Patents

Literature

3257 results about "Pulp (paper)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibres from wood, fiber crops, waste paper, or rags. Many kinds of paper are made from wood with nothing else mixed into them. This includes newspapers, magazines and even toilet paper. Pulp is one of the most abundant raw materials.

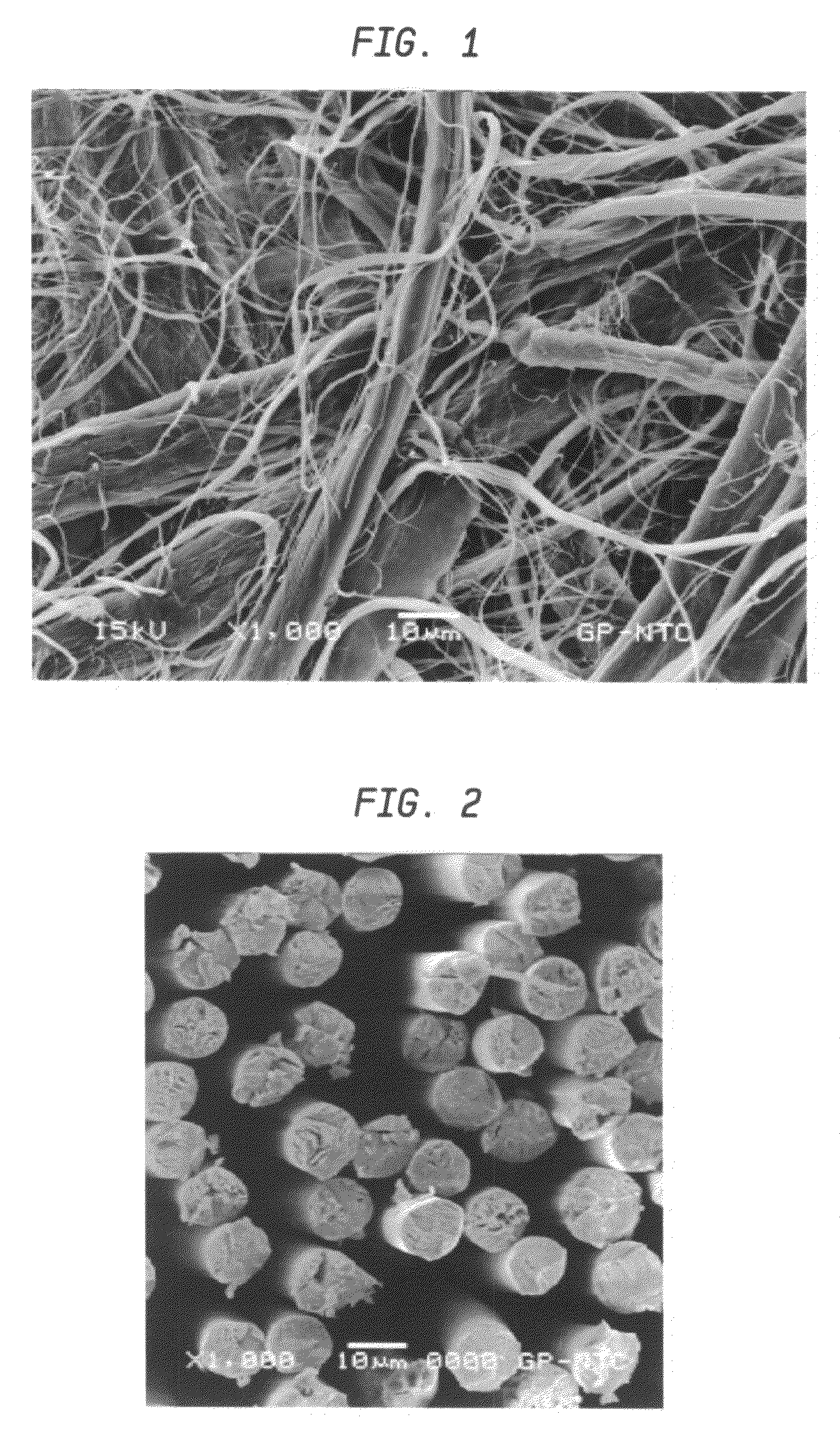

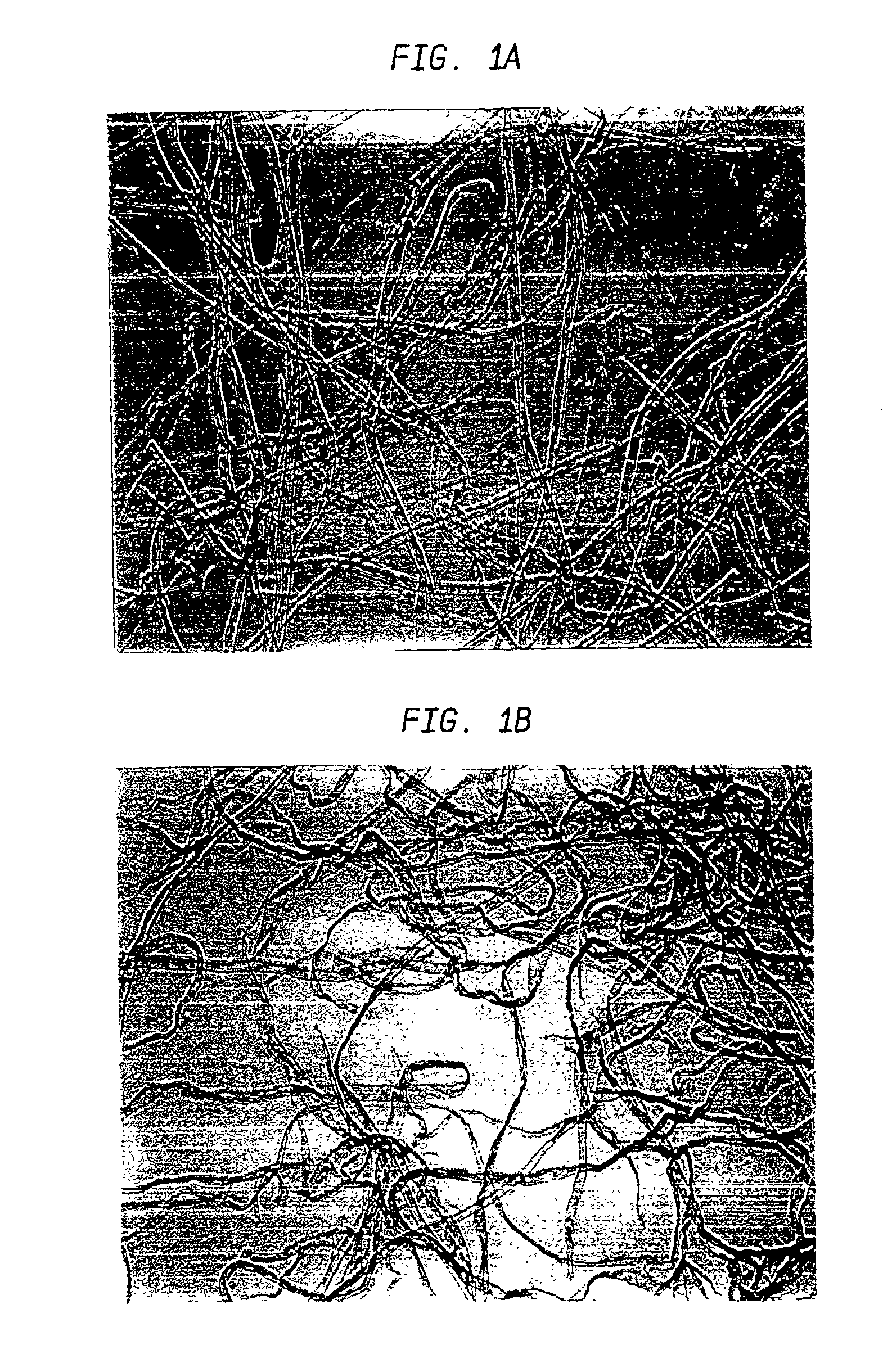

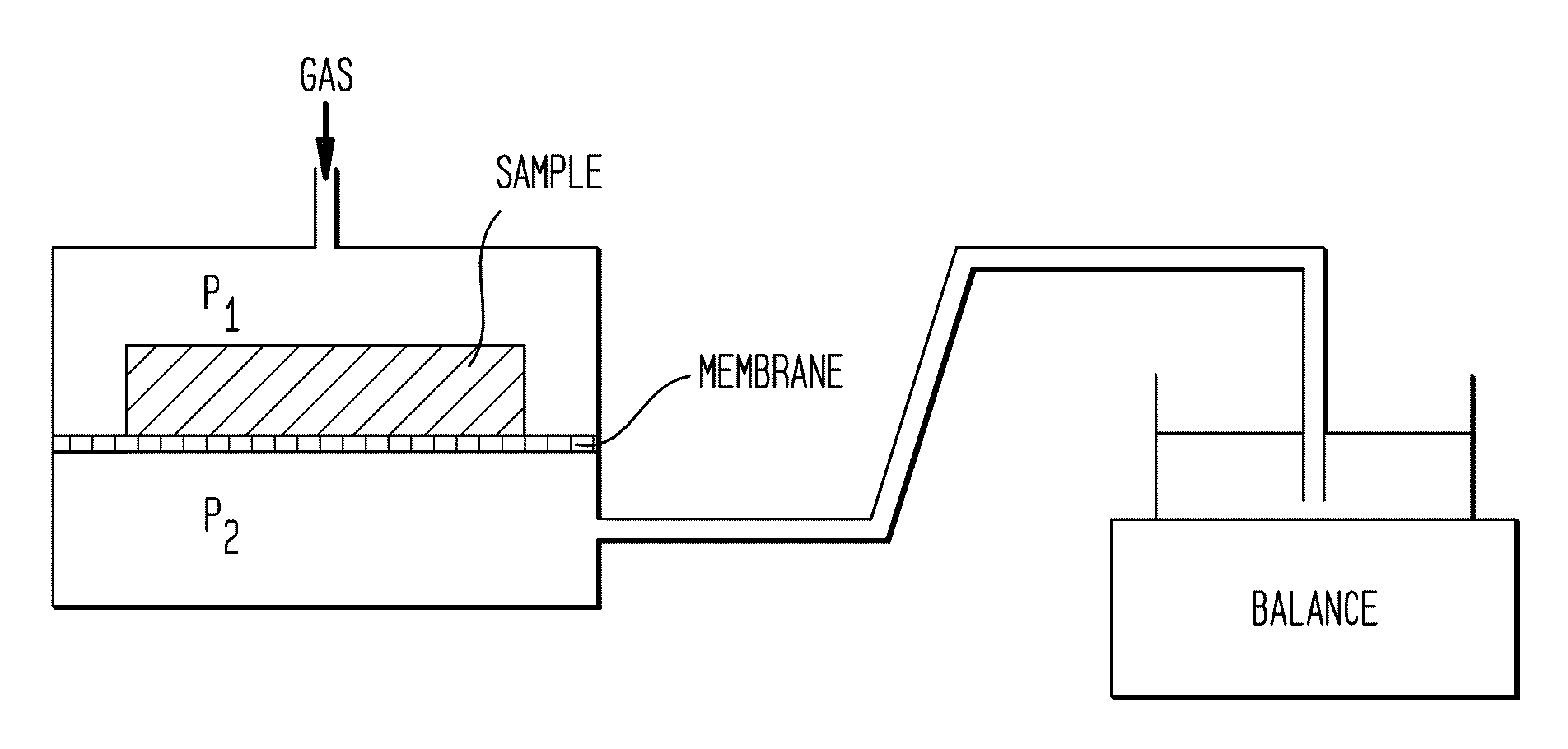

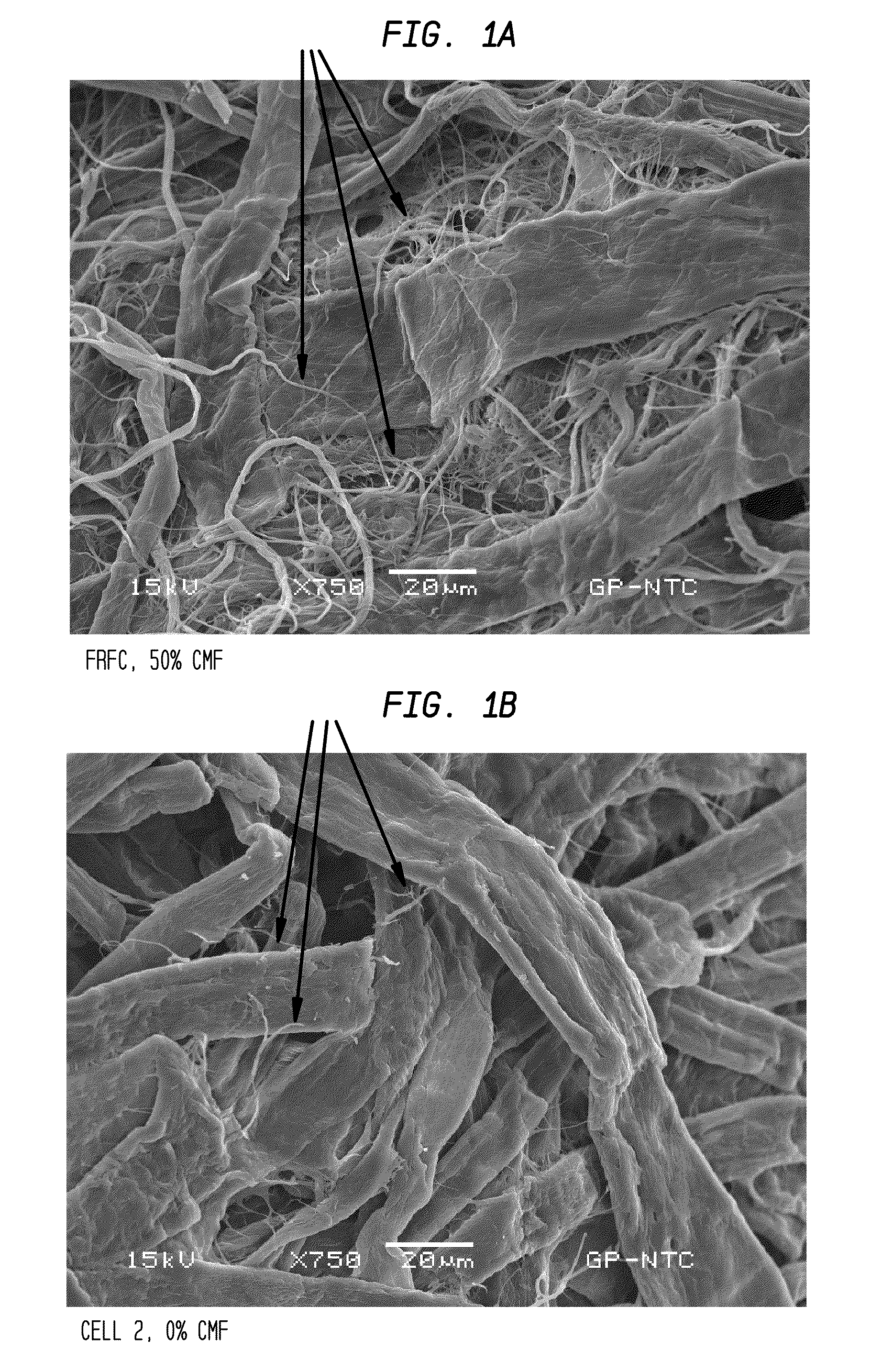

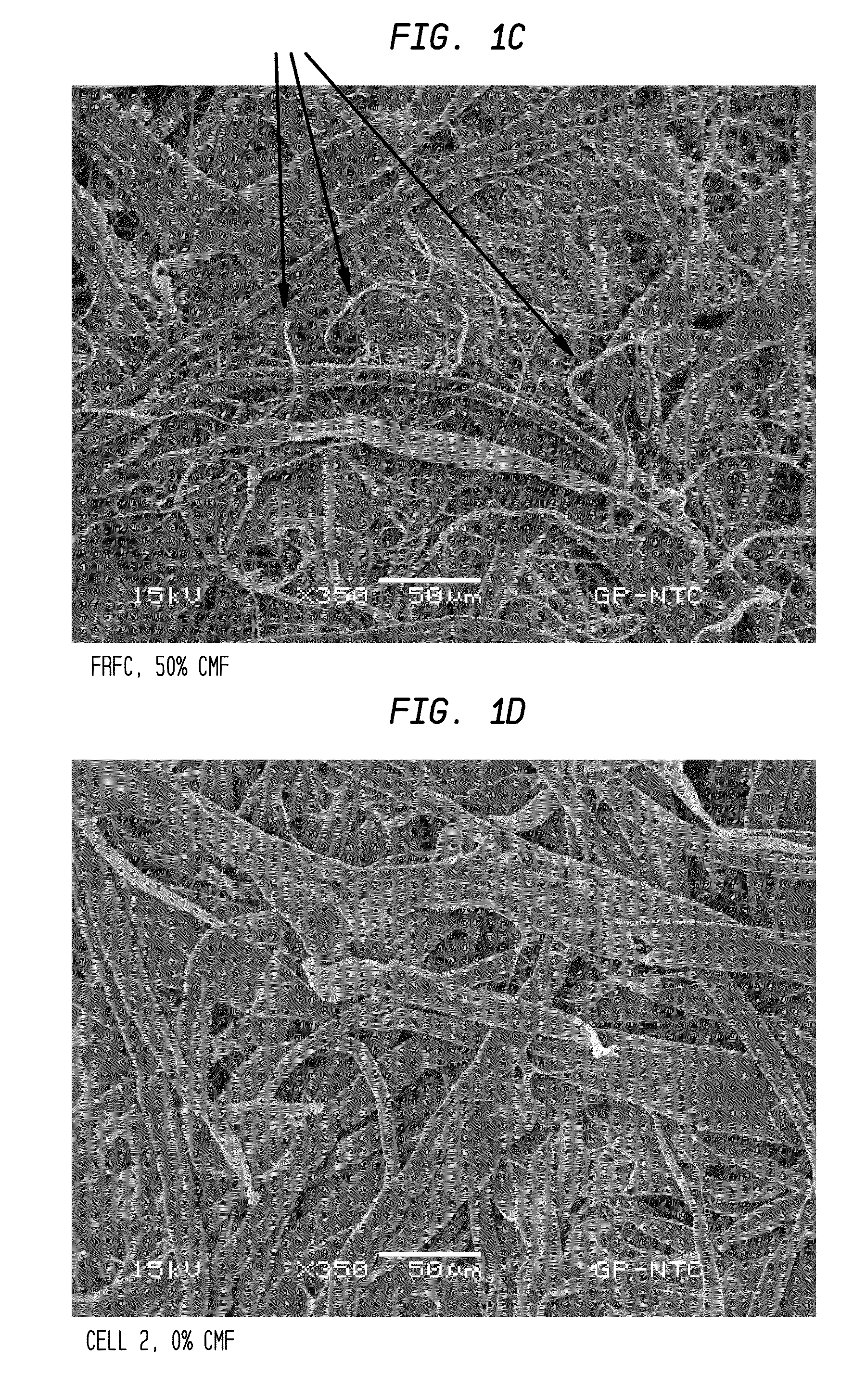

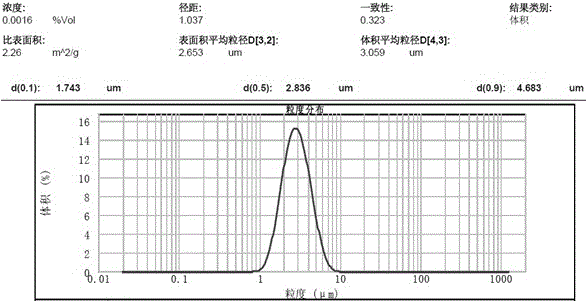

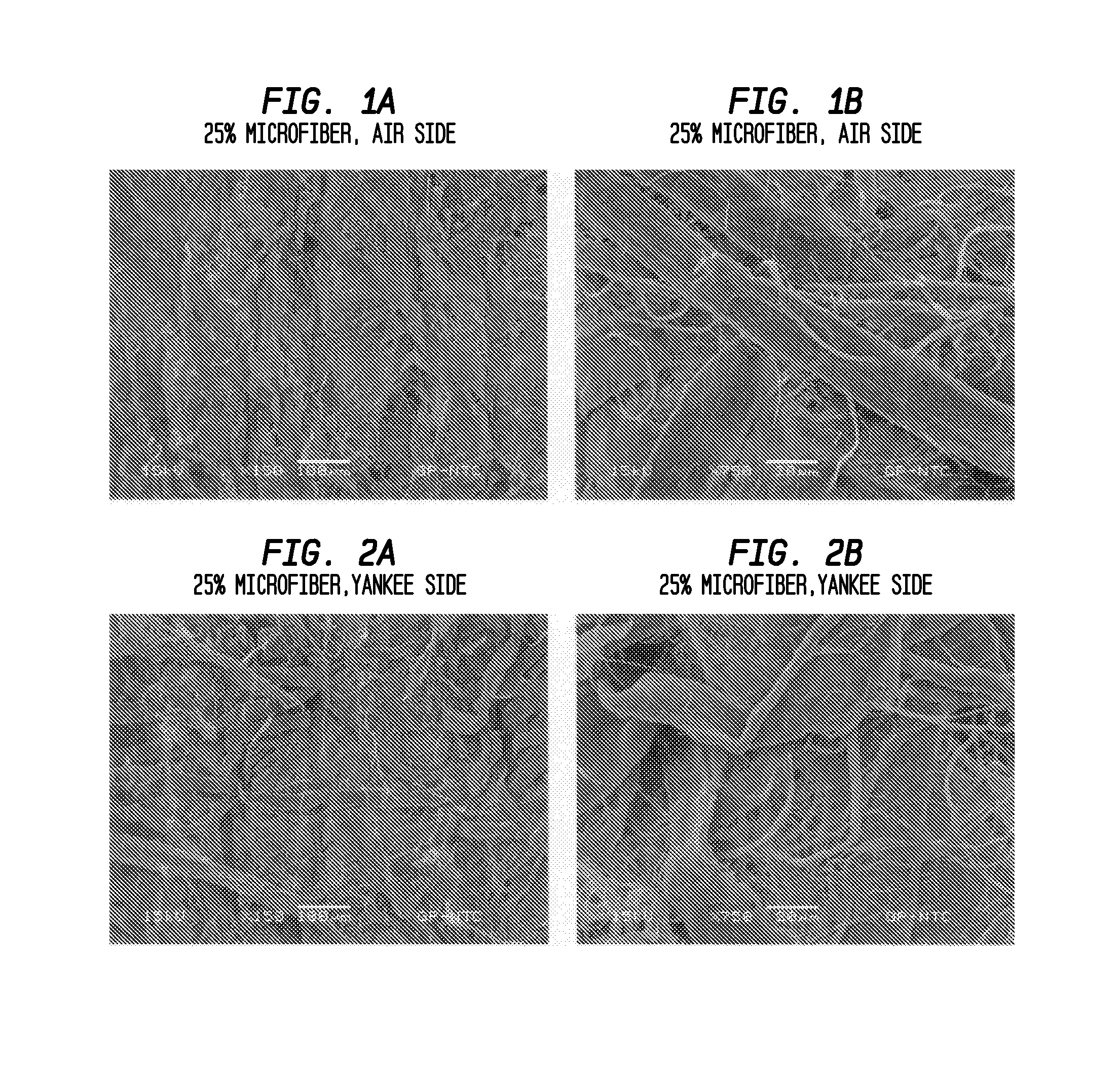

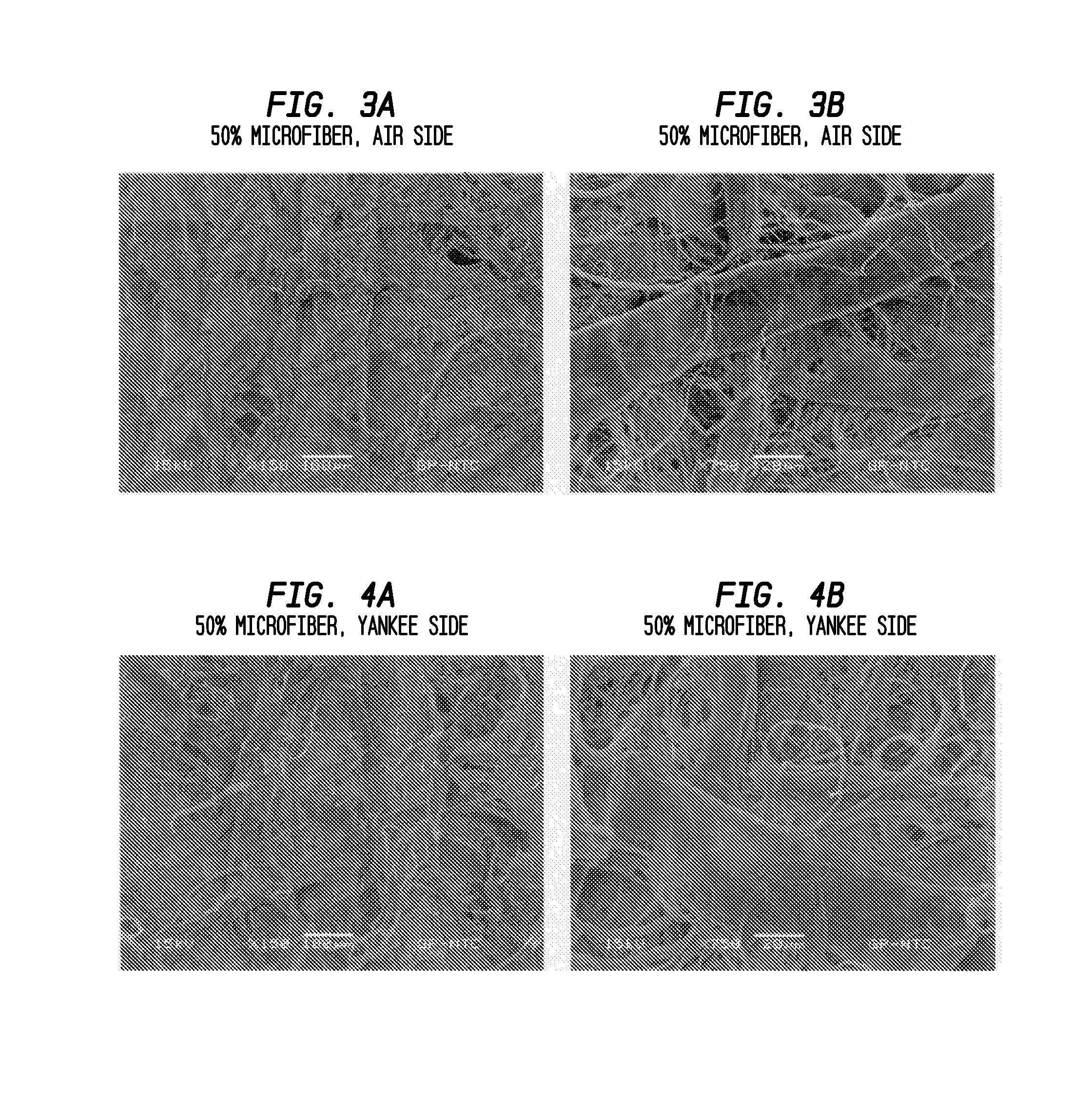

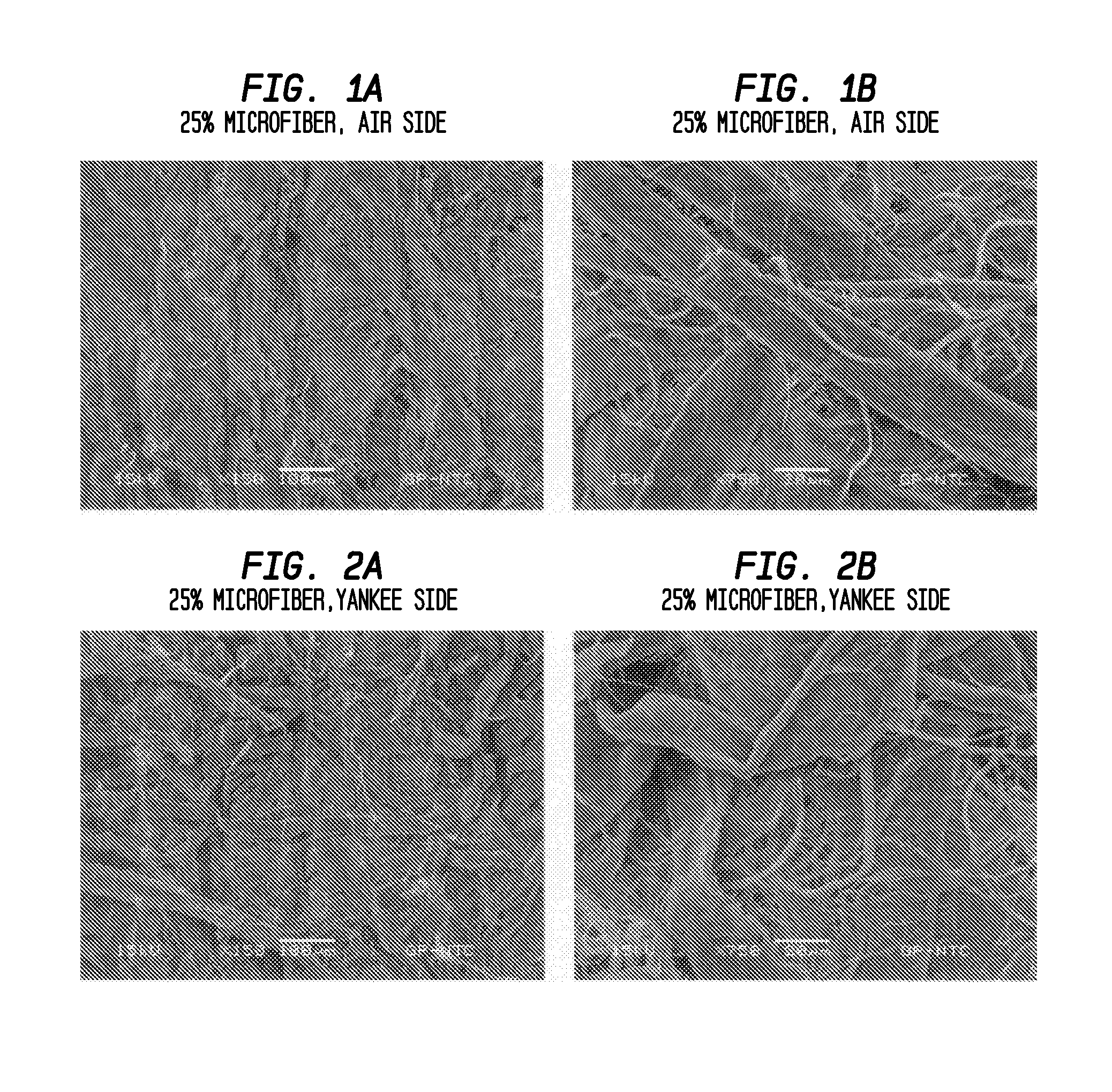

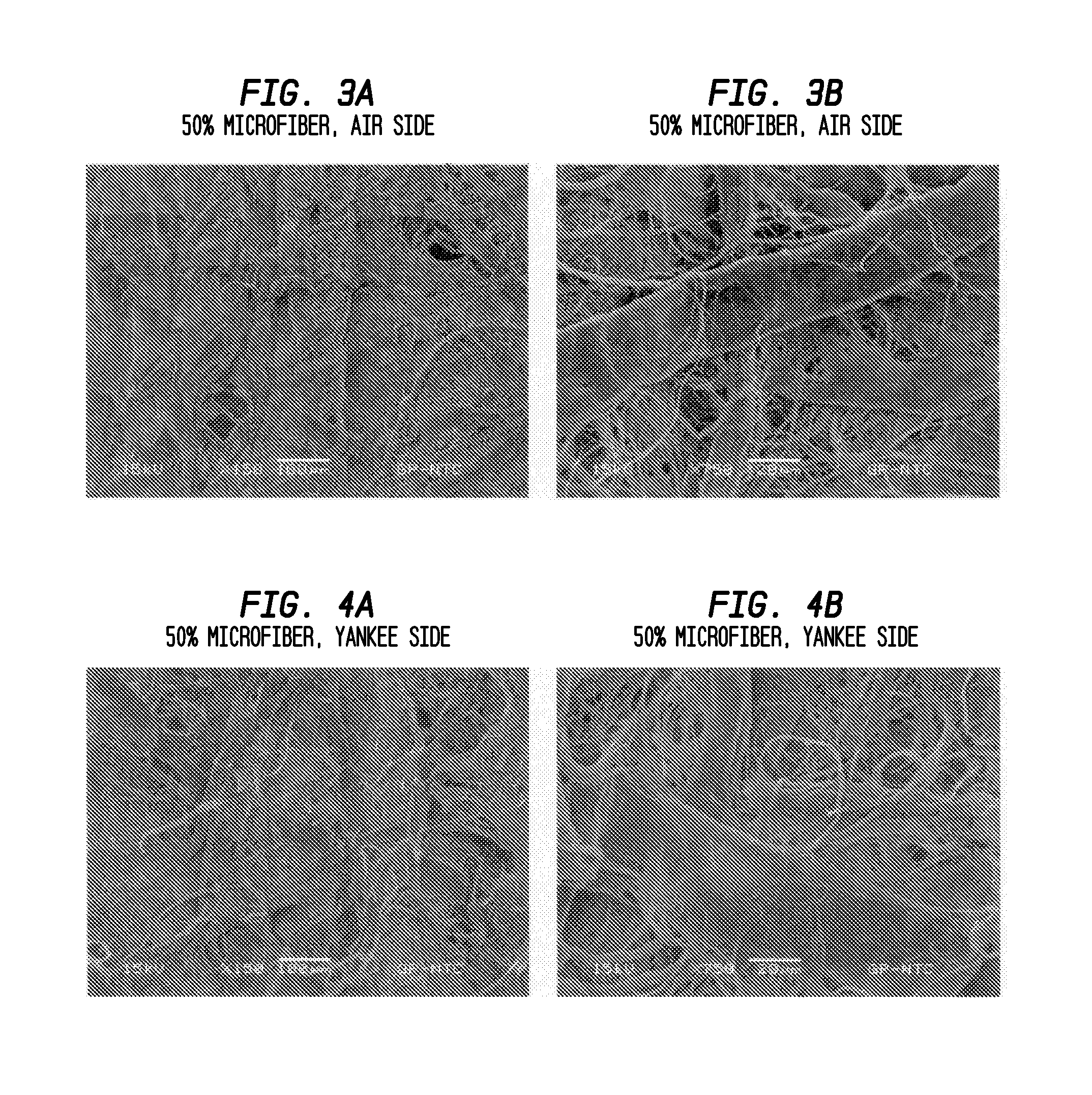

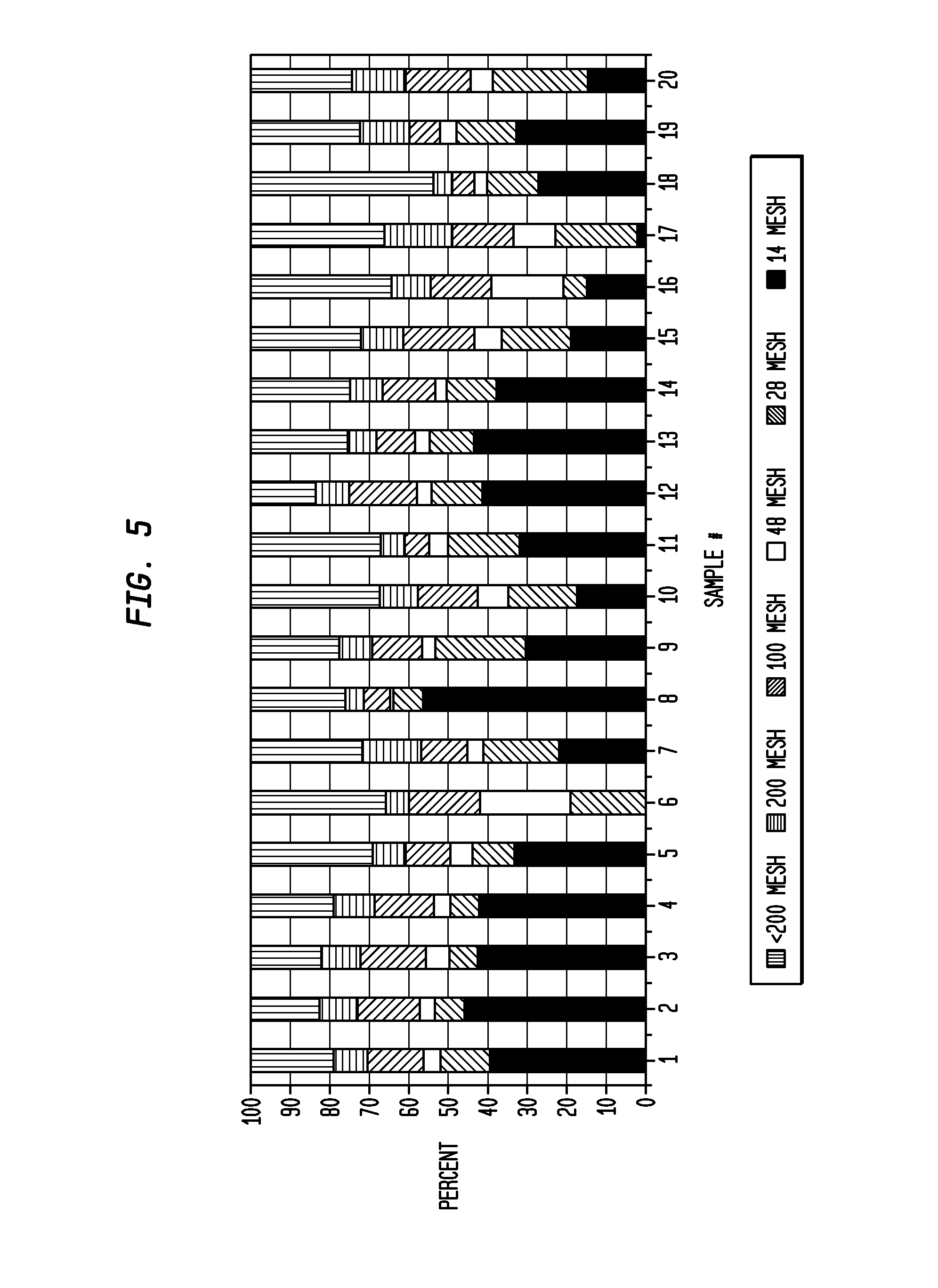

Absorbent sheet having regenerated cellulose microfiber network

An absorbent paper sheet for tissue or towel includes from about 99 percent to about 70 percent by weight of cellulosic papermaking fiber and from about 1 percent to about 30 percent by weight fibrillated regenerated cellulose microfiber which was regenerated form a cellulosic dope utilizing a tertiary amine N-oxide solvent or an ionic liquid. Fibrillation of the microfiber is controlled such that it has a reduced coarseness and a reduced freeness as compared with unfibrillated regenerated cellulose microfiber from which it is made and provides at least one of the following attributes to the absorbent sheet: (a) the absorbent sheet exhibits an elevated SAT value and an elevated wet tensile value as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (b) the absorbent sheet exhibits an elevated wet / dry CD tensile ratio