Patents

Literature

641results about How to "Increase volumetric energy density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Doped multi-layer core-shell silicon-based composite material for lithium ion battery and preparation method thereof

ActiveCN109599551AInhibits and buffers swellingPrevent partial failureMaterial nanotechnologySecondary cellsCarbon filmComposite film

The present invention relates to a doped multi-layer core-shell silicon-based composite material for a lithium ion battery, and a preparation method thereof. Other than being doped with a necessary lithium element, the material is also doped with at least a non-metallic element and a metal element; the material has a structure in which a silicon oxide particle doped with elements is taken as a core, and a multilayer composite film which is tightly coated on the surface of the core particle is taken as a shell; the core particle contains uniformly dispersed monoplasmatic silicon nanoparticles,the content of doping elements gradually decreases from the outside to the inside without a clear interface, and a dense lithium silicate compound is formed on the surface of the core particle by embedding and doping the lithium element; and the multilayer composite film is a carbon film layer and a doped composite film layer composed of the carbon film layer and other elemental components. The doped multi-layer core-shell silicon-based composite material provided by the present invention has a high capacity, good rate performance, high coulombic efficiency, good cycle performance, a low expansion rate, and other electrochemical characteristics when the material is used for the negative electrode of lithium ion battery.

Owner:BERZELIUS (NANJING) CO LTD +1

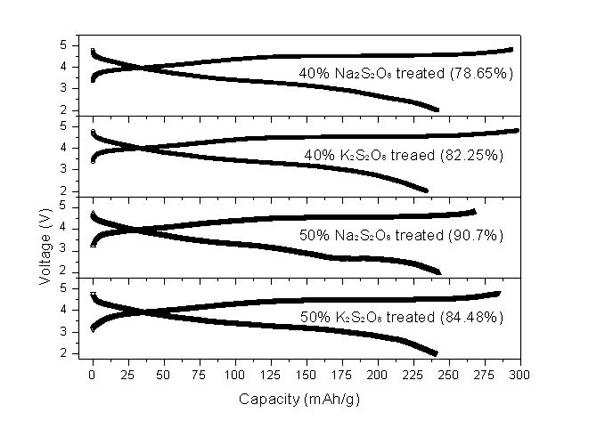

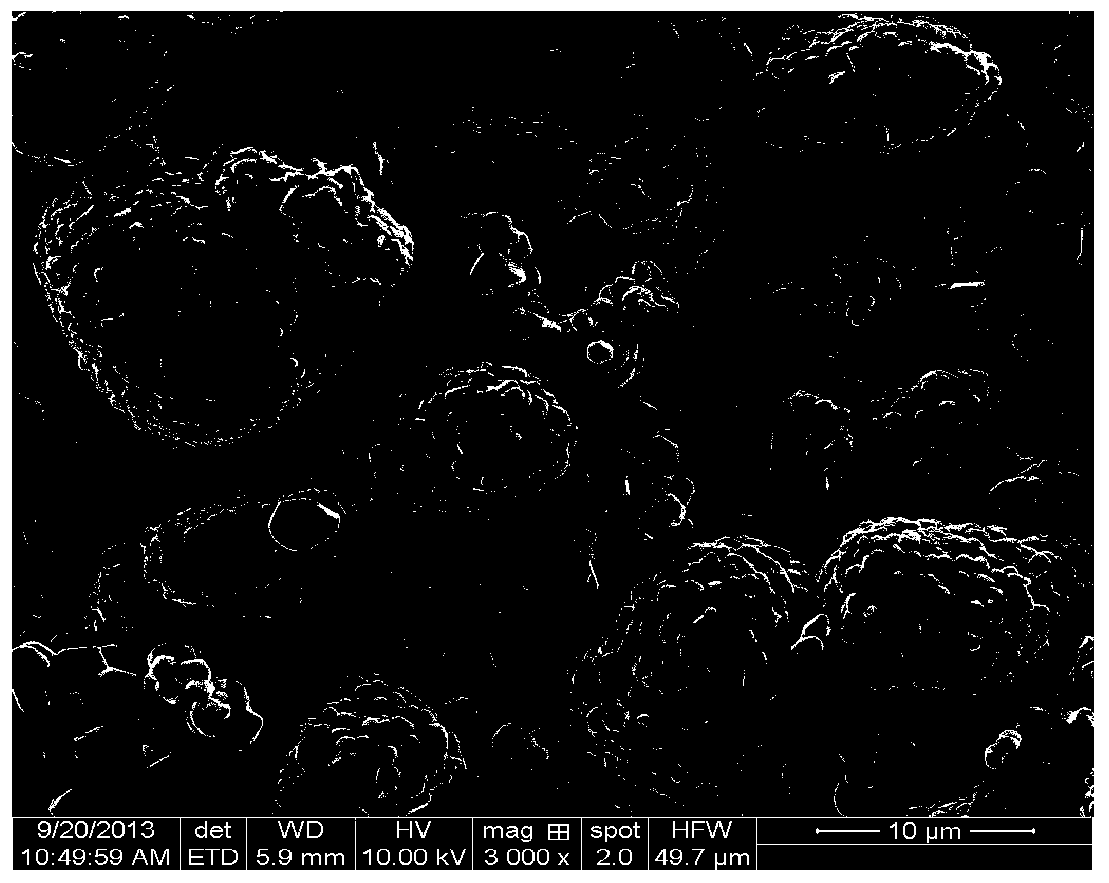

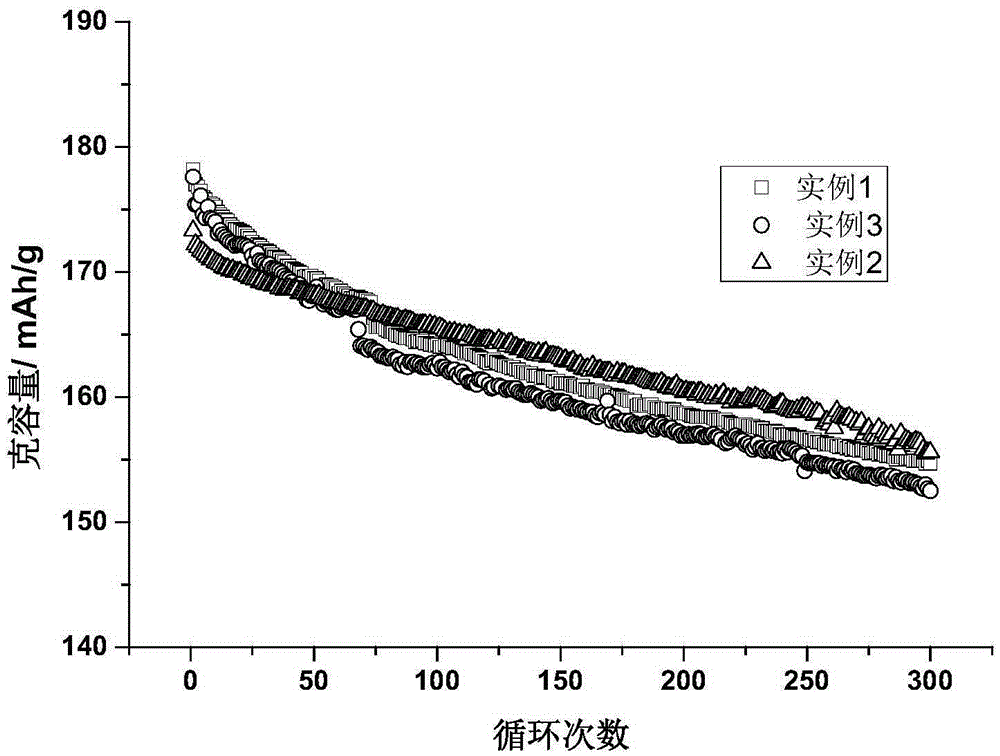

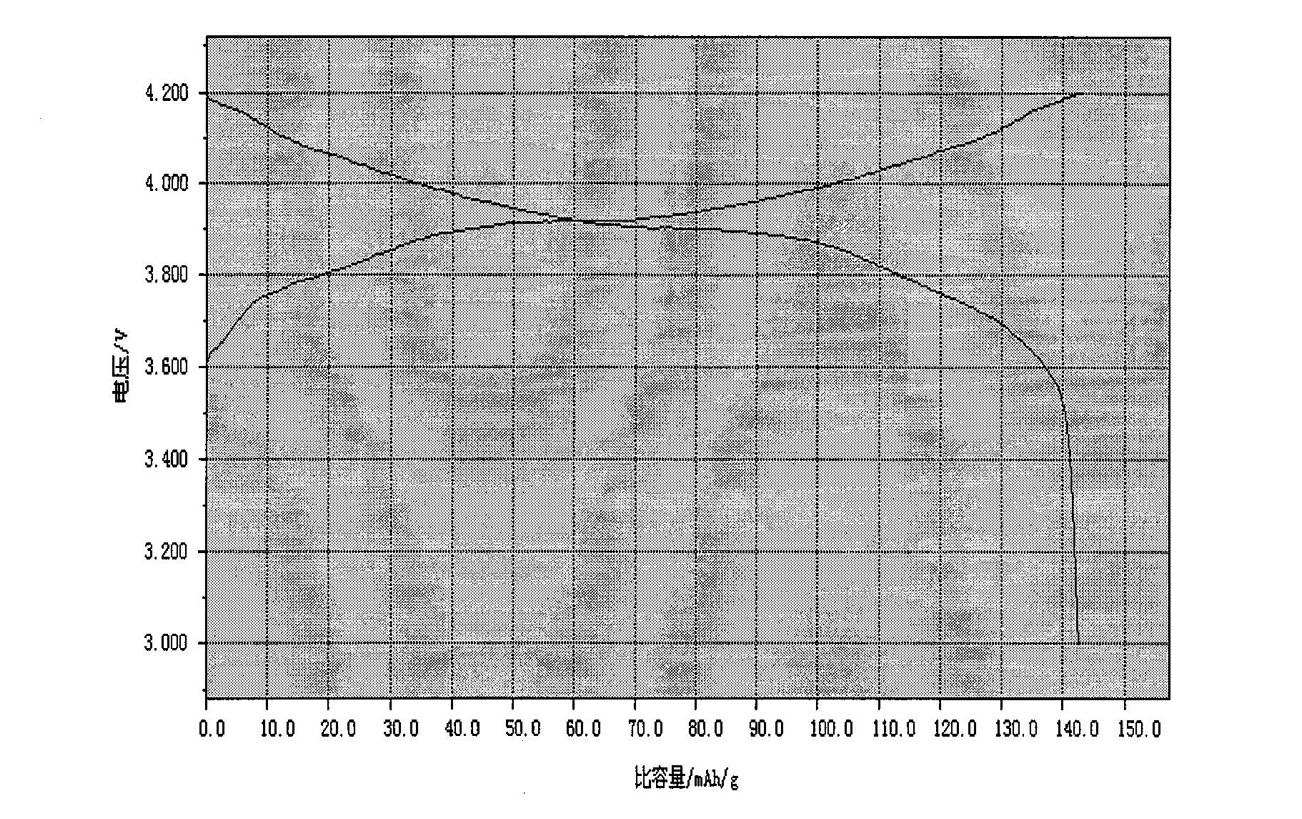

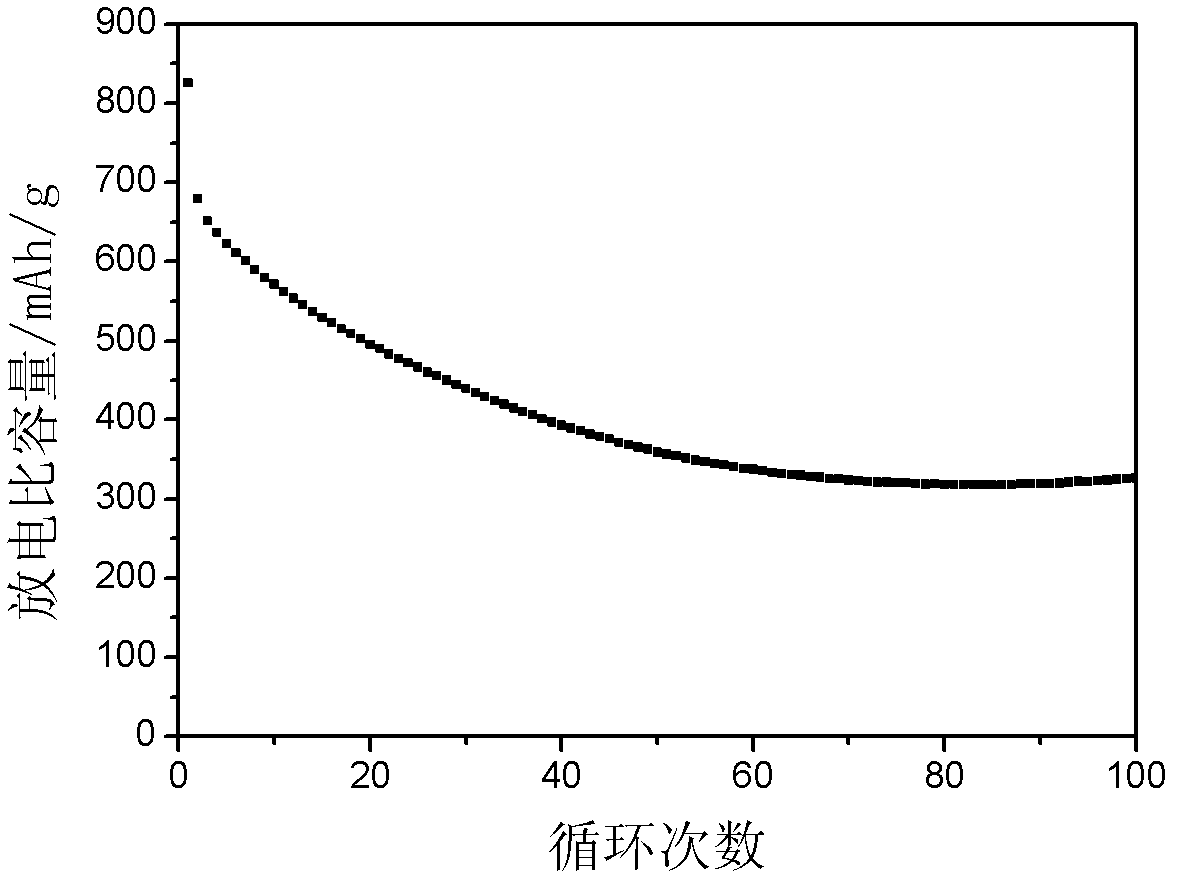

Synthesis and surface modification method of lithium excessive laminar oxide anode material

The invention relates to a synthesis and surface modification method of a lithium rich anode material Li1+xM1-xO2 (M is one or more of Ni, Co and Mn, and X is more than or equal to 0 and less than or equal to 1 / 3) for a lithium ion battery. The method comprises the following steps of: synthesizing a precursor by using a carbonate precipitation method, mixing the precursor and a lithium salt, and calcining for 2 to 20 hours at the temperature of between 800 and 1,100 EG C to obtain a lithium rich material, wherein the prepared lithium rich material has controllable particle size and higher reversible capacity; and dissolving persulfate or sulfate in an amount which is 5 to 80 mass percent of the lithium rich material into deionized water, adding the lithium rich material, stirring for 2 to 100 hours at the temperature of between 25 and 80 DEG C, heating the materials to the temperature of between 100 and 500 DEG C in a muffle furnace, calcining the materials for 2 to 20 hours, fully filtering the obtained materials, and washing off impurities to obtain the surface modified anode material Li1+x-yM1-xO2. The synthesized lithium rich material has controllable particle size; the first charge / discharge efficiency of the lithium rich material and the discharge specific capacity and the cyclical stability under high magnification can be improved; and the method is simple, low in cost, convenient for operation and suitable for industrialized production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

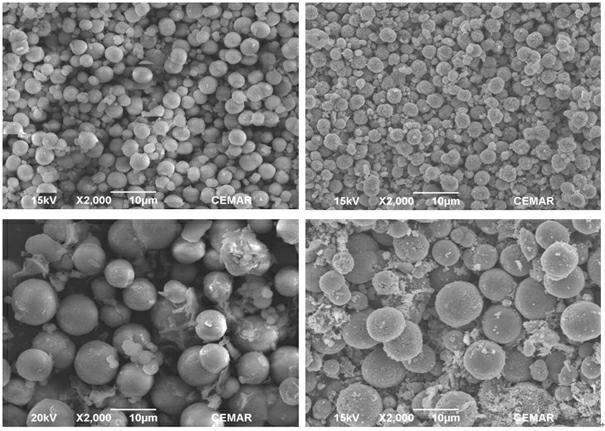

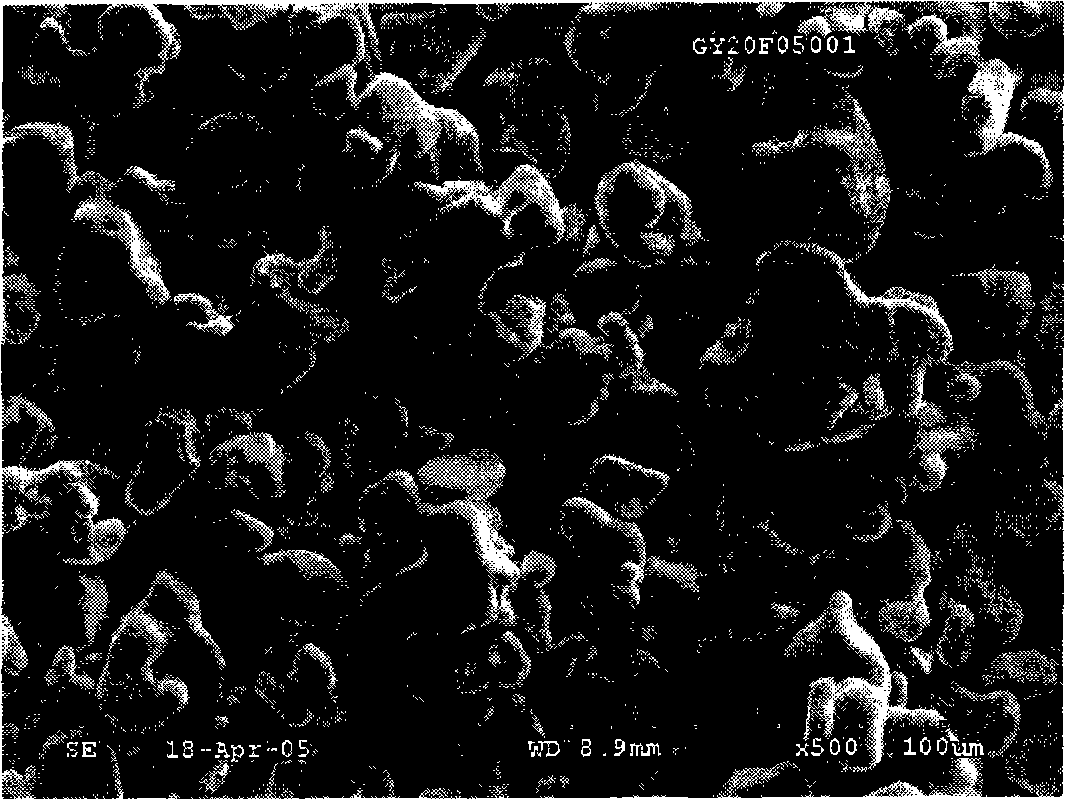

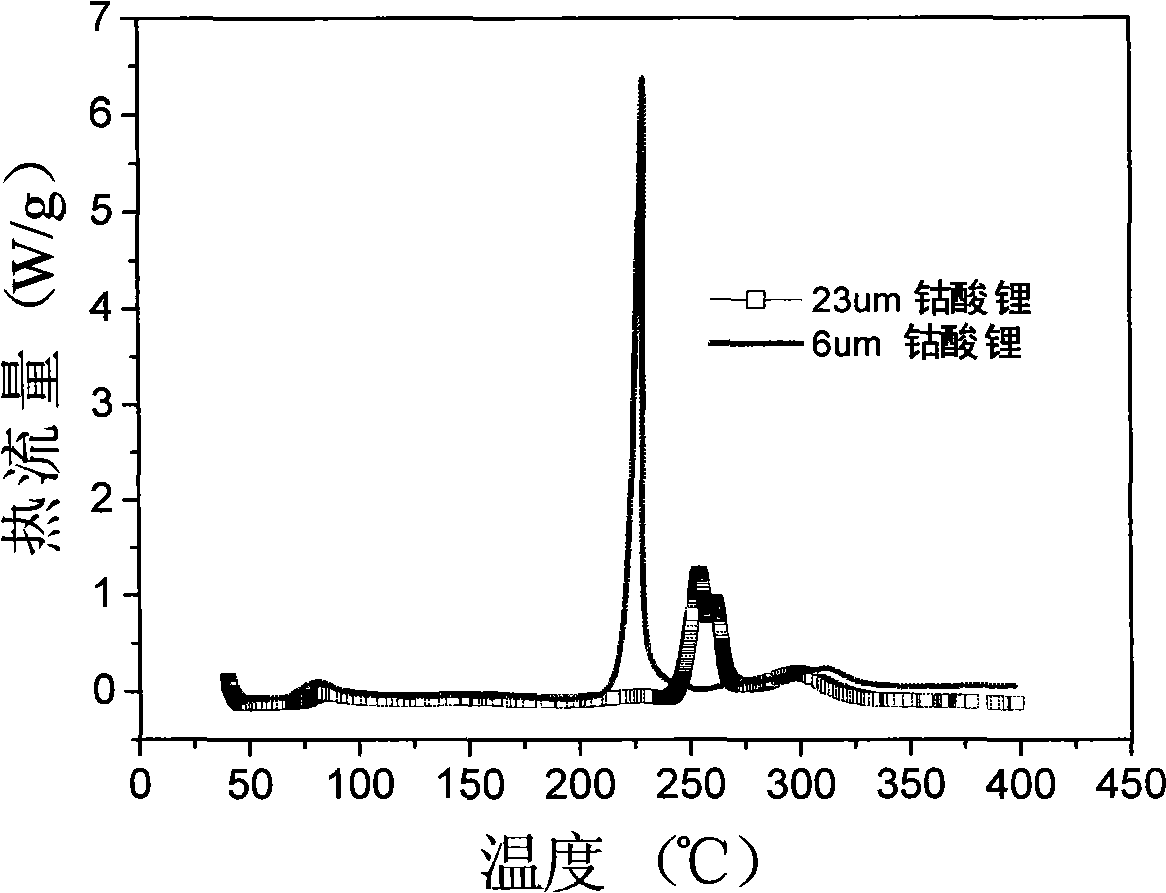

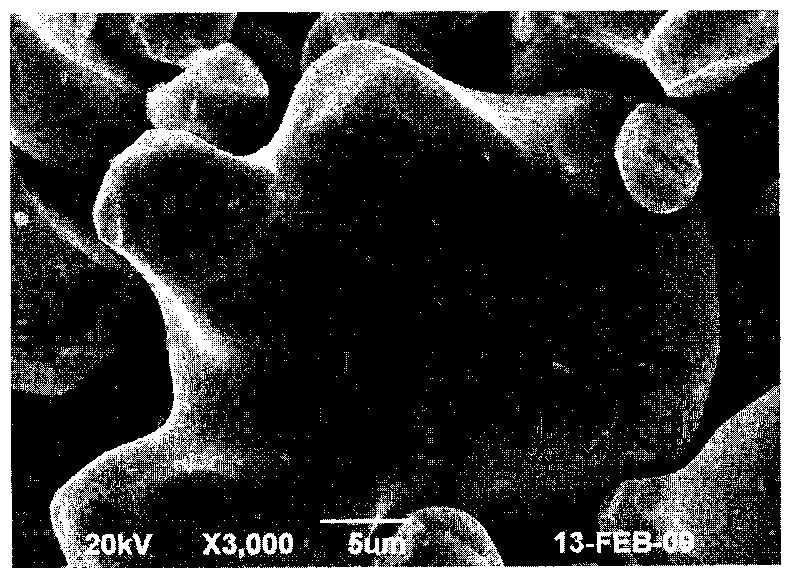

Super-size and high-density lithium cobalt oxide and method for preparing the same

