Patents

Literature

472 results about "Chemical pulp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pulp is wood fiber that is generally used to make paper. Chemical pulp is created by a method that uses chemicals and heat to convert wood into pulp. This process can be, and generally is, used as an alternative to mechanical pulping, which involves obtaining wood fibers by way of a grinding process.

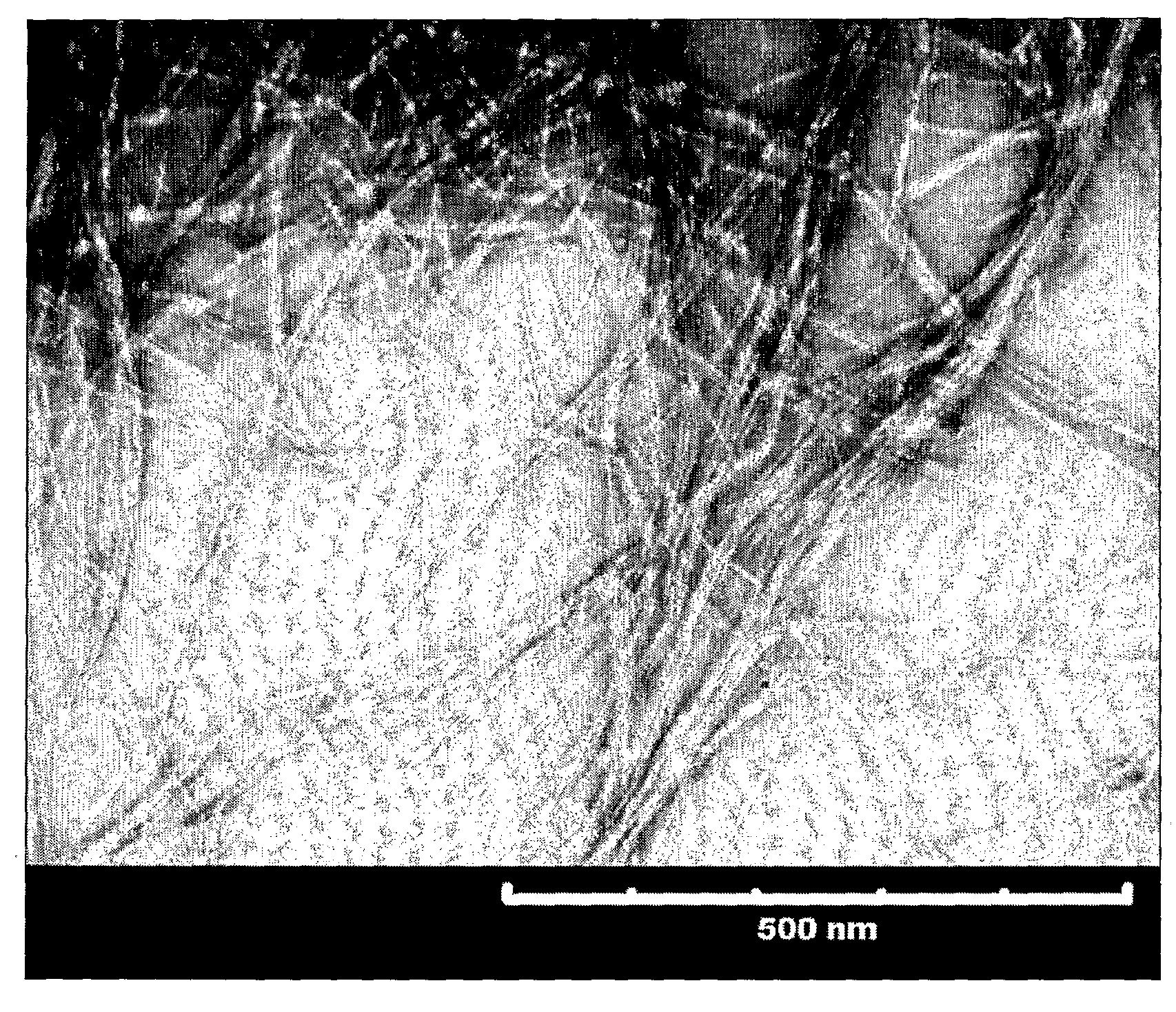

Method for the manufacture of microfibrillated cellulose

ActiveUS20090221812A1Reduce energy consumptionCellulose treatment using microorganisms/enzymesMultistage pulping processHemicelluloseEnzyme

A method for treatment of chemical pulp for the manufacturing of microfibrillated cellulose includes the following steps: a) providing a hemicellulose containing pulp, b) refining the pulp in at least one step and treating the pulp with one or more wood degrading enzymes at a relatively low enzyme dosage, and c) homogenizing the pulp thus providing the microfibrillated cellulose. According to a second aspect of the invention a microfibrillated cellulose obtainable by the method according to the first aspect is provided. According to a third aspect of the invention, use of the microfibrillated cellulose according to the second aspect in food products, paper products, composite materials, coatings or in rheology modifiers (e.g. drilling muds) is provided.

Owner:STFI PACKFORSK AB

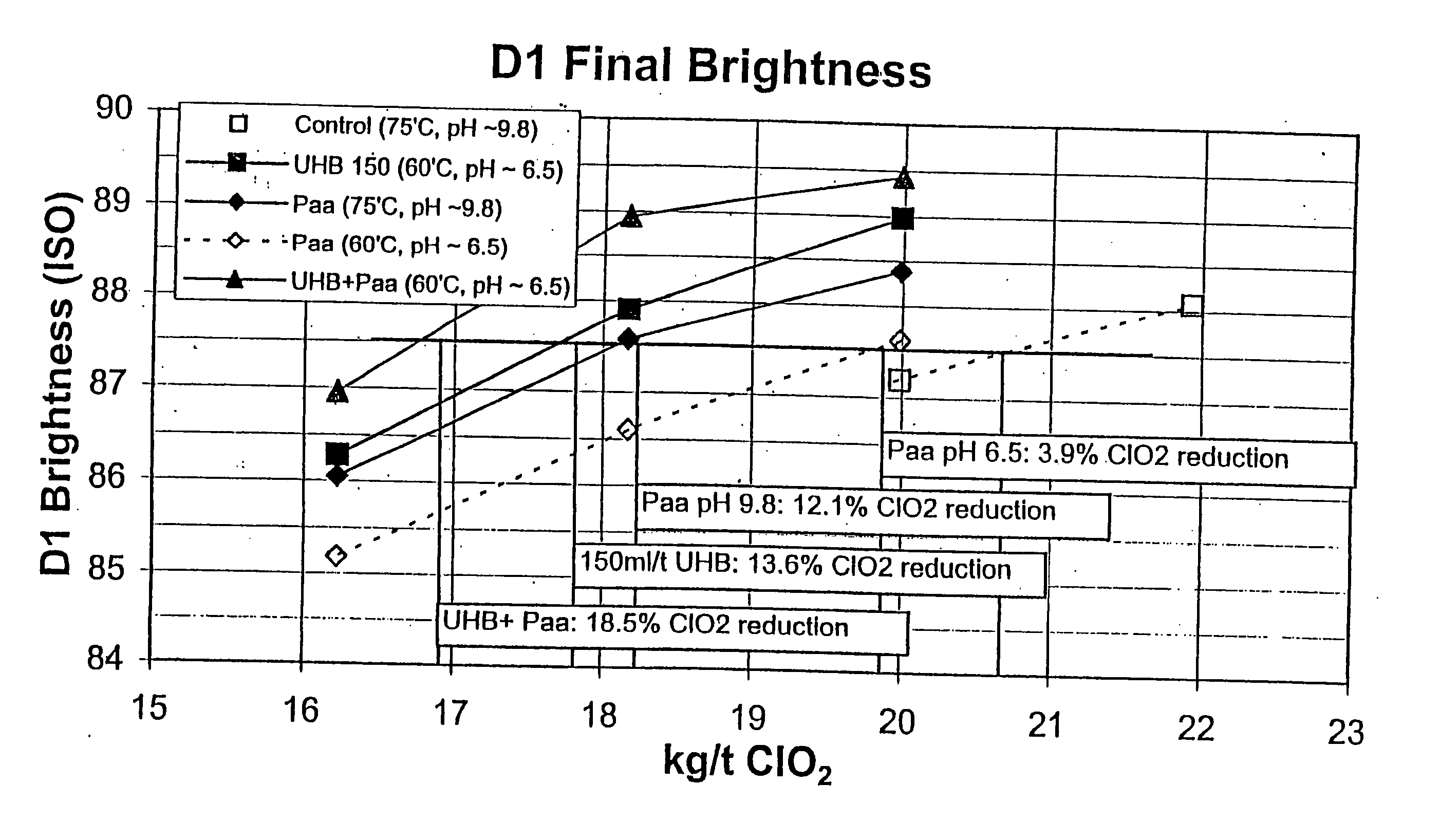

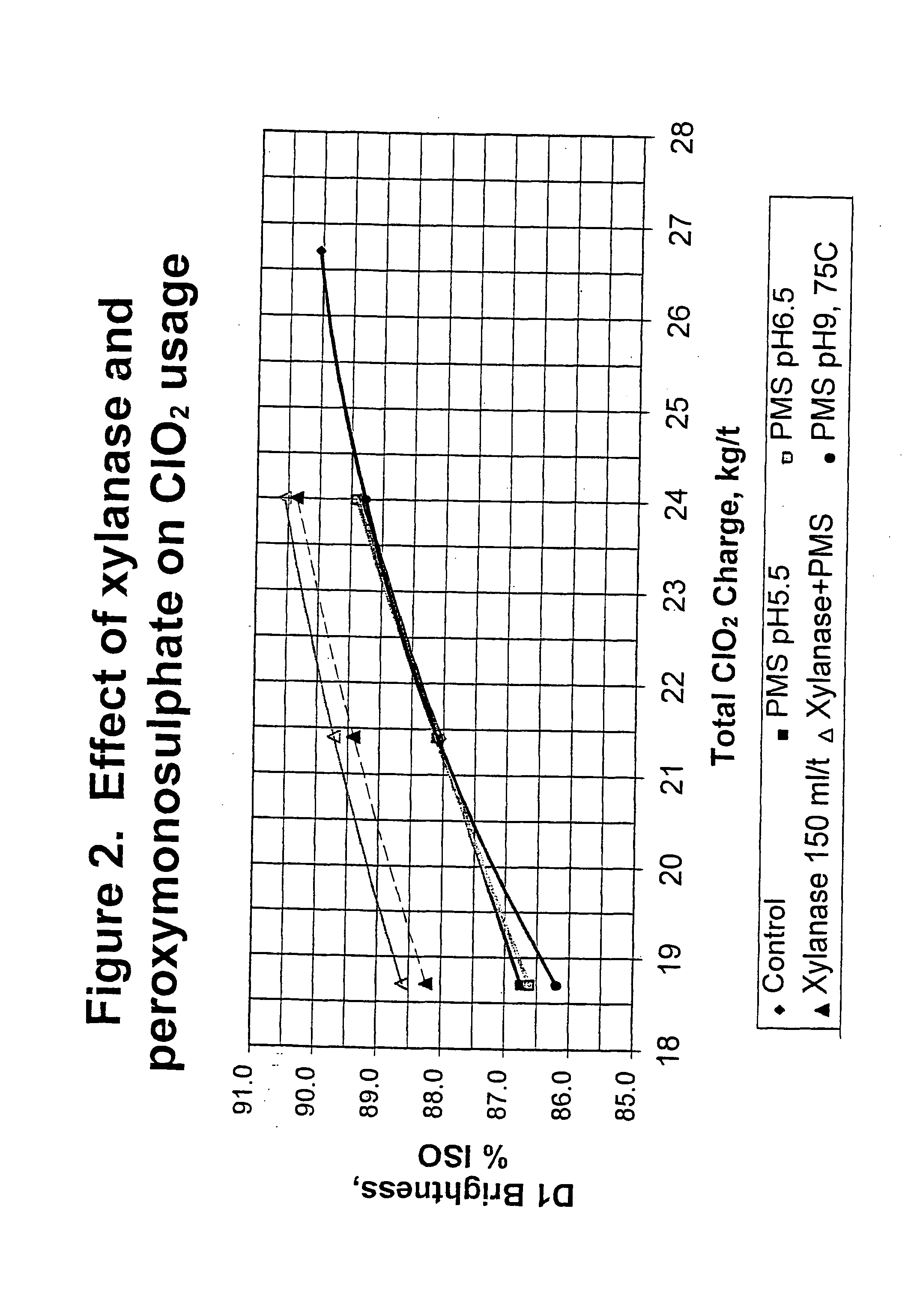

Bleaching stage using xylanase with hydrogen peroxide, peracids, or a combination thereof

InactiveUS20040112555A1Less-costly bleaching operationReduce usagePulp bleachingPulping with inorganic basesChlorine dioxideXylanase Y

The present invention discloses methods of bleaching chemical pulp that combine xylanase enzymes with hydrogen peroxide, peracids, or a mixture. The method comprises the steps of carrying out a chemical pulping operation, optionally followed by delignifying the pulp with oxygen, then combining xylanase enzymes with hydrogen peroxide, peracids, or a mixture to bleach the pulp. The method allows the mill to use both xylanase and peracids in a single bleaching tower to decrease the usage of chlorine dioxide and other bleaching chemicals. The pulp bleaching method of the present invention may be performed in a pulp mill as part of a complex pulp bleaching process.

