Patents

Literature

114results about How to "Improve paper strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

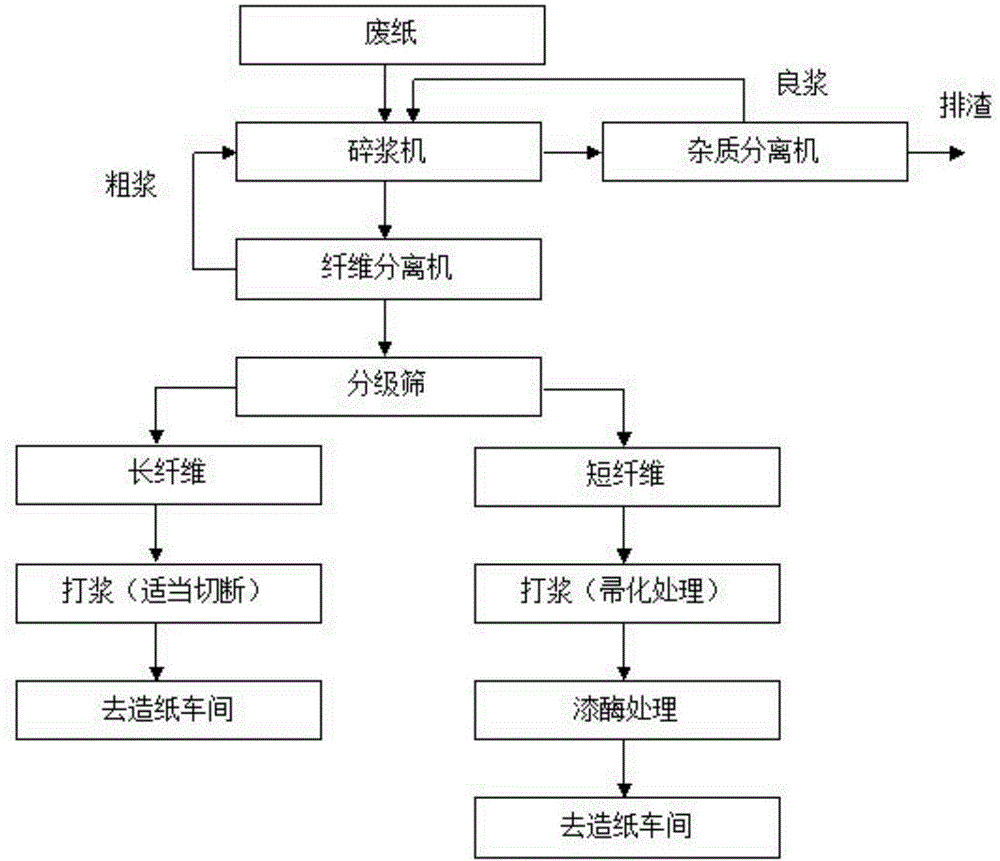

Filled paper and method of manufacturing the same

ActiveUS8414739B2Improve paper strengthEasy maintenanceNatural cellulose pulp/paperSpecial paperSlurryPolysaccharide

There is provided a filled paper containing a coated filler obtained by coating a filler with a acrylamide copolymer (composite PAM) comprising (A) an anionic polysaccharide and (B) a cationic and / or an amphoteric acrylamide copolymer. The composite PAM is obtained, for example, by mixing the component (A) and the component (B). Since the filler is treated with a combination of the components (A) and (B) different from each other in charge properties and structure, suitable coagulation effect can be attained and the coated filler has excellent affinity for pulp slurry. Therefore, even in the case of a highly filled paper, a large paper strengthening effect can be attained by using a small amount of the chemical agent.

Owner:HARIMA CHEM INC +1

Filled Paper and Method of Manufacturing the Same

ActiveUS20090020250A1Improve paper strengthEasy maintenanceNatural cellulose pulp/paperSpecial paperPolymer scienceSlurry

There is provided a filled paper containing a coated filler obtained by coating a filler with a acrylamide copolymer (composite PAM) comprising (A) an anionic polysaccharide and (B) a cationic and / or an amphoteric acrylamide copolymer. The composite PAM is obtained, for example, by mixing the component (A) and the component (B). Since the filler is treated with a combination of the components (A) and (B) different from each other in charge properties and structure, suitable coagulation effect can be attained and the coated filler has excellent affinity for pulp slurry. Therefore, even in the case of a highly filled paper, a large paper strengthening effect can be attained by using a small amount of the chemical agent.

Owner:HARIMA CHEM INC +1

Process for the production of paper

InactiveUS6100322AImprove performanceHigh retention ratePaper/cardboardInorganic compound additionInorganic saltsPolymer science

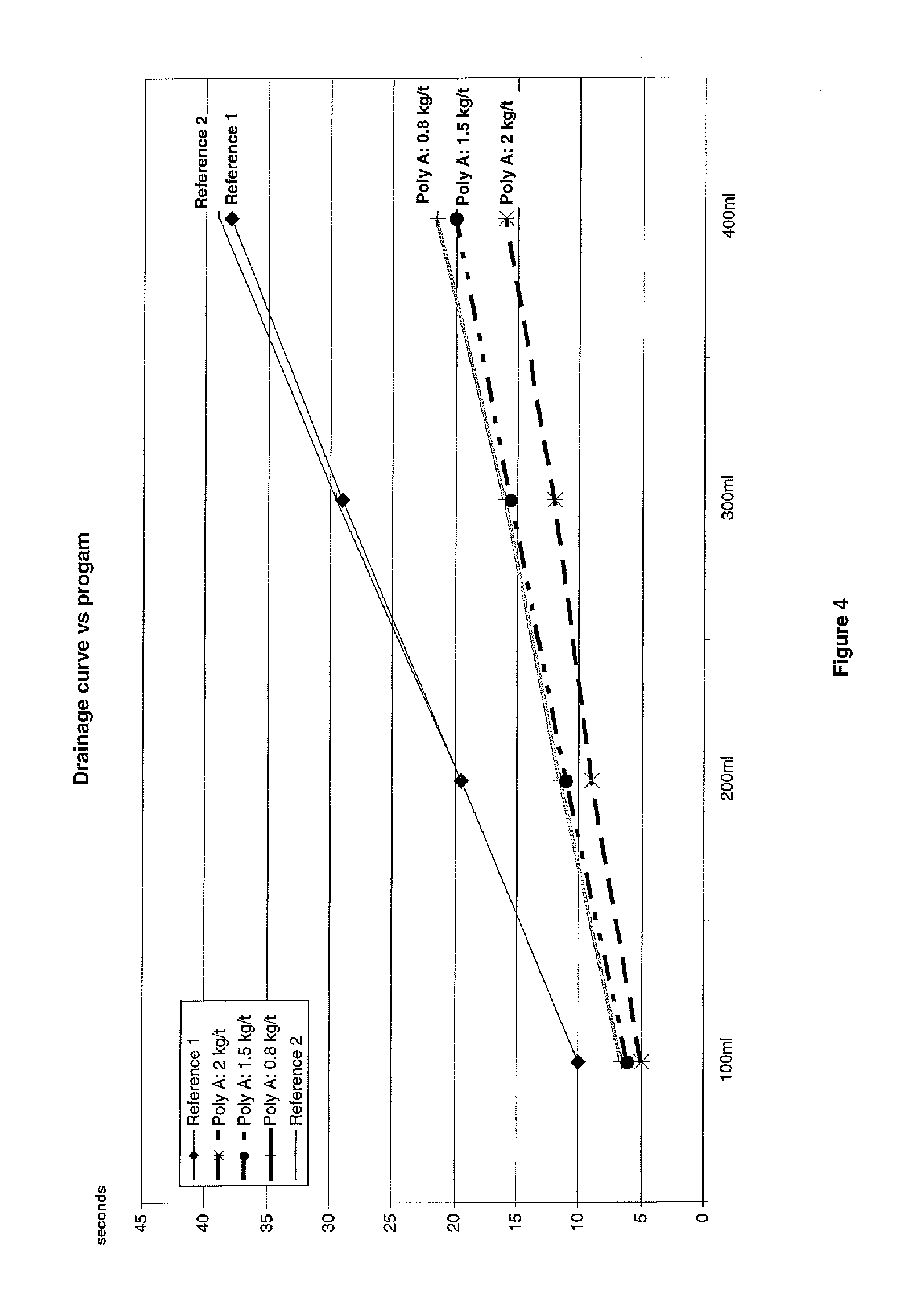

The invention relates to a process for the production of paper from a suspension of cellulose containing fibers, and optional fillers, comprising adding to the suspension a low molecular weight cationic organic polymer, a high molecular weight cationic or amphoteric polymer and anionic inorganic particles, forming and draining the suspension on a wire, wherein the low molecular weight polymer has a molecular weight below 700,000 and the high molecular weight polymer has a molecular weight above 1,000,000, said polymers being simultaneously added to the suspension. The invention further relates to a polymer mixture in the form of an aqueous dispersion comprising at least one high molecular weight cationic or amphoteric acrylamide-based polymer having a molecular weight above 1,000,000, at least one low molecular weight cationic organic polymer having a molecular weight below 700,000 and at least one water-soluble inorganic salt, the weight ratio of said high molecular weight polymer to said low molecular weight polymer being within the range of from 9:1 to 1:2.

Owner:EKA CHEM AC LTD

Use of sugar beet pulps for making paper or cardboard

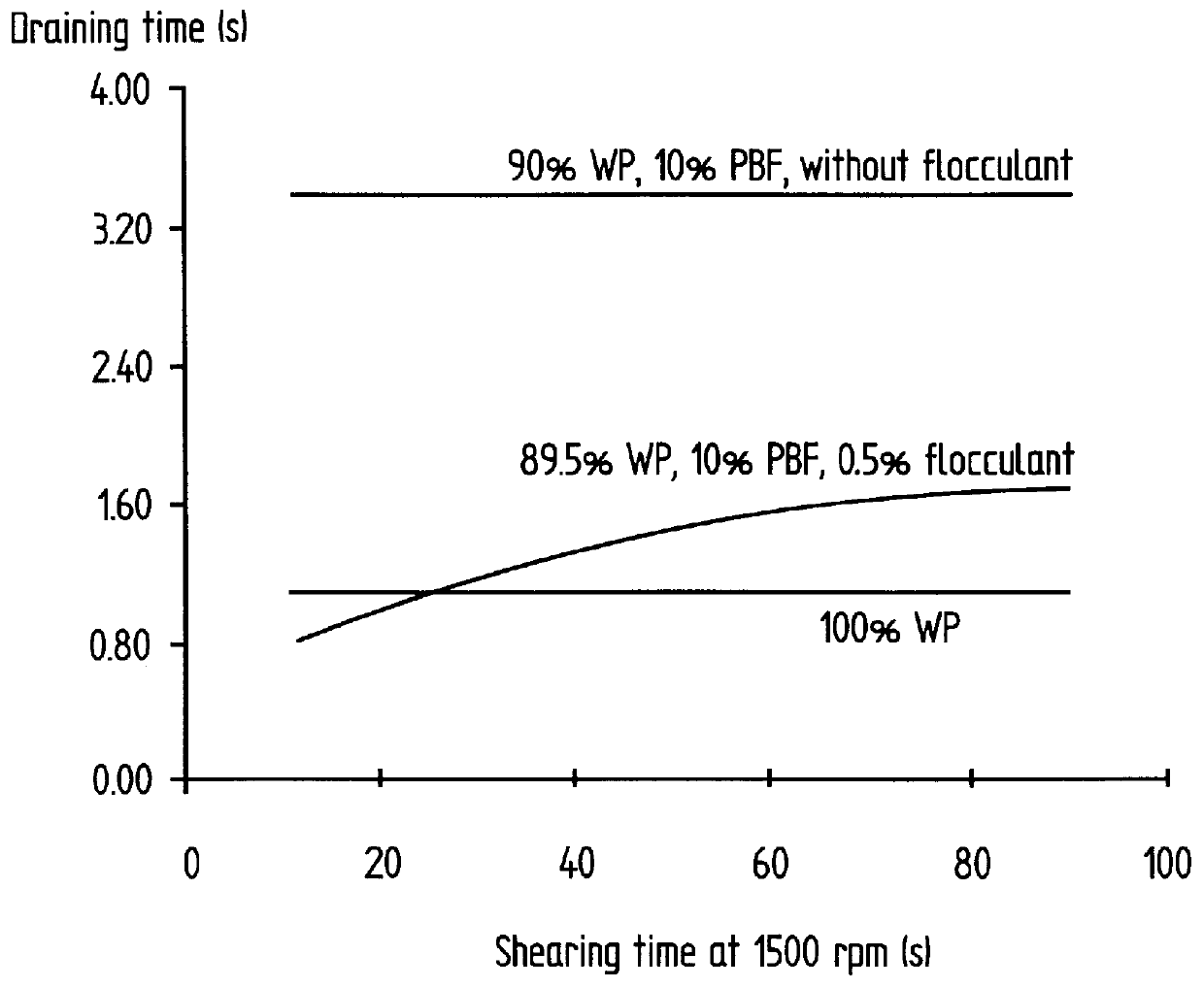

InactiveUS6074856AShorten drain timeImprove paper strengthVegetable material additionAnimal feeding stuffDry matterLactic acid fermentation

PCT No. PCT / FR97 / 00224 Sec. 371 Date Aug. 21, 1998 Sec. 102(e) Date Aug. 21, 1998 PCT Filed Feb. 5, 1997 PCT Pub. No. WO97 / 30215 PCT Pub. Date Aug. 21, 1997The use of fermented sugar beet pulp for making paper or cardboard is disclosed as well as a fermented sugar beet pulp composition produced according to a method which comprises the steps of (a) storing the sugar beet pulp under conditions suitable for lactic acid fermentation, particularly until the pH is less than around 5 and advantageously higher than around 3.5, to give fermented pulp, (b) diluting the fermented pulp, particularly until its dry matter content is of around 1-10%, (c) mechanically processing the diluted fermented pulp to separate the parenchymal cells from the pulp and achieve a pulp size of less than around 1000 micrometers, and (d) optionally bleaching the fermented pulp from step (a) simultaneously with step (b), or bleaching the fermented pulp from step (c).

Owner:ERIDANIA BEGHIN SAY

Enzymatic pre-treatment of market pulp to improve fiber drainage and physical properties

ActiveUS20170328006A1Increasing pulp drainage and strength propertyQuality improvementMicroorganism/enzyme additionPaper recyclingFiberPulp and paper industry

Owner:ENZYMATIC DEINKING TECH LLC

Paper containing preggregated filler and process for producing the same

InactiveUS20090162642A1Less blisteringReduce delaminationNatural cellulose pulp/paperCoatings with pigmentsPolymer sciencePolysaccharide

Provide a paper offering good paper strength properties in terms of strength and stiffness, high smoothness and excellent printing quality by adjusting the ash content in paper to a range of 3 to 40 percent by solid weight and allowing the paper to contain a pre-coagulated filler having an average particle size of 10 to 80 μm as measured by the laser diffraction method, wherein such filler is obtained by processing a filler using a composite acrylamide copolymer comprising (A) an anionic polysaccharide and (B) a cationic and / or amphoteric acrylamide copolymer.