ActiveCN101284681ALarge particle sizeHigh tap densityCell electrodesLithium compoundsHigh densityThermal impact

The invention relates to a high-density lithium cobalt oxide power material with a super-large grain diameter. The method comprises the steps of mixing a cobalt compound, a lithium compound or meanwhile a small amount of doping element compounds; sintering for 3 to 30 hours at the high temperature of 950 to 1,100 DEG C to form a block sintered product; crushing and grading the product to obtain the lithium cobalt oxide power material (molecular formula is LiaCo1-bMbO2), wherein, when b is not equal to 0, the middle diameter of the lithium cobalt oxide containing the doping elements is larger than or equal to 15 Mum, and the tap density is higher than or equal to 2.5g / cm<3>; when b is equal to 0, the middle diameter of the lithium cobalt oxide without the doping elements is larger than 20 Mum, and the tap density is higher than or equal to 2.6g / cm<3>. the 3.6V platform capacity rate of the material as the anode active substance for a lithium battery is higher than or equal to 75%; in the thermal impact test in a 150 DEG C thermotank, the lithium battery with the material is free from leakage and does not catch fire or explode for 60 minutes; the 1C5A specific capacity of the material in the battery is larger than or equal to 135mAh / g.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Positive electrode active material for lithium secondary battery and positive electrode including same

ActiveUS20150093580A1Increase volumetric energy densityGood rate characteristicsCell electrodesSynthetic resin layered productsLithium-ion batteryMaterials science

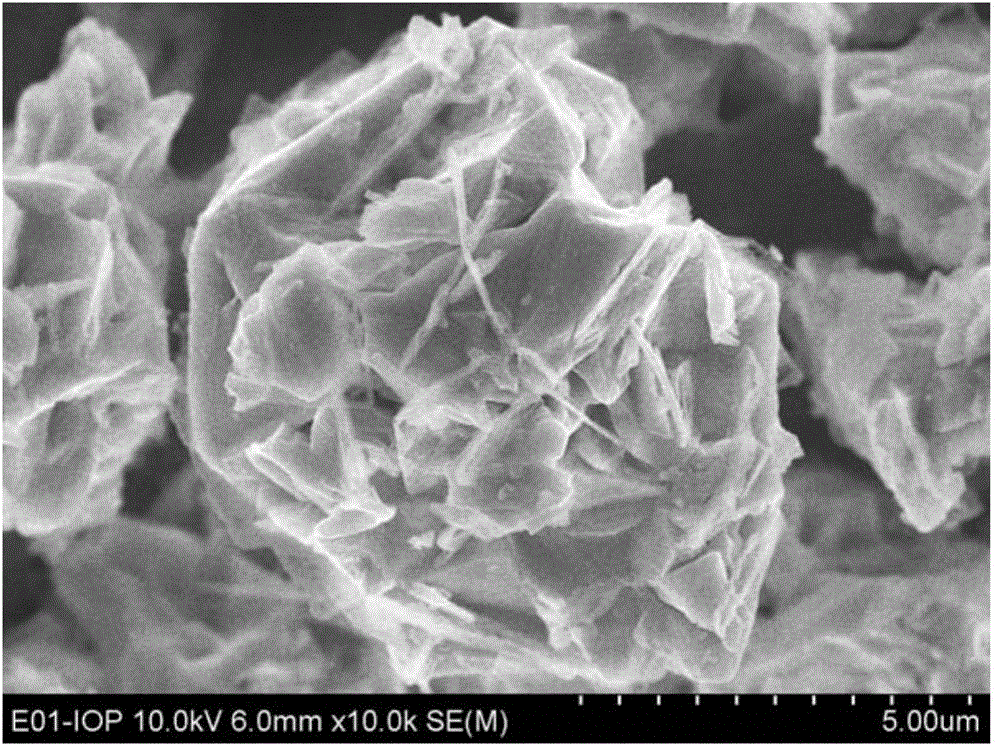

There is provided a positive electrode active material capable of achieving a high volume energy density and yet superior rate characteristics when configured as a positive electrode for lithium secondary batteries. This positive electrode active material comprises a plurality of secondary particles each comprising primary particles composed of a lithium-nickel based complex oxide having a layered rock-salt structure. The plurality of secondary particles have a volume-based average particle diameter D50 of 5 to 100 μm, and at least part of the plurality of secondary particles are coarse secondary particles having a particle diameter of 9 μm or greater. The coarse secondary particles have a voidage of 5 to 25%, and the ratio of through holes among all voids in the coarse secondary particles is 70% or greater.

Owner:NGK INSULATORS LTD

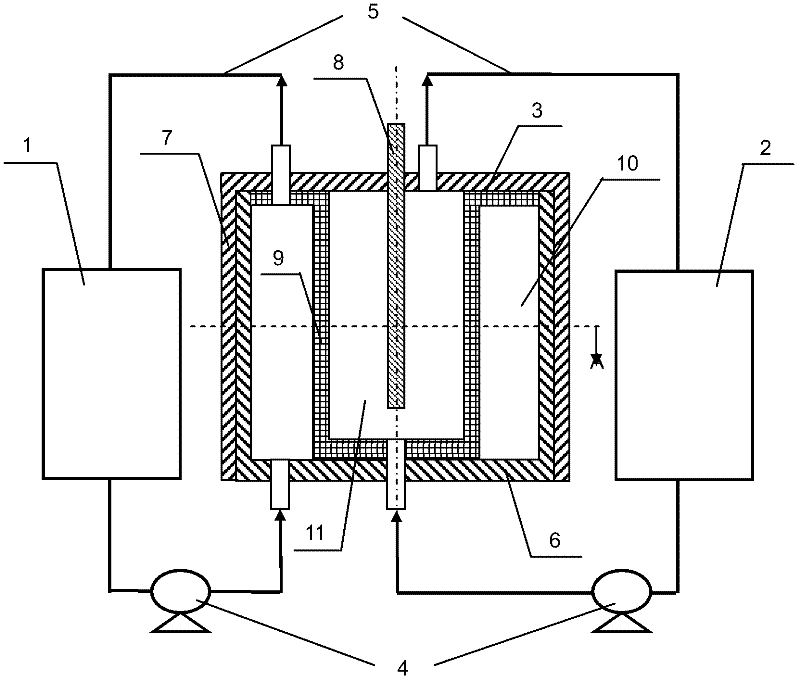

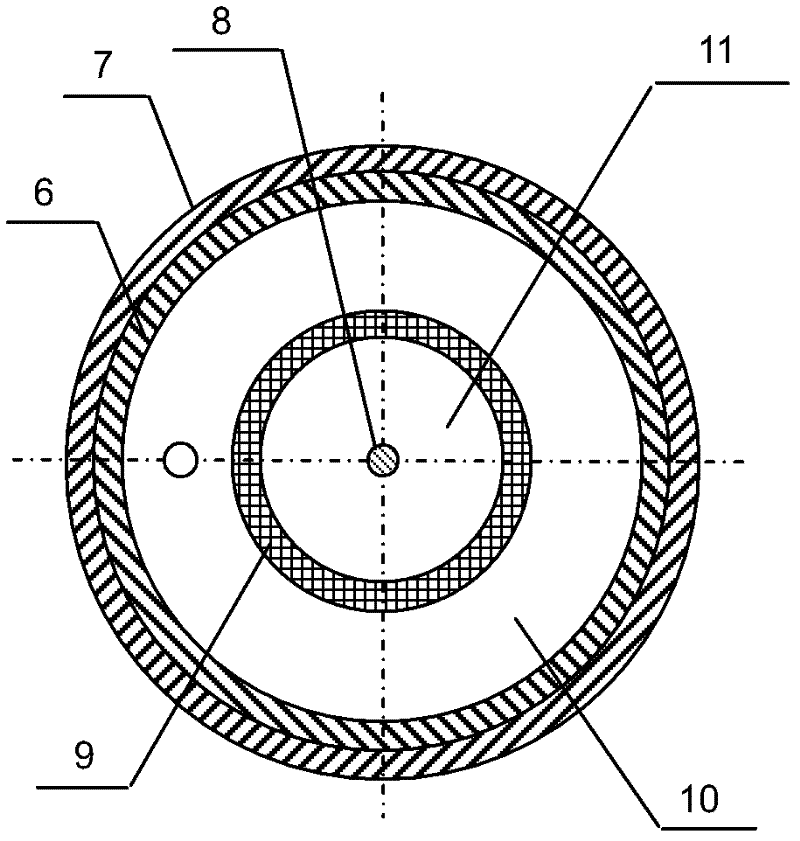

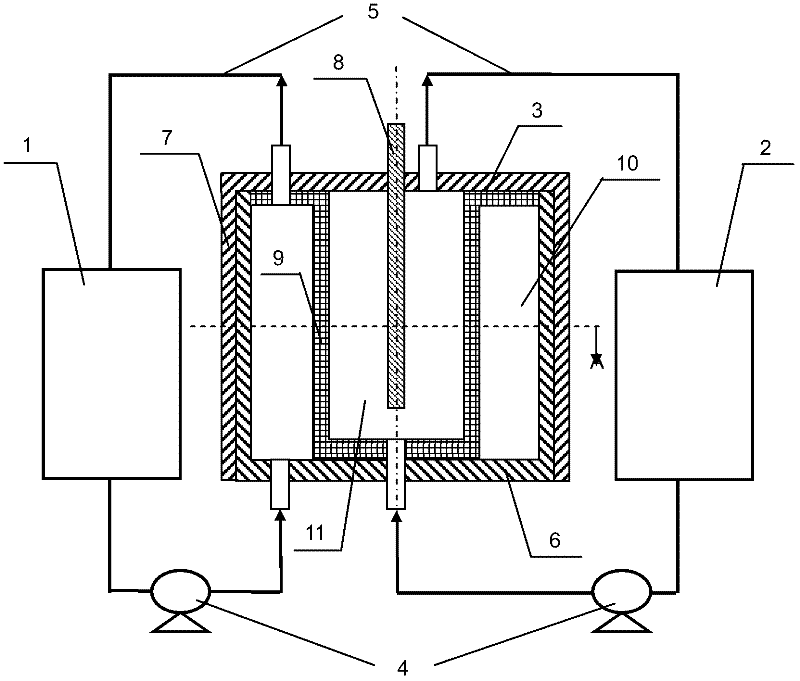

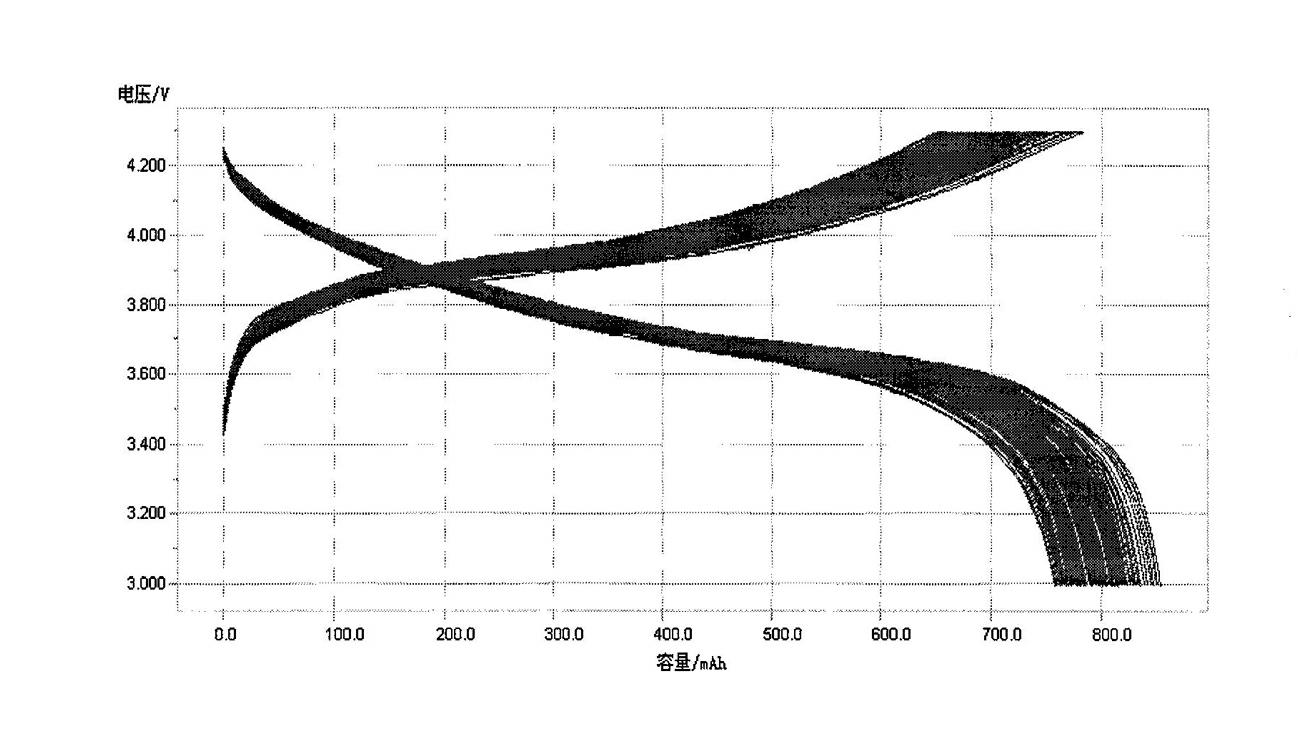

Lithium ion flow redox battery

InactiveCN102315473AScale upSolution to short lifeCell electrodesRegenerative fuel cellsHigh energyRedox

The invention provides a lithium ion flow redox battery, belonging to the technical field of lithium ion batteries. The lithium ion flow redox battery comprises a positive electrode suspension tank, a negative electrode suspension tank and a battery reactor, wherein the positive electrode suspension tank contains the mixture of positive electrode composite material particles and an electrolyte; the negative electrode suspension tank contains negative electrode composite material particles and an electrolyte; the battery reactor comprises a positive electrode current collector, a negative electrode current collector and one layer or a plurality of layers of microporous separators; the microporous separators separate the positive electrode current collector from the negative electrode current collector in an insulation mode so as to respectively form a positive electrode chamber and a negative electrode chamber; the positive electrode chamber is communicated with the positive electrode suspension tank through a seal pipeline; and the negative electrode chamber is communicated with the negative electrode suspension tank through a seal pipeline. Compared with a full vanadium flow redox battery, the lithium ion flow redox battery has the advantage of high energy density, the adoption of the environmentally-friendly and non-toxic electrolyte and low cost, and is applicable to large-scale energy storage of power grids.

Owner:BEIJING HAWAGA POWER STORAGE TECH +1

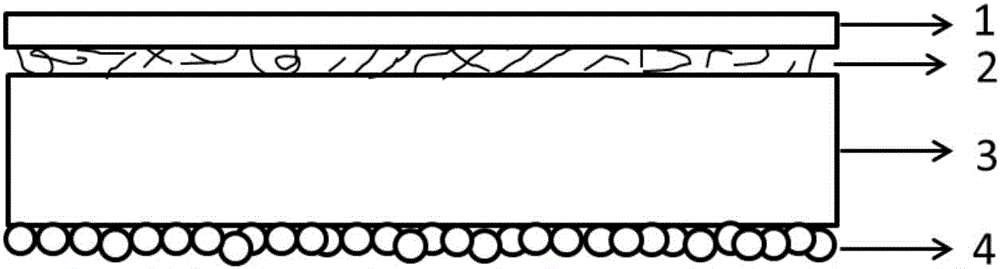

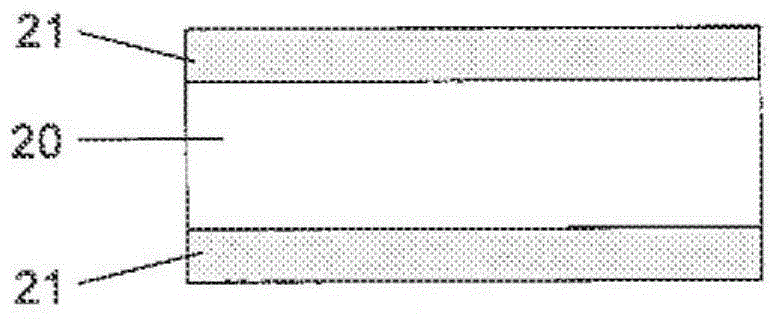

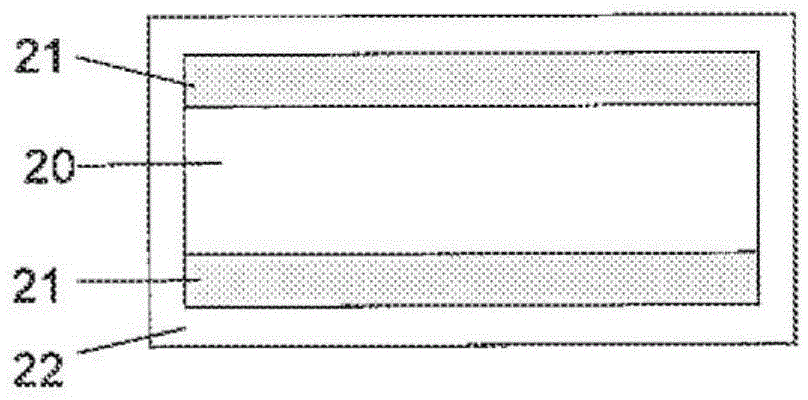

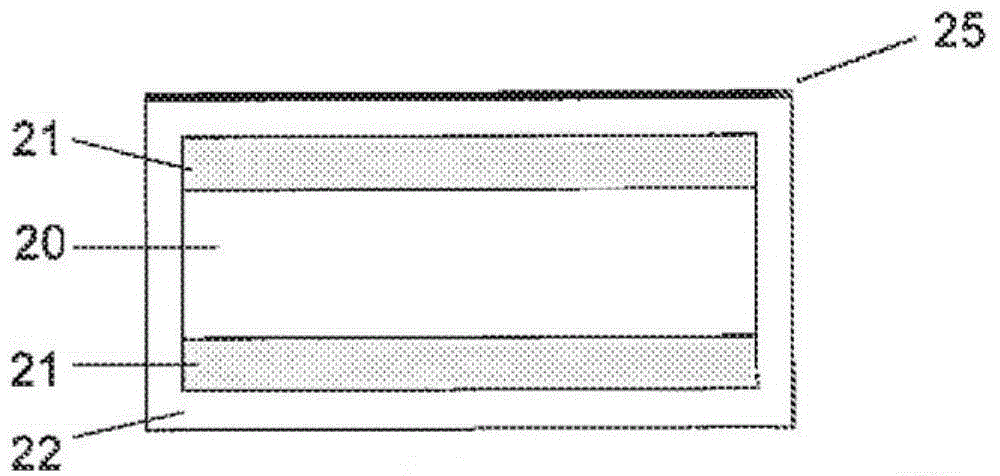

Lithium-ion battery separator subjected to composite coating treatment and preparation method thereof

ActiveCN106252565ATight bondIncrease volumetric energy densityFireproof paintsCell component detailsLithium-ion batteryAramid

The invention discloses a lithium-ion battery separator subjected to composite coating treatment and a preparation method thereof. The lithium-ion battery separator comprises a basement membrane, a polymer coating coated at one side of the basement membrane, and an inorganic particle coating coated at the other side of the basement membrane; the polymer coating is composed of an aramid coating coated on the basement membrane and a polyvinylidene fluoride coating coated on the aramid coating, and the thickness of the polymer coating is 0.3 to 5 [mu] m; and the inorganic particle coating is composed of inorganic particles of different particle sizes and a binding agent, and the thickness of the inorganic particle coating is s 0.5 to 5 [mu] m. The lithium-ion battery separator provided by the invention has the characteristics of being excellent in mechanical property and heat resistant property, having good wettability and solution preserving property to electrolyte, and excellent in cycle performance and high in safety performance.

