Patents

Literature

358results about How to "Even heat distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

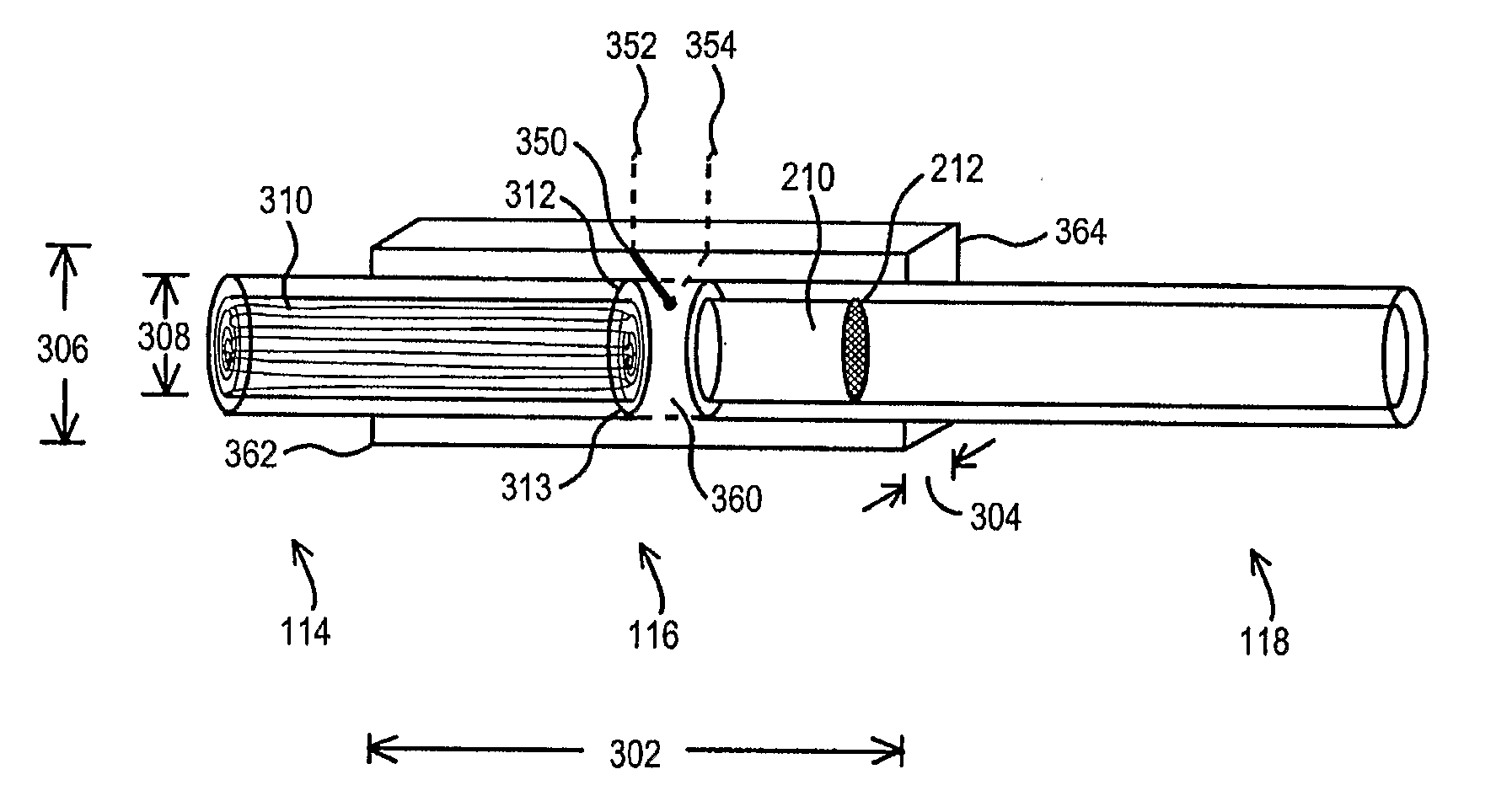

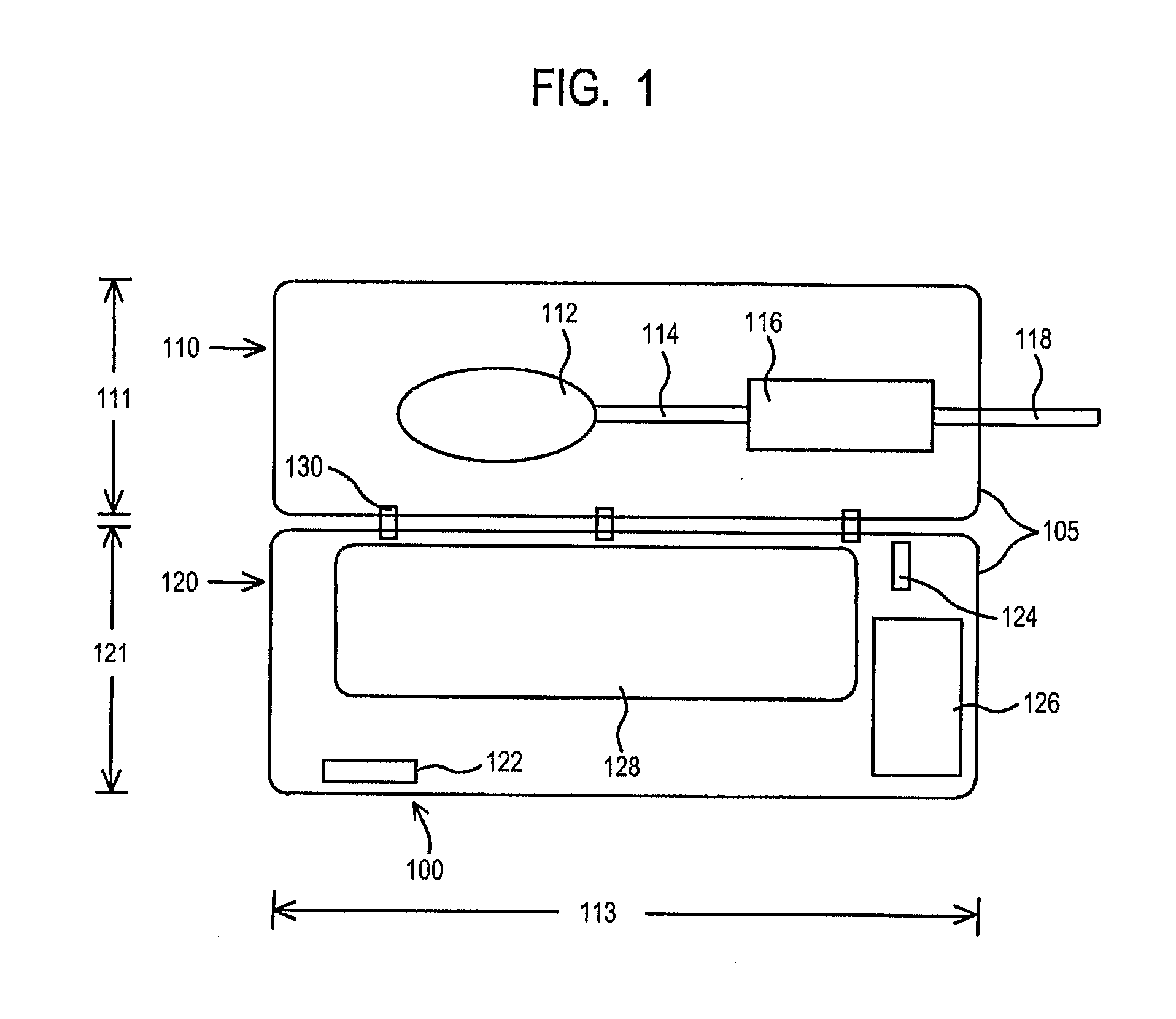

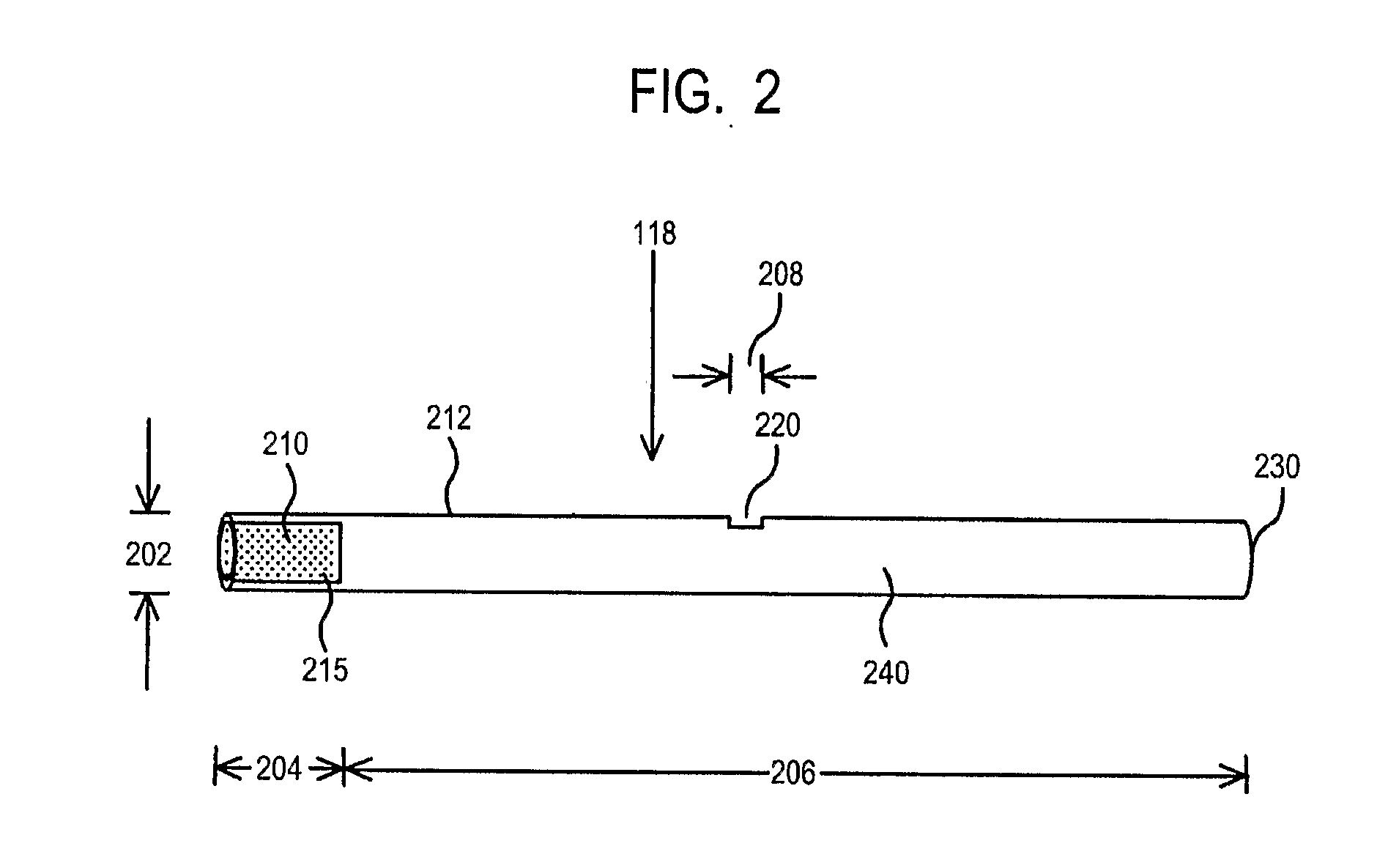

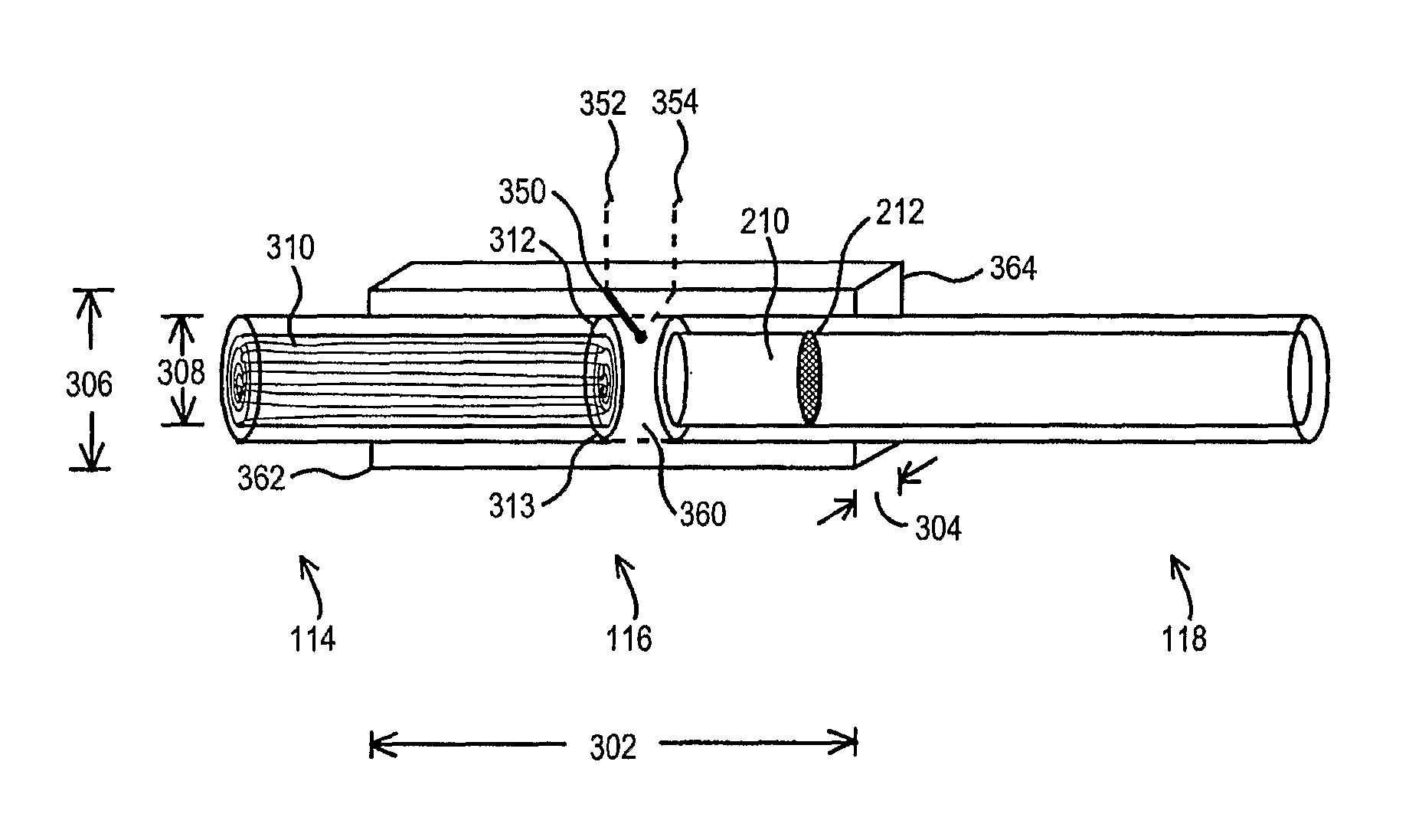

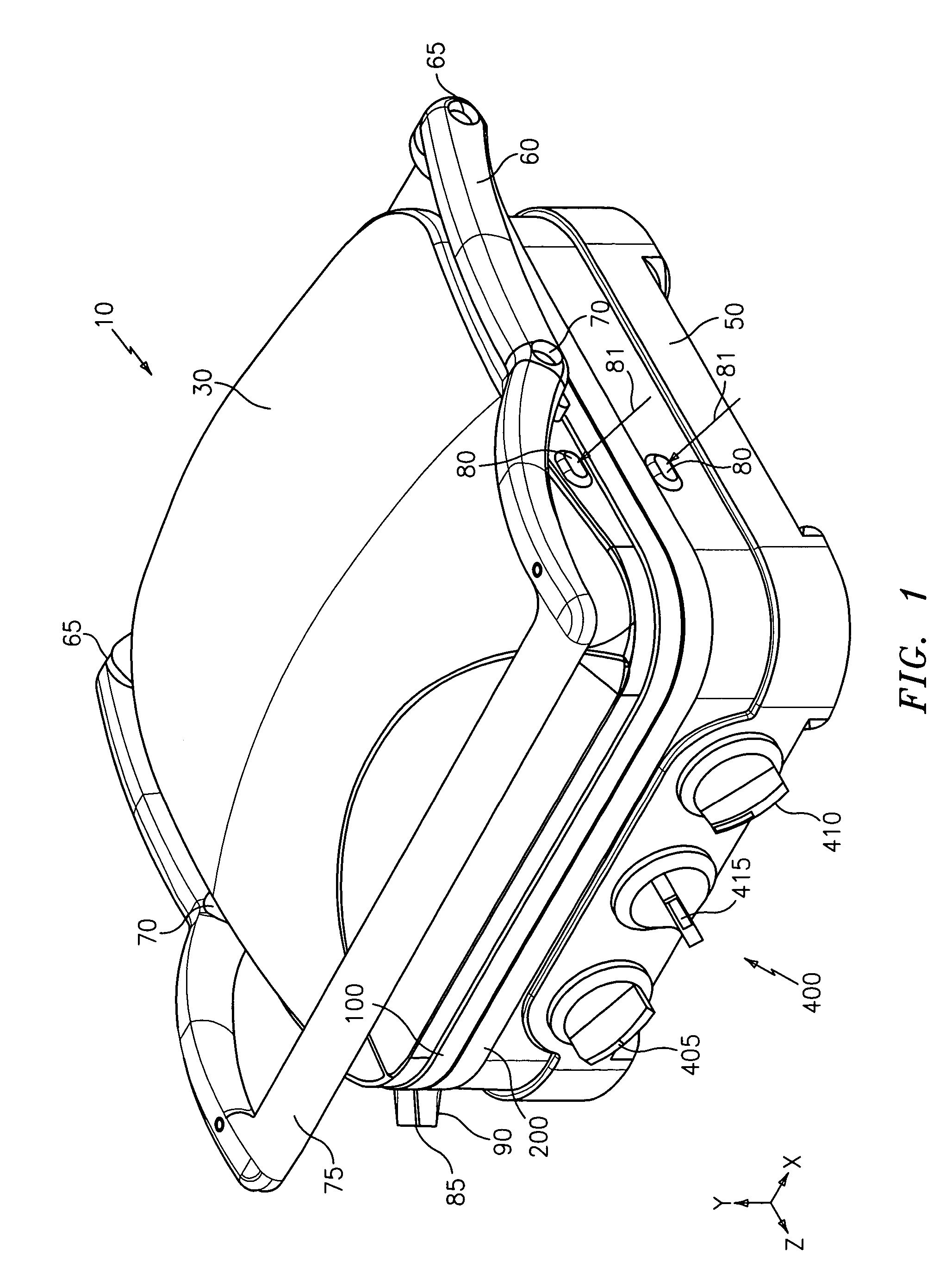

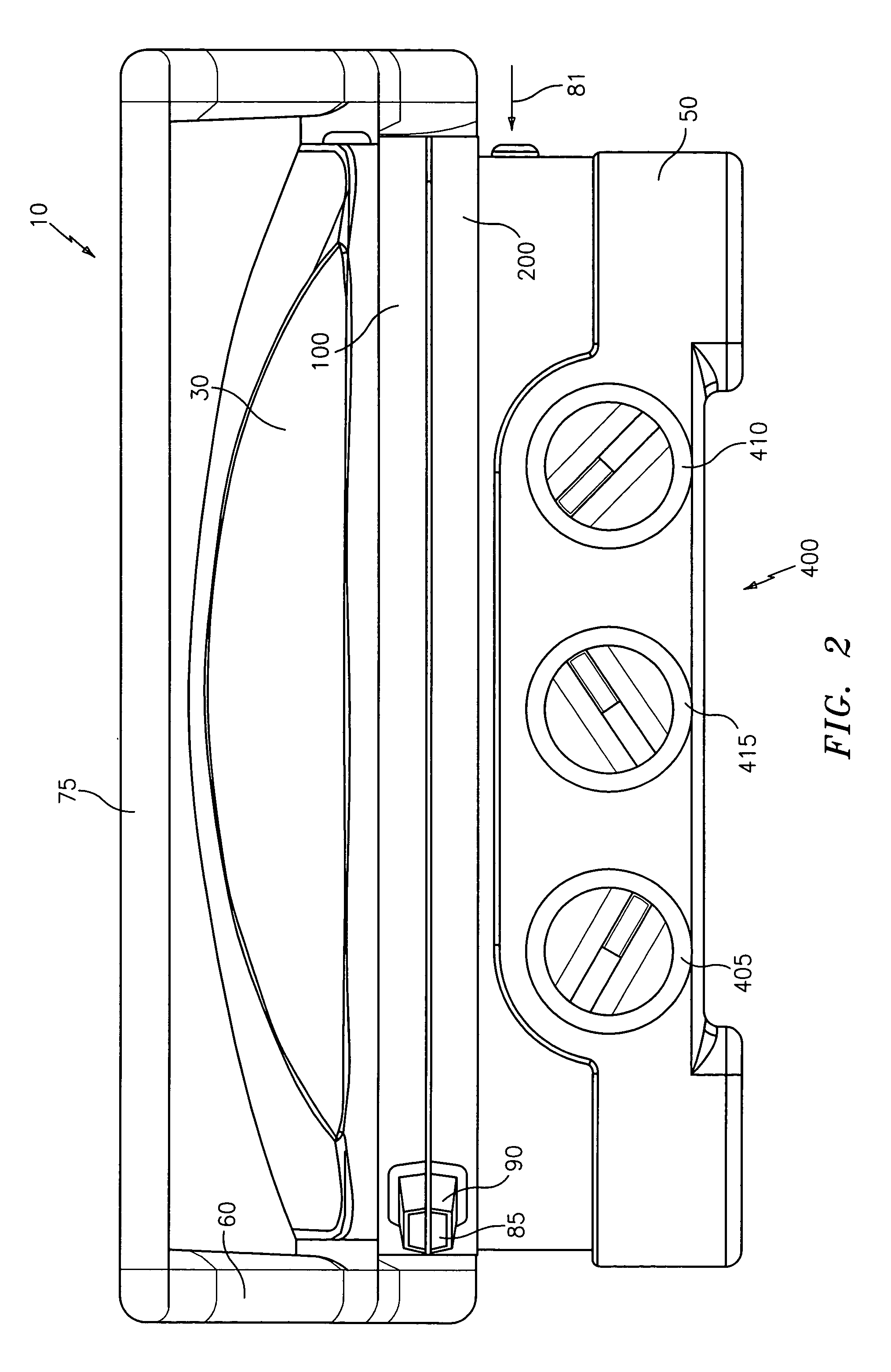

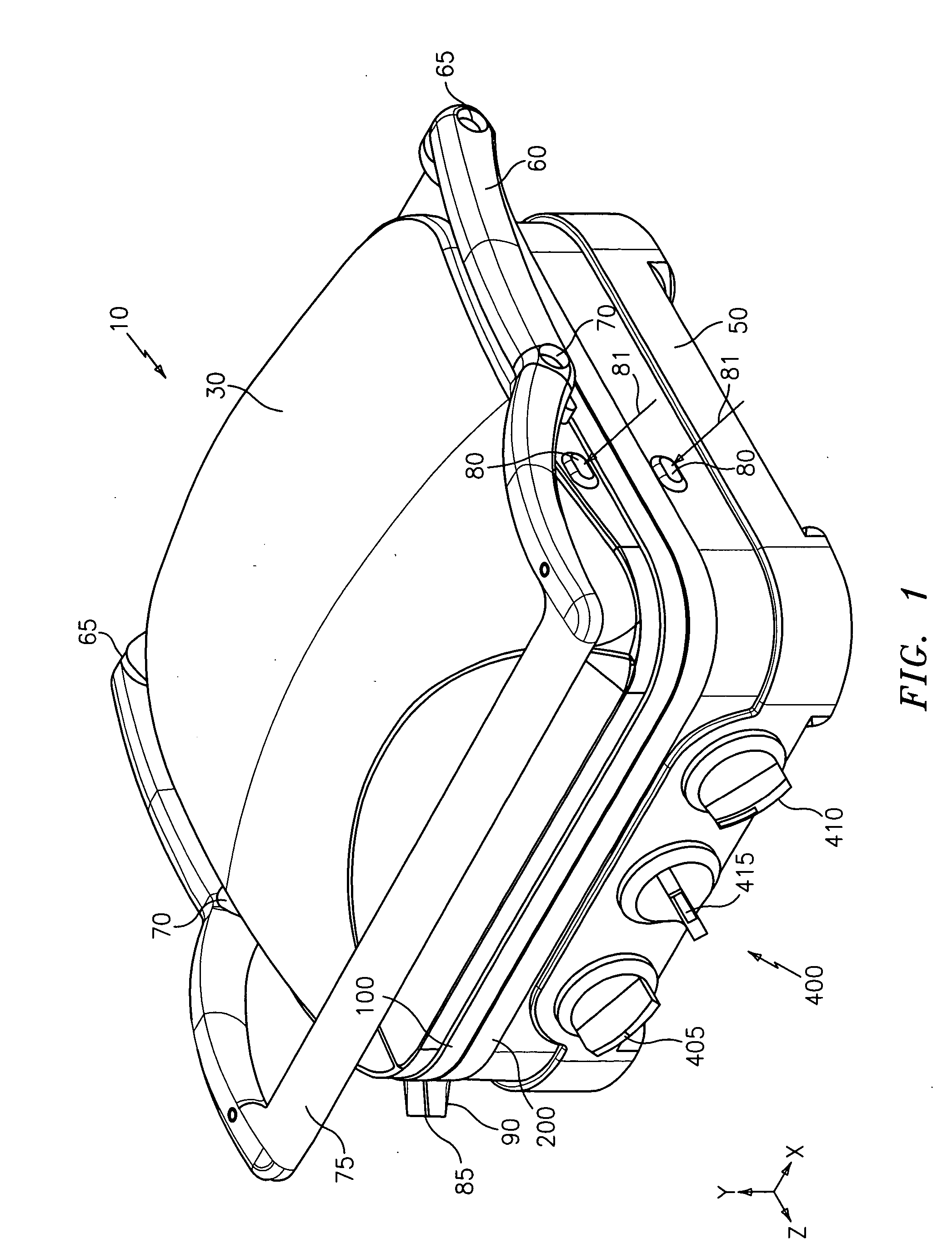

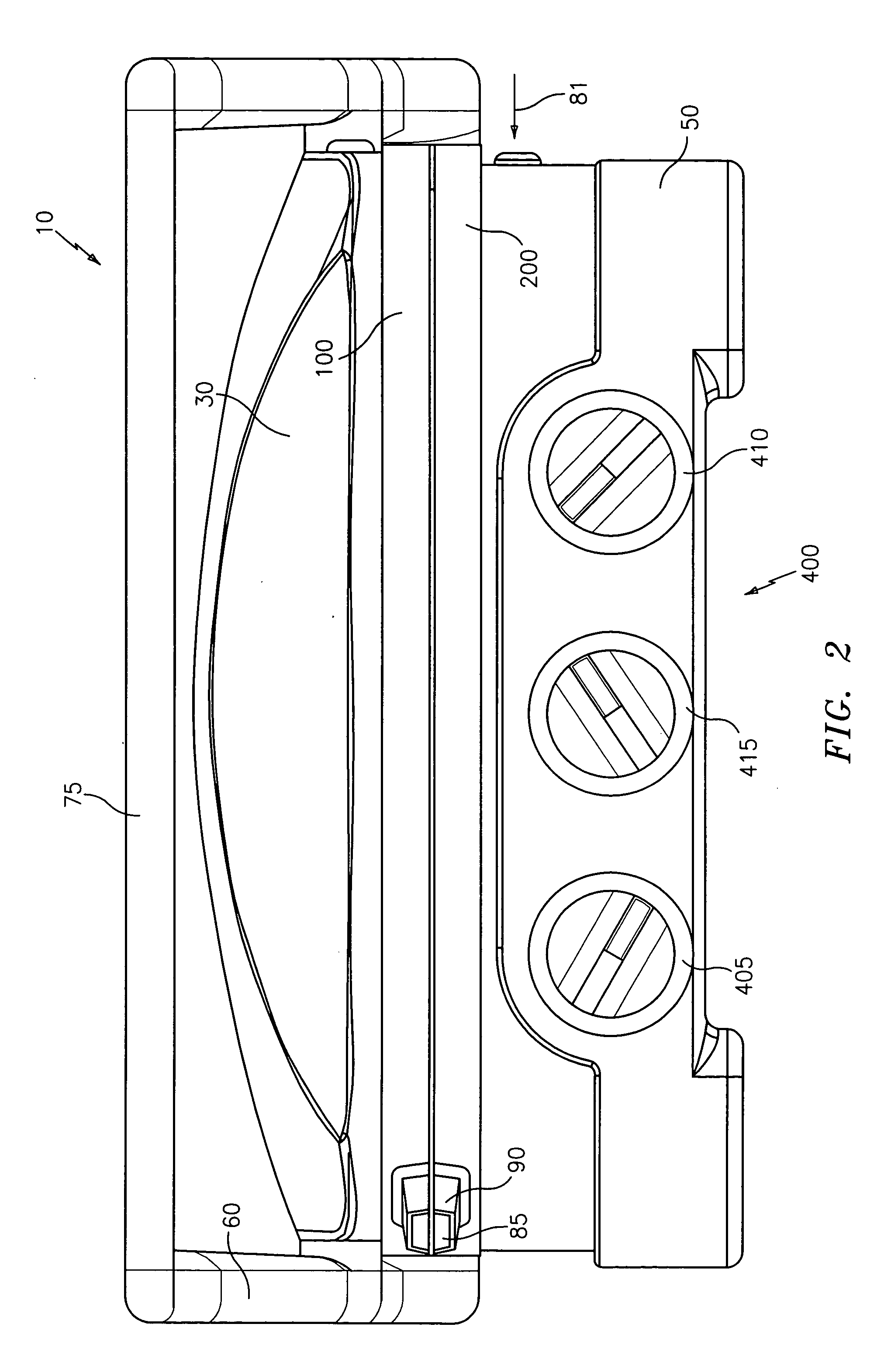

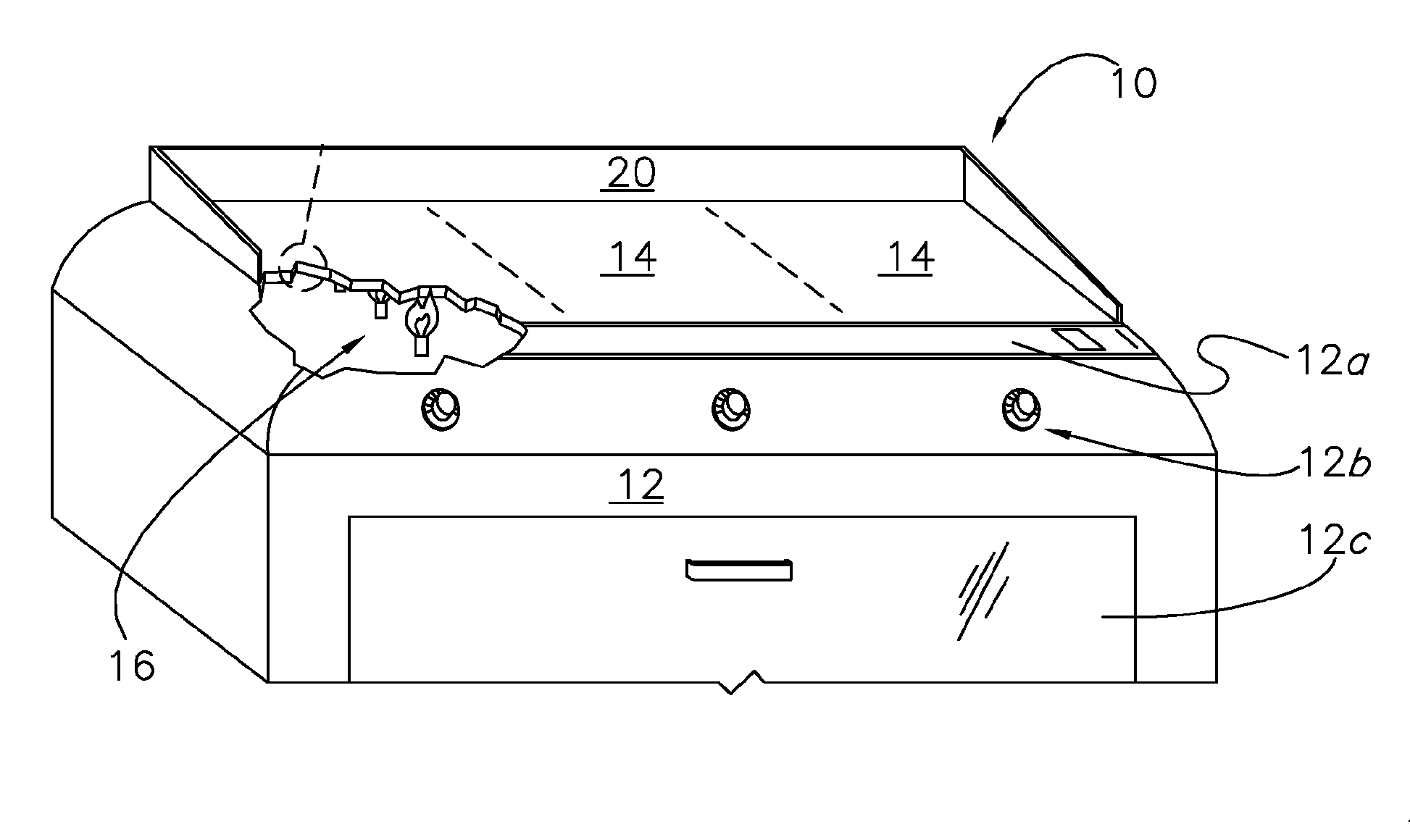

Portable vaporizing device and method for inhalation and/or aromatherapy without combustion

ActiveUS20110120482A1Even heat distributionAvoid problemsRespiratorsMedical devicesAromatherapyCombustion

