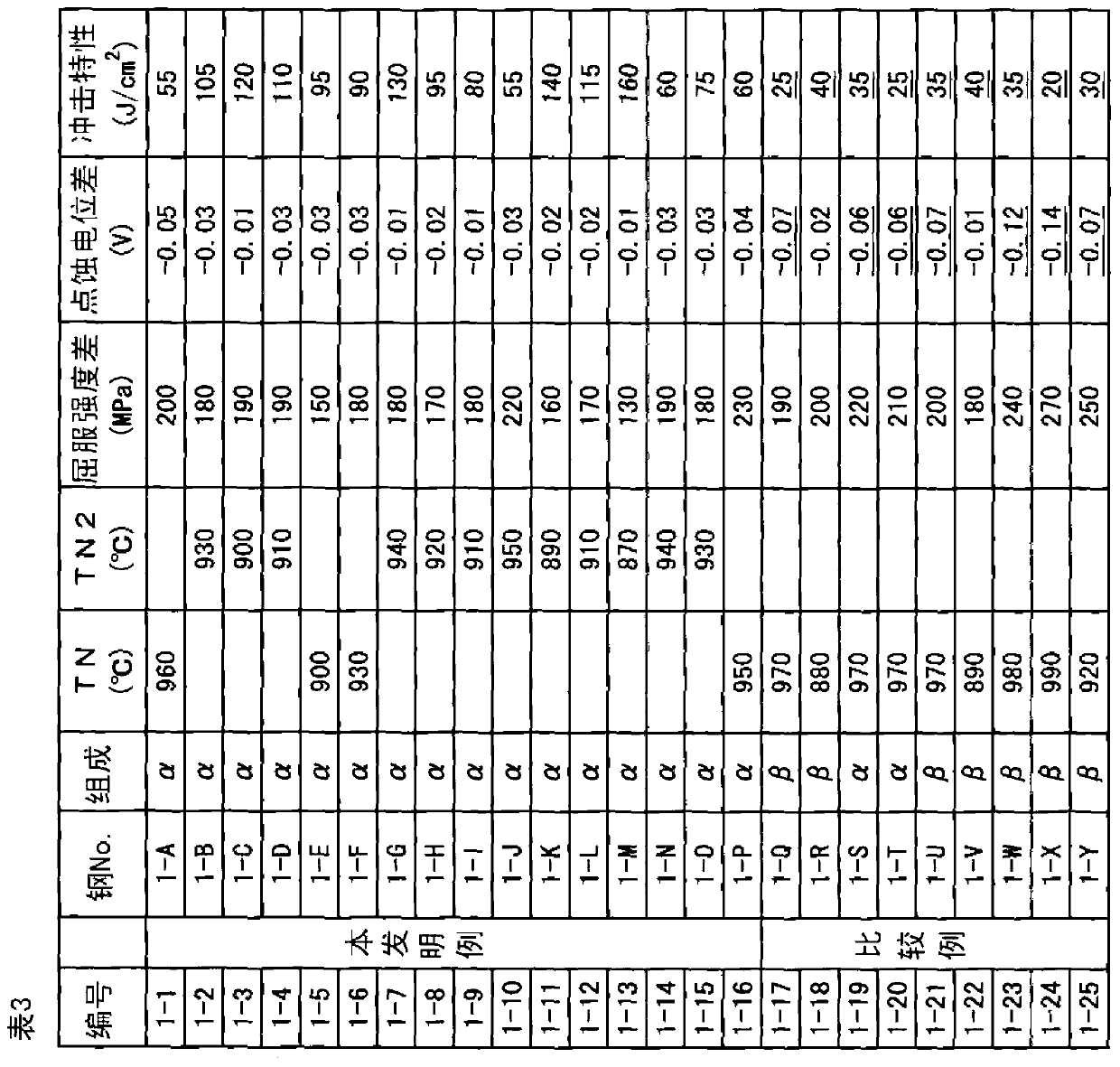

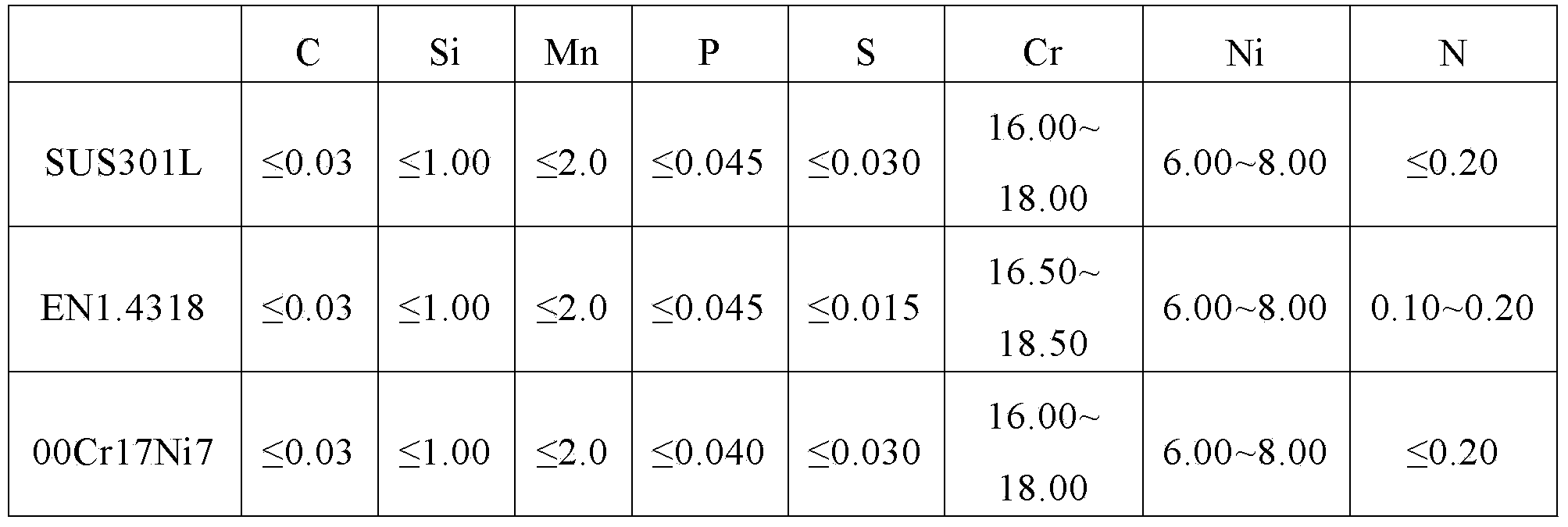

Alloying element-saving hot rolled duplex stainless steel material, clad steel sheet having duplex stainless steel as mating material therefor, and production method for same

ActiveCN103298965ACheap manufacturingSave energyWelding/soldering/cutting articlesThin material handlingDeposition temperatureSheet steel

An alloying element-saving hot rolled duplex stainless steel material comprising, in % by mass, 0.03% max. of C, 0.05%-1.0% of Si, 0.5%-7.0% of Mn, 0.05% max. of P, 0.010% max. of S, 0.1%-5.0% of Ni, 18.0%-25.0% of Cr, 0.05%-0.30% of N, and 0.001%-0.05% of Al, with the remainder comprising Fe and unavoidable impurities. Said material is produced by hot rolling, has a chromium nitride deposition temperature (TN) of 960 DEG C max., has a yield strength 50 MPa min. greater than that of solution heat-treated hot rolled steel material, has not received treatment after hot rolling, and has not been solution heat treated. The clad steel sheet comprises a duplex stainless steel as the mating material therefor. Said duplex stainless steel has the above composition and the chromium nitride deposition temperature (TN) thereof is 800-970 DEG C.

Owner:NIPPON STEEL STAINLESS STEEL CORP

Apparatus for the transport and storage of proppant

ActiveUS9809381B2Facilitating ability to quickly and inexpensively off-load proppantImprove velocity and turn-around and revenue-generating capacityConveyorsLarge containersEngineeringStainless steel material

An apparatus for the transport and storage of proppant has a container with a top wall, a pair of end walls and a pair of side walls. The pair of side walls extend between the pair of end walls. The container has a bottom discharge opening. The container includes a funnel extending from the pair of side walls and from the pair of and walls toward the bottom discharge opening. The funnel has sides extending in an angle of greater than 25° with respect to horizontal. The funnel includes a pair of side plates extending respectively from the pair of side walls toward the bottom discharge opening and a pair of end plates extending respectively from the pair of end walls toward the bottom discharge opening. Each of the side plates and the end plates is formed of a stainless steel material.