Owner:深圳市鼎泰祥新能源科技有限公司

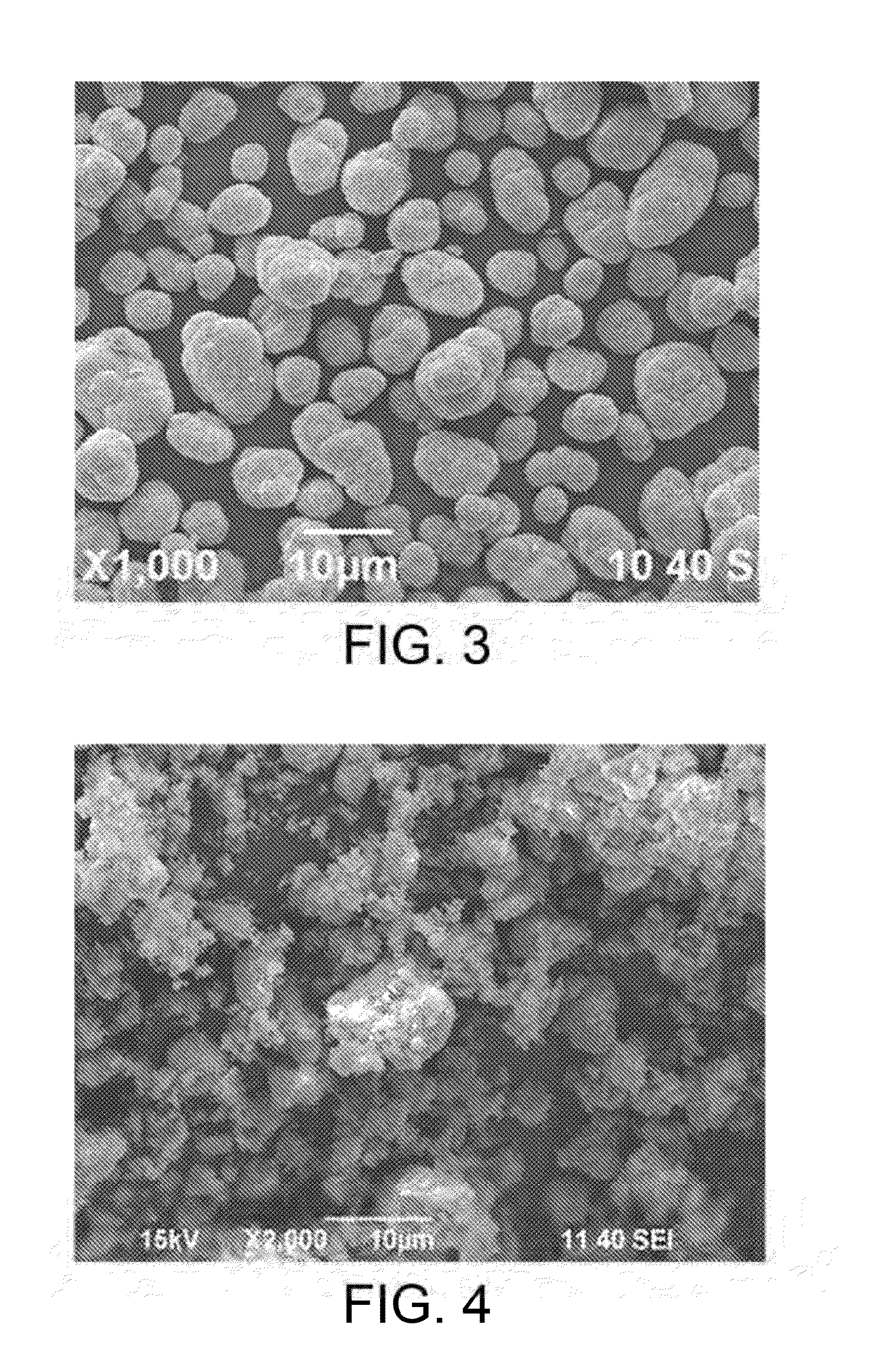

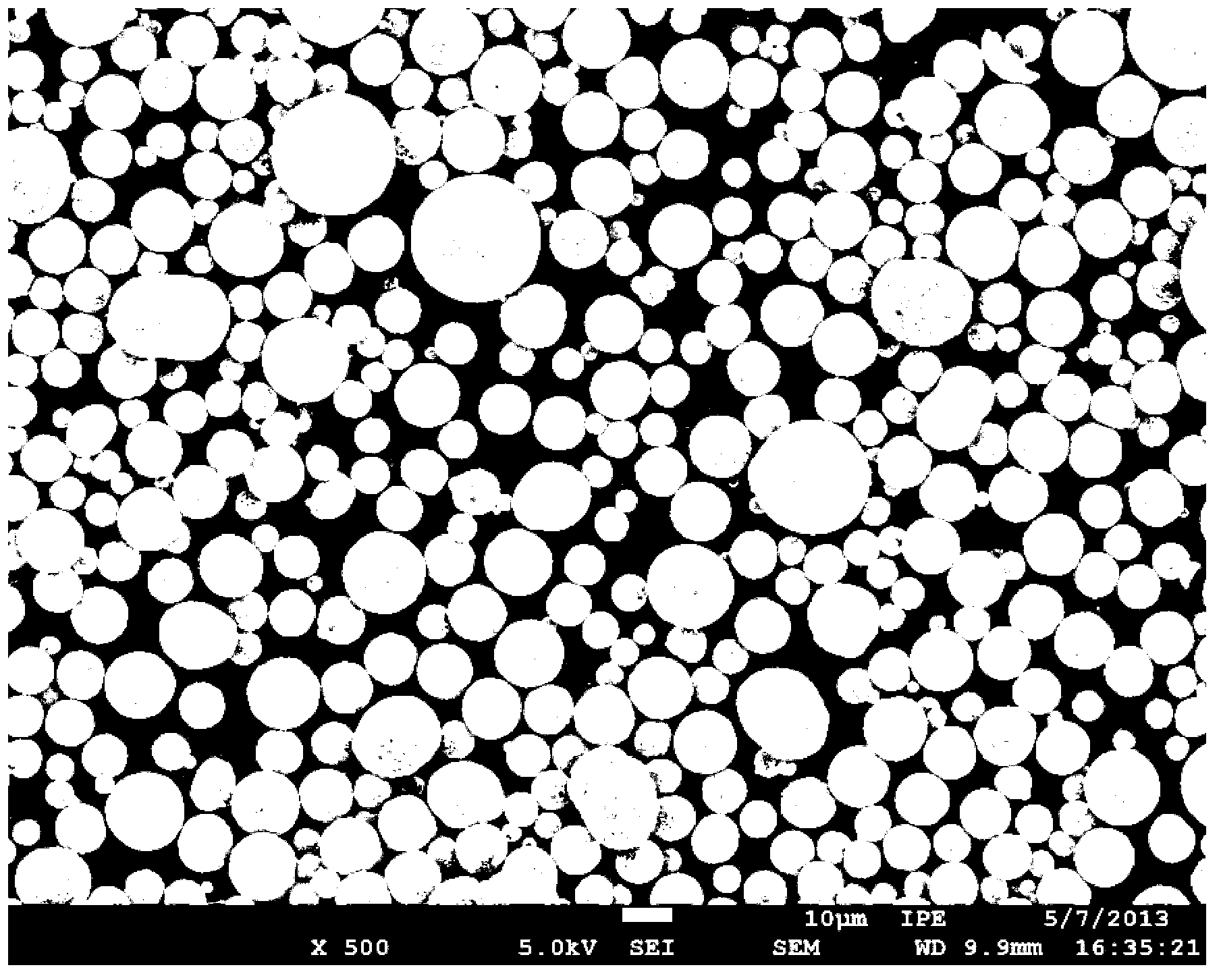

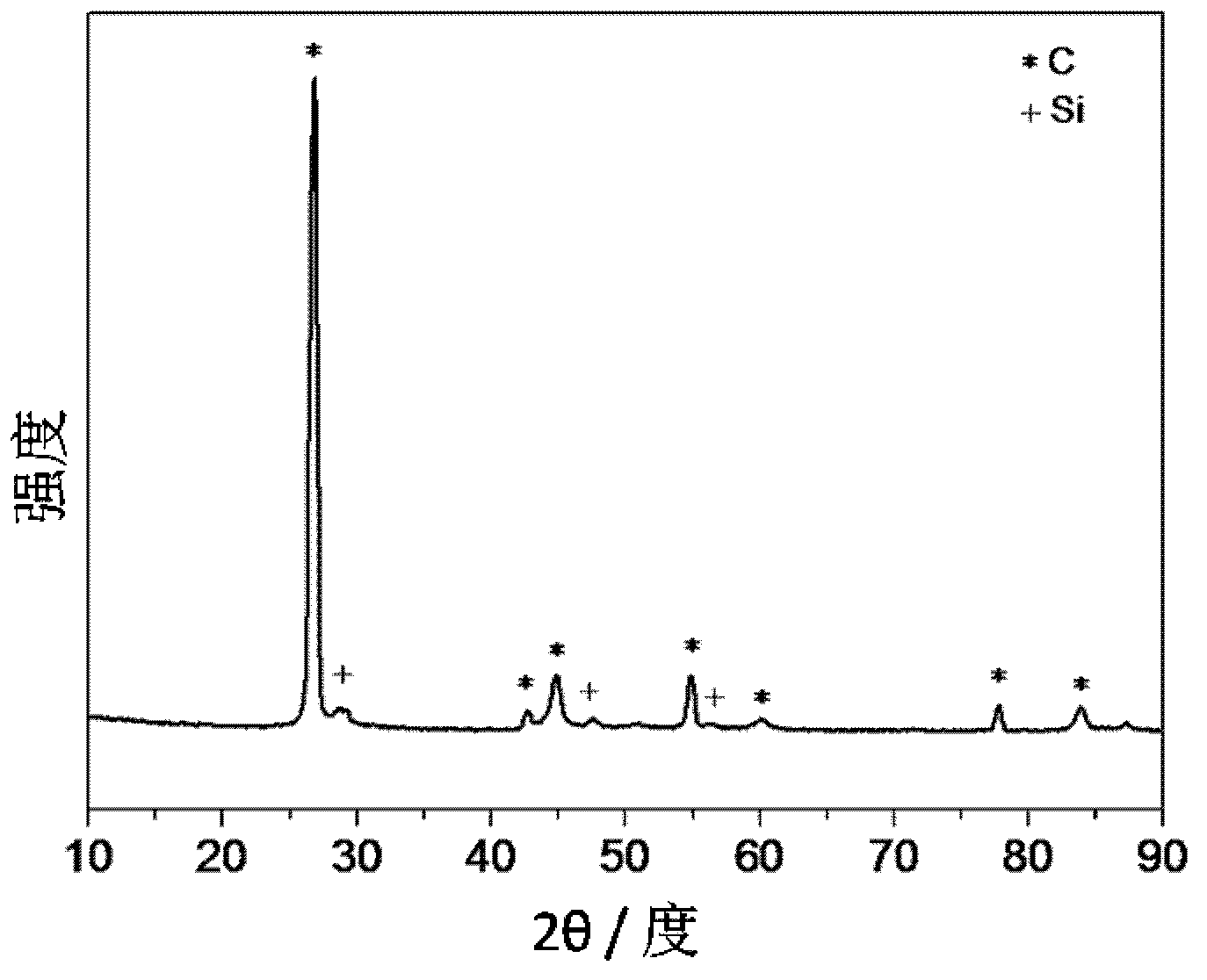

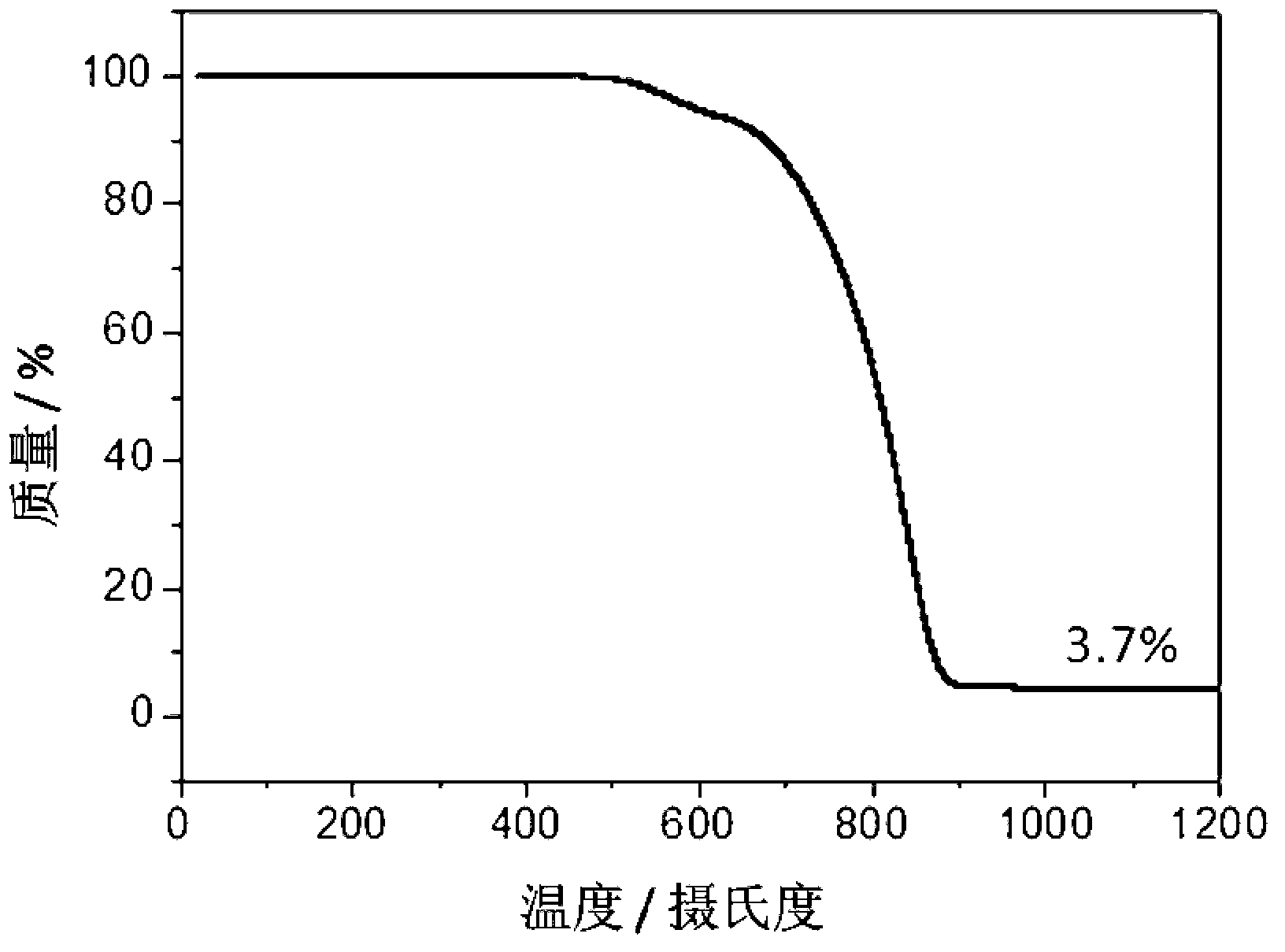

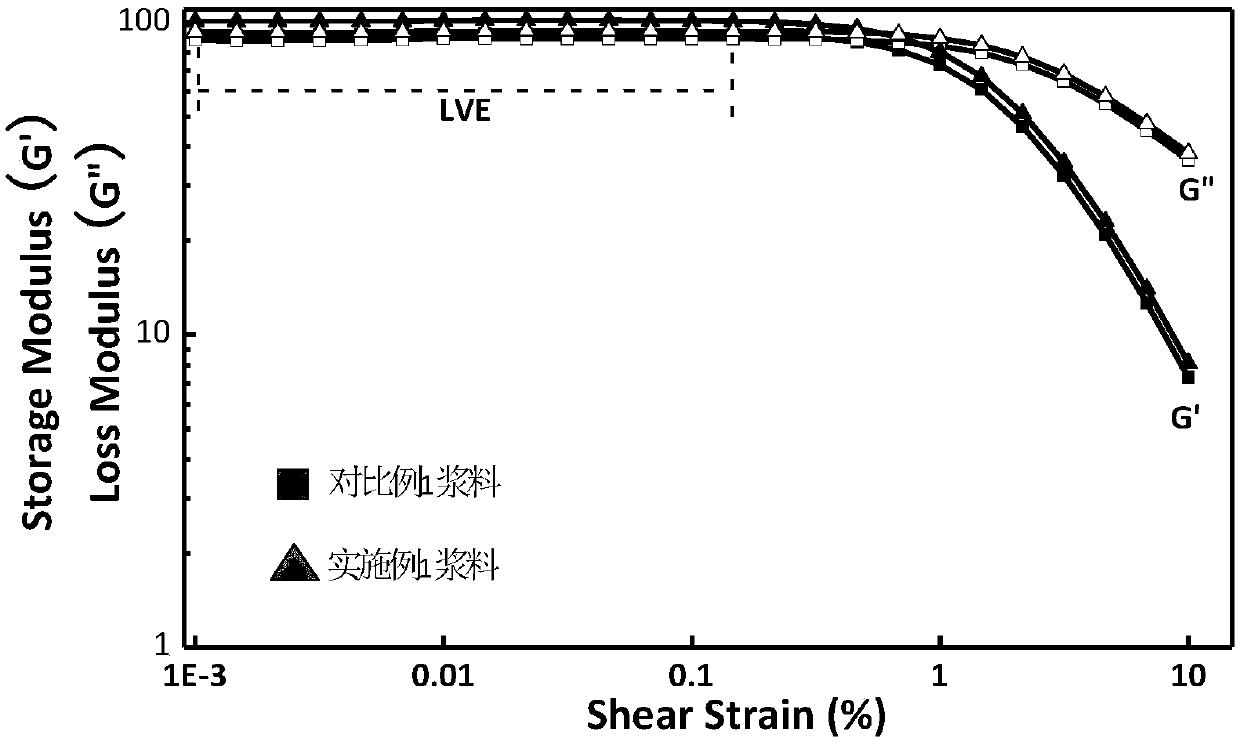

Silicon/carbon composite microsphere negative electrode material as well as preparation method and application for same

ActiveCN103311522AStable structureImprove charge and discharge cycle lifeCell electrodesSolventCarbon black

The invention relates to a silicon / carbon composite microsphere negative electrode material as well as a preparation method and an application for the same. The silicon / carbon composite microsphere negative electrode material is silicon / carbon composite microspheres internally provided with pore structures; and each microsphere comprises a matrix material of hard carbon, and an active material of silicon powder. The preparation method for the silicon / carbon composite microsphere negative electrode material comprises the following steps of: uniformly mixing silicon powder, soft carbon, carbon black, a soluble carbon-containing organic adhesive and a solvent with formula amounts to obtain a slurry; and performing spray-drying and carbonization on the slurry to obtain the silicon / carbon composite microsphere negative electrode material. The silicon / carbon composite microsphere negative electrode material provided by the invention has the advantages of being high in tap density, high in reversible capacity, good in cyclicity, good in rate capability, safe and reliable, and high in first-week coulombic efficiency; the preparation method provided by the invention is simple in process, environment-friendly, low in energy consumption and cost, and easy to realize large-scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High density lithium ion battery cathode material lithium cobalt oxide and preparation method thereof

InactiveCN102447107AIncrease compaction densityIncrease volumetric energy densityCell electrodesCobalt compoundsManufacturing technologySodium-ion battery

The invention relates to a manufacture technology of a lithium ion battery cathode material and specifically provides a high density lithium ion battery cathode material lithium cobalt oxide and a preparation method thereof. The high density lithium ion battery cathode material lithium cobalt oxide of the invention has a chemical formula of Li1+xCo(1-a-b-c) MgaTibAlcFdO(2-d), wherein a, b, c, d and x satisfy relations of: 0<=a<=0.03, 0.001<=b<=0.02, 0<=c<=0.01, 0<=d<=0.02 and 0<=x<=0.08; and a preferable value of a, a preferable value of b, a preferable value of c and a preferable value of d satisfy relations of: 0.005<=a<=0.01, 0.002<=b<=0.01, 0<=c<=0.005 and 0<=d<=0.005; and a cation M is doped or cladded by one or a composition of several selected from magnesium, titanium and aluminium. The invention can enhance stability of material structure, cycle performance and safety performance of the lithium ion battery as well as effectively increase space utilization rate of the material and compacted density of the cathode material, thereby substantially raising volume energy density of the material.

Owner:JIANGSU KING LITHIUM CELL

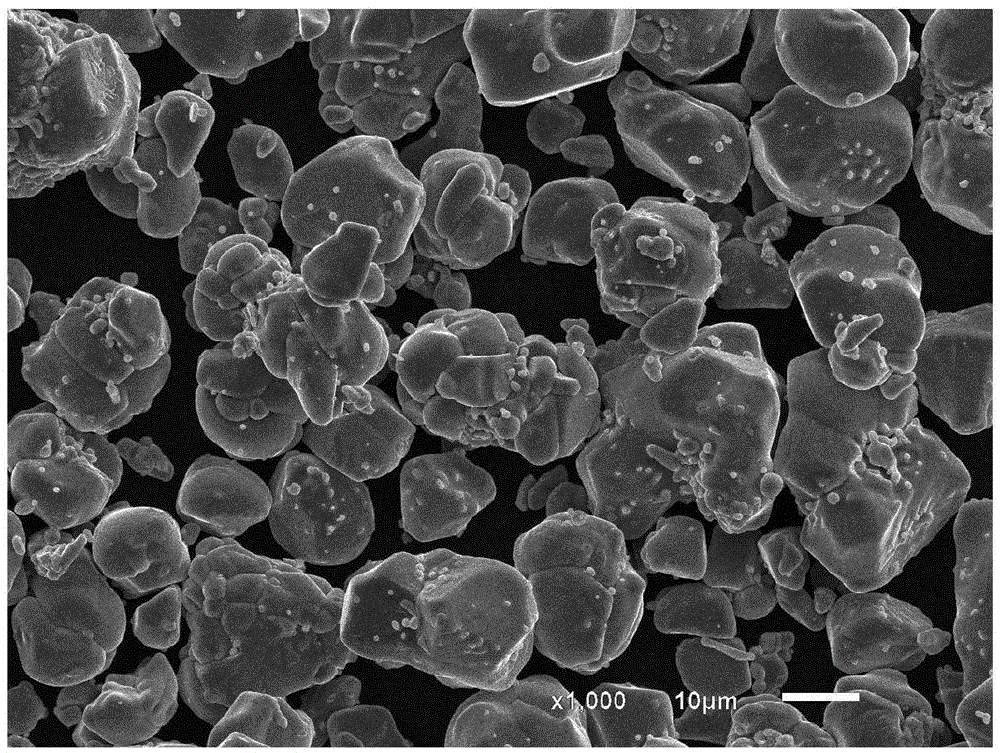

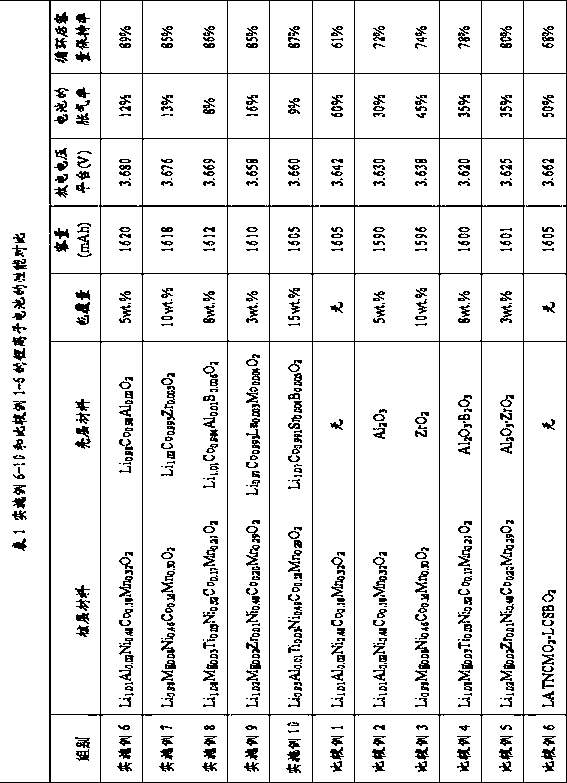

Method for preparing ternary positive electrode material of lithium ion battery

ActiveCN103811744AImprove space utilizationIncrease volumetric energy densityCell electrodesSecondary cellsEnergy densityLithium electrode

The invention relates to a method for preparing a ternary positive electrode material of a lithium ion battery. The method comprises the following steps: preparing an aggregate material A from a lithium source and a precursor, preparing a single-crystal or single crystal-like material B from a lithium source and a precursor, uniformly mixing the aggregate material A and the single-crystal or single crystal-like material B, sintering to form a material C, and coating powder of the material C with a coating, thereby obtaining the lithium-ion ternary positive electrode material. The aggregates with different granularity and shapes and the single-crystal or single crystal-like ternary material are mixed, and single-crystal particles can be effectively arranged among aggregate particles, so that the graded material is in full contact with a conductive agent and an adhesive, the space utilization rate and the compaction density of the material can be improved, the volume energy density of the material is improved, the electrical property of the material is fully exerted, the effect of heat stability of the material is improved, and the safety of the battery is improved.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

High-voltage lithium cobalt oxide cathode material for lithium-ion battery and preparation method of high-voltage lithium cobalt oxide cathode material

ActiveCN105406036AIncrease volumetric energy densityImprove cycle performanceCell electrodesSecondary cellsPhysical chemistryHigh voltage

The invention discloses a high-voltage lithium cobalt oxide cathode material for a lithium-ion battery and a preparation method of the high-voltage lithium cobalt oxide cathode material. The high-voltage lithium cobalt oxide cathode material is prepared from a doped lithium cobalt oxide matrix and a coating on the surface of the doped lithium cobalt oxide matrix, wherein a general formula of the doped lithium cobalt oxide matrix is Li<x>Co<1-y>M<y>O<2-z>N<z>; the general formula of the coating is LiNi<x'>Co<y'>Al<z'>O<2>; and the preparation method comprises the following steps: firstly, obtaining the lithium cobalt oxide matrix Li<x>Co<1-y>M<y>O<2-z>N<z> through once sintering; secondly, preparing a lithium cobalt oxide cathode material precursor coated with Ni<x'>Co<y'>Al<z'>(OH)<2> on the surface by liquid-phase co-precipitation reaction; and finally obtaining the high-voltage lithium cobalt oxide cathode material through twice sintering. The high-voltage lithium cobalt oxide cathode material prepared by the method is good in processability and high in compaction density, has relatively high specific capacity and good cycle performance in a high-voltage state, and can be stably circulated at high voltage of 3.0V to 4.5V.