as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (c) the absorbent sheet exhibits a lower GM Break Modulus than a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber; or (d) the absorbent sheet exhibits an elevated bulk as compared with a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber. In some embodiments, the pulp is pre-treated with debonder to enhance the wet / dry CD tensile ratio of the sheet.

Owner:GPCP IP HLDG LLC

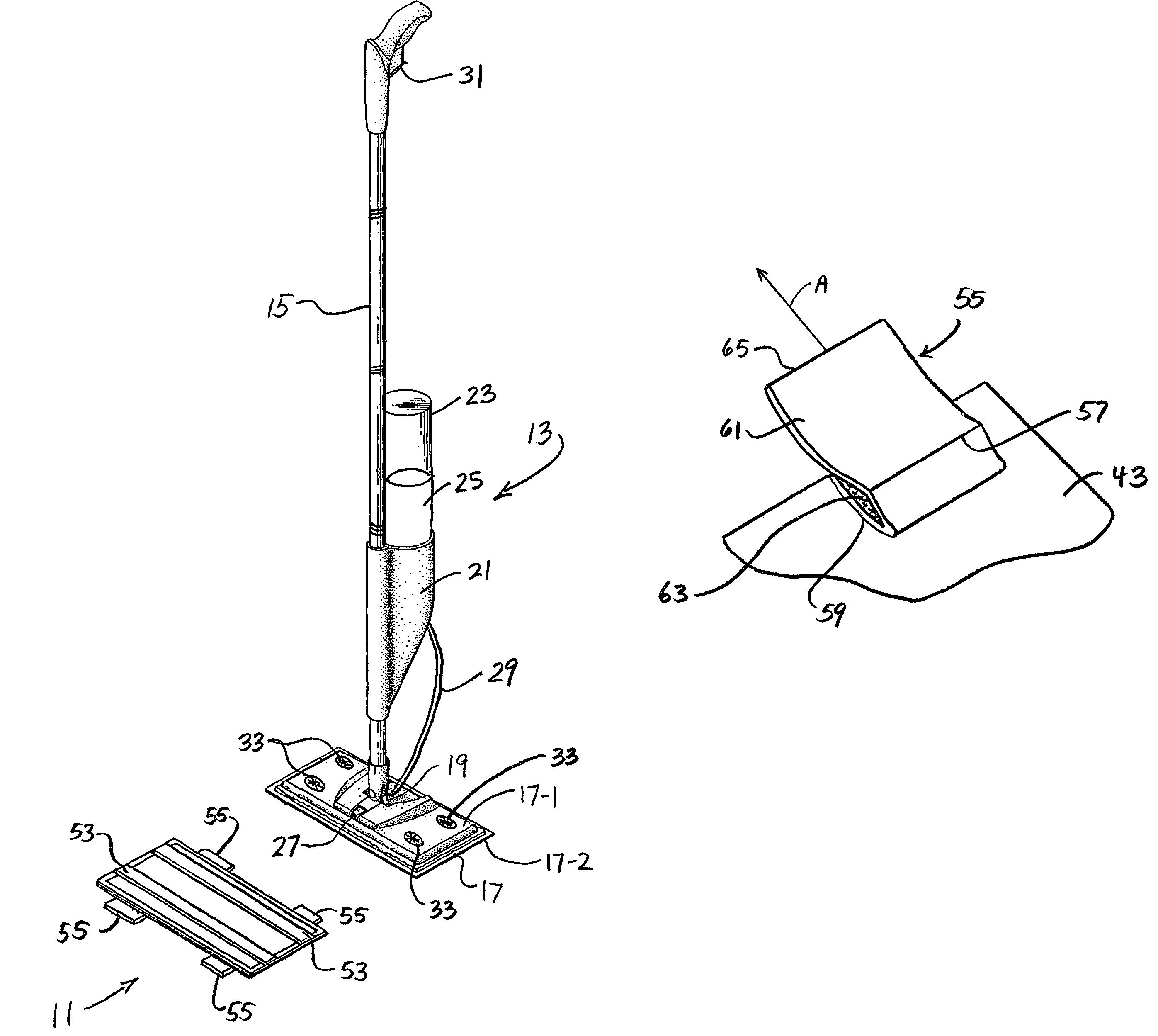

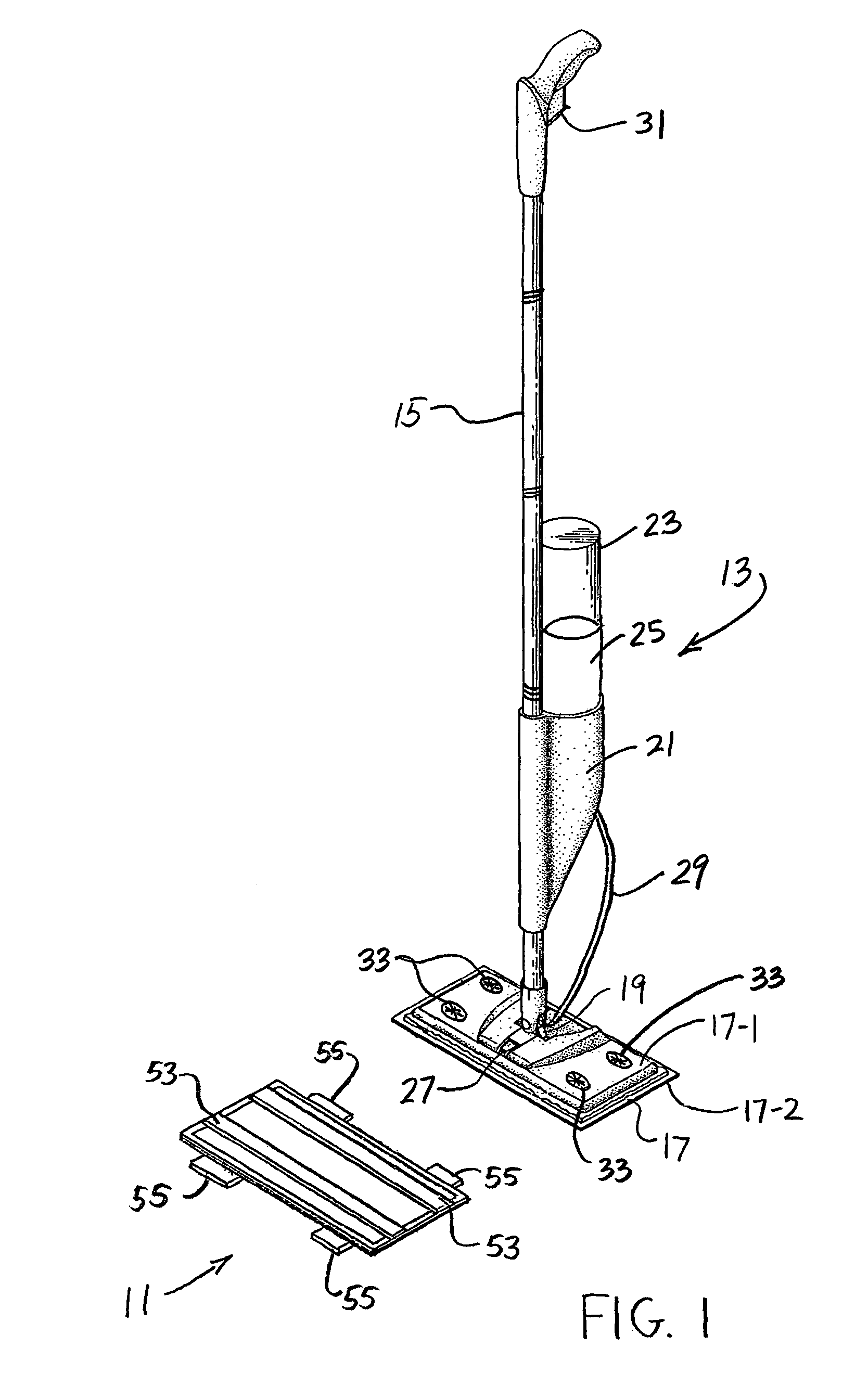

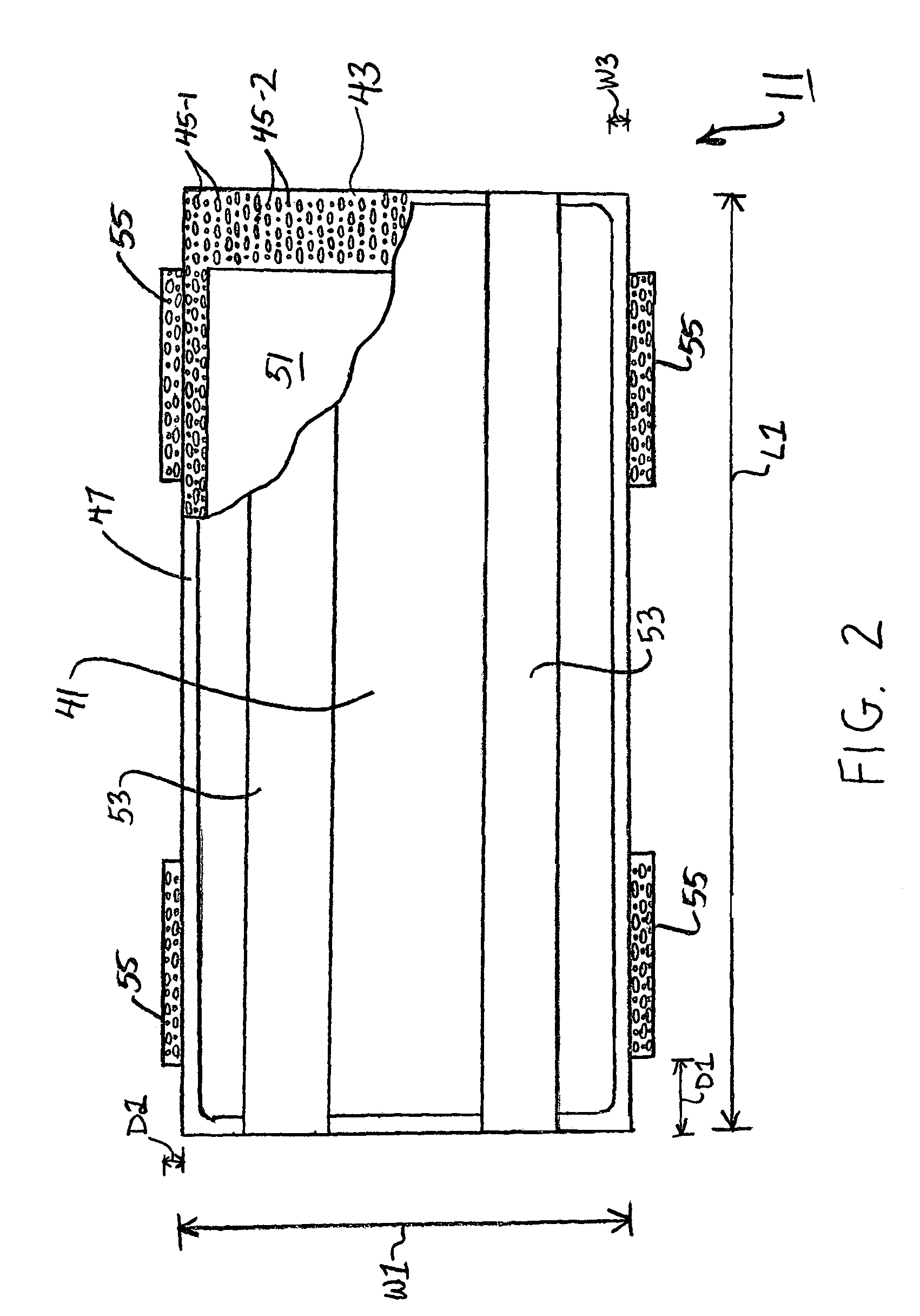

Cleaning pad

InactiveUS7191486B1Inexpensive to manufactureEasy to useBoard cleaning devicesCarpet cleanersBond linePaper sheet

A cleaning pad is adapted to be releasably retained on a cleaning implement which includes on its cleaning head either multiple strips of pile-type fastener material or a plurality of attachment structures. The cleaning pad includes a top layer constructed of polyethylene and a bottom layer constructed of rayon. The top and bottom layers are affixed together along their peripheries by a bond line so as to define an enclosed pocket therebetween which is sized and shaped to receive a middle layer constructed of wood pulp paper. Multiple strips of hook-type fastener material are secured on the top layer and are adapted to releasably engage complimentary strips of pile-type fastener material on the cleaning implement. One or more mounting tabs are secured on the bottom layer and are adapted to releasably engage complimentary attachment structures on the cleaning implement. Each mounting tab can be disposed between a retracted, or folded, position and an extended, or unfolded, position.