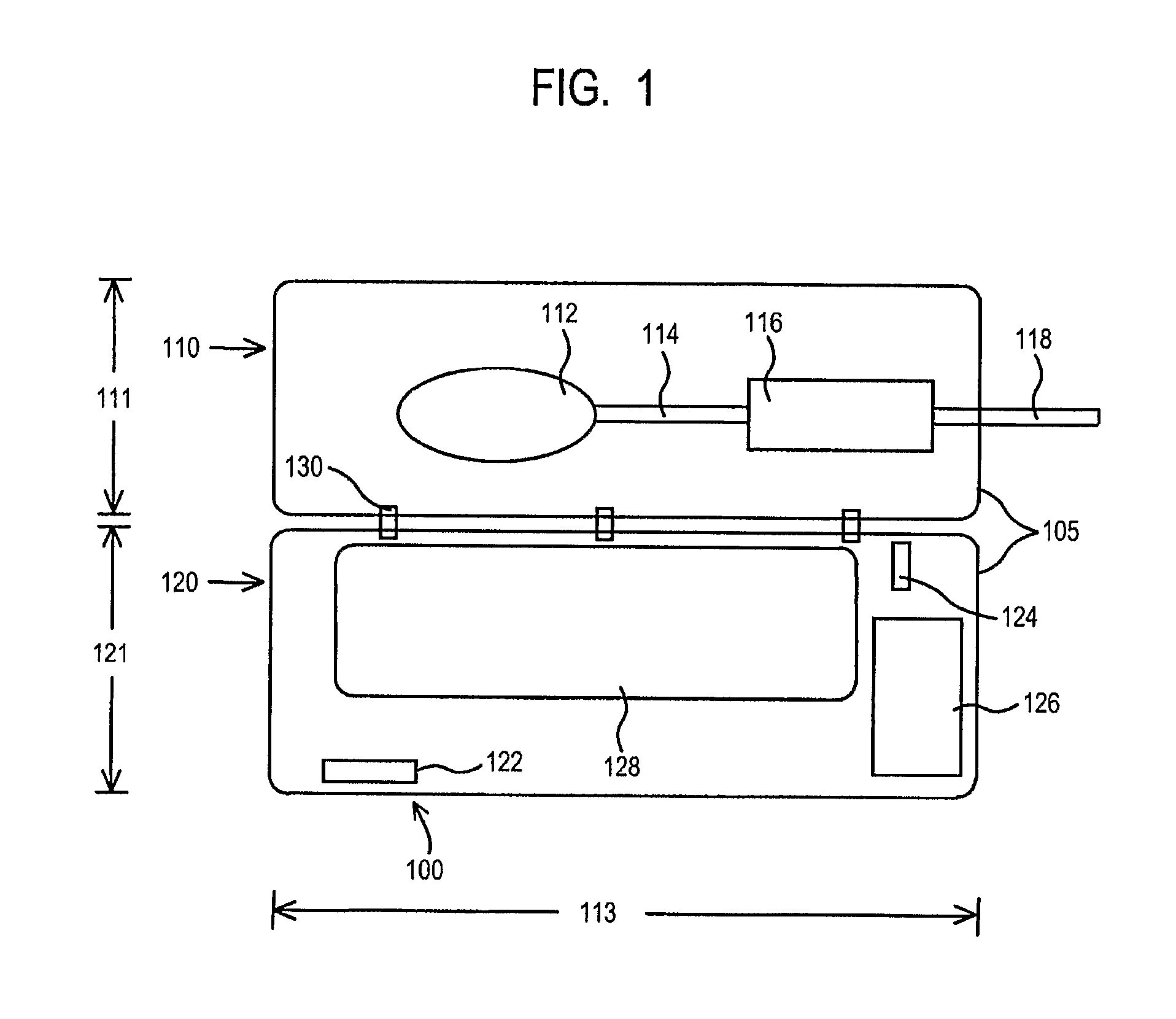

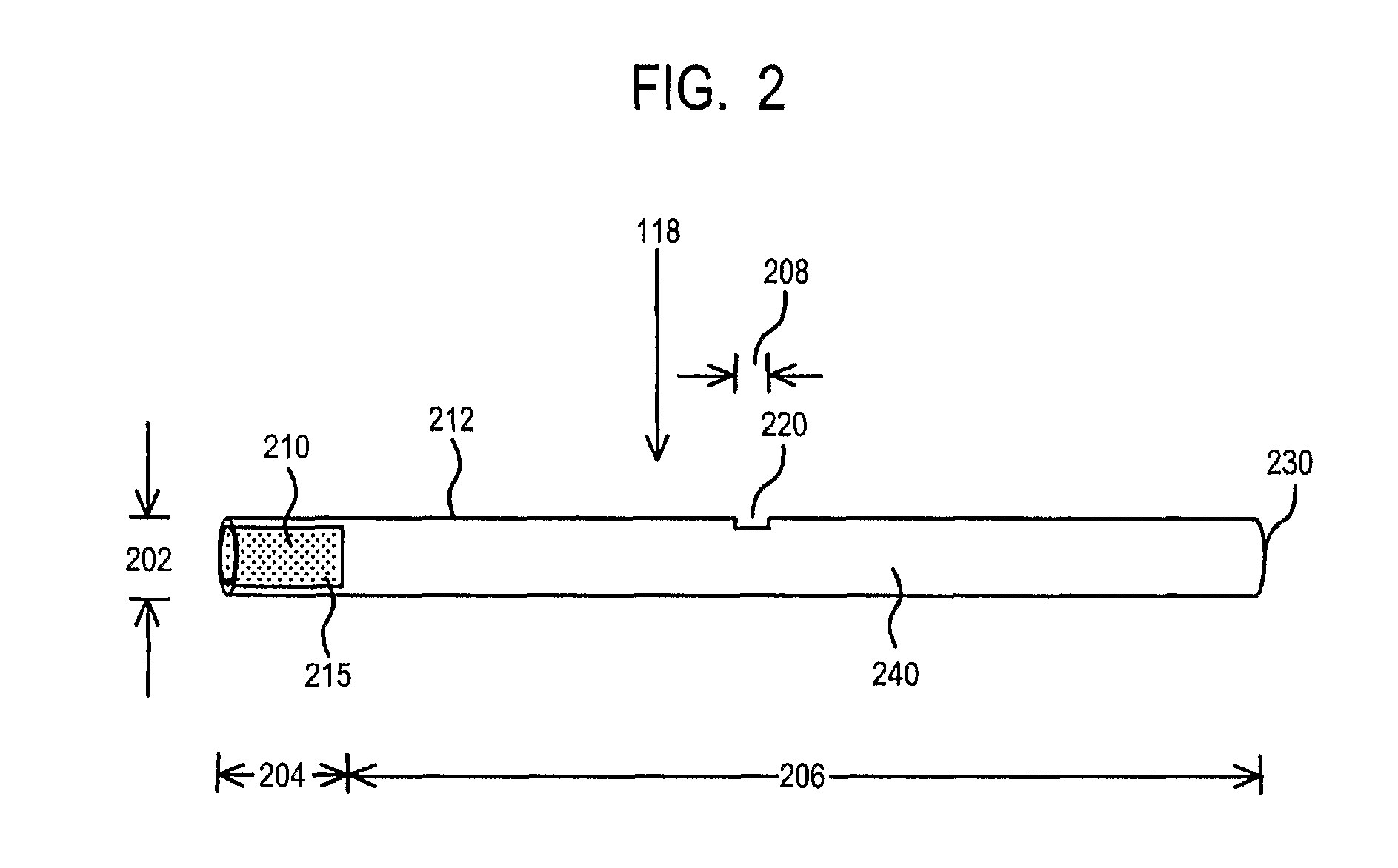

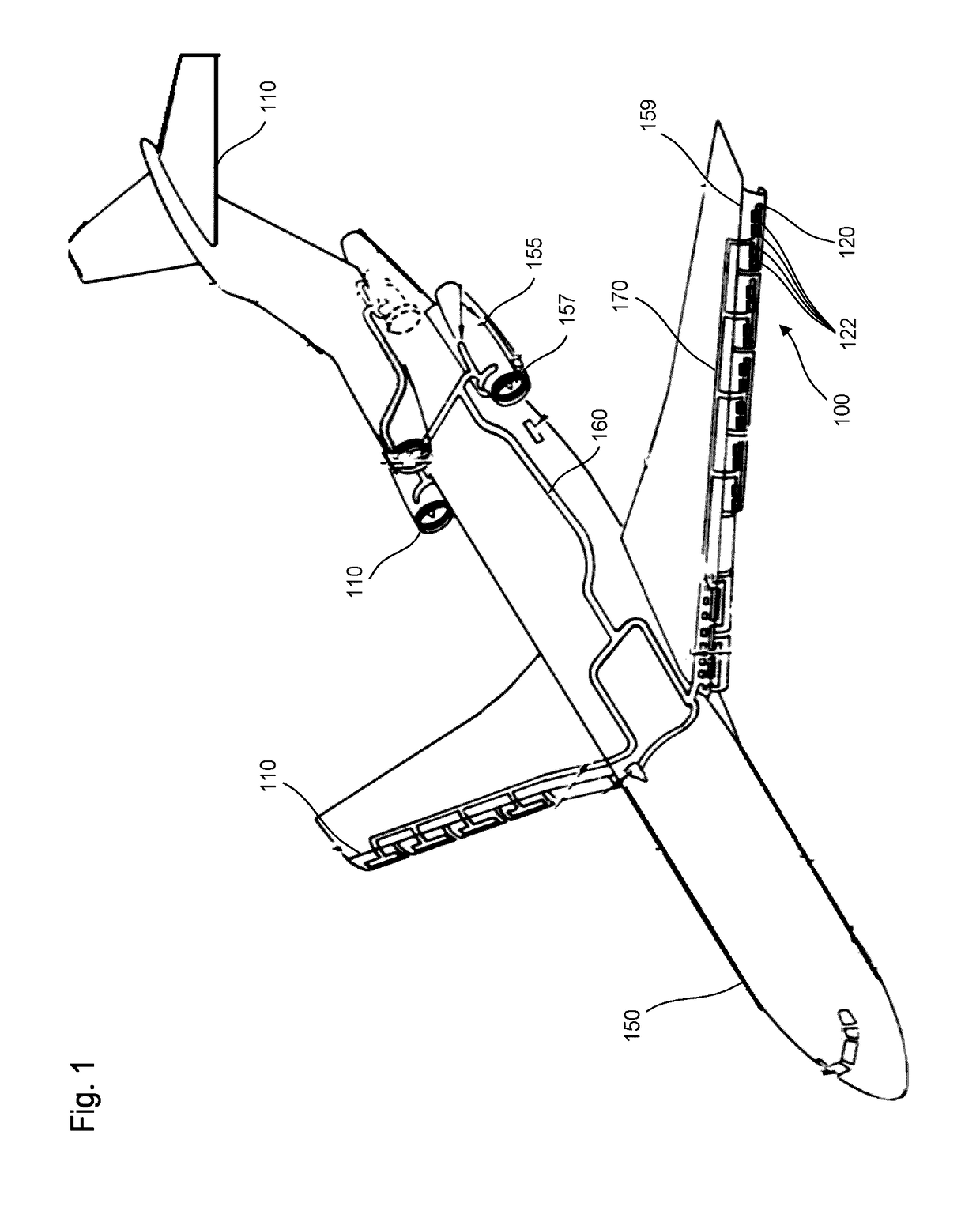

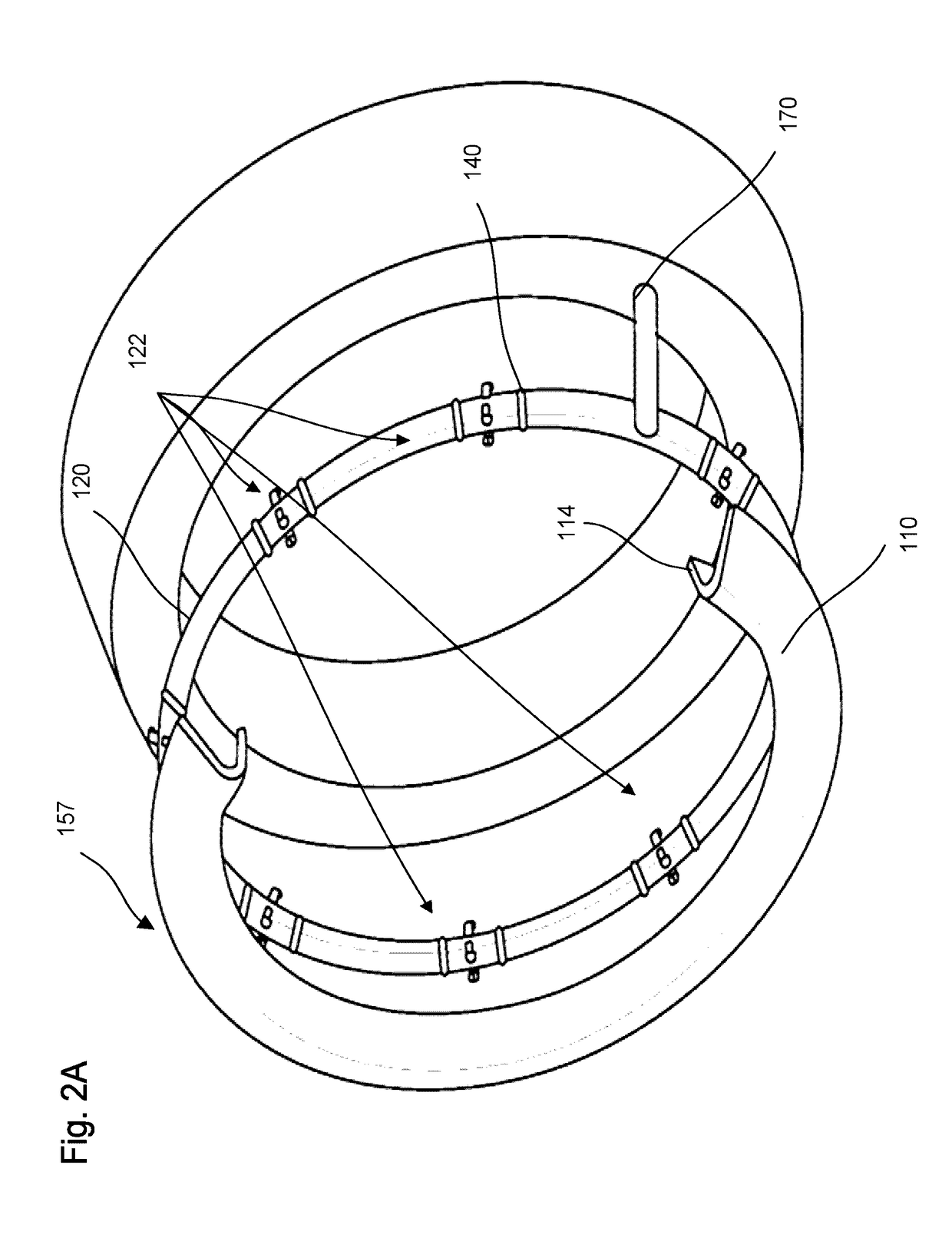

A hand-held apparatus (100) to vaporize volatile compounds disposed in a solid source material is disclosed. The hand-held apparatus comprises a housing (105), a mouthpiece tube (118) removeably disposed within, and extending outwardly from, said housing, a heating element assembly (114) in communication with said mouthpiece tube, wherein said heating element assembly heats to an operating temperature of about 450° F. in about 60 seconds.

Owner:BRENNEISE JAKE

Portable vaporizing device and method for inhalation and/or aromatherapy without combustion

ActiveUS8371310B2Even heat distributionAvoid problemsRespiratorsMedical devicesAromatherapyCombustion

A hand-held apparatus (100) to vaporize volatile compounds disposed in a solid source material is disclosed. The hand-held apparatus comprises a housing (105), a mouthpiece tube (118) removeably disposed within, and extending outwardly from, said housing, a heating element assembly (114) in communication with said mouthpiece tube, wherein said heating element assembly heats to an operating temperature of about 450° F. in about 60 seconds.

Owner:BRENNEISE JAKE

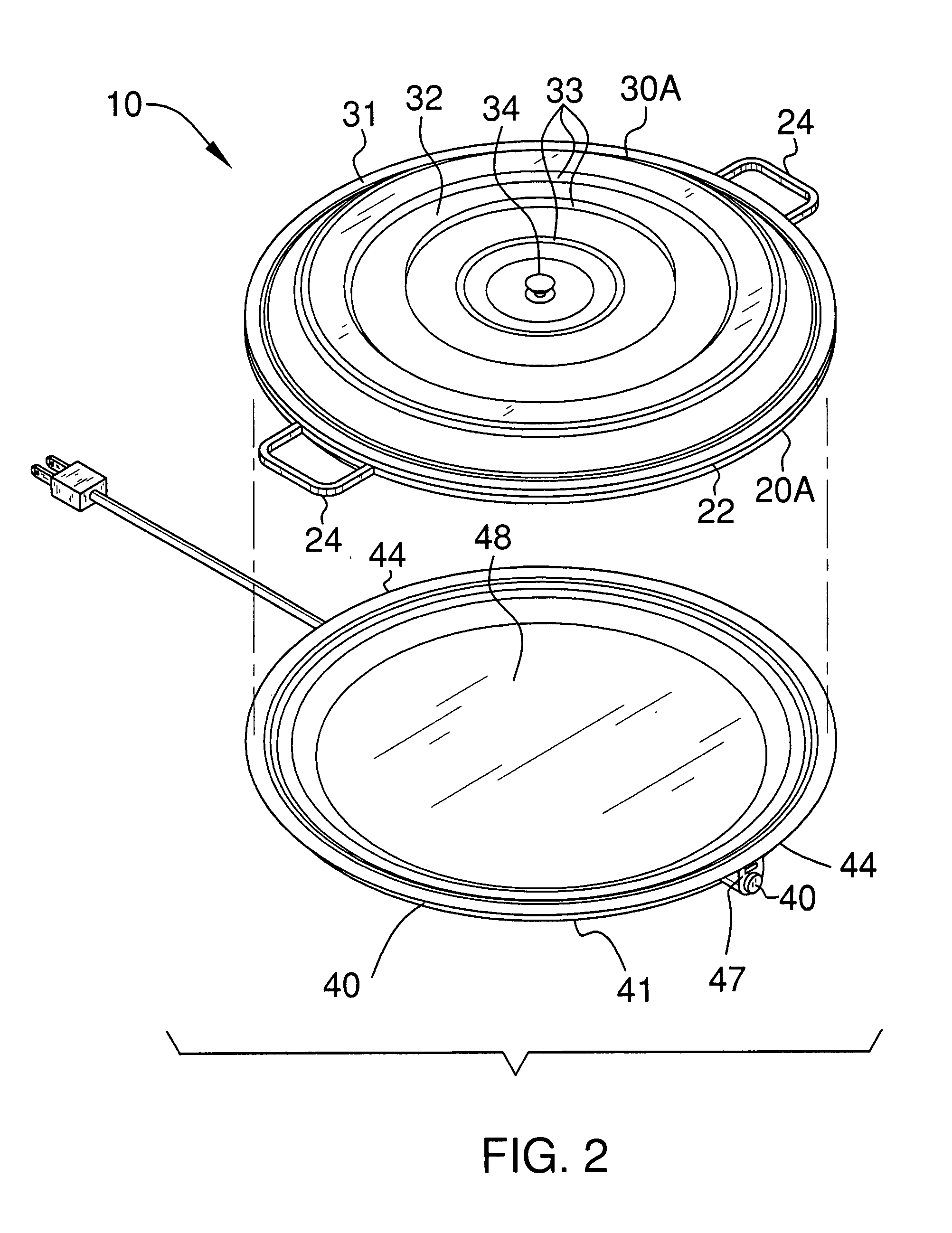

Combined food and food-plate warming device

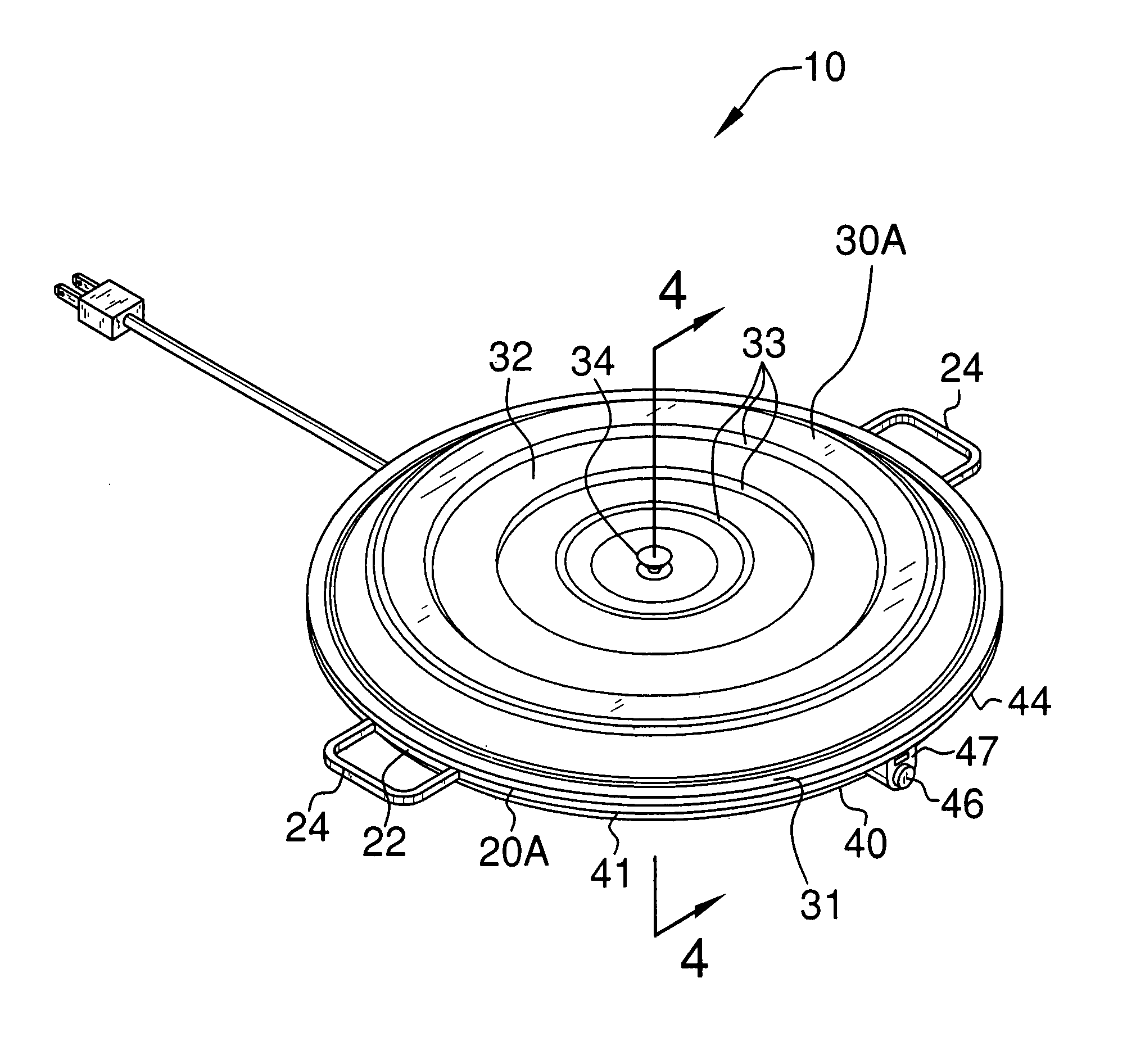

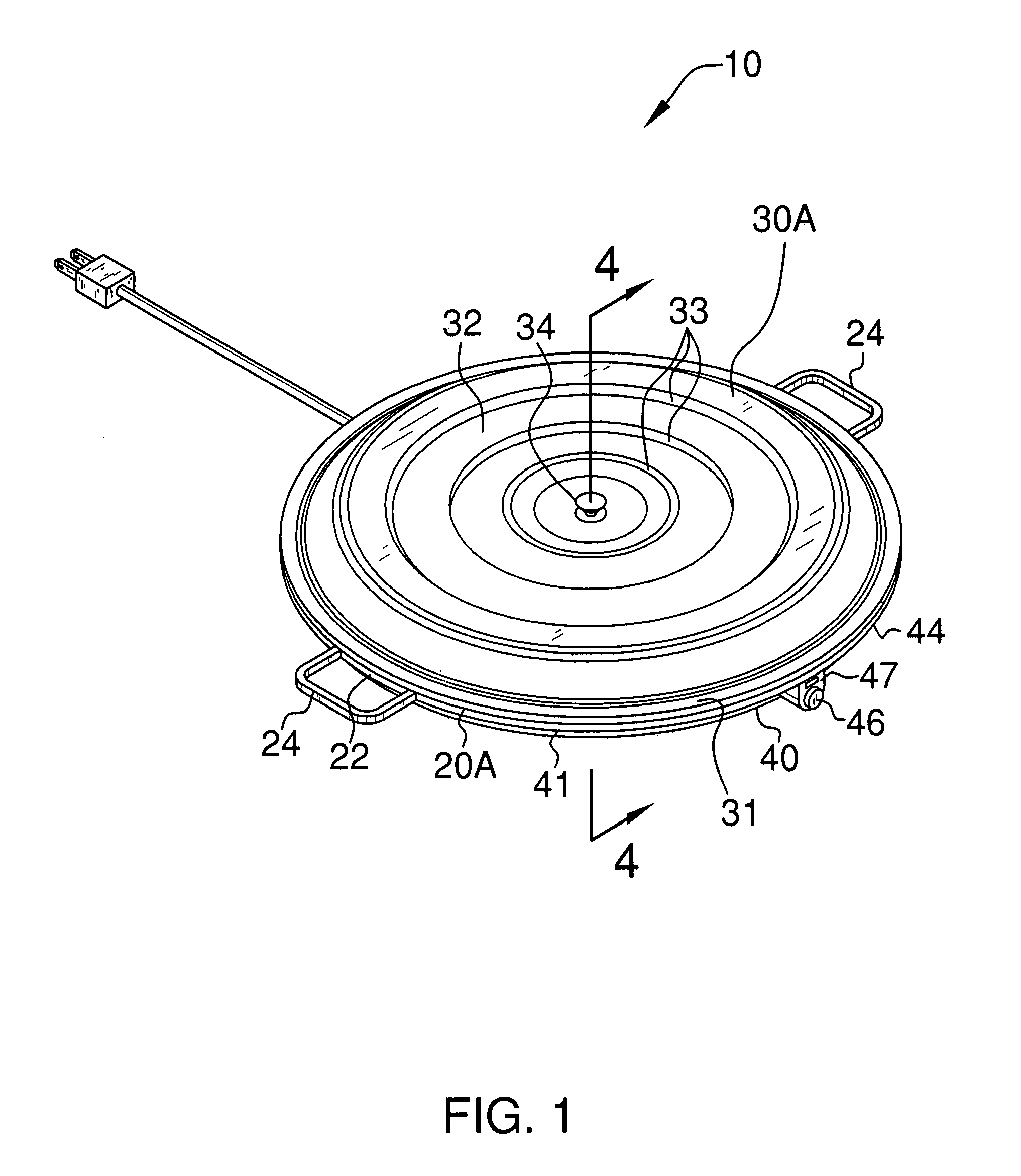

InactiveUS7276676B1Power interruptionEffectively allowDomestic cooling apparatusBaking ovenEngineeringThreshold temperature

A food and food-plate warming device includes a base plate that has a planar top surface and has an outwardly beveled edge provided with laterally stepped ridges concentrically spaced from the top surface center. A cover plate is positioned on the base plate and has an outer lip that is nested on one of the stepped ridges. Handles are conjoined to the outer lip for receiving at least four contiguous metacarpals therethrough. A mechanism is included for heating the base plate top surface such that the food and food-plate interfitted between the base plate and the cover plate can be heated. The heating mechanism includes a heating element intercalated between the top and bottom surfaces of the first base plate. An automatic shut off switch is coupled to the heating element for interrupting power to the heating element when an interior temperature of the device reaches a maximum threshold temperature.

Owner:THOMPSON JENNIFER J

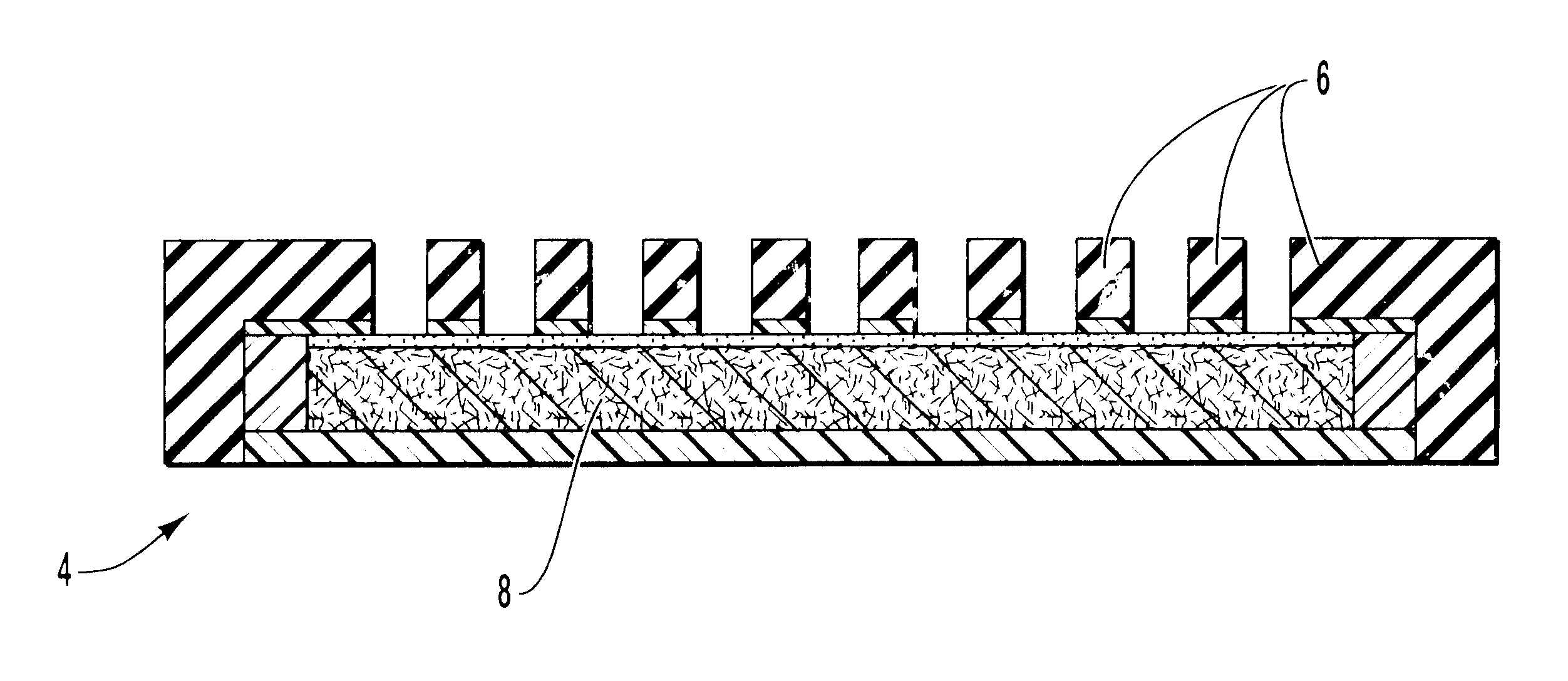

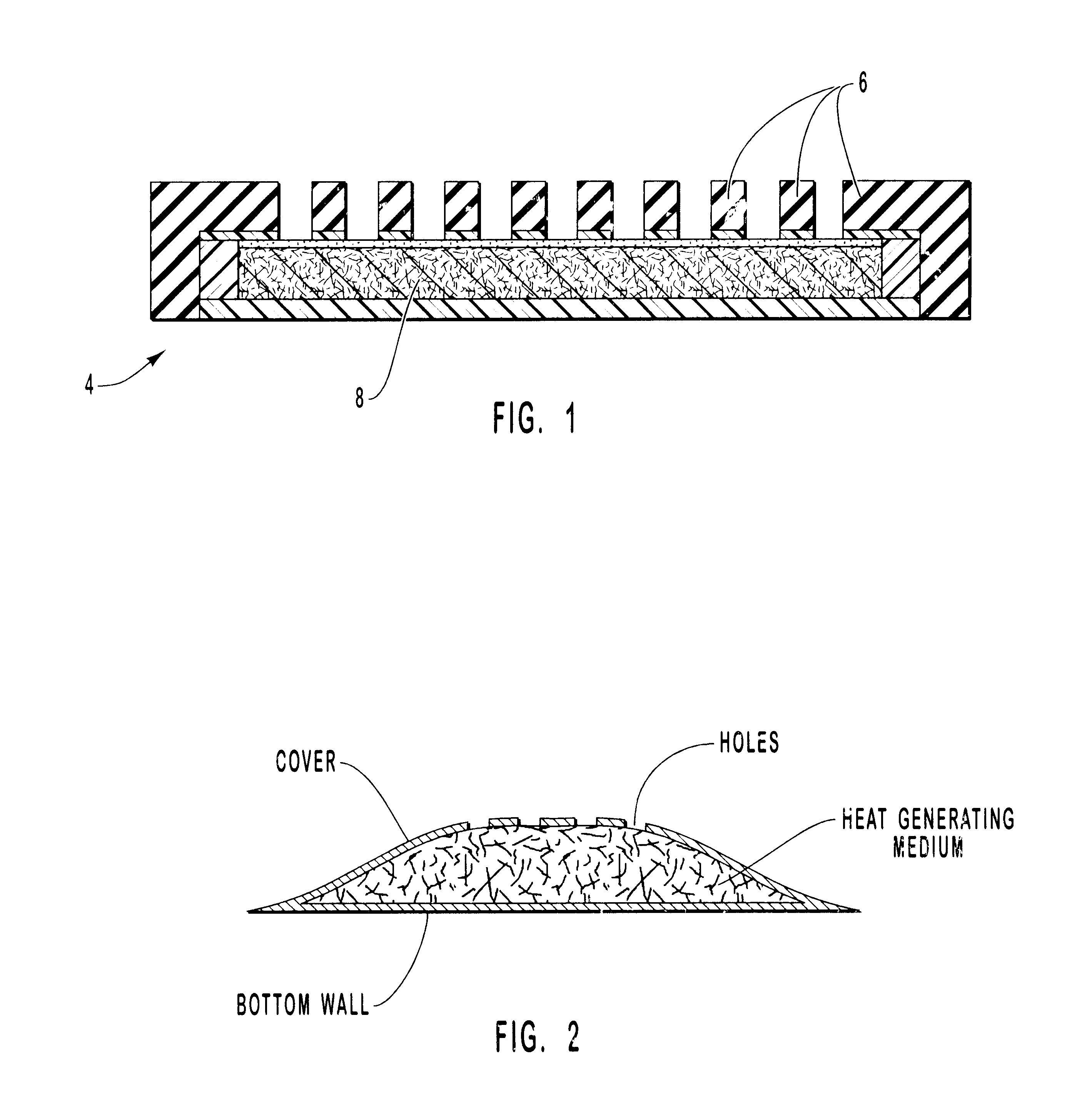

Method for manufacturing a heat generating apparatus

InactiveUS6453648B1Even heat distributionPrevent oxidationSolid materialLiquid materialActivated carbonEngineering

Owner:NUVO RES

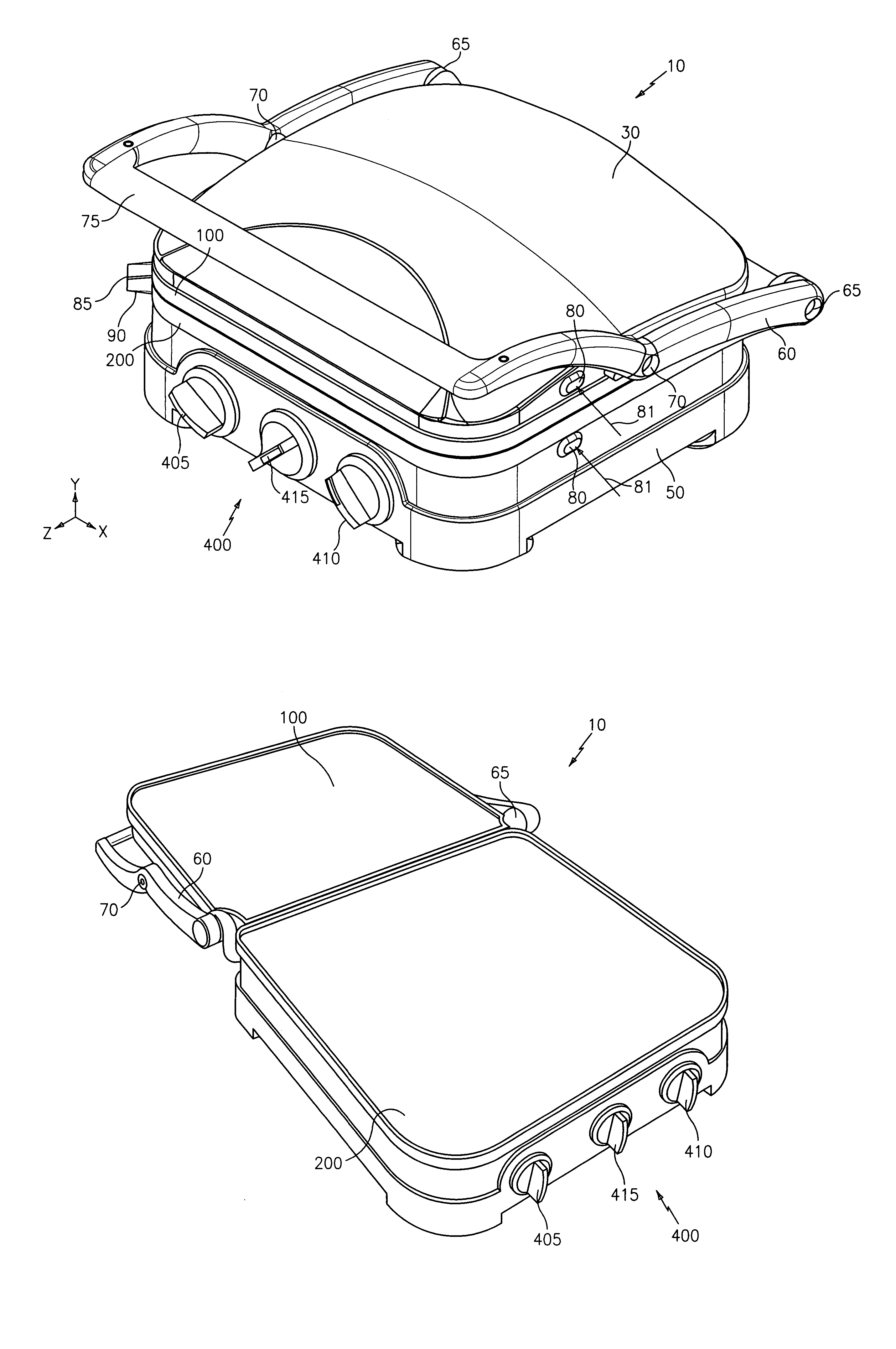

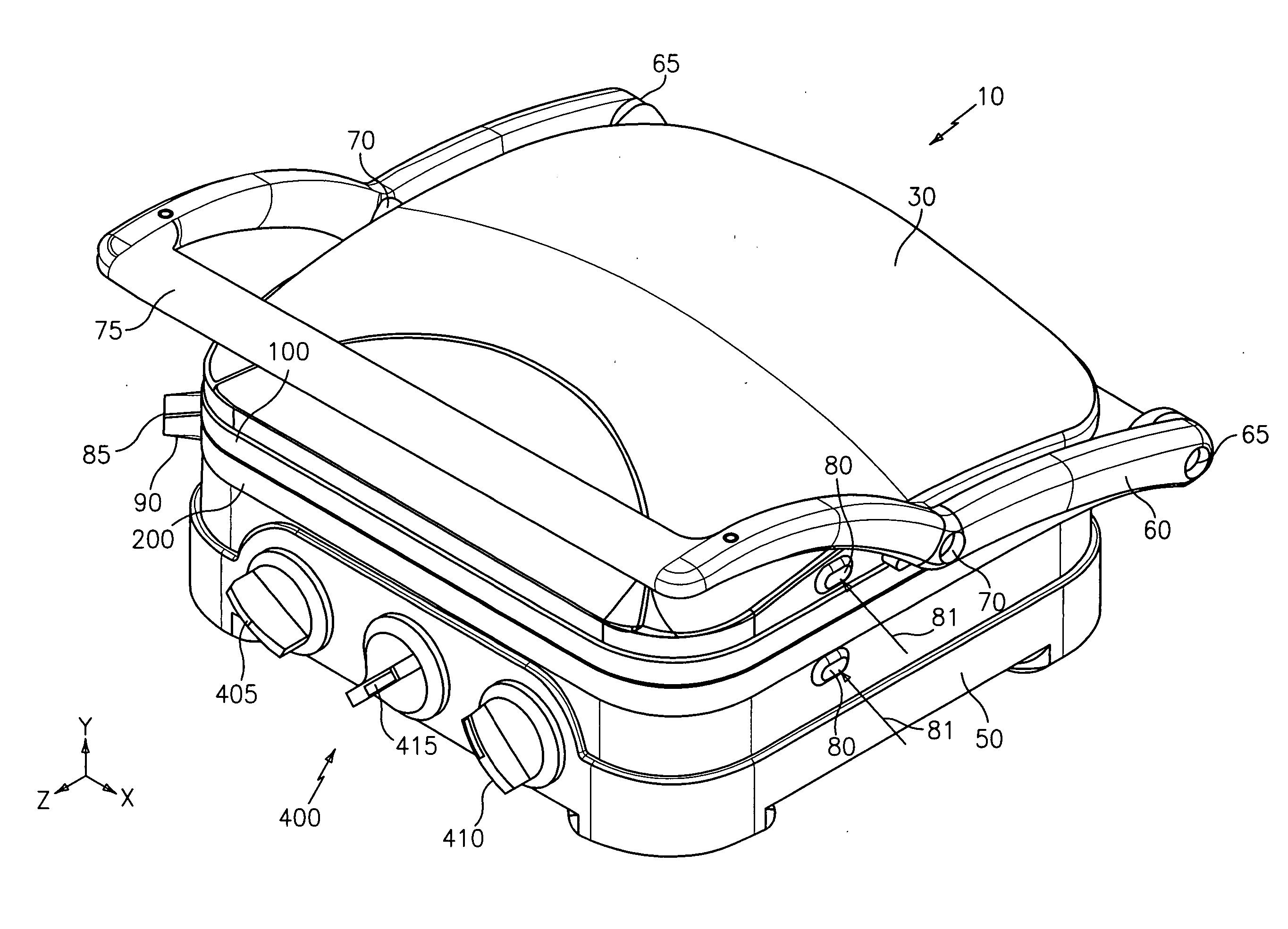

Grill

ActiveUS7109442B2Improve thermal efficiencyEven heat distributionDomestic stoves or rangesElectrical heating fuelEngineeringMechanical engineering