Owner:NIPPON PAPER IND CO LTD +1

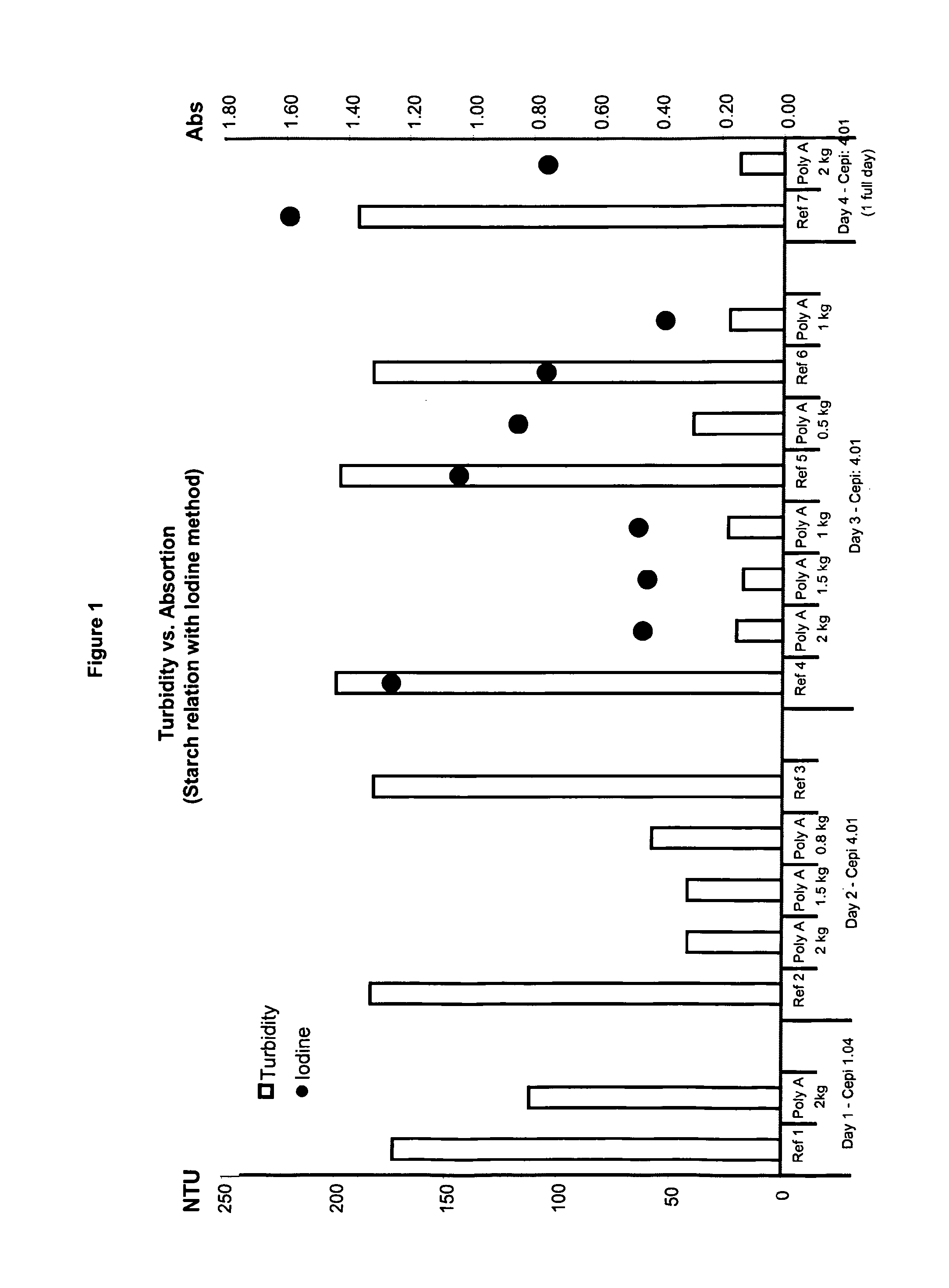

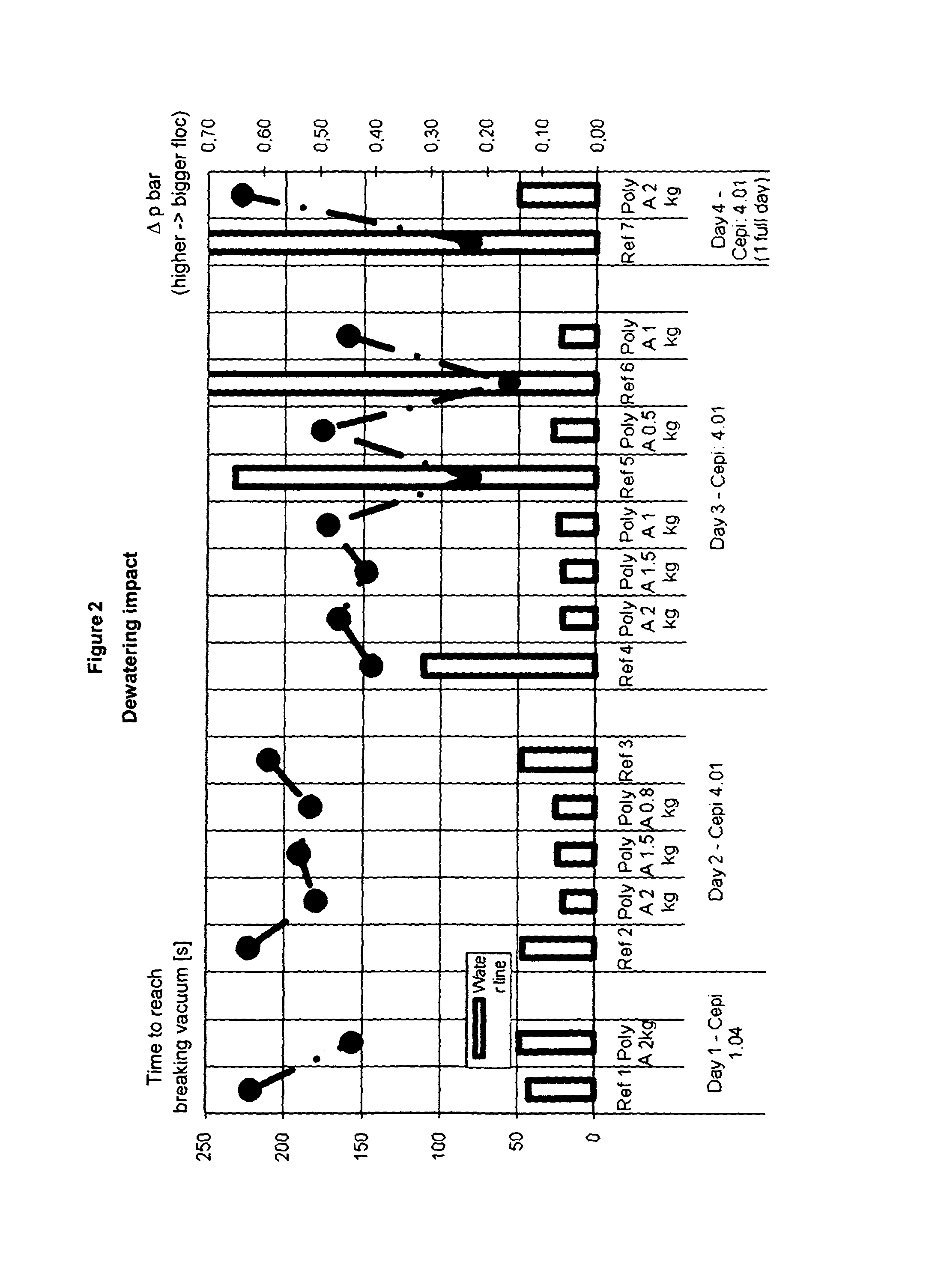

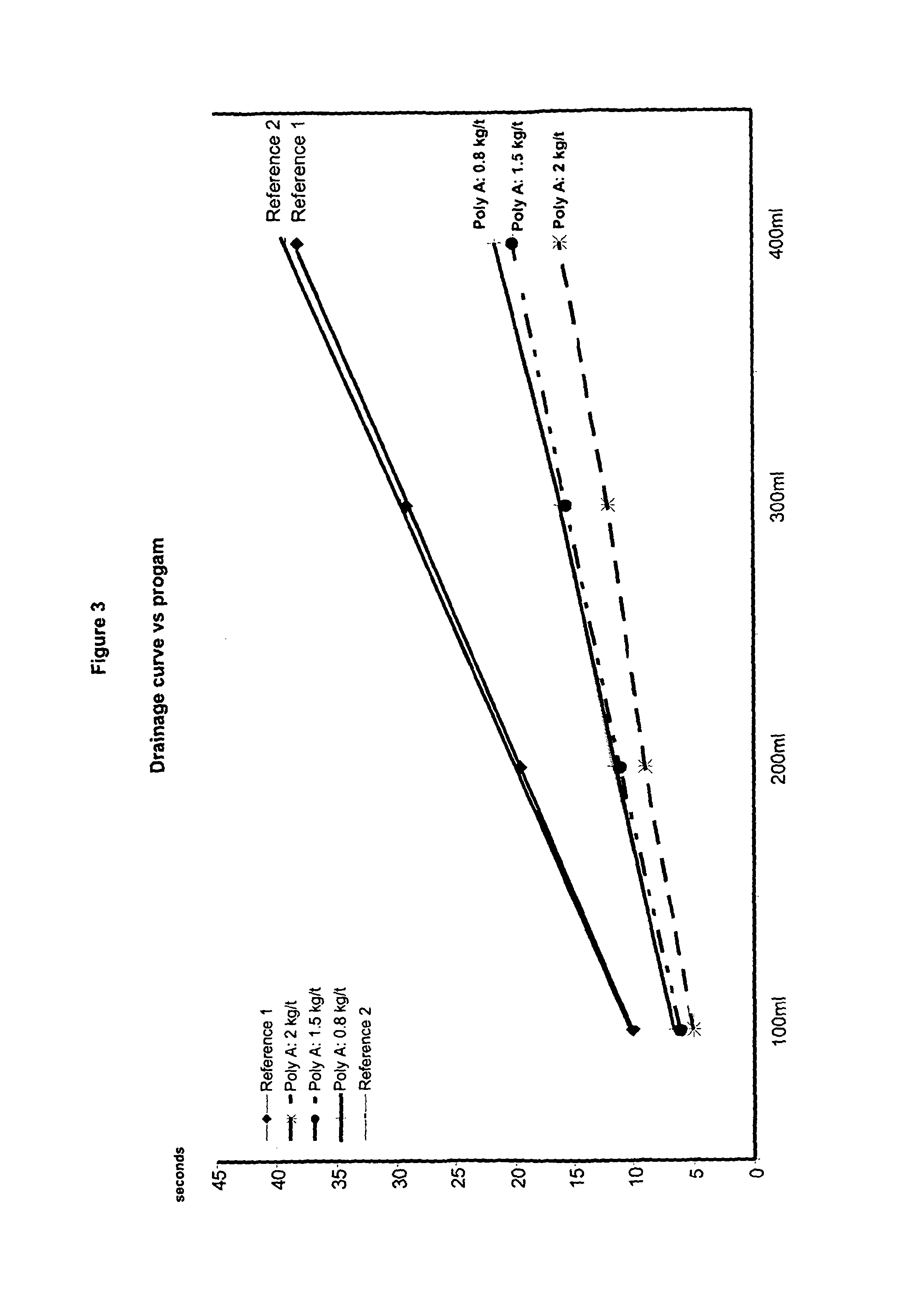

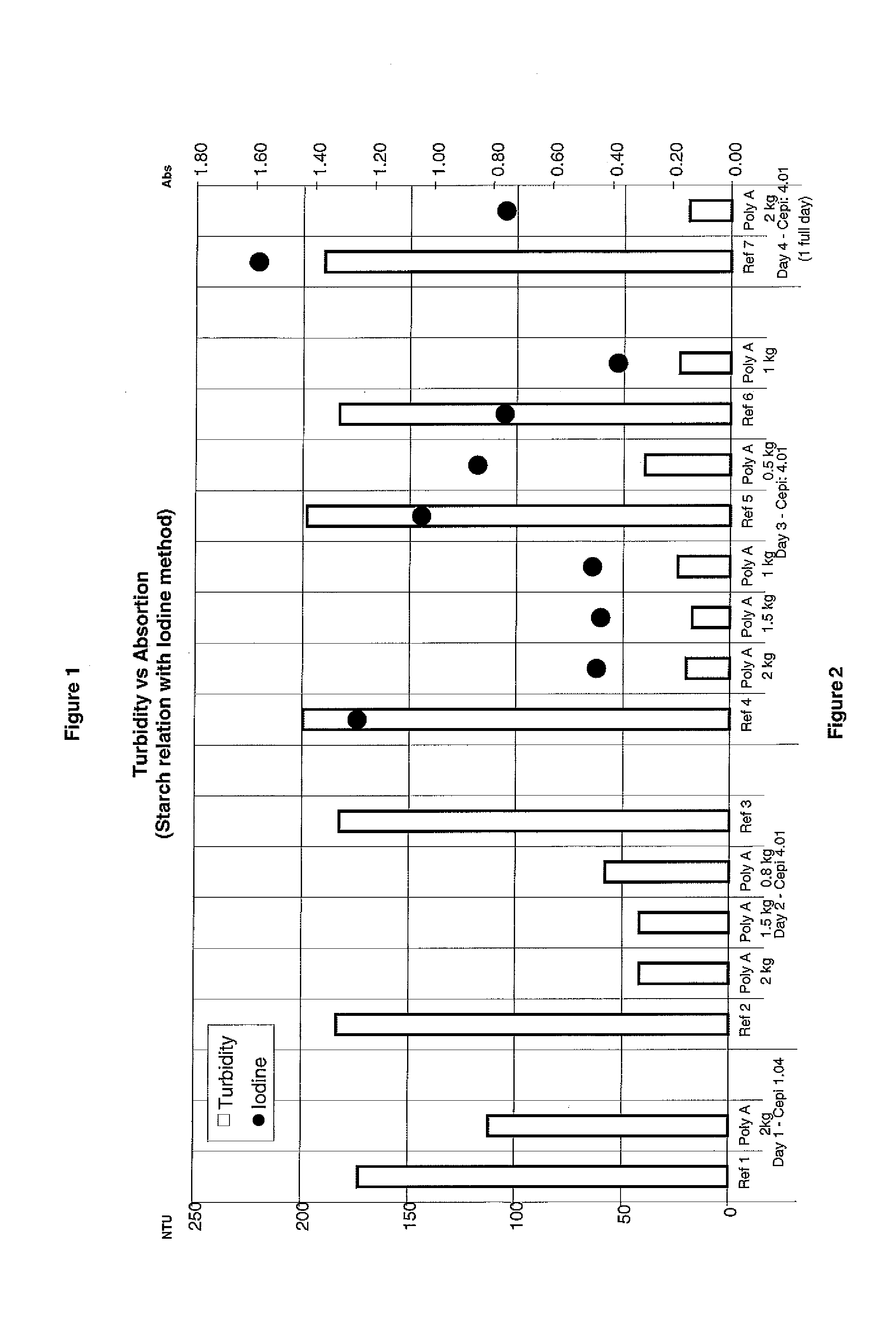

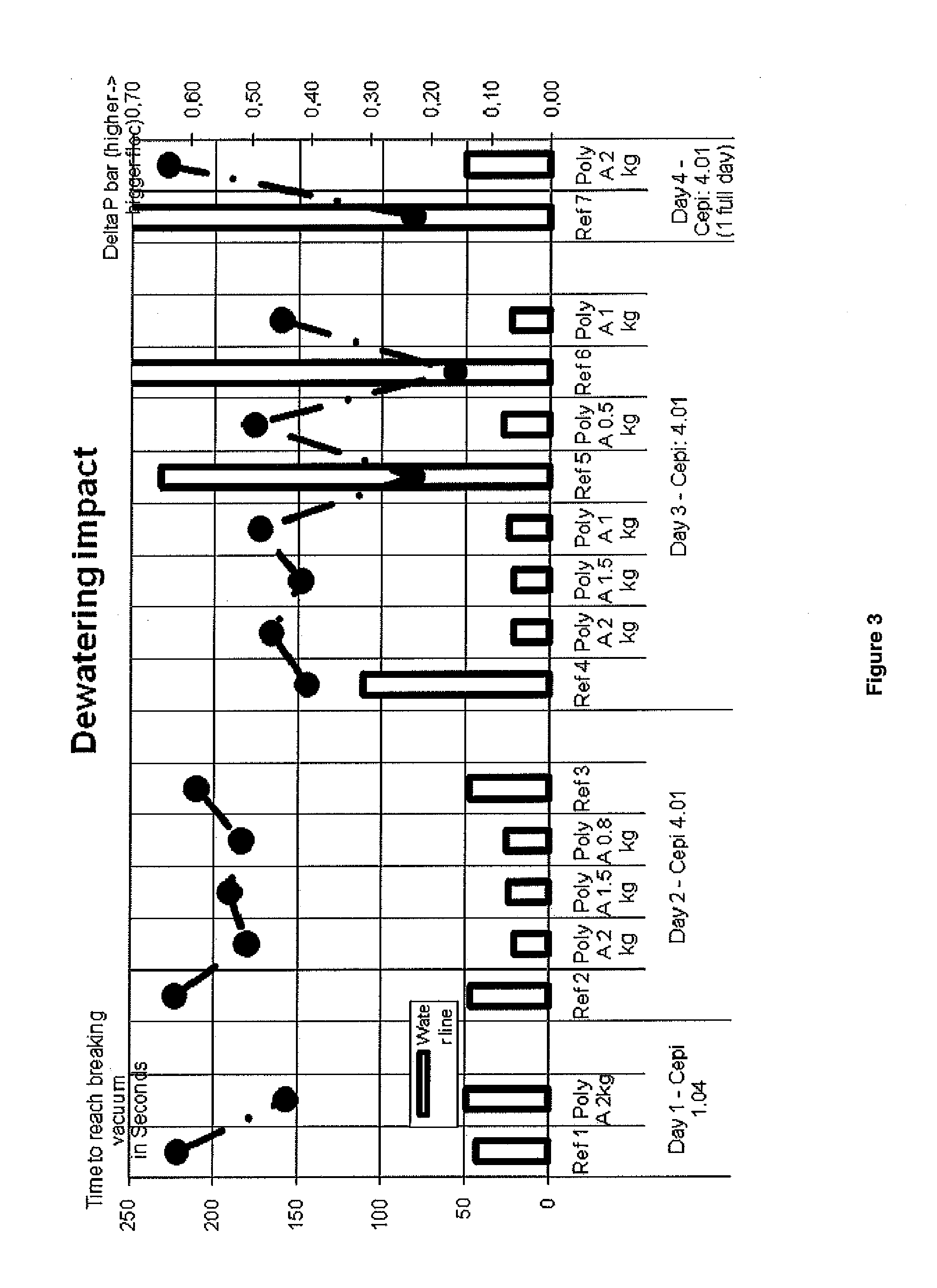

Method for increasing the advantages of starch in pulped cellulosic material in the production of paper and paperboard

ActiveUS8758562B2Avoid degradationPrevent degradationNatural cellulose pulp/paperSpecial paperCellulosePaperboard

The invention relates to a method for increasing the benefit from starch in pulped, preferably repulped cellulosic material at paper or paperboard manufacturing comprising the steps of (a) pulping a cellulosic material containing a starch; (b) treating the cellulosic material containing the starch with one or more biocides, preferably in the thick stock area; and (h) adding an ionic polymer and preferably, an auxiliary ionic polymer to the cellulosic material; wherein the ionic polymer and the optionally added auxiliary ionic polymer preferably have a different average molecular weight and preferably a different ionicity, wherein the ionicity is the molar content of ionic monomer units relative to the total amount of monomer units.

Owner:SOLENIS TECH CAYMAN

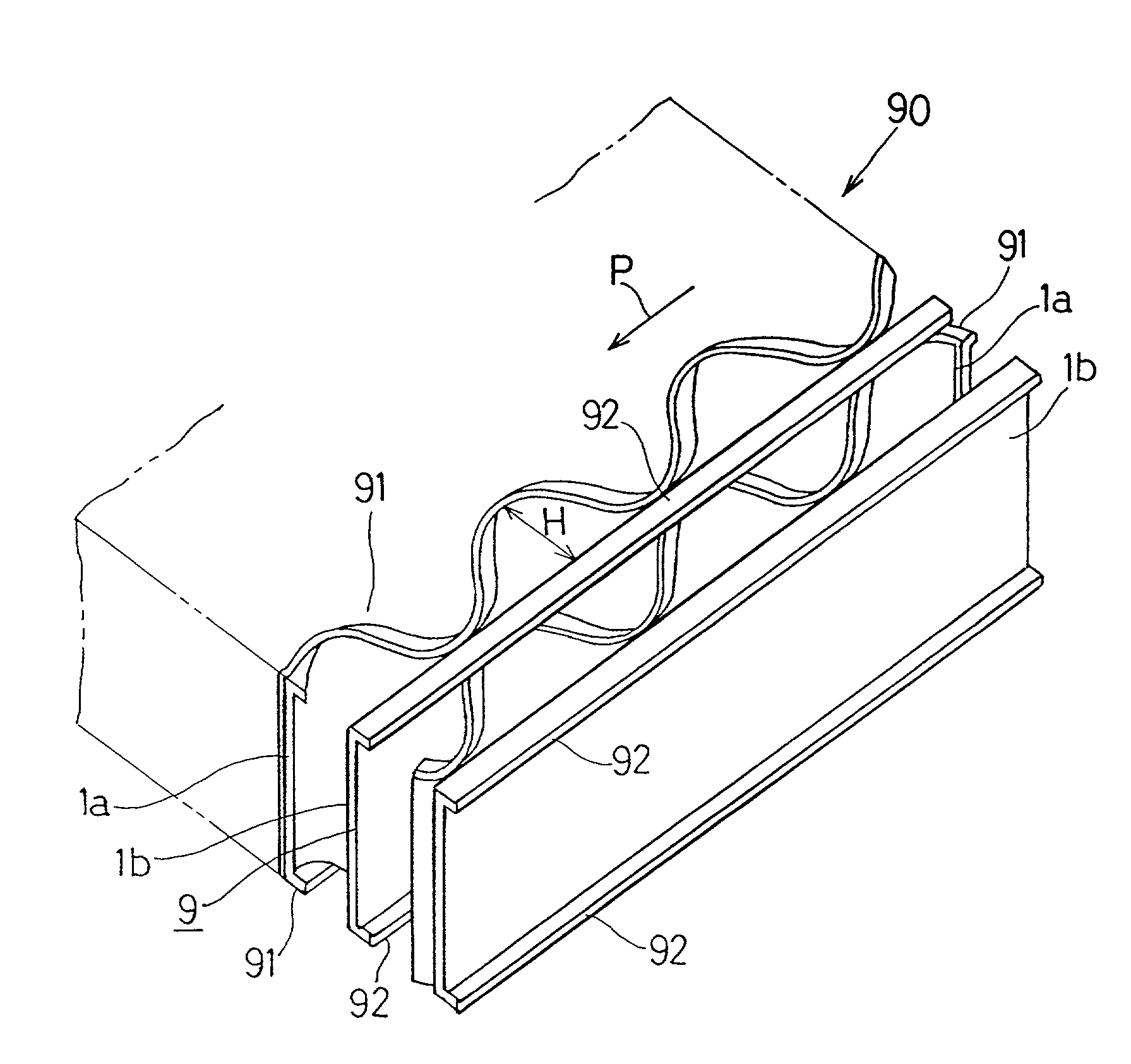

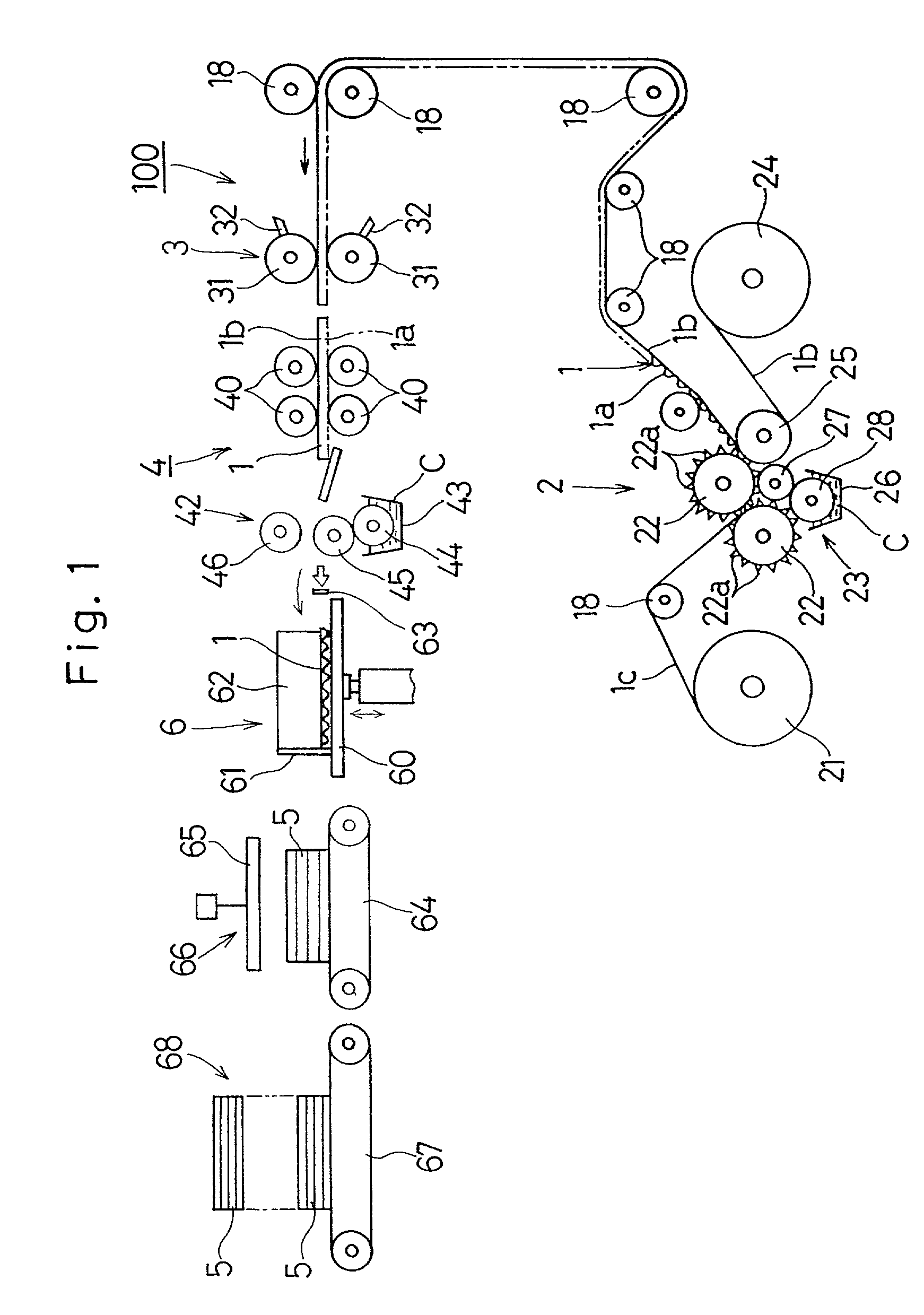

Corrugated cardboard plates, method of and apparatus for making the same

InactiveUS20020064629A1Low costExcellent heat and sound insulationMechanical working/deformationPaper/cardboard articlesCardboardEngineering

Corrugated cardboard plates are made by laminating and bonding corrugated cardboards 1, each including a corrugated sheet 1a and at least one liner sheet 1b bonded to the corrugated sheet 1a, to provide a corrugated cardboard laminate 5, which is in turn cut along a plurality of cutting lines b lying perpendicular to a direction parallel to ridge lines a of the corrugated sheet 1a to provide a plurality of corrugated blocks 7. The corrugated blocks 7 are then arrayed in a line to provide an elongated flat corrugated plank 9 in which the top face of one of the corrugated blocks 7 is bonded to the bottom face of the next adjoining corrugated block 7. At least one backing sheet 11a or 11b, made of paper, to one of opposite surfaces of the elongated flat corrugated plank 9 and is subsequently cut into a plurality of corrugated cardboard plates 14 of a predetermined size. In this way, the corrugated cardboard plates 14 or 90 can be obtained at a reduced cost, each of the plates 14 or 90 having an excellent heat insulation, a sound insulation and being lightweight and robust.

