Patents

Literature

2494results about "Coil arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

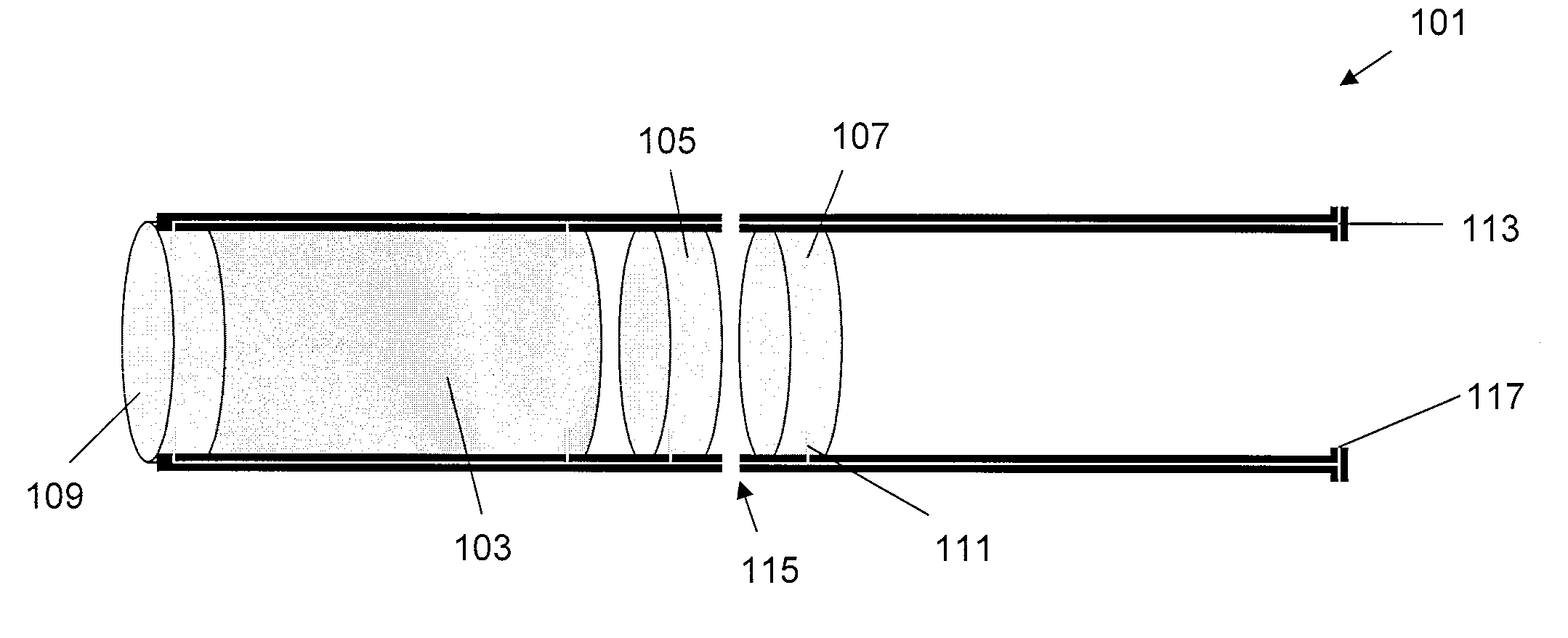

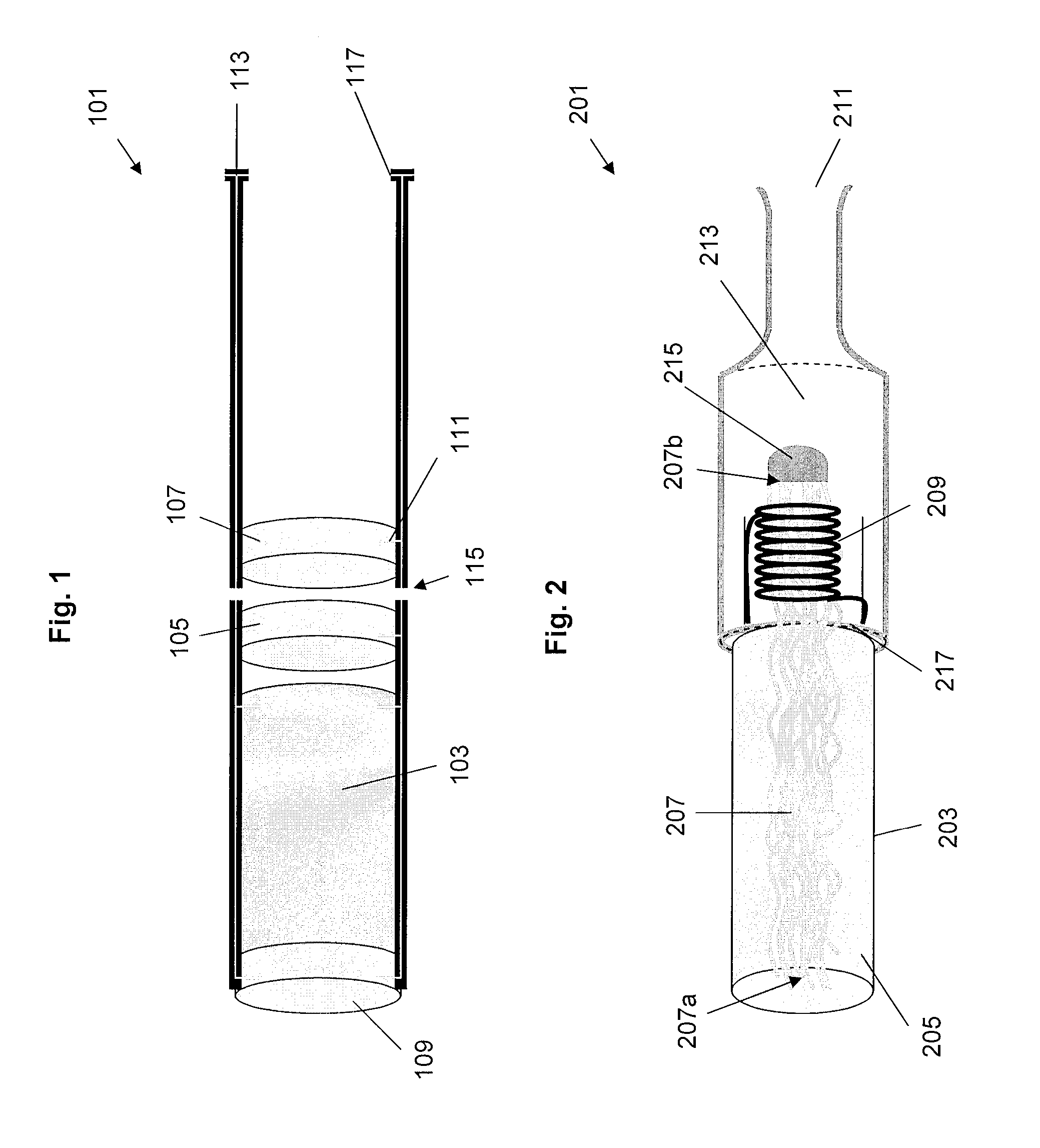

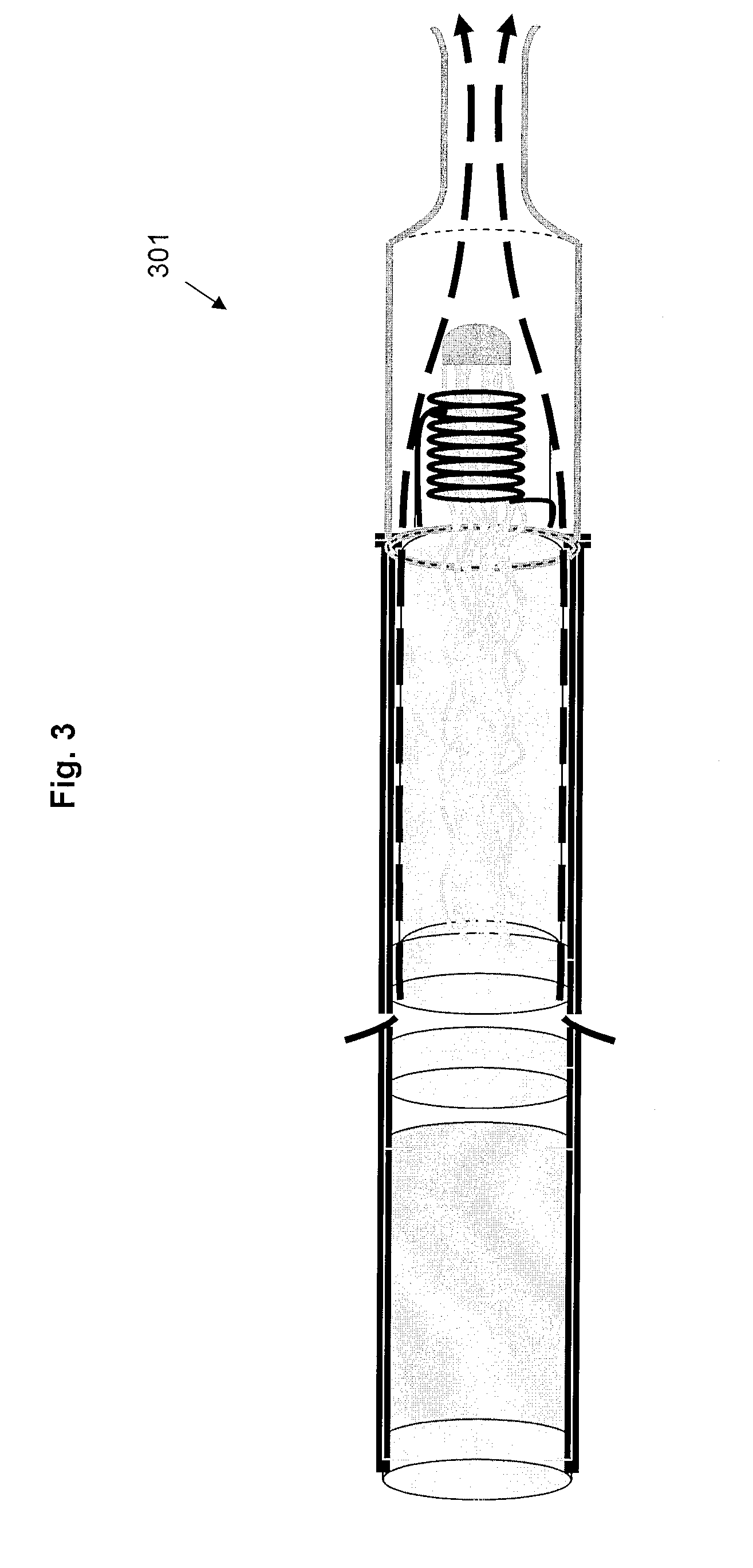

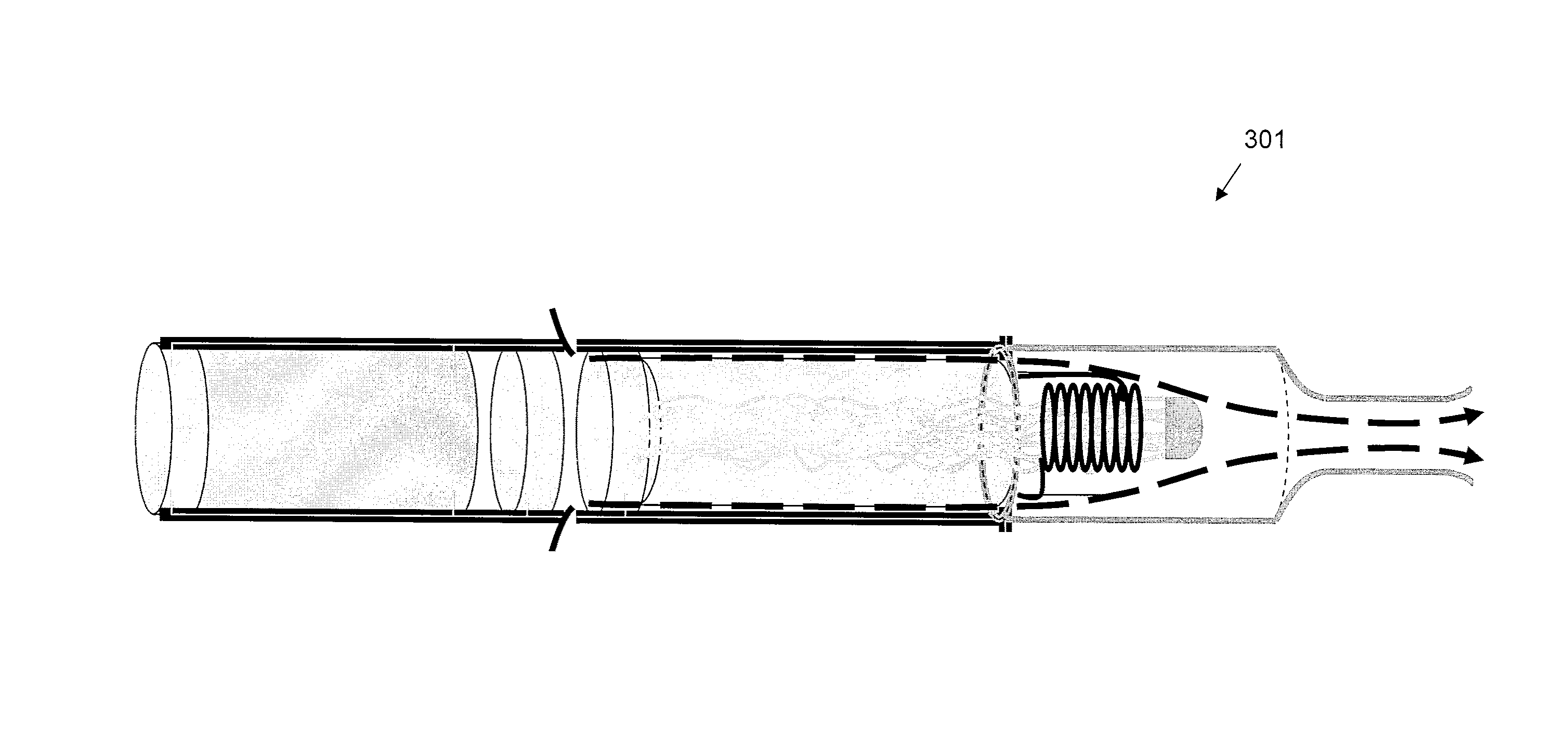

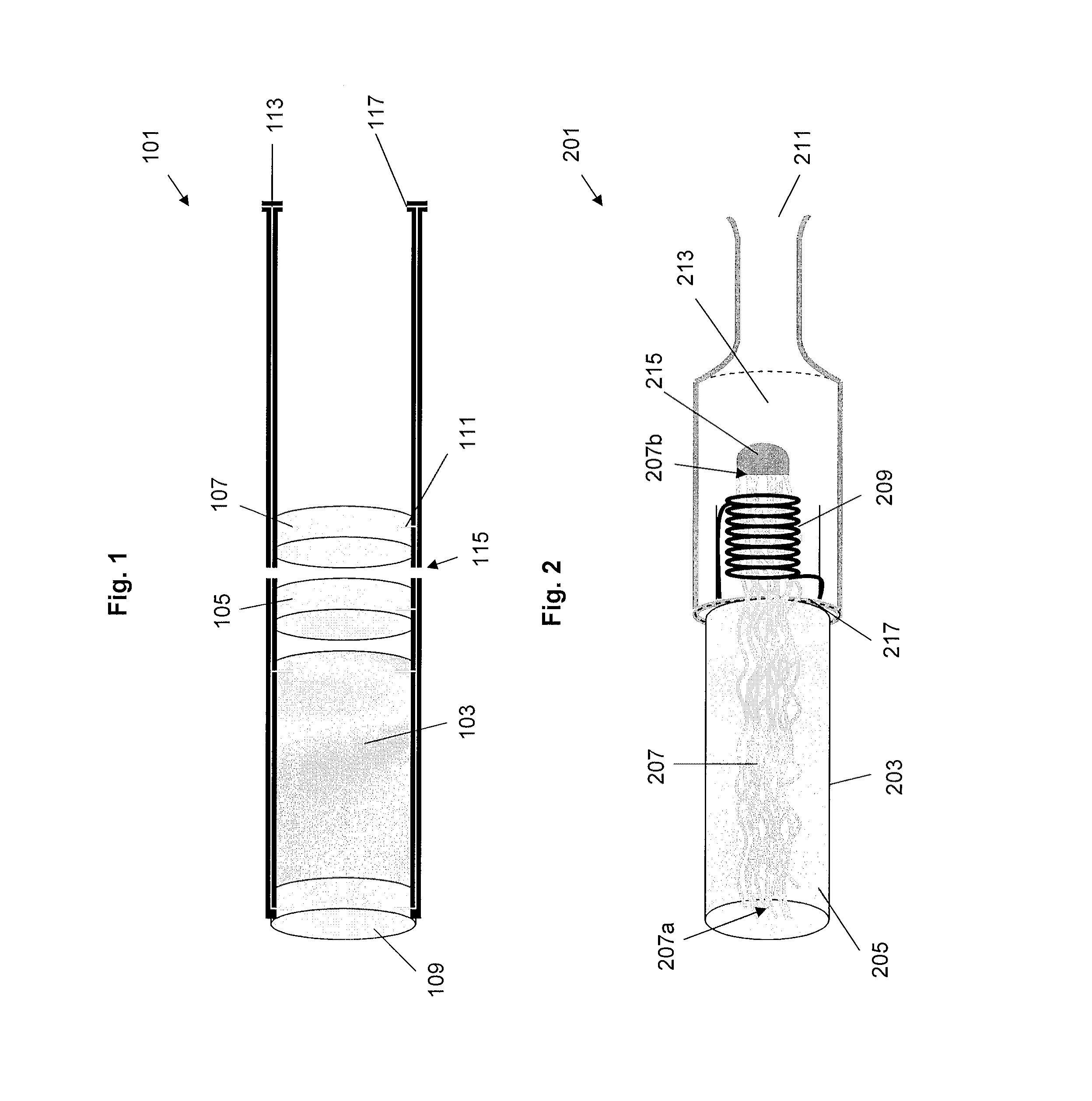

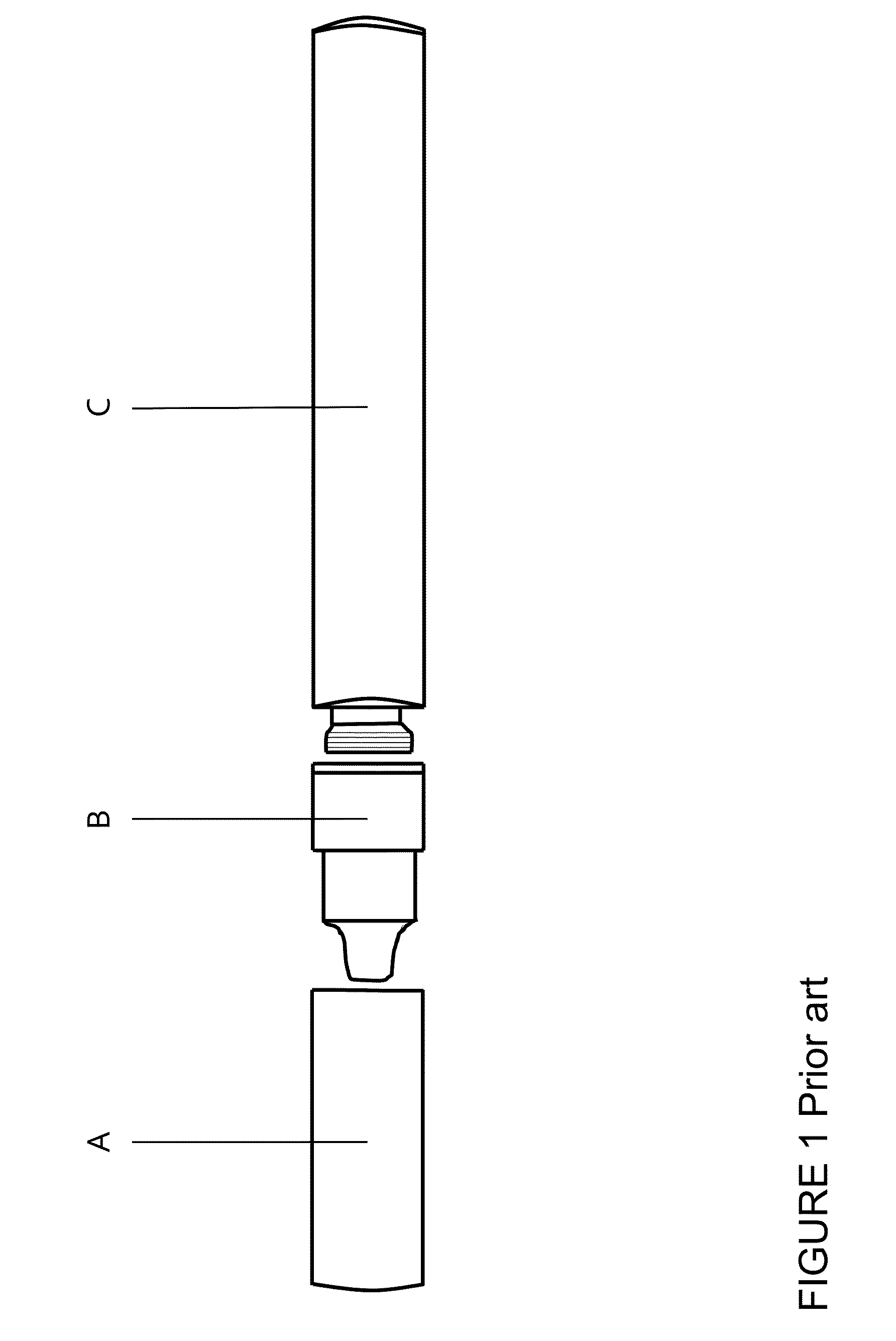

Electrically heated smoking system having a liquid storage portion

ActiveUS20090272379A1Prevent degradationSimple structureOhmic-resistance heating circuitsCoil arrangementsElectricityElectrical connection

An electrically heated smoking system includes a shell and a replaceable mouthpiece. The shell includes an electric power supply and electric circuitry. The mouthpiece includes a liquid storage portion and a capillary wick having a first end and a second end. The first end of the wick extends into the liquid storage portion for contact with liquid therein. The mouthpiece also includes a heating element for heating the second end of the capillary wick, an air outlet, and an aerosol forming chamber between the second end of the capillary wick and the air outlet. When the shell and mouthpiece are engaged or connected, the heating element is in electrical connection with the power supply via the circuitry, and a flowpath for air is defined from at least one air inlet to the air outlet via the aerosol forming chamber. In use, liquid is transferred from the liquid storage portion towards the heating element by capillary action in the wick. Liquid at the second end of the capillary wick is vaporized by the heating element. The supersaturated vapor created, is mixed and carried in the air flow from the at least one air inlet to the aerosol forming chamber. In the aerosol forming chamber, the vapor condenses to form an aerosol, which is carried towards the air outlet.

Owner:PHILIP MORRIS USA INC

Electrically heated smoking system having a liquid storage portion

ActiveUS8794231B2Avoid wastingReduce riskOhmic-resistance heating circuitsCigar manufactureElectricityElectrical connection

An electrically heated smoking system includes a shell and a replaceable mouthpiece. The shell includes an electric power supply and electric circuitry. The mouthpiece includes a liquid storage portion and a capillary wick having a first end and a second end. The first end of the wick extends into the liquid storage portion for contact with liquid therein. The mouthpiece also includes a heating element for heating the second end of the capillary wick, an air outlet, and an aerosol forming chamber between the second end of the capillary wick and the air outlet. When the shell and mouthpiece are engaged or connected, the heating element is in electrical connection with the power supply via the circuitry, and a flowpath for air is defined from at least one air inlet to the air outlet via the aerosol forming chamber. In use, liquid is transferred from the liquid storage portion towards the heating element by capillary action in the wick. Liquid at the second end of the capillary wick is vaporized by the heating element. The supersaturated vapor created, is mixed and carried in the air flow from the at least one air inlet to the aerosol forming chamber. In the aerosol forming chamber, the vapor condenses to form an aerosol, which is carried towards the air outlet.

Owner:PHILIP MORRIS USA INC

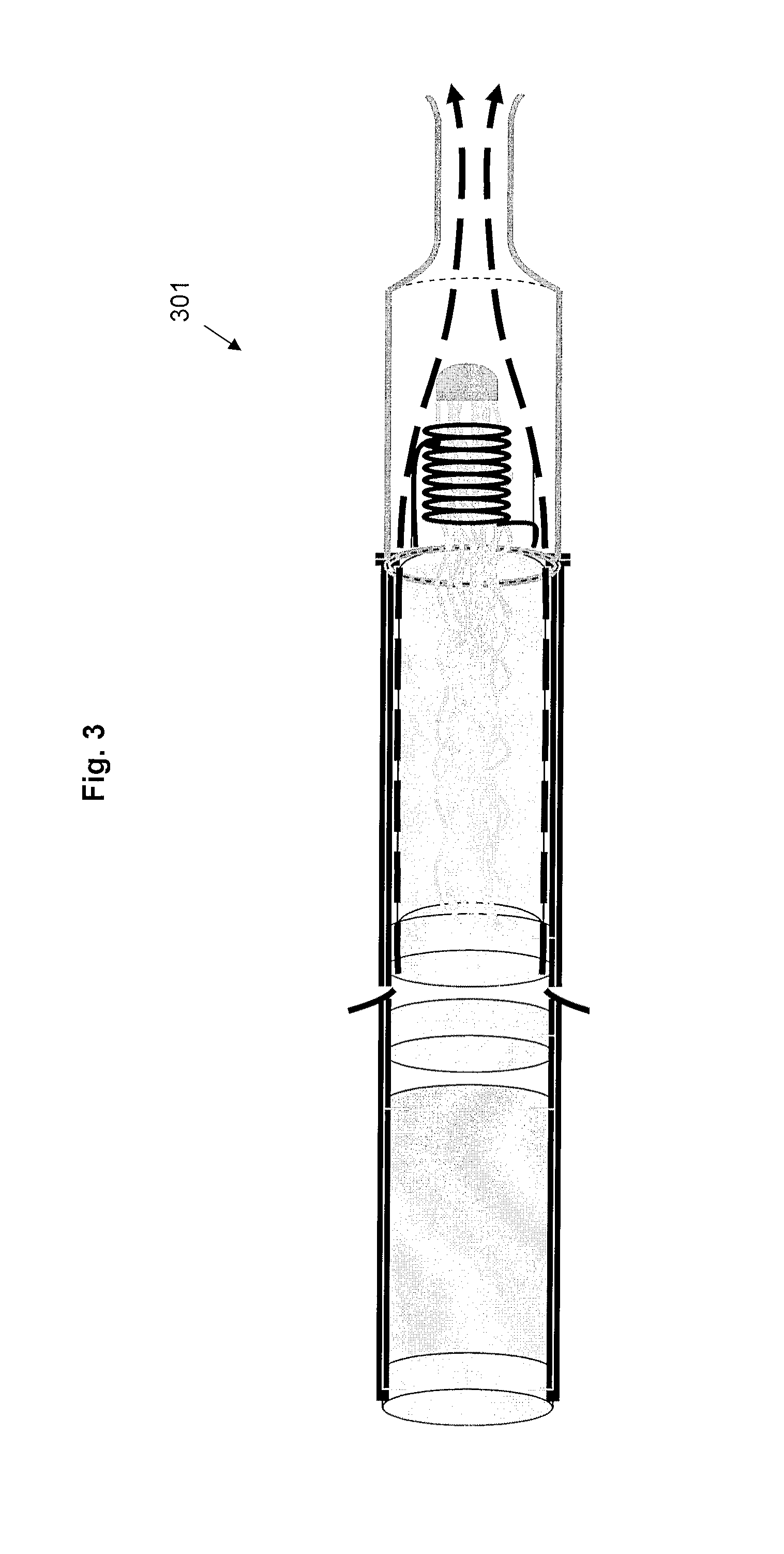

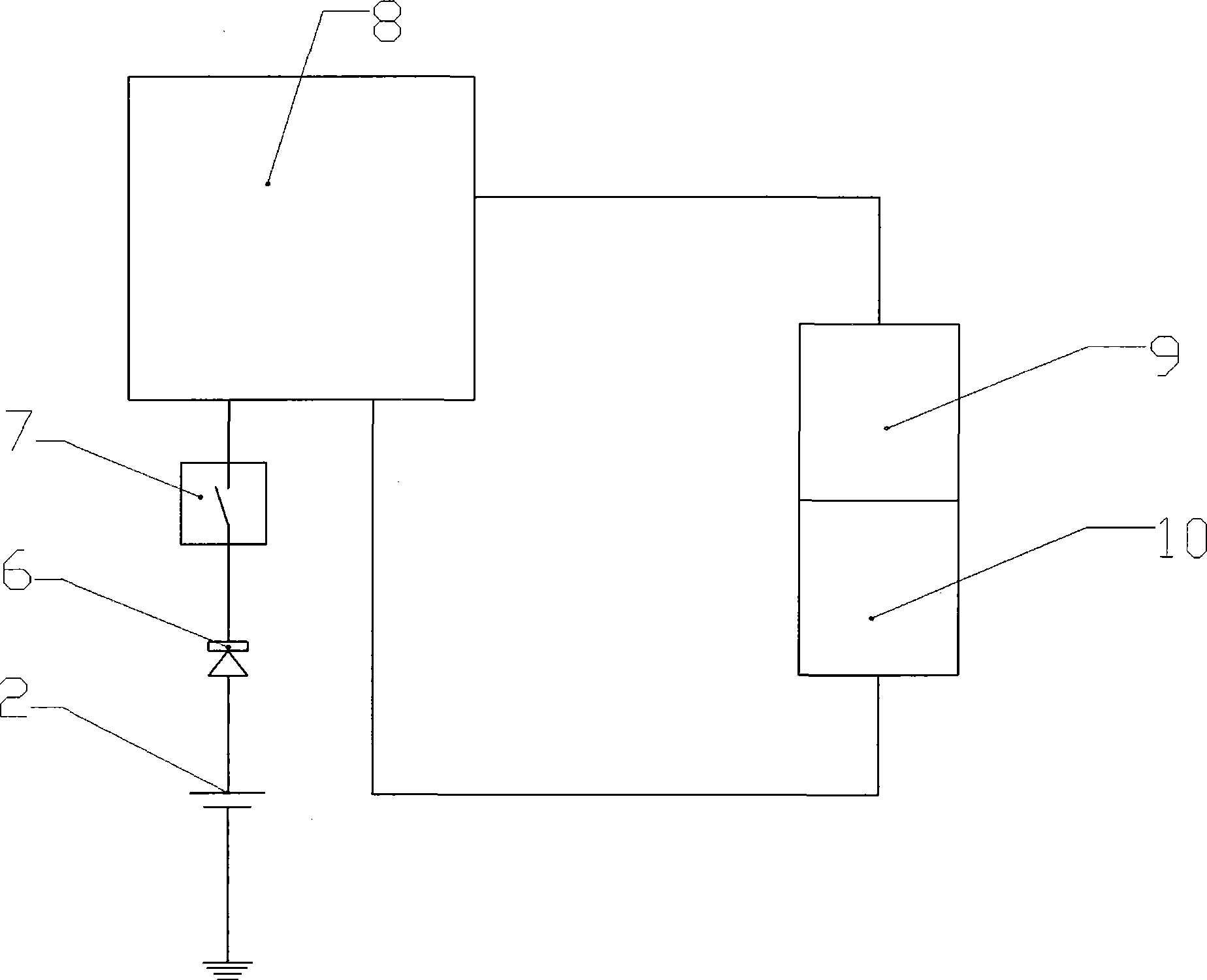

Electronic cigarette

ActiveCN101390659AWon't ageNot transgenderCoil arrangementsTobacco devicesElectronic cigaretteEngineering

The invention discloses an electronic cigarette which comprises a cigarette-like shell with a hollow cavity, an electrical source, a cigarette pellet and cigarette rod fittings. The electrical source, a pneumatic switch, a magnetostrictive vibrator and an electromagnetic induction heater are arranged in sequence inside the shell from the front end to the back end; wherein, a high frequency generator is respectively connected with the magnetostrictive vibrator, the electromagnetic induction heater and the pneumatic switch through leads. A light-emitting diode is arranged at the front end of the shell and is respectively connected with the pneumatic switch and the electric source through leads. The back end of the shell is connected with the cigarette pellet in which a tobacco solution chamber is arranged.