Owner:CONAIR CORP

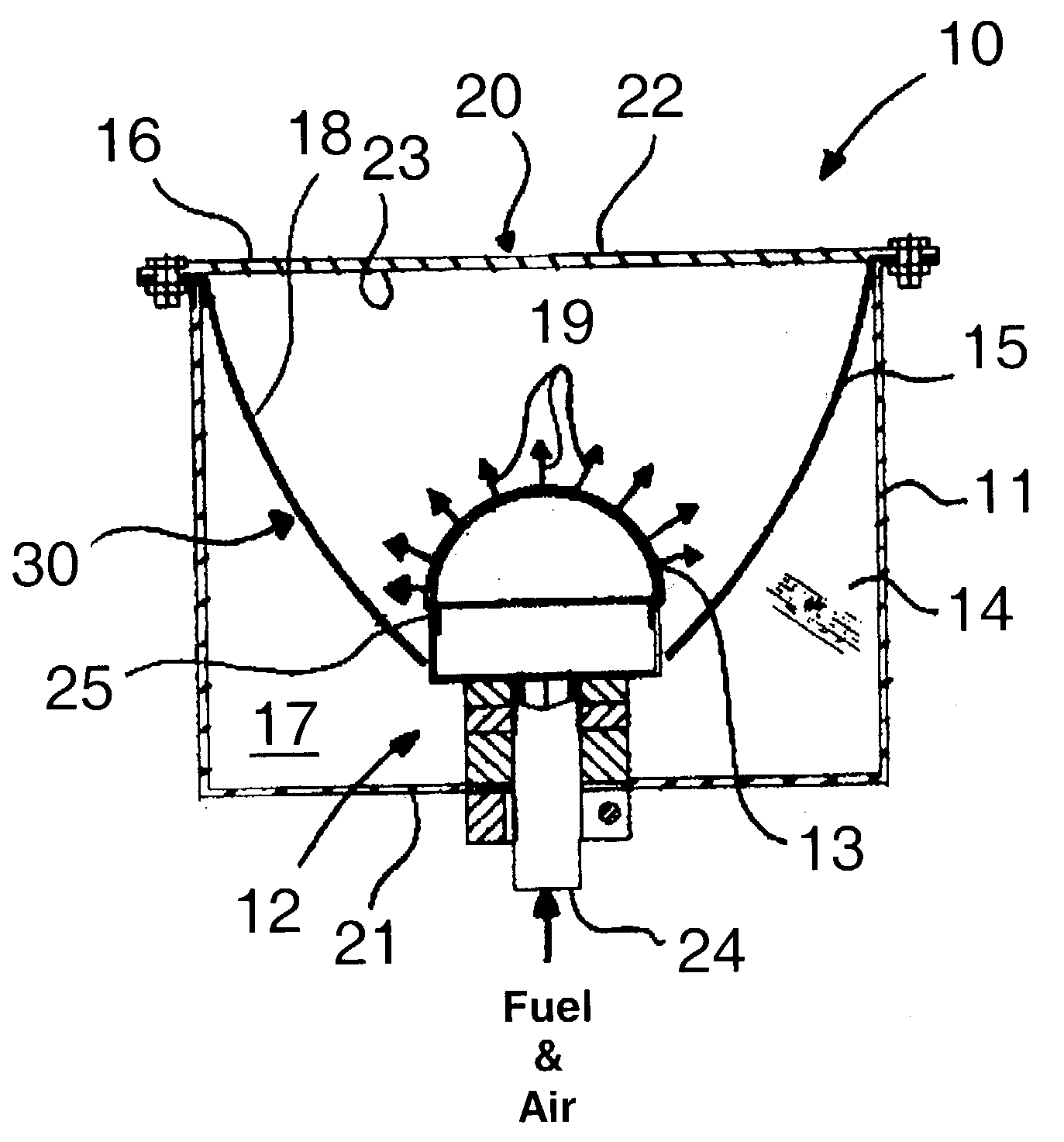

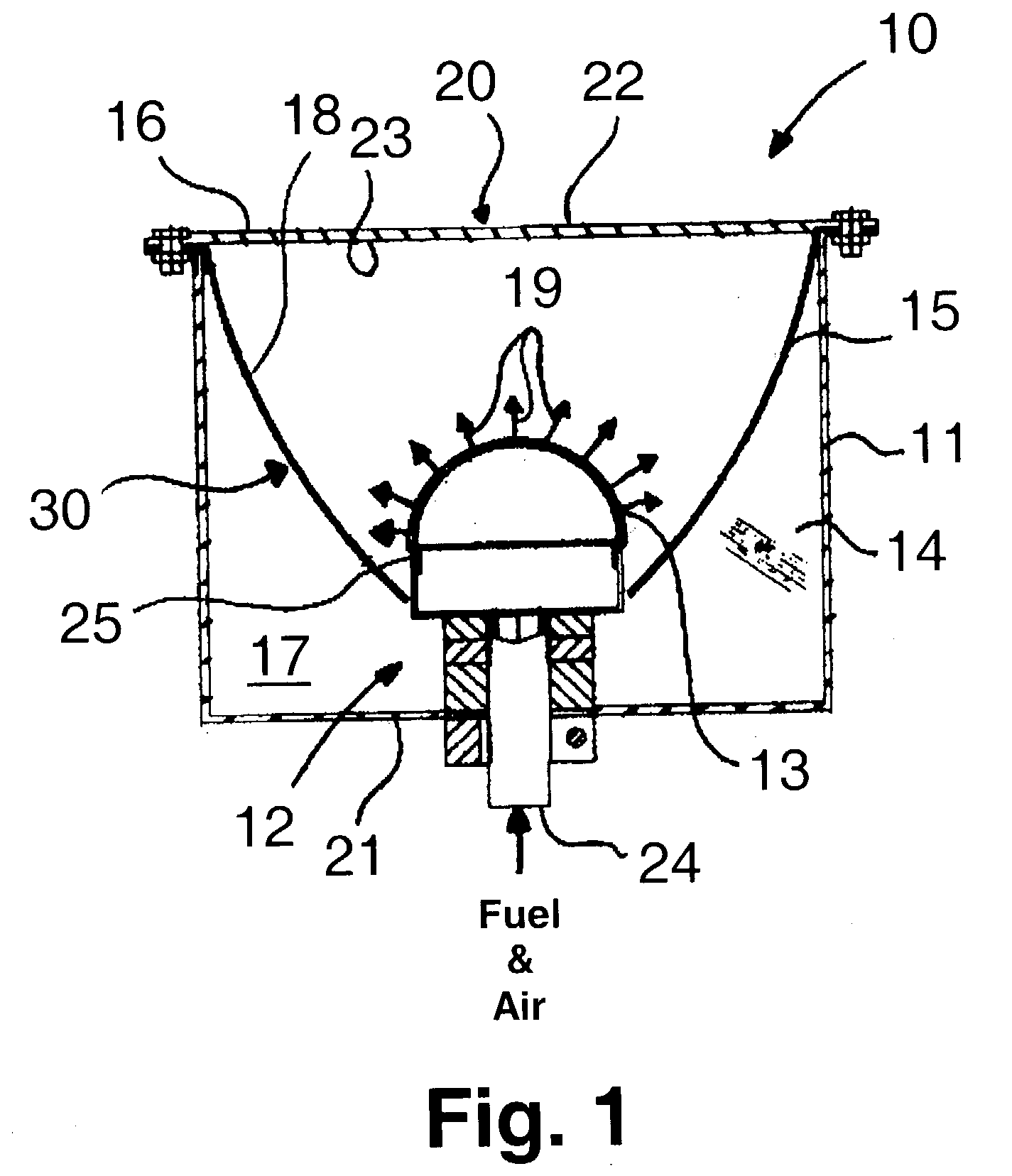

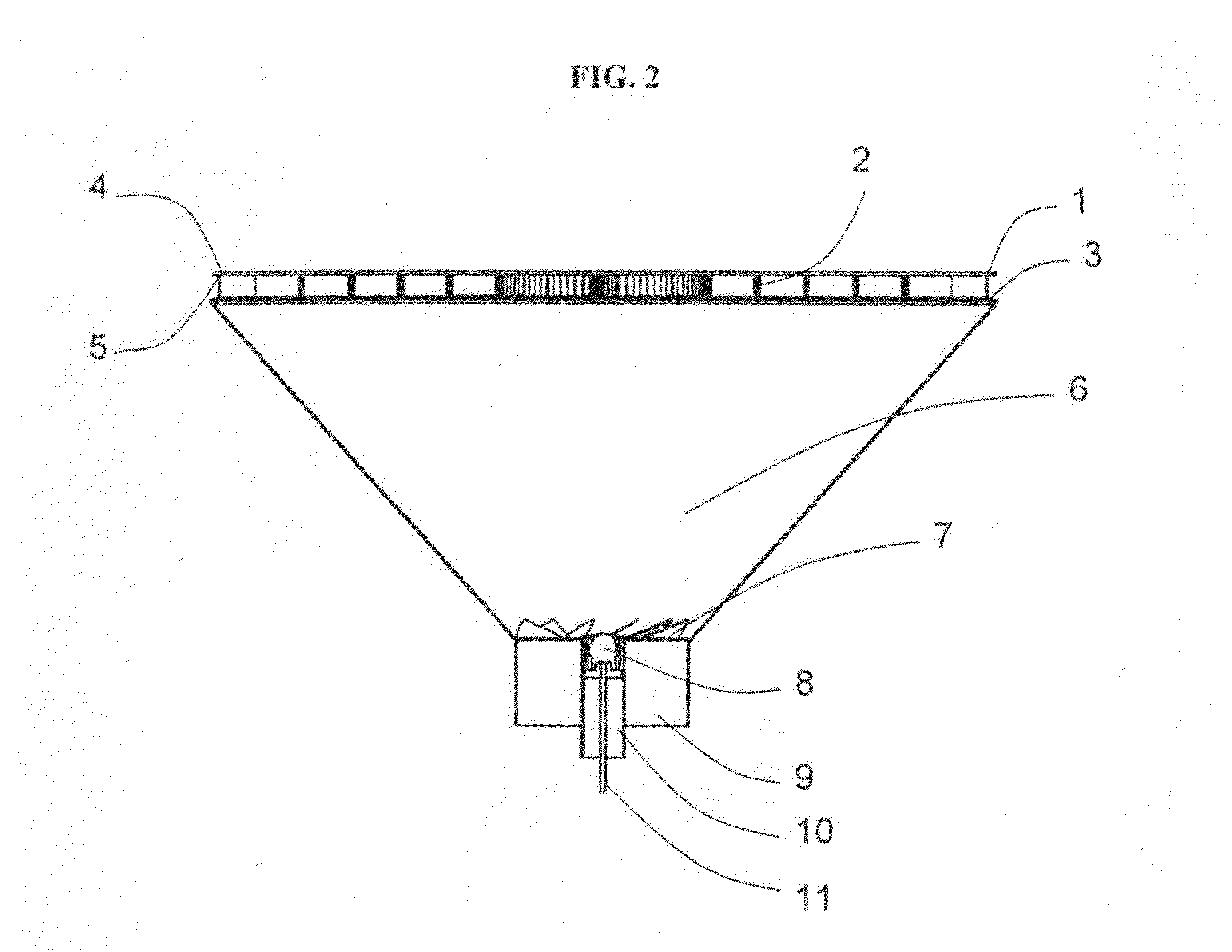

Flame-less infrared heater

InactiveUS20040152028A1Extended stayEven heat distributionDomestic stoves or rangesCapillary burnersCombustorEngineering

A heating apparatus including a housing having a radiant energy output side and an oppositely disposed burner side. The radiant energy output side includes at least one re-radiating surface. Disposed within the housing proximate the burner side and having a burner outlet facing the radiant energy output side is a burner. At least one concave reflector is disposed around the burner and is oriented to reflect heat from said burner toward said radiant energy output side of said housing.

Owner:GAS TECH INST

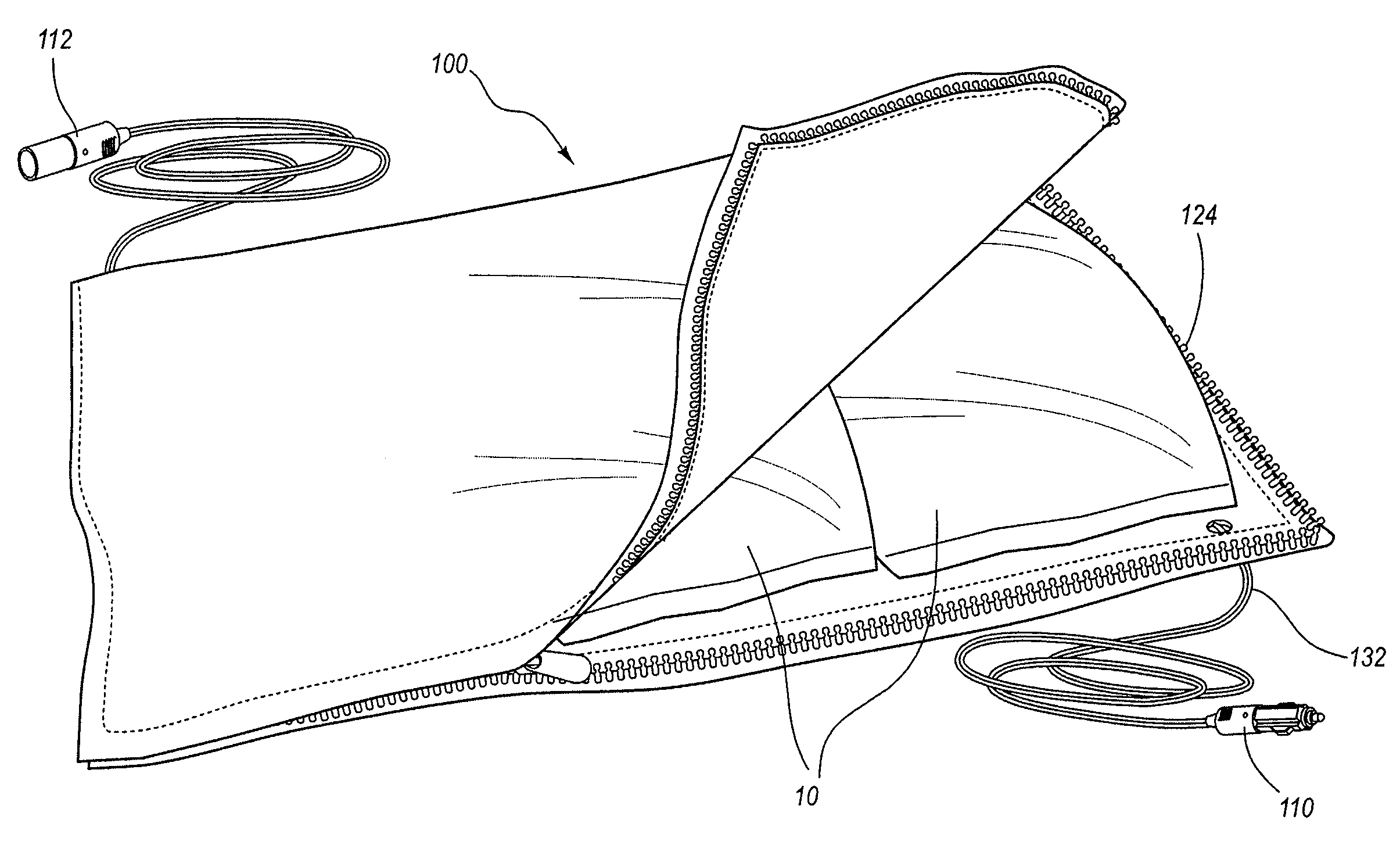

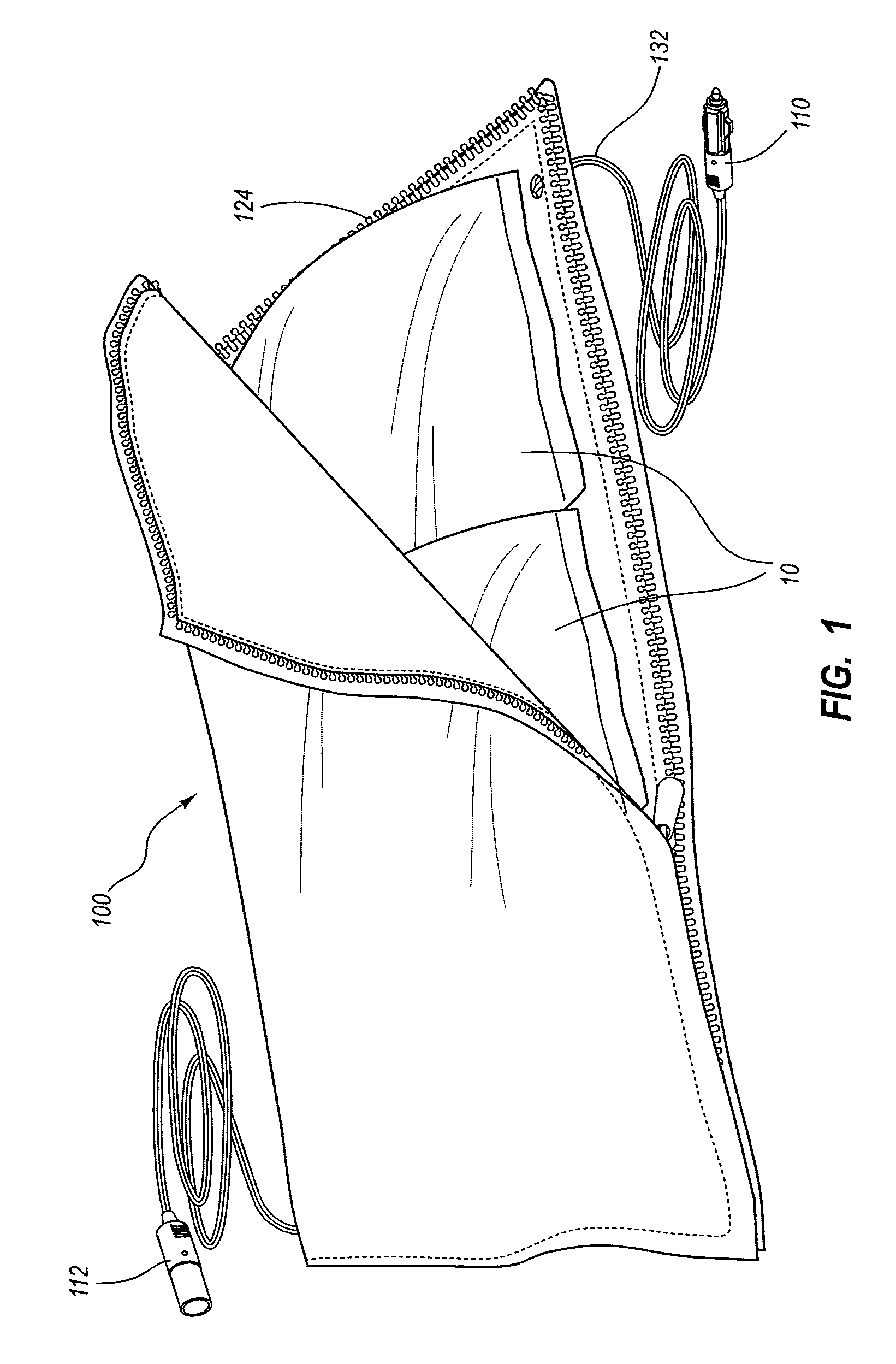

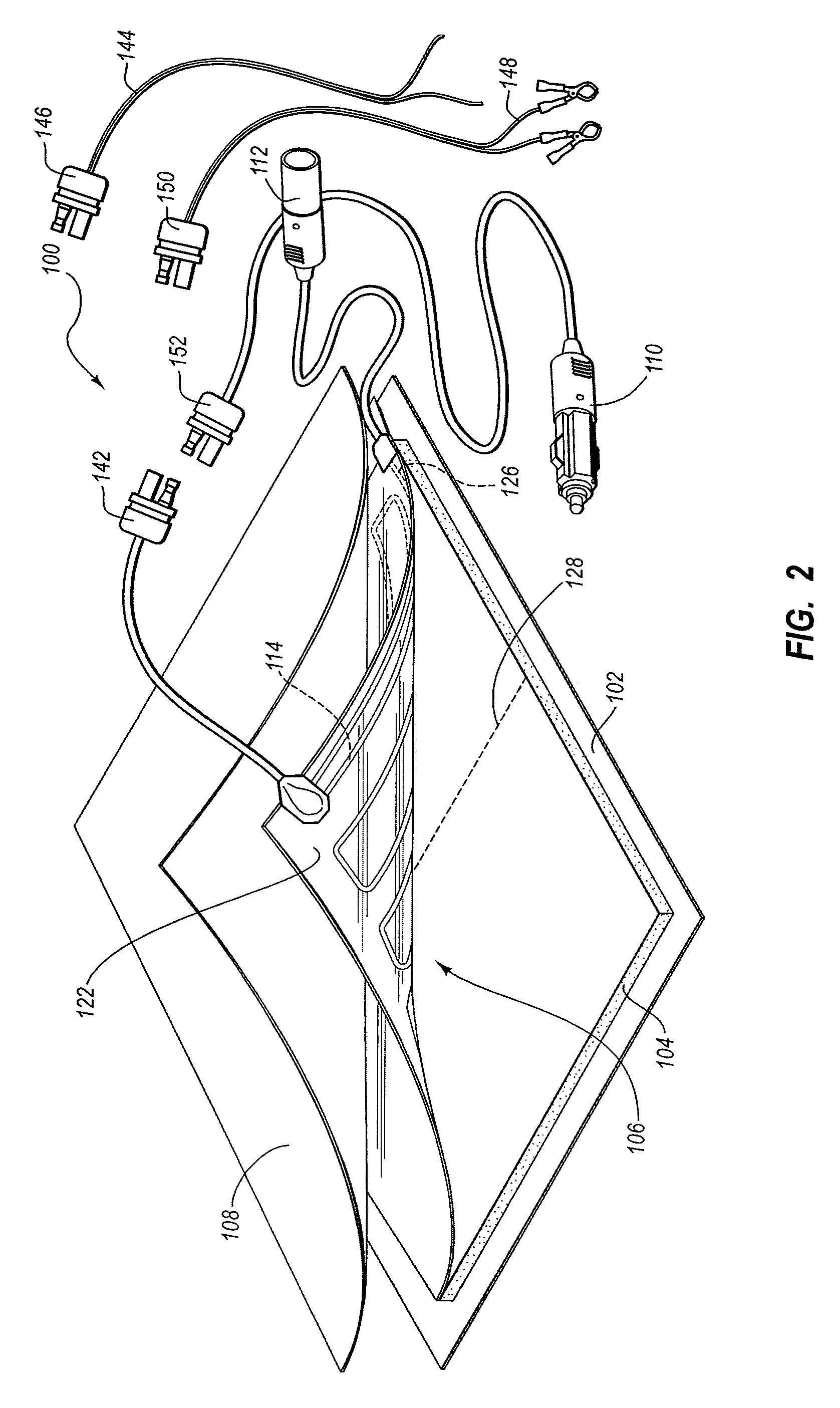

Portable Pouch Heating Unit

InactiveUS20090114633A1Even heat distributionLighting and heating apparatusElectric heating systemThermal insulationHeating temperature

A portable pouch for use in heating temperature sensitive materials is disclosed. The pouch includes a heating unit with one or more fasteners attached around its outer edges. The heating unit can be folded to allow the one or more fasteners to secure opposing outer edges of the heating unit together to form a pocket for substantially enclosing the materials to be warmed. The heating unit can be electrically connected to a direct current power source. The heating unit includes first and second cover layers enclosing a heat generating element and a carbon-based heat spreading element. A thermal insulation layer is also positioned between the first and the second cover layers. The heating element is adapted to generate and evenly spread heat over the interior surface of the pocket to evenly heat the materials disposed within the pocket.

Owner:GREENHEAT IP HLDG LLC

Grill

ActiveUS20050005777A1Improve thermal efficiencyEven heat distributionDomestic stoves or rangesElectrical heating fuelMechanical engineering

