Patents

Literature

205results about How to "Improve liquid absorption performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

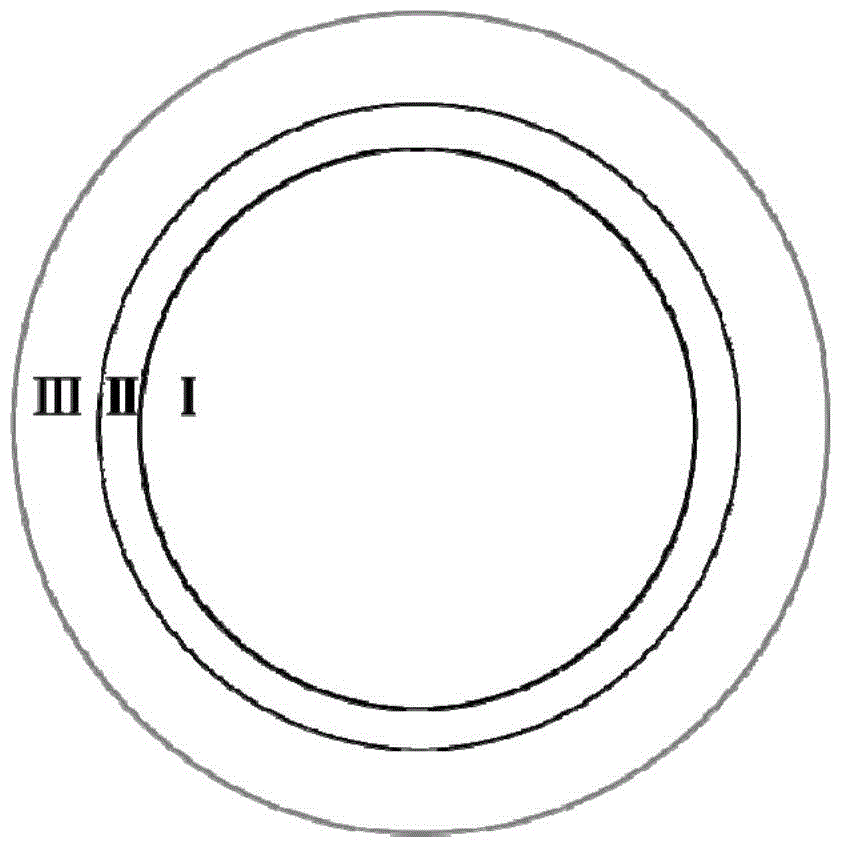

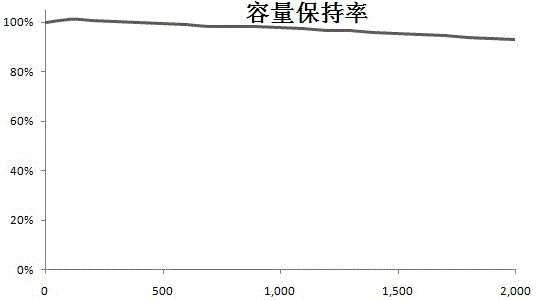

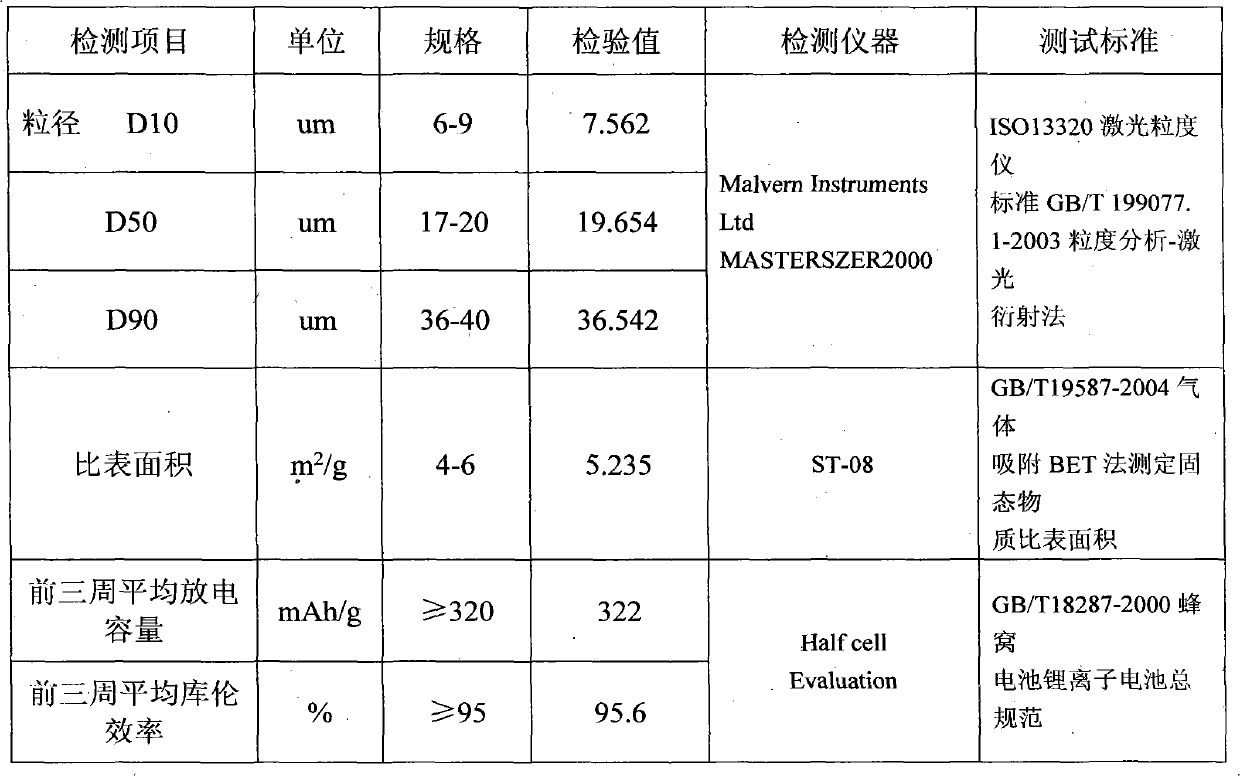

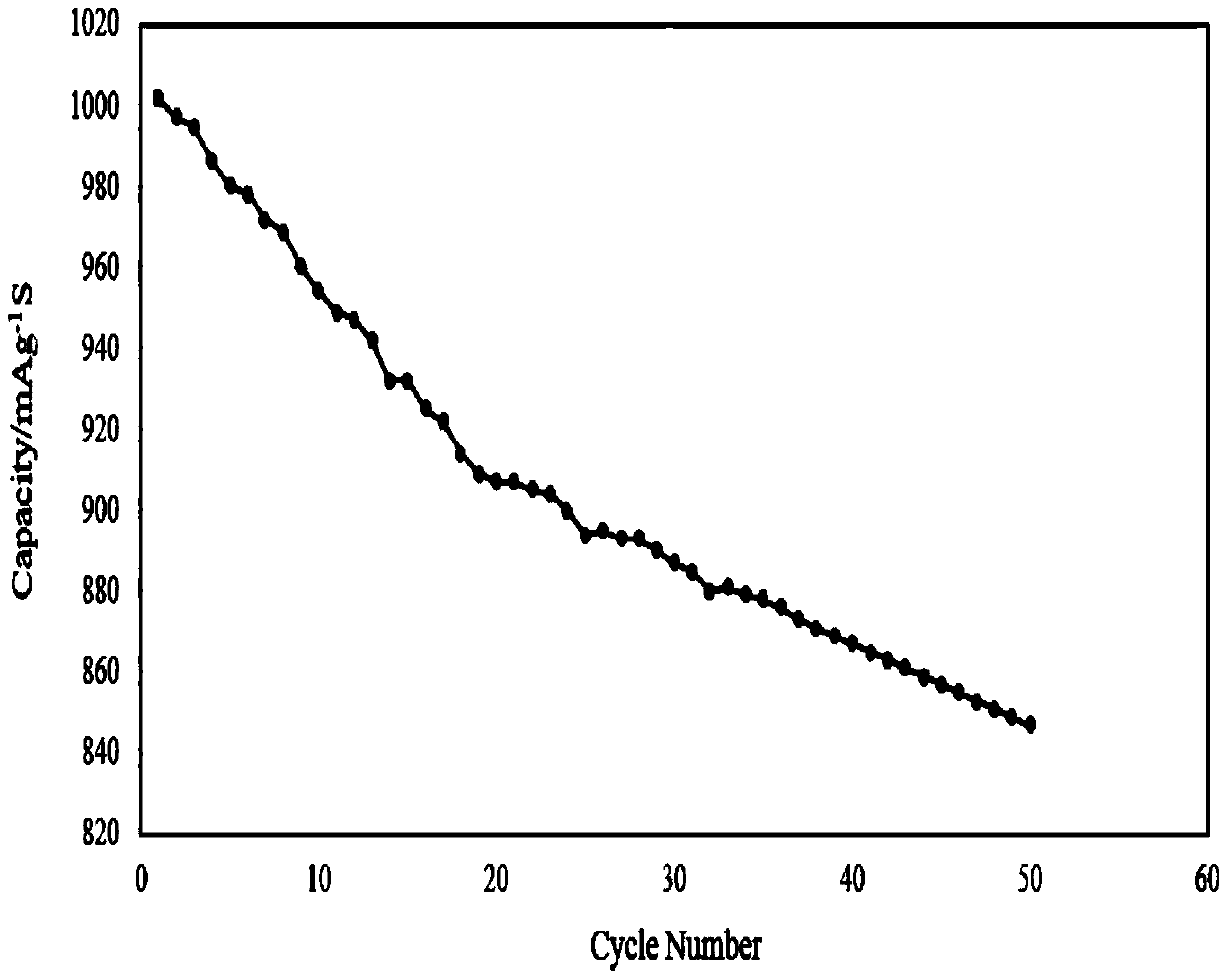

Coal-based anode material, preparation method and lithium-ion battery

The invention discloses a coal-based anode material, a preparation method and a lithium-ion battery. The coal-based anode material consists of a coal-based material graphitized inner layer, a middle layer and an outer layer distributed on the surface. The preparation method of the coal-based anode material comprises steps as follows: crushing a coal-based material; then adding a binder or mixing the binder and a modifier; then performing pressing and high-temperature graphitization to form a finished product. The coal-based anode material adopts a stable graphite structure, the surface has good compatibility with an electrolyte, and the coal-based anode material has the high specific capacity, the high conductivity, the high rate capability as well as excellent electrolyte absorbing performance and cycle performance. According to the preparation method, the anode material is prepared from the low-price coal-based material used as a raw material, the technology is simple, industrialization is easy to realize, and meanwhile, the application of the coal-based anode material in the field of the lithium-ion battery is promoted.

Owner:BTR NEW MATERIAL GRP CO LTD

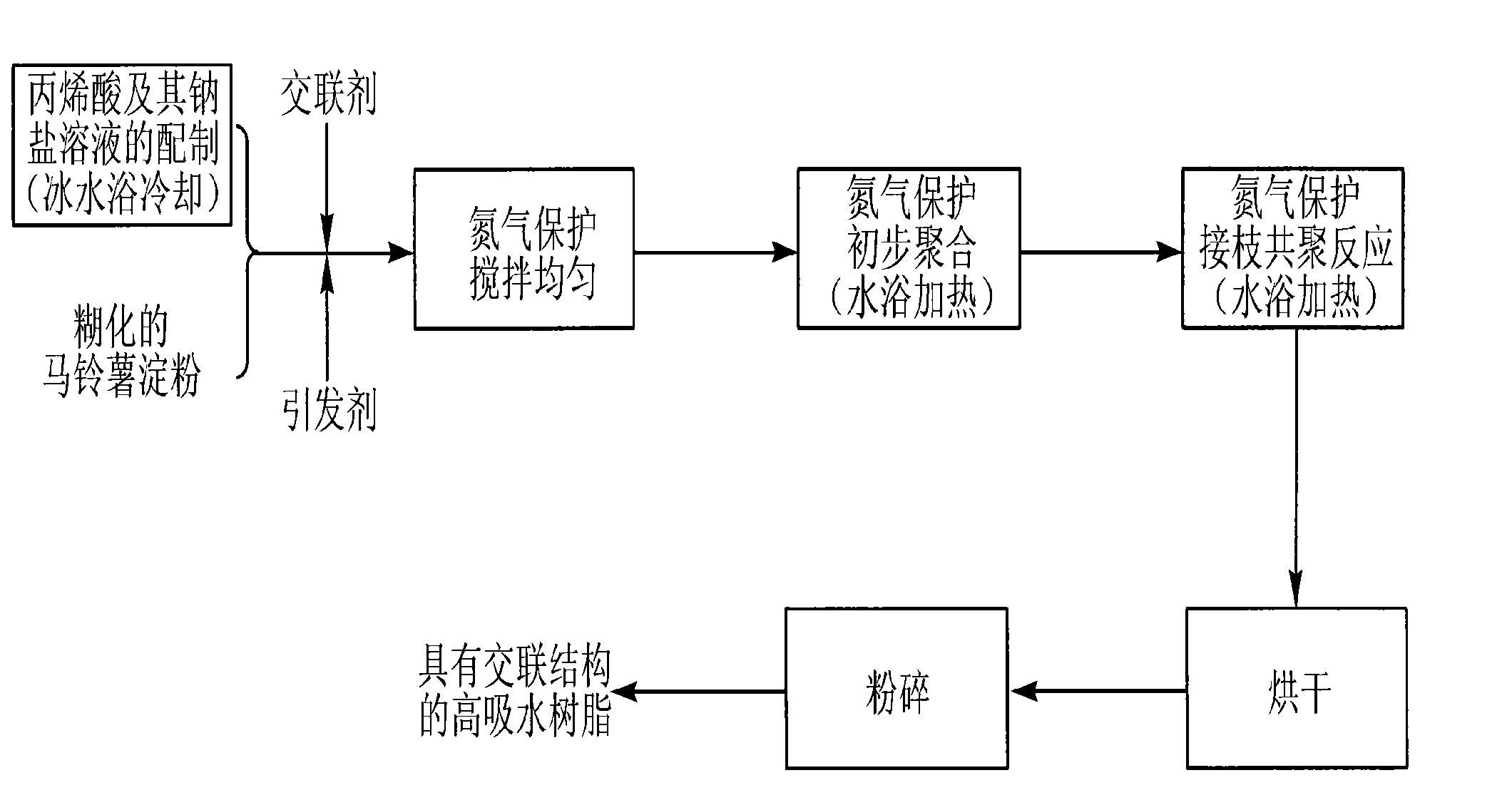

Method for preparing super absorbent resin with cross-linked structure by using potato starch as raw material