Owner:HUNAN CHANGYUAN LICO CO LTD +1

Battery module and secondary battery

InactiveCN101312240AIncrease temperatureAvoid spreadingSecondary cellsCell component detailsEngineeringConductive materials

The invention provides a battery cell able to avoid fire spreading or heating of the battery effectively, undergo fire extinguishment of a battery on fire, and may has compact structure so as to have high volume energy density. The battery cell of the invention is formed as follows, e.g., a spacer (52) interposed between a plurality of batteries in a battery module has an inner cavity. A filling agent having fire-extinguishing capability is filled in the inner cavity. An opening can be formed at a portion (low-melting point portion 14) of the spacer (52) by heat so that the filling agent can flow out of the spacer. The invention also provides a secondary battery packaged with flexible outer package; wherein a thermal conductive material layer formed of gelatinous matter is formed on a surface of the outer package.

Owner:SANYO ELECTRIC CO LTD

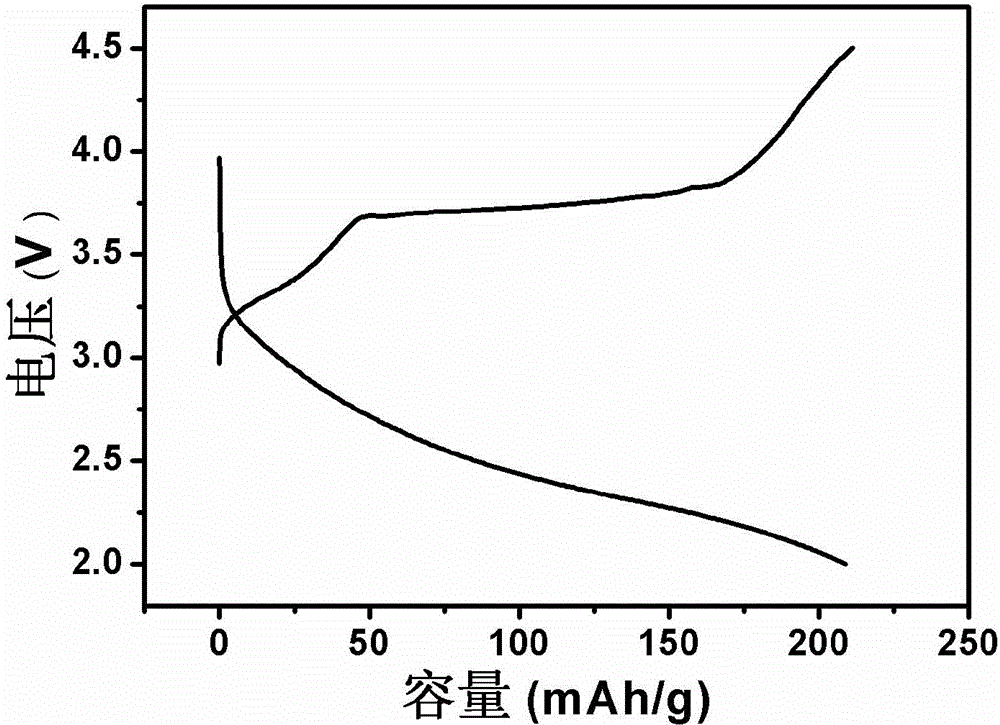

Lithium molybdate serving as secondary battery electrode material

InactiveCN104577088AImprove cycle performanceImprove securityCell electrodesSecondary cellsMetallurgyLithium molybdate

The invention discloses lithium molybdate serving as a secondary battery electrode material. In an execution mode, a chemical formula of the electrode material is Li (2-x)MoyMzO(3-u), wherein x is larger than or equal to minus 2 and smaller than or equal to 2, y is larger than 0 and smaller than or equal to 5, z is larger than or equal to 0 and smaller than or equal to 9, u is larger than or equal to minus 9 and smaller than or equal to 3, and M comprises one element selected from C, N, F, Na, Mg, Al, Si, P, S, Cl, K, Ca, Sc, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ga, Ge, As, Se, Br, Rb, Sr, Y, Zr, Nb, Mo, Tc, Ru, Rh, Pd, Cd, In, Sn, Sb, Te, I, Cs, Ba, Ta, W, Re, Os, Ir, Pt, Au, Hg, Pb, Bi, Po, At, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu or combination of the elements. The electrode material is characterized by having very high specific capacity, excellent cycle performance, rate capability and safety.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Composite anode material of high-voltage lithium ion battery and lithium ion battery

ActiveCN102891307AIncrease volumetric energy densityMeet the needs of thinningCell electrodesCyclic processElectrical battery

The invention discloses a composite anode material of a lithium ion battery. The composite anode material has a core-shell structure, a core layer material is Li1+nAwNi0.5+xCo0.2+yMn0.3+zO2, a shell layer material is Li1+aCo1-bMbO2, and the shell layer material accounts for 0.1-20% of the composite anode material in mass percent. Compared with the prior art, the composite anode material disclosed by the invention has the advantages that because a cladding layer can exert effective gram volume and discharge voltage platform under high voltage, the energy density of the battery is improved, and in addition, the structural stability of an enhancement matrix material of the cladding layer is good for effectively inhibiting the dissolution of Mn among the materials in a cyclic process, and the oxidation of electrolyte by the anode material is reduced; and in addition, the invention further discloses a preparation method of the anode material and the lithium ion battery containing the anode material.

Owner:DONGGUAN AMPEREX TECH +1

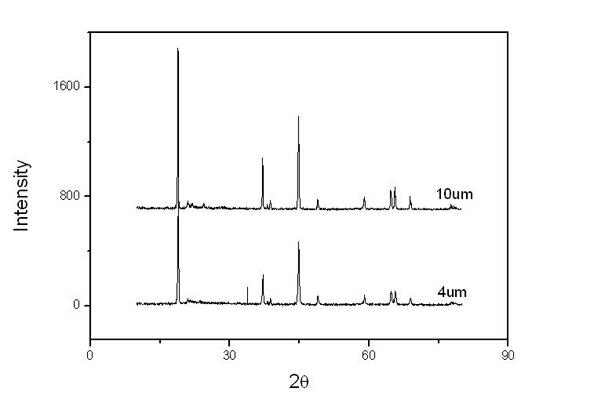

Process for preparing lithium cobalt oxide of lithium-ion secondary battery cathode materials

ActiveCN101694874AImprove featuresImprove discharge capacityCell electrodesSecondary cellsLaser scatteringOxygen

The invention provides a process for preparing lithium cobalt oxide of lithium-ion secondary battery cathode materials. The process includes that cobalt oxide or hydroxyl cobalt oxide powders and lithium carbonate powders are mixed according to a lithium / cobalt molar ratio of 1.0-1.1 and calcined in an atmosphere containing oxygen at the temperature of 850-1100 DEG C; obtained mixture is calcined for 5-55 hours in the atmosphere containing oxygen at the temperature of 850-1100 DEG C; calcined products are naturally cooled to reach room temperature and then grinded; laser scattered grain size distribution measuring device is used for classifying; lithium cobalt oxide semi-finished products are obtained by selecting an average grain diameter D50 of 8-20 micrometers; and a device with high-speed shear strength function is used for conducting coating composition treatment process on the surfaces of the lithium cobalt oxide semi-finished products. The process has the advantages of low raw material cost, high volume energy density, good safety, fine charge-discharge cycle performance, high pressurizing density and superior productivity.

Owner:NANTONG RESHINE NEW MATERIAL

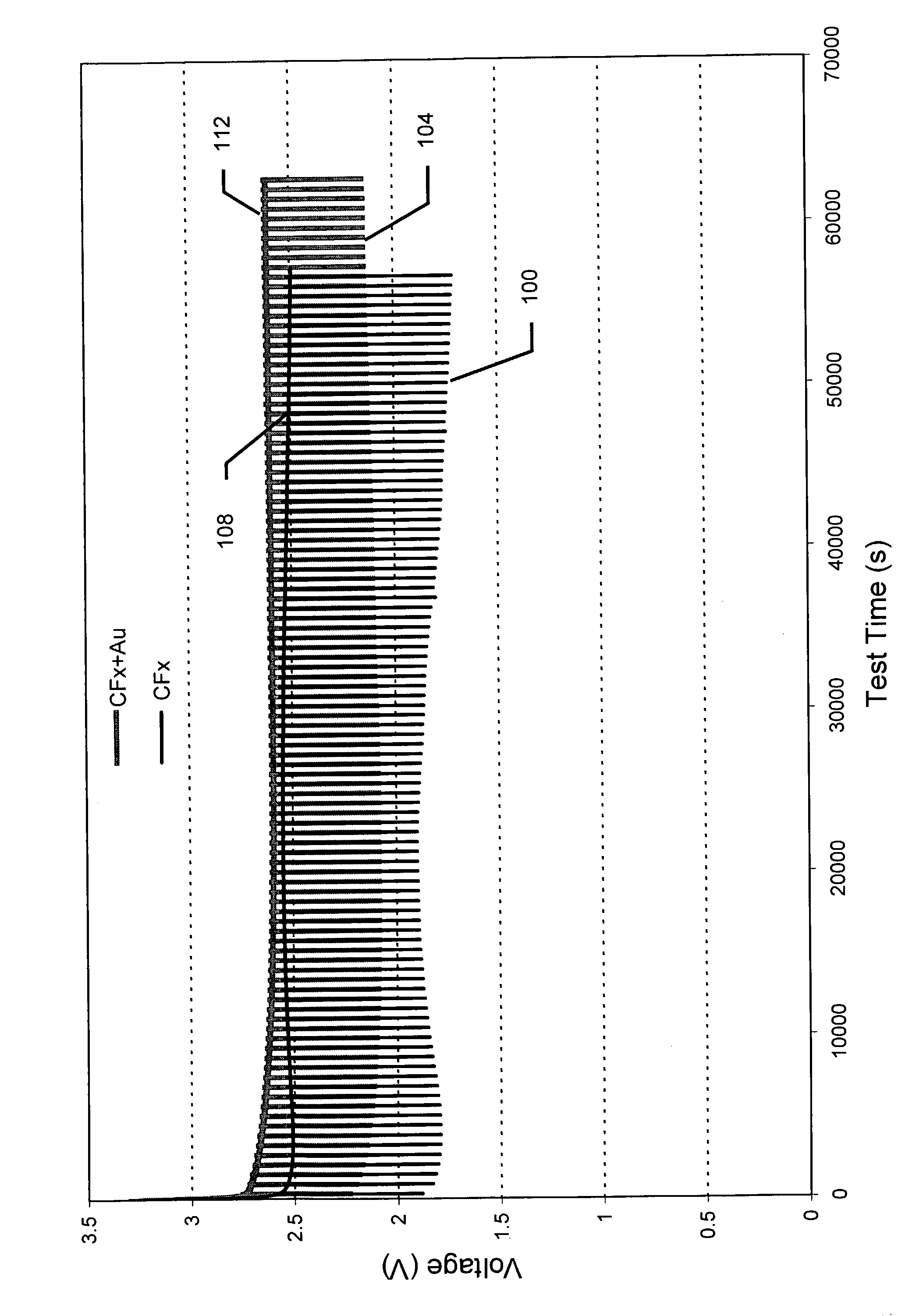

Fluorinated carbon active material

ActiveUS20040072075A1Improve featuresImprove conductivityHybrid capacitor electrodesLiquid electrolytic capacitorsElectrical batteryLithium metal

Disclosed is an improved type of fluorinated carbon (CFx) for use in electrical storage devices such as batteries and capacitors. The CFx is coated with a conductive material such as gold or carbon using vapor deposition. The resulting material exhibits better conductivity with concomitant lower impedance, higher electrical stability, and improved potential throughout the useful life of the device, as compared to uncoated CFx. The improved conductivity reduces the amount of nonactive material (e.g., carbon black) that needs to be added, thus improving the volumetric energy density. In addition, cells made with the subject CFx exhibit more constant voltages and higher overall voltage (2.0 volts with a lithium metal anode) throughout their useful life. Chemical or physical vapor deposition techniques to deposit a variety of metals or carbon may be used to create the improved CFx. The coated CFx may be used in primary or secondary batteries, as well as capacitors and hybrid devices. Methods for making and using the coated CFx are described.

Owner:QUALLION

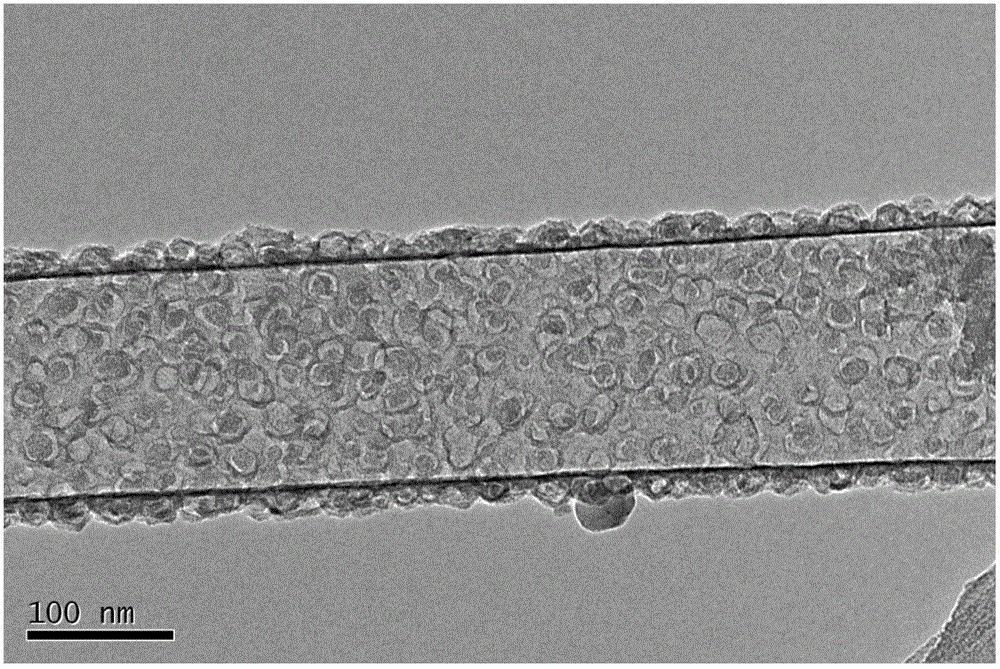

Graphene hollow nano fiber and preparation method thereof

The invention relates to a graphene hollow nano fiber and a preparation method thereof. The external diameter of the graphene hollow nano fiber is 7-700nm, the internal diameter is 6-698nm, the length-diameter ratio is 20:1-2000:1, and the specific area is 300-2600 m<2> / g. The preparation method comprises the following steps: by using an inorganic fiber as a template, heating to 400-1000 DEG C in a carrier gas, introducing a carbon source, and decomposing at the same temperature to directly form the graphene hollow fiber or form a carbon-inorganic template composition fiber; and cooling the composition fiber, treating with acid or alkali, filtering, washing and drying. The preparation method is simple; and the product has the advantages of high purity, complete structure and high mechanical strength, and is suitable to be used as a separation or adsorbing material, an electrode material for electrochemical energy storage or a conducting agent.