Owner:CONAIR CORP

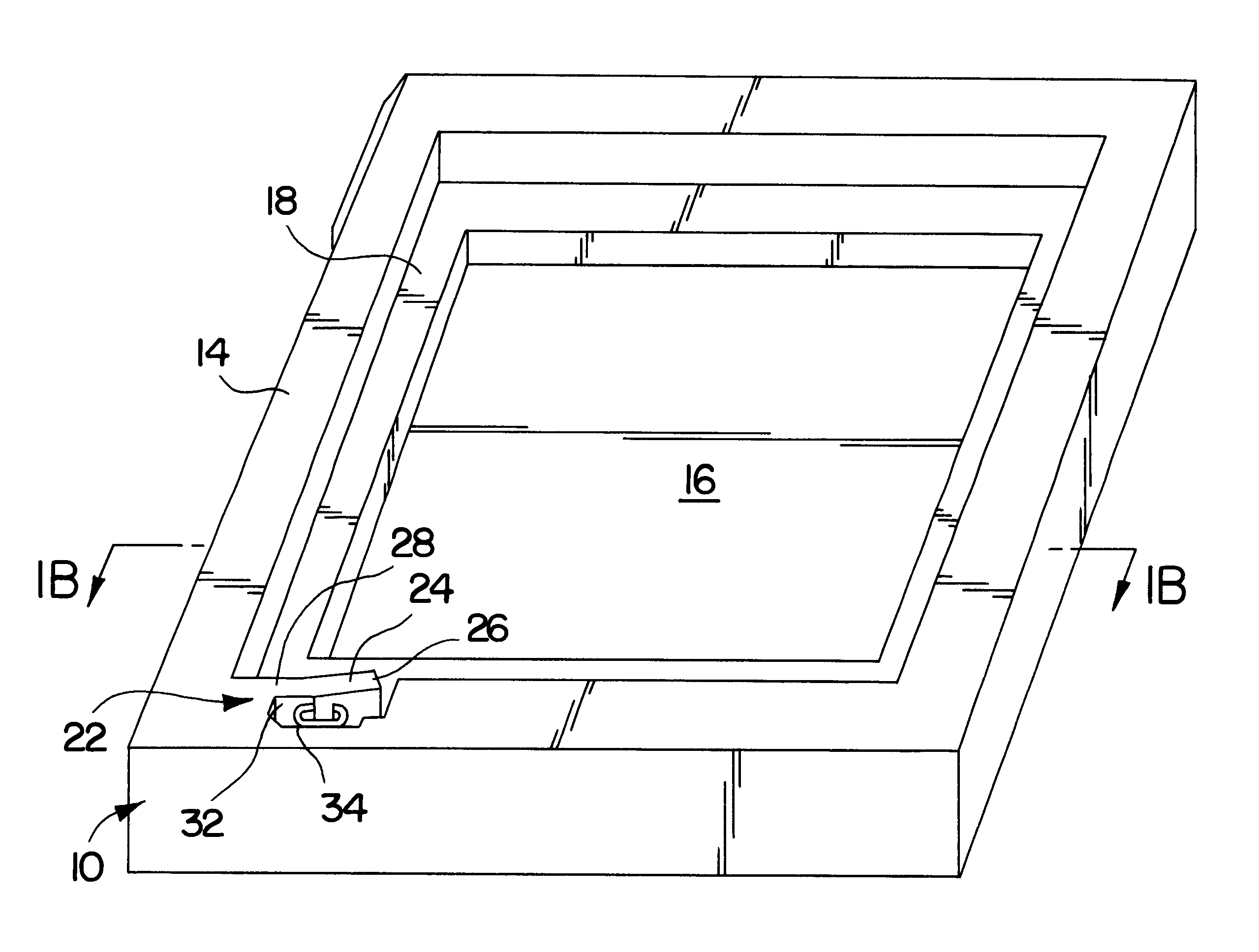

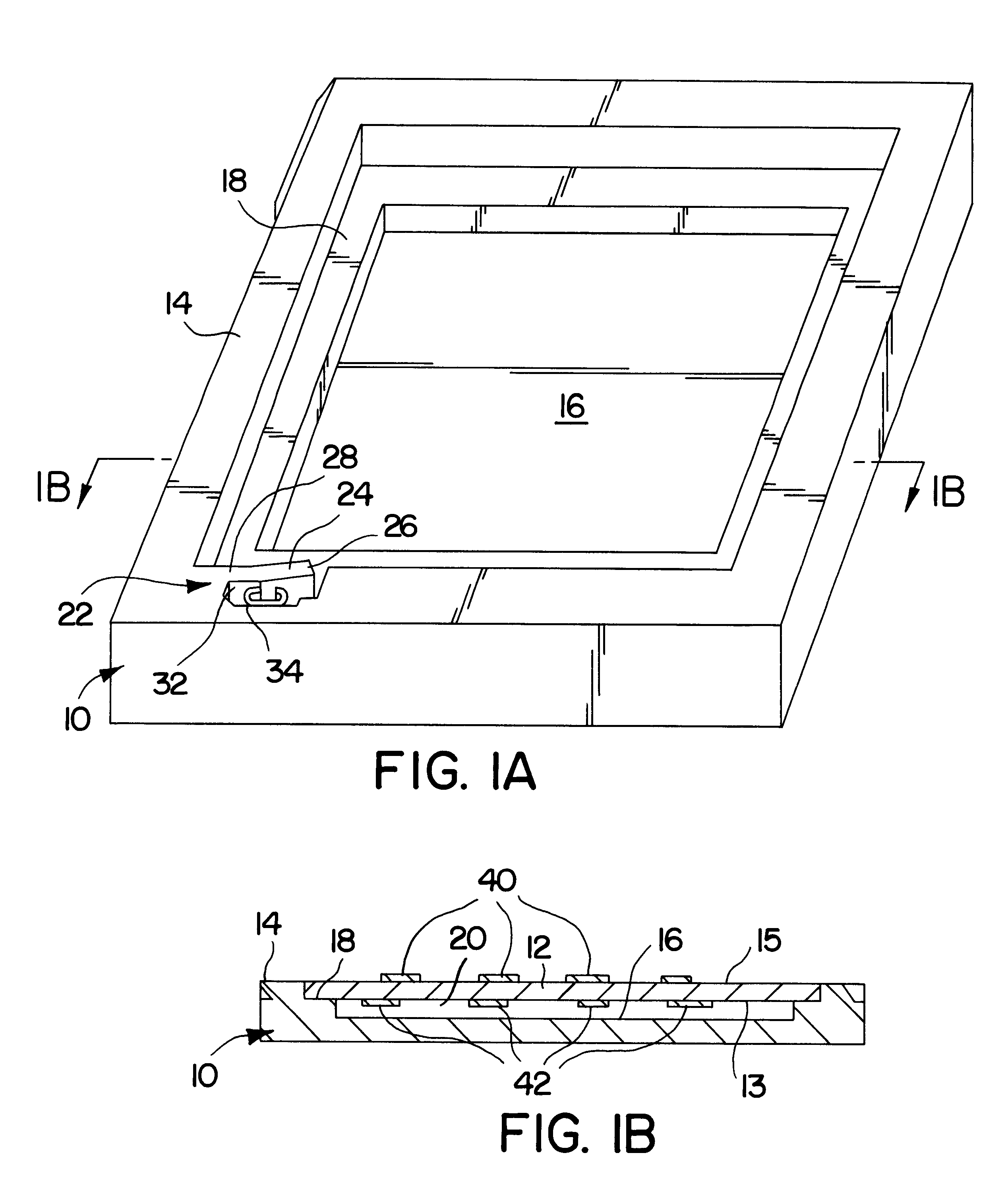

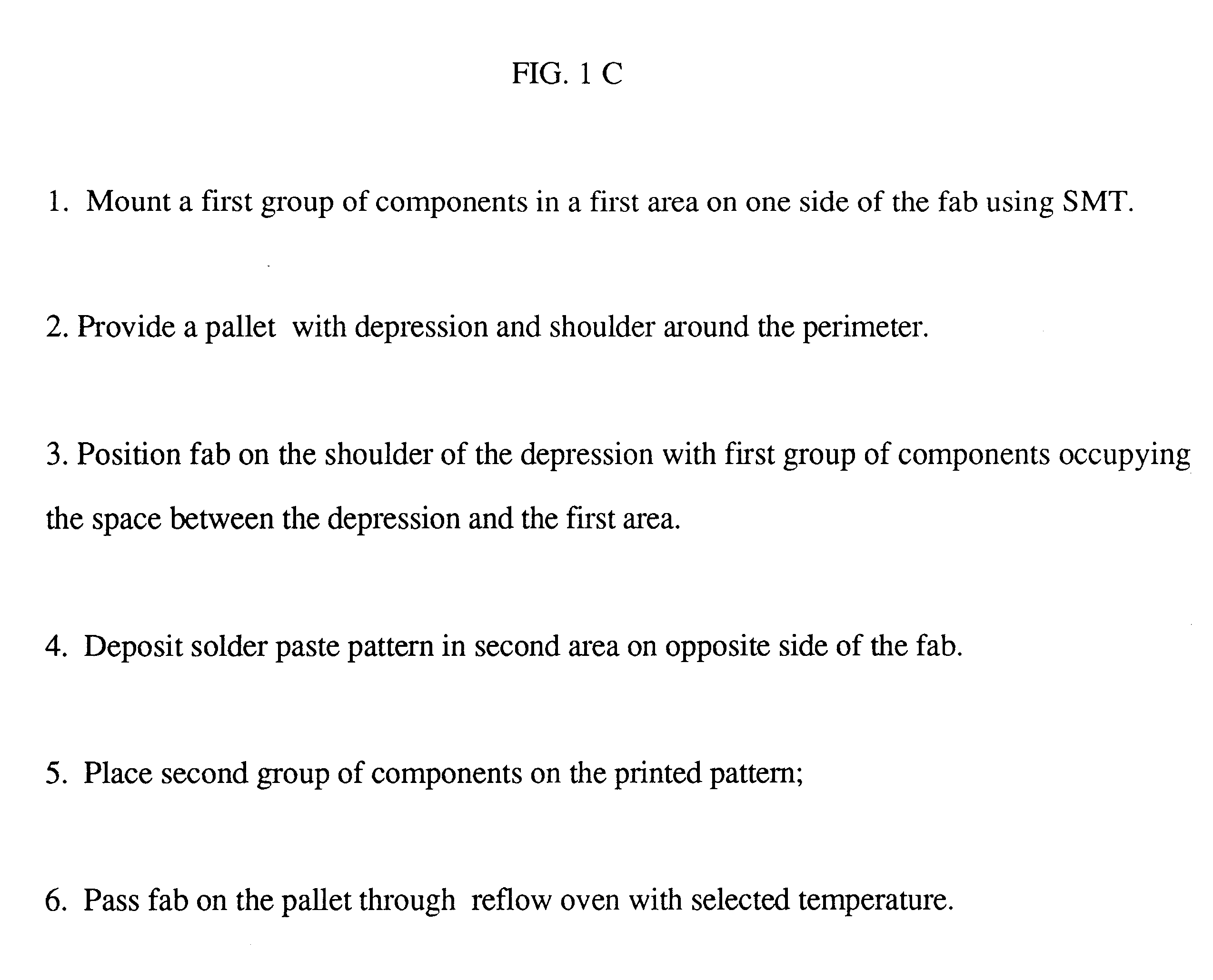

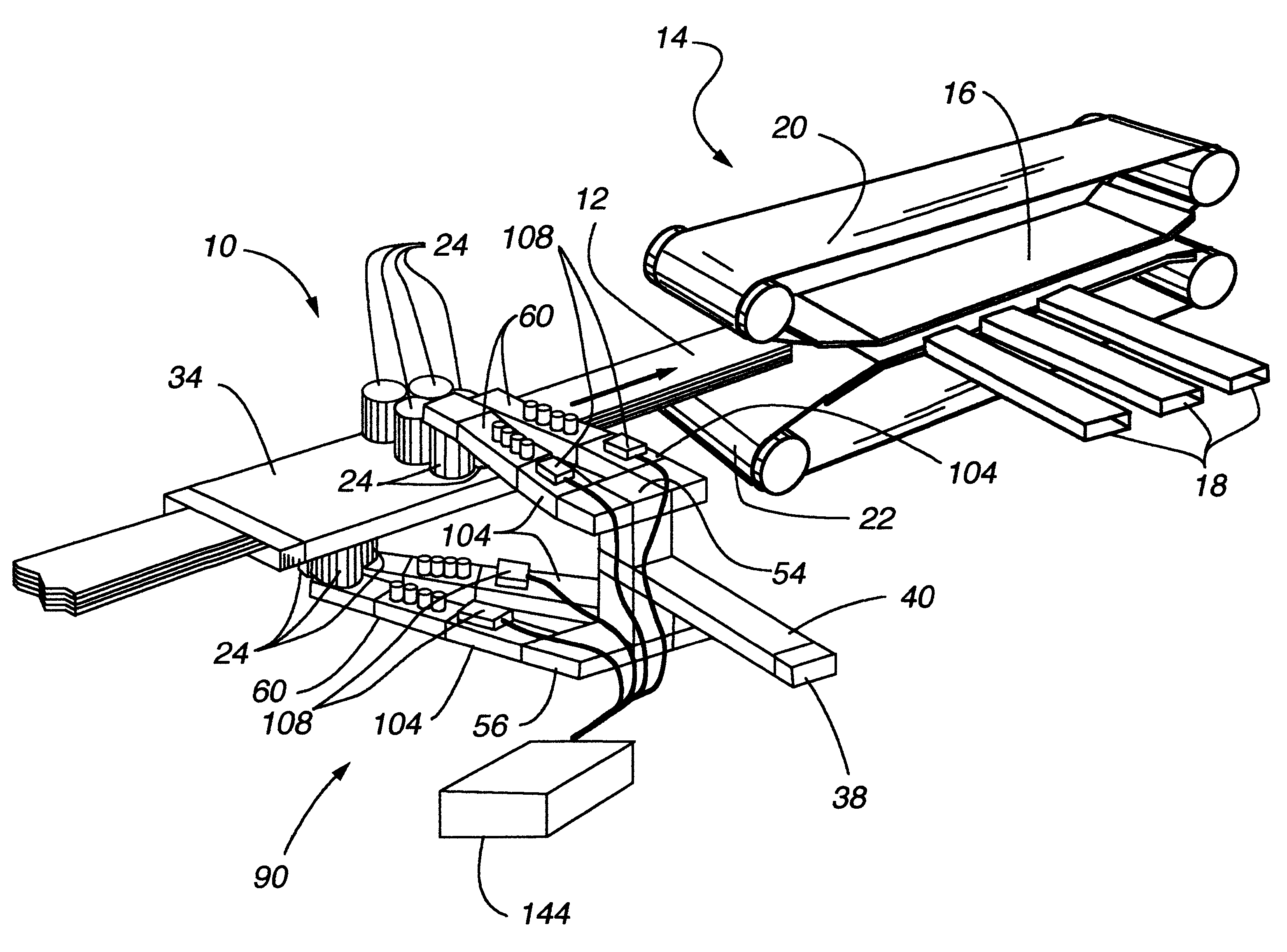

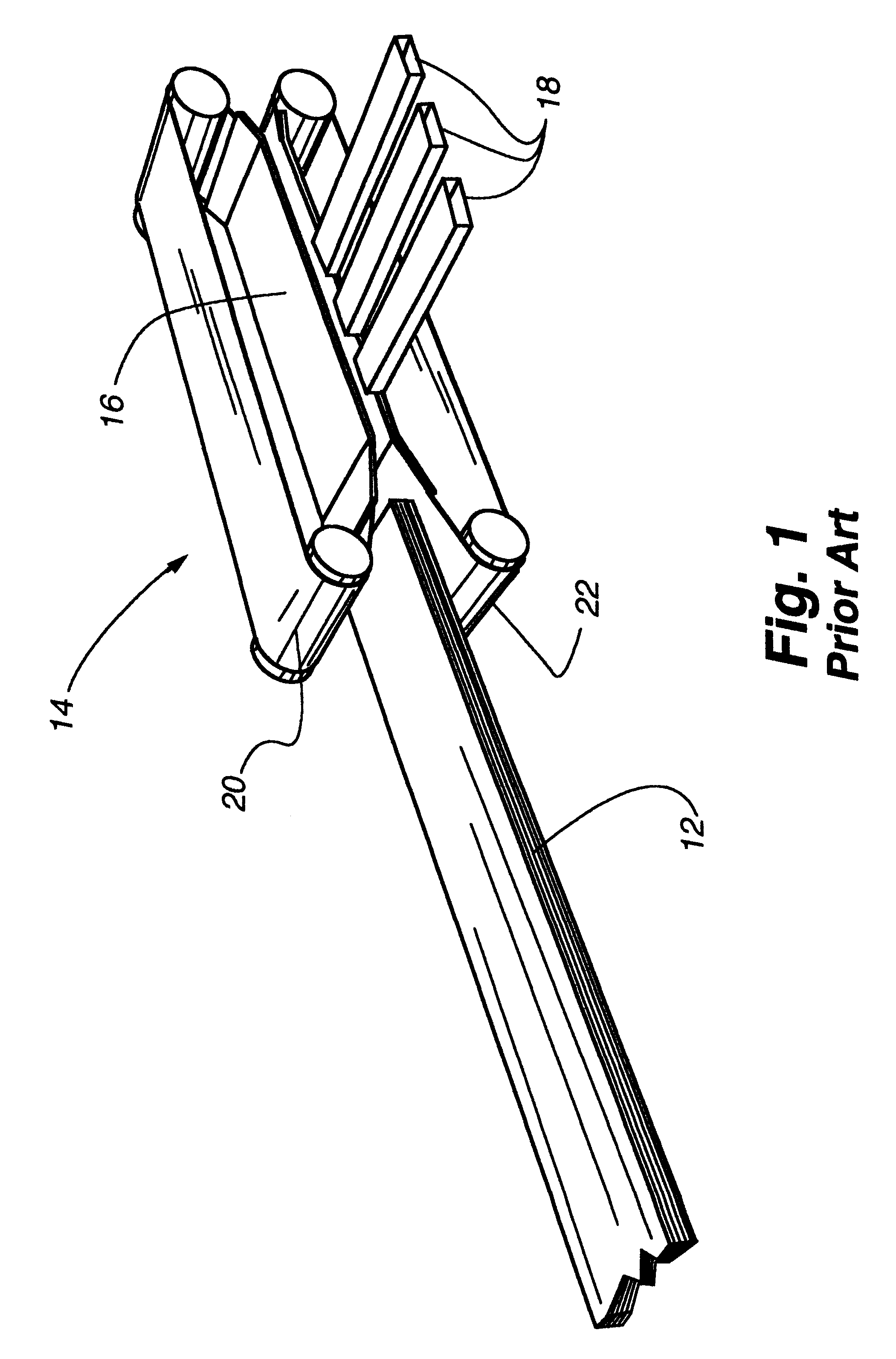

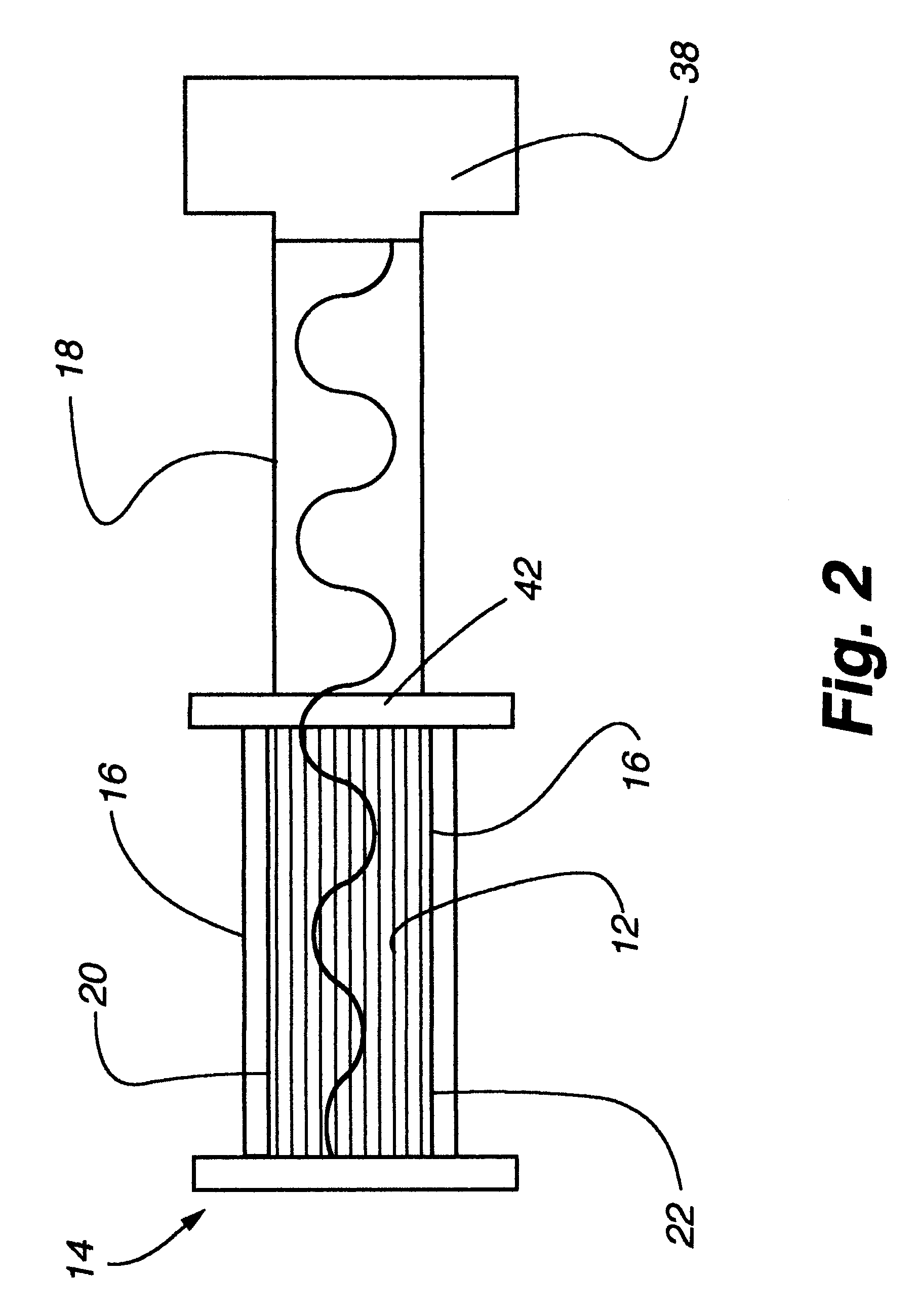

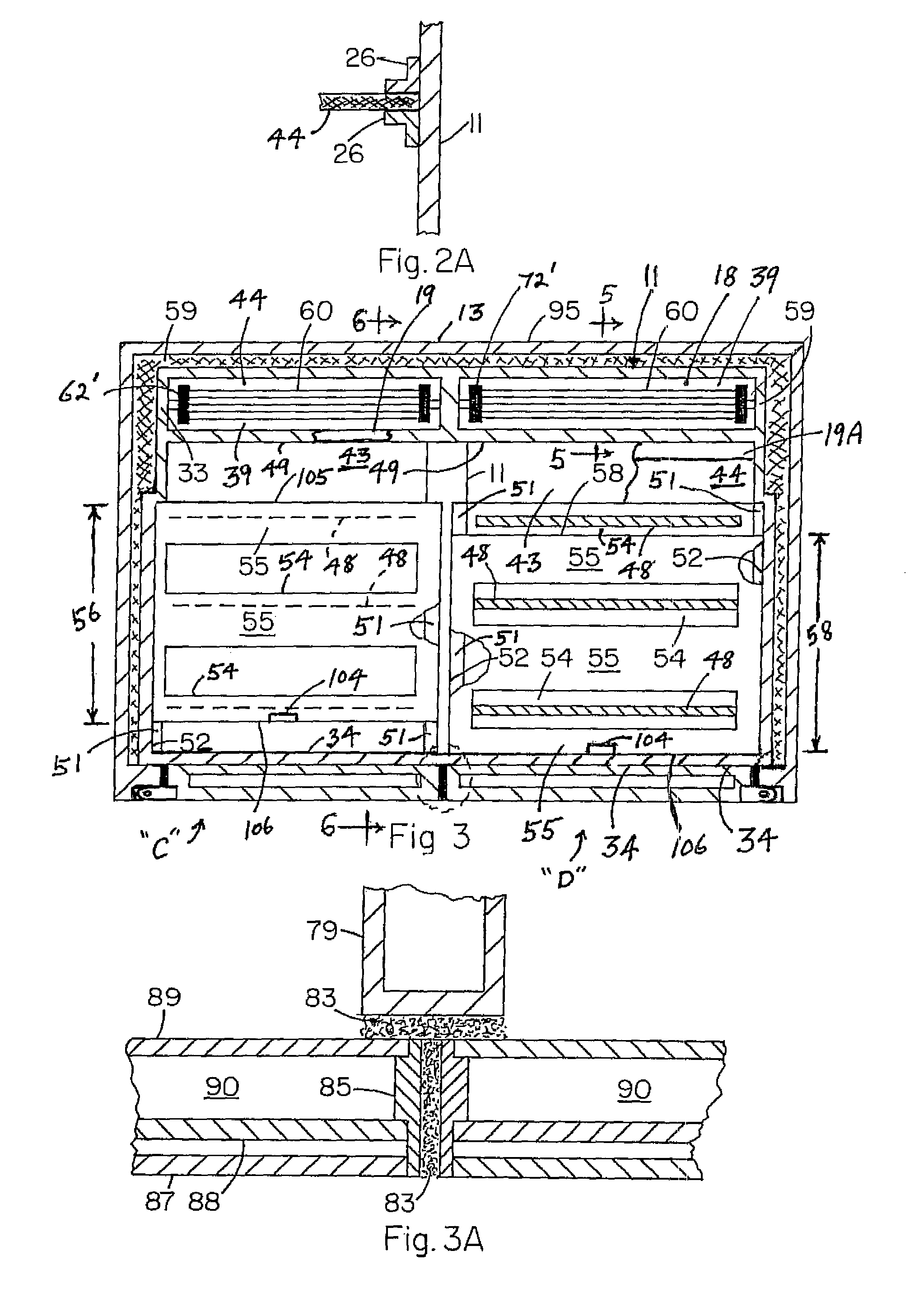

Pallet for combined surface mount and wave solder manufacture of printed ciruits

InactiveUS6267288B1Even heat distributionMinimize warpagePrinted circuit assemblingFinal product manufactureSurface mountingEngineering

A pallet for mounting components on a double sided PCB including a fab (panel) having a frame area surrounding a depression. A shoulder around the depression is dimensioned to support the fab. The fab is laid on the shoulder with the a group of components mounted in a previous reflow operation in the space between the depression and a first area of the fab. The print, pick and place and reflow operations are performed to mount a second group of components on the opposite side of the fab. The first area of the fab is shielded from the heat of the oven so that the first components do not separate from the fab during the second reflow step. Standoffs in the depression prevent sagging of the board. Another area of the pallet has a recessed area with cutouts for wave soldering components located on the third area of the fab.

Owner:CHUNG HENRY

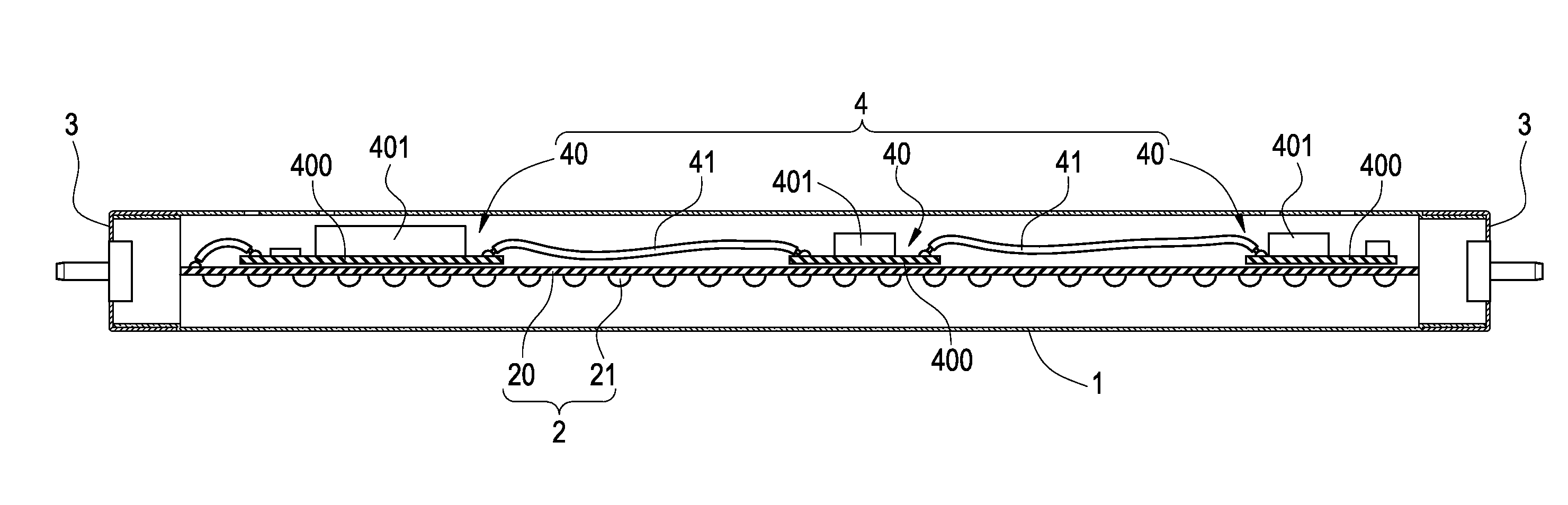

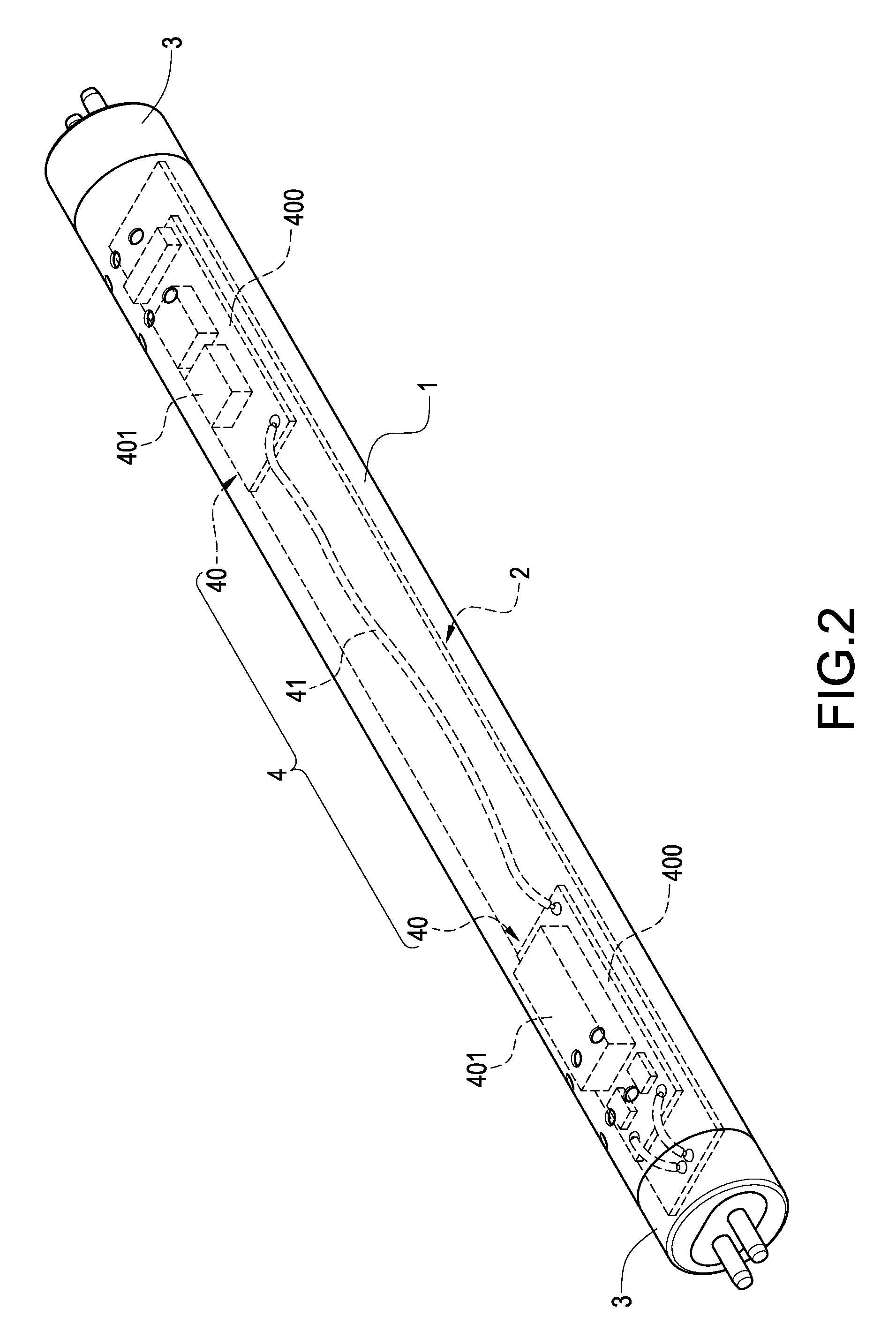

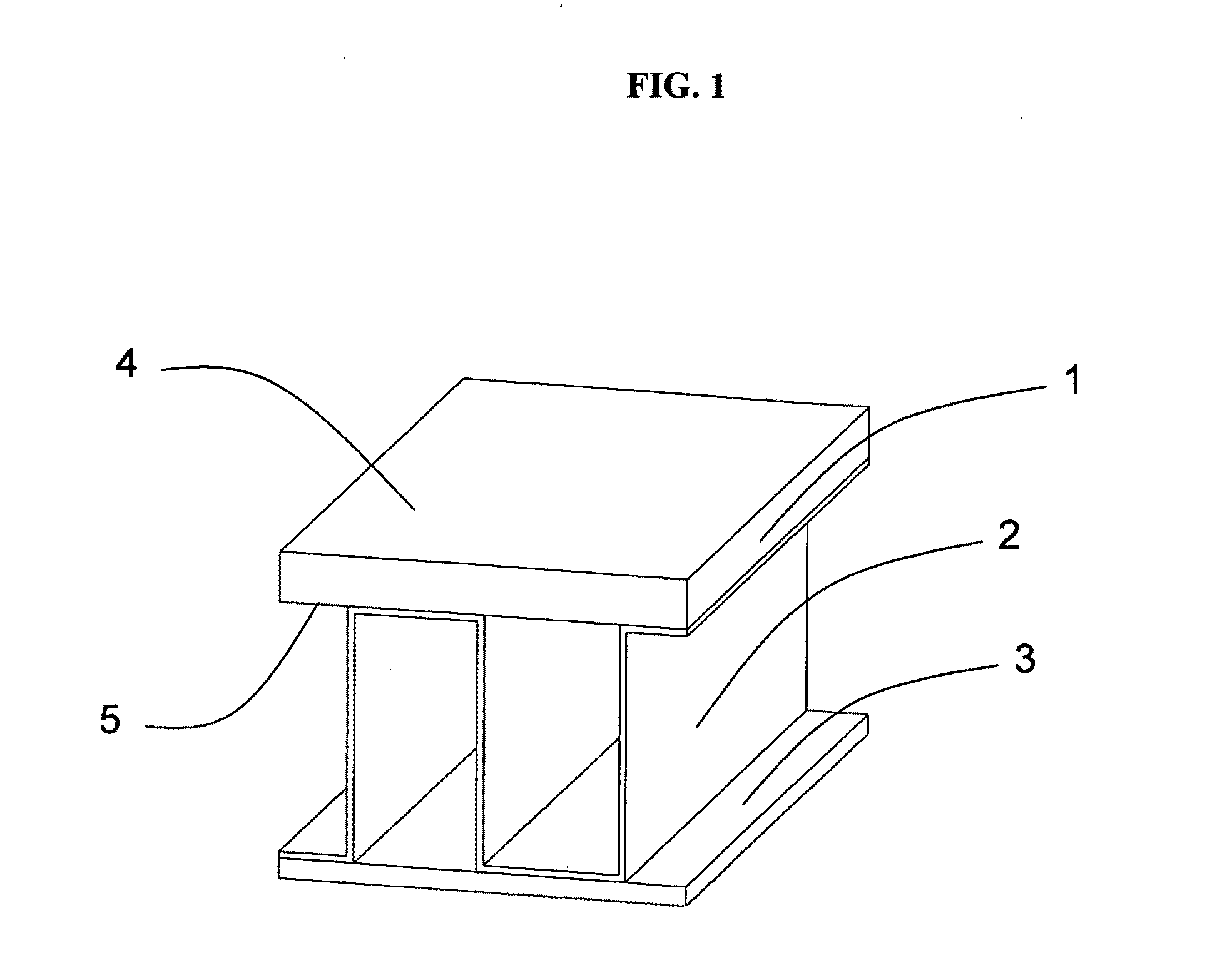

LED lamp tube with heat distributed uniformly

ActiveUS8092043B2Reduce the temperatureImprove cooling effectPoint-like light sourceLighting support devicesLight pipeEngineering

A LED lamp tube which includes a hollow transparent tube, a LED lamp assembly disposed in the transparent tube, two conductive caps provided on both ends of the transparent tube respectively, and a circuit control unit. The circuit control unit includes a plurality of separated sub-portions. The respective sub-portions of the circuit control unit are distributed uniformly on the circuit board of the LED lamp assembly. Via the uniform arrangement of respective sub-portions of the circuit control unit, the heat within the LED lamp tube can be distributed uniformly, thereby lowering the temperature and facilitating the heat dissipation.

Owner:KITAGAWA HLDG

Mold apparatus for forming polymer and method

ActiveUS20080303194A1Utilizes less energyHeating fastCoil arrangementsAuxillary shaping apparatusShell moldingCycle time

Various mold apparatuses and methods for forming a polymer with induction heat energy are provided. In one embodiment of the present invention, a mold apparatus for forming polymer includes a mold having a top mold portion and a top mold surface that is magnetic. The bottom mold portion of the mold includes an induction heating unit that is at least partially embedded in the bottom mold portion that provides induction heat energy to the mold. The mold apparatus is constructed and arranged to dissipate greater than about 50% of the induction heat energy in the top mold portion. The induction heating unit of the bottom portion of the mold provides rapid heating the top mold surface to provide high surface quality polymer parts a shorter molding cycle time while utilizing less energy.

Owner:SHPP GLOBAL TECH BV

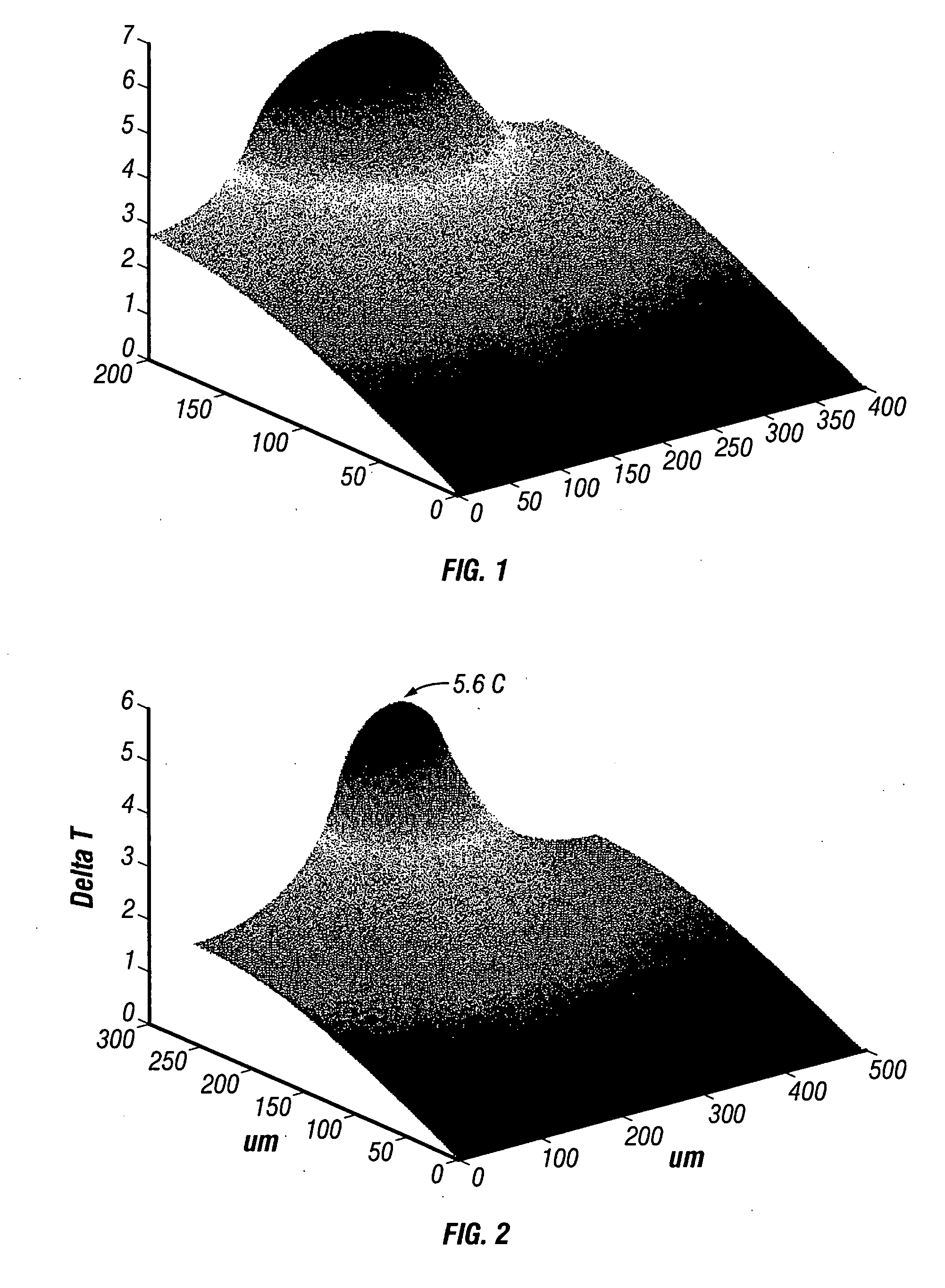

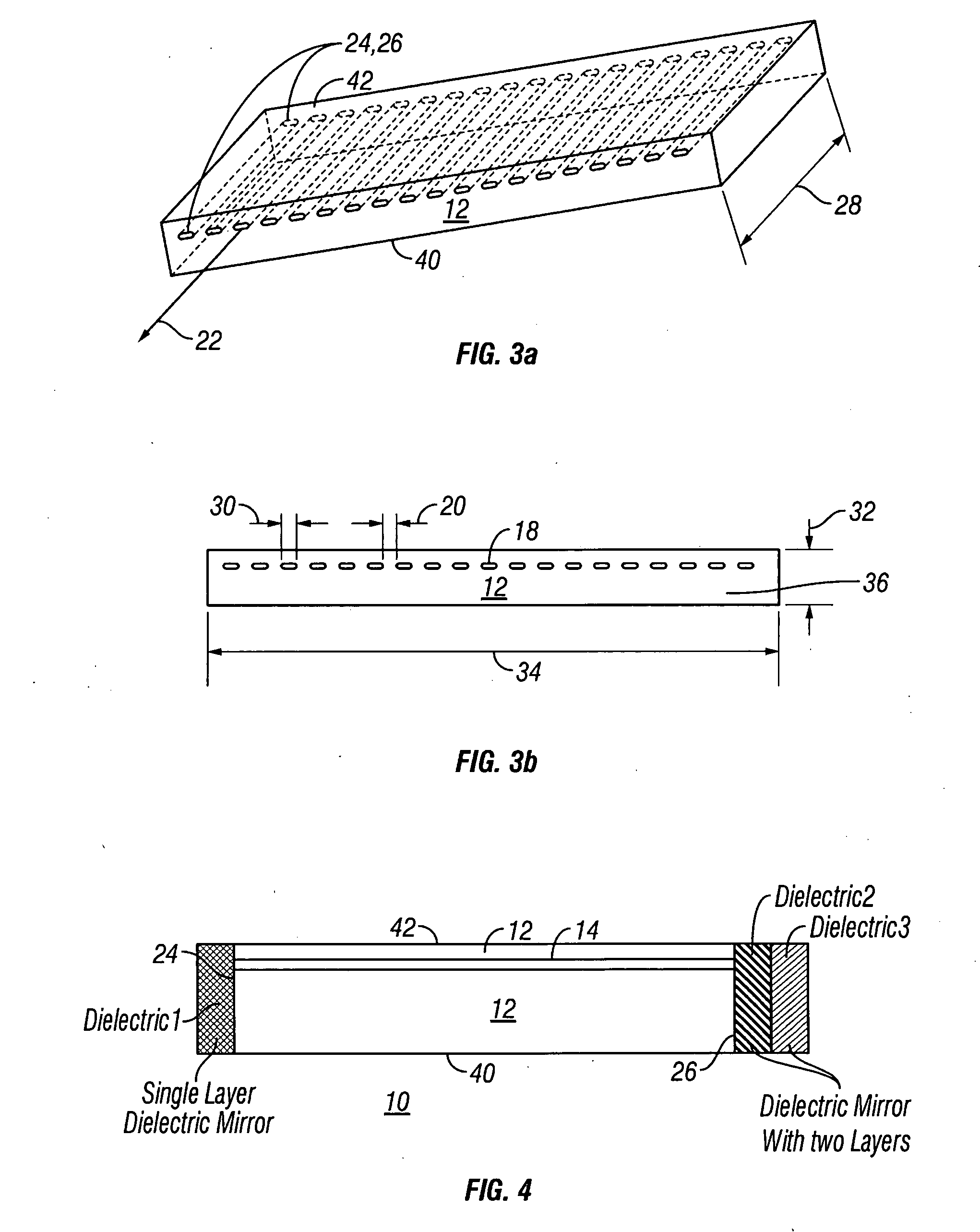

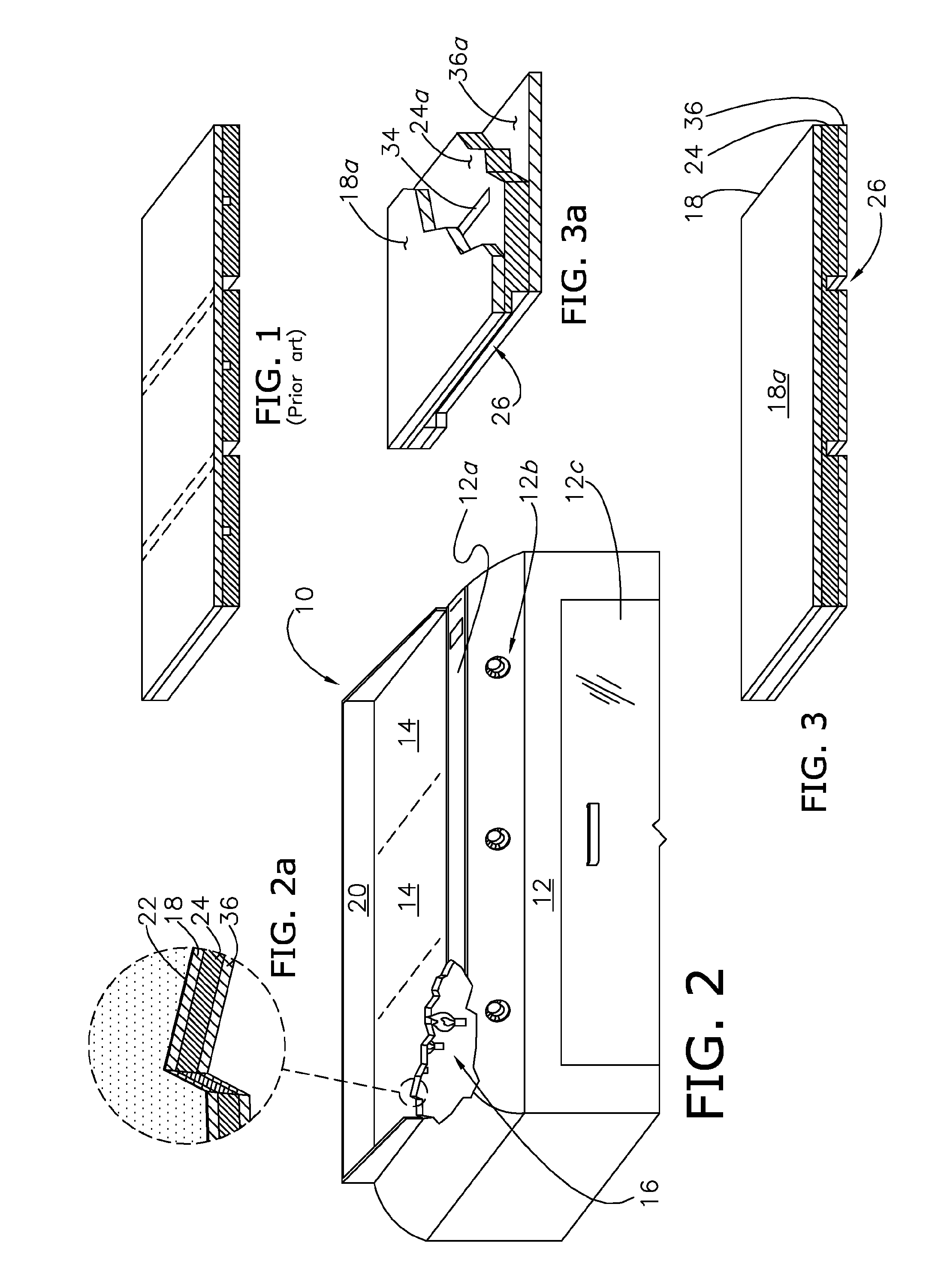

Laser diode arrays with reduced heat induced strain and stress

InactiveUS20060018355A1Improve reliabilityReduce disagreementLaser detailsSemiconductor lasersLaser transmitterHeat sink

A laser diode array has a semiconductor layered structure that includes at least one active layer. A heat sink is coupled to semiconductor layered structure. A plurality of laser emitters are formed in the active layer. A majority of the plurality of laser emitters have a spacing between adjacent laser emitters that provides for a more uniform heat distribution.

Owner:COMLASE

Multi-zone composite cooking griddle with unitary thermally conductive plate

InactiveUS20100199857A1Easy constructionEasy to manufactureCooking-vessel materialsRoasters/grillsThermal breakEngineering

A composite cooking structure adapted for use as a griddle top, presenting a plurality of thermally autonomous cooking zones when engaged by at least one heat source, and having a multi-layered configuration, including an uppermost hard planar member for presenting a cooking surface, a unitary thermally conductive planar member defining at least one thermal break for improving heat distribution within a zone and reducing thermal bleeding among adjacent zones, and preferably a lowermost hard planar member for improving the structural capacity of the structure, wherein the members are preferably metallurgically bonded and the thermal breaks cooperatively define the zones.