Owner:SANDBOX ENTERPRISES LLC

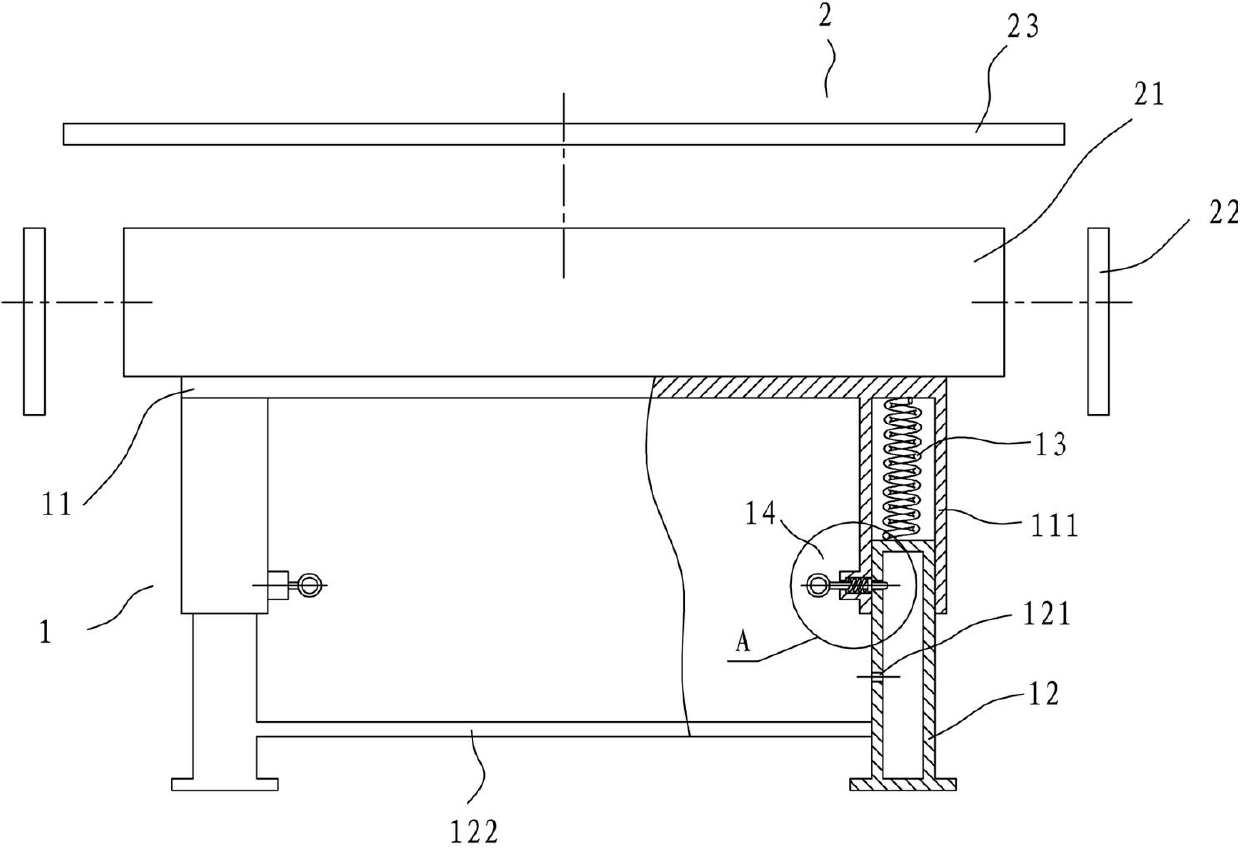

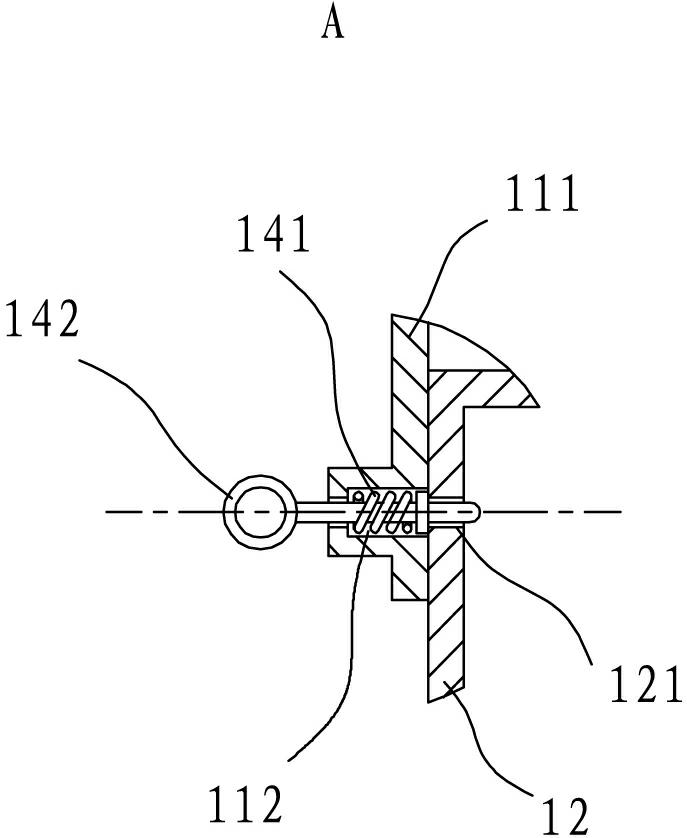

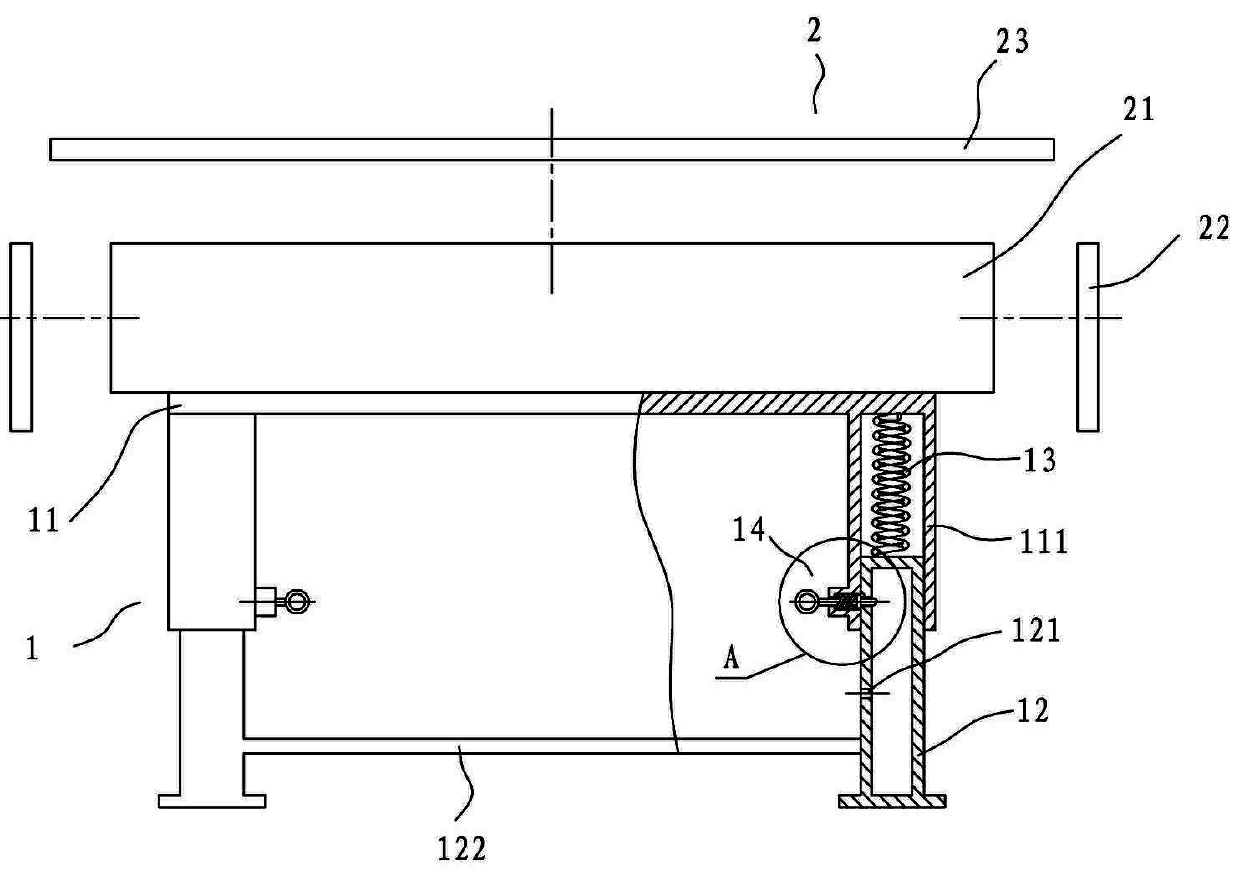

Multifunctional mahjong table

InactiveCN102166066ARaise the gradeHeight adjustableCard tablesFoldable tablesComputer scienceGlass material

The invention discloses a multifunctional mahjong table comprising a base and a multifunctional table top, wherein the height of the base is adjustable; the base comprises a bracket and a plurality of telescopic table legs, wherein the bracket and the table legs are all in frame structure made of stainless steel material; the periphery of the bracket is evenly distributed with table leg sleeves sheathed on the table legs; the multifunctional table top comprises a mahjong table top fixed on the bracket, dismountable side plates and a dismountable multifunctional panel, wherein the dismountable side plates are fixed on the side edge of the multifunctional table top; and the dismountable multifunctional panel is fixed on the top of the mahjong table top. The multifunctional mahjong table proposed by the invention is characterized in that the height of the mahjong table can be regulated, different table tops can be used for adapting to different applications, the application range of the mahjong table is expanded, and space is saved. In addition, the adopted stainless steel and the glass material are beautiful and elegant, and the grade of the product is improved.

Owner:开平市三埠区尊爵全自动麻雀台总汇

Stainless steel welding material

ActiveCN101844281AIncrease the cost of useProne to galvanic corrosionArc welding apparatusWelding/cutting media/materialsMartensiteImpurity

The invention relates to a stainless steel material, a welding wire and a welding wire coil; and the material comprises the following components in percentage by weight: 0 to 0.03 percent of C, 0.5 to 1.0 percent of Mn, 0.5 to 1.0 percent of Si, 12.5 to 14.5 percent of Cr, 0.2 to 0.3 percent of Ti, 5.5 to 6.5 percent of Ni, 0 to 0.015 percent of S, 0 to 0.02 percent of P, and the balance Fe and other inevitable impurity elements. When being applied in ferritic stainless steel and martensitic and ferritic dual-phase stainless steel welding, the stainless steel welding material can replace austenitic stainless steel. The stainless steel welding material is applicable to welding under the condition that the heat input is 5 to 7kJ / cm.