Owner:TAIZEN CO LTD

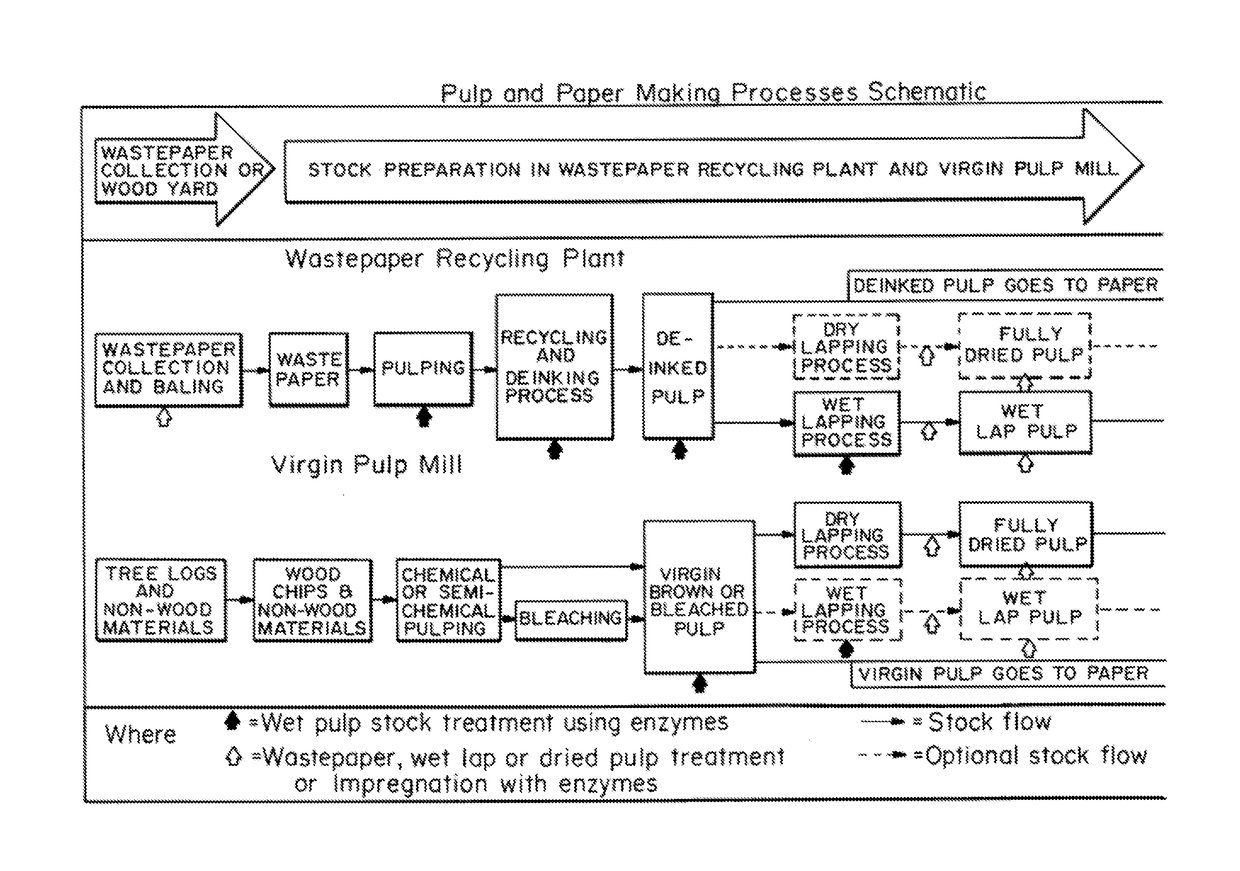

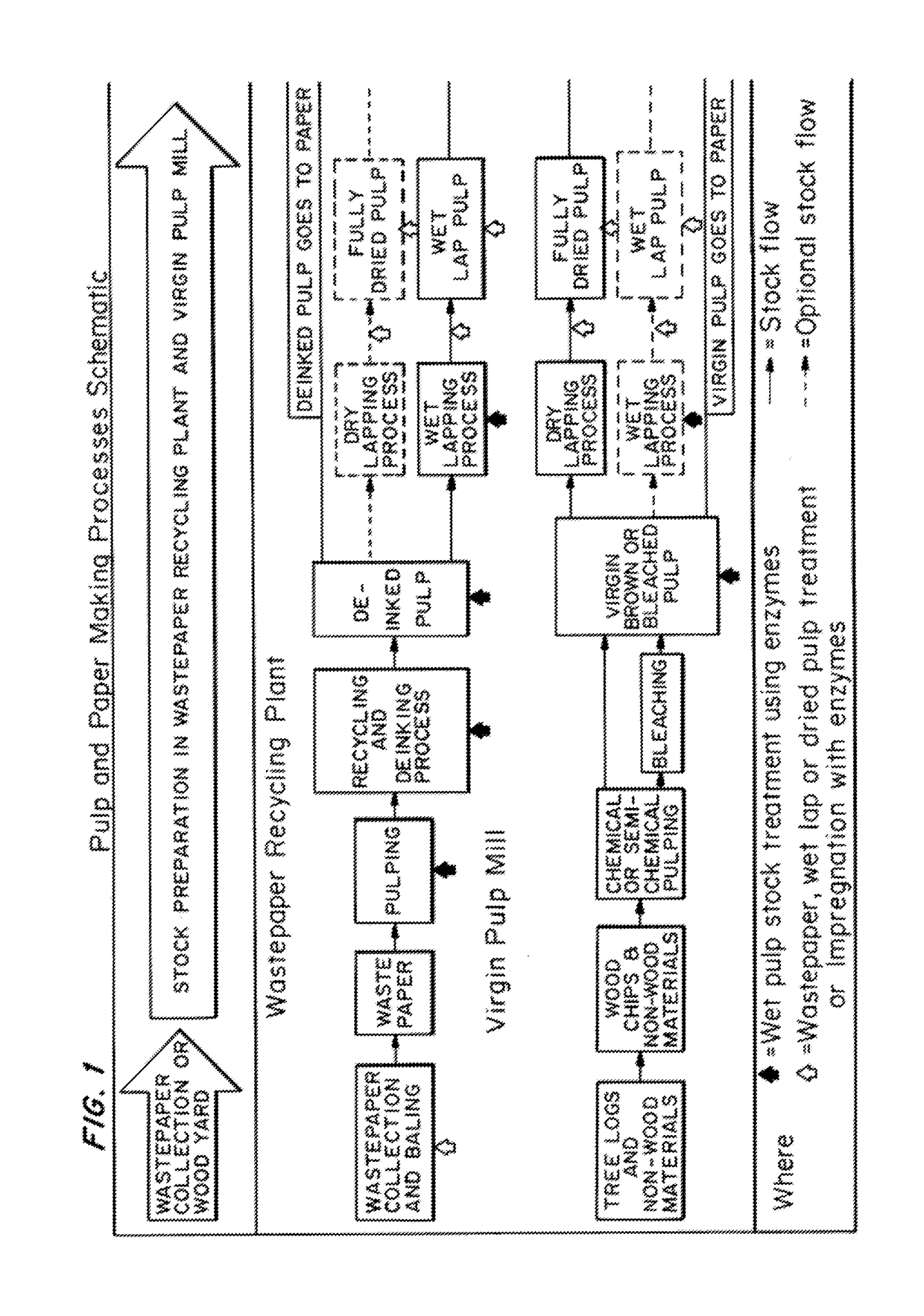

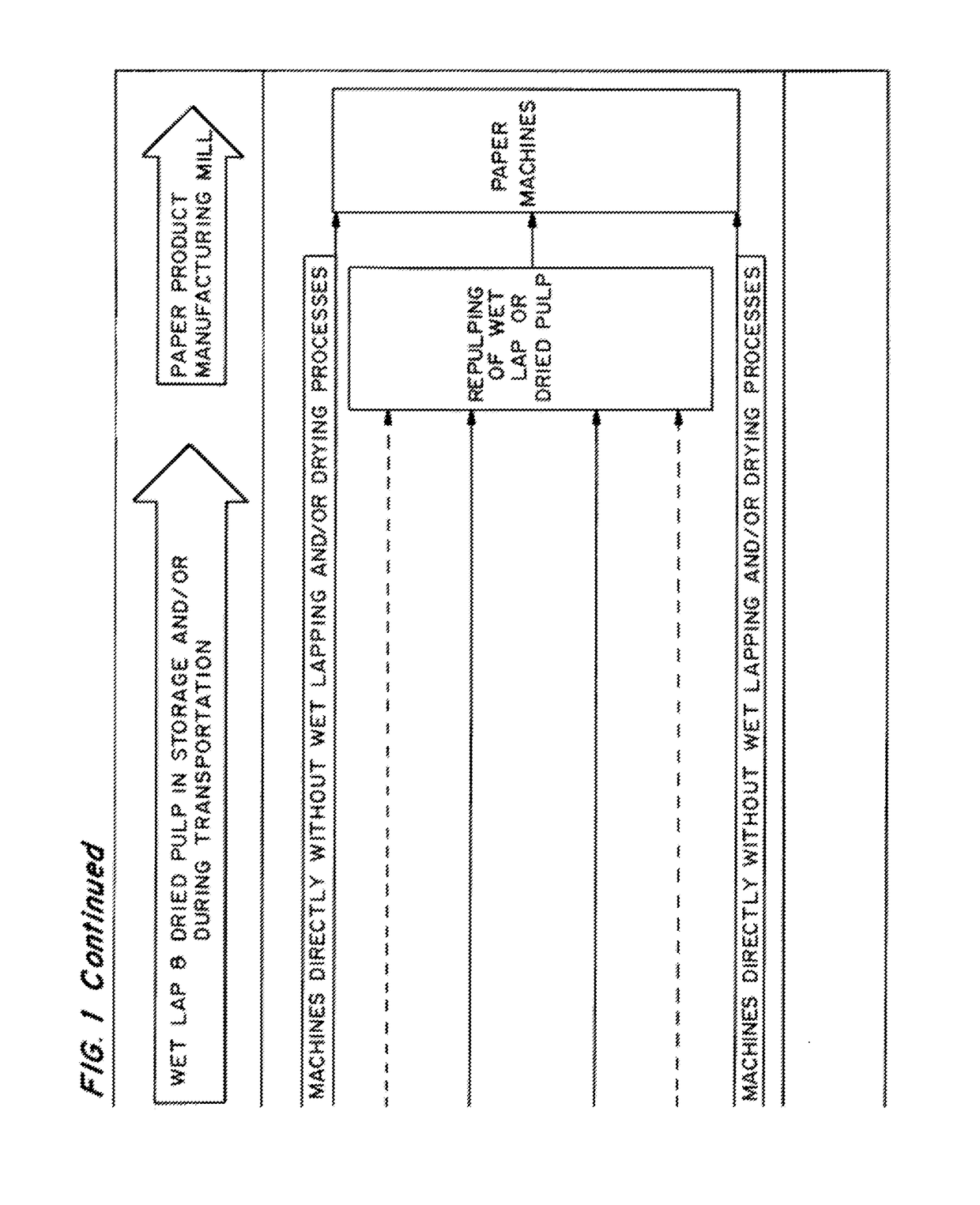

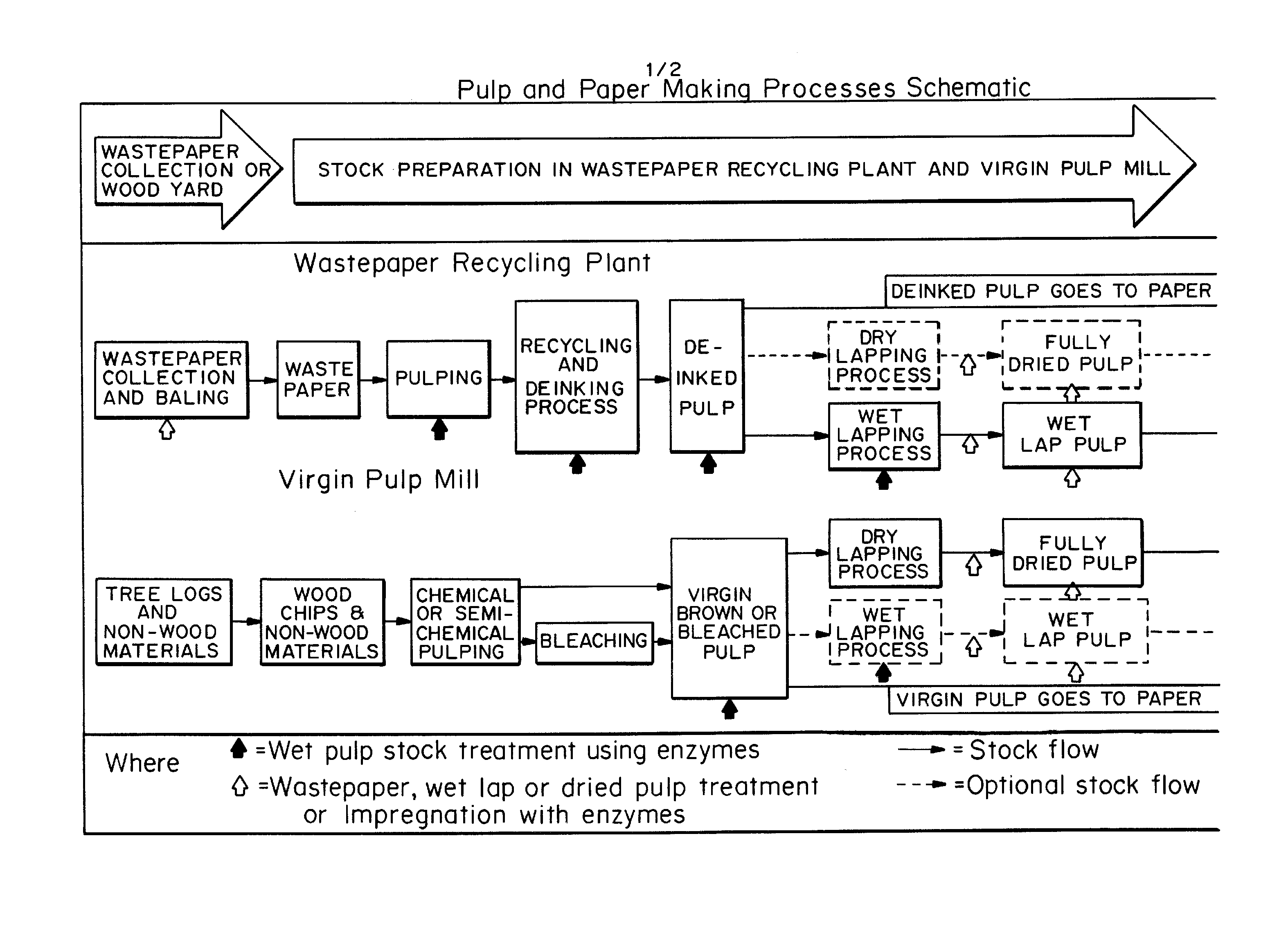

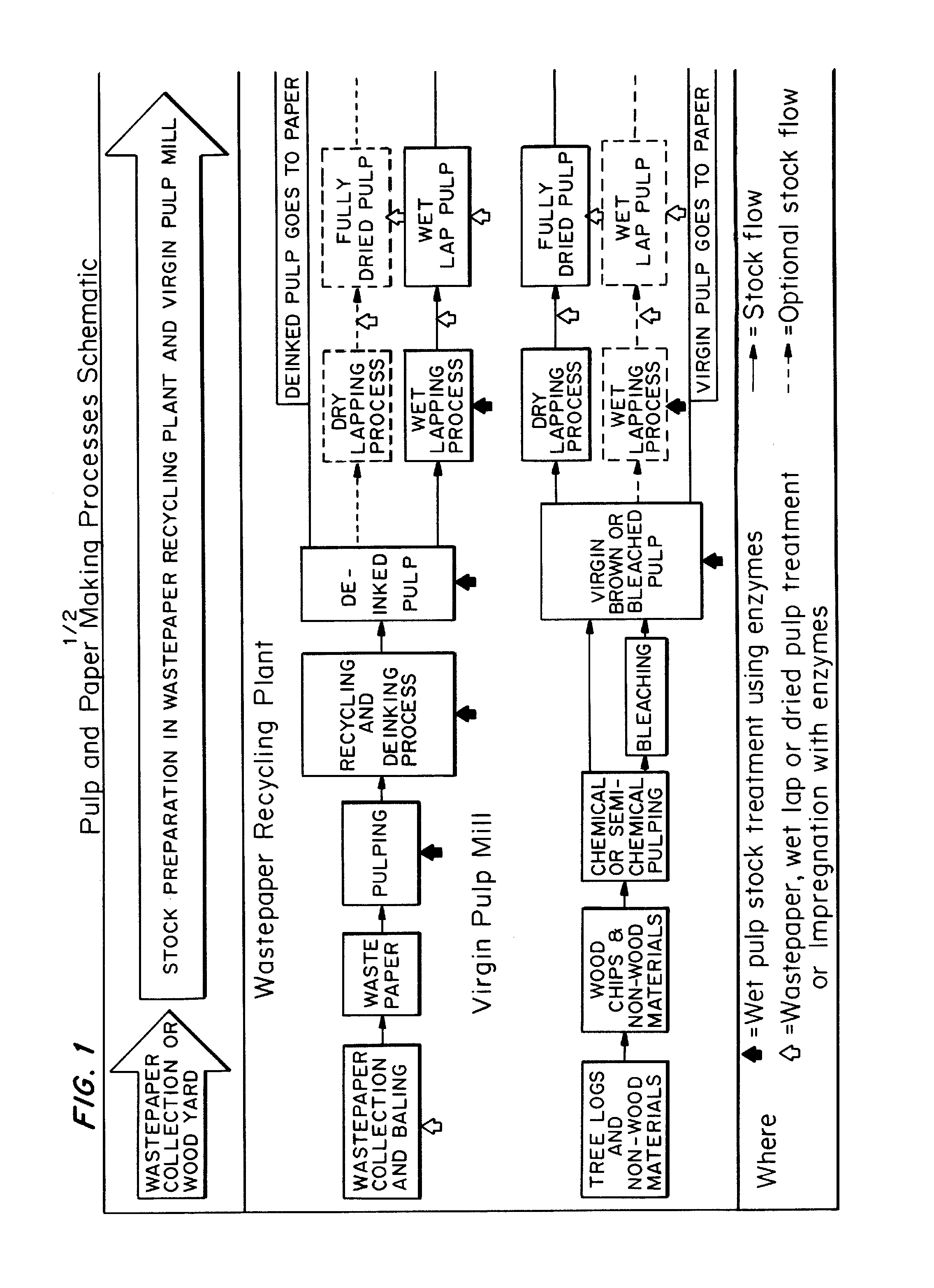

Enzymatic pre-treatment of market pulp to improve fiber drainage and physical properties

ActiveUS20130146239A1Increasing pulp drainageImprove strength propertiesMicroorganism/enzyme additionPaper recyclingFiberPulp and paper industry

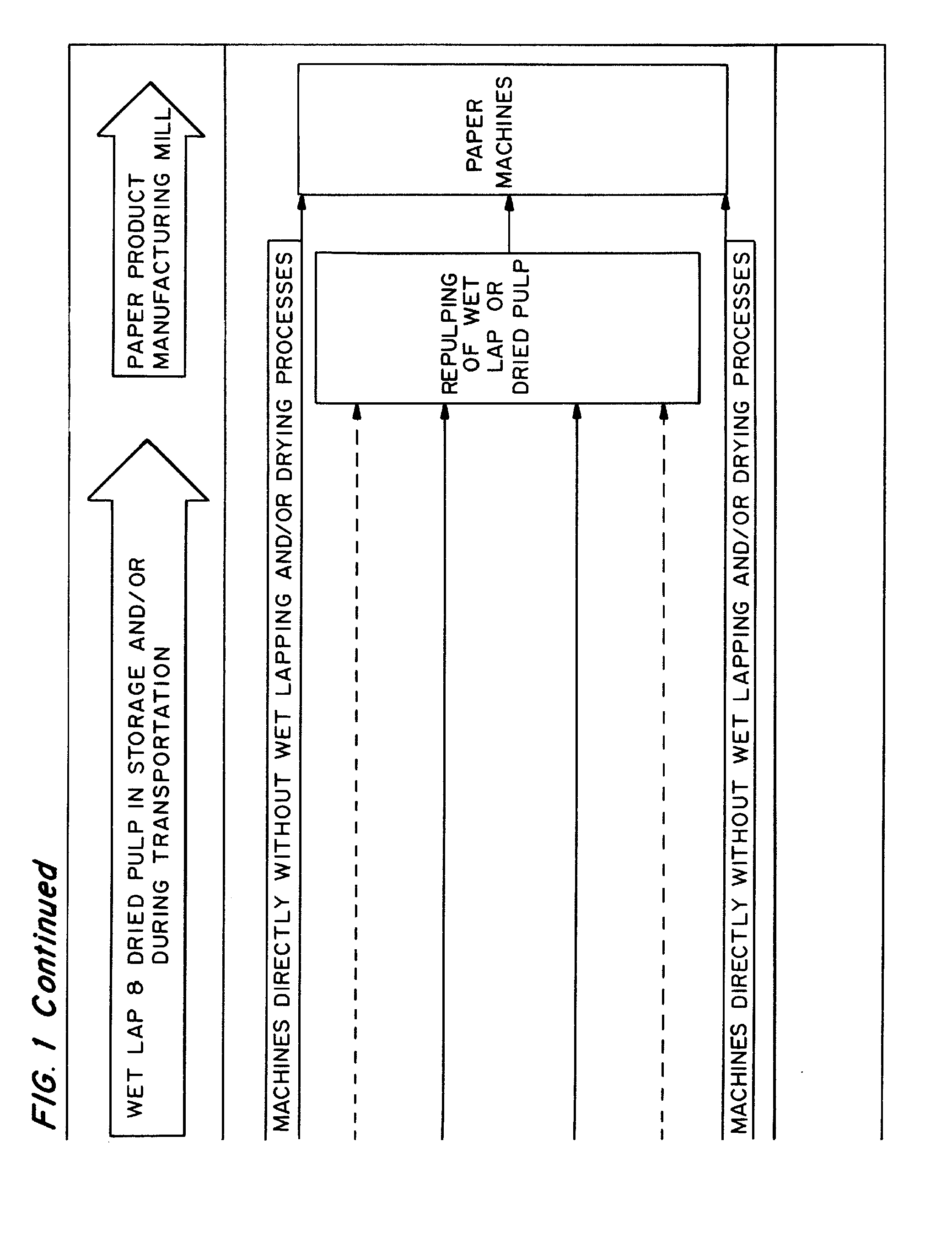

Methods for reducing the effects of wetlapping, drying, and hornification of pulp fibers and consequently increasing the pulp drainage and strength properties in the final product (i.e., paper) are provided. The method which has been developed creates a “value-added” product by the wastepaper supplier or at the pulp and / or deinking (recycled paper) mill—a wastepaper load / bale, wet pulp stock or wet lap, or dried pulp treated with or impregnated with enzymes that enhance the quality of the pulp or paper product when it is repulped and processed at the paper mill.

