Patents

Literature

131results about "Endless core furnaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

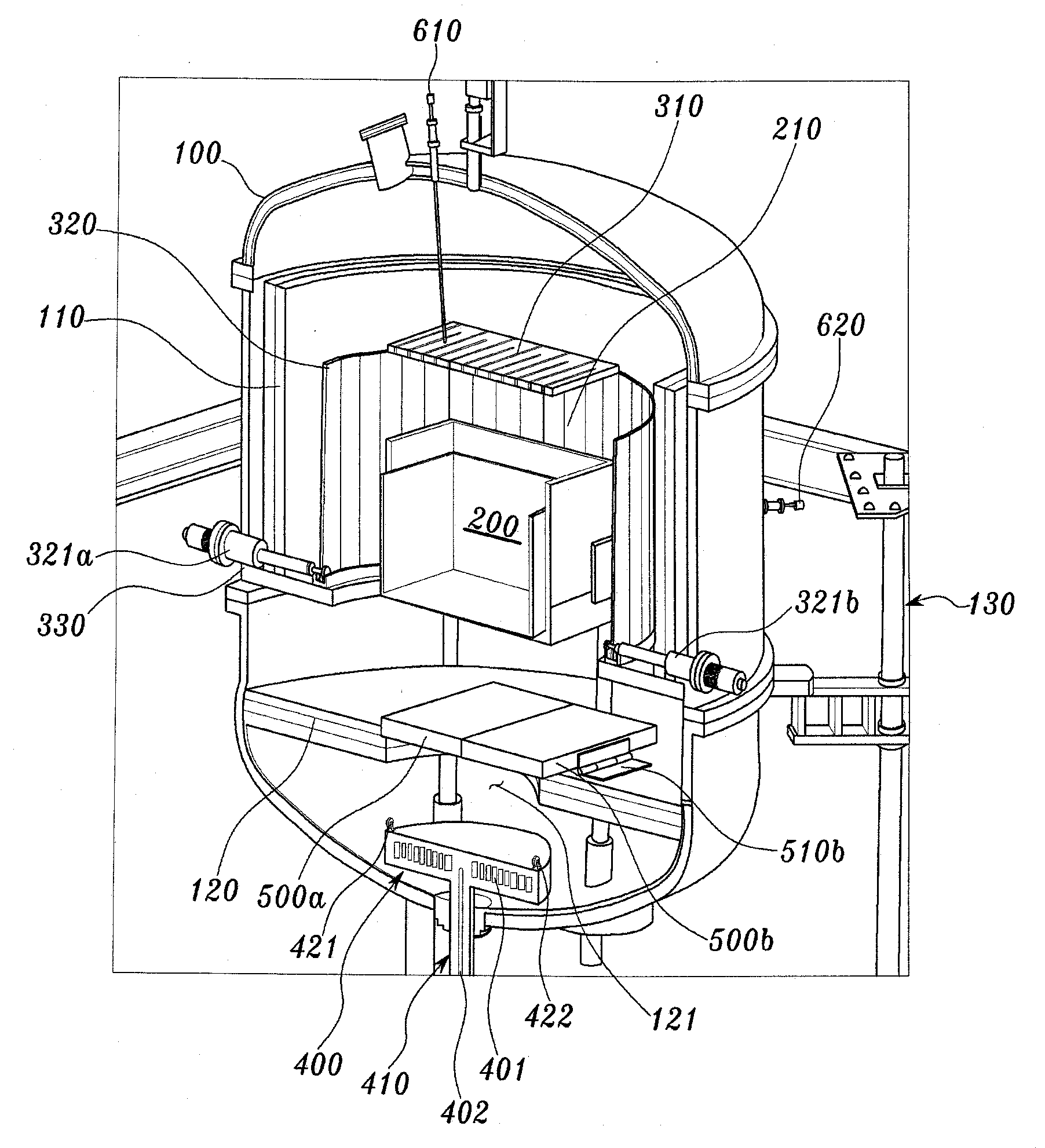

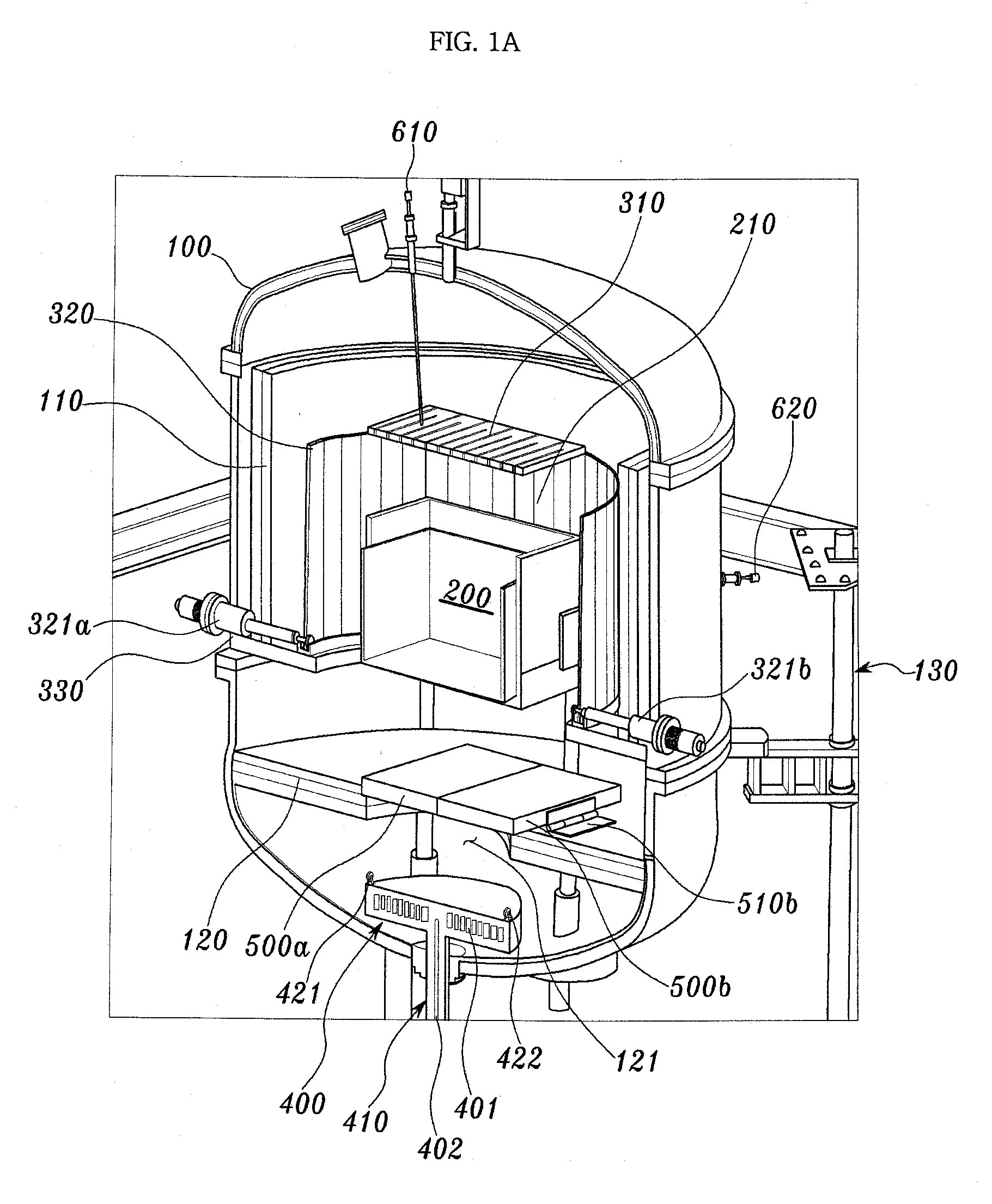

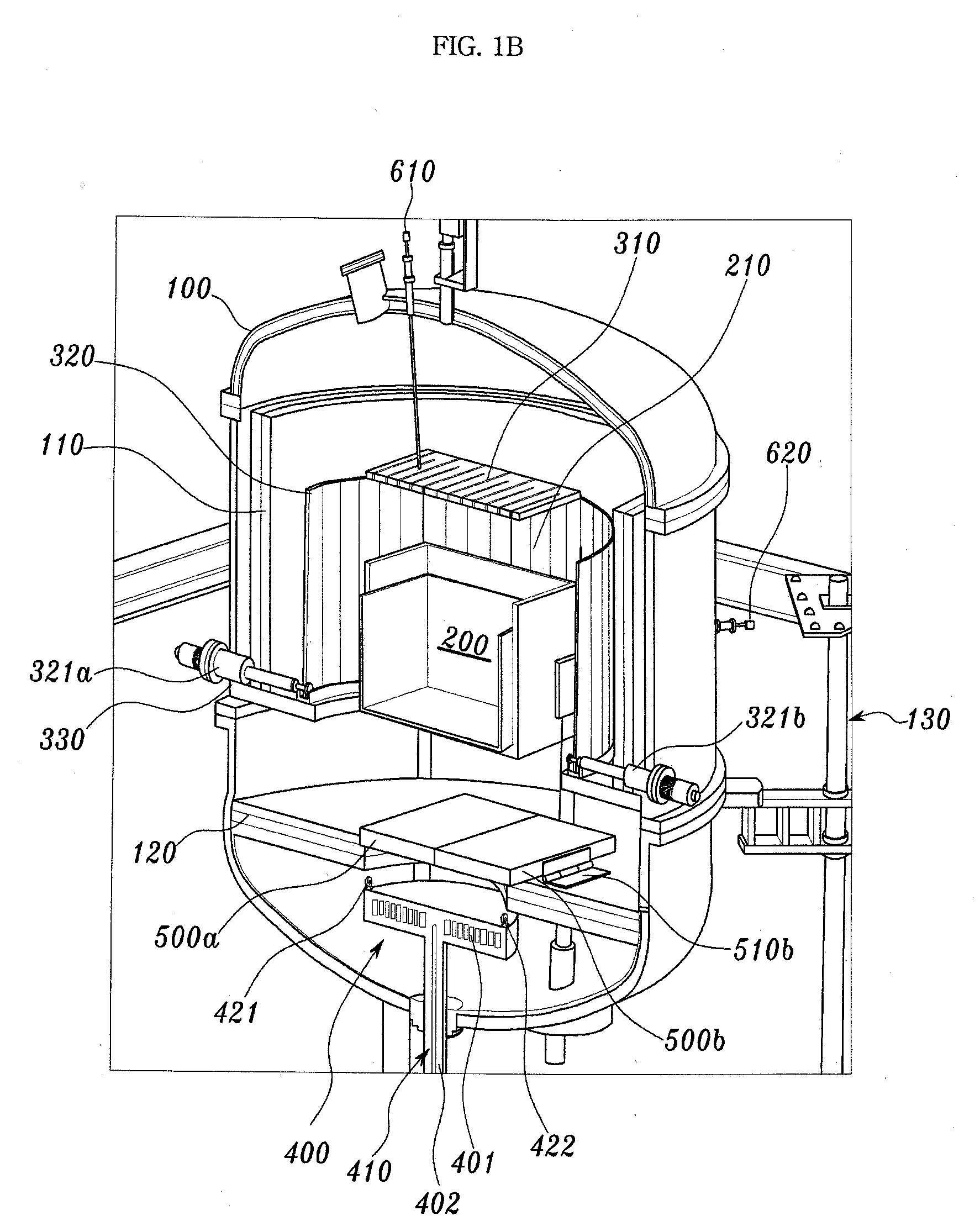

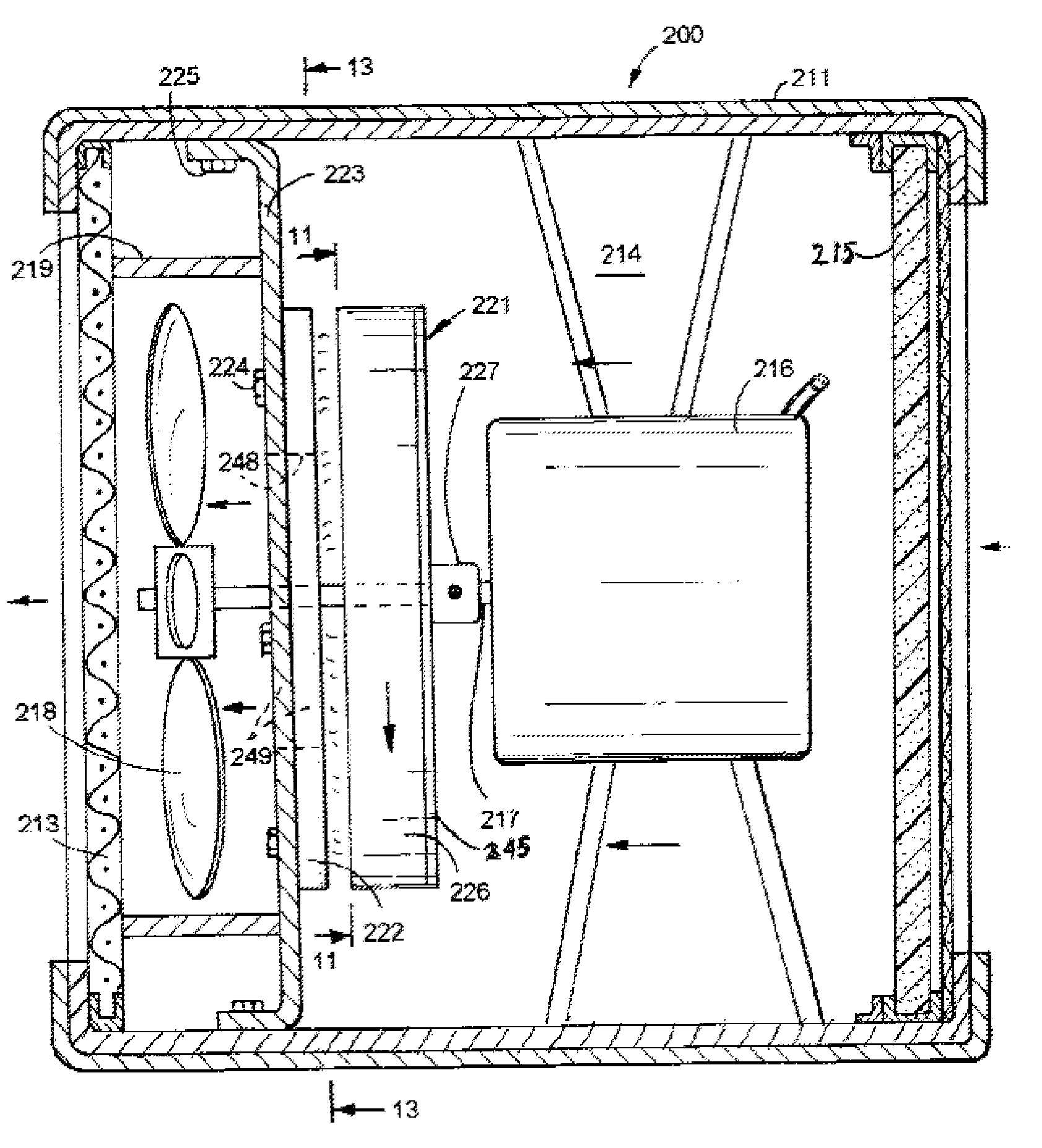

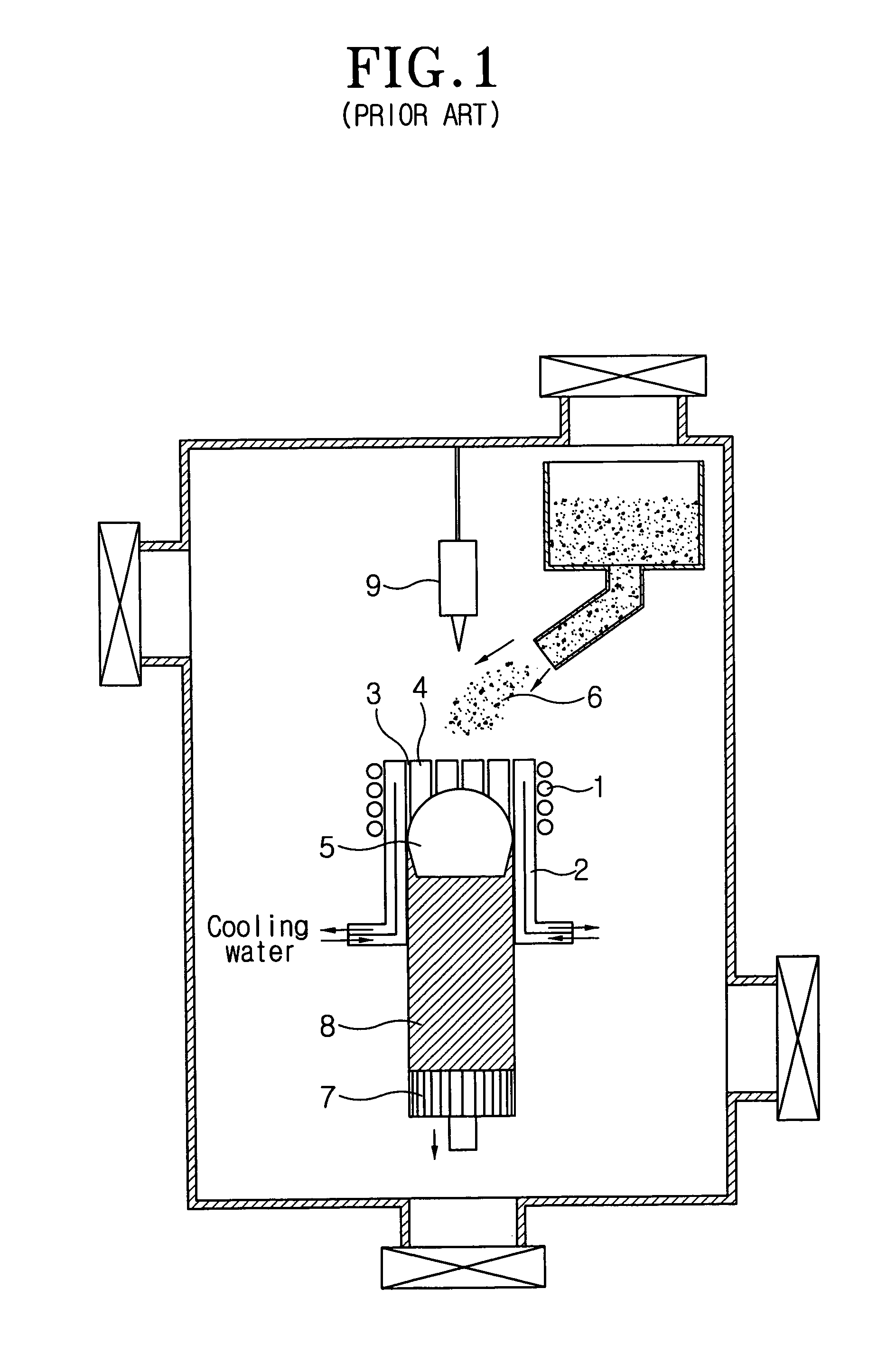

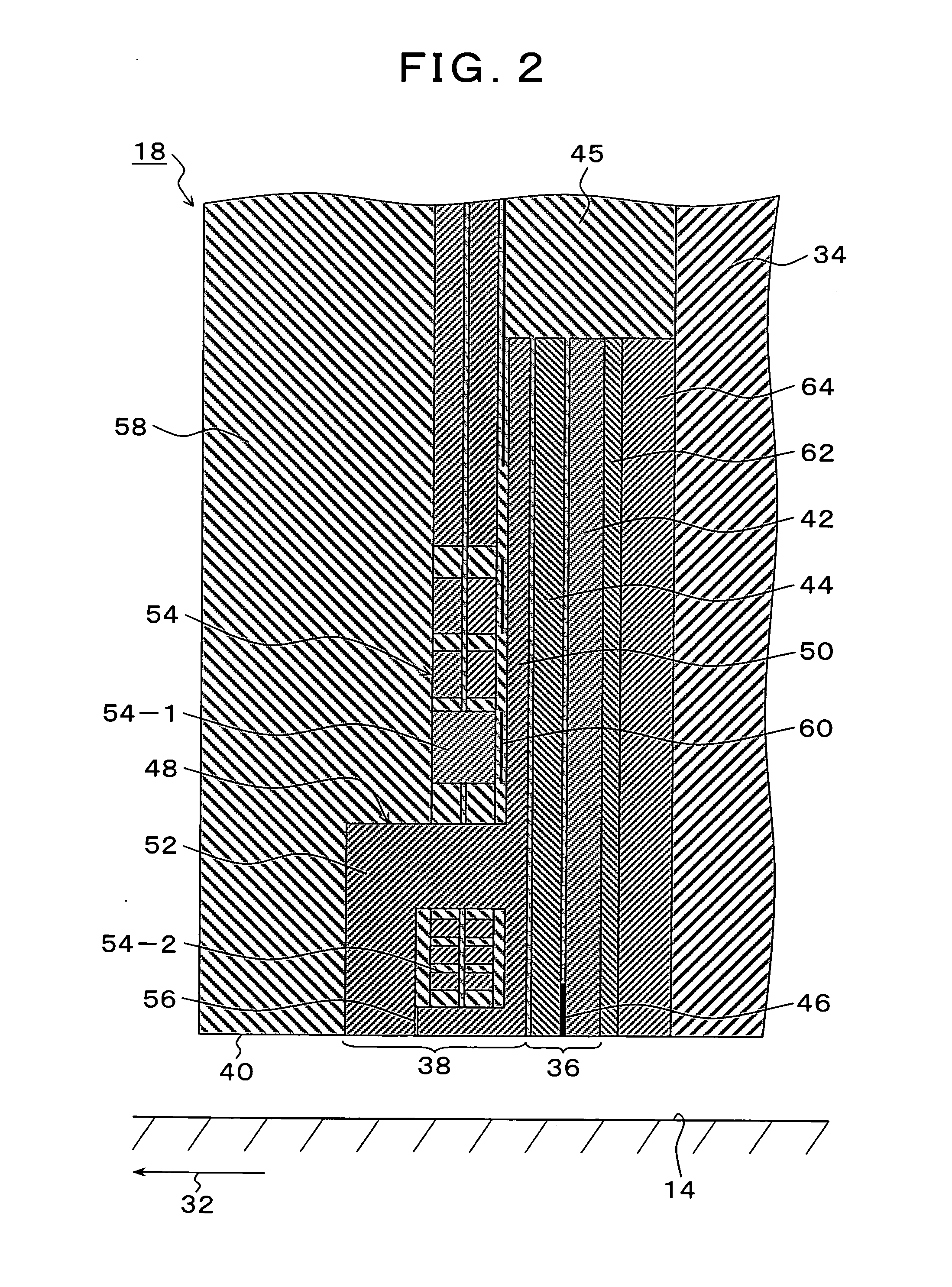

System for heat treatment of semiconductor device

InactiveUS7989736B2Avoid damageIncrease temperatureFurnaces without endless coreSemiconductor/solid-state device manufacturingElectromotive forceSilicon thin film

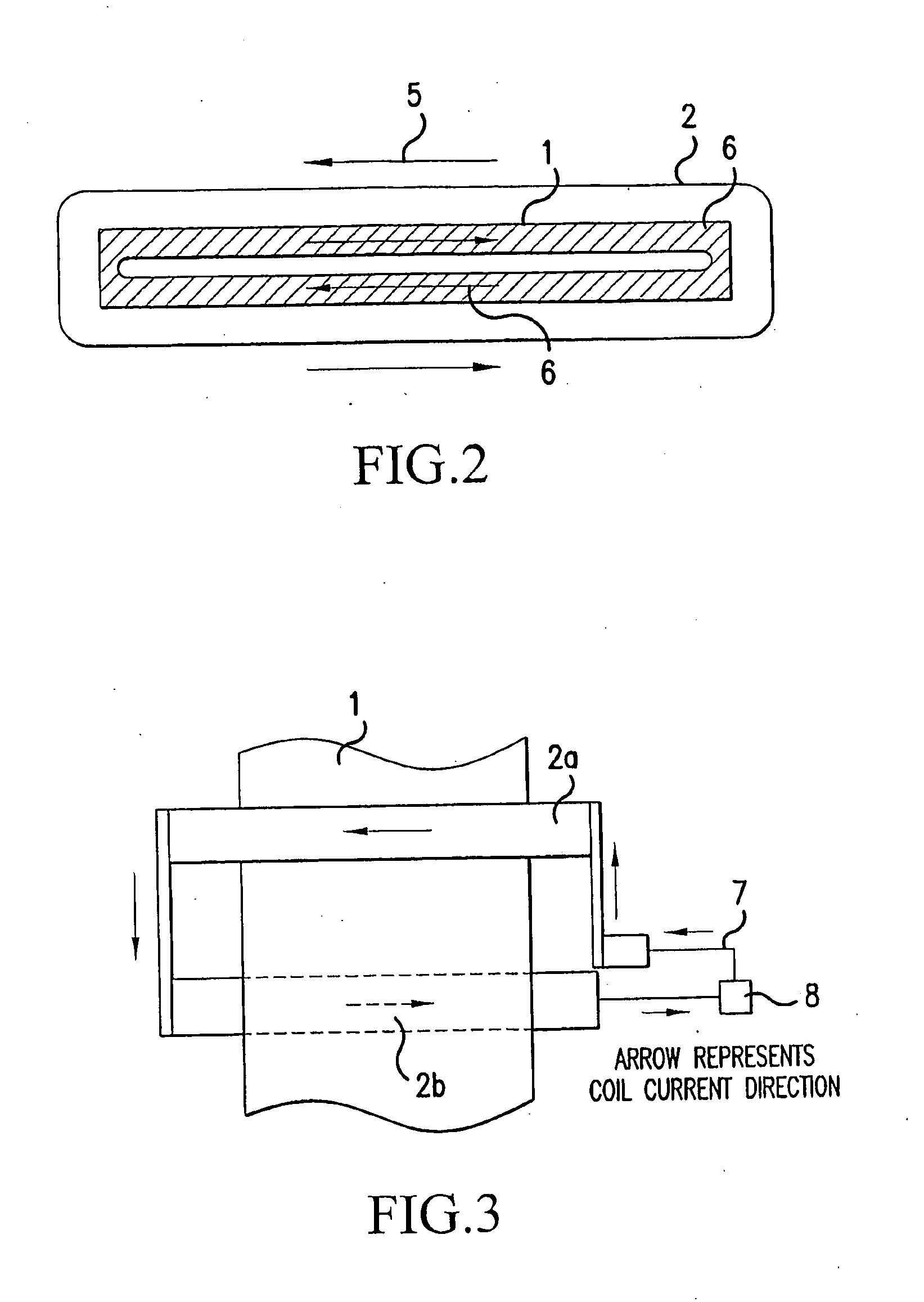

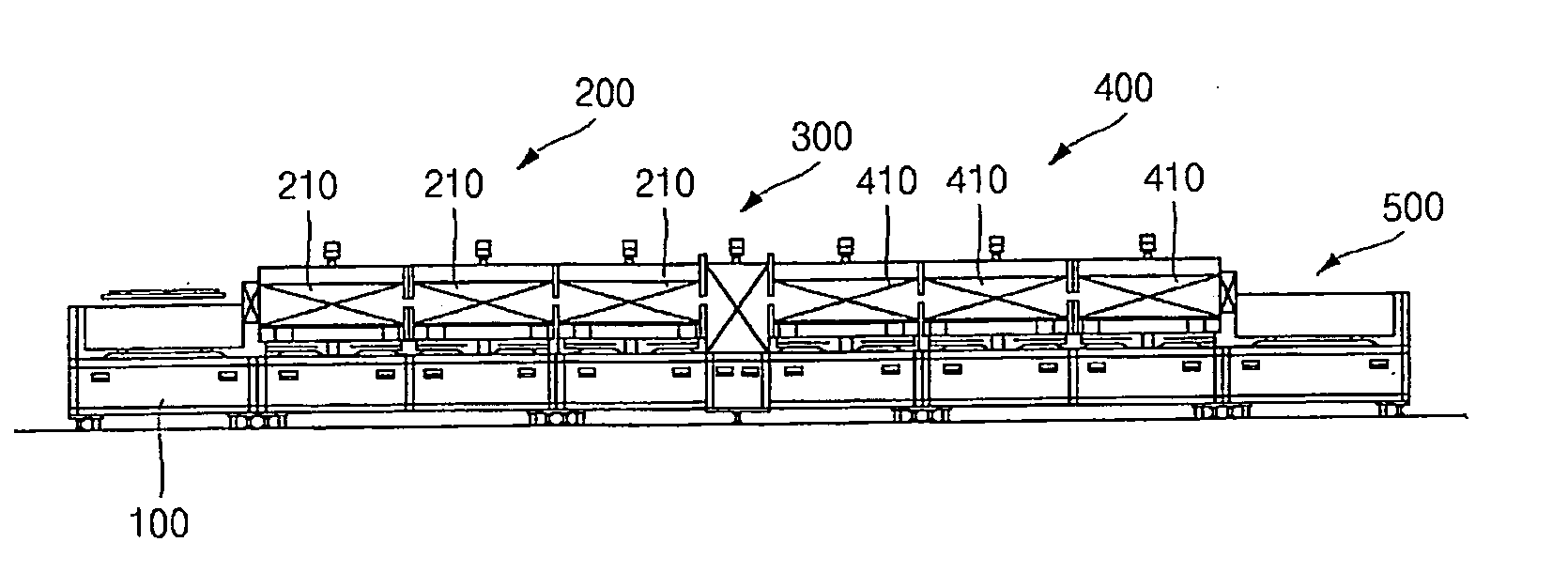

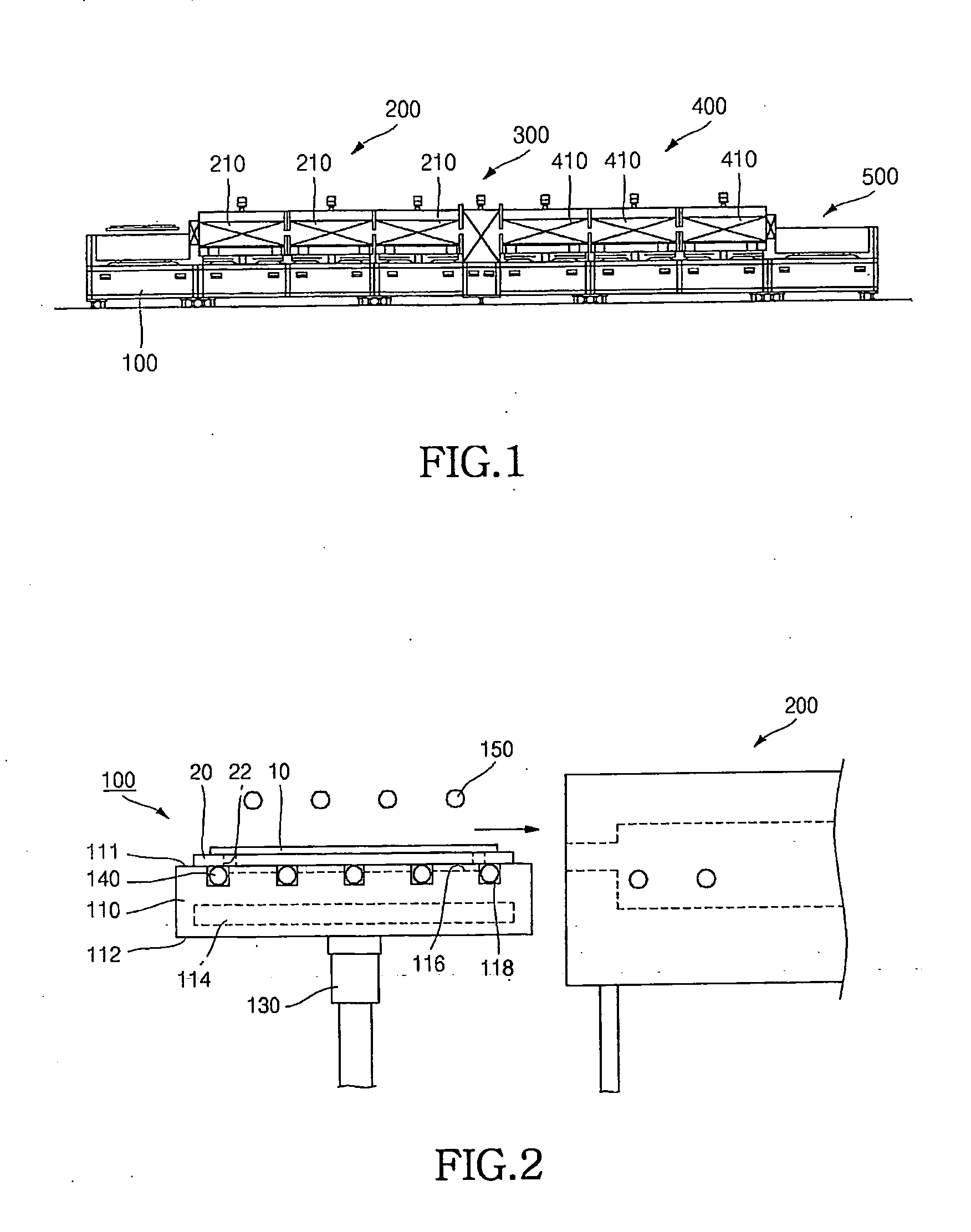

Disclosed is a heat treatment system for semiconductor devices. The heat treatment system is used in a heat treatment process for semiconductor devices, such as a crystallization process for an amorphous silicon thin film or a dopant activation process for a poly-crystalline silicon thin film formed on a surface of a glass substrate of a flat display panel including a liquid crystal display (LCD) or an organic light emitting device (OLED). The heat treatment system transfers a semiconductor device after uniformly preheating the semiconductor device in order to prevent deformation of the semiconductor device during the heat treatment process, rapidly performs the heat treatment process under the high temperature condition by heating the semiconductor device using a lamp heater and induction heat derived from induced electromotive force, and unloads the semiconductor device after uniformly cooling the semiconductor device such that the semiconductor device is prevented from being deformed when the heat treatment process has been finished. The heat treatment system rapidly performs the heat treatment process while preventing deformation of the semiconductor device by gradually heating or cooling the semiconductor device.