Owner:BUTLER HOME PRODUCTS LLC

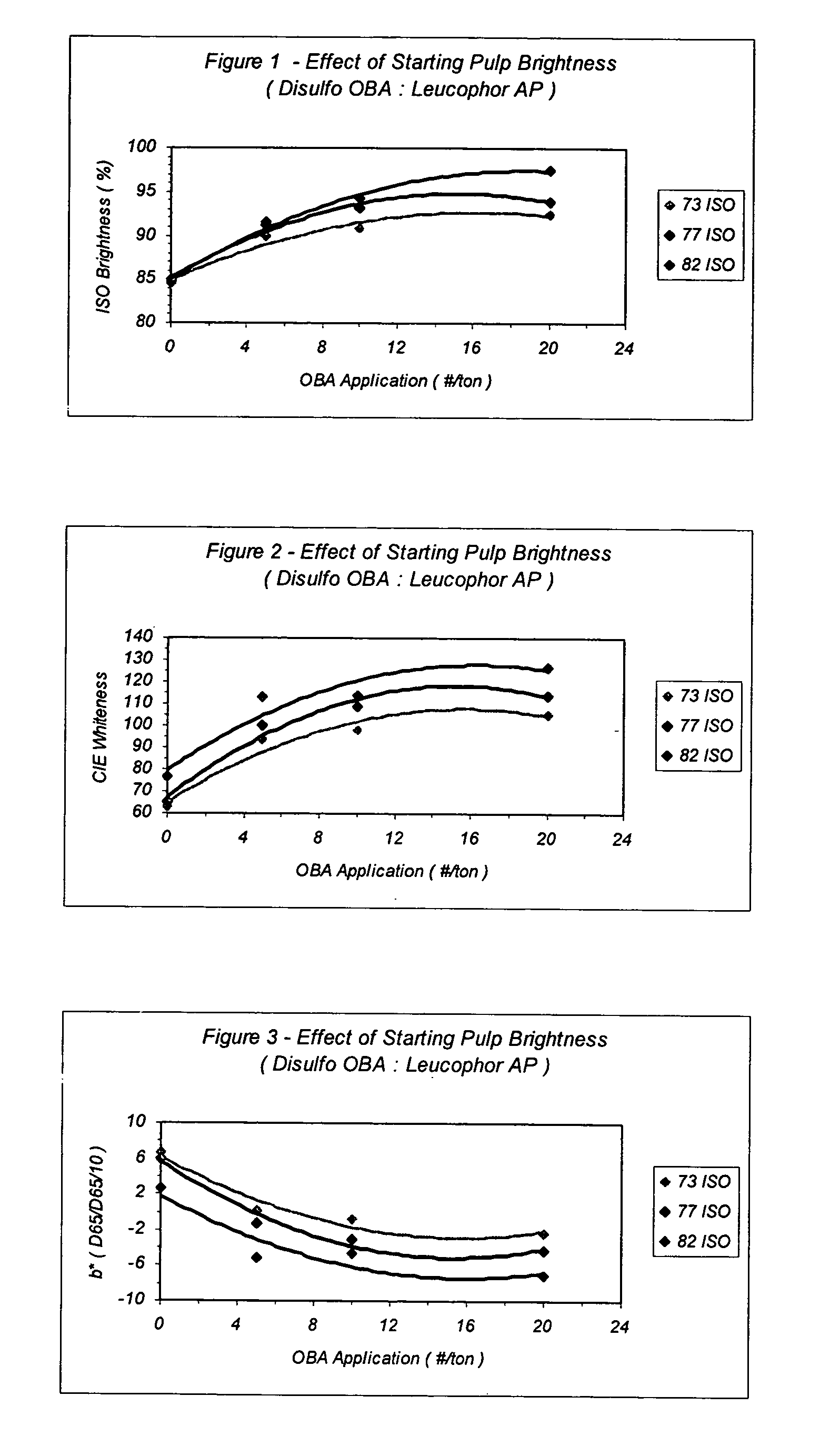

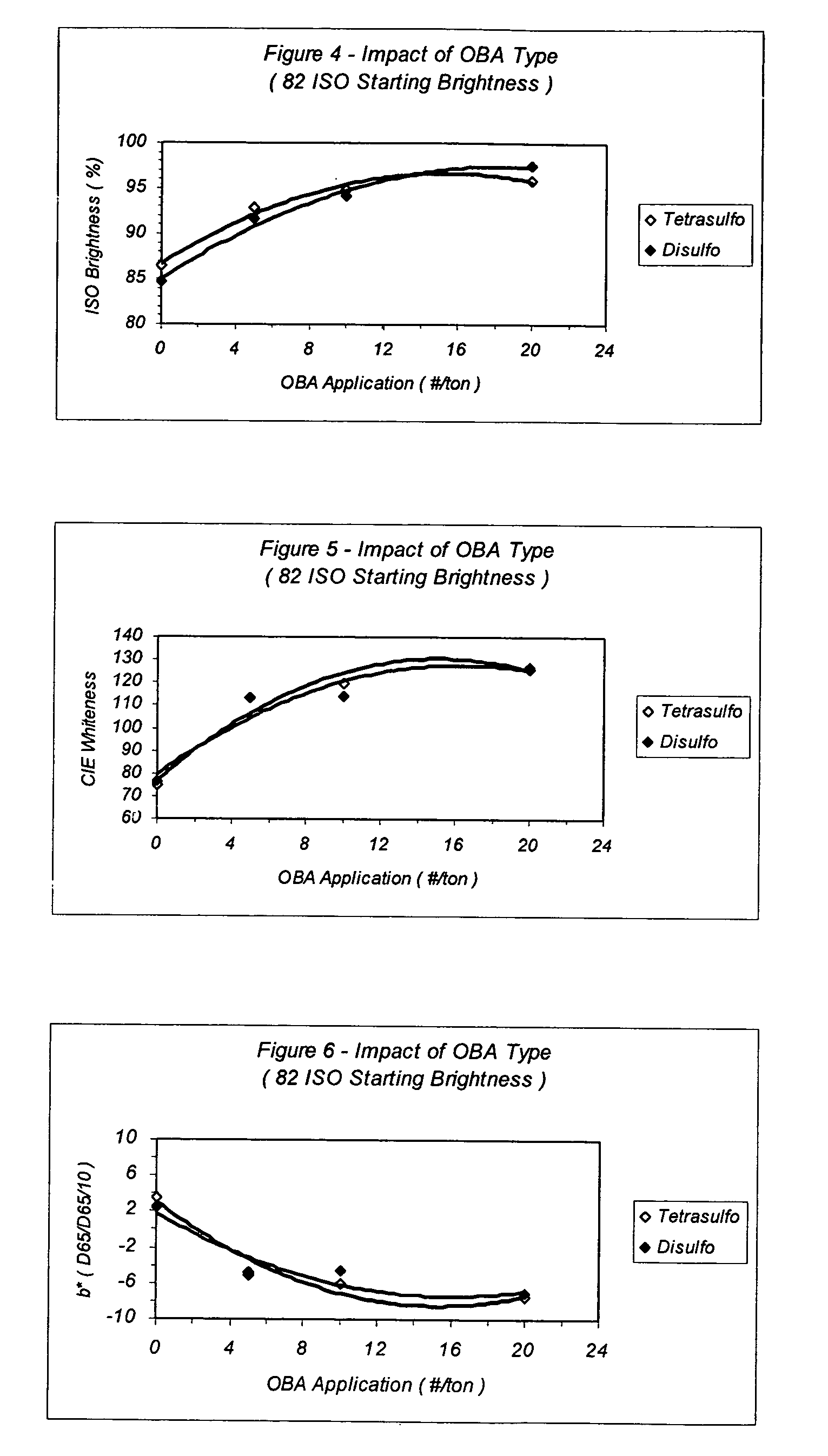

Process for manufacturing pulp, paper and paperboard products

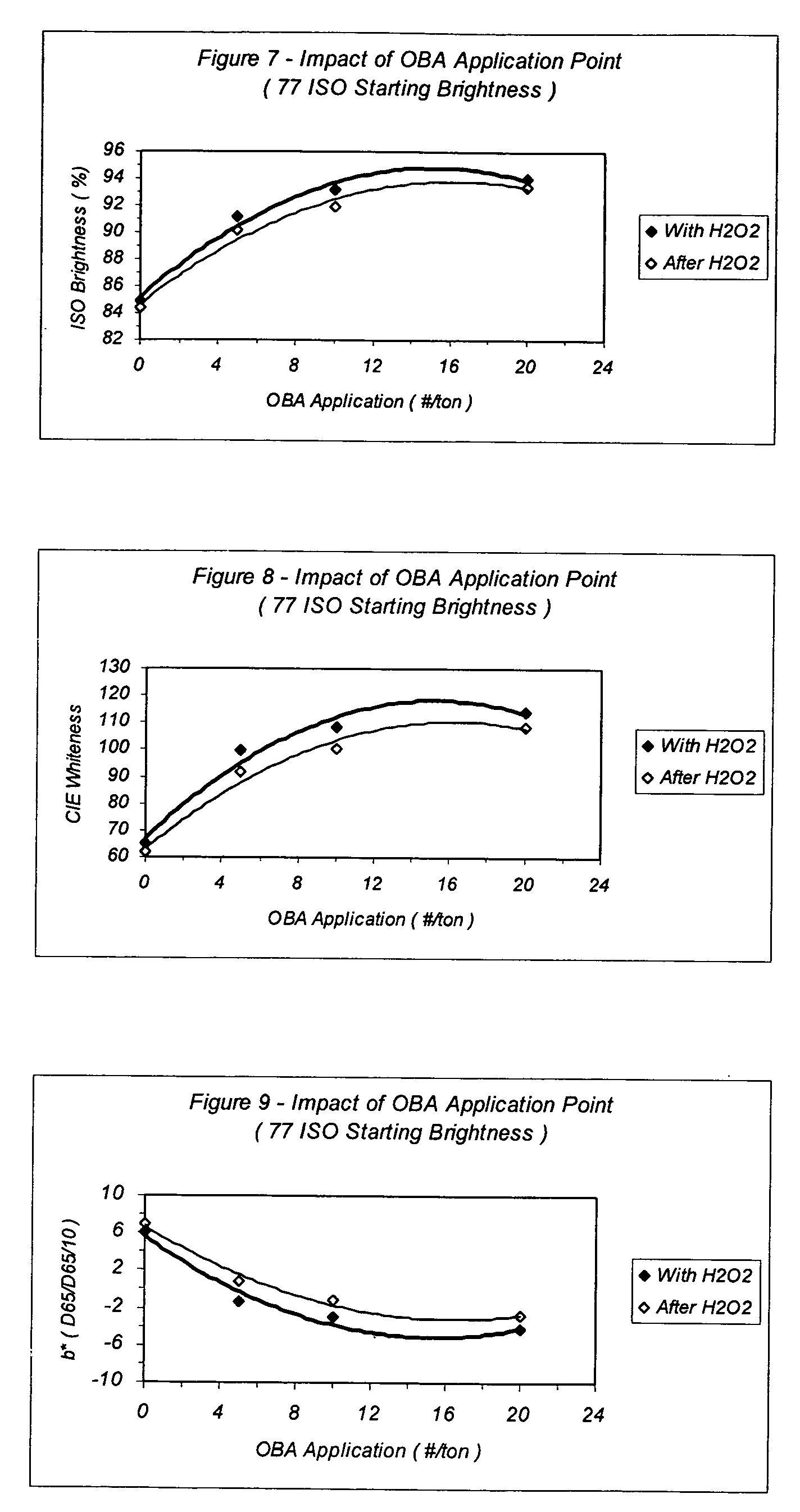

InactiveUS20070277947A1Speed up the processReduce the amount requiredPulp bleachingPulping with organic solventsChlorine dioxidePaperboard

A process for bleaching mechanical wood pulp is provided comprising subjecting the wood pulp to at least one bleaching stage with one or more bleaching agents in the presence of one or more optical brightening agent, wherein the bleaching agents are selected from the group consisting of oxidative bleaching agents other than chlorine based bleaching agents such as chlorine dioxide, elemental chlorine or a combination thereof, reductive bleaching agents or any combination of two or more thereof.

Owner:INT PAPER CO

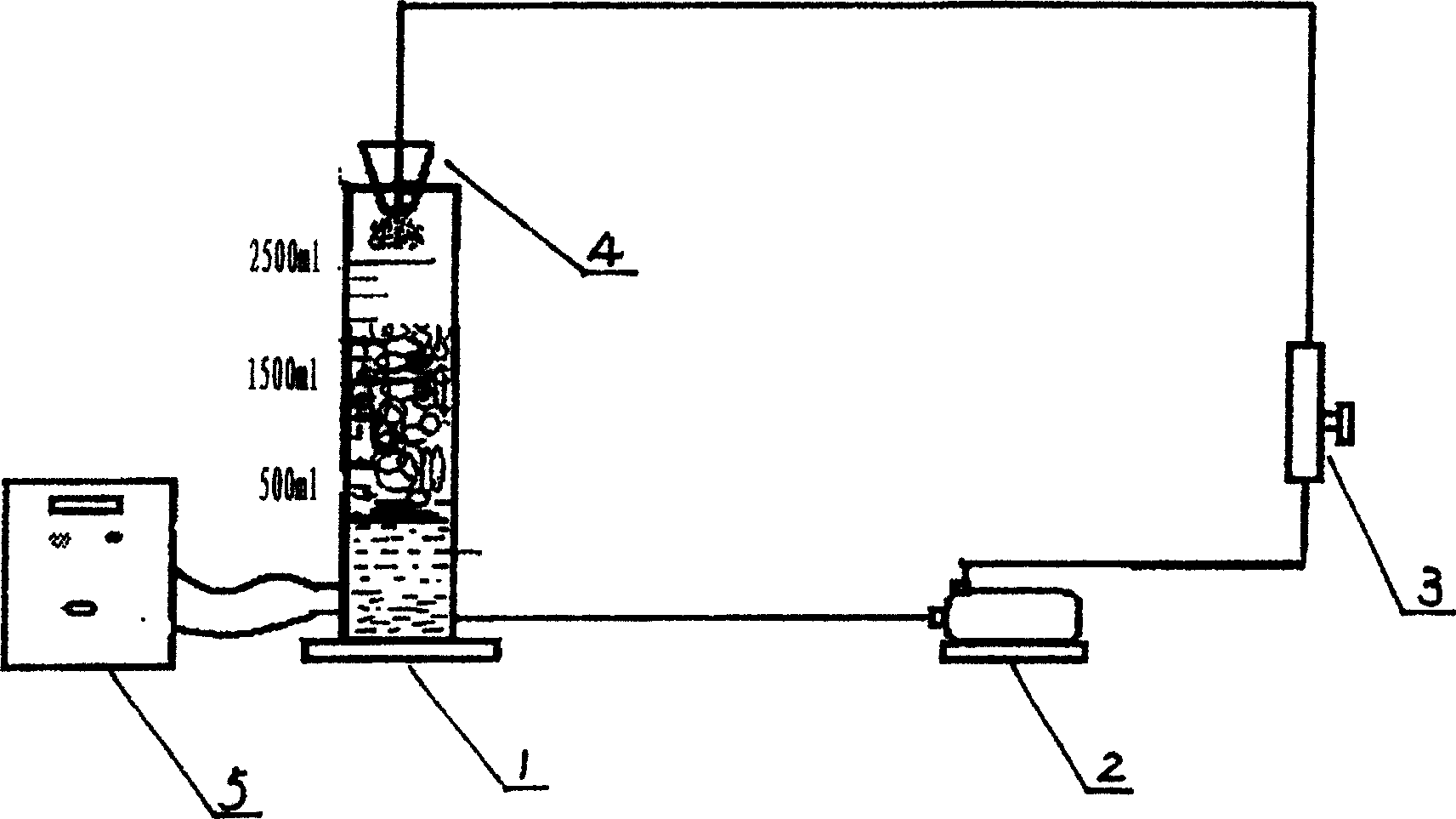

Prepn process of active defoaming agent composition

The present invention is one kind of active defoaming composition suitable for eliminating harmful foams under high temperature and strong alkaline condition in high efficiency, and may be used in washing paper pulp, treating metal surface and other fields. The active defoaming composition is prepared with organic siloxane, silicone resin, inorganic oxide particle, hydrophobic treating agent, catalyst and other material. The preparation process includes the following steps: 1. mixing organic siloxane, silicone resin and catalyst, and heating the mixture to 80-200 deg.c for controllable polymerization; 2. adding inorganic oxide particle and hydrophobic treating agent; and 3. further heating to reaction at 80-200 deg.c temperature and 0.01-0.08 MPa vacuum for 2-10 hr, and cooling to room temperature to obtain white polymer as the active defoaming composition.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