Owner:BEIJING SHUIWUTANG TECH & TRADE CO LTD

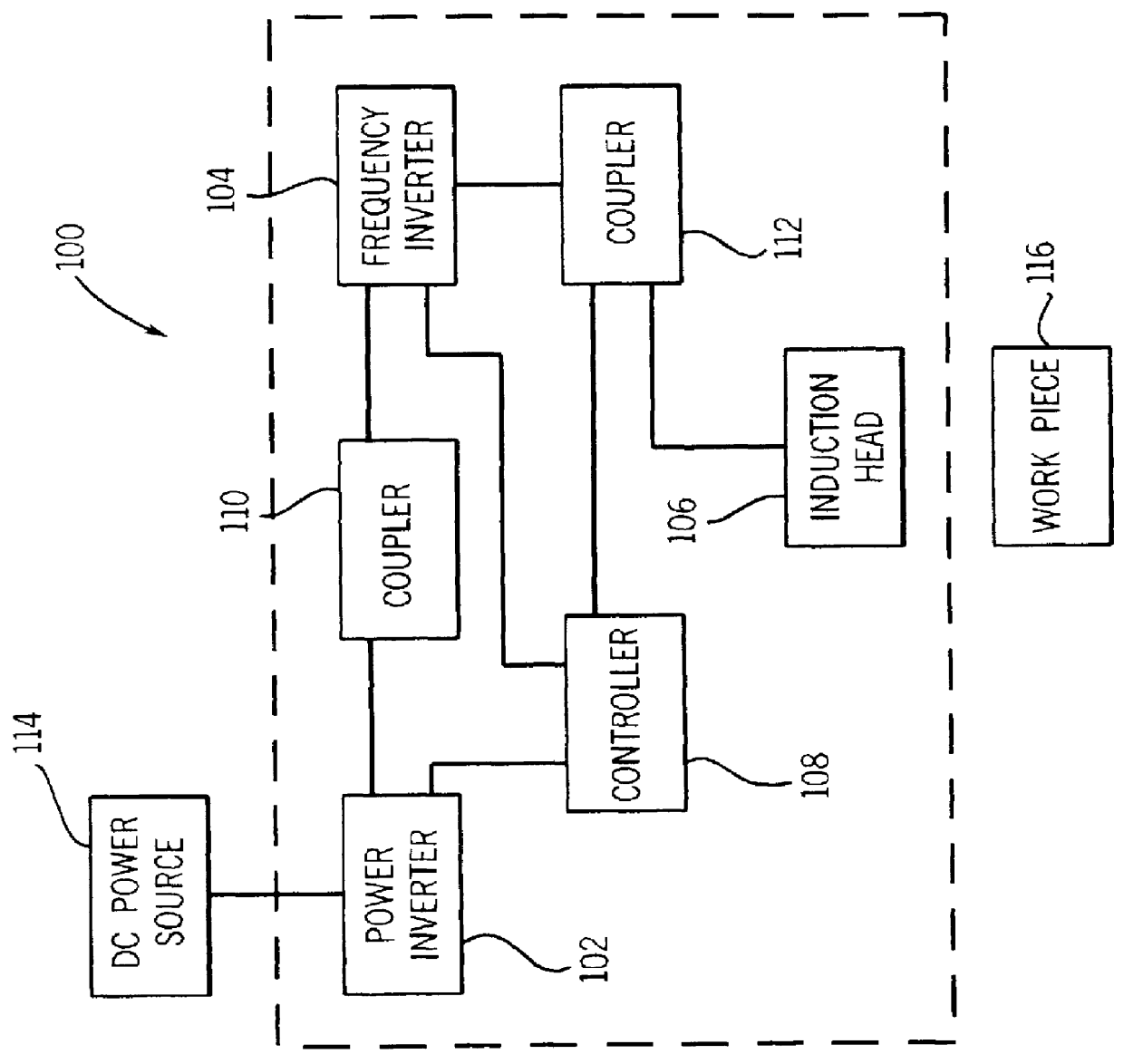

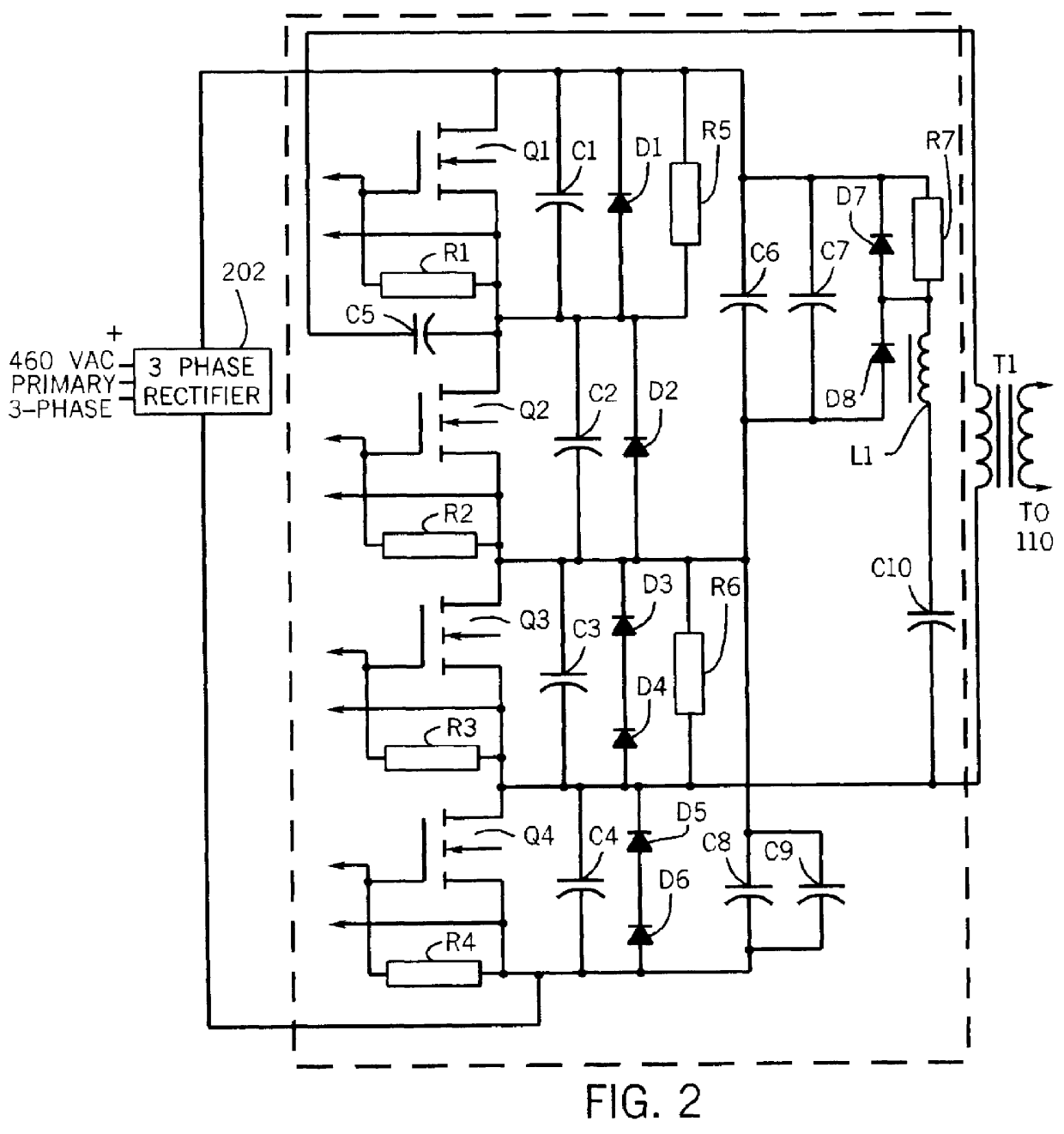

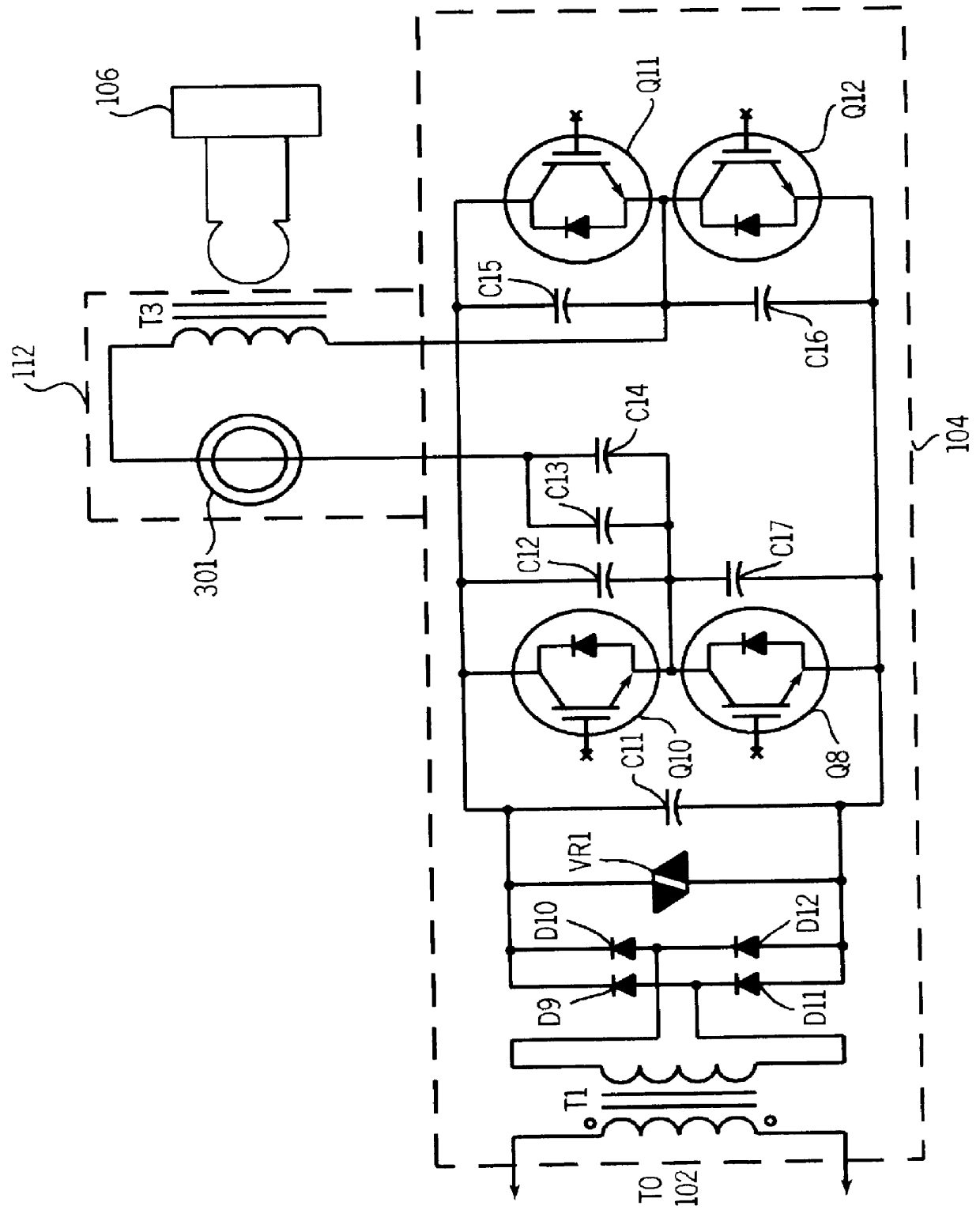

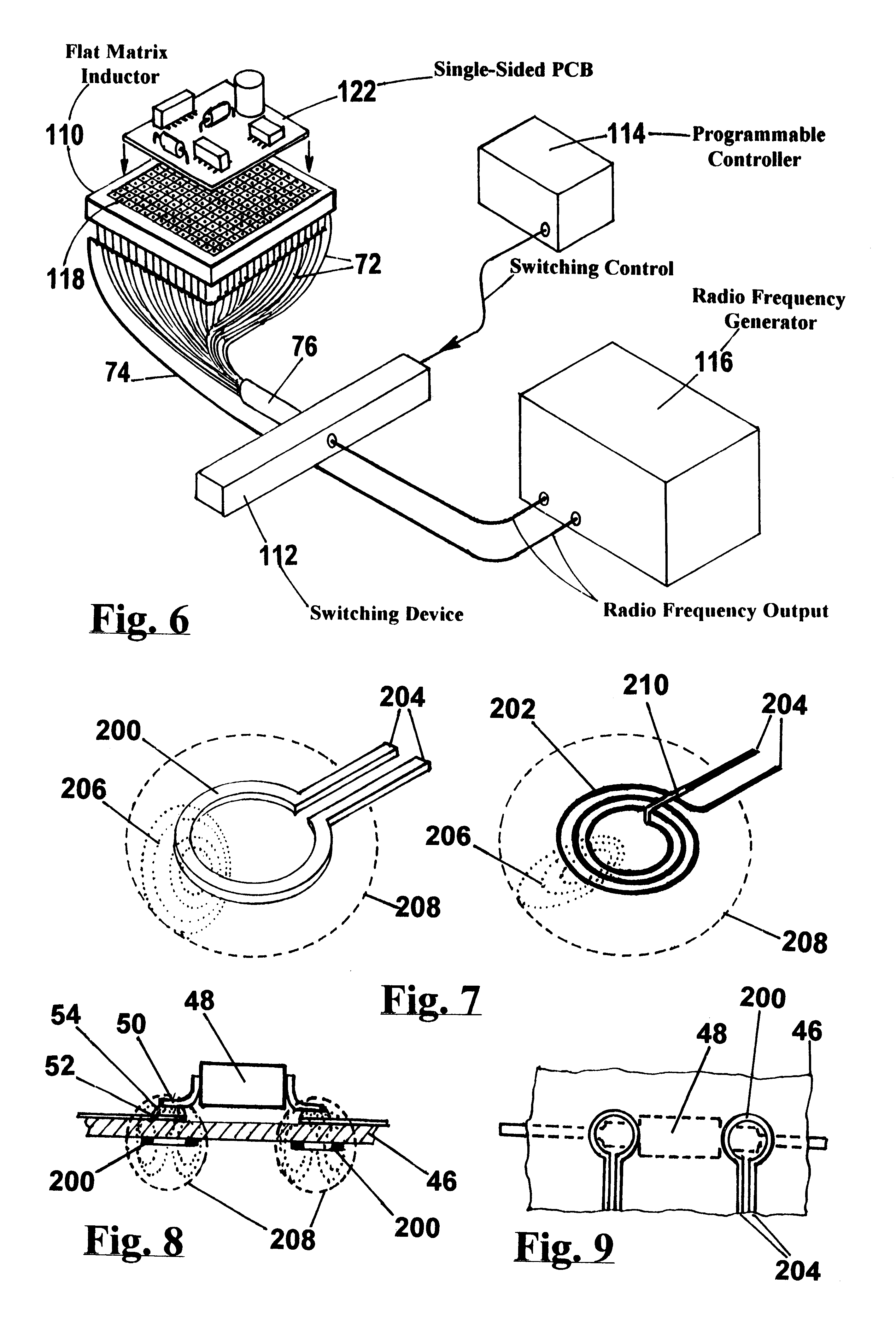

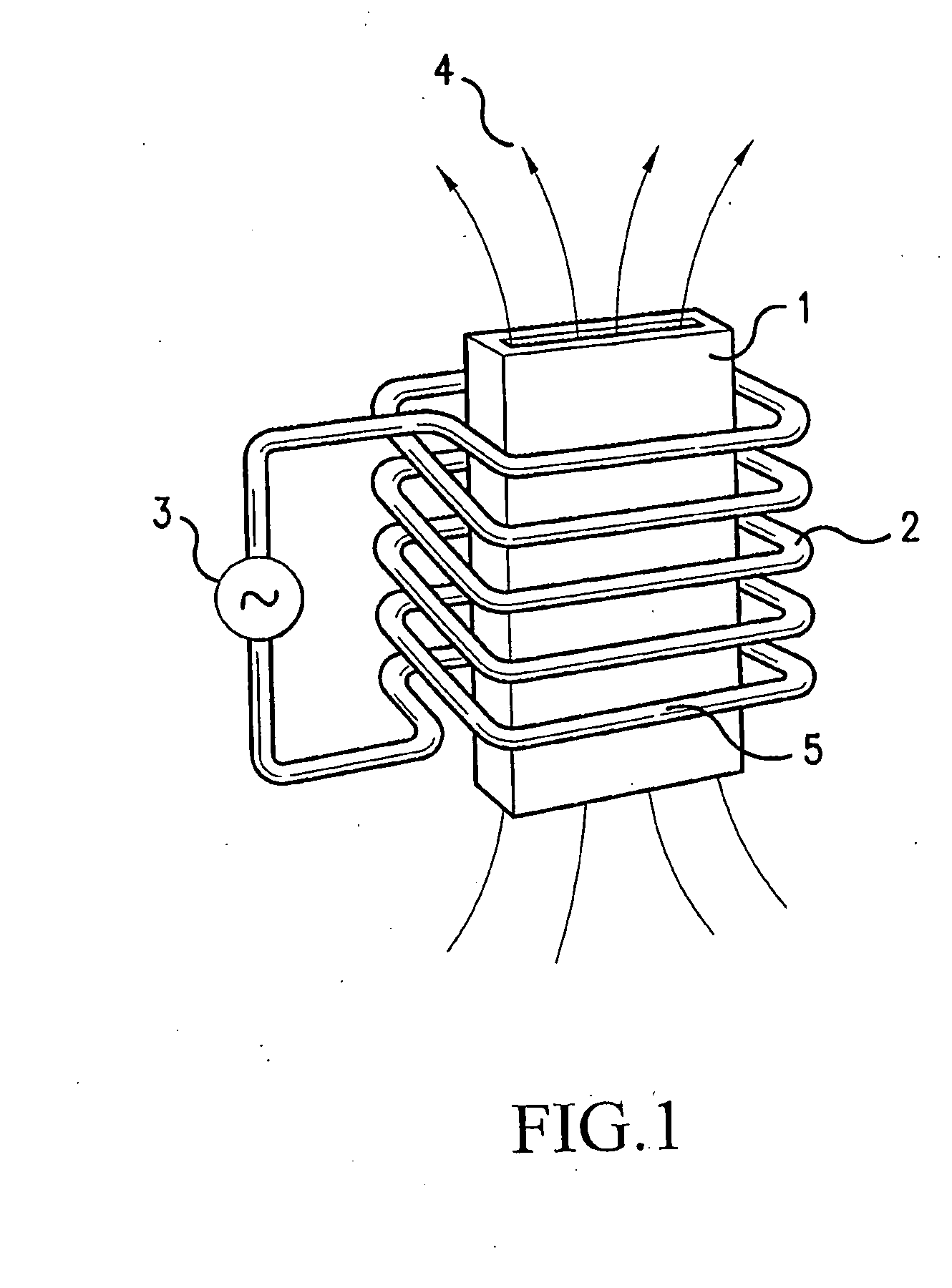

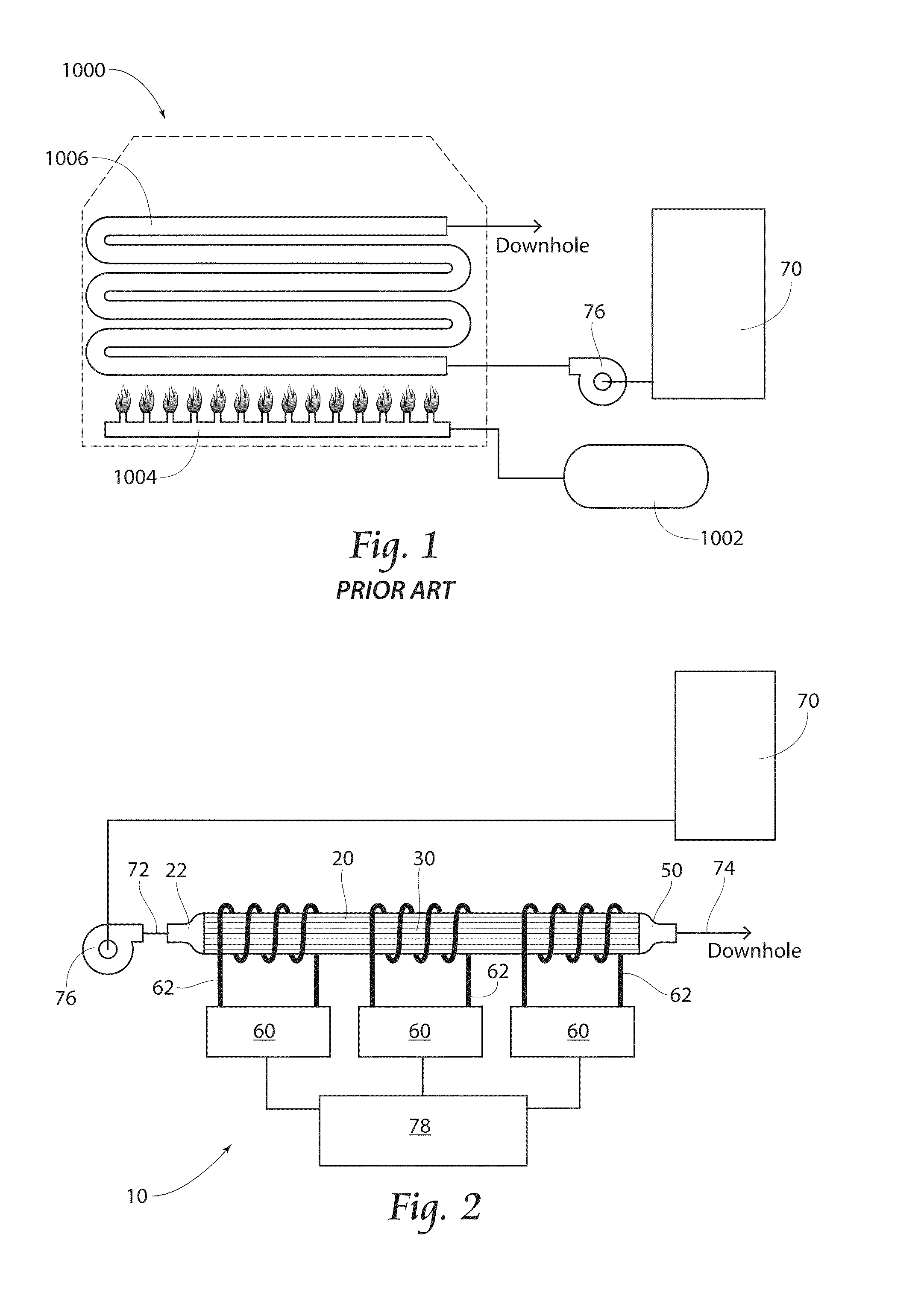

Multiple head inductive heating system

InactiveUS6043471ACoil arrangementsInduction current sourcesHeating systemElectrical and Electronics engineering

A system and method for inductively heating a workpiece includes a controller and a plurality of power supplies that receive and send signals to the controller. Induction heads receive power from the power supplies. The induction heads may be aligned with adjacent segments of the workpiece, and can span the perimeter of the workpiece. The gap between adjacent induction heads is less than one half the size of the adjacent induction heads, and preferably the induction heads abut or substantially abut. Each of the power supplies include feedback for controlling the power delivered to the segments of the workpiece. In alternative embodiments the feedback may be based on the current or power provided to the induction heads, or the power provided to the workpiece.

Owner:ILLINOIS TOOL WORKS INC

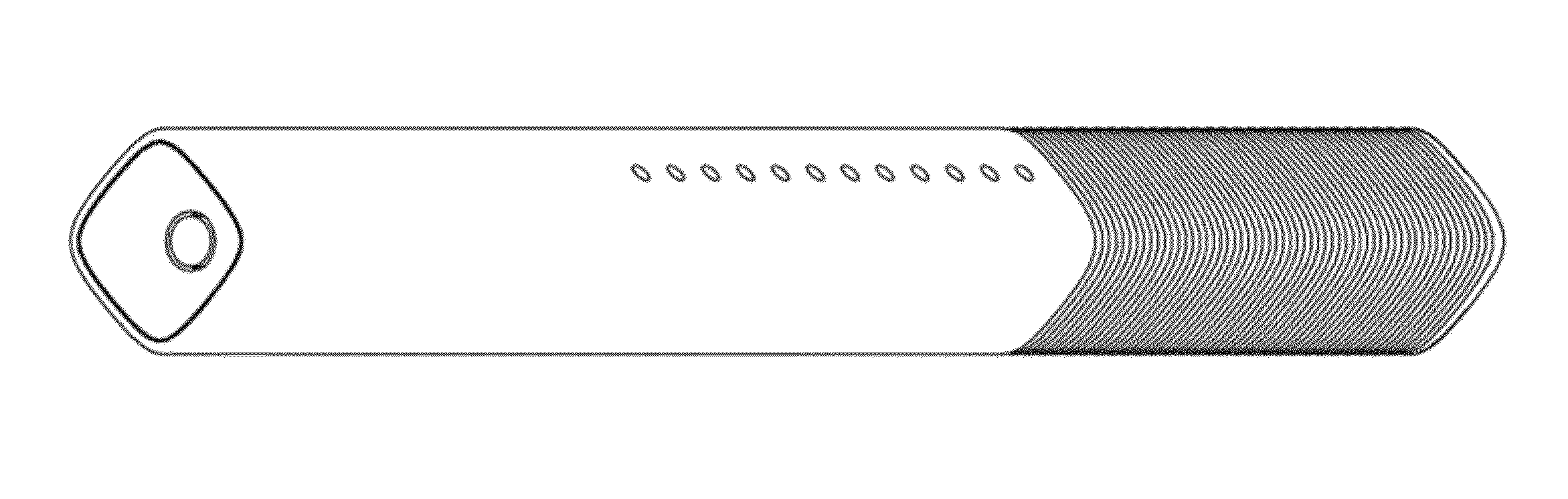

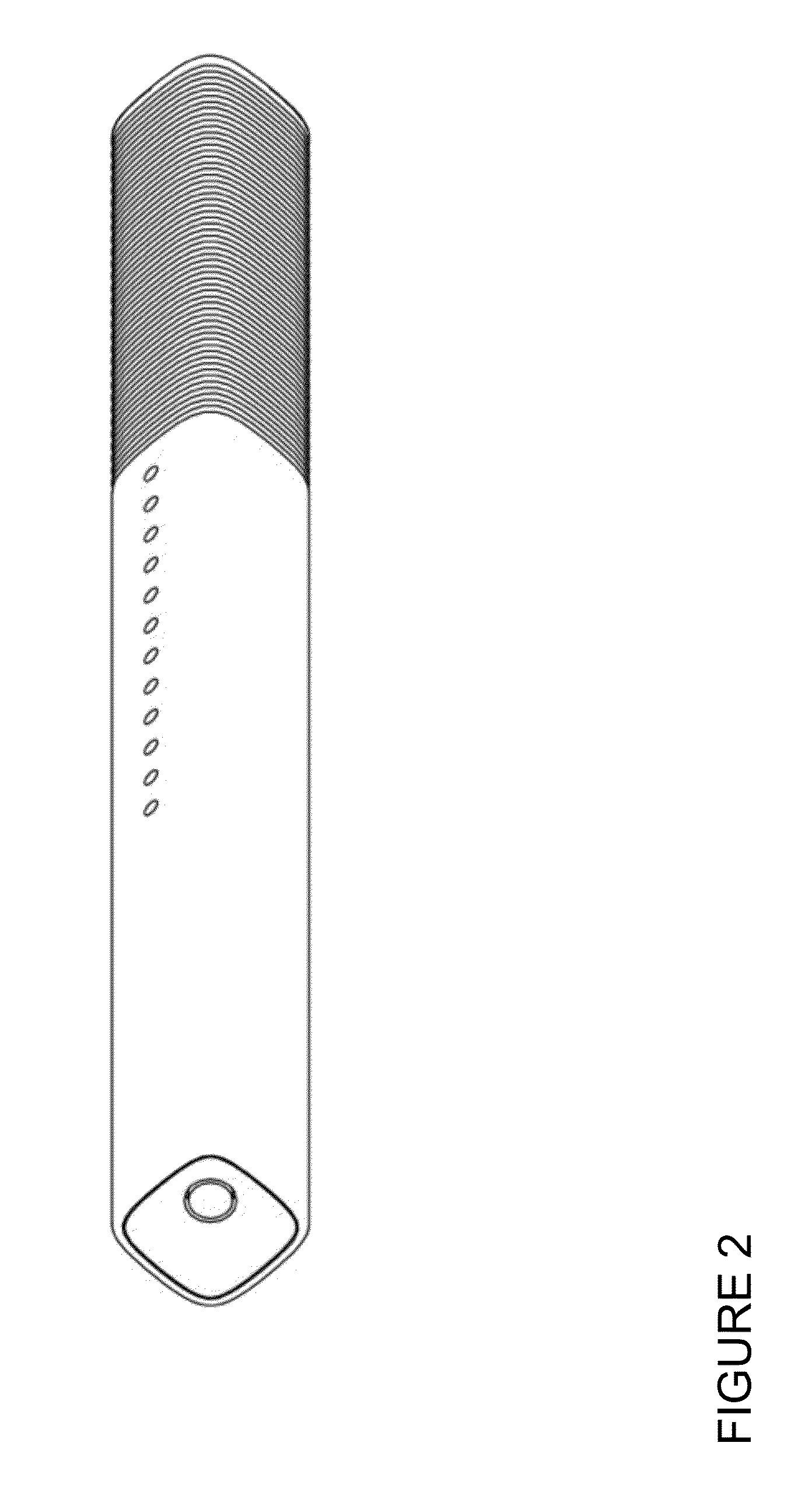

E-cigarette personal vaporizer

InactiveUS20150245662A1Tobacco treatmentPackaging cigaretteElectronic cigaretteMechanical engineering

A user-replaceable e-liquid cartridge adapted to be inserted into or attached to a portable, personal storage and carrying case for an e-liquid e-cigarette PV. The combination of cartridge and case forms in normal use a portable, personal device for the storage and carrying of the PV and its re-filling with e-liquid.

Owner:AYR LTD

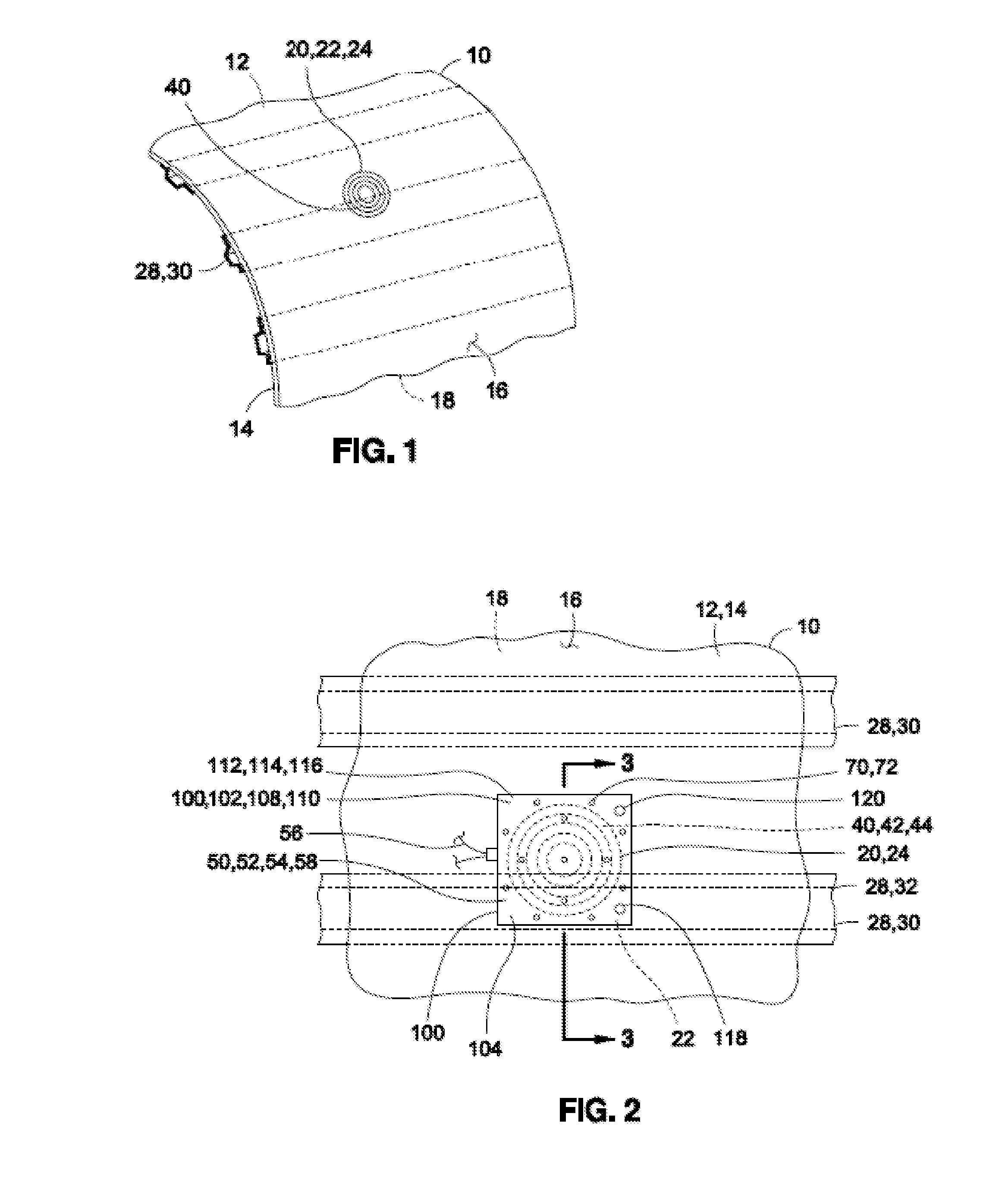

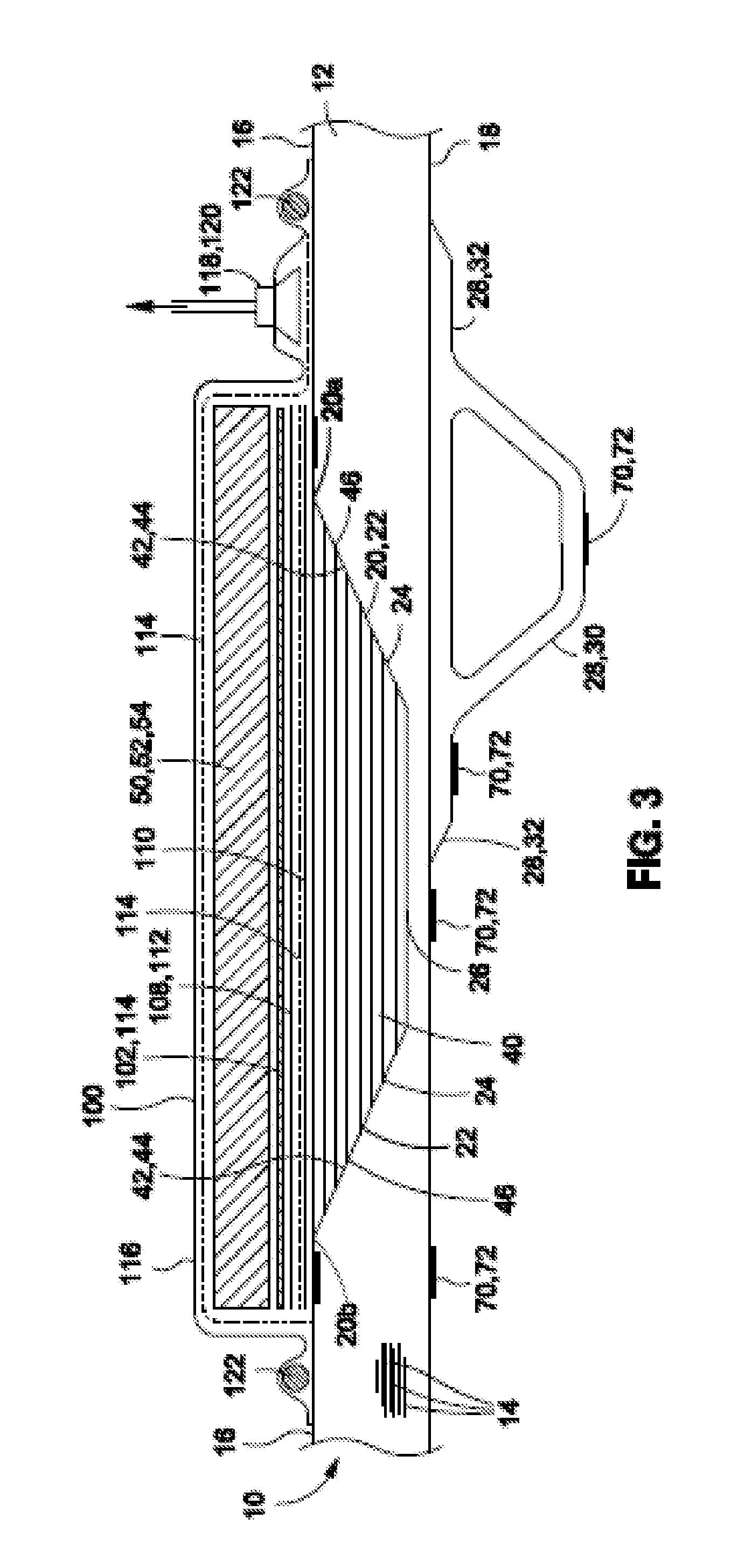

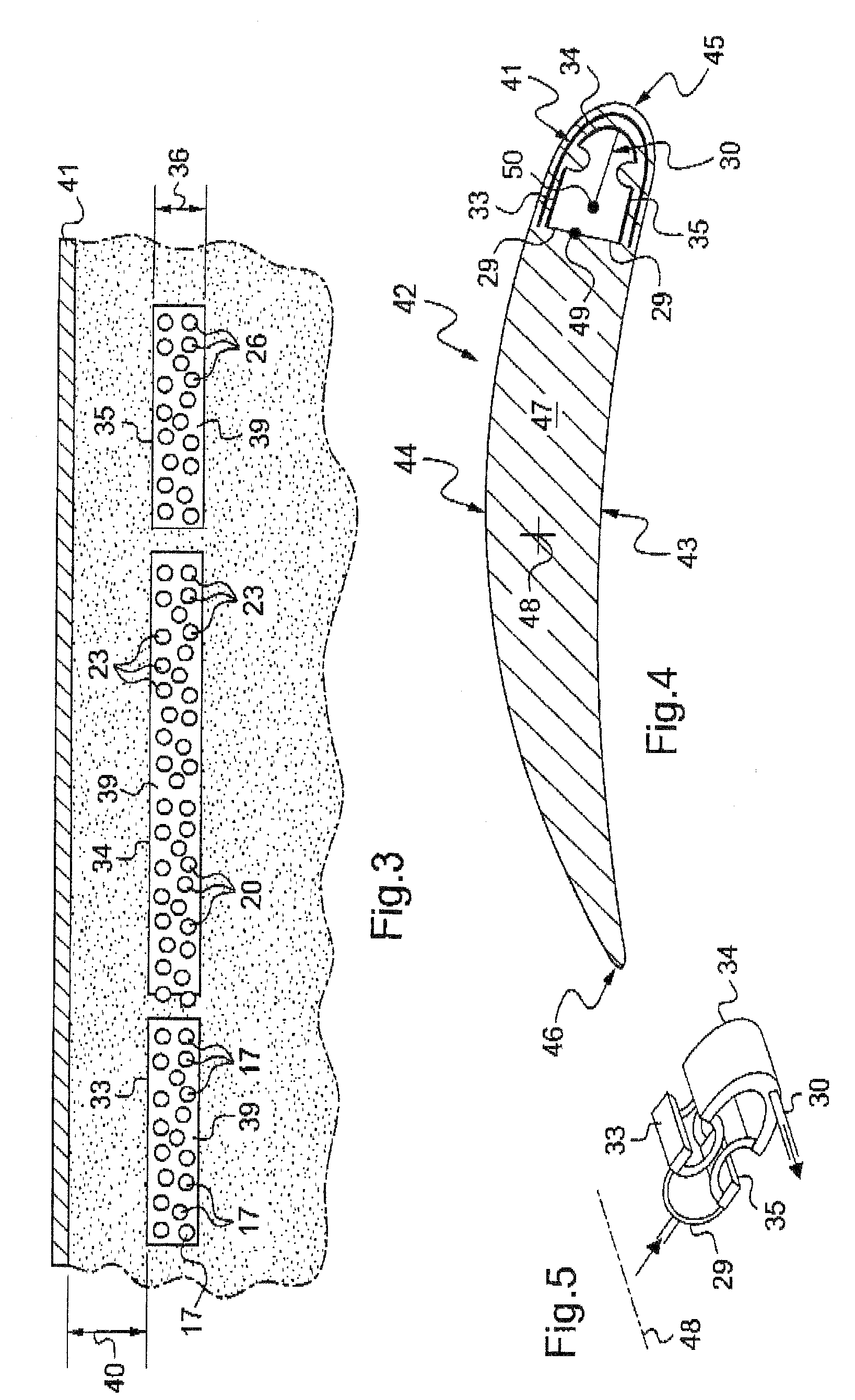

Curing Composites Out-Of-Autoclave Using Induction Heating with Smart Susceptors

ActiveUS20120145703A1Precise and uniform temperature controlSimple and relatively inexpensive to fabricateCoil arrangementsOhmic-resistance heatingSusceptorMaterials science

A composite part is cured out-of-autoclave using an inductively heated, stand-alone tooling. The part in placed on a tool and is covered by a heating blanket. One side of the part is heated by inductive coil circuits in the tool, and the other side of the part is heated by inductive coil circuits in the blanket.

Owner:THE BOEING CO

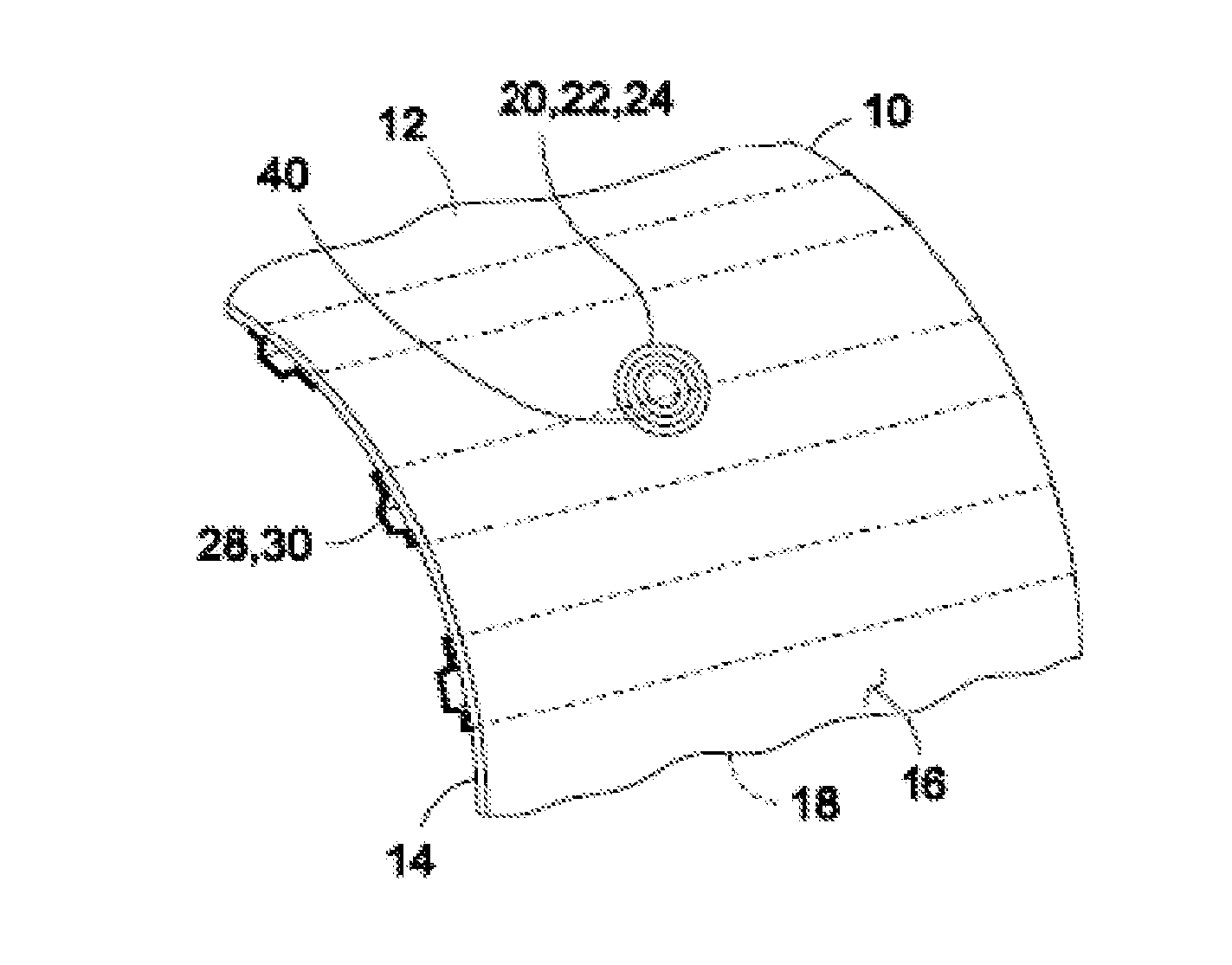

Electronic Vapour Inhalers

ActiveUS20170156403A1Reduce the possibilityIntegrity safetyTobacco treatmentCoil arrangementsMedicineInhalation

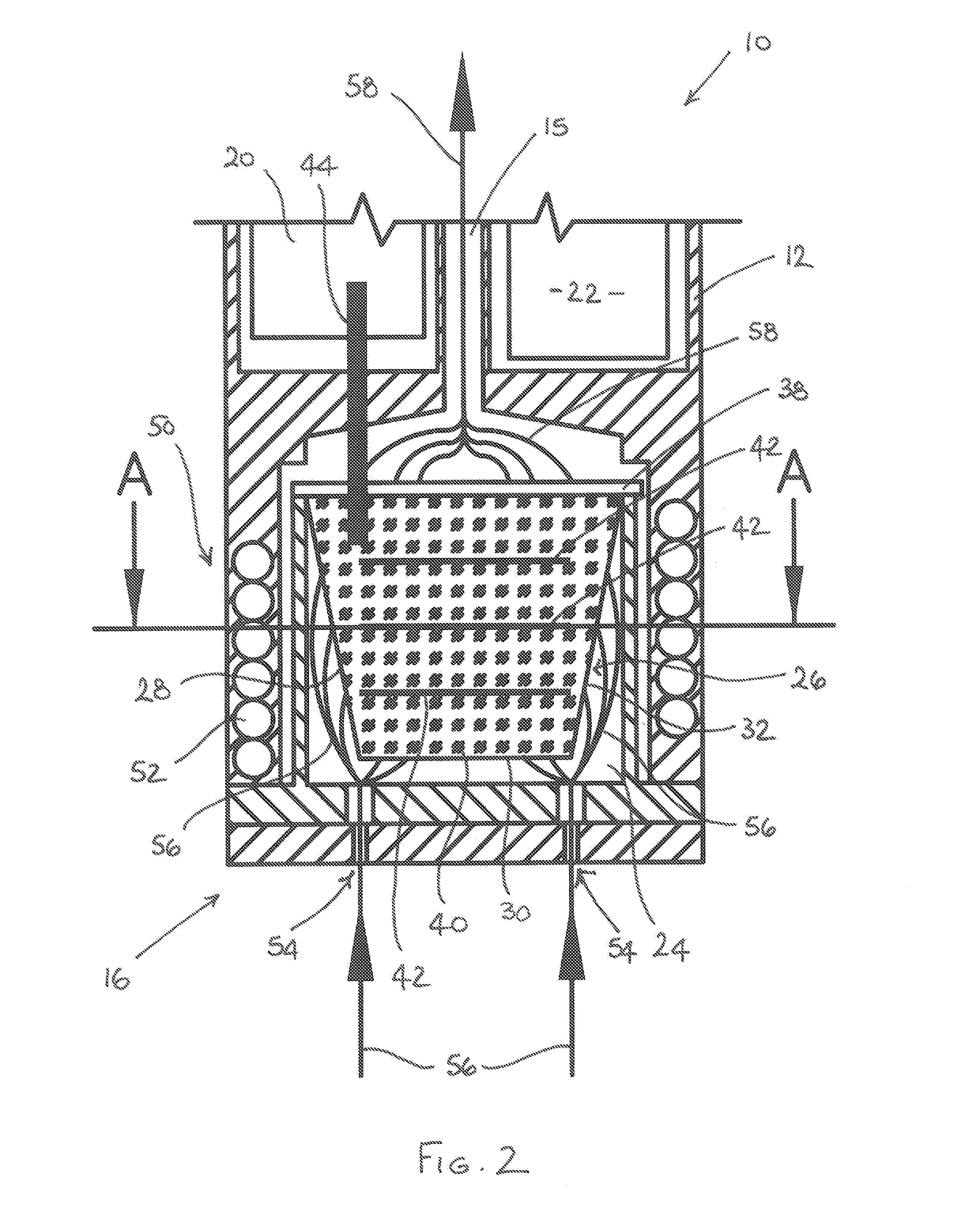

A capsule (26) for an electronic vapour inhaler comprises a shell (28) containing a flavour-release medium (40) and one or more induction heatable elements (42) disposed inside the shell (28) and arranged to heat the flavour-release medium (40) to produce a vapour for inhalation by a user. At least part of the shell (28) is formed of an air permeable material.