Owner:VIATRON TECH INC

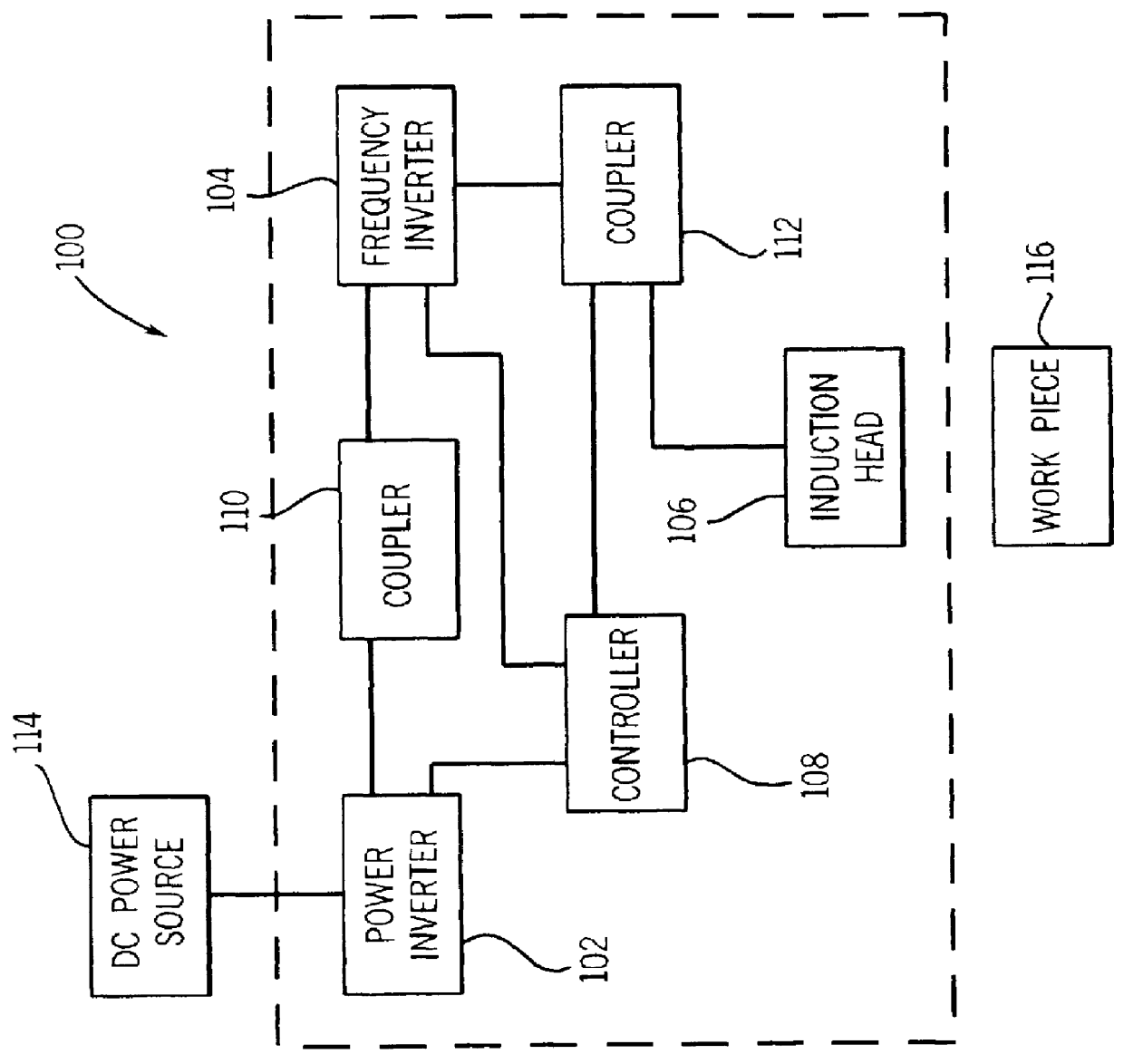

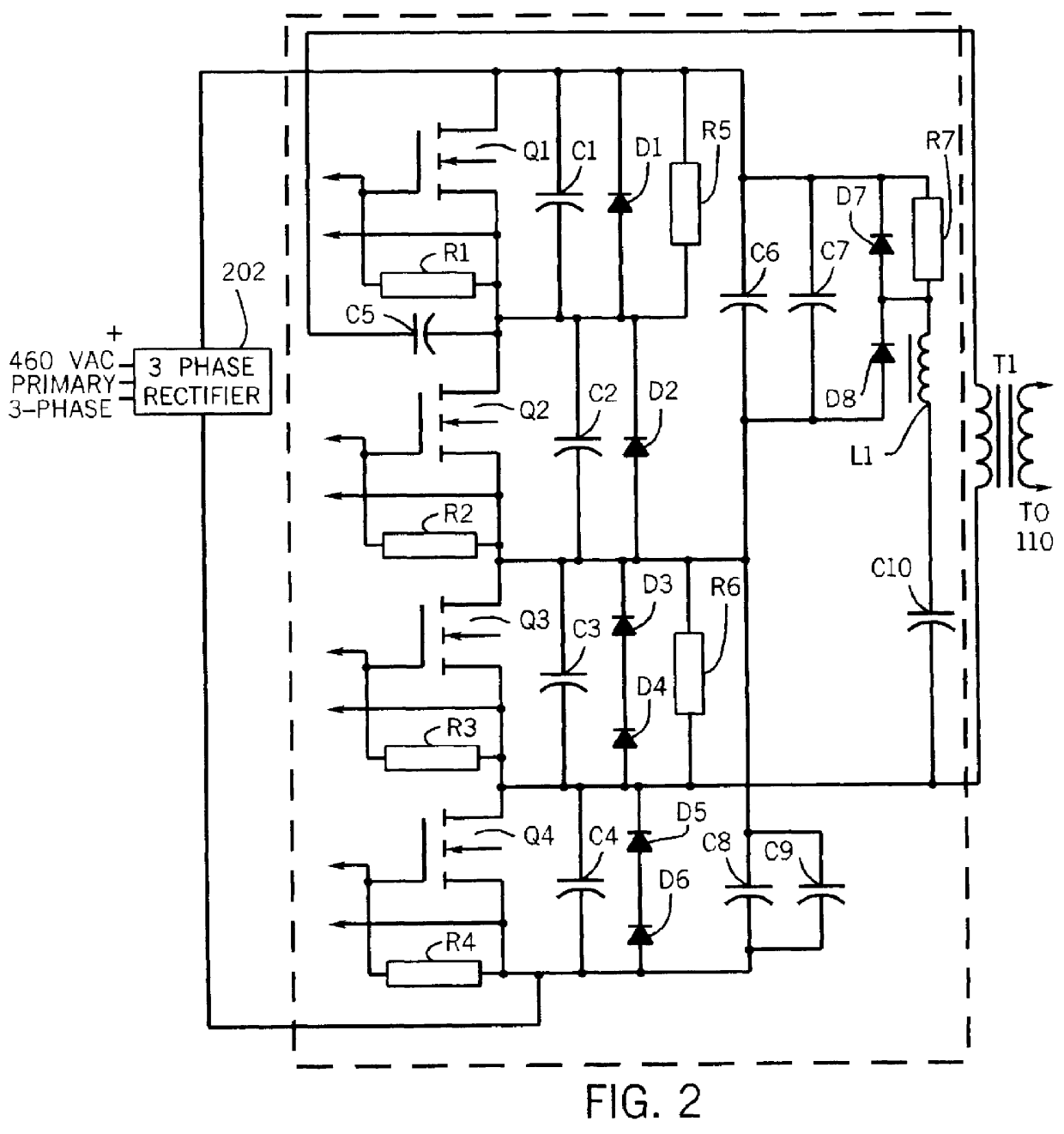

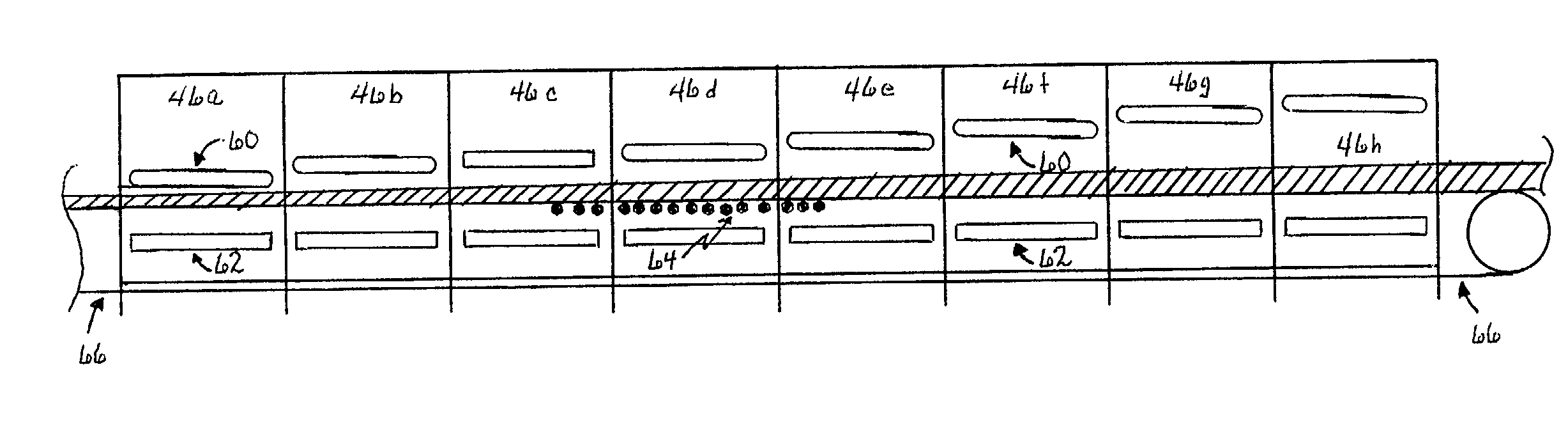

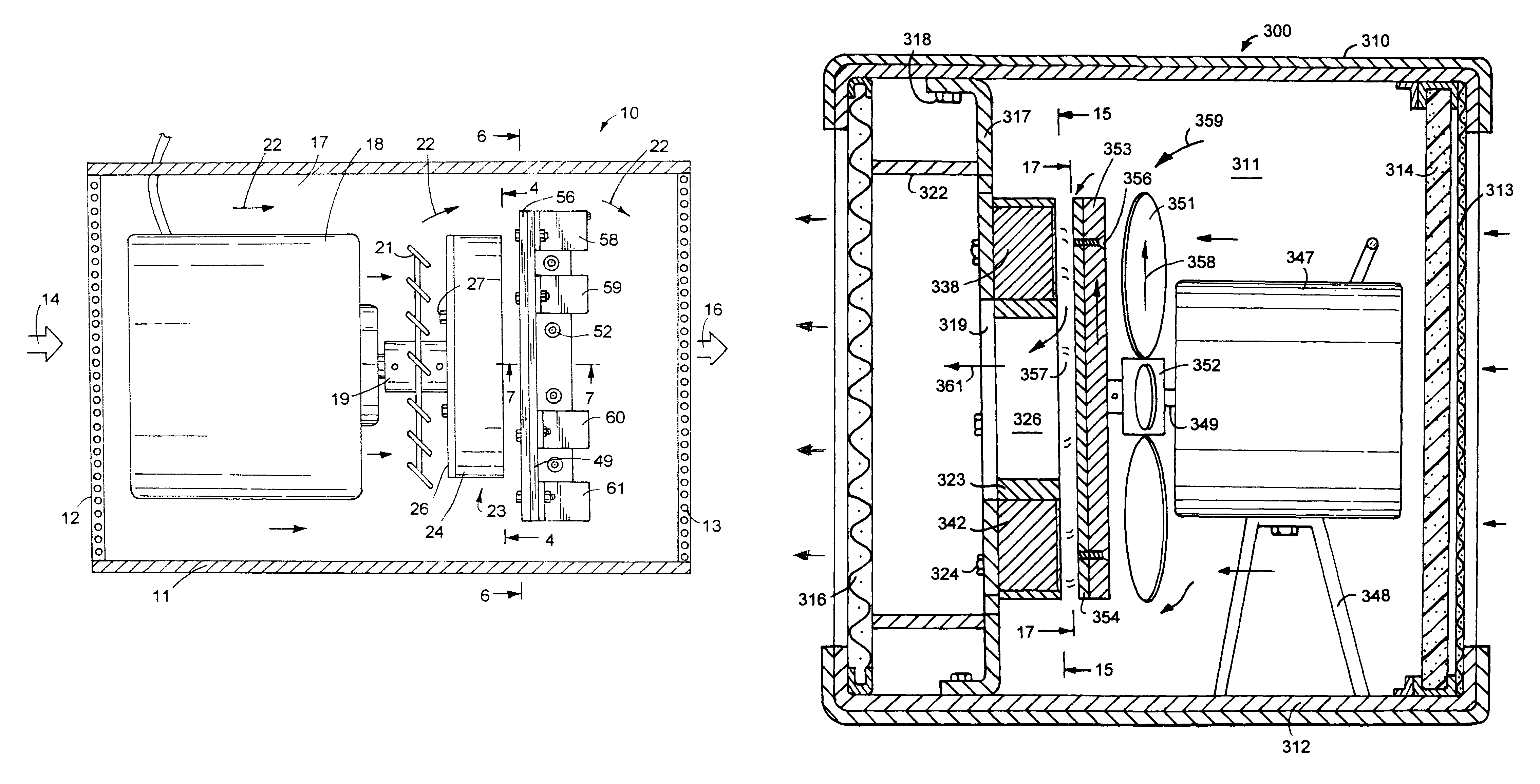

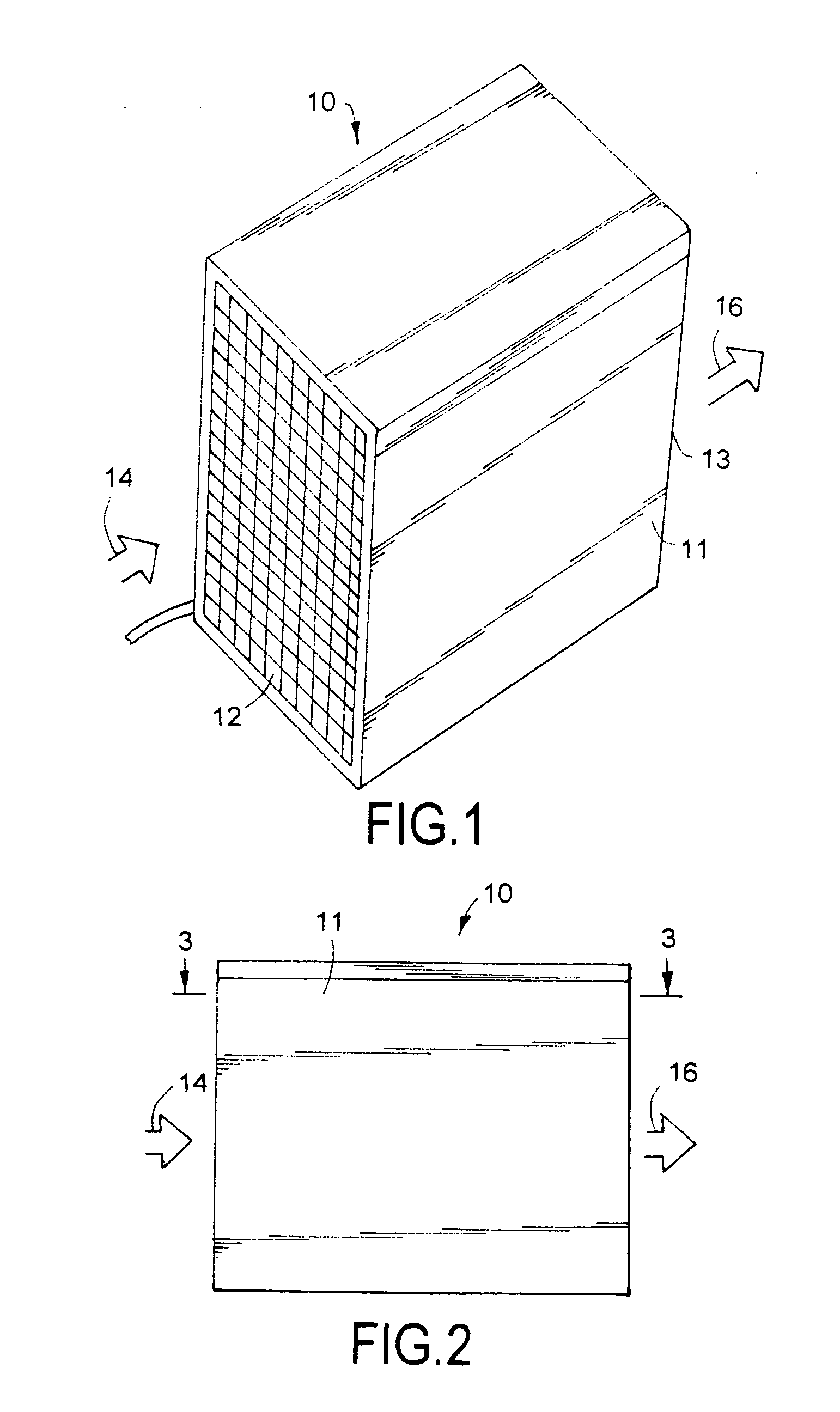

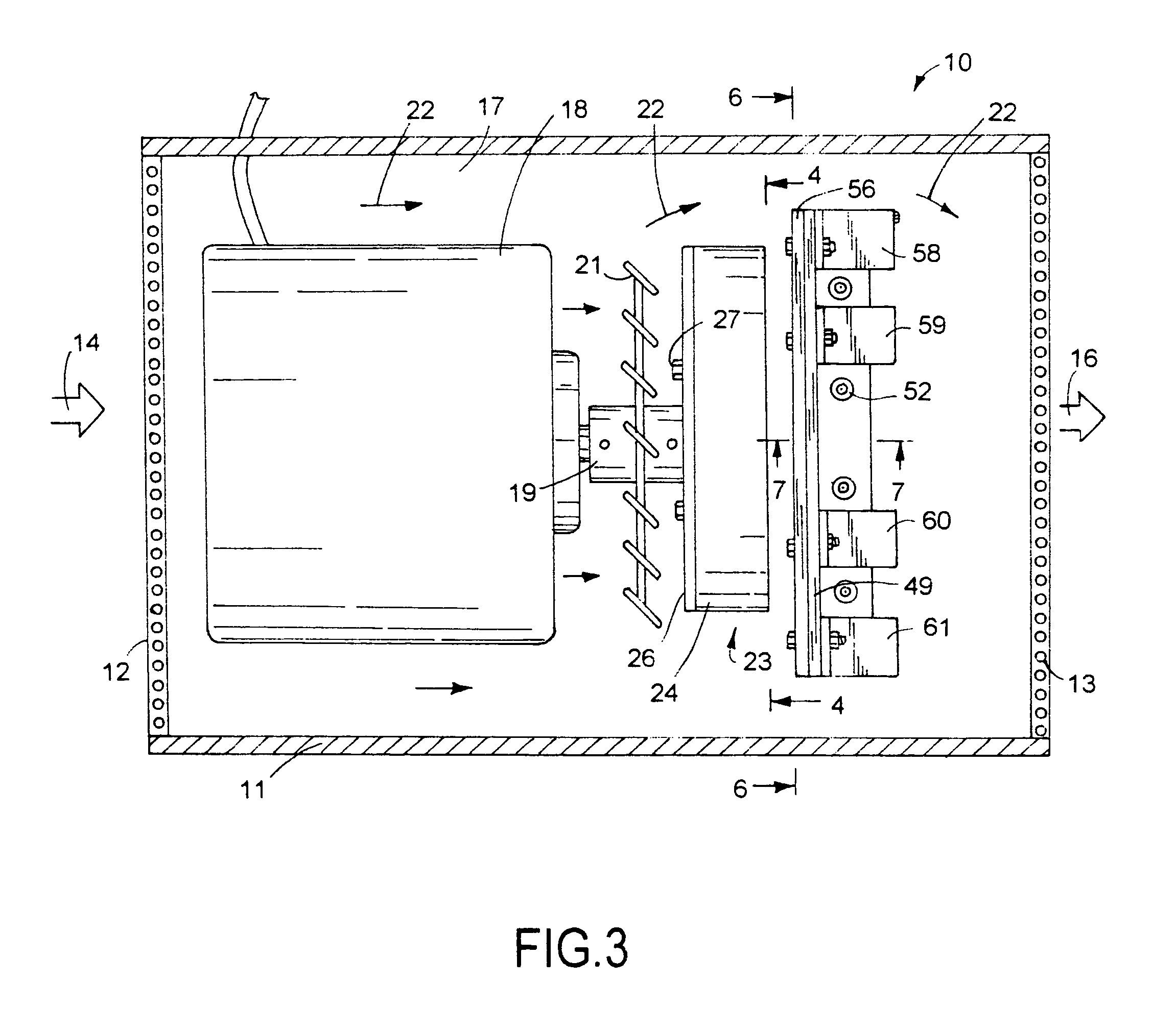

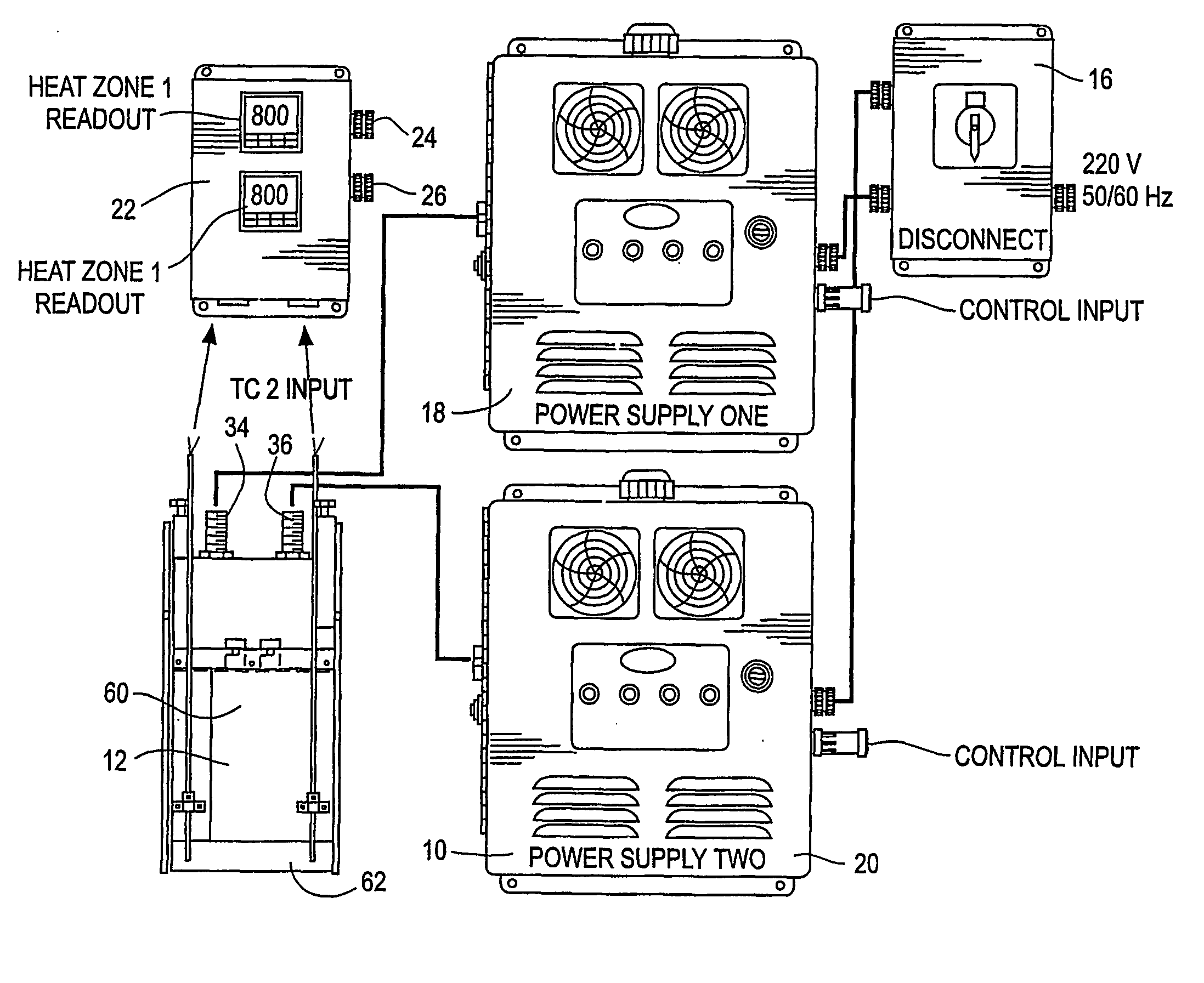

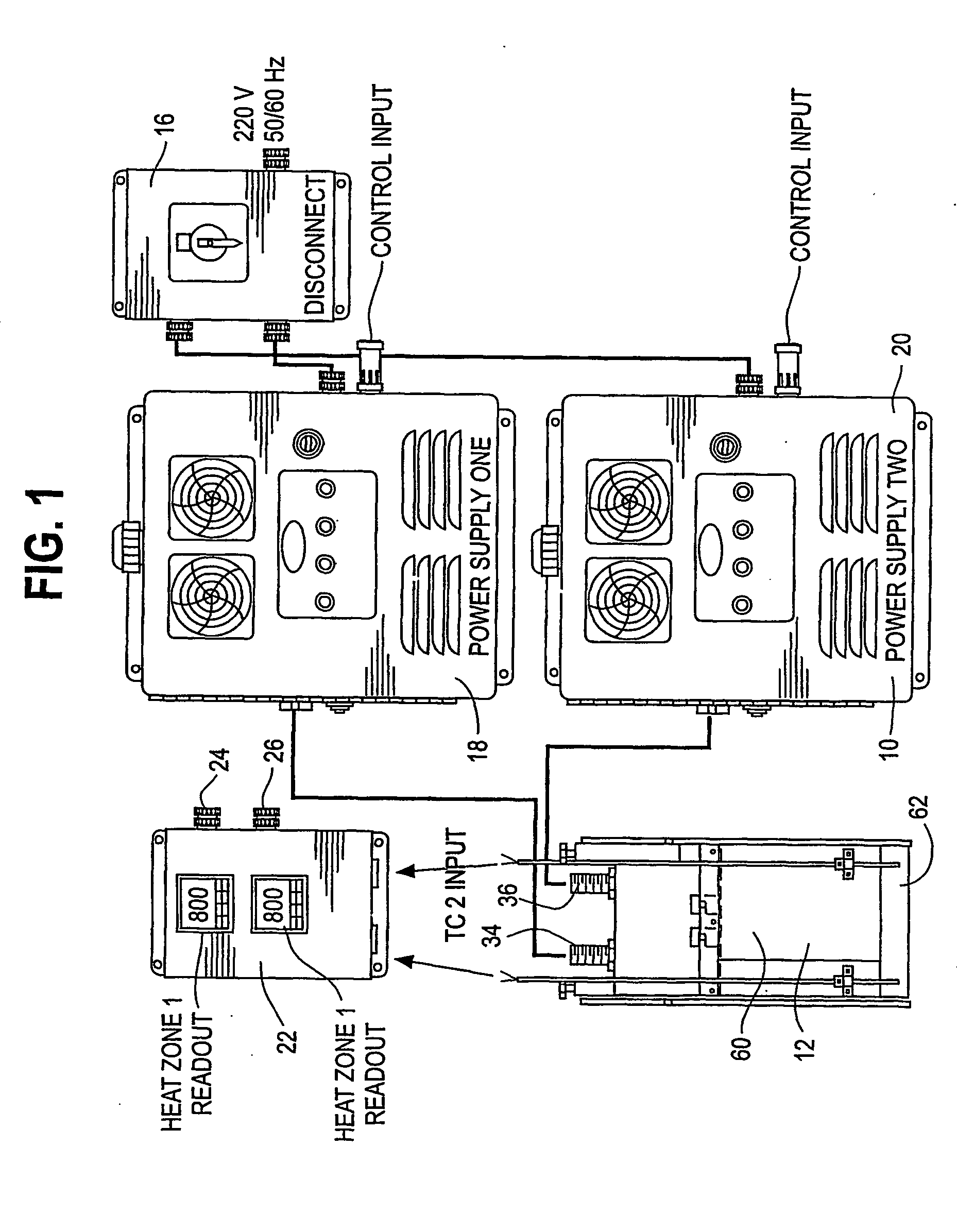

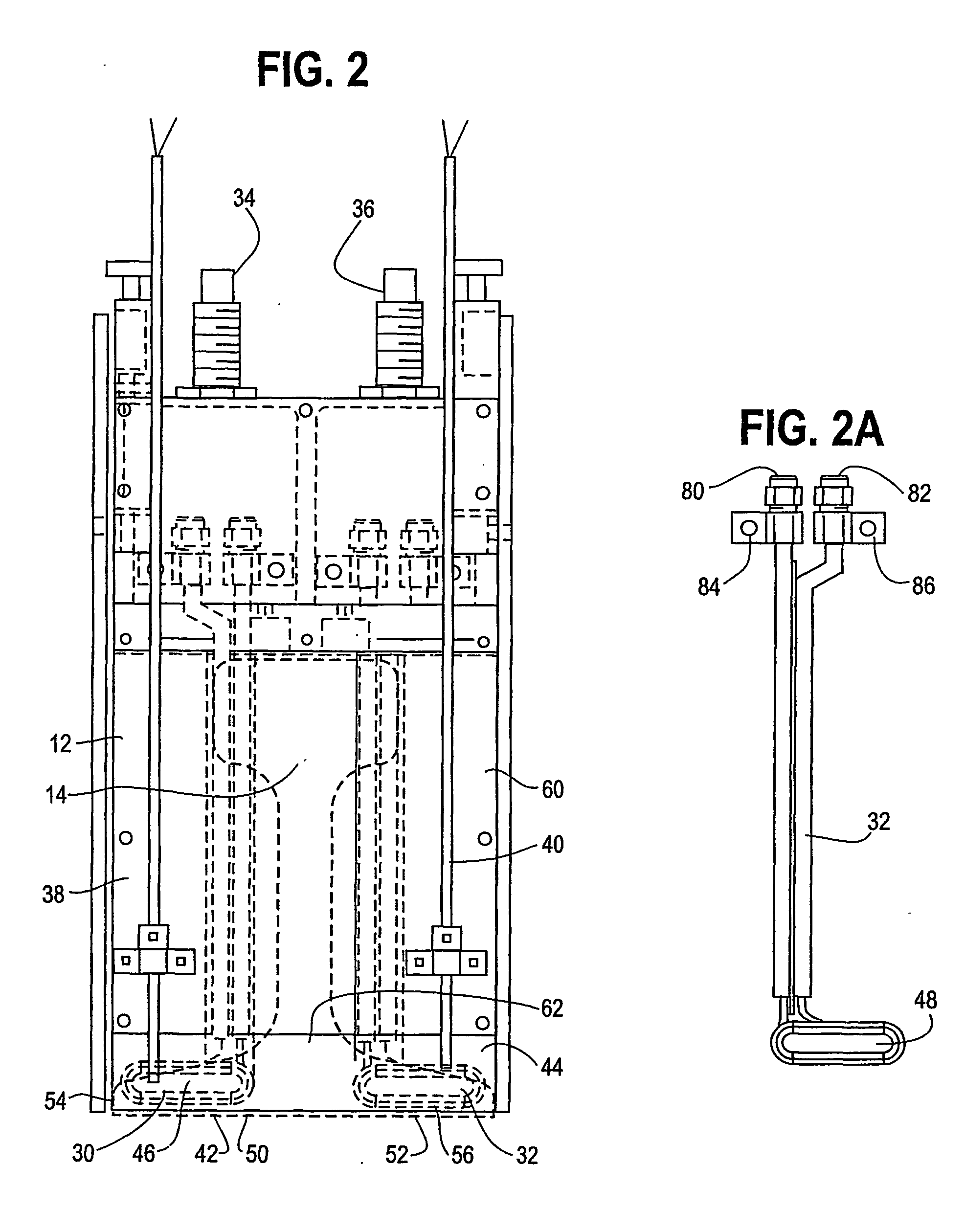

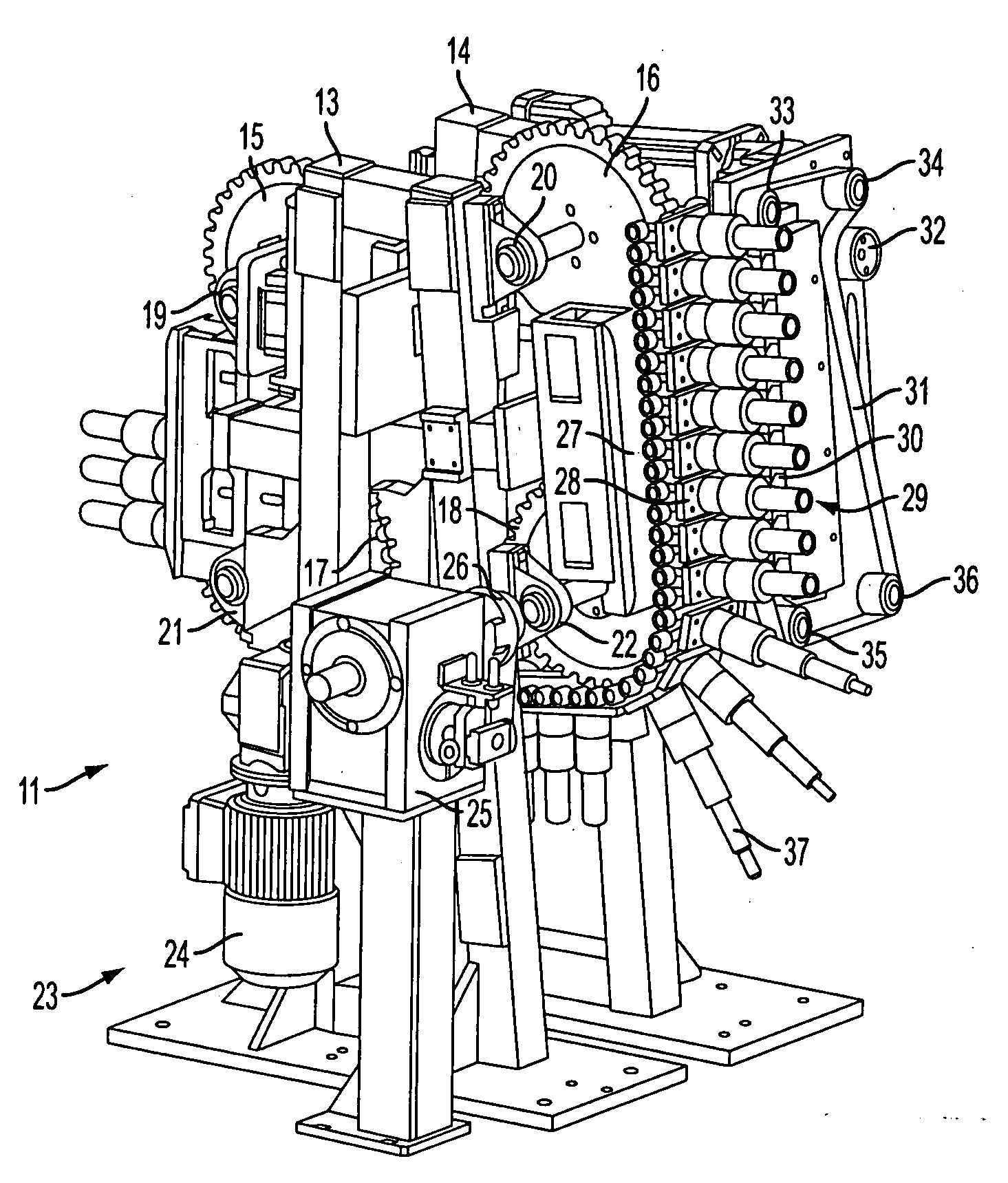

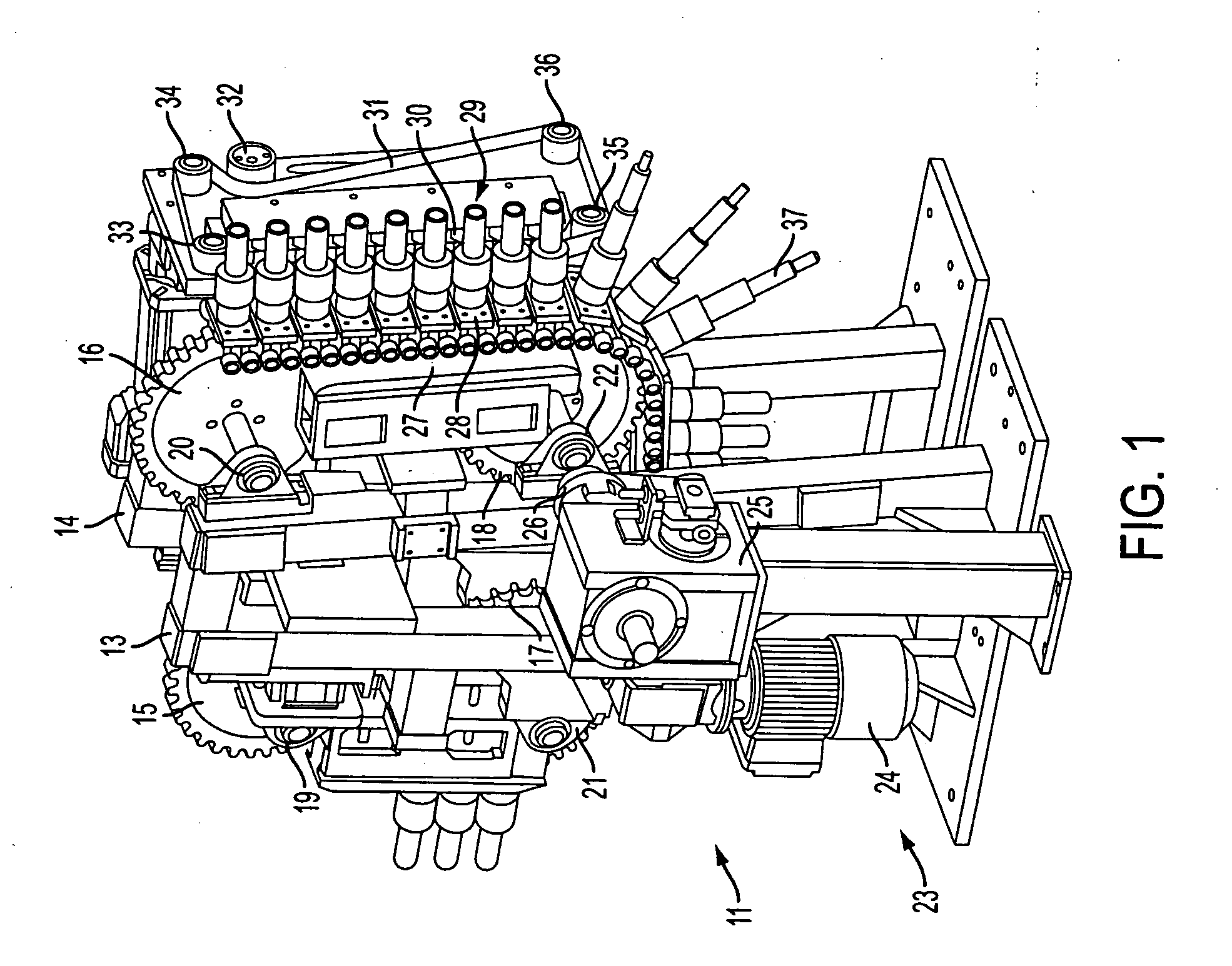

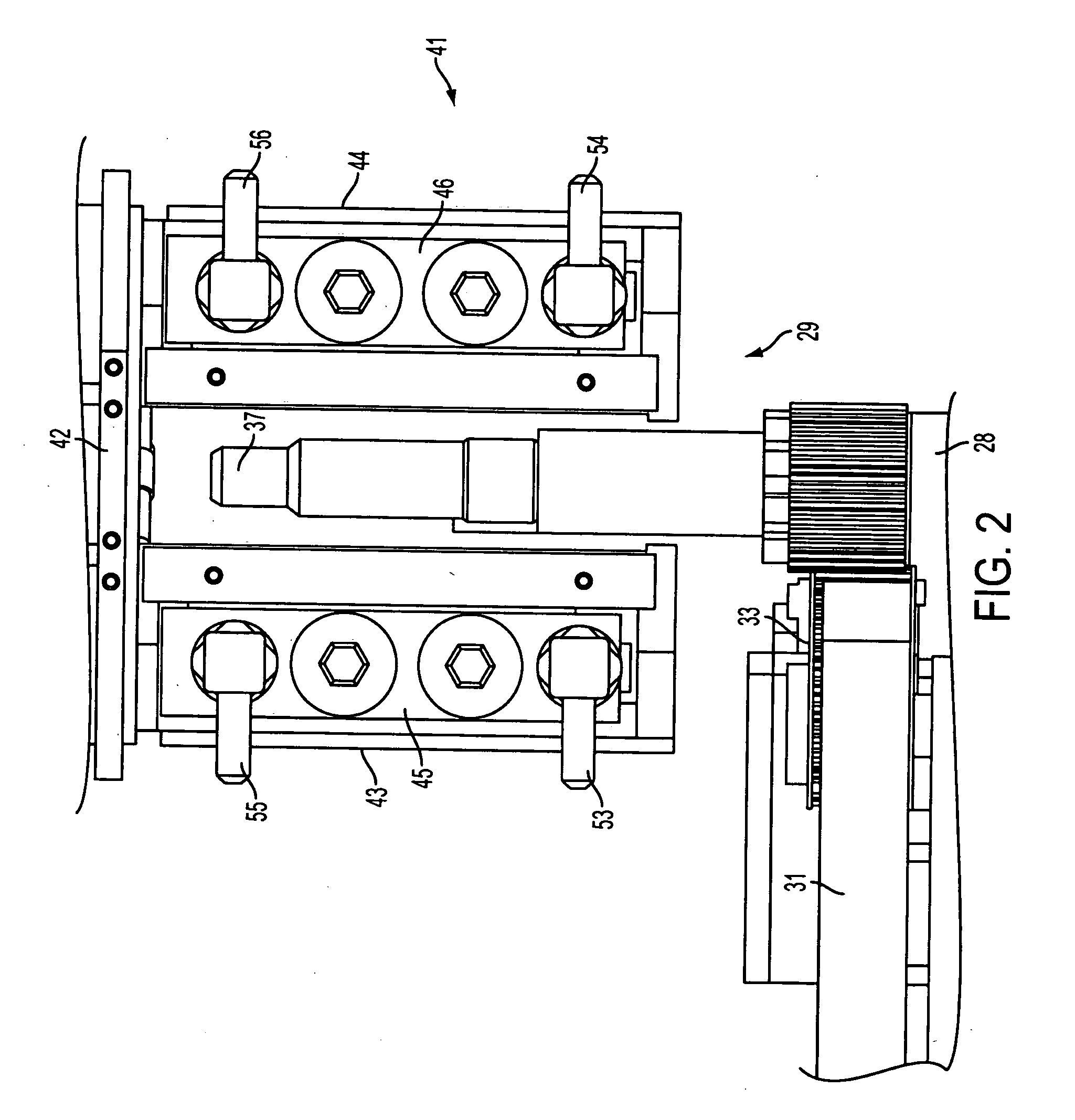

Multiple head inductive heating system

InactiveUS6043471ACoil arrangementsInduction current sourcesHeating systemElectrical and Electronics engineering

A system and method for inductively heating a workpiece includes a controller and a plurality of power supplies that receive and send signals to the controller. Induction heads receive power from the power supplies. The induction heads may be aligned with adjacent segments of the workpiece, and can span the perimeter of the workpiece. The gap between adjacent induction heads is less than one half the size of the adjacent induction heads, and preferably the induction heads abut or substantially abut. Each of the power supplies include feedback for controlling the power delivered to the segments of the workpiece. In alternative embodiments the feedback may be based on the current or power provided to the induction heads, or the power provided to the workpiece.