Owner:BAOSHAN IRON & STEEL CO LTD

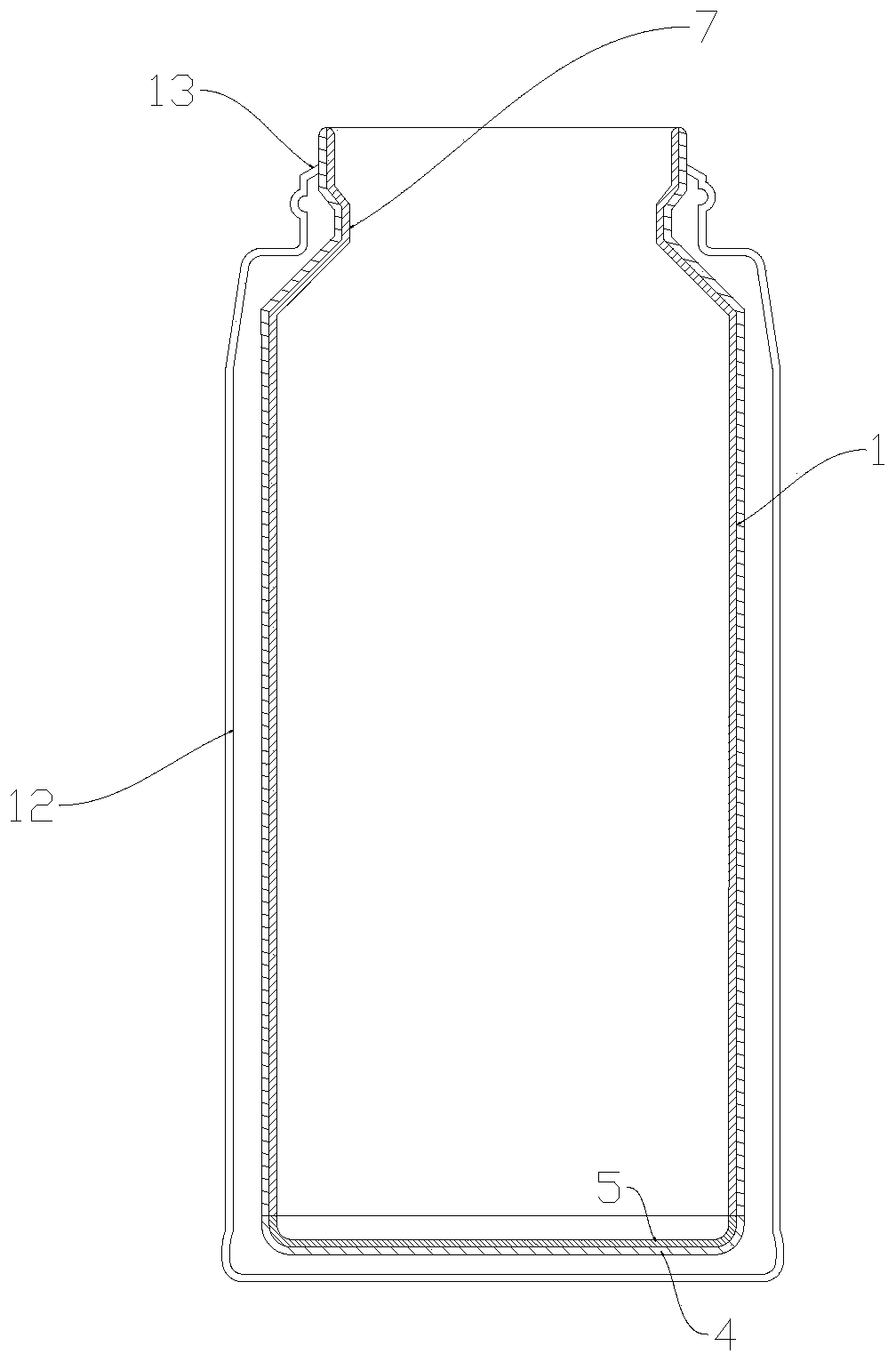

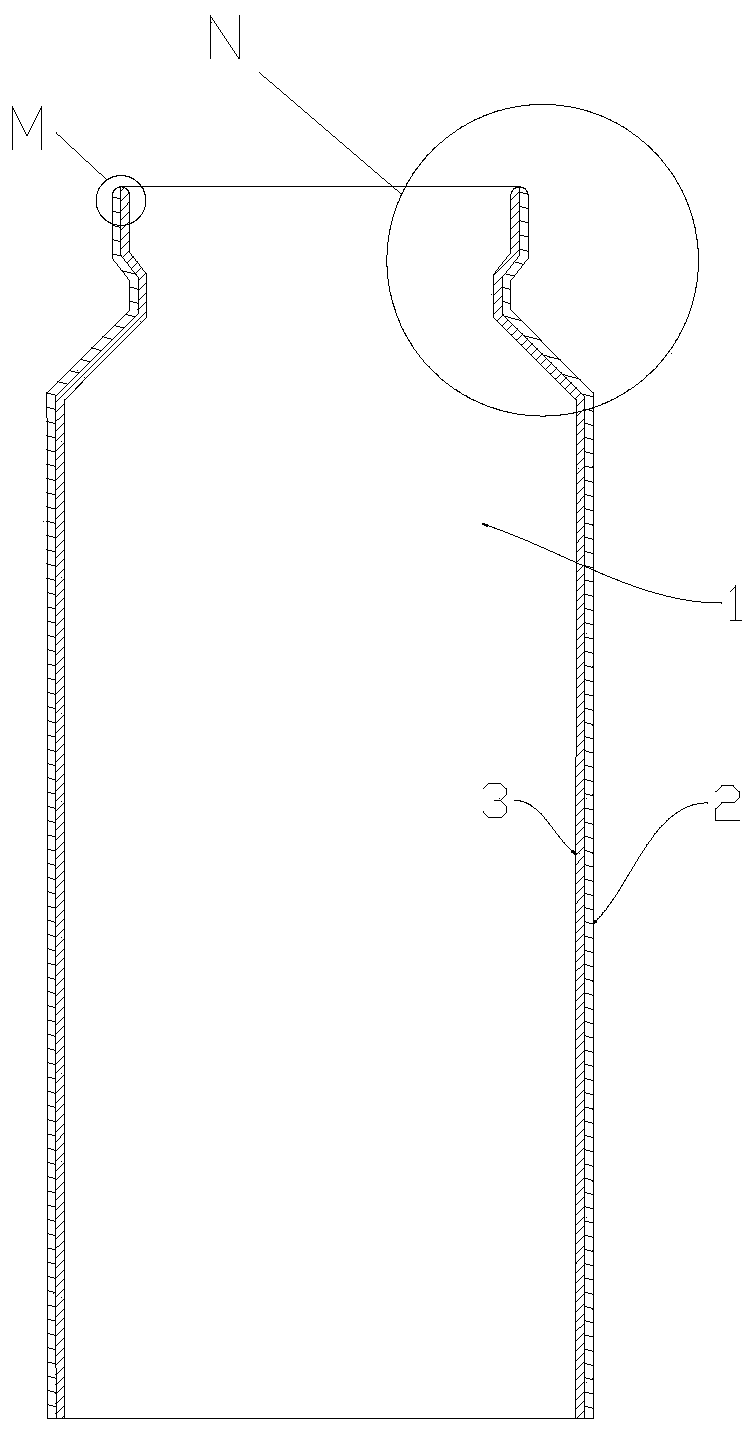

Insulation cup with titanium composite inner tank and manufacturing process thereof

ActiveCN111250620AReduce manufacturing costGuaranteed manufacturing costDwelling equipmentDrinking vesselsTitaniumStainless steel material

The invention relates to the technical field of insulation cups, and discloses an insulation cup with a titanium composite inner tank and a manufacturing process thereof. The insulation cup with the titanium composite liner includes an inner tank body (1); the inner tank body (1) includes a first inner tank layer (2) and a second inner tank layer (3); the first inner tank layer (2) and the secondinner tank layer (3) are arranged concentrically; the first inner tank layer (2) is made of a stainless steel material, a copper material, an iron material or an aluminum material; the second inner tank layer (3) is made of a titanium material; the lower end of the inner tank body (1) is provided with a first bottom layer (4) and a second bottom layer (5); the first bottom layer (4) is made of thestainless steel material; the second bottom layer (5) is made of the titanium material; the first bottom layer (4) is fixedly connected to the lower end of the first inner tank layer (2); and the second bottom layer (5) is fixedly connected to the lower end of the second inner tank layer (3). The invention reduces the consumption of the precious metal titanium material, reduces the manufacturingcost of the inner tank body, and ensures the health of the water quality.

