Long-distance hole distance measuring device and method, storage medium, equipment and rail vehicle

A measuring device and measuring method technology, applied in the direction of measuring devices, optical devices, neural learning methods, etc., can solve the problems of complex operation, inaccurate measurement data, poor distance repeatability and other problems of the three-coordinate measuring method, and achieve repeated positioning Accuracy, the effect of realizing the measurement process and avoiding systematic errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

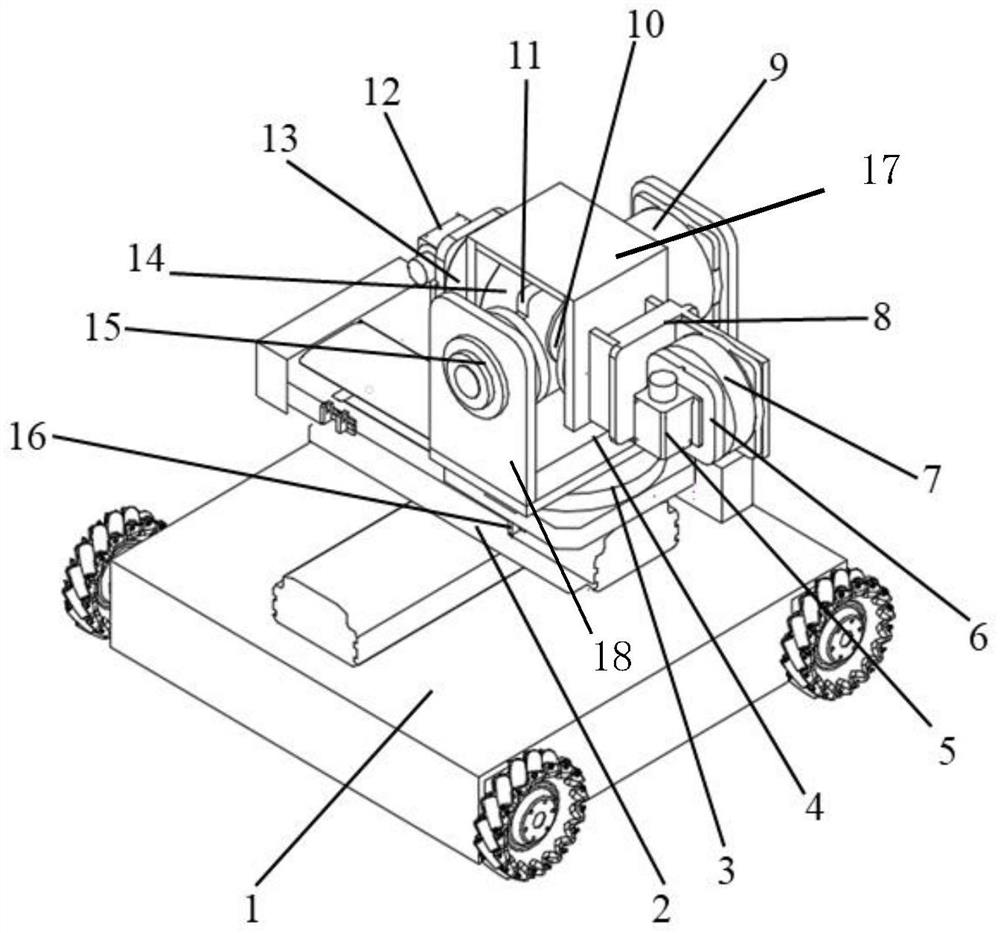

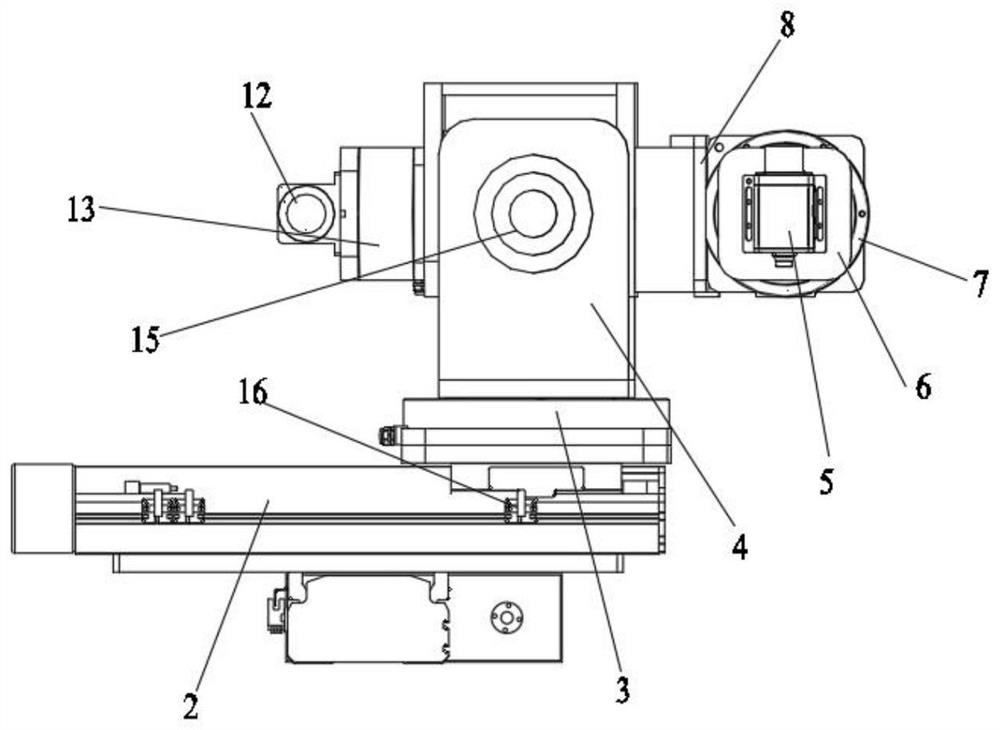

[0064] In a typical embodiment of the invention, such as figure 1 As shown, a long-distance piercing measuring device includes a moving member 1, a moving member 1, and a moving member 2, and a first power device 3 is fixedly disposed at the top of the driving member 2. The first power unit 3 is fixed to XY pitch. The adjustment platform 4, the XY pitch adjustment platform 4 fixed to the second power device 13, the XY pitch adjustment platform 4 fixed to the right side fixed to provide the third power device 7, the image acquisition element is fixedly mounted on the slewing platform driven by the third power device 7. The laser range finder 12 is fixed to the swivel platform driven by the second power device 13.

[0065] In this embodiment, the image acquisition element uses a CCD industry camera 5.

[0066] The measuring device is provided with a CCD industrial camera and a laser range finder, which is fixed to both sides of the XY pitch adjustment platform. Under the driving mem...

Embodiment 2

[0086] This embodiment provides an operation method using a hole distance measurement using the long distance pores measurement device as described above, and its steps are:

[0087] A. Move the measuring device through the moving member 1 to the front of the measured first to be measured, by the servo motor to adjust the drive member 2 to cause the CCD industry camera 5 in an accurate working position, and the two-to-measure hole plane is measured. The side wall is prepared on the side to measure the vertical distance of the laser range finder 12 and the side wall; control the first power device 3 to rotate the above measurement device at a suitable angle; complete the preparation of the measurement;

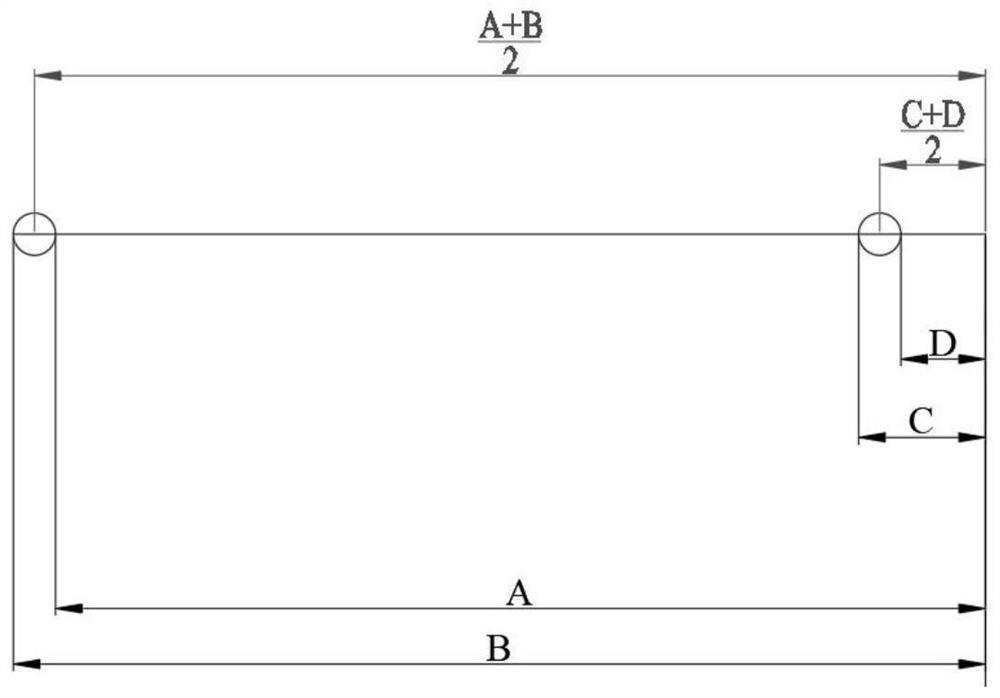

[0088]b, the fifth power device 9 in which the XY pitch adjustment platform 4 is controlled, the fourth power device 14 drives the second rotating device 15 and the first rotating device 10, and the third power device 7 mounted on the right side of the XY pitch adjustment platform ...

Embodiment 3

[0092] This embodiment proposes a method of measurement using a long-distance pore measuring device as described above, including the following steps:

[0093] S1: A image of different long distance spacious separation holes in real time;

[0094] S2: A gray graph, edge diagram, and gradient diagram of the image to obtain an image of the image.

[0095] S3: Feature extraction of the edge map and gradient map to obtain the directional gradient histogram feature parameters;

[0096] S4: Training neural network according to feature parameters to obtain target neural networks;

[0097] S5: Collecting a plurality of pitch images in real time, performing feature extraction of the collected bore image to be tested by the tape hole image according to the edge extraction and feature parameters of the measurement hole image, and the extracted feature data input target neural network , Obtain the edge recognition result of the long distance to be tapered, that is, the neural network analysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com