Owner:PREMARK FEG L L C

Adjustable microwave field stop

InactiveUS6242726B1Decreased amount of heatOptimizes energy usePlywood pressesDrying solid materials with heatRadiationMicrowave

An improved magnetic field stop. The field stop adjusts to allow different sizes of products to be passed through a microwave heating system. The field stop prevents undue radiation from escaping a heating chamber which is used in a microwave heating process for a variety of substrates.

Owner:EWES ENTERPRISES L L C

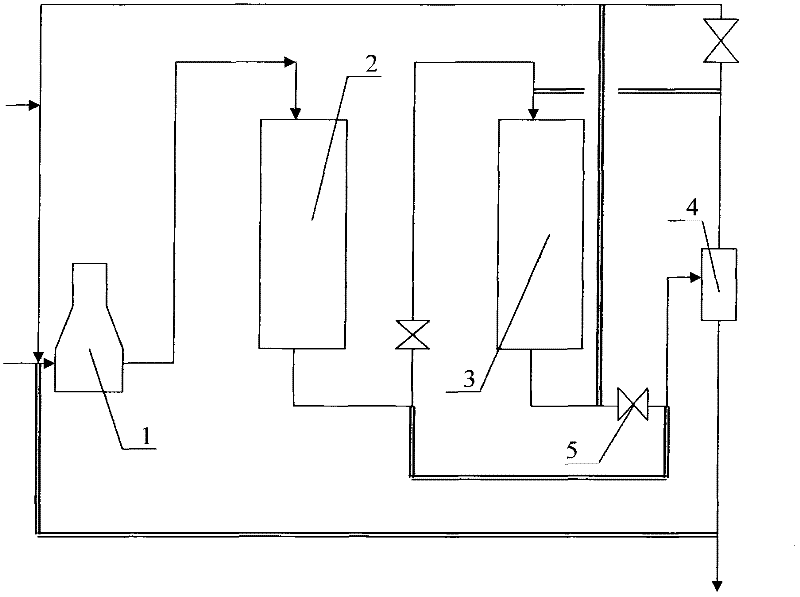

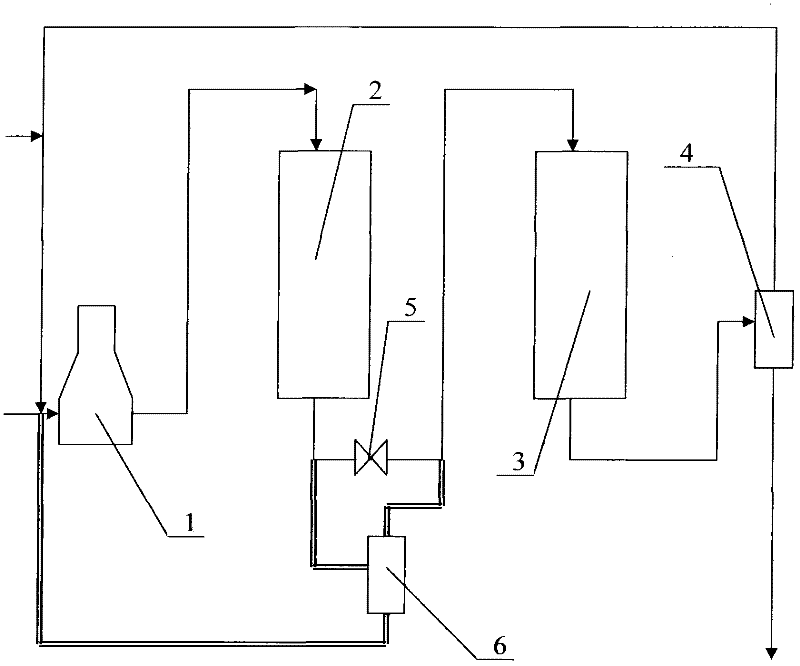

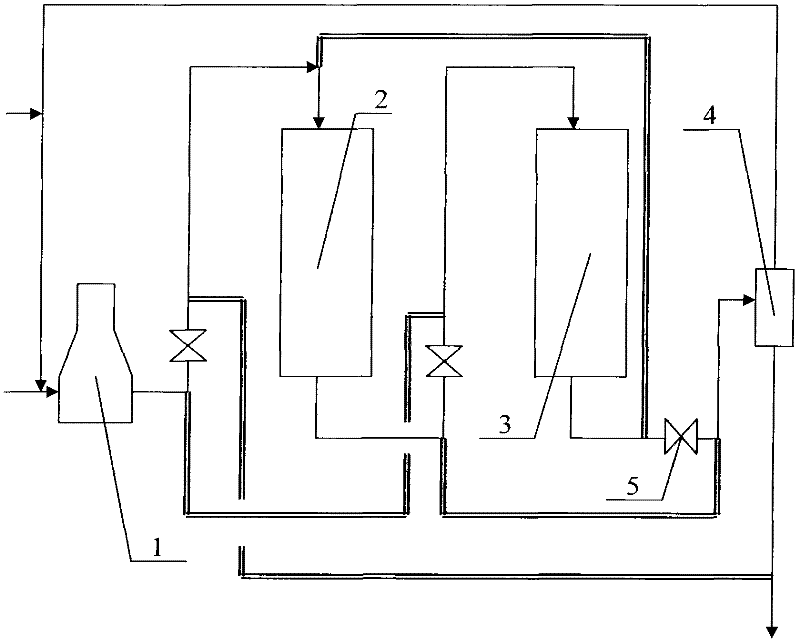

Start-up activation method for hydrogenation cracking process

ActiveCN102443426AImprove the activation effectLess investmentTreatment with hydrotreatment processesChemistryActivation method

The invention discloses a start-up activation method for a hydrogenation cracking process, which comprises the following steps that: (1) a hydrogenation cracking pre-refining reactor and a hydrogenation cracking reactor are adopted in the hydrogenation cracking process, and catalysts are ex-situ presulfurizing catalysts; (2) the hydrogenation cracking pre-refining reactor and the hydrogenation cracking reactor are used for carrying out operation including gas displacement, device airtightness and the like; and (3) activation oil and hydrogen gas enter a gas-liquid separator after entering the hydrogenation cracking pre-refining reactor under the ex-situ presulfurizing catalyst activation condition, a liquid phase separated out from the gas-liquid separator is circulated back to the hydrogenation cracking pre-refining reactor, the closed loop circulation is carried out in the hydrogenation cracking pre-refining reactor, a gas phase separated out from the gas-liquid separator enters the hydrogenation cracking reactor, and the gas phase discharged from the hydrogenation cracking reactor is circulated back to the hydrogenation cracking pre-refining reactor. Compared with the prior art, the method has the advantages that the catalyst sulfurization effect is good, and the excellent reaction effect is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

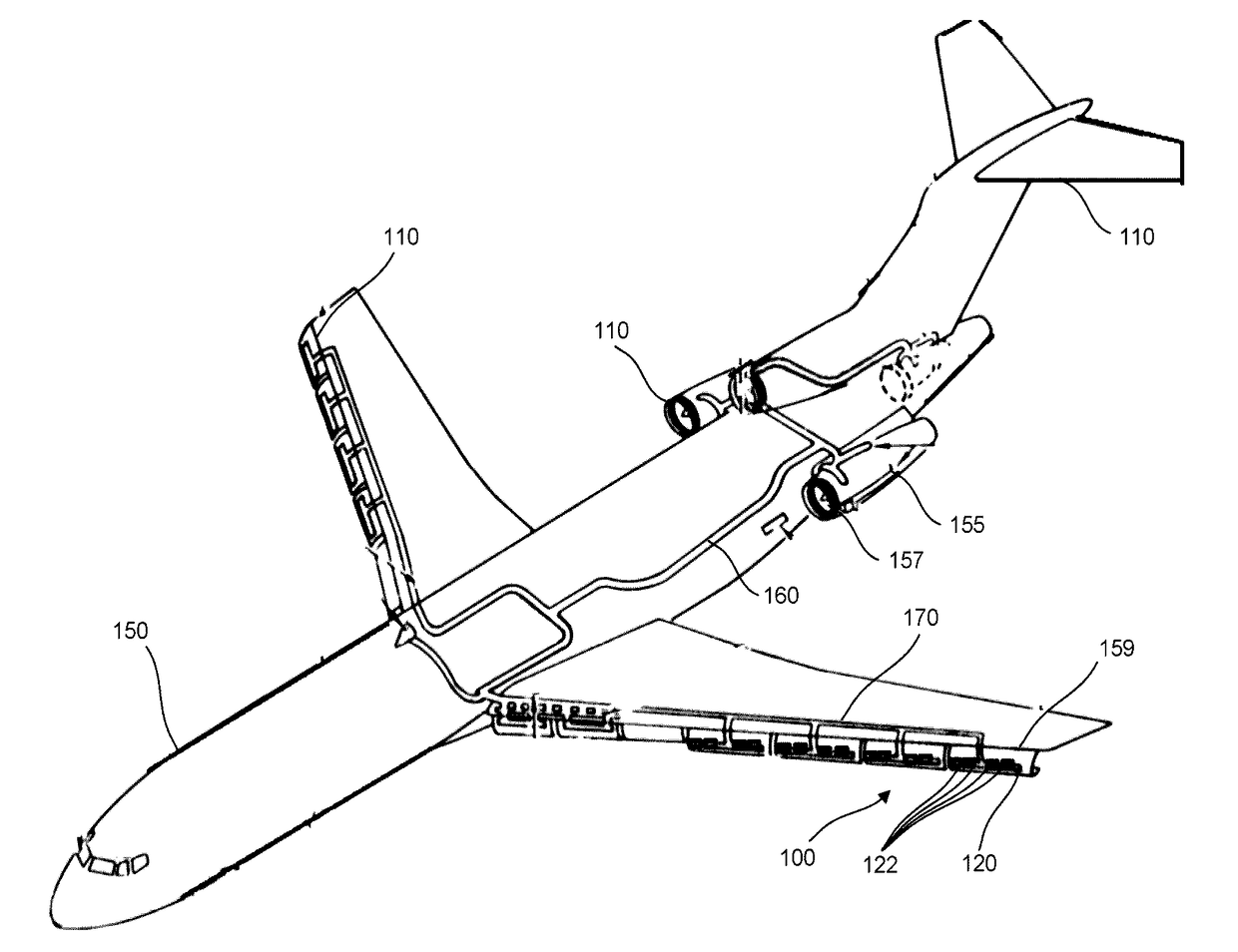

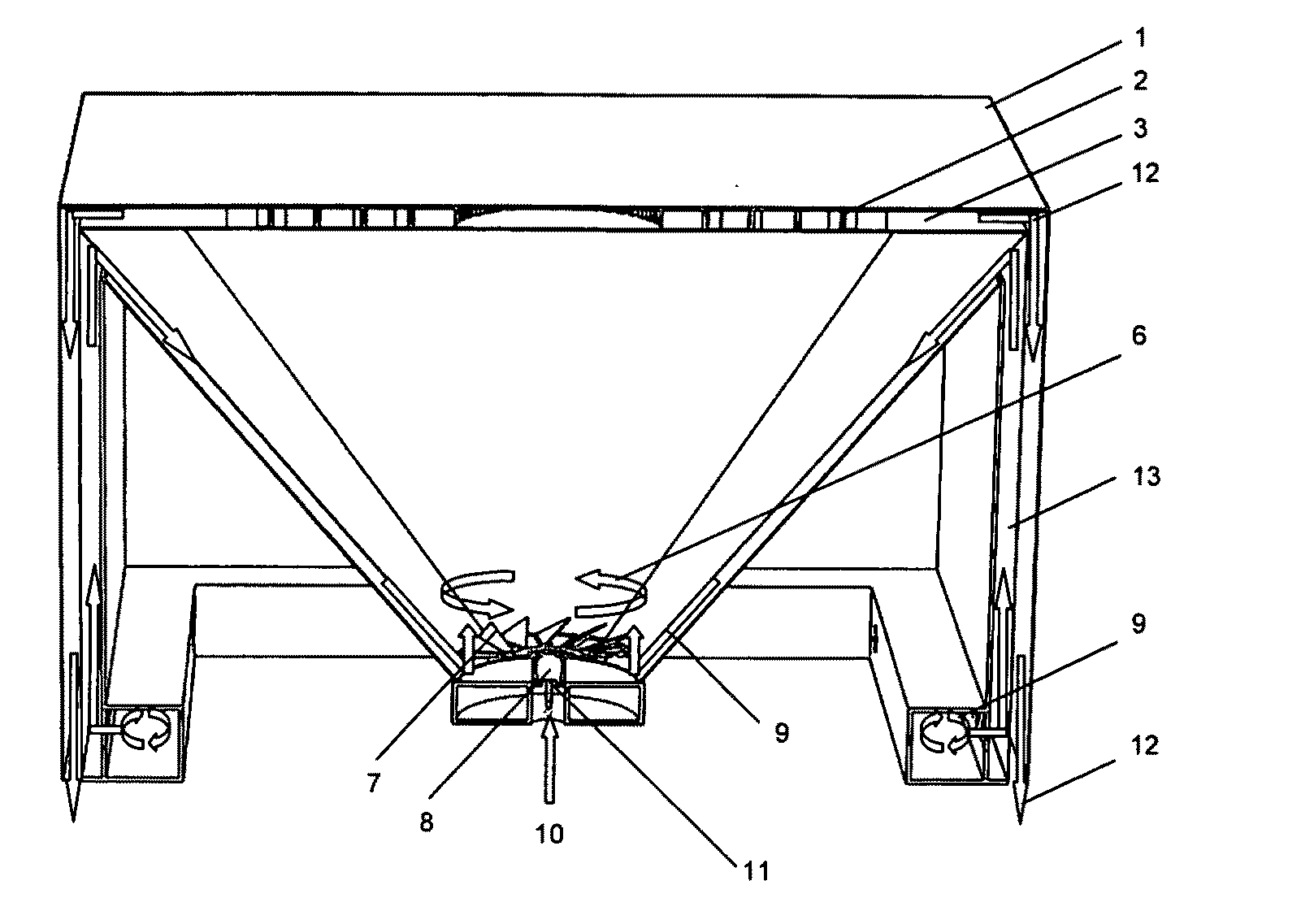

Anti-icing apparatus and system

InactiveUS20170166313A1Effectiveness and efficiencyEnsure efficiency and effectivenessAircraft power plant componentsDe-icing equipmentsWorking fluidEngineering

An anti-icing apparatus includes an anti-icing piccolo tube for an aircraft component with a plurality of self rotating elements. Each self rotating element of the plurality of self rotating elements includes a first inlet to receive a working fluid, a second inlet to receive the working fluid, a peripheral layer that connects the first inlet and the second inlet, and a plurality of outlets placed on the peripheral layer that expulses the working fluid through jets. The jets rotate each self rotating element and dynamically impinges the working fluid on an internal surface of the aircraft component.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

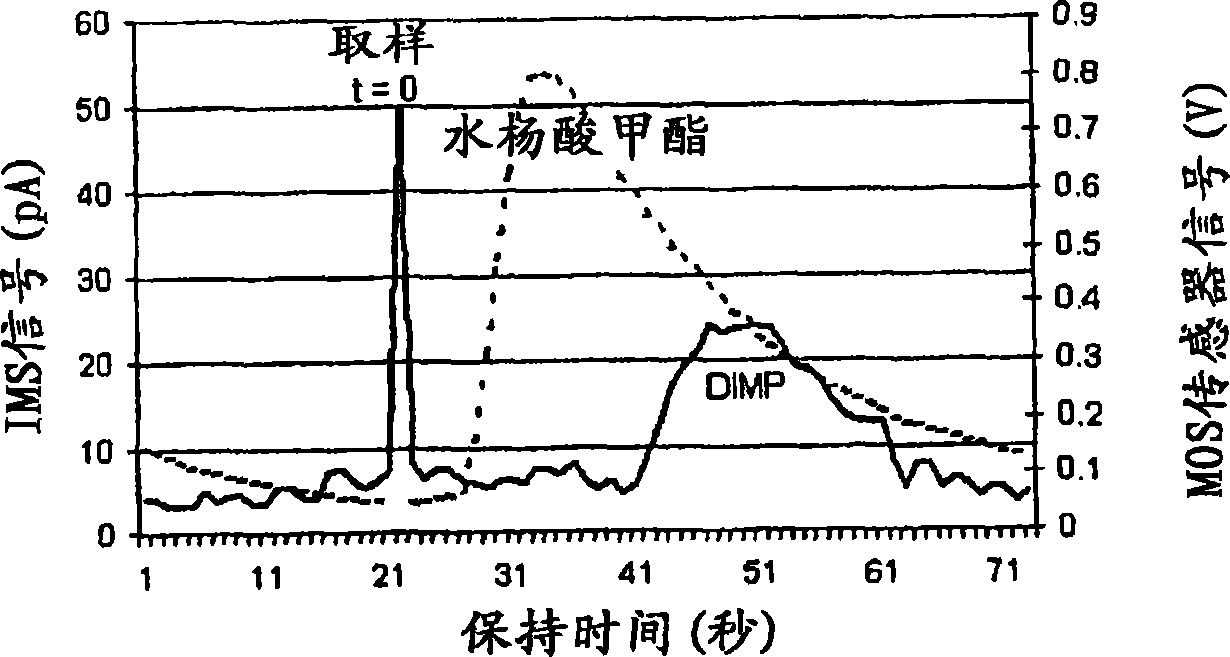

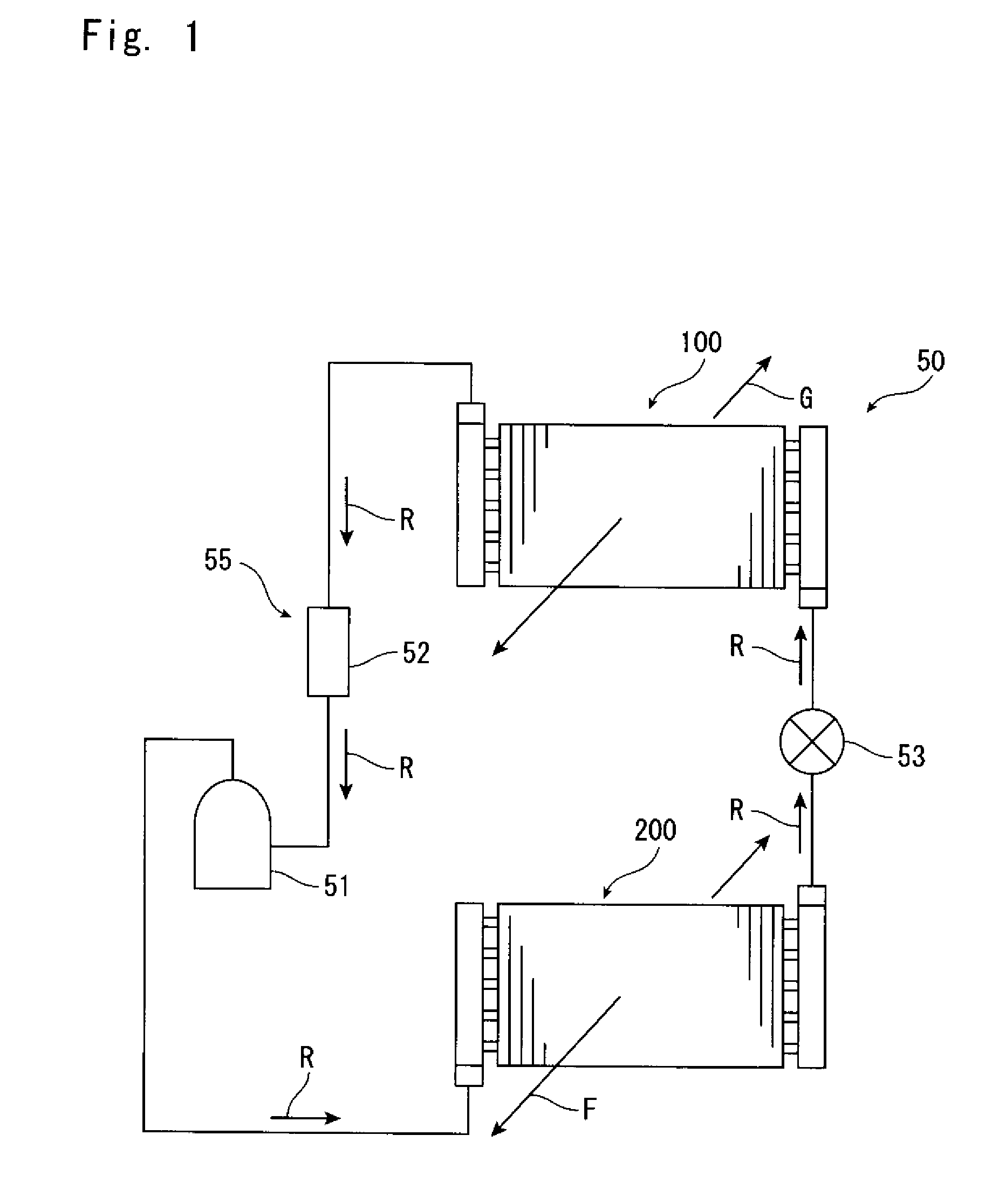

Gas chromatograph

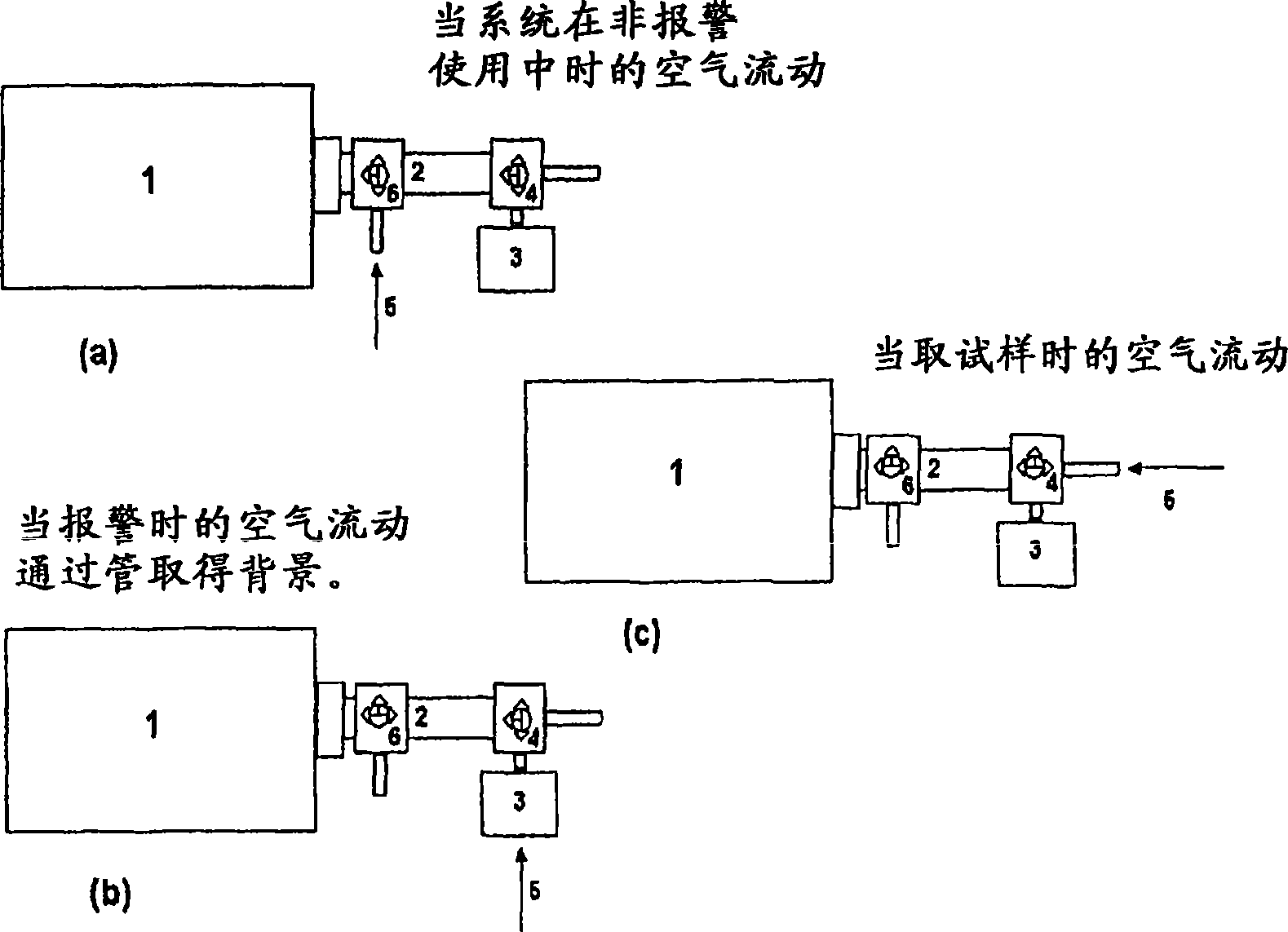

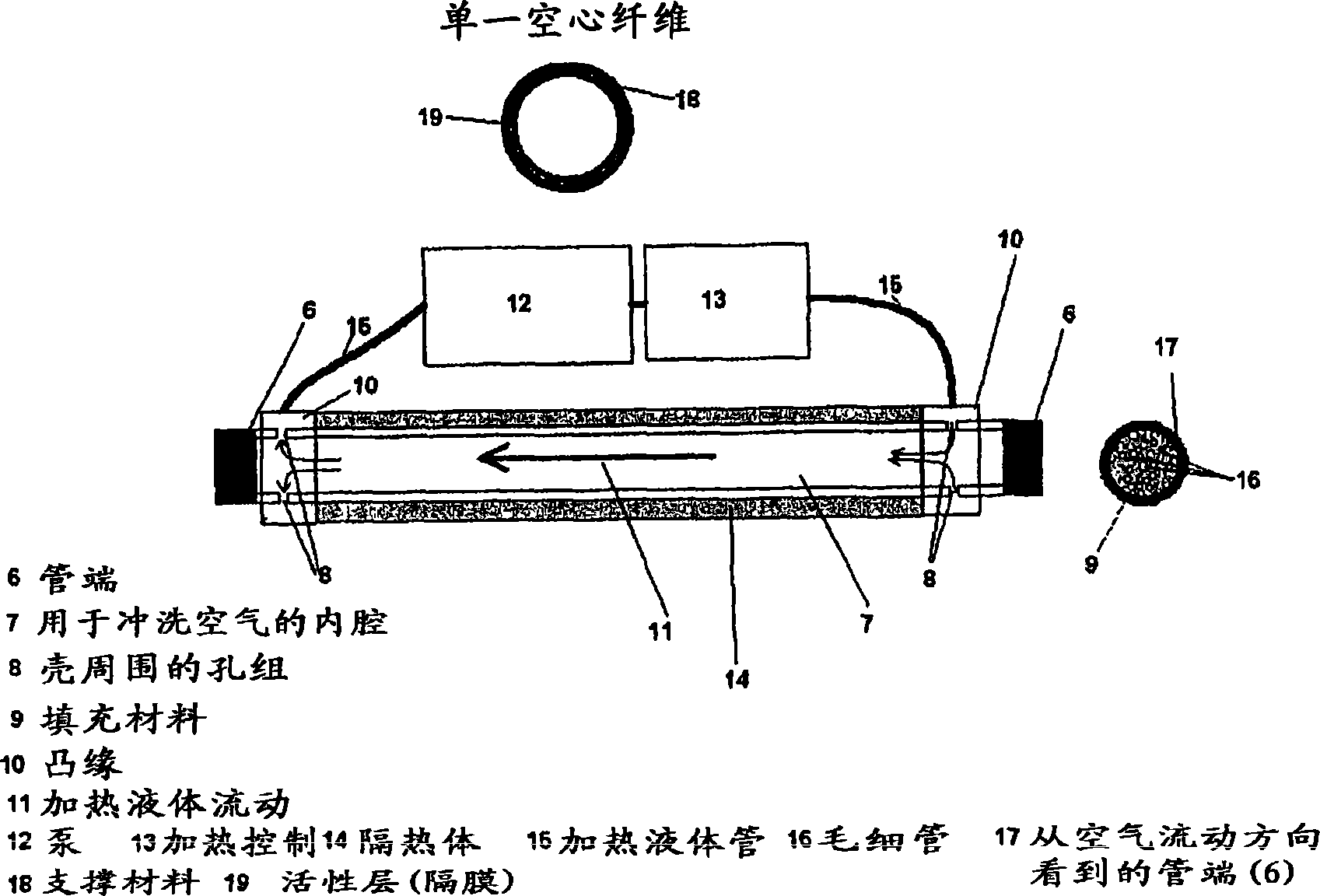

InactiveCN1910453ALittle thermal impactEasy disposalMembranesSemi-permeable membranesTemperature controlHand held

The invention relates to a gas chromatograph for the analysis of gas samples. It has a feed arrangement for feeding the sample, an open tubular capillary column for separating the components of the sample, temperature control means for controlling the temperature of the column, and a detector for detecting the separated components of the sample. The efficiency has been improved and a convenient hand-held version has been made possible by constructing the column of a bundle of open tubular capillaries having a gas permeable wall comprising a polymer membrane. The invention also relates to the use of such a column together with a detector for identifying gaseous samples.

Owner:ENVIRONMENTAL STUDIES LTD

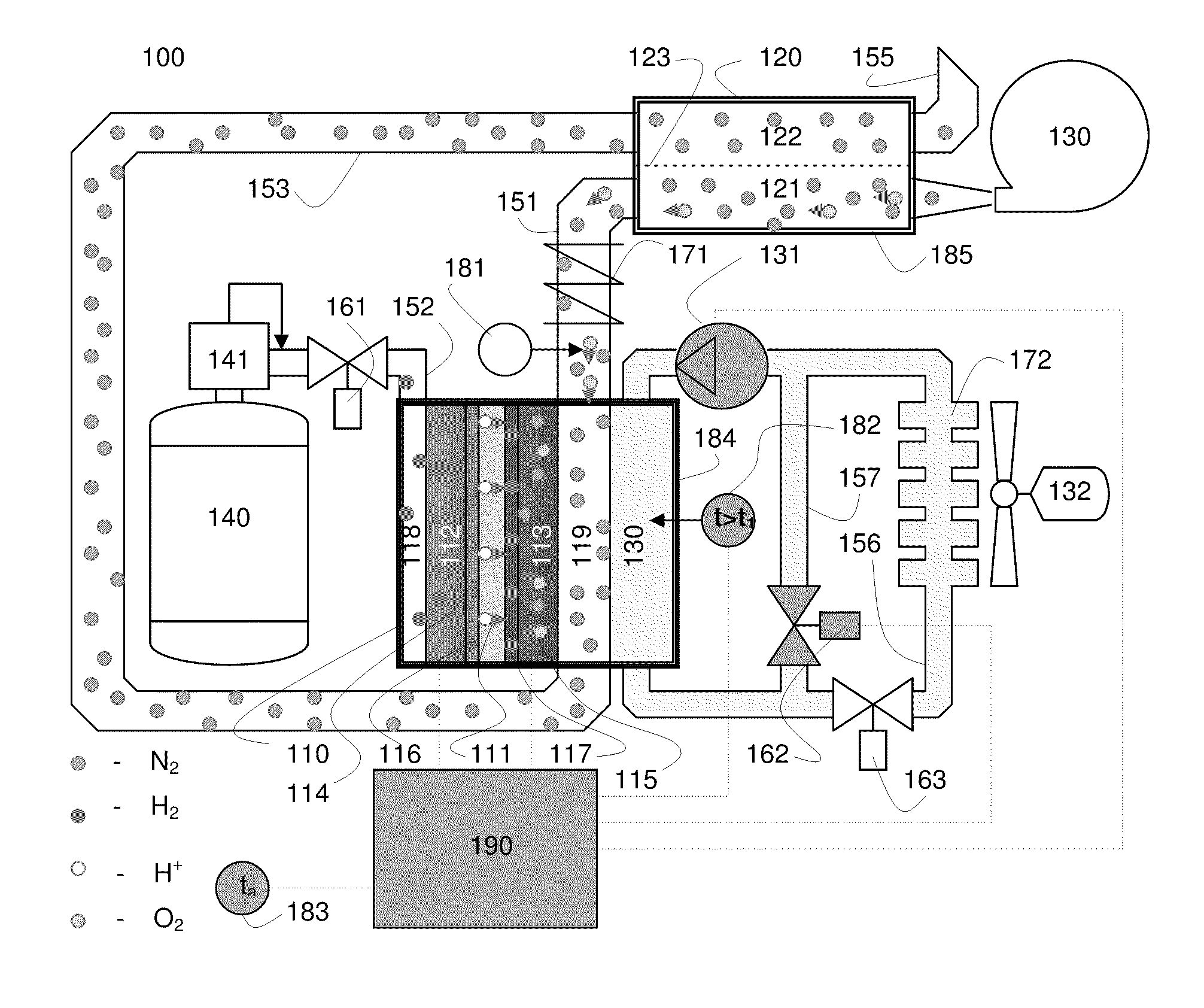

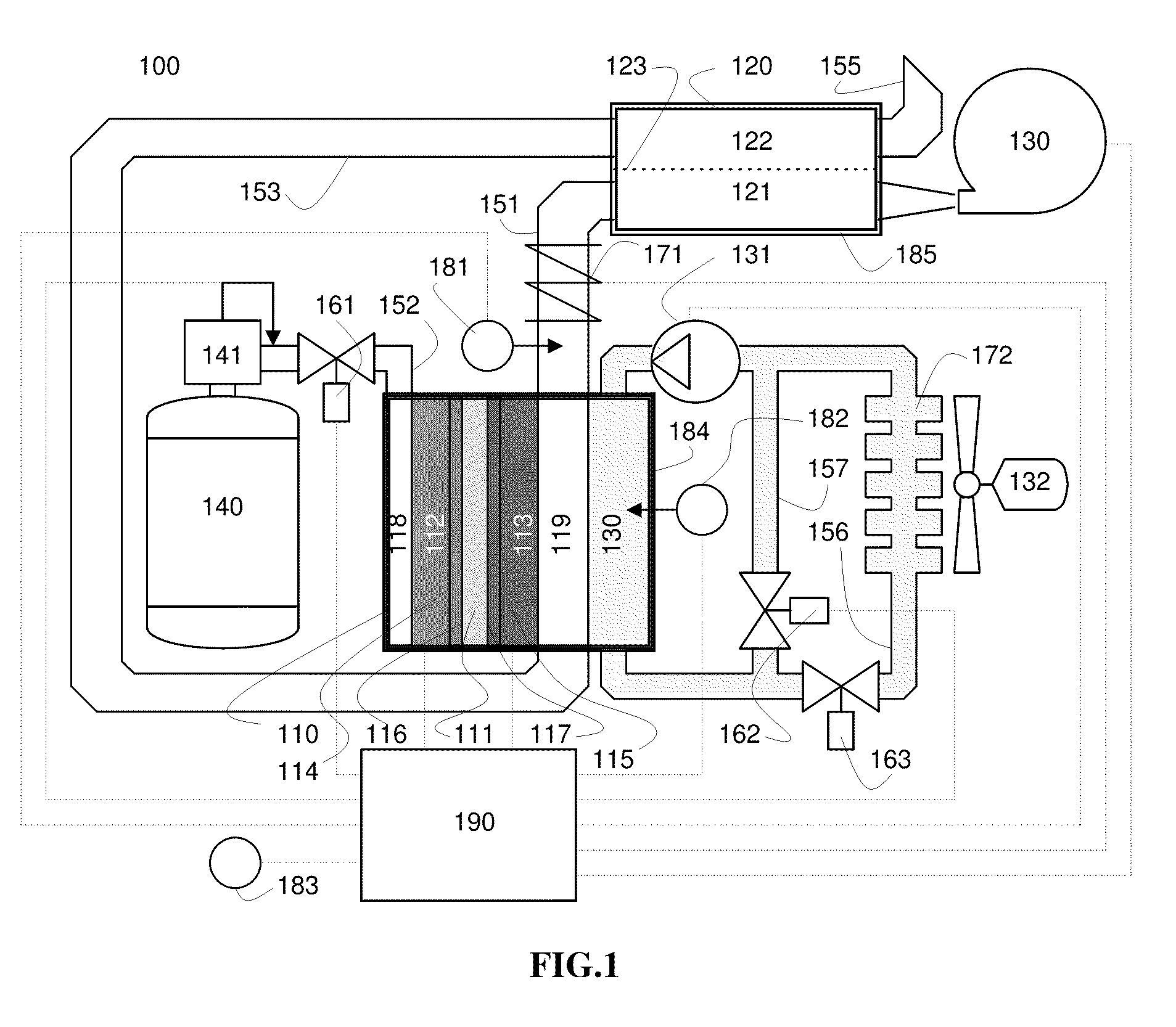

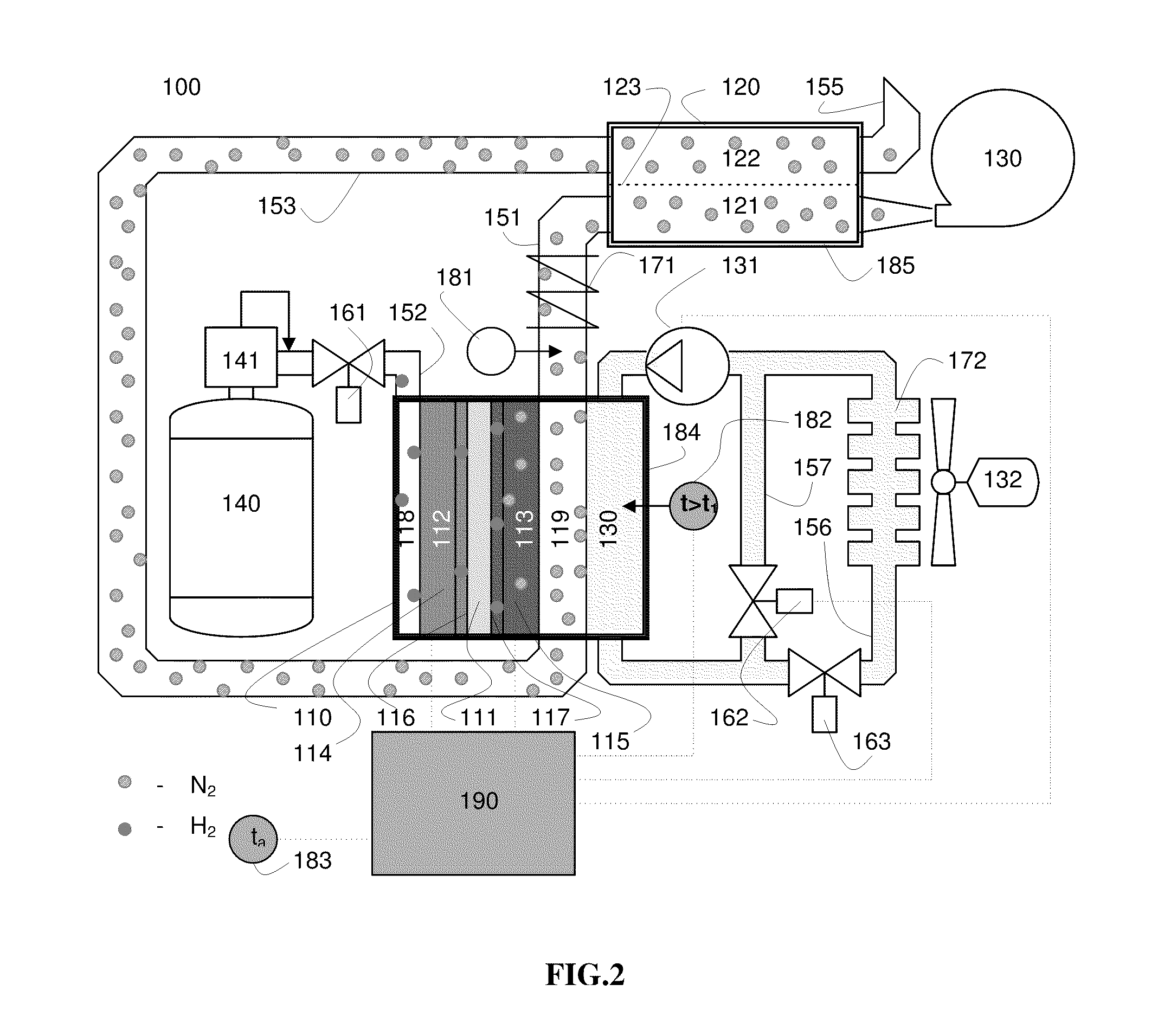

Method and apparatus for PEM fuel cell freezing protection

InactiveUS20110081588A1Overcome disadvantagesSuitable for operationFuel cell heat exchangeRegenerative fuel cellsChemical reactionHydrogen

A low temperature PEM fuel cell system is prevented against freezing after a shutdown in sub-freezing conditions. The fuel cell can be heated by filling an anode chamber with a fuel (the hydrogen or a hydrogen-rich reactant gas) and generating the hydrogen on a cathode. A defined amount of air is supplied to the cathode chamber. The fuel cell is locally heated to a defined temperature by the exothermic chemical reaction between the hydrogen and the oxygen on a cathode catalyst. Once the fuel cell is warmed to the defined temperature, the hydrogen generation on the cathode and the air supply can be discontinued. Water formed at the cathode can be evaporated by means of pre-heating of an air flow. This procedure provides plain saturation of the cathode with the hydrogen and, as result, mild, safe heating the fuel cell without use of an additional external power supply.