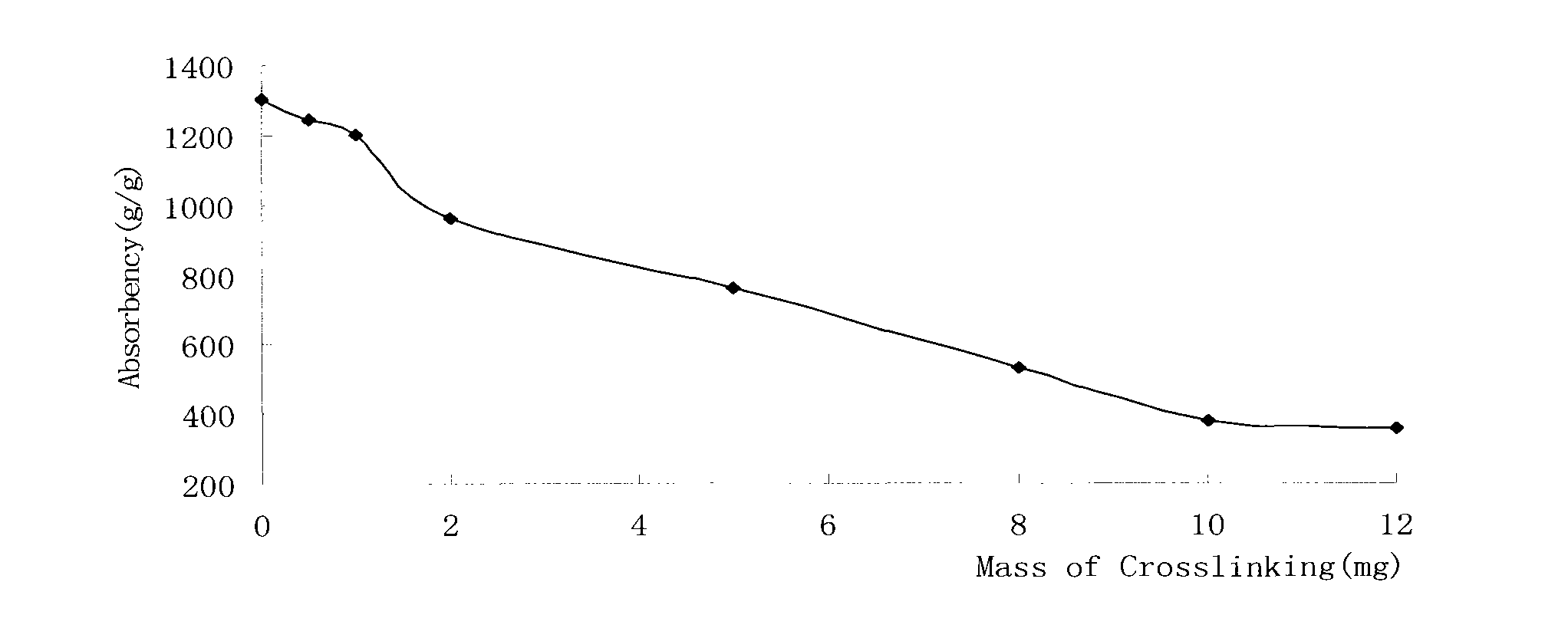

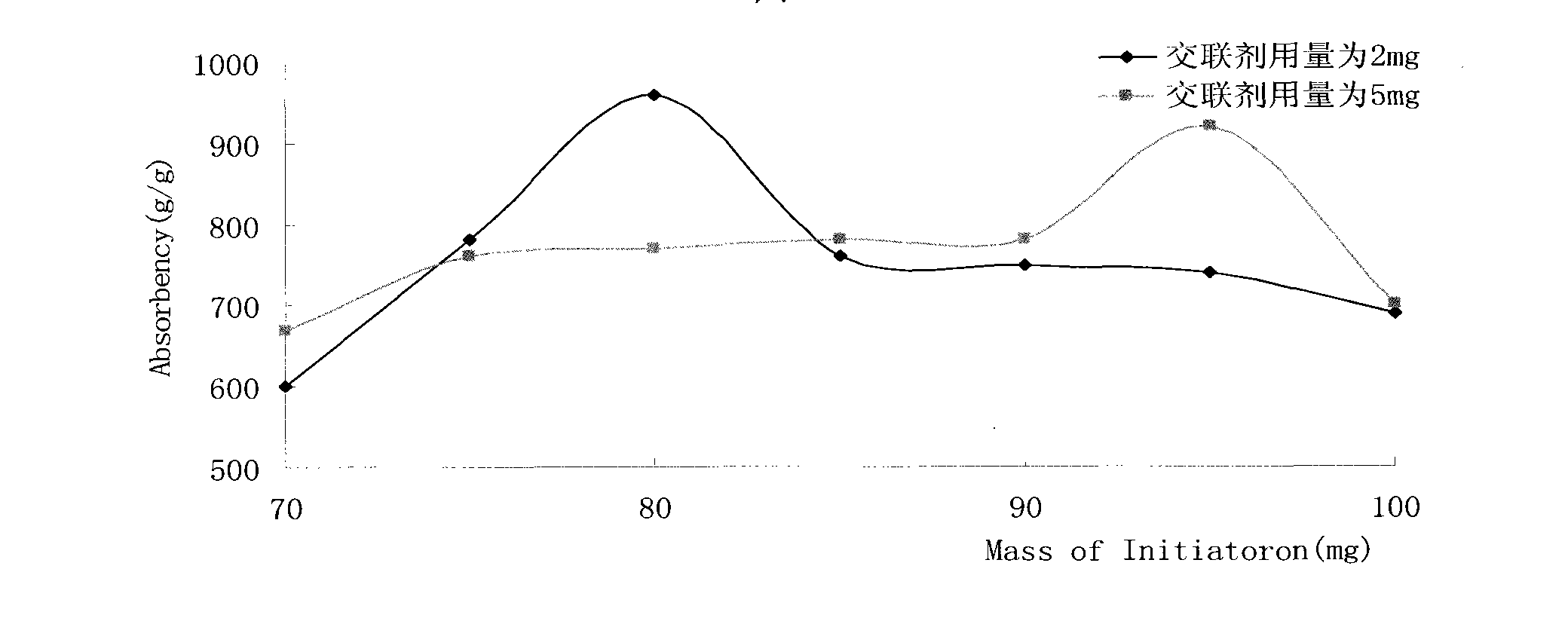

The invention discloses a method for preparing super absorbent resin with a cross-linked structure by using potato starch as the raw material, which comprises the following main processes: carrying out neutralization reaction between a sodium hydroxide solution and acrylic acid from which polymerization inhibitor is removed under the cooling of ice-water bath; mixing potato starch with de-ionizedwater and pasting the mixture; mixing the neutralized acrylic acid and the sodium salt solution thereof with the pasted potato starch; adding an evocating agent persulfate and a cross-linking agent N,N'- methylene-bisacrylamide; uniformly stirring the mixture under the protection of nitrogen; heating the mixture by water bath to rise the temperature so as to ensure that the potato starch and the acrylic acid and the sodium salt thereof generate graft copolymerization reaction under the protection of nitrogen; keeping the temperature of the reaction; and baking and crashing to obtain the superabsorbent resin with a cross-linked structure. Compared with similar products, the water absorption of the super absorbent resin is greatly enhanced and the super absorbent resin can absorb a certainamount of heavy metal ion. The super absorbent resin has great effect on the water conservation, the desert control, the environmental improvement and the like of soil in dry regions.

Owner:CHIFENG TIANZE BIO TECH

Chitosan/polyvinyl alcohol (PVA) porous composite material and preparation method thereof

InactiveCN102108172AGood biocompatibilityImprove liquid absorption capacityAbsorbent padsBandagesWound dressingBiocompatibility Testing

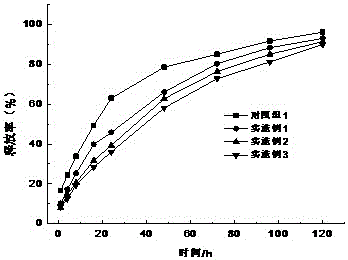

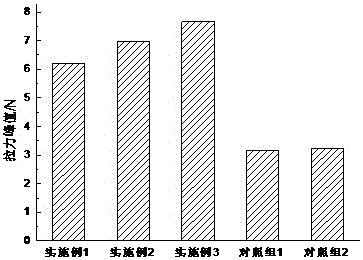

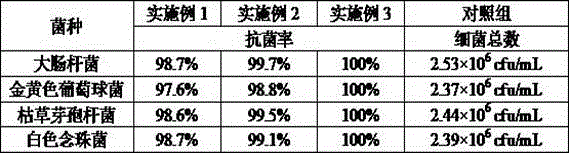

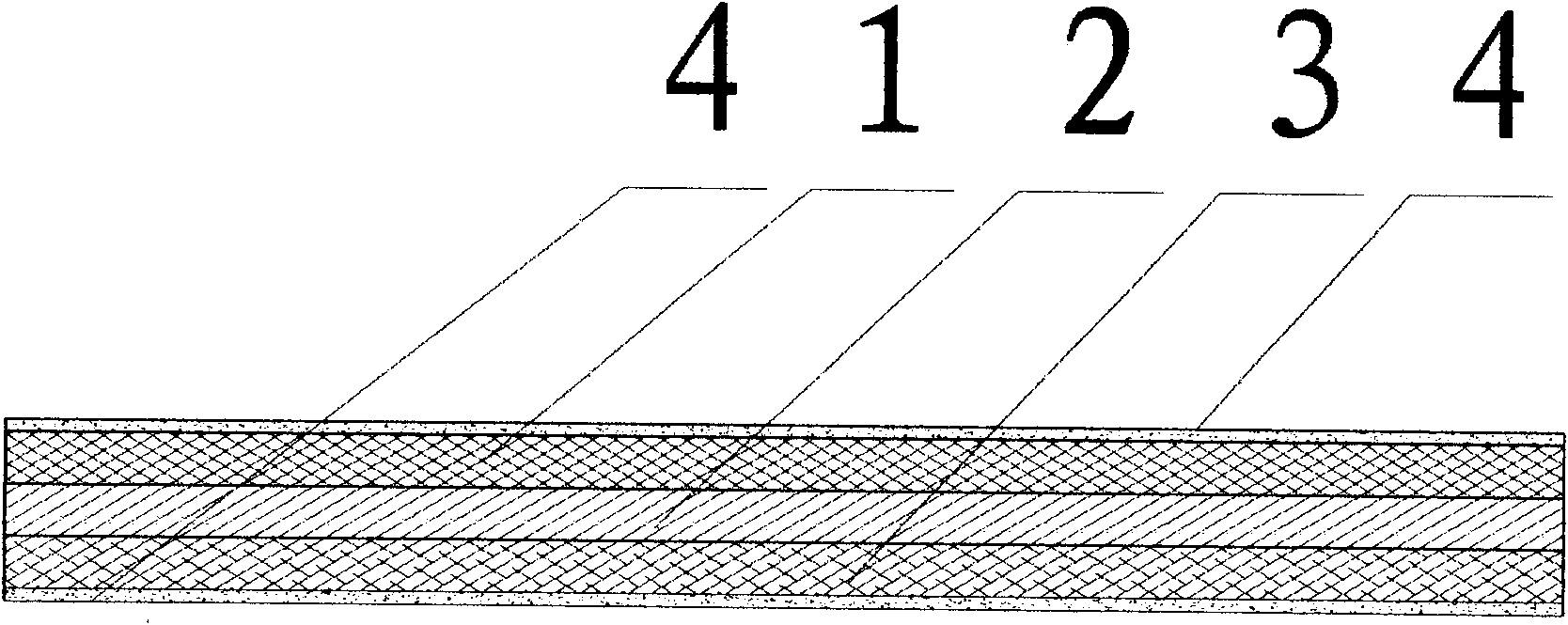

The invention relates to a chitosan / polyvinyl alcohol (PVA) porous composite material. The material is prepared from the following raw materials in percentage by weight: 1-5% of chitosan, 10-30% of PVA, 1-5% of acetic acid, 5-10% of inorganic acid, 5-10% of cross-linking agent, 6-10% of foaming agent, 0.5-2% of antibacterial agent, 1-5% of softening agent and the like. The preparation method of the material comprises the following steps: stirring for fully dissolving the PVA; pouring the dissolved PVA into the dissolved chitosan, adding the inorganic acid, the cross-linking agent, the foaming agent, the softening agent and the antibacterial agent to the obtained mixed solution, heating the solution to 90-100 DEG C, and pouring the solution into a die for continuously reacting at the temperature of 60-100 DEG C for 6-15 hours; and finally cooling and washing the obtained product with distilled water. The obtained material has the characteristics of good biocompatibility, excellent antibacterial effect, strong liquid absorption capability, biodegradability, good adhesion to skin and the like, and has functions of rapid hemostasis, antibiosis, anti-inflammation and acceleration of wound healing, thus the material is suitable for serving as various wound dressings.

Owner:WEIHAI SHICHUANGXIN MATERIAL TECH

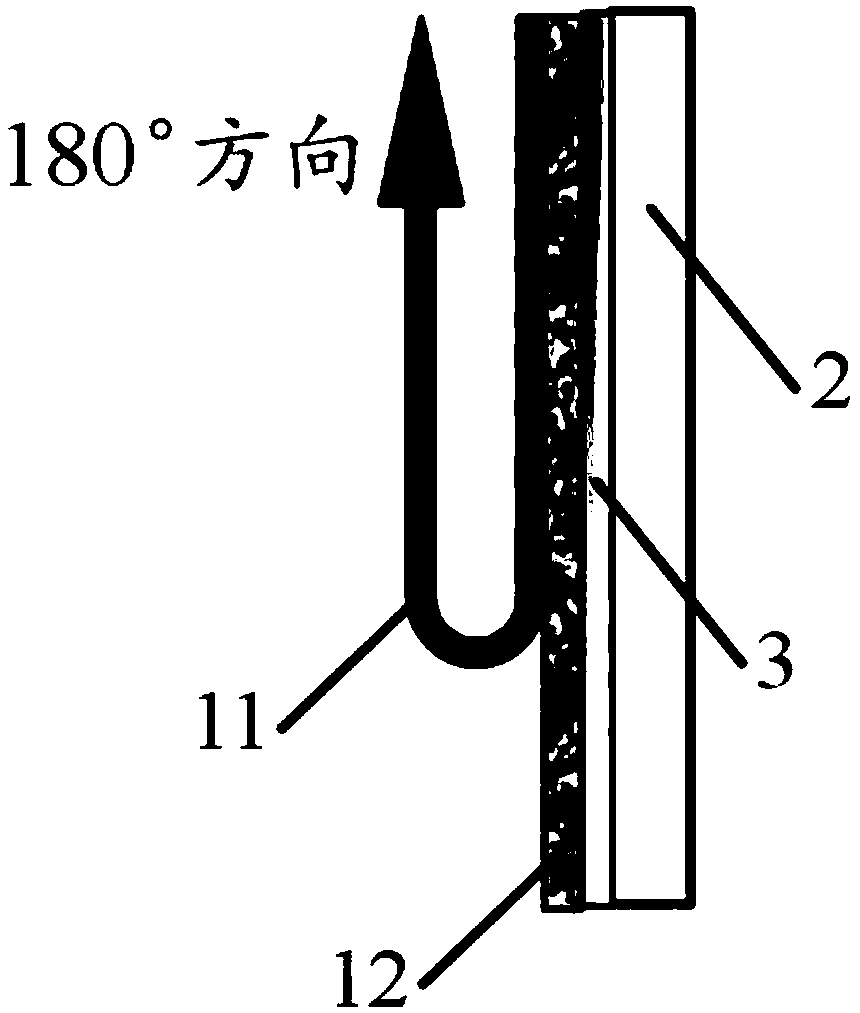

Lithium ion battery electrode slice, electric core and its making method

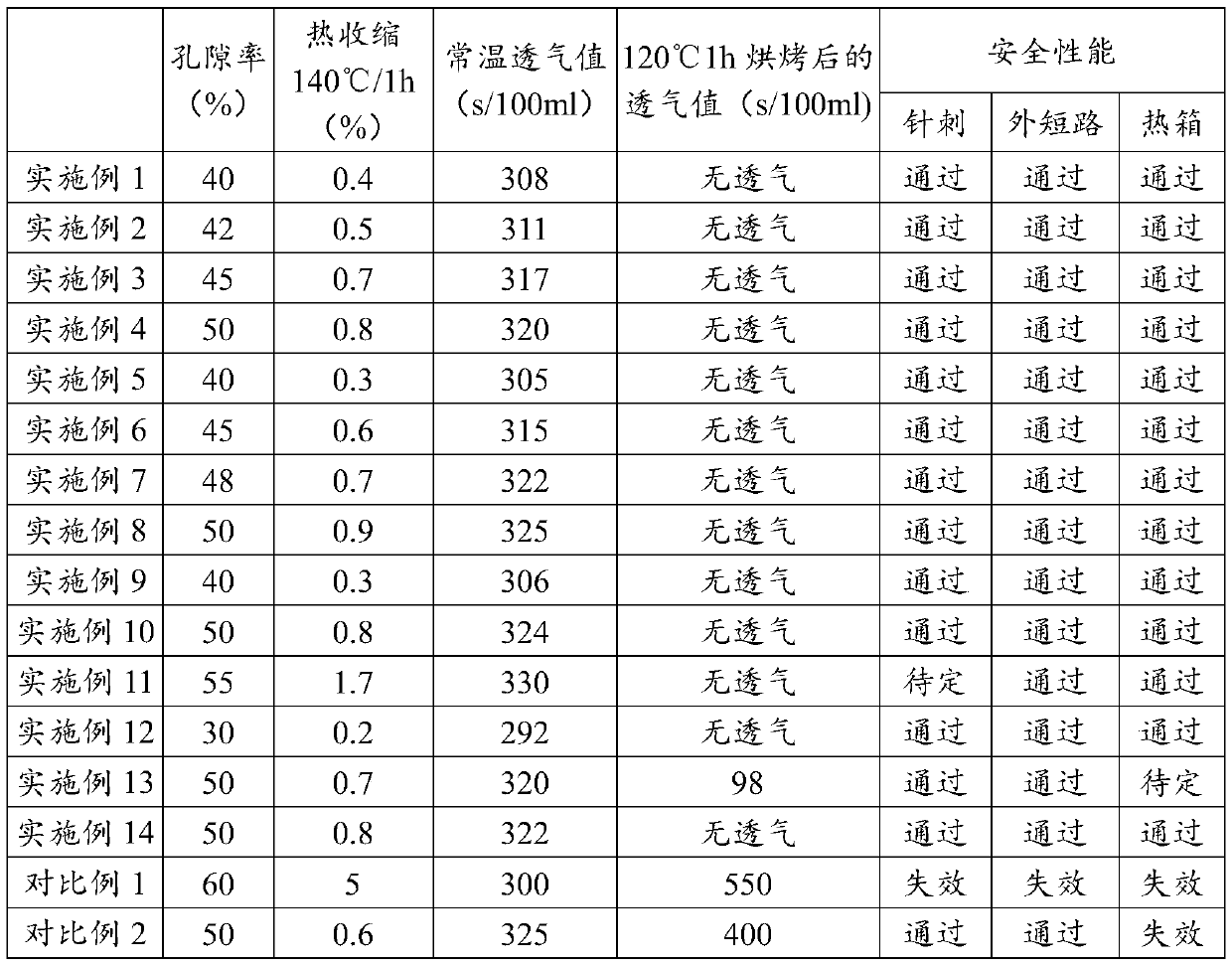

ActiveCN101150182AImprove high temperature melting strengthLow melt fluidity at high temperatureElectrode carriers/collectorsSecondary cellsCross-linkPolyolefin

This invention discloses pole plates of Li ionic cells, in which, a micro-porous film is set on the pole plate with PVDF as the matrix and chemical gel formed by chimical cross-link is set in the micro-porous film.This invention also discloses a Li-ionic cell core with said pole plates and a preparation method including: the PVDF film forming chemical gel inside by irradiation and cross-link has the heat contraction rate of nearly zero under 100-220deg.C, which can prevent electronic short circuit of positive and negative pole plates caused by over contraction of intensified switchable Polyolefin micro-hole septums under high temperature when being coated on the pole plates.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