Owner:ILLINOIS TOOL WORKS INC

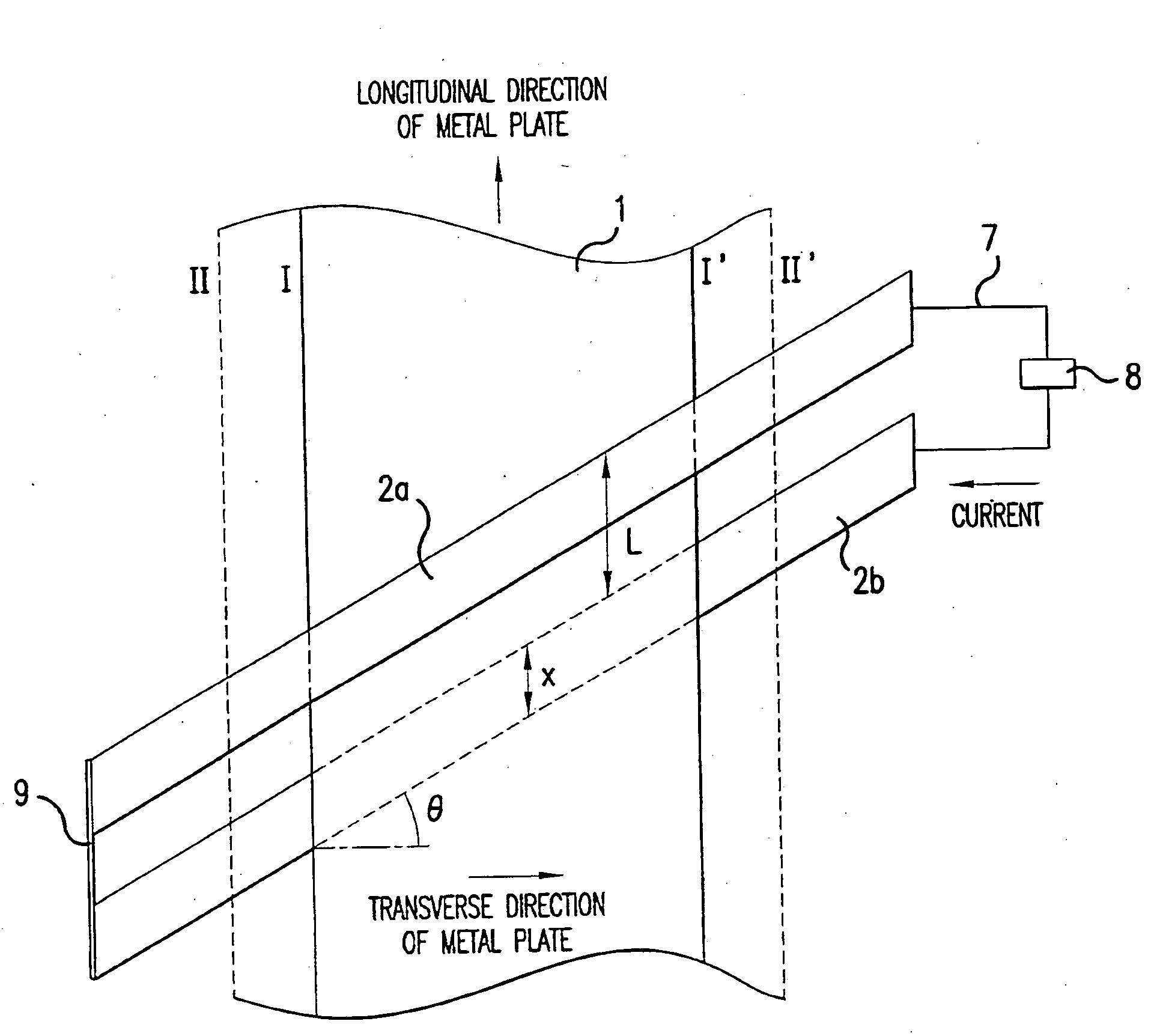

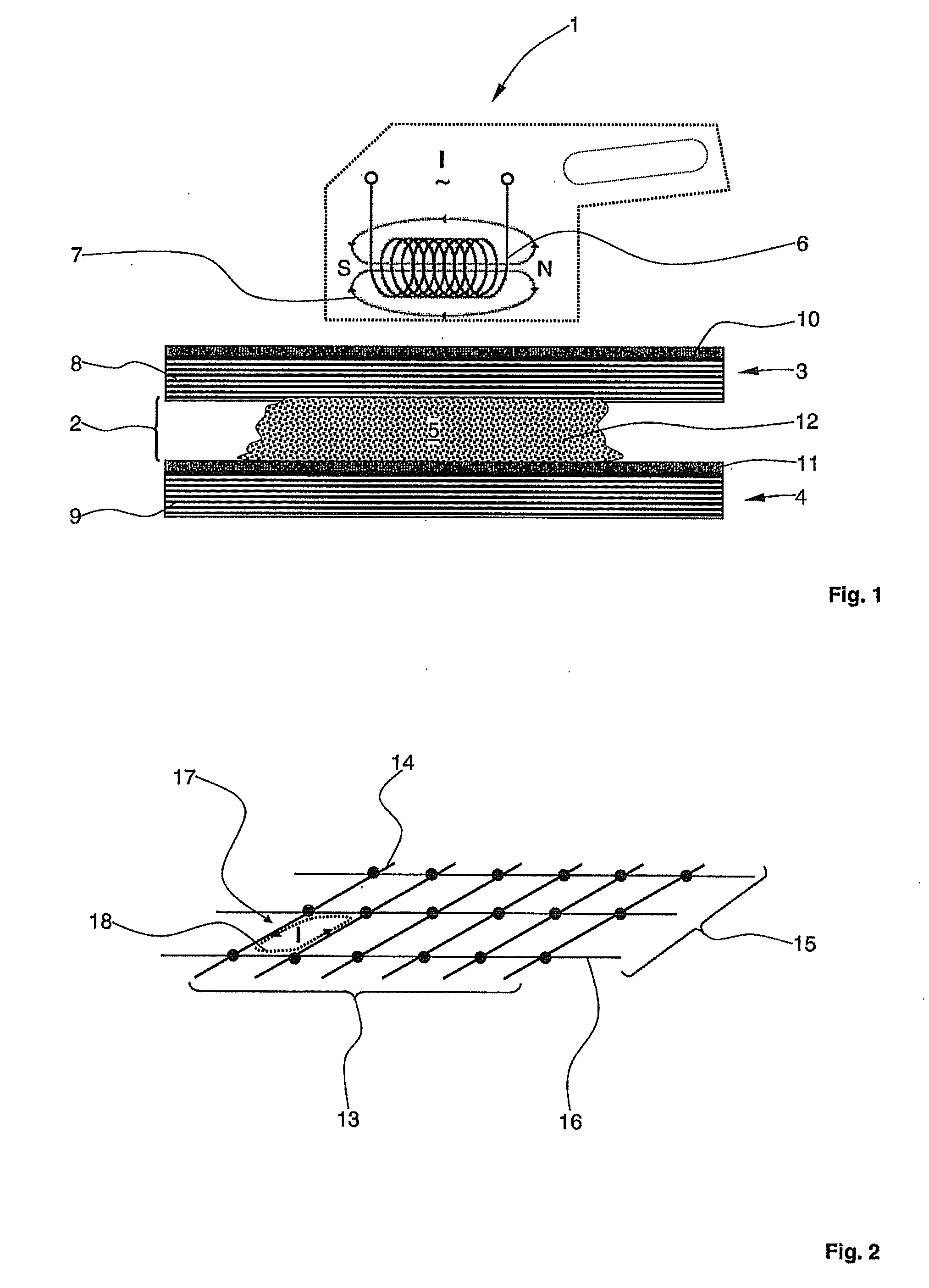

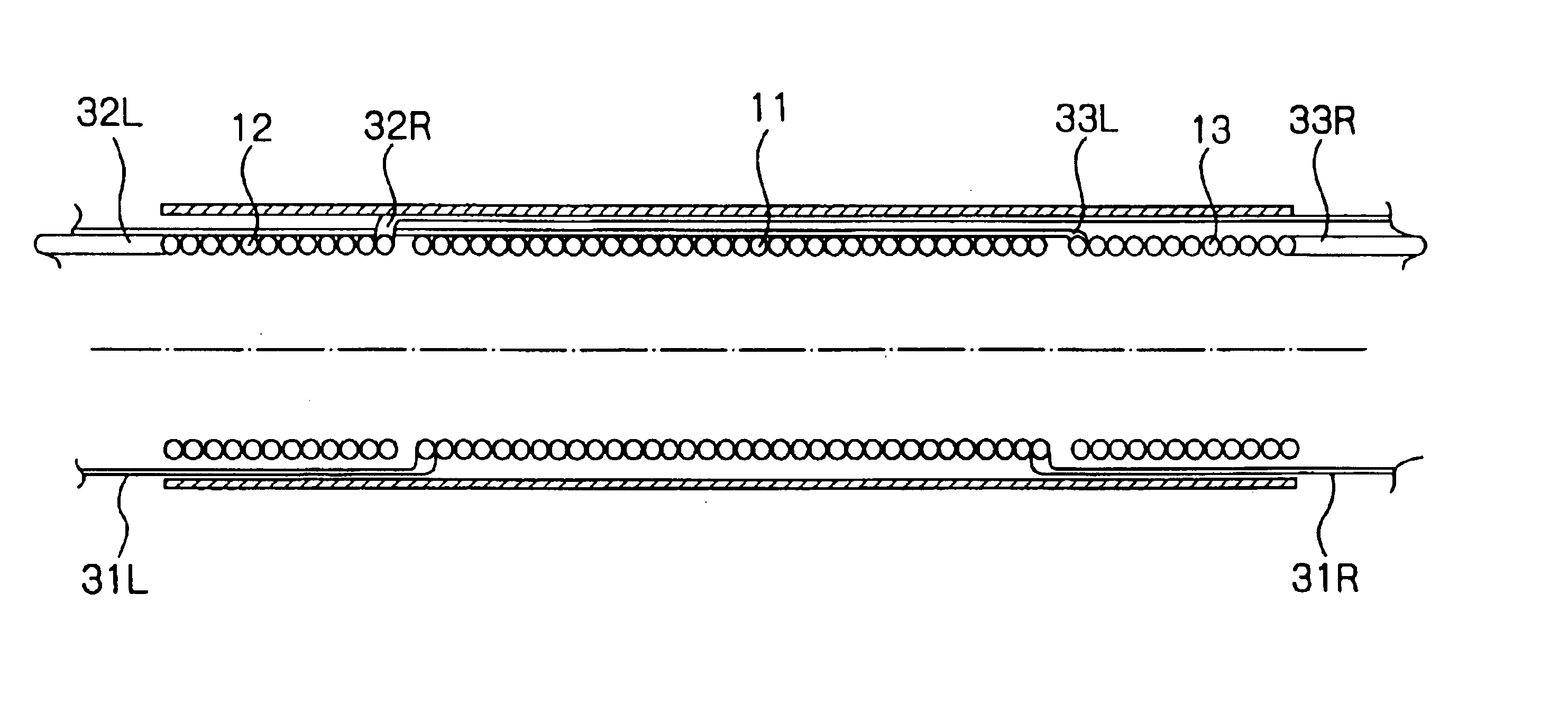

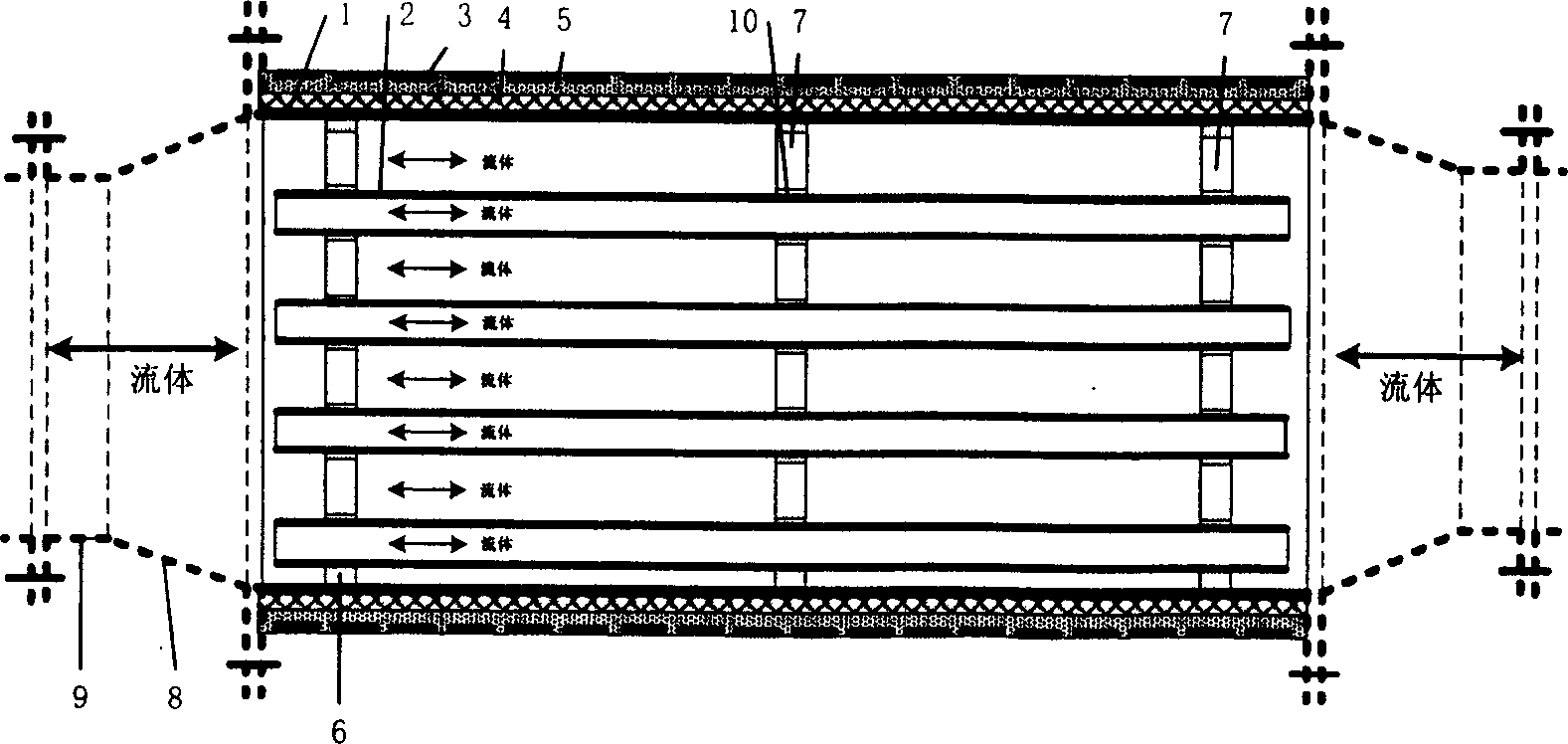

Induction Heating Device for a Metal Plate

ActiveUS20080264932A1Avoid overall overheatingEasy to realize desired temperature distributionLiquid surface applicatorsCoil arrangementsOblique angleMetal

An induction heating apparatus for heating a traveling metal plate includes an induction coil for surrounding the metal plate. The induction coil includes an upper induction coil for being located above the metal plate and a lower induction coil for being located below the metal plate. The upper and lower induction coils are spaced from each other in a longitudinal direction of the metal plate a constant distance across a transverse direction of the metal plate. Each of the upper induction coil and the lower induction coil is arranged obliquely at an edge area of the metal plate so as to form an oblique angle with the transverse direction of the metal plate.

Owner:NIPPON STEEL CORP

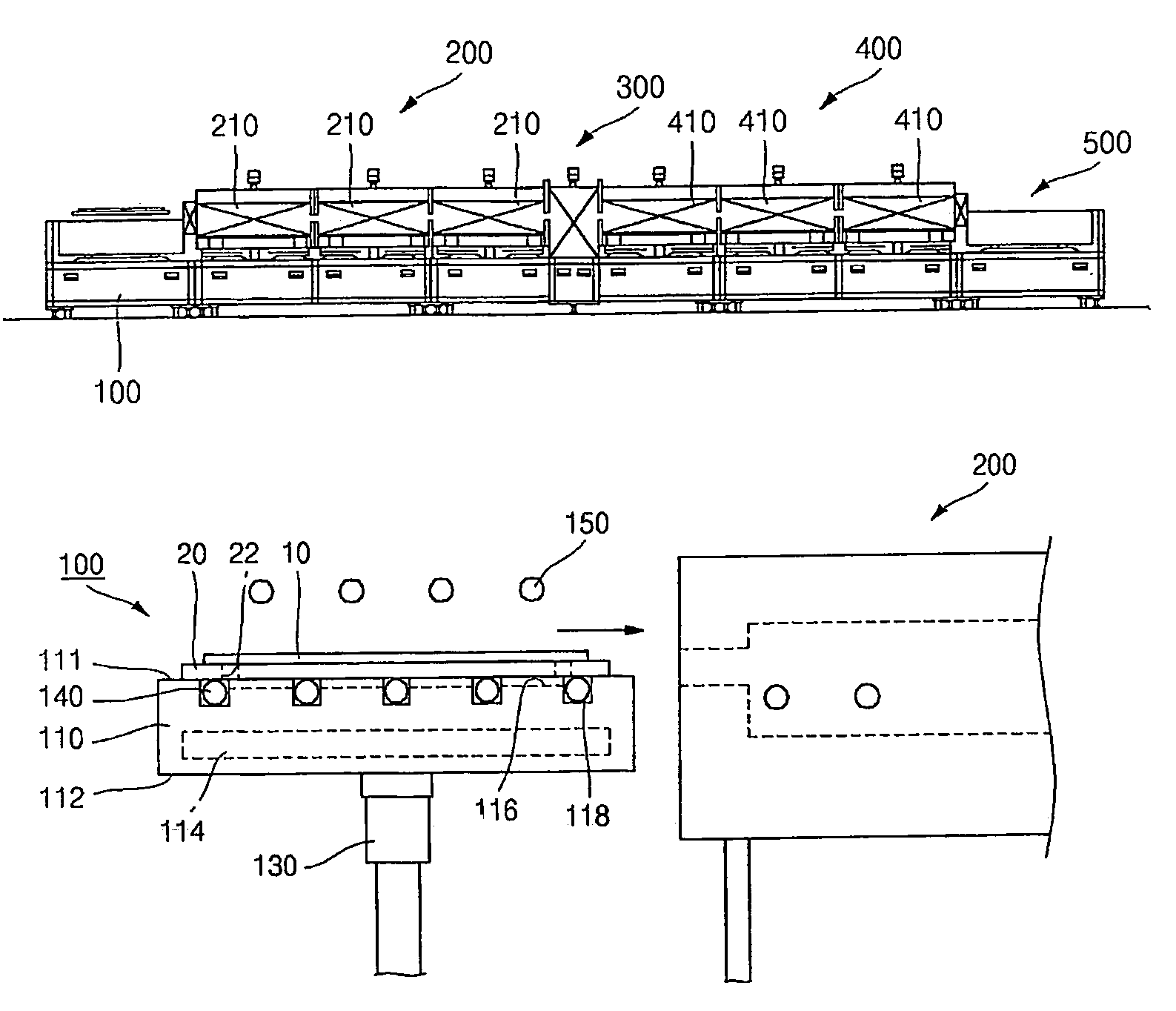

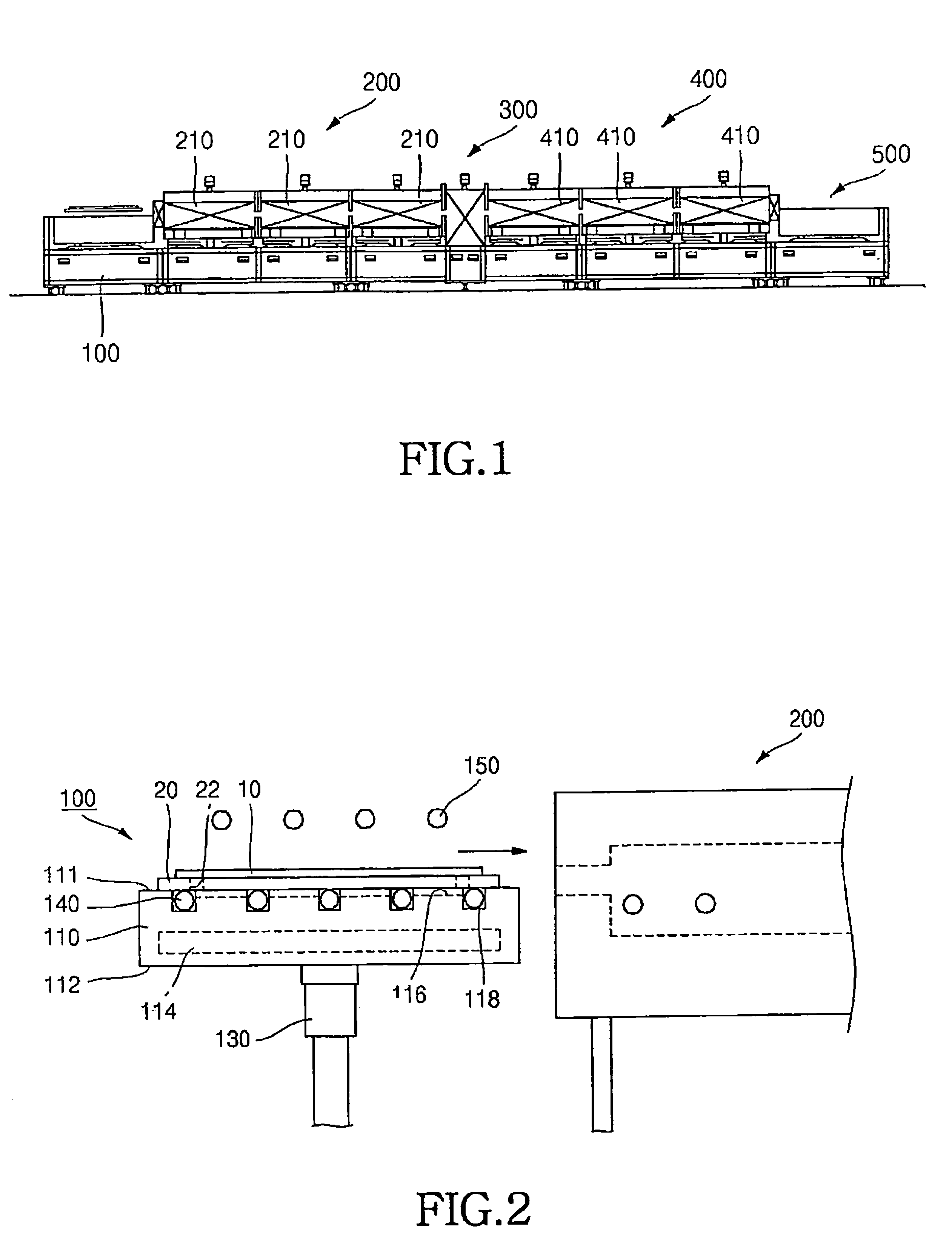

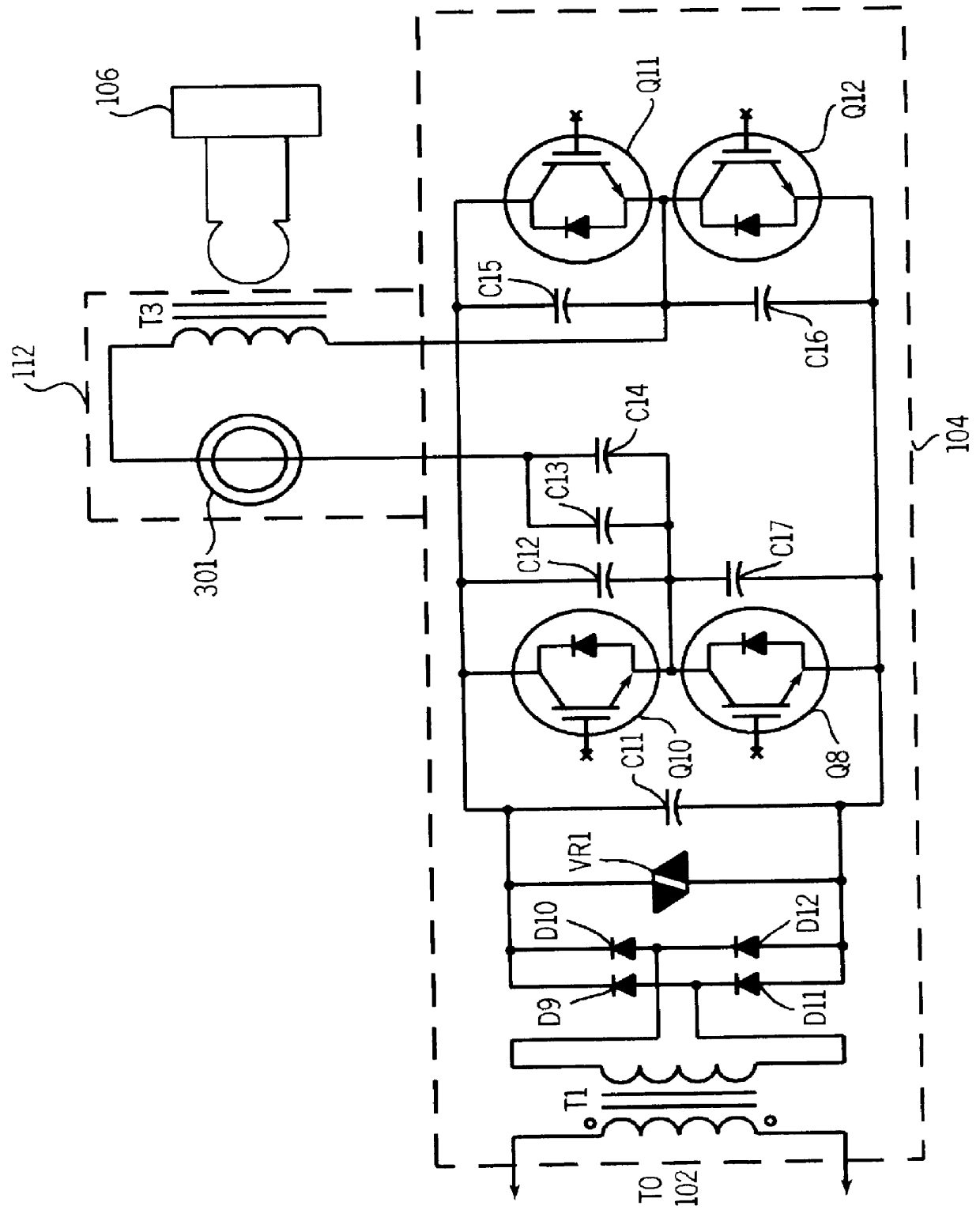

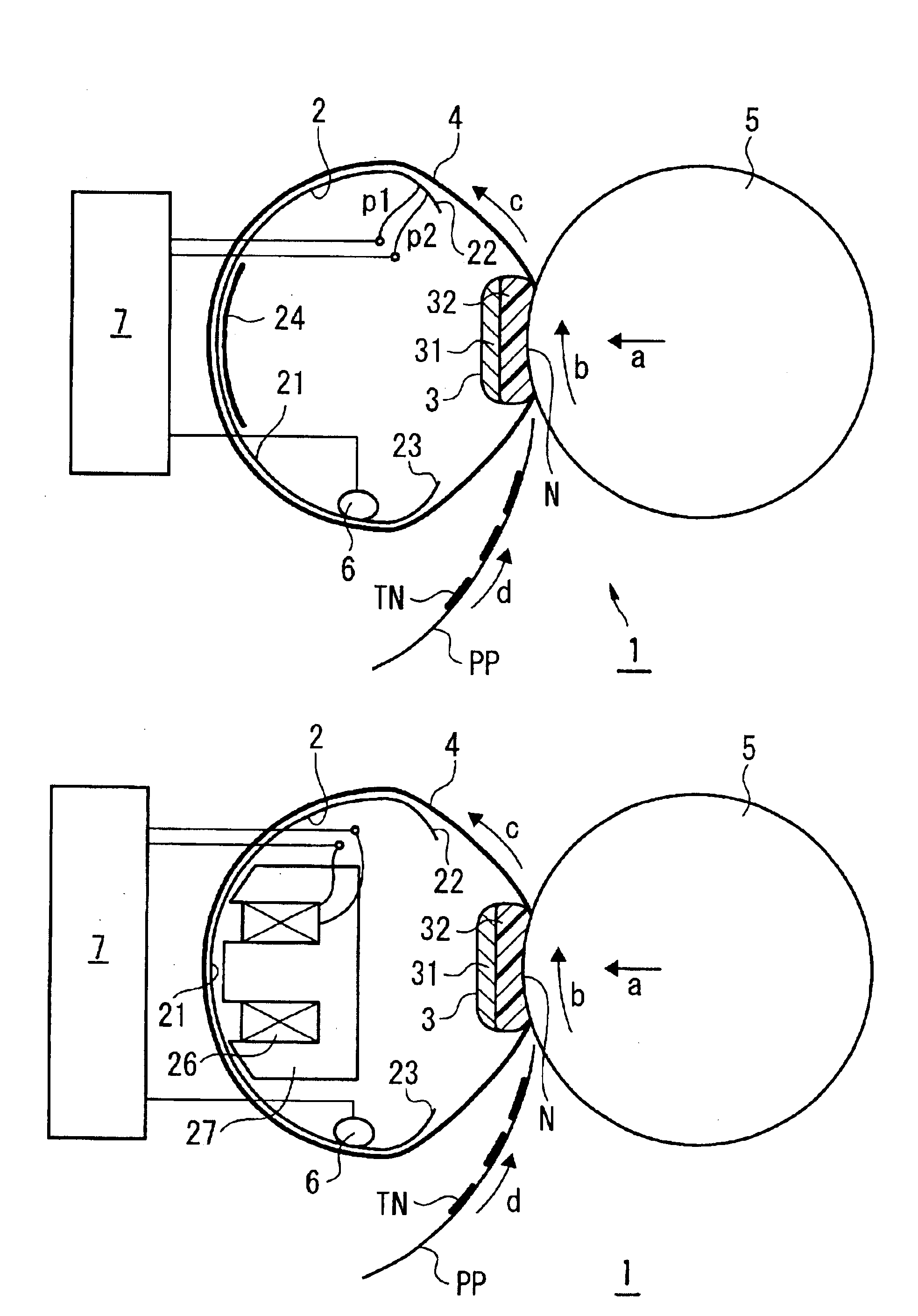

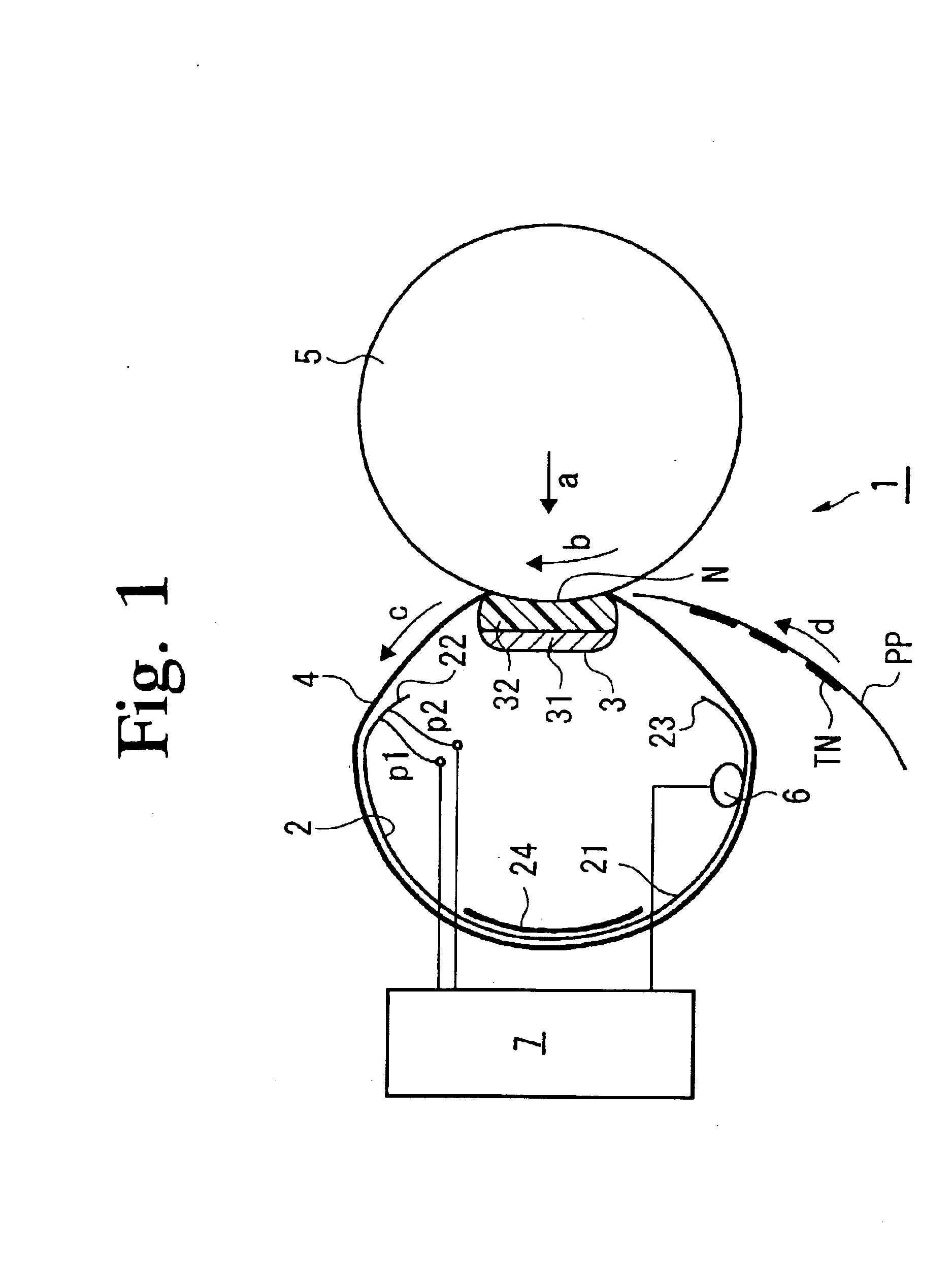

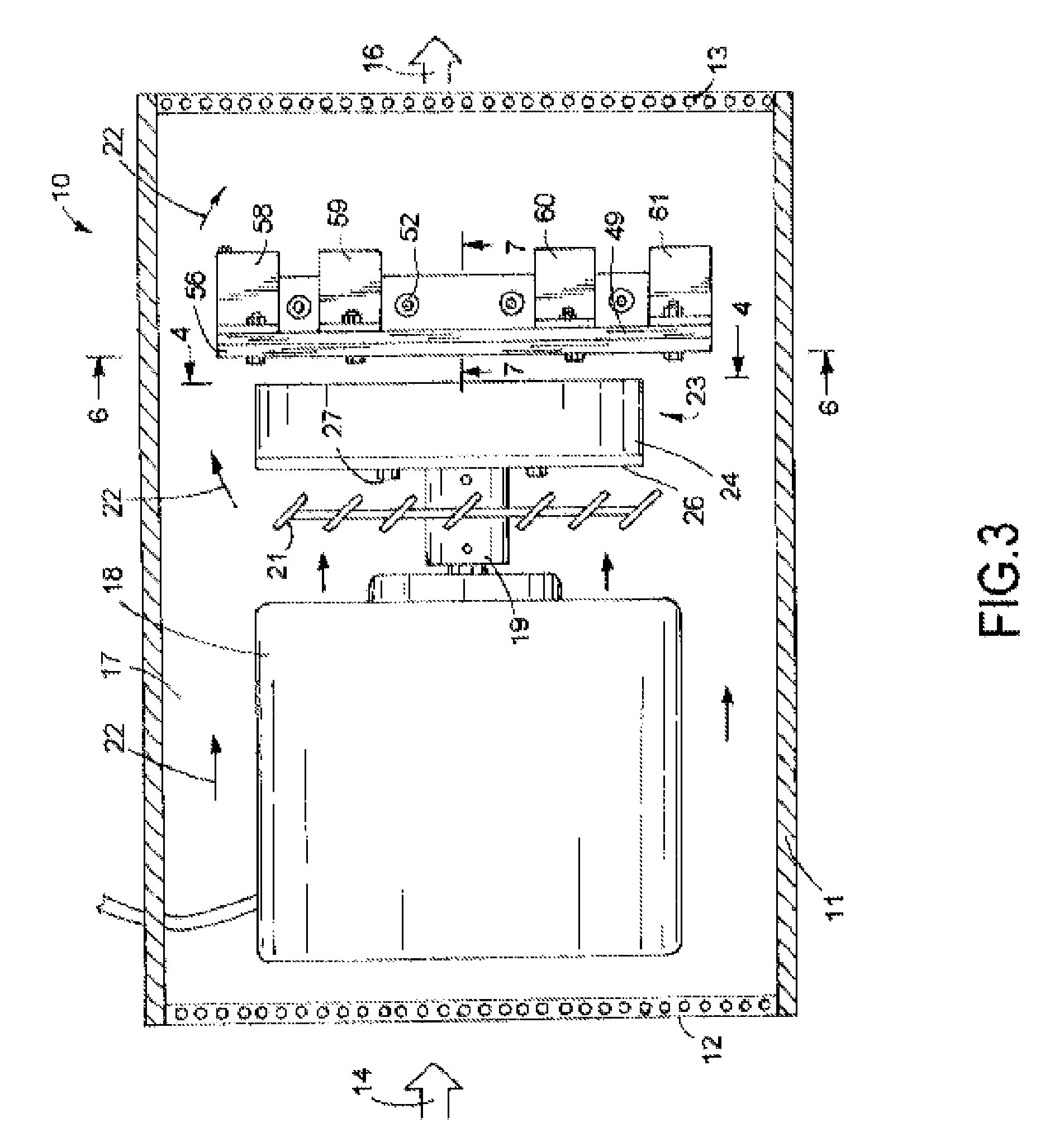

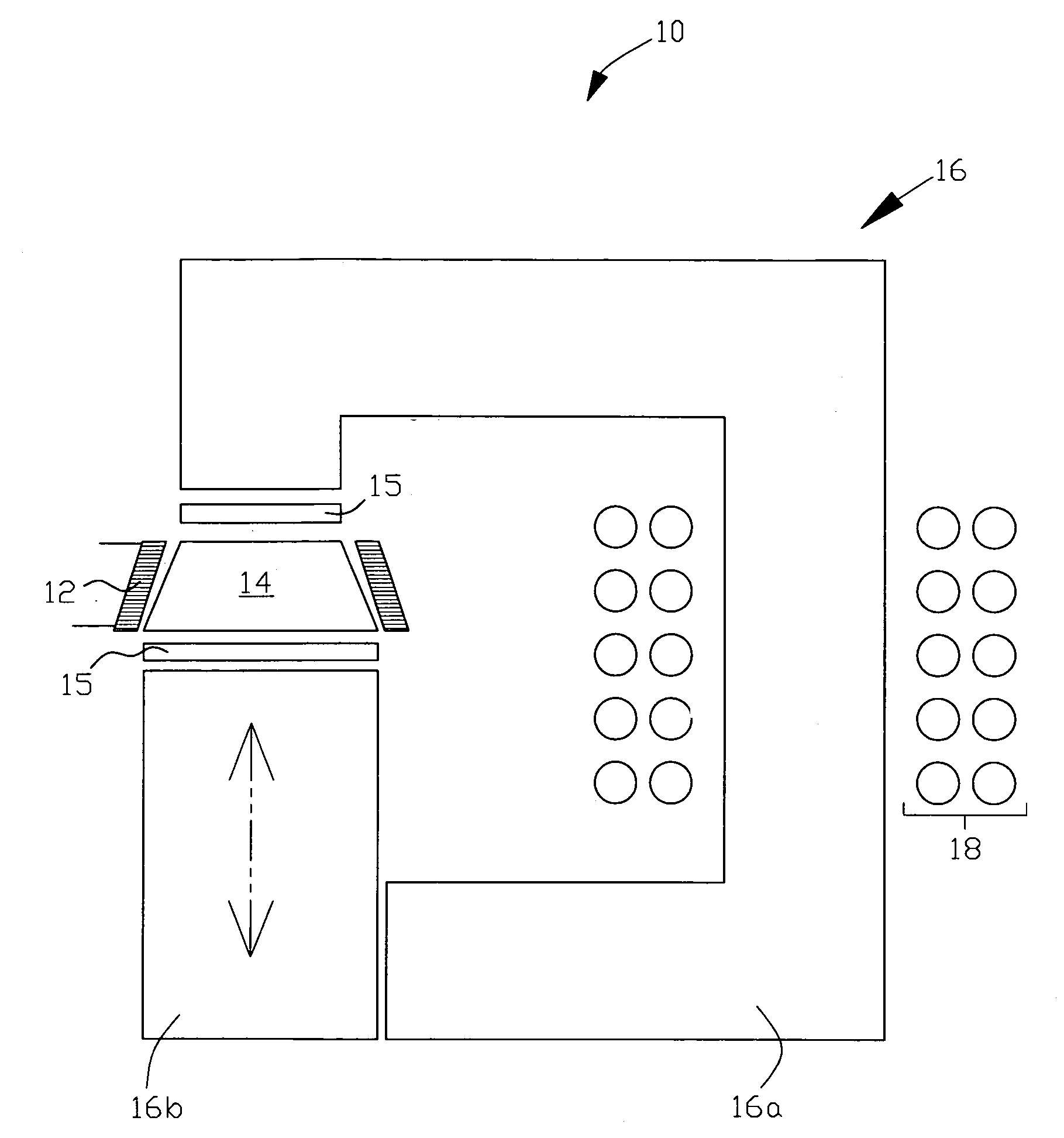

System for heat treatment of semiconductor device

InactiveUS20070122936A1Avoid damageIncrease temperatureFurnaces without endless coreSemiconductor/solid-state device manufacturingDevice materialElectromotive force

Disclosed is a heat treatment system for semiconductor devices. The heat treatment system is used in a heat treatment process for semiconductor devices, such as a crystallization process for an amorphous silicon thin film or a dopant activation process for a poly-crystalline silicon thin film formed on a surface of a glass substrate of a flat display panel including a liquid crystal display (LCD) or an organic light emitting device (OLED). The heat treatment system transfers a semiconductor device after uniformly preheating the semiconductor device in order to prevent deformation of the semiconductor device during the heat treatment process, rapidly performs the heat treatment process under the high temperature condition by heating the semiconductor device using a lamp heater and induction heat derived from induced electromotive force, and unloads the semiconductor device after uniformly cooling the semiconductor device such that the semiconductor device is prevented from being deformed when the heat treatment process has been finished. The heat treatment system rapidly performs the heat treatment process while preventing deformation of the semiconductor device by gradually heating or cooling the semiconductor device.

Owner:VIATRON TECH INC

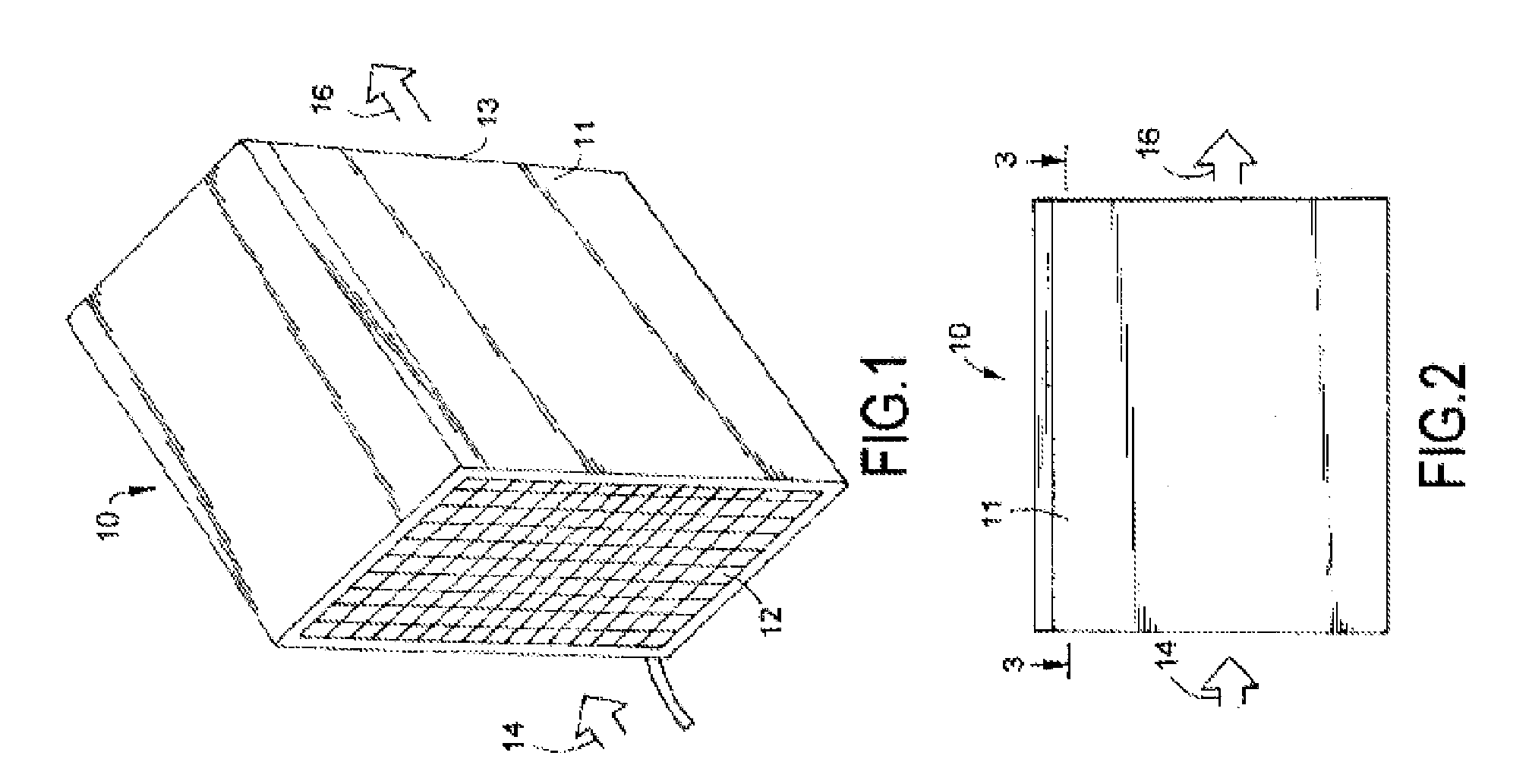

Apparatus for manufacturing poly crystaline silicon ingot for solar battery having door open/close device using hinge

InactiveUS20090090296A1Avoid scratchesBy zone-melting liquidsMaintainance of heating chambersSusceptorElectrical battery

Disclosed herein is an apparatus for manufacturing a polycrystalline silicon ingot for solar batteries having a door control device using a hinge. The apparatus includes a vacuum chamber, a crucible, a susceptor which surrounds the crucible, a heater which heats the crucible, and an insulation plate which is disposed below the susceptor and has an opening therein. The apparatus further includes a cooling plate which moves upwards through the opening of the insulation plate and comes into close contact with or approaches the lower end of the susceptor, a cooling plate moving unit which actuates the cooling plate, a temperature sensor which measures the temperature of the crucible, and a control unit which controls the temperature in the crucible and the cooling plate moving unit. Furthermore, a door is provided on the insulation plate to open or close the opening of the insulation plate. The hinge is provided between the door and the insulation plate. Thus, after the raw silicon material is melted, when the cooling plate moves upwards to cool the crucible and thus pushes the lower surface of the door upwards, the door is opened by the hinge in a swinging manner, and when the cooling plate approaches or comes into contact with the lower end of the susceptor, one end of the opened door is leaned on a corresponding surface of the cooling plate.

