Low-temperature type lithium ion battery with high voltage and high volume energy density

A lithium-ion battery and energy density technology, applied in the field of lithium-ion batteries, can solve the problems of increased lithium-ion diffusion resistance, poor low-temperature performance of lithium-ion batteries, and reduced safety performance and cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

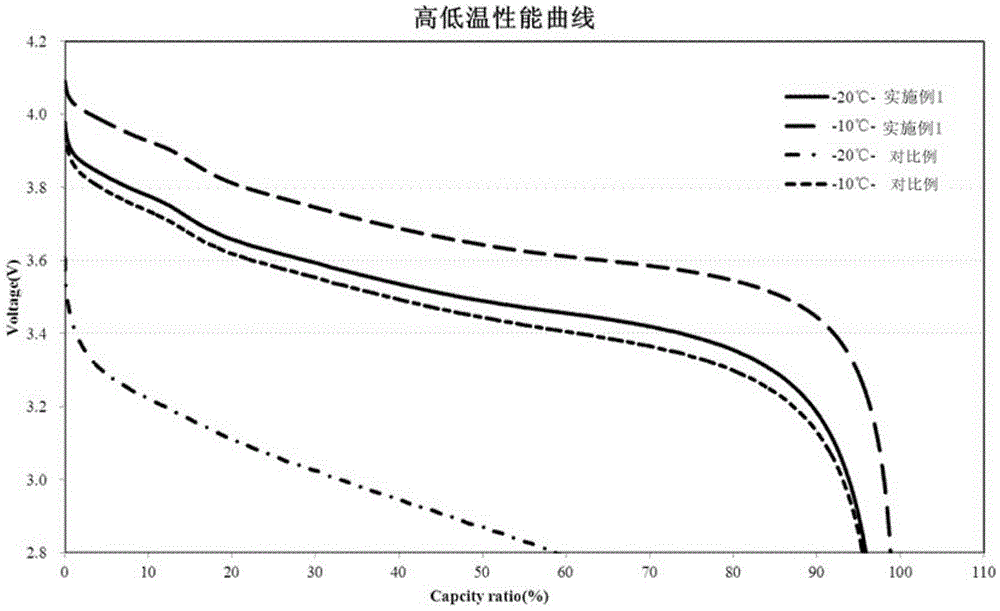

Embodiment 1

[0039]a. Preparation of positive electrode sheet: 4.35V modified lithium cobaltate, conductive carbon black and polyvinylidene fluoride (PVDF) are mixed with solvent nitrogen methyl pyrrolidone (NMP) according to the mass percentage of 96.5::1.5:2. Positive electrode slurry, coated on a double-sided glossy aluminum foil with a thickness of 12 μm and a material of 1060, with a coating surface density of 40.2 mg / cm 2 , after coating, carry out roll pressing to make a positive electrode sheet for later use, and the compacted density is 4.2g / cm 3 ;

[0040] b. Preparation of negative electrode sheet: natural graphite and artificial graphite are mixed into a negative electrode active material according to a mass ratio of 1:1, and then the negative electrode active material, conductive carbon black and polyvinylidene fluoride (PVDF) are 96% by mass : The ratio of 1:3 is mixed with the solvent nitrogen methyl pyrrolidone (NMP) to make negative electrode slurry, which is coated on a ...

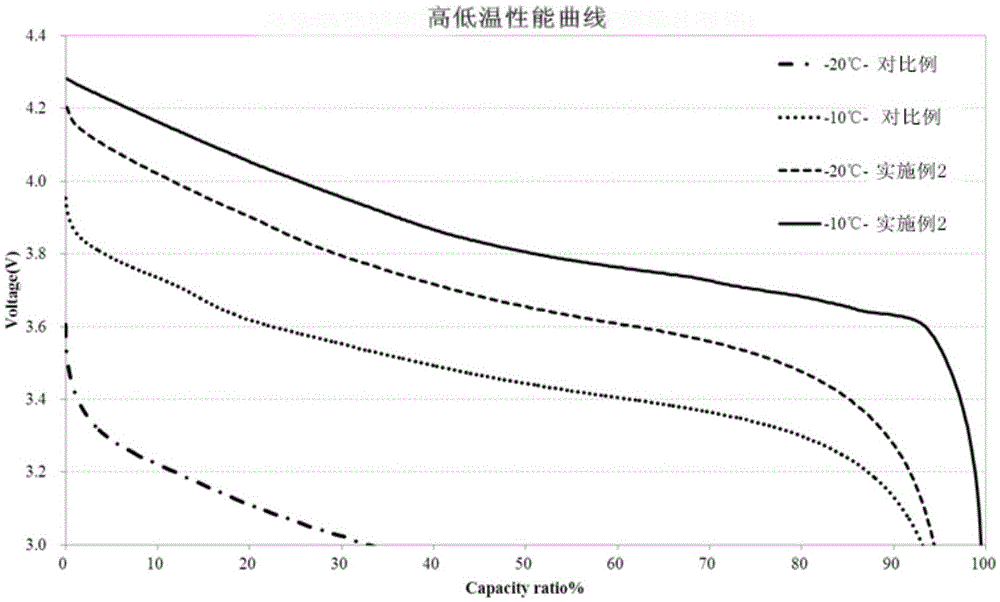

Embodiment 2

[0045] a. Preparation of positive electrode sheet: 4.40V lithium cobaltate, conductive carbon nanotubes (CNTS) and polyvinylidene fluoride (PVDF) are mixed with solvent nitrogen methyl pyrrolidone (NMP) according to the ratio of mass percentage of 97.5:1:1.5 Make a positive electrode slurry, and coat it on a double-sided aluminum foil with a thickness of 12 μm and a material of 1060, and the coating surface density is 42.4 mg / cm 2 , after coating, carry out roll pressing to make a positive electrode sheet for later use, and the compacted density is 4.2g / cm 3 ;

[0046] b. Preparation of negative electrode sheet: natural graphite and artificial graphite are mixed into a negative electrode active material according to a mass ratio of 1:1, and then the negative electrode active material, conductive carbon black and polyvinylidene fluoride (PVDF) are 96.5% by mass : The ratio of 0.5:3 is mixed with the solvent nitrogen methyl pyrrolidone (NMP) to make negative electrode slurry, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com