Owner:ZHEJIANG SUNTRUE TITANIUM TECHNOLOGY CO LTD

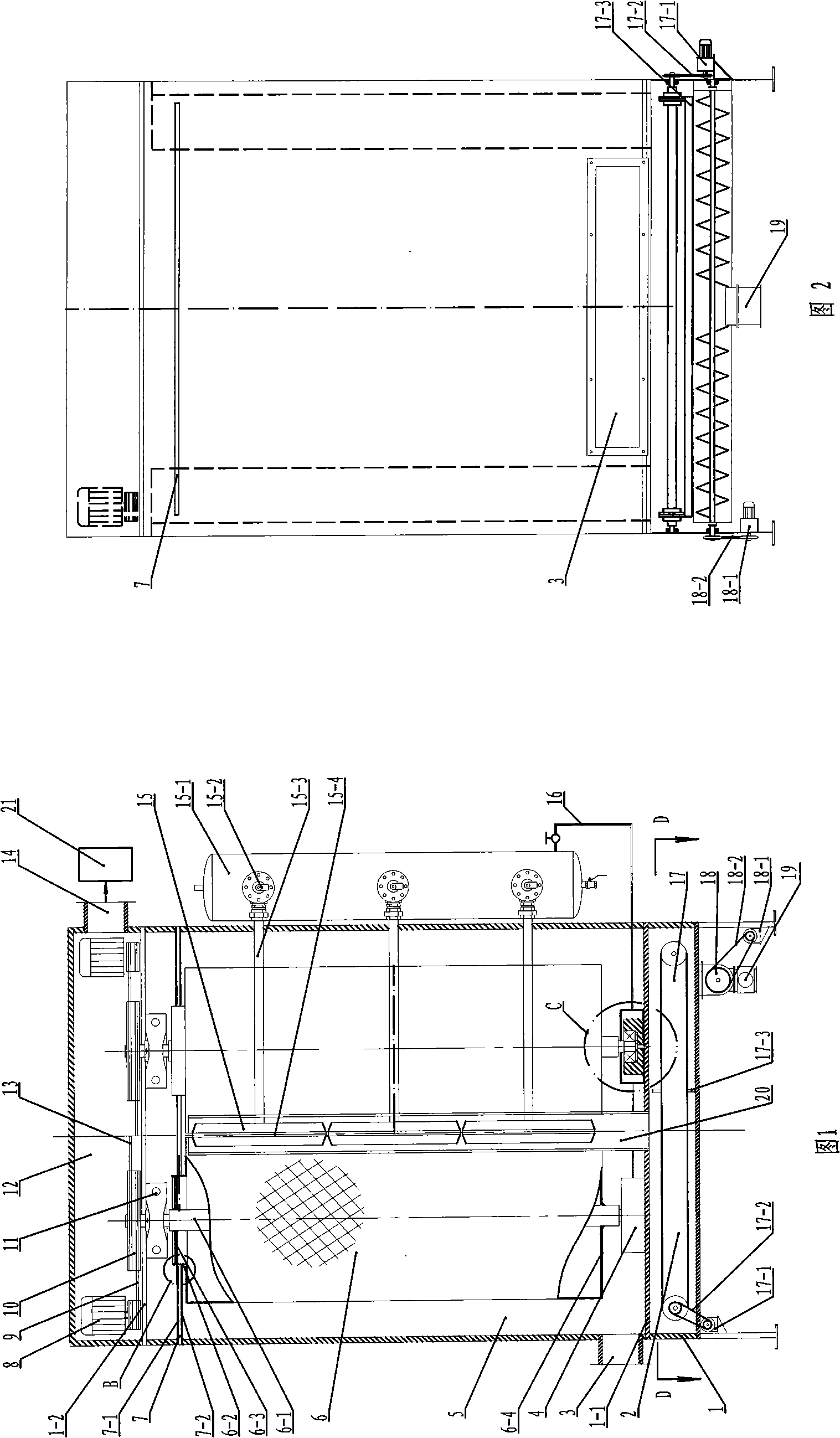

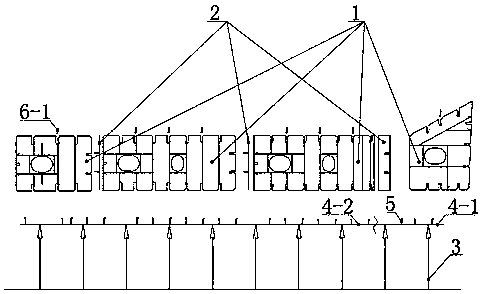

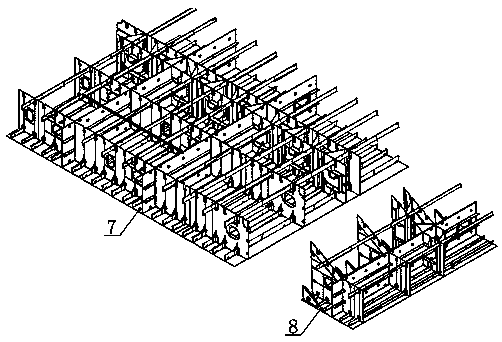

Manufacturing method of duplex stainless steel chemical ship side section

The invention discloses a manufacturing method of a duplex stainless steel chemical ship side section and belongs to the technical field of ship construction. The method includes the following steps of firstly, carbon steel outer plate secondary medium assembly construction, secondly, stainless steel inner longitudinal wall plate secondary medium assembly construction, thirdly, inner longitudinalwall plate flat straight section medium assembly construction, fourthly, deck medium assembly construction and fifthly, ship side section large assembly combination. In the method, when stainless steel inner longitudinal wall plate secondary medium assemblies are constructed, stainless steel molding beds are adopted, and carbon pollution caused by a common carbon steel material to a duplex stainless steel material can be effectively prevented; and through reasonable selection of the assembling sequence and the assembling pose, an automatic angle welding machine can be conveniently used for welding stainless steel, deformation of the duplex stainless steel is effectively reduced, the duplex stainless steel ship side section is divided into flat straight section medium assemblies and deck medium assemblies, the modes of same molding bed construction and medium assembly separate combination are used, the construction accuracy is guaranteed, and section construction efficiency is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Rare-earth doped leadless and low-melting point sealing glass and its preparation method

InactiveCN101456674AMaintain the ability to formExpand the scope of glass formingRare earthCopper oxide

The invention relates to a method for preparing rare earth doped lead-free sealing glass with low melting point, which comprises the following steps: based on raw materials adopted by a Bi2O3-ZnO-B2O3 glass system, adding proper amount of rare earth oxide into the raw materials, and mixing, melting, annealing, grinding and sieving the mixture to obtain the rare earth doped lead-free sealing glass with the low melting point. The sealing glass comprises the following main components by weight portion: 65.22 to 85.22 portions of bismuth oxide, 4.63 to 11.78 portions of boric acid, 5.76 to 10.76 portions of zinc oxide, 0.80 to 2.80 portions of copper oxide, 0.42 to 2.42 portions of cobalt oxide, 3.32 to 8.47 portions of barium carbonate, 0.4 to 1.8 portions of aluminum oxide, and 0.1 to 6.0 portions of rare earth oxide. The method solves the problems that the sealing glass with the low melting point has low sealing temperature, high sealing strength, stable glass structure and the like under lead-free conditions, and has the advantages of simple process, practicability and reliability; and the prepared rare earth doped lead-free sealing glass with the low melting point is particularly suitable for sealing and closing of stainless steel materials, electrons and electric appliances.

Owner:WUHAN UNIV OF TECH

Austenitic antibiotic stainless steel and method for manufacturing same

InactiveCN101230438ASimple smelting processImprove mechanical propertiesChemical compositionCu element

The invention discloses an austenitic antimicrobial stainless steel and the manufacturing method thereof. The stainless steel contains an Ag-Cu binary master alloy with a weight percentage of 0.10 to 4.0 percent and the weight percentage (wt %) for the rest chemical components are as follows: C less than or equal to 0.08 percent, Si less than or equal to 1.0 percent, Mn less than or equal to 2.0 percent, P less than or equal to 0.04 percent, S less than or equal to 0.03 percent, Ni 7.0 to 15.0 percent, Cr 17.0 to 20.0 percent, Mo less than or equal to 4.0 percent, N less than or equal to 0.15 percent and the rest are Fe and unavoidable impurities. The method of manufacturing the antimicrobial stainless steel is as follows: the Ag element and the Cu element, of which Ag takes up 1.0 to 40 percent, are smelted to be a master alloy and then added to the antimicrobial stainless steel material to be smelted. The steel has the advantages of simple and effective smelting technique, excellent mechanical property, excellent corrosion resistance and excellent antibacterial property, can be made into shapes of various types applicable to kitchens, household appliances, medical apparatuses and so on.