Owner:JT INT SA

Device and method for controlling energy

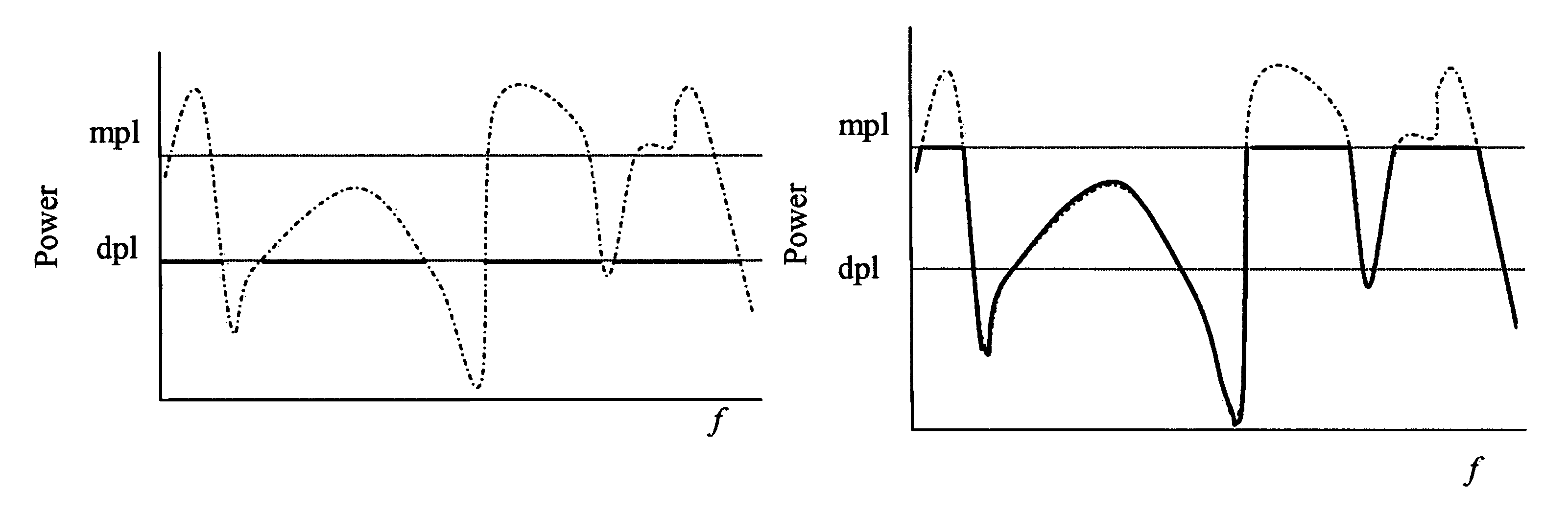

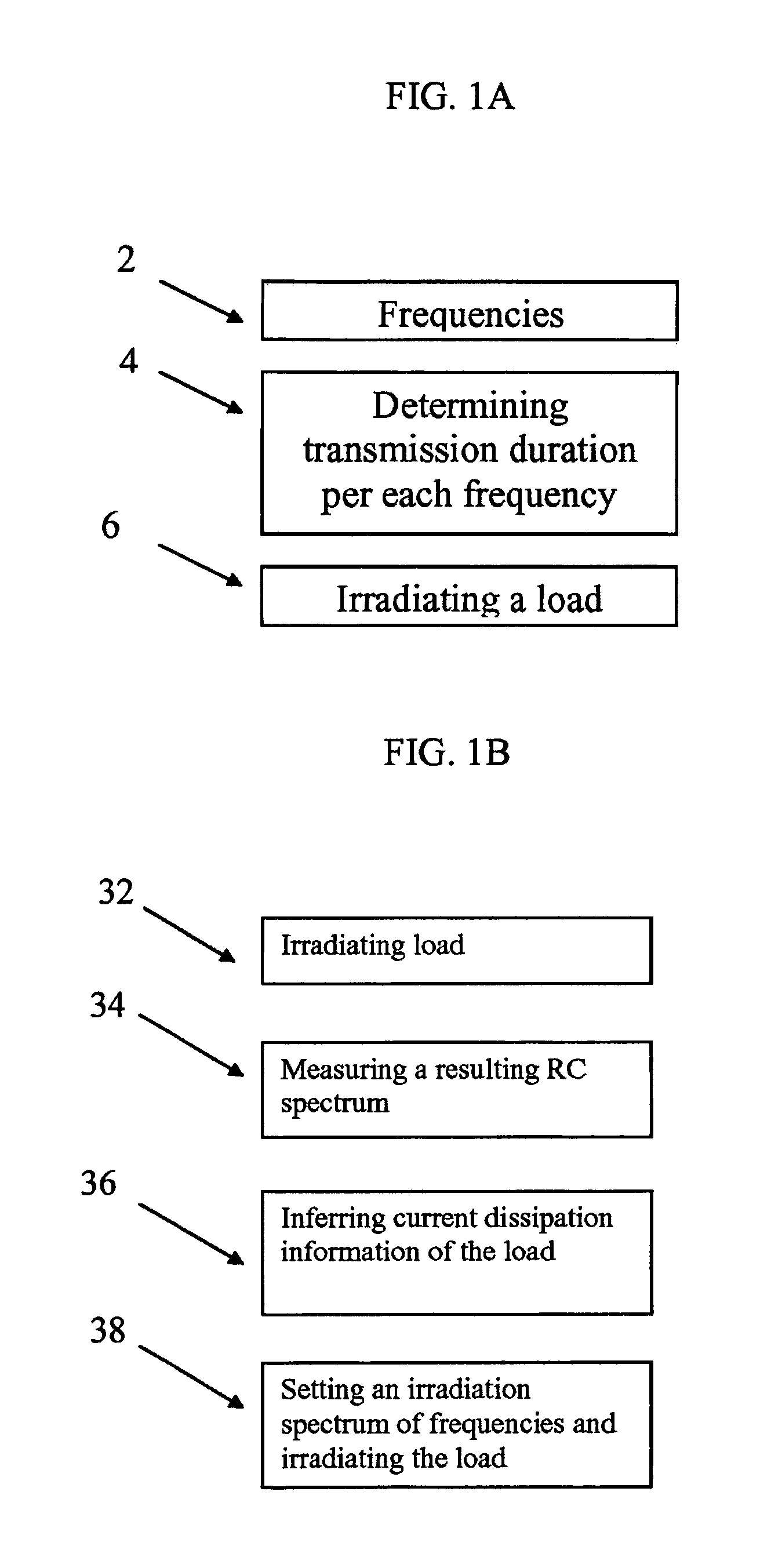

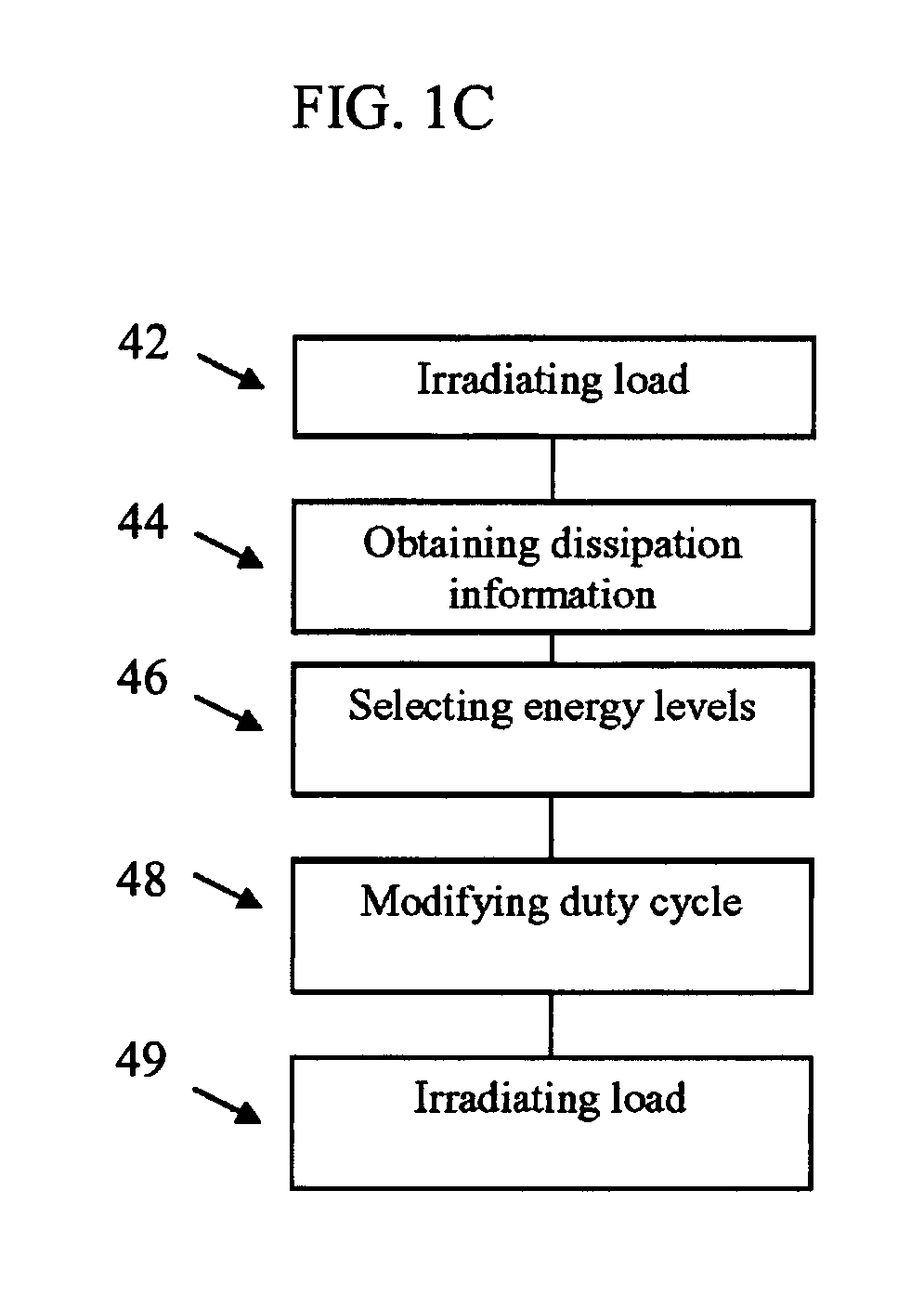

ActiveUS9215756B2Cheap amplifierCoil arrangementsOhmic-resistance heatingPower applicationEngineering

Apparatuses and methods for applying EM energy to a load. The apparatuses and methods may include at least one processor configured to receive information indicative of energy dissipated by the load for each of a plurality of modulation space elements. The processor may also be configured to associate each of the plurality of modulation space elements with a corresponding time duration of power application, based on the received information. The processor may be further configured to regulate energy applied to the load such that for each of the plurality of modulation space elements, power is applied to the load at the corresponding time duration of power application.

Owner:JOLIET 2010 LTD

Cooking surface for cooking food having a glass ceramic surface with a glass coating thereon

InactiveUS6525300B1Reduction factorEasy to processCoil arrangementsHot plates heating arrangementsGlazeThermal expansion

The invention relates to lead- and cadmium-free glass for glazing, enamelling and decorating glasses or glass-ceramics which have a low coefficient of thermal expansion of less than 2x10-6 / K, having the composition (in % by weight) 0-6 Li2O, 0-5 Na2O, 0 to less than 2 K2O, where the sum Li2O+K2+Na2O is between 2 and 12, 0-4 MgO, 0-4 CaO, 0-4 SrO, 0-1 BaO, 0-4 ZnO, 3 to less than 10 Al2O3, 13-23 B2O3, 50-65 SiO2, 0-4 TiO2, 0-4 ZrO2 and 0-4 F, as replacement for oxygen and containing up to 30% by weight of a pigment which is resistant at the firing temperature, where the glass is suitable for glazing, enamelling and decoration in both primary and secondary firing, and both the full-area and sparse glaze, enamel or decoration layers have low abrasion susceptibility after firing, and it relates to processes for the production of a glass-ceramic coated therewith.

Owner:SCHOTT AG

Heat generator comprising a magneto-caloric material and thermie generating method

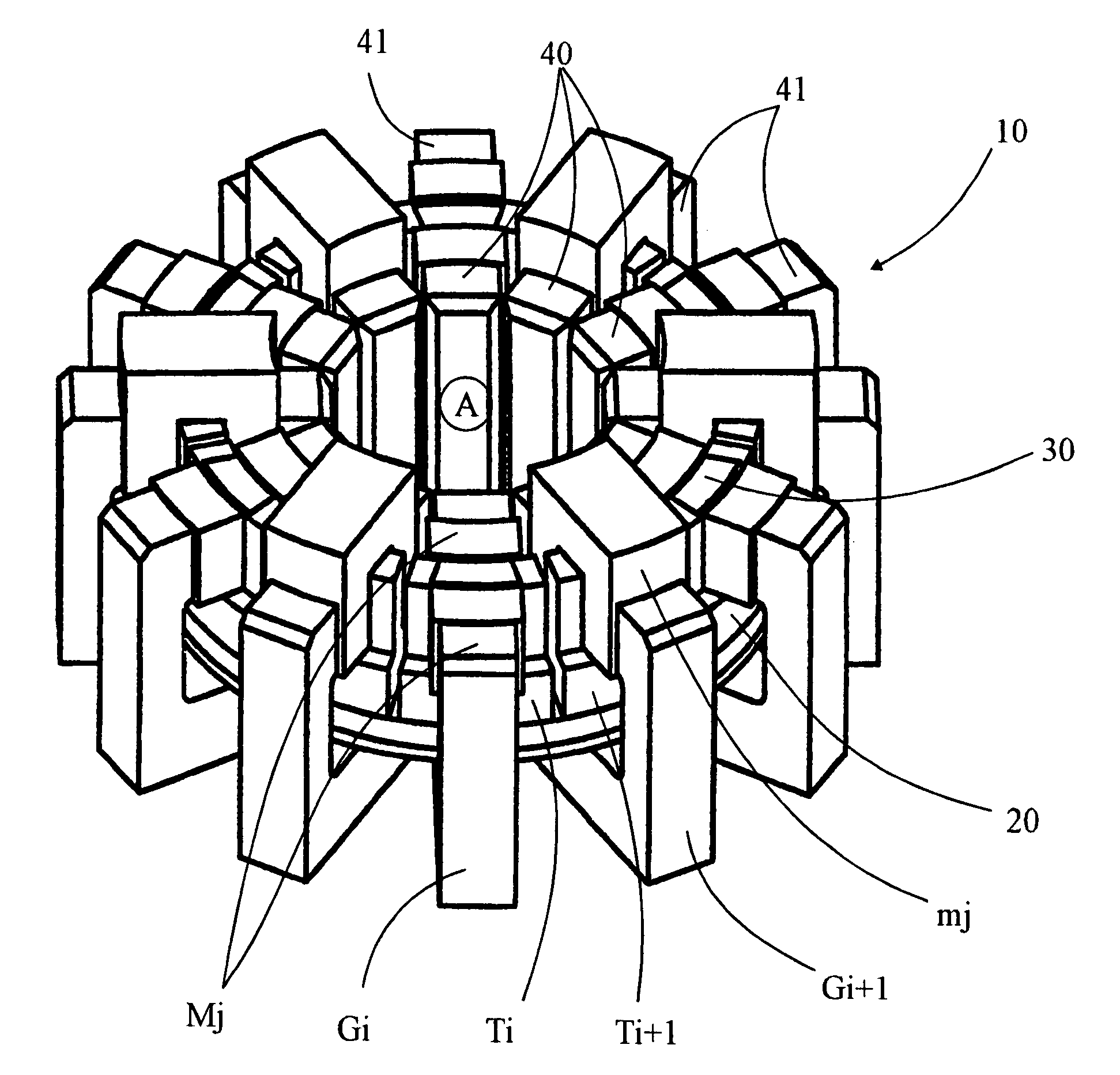

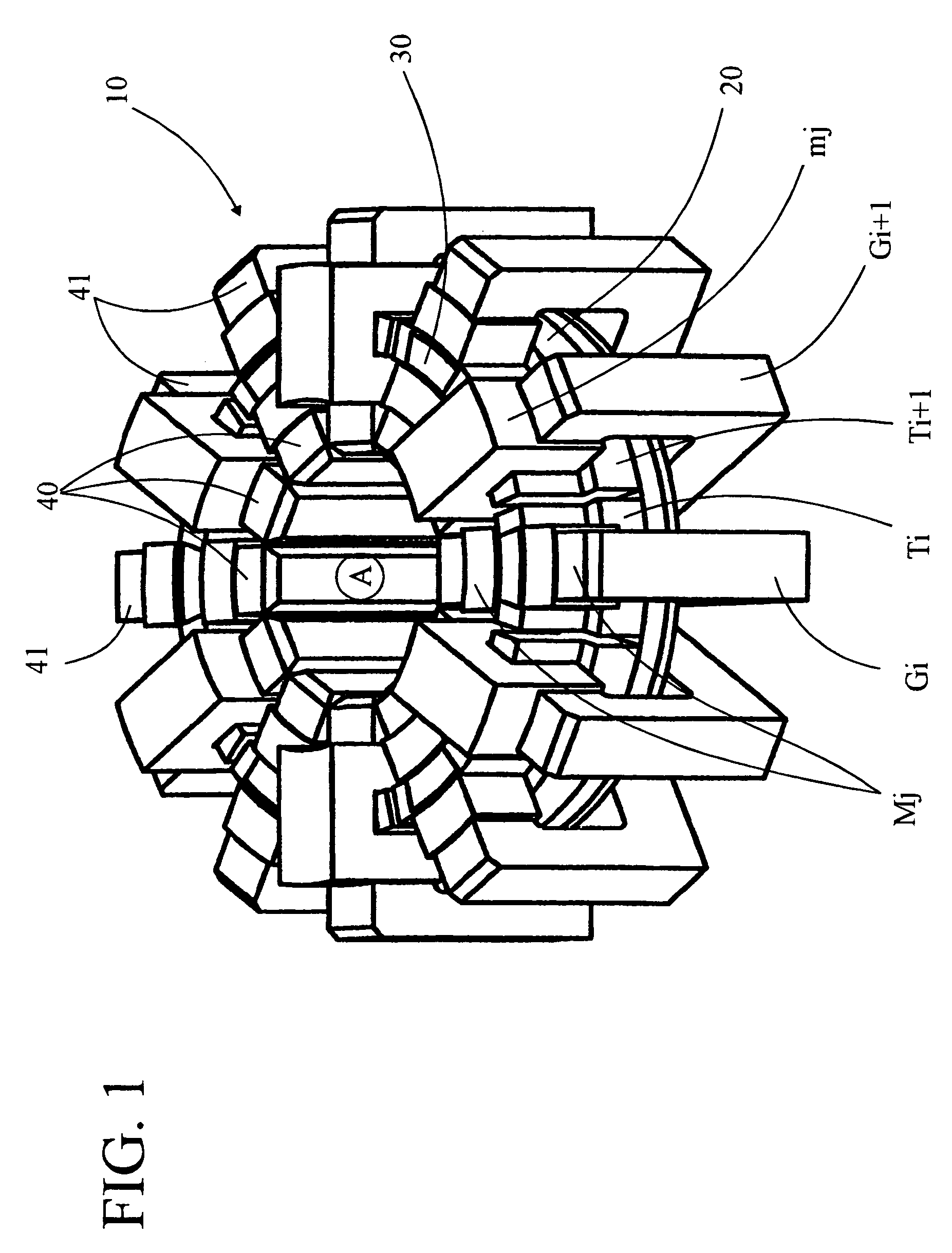

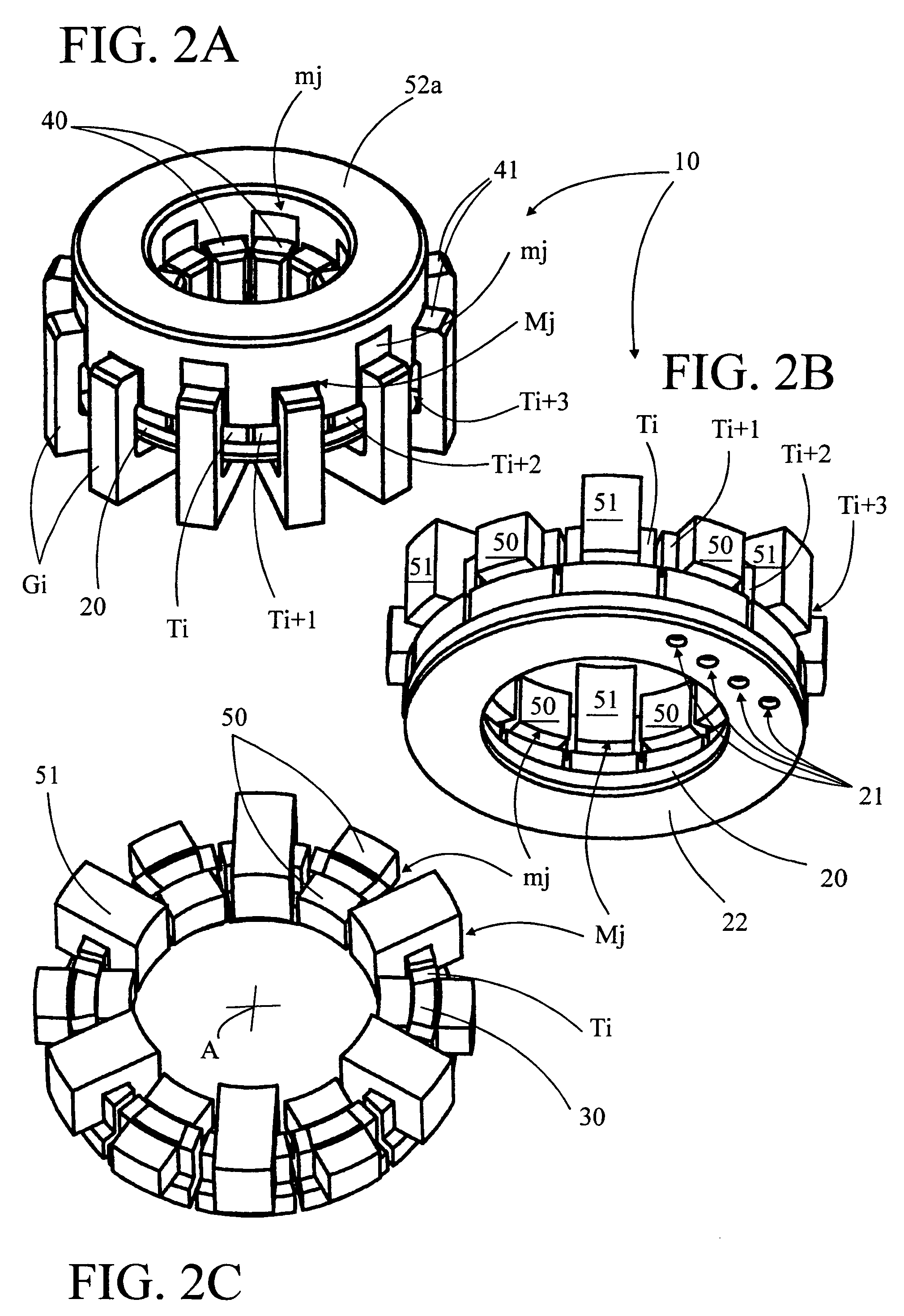

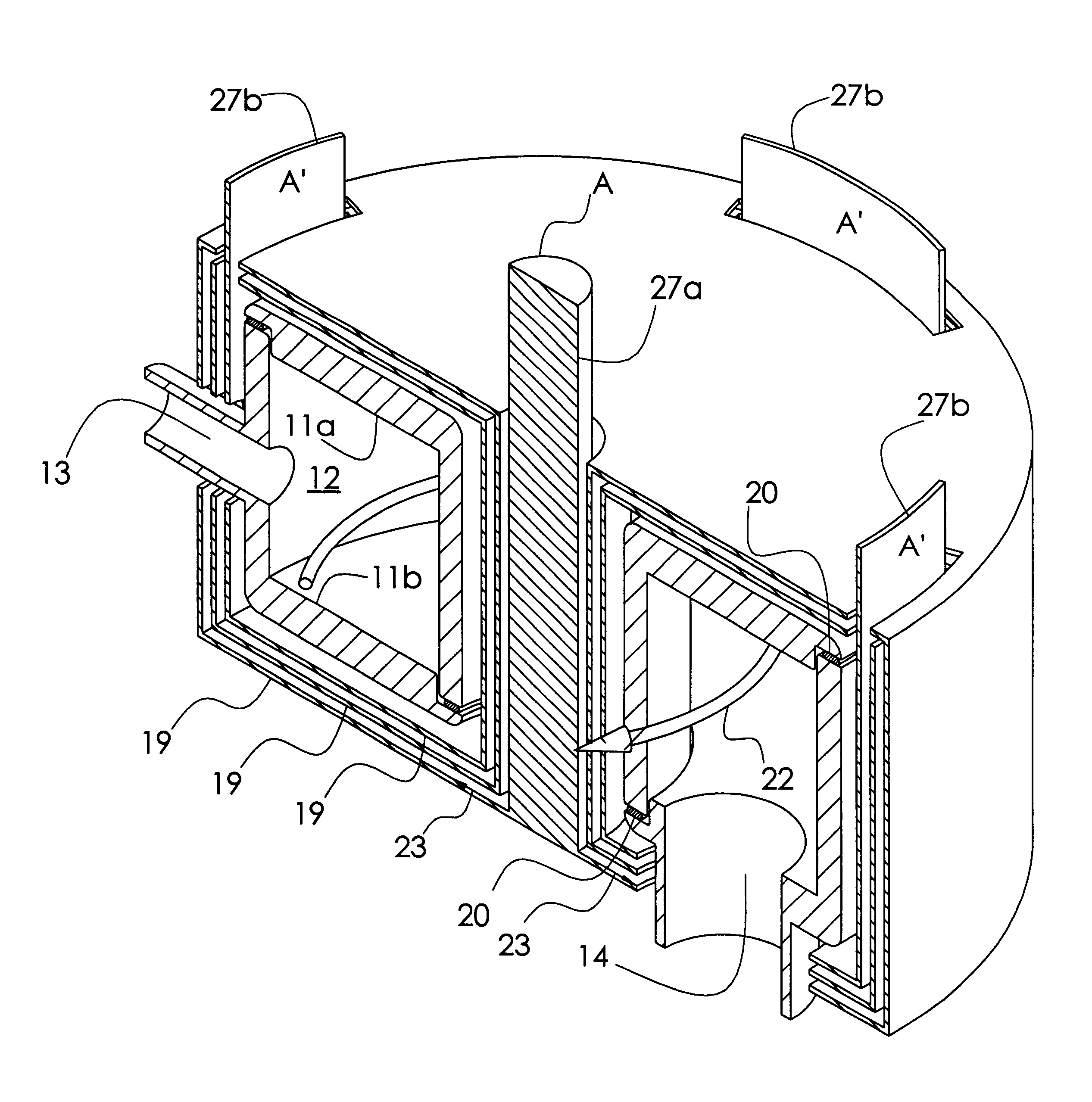

A heat generator comprising a magneto-caloric material and a method for generating efficient and reliable thermies enabling of substantially limiting displaceable inert masses in order to produce a magnetic field variation required for obtaining a magneto caloric effect and usable by individuals and / or industries. The generator (10) comprises magneto caloric thermal elements (Ti) which are circularly arranged and crossed by conduits containing coolant flowing therethrough and magnetic elements (Gi) exposing the thermal elements (Ti) to a magnetic field action. The generator (10) also comprises magnetic divergence (mj) elements arranged between the thermal elements (Ti) and the magnetic elements (Gi) and coupled to displacement mechanism (not represented) for moving from one thermal element (Ti) to another thermal element (Ti+1) and initiating the magnetic flux variation in the thermal elements (Ti), thereby promoting the calorie and / or frigorie generation. The generator (10) can be used for tempering, cooling, heating, conserving, drying and air-conditioning.

Owner:COOLTECH APPL S

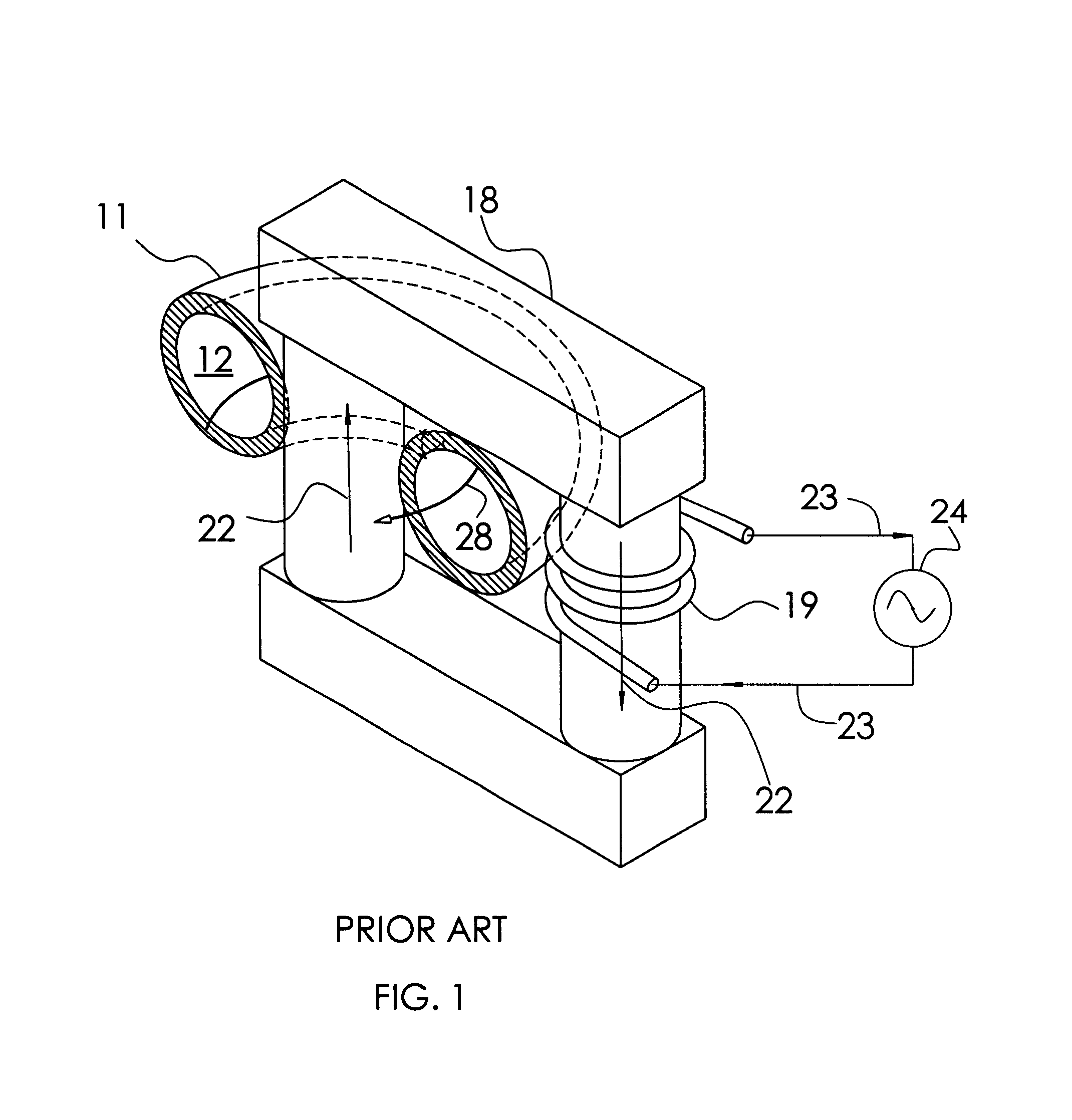

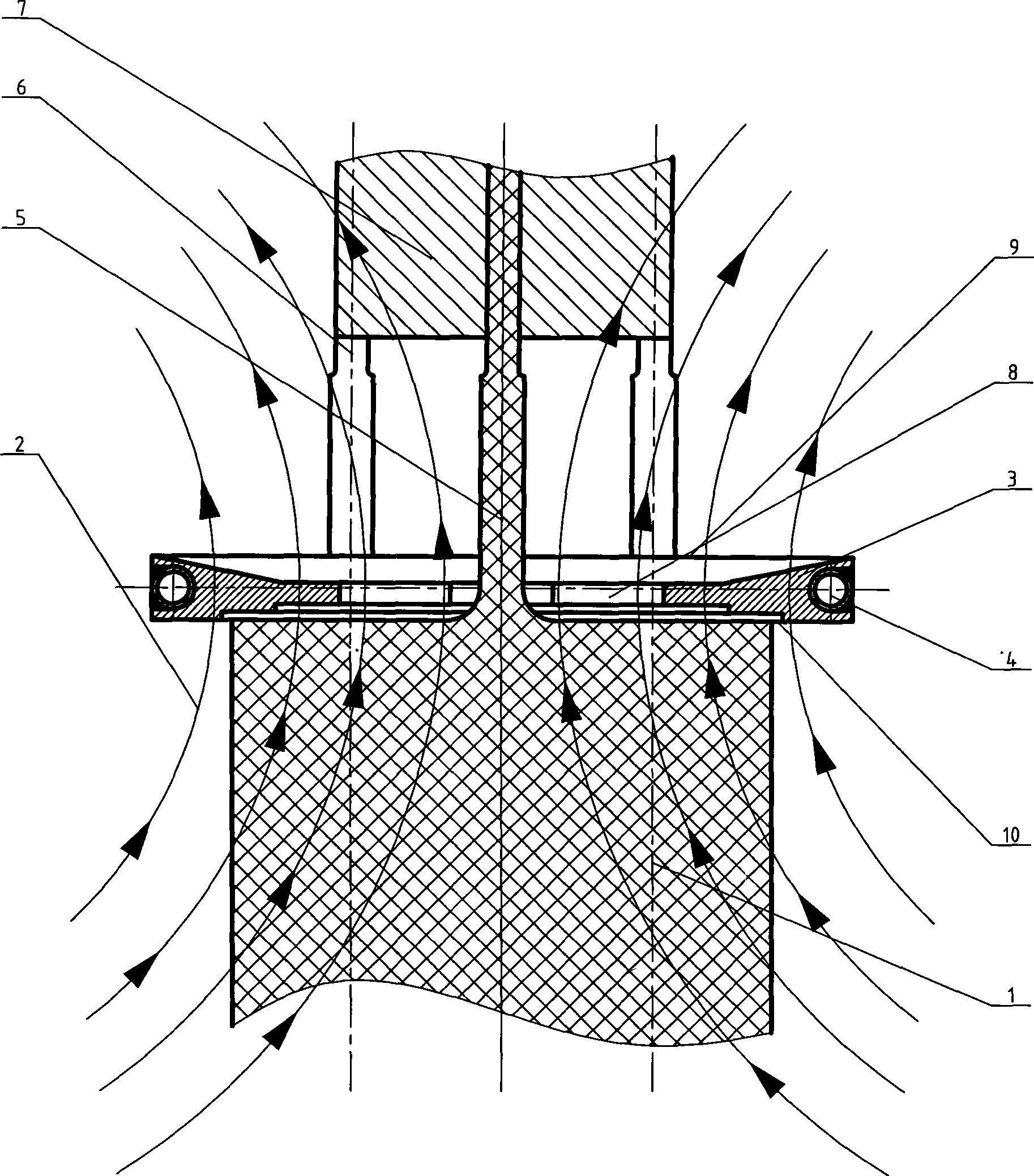

Induction plasma reactor

InactiveUS6855906B2Increase plasma densityImprove productivityCoil arrangementsSemiconductor/solid-state device manufacturingEffective powerElectricity

The invention is a plasma-generating device useful in a wide variety of industrial processes. The plasma is formed in a chamber having a toroidal topology, and is heated inductively. As with all inductive plasmas, a primary coil carries an applied AC current, which, in turn, generates a corresponding applied AC magnetic flux inside the plasma. This flux induces current to flow through the plasma in closed paths that encircle the flux, thereby heating and maintaining the plasma. In this invention, the applied AC current flows through the primary coil around substantially the short poloidal direction on the torus. Accordingly, the applied magnetic flux is caused to circulate through the plasma along the larger toroidal direction. Finally, the current induced within the plasma will flow in the poloidal direction, anti-parallel to the applied primary current. The plasma chamber wall is preferably made of metal such as aluminum and includes one or more electrical breaks that extend fully around the chamber wall in the toroidal direction. This prevents poloidal currents from being induced in the chamber wall, ensuring effective power transfer to the plasma. Elastomeric seals made from electrically insulating material seal the breaks.

Owner:BRAILOVE ADAM ALEXANDER

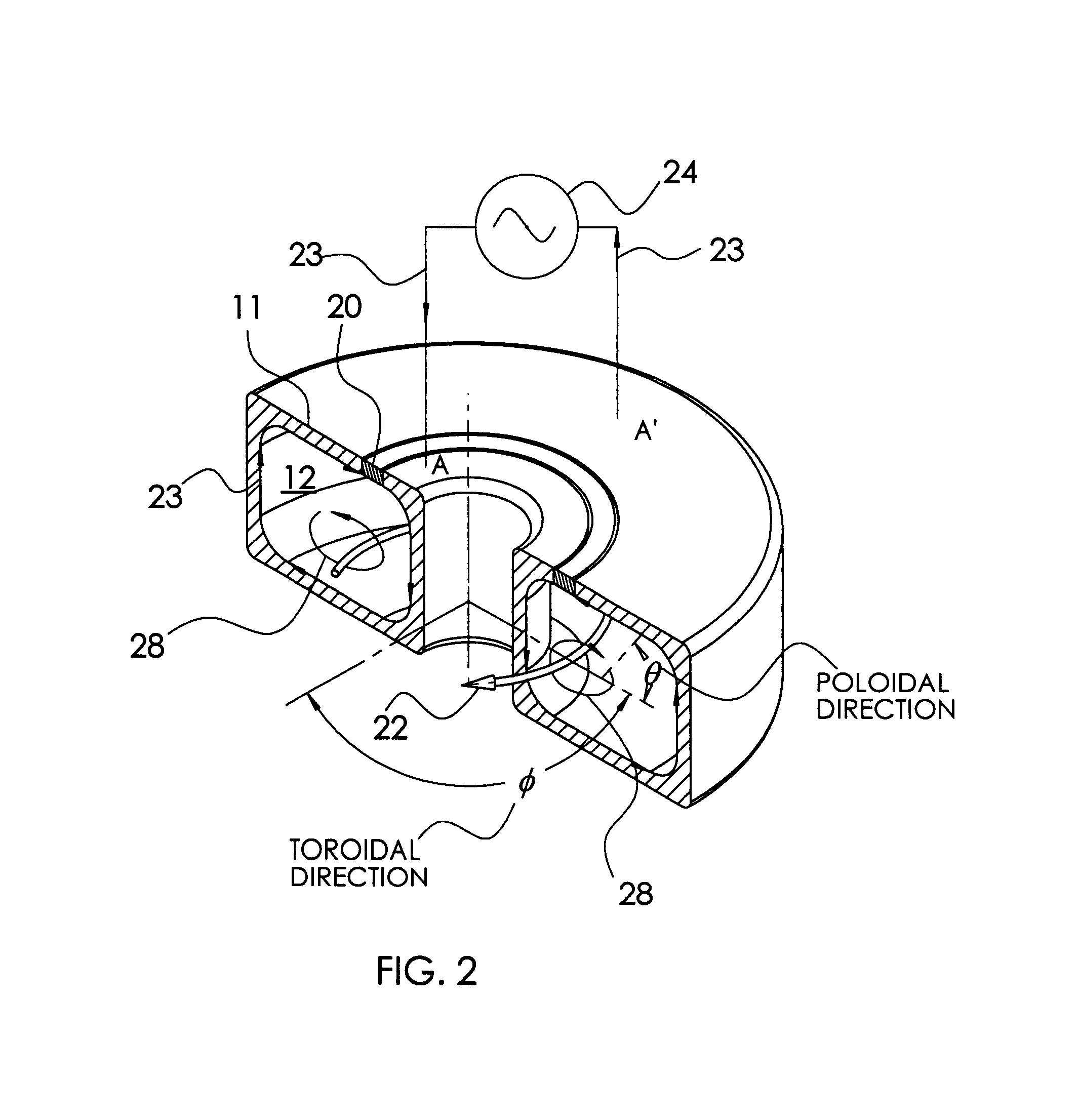

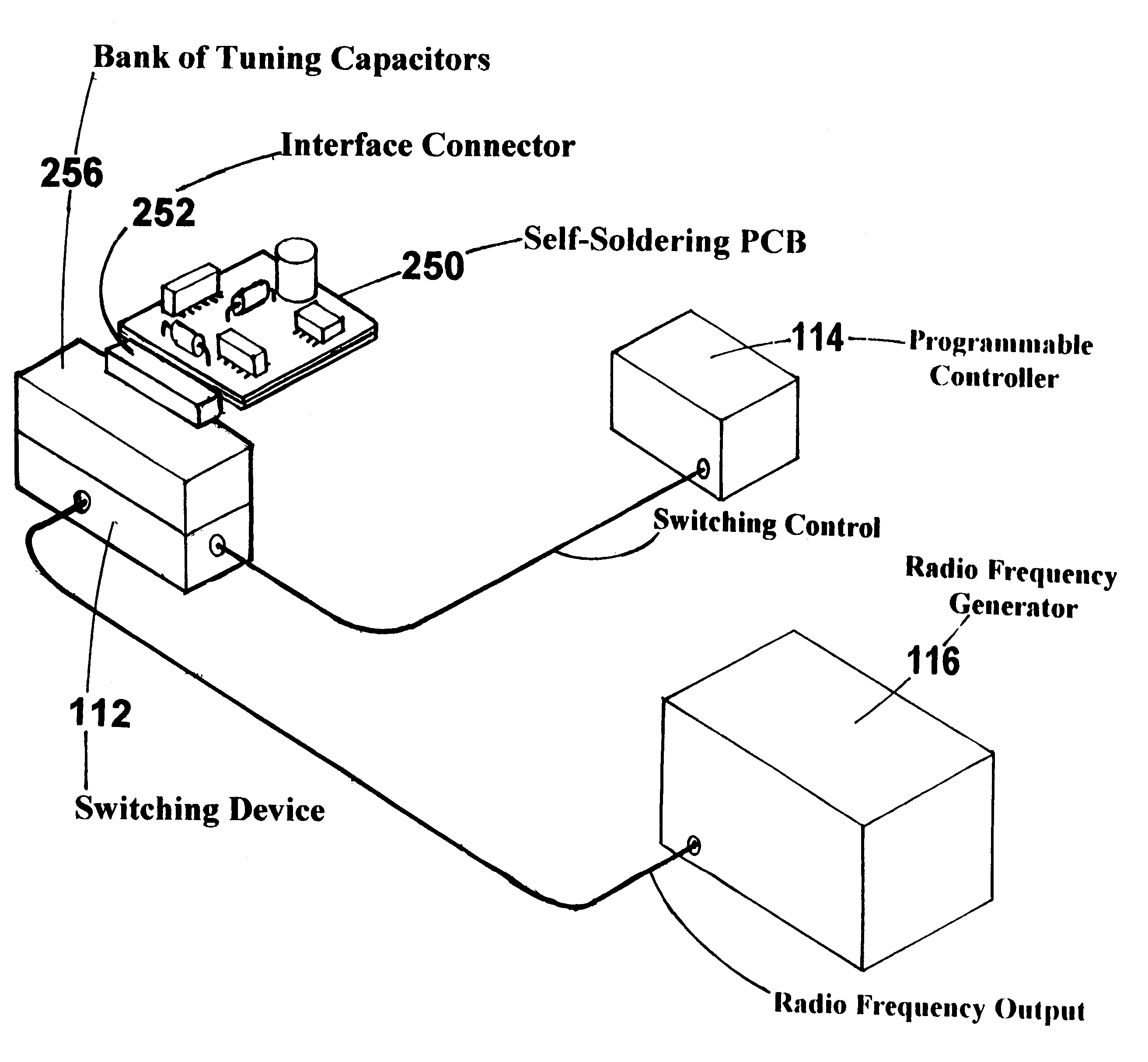

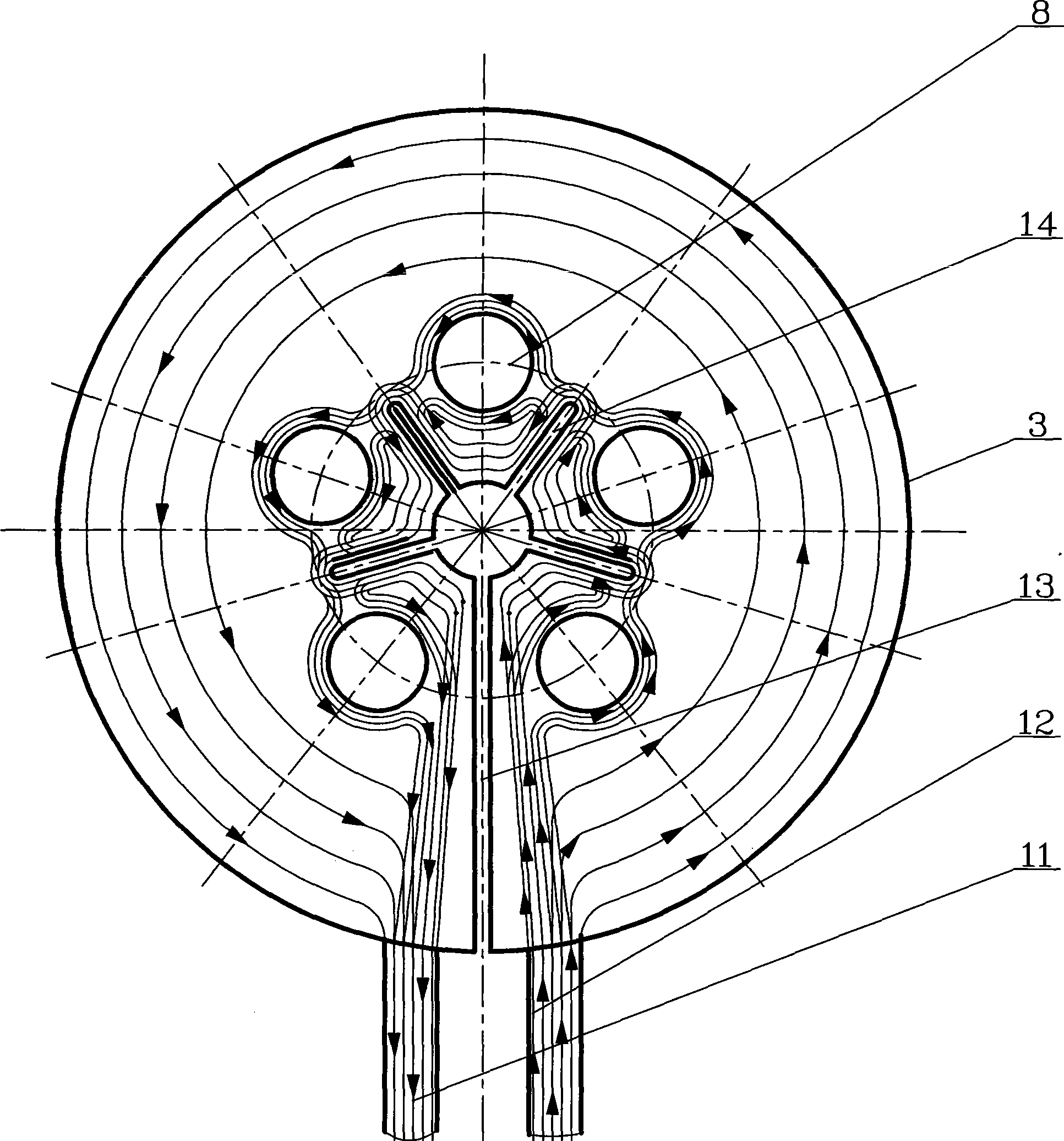

Inductive self-soldering printed circuit board

InactiveUS6229124B1Improve quality and reliabilityReduce formationPrinted circuit assemblingCoil arrangementsManufacturing technologyHeat sensitive

A new apparatus for inductively soldering surface-mount, straddle-mount and through-hole type electronic components into a self-soldering PCB (printed circuit board) in an automated fashion utilizing localized Electromagnetic Induction Heating (E.I.H.). Current manufacture technology for packaging electronic components depends on the reflow and wave soldering processes. Both processes heat up to relatively high temperatures the entire assembly, namely its PCB and all the electronic components being soldered into it. Such harsh high-temperature environment frequently causes components damage resulting in rejects and / or demanding rework. With this invention reflow oven and / or wave soldering equipment is not required. During a soldering operation only the leads and pads being soldered are heated but neither the body of said electronic components nor the dielectric material forming said self-soldering PCB and its interconnecting traces are heated. Because of this selectively localized inductive heating, the invention permits to reduce cost and improve the quality and reliability of manufactured products. The invention consumes about 200 times less energy than the reflow and wave soldering processes. This invention can readily be utilized to complement and / or supplement the reflow and wave soldering processes by providing selective inductive self-soldering of odd-form and / or heat-sensitive components. The invention also allows in-process, and in-situ, testing of soldered joints quality thus permitting rework before final assembly of a self-soldering PCB is completed. This invention also provides for a useful inductive de-soldering apparatus.