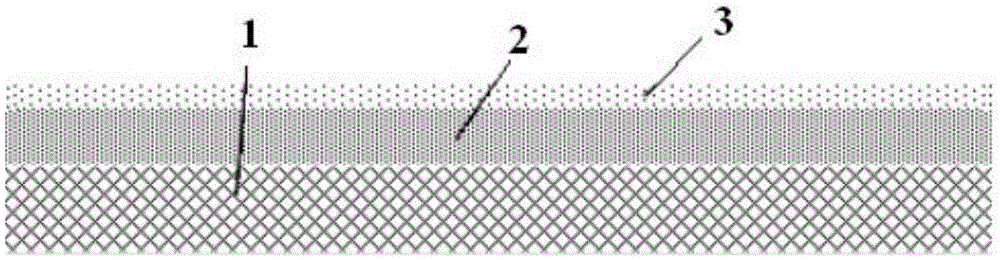

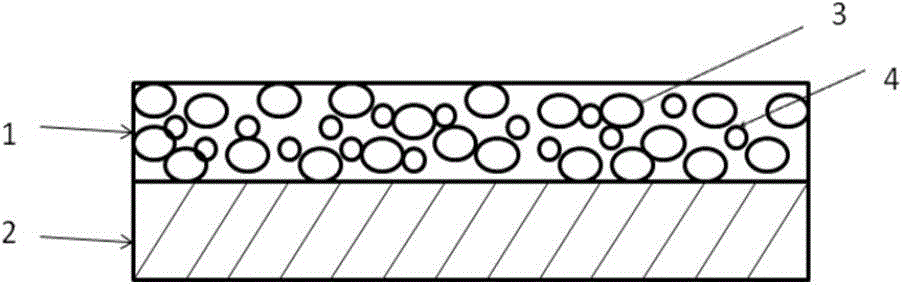

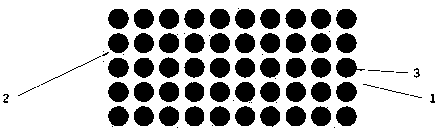

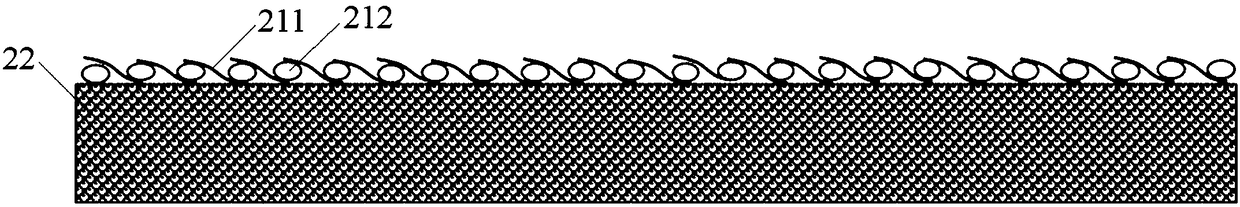

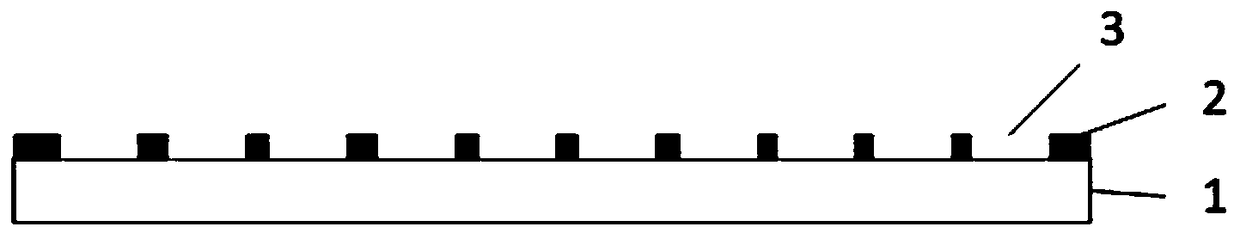

Non-woven fabric based multi-layer composite diaphragm for lithium ion battery and preparation method of multi-layer composite diaphragm

ActiveCN105470435AImprove high temperature closed cell performanceHigh tensile strengthCell component detailsEmulsionInorganic particle

The invention discloses a non-woven fabric based multi-layer composite diaphragm for a lithium ion battery and a preparation method of the multi-layer composite diaphragm. The non-woven fabric based multi-layer composite diaphragm comprises a non-woven fabric base material, an intermediate thermoplastic material coating and an outer-layer ceramic coating. The preparation method comprises the following steps of (1) mixing and uniformly stirring thermoplastic material particles, a binding agent and a solvent to form a mixed emulsion 1, and mixing and uniformly stirring inorganic particles, the binding agent and the solvent to form a mixed emulsion 2; and (2) uniformly applying the mixed emulsion 1 on one surface of the non-woven fabric base material, drying the mixed emulsion 1 to form the thermoplastic material coating, applying the mixed emulsion 2 on the thermoplastic material coating, drying the mixed emulsion 2 to form a ceramic coating, and rolling the ceramic coating to prepare a three-layer composite diaphragm. The three-layer composite diaphragm prepared according to the method has high-temperature obturator performance, favorable liquid absorption capability and mechanical property.

Owner:TIANNENG SAFT ENERGY JOINT CO

Battery diaphragm and application thereof

InactiveCN104600230AHigh porosityReduced ionic conductivitySecondary cellsCell component detailsCeramic particleLithium electrode

The invention discloses a battery diaphragm and application thereof. The battery diaphragm provided by the invention is composed of a base membrane and a nanoparticle coating coated on at least one surface of the base membrane. The nanoparticle coating contains at least two nanoparticles, which include ceramic particles and organic polymer particles. According to the battery diaphragm provided by the invention, the organic polymer particles are firstly added into the nanoparticle coating, thus not only enhancing the porosity of the nanoparticle coating, reducing the ionic conductivity of the battery diaphragm, but also enhancing the heat resistance of the battery diaphragm, decreasing the dosage of ceramic particles, and reducing the thickness of the nanoparticle coating. In addition, by adding the organic polymer particles, certain caking property exists between the battery diaphragm and the battery anode and cathode, so that the prepared battery has better oneness, and the diaphragm electrolyte solution wettability and absorption performance can also be improved, thus laying the foundation for providing lithium ion batteries with high security performance.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

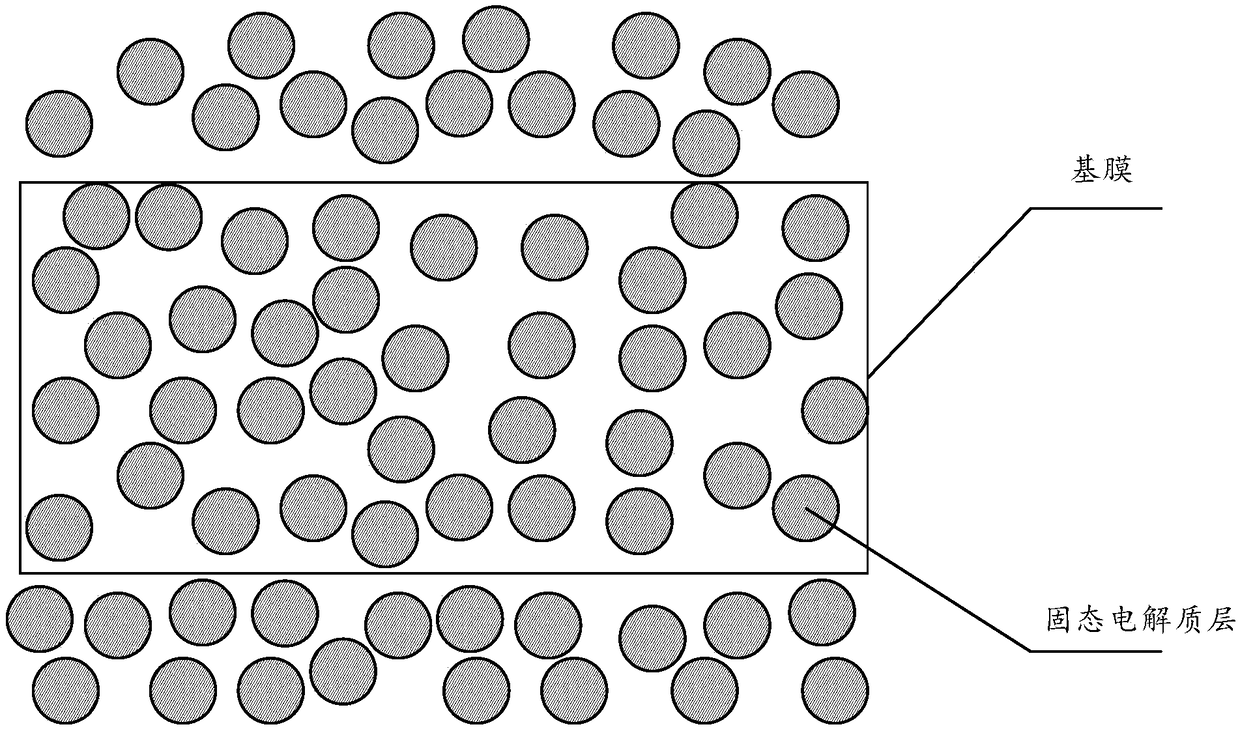

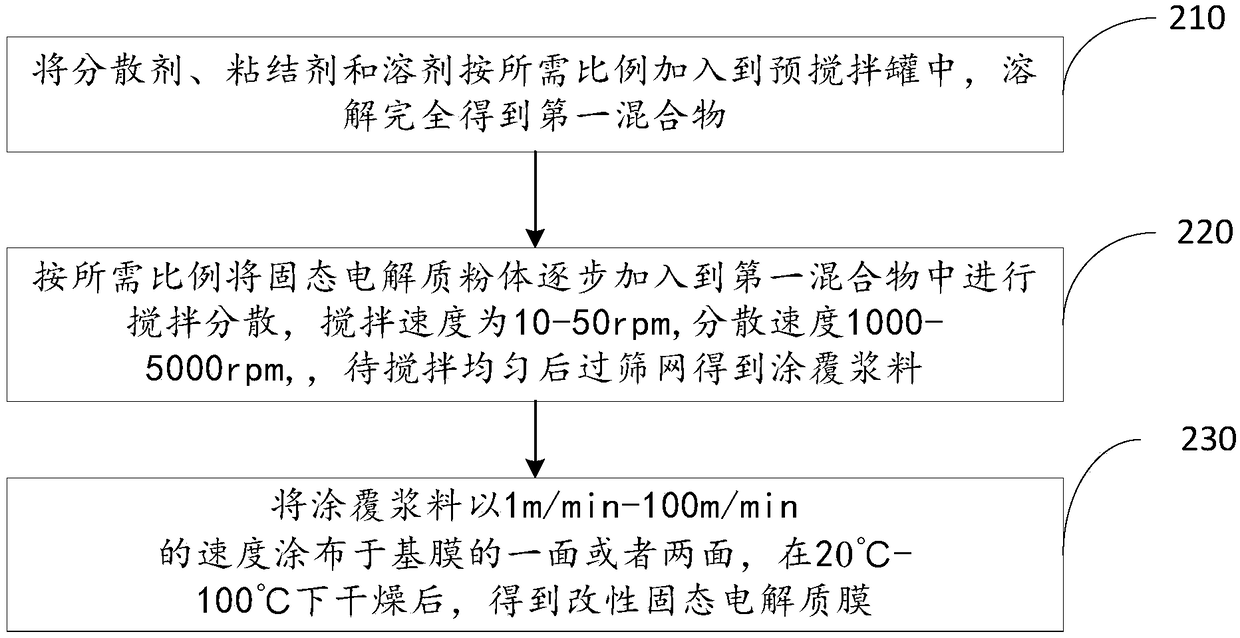

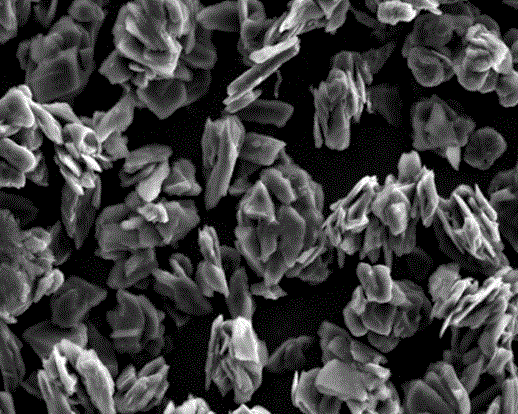

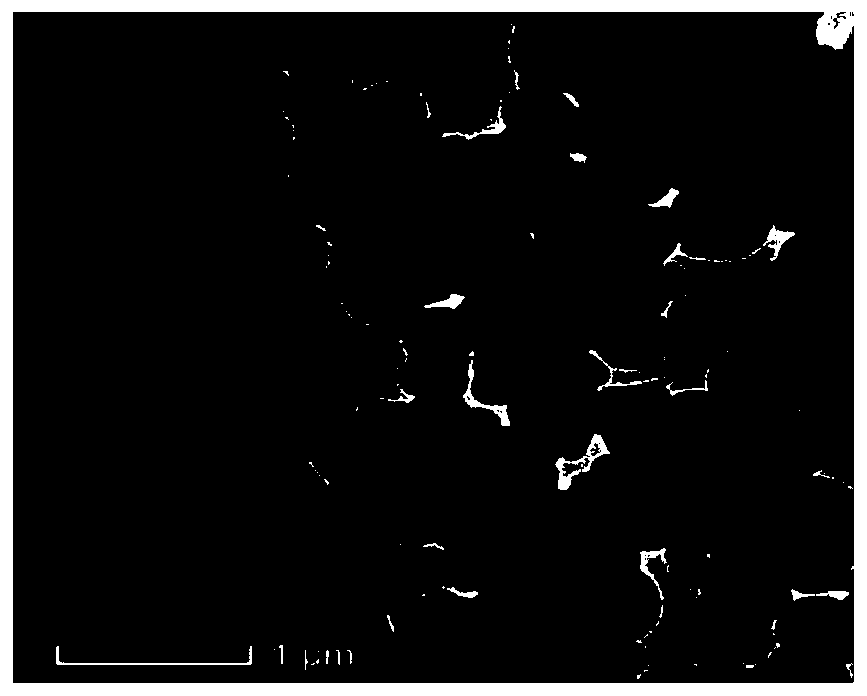

Modified solid electrolyte membrane, preparation method thereof and lithium battery

InactiveCN109494390AImprove liquid absorption performanceUniform thicknessSolid electrolytesLi-accumulatorsSolid state electrolyteChemical physics

The invention discloses a modified solid electrolyte membrane, a preparation method thereof and a lithium battery. The modified solid electrolyte membrane comprises a basic membrane and a solid electrolyte layer. The solid electrolyte layer is formed by a coating slurry which is coated on the basic membrane or is coated on the basic membrane and even permeate into the basic membrane, a thickness ratio of a coating layer on the basic membrane to the basic membrane is 10:1-1:10, the thickness of the coating layer is in a range of from 1 micrometer to 10 micrometers, and the density of the coating layer is in a range of from 50% to 100%. The solid electrolyte layer is formed by a NAS I CON type solid electrolyte material, have practical size smaller than 1 micrometer and is specifically represented as Li1+xAxB2-x(PO4)3, wherein x is in a range of from 0 to 0.6, A is one or more of Al, Y, Ga, Cr, In, Fe, Se or La, B is one or more of Ti, Ge, Ta, Zr, Sn, Fe, V or hafnium element Hf, and after the solid electrolyte membrane is circularly formed, a photoelectronic energy spectrum of an X-ray of the solid electrolyte membrane has a peak between 685eV to 690eV.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

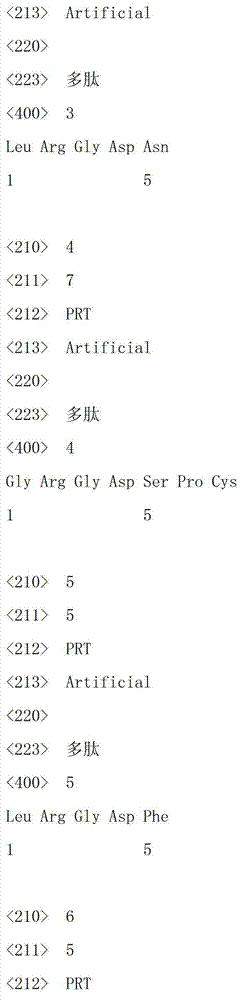

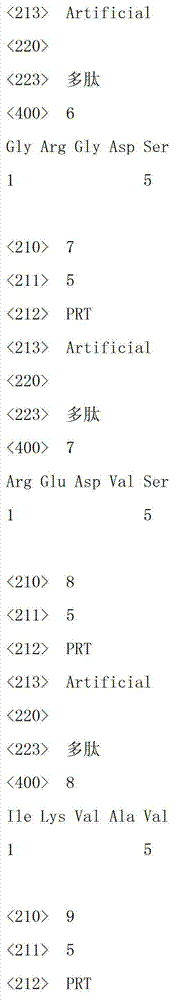

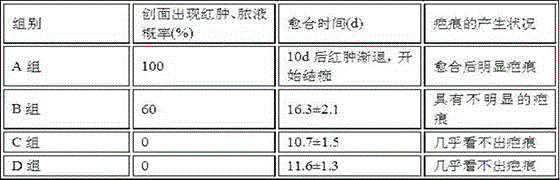

Absorbable and hemostatic multifunctional particle with tissue induction and preparation and application of multifunctional particle

ActiveCN102772821AGood hemostasisImprove liquid absorption performanceAbsorbent padsBandagesHyaluronic acidPharmaceutical Excipient

The invention relates to a multifunctional particle used for stopping human body wounds bleeding, filling, absorbing fluid, preventing adhesion and inducing tissue regeneration and repair. The absorbable particle with multiple functions of stopping bleeding, filling, absorbing the fluid, preventing the adhesion and inducing the tissue regeneration and repair comprises the following raw materials in weight percentage: 30-98.95 percent of polyanionic substance, 1-70 percent of cationic substance and / or polycationic substance, 0.05-2 percent of hyaluronic acid and / or functional factor polypeptide and 0-68.95 percent of pharmaceutical excipient. The particle is 0.01-1.0mm in particle size, and the particle is irregular in shape. The absorbable particle material with the multiple functions of stopping bleeding, filling, absorbing the fluid, preventing the adhesion and inducing the tissue regeneration and repair can be used for stopping the human body wounds bleeding, filling, absorbing fluid, preventing the adhesion and inducing the tissue regeneration and repair and is especially suitable for the wounds and defective tissues during minimally invasive surgery.

