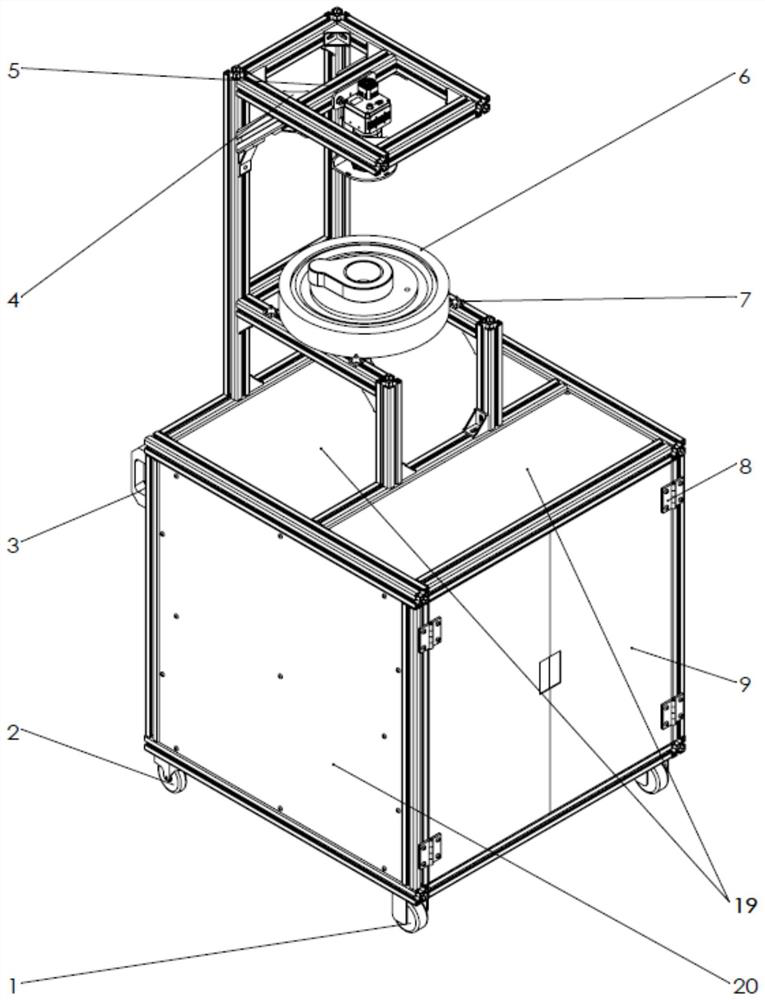

Rotary opening adjusting area measuring device based on visual inspection

A measuring device and visual inspection technology, applied in the direction of measuring devices, optical devices, image data processing, etc., can solve the problems of material pores, burrs, influence of visual measurement accuracy, difficulty in ensuring measurement accuracy, etc., and achieve reliable fixation and integration Accurate area measurement, real-time data communication and real-time measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