Owner:VPJP

Flameless cooking appliance

ActiveUS20110165300A1High surface areaImprove heating efficiencyDomestic stoves or rangesCatalytic ignitersJP-8Cooker

A flameless cooking apparatus for use with liquid fuels and for indoor or outdoor use under field operations. The burner exhibits low CO and hydrocarbon emissions and meets standards for burner thermal efficiency when used with JP-8 fuel. The apparatus employs a catalytic burner having among its parts (i) a combustion catalyst; (ii) a conductive surface, e.g., cooking surface; and (iii) in between the catalyst and the conductive surface and in direct physical contact with both surfaces, a heat spreader for conductively transferring heat of combustion from the catalyst to the conductive surface. Also claimed are a method of heat flux and a method of cooking.

Owner:PRECISION COMBUSTION

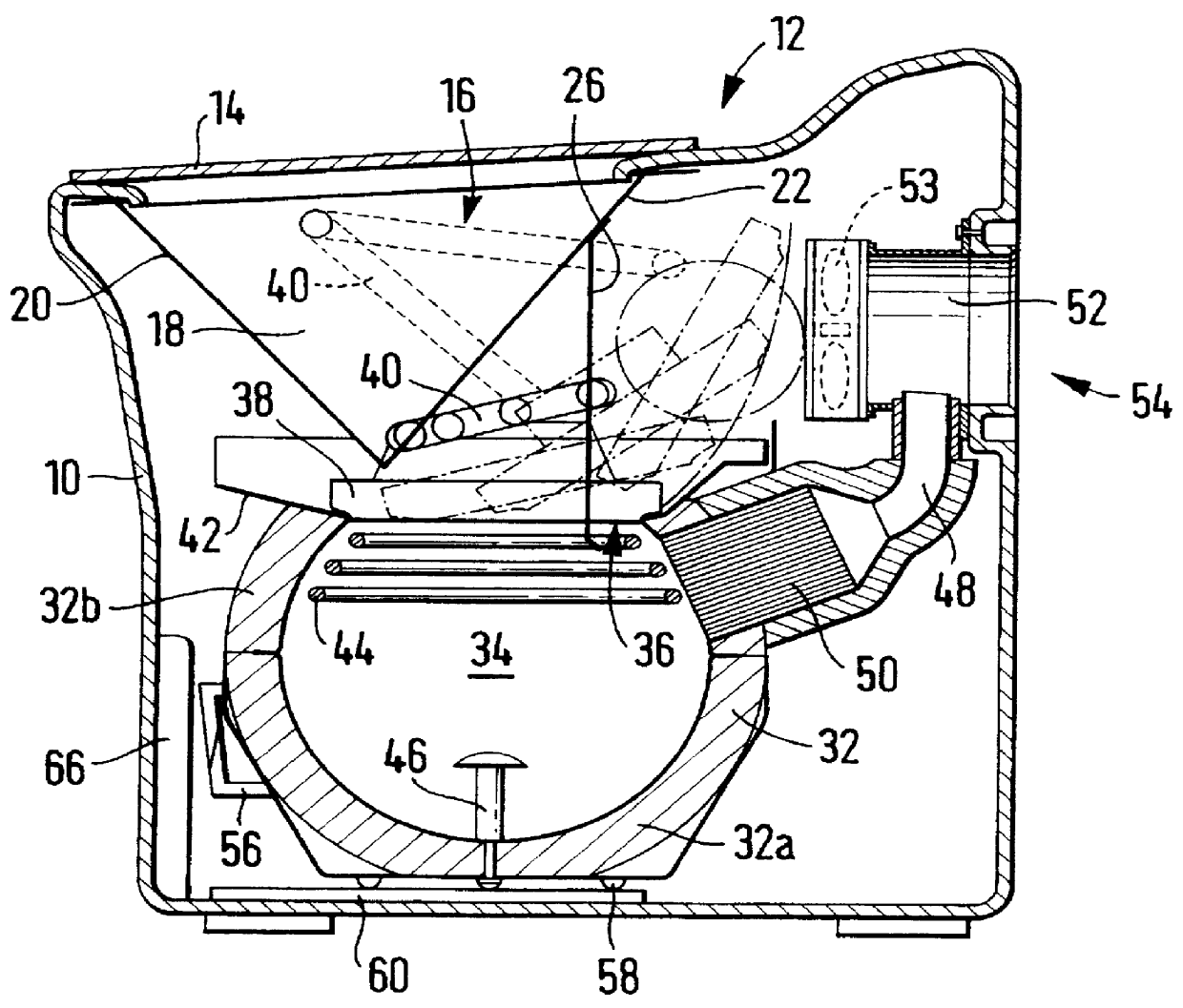

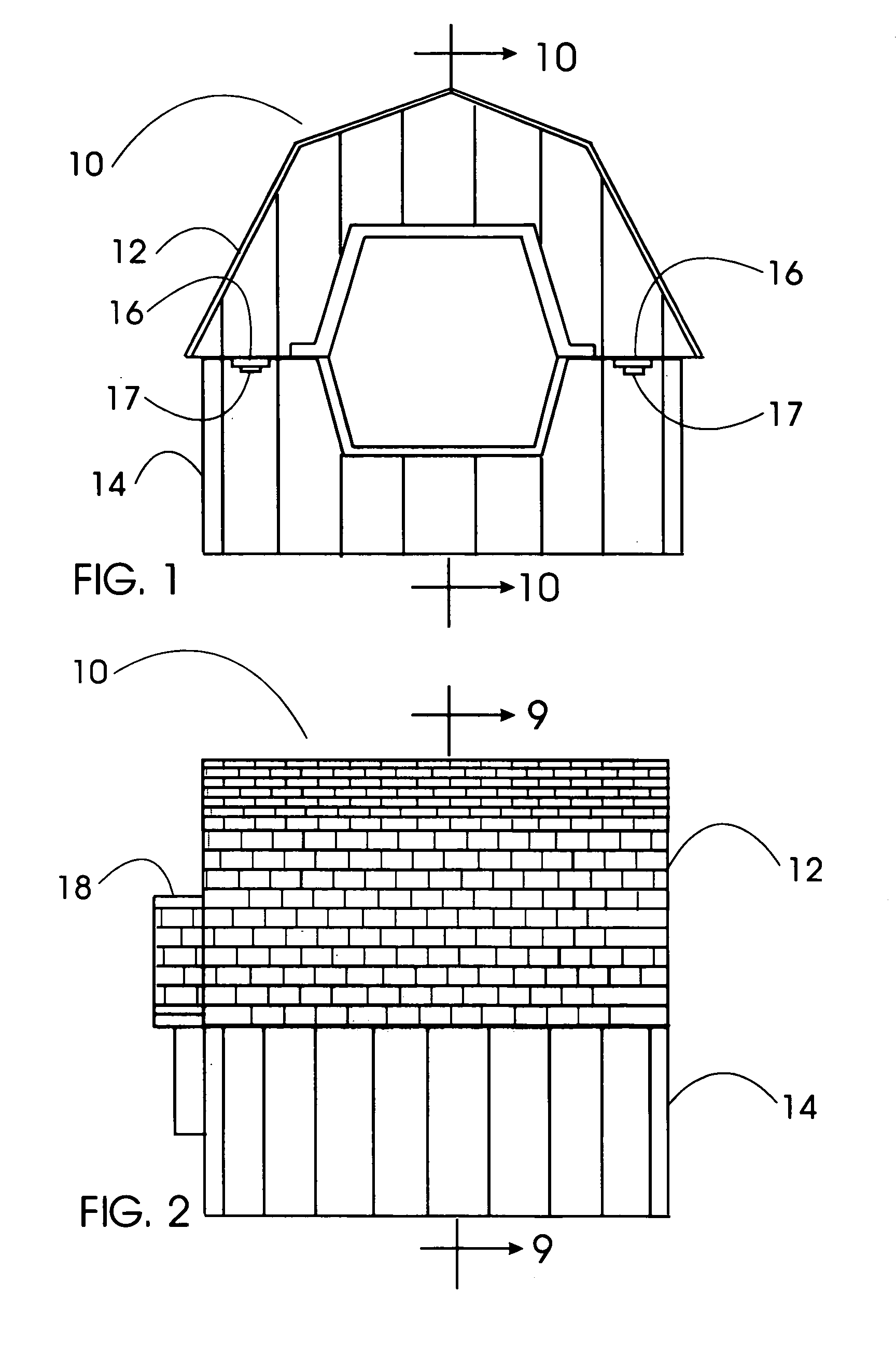

Electric toilet

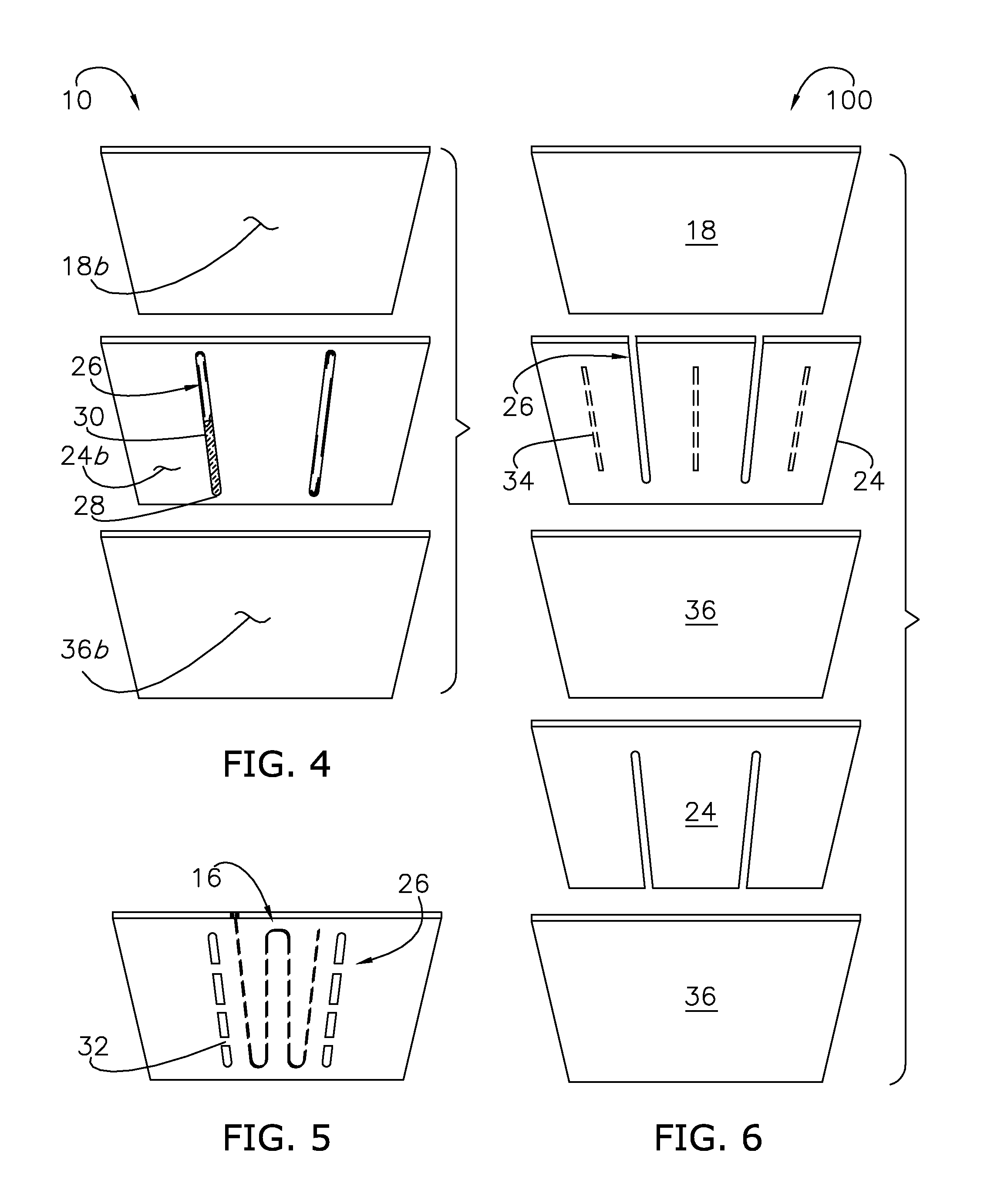

InactiveUS6052836AAvoid wastingEven heat distributionBathroom accessoriesAgainst vector-borne diseasesEngineeringToilet

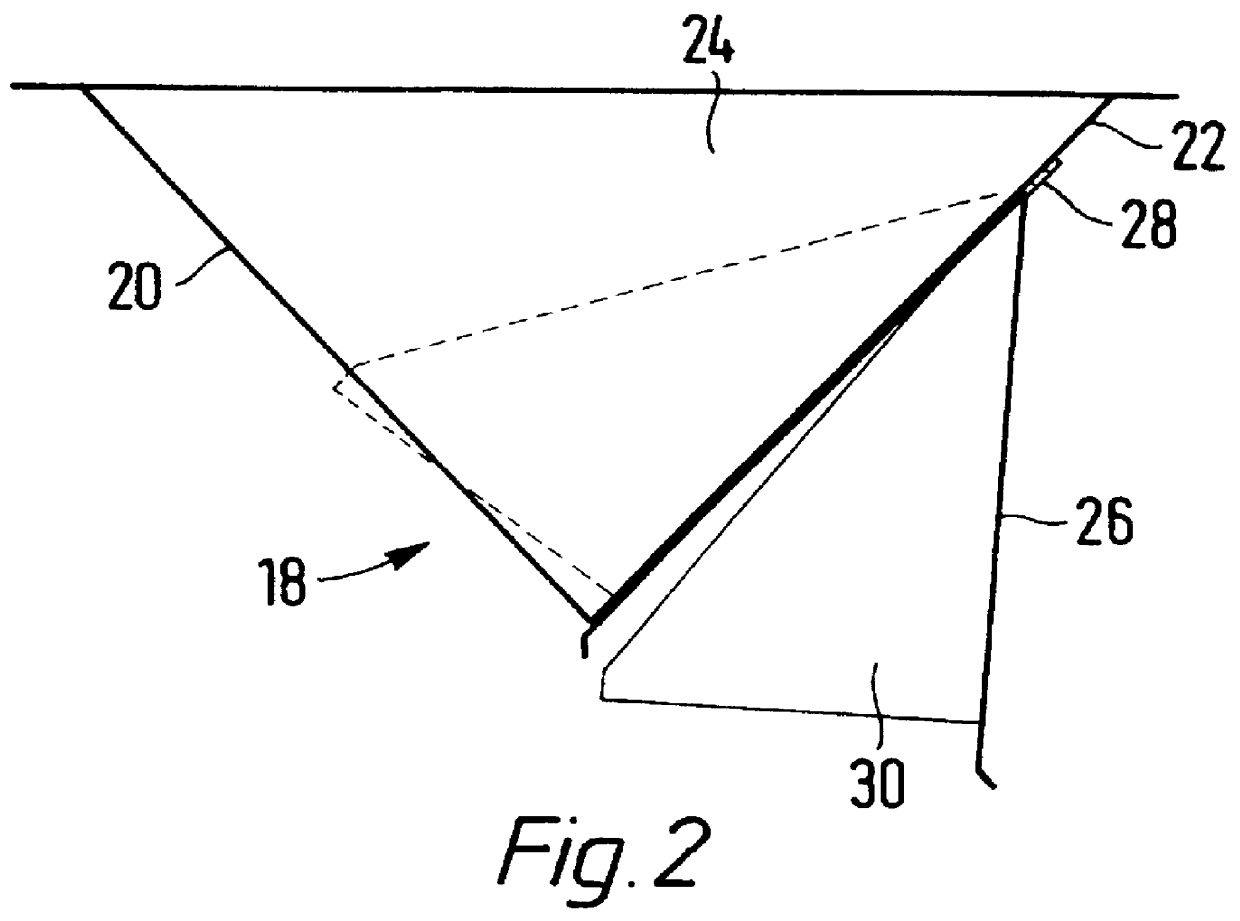

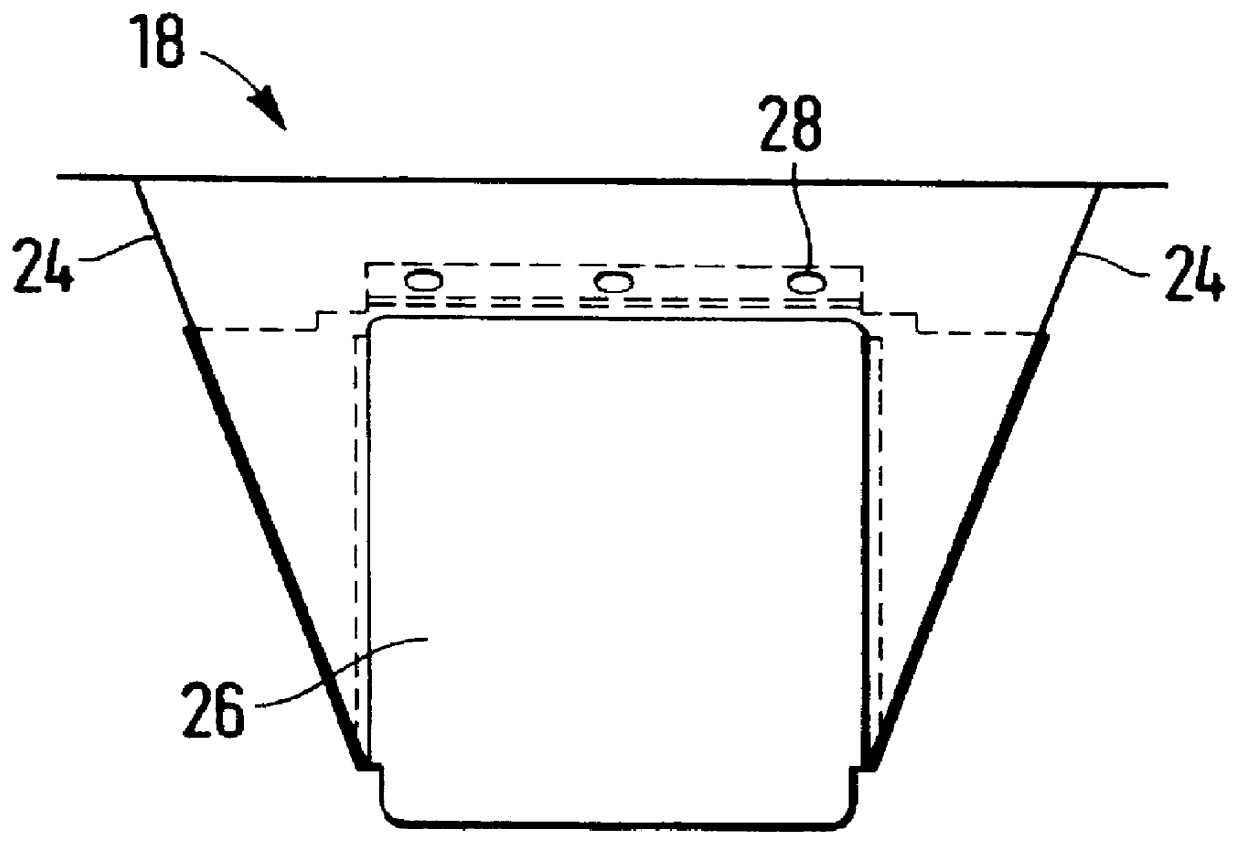

PCT No. PCT / SE97 / 01252 Sec. 371 Date Jan. 21, 1999 Sec. 102(e) Date Jan. 21, 1999 PCT Filed Jul. 10, 1997 PCT Pub. No. WO98 / 02079 PCT Pub. Date Jan. 22, 1998An electric toilet comprising a cabinet or housing (10), an opening (16) in the top side of the cabinet, a lid (14) assigned to the opening (14), an upper bowl (18) arranged inside the opening, which bowl is openable downwards, a combustion chamber (32) arranged beneath the upper bowl (18) with a combustion space (34) and provided with an opening (36) directed upwards, assigned to which opening is a lid (38), heating coils (44) arranged in the combustion space (34) and an evacuation device (48, 50, 52) connected to the combustion space (34). The invention is characterized in that at least the combustion space's (34) lower part is formed principally spherically and that the heating coils (44) are arranged in the upper part of the combustion space round its circumference.

Owner:SIRIUS TECH

Cooking oven

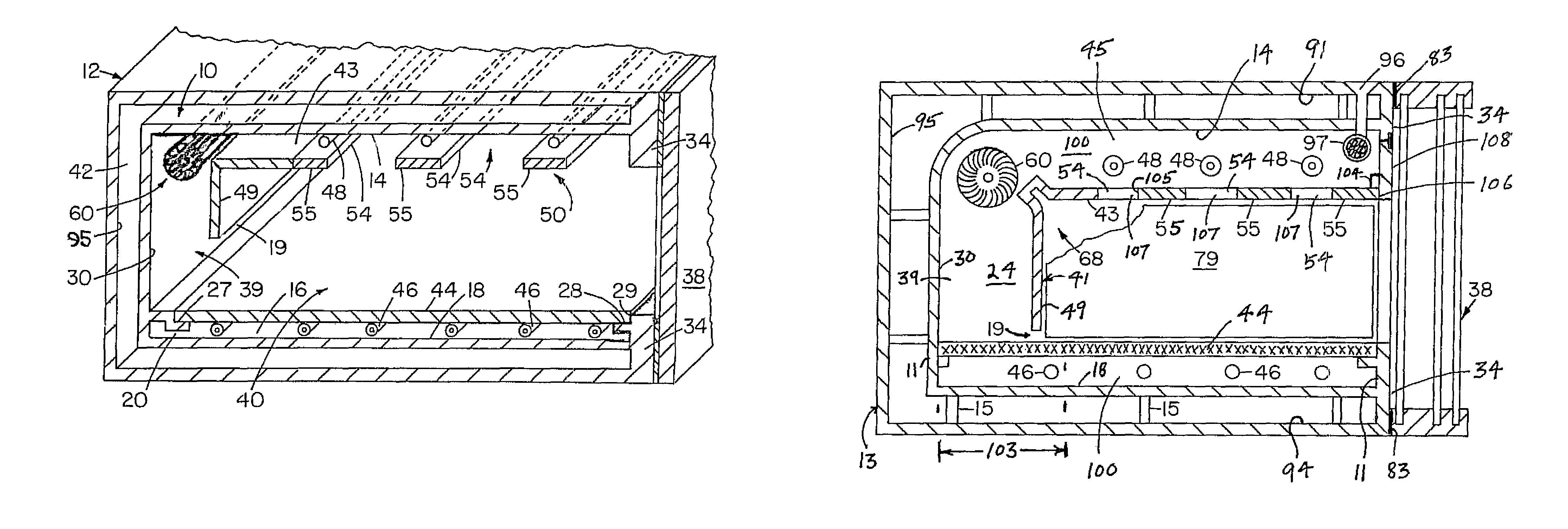

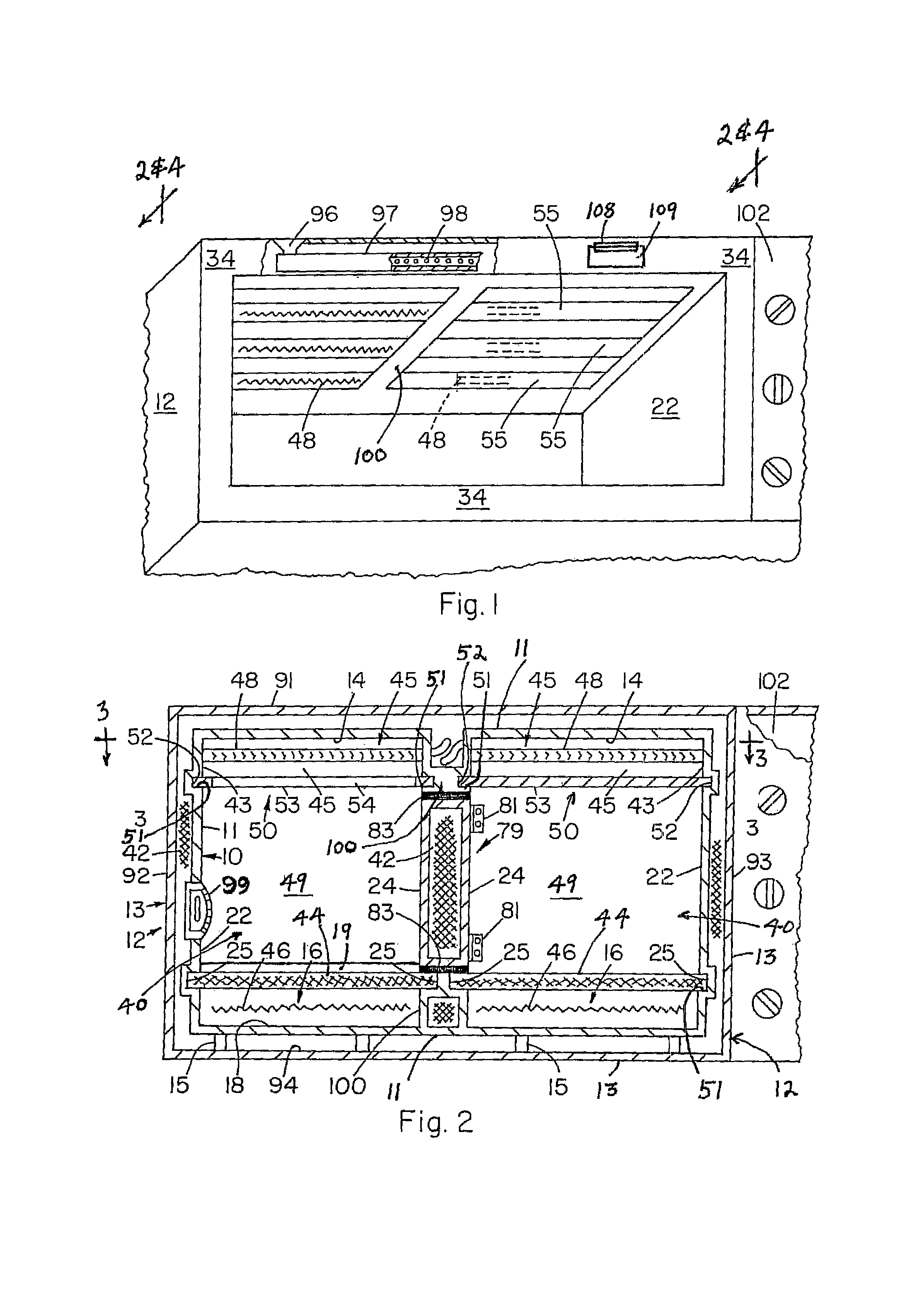

InactiveUS8063342B2Highly controlled heatingReduce the overall heightDomestic stoves or rangesElectrical heating fuelCooking & bakingStructure function

A cooking structure which provide for two or more side-by-side ovens separated by vertical, movable, hinged partition(s) whereby the oven structure may function as one large oven or as two or more smaller independent ovens, wherein for each oven a tangential fan blows air substantially evenly over upper electrical heating elements strung generally from side-to-side of the oven, wherein a flow director (baffle) structure functions as a radiant heat shield which is operator movable to either expose to or occlude from the oven cooking chamber the direct radiation from its heating elements, depending on the need to roast, bake, or broil the food product. Also provided are lower electrical heating elements positioned below a ceramic cooking surface for ensuring evenness of radiant heat transfer therefrom. Also provided is operator controlled top vs. bottom heating using a slide control that reciprocally affects the duty cycle of the top and bottom electrical heating elements, further allowing precision baking control.

Owner:HINES JR ROBERT STICKLEY

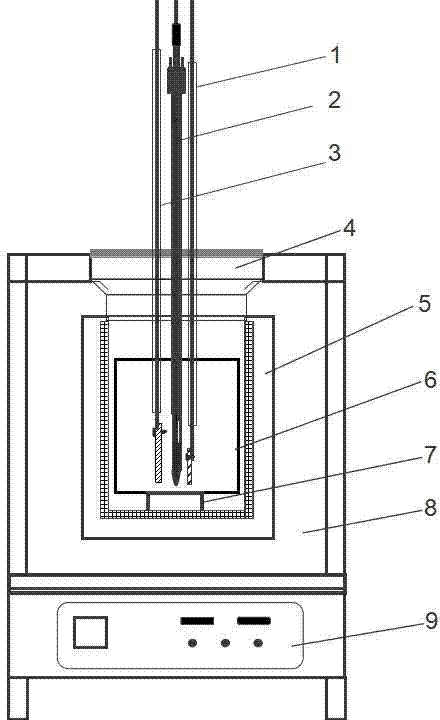

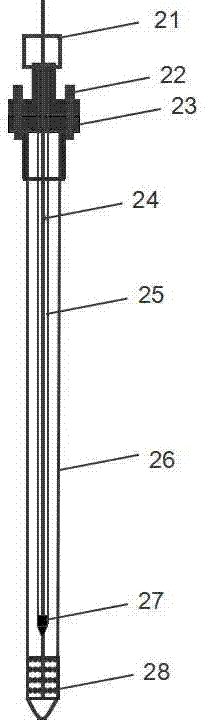

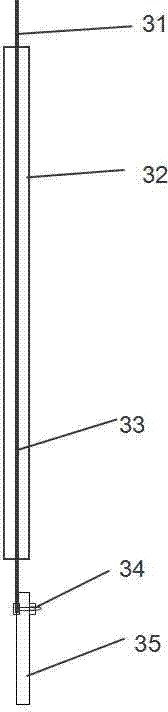

High-temperature molten salt electriochemistry testing system

InactiveCN104215678AFix stability issuesResolve volatilityMaterial electrochemical variablesMolten saltHot Temperature

The invention discloses a high-temperature molten salt electriochemistry testing system applicable to a temperature range of 750 DEG C - 900 DEG C; the high-temperature molten salt electriochemistry testing system comprises a high-temperature electric resistance furnace, high-temperature electriochemistry electrodes and a high-temperature molten salt crucible. A high-temperature molten salt reference electrode (2) is mainly composed of a first electrode stem (24) and a sleeve; the first electrode stem (24) is packaged in a first aluminum oxide sleeve (25) sealed by cement (27); a high-temperature molten salt working electrode (3) is mainly composed of a second electrode stem and a sleeve; the main body of the second electrode stem is packaged in a second aluminum oxide sleeve (32) including sealing cement, thus ensuring heat insulation and uniform distribution of heat under the condition of high temperature; a crucible cover (64) which is provided with a central hole (65) and made of ceramic is placed at the top of the crucible (6); the crucible cover (64) can effectively prevent electrolyte from volatilizing due to melting in high temperature, and thereby the furnace body of the electric resistance furnace is prevented from being eroded by volatilization of the molten electrolyte.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

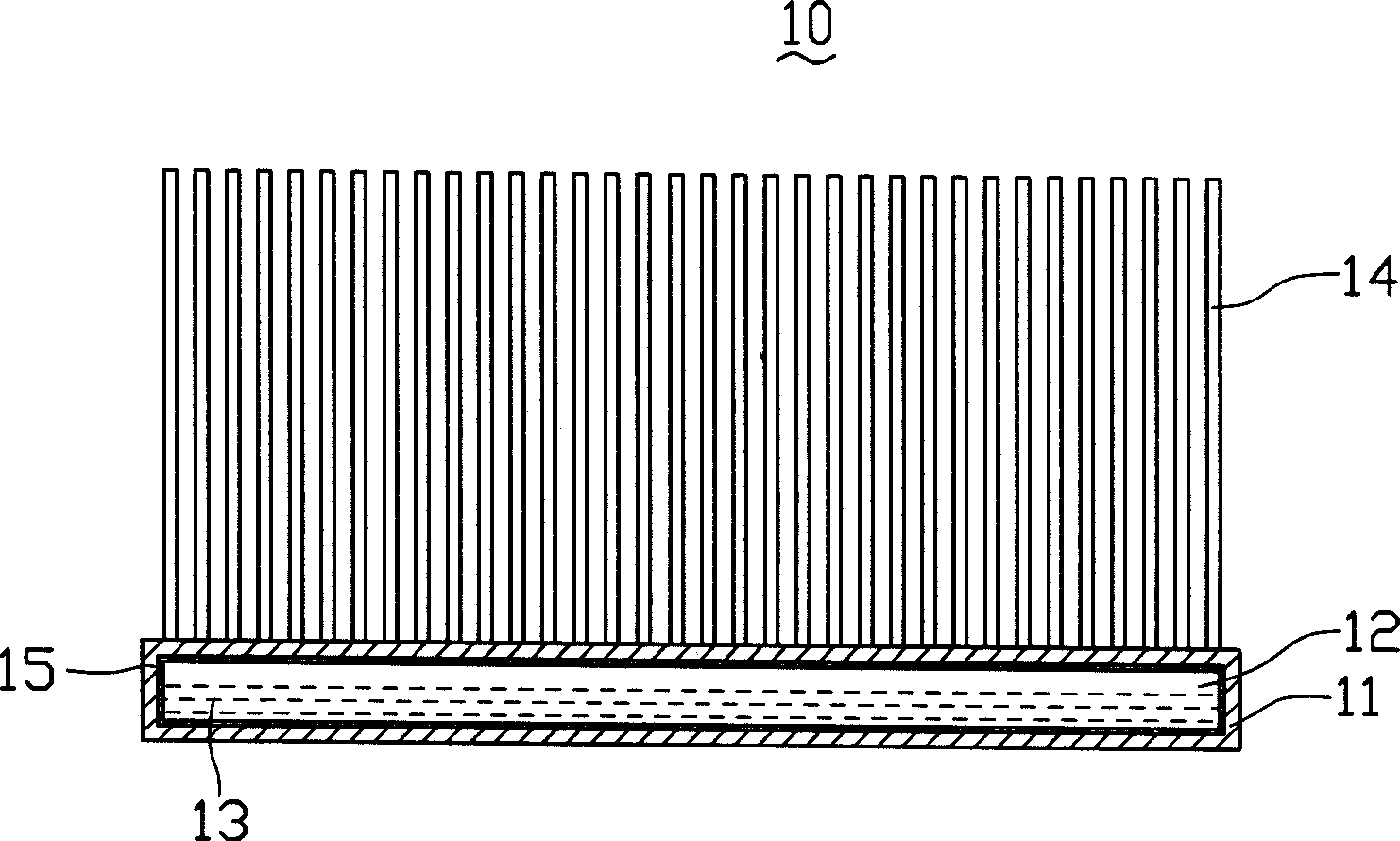

Heat radiator

InactiveCN1878451AImprove thermal efficiencyReduce the temperatureDigital data processing detailsSemiconductor/solid-state device detailsWorking fluidHeat transmission

