Diaphragm coat composition, slurry and preparation method thereof, diaphragm and lithium ion battery

A technology of coating composition and diaphragm, which is applied in the direction of secondary batteries, battery pack parts, circuits, etc., can solve the problems of reducing the wetting effect of wetting agents, affecting the permeability of the diaphragm, and not being able to wet, so as to improve the electric current. Core consistency and battery safety, improved battery performance, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a preparation method of the polymer slurry, comprising the steps of: first adding a dispersant and a wetting agent into a solvent and stirring to obtain a solution; then adding a polymer to the solution and stirring to obtain a polymer predispersion ; continue to add the binder into the polymer pre-dispersion and stir to obtain a polymer dispersion; finally add the defoamer to the polymer dispersion and stir to obtain a polymer slurry.

[0045] According to some embodiments of the present invention, the stirring operation can be performed using any suitable equipment known in the art, and any suitable stirring speed and stirring time can be selected for the purpose of dissolving or uniformly dispersing the substances after mixing. For example, add the dispersant and wetting agent into the solvent, stir at 200-500r / min for 20-50min, then add the polymer into it and continue to stir for 20-50min, and use a high-speed oscillator to vibrat...

Embodiment 1

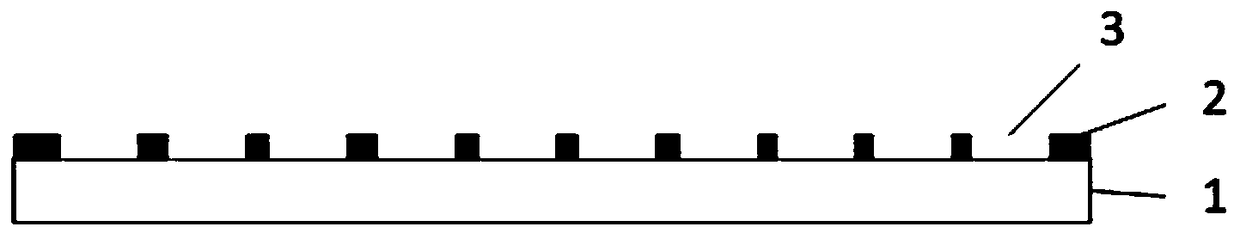

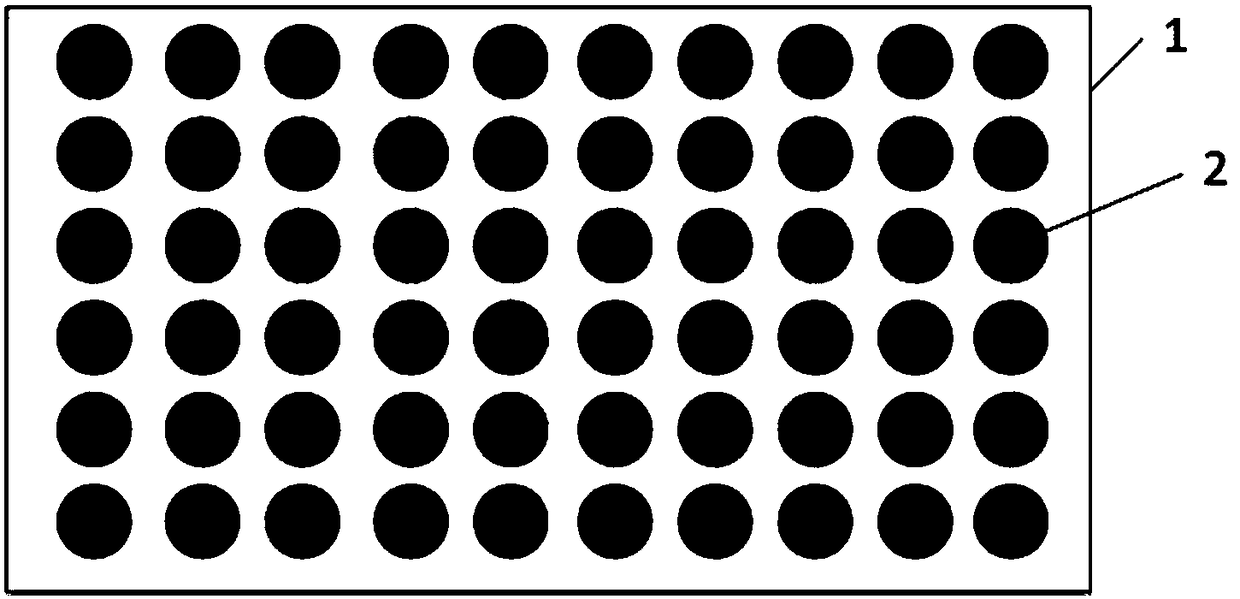