Owner:TSINGHUA UNIV

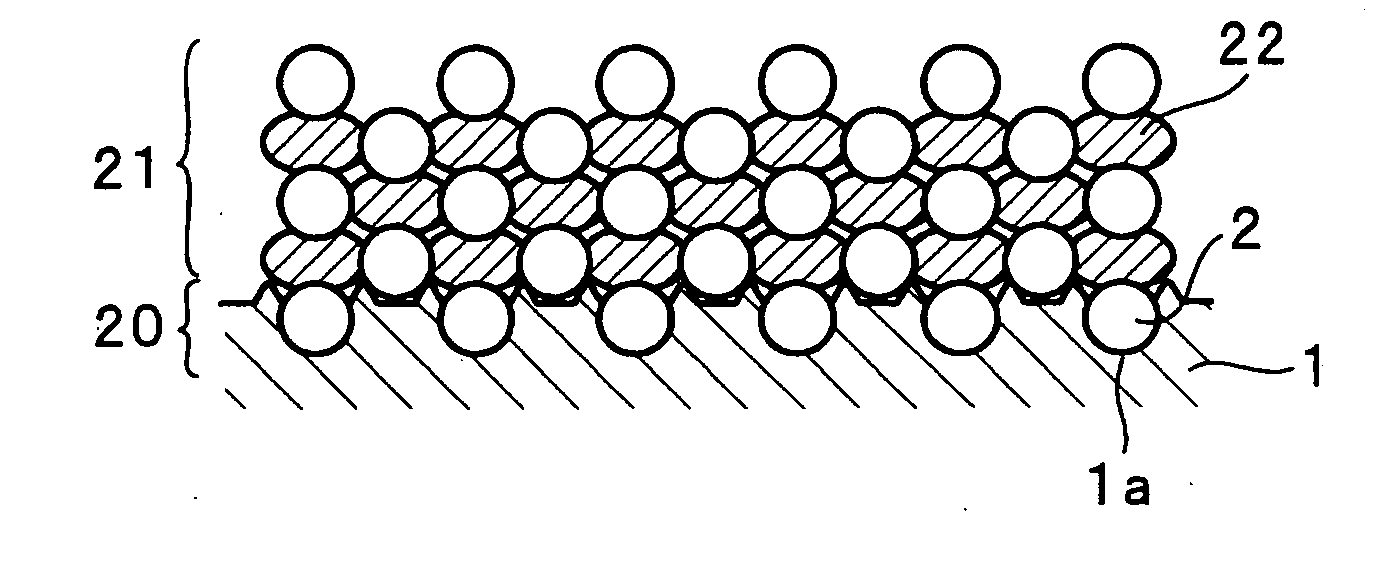

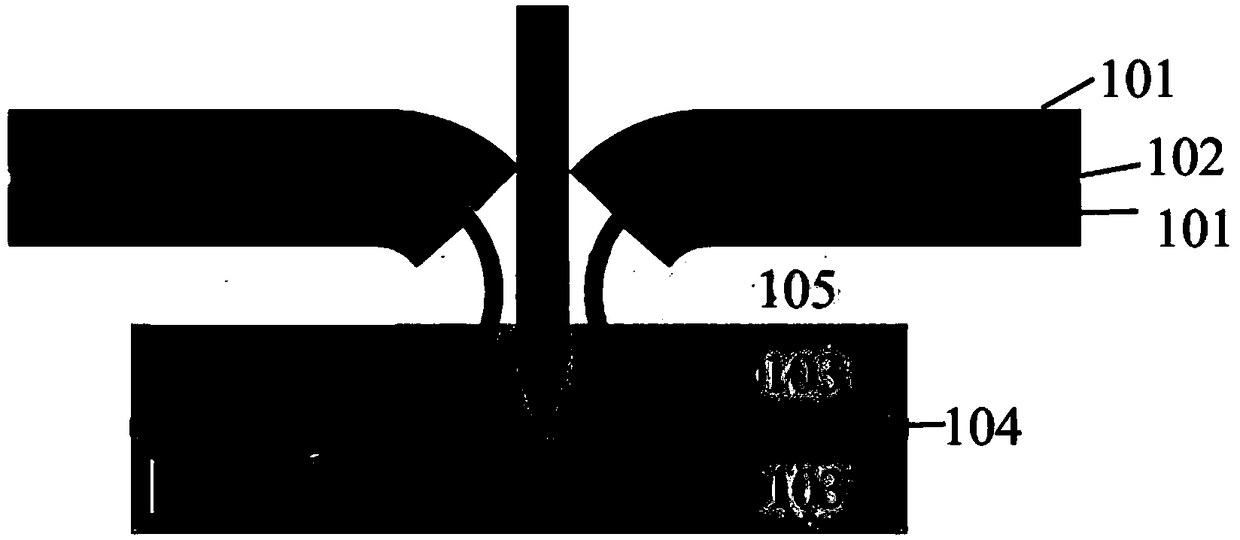

Electrode for lithium secondary battery and lithium secondary battery

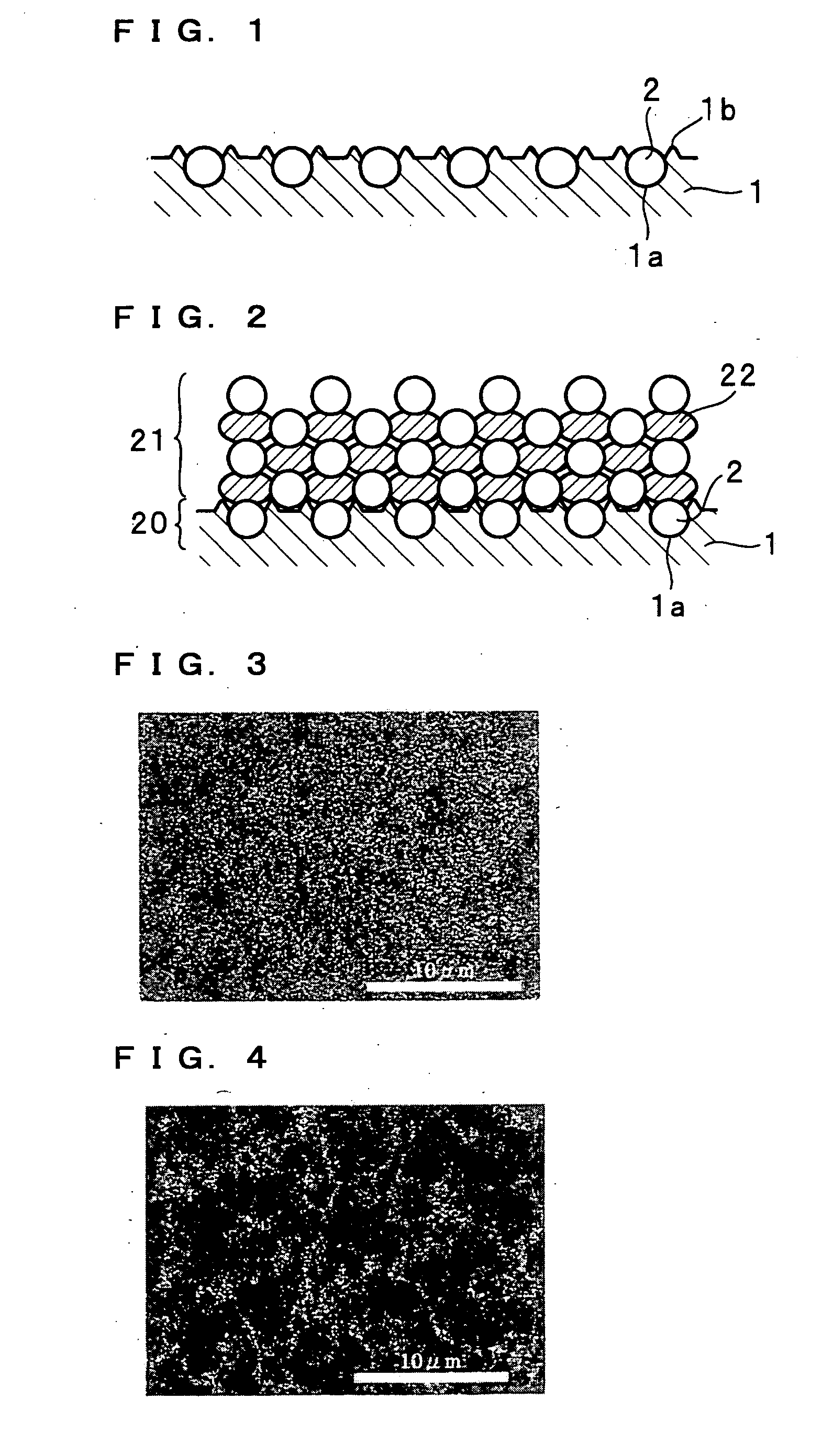

ActiveUS20060159997A1Increase volumetric energy densityImprove charge and discharge cycle characteristicsElectrode carriers/collectorsActive material electrodesLithiumEngineering

There is provided an electrode for a lithium secondary battery where particles, composed of an active material capable of occluding and releasing lithium, are arranged on a current collector, the active material particle being directly bonded to the surface of the current collector in a state where the bottom of the active material particle is imbedded in a concave portion formed on the surface of the current collector. A second particle layer may be provided on a first particle layer comprising the active material particles directly bonded to the surface of the current collector.

Owner:PANASONIC ENERGY CO LTD +1

Electrochemical device

InactiveCN108878748AImprove adhesionImprove protectionCell electrodesLi-accumulatorsConductive polymerElectrochemical cell

Owner:NINGDE AMPEREX TECH

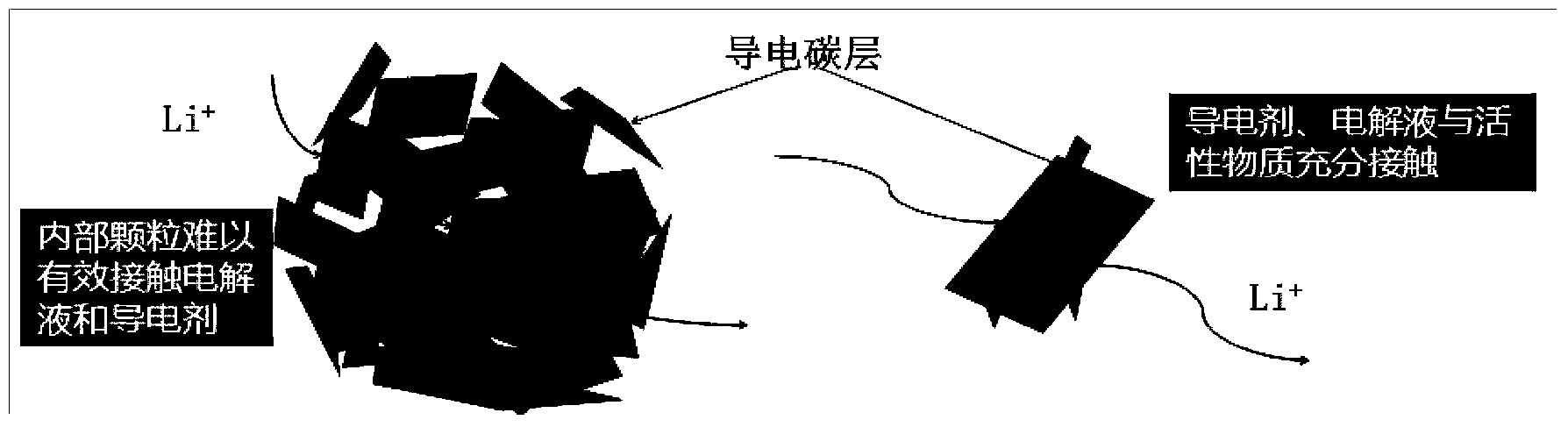

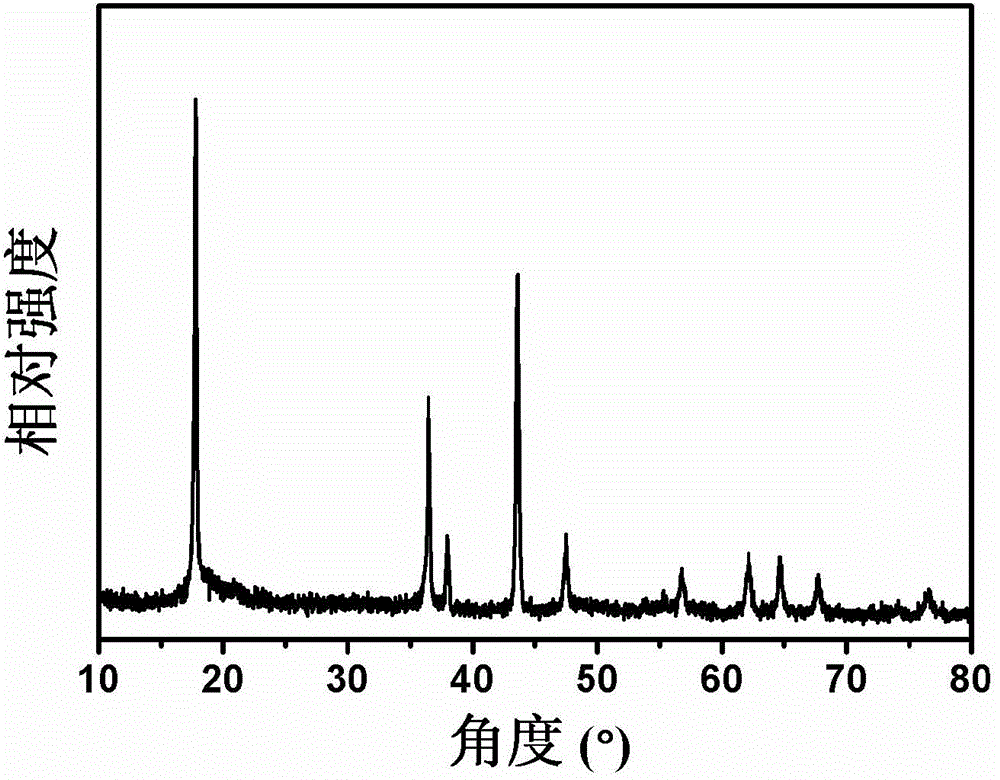

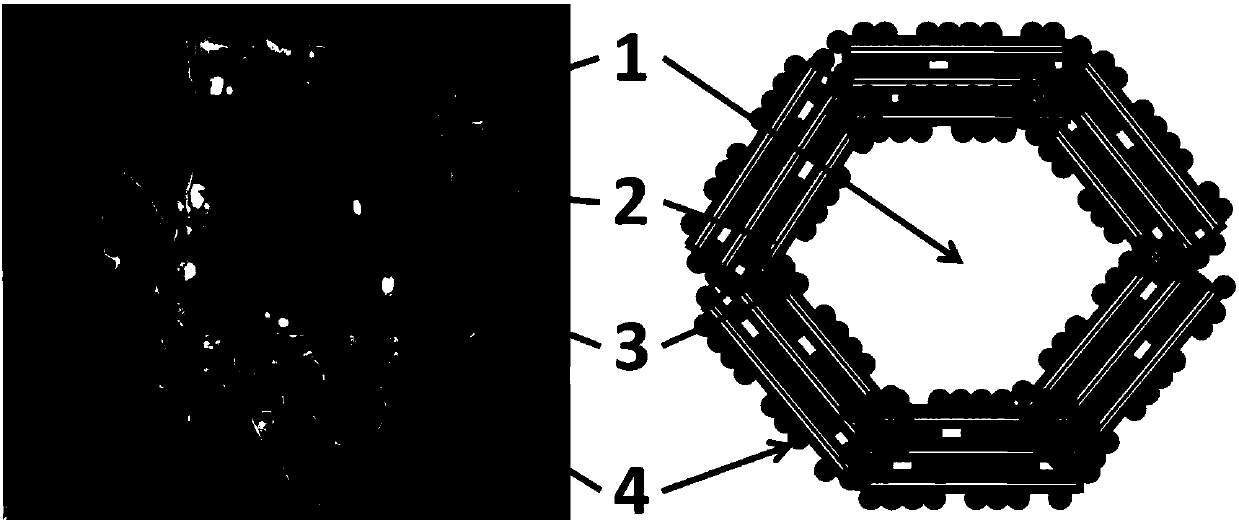

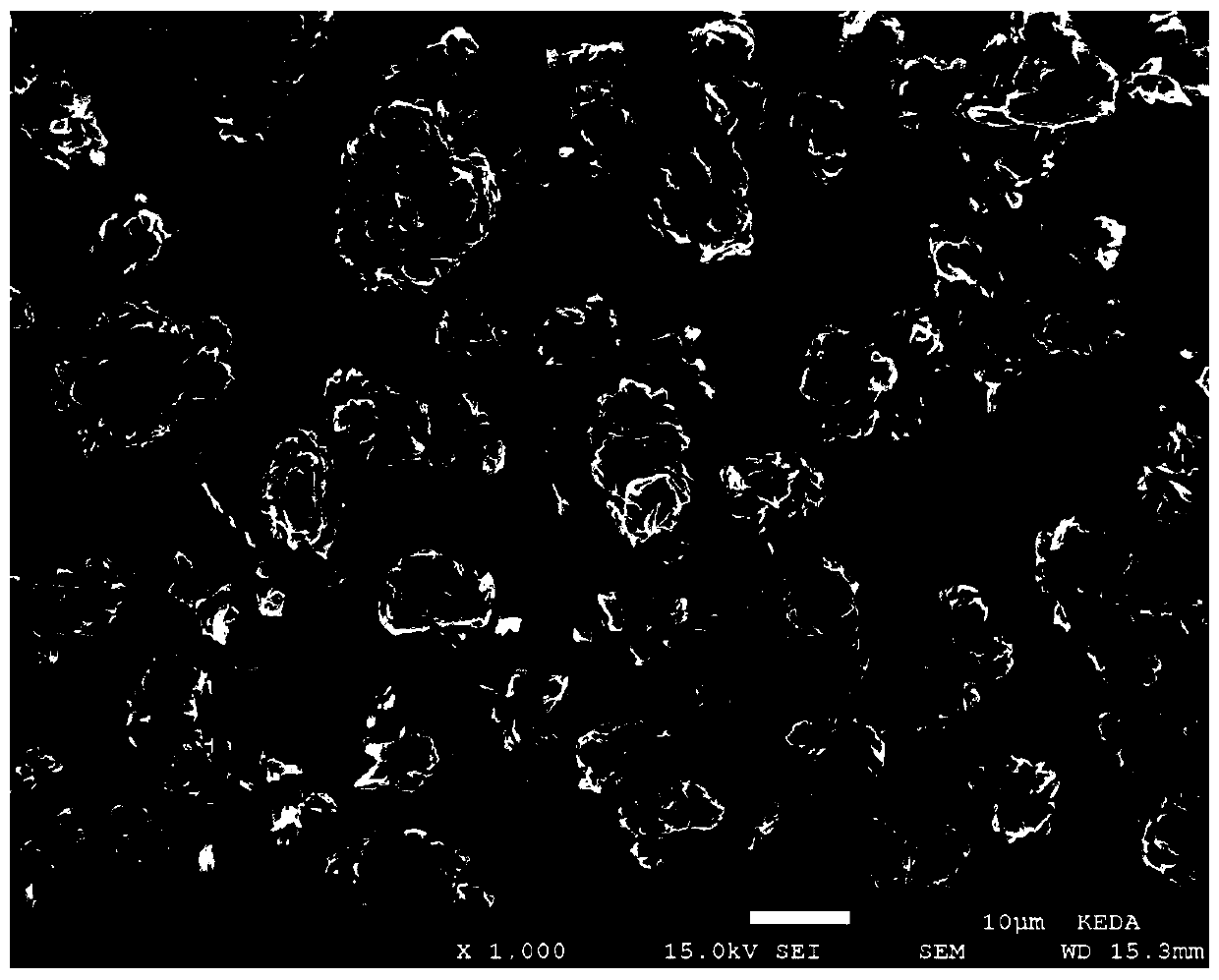

Hollow silicon-carbon composite material for lithium-ion batteries, and preparation method thereof

InactiveCN107799728AIncrease capacityImprove Coulombic efficiencyNegative electrodesSecondary cellsCarbon compositesElectrochemistry

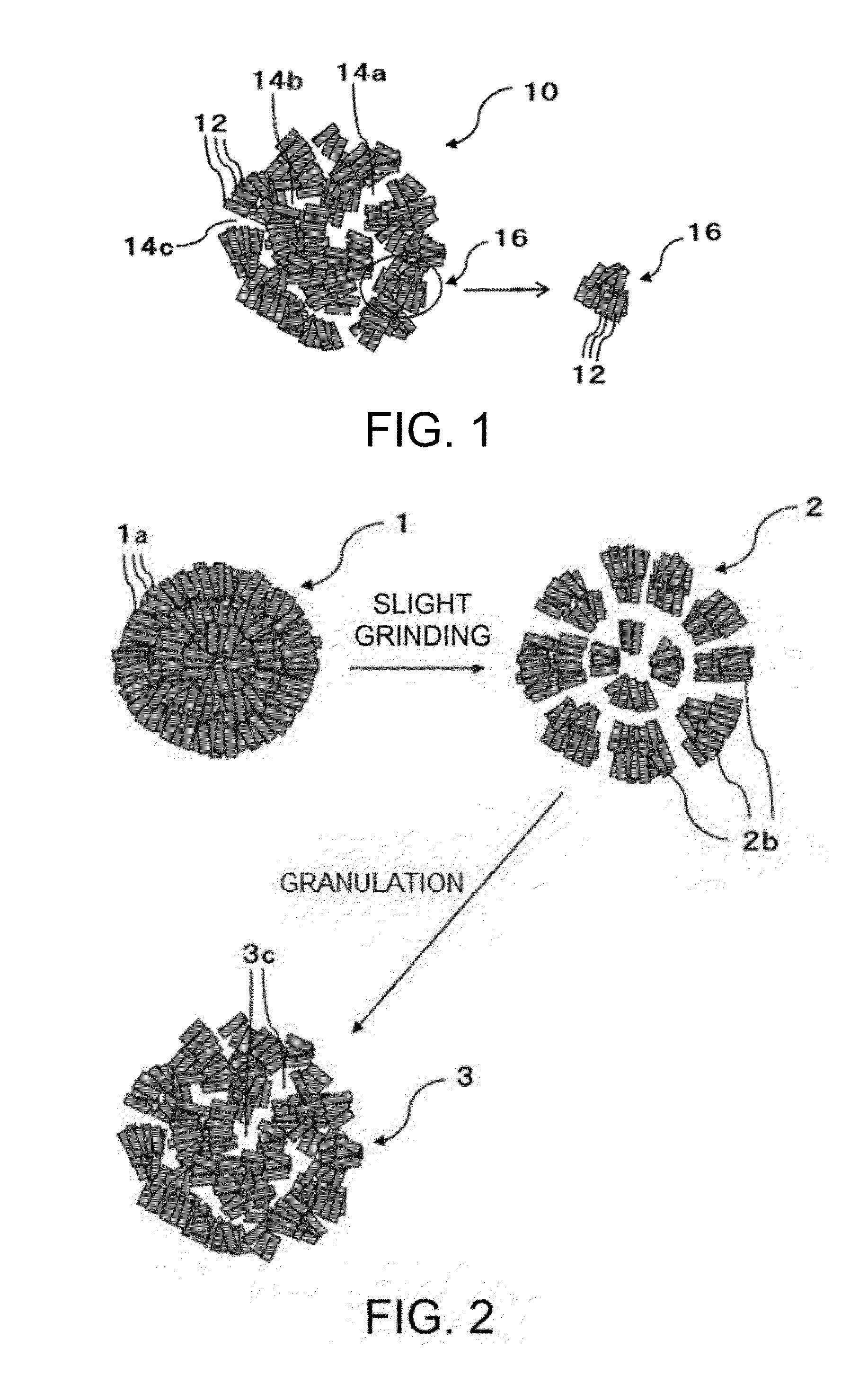

The invention relates to a hollow silicon-carbon composite material and a preparation method thereof. According to the hollow silicon-carbon composite material, the silicon-carbon composite material is spherical or ellipsoid secondary particles; the secondary particles have hollow structures, the shell is formed by compounding graphite sheets, a silicon material and amorphous carbon, the silicon material is uniformly adhered on the surface of the graphite sheet and between the graphite sheets, and the surfaces of all the graphite sheets and the silicon material are covered with an amorphous carbon protection layer; and the graphite sheets for forming the secondary particles are randomly oriented to each other. According to the present invention, the silicon-carbon composite material used as the lithium-ion battery negative electrode has electrochemical characteristics of high capacity, high Coulomb efficiency, low expansion and good cycle performance; the lithium-ion battery prepared from the silicon-carbon composite material has characteristics of high volume energy density, low expansion and good cycle performance; and the preparation process has advantages of simpleness, wide raw material source and low cost, and can achieve the industrial application of the silicon-carbon composite material in the lithium battery field.