Owner:KOREA RES INST OF CHEM TECH

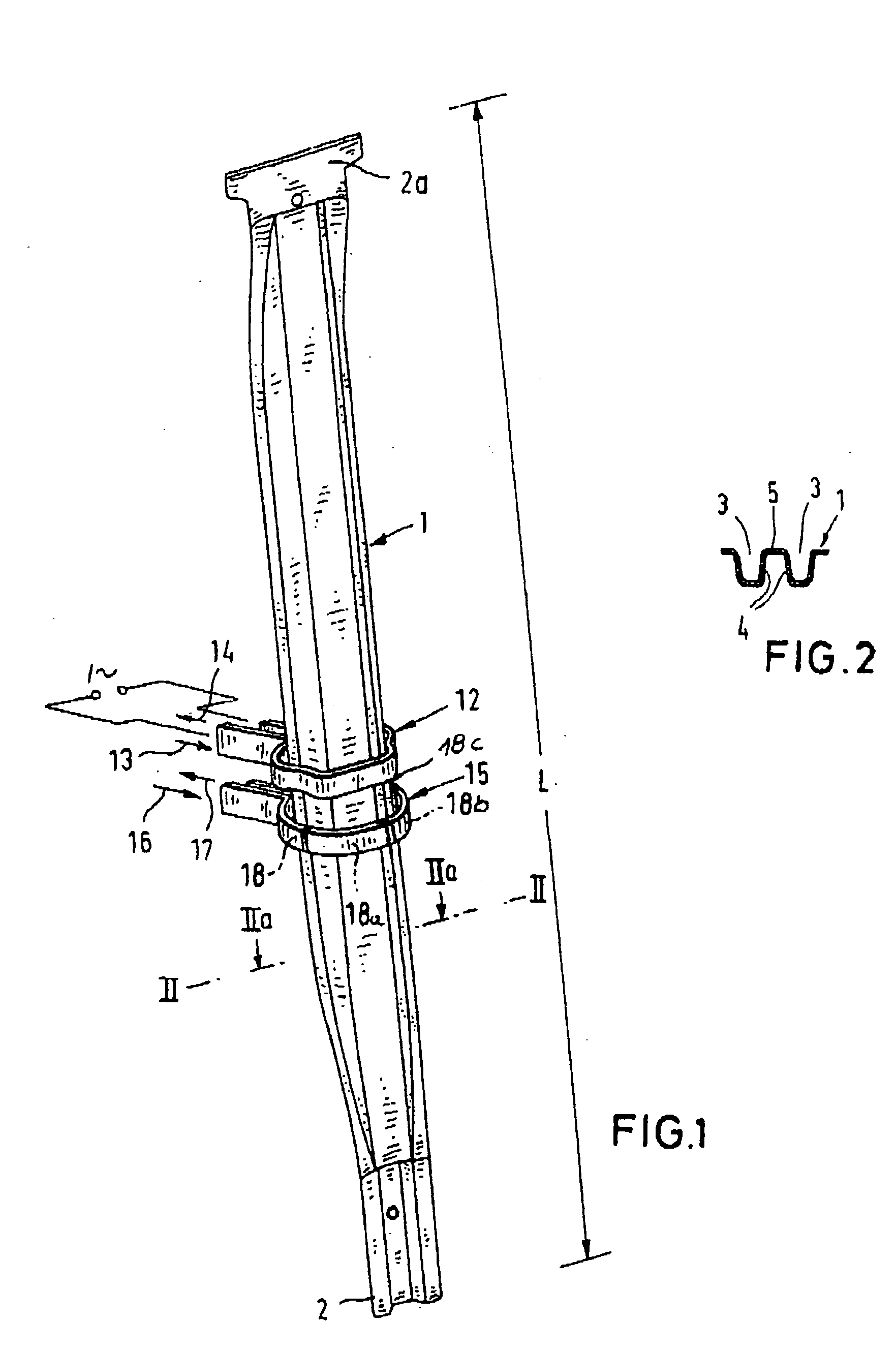

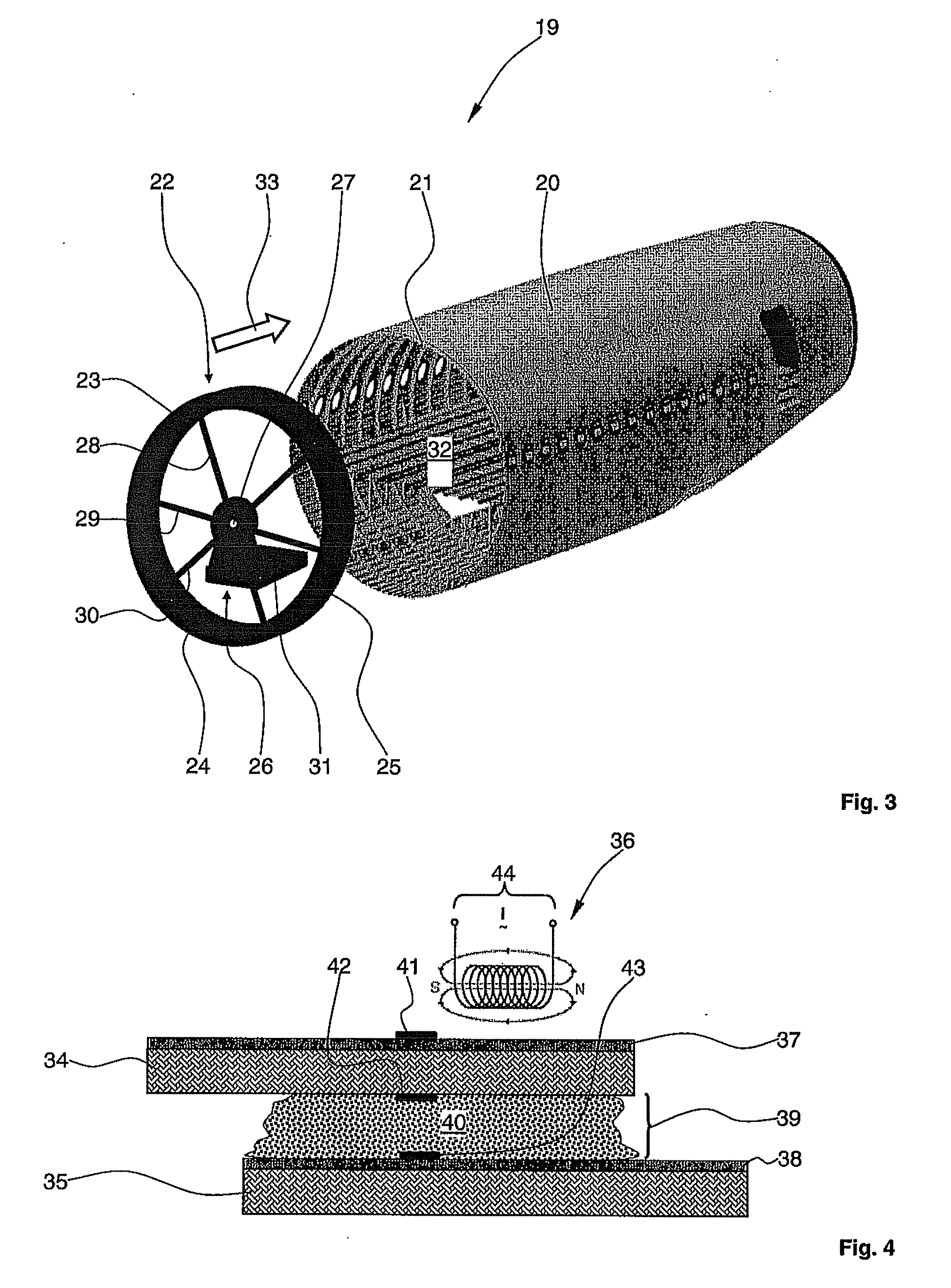

Apparatus for heat treatment of structural body parts in the automobile industry

InactiveUS20050006828A1Reduce maintenanceReduce wearFurnace typesIncreasing energy efficiencySheet steelHorizontal axis

Apparatus for heat-treating an elongate structural body part made from a blank compressed while being soft or from steel strip of hardenable 22 Mn B5 mod. steel sheet with a thickness of 1 mm to 3 mm, includes an apparatus for positioning the structural body part in substantially upright disposition. Placed in surrounding relationship to the structural body part is an induction element which can move from bottom to top, thereby being able to follow a contour of the structural body part and allowing to at least partially heat the structural body part to an austenitizing temperature suitable for hardening. Disposed adjacent to the induction element is a cooling unit which follows the induction element in movement direction. The induction element and the cooling unit are moveable relative to one another and connected to a tool carriage which is mounted to a column for movement in a vertical direction, in a transverse direction to the column and about a horizontal axis.

Owner:BENTELER AKTIENGES

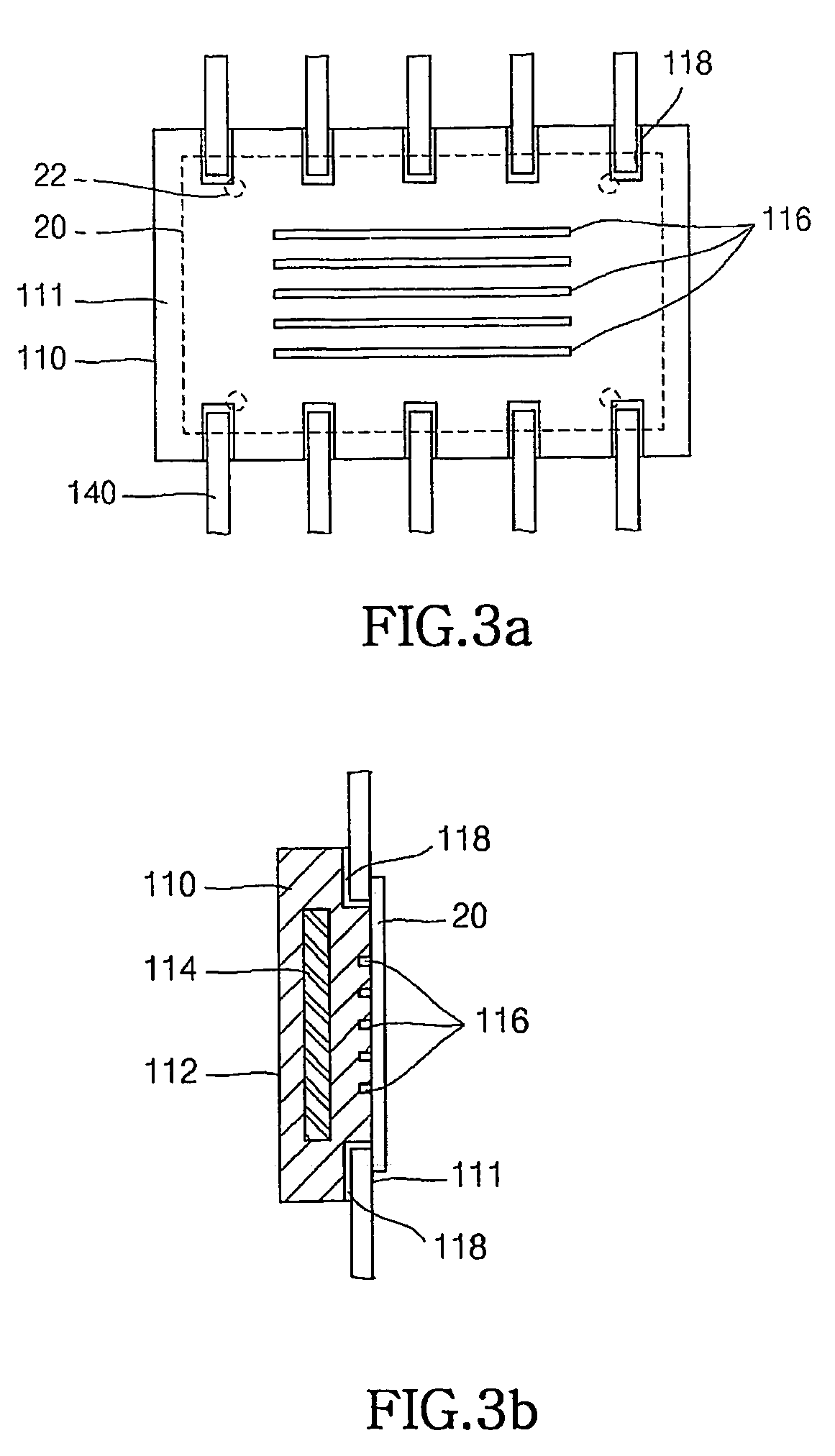

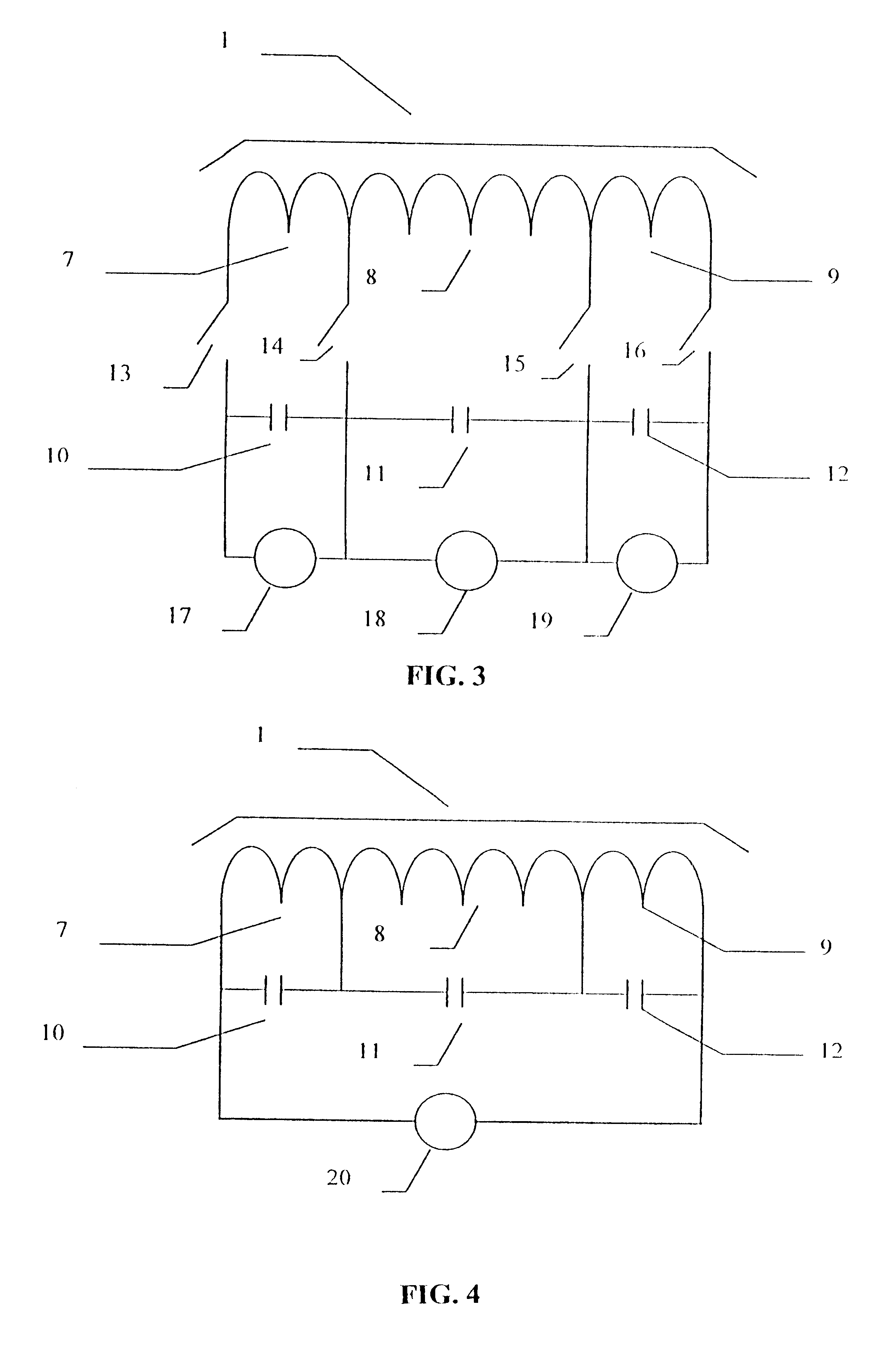

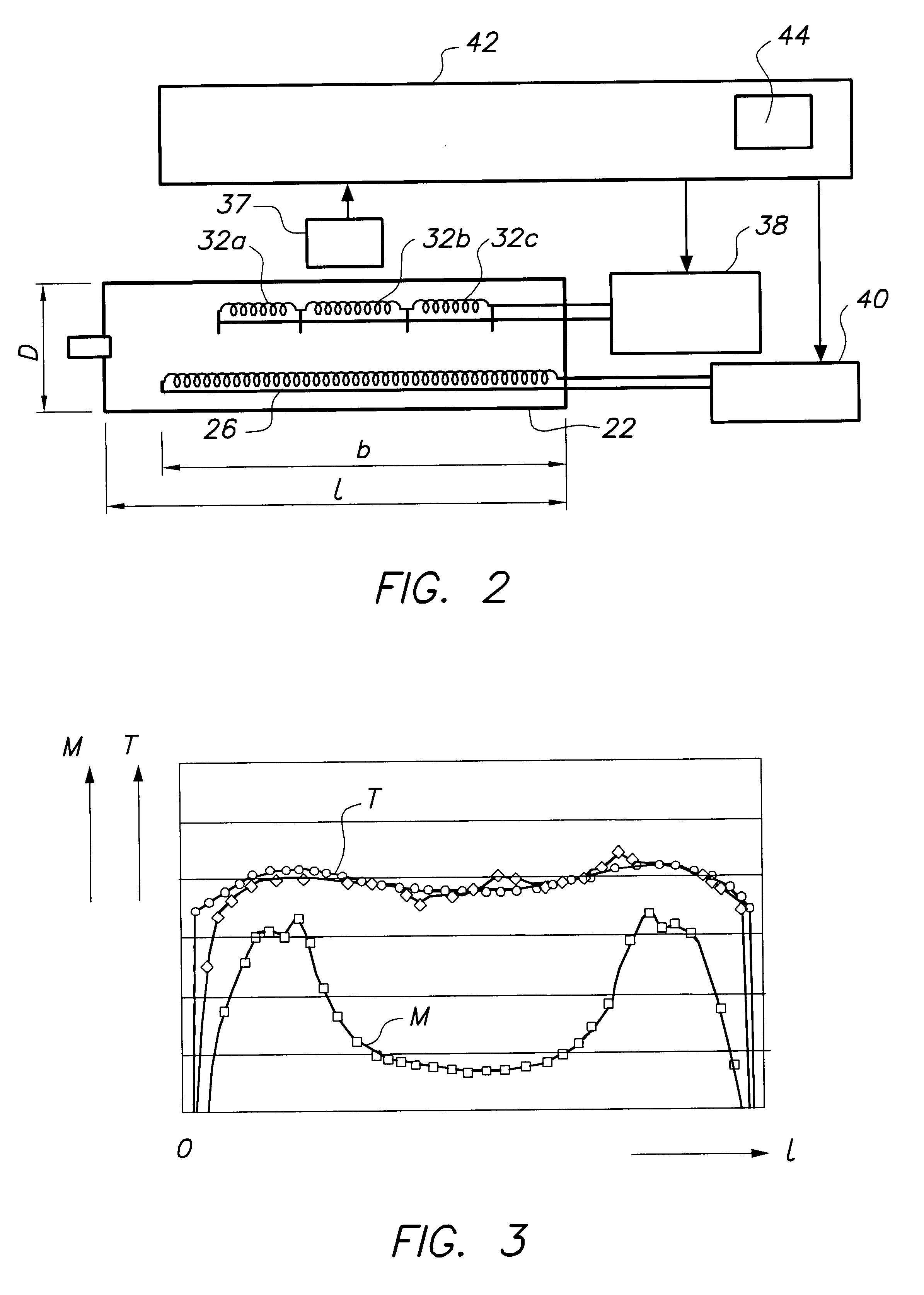

Frequency selected, variable output inductor heater system

InactiveUS6316754B1Rapid temperature changeMaintain temperatureCoil arrangementsSemiconductor/solid-state device manufacturingResonanceInductor

An induction heating systems using a plurality of zones in a coil provides selective heating control for better uniformity especially for semiconductor and other thin film processing applications. By arranging the zones to have different resonance frequencies, the power supply may control the various zones by altering its frequency output. The power supply may also act to control the differential heating by switching among zones in conjunction with the frequency control, by sweeping through a variety of frequencies, by simultaneously providing power over different frequencies, by altering the residence time at each frequency, or by outputting different powers to each frequency or the like. Each zone may thus be tuned as appropriate to achieve the desired induction heating characteristic.

Owner:ADVANCED ENERGY IND INC

Fixing device for image forming apparatus

InactiveUS6864461B2Efficient heat transferImprove the heating effectOhmic-resistance heating detailsRollsImage formationEngineering

A belt-type fixing device for an image forming apparatus is capable of raising a temperature to a level suitable for a fixing process in a short period of time with high heating efficiency. A fixing belt is entrained in spanning relation between a heating plate providing a heat generator on the inner surface of the semi-cylindrical plate and a pressing pad disposed at a distance from the heating plate. A pressing roller is disposed at a position opposing the pressing pad. The fixing belt is revolved by rotating the pressing roller. A recording medium having a toner adhered thereto is caused to pass through a nip portion of the fixing belt and the pressing roller.

Owner:MINOLTA CO LTD

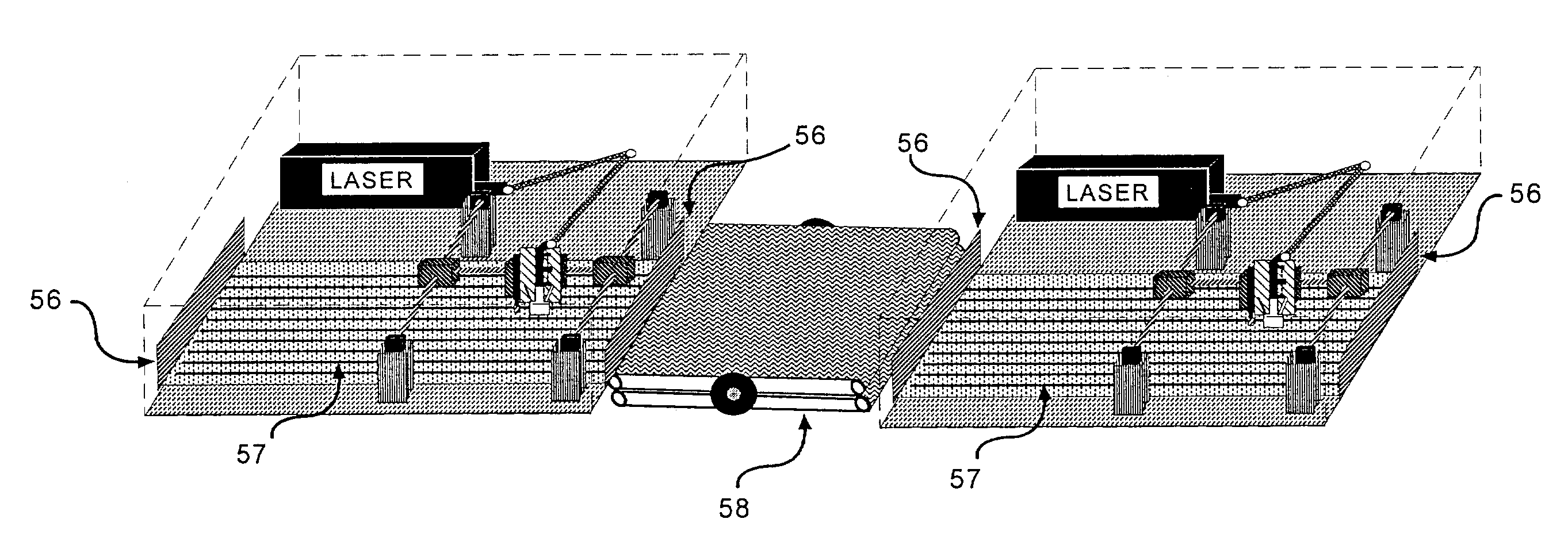

Conveyorized blind microvia laser drilling system

InactiveUS7062845B2High peak powerMaterial removalCircuit board tools positioningPrinted resistor incorporationComputer moduleEngineering

A laser drilling system for drilling blind vias in printed circuit board panels, multichip modules and chipscale packages with top and bottom surfaces and which include multiple dielectric polymer and metal layers. The system includes a first laser module comprising a laser able to form at least one via per pulse through one or more polymer layers. The vias are circular or non-circular in shape. An articulated arm is adapted to move at a speed of about 200 inches per second and at an acceleration of about 5 g's or more. A beam delivery unit is attached to the articulated arm and a conveyor adapted to move panels at a constant speed. The first laser module positioned on a separate track from the conveyor moves at a faster rate than the conveyor to drill the top surface. A second laser module is positioned to move on another separate track from the conveyor movable at a faster rate so as to drill the bottom surface.

Owner:MARGER JOHNSON & MCCOLLOM P C

Permanent magnet fluid heater

A permanent magnet air heater has a housing with an internal chamber accommodating an electric motor rotating a fan to move air through the housing. A non-ferrous member having bores for cylindrical magnets and a steel member with a copper plate secured to the steel member are rotated relative to each other by the motor whereby the magnetic field between the magnets and copper plate generates heat which is transferred to air in the housing moving through the housing by the fan.

Owner:POWERMAG

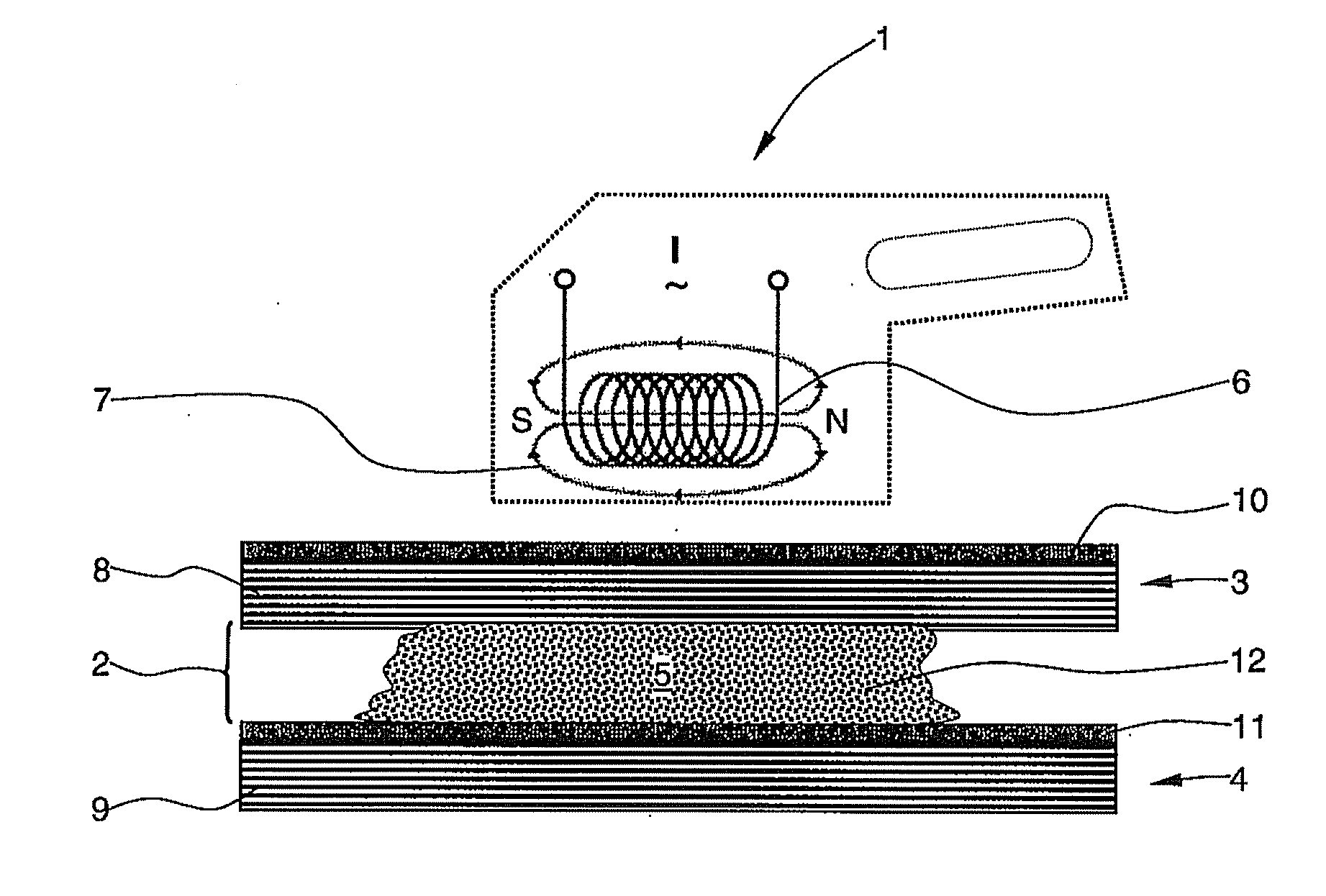

Device for curing a plastic material

InactiveUS20100133261A1Extension of timeImprovement effortsCoil arrangementsDomestic articlesEpoxyCarbon fibers

The invention relates to a device for curing a plastic material, in particular a sealing compound and / or a filling compound for tolerance adjustment or gap filling, respectively, wherein the plastic material is at least partly inserted in a gap area between two components, and wherein at least one of the components is made of a fiber reinforced plastic material, in particular of a carbon fiber reinforced epoxy resin. According to the invention the device is provided with at least one electromagnetic inductor for a locally defined heating of the gap area and for curing the plastic material arranged in the gap area. Due to the electromagnetic inductor which might be a linear inductor or a circular inductor a contact-less and fast curing of the plastic material is possible.

Owner:AIRBUS OPERATIONS GMBH

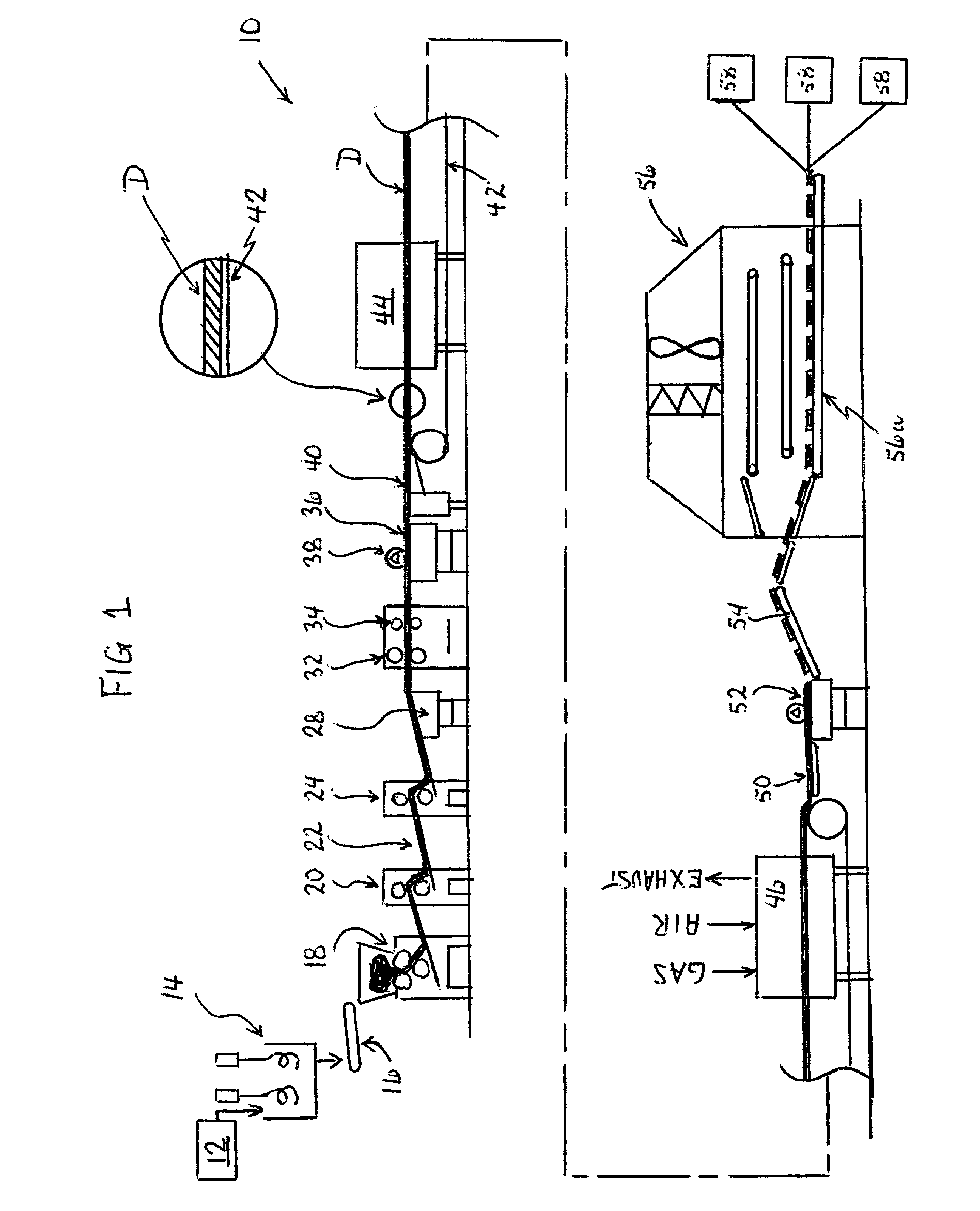

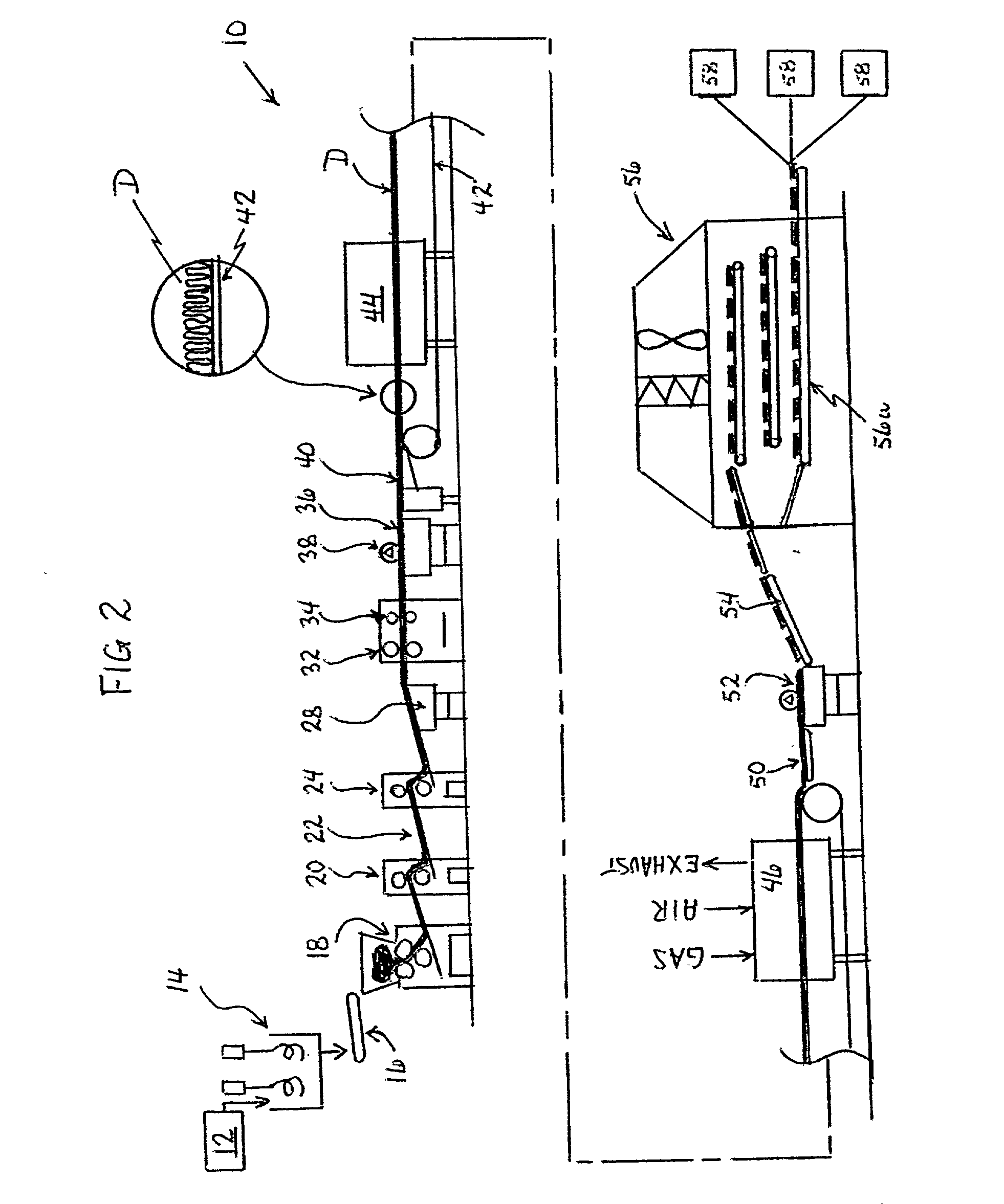

Breadcrumb processing line and method

InactiveUS20040000543A1Large capacityImprove abilitiesMilk preparationDough treatmentProduction lineCooking & baking

The present invention is directed toward a breadcrumb continuous processing line and process capable of producing multiple types of breadcrumbs, namely American style breadcrumbs, Japanese style breadcrumbs and cracker meal crumbs. Each type of bread crumbs has different characteristics including the thickness of the dough sheet the different baking requirements. The breadcrumb processing line, and the oven therein is capable of being adjusted to process of the bread dough sheet in the manner necessary to produce the type of breadcrumb desired at any given time on a single processing line.

