Stainless steel welding material

A welding material and stainless steel technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of galvanic corrosion of welded joints, reduce the service life of joints, increase the cost of users, etc., and achieve greater Cost of use, good cost performance, and the effect of reducing labor production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] According to the composition range of the present invention, the composition of the stainless steel welding wire of the three embodiments manufactured through the following processes such as smelting, rolling and drawing is shown in Table 1, and the diameter of the welding wire is 1.2 mm.

[0036]VOD (vacuum smelting)→die casting (30kg)→forging 48×48mm square slab→heating at 1050℃→rolling→ Wire rod → pickling → storage.

[0037] The wire rod is heated to 1050℃→drawing→annealing→drawing→pickling→annealing→drawing Welding wire→inspection→package→storage.

[0038] Table 1

[0039] serial number

C

Si

mn

P

S

Cr

Ni

Ti

1#

0.017

0.69

0.82

0.013

0.008

13.16

5.92

0.29

2#

0.018

0.64

0.80

0.012

0.005

14.23

6.36

0.22

3#

0.015

0.72

0.88

0.016

0.007

12.83

6.06

0.26

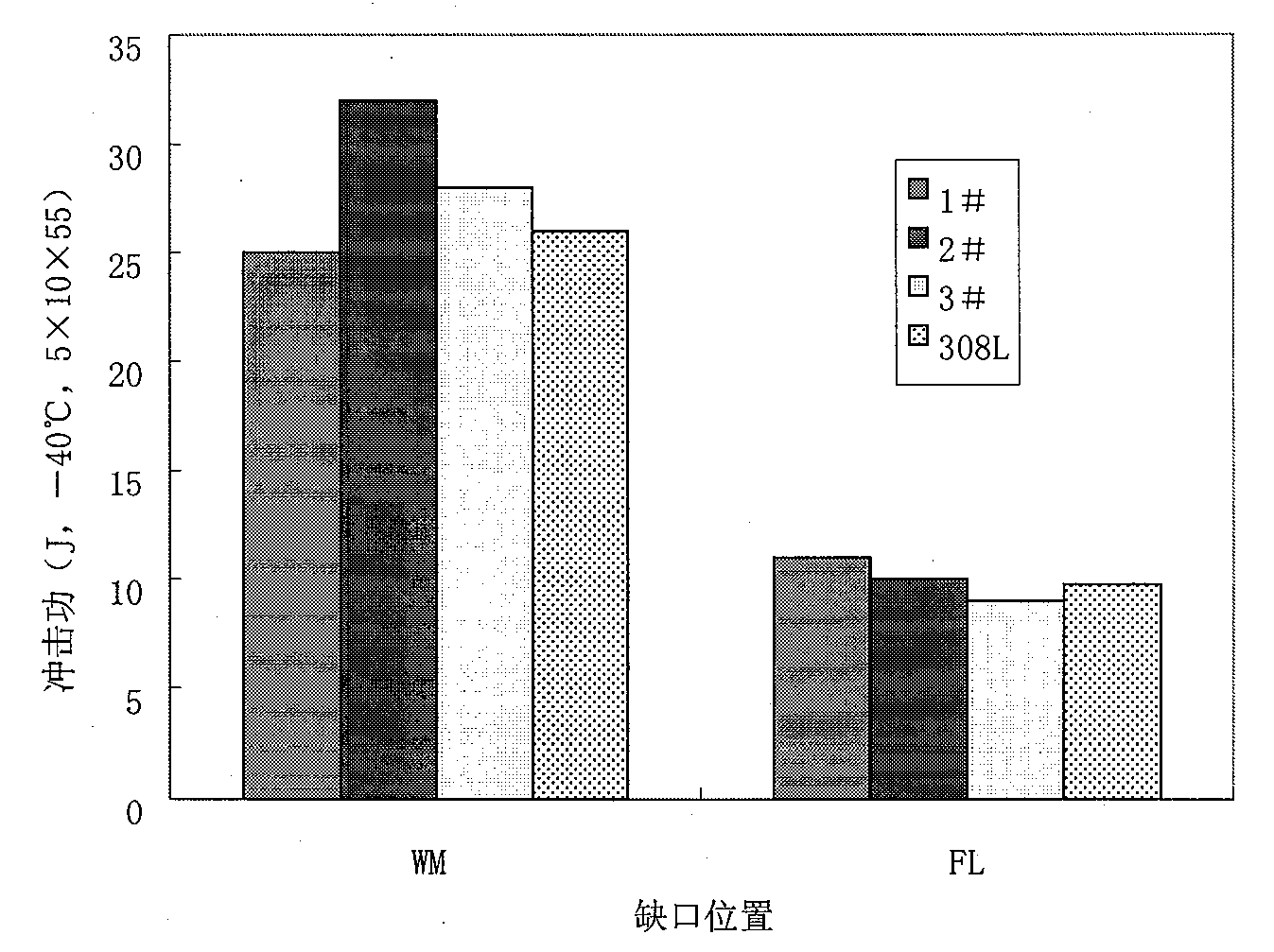

[0040] figure 1 It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com