Owner:SUZHOU BOCHUANG TONGKANG PHARM TECH CO LTD

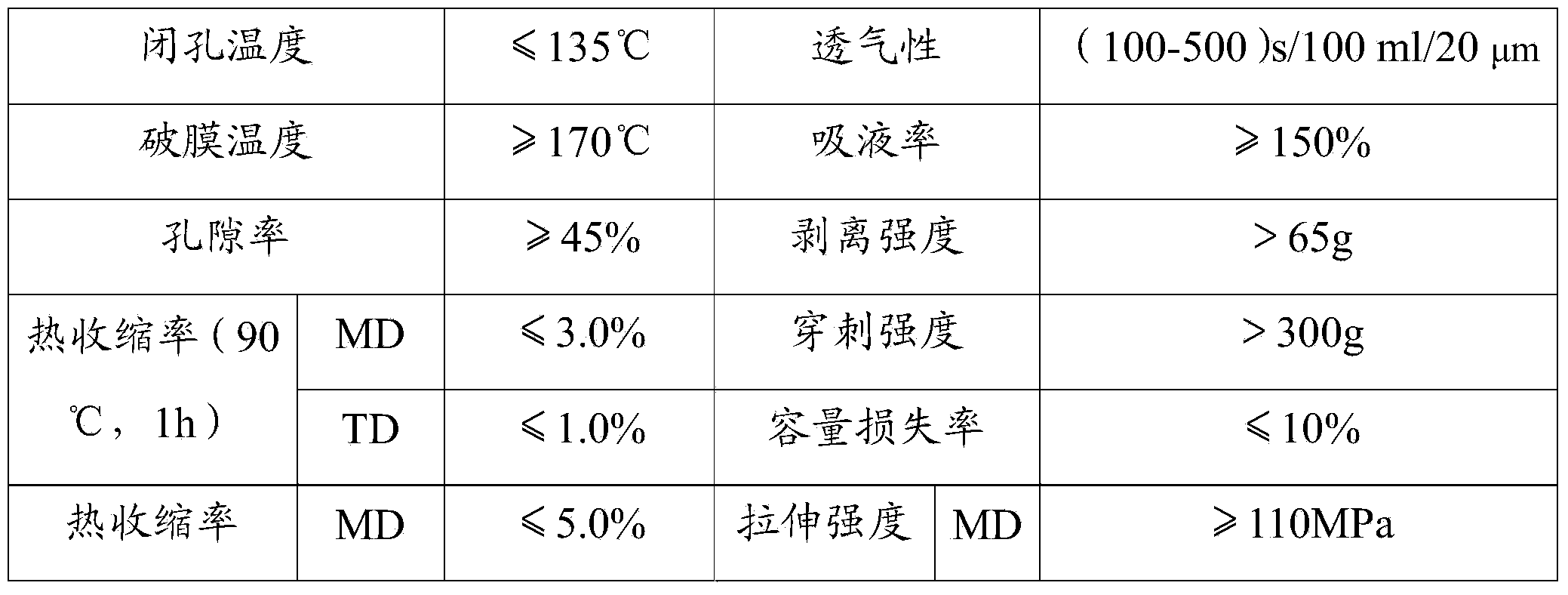

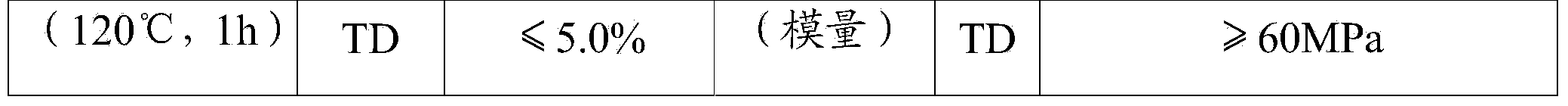

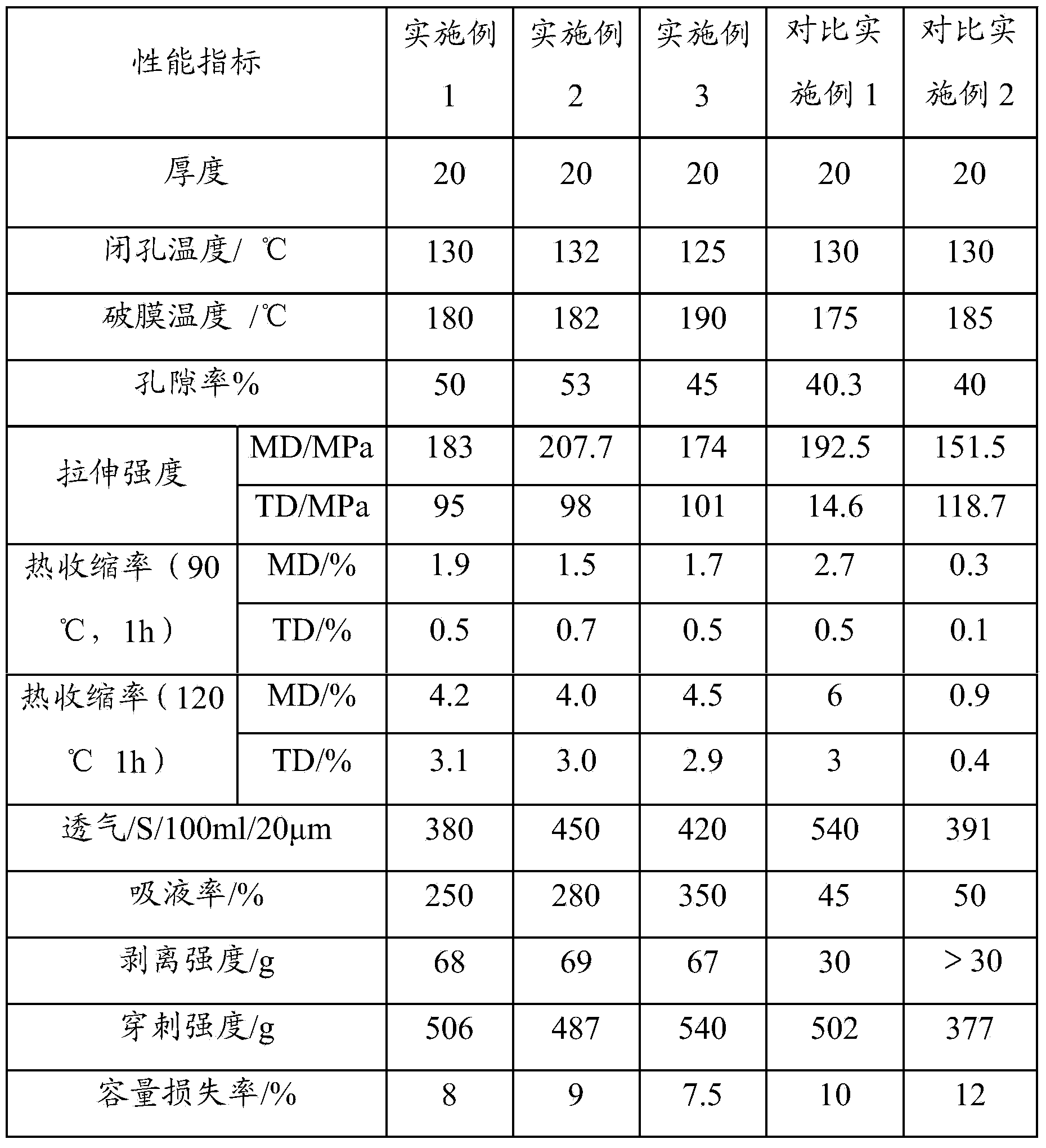

Polyolefin multilayer micro porous diaphragm for lithium ion battery and preparation method of polyolefin multilayer micro porous diaphragm

ActiveCN103531735AWith ion acceleration functionExcellent Adhesive FunctionCell component detailsPolyolefinHigh diaphragm

The invention relates to a polyolefin multilayer micro porous diaphragm for a lithium ion battery and a preparation method of the polyolefin multilayer micro porous diaphragm. The polyolefin multilayer micro porous diaphragm comprises a polyethylene micro porous layer, wherein an ion acceleration layer is arranged on each of the upper surface and the lower surface of the polyethylene micro porous layer, and a polypropylene micro porous layer is arranged on the outer surface of each ion acceleration layer. According to the polyolefin multilayer micro porous diaphragm, due to the adoption of a five-layer structure, a low hole closing temperature and a high diaphragm breaking temperature of the diaphragm can be provided, thus a safety window of the diaphragm is increased and the good safety performance is provided; and meanwhile, the ion acceleration layers provide low resistance, high electron conduction rate and good solution absorption performance and solution maintaining performance of the diaphragm, thus the charge-discharge power and the cycle service life of the lithium ion battery can be improved; and the ion acceleration layers have micro porous net-shaped structures and have excellent lyophilic performance and adhering performance, the ion transmission performance of the diaphragm is improved when all layers of the multilayer micro porous diaphragm are well compounded, and good gas permeability is kept.

Owner:河南惠强新能源材料科技股份有限公司

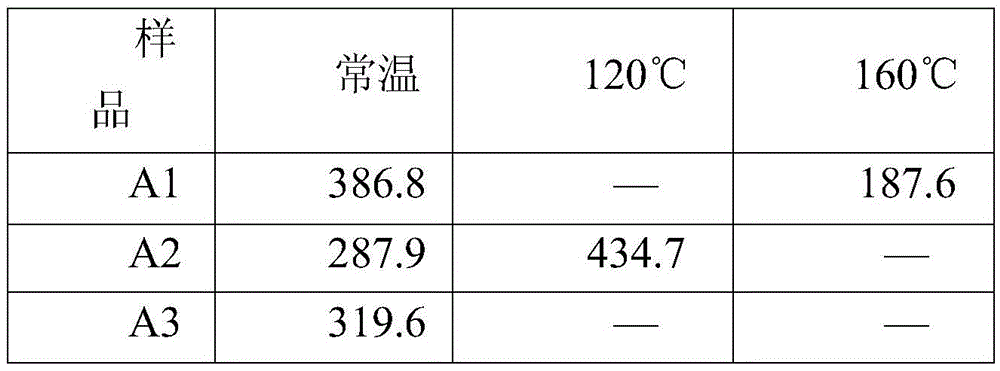

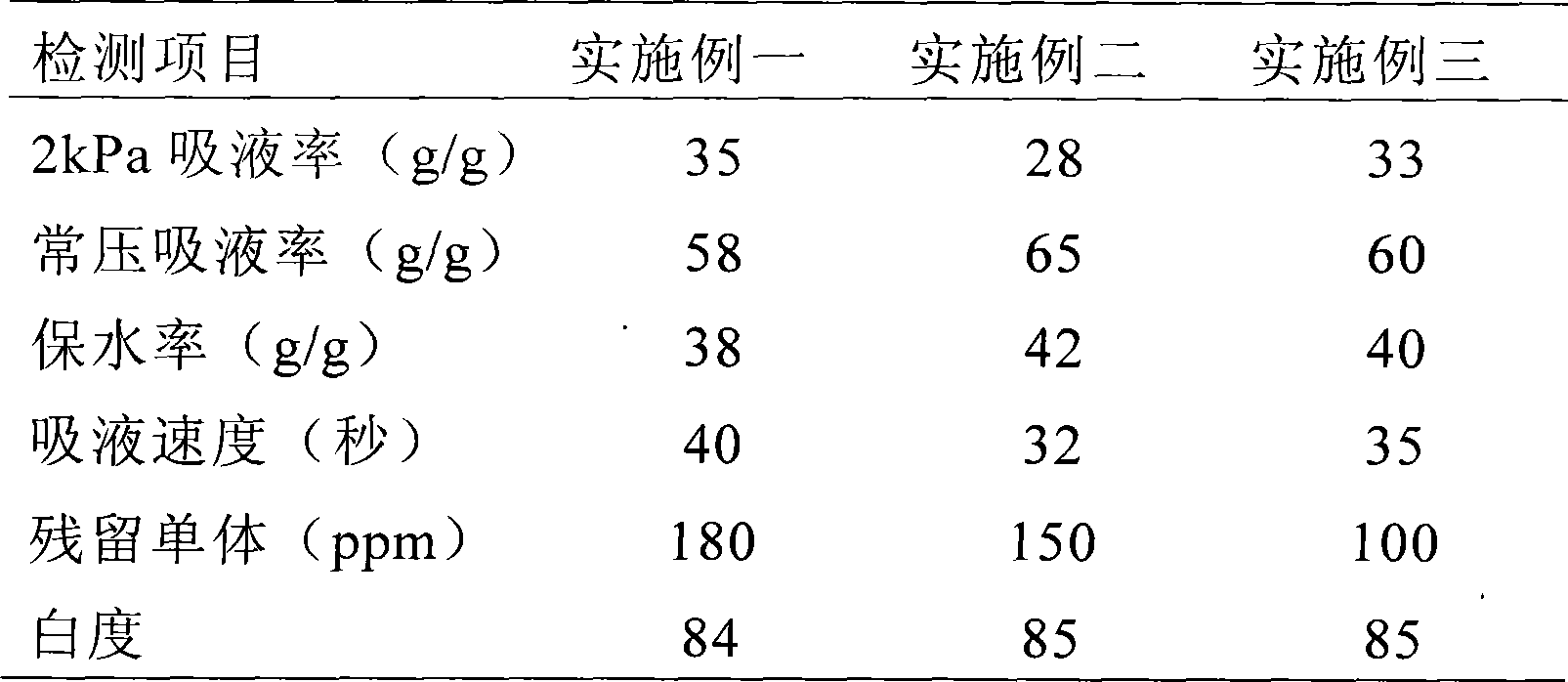

Method for preparing water-absorbing acrylic resin

The invention discloses a method for preparing water-absorbing acrylic resin, comprising the following steps: firstly, polymerizing acrylic acid monomer water solution with 60-90 mol percent of neutralization degree and polymerization reaction initiator; then adding whitening agent, cross linker and polymerization initiator into the polymerized product; drying the mixture by hot wind at the temperature between 110 and 200 DEG C, and crushing and screening the dried mixture; and after the mixture is packed and treated by the surface cross linker, heating the mixture to the temperature between 90 and 200 DEG C to carry out surface treatment, and adding inorganic salt into the mixture to form the water-absorbing acrylic resin. The water-absorbing acrylic resin has high and quick physiological-salt-absorbing ratio and good white content, and is suitable for sanitary product. The process can be continuously produced; and the product has little waste gas, powder layer and waste water.