Owner:KERRY GRP SERVICES INT

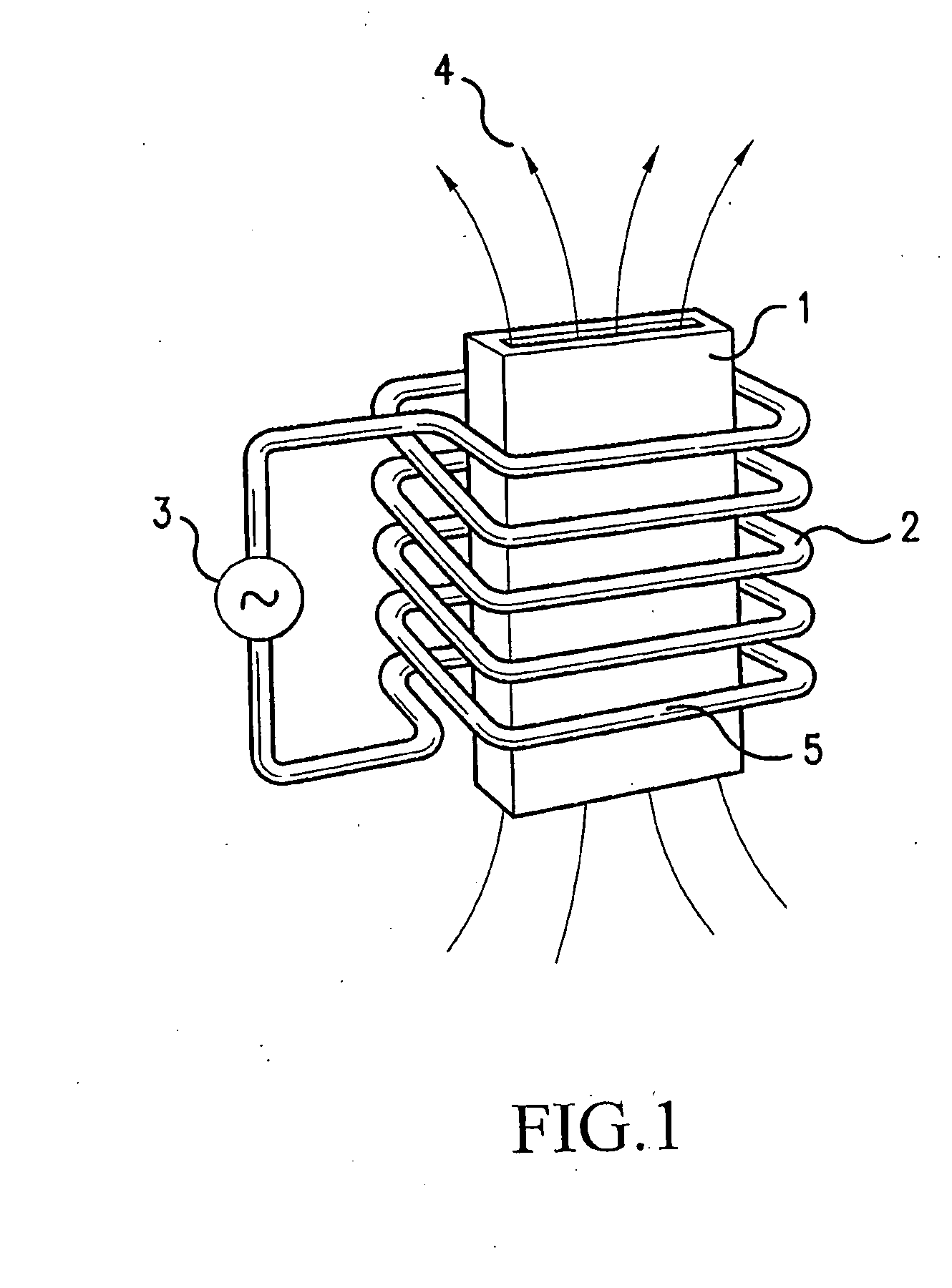

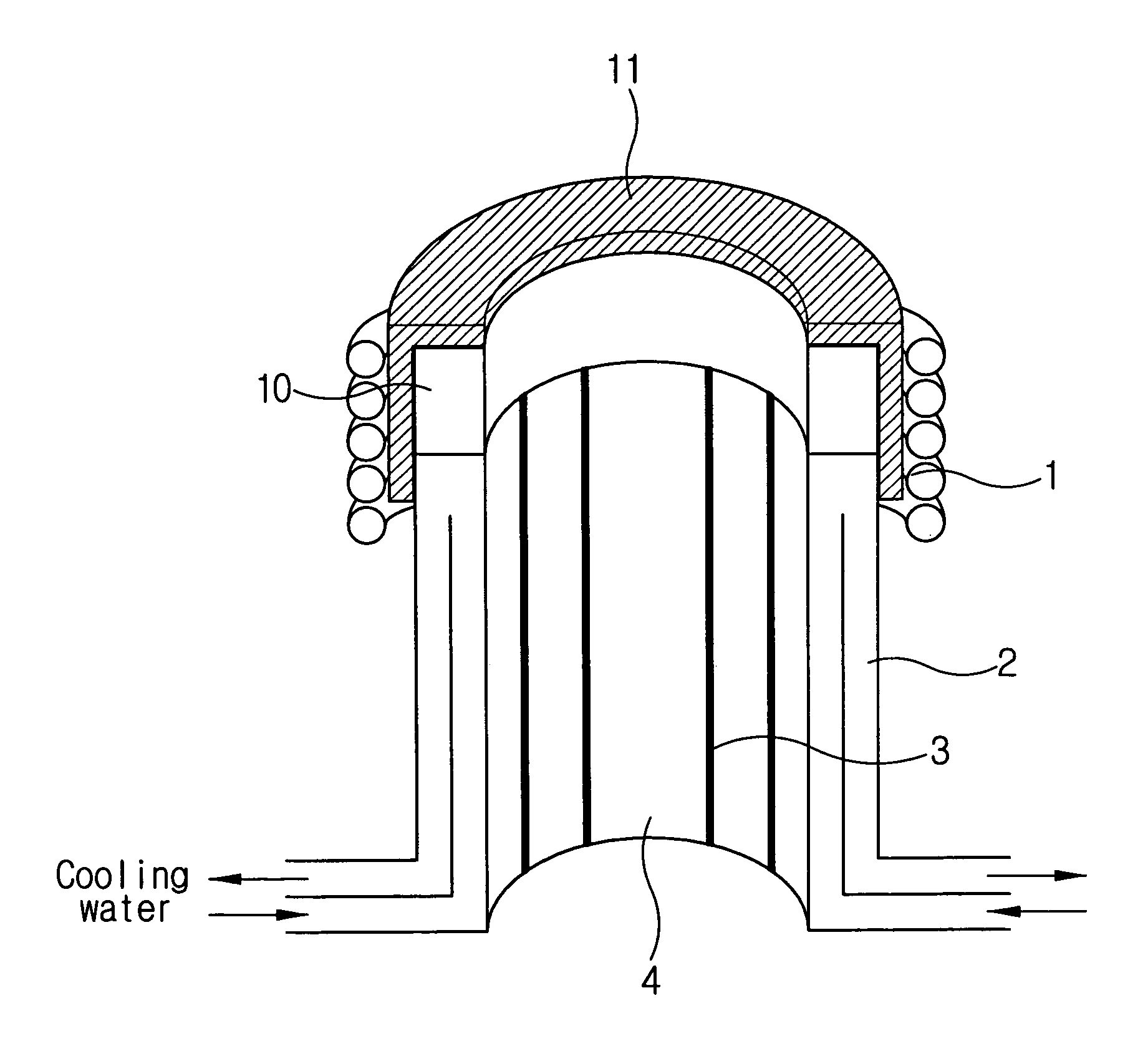

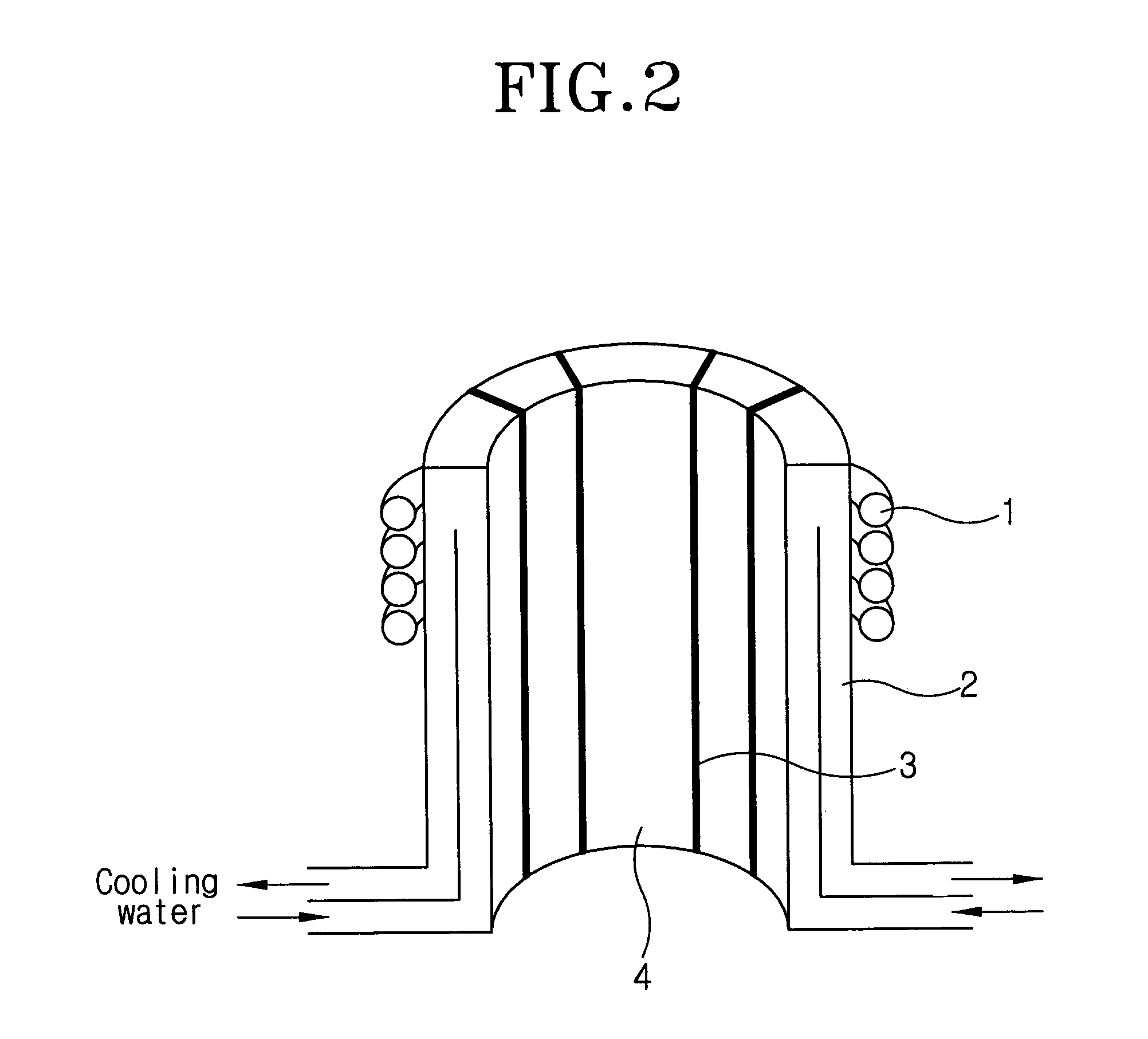

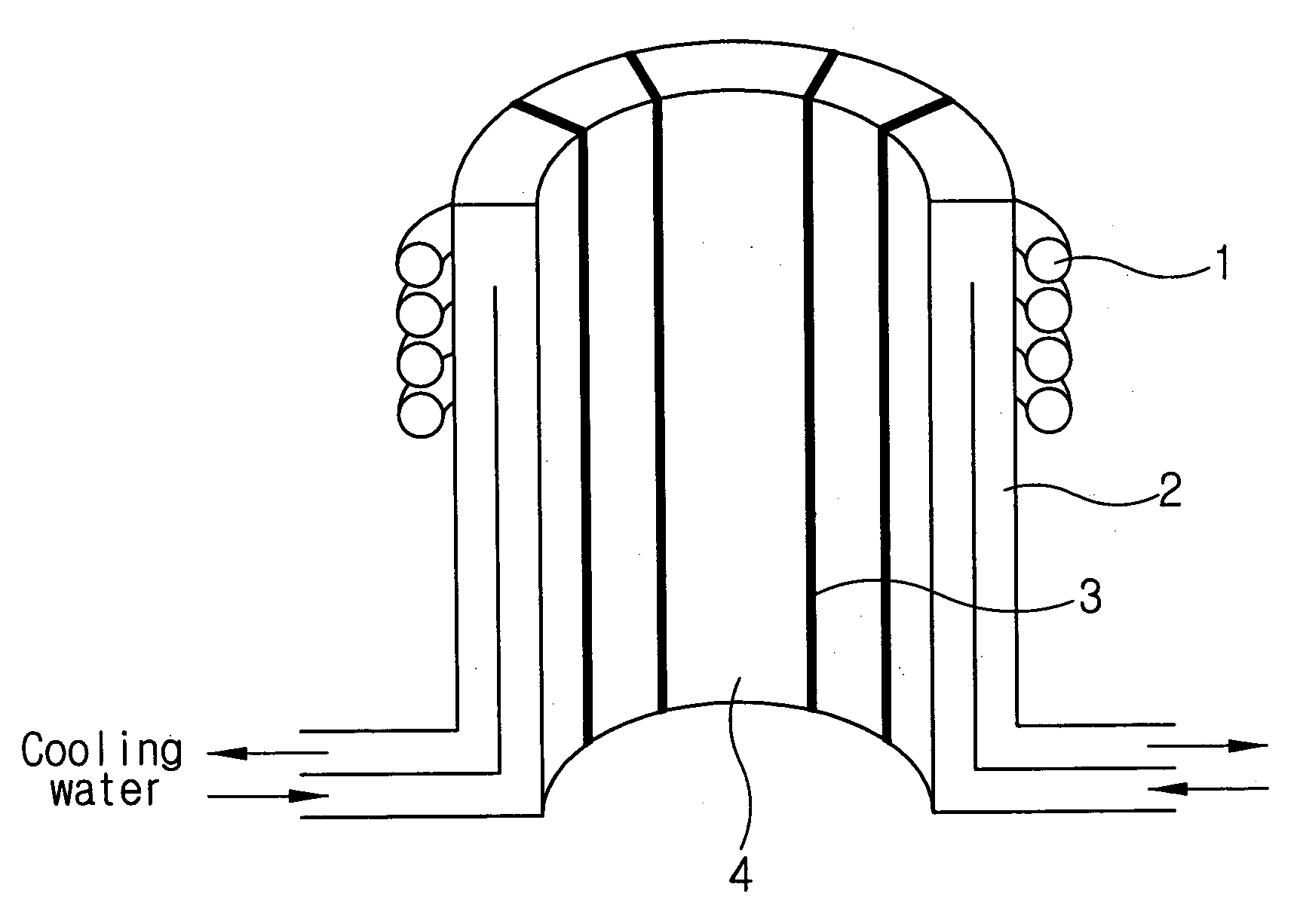

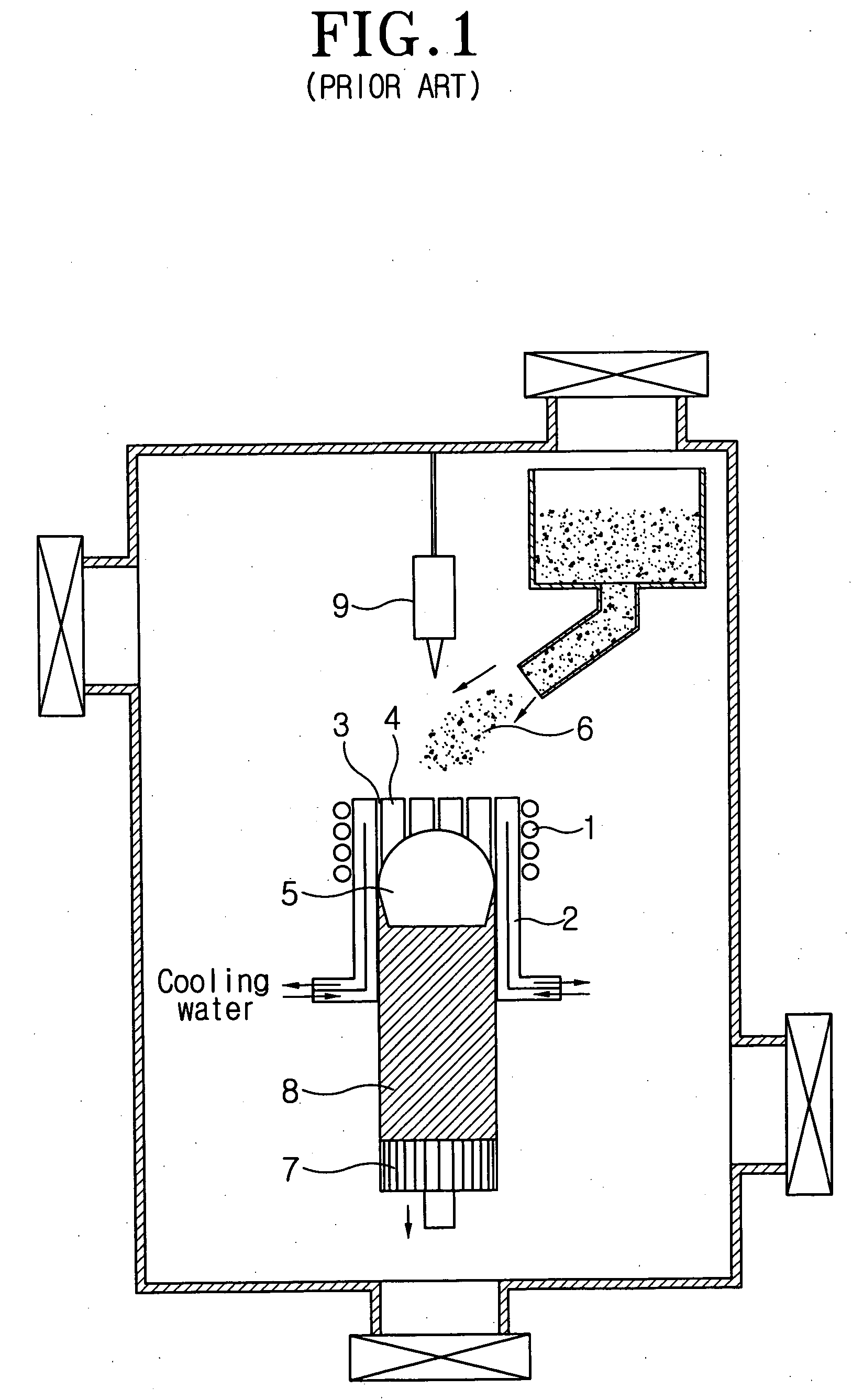

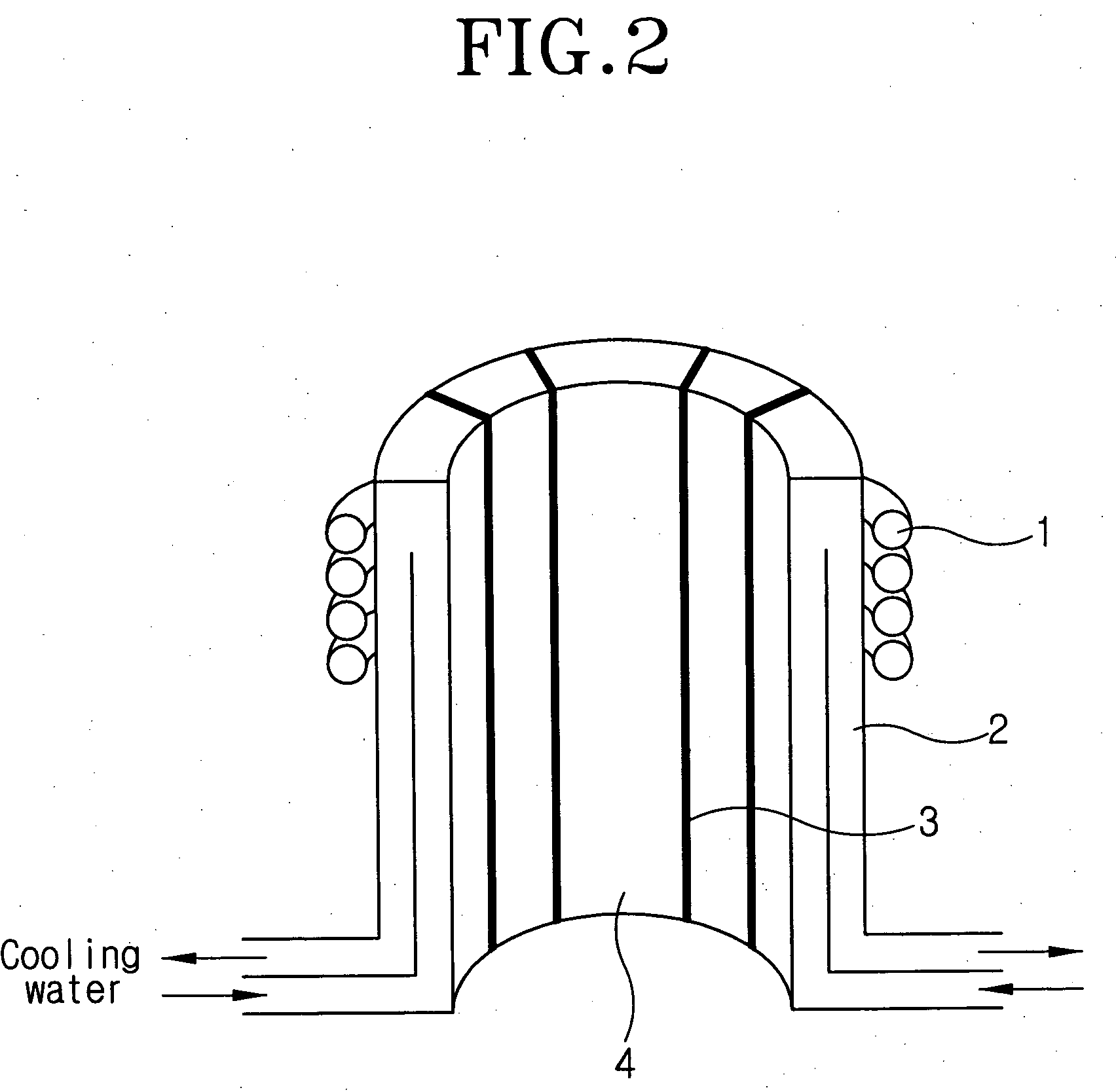

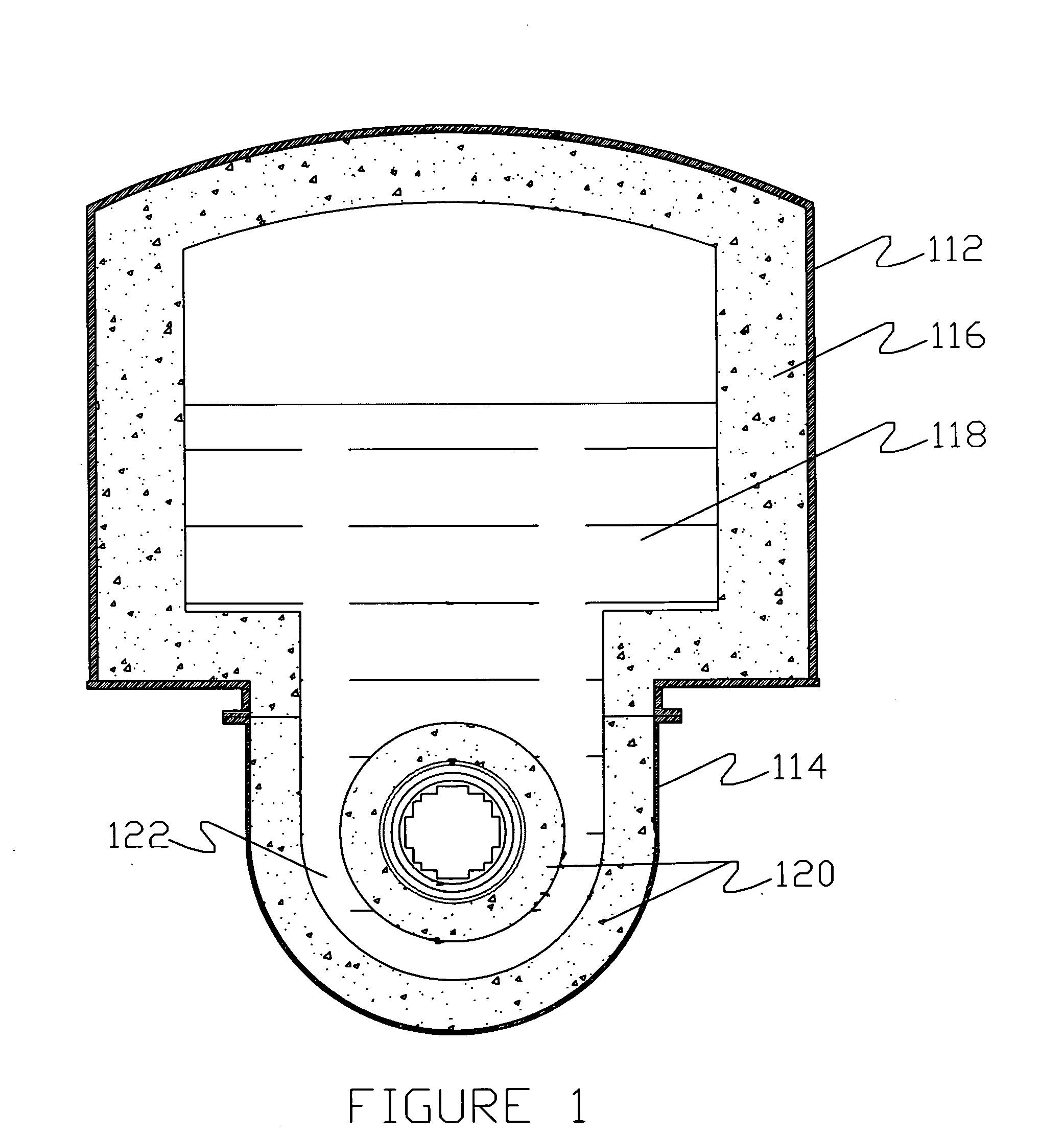

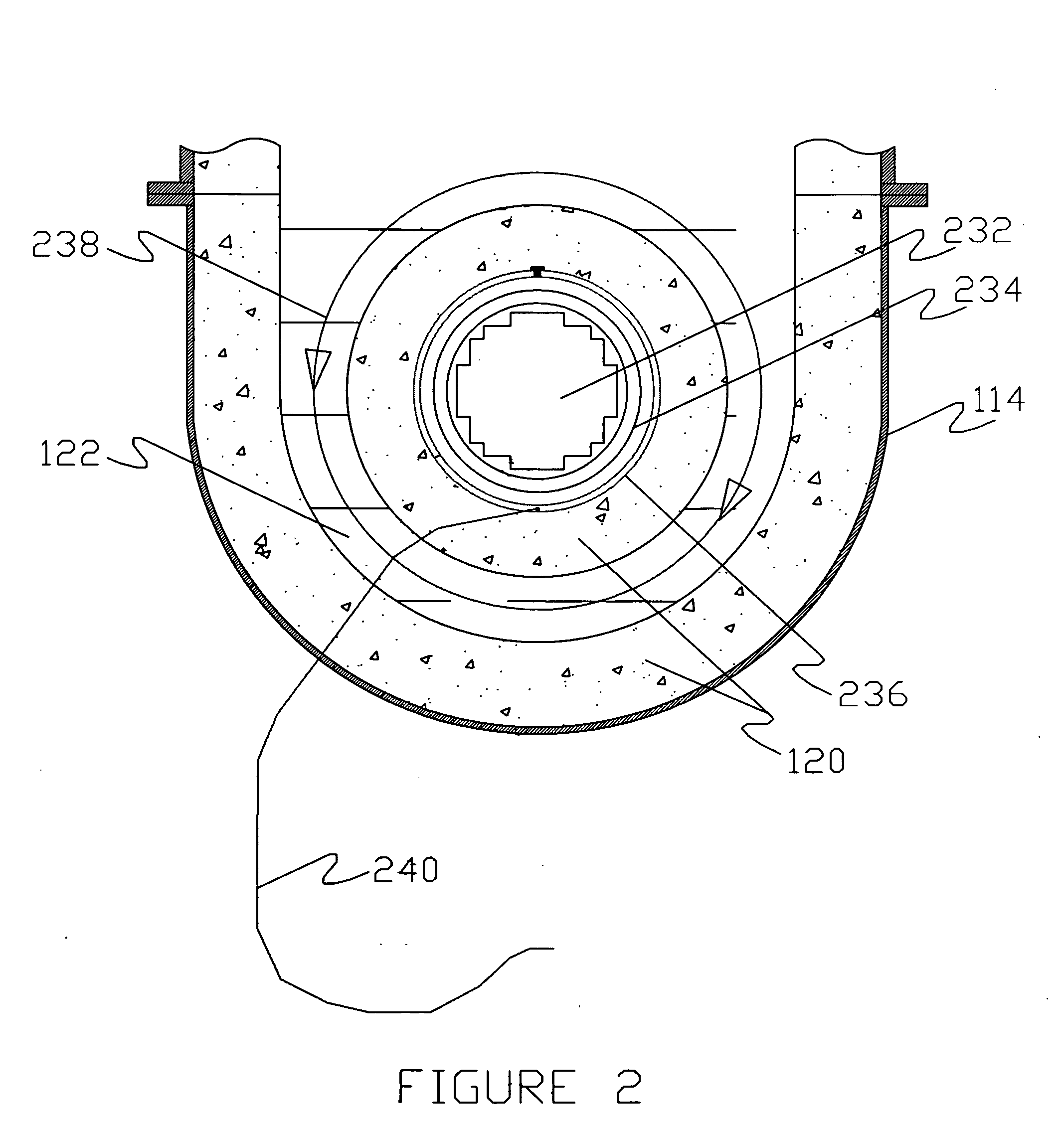

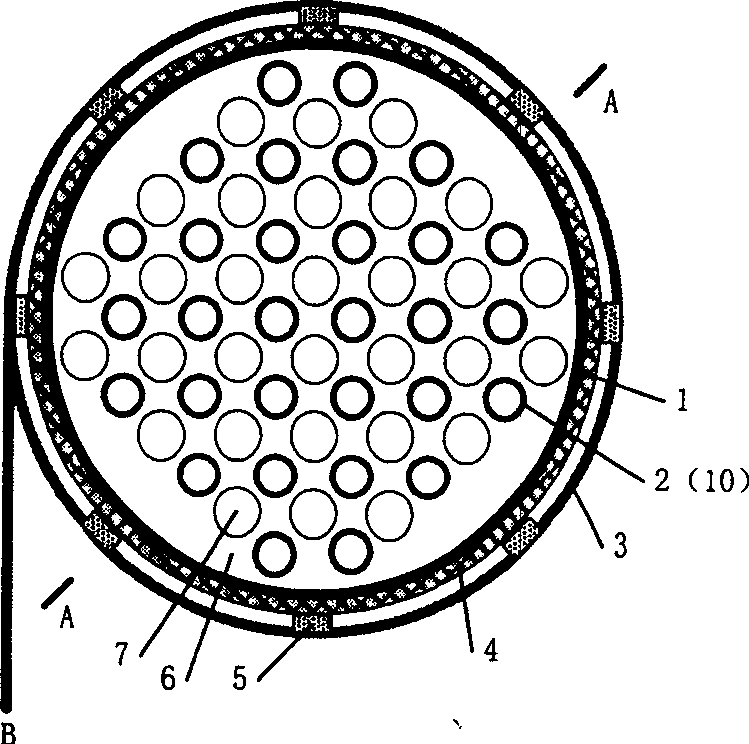

Electromagnetic continuous casting apparatus for materials possessing high melting temperature and low electric conductance

InactiveUS7000678B1High melting pointImprove melting efficiencyMelt-holding vesselsPolycrystalline material growthMetallic materialsVertical axis

Disclosed is an electromagnetic continuous casting apparatus for a material having a low electric conductivity. The casting apparatus includes a crucible having a vertical axis. The crucible comprises an upper hot crucible and a lower cold crucible. The crucible is surrounded with an induction coil. The hot crucible is formed of a non-metallic material having a high electric conductivity and is not water-cooled. The cold crucible has a cooling structure and is formed of a metallic material having a high thermal conductivity and a high electric conductivity.

Owner:KCC CORP CO LTD

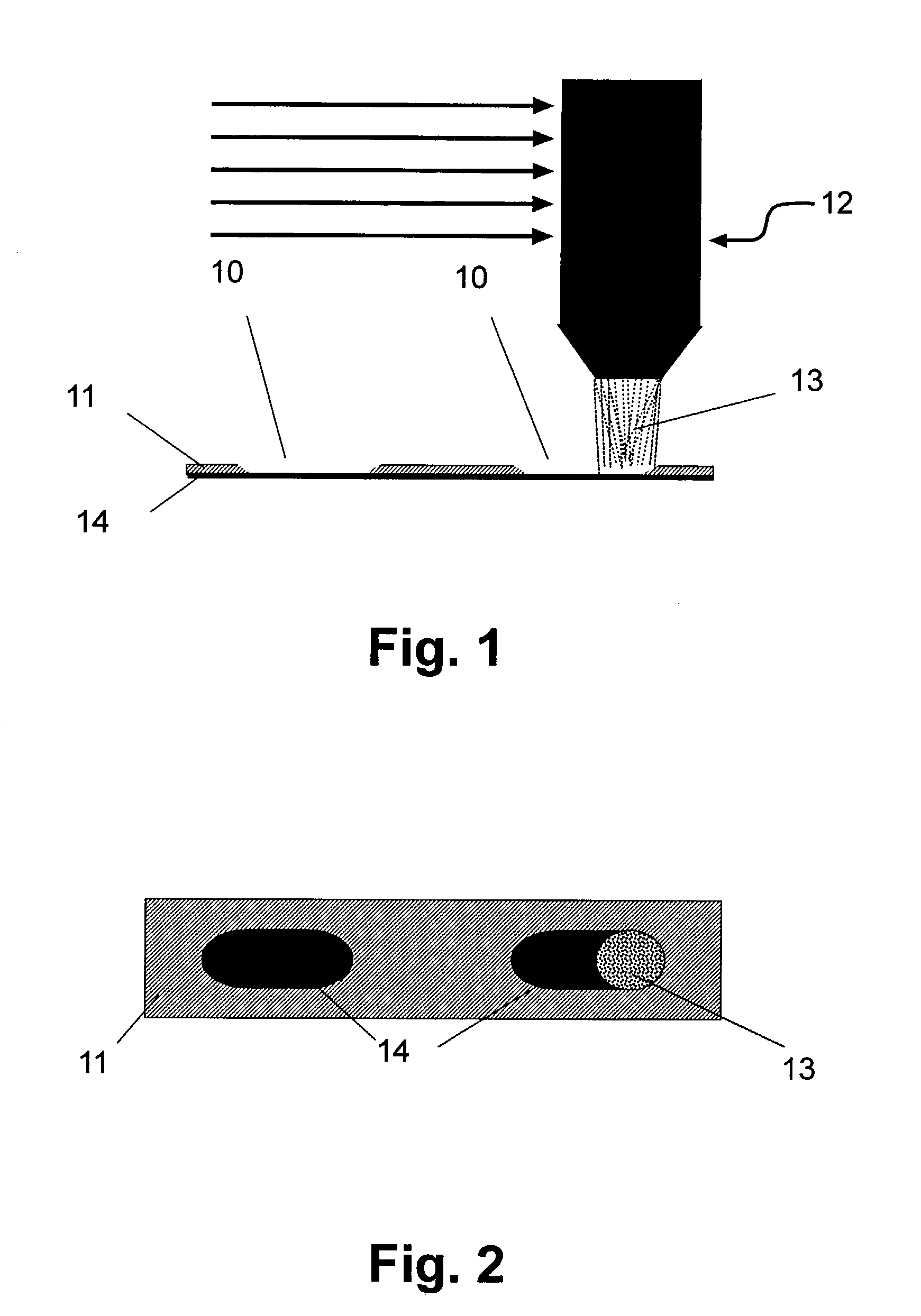

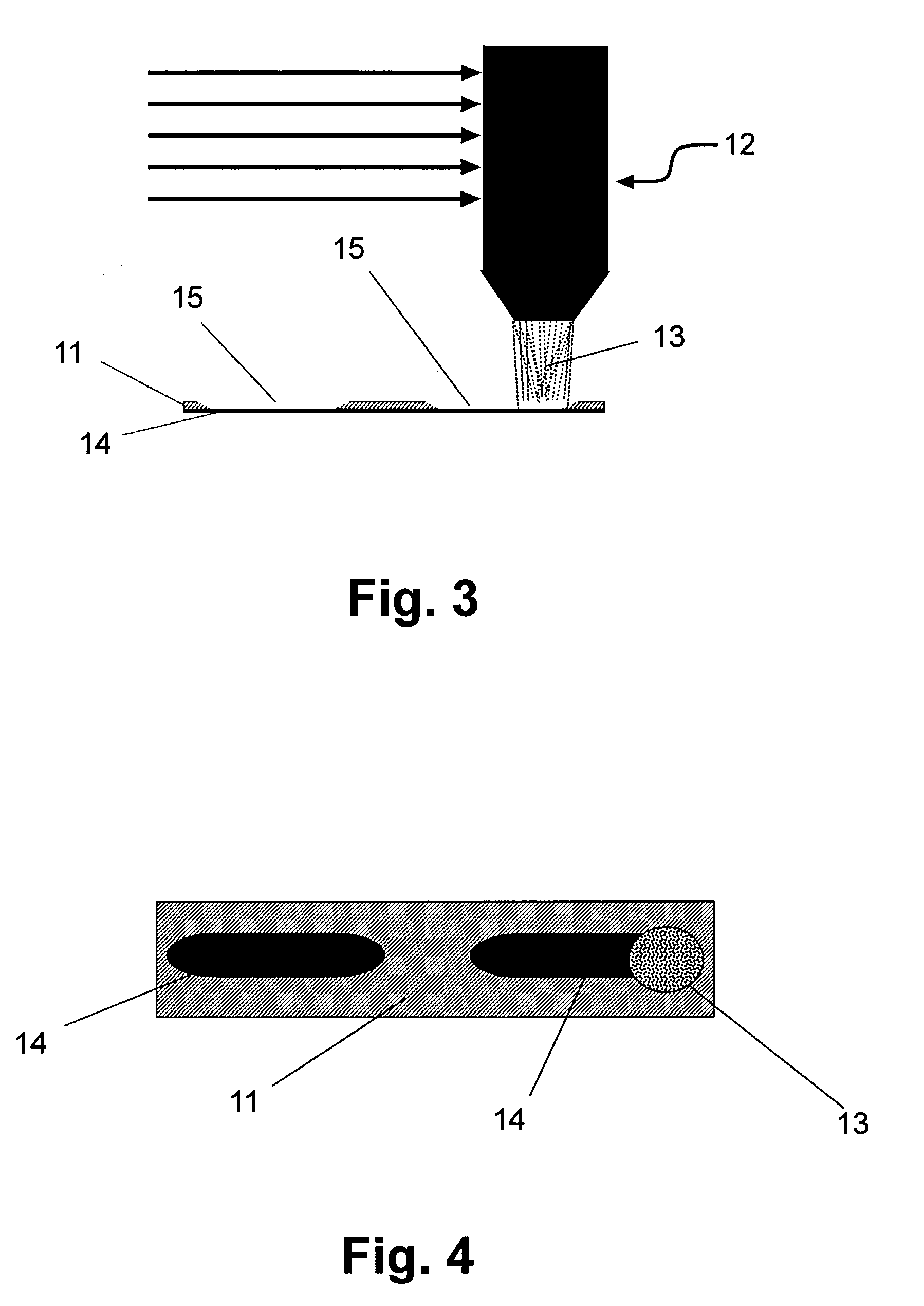

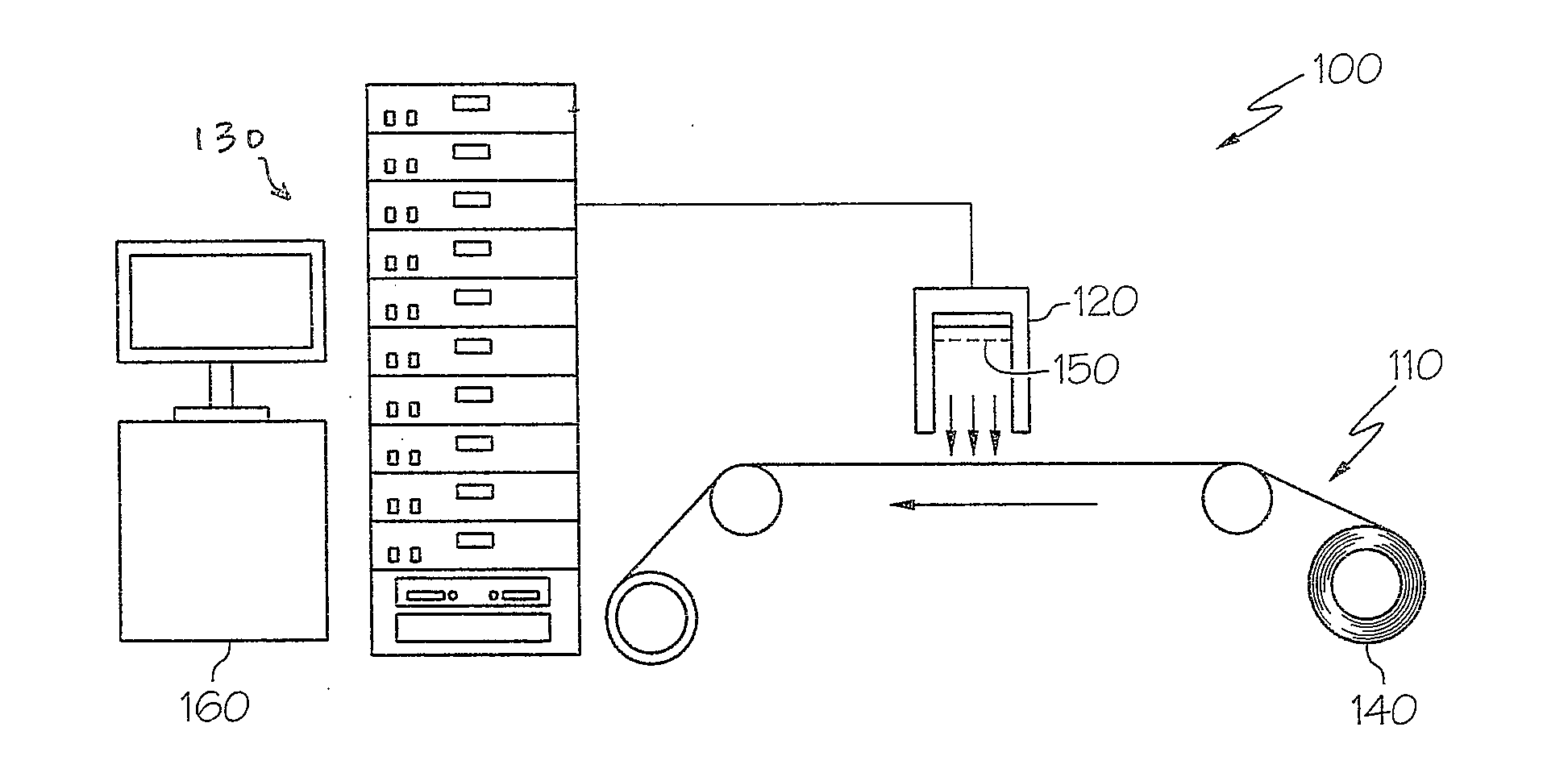

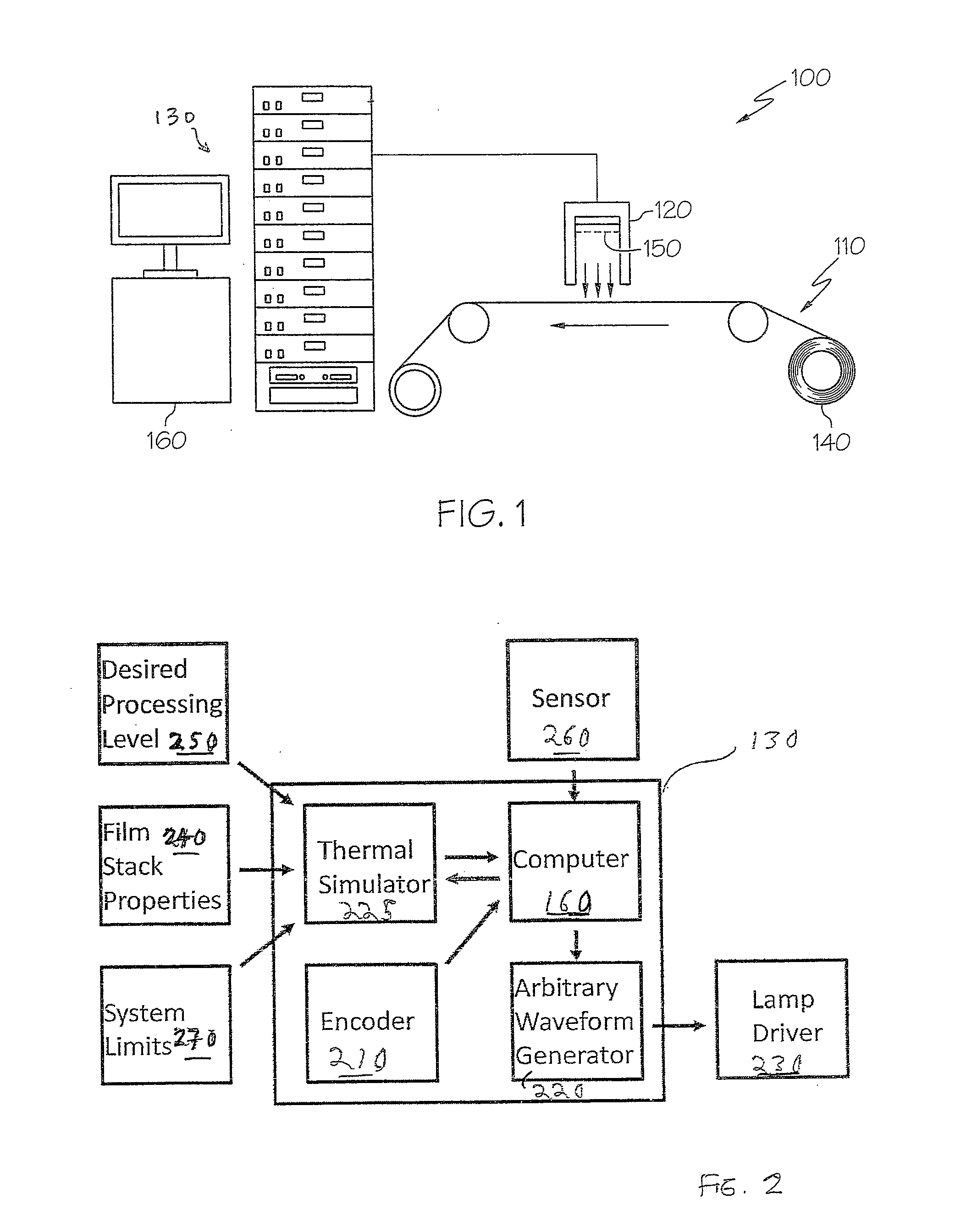

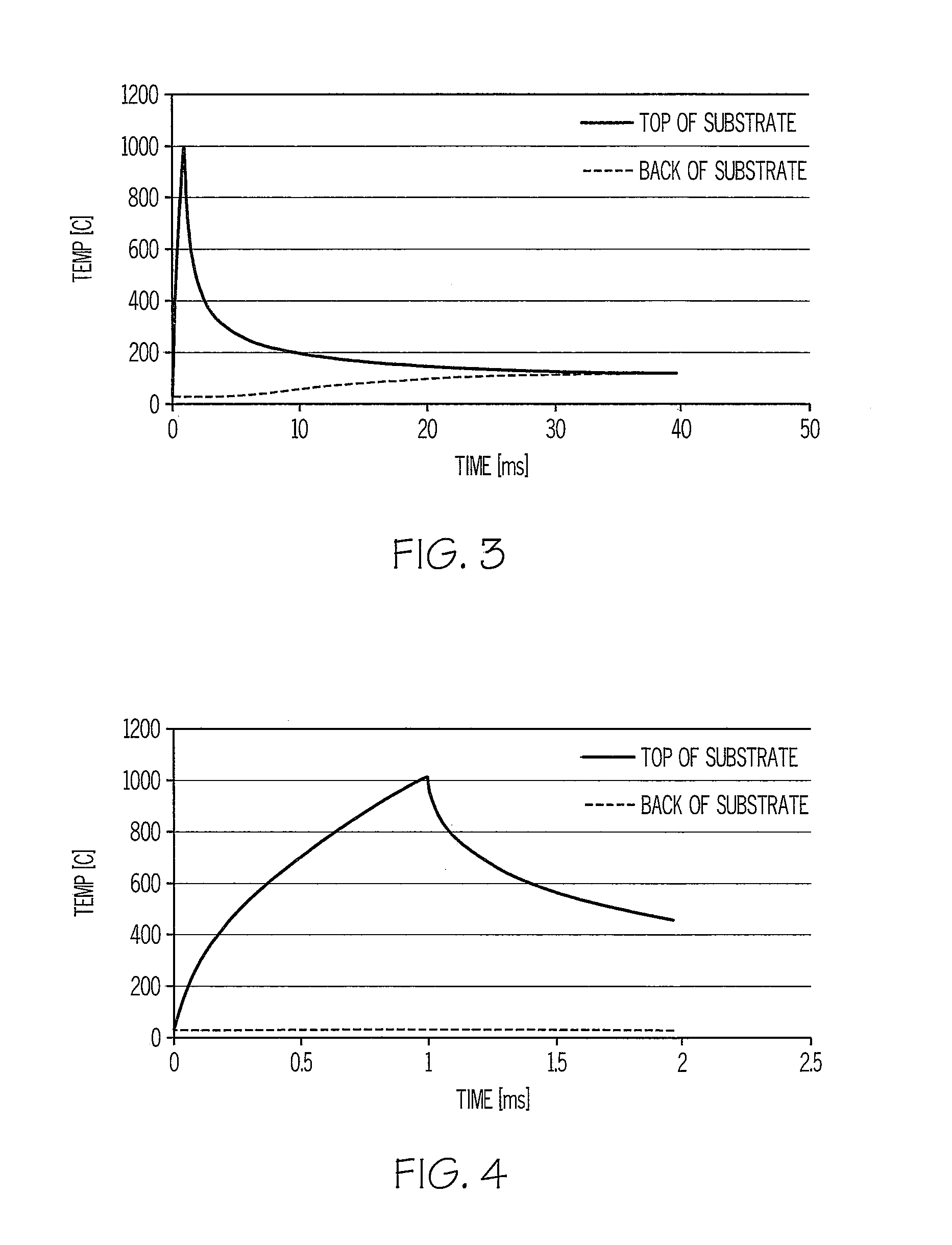

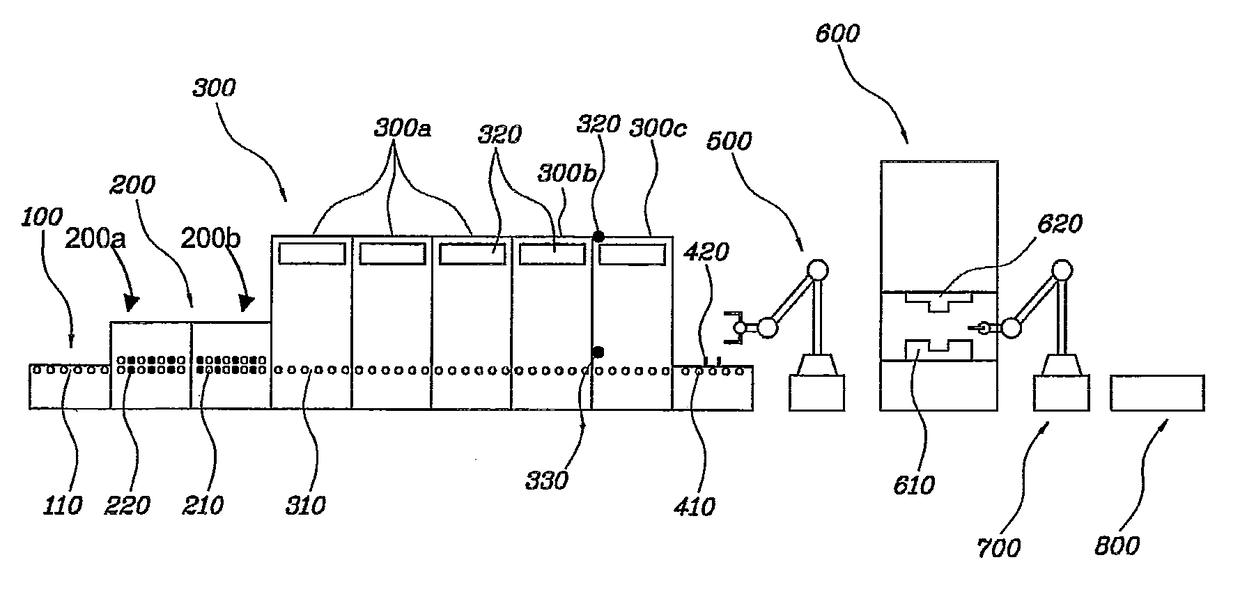

Apparatus for providing transient thermal profile processing on a moving substrate

ActiveUS20110248026A1Avoid damaging the materialIncrease speedDrying solid materials with heatElectric lighting sourcesPulse ratePulse shaping

A method and apparatus for thermally processing material on a low-temperature substrate using pulsed light from a flash lamp is disclosed. Material is conveyed past the flash lamp. The pulses of light are formed by Pulse Width Modulation to tailor the shape of the pulses to generate a thermal gradient in the substrate that enables the material to be heated beyond the maximum working temperature of the substrate without damage. Its shaped pulse rate is synchronized to the conveyance speed of a conveyance system. By using the information from a feedback sensor, the thermal gradient is recalculated to alter the shape of the pulses in real time for optimizing subsequent curings in real time without powering down the curing apparatus. The combined pulse shaping and synchronization allow a temperature profile to be tailored in the sample that is uniformly cured in the conveyance direction.