Owner:TRUCCO HORACIO ANDRES

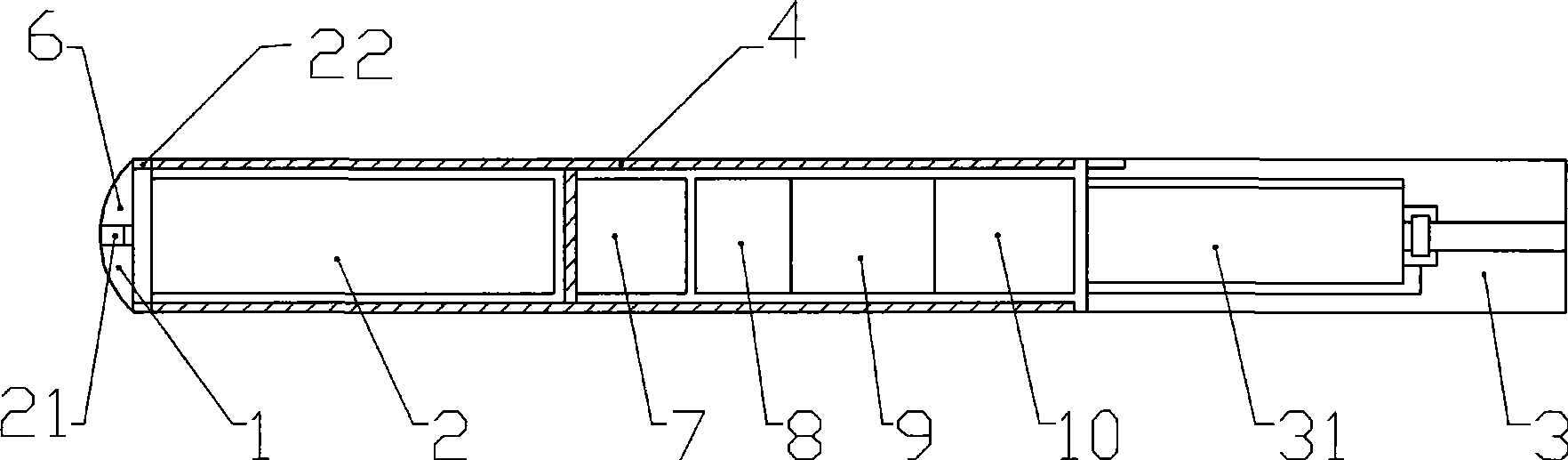

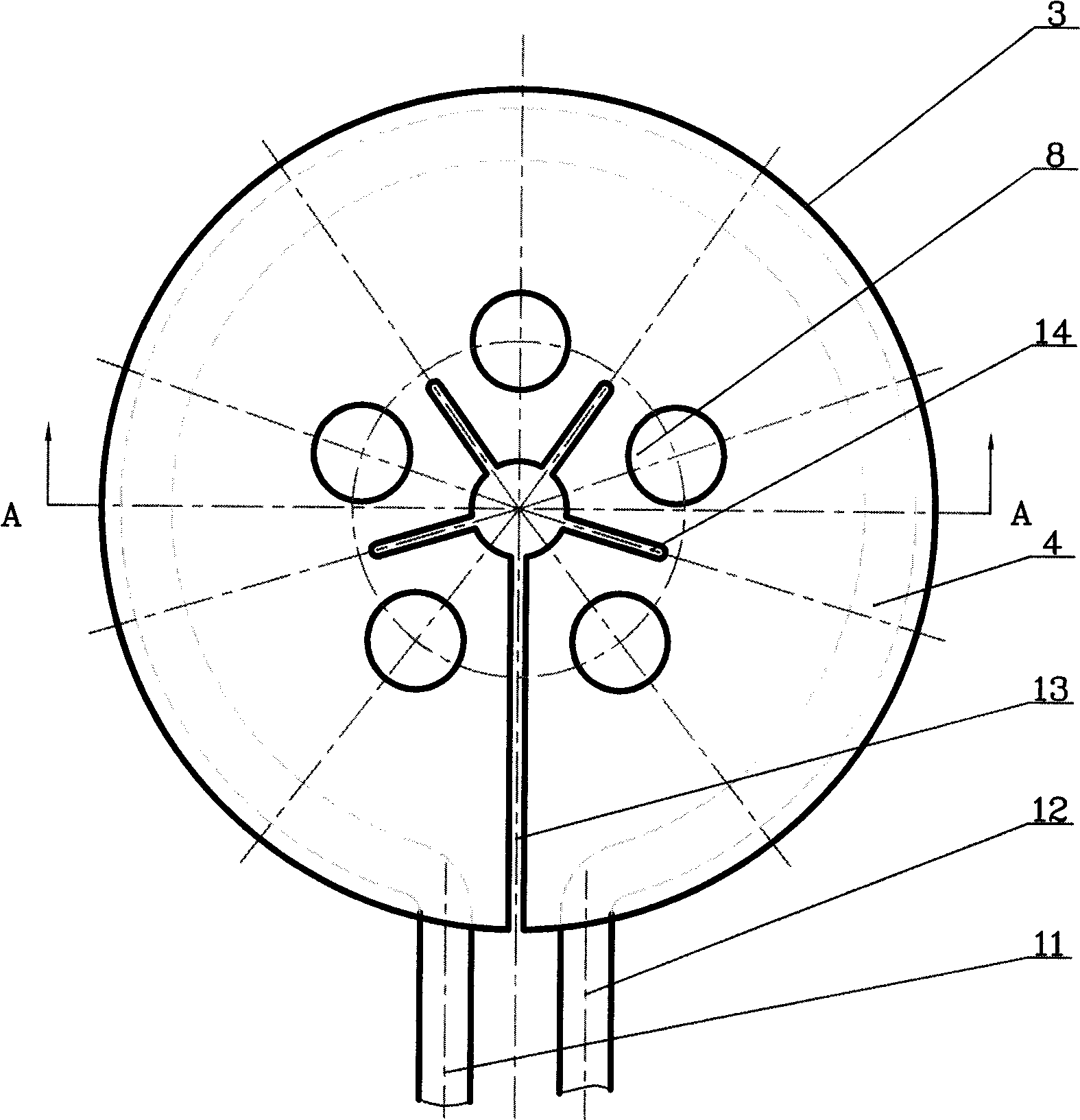

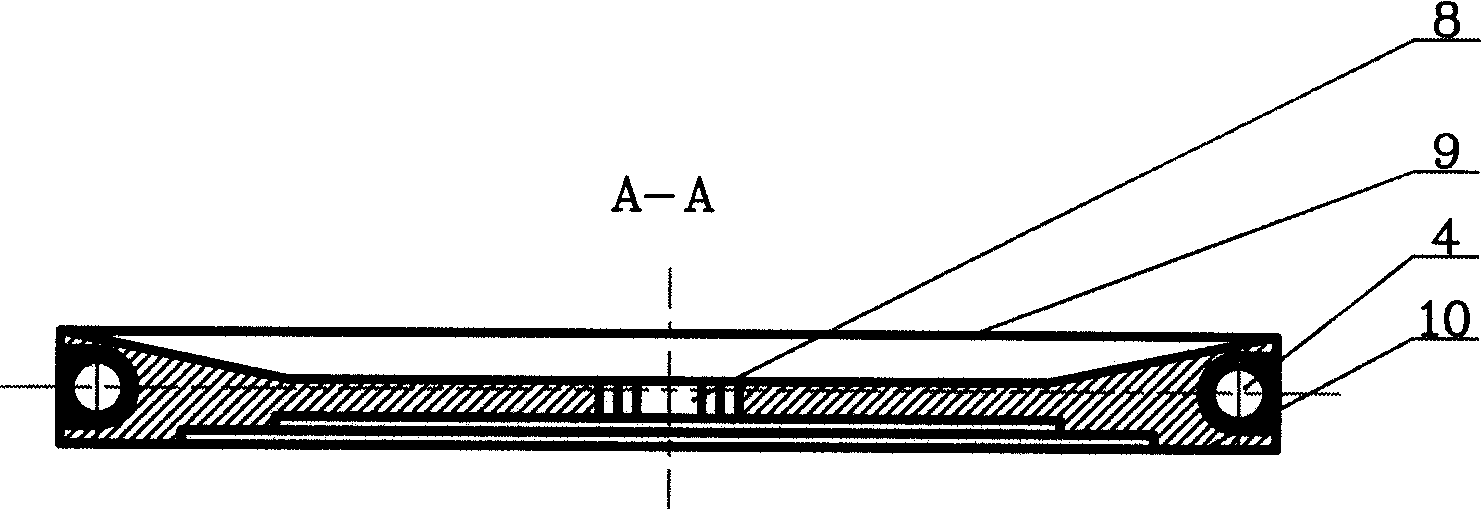

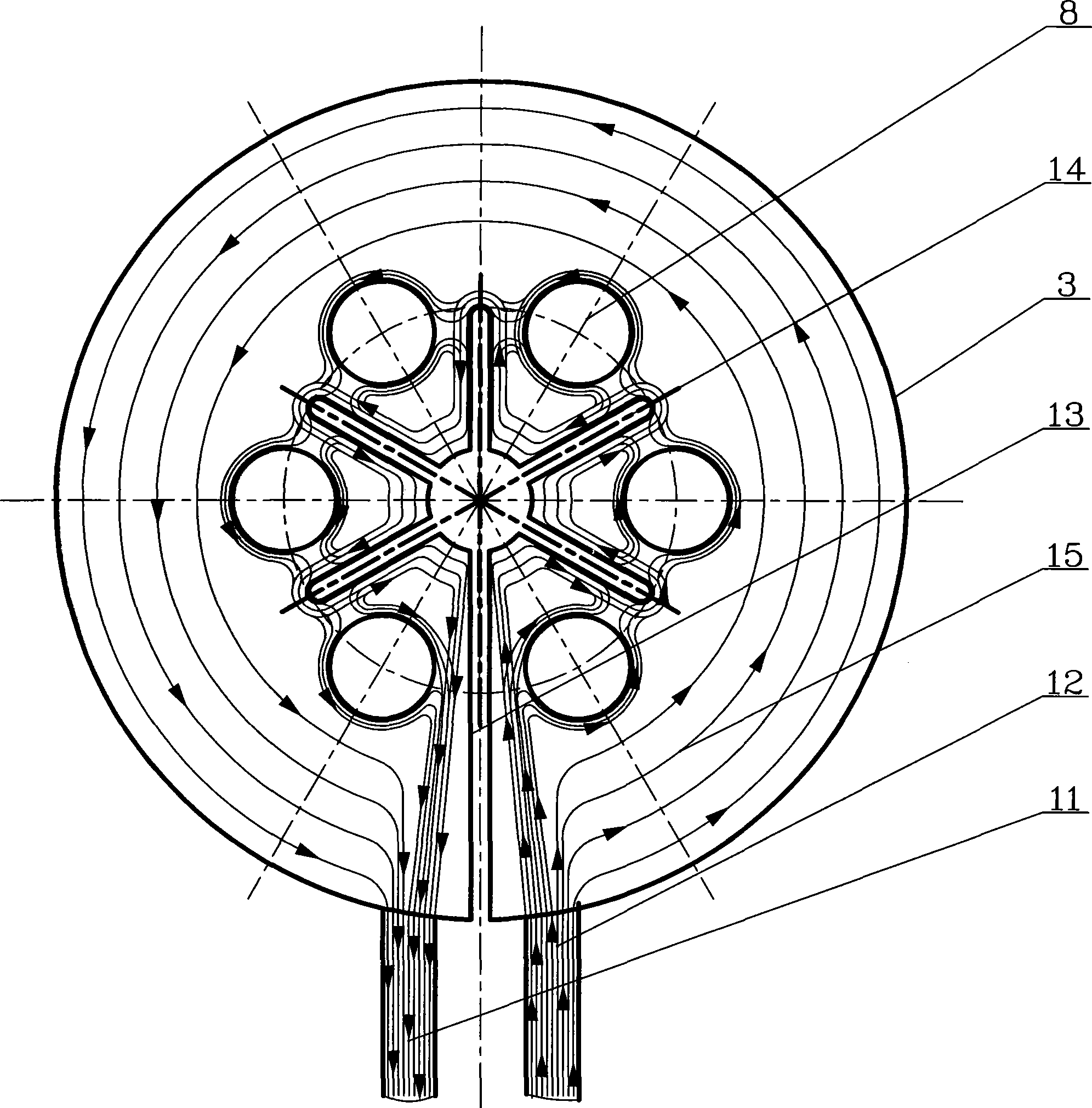

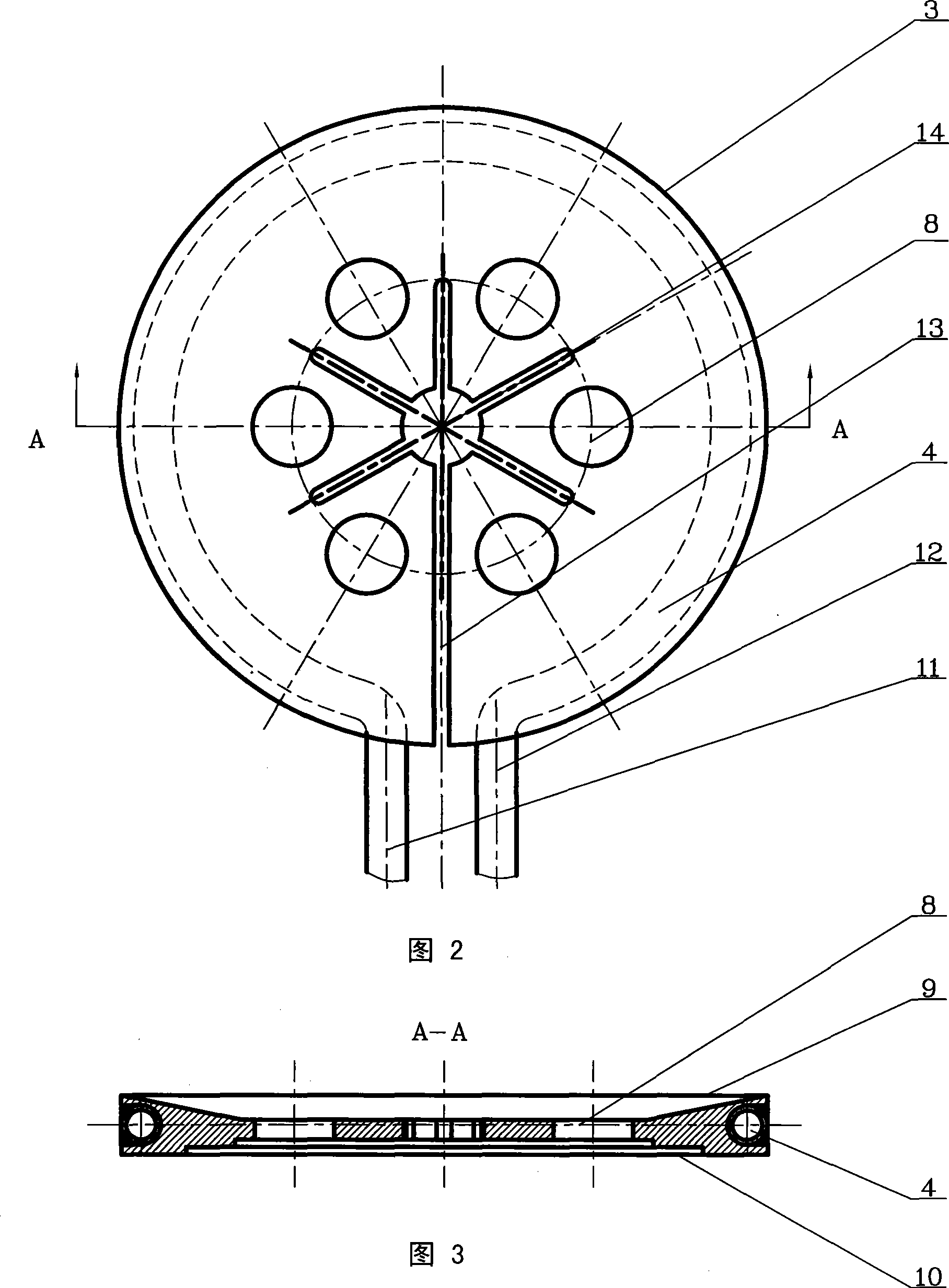

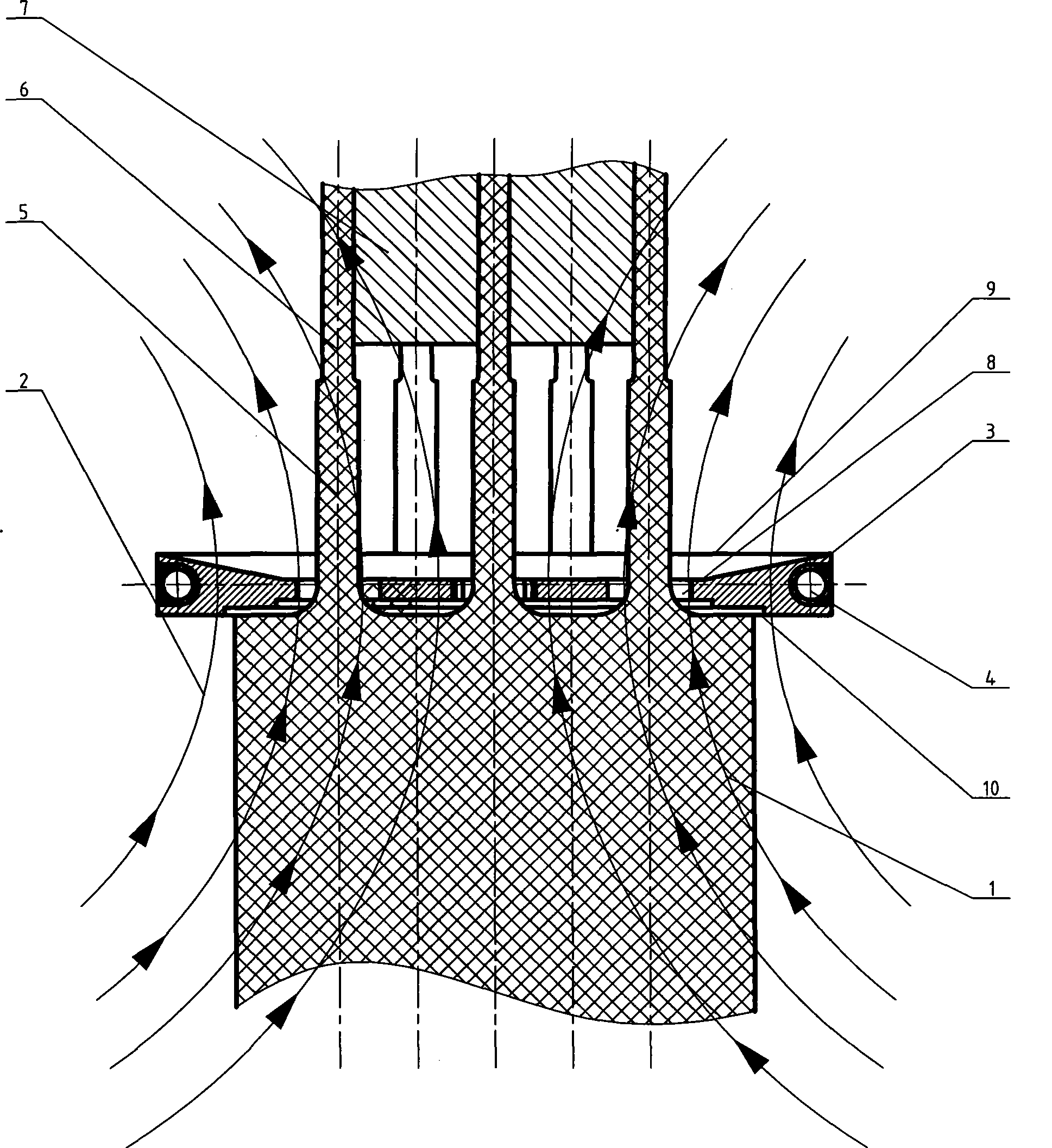

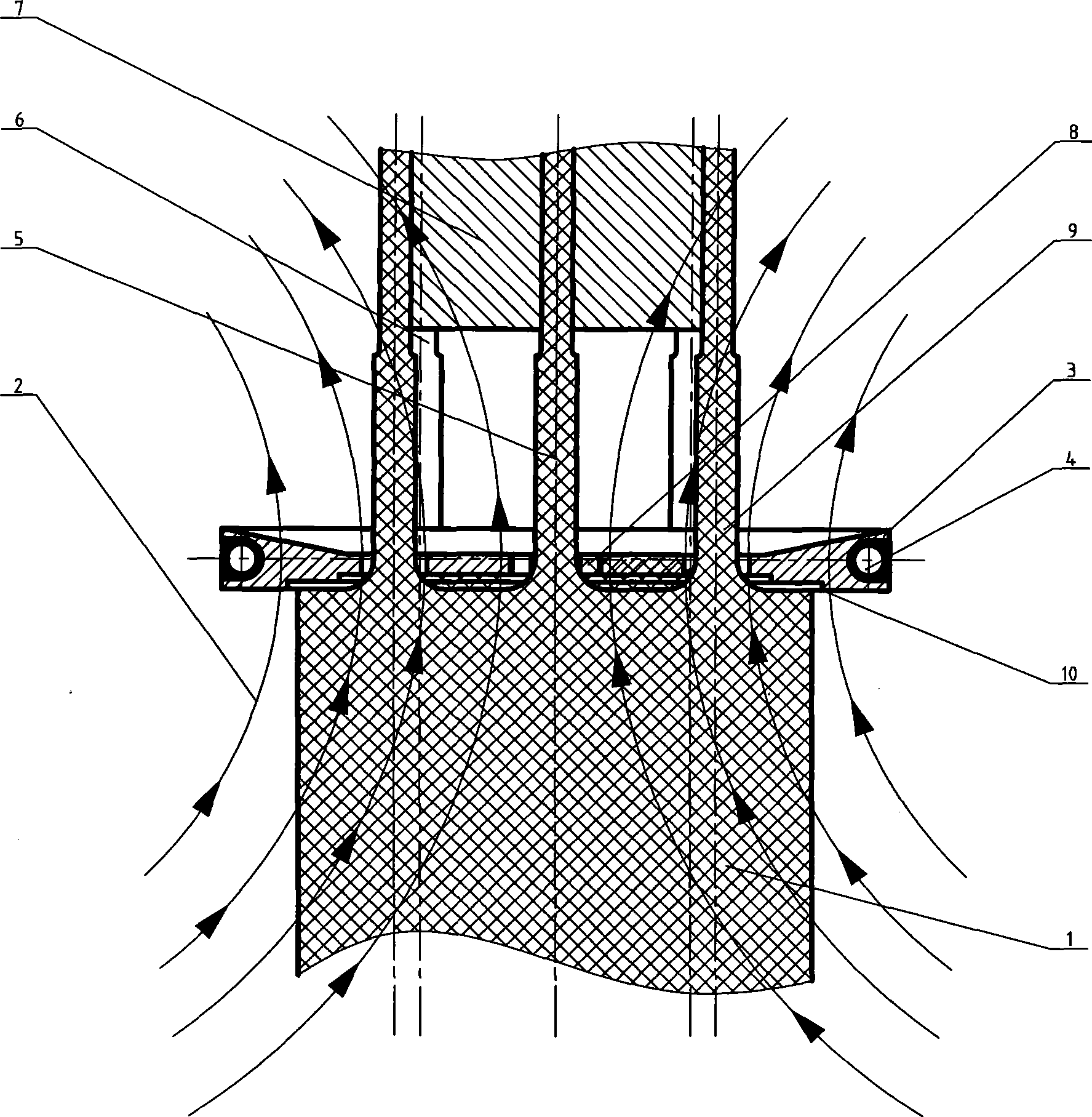

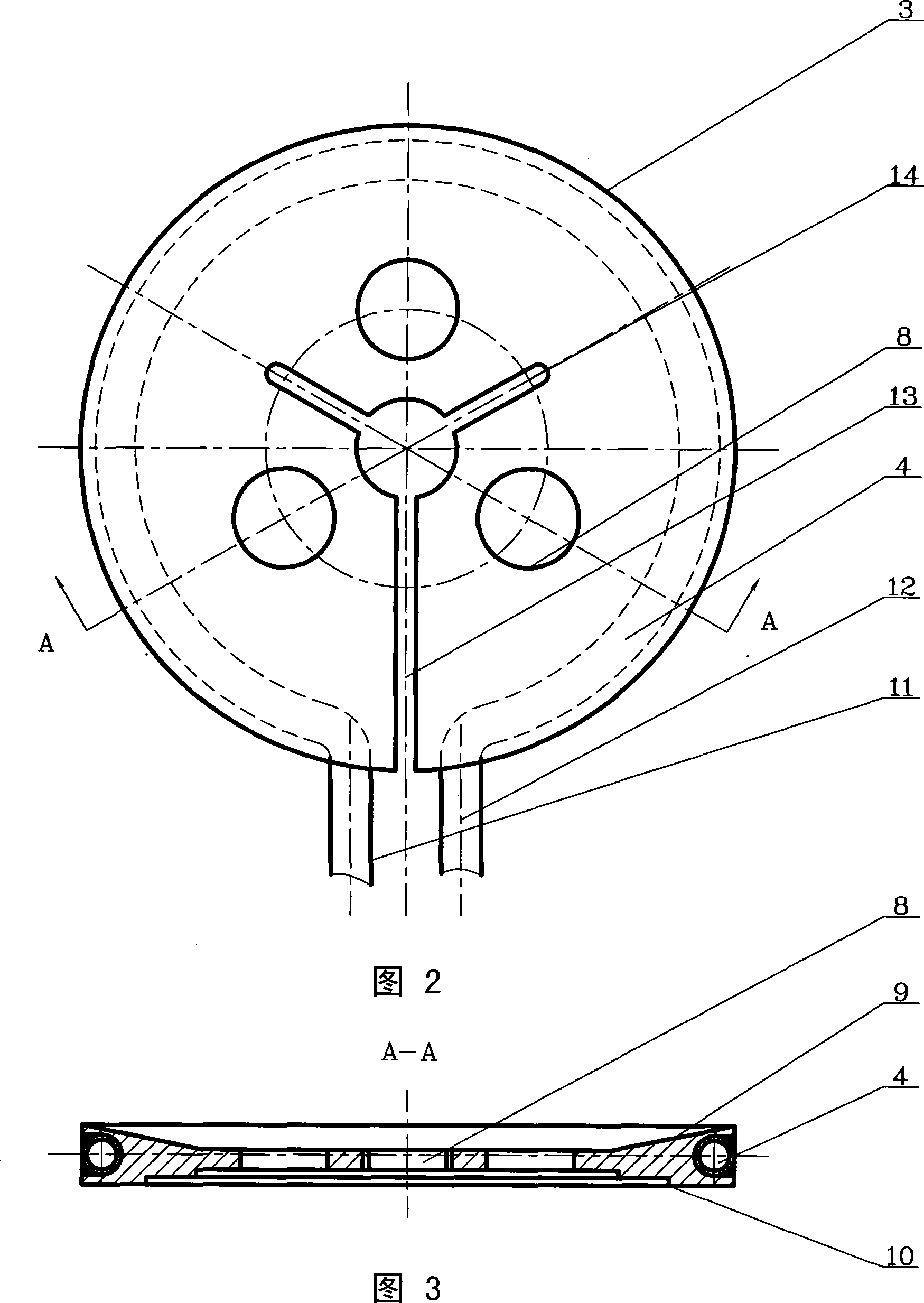

High-frequency coil structure capable of producing six silicon cores and other crystal material at the same time

ActiveCN101487136AEvenly distributedDistributed between every two peripheral inner holes to make the current run evenlyCoil arrangementsBy zone-melting liquidsEngineeringCopper

The invention provides a high-frequency coil structure which can produce six silica cores and other crystal materials simultaneously, relating to the technical field of high-frequency coils. The high-frequency coil structure comprises a radial shunt trough (14) which is used for diversion of current (15), and six internal holes (8), wherein, one internal hole is arranged at the middle part and other five internal holes are uniformly distributed around the middle internal hole in a petal-shape; an inclined opening (13) at one side of a copper pipe A(11) for conveying current and cooled water and a copper pipe B(12) for conveying current and cooled water is connected and communicated with the middle internal hole; the radial shunt trough extends out from the middle internal hole to a position between every two internal holes except the inclined opening; the inclined opening is connected with the middle internal hole; and the radial shunt trough is radially distributed between every two peripheral internal holes by the middle internal hole, thus leading the current to uniformly run by surrounding the six internal holes under the shunt effect of the shunt trough during the running process and achieving the objects that the current is uniformly distributed around the six internal holes.