Owner:BERZELIUS (NANJING) CO LTD

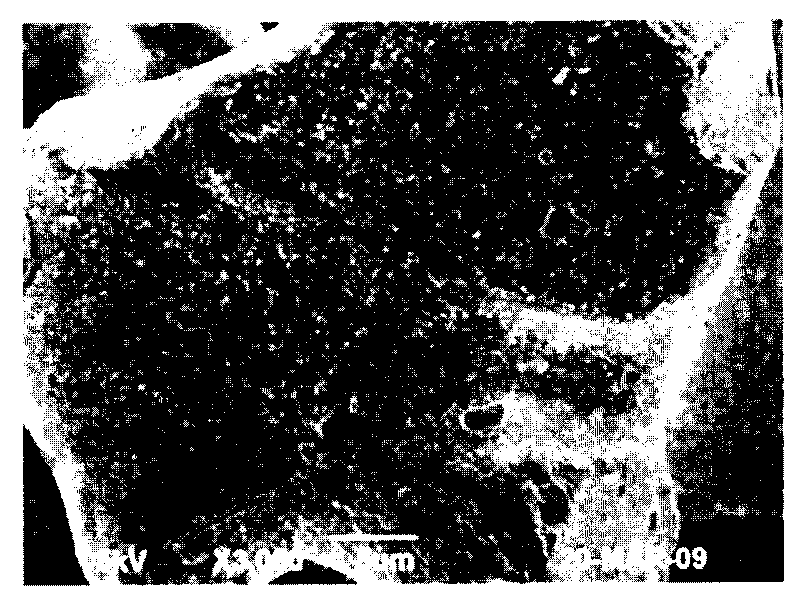

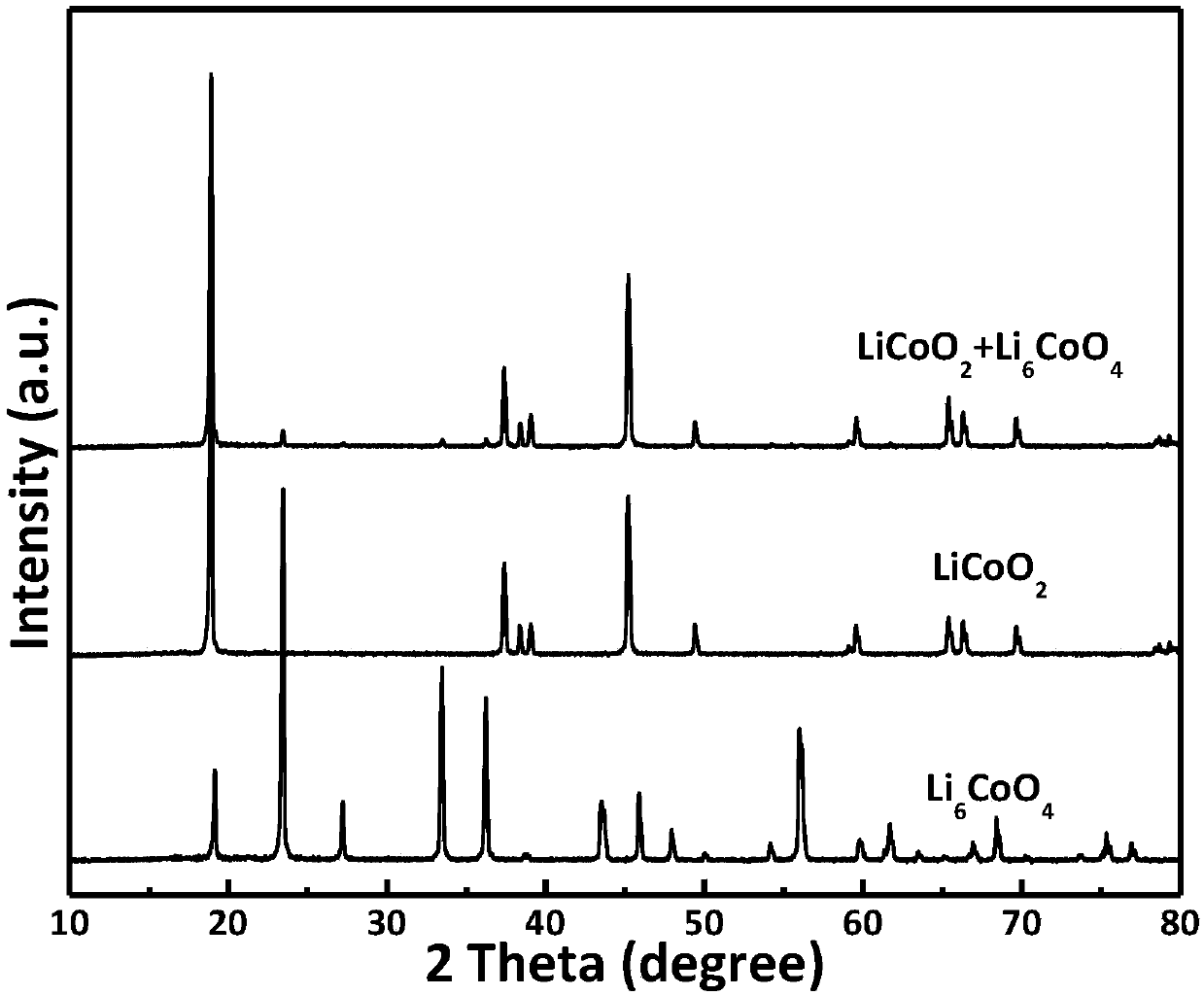

Method for preparing high-compaction high-voltage lithium cobaltite cathode material

InactiveCN102122712AImprove cycle performancePromote circulationCell electrodesCobalt(II,III) oxidePhysical chemistry

The invention relates to a method for preparing a high-compaction high-voltage lithium cobaltite cathode material. The method comprises the following concrete steps and implementation manners: by using a coprecipitation method, coating an NixMny(OH)z layer on the surface of a cobaltosic oxide in the preparation method to obtain a precursor of a gradient material [NixMny(OH)z]n.(Co3O4)1-n, wherein x is more than or equal to 0.1 and less than or equal to 0.75, y is more than or equal to 0.3 and less than or equal to 1.5, n is more than or equal to 0 and less than or equal to 0.35, and z is 2 or 4; tempering and sintering at a certain temperature to form an oxide in a gradient structure of [NixMnyOz]n.(Co3O4)1-n; and adding lithium and carrying out secondary sintering, thus obtaining the high-compaction high-voltage gradient cathode material. The lithium cobaltite cathode material has good cycle performance at high voltage, the product process is simple and is easy to control, and the cathode material is applicable to batch production.

Owner:NINGBO JINHE NEW MATERIALS

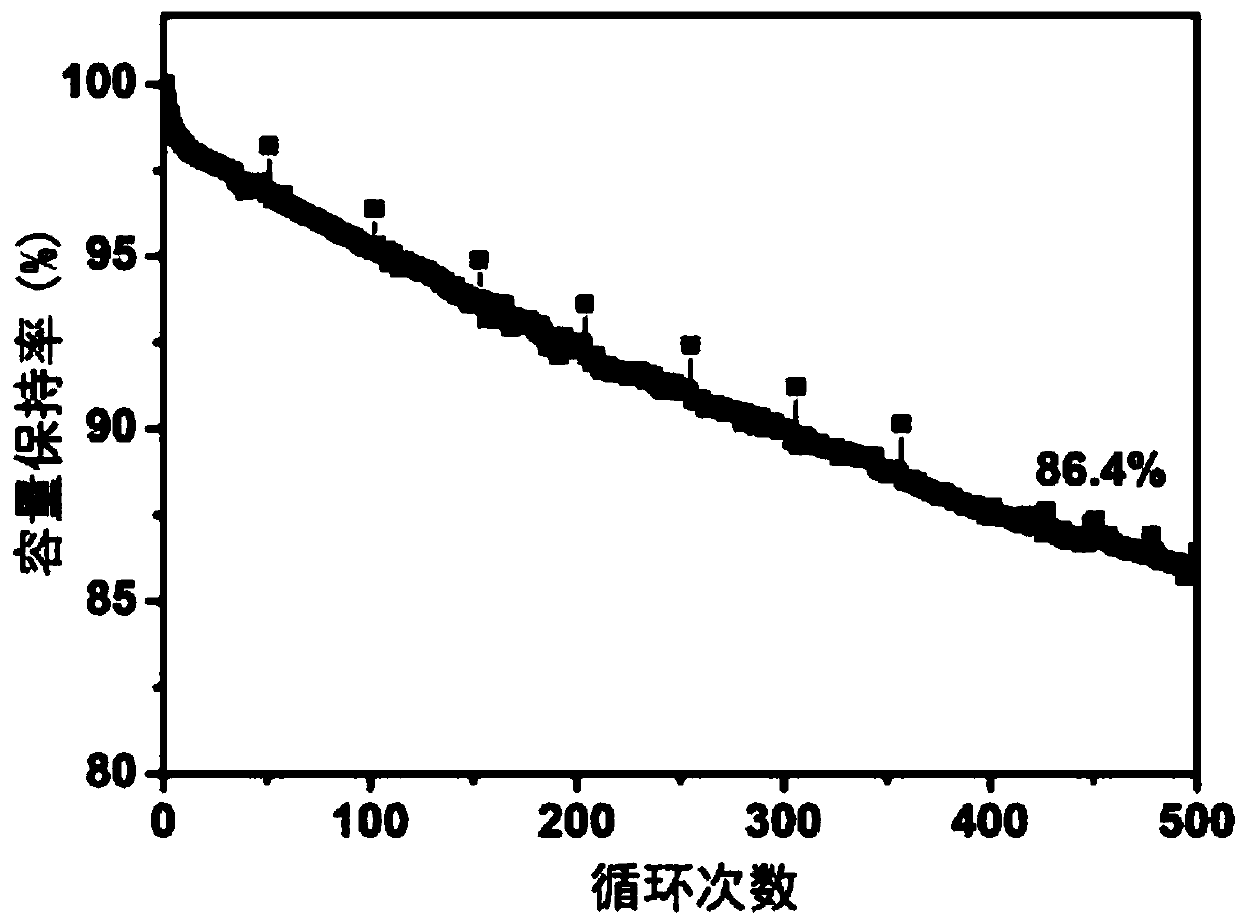

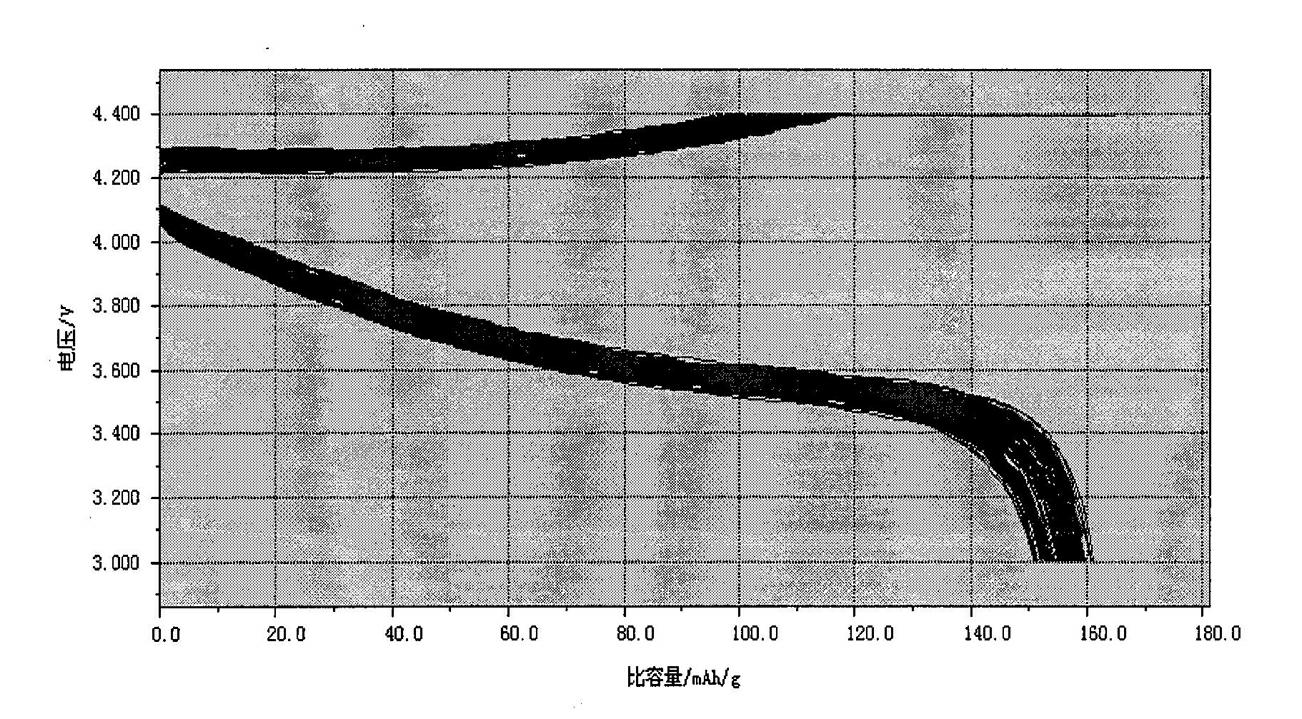

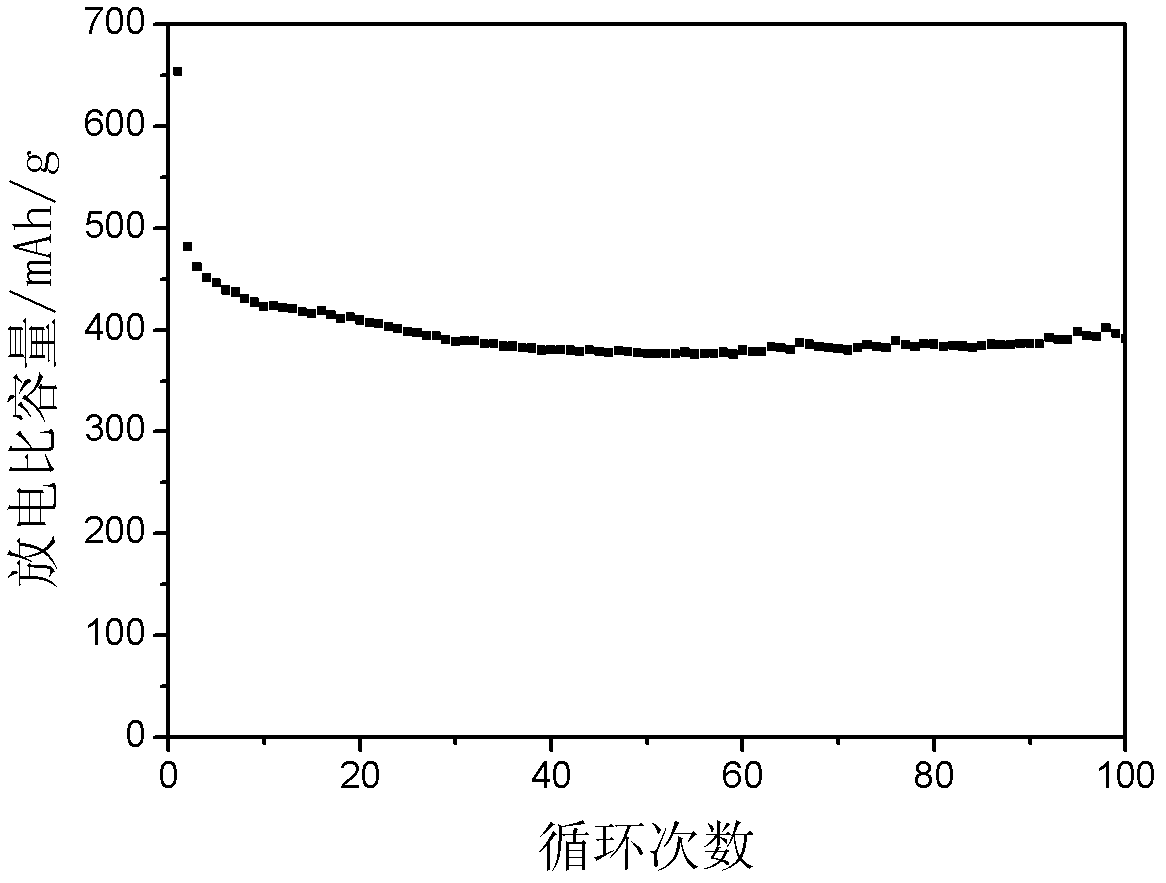

Lithium ion battery with high energy density

ActiveCN110224169AIncrease capacityImprove cycle performanceSecondary cellsPositive electrodesHigh energySodium-ion battery

The invention relates to a lithium ion battery, which comprises: (1) a positive electrode, (2) a negative electrode, (3) a diaphragm, (4) electrolyte and (5) a packaging material. The active materialin the positive electrode is made by simple physical mixing of a lithium-rich cobalt oxide material and other lithium-containing metal oxide positive materials. The active material is made into the positive electrode first, and then, the battery is made. A lithium ion battery with high energy density and good cycle performance can be obtained by making use of the high capacity characteristic of lithium-rich cobalt oxide. The preparation method of the lithium ion battery of the invention is simple and efficient and has good repeatability, and can truly realize large-scale production of lithiumion batteries with higher energy density.

Owner:BERZELIUS (NANJING) CO LTD +1

Composite carbon material, modified electrode material prepared from composite carbon material and lithium ion battery

ActiveCN107706403AImprove stabilityImprove coating uniformityCell electrodesCarbonizationSodium-ion battery

The invention discloses a composite carbon material, a modified electrode material prepared from the composite carbon material and a lithium ion battery. The composite carbon material contains a firstcarbon material, a second carbon material and a carbon source, wherein the first carbon material and the second carbon material are doped carbon materials. Compared with a conventional manner for firstly coating by virtue of a carbon source for carbonization to obtain a carbon material coating layer, the composite carbon material has the advantages that by introducing a proper amount of the firstcarbon materials and a proper amount of the second carbon materials, on one hand, the use amount of a common carbon source is reduced, and on the other hand, the electrochemical properties of structure stability, electrical conductivity, tap density, volume energy density, rate capability, cycle performance and the like of an electrode material modified by the composite carbon material can be cooperatively improved. By coating and modifying lithium iron phosphate by virtue of the composite carbon material, the rate capability and cycling stability of lithium iron phosphate can be substantially improved, the specific discharge capacity of lithium iron phosphate is more than or equal to 149mAh / g under a 6C rate condition, and the capacity retention ratio is more than or equal to 97% after 60 cycles.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for processing positive pole material of lithium cobalt acid in lithium ion battery

InactiveCN1697212AWeight increaseIncrease volumetric energy densityElectrode manufacturing processesInternal resistanceLithium-ion battery

Usage ratio of cobalt ion in material of positive pole is only 50% currently. The treating method disclosed in the invention includes following steps: coating a layer of metallic oxide film on surface of LiCoO2 granules; carrying out drying and sintering treatment. Features of the product produced from the method are: improving high temperature property, cyclical stability, stability of anti overcharge; postponing ascend of internal resistance in charging procedure. The battery is posible to be charged at higher voltage. The method raises weight of material and volume energy density more than 20%.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Lithium ion battery composite negative electrode material, its preparation method, negative electrode with application of material thereof and lithium ion battery

InactiveCN102427129ARich sourcesLow costCell electrodesSecondary cellsCarbon compositesLithium electrode

The invention relates to a lithium ion battery composite negative electrode material, its preparation method, a negative electrode with the application of the material thereof and a lithium ion battery. According to the preparation method, Fe2O3 and a carbon material are used as raw materials. The carbon material is one component, random two components or a mixture of three components, wherein the components are selected from the group consisting of acetylene black, graphite and carbon black. A Fe2O3-and-carbon composite powdered material is obtained by ball milling. Or an iron oxide and carbon material containing composite powdered material is obtained by calcining at a certain temperature, wherein the iron oxides contain one, two or three components selected from Fe2O3, Fe3O4 and FeO. The ratio of the iron oxides to the carbon material in the composite powdered material can be adjusted and controlled by changing the initial ratio. The type of the iron oxides can be controlled by controlling the calcining temperature and time. The preparation method of the composite powdered material is simple, has high production efficiency and is suitable for large-scale production. With the application of the composite powdered material, the lithium ion battery negative electrode material is endowed with high discharge capacity and good cycle stability. The electrode prepared by the material has high specific capacity and excellent circularity, and is very suitable for the industrial application of the lithium ion battery.

Owner:ZHEJIANG UNIV

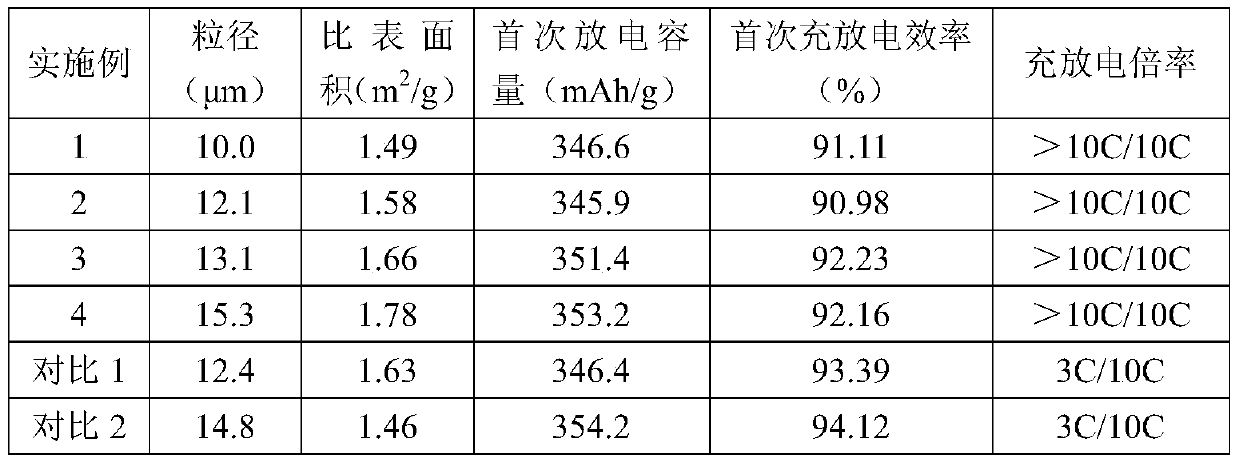

Method for preparing high-rate artificial graphite anode material

ActiveCN109830669AReduce processing costsReduce electrostatic attractionCell electrodesSecondary cells servicing/maintenanceHigh rateEconomic benefits

The invention belongs to the field of lithium ion batteries and relates to a method for preparing a high-rate artificial graphite anode material, comprising the following steps: (1) preferential selection of pulverized and shaped tailings; (2) mixing; (3) static coating and granulation; (4) breaking and spheroidization; (5) secondary mixing; (6) high-temperature graphitization; and (7) mixing andsieving. The anode material prepared by the method has excellent high rate charge / discharge performance, and has good cycle performance and low-temperature temperature. The method also fully processesand recycles the by-products produced in the processing of coke raw materials / asphalt raw materials in a high value-added manner, has broad market prospects, reduces the disposal cost of solid waste,and brings practical economic benefits.