The invention relates to a heat emitter, which comprises: a base and several heat emission fins extending from one surface of base. Wherein, said base contains one sealing hollow chamber filled with working fluid; the working fluid is added with nanometer thermal conducive material particles; when the heat emitter works, the heat of heating electric element is transmitted to the base; the internal working fluid will be heated and vaporized, to adsorb the phase-change heat into gas; when the gas reaches one side of heat emission fin, it is cooled to be condensed into liquid to release heat; and the heat emission fin will transmit the heat to environment, to reduce the temperature heating electric element. Since the heat emission base uses phase-change heat transmission, and the working fluid is added with high-conductivity nanometer thermal conductive material particles, the heat emission efficiency is improved significantly.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

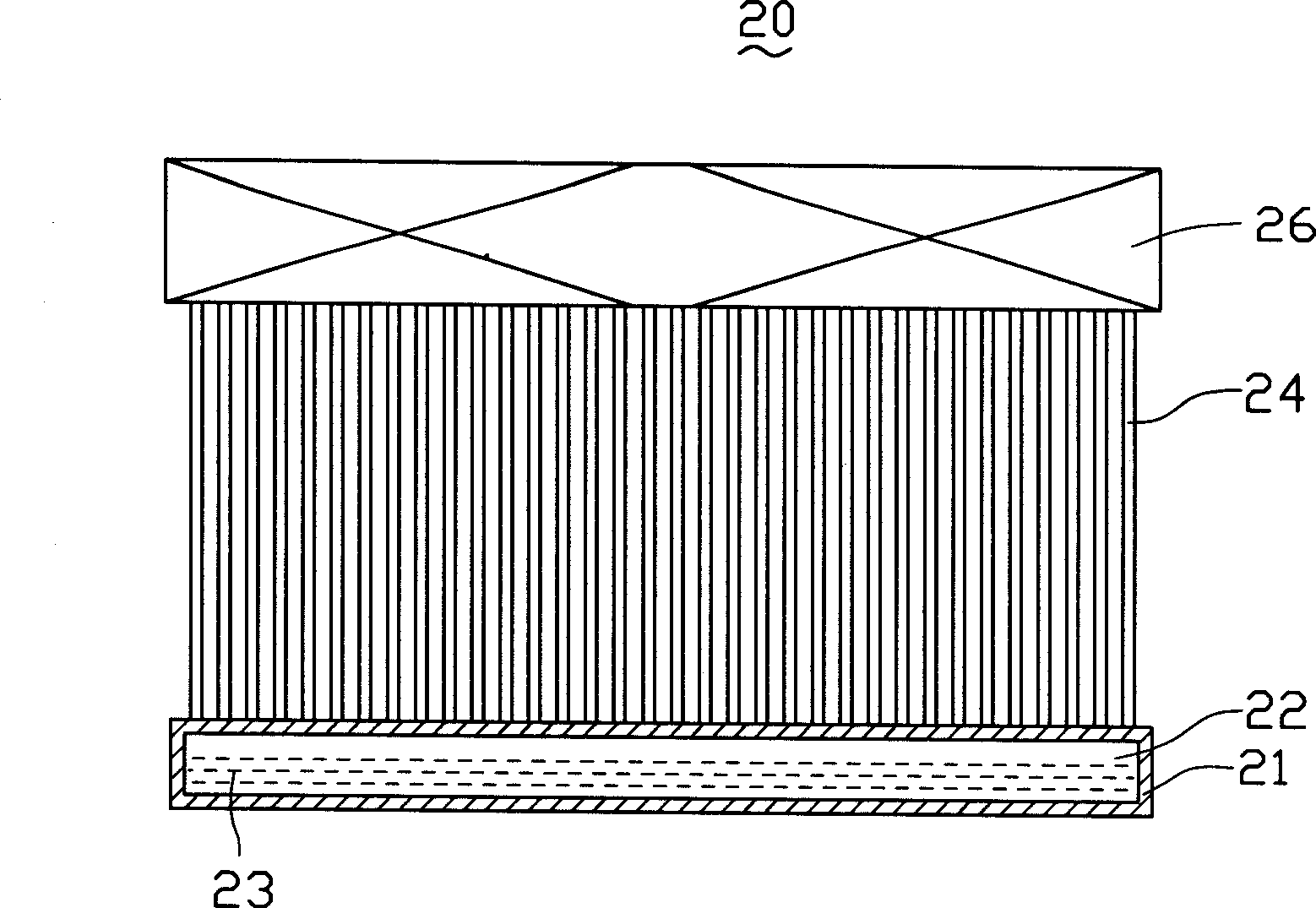

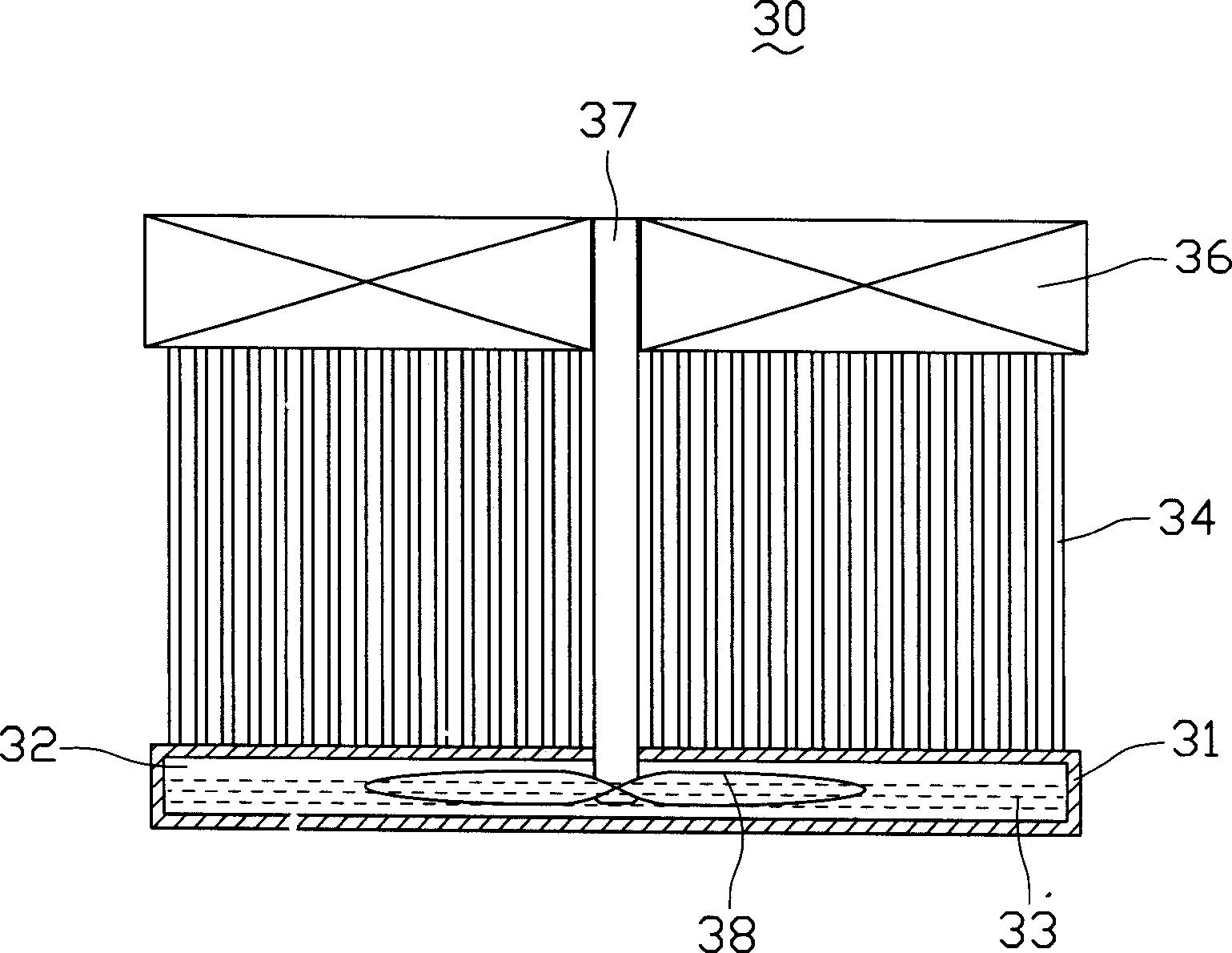

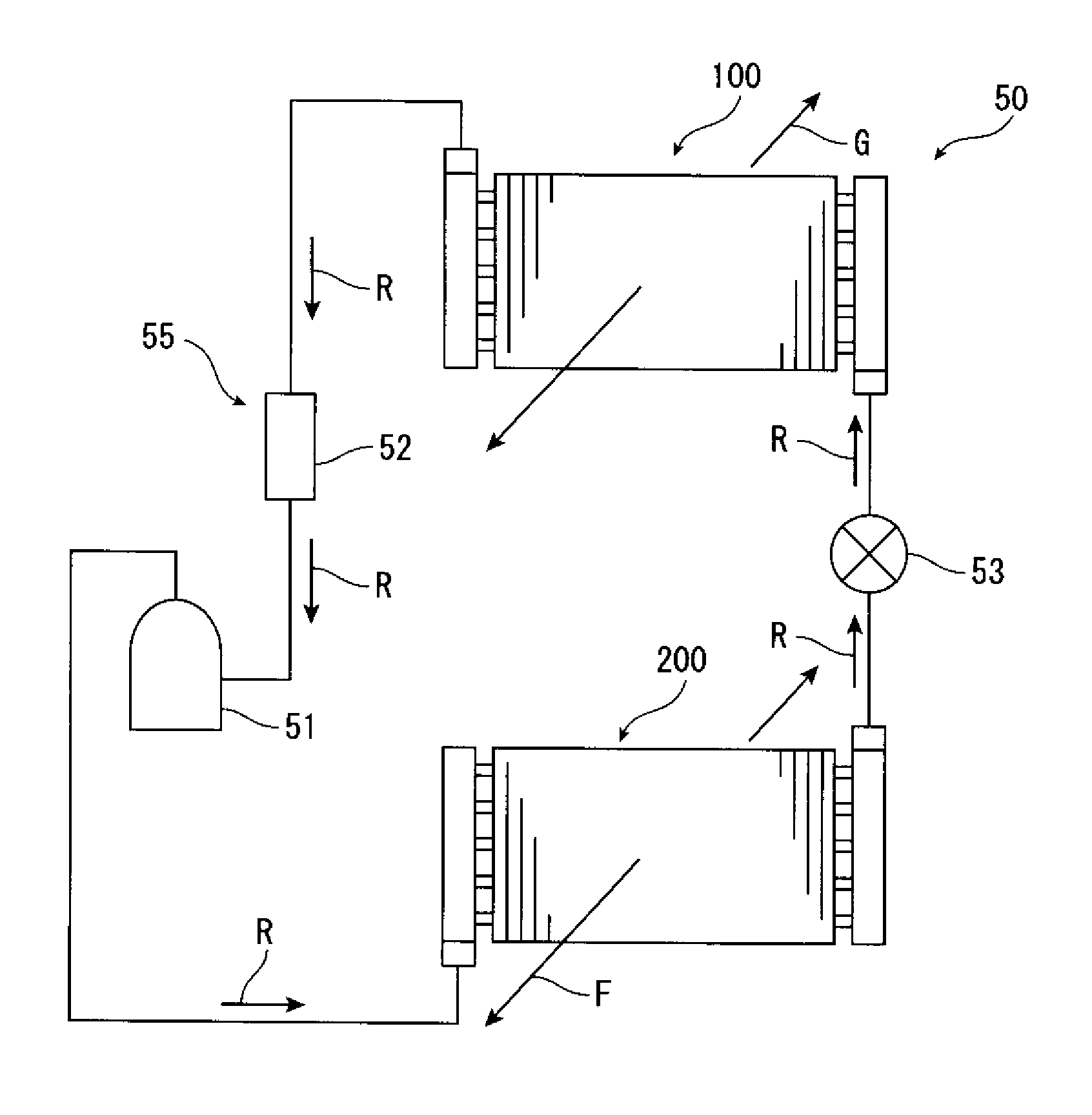

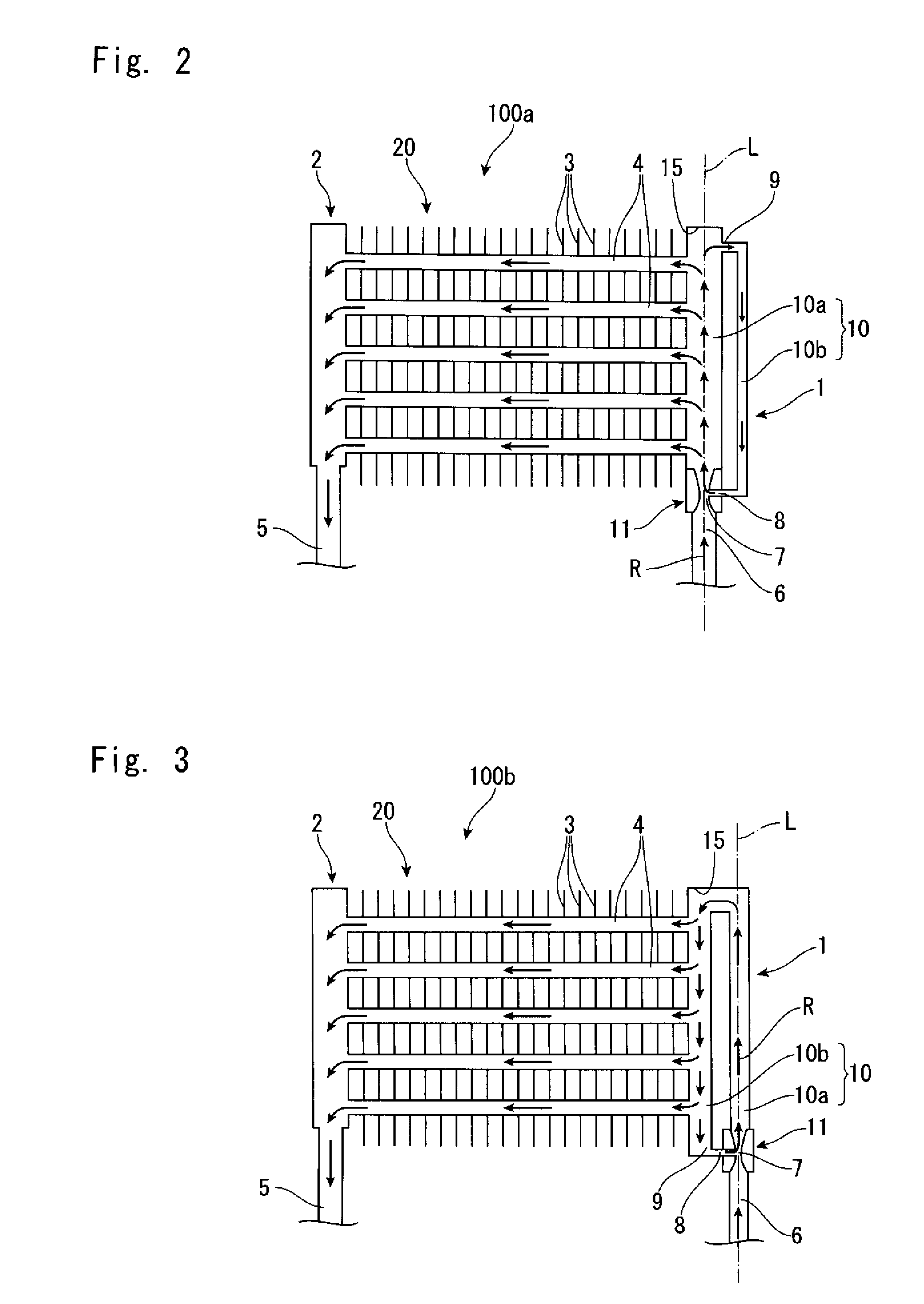

Heat exchanger

InactiveUS20100314090A1Avoid separationEvenly distributedEvaporators/condensersFluid circulation arrangementRefrigerant distributionPlate heat exchanger

A heat exchanger (100a) includes a plurality of tubes (4), an entrance header (1) for distributing a refrigerant to the tubes (4), and an exit header (2) for collecting the refrigerant from the tubes (4). The entrance header (1) includes a circulating conduit (10) capable of circulating at least part of the refrigerant that has flowed into the entrance header (1), and the plurality of tubes (4) are fluidly connected to the outward channel (10a) of the circulating conduit (10). The entrance header (1) also includes an ejector 11 that uses the refrigerant flowing into the entrance header to draw and mix at least part of the refrigerant that has flowed into the entrance header and spray out the mixed refrigerant. The entrance header (1) can supply refrigerant more uniformly to the tubes (4) connected to the circulating conduit (10).

Owner:GLOSTER

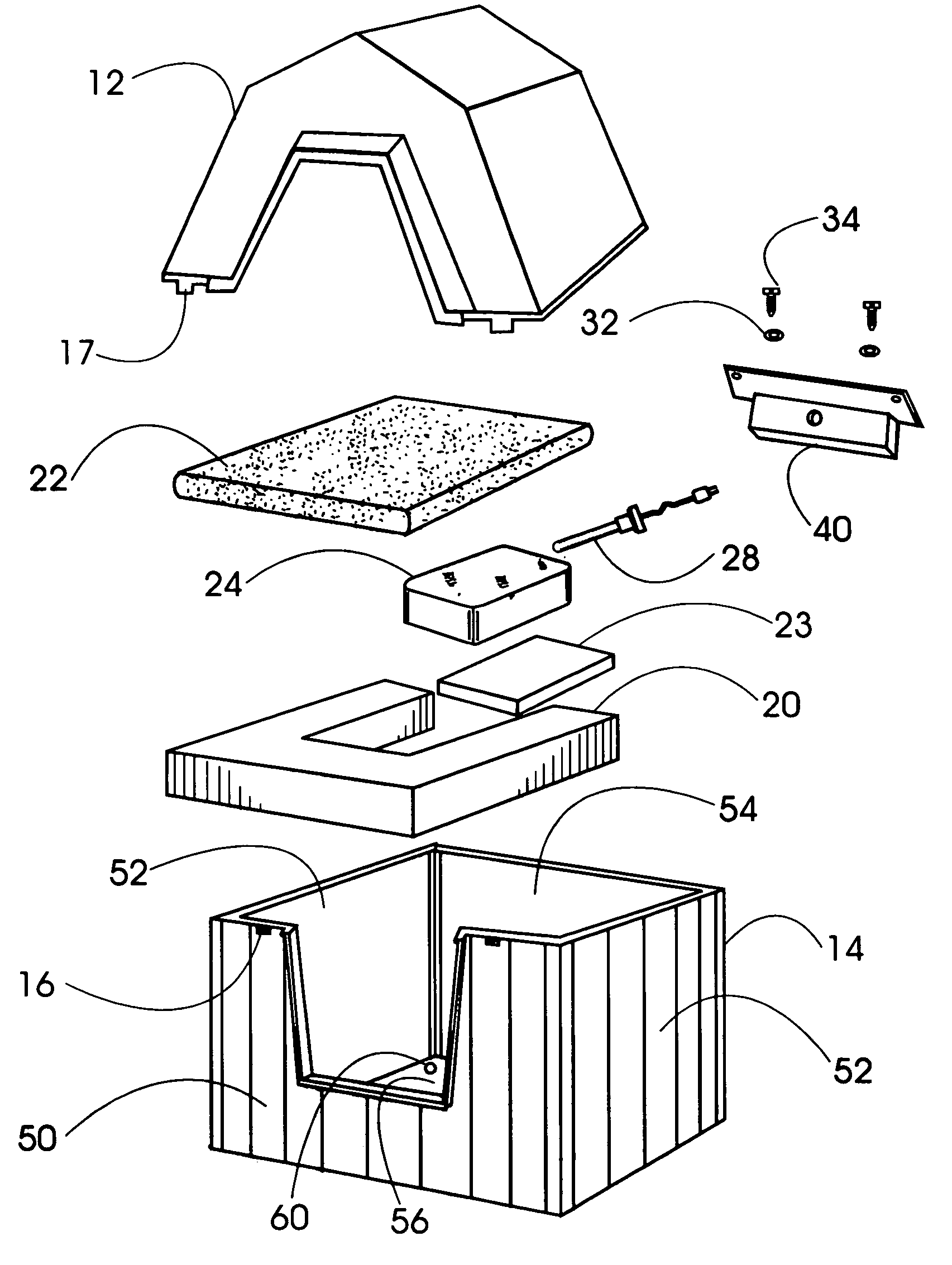

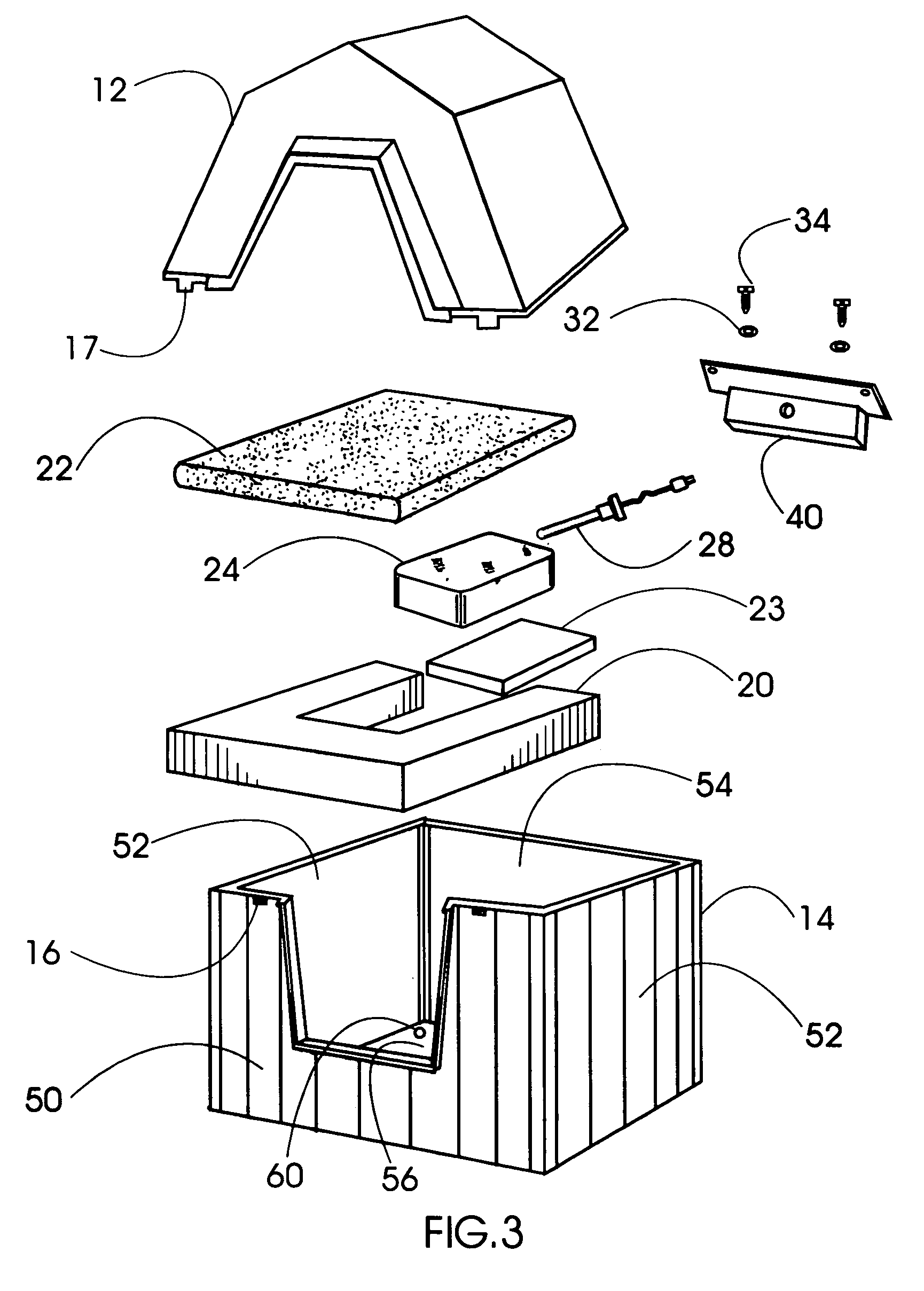

Heated pet enclosure

InactiveUS6923144B2Reduce heat lossPromote absorptionLighting and heating apparatusAnimal housingFiberCold winter

This invention provides a pet enclosure designed to provide comfort for a pet in the winter season. The pet enclosure provides for shelter by allowing the pet to get out of the weather and then provides a warm bed to lie upon. This warm bed is comprised of a rectangular rigid plastic container, similar to a tall, wide, narrow gas can, which is recessed into the floor of the pet enclosure. An internal, totally submersible aquarium type heater is utilized to keep the water solution tank at a user-defined temperature. The tank is recessed into the floor and is effectively insulated on five of its six surfaces. The remaining top surface is covered by a fiber-filled pet bed. This bedding, when not compressed by the pet, acts as an insulator, trapping the heat in the container. When the pet lies on the bedding, the insulating value of the bedding is drastically reduced and the heat travels through the bedding and the pet is warmed. This provides for a comfortable warm area for the pet to enjoy on cold winter days.

Owner:LITTLE RONALD B

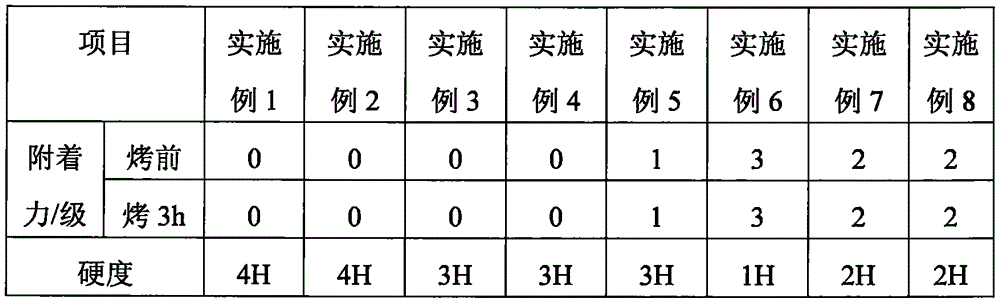

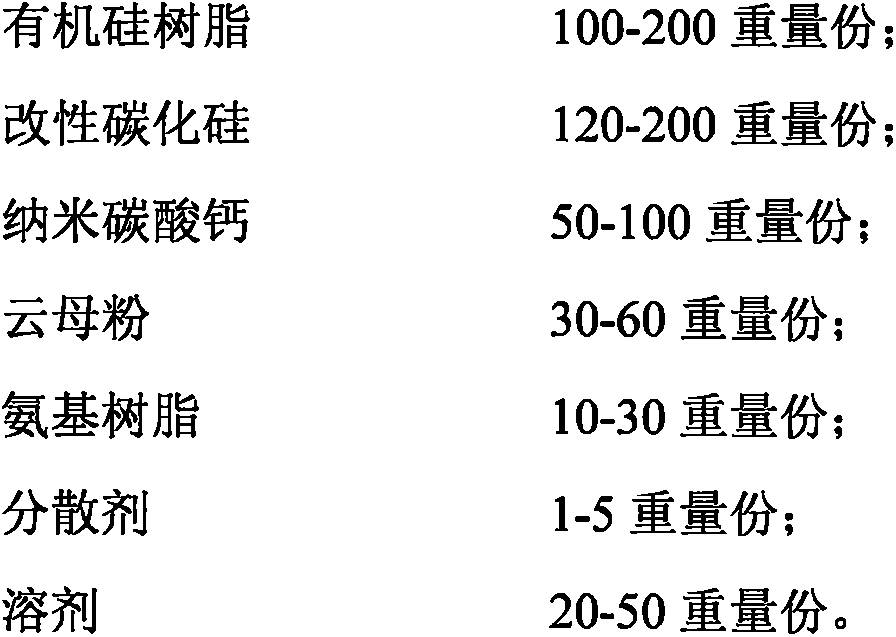

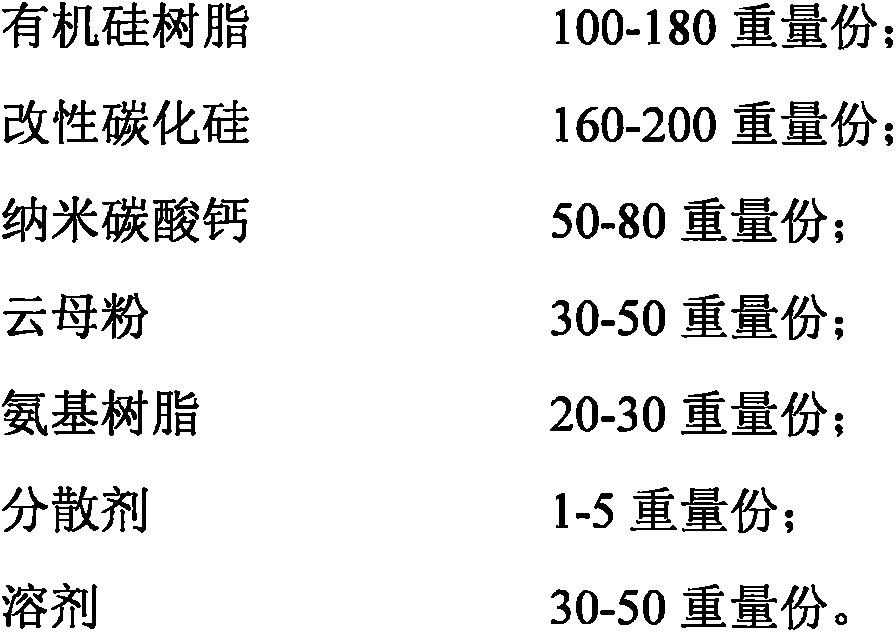

Nonstick pan coating layer, and production method and nonstick pan thereof

ActiveCN105925176AHigh hardnessImprove heat resistanceCooking-vessel materialsAnti-corrosive paintsPorositySolvent

The invention provides a nonstick pan coating layer, and a production method and a nonstick pan thereof. The production method comprises the following steps: mixing organosilicone resin, modified silicon carbide, nanometer calcium carbonate, mica powder, amino resin, a dispersant and a solvent, grinding the obtained mixture, dispersing the ground mixture, and filtering the dispersed mixture to obtain a coating; and spraying the coating on the surface of a metal pan matrix, and baking the sprayed metal pan matrix at 200-300DEG C for 10-30min to obtain the nonstick pan coating layer. The organosilicone resin, saturated modified silicon carbide and the nanometer calcium carbonate are simultaneously applied to the nonstick pan coating layer in order to form the coating layer with excellent performances of above three components. The modified silicon carbide has good thermal stability, corrosion resistance and thermal conduction performance, and guarantees the thermal distribution uniformity of the coating layer; the nanometer calcium carbonate makes the microscopic surface of the organosilicone coating layer be tight and have zero porosity, protects the matrix, and enhances the nonstick effect of the coating layer, and the nanometer calcium carbonate and the modified silicon carbide have synergism, and enhance the hardness and the heat resistance of the nonstick pan coating layer.

Owner:宁波贝得厨具有限公司

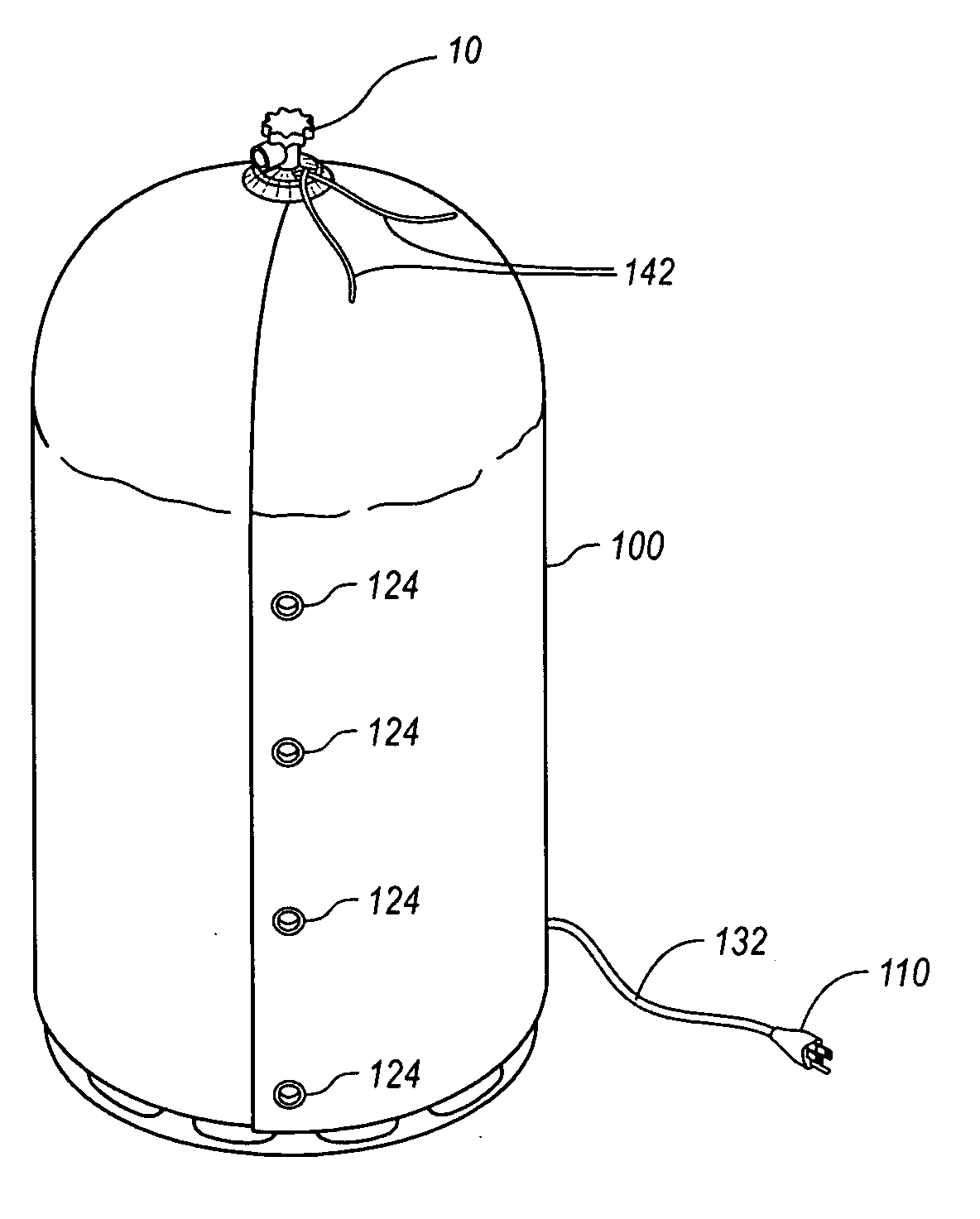

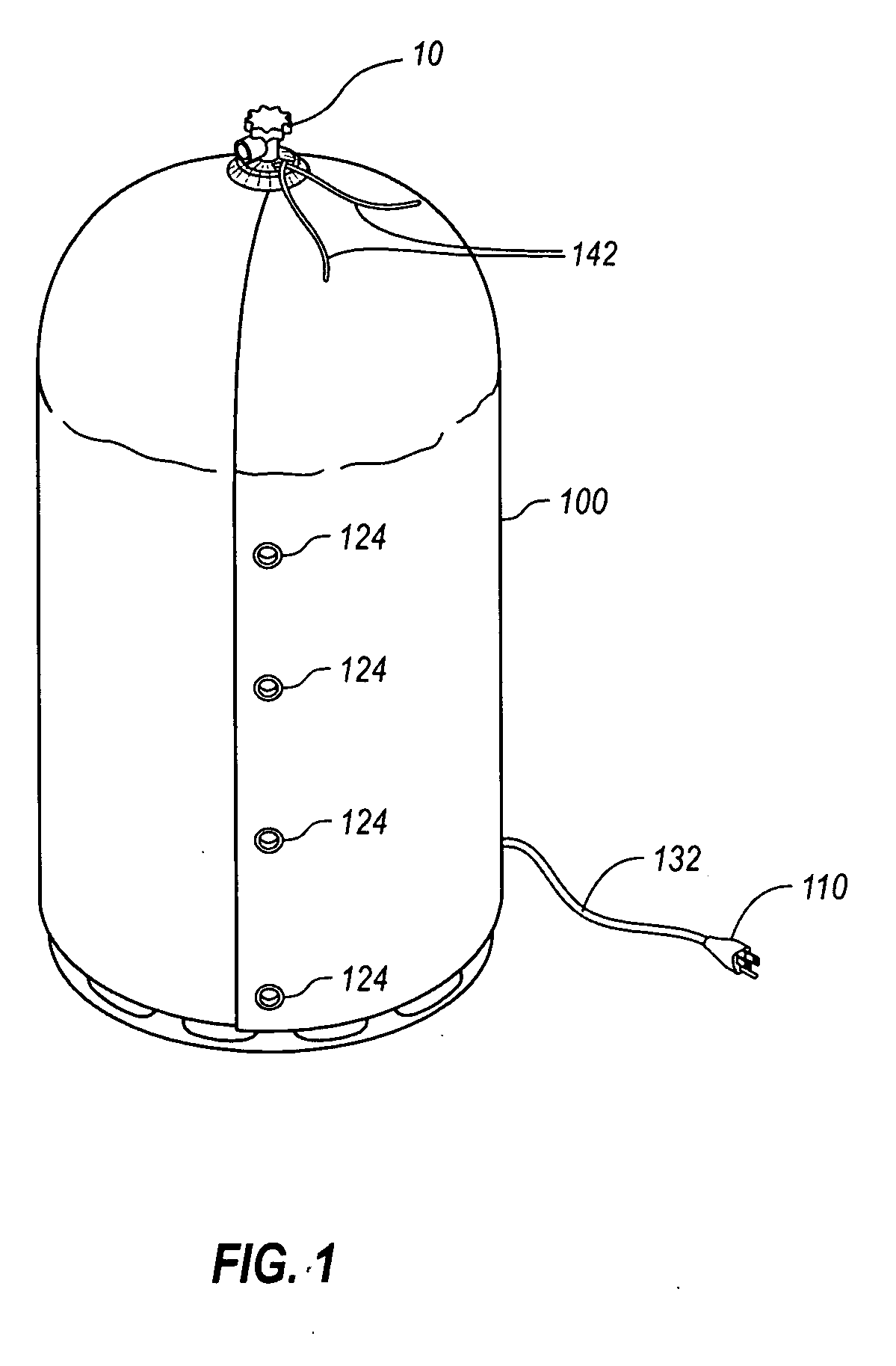

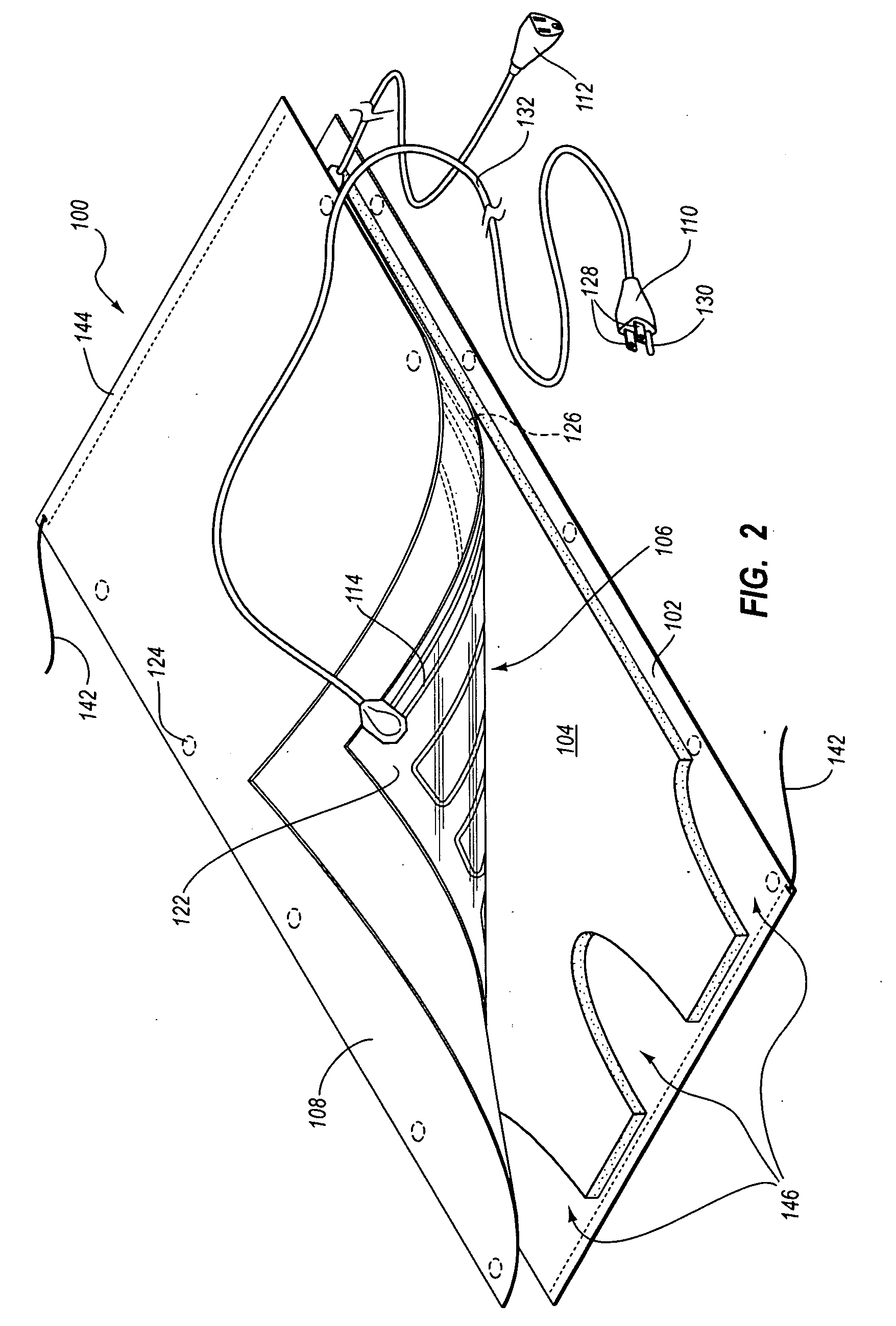

Heating unit for warming propane tanks

InactiveUS20090107972A1Even heat distributionLighting and heating apparatusElectric heating systemThermal insulationHeat spreading

A heating unit for use in heating a propane tank is disclosed. The heating unit includes a first pliable cover layer and a second pliable cover layer. A pliable electrical heating element is disposed between the first and the second cover layers. The pliable electrical heating element includes a heat generating element for converting electrical energy to heat energy and a heat spreading element that is attached to the heat generating element. The heat spreading element comprises carbon that is thermally coupled to the heat generating element for distributing the heat energy. A thermal insulation layer is attached to a second side of the pliable electrical heating element and is positioned adjacent the first cover layer. Additionally, a receiving power connector is electrically connected to the heat generating element and is configured to couple to an electrical power source. The heating unit is sized to substantially cover the sides and one or both ends of a propane tank.