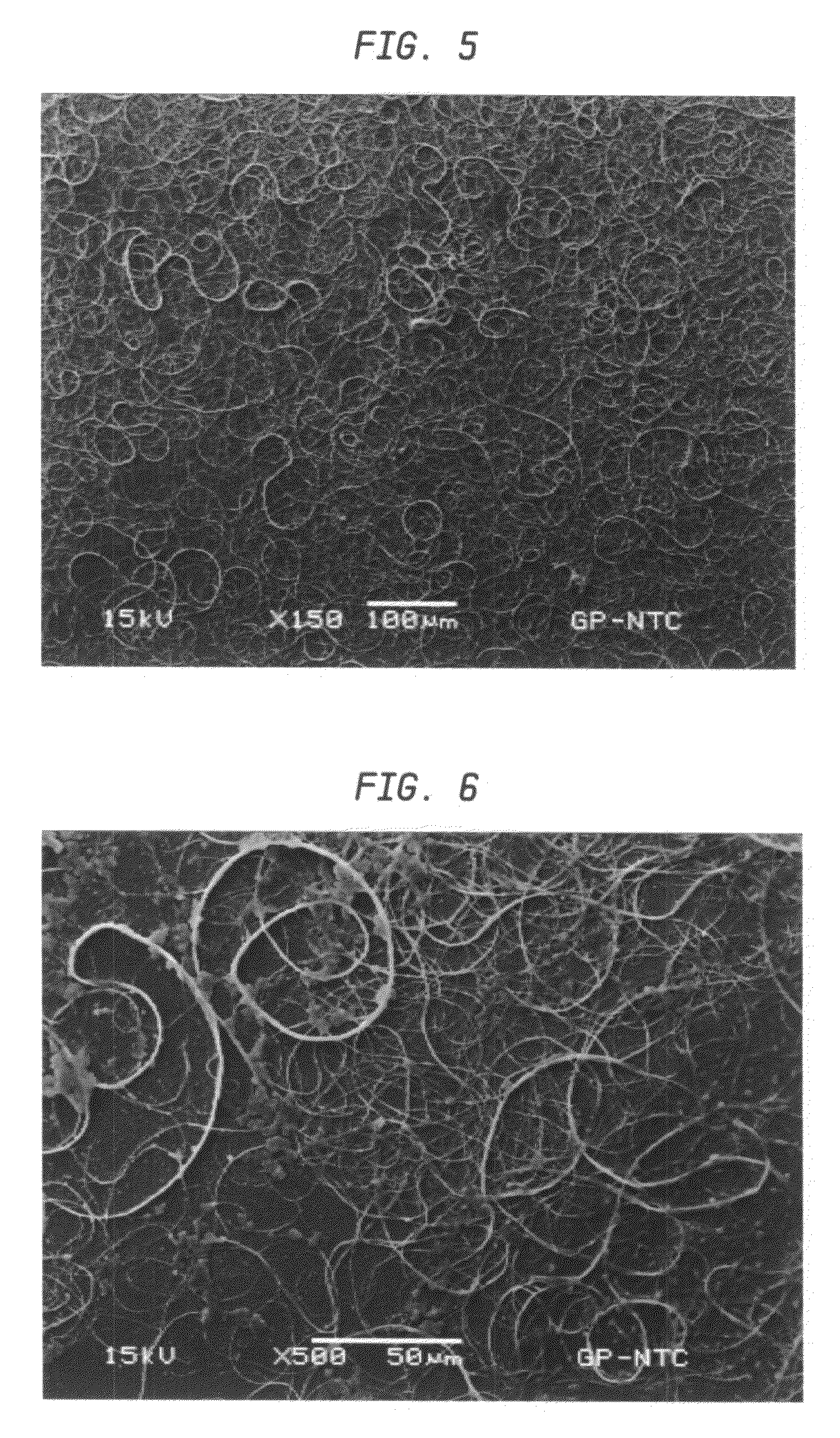

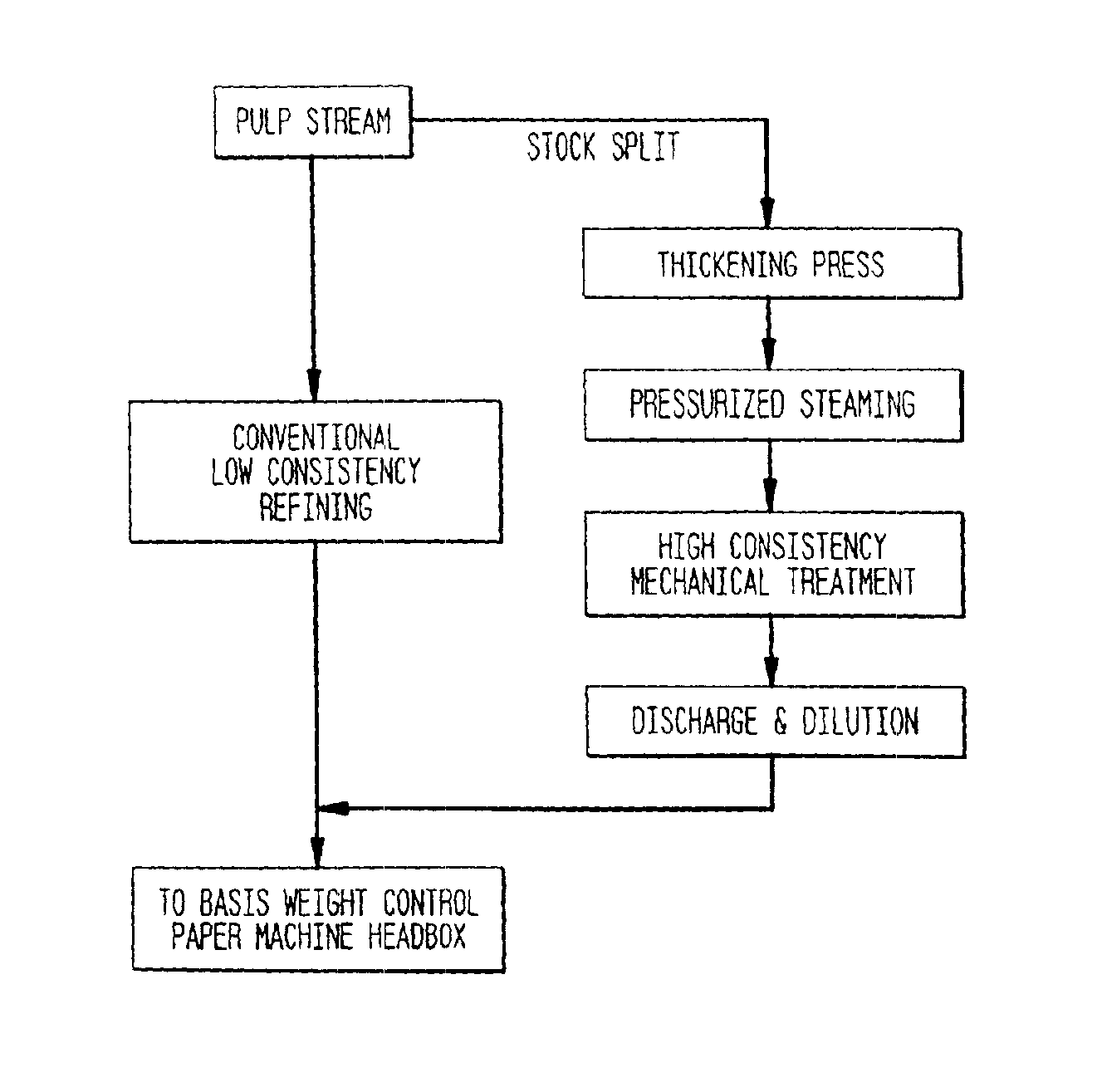

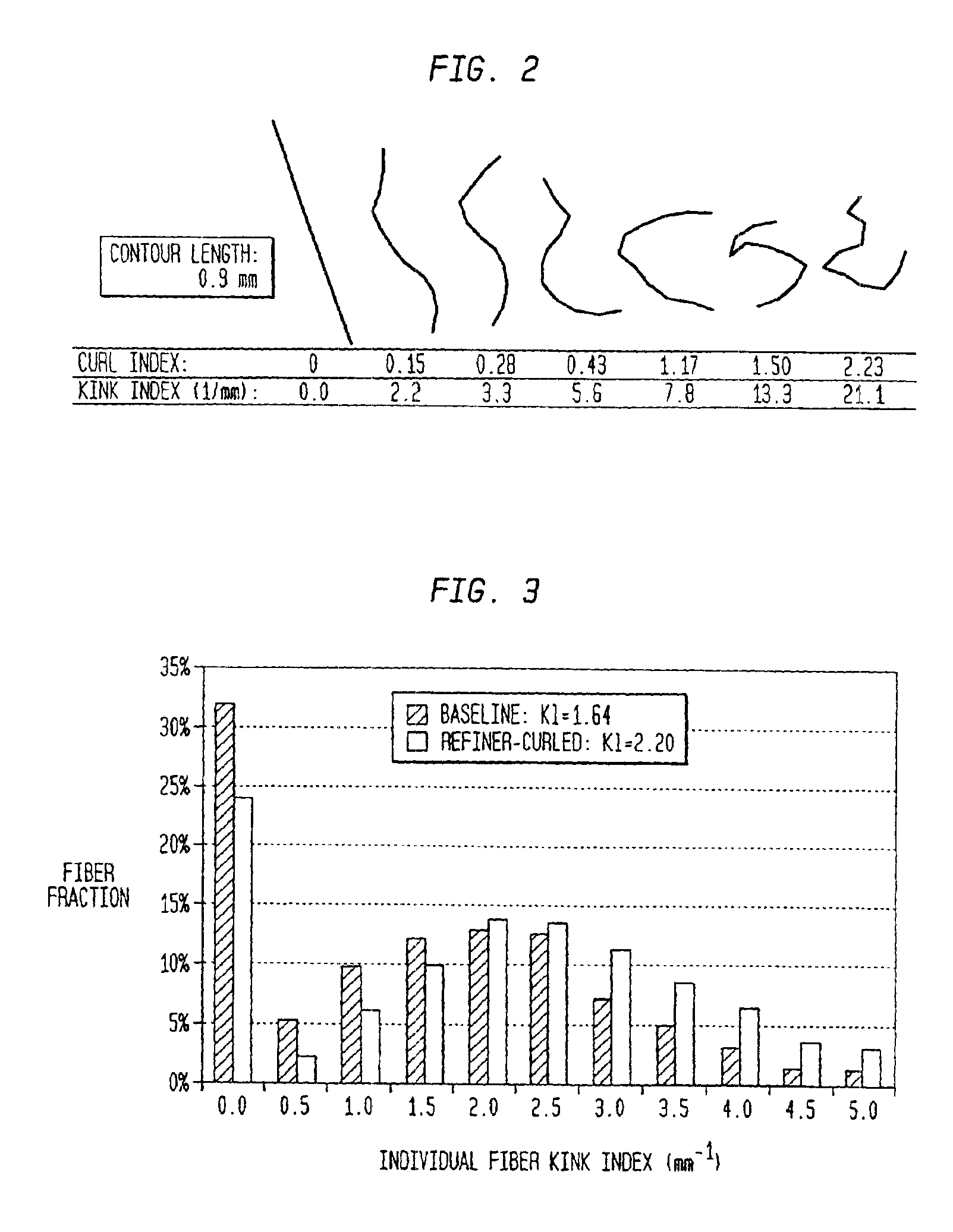

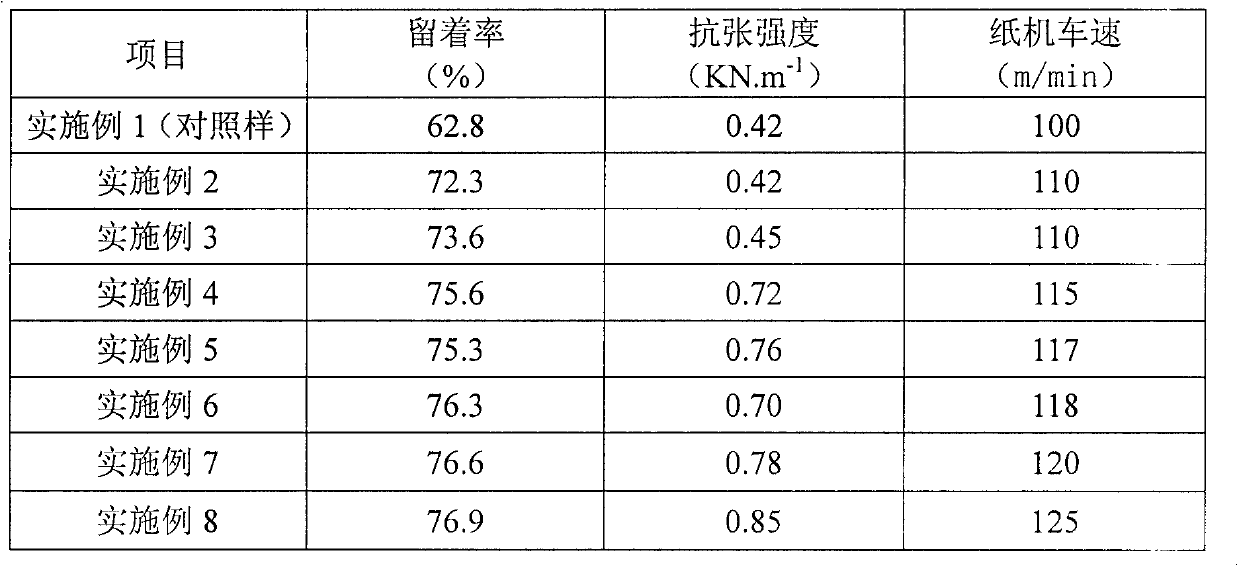

Method of providing papermaking fibers with durable curl

A process for producing high bulk cellulosic fiber exhibiting a durable elevated curl index includes: (a) concurrently heat treating and convolving cellulosic fiber pulp at elevated temperature and pressure at high consistency under conditions selected so as to preclude substantial fibrillation and attendant paper strength and fiber bonding development; and (b) recovering the pulp wherein the length weighted curl index of the treated fiber is at least about 20% higher than the length weighted curl index of the fiber prior to the heat treatment and convolving thereof. The curl imparted to the fiber persists upon treatment for 30 minutes in a laboratory disintegrator at 3000 rpm at 1% consistency at a temperature of 125° F. Moreover, the curl may be imparted to the fiber in a disk refiner at very short residence times, on the order of several seconds or less. In general, the process is carried out in the presence of saturated steam at a pressure of from about 5 to about 150 psig.

Owner:GPCP IP HLDG LLC

Method for manufacturing high-breathability non-woven wallpaper body paper and product

The invention discloses a method for manufacturing high-breathability non-woven wallpaper body paper and a product. The existing non-woven wallpaper has the disadvantages that the hand feel thereof is not soft enough, the principal plane stereoscopic impression is not strong and the opacity degree is low. The method of the invention comprises the following steps: beating plant fiber containing chemical wood pulp until the beating degree is 20-30OSR, and mixing with non-plant fiber containing chemical fiber; adding chemical addition agent into the mixed fiber; manufacturing the mixed fiber containing the chemical addition agent into body paper semi-finished products by utilizing a fourdrinier wire or inclined wire paper machine; mixing pigment, chemical addition agent and adhesive to form coating liquor, carrying out dip coating on the body paper semi-finished products inside or outside the machine; and drying and finishing the body paper subject to dip coating, and rolling the body paper to form finished paper of body paper, thus obtaining non-woven wallpaper which contains continuous fiber, has high breathability, and can be directly printed. The principal plane has natural lines; and the finished paper has the advantages of soft hand feel, good processability, excellent shape stability, rich color, distinct image and strong stereoscopic impression.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

Method for producing paper pulp, lignins, sugars and acetic acid by frantionation of lignocellulosic vegetable material in formic/acetic acid medium

InactiveUS7402224B1Low hydrationPromote dissociationWashing/displacing pulp-treating liquorsDigestersVegetable materialChemistry

A method for producing paper pulp from a lignocellulosie vegetable raw material. The method includes contacting the raw material with a mixture of formic acid and acetic acid (in an amount more than 5 wt. % of the mixture) at a temperature and for a suitable reaction time, the whole being performed at room temperature. The paper pulp is separated from the organic phase and optionally bleached with ozone. The organic phase is treated to enable the recycling of the formic and acetic acids and the extraction of lignins, sugars and excess acetic acid.

Owner:CIE IND DE LA MATIERE VEGETALE

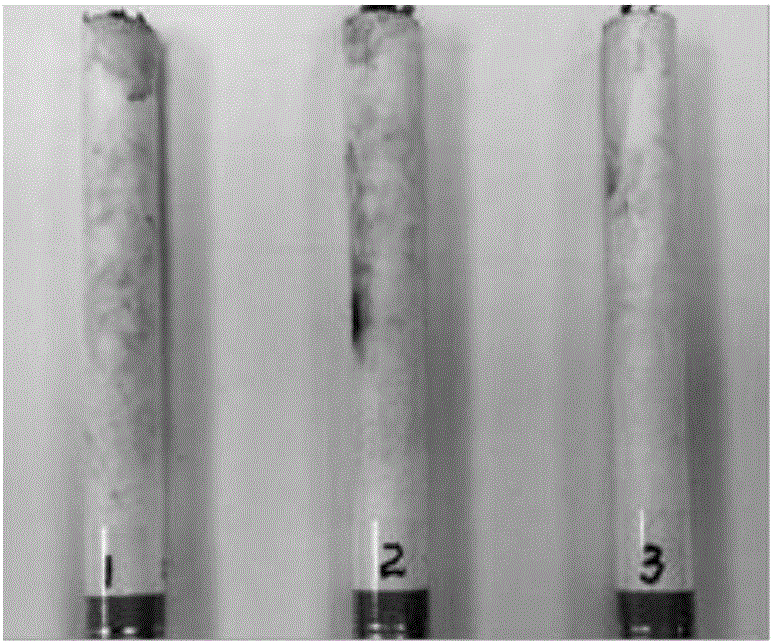

Preparation method for paper-making process tobacco sheet and finished product of paper-making process tobacco sheet

ActiveCN103141928AImprove single layer retentionImprove breathabilityTobacco preparationPlant fibrePaper based

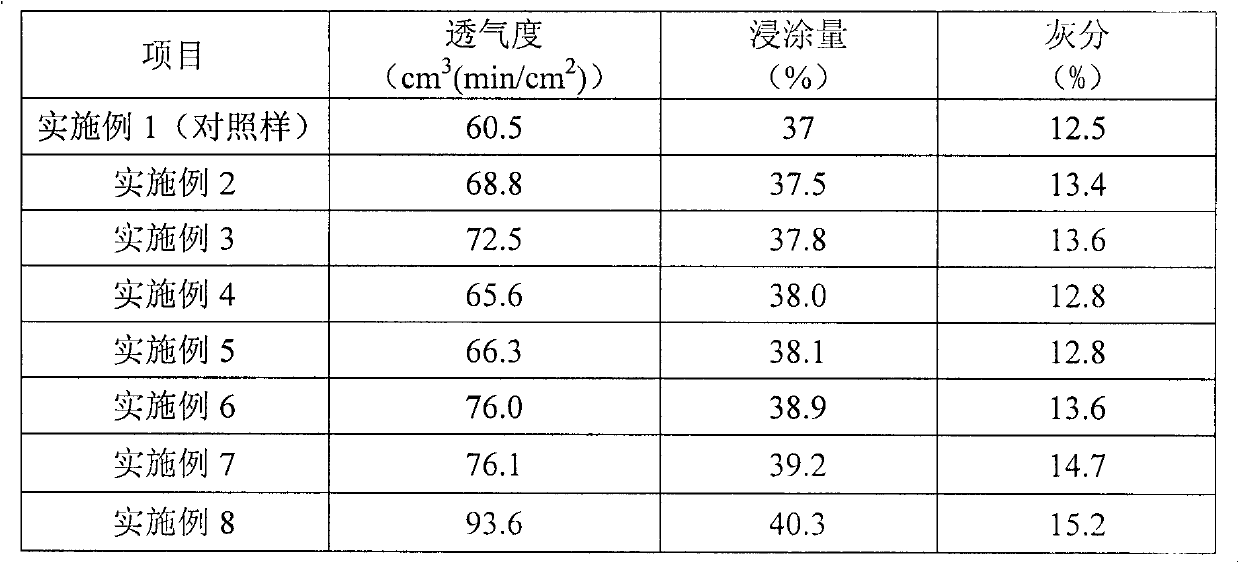

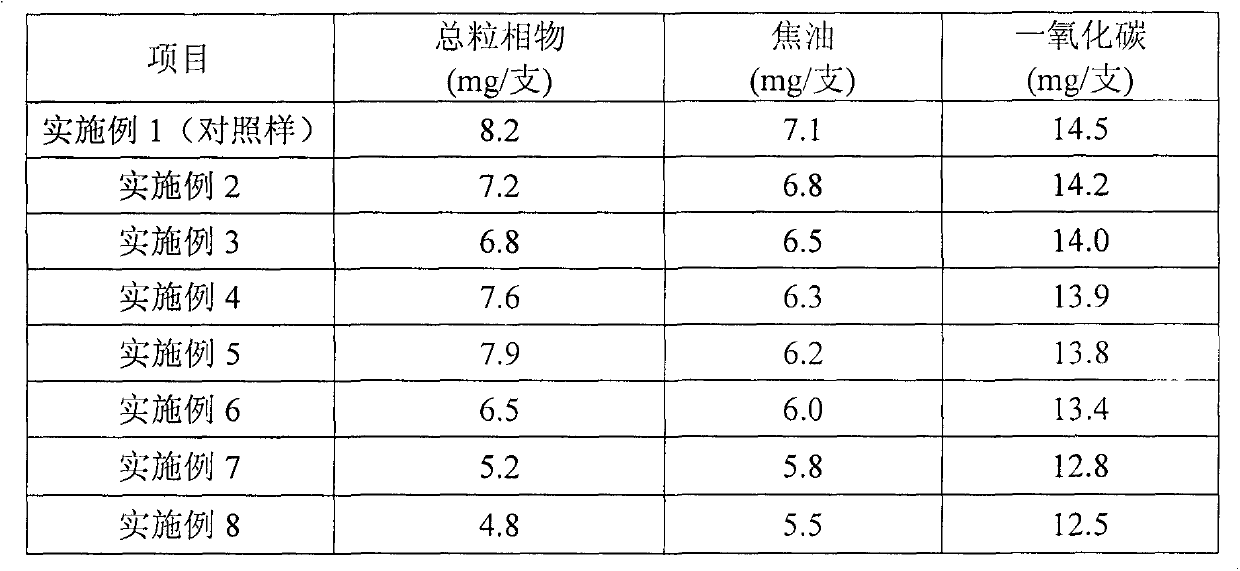

The invention belongs to the field of tobacco industry and relates to a preparation method for a functional harm-reduction and tar-reduction paper-making process tobacco sheet and a finished product of the paper-making process tobacco sheet. The preparation method for the paper-making process tobacco sheet comprises the following steps of extracting and concentrating effective components of tobacco; mixing formulas; pulping and blending fibers; manufacturing paper with pulp; dipping, drying and tearing and shaping. The blending process comprises the following steps of: adding non-tobacco plant fiber pulp of which the beating concentration is 3-4 percent and the Schopper-Riegler (SR) beating degree is 18-28 to tobacco mixed fiber pulp, adding filling to a machine chest, regulating the pulping concentration to 2-3 percent by water, and evenly mixing. By the use or the combine use of the filling and the non-tobacco plant fiber pulp, the combustion state of the sheet can be improved while physical properties, such as the air permeability, the retention and the tensile strength of a paper base, are improved, i.e., harmful ingredients of smoke, such as tar and carbon monoxide of the paper-making process tobacco sheet, can be effectively reduced, and hazard indexes of cigarettes are reduced. Meanwhile, technical-economic indicators, such as the speed and the input- output efficiency of a paper machine, also can be improved.

Owner:杭州利群环保纸业有限公司

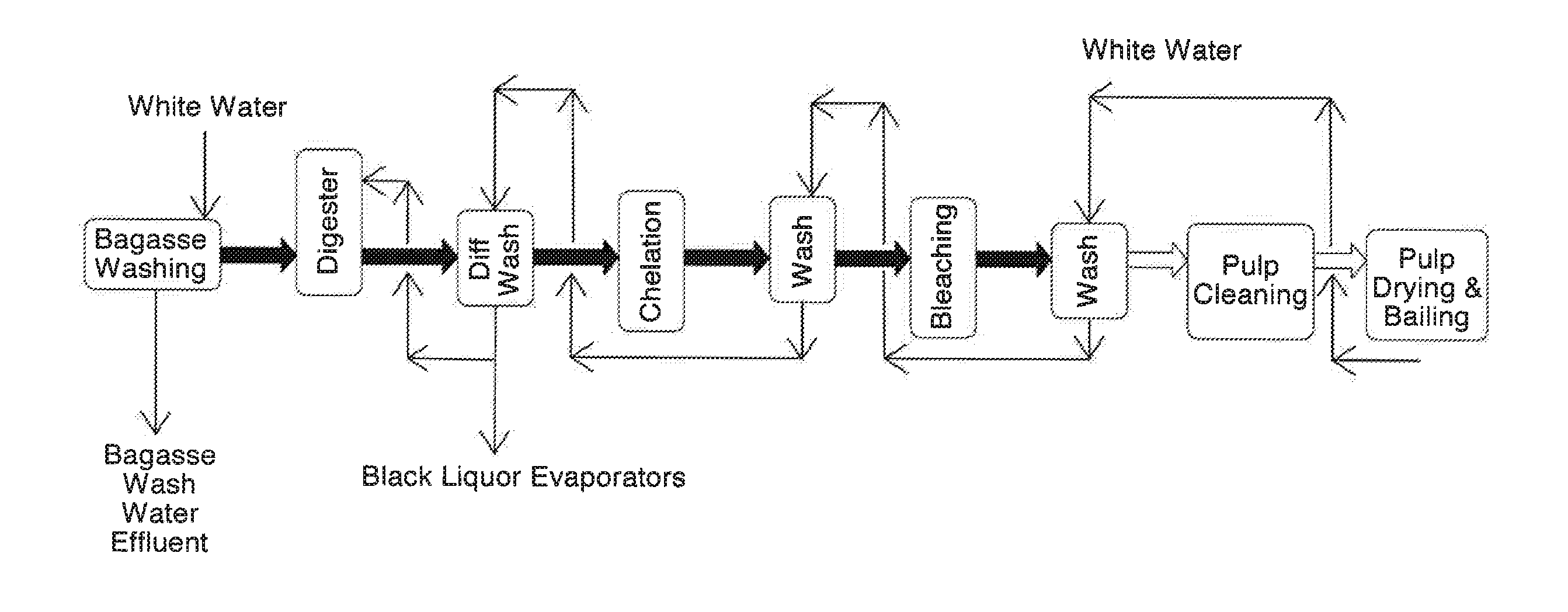

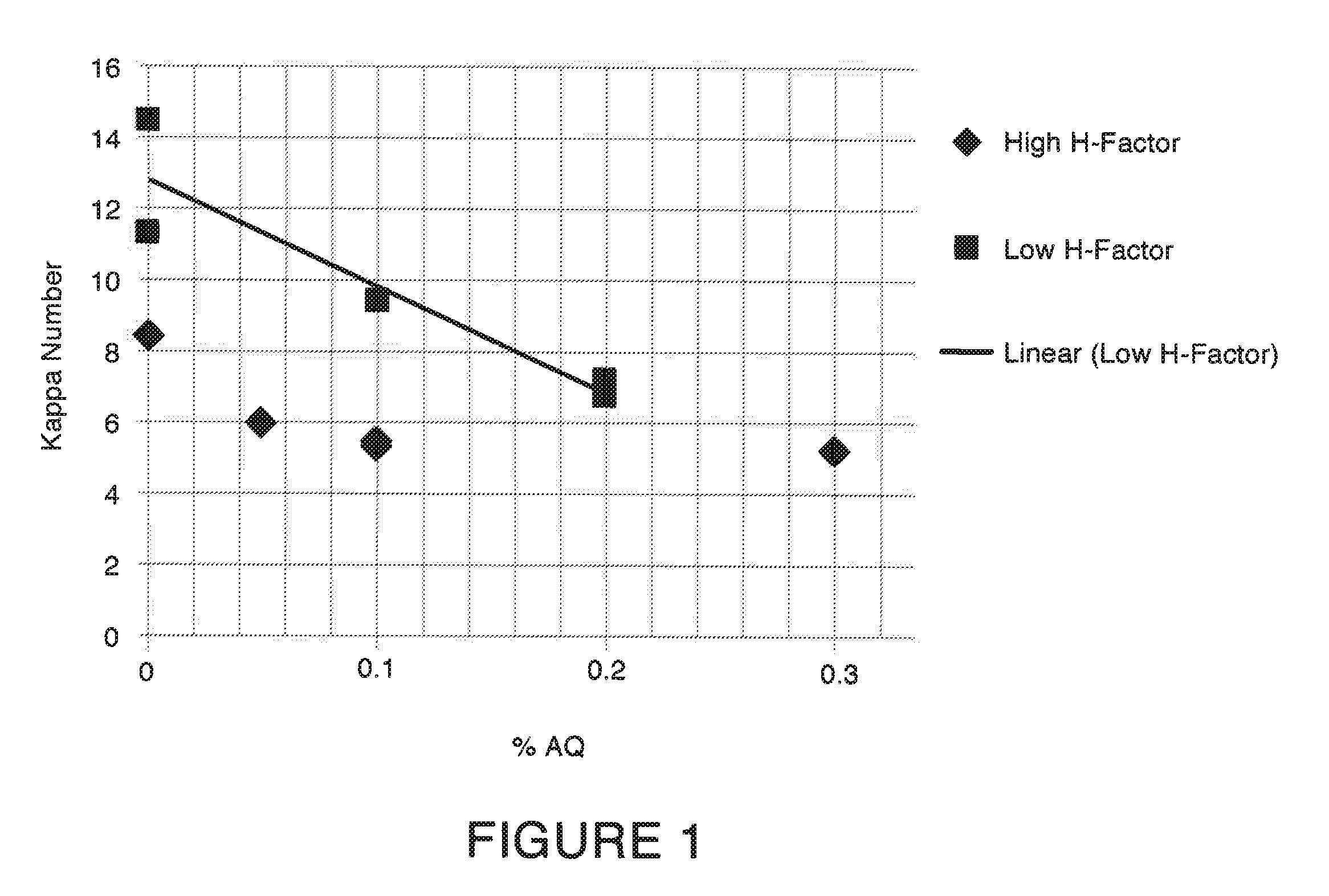

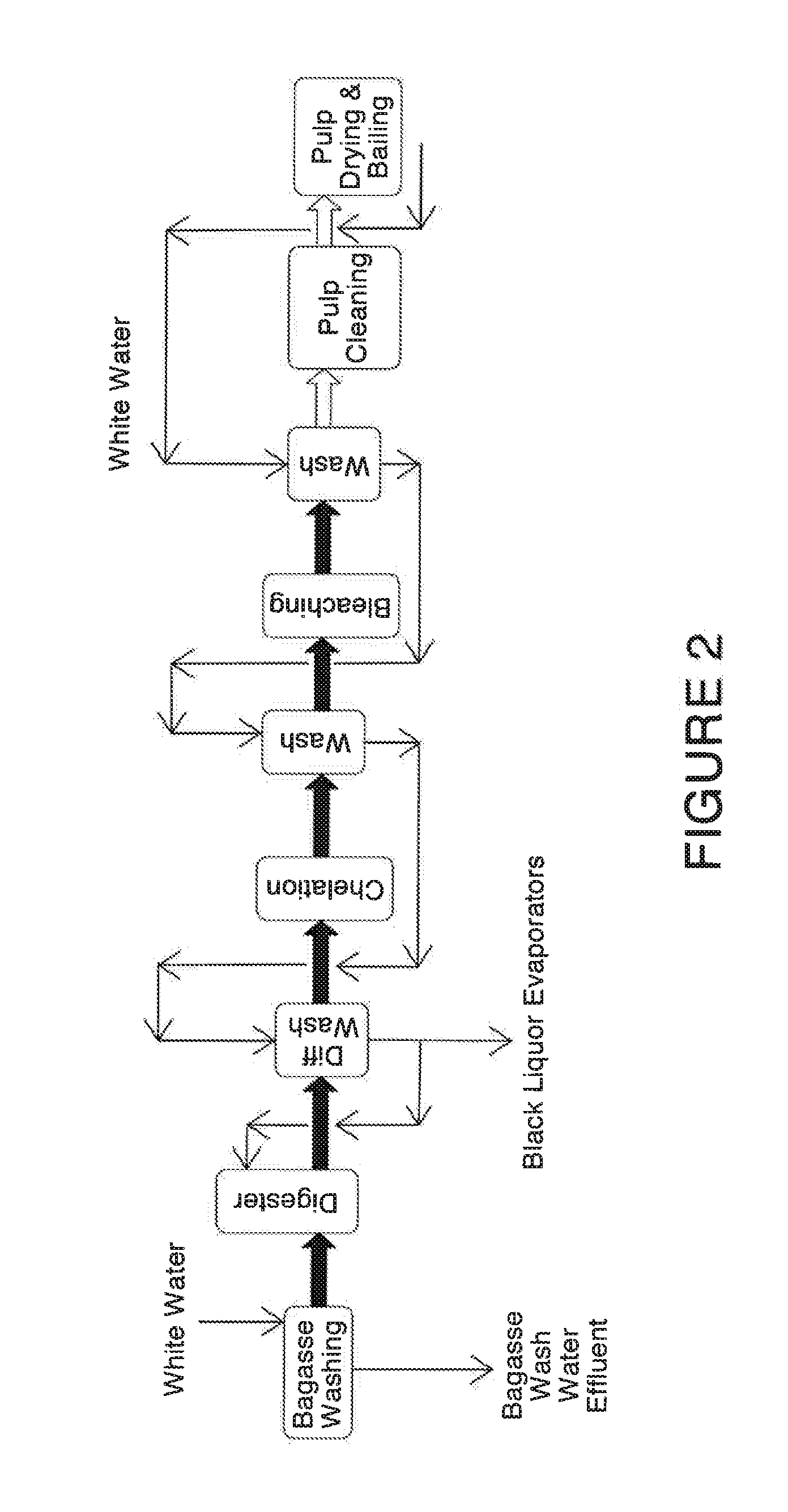

Pulping processes

A pulping process comprises using a high concentration of anthraquinone (AQ). The pulping process is capable of providing a pulp having low Kappa number with unexpectedly high strength. The pulping process can use wood or non-wood fibers (e.g., bagasse and corn stover) to provide pulp having good papermaking quality. The method for pulping a fiber comprising cooking a first mixture comprising the fibers, water, an alkali, and a delignification selectivity enhancing chemical for a cooking time and at a cooking condition sufficient to form a first pulp having a desired Kappa number of about 15 or less, and strength parameters that are sufficient for papermaking, where the starting material prior to cooking has a Kappa number of 60 or greater.