Owner:浙江卫星新材料科技有限公司

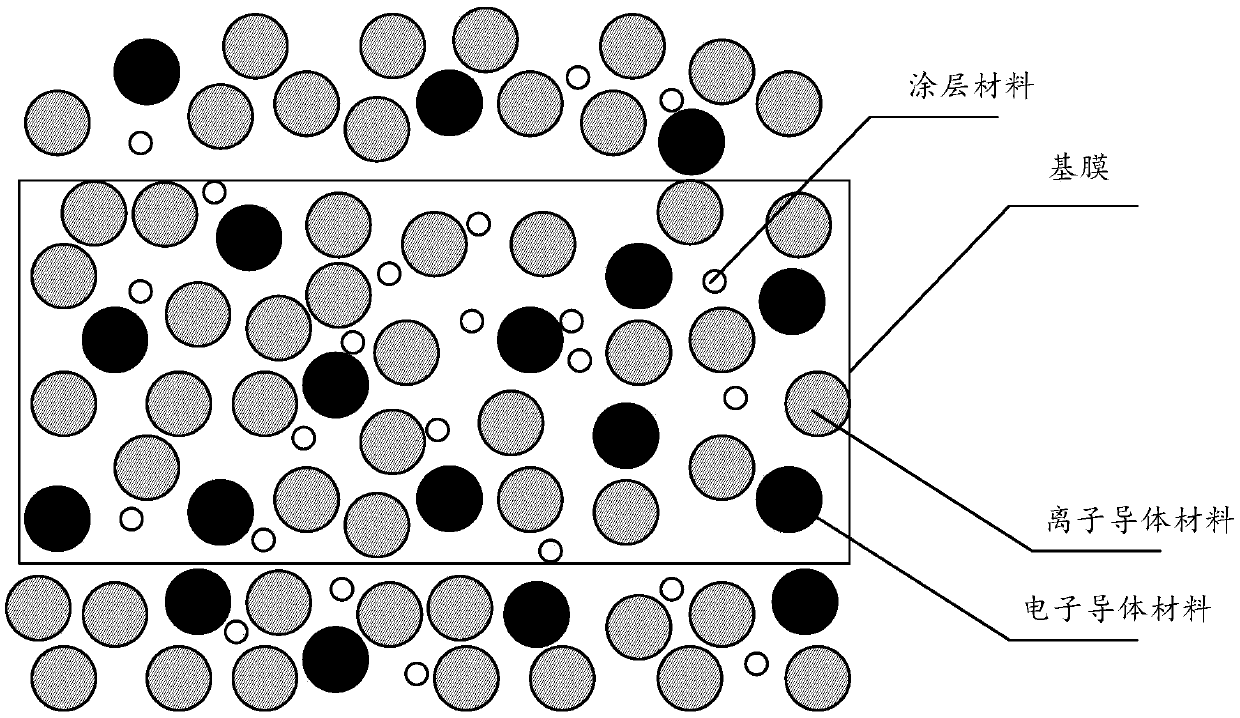

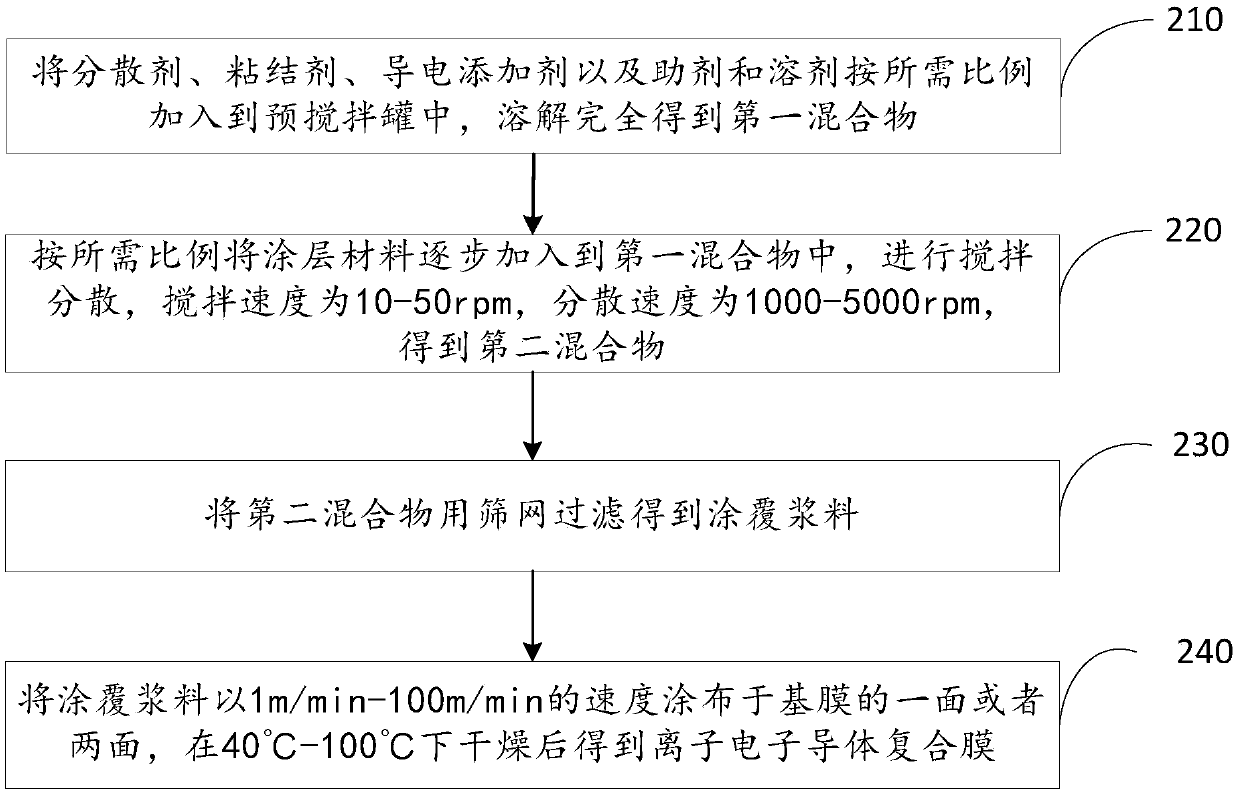

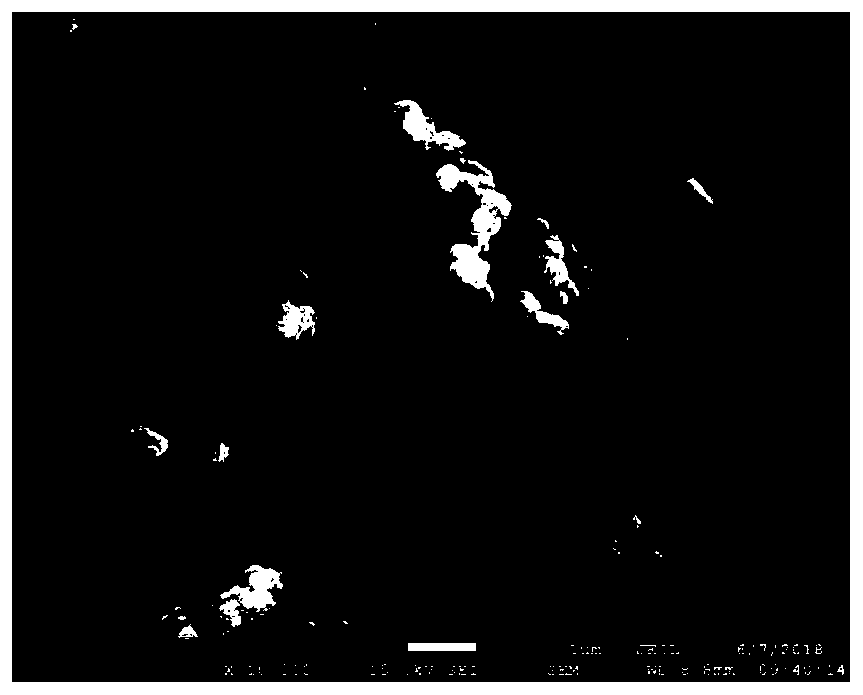

Ionic-electronic conductor composite film and preparation method thereof and lithium battery

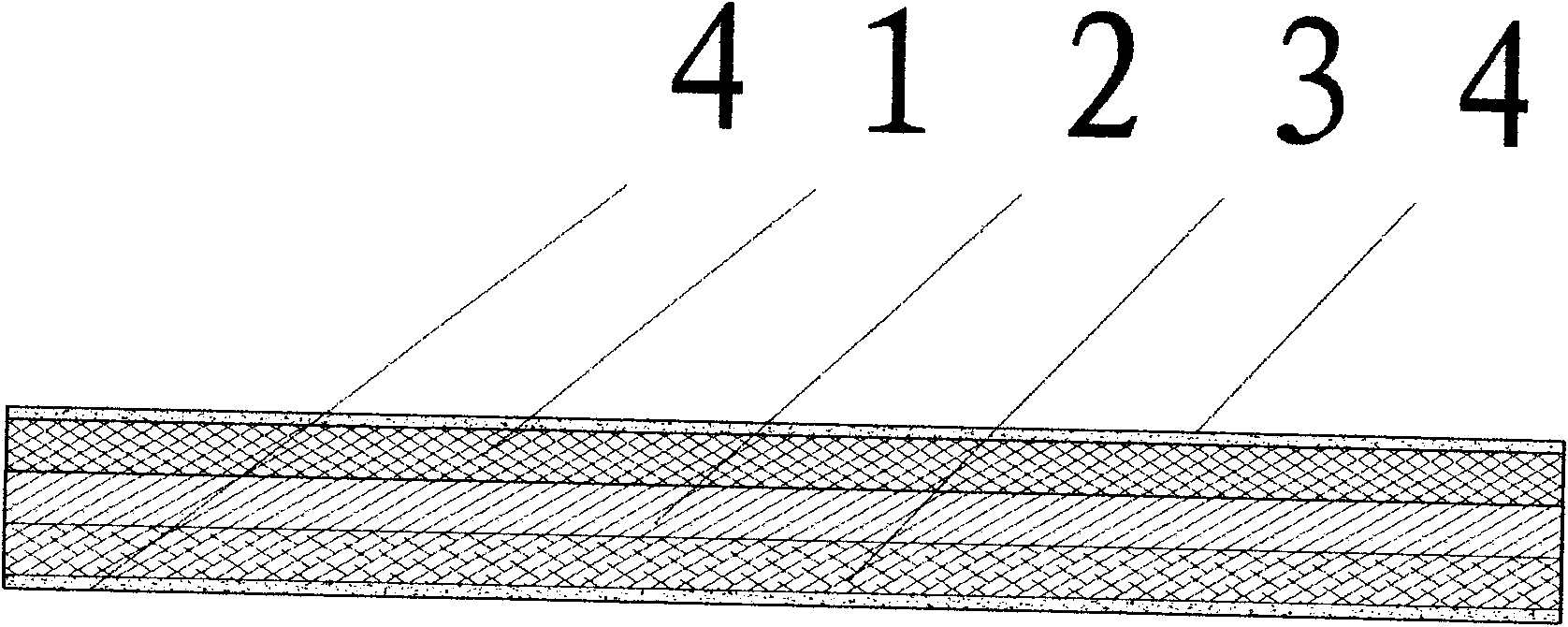

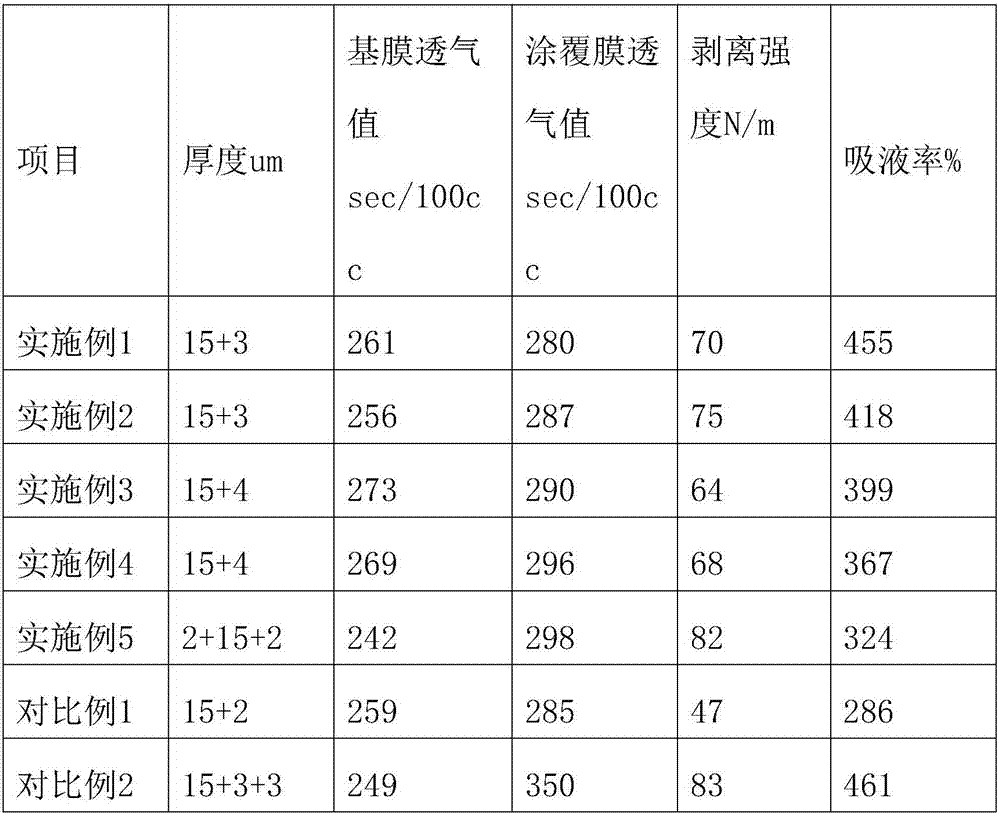

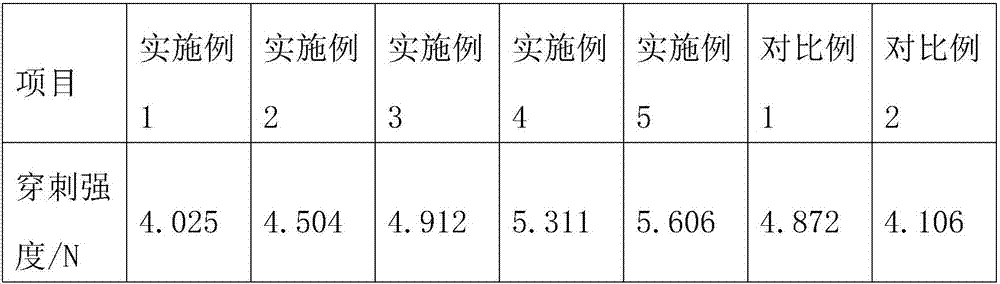

InactiveCN109638202AImprove liquid absorption performanceUniform thicknessCell seperators/membranes/diaphragms/spacersLi-accumulatorsIonCarbon nanotube

The invention discloses an ionic-electronic conductor composite film and a preparation method thereof and a lithium battery. The ionic-electronic conductor composite film comprises a base film rangingfrom 1 micron to 50 microns and a coating material ranging from 0.5 micron to 10 microns, wherein the coating material is spread on the base film or is spread on the base film and permeates into thebase film; the coating material comprises, by mass, ionic conductor materials [1wt%-99.98wt%], electronic conductor materials [0.01wt%-10wt%], coat materials [0wt%-98.98wt%], adhesives [0.01wt%-10wt%], dispersing agents [0wt%-2wt%] and auxiliaries [0wt%-2wt%]; the ionic conductor materials specifically include one or multiple mixtures of an LISCION solid electrolyte material, an NASCION solid electrolyte material, a perovskite solid electrolyte material or a garnet solid electrolyte material and a derivative material; and the electronic conductor materials include one or more of carbon black,conductive graphite, carbon fibers, carbon nano tubes, acetylene black, Ketjenblack, graphene, metallic silver, metallic gold, vapor phase growth carbon fibers VGCF, conductive graphite KS-6 and carbon black SUPER-P.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

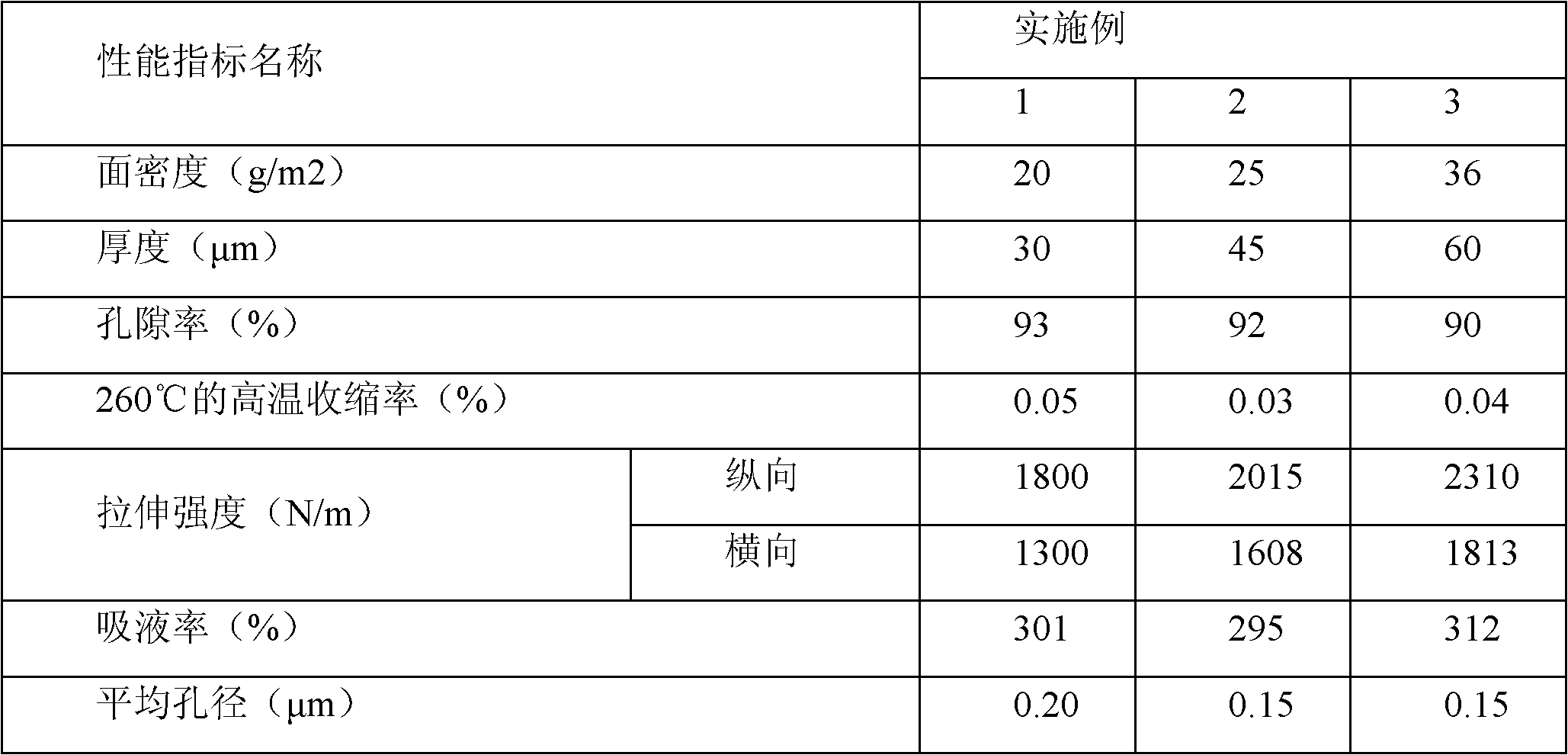

High-temperature resistant micropore thin film material and application thereof

ActiveCN102522514AImprove liquid absorption performanceExcellent liquid retentionCell component detailsPorosityAdhesive

The invention relates to a high-temperature resistant micropore thin film material prepared from inorganic fiber, synthetic fiber, natural organic fiber, nano-grade inorganic powder and an adhesive. The thin film material is a non-woven fabric material prepared through one-step molding with a wet papermaking technology combined with a coating technology. The material has a 3-dimensional network structure and porosity higher than 90%. The high-temperature resistant micropore thin film material has an outstanding high-temperature resistance. Under a temperature of 260 DEG C, excellent dimension and structure stabilities of the material are maintained for a long time. The material has excellent liquid absorbency, excellent liquid retaining capacity, and 3-dimensional stereo pores with good uniformity. An average pore size is 0.02-2.5mum. The high-temperature resistant micropore thin film material can be used as lithium ion power battery separation films, super-capacitor separation films, or filtrating materials.