Owner:ENZYMATIC DEINKING TECH LLC

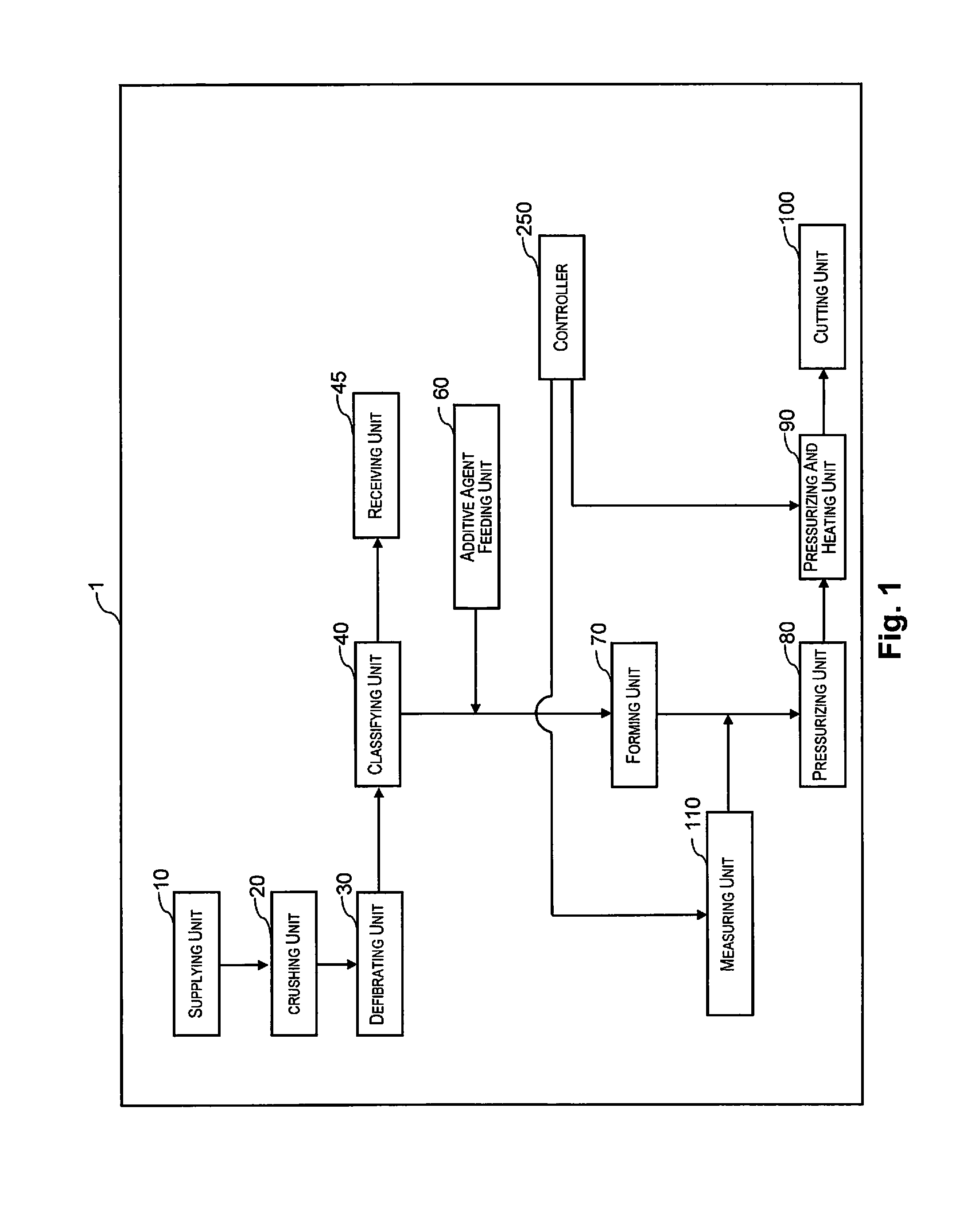

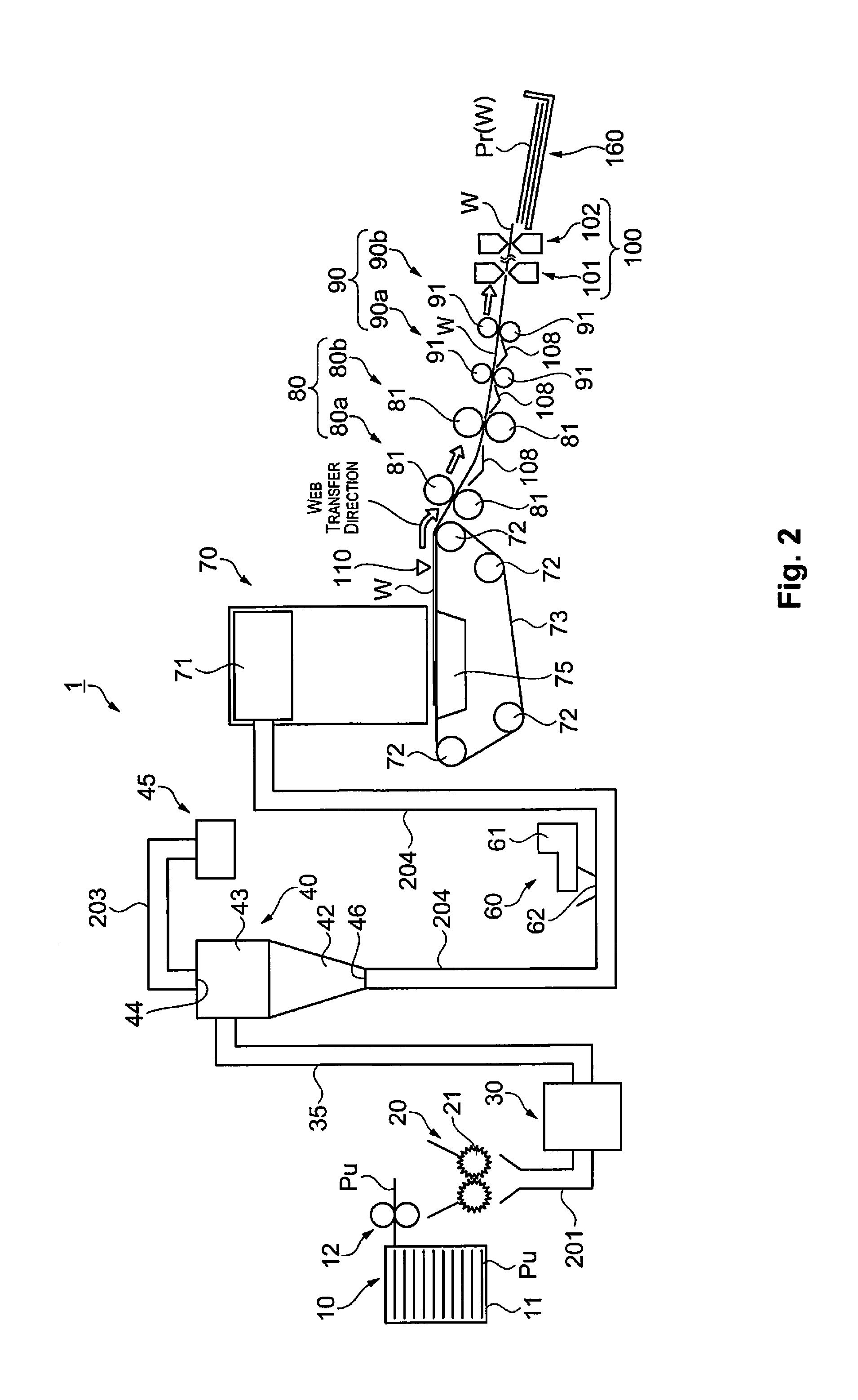

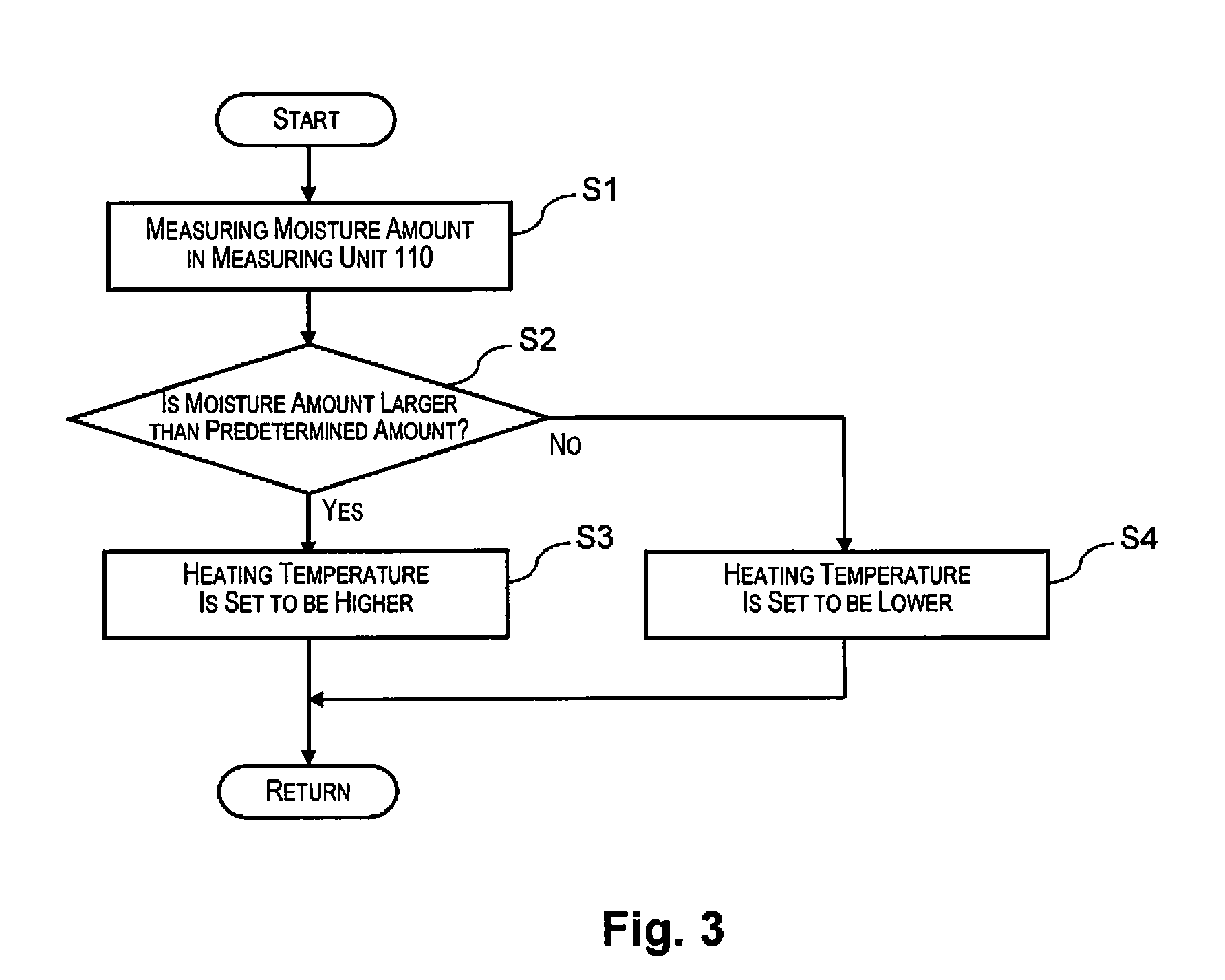

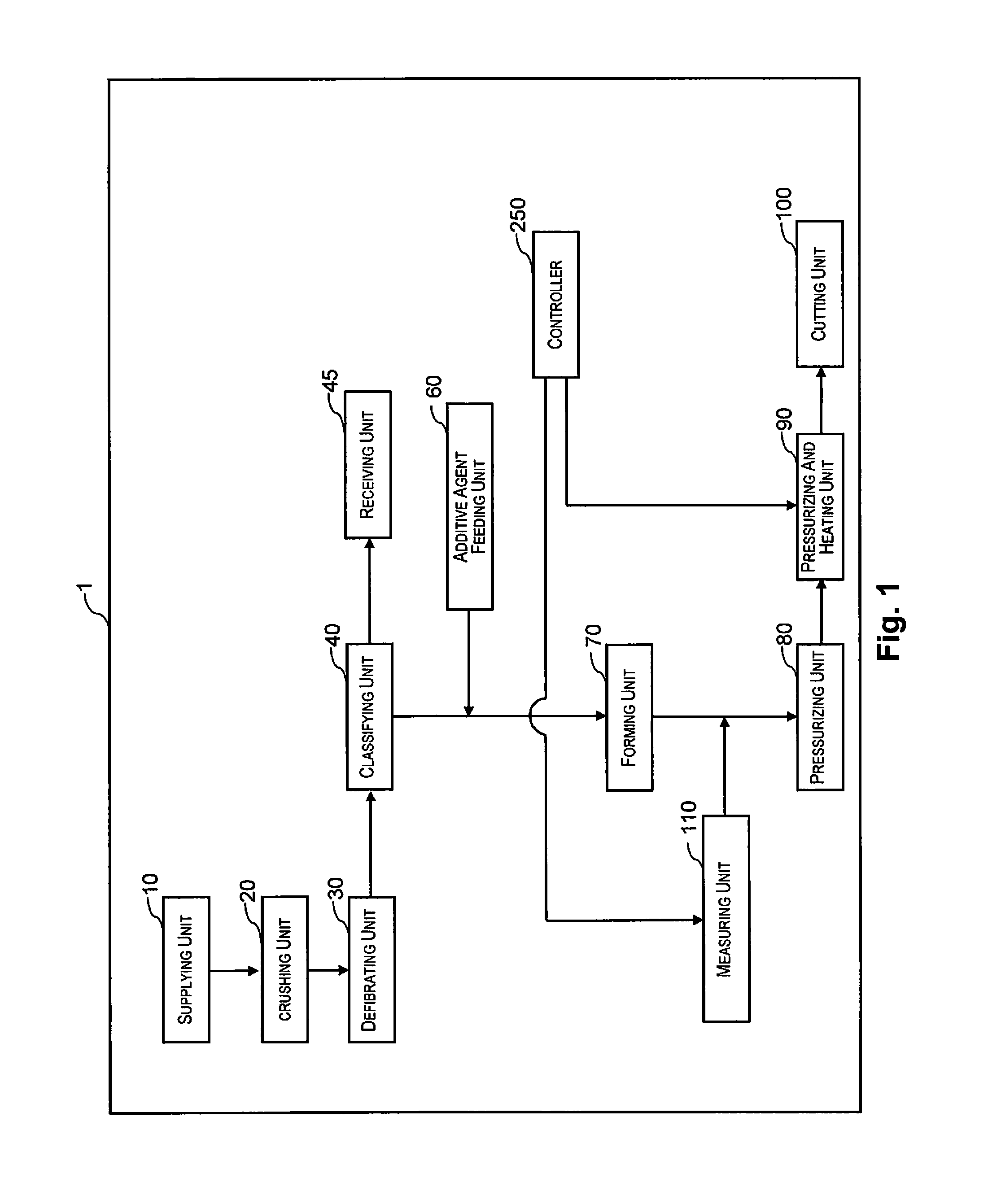

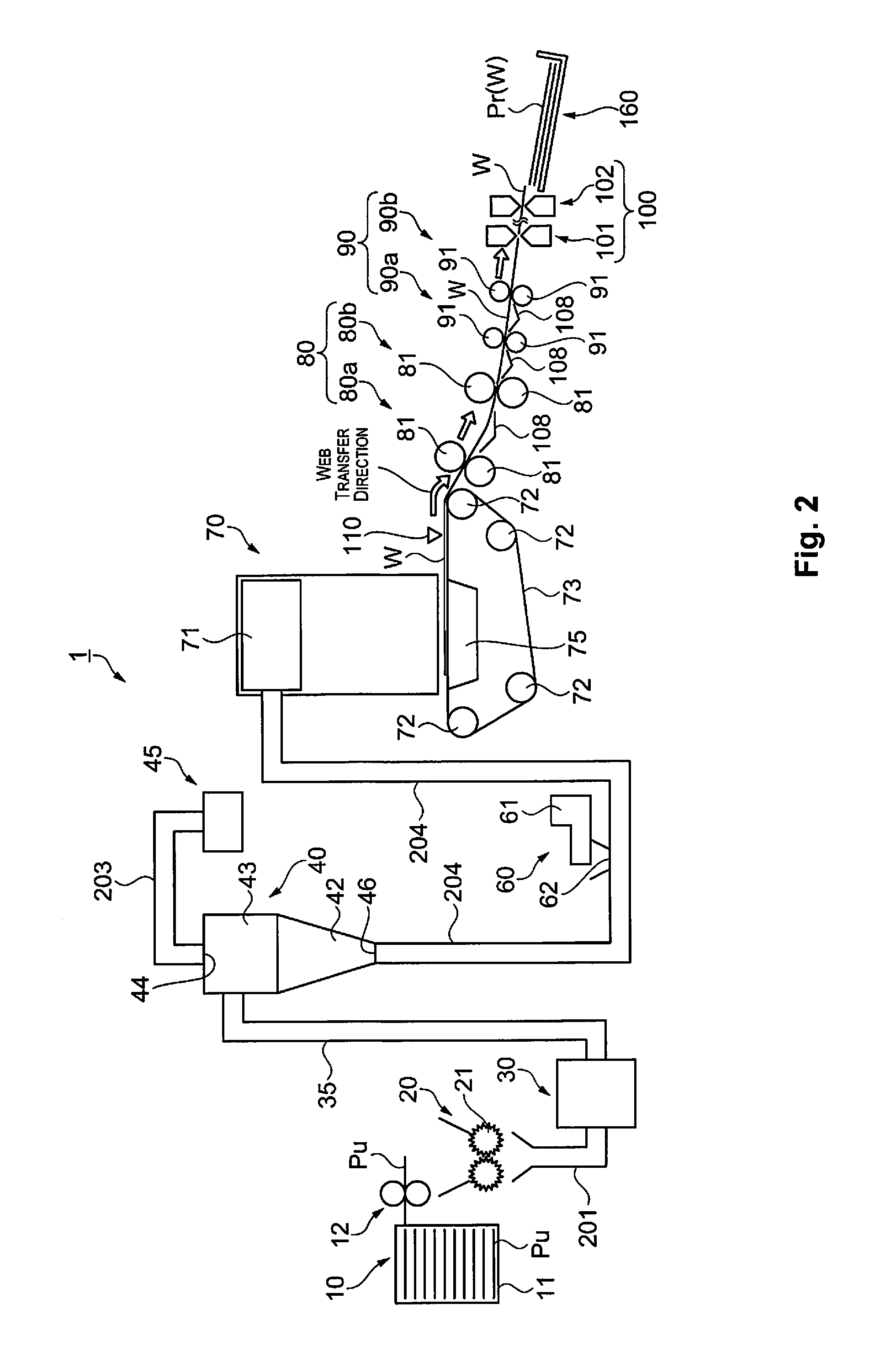

Sheet manufacturing apparatus

ActiveUS20140290886A1Enhanced strengthIncreased intensityPaper recyclingPhysical paper treatmentEngineeringFiber

A sheet manufacturing apparatus includes a defibrating unit configured to defibrate a defibration object including at least a fiber, in air. The sheet manufacturing apparatus forms a sheet by adding quantity of heat to a defibrated material defibrated at the defibrating unit. The sheet manufacturing apparatus includes a measuring unit configured to acquire moisture amount information of the defibrated material or the defibration object, and a controller configured to control the quantity of heat to be added to the defibrated material on the basis of the moisture amount information.