Owner:IOGEN BIO PRODUCKTS CORP

Oxygen delignify treating method for grass group unbleached chemical pulp

ActiveCN101082187ALow percussionImprove water filtration performanceCellulosic pulp after-treatmentPulping with inorganic basesCelluloseMagnesium salt

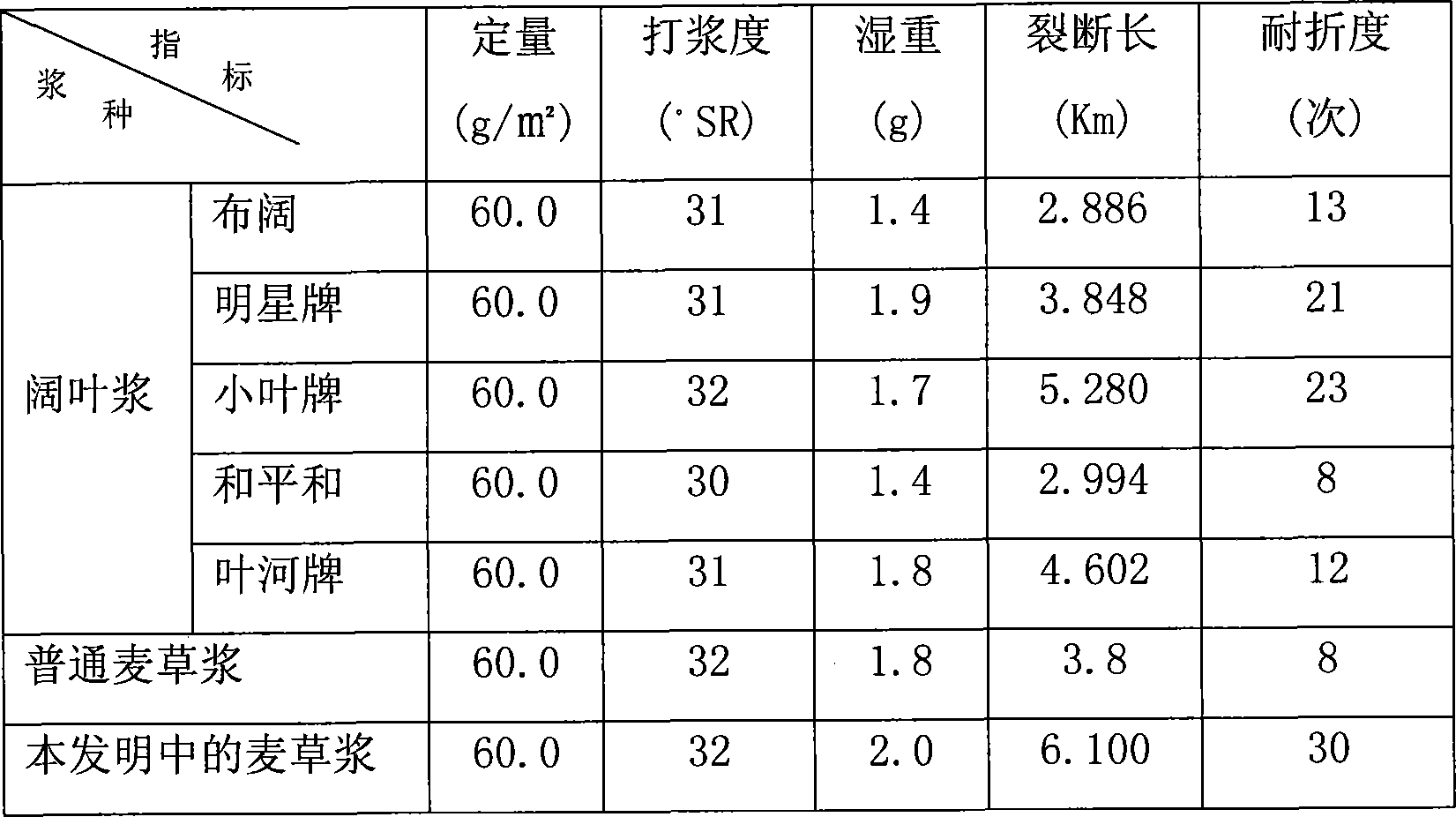

The invention relates to an oxygen delignification processing method of grass unbleached chemical pulp. The oxygen delignification of the pulp is processed after cooking and before bleaching. Its rigidity before the oxygen delignification is potassium permanganate value 16-28 (equals to karber value 26-50). After pumping into the oxygen delignification reaction tower and inflating sodium hydroxide, magnesium salt and oxygen, the chemical pulp happen the oxygen delignification in the reaction tower. The chemical pulp with rigidity of potassium permanganate value 10-14 (equals to karber value 14-18) is achieved after the oxygen delignification. The invention can remove the lignin in the pulp effectively and the removal rate is 86-98%. It reduces the degradation of the cellulose to simplify the bleaching process and cut down the dosage of the chemicals. The bleached pulp has good rigidity and drainability. The breaking length of the pulp can reach 4500-8000m and its fold-resistant times can reach 20-70.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

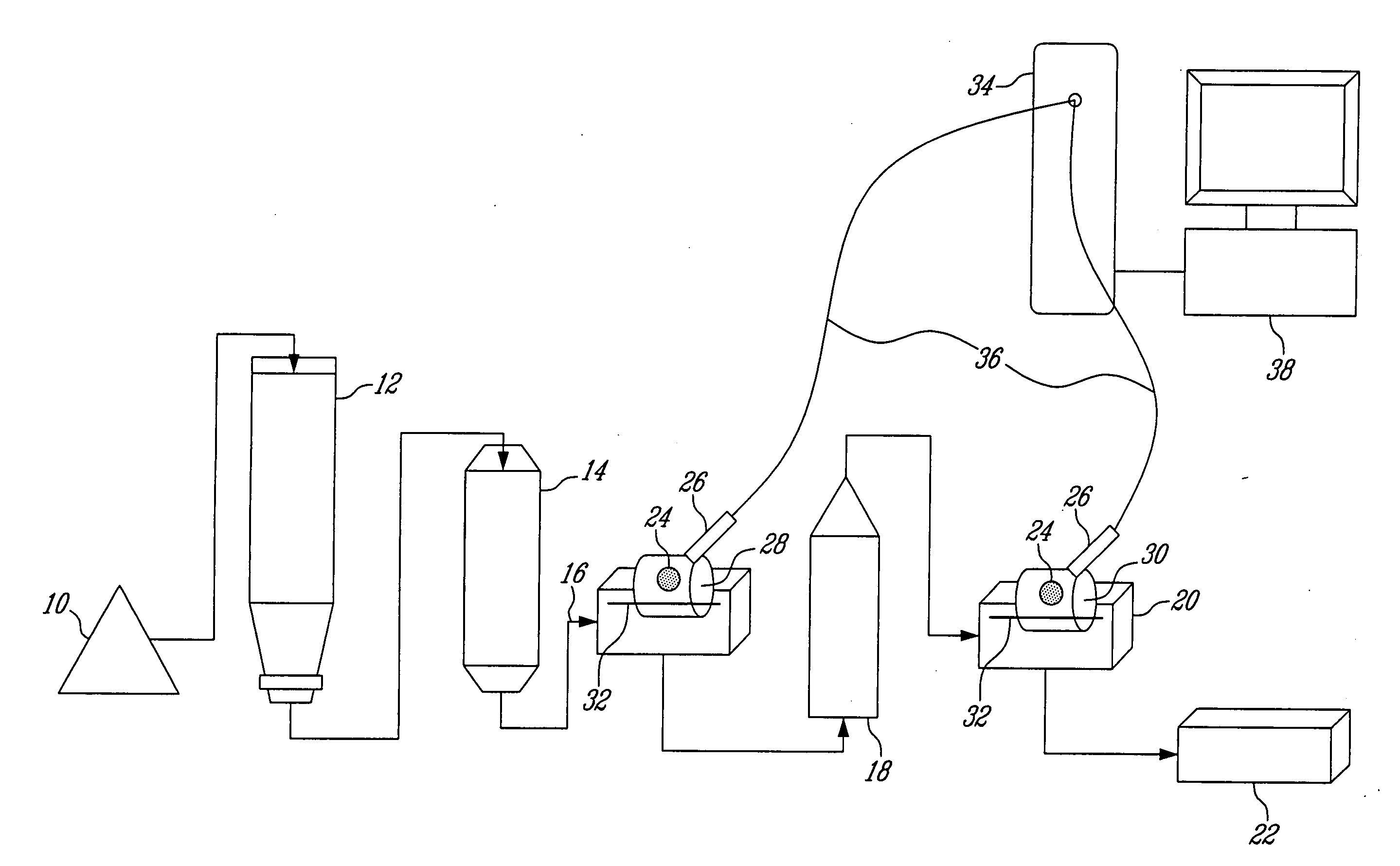

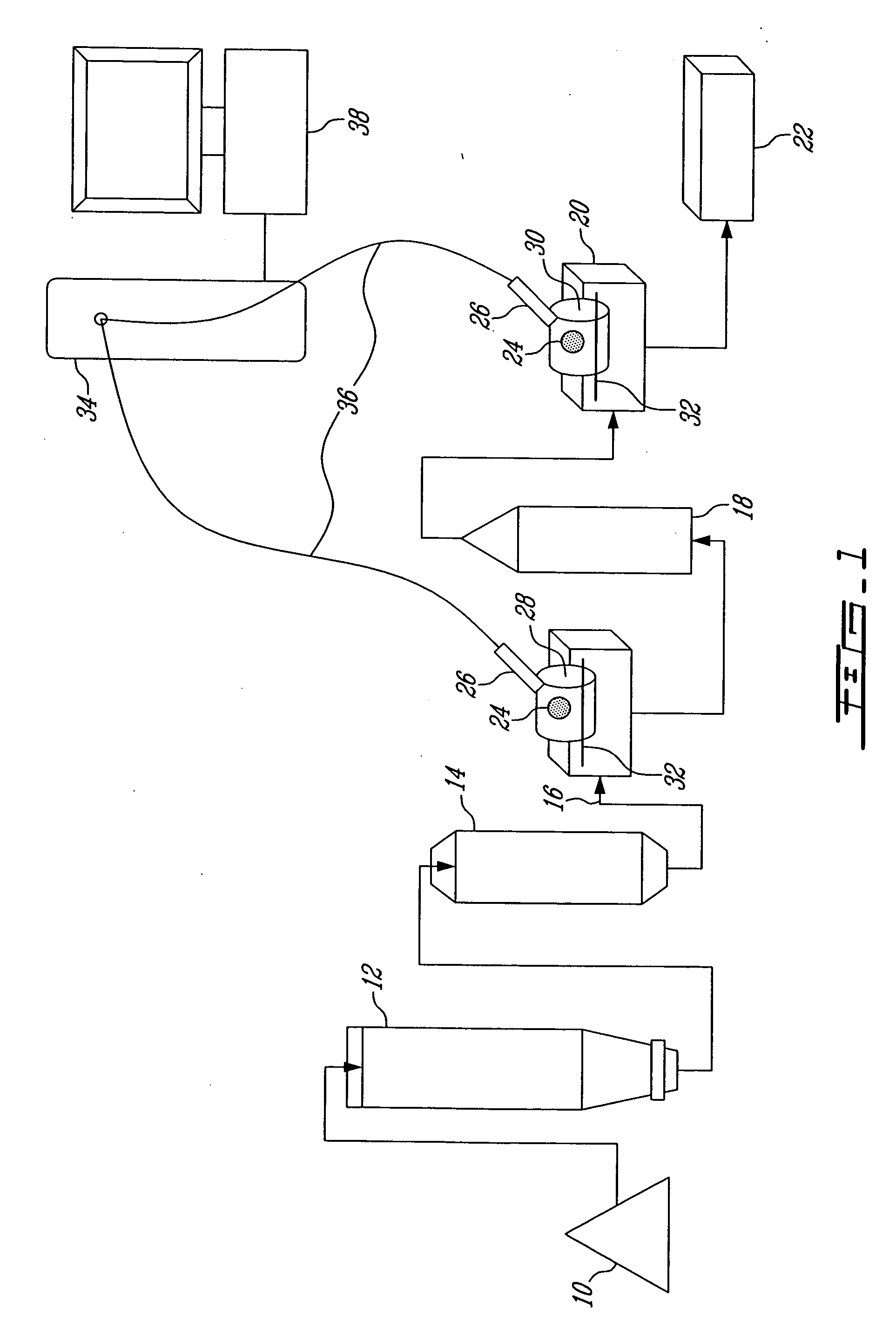

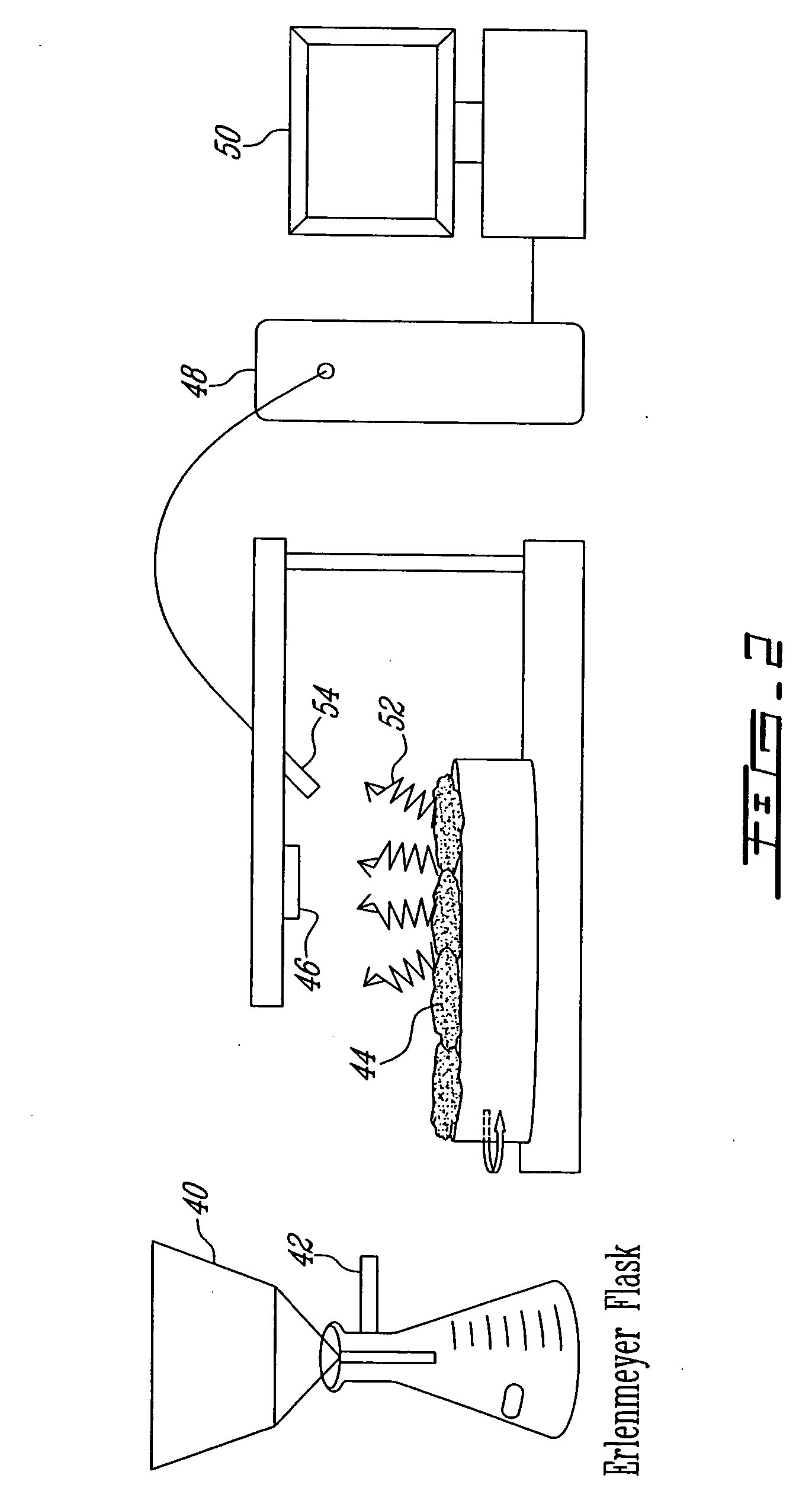

Method for determining chemical pulp Kappa number with visible-near infrared spectrometry