Owner:莱州联友金浩新型材料有限公司

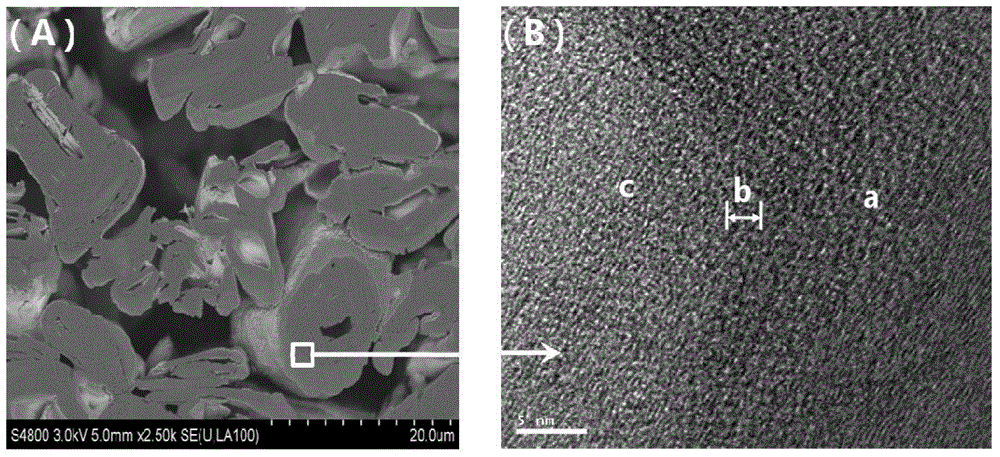

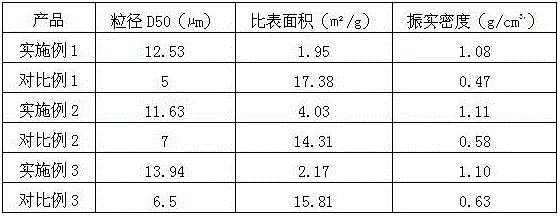

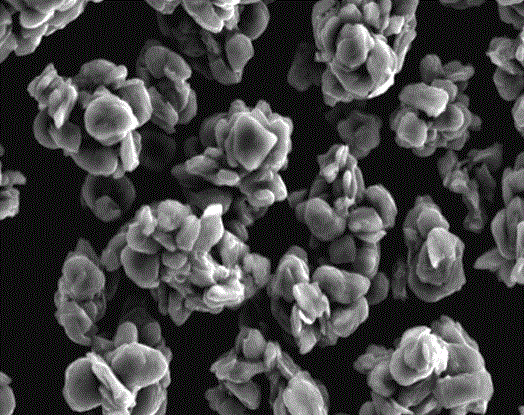

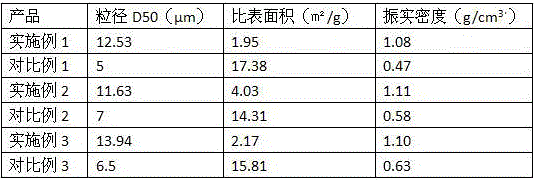

Preparation method for graphite anode material of lithium ion battery

InactiveCN105932281AReduce turnoverReduce lossesElectrode manufacturing processesSodium-ion batteryLithium-ion battery

The invention discloses a preparation method for a graphite anode material of a lithium ion battery. Fine graphite powder with a small particle size and an organic carbon source are taken as raw materials; through adoption of processes such as mixing, high temperature processing, graphitizing and sieving and through mixing of the fine powder and the organic carbon source in a heating environment, coating, kneading and secondary granulating effects can be realized; and under the adhering effect of the organic carbon source, the fine powder with the small particle size forms secondary particles. The anisotropy problem of the materials is solved, and the tap density of the materials is improved. According to the method, the turnover and device residual loss of the materials are reduced, the yield is high, the processes are simple, the energy consumption is low, the environment is protected, the surface coating effects of the materials are even, and the consistency is high. The prepared anode material is characterized in anisotropy, low iron impurity content, low initial irreversible capacity, low volume expansion, high liquid absorbency, high cycle performance, high cost performance and high comprehensive performance.

Owner:田东

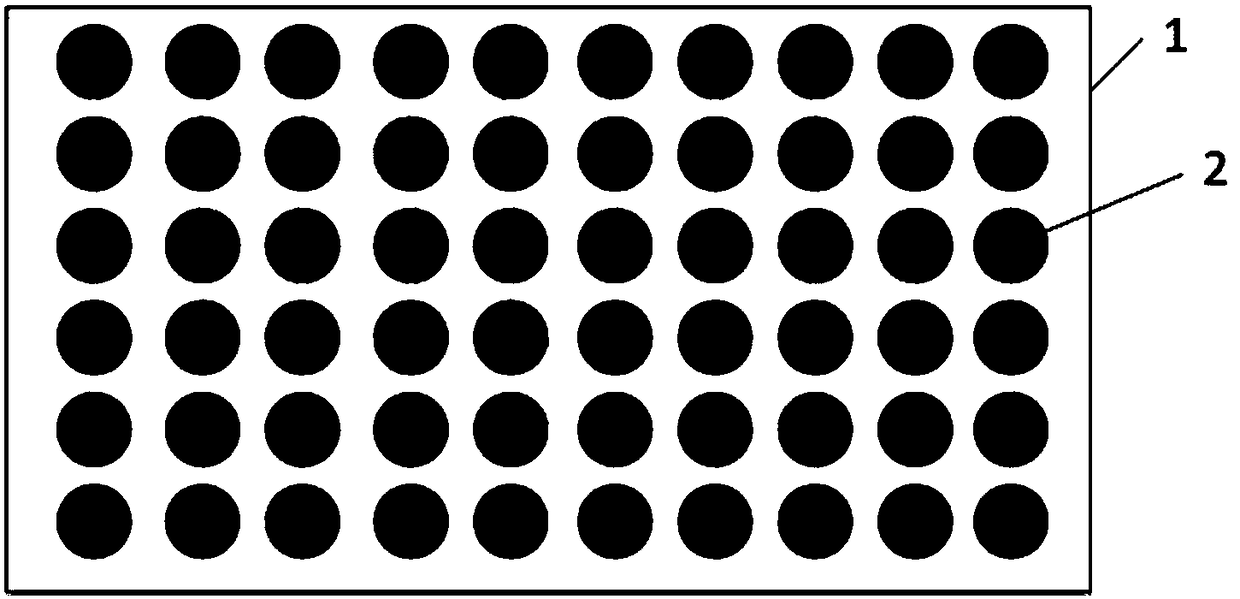

Polymer slurry, composite diaphragm and preparation method thereof

ActiveCN109994695AUniform sizeAvoid easy cloggingSecondary cellsCell component detailsPolymer scienceCeramic coating

The invention relates to the technical field of lithium ion battery diaphragm preparation and discloses polymer slurry, a composite diaphragm and a preparation method thereof. The polymer slurry includes, by weight, 10-30 parts of the polymer, 0.05-1.0 parts of the thickener, 5.1-26.5 parts of the wetting agent, 1.0-5.0 parts of the binder, 0.1-1.0 parts of the dispersant and 80-120 parts of the water. The composite diaphragm includes a base film, and a ceramic coating and a polymer dot coating coated on both sides of the base film, wherein the polymer dot coating is obtained by coating the above polymer slurry in a high pressure jet mode. The composite diaphragm has good thermal stability, strong adhesion stress and good permeability, when the composite diaphragm is applied to a lithium ion battery, performance of the lithium ion battery is improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Preparation method for artificial graphite negative electrode material for lithium ion battery

InactiveCN105958070ALow tap densityHigh tap densityCell electrodesSecondary cellsEnvironmental resistanceLithium-ion battery

Disclosed is a preparation method for an artificial graphite negative electrode material for a lithium ion battery. Artificial graphite coke powder with small grain diameter and an organic carbon source are taken as the raw materials; the raw materials are subjected to procedures of mixing, high-temperature treatment, graphitization treatment, sieving and the like; the coke powder and the organic carbon source are mixed in a heating environment, and the effects of coating, mixing and holding, secondary pelleting and the like can be achieved; the small-particle coke powder can form secondary particles under the cohesive action of the organic carbon source; therefore, the problem of anisotropy of the material is solved, and the tap density of the material is improved; meanwhile, the artificial graphite negative electrode material is capable of lowering the material turnover and equipment residual loss, high in yield, simple in procedures, low in energy consumption, environment-friendly, uniform in the coating effect on the surface of the material, and high in consistency; and in addition, the prepared negative electrode material has the characteristics of isotropy, low iron impurity content, low initial irreversible capacity, small volume expansion, high absorbency, high circulation performance, high performance cost ratio, excellent comprehensive performance and the like.

Owner:田东

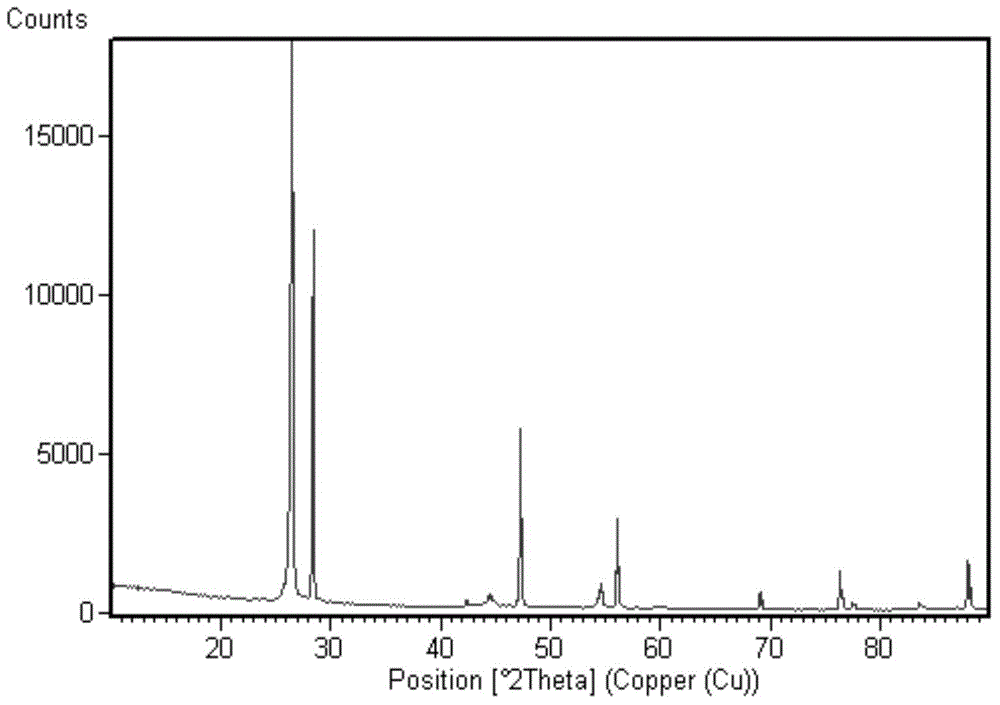

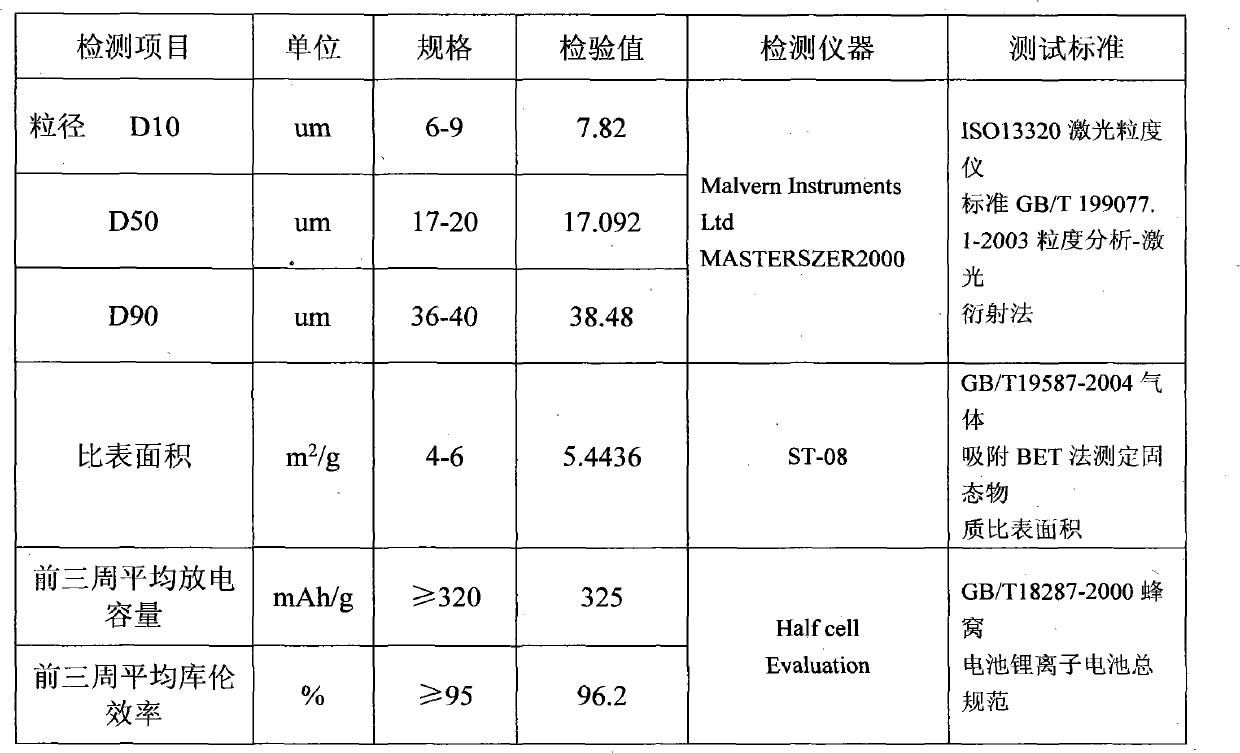

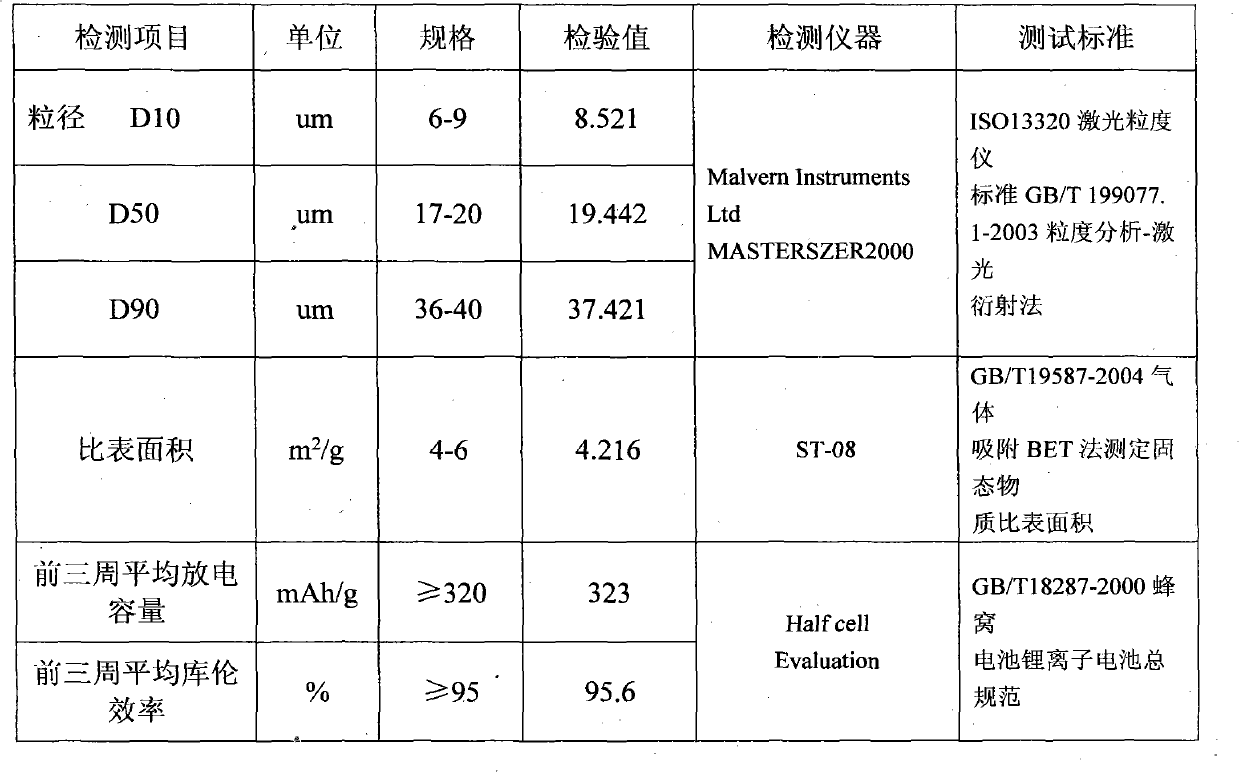

Cathode material of lithium ion secondary battery and preparation method thereof

The invention provides a cathode material of a lithium ion secondary battery, which is characterized in that additive for improving the degree of graphitization and a pore forming agent are added into carbonized green coke, so the prepared graphite cathode material has a porous structure and higher degree of graphitization; and the granularity is regulated, so the compacted density of the produced graphite cathode material is over 1.55g / cm<2>, and the specific area is below 6m<2> / g. The material has the following advantages: 1, the produced cathode material has stable performance and high cost performance, and an effective scheme for controlling battery cost is provided for lithium ion battery companies; 2, the degree of graphitization is over 95 percent, which provides powerful guaranteefor producing cathode materials with excellent performance; and 3, a certain amount of the pore forming agent is added before the graphitization treatment, so the cathode material has a nanometer porous structure, the lithium intercalation performance of the cathode material and the imbibing performance of a pole piece can be effectively improved.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