Owner:BAOSHAN IRON & STEEL CO LTD

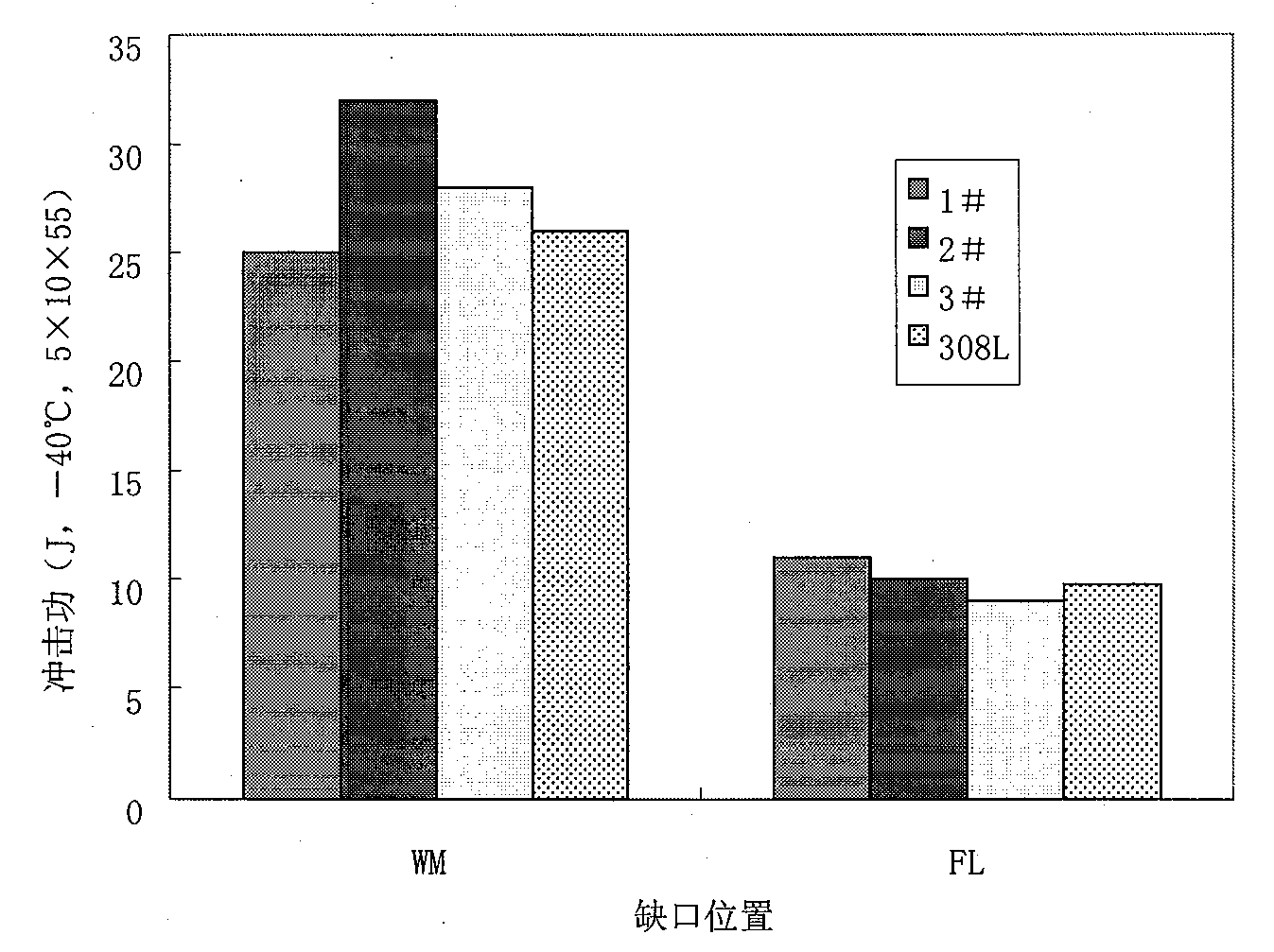

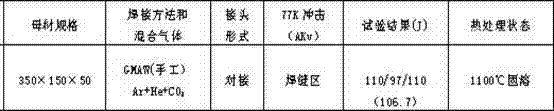

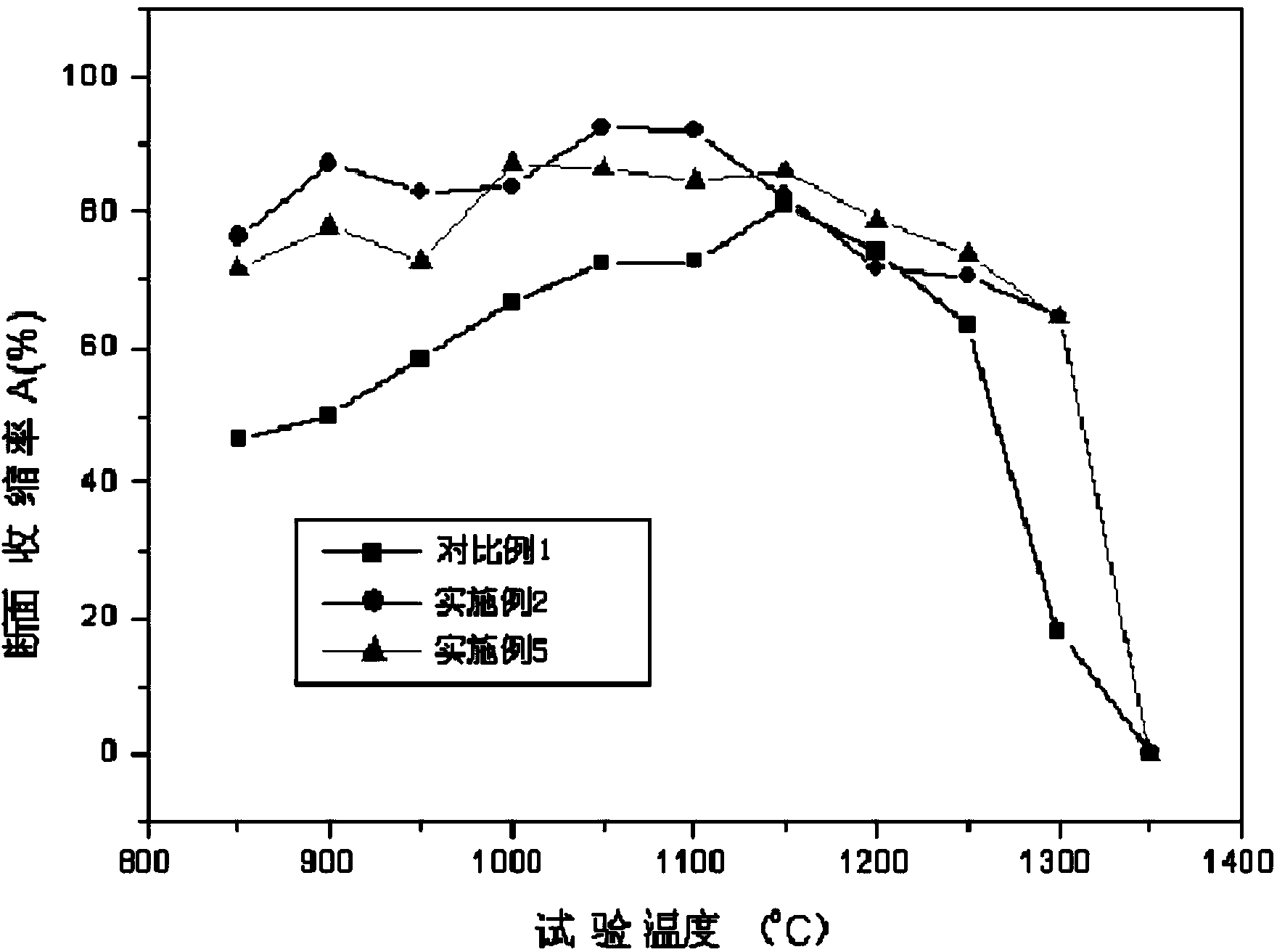

Ultra-low temperature austenite stainless steel solid core welding wire

The invention aims to the characteristic that ultra-low temperature stainless steel material is required to be good in low-temperature flexibility, and provides a stainless steel alloy welding wire. The stainless steel alloy welding wire can ensure that the austenite structure of weld metal achieves more than 99%; the welding seam center can achieve about 100J under the impact ductility of lower than 77K; the welding wire is good in low-temperature flexibility, and comprises the following ally components: smaller than or equal to 0.03% of C, smaller than or equal to 1.00% of Si, 18.0-26.0% of Cr, 10%-25% of Ni, 0-5.5% of Mo, 1.5%-7.0% of Mn, 0.05%-0.25% of N, smaller than or equal to 0.015% of S, smaller than or equal to 0.015% of P, 0-0.6% of RE, and the balance of Fe. The ultra-low temperature austenite stainless steel solid core welding wire can be widely applied to the technical field of welding ultra-low temperature stainless steel pressure containers and special structures.

Owner:WUHAN RUNZHIDA PETROCHEM EQUIP CO LTD +1

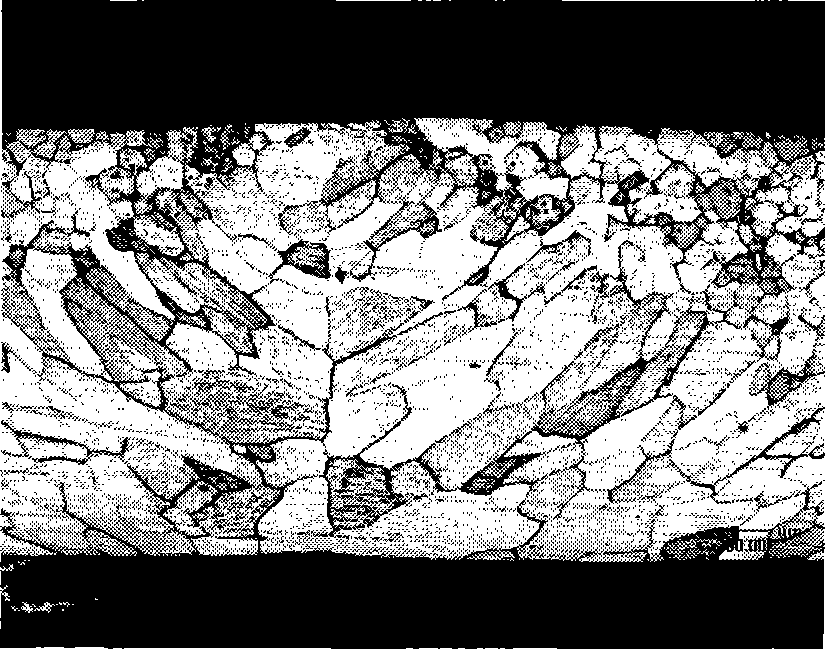

Austenitic stainless steel for urban rail vehicle face plates and manufacturing method of austenitic stainless steel

The invention discloses austenitic stainless steel for urban rail vehicle face plates and a manufacturing method of the austenitic stainless steel. The austenitic stainless steel comprises the following chemical compositions inpercentage by weight: less than 0.03% of C, 0.75-1.0% of Si, 6.5-8.0% of Mn, 16.0-17.5% of Cr, 3.0-4.5% of Ni, 0.15-0.25% of N, 0.5-1.0% of Cu, 0.02-0.05% of Ce, no greater than 0.040% of P, no greater than 0.03% of S, and the balance of Fe and inevitable impurities; the manufacturing method of the austenitic stainless steel comprises the following steps: through the operations of smelting, continuous casting, refining, tombarthite mixture block feeding, and soft stirring, continuous casting slabs are obtained by continuous casting, and the continuous casting slabs are heated; after hot rolling, cooling, reeling, air cooling, solution treating, shot blasting, acid cleaning, cold rolling and annealing acid cleaning are conducted, the finished product austenitic stainless steel is manufactured. According to the austenitic stainless steel for the urban rail vehicle face plates and the manufacturing method of the austenitic stainless steel, the oxidation of the edge part grain boundary caused by overheating of the slab edge part can be avoided; in the process of heating, a layer of dense chromium oxidation film with high adhesion is formed on the surface, the surface quality of the continuous casting slabs is protected, and the guarantee about surface quality control of stainless steel material used for the urban rail vehicle face plates can be provided.