ActiveUS20060196622A1Overcomes shortcomingCellulosic pulp after-treatmentRadiation pyrometryContinuous measurementPresent method

A method for the determination of cellulosic-fibre properties, such as, but not limited to, residual lignin content of chemical pulp, with the aid of a spectroscopic technique obtained over a range covering the visible and the near-infrared regions of the electromagnetic spectrum, comprising the steps of obtaining a sample from the process line, minimally removing some excess water, exposing the fibres in the sample to a large beam light source, optionally moving the sample at a constant speed, and acquiring the spectral data over a pre-determined length of time, and correlating the spectrum to a previously determined calibration so as to determine the Kappa number. Alternatively, as an arrangement for process control, along with other varying configurations, the instant invention includes the mounting of the excitation light source and fibre-optic probe along the various locations of the kraft cooking and bleaching process, such as 1) at the drum brownstock washers and 2) throughout the bleach plant deckers, located just before the doctored blade, the probe being connected to a fast scanning spectrometer, via fibre optic cables, with a computer sequencing spectral acquisition and correlating the spectrum against a predetermined calibration, and logging the results. The process configuration, with the use of the instant invention, overcomes all limitations of prior art, including sampling hardware and sample preparation, and provides true online Kappa number determinations of the order of seconds, as compared to current state of the art Kappa analyzers which require 10 to 15 minutes per analysis. The present method is capable of measuring residual lignin content of chemical pulps with varying consistency, accounts for species effects to provide species insensitivity and can provide analysis in less than 10 seconds. The method can provide true online continuous measurement of Kappa number for feedforward and feedback control of the bleaching, paper machine and kraft cooking processes.

Owner:FPINNOVATIONS INC

Prepared bleach chemical pulp using grass kind plant as raw material and preparation method thereof

ActiveCN101089291AReduce manufacturing costQuality improvementDigestersPulp de-wateringKappa numberFolding endurance

The present invention discloses a bleached chemical pulp prepared by using graminoid plant as raw material and its preparation method. Said invention is characterized by that it utilizes a high-hardness pulp which is obtained by using cooking process and whose permanganate number is 16-28 and equal to Kappa number 26-50 and makes said high-hardness pulp undergo the processes of pulp-washing and bleaching treatment so as to obtain the invented bleached chemical pulp whose breaking length is 4500-8000 m and folding endurance is 20-70 times.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

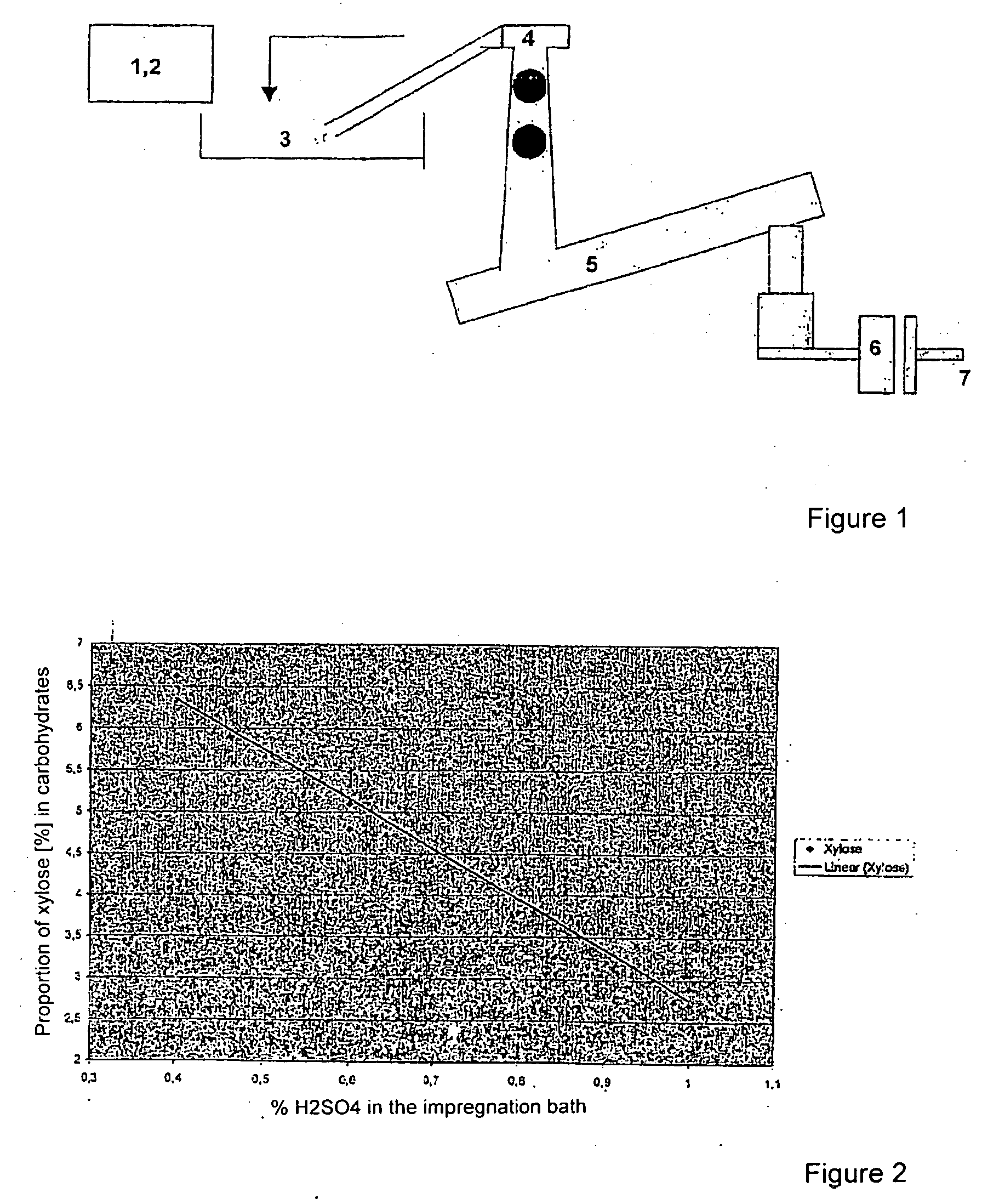

Method for separating xylose from lignocelluloses rich in xylan, in particular wood

InactiveUS20050065336A1Many solutionsHigh cellulose yieldSugar derivativesXylose productionXylanPre treatment

The invention is directed to a method for separating xylose from lignocelluloses rich in xylan, particularly wood, and for obtaining pulp, characterized by the following steps: (1) pretreating wood chips through mechanical destruction of the original structure; (2) impregnating the obtained wood mass with diluted mineral acid; (3) carrying out prehydrolysis of the obtained wood mass modified by the process under the influence of steam at an elevated temperature to hydrolyze the obtained hemicelluloses; and (4) removing the hemicelluloses from the residual pulp by washing, filtering and / or centrifuging while obtaining an aqueous solution rich in xylose. The combination of method steps according to the invention makes it possible to achieve high α-cellulose contents with very low proportions of xylose, that is, highly pure chemical pulp qualities, while at the same time enabling a virtually quantitative separation of the valuable xylose.

Owner:RHODIA ACETOW AG

Coated paper and process for producing same

InactiveUS20040180184A1Less smoothnessHigher proportion of mechanical fiberLayered productsCoated paper substrateChemical pulpFiber

In the conventional process of producing a coated paper, the use of a furnish that is characterized by a base sheet fiber content made of about 60 to 85 weight percent of a bleached thermomechanical pulp (TMP), about 10 to 35 weight percent of a bleached chemical pulp and 0 to about 15 weight percent of a deinked pulp, and also comprising about 12 to 20 weight percent of an inorganic filler, with a freeness below 50 ml Csf and a brightness over 75° ISO, gives a coated paper of the same or superior quality and at a much lower cost than the usual coated paper obtained through a conventional process.

Owner:BPR

Alkaline pectinase production method and application in papermaking pulping

ActiveCN101914510AHigh strengthImprove bleachabilityMicroorganism based processesEnzymesPectinaseBacterial strain

The invention discloses an alkaline pectinase production method and application in papermaking pulping. The alkaline pectinase production method comprises the steps of: selective breeding of a bacterial strain, culturing of the bacterial strain, fermentation through shaking a flask, and preparation of an enzyme liquid. The method is characterized in that the bacterial strain subjected to the selective breeding is achieved through separated screening of a naturally acquired bacterial sample and mutagenesis of the bacterial strain at cellular level, i.e. heat-resistant Bacillussubtillis with a laboratory number of MAPLE61 and preservation number of CCTCC NO:M2010004; and when the heat-resistant Bacillussubtillis is used for papermaking pulping, raw materials are soaked with an alkaline pectinase solution after the pickling treatment. When the invention is used for papermaking pulping, the prepared chemical pulp has favorable strength property and bleaching property; and after simple oxidation chlorine bleaching, the whiteness of the pump can reach 80-90 percent, breaking length can reach 6000-7000m, and meanwhile, alkali consumption is reduced about 20-40 percent and the production cost is reduced about 20 percent.

Owner:苏州盛泽科技创业园发展有限公司

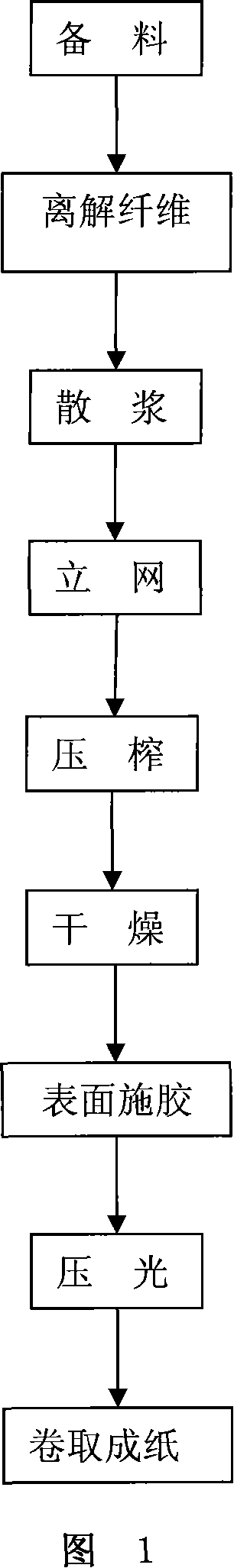

Method for producing glassine paper

InactiveCN102493284AReduce energy consumption for beatingReduce energy billsSpecial paperWater-repelling agents additionSulfateCellulase

The invention relates to a method for producing glassine paper, which is characterized by comprising the following steps: a. respectively carrying out pulping on bleached sulfate needle wood chemical pulp and bleached sulfate broadleaf wood chemical pulpboard, respectively adding an beater auxiliary agent modified cellulase in the pulp for beating; b. preparing the pulp according to weight ratio, adding a sizing agent for mixing, forming by net part dehydration, carrying out shoe pressing and drying; c. passing the paper through at least 3 pressing areas when superpressing. The method of the present invention saves beating energy consumption by 10-15% and steam consumption by 5%.

Owner:YUEYANG FOREST & PAPER CO LTD

Cardboard having great reigidity

InactiveUS6221212B1Low densityHigh tensile stiffness indexNon-fibrous pulp additionWrappersCardboardVolumetric Mass Density