[0055] ①Add 3g of dispersant (BYK LPC 22136) and 0.3g of wetting agent (BYK LPX 20990) into 100g of deionized water, stir and dissolve at 300r / min for 30min; ②Add 10g of polymer (Kynar Flex 2801) powder into it and continue Stir for 30 minutes, and use a high-speed oscillator to vibrate for 30 minutes to make a polymer pre-dispersion. ③ Add 2 g of binder (aqueous solution of styrene-butadiene rubber) to the polymer pre-dispersion, and stir at 300 r / min for 30 min; ④ Add 0.15 g of defoaming Add the additive (BYK 019) to the polymer dispersion, and stir at 500r / min for 15min to prepare the polymer slurry; ⑤Use an automatic coating machine to coat the polymer slurry on the PE base film; ⑥Use the vacuum at 70℃ After drying in a drying oven for 30 minutes, a polymer-coated diaphragm with dot distribution is prepared, and the average diameter of the dot coating of the diaphragm is about 1 mm.

Embodiment 2

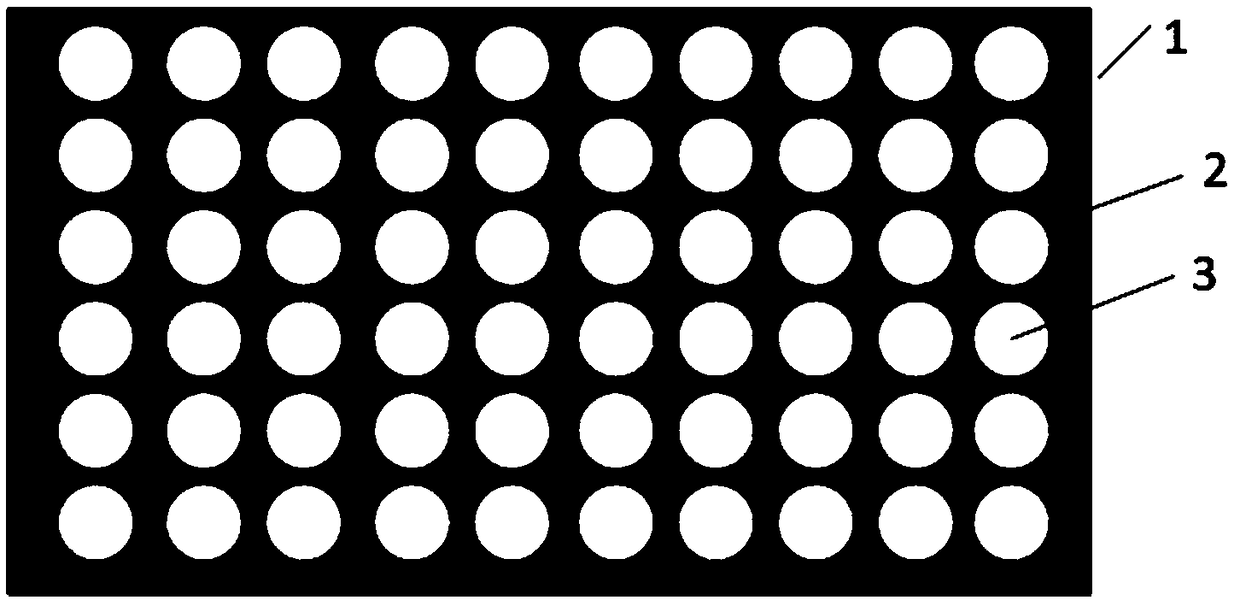

[0057] ① Add 3g of dispersant (BYK LPC 22136) and 0.6g of wetting agent (BYK LPX 20990) into 100g of deionized water, stir and dissolve at 300r / min for 30min; ②Add 10g of polymer (Kynar Flex 2801) powder into it and continue Stir for 30 minutes, and use a high-speed oscillator to vibrate for 30 minutes to make a polymer pre-dispersion ③Add 2g of binder (aqueous solution of styrene-butadiene rubber) to the polymer pre-dispersion, stir at 300r / min for 30 minutes to make a polymer dispersion; ④Add 0.06g of defoamer (BYK 019) into the polymer dispersion, and stir at 500r / min for 15min to prepare a polymer slurry; ⑤Use an automatic coating machine to coat the polymer slurry on the PE base film; ⑥Dry in a vacuum drying oven at 70°C for 30 minutes to prepare a polymer-coated diaphragm with pore-like distribution, and the average diameter of the pores of the polymer coating of the diaphragm is about 1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com