Owner:NCC NANO LLC

Electromagnetic continuous casting apparatus for materials possessing high melting temperature and low electric conductance

InactiveUS20060037733A1Efficient heatingEfficiency of materialMelt-holding vesselsPolycrystalline material growthCrucibleMetallic materials

Disclosed is an electromagnetic continuous casting apparatus for a material having a low electric conductivity. The casting apparatus includes a crucible having a vertical axis. The crucible comprises an upper hot crucible and a lower cold crucible. The crucible is surrounded with an induction coil. The hot crucible is formed of a non-metallic material having a high electric conductivity and is not water-cooled. The cold crucible has a cooling structure and is formed of a metallic material having a high thermal conductivity and a high electric conductivity.

Owner:KCC CORP CO LTD

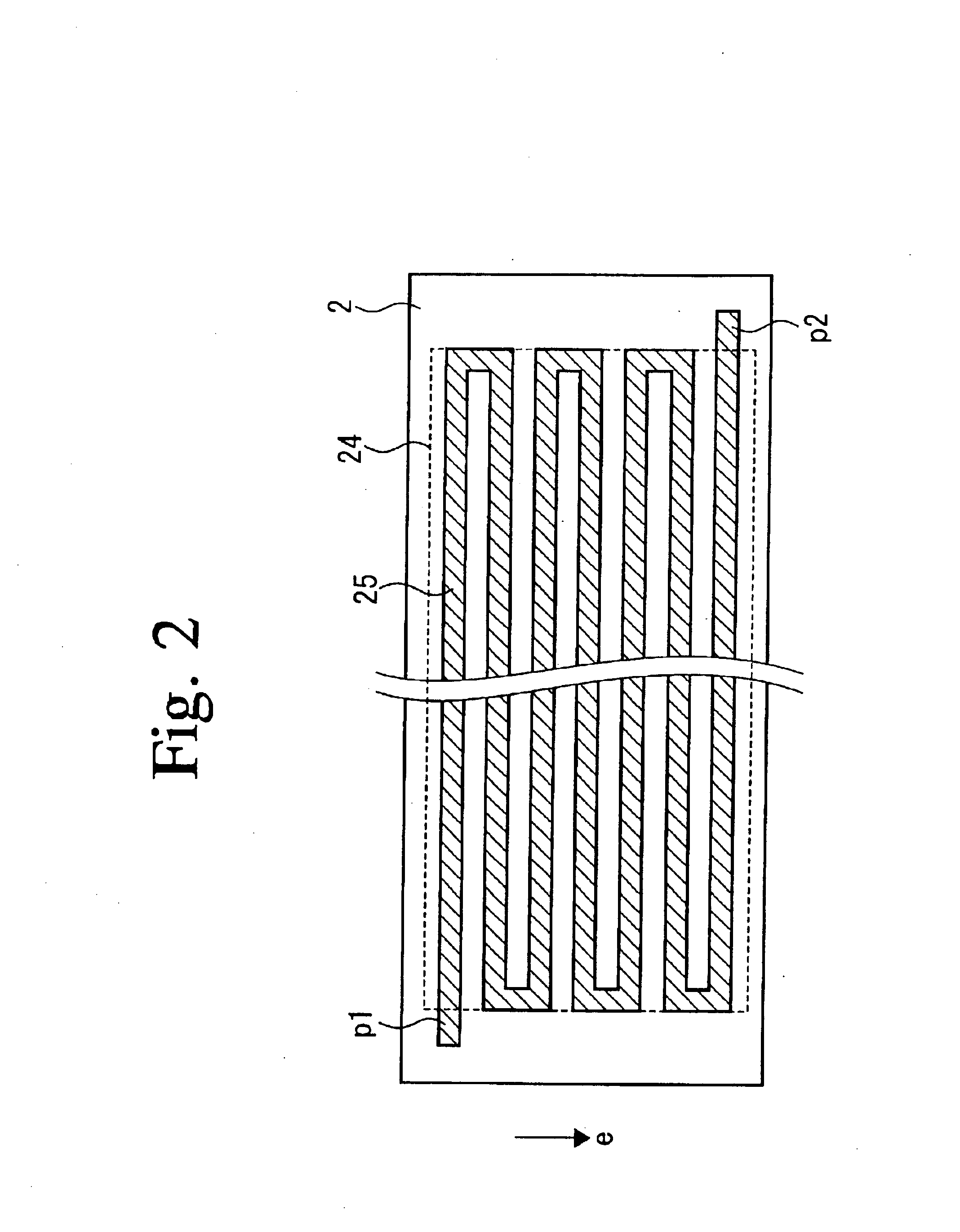

Induction heating type fixing device for an image forming apparatus and induction heating coil therefor

InactiveUS6946629B2Easy to controlReducing hot offsetCoil arrangementsElectrographic process apparatusBobbinElectrical conductor

An induction heating type fixing device for an electrophotographic image forming apparatus is disclosed. An inducting heating coil has a plurality of bobbins each having a particular diameter and assembled in a telescopic manner. A particular conductor is wound round each bobbin beforehand with leads being laid inside of the conductor. The bobbin may be implemented as a plurality of bobbin members removably connected together.

Owner:RICOH KK

Permanent magnet air heater

A permanent magnet air heater has a housing with an internal chamber accommodating an electric motor rotating a fan to move air through the housing. A non-ferrous member having bores for cylindrical magnets and a steel member with a copper plate secured to the steel member are rotated relative to each other by the motor whereby the magnetic field between the magnets and copper plate generates heat which is transferred to air in the housing moving through the housing by the fan.

Owner:POWERMAG

Induction heating of rail welds

InactiveUS20050173419A1Quality improvementPrecise heatingRailsCoil arrangementsEngineeringInduction coil

Owner:HOLLAND CO

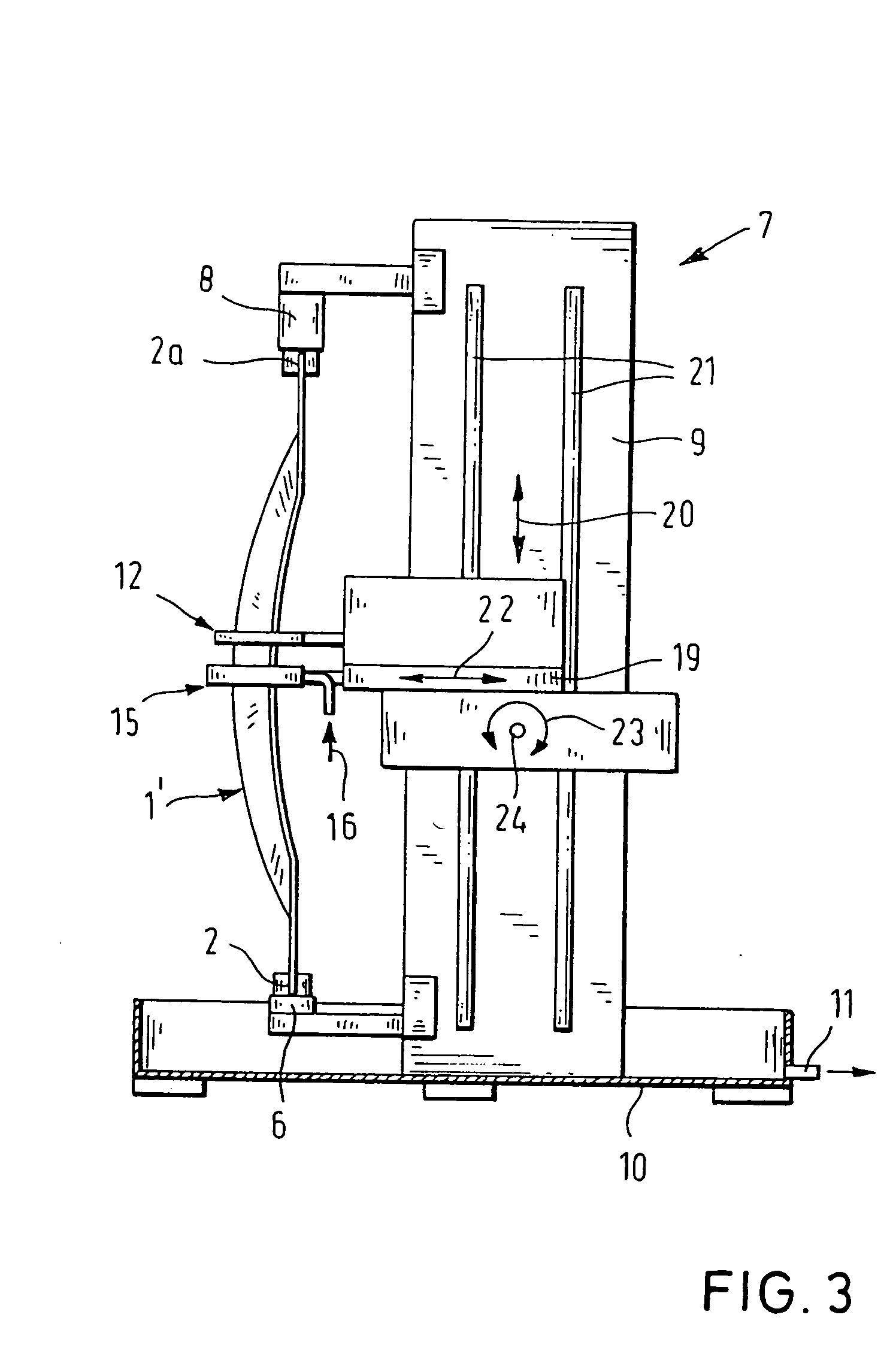

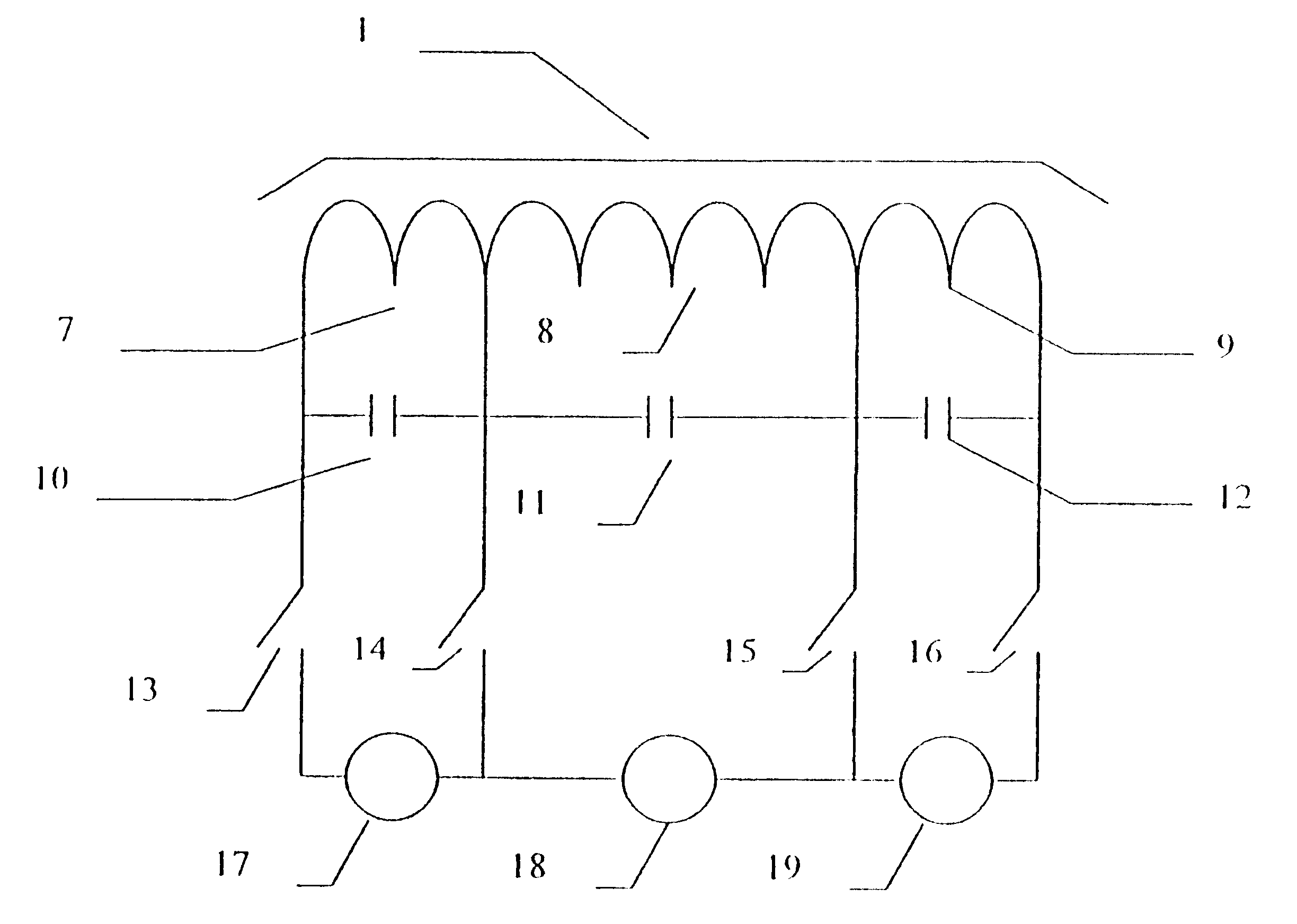

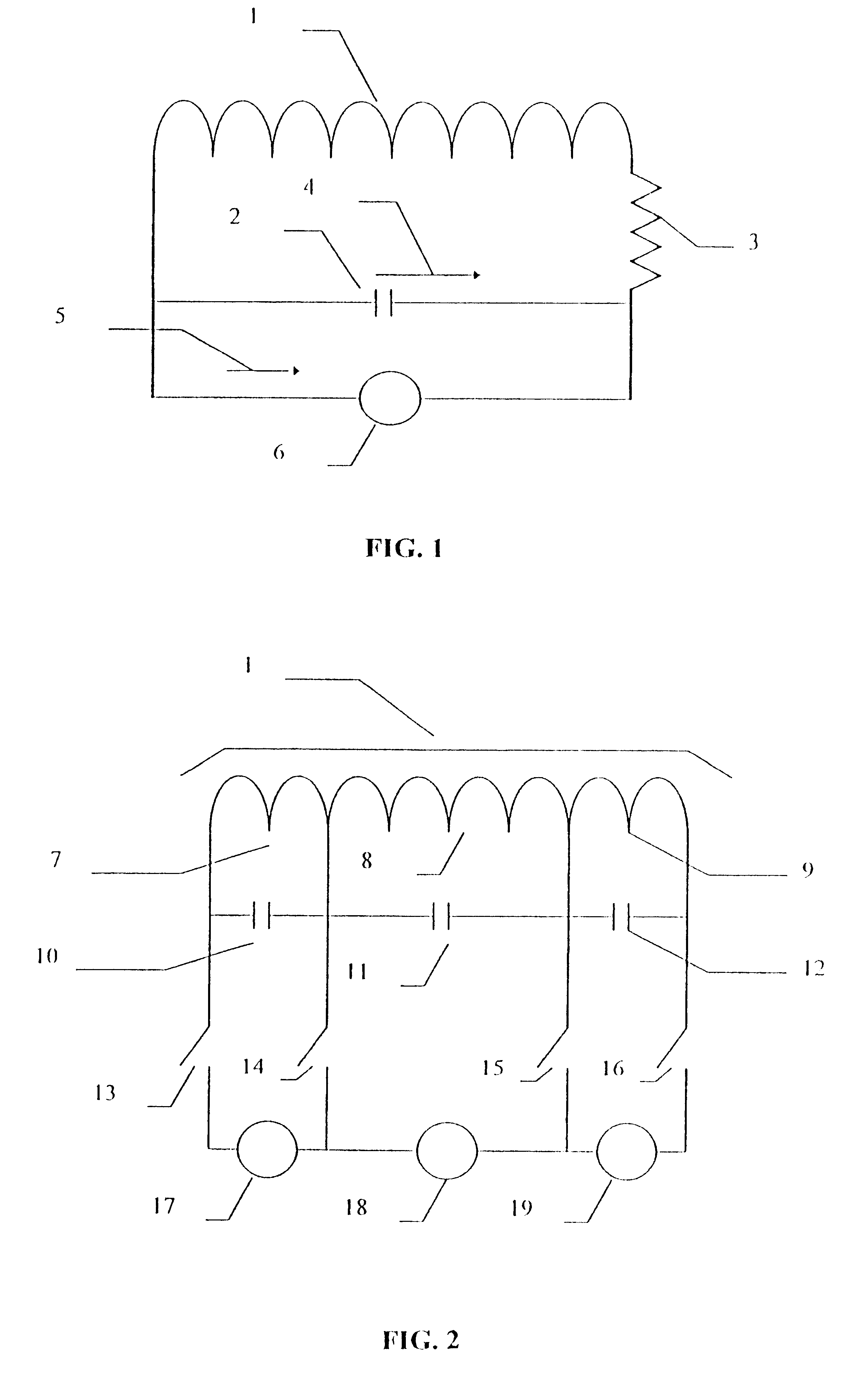

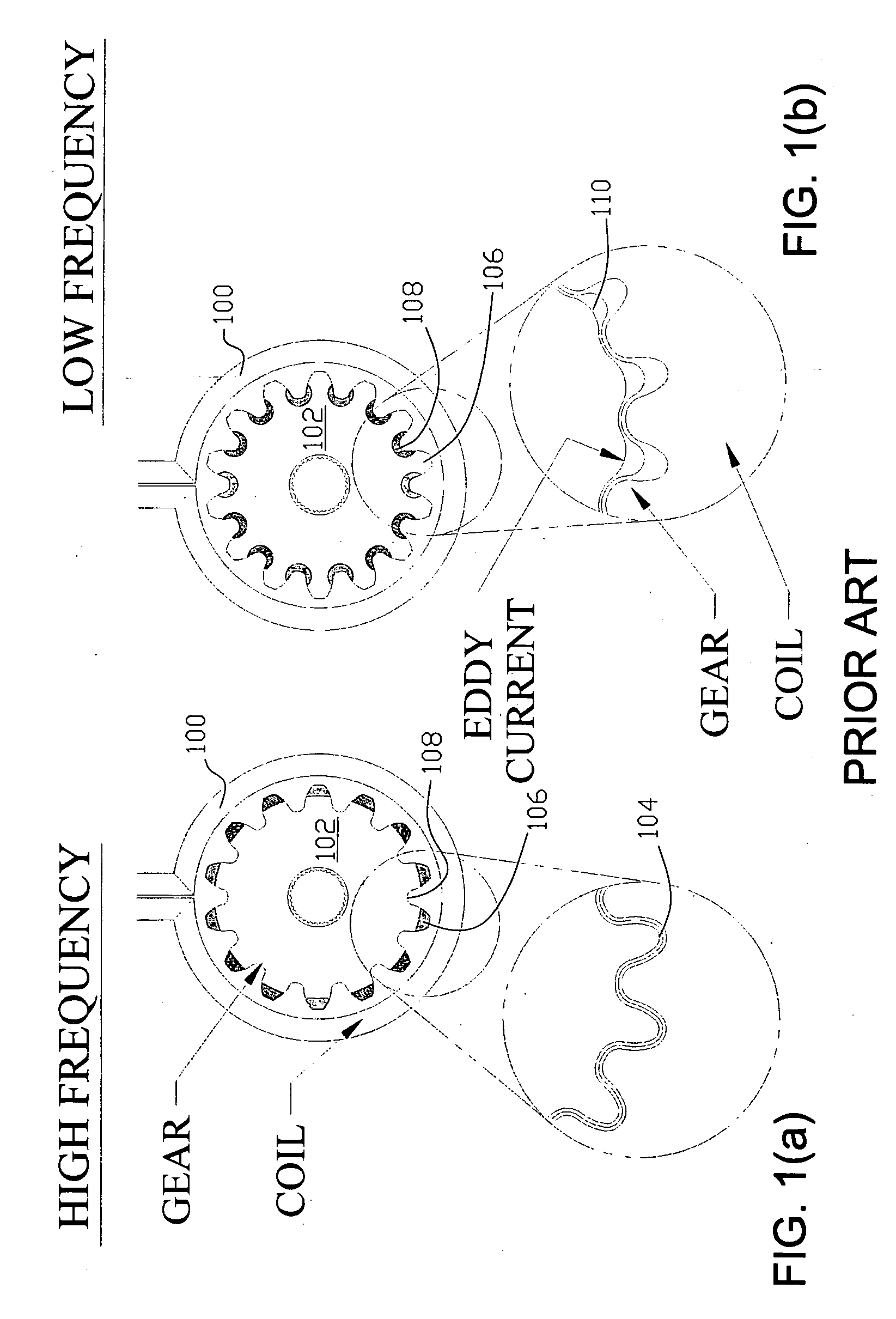

Multi-frequency heat treatment of a workpiece by induction heating

InactiveUS20050247704A1High resistivityReduce the amount requiredCoil arrangementsFurnace typesHigh frequency powerMagnetic field coupling

An apparatus and process are provided for multi-frequency induction heat treatment of workpieces including gears. High frequency power is applied to an induction coil that surrounds the workpiece so that a high frequency magnetic field couples with the workpiece to inductively heat the workpiece. A C-core inductor is coupled to a coil that has low frequency power applied to it. The workpiece is inserted in a gap in the C-core inductor magnetic circuit so that it experiences low frequency Joule effect heating when the low frequency current is applied to the coil coupled with the C-core inductor. Alternatively the workpiece may be inserted around the C-core inductor when the workpiece has an opening.

Owner:INDUCTOHEAT INC

Induction heating of springs

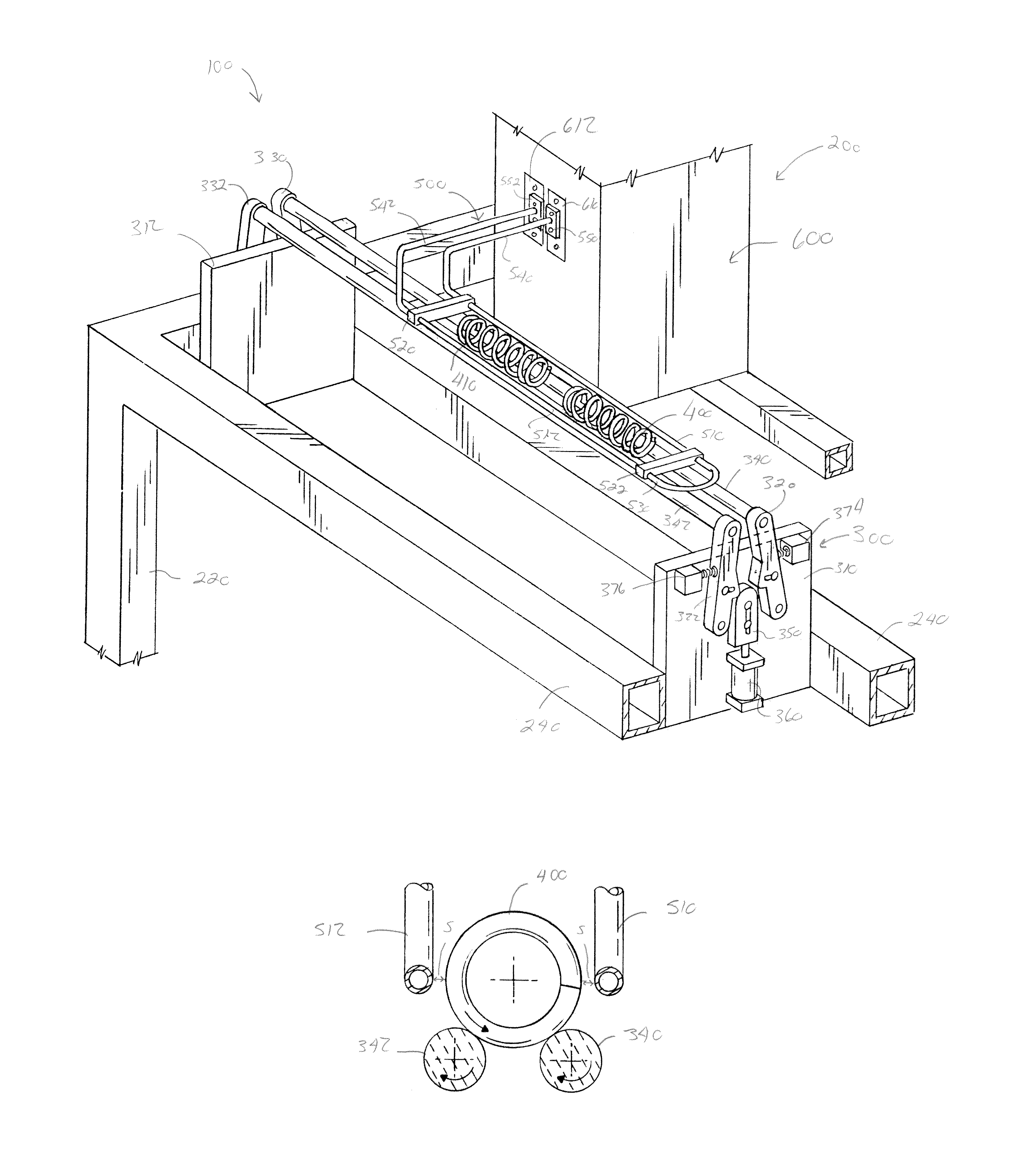

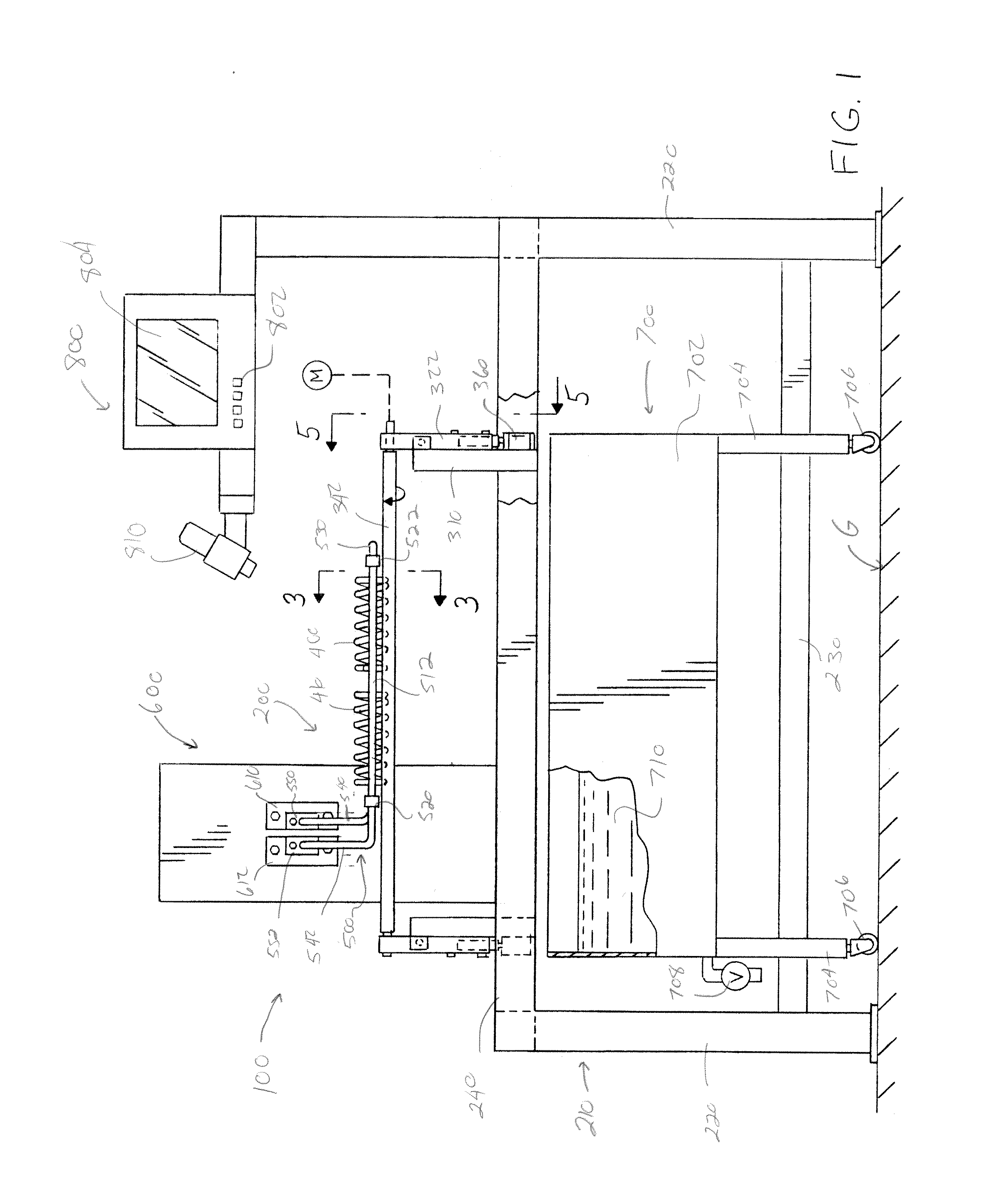

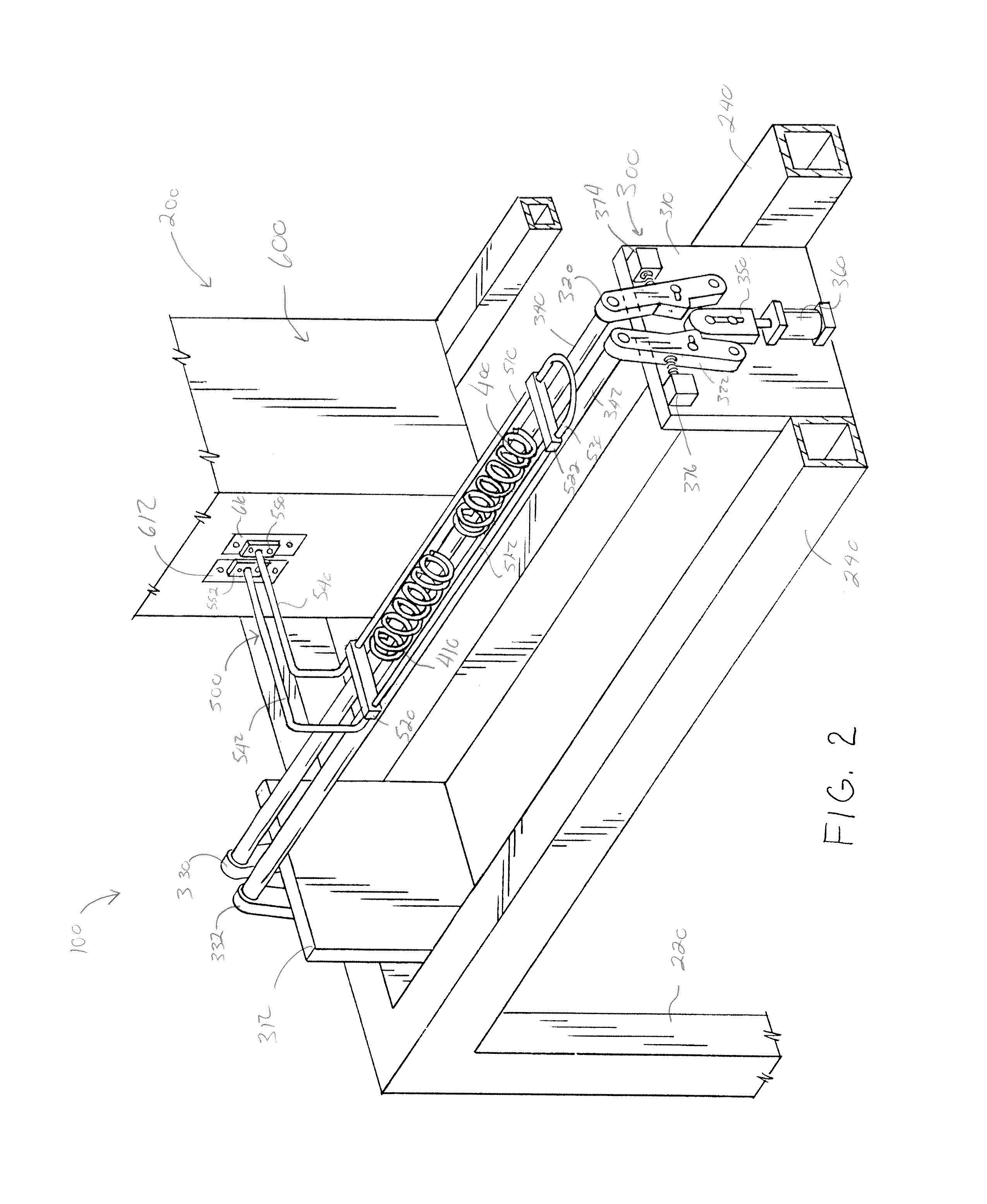

ActiveUS8912472B1Short durationEven heat distributionFurnaces without endless coreSpringsSupporting systemEngineering

An apparatus for hardening a spring having a helical or beehive shape. The apparatus has a rotation support system and an induction heating system. The rotation support system is designed to support the spring while the spring is heated by the induction heating system. The induction heating system has an induction coil system having a coil system. The coil system has a spaced region designed to receive the spring and to heat the spring while the spring is supported on the rotation support system.

Owner:BARNES GROUP

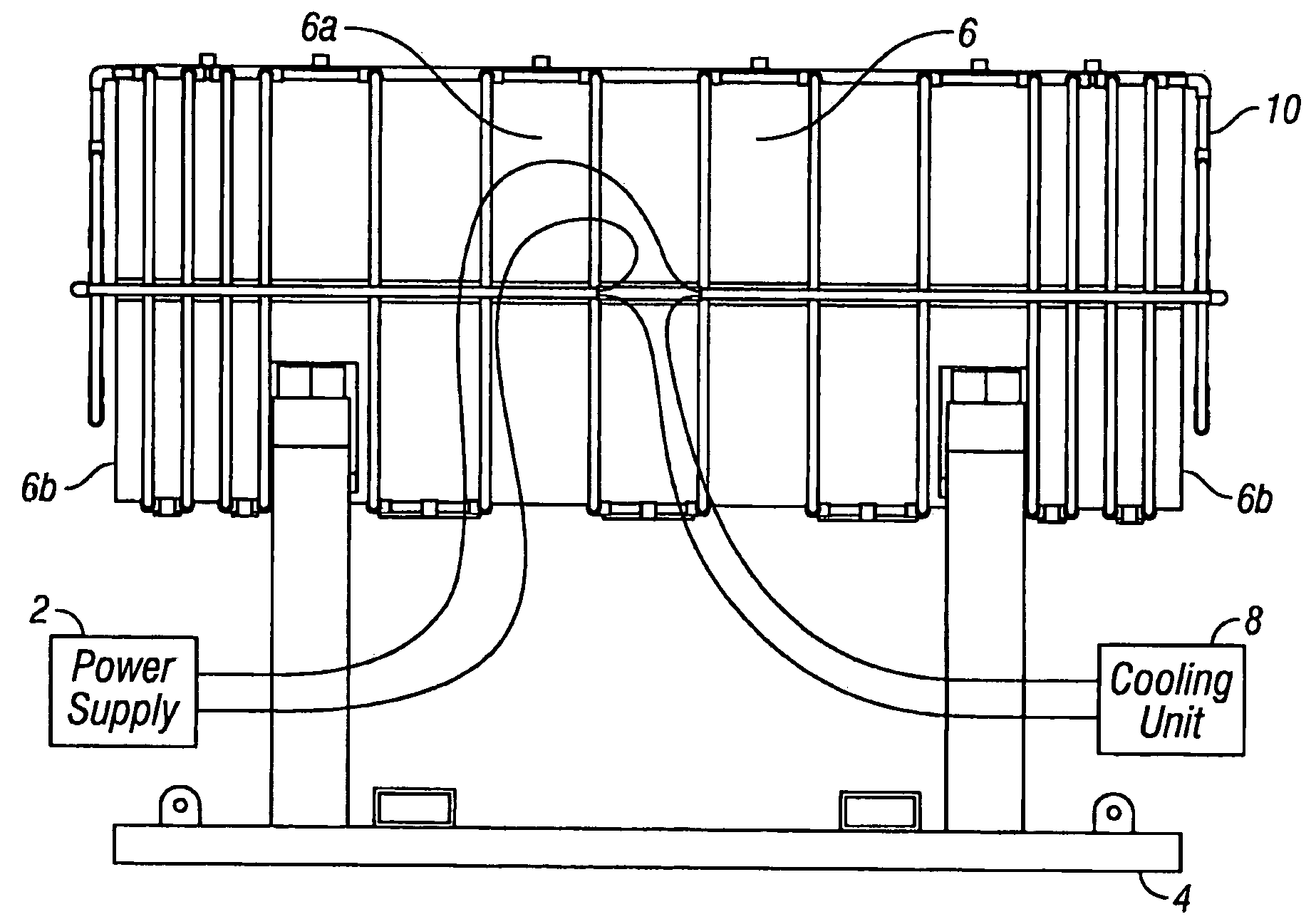

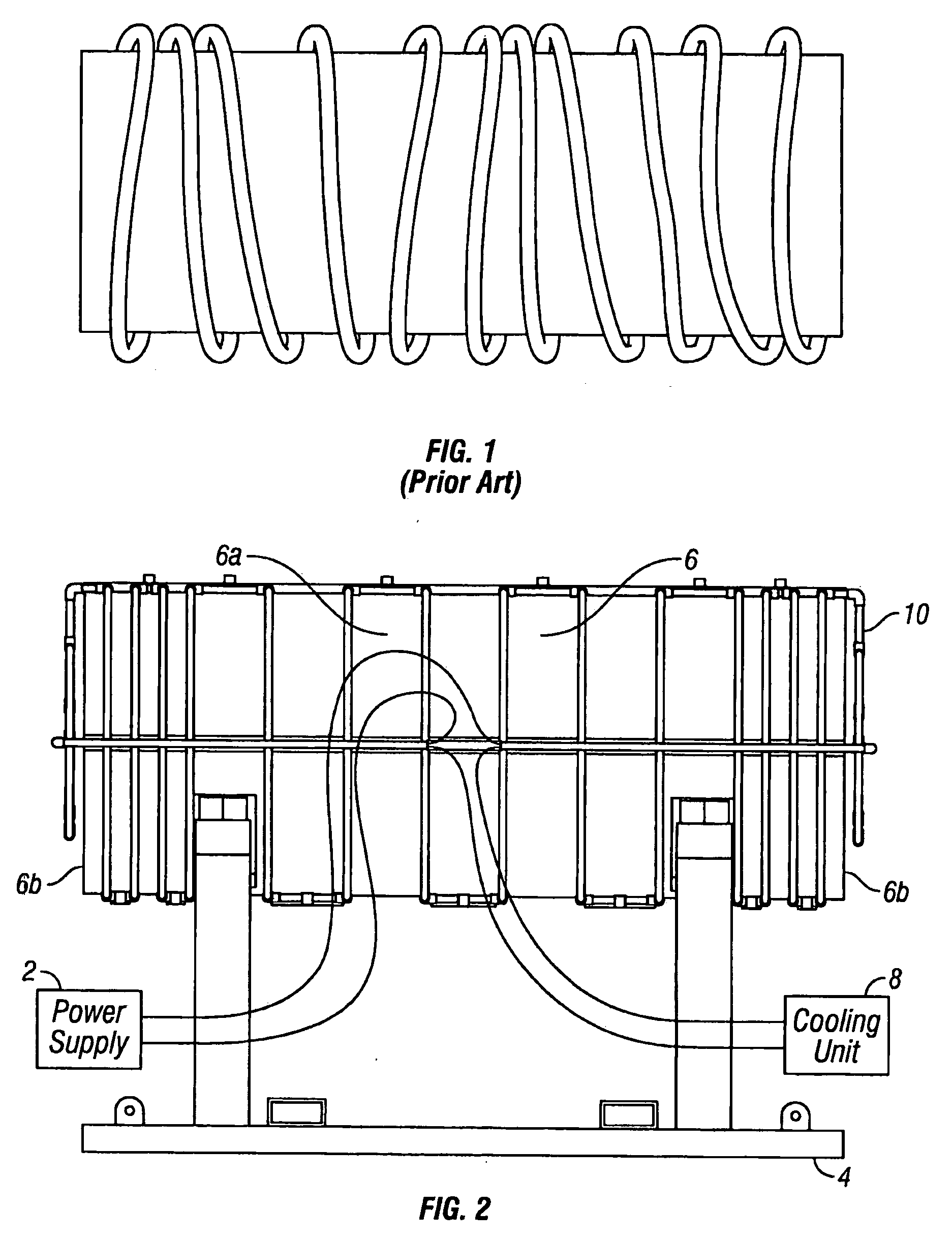

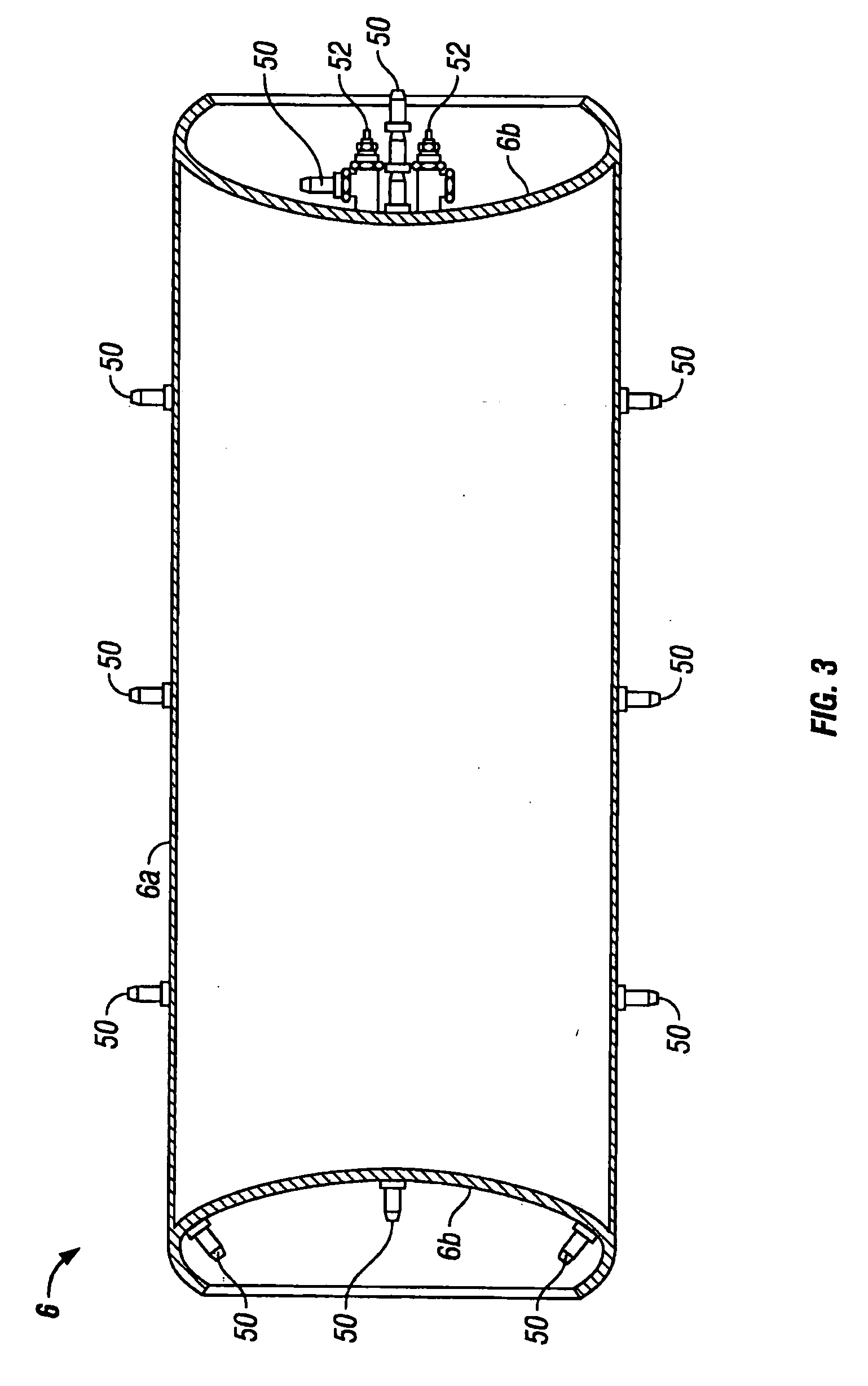

Inductive heating of workpiece using coiled assemblies, system and method

ActiveUS20090291018A1Coil arrangementsLavatory sanitoryElectrical and Electronics engineeringInduction heating

A system for inductively heating a workpiece including a heating coil that surrounds the sides and ends of the workpiece, wherein the heating coil comprises a first coil assembly that encloses a first portion of the workpiece and a second coil assembly that encloses a second portion of the workpiece. A power supply is operatively connected to the first coil assembly and the second coil assembly.