Owner:STORA ENSO AB

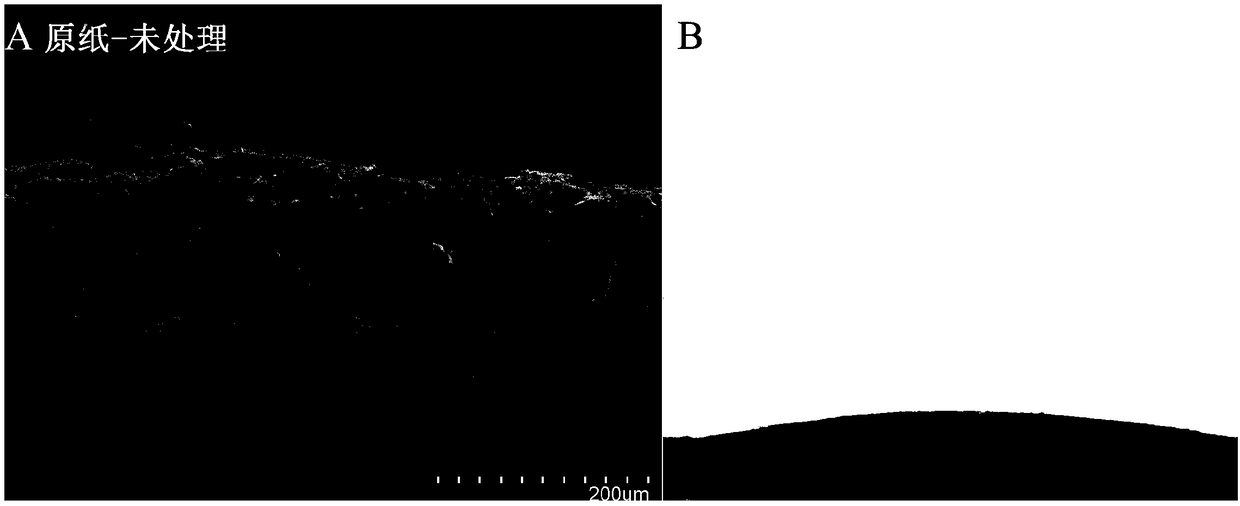

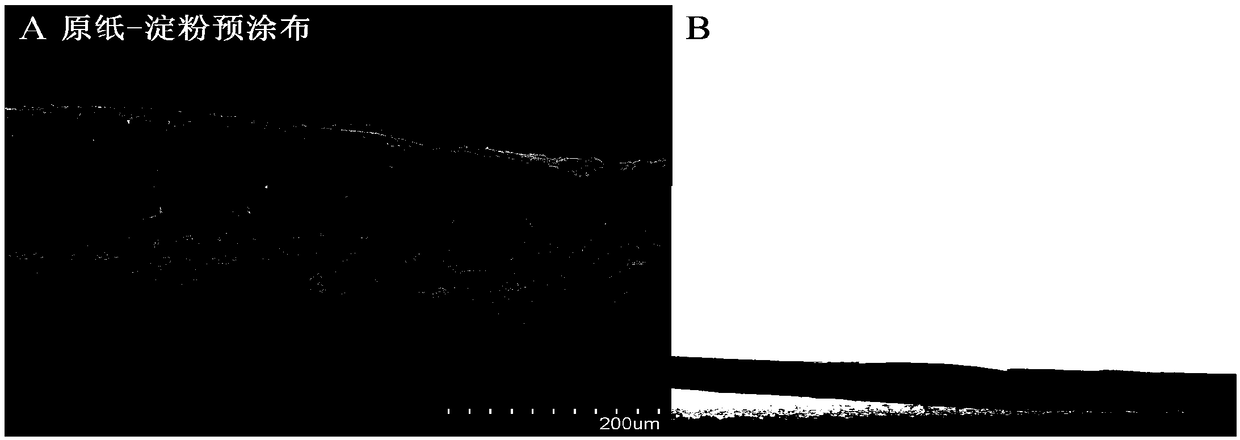

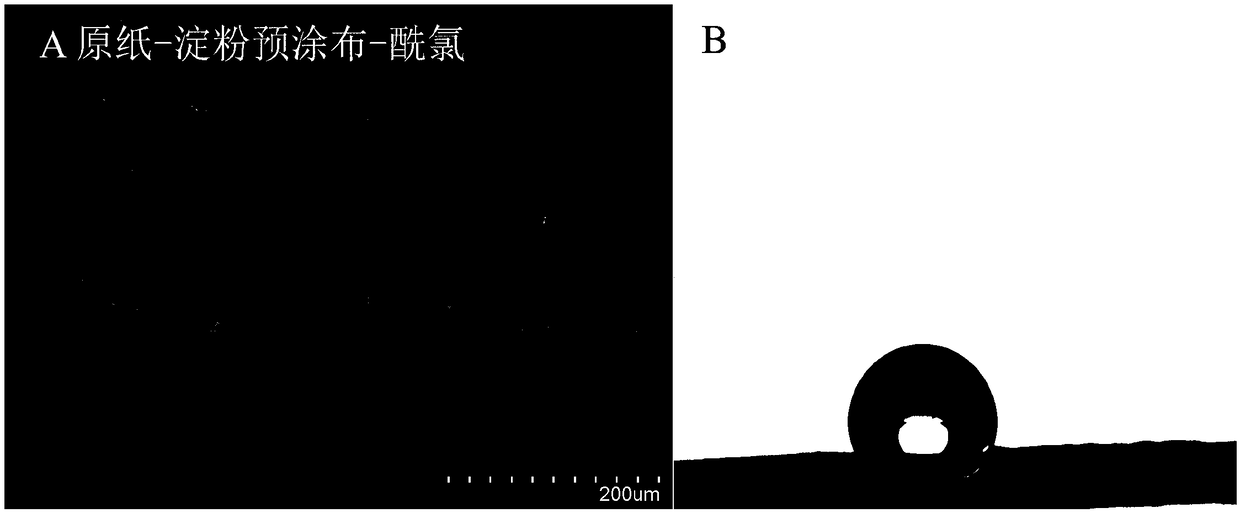

Preparation method of hydrophobic oilproof paper

ActiveCN108625219AImprove adhesionImprove water resistancePaper coatingPaper/cardboardPapermakingSoftwood

The invention relates to the field of papermaking and discloses a preparation method of hydrophobic oilproof paper. The preparation method includes: 1), making body paper: soaking bleached softwood chemical pulp, and pulping; mixing the bleached softwood chemical pulp, carboxymethyl cellulose, bacterial cellulose and dissolving pulp, making handsheet, and drying to obtain the body paper; 2), dissolving a natural polyhydroxy high molecular material in water, stirring, heating, holding temperature until a system is transparent, stirring, cooling to room temperature to obtain coating liquid, andcoating; 3), drying the body paper after being precoated, using an acyl chloride solution to treat the surface of the body paper, and drying to obtain a finished product. The problem that paper is porous is solved by means of coating the surface of the paper with the polyhydroxy high molecular material which is natural and easy to degrade, and an acyl chloride compound not containing fluorine is used to replace fluorine-containing polymer to endow the paper with hydrophobicity and oilproofness, so that environment friendliness is realized. In addition, paper prepared by the method has good strength performance and printability.

Owner:杭州市化工研究院有限公司 +1

Scouring process for grass pulping course

ActiveCN101082188AQuality exceedsWashing/displacing pulp-treating liquorsPulp and paper industryEngineering

The invention provides a washing process in the grass pulping. It contains the following steps: A) send the cooked pulp into the presser for pressing to get the coarse pulp. B) Process the coarse pulp through the jumping screen. C) Send the screened pulp into the pulp washer for washing. The rigidity of the screened pulp is potassium permanganate value 16-28 (equals to karber value 24-50). The washed solvent remains 90-150ppm. Take the high rigidity pulp in this invention as materials to prepare bleaching chemical pulp by pressing and washing. The whiteness of the chemical pulp is 68-82%ISO and the removal rate of the lignin is 84-98%. The quality of the bleaching chemical pulp prepared by the grass is similar, even better than that of the exciting hardwood pulp.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Xylanase treatment of chemical pulp

InactiveUS20050150619A1Reduce usageHigh strengthPulp bleachingPulping with organic solventsChlorine dioxidePulp mill

The present invention discloses methods of bleaching chemical pulp that use xylanase enzymes after chemical bleaching. The method comprises the steps of carrying out a chlorine dioxide stage to produce a partially bleached pulp, treating the partially bleached pulp with a xylanase enzyme, optionally in the presence of oxygen and hydrogen peroxide, in a mild extraction stage, then bleaching the pulp with a second chlorine dioxide stage. The method allows the mill to decrease the usage of sodium hydroxide or other alkali, while decreasing the use of chlorine dioxide, and possibly improving the yield and strength of the pulp, while maintaining a similar level of bleached brightness of the pulp. The pulp bleaching method of the present invention may be performed in a pulp mill as part of a complex pulp bleaching process.

Owner:NOVOZYMES AS

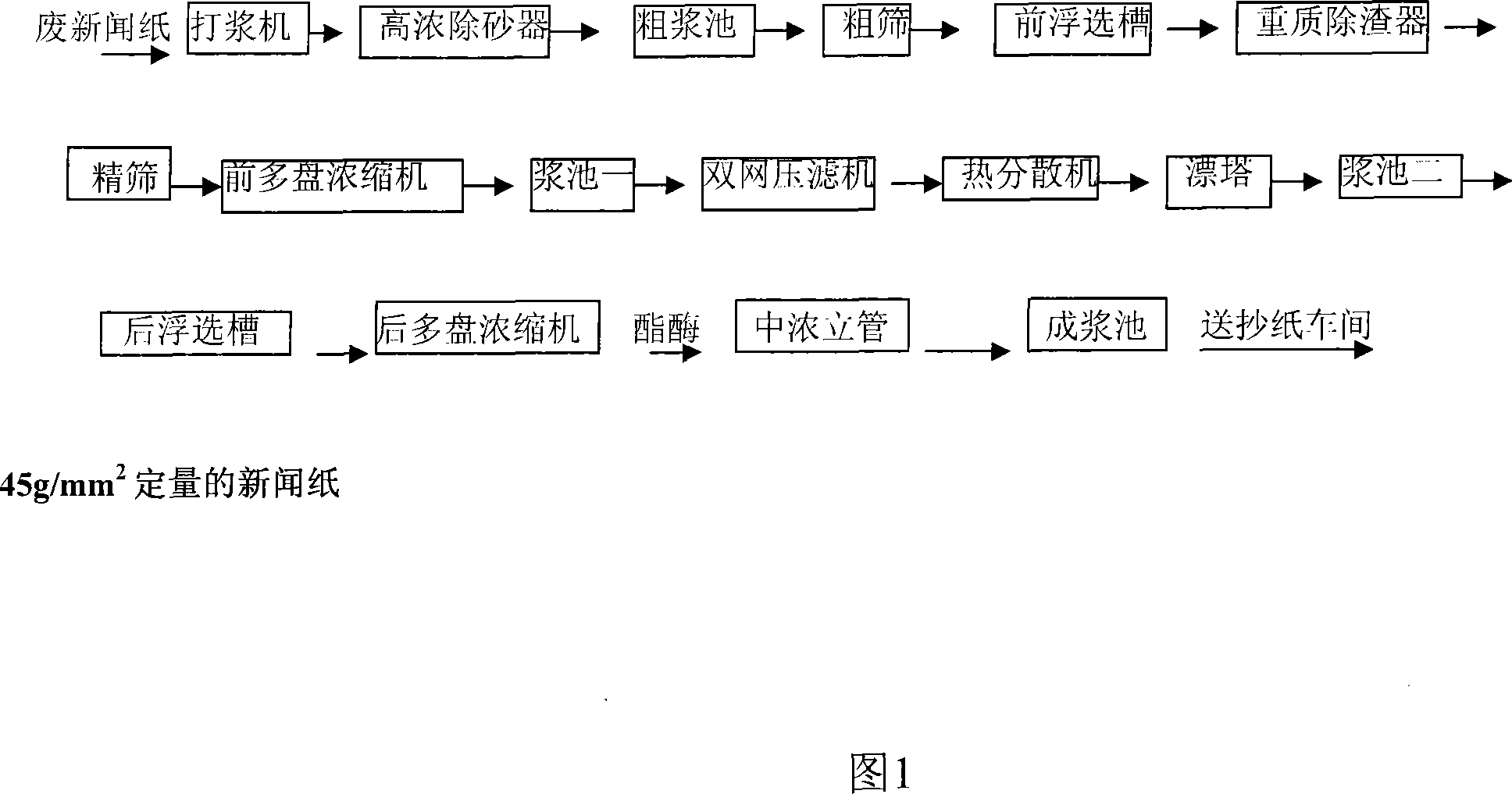

Method for controlling with 100aste newsprint paper deinked pulp esterase

InactiveCN101220567AReduce contentGuaranteed uptimePulp de-wateringPaper recyclingProcessing costPollution

The invention discloses a method that uses esterase obtained by 100 percent deinking and desizing of wasted newspaper controls sticky which mainly aims at producing the low fixed amount newspaper by using the 100 percent deinking and desizing of the wasted newspaper, adopts Optimyze 525 esterase control sticky and produces the newspaper with 45g / mm<2> fixed amount. The invention has the advantages of reducing the dosage of the sticky in the paper pulp, leading the sticky removing rate to be about 20 percent to 40 percent, reinforcing the operating performance of a paper machine, and helping to improve the speed and the output of the paper machine; by adopting deinking and desizing of 100 percent wasted newspaper to make 45g / m<2> lowing amount offset newsprint, the obtained products have good quality, chemical pulp and groundwood pulp which are high in pollution and high consumption are eliminated, the manufactory cost of the pulp material and the processing cost of the water are reduced, and the discharged waste water and the pollutants are reduced.

Owner:GUANGDONG IND TECHN COLLEGE +1

Special pigment finishing offset paper and producing method thereof

InactiveCN1584205AReduce particle contentIncrease bulkNon-fibrous pulp additionCoatings with pigmentsGreen environmentXerography

This invention discovers a special pigment groom hectograph paper and its preparation. It utilizes the advantages of high yields machine pulp (PRC-APMP) and deink pulp (DIP) which is well thickness and green environment. That is optimizing pigment spreading formulation, optimizing pulp to materials ratio and its wet end chemical and copy making technique to reach the white value of all bleaching chemical pulp proportioning copy paper. The advantages of the products are: better printing adaptability, better relaxation thickness, better printing effect features compared with all chemical pulp hectograph paper. It's capable of producing top grade office and printing culture special pigment groom hectograph paper which is made according to different clients' requirement and selecting different optimized features' technique for different application such as laser printing, xerography and hectograph etc. So, it's capable of decreasing all chemical pulp quantity, saving wood, protecting forest, protecting environment from pollution.

Owner:YUEYANG FOREST & PAPER CO LTD

Mitigation technique in use for producing bleached chemical pulp by using raw material of grass

ActiveCN101092805AFats/resins/pitch/waxes removal in pulpChemical/chemomechanical pulpState of artBleach

This invention relates to an easing technology for producing bleach chemical pulp with grasses including: 1, preparing bleach chemical pulp according to the current technology, 2, easing the material pulp to loosen fiber structure in terms of the current technology after steaming grasses materials and before bleaching the pulp so as to loosen leaf structure of the grass fibers, which forms a cubic net structure suitable for exposing lignin in the grasses since the specific surface area is increased.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