Owner:SEIKO EPSON CORP

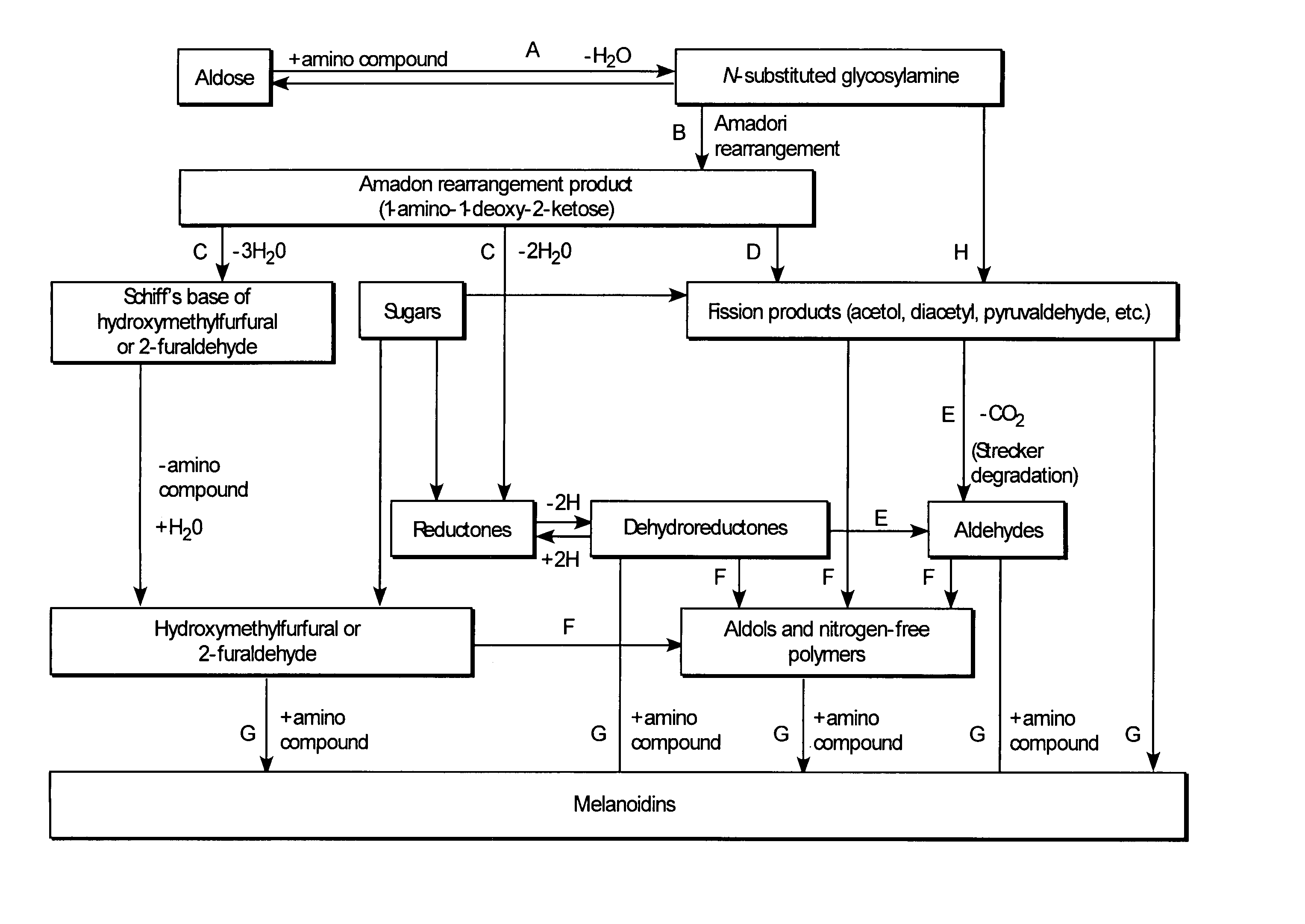

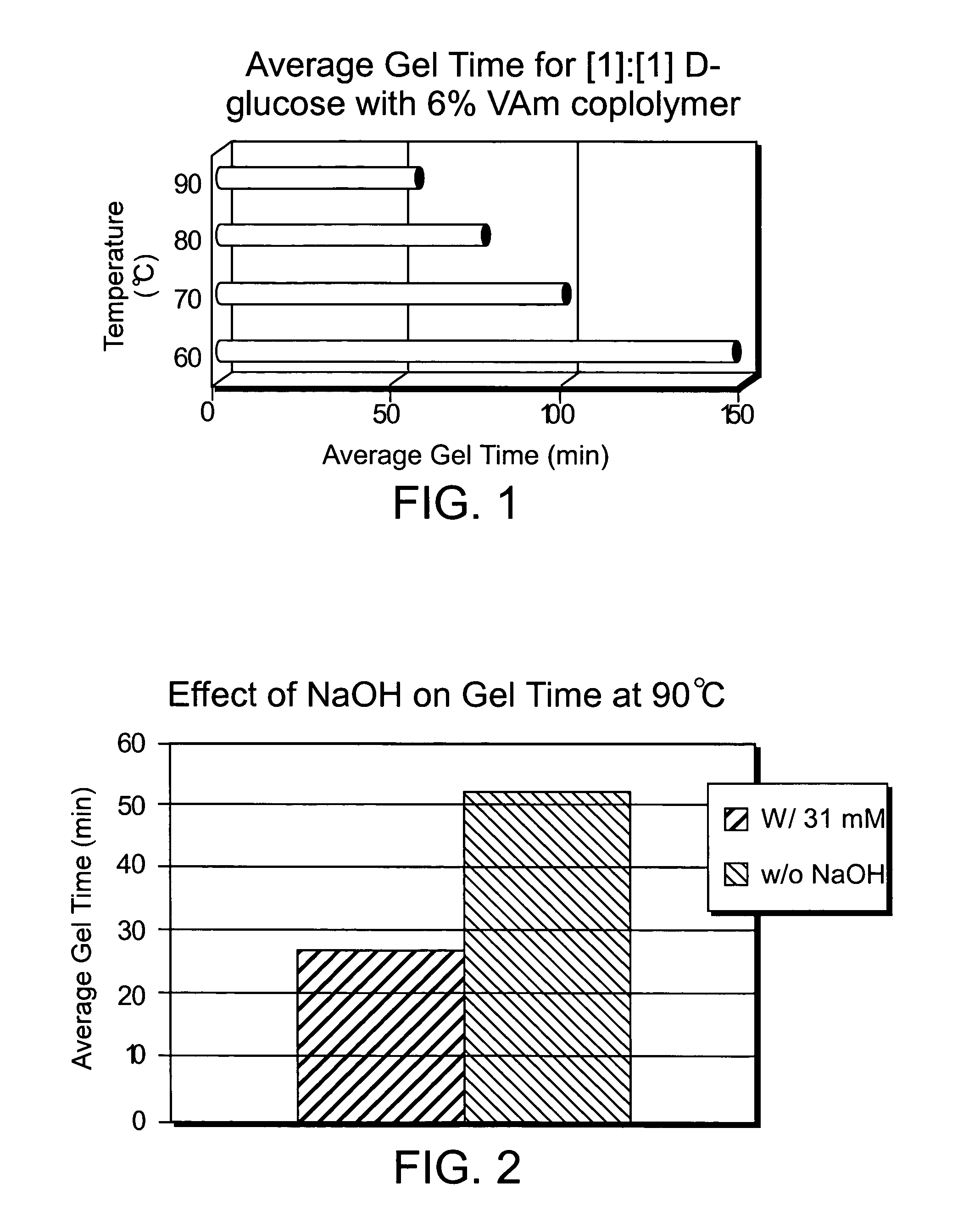

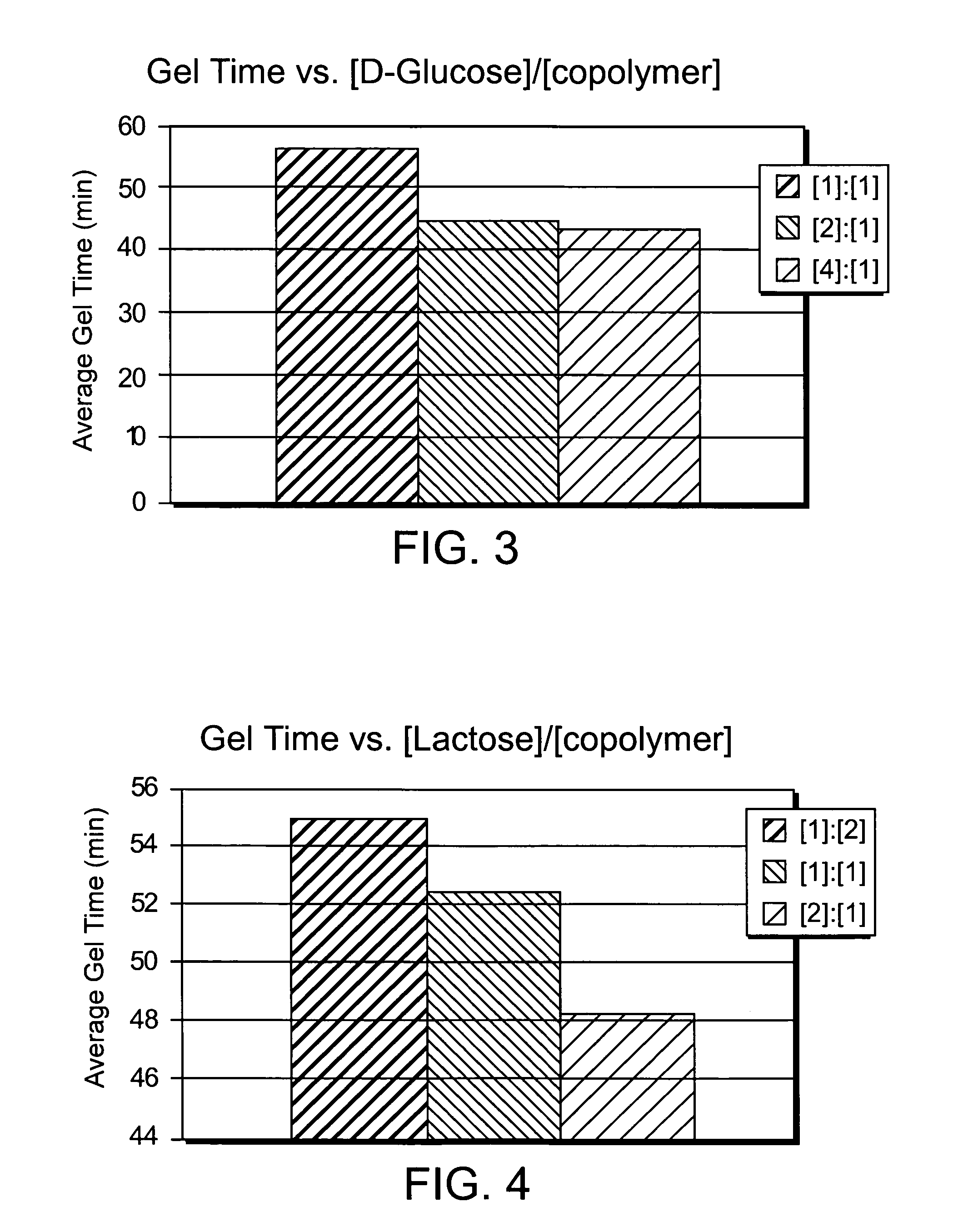

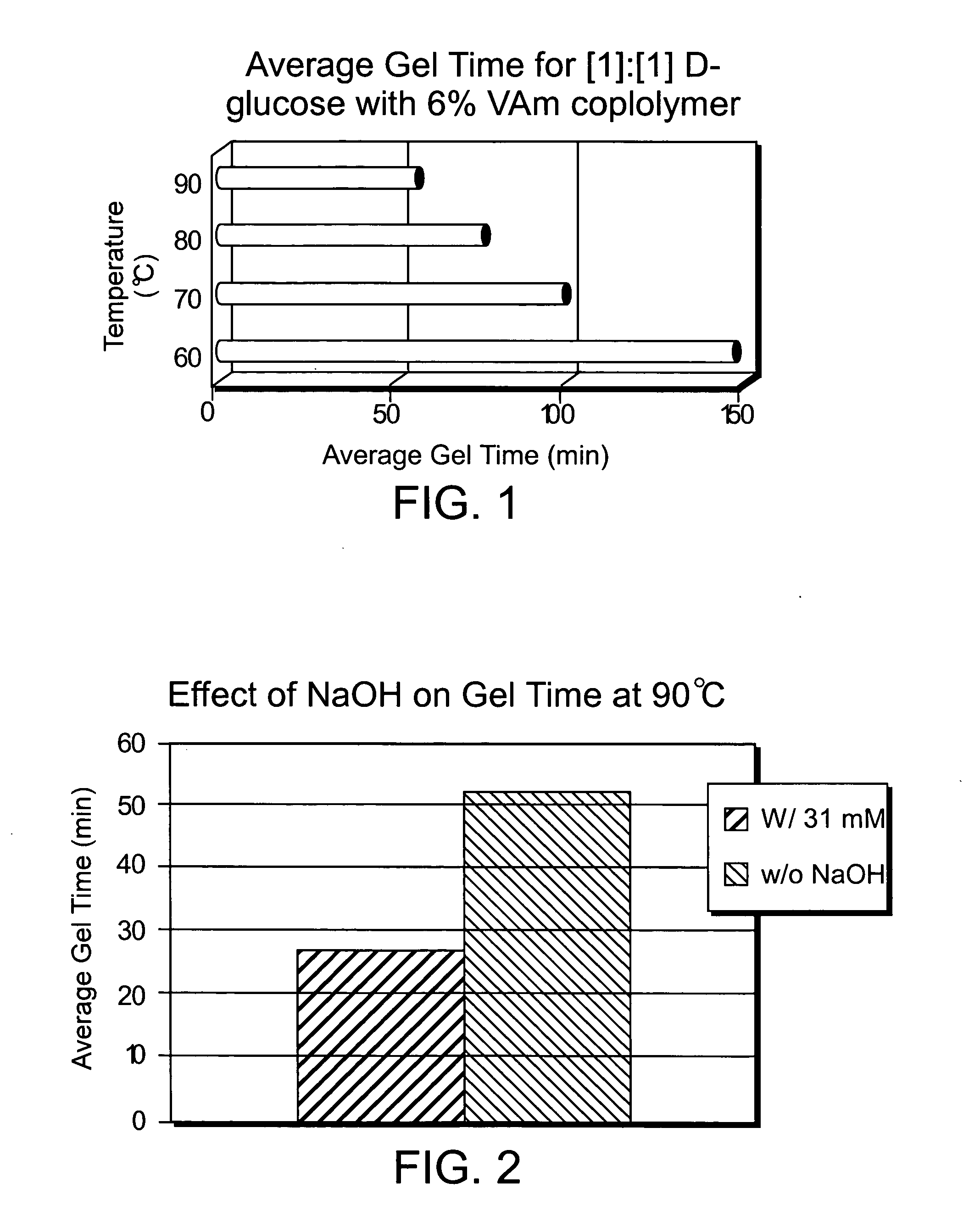

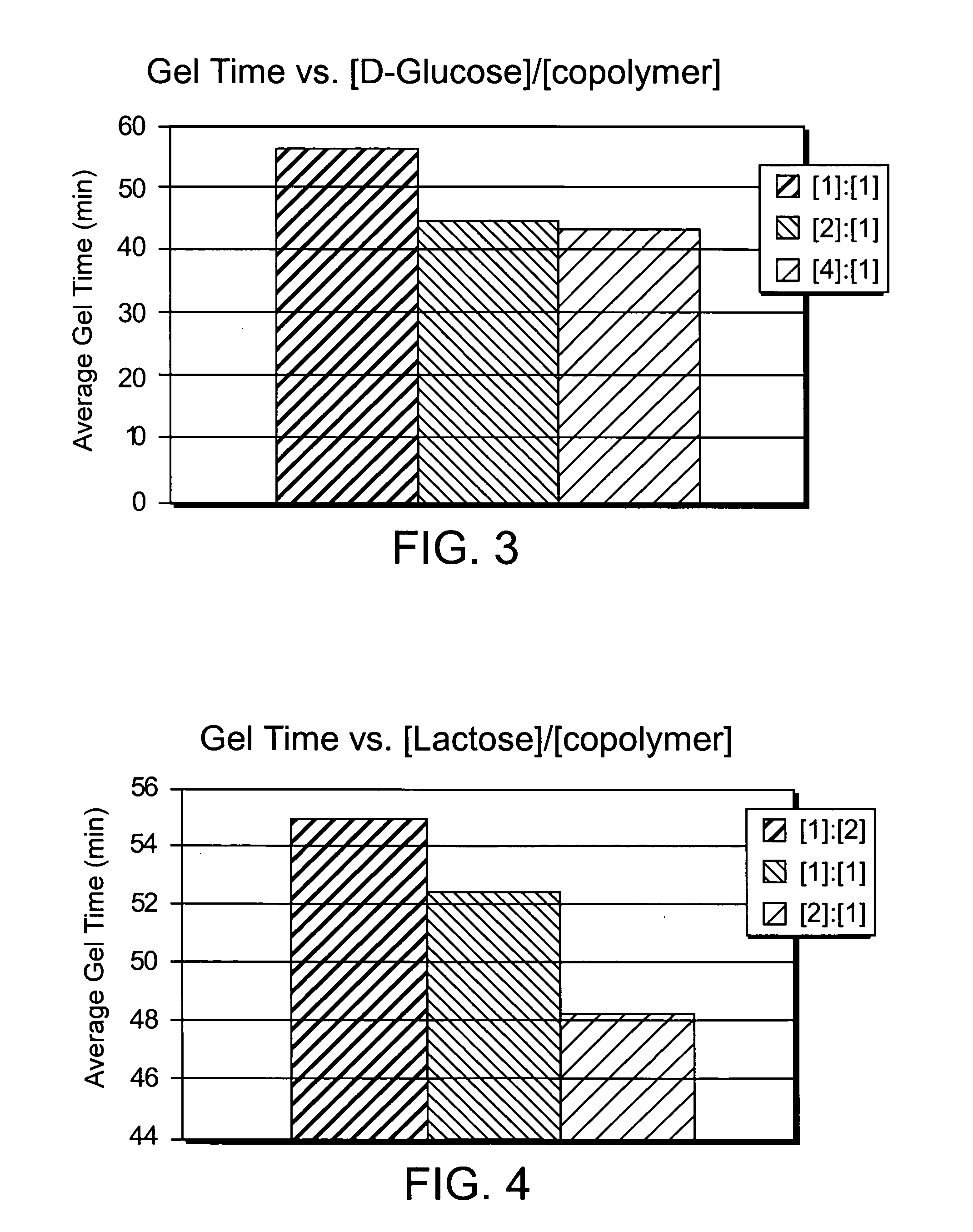

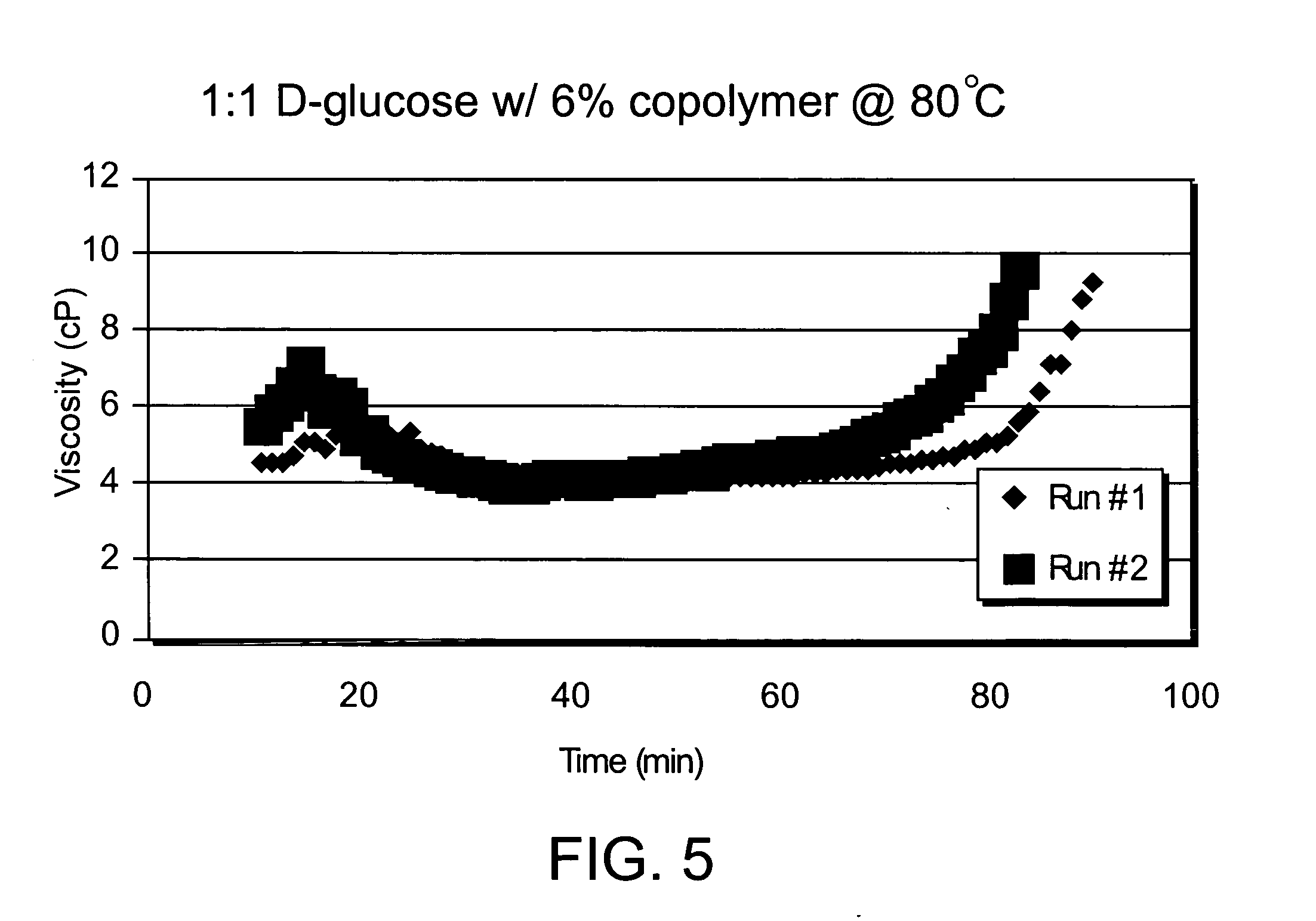

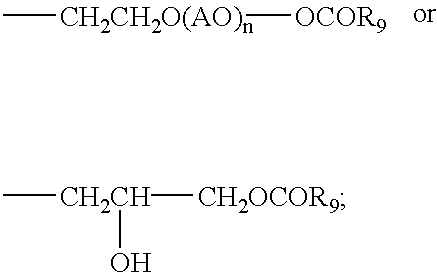

Composition for increasing cellulosic product strength and method of increasing cellulosic product strength

InactiveUS7494566B2Improve paper strengthEffective combinationNatural cellulose pulp/paperSpecial paperCellulose pulpViscosity

A composition includes water; at least one hydrophilic polymer containing at least two groups which are independently the same or different a primary amine group or a secondary amine group and at least one saccharide containing a reducible function as described above. The hydrophilic polymer and the saccharide are mixed to form a reaction mixture and reacted to increase the viscosity of the reaction mixture. The reaction is then substantially terminated by reducing the pH of the composition. A method of increasing the strength of a cellulosic pulp product includes the steps of: contacting wet cellulosic pulp with a composition comprising (i) at least one hydrophilic polymer containing at least two groups which are independently the same or different a primary amine group or a secondary amine group and at least one saccharide containing a reducible function, the hydrophilic polymer and the saccharide of the composition having been reacted in a crosslinking reaction prior to contacting the composition with the cellulosic pulp product to increase the viscosity the composition; and, after contacting the cellulosic pulp with the composition, causing the crosslinking reaction between the hydrophilic polymer and the saccharide of the composition to proceed further.