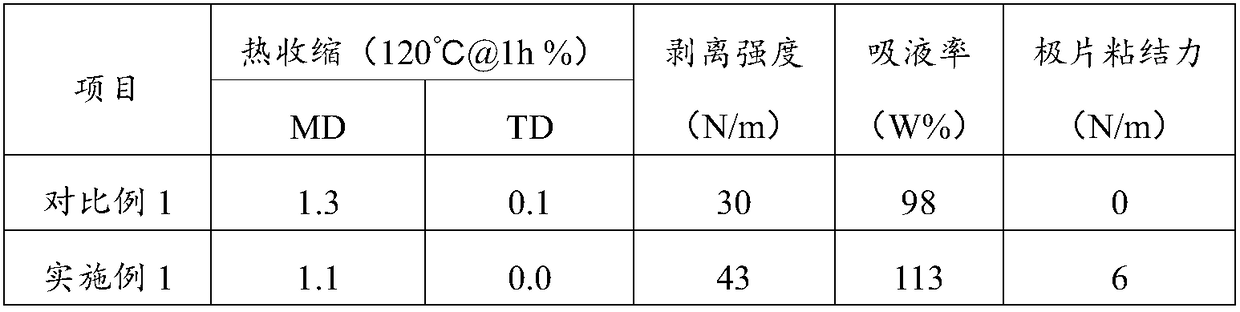

High-temperature resistant composite battery separator and preparation method thereof

ActiveCN108281592AGood thickening effectImprove hydrophilicityCell component detailsInorganic particleInorganic particles

The invention discloses a high-temperature resistant composite battery separator and a preparation method thereof. The high-temperature resistant composite battery separator comprises a base film anda high-temperature resistant coating layer, wherein the high-temperature resistant coating layer is coated on at least one surface of the base film and is formed by coating inorganic particles containing nanometer cellulose as a binding agent. In the composite battery separator, the nanometer cellulose is creatively used as the binding agent to prepare the high-temperature resistant coating layer,the interface bonding force of the coating layer and the base film is improved, the stripping strength of the composite battery separator is further improved, and the problems of falling and powder dropping of the coating layer are solved very well; with the addition of the nanometer cellulose, the inorganic particles are better in dispersion effect in water; moreover, the nanometer cellulose isused as the binding agent to form the coating layer, the high-temperature resistant composite battery separator is rapid in liquid conductivity and high in liquid absorption capability, gel is easilyformed after the electrolyte is absorbed, so that the composite battery separator can be attached onto a surface of an electrode very well, and the integral performance of the lithium ion battery is improved.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

Carbon quantum dot/nano-silver alginate dressing and preparation method and application thereof

ActiveCN106729936AImprove hydrophilicityImprove mechanical propertiesAbsorbent padsIn-vivo testing preparationsPEG 400Clinical supervision

The invention belongs to the technical field of medical dressing, and discloses a carbon quantum dot / nano-silver alginate dressing and a preparation method and application thereof. A carbon quantum dot / nano-silver composite material is prepared from silver nitrate, polyethylene glycol 400, sodium citrate, ascorbic acid and carbon quantum dots; and the carbon quantum dot / nano-silver composite material is added to a sodium alginate solution to prepare the carbon quantum dot / nano-silver alginate dressing through an electrostatic spinning technology and a non-woven technology. According to the dressing prepared by the technology, the mechanical property of the alginate dressing can be significantly improved; meanwhile, the dressing has an excellent fluorescent display tracking function; the migration change and the accumulation condition of silver ions in a body can be effectively inspected; and a fast and effective detection method is provided for clinical supervision of the silver ions.

Owner:广州锐晟科技有限公司

Process for producing high-molecular water-absorbent resin dust-free paper

InactiveCN102337701AEffective lockingReduce reverse osmosisNon-fibrous pulp additionSpecial paperReverse osmosisFluff pulp

The invention belongs to the papermaking technical field, more specifically relates to a process for producing the high-molecular water-absorbent resin dust-free paper. The process for producing the high-molecular water-absorbent resin dust-free paper takes fluff pulp wood pulp fiber, hot melt composite fiber and high-molecular water-absorbent resin (SAP) as the raw materials and the dust-free paper is composed of three-layer mixing layers. The process for producing high-molecular water-absorbent resin dust-free paper comprises the following steps: mixing the raw materials through a molding case, penetrating through hot air, wherein a heat bonding point between the hot melt fiber and wood pulp fiber formed by surface melting and flowing which are generated by the hot melt fiber during the heating process has the heat bonding effect, spraying latex on the double faces of the paper web and then drying by hot-air in a drying cylinder, rewinding to obtain the finished product. The present invention has the beneficial effects that the dust-free paper has good penetration performance and imbibition capability, is capable of effectively holding liquid, minimizing the reverse osmosis of liquid and maintaining the dry surface of the product, and has less dust and high tensile strength.

Owner:NANNING QIAOHONG NEW MATERIALS

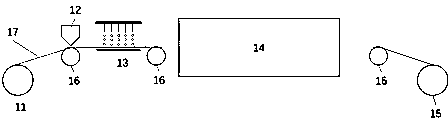

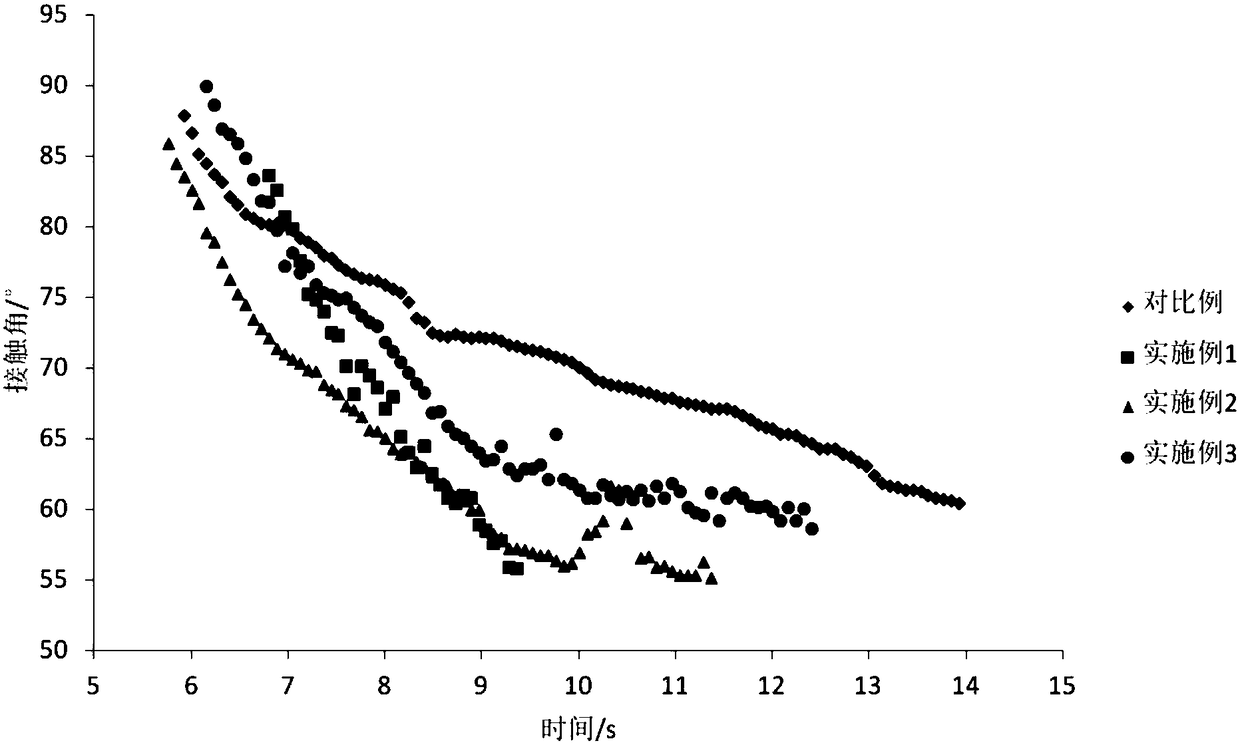

Preparation method for waterborne PMMA composite coating diaphragm

ActiveCN107046116AImprove thermal stabilityImprove mechanical propertiesLi-accumulatorsCell component detailsPolyolefinMixed materials

The invention provides a preparation method for a waterborne PMMA composite coating diaphragm. The coating diaphragm is formed by coating one side or two sides of a polyolefin base membrane with mixed paste of modified PMMA and ceramic in one time; and the modified PMMA is obtained by performing crosslinking and modifying on the PMMA and a copolymer thereof by a crosslinking agent based on a certain proportion. The diaphragm is prepared from the mixed materials of the modified PMMA and the copolymer thereof and ceramic in a coating manner; and the coating layer only needs coating of one time, so that production cost is lowered, ventilation loss caused by thickness of the coating layer also can be lowered, and meanwhile, the thermal stability of the diaphragm is improved.

Owner:NINGDE ZHUOGAO NEW MATERIAL TECH CO LTD

Carboxymethyl chitosan band-aid and preparation method thereof

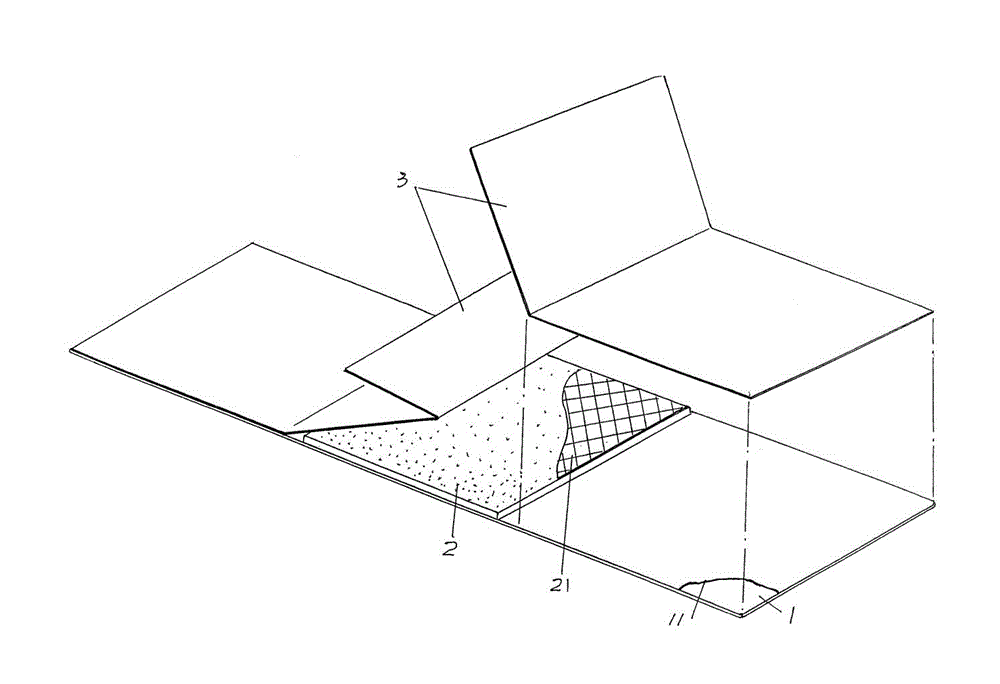

InactiveCN103143050AGood hemostasisGood antibacterialAdhesive dressingsAbsorbent padsNonwoven fabricProtection layer

The invention discloses a carboxymethyl chitosan band-aid and a preparation method thereof, belonging to the technical field of medical dressings. The carboxymethyl chitosan band-aid comprises a matrix layer, a wound protection layer which is combined with one side surface of the matrix layer and a peeling layer which covers one side of the matrix layer and shields and protects the wound protection layer, wherein a wavy non-woven medical air-permeable adhesive tape of which one side surface is provided with an adhesive-carrying layer is used as the matrix layer; a carboxymethyl chitosan fiber non-woven fabric is used as the wound protection layer, one side surface of the wound protection layer is combined with an anti-adhesion membrane, and the other side surface of the wound protection layer is combined with the adhesive-carrying layer; and glassine paper is used as the peeling layer. The carboxymethyl chitosan fiber non-woven fabric is used as the wound protection layer, so that ideal effects of stopping bleeding, resisting bacteria, promoting healing and relieving pain can be embodied, and the air permeability and the solution absorption performance of the carboxymethyl chitosan band-aid are excellent.

Owner:SUZHOU EMY MEDICAL SUPPLIES

Chitosan quaternary ammonium salt porcine acellular dermal matrix dressing material and preparation method thereof

InactiveCN106421868ALow antigenicityReduce releasePharmaceutical delivery mechanismAbsorbent padsFiberAcellular Dermis

The invention belongs to the technical field of biomedical engineering, and particularly relates to a chitosan quaternary ammonium salt porcine acellular dermal matrix dressing material and a preparation method thereof. The preparation method of the chitosan quaternary ammonium salt porcine acellular dermal matrix dressing material specifically comprises the following steps: S1, preparing a chitosan quaternary ammonium salt; S2, processing a porcine acellular dermal matrix; and S3, preparing the chitosan quaternary ammonium salt porcine acellular dermal matrix dressing material. The chitosan quaternary ammonium salt porcine acellular dermal matrix dressing material disclosed by the invention completely reserves morphological structures and components of cells, has the characteristic of low antigenicity, and meanwhile can induce fiber-forming cells and vascular endothelial cells with regeneration capacity to grow therein.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