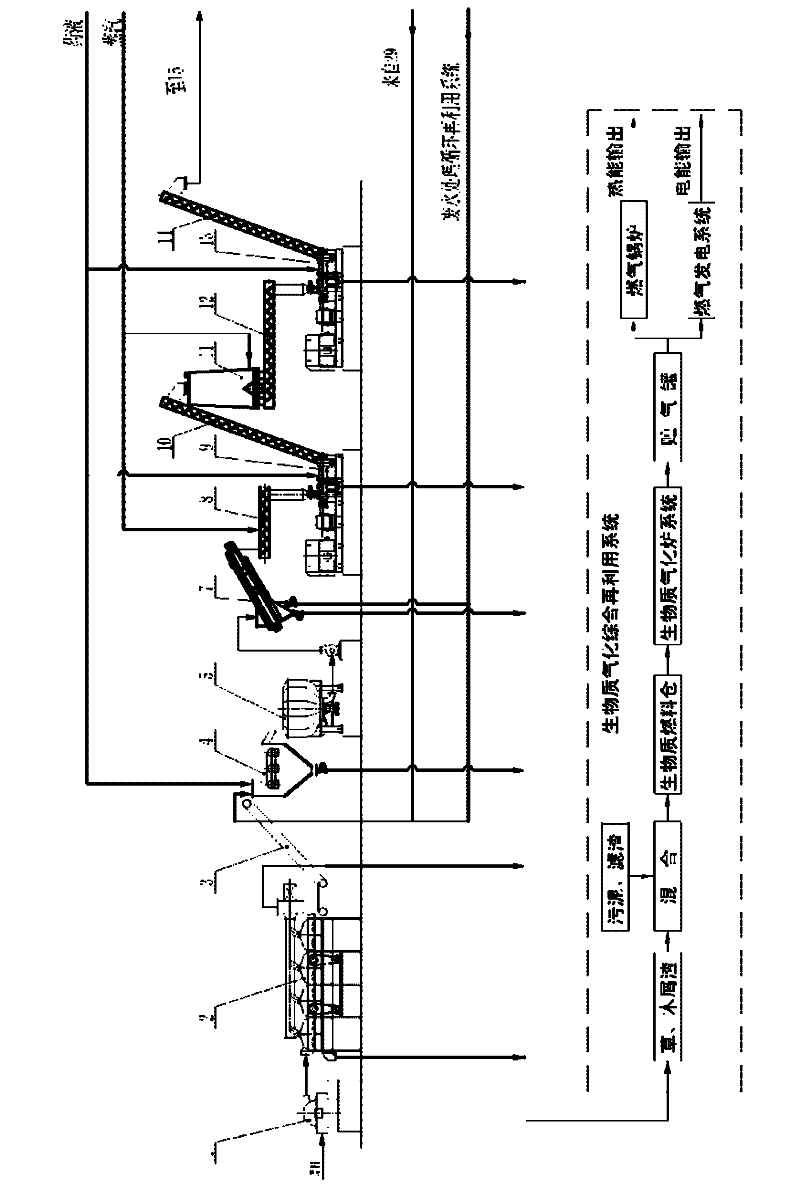

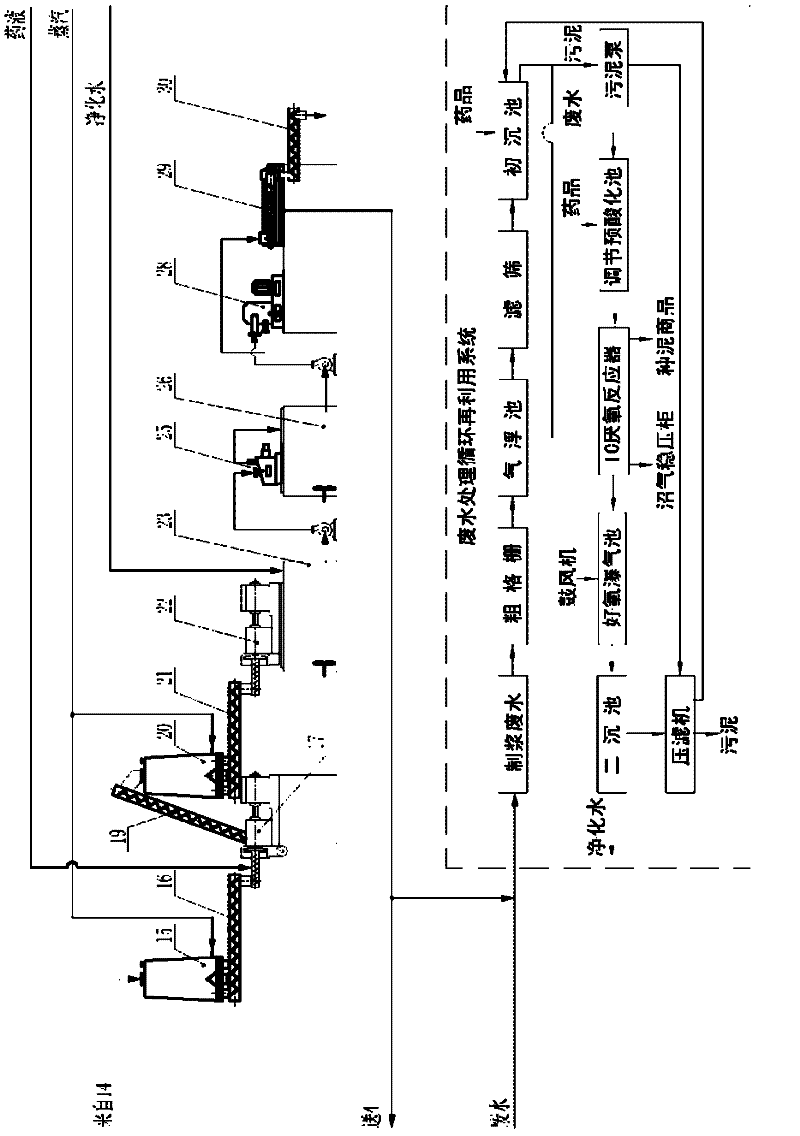

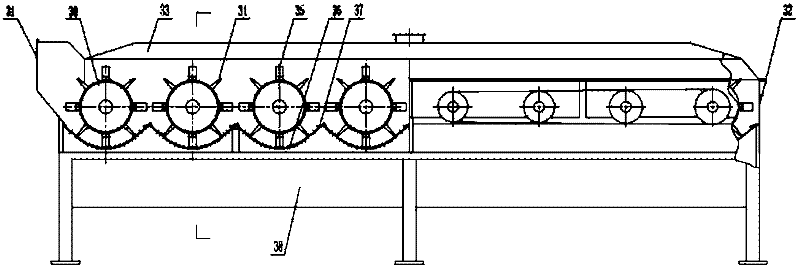

Pulping system and pulping method for environment-friendly mechanical pulp and chemical mechanical pulp of non-woody crops

The invention provides a pulping system for environment-friendly mechanical pulp and mechanical chemical pulp of non-woody crops, which comprises a cutting machine, a hammer filament duster, an impregnating washer, an I-section cracking impregnator, an II-section cracking impregnator, an I-section storage reaction bin, an II-section storage reaction bin, a high-concentration impregnating millstone mill, an III-section storage reaction bin and a pulping machine and screening, purification and concentration equipment in a subsequent process, wherein a steaming spiral conveyer, the I-section storage reaction bin, the II-section storage reaction bin and the III-section storage reaction bin are provided with steam injecting pipelines, and liquid medicine injecting pipelines are also arranged at the impregnating washer, the cracking tail end of the I-section cracking impregnator, the cracking tail end of the II-section cracking impregnator and the input position of the high-concentration impregnating millstone mill. A pulping method comprises the following steps of: preparing raw materials, performing pre-steaming spiral conveying, connecting two physical filamentation treatment sections in series, performing high-concentration disc impregnating filamentation treatment, and performing high-concentration pulping, screening, purifying and dehydrating to obtain commercial pulp. The technical scheme has the technical advantages of high yield, no pollution, low energy consumption and the like.