Owner:LUOYANG JINNUO MECHANICAL ENG

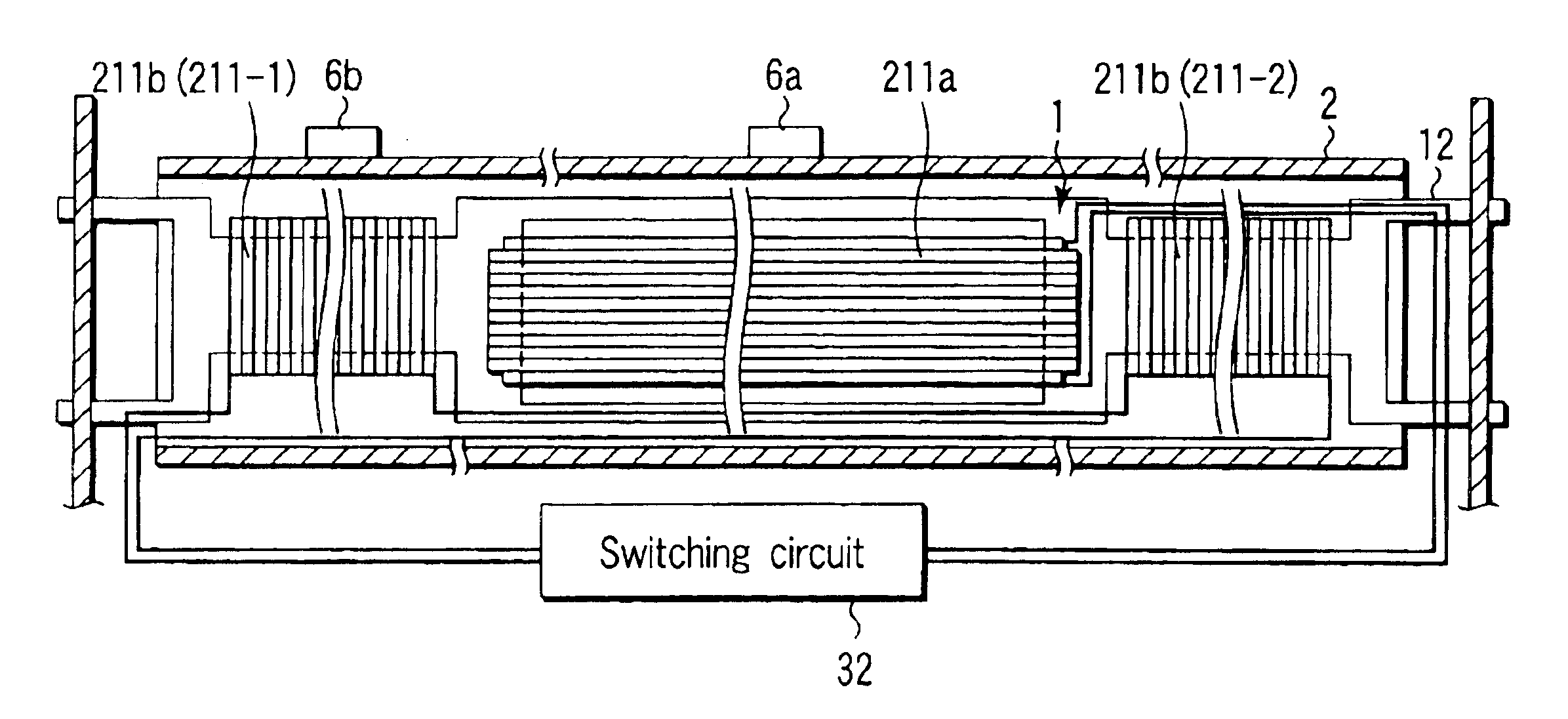

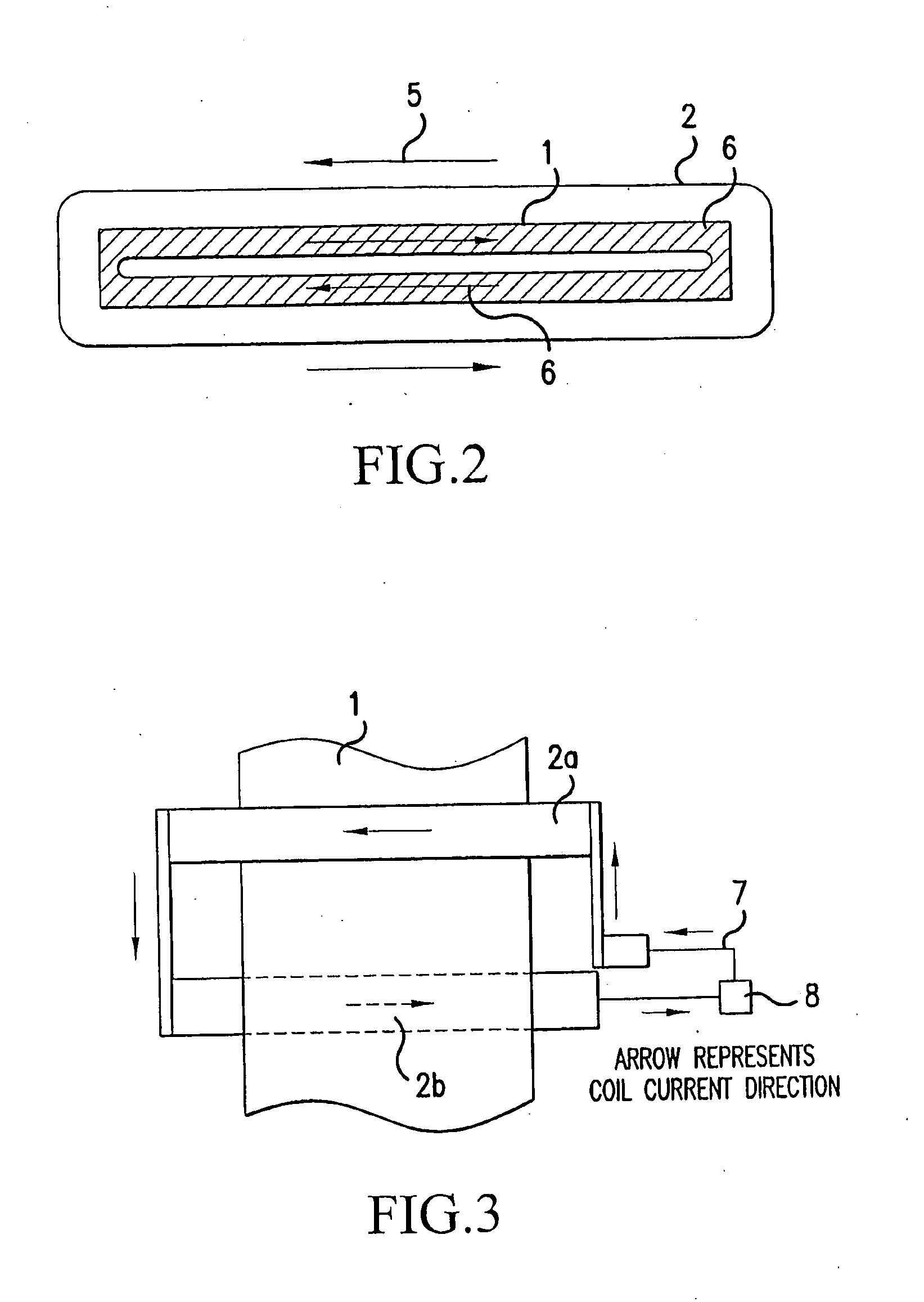

Induction-heating fusion device

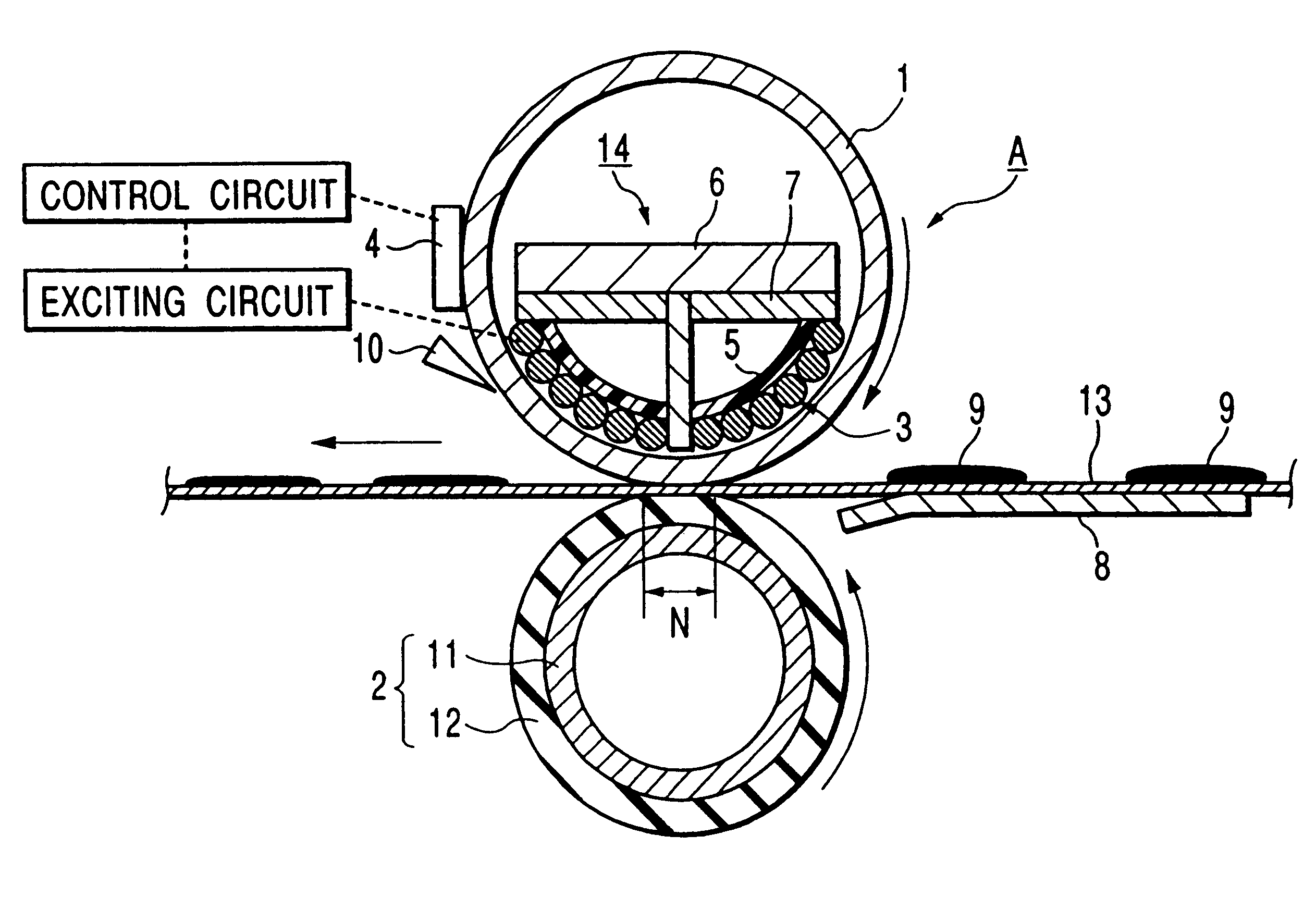

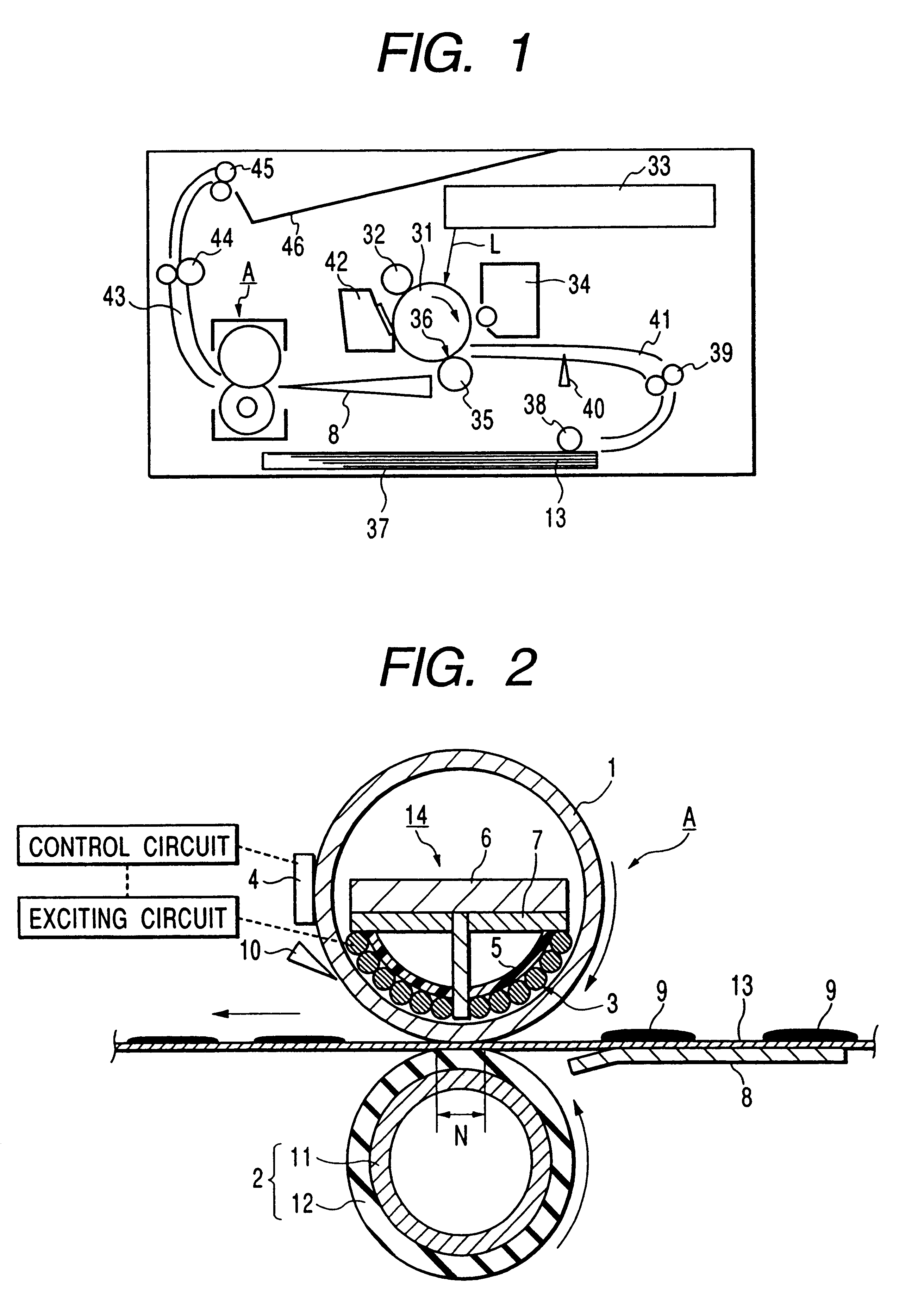

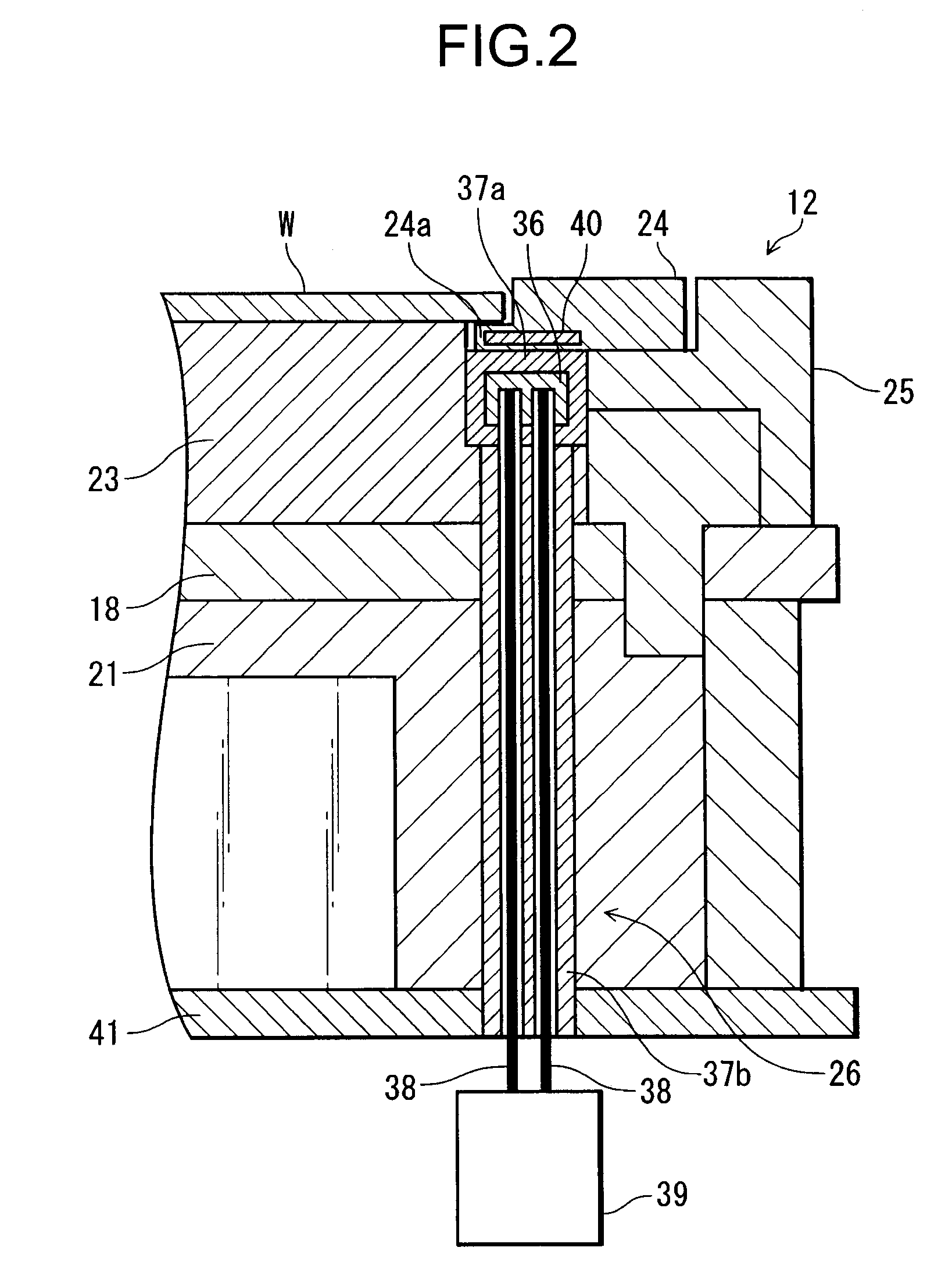

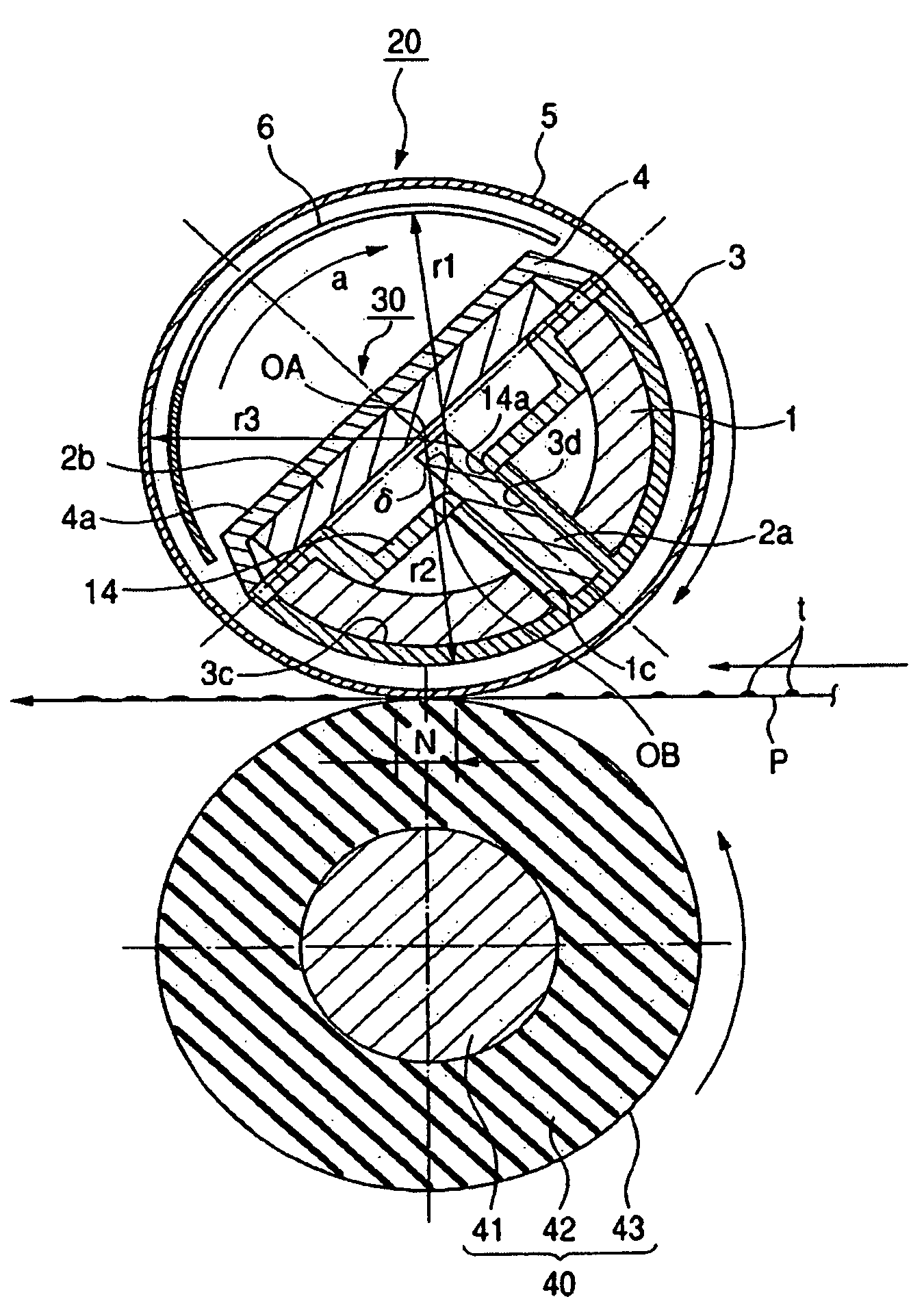

InactiveUS6320168B1Maintain temperatureCoil arrangementsElectrographic process apparatusEngineeringMagnetic flux

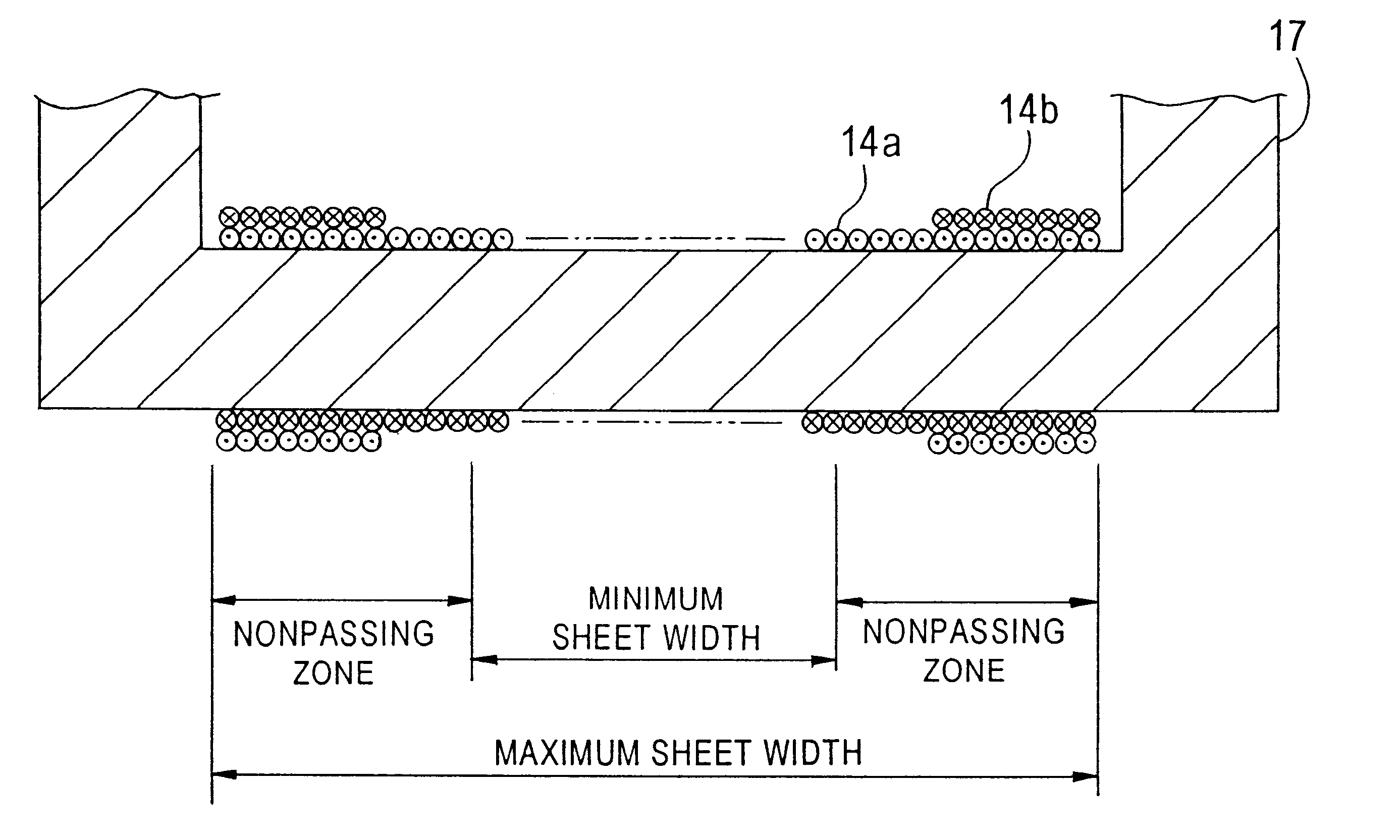

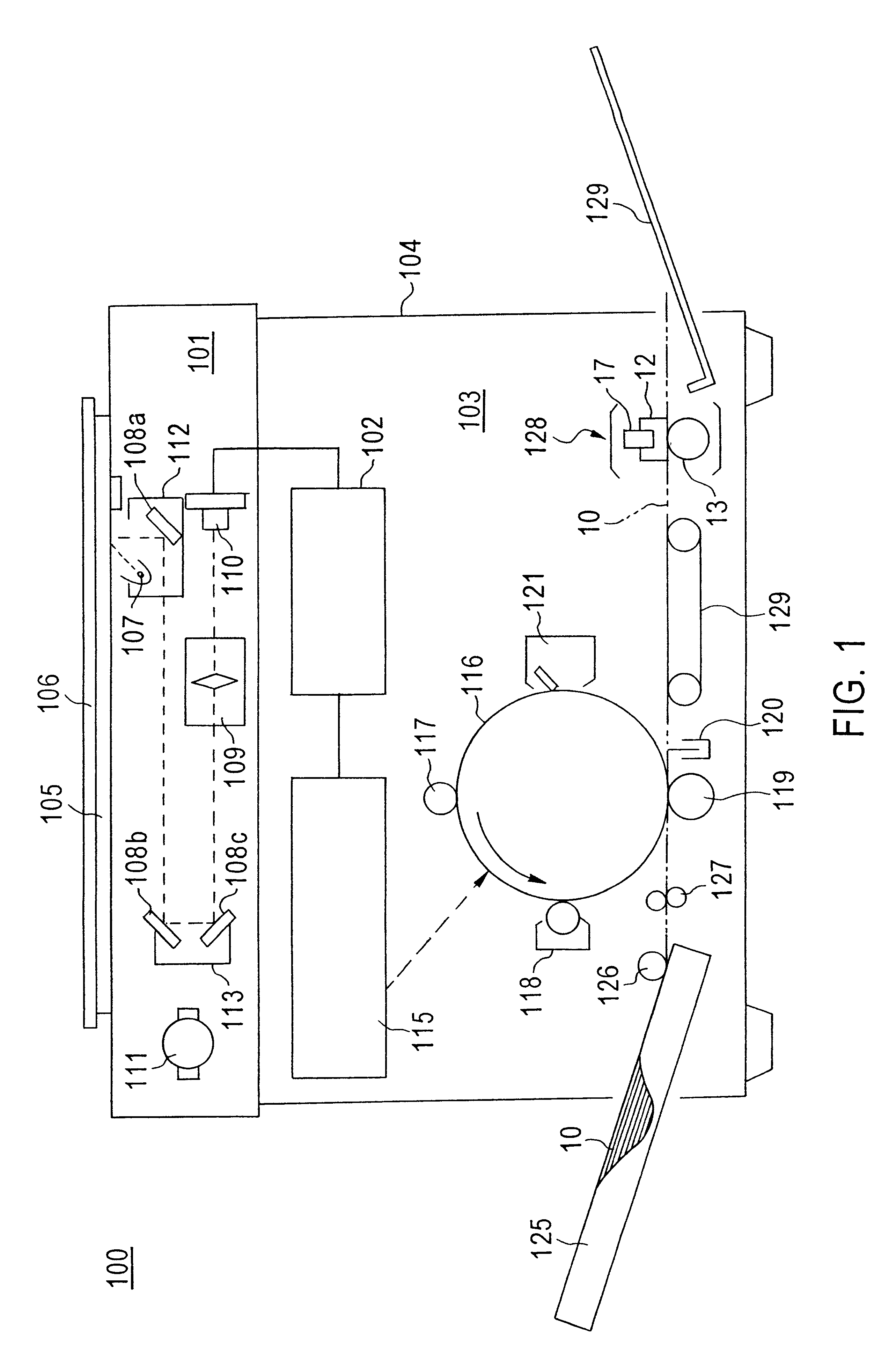

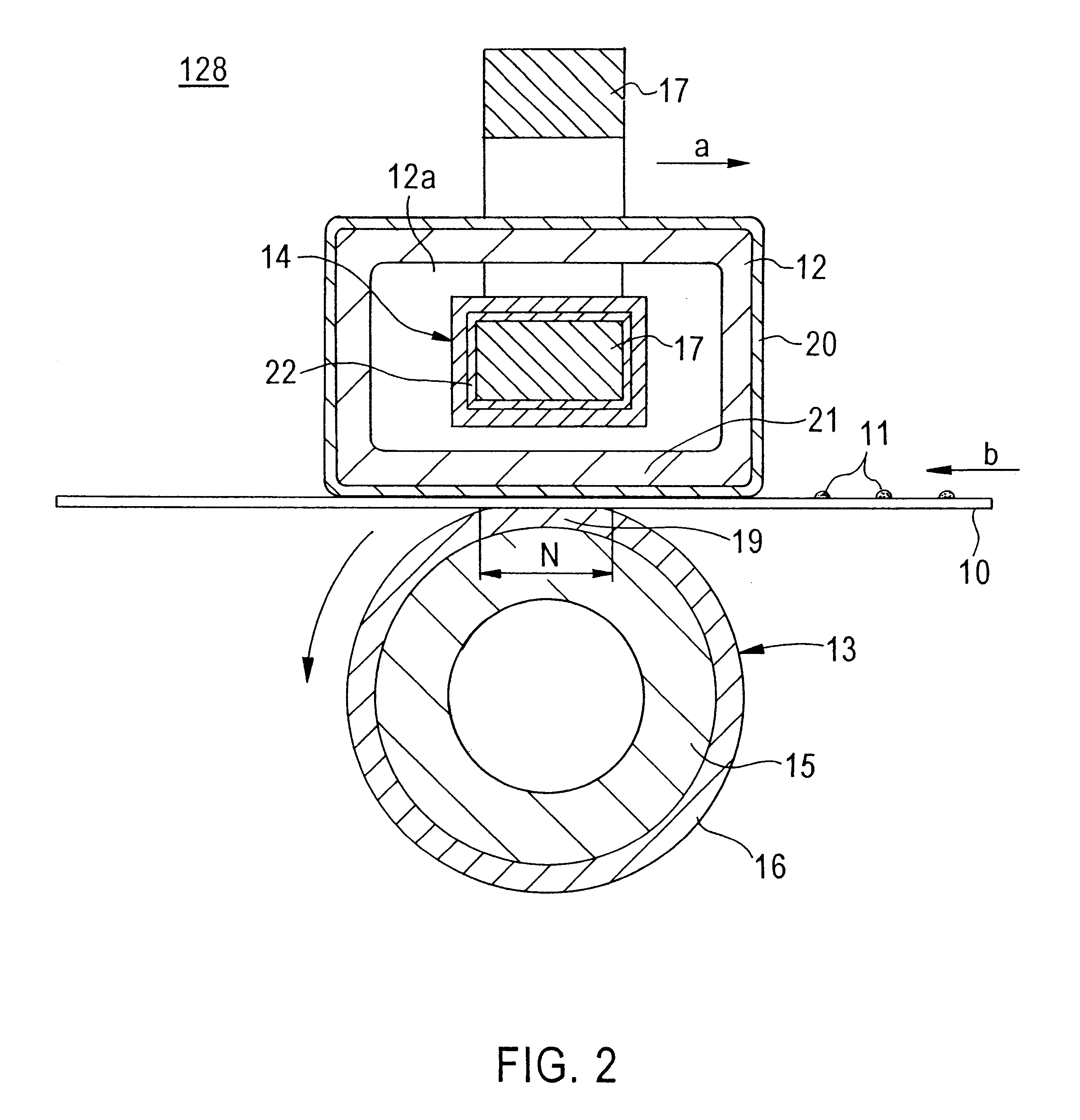

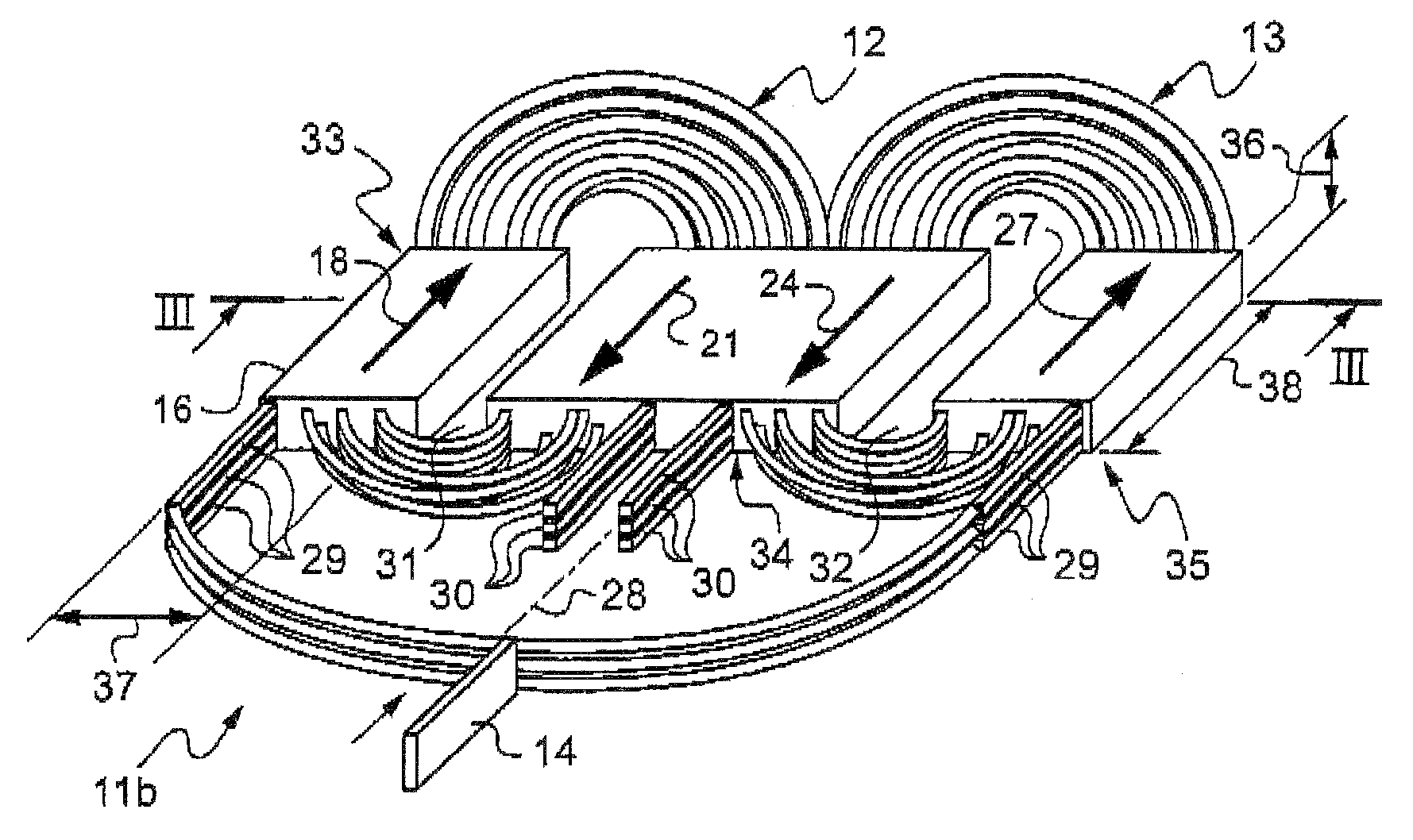

The present invention has an object to provide an induction-heating fusion device which is capable of stabilizing the fusing temperature over the entire width of a sheet therethrough by inhibiting an excessive temperature rise in a sheet-nonpassing zone defined when a small-size sheet is subjected to fusion. The induction-heating fusion device according to the present invention includes an iron core 17 forming a closed magnetic circuit, a main induction coil 14a wound around the iron core 17 for generating a magnetic flux which causes an electrically conductive member to generate an induction current circumferentially thereof, and at least one induction sub-coil 14b provided on an end portion of the main coil for generating a magnetic flux which causes the electrically conductive member to generate an induction current circumferentially thereof.

Owner:MINOLTA CO LTD

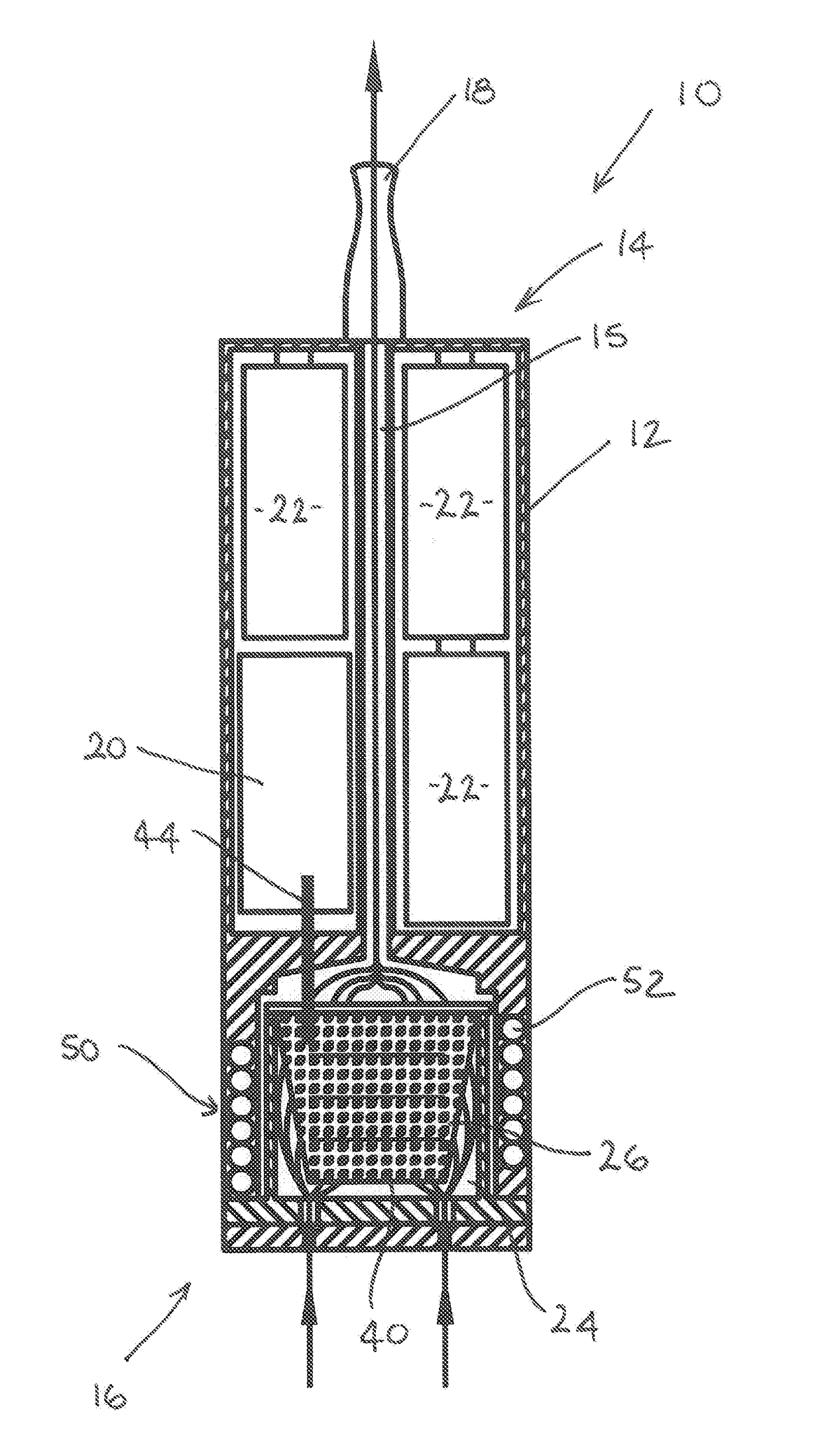

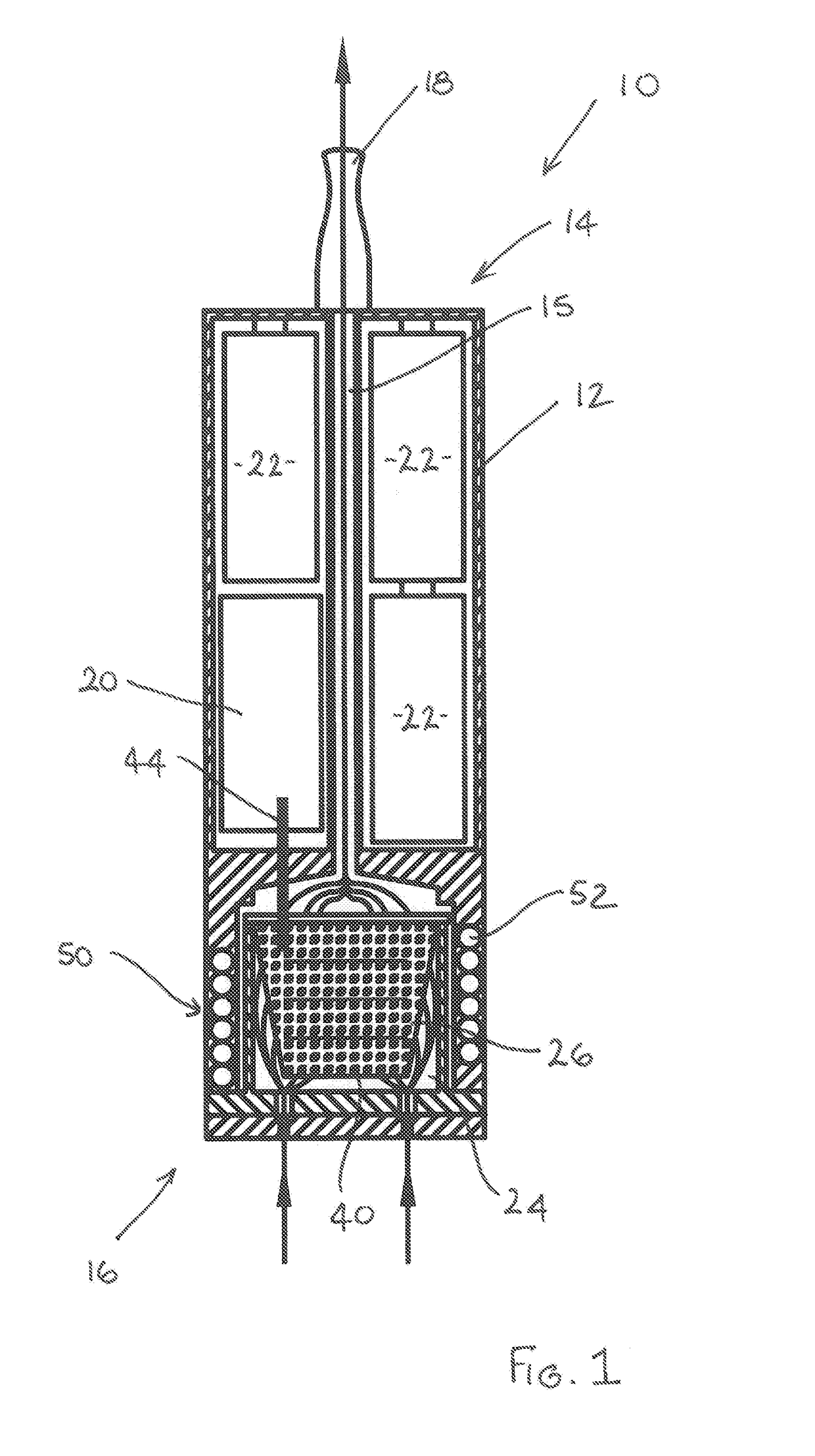

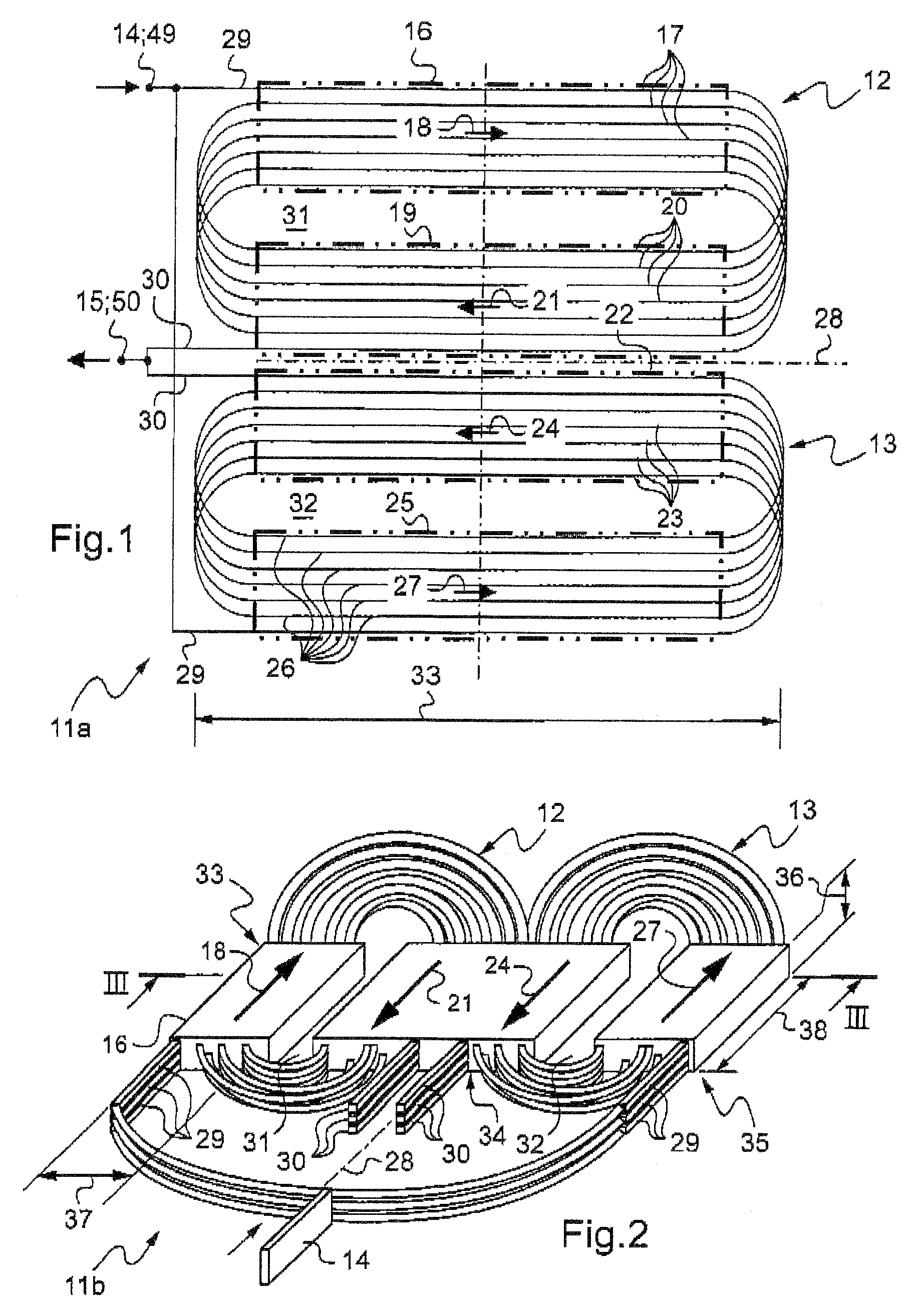

Method and a device for de-icing an aircraft wall

InactiveUS20080251642A1Improve efficiencySimple methodPropellersPump componentsInductorConductive materials

A device for de-icing an aircraft wall that comprises a composite structure (47) and layer (41) of electrically conductive material, which device comprises a plurality of thin inductor elements (33 to 35) designed to extend substantially parallel to the layer of conductive material at a distance therefrom that is small enough to ensure that when the inductor is powered by an AC source of appropriate frequency, the layer or skin heats rapidly and uniformly, without significantly heating the composite structure.

Owner:EUROCOPTER

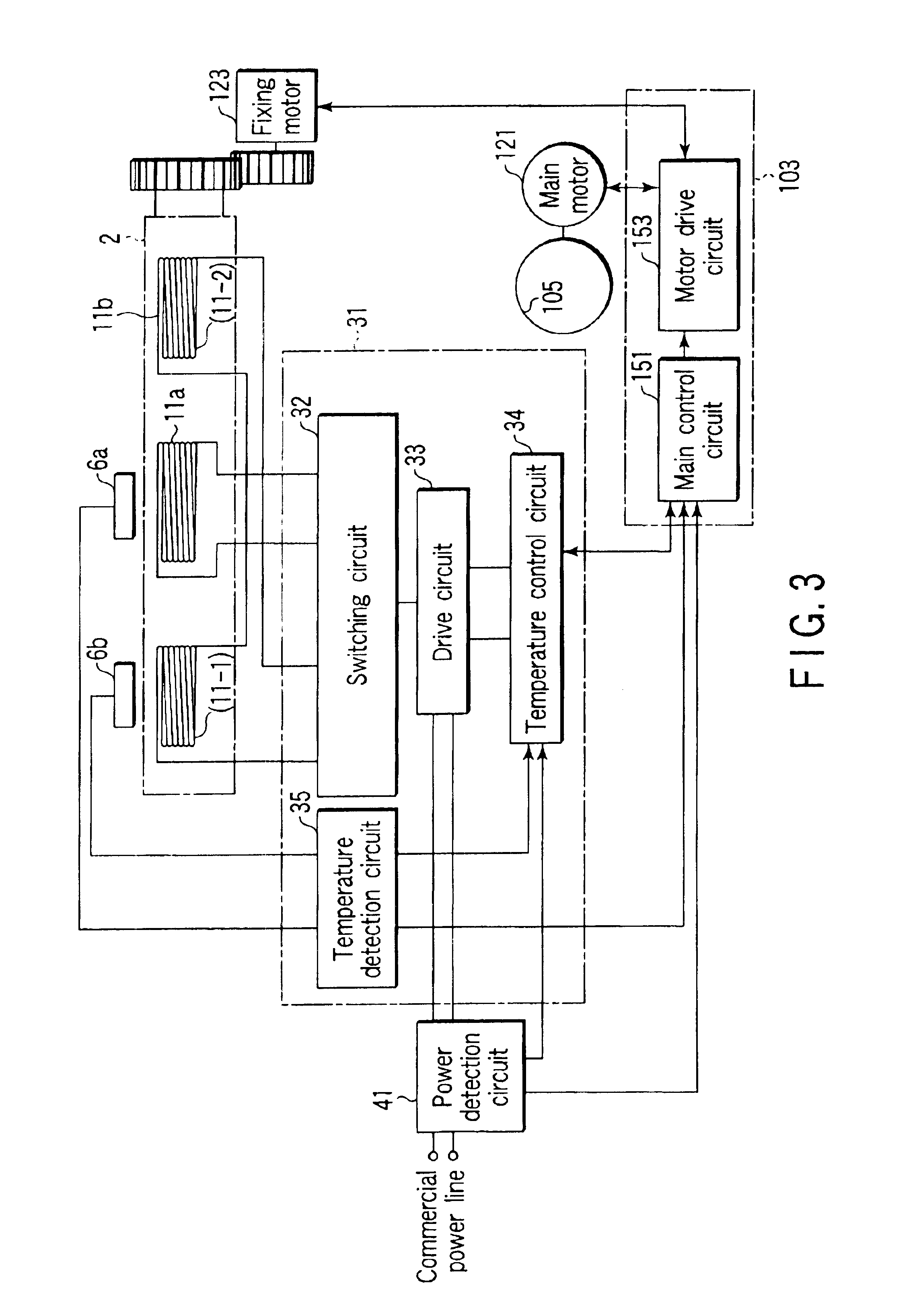

Fixing apparatus

InactiveUS6900419B2Avoid changeReduced dimensionCoil arrangementsElectrographic process apparatusSkin effectElectromagnetic induction

A fixing apparatus an aspect of the present invention includes, a heating object which generates the heat by a magnetic flux produced from a coil which generates a predetermined magnetic flux by electromagnetic induction in accordance with a frequency of an input current, and a pressurization mechanism which can provide a predetermined pressure to the heating object, and a coil of the heating object is formed of a litz wire obtained by twisting the number of conductors having a small cross section which are not affected by the skin effect caused due to the frequency of the input current, the number of which allows passage of a quantity of current to be inputted.