Owner:TEAM INDAL SERVICES

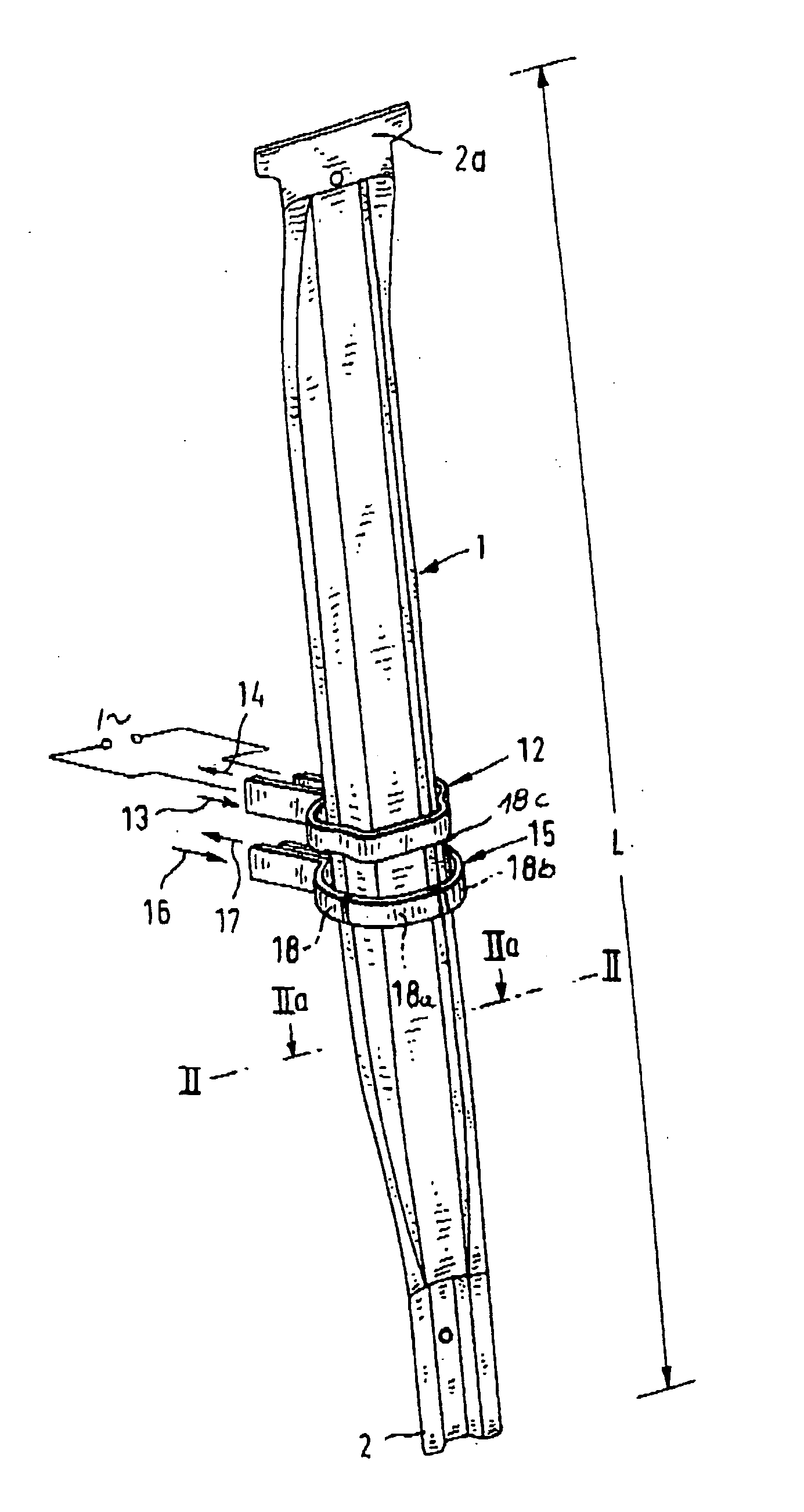

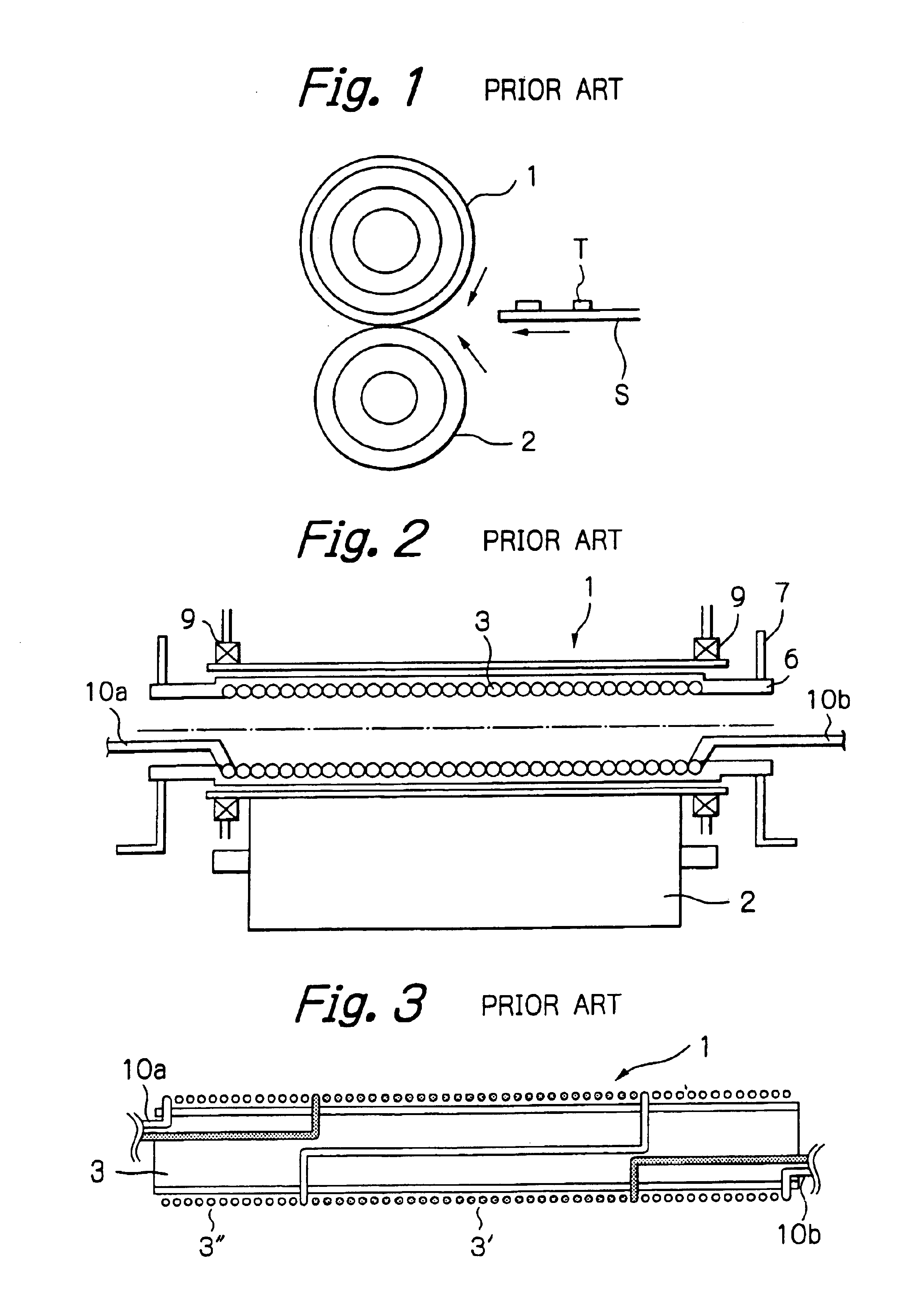

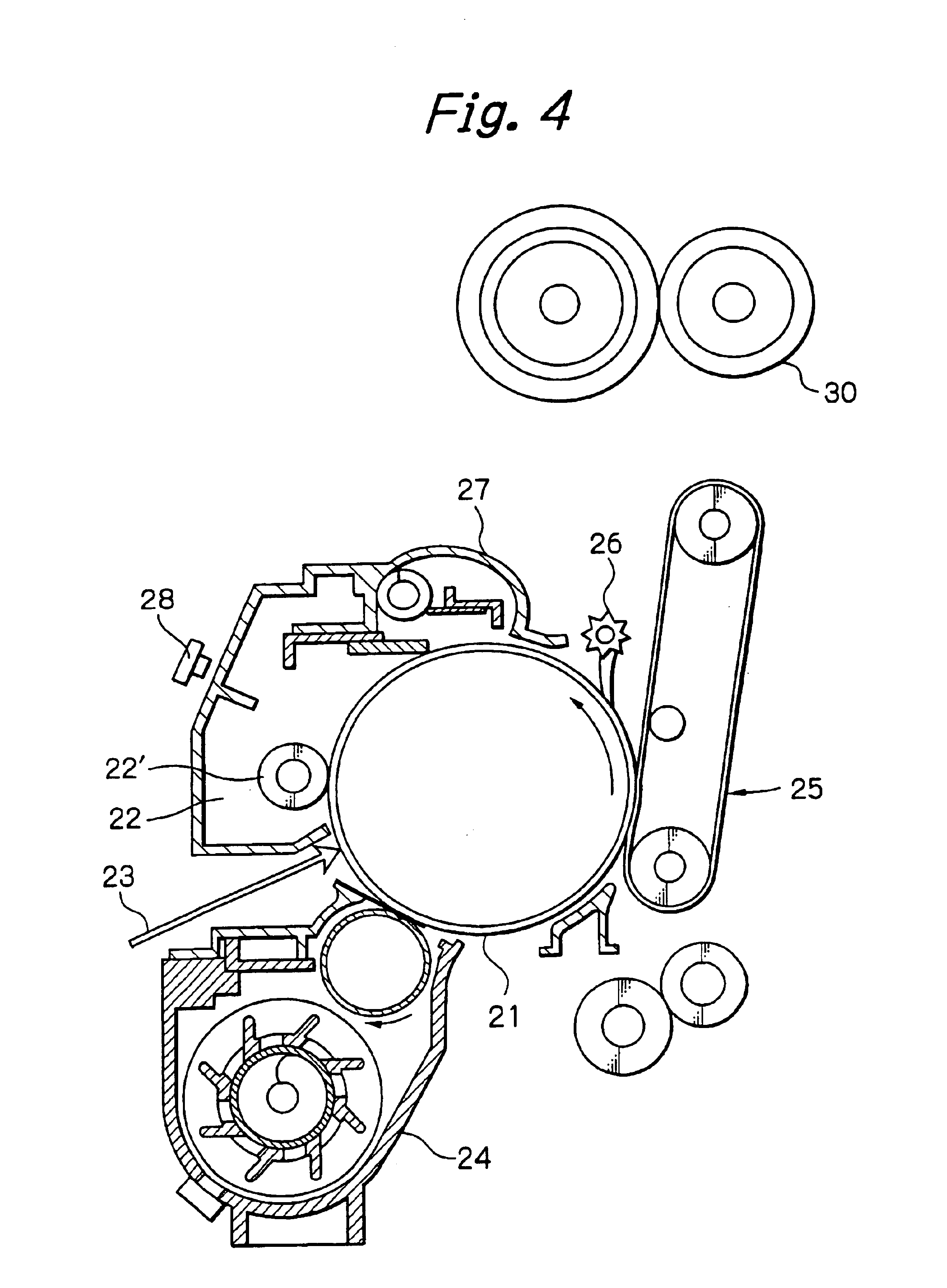

Process of and device for induction-hardening helical springs

InactiveUS20080128057A1Reducing any interfering factorsFurnaces without endless coreIncreasing energy efficiencyCoil springInduction hardening

A process of induction-heating helical springs, more particularly valve springs, for the purpose of carrying out subsequent hardening by quenching and tempering, wherein the helical springs, while being individually fixed and rotatingly driven, are guided through an electro-magnetic alternating field.

Owner:MUHR UND BENNDER KG

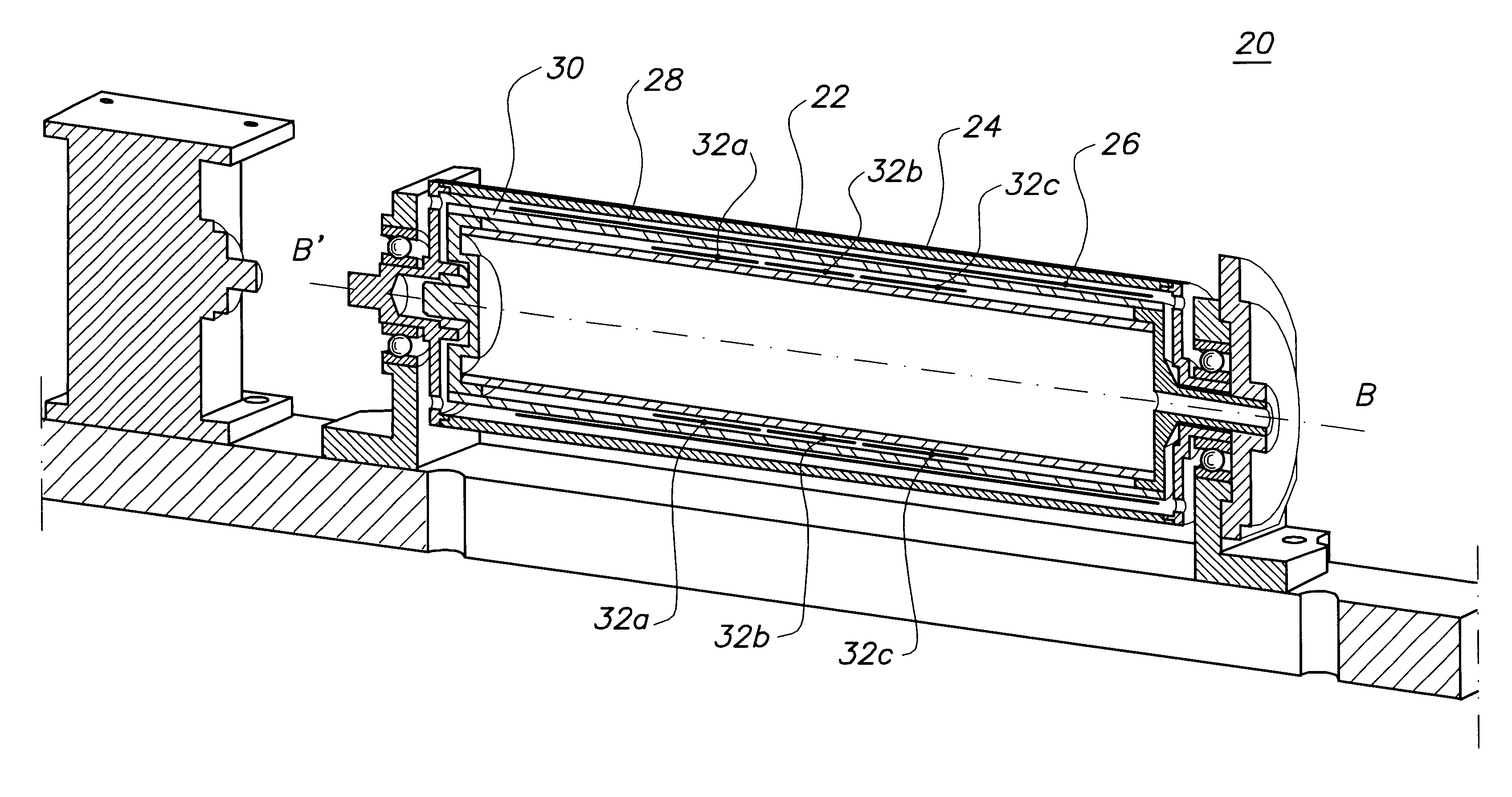

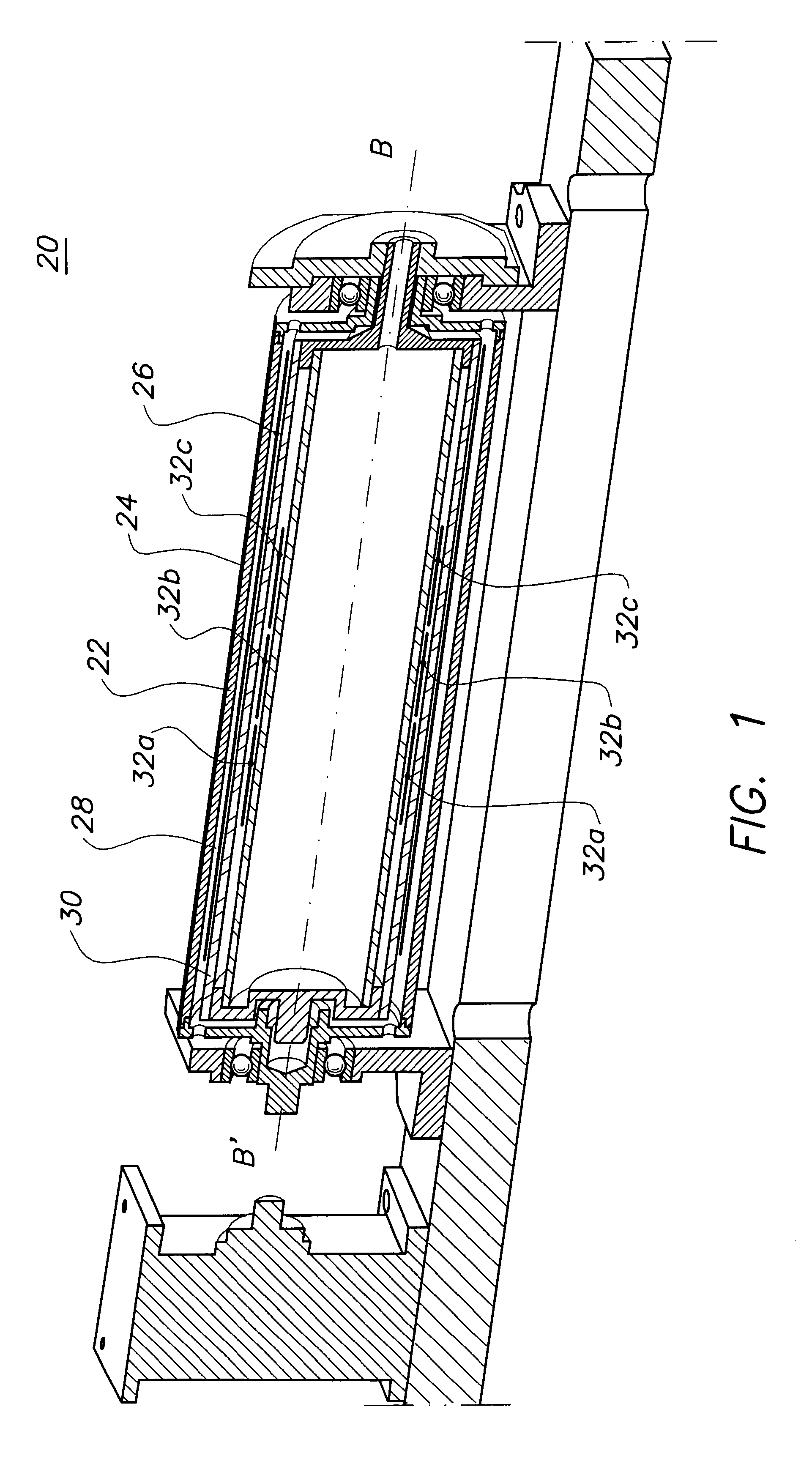

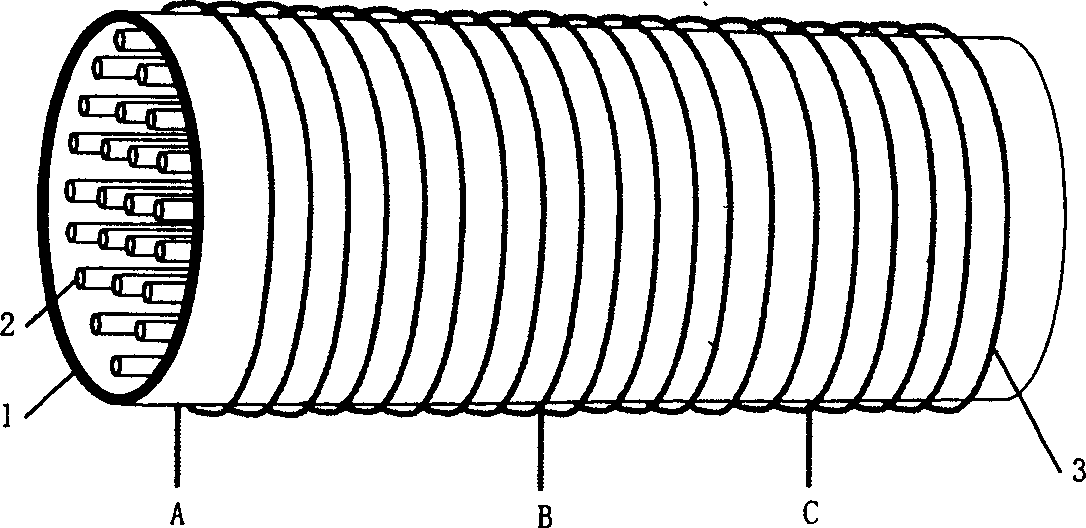

Induction heating device and method, and processor

InactiveUS6495811B2Meet the requirementsFurnaces without endless coreCoil arrangementsConductive materialsRecording media

An induction heating device having a hollow cylindrical body made of electrically conductive material, at least one primary induction coil and at least one auxiliary induction coil, the at least one primary induction coil and the at least one auxiliary induction coil being arranged in the cavity of the cylindrical body such that, by means of the at least one primary induction coil and the at least one auxiliary induction coil, first and second magnetic fields, respectively, can be produced in the cylindrical body. The at least one auxiliary induction coil and the at least one primary induction coil operate such that the second magnetic field, at least in one area of the cylindrical body, counteracts the first magnetic field. A corresponding method of operating such an induction heating device, and also a processor for processing a recording medium, having such an induction heating device, are also provided.

Owner:AGFA GEVAERT HEALTHCARE

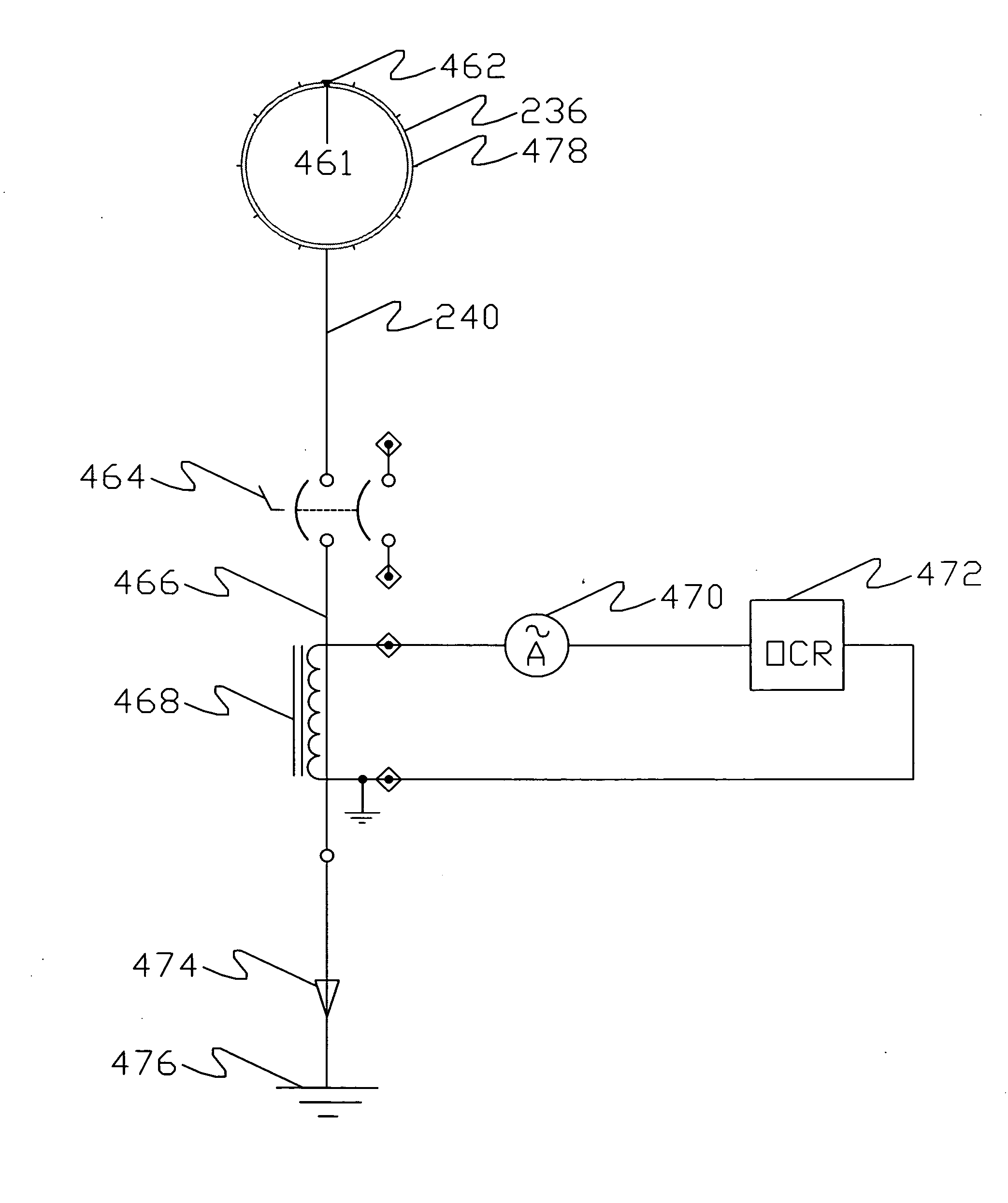

AC melt to bushing current detector

InactiveUS20080106830A1Stirring devicesArrangements responsive to excess currentInductorInduction furnace

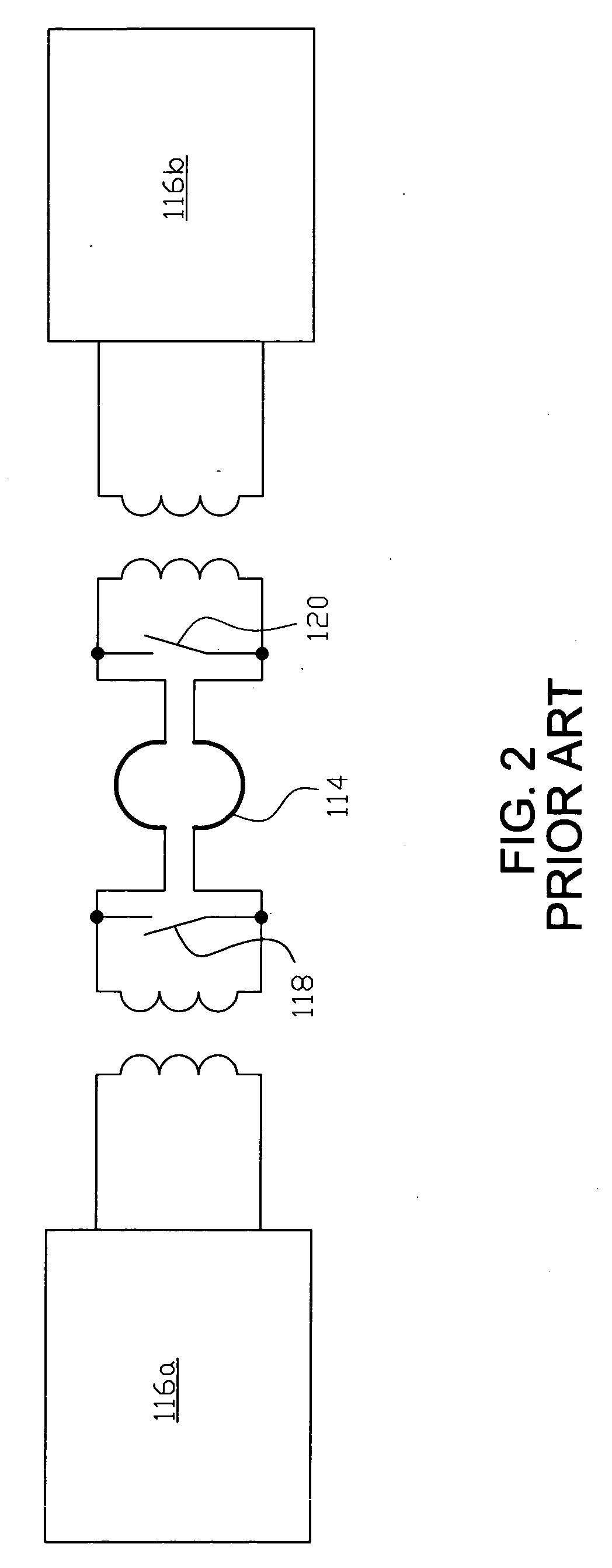

An AC melt to bushing current detector (FIG. 4) for a channel induction furnace (FIG. 1) which can detect when molten metal from the loop (122) in a saturated inductor (FIG. 5) has come in contact with the metal bushing (236) whereupon the power to the induction coil (234) is turned off, preventing a catastrophic molten metal run out through the bushing (236).

Owner:DUCA MFG & CONSULTING

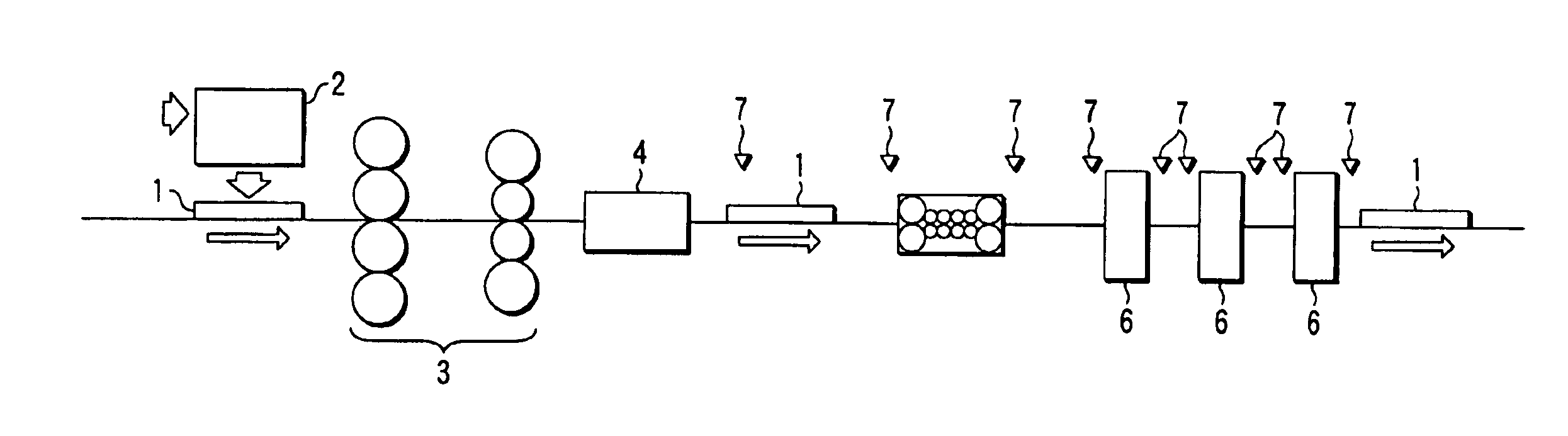

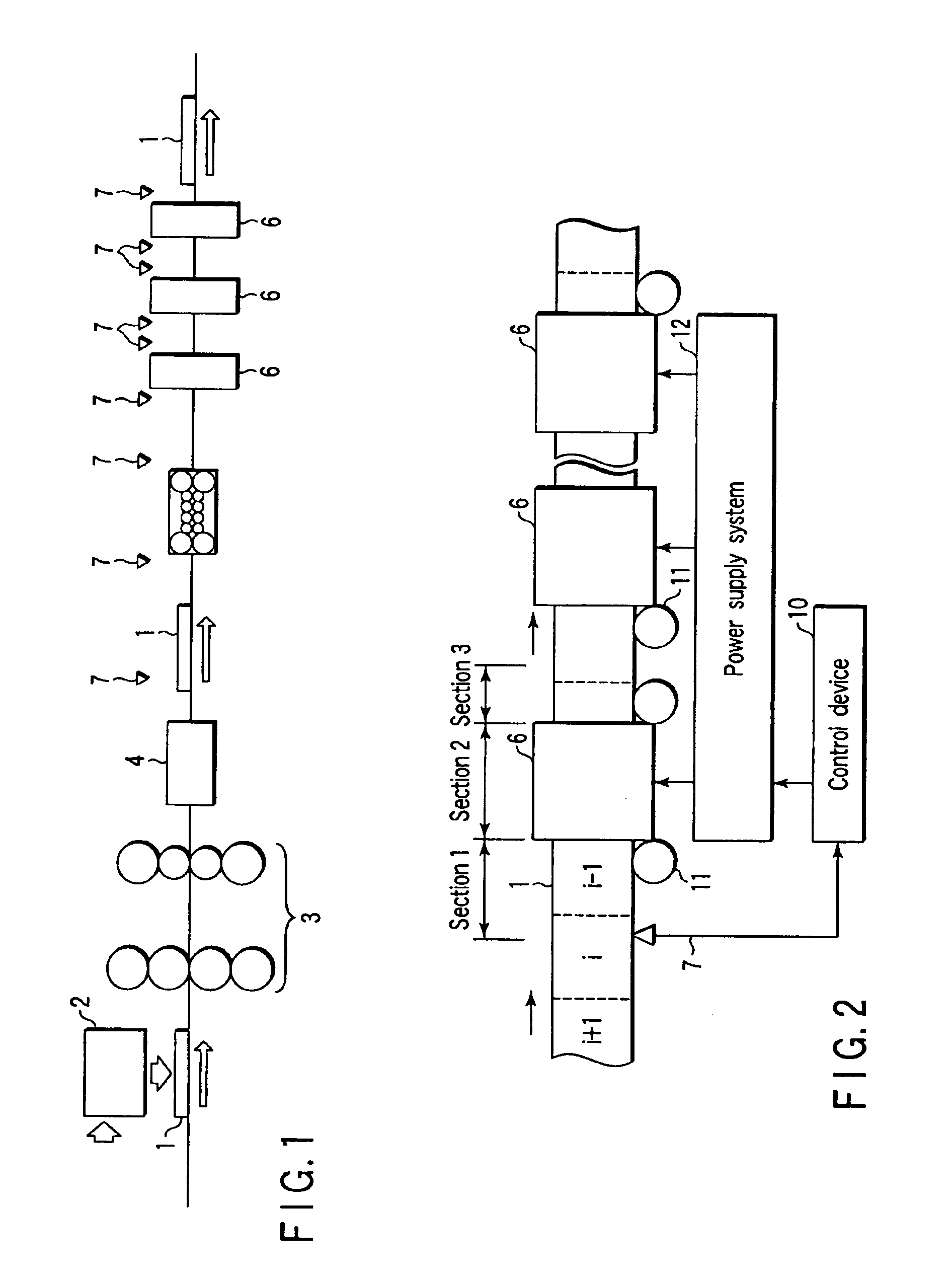

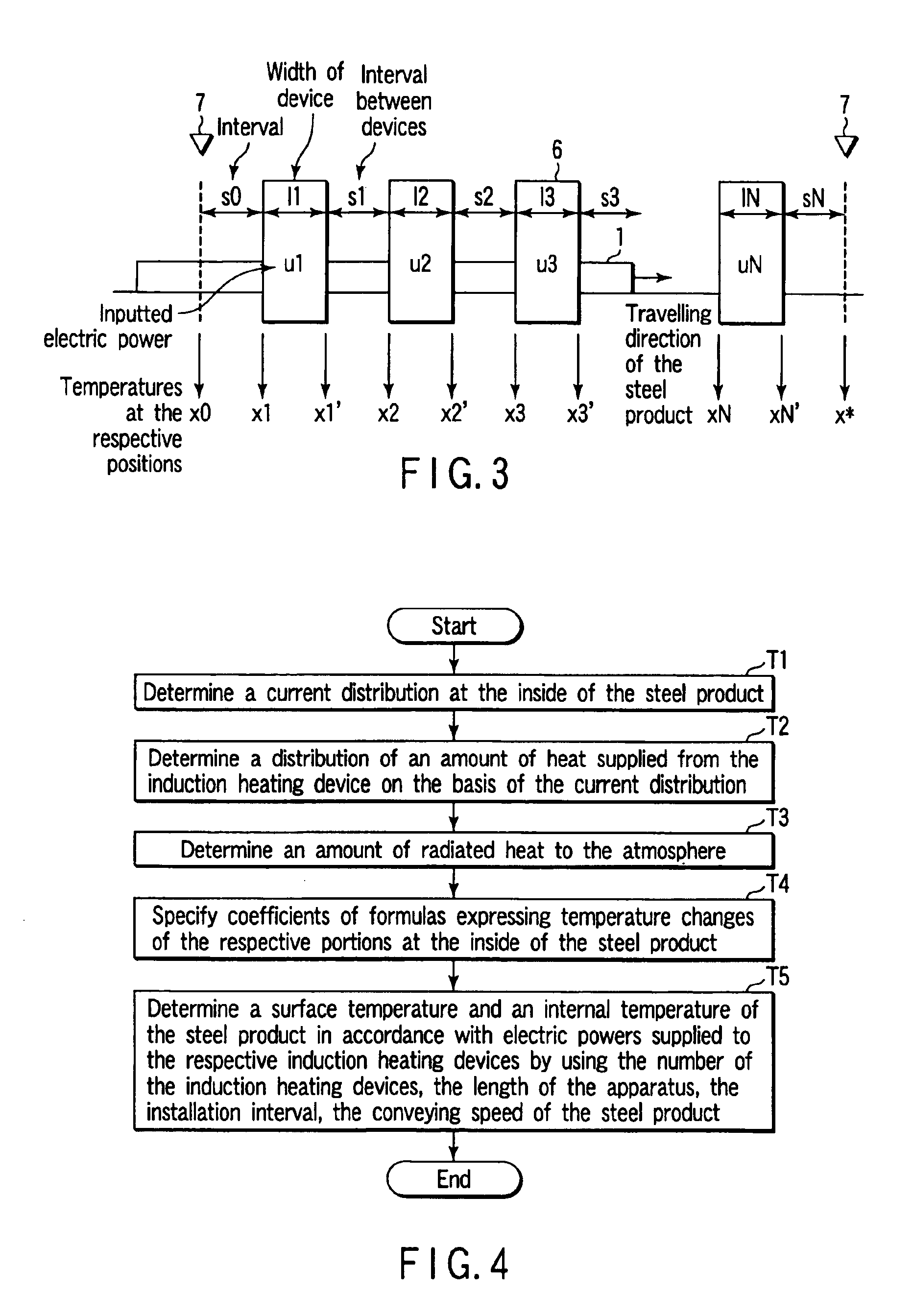

Heat treatment apparatus, heat treatment method, medium on which heat treatment program is recorded, and steel product

InactiveUS6891139B2Shorten heating timeSimplify structure of apparatusFurnace typesIncreasing energy efficiencySurface layerElectric power

A heat treatment apparatus includes a plurality of induction heating devices which heat a steel product, a correctional device which corrects the steel product, a computing device which computes supply predetermined electric power which is supplied to the induction heating device, on the basis of a size of the steel product, a conveying speed of the steel product, a heating target temperature of the steel product, and a predetermined temperature of the steel product at the previous stage of the induction heating devices, and a power supply unit which supplies the supply predetermined electric power computed by the computing device to the induction heating devices, and the computing device which computes electric power for uniform heating processing on the steel product or electric power for surface layer heating processing on the steel product.