Owner:刚荣环保科技(上海)有限公司

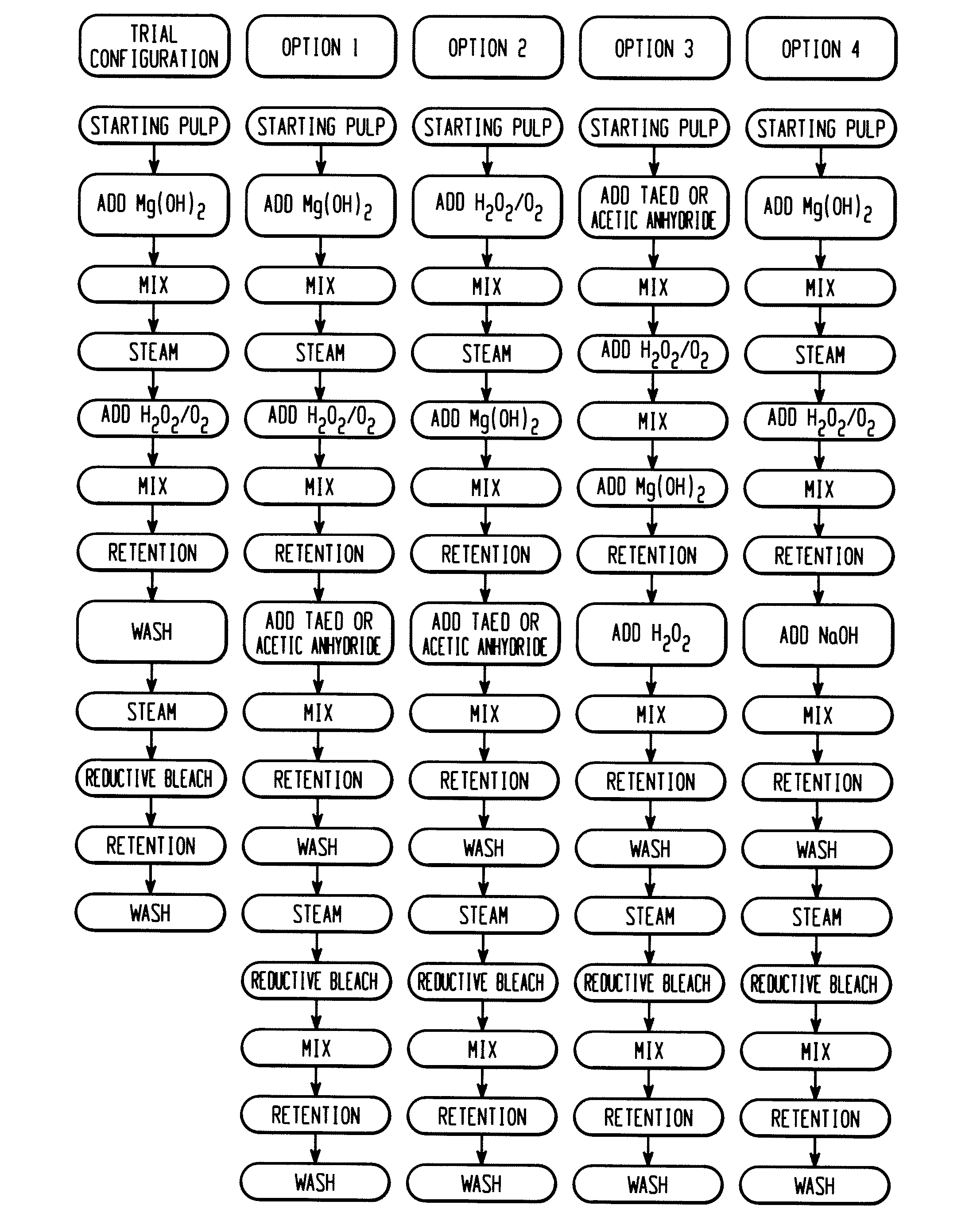

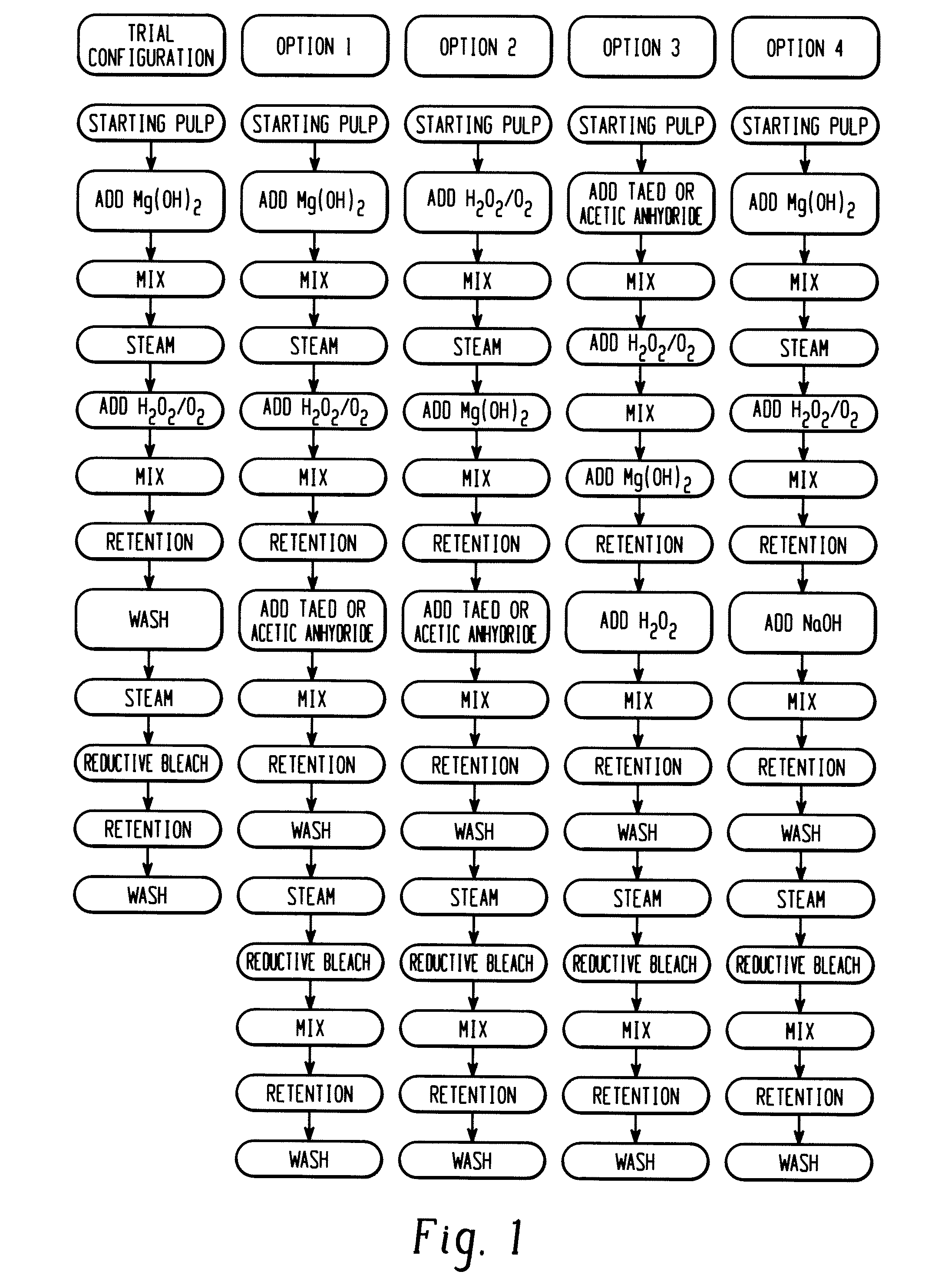

High Brightness Pulps From Lignin Rich Waste Papers

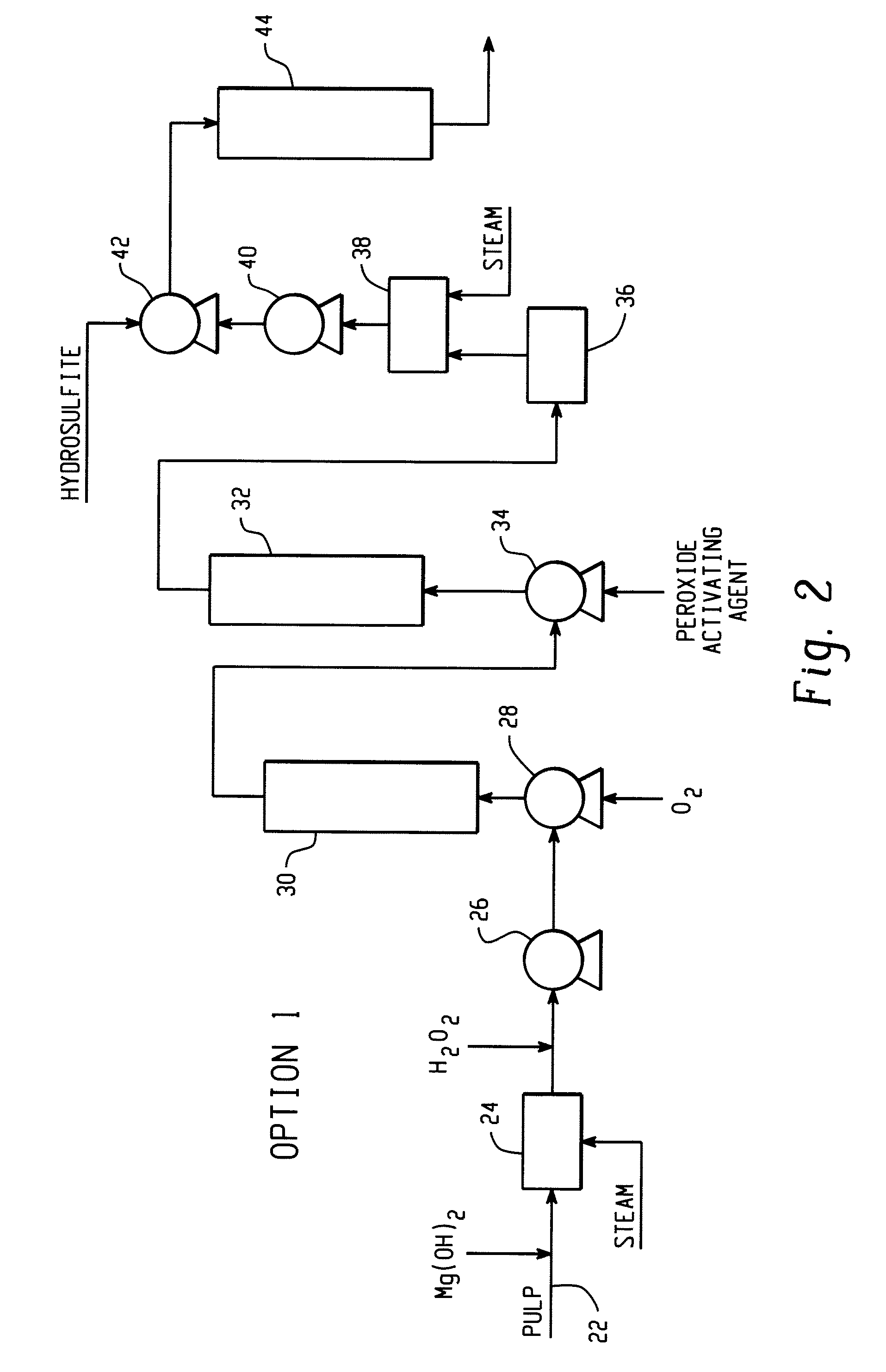

ActiveUS20120067532A1Avoid interferenceInhibition formationPaper recyclingPulp bleachingAcetic acidOxygen

This present invention relates to methods for preparing premium or near-premium brightness pulps for towel and tissue applications from fiber sources comprising substantial amounts of lignin-containing pulp and chemical pulp while controlling fines, scale and anionic trash. These methods use alkaline hydroxide in combination with peroxide and oxygen for initial bleaching stages followed by treatment with a peroxide activating agent to convert residual peroxide in the pulp into peracetic acid followed by a final reductive bleaching stage.

Owner:GPCP IP HLDG LLC

Method for the manufacture of microfibrillated cellulose

ActiveUS8546558B2Cellulose treatment using microorganisms/enzymesMultistage pulping processHemicelluloseEnzyme

A method of treating chemical pulp for the manufacture of microfibrillated cellulose includes the following steps: a) providing a hemicellulose containing pulp, b) refining the pulp in at least one step and treating the pulp with one or more wood degrading enzymes at a relatively low enzyme dosage, and c) homogenizing the pulp thus providing the microfibrillated cellulose. A microfibrillated cellulose obtainable by the method is also provided. The microfibrillated cellulose can be used in food products, paper products, composite materials, coatings or in rheology modifiers (e.g. drilling muds).

Owner:STFI PACKFORSK AB

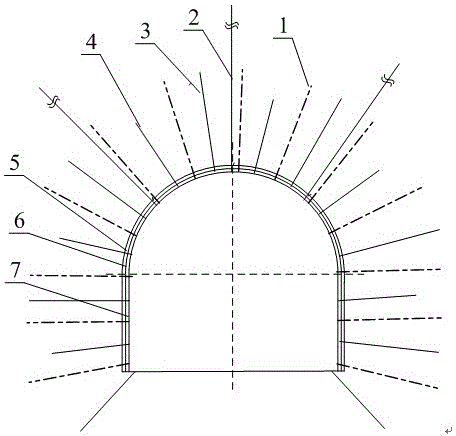

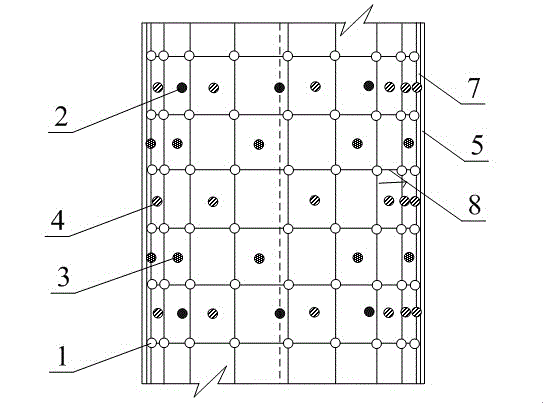

Supporting method of permeable soft broken rock stratum roadway

InactiveCN103603675AEffective deformationEffectively closedUnderground chambersTunnel liningSteel barCement slurry

The invention relates to a supporting method of a roadway in a coal mime, particularly to a supporting method of a permeable soft broken rock stratum roadway. The supporting method aims at solving the problems that soft broken rock stratum roadways especially permeable soft broken rock stratum roadways are poor in supporting effect, high in cost and the like. The supporting method comprises the steps of first concrete spraying; combined support through high strength deformed steel bar anchor rods and diamond metal nets; anchor cable installation; secondary concrete spraying; installation of chemical pulp grouting anchor rods; installation of cement slurry grouting anchor rods.

Owner:张瀚

Removal of inorganic elements from wood chips

InactiveUS20050034823A1Less energy consumptionIncrease moisture contentWashing/displacing pulp-treating liquorsPretreatment with acid reacting compoundsProduction linePregnant leach solution

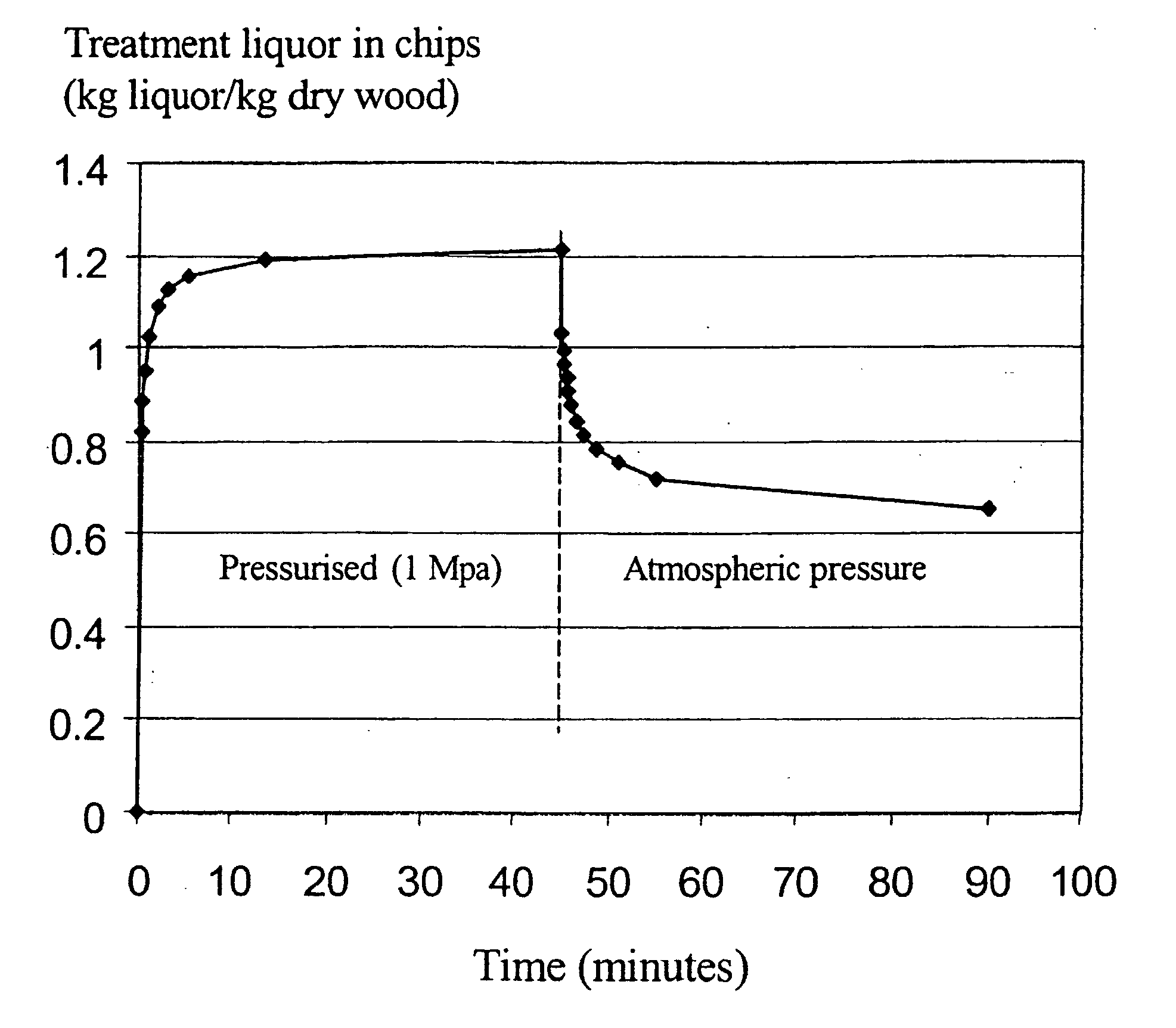

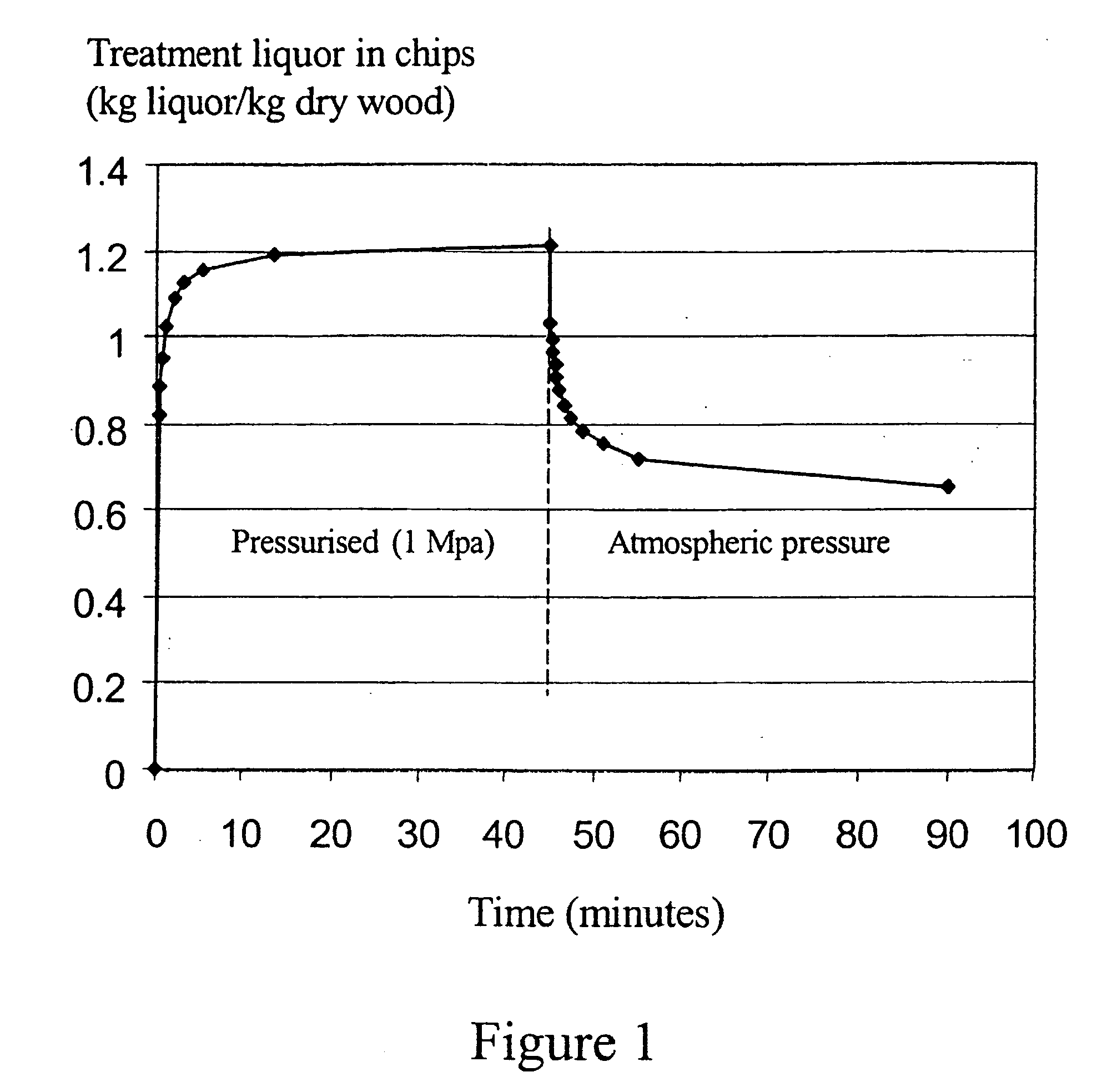

In a process of treating wood chips for reduction of the concentration of undesirable inorganic elements prior to cooking in a production line for chemical pulp, the wood chips, having entrapped air, are treated with an aqueous leaching liquor at elevated temperature and pressure, followed by draining at atmospheric pressure or below atmospheric pressure, the pressures being controlled to yield a moisture content in the wood chips as low as possible for adequate leaching result and behavior of the chips in a subsequent digester. The aqueous leaching liquor is e.g. pulp mill process water with a low content of undesirable inorganic components, such as bleach plant spent liquor or condensate. The aqueous leaching liquor drained from the treated wood chips may be purified and recycled back to the process.