Owner:UNIVERSITY OF PITTSBURGH +1

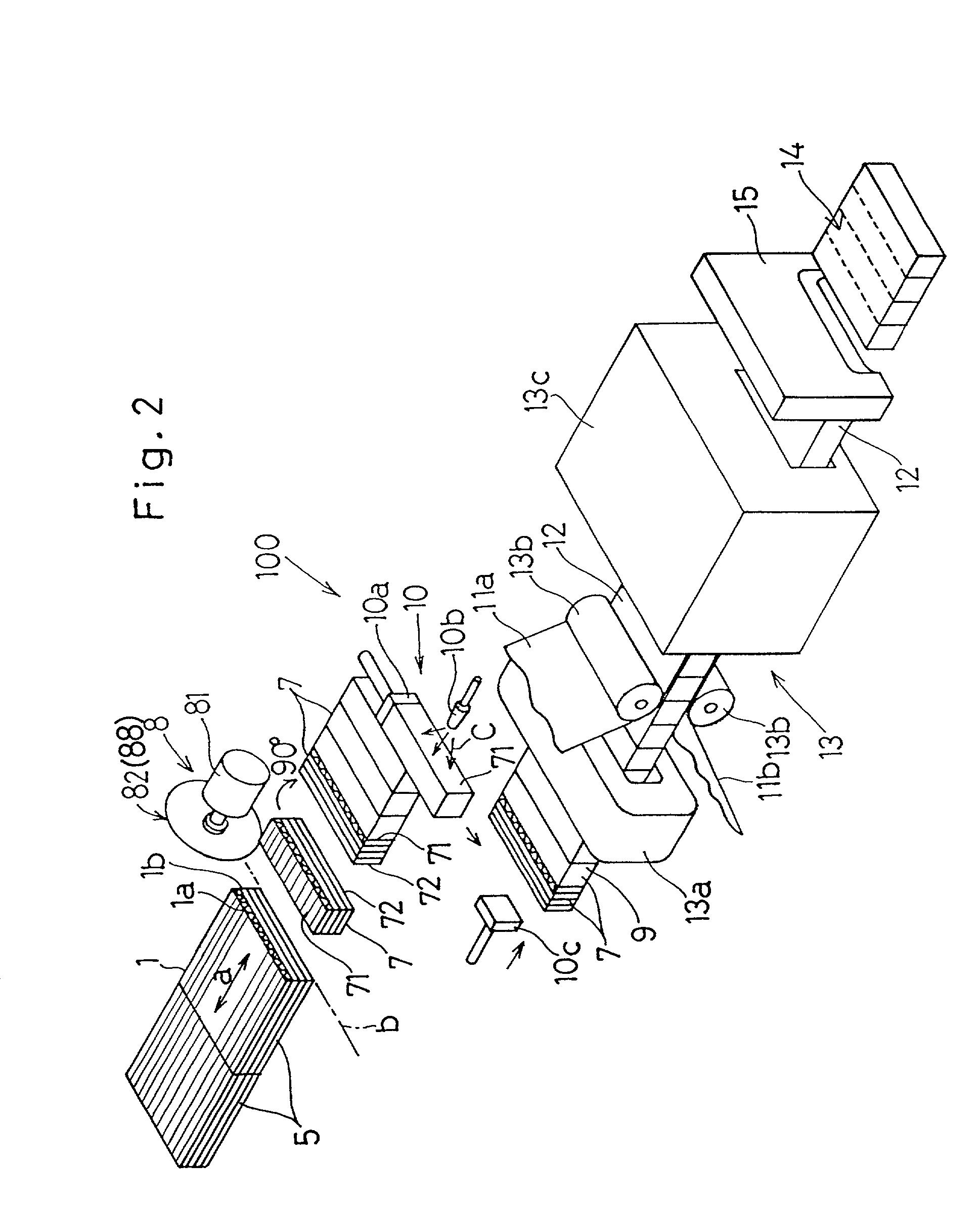

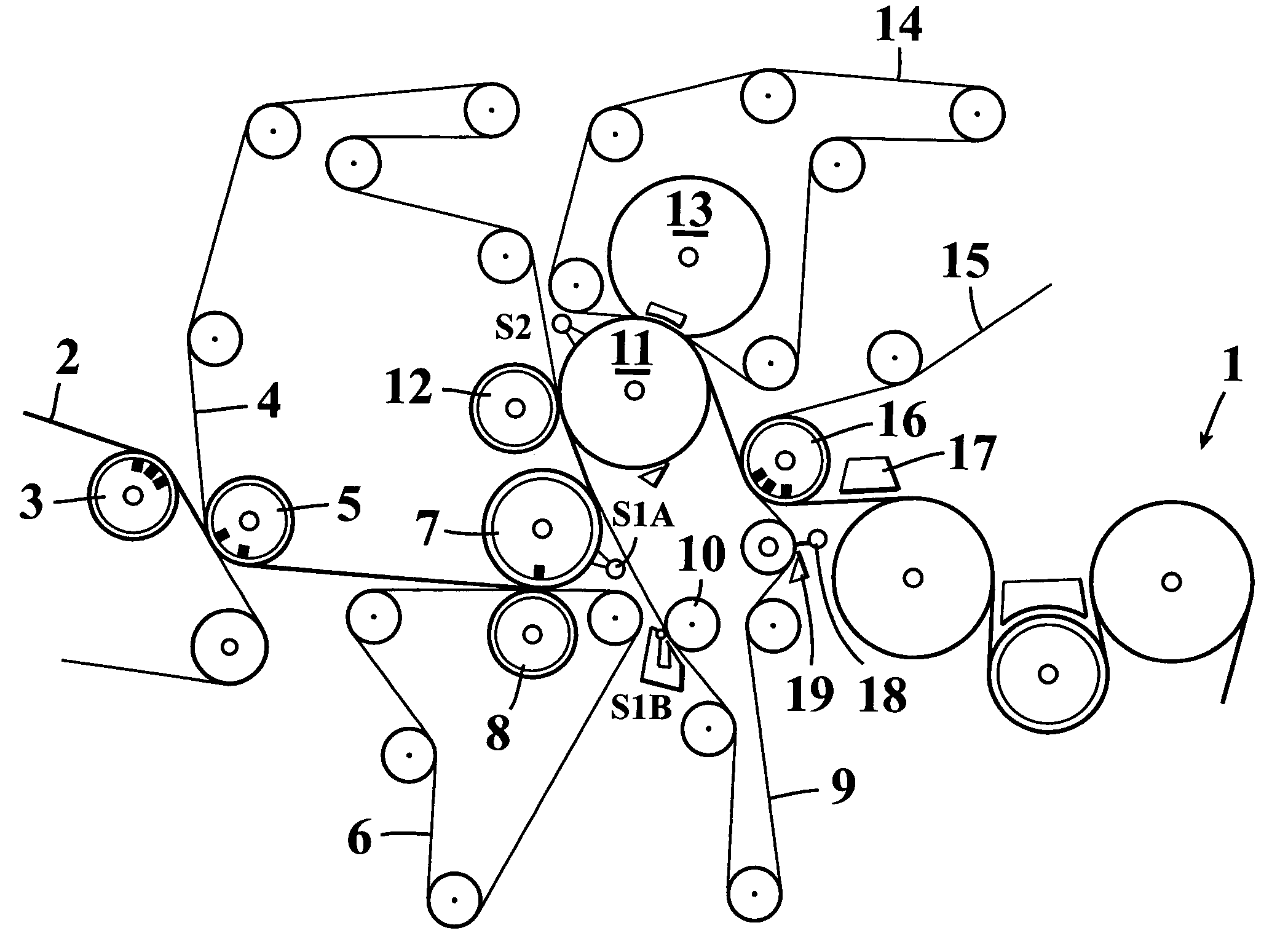

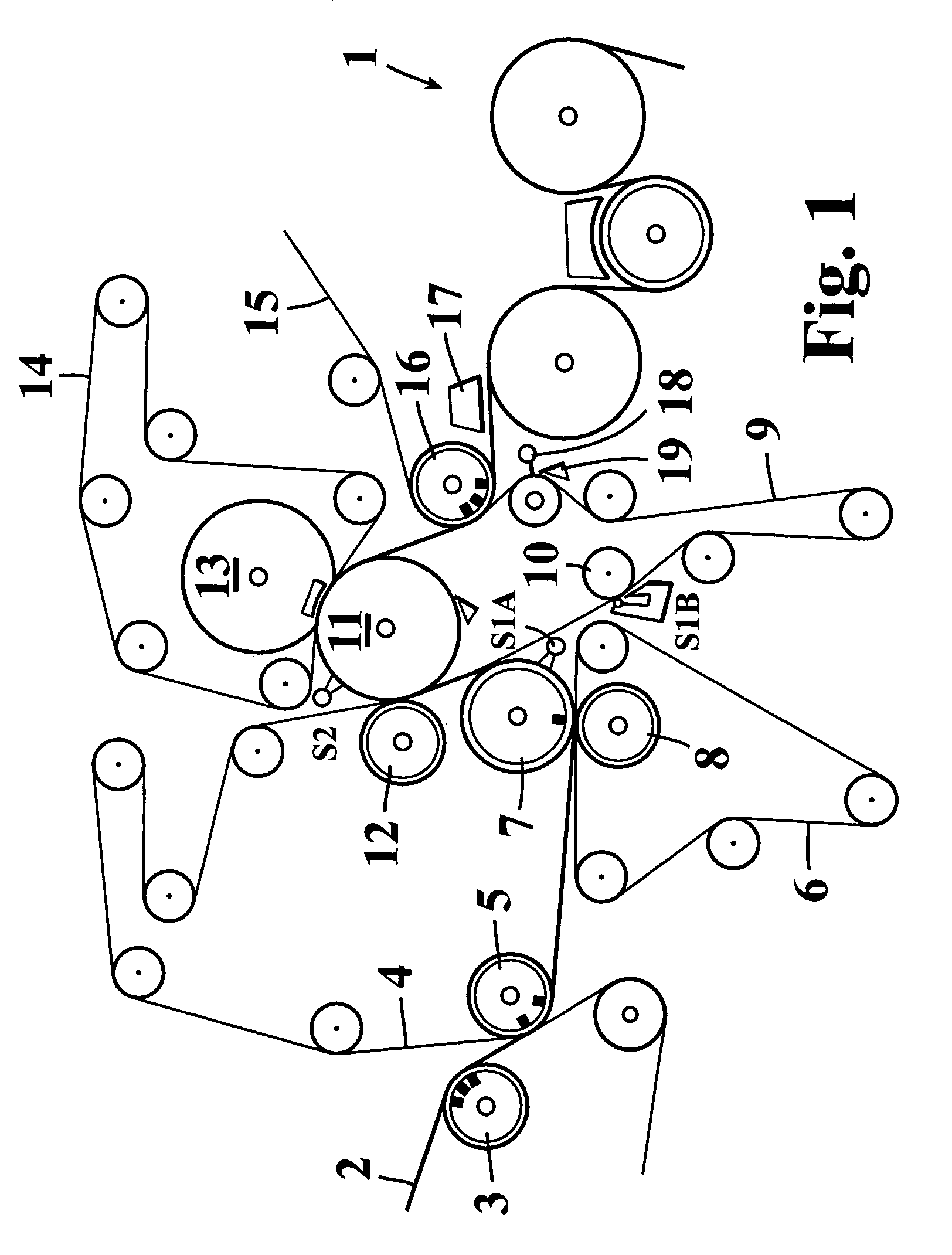

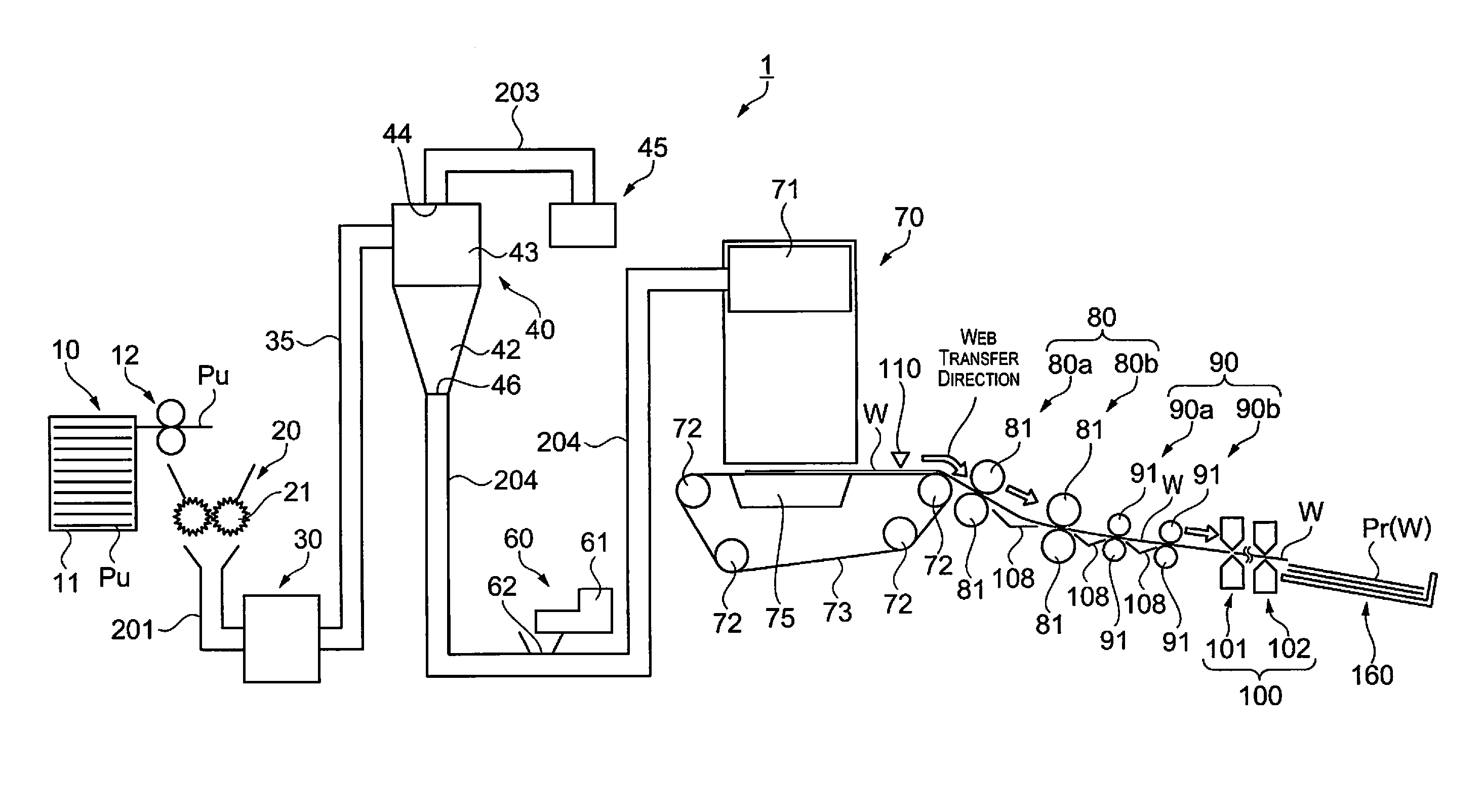

Method and apparatus for handling a paper or board web

InactiveUS6994771B1Good web surface smoothnessEfficient dryingMachine wet endPaper/cardboardCardboardWire rod

A method for treating a web of paper or board with a wetting substance or calendering the web prior to the cylinder dryer section of a paper- or boardmaking machine while the solids content of the web is still very low, typically in the range of 10–60%, wherein the web can be conveyed when so desired fully supported from the wire section of the paper- or boardmaking machine up to the winder, while simultaneously utilizing the quality benefits obtained from a controlled reduction of the web moisture content and dewatering of the same. The web is conveyed supported by a transfer belt (9) through at least one web surface treatment apparatus such as a coater station (S1B) or a calender prior to passing the web to the first dryer cylinder group (1) of the paper- or boardmaking machine. One nip (11, 13) supported by a transfer belt (9) is suitable for dewatering simultaneously with the application of a treatment substance to the web. The dewatering nip (11, 13) may be formed between a transfer belt (9) and the wire (2) of the wire section or the felt (14) of the press section.

Owner:VALMET TECH INC

Binder Fiber and Separator for Alkaline Cell Using Same

InactiveUS20070232175A1Excellent workabilityExcellent heat resistanceMonocomponent copolyamides artificial filamentSynthetic cellulose/non-cellulose material pulp/paperPolyamideAlkane

A binder fiber comprising a polyamide component in at least part of a surface thereof is prepared. The polyamide component contains a semi-aromatic polyamide at least having an aromatic ring unit and a C3-7 alkane unit which may have a branched CA 1-3 alkyl chain. In the binder fiber, the polyamide component may be (a) a semi-aromatic copolyamide having an aromatic ring unit, a C3-7 alkane unit which may have a branched C1-3 alkyl chain, and a C8-12 alkane unit which may have a branched C1-3 alkyl chain. The polyamide component may be (d) a combination of (b) a semi-aromatic polyamide and (c) a semi-aromatic polyamide, wherein the polyamide (b) has an aromatic ring unit and a C3-7 alkane unit which may have a branched C1-3 alkyl chain, and the polyamide (c) has an aromatic ring unit and a C8-12 alkane unit which may have a branched C1-3 alkyl chain.

Owner:KURARAY CO LTD

Method for preparing high-whiteness chemical pulp and paper products thereof by using corn stalk

InactiveCN101225620AImprove utilizationReduce pollutionPretreatment with alkaline reacting compoundsWater-repelling agents additionChemistryHardwood

The invention discloses a preparation method of chemical pulp with high whiteness by corn stalks and paper product, wherein steaming adopts soda cooking by adding anthraquinones and surface-active material; bleaching adopts totally-chlorine-free bleaching of short program of OPAPO in the pulp making processes, wherein OP segment is oxygenic delignification segment reinforced by small amount of hydrogen peroxide; A segment is acid treatment segment; PO> is oxygen-reinforced hydrogen peroxide bleaching segment. The preparation method of chemical pulp with high whiteness by corn stalks and paper product has the advantages of less steaming time, high steaming and bleaching efficiency, free of chlorine and chlorine compounds while bleaching, high whiteness and strength of the paper pulp, energy saving, water saving, low production cost, and favorableness to environmental protection. In addition, with whiteness rate of above 85% ISO, the paper pulp made from corn stalks is able to be made into high-grade cultural paper and paperboard as well as paper and paperboard with high sanitary indexes replacing bleached hardwood pulp or bleached hardwood pulp mixed with bleached softwood kraft pulp.

Owner:TIANJIN HUAJUN SCI & TECH

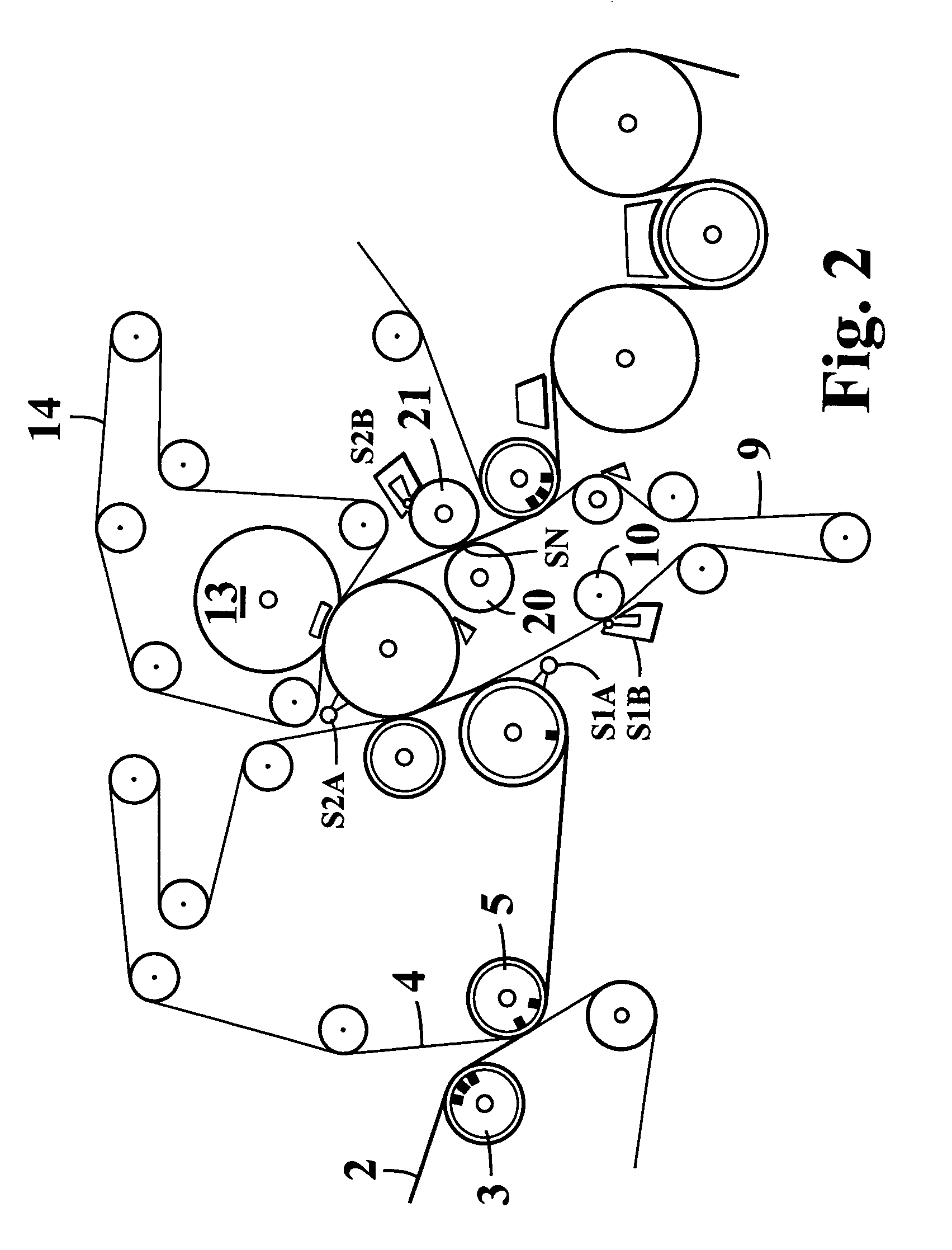

Production method of low-basis-weight environment-friendly high-strength kraft face liner board

ActiveCN104099793AIncrease hydrogen bondingHigh paper strengthPaper recyclingCellulose material pulpingCardboardFiber

The invention provides a production method of a low-basis-weight environment-friendly high-strength kraft face liner board. Long and short fibers in waste paper fibers are separated to be subjected to beating processing separately, and the short fibers are further subjected to laccase treatment, so that the paper forming strength is enhanced. According to the invention, the traditional kraft face liner board pulping production line is subjected to technical transformation to realize the separate beating control of the long and short fibers, and the short fibers are further subjected to laccase treatment to further improve the hydrogen bonding of the short fibers, so that the remarkable effect on the improvement of the paper forming strength of paper products is achieved, and further, the fact that the kraft face liner board is produced by totally adopting waste paper is realized; through the adoption of the method, the production of the low-basis-weight environment-friendly high-strength kraft face liner board can be implemented, and the product has prominent environmental protection advantage and cost advantage as totally adopting waste paper.

Owner:ZHEJIANG RONGSHENG PAPER IND HLDG

Production method of facial tissue capable of being wetted with water

InactiveCN107313283AHigh bonding strengthIncrease contact areaReinforcing agents additionMechanical/thermomechanical pulpFiberWet strength

The invention relates to a production method of a facial tissue capable of being wetted with water. The production method comprises: respectively adding water to needlebush pulp and hardwood pulp, adjusting the needlebush pulp concentration and the hardwood pulp concentration to 5.0-7.0 wt%, and crushing for 8-15 min; adjusting the needlebush pulp concentration to 4.0-5.0 wt%, and carrying out fiber cutting and fibrillation in a grinder; adding water to adjust the hardwood pulp concentration to 4.0-5.0 wt%, and carrying out fiber defibrating in a defibrating machine; mixing 50-60% of the needlebush pulp and 50-40% of the hardwood pulp, adjusting the concentration to 3.0-4.0 wt%, and carrying out further cutting and fibrillation through the grinder; adding a wet strength agent and a softener to the mixed pulp, and adjusting the concentration to 2.9-3.1 wt%; and diluting the obtained mixed pulp to 0.2-0.25 wt% by using a pulp beating pump, feeding into a papermaking machine, molding, squeezing, and drying to finally prepare the product. According to the present invention, when the prepared facial tissue used for water wiping and sweat wiping, the facial tissue is not broken, and no residue paper exists; the prepared facial tissue can be used as the wet wipe and the face washing towel after the prepared facial tissue is wetted with the water; and the hand feeling and the smoothness of the facial tissue are improved, such that the use is comfortable.