Owner:CARGILL INC

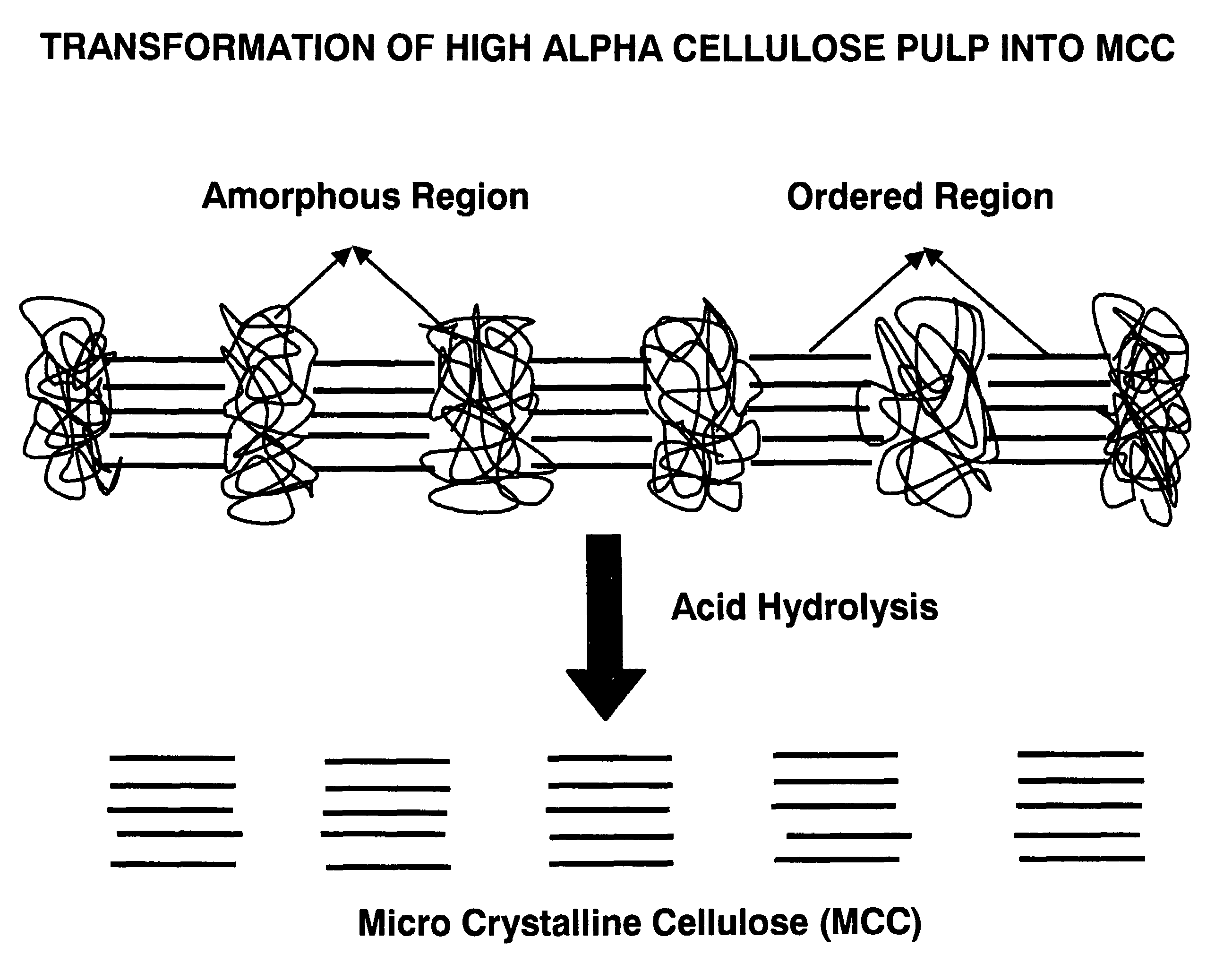

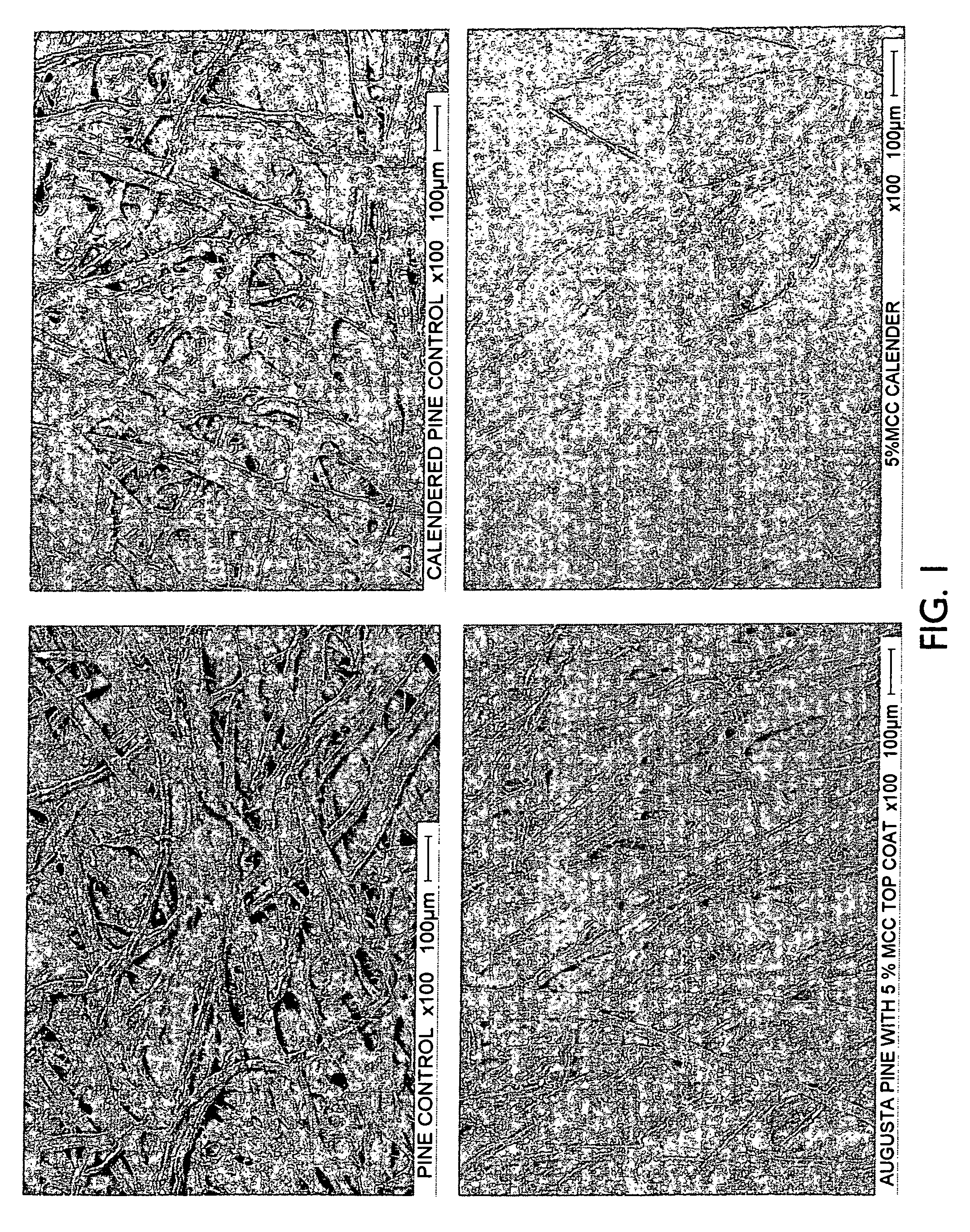

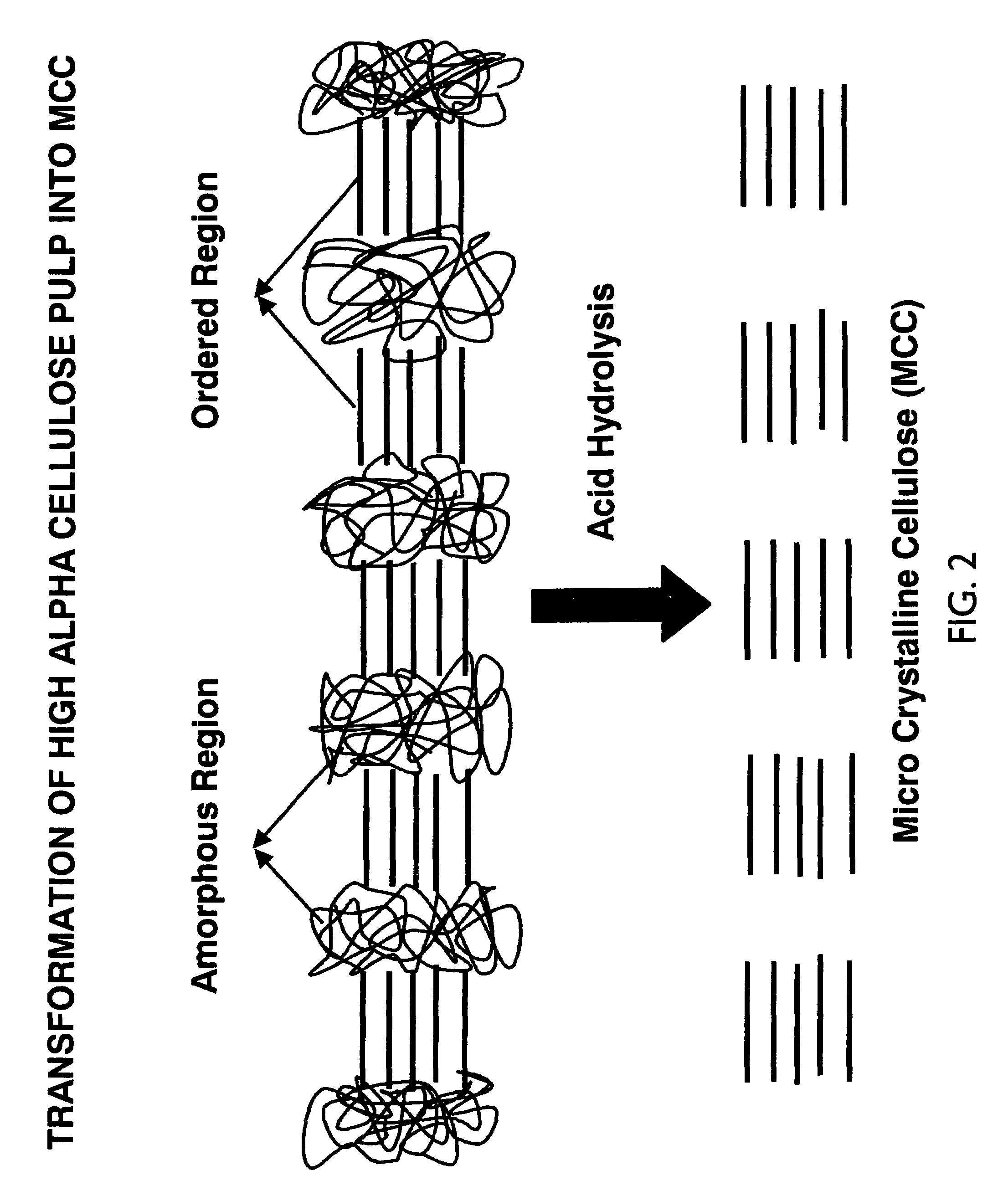

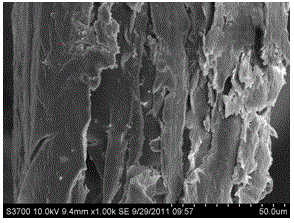

Surface treatment with texturized microcrystalline cellulose microfibrils for improved paper and paper board

The present invention relates to the production of texturized microcrystalline cellulose from raw pulp material. This texturized microcrystalline cellulose can then be used for surface treatment of paper or paper board. Additionally, the texturized microcrystalline cellulose may be used as a starting material for production of paper or paper board.

Owner:INT PAPER CO

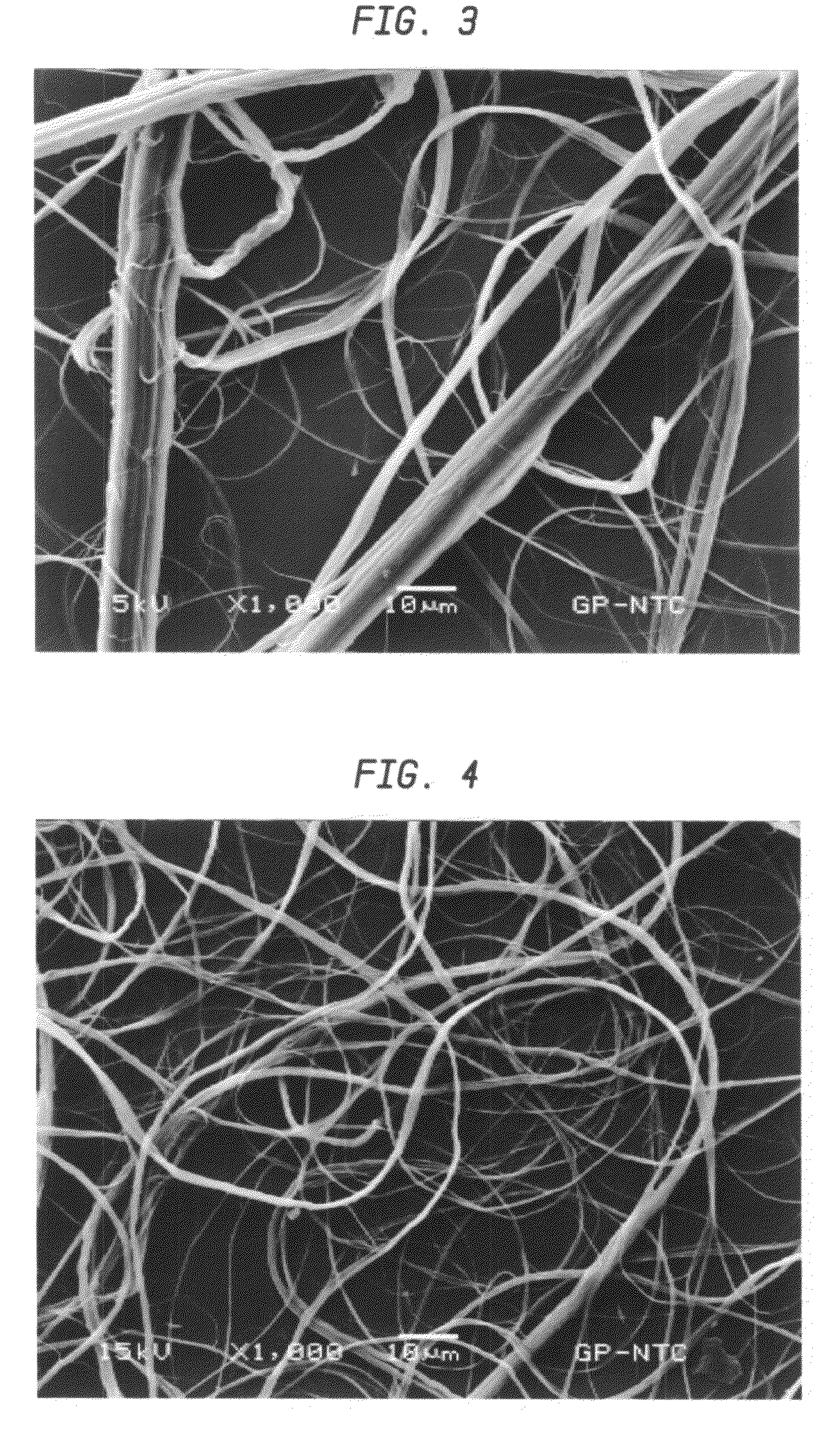

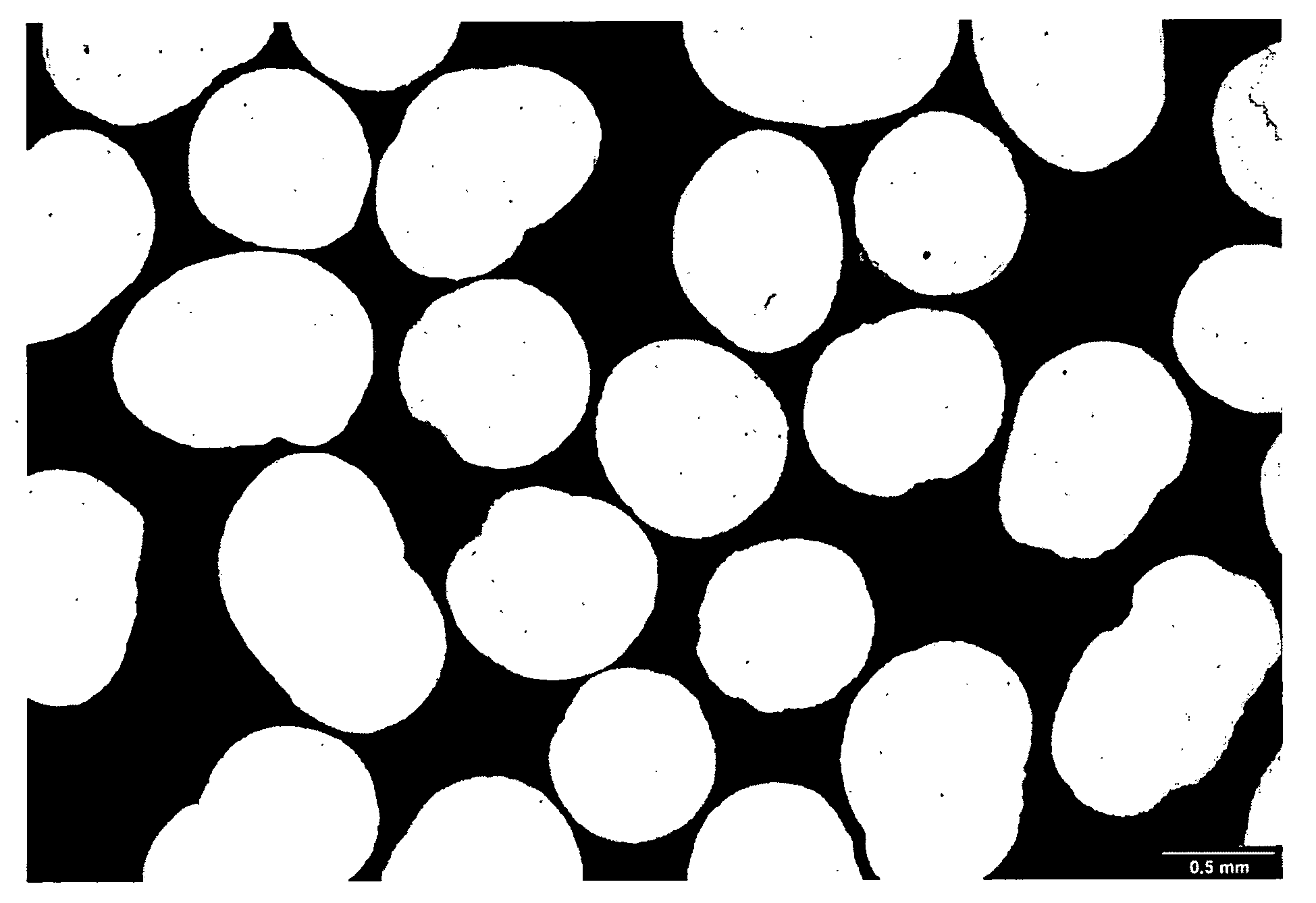

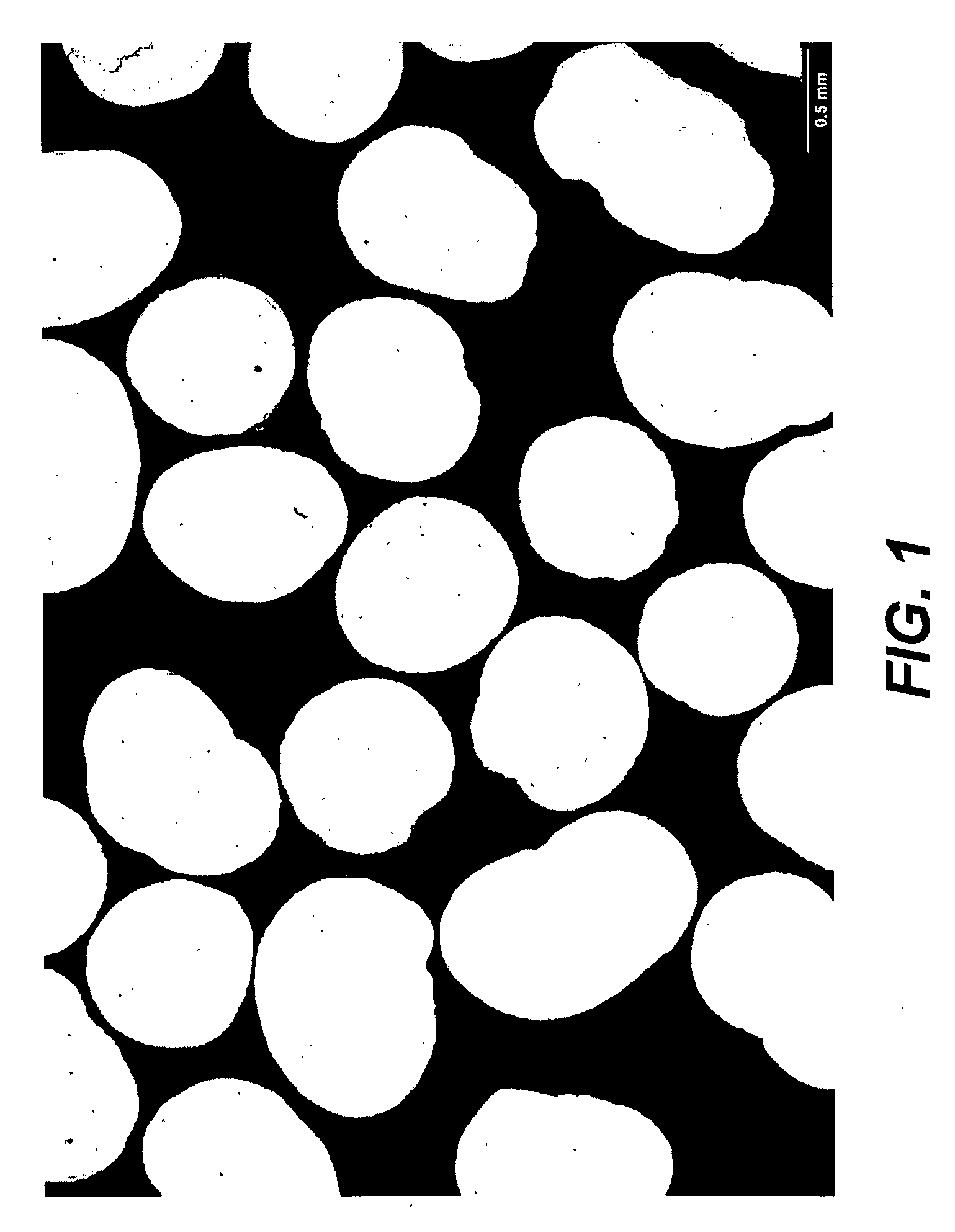

Cellulosic Particulates and Method of Manufacture and Use Thereof

InactiveUS20090044942A1Reducing substantially preventing passageFluid removalFlushingParticulatesCellulose

Spherical porous and non-porous cellulose particulates for use in sand control as well as stimulation procedures, may be prepared by first dissolving cellulosic materials (such as fibrous cellulose, wood pulp linters, cotton balls and / or paper), in the substantial absence of water or a nitrogen-containing base, in an ionic liquid. The solution is then combined with a cellulose-insoluble liquid to render the spherical particulates. The surface of the cellulosic particulates may be treated with a coating or penetrating layer.