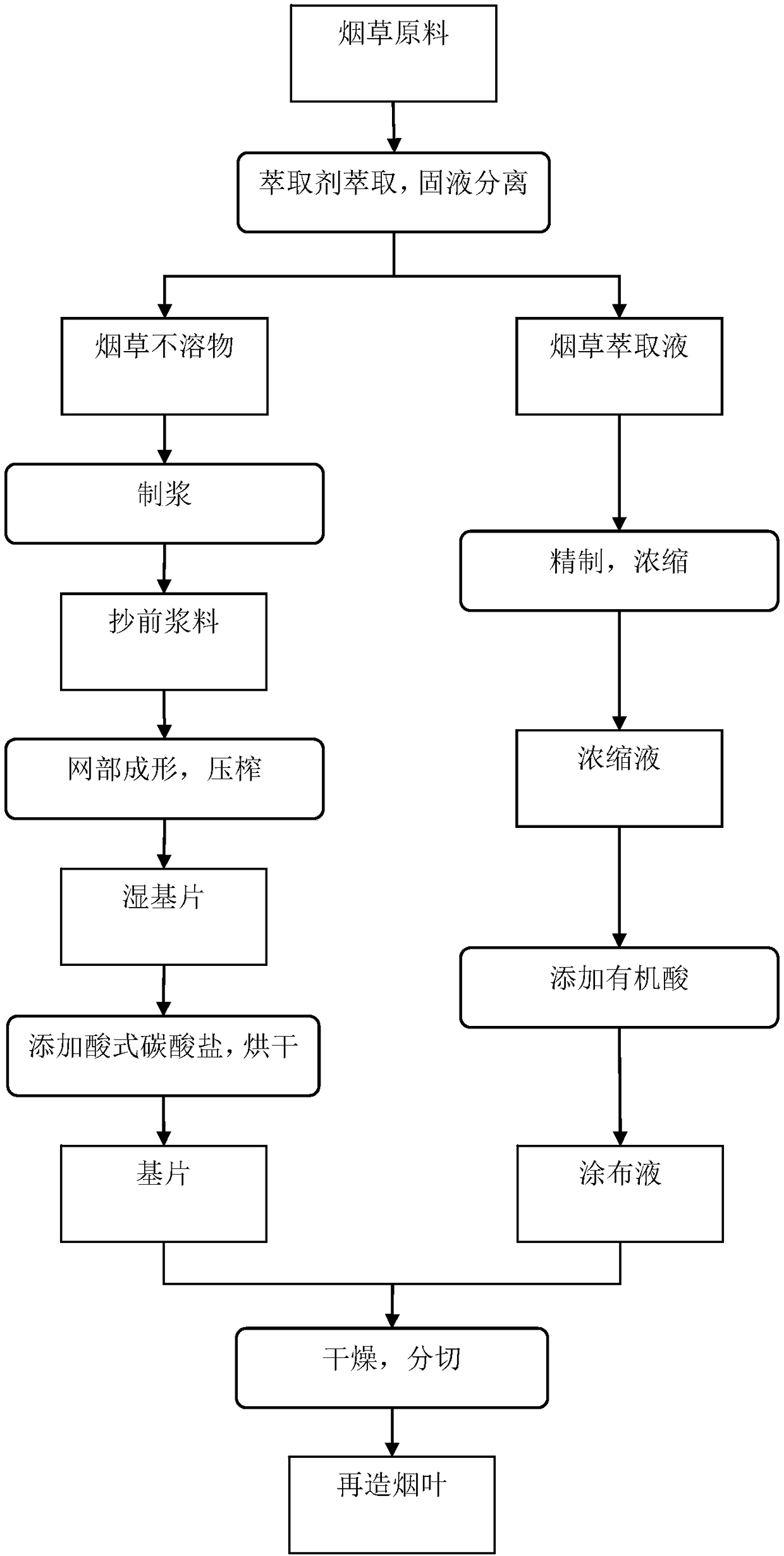

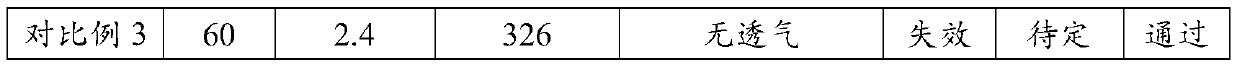

Paper-making reconstituted tobacco preparation method and method for improving coating liquid absorbability of paper-making reconstituted tobacco substrate

The invention provides a paper-making reconstituted tobacco preparation method and a method for improving coating liquid absorbability of a paper-making reconstituted tobacco substrate. The paper-making reconstituted tobacco preparation method includes steps: 1) after extracting with an extracting agent, performing solid-liquid separation to obtain tobacco insoluble matters and tobacco extract liquid; 2) subjecting the tobacco insoluble matters to pulping, and performing net forming and pressing to obtain a wet substrate; 3) subjecting the wet substrate to drying, coating of bicarbonate and drying to obtain a substrate; 4) subjecting the tobacco extract liquid to refining concentration to obtain coating liquid; or adding organic acid after refining concentration to obtain the coating liquid; 5) coating the substrate with the coating liquid, and drying and slitting to obtain reconstituted tobacco. Liquid absorbability of the substrate is improved by thermal decomposition action of bicarbonate; preferably, coating liquid absorbability of the paper-making reconstituted tobacco substrate is improved by improving substrate infiltration performance of the coating liquid through reductionof residue content of the coating liquid.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Method for preparing lithium-sulfide ion battery modified diaphragm

InactiveCN109585753AGuaranteed contentLower internal resistanceCell component detailsHigh rateInternal resistance

The invention relates to a method for preparing a lithium-sulfide ion battery modified diaphragm and belongs to the technical field of batteries. In order to solve the shuttle effect of the lithium-sulfur battery and improve the cycle performance of the battery, the method for preparing the lithium-sulfide ion battery modified diaphragm is provided, which comprises roughening the surface of the base film of the diaphragm; then immersing the base film in a hydrochloric acid solution of metal chloride; drying the base film to obtain the corresponding preprocessed base film; dissolving a dispersant and a binder in a corresponding solvent, and then adding a conductive agent so as to obtain conductive paste having the conductive agent with a solid content of 0.5% to 40%; coating the single sideor both sides of the preprocessed base film with the conductive paste to form a conductive coating; and drying the conductive coating to obtain the corresponding lithium-sulfide ion battery modifieddiaphragm. The method has a good liquid retention capacity and a good liquid absorption capacity, reduce contact resistance, reduce the internal resistance of the battery using the battery diaphragm and improve the stability of the high rate of the battery.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD

Battery diaphragm and preparation method thereof, and lithium ion battery containing diaphragm

InactiveCN109841785AImprove performanceImprove insulation performanceCell component detailsSecondary cells servicing/maintenanceFiberGlass fiber

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a battery diaphragm. The battery diaphragm includes a diaphragm base layer and a hot-melt polymer layer arranged on at least one surface of the diaphragm base layer. The diaphragm base layer includes at least one of glass fibers and ceramic fibers, and first adhesive. The hot-melt polymer layer includes a hot-melt polymer and second adhesive. Compared with the prior art, the diaphragm has better thermal stability, higher mechanical strength and stronger liquid retention and absorption capacity. In addition, the invention provides a preparation method of the battery diaphragm and a lithium ion battery containing the diaphragm.

Owner:JIANGSU TAFEL NEW ENERGY TECH CO LTD +2

Method of preparing industrial wiping paper

InactiveCN101058957APaper flatTightly boundReinforcing agents additionPaper-making machinesFiberRaw material

The present invention discloses a manufacturing method of industrial wiping papers, the method uses wood pulp as raw material and makes paper by wet paper machine and prepares products through dry method wrinkling. Said wood pulp is mixed and composed of long fiber pulp which fiber length is 2. 4-2. 6 mm and short fiber pulp which fiber length is 0. 75-1 mm, the weight ratio of the both is long fiber pulp: short fiber pulp = 8:2, the beating current is 320-360A. The invention has small equipment investment, the production cost is low, the prepared industrial wiping paper fiber bonded finely and closely, and has good imbibition performance and deoiling capacity, especially it is suitable for machinery industry such as automobile.

Owner:SHANDONG HENGLIAN INVESTMENT

Diaphragm coat composition, slurry and preparation method thereof, diaphragm and lithium ion battery

InactiveCN109065812AImprove breathabilityImprove performanceSecondary cellsCell component detailsPolymer scienceAdhesive

A lithium ion battery separator coat composition, slurry and preparation method thereof, separator and lithium ion battery are disclosed. The membrane coating composition comprises, in parts by weight, 8-30 part of polymer, 3-10 part of dispersant, 0.2-1.0 part of wetting agent, 2-6 part of adhesive and 0.05-0.5 part of defoamer. The slurry comprises a diaphragm coating composition and a solvent;A dispersant and a wetting agent are dissolved in a solvent and added with a polymer, and after stirring, a binder and a defoaming agent are sequentially added and stirred to obtain the product. The diaphragm provided by the present invention includes a base film and a polymer coating coated on one or both sides of the base film, the polymer coating being formed by drying the slurry coated on oneor both sides of the base film. A membrane coat composition, a slurry and a preparation method thereof can be used to prepare a high permeability coat membrane without changing existing coating equipment, and when apply to a lithium ion battery, that performance of the battery can be improved.

Owner:RUYUAN DONGYANG LIGHT FLUORINE RESIN CO LTD

Preparation method of biological ink material for 3D printing

InactiveCN107744602AGood biocompatibilityGood hemostatic effectAdditive manufacturing apparatusSurgical adhesivesCross-linkBiocompatibility Testing

The invention discloses a preparation method of a biological ink material for 3D printing. The preparation method mainly comprises preparing modified sodium alginate, and preparing a biological ink material. According to the present invention, the materials used by the preparation method comprise active cells, a cell culture medium, a photoinitiator, modified sodium alginate and antioxidant enzyme; sodium alginate is modified through light curing, such that the modified sodium alginate can retain the original good biocompatibility and the original good hemostasis of the sodium alginate, and can further has double cross-linking property due to the linking of the light-curable group to the molecule chain of the sodium alginate, such that the rapid curing molding can be achieved; the biological material has good biocompatibility with active cells so as to achieve active printing; and the hydrogel formed through the curing molding of the biological ink material has advantages of good mechanical property, healing promoting, bleeding stopping and good biocompatibility.

Owner:GUANGDONG TAIBAO MEDICAL DEVICE TECH RES INST CO LTD

Polypropylene diaphragm compounded with kenyaite-silicon dioxide aerogel for lithium battery

ActiveCN108400272AImprove thermal stabilityImprovement and anti-spike abilityLi-accumulatorsCell component detailsCompound aPuncture resistance

The invention relates to the field of preparation of lithium battery diaphragms, and discloses a polypropylene diaphragm compounded with kenyaite-silicon dioxide aerogel for a lithium battery. The diaphragm is prepared by compounding a diaphragm base material, namely polypropylene, and a reinforcing material, namely kenyaite-silicon dioxide aerogel micro powder, wherein the mass ratio of the kenyaite-silicon dioxide aerogel micro powder is 1-10%. The polypropylene diaphragm for the lithium battery has excellent liquid absorption performance, thermal stability and anti-puncture resistance without a coating.

Owner:义乌市坤玥玩具有限公司

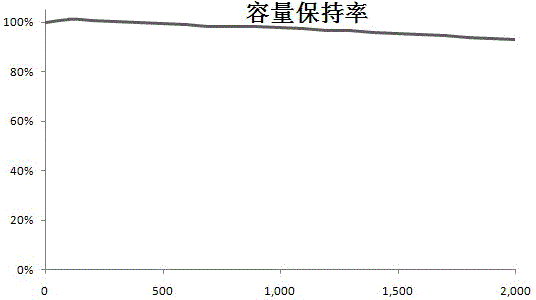

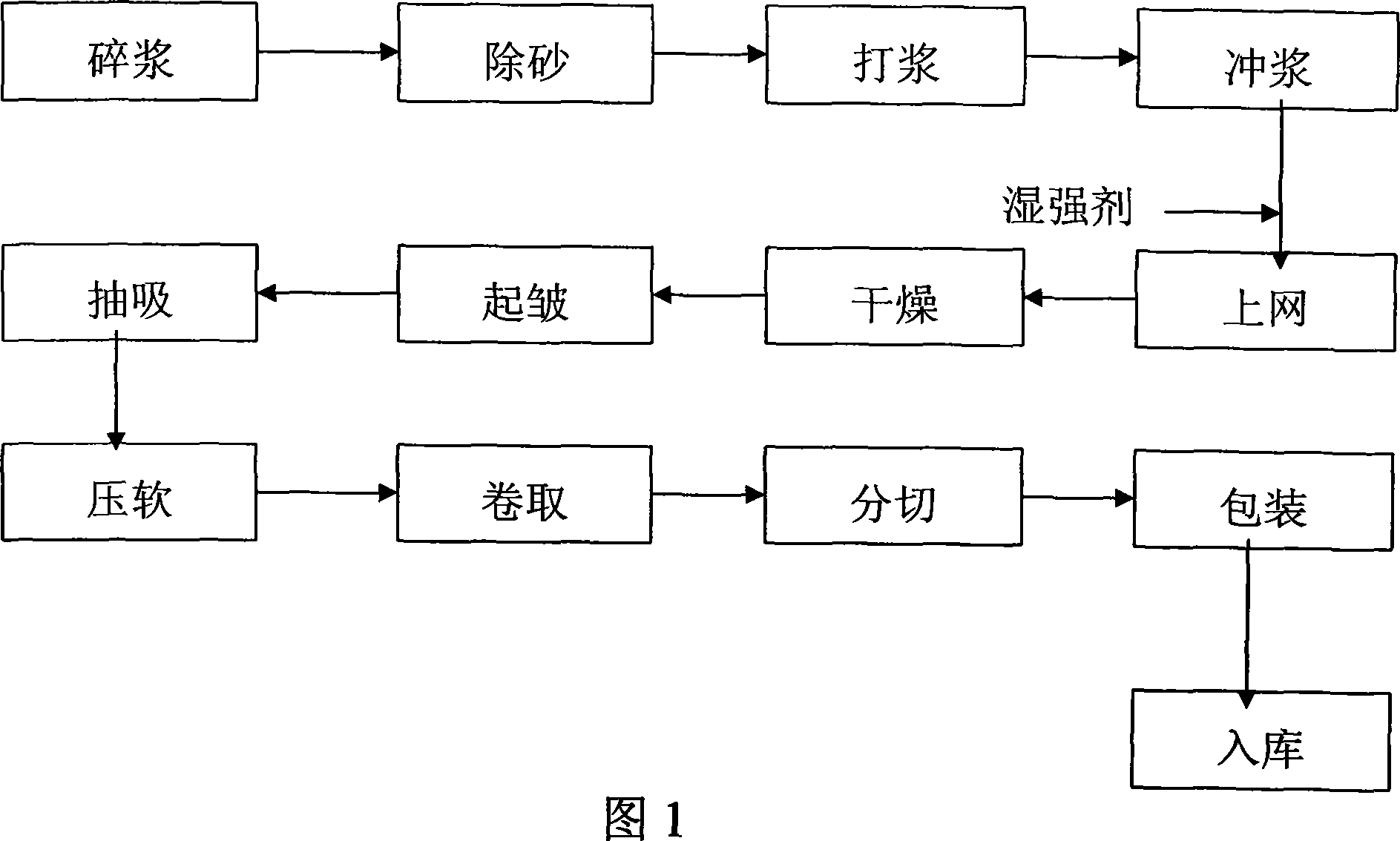

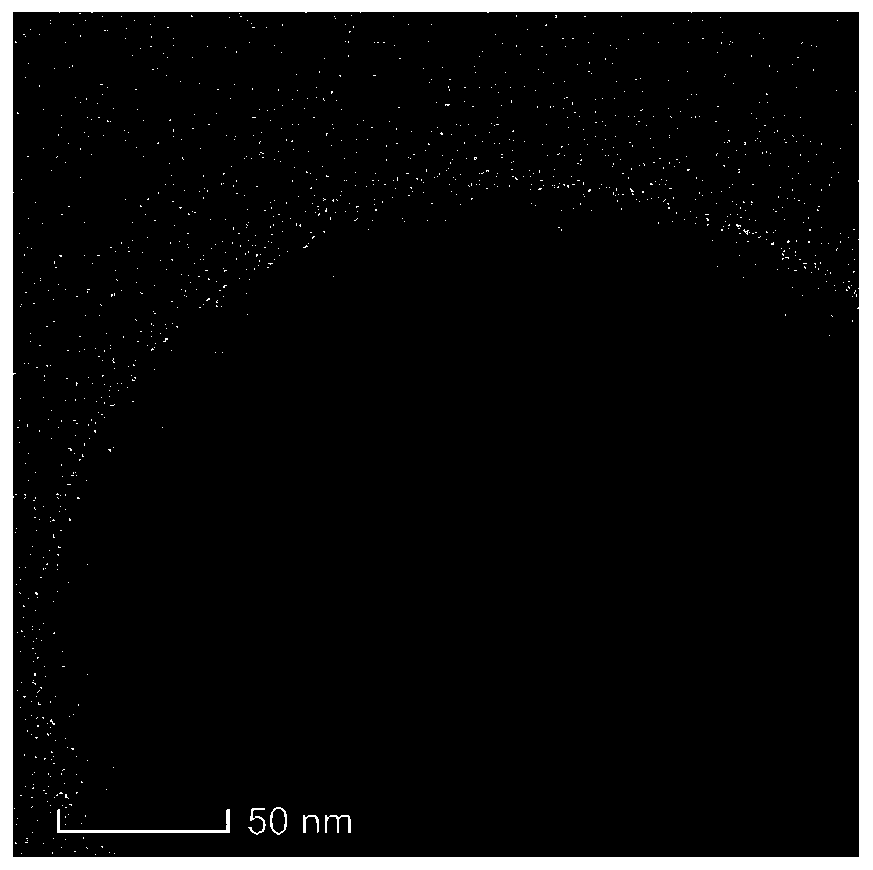

Mesoporous SiO2 microsphere lithium ion battery diaphragm and lithium ion battery

ActiveCN110416472AIncrease loading capacityImprove liquid absorption performanceFinal product manufactureSecondary cellsWater basedMicrosphere

The invention belongs to the technical field of a battery material, and particularly relates to a mesoporous SiO2 microsphere lithium ion battery diaphragm. The mesoporous SiO2 microsphere lithium ionbattery diaphragm comprises a diaphragm substrate and a mesoporous SiO2 microsphere layer, wherein the mesoporous SiO2 microsphere layer is coated on at least one surface of the diaphragm substrate and comprises a mesoporous SiO2 microsphere, a water-based binding agent, a dispersion agent, a thickening agent and water, and the mass of the mesoporous SiO2 microsphere accounts for 30%-50% of the total mass of the mesoporous SiO2 microsphere layer. Compared with the prior art, the lithium ion battery diaphragm has larger electrolyte loading quantity and has better wettability on the electrolyte. Moreover, the invention also provides a lithium ion battery comprising the mesoporous SiO2 microsphere lithium ion battery diaphragm, and the lithium ion battery has favorable safety and cycle properties.

Owner:东莞市赛普克电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com