Owner:STFI

Oil-tea camellia fruit shell semi-chemical pulp preparing process

InactiveCN103696306ASolve the use problemAlleviate resource constraintsFibrous raw materialsFiberCamellia oleifera

The invention discloses an oil-tea camellia fruit shell semi-chemical pulp preparing process, comprising main steps of preprocessing, boiling, black liquid extracting, washing, mechanical pulp grinding, abeyance eliminating, purifying and screening. Oil-tea camellia fruit shell waste with rich resources is used as a new pulping raw material to produce semi-chemical pulp, so the comprehensive use problem of the oil-tea camellia fruit shell waste is effectively solved, the condition of fiber resource shortage in the paper making industry is relieved, the wood resource consumption in pulping and papermaking is reduced, and the natural environment is protected; the oil-tea camellia fruit shell semi-chemical pulp preparing process overcomes the negative influence of chemical composition of oil-tea camellia fruit shells to the pulping performances, a semi-chemical pulping method massively retaining lignin and hemicellulose is adopted, and the prepared oil-tea camellia fruit shell semi-chemical pulp is less in chemical medicine consumption, high in paper pulp yield, good in strength and low in cost. The oil-tea camellia fruit shell semi-chemical pulp preparing process is strong in operability, low in production cost and easy for realizing large-scale production.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

Methods to enhance brightness of pulp and optimize use of bleaching chemicals

InactiveUS20050217813A1Low production costAchieve brightnessHydrogen peroxidePulp properties modificationDithionous acidALLYL SUCROSE

Mechanical or Chemical pulp is treated with about 0.01 weight % to about 5 weight % of a Mixture. The Mixture is water; diethylenetriaminepentakis(methyl)phosphonic acid or its known salts; polyacrylic acid or its known salts; and optionally one or more inert compounds. This Mixture acts to either maintain the brightness level of the pulp at the target level or to increase the brightness level of the pulp. In addition the Mixture allows for maintaining the pulp at the target level of brightness even when the amounts of other ingredients, such as hydrogen peroxide, hydrosulfite, sodium silicate and magnesium, that are typically added to the pulp, are reduced.

Owner:ECOLAB USA INC

Eucalyptus dissolving pulp and production method thereof

InactiveCN102493256AReduce productionReduce pollution loadPretreatment with water/steamNatural cellulose pulp/paperSulfateDissolving pulp

The invention discloses a eucalyptus dissolving pulp and a production method thereof, wherein the eucalyptus dissolving pulp is prepared after the steam prehydrolysis, sulfate cooking, oxygen delignification and D0EoPD1 bleaching of eucalyptus pieces, the whiteness is not less than 88%, the alpha cellulose is not less than 94.5%, the pentosan is not higher than 3.0%, the dynamic viscosity is 9-25mPa s, the ash content is not higher than 0.1%, and the iron content is not higher than 15mg kg<-1>. The production method of the eucalyptus dissolving pulp comprises the following steps that: the eucalyptus pieces undergo the steam prehydrolysis, and the P- factor of the steam prehydrolysis is 300-800; the sulfate cooking is carried out after the steam prehydrolysis of the eucalyptus pieces to obtain the pulp; the eucalyptus chemical pulp undergoes the D0EoPD1 bleaching after the oxygen delignification; and after the bleaching, the pulp is washed, dried and processed into the eucalyptus dissolving pulp.

Owner:湖南骏泰新材料科技有限责任公司 +1

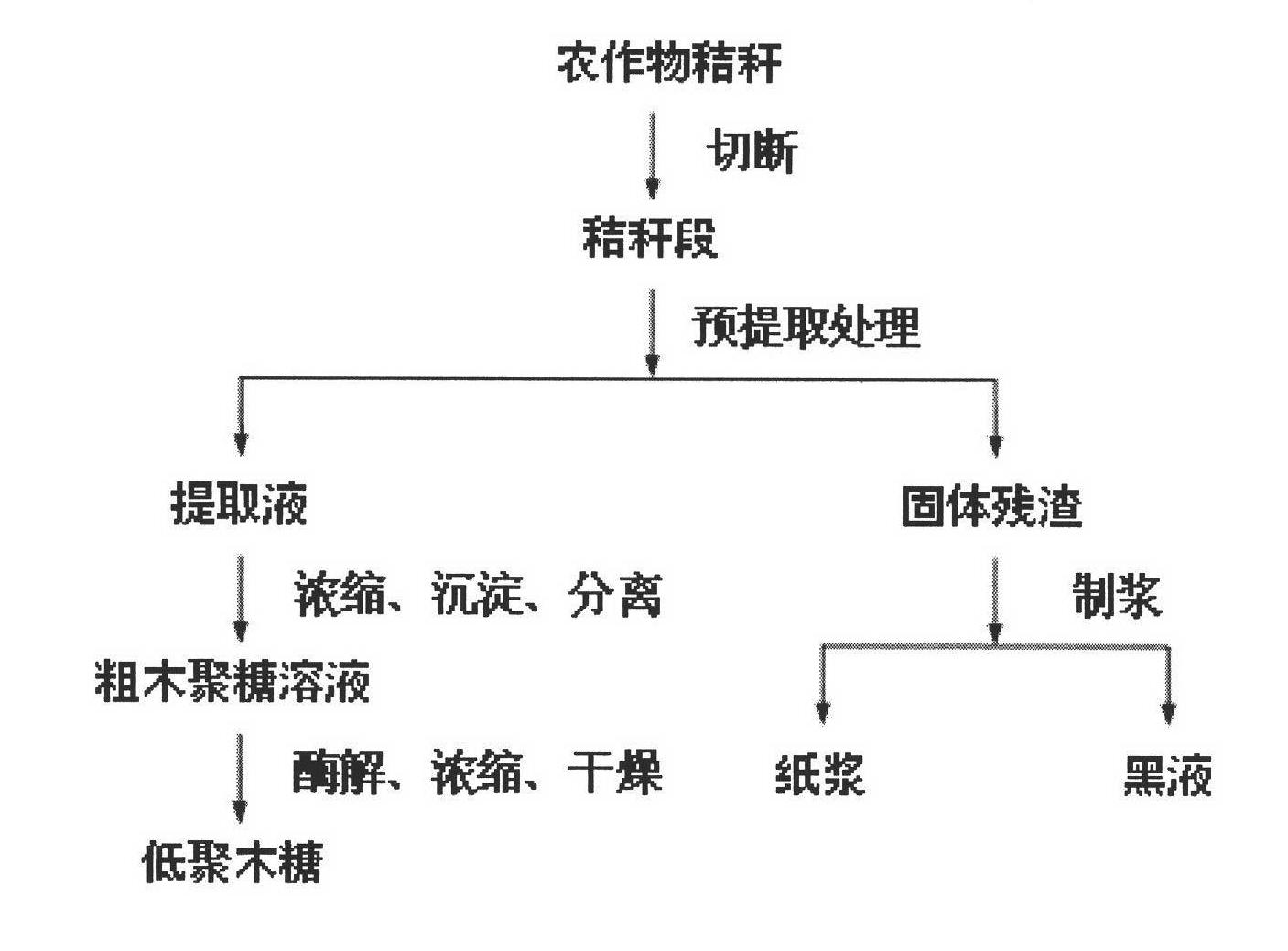

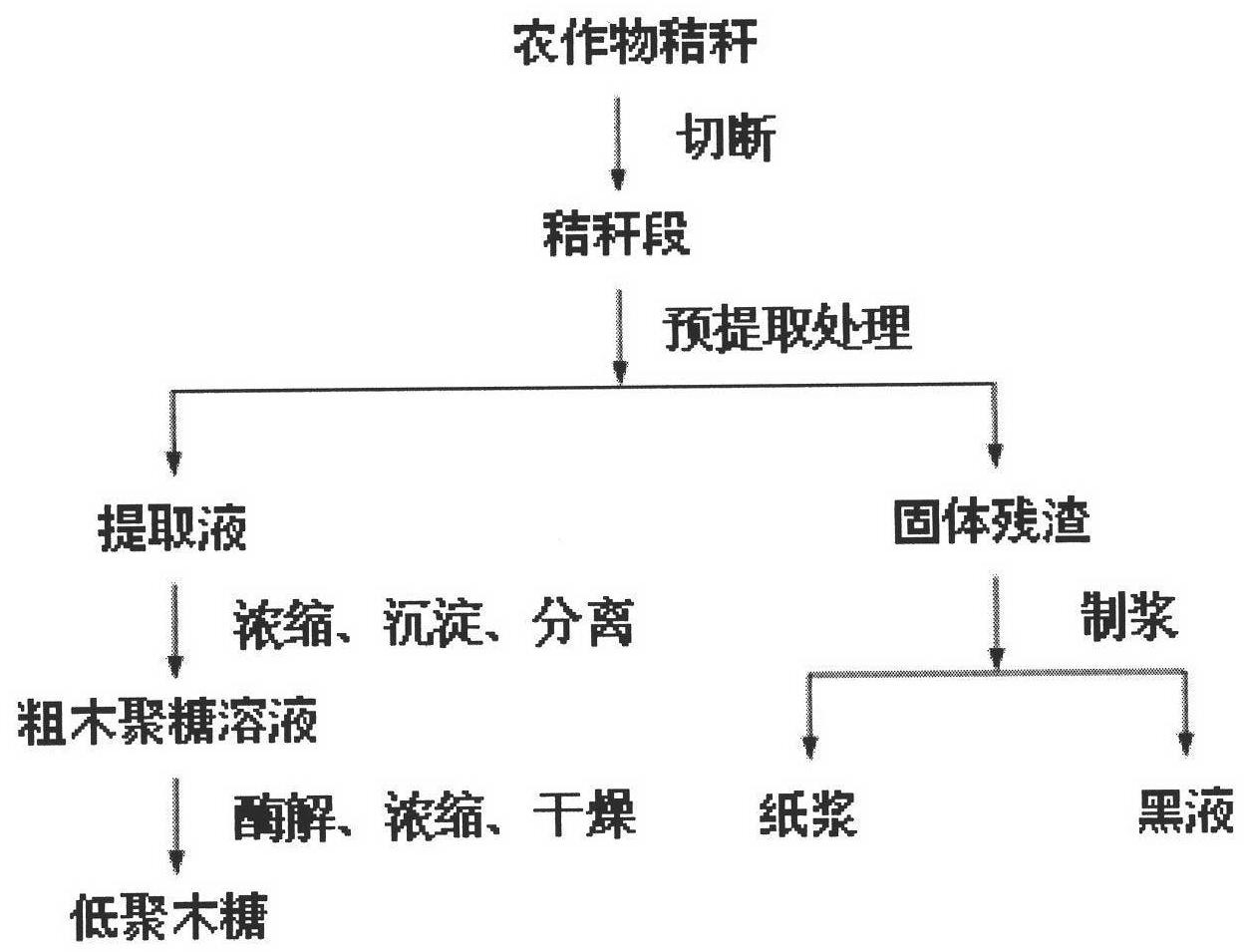

A kind of method for preparing xylo-oligosaccharide and paper pulp

ActiveCN102277761AImprove fiber qualityImprove physical performance indicatorsPretreatment with alkaline reacting compoundsPulping with inorganic basesFiberOligosaccharide

The invention discloses a method for preparing oligosaccharide and paper pulp, belonging to the technical fields of pulping and the comprehensive utilization of pulping. The method comprises the steps of: using crop straws as raw materials, pre-treating the raw materials to obtain a pre-extracting solution, concentrating the pre-extracting solution by a membrane separation method, then obtaining a crude xylan solution via precipitation and centrifugal separation, and then preparing oligosaccharide via enzymolysis, vacuum concentration and frozen-drying. The pre-treated solid residues are stewed via an alkaline process so as to prepare unbleached paper pulps of which the indexes such as fiber length, whiteness, fracture length, tear resistance, folding strength and the like are all improved. The generated black liquid has the characters of low viscosity and high heat productivity. The method for preparing oligosaccharide and paper pulp integrates the comprehensive utilization method with the biomass transformation method on the premise of optimizing the traditional alkaline chemical pulping technique to prepare products with high additional values, namely oligosaccharide, thereby increasing the quality of the paper pulp and the extraction, vaporization and combustion performances of the black liquid.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Paper-making technique employing bio-fermentation pulping method instead of chemical pulping technique

InactiveCN101225614ASolve pollutionRealize cleaner productionDigestersPaper-making machinesFiberChemical treatment

The invention discloses a paper making craft which replaces the chemical pulp making with biological fermentation pulp making, comprising process sections of pulp making and paper making. The procedures can be described as follows: (1) material preparation: fiber plants are grinded; (2) dissociation of the fiber: the grinded fiber plants are sterilized through steaming and boiling; after being cooled, mould that can decompose cellulose and lignin is added in; then the mixture is evenly stirred and put into a fermentation tank to be fermented; when the fiber plants are dissociated fluffy, the paper pulp is made. Since a plurality of chemical treating procedures are avoided due to the spare of chemical source materials, more than twenty procedures in previous paper making process are reduced into only several procedures, therefore, the paper making procedures are greatly simplified and a large amount of producing materials and energy is saved; thus the paper making craft has the advantages of greatly reduced production cost, source-saving and energy-saving effects.

Owner:陈淑华 +1

Method for preparing pulp by gramineous straw and use of obtained pulp

The invention discloses a method for preparing pulp by gramineous straw. The method sequentially comprises the following steps: (1) pre-treating the gramineous straw as a raw material; (2) physically pulping to obtain a straw fiber reinforced polymer (FRP); (3) adding water to the straw FRP obtained in step (2), thread-rolling and grinding until length of the straw FRP is 10-20mm to obtain fiber pulp; (4) decoloring or coloring the fiber pulp; and (5) mixing the fiber pulp treated in step (4) with the conventional chemical pulp or waste pulp based on the dry weight ratio of 1:0.1-10, then adding water for diluting the obtained mixed pulp, and finally obtaining the mixed pulp raw material. The invention further discloses use of the obtained pulp in preparation of the pulp molding product. The pulp obtained by the method takes the waste crop-the gramineous straw as the raw material and has the characteristics of low raw material cost, wide use, good industrial application prospect and the like.