Owner:BAKER HUGHES INC

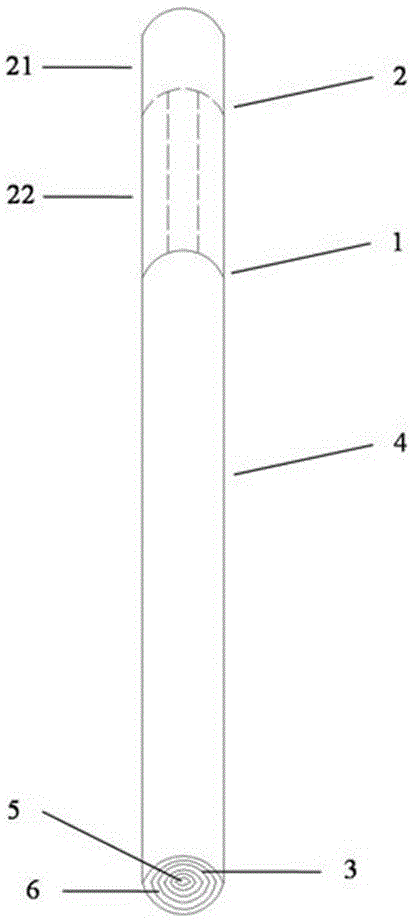

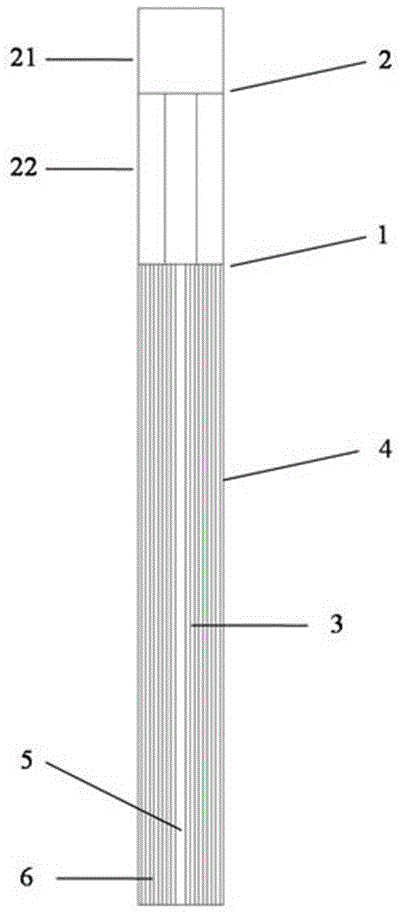

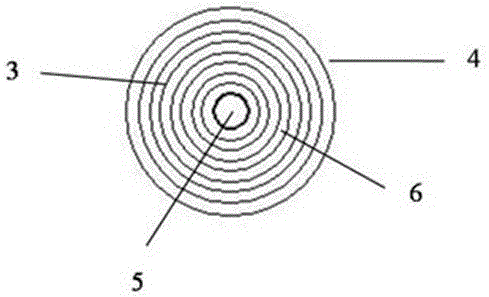

Reconstituted tobacco and heated non-combustible cigarette prepared by using same

ActiveCN105768191AMeet application needsGuaranteed releaseTobacco preparationTobacco devicesPulp (paper)Engineering

The invention belongs to the technical field of heated non-combustible cigarettes, and particularly relates to a reconstituted tobacco and a heated non-combustible cigarette prepared by using same. Preparation for the reconstituted tobacco comprises the following steps: firstly preparing a tobacco substrate by manufacturing paper with pulp through a paper-making process; and then, coating spice onto the tobacco substrate, and drying the tobacco substrate to obtain the reconstituted tobacco. The heated non-combustible cigarette prepared by using the reconstituted tobacco comprises a tobacco barrel, cigarette paper packaged outside the tobacco barrel and a composite filter stick connected with one end of the tobacco barrel, wherein a cavity is arranged in the center of the tobacco barrel; a lamellar spacing is arranged between adjacent two layers of the reconstituted tobaccos; the composite filter stick comprises a hollow section and a solid section, wherein the hollow section is in direct contact with the tobacco barrel. The reconstituted tobacco provided by the invention is designed for a heated non-combustible cigarette product, has the advantages of being relatively good in universality and applicability, wide in range of application, capable of simultaneously adsorbing certain harmful substances, capable of meeting physical and mental needs of a consumer, and the like, and has a relatively high practical value and relatively good popularization and application significance.

Owner:CHINA TOBACCO HENAN IND +1

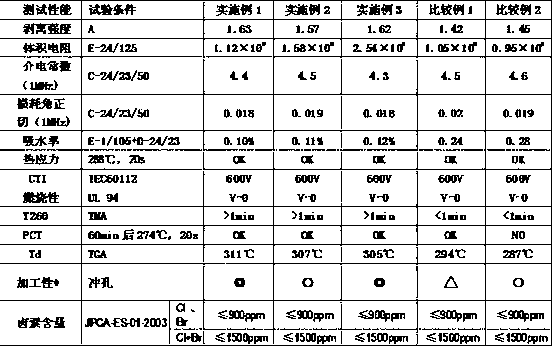

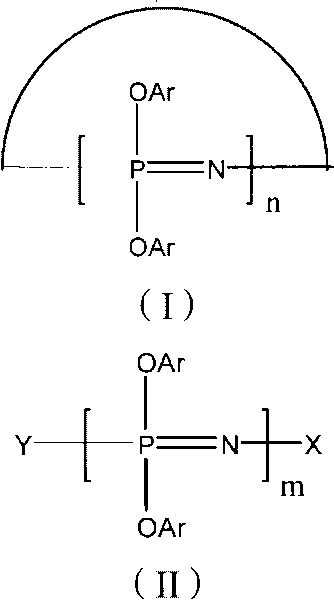

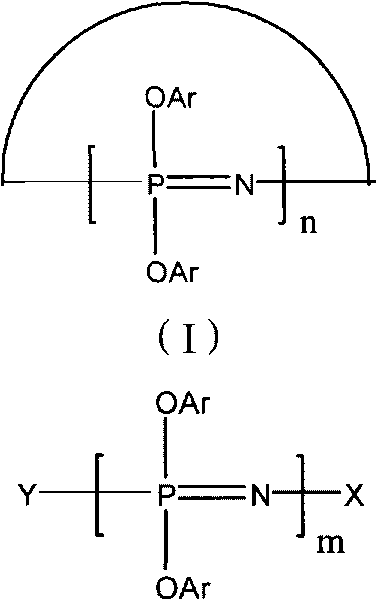

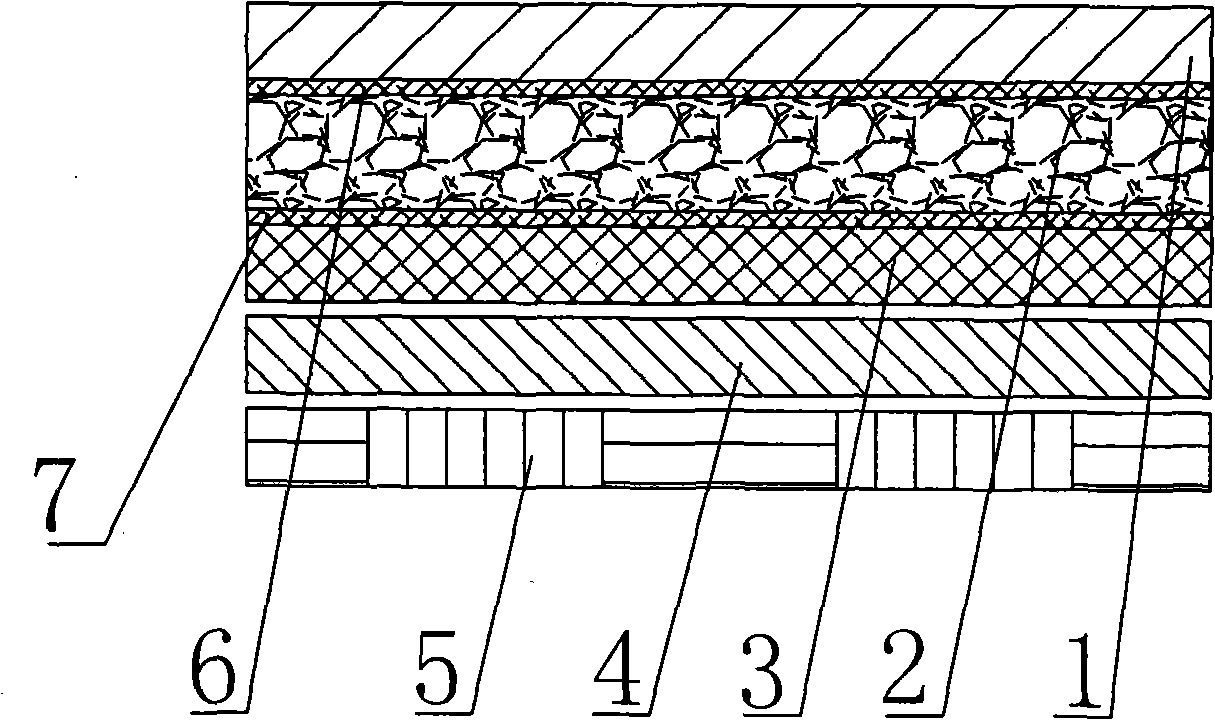

Preparation technology of copper-clad laminate based on halogen-free flame-retardant resin compositions

ActiveCN103182831ALow resistance to moisture absorptionLow hygroscopicityLaminationLamination apparatusPulp (paper)Copper foil

A preparation technology of a copper-clad laminate based on halogen-free flame-retardant resin compositions comprises the following steps: a fabric glue solution, a glue solution A and a glue solution B are sequentially manufactured; the fabric glue solution is impregnated by 7628 or 2116 glass fabric; solvent is removed in a drying oven to prepare a fabric prepreg; the glue solution A and the glue solution B are sequentially impregnated by wood pulp paper; baking is carried out in the drying oven to prepare a core material prepreg; and finally, two fabric prepregs are respectively pasted on both sides of each of 1-12 core material prepregs, an electrodeposited copper foil is pasted on one side or two sides of each core material prepreg, and the core material prepregs are overlapped and subjected to hot-forming. The copper-clad laminate prepared by adopting the preparation technology has the advantages of low hygroscopicity, high heat resistance, high reliability, high CTI (Comparative Tracking Index), halogen-free and flame-retardant performance, and excellent machinability, and meets the lead-free demand.

Owner:SHAANXI SHENGYI TECH

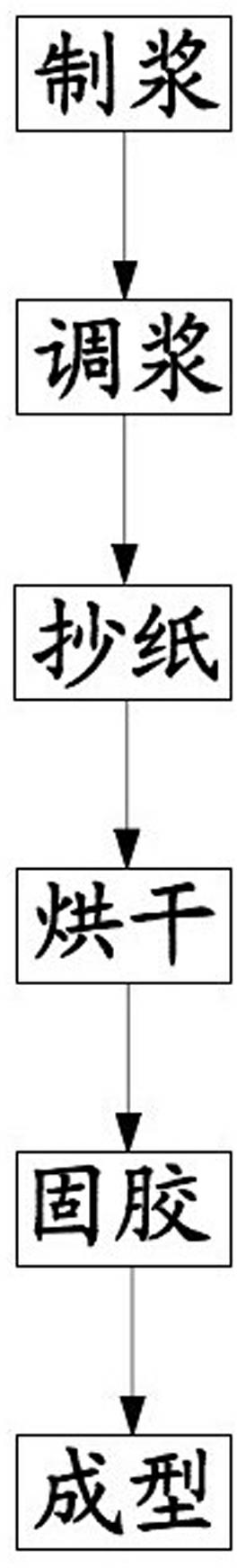

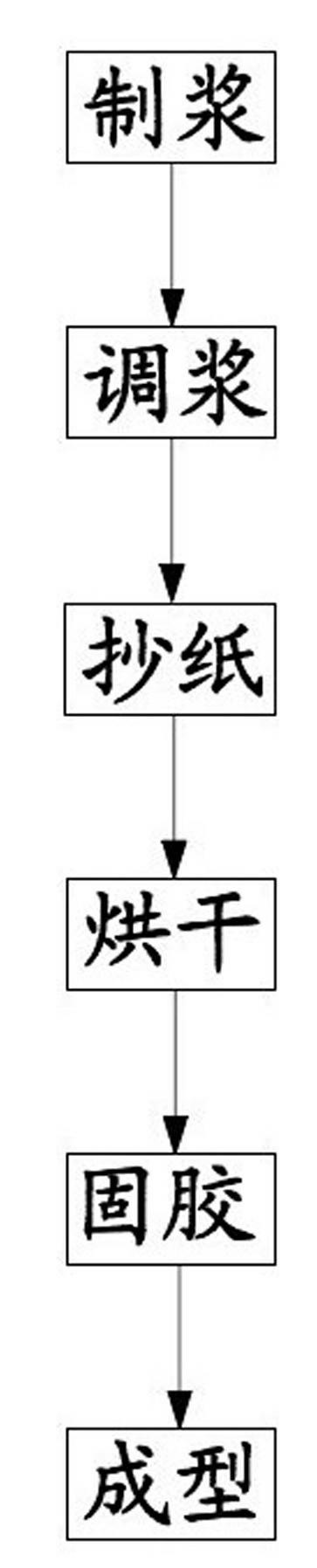

Filter paper for cooling system in wire electrical discharge machining (WEDM) and production method of filter paper

InactiveCN102444054AReduce the maximum apertureReduce the average pore sizeNon-fibrous pulp additionPaper/cardboardPolyesterGlass fiber

The invention relates to filter paper for a cooling system in wire electrical discharge machining (WEDM), which comprises the following components in percent by weight: 18-25 percent of phenolic resin, 0.5-5 percent of glass fiber, 0.5-5 percent of polyester fiber and 65-82 percent of wood pulp fiber. A production method of the filter paper comprises the steps of pulping, pulp mixing, paper making, drying, glue setting and forming. The filter paper adopts the wood pulp fiber as the main material which is matched with a proportion of glass fiber and polyester fiber, so that the bore diameter of the filter paper can be reduced, and the filtering accuracy can be improved; and in addition, since the polyester is chemically-synthesized fiber and has high strength, the bursting strength of the filter paper is improved, and the service life of the filter paper is prolonged. In the production process of the filter paper, thermosetting phenolic resin is introduced by dipping setting glue, and the size stability, the high temperature resistance and the water resistance of the filter paper are further improved. When being applied to a cooling liquid circulating system in WEDM, the filter paper is not deformed or expanded and has good strength in water, and the phenomena of water jetting and black water generating due to bursting are avoided.

Owner:SUZHOU XINYE PAPER - MAKING

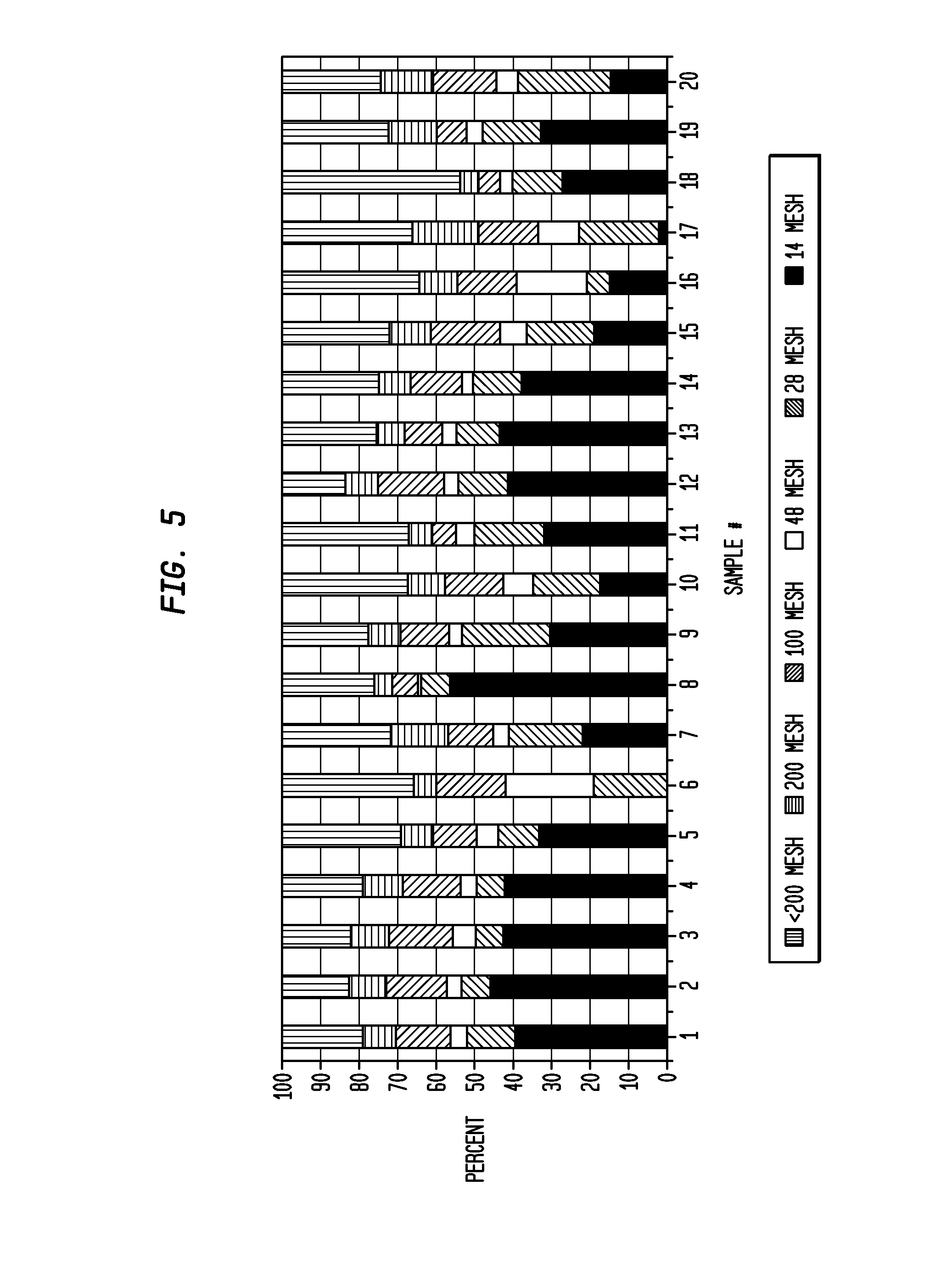

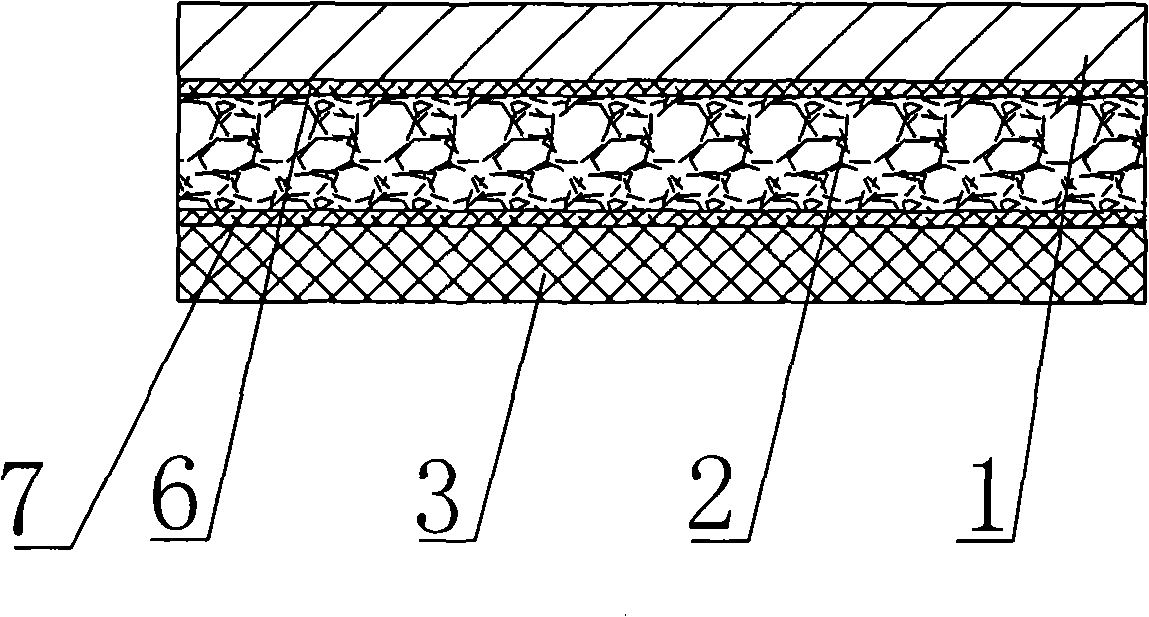

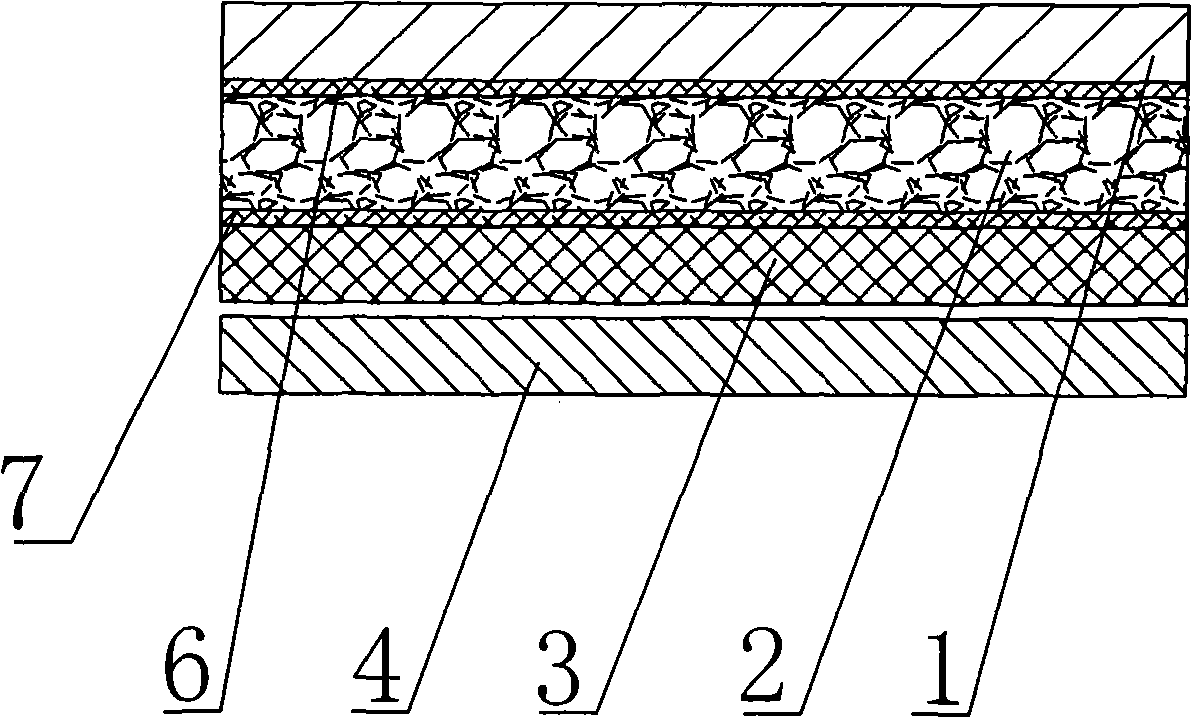

Belt-creped, variable local basis weight multi-ply sheet with cellulose microfiber prepared with perforated polymeric belt

ActiveUS20120021178A1High absorbency (SAT)Eliminate needMechanical working/deformationLayered productsPaper towelEngineering

A multi-ply absorbent sheet includes at least a first and second ply bonded together. In one construction, the first and second ply are provided with from about 90% by weight to about 25% by weight pulp-derived papermaking fiber and from about 10% to about 75% by weight fibrillated regenerated cellulosic microfiber having a characteristic CSF value of less than 175 ml; the sheet having a caliper of from 180-250 mils / 8 sheets and exhibiting a wipe-dry time of less than 20 seconds, an SAT capacity in the range of 350-500 g / m2, an SAT rate in the range of 0.05-0.25 g / s0.5, a CD wet tensile in the range of 400-2500 g / 3″ and a wet / dry CD tensile ratio of from 35% to 60%. The multi-ply sheets are efficient, high capacity wipers and have enough absorbent capacity to be used as ordinary paper towels. Preferred wiper towel products exhibit a differential pore volume for pores under 5 microns in diameter of at least about 75 mm3 / g / micron.

Owner:GPCP IP HLDG LLC

Raw paper of high-performance environment-friendly paper based friction material and manufacturing method of friction plate

ActiveCN101805589AGood physical and mechanical propertiesIncrease coefficient of frictionOther chemical processesNon-macromolecular organic additionAdhesiveStatic friction

The invention discloses raw paper of a high-performance environment-friendly paper based friction material and a manufacturing method of a friction plate. The high-performance environment-friendly paper based friction material is characterized by comprising the following components in percentage by weight: a substrate comprises 7-15% of carbon fiber, 5-10% of chopped aramid fiber, 5-10% of aramidpulp and 9-30% of bamboo fiber pulp; a friction agent comprises 10-20% of kieselguhr and 8-12% of cashew nut shell powder; a frictional property regulator adopts 2-4% of rubber particles, 5-10% of calcium carbonate and 10-15% of flake graphite; and a forming adhesive comprises 1-2% of fluororubber, 3-15% of silicone resin and 3-15% of phenolic resin. The invention fully forms the materials of thefriction material into a whole by changing the traditional impregnation process, effectively improves the physical and mechanical properties of the friction plate, improves the friction factors, regulates the dynamic and static friction ratio factors, and reduces the abrasion ratio of the friction plate.