Owner:上海东冠纸业有限公司

Thermosensitive recording material and method of production thereof

InactiveUS6890698B2Improve water resistanceShorten the timePhotosensitive materialsCoatingsLeuco dyeMethods of production

A thermosensitive recording material having a support, a thermosensitive coloring layer provided on the support and containing a leuco dye and a color developer for developing the leuco dye upon application of heat, and a protective layer provided on the thermosensitive coloring layer and containing polyvinyl alcohol having reactive carbonyl groups, a hydrazide compound which crosslinks the polyvinyl alcohol through the reactive carbonyl groups, and a basic filler. The protective layer may be formed by applying a coating composition containing polyvinyl alcohol having reactive carbonyl groups, a hydrazide compound which crosslinks the polyvinyl alcohol through the reactive carbonyl groups, and a basic filler onto a thermosensitive coloring layer provided on a support, and drying the applied coating composition to crosslink the polyvinyl alcohol.

Owner:RICOH KK

Method for preparing cationic rosin/C9 petroleum resin sizing agent

InactiveCN102995488AOvercoming easy foamingOvercome stabilityWater-repelling agents additionFiberAcrylate polymer

The invention discloses a method for preparing a cationic rosin / C9 petroleum resin sizing agent. The method comprises the following steps of: preparing a cationic styrene and acrylate polymer through solution polymerization under the action of an organic solvent which can be insoluble with water by taking styrene, an acrylate monomer, acrylamide, a cationic monomer and other vinyl monomers as comonomers; and emulsifying and dispersing a mixture of rosin and C9 petroleum resin by taking the cationic styrene and acrylate polymer as a cationic high polymer surfactant, so as to prepare the cationic rosin / C9 petroleum resin emulsion which has high stability and good sizing performance. According to the prepared cationic rosin / C9 petroleum resin emulsion, the excellent performances of rosin and C9 are comprehensively utilized; the cationic rosin / C9 petroleum resin emulsion has high cationic performance; the particles of the cationic rosin / C9 petroleum resin emulsion have positive charges, which contribute to retention and binding with paper fibers; and moreover, the cationic high polymer surfactant has the capacity of protecting colloid and has a certain sizing synergistic effect, and therefore, the stable performance and sizing performance of the emulsion can be greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

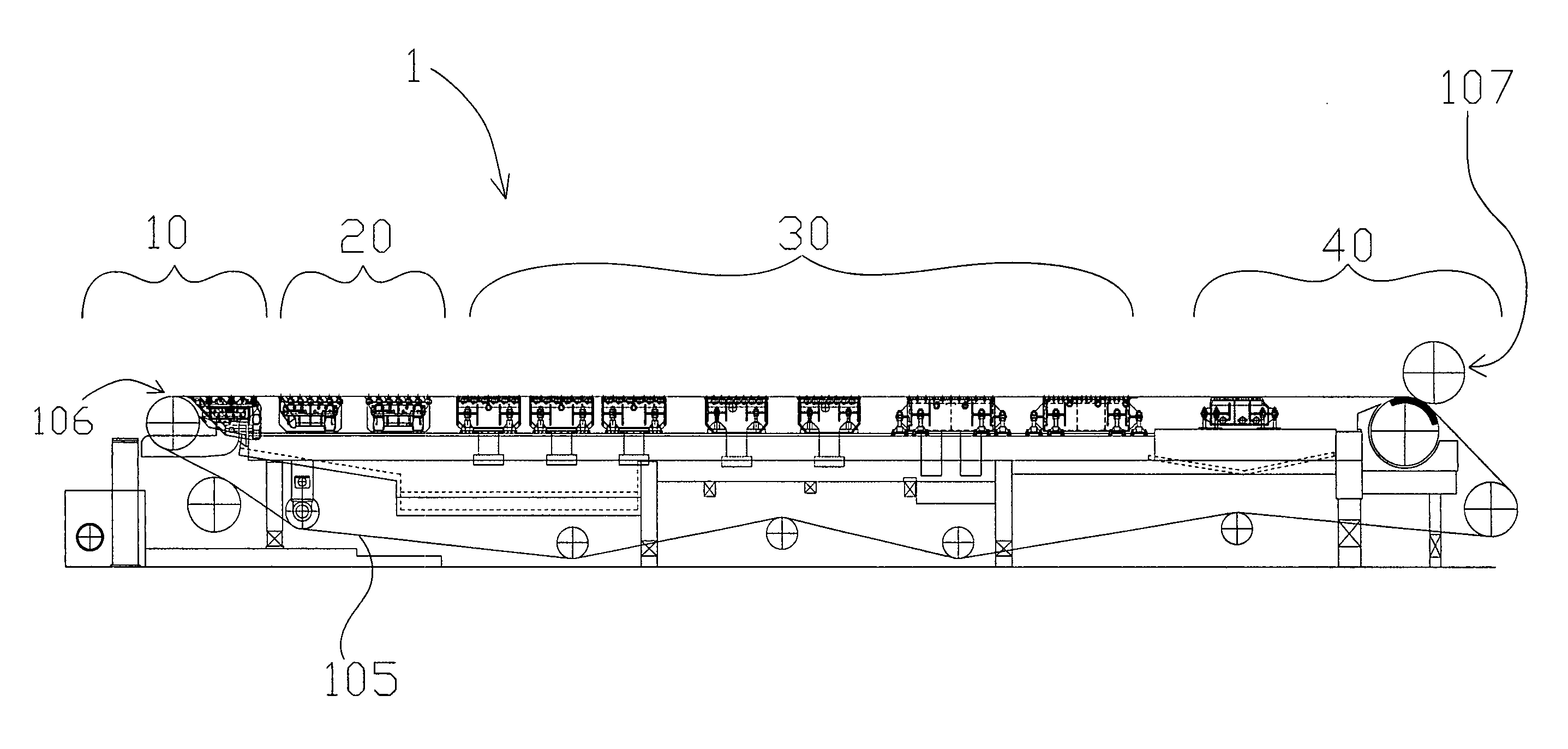

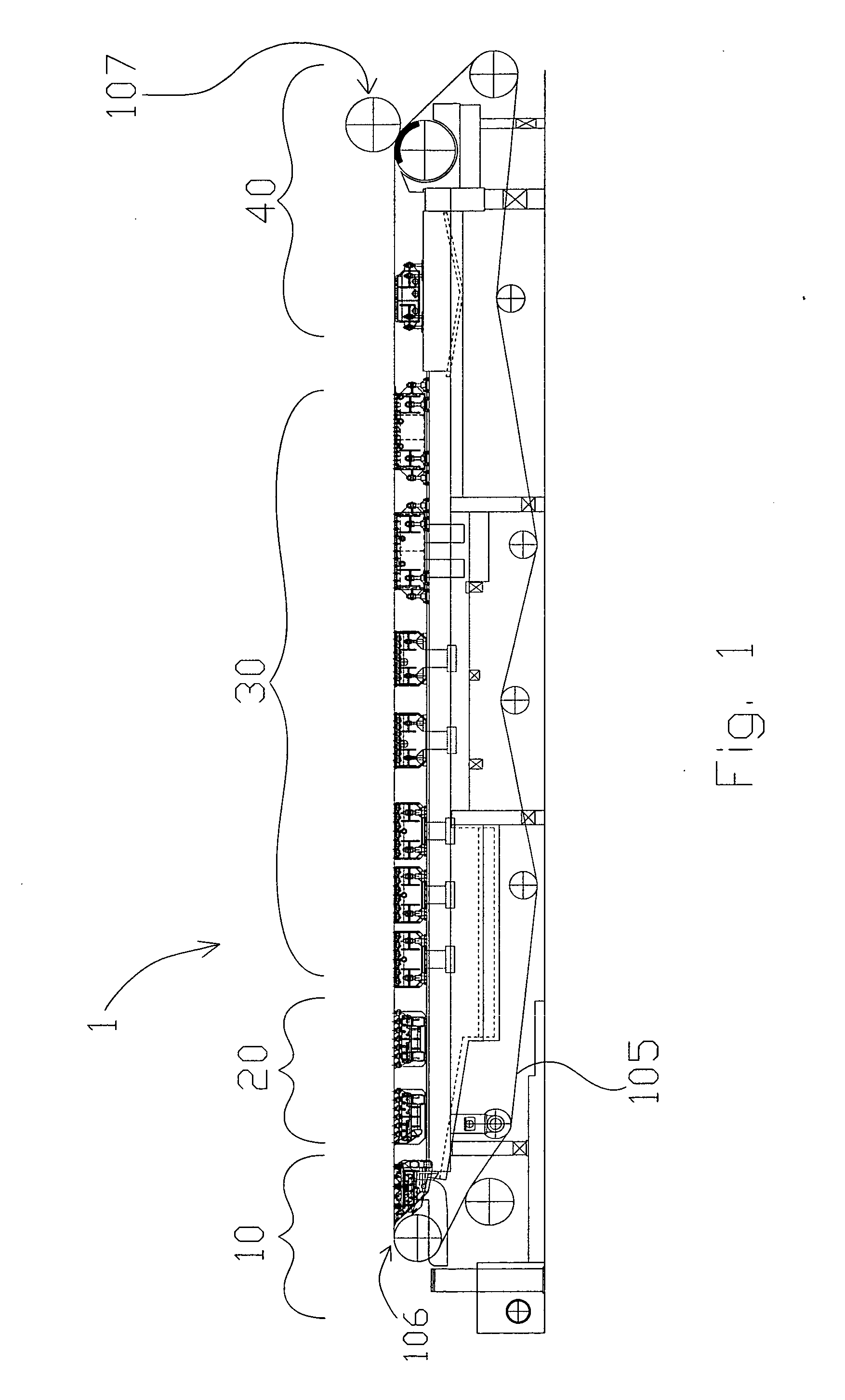

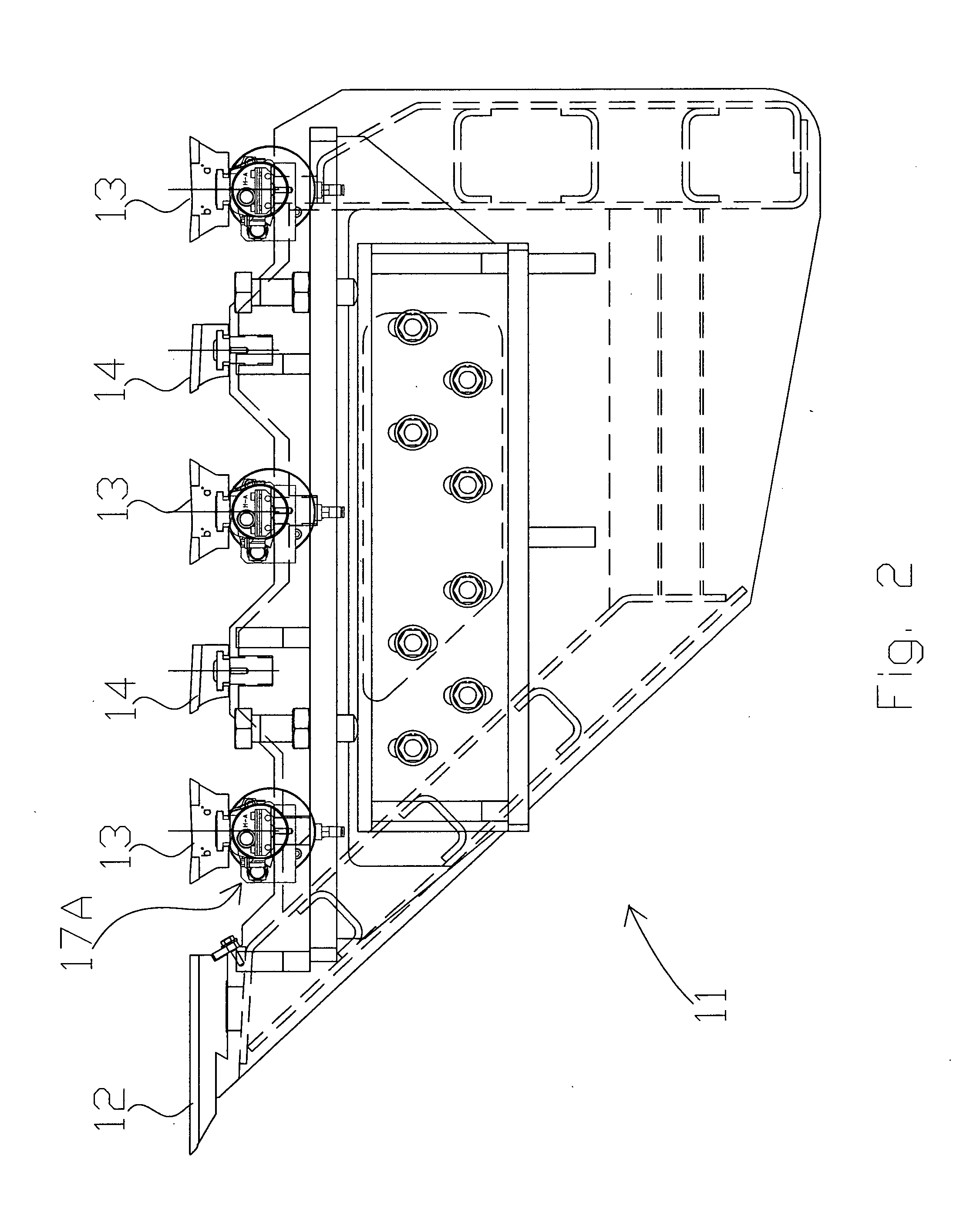

Method and machine for manufacturing paper products using fourdrinier forming

ActiveUS20120267065A1Improve paper strengthEasy to switchFibreboardMachine wet endFiberVacuum assisted

An improved method for producing paper from pulp includes a plurality of subassemblies arranged in the forming or wet section of a Fourdrinier. The Fourdrinier includes a dewatering table having a plurality of blades that are static and on-the run adjustable in height and / or angle to control orientation of paper fibers in the stock to create a superior quality of paper and improved paper strength characteristics. Gravity and vacuum assisted drainage elements are equipped with on-the-run adjustable angle and height dewatering foil blades starting from a paper dryness of 0.1% and extending all the way to 5% dryness. The result of this process and machine is to improve the paper quality, save fibers and chemicals and fulfill the required paper properties.

Owner:IBS OF AMERICA

Sheet manufacturing apparatus

ActiveUS9039868B2Increased intensityReduced strengthPaper recyclingMachine wet endFiberManufactured apparatus

Owner:SEIKO EPSON CORP

Method for increasing the advantages of starch in pulped cellulosic material in the production of paper and paperboard

ActiveUS20130186584A1Avoid degradationImprove retentionNatural cellulose pulp/paperSpecial paperIonChemistry

The invention relates to a method for increasing the benefit from starch in pulped, preferably repulped cellulosic material at paper or paperboard manufacturing comprising the steps of (a) pulping a cellulosic material containing a starch; (b) treating the cellulosic material containing the starch with one or more biocides, preferably in the thick stock area; and (h) adding an ionic polymer and preferably, an auxiliary ionic polymer to the cellulosic material; wherein the ionic polymer and the optionally added auxiliary ionic polymer preferably have a different average molecular weight and preferably a different ionicity, wherein the ionicity is the molar content of ionic monomer units relative to the total amount of monomer units.

