Method of preparing industrial wiping paper

A manufacturing method and technology of wiping paper, applied in the field of paper manufacturing, can solve the problems of scratching the surface of the wiped object, poor absorption performance, large equipment investment, etc., and achieve good oil removal ability, low production cost, and small equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] A method for manufacturing industrial wiping paper, using natural wood pulp as raw material, using wet paper machine to make paper, and wrinkling by dry method, it is characterized in that: said wood pulp is made of long fibers with a fiber length of 2.4-2.6mm Wood pulp and short-fiber wood pulp with a fiber length of 0.75-1 mm are mixed, the weight ratio of the two is long-fiber wood pulp:short-fiber wood pulp=8:2, and the beating current is controlled at 320-360A. The online concentration of paper pulp is 0.05%. A wet strength agent is also added to the pulp, and the amount of the wet strength agent is 25kg per ton of paper. A dry strength agent CMC is also added to the pulp, and the dosage of the dry strength agent CMC is 1.5kg per ton of paper.

Embodiment 2

[0013] The invention adopts 100% virgin wood pulp, is matched with paper-making auxiliary agent, adopts wet method paper machine to carry out papermaking, and makes industrial wiping paper by dry method wrinkling. The wood pulp is composed of long-fiber wood pulp and short-fiber wood pulp. The long-fiber wood pulp is German Mason pulp, the fiber length is 2.4mm-2.6mm, the whiteness is ≥87% (ISO), and the dustiness is ≤10mm. 2 / 500g. The short fiber wood pulp is made of Indonesian KK pulp, the fiber length is 0.75mm-1mm, the whiteness is ≥85% (ISO), and the dustiness is ≤10mm 2 / 500g. The weight ratio of long-fiber wood pulp to short-fiber wood pulp is 8:2, and the beating current is controlled at 340±20A. If the beating of plant fiber is too high, the fibrillation of the pulp will be intensified, and there will be lint and powder loss during production, so the beating current should not be too high, and the fiber loosening should be the main method.

[0014] In order to imp...

Embodiment 3

[0017] Proportion of fiber raw materials: long-fiber wood pulp with a fiber length of 2.4-2.6mm and short-fiber wood pulp with a fiber length of 0.75-1mm are mixed, and the weight ratio of the two is long-fiber wood pulp:short-fiber wood pulp= 8:2;

[0018] The wet strength agent adopts PAE papermaking wet strength agent, and the dosage is 40kg per ton of paper;

[0019] The dry strength agent adopts CMC (carboxymethyl cellulose), and the dosage is 1.5kg per ton of paper;

[0020] The long-fiber wood pulp and short-fiber wood pulp are mixed and crushed, the beating current is controlled at 340±20A, and the paper is made with a crescent paper machine, the concentration of the net: 0.05%, the speed: 1000m / min, after drying, wrinkling, suction, After softening, coiling, slitting and packaging, the finished product is made.

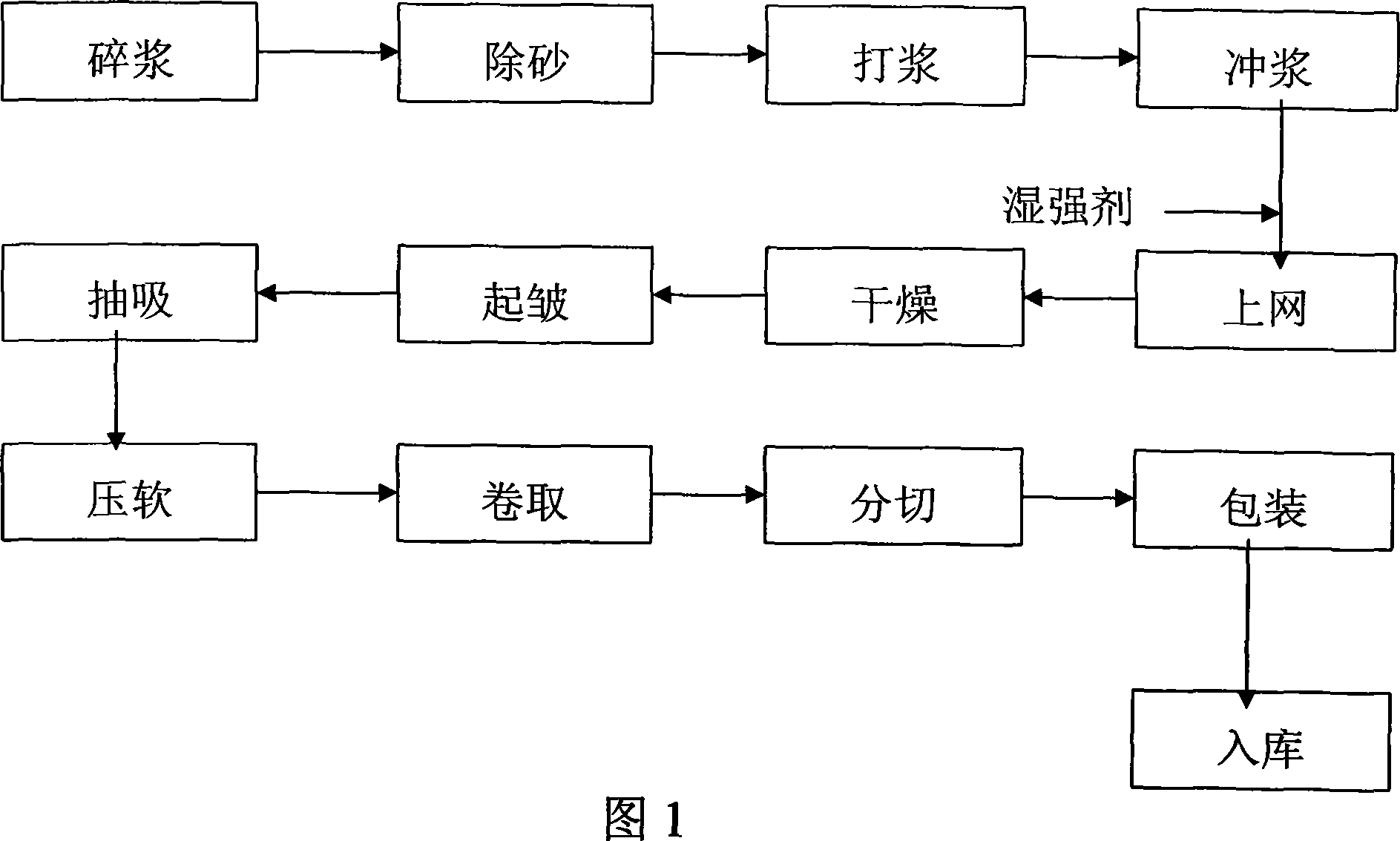

[0021] The production process is shown in Figure 1.

[0022] Test items

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com