Owner:陕西帕若德新材料科技有限公司

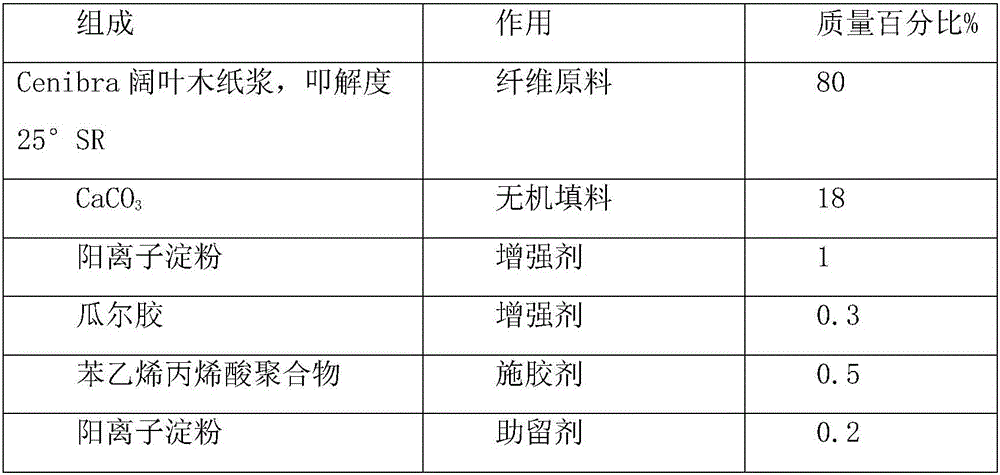

Method for improving reconstituted tobacco paper-base quality through adding calcium carbonate and reconstituted tobacco paper-base

ActiveCN102715642APlay the role of reducing focus and harmImprove surface propertiesTobacco preparationTobacco treatmentPaper basedGuar gum

The invention discloses a method for improving the reconstituted tobacco paper-base quality through adding calcium carbonate and a reconstituted tobacco paper-base, belonging to the technical field of cigarette production. The method for improving the reconstituted tobacco paper-base quality through adding calcium carbonate comprises the steps of soaking and extracting tobacco stems and tobacco powder, grinding, pulping, sheet making, squeezing and drying, wherein in the sheet making step, the calcium carbonate and guar gum which respectively occupies 10-70% and 0.05-0.5% of the mass percent of the tobacco raw pulp are added into the tobacco raw pulp. Researches show that after the calcium carbonate and the guar gum are added according to an appropriate proportion, the tensile index, tear index and air permeability of the produced reconstituted tobacco paper-base are obviously improved, the whole water-absorption performance of the reconstituted tobacco paper-base is also improved, the tar yield, CO content and total particle matter content of the sheet paper-base are obviously decreased, so that the tar and harm reduction function of the reconstituted tobacco is better played, the combination property of the tobacco sheet is effectively improved, and the operation performance and effectiveness of a reconstituted tobacco production line are improved.

Owner:CHINA TOBACCO GUANGDONG IND +1

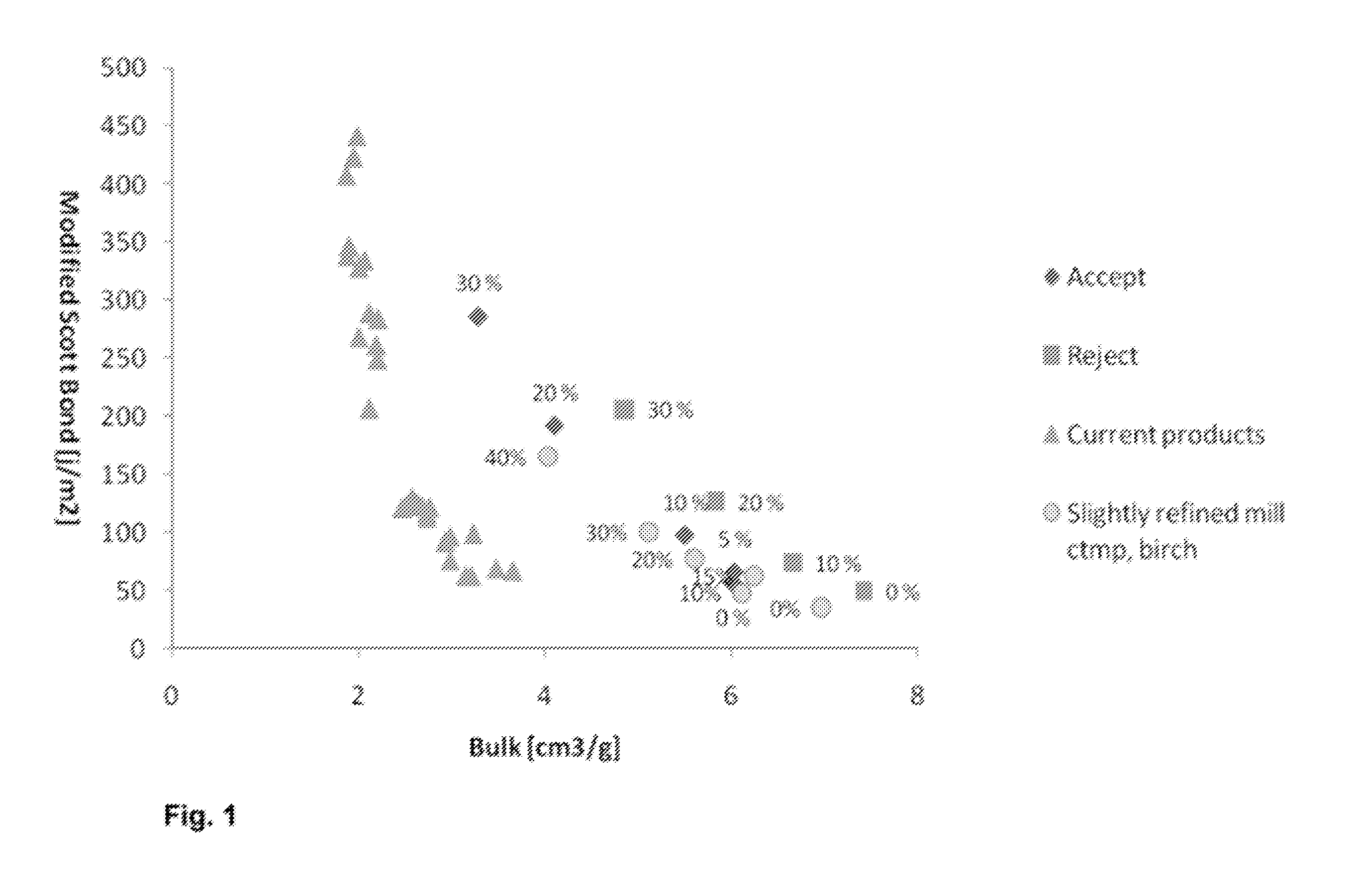

Fibrous web of paper or board and method of making the same

The invention relates to a fibrous web product such as paper, and a method for the preparation of such fibrous web. According to the method microfibrillated cellulose (MFC) together with a pulp of a greater fibre length, such as chemithermomechanical pulp (CTMP), are mixed with a foam of water and a sur-factant, the foam is supplied to a forming fabric of a paper or board machine, dewatered by suction of air through the forming fabric, and dried to the final web product. The method brings a high bulk in combination with a high Scott bond value, to provide improved wet and dry tensile strength for the paper and board products.

Owner:STORA ENSO OYJ

Filled Paper and Method of Manufacturing the Same

ActiveUS20090020250A1Improve paper strengthEasy maintenanceNatural cellulose pulp/paperSpecial paperPolymer scienceSlurry

There is provided a filled paper containing a coated filler obtained by coating a filler with a acrylamide copolymer (composite PAM) comprising (A) an anionic polysaccharide and (B) a cationic and / or an amphoteric acrylamide copolymer. The composite PAM is obtained, for example, by mixing the component (A) and the component (B). Since the filler is treated with a combination of the components (A) and (B) different from each other in charge properties and structure, suitable coagulation effect can be attained and the coated filler has excellent affinity for pulp slurry. Therefore, even in the case of a highly filled paper, a large paper strengthening effect can be attained by using a small amount of the chemical agent.

Owner:HARIMA CHEM INC +1

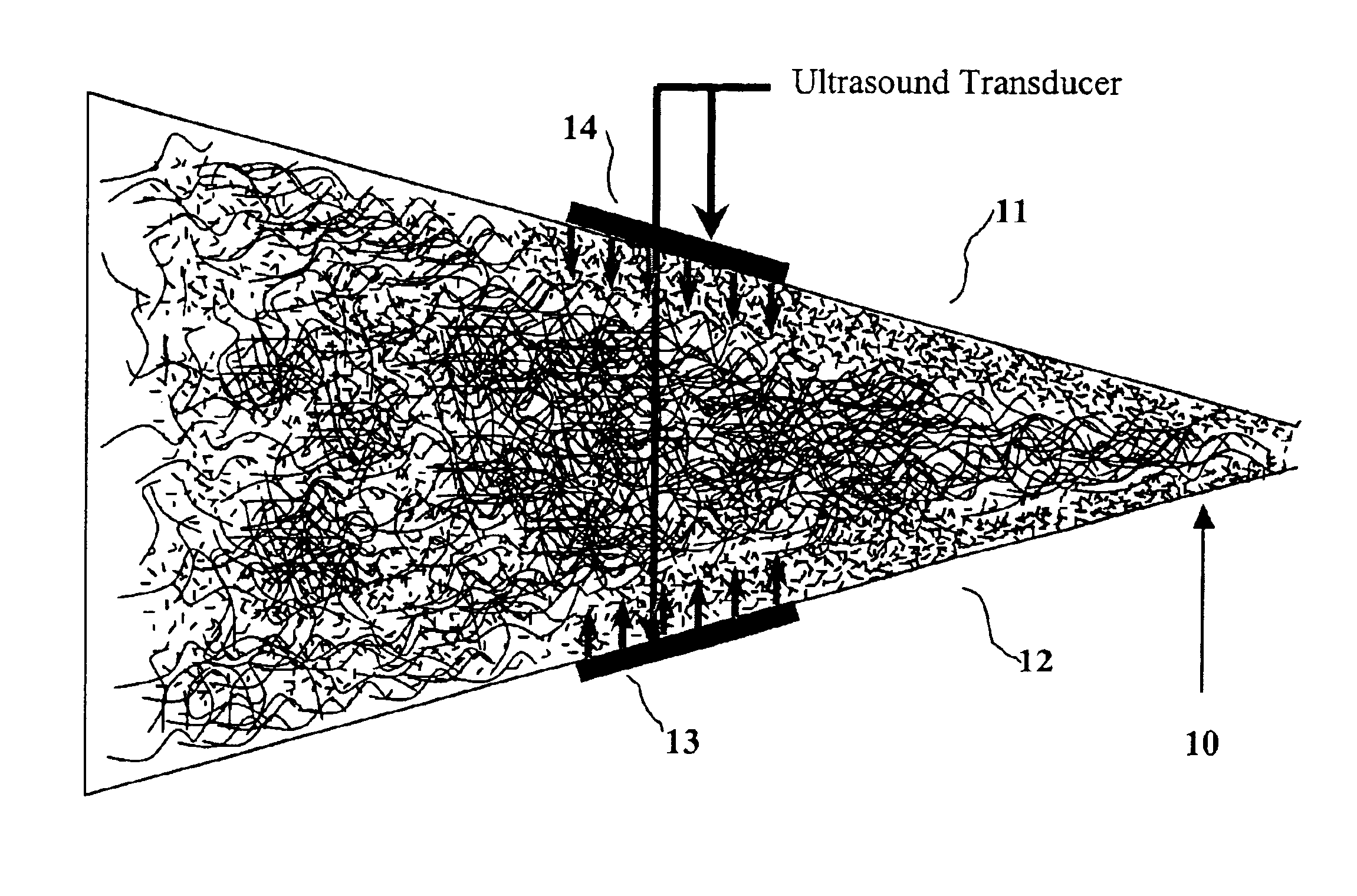

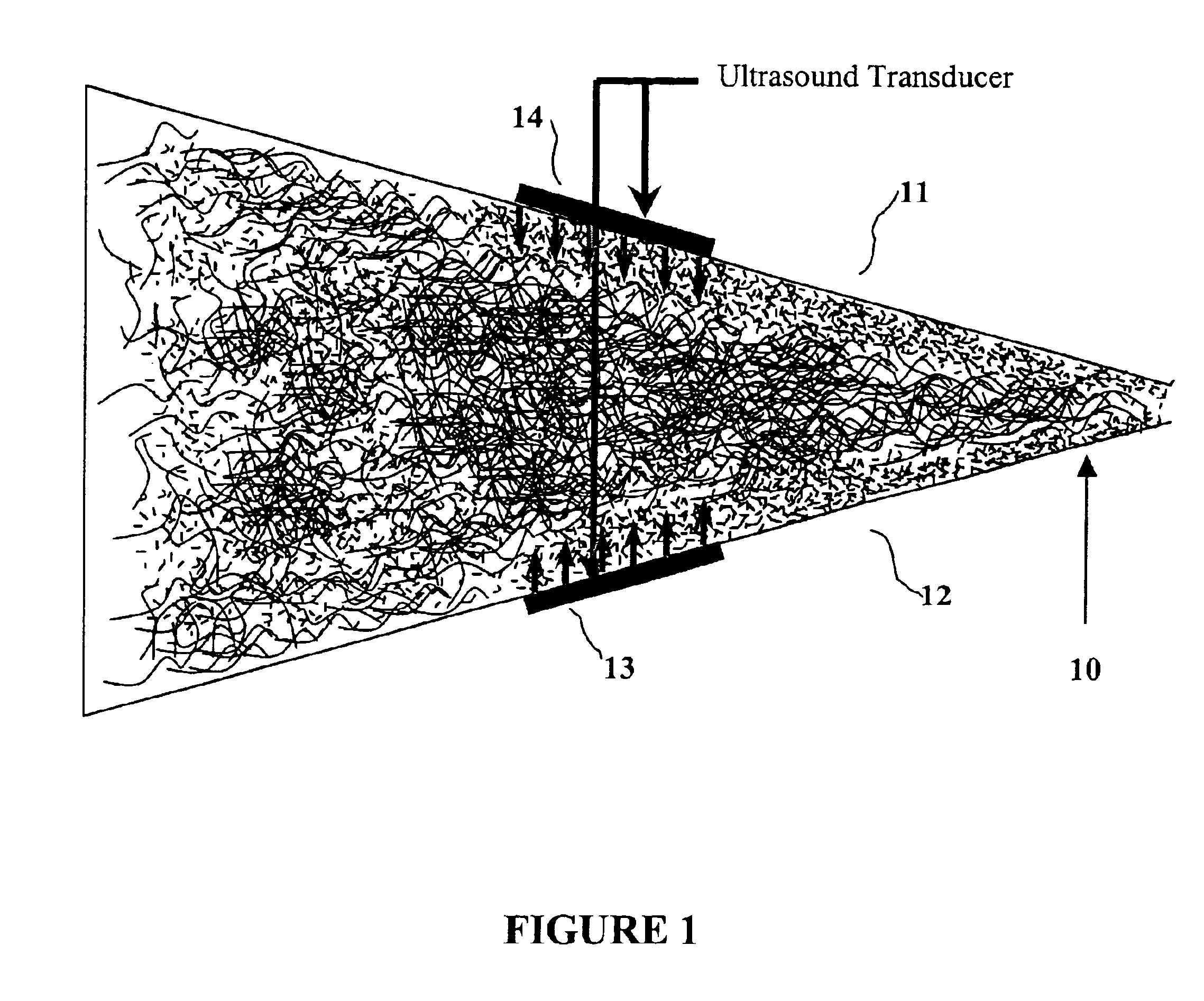

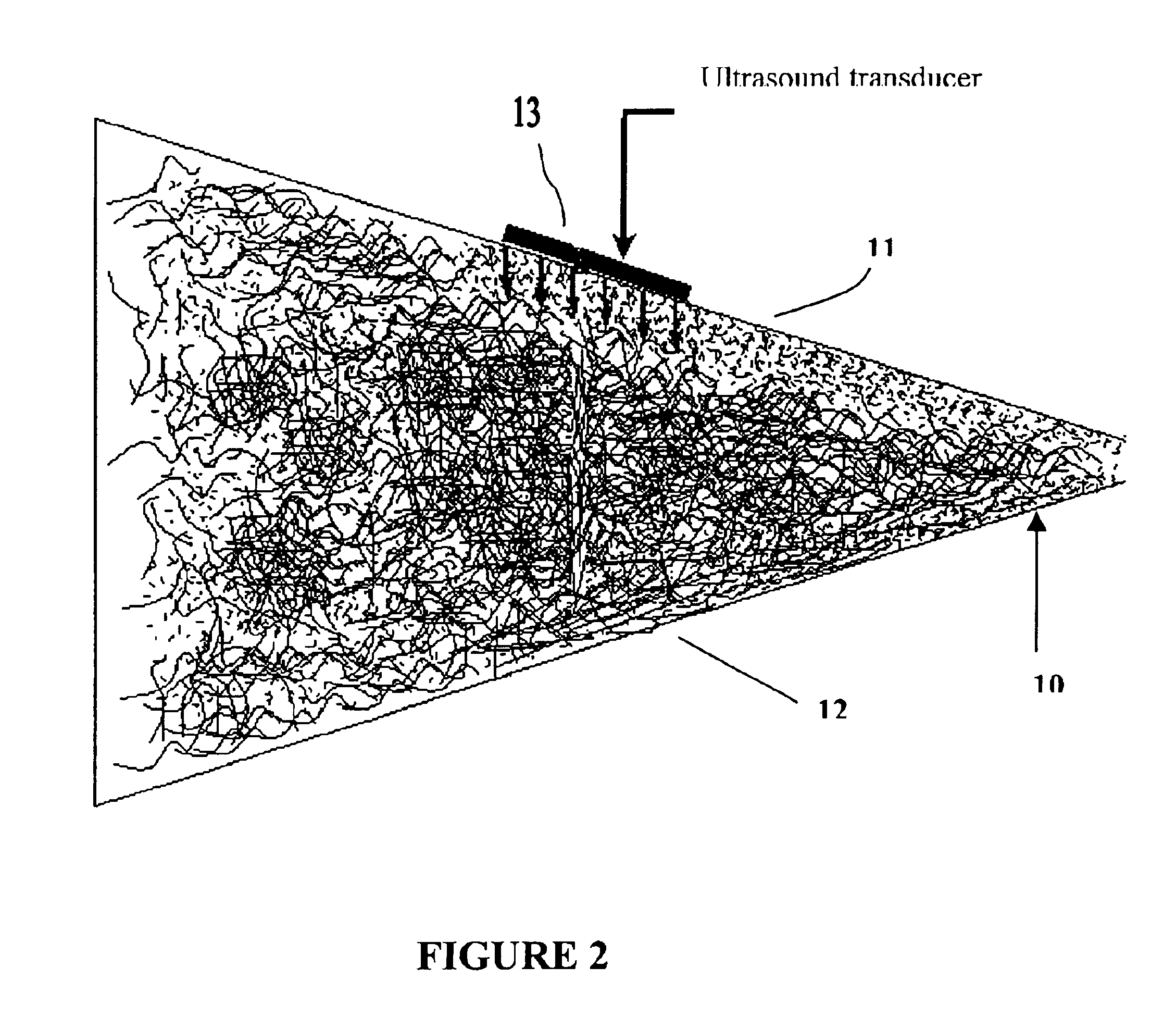

Method of making a stratified paper

The present invention provides a method making stratified paper by redistributing the pulp suspension inside the headbox nozzle using acoustic radiation waves. Acoustic radiation forces fractionate fibers based on fiber radius. The acoustic radiation waves separate the fibers by pushing the coarse and longer fibers to the inner area while fines and smaller fibers remain in the outer area. This has a similar effect of multi-layer stratification headbox, and provides paper with a smoother surface.

Owner:INT PAPER CO

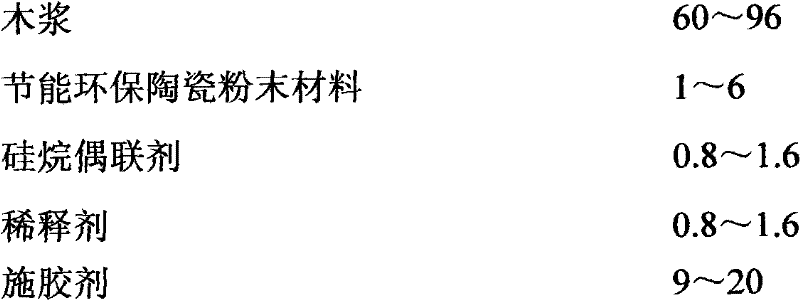

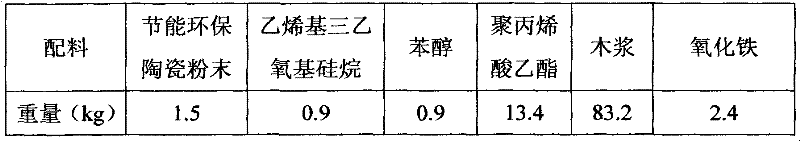

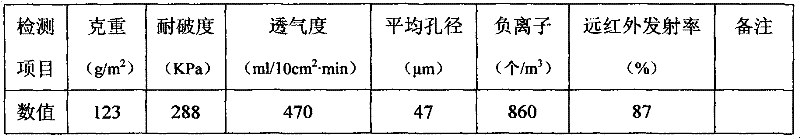

Filter paper of energy-saving and environment-friendly filter and making method thereof

ActiveCN102199903AHigh filtration precisionHigh burst resistanceInorganic fibres/flakesFiltration separationAir filterFuel filter

The invention relates to filter paper of an energy-saving and environment-friendly filter and a making method thereof. The filter paper is made from an energy-saving and environment-friendly ceramic powder material, a silane coupling agent, a dilute, a sizing agent and wood pulp. The filter paper can be made into an air filter and a fuel filter so as to improve the power performance by 6-12%, save the fuel by 2-5% and reduce pollutants in discharged tail gas by 16-47%.

Owner:北京联飞翔科技股份有限公司

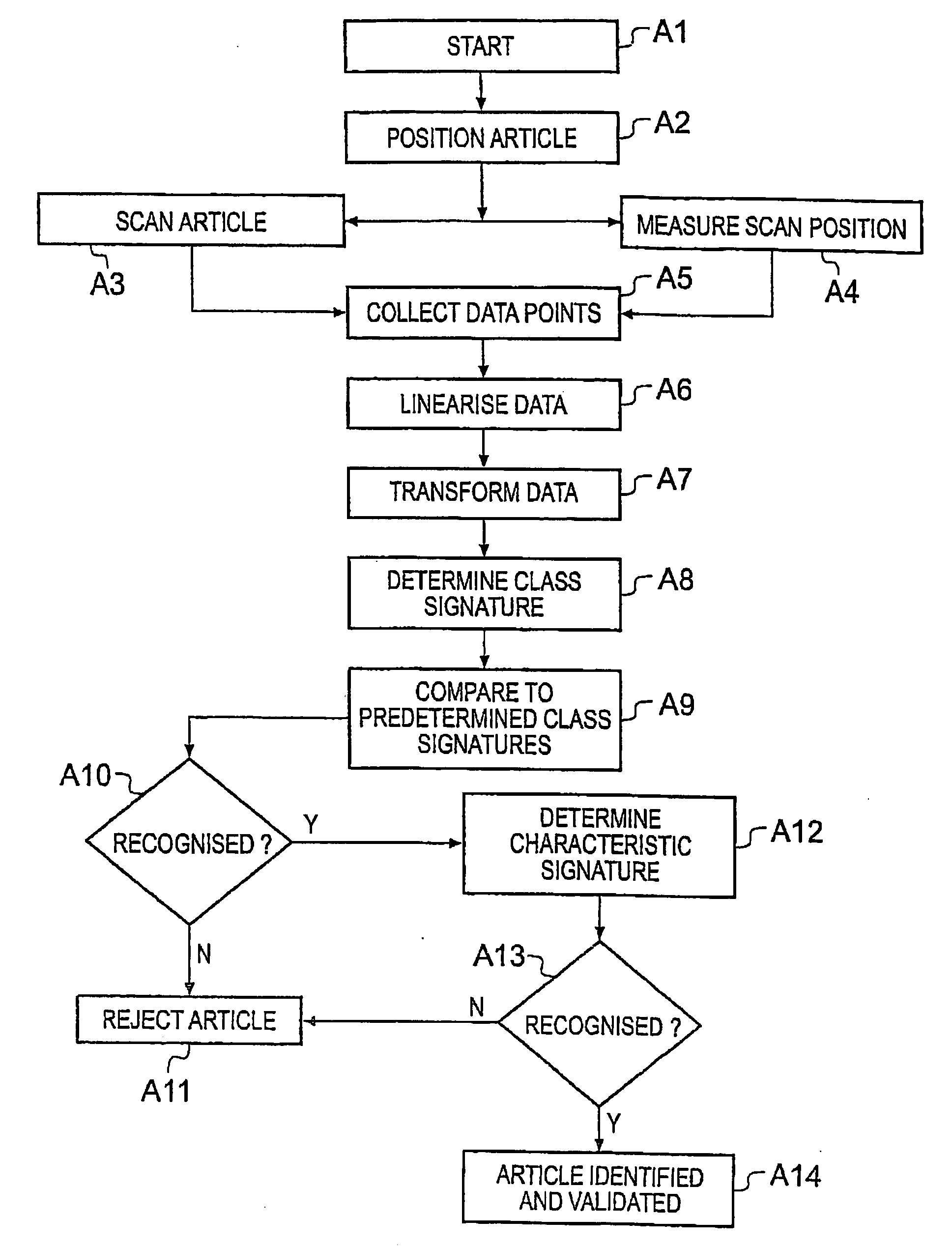

Authenticity Verification Methods, Products and Apparatuses

InactiveUS20080260199A1Increase the number ofNot easy to copyDigitally marking record carriersPaper-money testing devicesCardboardComputer science