Owner:BAOSTEEL STAINLESS STEEL

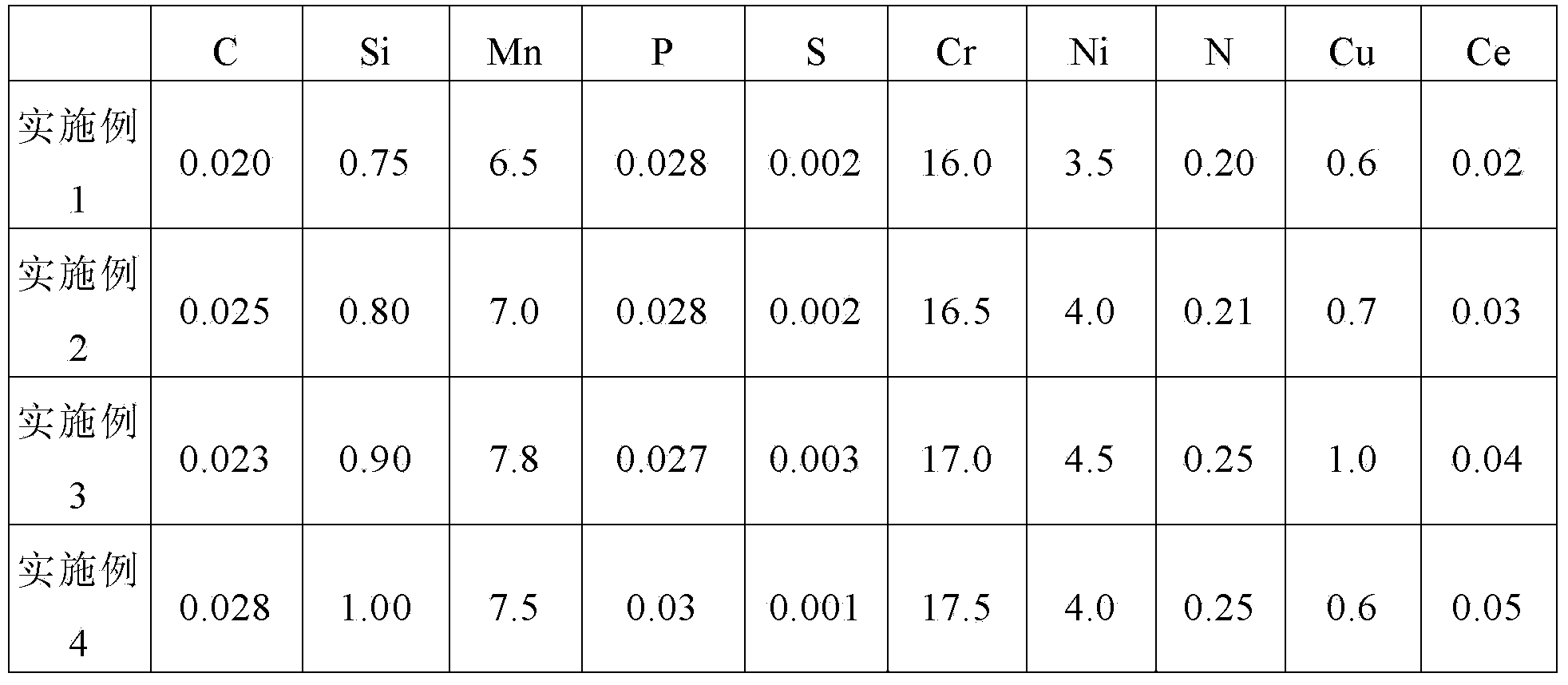

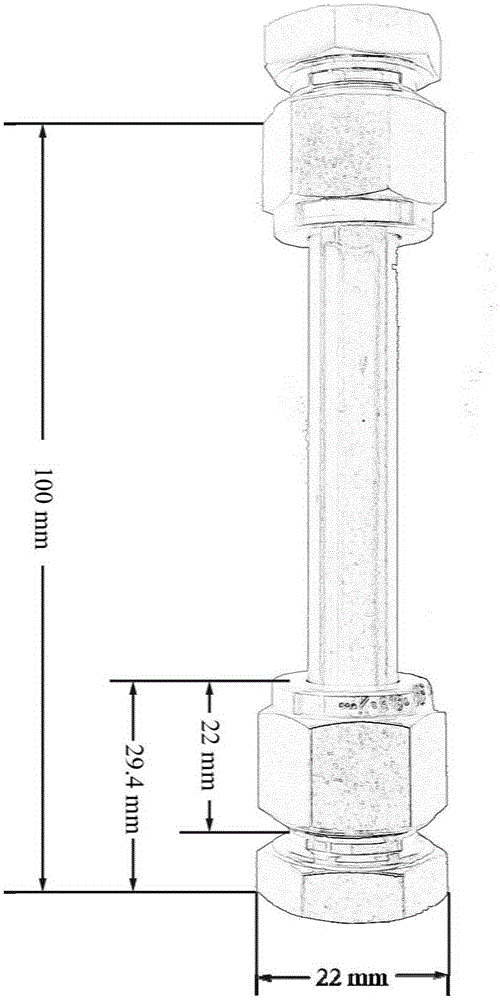

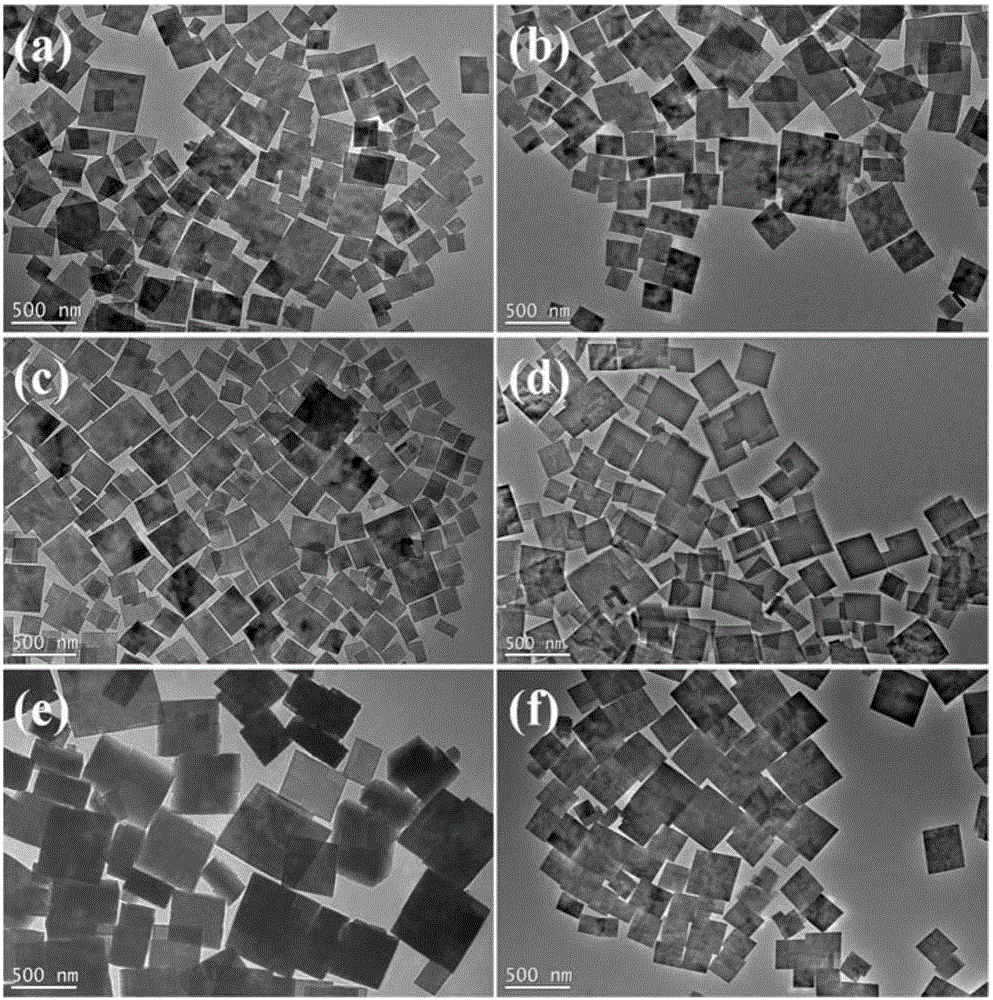

Nanpsheet-shaped SAPO-34 molecular sieve as well as ultrafast preparation method and application thereof

InactiveCN105174280AIncrease the areaLarge pore volumeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveHeat transmission

The invention discloses a nanosheet-shaped SAPO-34 molecular sieve with a larger specific surface area as well as an ultrafast preparation method and an application of the nanosheet-shaped SAPO-34 molecular sieve and belongs to the technical field of molecular sieves. The nanosheet-shaped SAPO-34 molecular sieve is rapidly synthesized by adopting a reaction kettle wholly made of a stainless steel material and introducing seed crystals, and the crystallization time of the SAPO-34 molecular sieve is successfully shortened to 5 min due to excellent heat transmission rate of the stainless steel reaction kettle and seed crystal induced fast crystal nucleation. The synthetic method is simple, the crystallization time is extremely short, the synthesis cost is greatly reduced, the synthesis time is greatly shortened, and meanwhile, the liquid waste pollution caused by synthesizing is effectively reduced. The yield of synthesized nanosheet-shaped SAPO-34 samples is very high and can be higher than 90%; the nanosheet-shaped SAPO-34 molecular sieve has very high light olefin selectivity in MTO (methanol to olefins) reaction, especially, the total yield of ethylene and propylene can be higher than 85%, and the nanosheet-shaped SAPO-34 molecular sieve is very suitable for industrial scale-up application.

Owner:JILIN UNIV

Low-temperature nickel-based solder for soldering

InactiveCN101898283AExcellent high temperature strengthExcellent corrosion resistanceWelding/cutting media/materialsSoldering mediaDecompositionNitrogen

The invention discloses low-temperature nickel-based solder for soldering. The nickel-based solder based on a NiCrSiP system comprises the following components by weight percentage: 21.5%-28% of Cr, 2.0%-3.5% of Si, 7.0%-9.0% of P and 59.5%-69.5% of Ni. The solder of the invention is superior to BNi-5 solder in both high-temperature strength and corrosion resistance, and the nickel-based solder is applicable to both the vacuum-soldering method and the method for soldering in a continuous soldering furnace under the protective atmosphere (such as nitrogen and ammonia decomposition atmosphere) and particularly suitable for soldering the metal carriers (stainless steel materials) in the automobile exhaust purifiers and automobile EGR (exhaust gas recirculation) system, thus absolutely substituting the existing BNi-5 solder.