Owner:NANJING BIOFUNCTION CO LTD

Method for applying peanut shells to synchronously prepare nanocellulose crystal and sugar

The invention discloses a method for applying peanut shells to synchronously prepare nanocellulose crystal and sugar. The method uses the peanut shells as a raw material to extract cellulose, adopts an enzymatic hydrolysis method to prepare the nanocellulose crystal, controls the enzymolysis degree and obtains sugar liquor at the same time, belonging to the technical field of nanostructure materials. The nanocellulose crystal preparation method does not adopt an inorganic acid hydrolysis method generating a lot of waste acid and impurities but adopts the cellulose enzymatic hydrolysis method with mild process conditions and strong specificity, being green and environmentally-friendly and conforming to the national strategy of sustainable development requirements. The method uses the peanut shells as the raw material to replace high-cost raw materials such as cotton, chemical pulp or microcrystalline cellulose and the like, so that the comprehensive utilization value of the peanut shells is increase, the current situations of waste of resources and economic losses as most of the agricultural and sideline products are used as wastes or fuels are changed, and the economic and social benefits are brought while the environment is improved. A lot of sugar liquor is produced during preparation, and the purpose of making the most of things is achieved.

Owner:QINGDAO AGRI UNIV

Production process of bleached chemical pulp with hemp stalk core

InactiveCN1811055ATake advantage ofEfficient use ofFats/resins/pitch/waxes removal in pulpPulp bleachingHypochloriteSulfate

The production process of bleached chemical pulp with hemp stalk core includes the following steps: 1. cutting hemp stalk core as material into 2-3 cm long sections, sieving and digesting in sulfate process to produce pulp; 2. washing and sieving the obtained pulp and oxygen delignifying; and 3. bleaching pulp with small amount of hypochlorite in a short program. Of the process, the medium concentration oxygen delignifying technology is one clean environment friendly bleaching technology with the bleached effluent being recovered and reused completely without environmental pollution, and the medium concentration hypochlorite bleaching can lower the exhausted waste water and reduce chemical and power consumption effectively. The pulp of the present invention can meet the requirement of making common paper.

Owner:SOUTH CHINA UNIV OF TECH

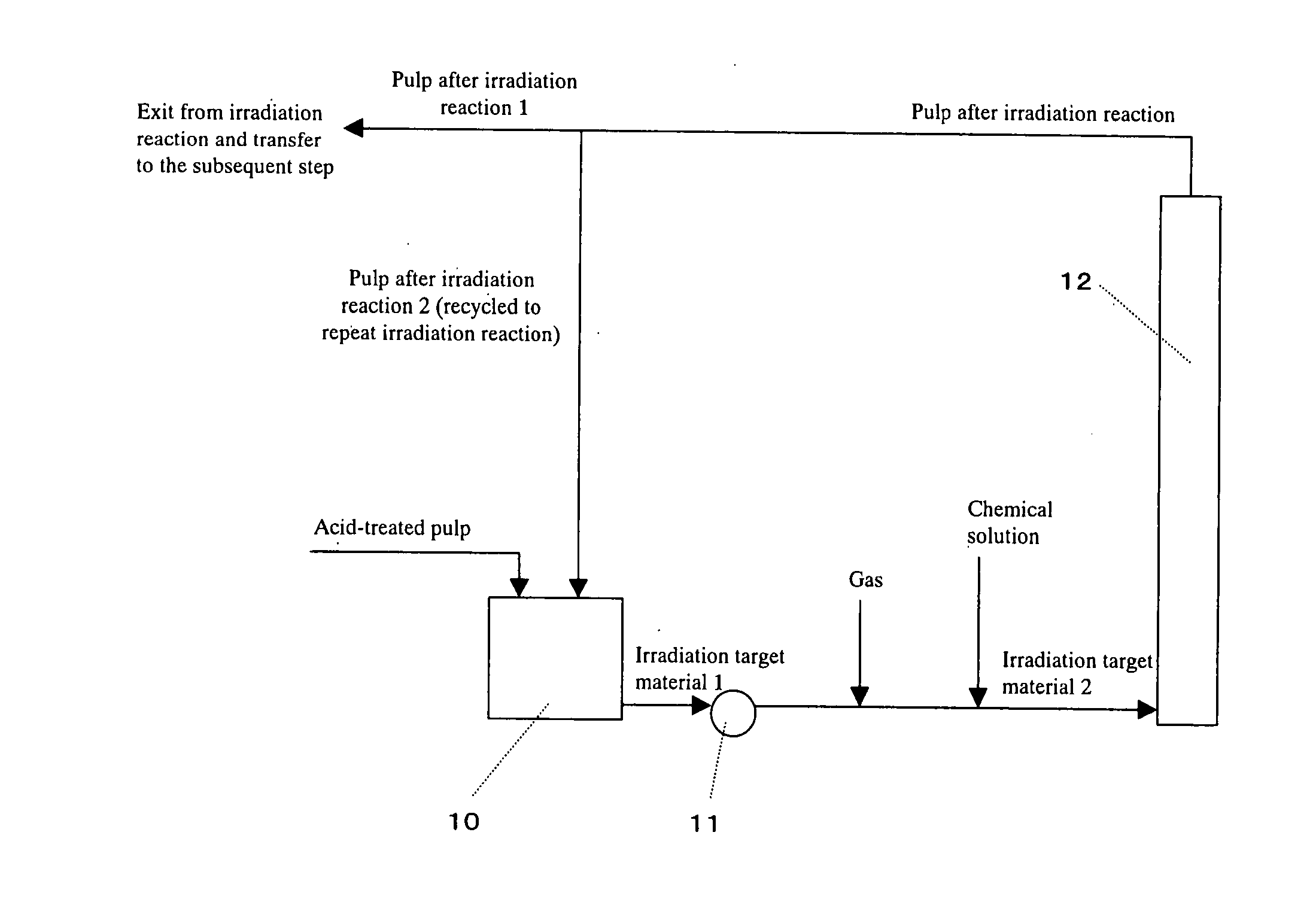

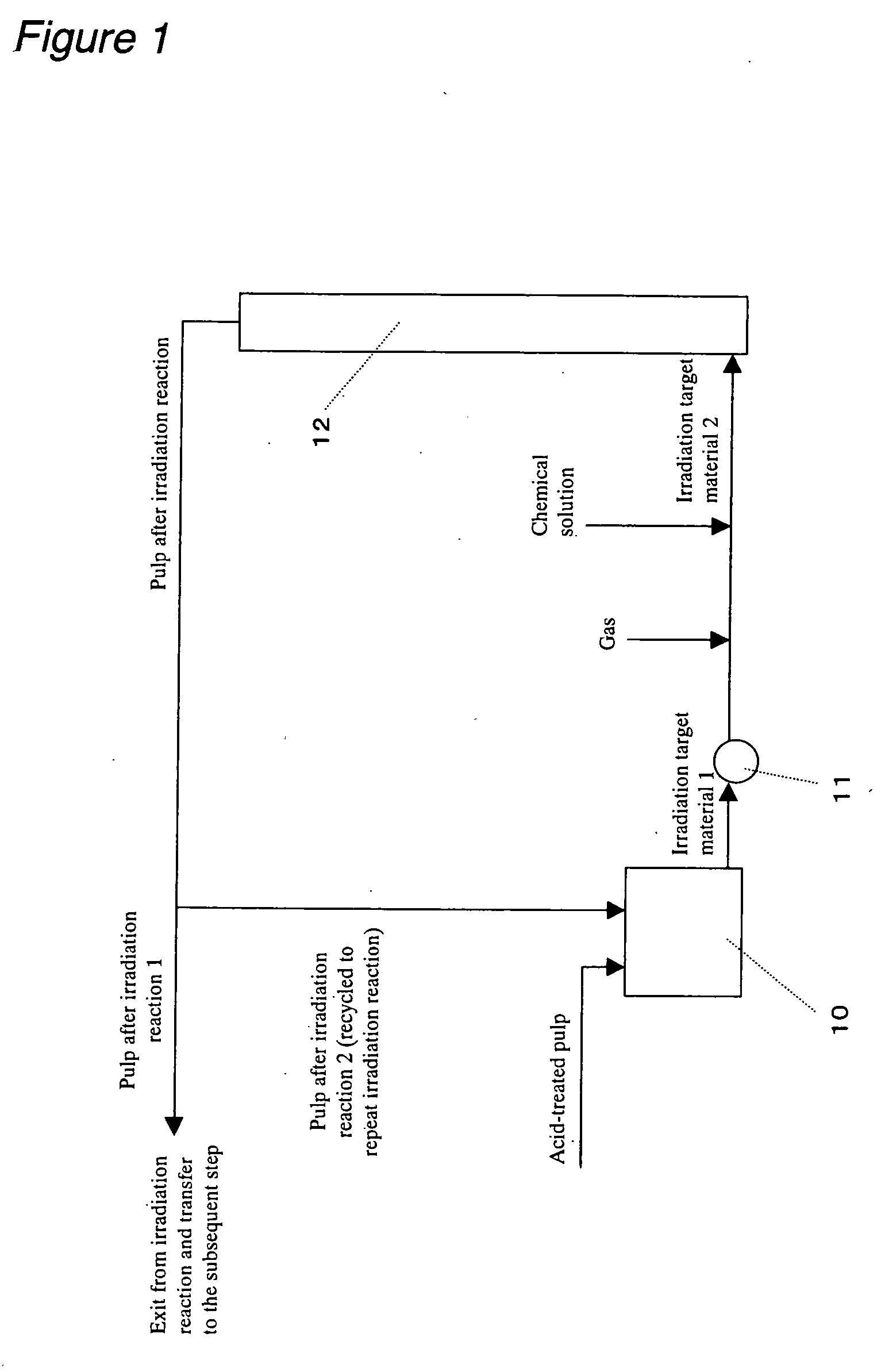

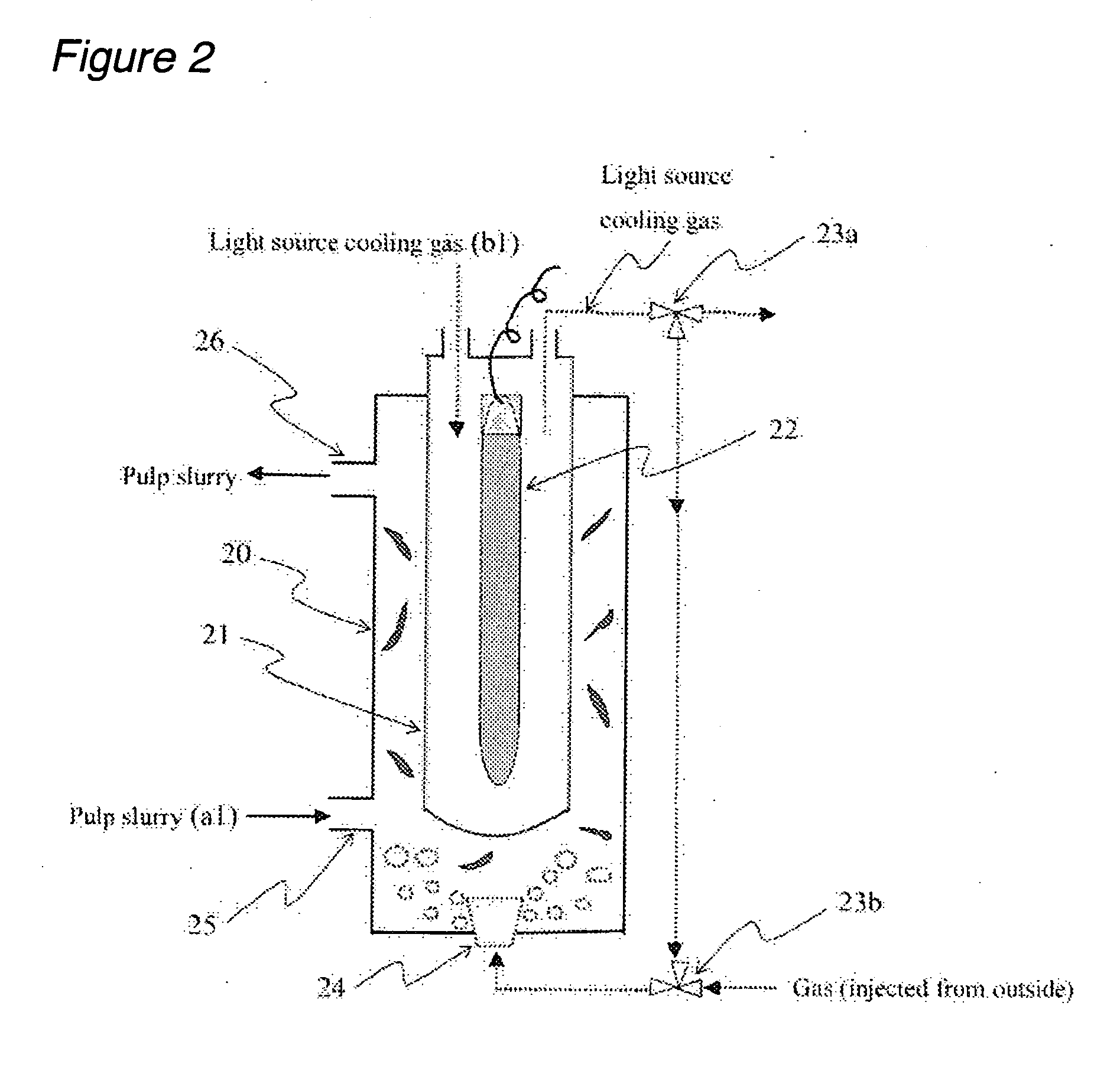

Pulp Bleaching Processes

InactiveUS20070246176A1Improve bleaching efficiencyHigh ozone-generating efficiencyPulp bleachingEnergy based chemical/physical/physico-chemical processesOrganic compoundPhotochemistry

The present invention aims to further advance the acid treatment or irradiation technology for pulp to develop a bleaching process using smaller amounts of chlorine chemicals with higher efficiency as compared with conventional bleaching processes. It also aims to provide an excellent high brightness pulp having a low environmental impact and no discoloration as well as a paper containing it. The present invention provides a chlorine-free bleaching process with very high efficiency by irradiating a pulp washed after an acid treatment with UV light and / or visible light at a wavelength of 100-400 nm under alkaline conditions, preferably in a pH range of 10-13. The acid treatment can be performed under conditions of pH 1-6 and a temperature of 80° C. or more. The irradiation treatment can be performed in the presence of at least one compound selected from the group consisting of reducing agents, peroxides, and hydrogen-donating organic compounds. The present invention also provides a high brightness chemical pulp having an ISO brightness of 88% or more and a brightness loss of 1.0% or less in a specific fading test.

Owner:NIPPON PAPER IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com