Owner:KK TOSHIBA +1

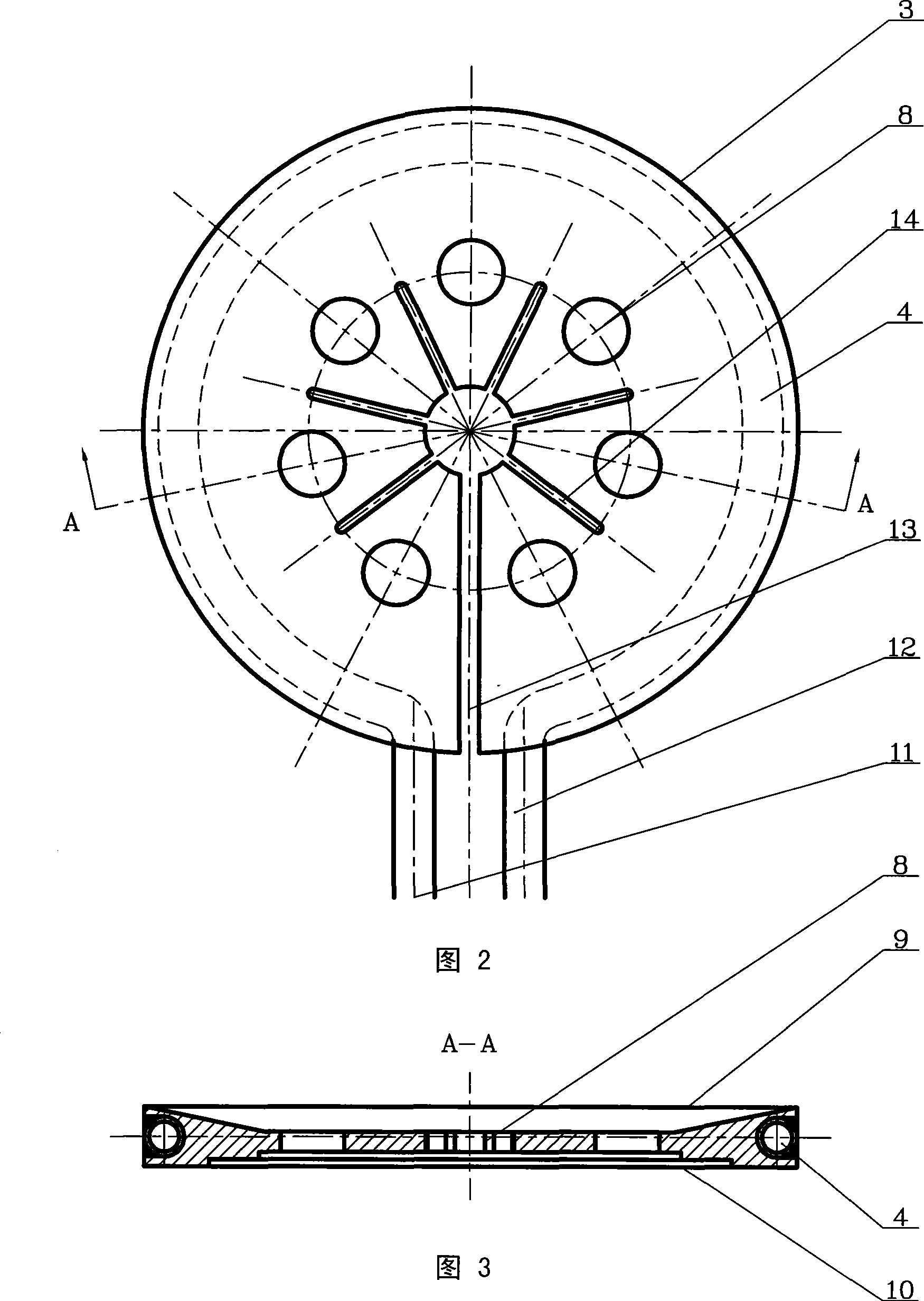

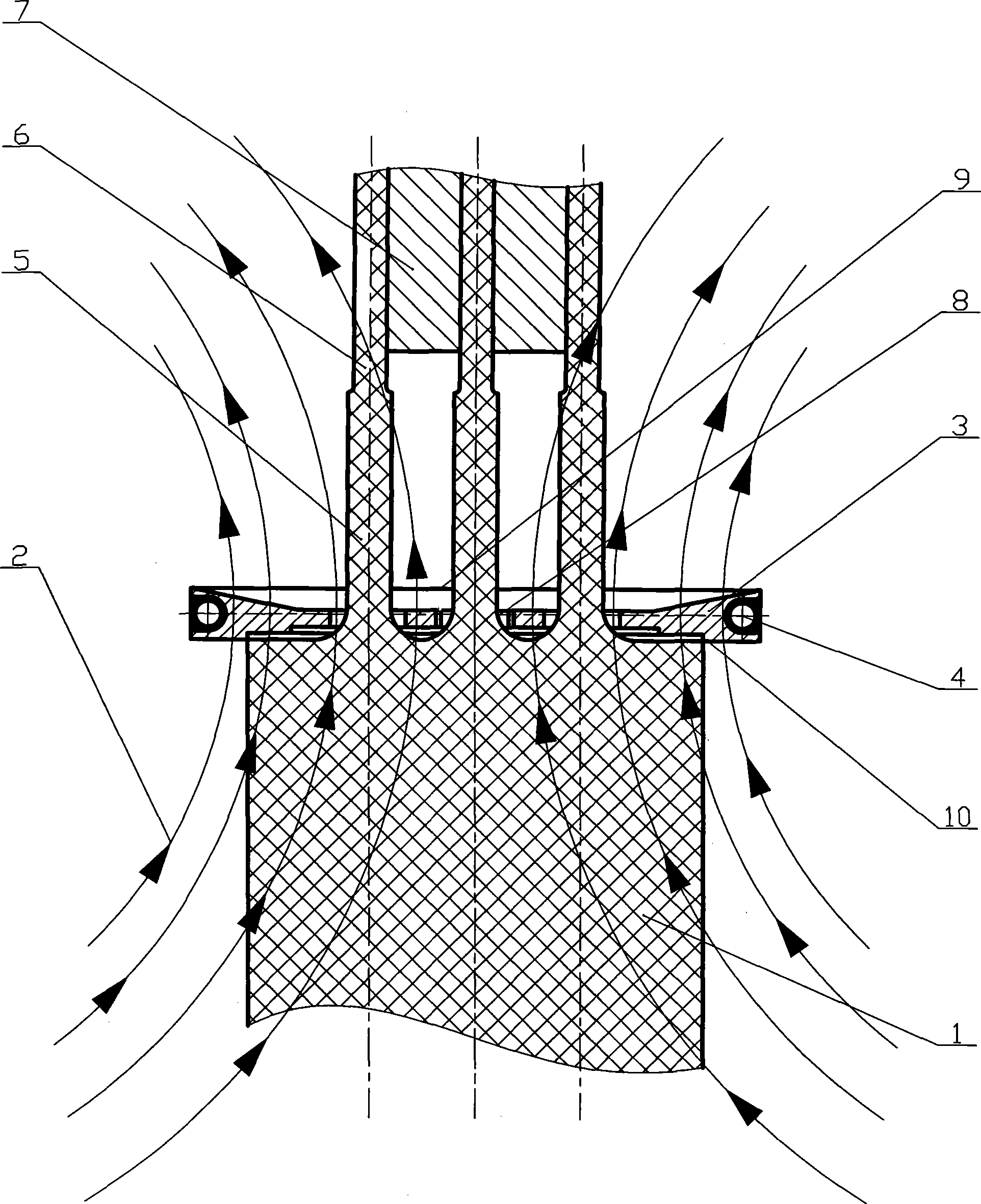

High-frequency coil structure capable of simultaneous producing seven silicon cores and other crystal material

ActiveCN101457389AEvenly distributedDistributed between every two peripheral inner holes to make the current run evenlyCoil arrangementsBy zone-melting liquidsCrystalline materialsCopper

The invention discloses a high-frequency coil structure capable of simultaneously producing seven silicon cores and other crystalline materials, and relates to the technical field of the high-frequency coils. The high-frequency coil structure comprises a radial splitter box (14) for guiding current (15), and seven inner bores (8) one inner bore of which is arranged at the middle part of the high-frequency coil and six inner bores of which are evenly distributed around the inner bore at the middle part in a petaline shape; an oblique opening (13) arranged on one side of a current delivery and cooling water delivery copper pipe A(11) and a current delivery and cooling water delivery copper pipe B(12) is in through connection with the inner bore at the middle part; and the radial splitter box extends outwards to the position between every two inner bores except for the oblique opening from the inner bore at the middle part. The oblique opening is connected with the inner bore at the middle part, and the radial splitter box is radially distributed at the position between every two peripheral inner bores by the inner bore at the middle part, which causes the current to evenly surround the seven inner bores for running under the current splitting action of the splitter box while the current is running, thus realizing the purpose that the current is evenly distributed around the seven inner bores.

Owner:LUOYANG JINNUO MECHANICAL ENG

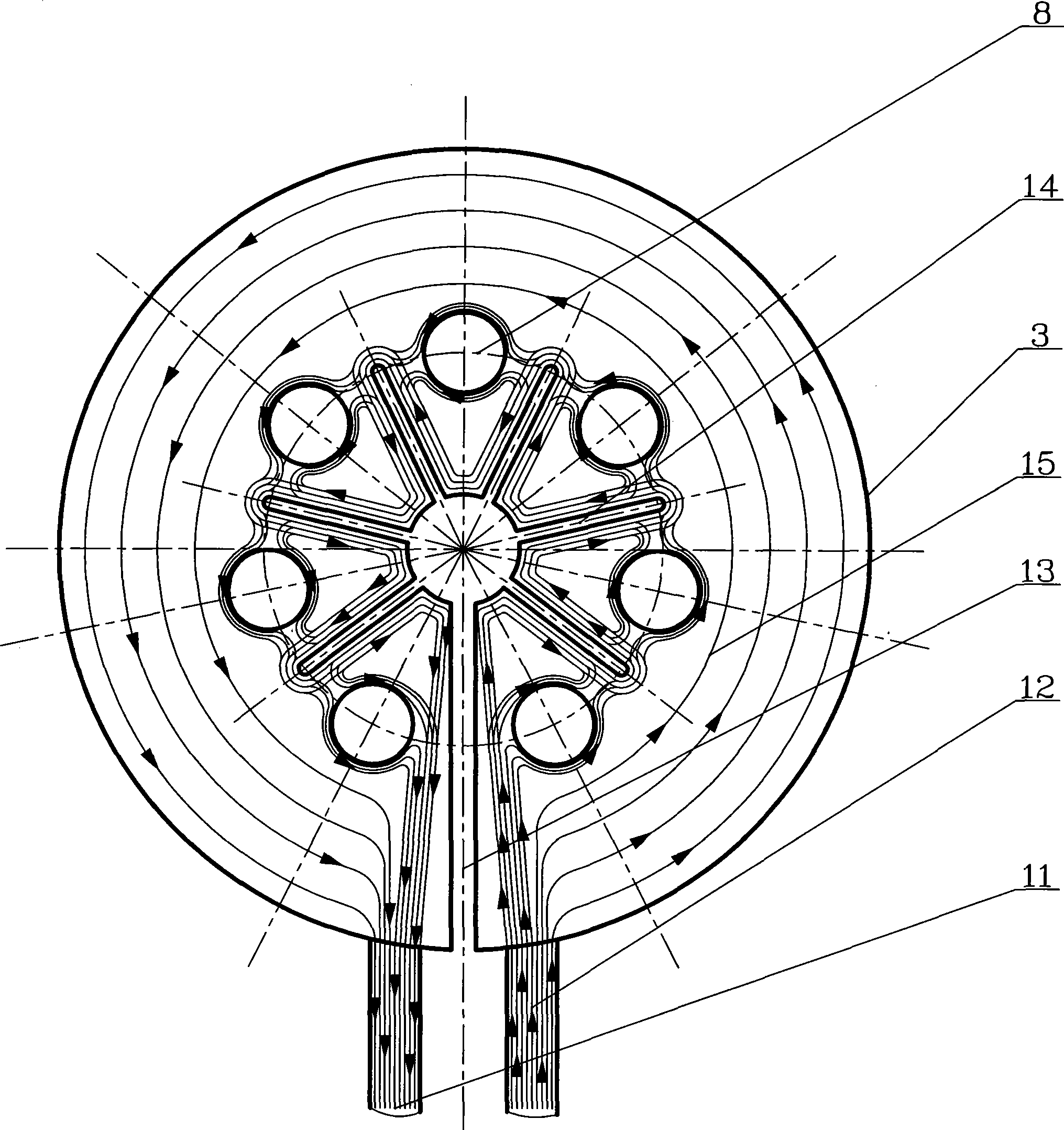

High-frequency coil structure capable of simultaneous producing eight silicon cores and other crystal material

ActiveCN101457390AEvenly distributedDistributed between every two peripheral inner holes to make the current run evenlyCoil arrangementsBy zone-melting liquidsCrystalline materialsCopper

The invention discloses a high-frequency coil structure capable of simultaneously producing eight silicon cores and other crystalline materials, and relates to the technical field of the high-frequency coils. The high-frequency coil structure comprises a radial splitter box (14) for guiding current (15), and eight inner bores (8) one inner bore of which is arranged at the middle part of the high-frequency coil and seven inner bores of which are evenly distributed around the inner bore at the middle part in a petaline shape, an oblique opening (13) arranged on one side of a current delivery and cooling water delivery copper pipe A(11) and a current delivery and cooling water delivery copper pipe B(12) is in through connection with the inner bore at the middle part; and the radial splitter box extends outwards to the position between every two inner bores except for the oblique opening from the inner bore at the middle part. The oblique opening is connected with the inner bore at the middle part, and the radial splitter box is radially distributed at the position between every two peripheral inner bores by the inner bore at the middle part, which causes the current to evenly surround the eight inner bores for running under the current splitting action of the splitter box while the current is running, thus realizing the purpose that the current is evenly distributed around the eight inner bores.

Owner:LUOYANG JINNUO MECHANICAL ENG

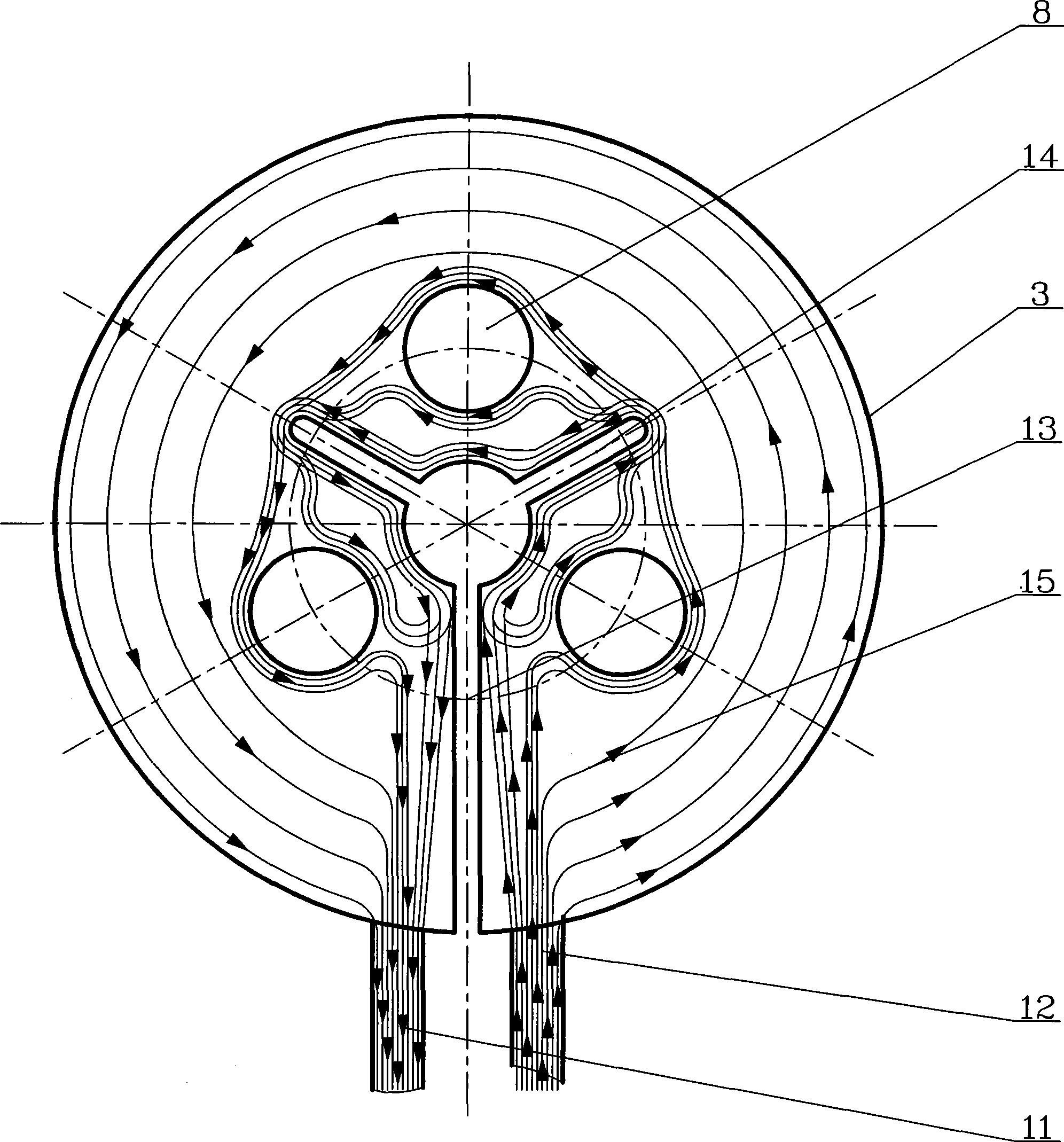

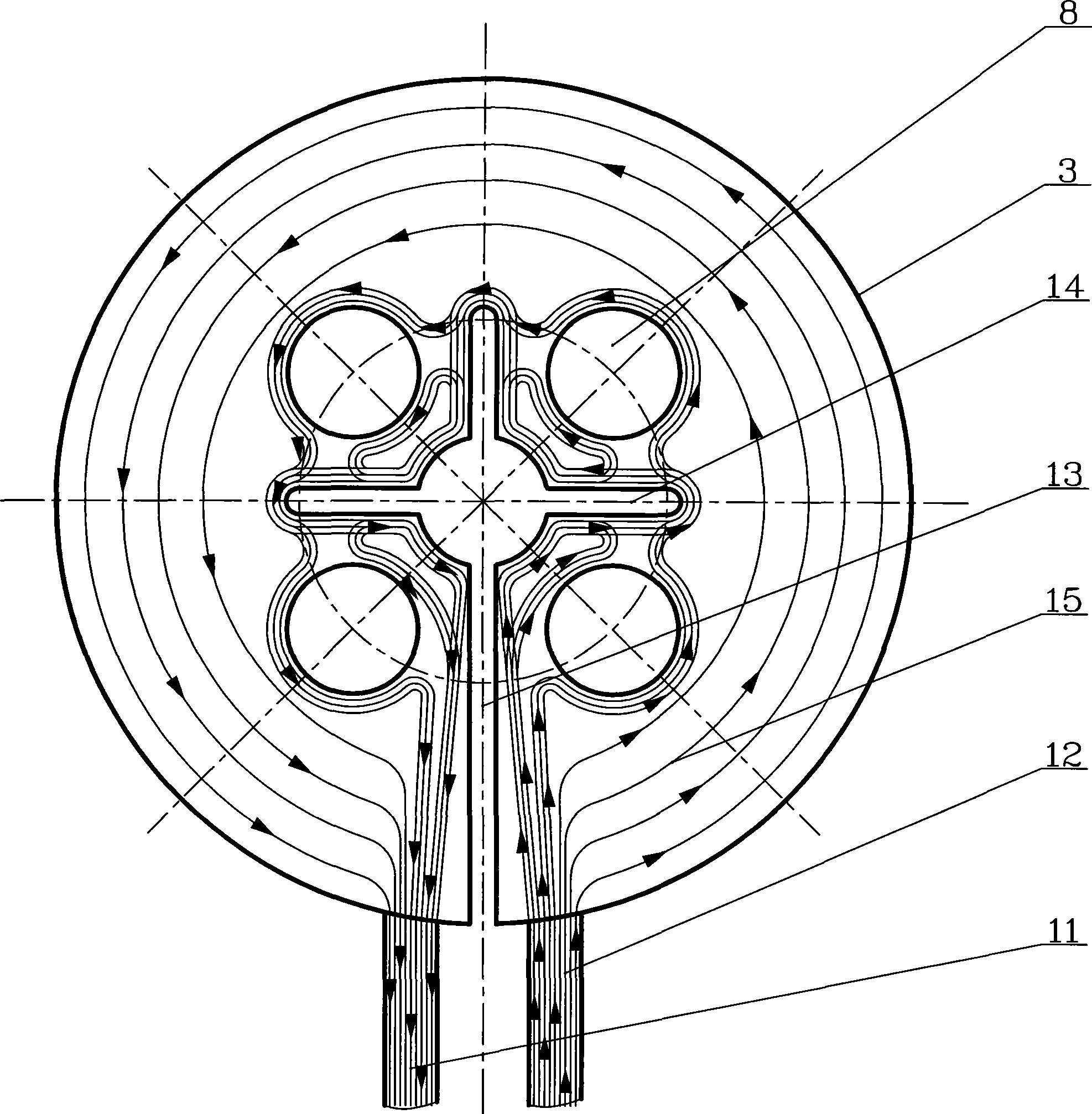

High-frequency coil structure capable of simultaneous producing four silicon cores and other crystal material

InactiveCN101457391AEvenly distributedHeating evenlyCoil arrangementsBy zone-melting liquidsCrystalline materialsCopper

The invention discloses a high-frequency coil structure capable of simultaneously producing four silicon cores and other crystalline materials, and relates to the technical field of the high-frequency coils. The high-frequency coil structure comprises splitter boxes (14) for guiding current (15), and four inner bores one inner bore (8) of which is arranged at the middle part of the high-frequency coil and three inner bores of which are evenly distributed around the inner bore at the middle part; an oblique opening (13) arranged on one side of a current delivery and cooling water delivery copper pipe A(11) and a current delivery and cooling water delivery copper pipe B(12) is in through connection with the inner bore at the middle part; and the splitter boxes extend outwards to the position between every two inner bores except for the oblique opening from the inner bore at the middle part. The oblique opening is connected with the inner bore at the middle part, and the two splitter boxes extend upwards to the position between two inner bores without the oblique openings from the inner bore at the middle part, which causes the current to evenly surround the four inner bores for running under the current splitting action of the splitter boxes while the current is running, thus realizing the purpose that the current is evenly distributed around the four inner bores.

Owner:LUOYANG JINNUO MECHANICAL ENG

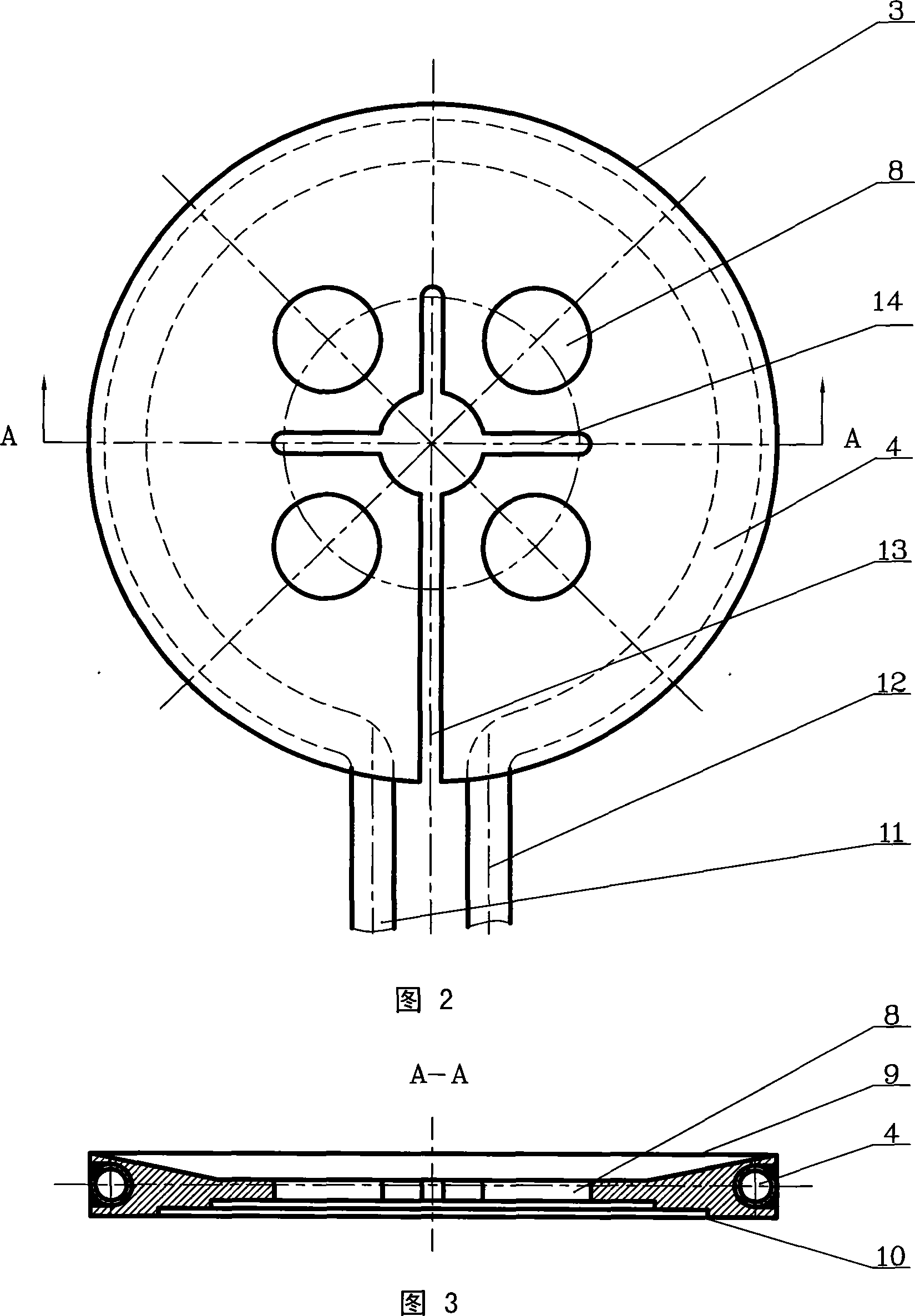

High-frequency coil structure capable of simultaneous producing five silicon cores and other crystal material

InactiveCN101457392AEvenly distributedHeating evenlyCoil arrangementsBy zone-melting liquidsCrystalline materialsCopper

The invention discloses a high-frequency coil structure capable of simultaneously producing five silicon cores and other crystalline materials, and relates to the technical field of the high-frequency coils. The high-frequency coil structure comprises a splitter box (14) for guiding current (15), and five inner bores (8) one inner bore (8) of which is arranged at the middle part of the high-frequency coil and four inner bores (8) of which are evenly distributed around the inner bore at the middle part in a 'cross' shape; an oblique opening (13) arranged on one side of a current delivery and cooling water delivery copper pipe A(11) and a current delivery and cooling water delivery copper pipe B(12) is in through connection with the inner bore (8) at the middle part; and the splitter box (14) extends outwards to the position between every two inner bores (8) except for the oblique opening (13) from the inner bore (8) at the middle part. The high-frequency coil structure can cause the current to evenly surround the five inner bores for running under the current splitting action of the splitter box while the current is running, thus realizing the purpose that the current is evenly distributed around the five inner bores.

Owner:LUOYANG JINNUO MECHANICAL ENG

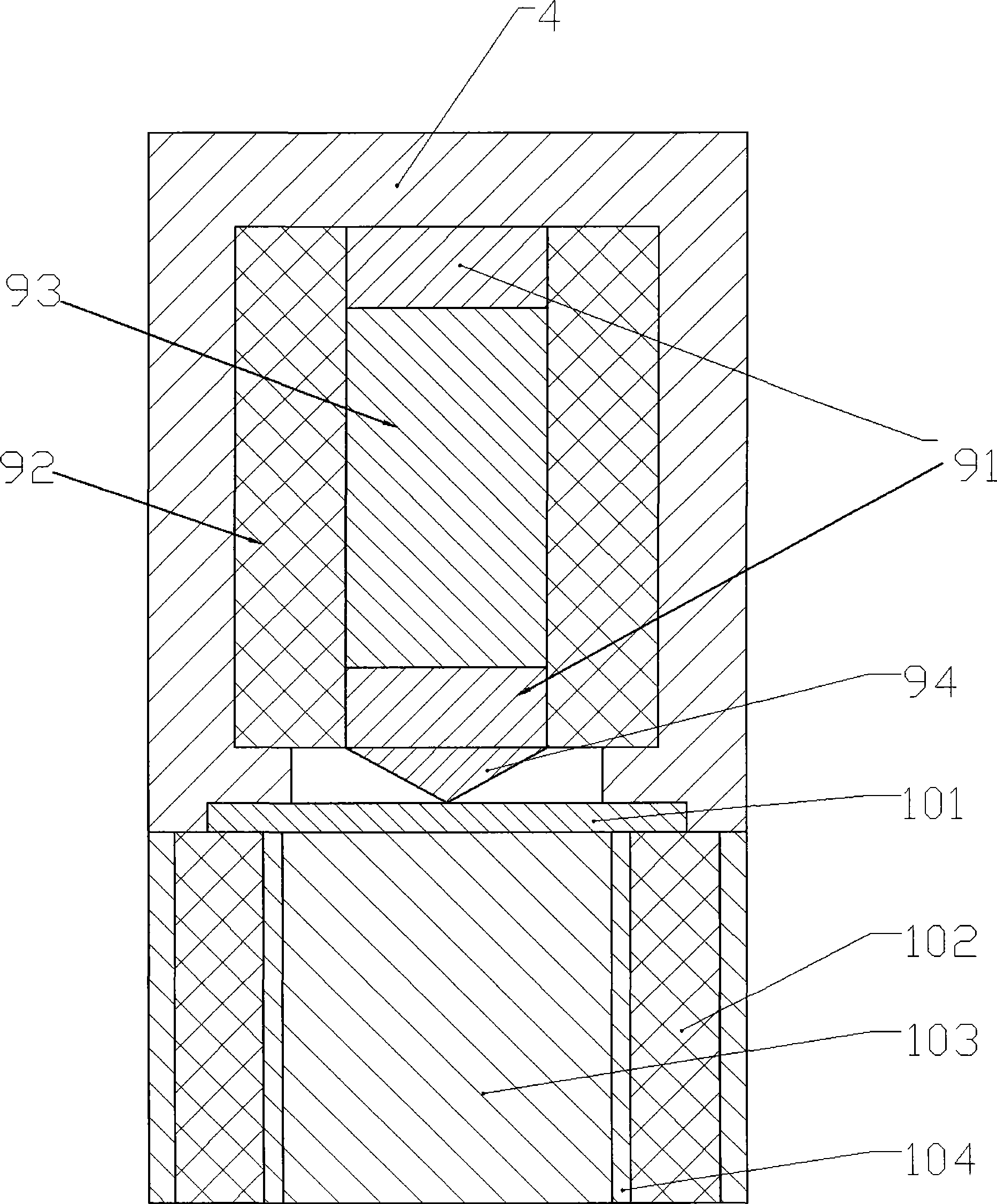

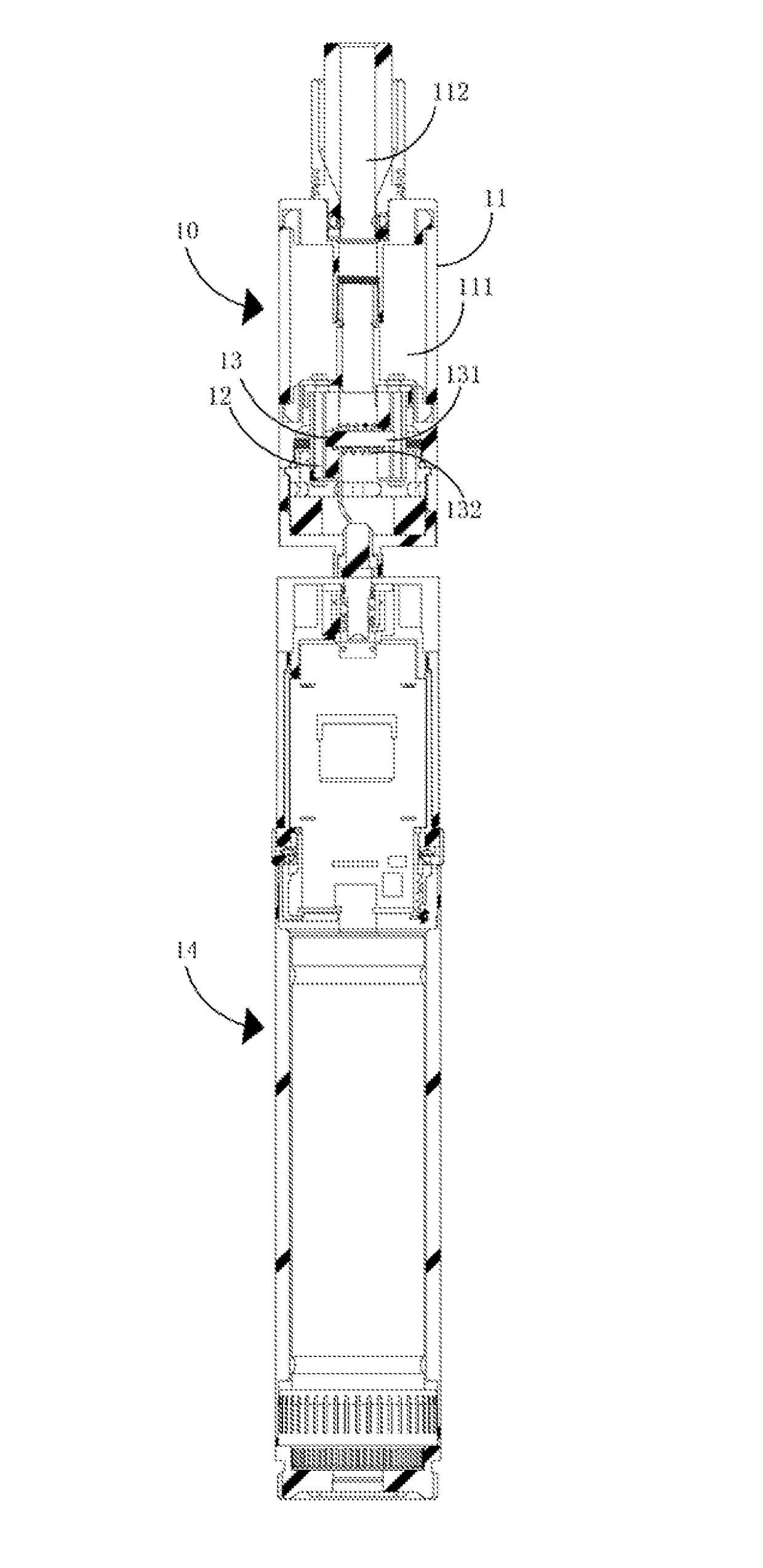

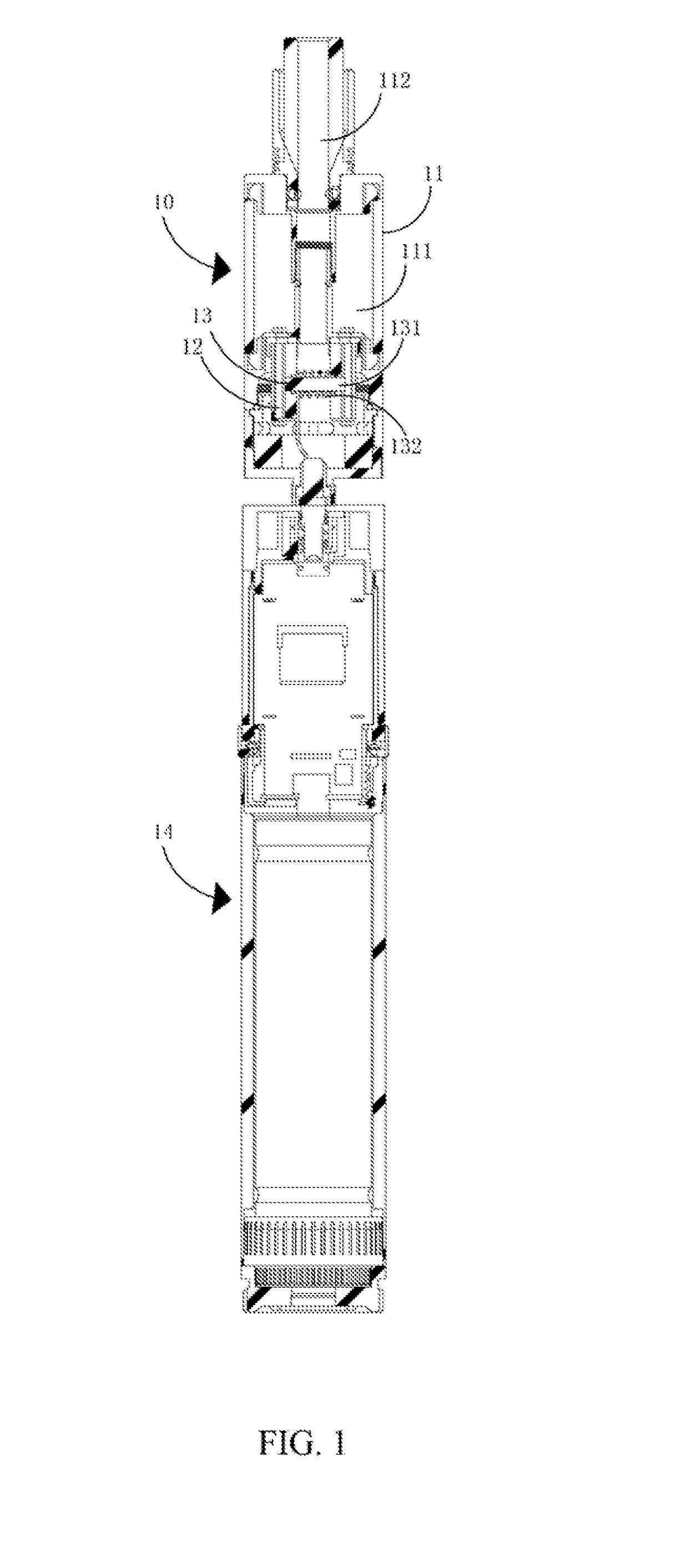

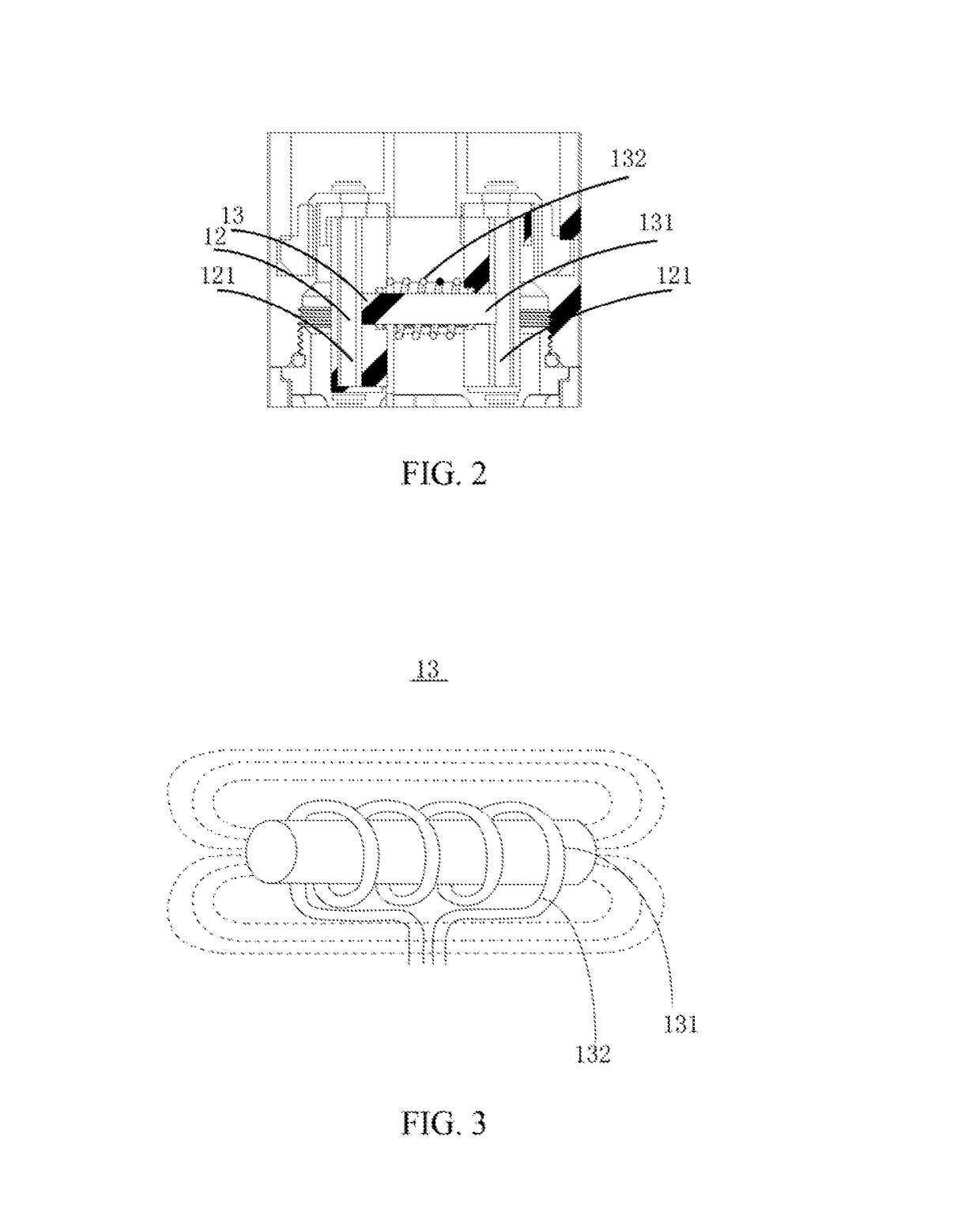

Heating assembly, atomizer and electronic cigarette having same

An exemplary heating assembly includes a liquid conducting and heating body and an inductive coil corresponding to the liquid conducting and heating body. The liquid conducting and heating body includes a micro-porous ceramic main body and a metallic powder evenly distributed in the ceramic main body. The inductive coil is configured for generating high frequency magnetic field in response to an alternating current, so that eddy current and heat are generated in the liquid conducting and heating body. The liquid conducting and heating body is configured for absorbing tobacco liquid and heating the tobacco liquid to form aerosol.

