High-temperature molten salt electriochemistry testing system

A high-temperature molten salt and testing system technology, applied in the field of testing systems for high-temperature electrochemical test research, can solve problems such as instability, unstable current loop, damage, etc., and achieve uniform heat distribution, good thermal insulation effect, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

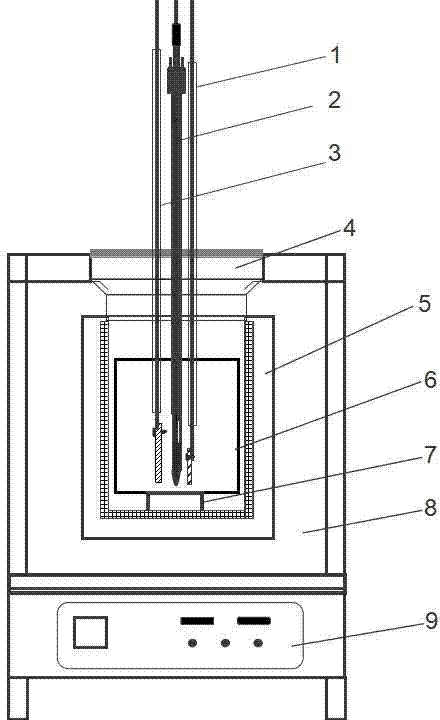

[0015] See attached figure 1 ~attached Figure 4 , The high-temperature molten salt electrochemical test system includes three parts: high-temperature electric furnace, high-temperature electrochemical electrode and high-temperature molten salt crucible; auxiliary electrode 1, reference electrode 2, and working electrode 3 are used as a three-electrode system to pass through the high-temperature electric furnace cover 4 and placed in the hearth In the crucible 6; the heating resistance wire 5 is used to heat the furnace area, and the intelligent temperature control system 9 is used to achieve reliable temperature control of the furnace; the crucible 6 is placed on the alumina crucible carrier plate 7; to maintain the high temperature inside the furnace, Heat preservation material 8 is arranged on the side of the high temperature electric furnace.

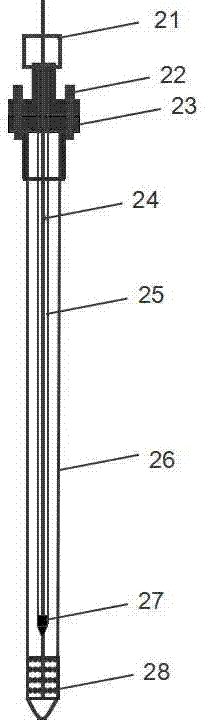

[0016] The high-temperature molten salt reference electrode 2 is mainly composed of a first electrode rod 24 and a sleeve; the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com