Owner:KEDA (ANHUI) NEW MATERIAL CO LTD

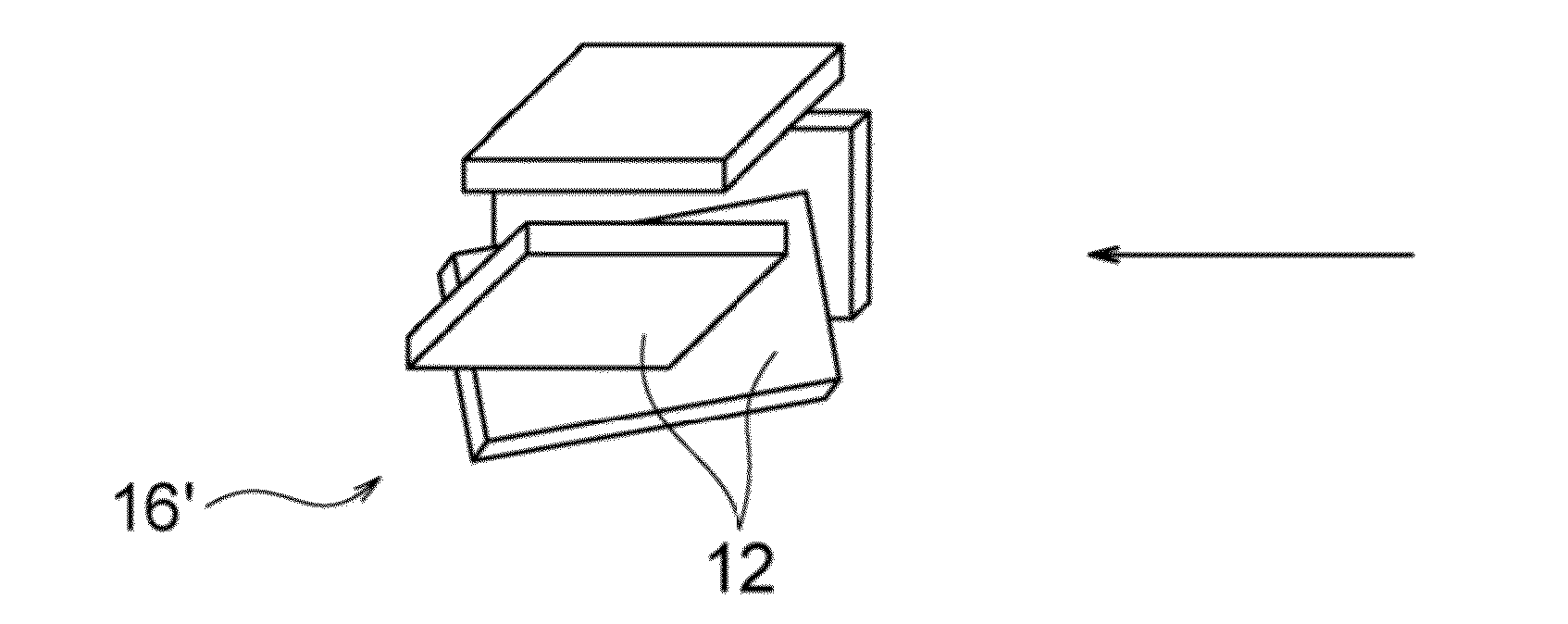

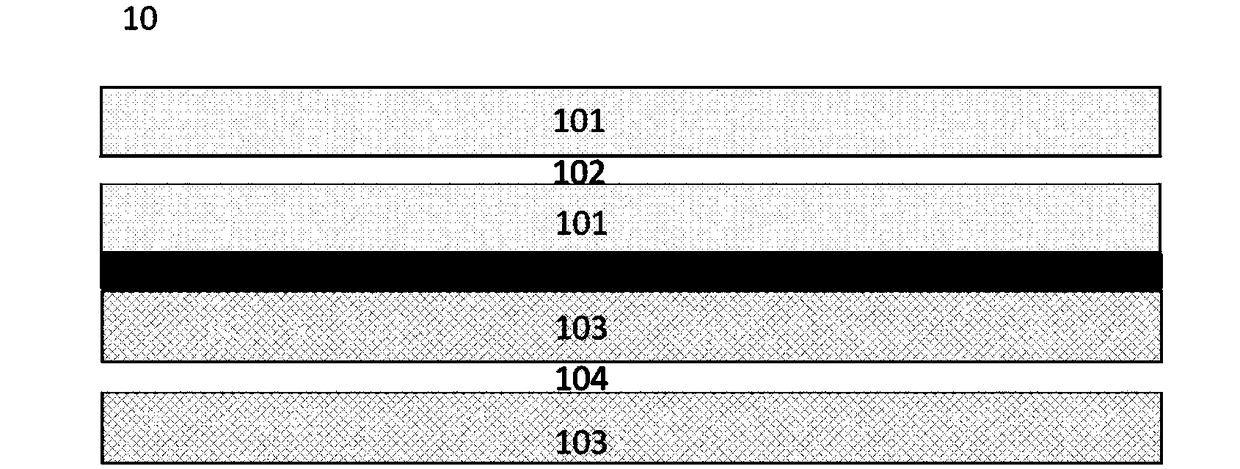

Method for manufacturing all-solid-state batteries in a multilayer structure

ActiveCN104904039AIncrease volumetric energy densityElectrode manufacturing processesFinal product manufactureAll solid stateElectrical battery

The invention relates to a method for manufacturing all-solid-state batteries, said batteries including at least one layer containing anode materials ("anode layer"), at least one layer containing solid electrolyte materials ("electrolyte layer"), and at least one layer containing cathode materials ("cathode layer"), each of said three layers being deposited by electrophoresis, method in which two layers obtained by electrophoresis are stacked surface-to-surface in order to obtain a multi-layer, all-solid-state battery consisting of an assembly of a plurality of elementary cells connected to one another in parallel, said method being characterised in that, prior to stacking said layers obtained by electrophoresis surface-to-surface, a layer of linking material M is deposited on the surface of at least one of said two layers obtained by electrophoresis which will be stacked surface-to-surface.

Owner:I TEN

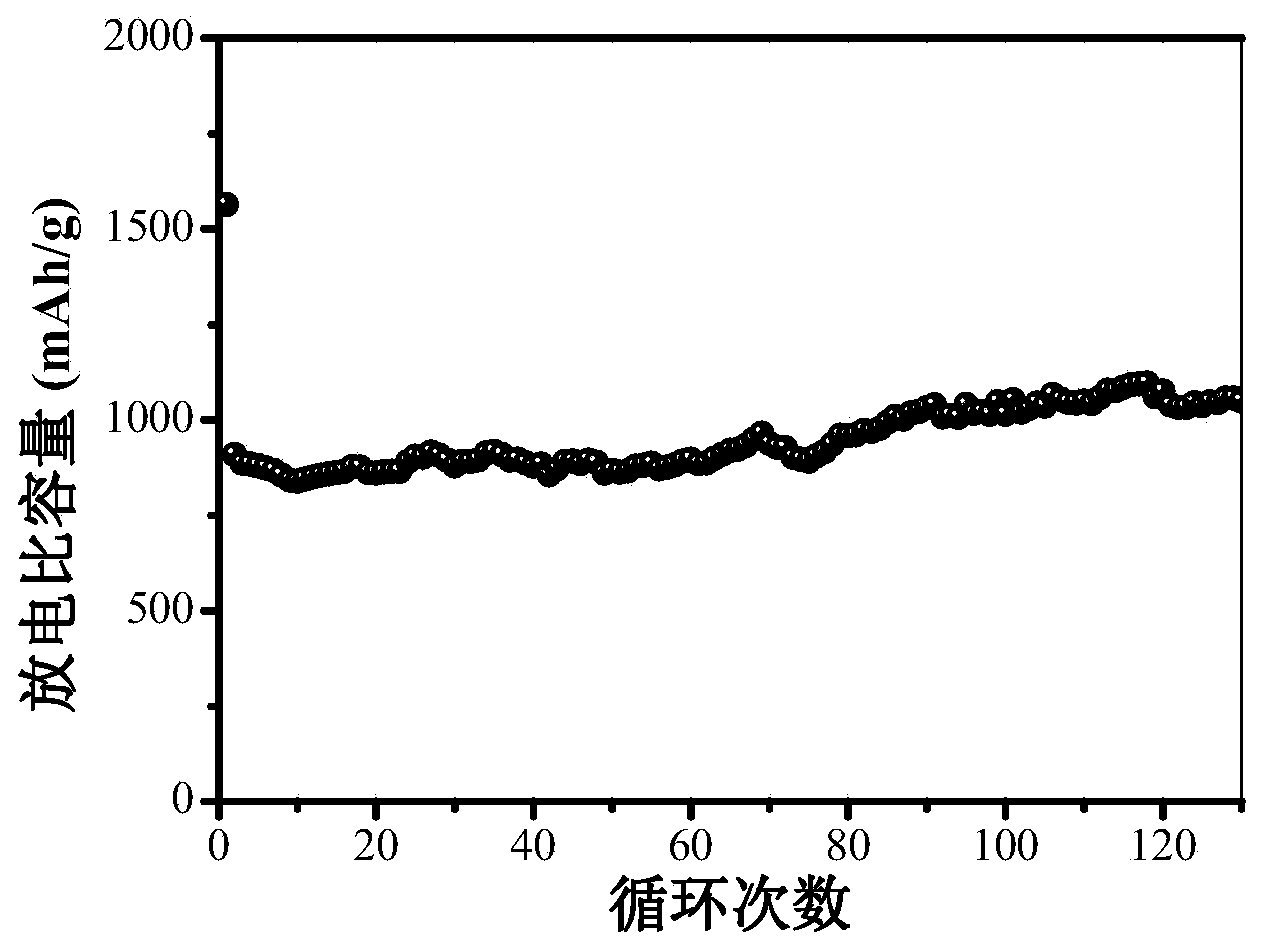

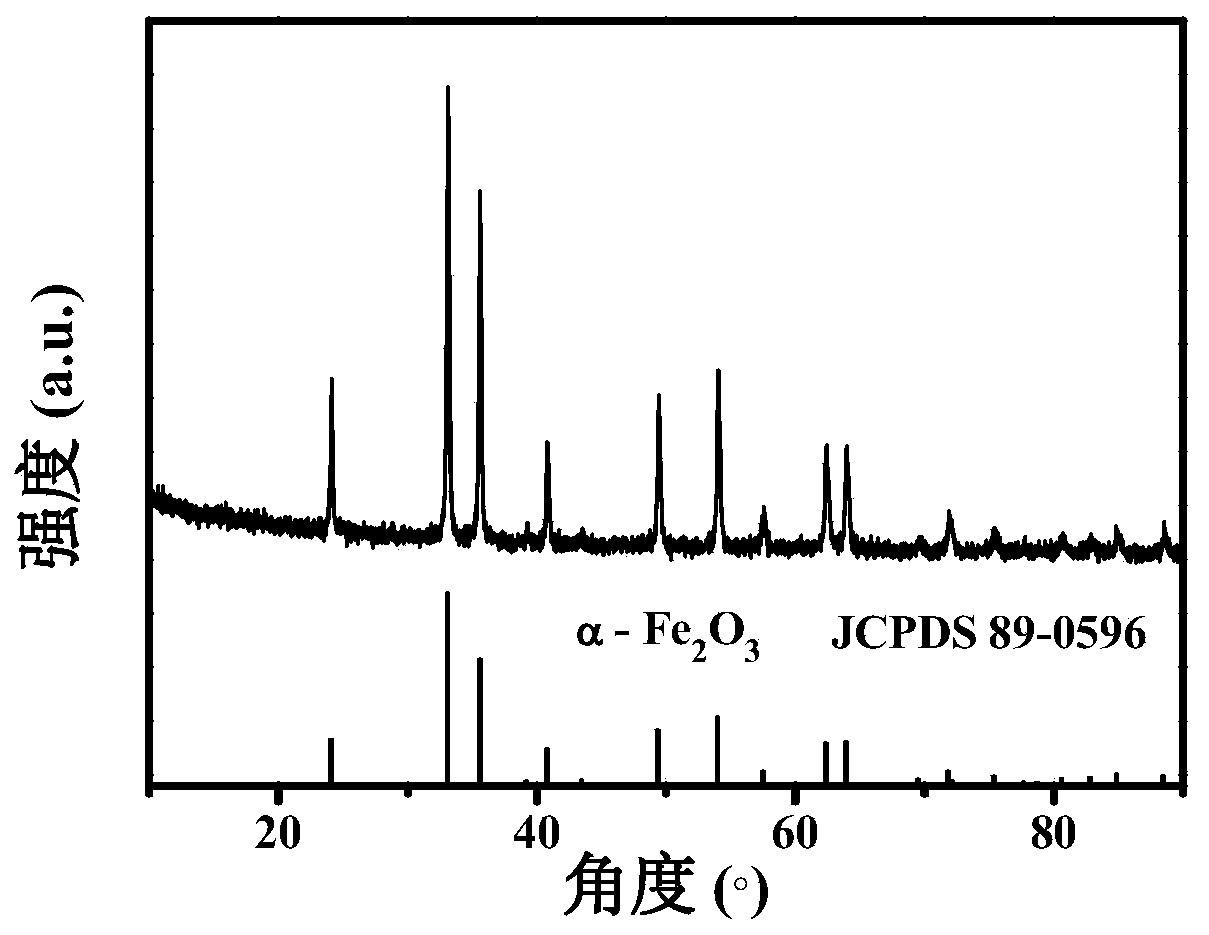

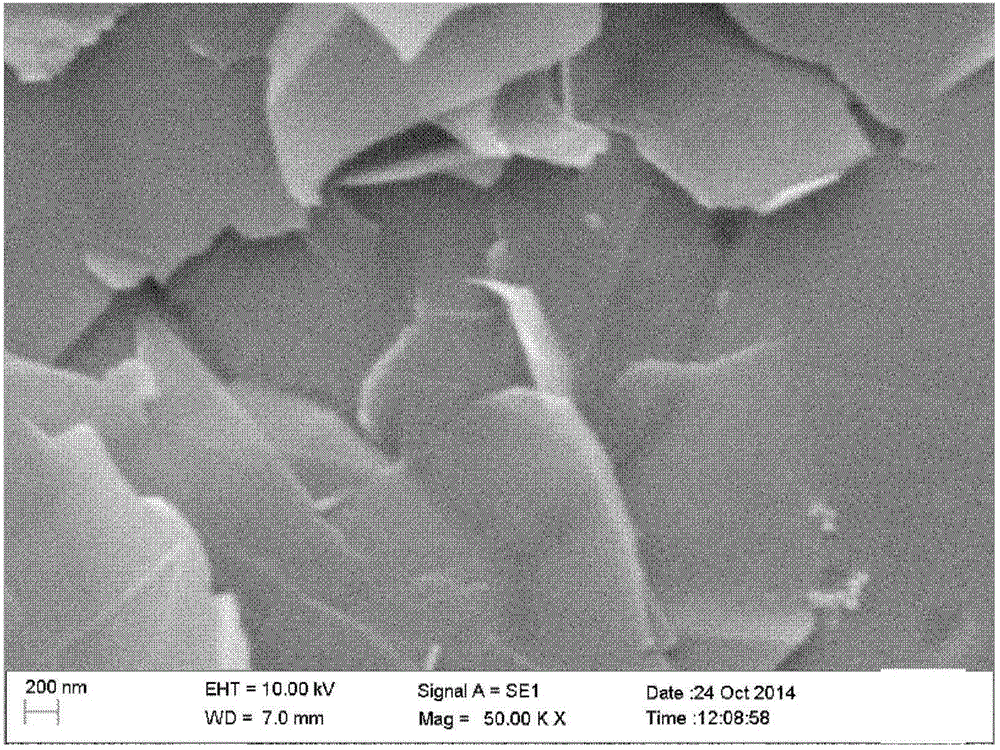

Porous ferric oxide/carbon nanometer plate composite material as well as preparation method thereof and application in preparing lithium ion battery

ActiveCN103682251AThe process is simple and easy to controlHigh product purityMaterial nanotechnologyCell electrodesAmmonium sulfateChemistry

The invention relates to a porous ferric oxide / carbon nanometer plate composite material as well as a preparation method of the porous ferric oxide / carbon nanometer plate composite material and application in preparing a lithium ion battery. The method comprises the following steps of uniformly mixing raw materials including ferrocene and ammonium sulfate in a given mass ratio; calcining the mixture in an inert gas high-pressure reaction kettle, then calcining the mixture in the air at a low temperature to obtain the porous ferric oxide / carbon nanometer plate composite material. The preparation method is simple in process, easy to operate, high in yield and applicable to the mass production. When being used as a lithium ion battery cathode material, the prepared porous ferric oxide / carbon nanometer plate composite material is high in specific capacity and excellent in circulation stability, and the capacity of the material is more than 1000mAh / g after being circulated for 100 times.

Owner:江苏海四达电源有限公司

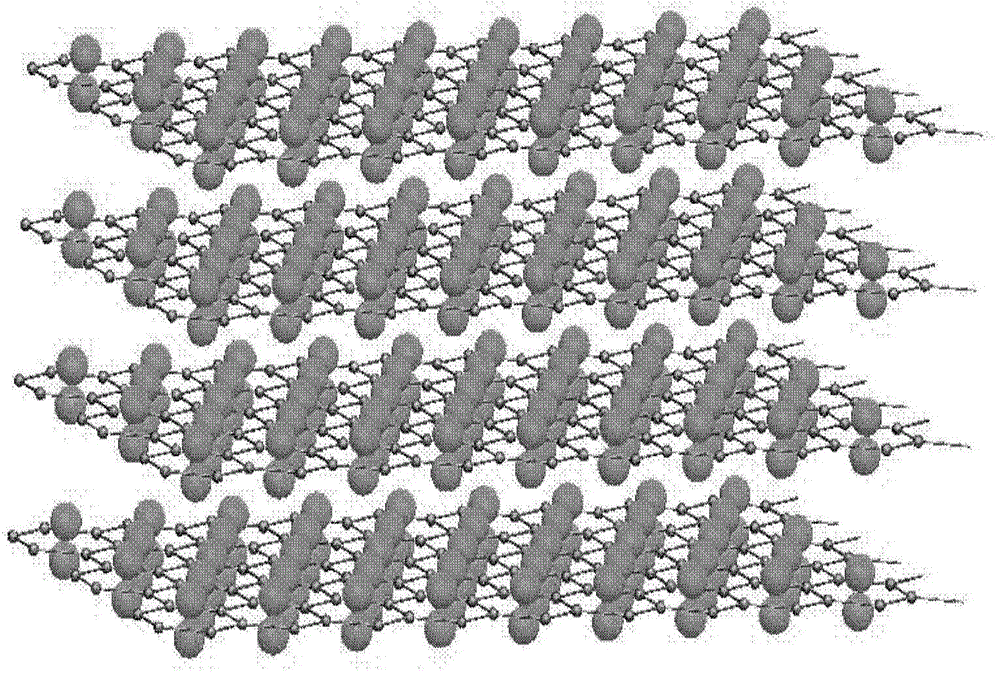

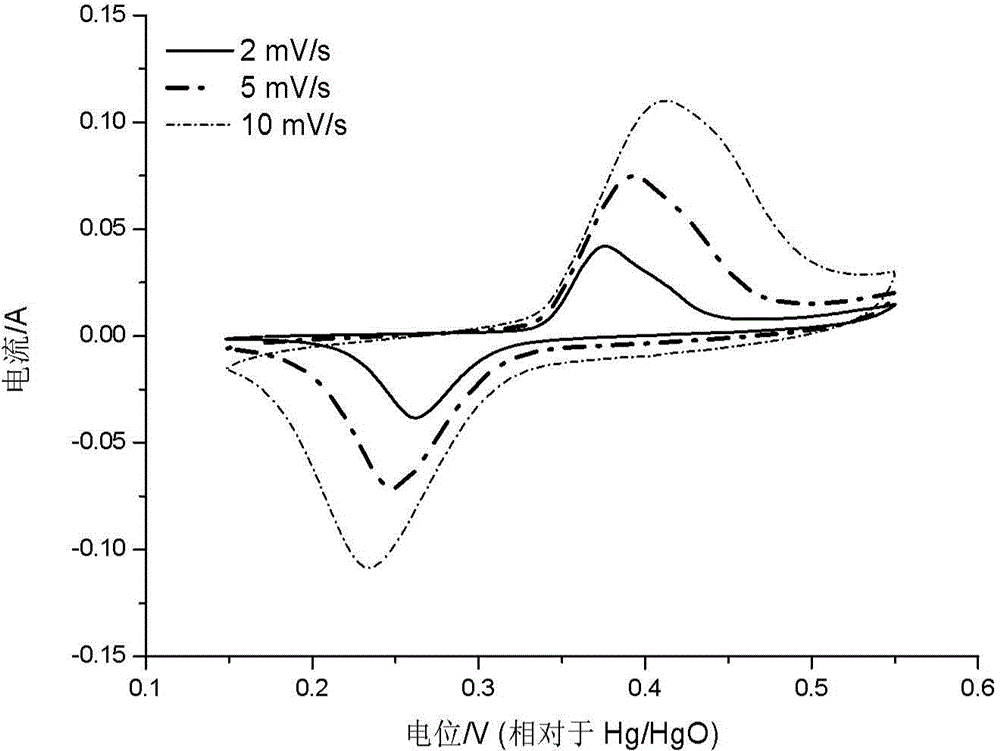

Composite material of nickel hydroxide/graphene or graphite and preparation method for composite material

InactiveCN104616908AIncrease volumetric energy densityLow costMaterial nanotechnologyHybrid capacitor electrodesGraphiteGraphene

The invention discloses a composite material of nickel hydroxide / graphene or graphite which is structurally Ni(OH)2 / graphite or layered Ni(OH)2 / graphene composite material alternated with Ni(OH)2 and graphene, wherein the weight content of the nickel hydroxide is 10-90%. The invention further discloses a method for preparing the composite material. The composite material is simple in process, low in cost, environment-friendly and easy for batch production.