Owner:SHENZHEN FIRST UNION TECH CO LTD

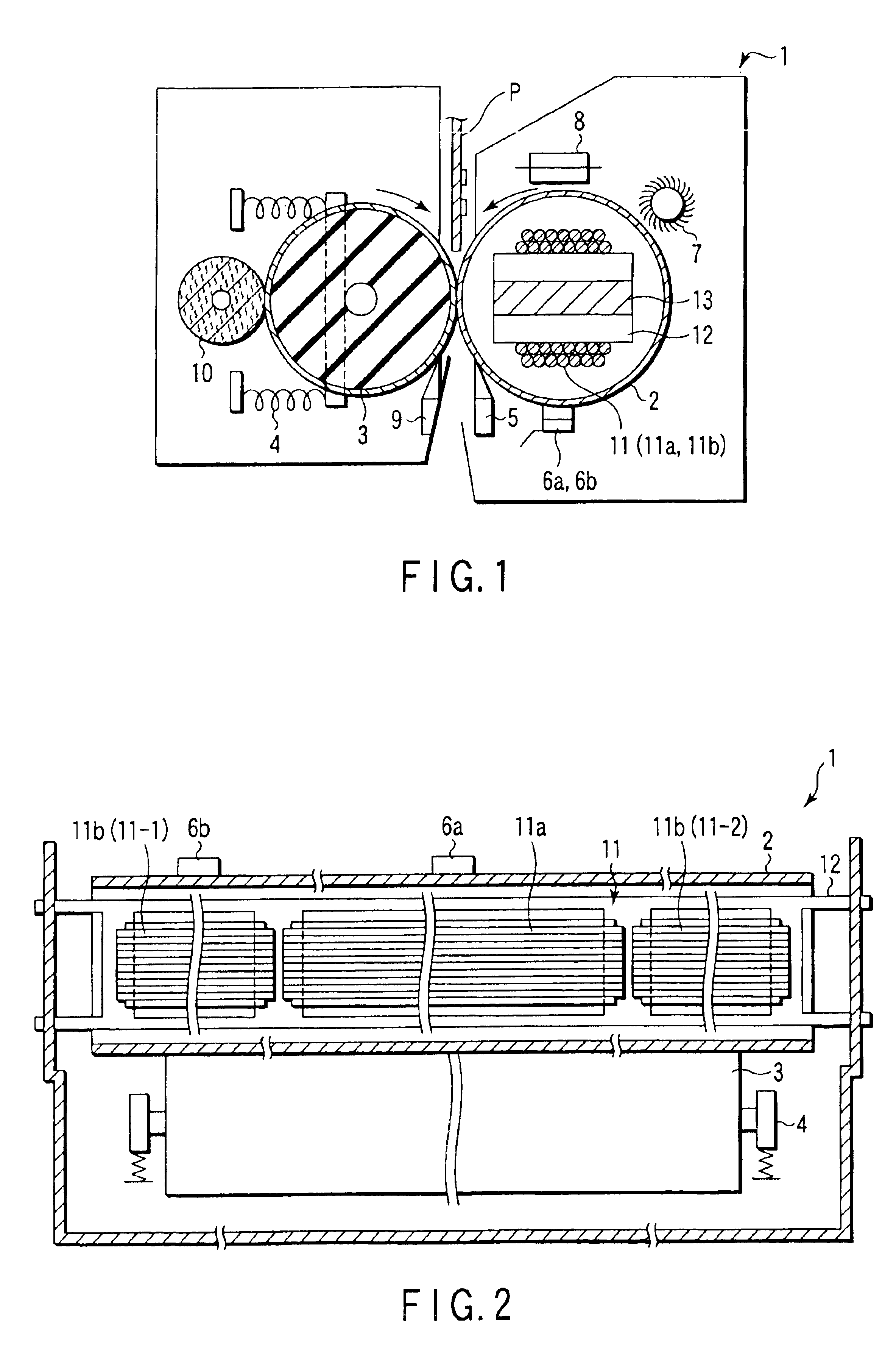

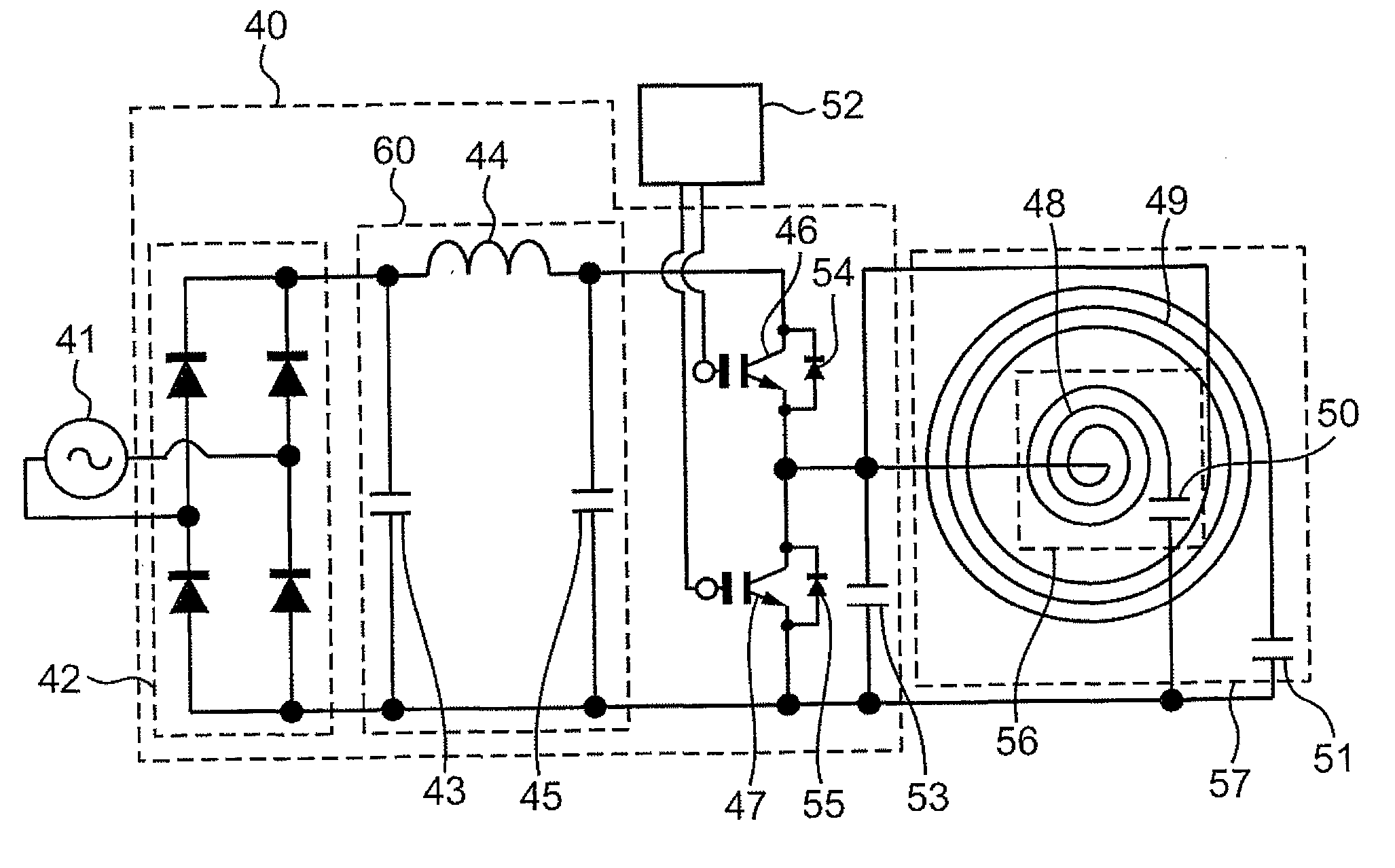

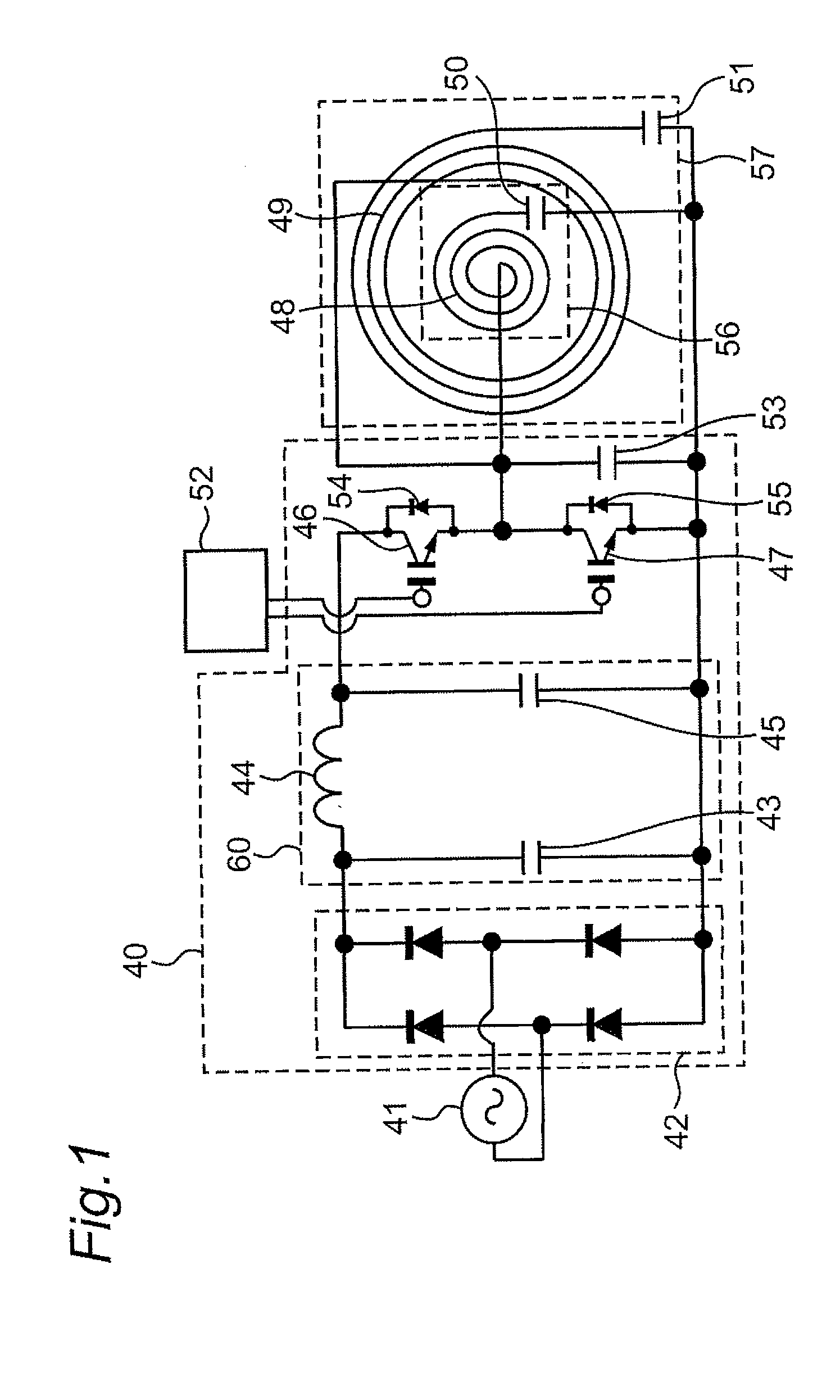

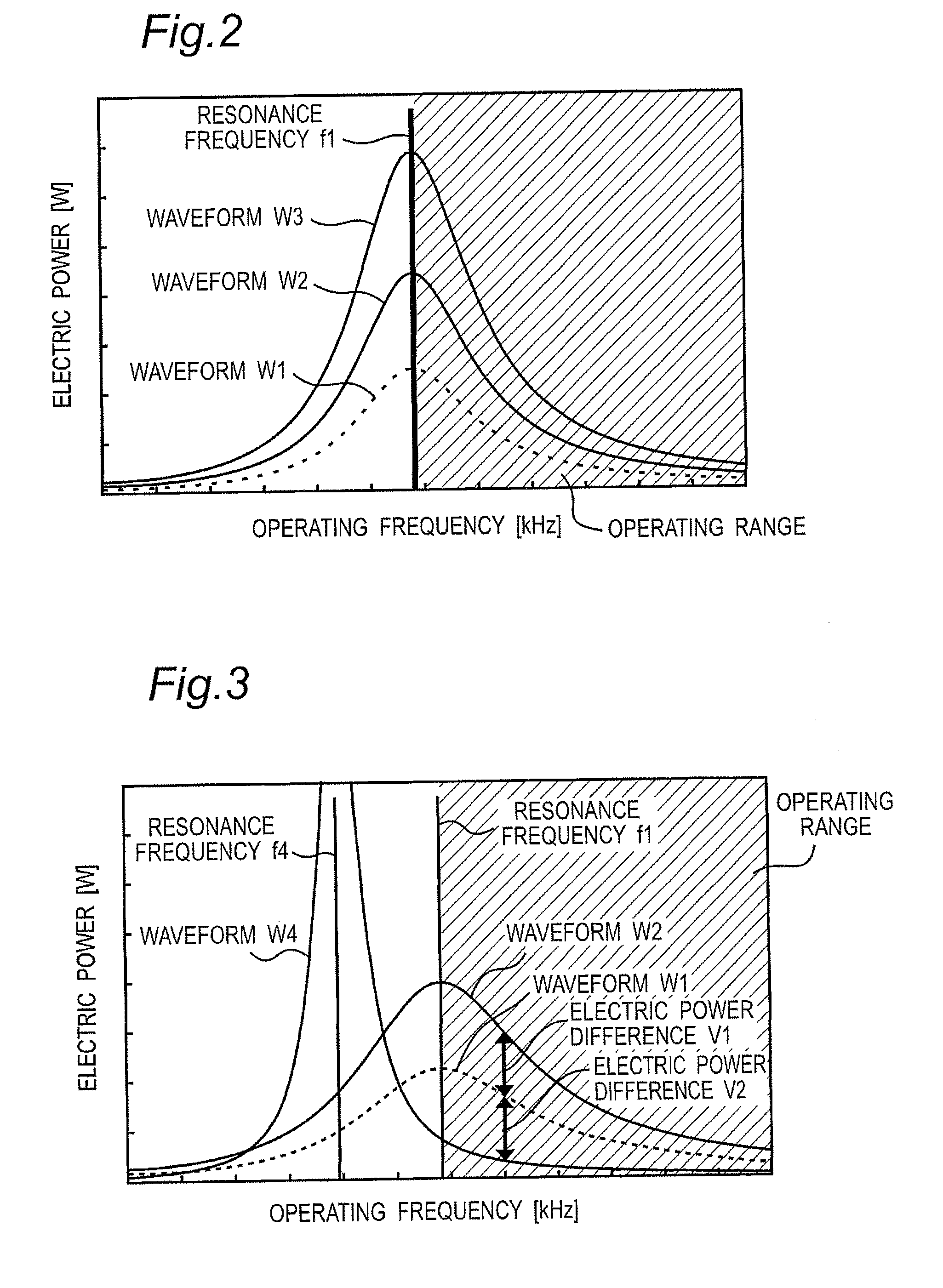

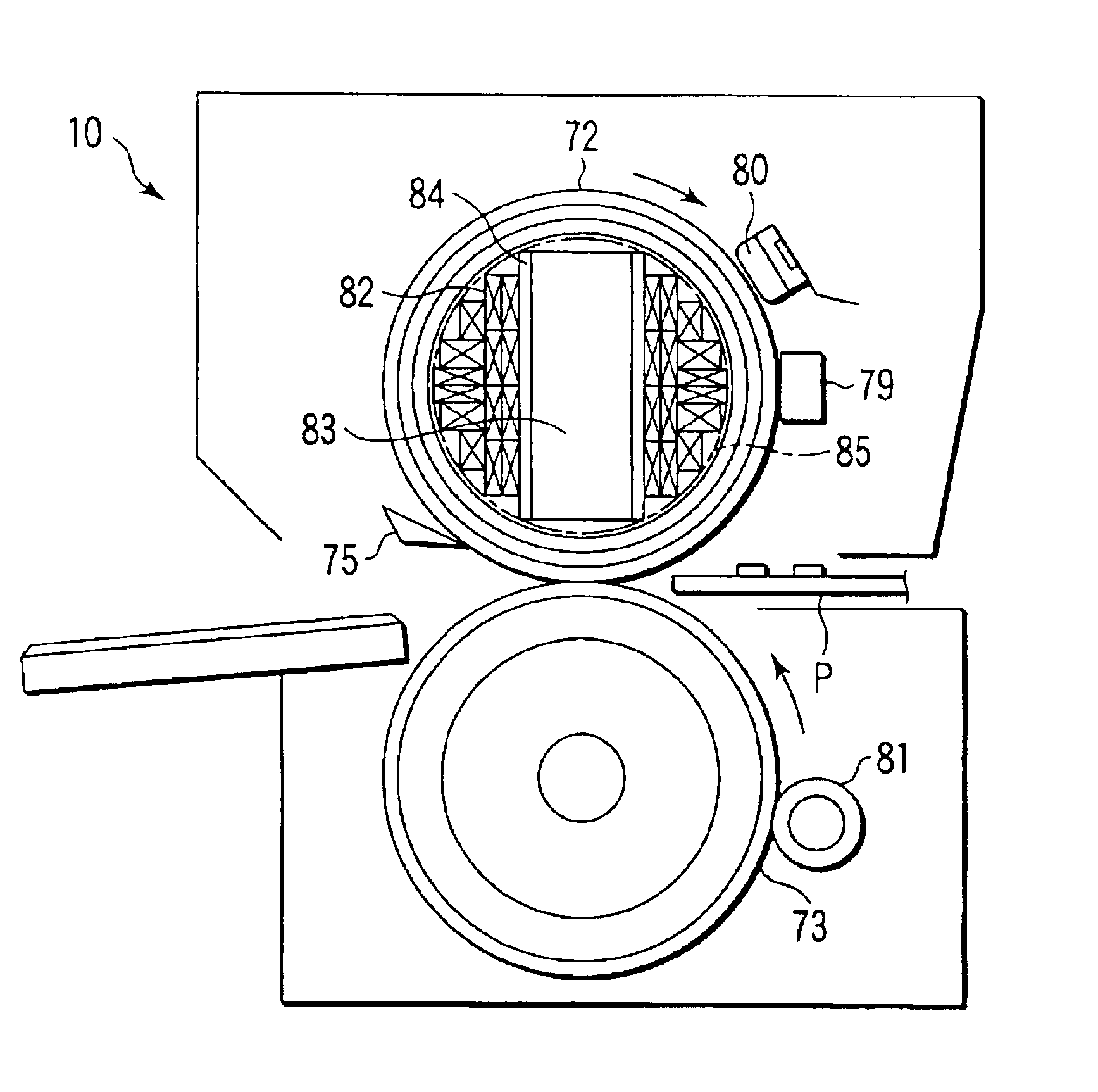

Induction heating apparatus and induction heating cooker provided with same

InactiveUS20120261405A1Improve securityReduce manufacturing costCoil arrangementsInduction current sourcesResonanceResonant capacitor

An induction heating apparatus according to the present invention includes: an inverter circuit which outputs an AC signal through ON and OFF operations of a plurality of switching devices; a control portion which drives and controls the plurality of switching devices; and a plurality of resonant circuits which includes respective resonant capacitors and respective heating coils for inductively heating an object to be heated; wherein the switching devices are driven and controlled, by using, as an operating range, a frequency range higher than a highest resonance frequency, or a frequency range lower than lowest resonance frequency, out of respective resonance frequencies of the plurality of resonant circuits, and the respective heating coils in the plurality of resonant circuits are combined to form at least a single induction heating source.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

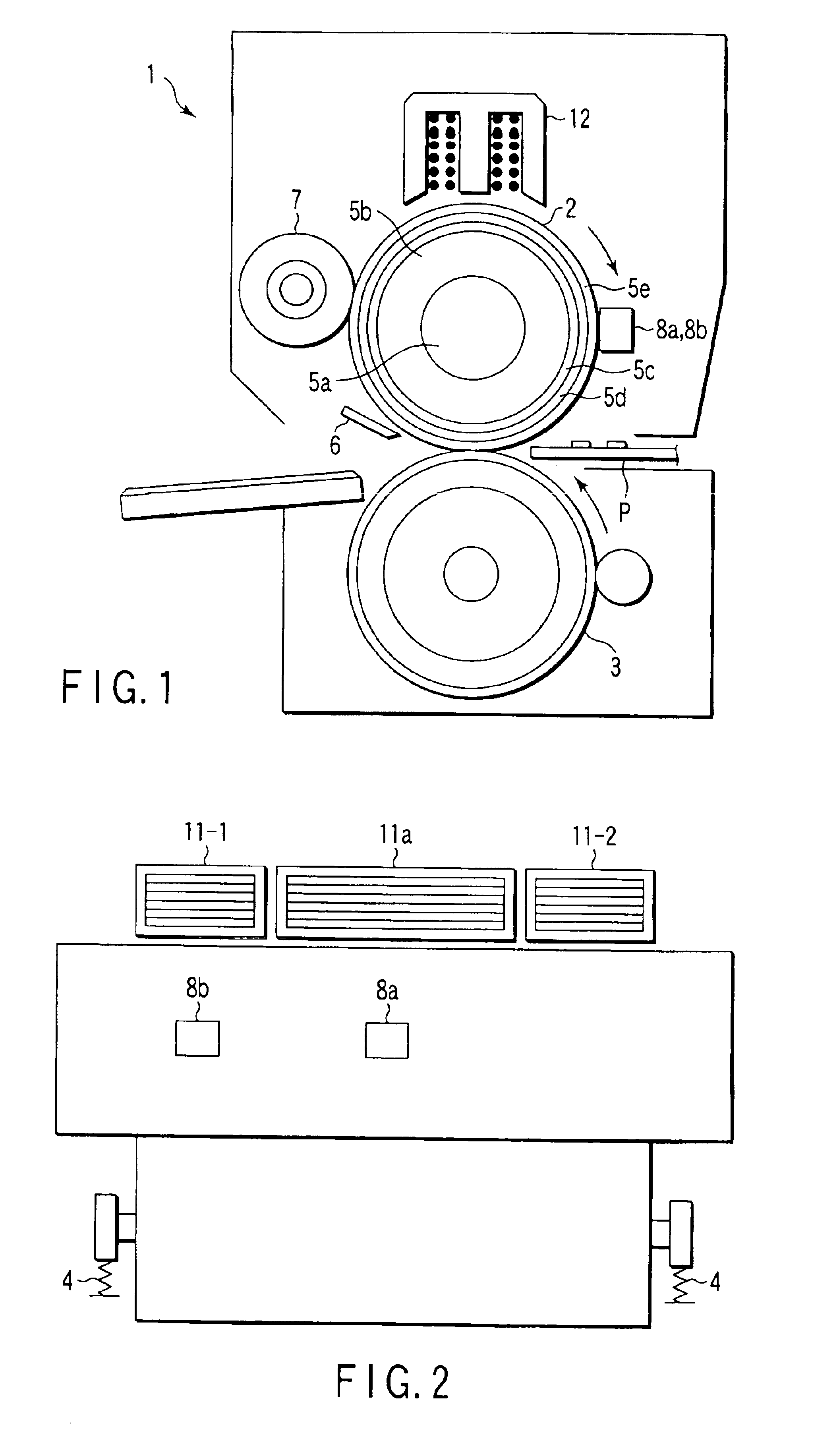

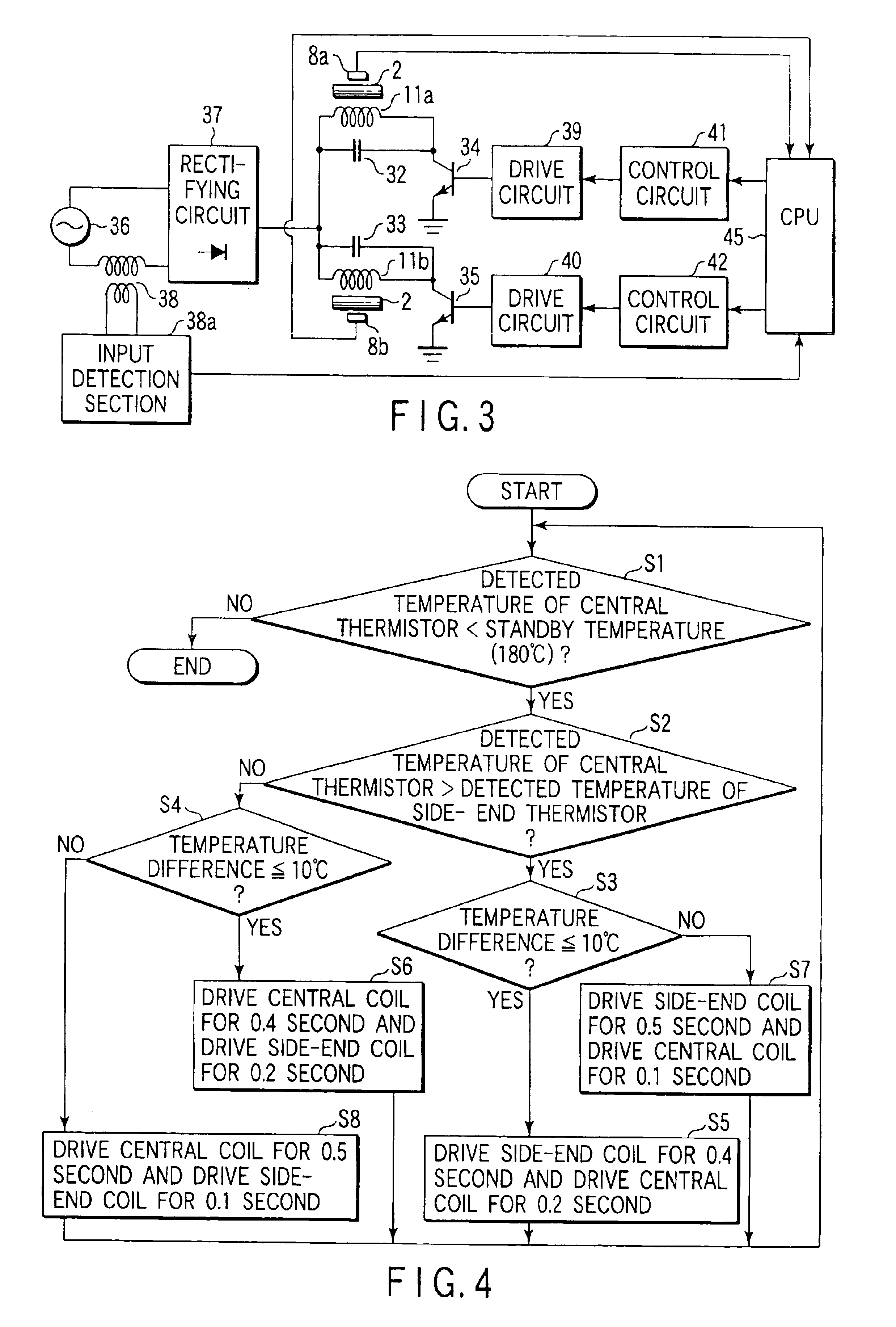

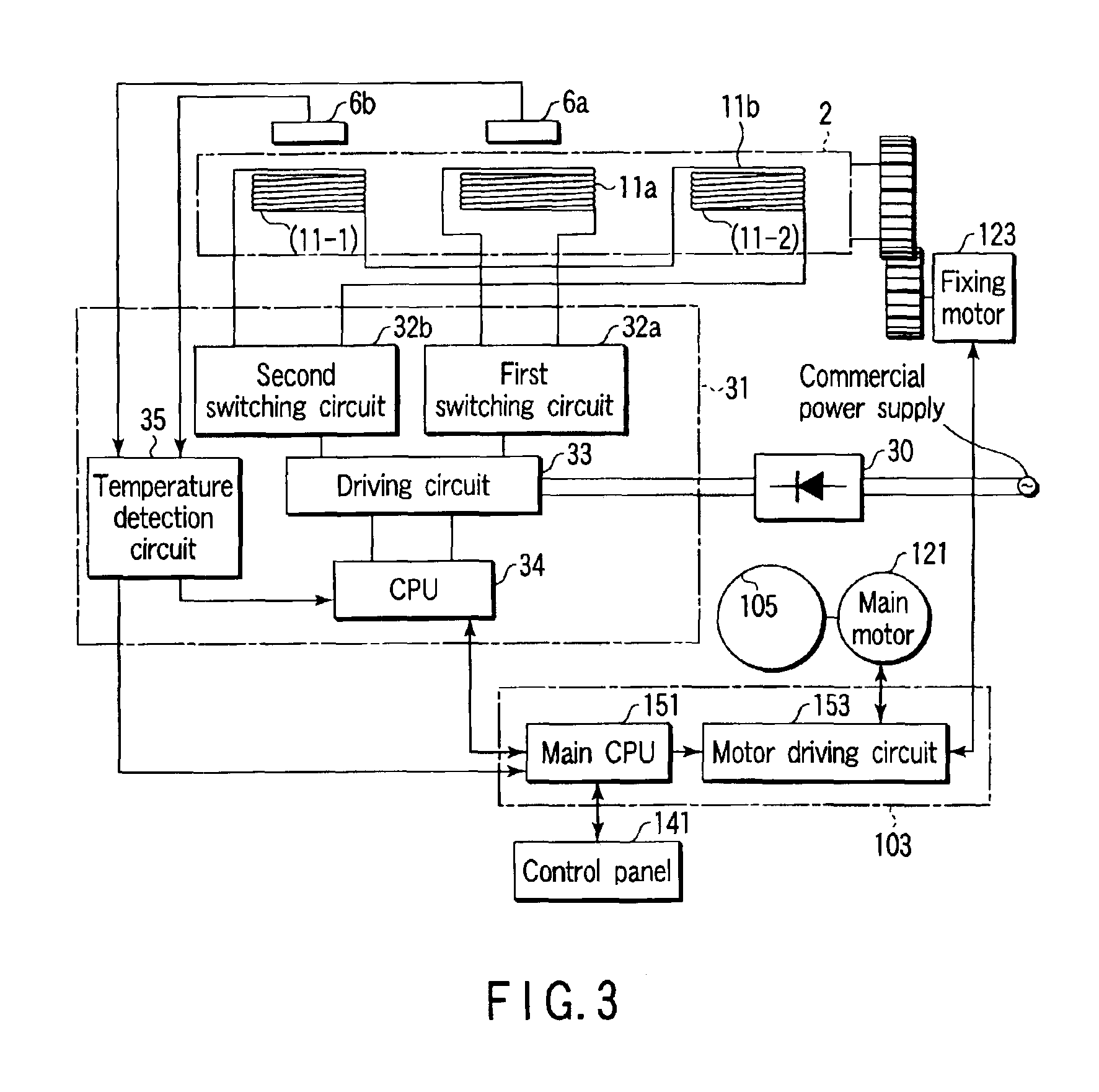

Heating device and fixing device

InactiveUS6861630B2High densityCoil arrangementsElectrographic process apparatusTemperature differenceEngineering

A CPU detects a temperature of a central part of a heating roller. If the detected temperature does not exceed 180° C., the CPU drives a central coil or a side-end coil for 0.4 second in accordance with a temperature difference between the central part of the heating roller and a side-end part of the heating roller. Then, the CPU drives the side-end coil or central coil for 0.2 second. Thereafter, the CPU detects the temperature of the central part and repeats the driving control until the detected temperature reaches 180° C.

Owner:KK TOSHIBA +1

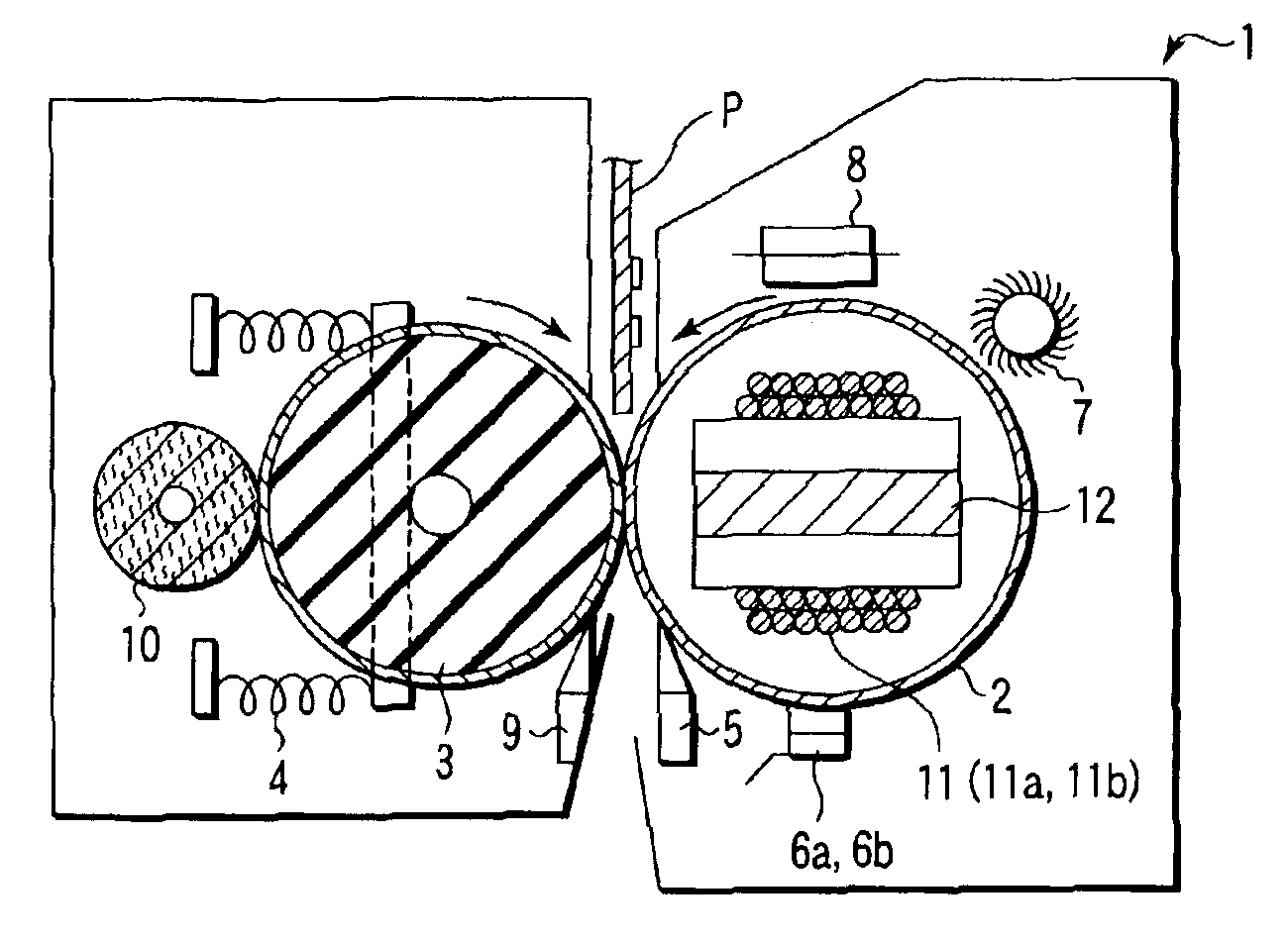

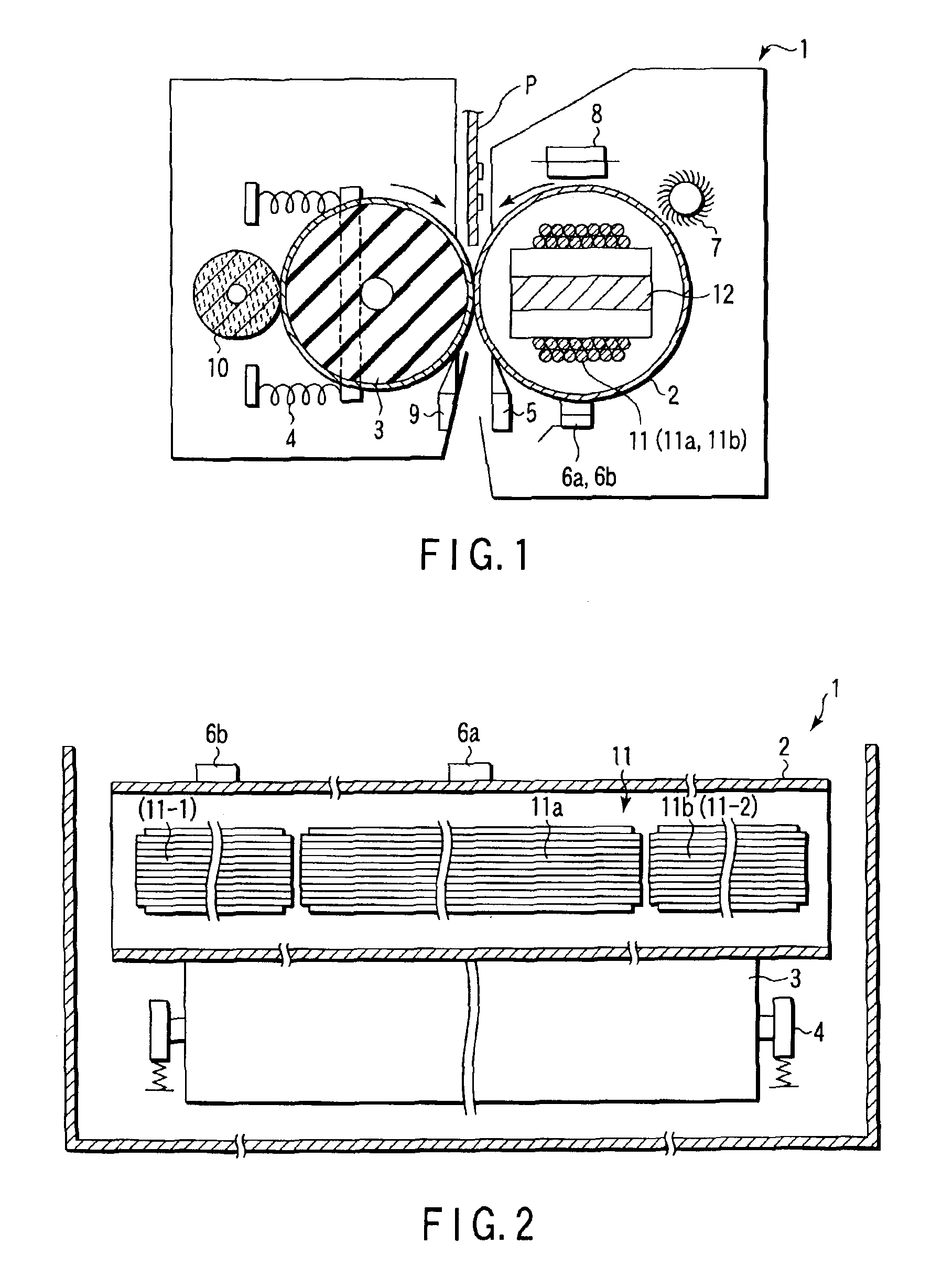

Fixing unit

InactiveUS6889018B2Suppress interference noiseAvoid flickeringCoil arrangementsElectrographic process apparatusElectrical resistance and conductanceEngineering

A fixing device of the present invention has first and second thermistors which detect the temperatures at predetermined positions in the longitudinally direction of a heating roller, first and second coils which can increase independently the temperatures at the center and the end of the heating roller, a driving circuit which supply power alternately to the coils, first and second switching circuits which supply a predetermined power to each coil, a control unit, and a temperature detection circuit.

Owner:KK TOSHIBA +1

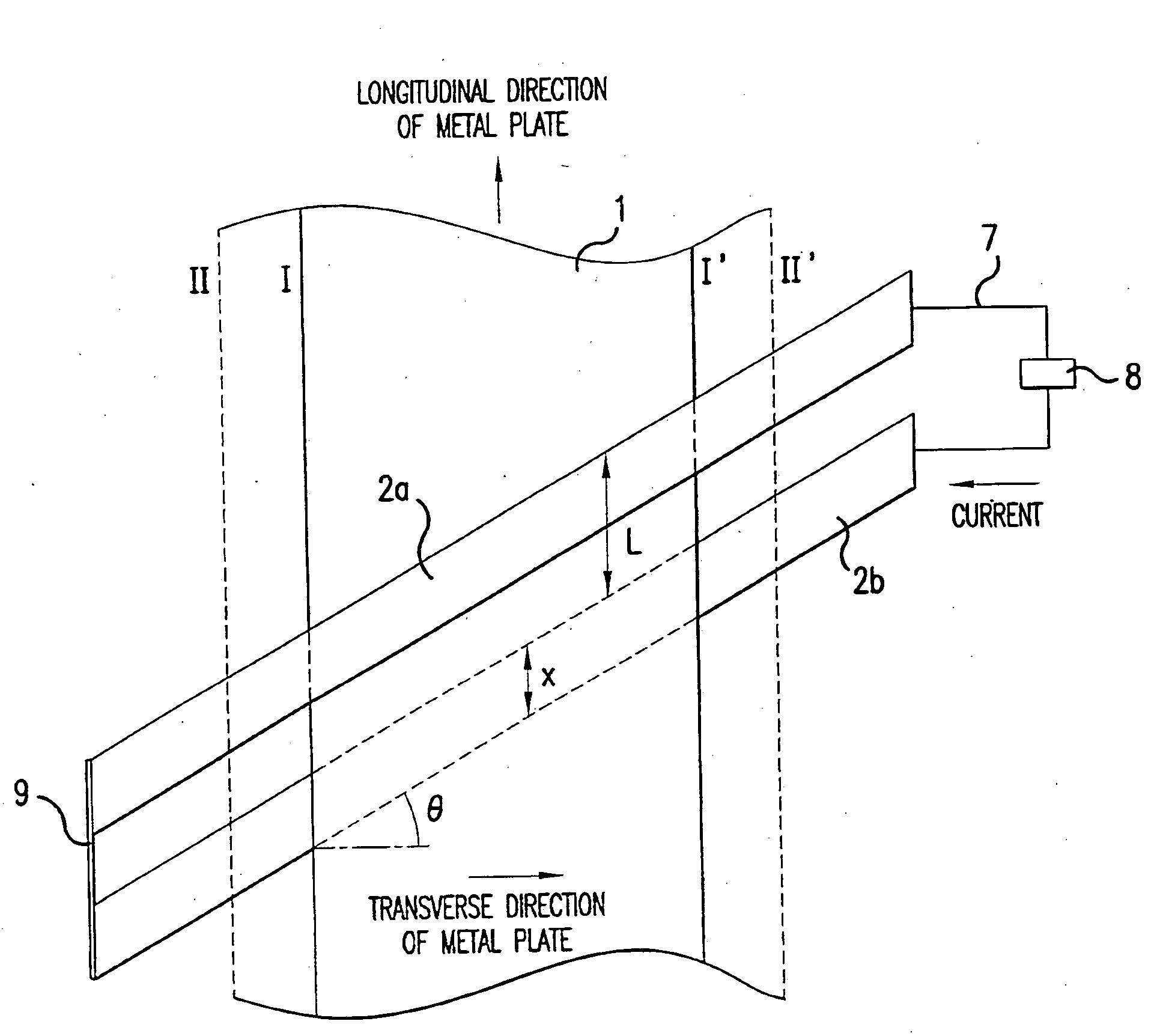

Induction Heating Device for a Metal Plate

ActiveUS20080264932A1Avoid overall overheatingEasy to realize desired temperature distributionLiquid surface applicatorsCoil arrangementsOblique angleMetal

An induction heating apparatus for heating a traveling metal plate includes an induction coil for surrounding the metal plate. The induction coil includes an upper induction coil for being located above the metal plate and a lower induction coil for being located below the metal plate. The upper and lower induction coils are spaced from each other in a longitudinal direction of the metal plate a constant distance across a transverse direction of the metal plate. Each of the upper induction coil and the lower induction coil is arranged obliquely at an edge area of the metal plate so as to form an oblique angle with the transverse direction of the metal plate.