Owner:李昕

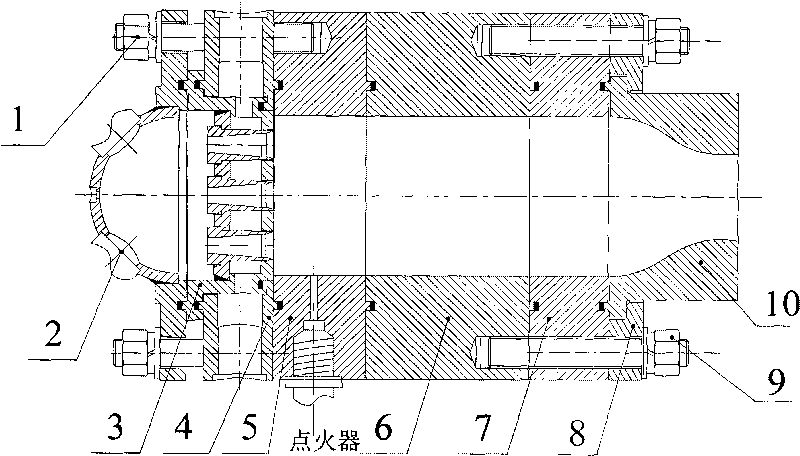

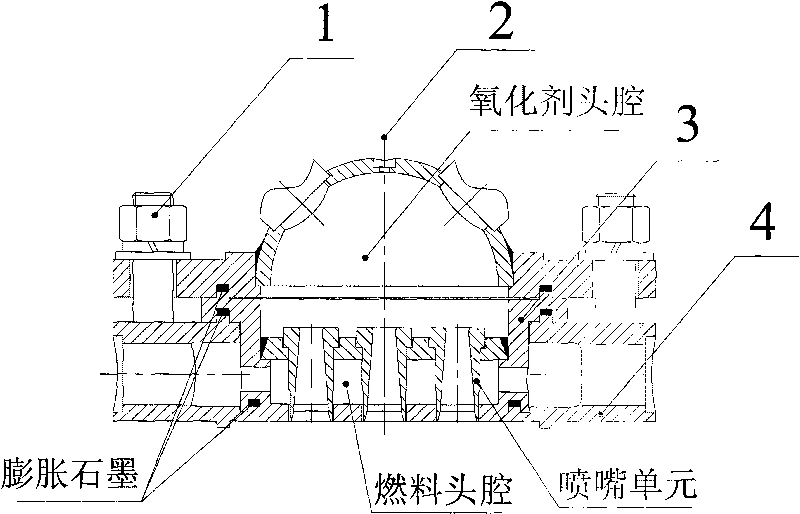

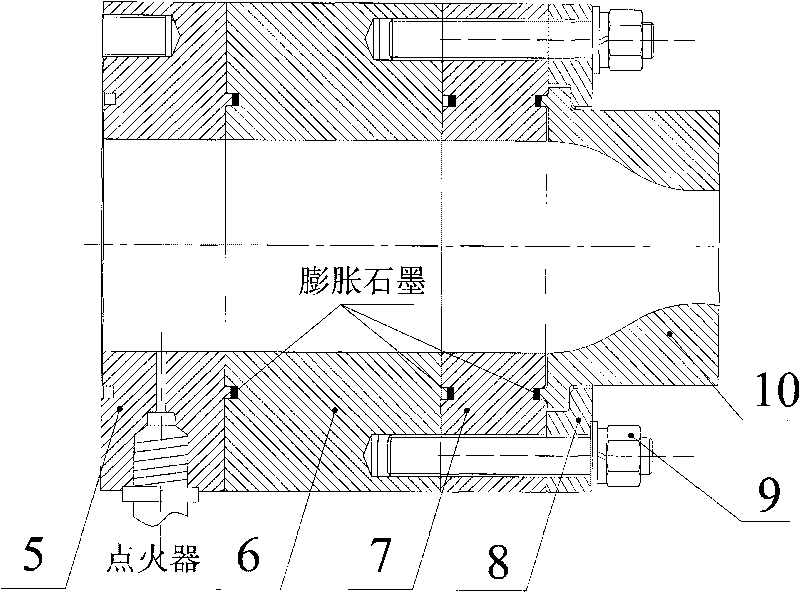

Modularized heat-capacity type thrust chamber

The invention relates to a modularized heat-capacity type thrust chamber comprising an injector assembly, a head top cap, a head bottom cap, a body cylinder section and a tail spray pipe, wherein the injector assembly, the head top cap and the head bottom cap are connected by adopting bolts to form the head of the thrust chamber; the body cylinder section is in a sectional type structure; and each section of the cylinder section, the tail spray pipe and the head of the thrust chamber are connected by adopting bolts. The head and the body of the thrust chamber, and the cylinder section and the spray pipe section are sealed in the mode of compacting expanded graphite sealing rings between a boss and a groove. The head can be made of a stainless steel material, the body cylinder section is made of red copper, and the spray pipe section is made of a high temperature-resistant material. By adopting the invention, when performing the experimental study on a rocket engine, experimenters can conveniently replace the module of the engine to change the studied parameter for carrying out comparative analysis, therefore, the cost is obviously reduced.

Owner:BEIHANG UNIV

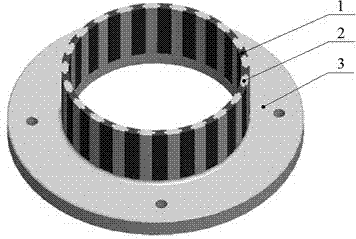

Stainless steel magnetic field regulating device

InactiveCN104753313AHigh mechanical strengthImprove heat resistanceDynamo-electric gearsPermanent-magnet clutches/brakesEpoxyThermal expansion

The invention relates to magnetic drive and in particular relates to a stainless steel magnetic field regulating device. The stainless steel magnetic field regulating device is composed of a magnetic field regulating iron block, a stainless steel substrate and a support frame. The magnetic field regulating iron block and the stainless steel substrate are compounded into an integrated structure, and due to the characteristics of the stainless steel, namely no magnetism, high mechanical strength, good heat resistance, small thermal expansion, good dimensional stability and long-term outdoor usability, and the excellent machinability and weldability of the stainless steel material, the defects of high polymer materials (nylon, epoxy resin and polyformaldehyde) used for common magnetic field regulating devices as substrates are overcome. Due to the corrosion resistance and the high temperature resistance of the stainless steel, the magnetic field regulating device becomes a novel insulating sleeve resistant to corrosion and high temperatures and having a magnetic field regulating function, and will play an important role under working conditions having requirements on high temperatures and corrosion prevention in the industries such as chemical engineering and ships. Besides, based on the magnetic shielding principle of a low-frequency magnetic field and the high mechanical strength of the stainless steel, a new magnetic field regulating device having an excellent magnetic field regulating effect also can be constructed.

Owner:JIANGSU UNIV

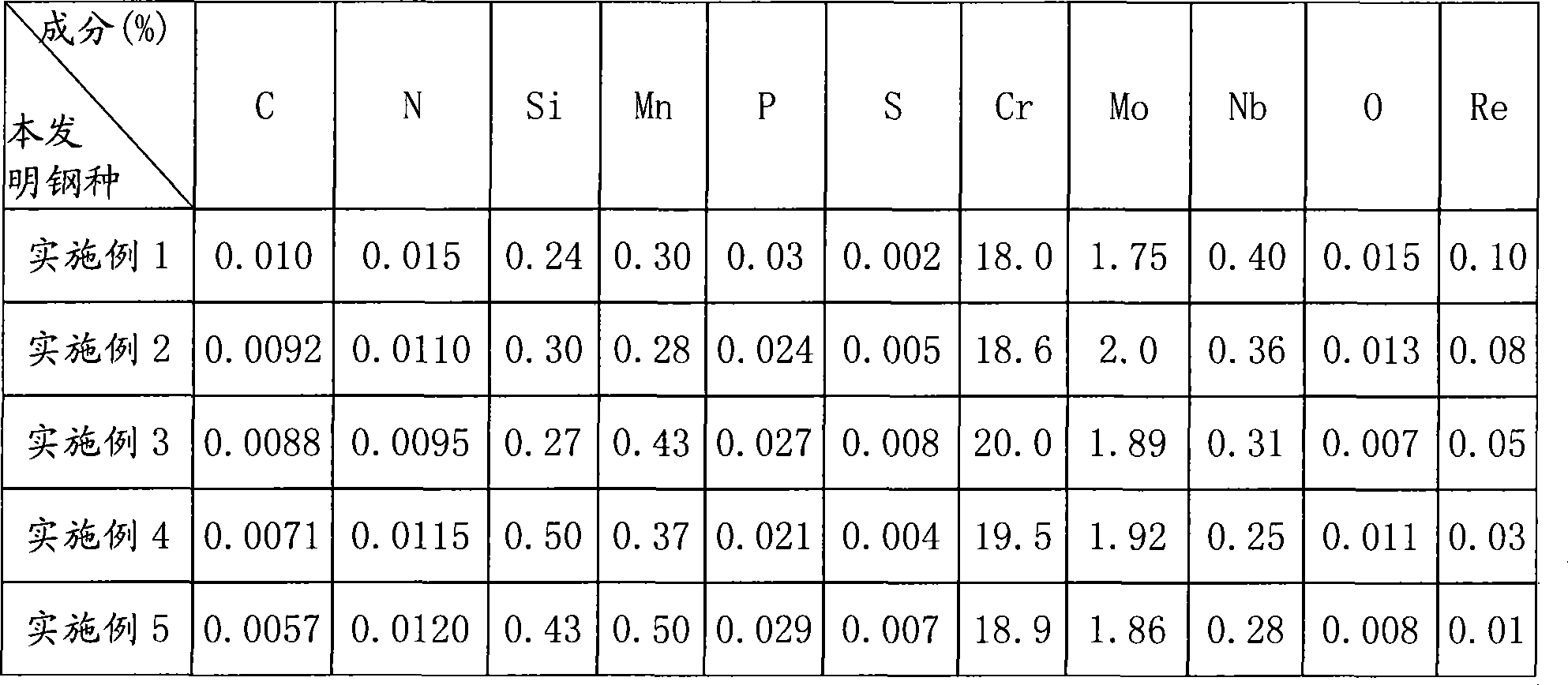

High-purity ferrite stainless steel material and manufacturing method thereof

InactiveCN101381845AGood welding performanceImprove welding effectMolten metal pouring equipmentsTemperature control deviceRare-earth elementChemical composition

The invention discloses high-purity ferritic stainless steel, which comprises the following chemical compositions in percentage by weight: less than or equal to 0.025 percent of C and N, less than or equal to 0.50 percent of Si, less than or equal to 0.50 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.01 percent of S, 18 to 20 percent of Cr, less than or equal to 0.30 percent of Ni, 1.75 to 2.00 percent of Mo, 0.25 to 0.40 percent of Nb, less than or equal to 0.015 percent of O, 0.01 to 0.10 percent of rare earth elements, 0 to 0.10 percent of other elements, and the balance being balance element Fe. The manufacturing process of the high-purity ferritic stainless steel comprises processes such as smelting, casting, cogging of casting ingots or casting blanks, hot rolling, annealing and acid-washing after the hot rolling, cold rolling, annealing and acid-washing after the cold rolling. The high-purity ferritic stainless steel can improve the plasticity of welding seams.