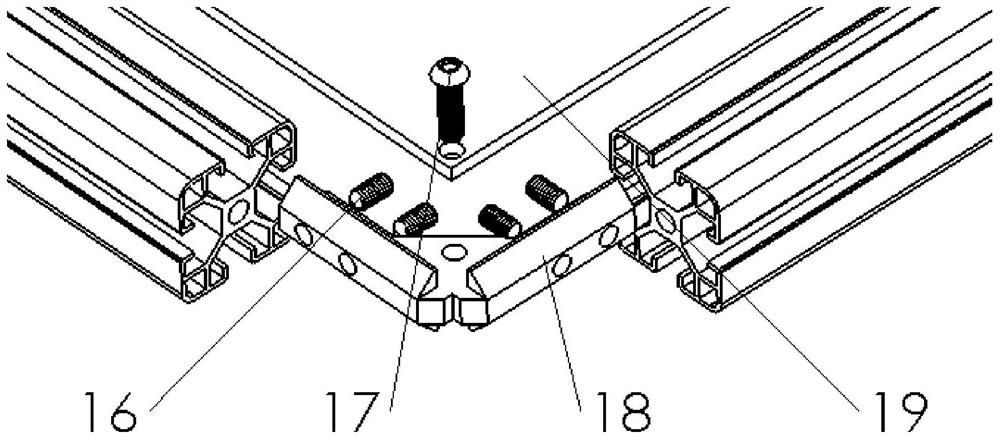

Method used

Image

Examples

specific Embodiment

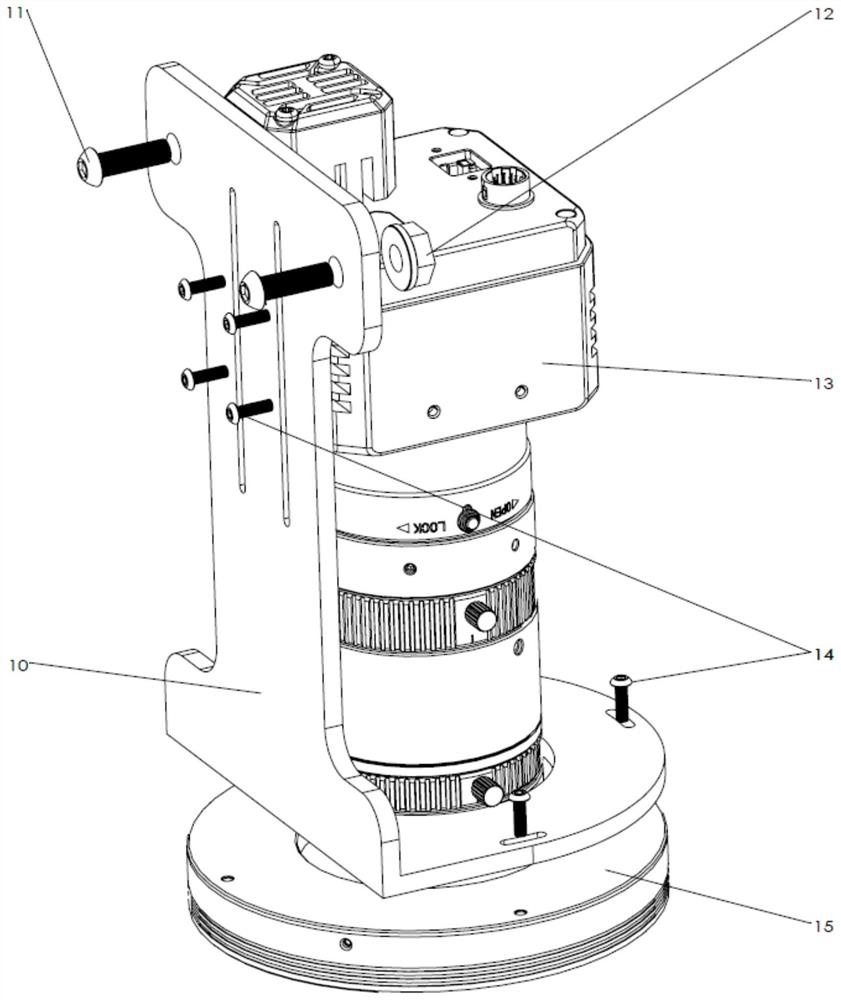

[0047] Step 1: Device Control

[0048] First click the camera calibration button, and according to the collected images of the circular calibration plate, use Zhang’s calibration method to calculate the internal and external parameters of the camera, and the result is used to correct the subsequent working images; use the actual center distance and The distance between the centers of the circles on the figure is calibrated for the magnification factor. Then click the camera open button to receive and display the original working image returned by the camera in real time. Adjust the lens aperture or use the software exposure / gain adjustment function to process the brightness of the image to ensure that the obtained image will not be overexposed or too dark. Then use the software control function to realize that the upper computer sends control instructions to the motor controller, so that the motor rotates to change the opening of the valve port. The initial valve opening is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com