Owner:SOLENIS TECH CAYMAN

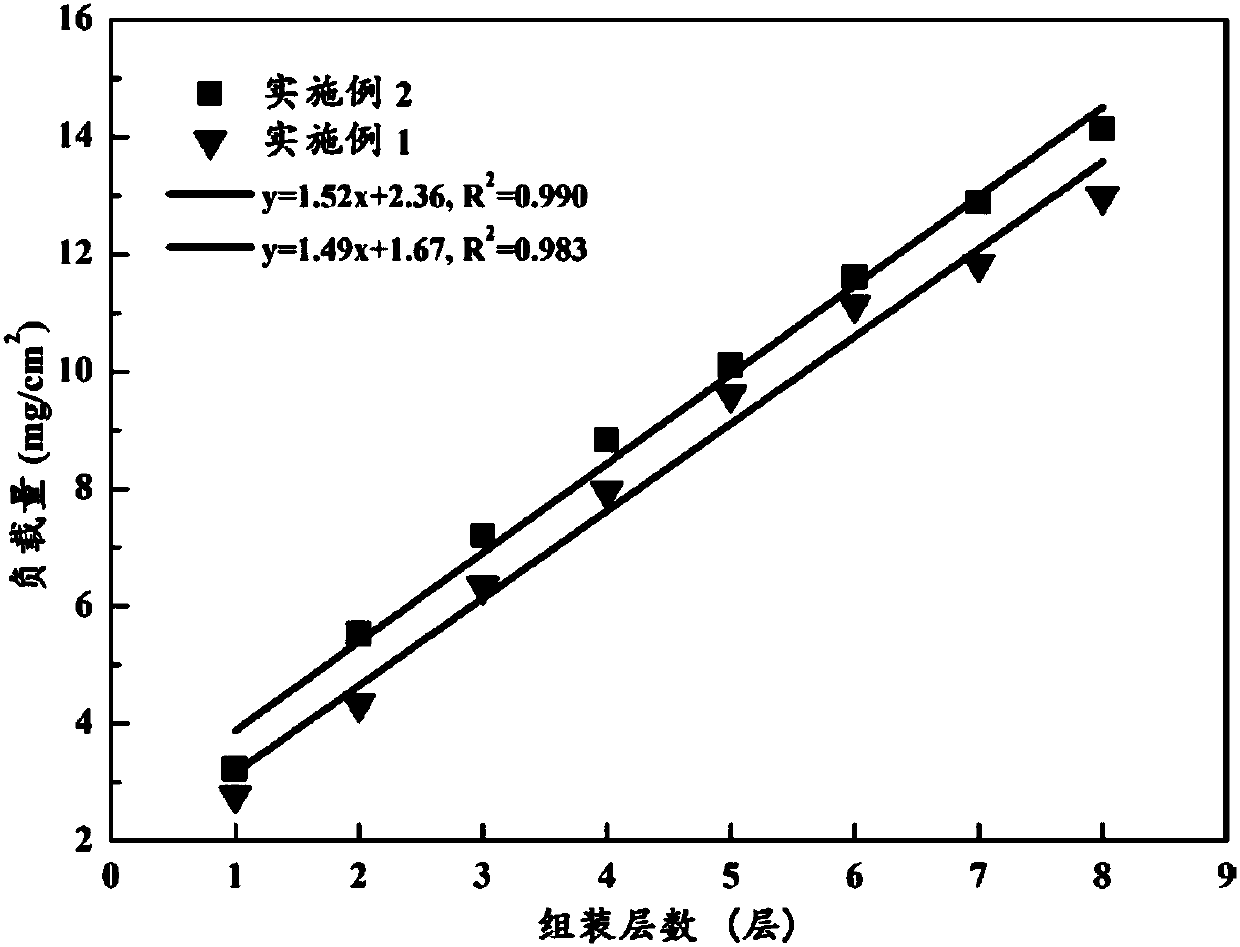

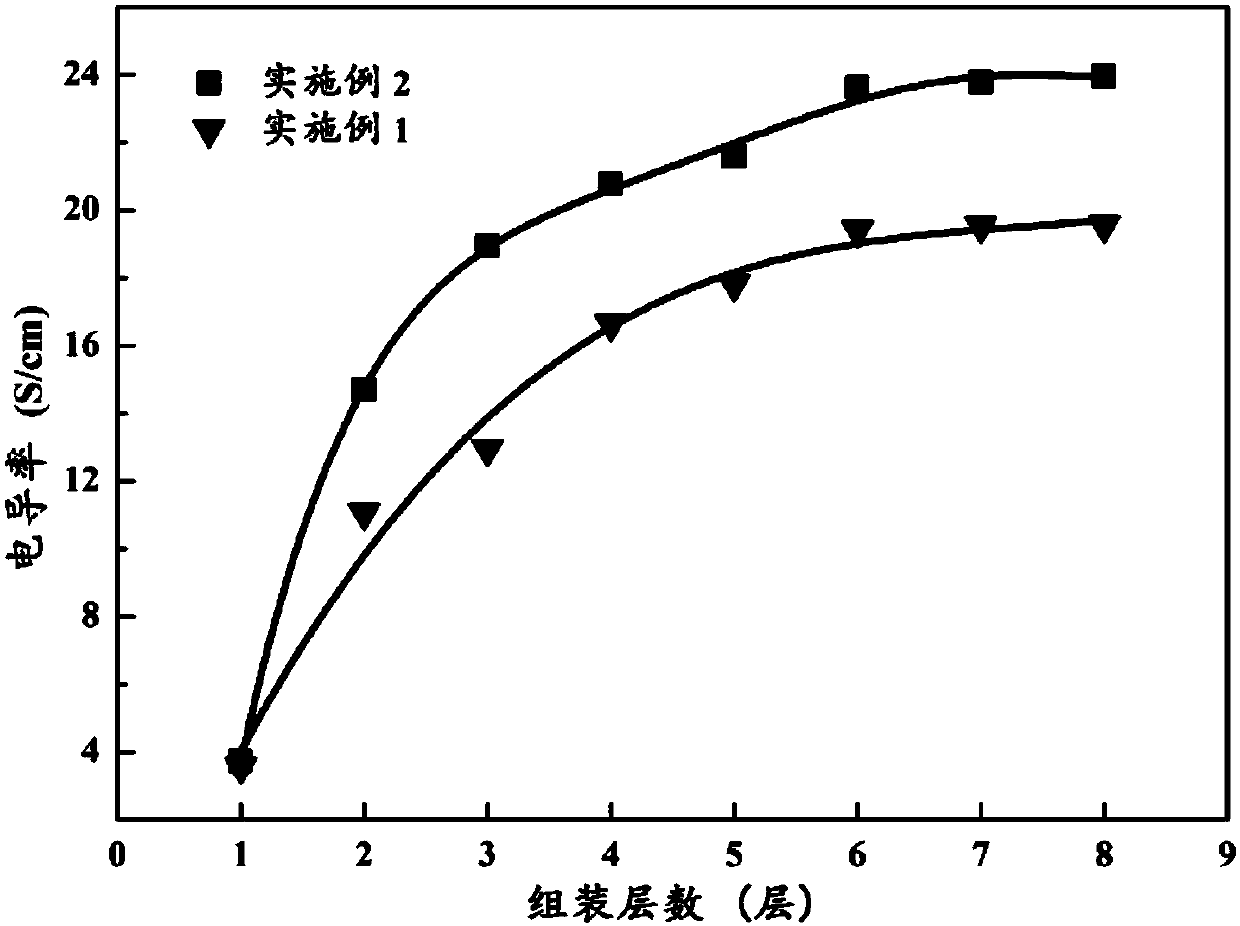

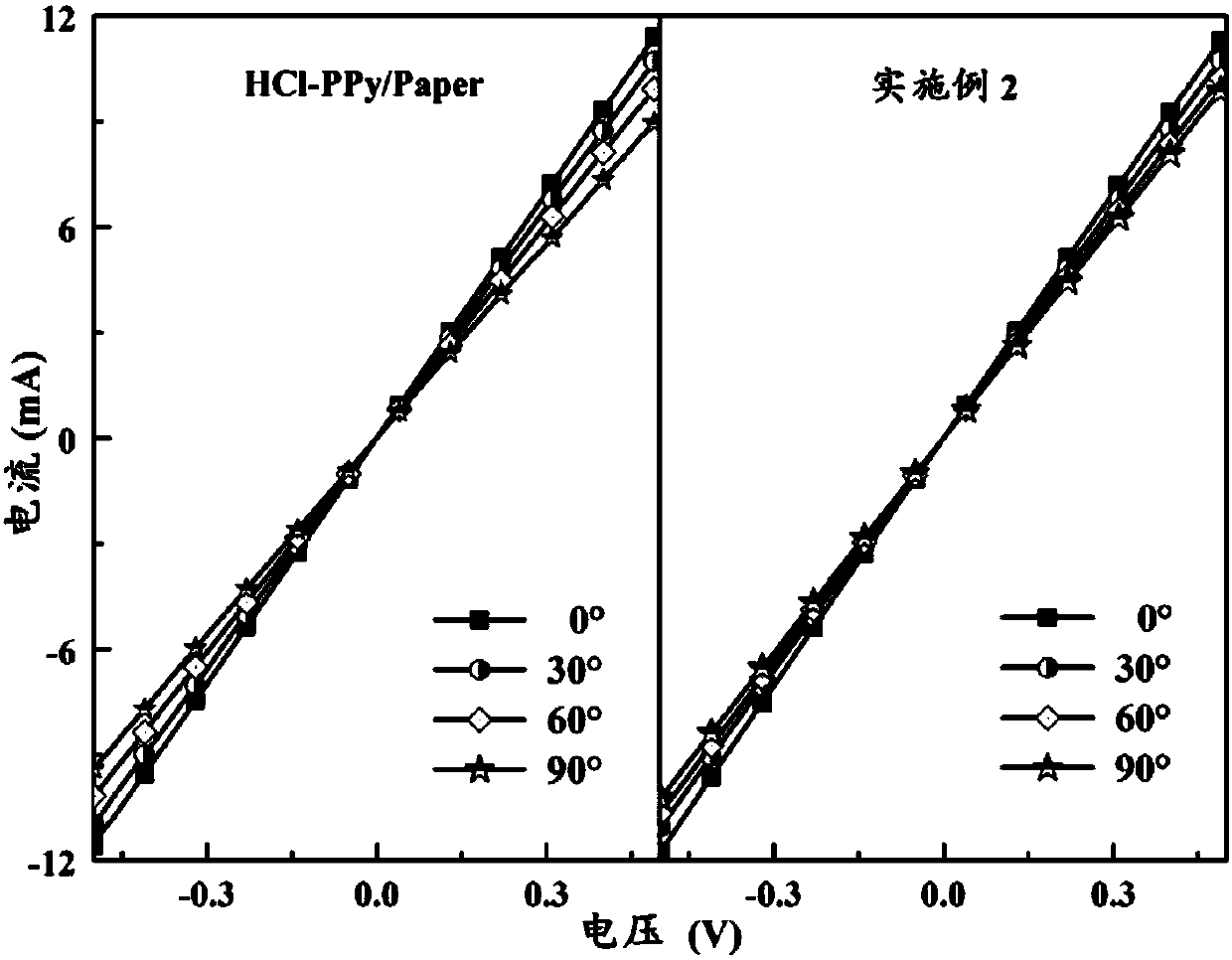

Lignosulfonic acid-reinforced polypyrrole conductive paper and preparation method thereof

ActiveCN107630390AImprove adsorption capacityImprove adsorption strengthSpecial paperNon-macromolecular organic additionUltrafiltrationPolypyrrole

The invention belongs to the technical field of functional materials and discloses a lignosulfonic acid-reinforced polypyrrole conductive paper and a preparation method thereof. The method comprises (1) separating a lignosulfonate through an ultrafiltration membrane and then purifying the lignosulfonate through a cation exchange resin to obtain lignosulfonic acid, (2) soaking a paper in the lignosulfonic acid for 10-30min, then soaking the paper in an aldehyde aqueous solution for 10-30min and heating the paper to 80-110 DEG C for a condensation reaction for 1-2h, (3) soaking the paper in a pyrrole solution for 10-30min, and (4) soaking the paper in a mixed solution of an oxidant and an inorganic acid for a reaction for 10-120min to obtain a self-assembled single-layer conductive paper andrepeating the above steps (2) to (4) to obtain a self-assembled multi-layer conductive paper. The lignosulfonic acid-reinforced polypyrrole conductive paper has high conductivity, good stability, adjustable loading capability and no dusting and can be used in the fields of surface heating materials, electromagnetic shielding materials and flexible electrode materials.

Owner:SOUTH CHINA UNIV OF TECH

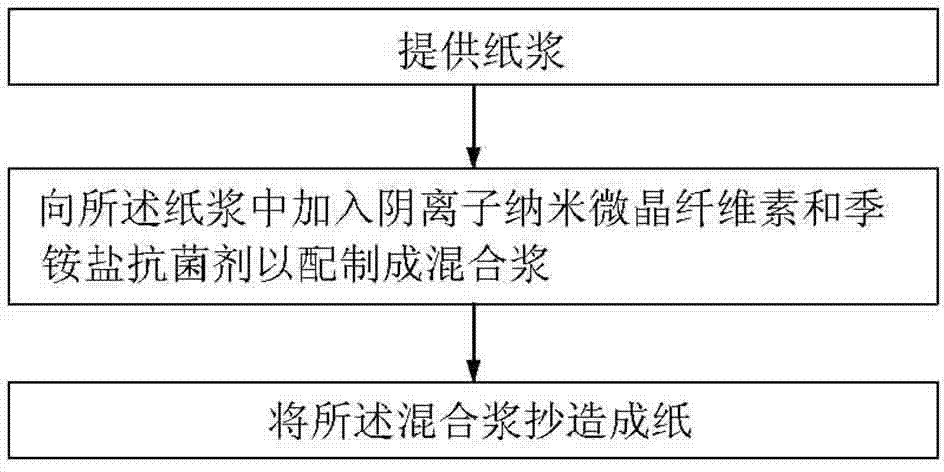

Production process of antibacterial paper and antibacterial paper

ActiveCN103114501AImprove paper strengthImprove antibacterial propertiesNon-fibrous pulp additionSpecial paperAntibacterial agentPaper sheet

The invention relates to a production process of antibacterial paper. The production process comprises the following steps: providing paper pulp; adding anion nano-microcrystalline cellulose and an quaternary ammonium salt into the paper pulp to prepare mixed pulp; and producing the paper with the mixed pulp. The invention further relates to the antibacterial paper produced by utilizing the process. Compared with the prior art, the production process of the antibacterial paper can ensure that an antibacterial agent added into the paper pulp has good retention rate, and the antibacterial paper produced according to the production process of the antibacterial paper has good paper strength and antibacterial capability.

Owner:GOLD HONG YE PAPER

Paper improver

InactiveUS7547376B2Increase distanceImprove adsorption capacityNatural cellulose pulp/paperSpecial paperPolymer scienceOptical property

The invention provides a paper quality improver for papermaking that allows improvement in the bulky value and the optical properties such as brightness and opacity as well as in the paper strength of a sheet obtained by papermaking a pulp material. The paper quality improver for papermaking is a paper quality improver for papermaking containing a copolymer (A) having a constituent unit derived from at least one nonionic monomer having a solubility parameter of 20.5 (MPa)1 / 2 or less and a constituent unit derived from at least one anionic or cationic monomer and a surfactant (B) at a certain ratio, the quality improver providing at least one paper quality improving effect of: (i) standard improved bulky value: 0.02 g / cm or more; (ii) standard improved opacity: 1.0 point or more; and (iii) standard improved brightness: 0.5 point or more.

Owner:KAO CORP

Composition for increasing cellulosic product strength and method of increasing cellulosic product strength

InactiveUS20050082025A1Improve paper strengthEffective combinationNatural cellulose pulp/paperSpecial paperCelluloseViscosity

A composition includes water; at least one hydrophilic polymer containing at least two groups which are independently the same or different a primary amine group or a secondary amine group and at least one saccharide containing a reducible function as described above. The hydrophilic polymer and the saccharide are mixed to form a reaction mixture and reacted to increase the viscosity of the reaction mixture. The reaction is then substantially terminated by reducing the pH of the composition. A method of increasing the strength of a cellulosic pulp product includes the steps of: contacting wet cellulosic pulp with a composition comprising (i) at least one hydrophilic polymer containing at least two groups which are independently the same or different a primary amine group or a secondary amine group and at least one saccharide containing a reducible function, the hydrophilic polymer and the saccharide of the composition having been reacted in a crosslinking reaction prior to contacting the composition with the cellulosic pulp product to increase the viscosity the composition; and, after contacting the cellulosic pulp with the composition, causing the crosslinking reaction between the hydrophilic polymer and the saccharide of the composition to proceed further.

Owner:UNIVERSITY OF PITTSBURGH +1

Dehydrated potato flakes

InactiveUS7060318B2Low variabilityImprove efficiencyBaking mixturesFood preparationAdhesiveSolanum tuberosum

Owner:KELLOGG NORTH AMERICA

Paper quality improver composition for papermaking

InactiveUS6565708B2Bulky brightnessBulky opacityNatural cellulose pulp/paperSpecial paperCLARITYPapermaking

The present invention provides a paper quality improver composition for papermaking, which is excellent in improved efficiencies of bulky value, brightness, opacity and the like of pulp sheet, demanded at lightening paper and increasing a blending amount of deinked pulp, even by adding a small amount thereof as well as which is further excellent in an improved efficiency of paper-strength. That is, the present invention provides a paper quality improver composition for papermaking; which comprises (A) a compound having lyotropic degree measured by a specific method of not less than 4% and satisfying at least two of (i) standard improved bulky value of not less than 0.02 g / cm3, (ii) standard improved brightness of not less than 0.5 point, and (iii) standard improved opacity of not less than 0.5 point and (B) a water-soluble polymer satisfying an average molecular weight and / or a viscosity thereof of specific value.

Owner:KAO CORP

Coating compositions

InactiveUS7217316B2High strengthIncreased durabilityFibreboardNatural cellulose pulp/paperSolid contentViscosity

The present invention relates to an aqueous coating composition which comprises an alkali oxidised aqueous gelatinised starch / protein mixture, said composition having a viscosity between 1 and 100 centapoise (cps), and a pH from pH 7.5 to pH 9, particularly compositions wherein said alkali oxidised aqueous gelatinised starch / protein mixture comprises a solids content of from 3% w / w to 50% w / w, and processes in the preparation of the same and also processes employing the said composition in the preparation of paper or fiberboard.

Owner:WESTON FOODS

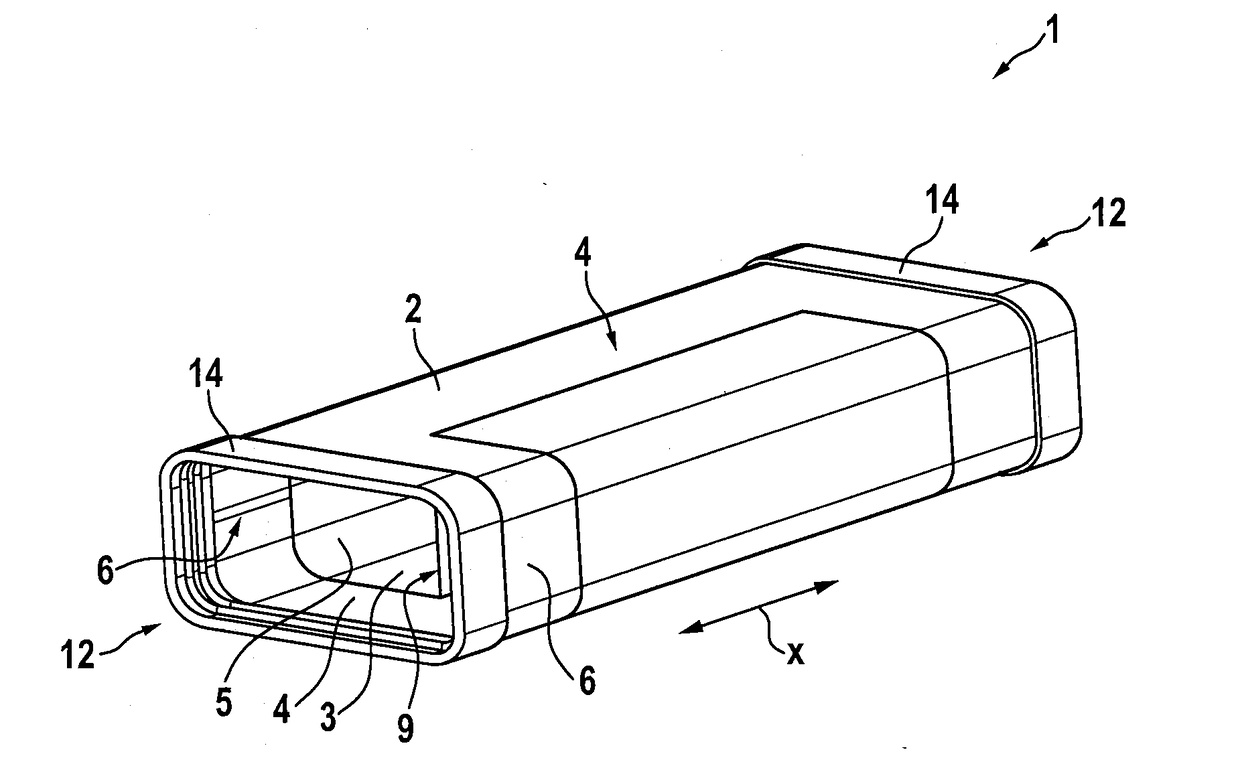

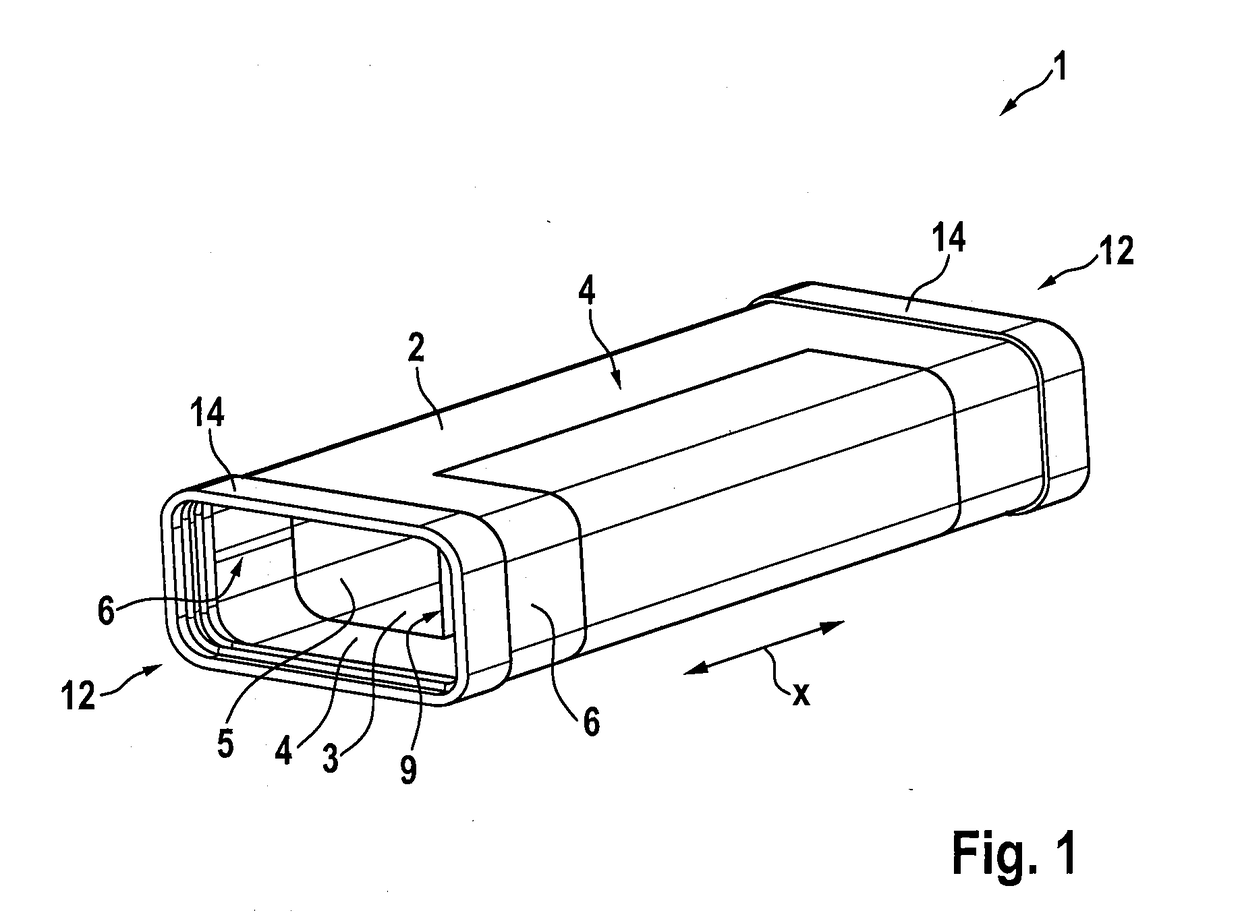

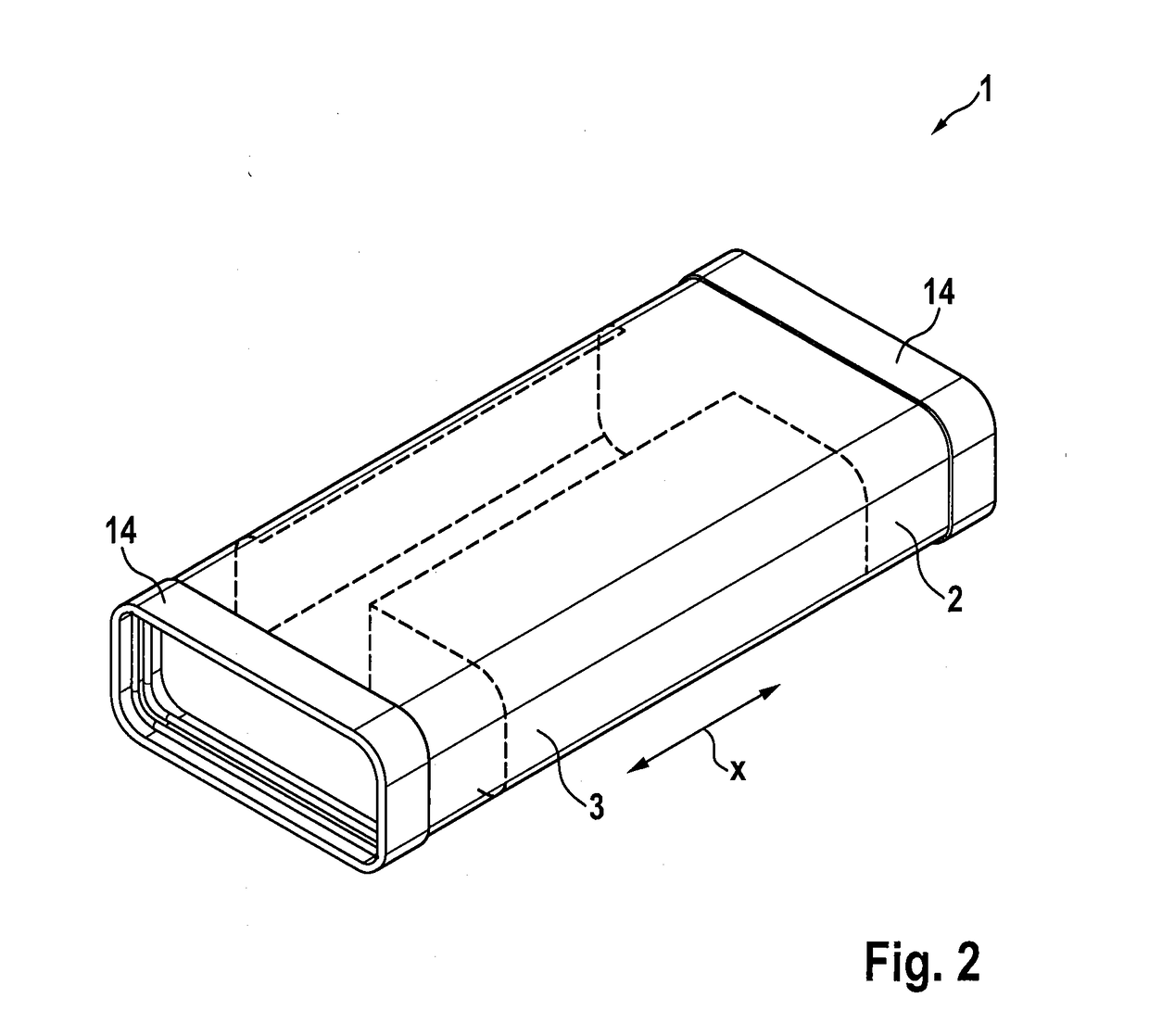

Exhaust Air Channel Arrangement for a Kitchen Exhaust Air Channel System

ActiveUS20180328617A1Reduce the risk of injurySmall wall thicknessDucting arrangementsLighting and heating apparatusEngineeringMechanical engineering

An exhaust air channel arrangement for a kitchen exhaust air channel system is provided in which the exhaust air channel arrangement is composed of a sheet metal pipe and a supporting structure, which is movably received within the sheet metal pipe along the longitudinal direction (x) of the sheet metal pipe, wherein both opposed wall portions of the sheet metal pipe are mutually supported by the supporting structure.

Owner:NABER HOLDING GMBH & CO KG

Filter Paper That Disintegrates Quickly in Water

ActiveUS20150173414A1High mechanical strengthDisintegrates quicklyNon-fibrous pulp additionCigar manufactureCellulose fiberFilter paper

The invention relates to a paper that disintegrates quickly in water, for use as a filter material or filter wrapper paper of a cigarette filter. At least 80 wt % of the paper is formed by cellulose fibers. Of the cellulose fibers, at least 80 wt % are a mixture of long fiber pulp and mercerized pulp. 0 to 90 wt % of the content of the mixture is formed by mercerized pulp, and the rest is formed by long fiber pulp. The cellulose fibers of the mixture have a freeness of at most 30° SR according to ISO 5267. In the disintegration test using an apparatus as described in TAPPI T 261, the paper exhibits a disintegration of at least 60% after 30 seconds.

Owner:DELFORTGROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com