Owner:BAOSHAN IRON & STEEL CO LTD

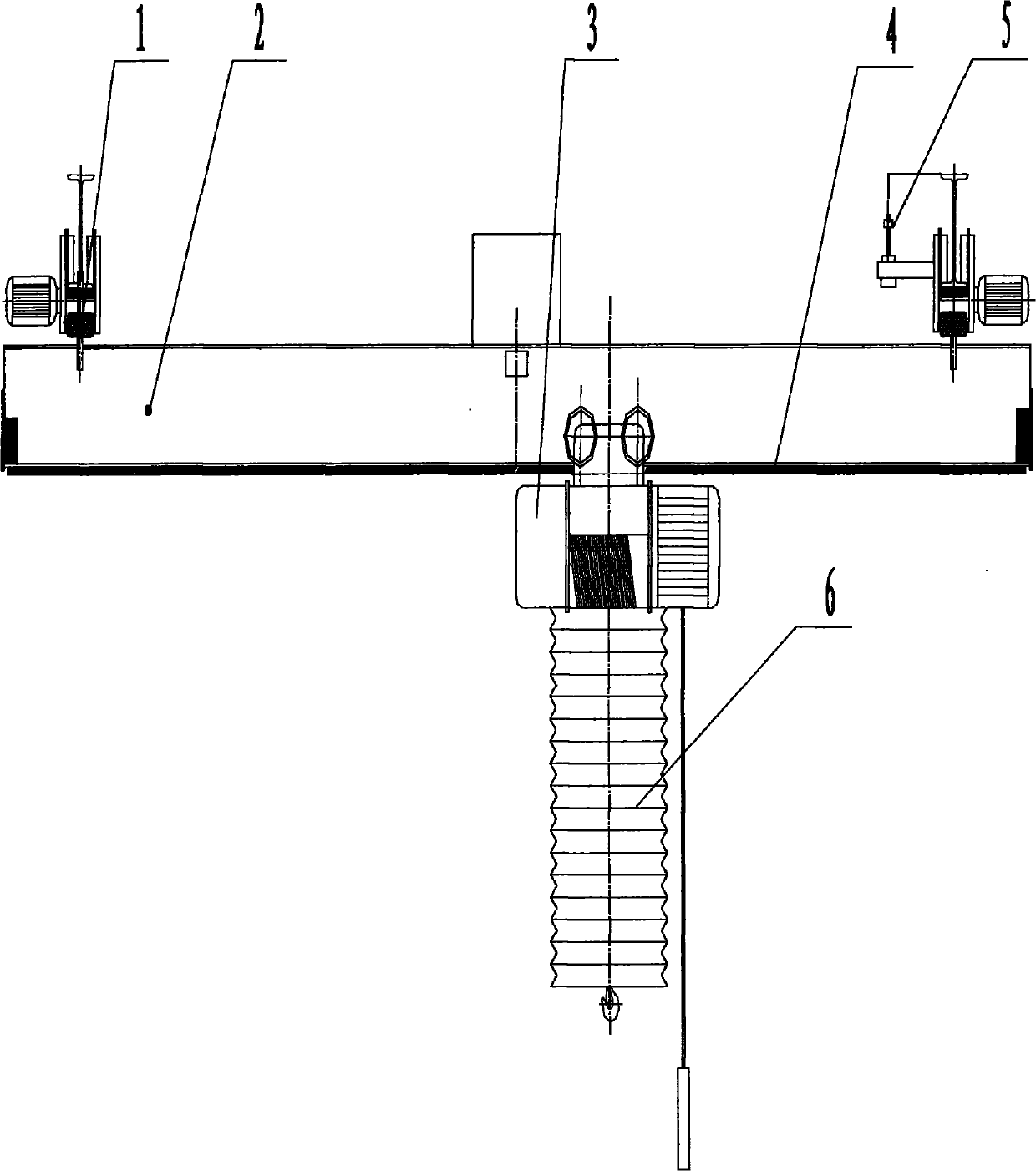

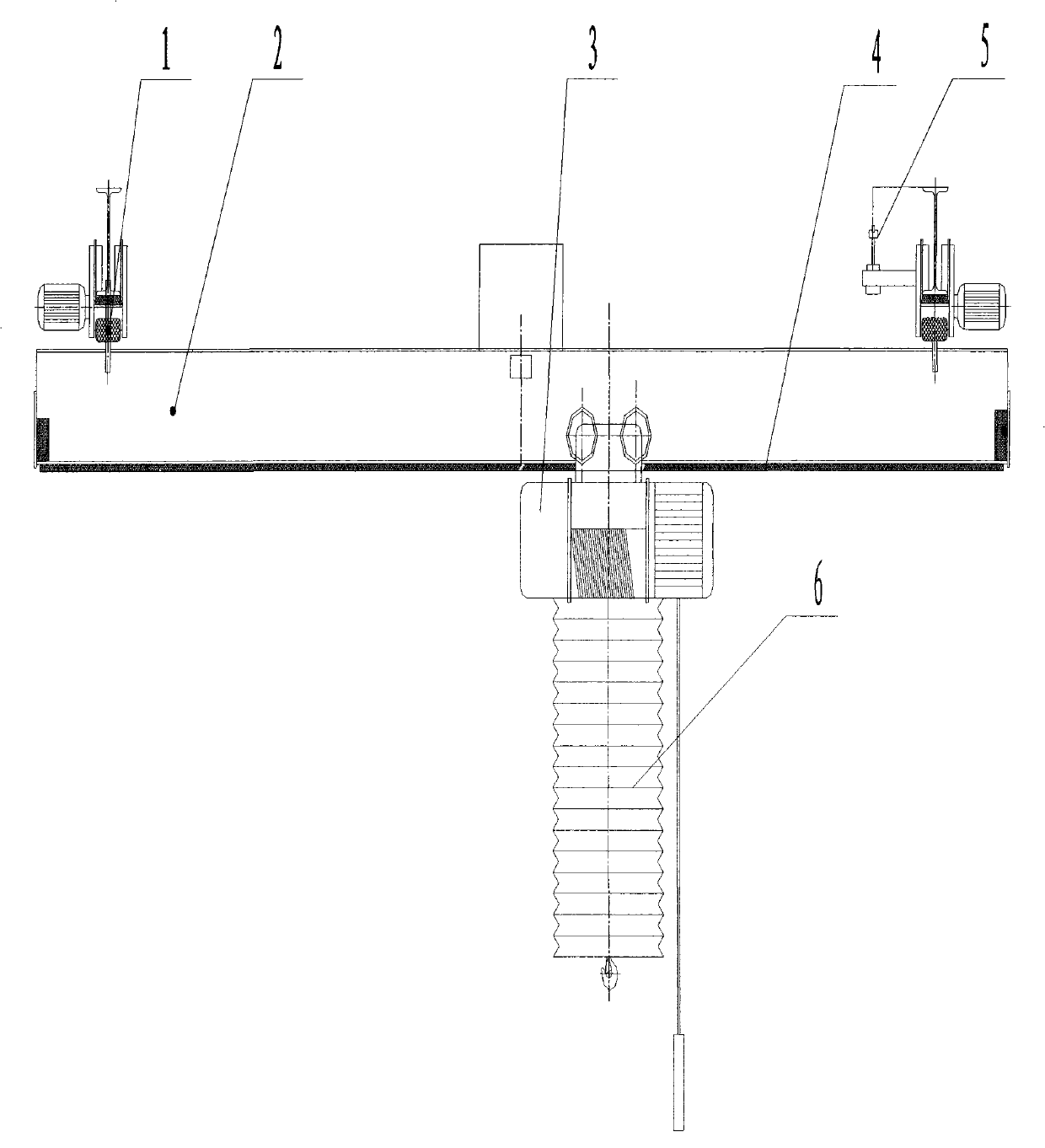

Clean and dust-proof crane

InactiveCN102020205AImprove dustproof effectImprove efficiencyCombination devicesTravelling cranesCycloneSlip line

The invention discloses a clean and dust-proof crane which comprises a crane and a dust remover. The crane comprises a crane cart end beam structure, a main beam, and a trolley; exsertion gears and wheels are both made of dust-free materials such as nylon or hard plastic; the cart end beam structure and the main beam are both made of stainless steel material; wheels of the cart and wheels of the trolley respectively have a dust-proof difference; the lifting steel wire rope is formed of stainless steel wires and the lifting steel wire rope and the pulley are all sealed in a dust-proof cover; a dust-proof safety slip line with a dust-proof device disposed at the lower part is adopted; the turbine fan of the wind-guiding wheel of the dust remover is fixed on the shaft of a motor, and the motor is fixed on a rectangular body by mounting feet; a dust collecting filter is disposed at the lower part of the turbine fan; the whirlwind dust collector includes a multi cyclone unit having a first cyclone and a secondary cyclone disposed outside the first cyclone. The crane has the advantages of excellent dust-proof effect and high efficiency, and is convenient to use.

Owner:CHENGDU WEST TAILI INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com