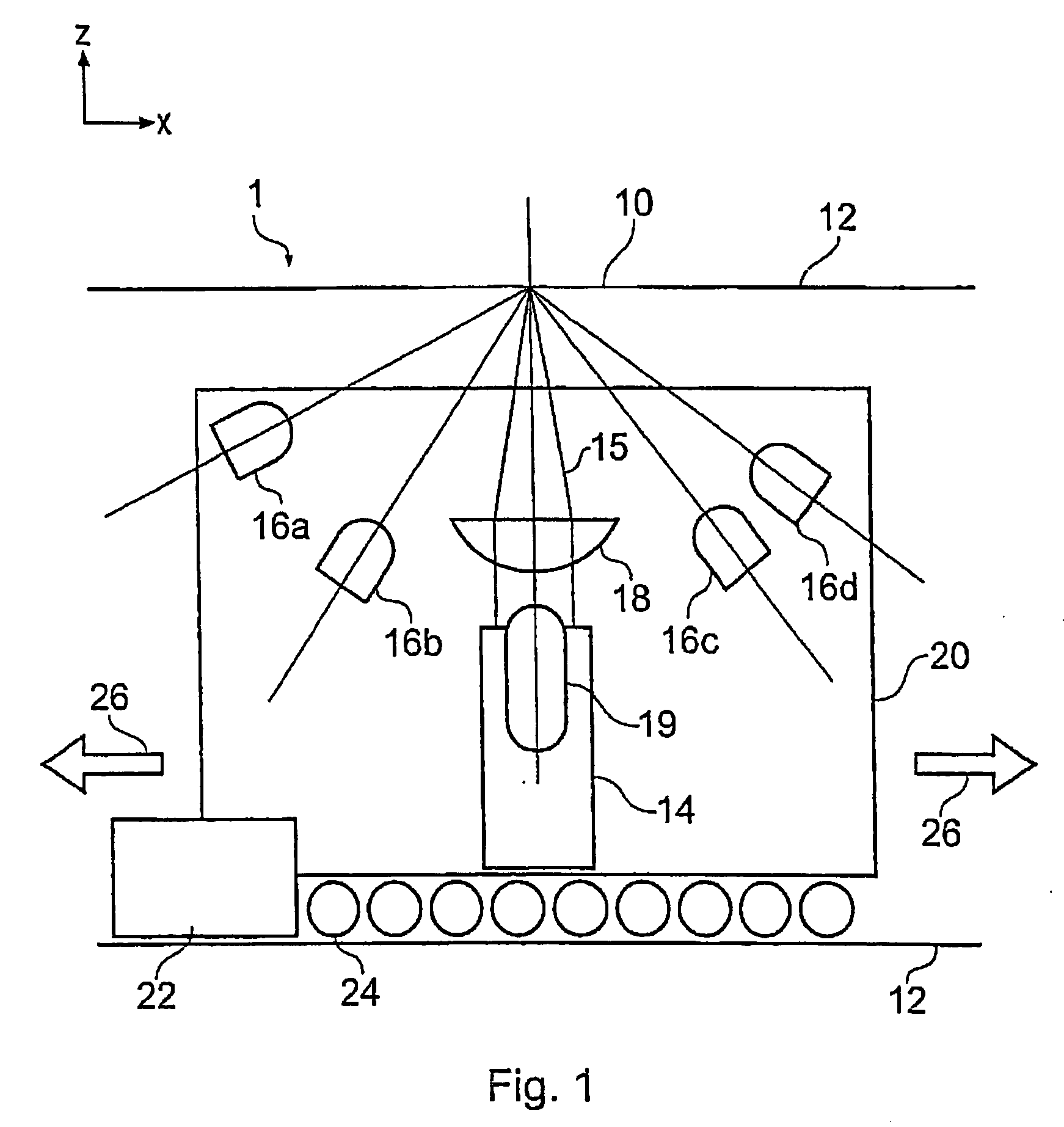

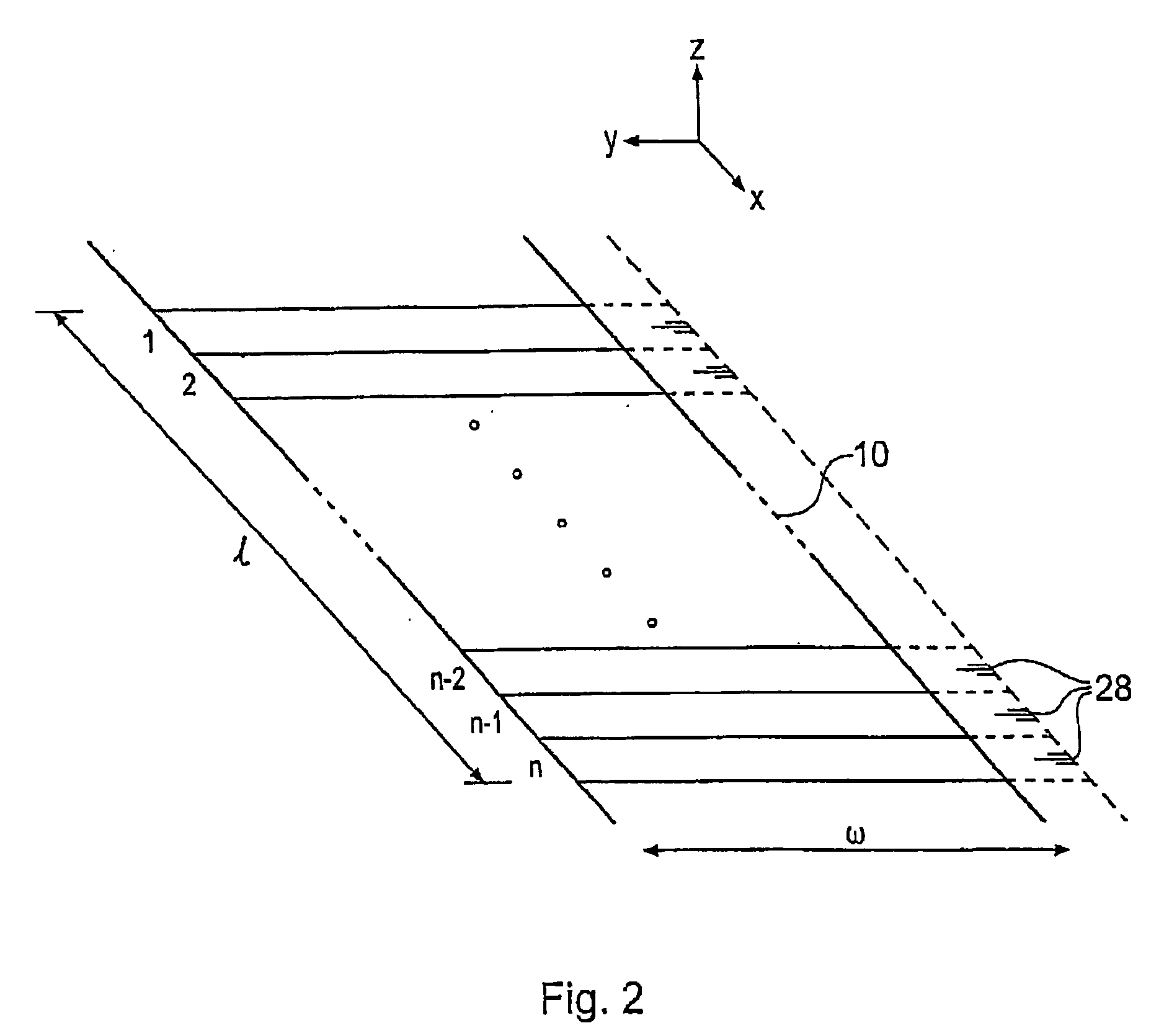

A method and apparatus for determining a class signature from an article made of paper or cardboard in order to identify a generic type of class to which the article belongs. An optical beam illuminates the article and a detector arrangement collects data points from light scattered from many different parts of the article as the article is scanned by the beam. The class signature derives from intrinsic properties imparted to the paper / cardboard during manufacture by, it is believed, the screen used during dewatering of paper pulp. Detection of the class signature allows the manufacturer or the particular paper making machine that made the paper to be identified.

Owner:INGENIA HLDG LTD

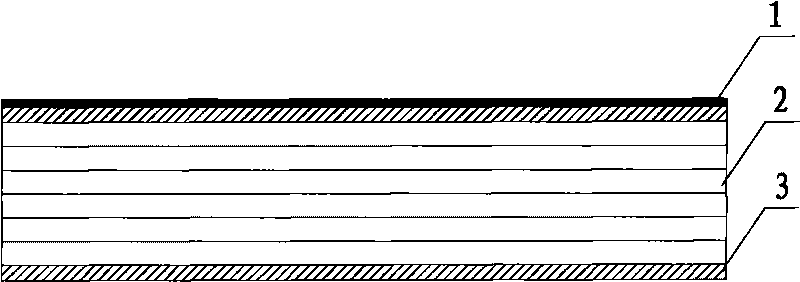

Compound base copper-clad laminate and manufacturing method thereof

ActiveCN101746102ASmall water absorptionGood solder dip resistanceLamination ancillary operationsLaminationEpoxyGlass fiber

The invention discloses a method for manufacturing a compound base copper-clad laminate, which comprises the following steps of: rubberizing a glass fiber cloth through a first maceration extract, and drying prepregs to manufacture surface prepregs; rubberizing wood pulp paper through a second maceration extract, and drying core prepregs; and cutting more than two of the core prepregs to superpose the core prepregs together, superposing the surface prepregs on two sides respectively, then superposing a copper foil on a single surface or two surfaces, and performing hot press molding to obtain the compound base copper-clad laminate. The method for manufacturing the compound base copper-clad laminate can reduce the water absorbability of the laminate and prevent plate explosion by using the first maceration extract and the second maceration extract to perform optimization and using a phosphazene compound flame retardant to replace part of phosphorus-containing epoxy resin or phosphate, and the prepared compound base copper-clad laminate has the advantages of small content of chlorine and bromine, low water absorption, good dip soldering resistance, improved electrical property, high flame retardance capable of reaching the level of UL94V-0, and increased tenacity.

Owner:建滔积层板(昆山)有限公司

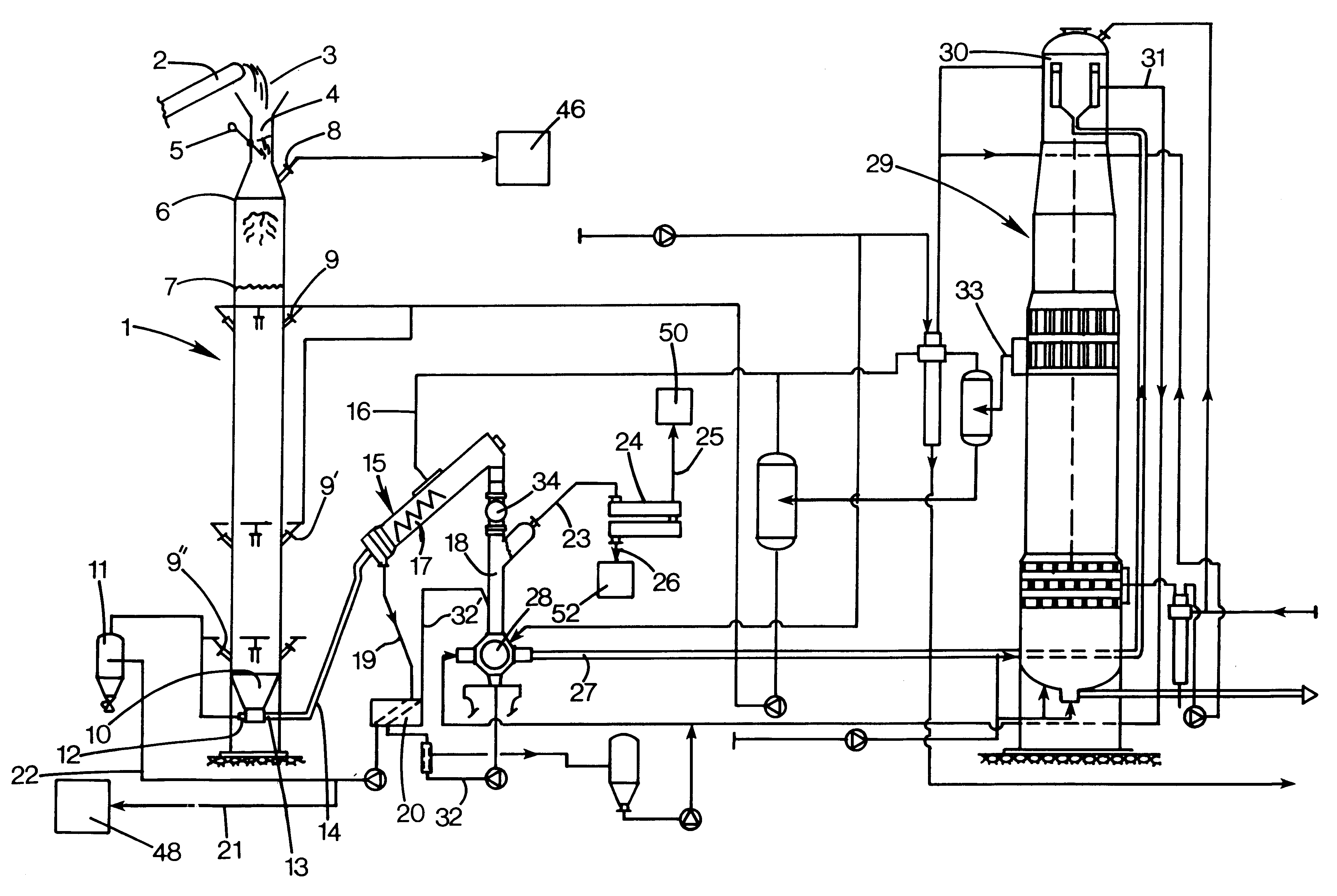

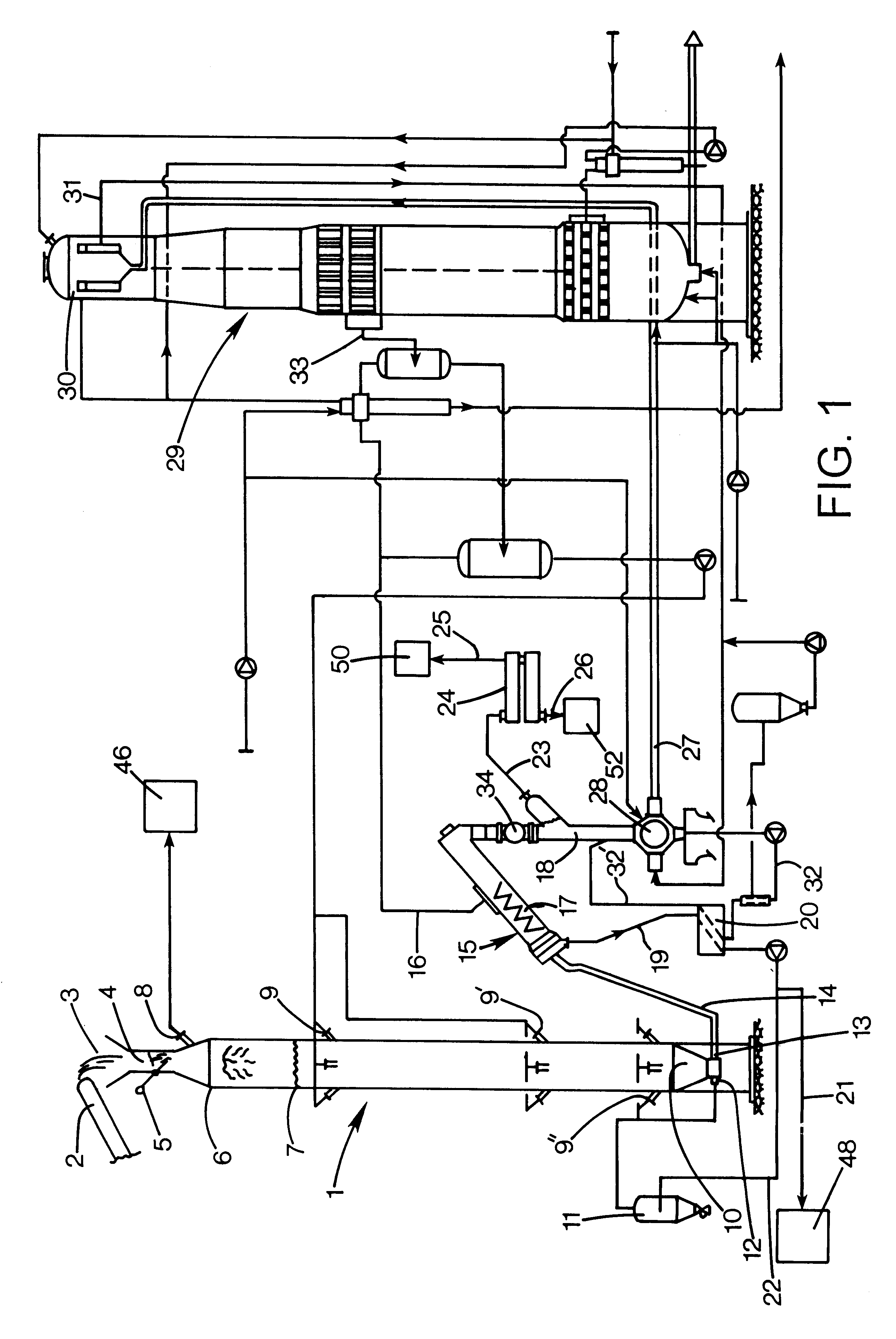

System and method for treatment of cellulose-containing material prior to pulp digestion

The invention relates to a process system and a method for preliminary treatment of disintegrated cellulose-containing material, preferably wood chips, prior to pulp digestion. The process system and the method according to the invention make use of a process vessel intended to function both as a so-called chip bin and as a pre-impregnation vessel. The characteristics of the invention are that a sloping steaming vessel is arranged downstream of the process vessel for the purpose of separating an excess of pre-impregnation liquid from the pre-impregnated cellulose-containing material, that the sloping steaming vessel is arranged for supplying steaming vapor which preferably has been generated by flashing of extraction liquor from a pulp digester, and that the sloping steaming vessel is connected to a chip chute communicating with a condenser for connection to a system for managing foul-smelling process gases. The invention can be applied in the production of pulp which is intended for paper manufacture or other applications where cellulose fibers are used.

Owner:METABO PAPER SWEDEN

Method of cleaning residue from a surface using a high efficiency disposable cellulosic wiper

A method of cleaning residue from a surface includes providing a disposable cellulosic wiper including a percentage by weight of pulp-derived papermaking fibers. The pulp-derived papermaking fibers have a characteristic scattering coefficient of less than 50 m2 / kg. The wiper also includes a percentage by weight of fibrillated regenerated independent cellulosic microfibers having a number average diameter of less than about 2 microns, and a characteristic Canadian Standard Freeness (CSF) value of less than 175 ml. The microfibers are selected and present in amounts such that the wiper exhibits a scattering coefficient of greater than 50 m2 / kg. The wiper is applied, with a predetermined amount of pressure, to a residue-bearing surface, and the surface is wiped, while applying the predetermined amount of pressure, to remove residue from the surface, such that the surface has less than 1 g / m2 of residue after being wiped under the predetermined amount of pressure.

Owner:GPCP IP HLDG LLC

Composite air filtering material for filtering bag and preparation method thereof

InactiveCN101491742AHigh strengthImprove breathabilityDispersed particle filtrationFiltration separationSodium bicarbonateAir filter

The invention relates to a compound air filter material and a method for preparing the same. The composite air filter material used for filter bags comprises a protective layer, a deodorizing layer and a filter layer, wherein the protective layer and the filter layer are compounded on two side faces of the deodorizing layer respectively; the protective layer is made of wood pulp fiber filter paper, spun-bond non-woven fabric or spun-lace non-woven fabric, and the gram weight of the material of the protective layer is 10 to 200g / m; the deodorizing layer is made of one of active carbon, zeolite , sodium bicarbonate, magnesium aluminum silicates and silica gel or a mixture of any two of the wood pulp fiber filter paper, the spun-bond non-woven fabric and the spun-lace non-woven fabric, and the gram weight of the material of the deodorizing layer is 10 to 300g / m; and the filter layer is made of melt-blown non-woven fabric, wood pulp fiber filter paper or SMS non-woven fabric, and the gram weight of the material of the filter layer is 10 to 100g / m. The compound air filter material has high filtration efficiency and deodorization efficiency, low filtration resistance and high dust capacity.

Owner:上海曾韩进出口有限公司

Hydroxyalkyl cationic guar gum and its preparation method and application

InactiveCN1757827ASolve forming problemsImprove adsorption capacityPaper/cardboardRetention agents additionAlcoholGraft reaction

A process for preparing the cationic hydroxyalkyl guar gum includes such steps as dispersing the raw powder of guar gum in the aqueous solution of low-carbon alcohol, adding high-alkaline catalyst, immersing, adding cationic etherifying agent, cationic graft reaction, adding phase-transfer catalyst and alkoxy etherifying agent, hydro-xyalkylating reaction, neutralizing and filtering. It can be used as the retention aid or filter aid of paper pulp.

Owner:SOUTH CHINA UNIV OF TECH

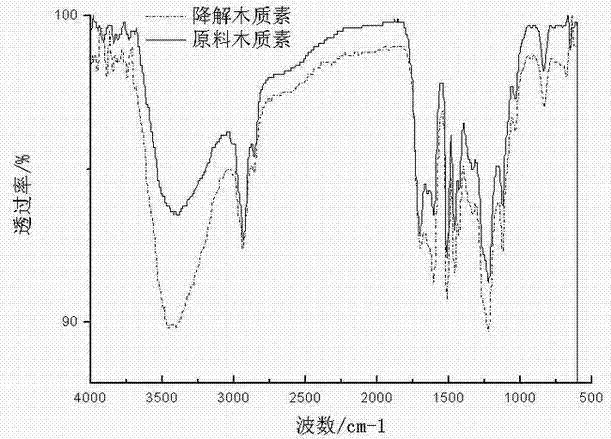

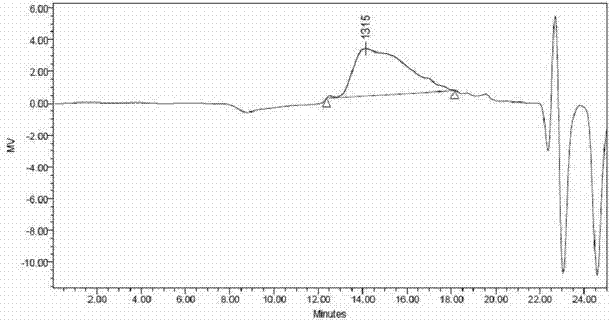

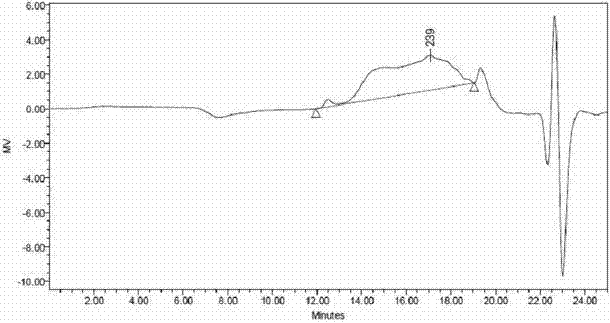

Lignin-modified phenolic foam and preparation method thereof

The invention relates to a preparation method of lignin modified phenolic foam, comprising the following steps: modifying high molecular weight lignin in order to degrade into low molecular weight lignin, wherein the activity is improved, replacing the phenol by the degraded lignin, preparing lignin modified resol, mixing with curing agent, foaming agent and surfactant, foaming at room temperature (25-30 DEG C) or in an oven of temperature 40-80 DEG C, finally the modified phenolic foam plastic is obtained after the curing process. The preparation method of the invention has the following advantages: the cost of the phenolic foam is greatly reduced, the toughness of the foam is increased and the brittles is decreased, thus the foam of the lignin modified phenolic foam has good market prospect; the preparation method of the invention provides a high-addition way to the abundant pulp paper-making waste liquid and forestry and agricultural residues, and reduces the dependency of phenolic foam industry on petrochemical raw material phenol.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method of cleaning residue from a surface using a high efficiency disposable cellulosic wiper

A method of cleaning residue from a surface includes providing a disposable cellulosic wiper including a percentage by weight of pulp-derived papermaking fibers. The pulp-derived papermaking fibers have a characteristic scattering coefficient of less than 50 m2 / kg. The wiper also includes a percentage by weight of fibrillated regenerated independent cellulosic microfibers having a number average diameter of less than about 2 microns, and a characteristic Canadian Standard Freeness (CSF) value of less than 175 ml. The microfibers are selected and present in amounts such that the wiper exhibits a scattering coefficient of greater than 50 m2 / kg. The wiper is applied, with a predetermined amount of pressure, to a residue-bearing surface, and the surface is wiped, while applying the predetermined amount of pressure, to remove residue from the surface, such that the surface has less than 1 g / m2 of residue after being wiped under the predetermined amount of pressure.

Owner:GPCP IP HLDG LLC

Heating non-combustible cigarette paper and preparation method thereof

ActiveCN106368069ANo tar spotsDoes not start carbonationInorganic fibres/flakesSpecial paperFiberBurn cigarette

The invention discloses heating non-combustible cigarette paper and a preparation method thereof. The preparation method of the heating non-burning cigarette paper comprises the following steps: 1) pulping the plant fiber with the length of 0.5 to 4mm, or adding the appropriate proportion of inorganic fiber; 2) adding the inorganic filler in the process of dilution of the pulp, wherein the addition ratio of the inorganic filler is 5 to 50% of the mass of the pulp; 3) sizing the paper to improve water and oil resistance, and cigarette paper is quantified at 50 to 120 g / m<2>. Compared with the existing heated non-combustible cigarette paper that is heated at 350 DEG C, the non-combustible cigarette paper of the present invention has very few yellow stitches, and no tar spots and carbonization, while the entire surface of the existing non-combustible cigarette paper turns yellow, with large tar penetrating and carbonized. In addition, the non-combustible cigarette paper of the present invention is rarely present broken in actual production, and there is almost no deformation and wrinkling after being sucked as the heated cigarette paper.

Owner:中烟摩迪(江门)纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com