Owner:NIPPON STEEL CORP

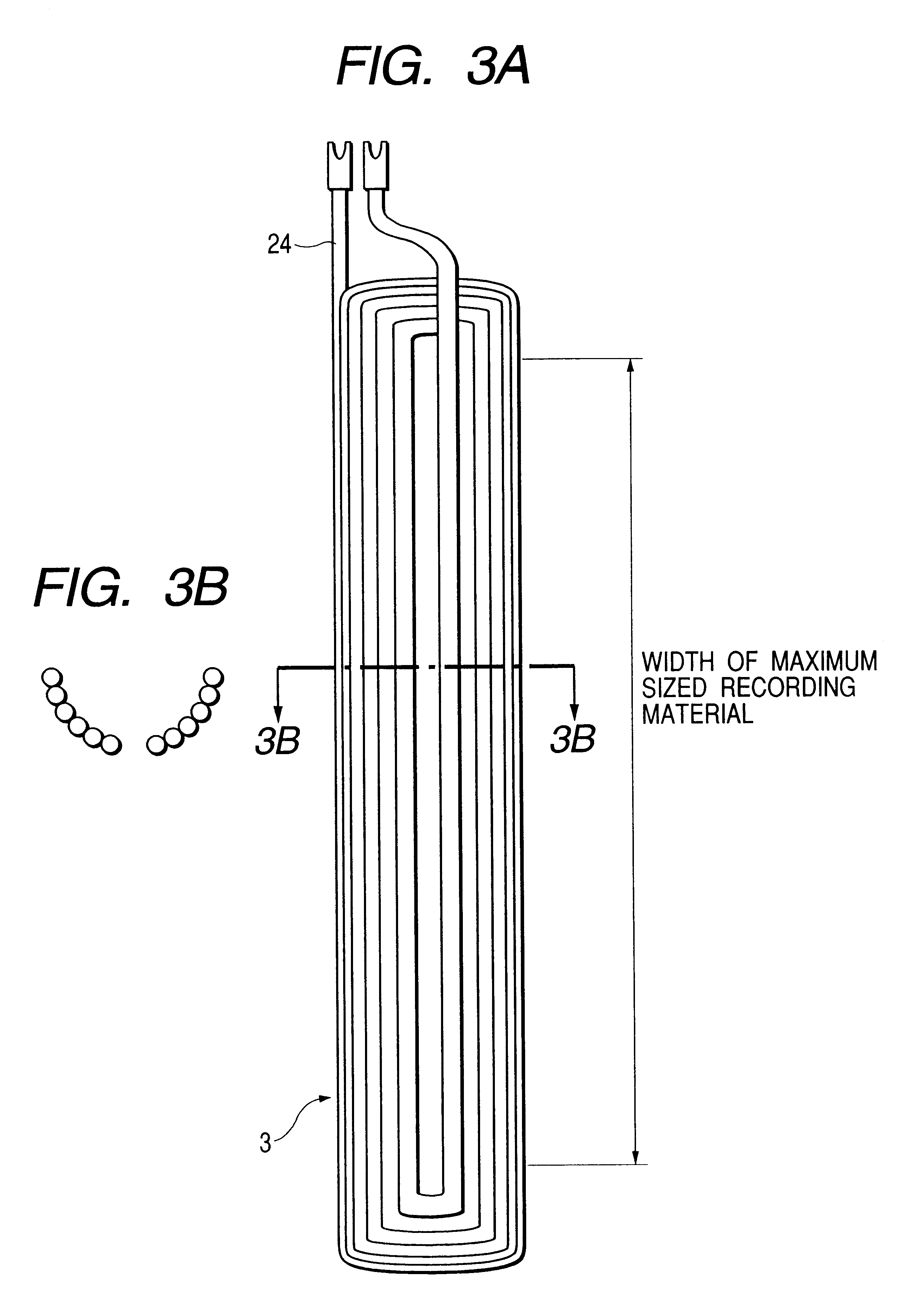

Image heating apparatus

The present invention relates to any image heating apparatus which has a heating member and a coil for generating magnetic flux, and an eddy current is generated in the heating member by the magnetic flux generated by the coil, the heating member is heated by the eddy current, an image on a recording material is heated by the heat from the heating member, the coil is constituted by a litz wire obtained by twisting a plurality of insulation coated conductive wires, current of 5 Amperes to 50 Amperes are applied to the coil, and an outer diameter of each insulation coated conductive wire is selected to 0.01 mm to 0.4 mm.

Owner:CANON KK

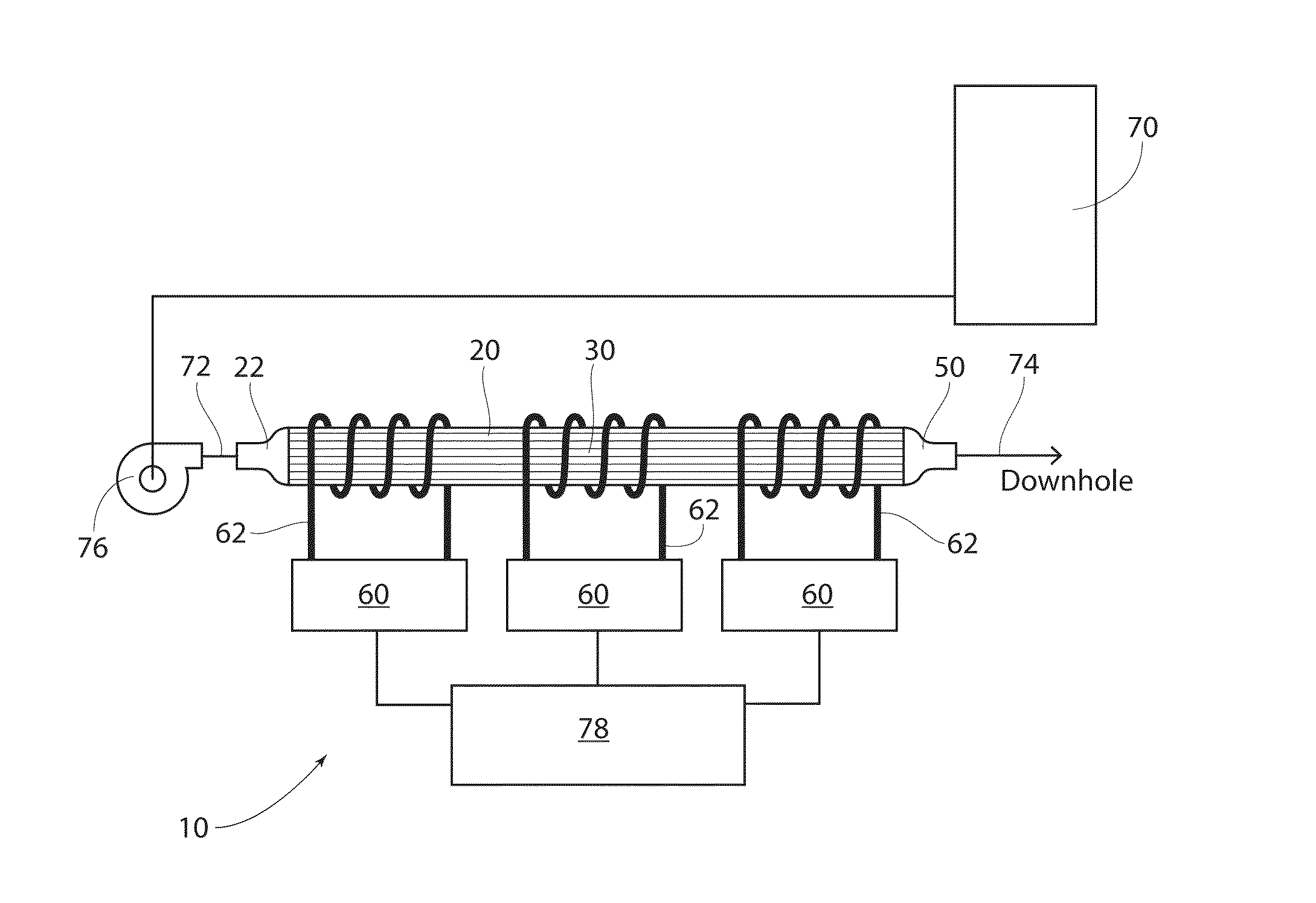

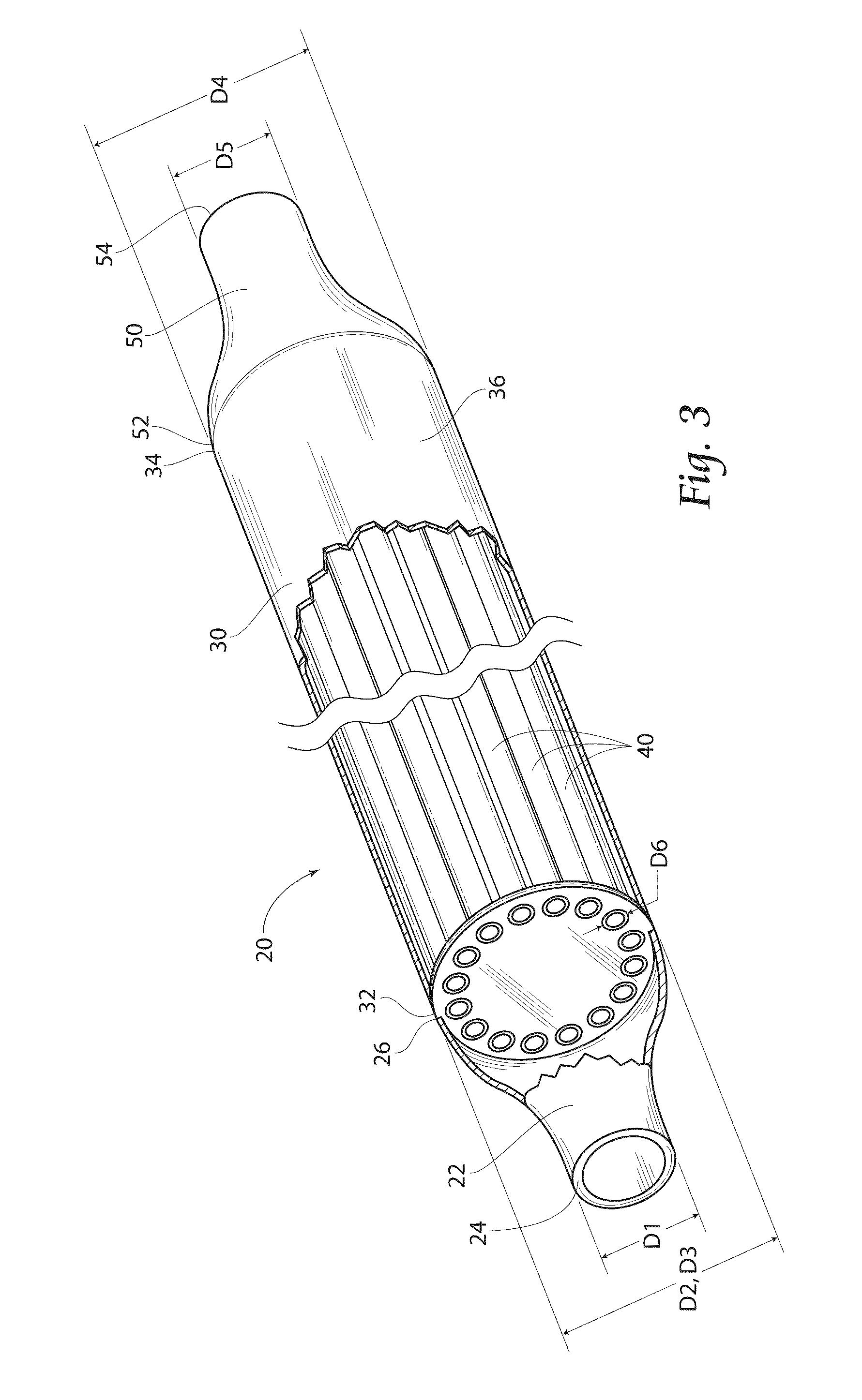

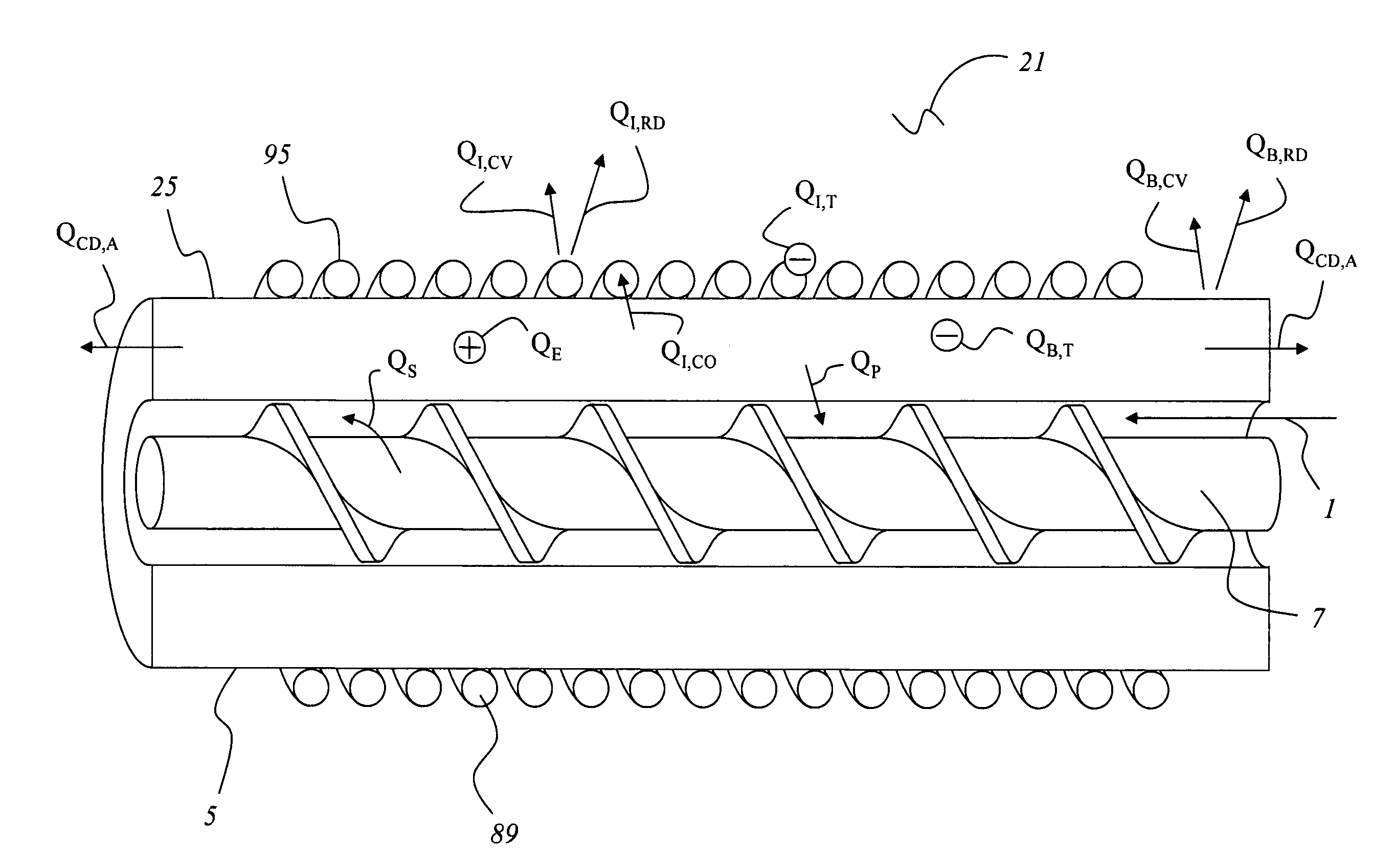

Multi-channel conduit and method for heating a fluid for use in hydraulic fracturing

System and method directed to the art of heating a fluid for use in a hydraulic fracturing system. A heat tube having a plurality of pipes disposed axially along and substantially near the periphery of a medial portion of the heat tube. The heat tube is heated by induction heaters.

Owner:FREEDOM OILFIELD SERVICES

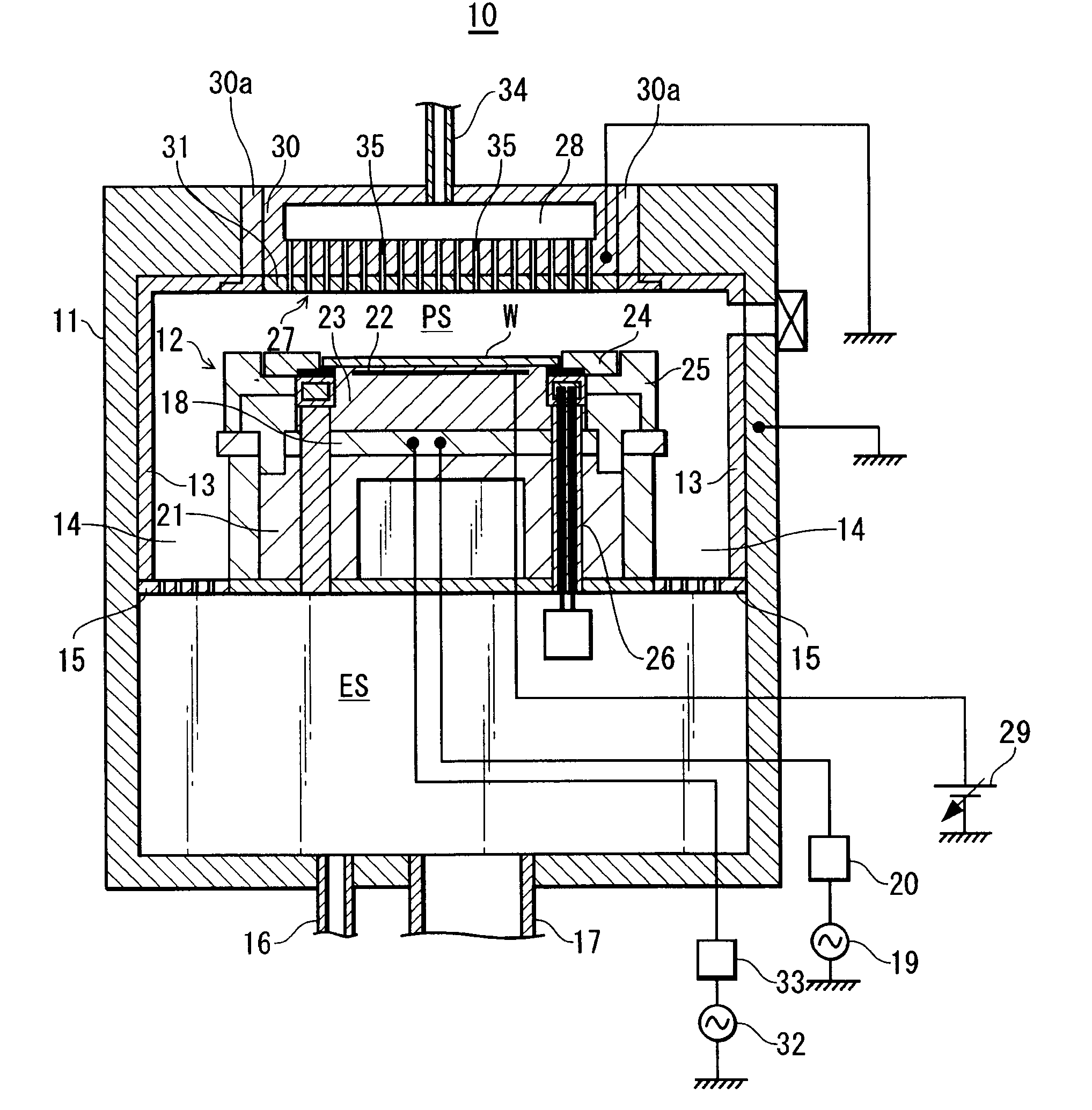

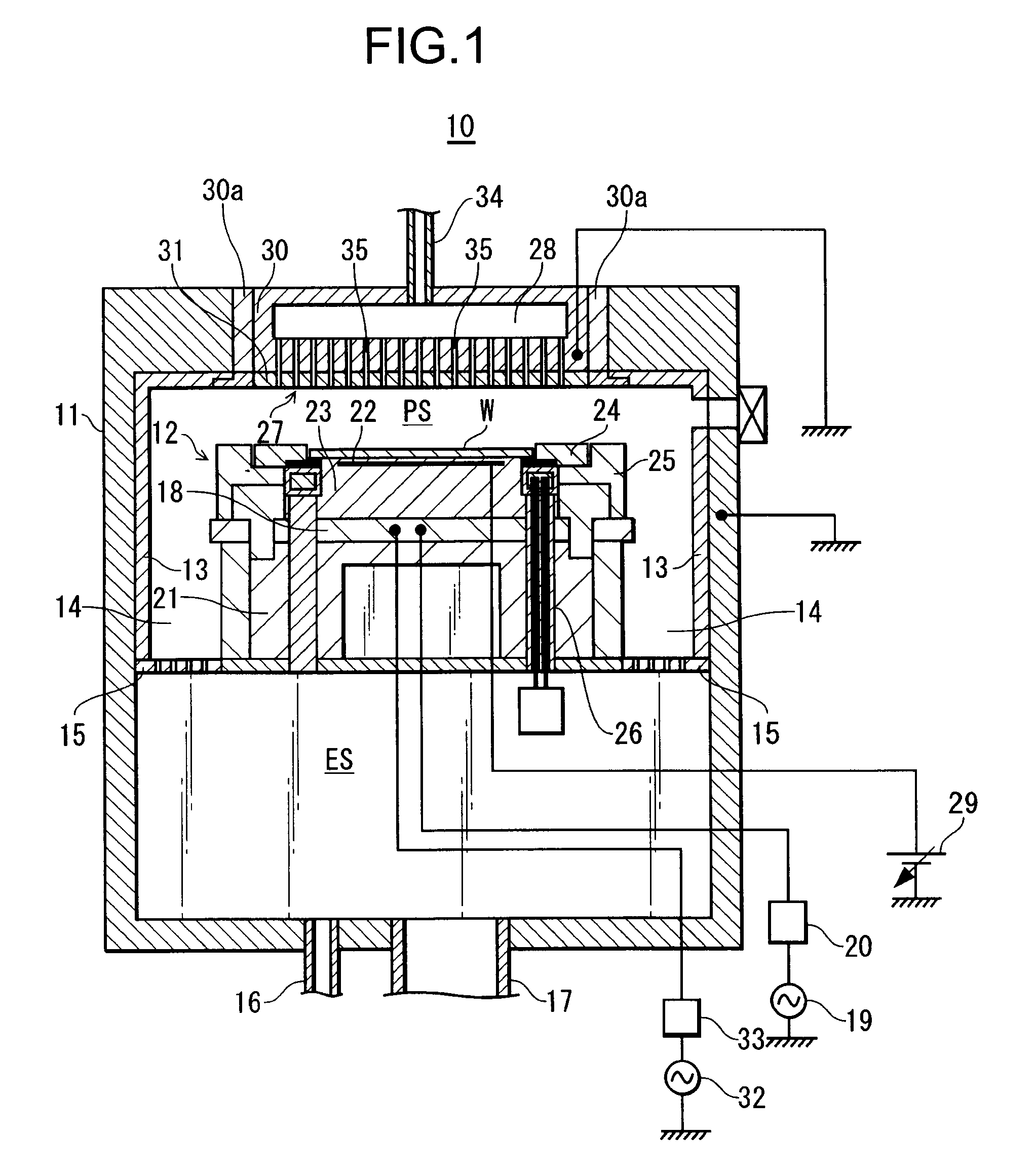

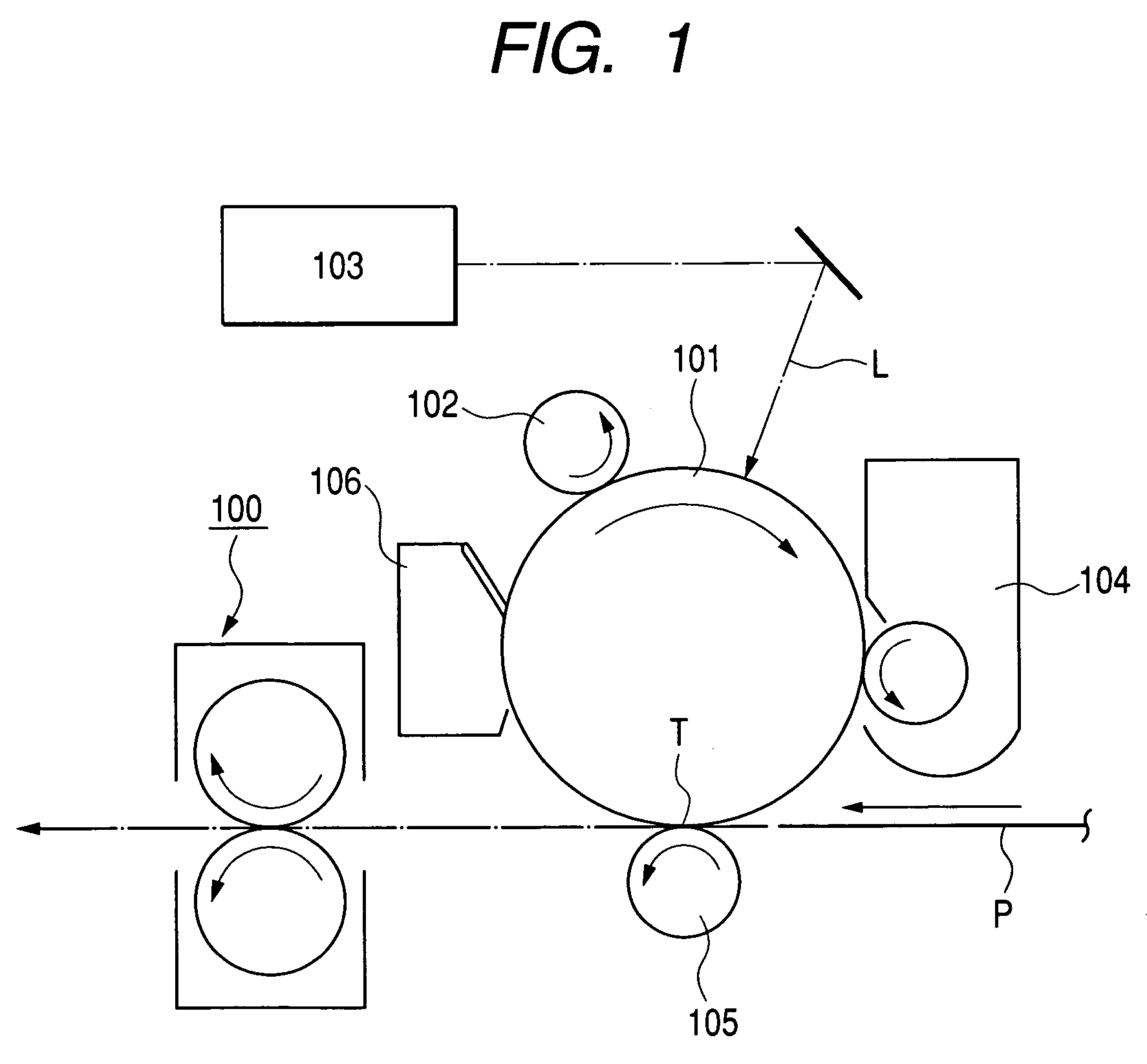

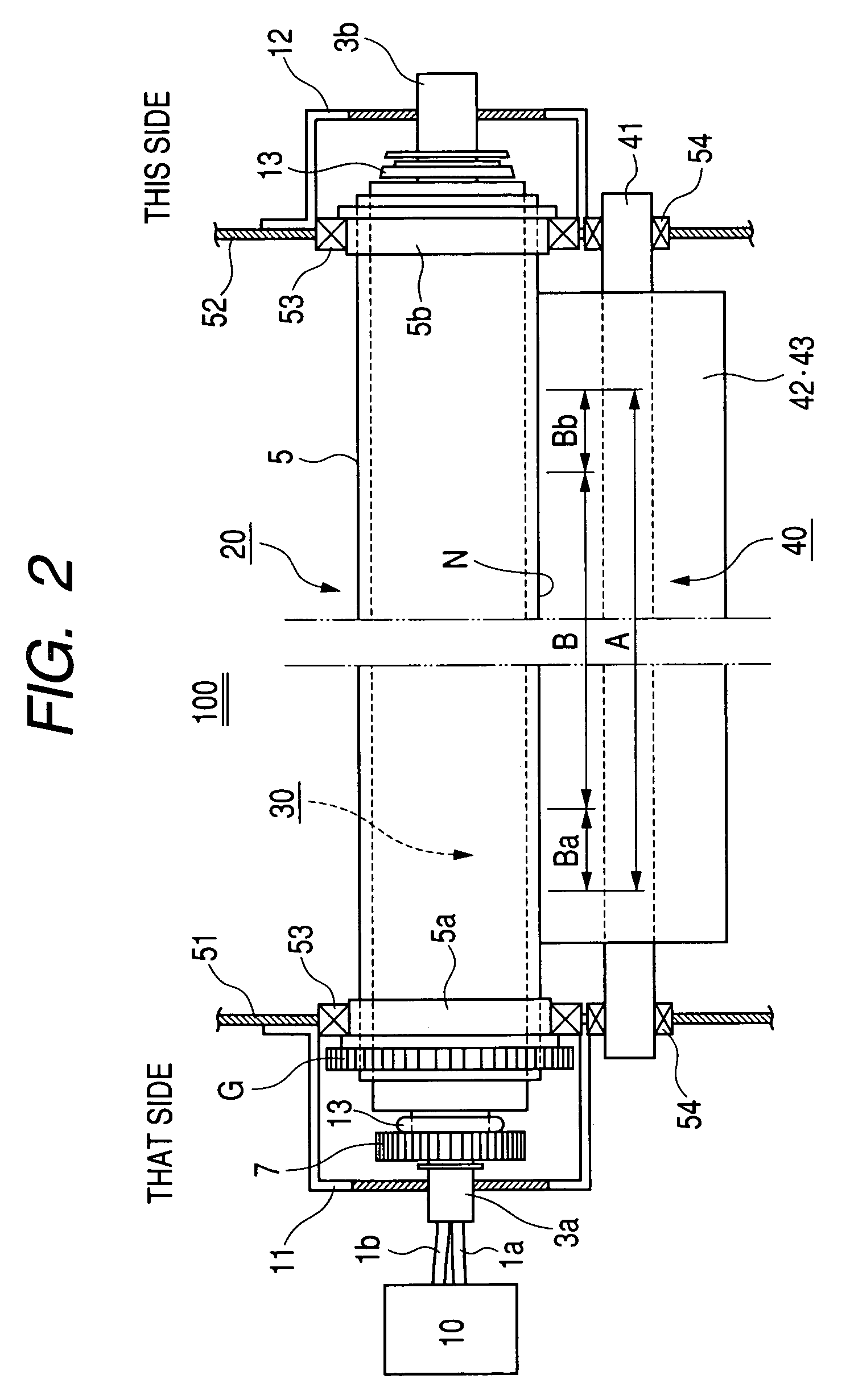

Substrate processing apparatus, focus ring heating method, and substrate processing method

ActiveUS20080149598A1Easy to controlUniform resultCoil arrangementsElectric discharge tubesRadio frequencyEngineering

A substrate processing apparatus that can accurately control the temperature of a focus ring without causing abnormal electric discharge and the back-flow of radio frequency electrical power during the application of radio frequency electrical power. A wafer is mounted on a mounting stage disposed in a housing chamber. An annular focus ring is mounted on the mounting stage in such a manner as to surround the peripheral portion of the mounted wafer. The pressure in the housing chamber is reduced, radio frequency electrical power is applied to the mounting stage, and the focus ring generates heat by itself.

Owner:TOKYO ELECTRON LTD

Heating apparatus and image heating apparatus

InactiveUS7099616B2Improve misuseReduce noiseCoil arrangementsOhmic-resistance heatingEngineeringMagnetic flux

A heating apparatus of an electromagnetic inductive heat generating type using a magnetic flux shield member, the heating apparatus including a coil for generating a magnetic flux, a roller member for generating heat by the magnetic flux from the coil, and heating a material to be heated, the magnetic flux shield member for shielding the magnetic flux from the coil to the roller member to thereby vary the generated heat distribution of the roller member, and a guide member provided in non-contact with the roller member for guiding the movement of the magnetic flux shield member to a predetermined magnetic flux suppressing position, thereby realizing an improvement in the faulty operation of the magnetic flux shield member.

Owner:CANON KK

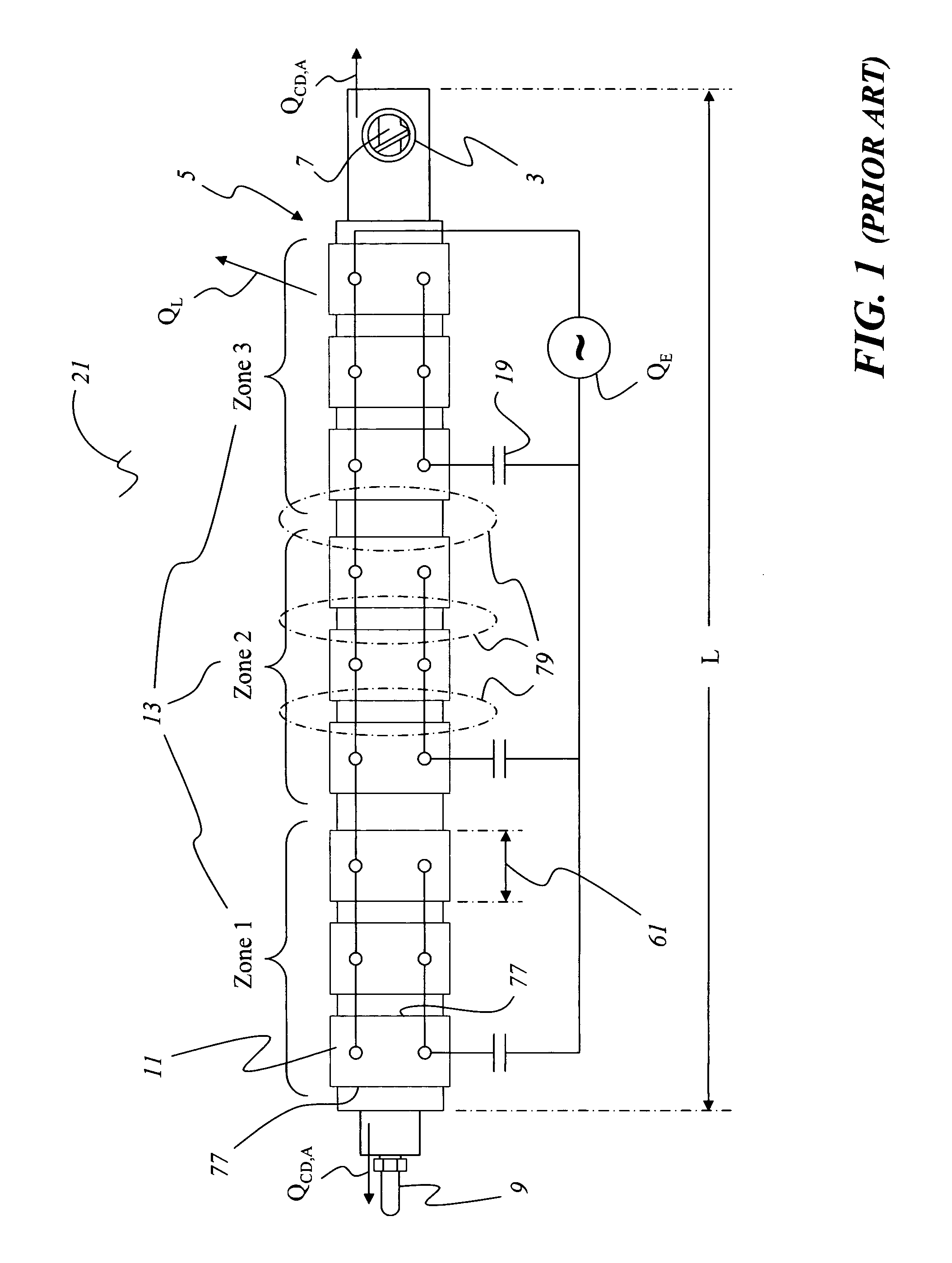

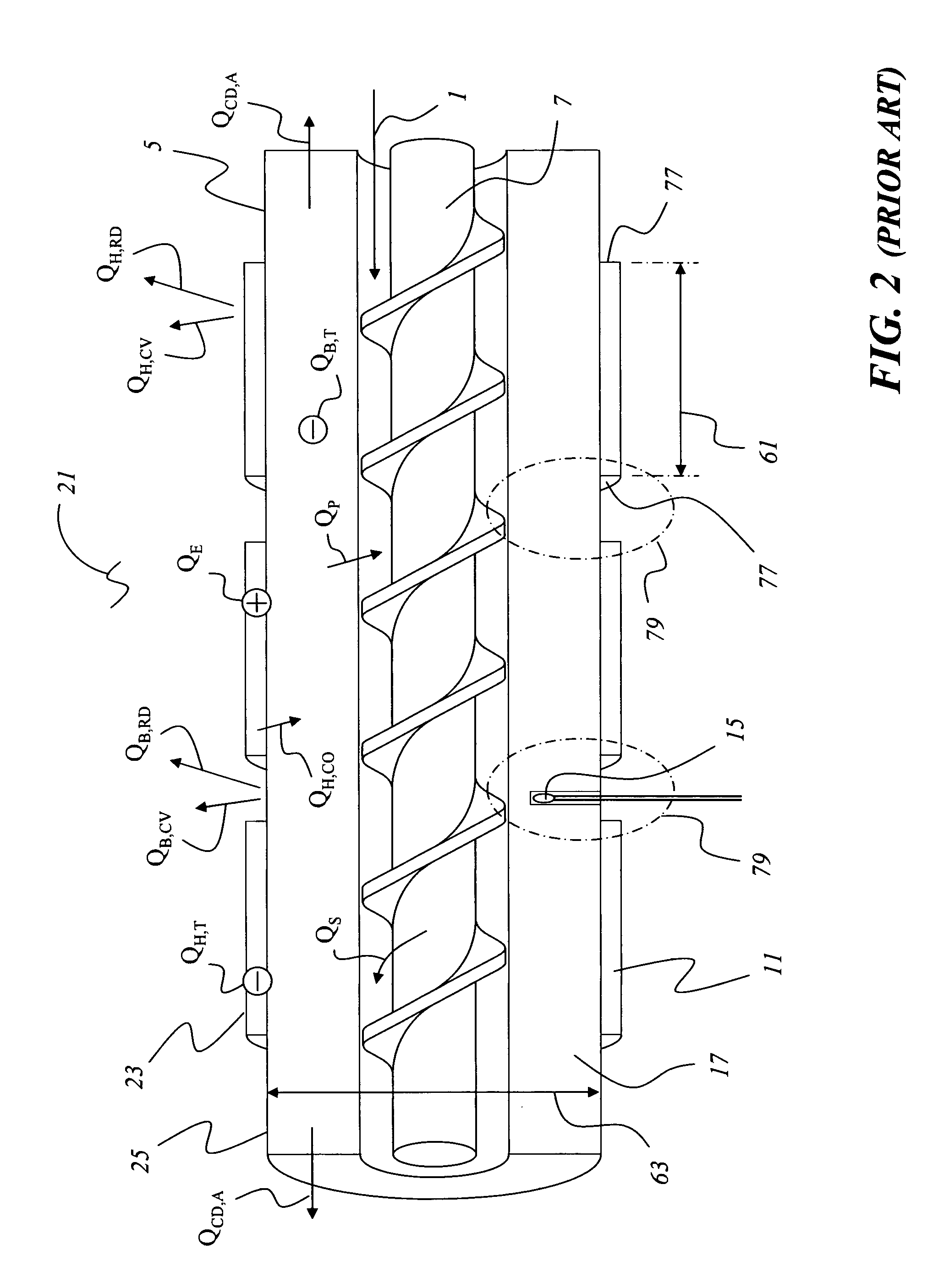

Apparatus and method for inductive heating a workpiece using an interposed thermal insulating layer

InactiveUS20080136066A1Improve heating efficiencyReduce resistanceCoil arrangementsConfectioneryThermal insulationEngineering

Disclosed herein is an apparatus and method with inductive heating of an electrically conductive workpiece such as a barrel used in molding or extrusion, having a layer of thermal insulation interposed between the induction windings and the workpiece, and using alternating current (AC) at an elevated frequency. Further, variable pitch induction windings may be used to generate a non-uniform and calculated heat input profile, such as to compliment the configuration of a screw for transporting material through the barrel.

Owner:COMAINTEL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com