Owner:SOUTHWEST PETROLEUM UNIV

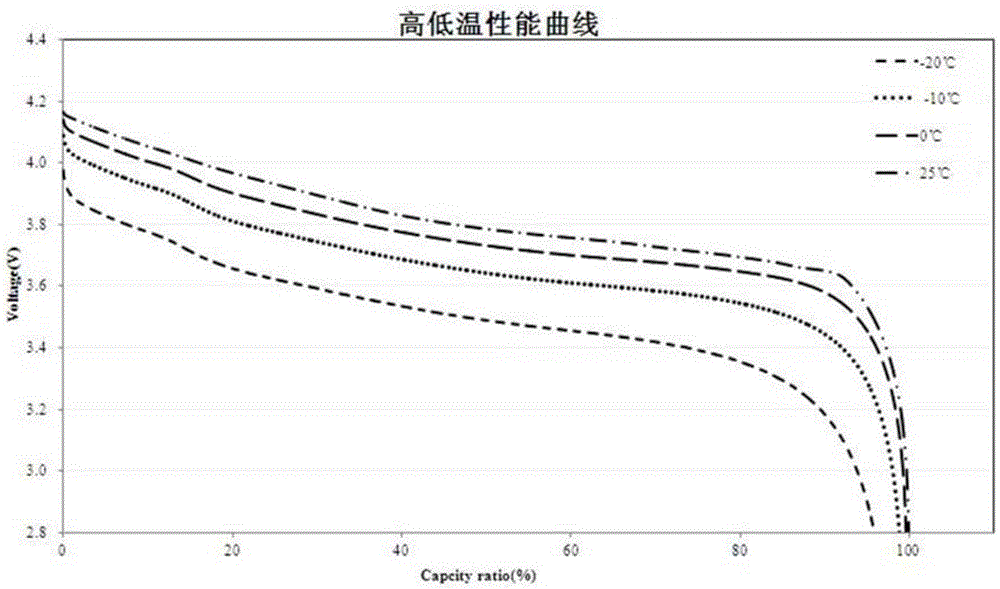

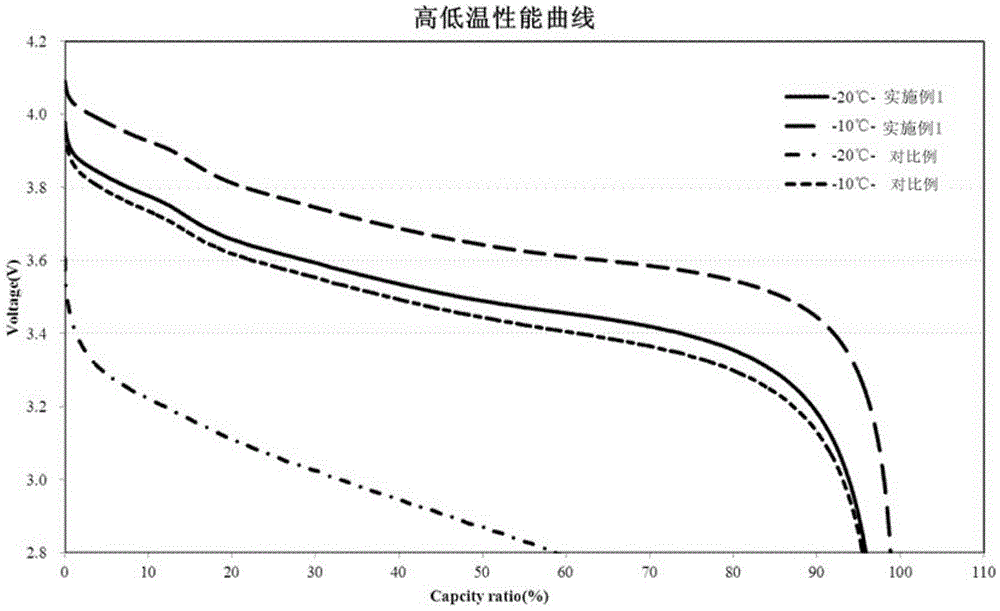

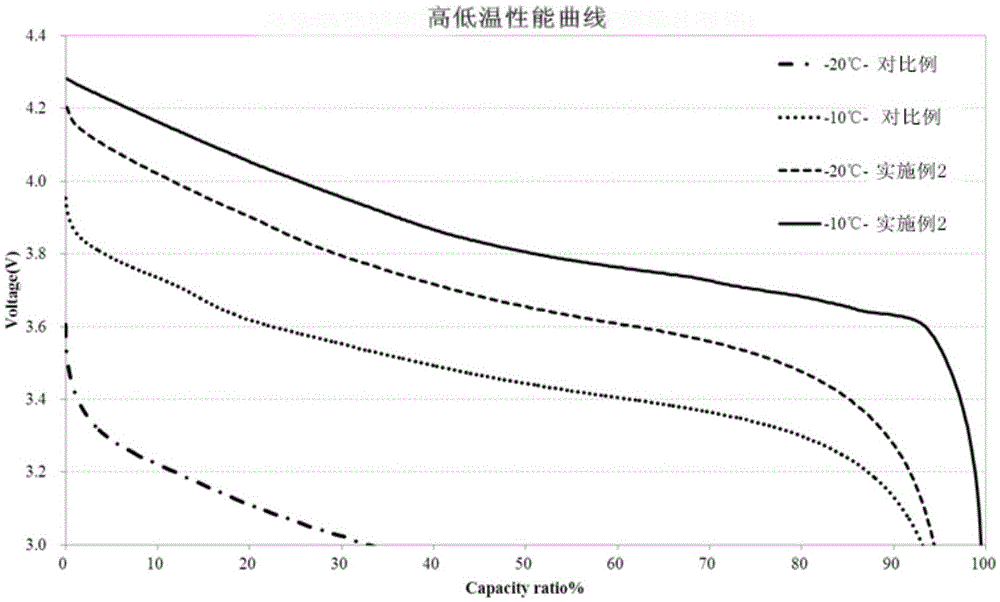

Low-temperature type lithium ion battery with high voltage and high volume energy density

InactiveCN105470519AExcellent liquid retentionReduce bloatCell electrodesFinal product manufacturePolyvinylidene fluoridePolyolefin

The invention provides a low-temperature type lithium ion battery with high voltage and high volume energy density. The low-temperature type lithium ion battery comprises a cathode, an anode, an isolating membrane and an electrolyte solution, wherein the isolating membrane is formed by coating polyvinylidene fluoride-hexafluoropropylene copolymer coatings on both sides of a polyolefin isolating membrane substrate. According to the low-temperature type lithium ion battery with high voltage and high volume energy density provided by the invention, the polyvinylidene fluoride-hexafluoropropylene copolymer coated on the surfaces of the isolating membrane can polymerize with polyvinylidene fluoride in positive and negative pole pieces, so that the cathode and the anode are tightly attached with the isolating membrane together, the expansion of the cathode and the anode is reduced, the inner volume of the battery is further reduced, and the energy density is improved; moreover, the polyvinylidene fluoride on the surfaces of the isolating membrane has good electrolyte retention, and is matched with the low-temperature type lithium ion electrolyte solution and good cathode and anode space conducting network, so that lithium ions can be relatively high in diffusion and disembedding speed between the electrolyte solution and the cathode and the anode under low temperature, and the discharging capacity of greater than or equal to 90% at -20 DEG C can be realized.

Owner:TIANJIN ENERGIES

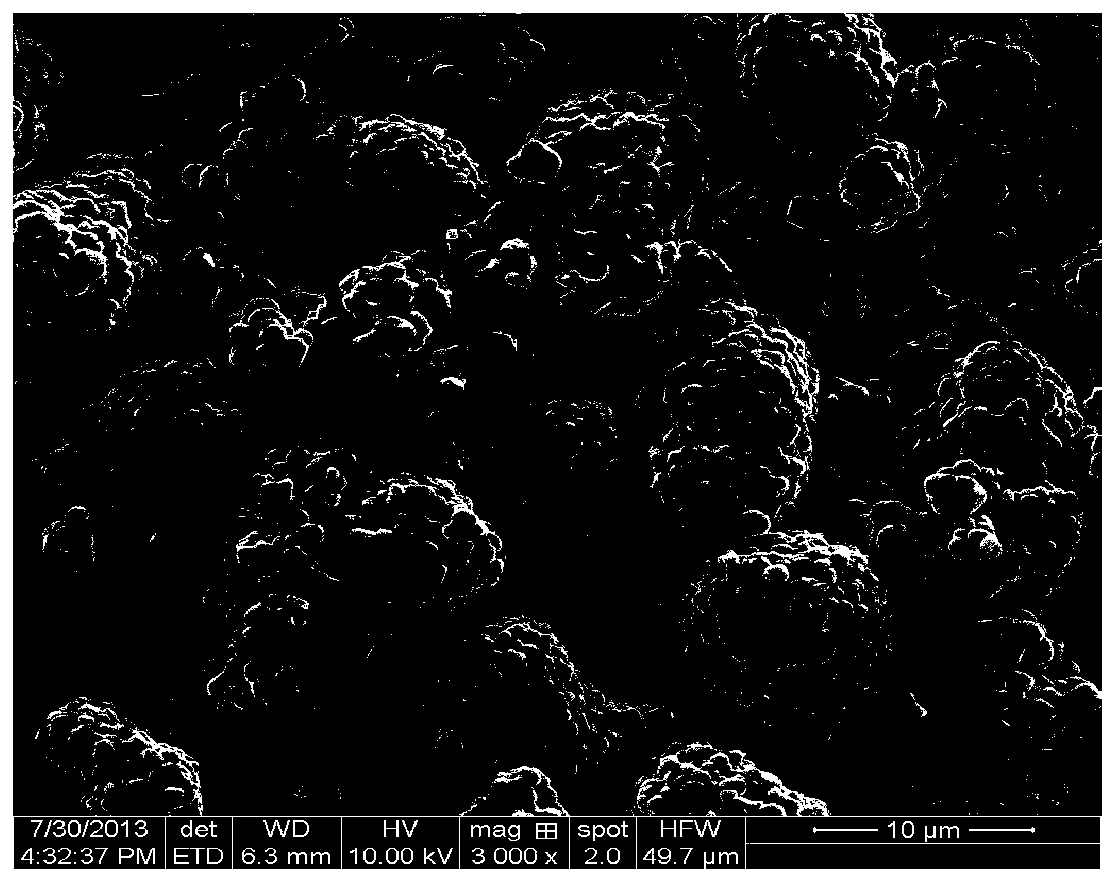

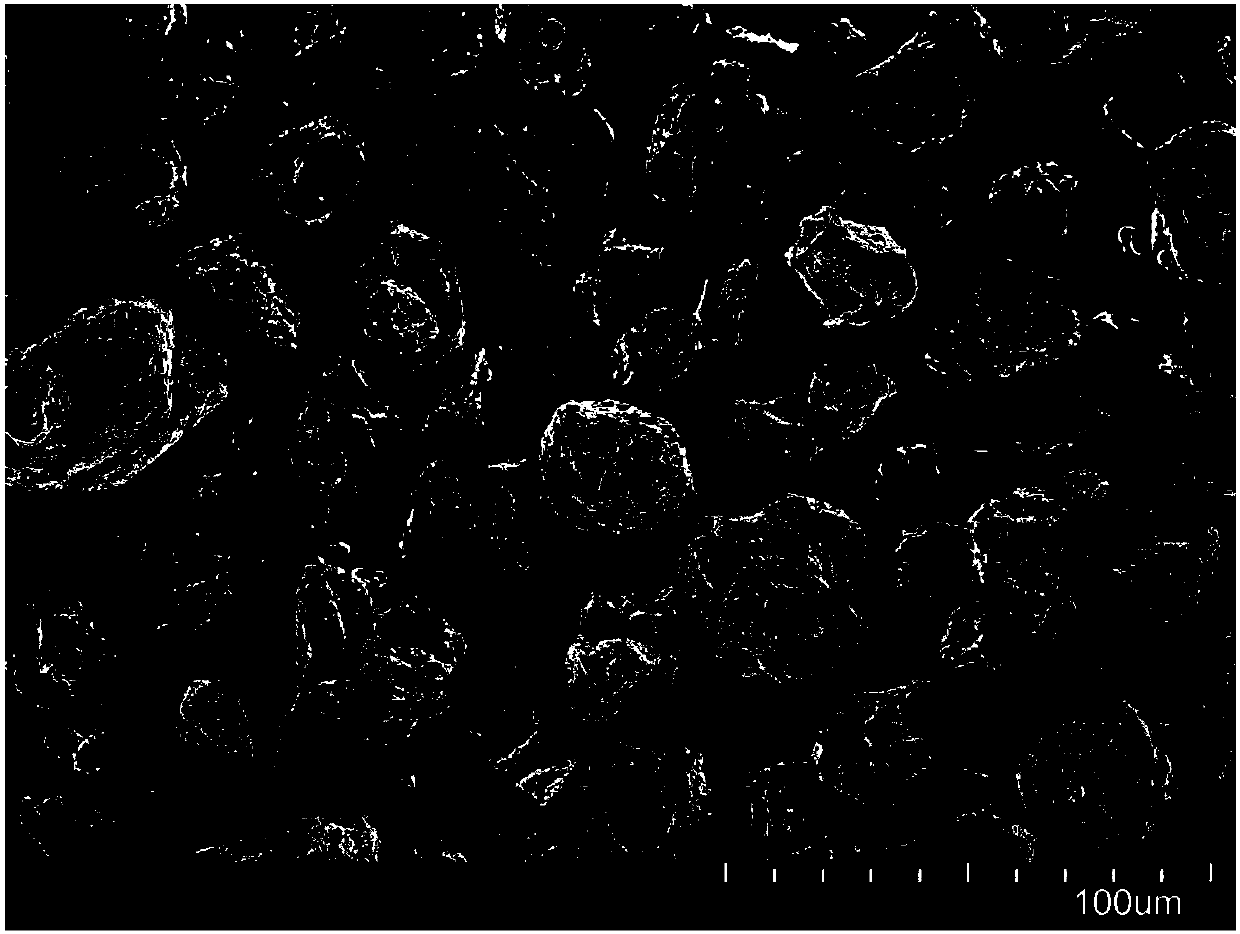

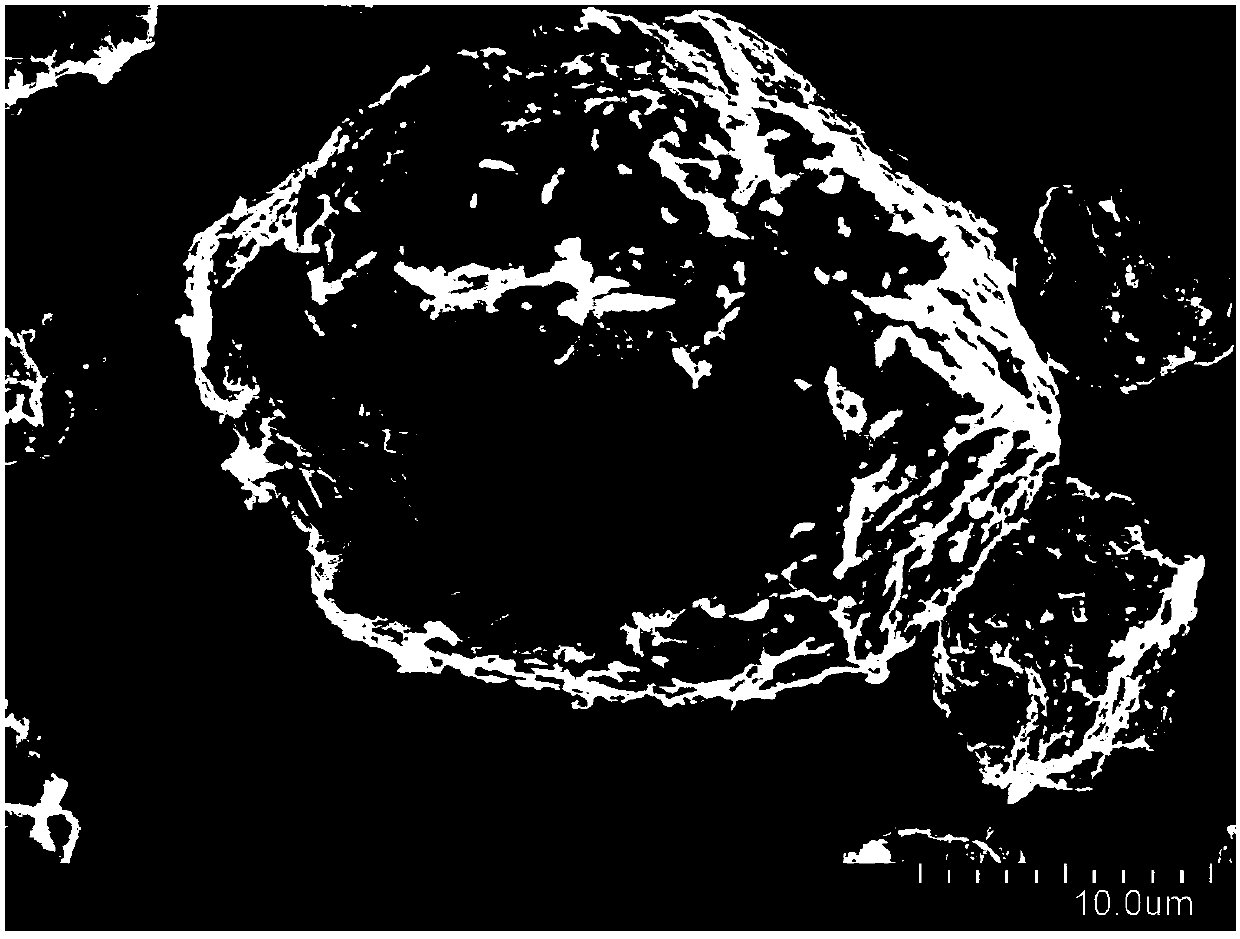

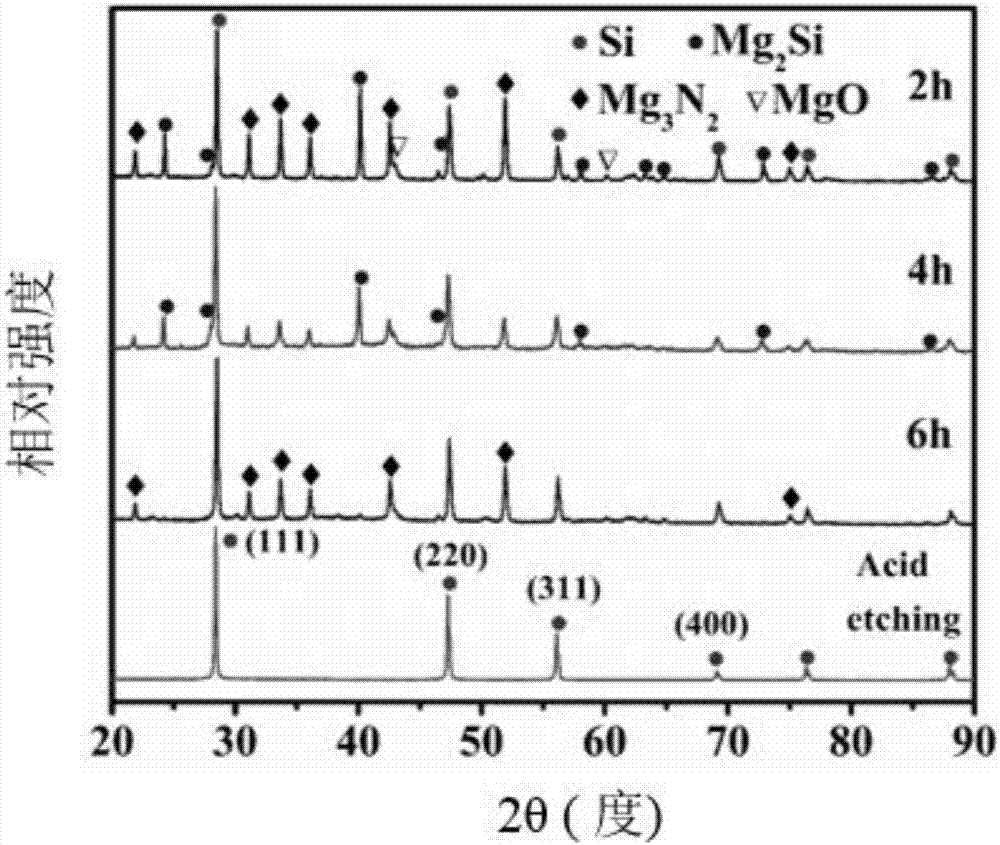

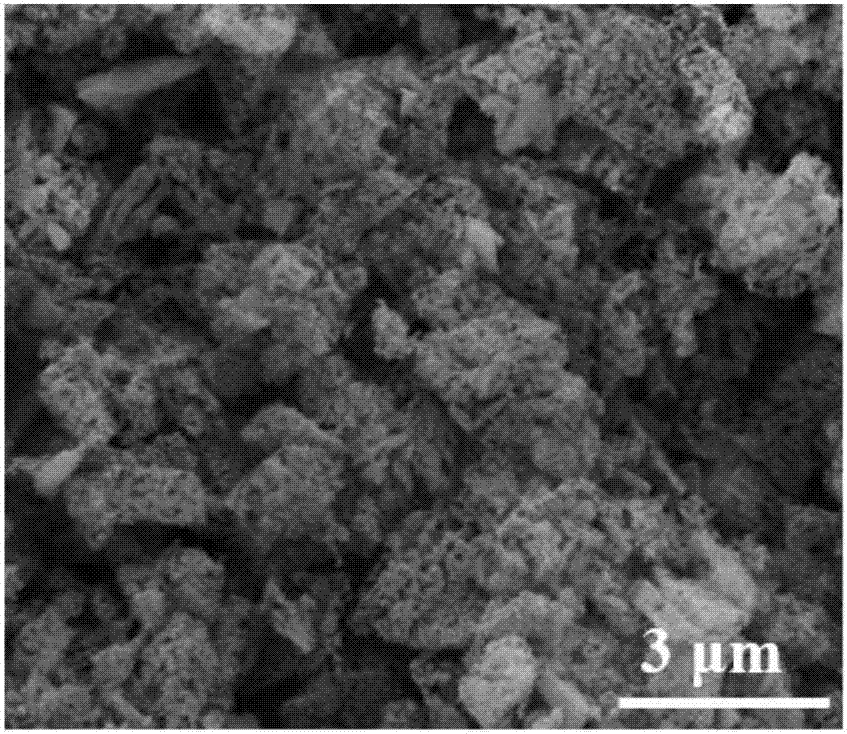

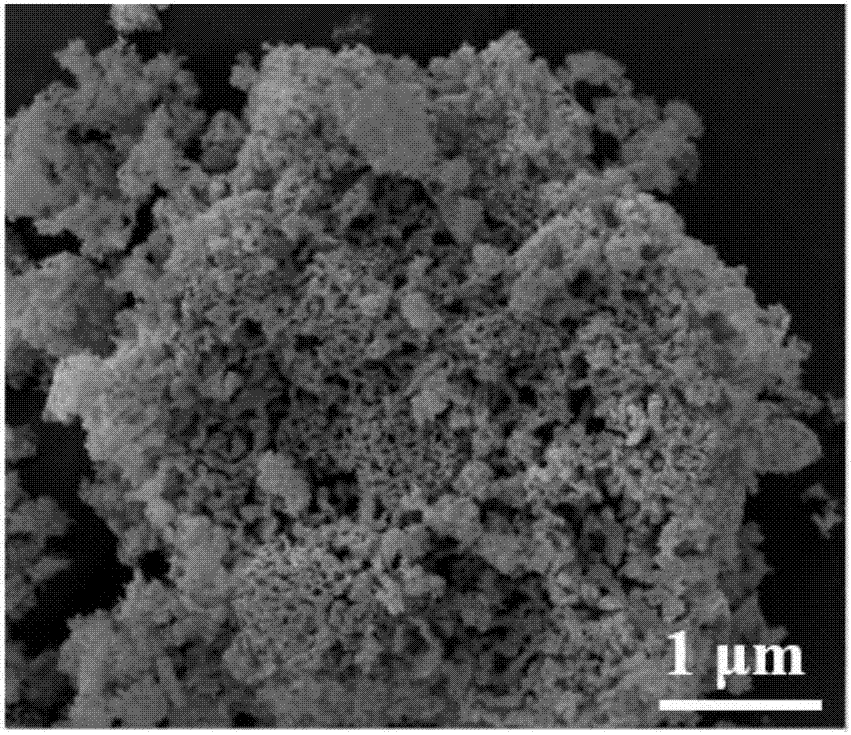

Preparation method of formicary-shaped porous silicon for lithium ion battery

ActiveCN107215874ASave raw materialsThe synthesis method is simpleCell electrodesSecondary cellsLithium-ion batteryReaction step

The invention discloses a preparation method of formicary-shaped porous silicon for a lithium ion battery. The preparation method comprises the following steps: (1) enabling a magnesium silicide raw material to react for 2 to 24h in an ammonia gas atmosphere at a temperature of 600 to 900 DEG C, and obtaining a crude product containing porous silicon (3Mg2Si+4NH3 to 3Si+2Mg3N2+6H2), wherein a particle size of the magnesium silicide raw material is 0.2 to 10 micrometers; and (2) acid pickling the crude product containing the porous silicon to obtain the formicary-shaped porous silicon for the lithium ion battery. By improving an overall process flow of the porous silicon key preparation method and parameters and conditions of various reaction steps, compared with the prior art, the preparation method has the advantage of simplicity and easiness, a great number of porous micrometer silicon can be obtained by directly heating the obtained magnesium silicide in ammonia gas (or mixed gas of the ammonia gas and inert gas), and the yield is high.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com