Owner:GREENHEAT IP HLDG LLC

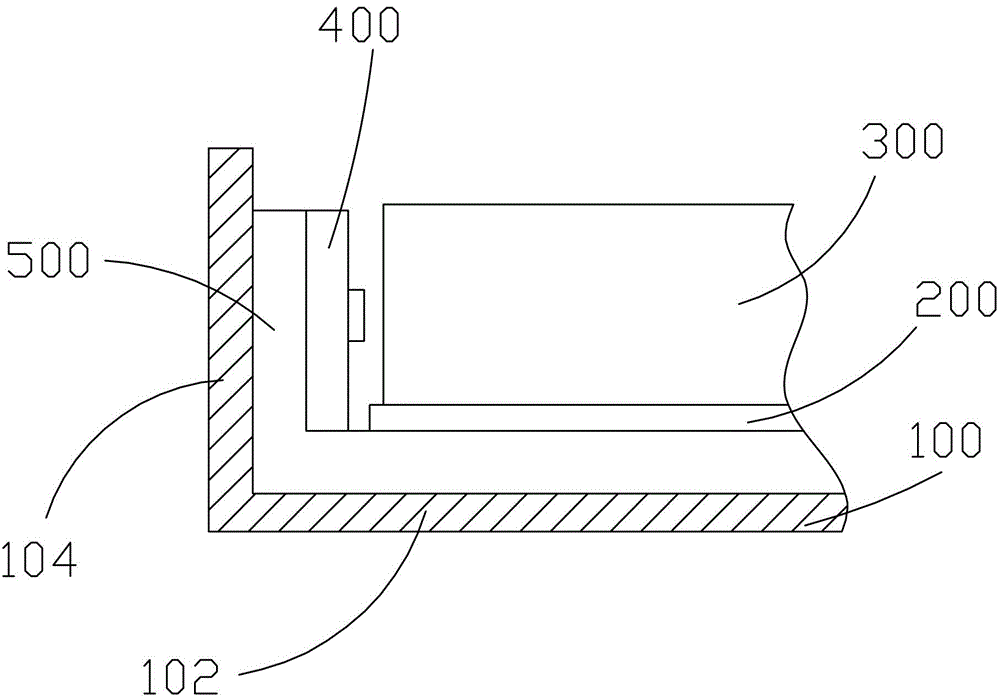

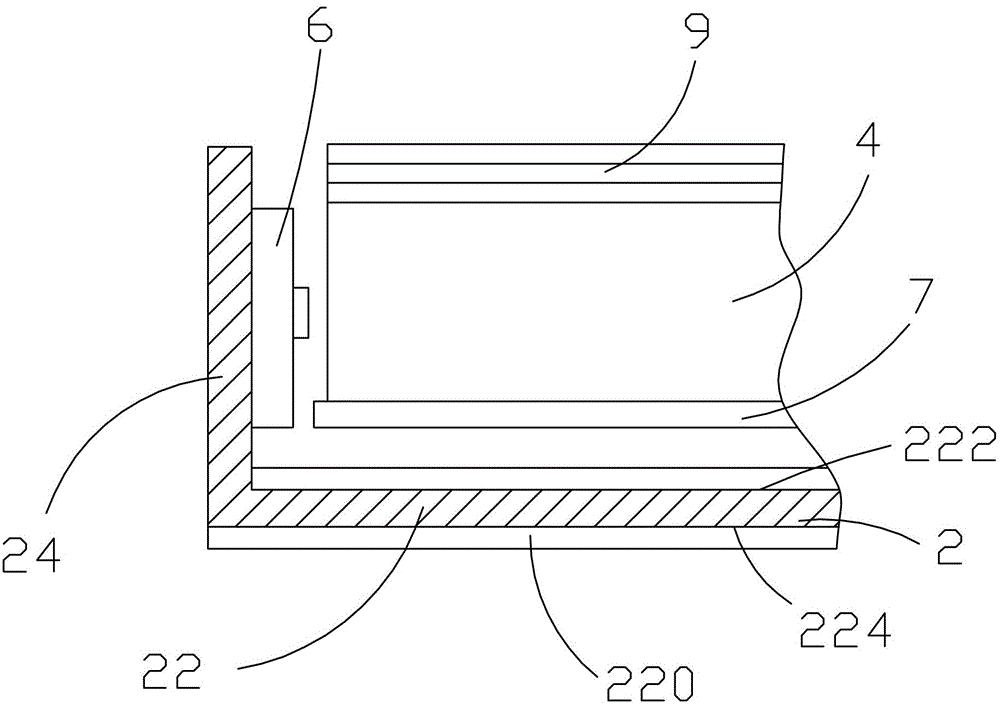

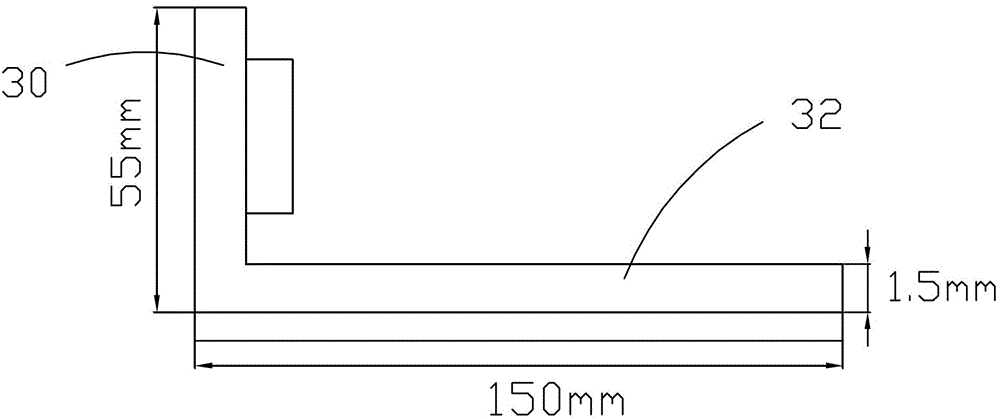

Backlight unit

InactiveCN103336388AImprove cooling effectEven heat distributionPoint-like light sourceLighting heating/cooling arrangementsBackplaneEngineering

The invention provides a backlight unit which comprises a back plate (2), a light guide plate (4) arranged in the back plate (2), a back light source (6) arranged on the back plate (2), and a heat dissipating film (220) arranged on the back plate (2). The heat dissipating film (220) is made of grapheme and is 0.01-0.05 thick. The backlight unit is effectively improved in heat dissipating effect through the arrangement of the heat dissipating film made of the grapheme on the back plate, enables heat to be evenly distributed on the whole surface in the plane direction of the heat dissipating film, and removes local heat points. Moreover, grapheme materials are light, so that the further-arranged heat dissipating film made of the grapheme can not obviously increase the weight of the backlight unit.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

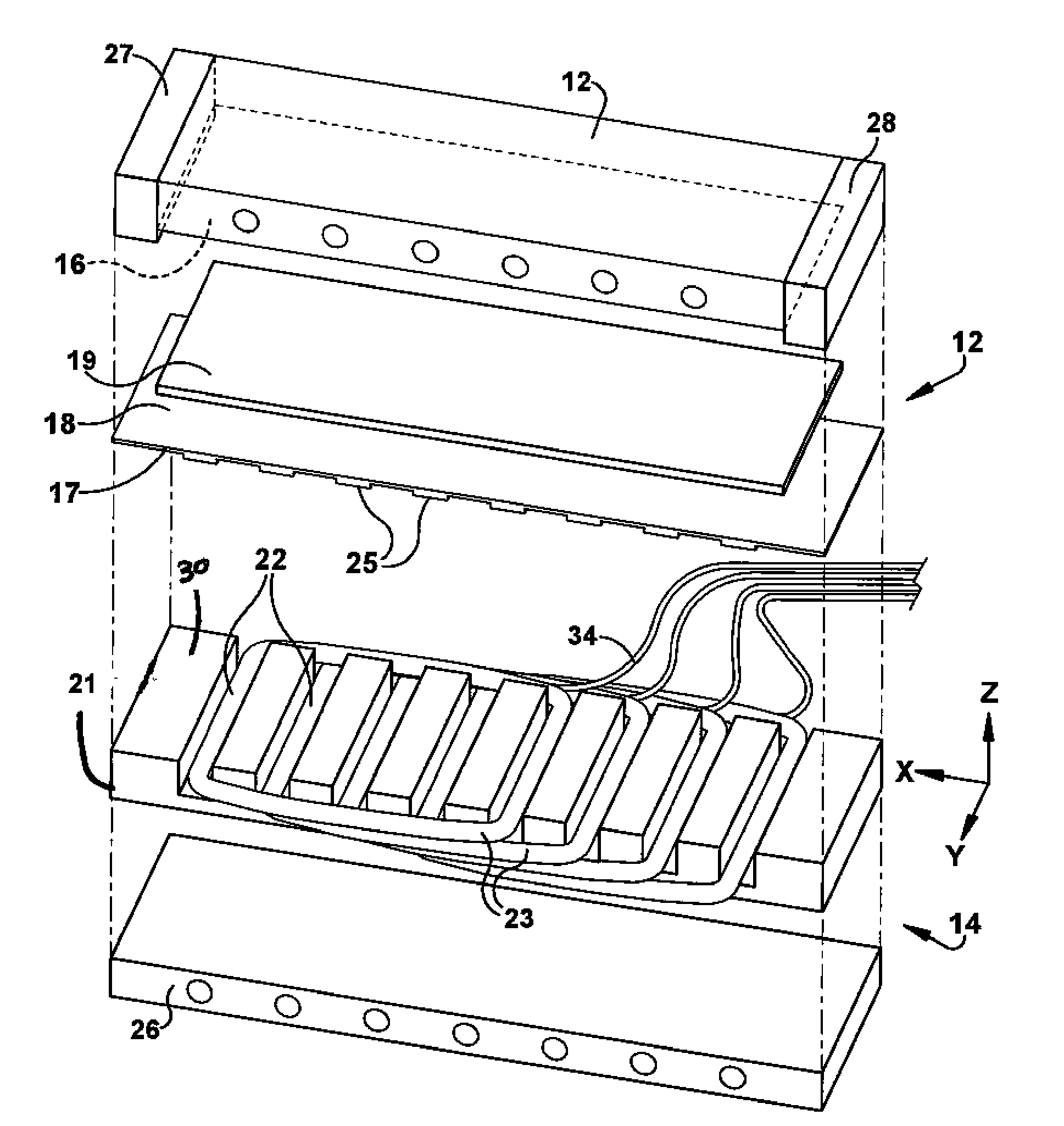

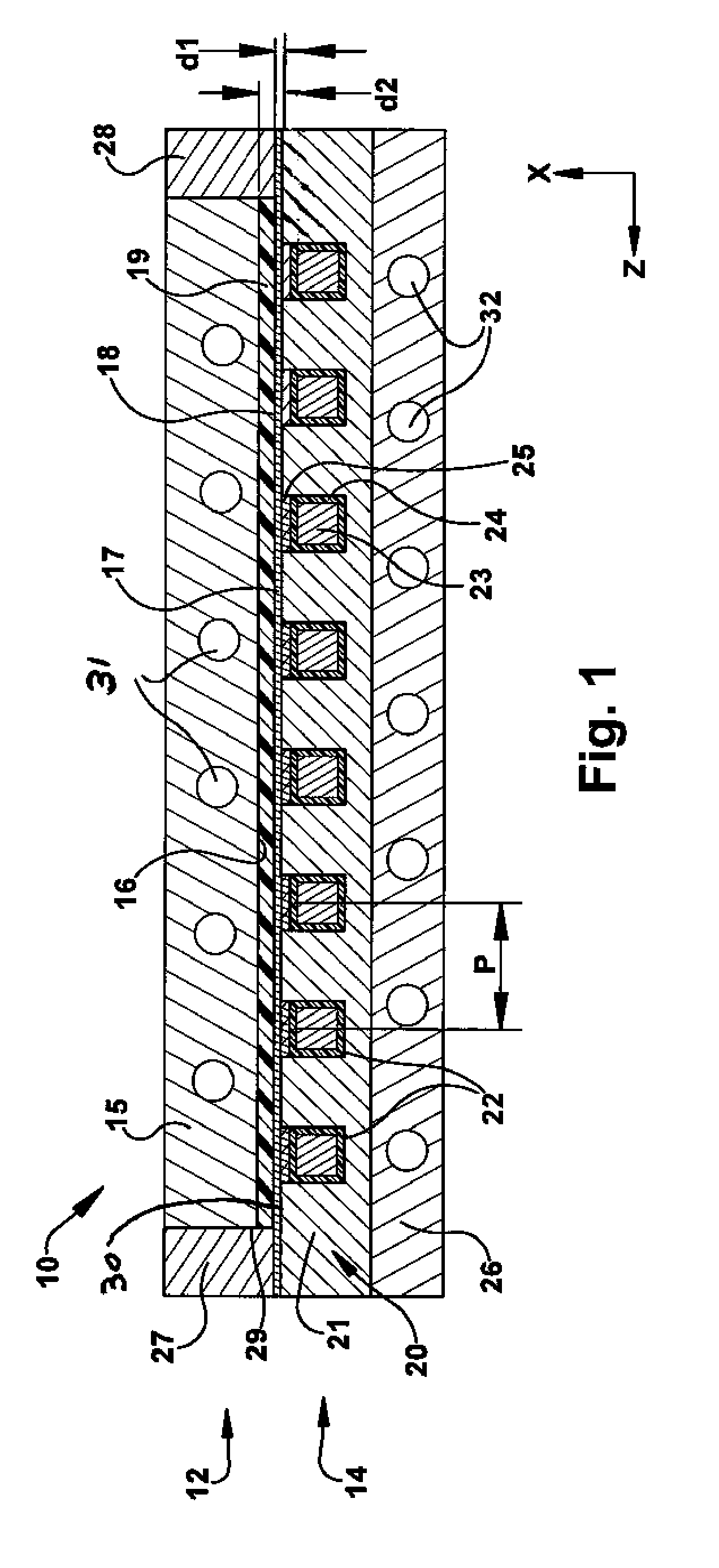

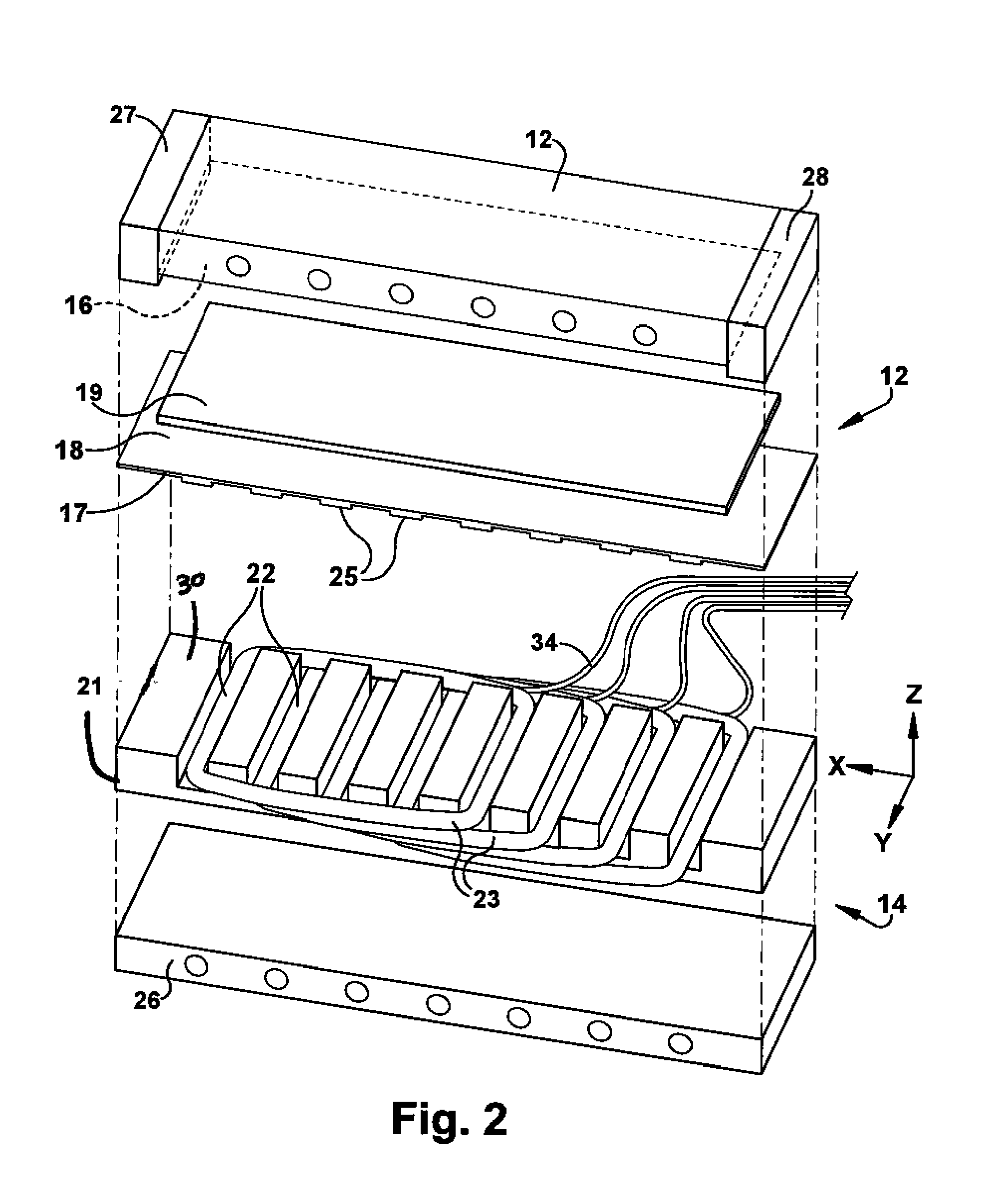

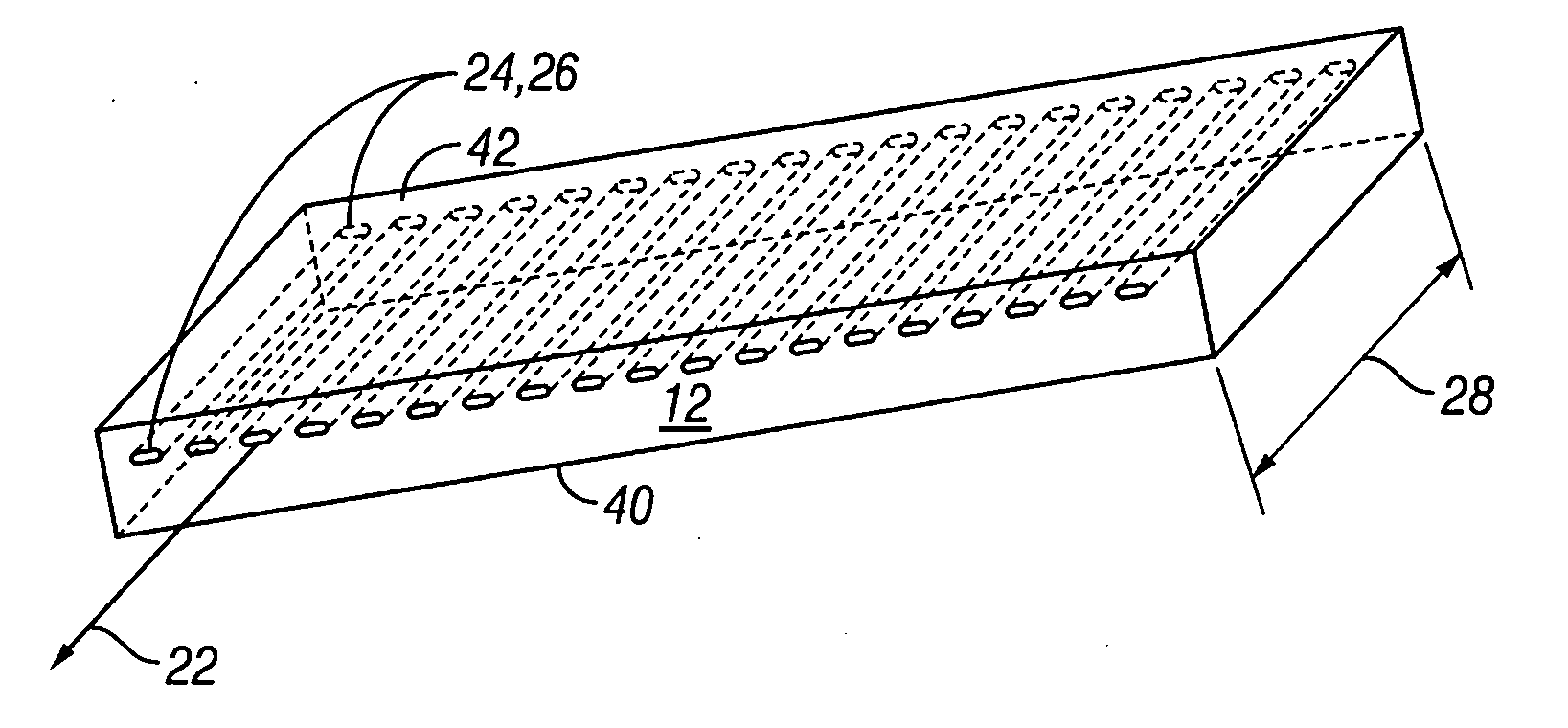

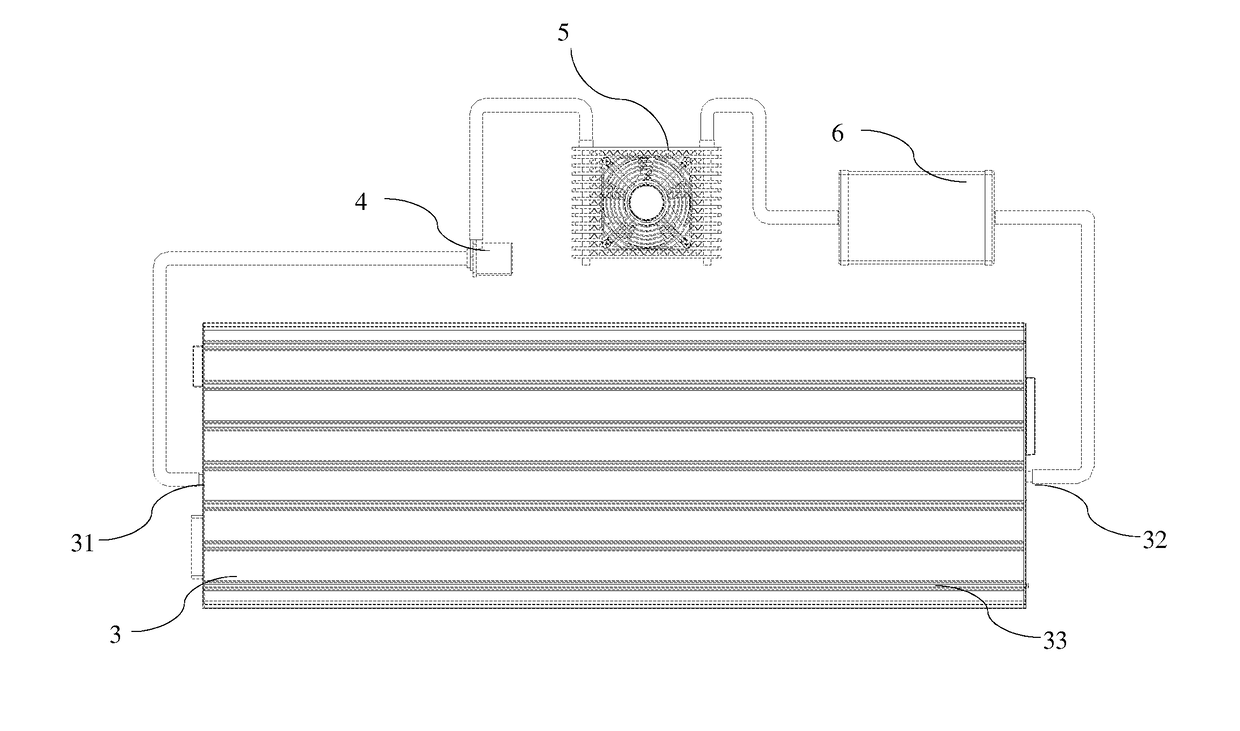

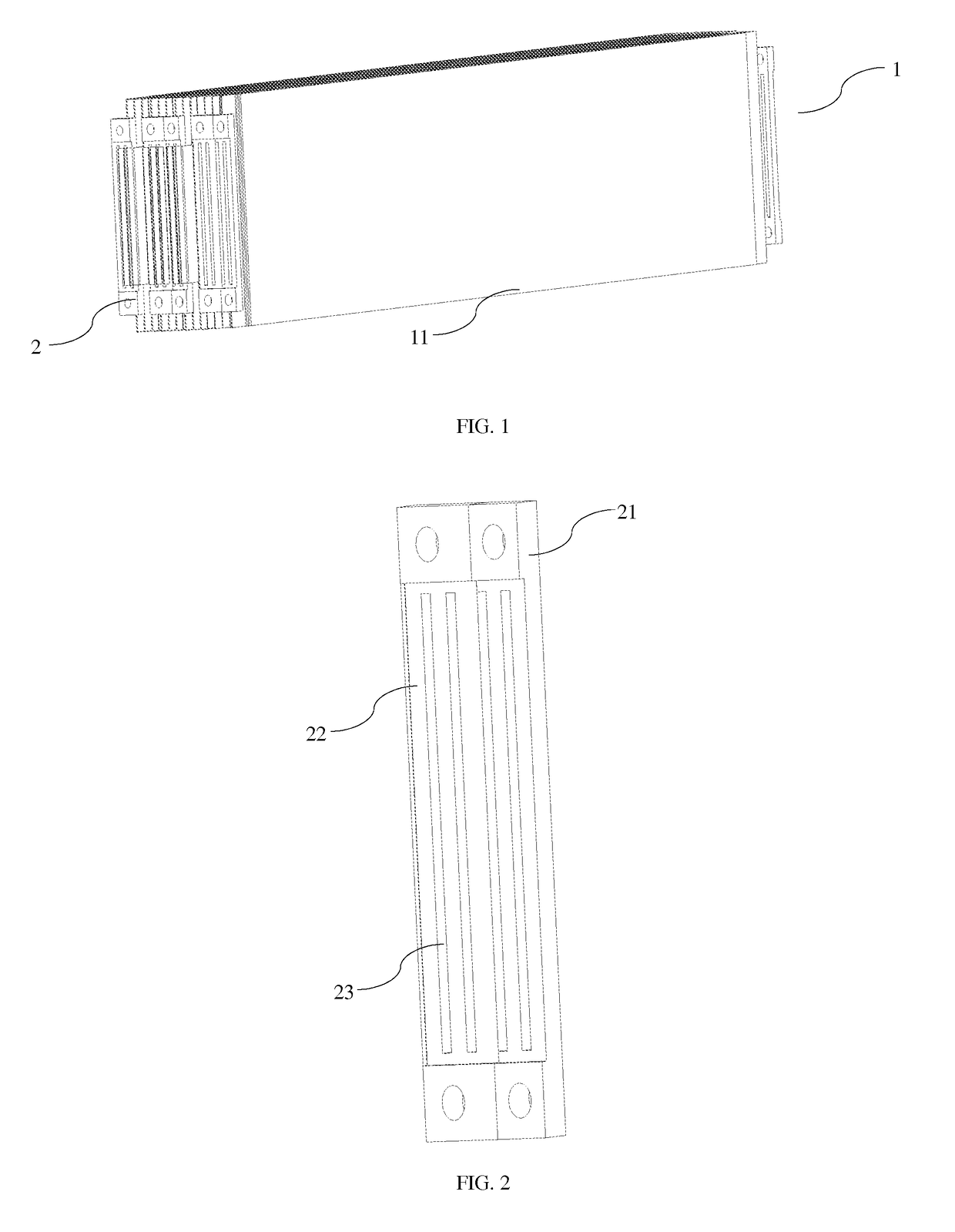

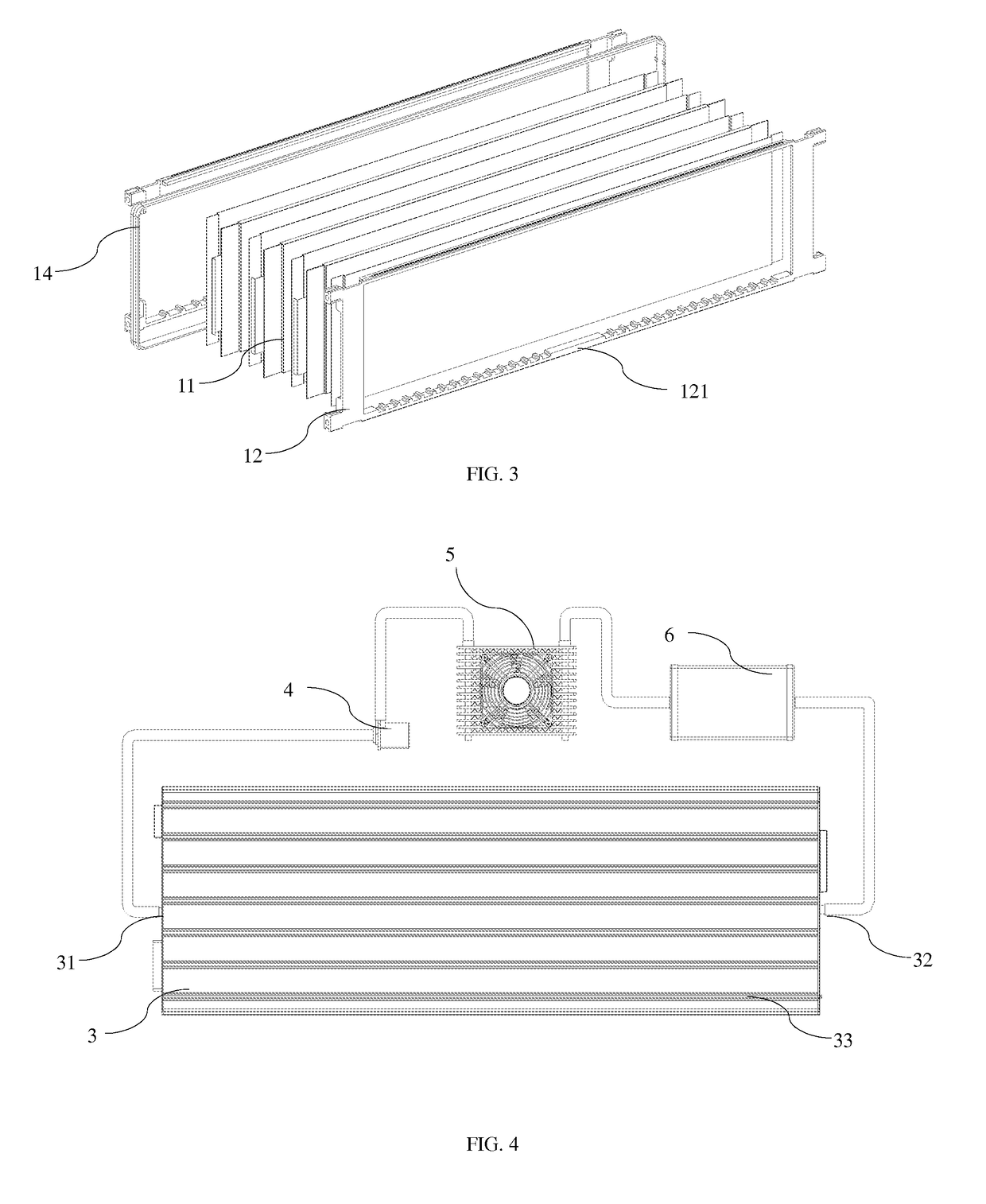

Liquid-cooled battery pack system

ActiveUS20170162923A1Improve securityIncrease energy densitySecondary cellsCell component detailsEngineeringDesoldering

The present invention provides a battery module and a liquid-cooled battery system that uses it, a battery cell and a current collector sheet, on the premise that the materials like the electrode and separator and so on are completely the same, energy density of the battery pack is greatly increased; the cell and the current collector sheet are fully welded connections, the joints are fewer and it is not prone to produce desoldering, also ensuring the stability of the of the cell tab and high current carrying capacity, and when putting the parallel battery module in series, the use of wires are avoided, thus reduces the volume of the battery pack; the innovative design for the liquid-cooled battery pack system, improves the thermal balance between the cells, and the heat-dissipation in battery pack distributes more evenly, the insulation property of the battery package is highly improved, controlling the heat-dissipation capacity of the system by adjusting the flow rate of the circulating pump, not only the unnecessary energy consumption can be avoided, but also have a better impact resistance.

Owner:MICROVAST

Process for obtaining petrochemical products from carbonaceous feedstock

ActiveUS20130214207A1Improve efficiencyEasy to operateCatalytic crackingDirect heating destructive distillationSyngasPetrochemical

A process for obtaining petrochemical products from a carbonaceous feedstock is provided. The carbonaceous feedstock may be coal, coke, lignite, biomass, bitumen and the like. The carbonaceous feedstock is pulverized and fed to a pyrolysis reactor where the feedstock is pyrolyzed at 700-1000° C. at a pressure of 2-25 bar for 2-10 seconds, wherein the feedstock is entrained in hot syngas during the pyrolysis process.

Owner:GHARDA KEKI HORMUSJI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com