Owner:JFE STEEL CORP

Electromagnetic induction heating apparatus

InactiveCN1805628AReduce resistanceAvoid isolationWater heatersInduction heating apparatusChemical reactionEngineering

The invention relates to an electromagnetic induction heater, which is formed by a inductance coil coiled on the outer cylinder, and at least axial magnetic conductive inner tube supported by the non-magnetic material and arranged inside the outer cylinder. The invention is characterized in that: the outer cylinder is made from heat resistant material which is conductive and non-magnetic conductive; and a heat insulating layer is arranged between the outer cylinder and the inductance coil. The invention has simple structure, easy operation and high input power which can reach thousand tiles, while its heating temperature is higher hundred degrees than the temperature of electric heating tube. The invention can be used to heat air in the turbine refrigeration and cycle fluid-bed boiler, and heating the oil in the oil transmission pipeline, etc. The invention has high reliability, less maintenance, high heat efficiency, high power, less fluid pressure loss, and significant social and economic benefits.

Owner:王鹏

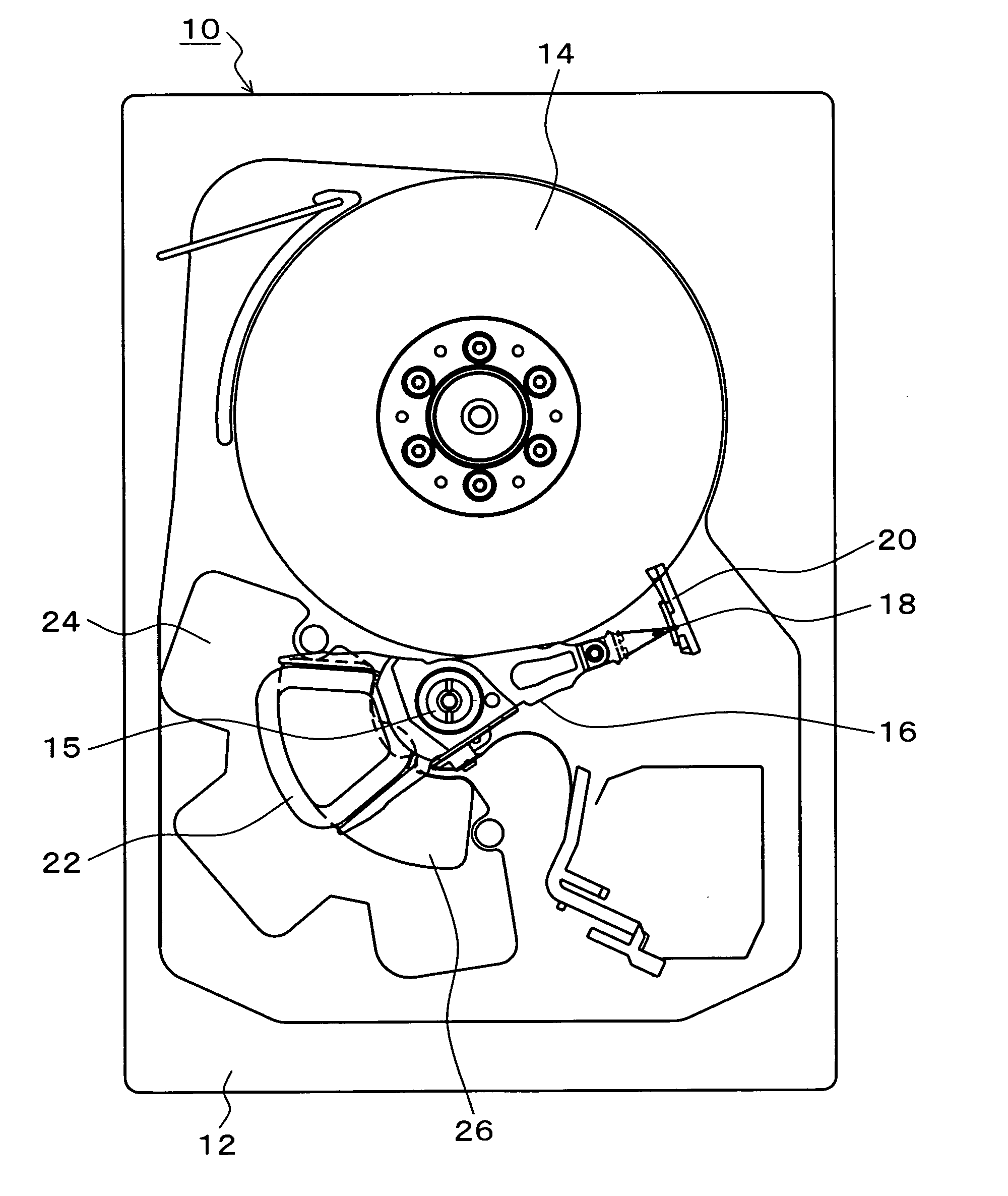

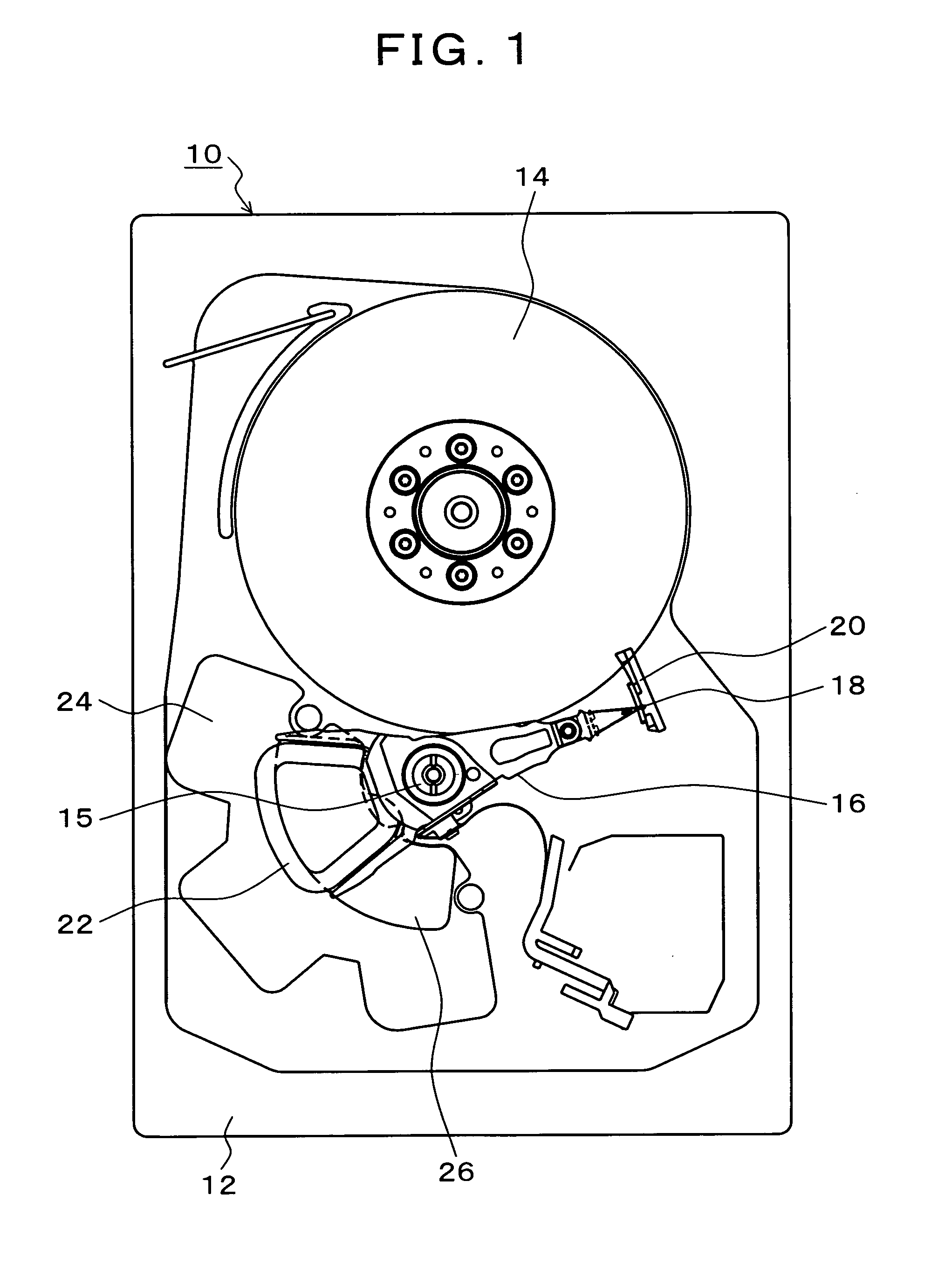

Magnetic head

InactiveUS20080023468A1Enhance heater efficiencyImproving heater efficiencyNanomagnetismNanoinformaticsMagnetic polesElectric power distribution

A magnetic head has a read head in which a read element which converts recording magnetic flux emitted from the magnetic disk into an electric signal is disposed between a pair of shield layers on a substrate, and magnetically records information by emitting magnetic flux generated by a write current flowing through a write coil from a magnetic pole unit to a magnetic disk. A heater coil is disposed to face the write coil via an insulating layer, and a medium facing surface is caused to protrude toward the recording medium side by thermal expansion caused by electric power distribution and heating. Subsequent to the shield layer in the substrate side, a low thermal conducting layer made of a material having a low thermal conductivity which suppresses transmission of the heat caused by electric power distribution to and heating of the heater coil and a low thermal expansion layer which is disposed in the substrate side of the low thermal conducting layer and is made of a material having a low thermal expansion coefficient are disposed.

Owner:TOSHIBA STORAGE DEVICE CORP

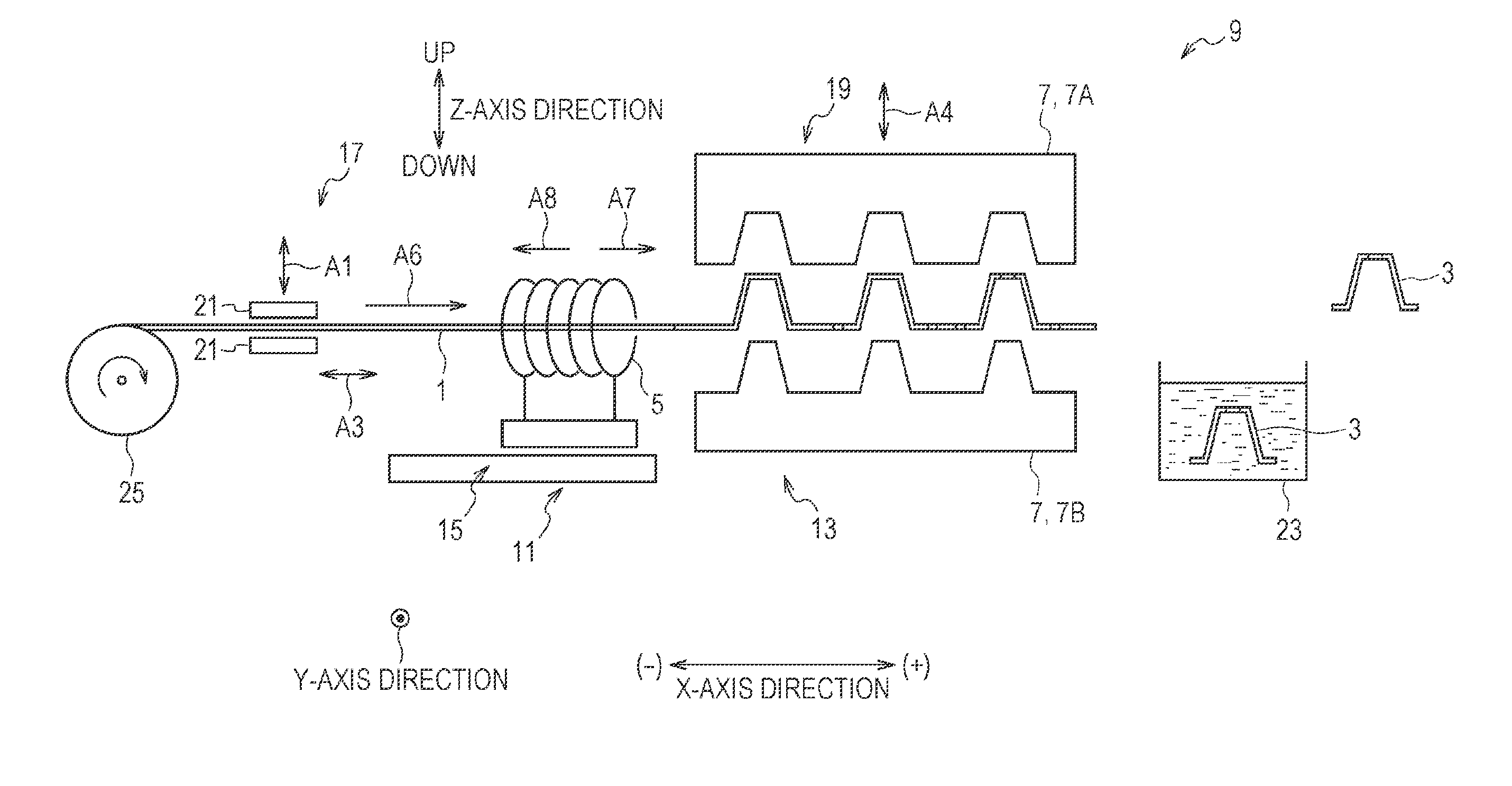

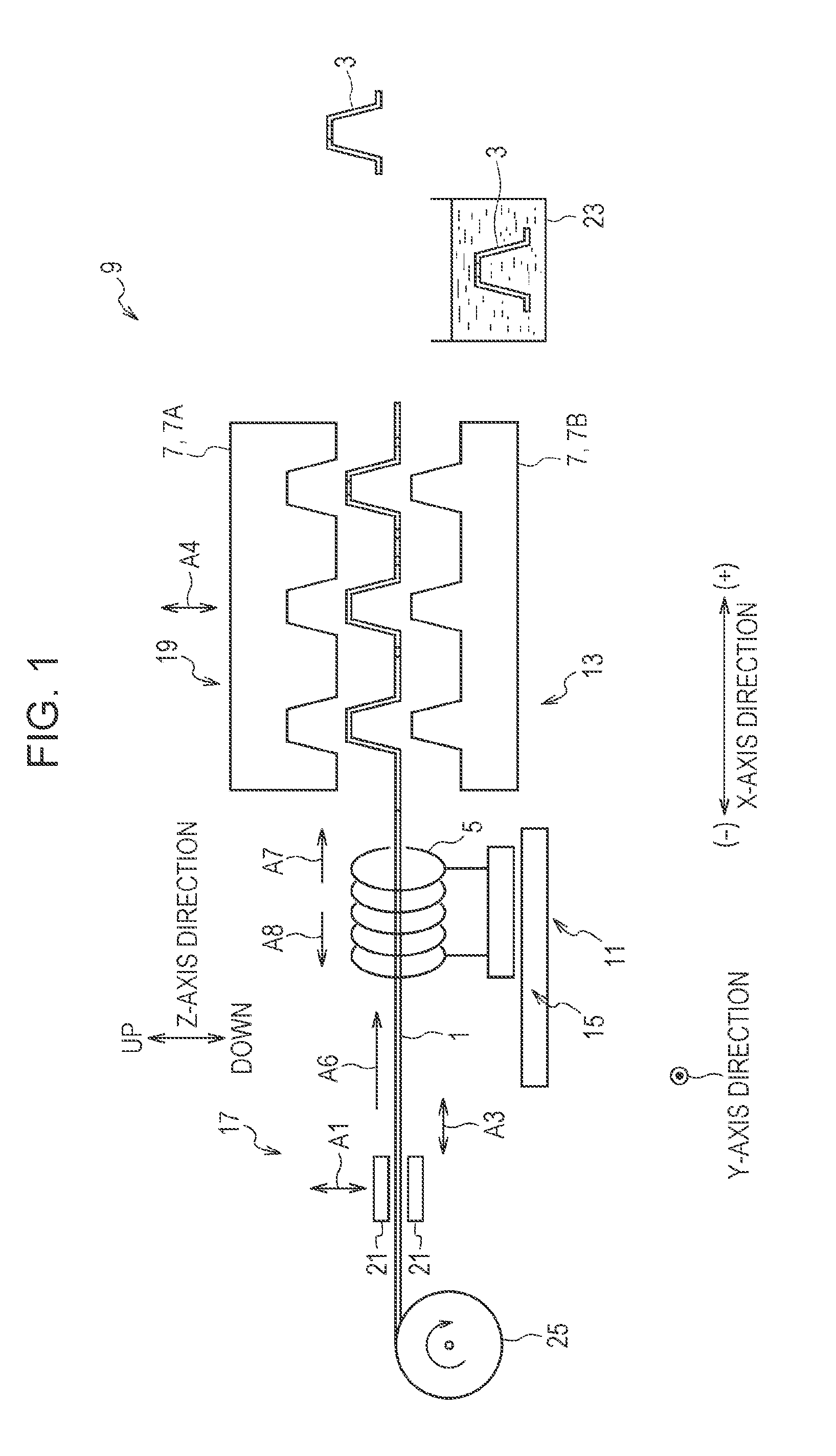

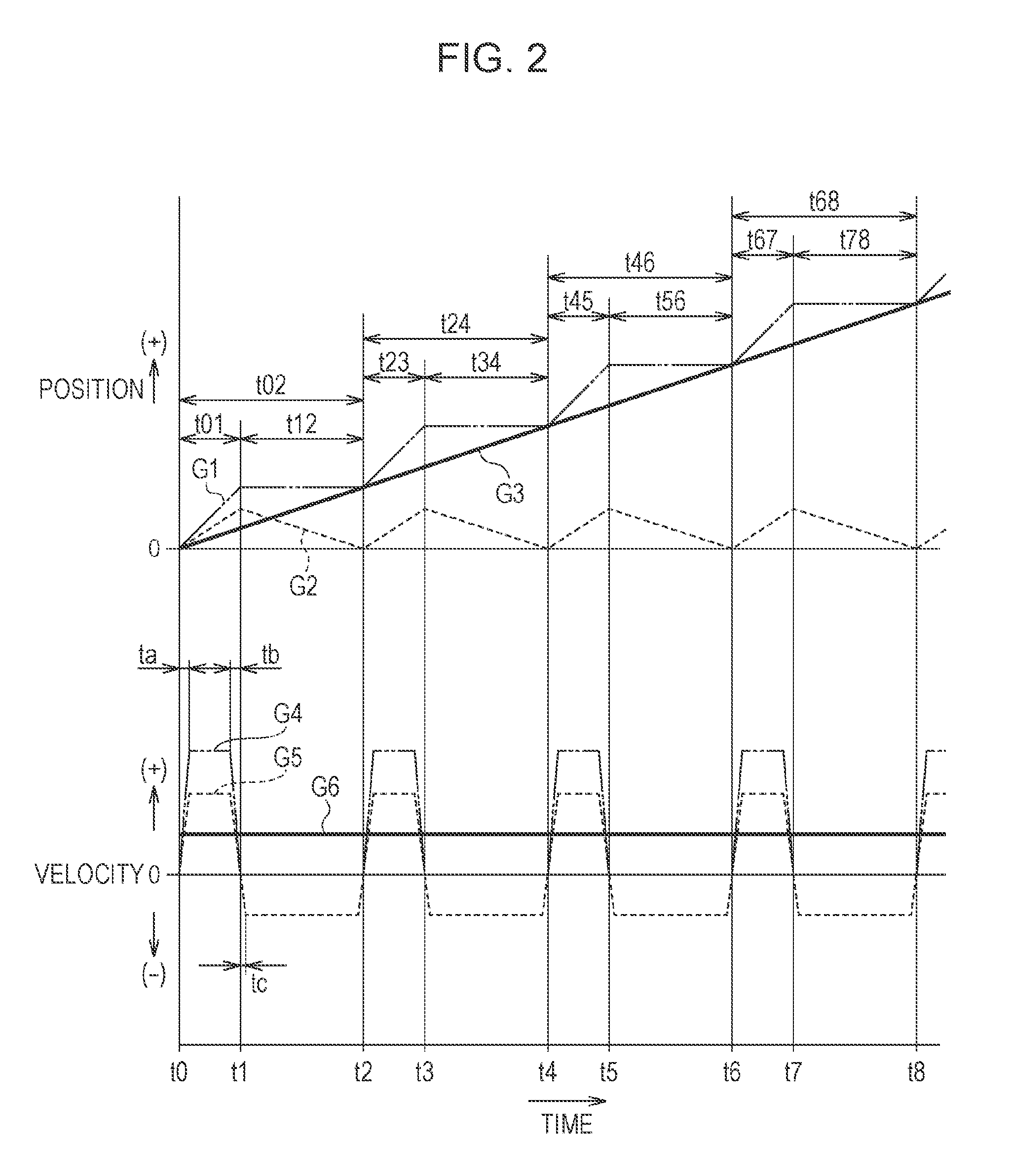

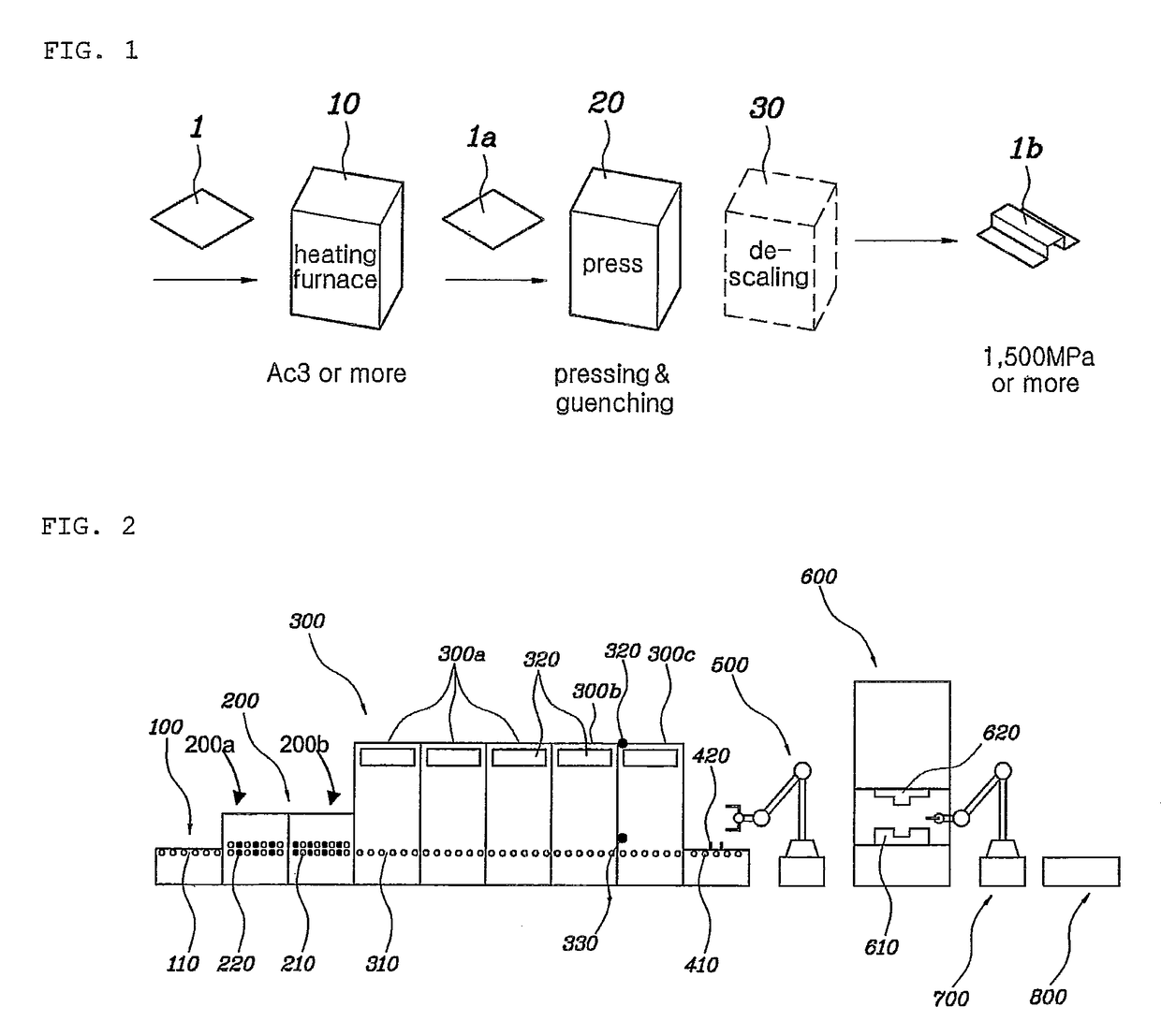

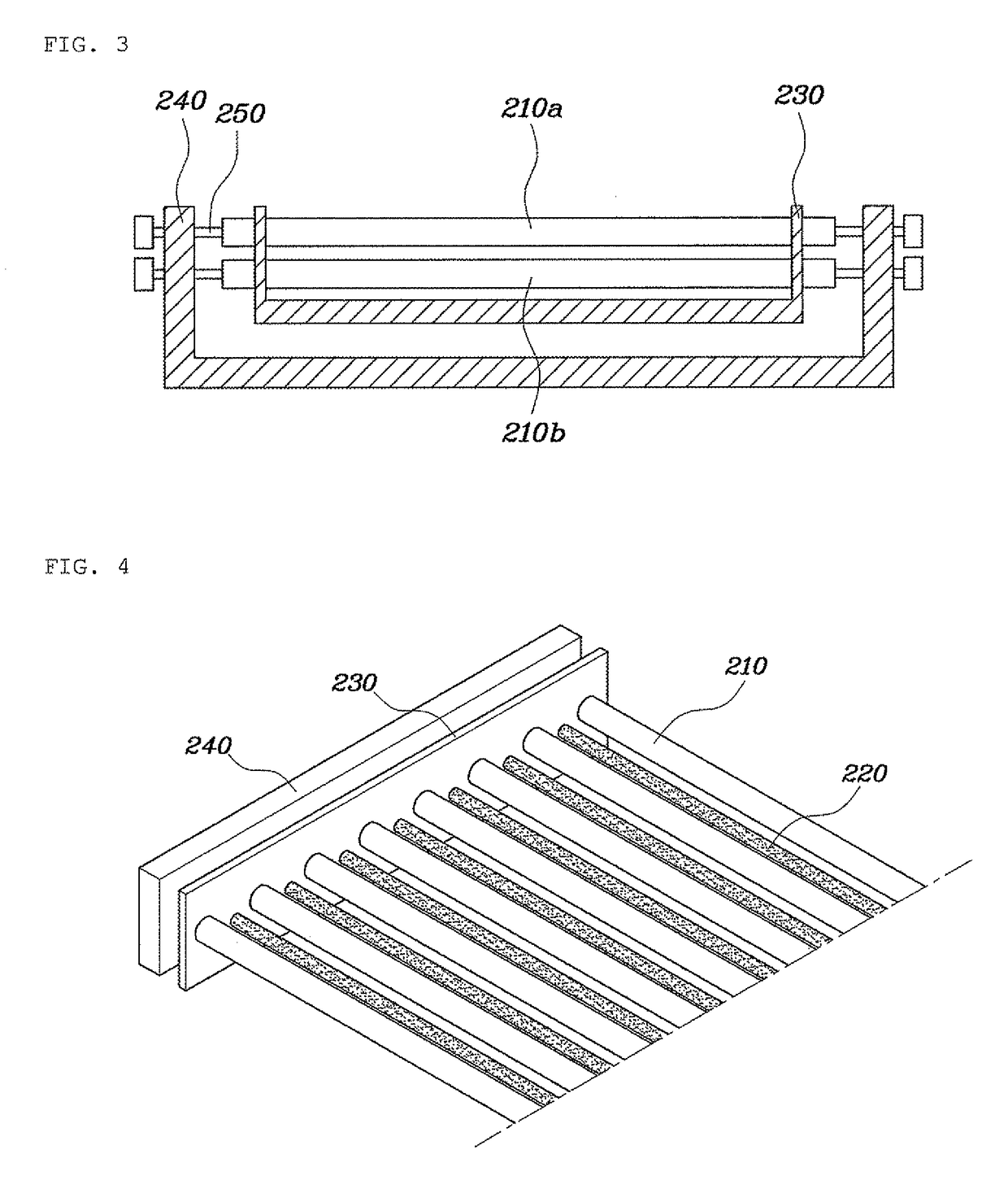

Method of manufacturing hot pressed product and hot pressing apparatus

Provided is a method of manufacturing a hot pressed product with which a heating coil of the induction heating device is moved in a feeding direction of the metal strip and in a direction opposite to the feeding direction of the metal strip so as to reduce variation in a feed velocity of the metal strip relative to the heating coil of the induction heating device.

Owner:TOPRE

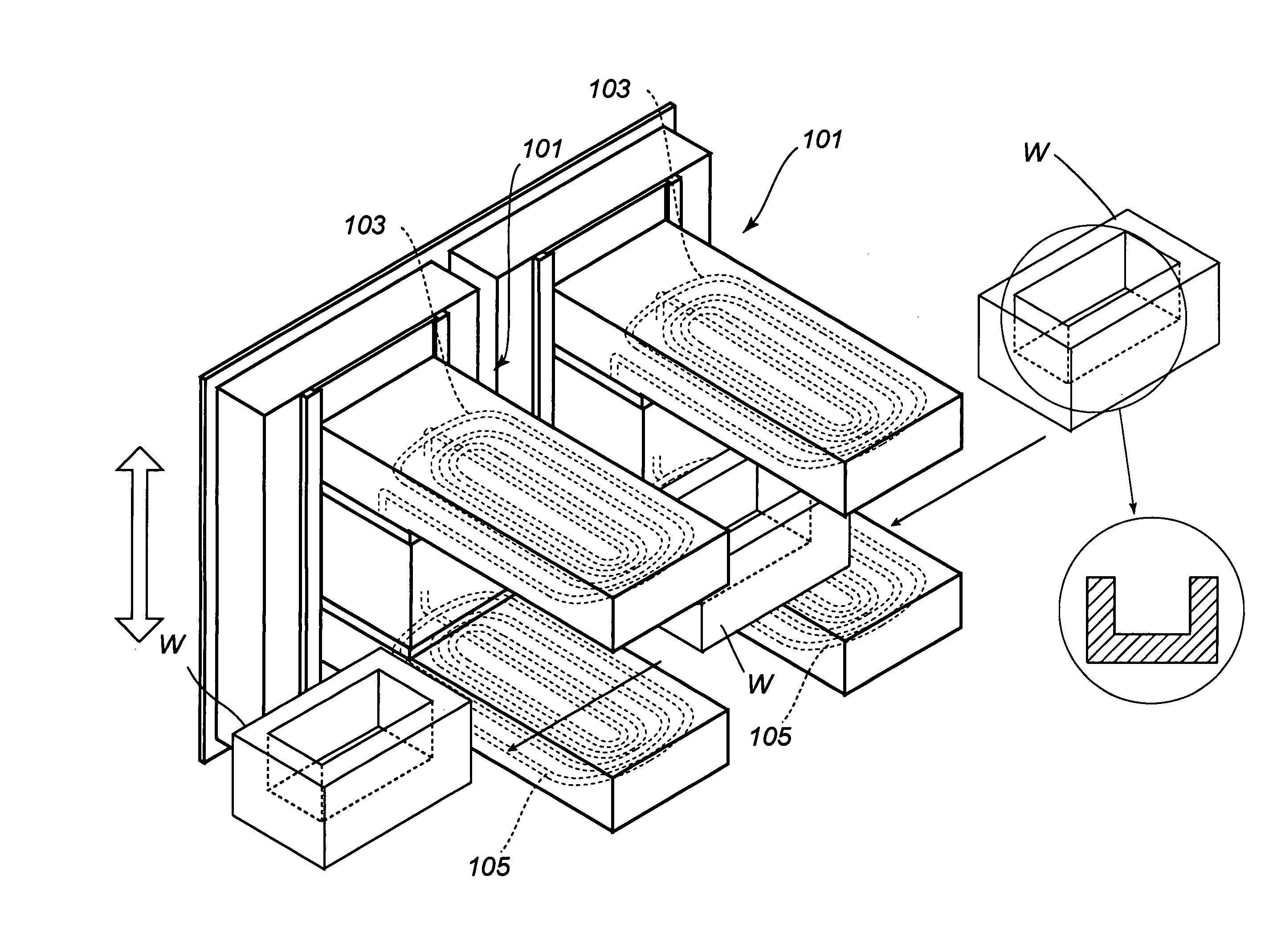

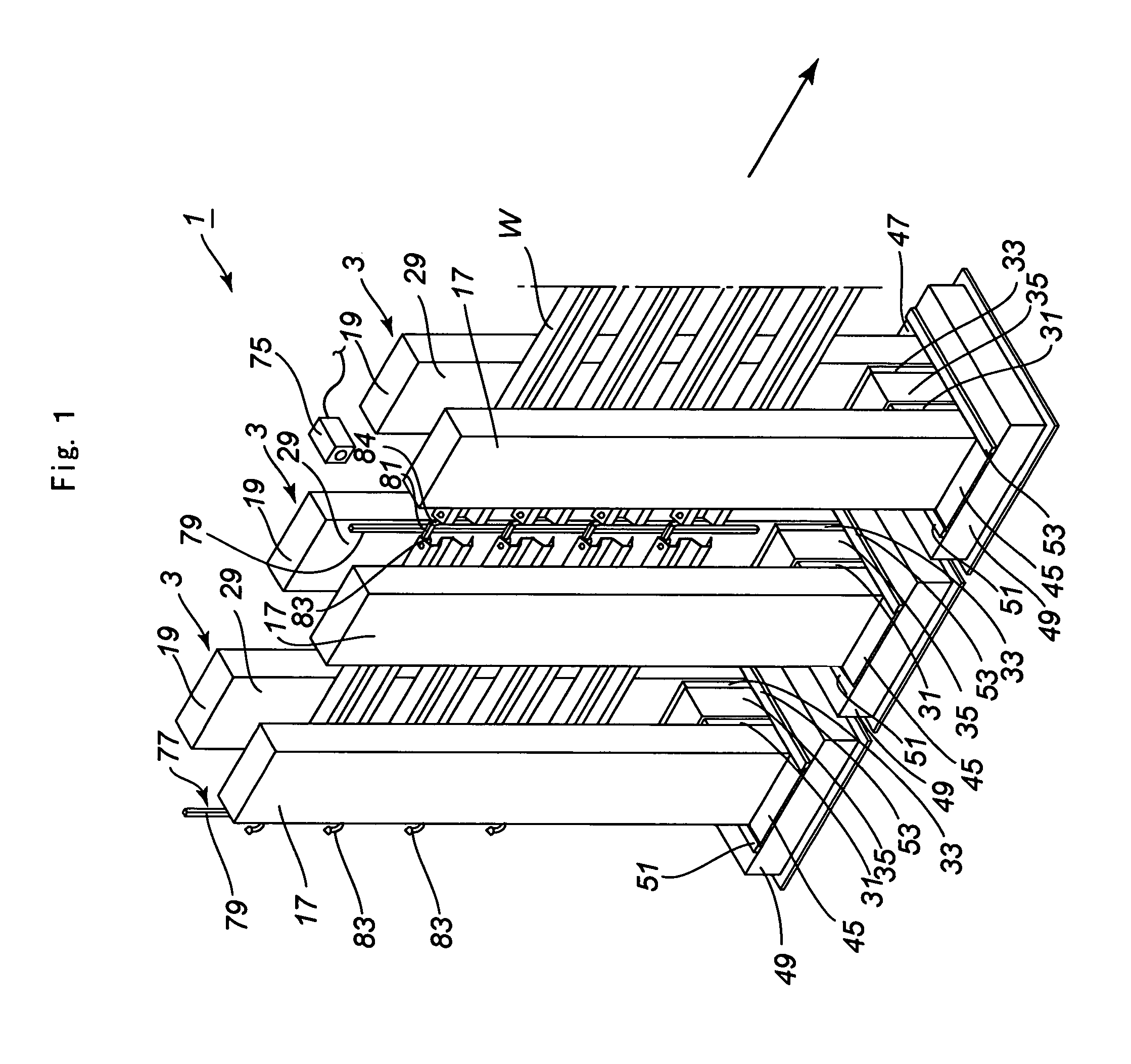

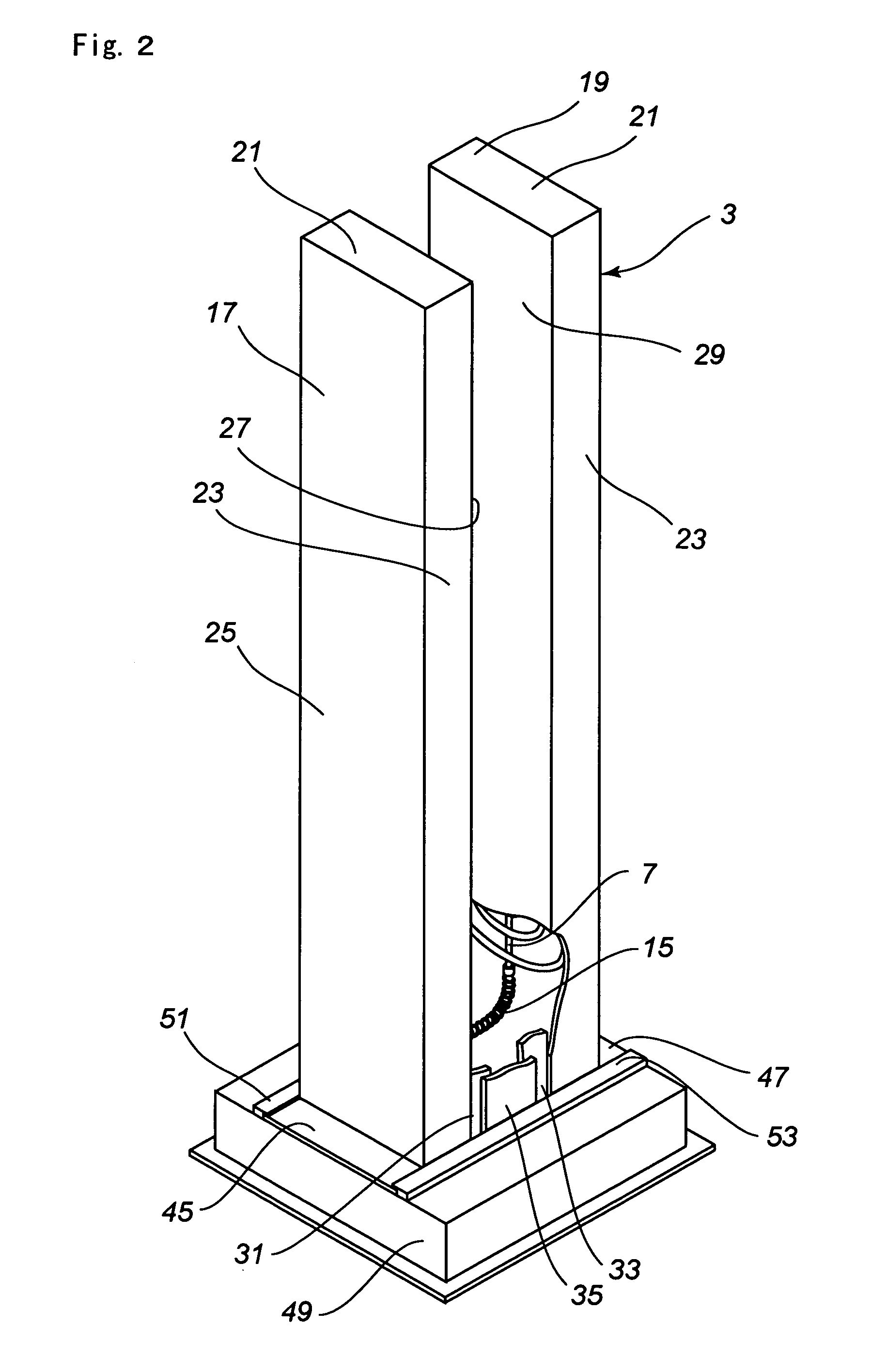

Apparatus and method for heating works uniformly through high frequency induction coils

A high frequency induction-heating device 3 of the apparatus 1 for heating work includes a pair of opposite work coils accommodated within the coil casings 17 and 19 respectively. The casings 17 and 19 can be displaced in a unit by a motor provided under the device. Thus, the distance between the pair of work coils, and the distance between the work (W) and each work coil can be adjusted. The apparatus includes a plurality of heating devices 3 to which high frequency power sources are provided respectively. The apparatus and method for heating of a work with the apparatus is capable of treating a plurality of works (W) continuously under controlled conditions on work coil shapes and positions depending on the size and / or the shape of the works (W).

Owner:YOSHINO KOSAKUJO

Heating furnace system for hot stamping

ActiveUS9631248B2Small facilityImprove productivityFurnace componentsFurnace typesHot stampingHeating furnace

In a heating furnace system for hot stamping, a first heating furnace has a plurality of pairs of upper and lower rolls arranged in a lengthwise direction thereof in order to transfer a steel plate, and high-frequency coils alternately arranged with the pairs of upper and lower rolls in the lengthwise direction thereof. A second heating furnace continuously transfers the steel plate from the first heating furnace during heating the steel plate at temperature of Ac3 or more, and has a plurality of transfer rollers arranged in a lengthwise direction thereof. The second heating furnace includes an electric furnace or a gas furnace. This heating furnace system can reduce space required for facilities by 50% or more compared to the related art.

Owner:MYUNGSHIN IND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com