Small-target surface vertical target dispersion photoelectric measurement device

A photoelectric measurement and density technology, which is applied to targets, target indication systems, offensive equipment, etc., can solve the problem of inability to measure the density of projectiles with a caliber below 30mm, and solves the problem of unstable illumination and high safety of personnel and equipment. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

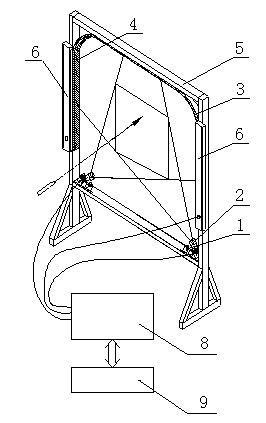

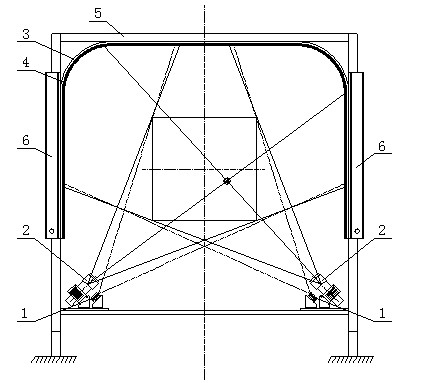

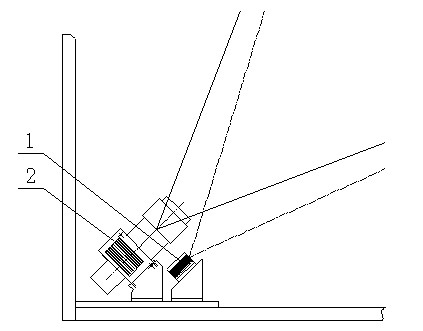

[0023] Example 1: see figure 1 , figure 2 with image 3 , a photoelectric measuring device for vertical target density on a small target surface, comprising a laser light source assembly, an original reflective film 4, a light curtain target 6, a data acquisition controller 8, a main control computer 9 and two orthogonal linear array CCD cameras 2. Said laser light source assembly is two laser light sources 1 capable of producing a fan-shaped light curtain surface. The power of the semiconductor laser light source is 70mW, which are respectively arranged on the inner side of two linear array CCD cameras 2 and the main axis is coplanar with the optical axis of the linear array CCD camera. , the emitted fan-shaped beam is coplanar with the field of view of the CCD camera. Said original reflective film 4 is strip-shaped with a width of 15 mm, which is arranged relative to the line CCD camera 2 and perpendicular to the light curtain emitted by the laser light source assembly...

Embodiment 2

[0031] Example 2: see Figure 4 . The difference with Embodiment 1 is that said laser light source assembly 1 is four laser light sources that emit fan-shaped light beams, which are respectively paired and symmetrically arranged on both sides of two line array CCD cameras 2 and the main axes are all aligned with the line array The optical axis of the CCD camera is in the same plane, and the emitted fan-shaped beam is in the same plane as the field of view of the line array CCD camera.

[0032] In this embodiment, the two laser light sources 1 are placed above and below the linear CCD camera 2 at the same time, and the main axes of the two laser light sources are in the same plane as the optical axis of the linear CCD camera. This design can improve the brightness of the field of view of the linear array CCD camera and effectively eliminate false projectile images.

Embodiment 3

[0033] Example 3: see Figure 5 . The difference with Embodiment 1 is that said laser light source assembly 1 includes two laser light sources 1 emitting fan-shaped light sources and corresponding half mirrors 7, and the main axis of laser light source 1 is perpendicular to the line array CCD camera 2 light beams. axis and the two light-emitting optical axes intersect, the half mirror 7 is placed at the intersection of the optical axis of the line array CCD camera 2 and the laser light source 1, and its reflective surface faces the laser light source and forms an angle of 45° with the laser light source optical axis.

[0034] This scheme ensures that the main axis of the laser is coaxial with the optical axis of the linear array CCD camera, and ensures that the light emitted by the projectile blocking the laser beam is in the same position as the light reflected back through the original reflective film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com